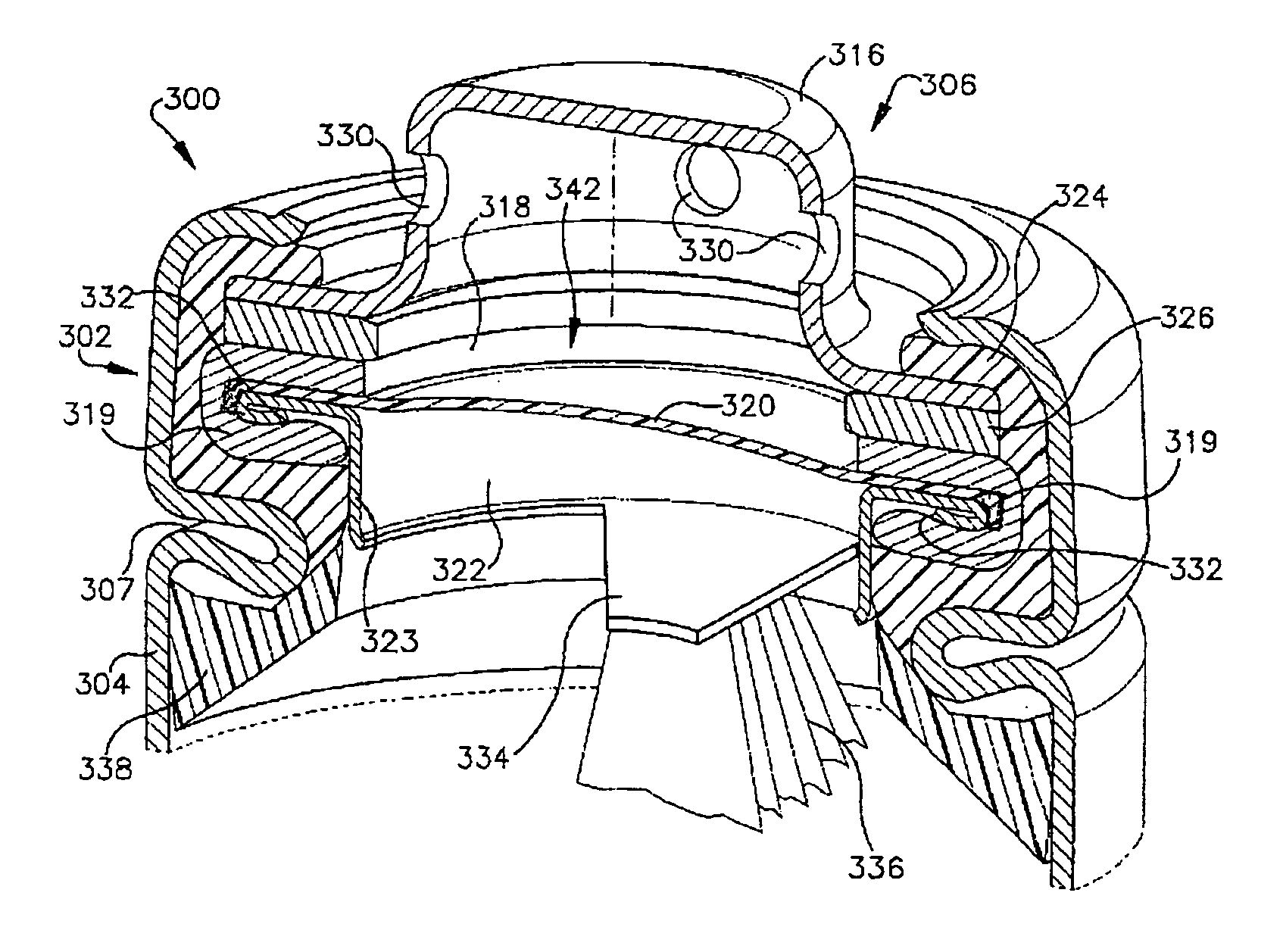

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4351results about "Cell sealing materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

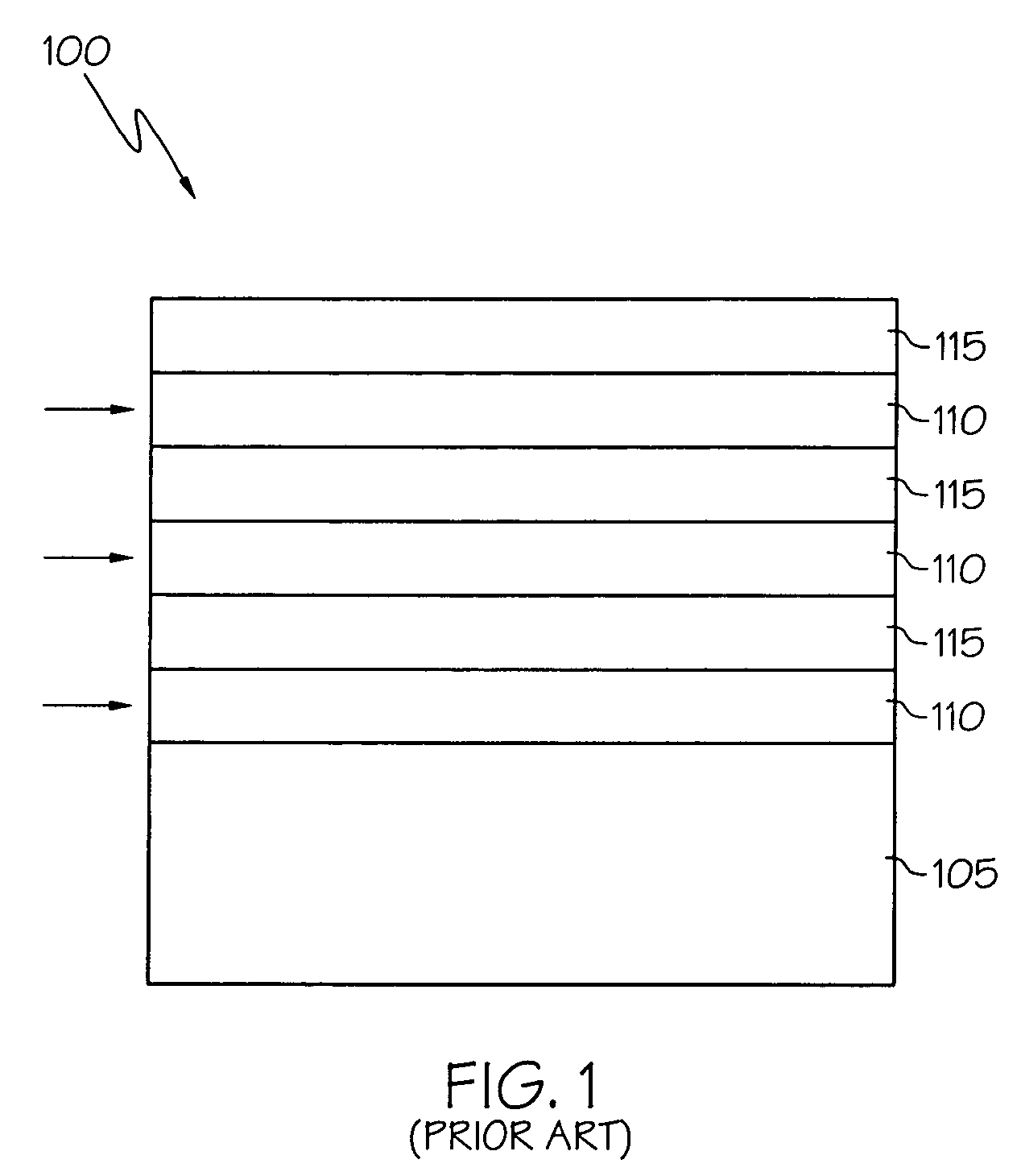

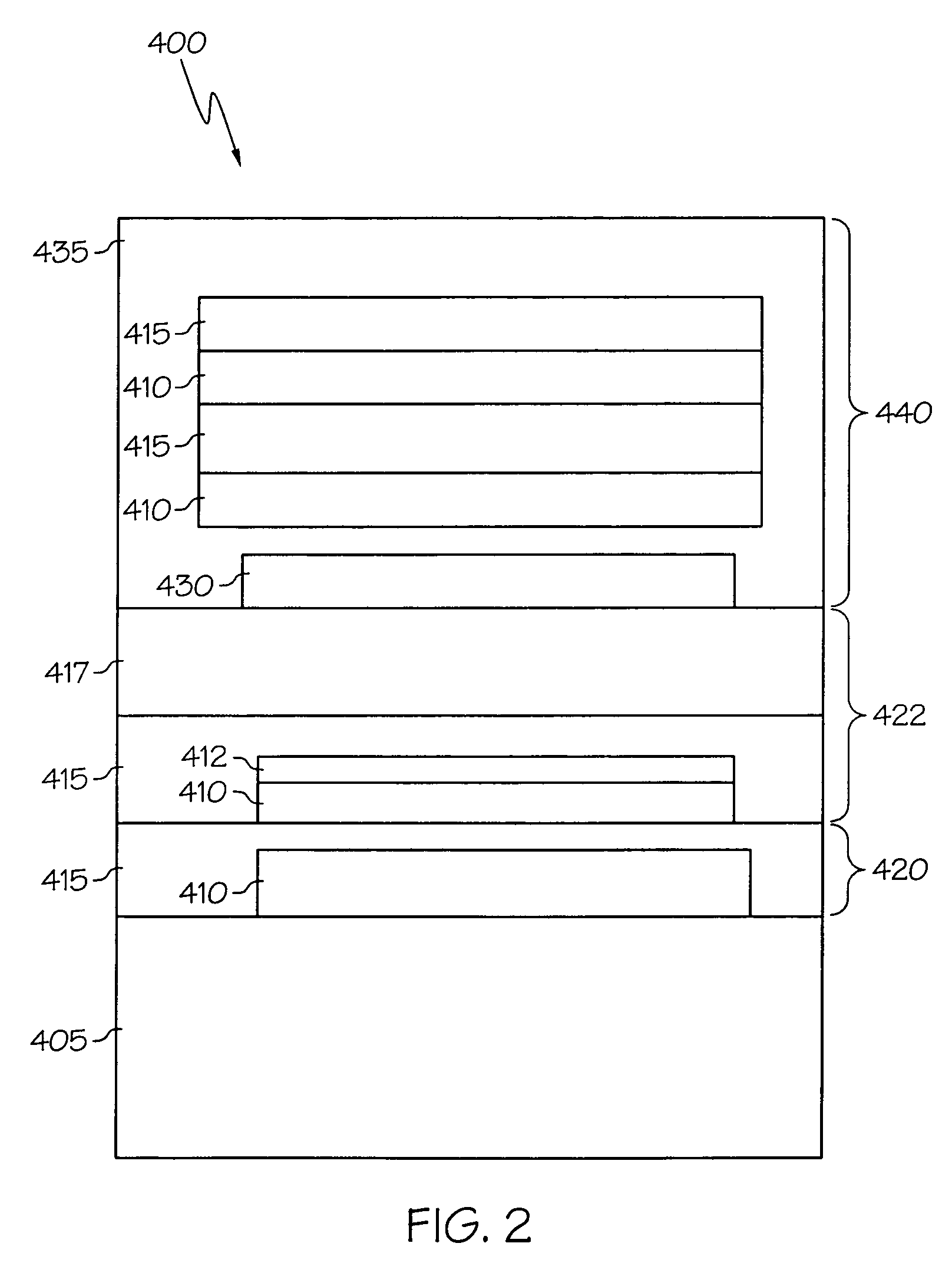

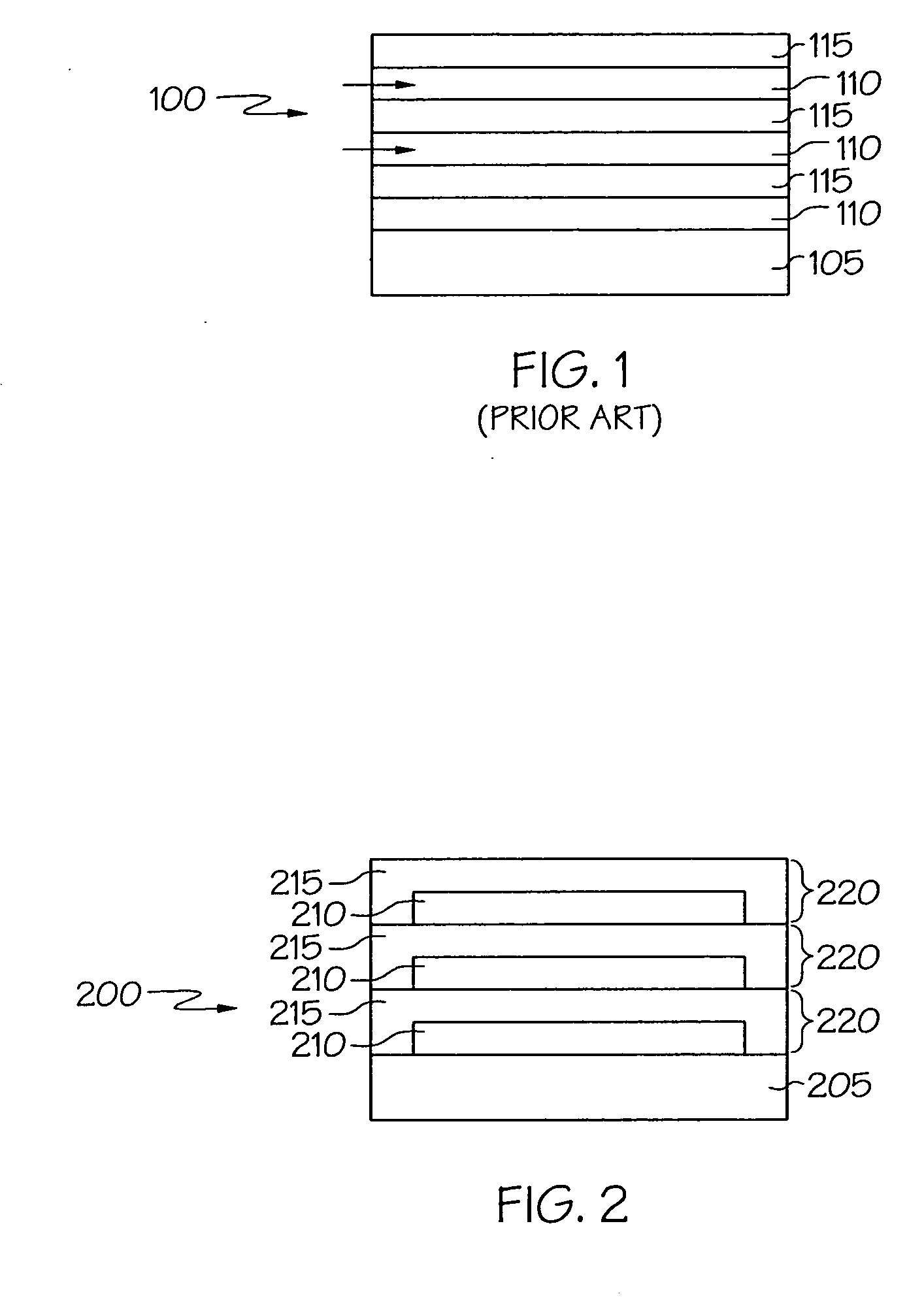

Method for edge sealing barrier films

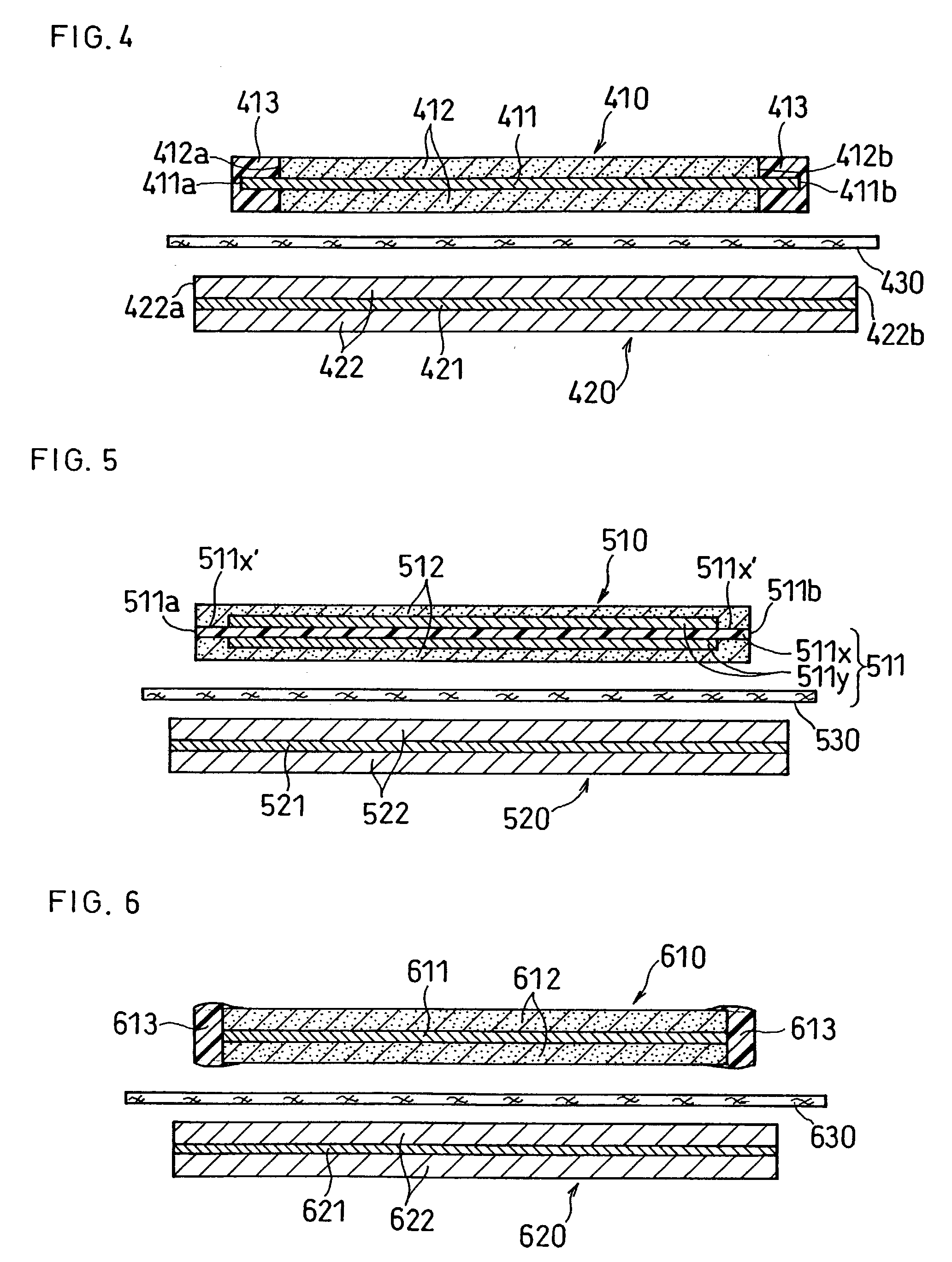

An edge-sealed barrier film composite. The composite includes a substrate and at least one initial barrier stack adjacent to the substrate. The at least one initial barrier stack includes at least one decoupling layer and at least one barrier layer. One of the barrier layers has an area greater than the area of one of the decoupling layers. The decoupling layer is sealed by the first barrier layer within the area of barrier material. An edge-sealed, encapsulated environmentally sensitive device is provided. A method of making the edge-sealed barrier film composite is also provided.

Owner:SAMSUNG DISPLAY CO LTD

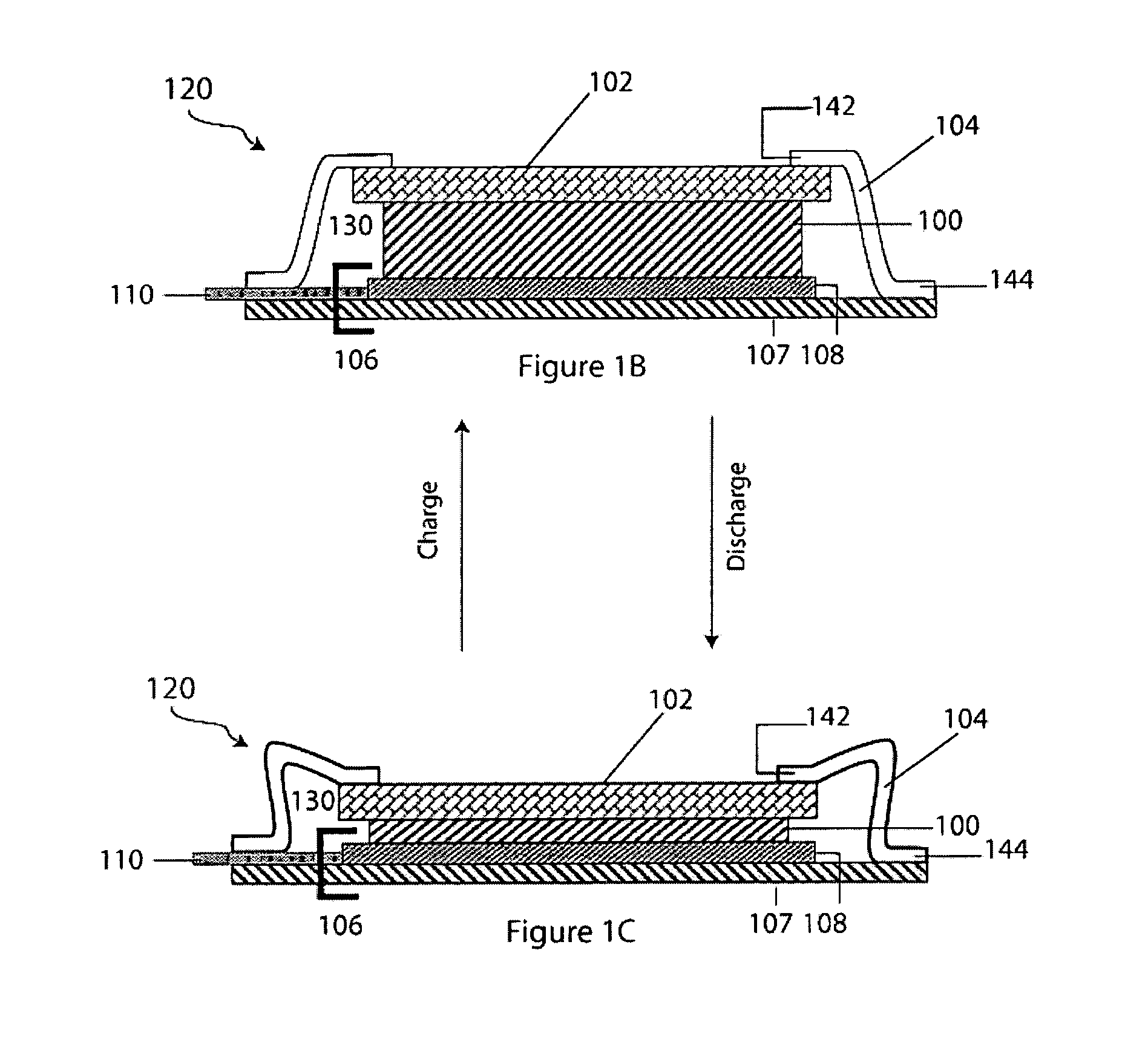

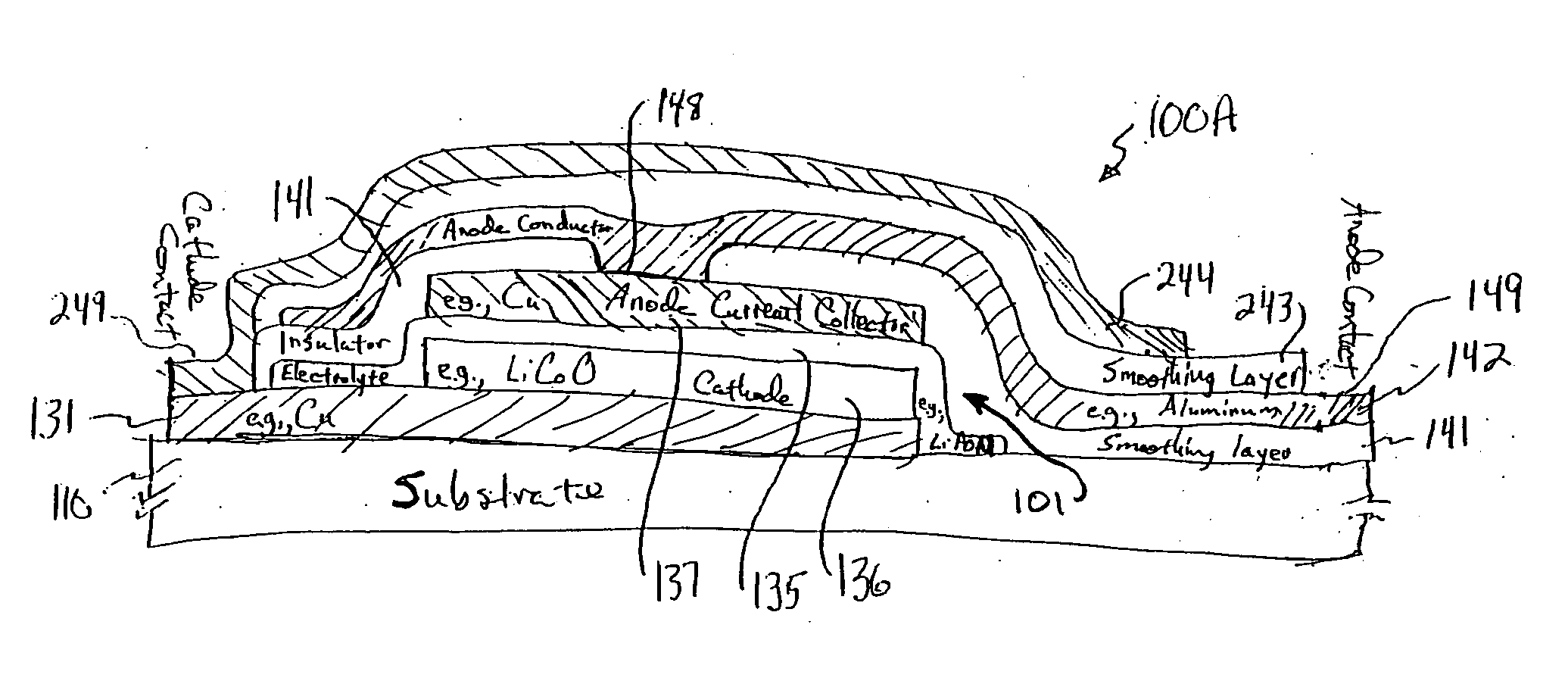

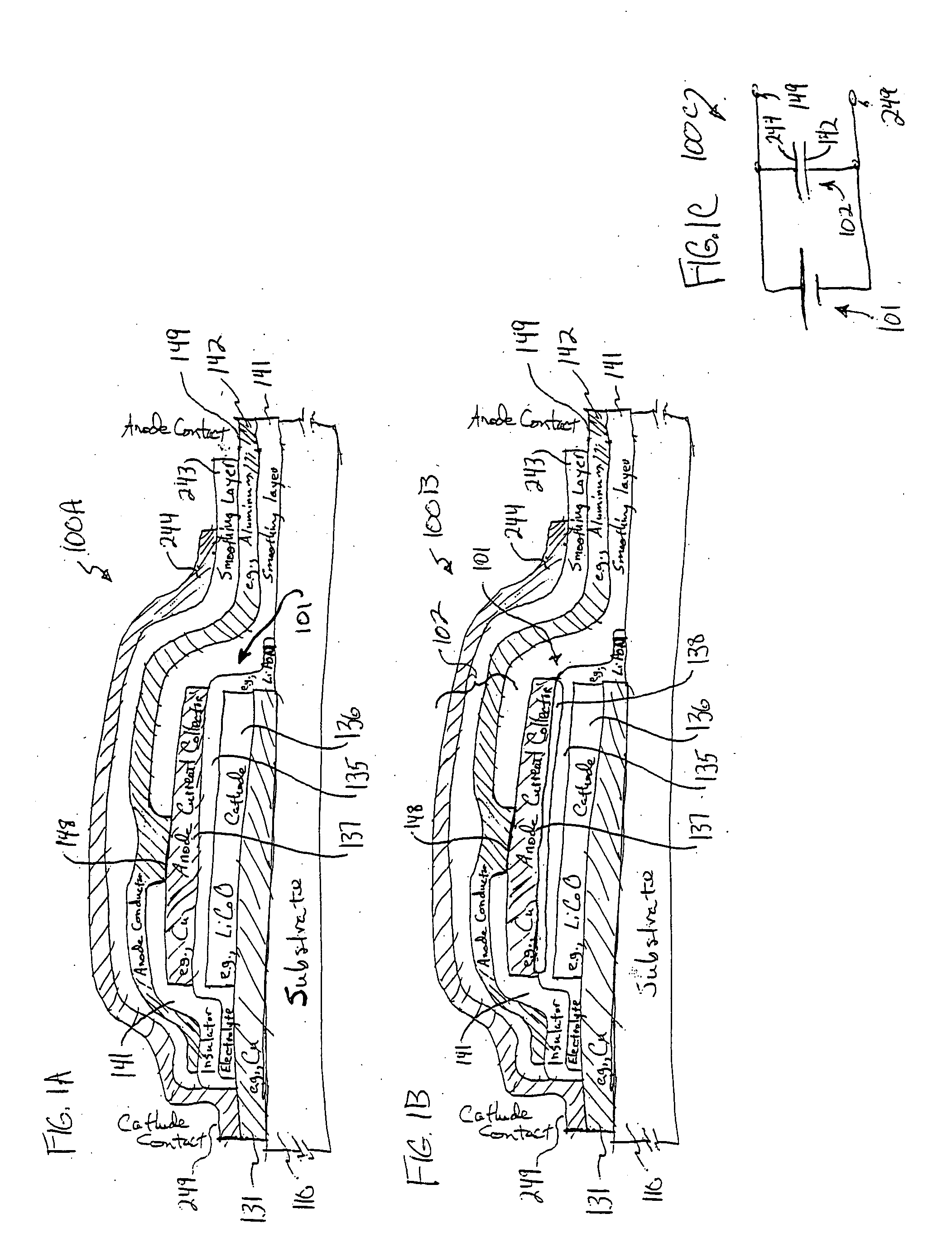

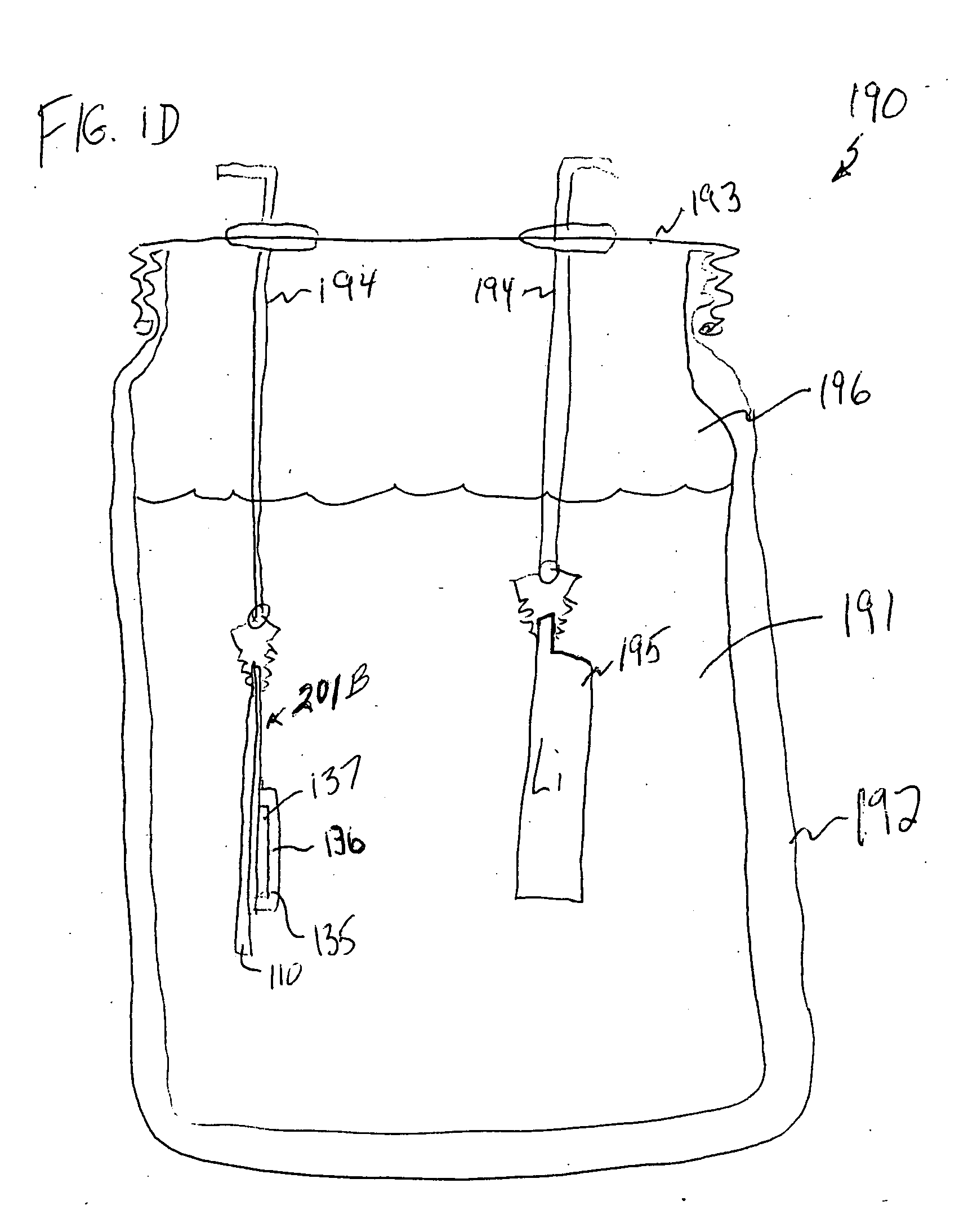

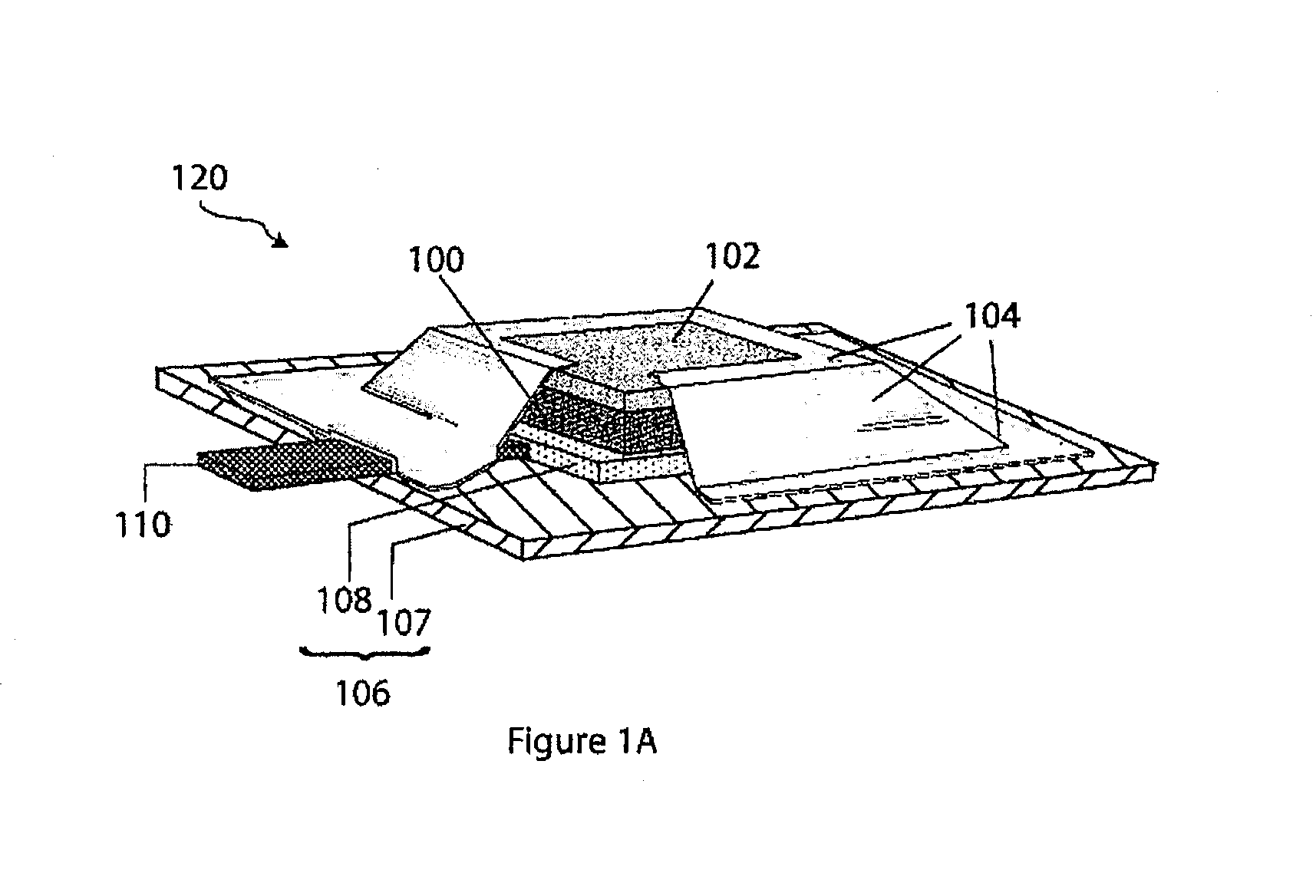

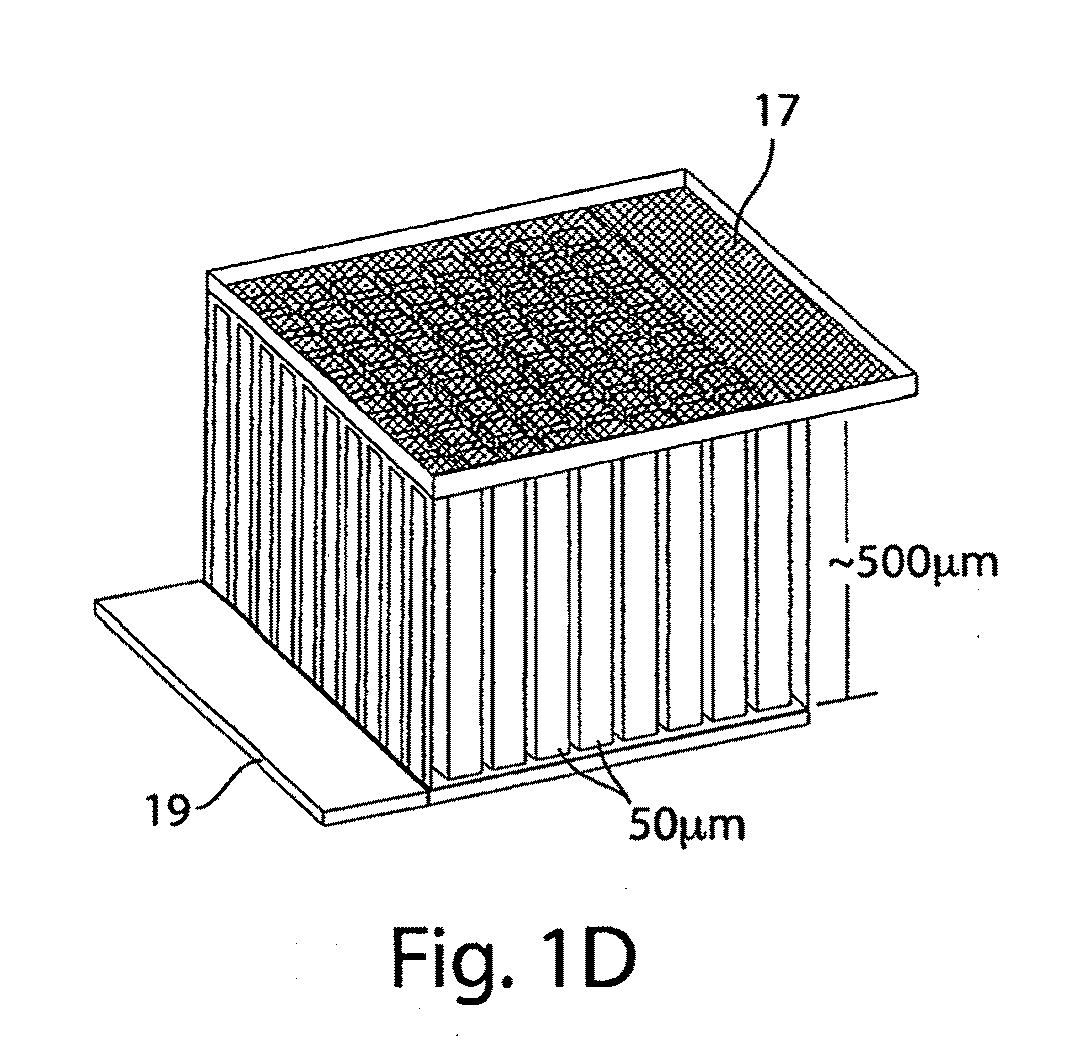

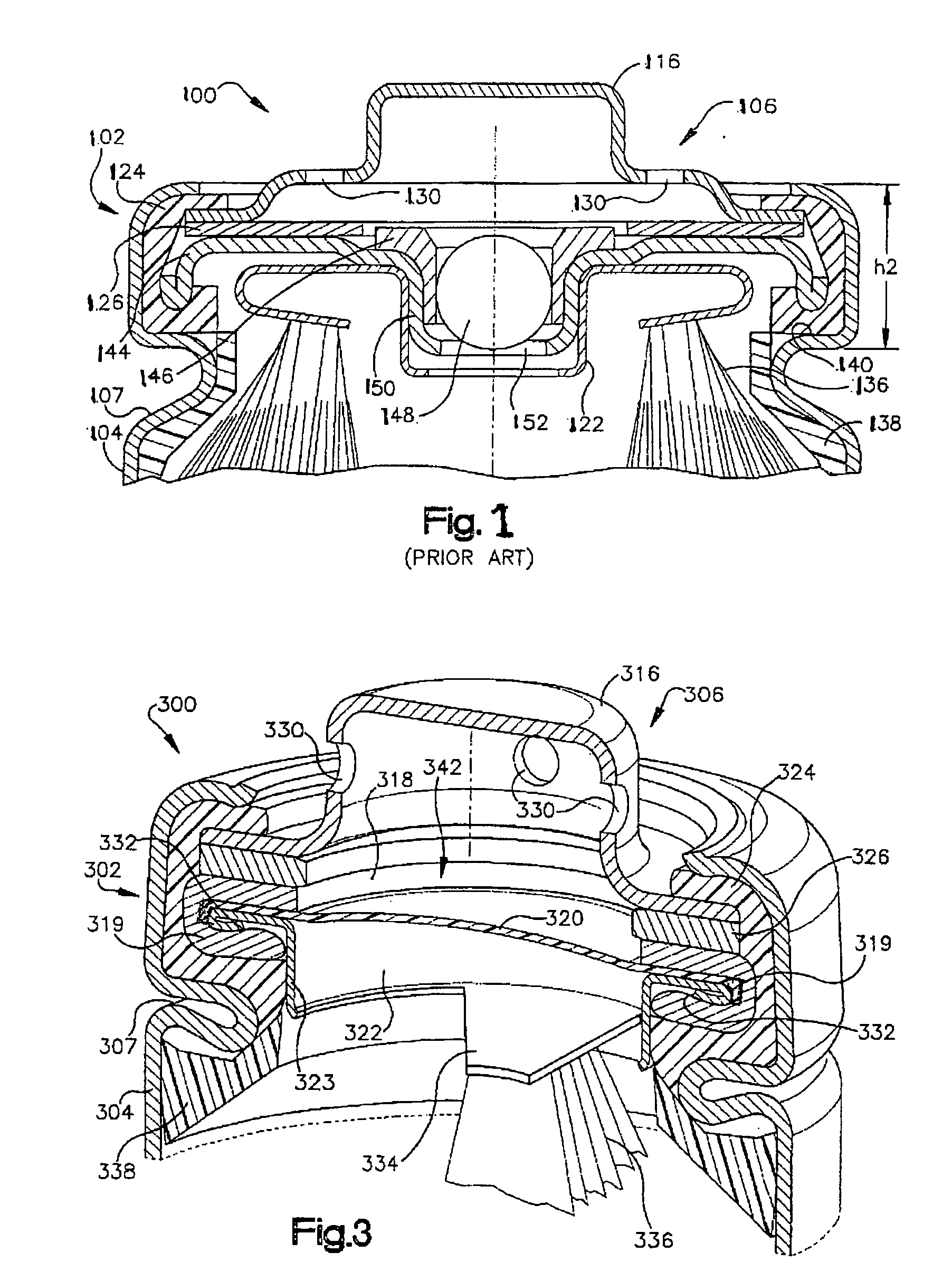

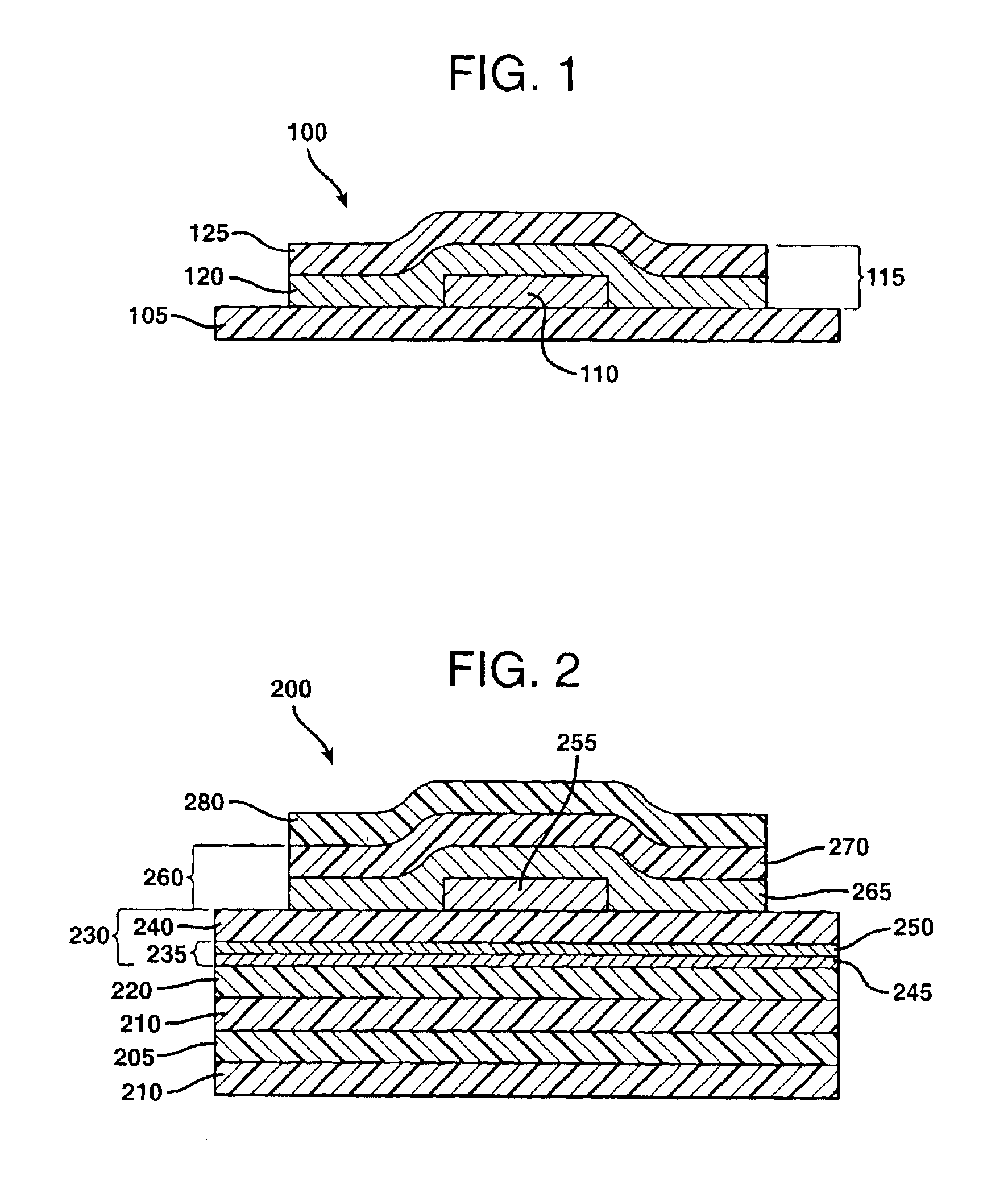

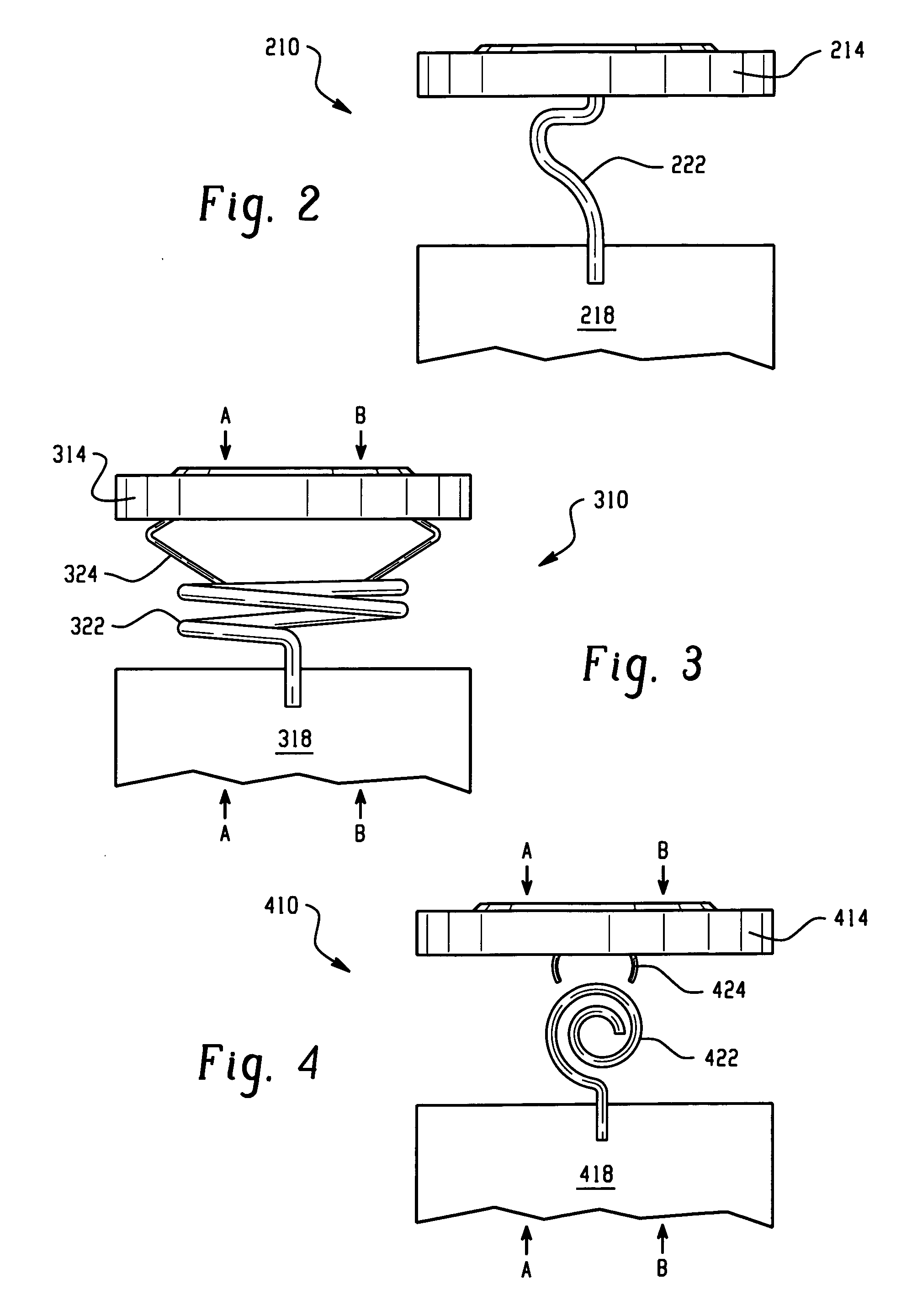

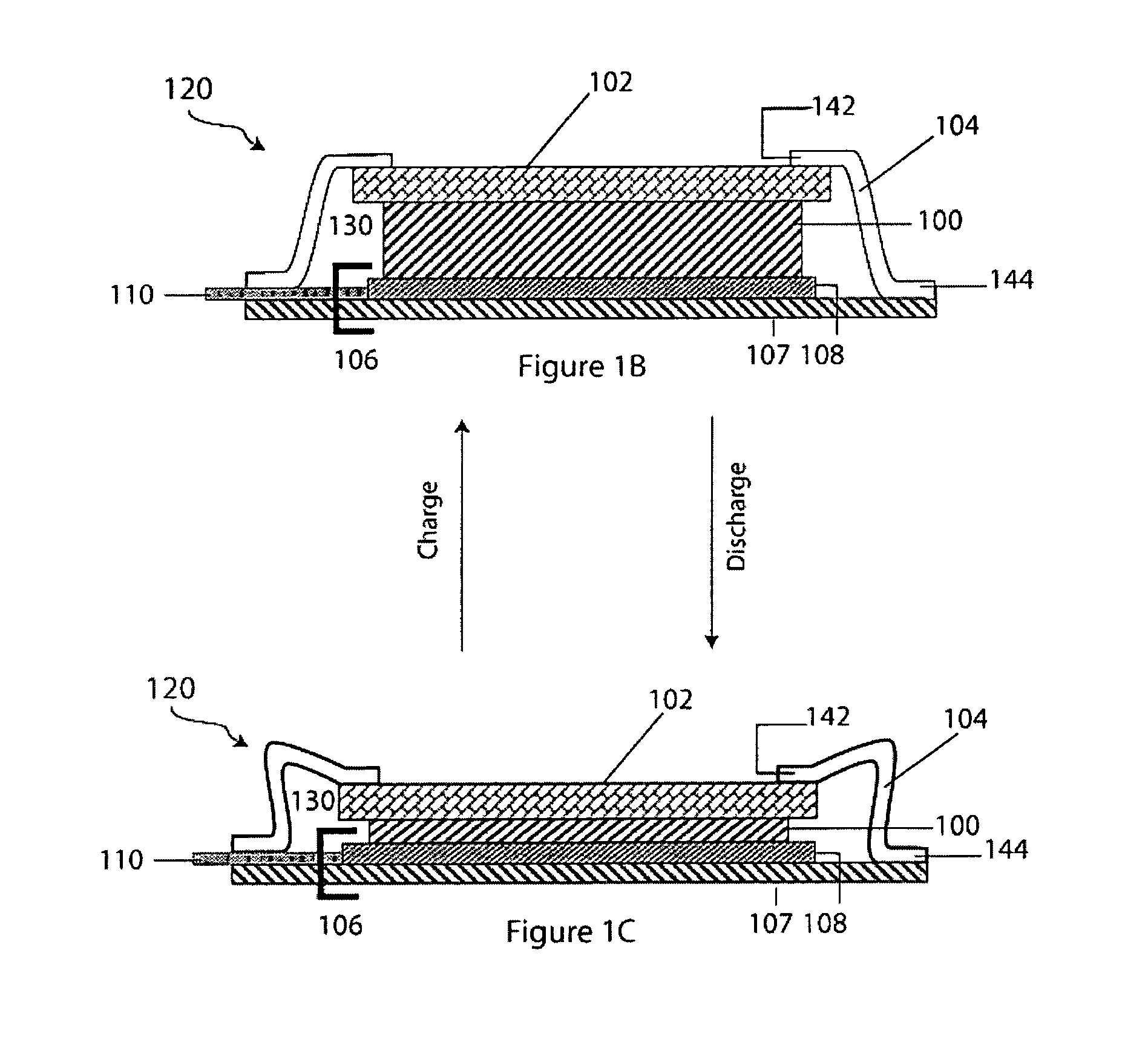

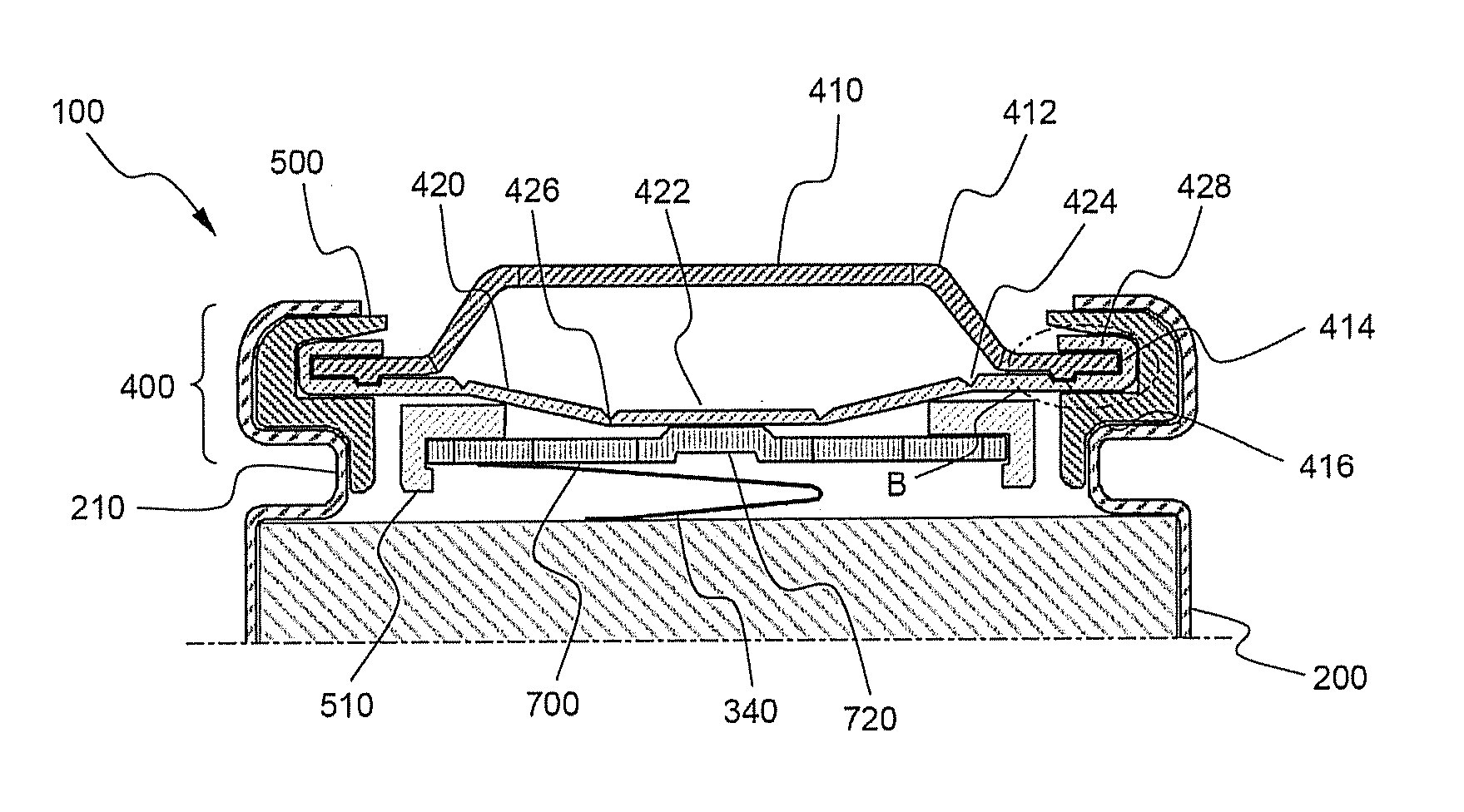

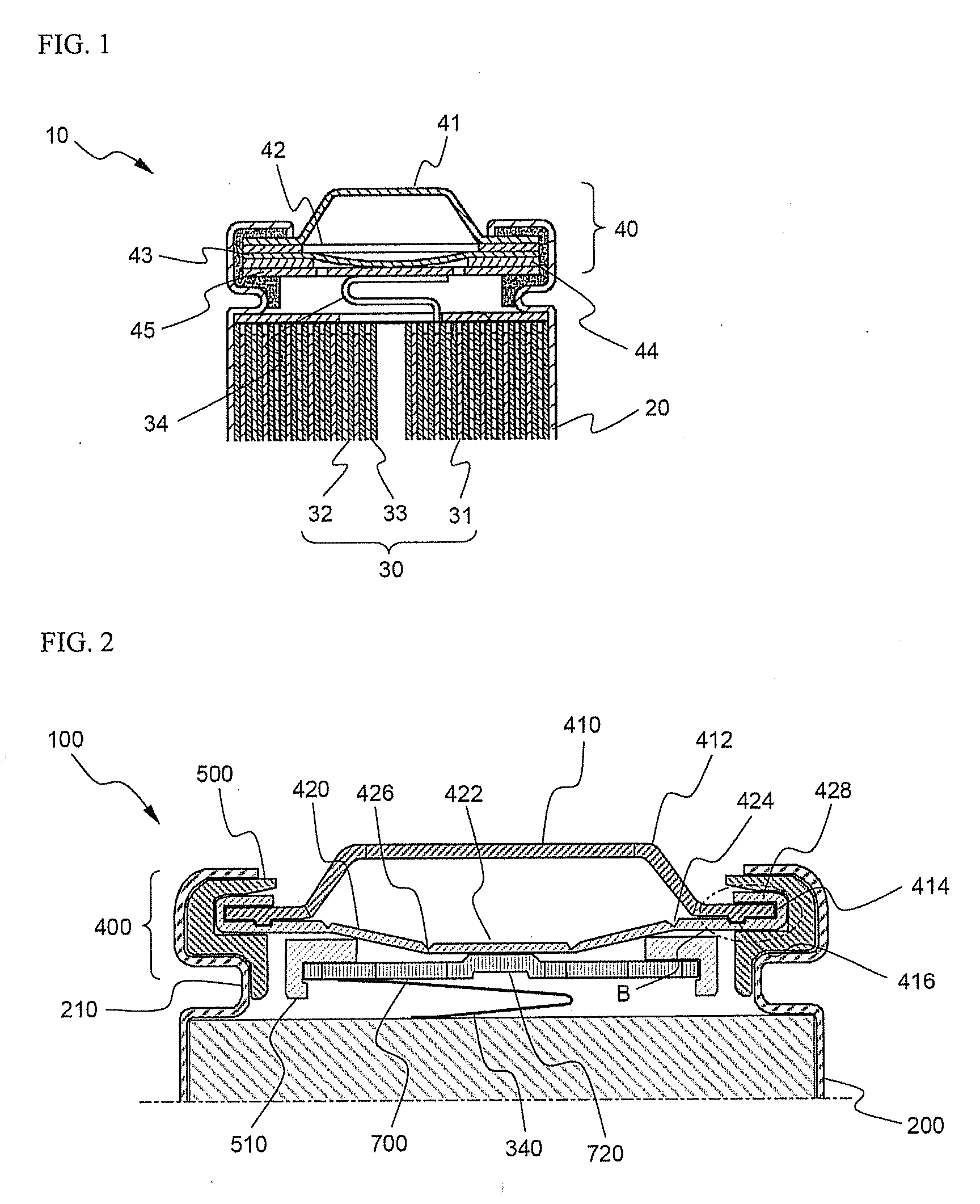

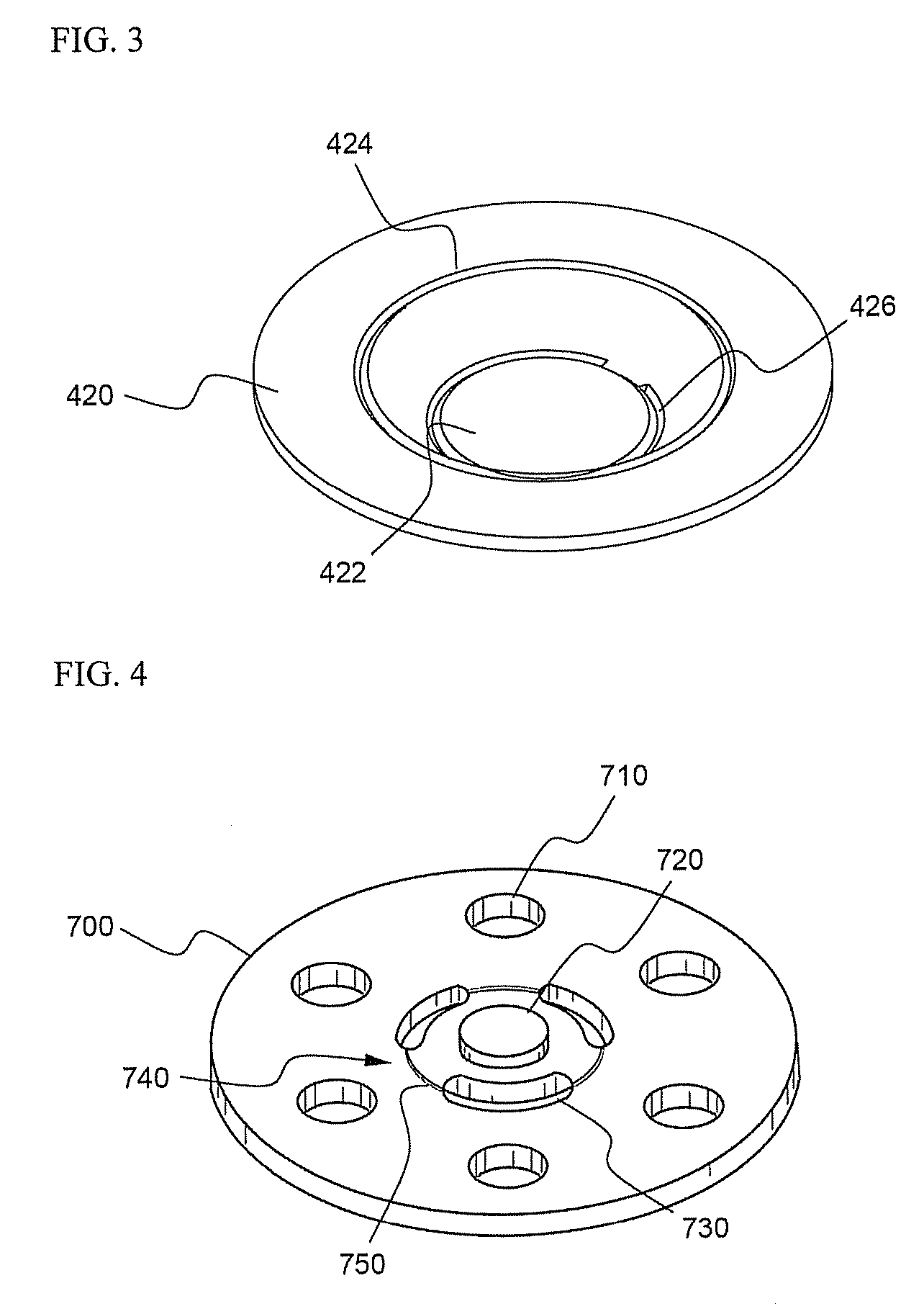

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

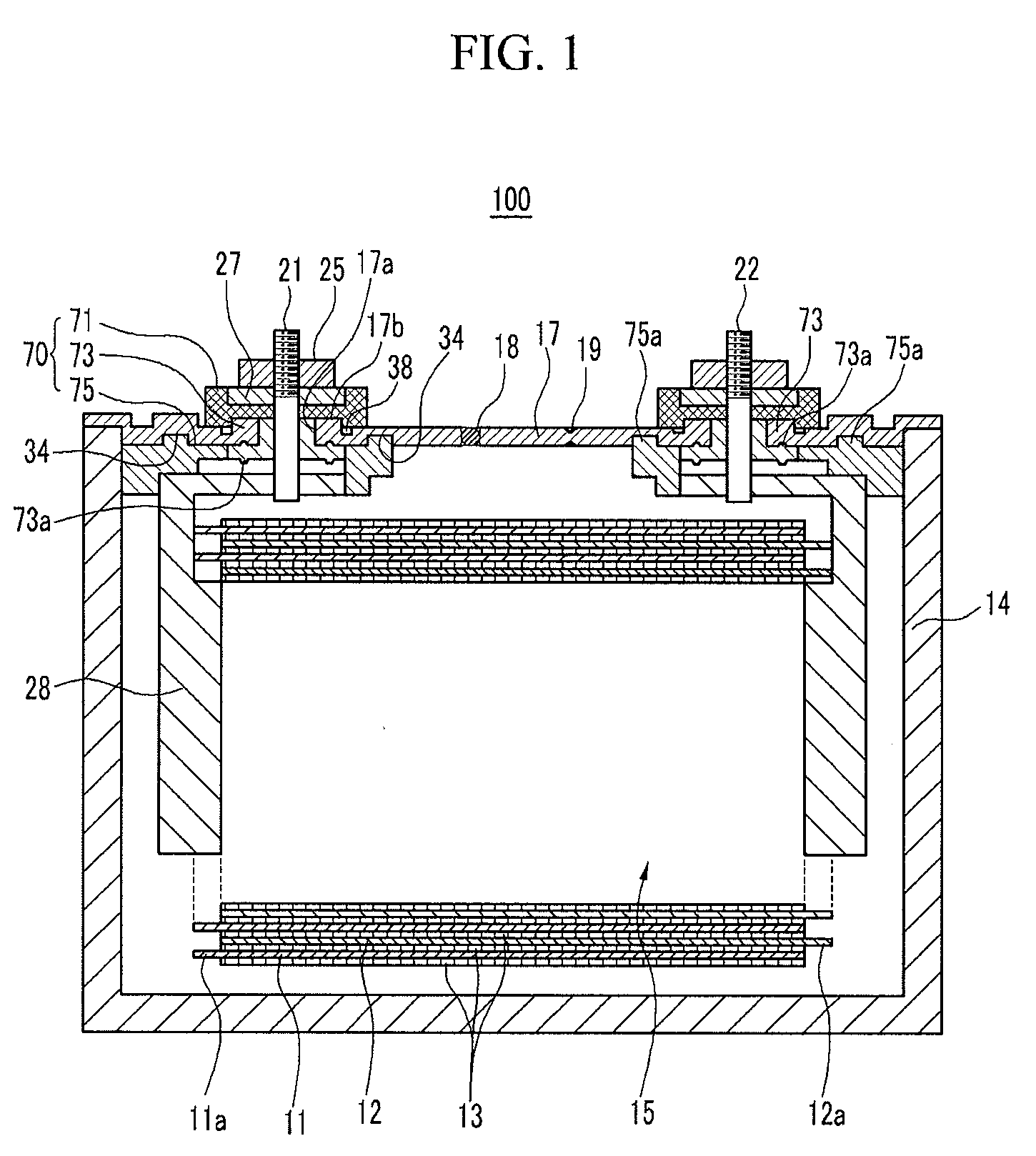

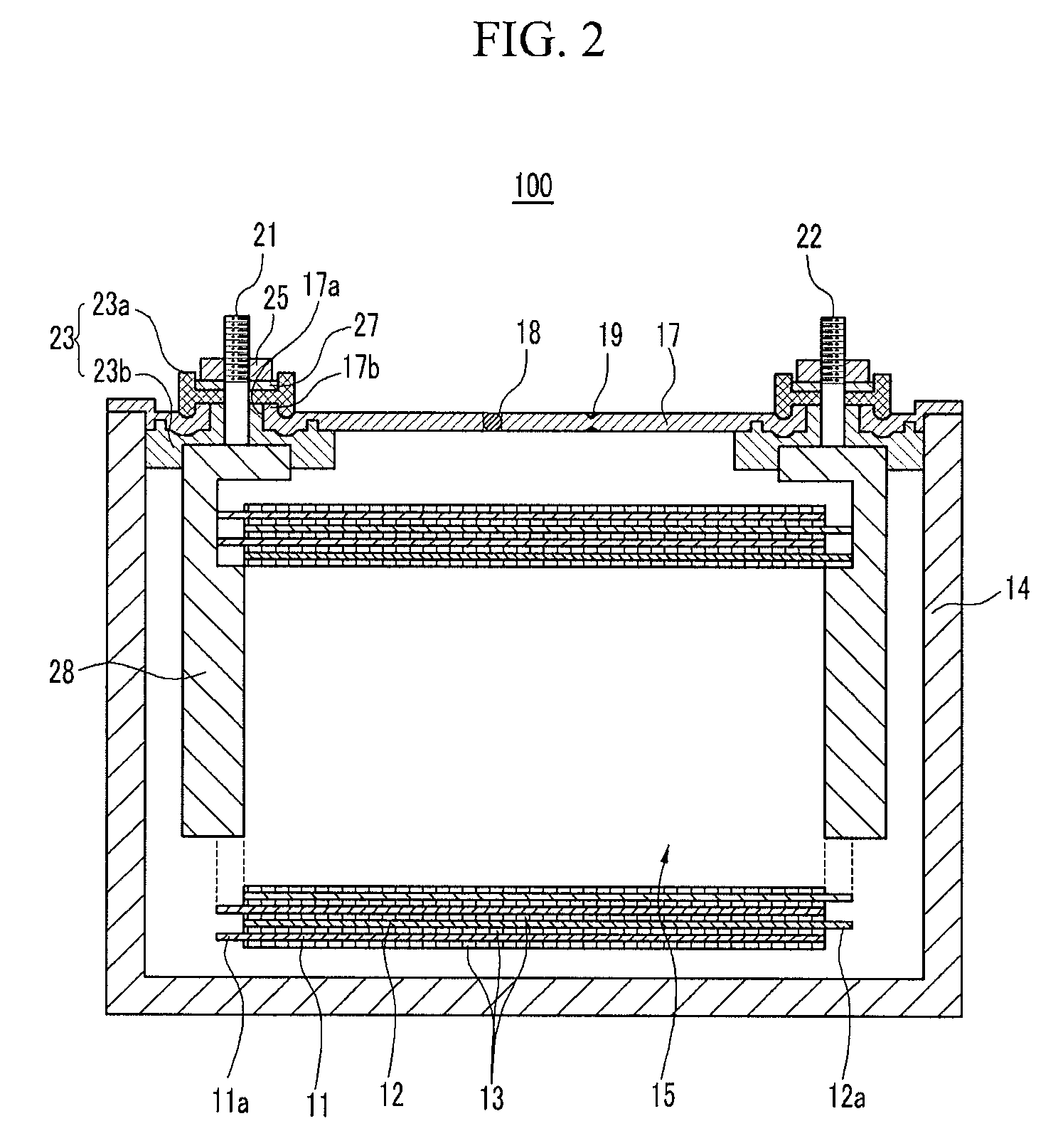

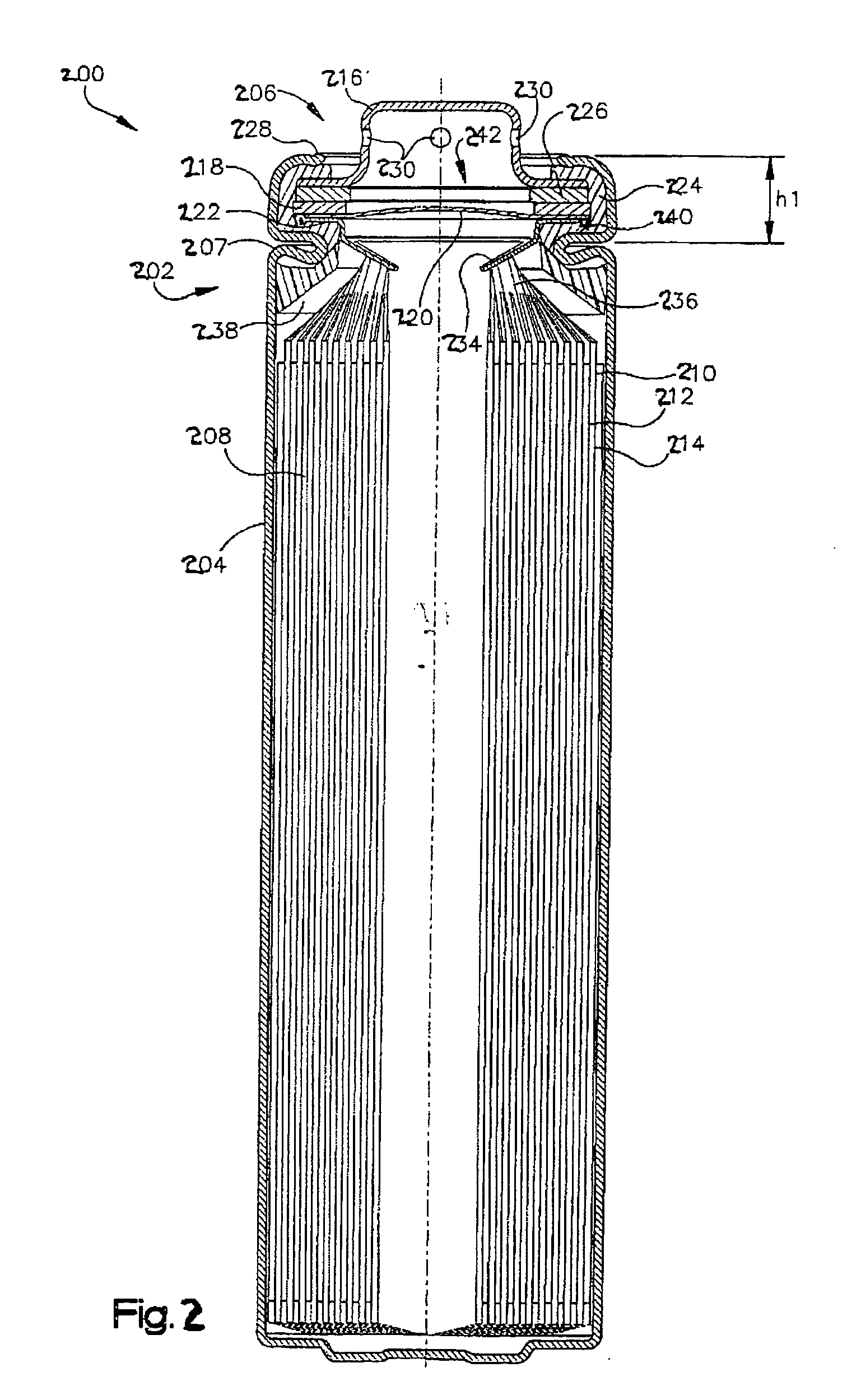

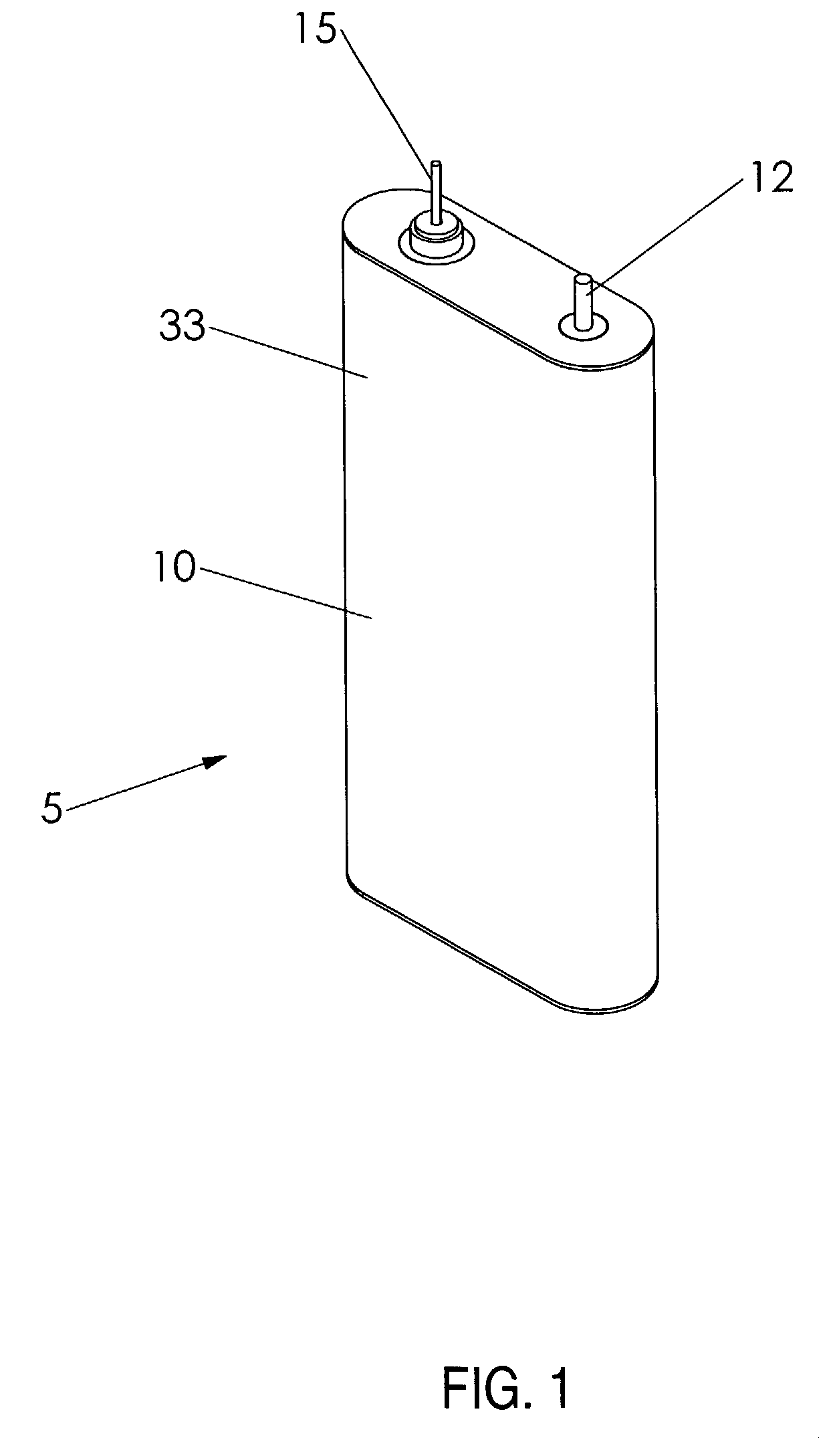

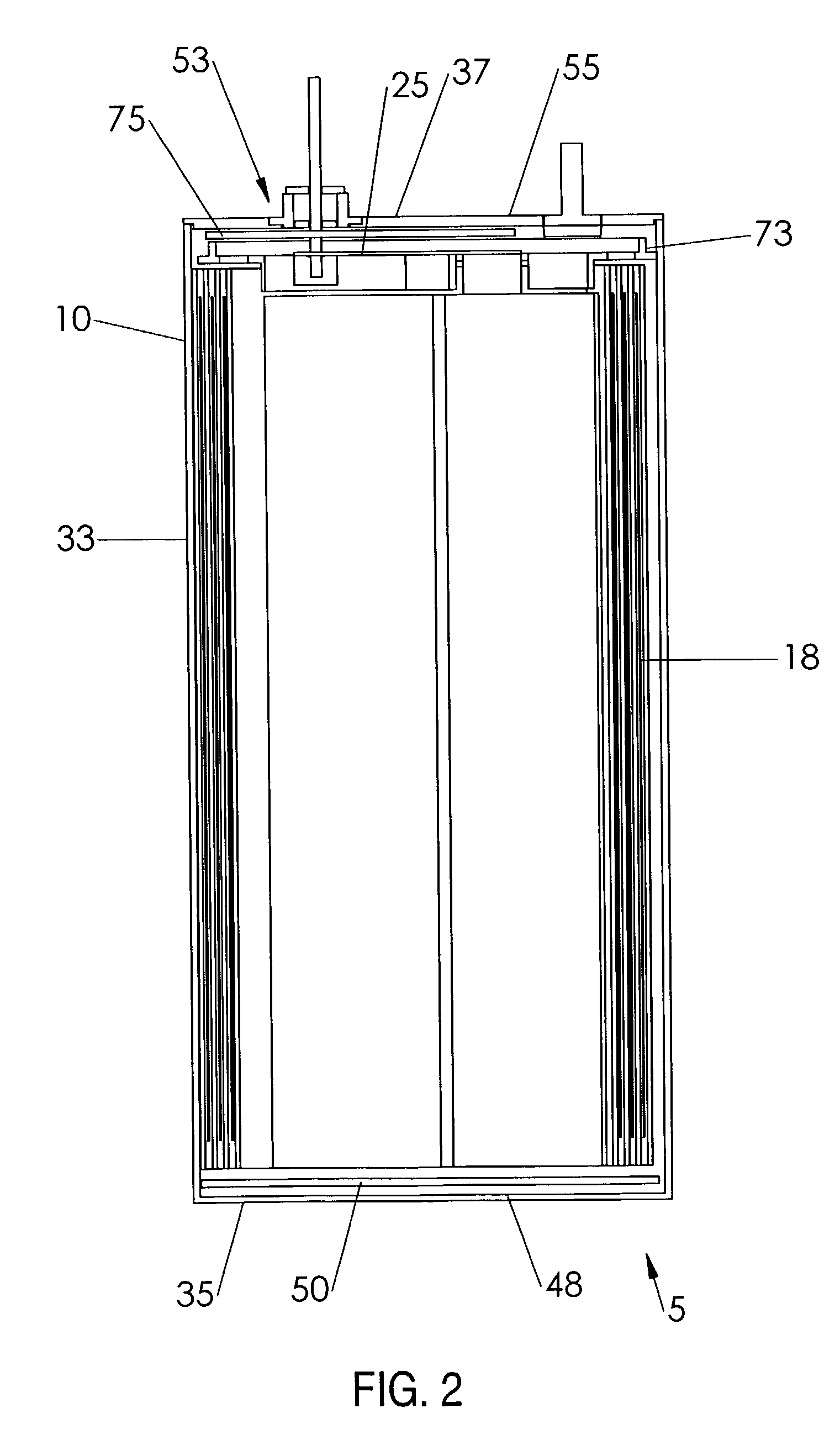

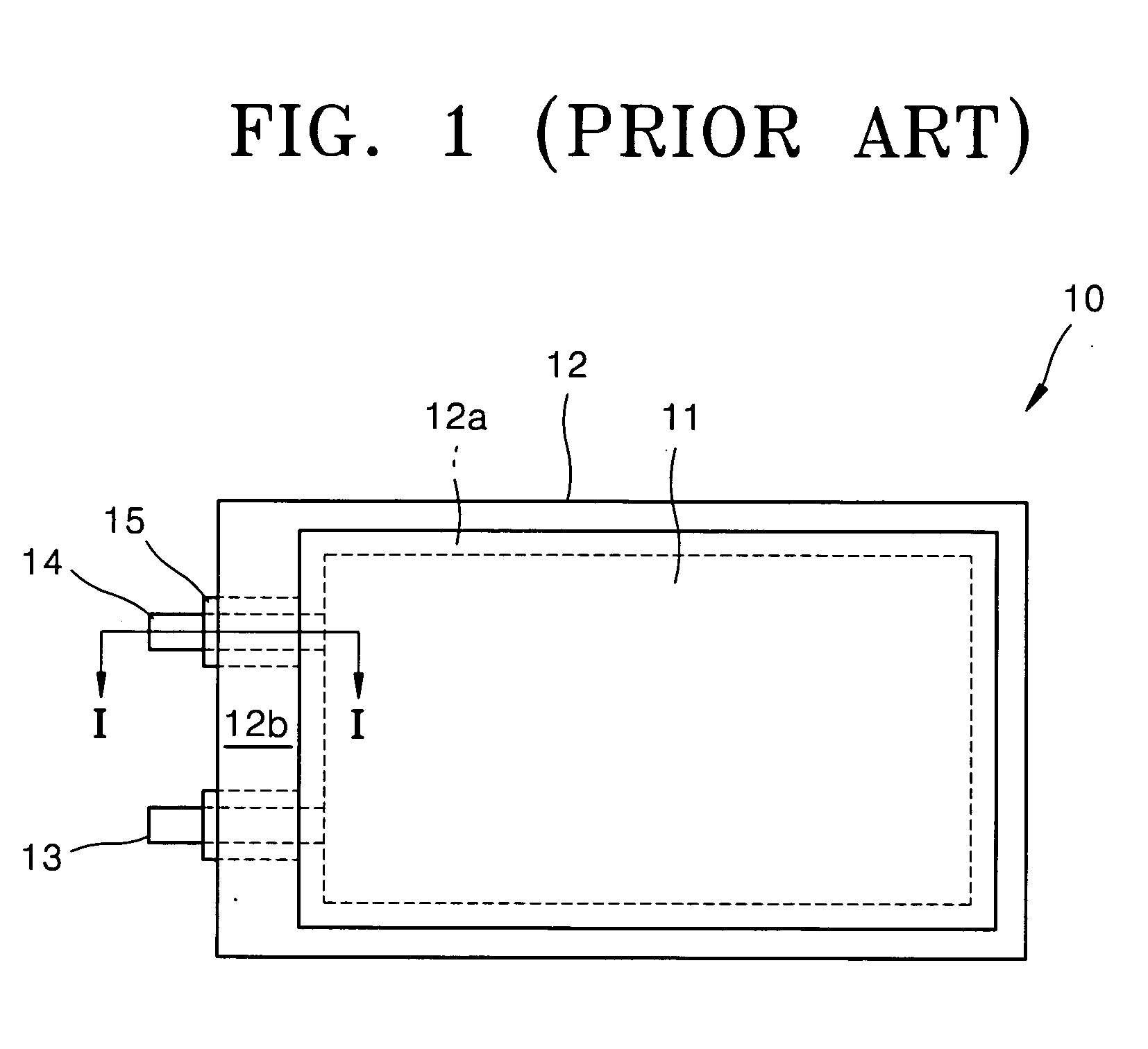

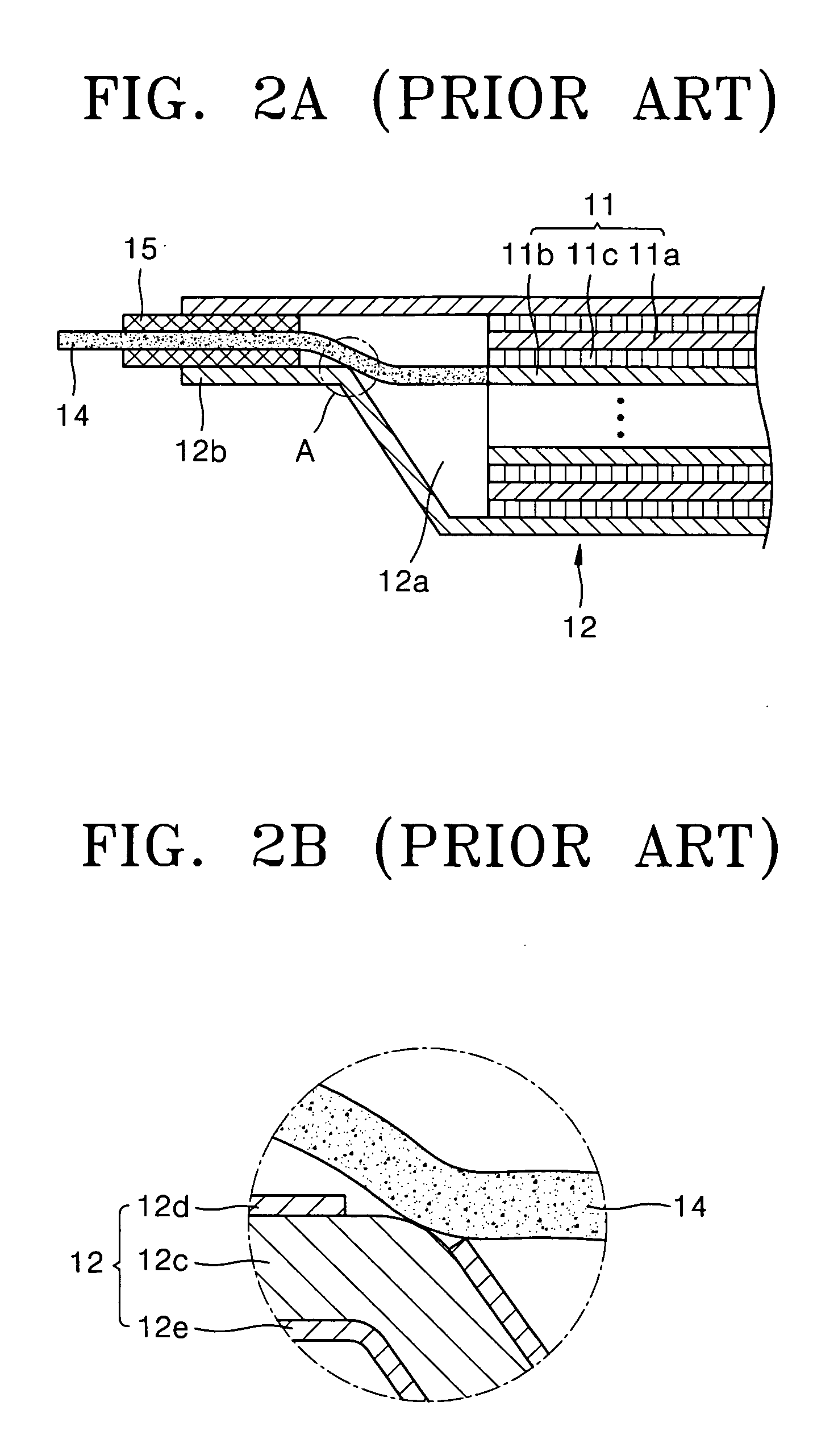

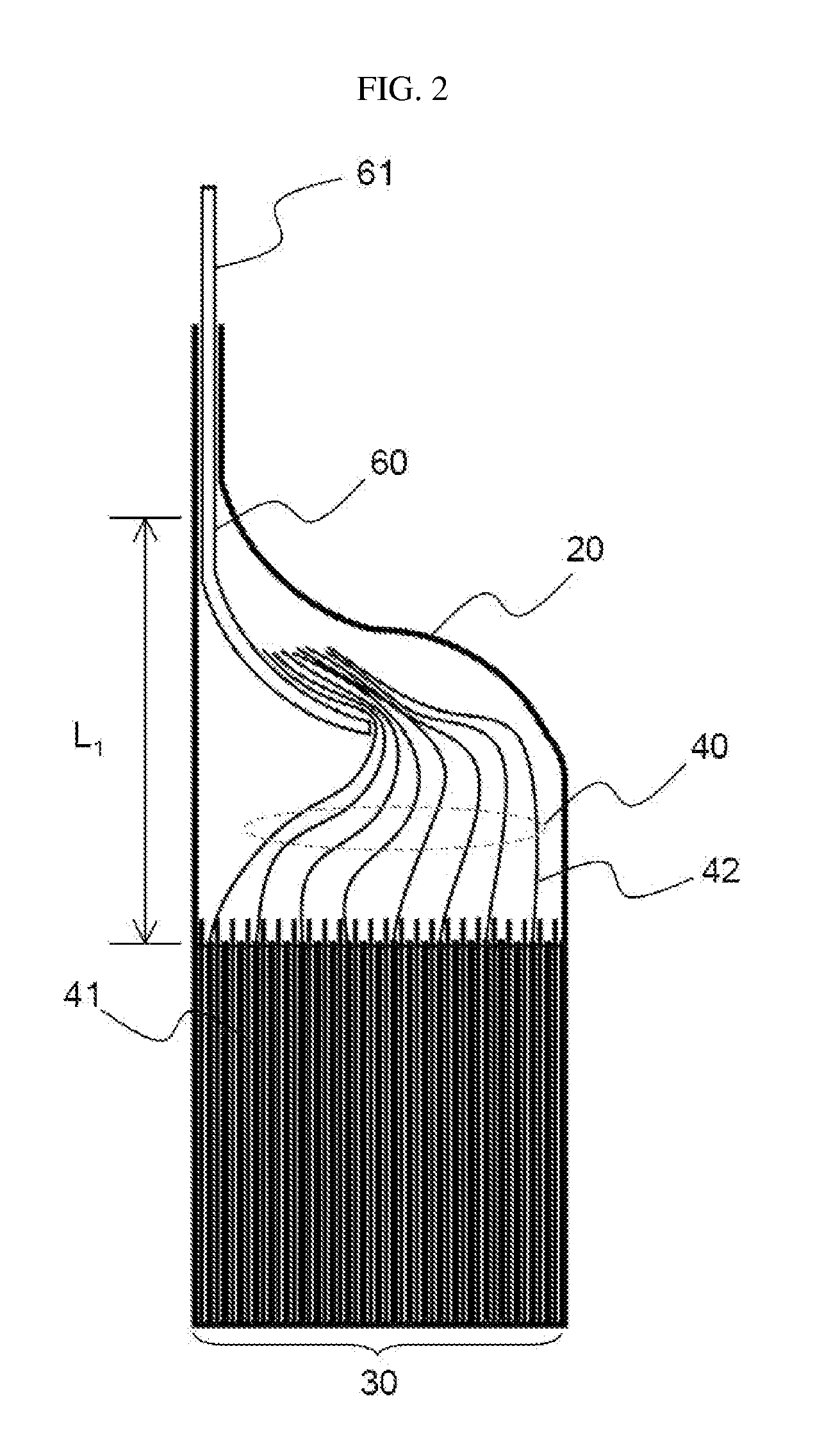

Lithium ion secondary battery

InactiveUS7335448B2Improve securityFinal product manufactureElectrode carriers/collectorsLithiumEngineering

A lithium ion secondary battery includes: (a) a positive electrode plate comprising an active material part and a current collector carrying the active material part, the active material part comprising a positive electrode active material capable of absorbing or desorbing a lithium ion during charge and discharge; (b) a negative electrode plate comprising an active material part and a current collector carrying the active material part, the active material part comprising a negative electrode active material capable of absorbing or desorbing a lithium ion during charge and discharge; (c) a separator interposed between the positive and negative electrode plates; (d) an electrolyte; and (e) a battery case accommodating the positive and negative electrode plates, the separator, and the electrolyte. The positive and negative electrode plates are wound with the separator interposed therebetween, thereby to form an electrode plate assembly. The electrode plate assembly is so configured that each lengthwise edge of the positive electrode current collector is positioned on an outer side of each lengthwise edge of the negative electrode active material part.

Owner:GK BRIDGE 1

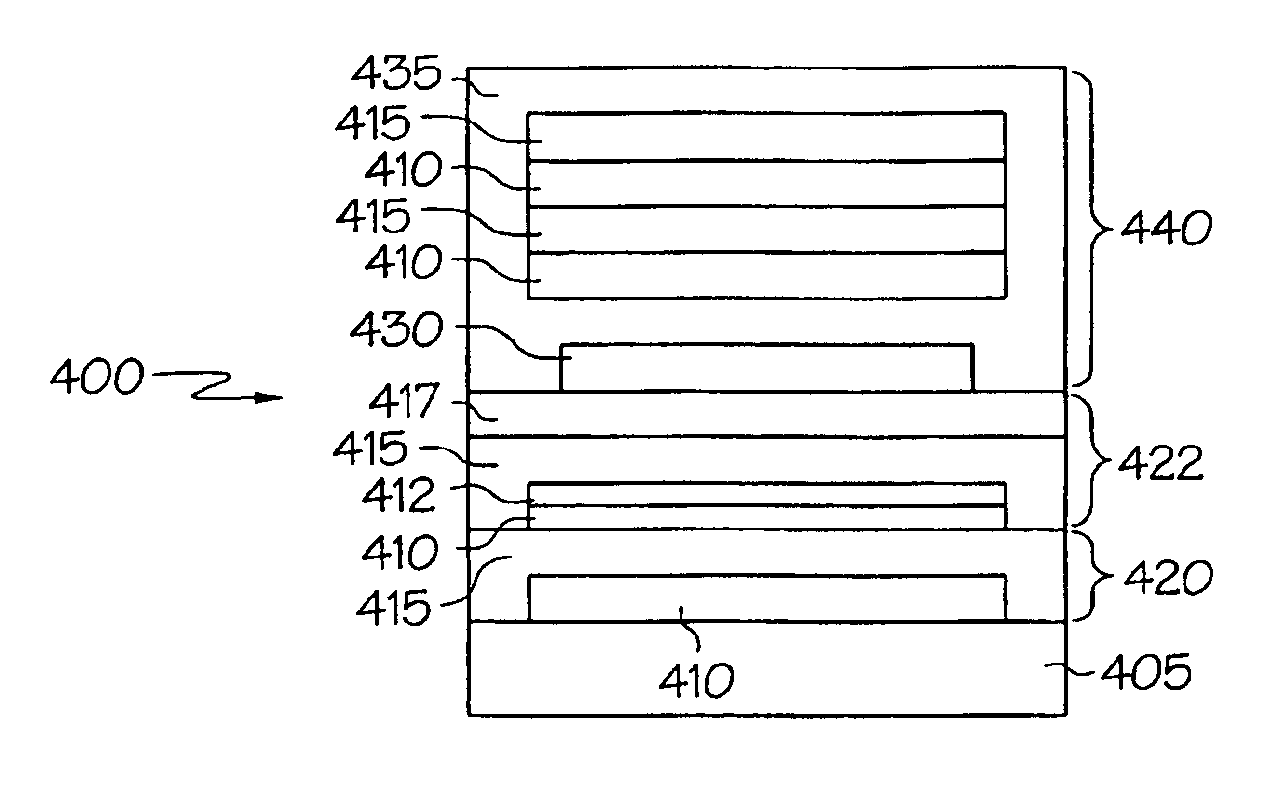

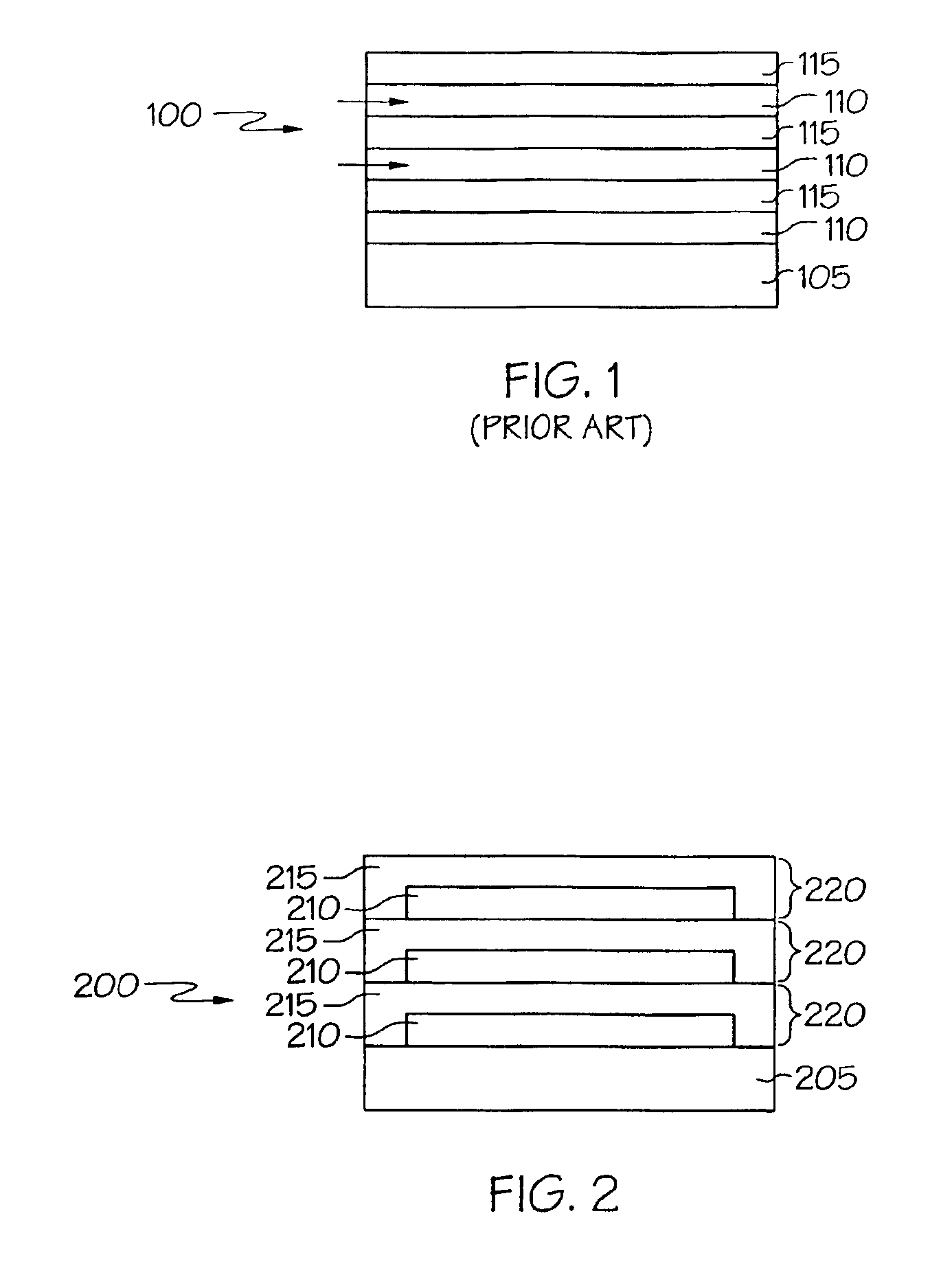

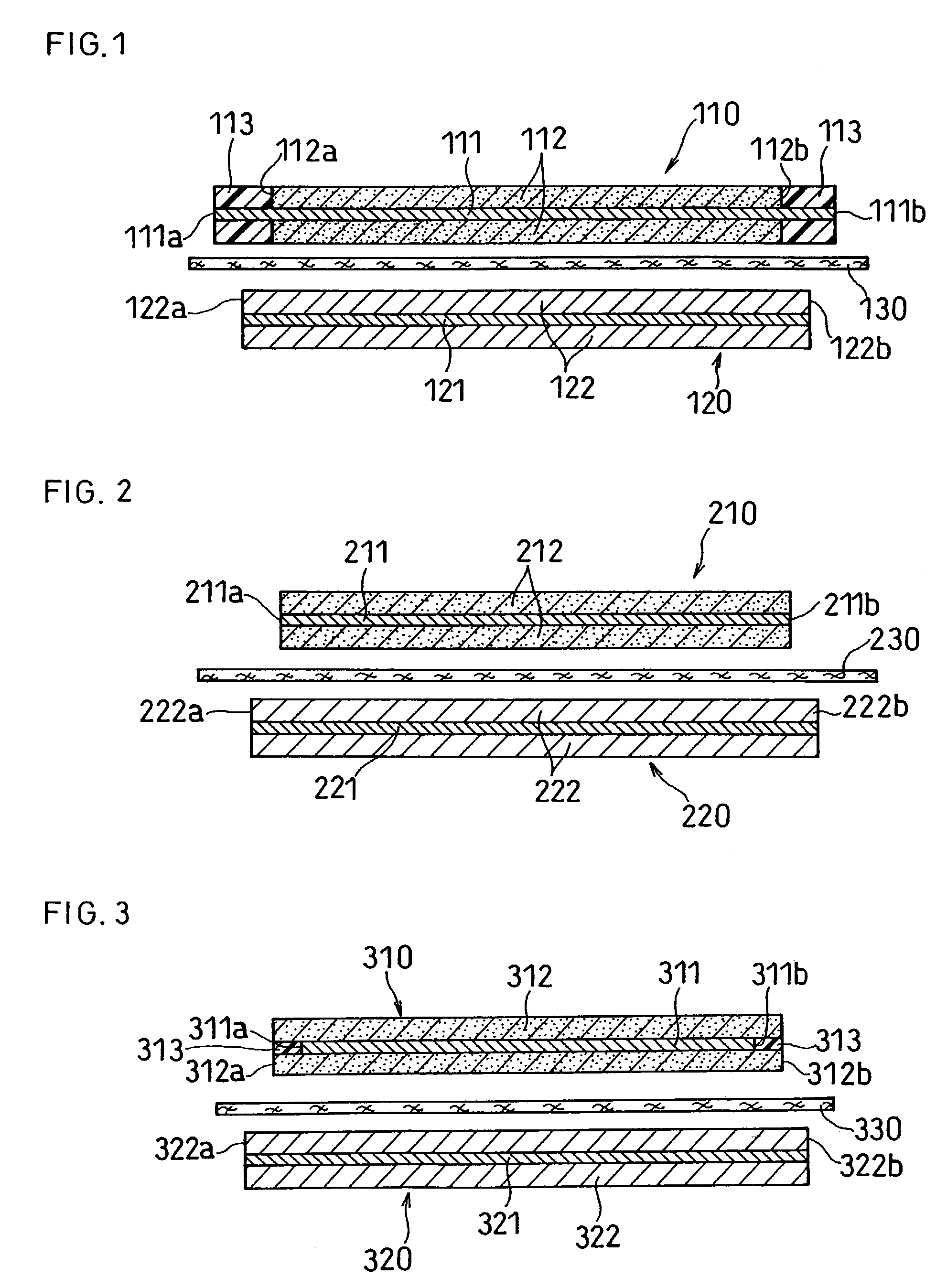

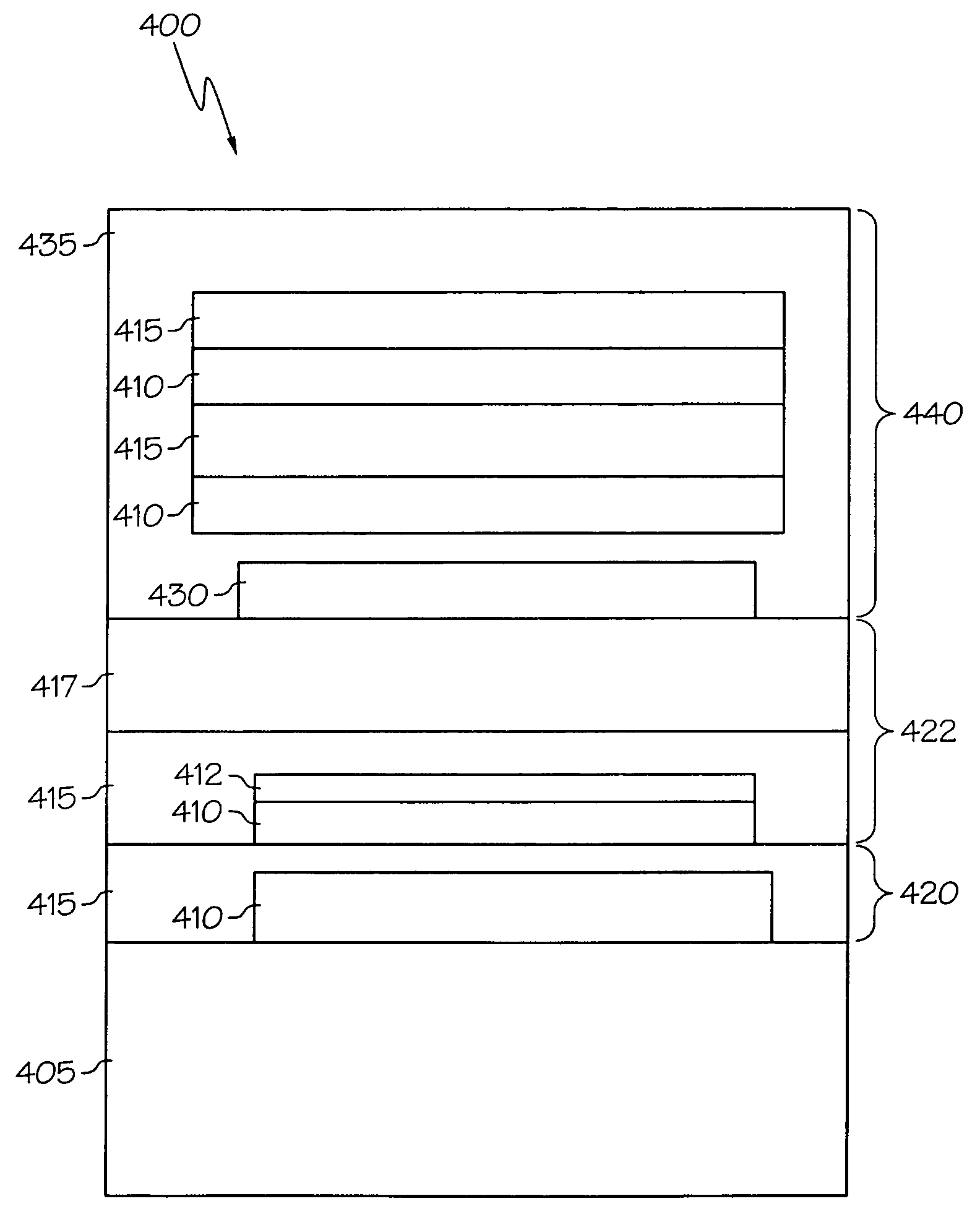

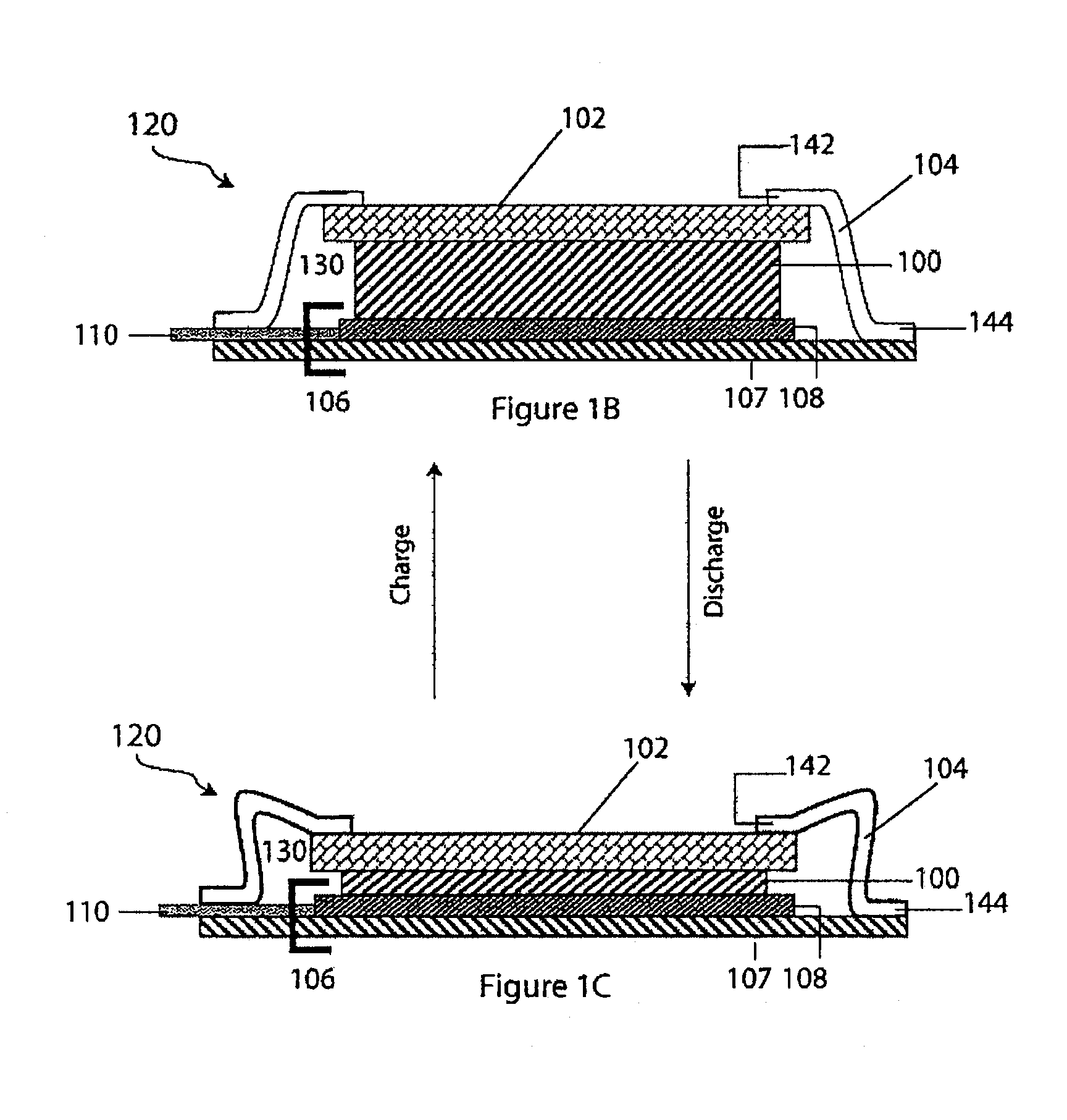

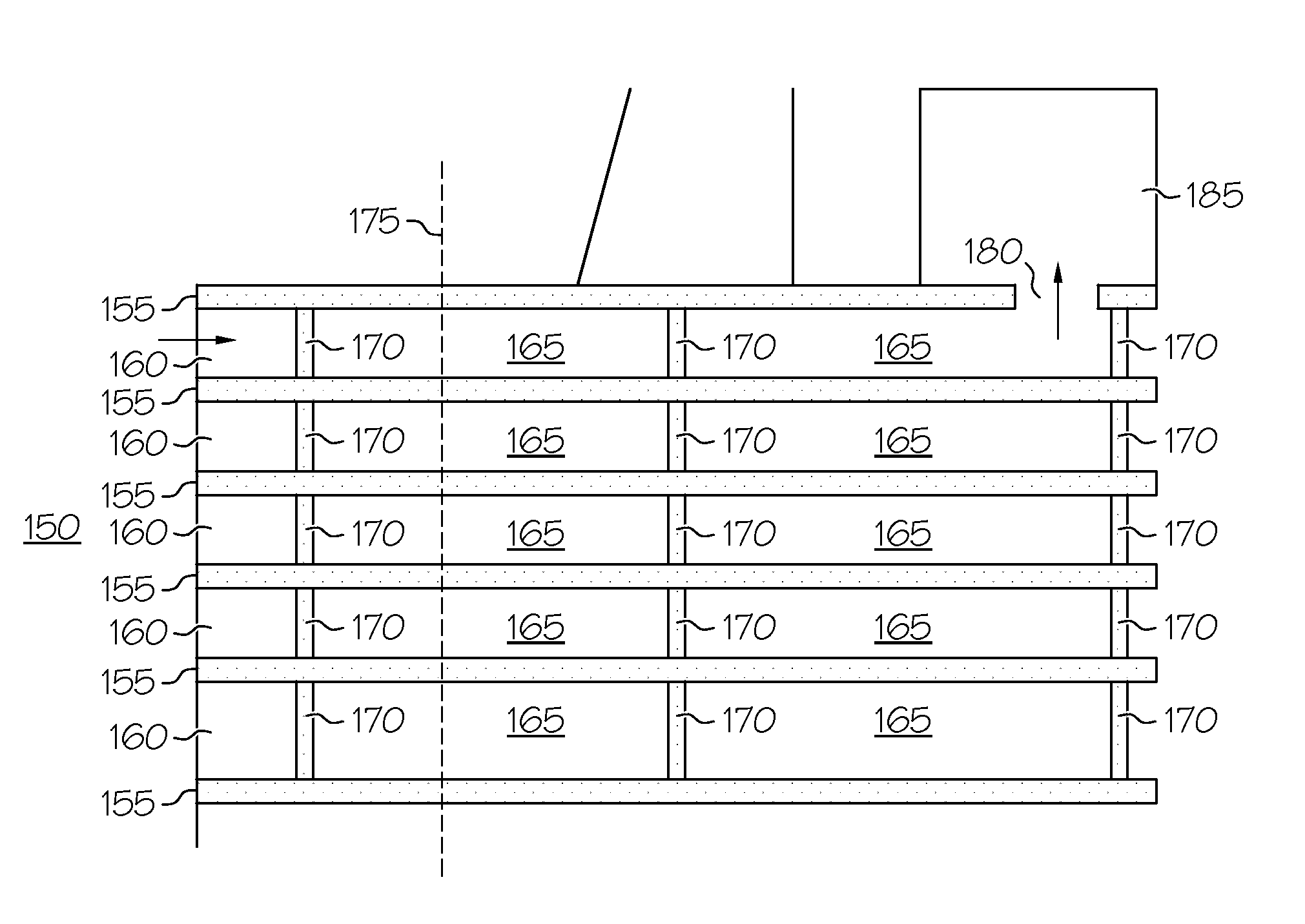

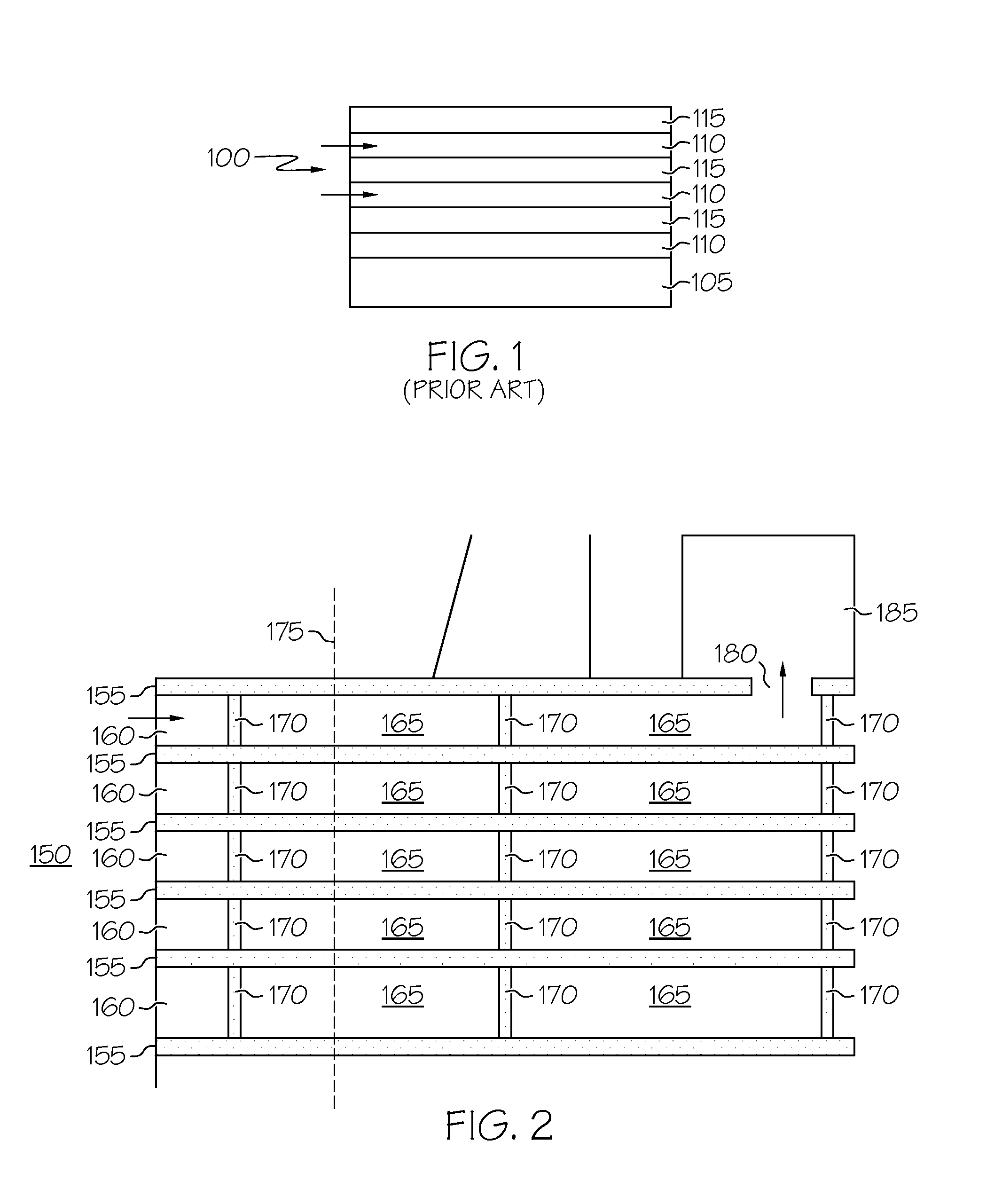

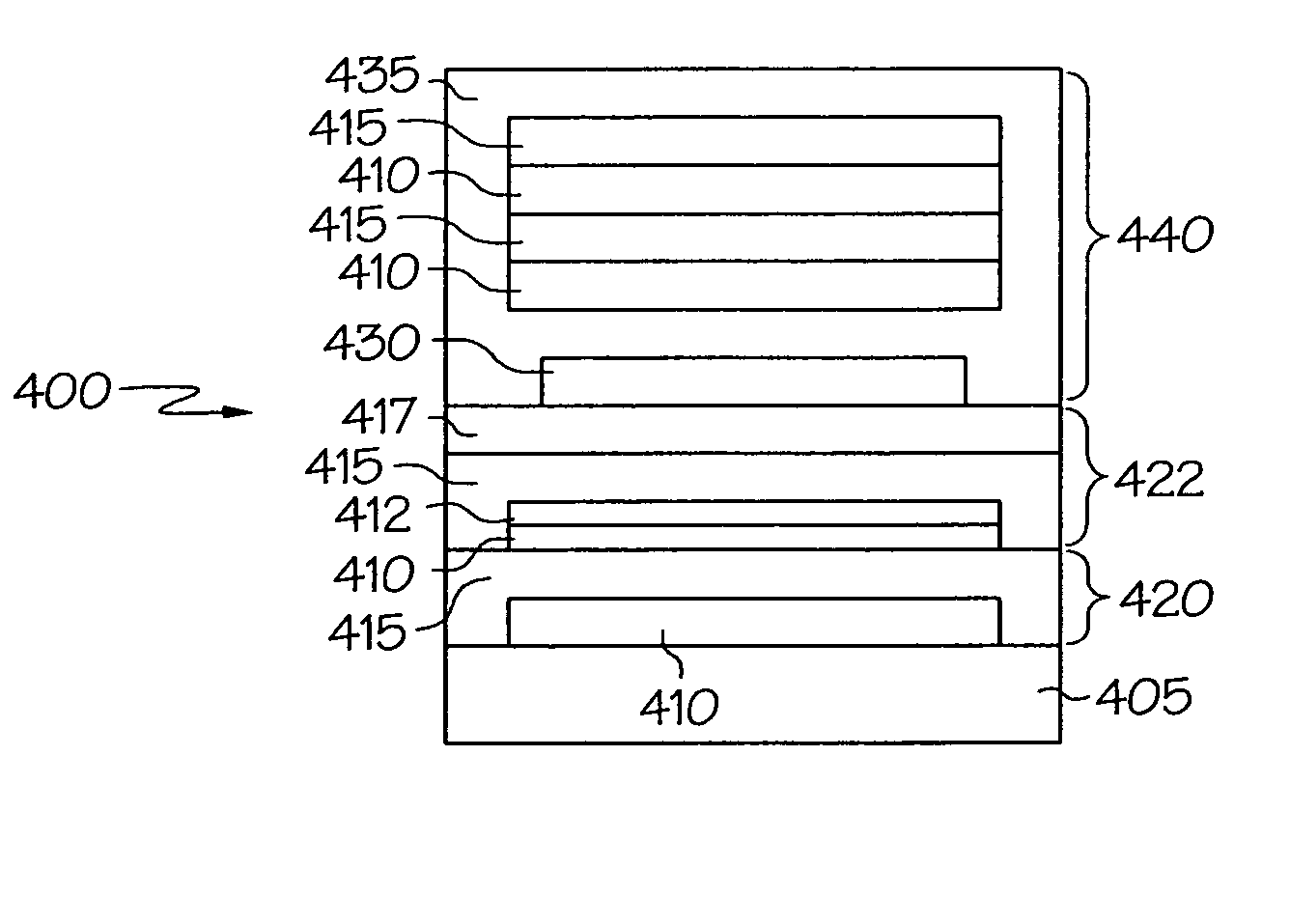

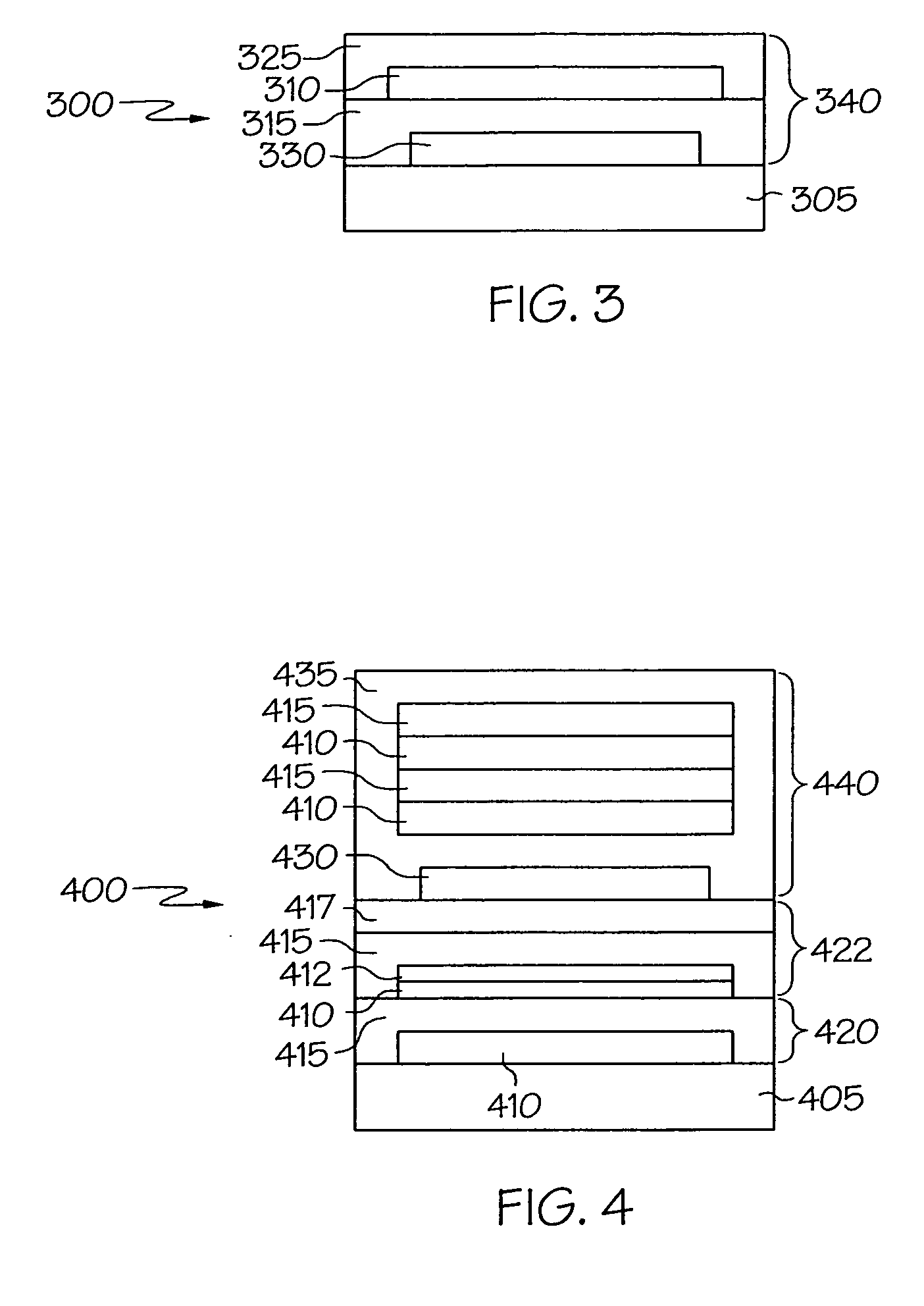

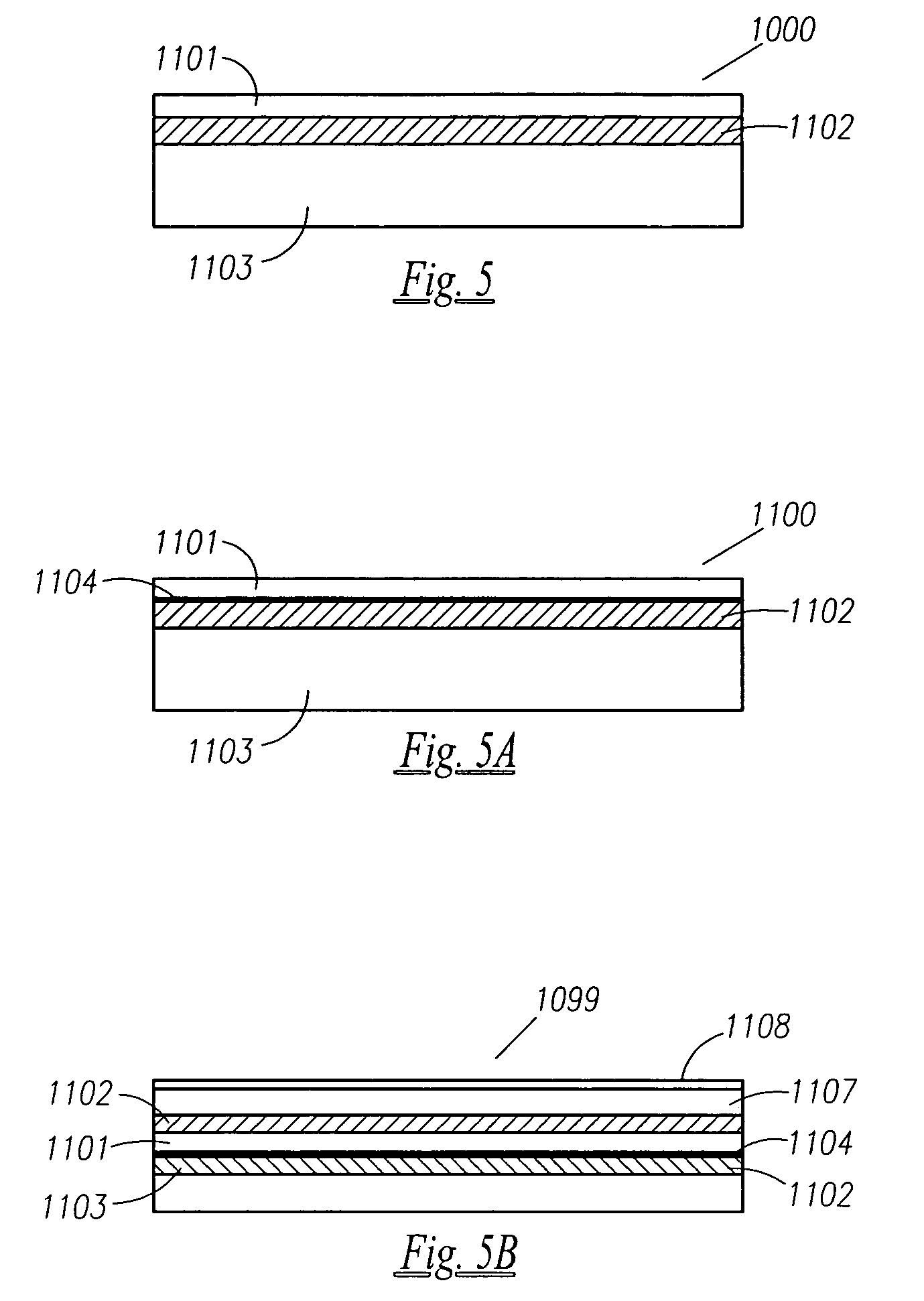

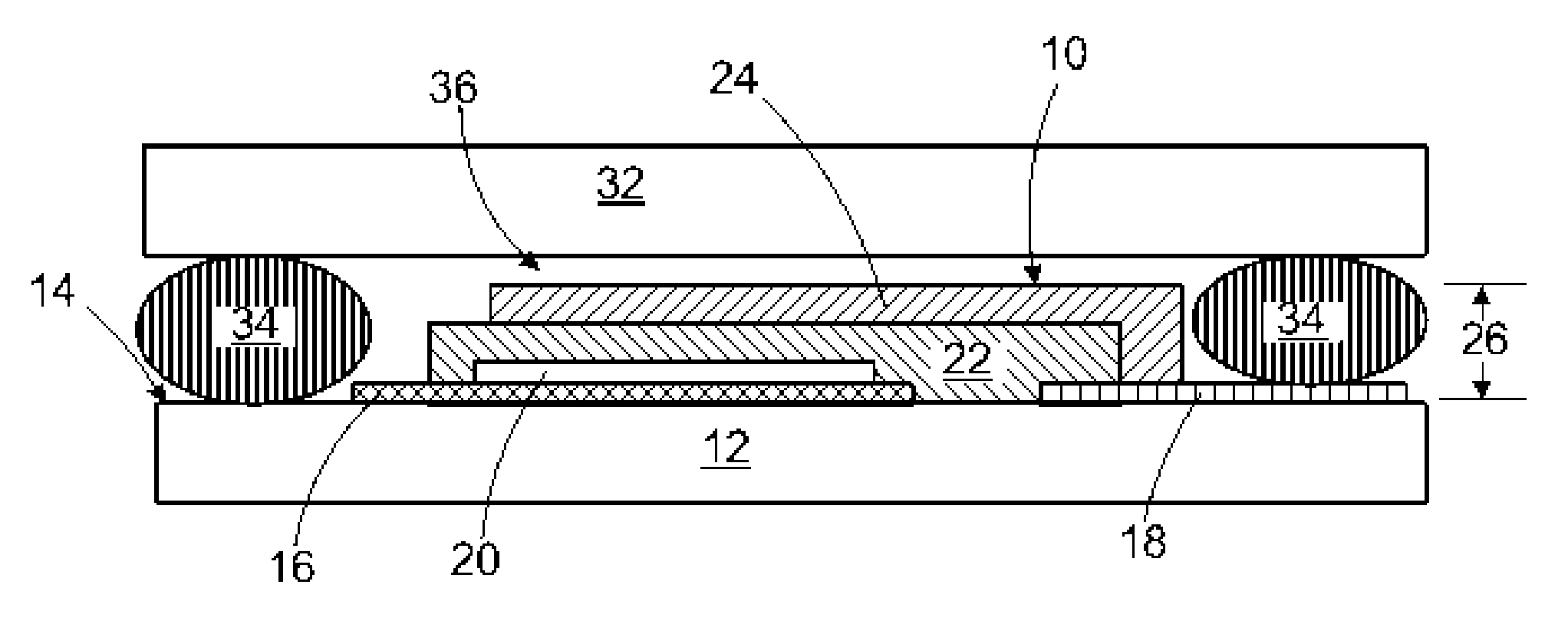

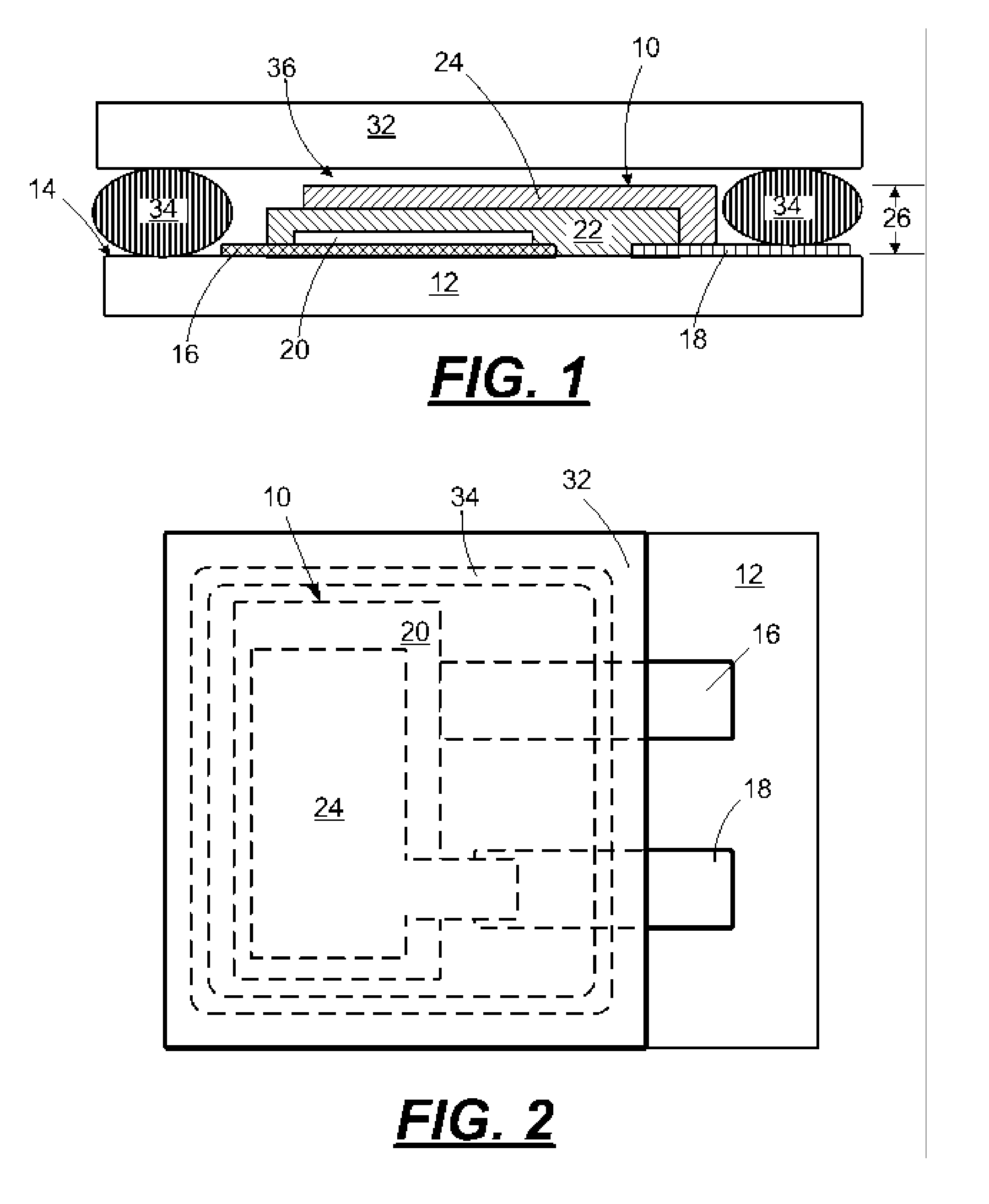

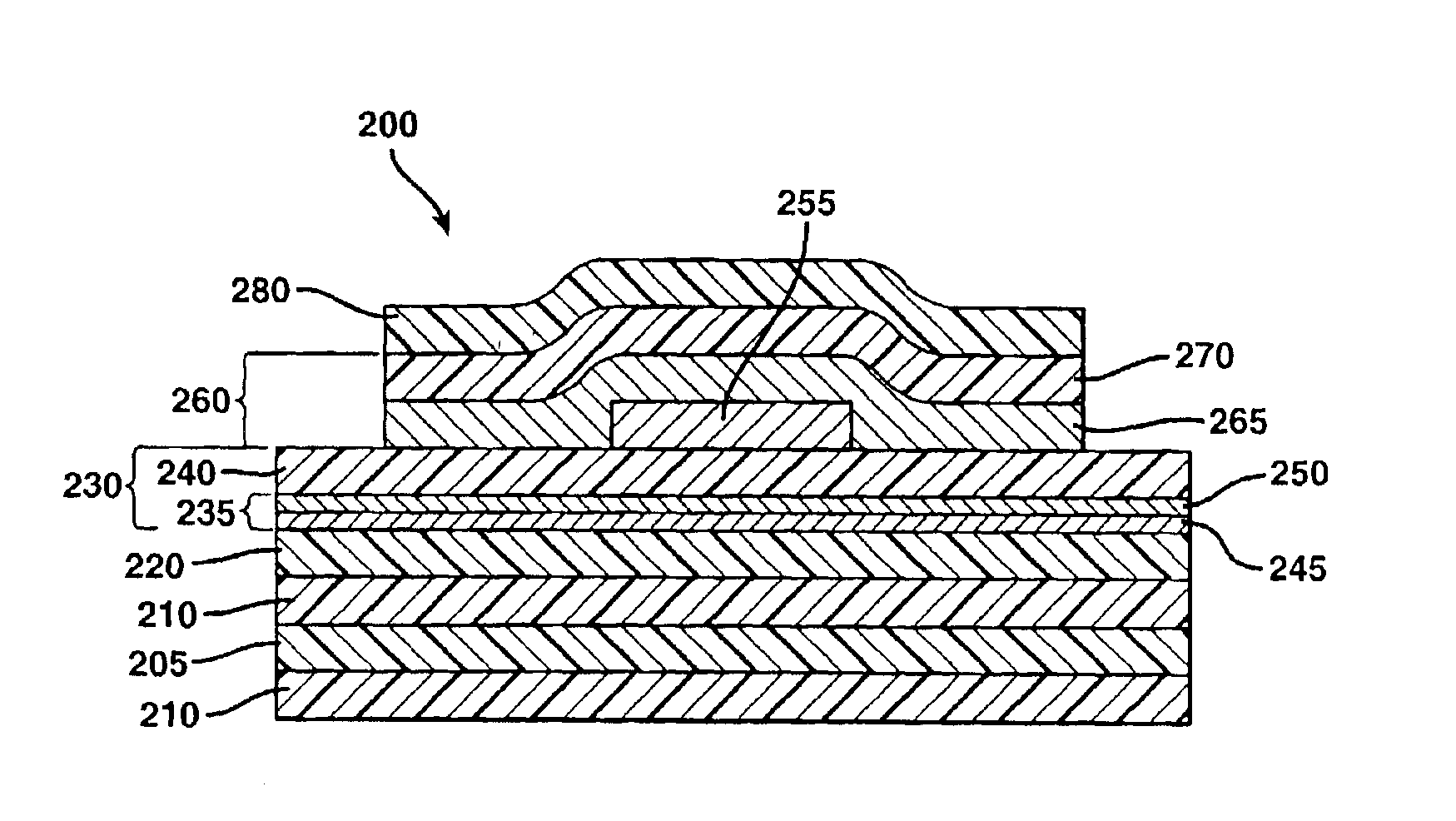

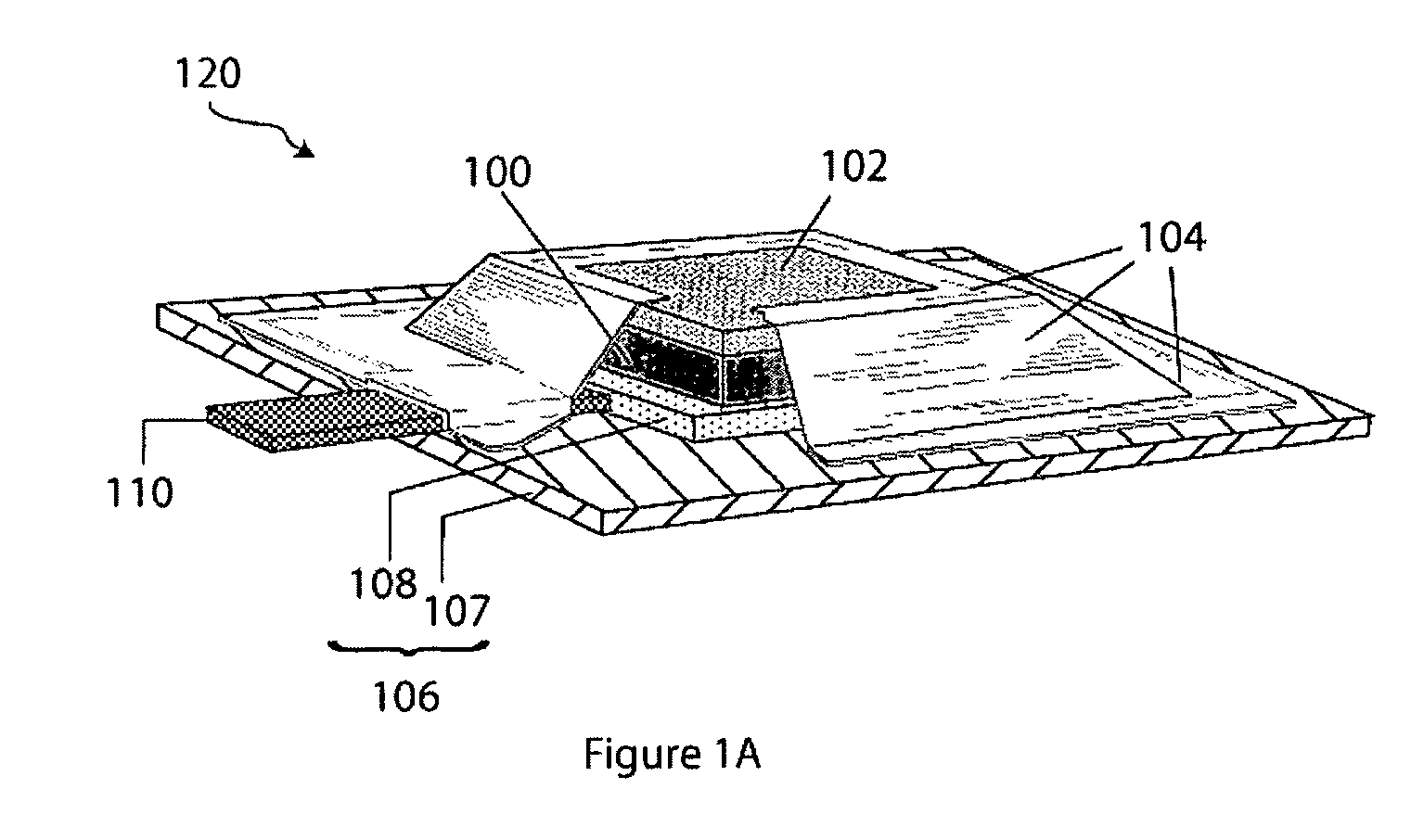

Layered barrier structure having one or more definable layers and method

InactiveUS20050147877A1Reduce transmissionLow rateFuel and primary cellsElectrode manufacturing processesDielectricLithium compound

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

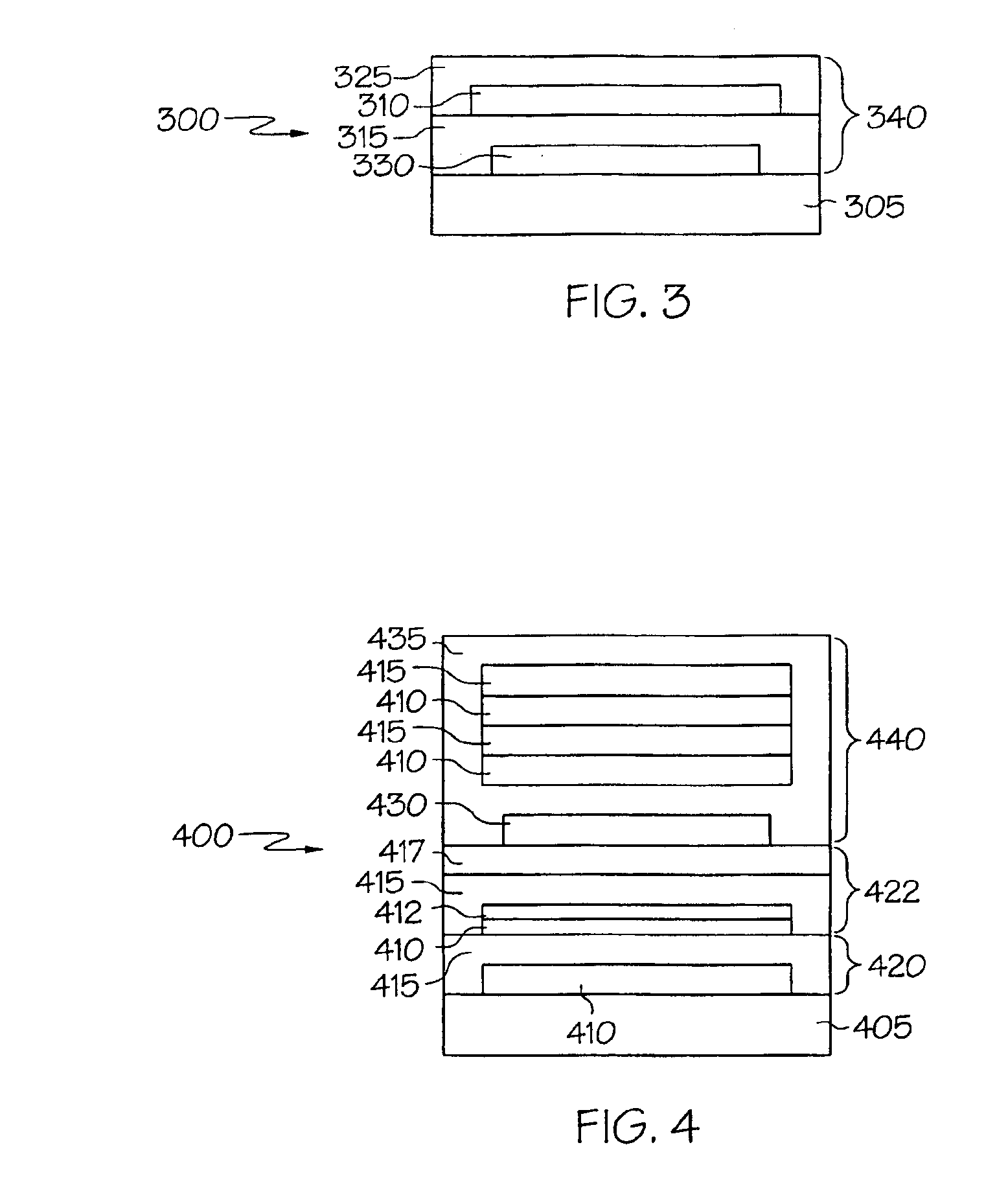

Method for edge sealing barrier films

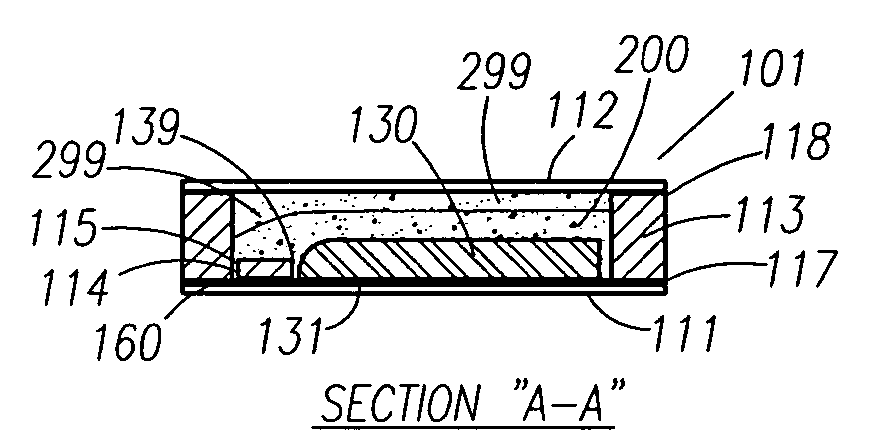

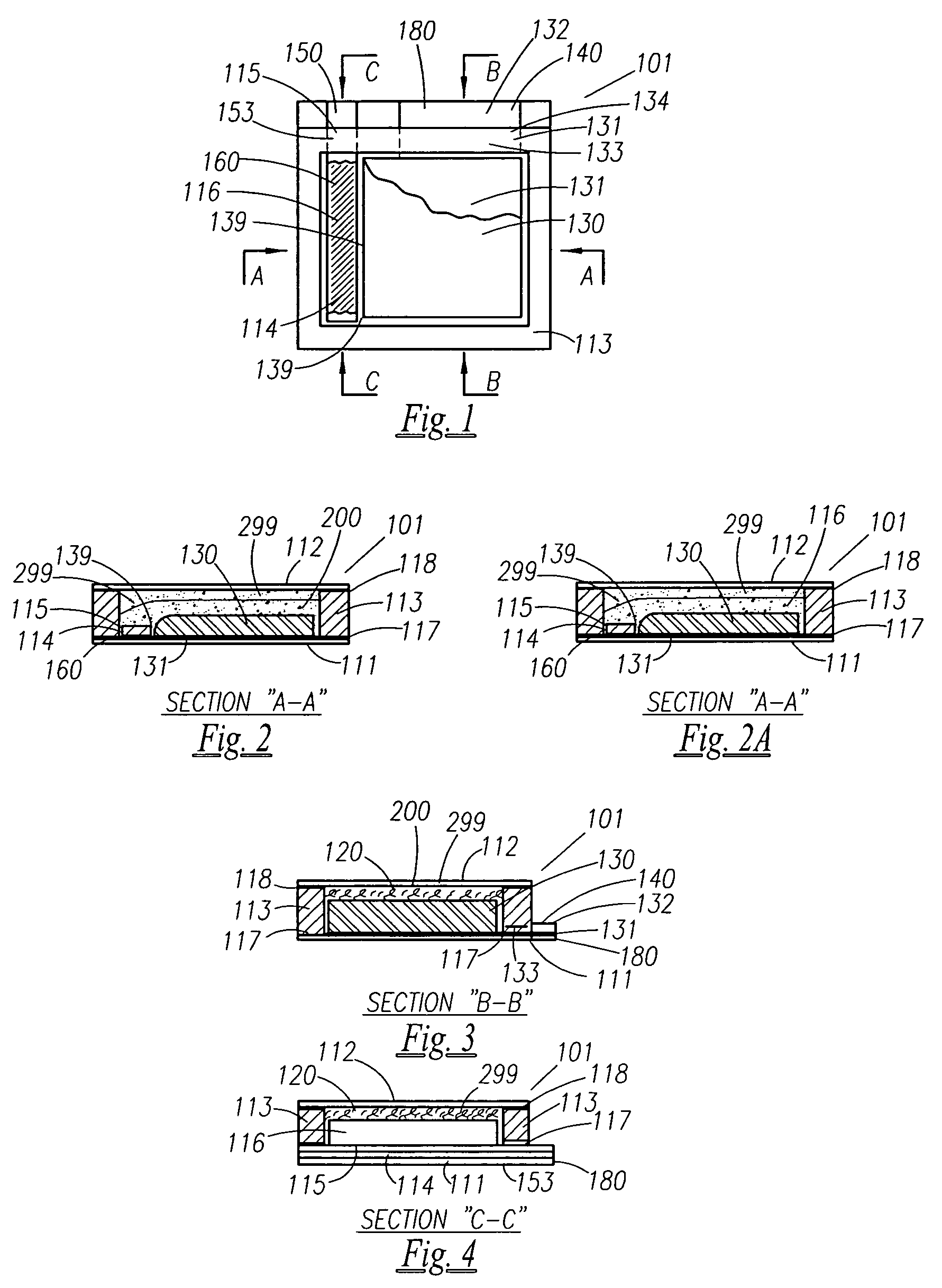

InactiveUS7198832B2Liquid crystal compositionsSemiconductor/solid-state device detailsBiomedical engineering

An edge-sealed, encapsulated environmentally sensitive device. The device includes at least one initial barrier stack, an environmentally sensitive device, and at least one additional barrier stack. The barrier stacks include at least one decoupling layer and at least one barrier layer. The environmentally sensitive device is sealed between the at least one initial barrier stack and the at least one additional barrier stack. A method of making the edge-sealed, encapsulated environmentally sensitive device is also disclosed.

Owner:SAMSUNG DISPLAY CO LTD

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

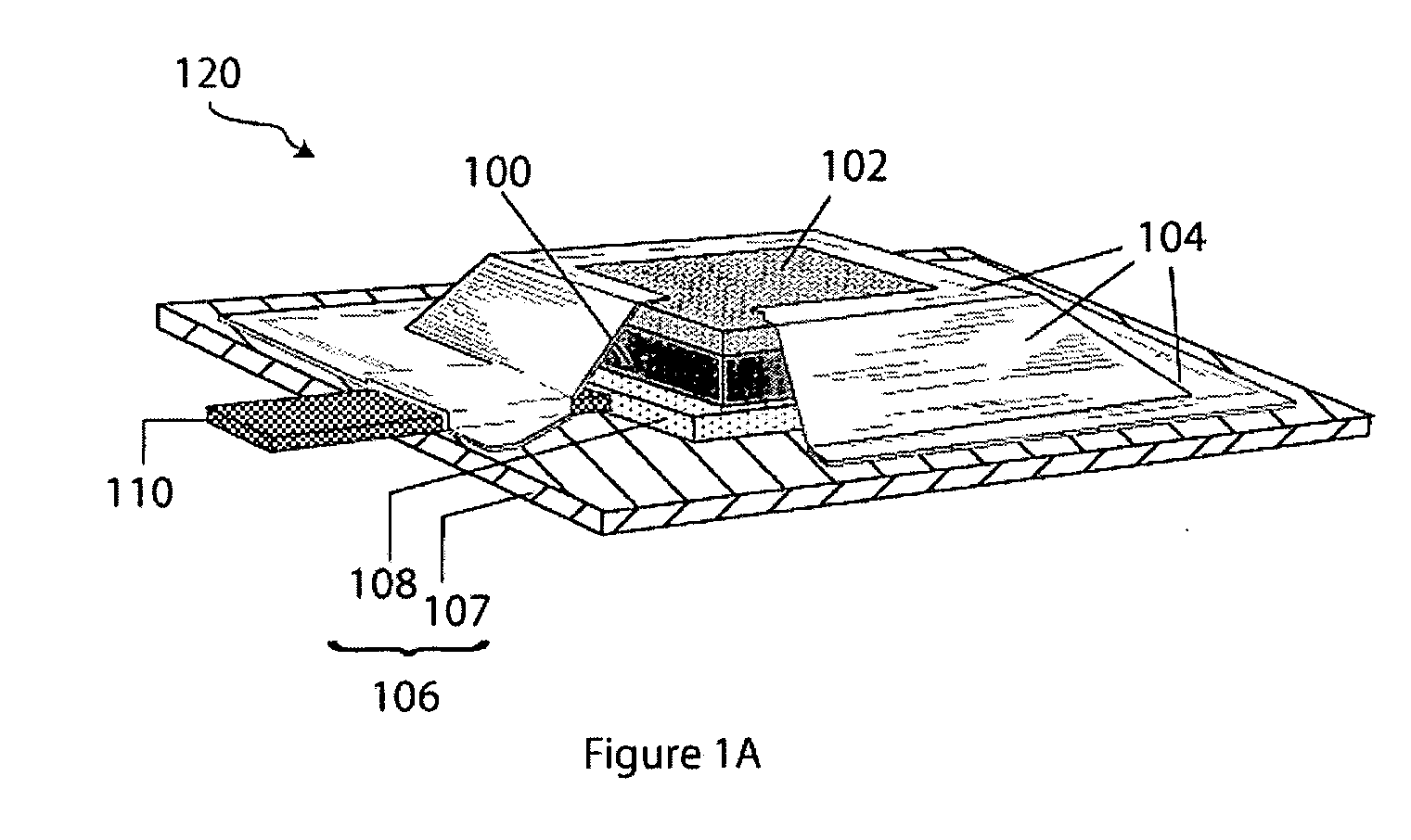

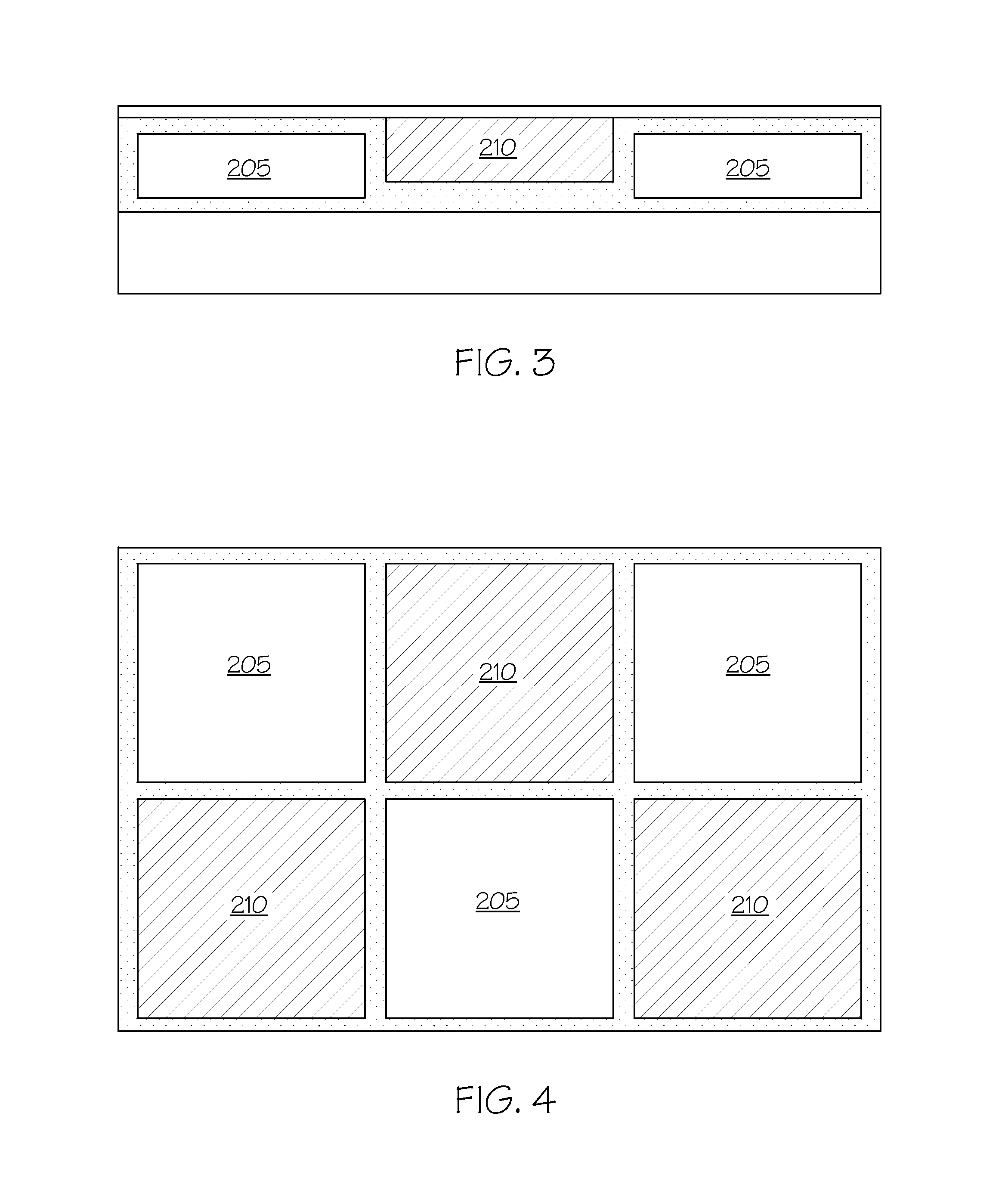

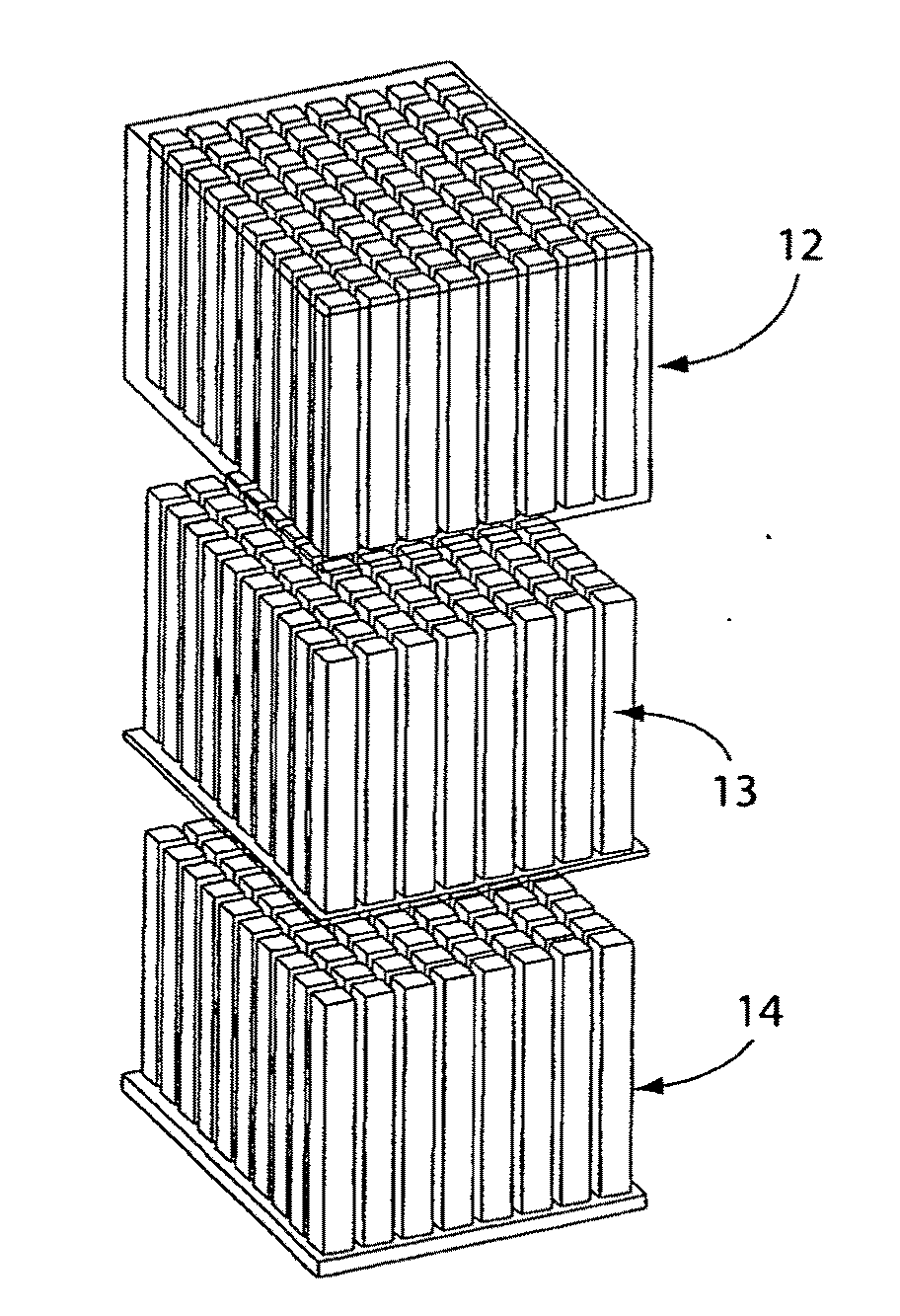

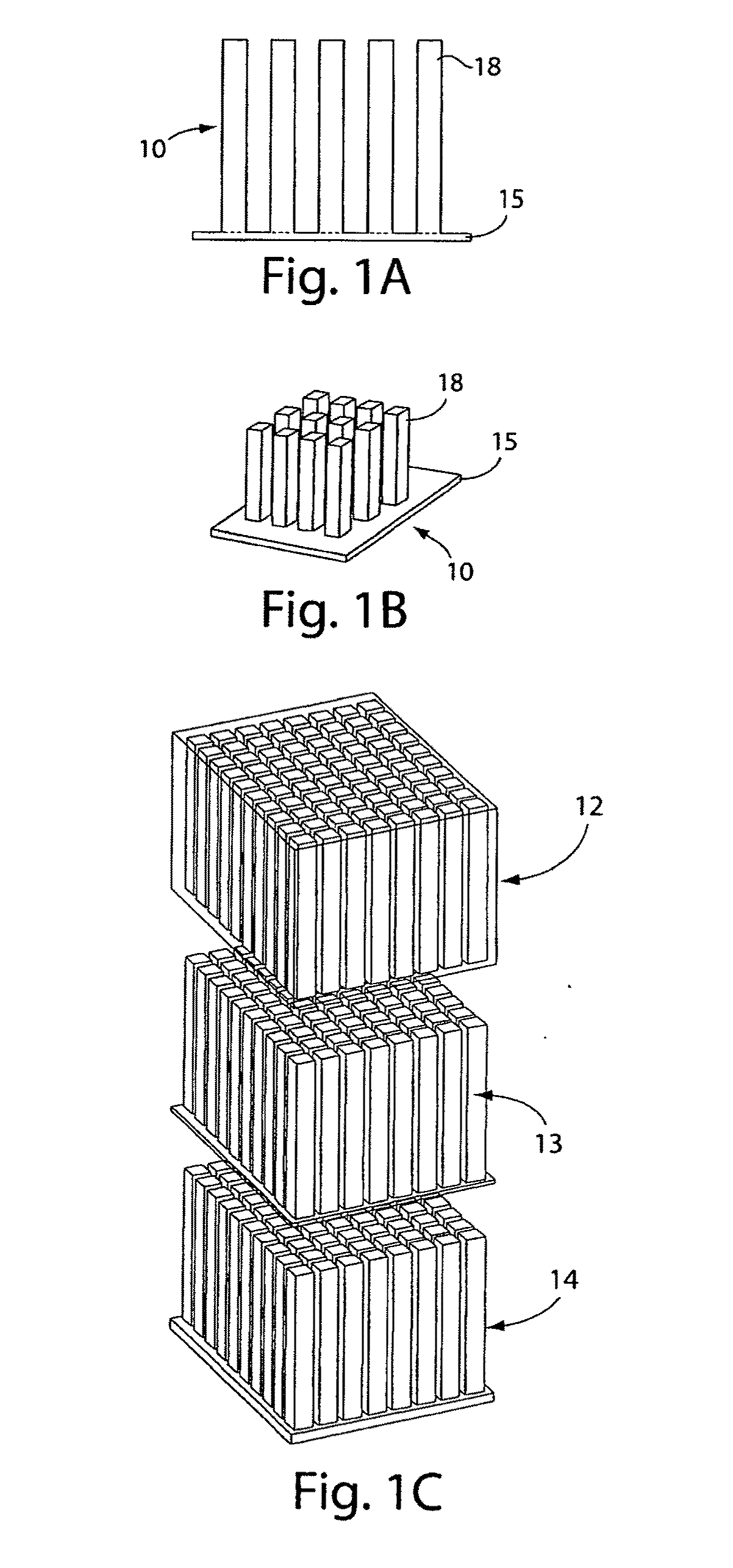

Three dimensional multilayer barrier and method of making

InactiveUS20070196682A1Reduce areaLateral diffusion rate of moisture and oxygen is finiteSemiconductor/solid-state device detailsSolid-state devicesMaterials science

A three dimensional multilayer barrier. The barrier includes a first barrier continuous layer adjacent to a substrate; a first discontinuous decoupling layer adjacent to the first continuous barrier layer, the first discontinuous decoupling layer having at least two sections; and a second continuous barrier layer adjacent to the first discontinuous decoupling layer, the second barrier forming a wall separating the sections of the first discontinuous decoupling layer. A method of making the three dimensional multilayer barrier is also described.

Owner:VITEX SYST

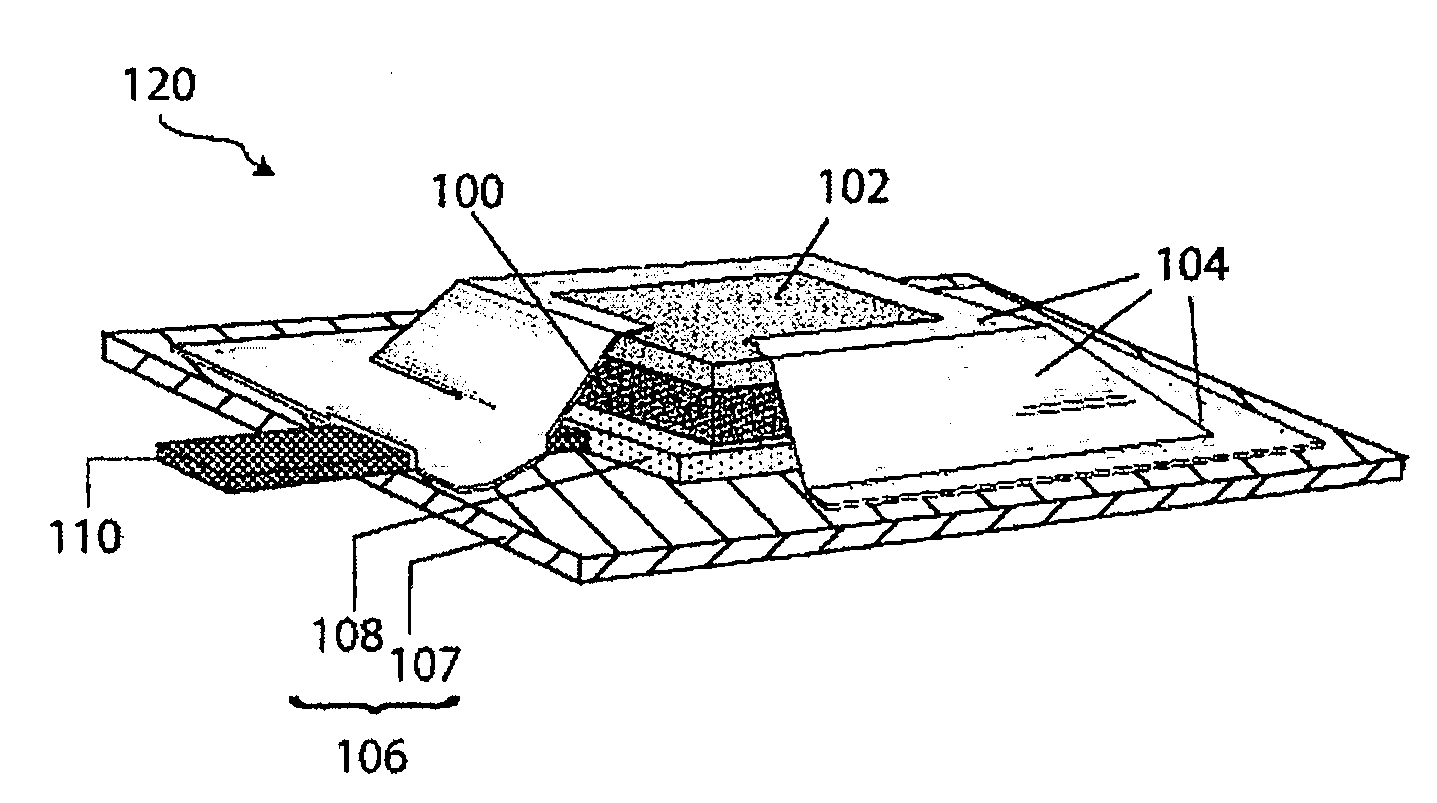

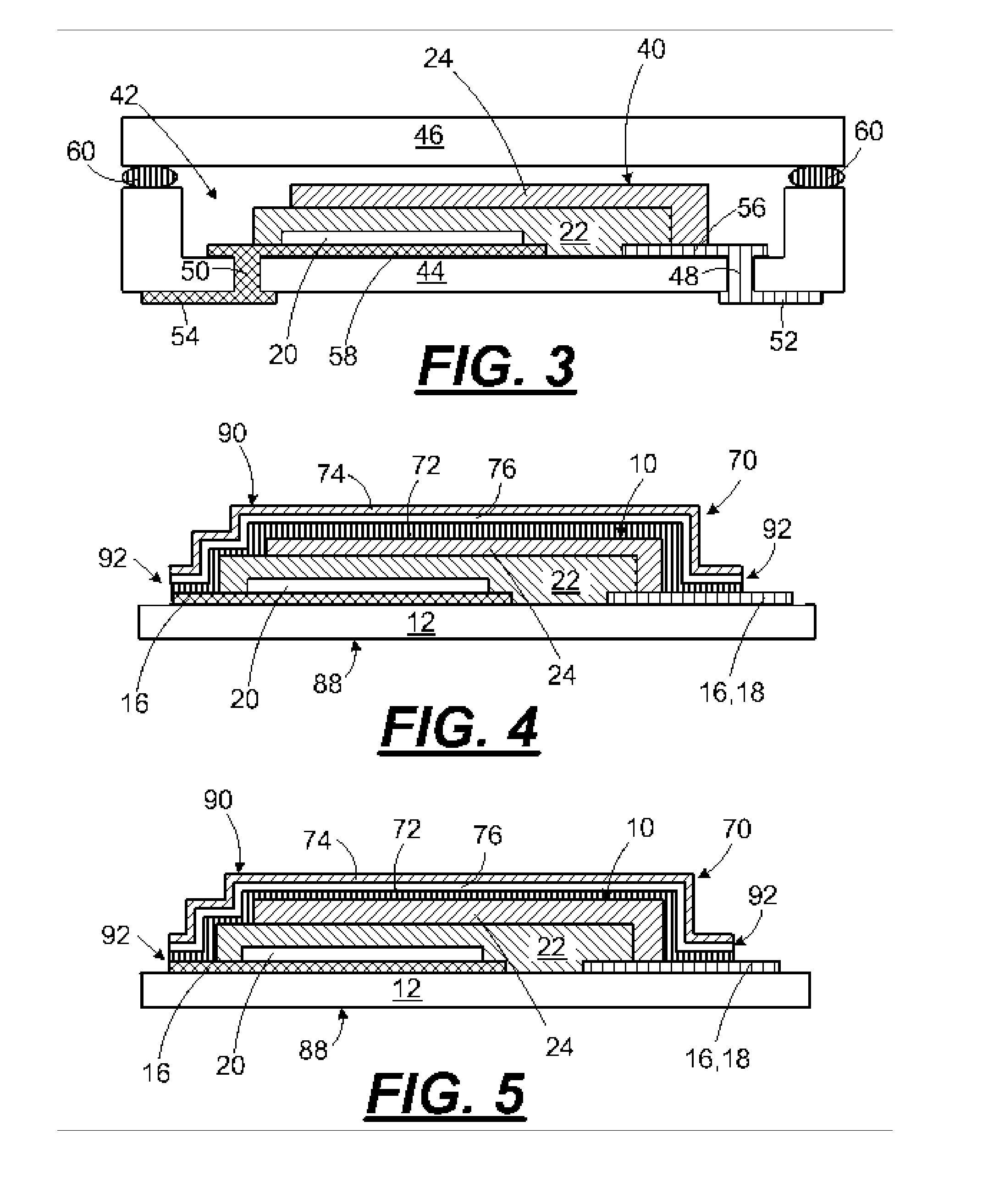

Methods of and device for encapsulation and termination of electronic devices

InactiveUS6916679B2Improve sealingPrevent buildupPV power plantsFinal product manufactureElectricityElectrical devices

A novel method for production of and an apparatus for an encapsulated solid-state electrochemical device is disclosed. The present invention provides for electrical devices, such as, for example, thin-film batteries with sensitive chemistries that can survive environmental exposure while providing external electrical contact to the internal cell chemistry. The method of packaging of the present invention may include bonding one or more protective multi-layer laminates to the environmentally sensitive surfaces of an electronic device. The present invention may provide the advantage of avoiding entrapped air beneath the laminates.

Owner:SAPURAST RES

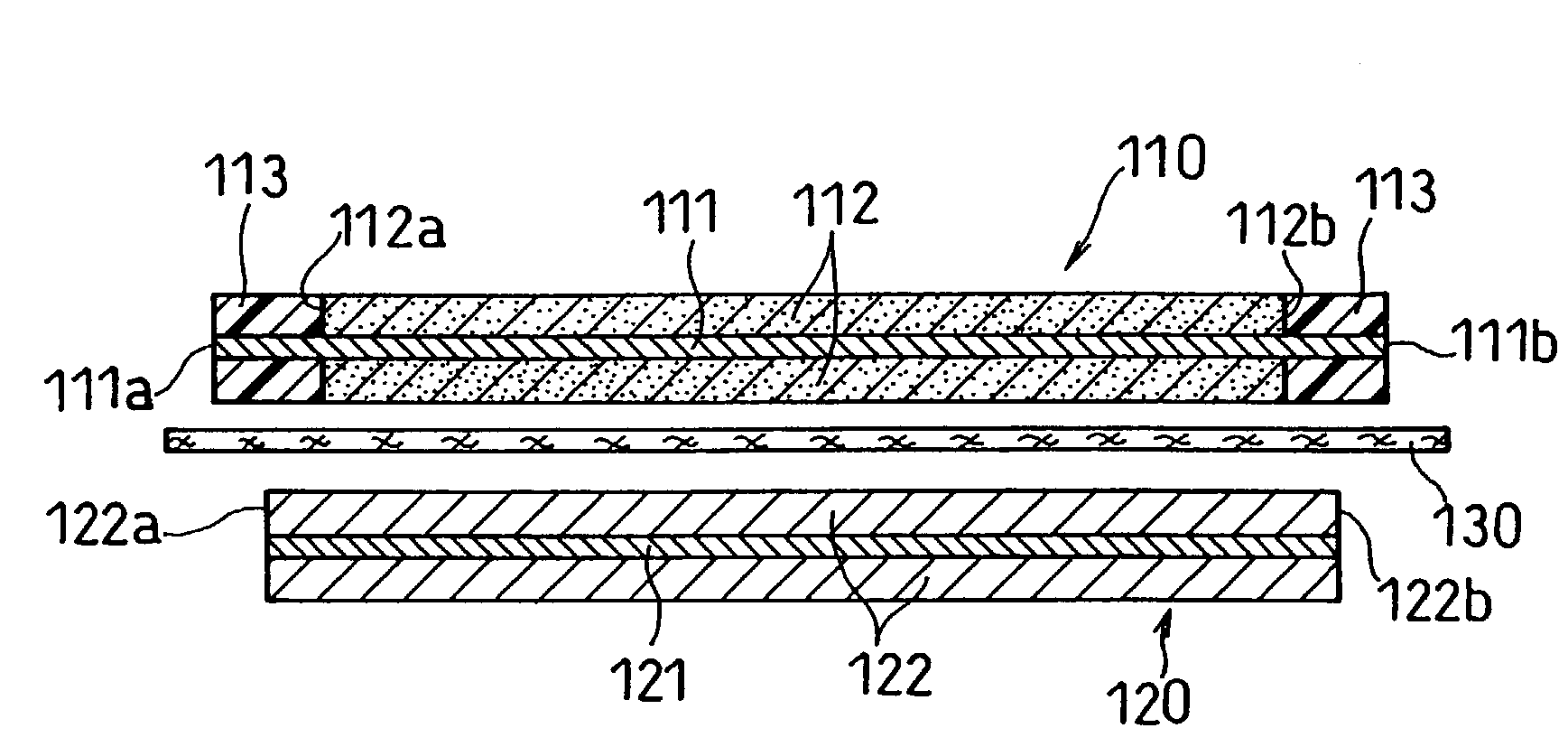

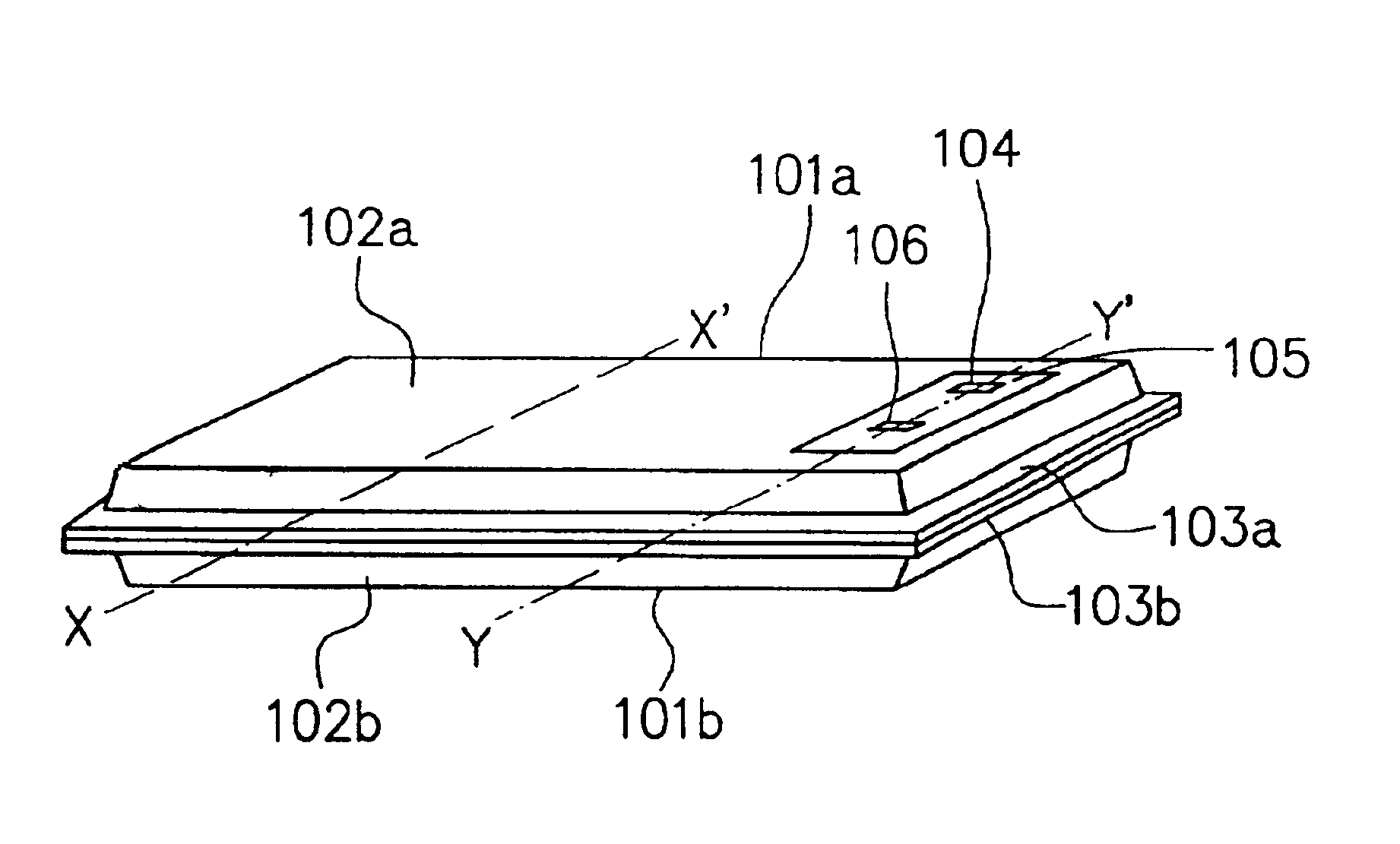

Material for packaging cell, bag for packaging cell, and its production method

InactiveUS7285334B1Excellent gas barrier performanceHigh mechanical strengthNon-aqueous electrolyte accumulatorsSynthetic resin layered productsEngineeringMethods of production

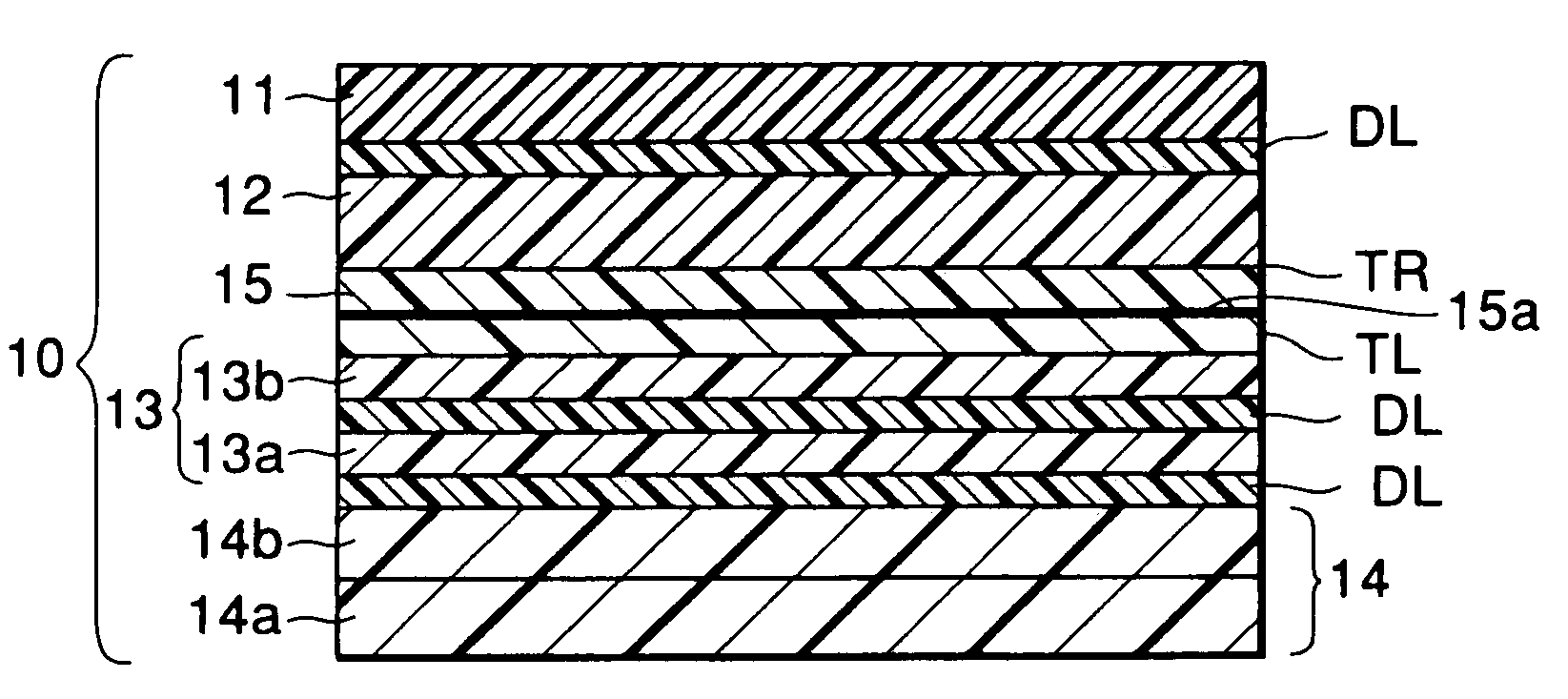

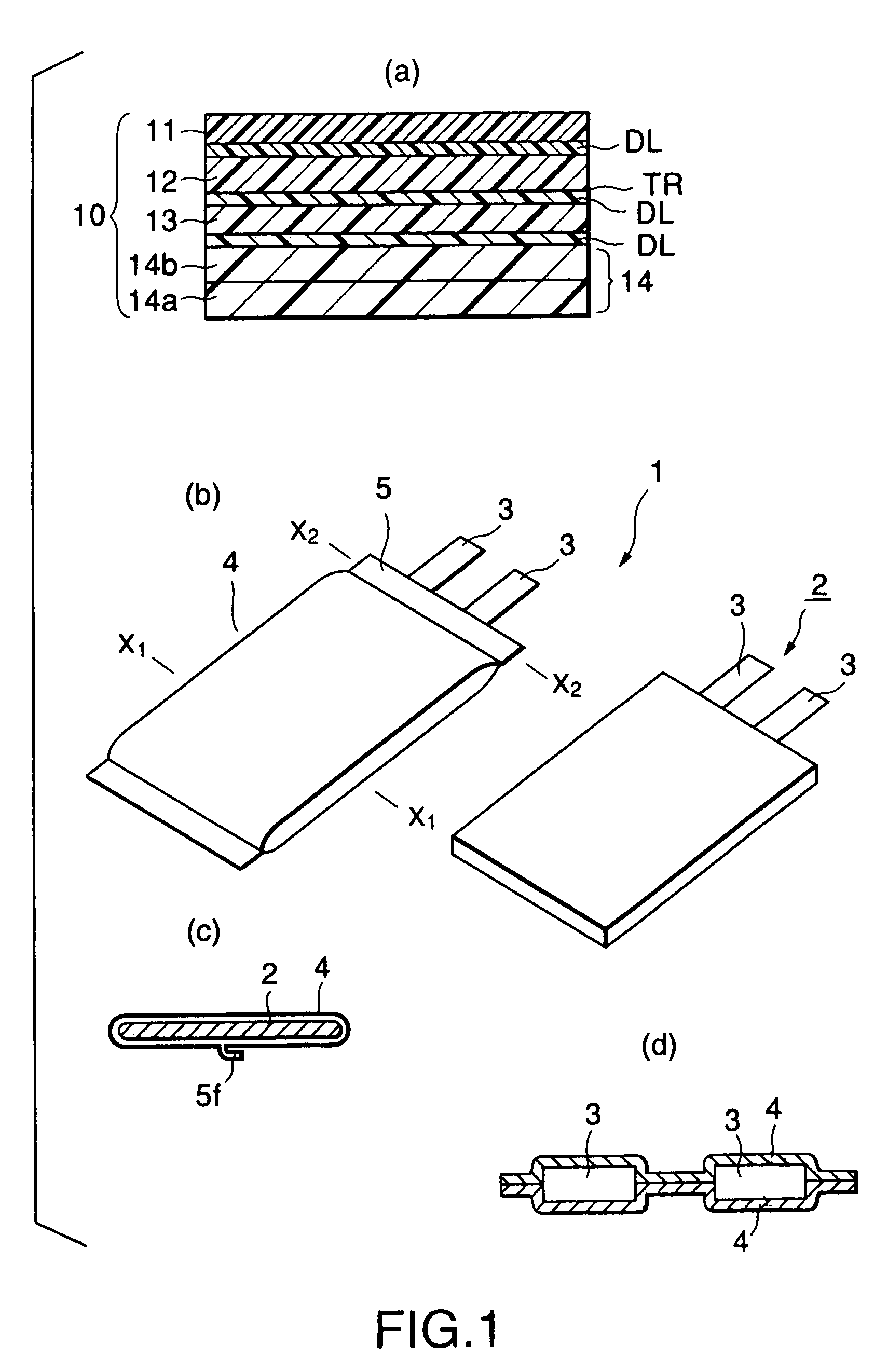

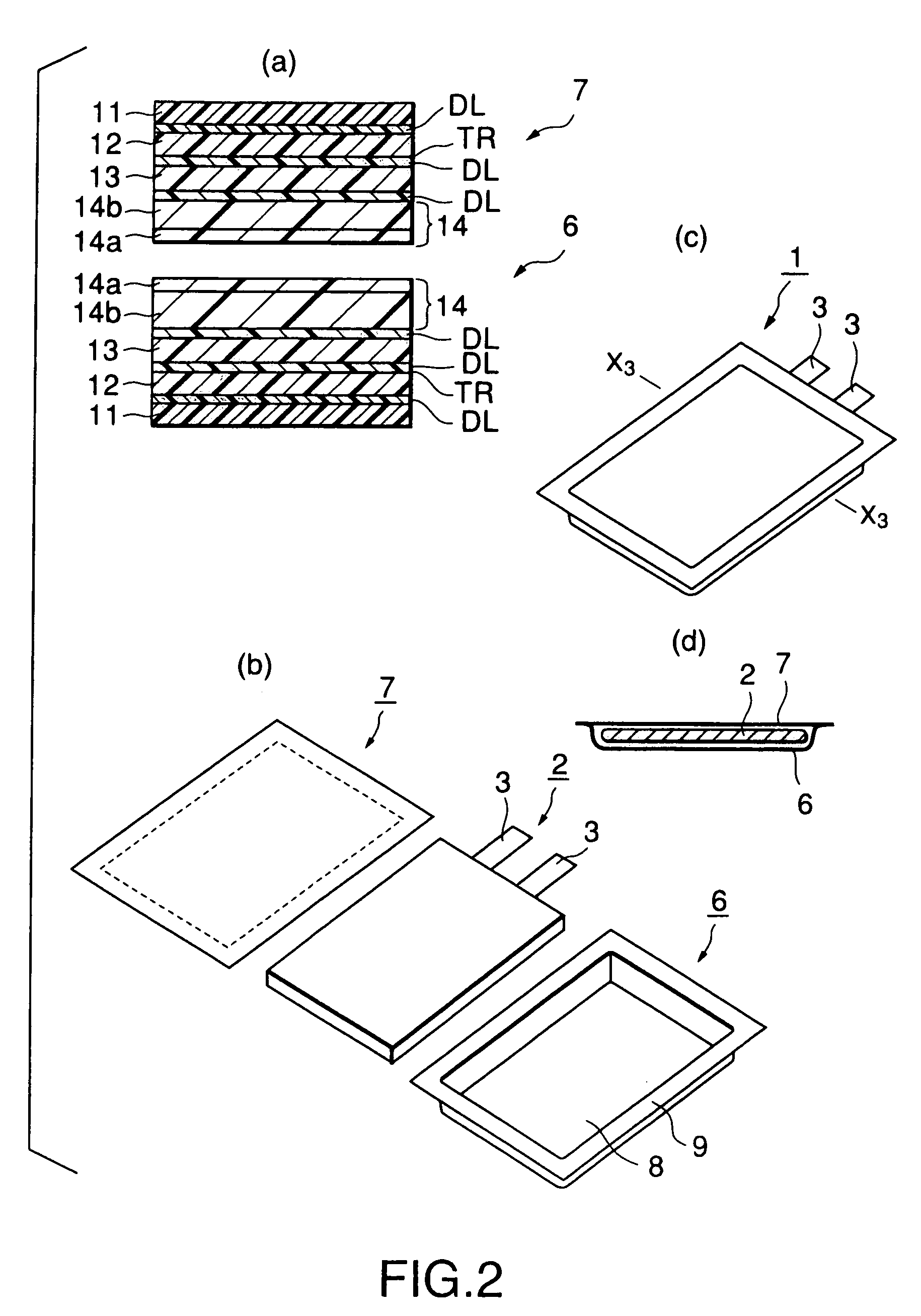

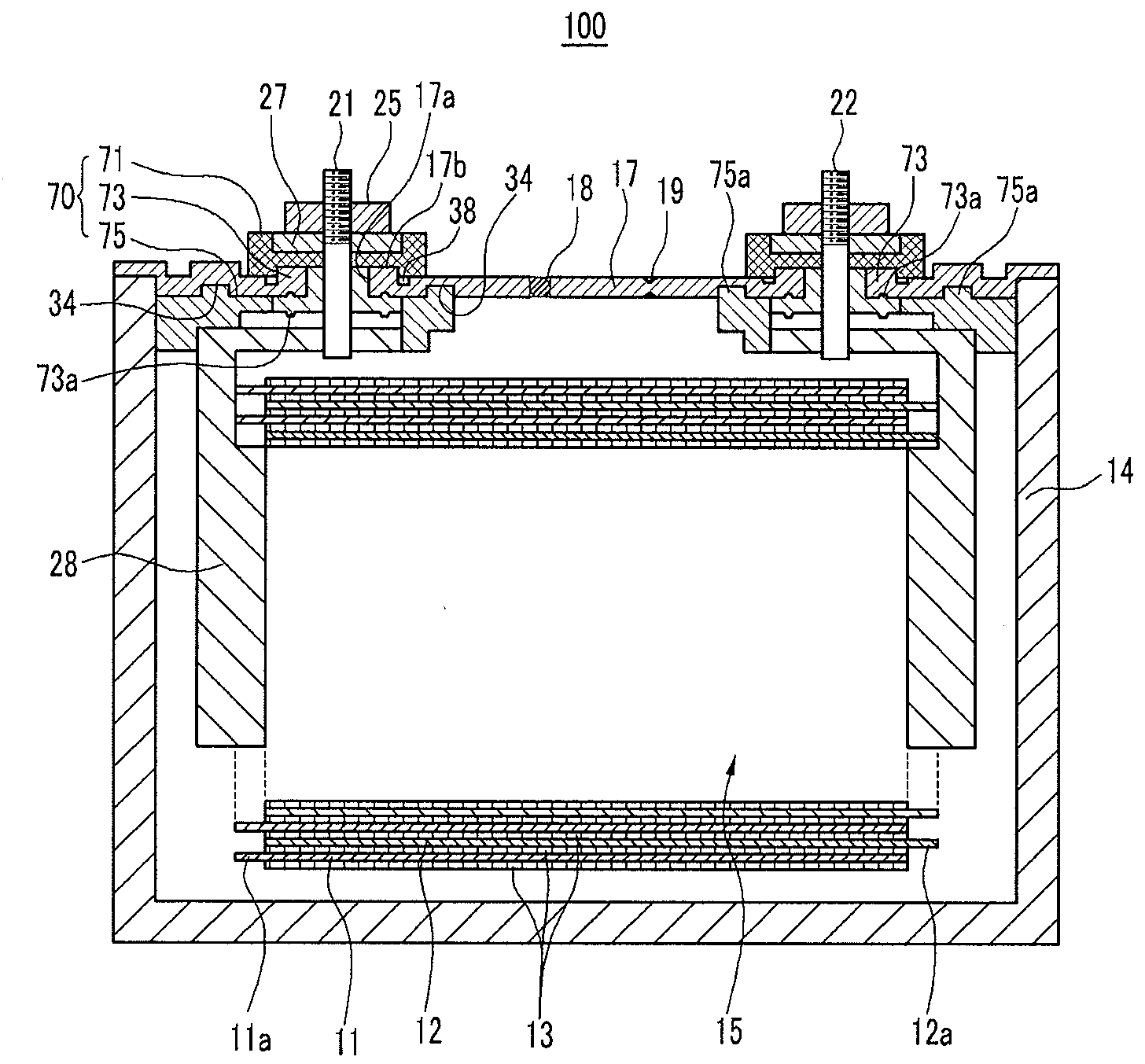

A lithium battery comprises a pouch (4) and a lithium battery module (2) packaged in the pouch (4). The pouch (4) is formed from a battery packaging laminated structure (10). The laminated structure (10) has an outermost layer (11), a barrier layer (12) and an innermost layer (14), or an outermost layer (11), a barrier layer (12), an intermediate layer (13) and an innermost layer (14) superposed in that order. The outermost layer (11) is formed of a formable base material, the barrier layer (12) is formed of a impermeable base material having a barrier property, the intermediate layer (13) is formed of a formable base material and the innermost layer (14) is formed of a heat-adhesive base material.

Owner:DAI NIPPON PRINTING CO LTD

Rechargeable battery

InactiveUS20090186269A1Sealing performanceIncrease contact areaSmall-sized cells cases/jacketsCell lids/coversRechargeable cellEngineering

The present invention relates to a rechargeable battery. The rechargeable battery includes an electrode assembly, a case, electrode terminals, and a cap plate. The electrode assembly includes a separator and an anode and a cathode disposed at both sides of the separator. The case houses the electrode assembly. The electrode terminals are electrically connected to the electrode assembly and protrude outwardly from the case. The cap plate closes and seals the case. The cap plate includes a terminal hole for receiving the electrode terminals and a sealing reinforcing member formed along a circumference of the terminal hole and having a greater thicker than a periphery thereof.

Owner:SAMSUNG SDI CO LTD

Method for edge sealing barrier films

An edge-sealed barrier film composite. The composite includes a substrate and at least one initial barrier stack adjacent to the substrate. The at least one initial barrier stack includes at least one decoupling layer and at least one barrier layer. One of the barrier layers has an area greater than the area of one of the decoupling layers. The decoupling layer is sealed by the first barrier layer within the area of barrier material. An edge-sealed, encapsulated environmentally sensitive device is provided. A method of making the edge-sealed barrier film composite is also provided.

Owner:SAMSUNG DISPLAY CO LTD

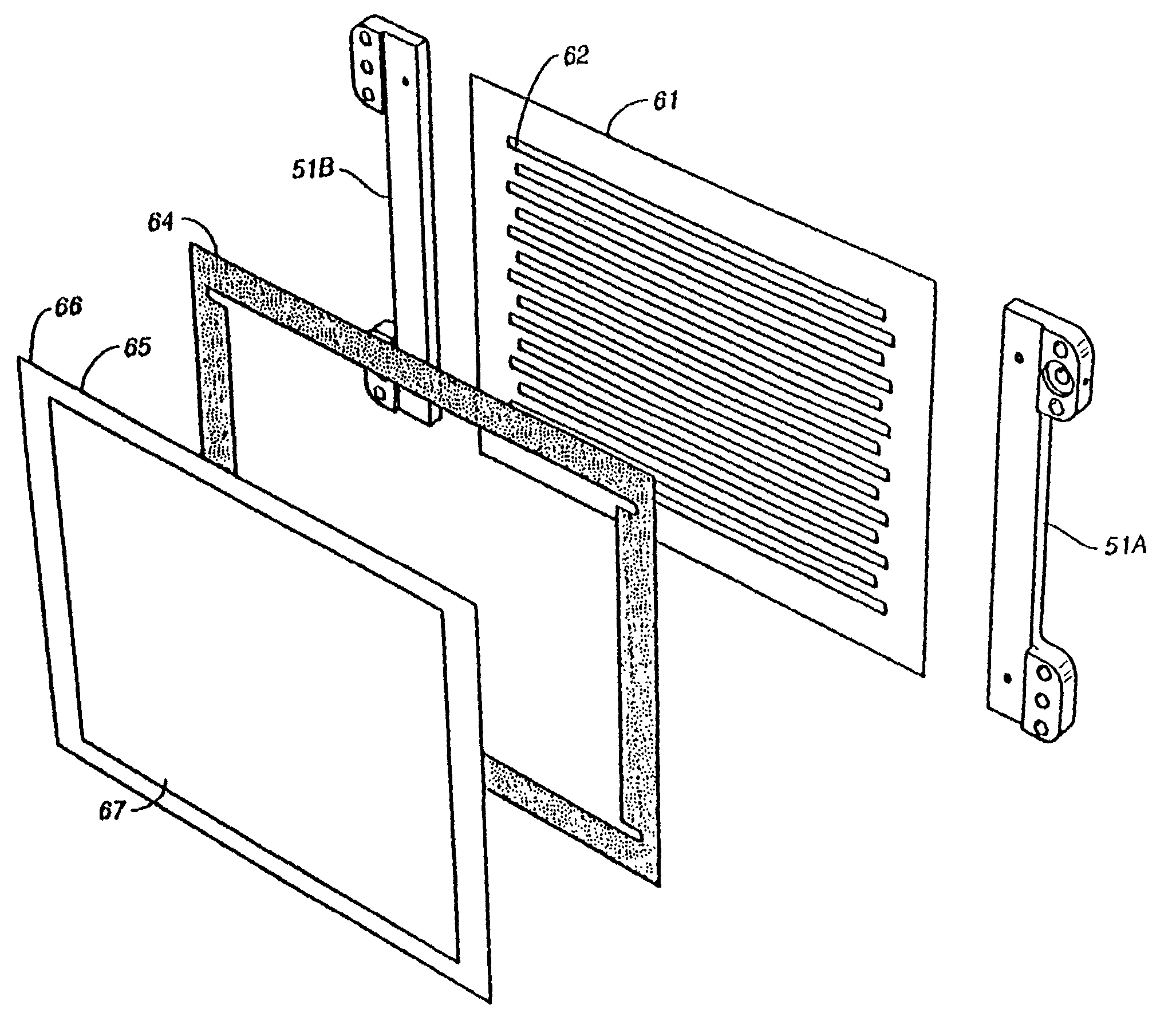

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

Small-scale batteries and electrodes for use thereof

The present invention generally relates to batteries or other electrochemical devices. In some embodiments, the present invention relates to small-scale batteries or microbatteries. For example, in one aspect of the invention, a battery may have a volume of no more than about 5 mm3, while having an energy density of at least about 400 Wh / l. Other aspect of the invention is directed to techniques of packaging such batteries.

Owner:CHARLES STARK DRAPER LABORATORY +1

Closure vent seal and assembly

InactiveUS20060228620A1Increase battery capacityThe production process is simpleClosuresFinal product manufactureEngineeringMechanical engineering

A closure assembly and rupturable vent seal adapted for use in an electrochemical battery cell is disclosed. The vent seal includes a series of peripheral projections that can be folded to insure proper sealing of the vent without wrinkles or overlapping folded portions. Methods of accomplishing the invention are also contemplated.

Owner:EVEREADY BATTERY CO INC

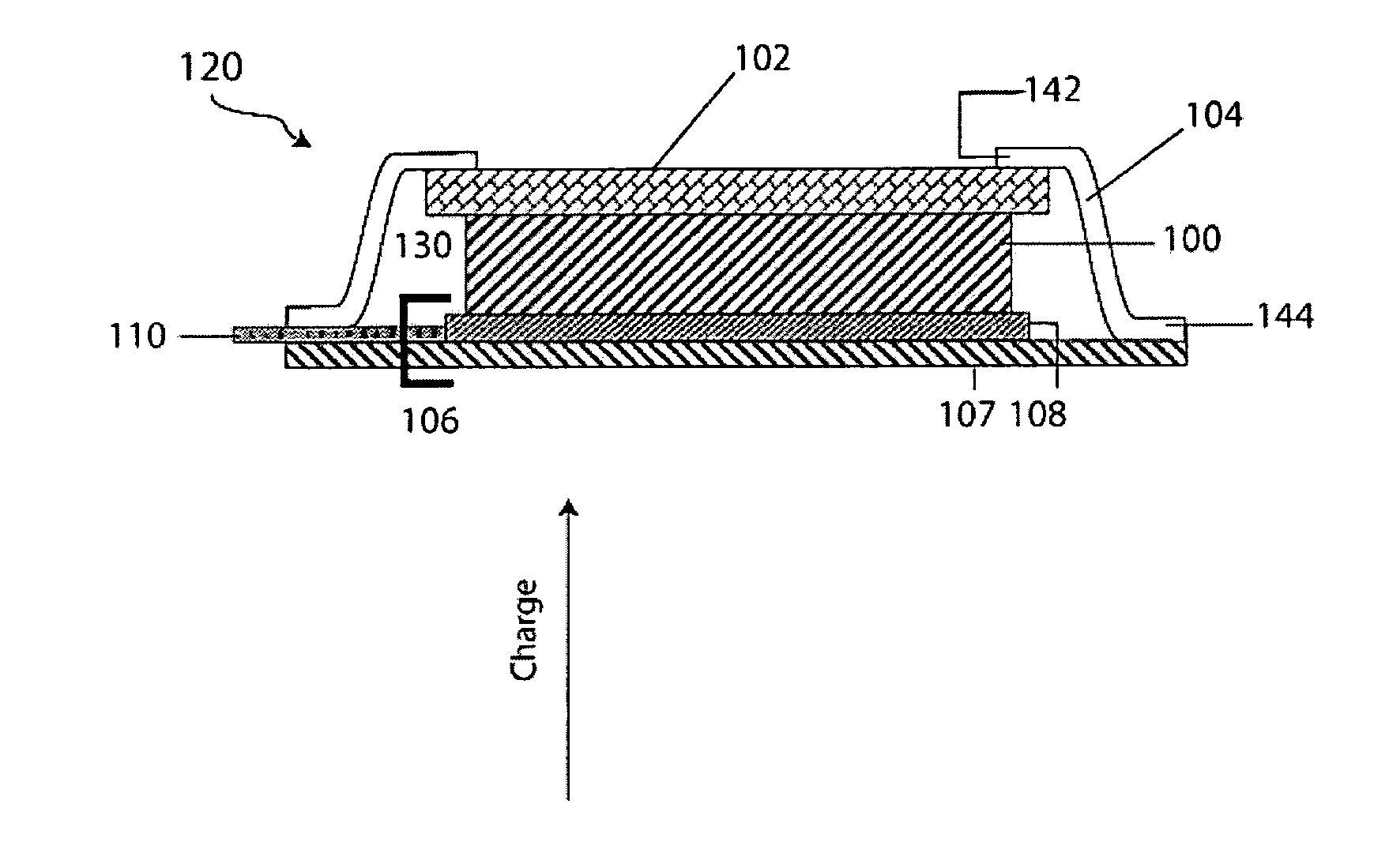

Long life thin film battery and method therefor

InactiveUS20080003492A1Improve air tightnessIncrease costSolid electrolytesFinal product manufactureEngineeringThin film rechargeable lithium battery

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

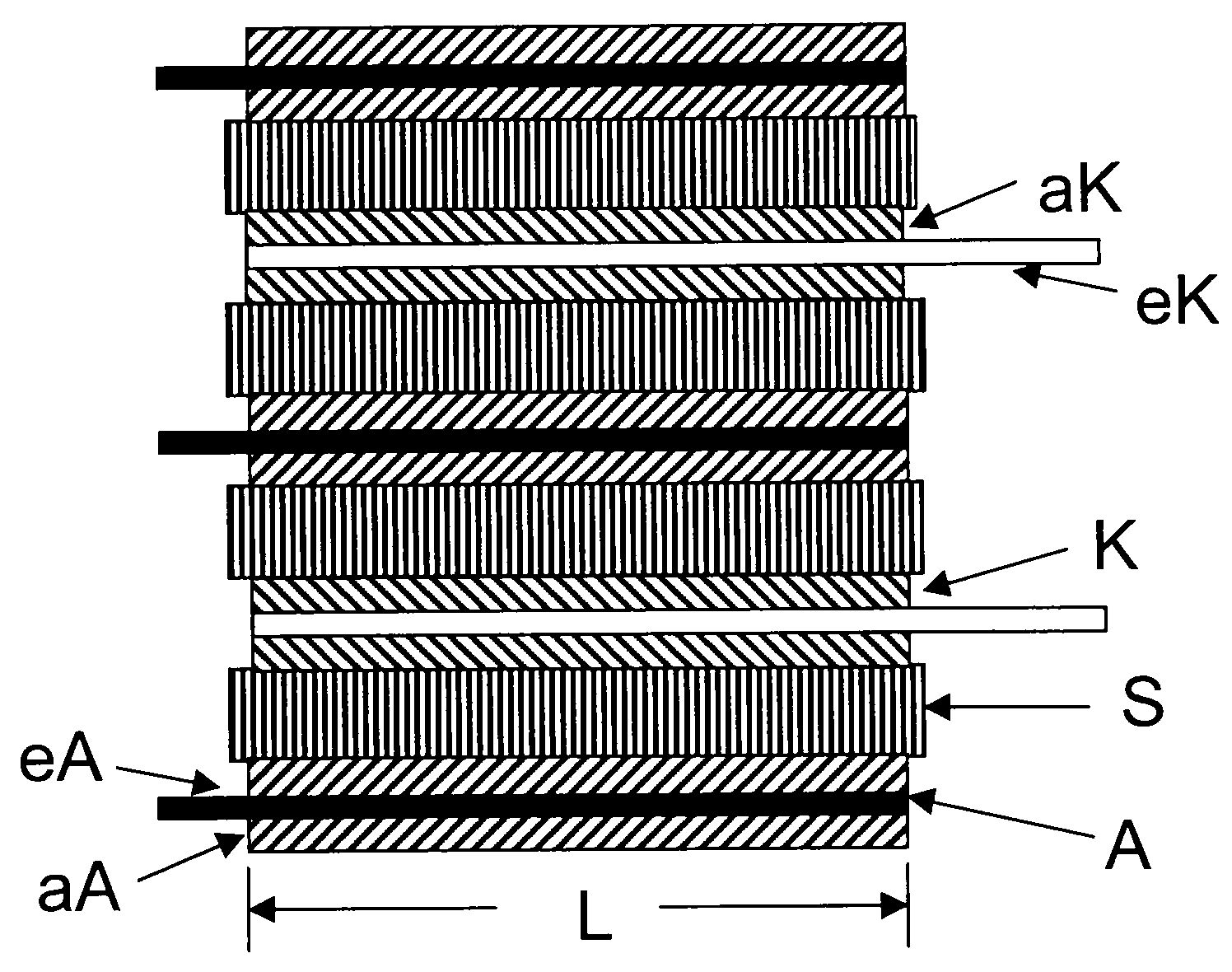

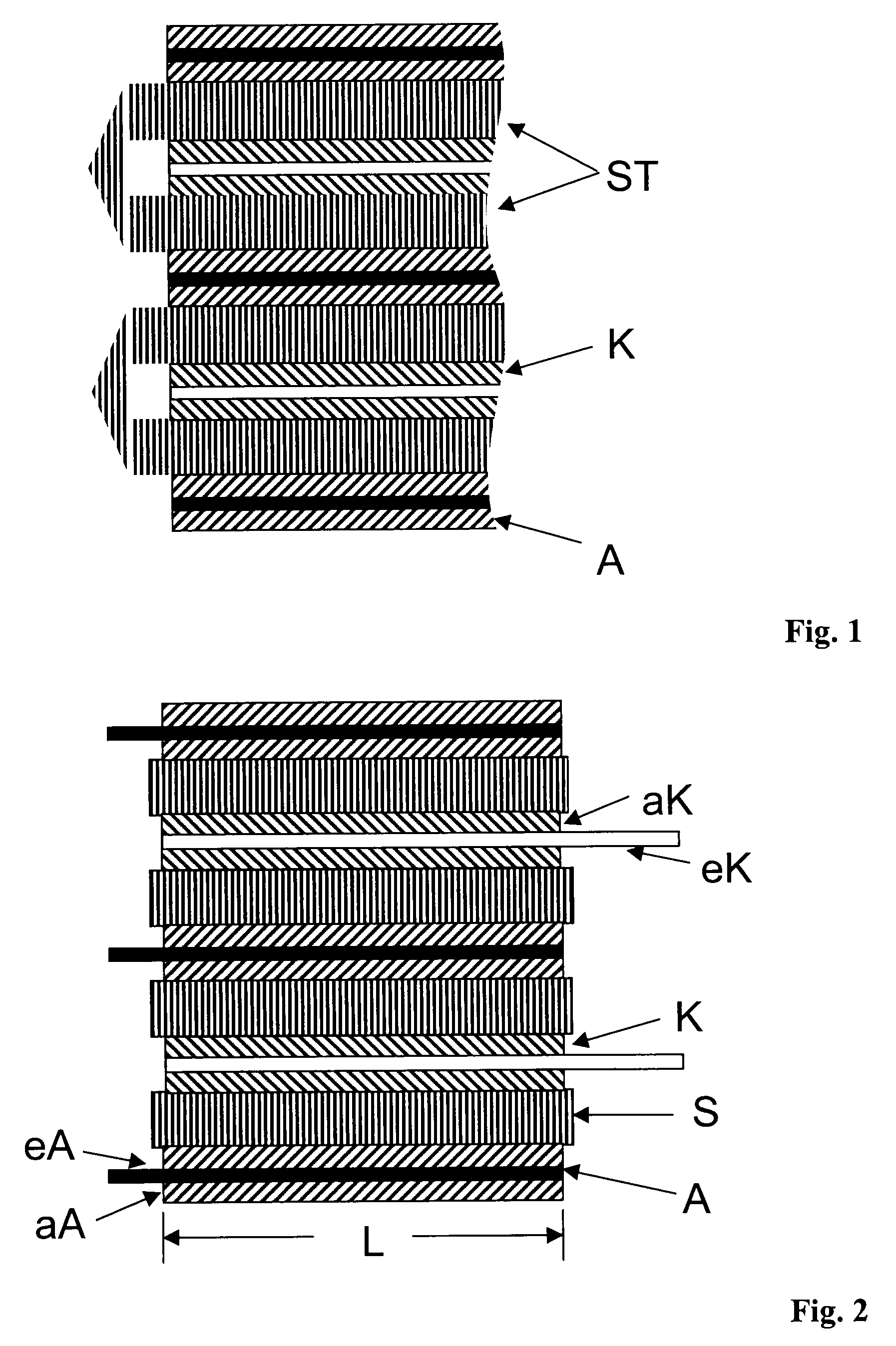

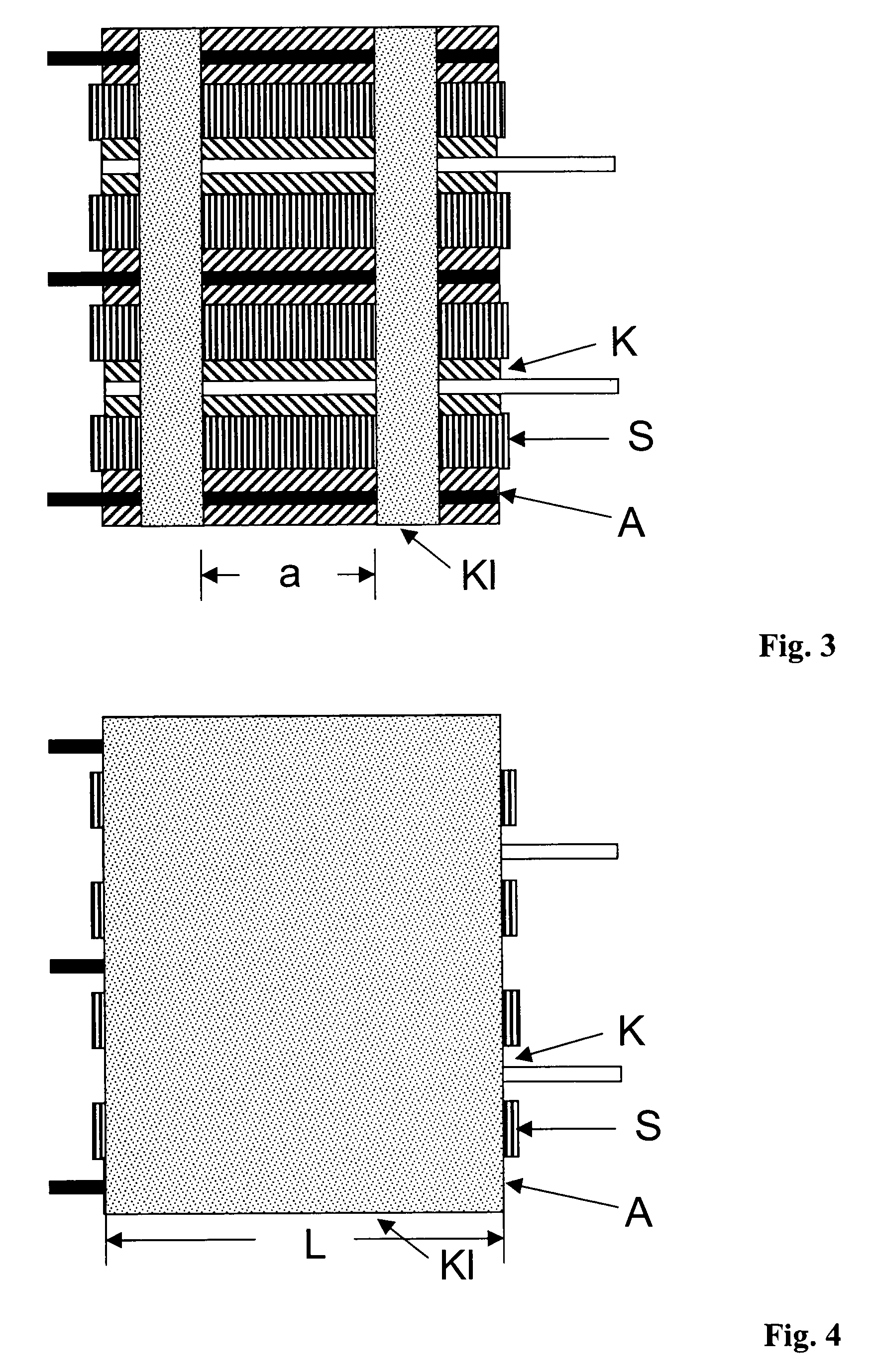

Stacks Of Separators And Electrodes Alternately Stacked One On Top Of The Other And Fixed For Li Storage Batteries

InactiveUS20080274394A1Improve securityCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringAdhesive bonding

The present invention relates to stacks comprising separators and electrodes stacked alternately one on top of the other and fixed, the stack having, on at least one side and / or edge of the stack, at least one adhesive bond comprising an organic adhesive, which bond adhesively bonds the electrodes and separators of the stack to one another, and a method for the production thereof and the use of these stacks in Li batteries.

Owner:EVONIK DEGUSSA GMBH

Method of making encapsulated display devices

InactiveUS6923702B2Static indicating devicesSemiconductor/solid-state device detailsDisplay deviceComputer science

An encapsulated display device. The device includes a substrate, an environmentally sensitive display device adjacent to the substrate, and at least one first barrier stack adjacent to the environmentally sensitive display device. The barrier stack encapsulates the environmentally sensitive display device. It includes at least one first barrier layer and at least one first polymer layer. The encapsulated display device optionally includes at least one second barrier stack located between the substrate and the environmentally sensitive display device. The second barrier stack includes at least one second barrier layer and at least one second polymer layer. A method for making an encapsulated display device is also disclosed.

Owner:SAMSUNG DISPLAY CO LTD

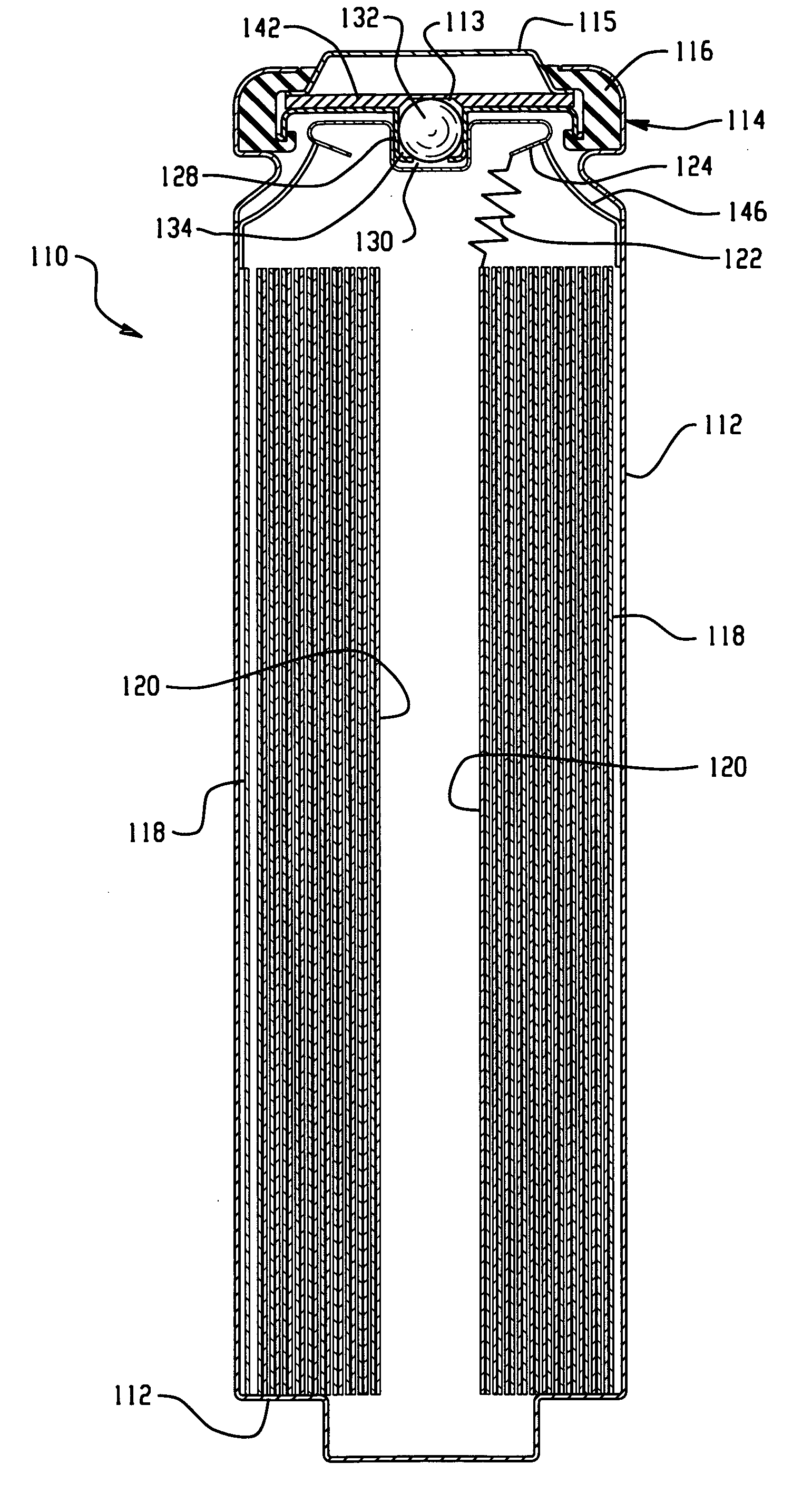

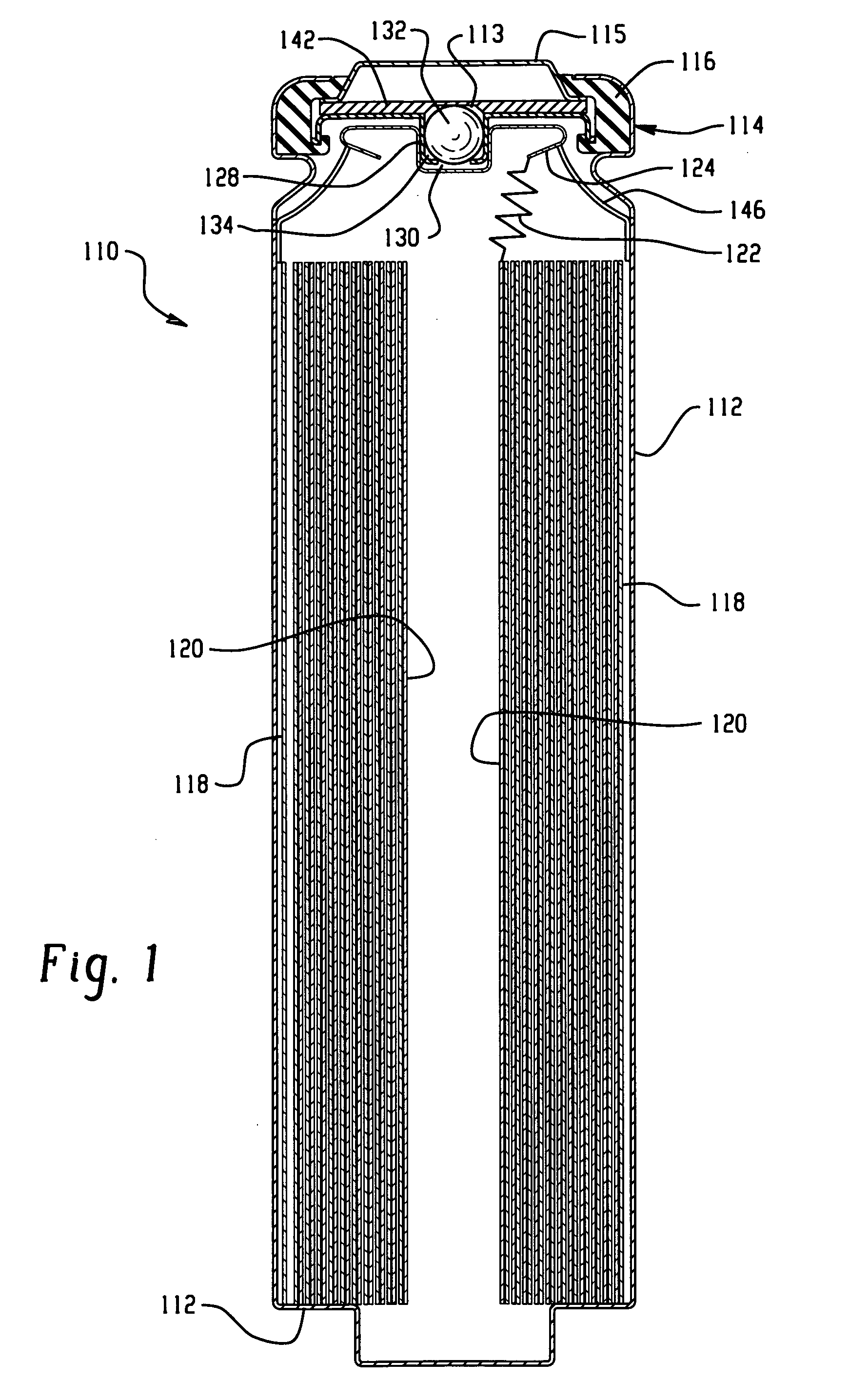

Electrochemical cell with positive container

InactiveUS20080026288A1Improve utilization efficiencyIncrease battery capacityFinal product manufactureElectrode carriers/collectorsSpiral woundEngineering

An electrochemical cell, particularly an electrochemical cell having a container with a positive polarity. In one embodiment, the cell is a primary cell that includes an electrode assembly having a lithium negative electrode and a positive electrode, preferably comprising iron disulfide. The cell is provided with a spiral wound electrode assembly with a portion of the positive electrode contacting the container. The positive electrode current collector contacts the container in one embodiment. The negative electrode includes an electrically conductive member that electrically contacts a cover of the cell and provides the cover with a negative polarity. In a preferred embodiment, the electrically conductive member makes pressure contact with a portion of the cell cover. A method of manufacturing such a cell is also provided.

Owner:EVEREADY BATTERY CO INC

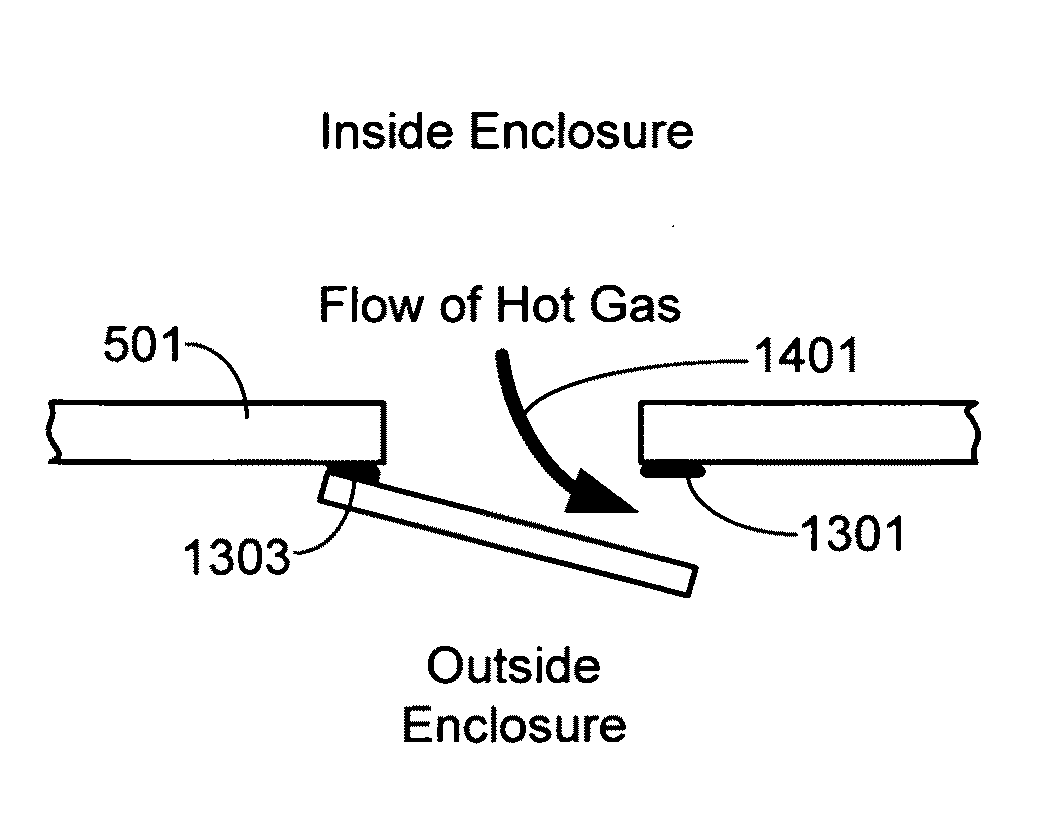

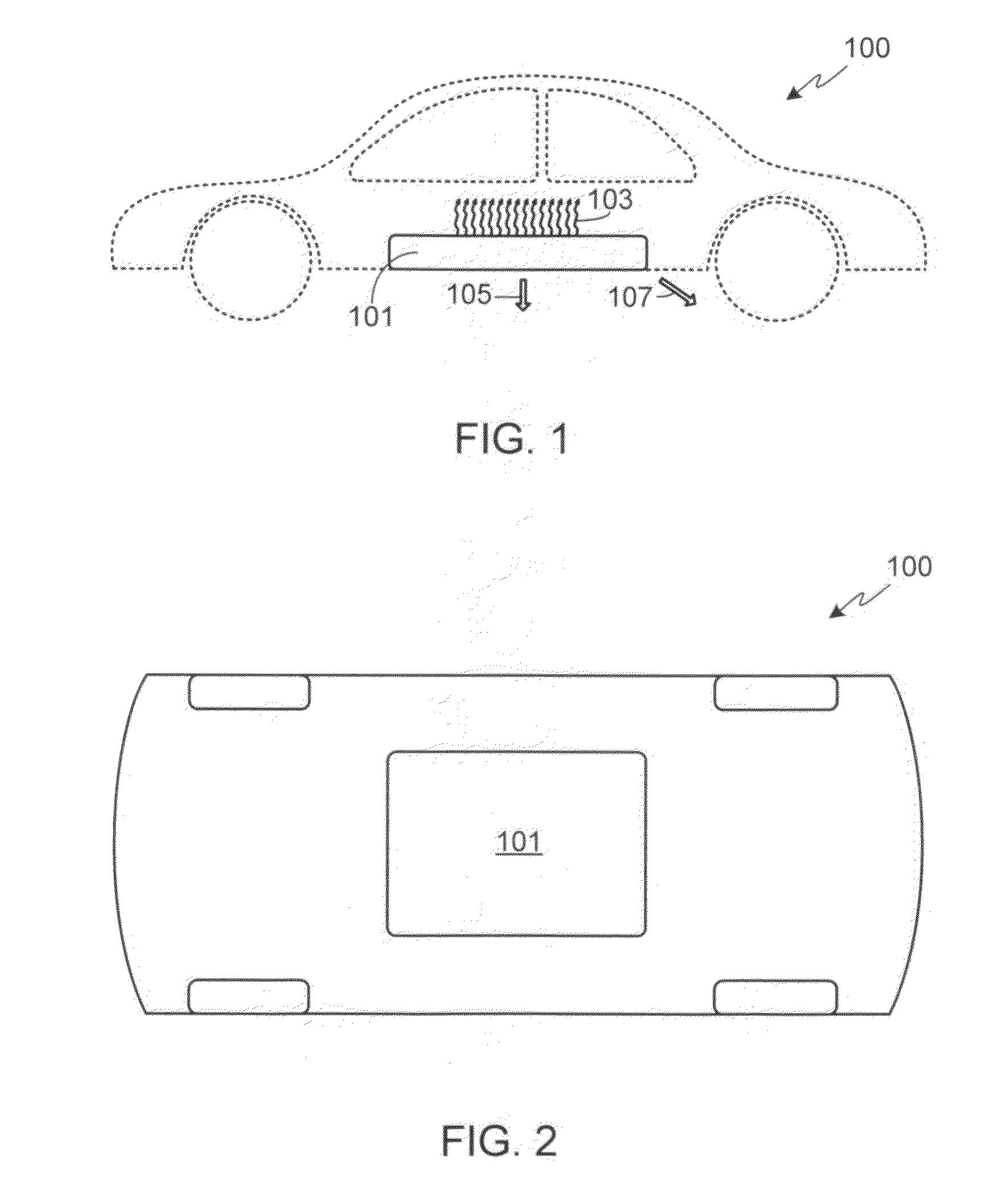

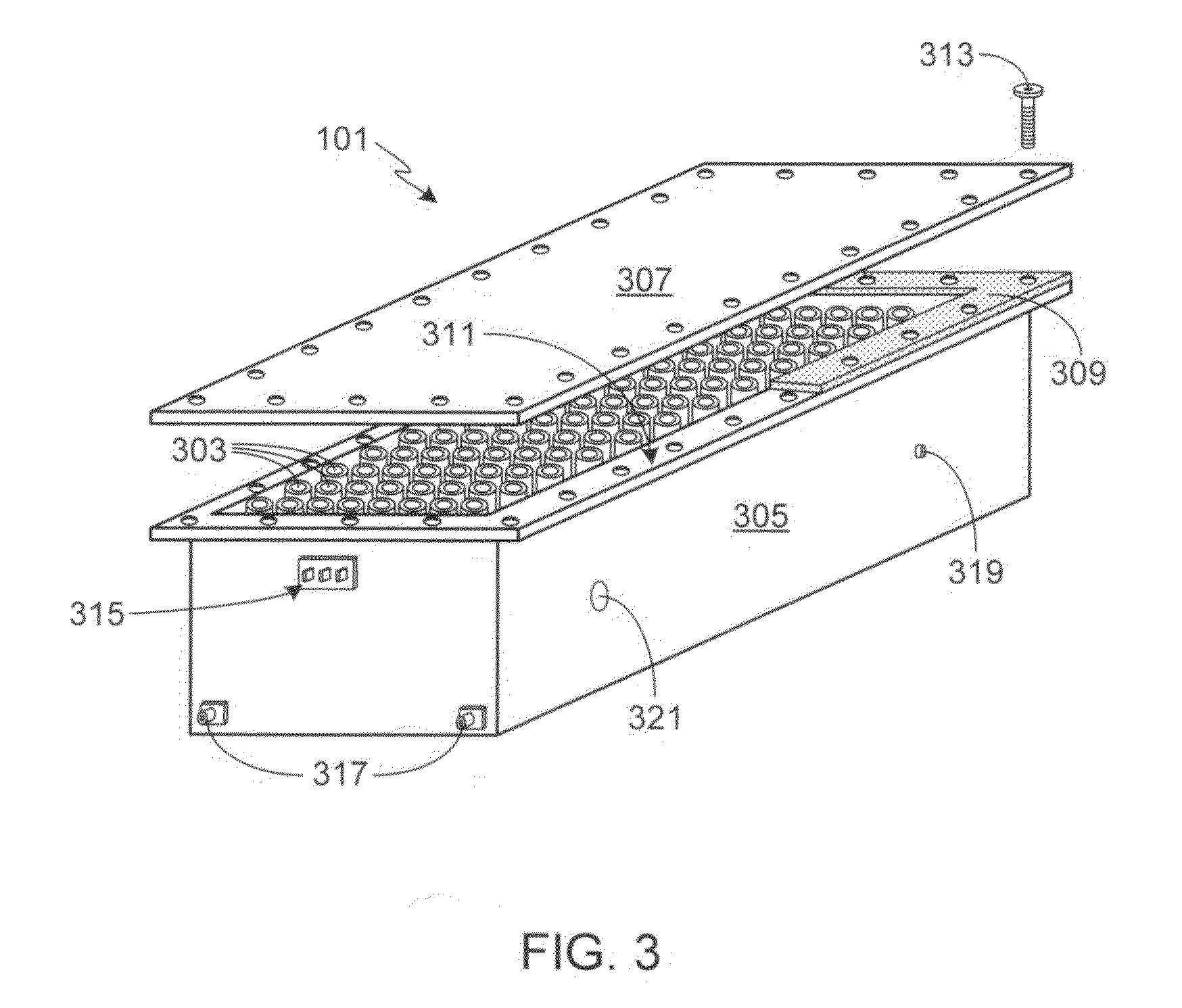

Battery pack enclosure with controlled thermal runaway release system

ActiveUS20100273034A1Cell temperature controlElectric propulsion mountingThermal management systemEngineering

A battery pack thermal management system is provided that is comprised of at least one enclosure failure port integrated into at least one wall of a battery pack enclosure, where the enclosure failure port(s) remains closed during normal operation of the battery pack, and opens during a battery pack thermal runaway event, thereby providing a flow path for hot gas generated during the thermal runaway event to be exhausted out of the battery pack enclosure in a controlled fashion.

Owner:TESLA INC

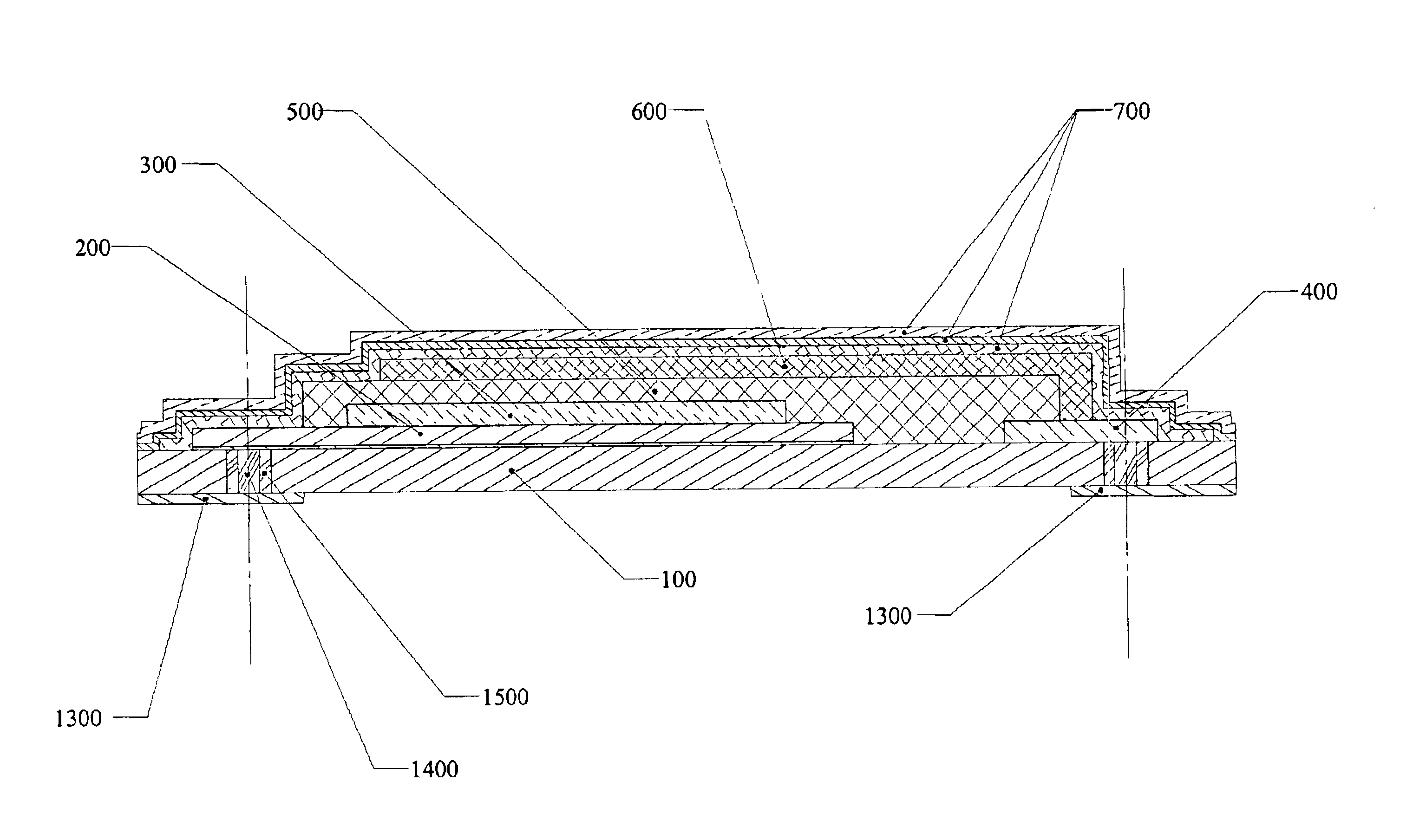

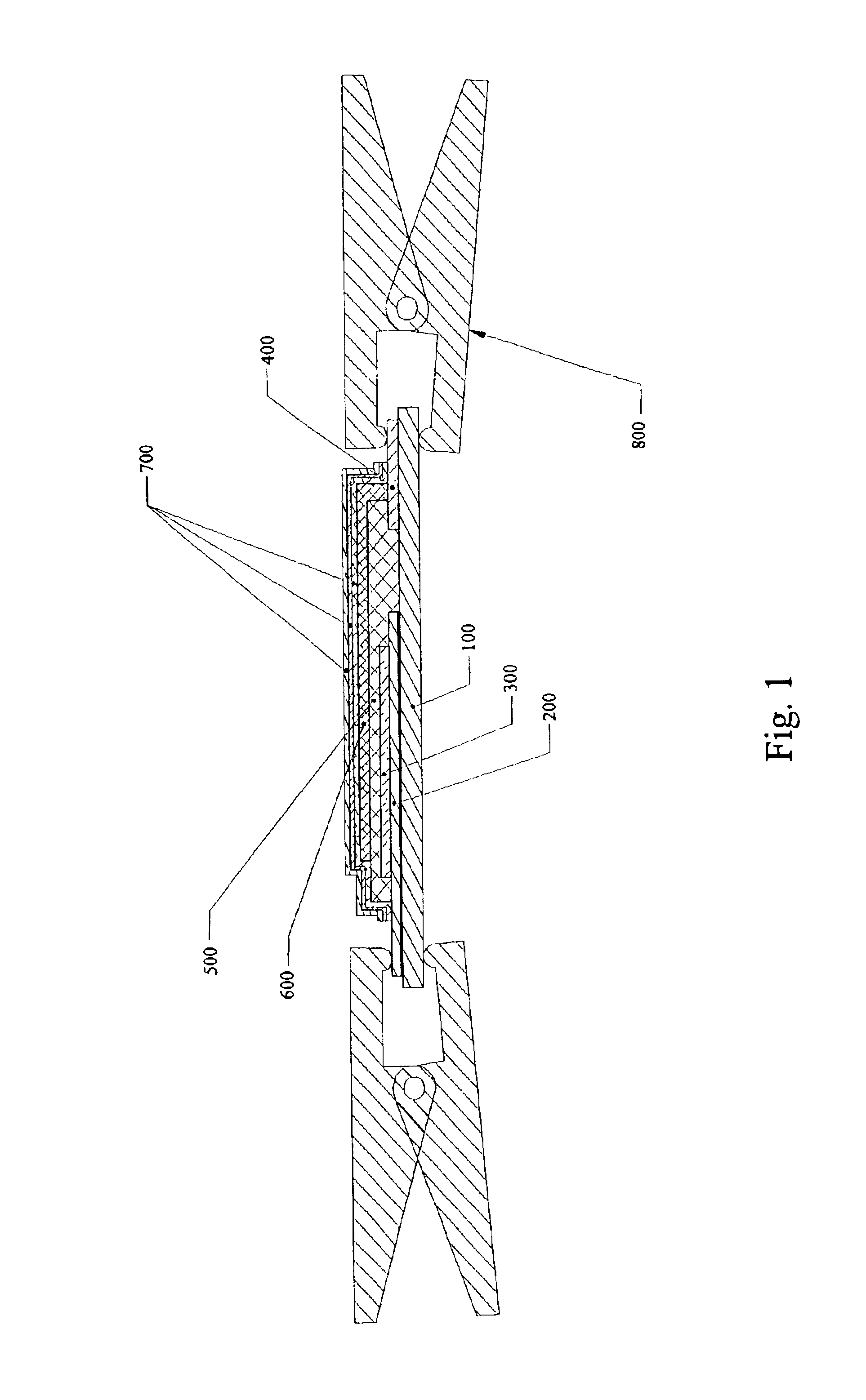

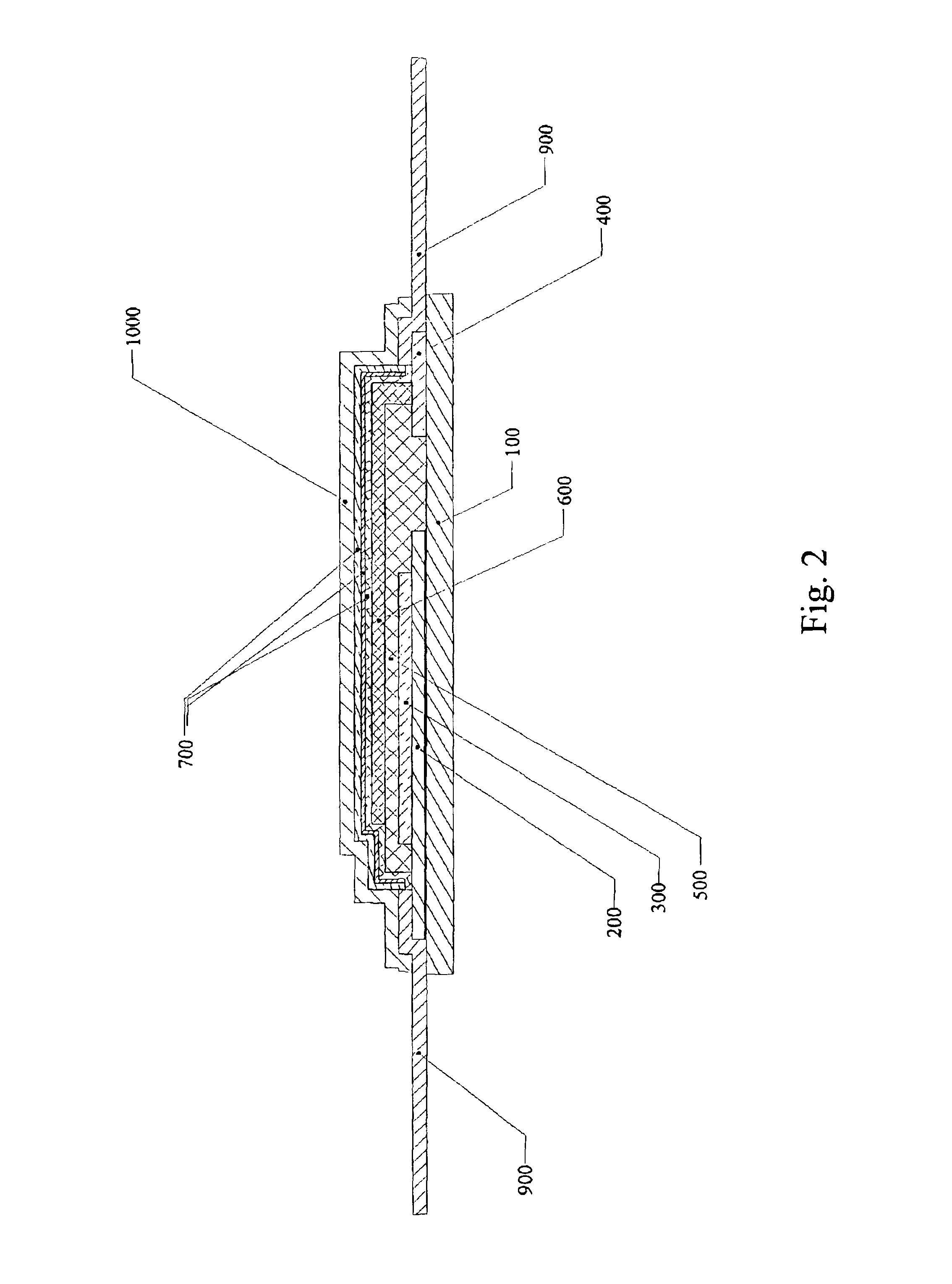

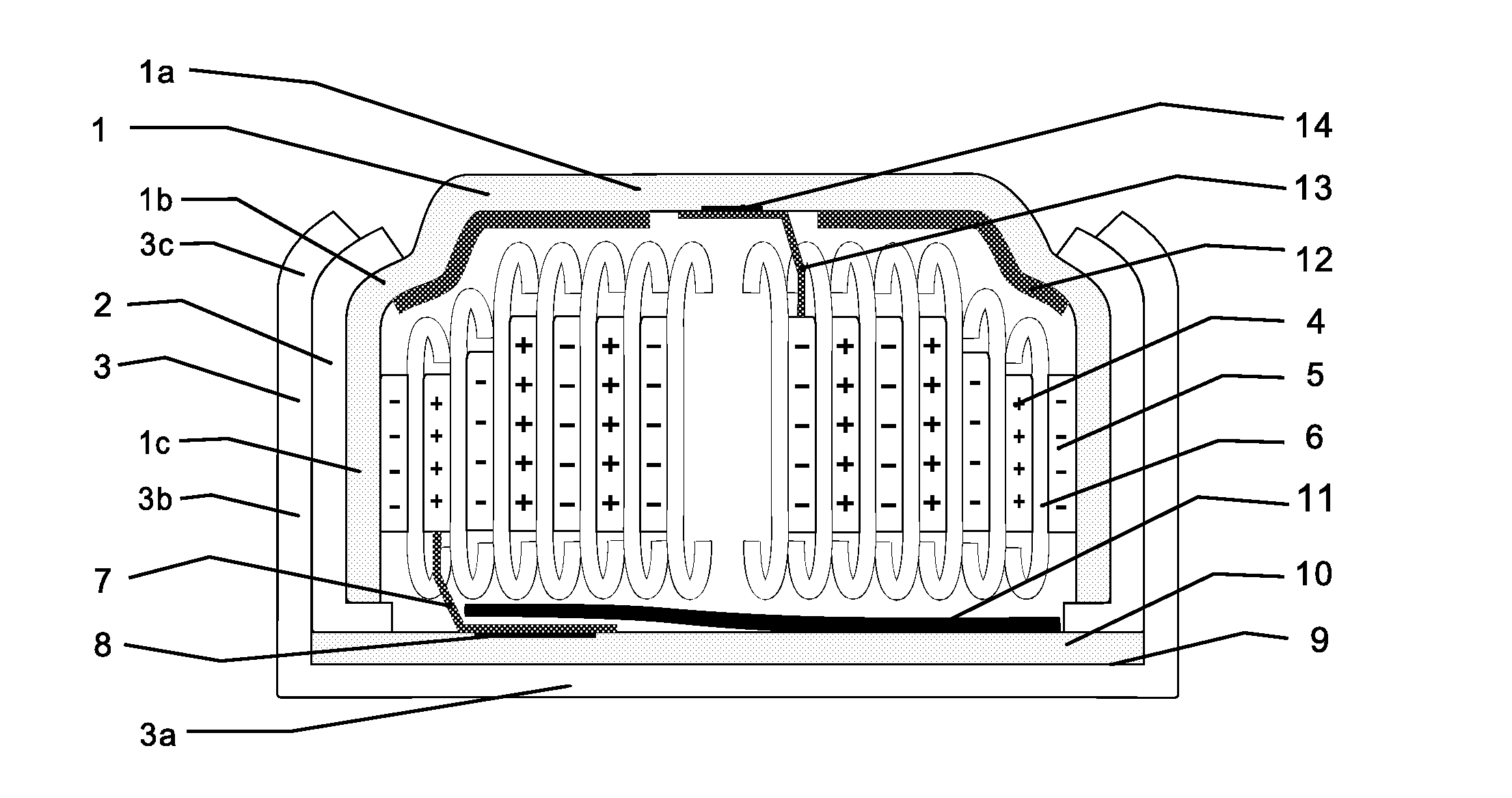

Electrical battery assembly and method of manufacture

InactiveUS7070881B2Reliable functionEnsure uniformityElectrotherapyCell seperators/membranes/diaphragms/spacersElectricityElectrical battery

The invention provides electrical storage battery assemblies and related methods for assembling such batteries. A battery assembly includes positive and negative electrode sheets and separator sheets sandwiched together and wrapped around a central mandrel to provide a spiral sandwich electrode assembly. The electrode assembly is housed inside a case that includes a case housing open at two ends and covers closing the two openings. The central mandrel of the electrode assembly is in electrical contact with one of the electrode sheets and a first battery terminal that passes through the case. A projecting member on the central mandrel provides the electrical connection between the electrode and the first battery terminal. The other electrode is in electrical contact with the case. A first insulator lies between the electrode assembly and the projecting member. A second insulator is positioned between the projecting member and the case.

Owner:QUALLION

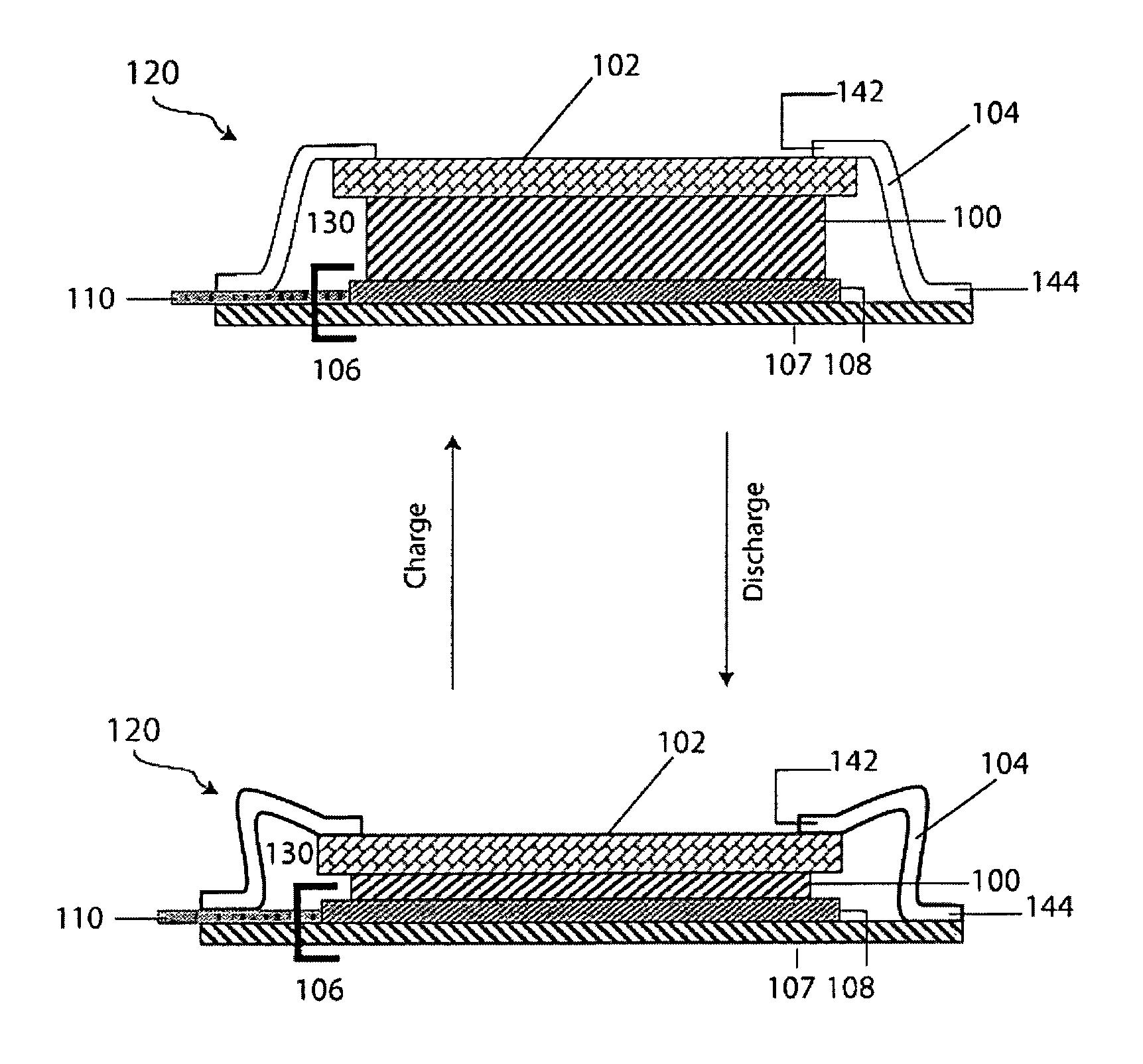

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

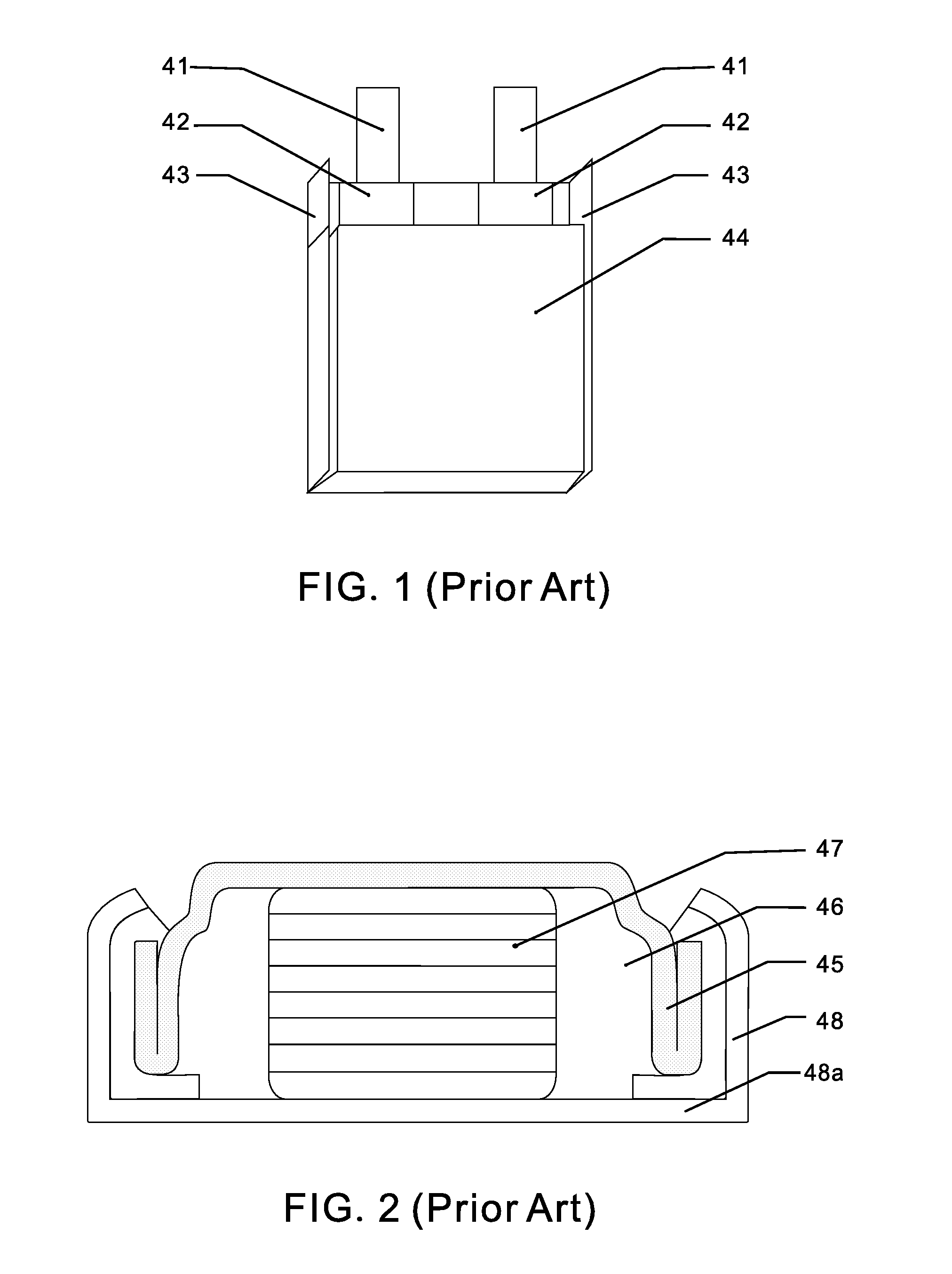

Rechargeable lithium ion button cell battery

ActiveUS20110091753A1Reliable contactEasy to weldCell electrodesFinal product manufactureButton batteryHigh energy

A rechargeable lithium ion button cell battery having a sealed housing comprises an inner casing and an outer casing, both casings have at least one flat area as top or bottom of the battery, and a round or oval side wall vertically formed to the flat area. Said side walls are single wall not folded double walls. An insulation gasket is positioned between said side walls, and the outer casing opening is mechanically crimped to complete the seal of the battery. Inside the sealed housing the anode & cathode electrodes are spiral wound with separator to be a round or oval roll. Said roll axis is vertical to the said flat areas of the casings. The two electrodes are tapered in width and comprise current collectors of metal foils coated with lithium-intercalating active materials, leaving small area of uncoated metal foils as welding tabs for connecting to the casings. The tabs are welded to the casings respectively, or for the tab of the electrode which connecting to outer casing, welded to an aluminum flake first and said flake is pressed on the outer casing by said gasket. Two insulation washers could be applied to inner side of the casings to prevent short circuit. Such battery has high energy density, low impedance, high reliability and long cycle life.

Owner:WANG FANG +1

Cap assembly and secondary battery with same

ActiveUS20050214634A1Avoid explosionCutoff excessive currentPrimary cell maintainance/servicingSmall-sized cells cases/jacketsInternal pressureEngineering

A secondary battery includes a container an electrode assembly mounted in the container having a positive electrode, a negative electrode, and a separator interposed between the positive electrode and the negative electrode, and a cap assembly fixed to the container to seal the container. The cap assembly includes a cap plate having a terminal, a current breaker electrically connected to the cap plate; and a vent plate having a safety vent electrically connected to the current breaker, the shape of the vent plate being altered by the internal pressure of the secondary battery to alter the shape of the current breaker, and the current breaker cutting off the current path of the cap assembly.

Owner:SAMSUNG SDI CO LTD

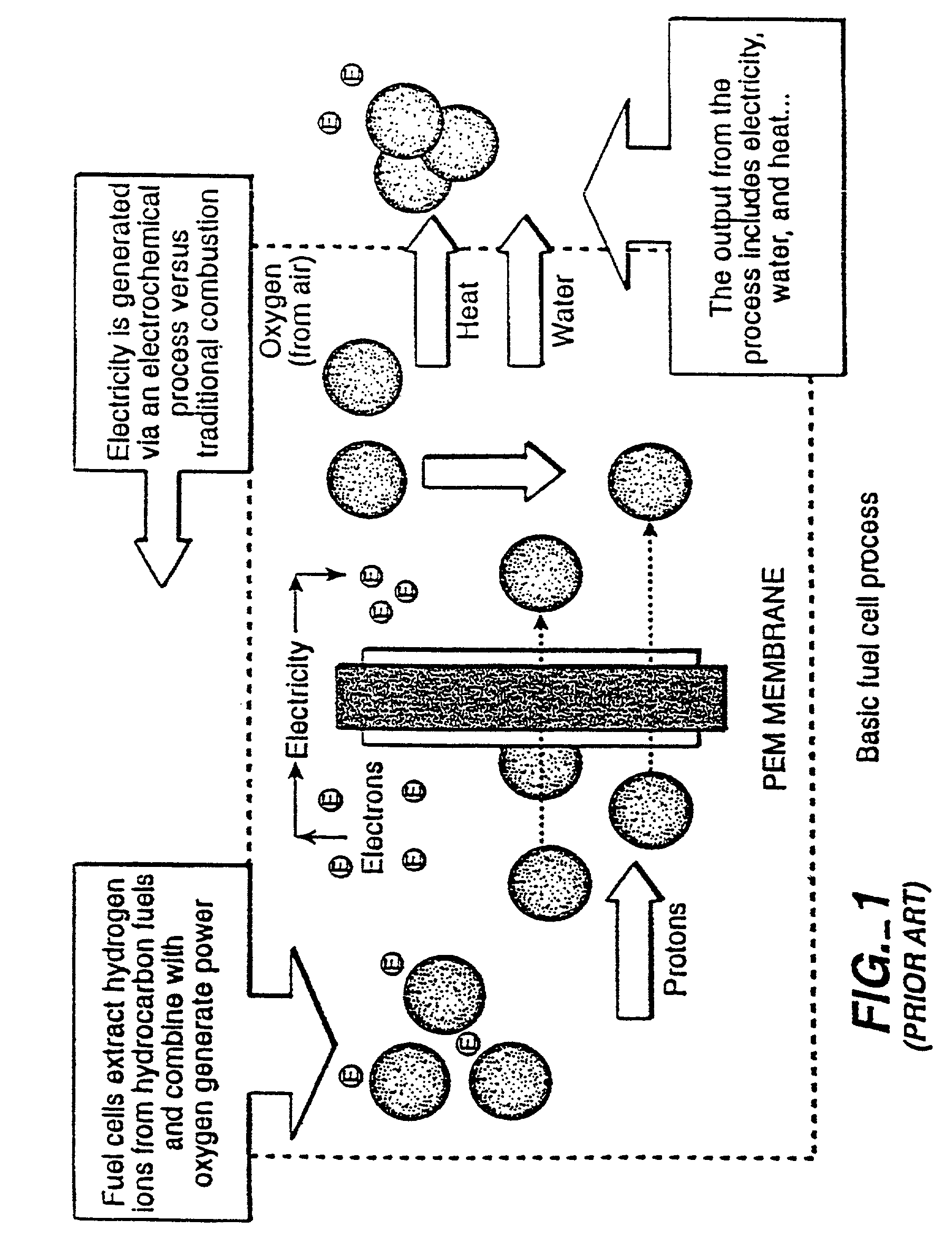

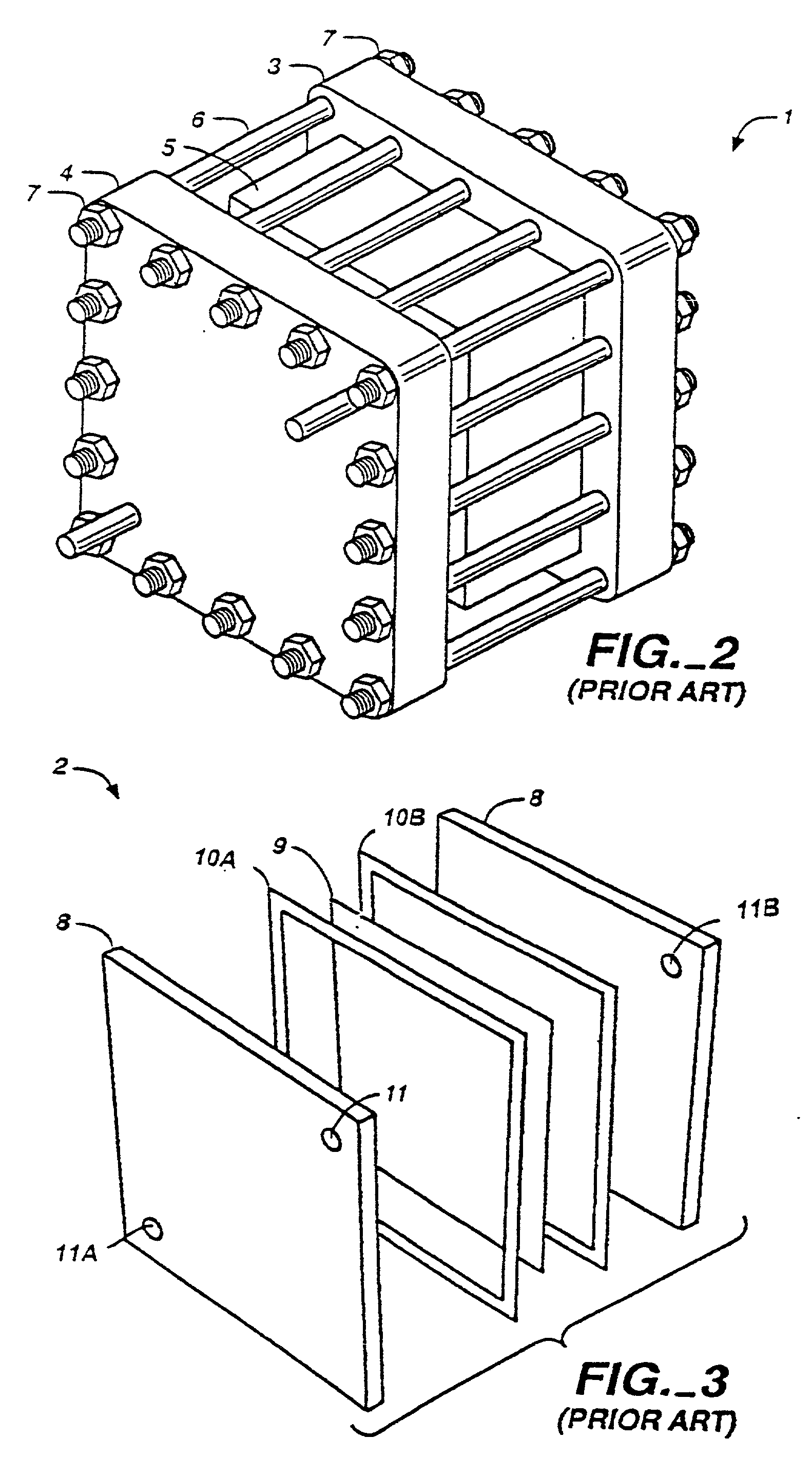

Integrated and modular BSP/MEA/manifold plates for fuel cells

The present invention concerns improvements in fuel cell fabrication. It concerns an improved, integrated and modular BSP / MEA / Manifolds, which facilitates single cell (module) leak and performance testing prior to assembly in a fuel cell stack as well as facilitating manufacturing and cost reduction. In particular, the present invention relates to a fuel cell, which includes: a) A single flexible or ridged separator plate; b) a flexible membrane electrode assembly; c) a flexible bond interposed between said single flexible or ridged separator plate and said flexible membrane electrode assembly, wherein said flexible bond between said flexible or ridged separator plate and said flexible membrane electrode assembly comprises the fuel cell, and wherein said flexible bond is an adhesive bond which encapsulates edge portions of said flexible or ridged separator plate and said flexible membrane electrode assembly and wherein said flexible bond seals the edge portions of said flexible membrane assembly to prevent the release of reactants from the fuel cell. In some embodiments the adhesive bond comprises a flexible gasket; d) manifold for the delivery and removal of reactants and reactant products to and from the fuel cell reactive areas where said manifolds may be either a single or multiple manifolds; and e) a bond interposed between said manifold and said single flexible or ridged separator plate, wherein said bond affixes said manifold to said flexible or ridged separator plate and wherein said bond provides a seal between said manifold and said flexible or ridged separator plate to prevent the release of reactants from the fuel cell. It also eliminates some gaskets and simplifies assembly.

Owner:JADOO POWER SYST LLC +1

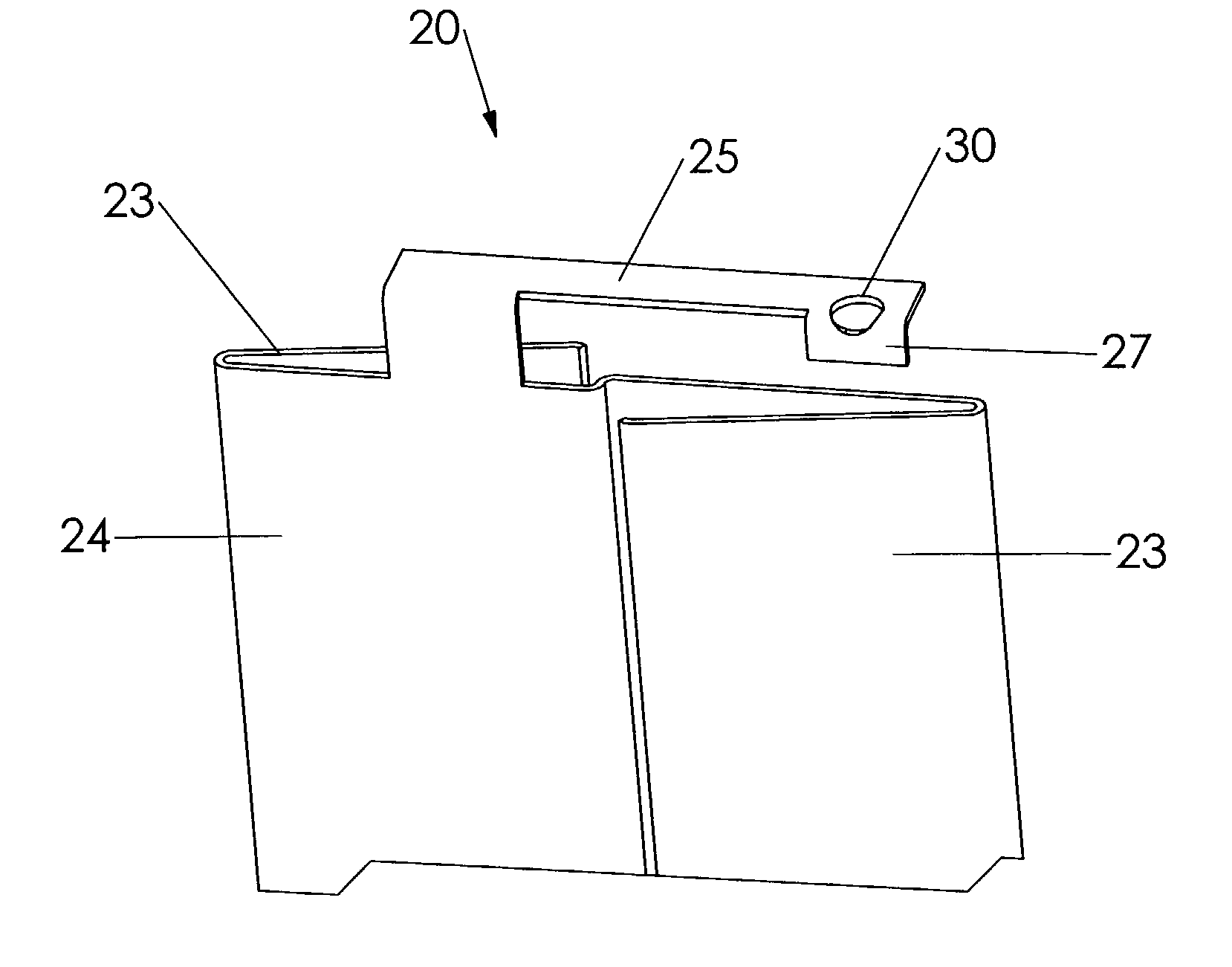

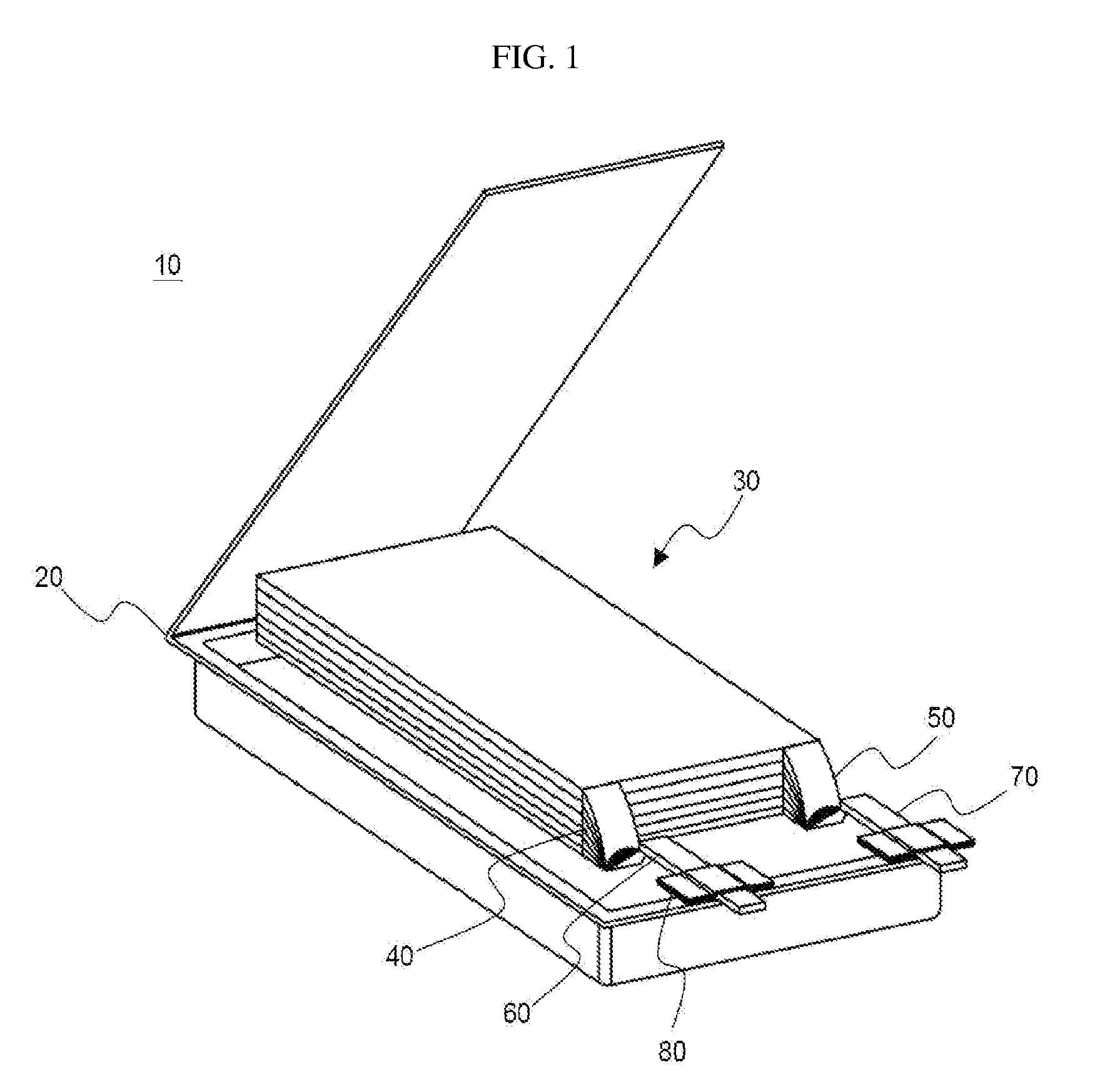

Battery module

ActiveUS20070141457A1Final product manufactureCell temperature controlElectrical and Electronics engineeringElectrode

A battery module includes a plurality of flat batteries stacked upon one another in a thickness direction. The plurality of flat batteries each have an outer cover and plate-shaped electrode terminals connected. A power generating element is sealed within the outer cover of each of the plurality of flat batteries. The electrode terminals include substantially flat plates connected to the power generating element and projecting out of the outer cover in a projecting direction. The electrode terminals of the plurality of batteries are electrically connected to each other. Each of a plurality of electrically insulating spacers receives the electrode terminals of more than one of the flat batteries and the spacers are stacked in the thickness direction of the flat batteries. At least one of the insulating spacers has an opening along a projecting direction of the electrode terminal so as to expose a portion of the electrode terminal while supporting the plurality of electrode terminals spaced from each other in the thickness direction of the flat batteries.

Owner:ENVISION AESC JAPAN LTD

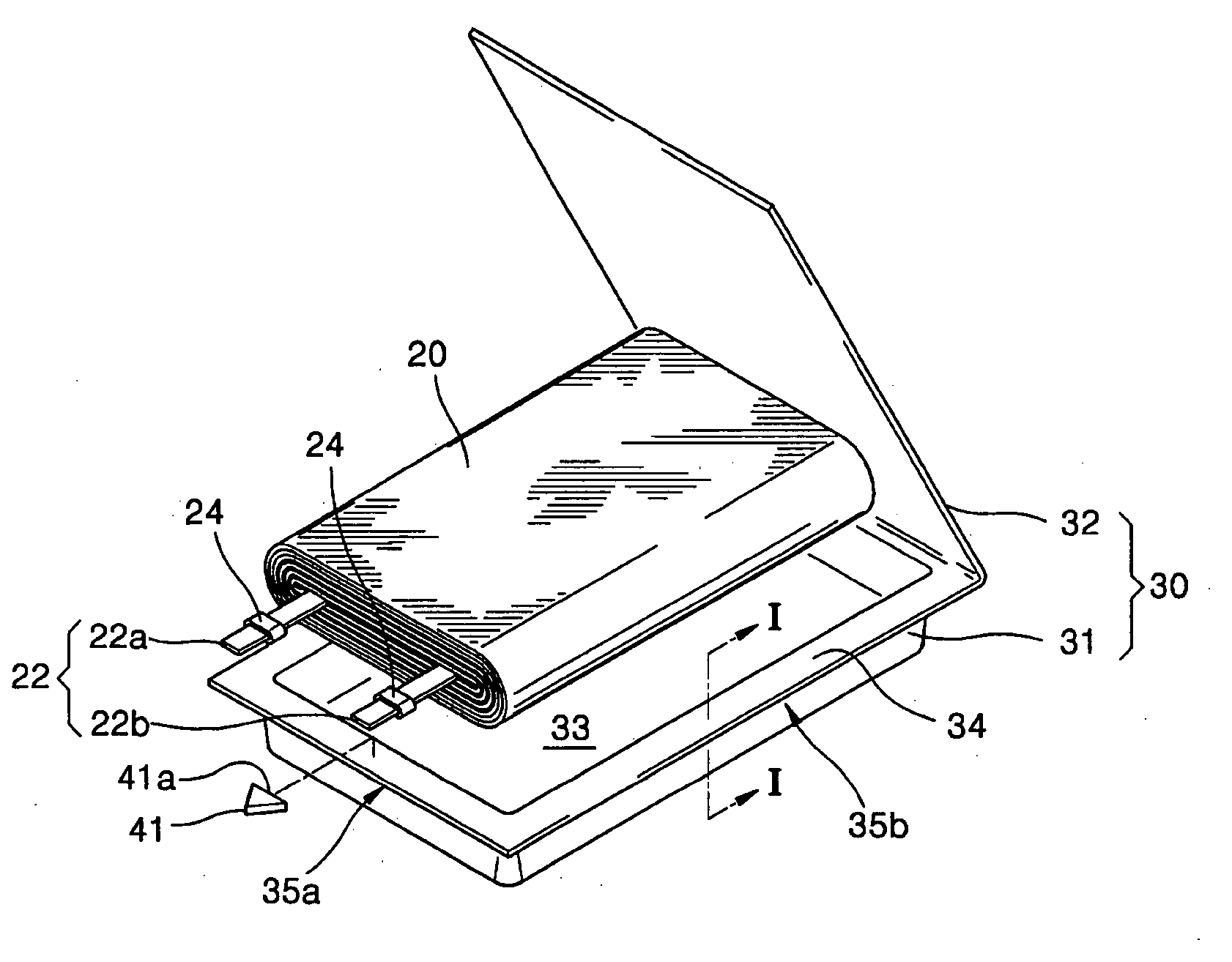

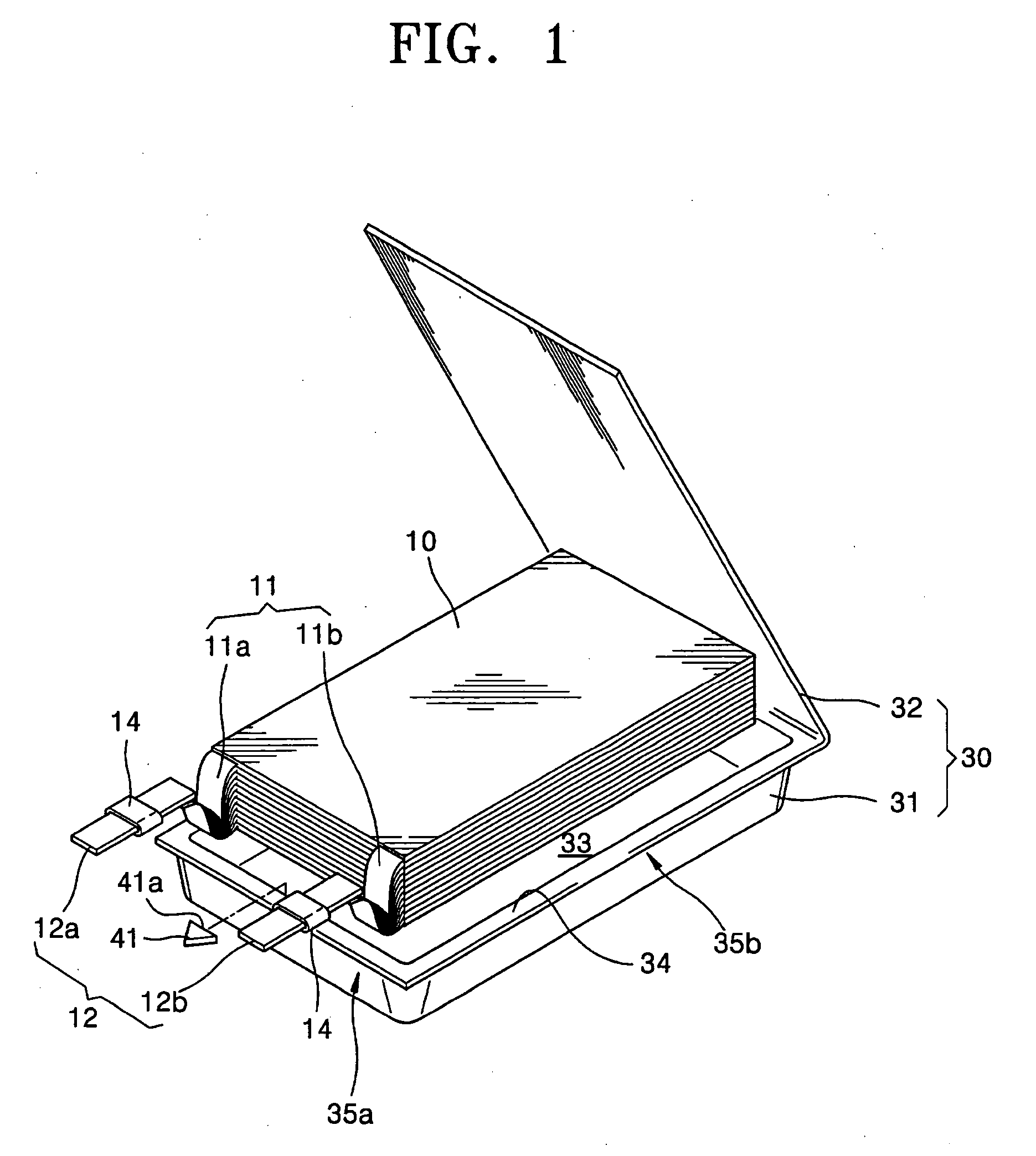

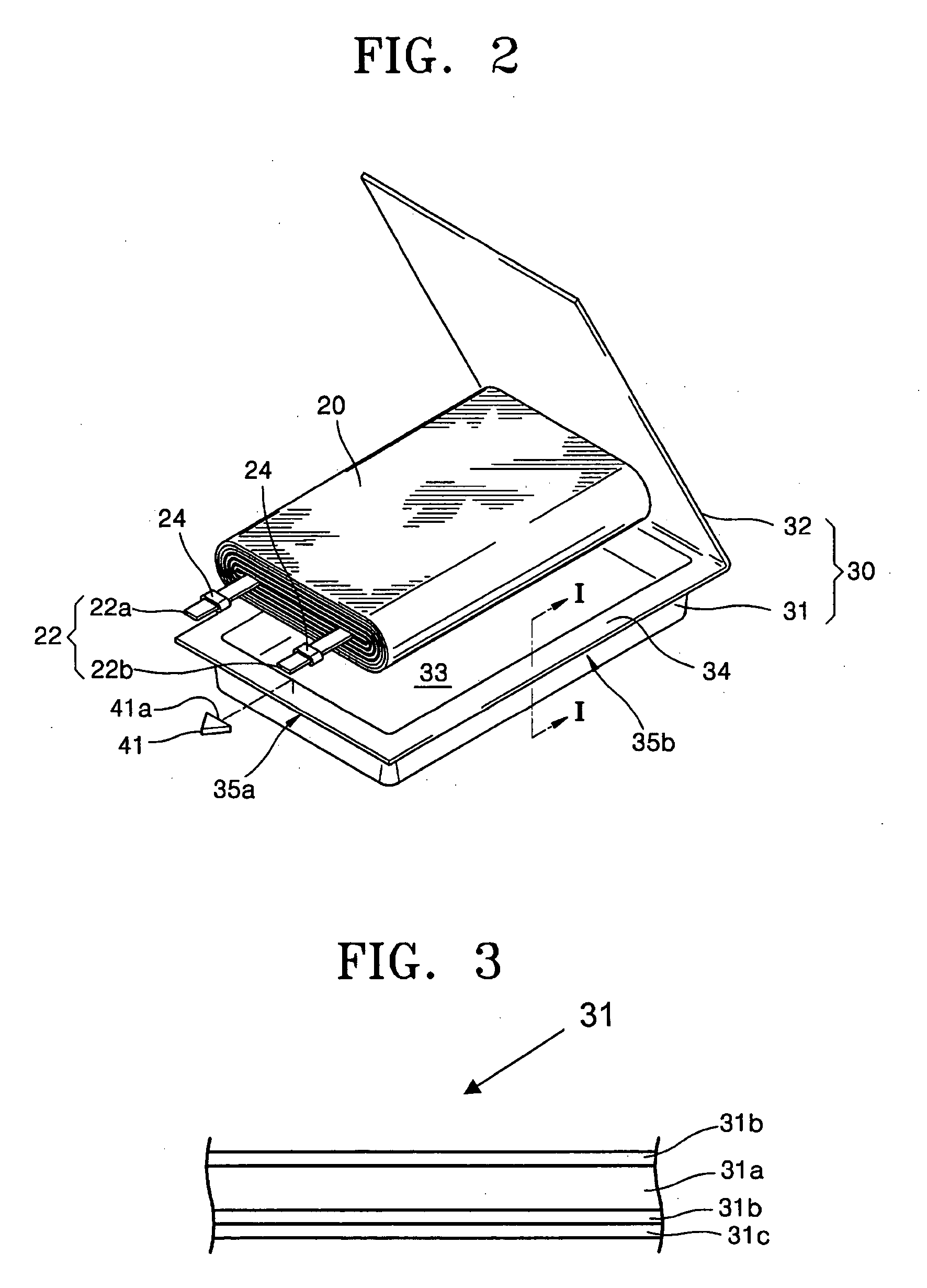

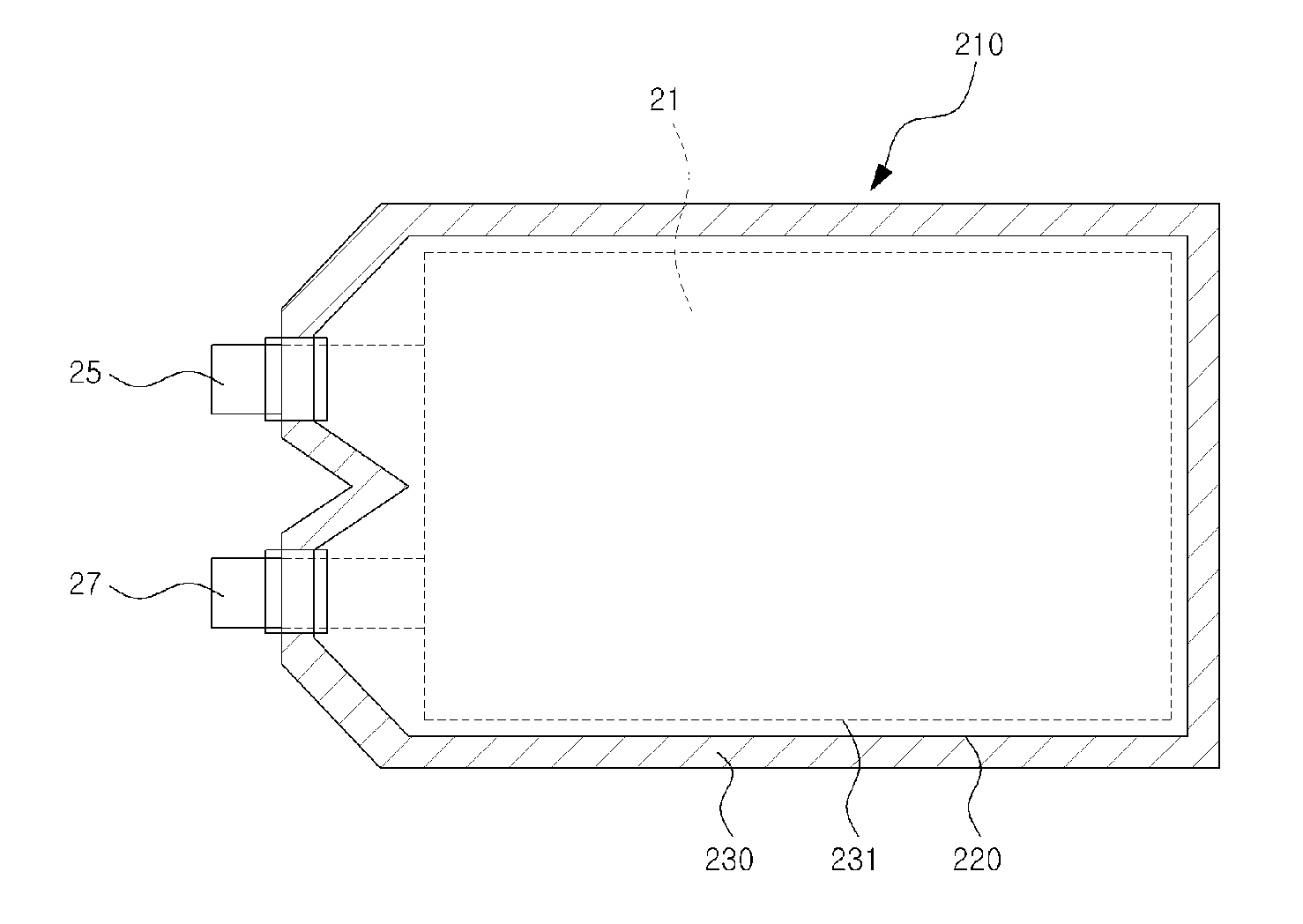

Pouched lithium secondary battery

ActiveUS20050014036A1Easy to detectVariation is detectedFinal product manufactureSmall-sized cells cases/jacketsLithiumEngineering

A pouched lithium secondary battery including a battery unit having a positive electrode plate, a negative electrode plate, and a separator disposed between the positive electrode plate and the negative electrode plate; a positive electrode tab electrically connected with the positive electrode plate; a negative electrode tab electrically connected with the negative electrode plate; a case having a space to accommodate the battery unit, and a sealing edge around the space; and a positive electrode voltage applying unit to apply a positive electrode voltage to both the positive electrode tab and the case.

Owner:SAMSUNG SDI CO LTD

Pouch type secondary battery with safety vent

InactiveUS20040038126A1Avoid explosionAvoid fireFinal product manufactureSmall-sized cells cases/jacketsInternal pressureEngineering

A pouch type secondary battery has a safety vent which prevents explosion and fire by removing a sealing mechanism of a pouch casing when the internal temperature increases due to overcharging, overdischarging or over-heating, and which exhausts internal gas before explosion and fire of the battery when the internal gas pressure excessively increases due to overcharging, overdischarging or internal short-circuit. The pouch type secondary battery includes an electrode assembly having positive and negative electrode plates with a separator interposed therebetween, and positive and negative electrode terminals extending from the positive and negative electrode plates, respectively, a pouch casing having a space in which the electrode assembly is housed to be sealed, a seal portion provided at the periphery of the space, and at least one of the positive and negative electrode terminals exposed to the seal portion, and at least one opening member disposed at the seal portion and made of a resin material having a lower melting point than a melting point of the seal portion of the pouch casing.

Owner:SAMSUNG SDI CO LTD

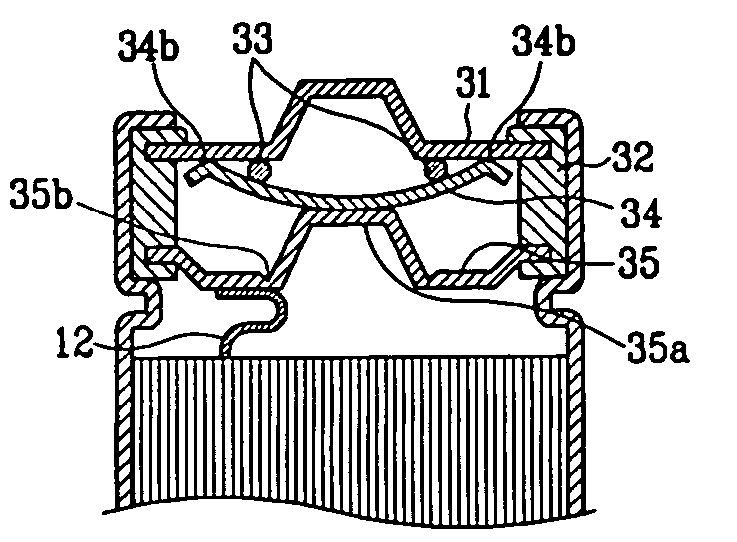

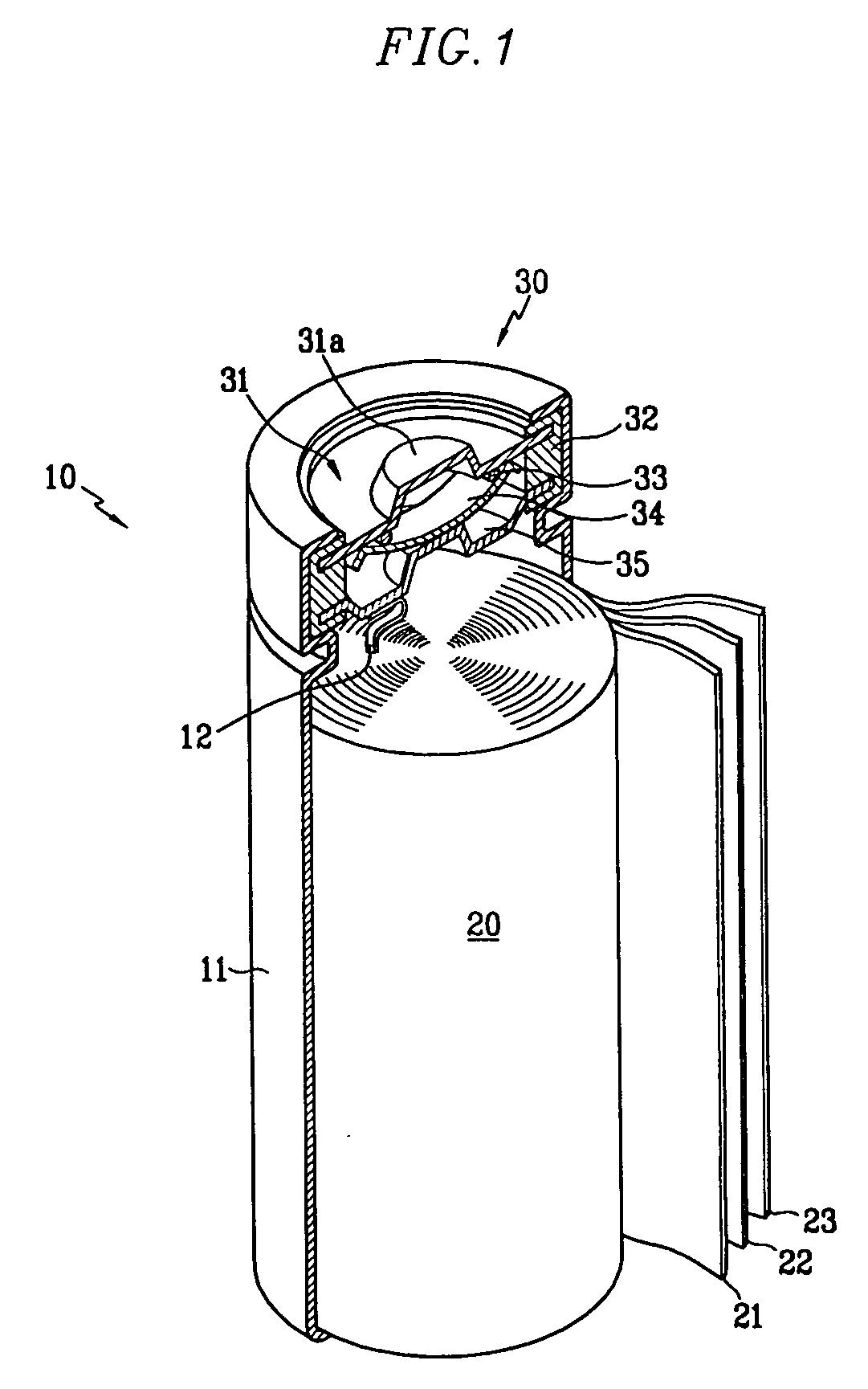

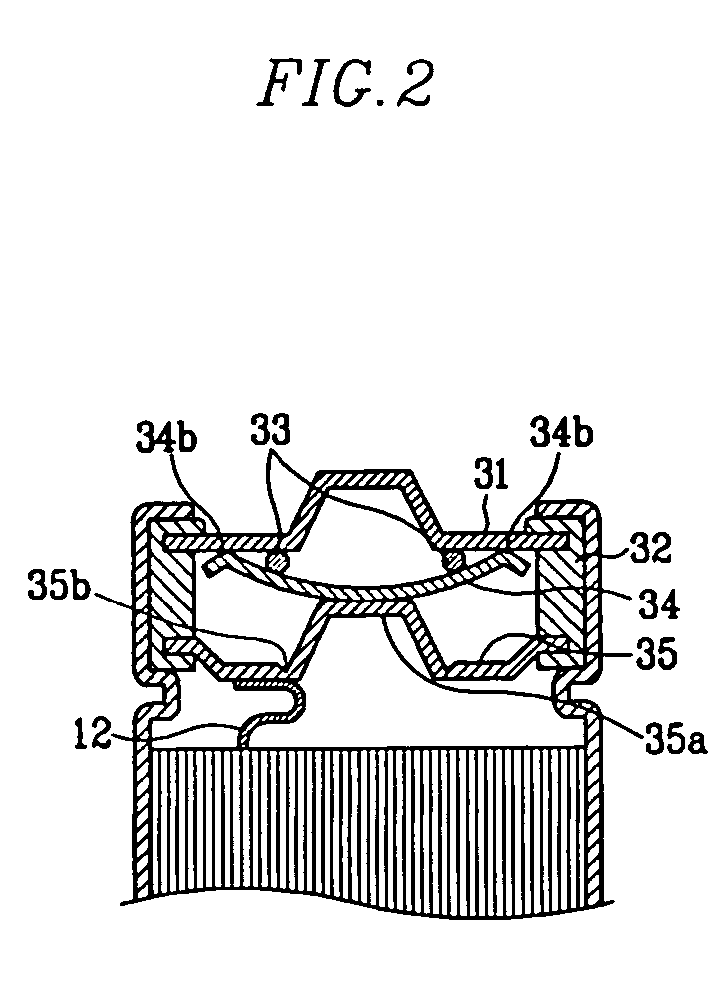

High rate charging and discharging cylindrical secondary battery

ActiveUS20070212595A1Significant stressBreakage of partFinal product manufactureVent arrangementsElectrolyte leakageInternal pressure

Disclosed herein is a cylindrical secondary battery including a cap assembly constructed in a structure in which a vent, which intercepts electric current and discharges pressurized gas when the interior pressure of the battery is increased due to abnormal operation of the battery, is in contact with a top cap having a protruding central part, wherein the end of the vent is bent to surround the outer circumferential surface of the top cap, and a groove for preventing the leakage of an electrolyte and preventing the occurrence of defectiveness of the battery during the assembly of the battery is formed at interfaces between the vent and the top cap such that the groove is arranged in parallel with the outer circumferential surface of the top cap. The secondary battery according to the present invention has the effect of accomplishing high charging and discharging rate, providing uniform output even when external physical impacts, such as vibration or dropping, are applied to the secondary battery, and preventing the occurrence of defectiveness during the assembly of the secondary battery. Furthermore, the leakage of the electrolyte out of the battery is restrained under these conditions. Consequently, the secondary battery according to the present invention can be preferably used as a high-output power source.

Owner:LG ENERGY SOLUTION LTD

Pouch type case and battery pack including the same

ActiveUS20110274955A1Reduce dead spaceMaximize space utilizationPrimary cell to battery groupingFinal product manufactureEngineeringBattery capacity

The present invention relates to a pouch type case having trimming portions formed on both sides or four corners thereof and a battery pack including the same. The trimming portions are formed on the corners of the pouch type case such that the trimming portions are indented toward an electrode assembly accommodating part to reduce a unit area so as to increase pressure applied to unit cells when a battery pack is assembled, thereby facilitating assembling of the battery pack and increasing cell capacity per unit area. Furthermore, the unit cells can be fixed in the battery pack more stably. The pouch type case reduces the unit area so as to include a relatively large number of cells for pressure applied to the cells when the battery pack is assembled to thereby increase the cell capacity.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com