Phase change fracturing method

A fracturing fluid and non-phase-change technology, applied in the field of fracturing, can solve problems such as gel breaking, fracturing failure, and increased residue content, and achieve the effects of good fluidity, improved toughness, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a phase change material liquid.

[0077] The preparation process of the phase change material solution provided in this embodiment is as follows:

[0078] First take 50g of xylene, then add 40g of 2,4-diamino-6-diallylamino-1,3,5-triazine, 30g of dicyclopentadiene resin, 0.5g of hydroxypropyl methylcellulose, twelve Sodium alkyl sulfate 0.5g, phosphoric acid 0.5g, calcium chloride 0.5g, dibenzoyl peroxide 1g. All are placed in the flask, stirred at room temperature to complete the preparation of the phase change material liquid (the prepared phase change material liquid is denoted as HPP 1 ).

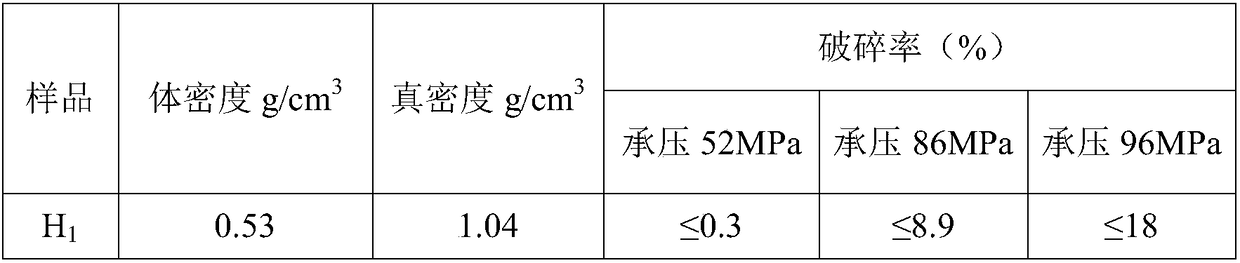

[0079] The phase change material solution in this example was placed in a constant temperature oil bath, and the temperature was raised to 90 ° C for 1 hour to react, and beads and massive solid phases appeared, that is, solid phase proppant (denoted as H 1 ). It can be seen that the phase change material liquid provided in this embodiment can realize...

Embodiment 2

[0084] This embodiment provides a phase change material liquid.

[0085] The preparation process of the phase change material solution provided in this embodiment is as follows:

[0086] First take 50g of xylene, then add 40g of propenyl substituted triazine, 30g of dicyclopentadiene resin, 0.7g of polyvinyl alcohol, 0.3g of sodium dodecylsulfonate, 0.5g of phosphoric acid, 0.5g of calcium chloride, peroxide Dibenzoyl 1g, ammonium bicarbonate 5g. All placed in a flask, stirred evenly at room temperature to complete the underground phase change material liquid HPP 3 preparation.

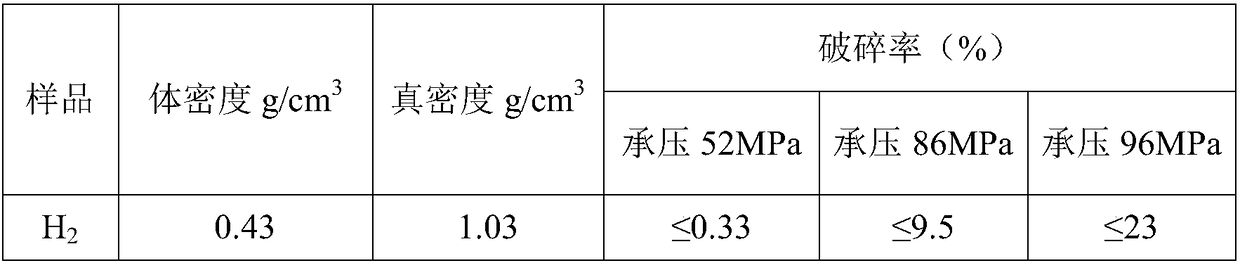

[0087] The phase-change material liquid N in this example was placed in a constant temperature oil bath, and the temperature was raised to 100°C for 0.5 hours to react. Bead-like and block-like solid phases appeared, that is, solid-phase proppant (denoted as H 2 ). It can be seen that the phase change material liquid N provided in this embodiment can realize the transition from liquid phase to sol...

Embodiment 3

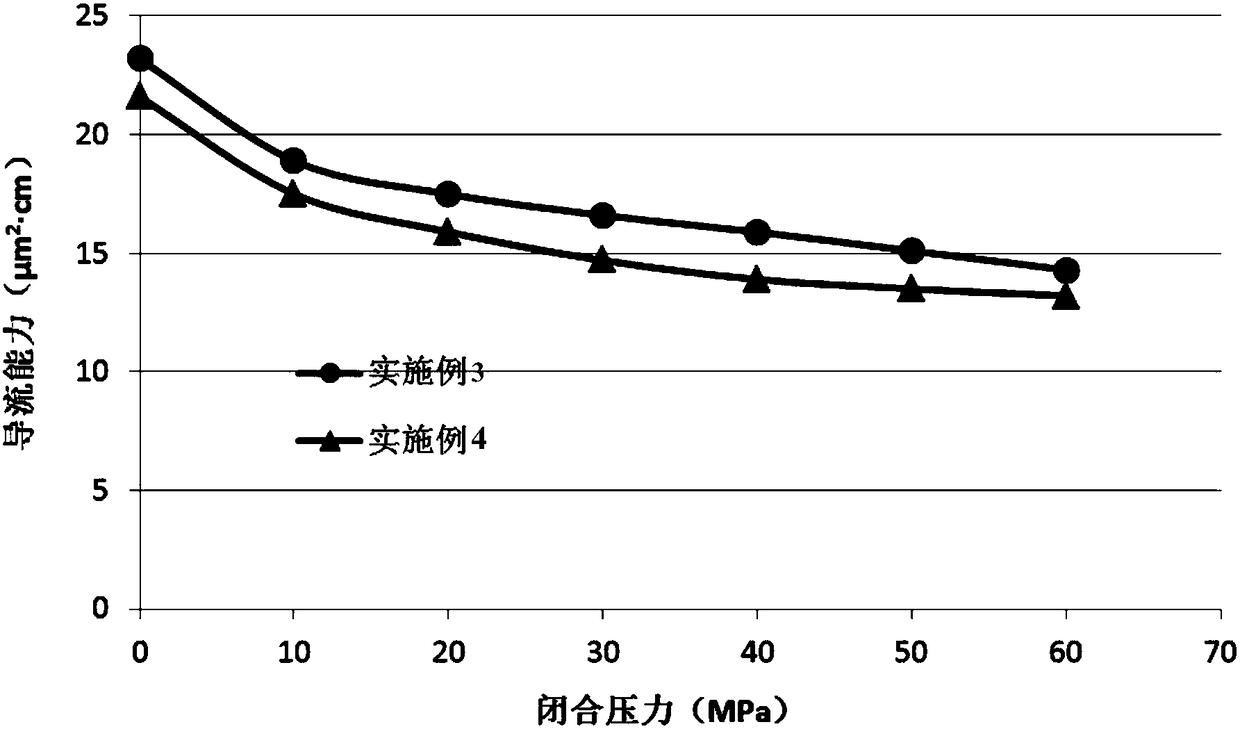

[0095] This embodiment provides a phase change fracturing method.

[0096] Taking the ground outcrop as the experimental material, the indoor experiment simulation is carried out by using the core fracture conductivity simulation device. First cut the outcrop into rock slabs (8cm×5cm×1.75cm) according to equipment requirements, and put the two rock slabs into the core holder. To simulate the fracturing construction process, at a temperature of 80°C, the injection pressure and confining pressure were changed to carry out the experiment on the conductivity of rock slab fractures.

[0097] According to "inject fracturing fluid A agent → inject non-phase-change material liquid M (phase-change material liquid M is added with the first heat-generating reagent B) and phase-change material liquid N from two acid injection tanks simultaneously → inject the second Heat-generating reagent C→inject displacement fluid to displace the reagent in the pipeline into the slab→suppress pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com