Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2134results about How to "Good warmth retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

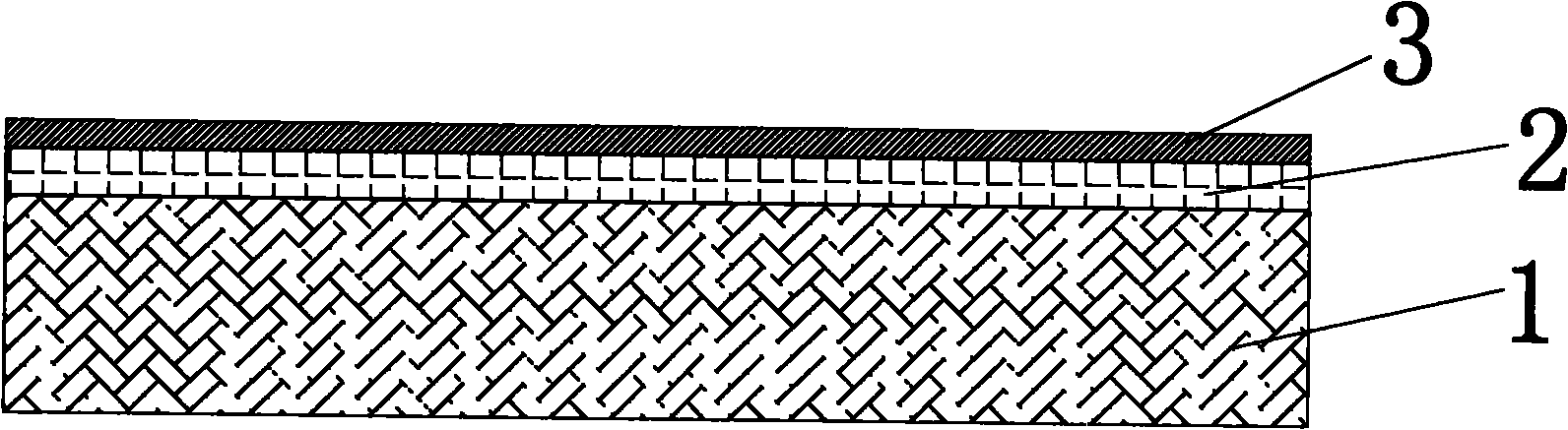

Luminous waterproof fabric

InactiveCN102152562AImprove waterproof performanceGood warmth retentionSynthetic resin layered productsDewEngineering

The invention discloses a luminous waterproof fabric. The luminous waterproof fabric comprises a fabric layer, wherein the outer surface of the fabric layer is covered with a luminous coating layer; and the outer surface of the luminous coating layer is also compounded with a thin film. The luminous waterproof fabric disclosed by the invention can emit light at night, and also has a good waterproof effect, a windproof effect and high heat retention performance; rain water or dew cannot permeate a formed waterproof layer, so that the luminous effect is relatively lasting; and the luminous waterproof fabric can be made into a raincoat, an outdoor tent, a sport suit and decorative cloth and the like.

Owner:WUJIANG FEIXIANG WARP KNITTING TEXTILE

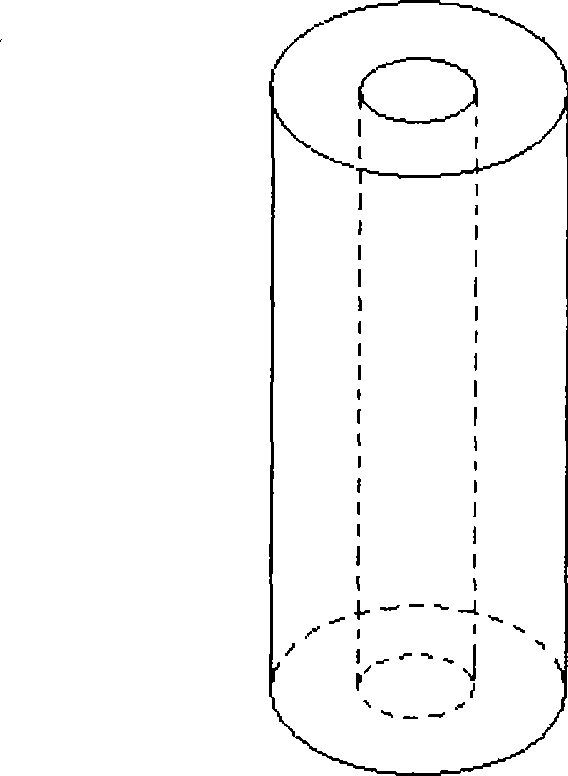

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

Multifunctional thermal underwear fabric and processing method thereof

InactiveCN102312342AFunction increaseGood warmth retentionWeft knittingFibre treatmentPolyesterTextile technology

The invention relates to a multifunctional thermal underwear fabric and a processing method thereof, belonging to the field of textile technology. The multifunctional thermal underwear fabric comprises a face weave and a bottom weave, wherein the face weave consists of cotton fibers, polyester fibers, spandex fibers, bamboo charcoal fibers, viscose fibers, wool fibers and plant protein fibers; and the bottom weave consists of polyester fibers. The content of the cotton fibers accounts for 34-60 percent of the total components, the content of the polyester fibers accounts for 26-39 percent of the total components, the content of the spandex fibers accounts for 5-6 percent of the total components, the content of the bamboo charcoal fibers accounts for 0.5-6 percent of the total components, the content of the viscose fibers accounts for 1-17 percent of the total components, the content of the wool fibers accounts for 1-5 percent of the total components, and the content of the plant protein fibers accounts for 0.5-7 percent of the total components. The multifunctional thermal underwear fabric has the advantages that the functions of the fabric are expanded by guaranteeing an excellent warmth keeping performance through the cotton fibers, by guaranteeing ideal elasticity through the spandex fibers, by reflecting a good moisture absorbing performance and air permeability through the polyester fibers and by reflecting a good antibiotic property through the bamboo charcoal fibers; and since function processing, baking and secondary ironing processes are increased, the fabric has an aromatic long-lasting effect.

Owner:CHANGSHU MENGXI FURNISHINGS

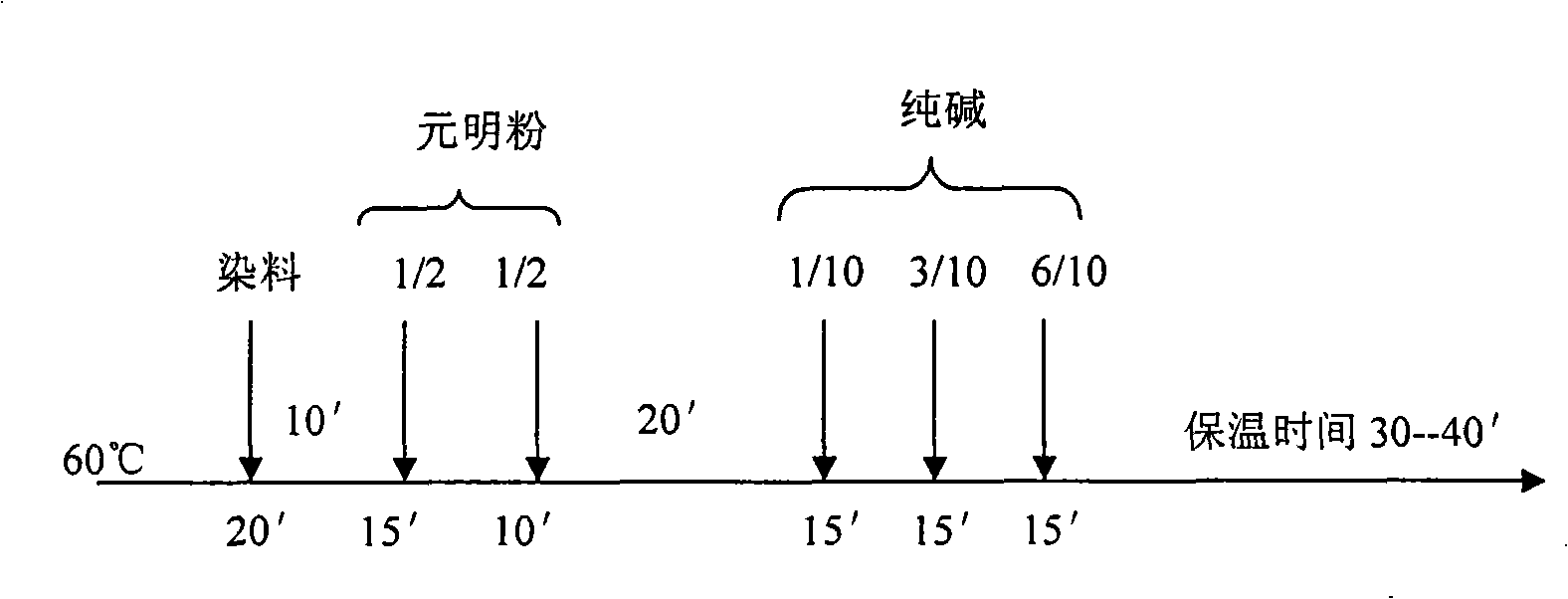

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

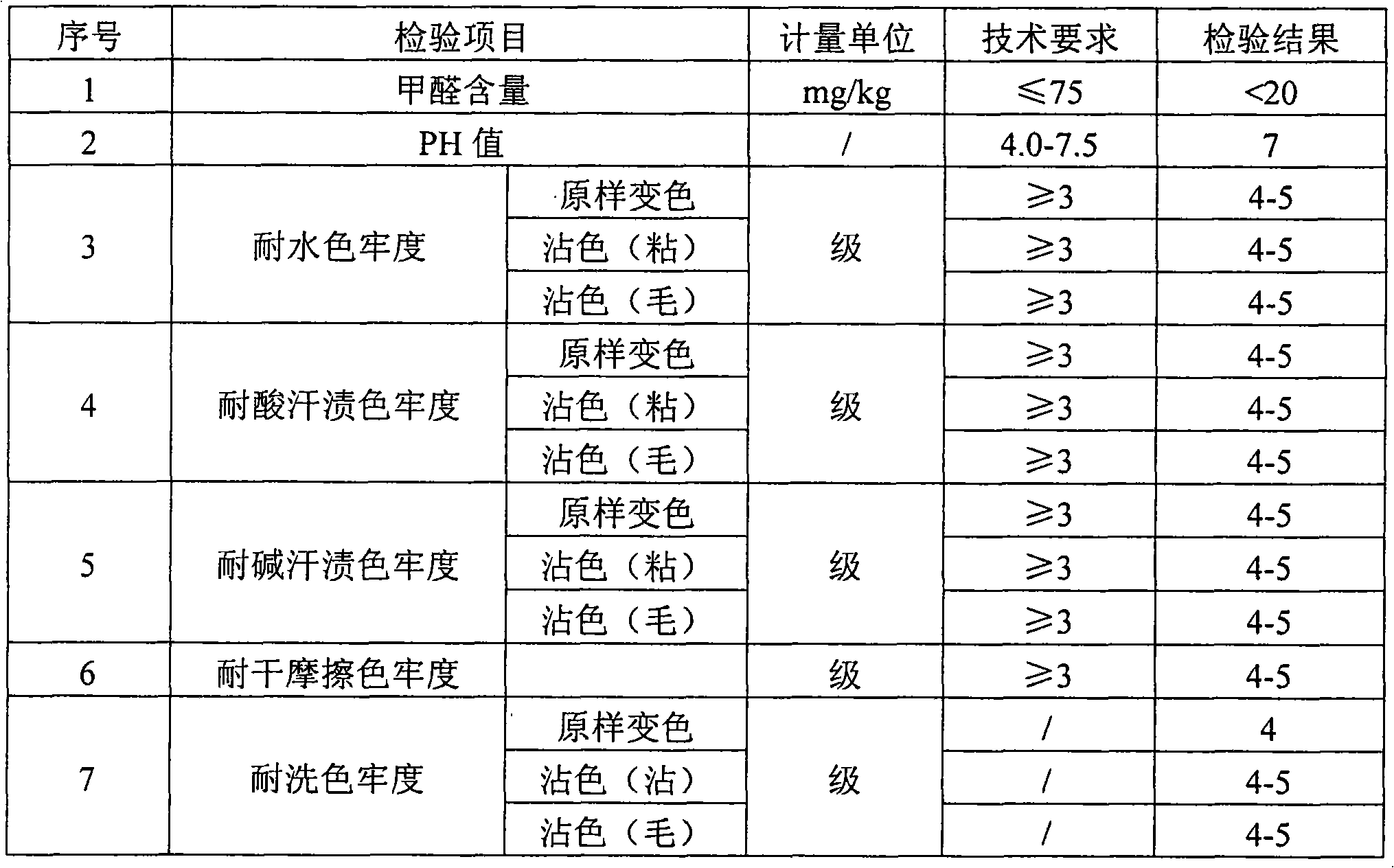

Production method of wool/Coolmax/mulberry silk/polyester fiber blended fabric

InactiveCN102560930ATo soften waterSolve the adhesionLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsFiberPolyester

The invention relates to a production method of a wool / Coolmax / mulberry silk / polyester fiber blended fabric, which is characterized in that the blended fabric is made of 60% of Australasian wool, 20% of Coolmax fibers, 15% of polyester fibers, and 5% of mulberry silk by dyeing, recombing, spinning, weaving and dyeing and finishing. The fabric has good color fastness, is non-fading and is breathable.

Owner:江苏华西村纺织服装有限公司

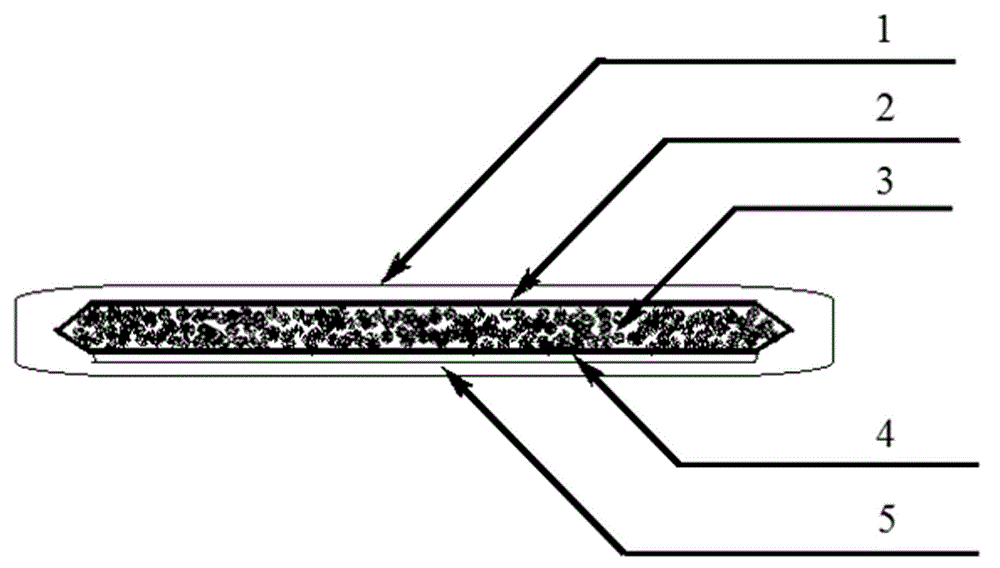

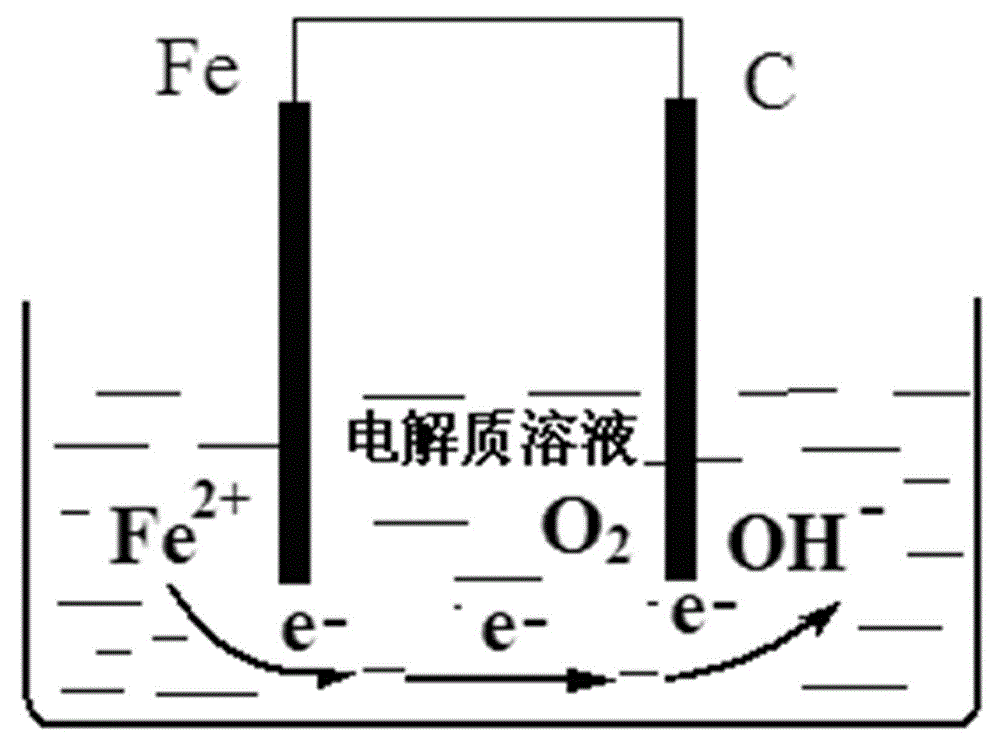

Self-heated type thermal paste

InactiveCN102715978AImprove insulation effectImprove water retentionHeat-exchange elementsTherapeutic coolingActivated carbonTap water

The invention provides a self-heated type thermal paste which comprises a vacuum external packaging bag and a breathable internal packaging bag. The internal packaging bag is filled with a heating material; one side of the internal packaging bag is provided with a gelatin layer; the gelatin layer is provided with a protecting film; the heating material is prepared from secondarily-reduced iron powder, sodium chloride, vermiculite, wood powder, active carbon powder and tap water at a certain proportion. Because the vermiculite is used as the heat preserving and insulating material of the self-heated type thermal paste, the heating time of the self-heated type thermal paste is prolonged greatly, and because the wood powder is used to prepare the self-heated type thermal paste, the heat preserving performance and the water retaining performance of the self-heated type thermal paste are improved effectively. A large number of experiments show that the self-heated type thermal paste can be heated to 40-50 DEG C, and the heat can be preserved for about 20 hours. In addition, the self-heated type thermal paste has the characteristics of low cost, easily-available raw materials, simple formula, quick long-time heating and balanced heat and can be used by people who can not tolerate cold and people who work or do activities outdoors in cold winter to keep warm.

Owner:GANSU RES INSTION OF CHEM IND GRICI

Antibacterial, moisture-absorbent and warming knitted fabric and manufacturing method thereof

The invention discloses antibacterial, moisture-absorbent and warming knitted fabric and a manufacturing method thereof. The antibacterial, moisture-absorbent and warming knitted fabric has a double-layer structure, wherein an outer layer of the fabric has a mesh structure woven from blended yarns which are blended from cellulosic fibers and nanosilver antibacterial agent-containing profiled polyester fibers; an inner layer of the fabric has a plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and the inner layer and the outer layer are connected through polyester filaments with grooved sections. The manufacturing method comprises the following steps: for the outer layer of the fabric, manufacturing the mesh structure woven from the blended yarns which are blended from the cellulosic fibers and the nanosilver antibacterial agent-containing profiled polyester fibers; for the inner layer of the fabric, manufacturing the plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and connecting the inner layer and the outer layer through the polyester filaments with the grooved sections. The antibacterial, moisture-absorbent and warming knitted fabric can meet requirements on moisture absorption for quick drying as well as wearing comfort, can meet an increasingly strong requirement on antibacterial sanitation and has a good warming effect.

Owner:SHANGHAI JIALE

Polyester woven fabric

ActiveUS20070202763A1Reduce weightHigh densityMechanical working/deformationBaby linensYarnPolyester

A polyester fabric having a total cover factor of not lower than 1500 and a mass per unit area of not higher than 45 g / m2, wherein said polyester fabric is composed of polyester multifilament A yarns having a total fineness of not higher than 25 dtex (decitex) and a single yarn fineness of not higher than 2.0 dtex and multifilament B yarns having a total fineness of not lower than 35 dtex, wherein the arrangements of the respective yarns in the warp and weft directions are such that the yarn constitution ratio “B yarn / A yarn” is 1 / 4 to 1 / 20 (number of yarns-to-number of yarns ratio) and wherein the A yarn-to-B yarn pitches are not longer than 7 mm. The polyester fabric is light in weight, high in density and flexible by using extra-fine polyester multifilaments finer as compared with the conventional polyester multifilaments and, at the same time, has a sufficient level of tear strength.

Owner:KB SEIREN LTD

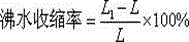

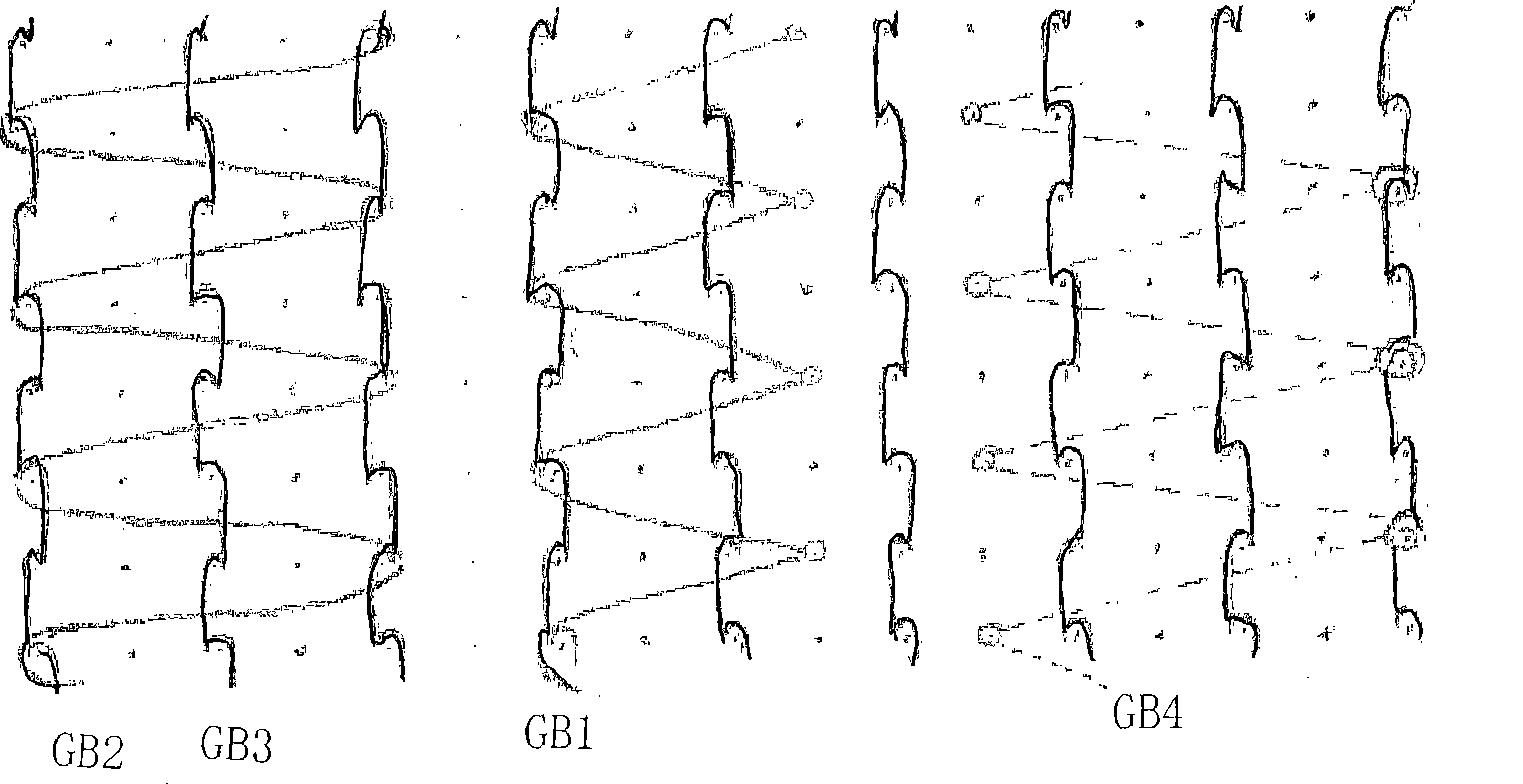

Raschel blanket and production method thereof

InactiveCN101476209AReduce weaving costIncrease productivityWarp knittingHeating/cooling textile fabricsYarnSingle fibre

The invention provides a raschel carpet and a producing method thereof which relates to a raschel carpet produced by a single neilbed tricot machine that terylene is used as raw material. The method includes steps as follows: using 83-333dtex terylene low elastic net yarn as a felted yarn raw material and 56-111dtex terylene FDY as a bottom yarn for knitting on a weft knitting fur machine, thermal finalization; fluffing on front; terylene dyeing or printing; post treatment and front lustre finishing; shearing; reverse surface fluffing; and thermal finalization. The carpet is knitted by using the single neilbed tricot machine and the produced grey cloth needs not slitting that lead to increase productive efficiency greatly and reduce knitting cost. The felted head yarn of the knitted grey cloth is an extensive yarn, fibre in the yarn is fully washed into single fibre state in post treatment. The carpet provided by the invention has characteristics of super soft, filling power, better warmth retention property and exquisite style.

Owner:TAICANG SHUMEITE TEXTILE

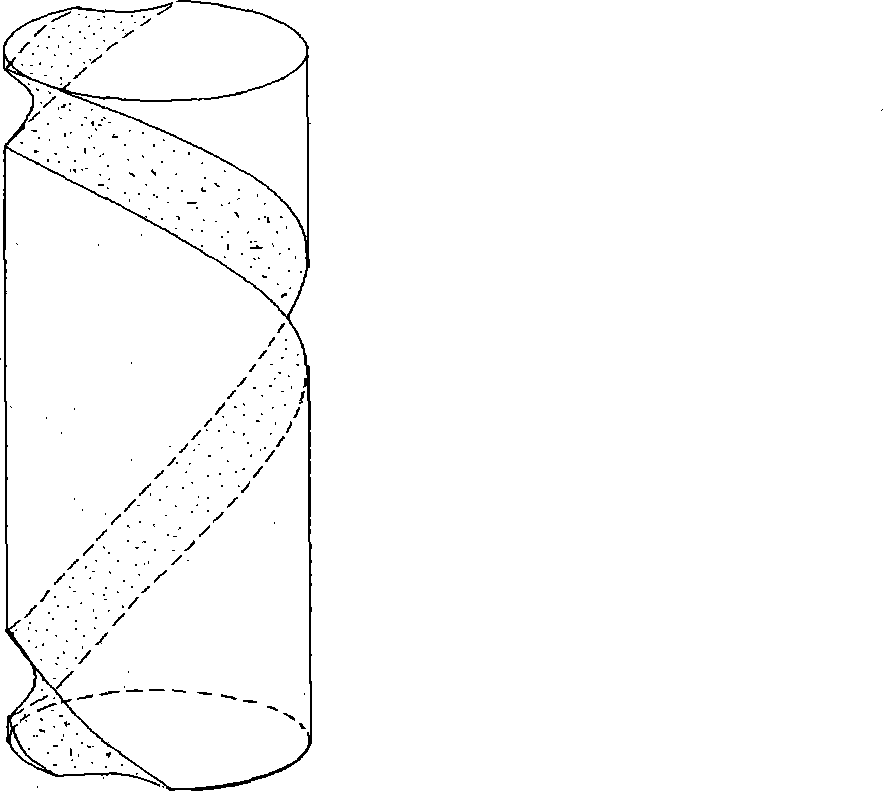

Thermal woven and producing method thereof

InactiveCN101463523AIncrease warmthFluffy and softDry-cleaning apparatus for textilesWoven fabricsYarnFiber

The invention provides a cold-proof fabric and a manufacturing method thereof, and is characterized in that the manufacturing method comprises the steps: water soluble fiber is taken as core yarn or spinning yarn, and cotton, wool, terylene or acrylic staple fibre is taken as outer wrapping fiber or winding fiber to be wrapped into core spun yarn or Sirofil yarn; the obtained core spun yarn or Sirofil yarn is utilized for weaving; and the water soluble fiber is the obtained fabric is dissolved by solution. The invention has the advantages of simple technology, easy realization, low cost price, fluffy and soft effect, good heat retention and excellent ventilation property.

Owner:DONGHUA UNIV +2

Antibacterial deodorant ultra-fine denier polyester raschel blanket and production method thereof

InactiveCN101781830ALong-lasting antibacterial and deodorant functionNot easy to combWarp knittingHeating/cooling textile fabricsUltra fineMoisture

The invention provides an antibacterial deodorant ultra-fine denier polyester raschel blanket and a production method thereof. The blanket uses antibacterial deodorant polyester fiber with the fineness of below 1 denier as blanket fluff yarn raw material and uses 100 to 150-denier polyester filaments as base cloth. The production method of the raschel blanket is characterized by sequentially comprising the following steps: a) preparing the raw material according to the formula; b) weaving the raw material into grey cloth; c) slitting the grey cloth into specification size; d) performing printing or dyeing; e) performing post-treatment, f) performing heat setting; g) performing combing; and h) performing shearing to obtain a finished blanket. Compared with the prior art, the blanket has the advantages of changing the water-repellent non-breathable performance of polyester fiber, selecting and developing appropriate moisture-absorbing sweat-discharging softener and achieving firm moisture-absorbing sweat-discharging function through after-finishing after washing. In order to achieve the fluff style of raschel blankets, an ultra-fine fiber polyester blanket with the fineness of below 1 denier needs to have the moisture-absorbing sweat-discharging function with such fine fiber, as well as fine soft fluff, fluffy straight fluff, bright clean smooth fluff surface, good compression-resisting rebounding property, light weight and good warmth retention property, and similar products cannot achieve the effect.

Owner:宁波西田信染织有限公司

Seamless plastered, watertight and down penetration resistant down garment and method for making same

InactiveCN1864574AImprove waterproof performanceReduce seam widthOvergarmentsEngineeringLaser cutting

The present invention discloses one kind of adhered waterproof no-seamline down wear and its making process. The making process includes cutting patterns, cutting, laser cutting, hot adhering, filling down, supplementary material sewing and other steps. Unlike traditional sewing process, the fabric is separated into several checks and all the checks are no-seam adhered. The down wear has no seamline and no trouble of down escape through the seamline, and is waterproof and good-looked. In addition, the down wear with no seamline has improved windproof warming performance.

Owner:黄国钦

Short fiber of polyethylene terephthalate and method for producing same

ActiveCN101525782AImprove performanceImprove breathabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention discloses short fiber of polyethylene terephthalate and a method for producing the same. A raw material for preparing the polyethylene terephthalate is glycol, wherein a carbon element of the glycol comes from a biological material. The cutting length of the short fiber obtained by adopting a conventional pre-spinning and post-spinning process is between 4 and 10 mm; the titer is between 6.5 and 6.8 dtex; the strength is between 3.0 and 4.0 cN / dtex; and the elongation is between 20 and 40 percent. Compared with the prior short fiber, the preparation of the short fiber of the polyethylene terephthalate utilizes bio-based glycol to replace glycol as a conventional petroleum source, reduces dependence on petroleum, relieves energy crisis, simultaneously improves the utilization of crops and achieves the effects of increment and profit generation.

Owner:TORAY IND INC

Fabric used for making warm underclothes

InactiveCN101002633AExcellent Texture and HygroscopicitySoft-touch texture and hygroscopicityHeating/cooling textile fabricsCircular knitting machinesPolyesterYarn

A fabric for heat-insulating underwear is composed of the surface structure made of polyester fibers and substrate made of polyurethane cored cotton yarn. Its productive method includes such steps as weaving by dual-surface loom, pre-treating, and dyeing, finishing, post-treating, scotching, pre-fixating shape, napping, combining, shearing, ironing, swinging, and fixating shape.

Owner:常熟市东方染整有限公司

Far infrared polyester and nylon composite superfine fiber and production method thereof

ActiveCN103290524AHigh tensile strengthLow thermal conductivityConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterThermal insulation

The invention discloses a far infrared polyester and nylon composite superfine fiber and a production method thereof. The far infrared polyester and nylon composite superfine fiber is formed by externally coating a modified nylon 6 fiber layer by taking a superfine polyester fiber as a core thread, wherein a far infrared nano-powder material is arranged in the externally coated modified nylon 6 fiber layer; modified nylon 6 is modified by adding nylon 6 into a silica nano-powder material under active catalysis of a cerium oxide nano-powder material. According to the obtained far infrared polyester and nylon composite superfine fiber, the infrared emitting ability can be up to 90-92 percent within the normal temperature wavelength range of 2-16; according to the modified nylon 6, the tensile strength of the nylon 6 is improved, the heat conductivity coefficient is reduced, and the drawing performance of the nylon 6 is high, so that coating and the drawing between the nylon 6 and the superfine polyester fiber can be realized, and a piece of obtained textile fabric has good thermal insulation properties.

Owner:宁波三邦日用品有限公司

Polyurethane Roman cloth with high stretching resilience and preparation method thereof

The invention relates to polyurethane Roman cloth with high stretching resilience and a preparation method thereof. The Roman cloth is formed by interweaving nylon-coated polyurethane and mucilage glue; the mucilage glue is weaved on the front and back surfaces of a fabric in a cotton wool weaving way; and the nylon-coated polyurethane is used for covering the front and back surfaces of the mucilage glue respectively in an up-down knitting way of a circular knitting machine. The preparation method comprises the following steps: (1) weaving, namely obtaining blanks and performing fabric slitting, curling and finishing; and (2) performing after-finishing on finished fabrics, namely performing open width washing, pre-shaping, dyeing, mellow finishing, dewatering, drying and re-shaping to obtain the polyurethane Roman cloth. The polyurethane Roman cloth has the characteristics of soft hand feel, good elasticity, massiness, good heat retention property, high stretching resilience, fold resistance and the like; the problems of poor stretching resilience and non fold resistance of general Roman cloth are solved; and the practicality of the Roman cloth is improved.

Owner:NINGBO DAQIAN TEXTILE

Waterproof non-woven heat-preservation material making method and waterproof non-woven heat-preservation material

ActiveCN103882714AStrong affinityImprove wash fastnessLiquid repellent fibresNon-woven fabricsGramFiber

The invention relates to a waterproof non-woven heat-preservation material making method and a waterproof non-woven heat-preservation material produced by the method. The waterproof non-woven heat-preservation material making method is as follows: a fiber net is formed from a main-body fiber and an optional low melting point fiber by a nonwoven technology, a waterproof agent is sprayed on one or two surfaces of the fiber net in a ratio of 0.5-20 grams per square meter, and then the fiber net is heated at the temperature of 110-200 DEG C for 2-10 minutes. The waterproof non-woven heat-preservation material making method can fast and safely prepare the waterproof non-woven heat-preservation material in low cost, and the produced waterproof non-woven heat-preservation material has good water repellency, and has excellent heat preservation effect both in dry and wet conditions.

Owner:3M INNOVATIVE PROPERTIES CO

Plush blanket and processing method thereof

The invention relates to a plush blanket and a processing method thereof, and belongs to the technical field of terylene fiber blankets. The plush blanket comprises a surface structure and base structure, wherein the surface structure is prepared from a raw material which is a 75-150D / 96F FDY (fully drawn yarn) irregular terylene yarn with 8-16 network points per meter and elongation of 2-5%; the base structure is prepared from a raw material which is a 68-100D DTY (draw textured yarn) terylene yarn; the mass percent of the FDY irregular terylene yarn in the blanket is 70-85%; and the mass percent of the DTY terylene yarn in the blanket is 30-15%. The plush blanket has the advantages that a pile surface with the pile height of 25-80 mm can be obtained; the noble and classic fashion pursuing of people is satisfied; and because the pile height reaches 25-80 mm, the blanket has perfect heat retention property, soft touch feeling and delicate sense. The processing method provided by the invention has no strict requirements on the processing steps and equipment, thus the technical effect of the plush blanket is guaranteed.

Owner:宿迁市群英纺织印染科技有限公司

Manufacturing technology for far-infrared polyester short fibers

InactiveCN102560732ALow costPromote environmental protectionHollow filament manufactureArtificial filament heat treatmentPolyesterManufacturing technology

The invention discloses a manufacturing technology for far-infrared polyester short fibers, which takes recycled PET (Polyethylene Terephthalate) as a raw material, and the recycled PET is processed sequentially through pretreatment, rotating drum drying, melt spinning, cooling formation, winding, drawing, curling, oil application, cutting and heat setting, so as to obtain finished products, wherein in the rotating drum drying step, the recycled PET is dried for 5.5 to 6.5 hours firstly, then far-infrared master batches are added, the final mass fraction of the far-infrared master batches ranges from 5 to 7 percent, the total drying time ranges from 9.5 to 10.5 hours, and far-infrared ceramic powders account for 19 to 21 percent in the far-infrared master batches; in the melt spinning step, the temperatures of a screw bolt and a spinning box body of a screw bolt extruder range from 268 to 278 DEG C, and cooling formation is carried out through circular air blow; in addition, the total drawing ratio is 3.0 to 3.5, the heat setting temperature ranges from 162 to 168 DEG C, and the heat setting time ranges from 8 to 12 minutes. The manufacturing technology can save cost and is beneficial to environmental protection, and the prepared finished products achieve good warmth retention and health protection properties.

Owner:HANGZHOU BEST CHEM FIBER

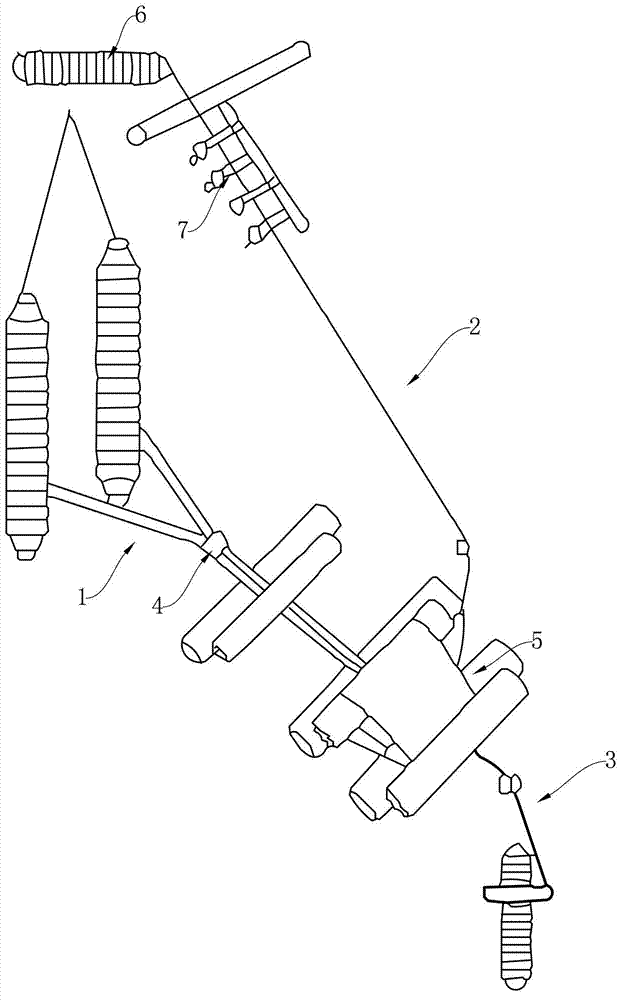

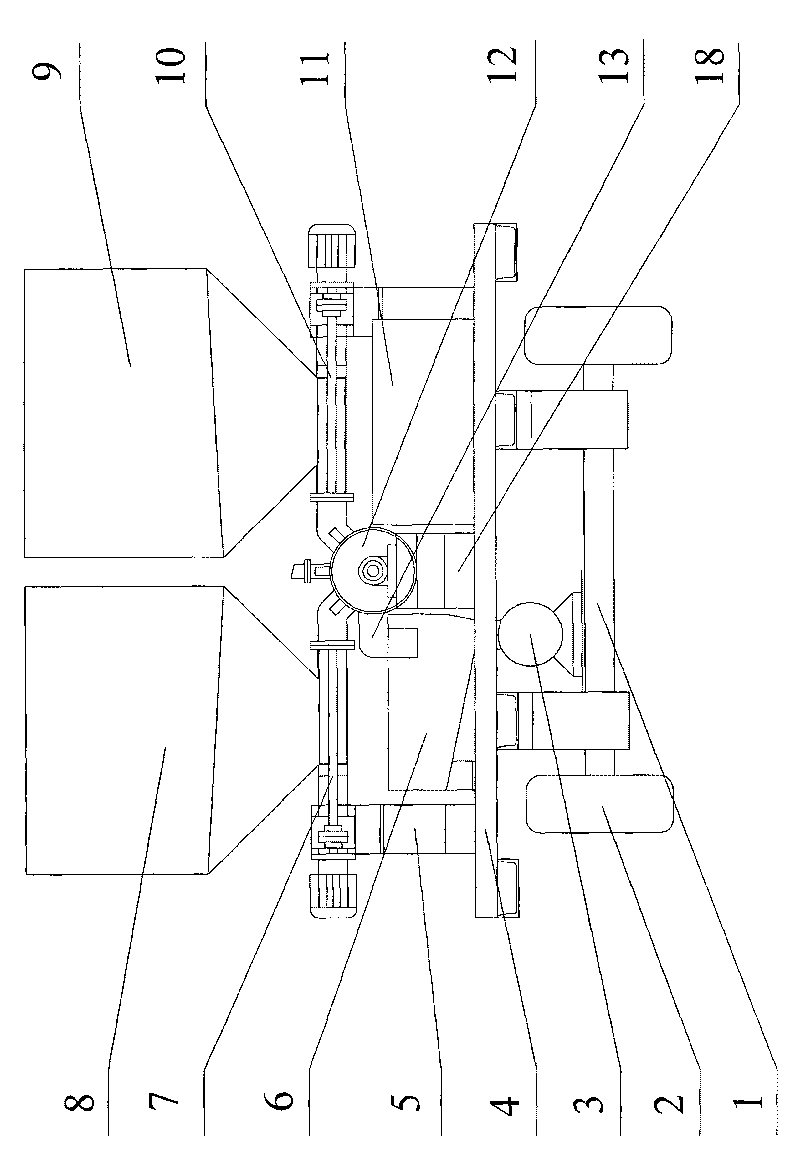

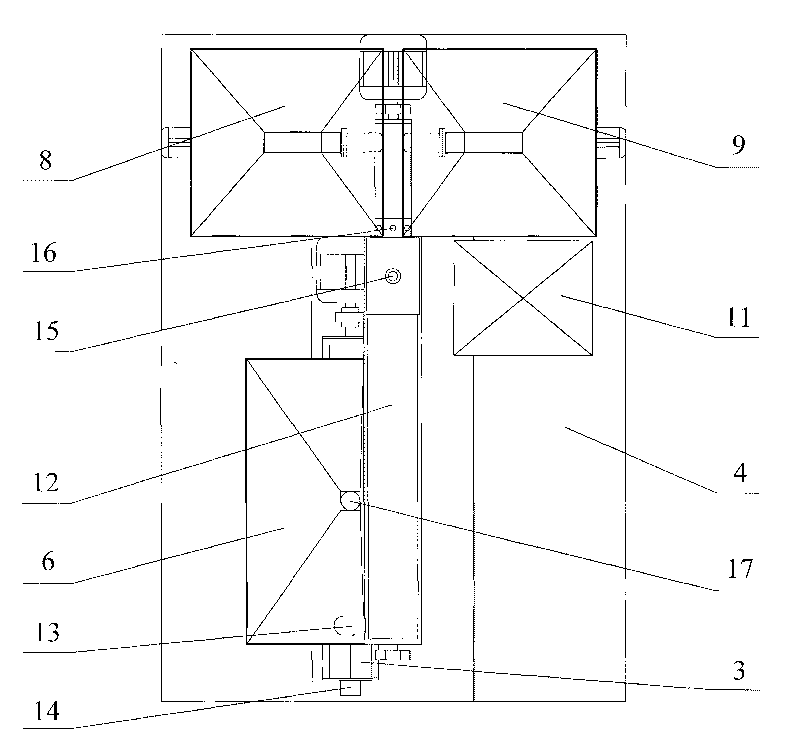

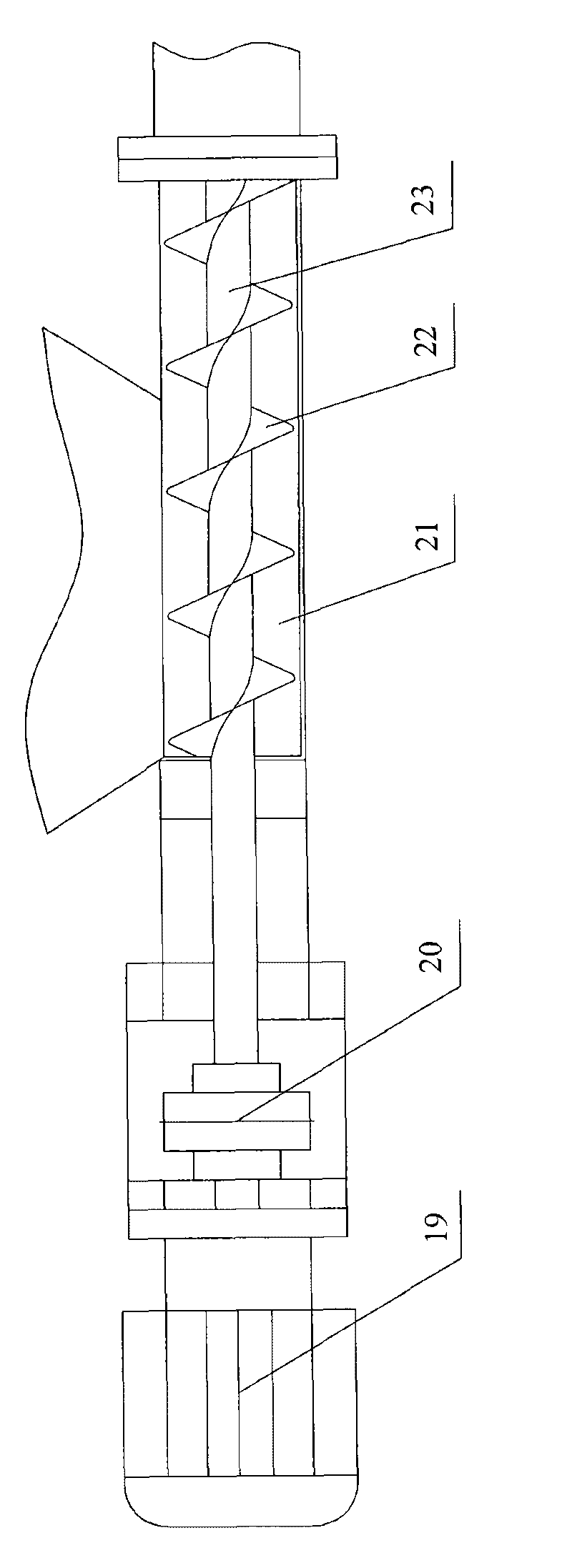

Stirring conveying device for polystyrene granule foaming cement composite material

InactiveCN101758559AWell mixedEasy to pumpMixing operation control apparatusSold ingredients supply apparatusCement compositesPolystyrene

The invention discloses a stirring conveying device for polystyrene granule foaming cement composite material, which comprises a pedestal, a cement bunker, a polystyrene granule bunker, material conveying units, a foaming machine, a stirring conveyor, a slurry storage tank and an underflow pump, wherein the cement bunker and the polystyrene granule bunker are mounted on the pedestal, the lower part of the cement bunker is equipped with a first material conveying unit and the lower part of the polystyrene granule bunker is equipped with a second material conveying unit, the pedestal is provided with the foaming machine and the stirring conveyor, the first material conveying unit, the second material conveying unit and the foaming machine are all connected with the stirring conveyor, a pedestal at a side of the stirring conveyor is equipped with the slurry storage tank, with which a discharging port of the stirring conveyor is connected and an outlet of which is connected with the underflow pump arranged at the lower part of the slurry storage tank.

Owner:沈阳金铠建筑科技股份有限公司

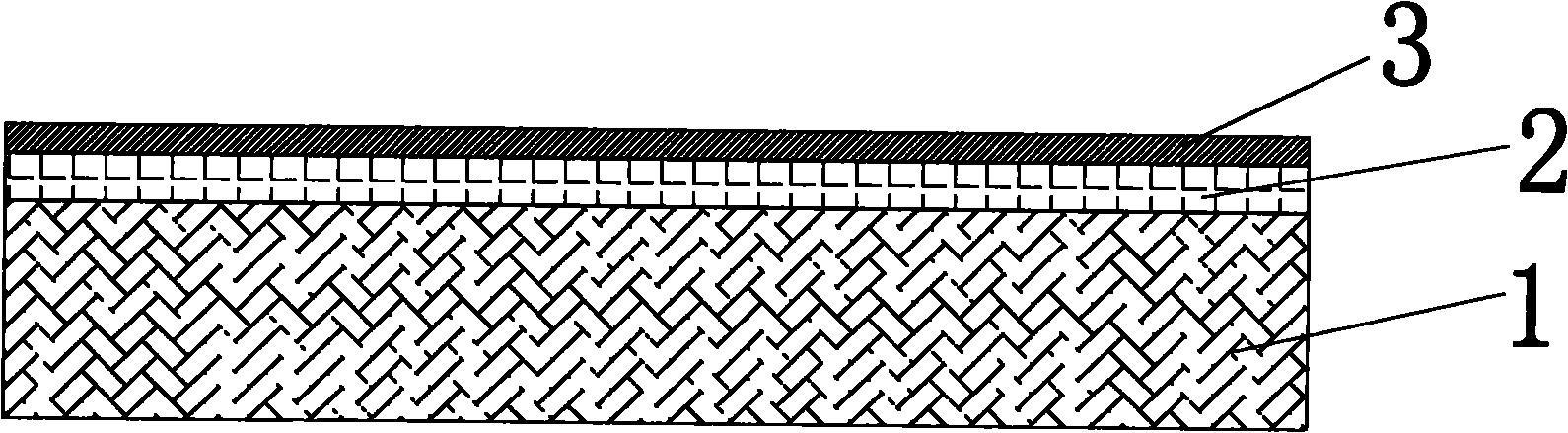

Ecological warm-keeping cotton and manufacturing process thereof

InactiveCN105603634AImprove the bactericidal effectNot easy to passNon-woven fabricsCardingEngineering

The invention provides ecological warm-keeping cotton and a manufacturing process thereof. The ecological warm-keeping cotton has good wind-resistant water-repellent effects, also has a certain sterilization function and is better in warm-keeping effect, lots of raw materials are renewable raw materials, and an environmental protection effect is good. The ecological warm-keeping cotton comprises a warm-keeping layer and a waterproof breathable sterilization layer adhered to one side of the warm-keeping layer, wherein the thickness of the waterproof breathable sterilization layer is 10%-15% of the thickness of the warm-keeping layer, the warm-keeping layer is manufactured from, by weight, 30% of Sorona polymer fiber, 30% of superfine warm-keeping fiber, 30% of three-dimensional hollow warm-keeping fiber and 10% of native cotton fiber through mixing, the waterproof breathable sterilization layer is manufactured from, by weight, 40% of collagen fiber, 20% of bamboo fiber, 20% of seaweed carbon fiber and 20% of nanoscale antibacterial silver ion masterbatch native fiber through mixing, the surfaces of the two sides of the waterproof breathable sterilization layer are coated with treatment layers formed by blending silicon nanoparticles and nano titanium dioxide, and the surfaces of the treatment layers are coated with hydrophobic fluorine quaternary amine silane coupling agent coatings. The manufacturing process of the ecological warm-keeping cotton comprises the steps of automatic material preparation and mixing through a machine, opening, carding, web laying, adhesive spraying, heat setting and rolling.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

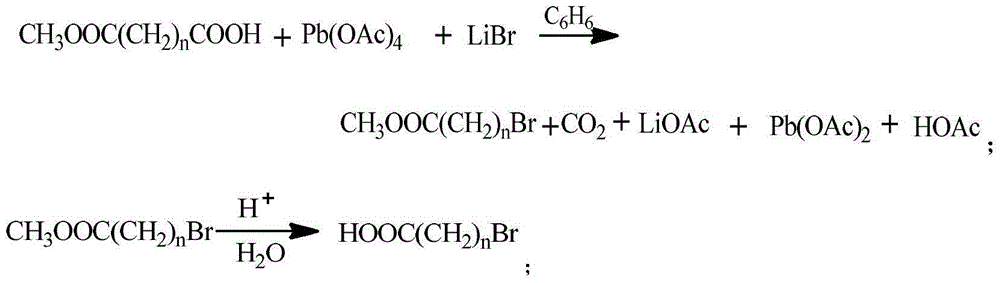

Differential-shrinkage cotton-like composite filament and preparation method thereof

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

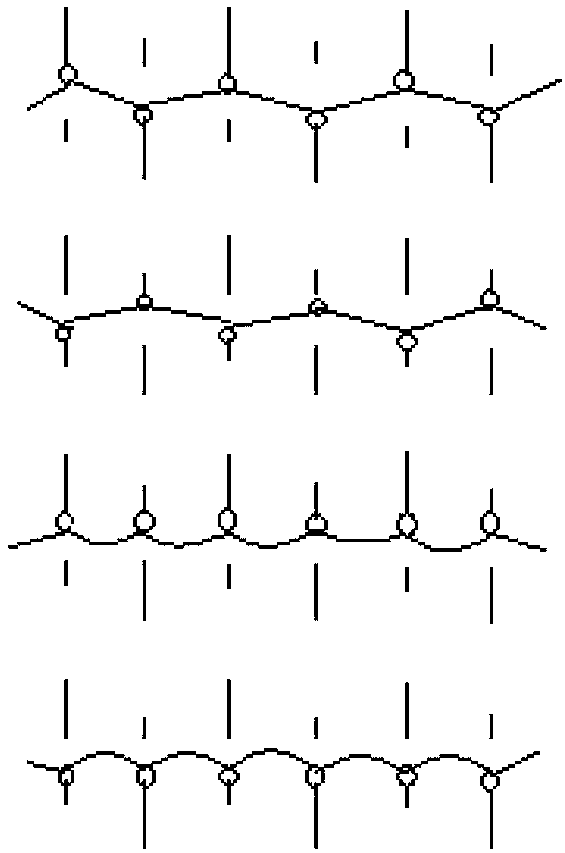

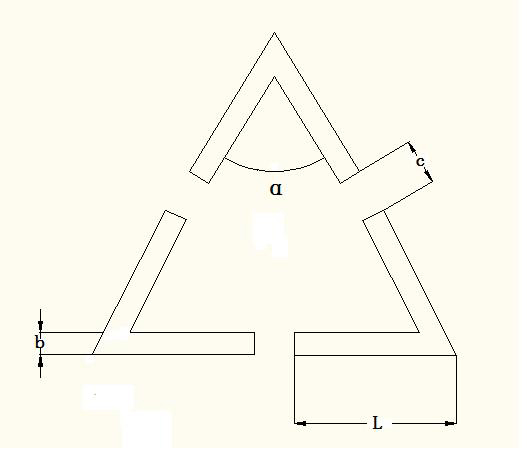

Flexible and heterogeneous nylon-6 fiber and preparation method thereof

ActiveCN102409419AStable structureLow apparent densityHollow filament manufactureFilament/thread formingSOCKSNylon 6

The invention relates to the technical field of functional and differentiated fiber production, and aims to provide flexible and heterogeneous nylon-6 fiber and a preparation method thereof. The flexible and heterogeneous nylon-6 fiber is formed by V-shaped jet micropore spinning and a melting spinning method by using fiber-level nylon-6 chips as substrates; the internal part of the section of the flexible and heterogeneous nylon-6 fiber is hollow, and the periphery of the section is triangular; and the relative radial profile degree of the cross section of the flexible and heterogeneous nylon-6 fiber is 20 to 30 percent, and the relative section profile degree is 35 to 55 percent, and hollowness of the flexible and heterogeneous nylon-6 fiber is 10 to 30 percent. The fiber has good mechanical properties, and high elasticity, hygroscopicity and heat retention, and can be widely used for the fields of underwear, socks, clothing and the like.

Owner:YIWU HUADING NYLON

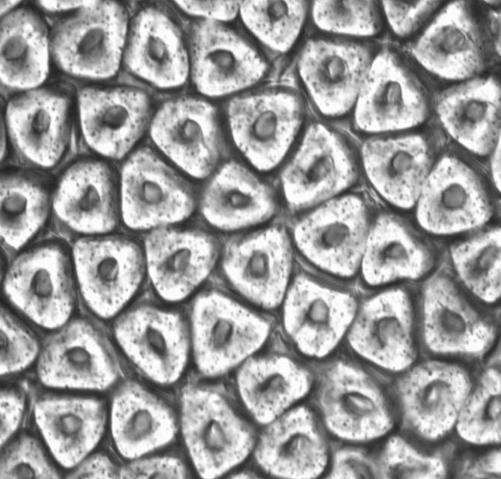

Terylene superfine-denier coral fleece blanket and production method thereof

This invention relates to a trueran ultra-fine coral bayeta, characterized in that it applies 0.52D or below trueran silk or floss compound silk as the yarn material, and 100~150D trueran FDY is made up of bottom silk, wherein the percentage by weight of the material is: trueran silk or floss compound silk 60~80%, 100~150D trueran FDY 40~20%; the making steps in turn is: preparing the raw material, waving in the double needle bar Raschel machine, slitting, heated shaping, dyeing or printing, post-processing, plucking, back shearing, heated shaping, inspecting and packing. The lint of the blanket is similar to the coral in seabed.

Owner:VEKEN HLDG GROUP

Bulk blended yarn and production method thereof

The invention discloses a bulk blended yarn and a production method thereof. The bulk blended yarn is a staple fiber yarn having a skin core structure, wherein the staple fiber yarn is obtained by removing water-soluble polyvinyl alcohol fibers through dissolving, and the staple fiber yarn is formed by at least high shrinkage staple fibers and common staple fibers; meanwhile, the filling power of the bulk blended yarn is up to 90 % and more. The obtained bulk blended yarn is characterized in light weight and warm-keeping; the filling power is stable and durable; the bulk blended yarn is suitable for making sweaters, underwear, blankets, and the like.

Owner:东丽国际贸易(中国)有限公司

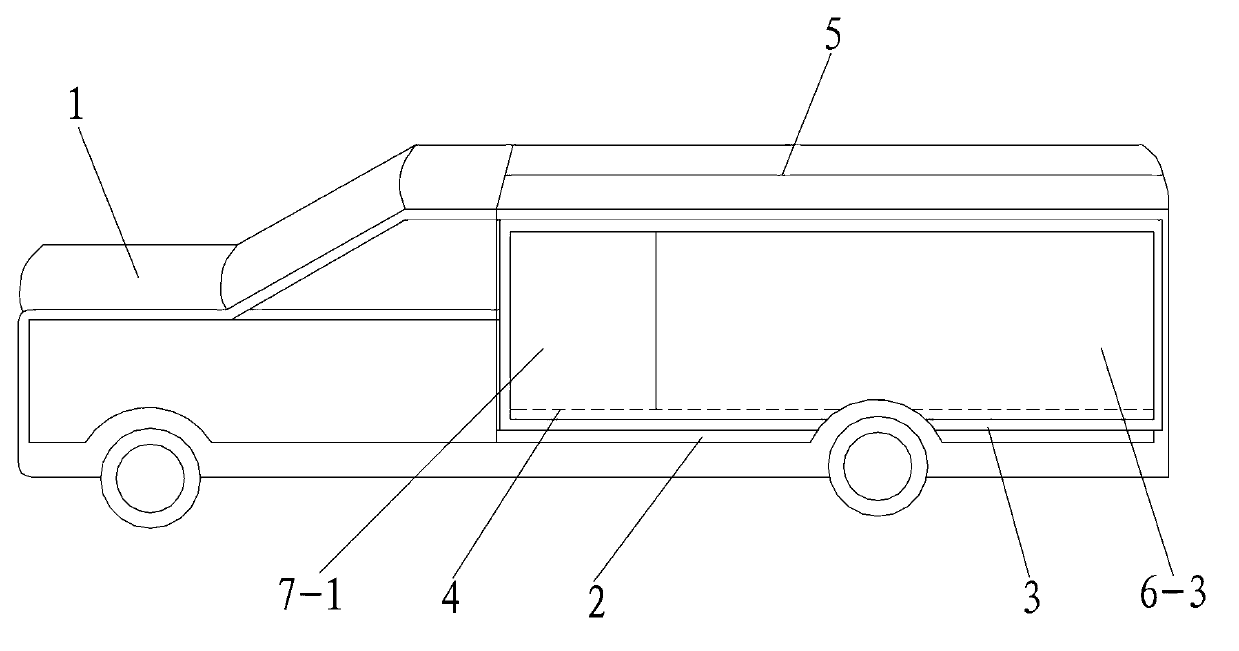

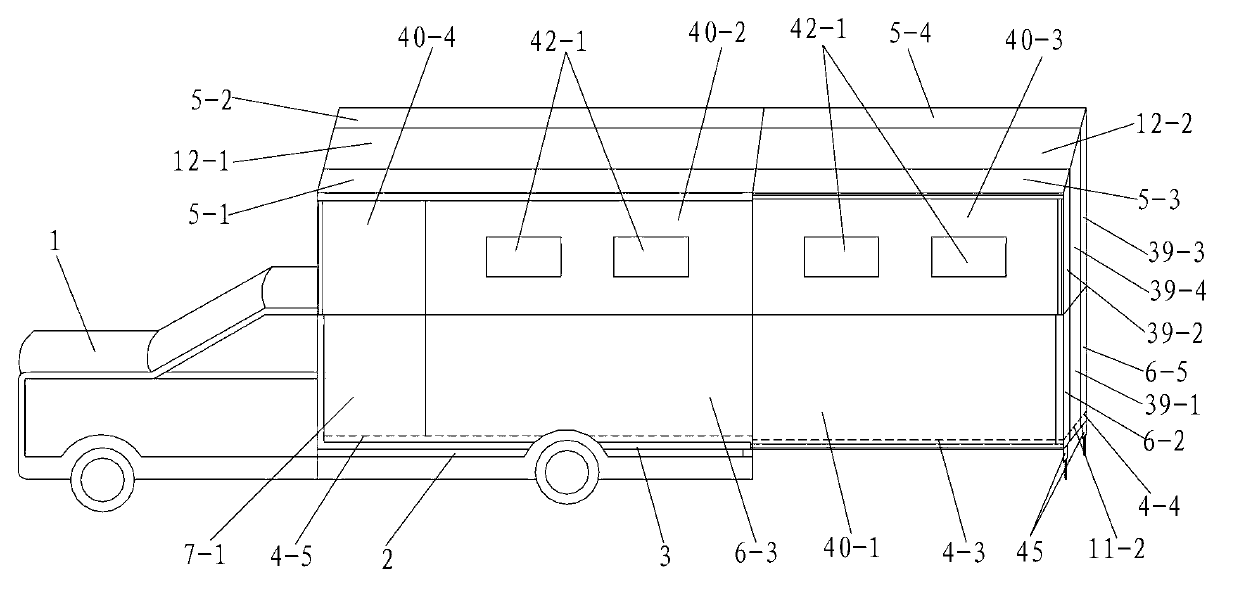

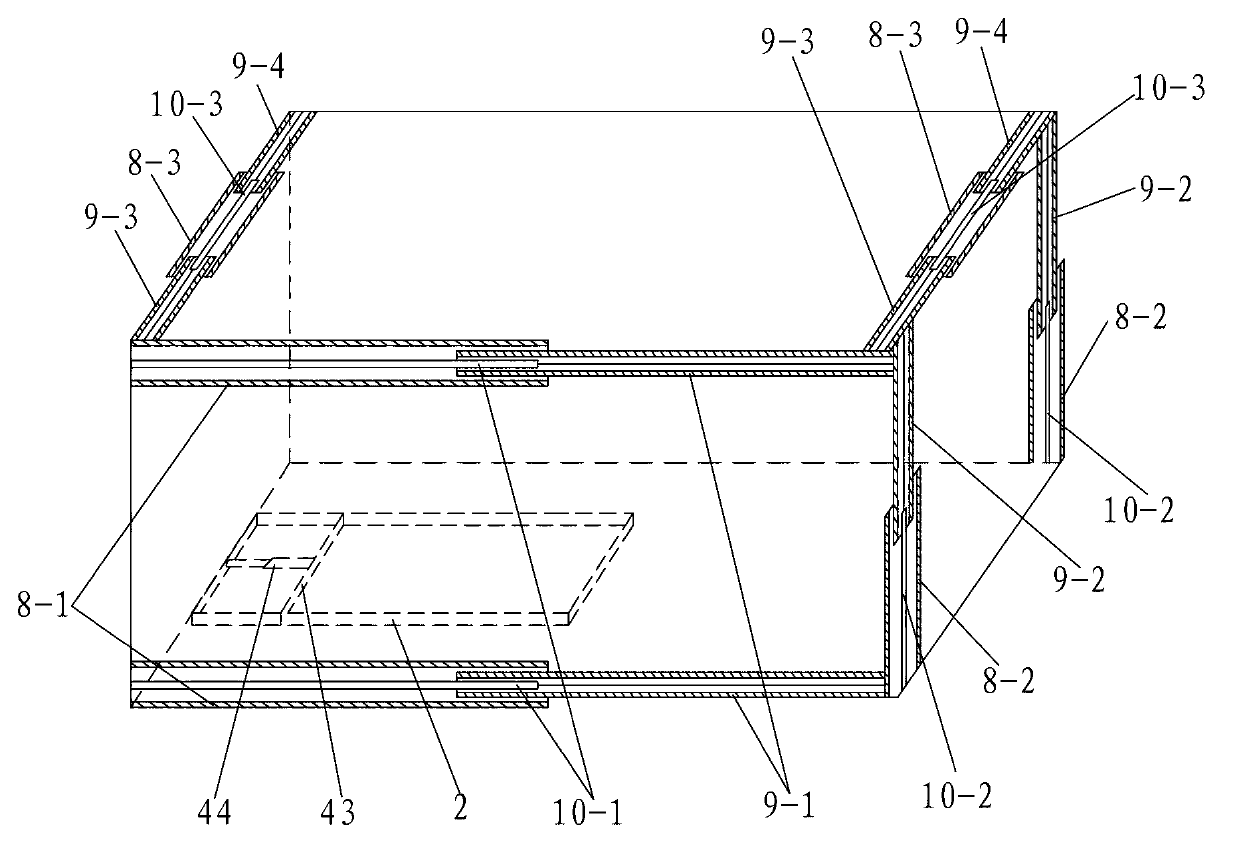

Multifunctional automatic elastic compartment automobile

ActiveCN102991406AImprove adaptabilityCompact structureVehicle with living accommodationItem transportation vehiclesVehicle frameDrivetrain

The invention discloses a multifunctional automatic elastic compartment automobile which comprises an automobile body, an automobile frame and a compartment which is elastic, wherein the elastic compartment comprises an elastic compartment framework connected to the automobile frame, an elastic bottom frame connected to the bottom of the elastic compartment framework, an elastic top cover connected to the top of the elastic compartment framework, a compartment wall connected to the periphery of the elastic compartment framework as well as an elastic mechanism which is connected to the elastic compartment framework, the elastic bottom frame and the elastic top cover; the elastic bottom frame is internally provided with a bottom surface clearance closed device; the elastic top cover is internally provided with a top cover clearance closed device; the compartment wall is provided with a compartment door; an elastic power drive system and a covering mechanism component are placed in the elastic compartment; and the elastic mechanism and the elastic power drive system are connected. The multifunctional automatic elastic compartment automobile provided by the invention is compact in structure, is novel and reasonable in design, has good driving stability, has a large internal space after the compartment unfolds, and has rapid elastic speed of the compartment, high accuracy, high practicability, and high popularization and application value.

Owner:丁伟林

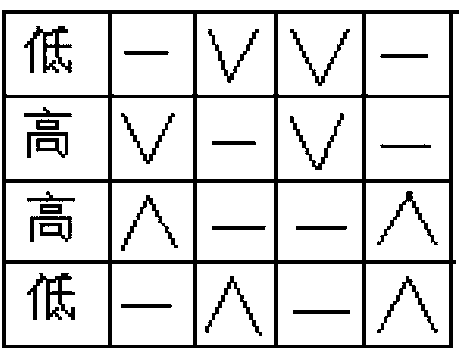

Heating and moisture-absorption shell fabric and production method thereof

InactiveCN102995260AGood warmth retentionWeft knittingHeating/cooling textile fabricsViscoseMoisture absorption

The invention discloses a heating and moisture-absorption shell fabric in the field of textiles. The heating and moisture-absorption shell fabric comprises a lining fabric woven by heating fibers and an outer-layer fabric woven by moisture-absorption fibers, wherein an air layer is formed between the lining fabric and the outer-layer fabric; the heating fabrics are blended by 40% of eks fibers and the balance of acrylic fibers; and the moisture-absorption fibers are blended by 50wt% to 70wt% of viscose and the balance of acrylic fibers. The heating and moisture-absorption shell fabric has the technical effects of having a good warming effect and being light, thin and soft. A production method of the heating and moisture-absorption shell fabric comprises the steps of preparation of the heating fibers, preparation of the moisture-absorption fibers, and weaving of the fibers. The heating and moisture-absorption shell fabric produced by the method has a good warming effect and is light, thin and soft.

Owner:SHANGHAI YANGFAN INDAL CO LTD

Woollen sweater and production thereof

The invention discloses a knitted sweater and the production technology thereof. The raw material of the knitted sweater is yarn blended with spun silk, Modal fiber, milk fiber and cashmere. The weight ratio of the spun silk ranges from 50 to 60 percent, that of the Modal fiber ranges from 20 to 30 percent, that of milk fiber ranges from 10 percent to 15 percent and that of cashmere is between 5 to 15 percent. The production technology for knitted silk comprises (1) selection of raw white yarn, (2) dyeing, (3) rewinding, (4) panel knitting, (5) linking, (6) stitches, (7) hand sewing, (8) rinsing, (9) drying and (10) ironing. The knitted sweater has natural wrinkle resistance, higher hygroscopicity and warmth, and soft handfeel.

Owner:周婉

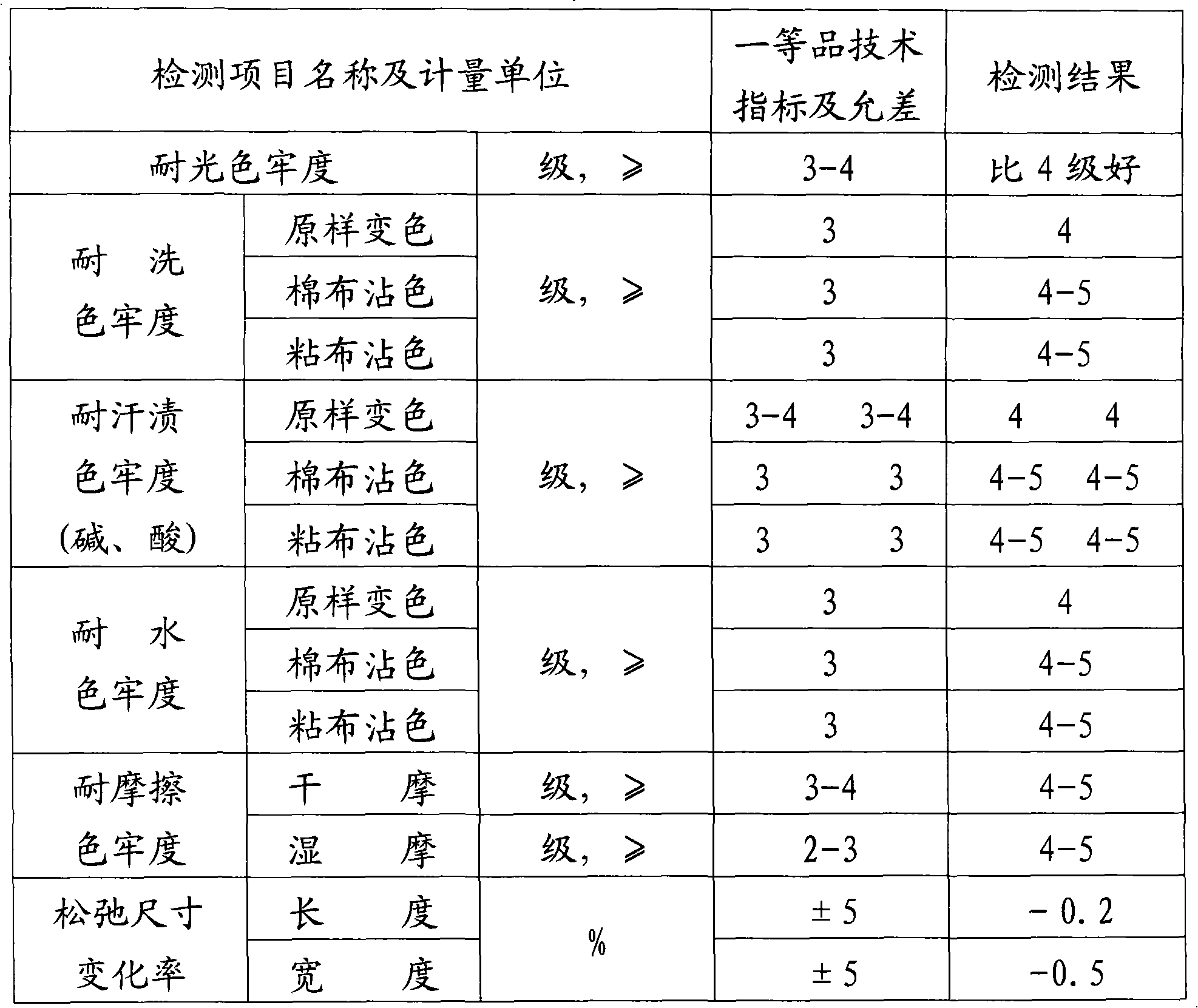

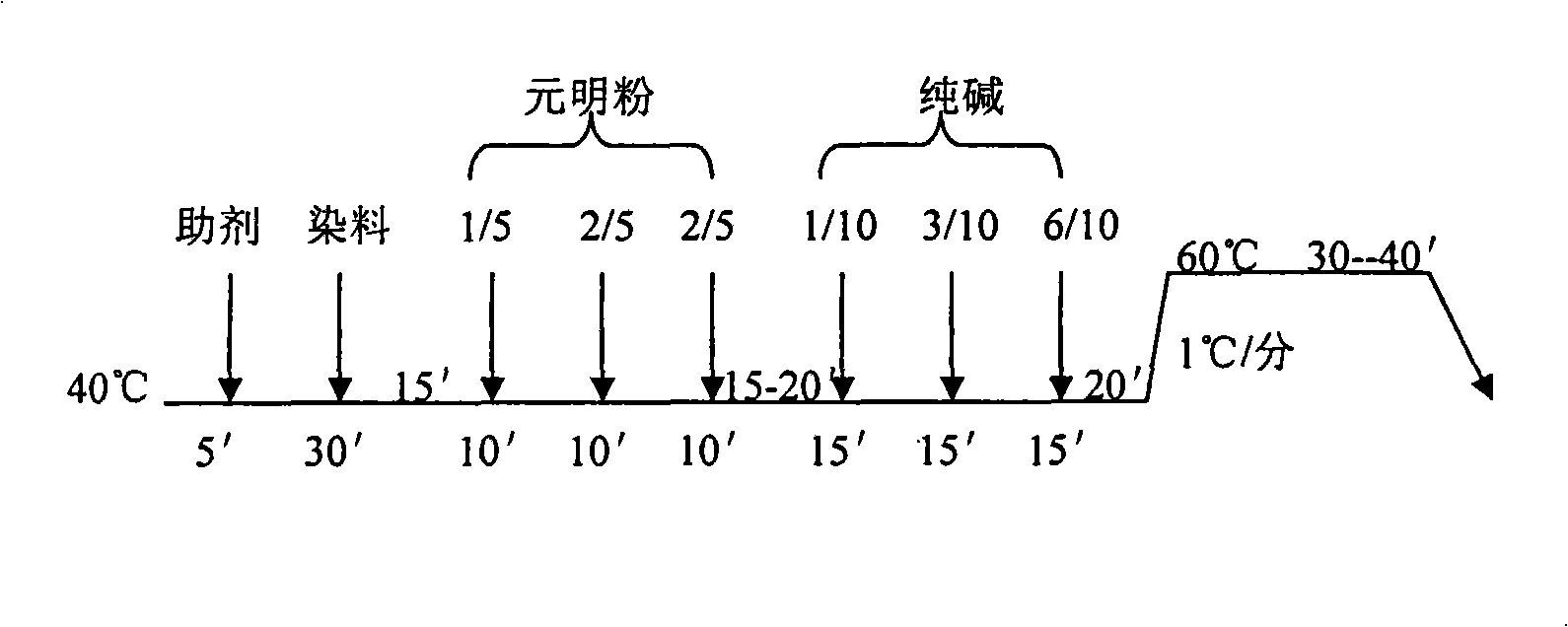

Nursing type mixed fabric and production method thereof

InactiveCN101525803AHas broad-spectrum antibacterial functionStrong persistenceWeft knittingWarp knittingGramNational standard

The invention discloses a nursing type mixed fabric and a production method thereof. The nursing type mixed fabric is characterized by being formed by mixing milk silk fibres, Modal fibres, Newdal fibres and urethane elastic fibres which are taken as raw materials and being counted by raw material percentage by weight, a finished fabric is made of the following raw materials by weight: 10-55 percent of milk silk fibres, 20-50 percent of Modal fibres, 20-60 percent of Newdal fibres and 2-8 percent of urethane elastic fibres, and the gram weight of the finished fabric is 250-300g / M<2>. The nursing type mixed fabric has the aroma of milk silk, good heat preservation and ventilation property, natural skin nursing function and soft, smooth and silky feel. The invention also provides two coloration methods aiming at the nursing type mixed fabric. With the two coloration methods, each dyefastness index reaches or surpasses national standards.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Method for processing coloured foreign fiber burnt-out fabric

InactiveCN101440551AClear patternStrong three-dimensional senseDouble pile fabrics splittingPattern makingEngineeringBurning out

The invention provides a method for processing color foreign fiber burnt-out fabric. The method comprises the following steps: material selection; first weaving; pile cutting; rinsing; pre-drying; burnt-out print; water washing, softening and dewatering; drying; scalding-shearing; and tailoring. The method is characterized in that: the material selection comprises the selection of covering weave material and the selection of ground weave material; and, the covering weave material is frame spinning purified cotton yarn or viscose glue cotton blended yarn, and the ground weave material is colored terylene filament, wherein the colored terylene filament is 23 to 40 mass percent, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is 60 to 77 mass percent. The method has the advantages that: because the colored terylene filament is selected as the ground weave, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is selected as the covering weave, after burnt-out print, the fabrics can achieve the effects of clear pattern, reasonable three dimensional appeal and dusky gentleness; moreover, the fabrics also have good softness and ideal heat insulating ability.

Owner:CHANGSHU SHENHUA KNITTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com