Method and system for measuring wool fiber fineness measurement

A wool fiber and measurement method technology, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve problems such as affecting the accuracy and stability of the motion of the workbench, increasing the number of signal transformations, and increasing the difficulty of system maintenance. , to achieve the effect of flexible and diverse output methods, many measurement parameters, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

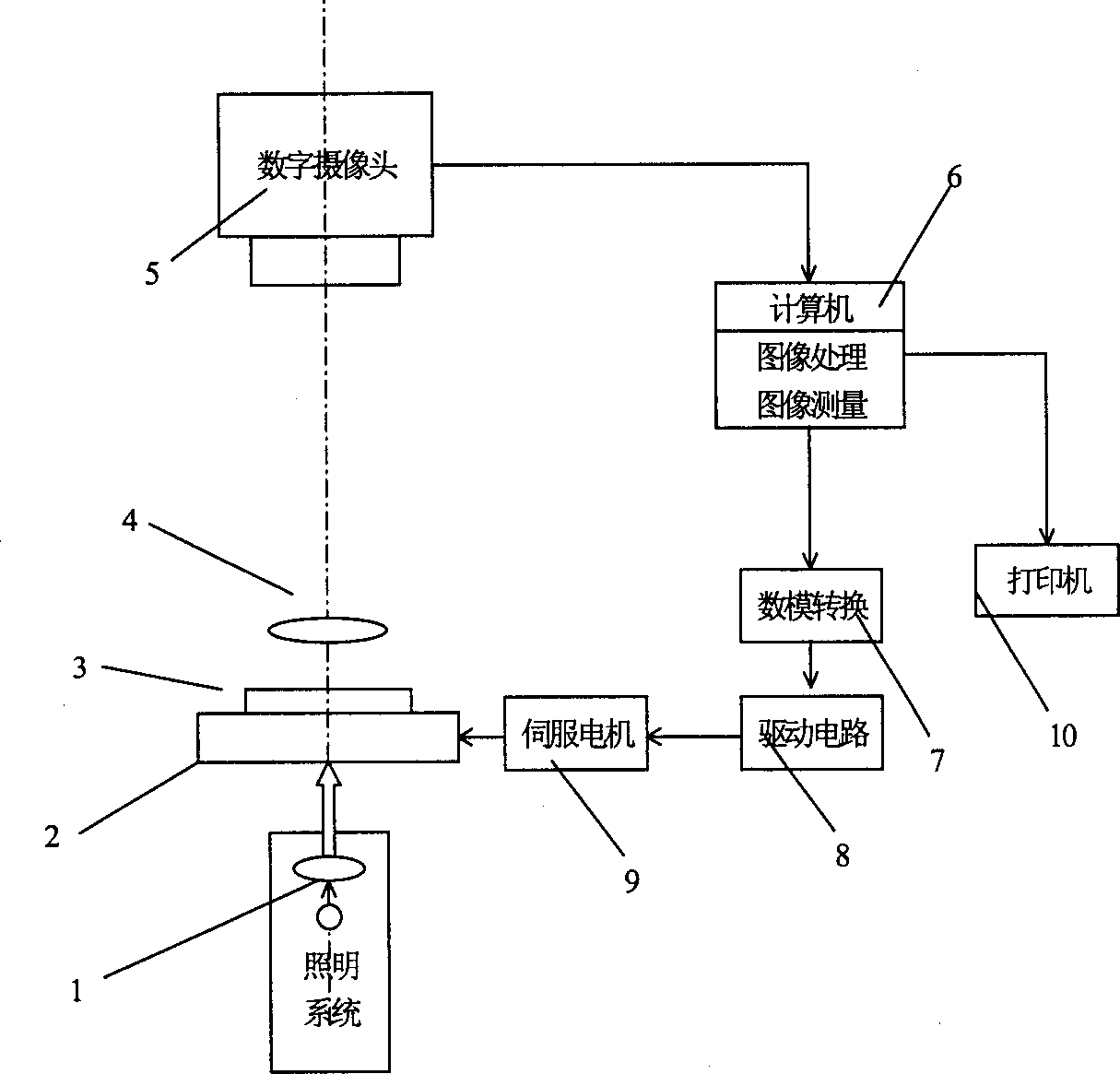

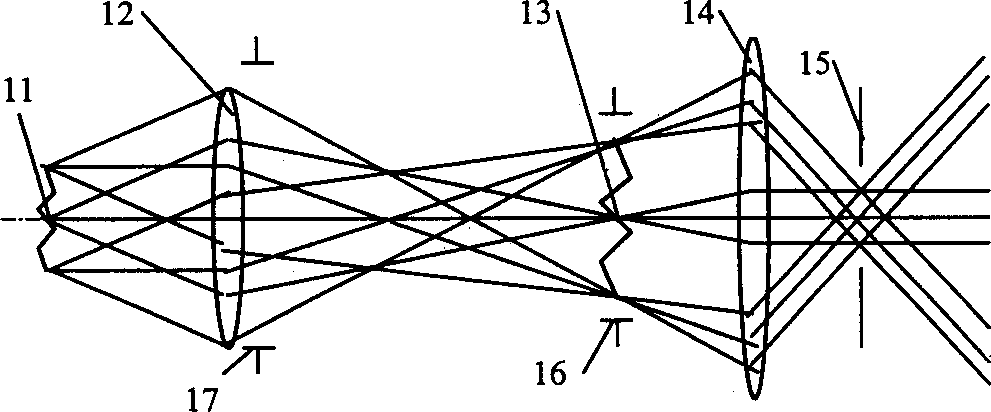

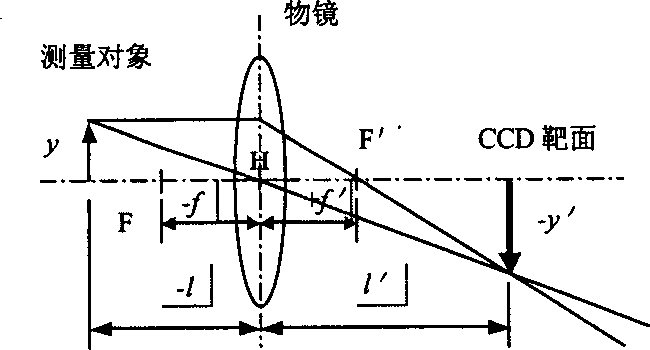

[0028] The invention mainly includes a precision workbench, an optical microscopic imaging system, an image acquisition and processing system, an image processing and measurement algorithm, and measurement accessories. Its measurement principle is as figure 1 As shown: the illumination system 1 provides uniform illumination to the fiber slice 3 on the workbench 2, and the microscopic segment on the fiber slice 3 is imaged on the target surface of the digital camera 5 through the micro-magnification system 4, and the digital camera 5 converts the enlarged fiber image into Digital image, the computer 8 reads the digital image and performs real-time processing to obtain the fiber profile, calculate the fineness of a single fiber, and calculate the average fineness, fineness distribution, coefficient of variation and other data of all measured fibers to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com