Environment-friendly type sludge firming agent

A curing agent and an environmentally friendly technology, applied in the field of municipal and construction engineering, can solve the problems of unsuitable dredging mud treatment engineering and limited treatment capacity, and achieve the effect of good curing effect, saving raw materials and protecting the natural environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

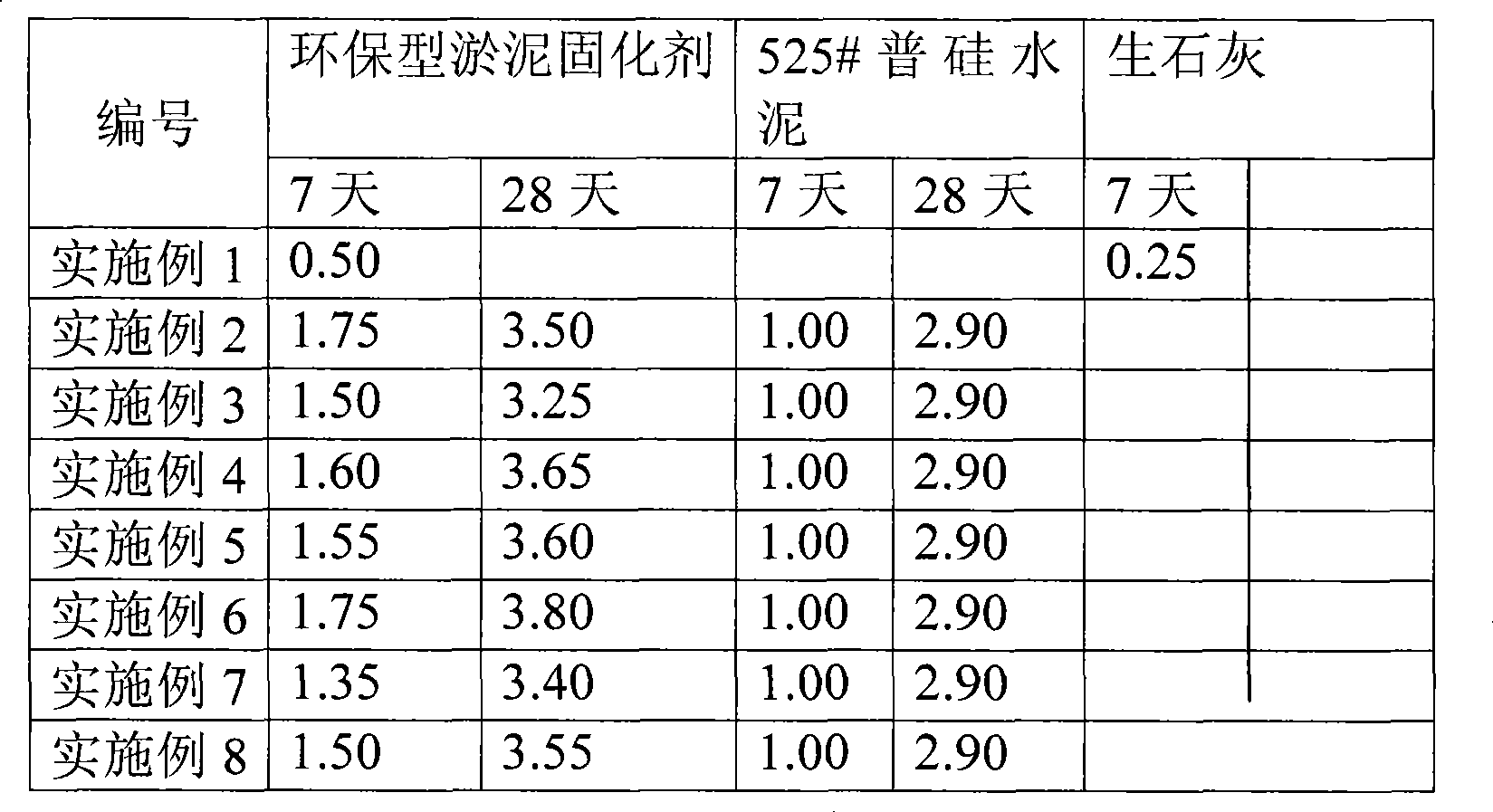

Examples

Embodiment 1

[0028] Grind calcium carbide slag, slag, fly ash, and potassium hydroxide to a Blaine specific surface area of 400m 2 / kg, in parts by weight: 20 parts of calcium carbide slag, 49 parts of slag, 30 parts of fly ash, and 1 part of potassium hydroxide are mixed to obtain the sludge solidifying agent of the present invention, which can replace lime as the sludge solidifying material. Wherein the calcium carbide slag can be replaced by quicklime or slaked lime or gypsum or any combination thereof in equal parts by weight, and the slag can be replaced by ferrochrome slag or phosphorus slag or silicon manganese slag or steel slag or any combination thereof in equal parts by weight .

Embodiment 2

[0030] Grind calcium carbide slag, slag, fluidized slag, and calcium sulfate separately until the Blaine specific surface area is 400m 2 / kg, in parts by weight: 10 parts of carbide slag, 50 parts of slag, 39 parts of boiling slag, 1 part of calcium sulfate are mixed to obtain the sludge solidifying agent of the present invention, which can replace cement as the sludge solidifying material.

Embodiment 3

[0032] The Blaine comparison area of grinding calcium carbide slag, slag and fly ash, potassium carbonate and sodium lignosulfonate separately is 400m 2 / kg, in parts by weight: 15.5 parts of calcium carbide slag, 66 parts of slag, 15 parts of fly ash, 3 parts of potassium carbonate, and 0.5 part of sodium lignosulfonate are mixed to obtain the sludge solidifying agent of the present invention, which can replace Cement is used as sludge solidification material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com