Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1442results about How to "Reduce construction risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

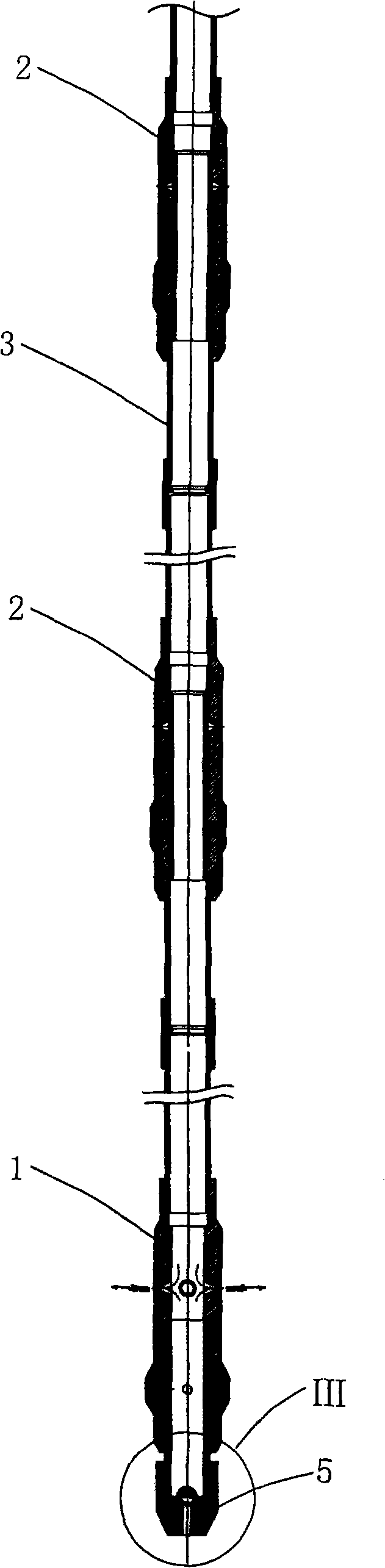

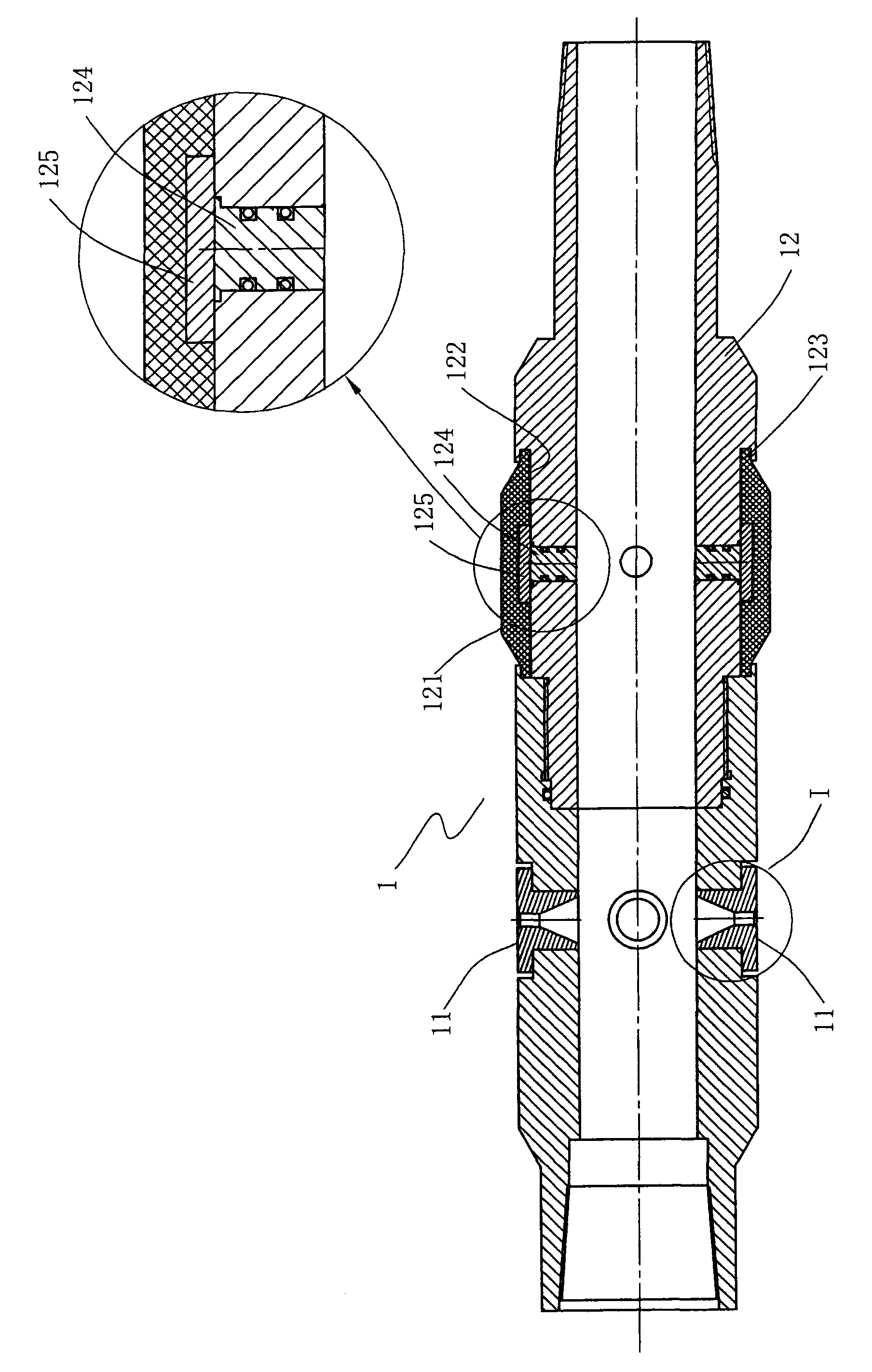

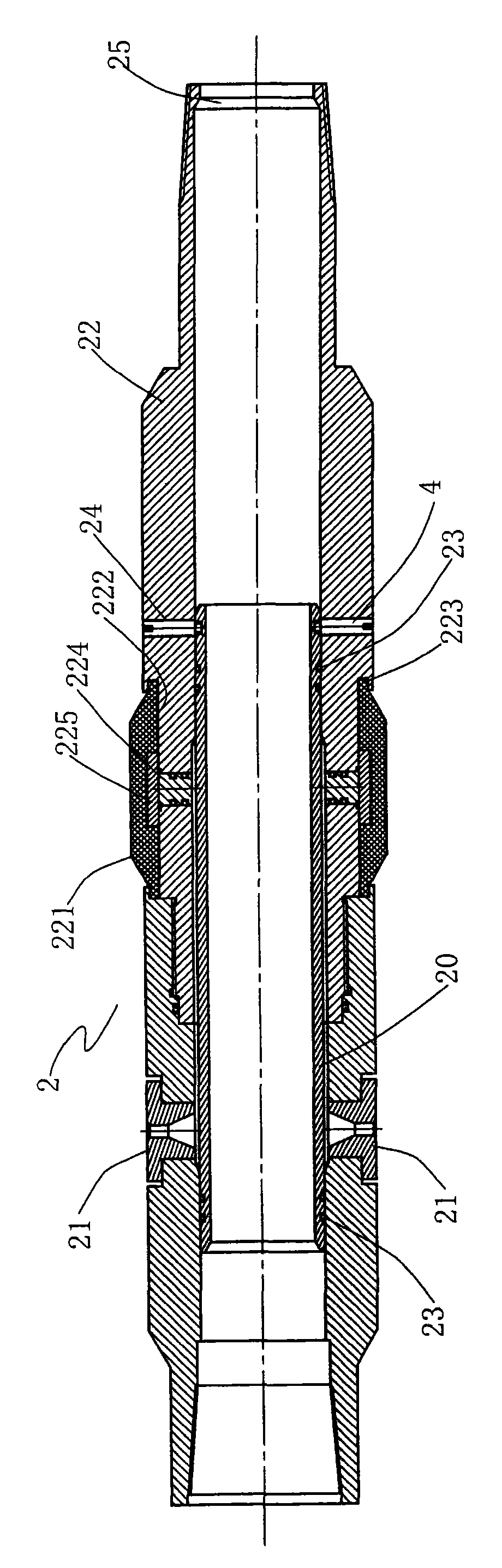

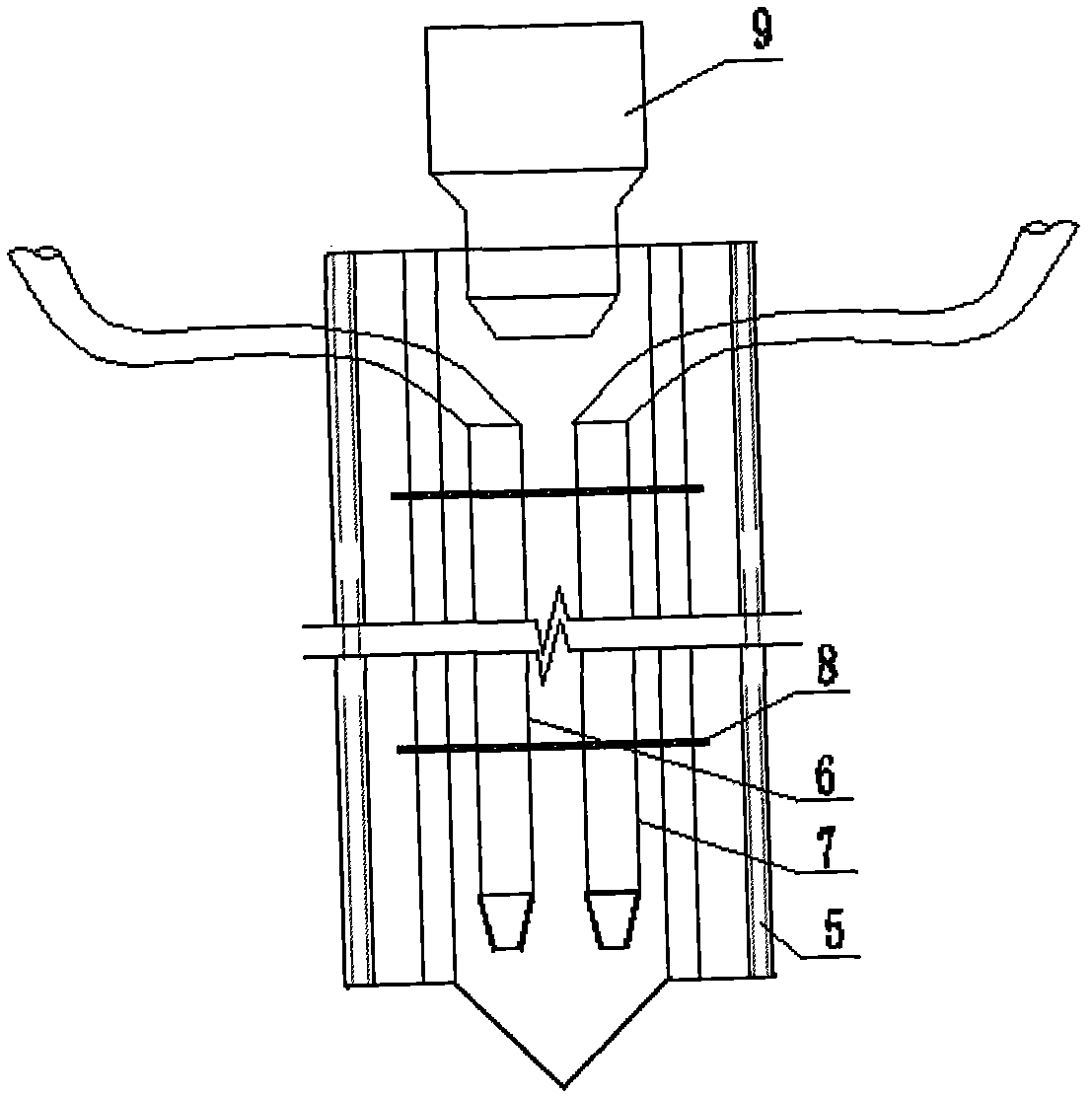

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

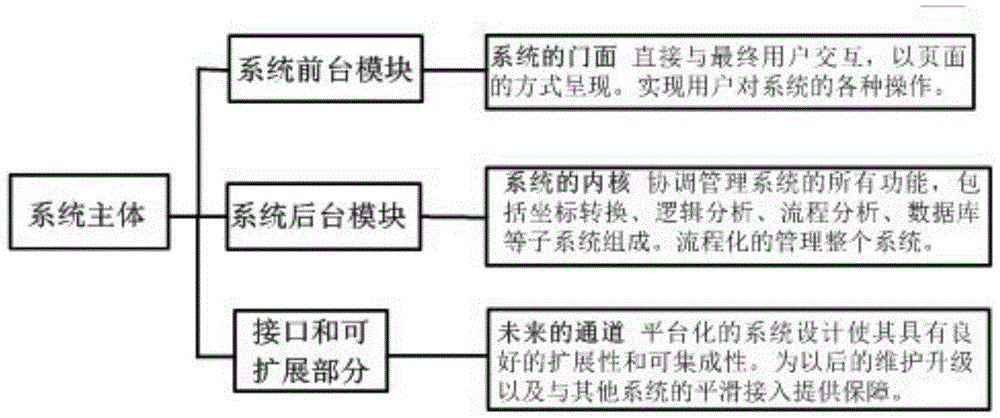

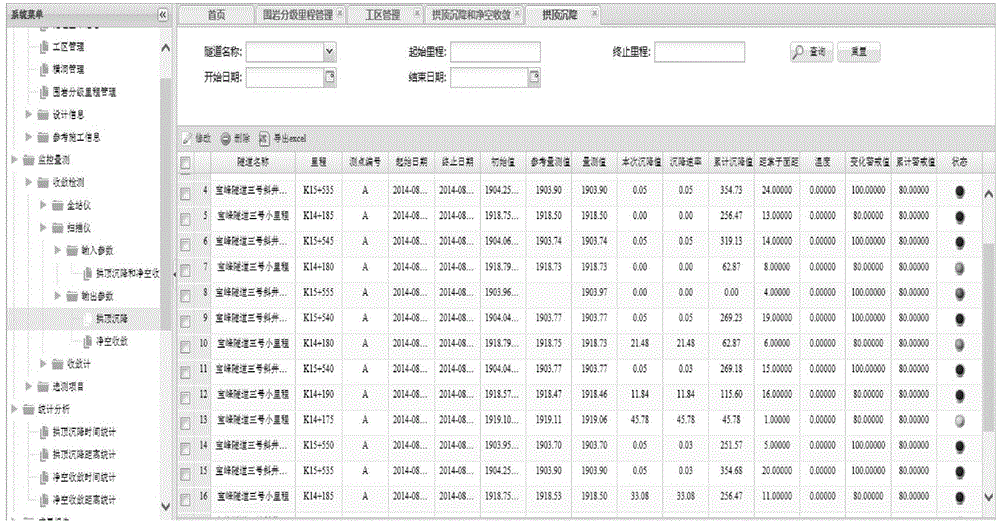

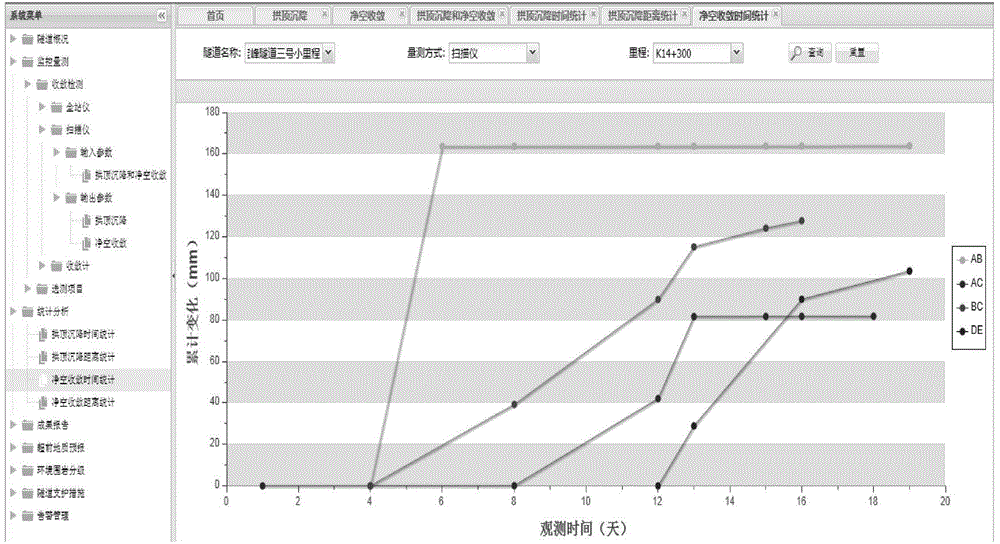

Tunnel construction information monitoring system based on three-dimensional scanning point cloud

ActiveCN104680579AQuick scanFast transferData processing applications3D modellingVertical planeStructure of Management Information

The invention relates to a tunnel construction information monitoring system based on three-dimensional scanning point cloud. The system comprises the following realization steps: acquiring coordinate information, intensity information, grey information, pixel information and the like of a tunnel full-section spatial structure by adopting a three-dimensional scanning point cloud measuring technology, performing automatic filtering processing and point cloud data automatic splicing and generating a tunnel two-dimensional plane model and a three-dimensional space model; realizing the continuous real-time transmission of monitoring data and data flow by adopting a '5S' parallel communication method; introducing a time, motion and rotation multi-dimensional coordinate axis, describing the change posture in a plane, the change posture of a vertical plane and the change posture along with time, performing data filtering and data analysis and realizing seamless butt joint between a monitoring and analysis structure and project construction information; based on an internet of things technology, by adopting a B / S framework and a three-layer system mode as well as seven-level security management, realizing the data monitoring as well as advanced forecasting and construction information real-time processing, update, inquiry, browsing, three-stage early warning and forecasting and three-level risk management.

Owner:武汉岩石科技有限公司

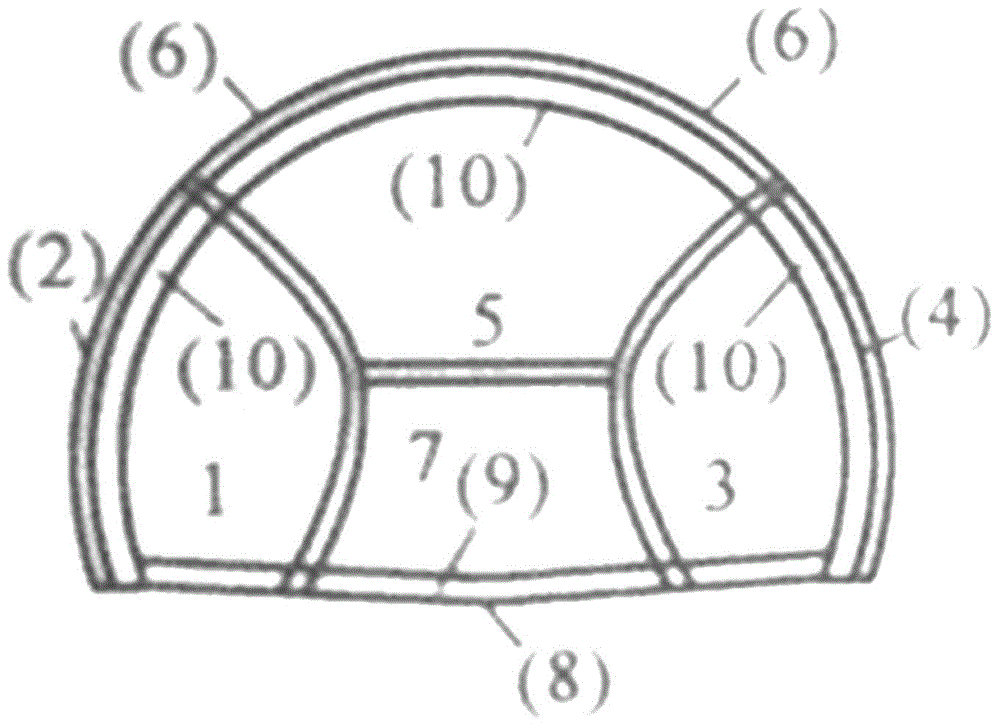

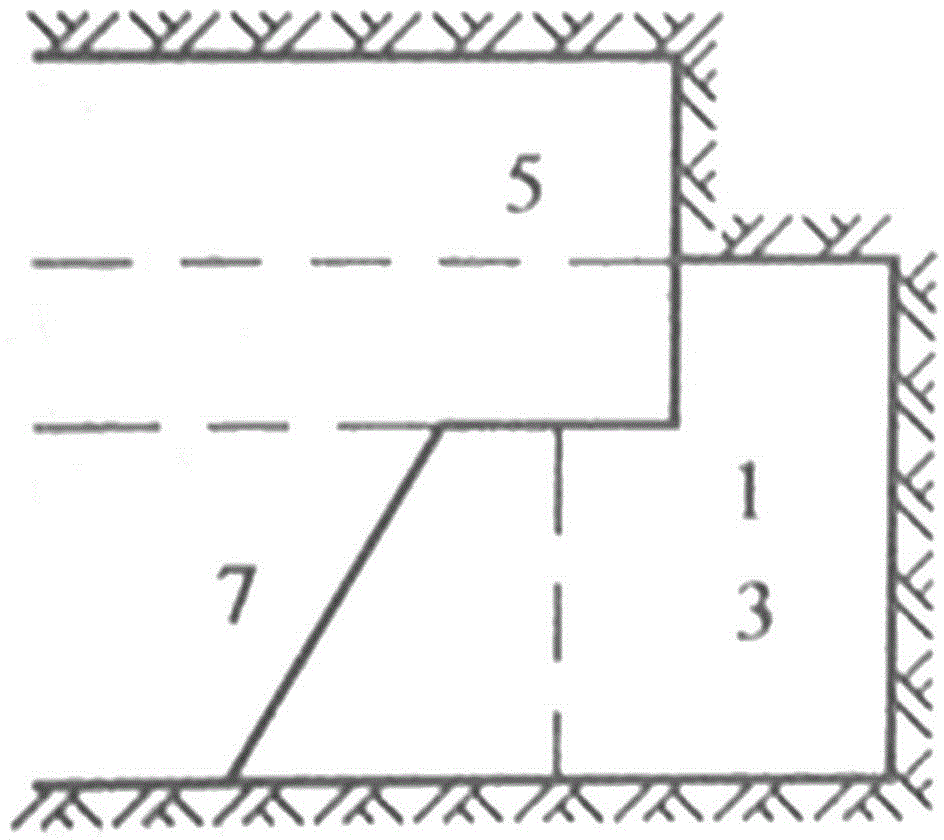

Method for constructing branch guide pits of tunnels

InactiveCN104929648AAvoid accidentsAccurate measurement dataUnderground chambersTunnel liningEngineeringBuilding construction

The invention discloses a method for constructing branch guide pits of tunnels. The method includes steps of (1), carrying out preparation work; (2), constructing advanced pipe sheds and small guide pipes; (3), carrying out ring-type excavation on arches; (4), primarily supporting and temporarily supporting the arches; (5), excavating and supporting left and right guide pits; (6), excavating core soil and inverted arches; (7), primarily supporting the bottoms of the tunnels; (8), pouring and filling the inverted arches; (9), secondarily lining the tunnels. Compared with the prior art, the method for constructing the branch guide pits of the tunnels has the advantages that the arches of the large-span shallow-buried tunnels with fractured surrounding rock can be prevented from collapsing, and full construction procedures are in safe, stable and quick controllable states; the good rate of the engineering quality can reach 95% at least, and safety production accidents can be assuredly prevented.

Owner:XIHUA UNIV

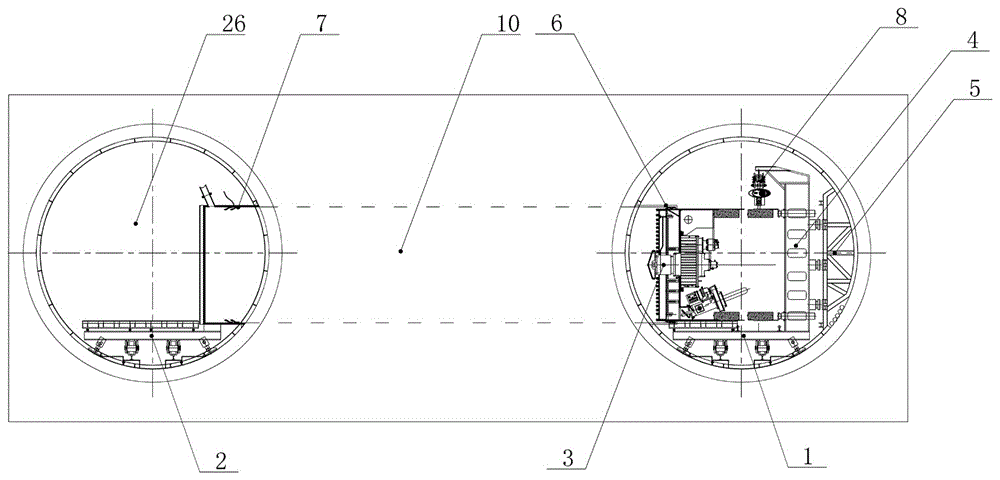

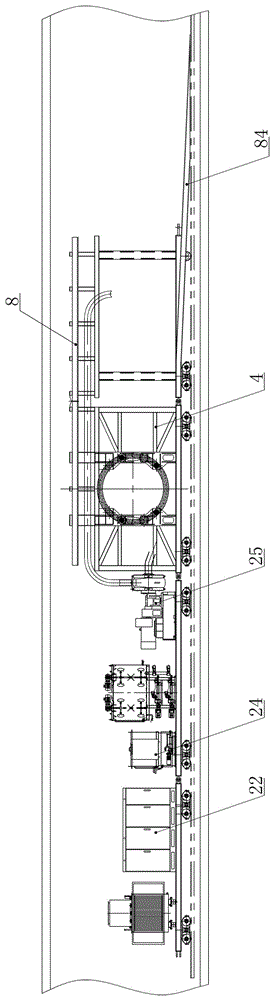

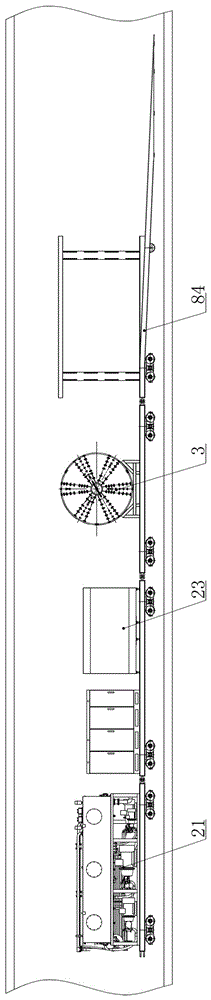

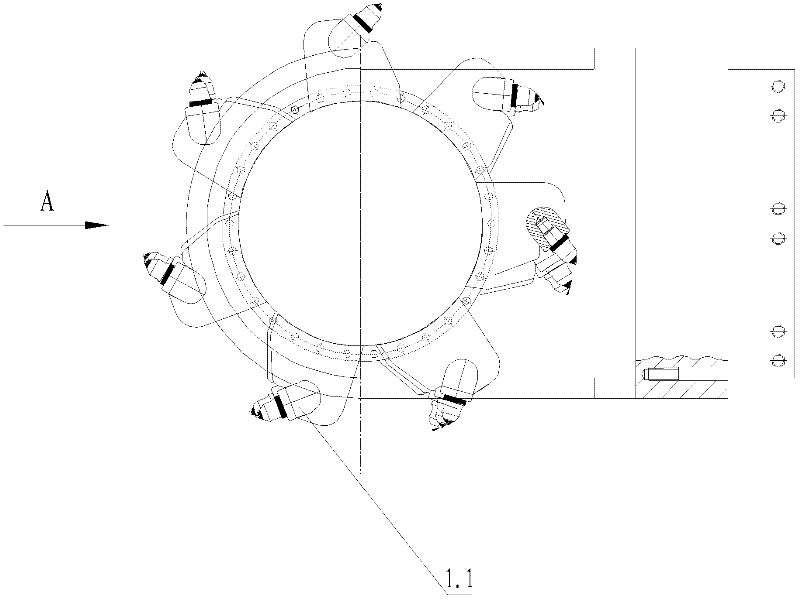

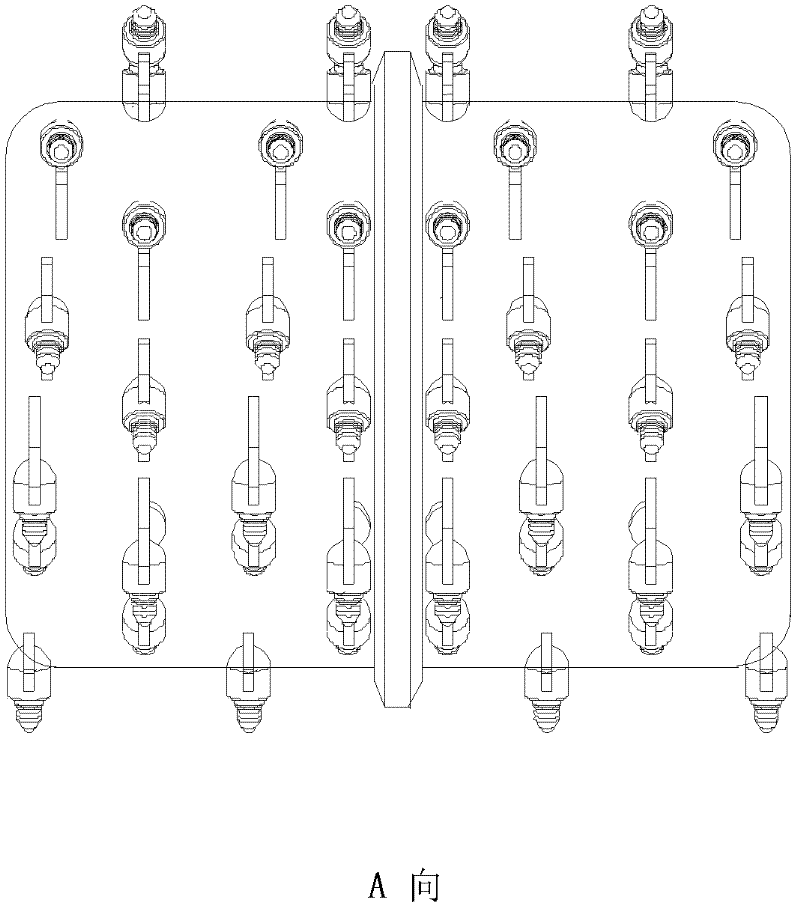

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

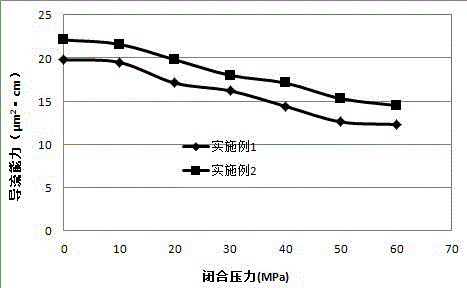

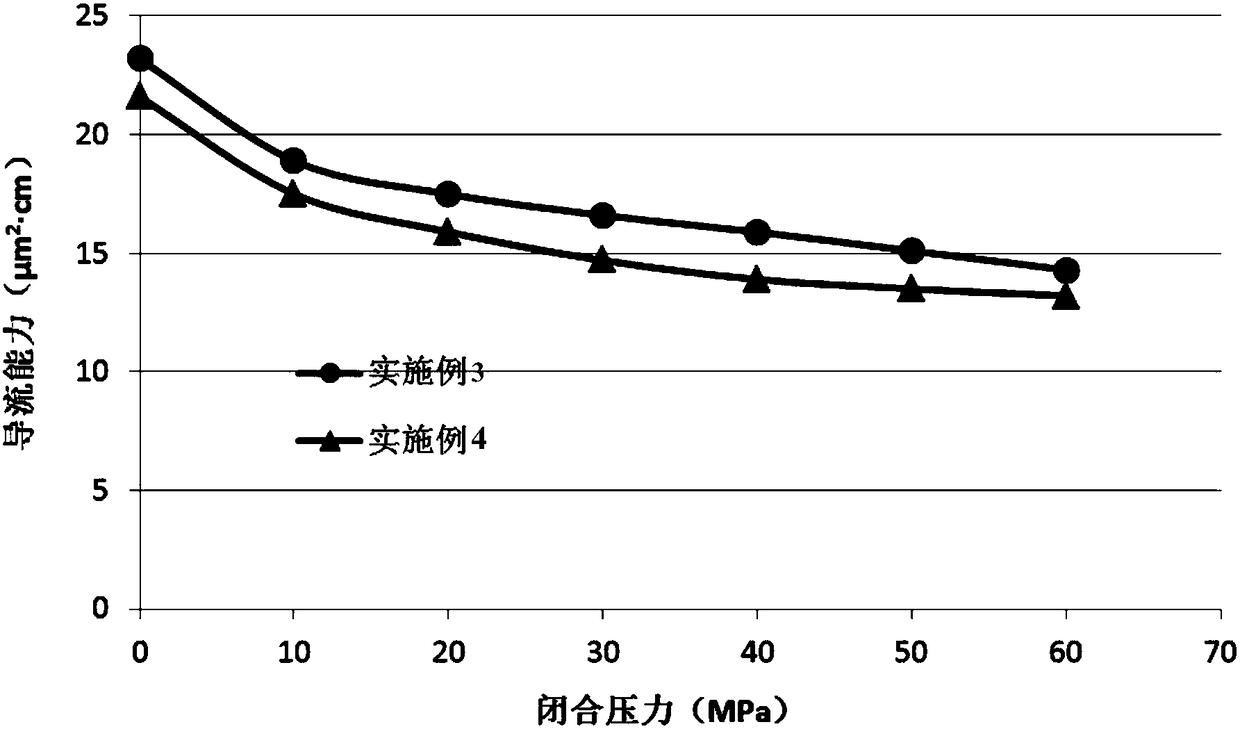

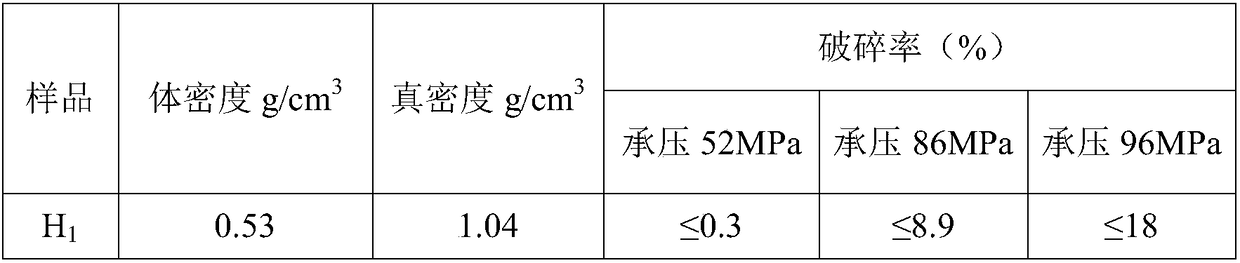

Phase-change hydraulic fracturing technology

ActiveCN105971579AReduce frictionLower requirementFluid removalDrilling compositionActive agentSeawater

The invention discloses a phase-change hydraulic fracturing technology. The technology includes the steps that firstly, clean water or conventional fracturing fluid is injected to a stratum, so that the stratum cracks; secondly, non-phase-change liquid M and phase-change liquid N are placed in different liquid mixing tanks and injected into a shaft at the same time, wherein the injection volume ratio of the liquid M to the liquid N is (0-0.7):(0.3-1); thirdly, displacement fluid is injected into the shaft, so that the non-phase-change liquid M and the phase-change liquid N in the shaft completely enter a reservoir; fourthly, well shut-in and pressure building are conducted for 30-200 min, so that solid-phase matter generated by the phase-change liquid N is laid in cracks; fifthly, decompression is conducted, and construction is finished. The liquid M is conventional fracturing fluid, seawater, stratum water or ground fresh water, and the liquid N is composed of a super-molecular construction unit, surfactant, inorganic salt, oxidant and the like. Channels and ditches for underground oil gas seepage can be formed without solid supporting agents, flow guide capacity of hydraulic fracturing cracks is greatly improved, and the technology is simple, safe and efficient in construction operation.

Owner:PETROCHINA CO LTD +1

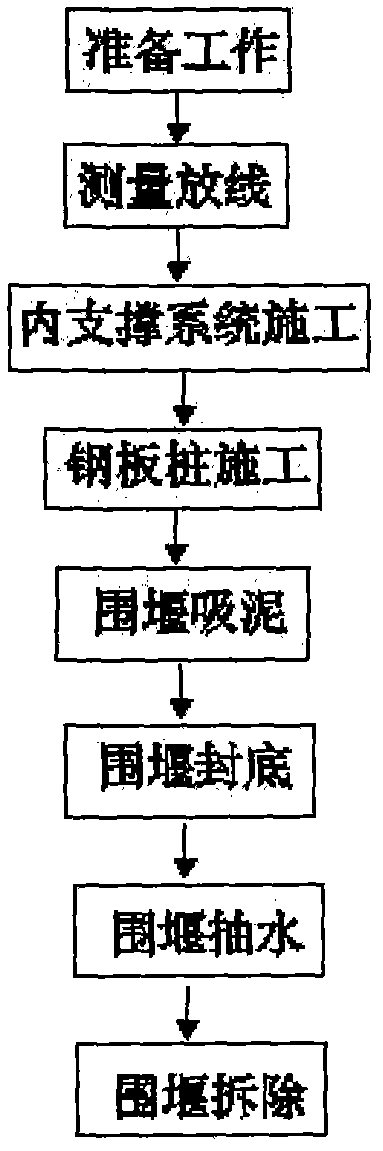

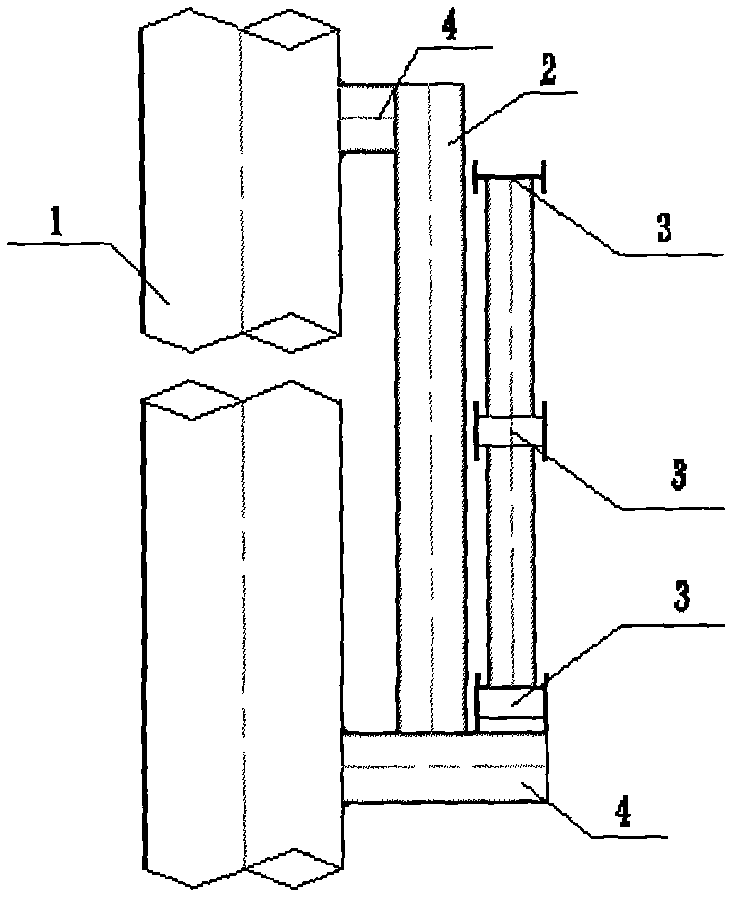

Construction method of steel plate pile cofferdam

InactiveCN102409688AReduce stressShorten the construction periodBulkheads/pilesSupporting systemJoist

The invention discloses a construction method of a steel plate pile cofferdam, which is characterized in that the construction method comprises the following steps: (1) performing construction preparation work; (2) surveying and setting out: surveying and setting out to determine four corner points of the cofferdam according to the design size of the cofferdam and the center position of a support platform, and driving positioning piles at the corner points as control points for positioning the steel plate pile cofferdam; (3) constructing an internal support system constituted by a guide beam, a waling, an inner support, a connecting beam and a supporting beam; (4) firstly welding the waling and the inner support, assembling into a whole, lowering and then inserting and driving steel plate piles for construction; (5) performing mud suction on the cofferdam; (6) sealing the bottom of the cofferdam; (7) performing water pumping and foundation cleaning on the cofferdam; and (8) dismantling the cofferdam.The construction method can further expand the range of applications of the steel plate pile cofferdam by improving the construction sequence and adopting special construction equipment, and successfully realize the steel plate pile cofferdam under the geological condition of a super-thick sandy gravel layer.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Water supply and drainage pipeline repair technique adopting size film lining method

A water supply and drainage pipeline repair technique adopting a size film lining method comprises the steps of: (1) dredging and cleaning a pipeline; (2) inspecting a pipeline internal observing video; (3) producing a working pit; (4) welding a lining pipe; (5) plugging, deflecting and transferring water to the pipeline; (6) internally pretreating and repairing the pipeline to be repaired; (7) drawing the lining pipe into the pipeline to be repaired; (8) sealing the two ends of the lining pipe and embedding a pipe fitting; (9) filling water into the lining pipe and pressurizing; (10) preparing size and auxiliary vacuum casting; (11) keeping the internal water pressure of the lining pipe, and supplying water again after the size is solidified; (12) videoing the inner side of the pipeline and recording the videos after the repair; and (13) the step 1 to step 12 belong to repair construction, taking every two continuous inspection wells as a construction working segment, constructing towards the upstream and downstream sequentially from the inspection well which is next to the working pit, after completing all the working pipeline segments, laying a new pipeline in the working pit, refilling the soil and compacting to restore the pavement; and the pipeline has long service life, high water flow, fast construction speed, less pollution and small influence to roads.

Owner:杨兵

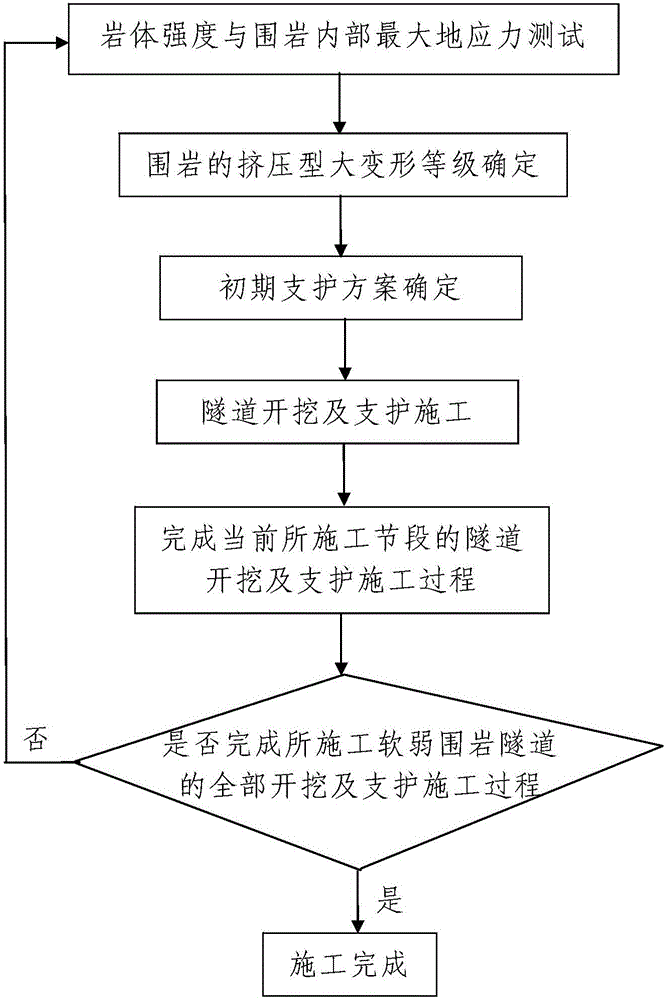

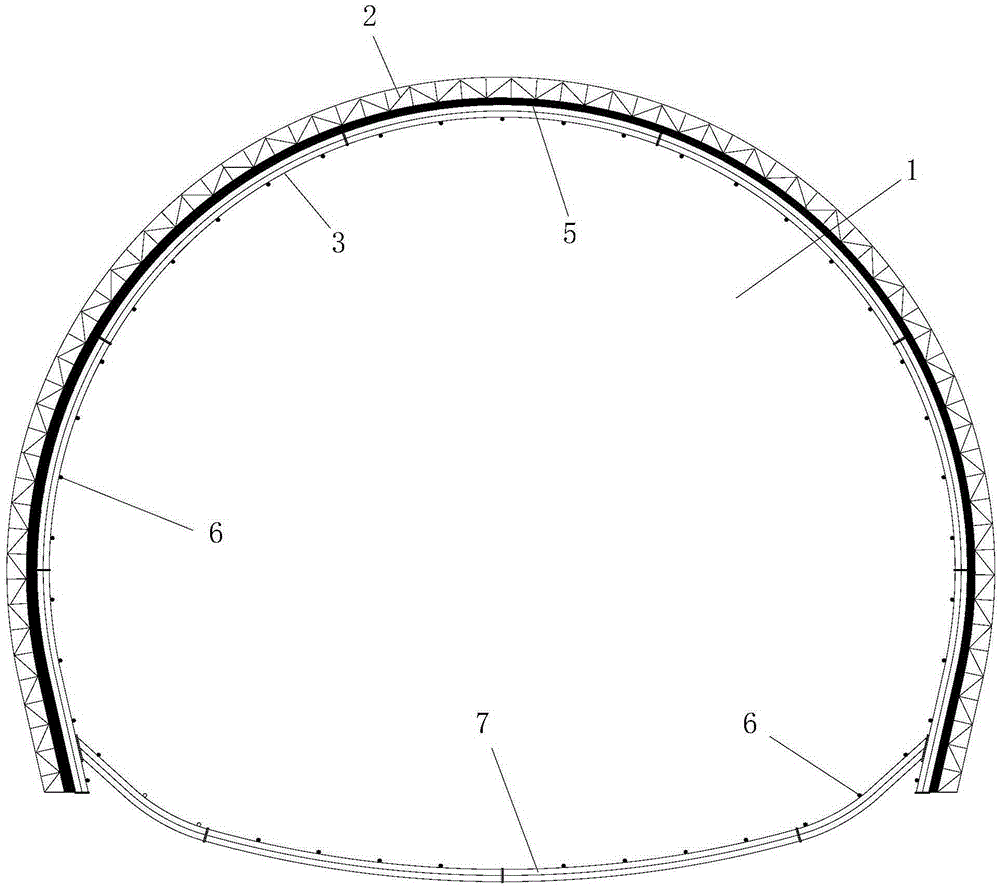

High ground stress weak surrounding rock tunnel excavation and support construction method

ActiveCN105156118AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameRock tunnel

The invention discloses a high ground stress weak surrounding rock tunnel excavation and support construction method. Excavation and support construction are conducted on a weak surrounding rock tunnel to be constructed in multiple sections from rear to front in the longitudinal extension direction of the tunnel. The method comprises the steps that 1, rock body strength and the maximum ground stress inside surrounding rock are tested; 2, the extrusion-type large-deformation level of the surrounding rock is determined; 3, a primary support scheme is determined, wherein the primary support scheme is determined according to the determined extrusion-type large-deformation level, and the primary support scheme is a profile steel frame support scheme or a grid steel frame and cover arch combined support scheme; 4, tunnel excavation and support construction are conducted; 5, excavation and support construction of the next section are conducted; 6, the fifth step is repeated for many times till the whole excavation and support construction process of the weak surrounding rock tunnel to be constructed is completed. According to the high ground stress weak surrounding rock tunnel excavation and support construction method, the steps are simple, the design is reasonable, construction is convenient, the use effect is good, the tunnel excavation and support construction process of the high ground stress weak rock tunnel can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

Construction method for subway contact passage

The invention provides a construction method for a subway contact passage suitable for a very thick Cenozoic stratum region with low heat conductivity and strong heat insulation effect. The method comprises five stages, namely construction preparation, construction of freezing holes, freezing, digging and supporting of the passage and a water collecting well and slurry filling in the back of a wall. The method specifically comprises the following steps of: performing the construction preparation, then forming the freezing holes under the condition that the thickness of a frozen soil curtain is ensured, adding short-range freezing holes on the upper parts of the bell mouths of the freezing holes, and detaching reserved steel pipe sheets at the opening of the passage by adopting a secondary hole forming technology; performing positive freezing after a freezing system runs normally, and making the freezing system perform maintenance freezing after the frozen soil curtain meets the design requirement; after the procedures are finished, performing the digging and supporting stage of the passage and the water collecting well; and pre-burying slurry pipes and filling slurry. By the construction method, the construction difficulty is reduced, the safety and the reliability of engineering are improved, the construction period is shortened, the construction efficiency is improved, and the quality of the engineering is ensured.

Owner:TIANJIN URBAN CONSTR TUNNEL

Water shut off technological process for viscous crude well

InactiveCN1594827AReasonable designReduce construction riskSealing/packingOrganic matterPressure controlled ventilation

The present invention relates to a thick oil well water shut off technological process for thick oil well water shut off layer and improving exploitation effect. The process bases on 'deep move shallow shut off' principal, first selectively shutting off the big diameter for the oil layer by degradable organic shut off additives, then sealing the opening by high temperature resistant inorganic shut off additives, and realizing selective water shut off by pressure control and degradation of organic matter. The water shut off process is reasonable in design, reliable in criterion, and has the characteristic of small construction risk, high success rate and long validity period compared with other thick oil well water shut off processes, and provides a new effective process for solving the water shut off problem for thick oil especially middle thick oil well.

Owner:杨双虎 +2

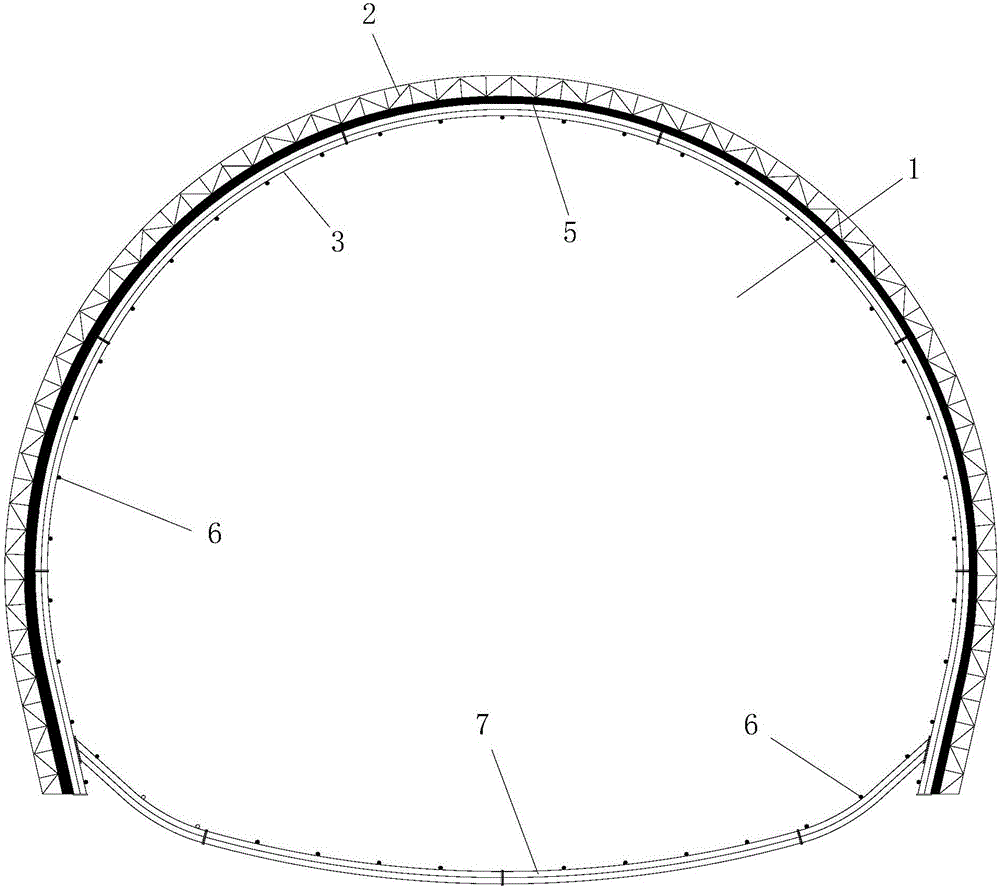

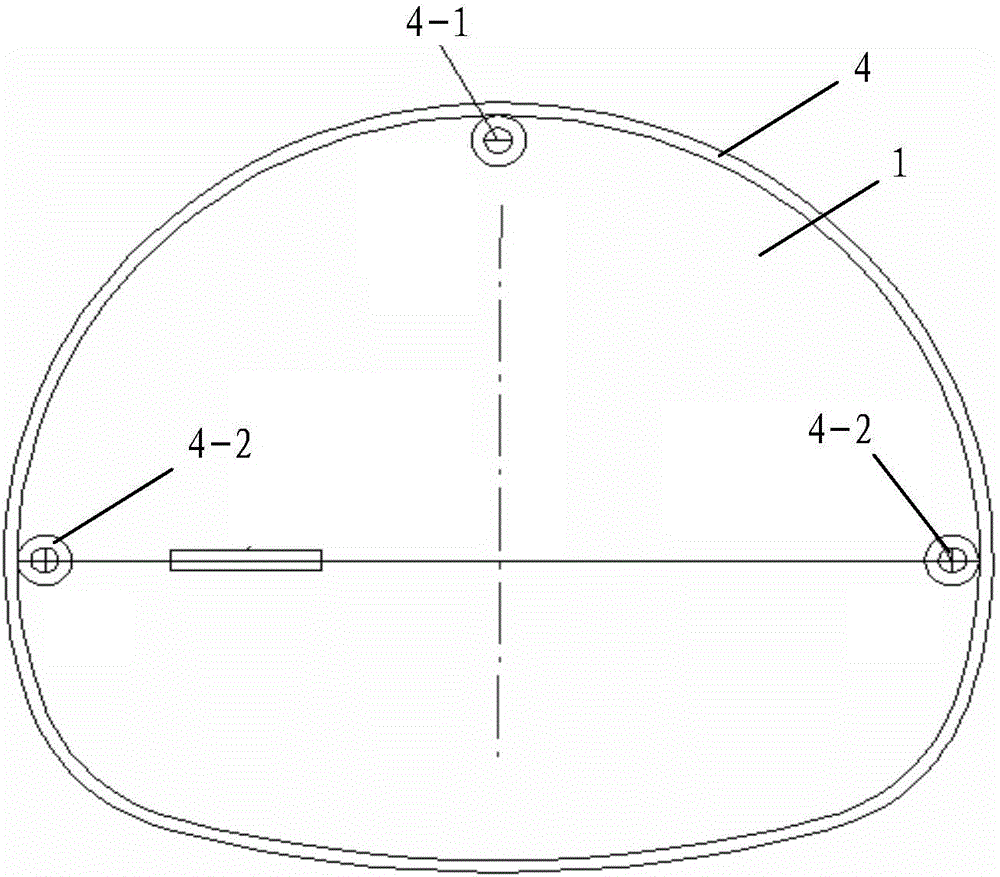

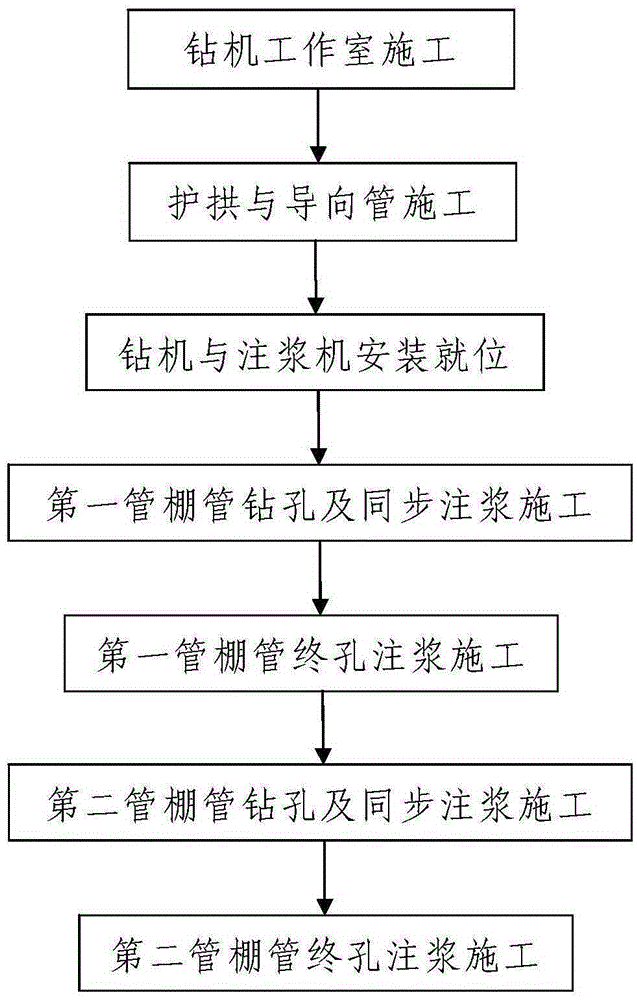

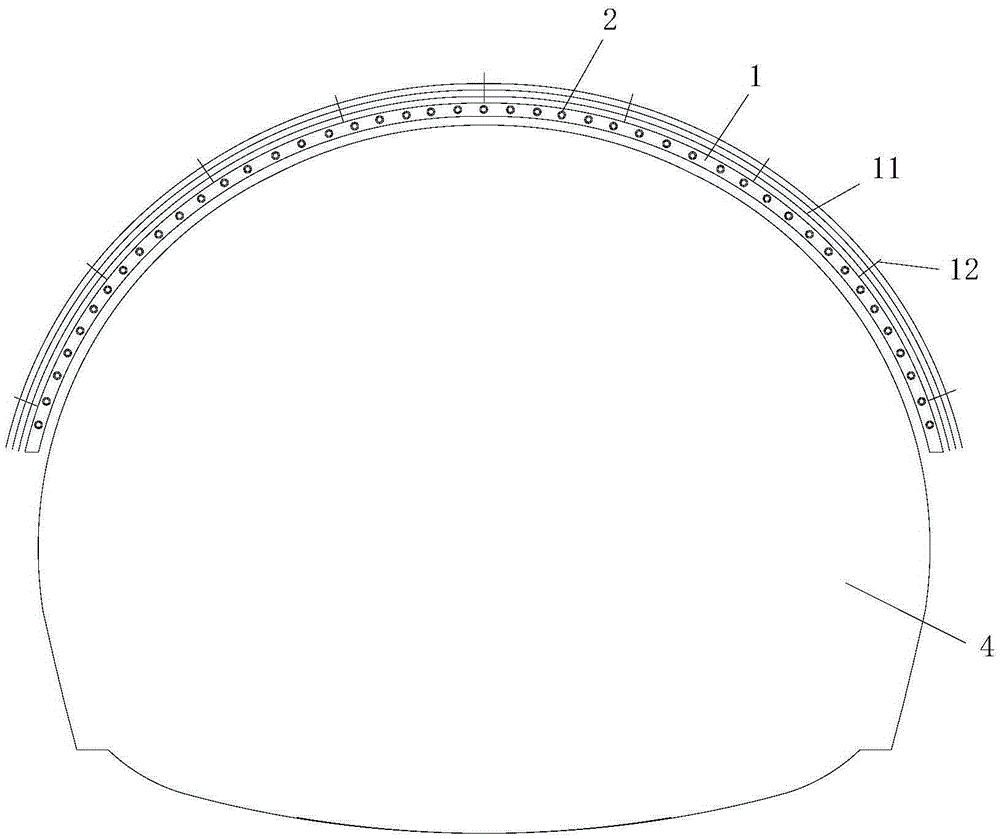

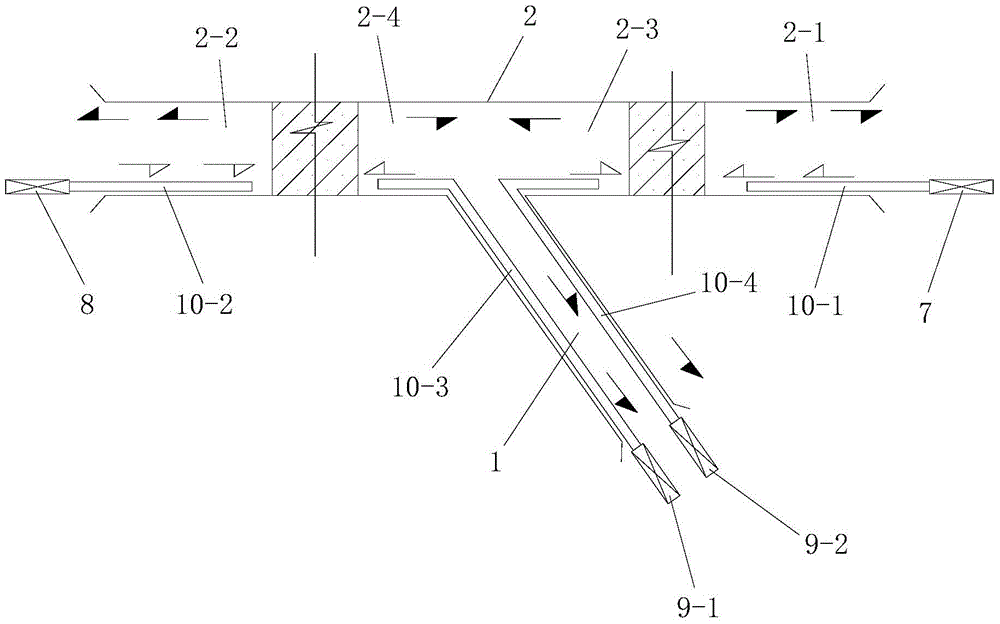

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

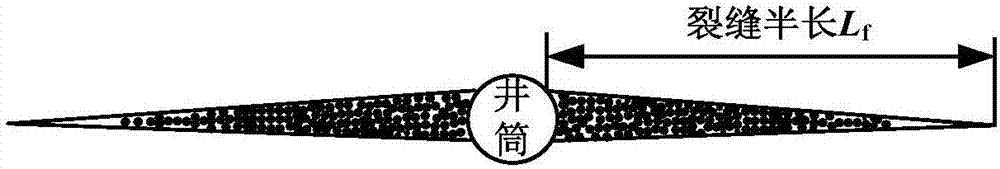

Evaluation method for low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential

ActiveCN107044277AIn line with the actual production dynamicsImprove accuracySurveyFluid removalRepeated fracturesEclipse

The invention discloses an evaluation method for low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential. The evaluation method sequentially comprises the following steps that (1), a crack expansion model is built by utilizing Meyer software, and inversion of first-time fracturing hydraulic crack parameters is conducted; (2), an oil reservoir heterogeneous geological model is built by utilizing oil reservoir numerical value simulation software Eclipse, the first-time fracturing hydraulic crack parameters are planted into the heterogeneous geological model to conduct production dynamic history fitting, and remaining oil saturation field and stratum pressure field distribution is obtained; and (3), quantitative evaluation is conducted on the horizontal well repeated fracturing yield increasing potential according to the remaining oil saturation field and stratum pressure field distribution, first-time fracturing hydraulic cracks are classified, and pertinence repeated fracturing modes are proposed. The problems of the stress sensitivity phenomenon and poor pertinence of the repeated fracturing modes and the like existing in evaluation of the low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential are effectively solved, the effect of repeated fracturing transformation is improved, the risk of engineering construction is reduced, and the evaluation method has wide market application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

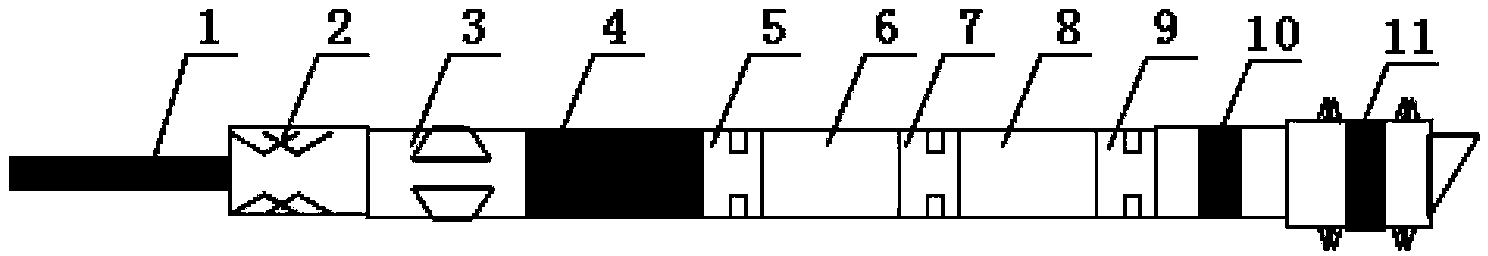

Soluble bridge plug fracturing technology pipe string and fracturing method thereof

The invention discloses a soluble bridge plug fracturing technology pipe string and a fracturing method of the soluble bridge plug fracturing technology pipe string. The soluble bridge plug fracturing technology pipe string and the fracturing method are designed to improve construction efficiency and bring convenience to later transformation of oil-gas wells. The pipe string is connected with a cable head, a magnetic position indicator, a weighing rod, a three-level ignition head, a second-level perforating gun, a second-level ignition head, a first-level perforating gun, a first-level ignition head, a setting tool and a soluble bridge plug sequentially through cables. The processes of drifting, well washing, deeper operation, setting of the soluble bridge plug, perforation of sections, fracturing of light casing pipes, blowout, flow back of the bridge plug and well completion are implemented. The soluble bridge plug replaces a quick drilling bridge plug, construction risks of the cable operation can be reduced, the rest of parts of the bridge plug flow out of the ground through blowout after fracturing construction is finished, construction efficiency is high, the large diameter of casing pipes can be kept, and later transformation work of oil-gas wells is convenient.

Owner:PETROCHINA CO LTD

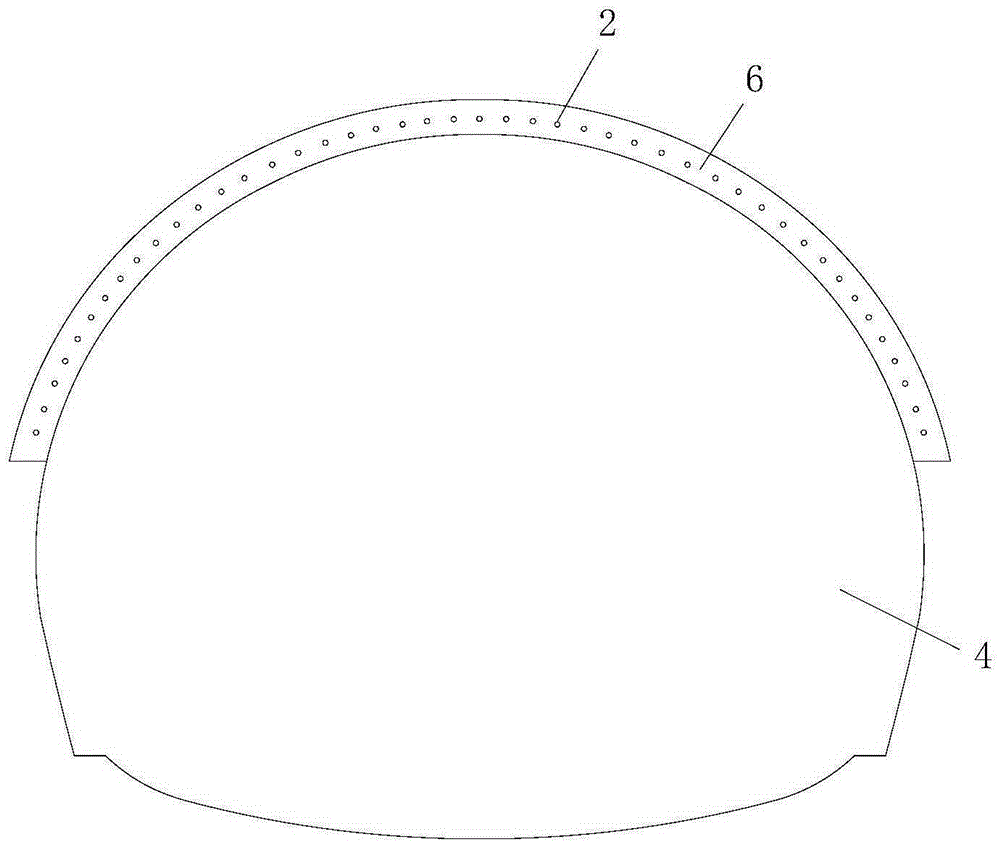

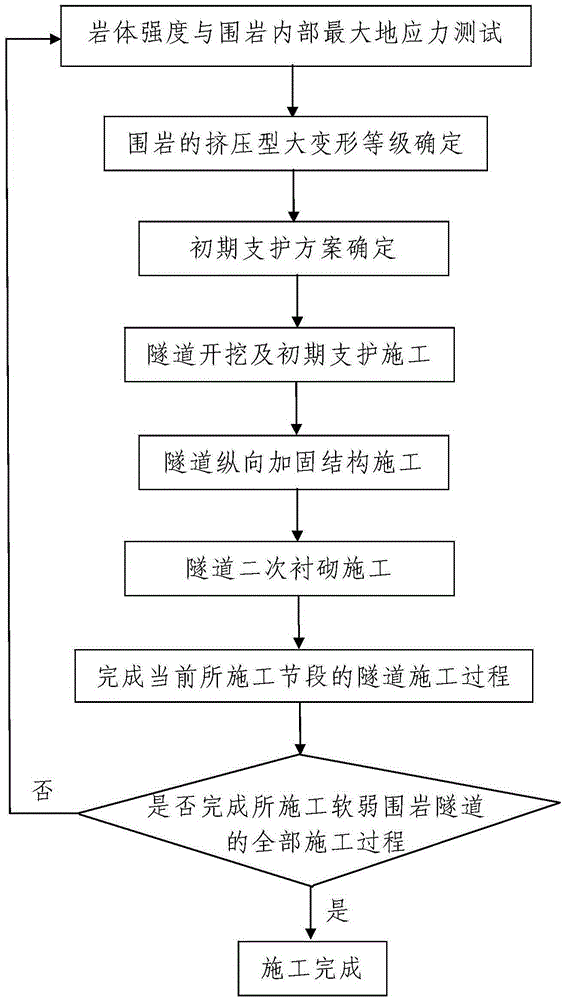

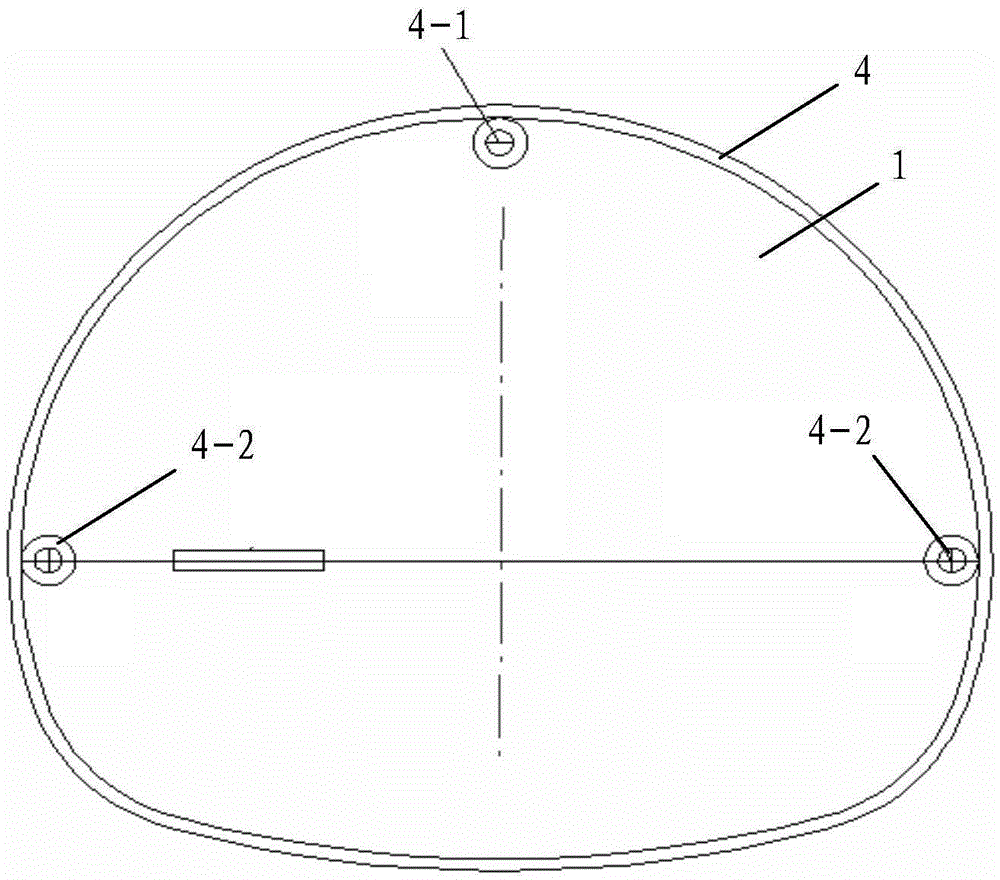

Large-deformation control construction method for high ground stress weak surrounding rock tunnel

ActiveCN105401947AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructure of the EarthRock tunnel

The invention discloses a large-deformation control construction method for a high ground stress weak surrounding rock tunnel. A plurality of segments are arranged in the longitudinal extending direction of the tunnel from back to front to construct the constructed weak surrounding rock tunnel. The method comprises the steps that firstly, the rock strength and surrounding rock interior maximum ground stress test is carried out; secondly, the large extrusion deformation grade of the surrounding rock is determined; thirdly, a primary support scheme is determined; fourthly, tunnel excavation and primary support construction are carried out; fifthly, longitudinal tunnel strengthening structure construction is carried out; sixthly, tunnel secondary lining construction is carried out; seventhly, construction of the next segment is carried out according to the first step to the sixth step; and eighthly, the seventh step is repeated many times till the whole construction process of the constructed weak surrounding rock tunnel is finished. According to the method, the steps are simple, the design is reasonable, construction is convenient, and the using effect is good. The tunnel construction process of the high ground stress weak surrounding rock tunnel can be easily, conveniently and rapidly finished, the construction process is safe and reliable, and the large deformation of the weak rock can be effectively controlled.

Owner:CHINA RAILWAY 20 BUREAU GRP

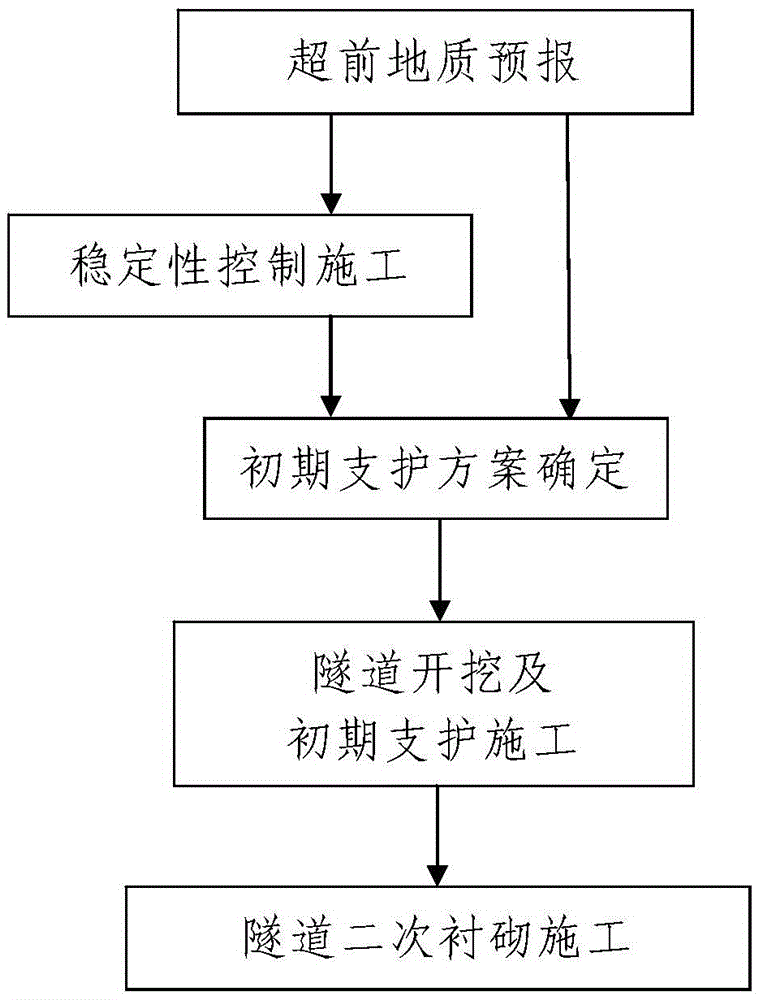

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

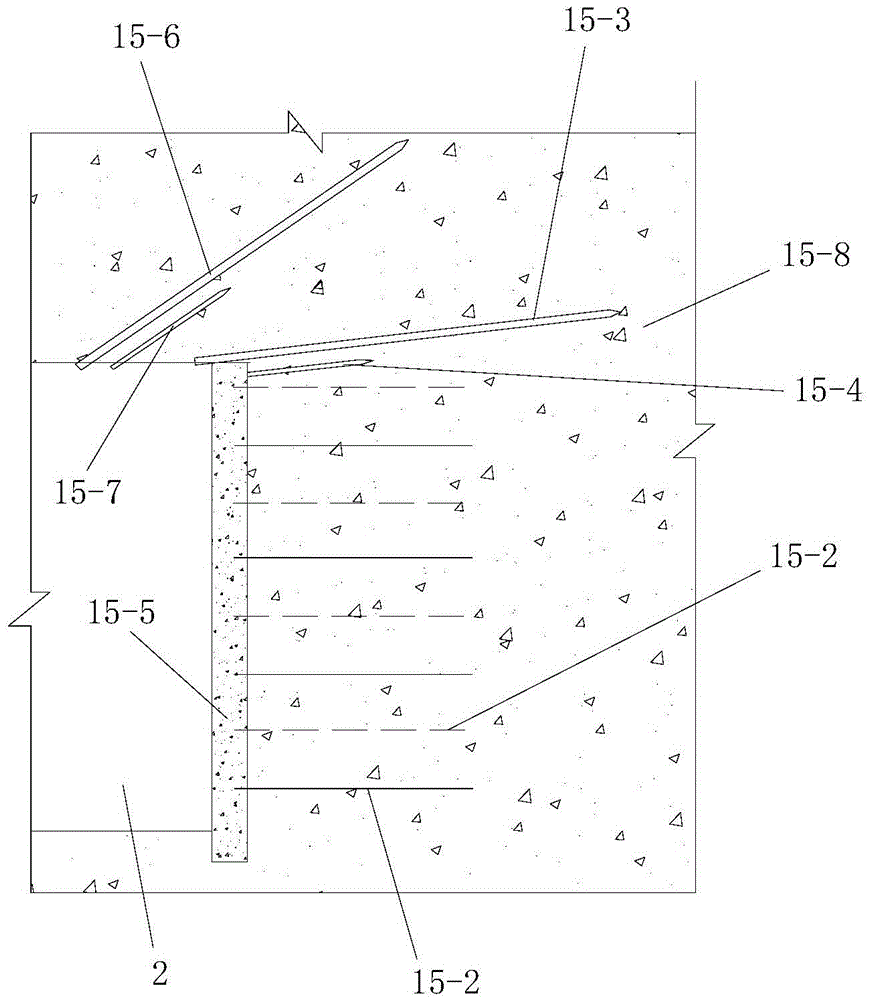

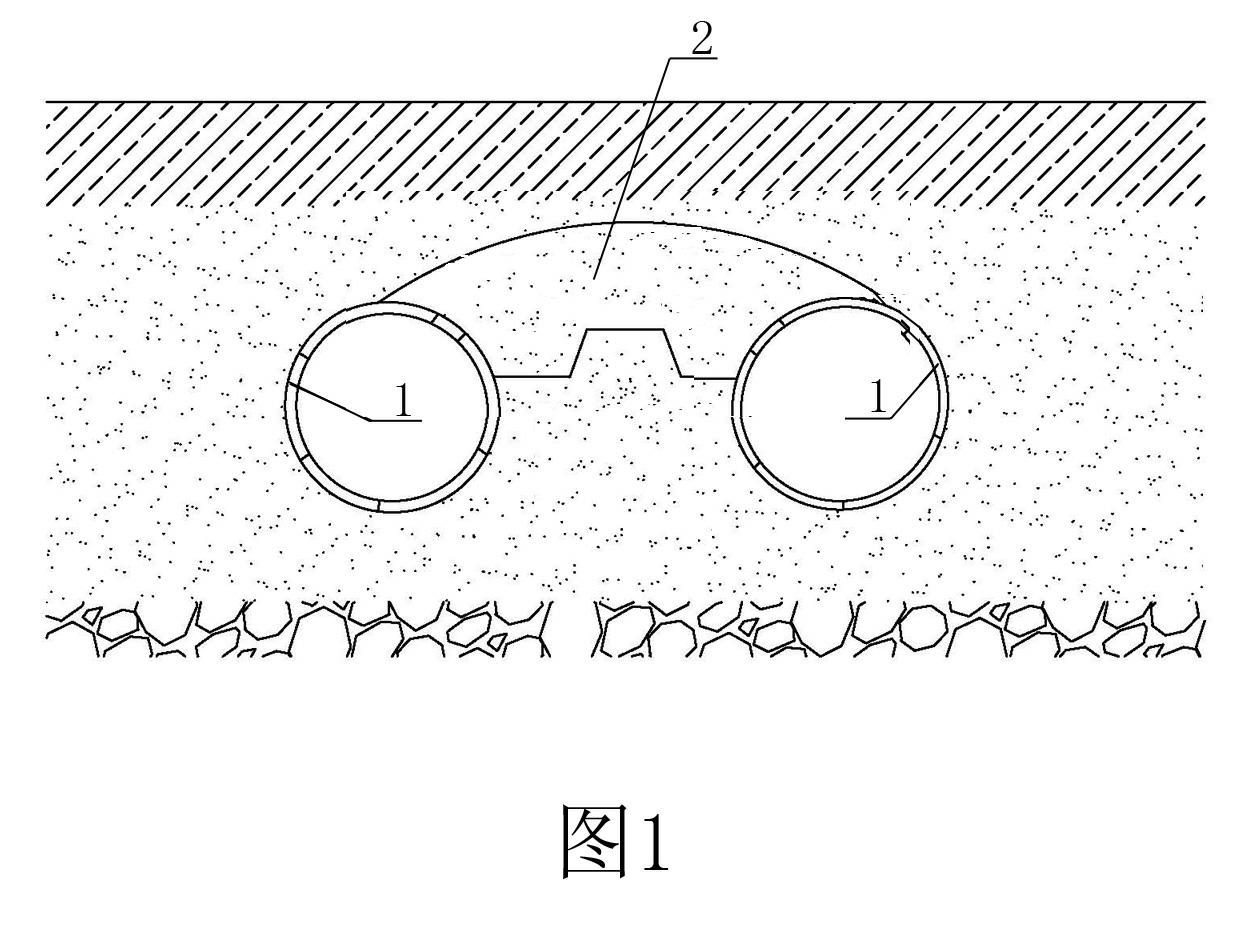

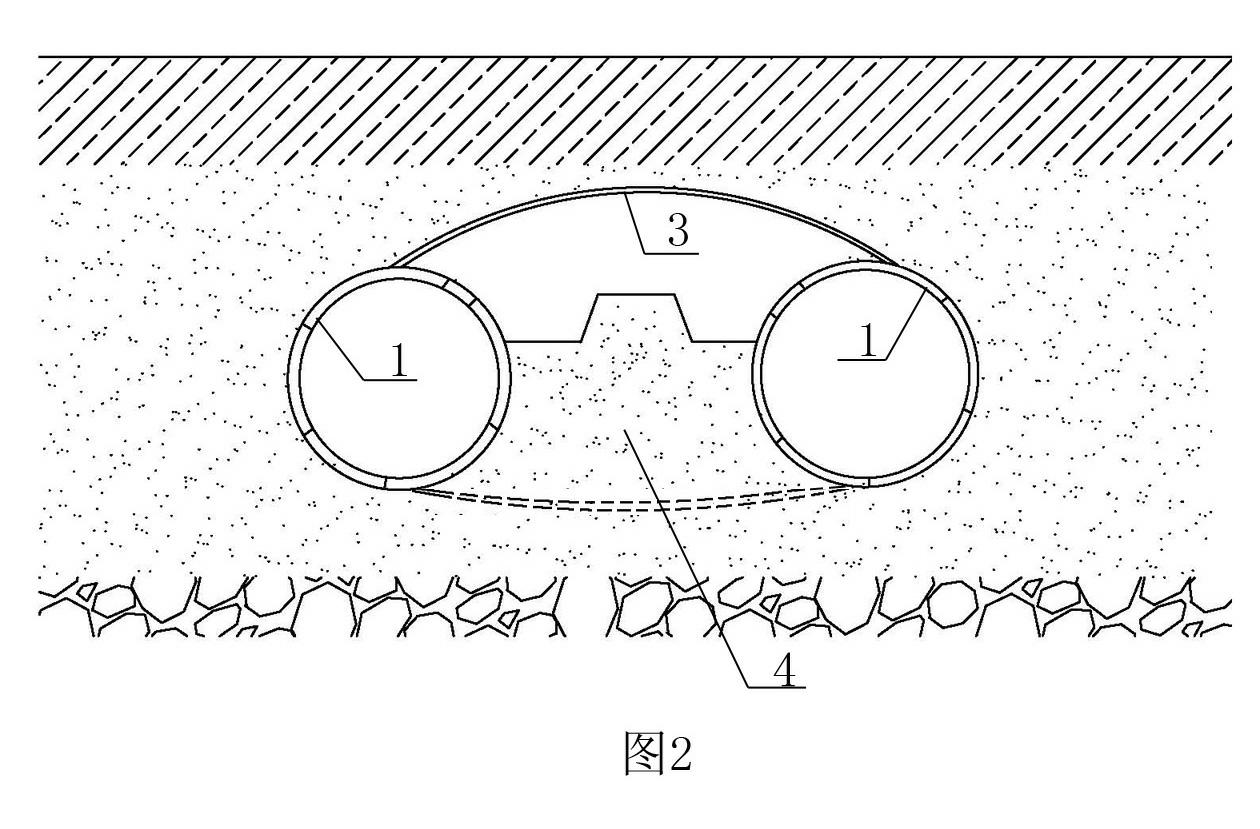

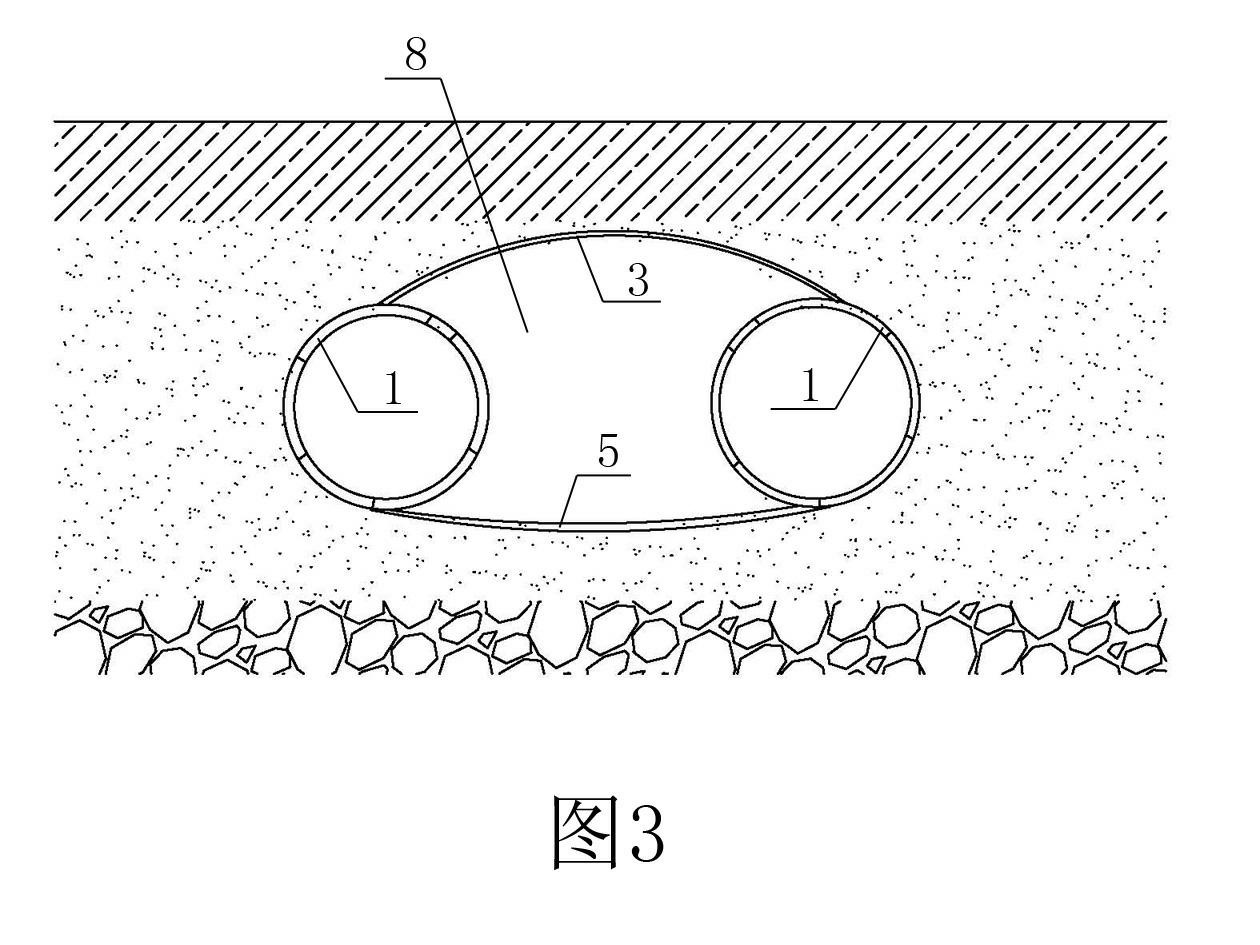

Method for constructing underground space by shield-shallow buried covered excavation composite method

InactiveCN102094649AReduce disturbanceReduce construction riskUnderground chambersTunnel liningStructural engineeringShield tunnelling

The invention relates to a method for constructing an underground space by a shield-shallow buried covered excavation composite method, and belongs to the technical field of construction methods of the underground space. The construction method comprises the following steps of: constructing two or more shield tunnels in advance by a shield method; and excavating a soil body between the shield tunnels by a shallow buried covered excavation method. By the method, the construction of the underground space with a large cross section is safe and high-efficiency, a structure is definitely stressed, construction speed is high and construction cost is low. The method can be used for constructing large-scale underground spaces in various forms.

Owner:乐贵平 +1

Supporting arch hidden digging top-down construction method

ActiveCN101338678AFew construction divisionsIncrease the construction work areaUnderground chambersTunnel liningClerestoryFloor slab

The present invention relates to a one time supporting arch subsurface excavation reversed construction method. The steps of the method are as follows: at least a pair of upper guide hole and lower guide hole are respectively excavated in a top body and a bottom body corresponding with an underground structure design space; each pair of guide holes forms one span; then the hole wall is processed for primary supporting; the bottom of the lower guide hole is laid with a waterproof layer; the waterproof layer is casted with an underlayer frame structure soleplate; a slope stake and a middle upright post are constructed from the upper guide hole; the arc top of the upper guide hole is laid with the waterproof layer, and an arc top permanent structure is cast; then a midspan soil body is excavated between two upper guide holes by a subsurface excavation method to form a midspan upper guide hole and to be constructed as a midspan upper guide hole arc top permanent structure; the primary support at the bottom of the upper guide hole is chiseled and removed; a soil body is excavated downwards, and a structure lateral wall and a middle floor slab are cast; the rest partial solid between the primary support at the top of the lower guide hole and the middle floor slab is excavated, at the same time, the primary support at the top of the lower guide hole is chiseled and removed, the rest lateral wall structure is cast, and an even span structure soleplate is closed. The method has small construction risk, large construction field and fast construction speed, uses few big guide holes and solves the technical problems of the large amount of the guide hole, the small size of the guide hole, small construction space, multiple times of structure stress conversions, the repeated perturbation of wall rock, etc of the traditional subsurface excavation method.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

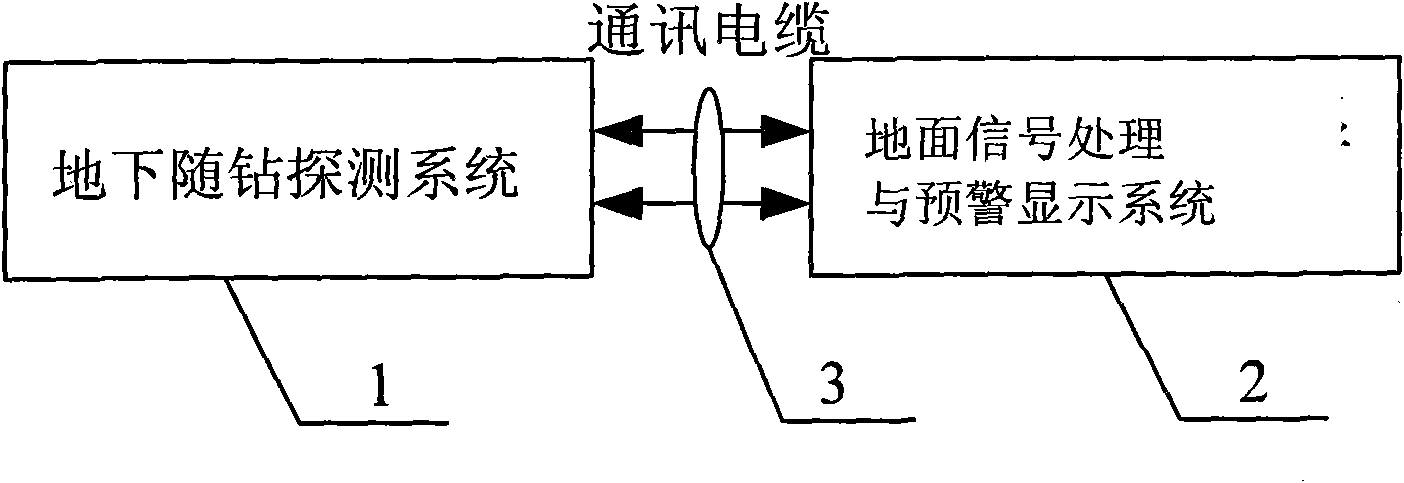

Horizontal guiding drill while-drilling detection early warning system

InactiveCN101676518AImprove detection accuracyReduce construction riskSurveyMining devicesData acquisitionAcoustic wave

The invention provides a horizontal guiding drill while-drilling detection early warning system which comprises an underground while-drilling detection system and a ground signal processing and earlywarning display system that are connected with each other by a two-core communication cable, so that high speed data communication can be realized; in the construction process, the underground while-drilling detection system works under the ground and adopts active acoustic detection technology for detecting, thus completing acquisition and transmission of data of underground pipeline detection; and the ground signal processing and early warning display system works on the ground and is used for controlling the underground while-drilling detection system, processing and displaying the detection data and alarming by sound and an indicator light according to the danger level of underground obstacles. The system combines the detection technique and the drilling construction technique so as torealize while-drilling detection early warning, can effectively detect the obstacle which is about 1m far from the advance locus of a horizontal guiding drill, has higher detection accuracy and effectively reduces the construction risk.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

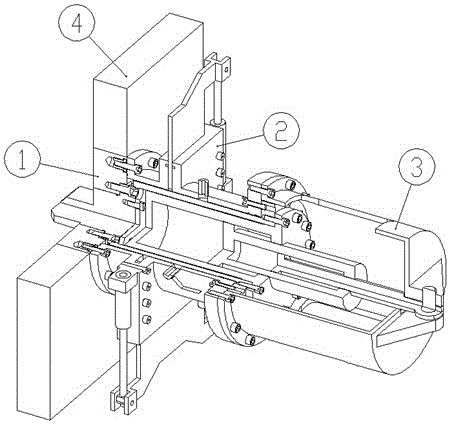

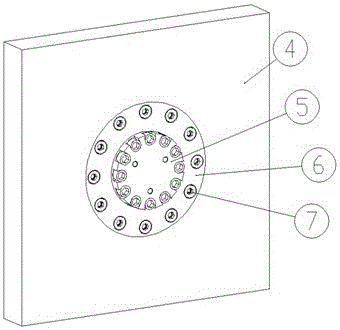

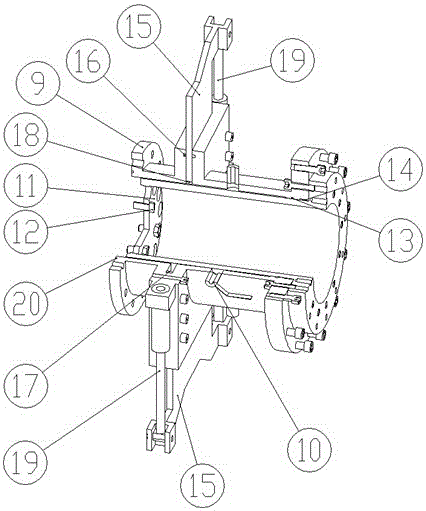

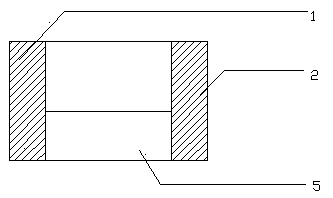

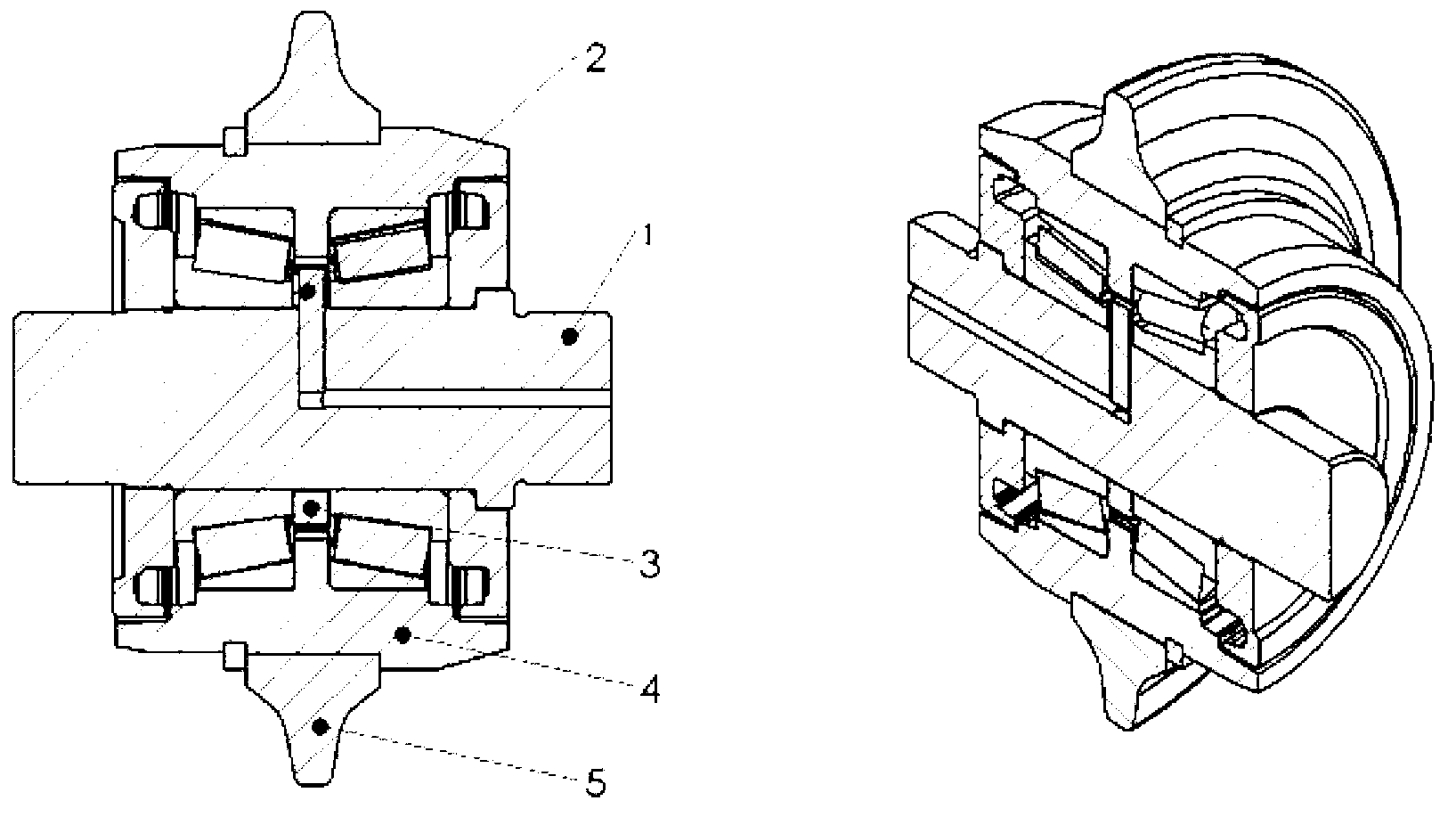

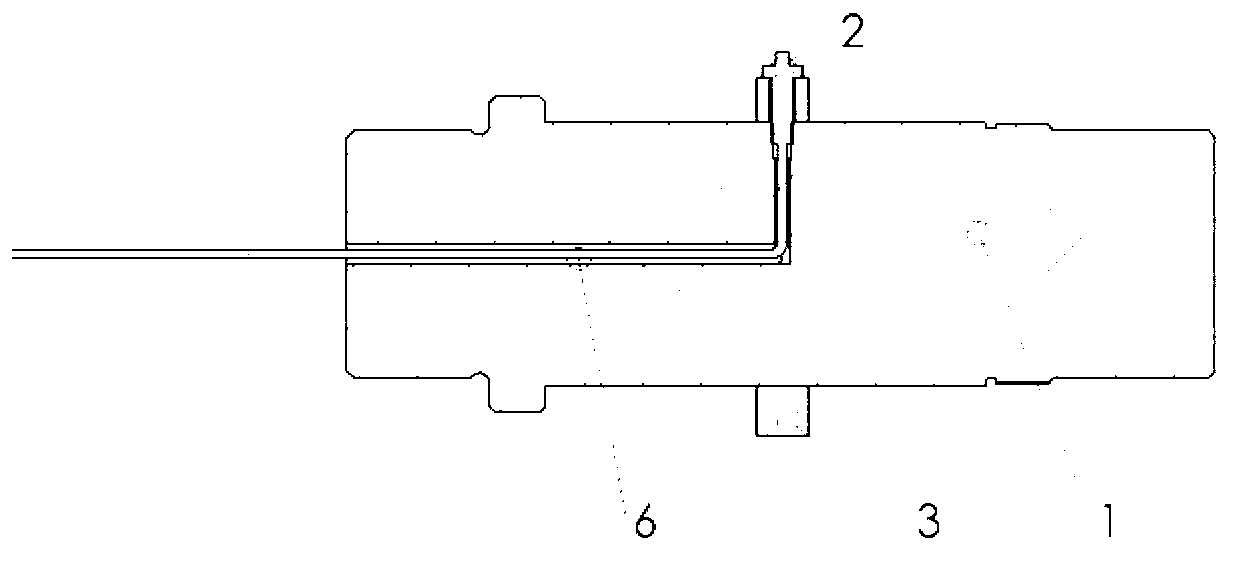

Detachable normal-pressure tool change device

ActiveCN105736005AProtection securityReduce construction risk and difficultyTunnelsTunnel boring machineWater pressure

The invention provides a detachable normal-pressure tool change device. The tool change device consists of a tool apron cutter device, a tool change safety cabin device and a cutter change device. Through close coordination of the tool change safety cabin device, the cutter change device and the tool apron cutter device, a shield under high water pressure is subjected to cutter change in a normal-pressure environment, the problem that a sealing element of a tool change safety cabin cannot be changed after being worn is solved, and the working comfort during normal-pressure tool change is improved; and the tool change device can be widely applied to a normal-pressure tool change cutter plate of a tunneling machine under high water pressure so as to protect the safety of cutter change workers and lower the construction risk and difficulty.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

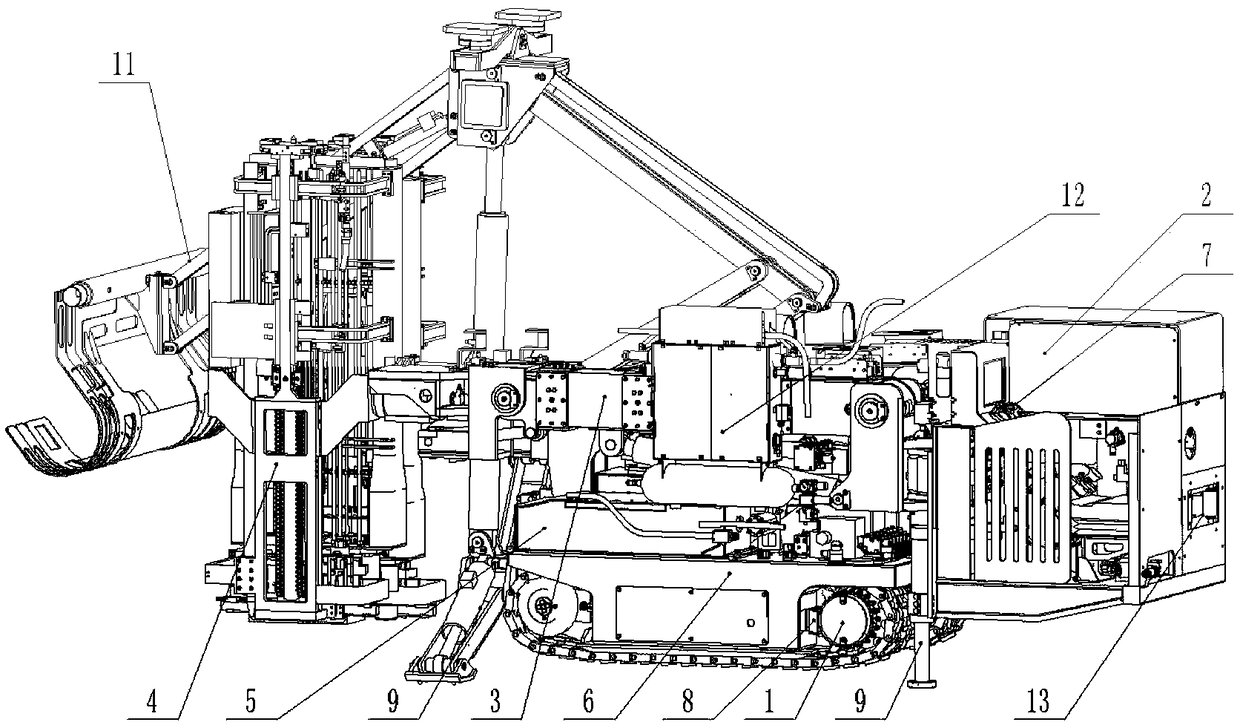

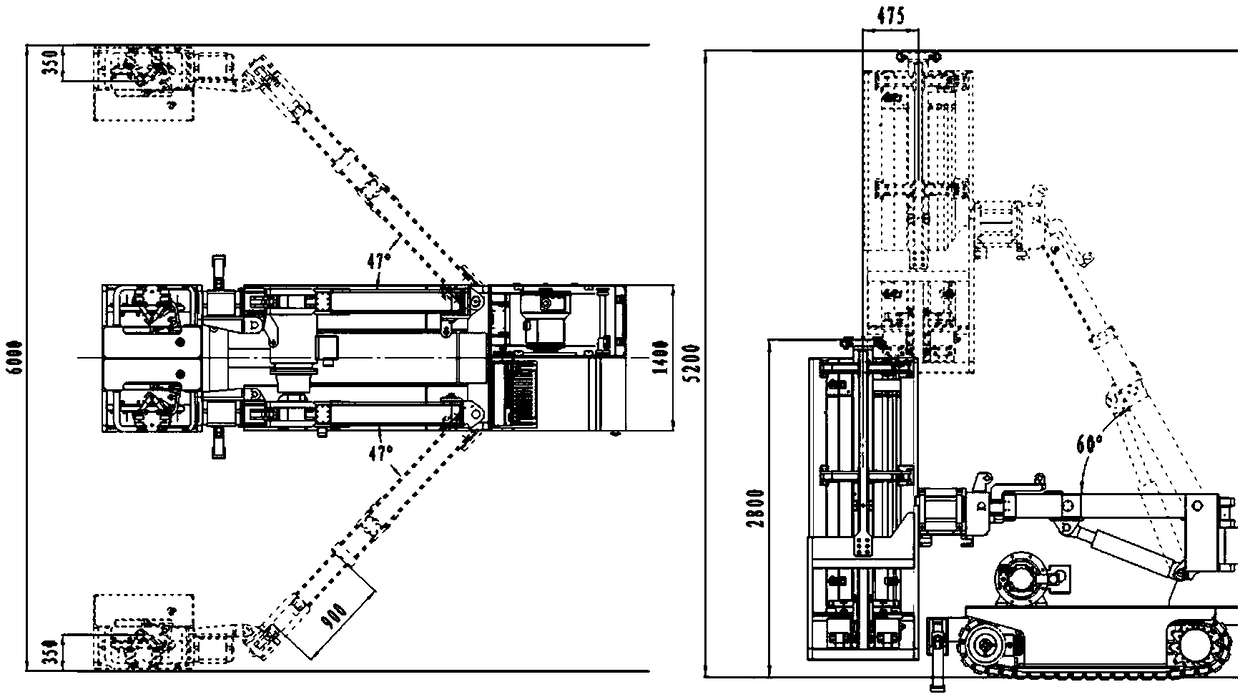

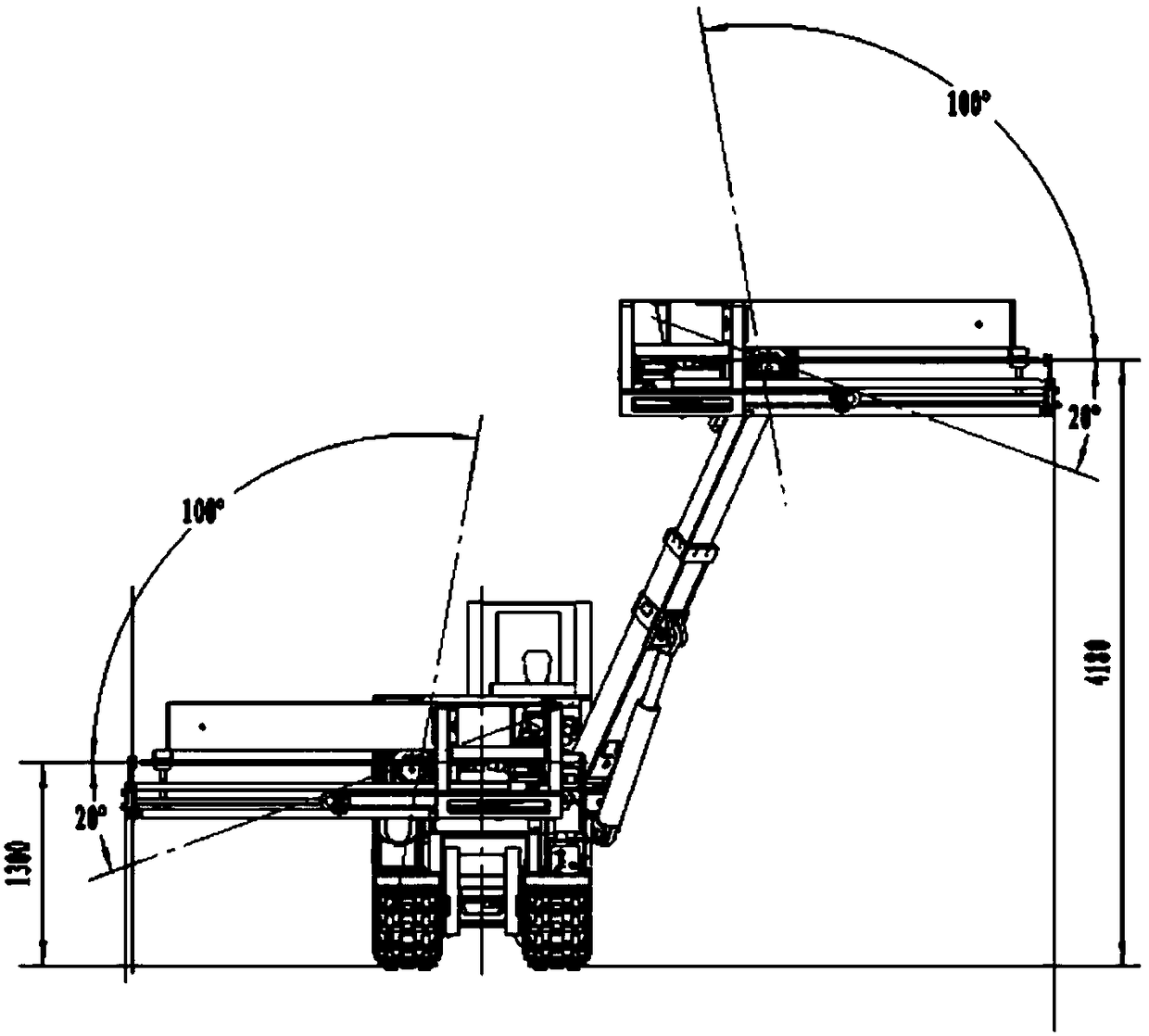

Anchor rod drill truck

InactiveCN108756965ASolve the problem of high energy consumptionSolve environmental problemsAnchoring boltsFrequency conversionCruise control

The invention provides an anchor rod drill truck. The anchor rod drill truck includes a machine frame body, a frequency conversion speed regulation walking mechanism, an electrical control system, a hydraulic system, a directional cruise control and step distance measurement system, front and rear stabilizing devices and an anchor drill system. The anchor drill system comprises a telescopic working arm, a drilling frame, a laying net and temporary support mechanism and an automatic catridge jetting system. The frequency conversion speed regulation walking mechanism is installed on a chassis ofthe anchor rod drill truck, the telescopic working arm is connected with the machine frame body in a pinned mode, and the drilling frame is connected with the front end of the telescopic working armthrough a rotating hydraulic device of the telescopic working arm. The hydraulic system and the rotating hydraulic device are arranged correspondingly, and the directional cruise control and step distance measurement system and the variable frequency speed regulating walking mechanism are arranged correspondingly. The front and rear stabilizing devices are arranged at the front and rear ends of the machine frame body separately. The anchor rod drill truck solves the technical problems that in the prior art, installation of an anchor, disassembly and assembly of a drilling rod and catridge workare carried out manually so that physical consumption of operators is large, and the operators are threatened by dust environment and roof collapse which is prone to being occurring in roof areas.

Owner:CHINA SHENHUA ENERGY CO LTD +2

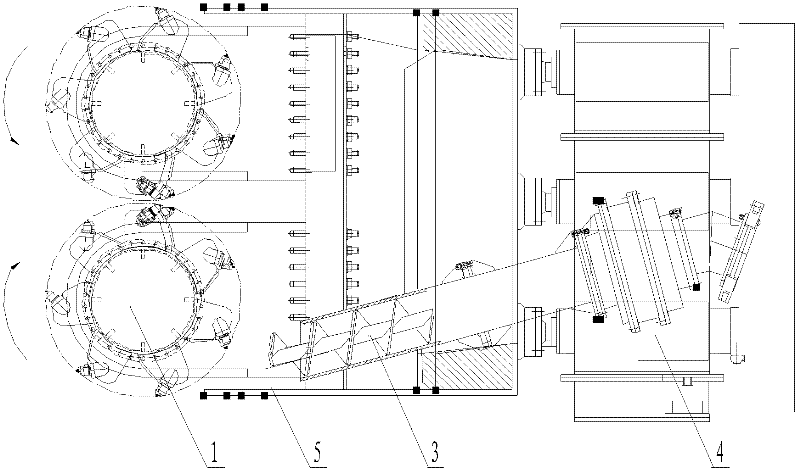

Roller type cutter rectangular pipe jacking machine

The invention relates to a roller type cutter rectangular pipe jacking machine, which comprises a cutter, a cutter driving system, a spiral mechanical unearthing system, a hydraulic propulsion system and a rectangular shell. The cutter adopts a composite formation roller type cutter, is sleeved on the cutter driving system and is driven by the cutter driving system to rotate, the composite formation roller type cutter comprises a plurality of ordinary tools, a swinging tool and an over-excavation tool, a cutter shell adopts a round tubular component, the inner wall of the cutter shell is provided with a separating wall vertical to the axial line of the cutter shell, the ordinary tools are uniformly and fixedly arranged on the outer wall of the cutter shell, the swinging tool is hinged on the inner side of the outer wall of the cutter shell through a pin shaft and can rotate around the pin shaft, and the over-excavation tool is fixedly arranged on the outer side of the outer wall of the cutter shell. The invention has the advantages of high adaptability to formations and high tunneling efficiency. Meanwhile, construction risks can be reduced greatly, construction safety can be ensured, and the machine can adapt to construction of slightly weathered rock formations, composite formations, backfilled formations, continuous walls through the ground, pile foundations and other complex formations and working conditions.

Owner:上海盾构设计试验研究中心有限公司 +1

Mechanical underground excavation construction method for large underground parking lot

ActiveCN105370287ASolve construction problemsReduce construction riskUnderground chambersTunnel liningEnvironment effectReinforced concrete

The invention discloses a mechanical underground excavation construction method for a large underground parking lot, comprising the following steps: constructing two parallel construction tunnels at two ends of the position of the proposed space of the parking lot according to the design condition of the parking lot, marking the rectangular section of the space of the parking lot on the side wall of the construction tunnel, and dividing the rectangular section of the whole space of the parking lot into a plurality of small rectangular sections with same size; and then carrying out segmental jacking construction sequentially on the small rectangular sections, namely the linear distance between the two construction tunnels, by adopting a rectangular tube push bench, and synchronously arranging the rectangular tube push bench inside, then removing profile steel parts between two adjacent rectangular pipe jacking rooms, and constructing reinforced concrete stand columns, beams and bottom plates, thus completing construction of the underground parking lot. The method can be used for solving the difficulty of constructing an underground parking lot without disturbing the ground environment conditions of urban areas; is high in construction speed, small in environmental influence and high in economic benefits; and is high in mechanization degree and small in construction risks.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

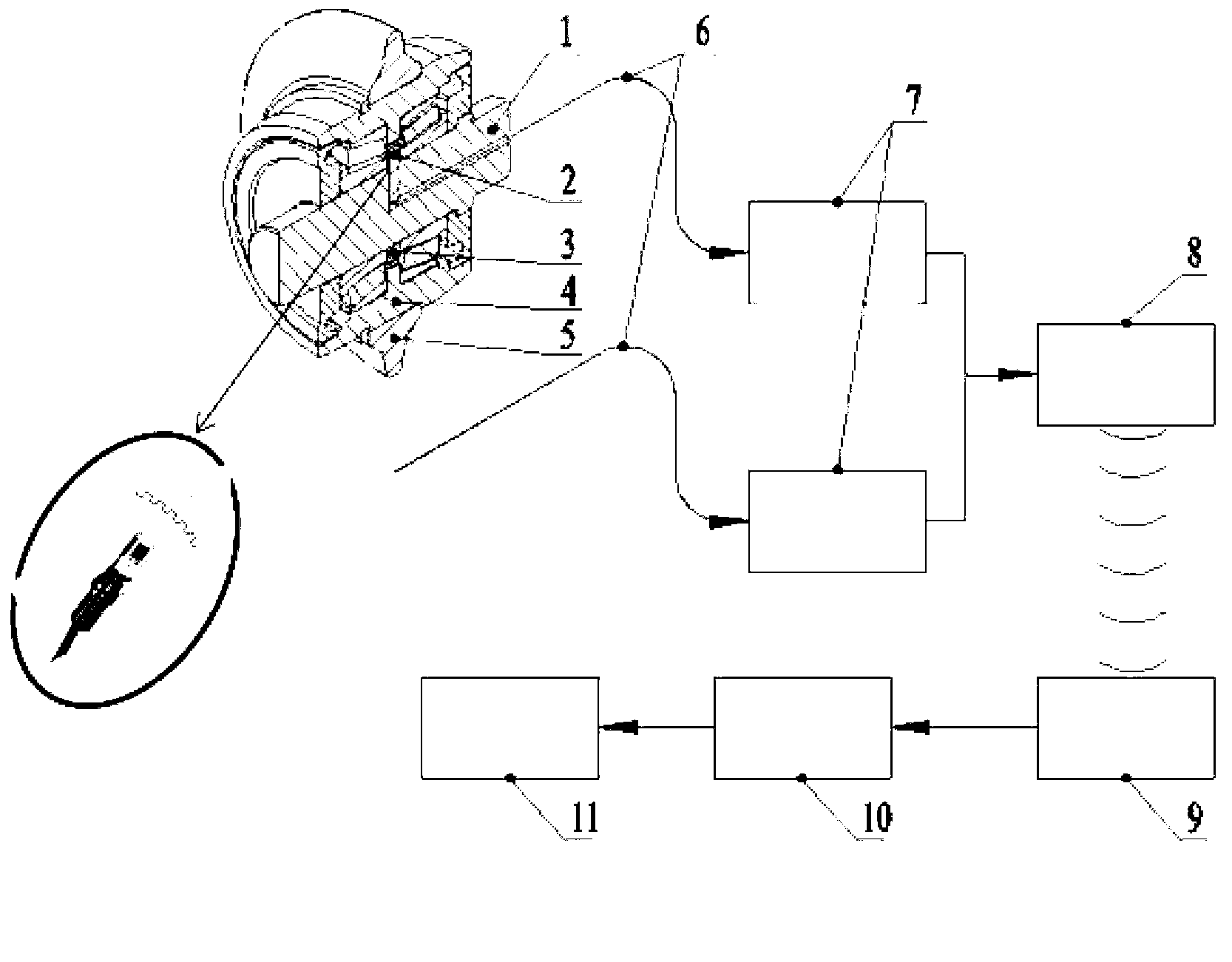

System and method for monitoring operation state of disc cutter group of cutterhead of tunneling machine

ActiveCN103226151AGroup performance is goodGuaranteed uptimeMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesMonitoring systemControl room

The invention discloses a system and a method for monitoring the operation state of a disc cutter group of a cutterhead of a tunneling machine. The method comprises the following steps: detecting the autorotation speed of each disc cutter by using a sensor; and transmitting a rotating speed signal to a computer in a control room of the tunneling machine by using a wireless data transmission device so as to judge the operation state of the disc cutters according to the rotating speed signal and the preset reference value relationship. The system and the method have the technical effect that the individual reference value of each individual of the disc cutter group is subjected to data processing and visual display, so that the operation state and the wear state of the disc cutter group of the tunneling machine can be displayed in real time. The monitoring system can provide selection help for an operator of the tunneling machine so as to determine whether to replace and maintain cutters or not, or change a tunneling control parameter to reach higher cutter group operation performance. By the method, manpower consumption can be reduced obviously, construction risk can be reduced, and work efficiency can be improved.

Owner:湖南奥通智能研究院有限公司

Phase change fracturing method

ActiveCN108561111ALow viscosityShorten the timeFluid removalDrilling compositionTime delaysFracturing fluid

The invention provides a phase change fracturing method. The method includes the following steps that a fracturing fluid is injected into a stratum to generate cracks in the stratum, and injection ofthe fracturing fluid is stopped after the to-be-generated cracks reach preset requirements; a phase change reaction liquid and a time delay heat generating agent which can be subjected to a phase change reaction at preset temperature are injected into the stratum; after injection of the phase change material liquid is substantially completed, the time delay heat generating agent exerts a heat generating action to make phase change of the phase change material liquid to complete phase change fracturing. According to the provided technical scheme, since there is no solid phase injection, not only can the friction resistance of tubular columns be effectively reduced, but also the happening time and progress of the phase change reaction can be effectively controlled due to the use of the delayheat generating agent, so that a better fracturing effect is achieved. Especially for low-temperature reservoirs, a heat generation effect of the delay heat generating agent greatly increases the rate of the phase change reaction so that the phase change material liquid can rapidly form a solid phase at a preset position, the phase change time is shortened, and the probability of successful construction is increased.

Owner:PETROCHINA CO LTD

Grouped second liner construction method for large cross-section tunnel

ActiveCN103016029AIncrease the construction processLong construction periodUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention discloses a grouped second liner construction method for a large cross-section tunnel. A whole toroidal second liner is constructed after being divided into 6 parts. The method comprises the following steps: 1), pouring and backfilling an inverted arch of a left lower hole; 2), pouring and backfilling an inverted arch of a right lower hole; 3), pouring a side wall second liner of the left lower hole through a lower hole trolley; 4), moving the lower hole trolley to the right lower hole to pour a side wall second liner of the right lower hole; 5), erecting a bracket in the right lower hole, assembling a right upper hole trolley, and pouring a right upper arch second liner; 6), erecting a bracket in the left lower hole, assembling a left upper hole trolley, and pouring a left upper arch second liner. According to the grouped second liner construction method, a relatively large cross section is divided into a plurality of small cross sections to carry out construction, although the construction procedures the time limit for a product are slightly increased in comparison with those of a traditional two-step construction method, the construction risk is yet reduced to a great extent, the construction safety guarantee coefficient is increased, an extremely important guide value is provided for the tunnel constructed with a CRD (center cross diaphragm) method in certain special urban environment conditions, the construction is smoothly completed on the premise of guaranteeing safety, and remarkable social benefits are achieved.

Owner:RANKEN RAILWAY CONSTR GROUP

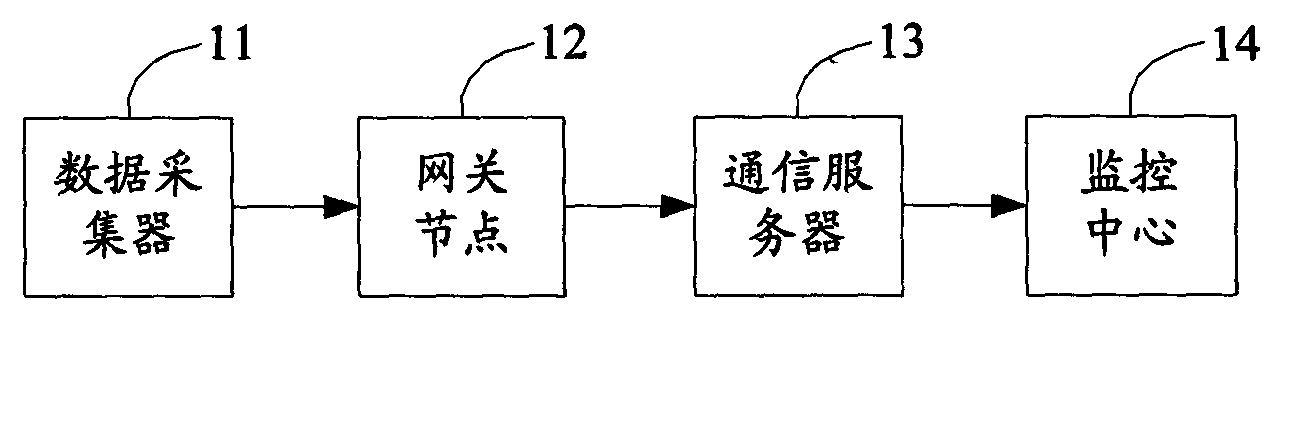

Monitoring system for construction safety

The invention is suitable for the technical field of monitoring and provides a monitoring system for construction safety. The monitoring system comprises a data acquisition unit, a gateway node, a communication server and a monitoring center, wherein the data acquisition unit is used for utilizing a radar to collect a geological image, laser ranging data of a dangerous section, harmful gas concentration data of a detected section and various format data of an on-site visual monitoring video and also is used for collecting the data; the gateway node is used for transmitting the collected data in real time; the communication server is used for analyzing the data transmitted by the gateway node and storing the analyzed data into a database; and the monitoring center is used for analyzing the data and giving an alarm for the dangerous section and reasons. According to the monitoring system, a detecting interval is added through a sensor, more monitoring data is obtained, a construction risk system is more accurately foreknown, the construction risk is effectively reduced, the on-site measurement of detectors is reduced, the automatic monitoring is realized, the working risk of monitoring personnel is reduced, the cost is saved, and the efficiency is increased.

Owner:CHANGAN UNIV

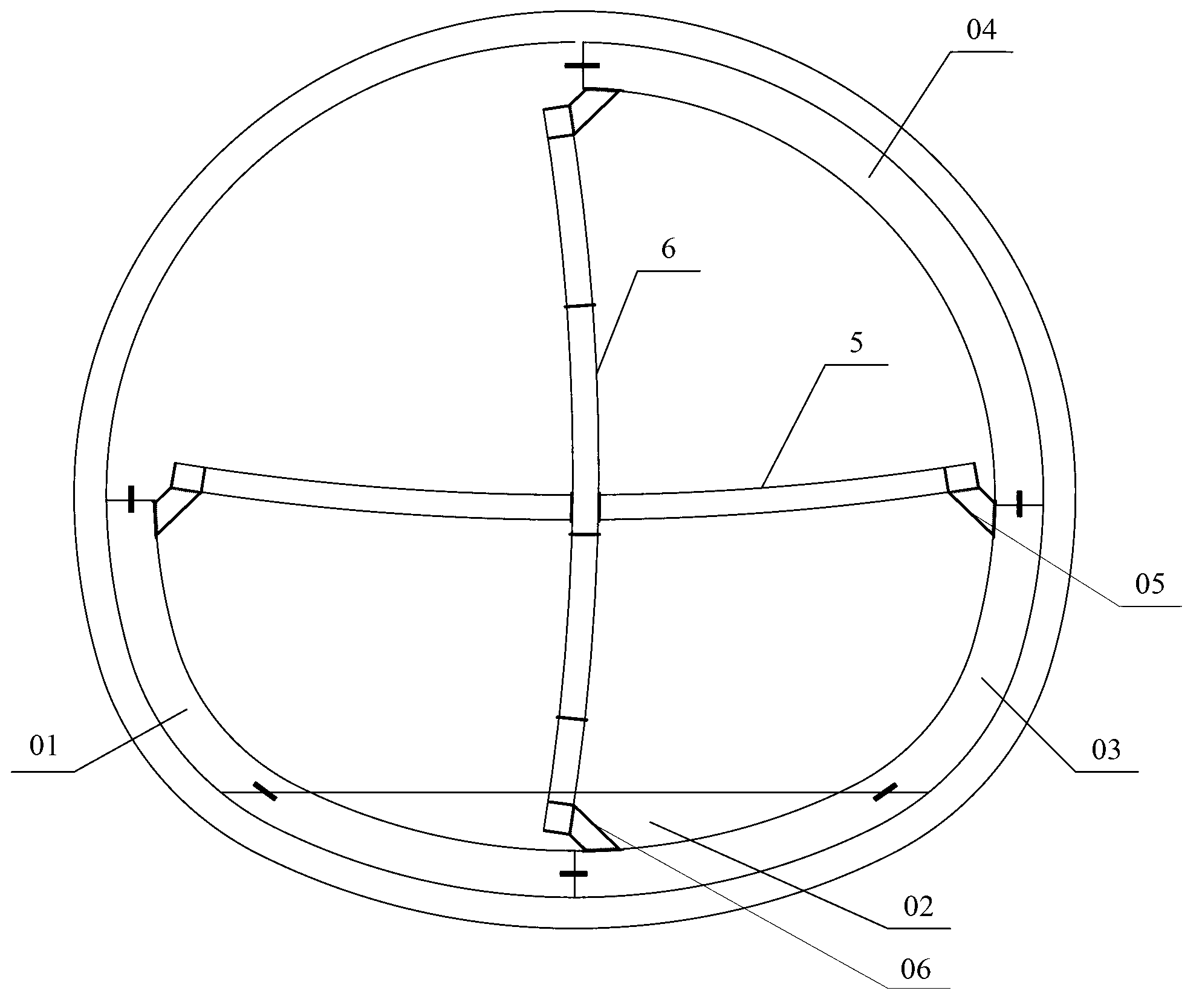

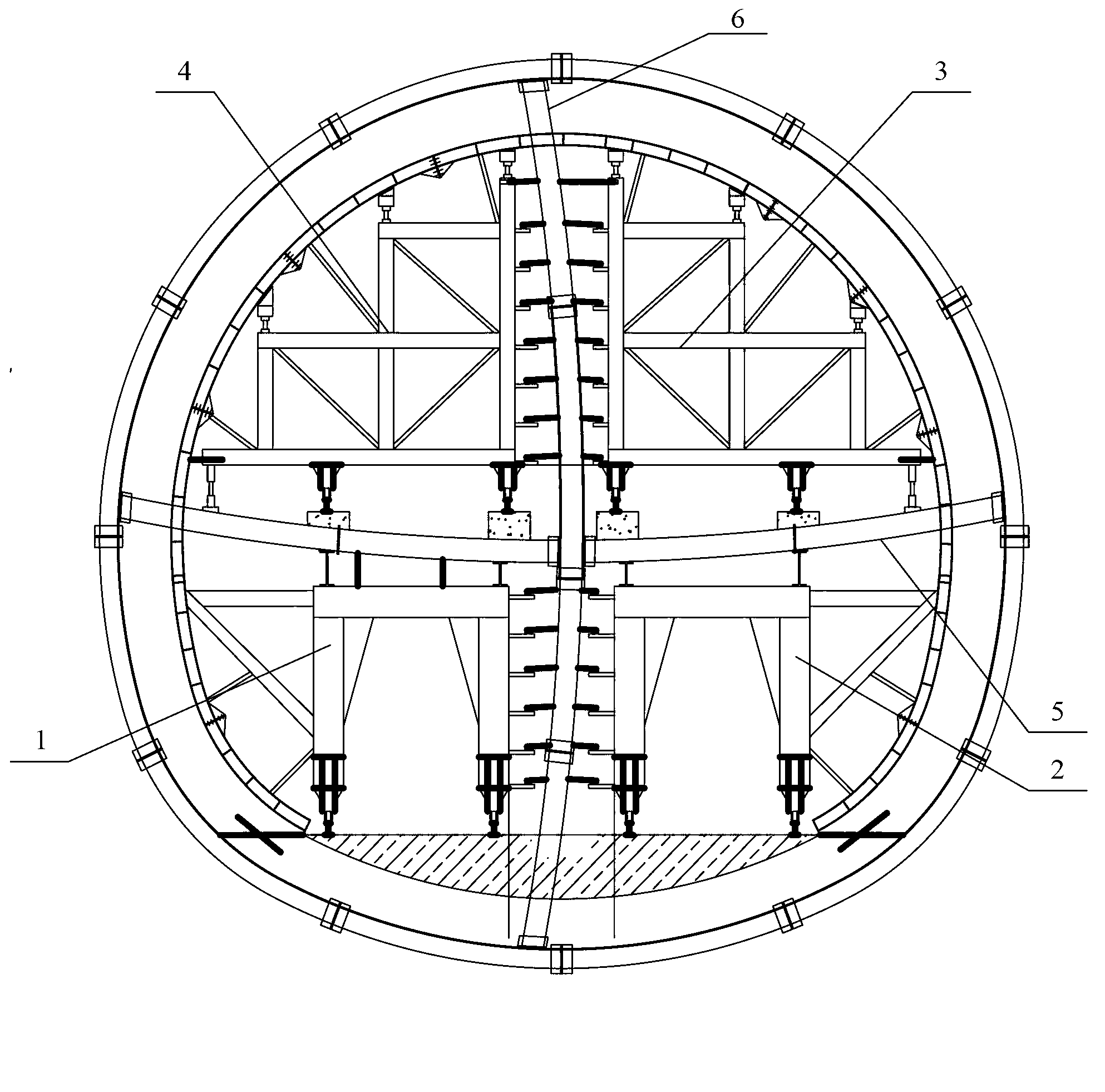

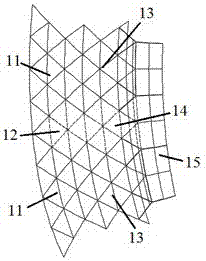

Unsupported construction method of circular rope-supported grid structure

ActiveCN107246153ALow construction costImprove protectionExtraordinary structuresBuilding material handlingEngineeringCounterforce

The invention discloses an unsupported construction method of a circular rope-supported grid structure; an upper grid is lifted to a pre-constructed rope network for assembly in unit manner; the circular rope-supported grid structure mainly comprises pillars, outer ring beams, upper grids, radial ropes, circular ropes and support rods. The radial ropes and circular ropes of the structure are elevated by means of oblique traction, tooling counterweight ropes and counterforce frame devices are mounted below a rope network of the structure, the tooling counterweight ropes are tensioned, and a supporting rope network is formed; the upper grid is lifted to the support rope network in unit manner, and the tooling counterweight ropes are adjusted through the counterforce frame devices to control joints to be at design elevation; the tooling counterweight ropes and the counterforce frame devices are finally removed, and the structure is formed. The method has the advantages that construction cost of supports is omitted, elevations of control joints can be adjusted bidirectionally and precisely in real time during construction, tensioning the ropes is not required, a stand can be protected, and green prefabricated construction of a rope-supported grid structure is achieved.

Owner:SOUTHEAST UNIV

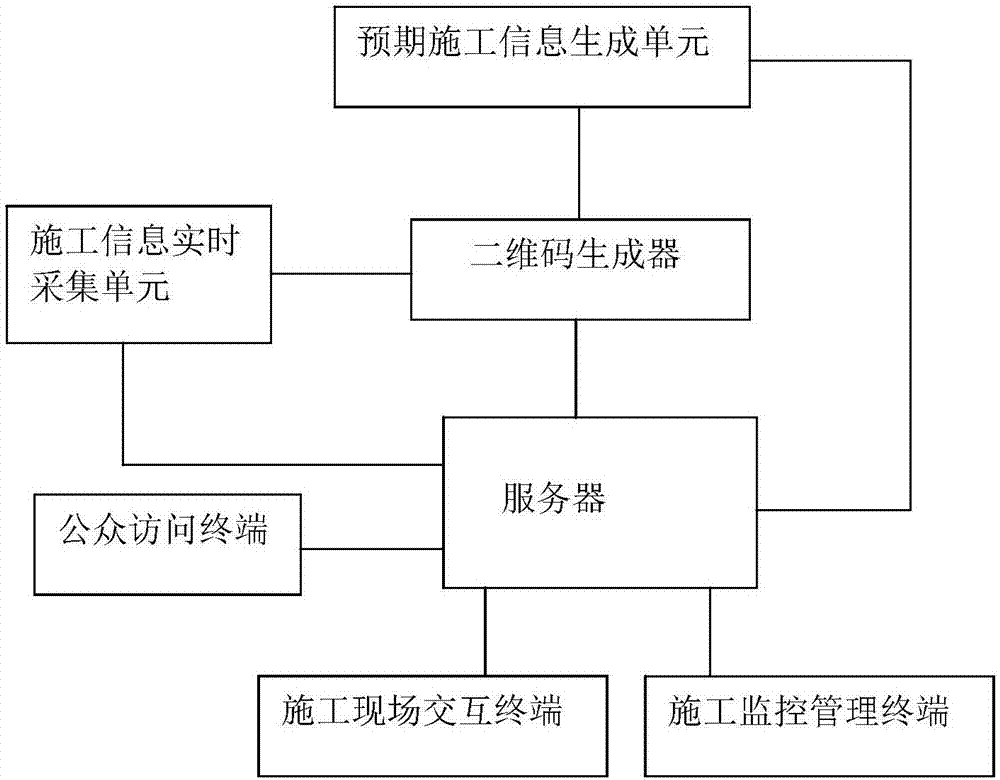

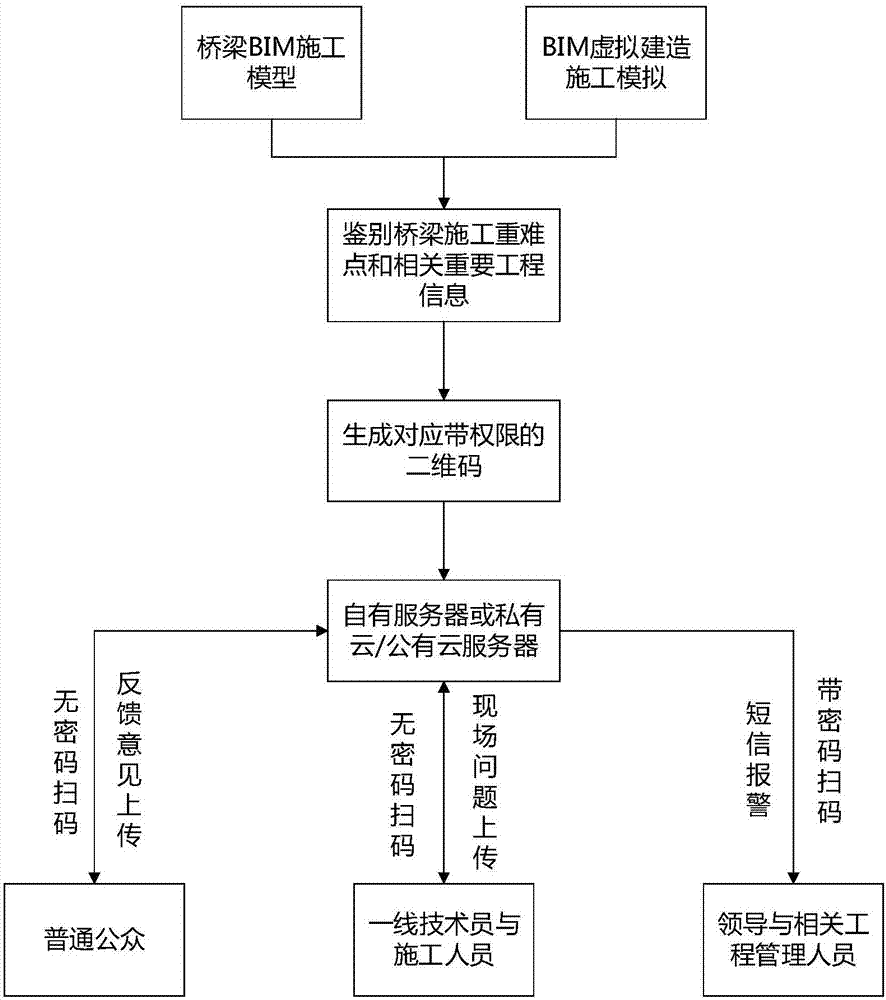

Bridge construction management system and method based on two-dimensional codes and BIM technology

InactiveCN107194588AReduce construction riskGood serviceResourcesSensing by electromagnetic radiationReal time acquisitionConstruction management

The invention relates to a bridge construction management system and method based on two-dimensional codes and a BIM technology. The system includes a two-dimensional code generator, a server, a generation unit of expected construction information, a real-time acquisition unit of construction information, a construction site interaction terminal, a construction monitoring management terminal and a public accessing terminal. The two-dimensional code generator generates the two-dimensional codes of different authorities according to the information input by the generation unit of the expected construction information and the real-time acquisition unit of the construction information, and outputs the two-dimensional codes to the server for storage. The server receives and stores the expected and real-time bridge construction information, and associates the expected and real-time construction information with the two-dimensional codes of the different authorities. The three types of terminals access, through scanning the two-dimensional codes corresponding to authorities thereof, the server to view the bridge construction information. According to the system and method, the BIM technology is utilized to build a bridge construction model, a hierarchical management technology of the two-dimensional codes is used at the same time, differentiated services are presented after personnel of the different authorities scan the codes, the bridge construction management efficiency is improved, and bridge construction quality improvement is promoted.

Owner:中铁南方投资集团有限公司 +1

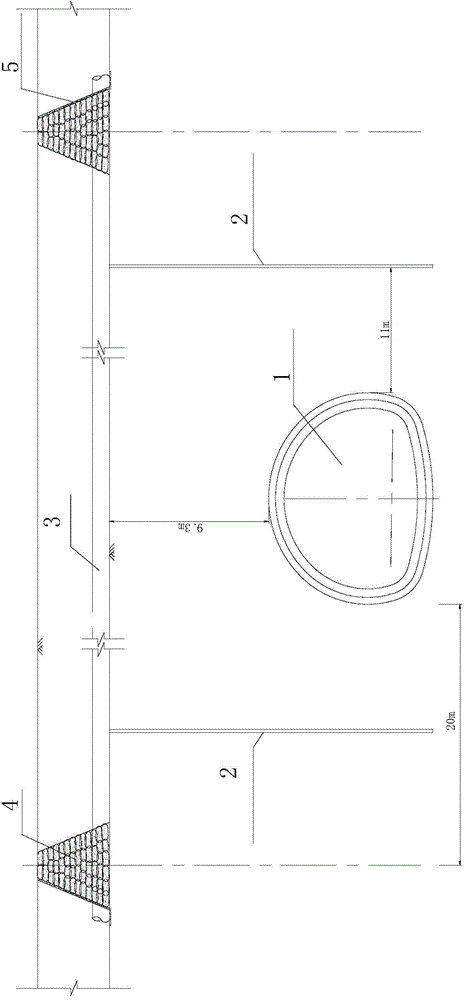

Safe and fast construction method of down-traversing river shallow depth bored tunnel

InactiveCN104631475AReduce vertical infiltrationReduce moisture contentUnderwater structuresTunnelsCofferdamFluvial

The invention discloses a safe and fast construction method of a down-traversing river shallow depth bored tunnel. The method includes the steps that on the two sides of the tunnel, the upstream and the downstream of a river are each provided with a clay cofferdam so that the river can be intercepted, and a dry river bed is formed in a tunnel construction area; the two constructed clay cofferdams are communicated through a flow guiding pipe, and therefore upstream river water and downstream river water can flow; the two sides of the tunnel are each provided with at least one row of Larsen steel plate piles, and the tunnel is excavated after the Larsen steel plate piles extend to a river bank in the axial direction of the tunnel. The clay cofferdams, the flow guiding pipe and the Larsen steel plate piles are matched coordinately and comprehensively utilized, and tunnel construction safety is guaranteed by the clay cofferdams, the flow guiding pipe and the Larsen steel plate piles jointly. The method is good in construction safety and high in construction efficiency, treatment measures are flexible, pertinent adjustment can be performed according to different geological conditions, and manufacturing cost of projects is saved as much as possible on the premise that safety is guaranteed.

Owner:中铁隧道局集团有限公司市政工程公司

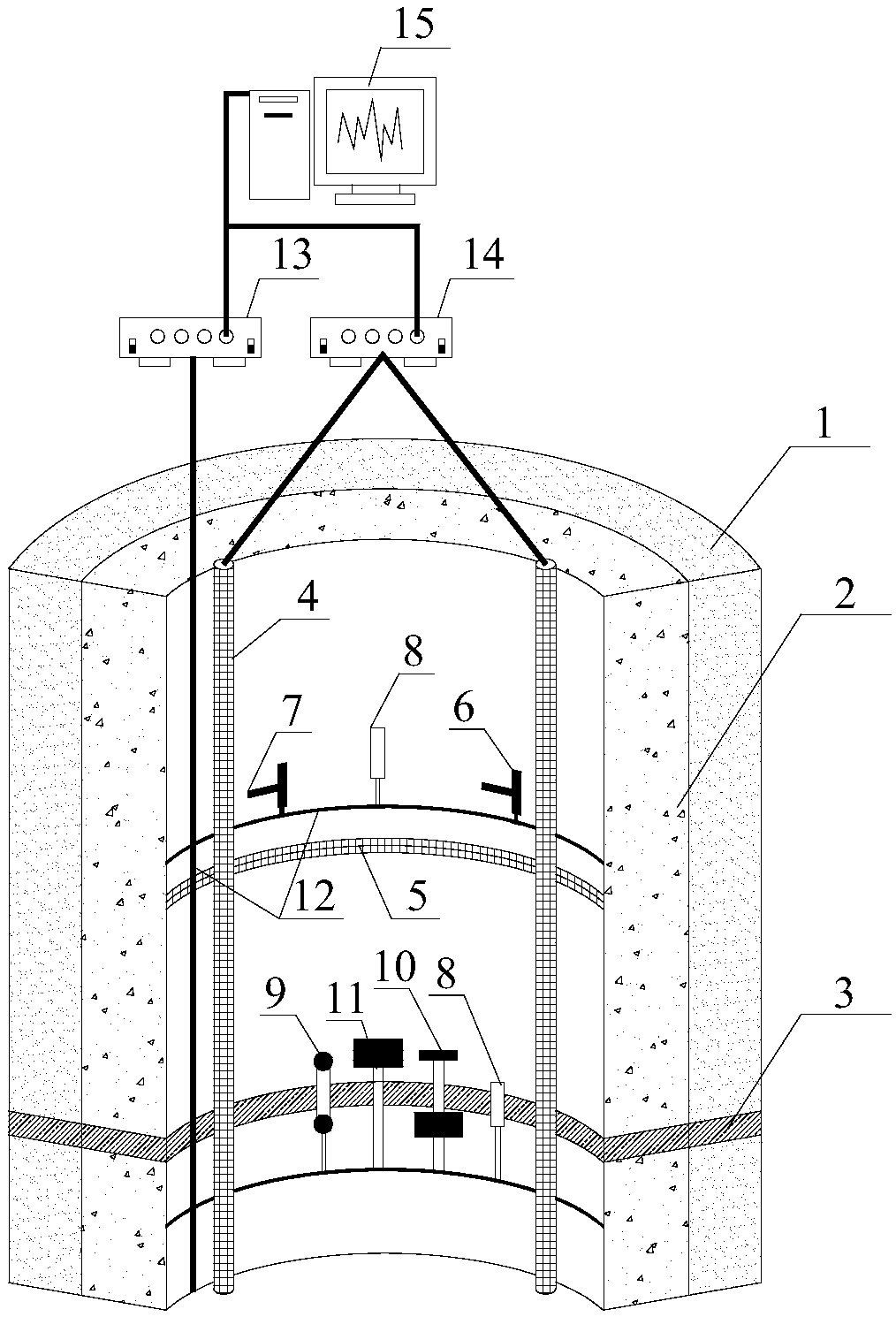

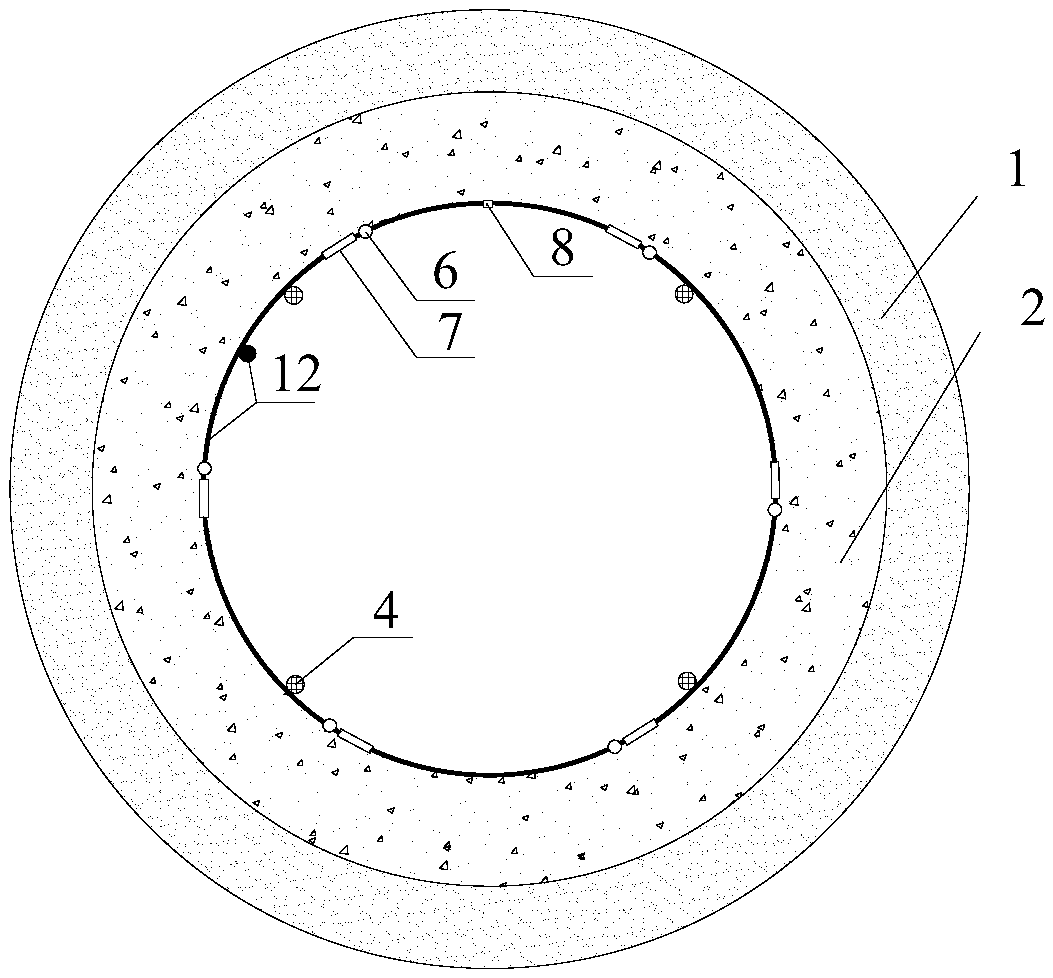

Optical fiber sensor system for monitoring well wall and deformation early warning method

PendingCN108627186AGuarantee stabilityEnsure reliabilityThermometers using physical/chemical changesUsing optical meansGratingFiber Bragg grating

The invention provides an optical fiber sensor system for monitoring a well wall and a deformation early warning method. The optical fiber sensor system comprises distributed optical fiber sensors, fiber bragg grating strain sensors, external fiber bragg grating temperature sensors, an optical cable, a distributed optical fiber demodulation instrument, a fiber bragg grating demodulation instrumentand a computer. The several distributed optical fiber sensors, the several fiber bragg grating strain sensors and the several external fiber bragg grating temperature sensors are arranged on the internal surface of the well wall. The several distributed optical fiber sensors are connected to the distributed optical fiber demodulation instrument through the optical cable. The distributed optical fiber demodulation instrument is connected to the computer. The fiber bragg grating strain sensors and the external fiber bragg grating temperature sensors are connected to the fiber bragg grating demodulation instrument through the optical cable. In the invention, grouting pressure on the inner layer of the well wall , the deformation of the inner layer of the well wall and a well wall temperaturecan be monitored.

Owner:ANHUI UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com