Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

315 results about "Single fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet type nonwoven fabric and filter

ActiveUS20100133173A1Suitable for collectionLayered productsSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceSingle fiber

The present invention is a wet type nonwoven fabric that includes two or more kinds of fibers, wherein the wet type nonwoven fabric includes a short fiber A that is constituted of a fiber-forming thermoplastic polymer and has a fiber diameter D of from 100 to 1000 nm and the ratio of a fiber length L to the fiber diameter D, L / D, in the range of from 100 to 2500 in from 4 to 50% by weight relative to the total weight of the nonwoven fabric, and a binder fiber B that has a single fiber fineness of 0.1 dtex or less in from 10 to 50% by weight relative to the total weight of the nonwoven fabric.

Owner:TEIJIN FRONTIER CO LTD

Electrode to Nerve Distance Estimation

ActiveUS20180110987A1Promote resultsComplicate to effectElectrotherapyArtificial respirationEvoked compound action potentialMedicine

Estimating a nerve-to-electrode distance involves applying a stimulus from a stimulus electrode to a nerve. Neural measurements of at least one evoked compound action potential are obtained, and processed in order to estimate an originating state of stimulation exhibiting at least one characteristic defined by a single fibre size. A single fibre model is then applied to produce a measure of the nerve-to-electrode distance. Also provided for is estimation of a distribution of recruited fibres. Measurements of a compound action potential are obtained from sense electrodes spaced apart along a neural pathway. A conduction velocity of the compound action potential is determined from the latency between the measurements. From the conduction velocity a dominant recruited fibre diameter is determined. A rate of dispersion of the compound action potential between the sense electrodes is determined. From the rate of dispersion a distribution of diameters of the recruited fibre population is determined.

Owner:SALUDA MEDICAL

Address identifier scaling in converged networks

ActiveUS20100115132A1Multiple digital computer combinationsNetwork connectionsVirtualizationSingle fibre

Embodiments of the present invention allow for address scaling of existing addresses in a FC, FCoE, CEE or other type of network. More specifically, subaddresses can be used in conjunction with existing addresses, so that a combination of a subaddress and existing address can identify an addressable entity. Thus, multiple entities can be share a single existing address and be distinguished among each other by way of their respective subaddresses. Some embodiments of the invention allow for use of the inventive subaddressing scheme in conjunction with devices or network elements (e.g., gateways, switches, etc.) that may not be subaddressing aware. Further embodiments allow for the multiple distinct devices to communicate with a single Fibre Channel switching element through a single port by using N_Port_ID Virtualization.

Owner:AVAGO TECH INT SALES PTE LTD

Carbon fiber reinforced resin composition, molding compounds and molded products therefrom

InactiveUS6998434B2Promote resultsMaterial nanotechnologySynthetic resin layered productsPolymer scienceCarbon fibers

The present invention relates to carbon fiber reinforced resin compositions comprising the following essential components (A), (B) and (C), and to molding compounds and molded products made by processing and molding the carbon fiber reinforced resin composition; Component (A): 0.01 to 0.7% by weight of vapor grown carbon fiber and / or nanotubes based on 100% by weight of the carbon fiber reinforced resin composition, of which the average diameter of single fiber ranges from 1 to 45 nm; Component (B): 6 to 40% by weight of carbon fiber based on 100% by weight of the carbon fiber reinforced resin composition, of which the average diameter of single fiber ranges from 1 to 20 μm; and Component (C): resin. The present invention provides carbon fiber reinforced resin composition, molding compounds and molded products therefrom, having good conductivity, mechanical properties and moldability by the above constitution.

Owner:TORAY IND INC

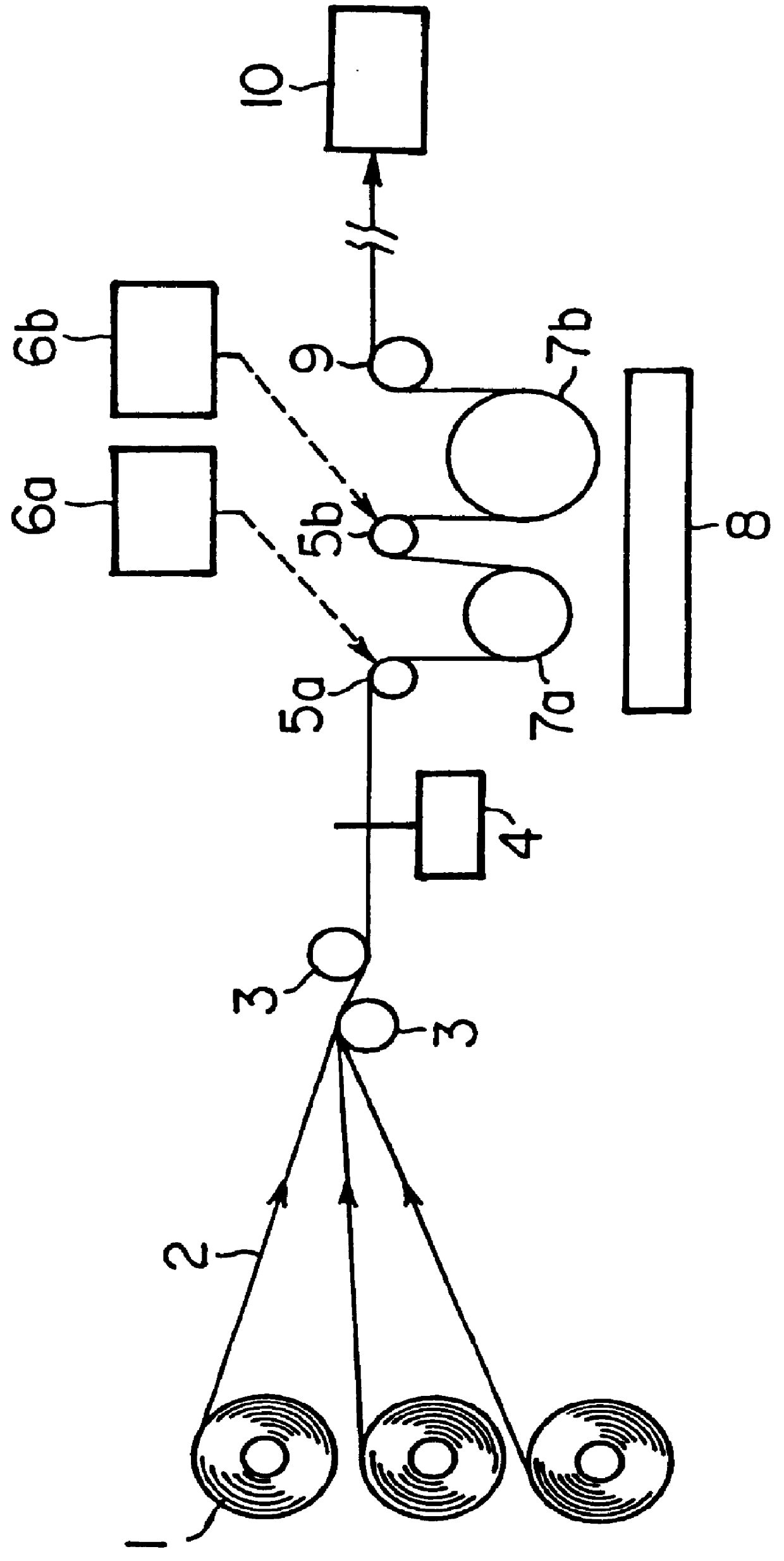

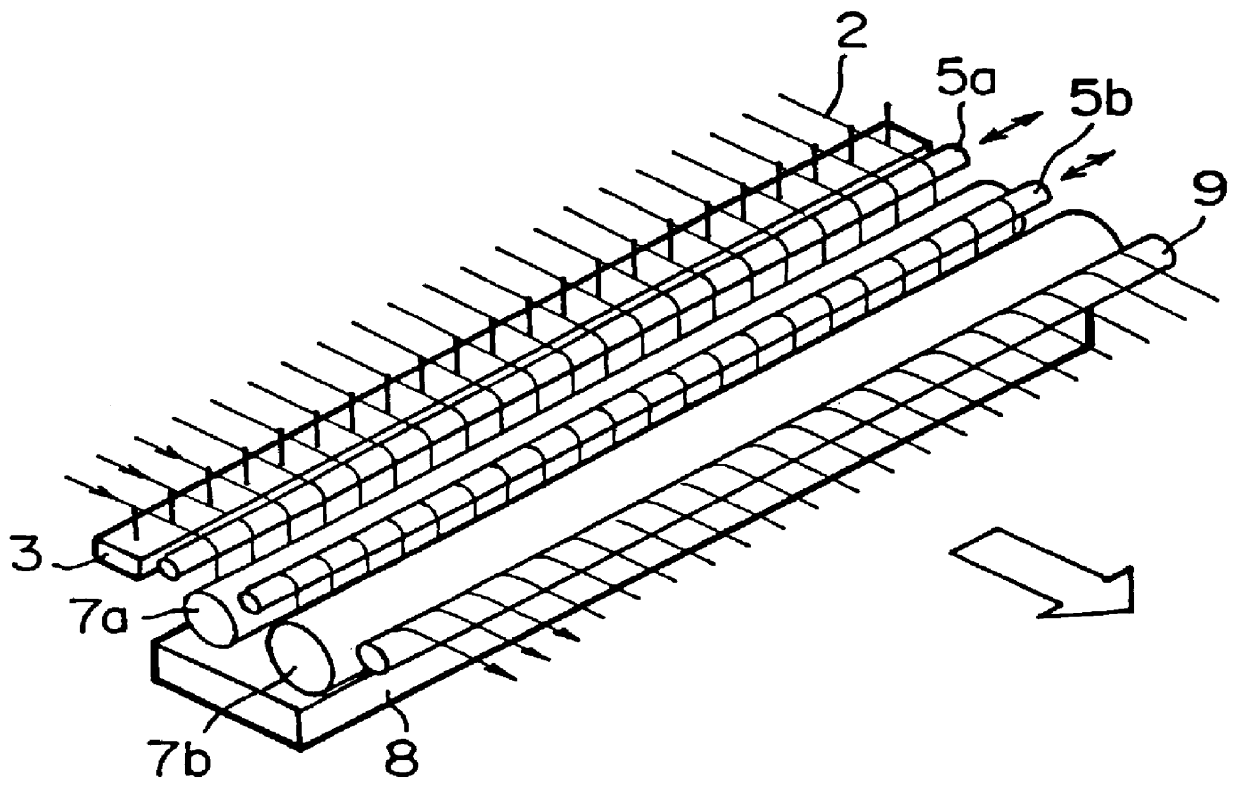

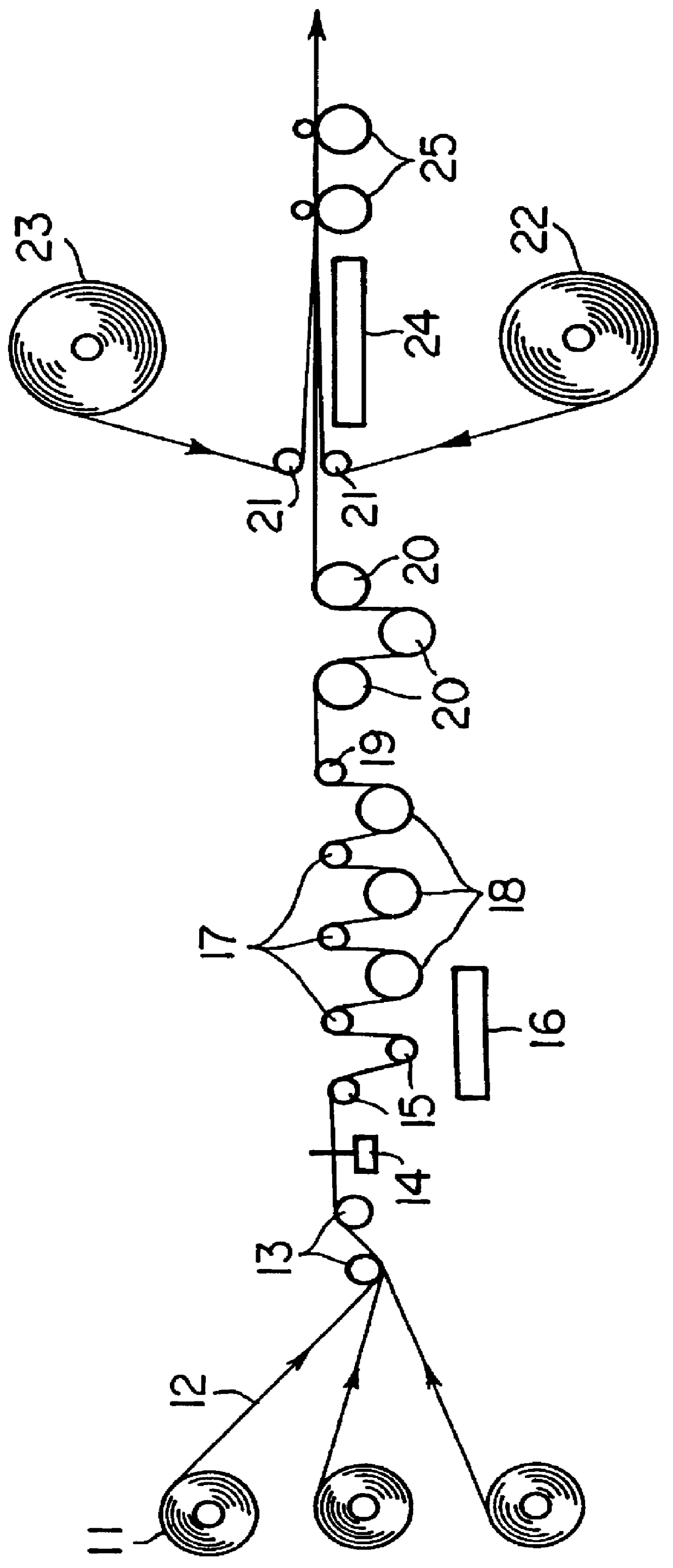

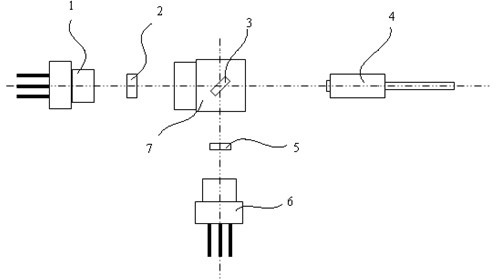

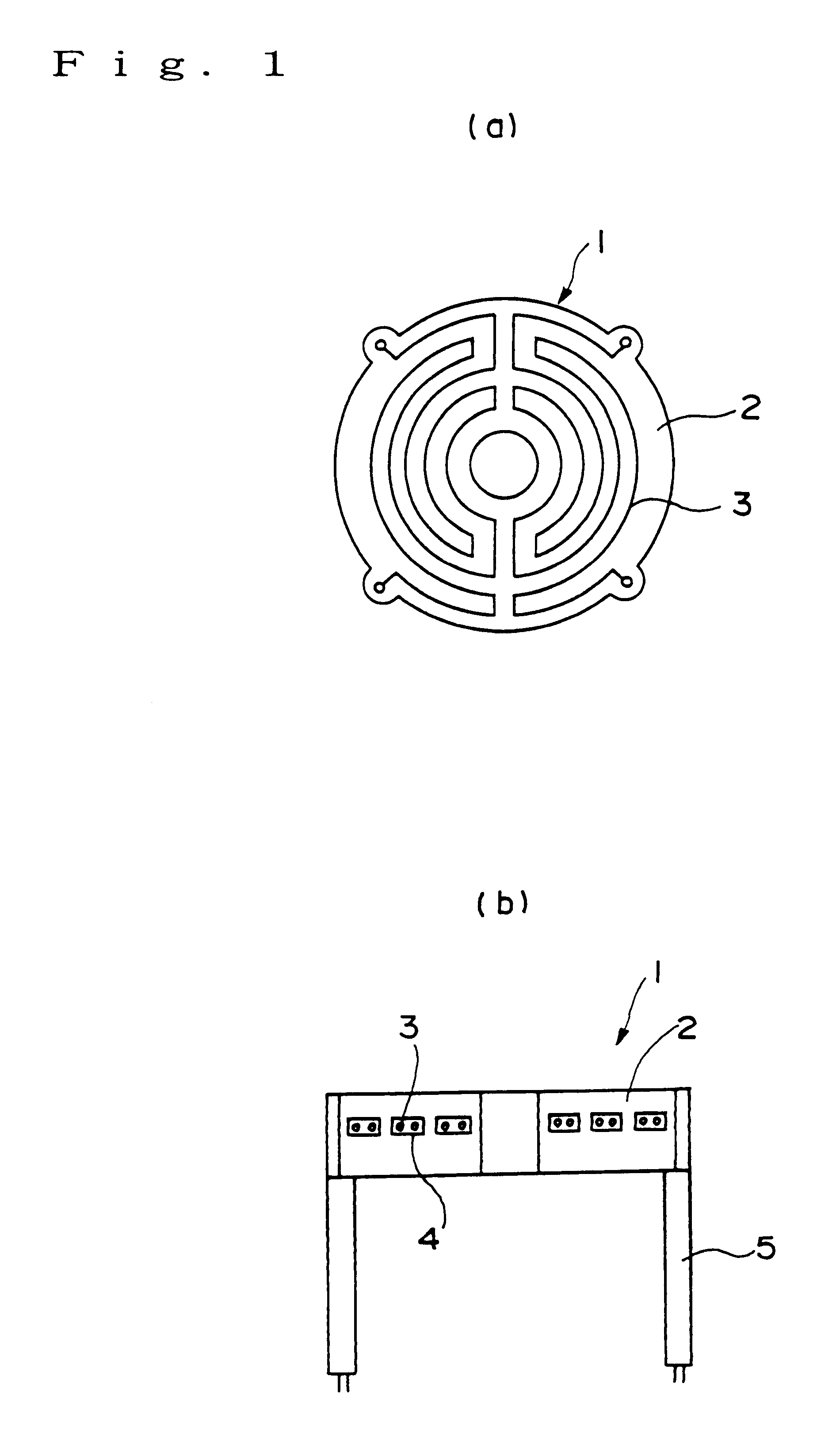

Method and apparatus for opening reinforcing fiber bundle and method of manufacturing prepreg

PCT No. PCT / JP97 / 04541 Sec. 371 Date Dec. 18, 1998 Sec. 102(e) Date Dec. 18, 1998 PCT Filed Dec. 10, 1997 PCT Pub. No. WO98 / 45515 PCT Pub. Date Oct. 15, 1998The present invention provides a method and apparatus, in which a reinforcing fiber bundle consisting of a plurality of paralleled single fibers is or a plurality of mutually paralleled reinforcing fiber bundles respectively consisting of a plurality of paralleled single fibers are driven to run through a plurality of rolls while being bent to open the fiber, and in which the opened reinforcing fiber bundle is impregnated with resin to produce a prepreg, comprising vibrating at least one of the rolls in the axial direction of the roll, to open the reinforcing fiber bundle(s), pressing the reinforcing fiber bundle(s) to the peripheral surface of a roll located immediately downstream of the vibrating roll without vibrating the roll, and bringing the opened reinforcing fiber bundle(s) into contact with the peripheral surface of the non-vibrating roll with a contact length of not less than twice the contact length of the reinforcing fiber bundle(s) on the vibrating roll, for retaining the opened state of the reinforcing fiber bundle(s). The present invention allows the reinforcing fiber bundle(s) to be opened stably with little fuzzing caused, for producing a uniform and thin reinforcing fiber sheet, and from the uniform and thin reinforcing fiber sheet, a uniform and thin crack-less prepreg with a good grade can be obtained.

Owner:TORAY IND INC

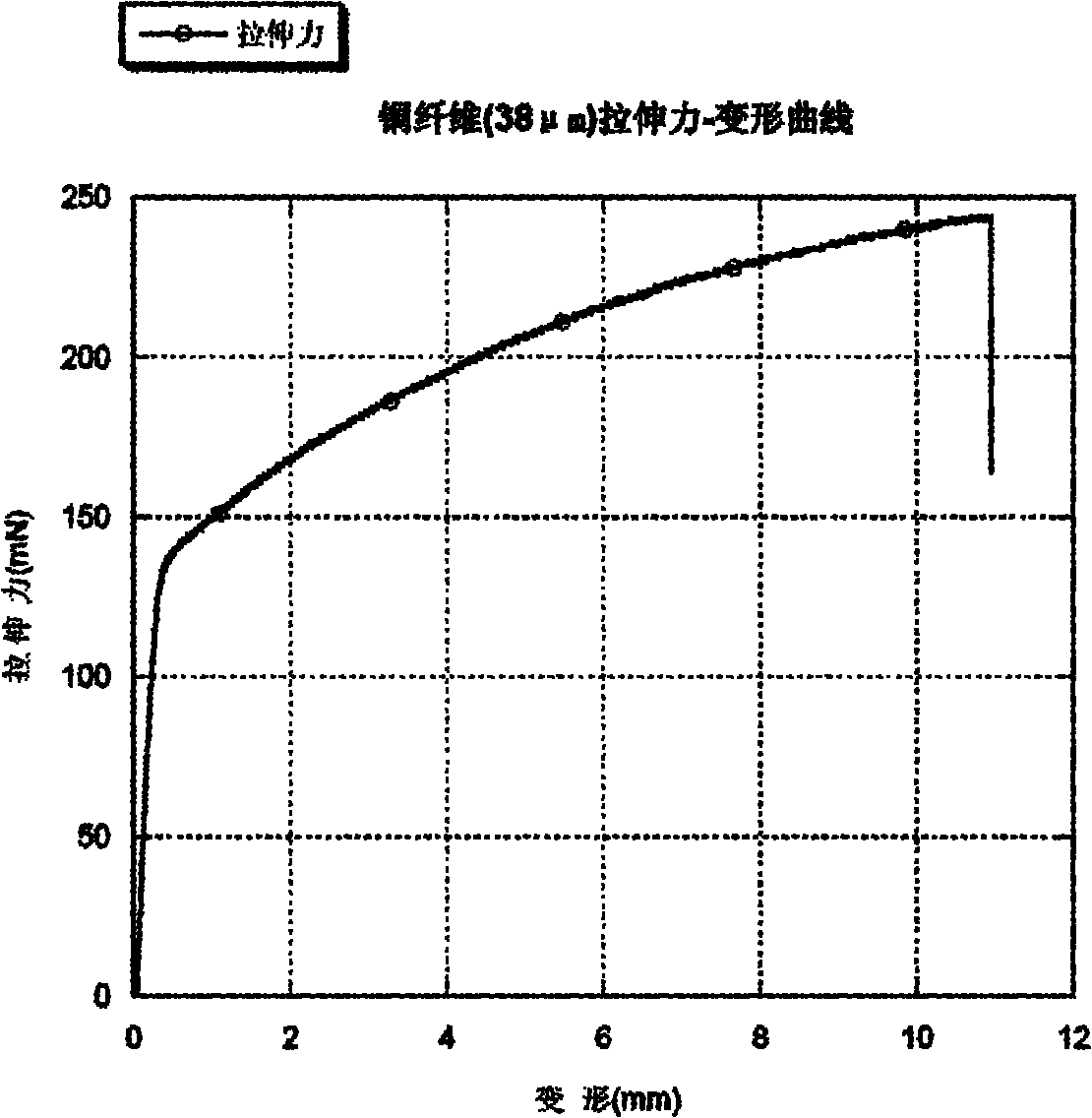

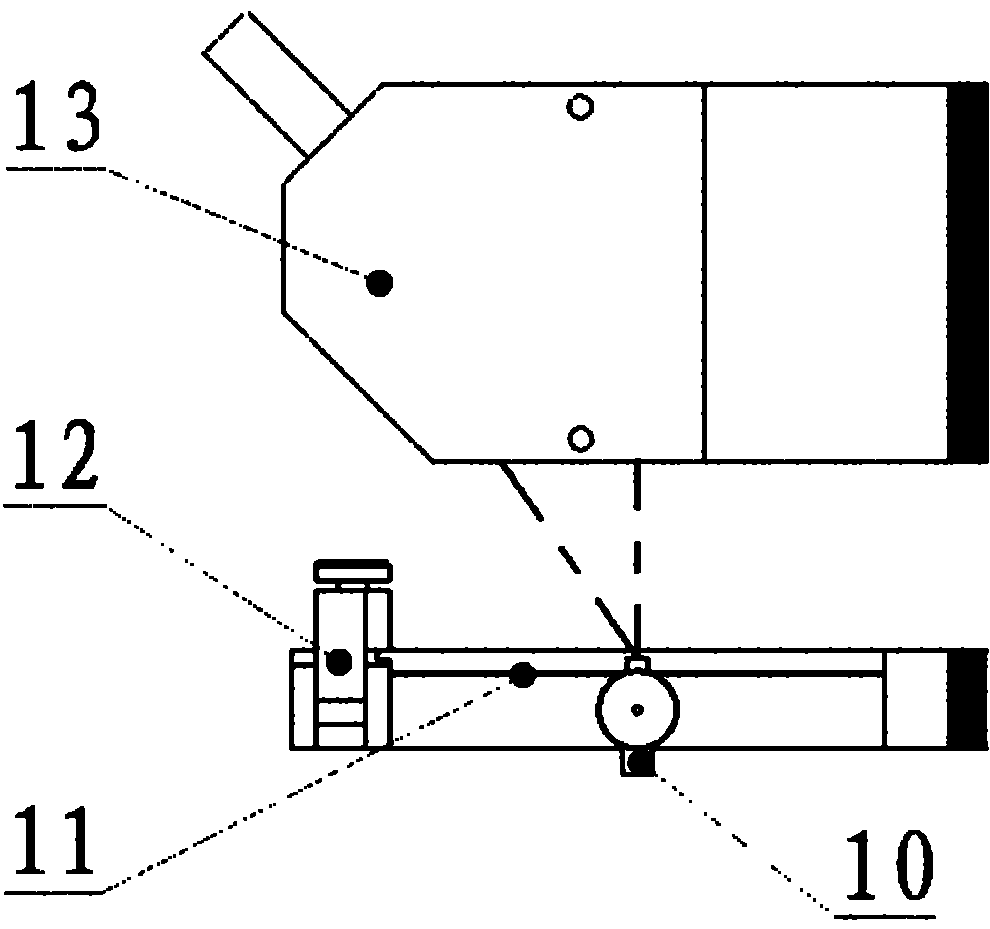

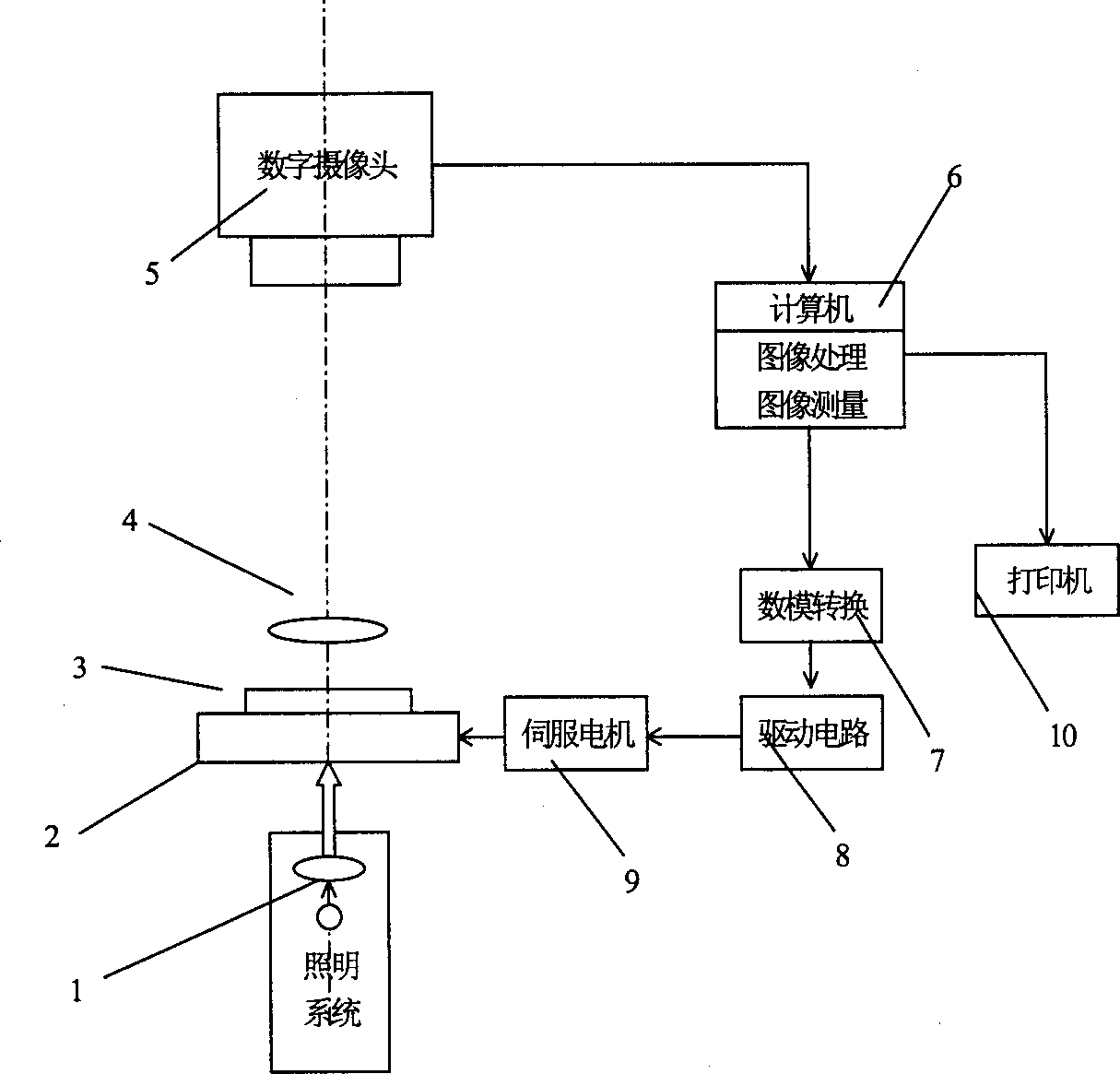

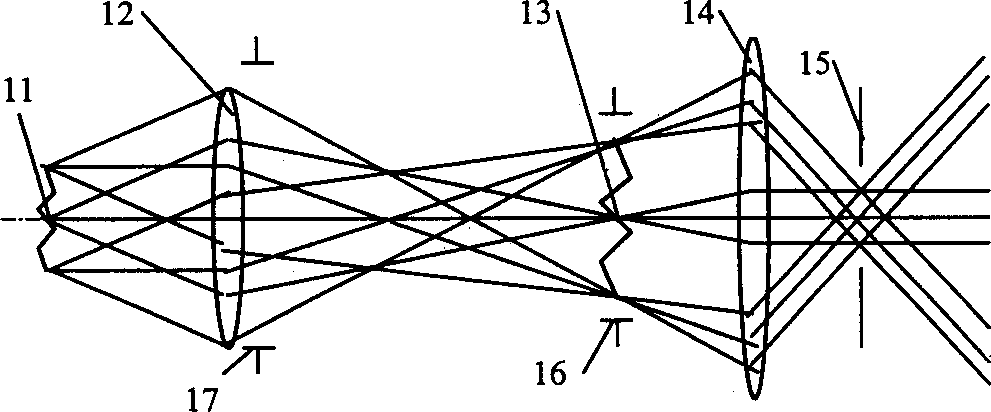

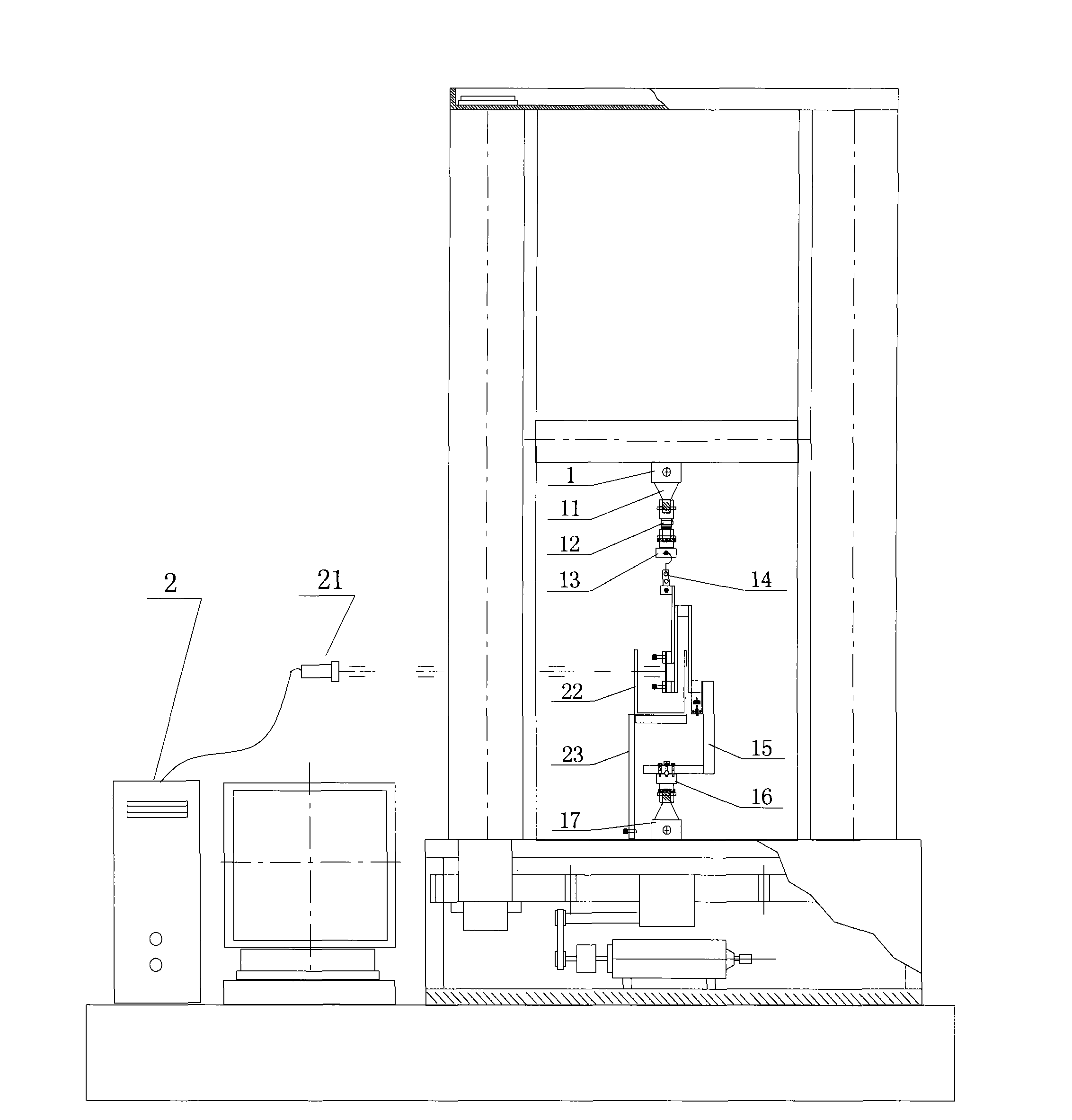

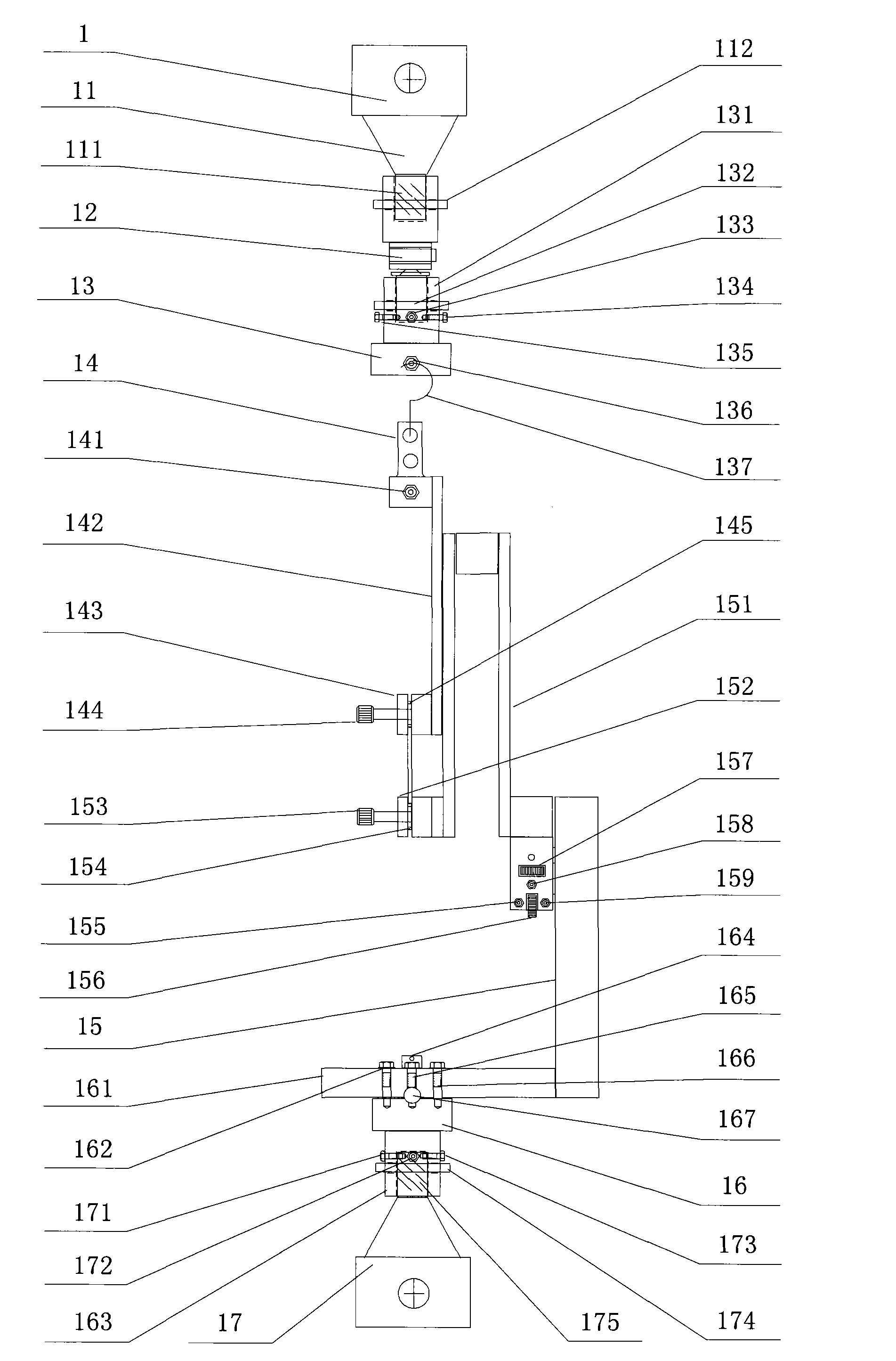

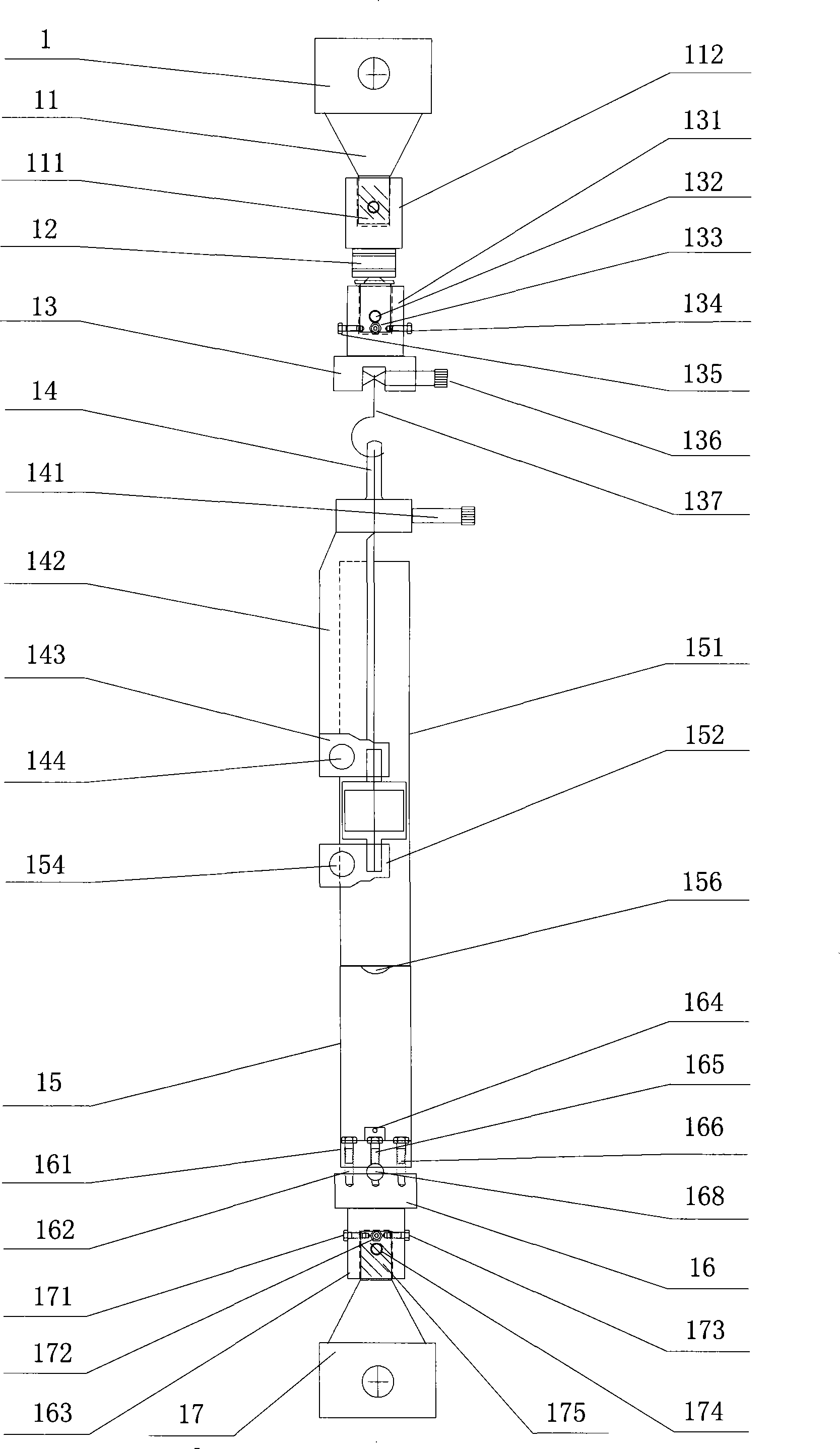

Method and device for testing micro-tensile mechanical properties of metal fiber

ActiveCN101949797AAdjust the measuring rangeAdjust measurement sensitivityMaterial strength using tensile/compressive forcesUsing optical meansTest sampleStress–strain curve

The invention discloses a method and a device for testing micro-tensile mechanical properties of a metal fiber. Being different from the existing tensile tester, the invention is characterized in that a force transducer is composed of a non-contact photoelectric displacement transducer and an elastic element, the force transducer can be used for measuring both the tensile force of a fiber and the displacement of the gripped end of the fiber and helping automatically and accurately obtain the tensile force-deformation curve of a test sample in real time so as to obtain the stress-strain curve of the test sample, and parameter values characterizing the micro-tensile mechanical properties of the metal fiber can be obtained by analyzing the stress-strain curve. By using the optical non-contact measurement method, the invention avoids the interference generated by the traditional contact measurement, and enables the measuring system to be more stable. Besides, the whole device has the advantages of ingenious structure, simple and convenient operation and stable performance, thereby being applicable to testing the micro-tensile mechanical properties of various single fibers (especially metal fibers).

Owner:HUAZHONG UNIV OF SCI & TECH

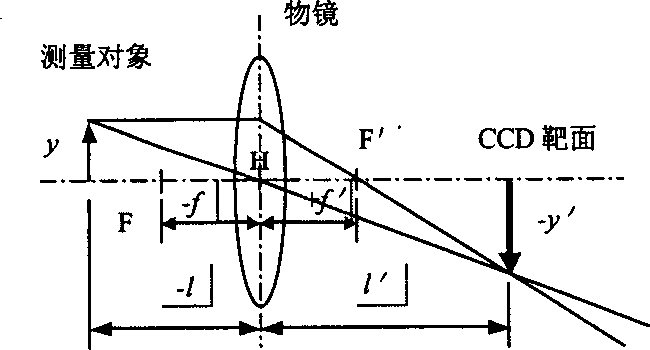

Method and system for measuring wool fiber fineness measurement

InactiveCN1359006AMany measurement parametersReliable resultsMaterial analysis by optical meansContinuous measurementSingle fibre

The present invention relates to a method for measuring wool fibre fineness and its system. Digital camera head (CCD) is adopted to convert the amplified fibre image into digital image, and transfer it into computer to mare real time processing to obtain fibre outline and calculate single fibre fineness, then it counts up the data of average fineness and fineness distribution of all the measured fibres. In said ivnention, general light source is used and the proper alogirhtm and software are designed with can measure animal fibre with the measurement range of 4-300 micrometers, and its measurement speed is 140 fibre / sec.

Owner:TSINGHUA UNIV

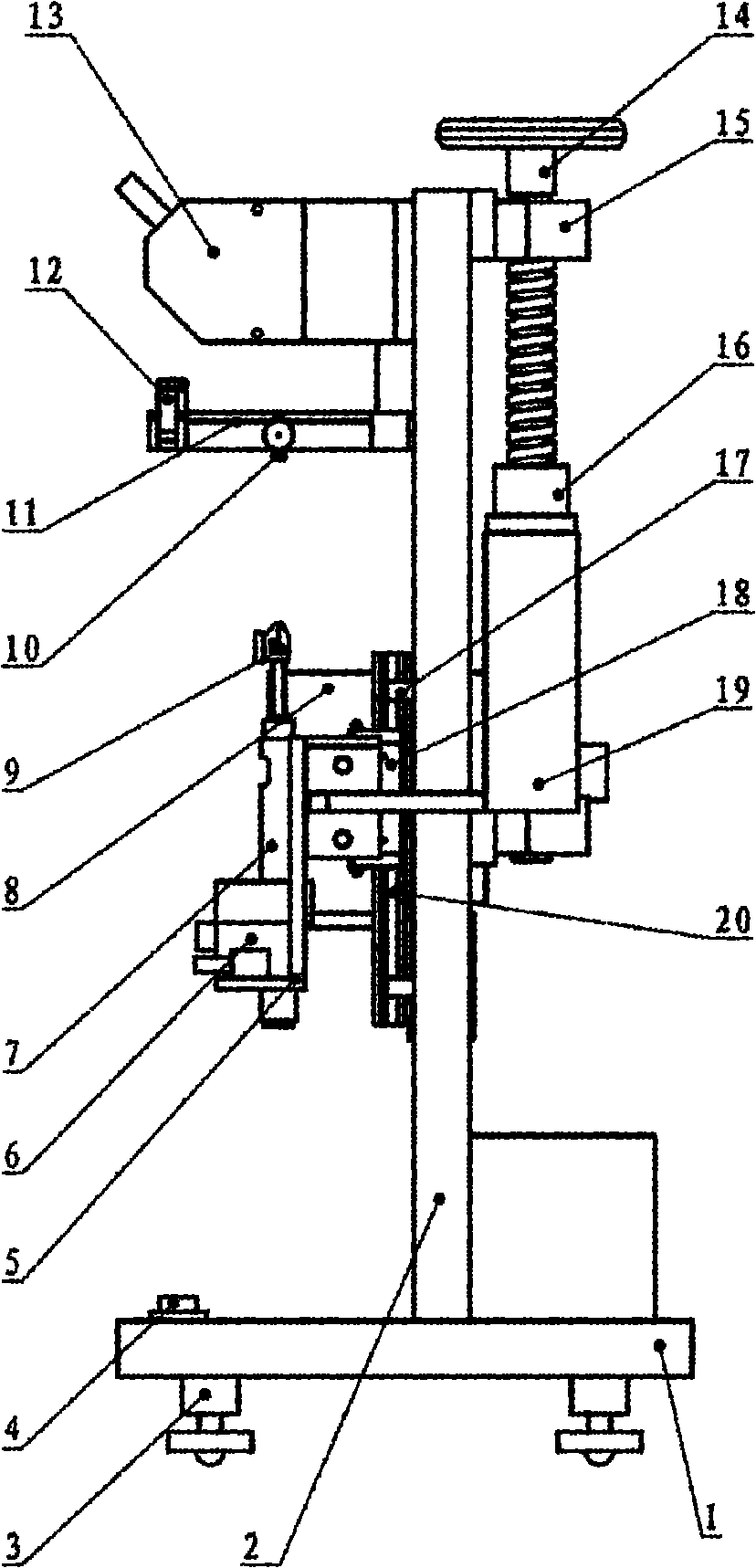

Testing machinery cellfiber clamper and method for measuring tensile strength

InactiveCN101251455AGuaranteed verticalityThe strain value is scientific and accurateMaterial strength using tensile/compressive forcesSingle fibreEngineering

The invention provides a tester single fibre clamp and a tensile strength measuring method relating to a clamp and tensile strength measurement. The invention provides a tester single fibre clamp and a method for measuring the tensile strength of ceramic single fibre. The clamp is provided with an upper collet device of a tester, a load sensor, a tenaculum device, an upper and lower clamping device, a horizontal adjusting device and a lower collet device of the tester. The adjusting clamp in proper alignment measures the load linearity in vertical direction and rectifies the focus of a photoelectric extensometer; the parameters of an measuring program are set; single fibre is put on the centerline of a hole of a square paper frame, then placed in the middle of the upper and lower clamping device; the vertical direction of the single-fibre is adjusted; the edge of the square paper frame is burned off; a strain collecting device is started to trace the edge distance between the upper and the lower paper frames; a tensile program is started up to begin the measurement; the relation between the load and the strain is recorded to obtain a fibre fracture load value and deformation data, thereby measuring a fibre strain value; a diameter value of a fracture is observed and input to the tester in order to acquire the fracture strength of the single fiber.

Owner:XIAMEN UNIV

Water-soluble polyalcohol, polyisocyanic acid ester and stalk fibrous composite material and preparation thereof

InactiveCN101234505AHigh bonding strengthImprove fracture toughnessFlat articlesDomestic articlesWater basedPolymer science

The invention relates to a composite material of water-based polymer, polyisocyanate and straw fiber and a manufacturing method thereof. The composition and quality percentage of the composite material are as follows: 83.0-90 percent of straw fiber, 9.0-14 percent of water-based polymer, 0.5-2.0 percent of polyisocyanate cross linker, and 0.5-1.0 percent of inorganic filler. The specific preparation method is as follows: processing of straw fiber, formulation of water-based polymer main glue, successively spraying of the main glue and isocyanate cross linker, pavement of gum fiber, precompression under a normal temperature, and hot-pressing solidification and molding, and ultimately the water-based polymer-polyisocyanate-straw fiber composite material is manufactured. The sheet manufactured by the method has the advantages that not only high adhesive strength, fracture toughness, and water-proof property are possessed, but the technique is simple; the production cost of the fiberboard is lower; a good market prospect is acquired.

Owner:南通双弘制线有限公司

Raschel blanket and production method thereof

InactiveCN101476209AReduce weaving costIncrease productivityWarp knittingHeating/cooling textile fabricsYarnSingle fibre

The invention provides a raschel carpet and a producing method thereof which relates to a raschel carpet produced by a single neilbed tricot machine that terylene is used as raw material. The method includes steps as follows: using 83-333dtex terylene low elastic net yarn as a felted yarn raw material and 56-111dtex terylene FDY as a bottom yarn for knitting on a weft knitting fur machine, thermal finalization; fluffing on front; terylene dyeing or printing; post treatment and front lustre finishing; shearing; reverse surface fluffing; and thermal finalization. The carpet is knitted by using the single neilbed tricot machine and the produced grey cloth needs not slitting that lead to increase productive efficiency greatly and reduce knitting cost. The felted head yarn of the knitted grey cloth is an extensive yarn, fibre in the yarn is fully washed into single fibre state in post treatment. The carpet provided by the invention has characteristics of super soft, filling power, better warmth retention property and exquisite style.

Owner:TAICANG SHUMEITE TEXTILE

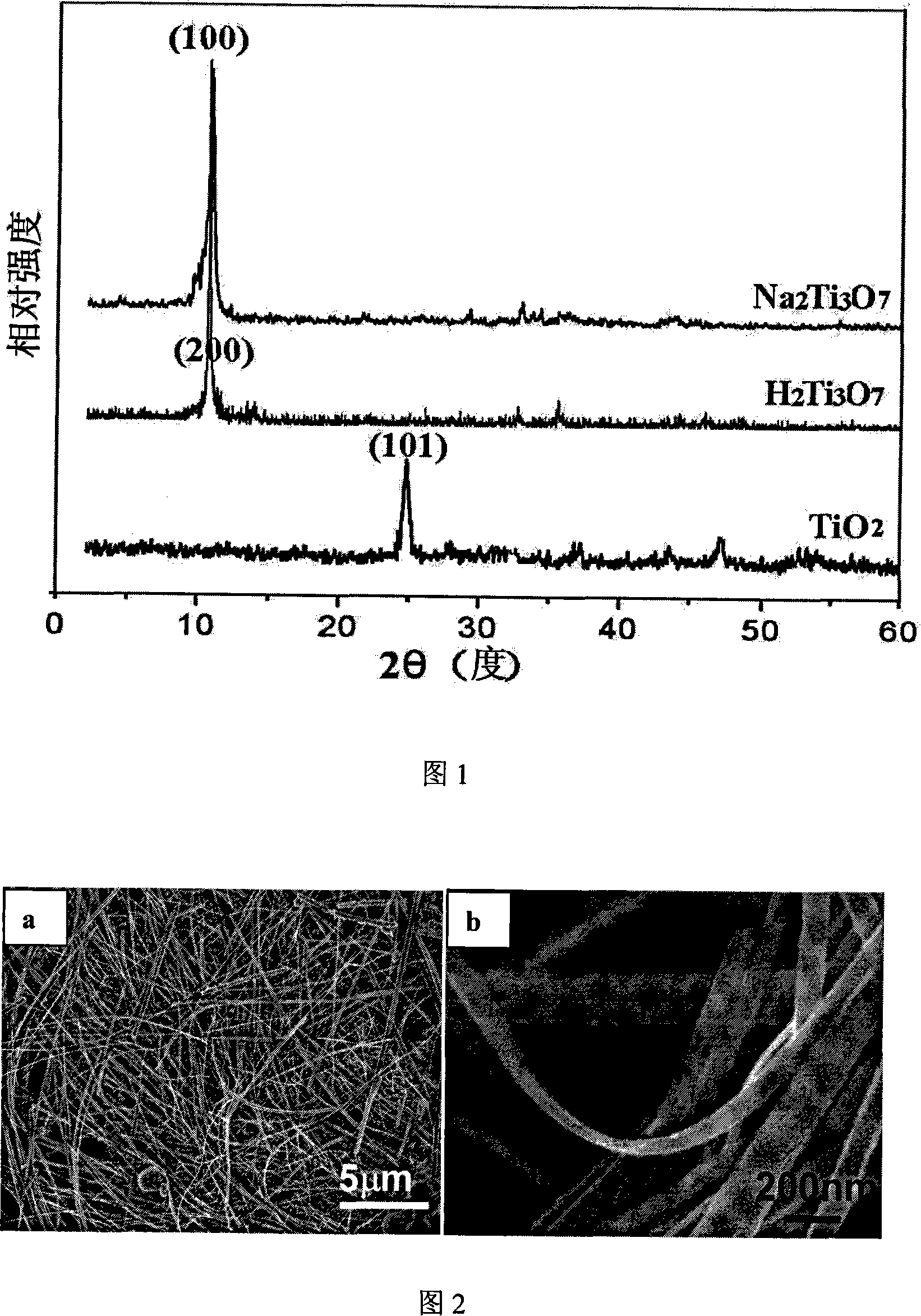

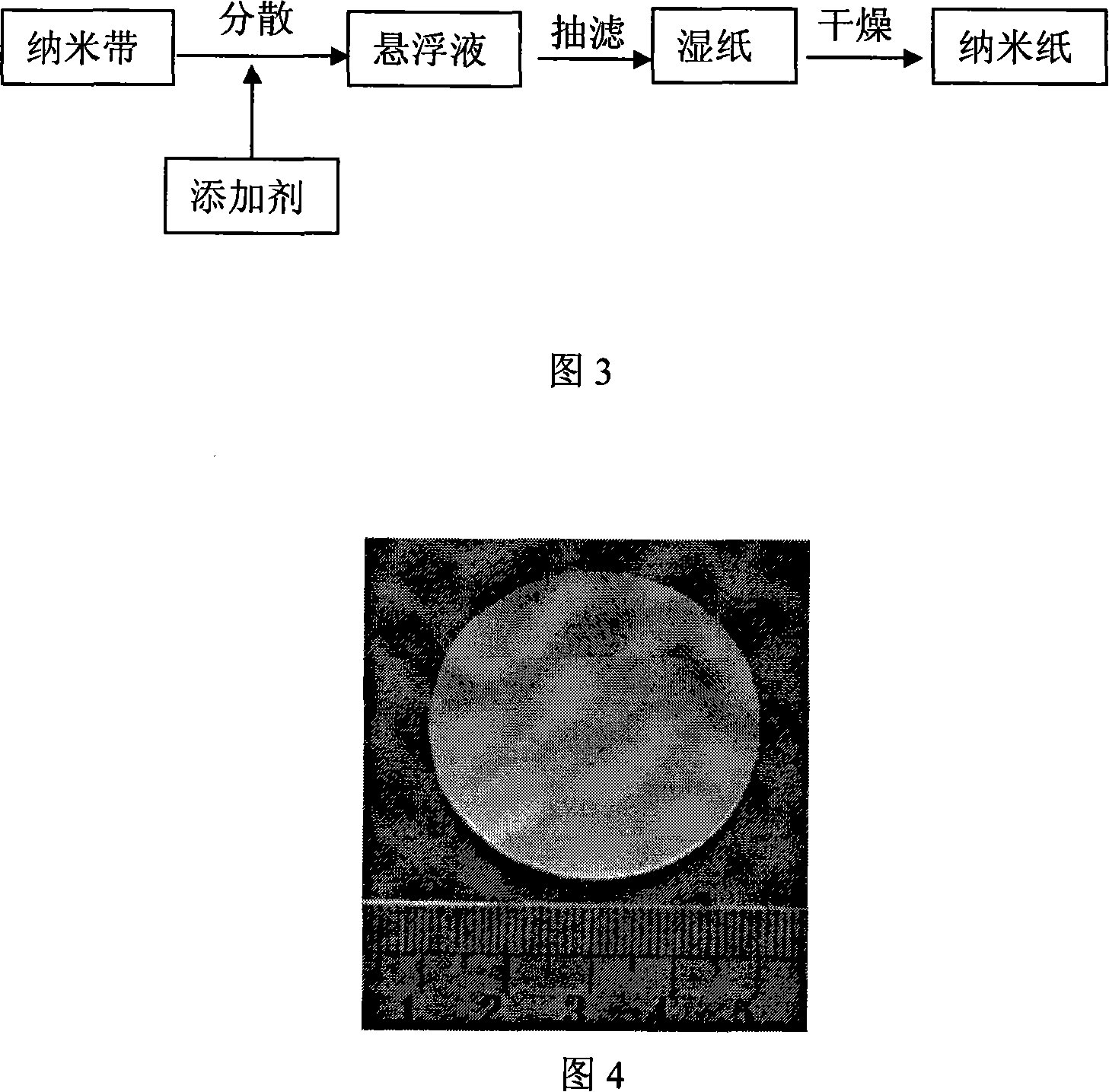

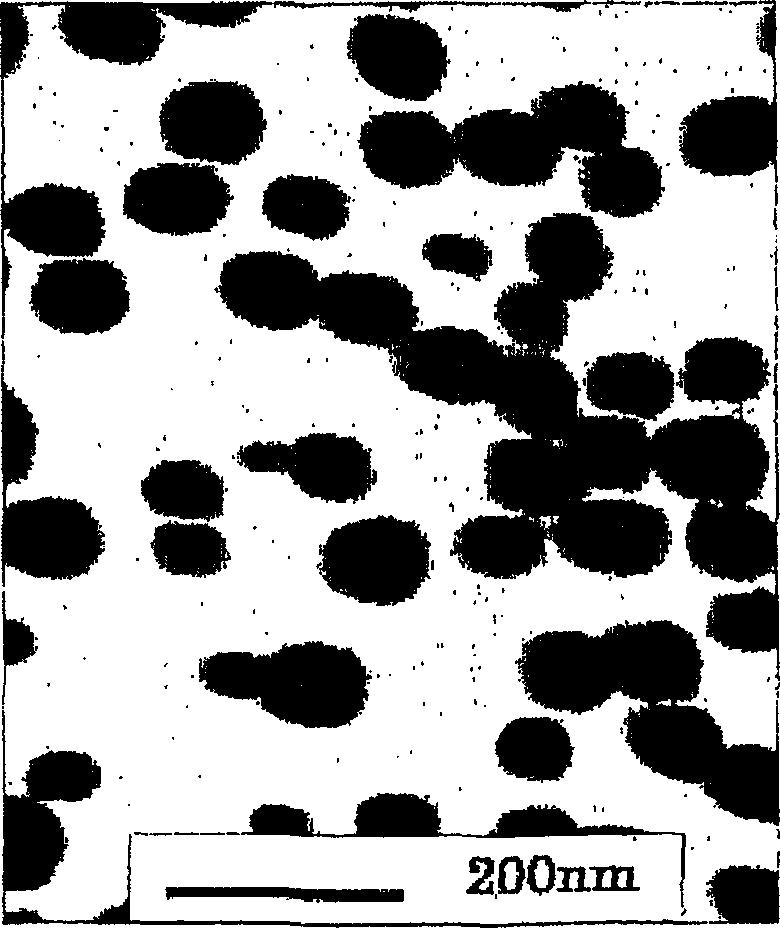

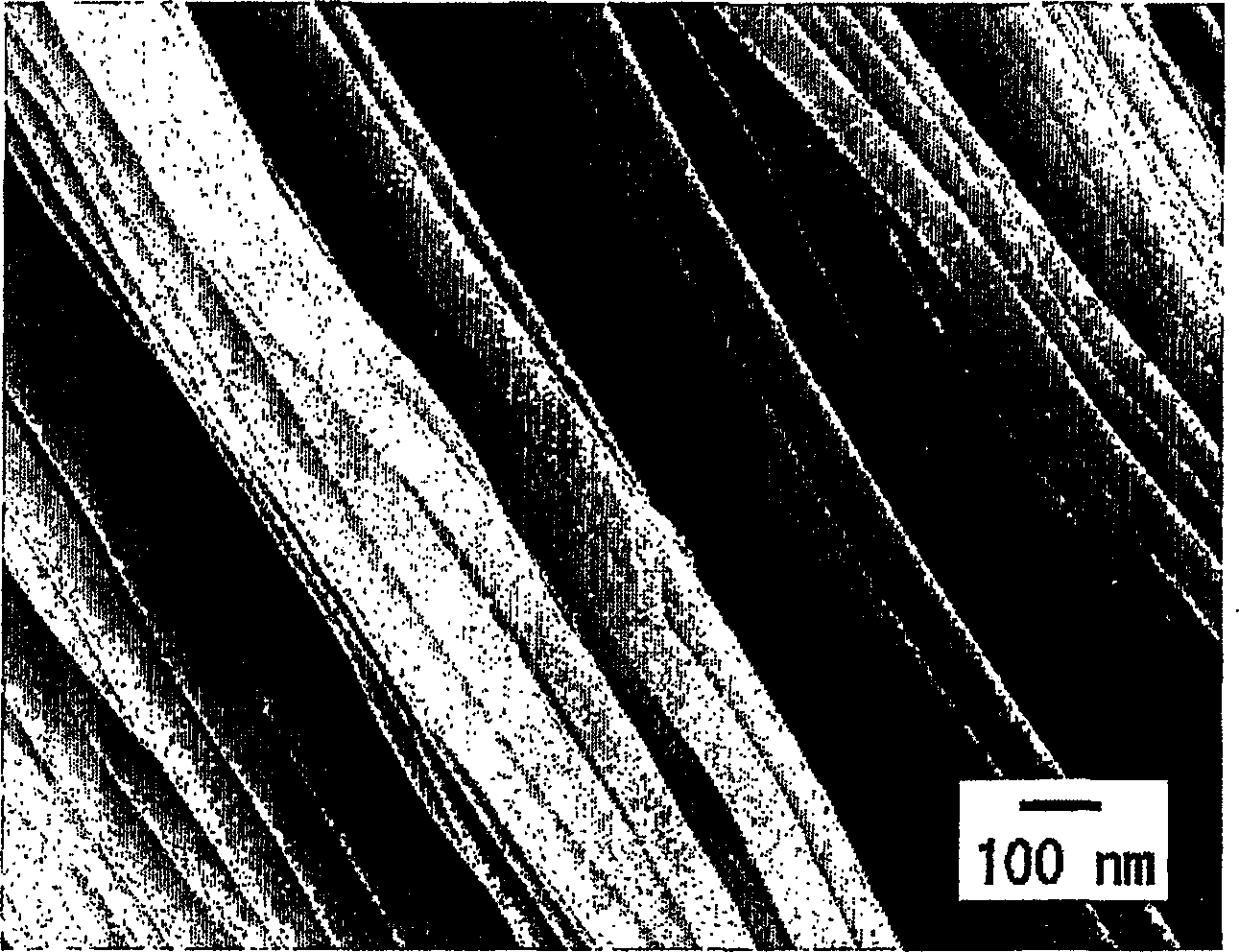

Titanium dioxide nano paper and preparation method thereof

InactiveCN101126213ALess fiberUniform pore sizeSpecial paperReinforcing agents additionPhotocatalysisTitanium dioxide

Owner:SHANDONG UNIV

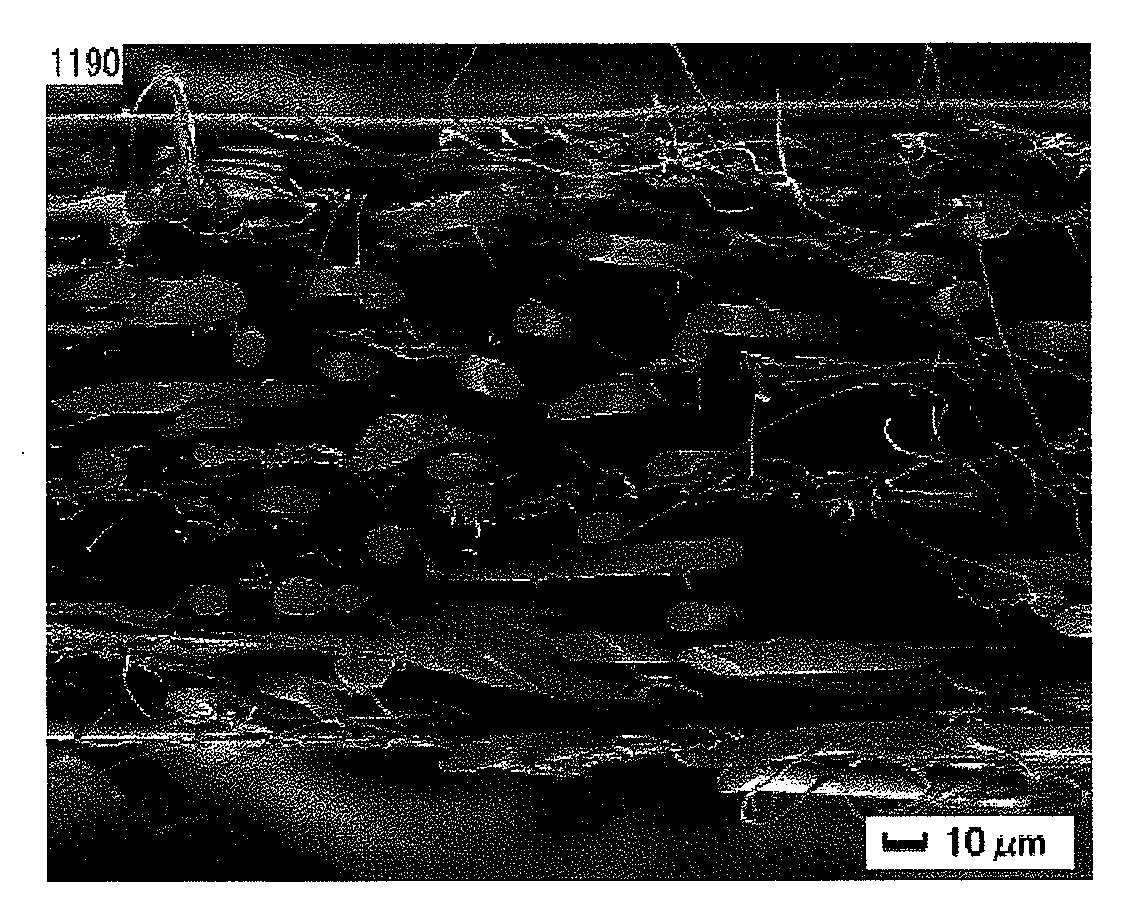

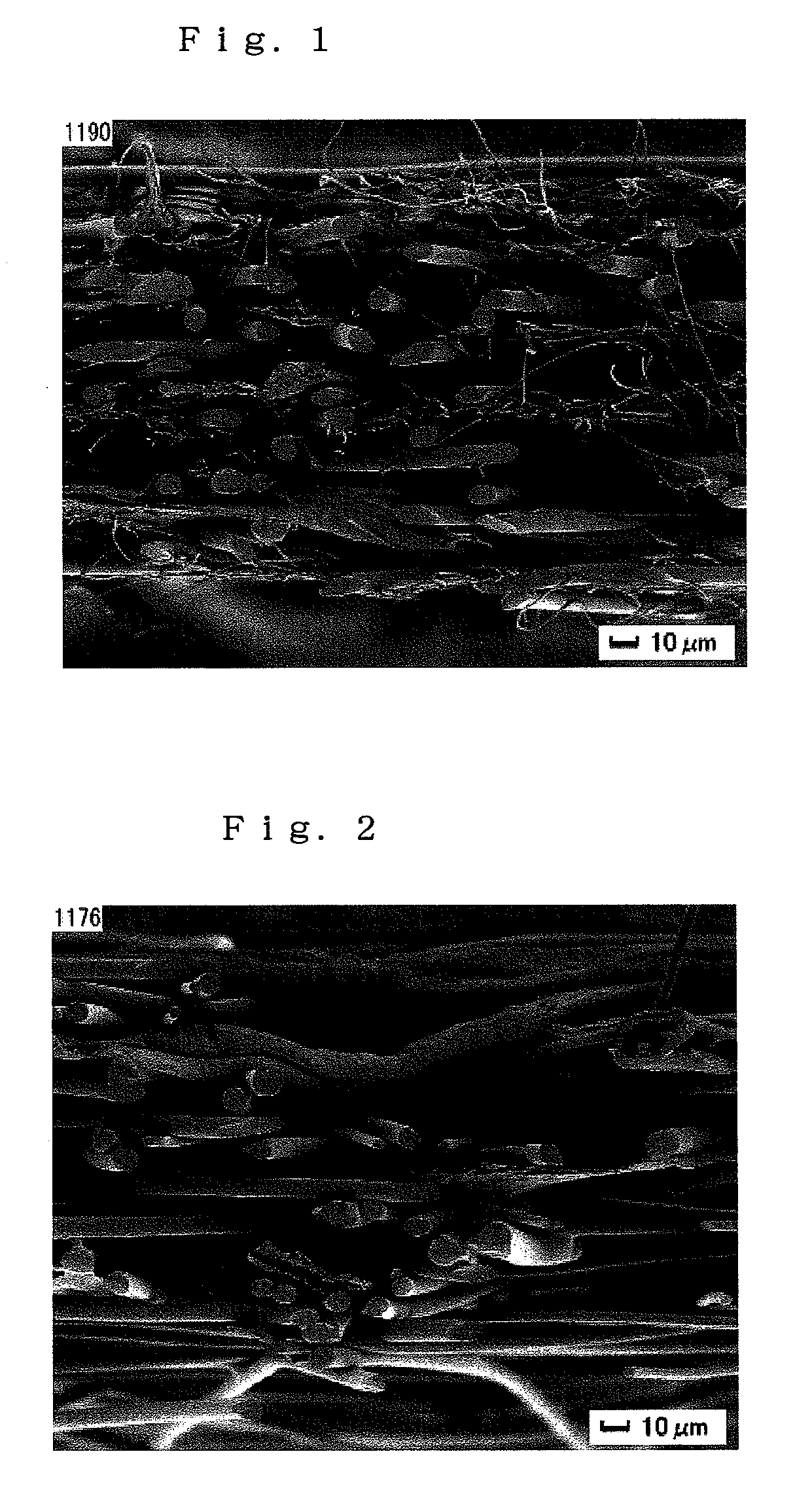

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveCN1720358AFibre treatmentMonocomponent synthetic polymer artificial filamentPolymer alloyPolymer science

The invention provides an aggregate of nanofibers which is not limited in shape or material polymer, is widely applicable and developable, and has a small dispersion of single fiber fineness, and a process for the production thereof. The invention relates to an aggregate of nanofibers which have a number-average single fiber fineness of 1 x 10<-7> to 2 x 10<-4> dtex and a proportion of single fibers having single fiber fineness ranging from 1 x 10<-7> to 2 x 10<-4> dtex of 60 % or above and which are made of a thermoplastic polymer.

Owner:TORAY IND INC

Image testing method for chemical fibre thermal contraction rate and testing apparatus thereof

InactiveCN1609603AImprove test accuracyStable structureTextile testingUsing optical meansMeasuring instrumentSingle fiber

The present invention belongs to the field of textile measuring instrument, and is one kind image test method and apparatus for the heat shrinkage of chemical fiber. The measuring method includes taking images of single fiber samples hung to cylindrical frame with CCD camera to obtain the length change before and after heating, and calculating in computer the heat shrinkage of chemical fiber. The measuring apparatus includes stepped motor, turntable, positioning pin, sample cylinder, elevator, metering calibration block, upper spring clamp, lower tensile clamp, holding circular ring, CCD camera, pulse distributor, casing, computer, display and printer. The present invention has the advantages of reliable test result, high precision, simple instrument structure and low fault rate.

Owner:SHANGHAI LIPU APPLIED SCI TECH INST

Carbon fiber bundle, process for producing the same, and thermoplastic resin composition and molded article thereof

A carbon fiber bundle is provided which can develop satisfactory interfacial adhesion to polyolefin-based resins, especially polypropylene resins. The carbon fiber bundle comprises a plurality of single fibers that was sized with a sizing agent comprising: a polymer having a main chain formed of carbon-carbon bonds, containing an acid group in at least part of side chains or at least a part of main chain ends, and representing an acid value of 23 to 120 mgKOH / g as measured in accordance with ASTM D1386; or a polymer having a main chain formed of carbon-carbon bonds and containing at least either of an epoxy group and an ester group in at least a part of side chains or at least a part of main chain ends.

Owner:MITSUBISHI CHEM CORP

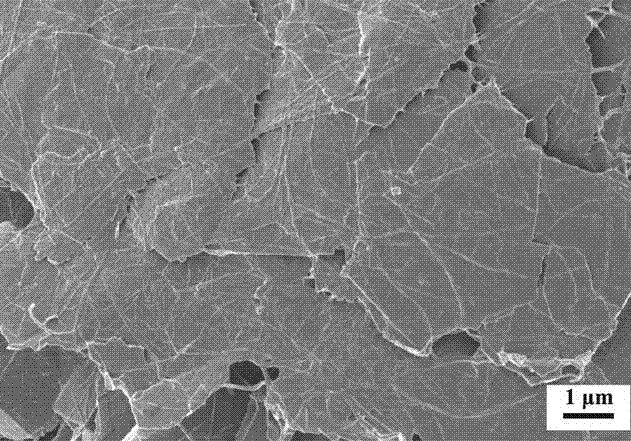

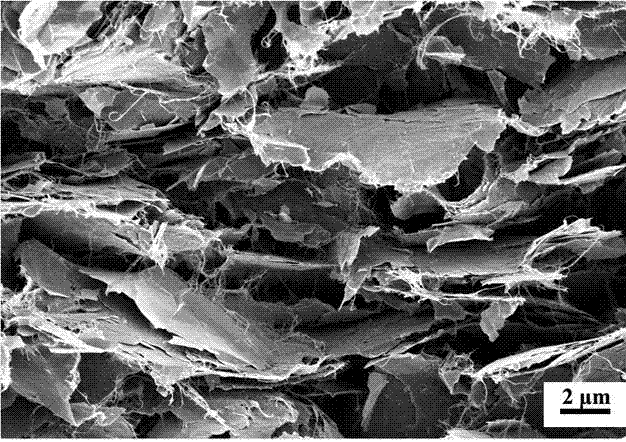

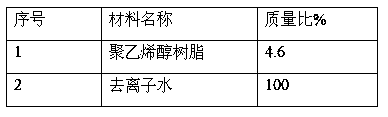

Preparation method of tough graphene/cellulose composite heat-conductive and electro-conductive film

InactiveCN107293377AReduce manufacturing costEasy to operateNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseFiber

The invention discloses a preparation method of a tough graphene / cellulose composite heat-conductive and electro-conductive film. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film comprises the following steps: firstly, dispersing the wood pulp into an aqueous solution to peel the wood pulp into single nano diameter single fibrous bundles under the action of liquid shear force; diluting the single fibrous bundles with deionized water and obtaining the low concentration cellulose aqueous solution through treating by a high-speed shearing machine for a certain period of time; then dispersing the industrial graphene nanosheets evenly into the aqueous solution containing the dispersant through ultrasonic treatment; then dripping the prepared cellulose aqueous solution gradually into the graphene dispersion; and preparing the graphene / cellulose composite film through ultrasonic mixing, suction filtration, drying and other processes. The obtained film has good flexibility, thermal conductivity and electrical conductivity, and the mechanical, thermal and electrical properties of the film can be further improved through hot pressing treatment. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film has the advantages of simple process, low cost, green environment protection and wide application value in the field of functional composite materials.

Owner:QILU UNIV OF TECH

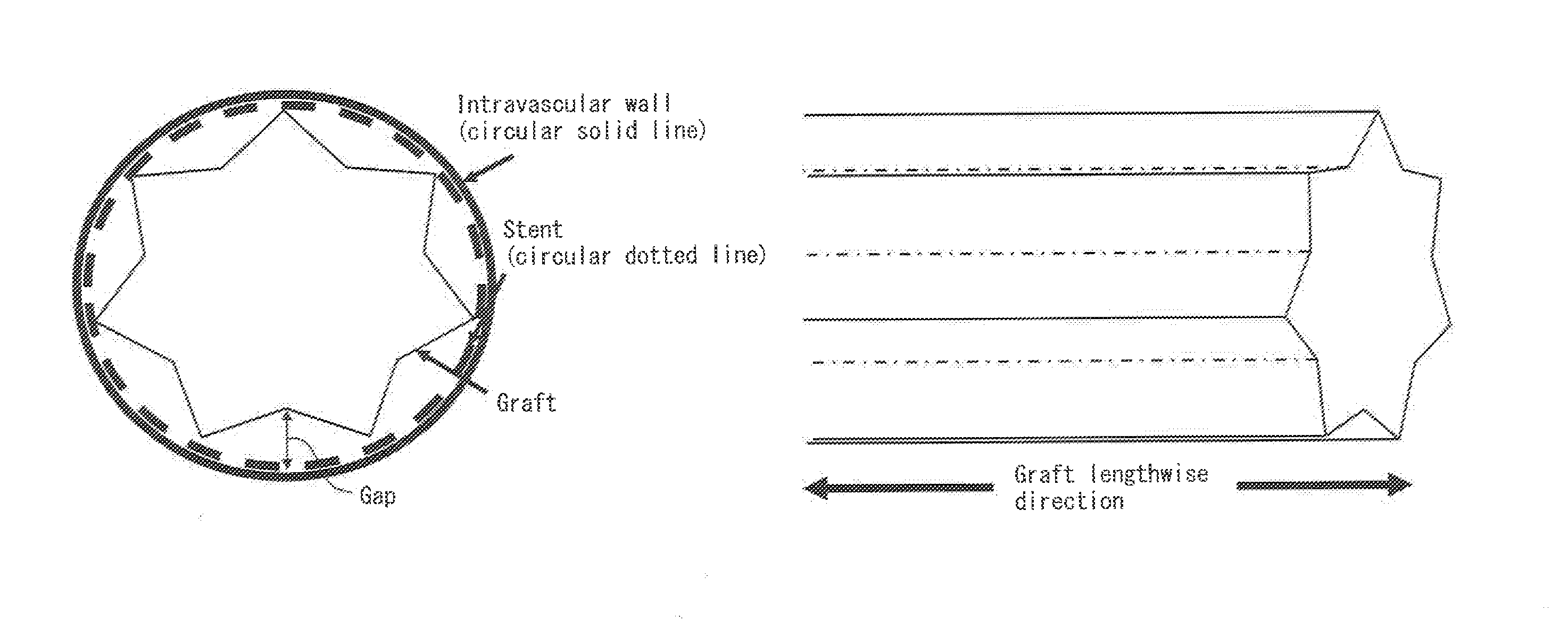

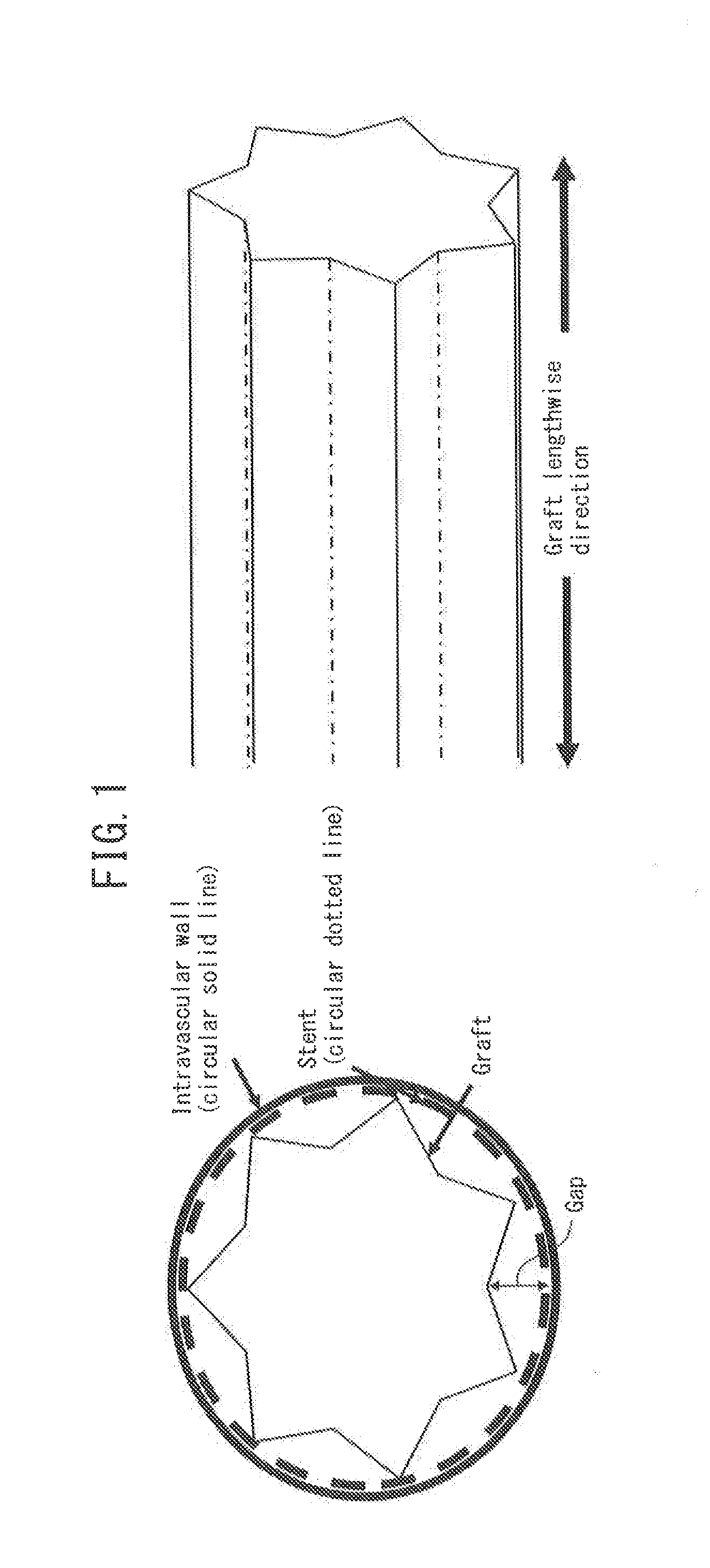

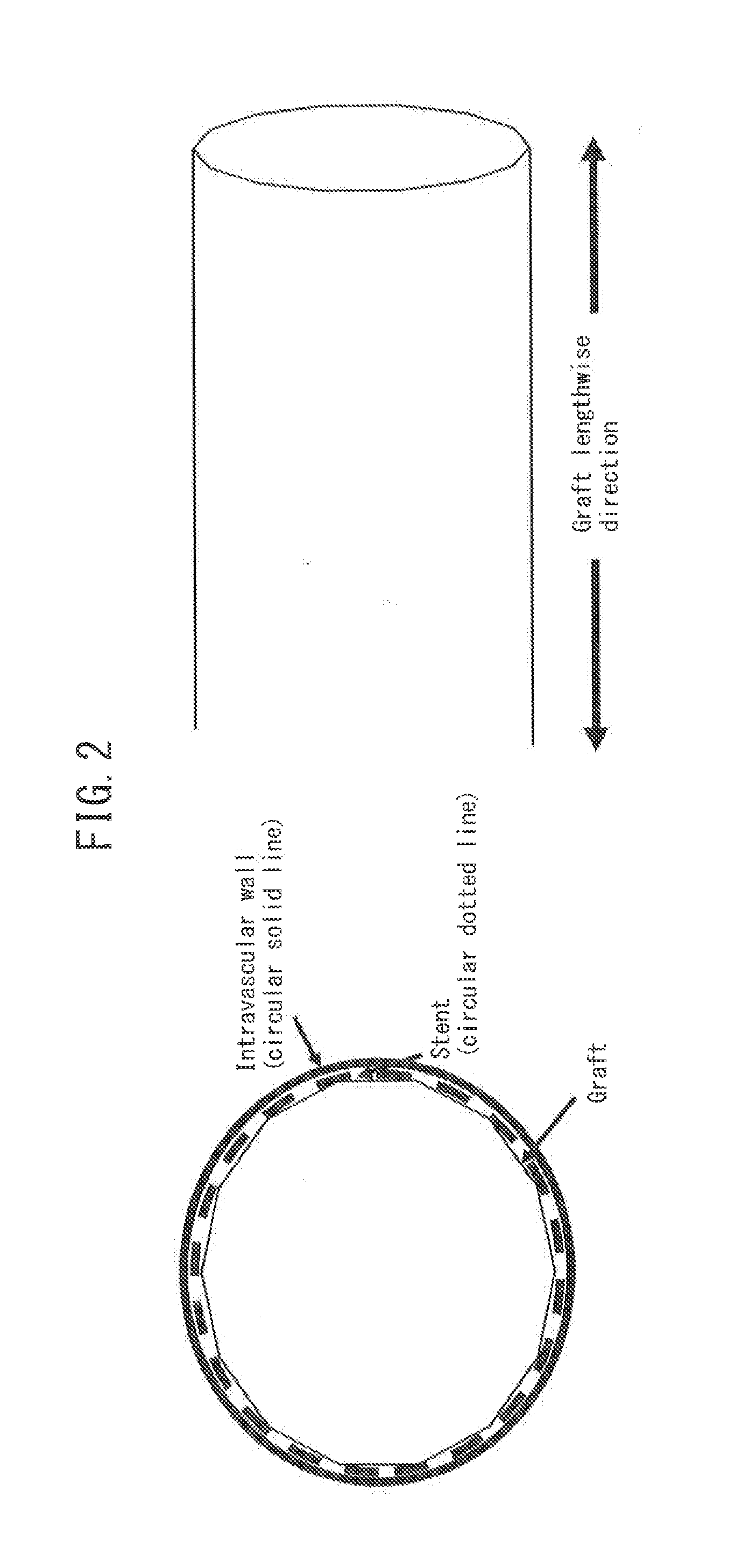

Ultrafine polyester fiber

InactiveUS20160184488A1Highly integratedEnsure long-term stabilityStentsSurgeryPolyesterPolyethylene terephthalate glycol

Provided is an ultrafine polyester fiber which is useful as a constituent material for a cloth for a stent graft or other medical device that is to be implanted in the body and which can simultaneously solve both a clinical need (diameter reduction) and a clinical challenge (integration of a stent with a stent graft). An ultrafine polyester fiber which has a polyethylene terephthalate content of 98 wt % or more, characterized by: having (1) a reduced viscosity (ηsp / c) of 0.80 dl / g or higher and (2) a total fineness of 7 to 120 dtex and a single-fiber fineness of 0.5 dtex or less; and exhibiting (3) a maximum thermal shrinkage stress of 0.05 cN / dtex or more in a temperature range of 80 to 200° C. or (4) a degree of crystallinity of 35% or more in a region spreading from the surface of the fiber to a depth of 0.1 μm.

Owner:ASAHI KASEI FIBERS CORPORATION

Fiber structure and method for production thereof

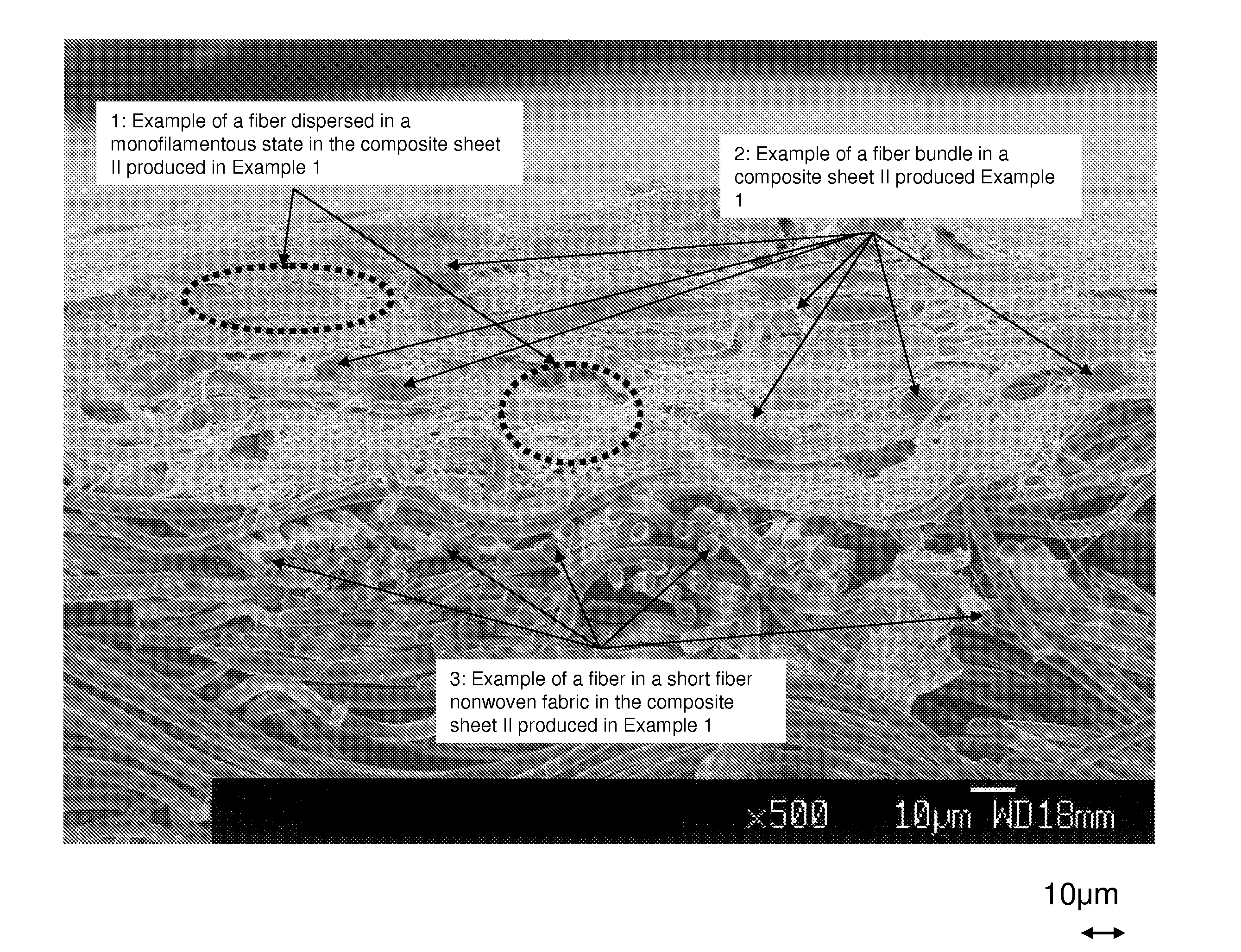

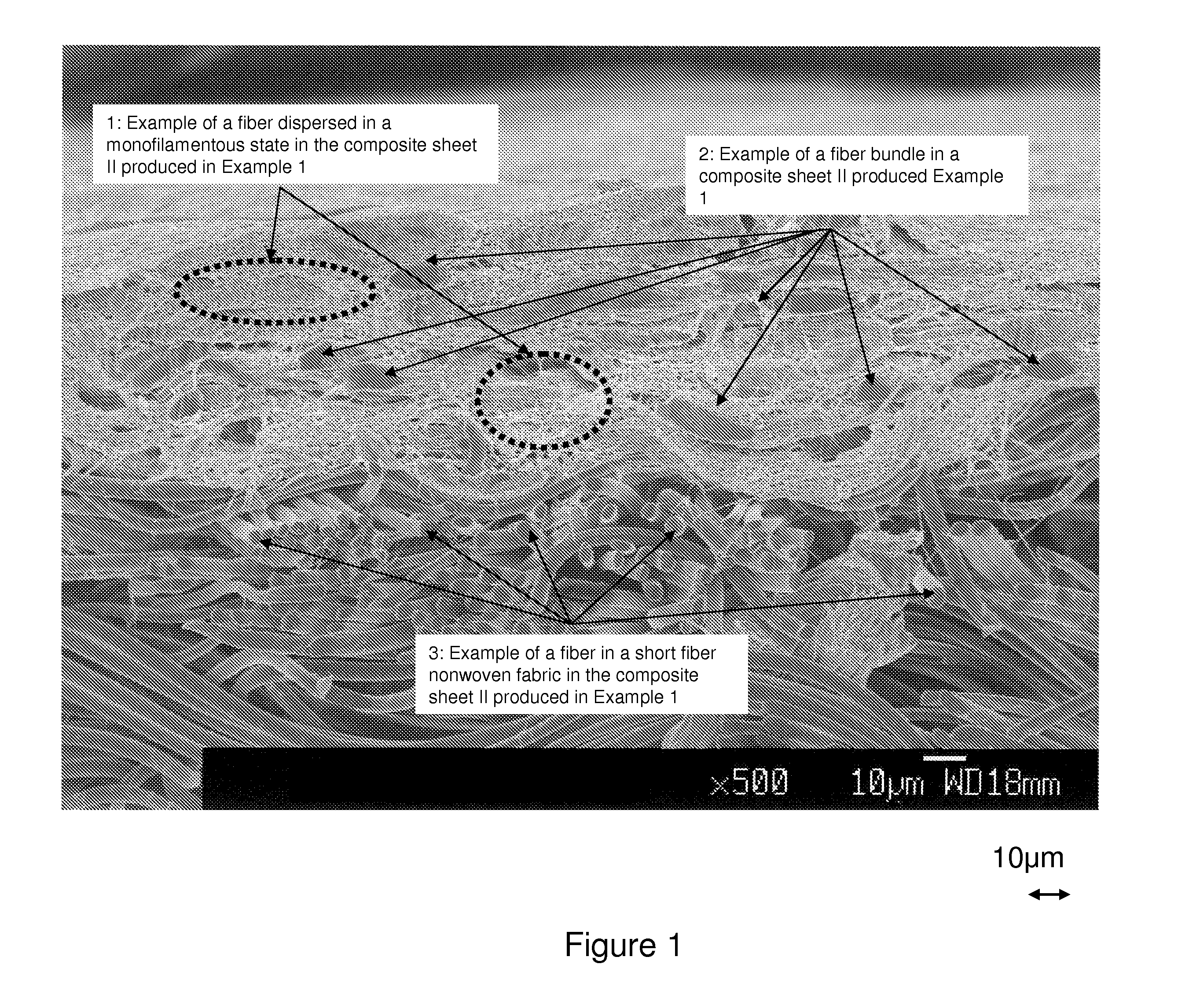

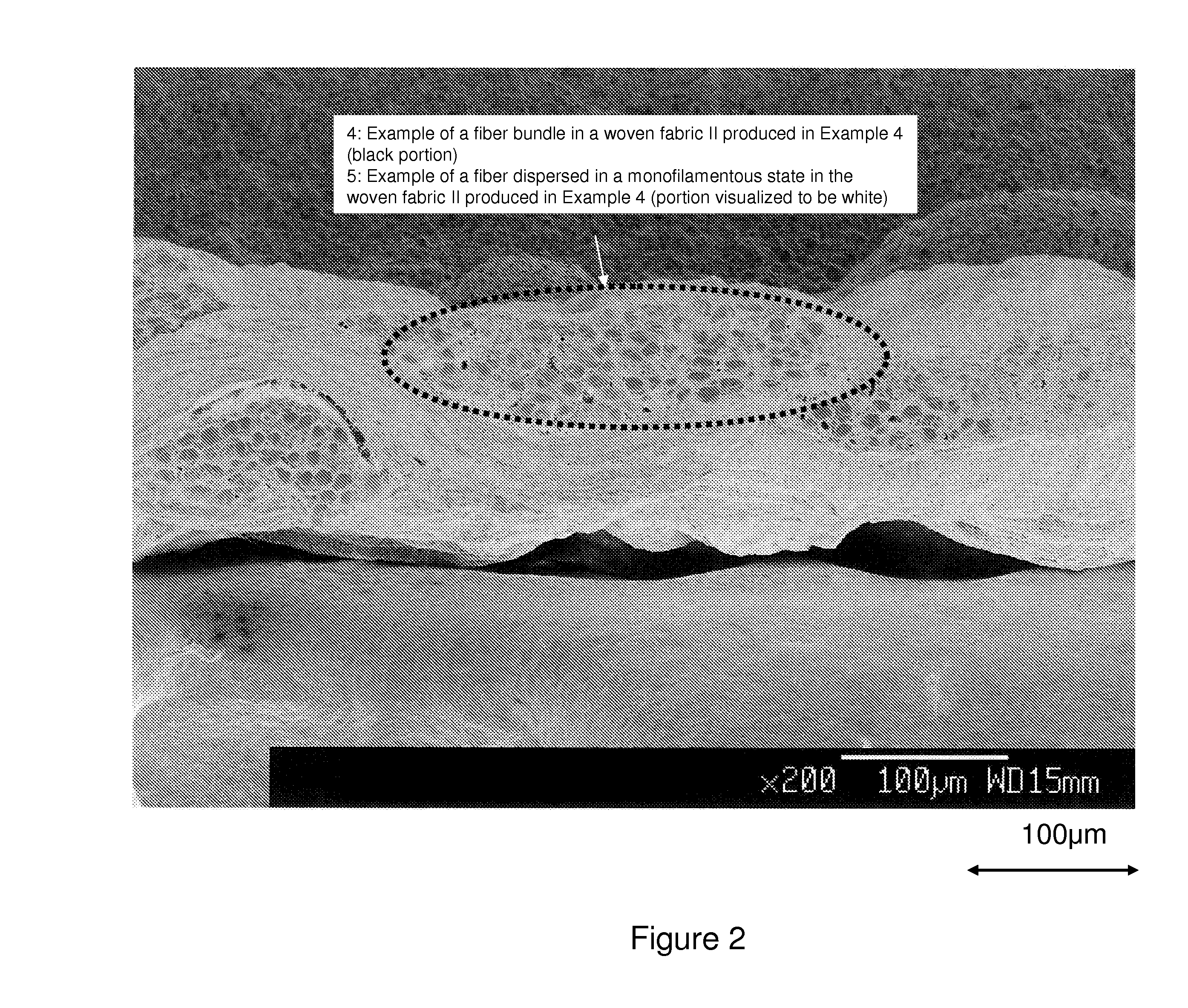

InactiveUS20100075143A1Easy to getImprove smoothnessWoven fabricsNon-woven fabricsFiber structureVoid space

A fiber structure including: (A) a single fiber having a fiber diameter of 3 μm or more and / or a fiber bundle having a fiber bundle diameter of 3 μm or more, and (B) a single fiber having a fiber diameter of 1 μm or less, wherein the component (A) has a number average fiber diameter and / or a number average fiber bundle diameter of 4 μm or more, at least a part of the component (B) is dispersed in the component (A) in a monofilamentous state in the cross-section taken in the thickness-wise direction of the fiber structure, at least a part of the component (B) dispersed in the monofilamentous state is bent and / or tangled to form a void space, and at least one surface of the fiber structure is covered with the component (B).

Owner:TORAY IND INC

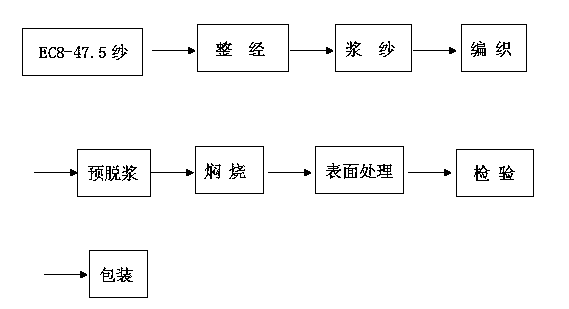

Production technology of glass fiber cloth for insulation

ActiveCN103741319ASolve the production processSimple processFibre treatmentHeating/cooling textile fabricsGlass fiberPolymer science

Provided is a production technology of glass fiber cloth for insulation. The production technology of the glass fiber cloth for insulation comprises the steps that EC8-47.5 glass fiber yarn serves as warp and weft; a warping working procedure technology is carried out, wherein the EC8-47.5 glass fiber yarn is placed on warping creels in sequence; a slashing working procedure technology is carried out; a knitting working procedure technology is carried out, wherein an air jet loom is used for carrying out weaving, drafting, reed insertion, gaiting and weaving are carried out on slashed warp beams in sequence according to plain weave, the warp and weft density is 17.3*14.2 pieces per centimeter, and the cropping length is 2000 meters per roll; a post-processing working procedure is carried out; drying is carried out at the temperature of 200DEG C, and the trimming working procedure, the take-up working procedure, the check working procedure and the packaging working procedure are carried out. The purpose of the production technology for using the EC8-47.5 glass fiber yarn to produce the high-grade glass fiber cloth for insulation is achieved, the warp and weft density of the glass fiber cloth is 17.3*14.2 pieces per centimeter, the thickness of the glass fiber cloth is 0.140mm, the basic weight is 150g / m<2>, the diameter of a filament of the glass fiber cloth is 8 microns, the warp and weft number is 47.5Tex, and the production technology of the glass fiber cloth for insulation has the advantages that the technology is more convenient to use, production management is easy, weaving is convenient, and the foundation is laid for producing the high-grade insulating glass fiber cloth through ordinary devices.

Owner:江西长江化工有限责任公司

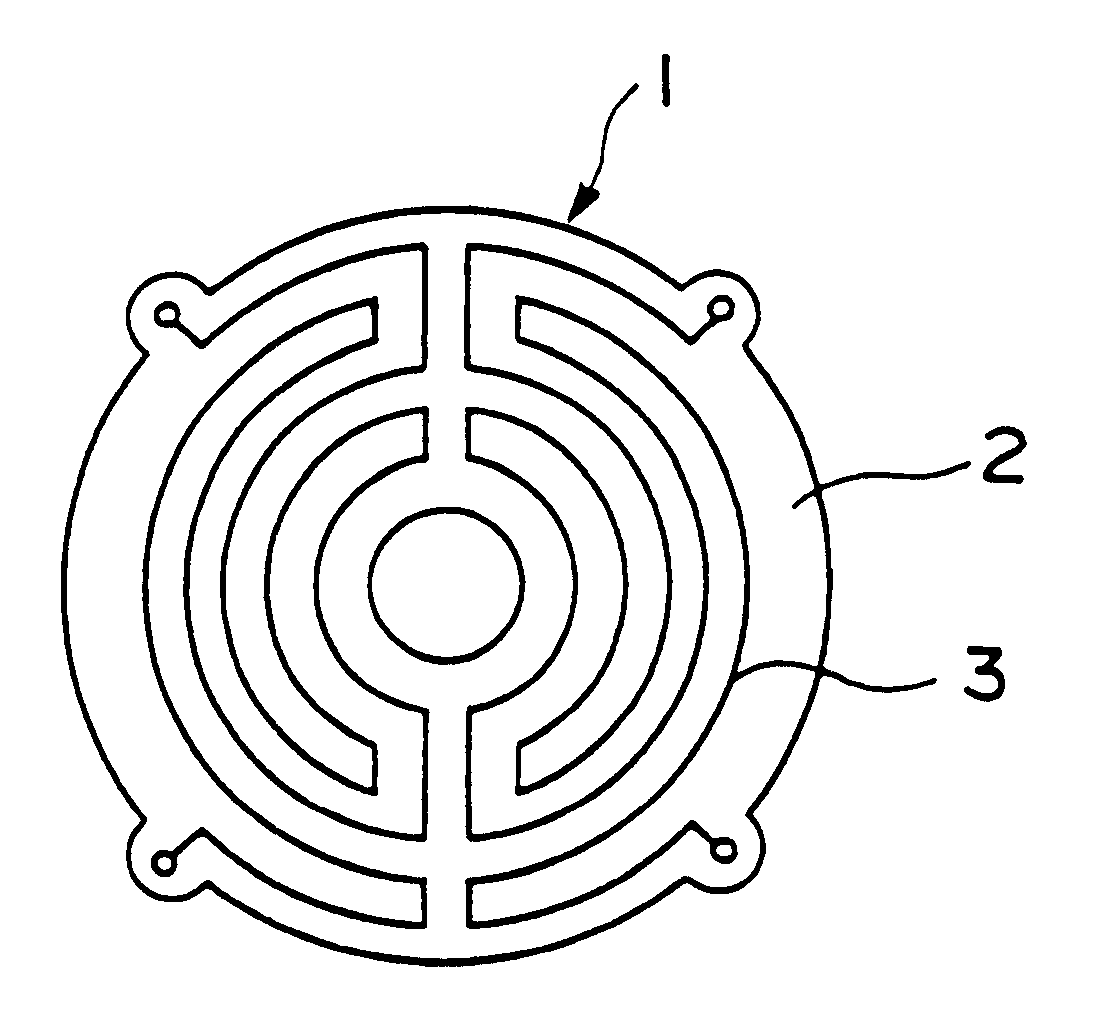

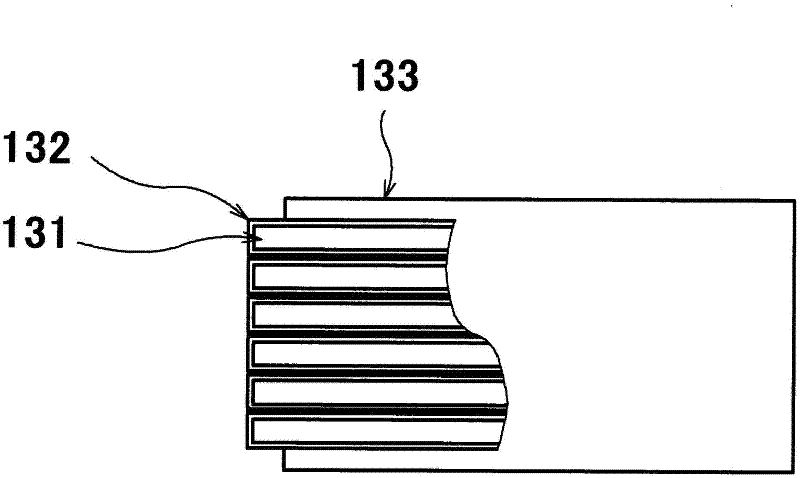

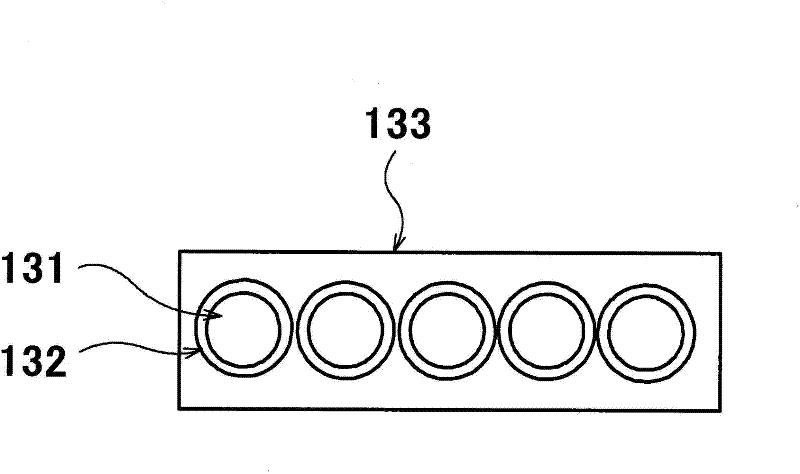

A single fibre bi-directional assembly

InactiveCN102183828AReasonable structureReduce manufacturing costCoupling light guidesBirefringent crystalSingle fibre

The invention relates to a single fibre bi-directional assembly comprising a TO tube seat, a laser, an isolating part, a 45-degree optical filter, a 0-degree optical filter, a fiber connector and a probe, wherein the laser is encapsulated in the TO tube seat. An isolator system and a wavelength division multiplexing system in the single fibre bi-directional component share one 45-degree multifunctional optical filter, which saves a popolaroid or a birefringent crystal in the isolator so that the assembly is more reasonable in structure, besides, the cost for producing the BOSA is reduced either.

Owner:PINGHU ZHONGTIAN HEBO COMM TECH

Banana fiber and its production and its blending wires and fabrics

InactiveCN1472372ALight materialGood hygroscopicityVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

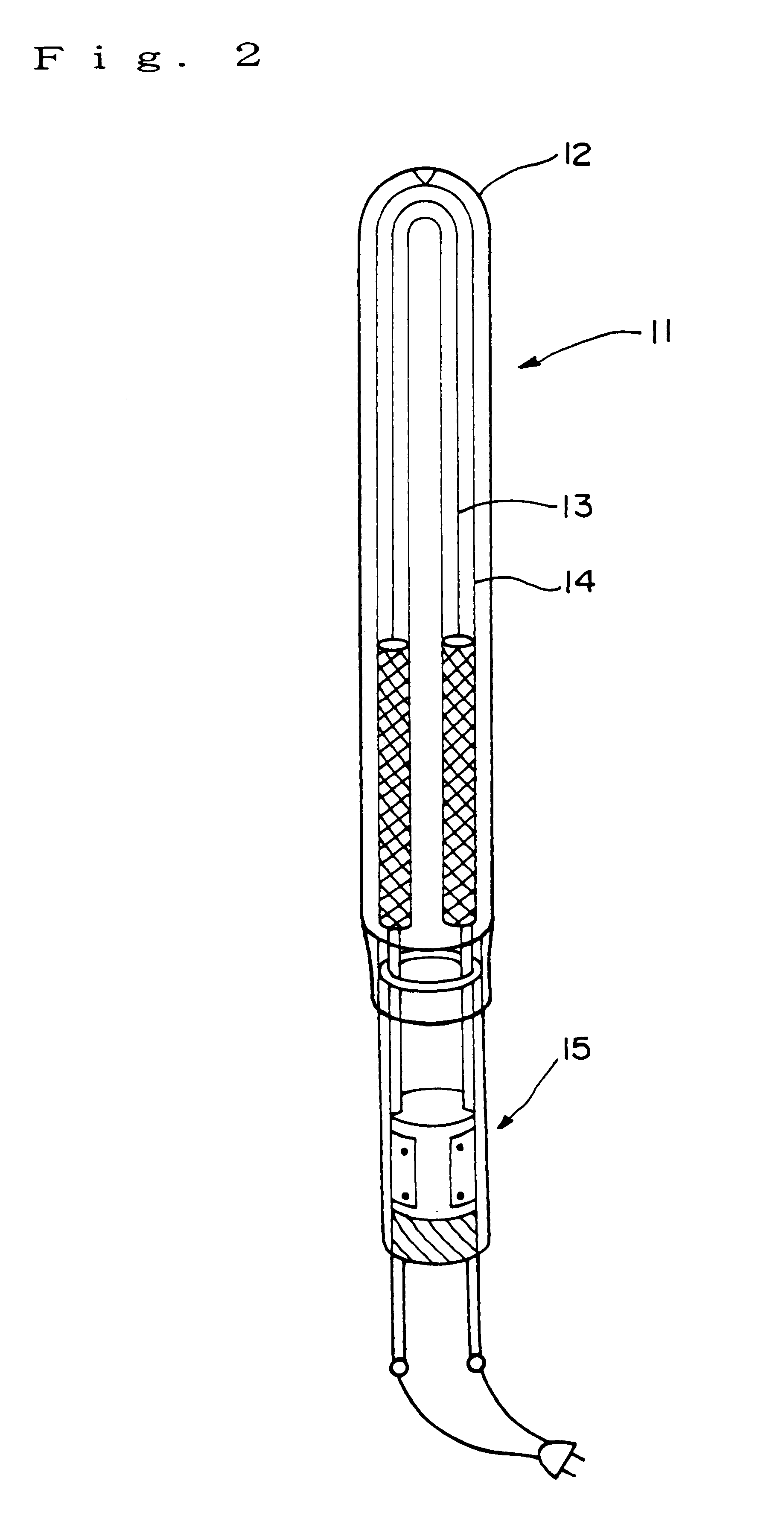

Heater sealed with carbon wire heating element

InactiveUS6584279B2Quality improvementExcellent anti-aging stability of electric resistanceDomestic stoves or rangesIncandescent ignitionSingle fiberCrystal structure

A heater sealed with carbon wire heating element has a carbon wire heating element sealed with a quartz glass member, the carbon wire being prepared by knitting carbon single fibers into a knitted cord of a braid, each wire having a crystal structure with a interlayer spacing d (002) thereof being 0.343 or less and crystallite size Lc (002) thereof being 4.0 nm or more.

Owner:COORSTEK INC +1

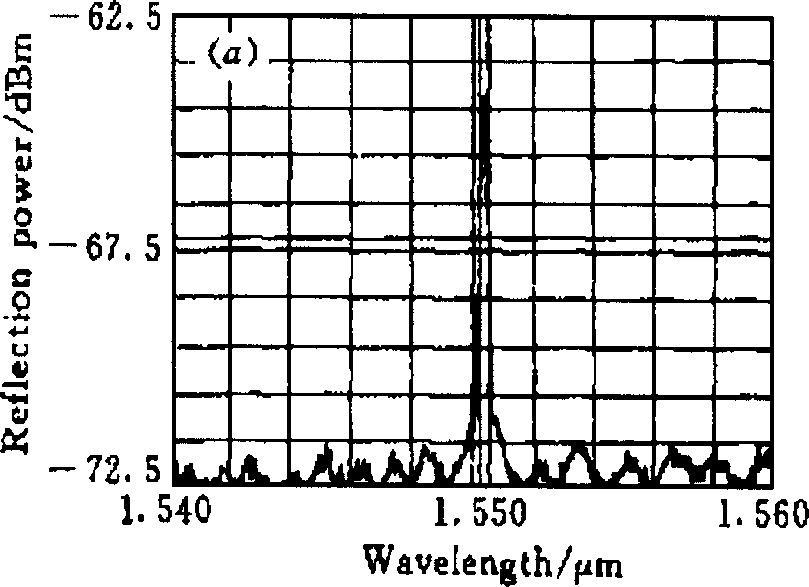

Slrain and temperature change simultaneously-measured single fibre grating packaging method and its sensor

The present invention relates to an encapsulation method of single-fibre grating capable of simultaneously measuring strain and temp. change and its sensor. One fiber-optical grating is divided into two parts, they can be encapsulated by using two different chemical polymers respectively, and its sensor can be assembled by using fiber-optical grating, wide-band light source, wavelengther tester, 2X2 fiber coupling device, matching liquor, pressure tank and pressure gauge. When the encapsulated fiber-optical grating is acted extemally, in the reflection spectrum of said fiber-optic grating tworeflection peaks are produced, only the wavelength difference between two reflection peaks is measured, so that it can implement simultaneous measurement of strain and temp. change.

Owner:NANKAI UNIV

Bamboo carbon polyester fiber/chitin viscose fiber blended yarn and producing method

The present invention is blended yarn of bamboo carbon polyester fiber and chitin viscose fiber in the ratio of 45-55 %. The production process of the blended yarn includes the following steps: mixing and spinning bamboo carbon polyester fiber of linear density 1-3 D and chitin viscose fiber of chitin content not lower than 5 % and linear density2-3 D to form the blended yarn of bamboo carbon polyester fiber and chitin viscose fiber. The blended yarn of bamboo carbon polyester fiber and chitin viscose fiber is superior to available yarn of bamboo carbon polyester fiber, and has the has functions of adsorbing and eliminating bad smell, emitting far infrared ray, releasing negative ion, resisting bacteria, high hydroscopicity, soft hand feeling and comfort, and is suitable for making underwear.

Owner:DONGHUA UNIV

Filtering material for filter, and water filtering apparatus provided with filtering material

InactiveUS20140014573A1Efficient collectionWater treatment parameter controlLayered productsWoven fabricAverage diameter

The present invention provides a filtering material for filtering water having high collection efficiency and long filtering life, and a water filtering apparatus including the material. The present filtering material includes a laminated sheet in which a nanofiber layer formed from a nanofiber having a single fiber average diameter of 10 to 1000 nm and meeting all the following conditions and a base material including a nonwoven or woven fabric containing a hydrophilic fiber having a single fiber average diameter of not less than 1 μm. Further, the present water filtering apparatus is configured by including the filtering material for filtering water. (1) The nanofiber layer has a basis weight of 0.1 to 10 g / m2. (2) The nanofiber is a continuous long fiber. (3) The nanofiber contains at least an ethylene-vinyl alcohol copolymer.

Owner:KURARAY CO LTD

Flame-retardant leather-like sheet substrate and production method thereof

InactiveUS7091139B2Improve flame retardant performanceImprove mechanical propertiesSynthetic resin layered productsHeat resistant fibresPolyesterElastomer

The flame-retardant leather-like sheet substrate of the present invention comprises a layer (A) that is made of an entangled nonwoven fabric comprising a polyester superfine fiber (a) of a single fiber fineness of 0.5 dtex or less containing no flame-retardant component and a flame-retardant polyester superfine fiber (b) of a single fiber fineness of 0.5 dtex or less containing a flame-retardant component in a ratio, (a) / (b), of 100 / 0 to 40 / 60 by mass, and a layer (B) that is made of an entangled nonwoven fabric comprising the polyester superfine fiber (a) and the flame-retardant polyester superfine fiber (b) in a ratio, (a) / (b), of 70 / 30 to 0 / 100 by mass. The entangled nonwoven fabrics of the layers (A) and (B) are impregnated with an elastomeric polymer (c) containing a flame-retardant component. The ratio of the polyester superfine fiber (a) and the flame-retardant polyester superfine fiber (b) in the flame-retardant leather-like sheet substrate is 10:90 to 90:10 by mass. The flame-retardant leather-like sheet substrate and the artificial leather made thereof have an excellent flame retardancy, a soft and high-quality feeling and appearance, a high abrasion resistance and peel strength, and excellent mechanical properties such as surface strength.

Owner:KURARAY CO LTD

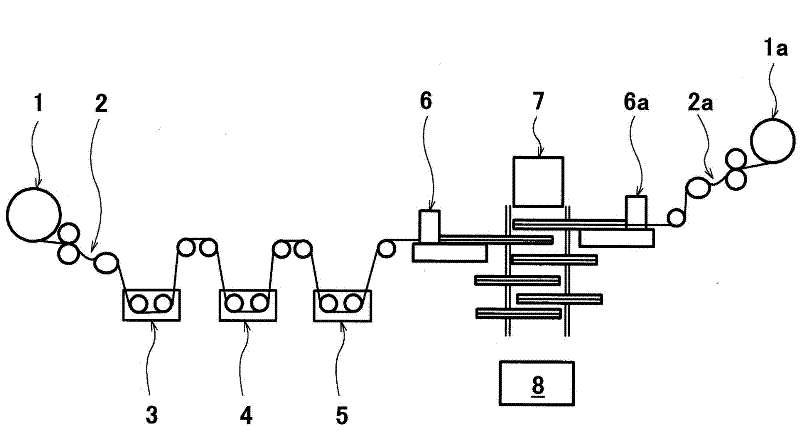

Fiber electrode and fiber cell, and method for producing same, facility for producing fiber electrode and fiber cell

InactiveCN102473903AEfficient manufacturingIncrease surface areaMicroscopic fiber electrodesHybrid capacitor electrodesFiber bundleSingle fibre

Disclosed is a method for efficiently producing a plurality of fiber electrodes simultaneously from a plurality of fibers, which takes advantage of the advantages that fiber electrodes conventionally have. The method for producing fiber electrodes has steps (2,2a) for opening a bundle of fibrous material, steps (3,4,5) for obtaining a fiber cathode or a fiber anode by means of forming a cathode active material coat layer or an anode active material coat layer on each monofilament obtained by means of opening, and steps (6,6a) for forming a separator coat layer on the abovementioned fiber cathode or fiber anode.

Owner:KAWASAKI HEAVY IND LTD +1

Fire resistant sheet substrate material like leather and producing method thereof

The flame-retardant leather-like sheet substrate of the present invention comprises a layer (A) that is made of an entangled nonwoven fabric comprising a polyester superfine fiber (a) of a single fiber fineness of 0.5 dtex or less containing no flame-retardant component and a flame-retardant polyester superfine fiber (b) of a single fiber fineness of 0.5 dtex or less containing a flame-retardant component in a ratio, (a) / (b), of 100 / 0 to 40 / 60 by mass, and a layer (B) that is made of an entangled nonwoven fabric comprising the polyester superfine fiber (a) and the flame-retardant polyester superfine fiber (b) in a ratio, (a) / (b), of 70 / 30 to 0 / 100 by mass. The entangled nonwoven fabrics of the layers (A) and (B) are impregnated with an elastomeric polymer (c) containing a flame-retardant component. The ratio of the polyester superfine fiber (a) and the flame-retardant polyester superfine fiber (b) in the flame-retardant leather-like sheet substrate is 10:90 to 90:10 by mass. The flame-retardant leather-like sheet substrate and the artificial leather made thereof have an excellent flame retardancy, a soft and high-quality feeling and appearance, a high abrasion resistance and peel strength, and excellent mechanical properties such as surface strength.

Owner:KURARAY CO LTD

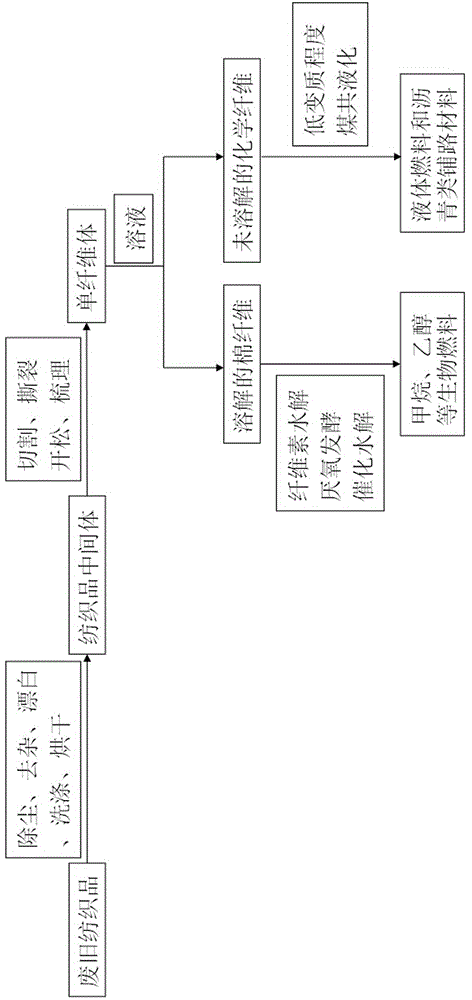

Method for producing fuel and road asphalt modifier by utilizing waste and old textiles

ActiveCN104531234ASolve processing problemsIncrease profitSolid waste disposalLiquid carbonaceous fuelsPtru catalystSingle fibre

A disclosed method for producing a fuel and a road asphalt modifier by utilizing waste and old textiles comprises the following steps: (1) pre-treating waste and old textiles, namely, successively performing dedusting, impurity removal, bleaching, washing and baking processing on waste and old textiles, and then performing cutting, tearing, loosening and carding to obtain single fibrous body; (2) dissolving the single fibrous body obtained in the step (1) by using an alkali solution, and performing solid-liquid separation to obtain a gossypin solution and undissolved chemical fiber; (3) adding cellulase into the gossypin solution for hydrolyzing, or adding a catalyst for hydrolyzing, or performing anaerobic fermentation, so as to prepare a biological fuel; and (4) adding low-coalification-degree coal, a catalyst and a solvent into the undissolved chemical fiber obtained in the step (2) for coliquefaction, so as to prepare a liquid fuel and the road asphalt modifier. The method converts waste and old textiles into the fuel and prepares the road asphalt modifier, comprehensively utilizes coal and waste and old textiles, and reduces environmental pollution.

Owner:河南卓谷科技有限公司

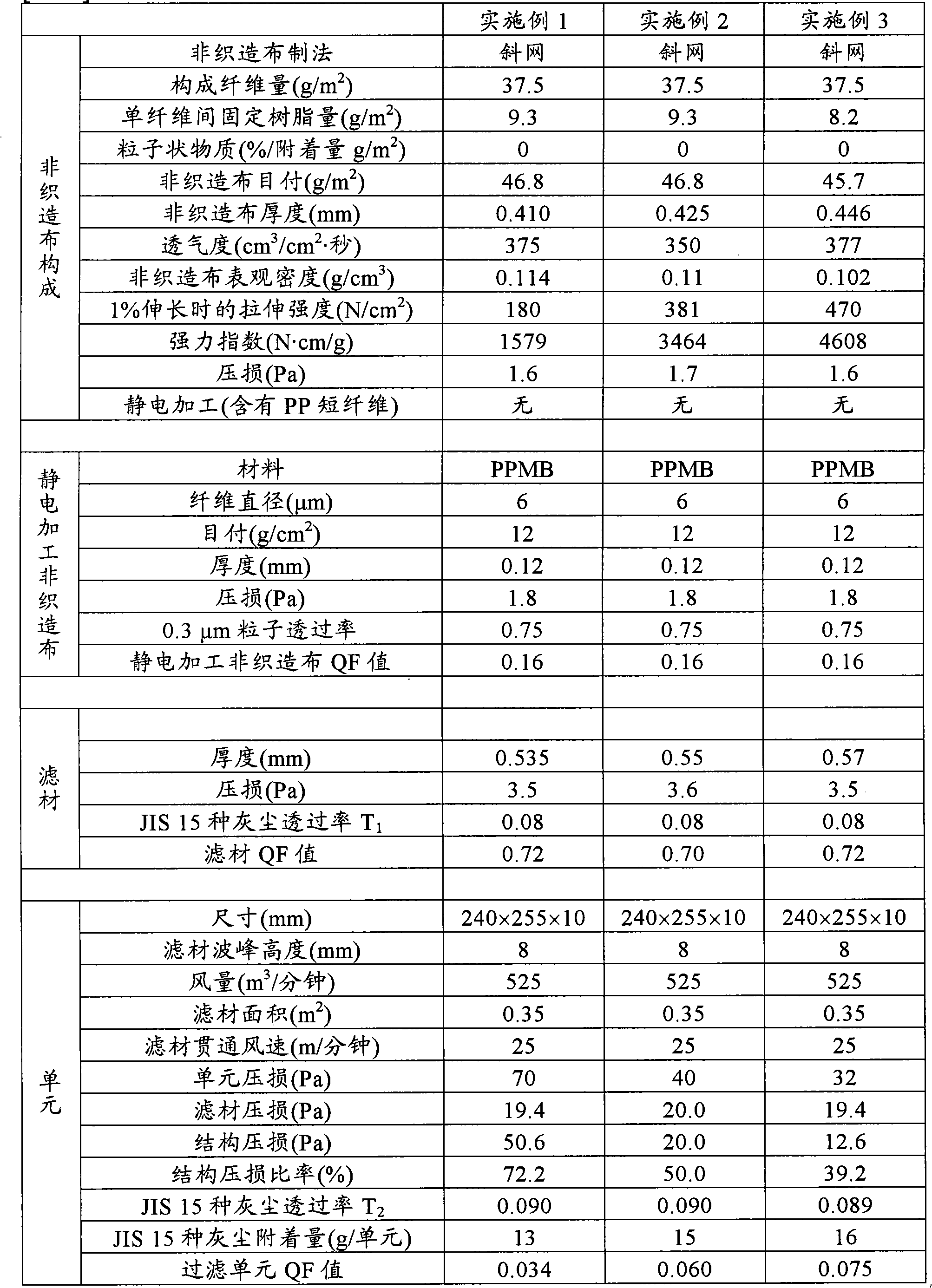

Filter medium and filter unit

ActiveCN101652167AImprove breathabilityLittle strengthDispersed particle filtrationMembrane filtersPolymer scienceSingle fibre

A filter medium which is not stretched by wind pressure even when having a small thickness; and a filter unit which enables a treatment in a large gas quantity. The filter medium is made of a nonwovenfabric which consists mainly of organic fibers and in which the single fibers have been fixed to one another. The nonwoven fabric is constituted of two or more kinds of single fibers differing in Young's modulus and fineness and contains noncrimped single fibers having a Young's modulus of 150 cN / dtex or higher and a fineness of 7 dtex or higher in a proportion of 20% or higher based on the totalmass of the fibers. The single fibers are fixed to one another with a resin having a glass transition temperature of 30 DEG C or higher.

Owner:TORAY IND INC

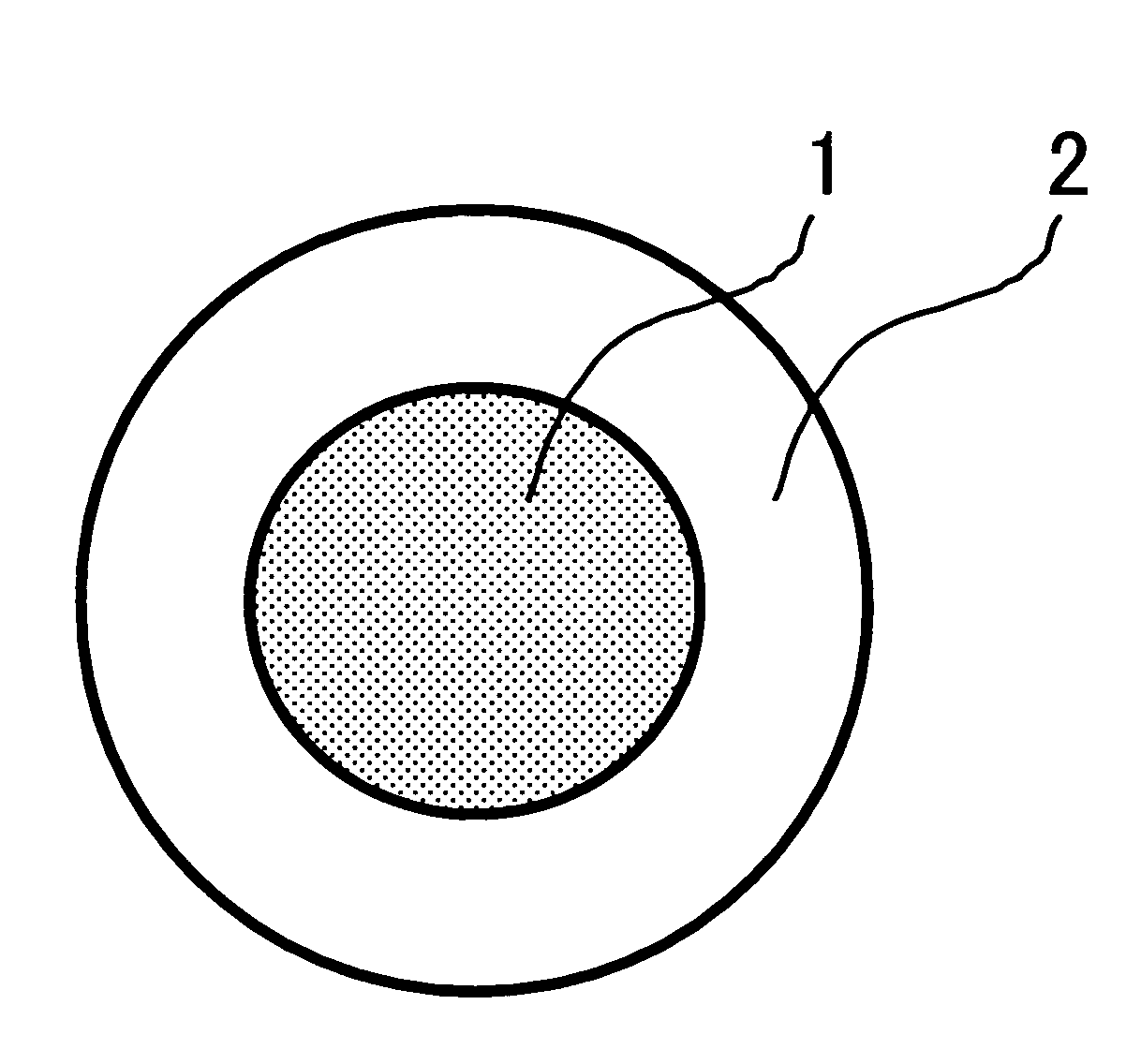

Rope fabricated by utilizing waste textile and fabrication method of rope

The invention discloses a rope fabricated by utilizing waste textile and a fabrication method of the rope. The fabrication method comprises the steps that non-woven fabric serves as a rope core (1), and rope skin (2) consisting of a dacron filament is formed on the outer side surface of the rope core (1) by a weaving method, wherein a weaving parameter is determined according to the diameter and the linear density of the rope. The rope core (1) is arranged into the non-woven fabric woven by a monofilament formed by textile leftovers, scraps, waste yarns, waste silk, offcut and cloth pieces as well as waste clothes and other waste textile, and the rope skin (2) is arranged to consist of the dacron filament, therefore, the waste textile is utilized, and the strength of the rope is improved.

Owner:SHANDONG ROPE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com