Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Mohair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mohair /ˈmoʊhɛər/ is usually a silk-like fabric or yarn made from the hair of the Angora goat (not to be confused with the Angora rabbit which produces Angora wool). Both durable and resilient, mohair is notable for its high luster and sheen, which has helped gain it the nickname the "Diamond Fiber", and is often used in fiber blends to add these qualities to a textile. Mohair takes dye exceptionally well. Mohair is warm in winter as it has excellent insulating properties, while remaining cool in summer due to its moisture wicking properties. It is durable, naturally elastic, flame resistant and crease resistant. It is considered to be a luxury fiber, like cashmere, angora and silk, and is usually more expensive than most wool that is produced by sheep.

High-proportion mohair tweed production process

The invention discloses a high-proportion mohair tweed production process. The high-proportion mohair tweed production process includes the first step of top dyeing and recombing, the second step of spinning, the third step of weaving and the fourth step of after finishing. The first step includes the substeps of ball loosening, dyeing, backwashing, silver mixing, secondary silver mixing, previous-one gilling, previous-two gilling, combing, later-one gilling, later-two gilling, later-three gilling and strip forming. The second step includes the substeps of silver mixing, first stitch sewing, second stitch sewing, third stitch sewing, fourth stitch sewing, roving, spinning, self-spooling, doubling, two-for-one twisting, yarn steaming and yarn forming. The third step includes the substeps of beaming, drafting and denting, weaving and matching detection. The fourth step includes the substeps of singeing, open-width boiling, tweed washing, water absorbing, open-width boiling, shaping, in-process inspection, cooked repair, brushing, shearing, in-process inspection, dewing, high-pressure steaming, pot steaming and finished product obtaining. High-proportion mohair tweed produced through the process is smooth in tweed surface, clear in line, silky in hand feeling, thin, cool, fine, smooth, natural and soft in floss, high in draping feeling and breathability and comfortable to wear.

Owner:江阴桓聚纺织品有限公司

Soft and abrasion-resistant denim fabric

InactiveCN102963047AImprove wear resistanceGood warmth retentionLayered productsSoft layerCamel hair

The invention discloses a soft abrasion-resistant denim fabric which comprises a surface abrasion-resistant layer and an inner elastic soft layer, wherein the abrasion-resistant layer is woven of warp yarns and weft yarns; the warp yarns are blended and woven of khaki fibers and sateen fibers, and the weft yarns are blended and woven of mohair fibers and camel hair fibers; and the elastic soft layer is blended and woven of imported long lint fibers and acrylic fibers. The abrasion-resistant layer is made from soft and thick fabrics with good abrasion resistance, such as the khaki fiber, the sateen fibers, the mohair fibers and the camel hair fibers, so the abrasion-resistant layer is soft in handfeeling and abrasion-resistant and has no rough feeling; and the inner layer is blended and woven of the imported long lint fibers and the acrylic fibers, so the inner layer is soft, elastic and comfortable and in well fit with a body and has a very good warm-keeping effect.

Owner:常熟市东鑫经纬编织造有限公司

Hollow fancy loop multifunctional health-care yarn and preparation method thereof

The invention provides hollow fancy loop multifunctional health-care yarn and a preparation method thereof. The yarn comprises lotus root fibers, lyocell fibers, bamboo charcoal fibers, Clean cool fibers, water-soluble vinylon fiber filaments, PTT shape memory fiber filaments, anti-ultraviolet polyester fiber filaments, cashmere fibers and mohair fibers, or comprises stainless steel fiber filaments, mint fibers, long stapled cotton fibers, water-soluble vinylon filaments, colorful negative ion multifunctional viscose filaments, bamboo charcoal fibers and coconut carbon fibers. The yarn prepared through the preparation method has excellent in hygroscopicity, natural, antibacterial, resistant to odor and capable of absorbing moisture and discharging sweat, has deodorization and anti-aging functions and the like, also has excellent radiation resistance, anti-static performance and a negative ion emission function, enhances the immune function, activates cells, promotes metabolism, has deodorizing performance, prevents mites, odor and insects, generates negative ion characteristic and is resistant to water, oil and dirt, and fabrics are prevented from being influenced by various harmful bacteria and pollution.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Stain repellent and durable fabric fibers

The invention discloses stain repellent and durable fabric fibers which are formed by blending and weaving stain repellent fabric fibers and durable fabric fibers. The stain repellent and durable fabric fibers are characterized in that the stain repellent fabric fibers comprise mohair fibers and viscose, the durable fabric fibers comprise polypropylene fibers and whalen fibers, and the stain repellent and durable fabric fibers comprise, by weight, 42%-53% of the mohair fibers, 10%-13% of the viscose, 22%-26% of the polypropylene fibers and 15%-19% of the whalen fibers. The stain repellent and durable fabric fibers are formed by blending and weaving the stain repellent fabric fibers and the durable fabric fibers, the woven fabric fibers are high in strength and good in abrasive resistance and comfort, and have strong stain repellent performance, and the fabric is kept clean.

Owner:WUJIANG JINDI JET WEAVING FACTORY

Flowing light and color porous elastic gradient ring fancy yarn and manufacturing method thereof

The invention provides a flowing light and color porous elastic gradient ring fancy yarn and a manufacturing method thereof. The yarn comprises a core yarn, a decoration yarn and a fixed yarn. The core yarn is a core-spun yarn made of a lightmax fiber, an antibacterial hollow polyester fiber, a natural colored cotton fiber and a spandex filament. The decoration yarn comprises a mohair fiber, a silver-loaded antibacterial polyester fiber and a water-soluble vinylon fiber filament. The fixed yarn is a bamboo charcoal anion viscose filament. The weight content of the lightmax fiber in the core yarn accounts for 15 to 80%, the weight content of the antibacterial hollow polyester fiber accounts for 10 to 75%, and the weight content of the natural colored cotton fiber accounts for 10 to 75%. Thefabric in the invention has natural antibacterial and anti-mite properties, good moisture absorption, moisture release, moisture permeability, breathability, comfortable performance, a draping property and stiffness, a bright and shining appearance, a smooth and soft hand feeling, a fast moisture absorption speed and fuller color absorption. The fabric is not easy to be wormed and rotted, can becompletely degraded in nature, and is a new textile fiber combining green health care and comfortable wearing into one body.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Wear-resisting high-strength fabric fiber

The invention discloses a wear-resisting high-strength fabric fiber which is woven by wear-resisting fabric fibers and high-strength fabric fibers in a blending mode, the wear-resisting fabric fibers comprise, percentage by weight, 18%-31% mohair fibers and 14%-19% camel fuzzy fibers, and the high-strength fabric fibers comprise, percentage by weight, 34%-37% gabardine fibers and 21%-26% polyester fibers. Due to the fact that the wear-resisting high-strength fabric fiber is woven by multiple kinds of wear-resisting fabric fibers and multiple kinds of high-strength fabric fibers in a blending mode, the wear-resisting high-strength fabric fiber has the advantages of being wear resistant, high in strength, durable, good in elasticity and good in warm keeping performance.

Owner:WUJIANG JINDI JET WEAVING FACTORY

Method for processing mohair from ordinary fiber fabric

The invention discloses a method for processing mohair from ordinary fiber fabric, and belongs to the technical field of needled fabric processing. The method comprises the following steps: introducing the ordinary fiber fabric obtained by weaving or knitting ordinary fiber yarns into a napping needling machine, extracting yarns from the bottom surface of the ordinary fiber fabric by using a fork-shaped needle arranged on a needle plate of the napping needling machine, and depositing the extracted yarns into a hairbrush on a hairbrush curtain of the napping needling machine in a terry form to form terries protruded on base cloth on the surface of one side, facing to the hairbrush, of the ordinary fiber fabric so as to obtain single-sided terry fabric; introducing the single-sided terry fabric into a carding roll in a state that the terries face to the carding roll, tearing apart the terries by the carding roll to form straight hairs, and controlling the rotating speed of the carding roll to obtain single-sided straight-hair fabric with the straight hairs on a single side; introducing the single-sided straight-hair fabric into a needling machine for needling, and snarling and positioning base parts of the straight hairs and the base cloth by using a triangular needle on a needle bed of the needling machine to obtain a finished product. By the method, the processing efficiency is improved, resources are saved, and good texture is guaranteed.

Owner:常熟市伟成非织造成套设备有限公司

Yarn spinning process of high-count combed pure mohair knitted yarns

The invention discloses a yarn spinning process of high-count combed pure mohair knitted yarns. The yarn spinning process comprises the following specific steps of: mixing hairs and adding oil, combing and forming strips, gilling, combining, gilling after combining, drawing, gilling after drawing, pre-roving, roving and spinning. By virtue of the manner, the pure mohair knitted yarns obtained by the yarn spinning process of the high-count combed pure mohair knitted yarns, disclosed by the invention, have good strength elongation property, and all indexes reach utilization requirements of a pure thin and light fabric; prepared knitted clothes are fine, clean and smooth, have a soft tone and a thin, cool, stiff and smooth hand feeling, and the product fills the blank in China.

Owner:ZHANGJIAGANG CHAFTA TEXTILE TECH +1

Soft leather fabric

InactiveCN102963051ASoftSoft and comfortable to wearSynthetic resin layered productsCamel hairSoft layer

The invention discloses a soft leather fabric which comprises a superficial soft layer, a leather layer and close-fitting layer, wherein the leather layer is located below the soft layer; the close-fitting layer is located below the leather layer; the soft layer is a thin-film layer which is formed by polyimide fibers; the leather layer is made of fish leather; the close-fitting layer is an elastic layer which is formed by mutually knitting warps and wefts; the warps are formed by blending and knitting tribute silk fibers and mohair fibers; and the wefts are formed by blending and knitting cashmere fibers and camel hair cloth fibers. The superficial soft layer is the thin-film layer which is formed by knitting the polyimide fibers, so that the mechanical property is good, abrasion is difficulty to occur and soft hand feel is provided; the leather layer is formed by the fish leather, so that the material is soft and the hand feel is good; the close-fitting layer is formed by blending and knitting elastic and soft fabrics, so that the prepared fabric is soft and comfortable to wear; and at the same time, according to the elastic fabric, the clothing is close-filling, warm and non-breathable.

Owner:CHANGSHU FUYI PRINTING & DYEING

Novel warm-keeping fabric

The invention discloses a knitting product, namely novel warm-keeping fabric. The novel warm-keeping fabric comprises warps and wefts, and the warps and the wefts are mutually interlaced in a manner of two yarns on the top and one yarn on the bottom, wherein a polyester fiber is adopted as the warps, a novel blended fiber is adopted as the wefts, and the novel blended fiber comprises a mohair fiber, a rabbit hair fiber and a kapok fiber. The novel warm-keeping fabric disclosed by the invention has excellent warm keeping property and also has the characteristics of softness, comfort, moisture absorption, ventilation, no mould, static resistance and the like.

Owner:CHANGSHU FUJIALI WEAVING

Multifunctional modal fabric

The invention discloses a multifunctional modal fabric. The multifunctional modal fabric is formed by blended waving of four fibers including modal fiber, mohair fiber, synthetic fiber filaments and polyester fiber, and the multifunctional modal fabric comprises the following components in percenttage by weight: 35 to 48 percent of the modal fiber, 20 to 24 percent of the mohair fiber, 18 to 22 percent of the synthetic fiber filaments and 14 to 19 percent of the polyester fiber. The fabric is formed by blended waving of the modal fiber, the mohair fiber, the synthetic fiber filaments and the polyester fiber, the woven fabric is good in fabric moisture absorption, and can keep skin to be dry and comfortable, meanwhile, the fabric is quick in moisture discharge, good in breathability, and good in oil stain preventing performance, and the fabric is stiff and smooth, free from wrinkles, wearable and long in service life.

Owner:WUJIANG MANTESI TEXTILE

Superfine mercerization Australian wool blended stocking yarn and processing technique thereof

The invention relates to an ultra-thin silkete Australian wool blended knitting yarn and processing technology thereof, wherein the yarn is 82NM / 2 strands, comprising 60% of ultra-thin silkete Australian wool, 40% of mohair. The process includes: (1) pre-spinning: wool moisture regaining for 24-36 hours, with a moisture regaining rate of 24%, adding a fearnaughting oil to make the oil content in wool at 1%, the fearnaughting oil having proportion of antistatic agent:oil:water:cohesive force reinforcing agent at 0.5:1:8:0.5; (2) spinning: drafting for 19 times, with the speed of the fly frame at 8000r / min, single twist at 860T / M; (3) post-spinning, wherein the twist is designed to be 510T / mm. Advantages of the invention is that: (1) ultra-thin silkete Australian wool and mohair blended knitting is implemented, and difficulty in the process is overcome; (2) the product combines excellent characteristics of the two fibers, lowers cost and enhances performance / cost ratio thereof in the mean time; (3) the product is suitable for manufacturing high class clothing and ornament, having great cost advantage and market prospect.

Owner:TIANJIN TEXTILE ENG RES INST

Production technology for fancy yarn and sweater with imitated fur handfeel

ActiveCN106245175AHighlight smooth featuresSolve the problem of easy hair lossYarnLiquid/gas/vapor textile treatmentFiberYarn

The invention relates to a production technology for fancy yarn and a sweater with imitated fur handfeel. The production technology comprises raw material selection, wool humidifying, fore-spinning, roving, fancy twisting, napping, yarn steaming, yarn clearing and sweater production. For the fancy yarn with the imitated fur handfeel, an imitated fur effect is realized through mutual influence and restriction of raw materials including mohair, Australasian wool, high-elasticity Lycra fibers and the like.

Owner:浙江赢时胜实业有限公司

Wear-resisting blended shell fabric

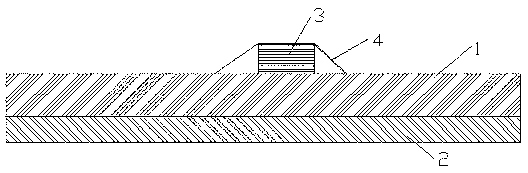

ActiveCN105369426AImprove wear resistanceIncrease elasticityAbrasion resistant fibresWoven fabricsMohairSurface layer

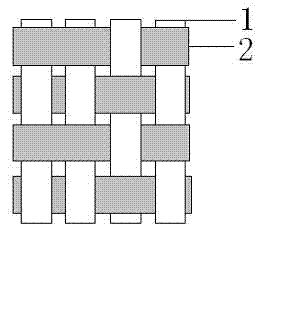

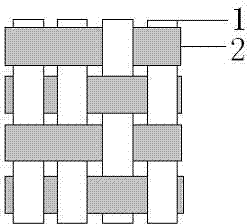

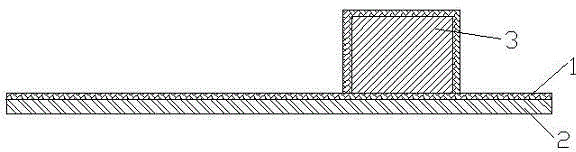

The invention discloses wear-resisting blended shell fabric. The wear-resisting blended shell fabric comprises a base cloth layer and a surface layer, wherein the base cloth layer is formed by interweaving warp yarn and weft yarn, the warp yarn includes the first warp yarn and the second warp yarn, the weft yarn includes the first weft yarn and the second weft yarn, the first warp yarn is mohair fiber, the first weft yarn is glazed polyester filament yarn, camel fiber is adopted as the second warp yarn, and polyester ramie blended yarn is adopted as the second weft yarn. The surface layer is a composite wear-resisting coating on the upper surface of the base cloth layer. The wear-resisting blended shell fabric integrates characteristics of various kinds of fiber, and the interwoven shell fabric is compact in fiber structure, good in wear resistance, high in elasticity, free of deformation, soft, light and breathable and absorbs moisture; the composite wear-resisting coating is arranged on the surface and capable of resisting friction and preventing pilling and fading, caused by wear, of the base cloth layer.

Owner:TONGXIANG YUXI KNITTING

Anti-fouling fabric knitted by warps and wefts

The invention discloses an anti-fouling fabric knitted by warps and wefts, wherein the anti-fouling fabric is formed by knitting of the warps and the wefts. The warps are formed by knitting and blending of polyamide fibers and palace fibers, and the wefts are formed by knitting and blending of mohair fibers and tencel fibers. The warps comprise, by weight, 35%-41% of the polyamide fibers and 59%-65% of the palace fibers, and the wefts comprise, by weight, 76%-82% of the mohair fibers and 18%-24% of the tencel fibers. According to the anti-fouling fabric knitted by the warps and the wefts, the anti-fouling fabric is formed by knitting of the warps and the wefts and is compact in structure, the warps and the wefts are composed of the polyamide fibers, the palace fibers, the mohair fibers and the tencel fibers, and the anti-fouling fabric has the advantages of being windproof and waterproof, good in anti-fouling property, elastic and formfitting and cool and comfortable.

Owner:WUJIANG XUYANG TEXTILE

Anti-static garment

InactiveCN103381677AGood anti-static effectFeel coolSynthetic resin layered productsMohairSurface layer

The invention discloses an anti-static garment. The anti-static garment comprises a surface anti-static fabric layer and an inner elastic comfortable fabric layer. The anti-static fabric layer are woven of organic conductive fiber and flax fiber through blending, and the elastic comfortable fabric layer is woven of warps and wefts, wherein the warps are woven of mercerized wool fiber and mercerized cotton fiber through blending, and the wefts are woven of mohair fiber and plumetis fiber through blending. According to the anti-static garment, the surface layer is woven of the organic conductive fiber and anti-static fiber through blending, so that the anti-static effects are good, and the hand feeling is nice and cool; the inner layer is woven of a plurality of fabric fibers through blending, thereby being elastic, close-fitting, good-hygroscopicity, breathable, soft and comfortable.

Owner:CHANGSHU HENGQIN GARMENT

High-strength blended chemical fabric

InactiveCN104026782AImprove wear resistanceImprove corrosion resistanceUndergarmentsProtective garmentMohairPolyolefin

The invention discloses a high-strength blended chemical fabric. The high-strength blended chemical fabric comprises, by weight, 12%-16% of three-acetate fibers, 23%-27% of elastodiene fibers, 28%-32% of polyolefin elastic fibers and 25%-37% of mohair fibers, and the three-acetate fibers, the elastodiene fibers, the polyolefin elastic fibers and the mohair fibers are blended and woven with one another to form the high-strength blended chemical fabric. The high-strength blended chemical fabric has the advantages that the three-acetate fibers, the elastodiene fibers, the polyolefin elastic fibers and the mohair fibers are blended and woven with one another to form the fabric, accordingly, the woven fabric is good in abrasion resistance, corrosion resistance, ageing resistance and acid and alkali resistance, is washable, durable and elastic and can closely fit with a wearer, and the wearer feels comfortable when wearing the high-strength blended chemical fabric.

Owner:TAICANG XINTAI KNITTING

Multifunctional corrosion-resistant fabric

InactiveCN103469431AIdeal anti-corrosion functionImprove wear resistanceWeft knittingWarp knittingMohairPolymer science

The invention discloses multifunctional corrosion-resistant fabric which is formed by blending and weaving four material fibers including vinylon fibers, nylon fibers, polyisoprene fibers and mohair fibers. The multifunctional corrosion-resistant fabric is composed of, by weight, 35-50% of the vinylon fibers, 15-20% of the nylon fibers, 11-16% of the polyisoprene fibers and 24-29% of the mohair fibers. The fabric is formed by blending and weaving the four material fibers including the vinylon fibers, the nylon fibers, the polyisoprene fibers and the mohair fibers, thereby having an obvious corrosion-resistant function, and the fabric has excellent wear resistance, soil resistance and high strength and is good in durability and high in practicability.

Owner:WUJIANG HAIFENG WEAVING

Multifunctional mohair fabric

The invention discloses a multifunctional mohair fabric which is formed by blended waving of four fibers including mohair fiber, mulberry bark fiber, apocynum venetum fiber and plush fiber. The multifunctional mohair fabric comprises the following components in percentage by weight: 42 to 57 percent of the mohair fiber, 8 to 13 percent of the mulberry bark fiber, 15 to 20 percent of the apocynum venetum fiber and 20 to 25 percent of the plush fiber. The fabric is formed by blended waving of the four fibers including the mohair fiber, the mulberry bark fiber, the apocynum venetum fiber and the plush fiber, and the woven fabric has the characteristics of high intensity, elasticity and body fitting, zero deformation, wear resistance, and stain prevention, and also has the characteristics of moisture absorption and breathability and health protection of the natural fibers.

Owner:WUJIANG MANTESI TEXTILE

Fabric with weather prompting device

InactiveCN102975413AReduce seek timeEasy to go outSynthetic resin layered productsSurface layerMohair

The invention discloses a fabric with a weather prompting device. The fabric comprises a weatherproof fabric layer on the surface layer, a warm-keeping fabric layer on the inner layer and a weather forecast wireless reading device arranged on the surface of the weatherproof fabric layer, wherein the weatherproof fabric layer is formed by knitting warps with wefts, the warps are blended and knitted from polyamide fibers and mohair fibers fibers, while the wefts are blended and knitted from viscoses and fibrilia; the warm-keeping fabric layer is blended and knitted from import long staples and mercerized cotton fibers; and one layer of weatherproof fabric is covered on the surface of the weather forecast wireless reading device. The weatherproof fabric on the surface layer is windproof, wearable, antistatic and anti-pilling; the warm-keeping fabric layer on the inner layer is warm, comfortable, soft and close-fitting; and the weather forecast wireless reading device mounted on the surface layer of the fabric is capable of saving the finding time of the users and providing effective weather forecast at any time, and also convenient for the users to prepare for going out.

Owner:WUJIANG GAOFA TEXTILE

Collagen-cashmere composite fabric with good drapability and preparation method of collagen-cashmere composite fabric

InactiveCN106637974AMitigating the problem of year-on-year declineImprove hydrophilicityLight resistant fibresConjugated cellulose/protein artificial filamentsMohairUltraviolet lights

The invention discloses a collagen-cashmere composite fabric with good drapability. The collagen-cashmere composite fabric is prepared from the following raw materials in parts by weight: 40-42 parts of cashmere fibers, 10-12 parts of tea leaf fibers, 14-17 parts of polyamide fibers, 16-18 pats of mohair, 8-10 parts of collagen powder, 2.1-2.4 parts of ethylene glycol diglycidyl ether, 7-9 parts of stems and bark of cottonrose hibiscus, 1-3 parts of konjac glucomannan, 0.5-0.8 part of nano-silver particles, 1.4-1.7 parts of 3-aminopropyltriethoxysilane, 2-3 parts of triethanolamine, 185-190 parts of 1-allyl-3-methylimidazole chlorine salt and a proper amount of water. According to a preparation method, oxygen low-temperature plasma is utilized for carrying out preprocessing, and ethylene glycol diglycidyl ether is used as a crosslinking agent for grafting modified collagen to the surface of the cashmere composite fiber; and the prepared collagen-cashmere composite fabric has good drapability and special functions of resisting ultraviolet light and bacteria, preventing worm damaging and the like, and the market prospect is wide.

Owner:ANHUI TIANWEI CASHMERE PROD

Shell fabric with manometer

The invention discloses a shell fabric with a manometer. The shell fabric comprises a warm keeping shell fabric layer at the surface layer, an elastic shell fabric layer at the inner layer, and an electronic manometer arranged on the surface of the warm keeping shell fabric layer, wherein the warm keeping shell fabric layer is blended and woven by cashmere fibers, mohair fibers and rabbit hair fibers; the elastic shell fabric layer is blended and woven by spun silk fibers and Melton fibers; and the surface of the electronic manometer is wrapped with a layer of base cloth and the electronic manometer is sewn on the surface of the warm keeping shell fabric layer through the base cloth. The shell fabric blended and woven by the cashmere fibers, the mohair fibers and the rabbit hair fibers is soft, comfortable in handfeel and good in warm keeping performance; the shell fabric blended and woven by the spun silk fibers and the Melton fibers is high in elasticity and keeps warm next to the skin; and as the electronic manometer is sewn on the surface of the shell fabric, the blood pressure of old people can be conveniently measured, and meanwhile, the electronic manometer is convenient to store so that the trouble of finding the electronic manometer is eliminated.

Owner:CHANGSHU FUJIALI WEAVING

Warming protection blend fiber

InactiveCN105256427AHeat storageMoisture-absorbing and breathableYarnMohairPolyethylene terephthalate

The present invention discloses a warming protection blend fiber. The warming protection blend fiber is blended and knitted by polytrimethylene terephthalate fiber, kapok fiber, ceramic thermal storage warming fiber and mohair fiber. The warming protection blend fiber comprises the components of, by weight, 17%-20% of polytrimethylene terephthalate fiber, 29%-38% of kapok fiber, 13%-16% of ceramic thermal storage warming fiber, and 32%-35% of mohair fiber. The warming protection blend fiber is blended and knitted by various fibers, has the characteristics of thermal storage and warming, health protection, moisture absorption and air permeability, and is comfortable to wear and is soft.

Owner:太仓市雄瑞化纺有限公司

Full acrylic mohair textile process and full acrylic mohair product

InactiveCN107653531ASimple processSolve the phenomenon of easy hair lossWeft knittingWarp knittingYarnMohair

The invention discloses a full acrylic mohair textile process and a full acrylic mohair product. The full acrylic mohair textile process includes: controlling moisture regain while spraying acrylic yarn; successively performing gilling and sliver mixing on the acrylic yarn, performing roving and spinning, and acquiring acrylic spun yarn; performing self-spooling, doubling and two-for-one twistingon the acrylic spun yarn, performing yarn steaming for the preset time, wherein the temperature range of steam is 85 DEG C-105 DEG C; performing dyeing and fuzzing, blend-weaving the yarns and pigment-dyed fibers, and acquiring a blend fabric; performing stone-washing on the blend fabric, performing washing and drying on the blend fabric, and performing galling and carding on the dried fabric. Thefull acrylic mohair textile process includes yarn steaming and stone-washing, hair exposed by the fluff yarn will not be pulled off, and hair falling of the mohair-like yarn can be solved thoroughly;and the full acrylic mohair textile process can lay a good production basis for the new process-stone-washing.

Owner:三问家居股份有限公司

Fabric for water-absorption mop

InactiveCN103654659AImprove water absorptionImprove water retentionCarpet cleanersFloor cleanersMohairWear resistant

The invention discloses a fabric for a water-absorption mop. The fabric for the water-absorption mop comprises, by weight, 10%-14% of polyacrylamide fibers, 13%-18% of polyoxyethylene fibers, 23%-27% of viscose fibers and 41%-54% of mohair fibers. The polyacrylamide fibers, the polyoxyethylene fibers, the viscose fibers and the mohair fibers are blended and woven to form the fabric. The fabric has the advantages that the polyacrylamide fibers, the polyoxyethylene fibers, the viscose fibers and the mohair fibers are blended and woven to form the fabric, the woven fabric is excellent in water absorption and water retention capacity, brings convenience for mopping floors cleanly, is wear-resistant, is not easy to wrinkle and is long in service life, and materials for making the fabric are high in strength.

Owner:WUJIANG HENGDELI TEXTILE MILL

Non-asbestos brake block containing animal fibers and manufacturing method thereof

InactiveCN103644230AGood dispersionImprove adsorption capacityOther chemical processesFriction liningMohairAnimal fiber

The invention discloses a non-asbestos brake block containing animal fibers. The non-asbestos brake block comprises, by weight, 14-16% of modified phenolic resin, 20-28% of fiber material, 53-61% of filling material and 5-8% of the animal fibers. The animal fibers are composed of one or more of sheep wool, cony hair, camel hair, goat hair, mohair, yakwool and silk, and the fiber material is composed of one or more of mineral fibers, glass fibers and paper fibers. The invention further discloses a manufacturing method for the non-asbestos brake block containing the animal fibers. The non-asbestos brake block containing the animal fibers is good in high-temperature resistance and abrasive resistance, the non-asbestos formula can have good strength in the cold-pressing performing process so that the purpose of transferring can be achieved, and the non-asbestos brake block containing the animal fibers is simple in manufacturing method and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Spandex fiber-containing dry cleaning-resistant flame-retardant cashmere composite fiber and manufacturing method thereof

InactiveCN104911733AWith dry cleaning characteristicsAntistaticElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberMohair

The invention discloses a spandex fiber-containing dry cleaning-resistant flame-retardant cashmere composite fiber. The fiber is prepared from 22-28 parts by weight of Tibetan antelope wool, 15-18 parts by weight of white goose down, 17-19 parts by weight of mohair fibers, 19-24 parts by weight of rice straw pulp fibers, 12-15 parts by weight of spandex fibers, 14-17 parts by weight of cuprammonium fibers, 2-4 parts by weight of nanometer far-infrared ceramic powder, 1.2-3.5 parts by weight of decabromodiphenyl oxide, 7-9 parts by weight of polypropylene glycol, 3-5 parts by weight of acrylamide, 2-3 parts by weight of pregelatinized starch, 0.4-0.8 parts by weight of magnesium chloride, 0.5-0.9 parts by weight of nanometer titanium dioxide, 1-3 parts by weight of prepared rehmannia root, 2-5 parts by weight of dendranthema indicum var aromaticum, 3-4 parts by weight of poria cocos, 85-95 parts by weight of 1-ethyl-3-methylimidazolium acetate, 90-110 parts by weight of 1-allyl-3-methylimidazolium chloride, 20-24 parts by weight of an auxiliary agent and a proper amount of water. Multiple types of fibers and Tibetan antelope wool are blended and spandex fibers and cuprammonium fibers are added into the mixture so that the cashmere composite fiber is obtained. The cashmere composite fiber has characteristics of dry cleaning resistance of spandex fibers and antistatic properties of cuprammonium fibers. Through use of other fibers and effective components, the cashmere composite fiber has the advantages of flame retardation, wear resistance, good serviceability, good processability and wide application scope.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Mohair blended stocking yarn and technique for processing same

The invention relates to an mohair blended knitting yarn and processing technology thereof, wherein the yarn is 82NM / 2 strands, comprising 60% of mohair, 40% of silkete Australian wool. The process includes: (1) pre-spinning: wool moisture regaining for 36 hours, with a moisture regaining rate of 24%, adding a fearnaughting oil to make the oil content in wool at 1%, the fearnaughting oil having proportion of antistatic agent:oil:water:cohesive force reinforcing agent at 0.5:1:8:1; (2) spinning: drafting for 19 times, with the speed of the fly frame at 7000r / min, single twist at 880T / M; (3) post-spinning, wherein an electronic yarn cleaner is provided for the winding, and yarns are spliced under air pressure between 0.6-0.8 Mpa. Advantages of the invention is that: (1) blended knitting of mohair with other fibers is implemented, and technological guarantee is provided for expanding application scope of mohair; (2) the product combines excellent characteristics of the two fibers, lowers cost, and enhances performance / cost ratio thereof in the mean time; (3) the product is suitable for manufacturing high class clothing and ornament, having great cost advantage and market prospect.

Owner:TIANJIN TEXTILE ENG RES INST

Fabric fiber easy to dye

The invention discloses a fabric fiber easy to dye. The fabric fiber easy to dye is formed by blending of multiple kinds of fabric fibers easy to dye in a woven mode. The fabric fiber easy to dye comprises, by weight, 15%-18% of viscose, 17%-21% of crepe fibers, 31%-46% of mohair fibers, 9%-14% of fibrilia and 13%-16% of cotton fibers. The fabric fiber easy to dye is formed by blending of multiple kinds of fabric fibers easy to dye in the woven mode, the woven fabric fiber is easy to dye and good in color, color fading is avoided, and the fabric is capable of absorbing moisture, breathable, smooth and comfortable.

Owner:WUJIANG JINDI JET WEAVING FACTORY

Fiber fabric which can be easily dyed

InactiveCN106666890AEasy to dyeBrightly dyedProtective garmentSpecial outerwear garmentsMohairViscose

The invention provides a fiber fabric which can be easily dyed. The fiber fabric comprises Shengma fiber, cotton fiber, jade fiber, aluminum fiber, nano-fiber, viscose fiber, crepe fiber, mohair fiber and imported long lint fiber. The fabric has the advantages of being convenient to dye, good in color, free of color fading, high in strength and elastic recovery rate, strong in anti-wrinkle property, good in anti-wearing property, good in natural luster and fresh in dying color. The fabric has moisture absorption and ventilation functions, is smooth and comfortable, and is strong in anti-fouling property, causes no pollution to the environment, and is both safe and reliable.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com