Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13053 results about "Firming agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Firming agents are food additives added in order to precipitate residual pectin, thus strengthening the structure of the food and preventing its collapse during processing.

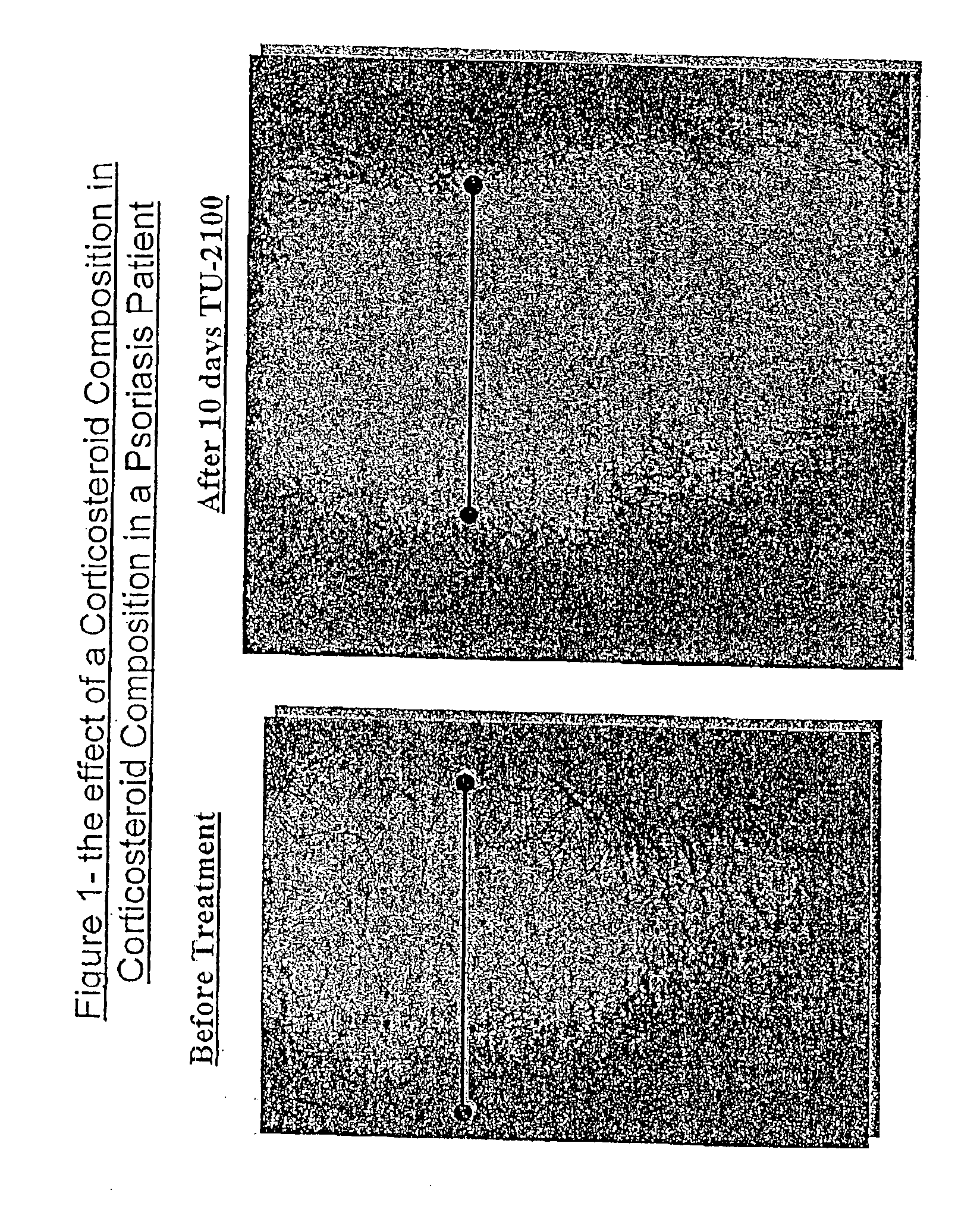

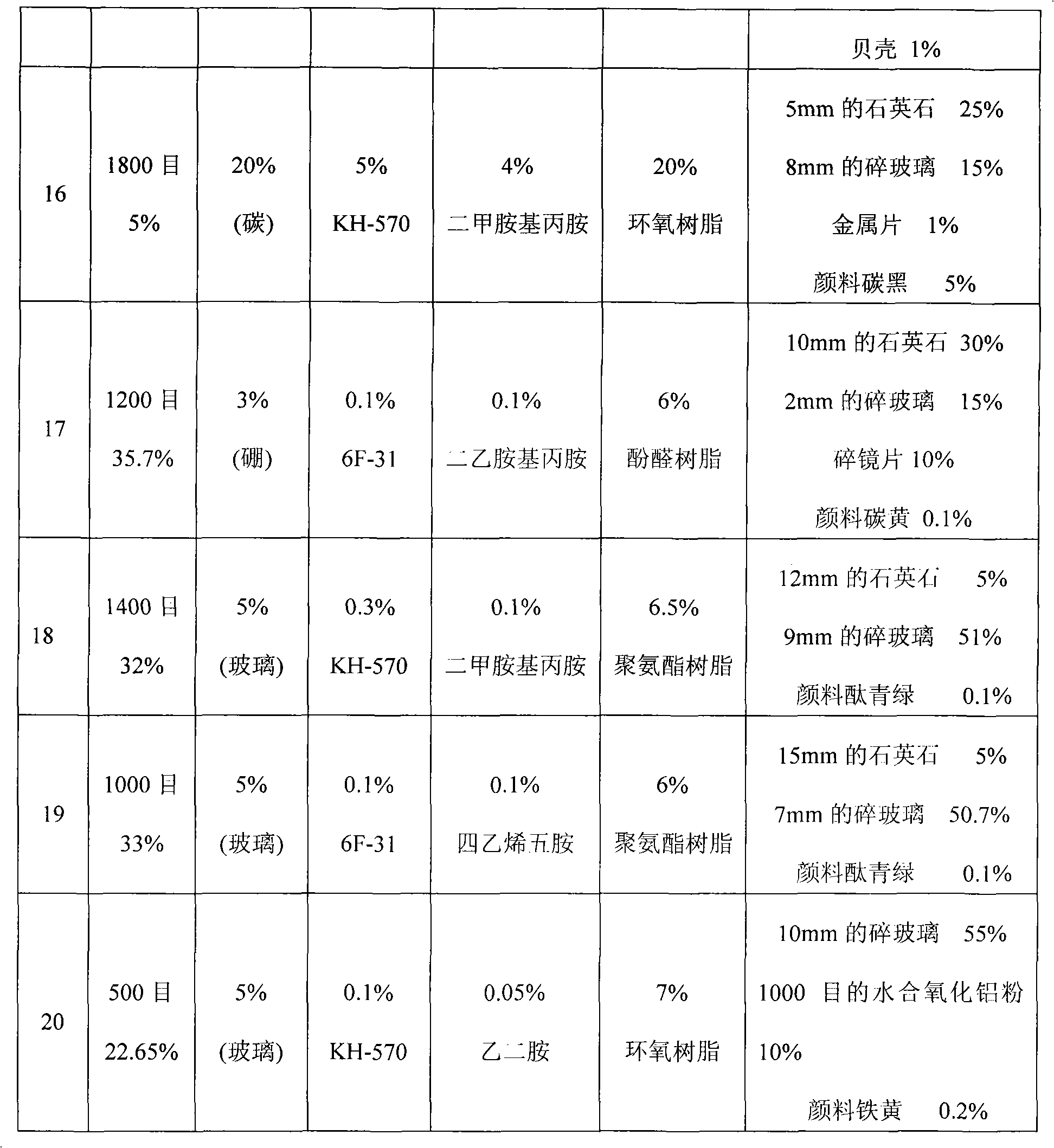

Pharmaceutical and cosmetic carrier or composition for topical application

A pharmaceutical or cosmetic carrier or composition for topical application characterized by rheological properties which render the carrier or composition semi-solid at rest and a liquid upon application of shear forces thereto. The composition or carrier are prepared by mixing 1-25 percent of a solidifying agent and 75-99 percent of a hydrophobic solvent, by weight, wherein at least one of them has therapeutic or cosmetic benefits, in the presence or absence of a biologically active substance.

Owner:VYNE PHARMA LTD

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

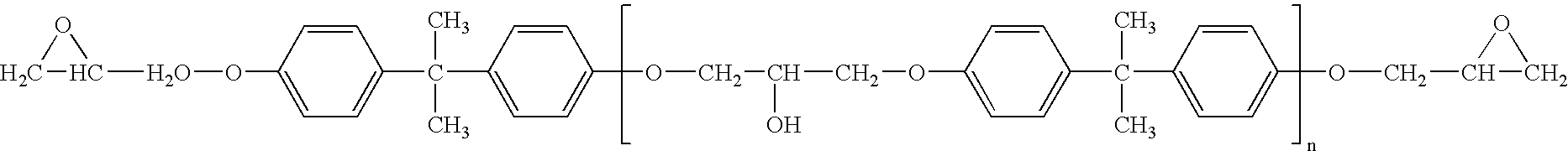

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

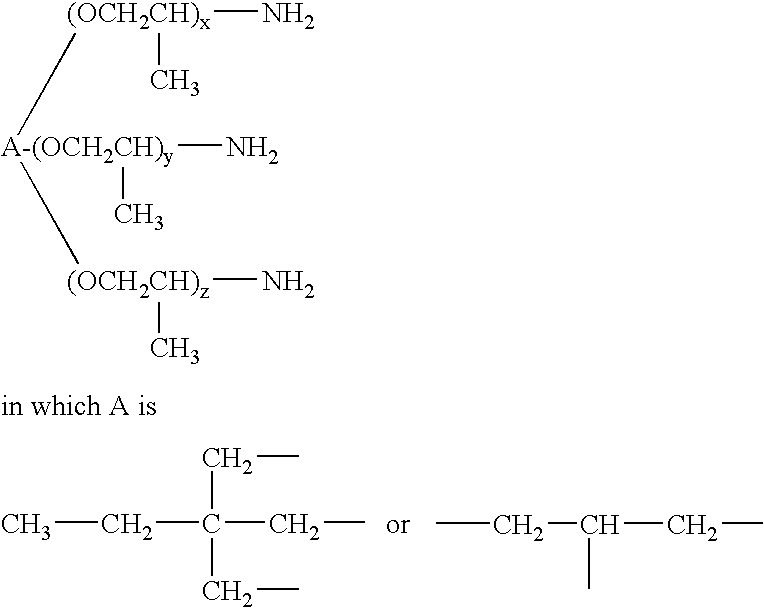

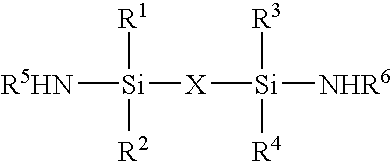

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

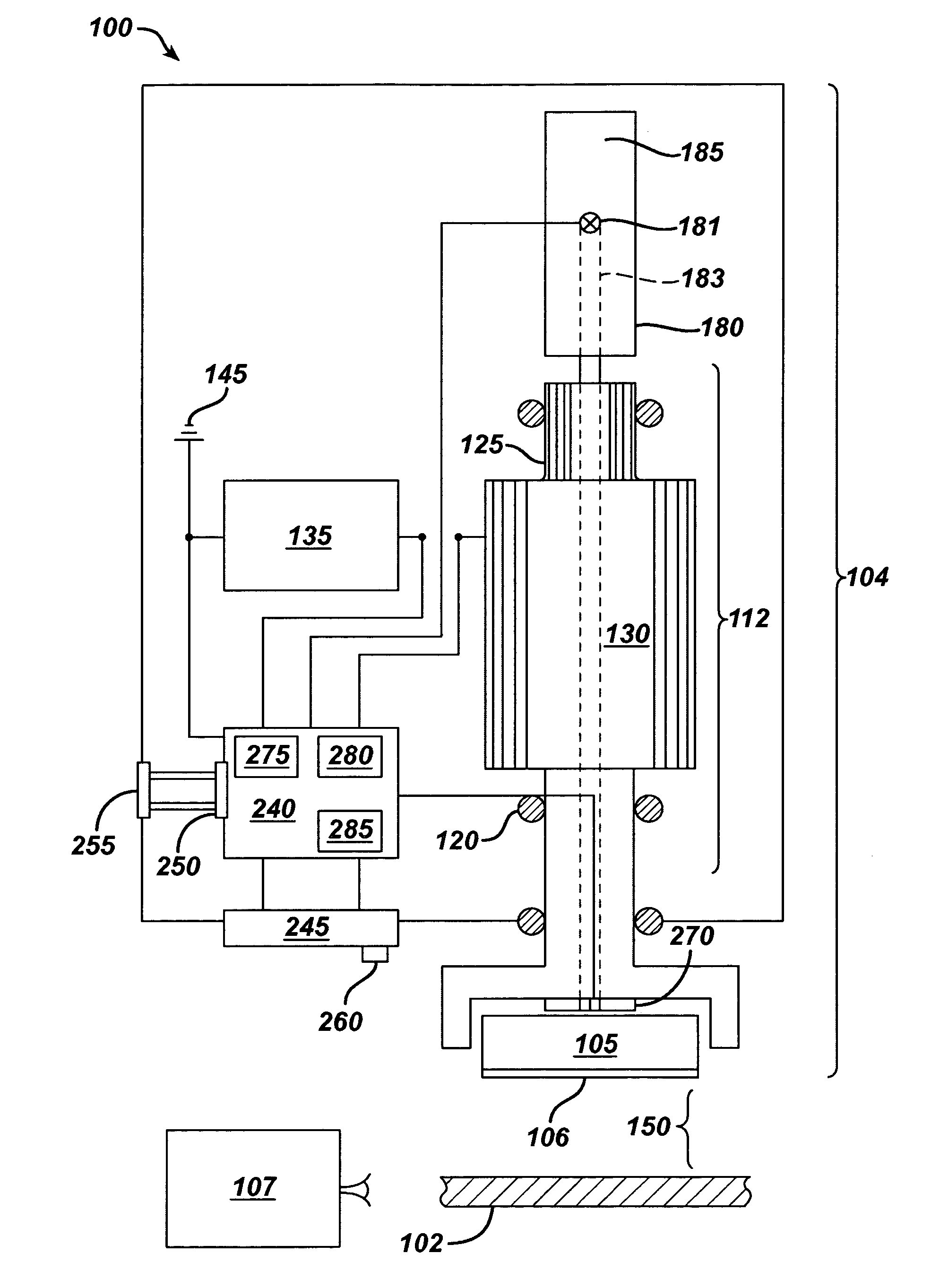

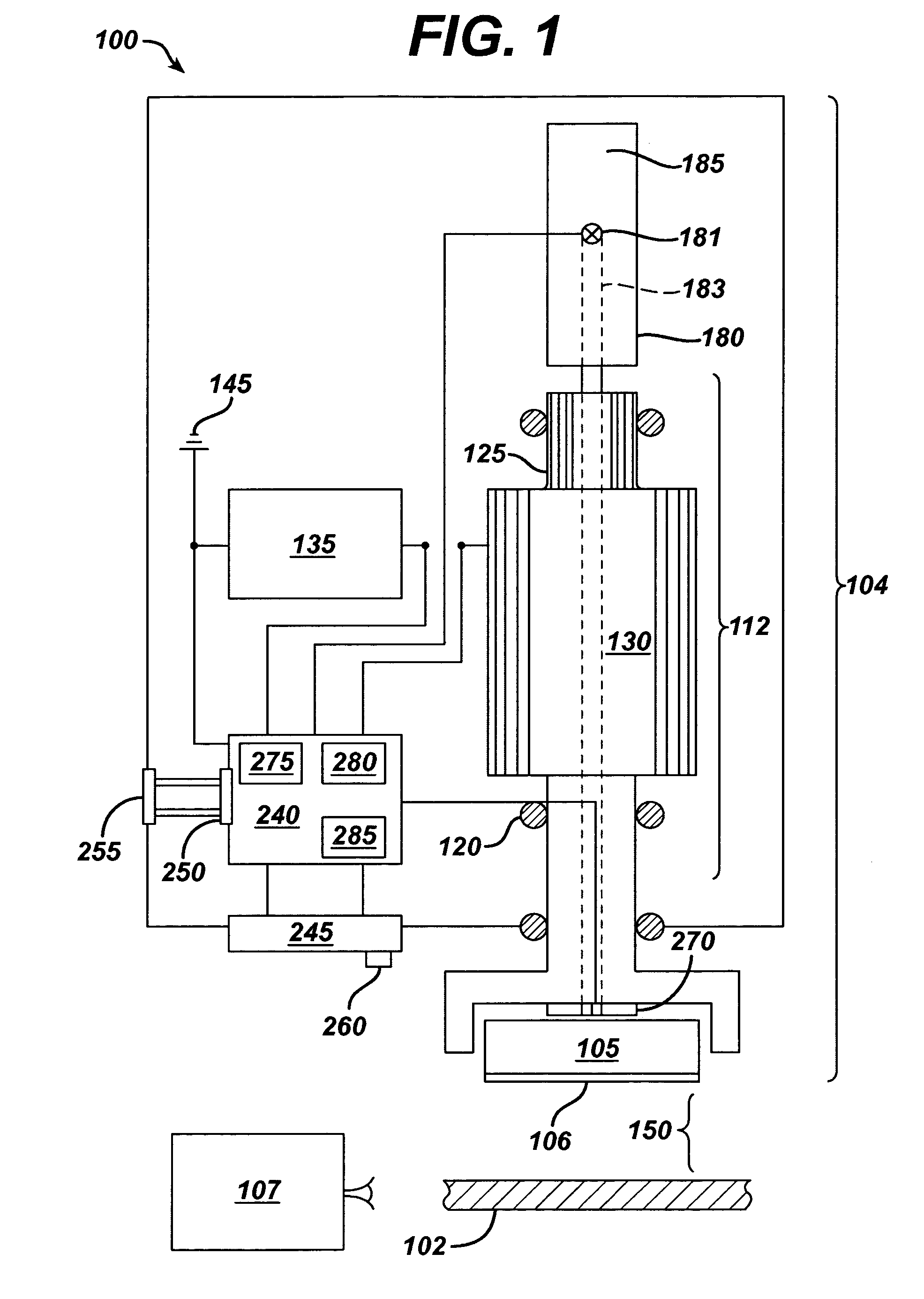

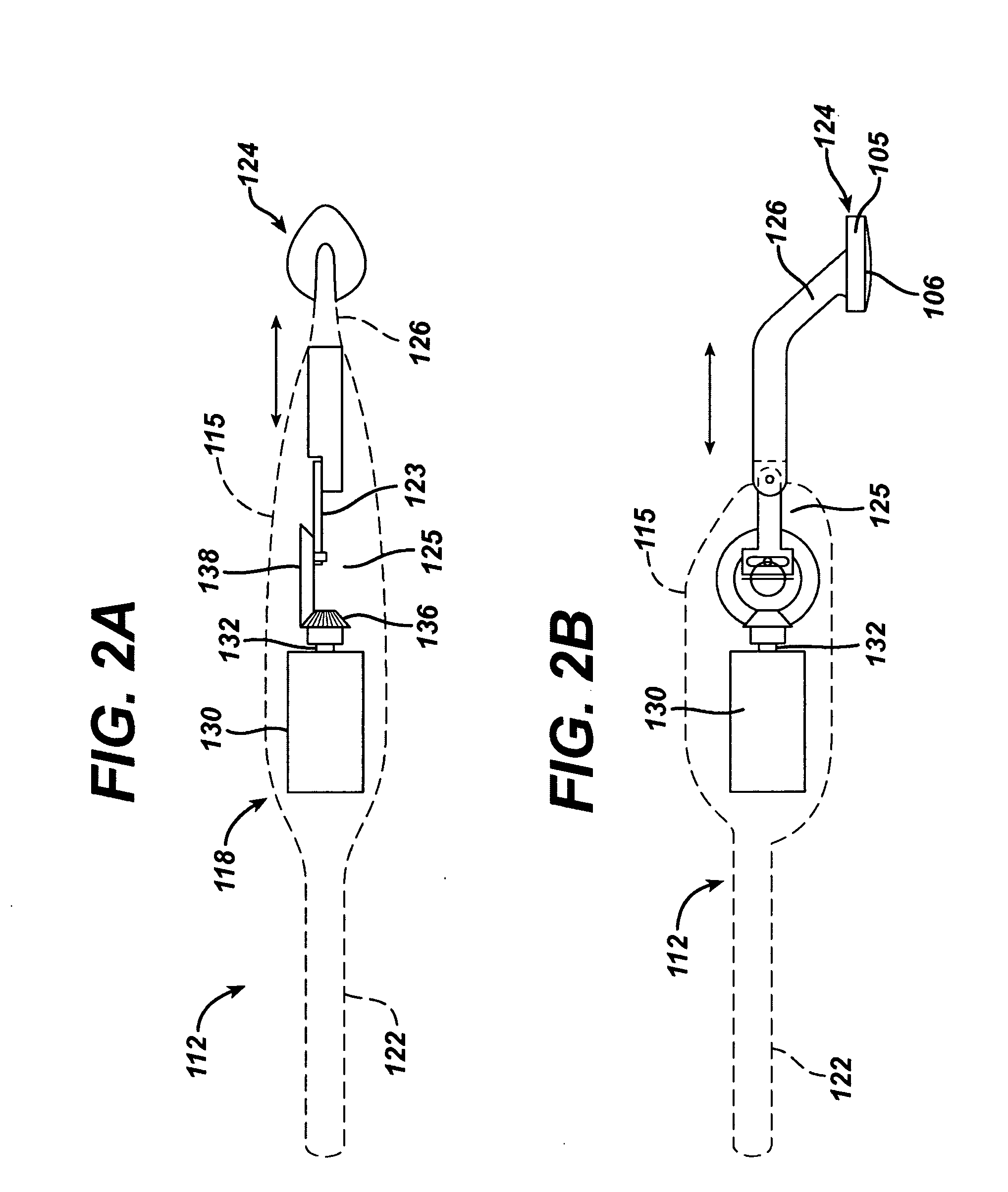

Treatment of skin with an apparatus and a benefit agent

The invention features a method of administering a skin benefit agent to an expanse of skin, wherein the method includes: (a) contacting the expanse of skin with an apparatus, the apparatus including: (i) a skin-contactable element having a skin-contactable surface; (ii) a motor; and (iii) a transfer member for transferring mechanical energy from the motor to the skin-contactable element in order to provide periodic motion to the skin-contactable surface; and (b) after contacting the expanse of skin with the apparatus has ceased, further contacting the expanse of skin with a benefit agent, wherein the benefit agent is selected from the group consisting of retinoids, copper moieties, skin-firming agents, depigmentation agents, and combinations thereof.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

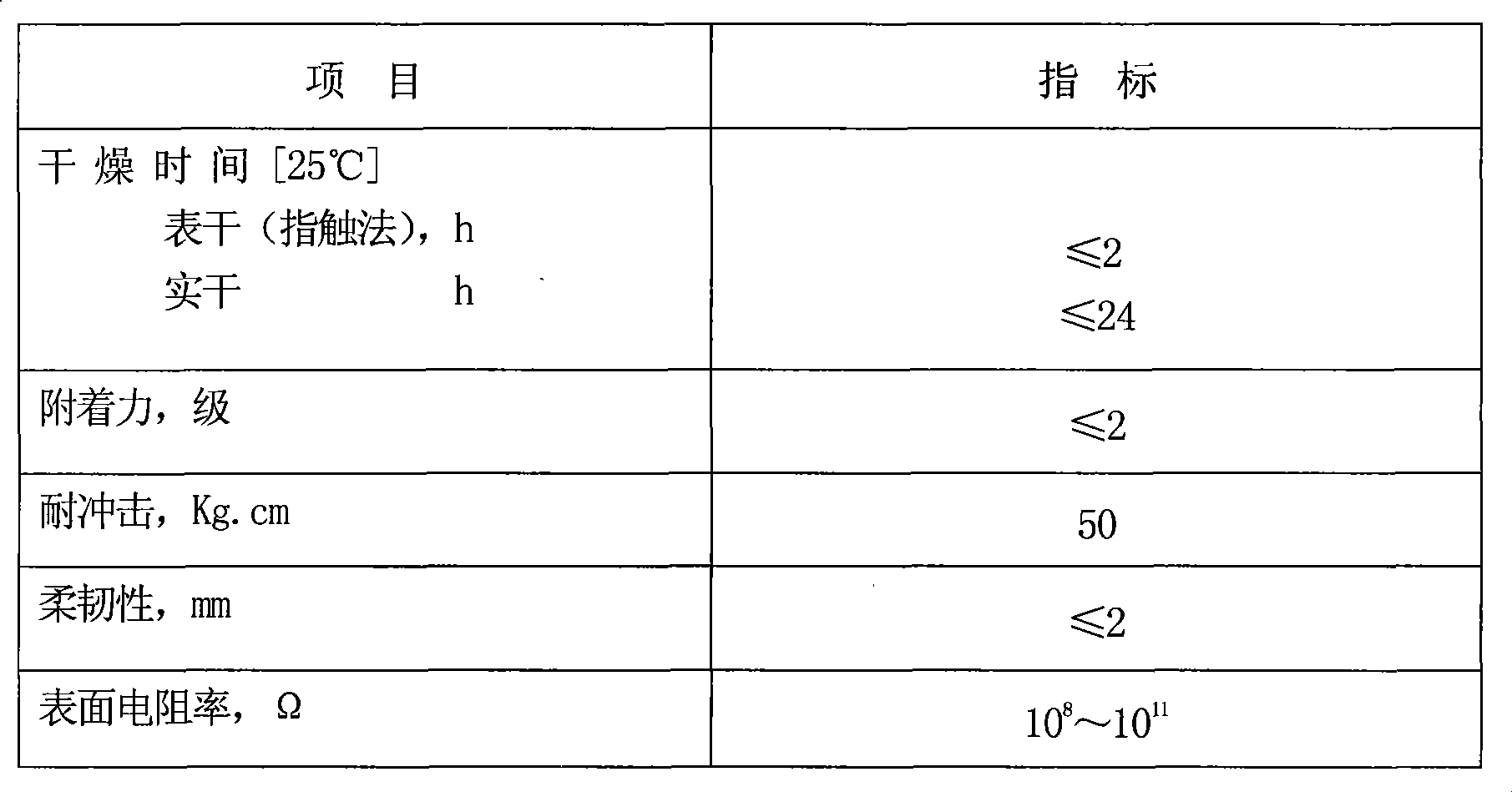

Oil resistant (solvent), heatproof static conducting anti-corrosive paint and preparation thereof

InactiveCN101372601AHigh solid contentReduce the number of coatsAnti-corrosive paintsPolyurea/polyurethane coatingsPlasticizerSolvent

The invention belongs to the corrosion protective coating technique field and provides an oil resistance (solvent) and temperature resistance electrostatic conducting corrosion protective coating and a preparation method thereof. The coating is mainly made by raw components by weight percentage of 20-35 percent of resinI which is used as basic material, 0-15 percent of modified resin II, 15-30 percent of conductive fillers, 1-3 percent of coupling agent, 8-20 percent of fillers, 10-15 percent of solvent, 2-10 percent of plasticizer, 0.5-1 percent of defoamer, 0.5-1 percent of flatting agent and 6-15 percent of curing agent. The coating is prepared according to the following steps: the resin I, the modified resin II, the coupling agent, the plasticizer, the flatting agent and the defoamer are put in a distributing tank. And part of mixed solvent is added to be stirred and distributed uniformly. The fillers are added proportionally and are put in a sand mill for sand milling after being dispersed and stirred uniformly at high speed, so as to obtain upper grinding pigment paste. The conductive fillers and the rest mixed solvent are added at low stirring speed. The conductive fillers are totally blended into the upper grinding pigment paste and stirring is carried out at middle speed, the viscosity is adjusted to be qualified and the fillers are filtered to obtain a qualified component A product. The curing agent is carried out subpackage according to proportion.

Owner:洛阳双瑞防腐工程技术有限公司

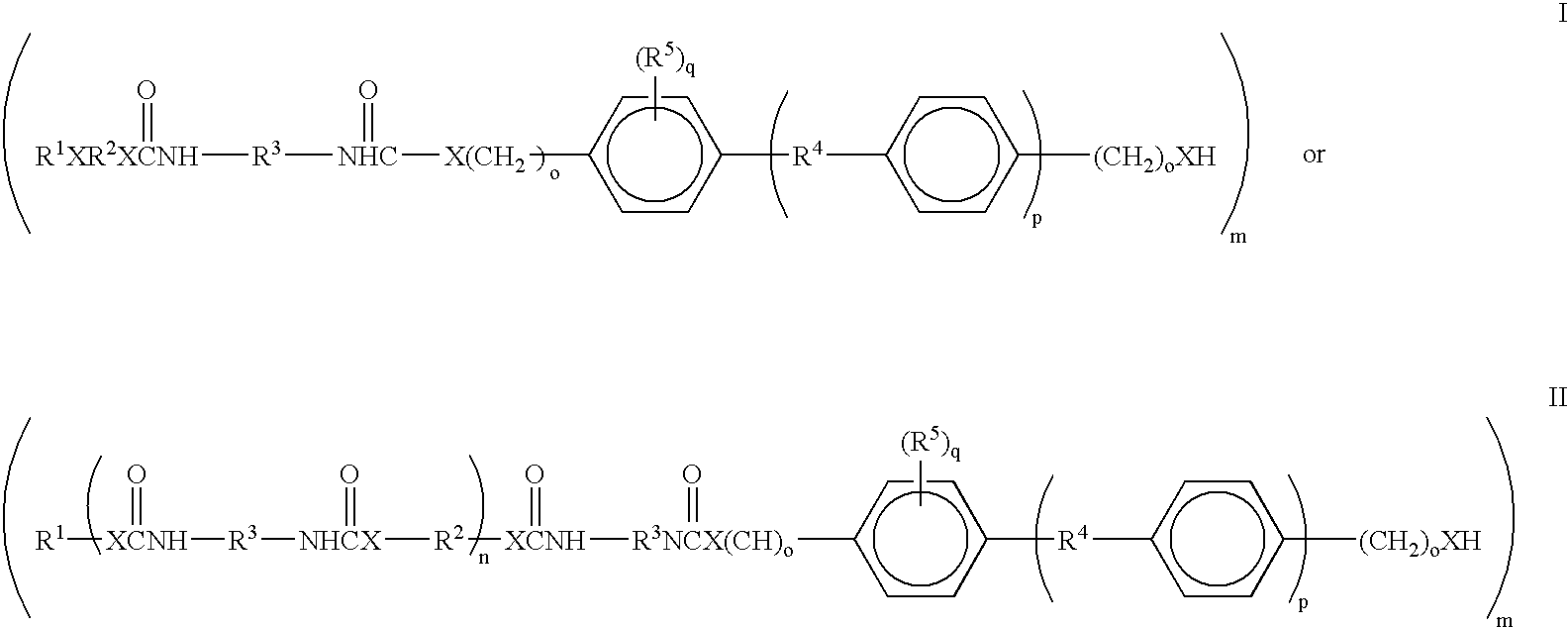

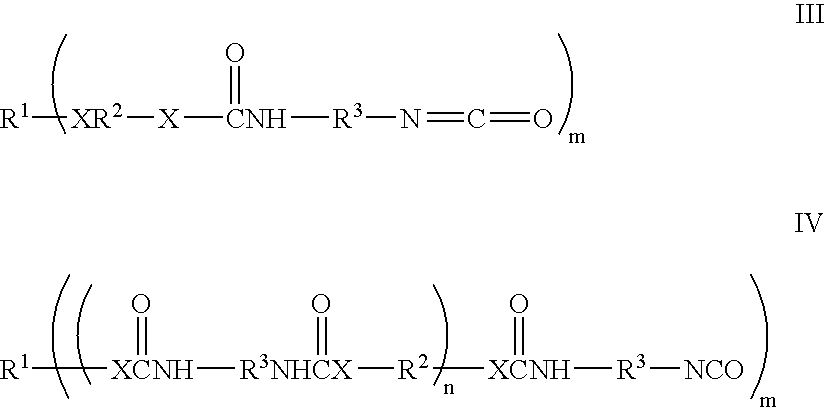

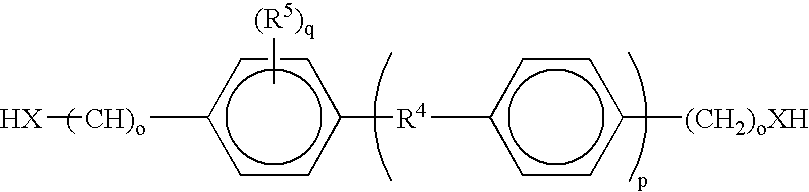

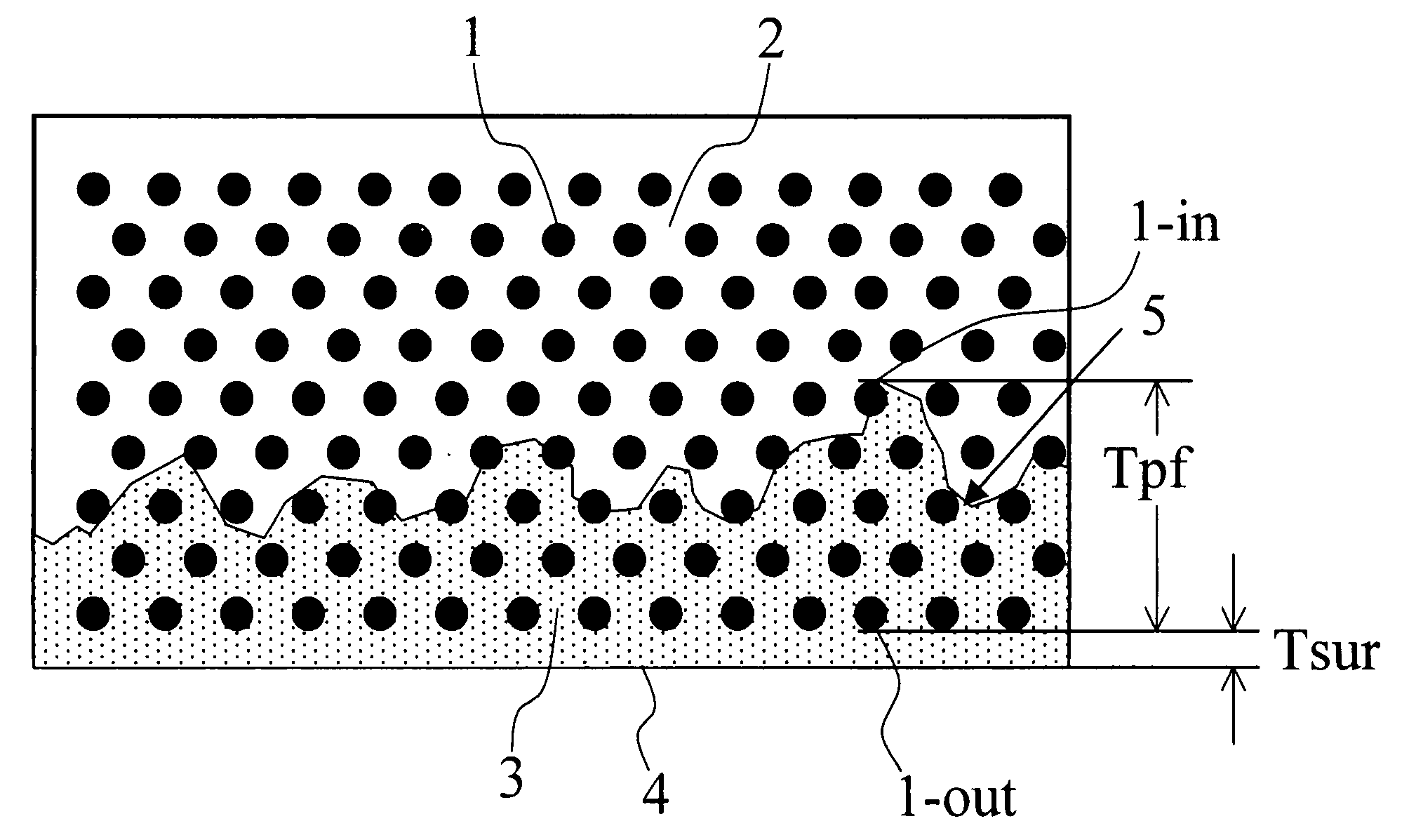

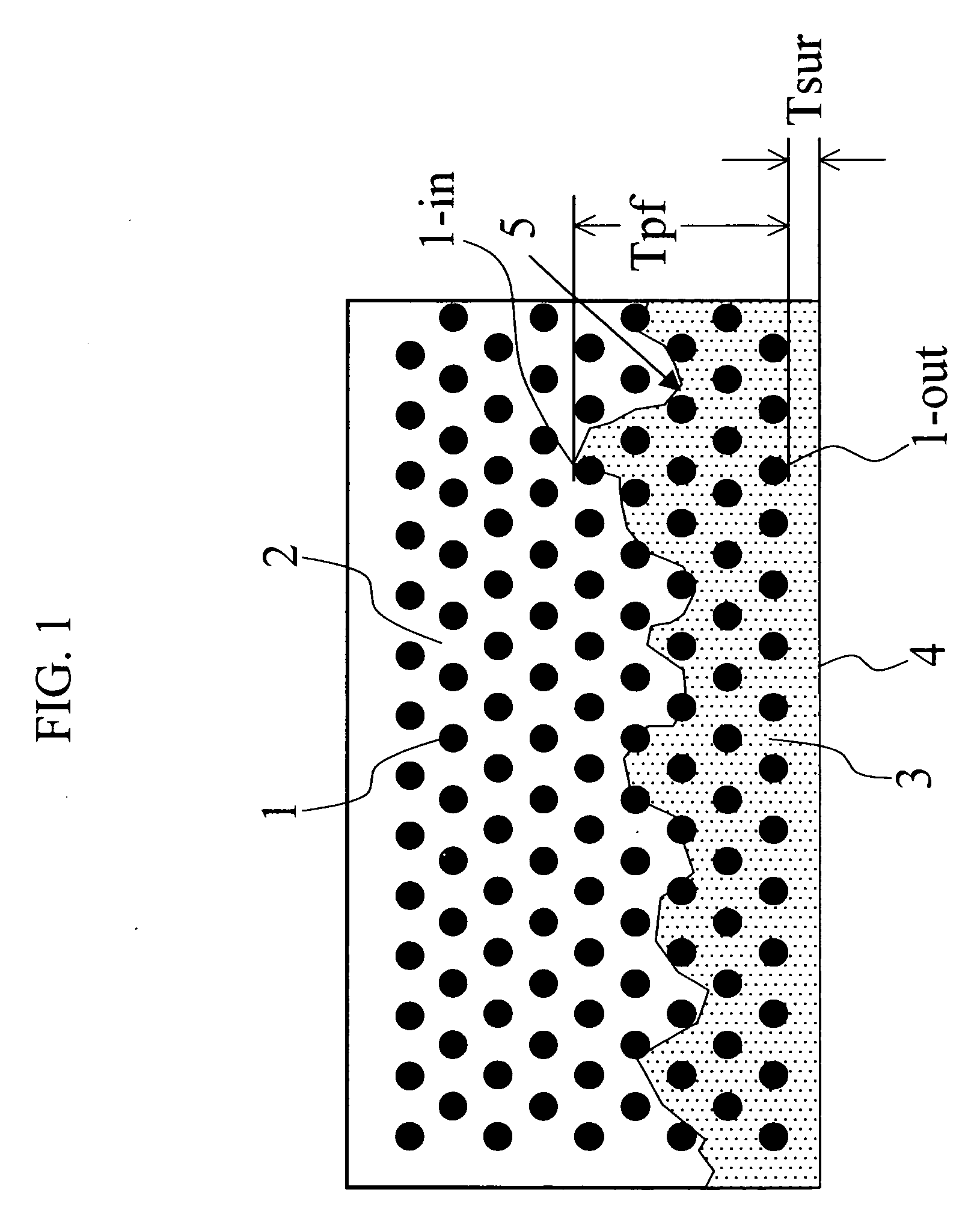

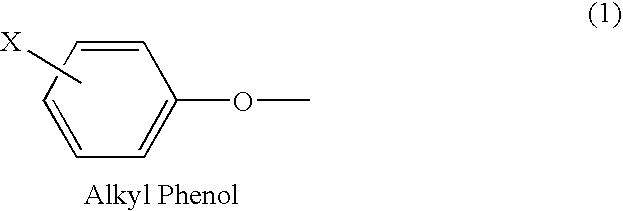

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

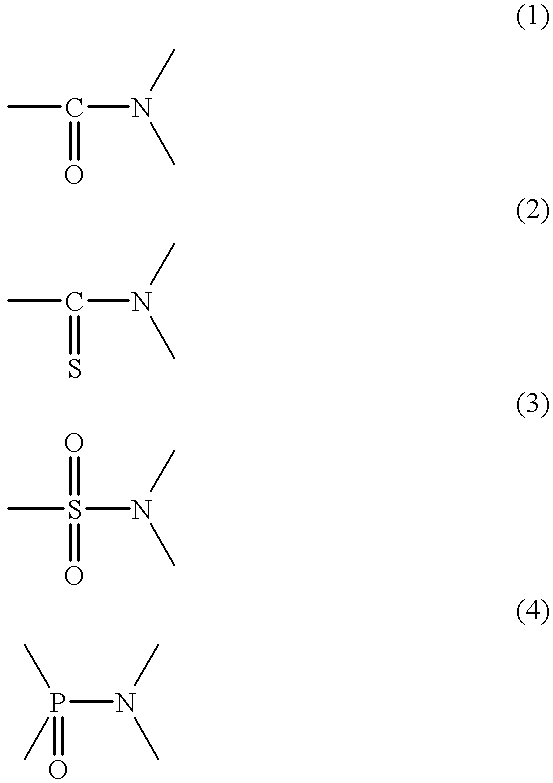

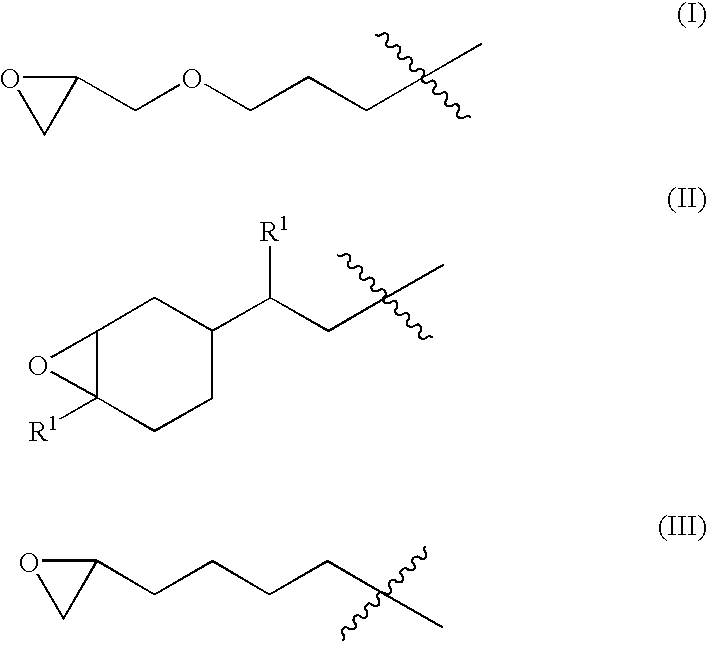

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

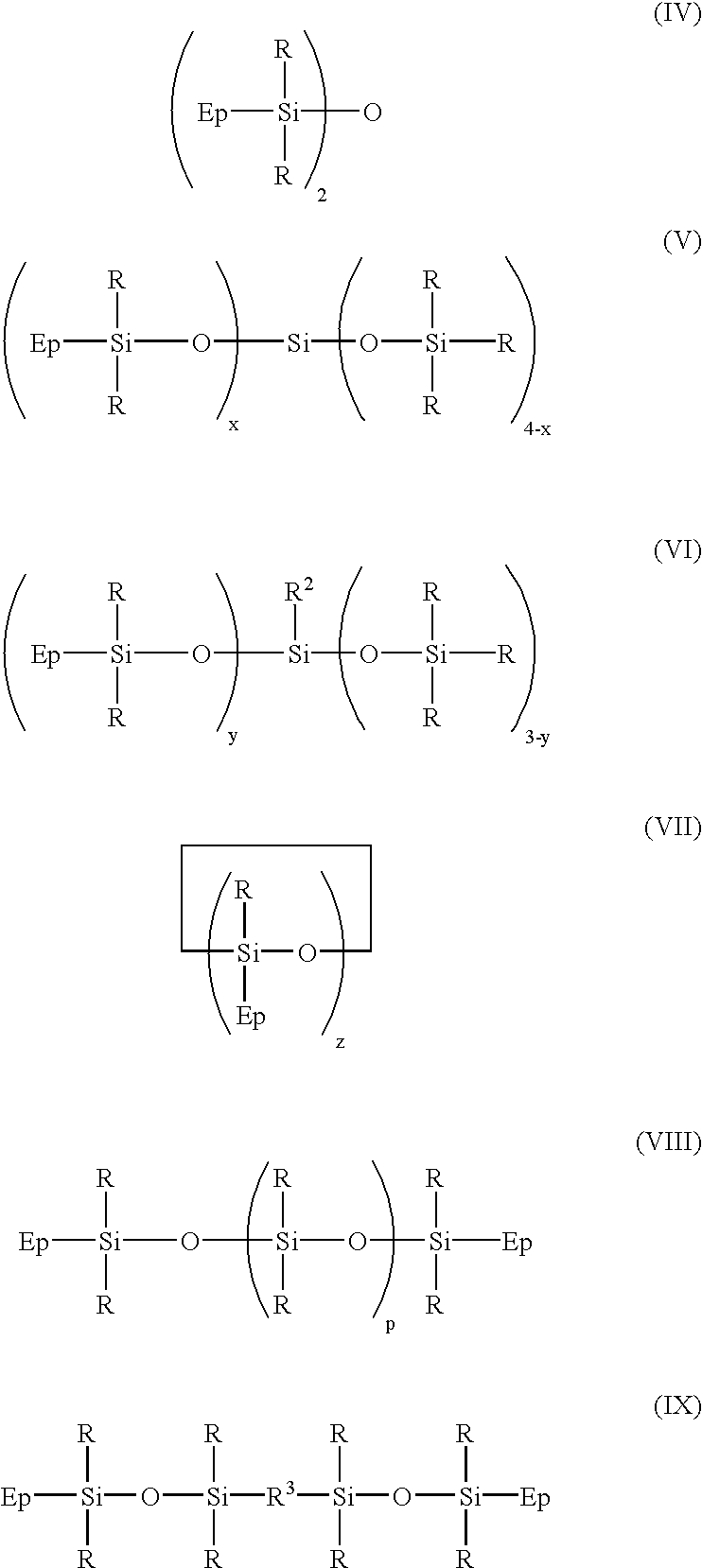

Epoxy resin compositions, solid state devices encapsulated therewith and method

InactiveUS20030071366A1High refractive indexImprove matchPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsPolymer sciencePtru catalyst

Epoxy resin compositions are disclosed which comprise (A) at least one silicone epoxy resin, (B) at least one hydroxyl-containing compound, (C) at least one anhydride curing agent, (D) at least one ancillary curing catalyst, and optionally at least one of thermal stabilizers, UV stabilizers, cure modifiers, coupling agents, or refractive index modifiers. Also disclosed are packaged solid state devices comprising a package, a chip (4), and an encapsulant (11) comprising an epoxy resin composition of the invention. A method of encapsulating a solid state device is also provided.

Owner:GENERAL ELECTRIC CO

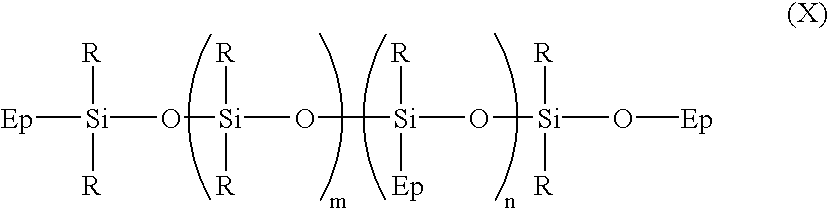

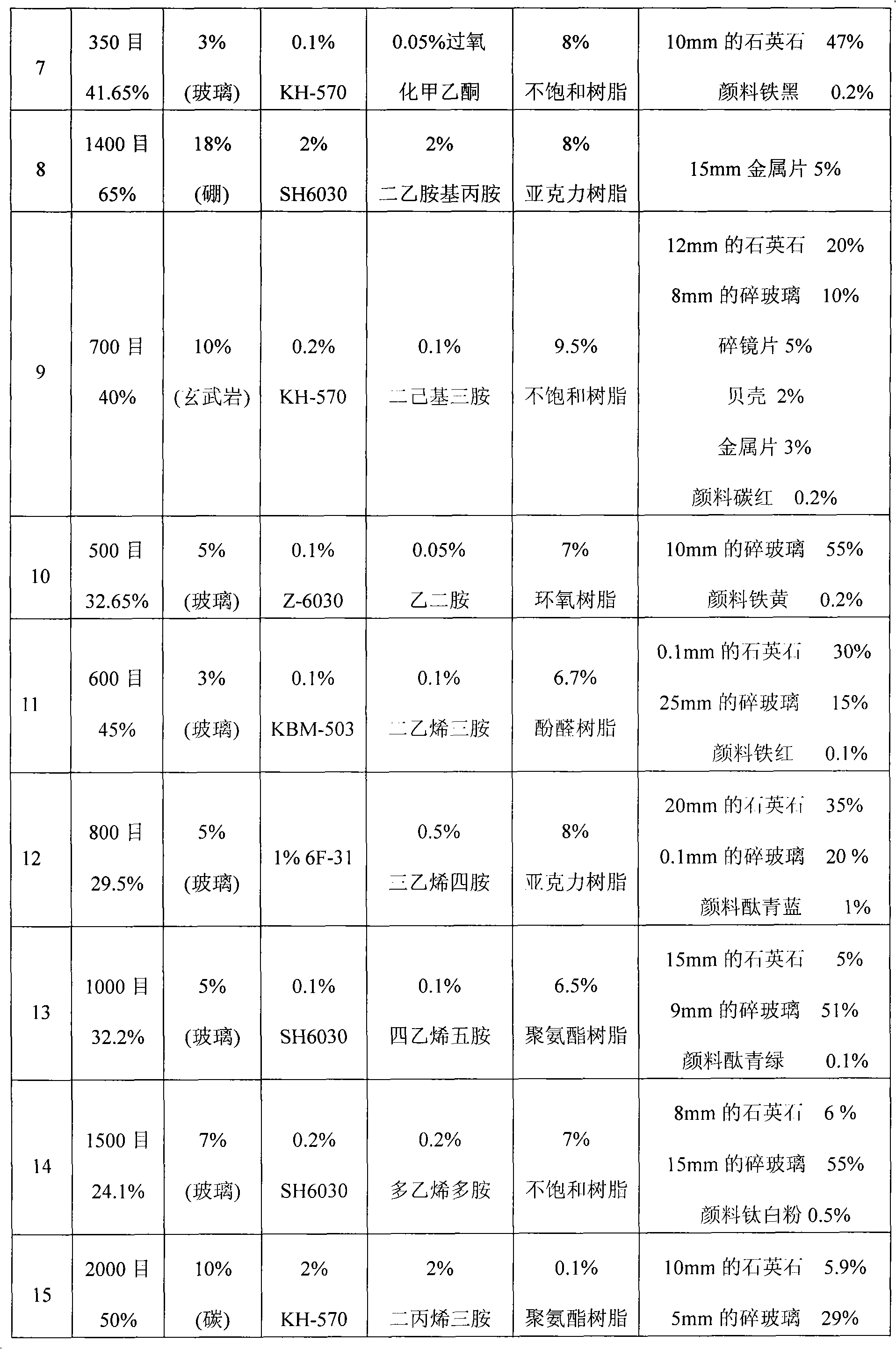

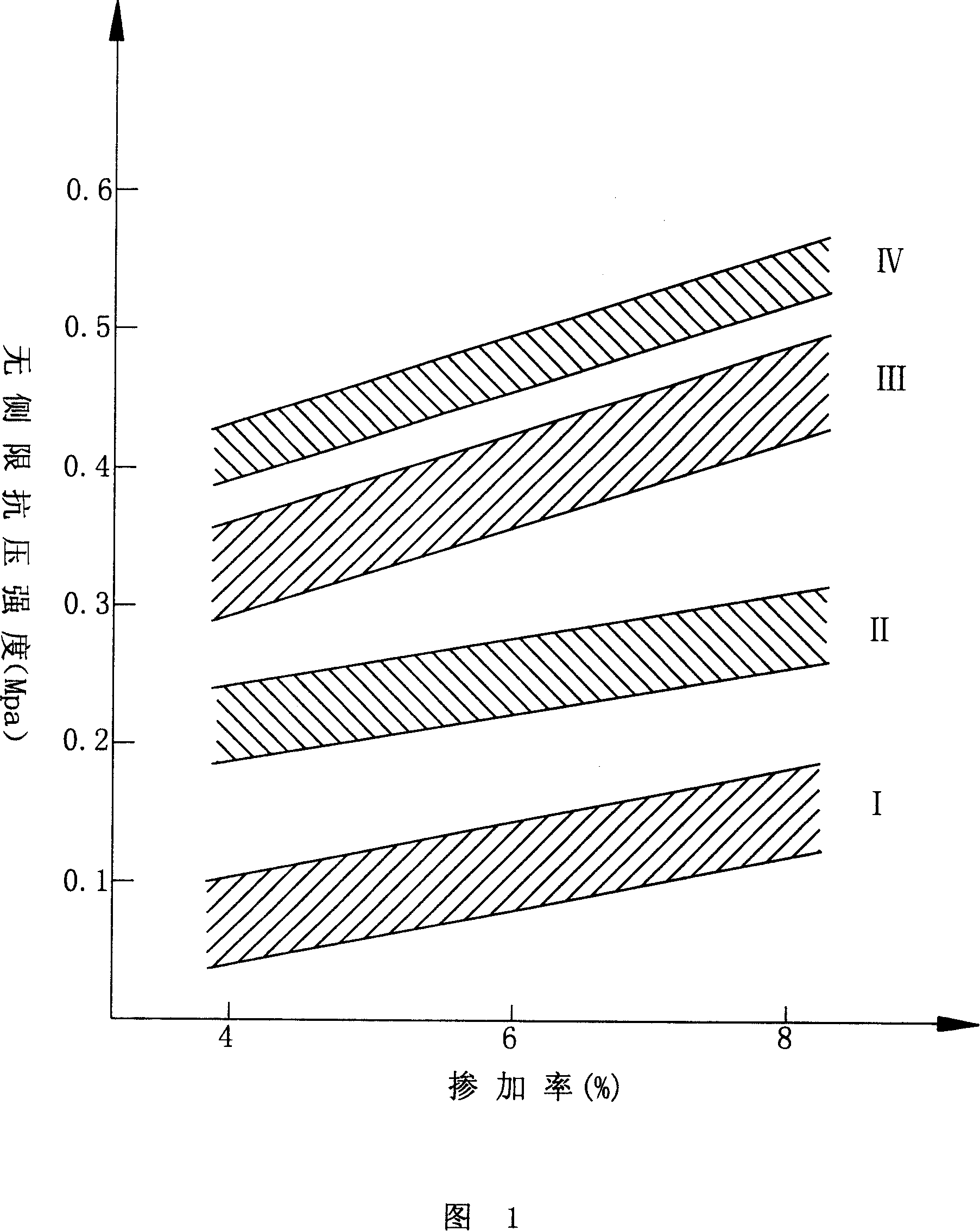

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

Dermatological application with solidified fat compositions

InactiveUS20030157138A1Antibacterial agentsEdible oils/fats ingredientsFirming agentCosmetic vehicle

A pharmaceutical or cosmetic carrier or composition for topical application characterized by rheological properties which render the carrier or composition semi-solid at rest and a liquid upon application of shear forces thereto. The composition or carrier are prepared by mixing 1-25 percent of a solidifying agent and 75-99 percent of a hydrophobic solvent, by weight, wherein at least one of them has therapeutic or cosmetic benefits, in the presence or absence of a biologically active substance.

Owner:VYNE PHARMA LTD

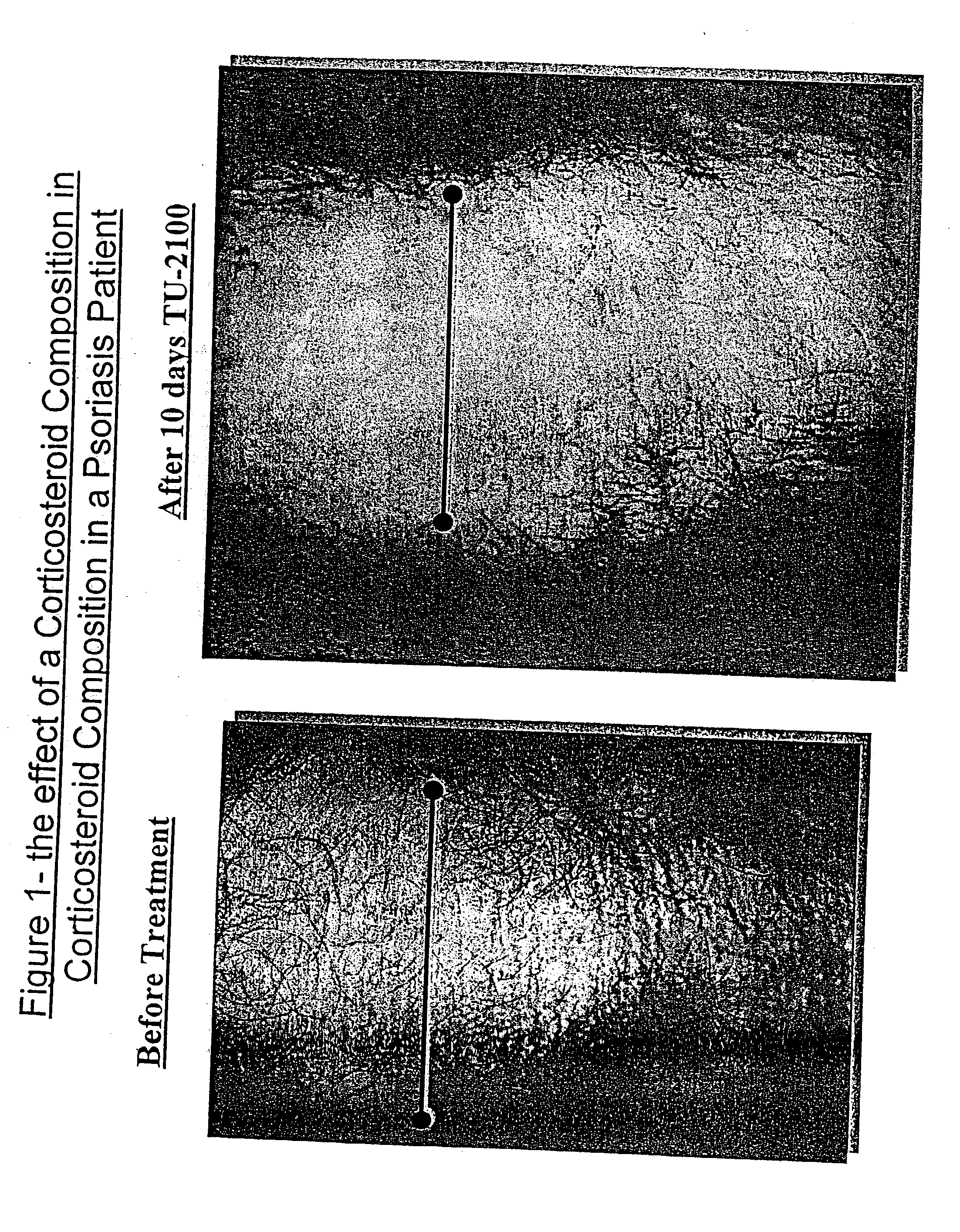

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

Coated and cured proppants

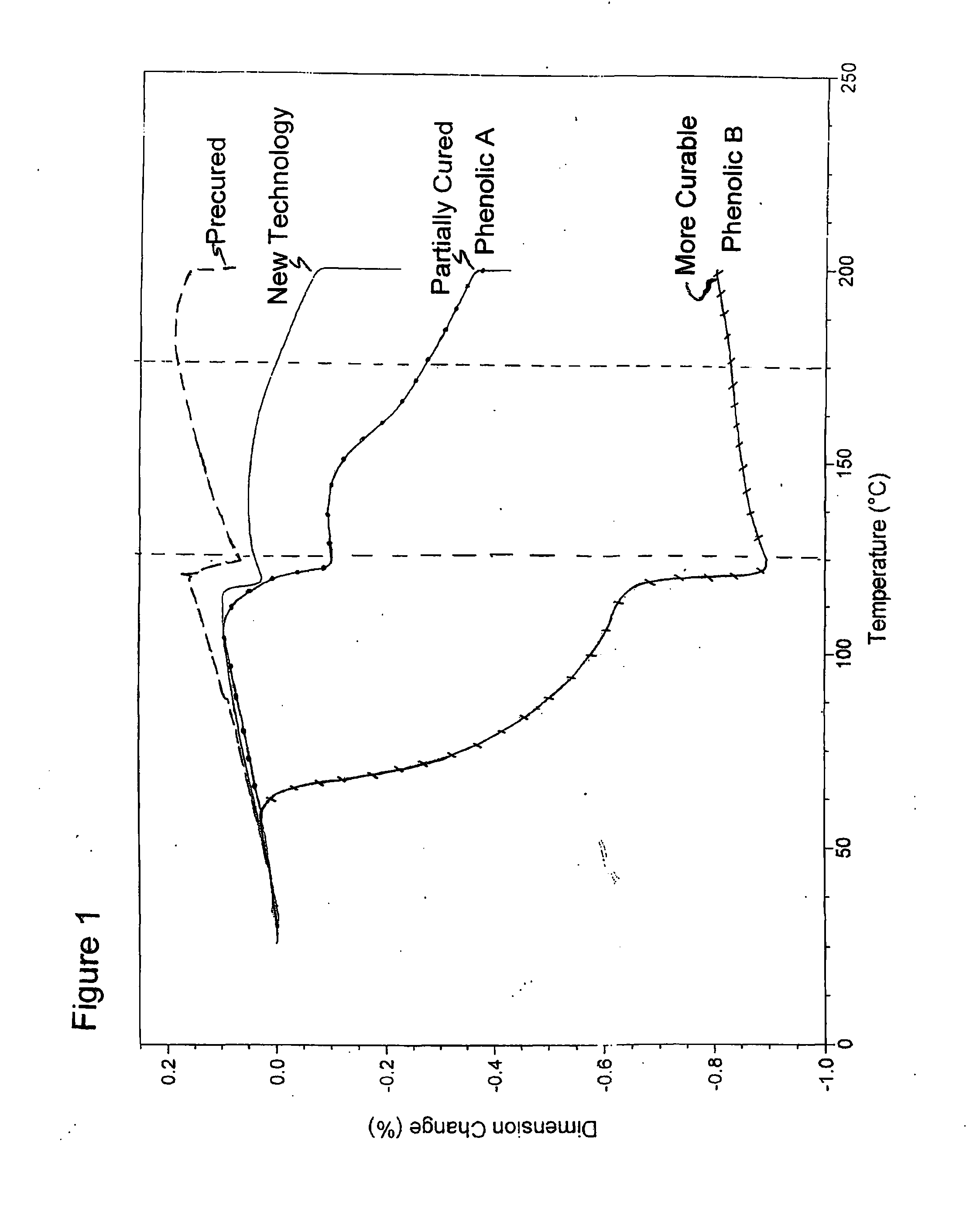

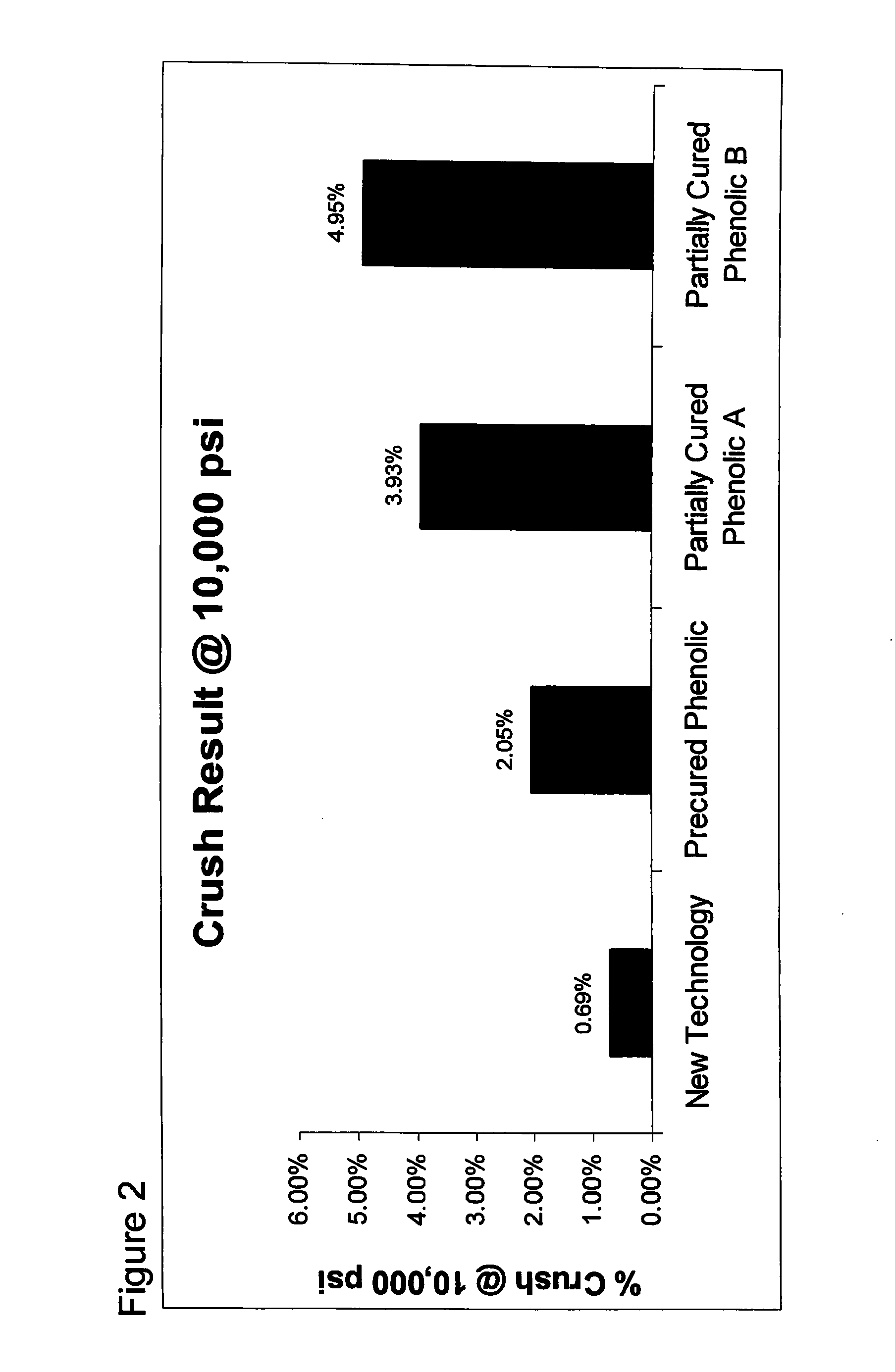

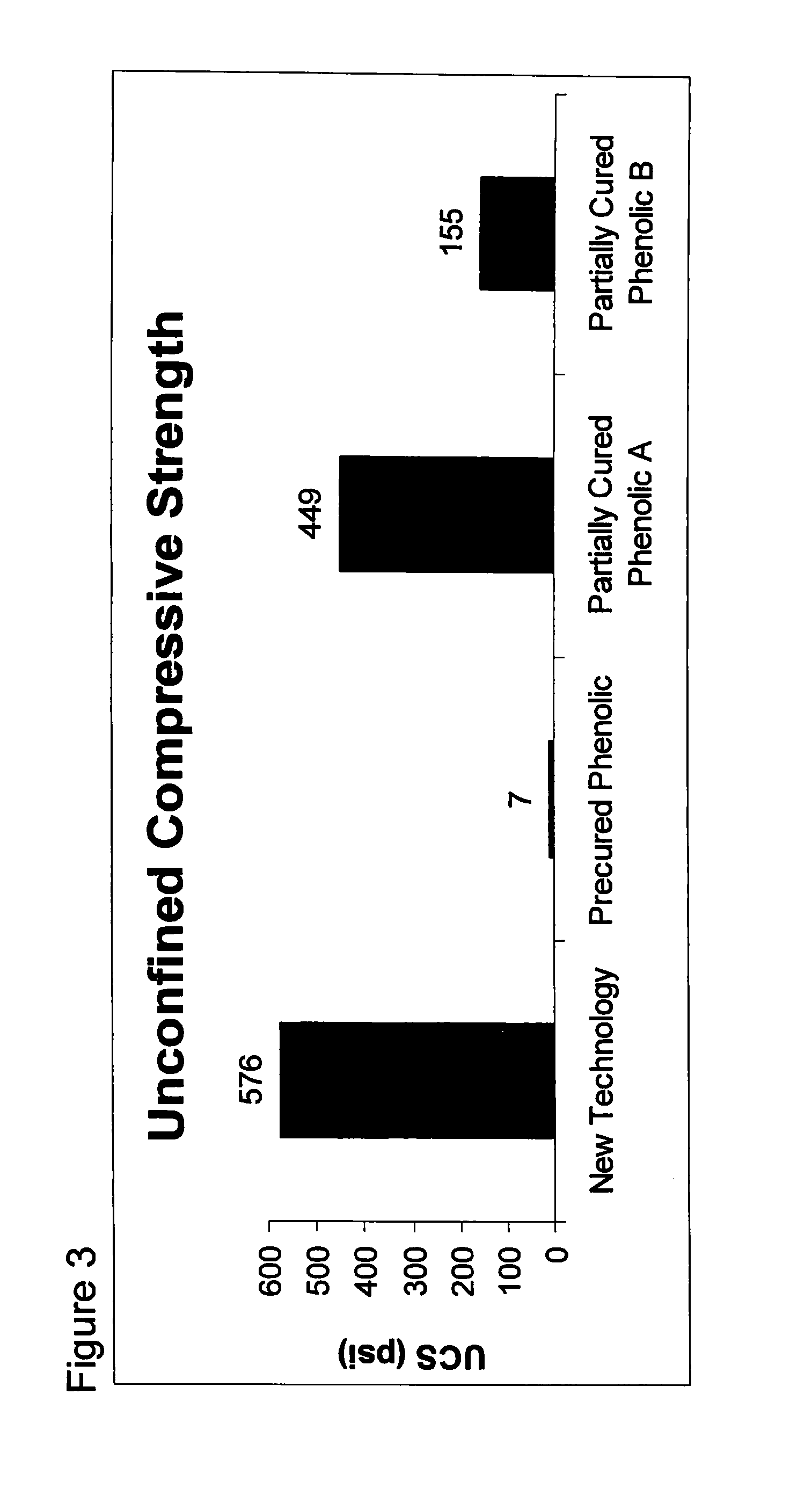

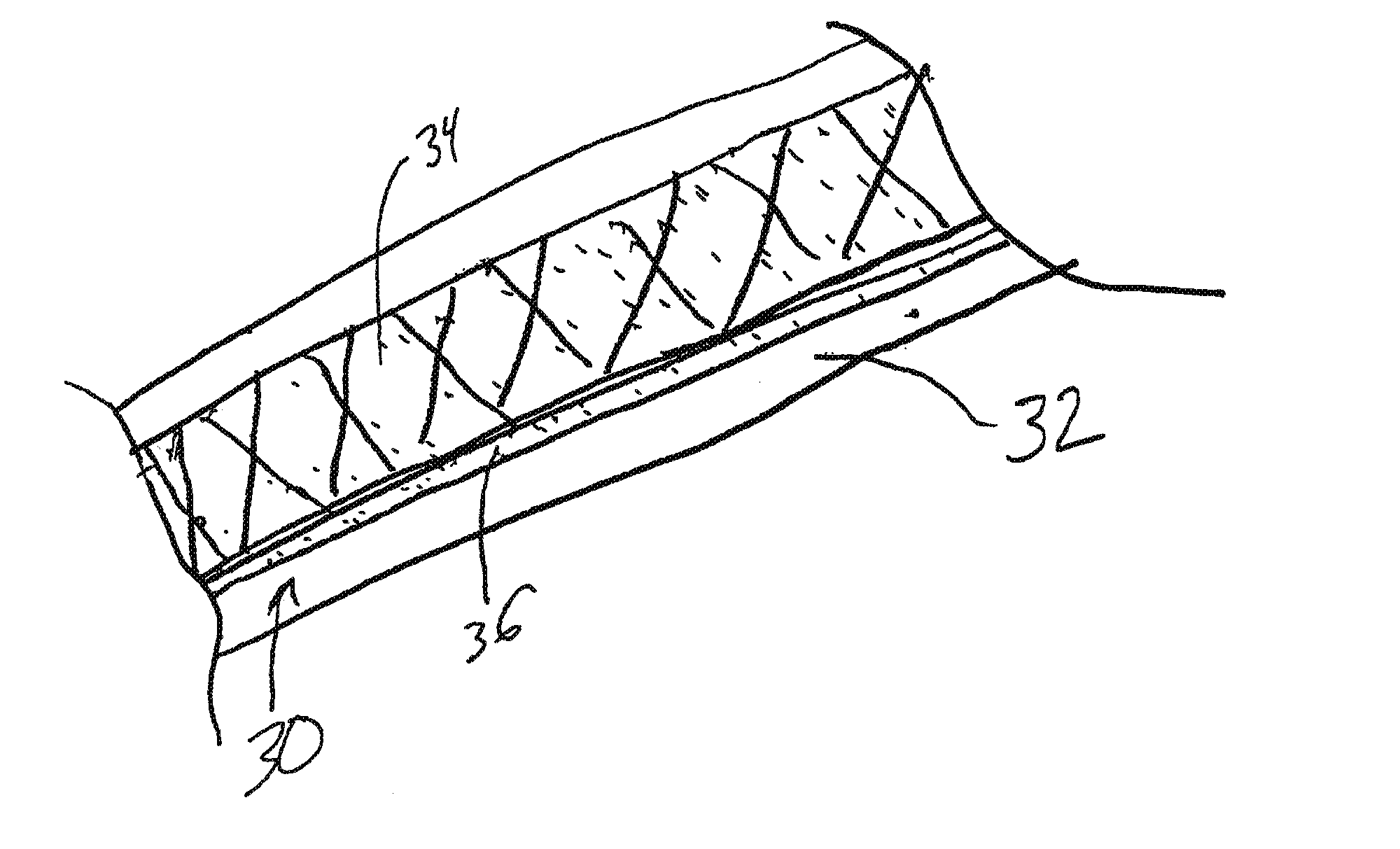

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

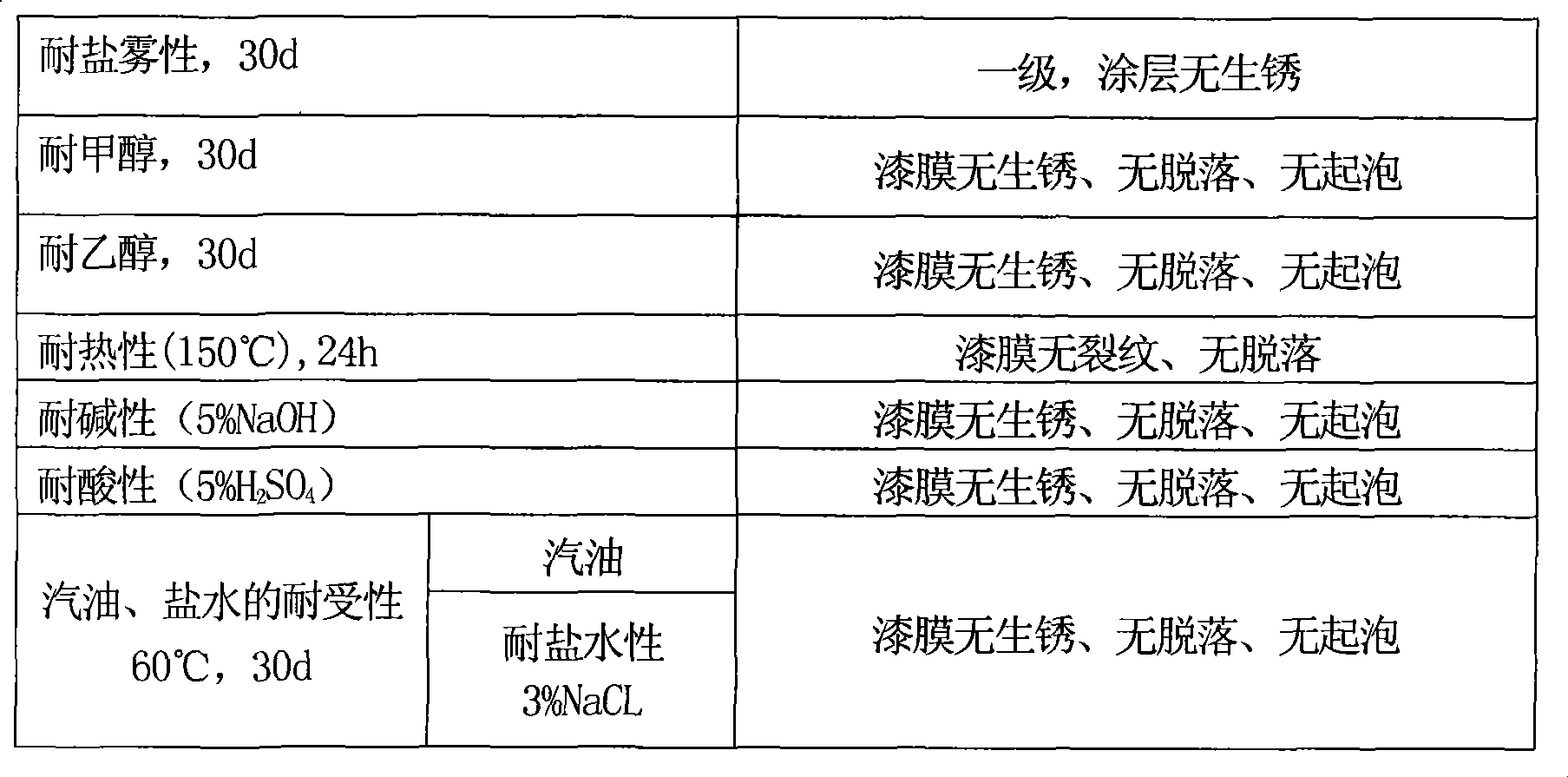

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Corrosion-resistant electromagnetic screen coating and preparation thereof

ActiveCN101275052AImprove anti-corrosion performancePlay a synergistic roleMagnetic/electric field screeningEpoxy resin coatingsElectromagnetic shieldingSolvent

The present invention provides a corrosion electromagnetic shielding coating and its preparing method, the corrosion electromagnetic shielding coating includes a solute part and a solvent part, the weight percentage of the components of the solute part is : film forming resin 25.4-39.6%, curing agent 3.5-14.8%, conductive filler 37.5-57.5%, anticorrosive agent 3.5-10.5%, coupling agent 0.5-1.5%, anti-sedimentation agent 0.8-2.2%, antioxidant 0.1-1.0%.The coating of the invention has excellent corrosion resistance and electromagnetic shielding effectiveness.

Owner:MARINE CHEM RES INST

Structural modified epoxy adhesive compositions

InactiveUS20020164485A1Reduce opening timeGood substrate adhesionSynthetic resin layered productsThin material handlingSilanesFirming agent

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Toughened adhesive material

An adhesive material and articles incorporating the same is disclosed. The adhesive material includes at least three of epoxy resin; impact modifier; flexibilizer, blowing agent; curing agent; and filler. The adhesive material is preferably used for structural adhesion but may be used for sealing, baffling or reinforcing an article of manufacture such as an automotive vehicle.

Owner:ZEPHYROS INC

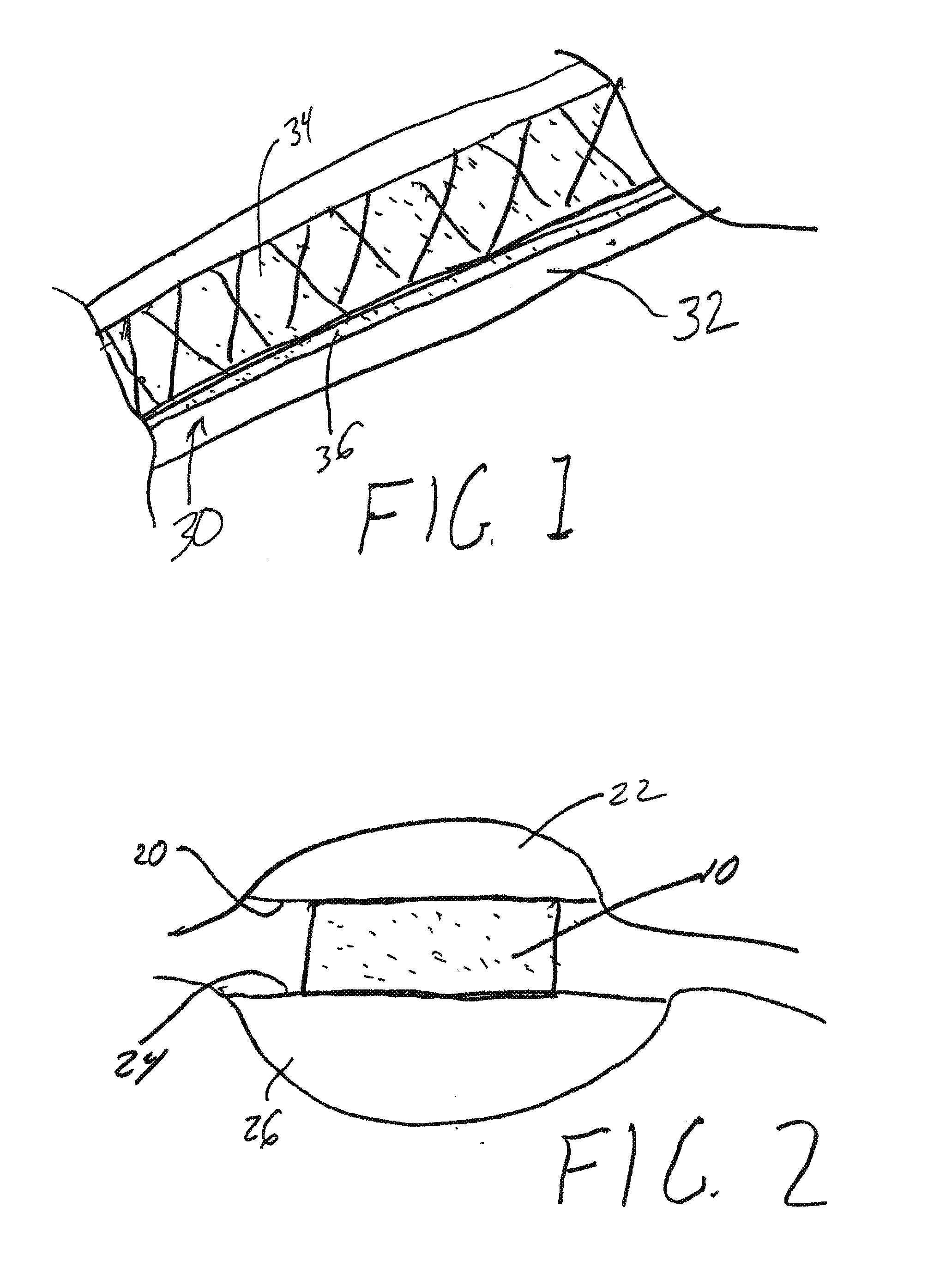

Heat curable, thermally expandable composition with high degree of expansion

Compositions containing at least one liquid epoxy resin, at least one solid epoxy resin, at least one propellant, at least one curing agent and at least one mica-containing filler produce expandable, thermally curable binder systems which may be used without the addition of hollow glass beads for the production of stiffening and reinforcing laminates and for the production of stiffening and reinforcing mouldings. Said laminates according to the invention are suitable for the stiffening and reinforcing of components, in particular in the automotive industry, such as car body frames, doors, boot lids, engine bonnets and / or roof parts. In addition, the mouldings that may be produced from said binders are suitable for the stiffening and reinforcing of hollow metal structures, in particular of hollow car body parts such as body frames, body supports and posts or doors in the automotive industry.

Owner:HENKEL KGAA

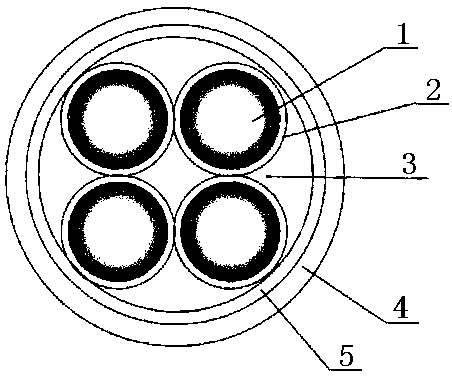

Fireproof and flame retardant mineral compound filling material and cable containing the same

ActiveCN103102134ANo harmImprove fire performanceInsulated cablesInsulated conductorsPolymer scienceFirming agent

The invention relates to a fireproof and flame retardant mineral compound filling material for cables. The filling material comprises a silicon-containing binder; an inorganic flame retardant compound; and a mineral compound. The filling material also can include a silicate modifier, a silicate curing agent and a pigment. Being free of any flammable substance, the fireproof and flame-retardant mineral compound filling material provided in the invention has an excellent fireproof effect, can lose moisture and absorb a lot of heat so as to achieve the flame retardant effect. With good flexibility, the fireproof and flame retardant mineral compound filling material has no hazard to the nature after it is abandoned.

Owner:上海宏胜电线电缆有限公司 +1

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Epoxy Resin Composition for Carbon-Fiber-Reinforced Composite Material, Prepreg, Integrated Molding, Fiber-Reinforced Composite Sheet, and Casing for Electrical/Electronic Equipment

ActiveUS20080166511A1Improve mechanical propertiesLight weightPigmenting treatmentPlastic/resin/waxes insulatorsEpoxyHalogen

The present invention provides a light-weight fiber-reinforced composite material that has excellent flame retardance and mechanical properties and never emits a halogen gas. The present invention also provides a prepreg and en epoxy resin composition suited to obtain the above described fiber-reinforced composite material. The present invention also provides an integrated molding which is produced using the above described fiber-reinforced composite material, thereby suitable for use in electric / electronic casings. The epoxy resin composition is such that it contains the following components [A], [B] and [C]:[A] epoxy resin,[B] amine curing agent, and[C] phosphorus compound,wherein the concentration of the component [C] is 0.2 to 15% by weight in terms of phosphorus atom concentration.

Owner:TORAY IND INC

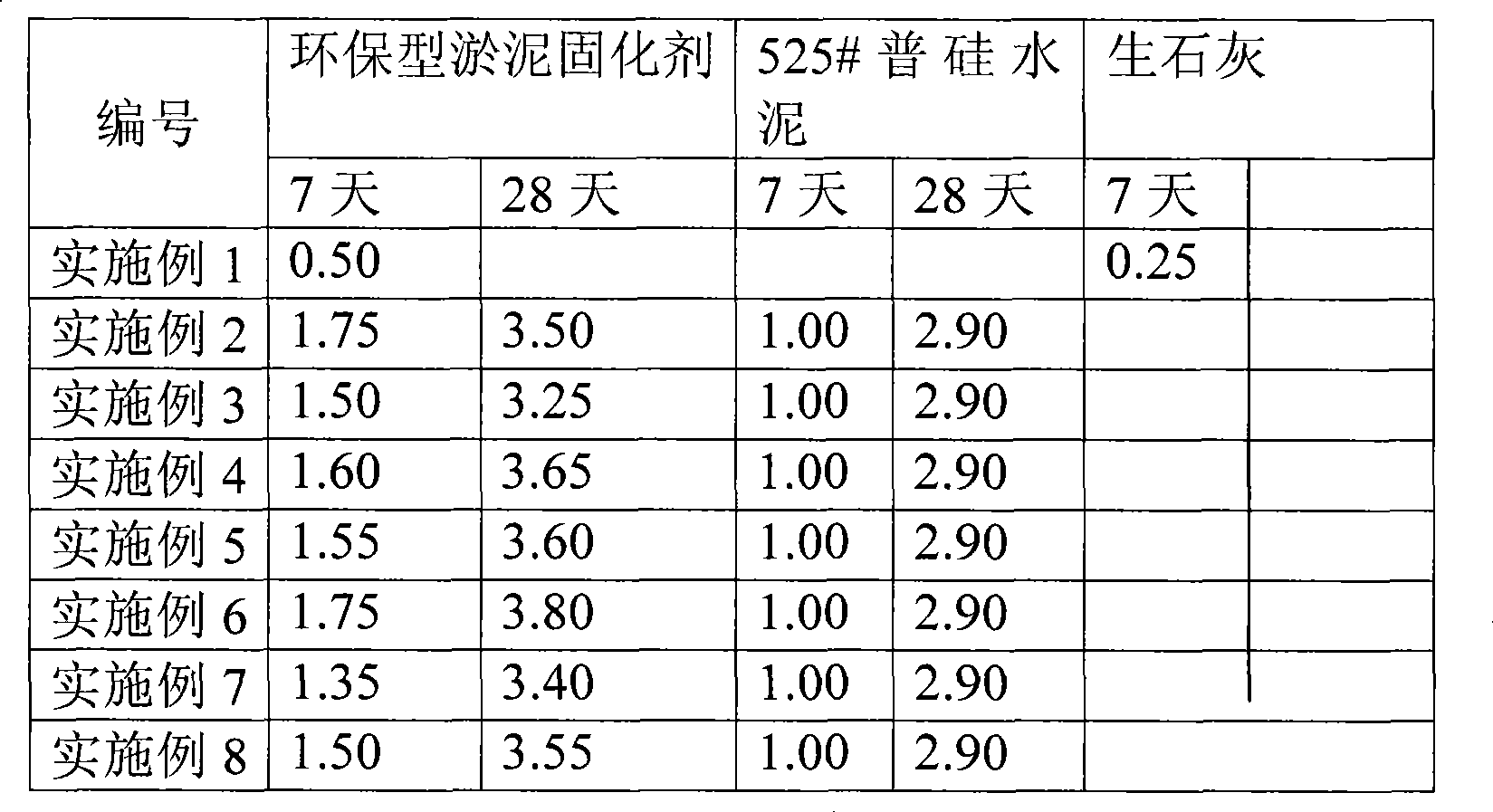

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

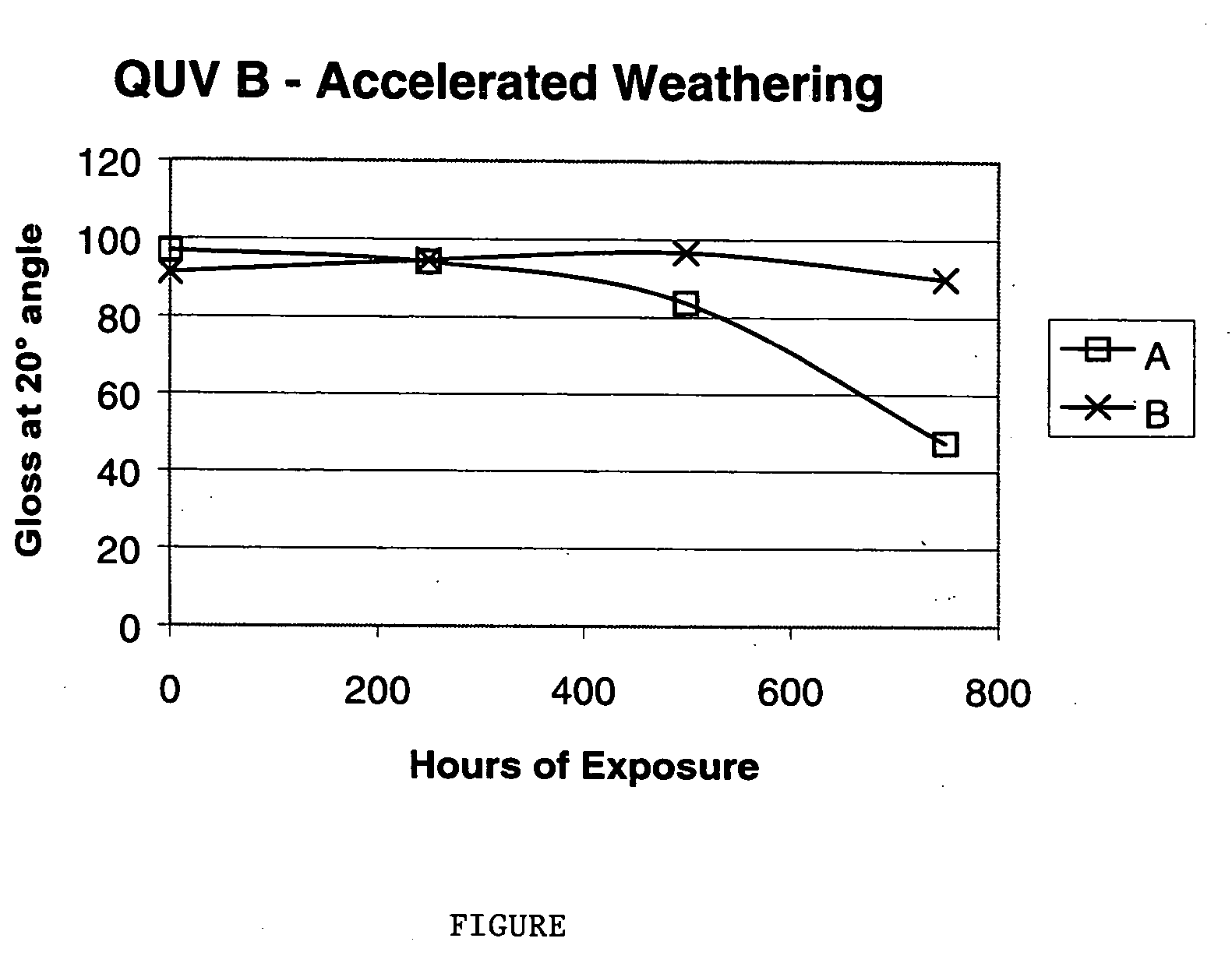

Flexible, super durable powder coating composition

InactiveUS20060079650A1Good weather resistanceImprove mechanical propertiesPolyurea/polyurethane coatingsPowdery paintsPolyesterPolymer science

Powder coatings having good impact resistance and weatherability characteristics are produced with an isophthalic acid-based polyester and an isocyanate-based curing agent.

Owner:BAYER MATERIALSCIENCE AG

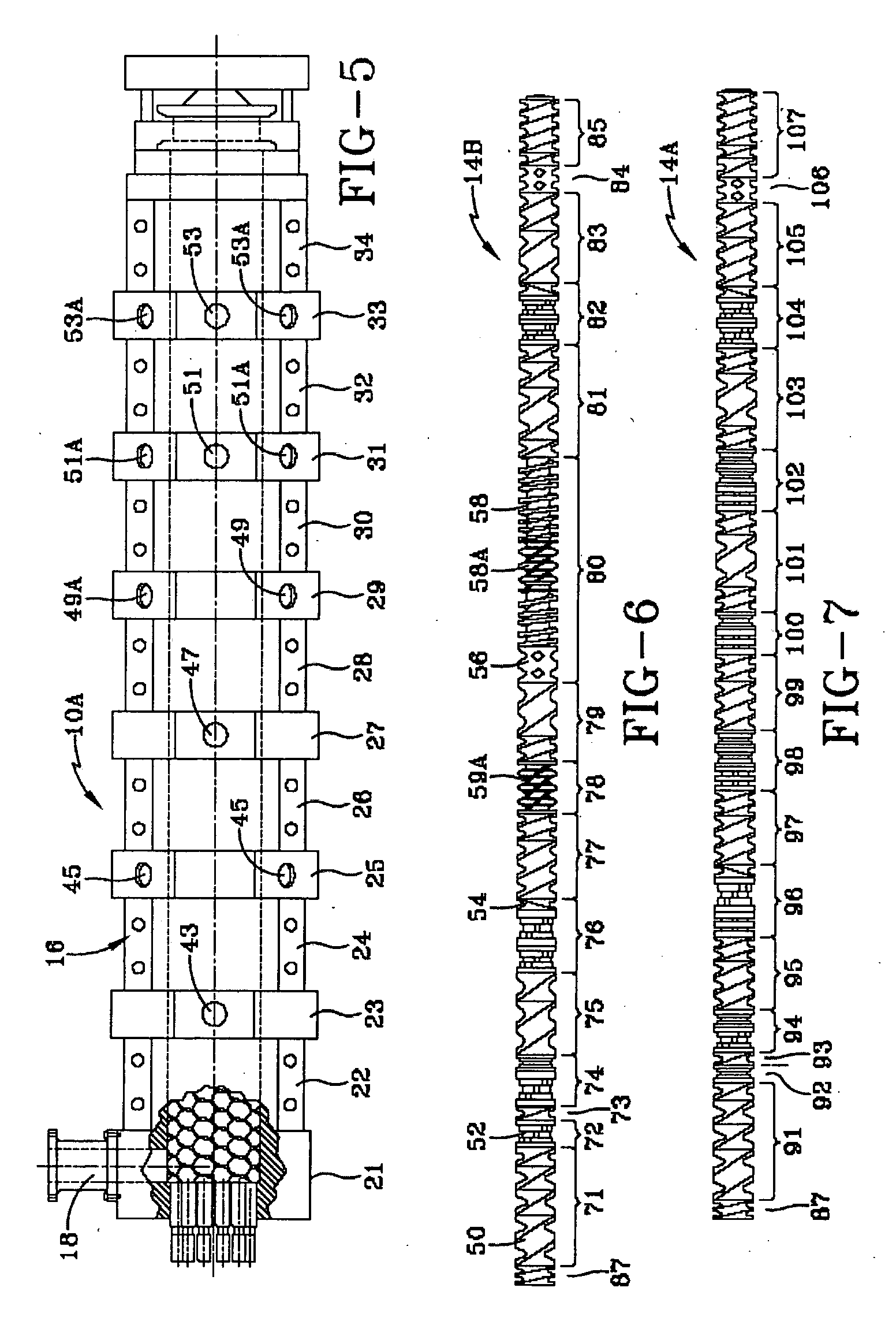

Preparation of thermoplastic elastomers by dynamic vulcanization in multi-screw extruders

The invention relates to a method of preparing a thermoplastic vulcanizate comprising: a) melt processing a blend of thermoplastic polymer and vulcanizable elastomer in a multi-screw extruder having at least three intermeshing screws, wherein said screws have 3-170 mixing zones, and said extruder having a L / D ratio of 15-100, and a screw profile that has 3 to 17 meshes per L / D; b) adding at least one curing agent to the melt-processed blend of a) in at least one location in the first 46% of the length of said extruder, or adding at least one curing agent to the melt-processed blend of a) in a second extruder, so as to initiate curing of the blend: and, curing at least partially said elastomer by reactive melt processing. Improved processing, reaction kinetics and efficiencies are achieved, as well as thermoplastic vulcanizate products having decreased weight gain when placed in mineral oils.

Owner:CELANESE INT CORP

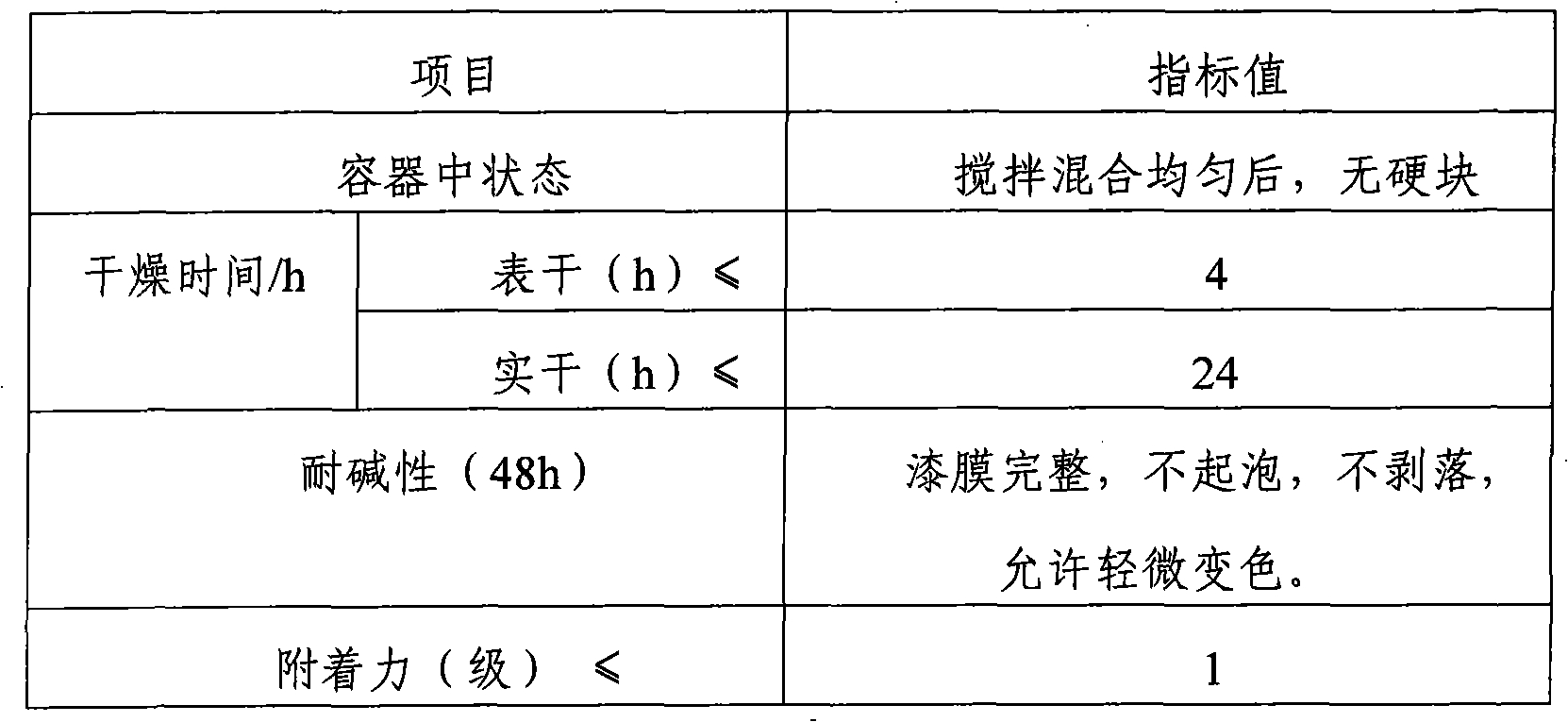

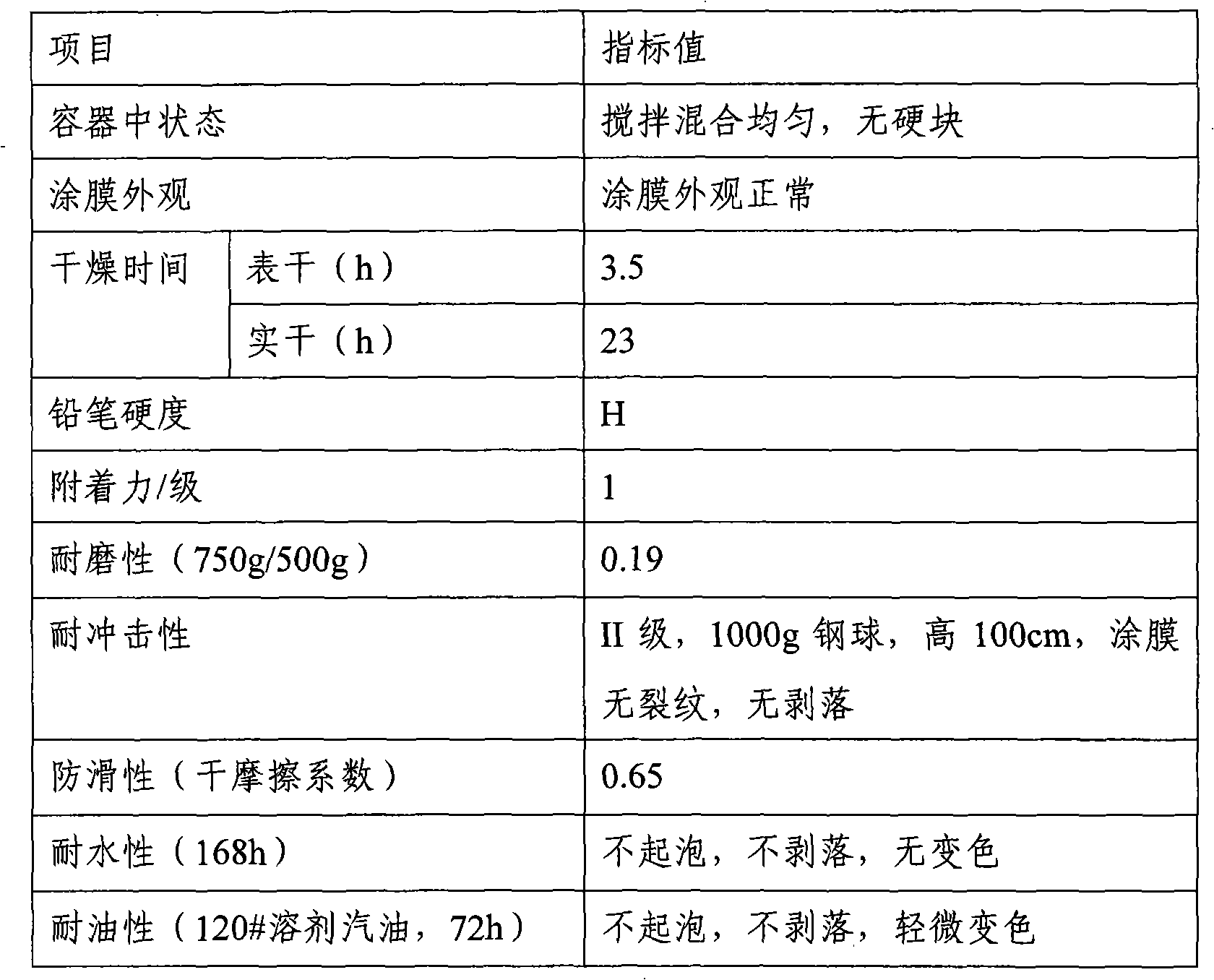

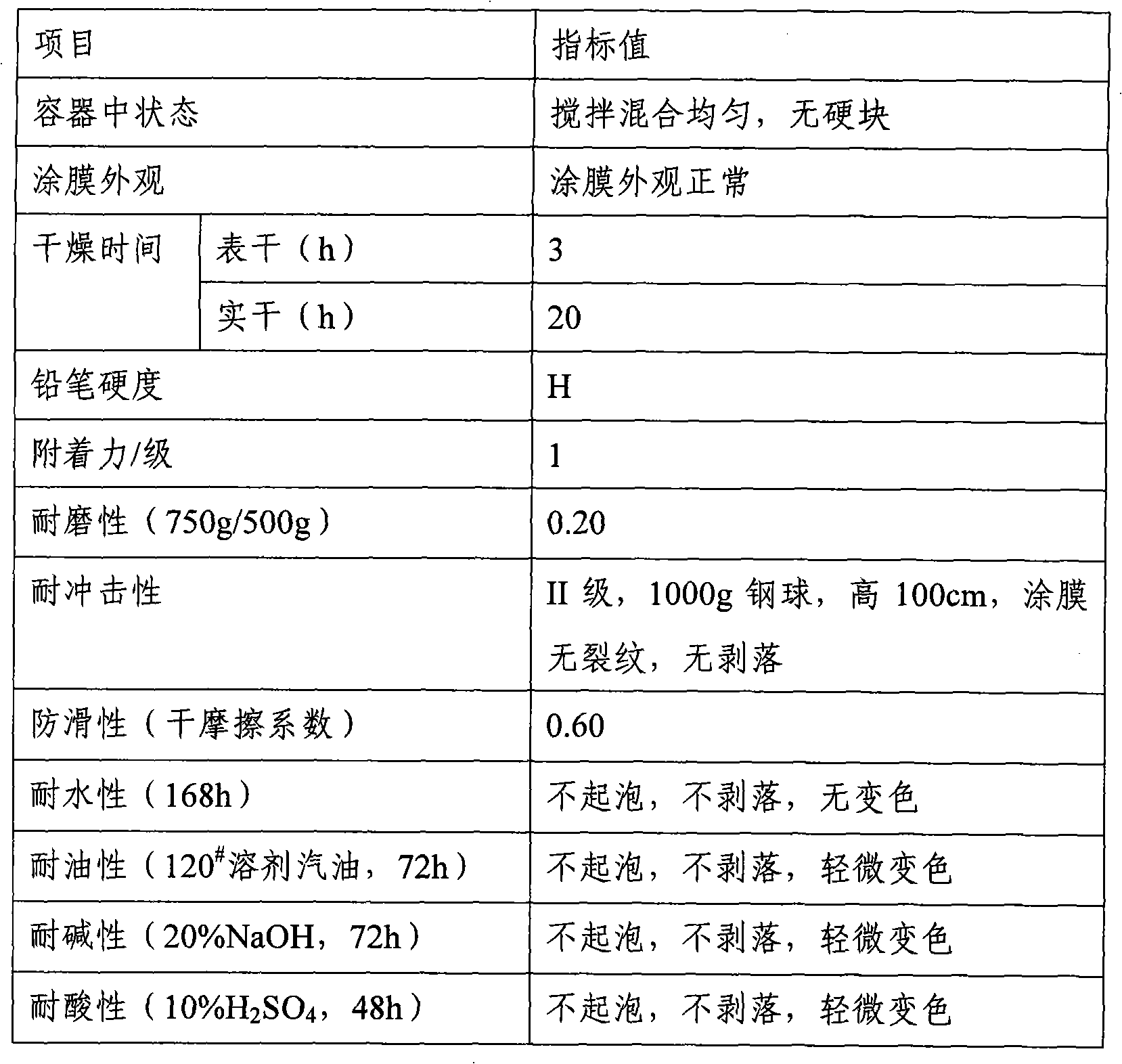

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

Composite rubber material

InactiveCN103627330ALow costReduce manufacturing costPolyureas/polyurethane adhesivesInorganic adhesivesRubber materialPolymer science

The invention relates to a bonding rubber material, especially provides a binder or a thermosetting molding rubber cement for bonding and reinforcement of door cores of a fireproof door an antitheft door and bonding and production of building and decoration materials, and aims to provide a composite rubber material, with low cost, good bonding strength and rapid surface dry, which can be cured at room temperature. The composite rubber material is characterized in that the composite rubber material is composed of a water-based A material and a polyurethane prepolymer-containing B material, the ratio (weight ratio) of the A material to the B material is 0.5-1:0.5-1, the A material comprises 30-70% of water and / or water glass and / or silica sol, 19.5-48% of organic modifiers, and 12-55% of additives, the B material comprises polyurethane prepolymers with a content of being more than 30%, 8-24% of -NCO group, and 0-30% of synergists, The synergists are one or combination of more than one selected from a polymerization inhibitor, a blocking agent, a water glass curing agent and a diluting agent. The composite rubber material is advantaged by good bonding strength, flame retardance, thermal insulation, low price and environmental protection.

Owner:CHONGQING LIERDA SCI & TECH DEV +1

Fertilizer coating composite, its making method and multicomponent coated granular fertilizer

InactiveCN1535939AIncrease profitExtend the fertilizer periodFertilizer mixturesOrganic acidAdjuvant

The present invention relates to a coating composite for making coated granular fertilizer and its production method, and the fertilizer made up by using said coating composite. The coating composite is formed from coating agent, solidfying agent, nitrogen synergist, inorganic acid or organic acid, surfactant and adjuvant. As compared with non-coated fertilizer the nitrogen utilization rate of fertilizer produced by adopting said invention can be raised by 6%-10%, the fertilizer can be saved by 15-45%, and its fertilizer efficiency time can be obviously prolonged, and can be reached to 60-120 days.

Owner:陈大顺

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Preformed adhesive bodies useful for joining substrates

InactiveUS20090104448A1Less tackyExcessive deformationLamination ancillary operationsDecorative surface effectsEpoxyChemistry

A first substrate may be joined to a second substrate using an adhesive body. The adhesive body is formed from an adhesive composition containing at least one epoxy resin, at least one heat-activatable curing agent, and at least one radiation-curable compound. A first surface of the adhesive body is exposed to an amount of radiation effective to cure at least a portion of the at least one radiation-curable compound present in proximity to such first surface, thereby rendering said first surface less tacky and / or more resistant to deformation. A second surface of the adhesive body is then applied to a surface of said first substrate. A surface of the second substrate is thereafter positioned proximate to or in contact with the first surface of the adhesive body and the adhesive body heated to a temperature effective to activate the heat-activated curing agent and induce curing of the at least one epoxy resin.

Owner:HENKEL KGAA

Coating composition and article coated therewith

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com