Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1116results about "Rosin coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

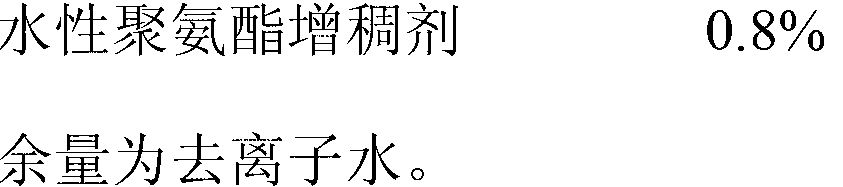

General water-based quick-drying anti-rust paint and preparation method thereof

InactiveCN102993810AAdvanced Technology FormulaAdvanced DesignRosin coatingsAnti-corrosive paintsWater basedLacquer

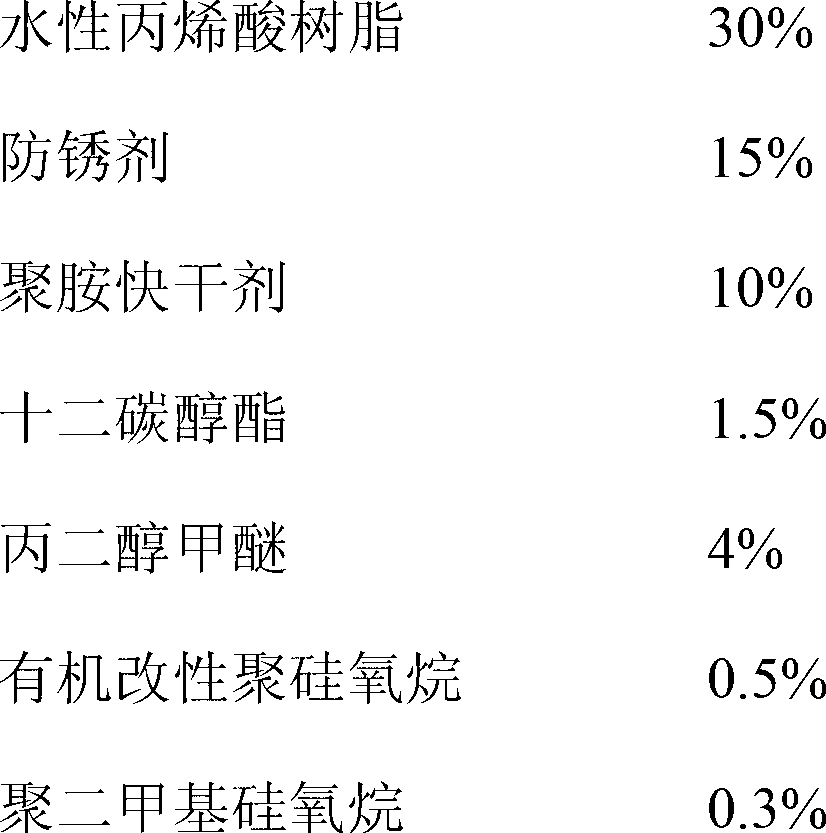

The invention relates to a general water-based quick-drying anti-rust paint and a preparation method thereof. The general water-based quick-drying anti-rust paint comprises the following components in percentage by weight: 18%-55% of film-forming substance, 6%-22% of anti-rust agent and the balance of water. The preparation method comprises the following steps of: firstly pre-dispersing the components except the anti-rust agent according to the formula ratio; then adding the anti-rust agent according to the formula ratio; and re-dispersing to obtain the general water-based quick-drying anti-rust paint. The general water-based quick-drying anti-rust paint disclosed by the invention is safe and nontoxic, contains no lead, chromium or other hazard pigments and derivatives, can not burn or explode, is suitable for safe production, has the advantages of plump paint film, excellent decoration and protection, excellent adhesive force and adjustable glossiness, and is simpler in production process compared with an oil paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

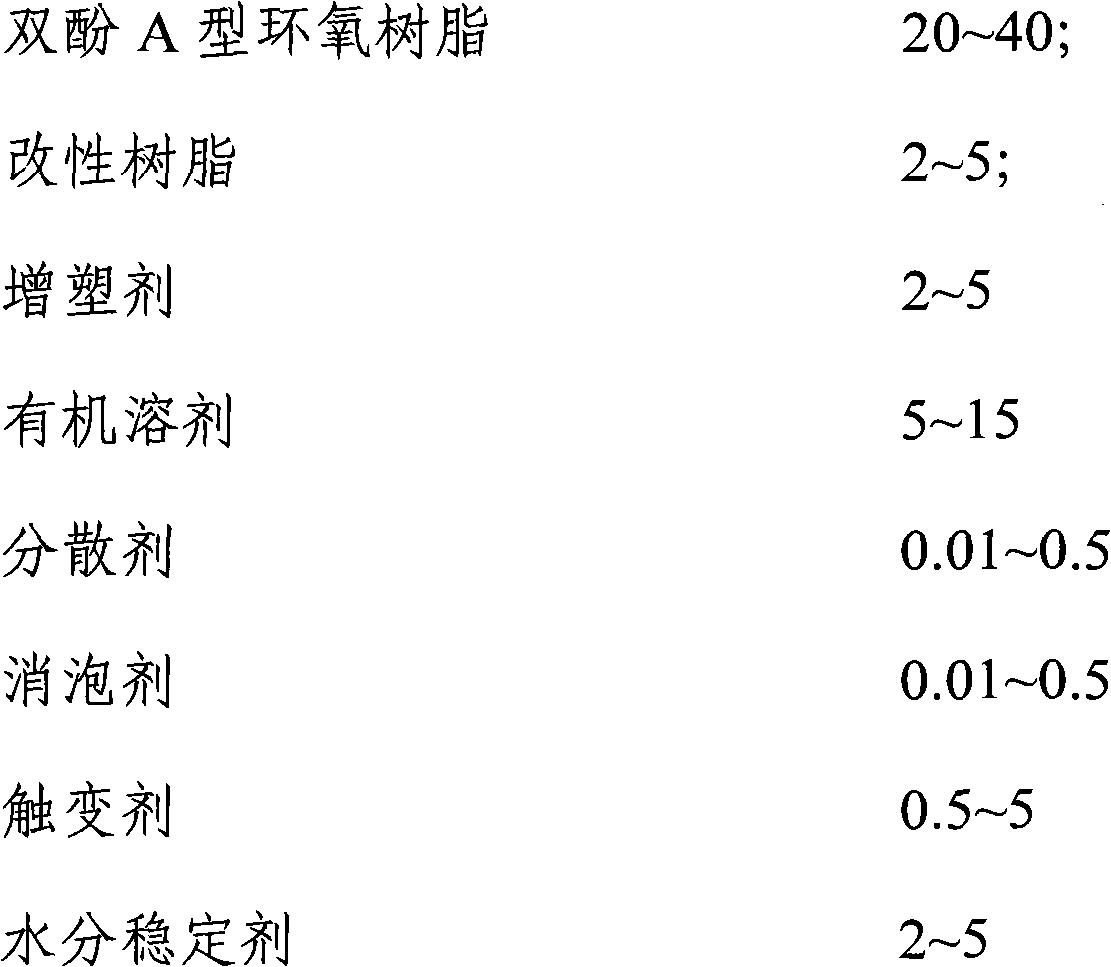

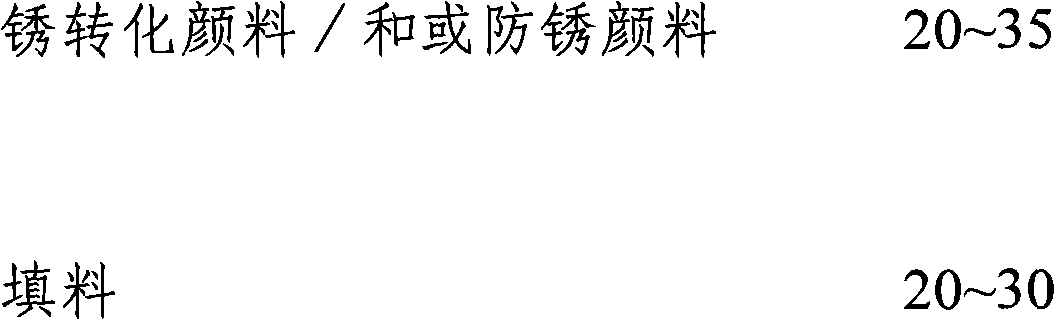

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Oxidized graphene insulating heat-radiating coating and preparation method thereof

ActiveCN105086688ABoth insulation propertiesBoth heat dissipation characteristicsRosin coatingsPolyurea/polyurethane coatingsPhosphide compoundThermal conductivity

The invention discloses an oxidized graphene insulating heat-radiating coating. The oxidized graphene insulating heat-radiating coating is characterized by being composed of, by weight, 300-30 parts of resin, 1 part of oxidized graphene and 100-10 parts of resin curing agent, and the oxidized graphene is synthesized by adopting an improved Hummers method or phosphorylated oxidized graphene modified by phosphide. The oxidized graphene insulating heat-radiating coating is prepared by mixing oxidized graphene dispersion liquid or phosphorylated oxidized graphene dispersion liquid prepared after dispersing oxidized graphene in a dispersion liquid solvent with resin and resin curing agent. By the oxidized graphene insulating heat-radiating coating, the problem that insulativity and thermal conductivity of existing materials are difficult to realize at the same time is solved.

Owner:山东利特纳米新材料有限公司

Waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement

ActiveCN103333555AImprove adhesionGood extensibilityRosin coatingsConjugated diene hydrocarbon coatingsMortise and tenonSynthetic rubber

The invention provides a waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement. The waterproof coating is characterized by comprising the following raw materials by weight: 20-50 parts of a synthetic rubber latex, 20-50 parts of emulsified asphalt, 0.5-2 parts of a functional additive and 0.5-2 parts of a dispersant, 20-40 parts of a filler and 10-25 parts of water. The principle is that through coupling effect of the functional additive, part of the molecules in the synthetic rubber and most molecules in the asphalt couple into large molecules with reaction activity; when the large molecules contact with a base plane, the non-reactive molecule segments of the rubber and asphalt and the base plane form physical adsorption, and the molecular segments with reaction activity conduct react with the base plane to form chemical bond effect, so as to generate strong adhesive force; and after bonding, the coating is hardly influenced by environmental factors. Therefore, the waterproof coating provided by the invention has excellent waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

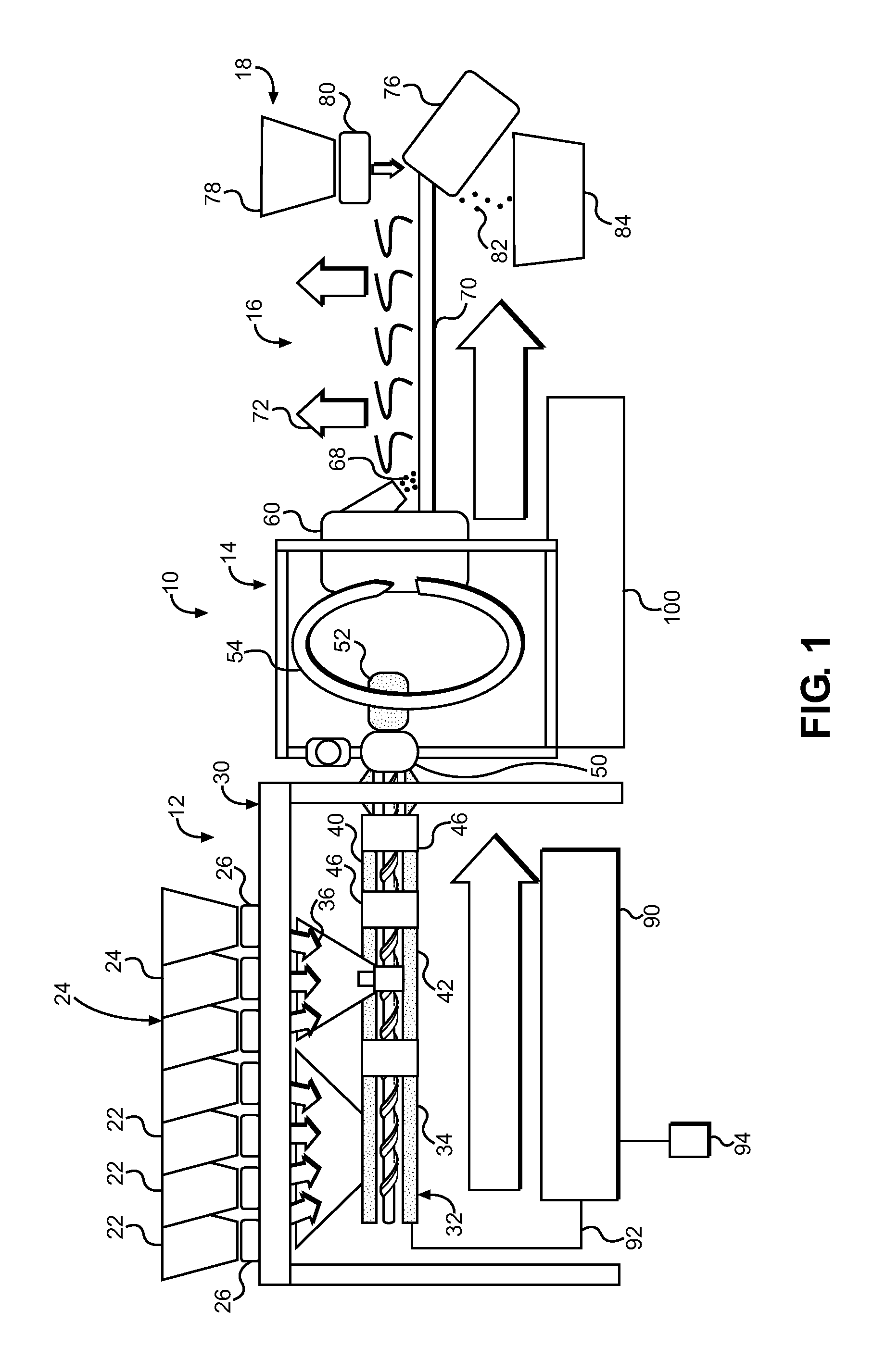

Low VOC additives for extending the wet edge and open time of aqueous coatings

ActiveUS20090326121A1Good coating effectPlastic/resin/waxes insulatorsOther chemical processesCyclohexanedimethanolWater dispersible

Disclosed is a low VOC coating additive employing a water-dispersible polymer, a water insoluble plasticizer, cyclohexanedimethanol, and optionally an amphiphilic component. The additive can be added to a coating to improve at least one performance characteristics of the coating, such as, wet-edge time, open time, scrub resistance, wet adhesion, and water resistance.

Owner:EASTMAN CHEM CO

Low-VOC additives for extending wet edge and open times of coatings

A low VOC coating additive employing a water-dispersible rosin, a high glass transition temperature water-dispersible polymer, and optionally an amphiphilic component. The additive can be added to a coating to improve the performance characteristics of the coating, such as wiped wet edge time, open time, block resistance, gloss, scrub resistance, tack-free time, dry-to-touch time, and yellowing.

Owner:EASTMAN CHEM CO

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

Nano composite hot melt type gage mark coating and preparation method thereof

InactiveCN1923929AExcellent wear resistanceImprove crack resistanceRosin coatingsTraffic signalsFiberAdjuvant

The invention discloses nanometer composite heat-fused reticle paint and preparing method, which comprises the following parts: 10-25% filming material, 3-8% dye, 40-70% filler, 0.5-4% specific reinforced material, 14-25% glass microball and 1-5% other adjuvants, wherein the specific reinforced material contains nanometer fiber, nanometer whisker, micrometer fiber, micrometer whisker. The preparing method comprises the following steps: pouring the filming material in the composite autoclave; adding adjuvant; stirring evenly; adding dye, filler, glass microball and specific reinforced material; stirring evenly; packing.

Owner:中科纳米涂料技术(苏州)有限公司

Hard wax oil and preparation method thereof

ActiveCN101974292AGood weather resistanceImprove UV absorption performanceWax coatingsRosin coatingsVegetable oilUltraviolet

The invention provides hard wax oil prepared from the following components in parts by weight: 40-80 parts of vegetable oil, 3-15 parts of biological wax, 5-15 parts of rosin glycerol resin, 0.2-1.0 part of drier, 0.1-0.5 part of anti-skinning agent, 0.1-0.3 part of mixed UV (Ultra-Violet) absorber and 0.1-0.3 part of defoaming agent. The preparation method of the hard wax oil, which is provided by the invention, comprises the steps of generating bodied oil with relatively smaller molecular weight under the action of nitrogen protection and adding an oil-based UV absorber with synergy and a hindered amine light stabilizer, and thus the UV absorption performance of the hard wax oil is improved. The prepared hard wax oil is suitable for outdoor woodenware products, has good weatherability, favorable water resistance and ideal durability effect under the condition that sunlight and UV rays exist, and the hard wax oil hardly sags and has tough firm formed in coating construction, belongs to natural coatings, accords with the environmental protection requirement and can be also used for decorating private indoor rooms.

Owner:CARPOLY CHEM GRP

Thermoplastic powder electrically-conducting paint/printing ink and manufacture method thereof

ActiveCN101245201AMeet the requirements of environmental certification standardsImprove photoelectric conversion efficiencyWax coatingsRosin coatingsChemical industryElectronic communication

The invention relates to a chemical industry electronic material, in particular to a thermoplastic powder conductive coating / ink applied in solar field and electronic communication field. The chemical industry electronic material comprises the following components according to weight percentage: (1) conductive powder: 60 to 80 percent; (2) adhesive: 5 to 30 percent; (3) film-forming strengthening agent: 0.3 to 10 percent; (4) lubricant: 0.1 to 3 percent; (5) solidification regulator: 0.1 to 3 percent; (6) adhesion promoter: 0.5 to 10 percent; (7) antioxidant: 0.1 to 3 percent; (8) doping elements:0 to 5 percent.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

Incorporation of a resin dispersion to improve the moisture resistance of gypsum products

This invention relates to a composition suitable for use in making moisture resistant gypsum products. In particular, this invention relates to resin dispersions and their use in combination with gypsum to form moisture resistant gypsum compositions which are settable by hydration. Further, the invention relates to moisture resistant products formed from such settable gypsum compositions, e.g. panels and boards, and a method for the manufacture of such moisture resistant gypsum products.

Owner:EASTMAN CHEM CO

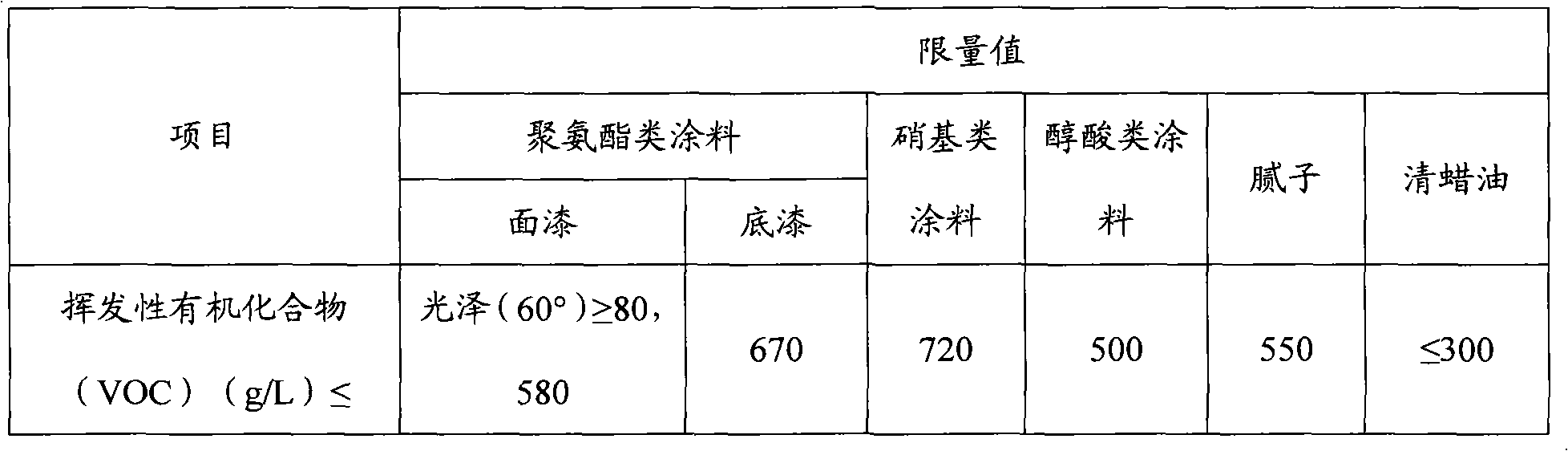

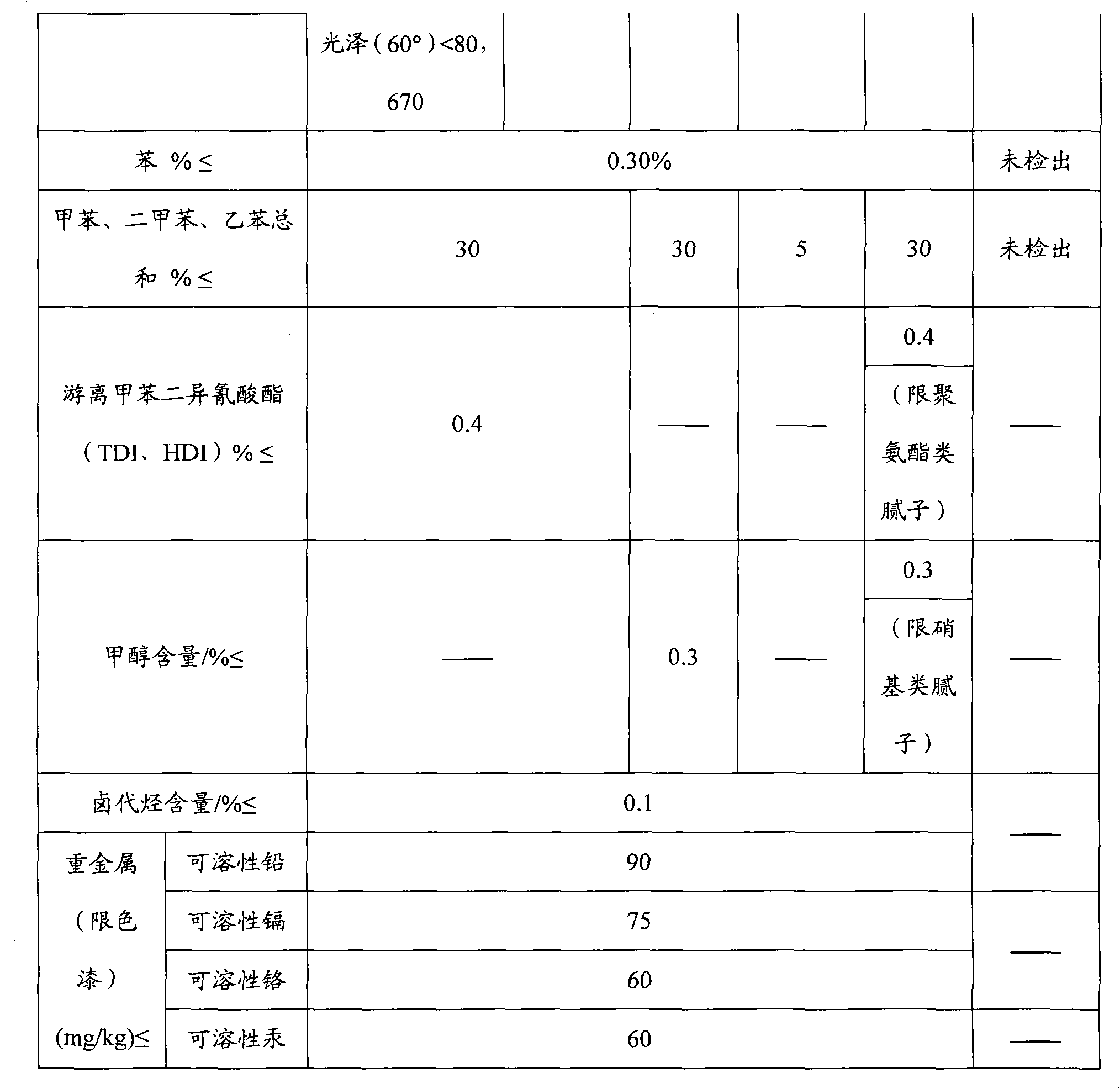

Low odor lacquer

ActiveCN101143985AConvenience guaranteedAvoid pollutionRosin coatingsPolyester coatingsAlcoholPlasticizer

The invention discloses a pyroxylin lacquer with low smell, wherein the pyroxylin lacquer has no benzene hydrocarbon, and the lacquer formula includes 10 percent-25 percent by weight of at least one resin, 25 percent-55 percent by weight of at least one of alcohol ether solvent, ester solvent or alcoholic solvent, , 20 percent-50 percent by weight of at least one curing agent, plasticizer and additive, the pyroxylin lacquer of the invention uses non-benzene solvent, and ensure the superiority of pyroxylin lacquer per se, so as to effectively avoid environmental pollution produced in production, construction and using process of the benzene hydrocarbon, and health hazard to production operator and constructer.

Owner:CHINA PAINT MFG CO SHENZHEN +1

Thermoplastic pavement marking composition and method

A composition of matter suitable for use as a road marking substance and a method thereof provides for the steps of mixing a binder mixture with a filler mixture, heating the mixed ingredients while mixing into a homogenous molten mixture and then extruding the molten mixture. The extruded material is cooled, cut into individual pellets, coated with an anti-clumping coating and packaged for use in making a road marking substance in situ. The binder can be alkyd-based or hydrocarbon based. The binder includes rosin resins, wax and a plasticizer, and a hydrocarbon resin is added for the hydrocarbon-based binder. The filler contains titanium dioxide, a pigment (if necessary) and ground calcium carbonate.

Owner:PUFFER DANIEL JOHN +1

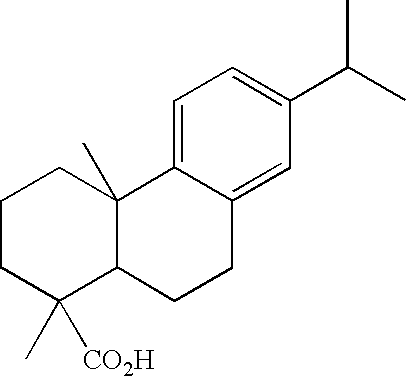

Rosin ester with low color and process for preparing same

A process for producing light color rosins ester resin, preferably based on tall rosin, is described. The process is conducted in the presence of less than 10 weight % of an acid functional organic compound and avoids the need for use of a stoichiometric excess of rosin acid, or a stoichiometric excess of polyol hydroxyl groups. The process allows for the use of lower colored or darker tall oil rosin in the production of low color rosin esters.

Owner:LAWTER

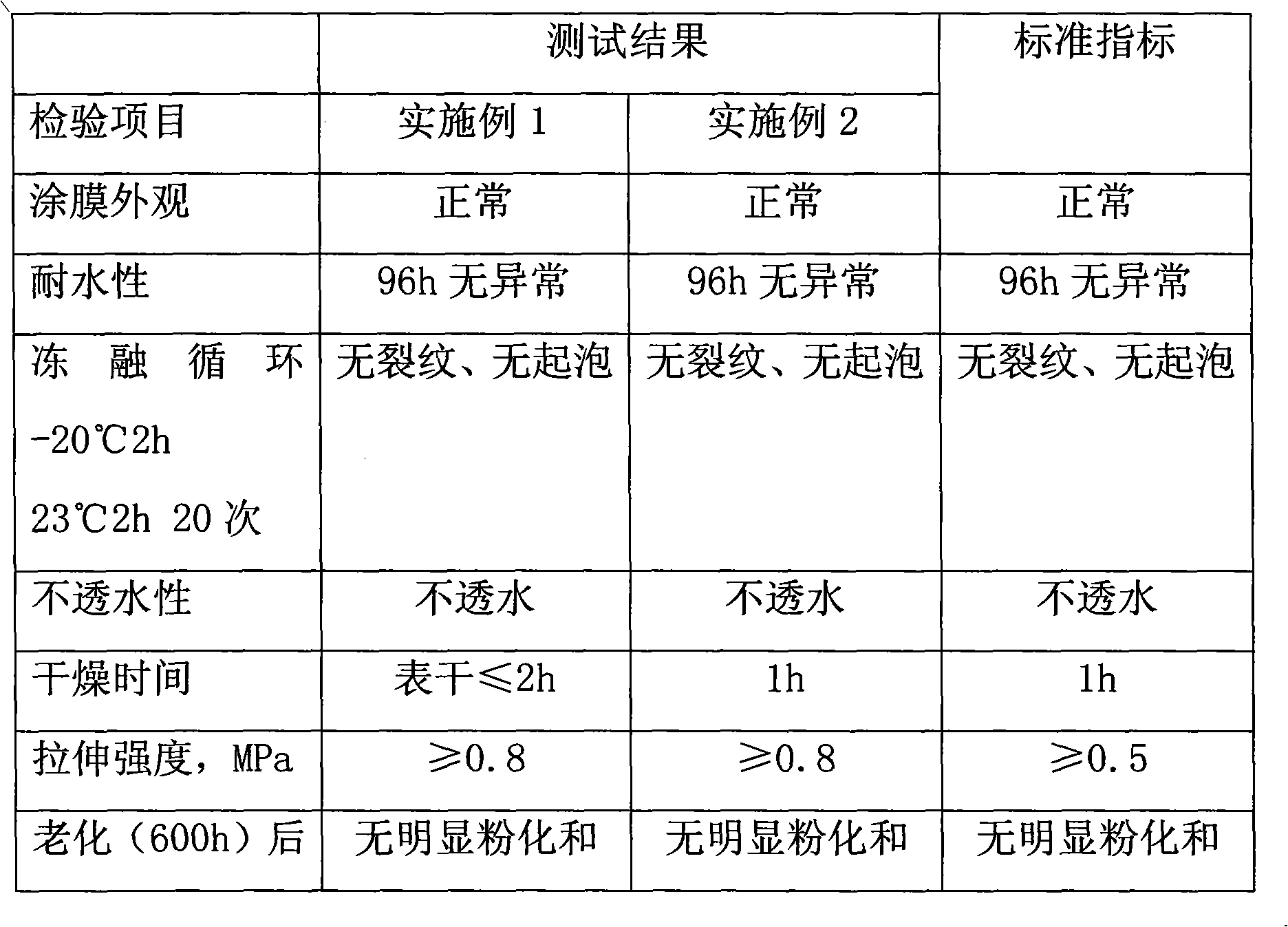

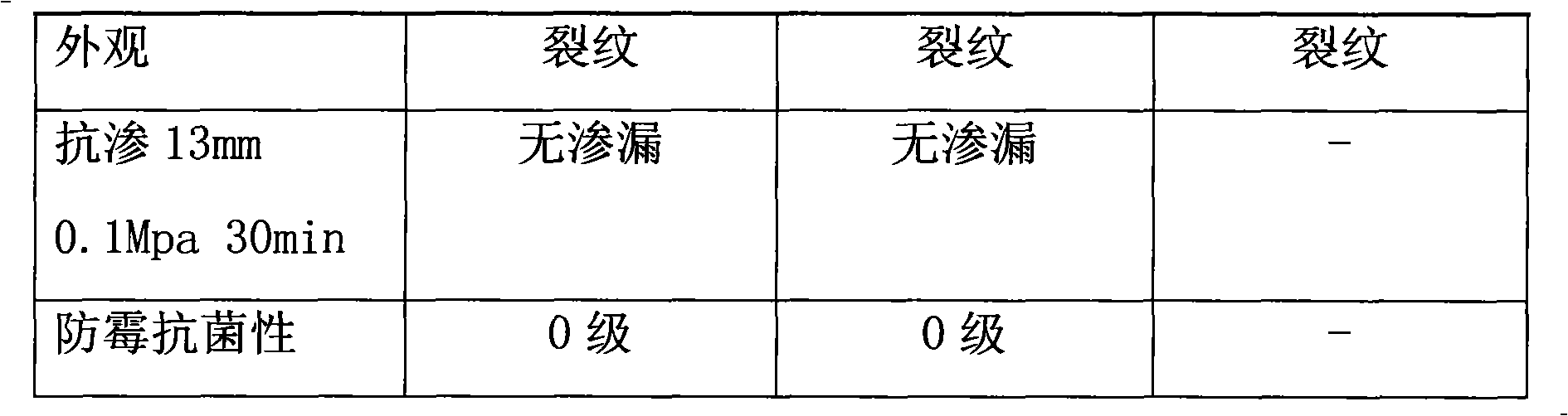

Mildewproof waterproof coating composition

ActiveCN101298533AStrong scrub resistanceHigh tensile strengthAntifouling/underwater paintsRosin coatingsPolymer scienceEmulsion

The invention relates to an anti-leakage, anti-seepage and anti-mildew acrylic ester waterproof coating compound used for buildings, which mainly consists of acrylic ester emulsion, polyamino acid emulsion, rosin resin, anti-mildew agent and filler. A coating film formed after the coating is used is characterized by high tensile strength and high elongation at break, which can make up cracks already existing and in developing on the wall and can be directly scrubbed, with strong scrubbing resistance. The coatings of the invention can be coated on moist building surfaces and can not go mouldy, thus being applicable to cement, metal, wood and paper surfaces and playing the role of waterproof, anti-seepage and anti-mildew.

Owner:NANJING CONSTR ENG GRP

Transfer print type decorative film suitable for cold wave technology

ActiveCN102658742AImprove peel forceGuaranteed cleanlinessRosin coatingsThermographyGraphicsPlastic packaging

The invention discloses a transfer print type decorative film suitable for a cold wave technology. The transfer print type decorative film comprises a base material, a release layer, a metal layer and a bonding layer, wherein the release layer comprises the following components in part by weight: 600 to 2,000 parts of acrylic resin, 100 to 400 parts of rosin resin, 30 to 120 parts of amino resin, 3 to 50 parts of aid and 2,000 to 3,000 parts of solvent. According to the decorative film, stripping force between the release layer and the base material can reach more than 100 grams, powder cannot fall in the cold wave process, and graphics and words are high in definition; and the decorative film can be widely applied to decorative processing of surfaces of plastic films, plastic packaging products and the like in a package printing industry.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

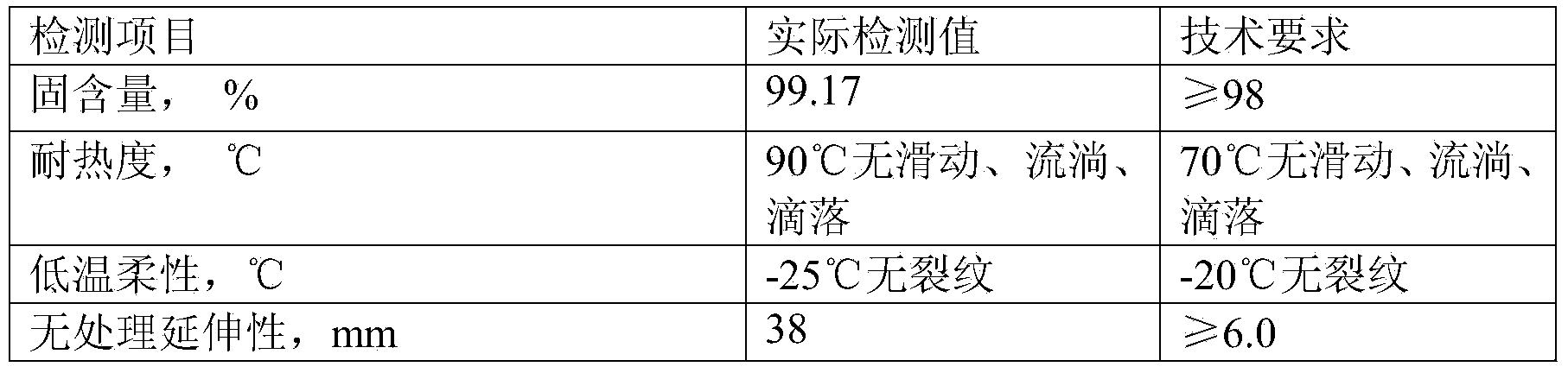

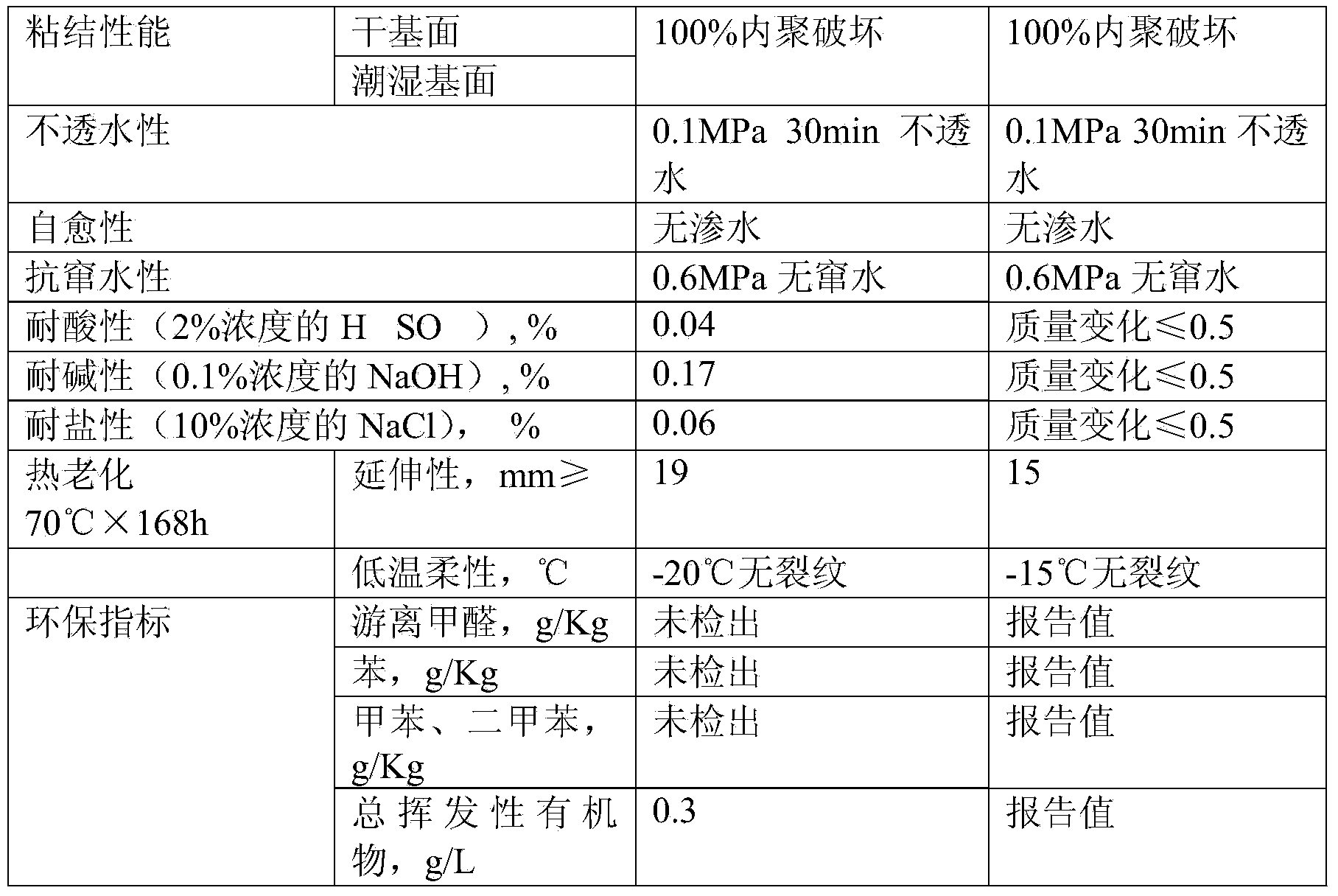

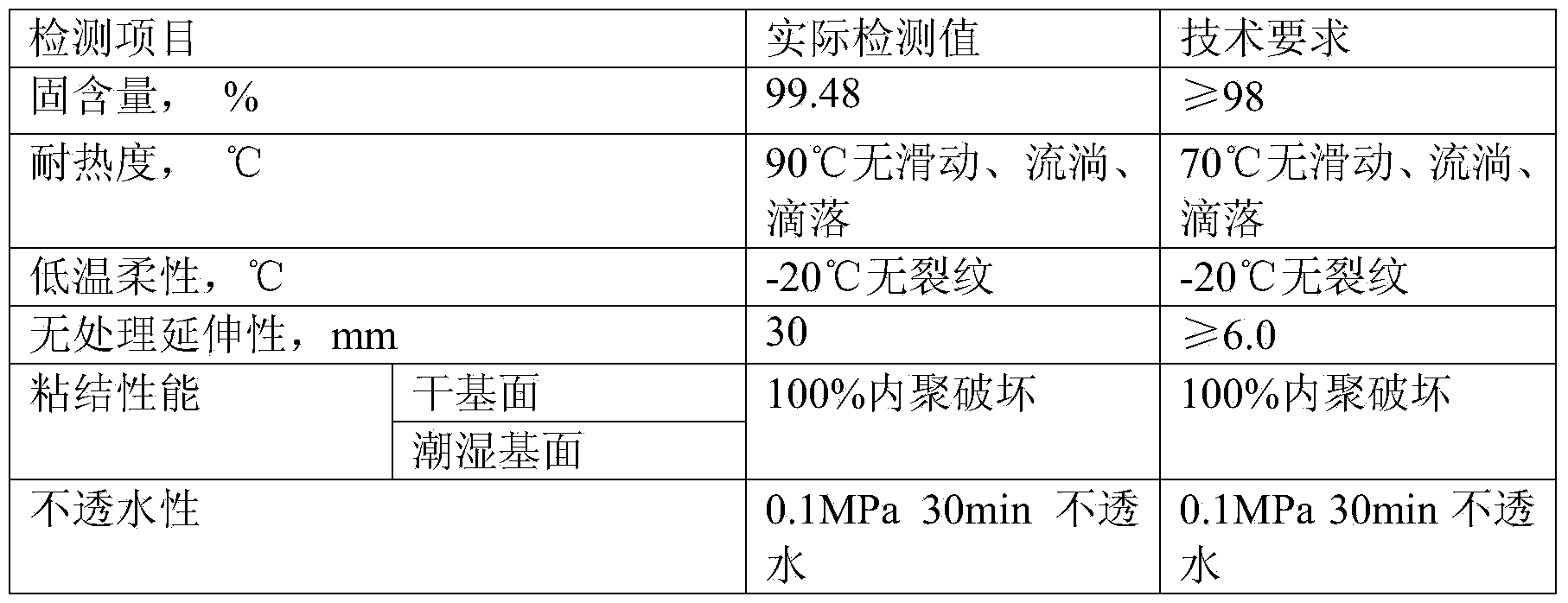

High-heat-resistance non-cured asphalt waterproof coating and preparation method thereof

InactiveCN104277715AStay flexible and colloidalImprove waterproof performanceRosin coatingsBituminous coatingsBituminous waterproofingPlasticizer

The invention relates to a high-heat-resistance non-cured asphalt waterproof coating and a preparation method thereof and belongs to the technical field of waterproof coating. The high-heat-resistance non-cured asphalt waterproof coating mainly comprises: 150-220 parts of asphalt, 30-55 parts of softening oil, 0-20 parts of rubber, 0-12 parts of rosin resin, 0-15 parts of rubber powder, 0-14 parts of a plasticizer, 2-10 parts of oxidized polyethylene wax, 60-150 parts of a filler and 0-10 parts of a defoaming agent. The non-cured asphalt waterproof coating has the advantages that the heat-resistant temperature can reach 90 DEG C, the adhesive performance is good, the waterproof performance is excellent, the construction temperature range is wide, and cracks in the waterproof base can be automatically repaired. The coating can be used alone and can be also used in combination with asphalt rolled waterproof materials.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

Insulation shielding method in grinding head plating process and coating

ActiveCN102797022AEasy to operateRealize automated productionWax coatingsRosin coatingsInsulation layerLiquid state

The invention discloses an insulation shielding method in a grinding head plating process, comprising the following steps: S1, pre-treatment: cleaning up and drying a grinding head base for standby; S2, liquefying an insulation coating: heating the organic insulation coating to be kept at liquid state for standby; S3, coating an insulation layer: immersing a part of the grinding head base to be shielded, into the liquid in the step of S2 for 1-2 seconds, and taking out and cooling the immersed part for 3-5 seconds to be solidified; S4, diamond grinding head plating: plating the insulated shield grinding head base. The invention also discloses a coating for the method and a coating processing method. The coating comprises the following components, in part by weight: 13-17 parts of paraffin, 18-22 parts of beeswax, 55-65 parts of stearic acid, and 5-7 parts of rosin. The invention has advantages of simple operation process, less artificial cost, and improved production efficiency.

Owner:SHENZHEN CHANGXING TECH

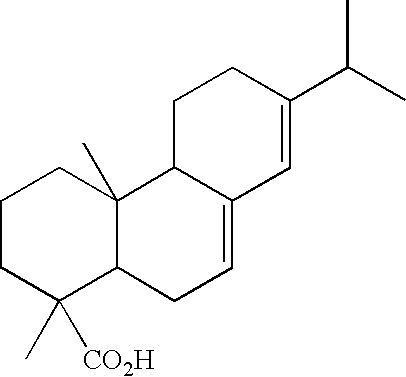

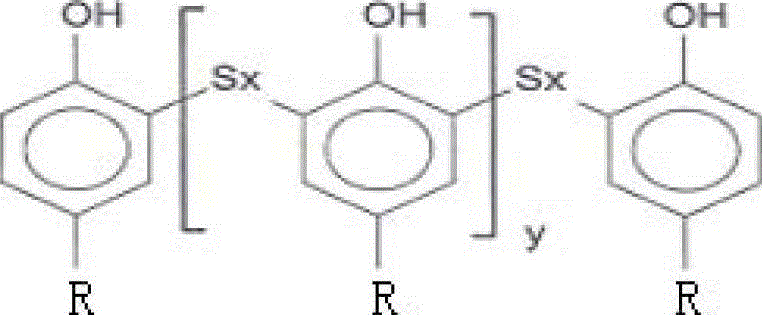

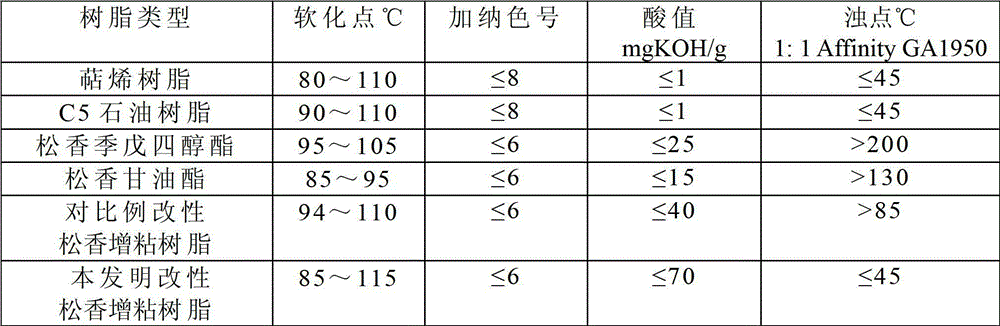

Modified rosin tackifying resin as well as preparation method and application thereof

The invention relates to modified rosin resin and discloses modified rosin tackifying resin as well as a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing rosin or rosin derivatives, monoterpene compounds, dicyclopentadiene fractions and catalysts in an autoclave; replacing air in the autoclave by use of nitrogen or carbon dioxide; reacting the mixture at a pressure of 0.2-0.6 Mpa and at 170-290 DEG C for 1 hour to 30 hours; and decompressing after the reaction, and removing low-boiling-point substances, thus obtaining the modified rosin tackifying resin, or adding an antioxidant stabilizer into the mixture at 200-230 DEG C, thus obtaining the modified rosin tackifying resin with higher quality. The softening point of the modified rosin tackifying resin ranges from 80 DEG C to 110 DEG C, the acid value of the tackifying resin is 15-70mg KOH per gram, and the color of the tackifying resin is less than No.6 Ghana color. The modified rosin tackifying resin can be widely applied to the field of tackifiers, coating paint, printing ink and the like, and especially can be applied to the field of metallocene catalysis polyolefin tackifiers.

Owner:广东科茂林产化工股份有限公司

Environment-friendly marine antifouling coating for finishing boat

ActiveCN101550304AEffective antifouling effectAntifouling/underwater paintsRosin coatingsAcrylic resinFishing

The invention discloses environment-friendly marine antifouling coating for a fishing boat, and relates to boat bottom antifouling coating used in a fishing boat, in particular to marine antifouling coating containing an antifouling agent system without cuprous oxide and other internationally non-permissible toxins, reaching the national environment-friendly requirements and having about one-year antifouling validity. The marine antifouling coating is characterized by comprising acrylic resin, composite antifouling agents, pigments, fillers, anti-sedimentation agents, solvents, and the like. The coating is suitable to be used at the boat bottom of a steel fishing boat or a wood fishing boat as the antifouling coating, can effectively prevent the boat bottom from fouling by marine organisms within one year, has low price, and is environment-friendly and constructed conveniently.

Owner:海悦涂料(昆山)有限公司 +1

Energy-saving and environment-friendly powder coating and preparation method thereof

ActiveCN103045044AStrong surface levelingHigh gloss retentionRosin coatingsPolyether coatingsEpoxyFatty amine

The invention discloses an energy-saving and an environment-friendly powder coating and a preparation method thereof. The energy-saving and an environment-friendly powder coating comprises the following composition raw materials: modified epoxy resin, high-density polyethylene resin, an organosilicone levelling agent, film-forming resin, polydimethylsiloxane, fatty amine, zinc powder, methacrylic resin, nanoscale titanium dioxide, 4,4'-diamido-diphenyl sulphone, resorcinol, bis-tetradecyl alcohol ester and chlorcosane. The powder coating disclosed by the invention is a green and environment-friendly coating which is non-toxic, is high-temperature-resistant, does not contain a solvent and is free from VOC (volatile organic compounds) discharge, and the powder coating disclosed by the invention is strong in surface levelling property and high in gloss retention, thus decoration property is improved; and the prepared finished product is high in pass percent, and capable of realizing industrialized mass production.

Owner:CHUZHOU HONGYUAN SPRAYING

Antifouling paint containing nano oxides

The invention provides an antifouling paint containing nano oxides. The antifouling paint is prepared from the following raw materials based on a weight ratio: 5-20% of nano oxide, 10-30% of cuprous oxide, 20-30% of chlorine-containing polymer, 3-5% of rosin, 1-7% of polymer dispersant, 3-6% of plasticizer, 2-5% of anti-settling agent and 20-40% of solvent. The preparation method comprises the following steps: proportionally adding chlorine-containing polymer powder to the solvent with equivalent mass, and shearing and stirring at a high speed to obtain a transparent chlorine-containing polymer solution; proportionally adding the polymer dispersant to a certain amount of the solvent, and then adding the nano oxides for high-speed dispersion to obtain nano-oxide slurry; proportionally adding the prepared nano-oxide slurry as well as the cuprous oxide, the rosin, the plasticizer, the anti-settling agent and the like to the chlorine-containing polymer solution under the condition of high-speed stirring or grinding and dispersion; and finally filtering the obtained mixed solution with a sieve mesh or silk cloth to obtain the nano-antifouling paint, sampling, weighing and packaging to obtain the finished product after the sample passes a test.

Owner:ZHEJIANG OCEAN UNIV

Patterned transparent back plate material

ActiveCN107759983ACoating and curing process is simple and easy to implementImprove reflectivityNon-macromolecular adhesive additivesRosin coatingsEffective powerWeather resistance

The invention relates to a patterned transparent back plate material which consists of a pattern layer, an adhesive layer, a substrate layer and a weather resistant layer in sequence, wherein the pattern layer has good reflection properties in visible light-near infrared areas of 400-1200nm and faces to the side of a battery piece when being used. Due to integration of good light permeability andgood reflection, a transparent back plate made of the patterned transparent back plate material is excellent in comprehensive property such as long-term weather resistance, adhesiveness and insulation. The patterned transparent back plate material is novel in design, simple in preparation process, easy to operate and excellent in product performance, an effective power gain effect is provided fordouble-side power generation crystalline silicon photovoltaic modules, a base is made for cost optimization of a crystalline silicon photovoltaic back plate material, and meanwhile long-term outdoor use reliability of the photovoltaic modules is powerfully ensured.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

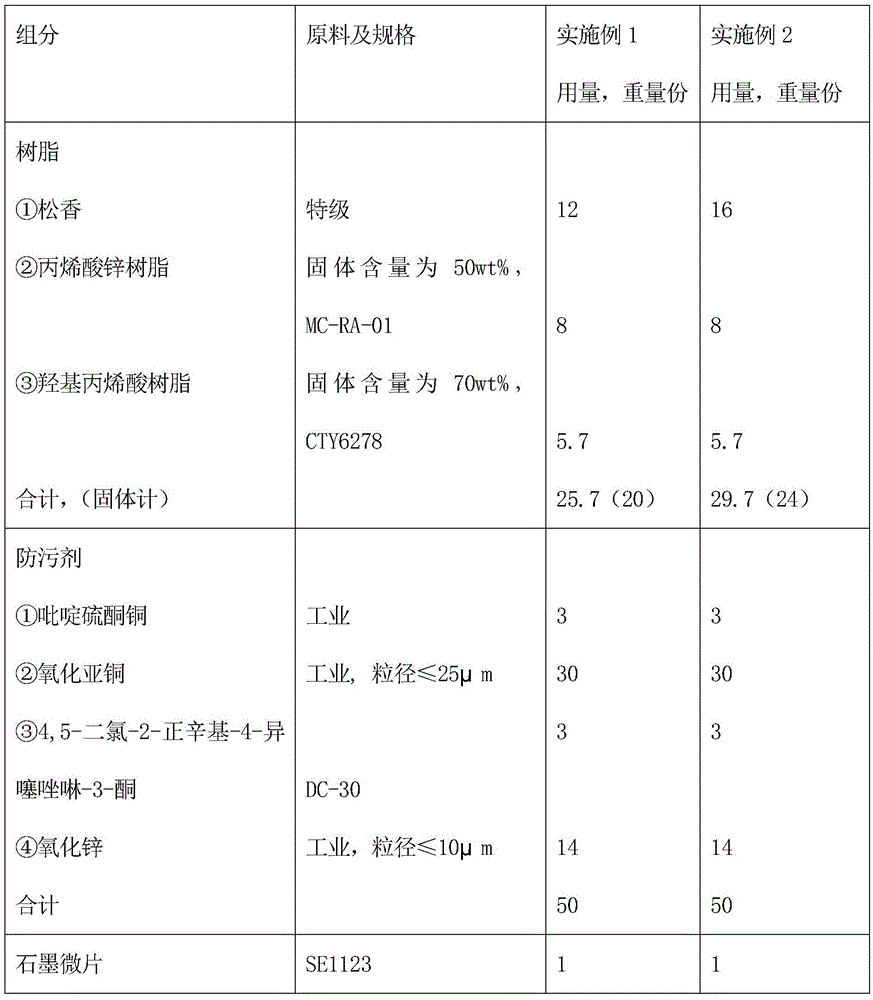

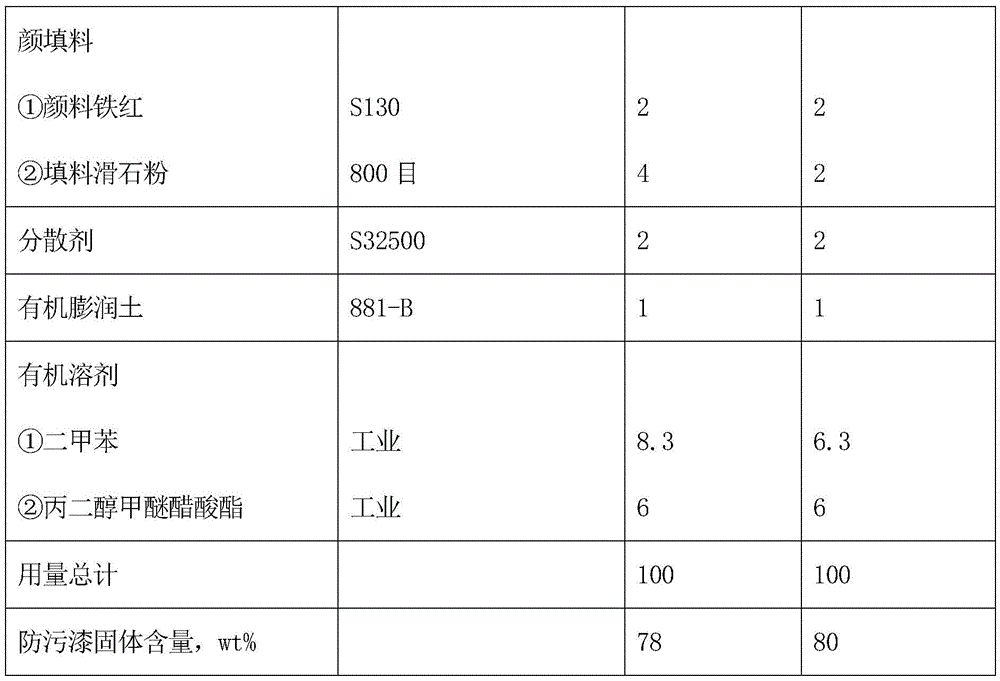

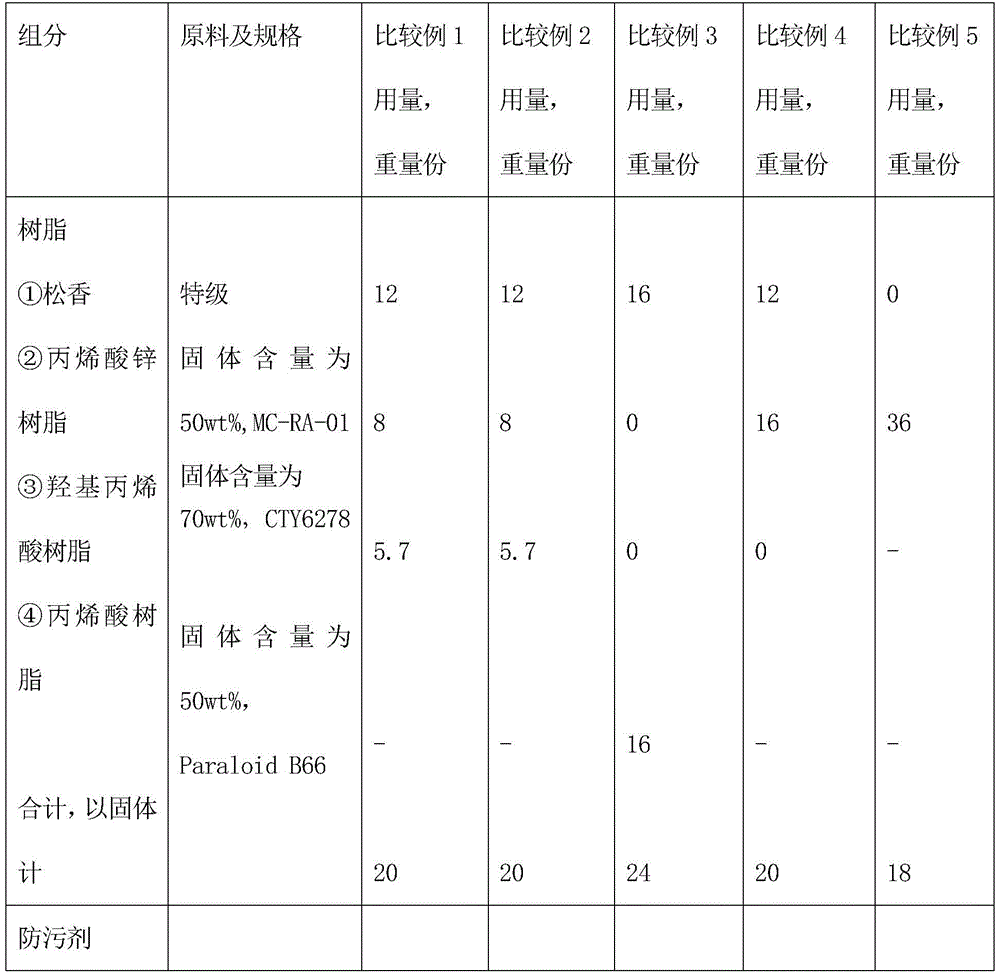

Self-polishing antifouling paint and preparation method thereof

ActiveCN105482702AHigh strengthImprove hydrophobicityAntifouling/underwater paintsRosin coatingsSodium PyrithioneCrack resistance

The invention relates to a self-polishing antifouling paint and a preparation method thereof. Every 100 parts by mass of the antifouling paint is composed of 18-24 parts of solid-based resin, 50-55 parts of antifouling compound, 0.5-1.5 parts of graphene microchip, 3-6 parts of pigment and filler, 1-2 parts of dispersing agent, 1-2 parts of organobentonite and the balance of organic solvent. The resin is composed of a hydroxy acrylic resin, a zinc acrylate resin and rosin. The antifouling compound is composed of zinc pyrithione, 4,5-dichloro-2-n-octyl-4-isothiazolinyl-3-one, cuprous oxide and zinc oxide. The preparation method comprises the following steps: respectively preparing the graphene microchip-zinc oxide-hydroxy acrylic resin slurry and cuprous oxide-rosin-zinc acrylate slurry, and mixing to obtain the self-polishing antifouling paint. The obtained self-polishing antifouling paint product has the advantages of stable quality, long antifouling period, favorable polishing effect, high strength, cracking resistance and low VOC (volatile organic compound).

Owner:CHINA NAT OFFSHORE OIL CORP +3

Coating composition and steel composite material

InactiveCN101892012AImprove appearance qualityExtended service lifeRosin coatingsAnti-corrosive paintsPolybrominated BiphenylsWater soluble

The invention provides a coating composition, which comprises maleic anhydride modified abietic resin, a water-soluble alkaline substance, a film-forming substance and a solvent. The solid content of the composition is 30 to 45 weight percent, and the pH value is 7 to 11. The invention also provides a steel composite material, which comprises a base material and an anticorrosive coating which is attached to the surface of the base material. The anticorrosive coating is a product which is cured by the provided coating composition. The coating composition can provide short-term anticorrosion for steel, in particular steel rails. Therefore, the coating composition can improve the appearance quality and service life of the steel. The coating composition does not contain Pb, Cd, Hg, Cr6+, polybrominated diphenyl ethers (PBDE) and polybrominated biphenyls (PBB) regulated in a RoHS instruction, and is environment-friendly.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

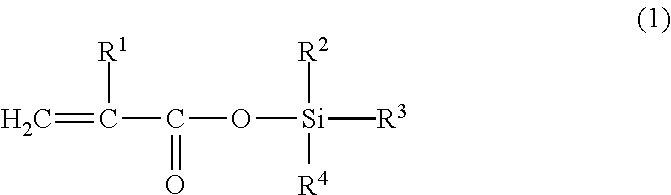

Antifouling coating composition, antifouling coating film formed using the composition, coated article having the coating film on the surface, and antifouling treatment method to form the coating film

ActiveUS20110172325A1Prevents and inhibits attachmentImprove waterproof performanceFireproof paintsAntifouling/underwater paintsMethacrylateMeth-

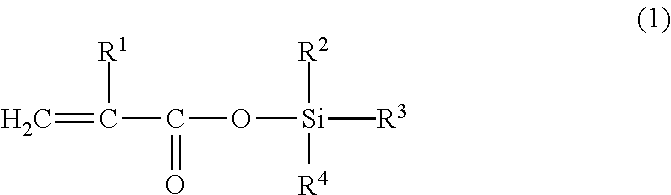

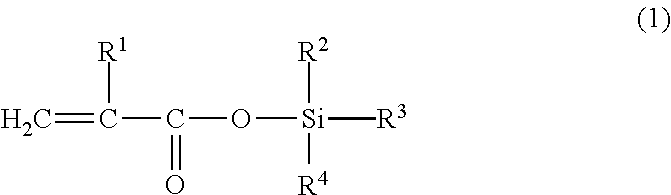

An object of the present invention is to provide a composition for forming an environment friendly antifouling coating film that is unlikely to cause a hairline crack and like coating film defects even when immersed in seawater for a long time, and that prevents or inhibits attachment of slime. An antifouling coating composition of the invention comprises: (A) a triorganosilyl ester-containing copolymer obtained by a mixture of (a) a triorganosilyl (meth)acrylate monomer represented by a general formula (1): R1 is a hydrogen atom or a methyl, and R2, R3, and R4 are equal or different each other, and each represent an alkyl group having 3 to 6 carbons and branched on α-position or a phenyl group, and (b) an ethylenically unsaturated monomer copolymerizable with the triorganosilyl (meth)acrylate monomer, (B) a modified rosin salt which is a salt of a modified rosin and zinc and / or copper, the modified rosin containing, in an amount of 80 weight % or more, two or more members selected from the group consisting of dihydroabietic acid, tetrahydroabietic acid, dehydroabietic acid, pimaric acid, isopimaric acid, and dihydropimaric acid.

Owner:NITTO KASEI CO LTD

Waterborne peelable protective paint

InactiveCN102850923ALow priceEasy to peel offRosin coatingsPolyurea/polyurethane coatingsCellulosePolymer science

The invention discloses a waterborne peelable protective paint which is composed of the components of, by weight: 60-100 parts of polyurethane emulsion, 30-40 parts of organosiloxane, 15-30 parts of modified polyacrylate, 10-20 parts of silicone, 20-40 parts of hydroxyethyl cellulose, 10-15 parts of rosin, 2-8 parts of a peeling accelerant, and balance of a water solvent. The waterborne peelable protective paint provided by the invention is green, environment-friendly, and low in cost. When a film is formed by using the paint, the film is aging-resisting, and is easy to peel. The film has good weatherability.

Owner:南通博宇机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com