Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Good tensile performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

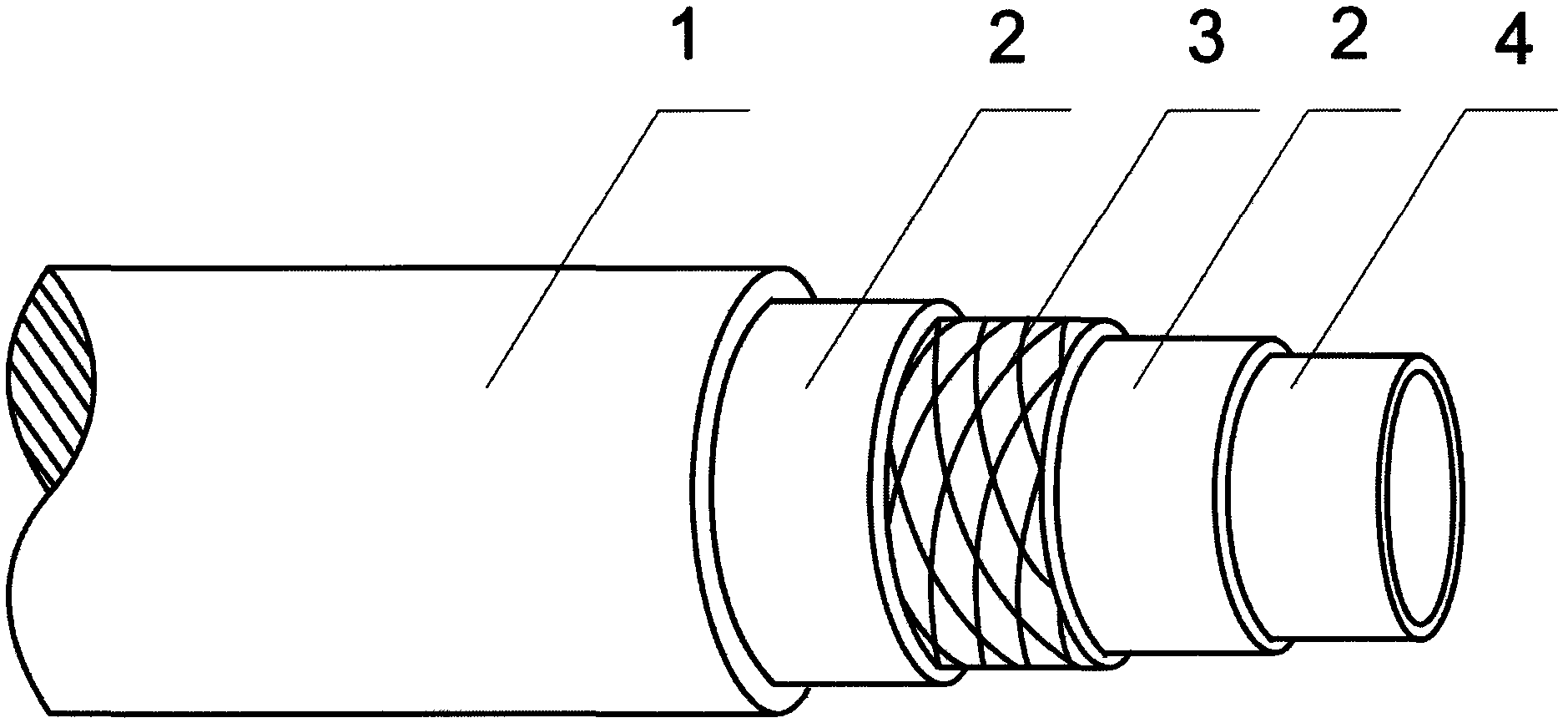

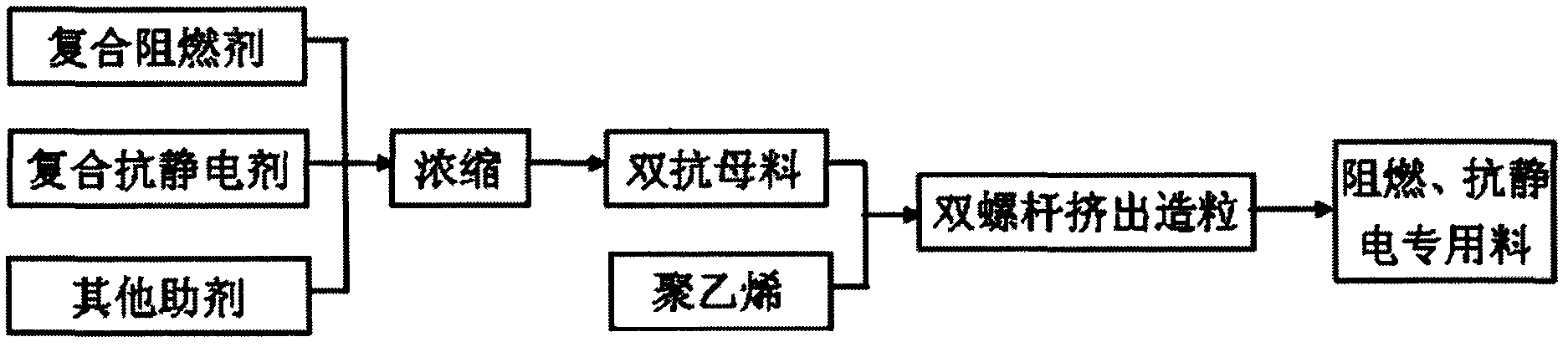

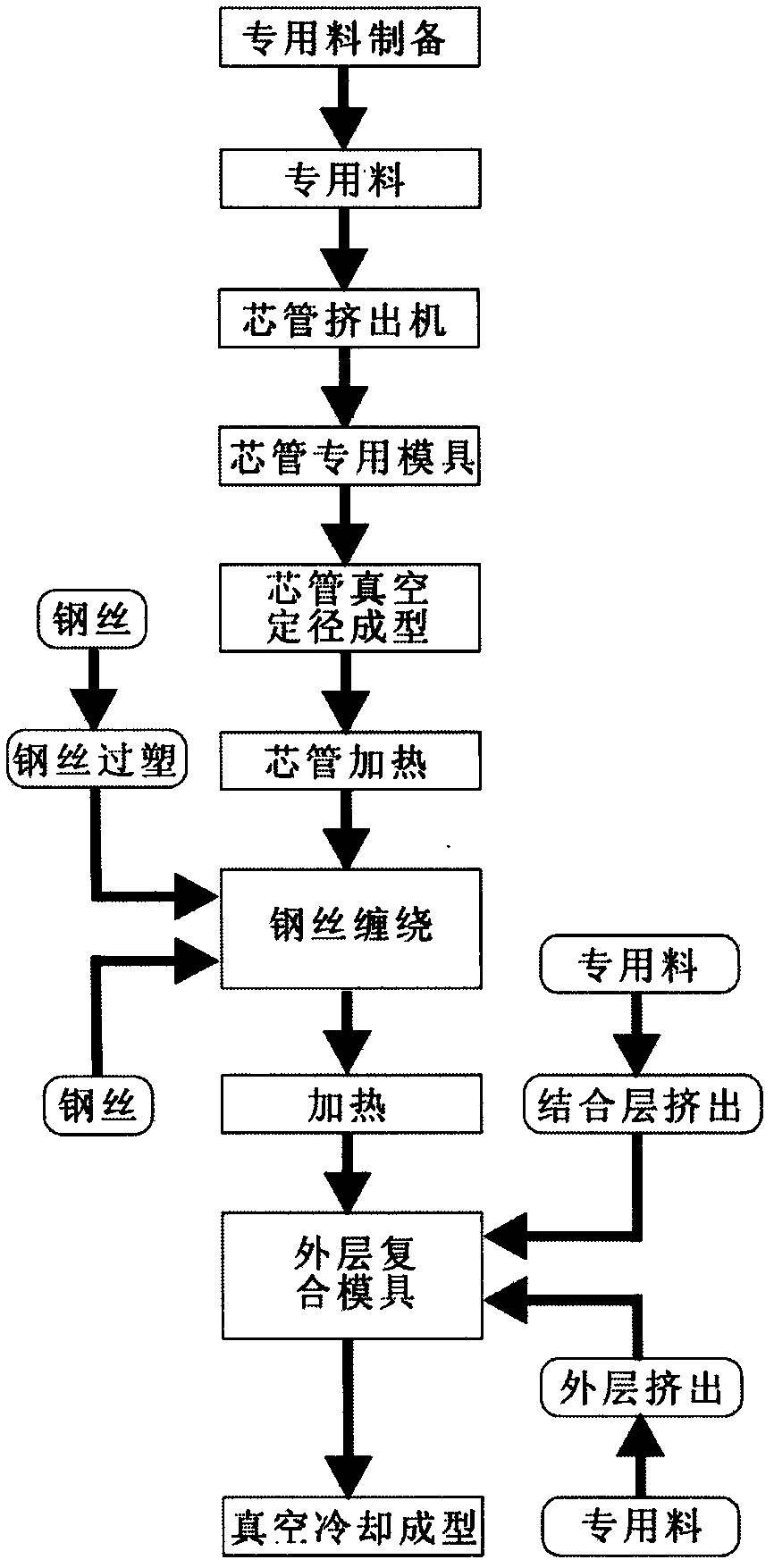

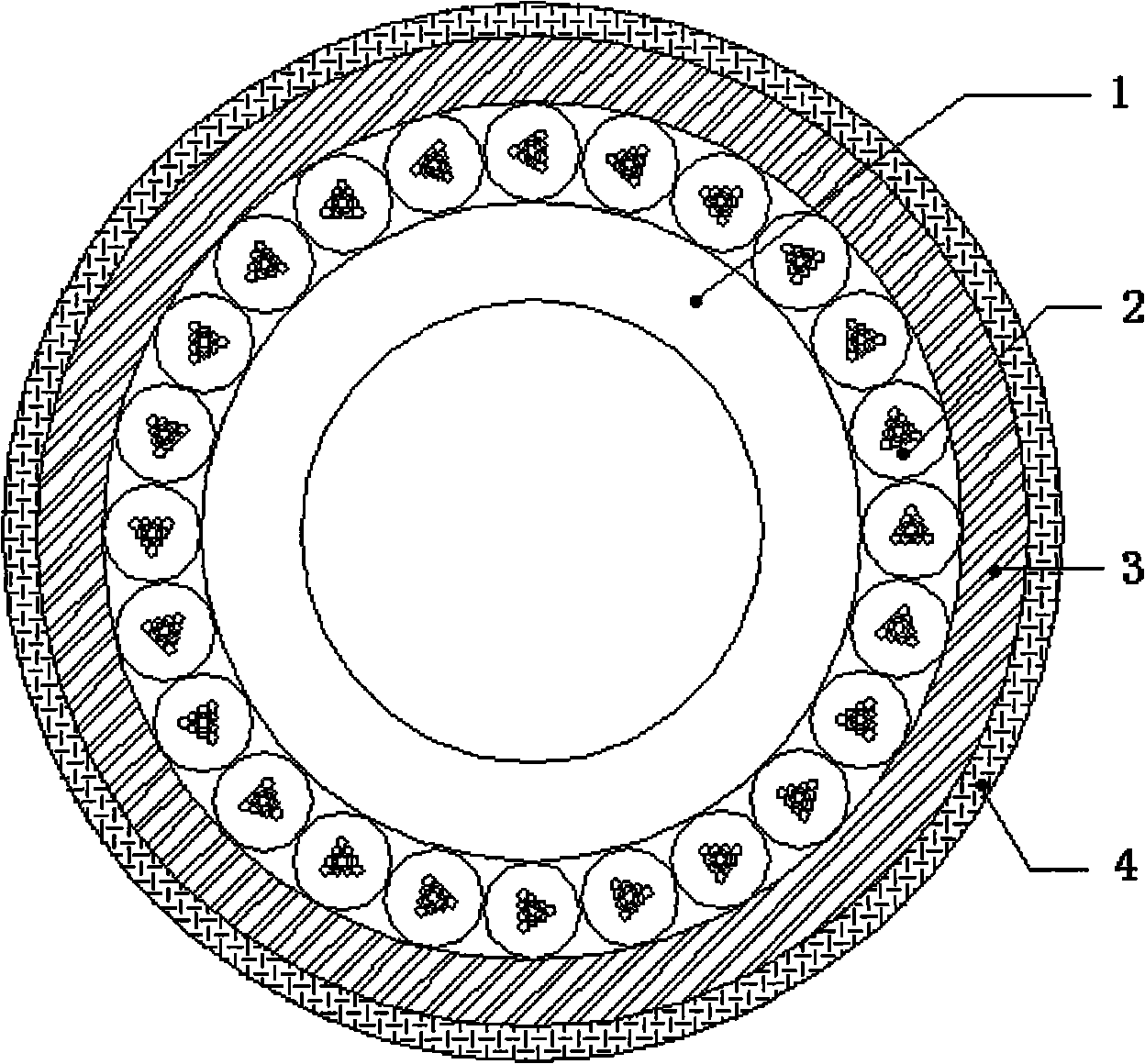

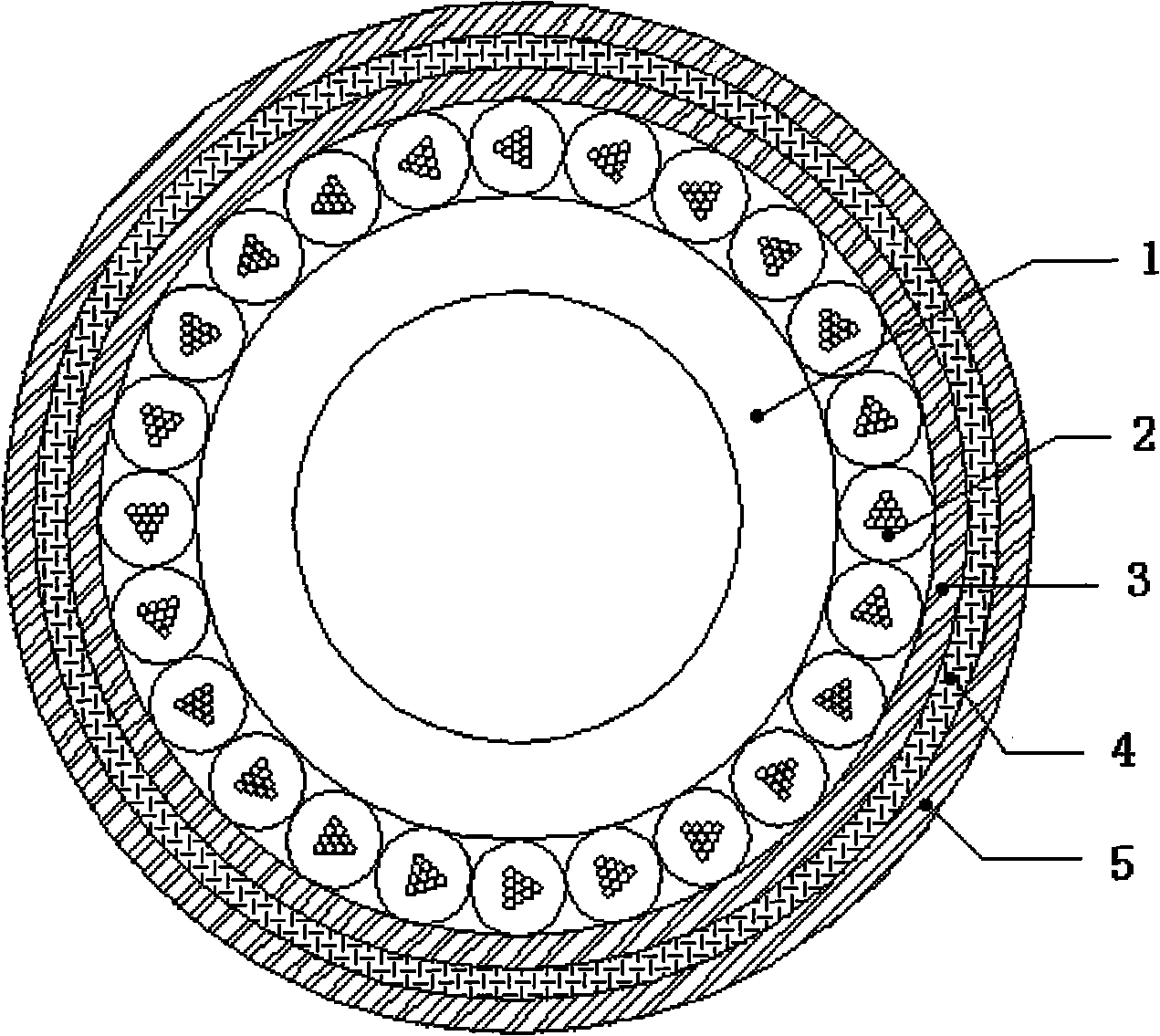

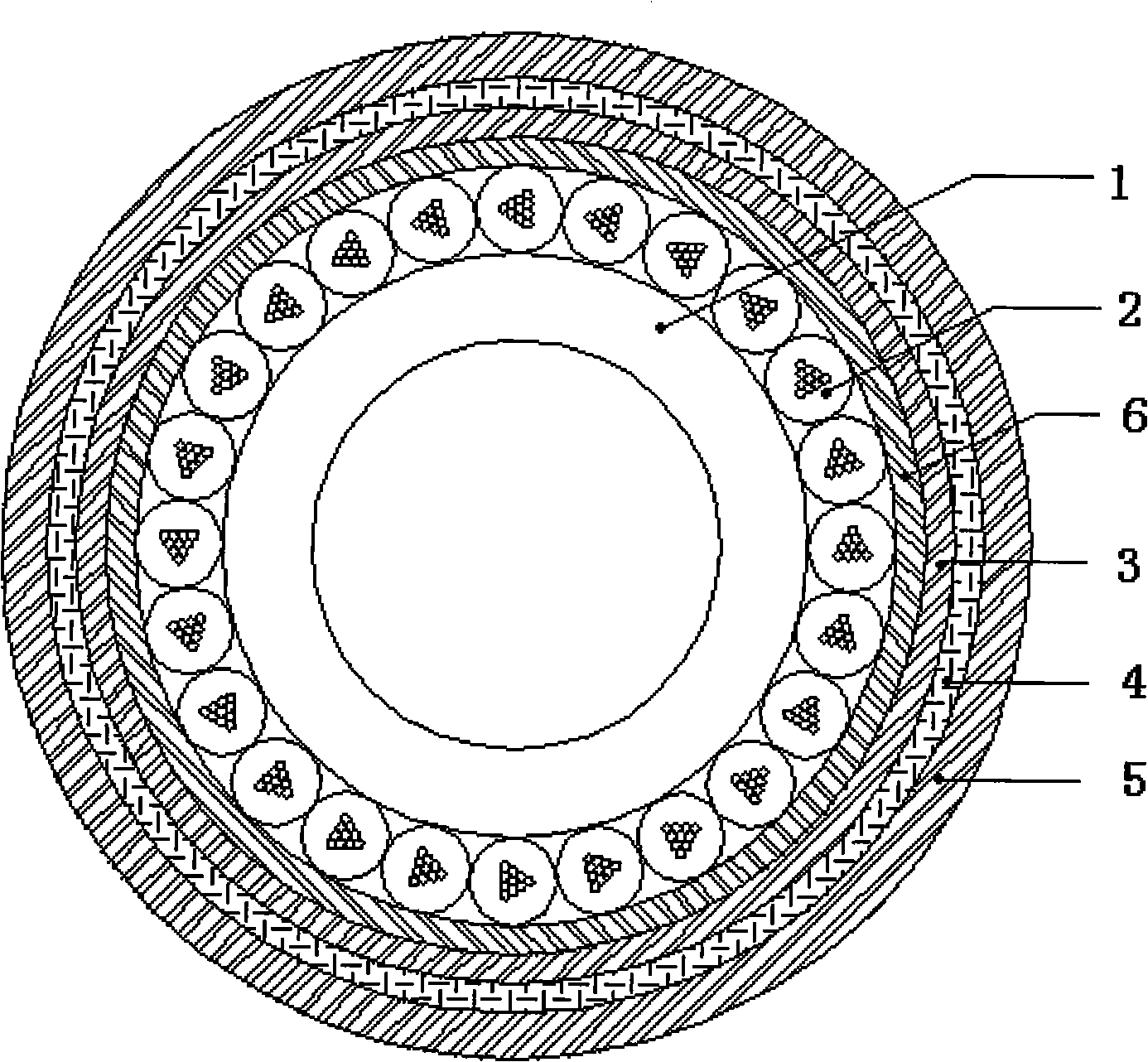

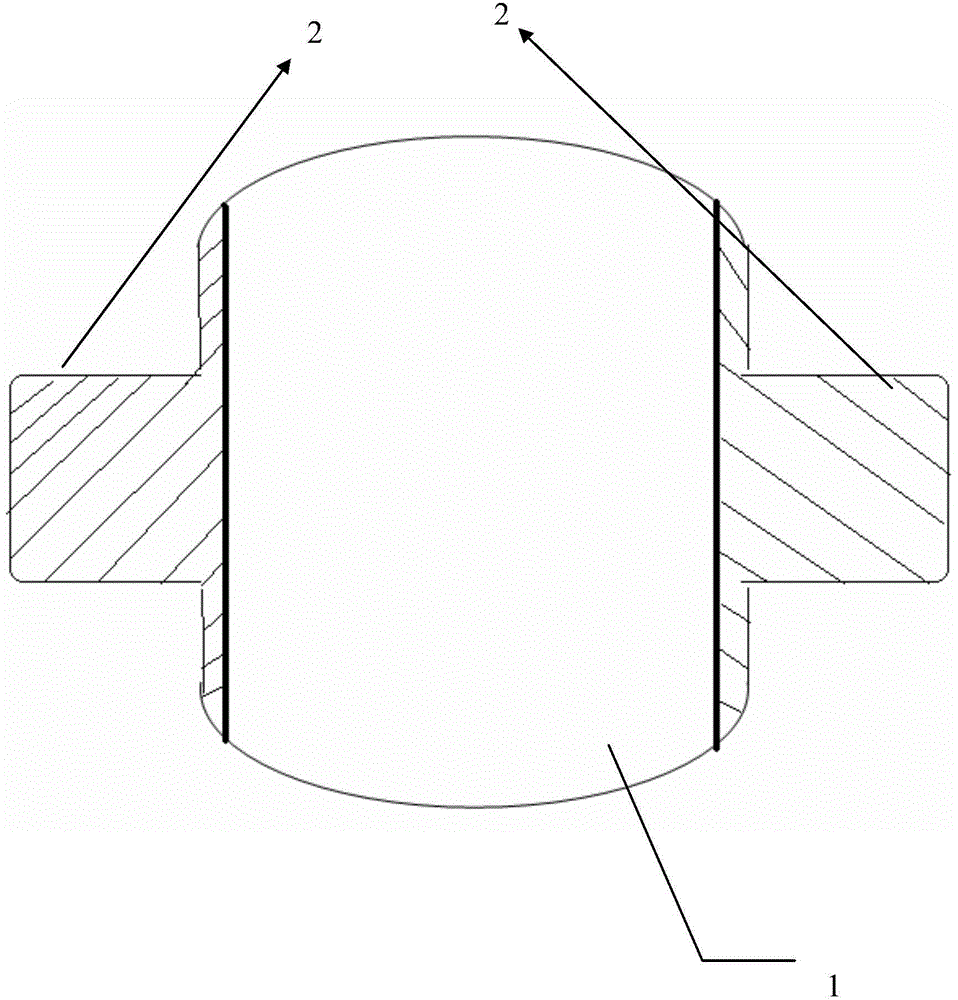

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

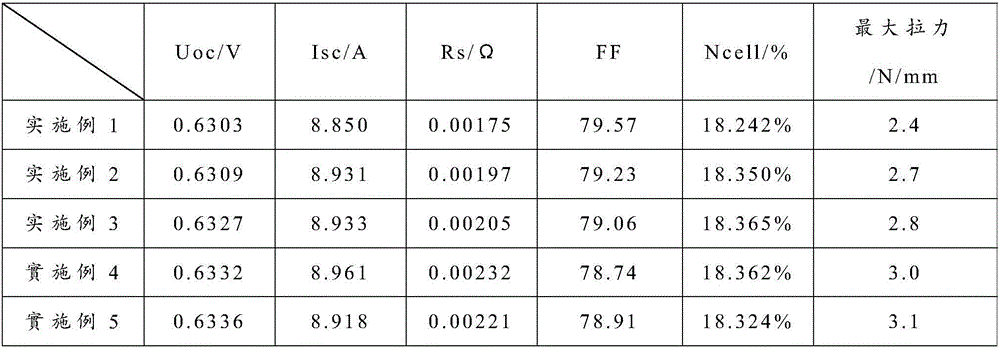

Glass powder, positive electrode silver paste prepared therefrom and solar battery

InactiveCN106477897AImprove structural strengthImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteChemical composition

The invention relates to glass powder. The glass powder contains the ingredients in percentage by mass: 20% to 60% of PbO, 10% to 50% of Bi2O3, 20% to 60% of TeO2 and 5% to 15% of SiO2. According to the glass powder, through adjusting and optimizing chemical composition, electrodes prepared from positive electrode silver paste prepared from the glass powder can have relatively high photoelectric conversion efficiency and relatively good tension property, and thus the service life of a solar battery is guaranteed. In addition, the invention further provides the positive electrode silver paste prepared from the glass powder and the solar battery prepared from the positive electrode silver paste.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +5

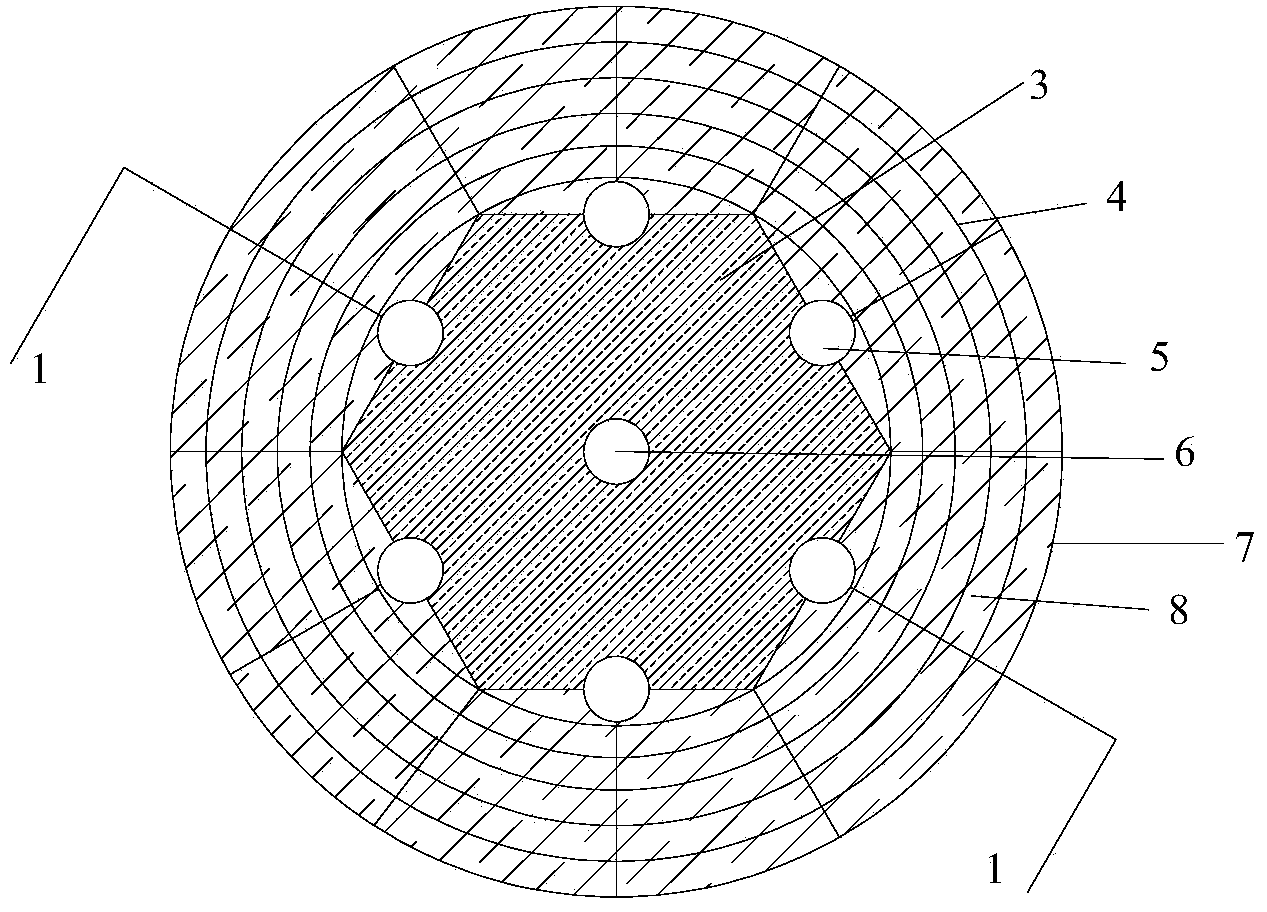

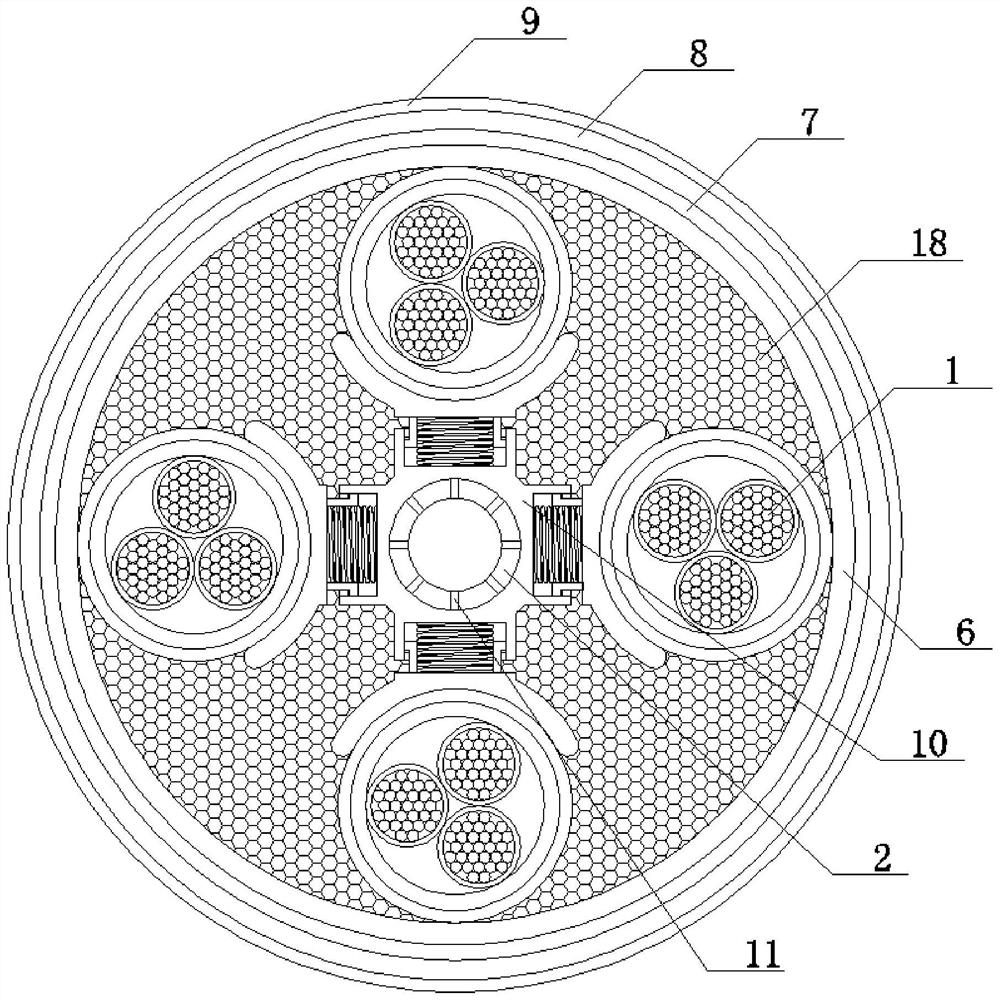

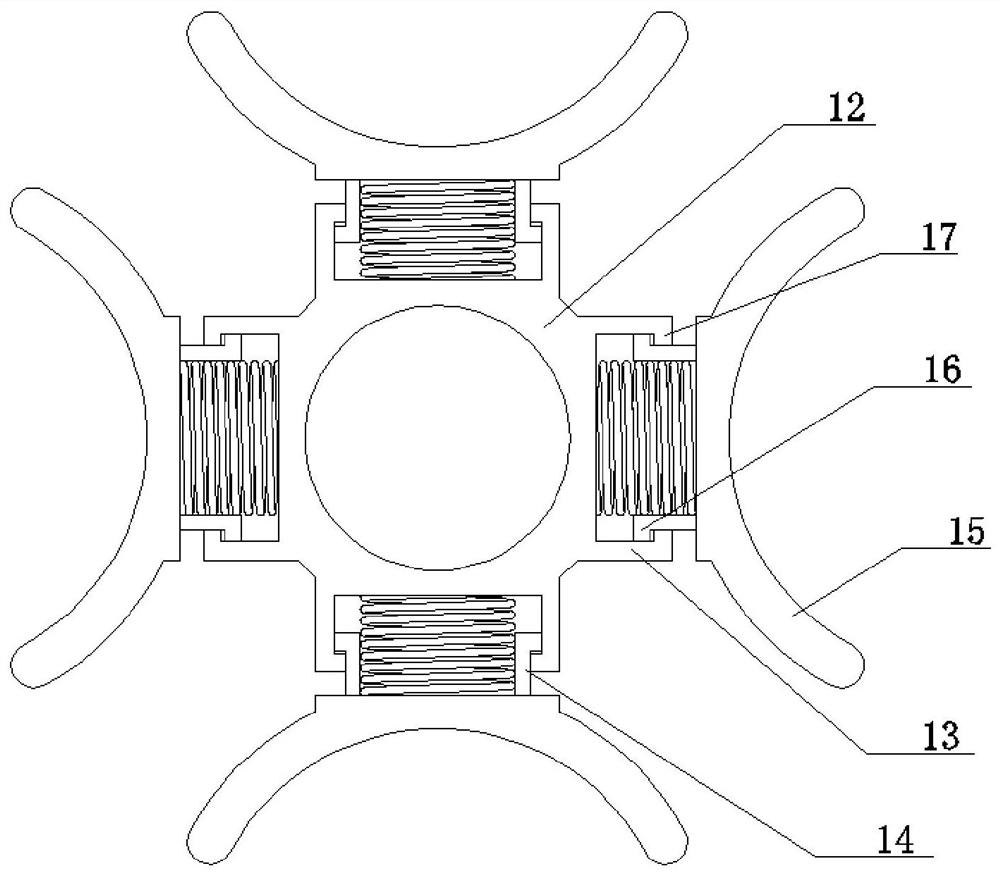

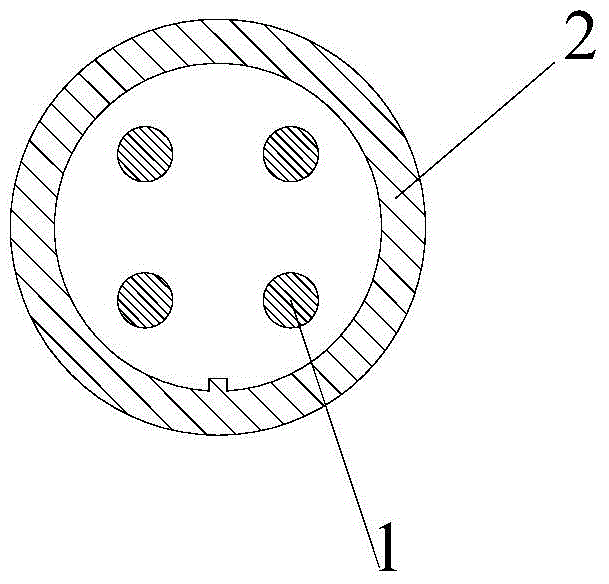

Multifunctional underwater towing line

InactiveCN101281801ASolve slidingUniform tensile forceSubmarine cablesInsulated conductorsUnderwaterEngineering

The present invention relates to a multi-functional submarine towing cable, which is characterized in: the towing cable comprises from center to exterior as follows: water transmission pipe, cables for power supply and data communication, waterproof bushing, and reinforcing rope. With consideration of leak tightness of the submarine towing cable and protection for the internal structure, an outer waterproof bushing is added outside of the reinforcing rope. A cable fixing glue layer is added outside of the cable. The water transmission pipe is made of Nylon 11 material, and the reinforcing rope is braided with Kevlar material. The present invention integrates water transmission, power transmission, and towing function to produce a towing cable that is different to steel wire cables or conventional armored cables. That is to say, the present invention provides a shipboard expendable continuous sampling system, particularly a towing cable that can be used to take water samples in real time, especially a towing cable that is loaded on a towing platform for a continuous water sampling system, with a water transmission pipe and conduction and signal transmission capability, and high tensile strength, designed to accomplish shipboard expendable continuous water sampling tasks at different predefined depths or implement shipboard expendable, quick, and online water quality monitoring.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

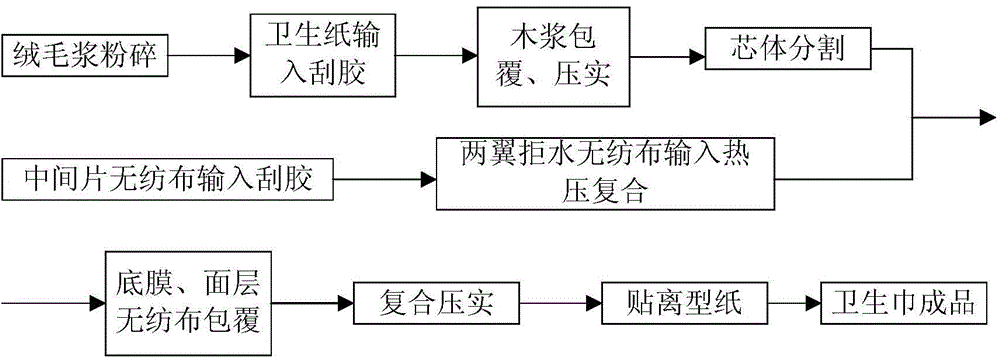

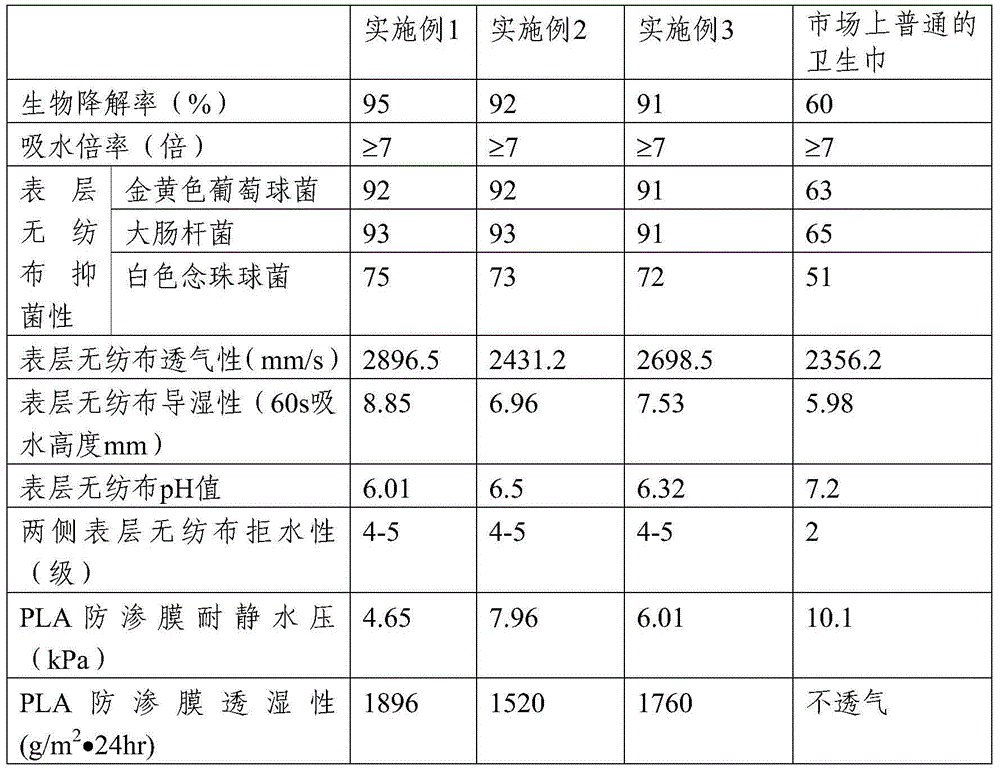

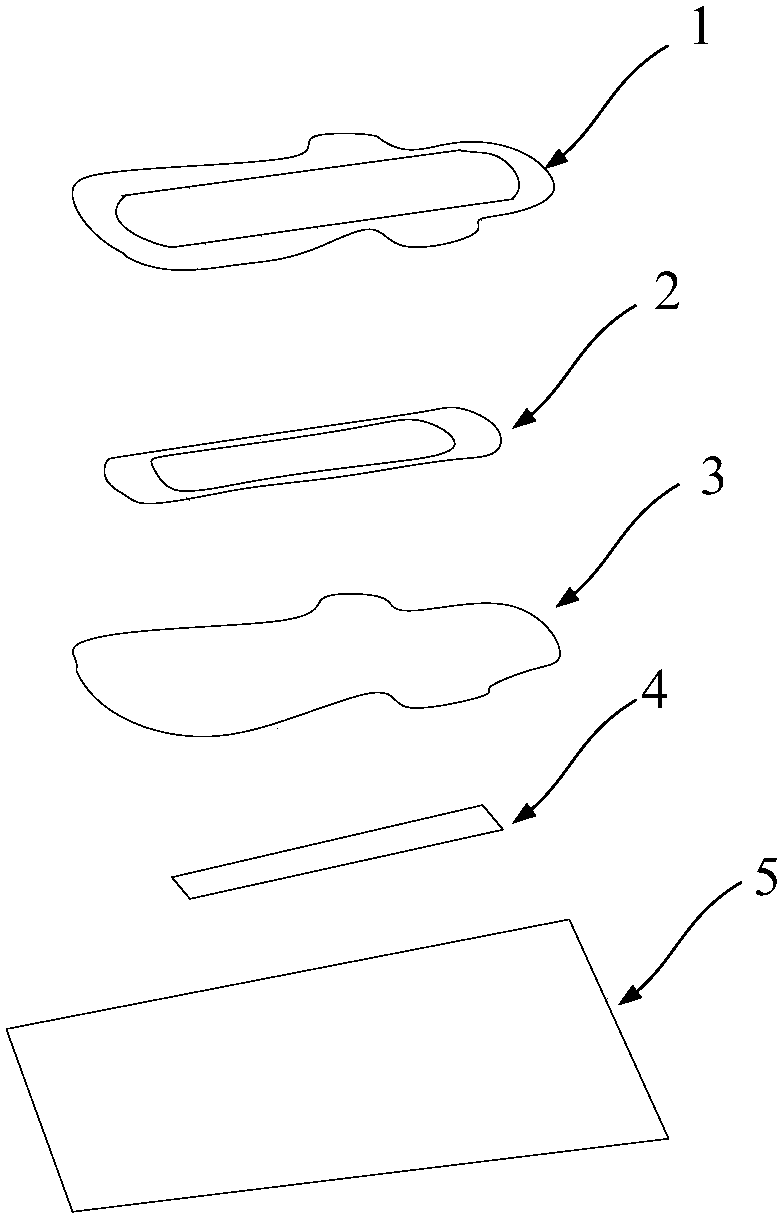

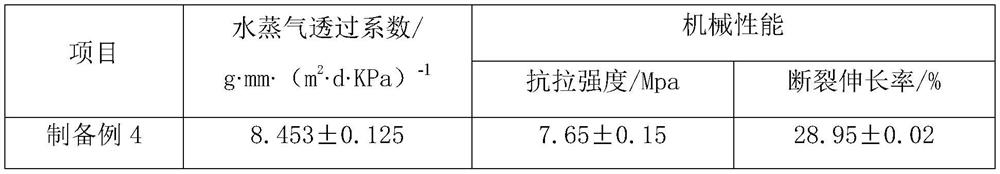

Anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

The invention provides an anti-side leakage sanitary napkin, which includes a surface non-woven fabric and a bottom impermeable membrane disposed from the inside out. The surface non-woven fabric has a three-piece structure, the intermediate piece of surface non-woven fabric and the two-wing surface non-woven fabrics are sticked together, and the space between the intermediate piece of surface non-woven fabric and the bottom impermeable membrane is filled with a toilet paper coated wood pulp cellulose absorption core. The surface of the sanitary napkin provided by the invention is composed of 100% polylactic acid fiber or PLA / PBHV fiber hot blast nonwoven fabric. The polylactic acid fiber retains the original characteristics and does not cause any damage. As polylactic acid is formed by polymerization of lactic acid molecules as monomers and spinning, polylactic acid molecules with short molecular chains possibly exist on the fiber surface, so that the pH value of a polylactic acid non-woven fabric surface shows weak acidity and is consistent with that of human body skin. Also an odor removal function is provided. The lateral two pieces of non-woven fabrics have greater gram weight and thickness than the intermediate piece, and side leakage cannot be caused.

Owner:马鞍山同杰良生物材料有限公司

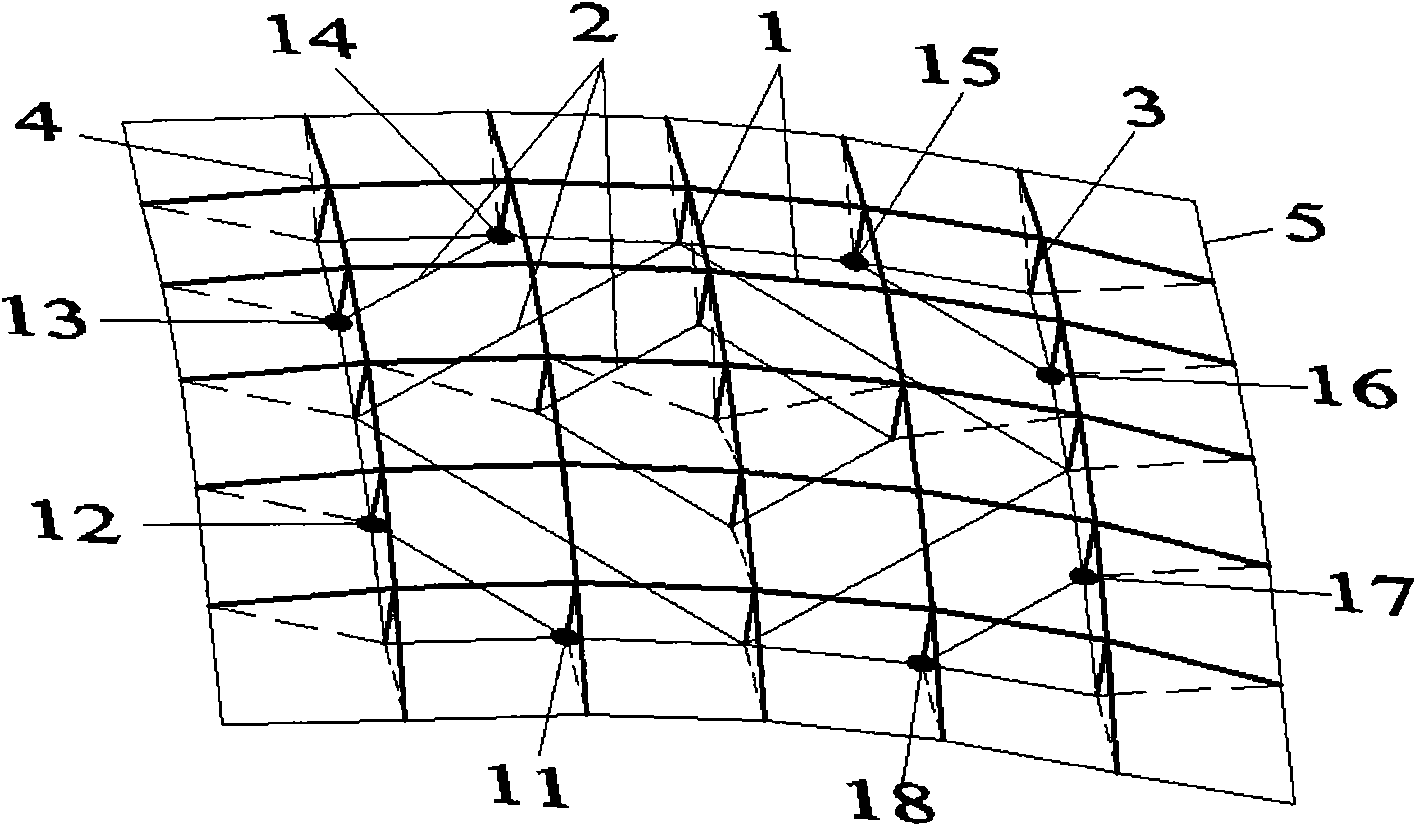

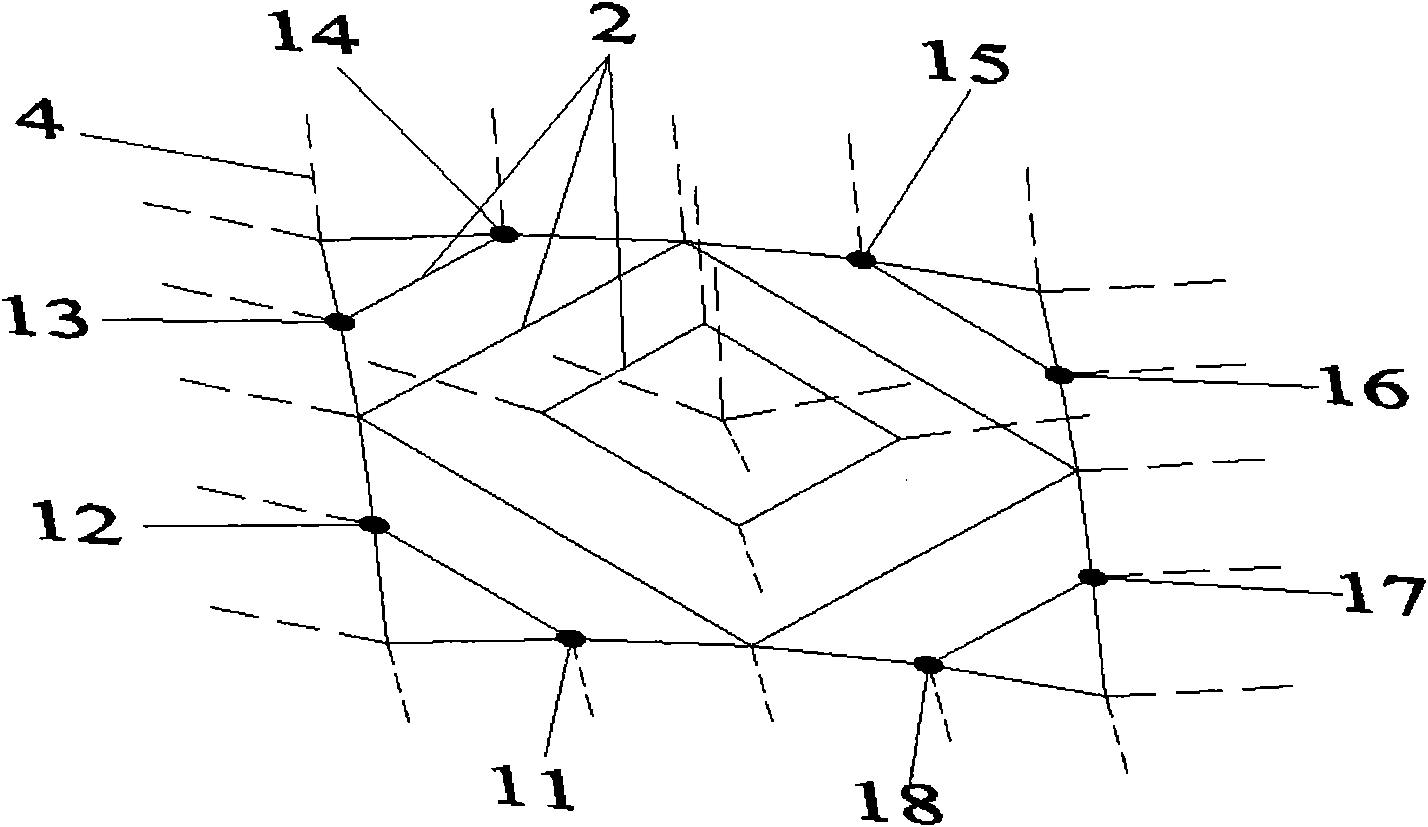

Square rigid cable dome structure

InactiveCN102071741ASimple structureLight weightBuilding roofsArched structuresHyperboloidSymmetric axis

The invention discloses a square rigid cable dome structure. Rigid members form mutually vertical grids and are positioned on a convex hyperboloid; boundary ring beams are arranged at the peripheries of the grids; vertical brace rods perpendicular to the ground are arranged under grid nodes of the rigid members on horizontal symmetric axes and vertical symmetric axes as well as grid nodes of the peripheral rigid members; oblique cords are connected between the network nodes of the horizontal symmetric axes and the vertical symmetric axes and the lower ends of the adjacent inside vertical brace rods; oblique cords are connected between nodes of the boundary ring beams and the rigid members and the lower ends of the adjacent inside vertical brace rods; square down string-nets are formed among the lower ends of the vertical brace rods on the horizontal symmetric axes and the vertical symmetric axes; down string-nets are connected among the adjacent nodes of the lower ends of the peripheral vertical brace rods; and four corners are provided with down string-nets. The square rigid cable dome structure is concise in structural form and excellent in stress performance, has improved bearing capacity and stability compared with beam string structures with same span and rise-span ratio, is gentle in deformation, and saves the space at the same time.

Owner:杭州华东钢结构制造有限公司 +1

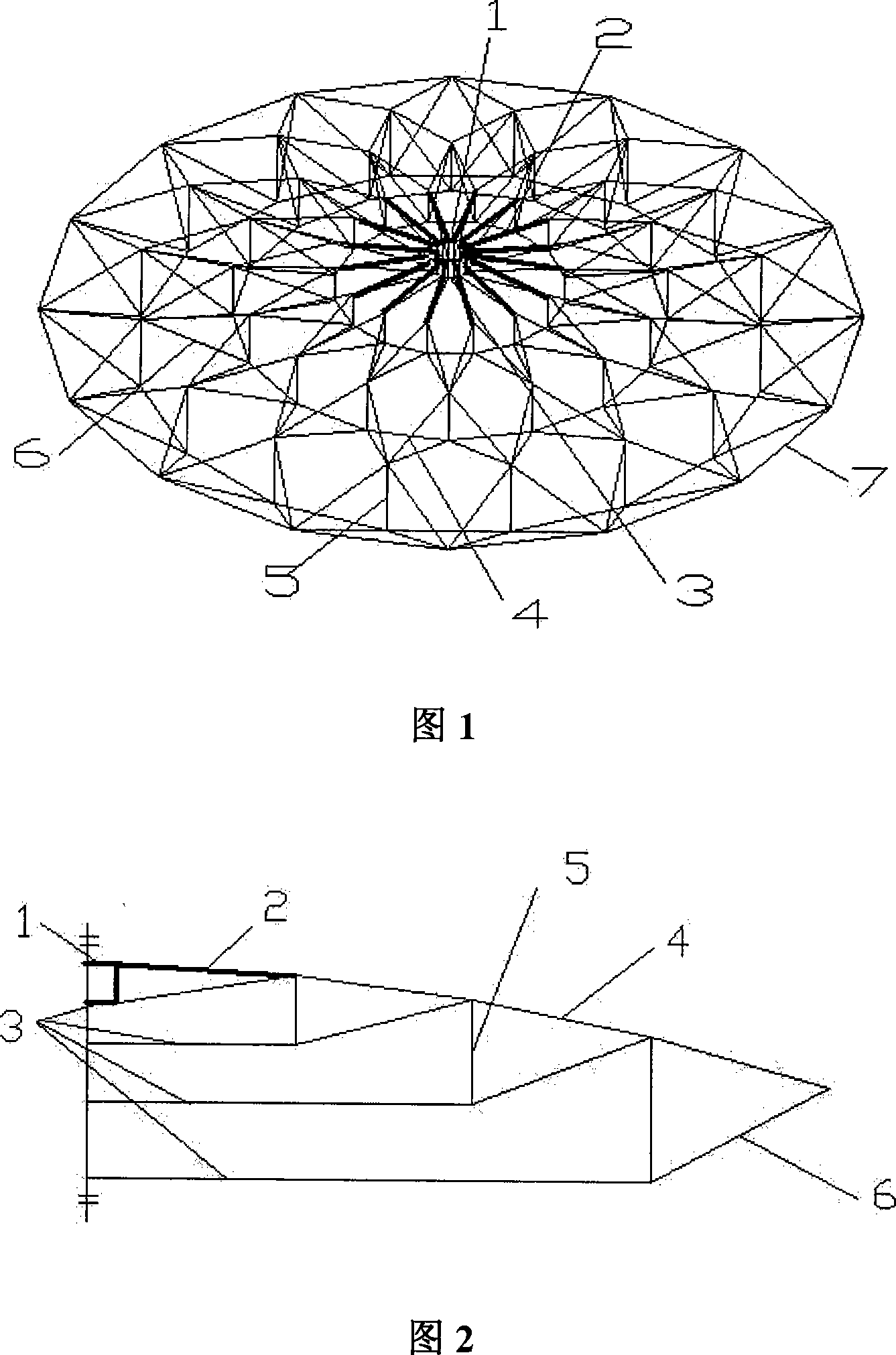

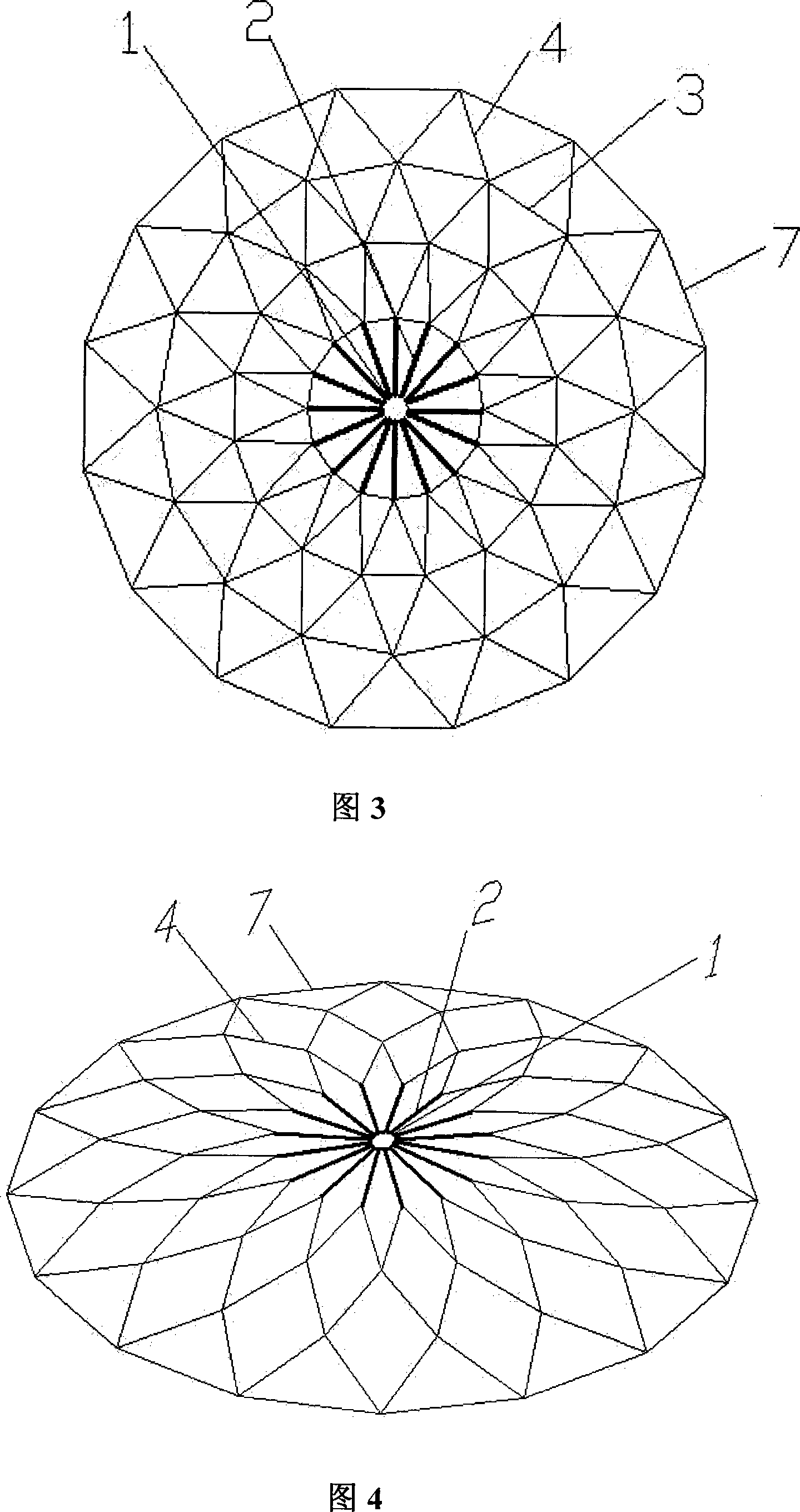

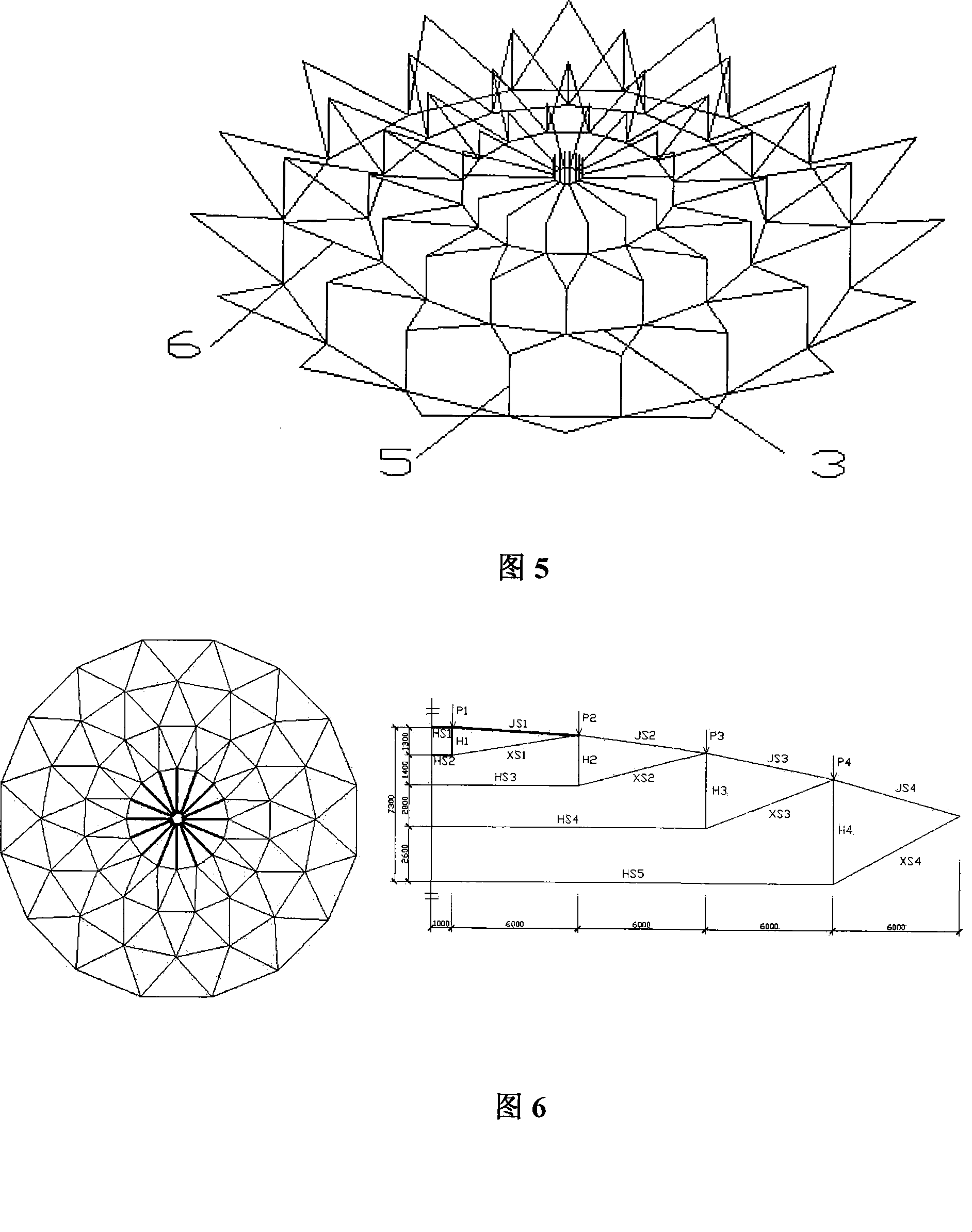

Sunflower-shaped cable dome structure

The invention discloses a sunflower-patterned cable dome, comprising a center inner ring girder, a stiffen member, a hoop cable, a ridge cable, a vertical strut, an inclined cable and a boundary ring girder; wherein, the center inner ring girder, the stiffen member, the ridge cable and the boundary ring girder form a sunflower-patterned net; one end of the stiffen member is hinged with the center inner ring girder, and the other end is hinged with one end of the ridge cable in the most inner circle; one end of the ridge cable in the most outer circle is anchored with the boundary ring girder; the upper end of the vertical strut is hinged with the ridge cable, and the lower end is hinged with one end of the inclined cable and the hoop cable, while the other end of the inclined cable is hinged with the ridge cable; the inclined cable in the most outer circle is anchored with the boundary ring girder; the hoop cable is closed along the hoop direction. The sunflower-patterned cable dome has the advantages of beautiful structure, excellent stress performance, improved bearing capacity and smooth transitional profile since the ridge cable easy to exit working of the prior art is changed into the stiffen member and the upper inner draw ring is changed into the inner ring girder.

Owner:ZHEJIANG UNIV

Rubber composite applicable to inside liner of tubeless tire

The invention discloses a rubber composite applicable to an inside liner of a tubeless tire. The composite comprises the following components in parts by weight: 70 to 100 parts of halogenated butyl rubber, 0 to 30 parts of natural rubber, 30 to 65 parts of carbon black, 20 to 45 parts of inorganic filler, 1 to 4 parts of vulcanizing agent, 1 to 2 parts of accelerant, 1 to 2 parts of active agent, 5 to 15 parts of softening agent and 6 to 10 parts of processing aid, wherein halogenated butyl rubber and natural rubber are blended to form a substrate material. The rubber composite is low in themogenesis, high in self-adhesion performance, outstanding in air impermeability and fatigue resistance, excellent in tensile property and ageing resistance, and applicable to the inside liner of the tubeless tire.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

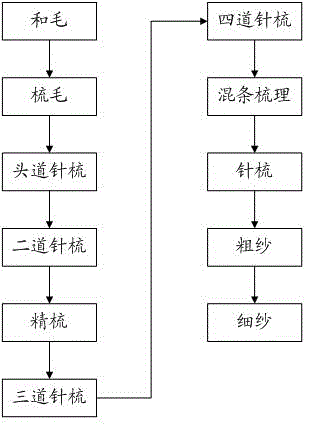

Spinning process for pure high-count combed camel hair woven yarn

The invention discloses a spinning process for a pure high-count combed camel hair woven yarn. By taking camel hair as a spinning raw material, the high-count combed spinning comprises the following steps: mixing hairs, combing hairs, gilling for a first time, gilling for a second time, combing, gilling for a third time, gilling for a fourth time, perform silver mixing and combing, gilling, roving and finely spinning. According to the spinning process for the pure high-count combed camel hair woven yarn disclosed by the invention, the obtained camel hair yearn is good in strength and extension property, and also has wear resistance, evenness, gloss, card nep and the like which reach using needs of high-level light and thin type pure combed woven fabric.

Owner:ZHANGJIAGANG CHAFTA TEXTILE TECH +1

Manufacturing method for high-performance composite yarn

The invention relates to a manufacturing method for high-performance composite yarn, and belongs to the technical field of special yarn manufacturing. The manufacturing method comprises the first step of spinning core yarn, the second step of spinning covering yarn and the third step of manufacturing the composite yarn, wherein the covering yarn is composed of a matrix fiber which is polypropylene, the core yarn is composed of a matrix fiber and a reinforced fiber, and the reinforced fiber is a mixture of one or more of a basalt fiber or a glass fiber or an aramid fiber or polyethylene. According to the high-performance composite yarn obtained by the adoption of the manufacturing method, the defect that the mechanical property of a single fiber is poor is overcome, the composite yarn is smooth in surface, the amount of yarn hairiness is small, the advantages of each fiber can be brought into full play, the fibers can be mutually complemented, and the high-performance composite yarn has the excellent performance which the single fiber does not have.

Owner:苏州盛泽科技创业园发展有限公司

Black sanitary towel

ActiveCN107898560AWith adsorption and deodorizationAntibacterialBio-packagingSanitary towelsEngineeringMoisture absorption

The invention provides a black sanitary towel. The black sanitary towel comprises a sanitary towel body, and the sanitary towel body comprises a surface non-woven fabric layer, an absorption core anda bottom impermeable membrane from top to bottom in sequence; the surface non-woven fabric layer comprises a middle sheet, retaining walls and side wings; the middle sheet is arranged in the middle ofthe surface non-woven fabric layer and used for cooperating with the bottom impermeable membrane and completely wrapping the absorption core; the side wings are arranged at the two sides of the surface non-woven fabric layer and used for fixing the sanitary towel body; the retaining walls are arranged at the two sides of the middle sheet and used for preventing an absorbed material which is absorbed by the middle sheet or the middle core from leaking from the sides; the side wings are fixedly connected with the middle sheet through partial retaining walls; the surface non-woven layer and thebottom impermeable membrane are both black. The black sanitary towel can meet the basic requirement of sanitary towels and have the advantages of bacterial inhibition, odor removal, moisture absorption and ventilation, soft and comfortable performance and complete degradation.

Owner:上海贝睿斯生物科技有限公司

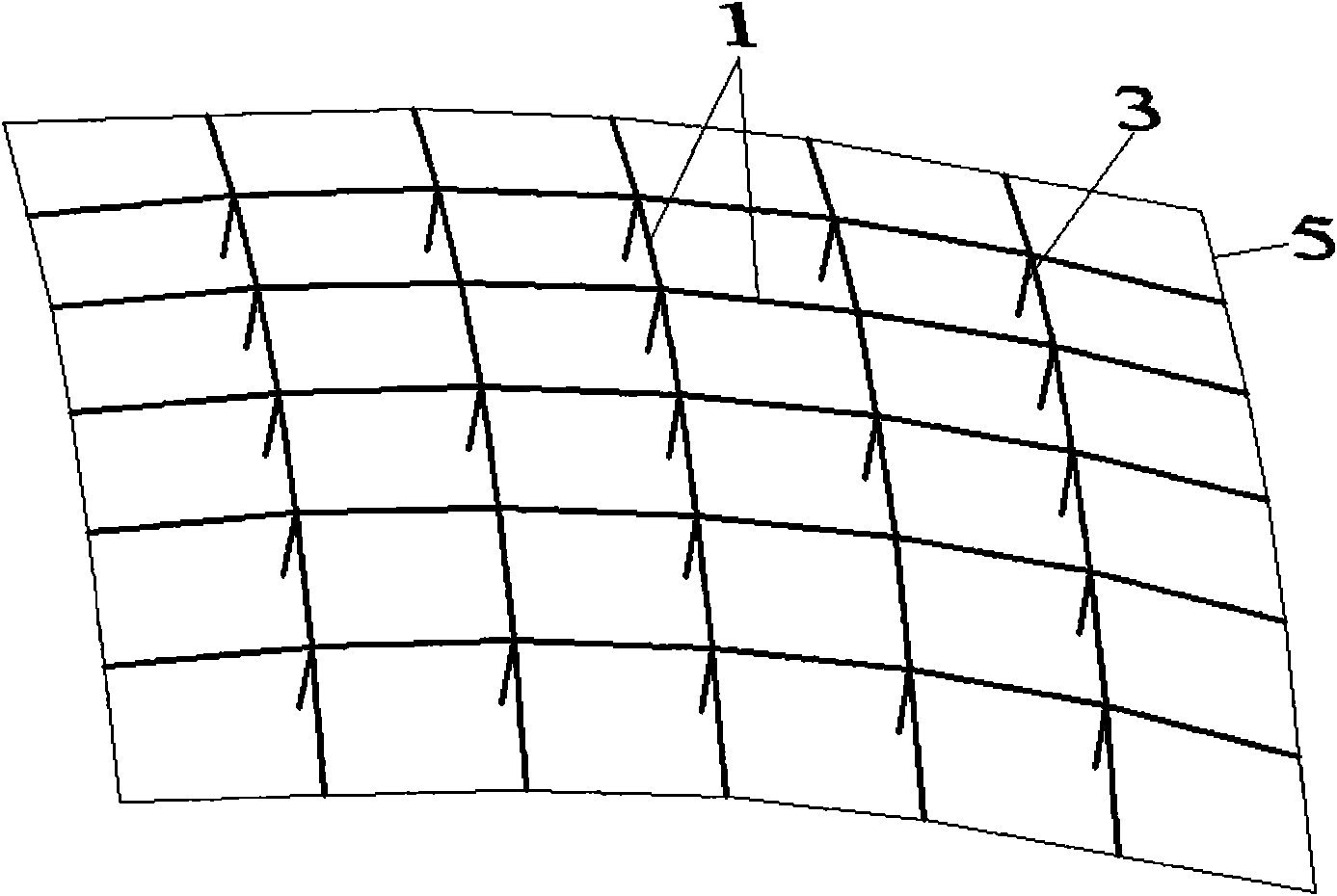

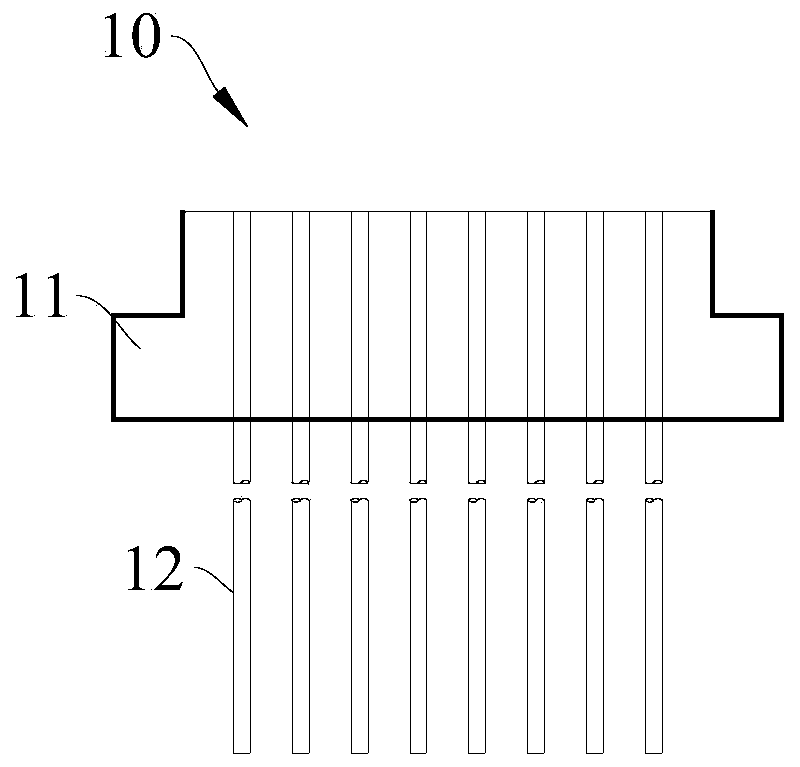

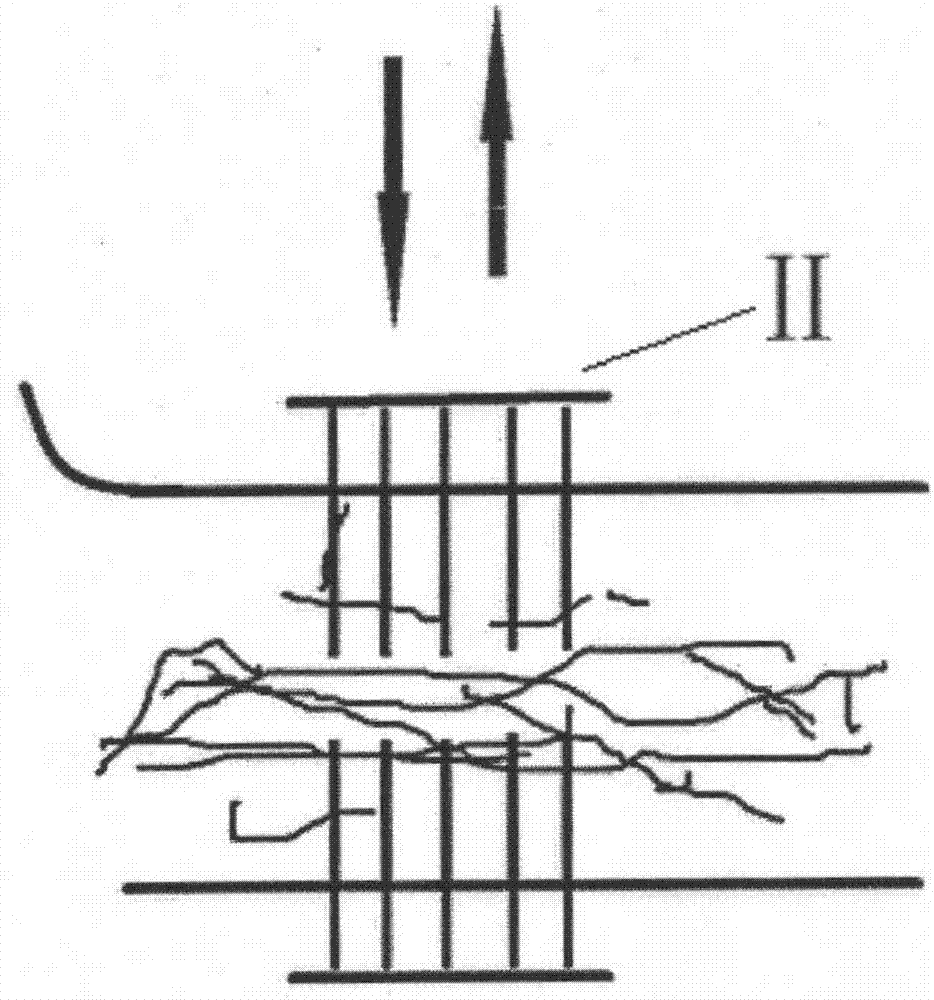

Airbag for a vehicle occupant restraint system

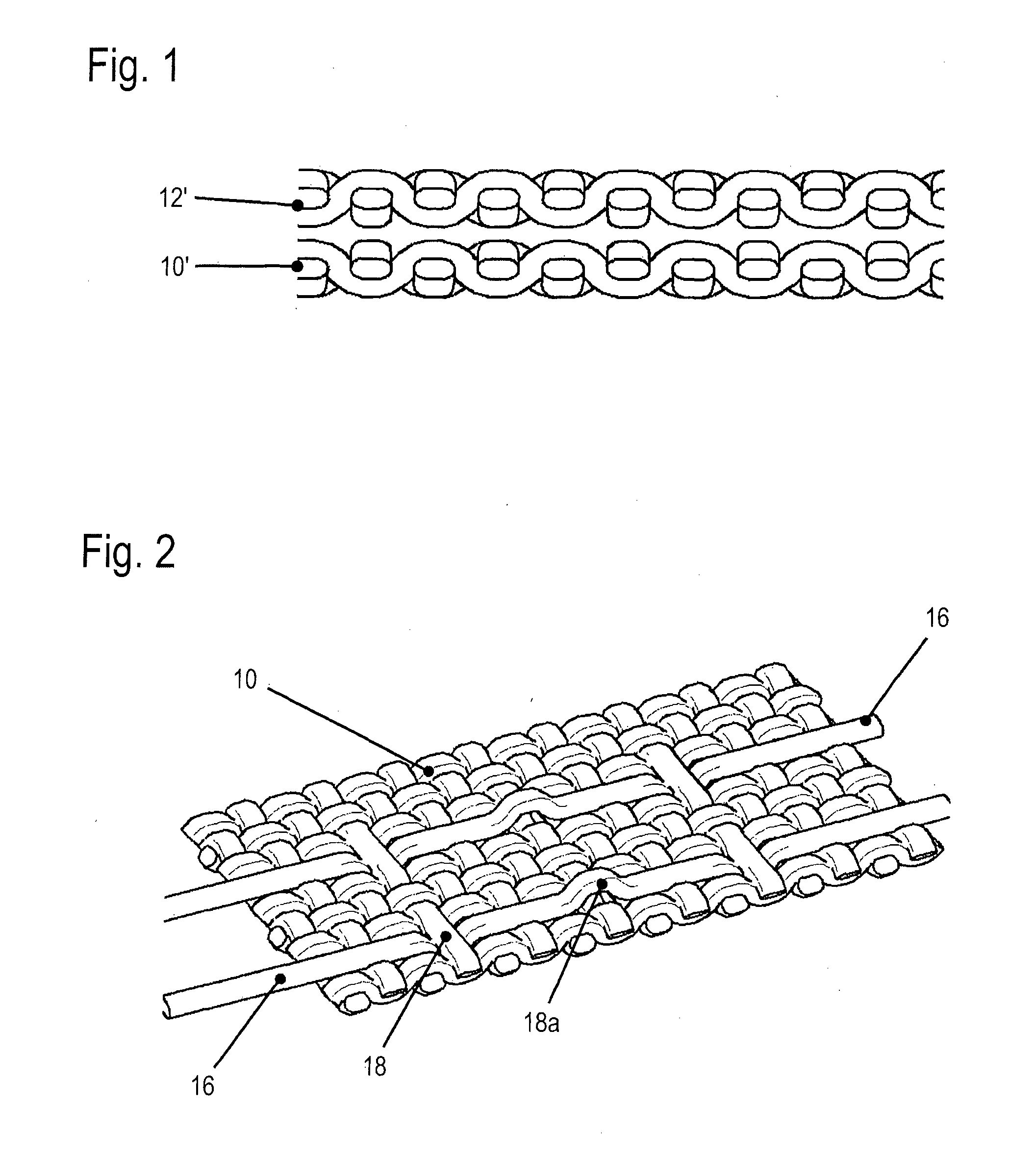

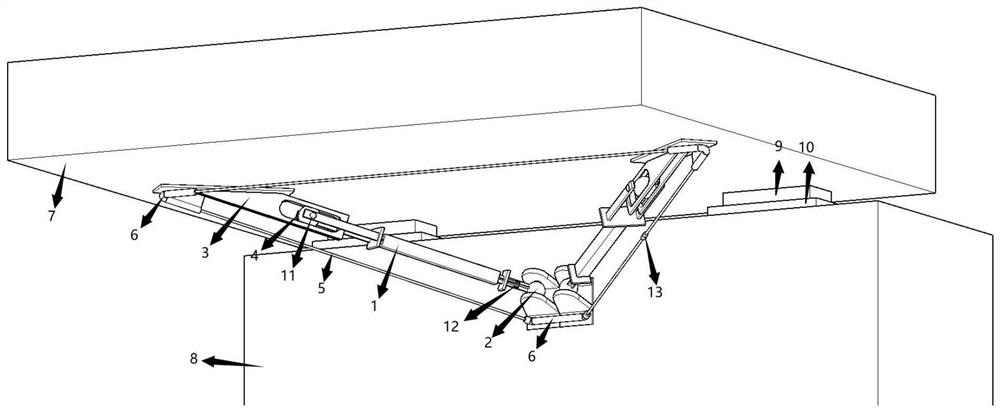

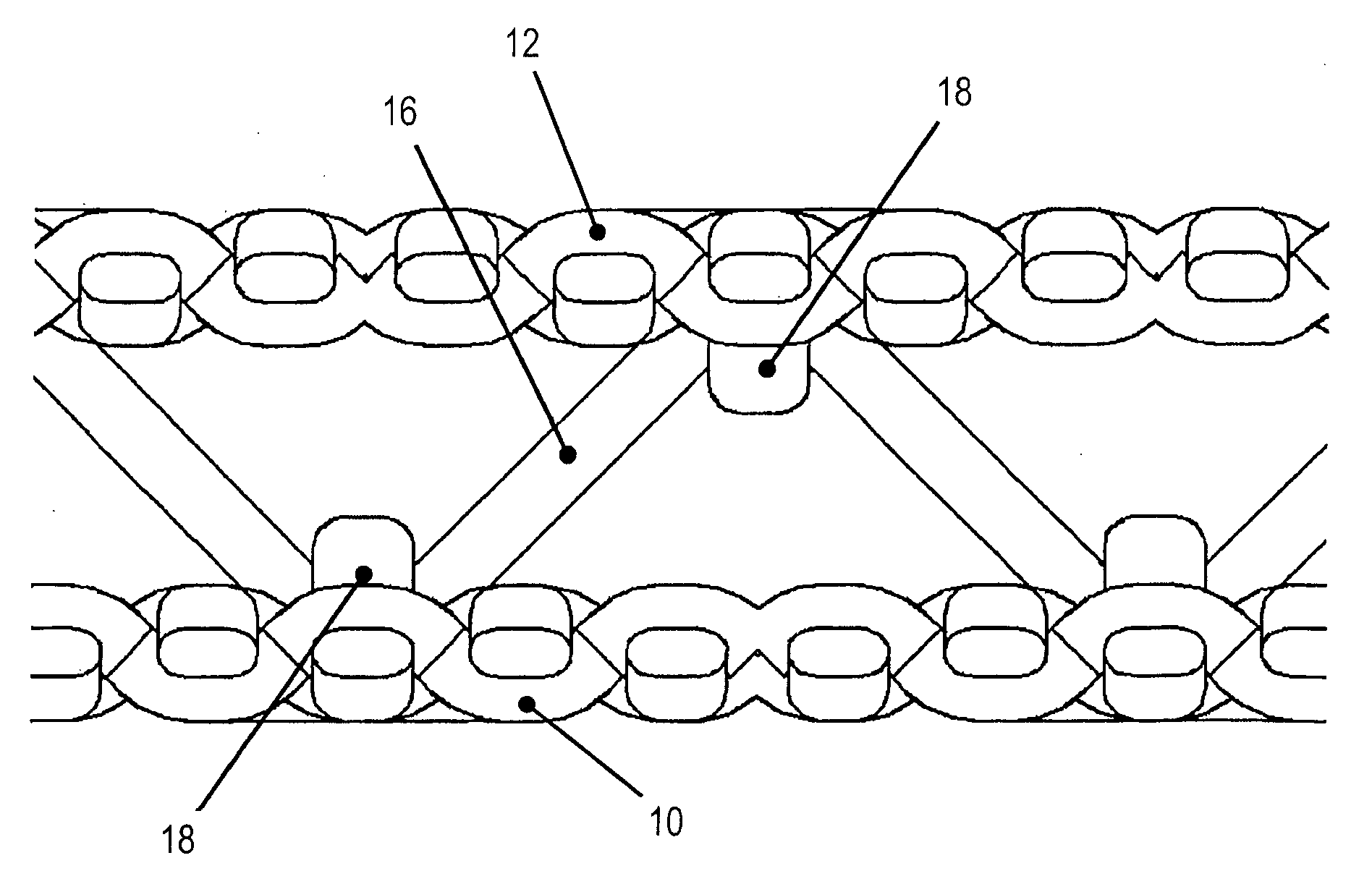

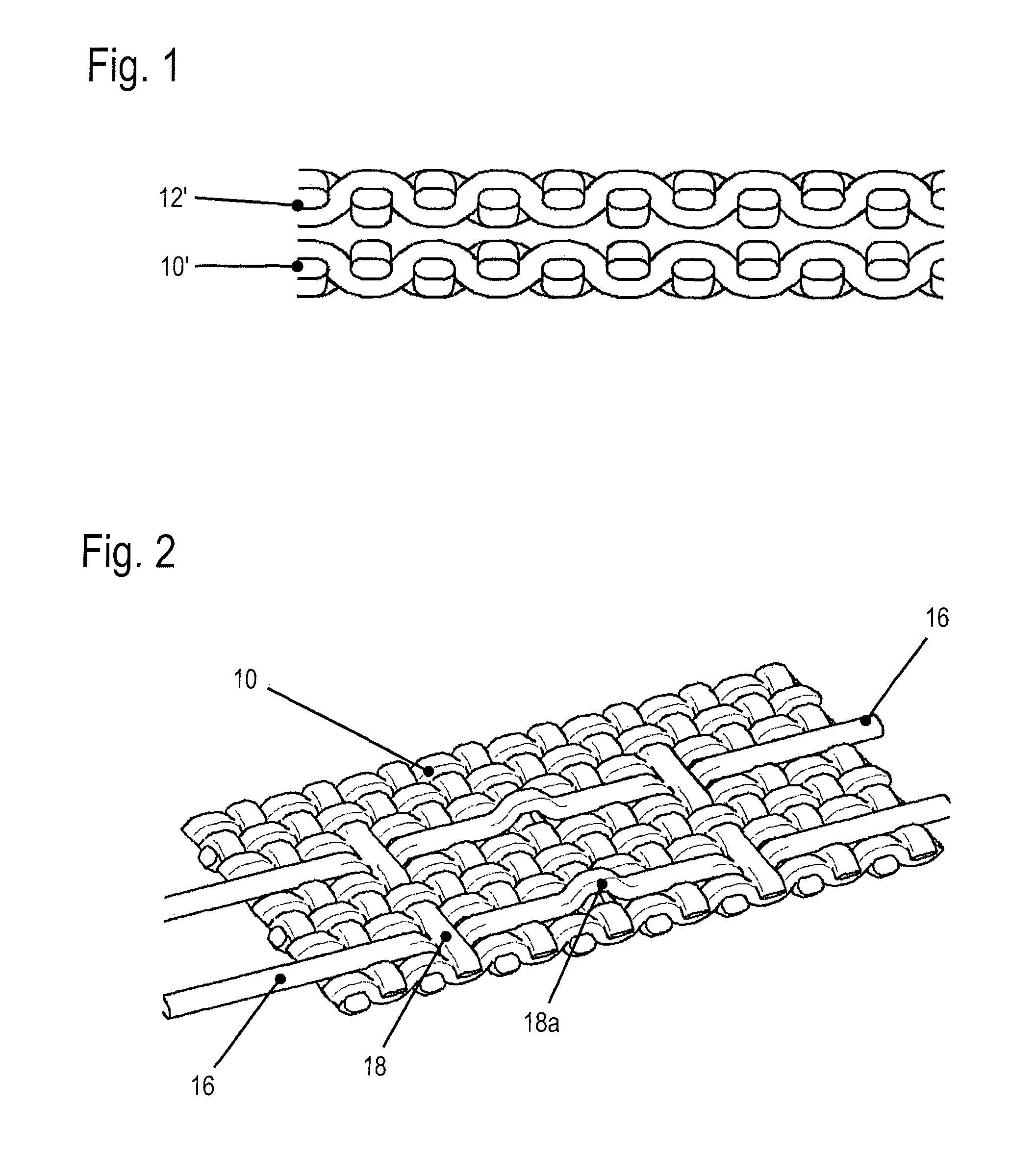

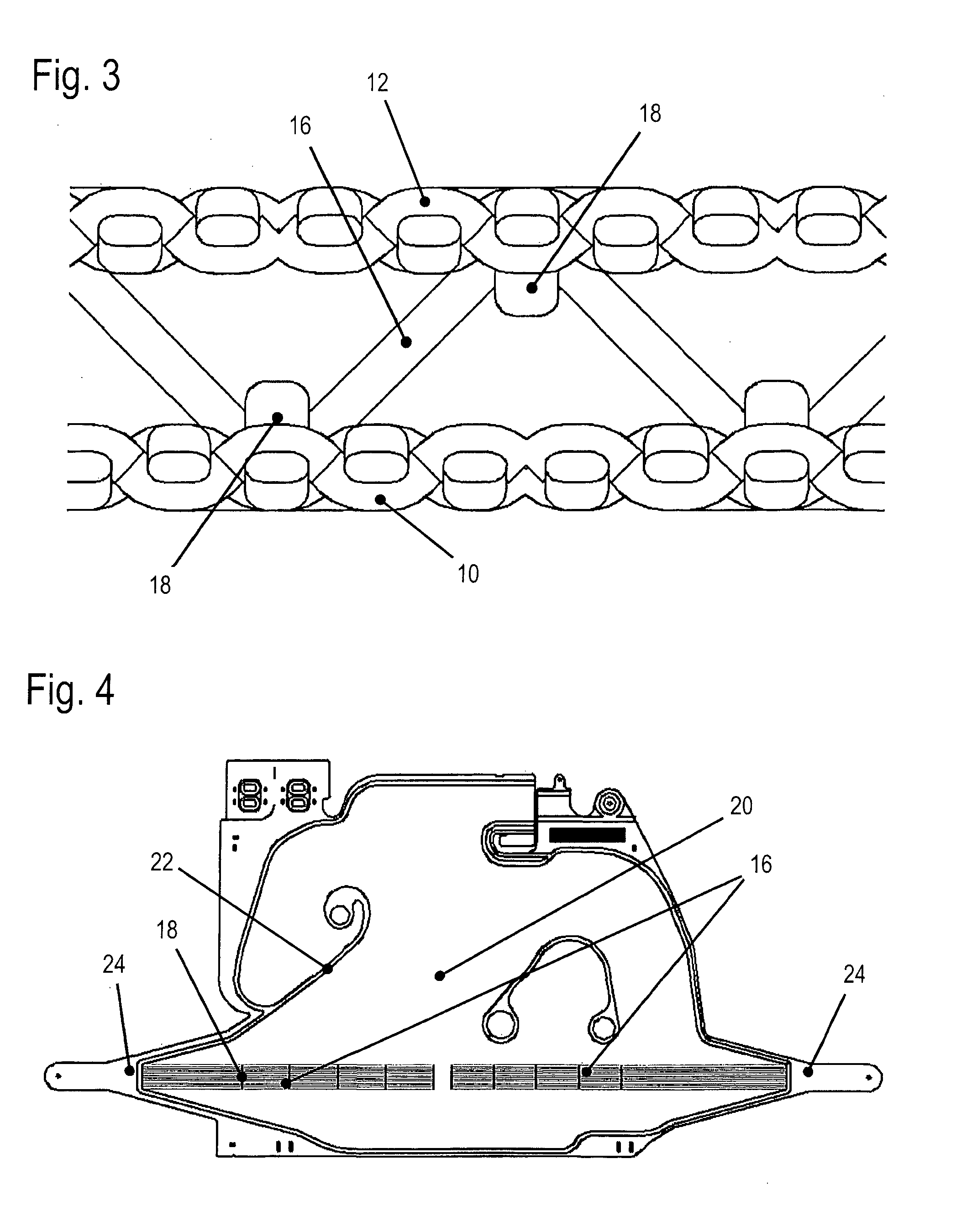

ActiveUS20150137488A1Good tensile performancePedestrian/occupant safety arrangementMulti-ply fabricsAirbagEngineering

An airbag (20) for a vehicle occupant restraint system comprises a first fabric layer (10) and an opposed second fabric layer (12) each being formed of a composite fabric of wefts and warps and delimiting a chamber (14) adapted to be filled with gas. Plural weaving threads (16) are provided which exit the composite fabric of a fabric layer (10, 12) in the direction of the other fabric layer (12, 10) and are freely floating in the chamber (14) before they enter into the composite fabric of the other fabric layer (12, 10). The weaving threads (16) are movable in their longitudinal direction relative to the inlet and outlet points.

Owner:TRW AUTOMOTIVE GMBH

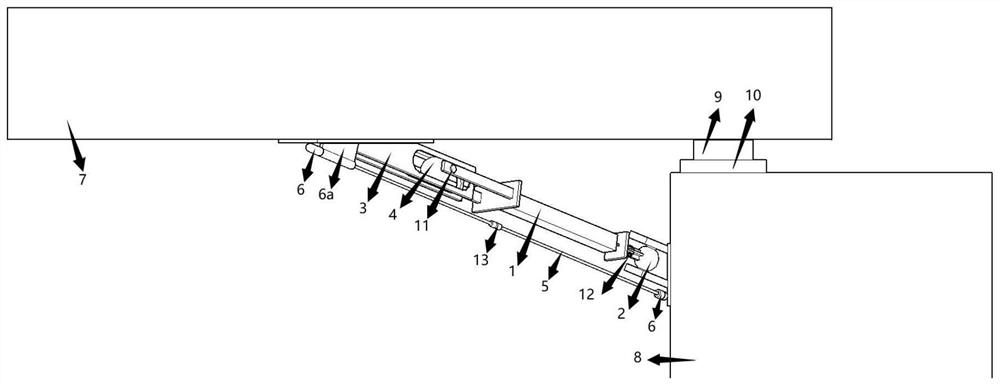

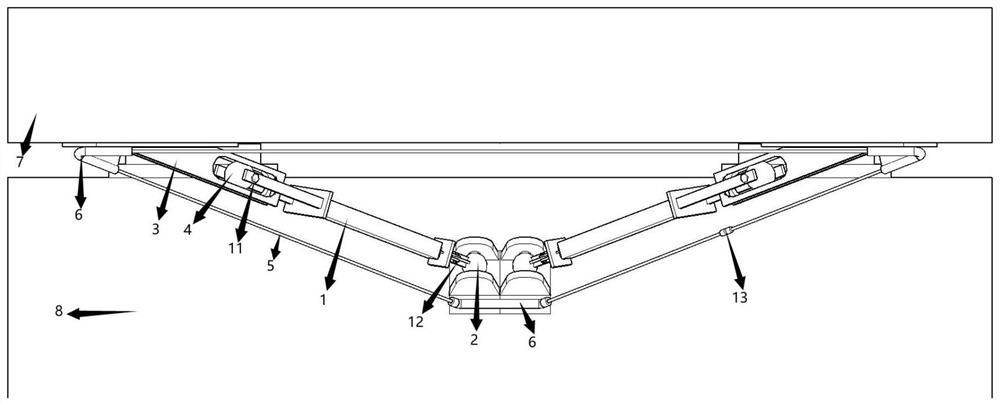

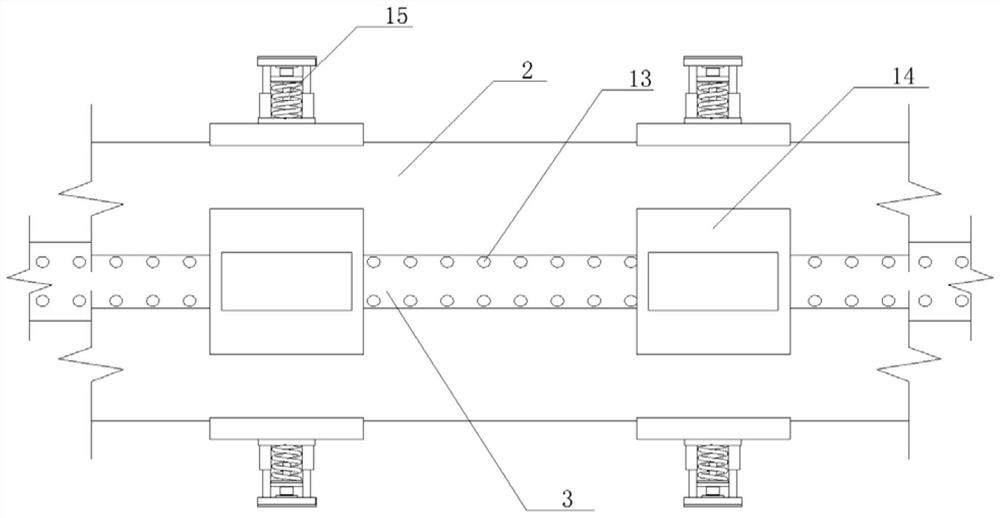

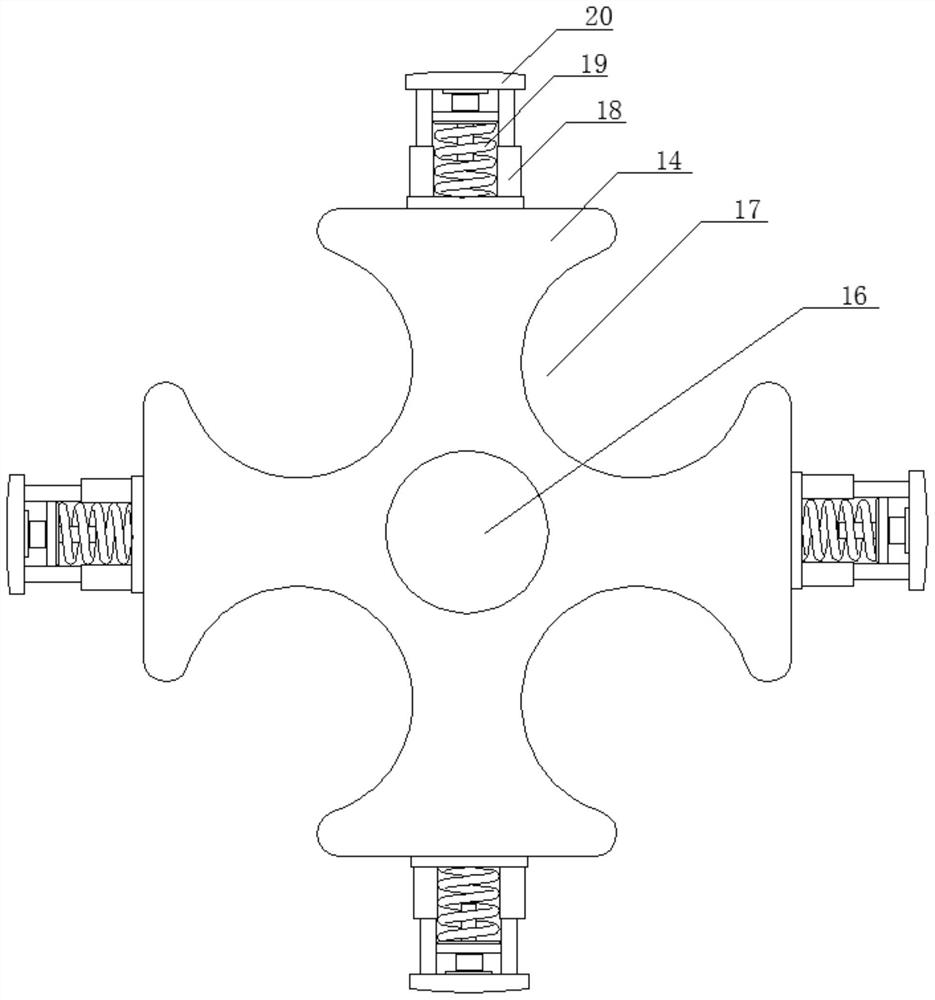

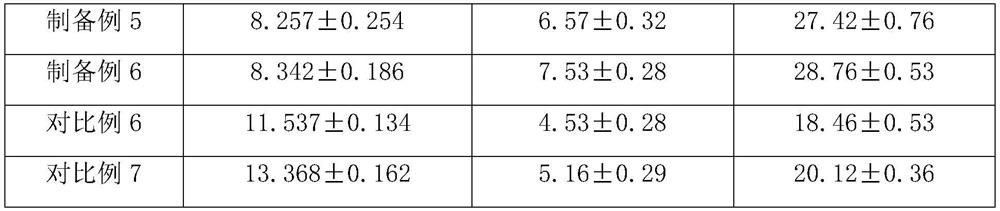

Combined multistage three-way anti-seismic bridge limiting device based on BRB technology

ActiveCN112575674ASafe and reliable structureLow costNon-rotating vibration suppressionBridge structural detailsEarthquake resistantBuckling-restrained brace

The invention relates to a combined multistage three-way anti-seismic bridge limiting device based on the BRB technology. The device comprises a beam body, a pier, two buckling restrained supporting structures arranged in a V shape, a limiting sliding connection assembly, a spherical hinge and an annular limiting inhaul cable. Two ends of the buckling restrained brace structure are connected withthe spherical hinge and the rigid smooth ball respectively, and the rigid smooth ball freely and relatively slides in a hole channel of the limiting sliding connection assembly under the condition ofsmall displacement of the beam body; when large earthquake displacement happens to the beam body, the buckling restrained brace structure consumes earthquake energy through elasticoplastic deformation. The annular limiting inhaul cable plays a limiting role after the buckling restrained brace structure is pulled and loses efficacy. According to the anti-seismic concept of multi-stage fortification, the traditional buckling restrained brace structure and inhaul cable limiter technology are combined, displacement of the beam body under longitudinal, transverse and vertical seismic oscillation can be effectively limited, and the structure is simple and reliable.

Owner:SHIJIAZHUANG TIEDAO UNIV

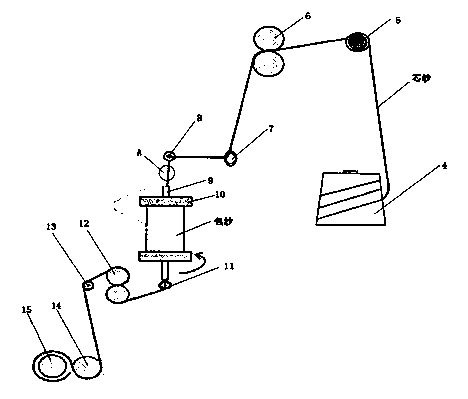

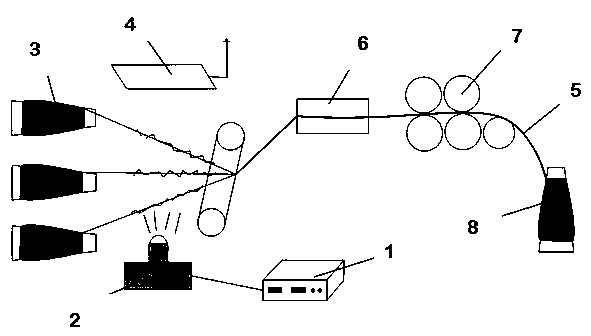

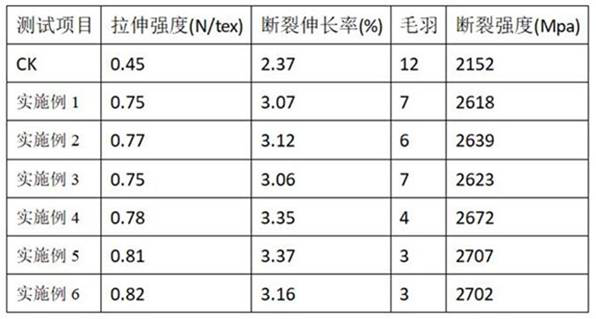

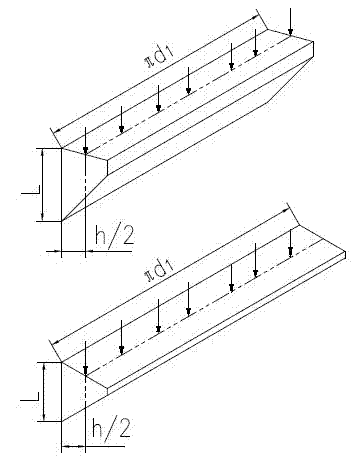

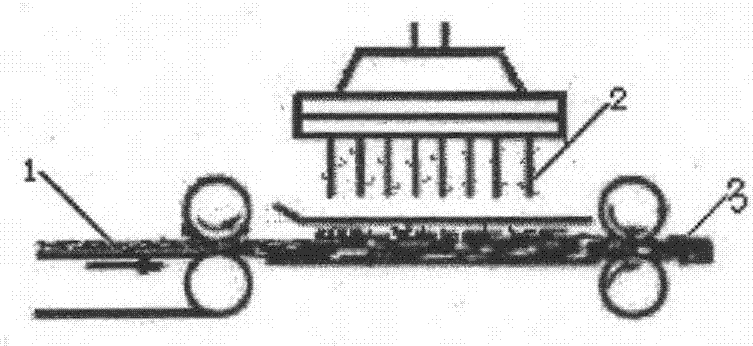

Method and device for preparing nano-composite yarns

InactiveCN103966675AGood tensile performancePoor contact comfortFilament/thread formingYarnYarnFiber

The invention discloses a method and device for preparing nano-composite yarns. The method for preparing the nano-composite yarns includes the following steps that core materials for preparing the composite yarns are pulled forwards at the speed ranging from 0.01m / min to 10m / min; nano-fibers are stretched through a bubble spinning device and deposited on the surfaces of the core materials; the core materials of which the surfaces are deposited with the nano-fibers are coagulated through coagulating bath, processed through a compression roller and then output. Compared with the prior art, the nano-fibers are deposited on the surfaces of the core materials through the bubble spinning device to form the nano-composite yarns, macromolecule nano-fibers are transferred outwards, the fibers good in strong stretching capacity, poor in contact comfort and low in cost are coated inside, and then real performance complementation and advantage enhancement are achieved. The nano-fibers generated in the bubble electrostatic spinning process are effectively deposited on the yarns passing through the middle portion when the nano-fibers are transferred to a receiving plate with opposite charges, operation is simple, cohesion performance of the yarns of which the surfaces are deposited with the nano-fibers through the coagulating bath is improved, the nanometer effect is well exerted, and therefore performance is improved.

Owner:南通百博丝纳米科技有限公司

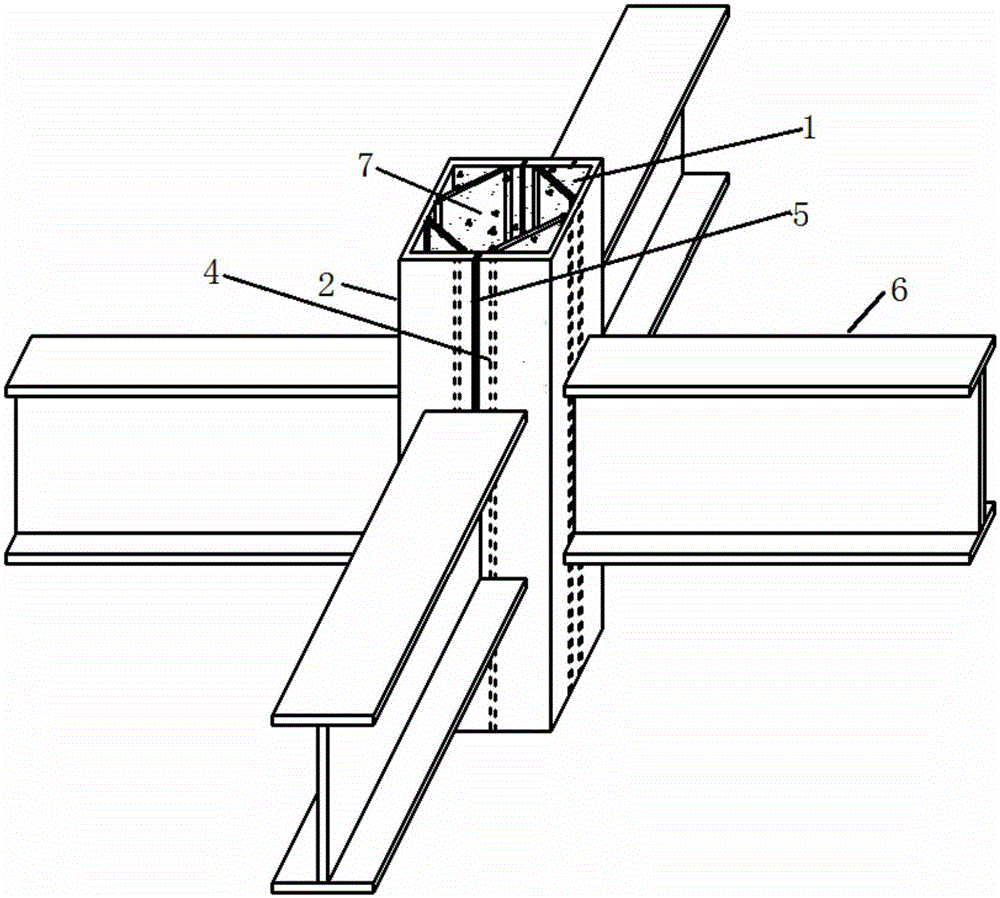

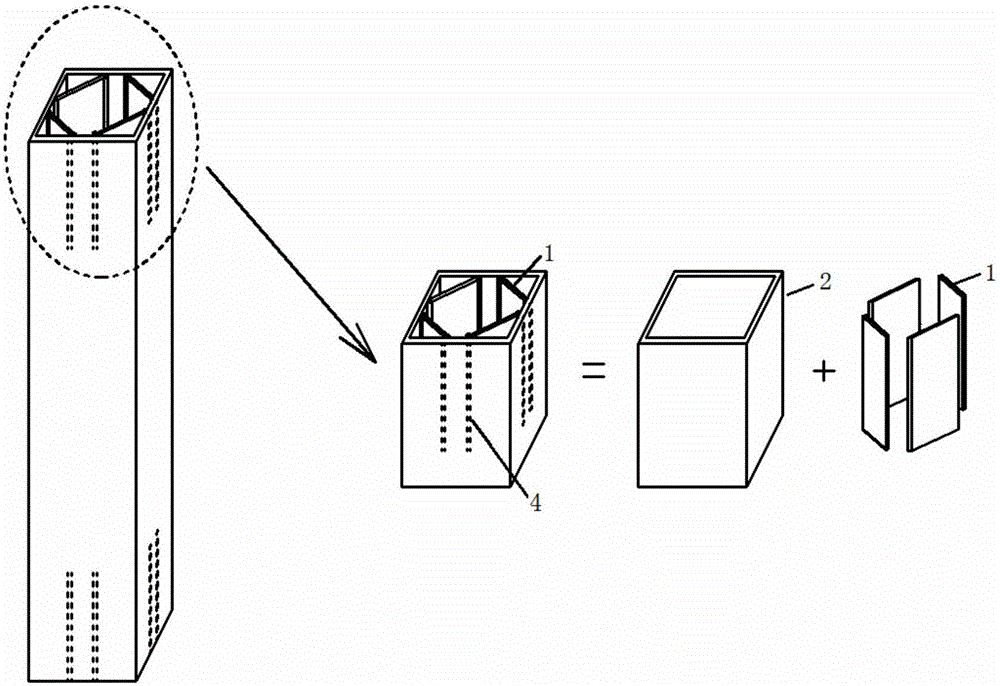

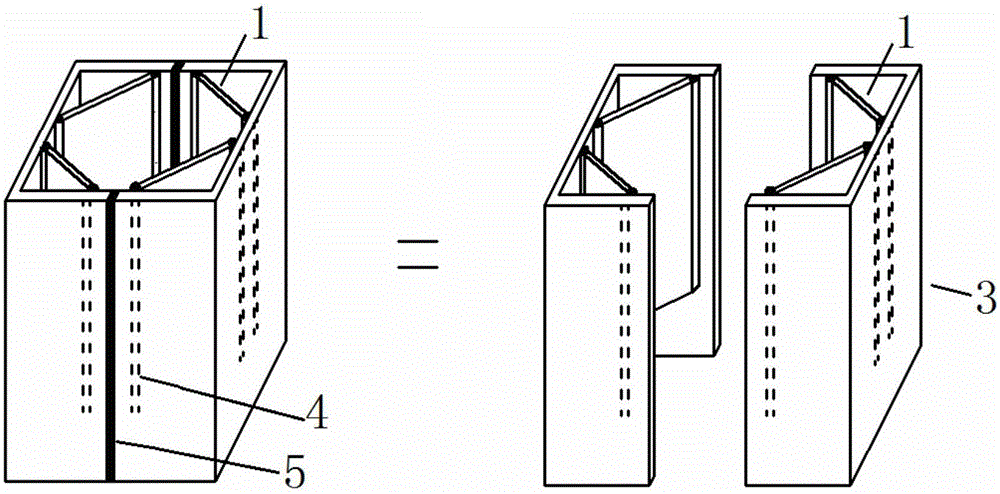

Frame joint of rectangular concrete-filled steel tube column employing knee-bracing stiffened steel plates

InactiveCN105019559AEnhanced binding effectImprove bearing capacityBuilding constructionsSteel platesSteel tube

The invention discloses a frame joint of a rectangular concrete-filled steel tube column employing knee-bracing stiffened steel plates. The frame joint comprises thin-walled rectangular steel tubes, cast-in-place concrete, I-steel beams and a knee-bracing steel plate stiffening rib.The knee-bracing stiffened steel plates are arranged in a joint core region and a plastic-hinge region for an end portion of a column steel tube. The stiffened steel plates and the inner wall of a steel tube are welded to three dividing points of a steel tube wall at 45-degree angles. The stiffened rectangular steel tubes and the I-steel beams are welded and are used for pouring concrete in order to form the frame joint of the rectangular concrete-filled steel tube column employing the knee-bracing stiffened steel plates.The frame joint of the rectangular concrete-filled steel tube column employing the knee-bracing stiffened steel plates has following beneficial effects: a novel joint form can effectively help delay local buckling of the steel tube, thereby improving constraint effect of concrete; tension of steel beam flanges can be effectively transferred by the knee-bracing steel plate stiffening rib and bending moment of the steel beams can be further effectively transferred such that the joint can satisfy the need of aseismic design; and the frame joint of the rectangular concrete-filled steel tube column employing the knee-bracing stiffened steel plates is novel framework node form featuring a fine mechanical property, convenient construction and economic feasibility.

Owner:CHONGQING UNIV

Airbag for a vehicle occupant restraint system

ActiveUS9283922B2Good tensile performancePedestrian/occupant safety arrangementMulti-ply fabricsEngineeringAirbag

An airbag (20) for a vehicle occupant restraint system comprises a first fabric layer (10) and an opposed second fabric layer (12) each being formed of a composite fabric of wefts and warps and delimiting a chamber (14) adapted to be filled with gas. Plural weaving threads (16) are provided which exit the composite fabric of a fabric layer (10, 12) in the direction of the other fabric layer (12, 10) and are freely floating in the chamber (14) before they enter into the composite fabric of the other fabric layer (12, 10). The weaving threads (16) are movable in their longitudinal direction relative to the inlet and outlet points.

Owner:TRW AUTOMOTIVE GMBH

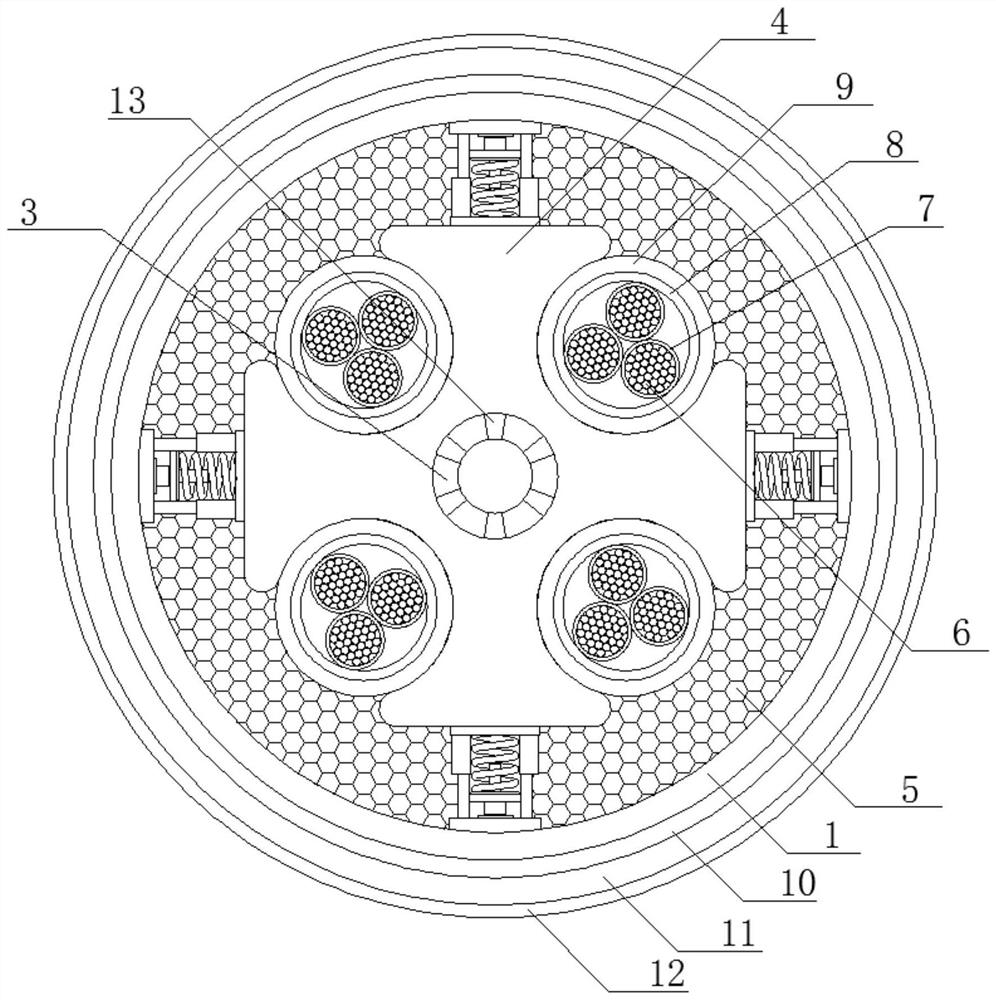

Compression and heat resistant practical wire cable

PendingCN112397239AFine textureHigh strength without mechanical impuritiesRubber insulatorsClimate change adaptationEngineeringPolyurethane elastomer

The invention discloses a compression and heat resistant practical wire cable, which comprises a fireproof lapped covering, a plurality of main wire cores and a reinforcing core tube are arranged in the fireproof lapped covering, the reinforcing core tube is arranged among the plurality of main wire cores, and a plurality of compression-resistant support frames are arranged among the plurality ofmain wire cores at equal intervals. The reinforcing core tube penetrates through the plurality of compression-resistant support frames to make contact with the inner wall of the fireproof lapped covering, the interior of the fireproof lapped covering is filled with heat-insulating and flame-retardant particles, and the exterior of the fireproof lapped covering is coated with a compression-resistant and flame-retardant layer. The plurality of compression-resistant support frames are arranged on the main wire cores and the reinforcing core tube, so that a good compression-resistant protection effect can be achieved on the wire cable, when the cable is extruded, a polyurethane elastomer material can achieve a protection effect on the main wire cores and the reinforcing core tube, and the problems of short circuit and the like caused by damage of an insulating layer can be avoided; and when the cable is subjected to external impact, an elastic connecting piece can play a role in buffering,so that the stress of the cable can be dispersed, and the flame-retardant outer sheath is prevented from being damaged.

Owner:安徽福日光电科技有限公司

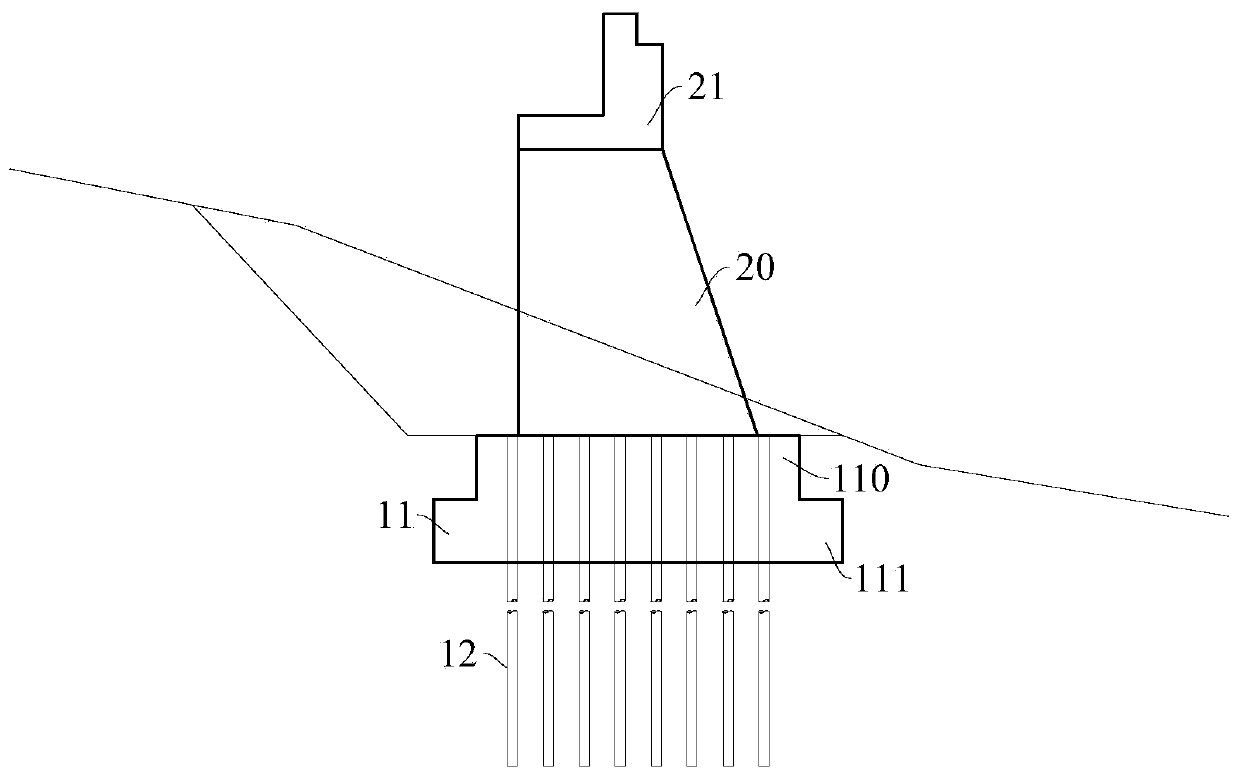

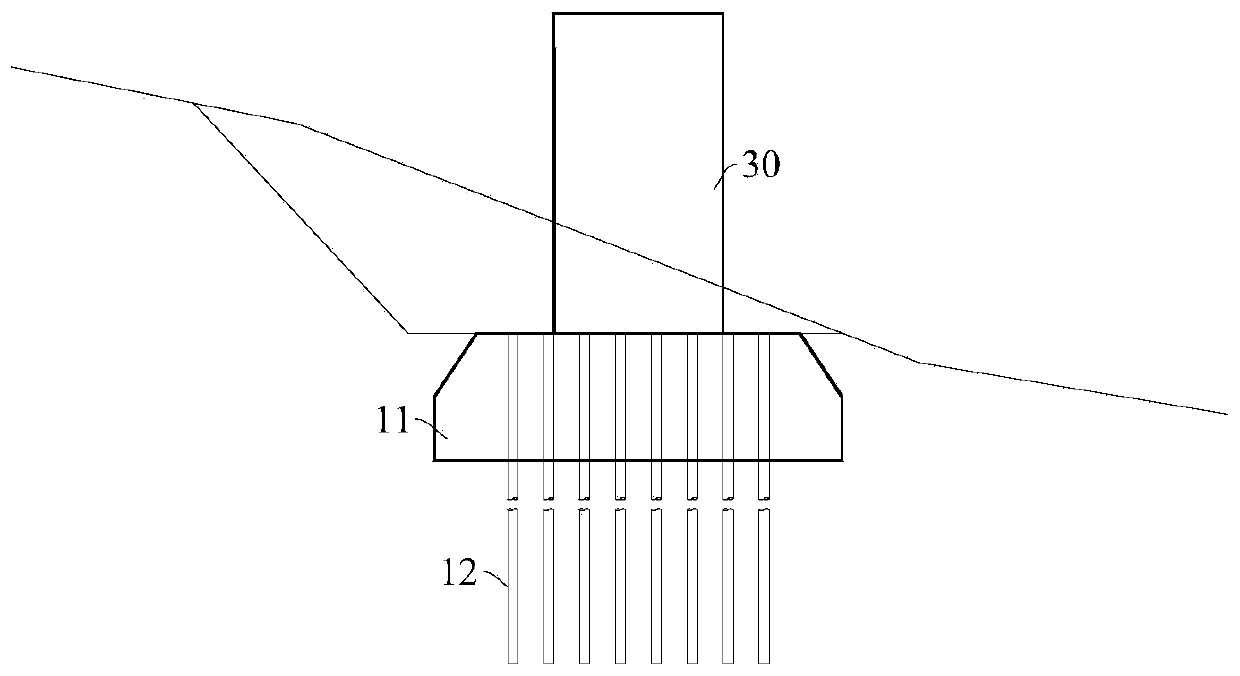

Mountainous-area abutment and pier column foundation structure and construction method thereof

PendingCN111254966AEasy constructionReduce construction riskBridge structural detailsBulkheads/pilesArchitectural engineeringAbutment

The invention discloses a mountainous-area abutment and pier column foundation structure and a construction method thereof. The mountainous-area abutment and pier column foundation structure comprisesan expanded foundation and an anchoring body, wherein the inside of the expanded foundation is provided with a steel bar framework, one end of the anchoring body is anchored in a foundation pit of amountain body, and the lower surface of the expanded foundation is connected with the other end of the anchoring body. The technical scheme can solve the problems of difficult construction and high operation risk of an existing mountainous-area bridge pile foundation.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Copper braided wire manufacturing method

InactiveCN108399976AImprove antioxidant capacityGood tensile performanceCable/conductor manufactureCopper wireWork in process

The invention relates to a copper braided wire manufacturing method, including the following steps: drawing polished and cleaned red copper into an oxygen-free copper rod, drawing the oxygen-free copper rod into an internal annealing wire, drawing the internal annealing wire into superfine copper wires through multiple wire drawing machines, twisting the superfine copper wires into a stranded wire, and then combining and twisting the stranded wire into a composite blank wire; and annealing the composite blank wire to obtain a composite wire, braiding the composite wire on a braiding machine toform a semi-finished wire, and removing the oil stain on the surface of the semi-finished wire by using a centrifugal dryer to manufacture a copper braided wire. Through the optimization design of anexisting copper braided wire manufacturing process, a finished product manufactured by using the copper braided wire manufacturing method disclosed by the invention has a strong anti-oxidation ability, and the finished product is not easy to blacken, is good in tensile strength and high in product quality, and has high application values.

Owner:铜陵集思意特种编织线有限公司

Supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions

InactiveCN103967004AGood tensile performanceSlow to overcome hardeningExcavationsBulkheads/pilesPre stressHigh intensity

A supporting and protecting composite anti-slide pile suitable for high-attitude and high-intensity regions is composed of a pile core and a pile cylinder, wherein the pile cylinder is tightly pasted on the outer side of the pile core. The pile core is composed of a prefabricated prestressed pile, grouting pipes and a center grouting pipe, wherein the cross section of the prefabricated prestressed pile is orthohexagonal. Each side face of the prefabricated prestressed pile is provided with a groove in the axis direction. The grouting pipes are arranged in the grooves. A center grouting hole is formed in the prefabricated prestressed pile in the central axis direction. The center grouting pipe is arranged in the center grouting hole. The pile cylinder is composed of multiple layers of reinforcing steel bar cages and a grouting body. The reinforcing steel bar cage on the innermost layer tightly wraps the pile core, the reinforcing steel bar cage on the outermost layer is tightly attached to the hole wall, and the rest layers of reinforcing steel bar cages are evenly distributed. The reinforcing steel bar cages are wrapped in the grouting body. The concrete strength of the pile core reaches more than 80 MPa, and therefore the defects that the cast-in-place concrete hardening speed is low at a low temperature, and the quality is difficult to ensure are overcome; the tension resistance of the pile is greatly improved due to the prestress of the pile core and the reinforcing steel bar cages of the pile cylinder, and therefore the horizontal bearing capacity is improved, and larger anti-slide force can be provided by the supporting and protecting composite anti-slide pile.

Owner:BEIJING UNIV OF TECH

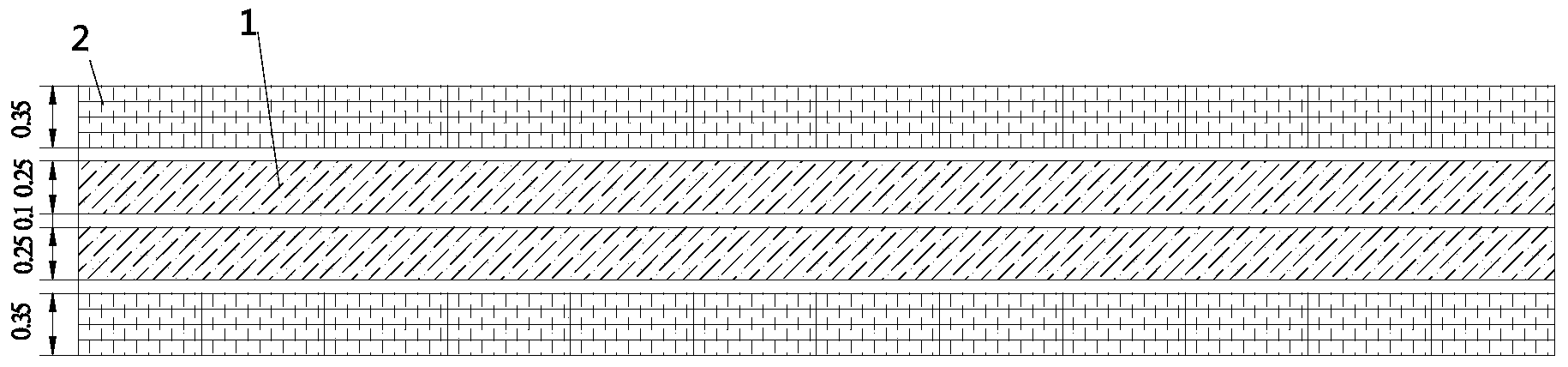

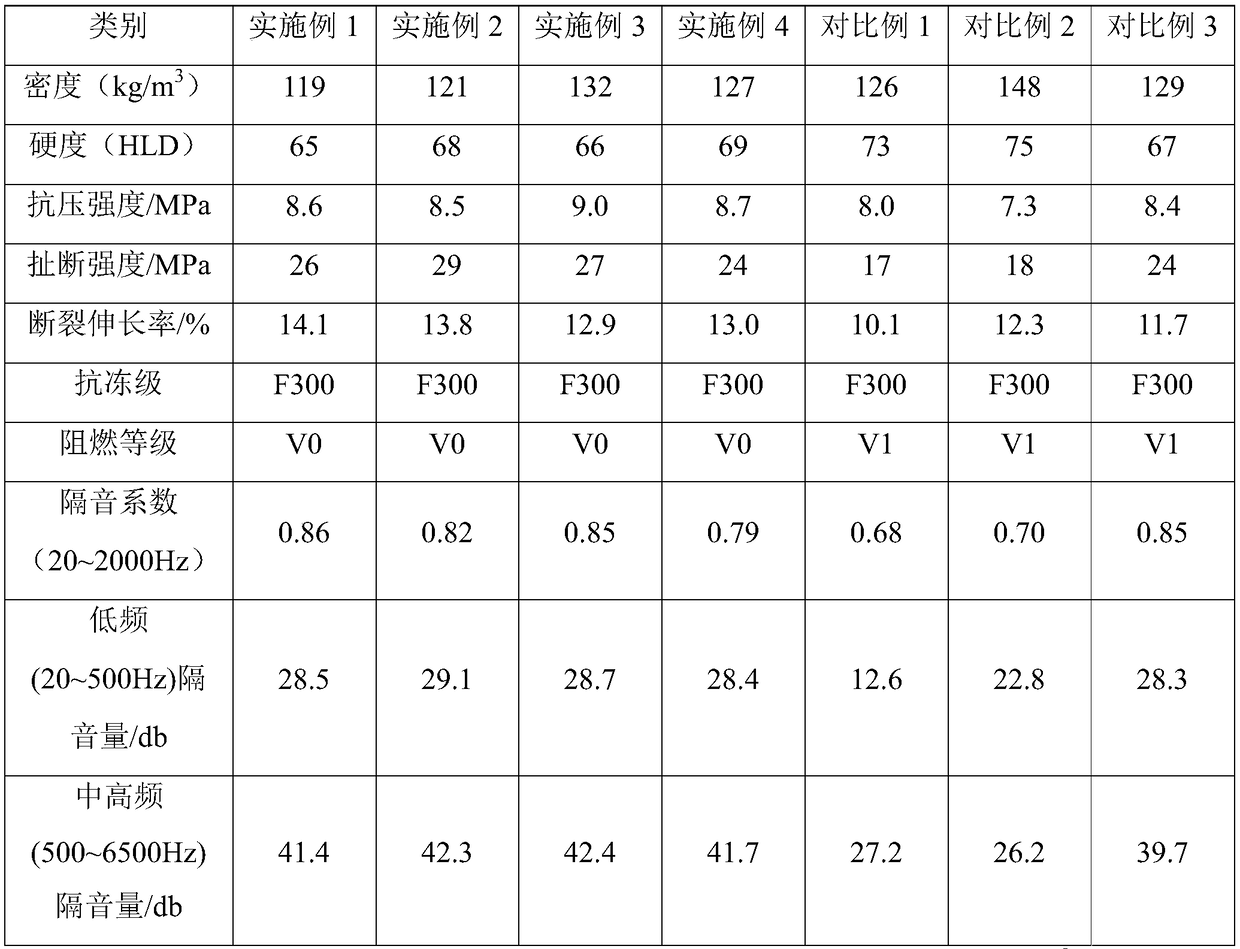

Sound insulating material and preparation method thereof

ActiveCN109054391AOvercome the disadvantages of poor sound insulationHigh impact strengthSodium stearateTurpentine

The invention discloses a sound insulating material. The sound insulating material is prepared from the following components in parts by weight: 60 to 80 parts of high damping silicone rubber, 4 to 6parts of hydroxy silicone oil, 12 to 25 parts of silica aerogel, 1 to 2 parts of dicumyl peroxide, 60 to 80 parts of PP resin, 18 to 25 parts of turpentine, 20 to 30 parts of white carbon black, 23 to38 parts of foam ceramic powder, 2 to 4 parts of barium sulfate, 0.4 to 0.9 part of sodium stearate, 0.3 to 0.5 part of active zinc oxide, 6 to 10 parts of diatomaceous earth, 3 to 7 parts of zinc borate, 5 to 8 parts of high vinyl silicone oil, 0.2 to 0.4 part of aluminate coupling agent, 3 to 5 parts of vulcanizing agent, and 1.4 to 1.9 parts of accelerator. The invention also discloses a preparation method of the sound insulating material. The sound insulating material provided by the invention has the characteristics of light weight, good mechanical performance, fire retarding, and effectively absorbing low-frequency sound waves, and has the advantages of simple preparation method, low cost and mass production.

Owner:广州凝博科技有限公司

Fire-resistant and high-temperature-resistant control cable and manufacturing method thereof

ActiveCN111799029AAnti aging catalysisGuaranteed service lifeClimate change adaptationInsulated cablesEngineeringElectrical conductor

The invention discloses a fire-resistant and high-temperature-resistant control cable including multiple sets of conductors and including a heat dissipation reinforcing tube, wherein the conductors are coated with insulating layers to form insulating wire cores; the plurality of insulating wire cores are coated with braided shielding layers, the braided shielding layers are coated with high-temperature-resistant loose tubes to form main wire cores, the plurality of main wire cores are combined and are sequentially coated with a fireproof heat-insulating layer, a flame-retardant inner sheath, abraided armor layer and a flame-retardant outer sheath, the heat dissipation reinforcing pipe is located among the plurality of main wire cores, a plurality of support frames are fixedly connected tothe heat dissipation reinforcing pipe at equal intervals, and the fireproof heat-insulating layer is also filled with heat-insulating flame-retardant particles; the heat dissipation reinforcing pipemade of polytetrafluoroethylene is arranged among the main wire cores, the appearance organization is fine, no mechanical impurity exists, the strength is high, the heat dissipation reinforcing tube are located in the center gap of the main wire cores, and the structural stability, the tensile property and the high temperature resistance of the cable are improved. And through a plurality of vent holes in the surface of the heat dissipation reinforcing pipe, a heat dissipation effect can be achieved, and the internal heat resistance of the cable is improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

Basalt fiber impregnating compound and preparation method thereof

The invention discloses a basalt fiber impregnating compound and a preparation method thereof, belongs to the field of functional materials, and aims at solving the problem of lack of related public reports for the basalt fiber impregnating compound at present. The basalt fiber impregnating compound is prepared from the following raw materials in parts by weight: 3-10 parts of a silane coupling agent, 20-60 parts of water-soluble epoxy resin, 400-1000 parts of water, 1-3 parts of organic acid, 40-120 parts of absolute ethyl alcohol, 10-25 parts of glucomannan, 0.5-1.5 parts of an antistatic agent and 3-10 parts of a wetting agent. The impregnating compound has strong binding force with the fiber surface of basalt fiber, has good permeability, and can be used for infiltration modification of basalt; by adopting the impregnating compound, the plasticity, the tensile property and the breaking strength of the basalt fiber can be improved, the bundling property of the basalt fiber is improved, and subsequent processing is facilitated; the basalt fiber treated by the impregnating compound has good hydrophilicity, antistatic property, tensile strength and breaking strength.

Owner:四川文理学院 +2

Bituminous mixture for high-environment-protection road and construction method of bituminous mixture

The invention relates to a bituminous mixture for a high-environment-protection road and a construction method of the bituminous mixture. The bituminous mixture is prepared from the following raw materials in parts by weight: 75 to 79 parts of aggregates, 7 to 9 parts of bitumen, 4 to 6 parts of bitumen modifier, 6 to 8 parts of anti-aging agent, 4 to 6 parts of mineral powder, 3 to 7 parts of combination fibers, 0.5 to 0.9 part of stabilizer and 0.5 to 0.9 part of auxiliaries. A large-scale application direction for coal gangue, cast waste sand, nickel slag and waste polyvinyl chloride plastic bottles is found out, wastes are turned into wealth, environmental pollution and land occupation of solidified wastes are reduced, resources are further utilized, and the bituminous mixture is energy-saving and environmentally friendly. A road surface paved by the bituminous mixture is good in ageing-resistant performance, good in weather fastness, good in wear resistance, good in heat resistance, not easy to fatigue or crack and good in rutting resistance, the production cost of the bituminous mixture is low, and the aggregates cannot be scattered easily in a production process.

Owner:SHENYANG SANXIN GROUP PANJIN ROAD MATERIALS

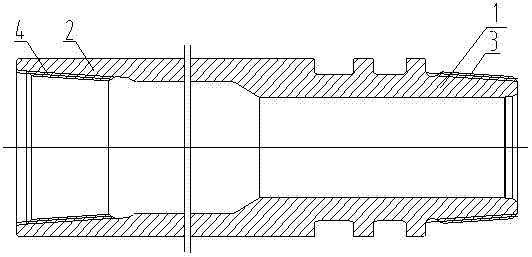

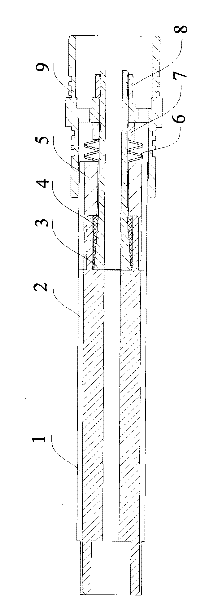

High load drill stem and raise boring machine with the same

InactiveCN103114816AGood tensile performanceImprove affordabilityDrilling rodsDrilling casingsAngle alphaDrill pipe

The invention discloses a high load drill stem which is used in a boring machine and particularly applicable to a raise boring machine. The high load drill stem comprises a hollow drill stem body. Two ends of the hollow body are respectively provided with a male joint and a female joint which are matched with each other. The male joint and the female joint are respectively in a hollow structure. An outer side wall of the male joint is provided with outer taper threads extending along the axial direction. An inner side wall of the female joint is provided with inner taper threads extending along the axial direction. A thread angle of the outer taper threads and the inner taper threads is 60 degrees and conic degree is 1:7 to 1:12. The outer taper threads are provided with a loading flank angle alpha 1 and an inner buckling flank angle beta 1. The inner taper threads are provided with a loading flank angle alpha 2 and an inner buckling flank angle beta 2 and corresponding to the outer taper threads. 10 degrees <=alpha 1=alpha 2<=20 degrees, 40 degrees <= beta 1=beta 2<=50 degrees, and alpha 1+beta 1=alpha 2+beta 2=60 degrees. The high load drill stem can bear large axial tension and torque and suitable for the large raise boring machine.

Owner:HUNAN CHUANGYUAN HIGH TECH MACHINERY CO LTD

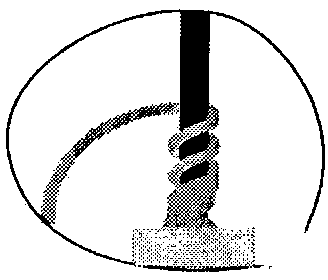

Mechanical finishing method for wool fabric

The invention discloses a mechanical finishing method for a wool fabric. The mechanical finishing method for the wool fabric is characterized by comprising the following steps: selecting a yarn, wherein the quantity of the yarn is 32 Nm / l to 58 Nm / l and the wool content of the yarn is 7%-100%; determining the type of a weaving machine and the weaving parameter according to the selected yarn; feeding a gray fabric into the weaving machine, boiling the fabric, removing an impurity, washing with water, conducting softening finishing by adding a silicone softener and an antistatic agent; mechanically finishing by using the combination of three needling machines; and finally shearing the fabric. The provided wool fabric finished through the needle punching technology adopts the combination of three needling machines in the needling processing process, the first needling machine chooses a thinner felting needle to slantly needle downwards, the second needling machine chooses a thicker felting needle to vertically oppositely needle on the same site, and the third needling machine chooses a thinner felting needle to vertically needle upwards, so that the fabric is more sufficiently needled and is higher in air permeability while the processing efficiency is improved.

Owner:DONGHUA UNIV +1

Electromagnetic wave logging tool coil supporting and pulling device

InactiveCN101054898BSimplify tensile structure designSimple structureElectric/magnetic detection for well-loggingBorehole/well accessoriesFailure rateCoil array

An bearing and pulling device for electromagnetic wave logging instrument coil array comprises a coil rack, an inner cone sleeve is housed on the inner circumference side of the end of the coil rack and is housed for bearing and pulling the coil rack; a protective sleeve is housed on the outer circumference side of the end of the coil rack and is housed for cramping the coil rack. The bearing andpulling device for electromagnetic wave logging instrument coil array of the invention simplifies design of the bearing and pulling structure for electromagnetic wave logging instrument, meanwhile improves the bearing and pulling performance and reliability of the instrument, reduces manufacturing cost and is convenient for carrying and dismantling and mounting, with low failure rate and convenient maintenance.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Test cable and test pipe column

ActiveCN105735974AGood tensile performanceSurveyConnections effected by permanent deformationCapillary TubingEngineering

The invention provides a test cable and a test pipe column. The test cable comprises a test cable capillary pipe, a test cable core and a connecting wire, wherein the test cable capillary pipe is provided with an accommodating through hole penetrating through the test cable capillary pipe in the axial direction; the test cable core is arranged in the accommodating through hole of the test cable capillary pipe; the first end of the test cable core is positioned between the first end of the test cable capillary pipe and the second end of the test cable capillary pipe; a first axial distance is formed between the first end of the test cable core and the first end of the test cable capillary pipe; and the connecting wire extends into the test cable capillary pipe from the first end of the test cable capillary pipe, and is connected with the test cable capillary pipe in a press connecting way. The force bearing capability of the test cable is high.

Owner:PETROCHINA CO LTD

Underwater concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses underwater concrete and a preparation method thereof. The underwater concrete is prepared from the following raw materials in parts by weight: cement, sand, gravels, water, a flocculating agent, a water reducing agent and modified composite fibers, the modified composite fiber is prepared by the following method: weighing basalt fiber and polyurethane fiber, and mixing to obtain composite fiber; weighing a chitosan film solution, and spraying the chitosan film solution on the surface of the composite insecticidal powder to prepare coated micro powder; placing the coating micro powder on the surface of the composite fiber, stirring and and mixing, and drying to obtain a modified composite fiber; the preparation method of the underwater concrete comprises the following steps: weighing the cement, the sand, the gravel and the water, mixing and stirring to obtain a mixture; weighing a flocculating agent, a water reducing agent, the modified composite fiber and the mixture, mixing and stirring, and curing to obtain the underwater concrete. The product has the advantage that the strength of the underwater concrete is prevented from being influenced by penetrating transverse cracks on the surface and in the concrete.

Owner:青岛磐石混凝土工程有限公司

Shear part joint composite structure of composite beam bridge and construction method of shear part joint composite structure

InactiveCN113774781AAvoid field weldingImprove construction efficiencyBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural composition

The invention discloses a shear part joint composite structure of a composite beam bridge and a construction method of the shear part joint composite structure. The composite structure comprises a steel structure composed of a steel beam and a connecting structure arranged on the steel beam in the length direction and provided with a left groove and a right groove, a left concrete slab and a right concrete slab which extend into the left groove and the right groove of the connecting structure respectively and are fixed through bolt connecting pieces, and a covering layer covering the connecting structure and the left concrete slab and the right concrete slab. According to the invention, welding operation is not needed, all components can be prefabricated in a factory, the field construction efficiency can be improved, and the construction quality is improved; besides, the high-strength bolts provide vertical pre-tightening force and in-plane shear rigidity at the same time, and act together with the penetrating steel bars, so that the shear resistance of the structure is improved, the stress of the joint concrete is improved, and the structural resistance is enhanced.

Owner:HUNAN ROAD & BRIDGE CONSTR GROUP +2

Preparation method of slurry pump wear-resistant corrosion-resistant valve rubber material

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of a wear-resistant and corrosion-resistant valve rubber material for a slurrypump. Chlorinated polyether and acrylate rubber are used for blending modification, and the prepared wear-resistant corrosion-resistant valve rubber material has excellent performance on resisting acid, alkali, muddy water, cement paste and the like. The material has the characteristics of wear resistance, scouring resistance, aging resistance, long service life and the like, and has good tensiletear resistance and high temperature resistance.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com