Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4259 results about "Moisture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent conductive film and method for manufacturing the same

ActiveUS20080050595A1Improve economyConductive layers on insulating-supportsSynthetic resin layered productsRocking curveFull width at half maximum

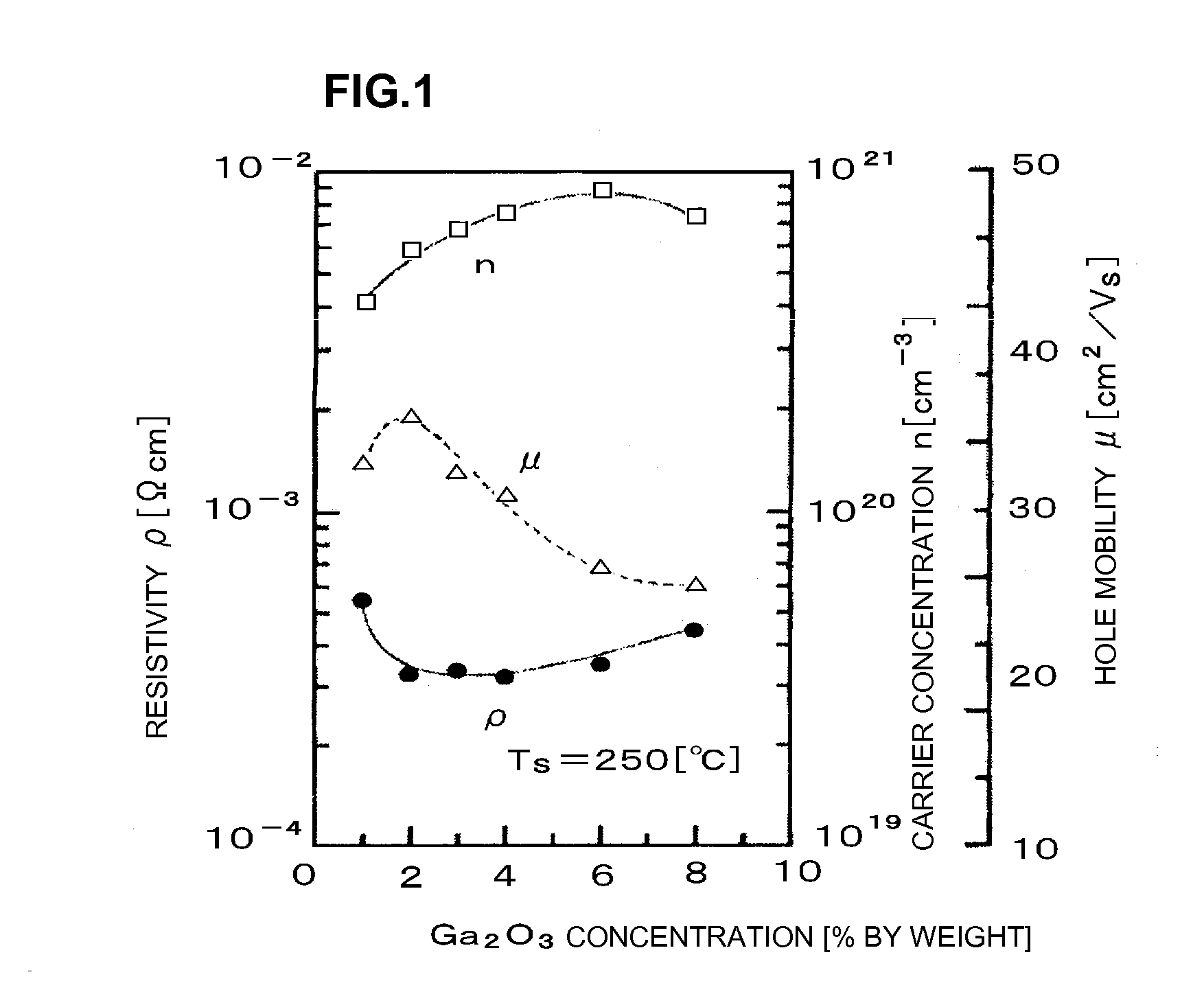

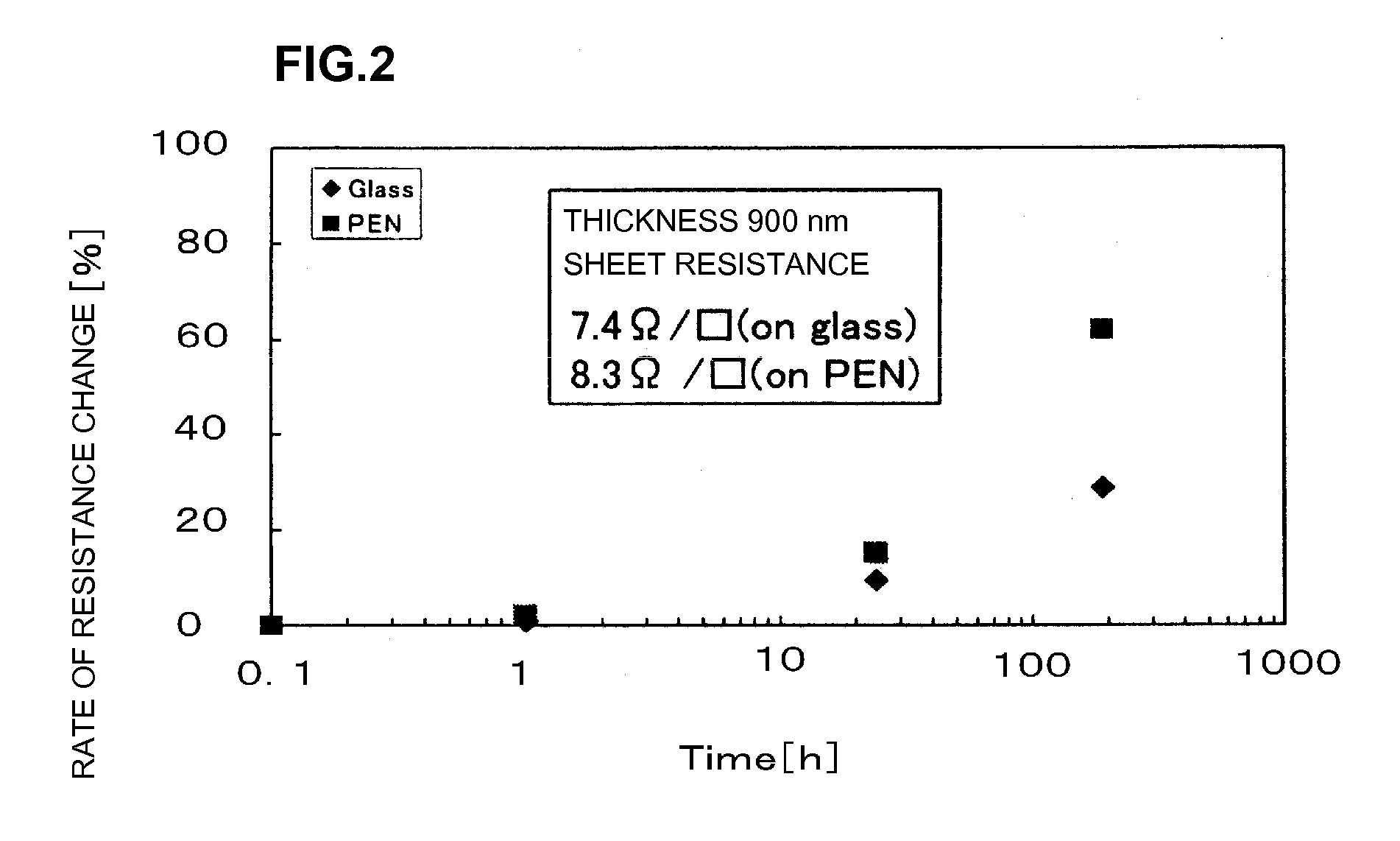

A ZnO-based transparent conductive film has practicable moisture resistance, desired characteristics of a transparent conductive film, and excellent economy. The transparent conductive film is produced by growing ZnO doped with a group III element oxide on a substrate and has a region with a crystal structure in which a c-axis grows along a plurality of different directions. The transparent conductive film produced by growing ZnO doped with a group III element oxide on a substrate has a ZnO (002) rocking curve full width at half maximum of about 13.5° or more.ZnO is doped with a group III element oxide so that the ratio of the group III element oxide in the transparent conductive film is about 7% to about 40% by weight.The transparent conductive film is formed on the substrate with a SiNx thin film provided therebetween.The transparent conductive film is formed on the substrate by a thin film formation method with a bias voltage applied to the substrate.

Owner:MURATA MFG CO LTD

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

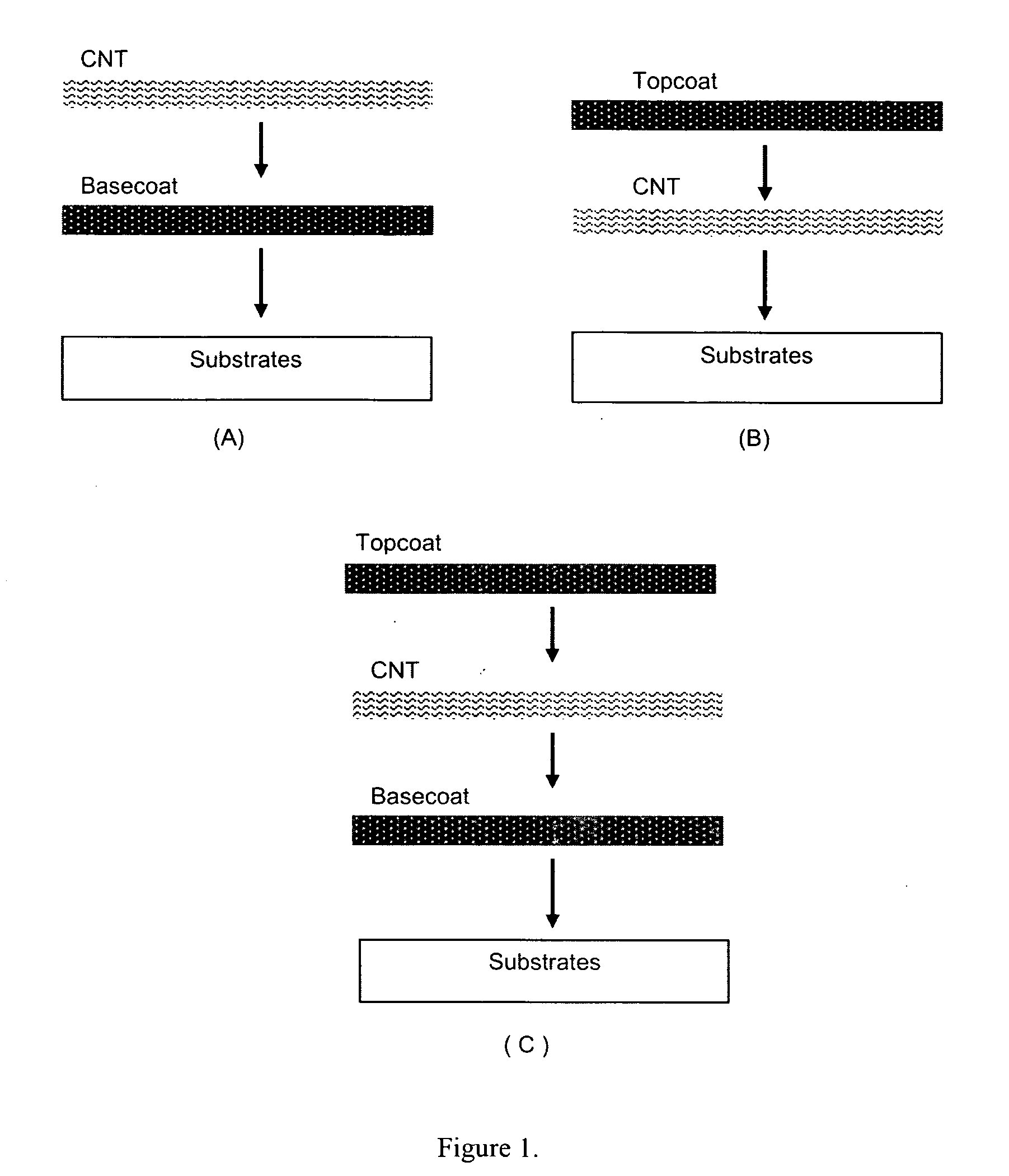

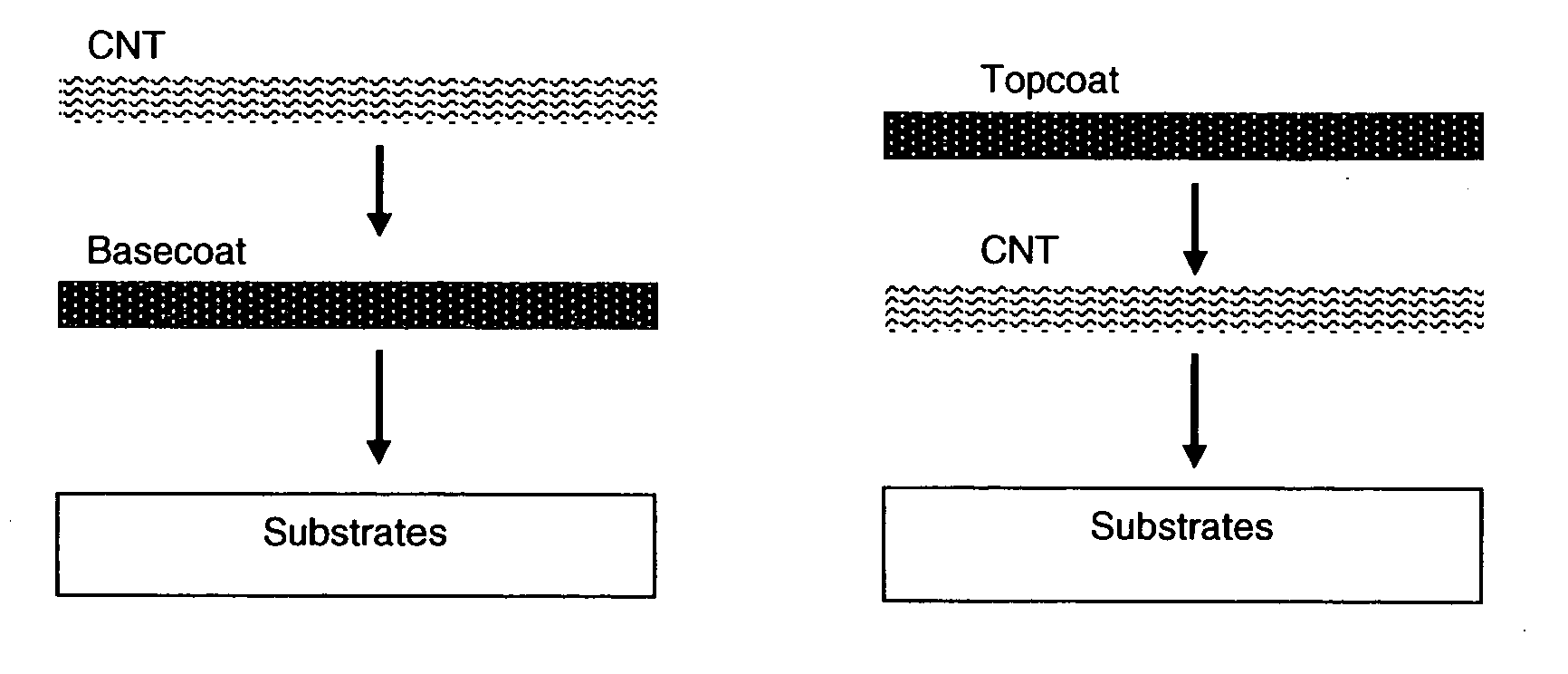

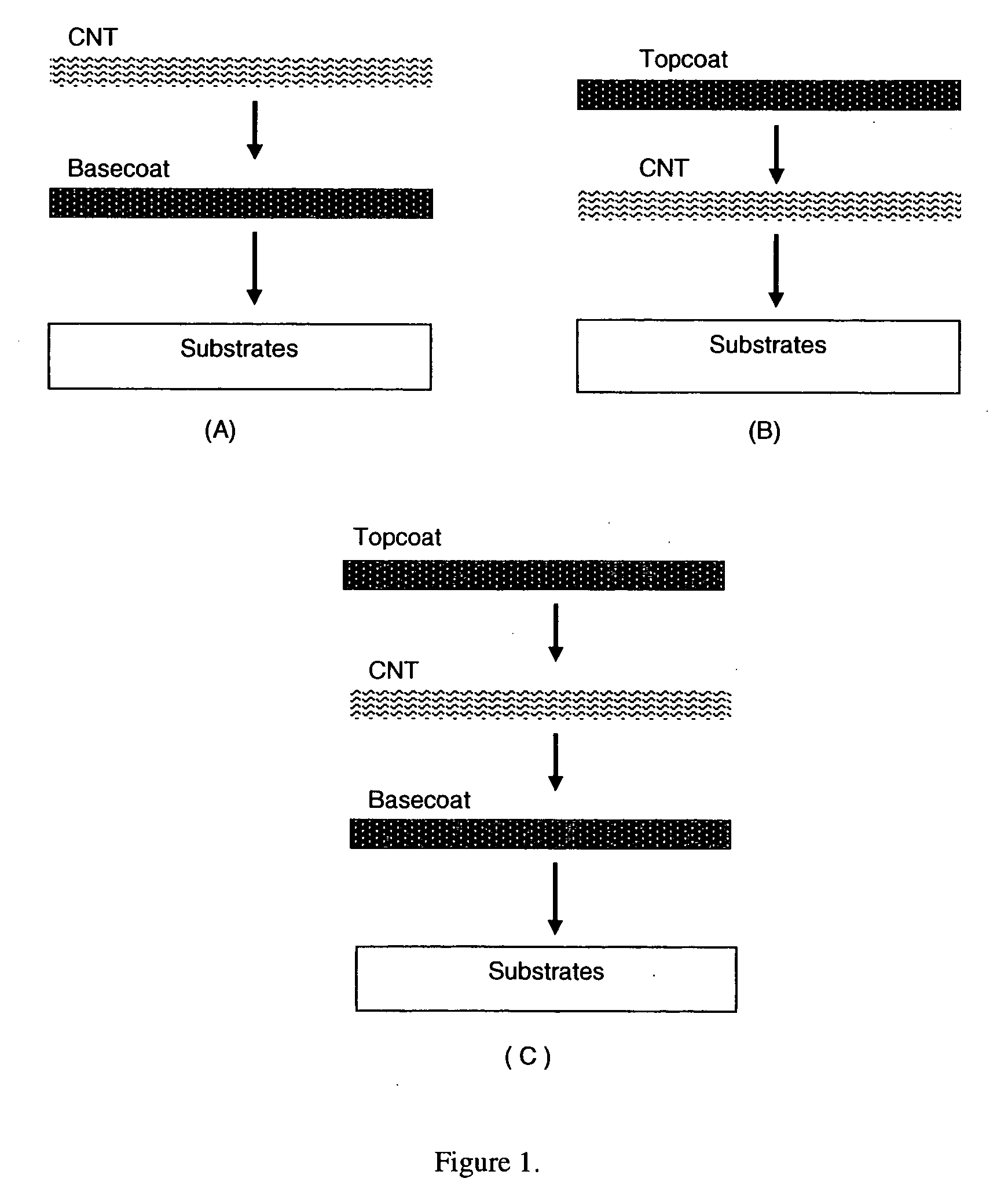

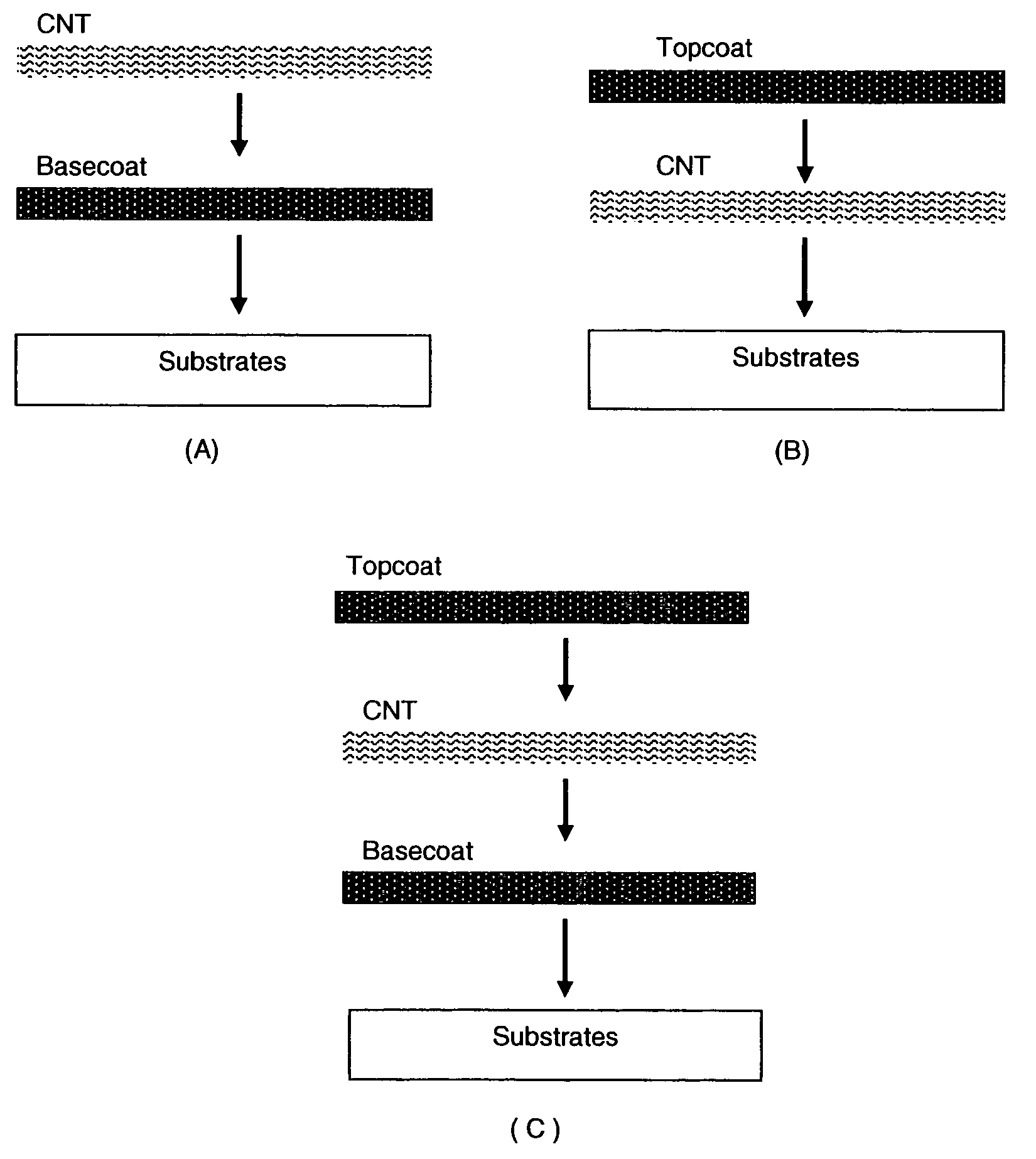

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

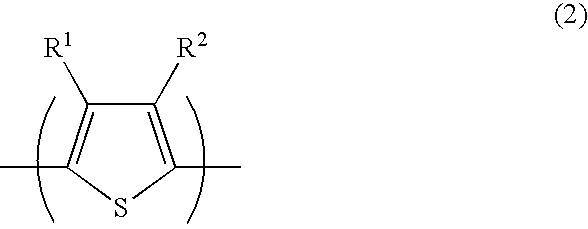

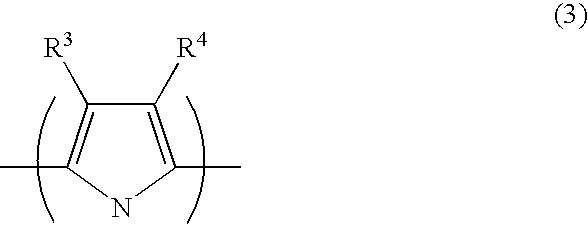

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

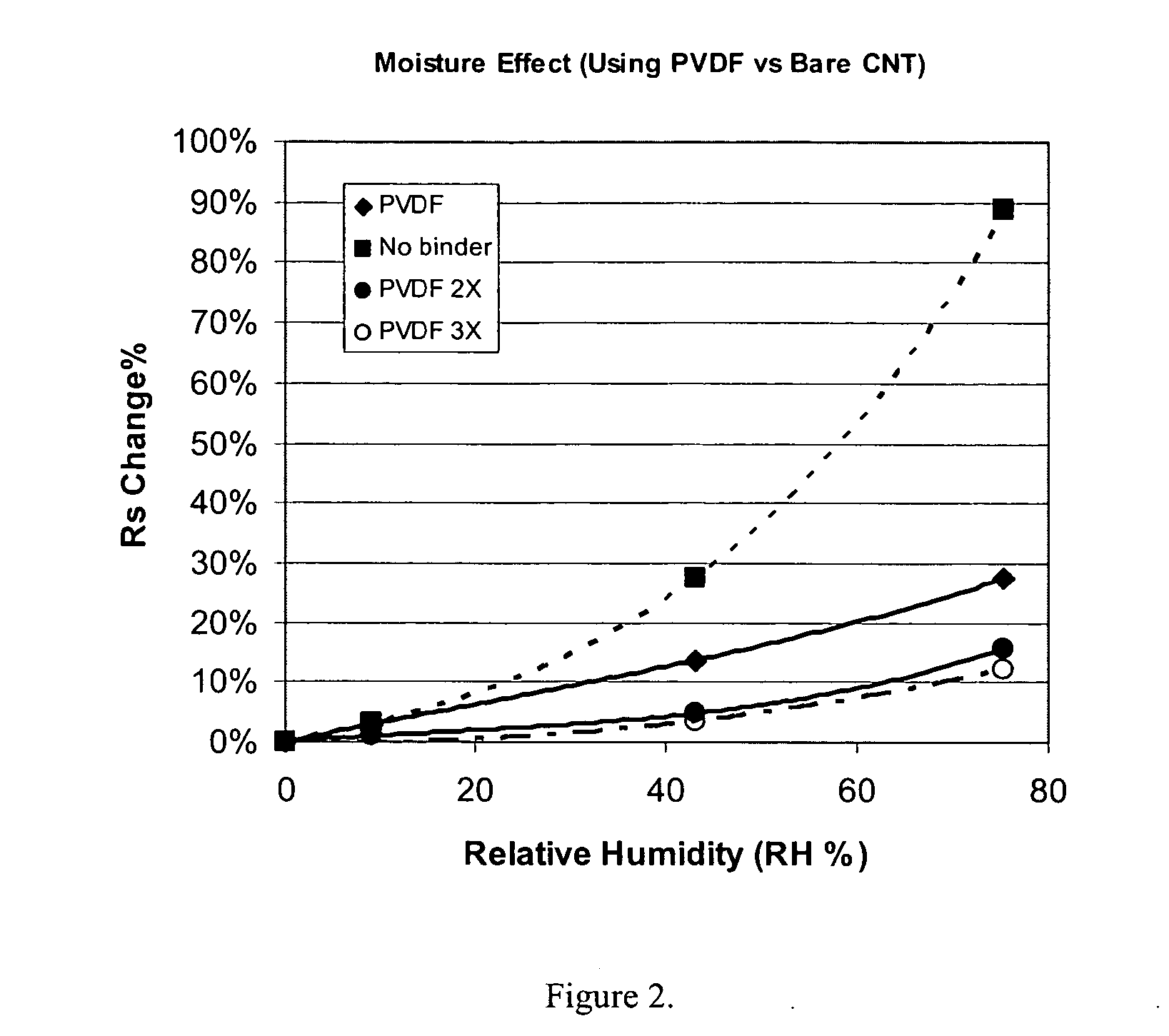

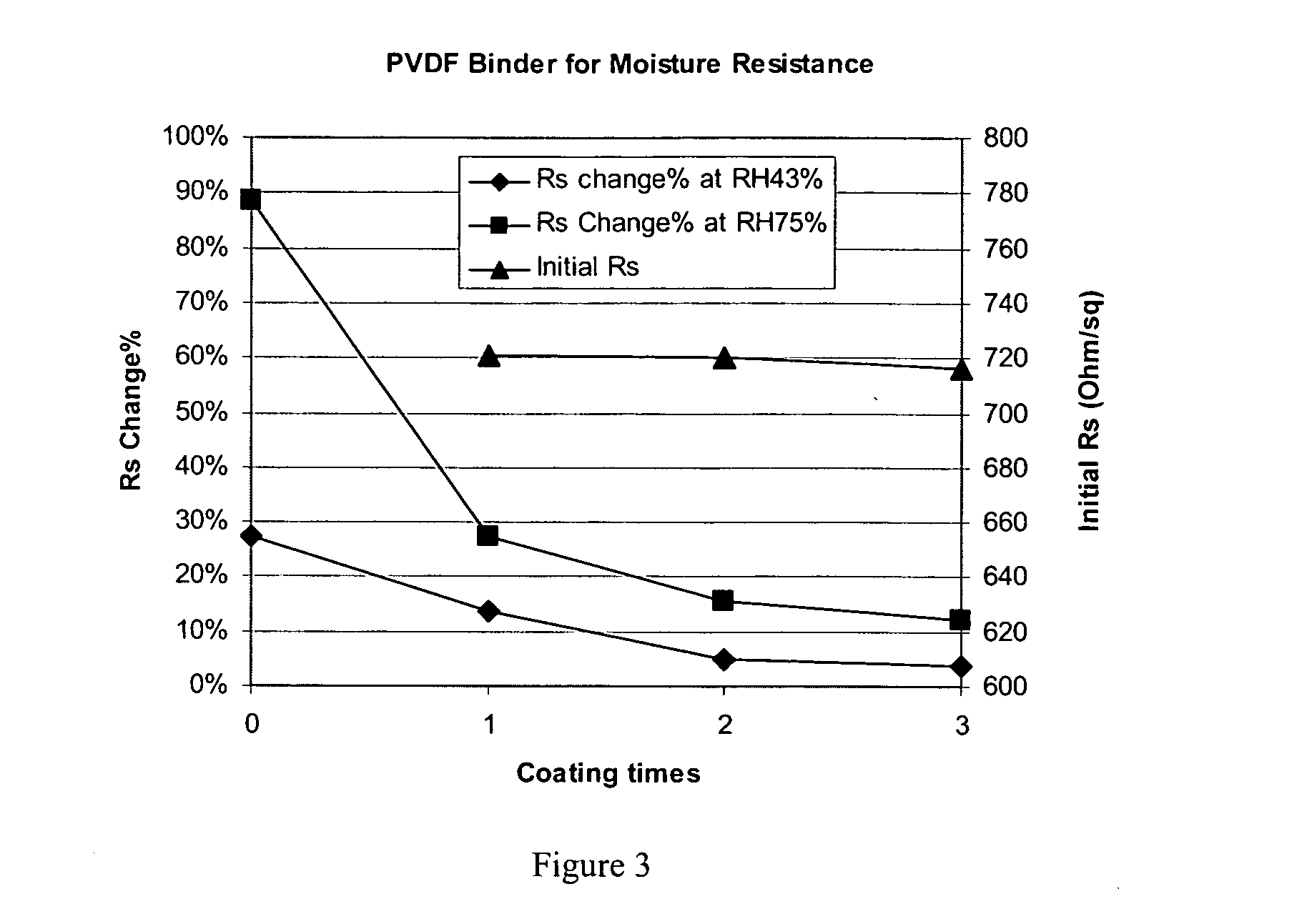

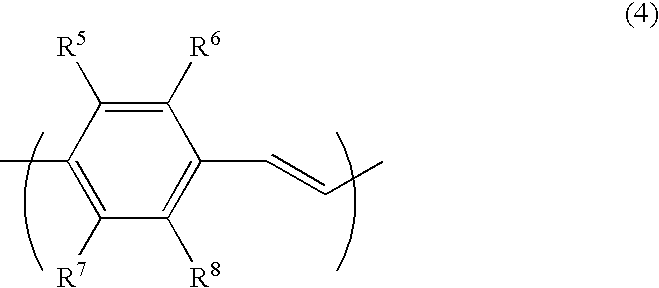

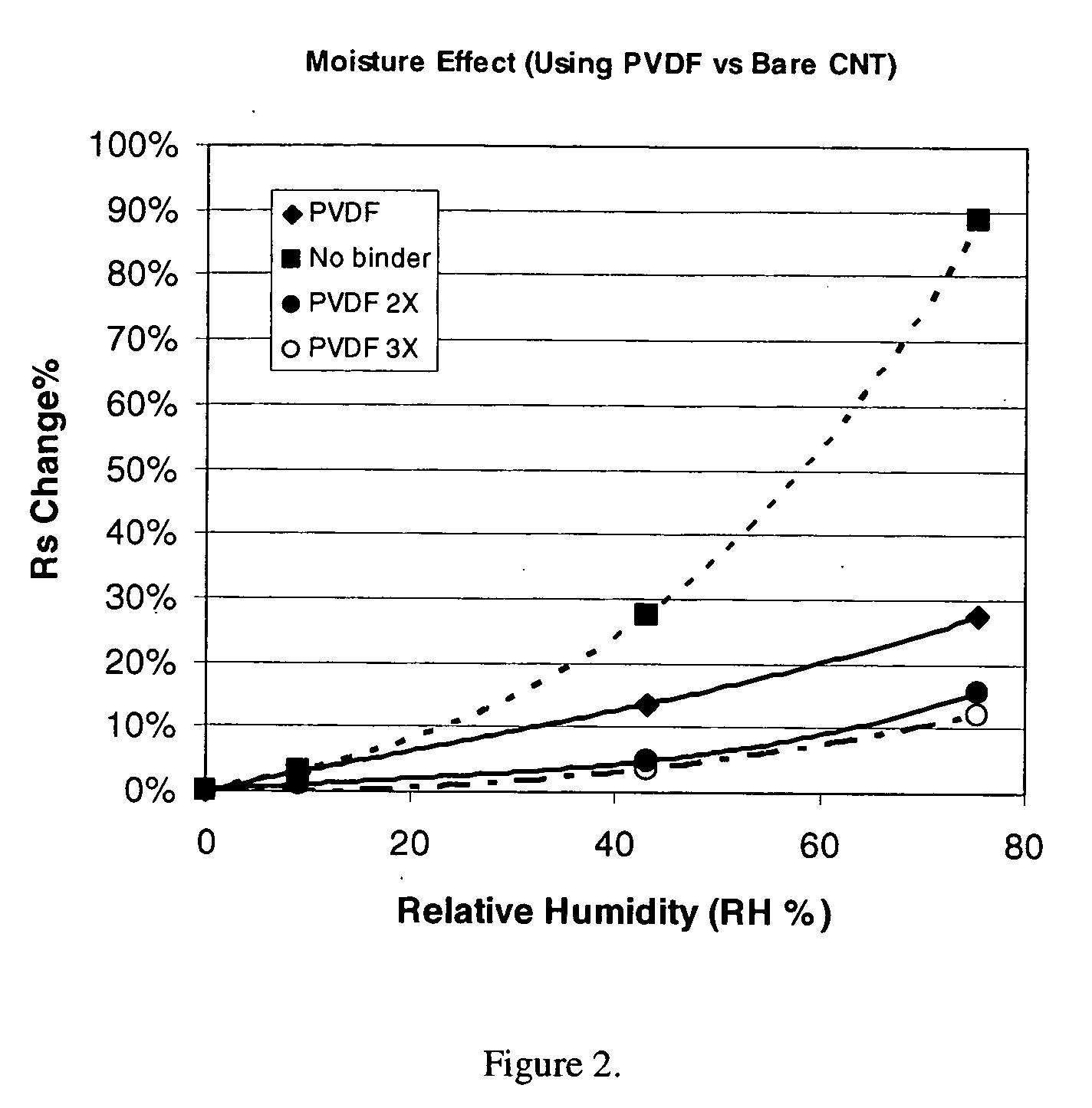

Fluoropolymer binders for carbon nanotube-based transparent conductive coatings

InactiveUS20060113510A1Reduce conductivityFunction increaseNanoinformaticsConductive materialThermoplasticOptical transparency

This invention relates to flexible, transparent and conductive coatings and films formed using carbon nanotubes (CNT) and, in particular, single wall carbon nanotubes, with polymer binders. Preferably, coatings and films are formed from carbon nanotubes applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or a combination thereof. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. A fluoropolymer containing binder, which is a solution of one fluoropolymer or a blend of fluoropolymers, which may be formulated with additives, is applied onto a carbon nanotube-based transparent conductive coating at nanometer level of thickness on a clear substrate such as PET and glass. The fluoropolymers or blend can be either semi-crystalline (with low level of crystallinity) or amorphous, preferably to be amorphous with low refraction index. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. This binder coating significantly improves optical transparency, and also maintain or increases conductivity of the CNT-based coating. With other benefits such as abrasion, thermal and moisture resistance, this binder coating and the resulting products is used for display and electronic applications.

Owner:EIKOS

Manufacturing method of semiconductor device and semiconductor device

InactiveUS20080099876A1Good coating performanceImprove moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh densityDevice material

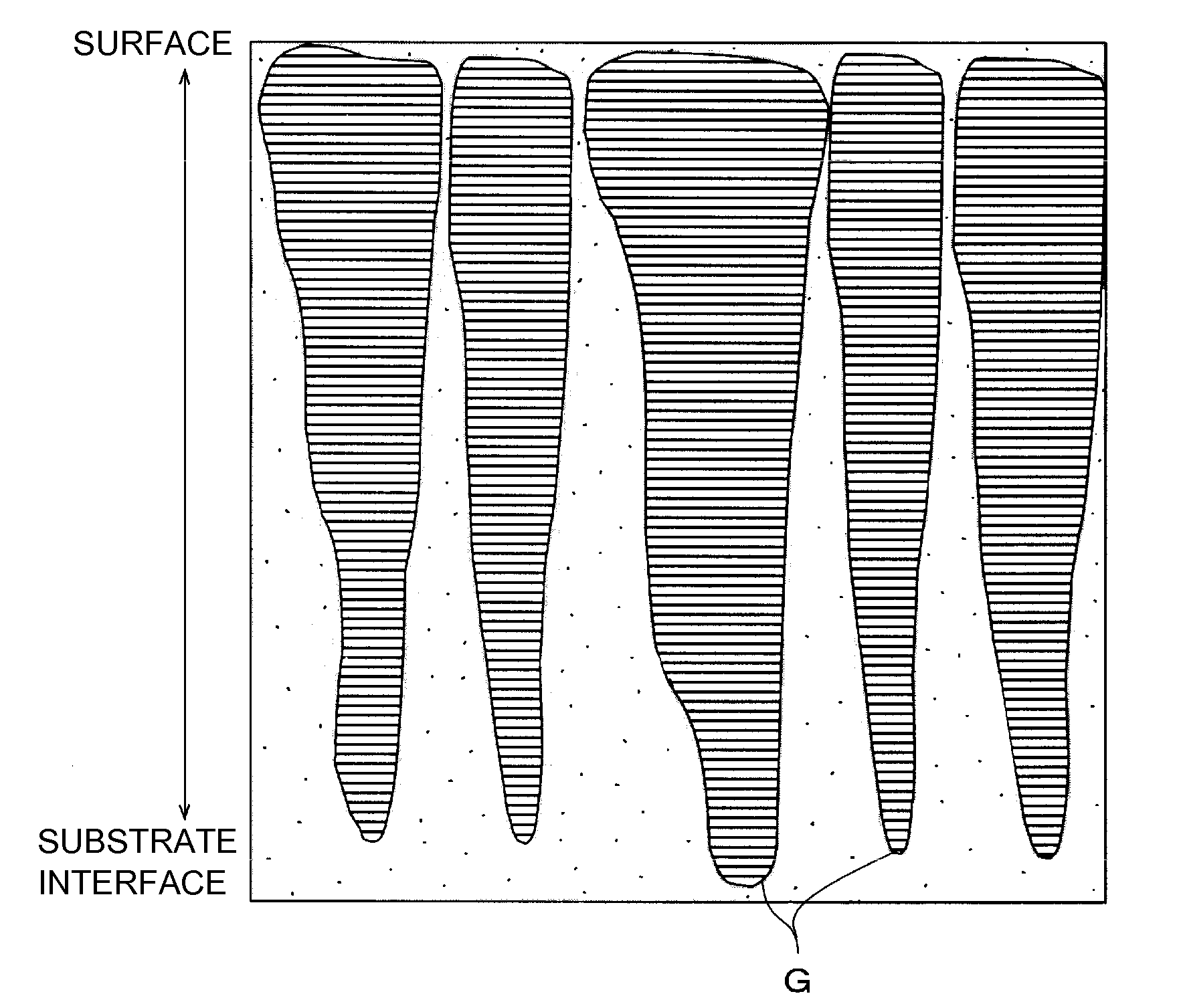

The present invention provides a method of manufacturing a semiconductor device, which comprises steps of forming a plurality of wirings on a first insulting film formed on a semiconductor substrate so as to adjoin one another, forming a second insulating film on the first insulating film by a plasma CVD method and covering the wirings with the second insulating film in such a manner that air gaps are formed between the respective adjacent wirings, forming a third insulating film on the second insulating film by a high density plasma CVD method, and forming a fourth insulating film high in moisture resistance on the third insulating film.

Owner:LAPIS SEMICON CO LTD

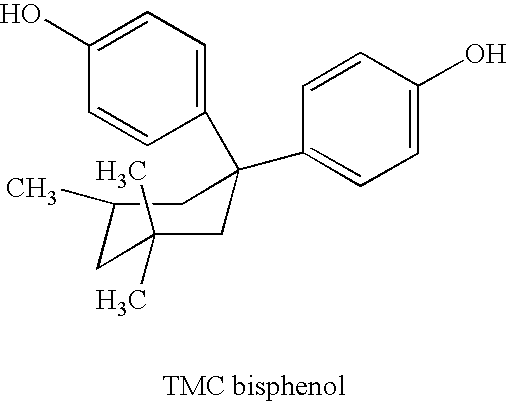

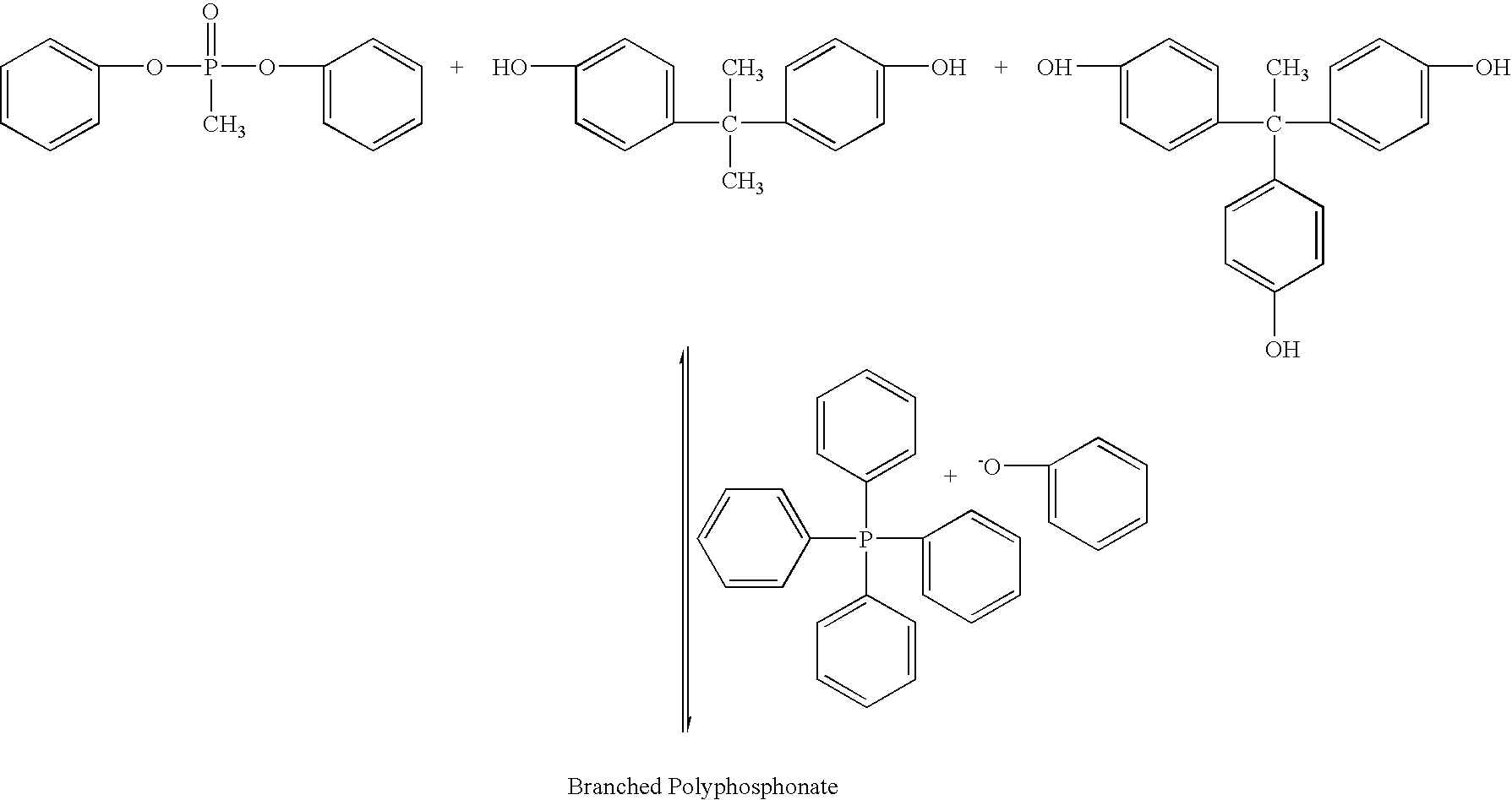

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

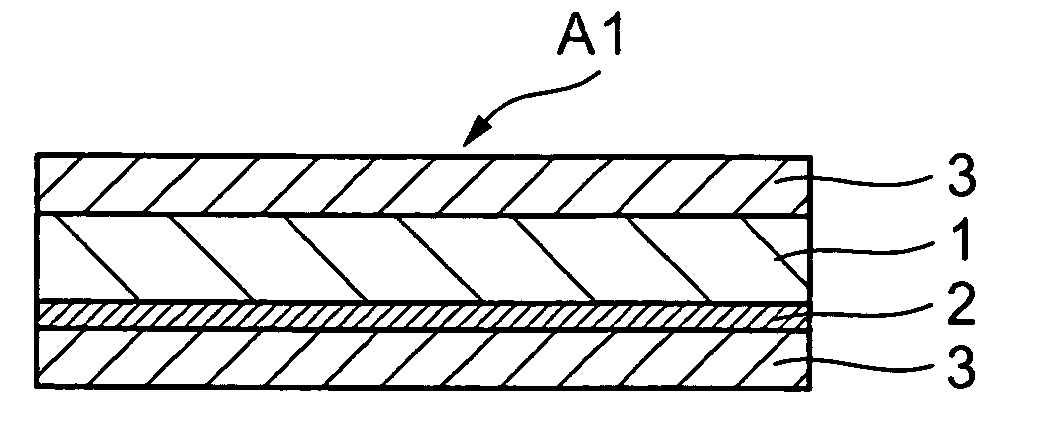

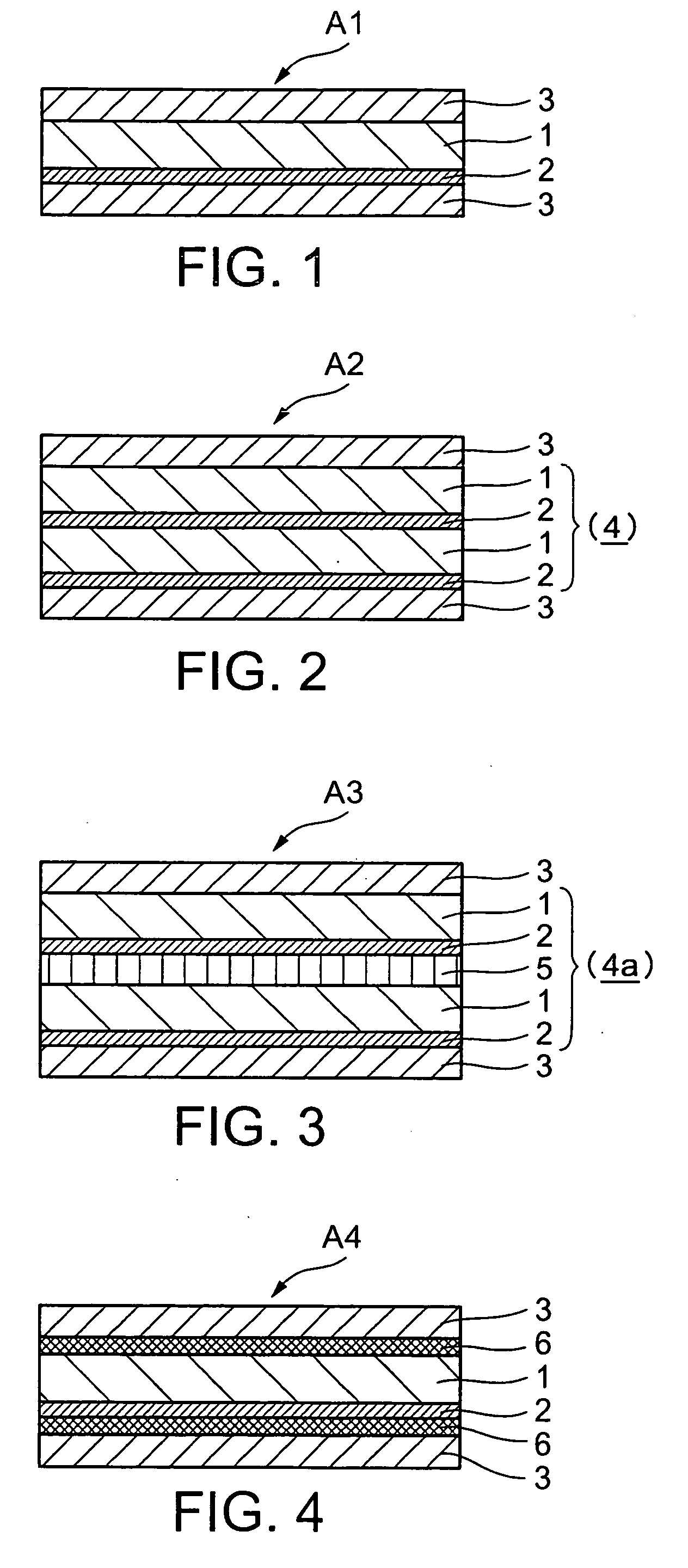

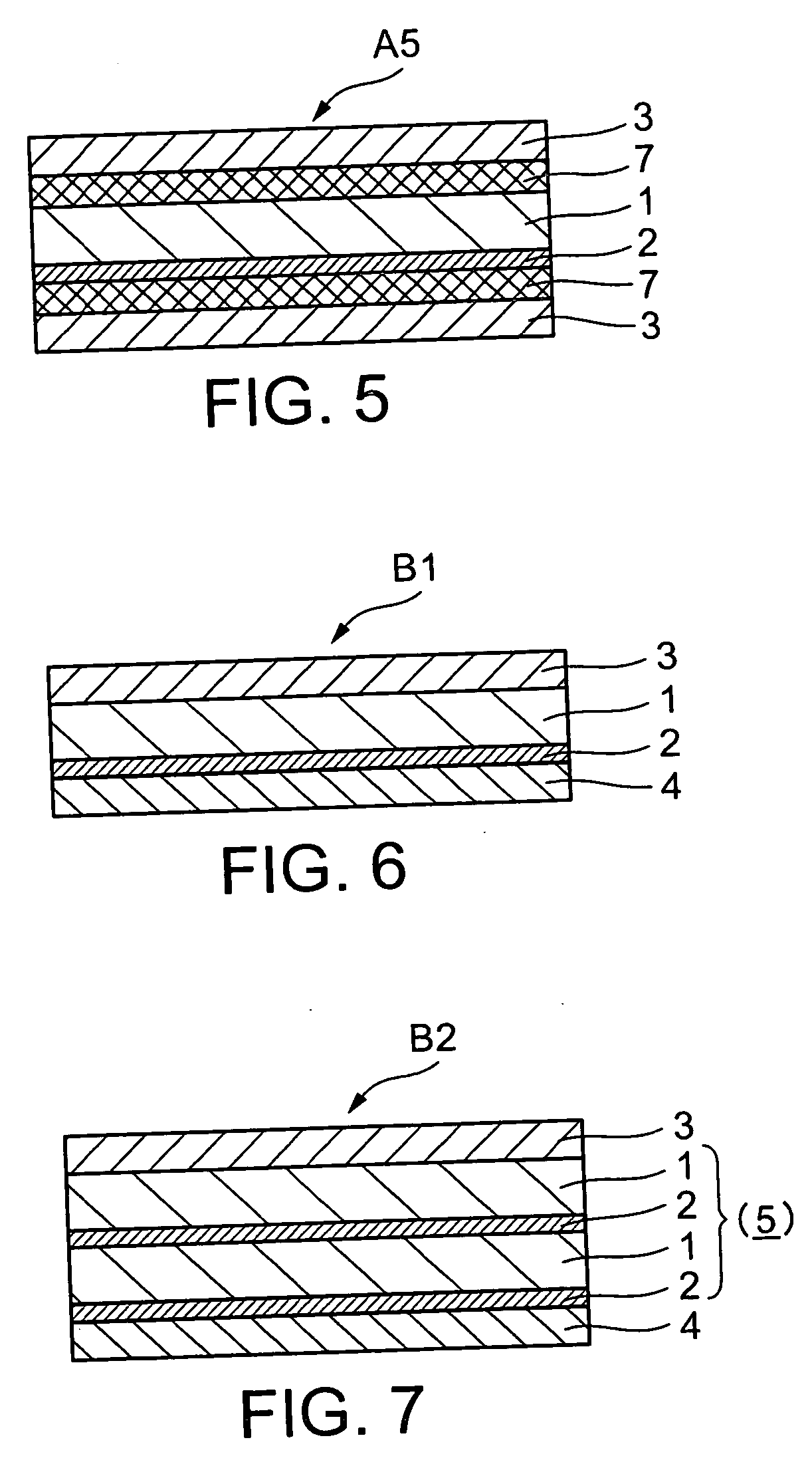

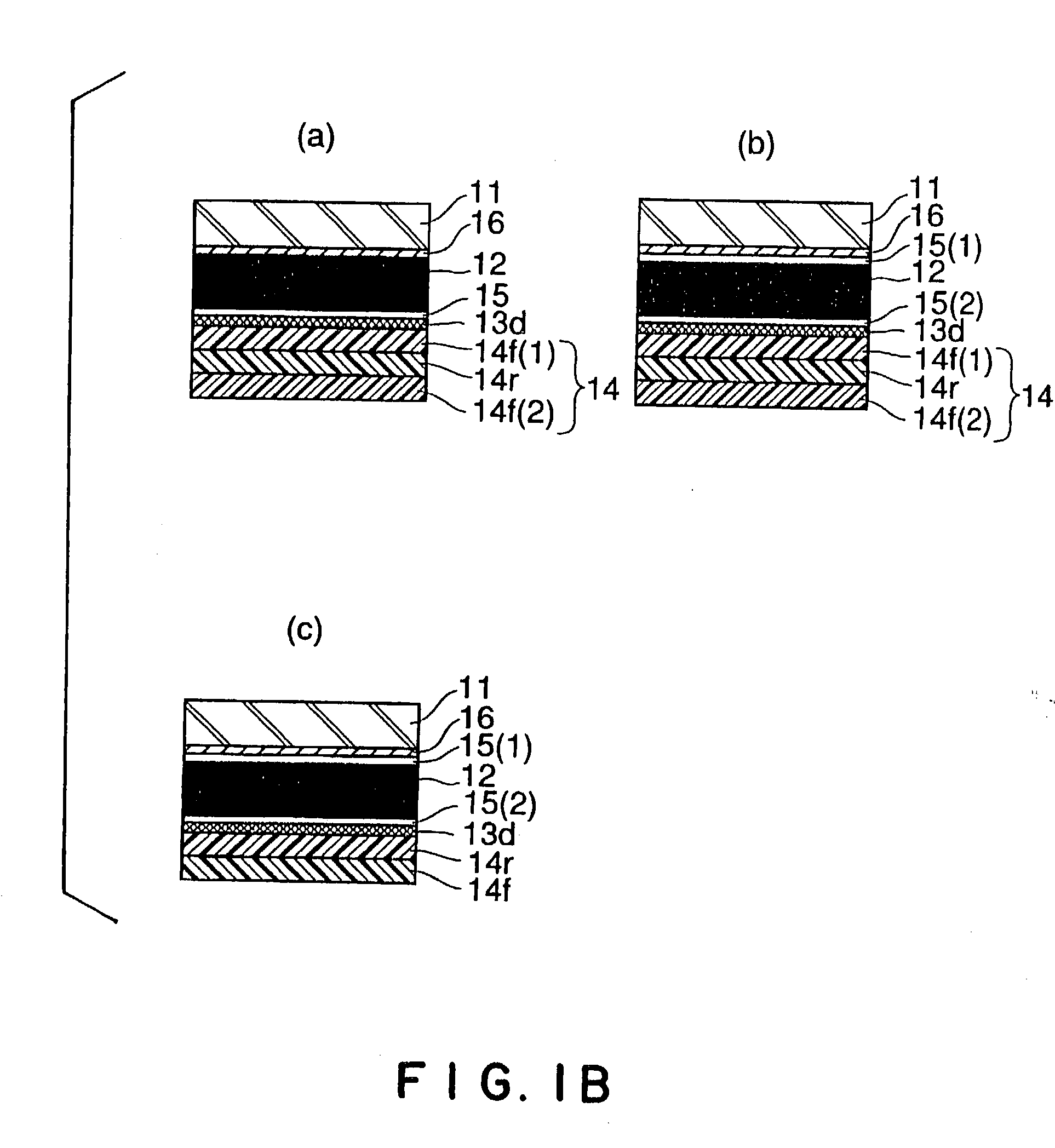

Backside protective sheet for solar battery module and solar battery module using the same

InactiveUS20060166023A1High strengthConvenient inventory managementSynthetic resin layered productsGlass/slag layered productsPolyolefinElectrical battery

There is provided a backside protective sheet for a solar battery module that is excellent in strength as well as in various properties such as weathering resistance, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, chemical resistance, moisture resistance, antifouling properties, light reflectivity, light diffusivity, and design, and is particularly excellent in the so-called “moisture resistance,” which is the ability to prevent the entry of moisture, oxygen and the like, and durability against performance degradation with time, particularly against hydrolytic degradation and the like, and is also excellent in protective capability. There is also provided a backside protective sheet for a solar battery module, which can facilitate inventory control by properly using the front side and back side of the protective sheet depending upon applications and is excellent in cost performance, and a solar battery module using the same. The backside protective sheet for a solar battery module comprises: a deposited assembly comprising a vapor-deposited film of an inorganic oxide provided on at least one side of a substrate; and a transparent or translucent heat-resistant polyolefin resin layer provided on both sides of the deposited assembly.

Owner:DAI NIPPON PRINTING CO LTD

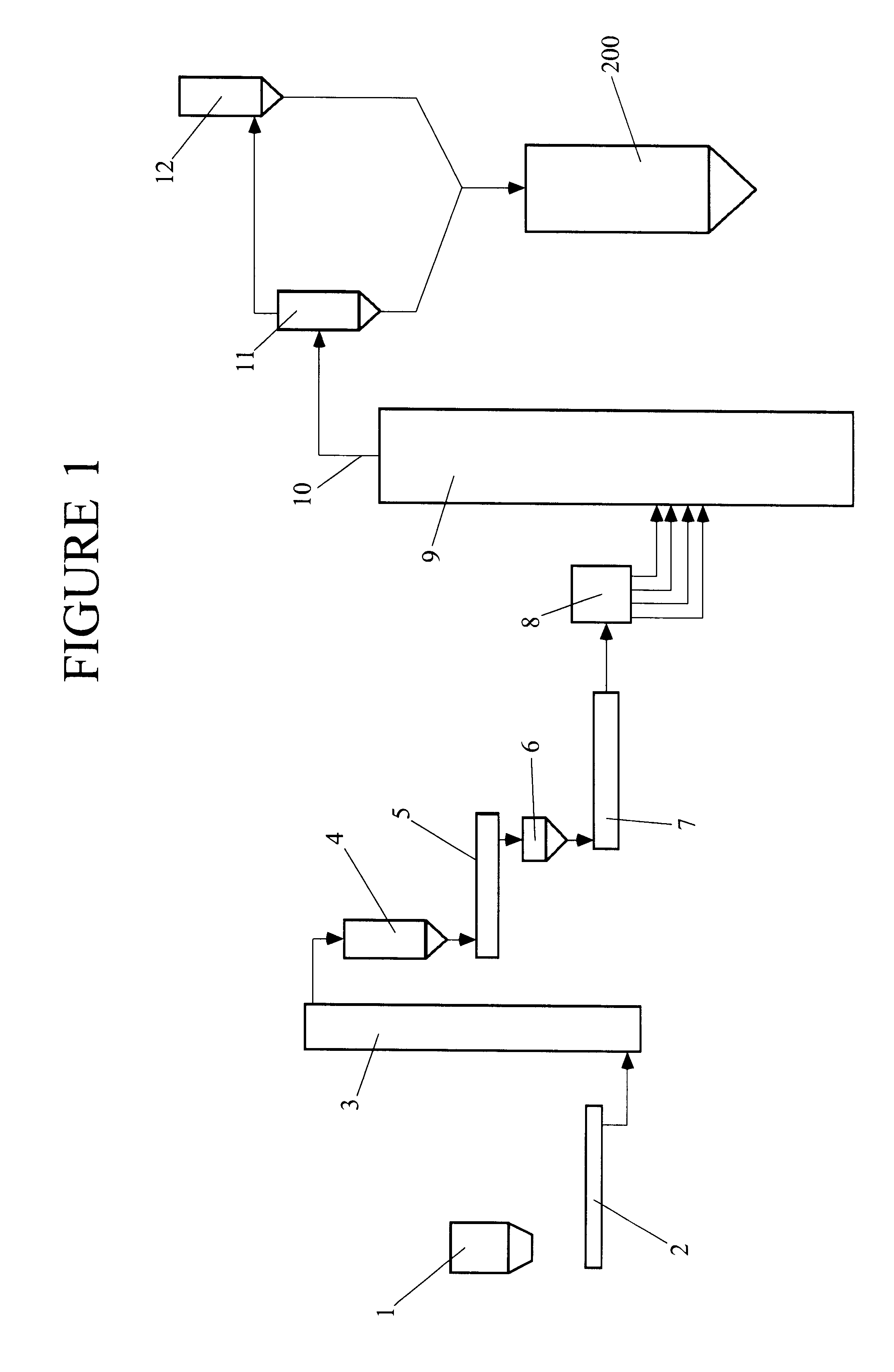

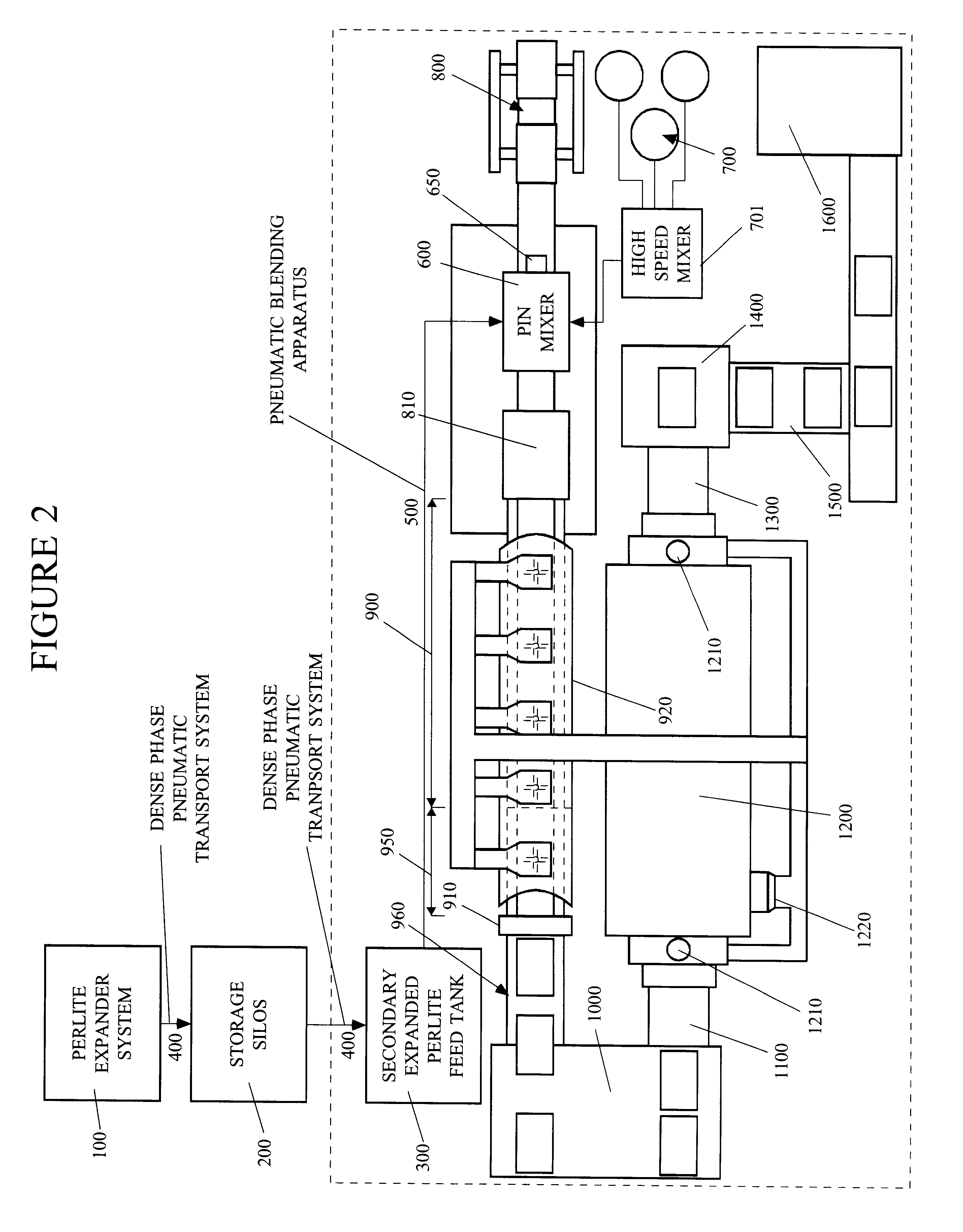

Strengthened, light weight wallboard and method and apparatus for making the same

InactiveUS6319312B1Easy to optimizeReduce amountConstruction materialCeramic shaping plantsSingle plateFlexural strength

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

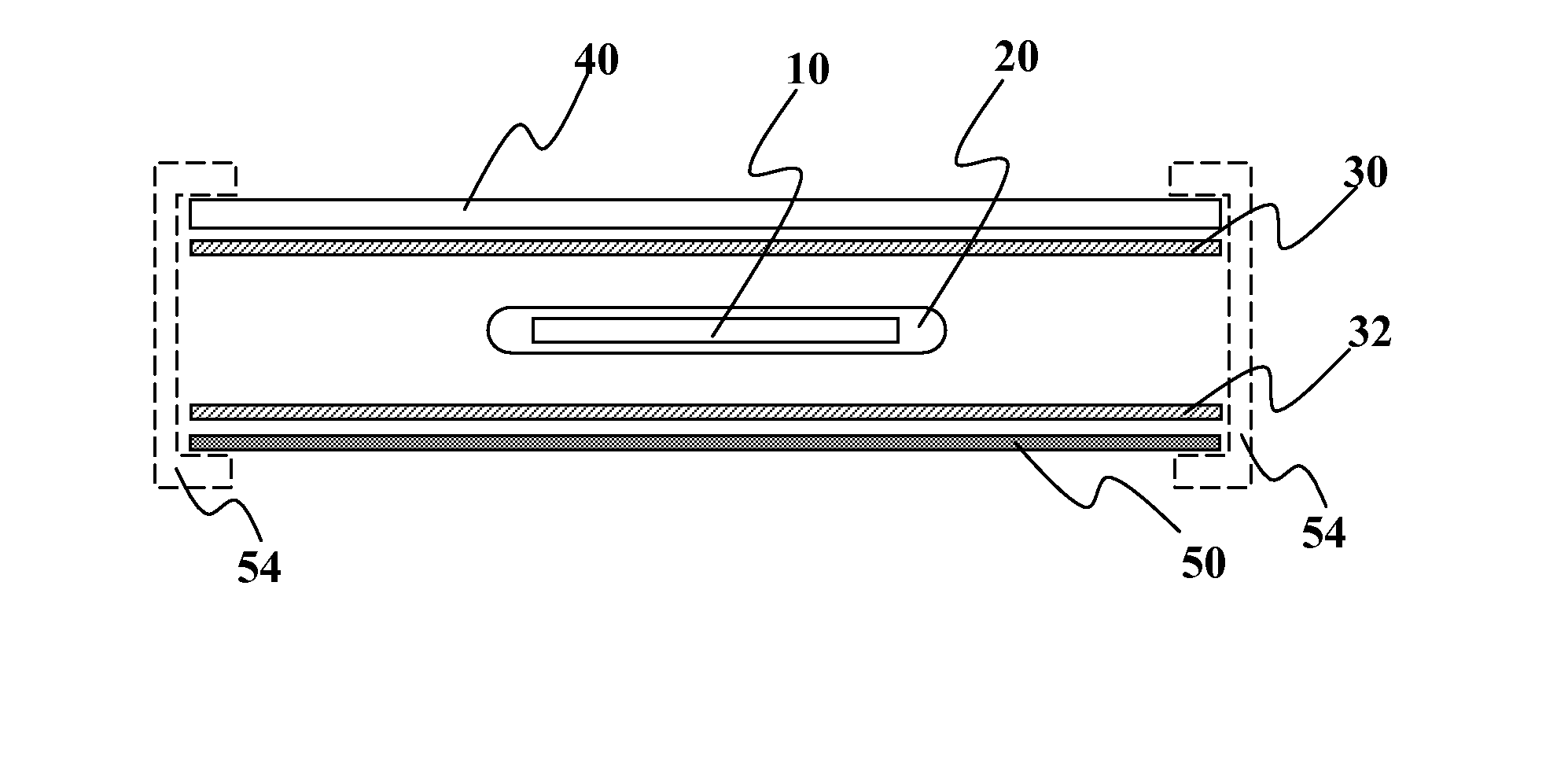

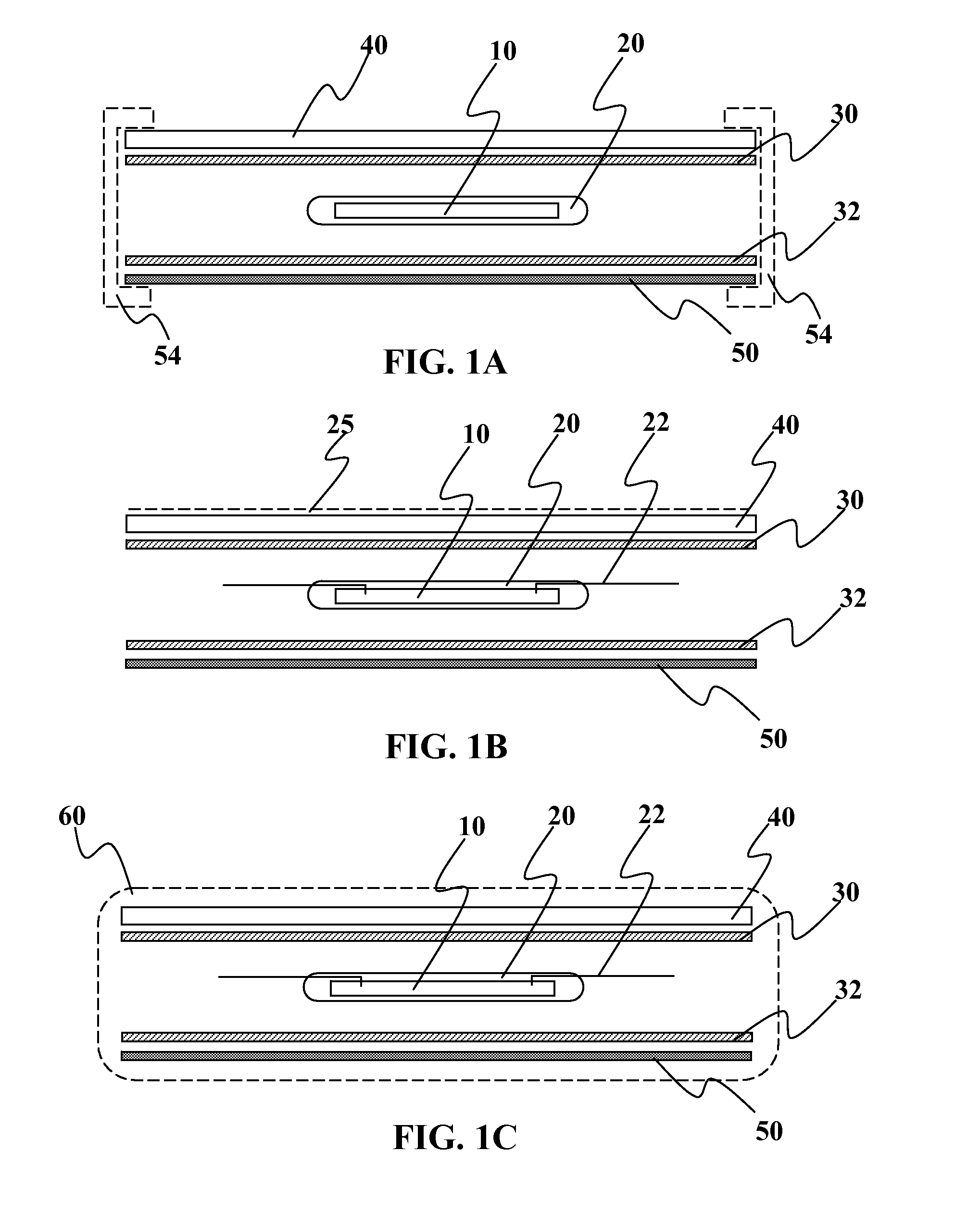

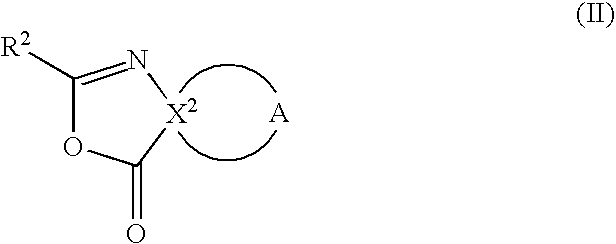

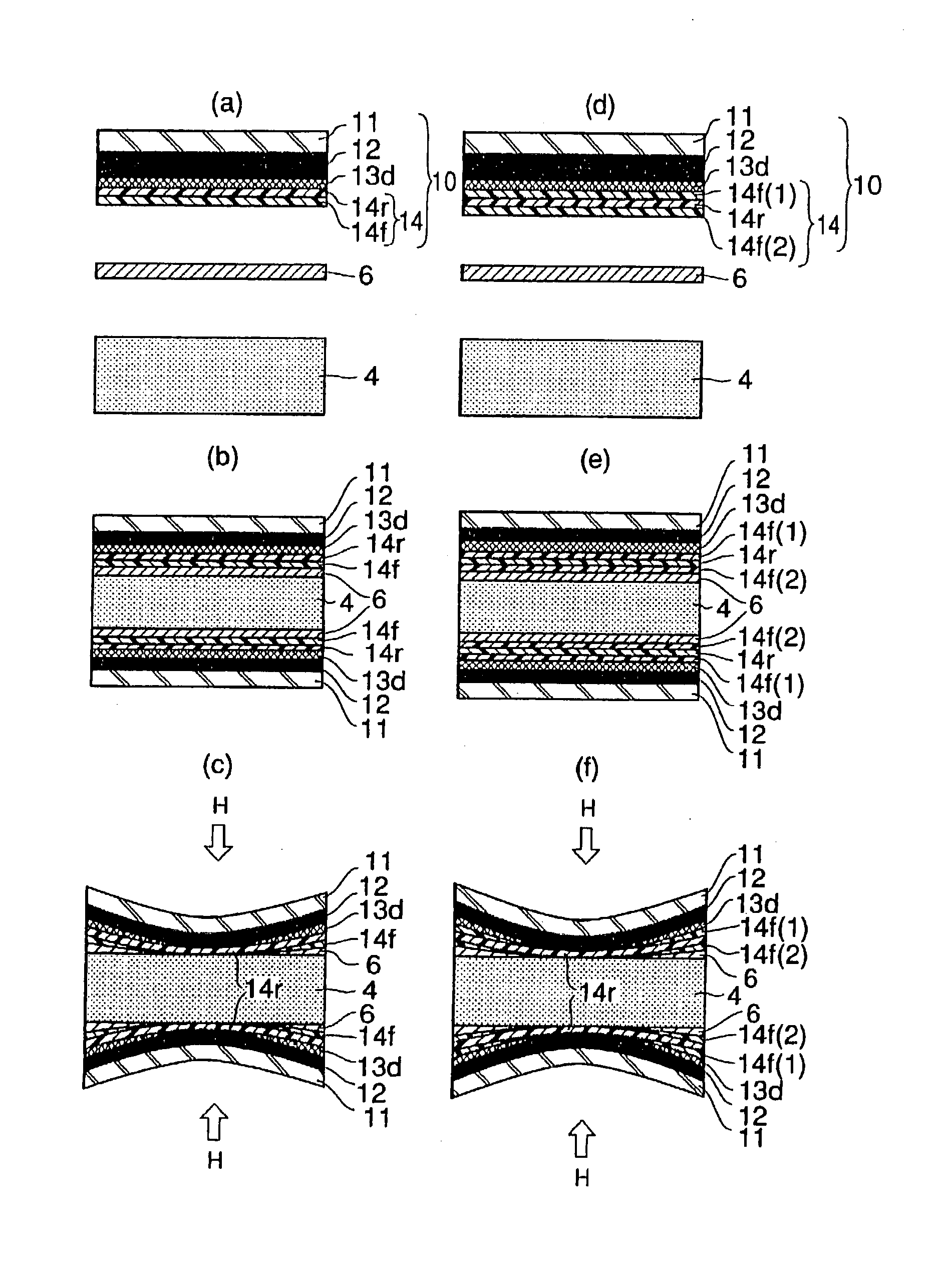

Solar assembly with a multi-ply barrier layer and individually encapsulated solar cells or solar cell strings

InactiveUS20070295388A1Avoid moisture damageLow costPhotovoltaic supportsPV power plantsEngineeringMoisture resistance

Methods and devices are provided for improved environmental protection for photovoltaic devices and assemblies. In one embodiment, a photovoltaic device module is provided comprising of a multi-ply module encapsulant, a bottom module layer, and a plurality of solar cells. The multi-ply module encapsulant includes one or more discrete layers comprising of at least a first module layer and at least a second module layer. The plurality of solar cells may be sandwiched between the multi-ply module encapsulant and the bottom module layer. At least one of the cells has a protective layer that provides a level of moisture resistance equal to or higher than any of the layers above the cells. The protective layer is typically above the solar cell and light passes through the multi-ply module encapsulant and the protective layer to reach the solar cell.

Owner:NANOSOLAR

Curing resin composition, adhesive epoxy resin paste, adhesive epoxy resin sheet, conductive connection paste, conductive connection sheet, and electronic component joined body

ActiveUS20060154078A1Adhesion reliability is highIncrease flexibilityNon-insulated conductorsSynthetic resin layered productsEpoxyHeat resistance

It is an object of the invention to provide a curable resin composition excellent in mechanical strength, heat resistance, moisture resistance, flexibility, resistance to thermal cycles, resistance to solder reflow, dimensional stability, and the like after curing and providing high adhesion reliability and conduction reliability and an adhesive epoxy resin paste, an adhesive epoxy resin sheet, a conductive connection paste, and a conductive connection sheet using the curable resin composition, and an electronic component joined body. The invention relates to a curable resin composition, which contains an epoxy resin, a solid polymer having a functional group to react with the epoxy group and a curing agent for an epoxy resin, no phase separation structure being observed in a matrix of a resin when a cured product is dyed with a heavy metal and observed with a transmission electron microscope.

Owner:SEKISUI CHEM CO LTD

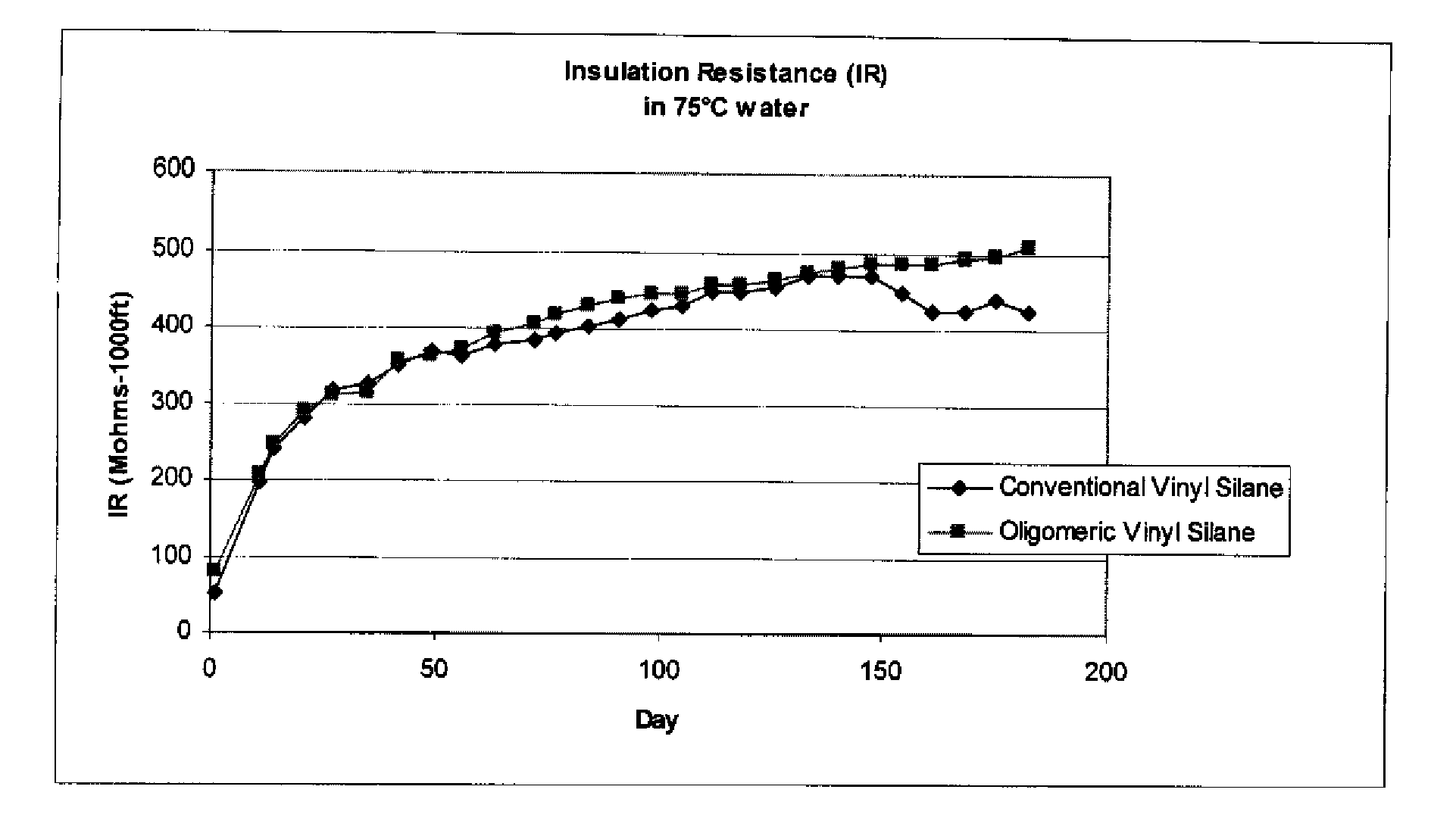

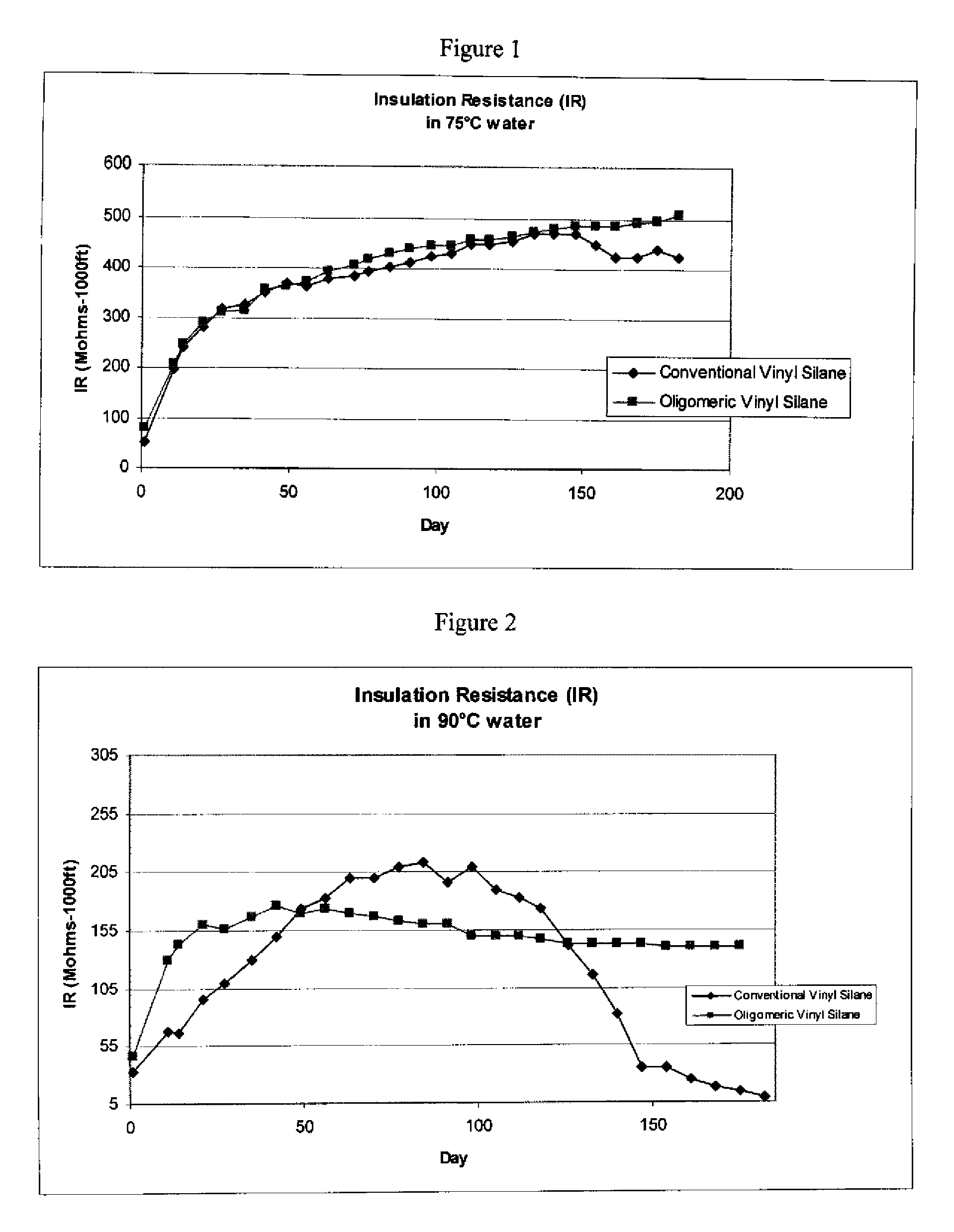

Low smoke, fire and water resistant cable coating

ActiveUS20090238957A1Limited smoke characteristicWet electrical performanceFireproof paintsRubber insulatorsMoisture resistanceOxygen

Cable coatings having effective low-smoke emission, fire resistance and moisture resistance provided by a single layer are described. The cable coatings contain an base polymer, a oxygen containing ethylene copolymer, a fire retardant and a synergistic blend of magnesium hydroxide and aluminum hydroxide. Cables coated with the described coatings have improved wet electrical performance, and satisfactory fire performance and smoke characteristics.

Owner:GENERAL CABLE TECH CORP

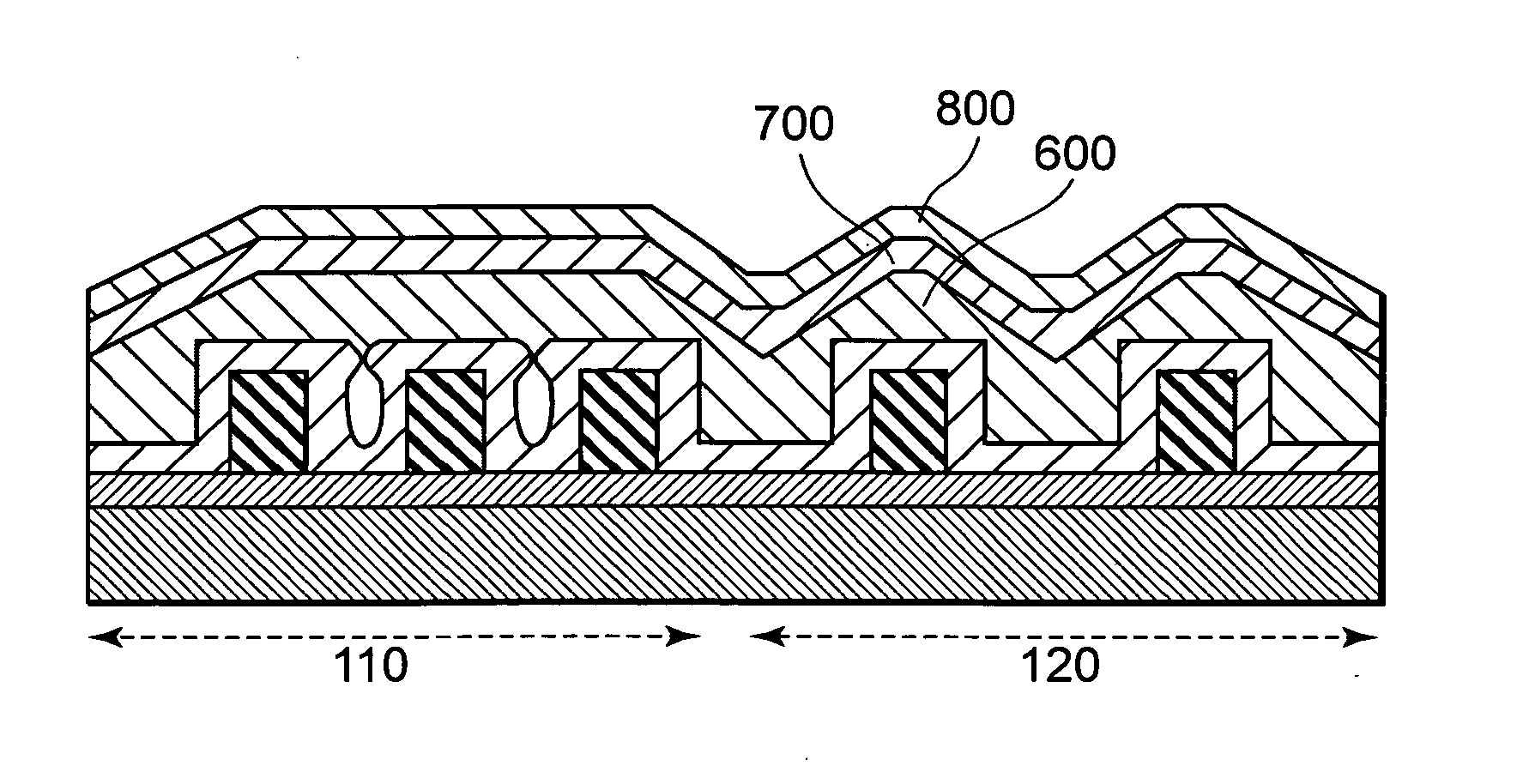

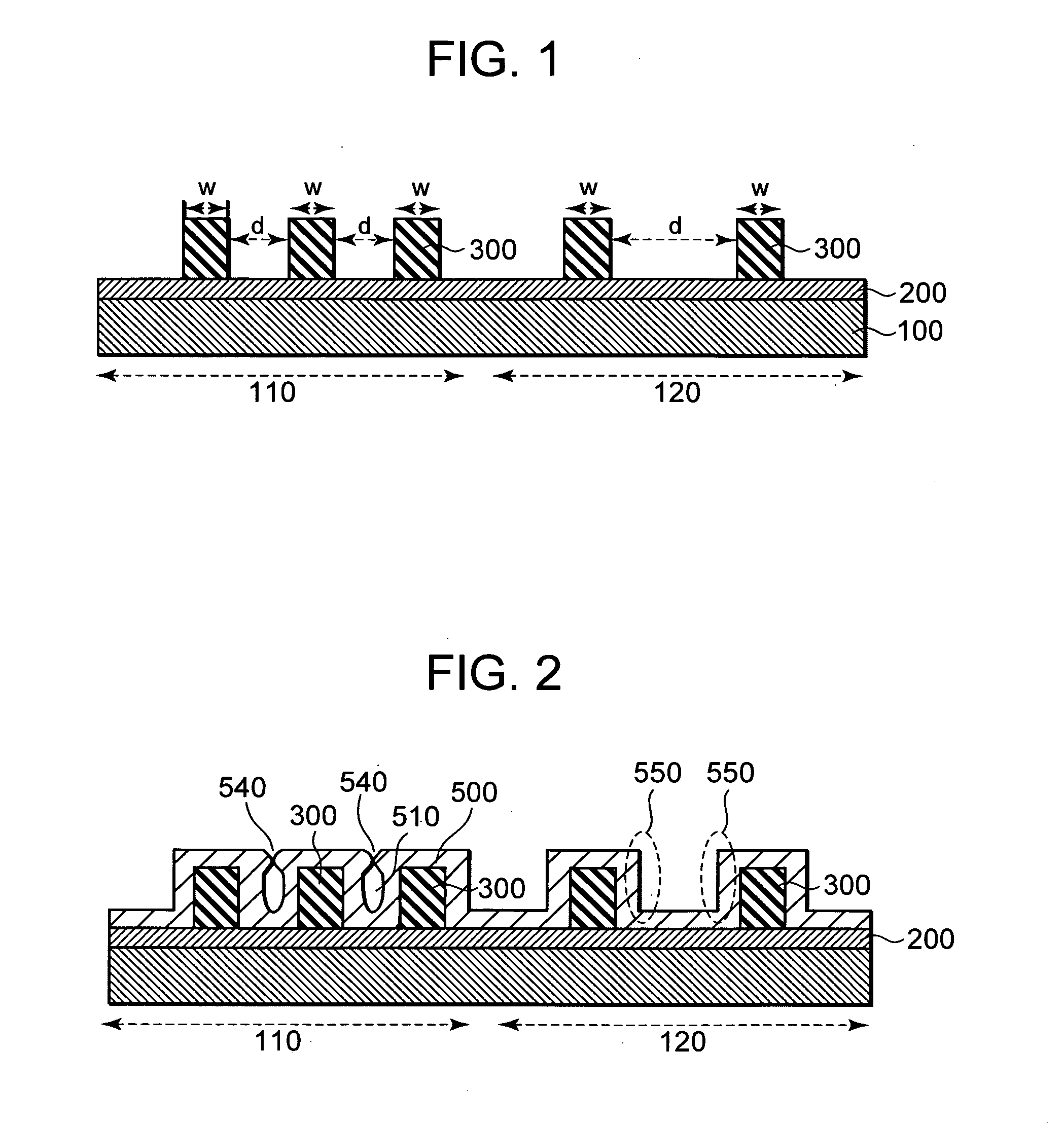

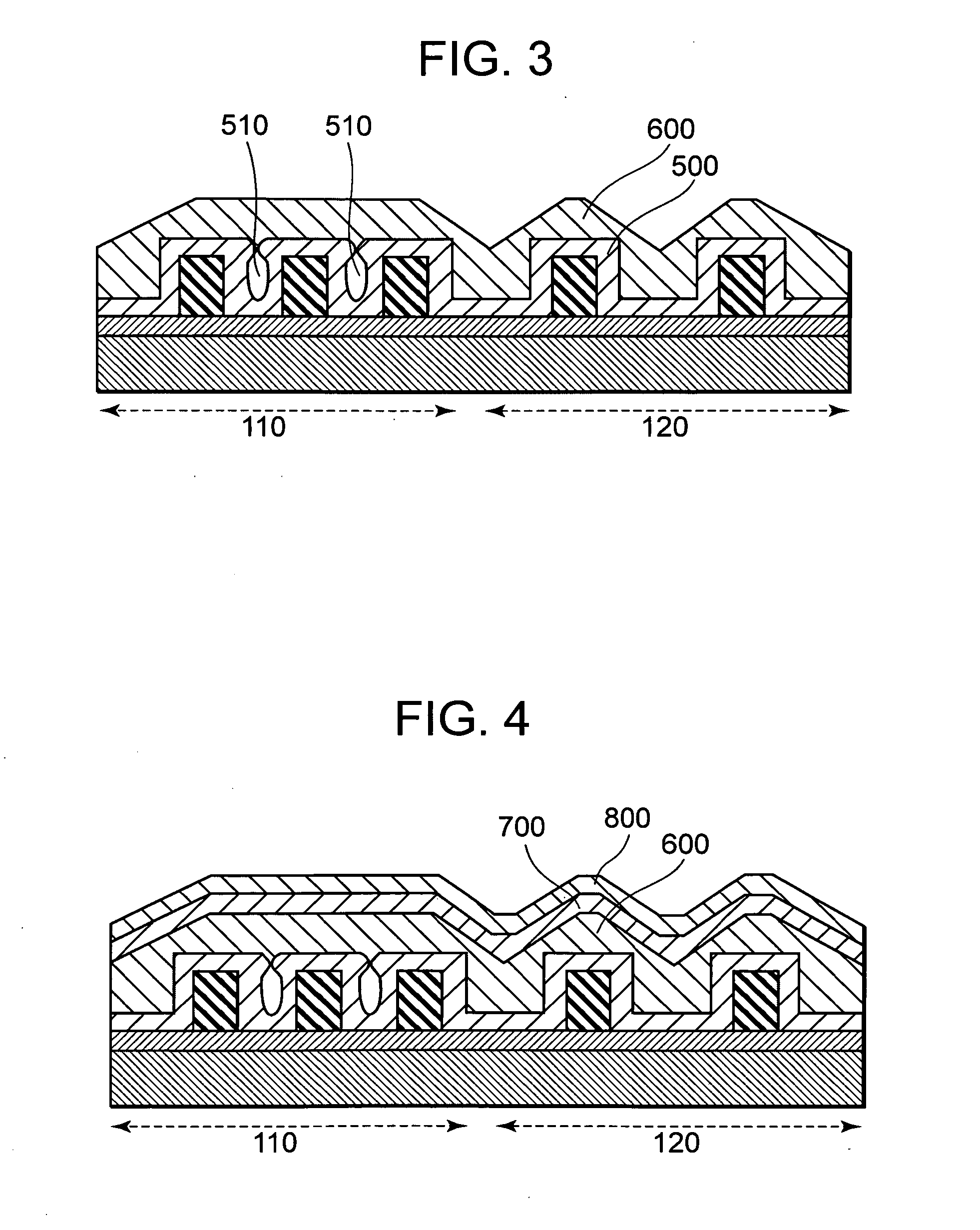

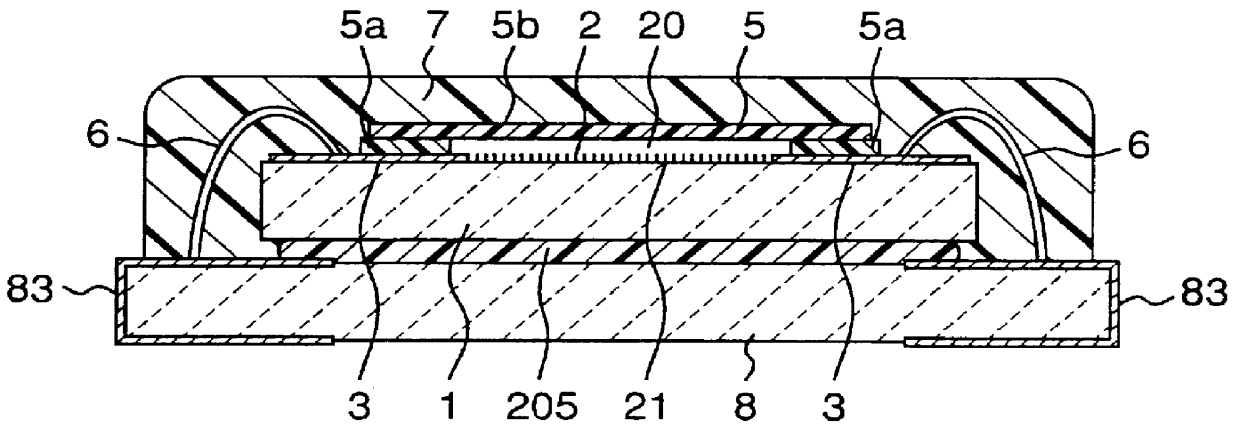

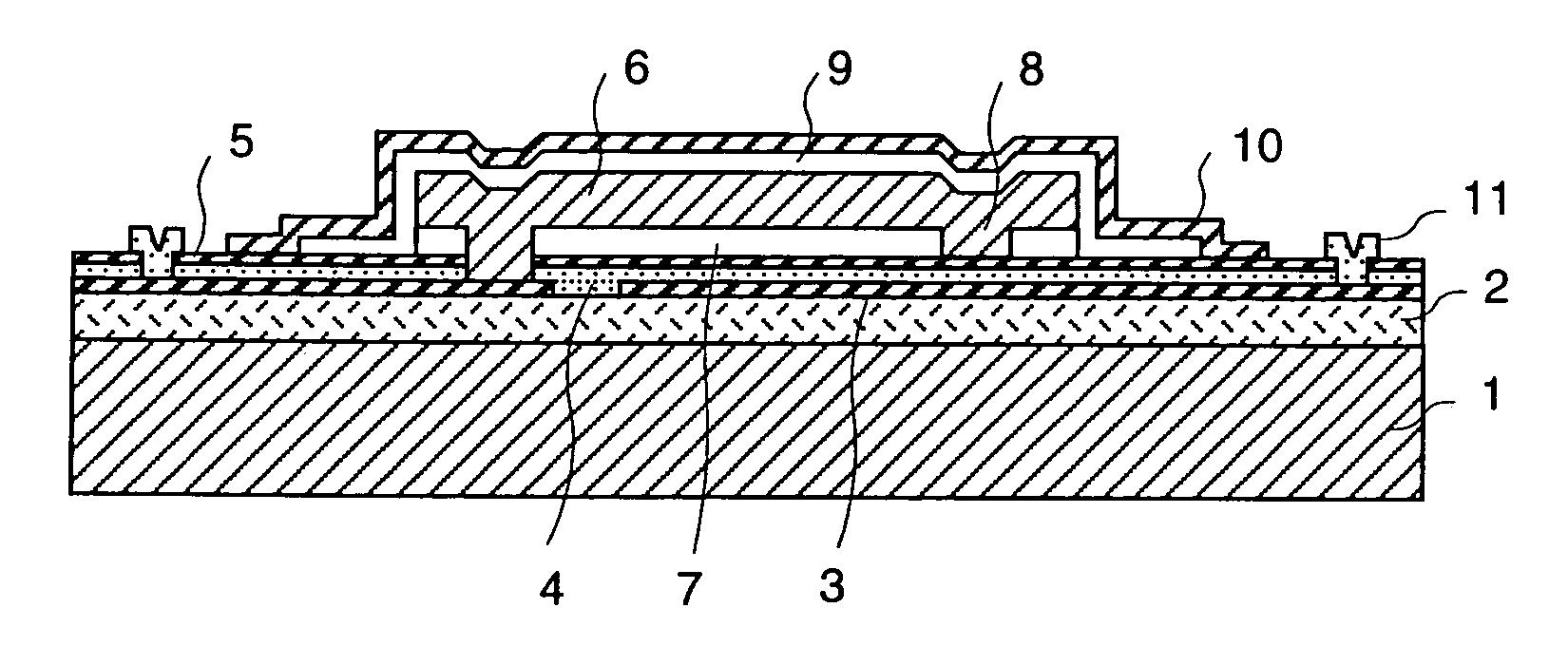

Electronic part and a method of production thereof

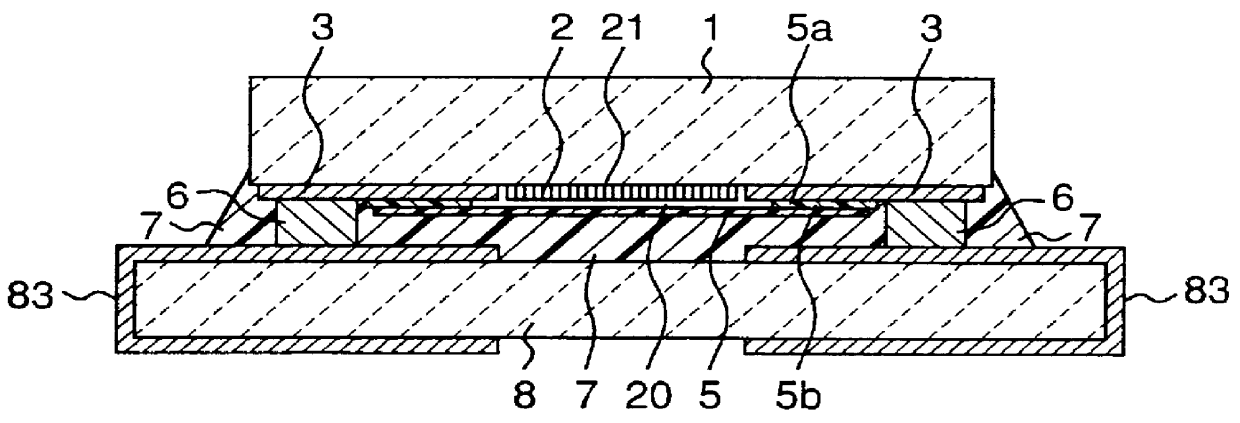

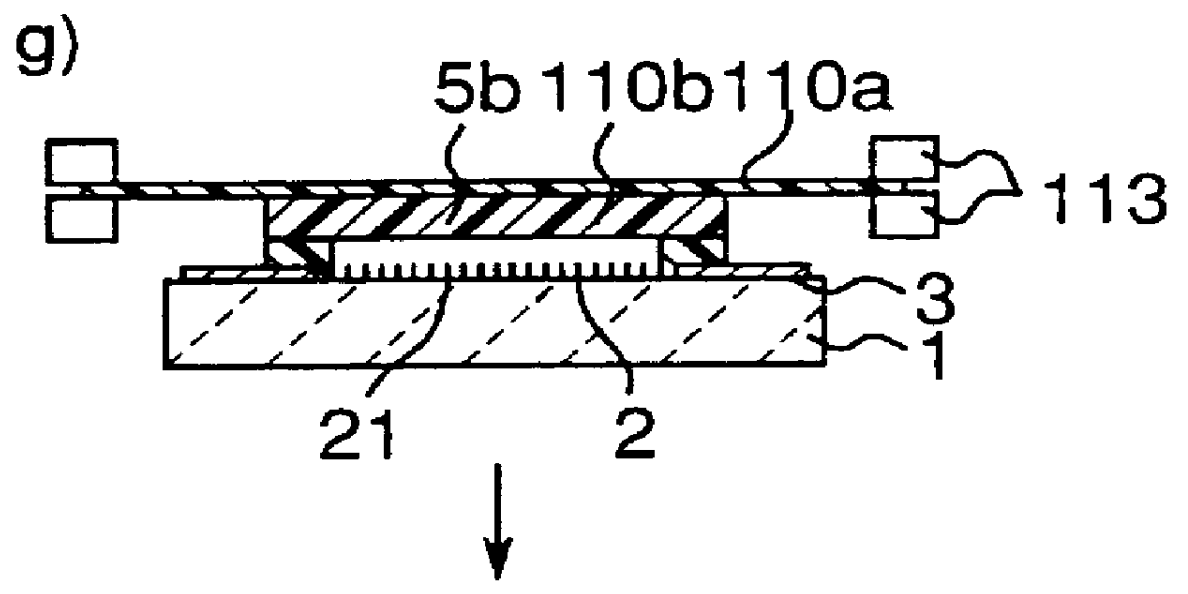

InactiveUS6154940APrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyHermetic sealInterconnection

The present invention relates to an electronic part used for mobile communications apparatuses and the like, and more particularly to an electronic part, such as an acoustic surface-wave device, a piezoelectric ceramic device or the like, which requires an oscillation space near the surface of the functional device chip thereof, and a method of production thereof. With this method, a space retainer for forming a sealed space at the functional portion of the chip can be hermetically sealed and have high moisture resistance, and the process of forming the space retainer can be carried out easily. The electronic part of the present invention comprises a functional device chip, a space retainer for forming a sealed space at the functional portion of the chip, a circuit substrate to which the chip is secured, electrode interconnection portions for establishing electric connection between the chip and the circuit substrate, and a sealing resin for covering and sealing at least the space retainer, wherein the space retainer comprises a support layer made of a synthetic resin film, provided with an opening enclosing the functional portion and joined onto the main surface, and a cover formed and joined onto the support layer so as to cover the functional portion and form a sealed space between the cover and the functional portion.

Owner:SKYWORKS PANASONIC FILTER SOLUTIONS JAPAN

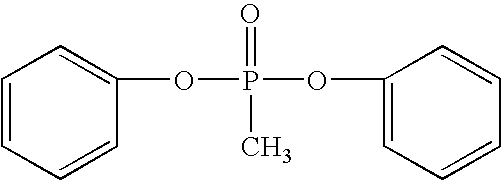

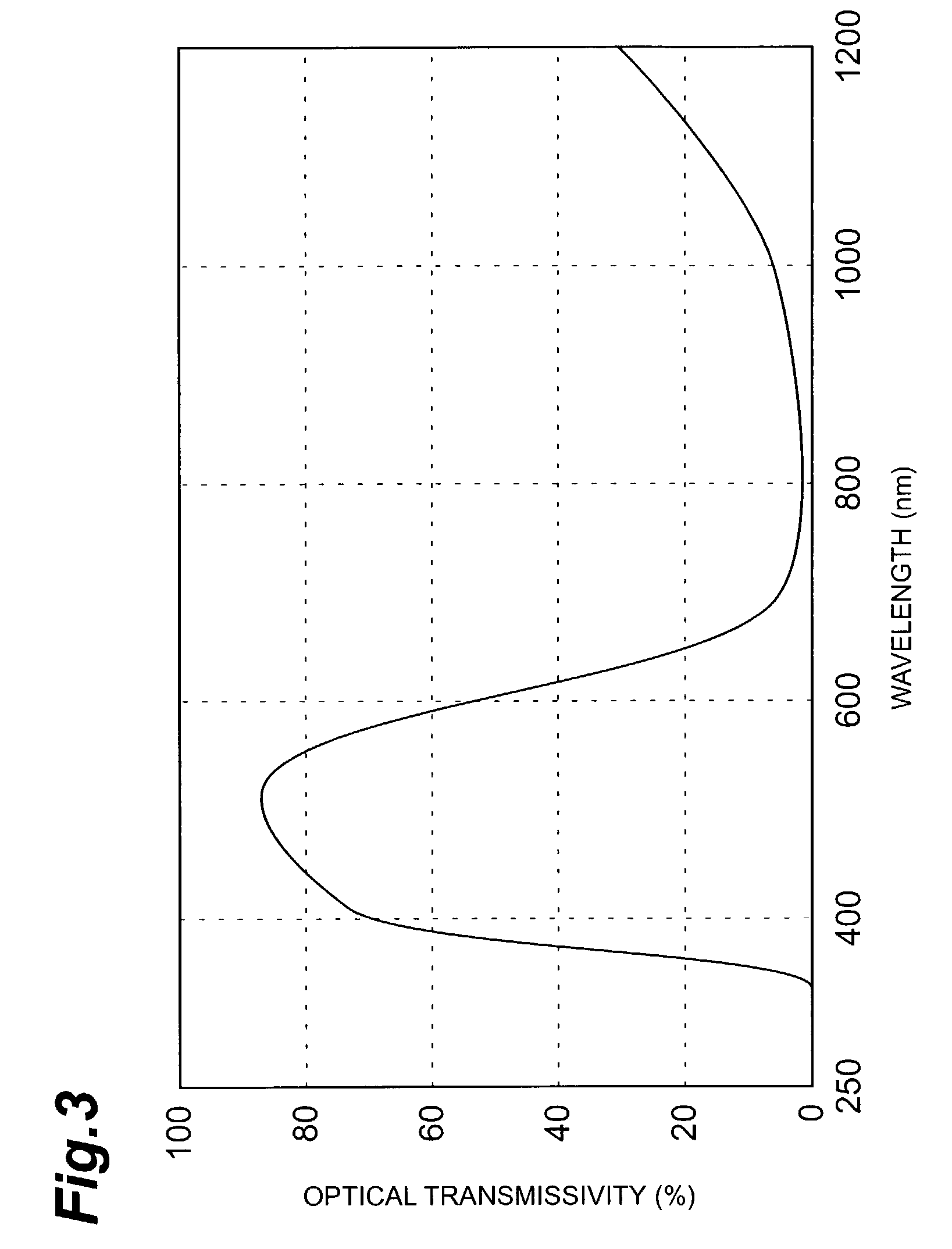

Optical filter and process for producing the same

InactiveUS7025908B1Improve stabilityHigh transparencyTransistorOther chemical processesPhosphoric Acid EstersIon content

The optical filter of the present invention is provided with a near infrared light absorption layer that contains a component composed of copper ions and a phosphoric ester compound expressed by the following Formula (10), in which the phosphorus atom content in the near infrared light absorption layer is 0.4 to 1.3 mol per mole of copper ions, and the copper ion content in the near infrared light absorption layer is 2 to 60 wt %. Thus keeping the phosphorus atom and copper ion content within specific ranges results in good near infrared light absorption and in improved moisture resistance whereby devitrification caused by whitening is suppressed

Owner:KUREHA KAGAKU KOGYO KK

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

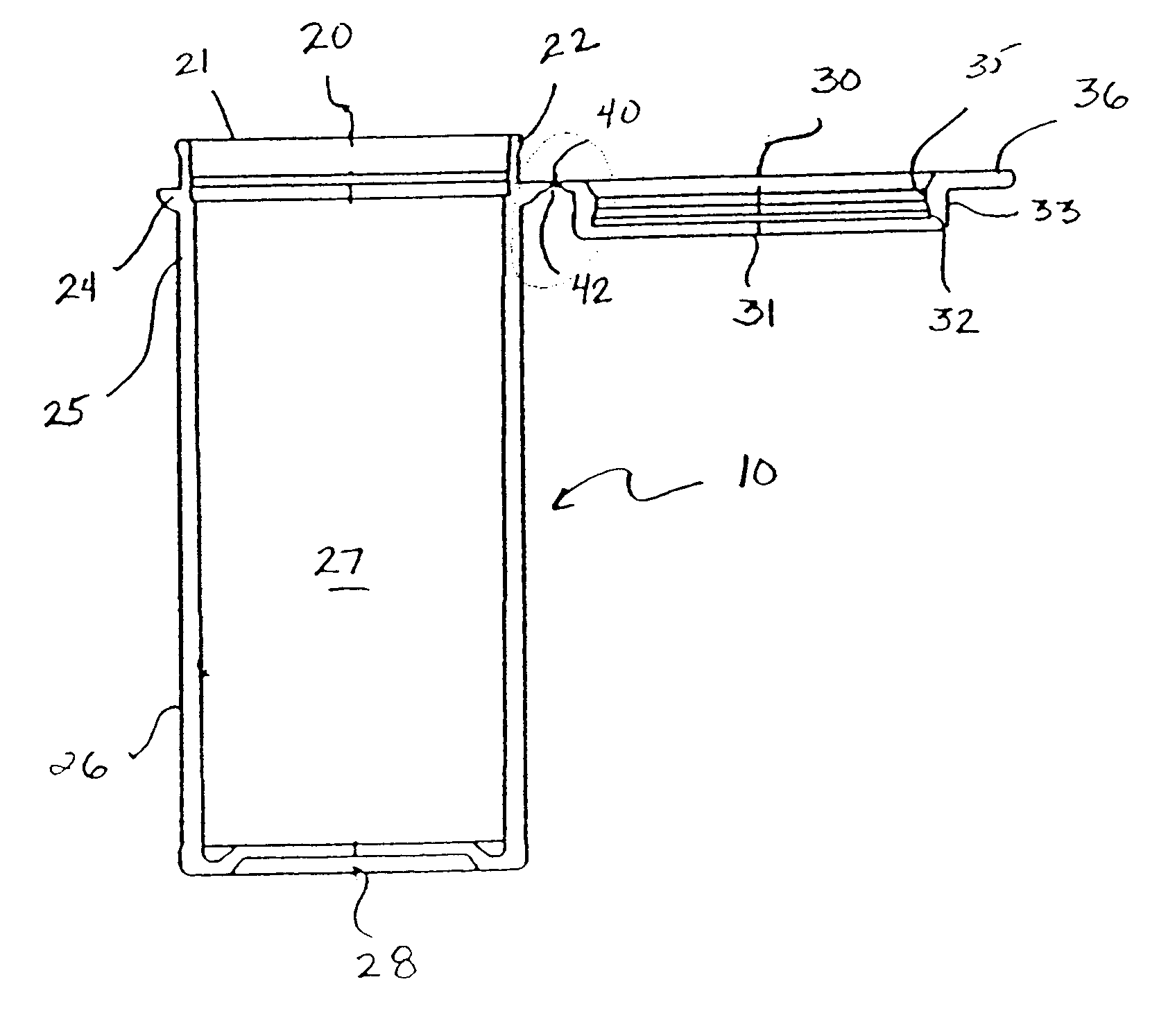

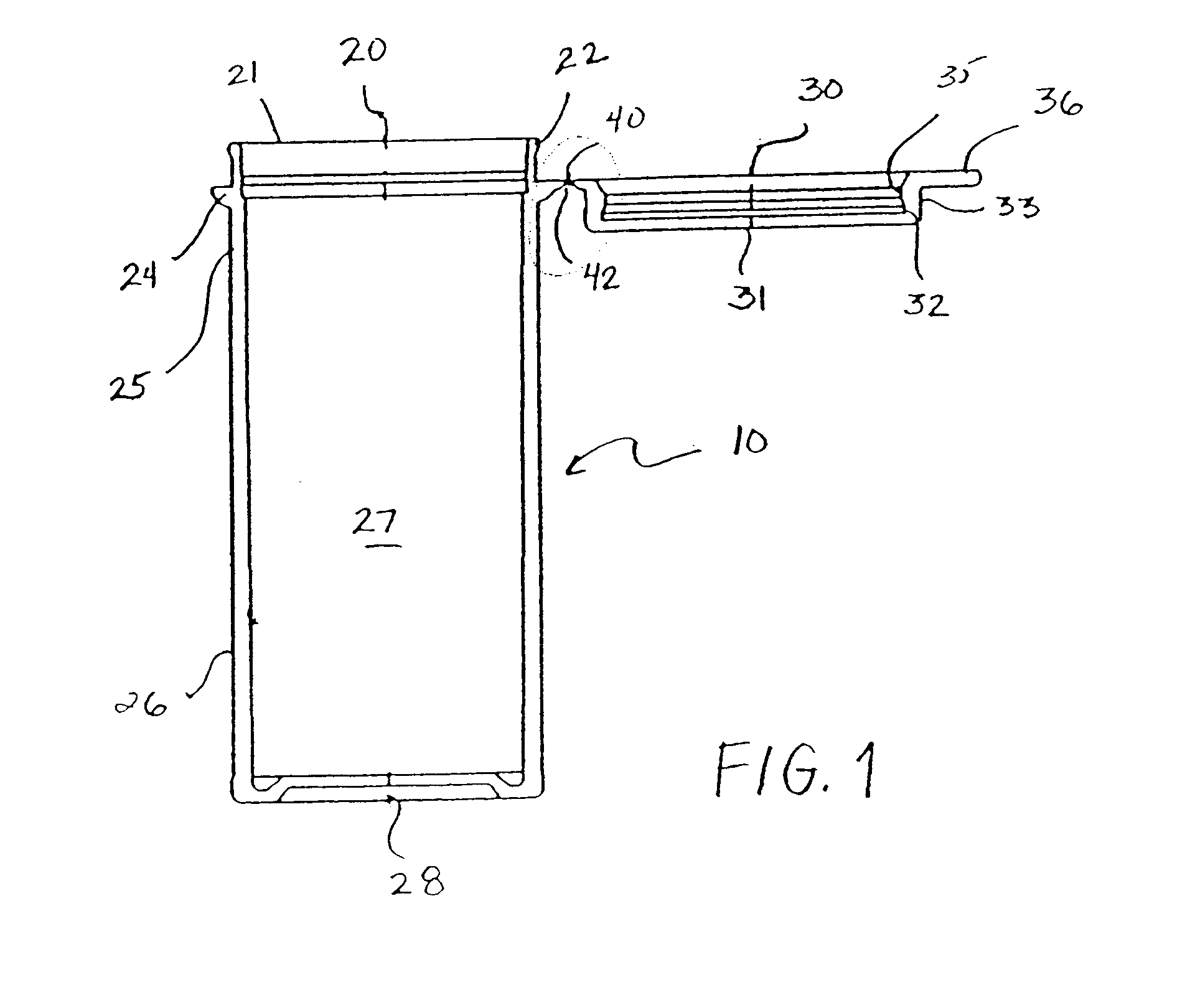

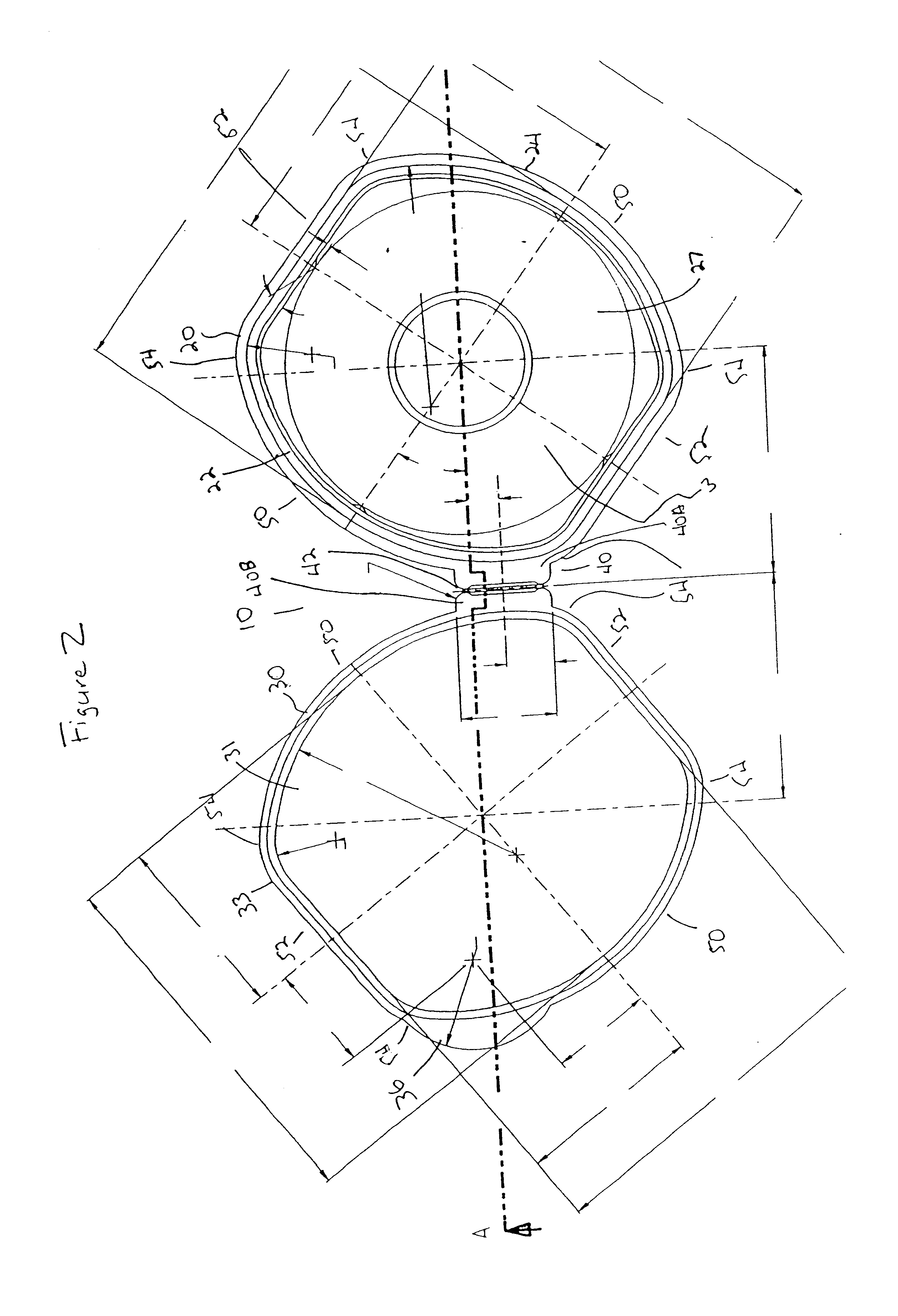

Flip top golf ball container assembly provided with moisture barrier properties

A golf ball and package assembly, comprising: at least one golf ball; a package separable from said golf ball defining a cavity within which said golf ball is positioned, said package comprising: (a) a moisture proof, resealable container and an integrally attached cap, wherein the package has a base, an internal cavity, an outer surface, an upper portion and lower portion, a rim at the upper portion, the cap has a base and a skirt extending perpendicularly around the outer periphery of the base, the cap is provided with a thumb tab for facilitating the opening and closing of the container, and is attached to the package by a hinge; (b) the cap and container are non-circular in shape having curved sides and flat sides, joined by rounded corners; (c) an outer wall of the ridge and wall surfaces of the cap rim define a gap into which rim is fitted to form a moisture proof seal when the cap is in the closed position; and (d) a desiccant insert.

Owner:CSP TECH INC

Method of forming fluoropolymer binders for carbon nanotube-based transparent conductive coatings

InactiveUS7378040B2Improve conductivityNanoinformaticsConductive materialThermoplasticOptical transparency

This invention relates to flexible, transparent and conductive coatings and films formed using carbon nanotubes (CNT) and, in particular, single wall CNT, with polymer binders. Preferably, coatings and films are formed from CNT applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration, and may comprise a basecoat, a topcoat, or a combination thereof, providing enhanced optical transparency, conductivity, moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics, thermosets, insulative, conductive or a combination thereof. A fluoropolymer containing binder is applied onto a CNT-based transparent conductive coating at nanometer level of thickness on a clear substrate. The fluoropolymers or blend can be either semi-crystalline or amorphous. This binder coating and the resulting products can be used for display and electronic applications.

Owner:EIKOS

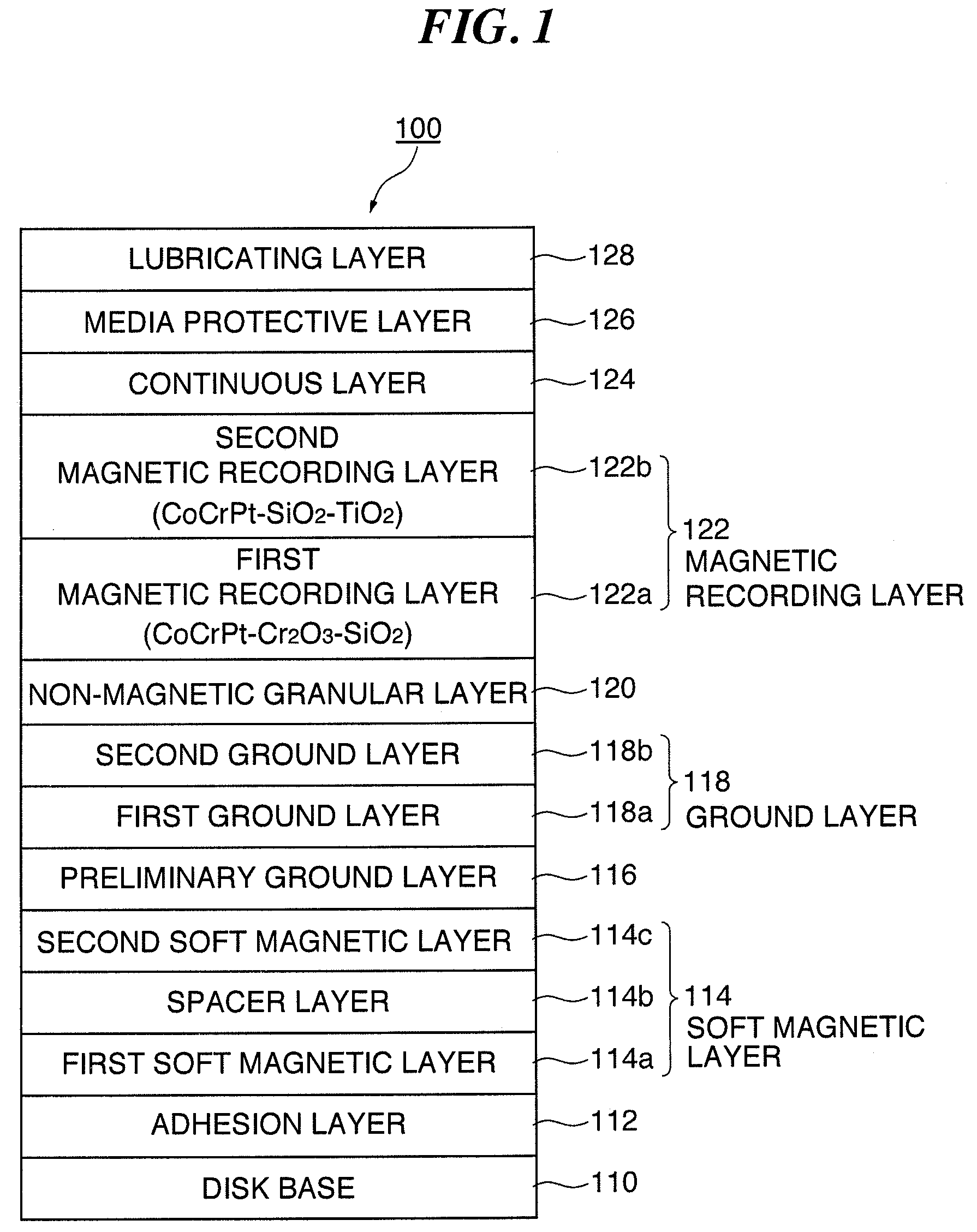

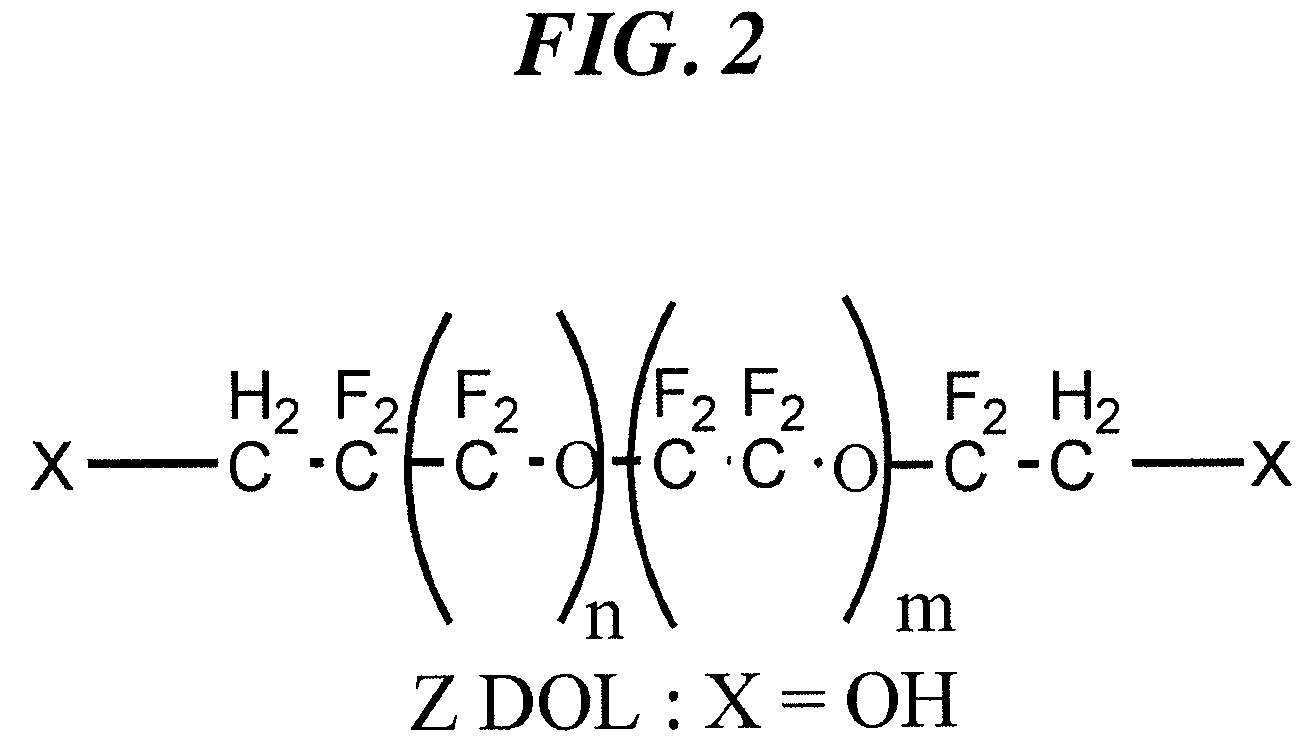

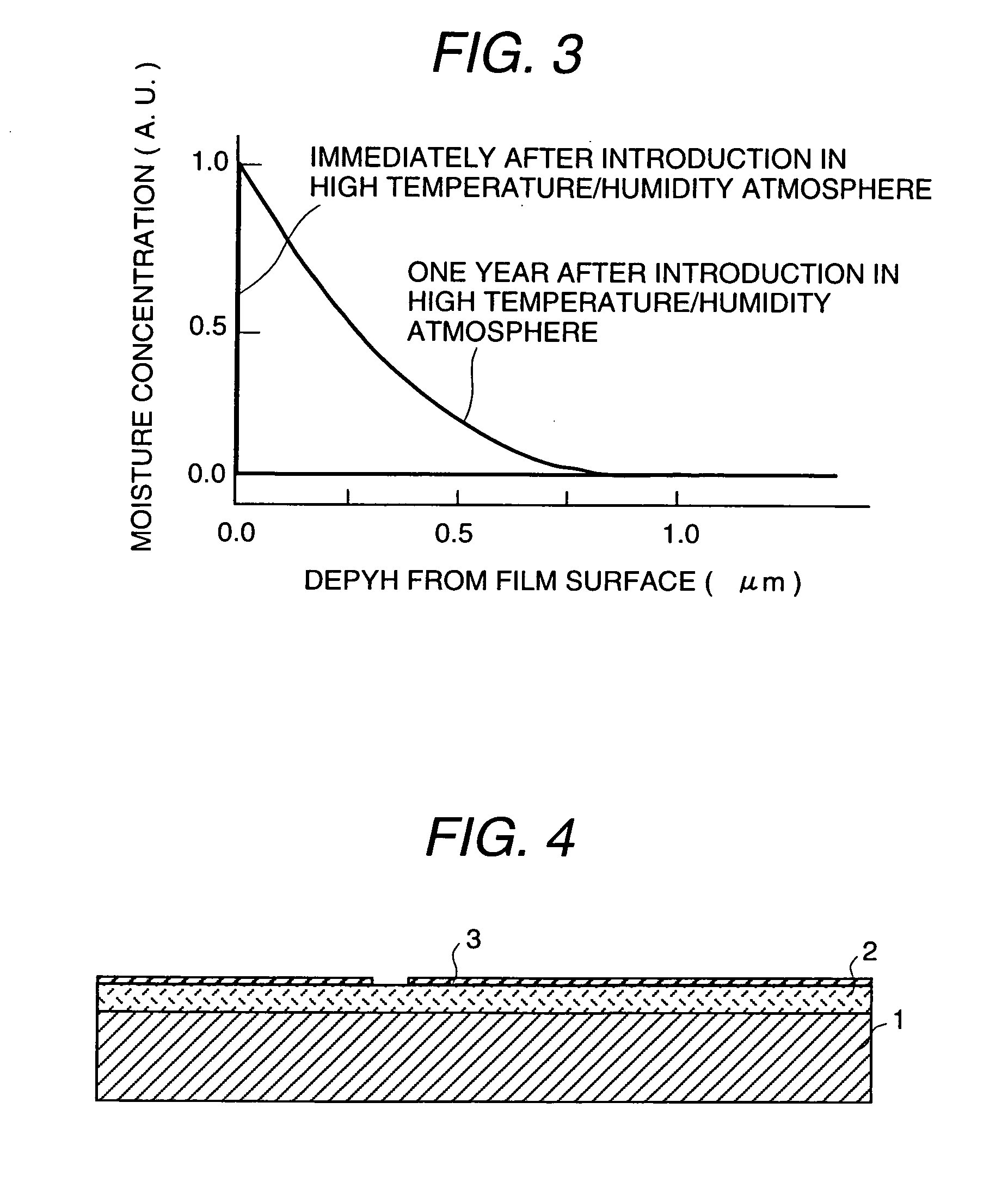

Method of producing a perpendicular magnetic recording medium and perpendicular magnetic recording medium

InactiveUS20140011054A1Solve the lack of durabilitySolve the lack of resistanceProtective coatings for layersRecord information storageBond densityMoisture resistance

Owner:WD MEDIA SINGAPORE PTE

Method of producing a perpendicular magnetic recording medium and perpendicular magnetic recording medium

InactiveUS8623529B2Solve the lack of durabilitySolve the lack of resistanceMagnetic materials for record carriersRecord information storageBond densityMoisture resistance

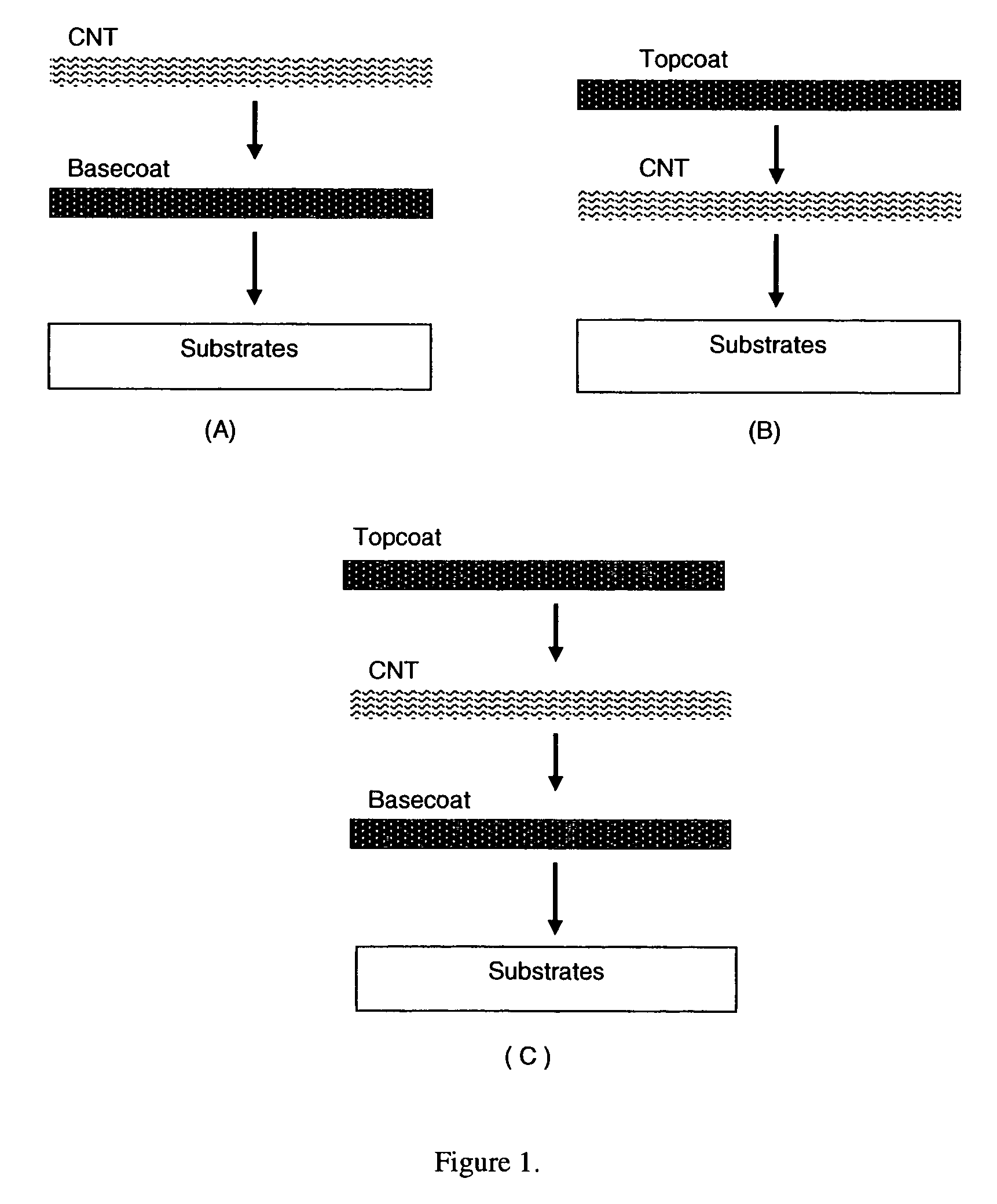

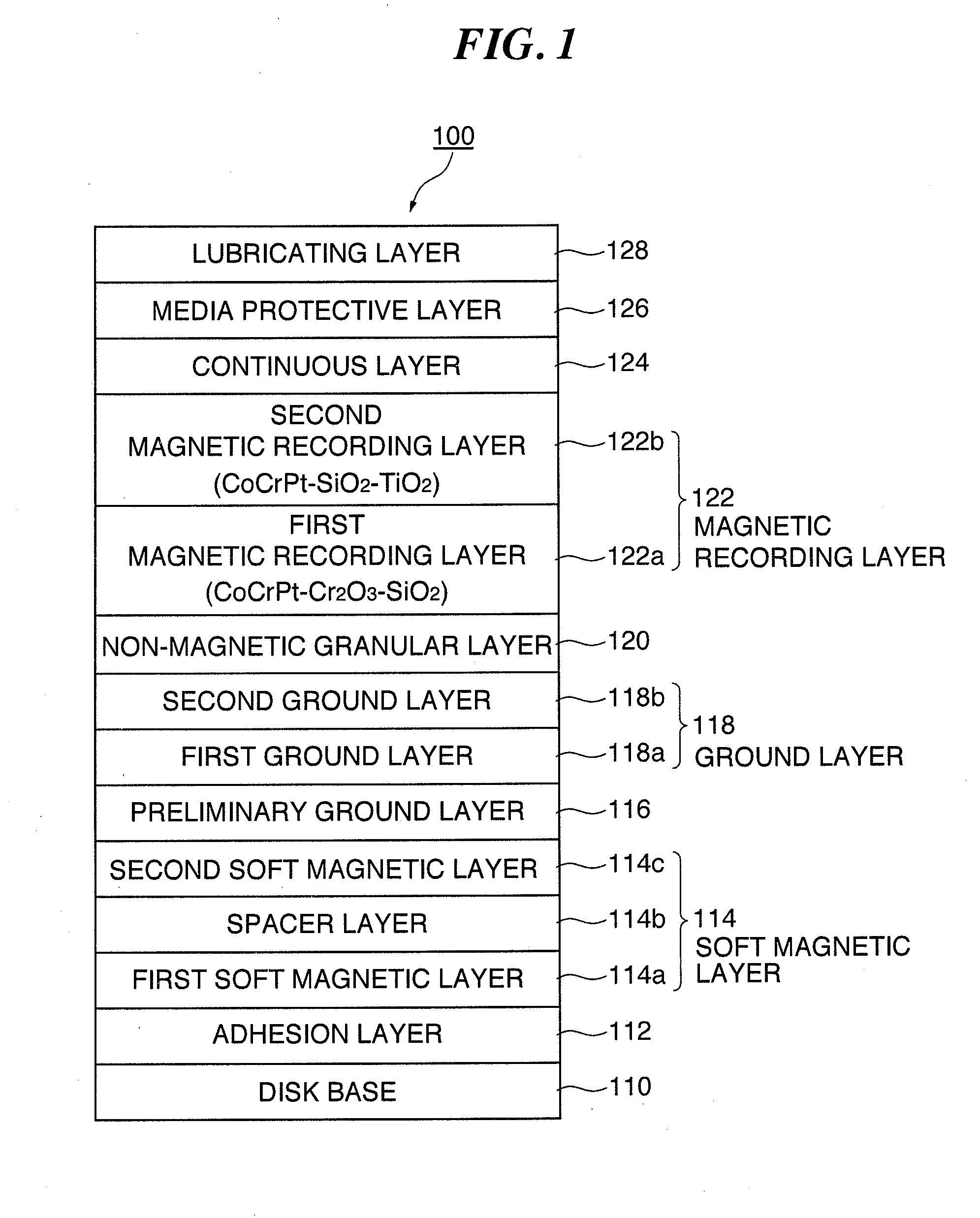

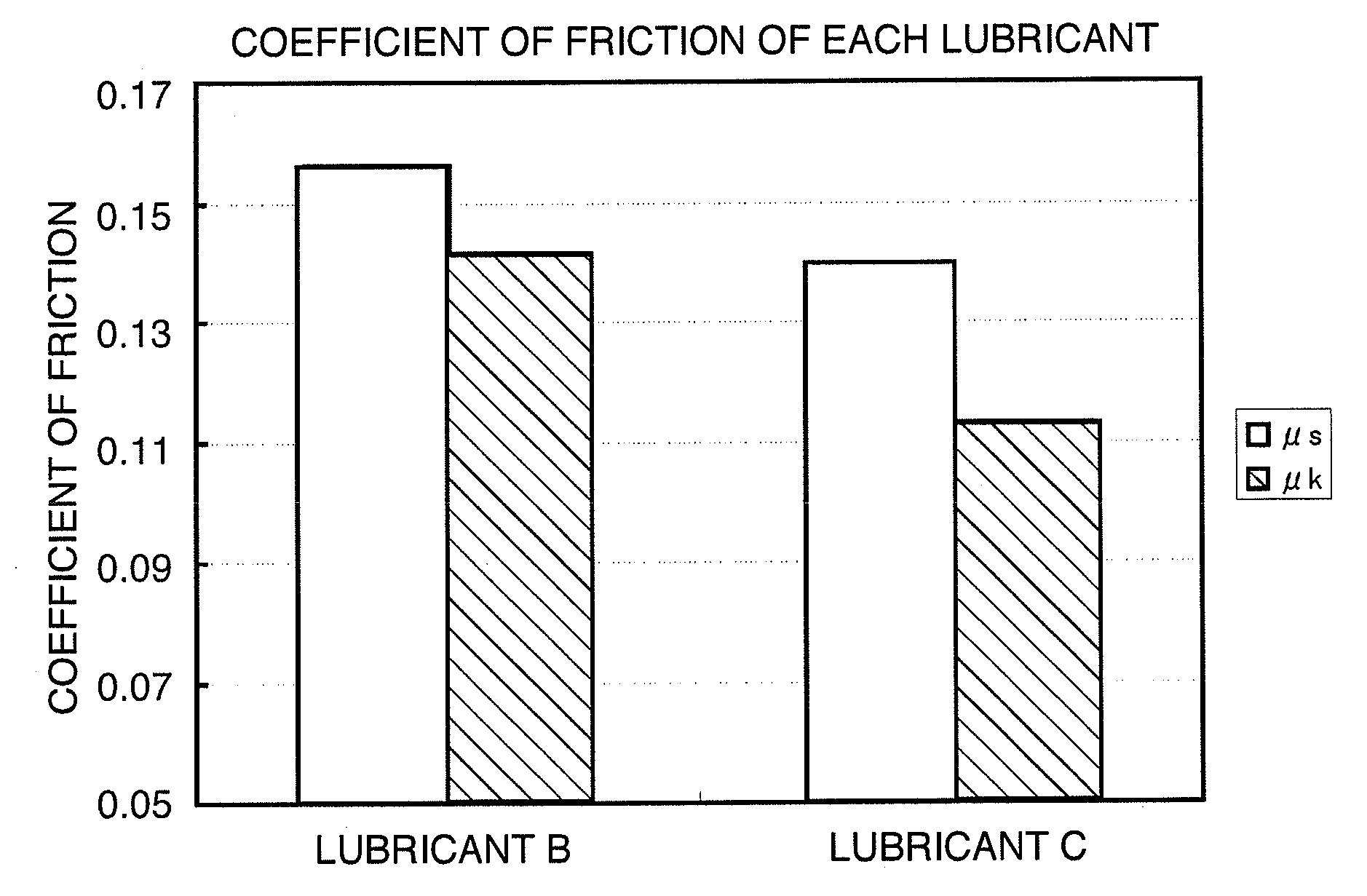

An object of the present invention is to provide a perpendicular magnetic recording medium including a suitable lubricating layer with sufficient durability, moisture resistance, and contamination resistance and also maintaining an R / W characteristic. In a typical structure of the present invention, a method of manufacturing a perpendicular magnetic recording medium 100 including a magnetic recording layer 122, a medium protective layer 126, and a lubricating layer 128 in this order on a base 110 includes: a CF bond density measuring step of measuring a CF bond density of a lubricant; and a lubricating layer forming step of forming a lubricating layer with the lubricant when the measured CF bond density is 2.0×1022 to 2.7×1022 atoms / cm3.

Owner:WD MEDIA SINGAPORE PTE

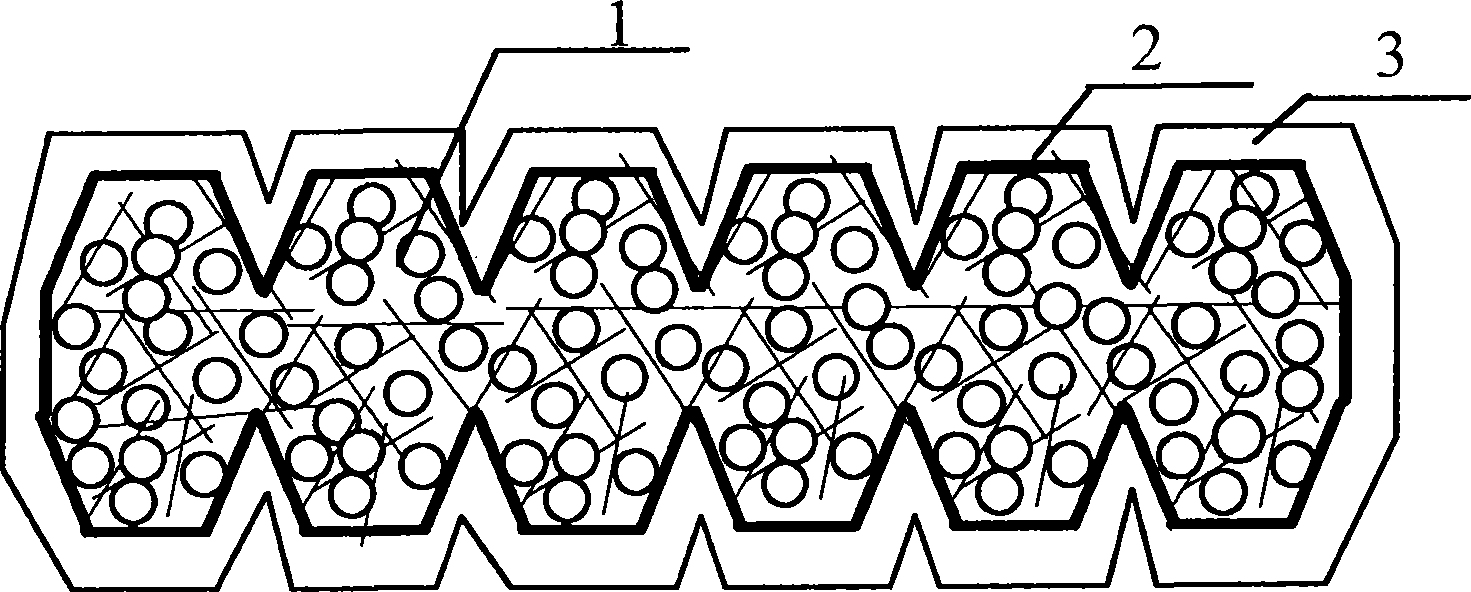

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

Easily Adhesive Polyester Film and Film for Protecting Back Side of Solar Cell Using the Same

InactiveUS20080050583A1Improve adhesionEasy to stickFilm/foil adhesivesSynthetic resin layered productsVitrificationPolyvinyl alcohol

An easily adhesive polyester film is provided which is used for protection of the back side of a solar cell, the adhesive polyester film comprising a polyester film and a resin film situated on a surface of the polyester film, the resin film comprising a crosslinking agent and a resin selected from the group consisting of a polyester resin having a glass transition point of 20 to 100° C., an acrylic resin having a glass transition point of 20 to 100° C., a combination of the resins and a combination of at least one of the resins and a polyvinyl alcohol having a saponification degree of 70 to 90 mol %. This film has excellent adhesion to EVA while having excellent mechanical properties, heat resistance and moisture resistance.

Owner:TEIJIN DUPONT FILMS JAPAN

Fast dissolving orally consumable films containing a modified starch for improved heat and moisture resistance

A consumable film adapted to adhere to and dissolve in the oral cavity of a warm-blooded animal including humans, comprising a modified starch, a pharmaceutically active agent and, optionally, at least one water soluble polymer.

Owner:MCNEIL PPC INC

Laminates comprising ionomer interlayers with low haze and high moisture resistance

A laminate comprises an ionomeric interlayer sheet which, in turn, comprises or is prepared from a sodium / zinc mixed ionomer that comprises carboxylate groups and a combination of counterions that consists essentially of sodium cations and zinc cations. The sodium / zinc mixed ionomer is the neutralization product of a precursor acid copolymer. The precursor acid copolymer comprises copolymerized units of an α-olefin and an α,β-ethylenically unsaturated carboxylic acid, and it has a melt flow rate of about 70 to about 1000 g / 10 min. In addition, the precursor acid copolymer, when neutralized to a level of about 40% to about 90%, and when comprising counterions that consist essentially of sodium ions, produces a sodium ionomer that has a freeze enthalpy that is not detectable or that is less than about 3.0 j / g, when determined by differential scanning calorimetry.

Owner:DOW GLOBAL TECH LLC

Dry powder for inhalation

InactiveUS7186401B2Reduce sensitivityMinimize impactBiocidePowder deliveryInhalable particlesInhalation

The aim of the invention is to improve the moisture resistance of dry powder formulations for inhalation which contain a pharmaceutically ineffective carrier of not-inhalable particle size and a finely divided pharmaceutically active compound of inhalable particle size and to also improve the storage stability of said formulations. To this end, magnesium stearate is used in said formulations. One of the features of the inventive dry powder is that a high fine particle dosage or fine particle fraction can be maintained also under relatively extreme temperature and humidity conditions.

Owner:JAGOTEC AG

Packaging material for battery

ActiveUS20030180609A1Small-sized cells cases/jacketsCell sealing materialsPolymer scienceHermetic seal

Disclosed is a packaging material for forming an armor body for a battery, the armor body being adapted for use in such a manner that a battery body is inserted into the armor body and the peripheral edge of the armor body is then heat sealed for hermetic sealing, the packaging material being a laminate comprising at least a substrate layer, an adhesive layer, a barrier layer, a dry laminate layer, and a sealant layer, characterized in that at least the sealant layer comprises a low-fluidity polypropylene layer having low susceptibility to collapse upon exposure to heat and pressure at the time of heat sealing and a high-fluidity polypropylene layer having high susceptibility to collapse upon exposure to heat and pressure at the time of heat sealing, and the innermost layer is the high-fluidity polypropylene layer. This battery packaging material can impart moisture barrier properties and resistance to contents of the battery.

Owner:DAI NIPPON PRINTING CO LTD

Semiconductor pressure sensor and pressure sensing device

InactiveUS6892582B1Increase productivityIncreased durabilityFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsPressure senseEngineering

The object of the present invention is to propose an etch channel sealing structure characterized by excellent impermeability to moisture and resistance to temporal change of the diaphragm in the pressure sensor produced according to the sacrificial layer etching technique, and to provide a pressure sensor characterized by excellent productivity and durability. After a very small gap is formed by the sacrificial layer etching technique, silicon oxide film is deposited by the CVD technique or the like, thereby sealing the etch channel. Further, impermeable thin film of polysilicon or the like is formed to cover the oxide film.This allows an etch channel sealing structure to be simplified in the pressure sensor produced according to the sacrificial layer etching technique, and prevents entry of moisture into the cavity, thereby improving moisture resistance. Moreover, sealing material with small film stress reduces temporal deformation of the diaphragm.

Owner:HITACHI LTD +1

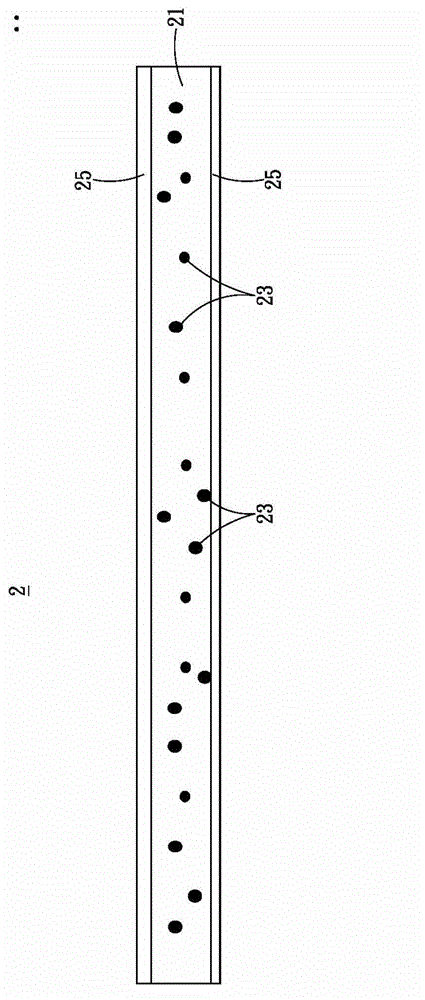

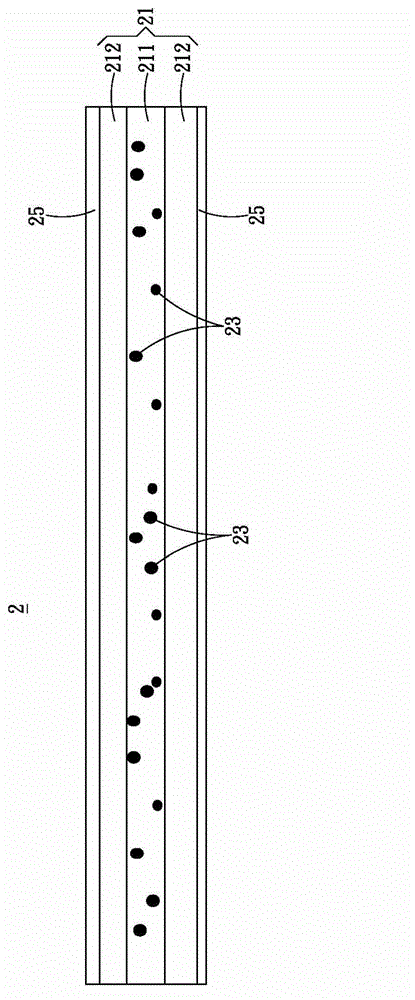

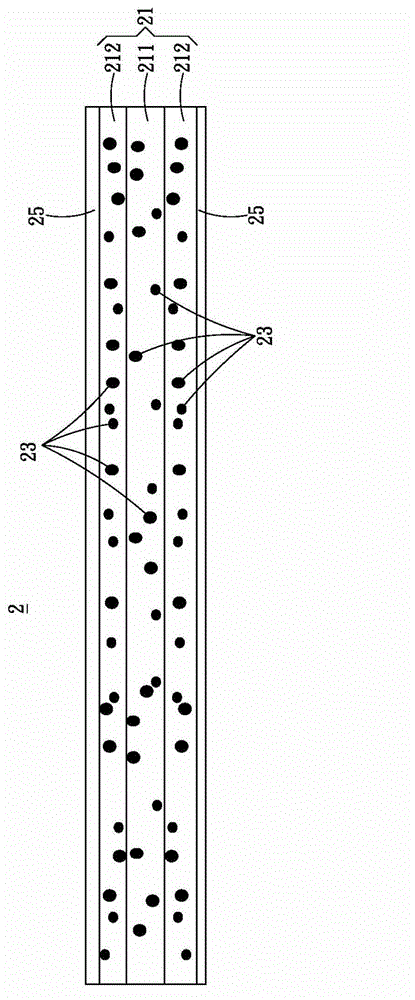

Direct type backlight module and light source diffusion structure thereof

InactiveCN102980136ASolve the problem of being exposed to short-wave light sourcesSolve heat recessionPoint-like light sourceSpectral modifiersPhosphorQuantum dot

The invention provides a direct type backlight module and a light source diffusion structure thereof, wherein the light diffusion structure comprises a diffusion body, a plurality of quantum dot phosphor powders and a plurality of moisture resistance layers; the quantum dot phosphor powders are diffused in the diffusion body; and the moisture resistance layers are positioned on a surface of the diffusion body. The quantum dot phosphor powders are diffused in the diffusion body of a diffusion board or a diffusion sheet, so service life is prolonged and light recession is retarded.

Owner:AU OPTRONICS CORP

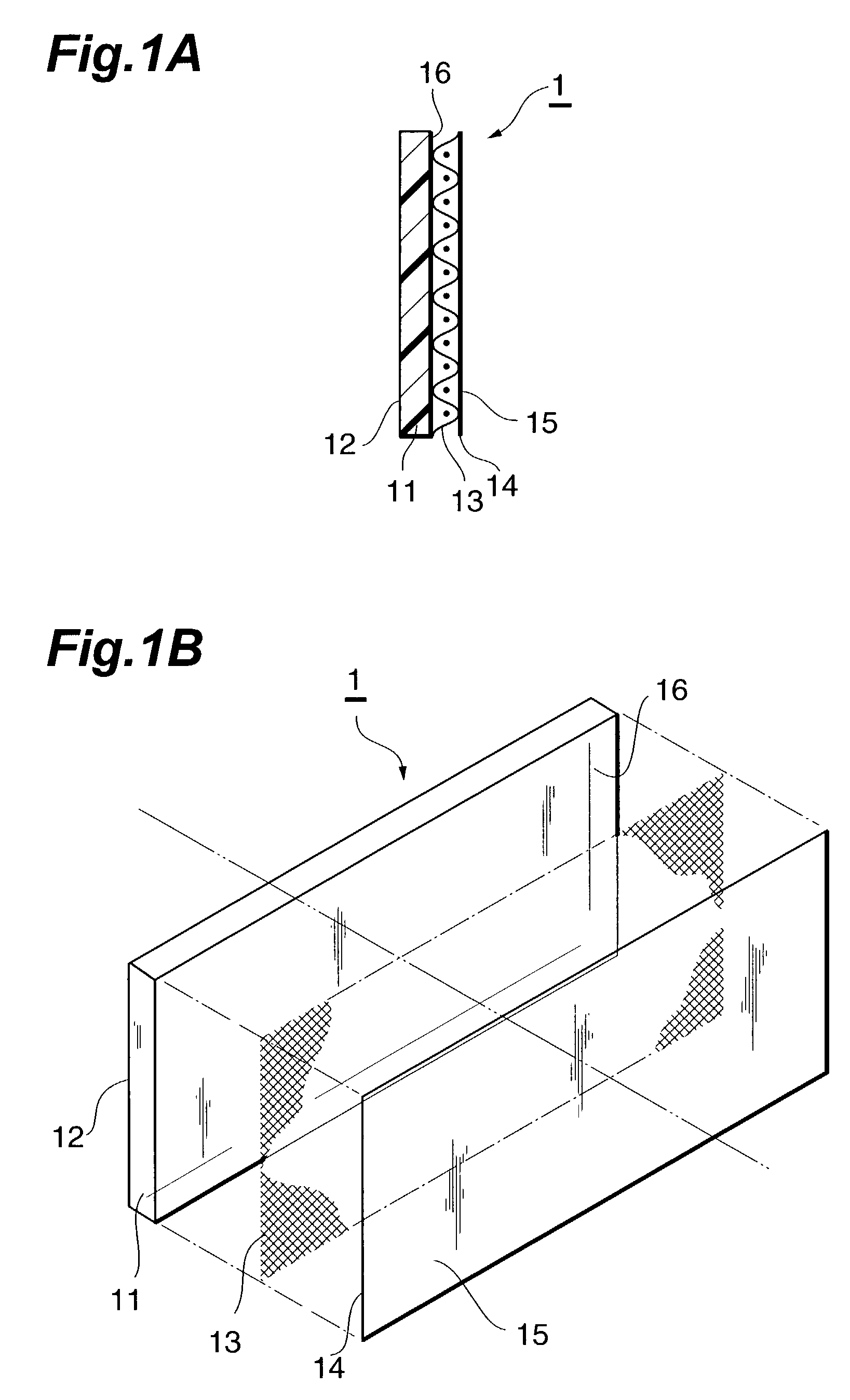

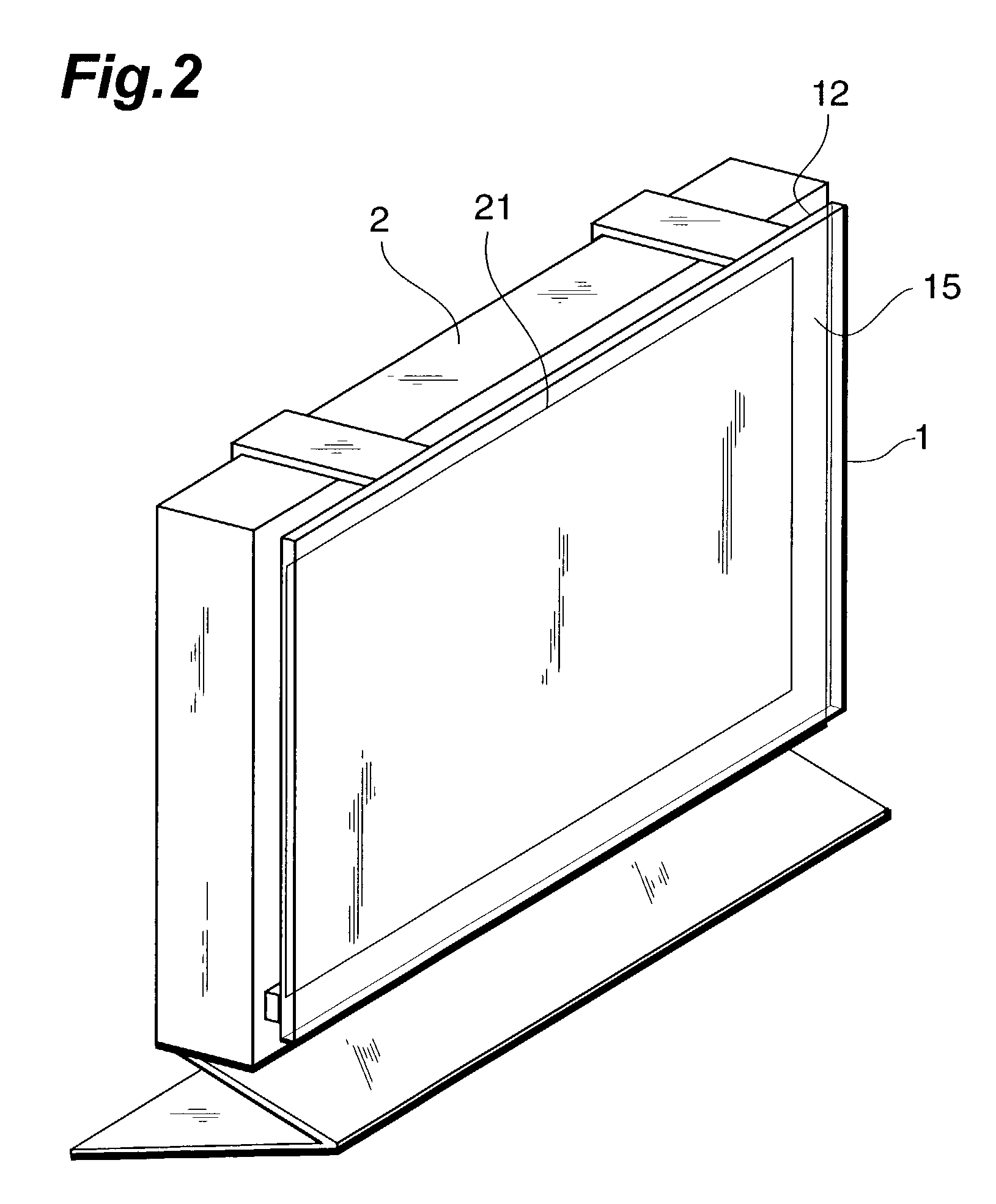

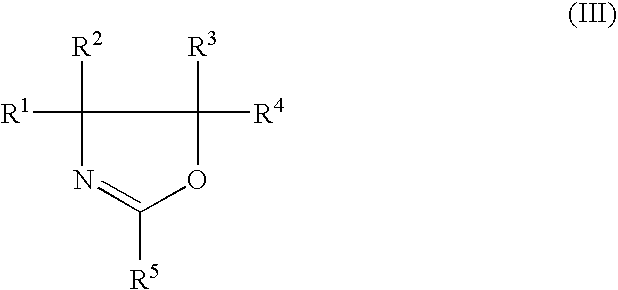

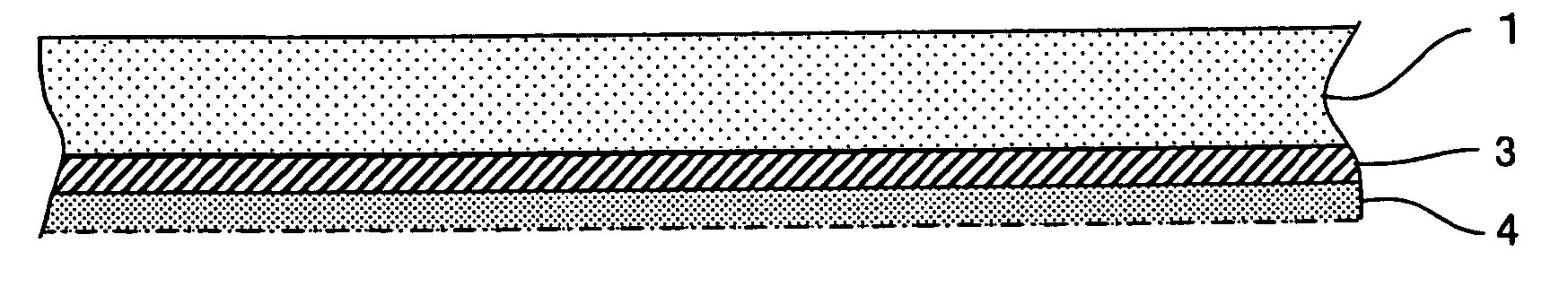

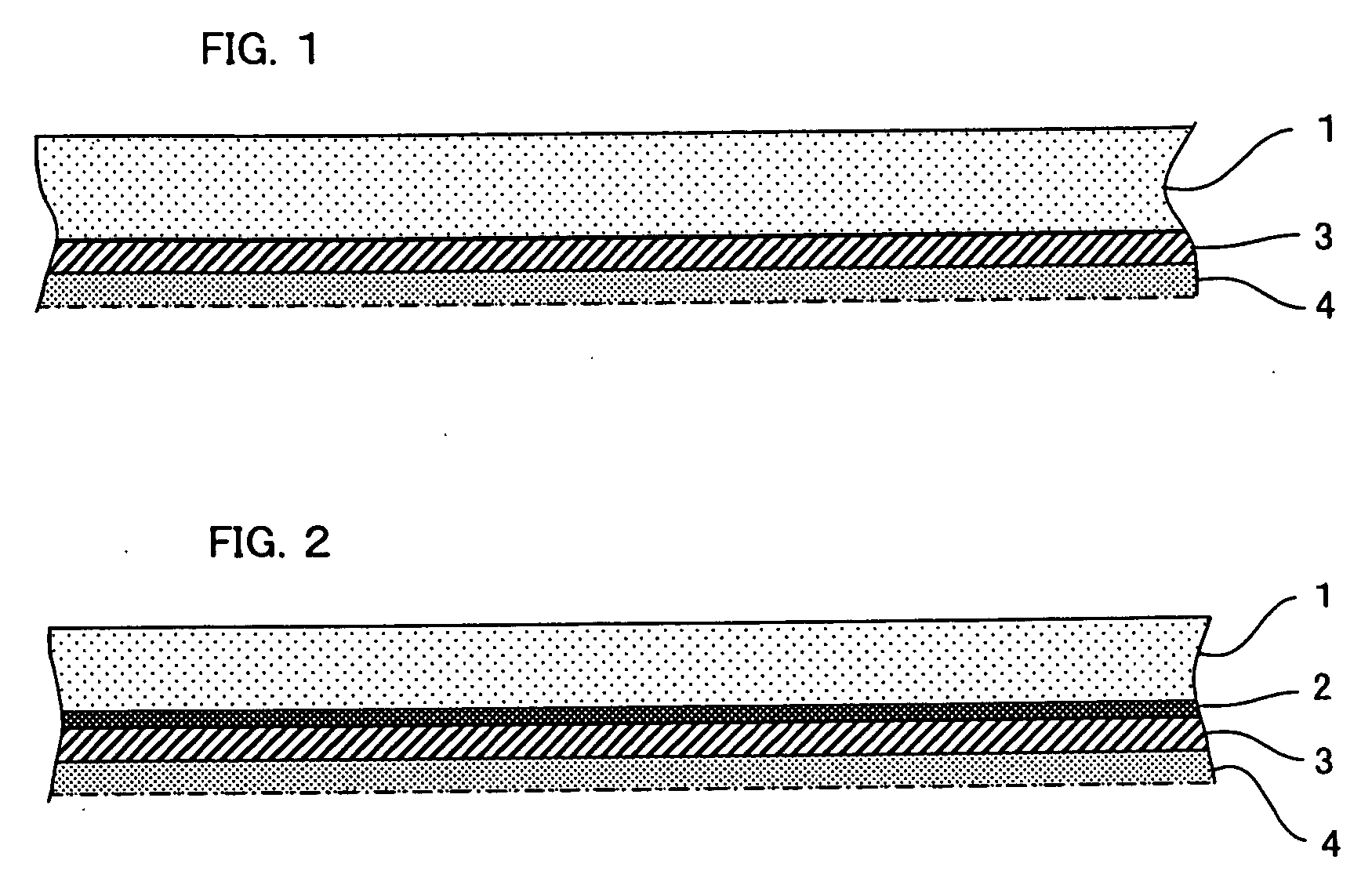

Adhesive composition, adhesive optical film and image display device

ActiveUS20060188712A1Improve adhesionImprove heat resistanceBlast furnace componentsSynthetic resin layered productsPolymer scienceMeth-

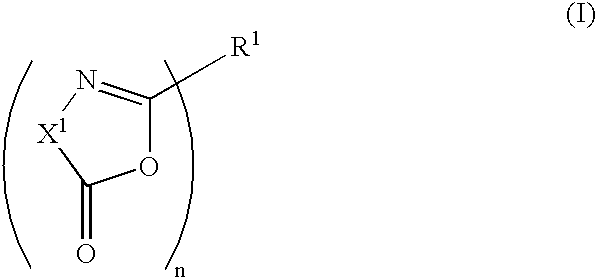

To provide an adhesive composition which shows high adhesion with a glass substrate and has excellent heat resistance, moisture resistance and moist heat resistance, an adhesive optical film comprising an adhesive layer made of the adhesive composition, which shows high adhesion between the adhesive layer and an optical film and effectively suppresses the occurrence of adhesive residue and lack of adhesive and also has excellent heat resistance, moisture resistance and moist heat resistance, and an image display device comprising the adhesive optical film, the adhesive optical film comprises an optical film 1, an adhesive layer 3 made of a water dispersible adhesive composition comprising, as raw monomers, an alkyl(meth)acrylate ester whose alkyl group has 4 to 18 carbon atoms, a carboxyl group-containing vinyl monomer, a phosphoric acid group-containing vinyl monomer, and a copolymerizable vinyl monomer which is optionally copolymerizable with the above monomers, wherein a carboxyl group concentration is from 0.05 to 1.50 mmol / g and a phosphoric acid group concentration is from 0.01 to 0.45 mmol / g in the raw monomers, an under coat layer 2 containing an oxazoline group-containing polymer, and being interposed between the optical film 1 and the adhesive layer 3, and the adhesive optical film is applied onto an image display device.

Owner:NITTO DENKO CORP

Method for preparing chitosan-based composite preservative film or coating

The invention relates to a method for preparing a chitosan-based composite preservative film or a coating, belonging to the technical field of food preservation. According to the technical scheme, the method comprises the following steps: dissolving chitosan in an aqueous solution of acetic acid, adding an aqueous solution of natural active substances with antioxidant and antibacterial functions, heating, stirring and ultrasonically defoaming to obtain the chitosan-based composite preservative film or a coating film solution; casting and drying the chitosan-based composite preservative film or the coating film solution to obtain a chitosan-based composite preservative film; and coating the chitosan-based composite preservative film or the coating film solution on the surface of food so as to obtain the chitosan-based composite preservative coating. According to the prepared chitosan-based composite preservative film or the coating, the antibacterial performance and the moisture resistance of the chitosan film are improved, and the chitosan-based composite preservative film or the coating is endowed with novel antioxidant functions and has degradable and edible characteristics. When meat, oil or fruit and vegetable foods are packaged or coated by the obtained chitosan-based composite preservative film or the coating, the quality guarantee period can be effectively prolonged, and the chitosan-based composite preservative film or the coating has wide application prospect.

Owner:JILIN UNIV

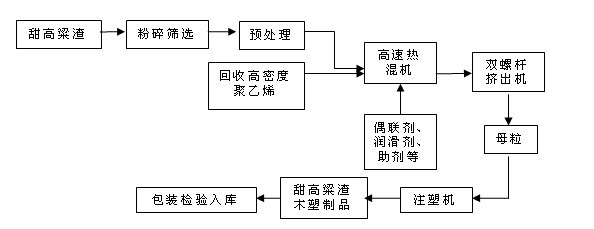

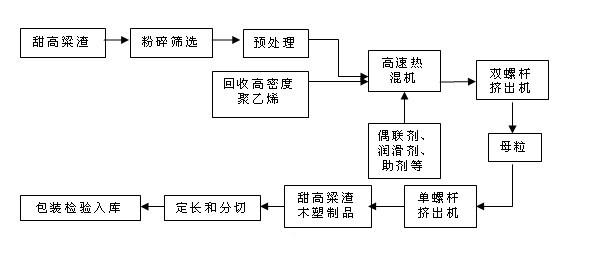

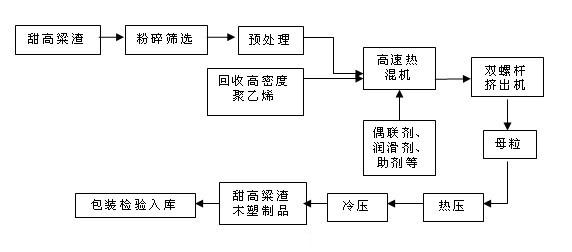

Wood-plastic composite material using sweet sorghum slag as enhanced phase and preparation method for wood-plastic composite material

InactiveCN102690525AGood mechanical propertiesImprove performanceCoatingsAgricultural engineeringMoisture resistance

The invention discloses a wood-plastic composite material using sweet sorghum slag as an enhanced phase and a preparation method for the wood-plastic composite material. The wood-plastic composite material comprises 10 to 80 parts of sweet sorghum slag and 20 to 90 parts of recycled plastic, wherein the sweet sorghum slag and the recycled plastic serve as a matrix phase; and the sweet sorghum slag is subjected to combined pretreatment by an alkali-oxygen method and a steam explosion method. Sectional materials such as a sweet sorghum slag wood-plastic four-pore board, a sauna board, garden protective process, walls and the like are manufactured by extruding a fixed die and forming, or sweet sorghum slag wood-plastic products are manufactured by formation such as injection molding, pressing and the like. The sweet sorghum slag wood-plastic products can be suitable for large-scale continuous batch production and has the advantages of high performance, low cost, moth resistance, moisture resistance, no formaldehyde and the like. Compared with the conventional wood powder fillings, the wood-plastic composite material has the advantages of light weight, high performance, low cost, high extrusion speed, low processing temperature and the like, wherein the mechanical performance of the sweet sorghum slag subjected to treatment is superior to that of wood powder. The sweet sorghum slag wood-plastic composite material has good economic benefits, social benefits and ecological benefits of reducing environmental pollution, protecting forest resource and promoting economic development.

Owner:BEIJING UNIV OF CHEM TECH

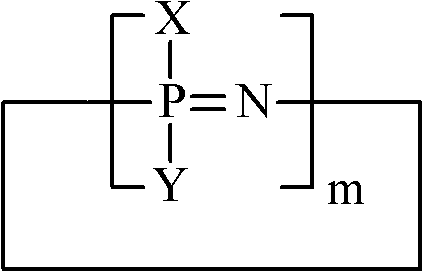

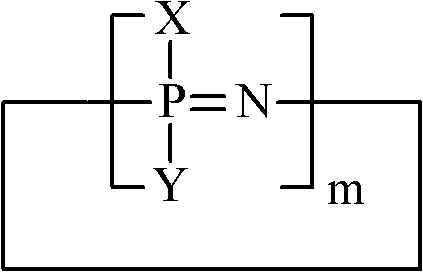

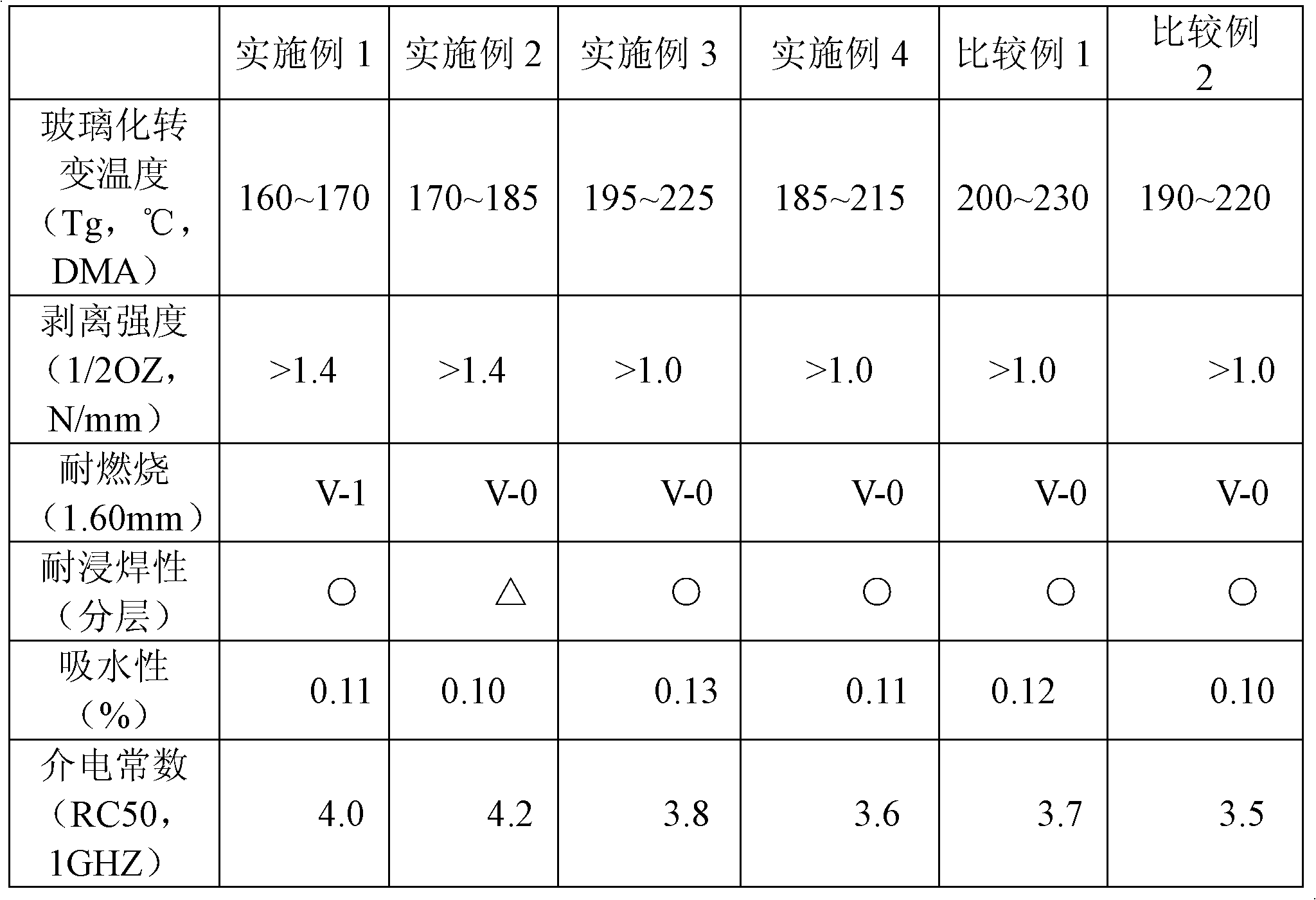

Halogen-free resin composition and method for preparing copper-clad plate from the halogen-free resin composition

ActiveCN102977551ASmall dielectric lossImprove electrical performanceSynthetic resin layered productsLaminationDielectric lossHeat resistance

The invention discloses a halogen-free resin composition and a method for preparing a copper-clad plate from the halogen-free resin composition. Based on the total weight part of solid ingredients of the halogen-free resin composition, the halogen-free resin composition comprises, by weight, 5 to 50 parts of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene, 15 to 85 parts of a thermosetting resin, 1 to 35 parts of a crosslinking curing agent, 0 to 5 parts of a crosslinking curing accelerator and 0 to 100 parts of a filling material. Through introduction of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene having very low water absorbency into the thermosetting resin, the halogen-free resin composition can satisfy halogen-free flame-retardation requirements, improve system electrical properties, and realize non-halogenation of a high-frequency high-speed substrate material. The copper-clad plate prepared from the halogen-free resin composition satisfies halogen-free requirements, has excellent heat resistance and moisture resistance and has a low dielectric loss.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com