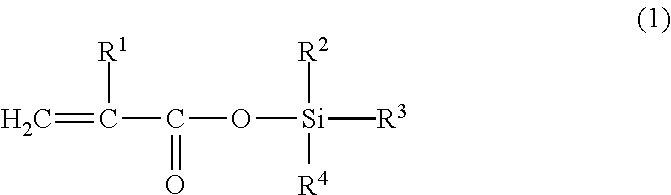

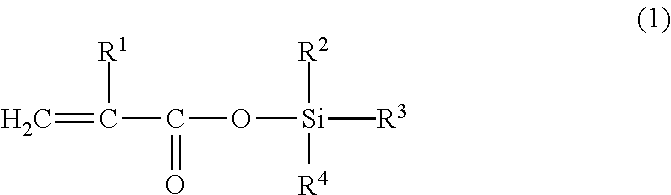

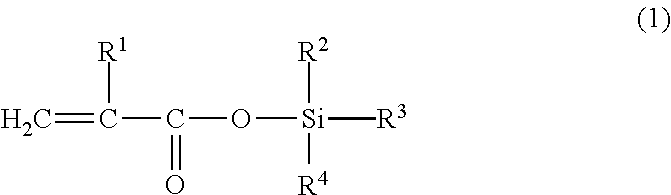

Antifouling coating composition, antifouling coating film formed using the composition, coated article having the coating film on the surface, and antifouling treatment method to form the coating film

a technology of antifouling coating and composition, which is applied in the direction of antimony organic compounds, natural mineral layered products, and paints with biocides, etc. it can solve the problems of hairline cracks, antifouling effect deterioration, and insufficient prevention of slime attachment, so as to prevent or inhibit slime attachment, suitable solubility, and prevent the adhesion of aquatic fouling organisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

Production of Copolymer Solution A-1

[0143]230 g of xylene was charged to a 1,000 ml flask equipped with a thermometer, a reflux condenser, a stirrer, and a dropping funnel, after which a mixture of 270 g of triisopropylsilyl methacrylate, 50 g of methyl methacrylate, 130 g of 2-methoxyethyl methacrylate, 30 g of 2-methoxyethyl acrylate, 20 g of ethyl acrylate, and 4 g of t-butyl peroxy-2-ethyl hexanoate (initially added) was added dropwise into the flask over a period of 1 hour, while stirring at 100±2 deg. C. in a nitrogen atmosphere. After the dropwise addition, the polymerization reaction was performed for 2 hours at 100±2 deg. C. Then, while stirring the resulting reaction solution at 100±2 deg. C., 1 g of t-butyl peroxy-2-ethyl hexanoate (subsequently added) was added three times with 2-hour intervals to perform the polymerization reaction. After that, 270 g of xylene (additional solvent) was added and dissolved, thus producing the triorganosilyl ester-containing copolymer solu...

production examples 2 to 6

Production of Copolymer Solutions A2 to A6

[0144]Polymerization reactions were performed according to the same procedure as Production Example 1, using the organic solvent, monomers, and polymerization initiator shown in Table 1, thus producing the triorganosilyl ester-containing copolymer solutions A-2 to A6. Table 1 shows the viscosity, non-volatile content, Mw, and Tg of each copolymer solution obtained.

TABLE 1Production ExampleIngredient ClassIngredient Name123456Solvent In Initial ContainerXylene230230230230230230Triorganosilyl Group-ContainingTriisopropylsilyl Methacrylate270300250Monomer (a)Triisopropylsilyl Acrylate270300T-Butyldiphenylsilyl Acrylate270Ethylenically UnsaturatedMethyl Methacrylate5050130130130150Monomer(b)N-Butyl Methacrylate202-Methoxyethyl Methacrylate130100505050Ethyl Acrylate20N-Butyl Acrylate20202020502-Methoxyethyl Acrylate3030303030PolymerizationInitially AddedT-Butyl Peroxy 2-Ethyl Hexanoate444444InitiatorSubsequentlyT-Butyl Peroxy 2-Ethyl Hexanoate1 ×...

production examples 7

Production of Xylene Solution B-1 of Modified Rosin Copper Salt

[0145]500 g of Chinese gum rosin (WW) was added to a 1,000 ml flask equipped with a thermometer and a stirrer, and the temperature was increased to 180 deg. C. under a nitrogen gas flow. After that, 0.5 g of 5% palladium carbon wad added thereto, and while stirring the mixture, the mixture was reacted for 4 hours at 270±5 deg. C. After the reaction, the mixture was cooled to 200 deg. C., and the palladium carbon was removed by a pressure filtration, and the filtrate was moved to a flask, and was concentrated under reduced pressure at 200 deg. C. to produce 475 g of a modified rosin (acid number 162 mgKOH / g). A part of the modified rosin was methylated by diazomethane, the componential analysis was conducted by gas chromatography (Column: diethylene glycol succinate (GEGS), 0.24 mmφ×25 m, Column temperature: 200 deg. C., Carrier gas: nitrogen, Detector: Flame Ionization Detector (FID)). The amount of the unconjugated dien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com