Artificial quartz in lump and fabrication technology thereof

A technology of artificial quartz stone and manufacturing process, which is applied in the field of artificial quartz stone and its manufacturing process, can solve the problems of artificial quartz stone's unsatisfactory fracture strength, compressive strength and bending strength, and achieve compressive strength and bending resistance Increased strength and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

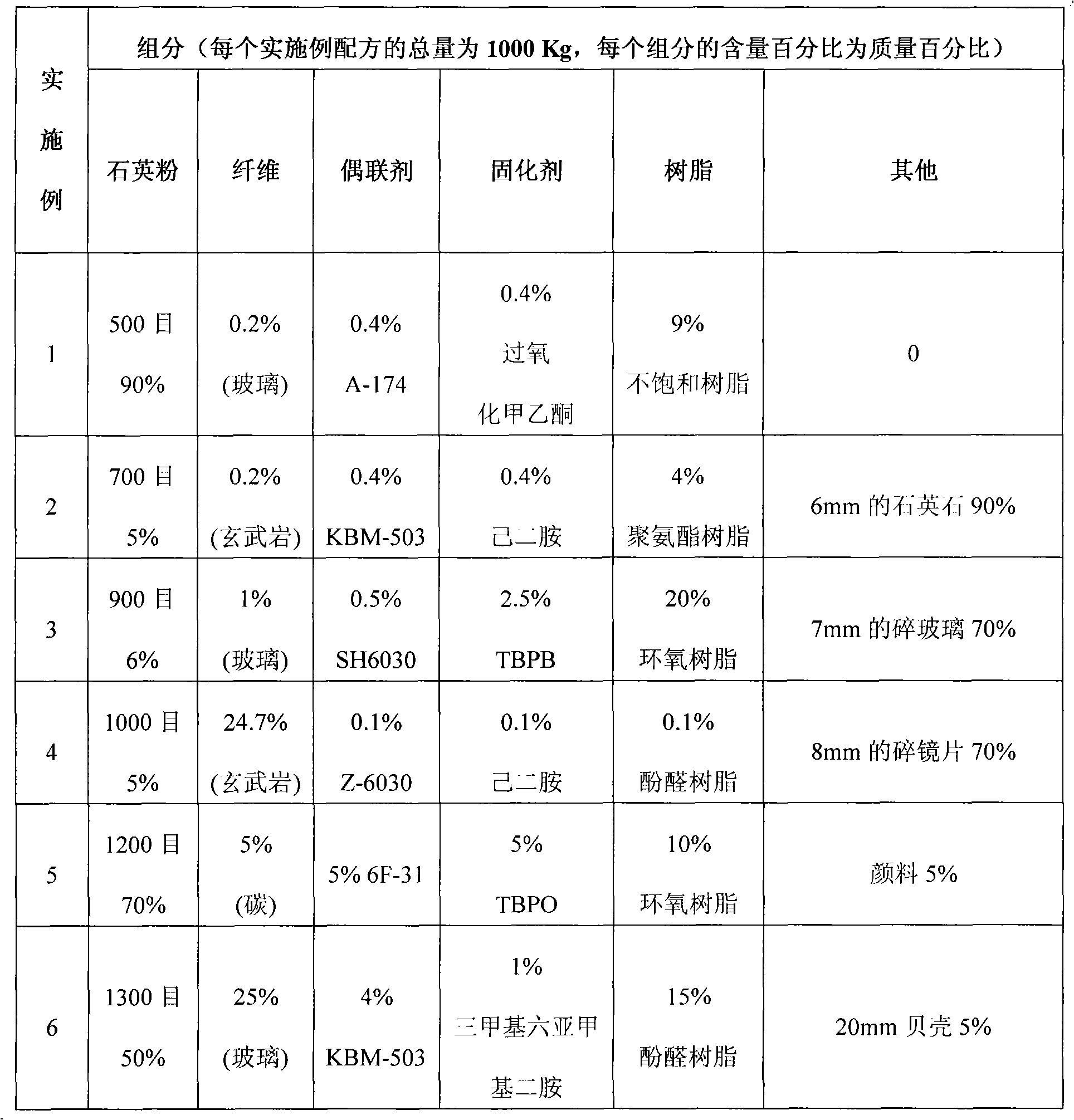

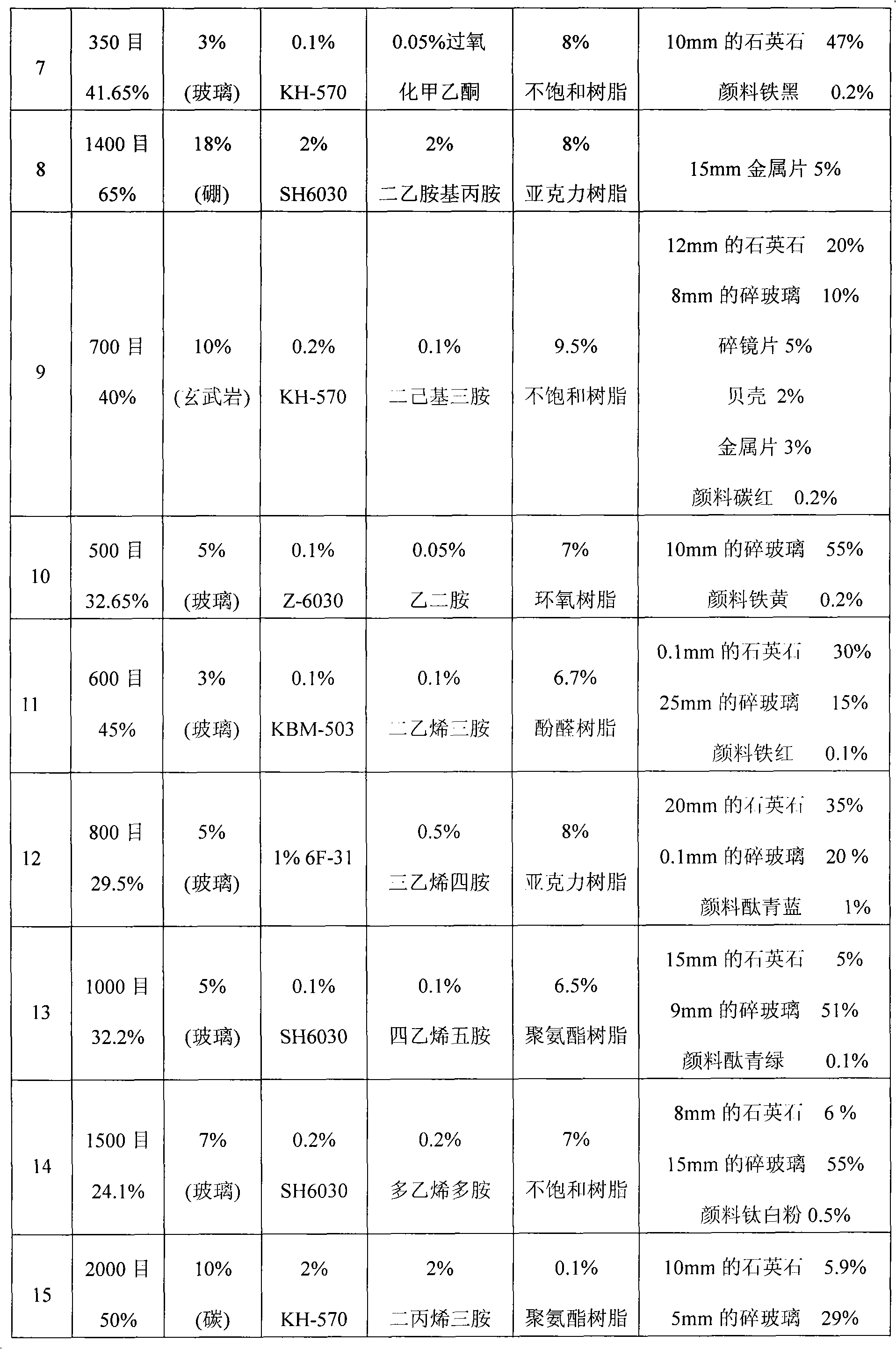

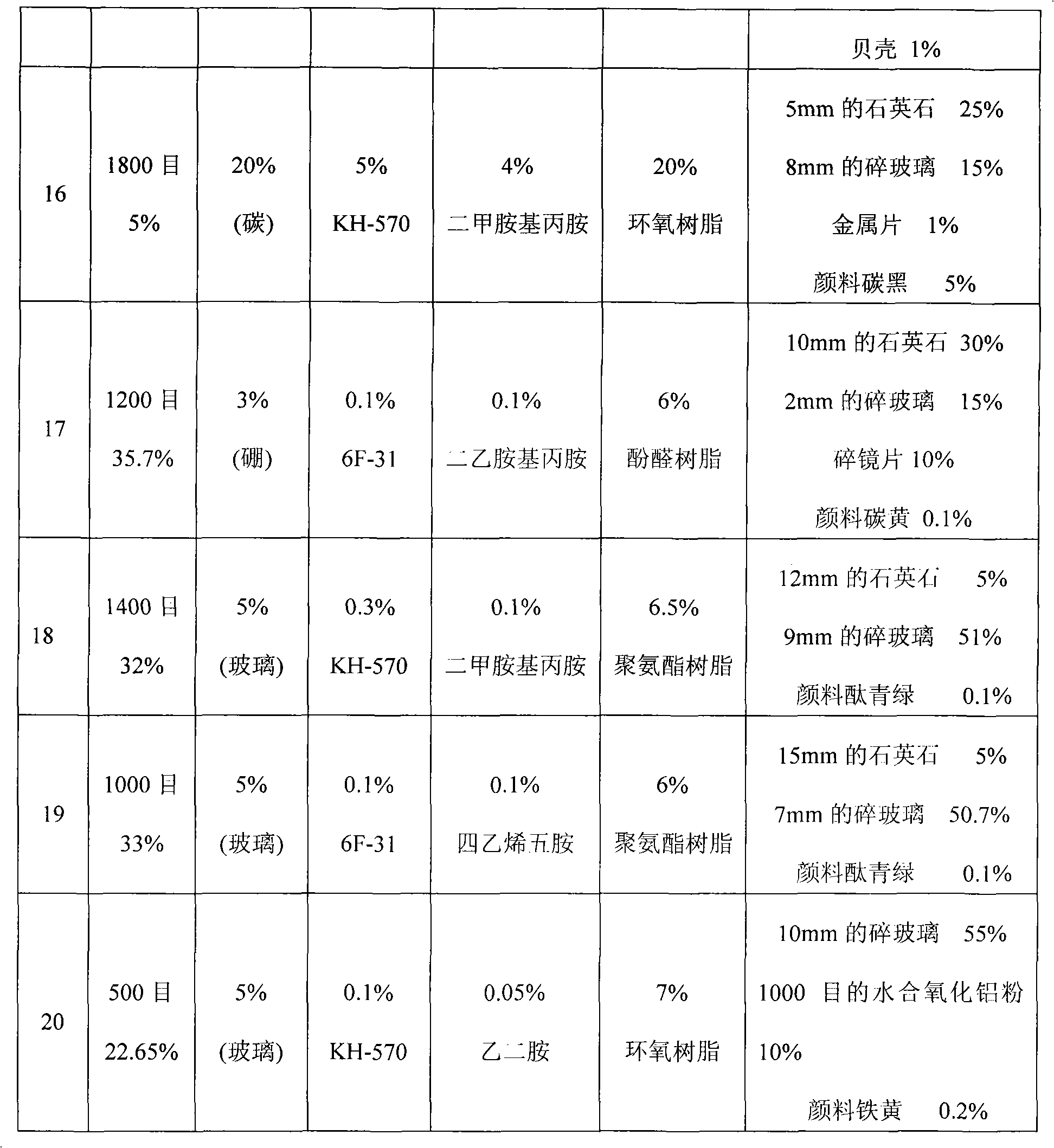

[0030] Table 1

[0031]

[0032]

[0033]

Embodiment 1

[0035] The preparation process of the artificial quartz stone plate of Example 1 is as follows: mix and stir the components in the proportion of the example to be uniform, distribute through the cloth system to a uniform thickness, and perform vacuum vibration pressing in a vacuum machine, and then at room temperature 10°C Naturally solidify to obtain a blank, which can be subjected to post-finishing, through scraping, turning, thickness setting and polishing, to obtain a finished high-density super-hard artificial quartz slab.

manufacture Embodiment 2

[0037] The preparation process of the artificial quartz stone slabs of Examples 2 to 3 is as follows: Mix and stir the components of the proportions of the examples until they are uniform, distribute them through the cloth system to a uniform thickness, and perform vacuum vibration pressing in a vacuum machine, and then at room temperature Naturally solidify at 25°C to obtain a blank, which can be subjected to post-finishing, after scraping, turning, thickness setting and polishing, to obtain a finished high-density super-hard artificial quartz slab.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com