Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

455 results about "Spiral wound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planar resonator for wireless power transfer

InactiveUS6960968B2Easy to useEasy wiringMultiple-port networksBatteries circuit arrangementsElectrical conductorTransformer

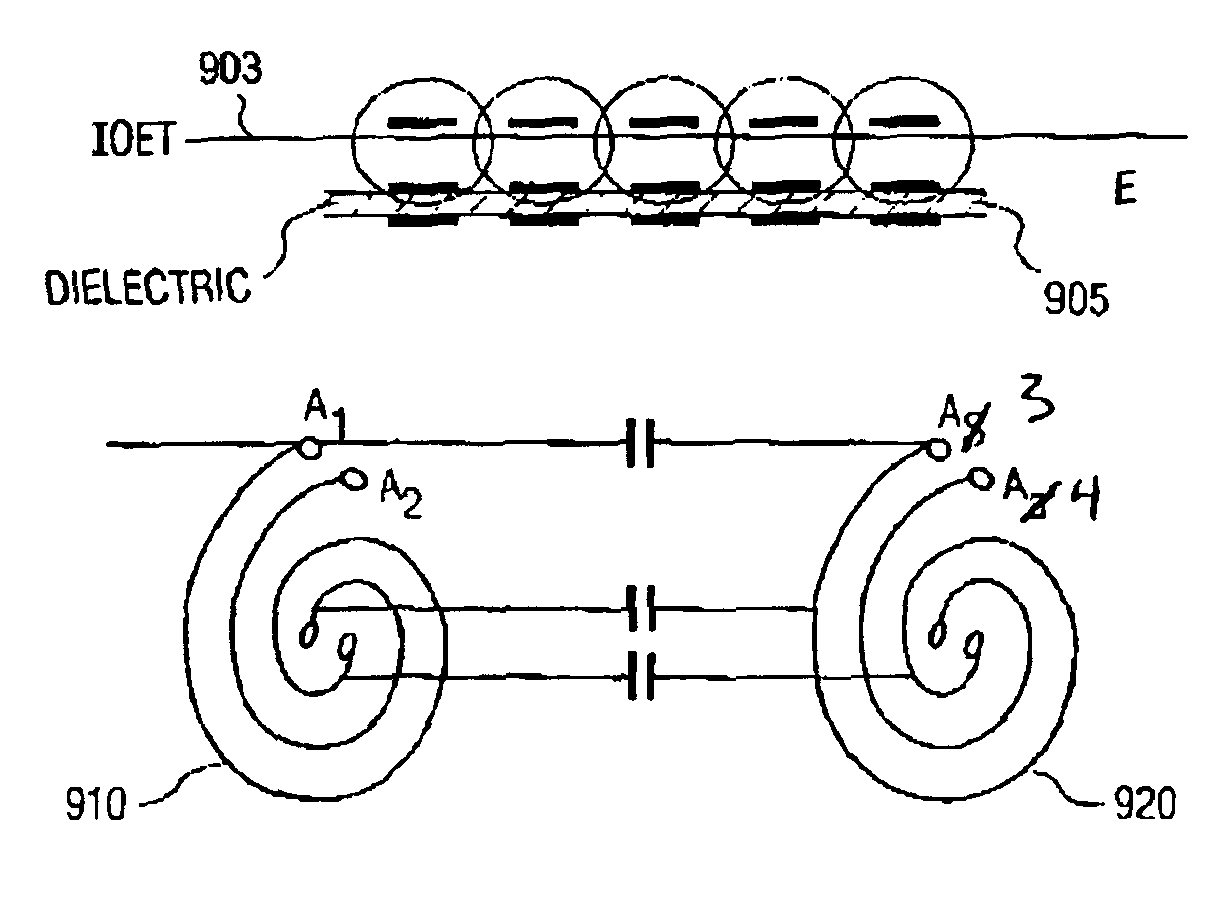

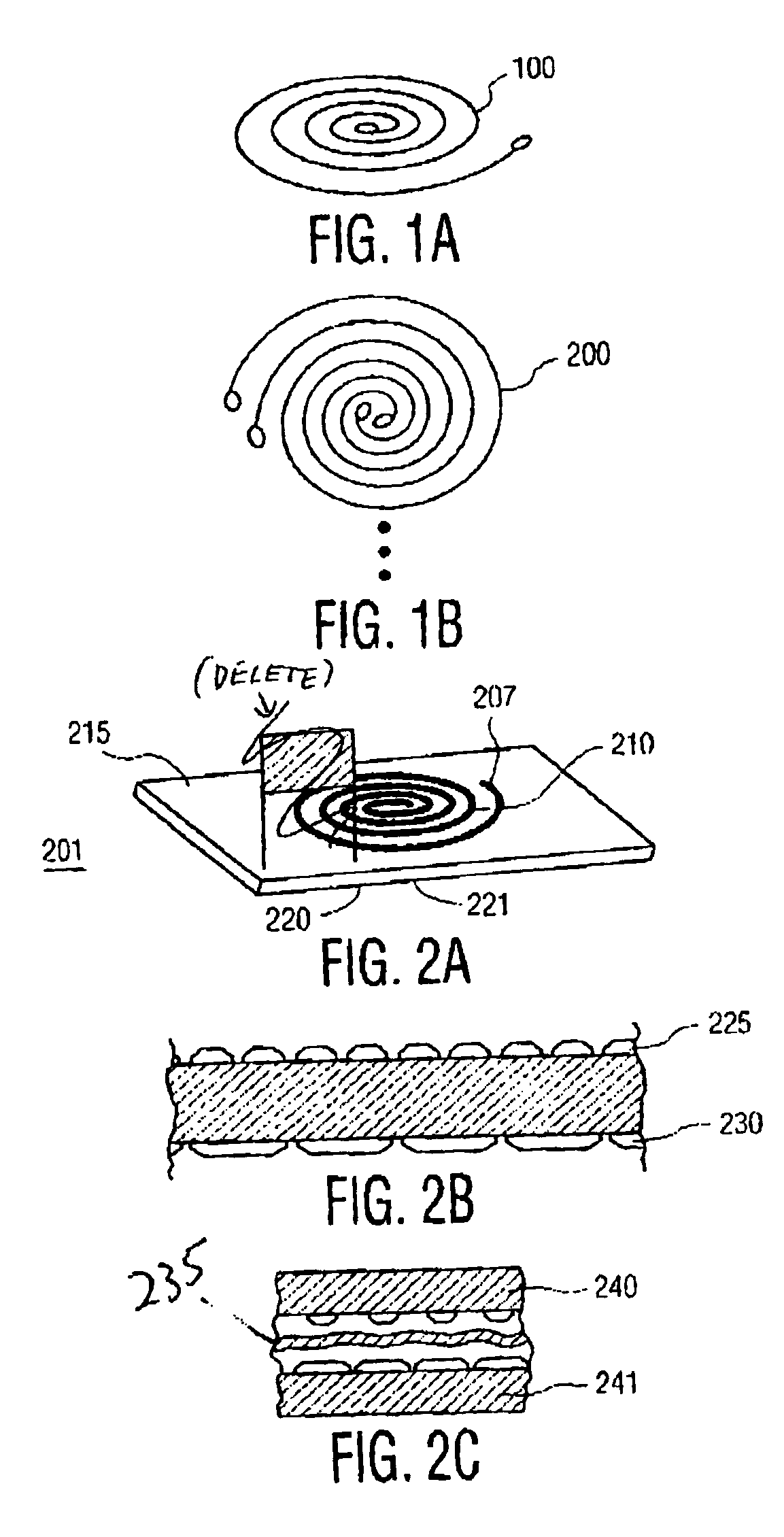

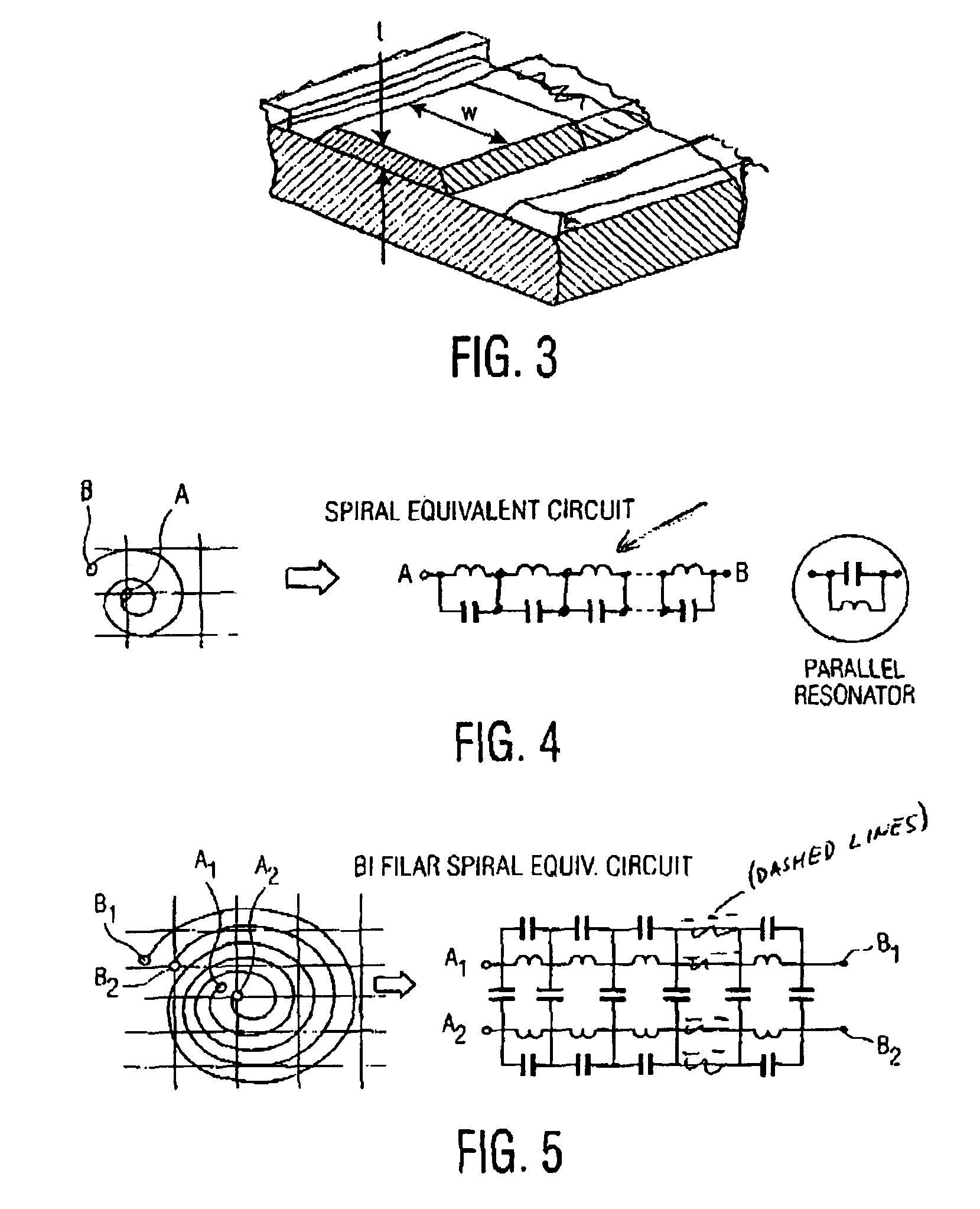

A planar resonator and method of manufacture provides contactless power transfer using at least two electrically isolated axis aligned conductive across the transfer interface in a coupled inductor or transformer configuration. Signal or power transfer is then accomplished by coupling of magnetic flux. The coupling of electric flux is also accomplished across a same interface and driven with the same conductive spiral-wound conductors. An interface of energy transfer(IOET) has a first spiral-shaped conductor arranged on the top surface of said IOET; a second spiral-shaped conductor arranged on the bottom surface of said IOET, has a vertical axis aligned with the first spiral-shaped conductor. The IOET and the first and second spiral-shaped conductors have a predetermined self-resonant frequency. The planar power resonator stores electric energy in the IOET, and at predetermined frequencies, the arrangement of the first and second spiral-shaped conductors and the IOET permits transfers of magnetic flux and electrical energy between the first and second spirals across the IOET. The resonator facilitates contactless battery charging in devices such as cellphones and wearable electronics where the resonator can be woven into fabric or attached to a person's clothes.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

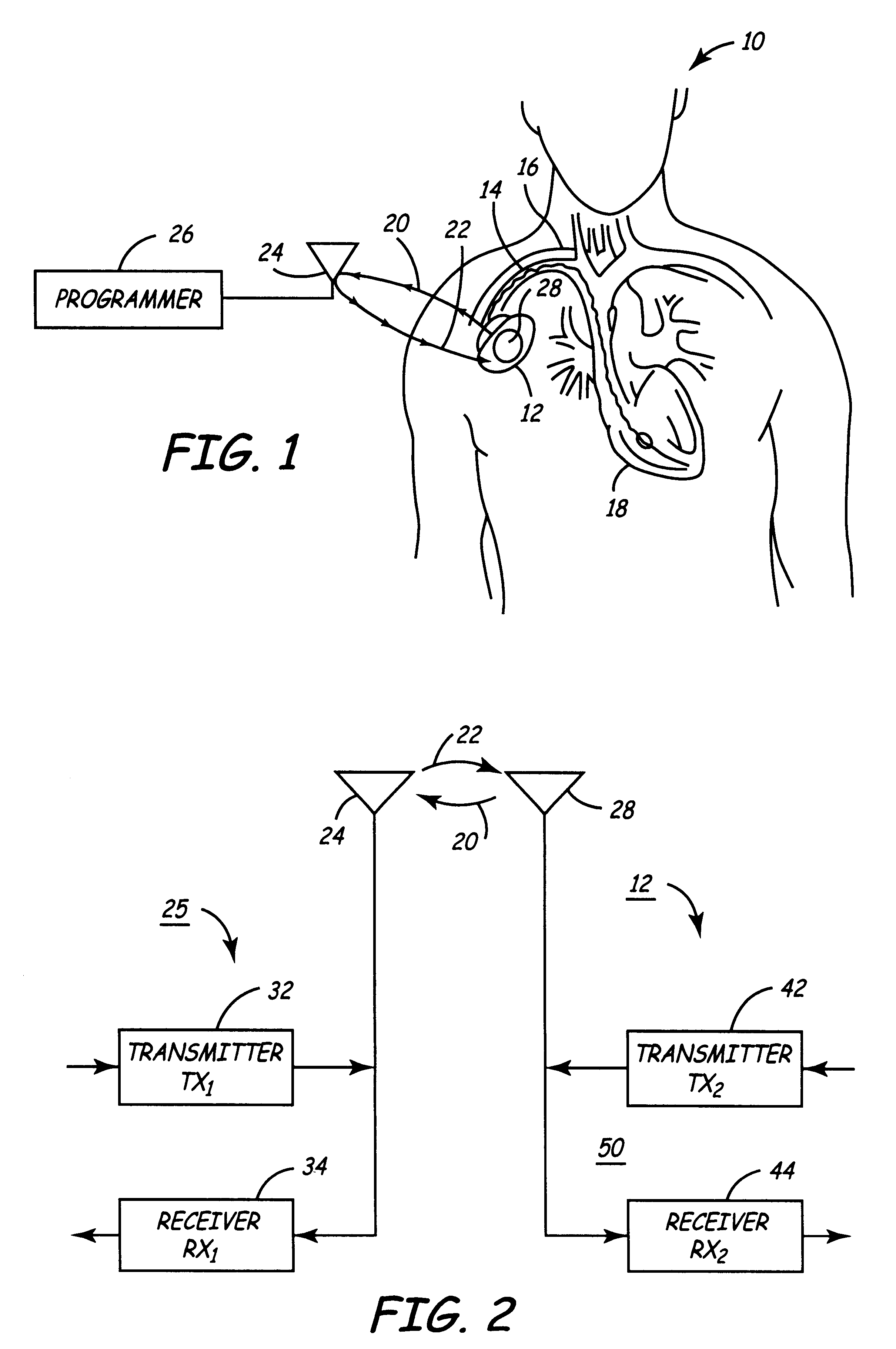

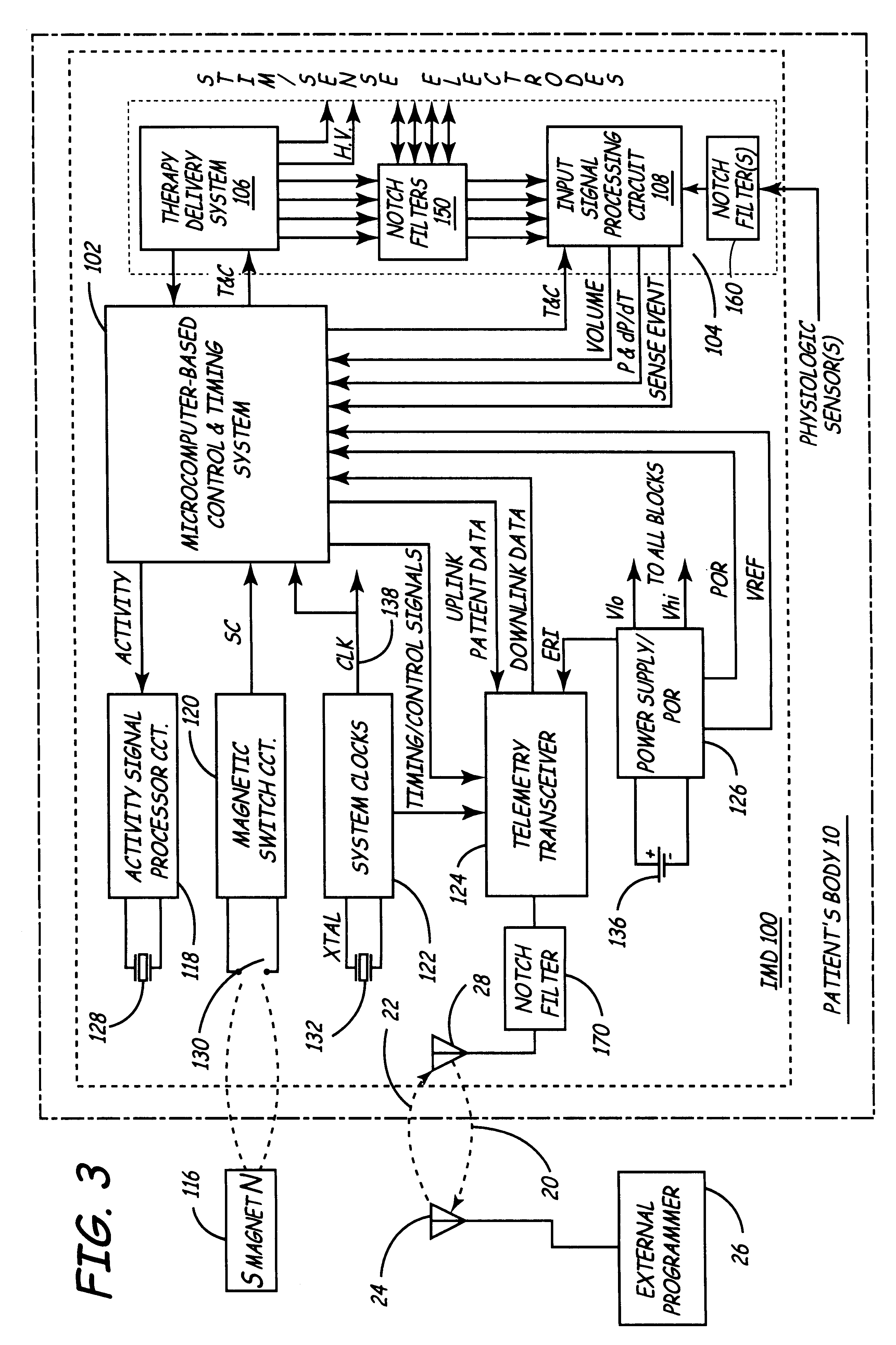

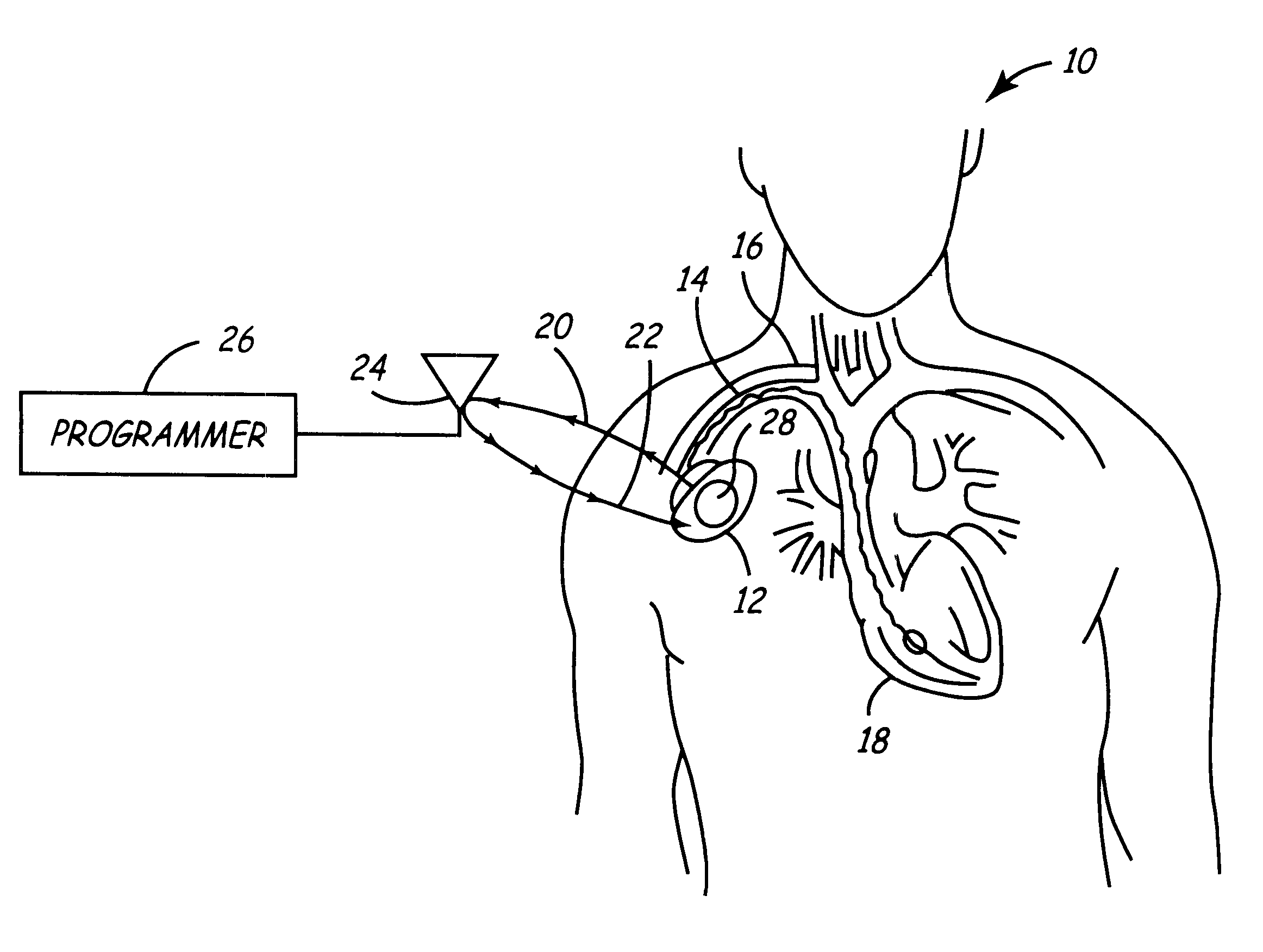

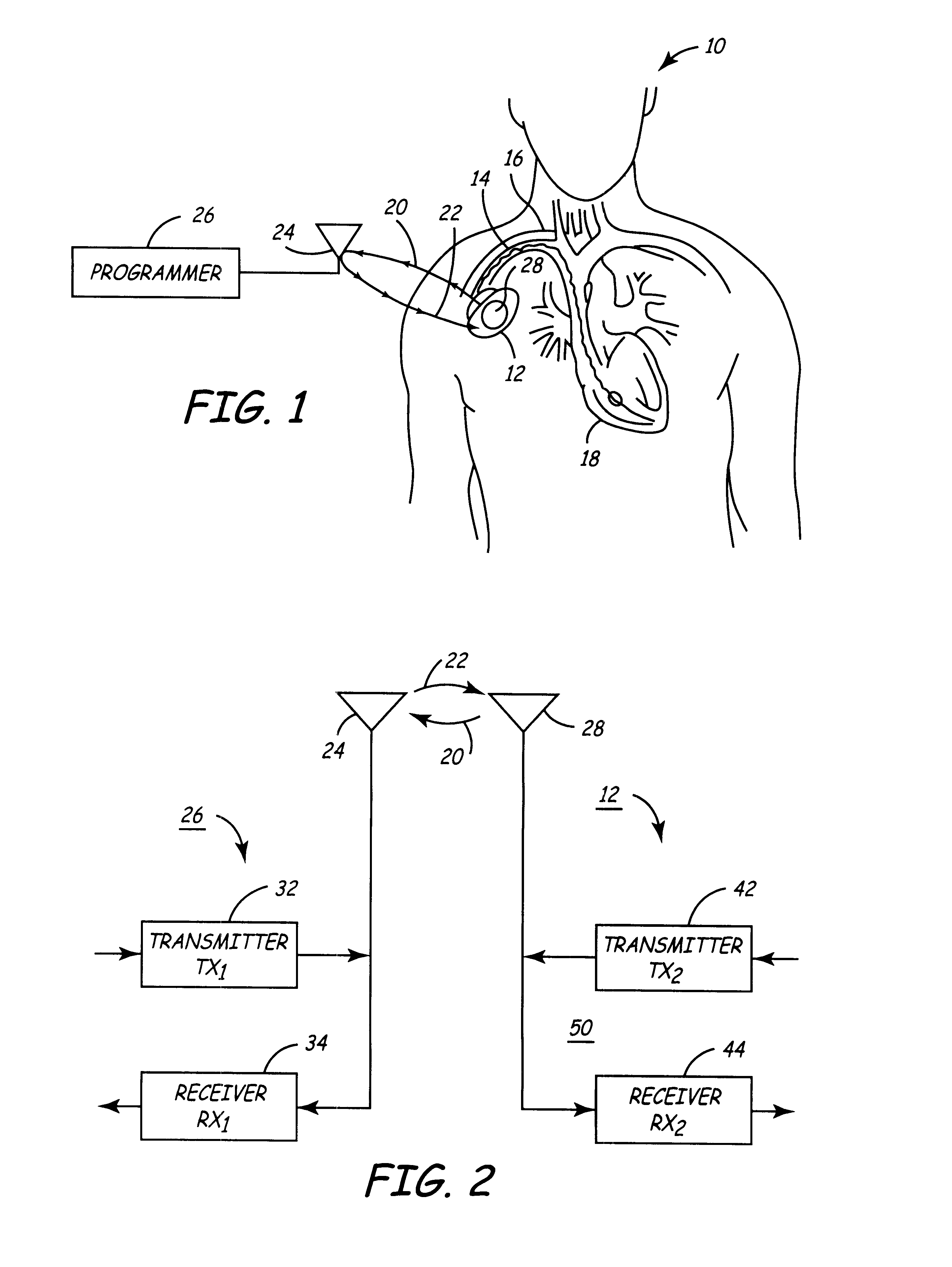

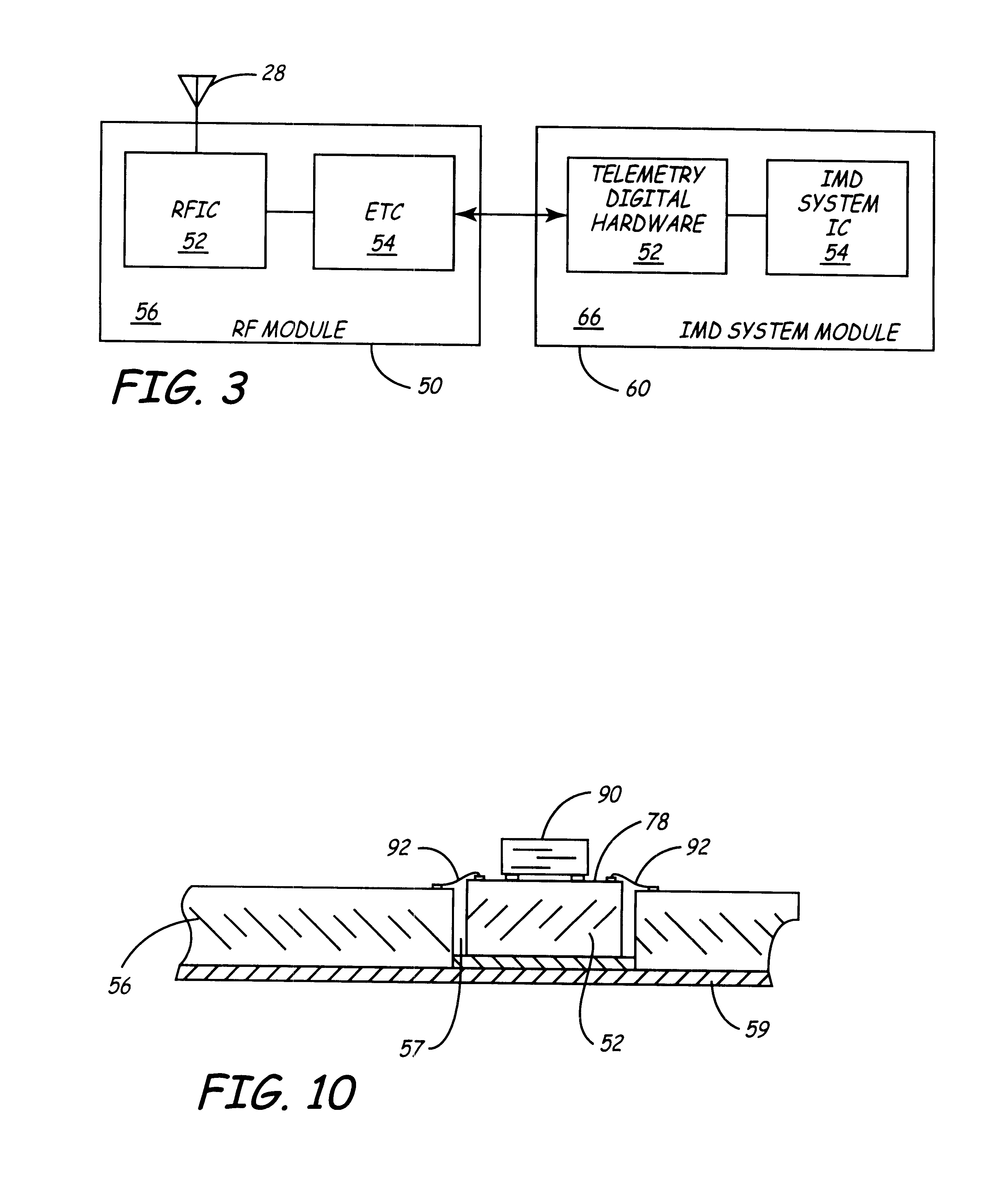

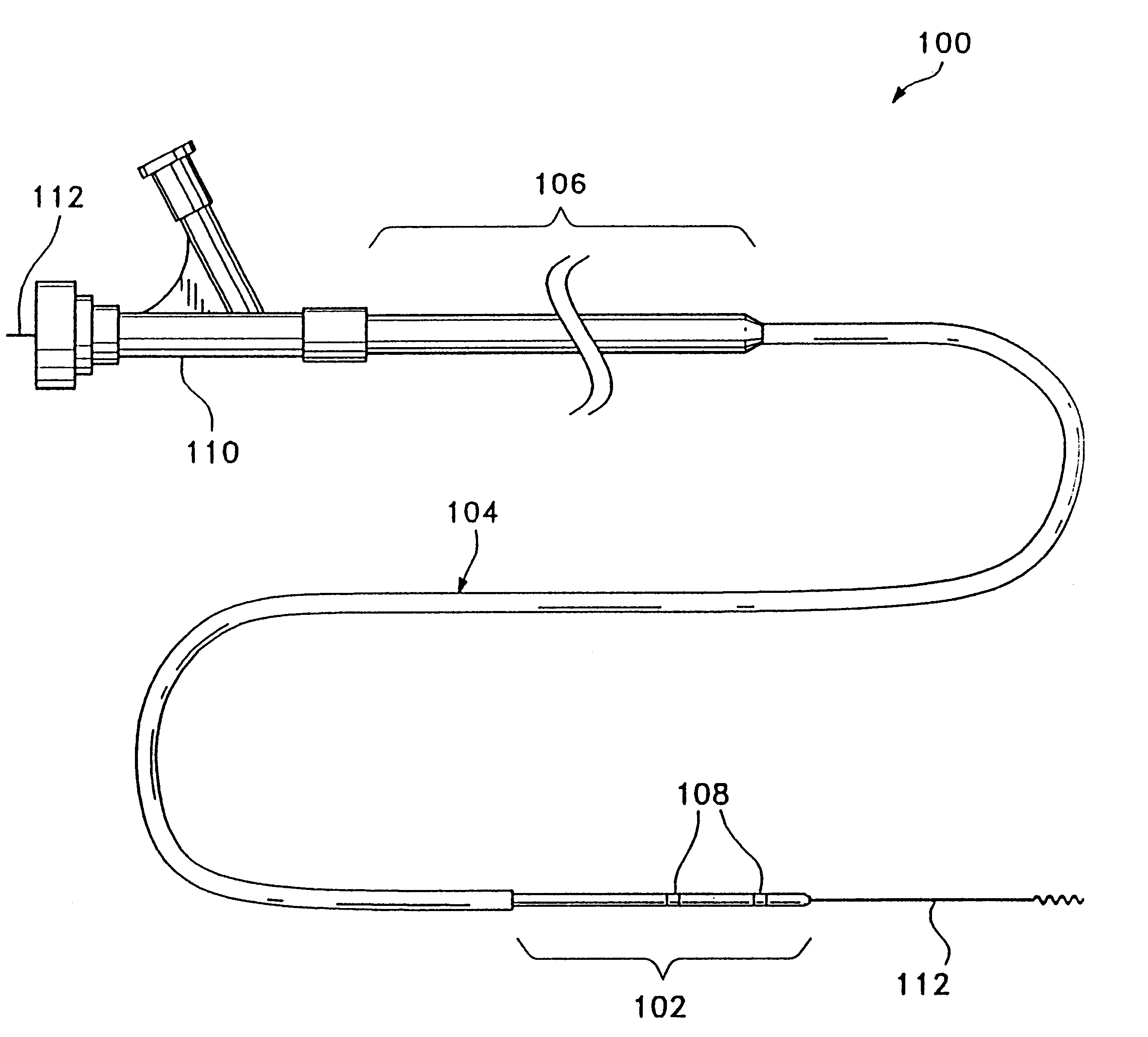

Implantable medical device incorporating integrated circuit notch filters

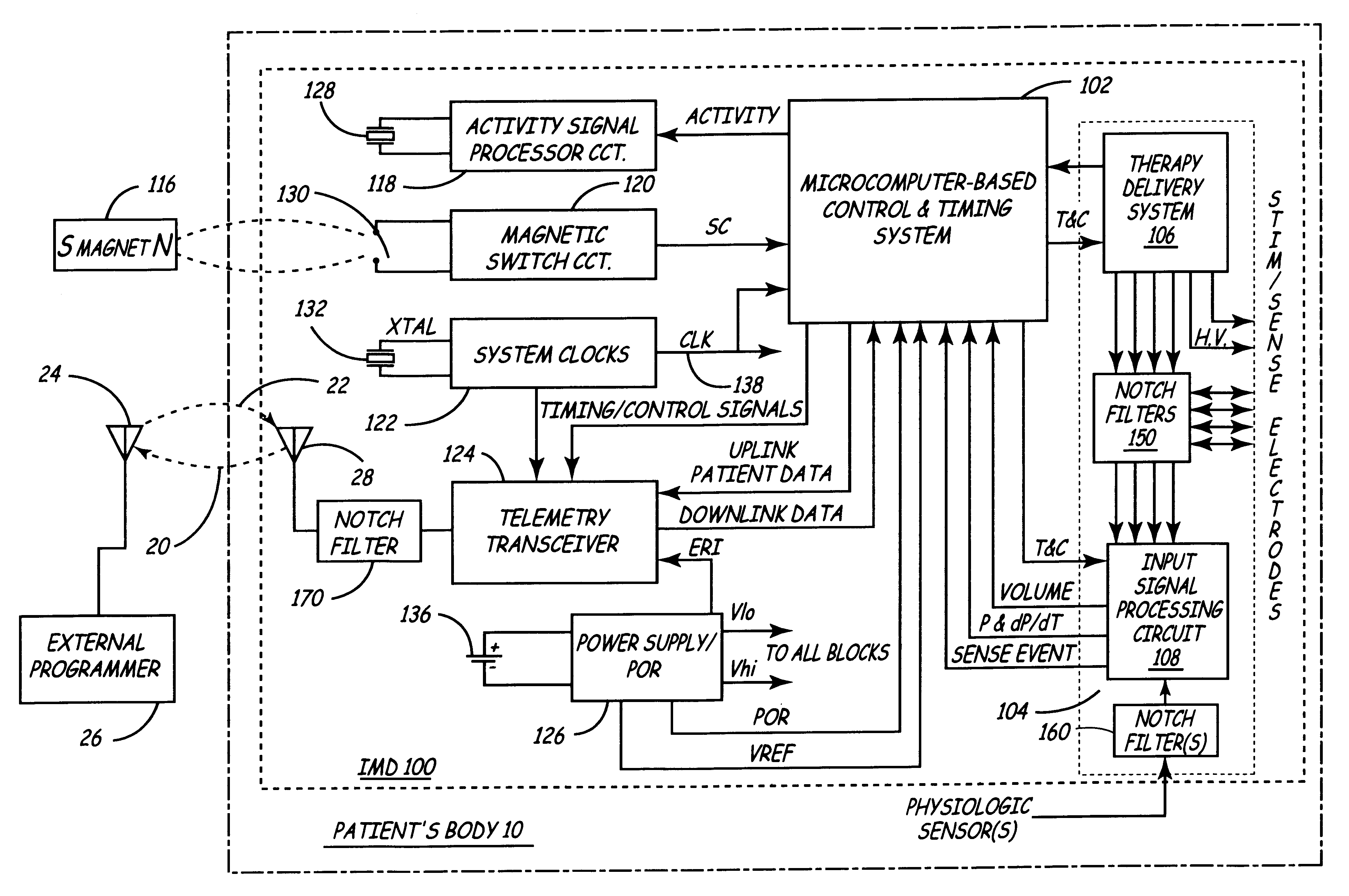

Implantable medical devices (IMDs) having sense amplifiers for sensing physiologic signals and parameters, RF telemetry capabilities for uplink transmitting patient data and downlink receiving programming and interrogation commands to and from an external programmer or other medical device are disclosed. At least one IC chip and discrete components have a volume and dimensions that are optimally minimized to reduce its volumetric form factor. Miniaturization techniques include forming notch filters of MEMS structures or forming discrete circuit notch filters by one or more of: (1) IC fabricating inductors into one or more IC chips mounted to the RF module substrate; (2) mounting each IC chip into a well of the RF module substrate and using short bonding wires to electrically connect bond pads of the RF module substrate and the IC chip; and (3) surface mounting discrete capacitors over IC chips to reduce space taken up on the RF module substrate. The IC fabricated inductors are preferably fabricated as planar spiral wound conductive traces formed of high conductive metals to reduce trace height and width while maintaining low resistance, thereby reducing parasitic capacitances between adjacent trace side walls and with a ground plane of the IC chip. The spiral winding preferably is square or rectangular, but having truncated turns to eliminate 90° angles that cause point-to-point parasitic capacitances. The planar spiral wound conductive traces are further preferably suspended over the ground plane of the IC chip substrate by micromachining underlying substrate material away to thereby reduce parasitic capacitances.

Owner:MEDTRONIC INC

Implantable medical device incorporating miniaturized circuit module

Implantable medical devices (IMDS) having RF telemetry capabilities for uplink transmitting patient data and downlink receiving programming commands to and from an external programmer having an improved RF module configured to occupy small spaces within the IMD housing to further effect the miniaturization thereof. An RF module formed of an RF module substrate and at least one IC chip and discrete components has a volume and dimensions that are optimally minimized to reduce its volumetric form factor. Miniaturization techniques include: (1) integrating inductors into one or more IC chips mounted to the RF module substrate; (2) mounting each IC chip into a well of the RF module substrate and using short bonding wires to electrically connect bond pads of the RF module substrate and the IC chip; and (3) surface mounting discrete capacitors over IC chips to reduce space taken up on the RF module substrate. The integrated inductors are preferably fabricated as planar spiral wound conductive traces formed of high conductive metals to reduce trace height and width while maintaining low resistance, thereby reducing parasitic capacitances between adjacent trace side walls and with a ground plane of the IC chip. The spiral winding preferably is square or rectangular, but having truncated turns to eliminate 90° angles that cause point-to-point parasitic capacitances. The planar spiral wound conductive traces are further preferably suspended over the ground plane of the RF module substrate by micromachining underlying substrate material away to thereby reduce parasitic capacitances.

Owner:MEDTRONIC INC

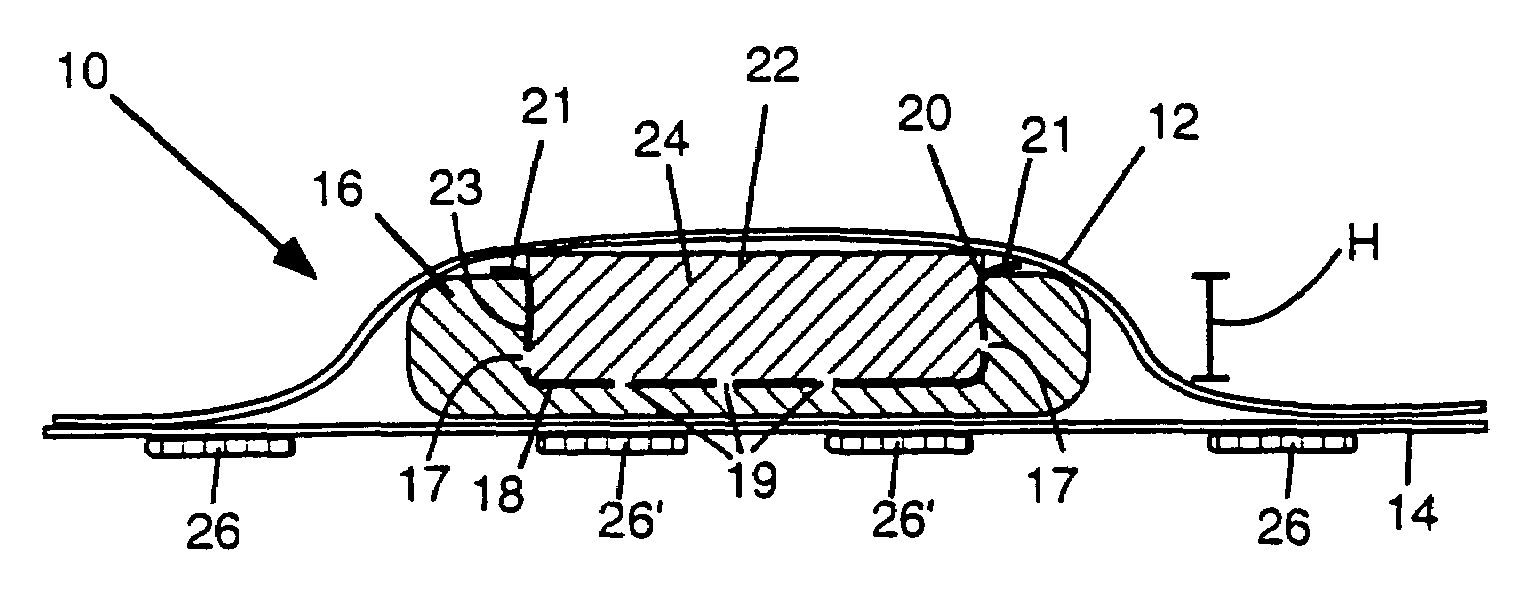

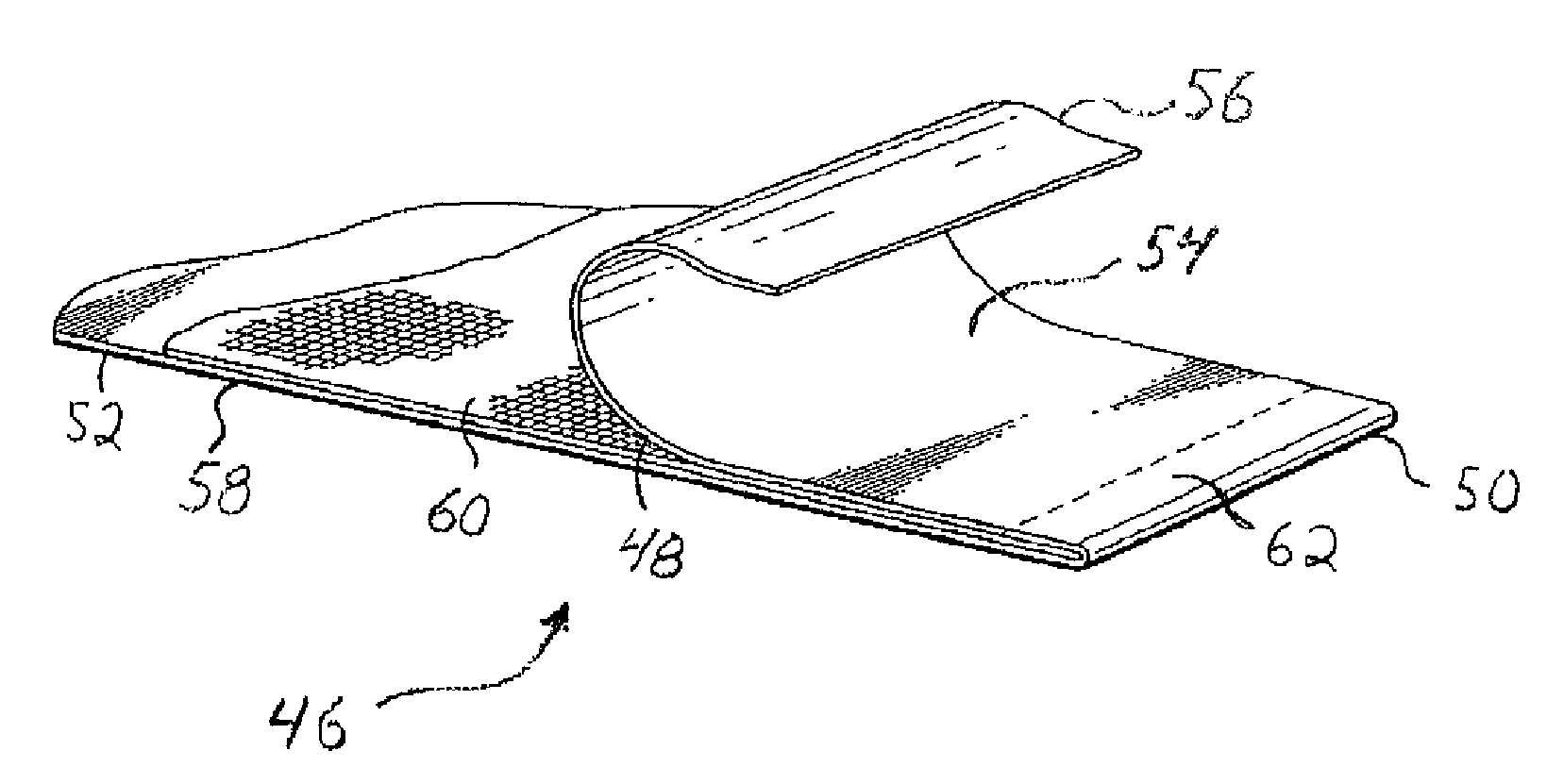

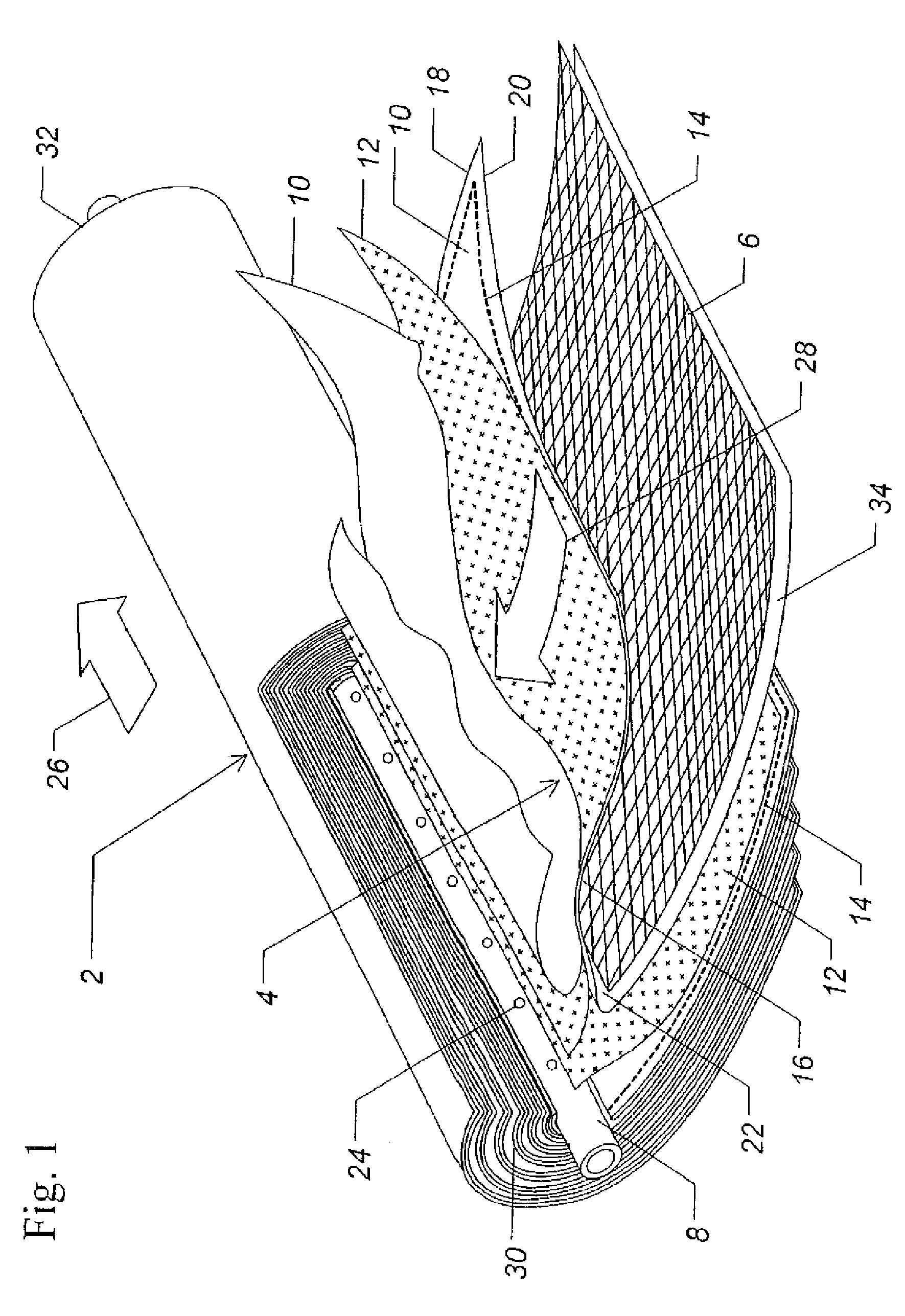

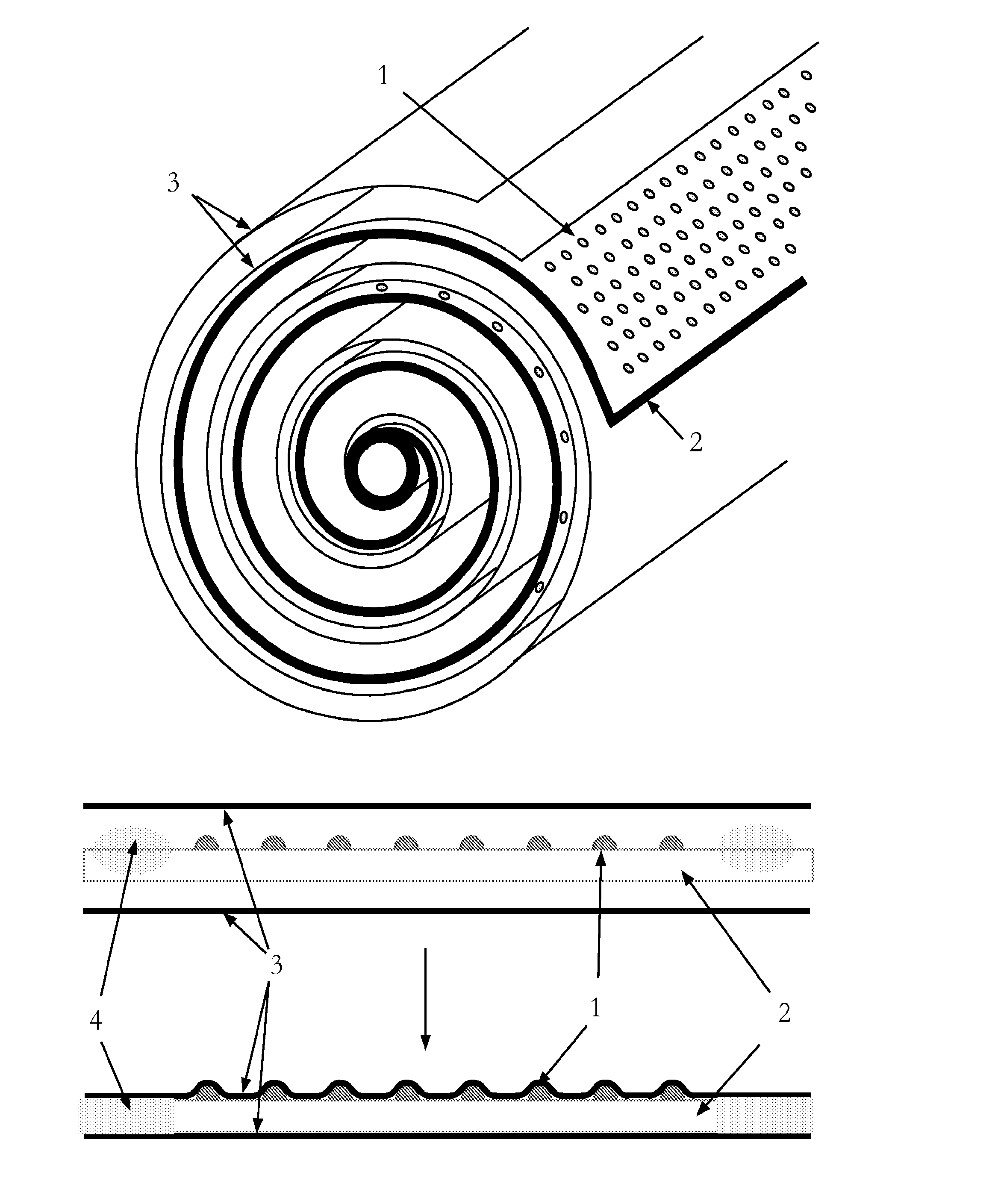

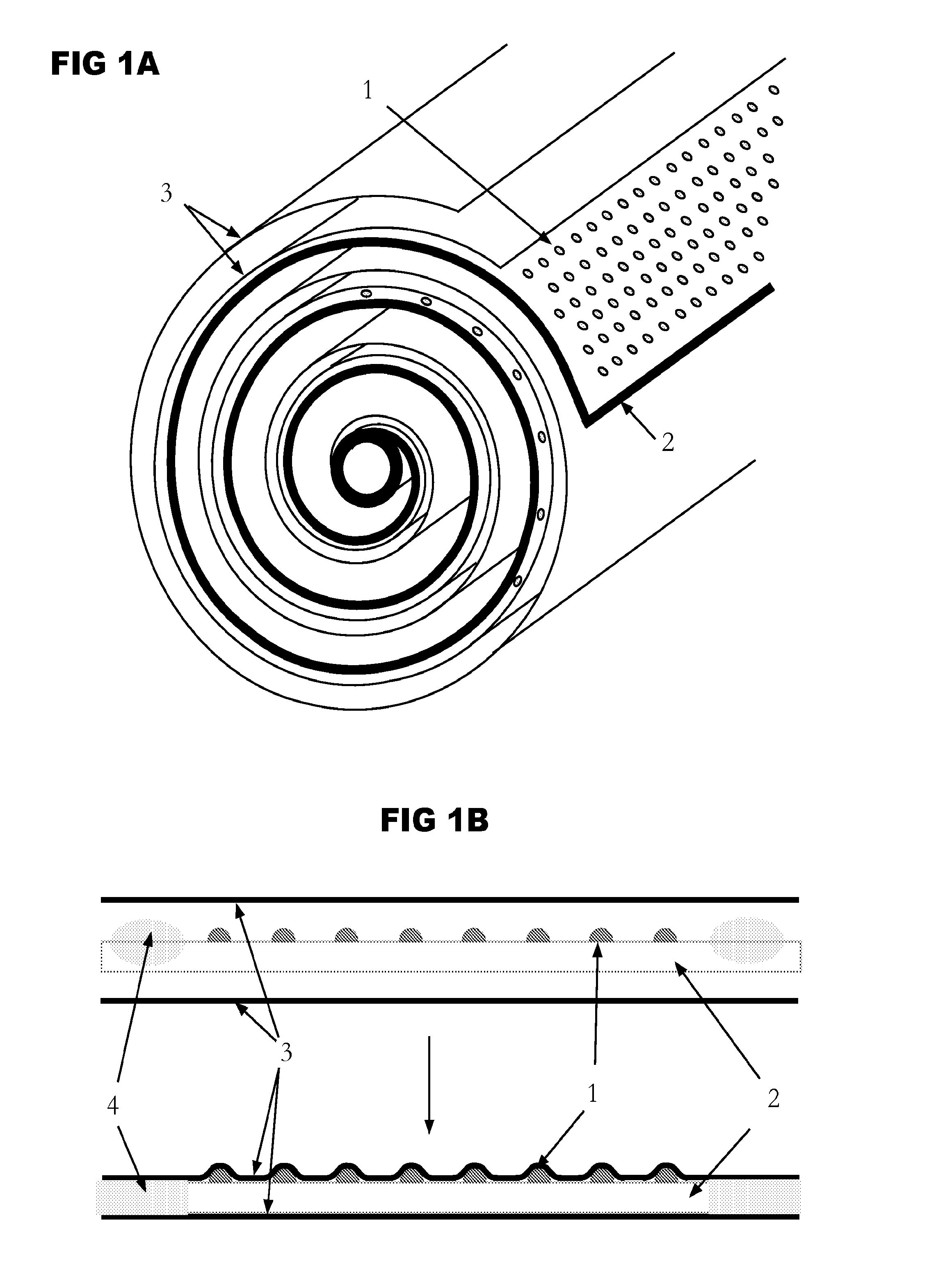

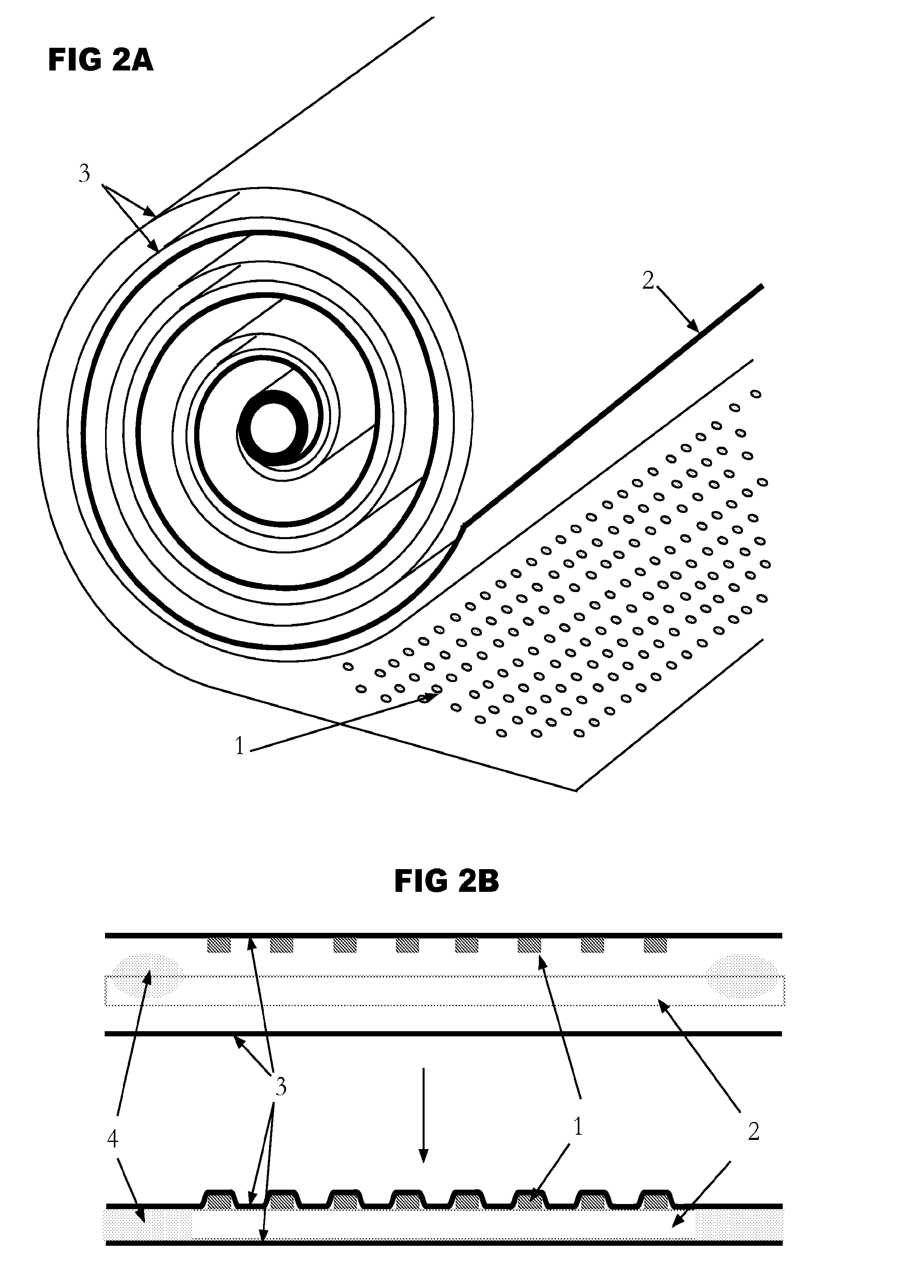

Absorbent article with center fill performance

An absorbent article comprising a central absorbent member and a lateral wicking barrier for inhibition of wicking from the central regions of the article to an outlying outer absorbent member. The wicking barrier has a vertical component for prevention of radial wicking in the plane of the article and thus promotes center filling of the article with fluid and reduces the likelihood of leaks from the sides of the article. The wicking barrier can also have a horizontal component to prevent leakage, redirect fluid flow, and improve fit and performance of the article. In one embodiment, the central absorbent member is a concentric absorbent structure having alternating rings of barrier material and absorbent material, including a spiral wound composite formed from a layer of barrier material wound with a layer of absorbent material and then sliced.

Owner:KIMBERLY-CLARK WORLDWIDE INC

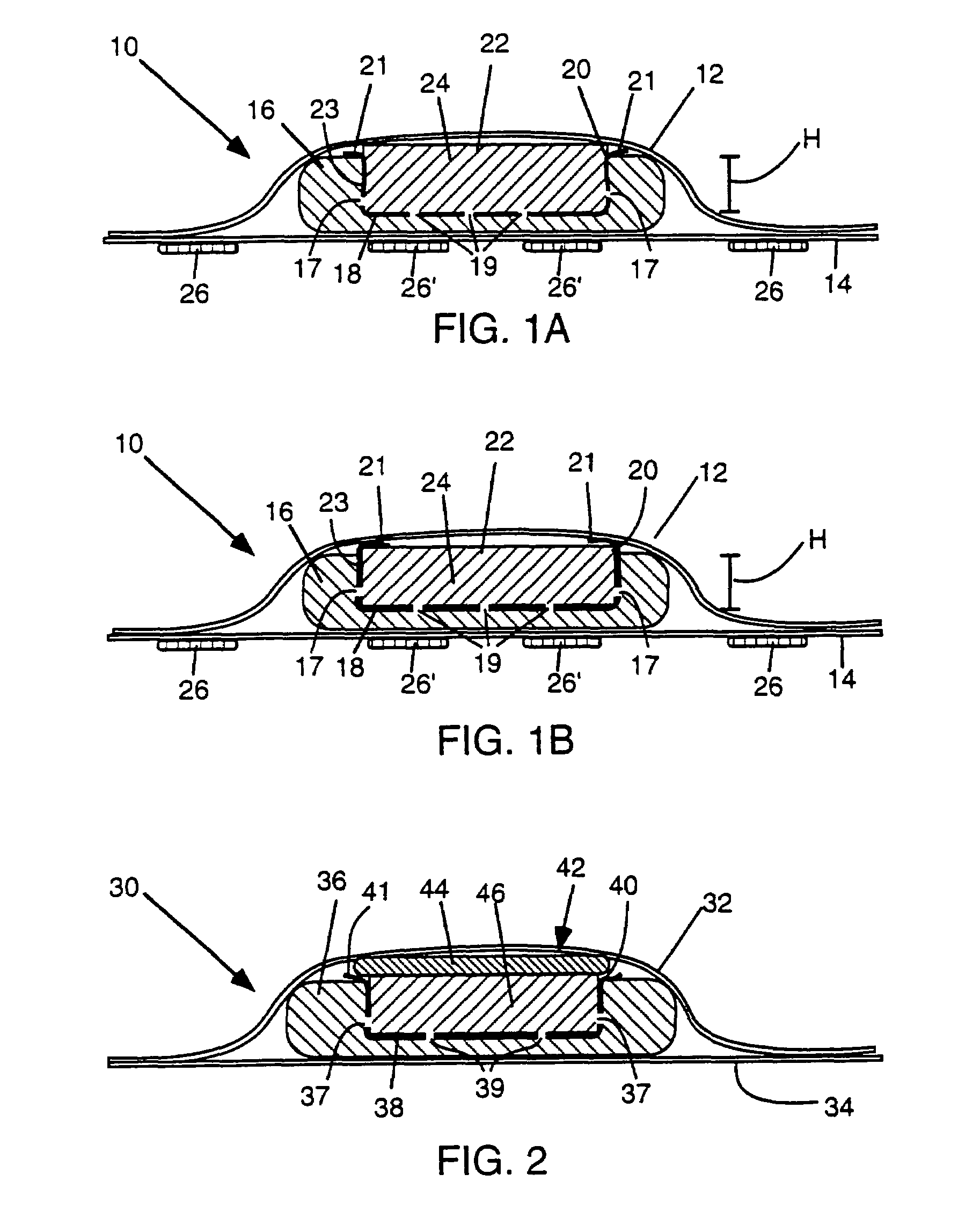

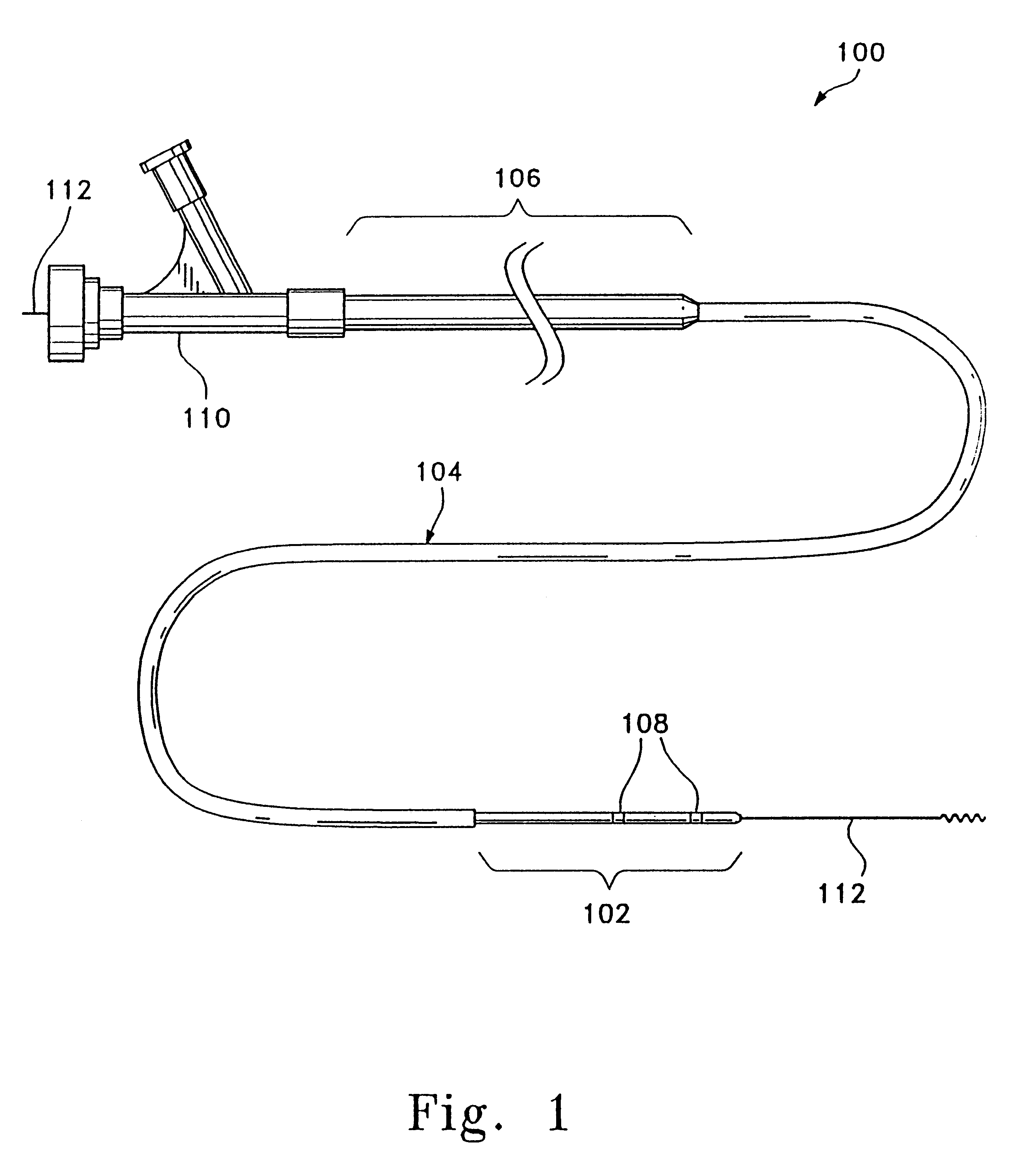

Kink-free spiral-wound catheter

This invention is a surgical device. In particular, it is a catheter suitable for treating a tissue target within the body, which target is accessible through the vascular system. Central to the invention is the use of stiffener ribbons, typically metallic, wound within the catheter body in such a way as to create a catheter having controllable stiffness.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

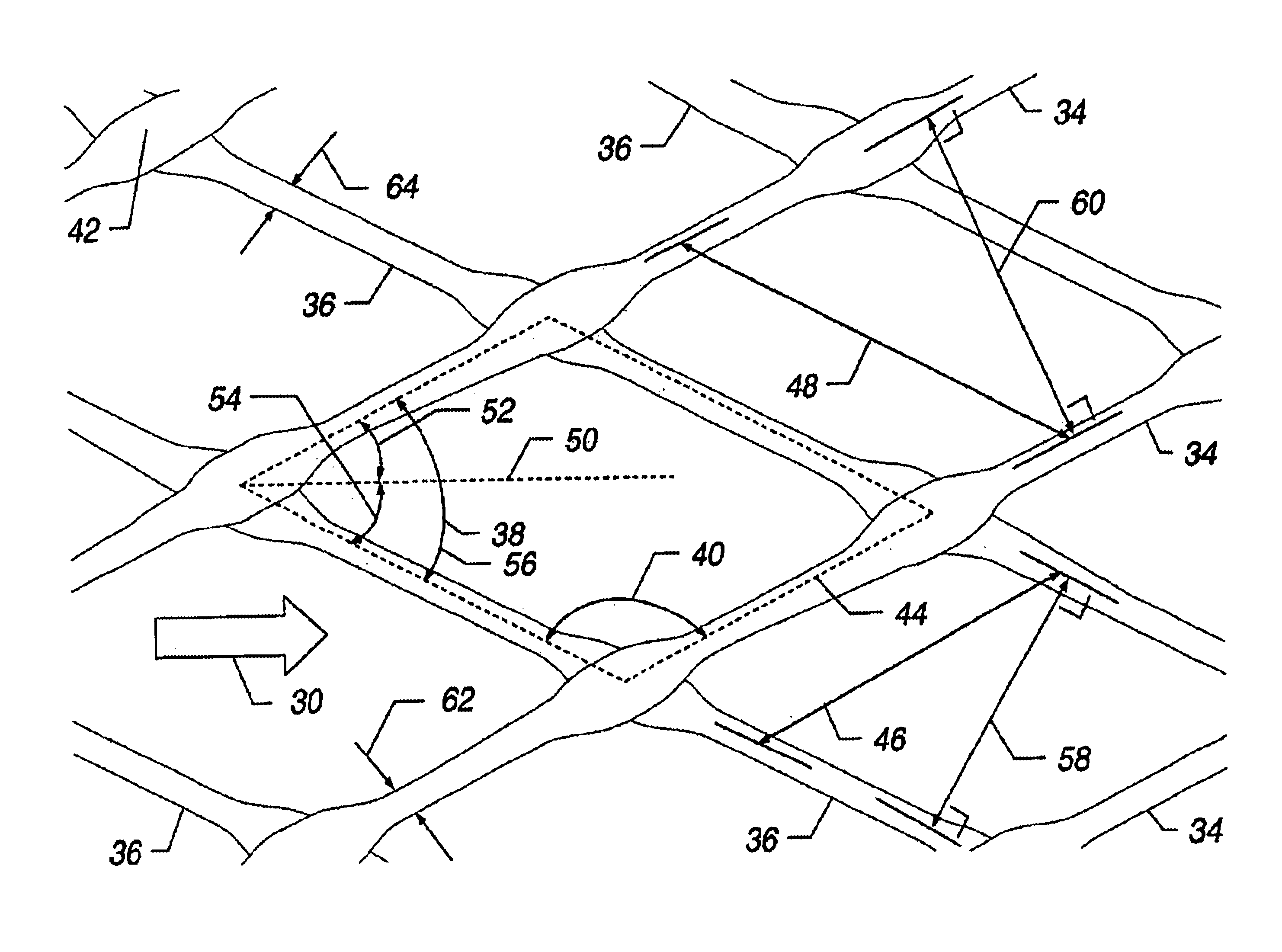

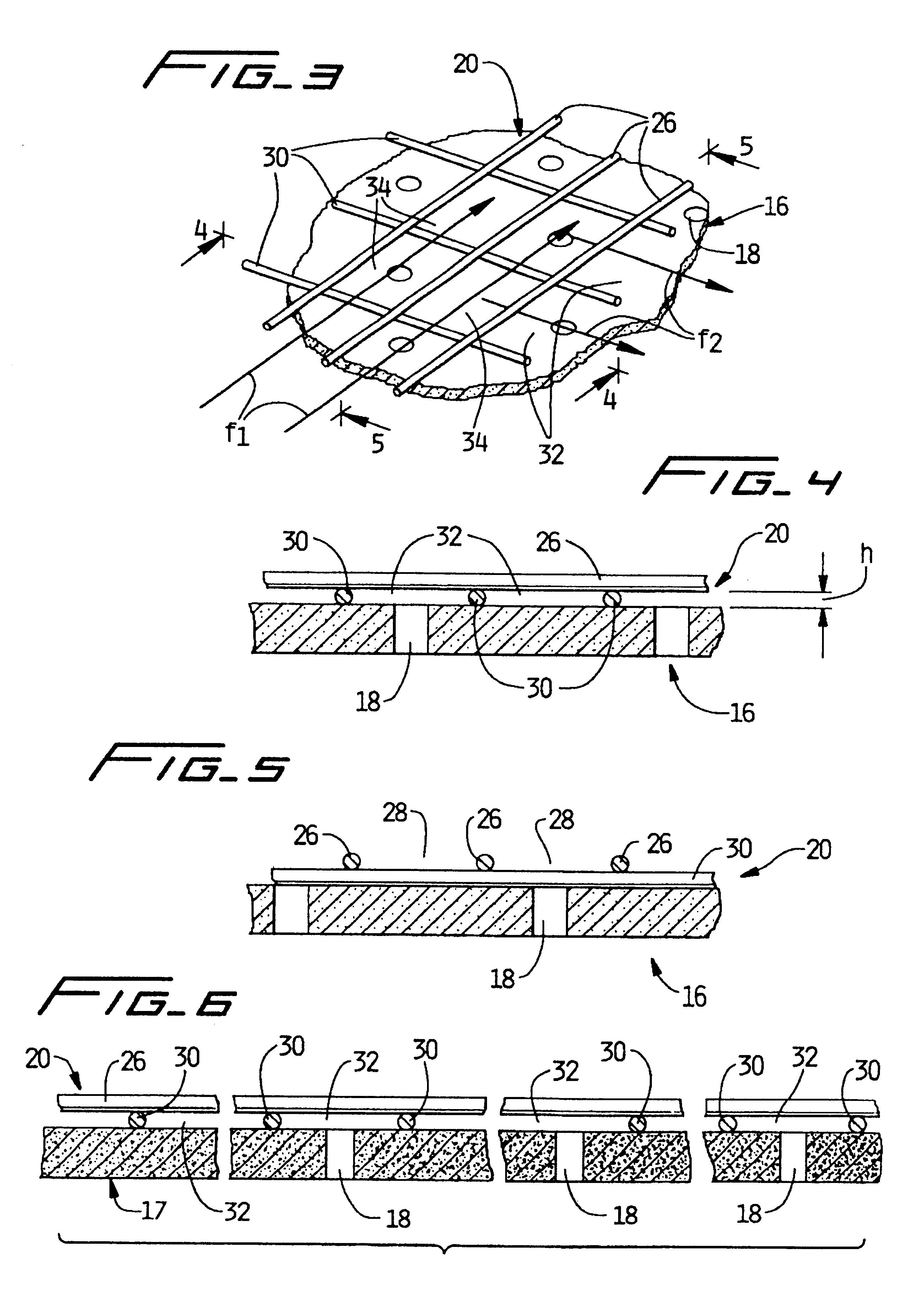

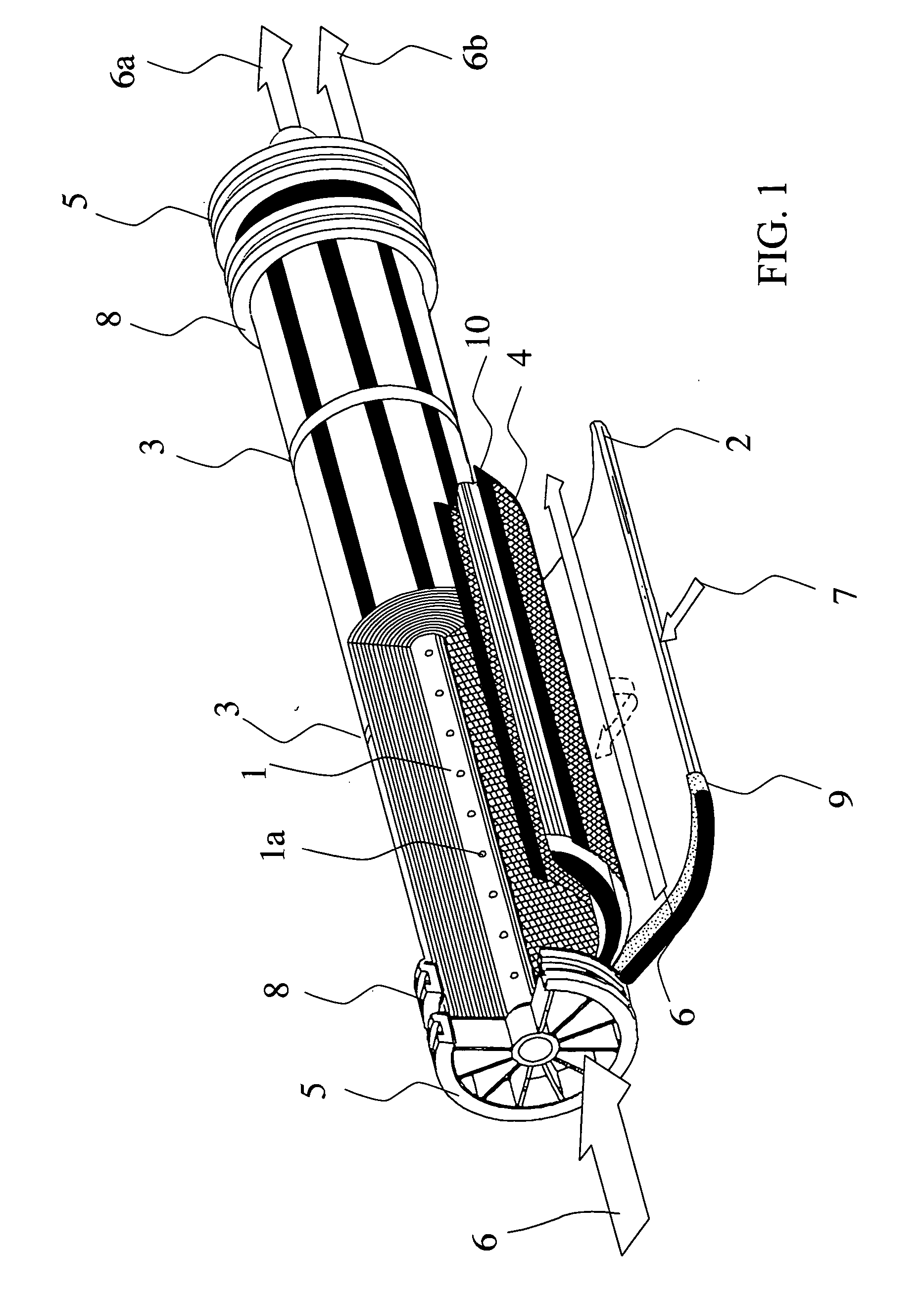

Spiral wound element with improved feed space

InactiveUS6881336B2Improve throughputLower overall pressure dropLayered productsIsotope separationFiltrationAcute angle

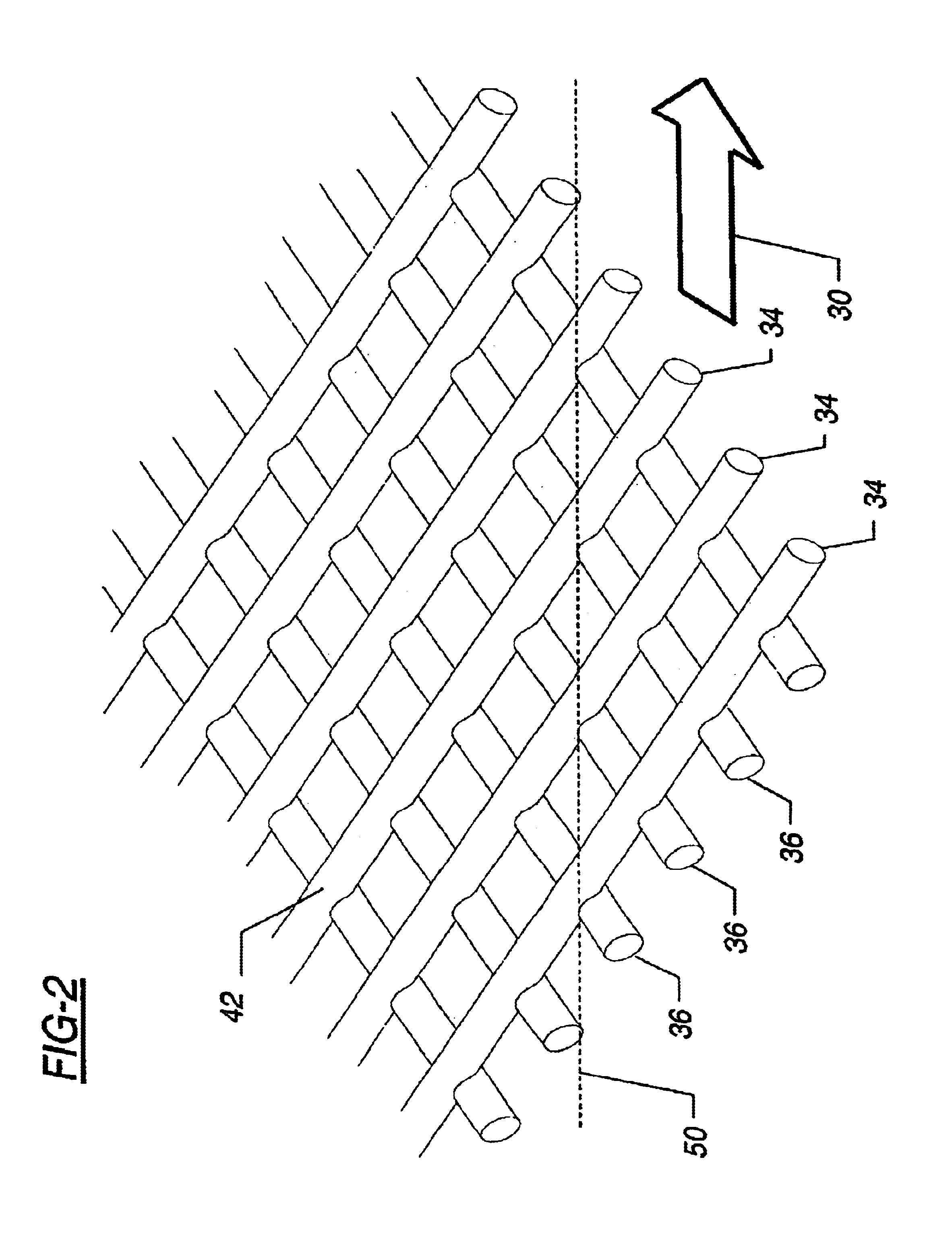

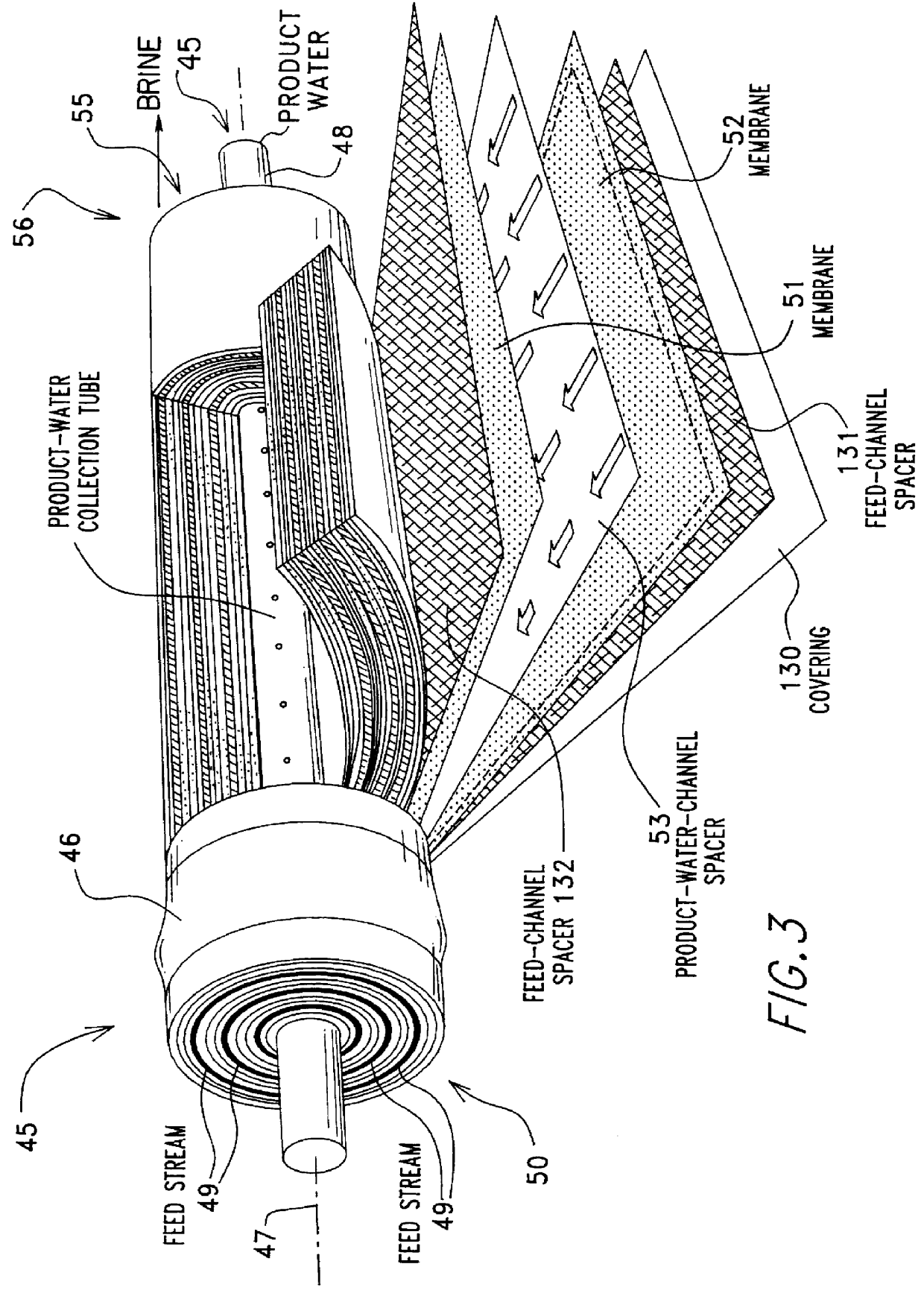

The present invention is an improved feed spacer, spiral wound element incorporating said feed spacer, filtration system and a method for making and using the same. In one embodiment the present invention includes an improved spiral wound element having: a central collection tube with a plurality of openings along its length to receive permeate; at least one filtration envelope extending outwardly from and wound about the tube and at least one feed spacer sheet wound about the collection tube wherein the feed spacer sheet being in planar contact with the outer surface of at least one filtration envelope. The feed spacer sheet is a net comprising a first set of substantially parallel filaments crossed with a second set substantially parallel filaments to form a plurality of parallelograms having an acute angle less than 70°, the net oriented such that a line bisecting said acute angle is approximately parallel to the axis of the central collection tube and wherein the net has a strand thinning parameter greater than 1.3.

Owner:FILMTEC CORPORATION

Method and apparatus for determining the state of fouling/cleaning of membrane modules

InactiveUS6161435AVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainSpiral wound

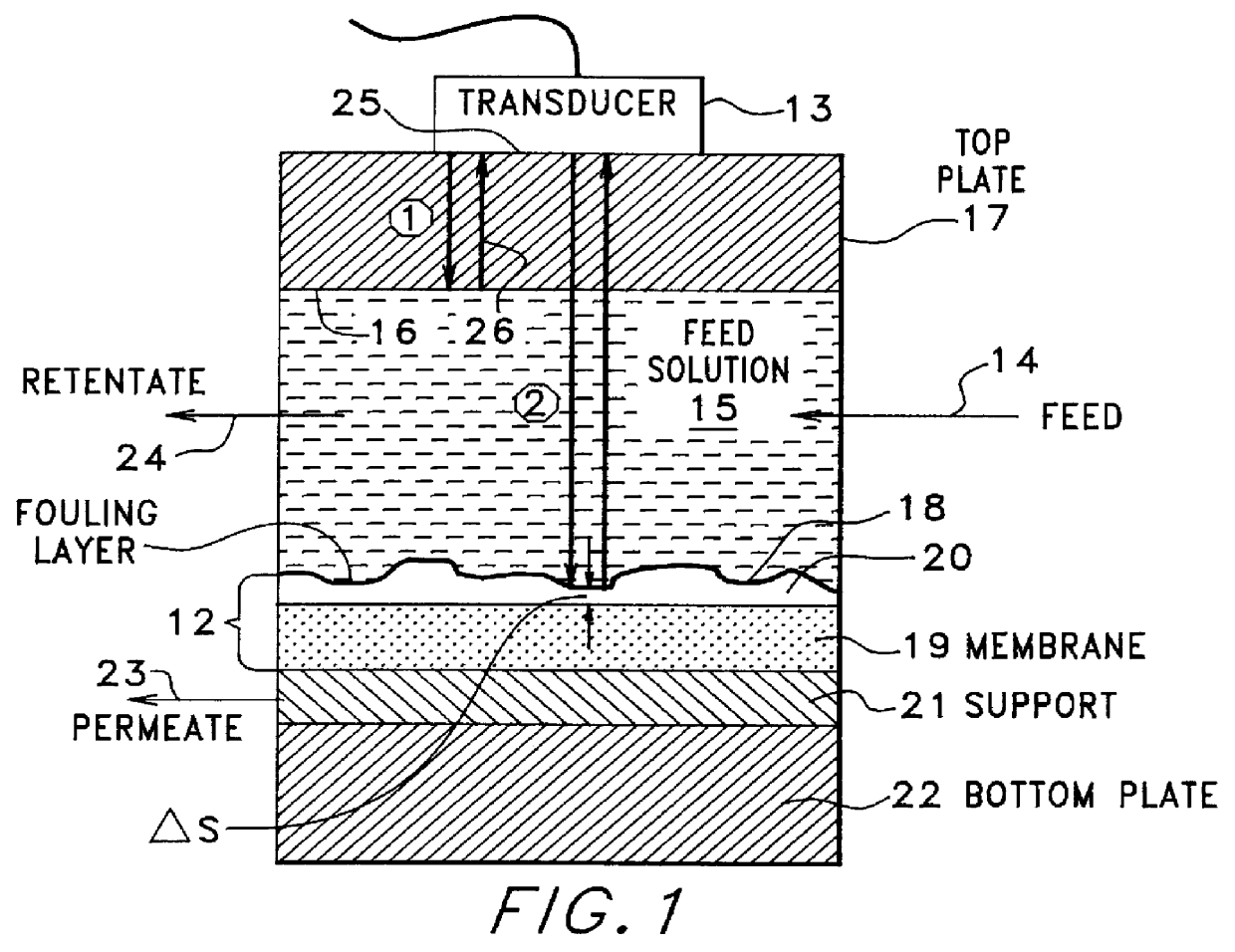

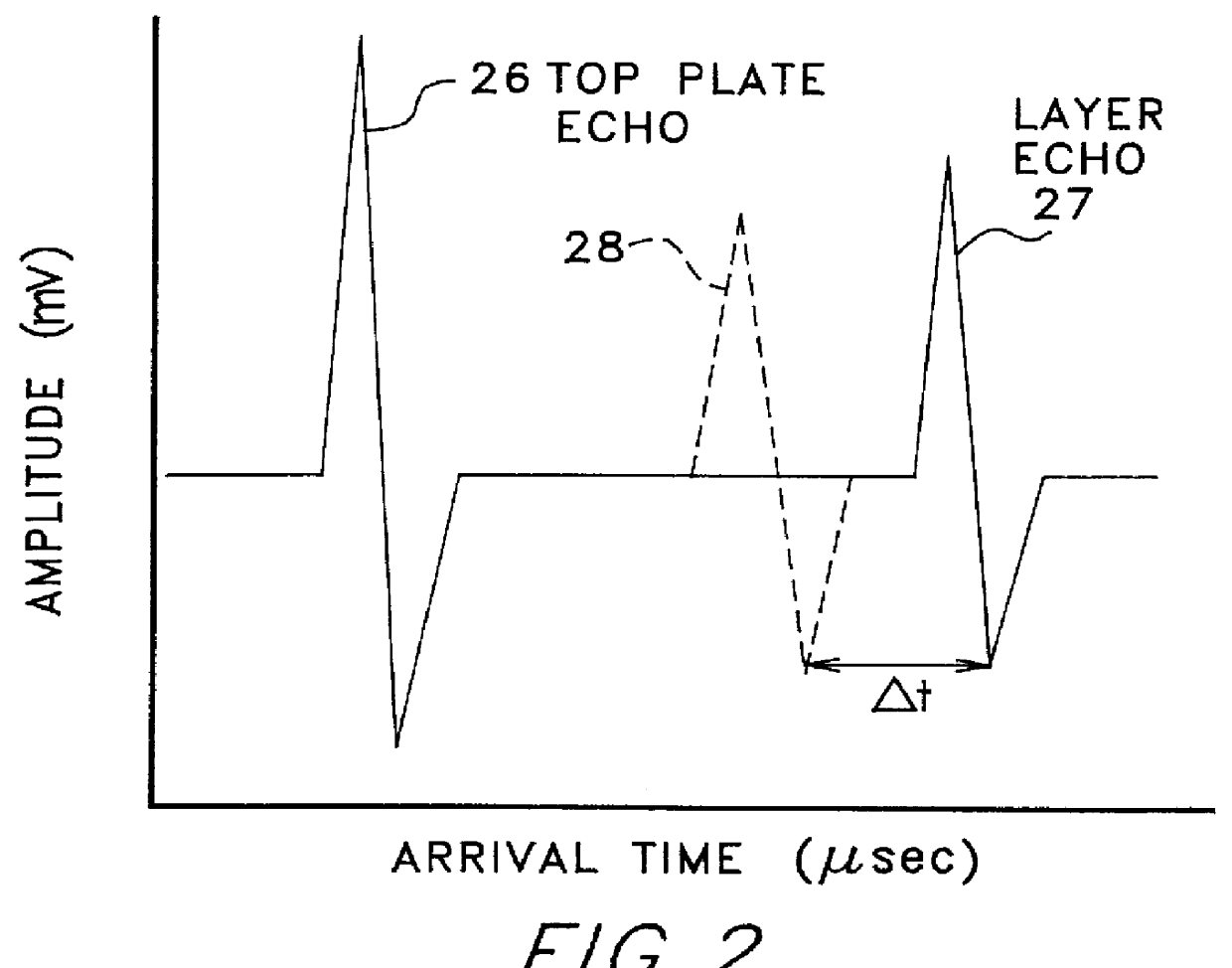

The fouling state of a polymeric membrane within the high pressure housing of a spiral wound or a hollow fiber membrane module is determined. An ultra sonic transducer positioned with its emitting face in physical engagement with the outer surface of the housing is pulse energized by a pulser / receiver device. A membrane echo signal is detected by a receiver of the pulser / receiver device. A reference echo signal indicative of a fouled or an unfouled state of the membrane is compared to the echo signal to determine the membrane fouling state. The echo to reference comparing step can be based upon comparing amplitude domain signals, comparing time-domain signals, comparing combinations of amplitude domain and time-domain signals, and comparing transformations of amplitude domain and time-domain signals. A clean or a fouled reference echo can be provided from a clean or a fouled membrane and then stored for use during a liquid separation process, or a clean reference echo signal can be obtained on-line from a second transducer whose echo signal is derived from an area of the membrane known to remain relatively unfouled during the liquid separation process, or a clean or fouled reference echo signal can be provided for later use during a cleaning process or during a liquid separation process. Multiple transducers and a switching network can sample the fouling state at different positions within the membrane module.

Owner:UNIV TECH

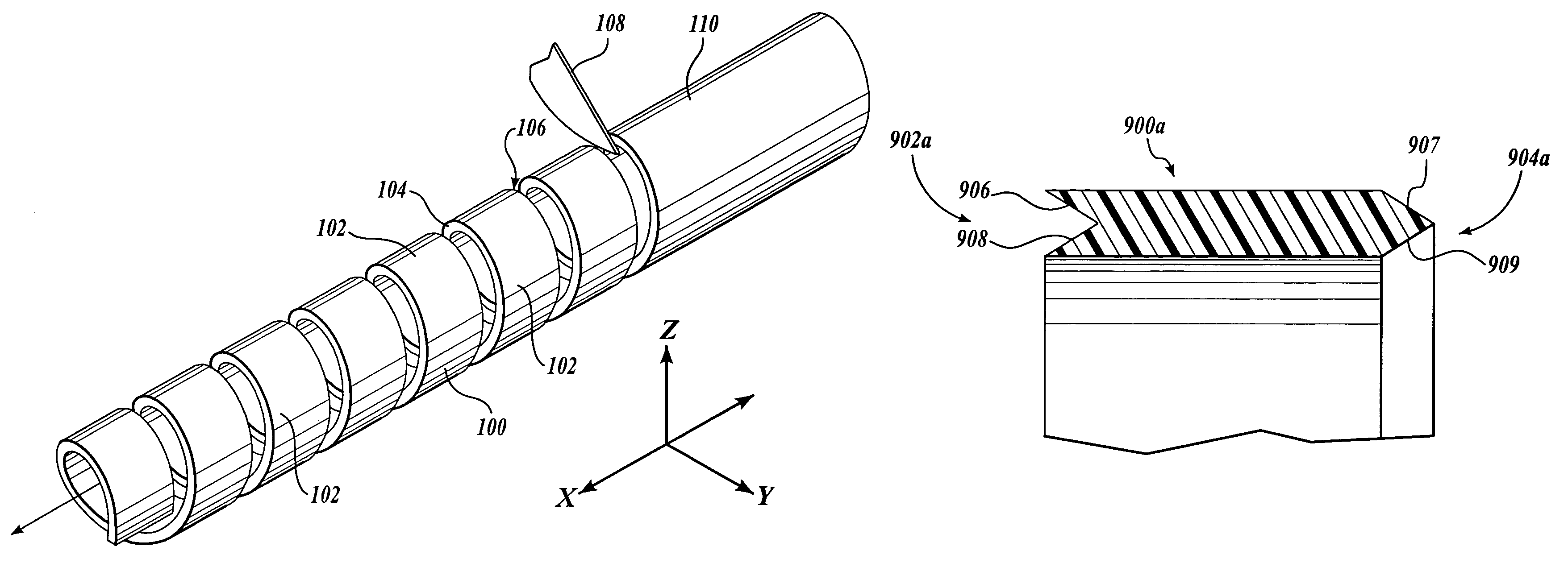

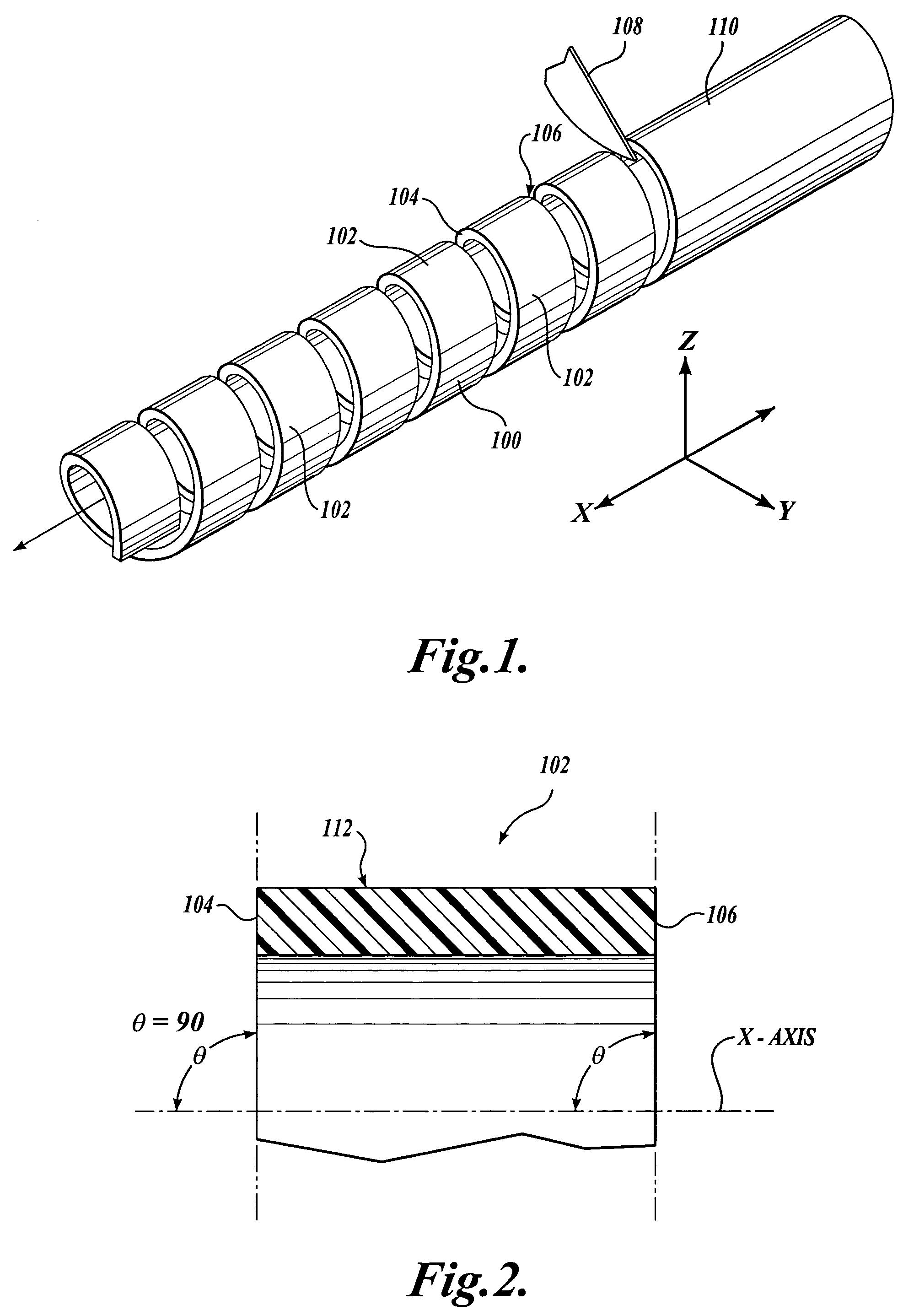

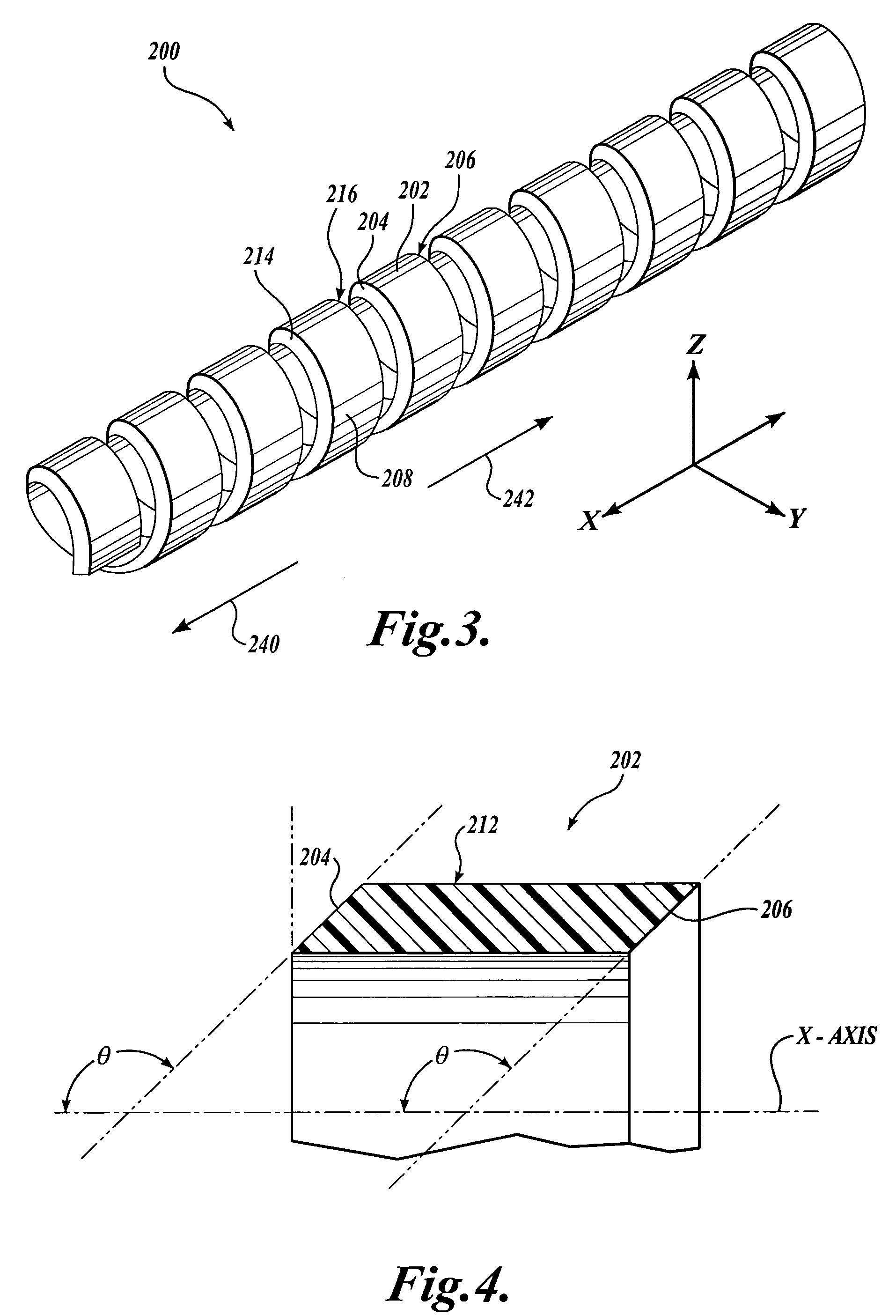

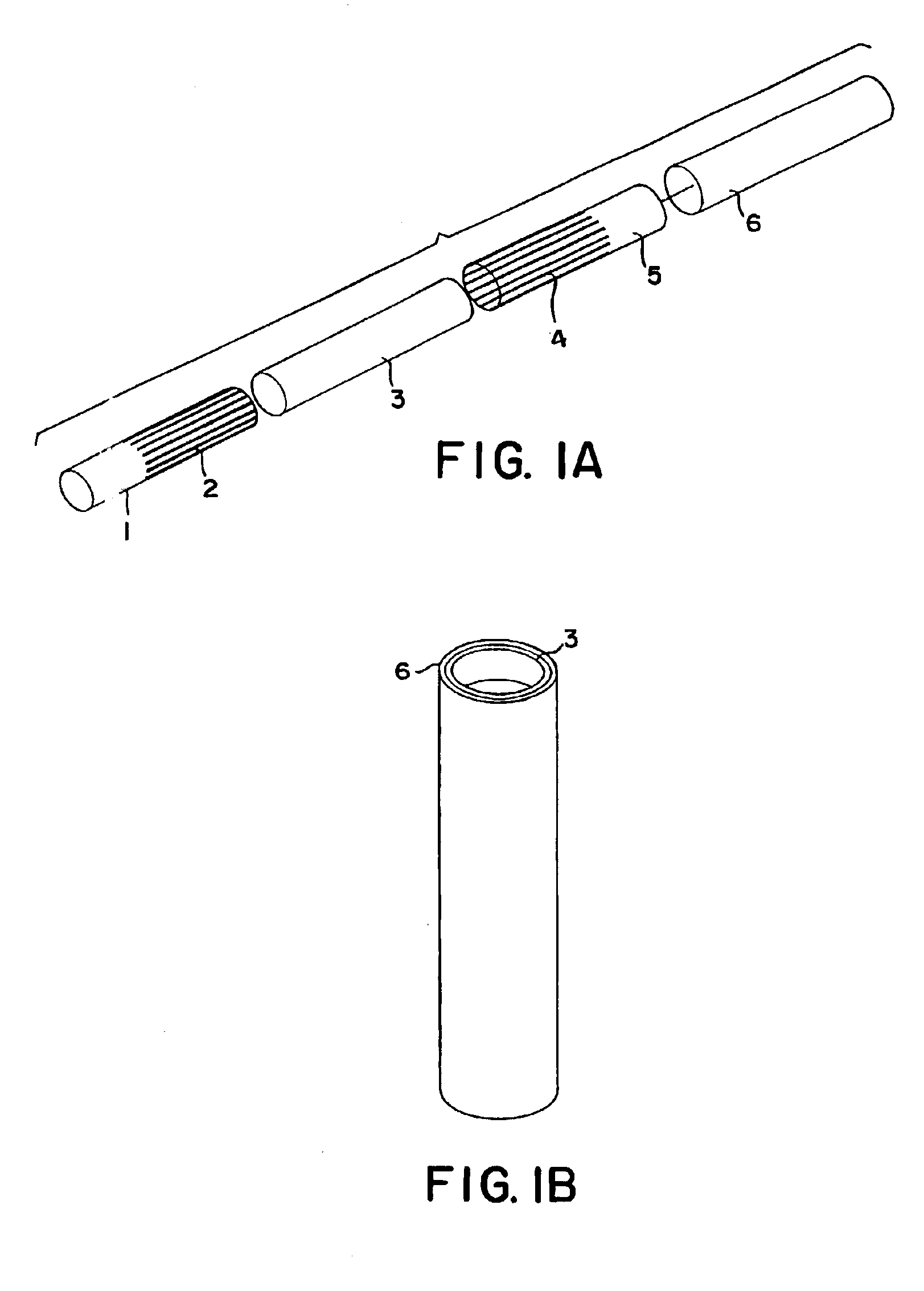

Flexible device shaft with angled spiral wrap

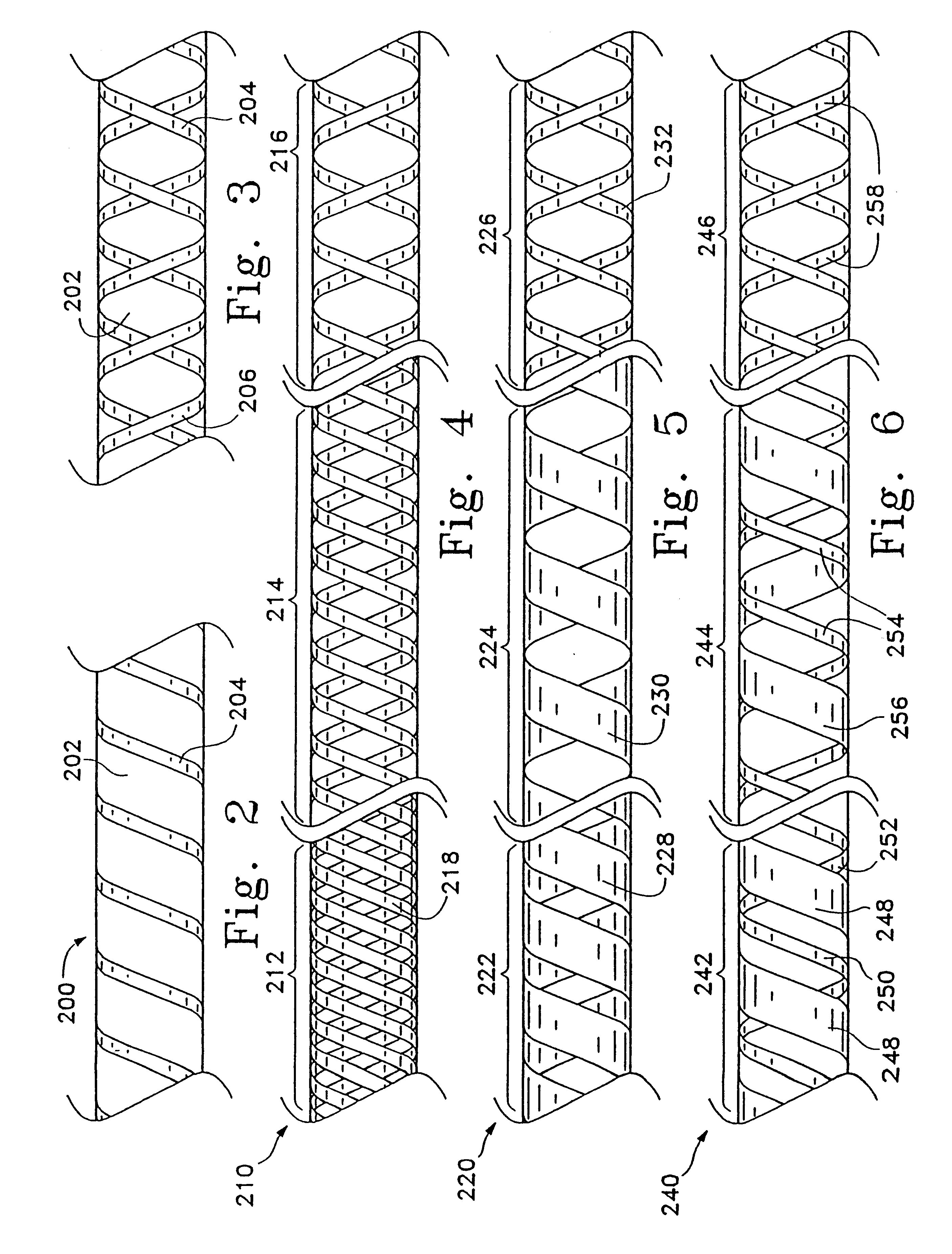

ActiveUS7579550B2Reduces inadvertent axial elongationGood flexibilitySurgeryEndoscopesSpiral woundEngineering

Spiral-wound materials, spirals, and shafts made therefrom that have wraps with edges that may nest within one another are described. Such edges allow the spiral to achieve a smaller bending radius, meaning tighter turns and more flexibility due to the ability of adjacent wraps to nest within each other when the shaft is bent. Spirals having wraps with edges capable of nesting can be used in the medical field for devices that track anatomy, such as endoscopes, colonoscopes, catheters, and the like.

Owner:BOSTON SCI SCIMED INC

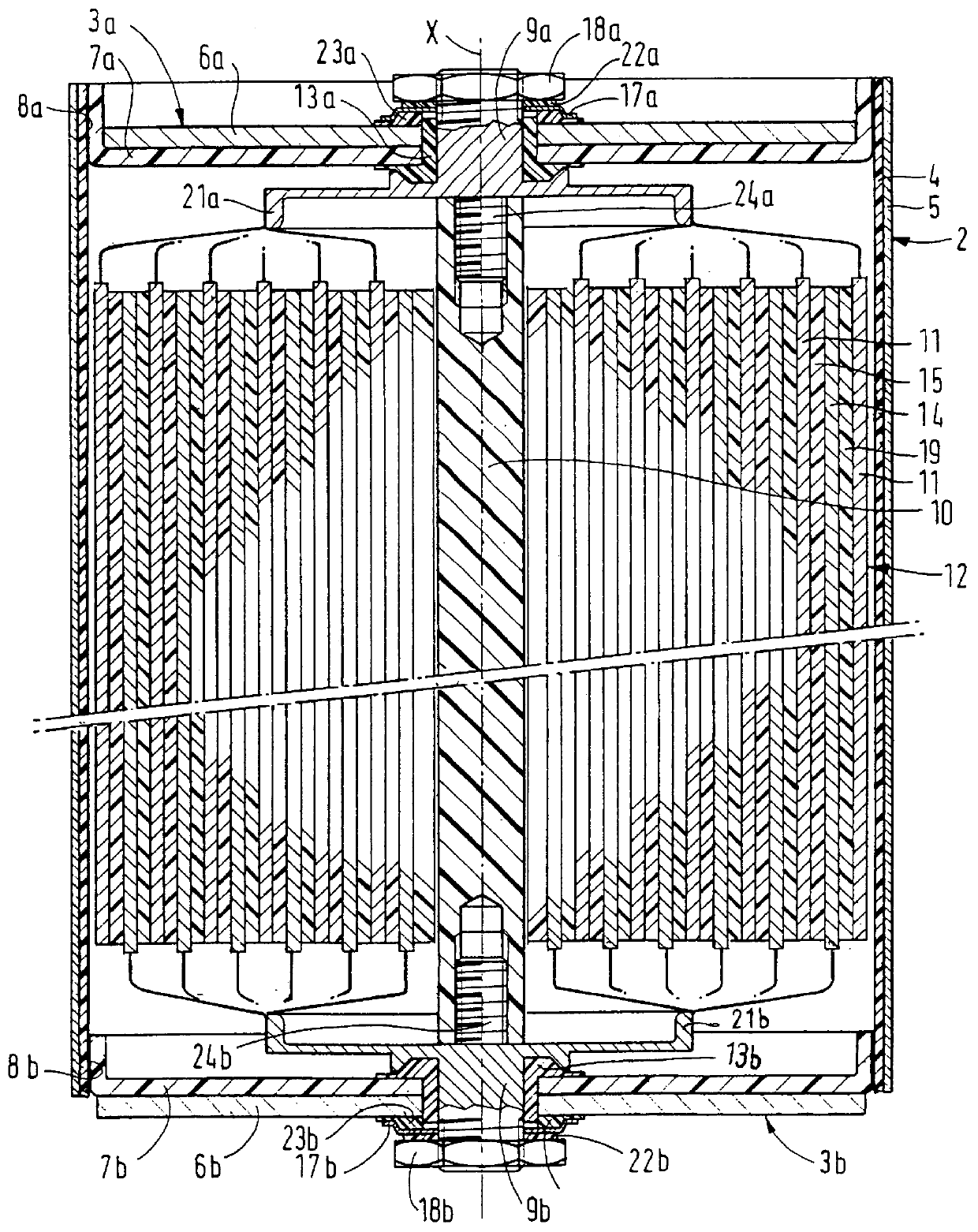

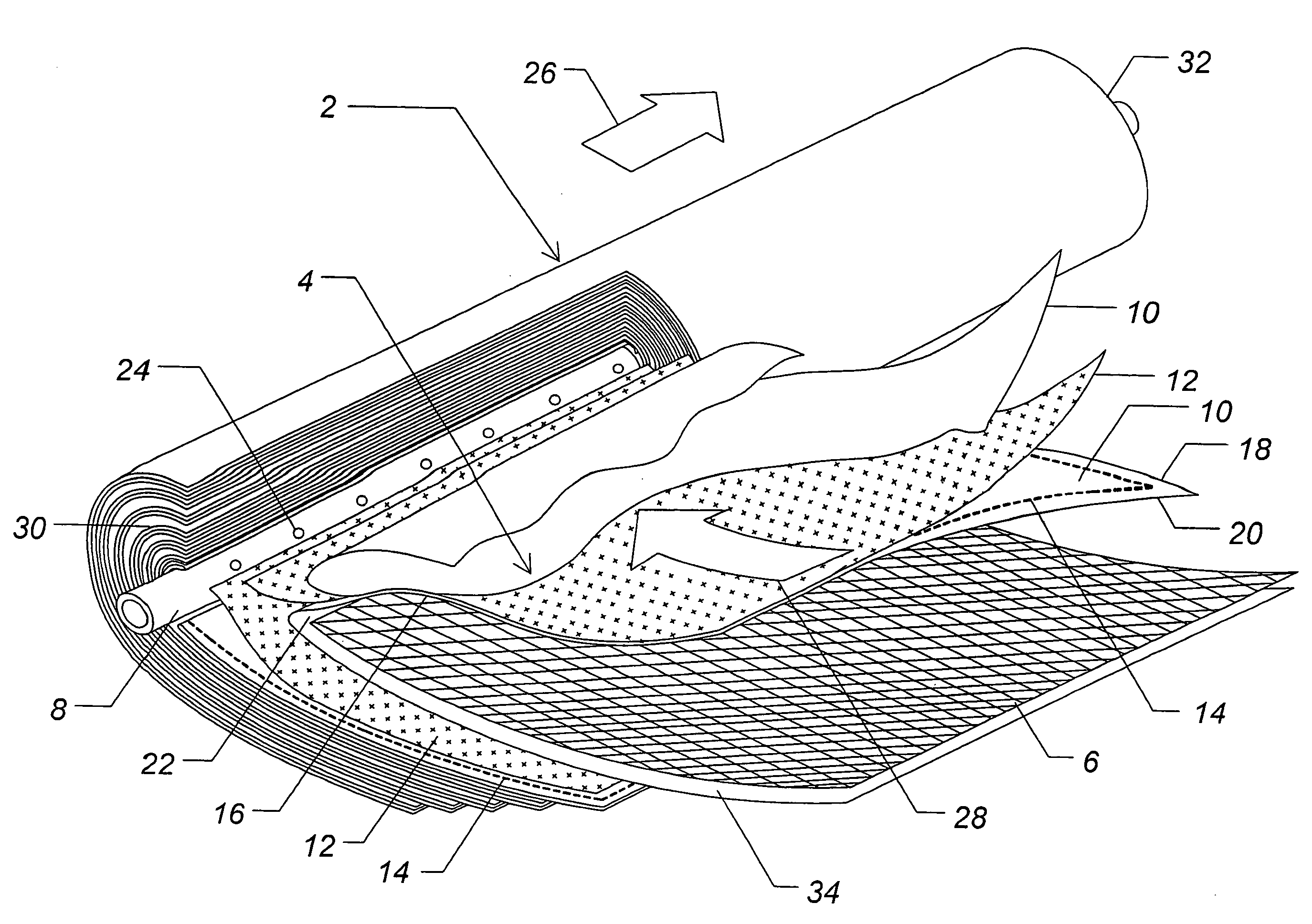

Filter and method of filtering a fluid

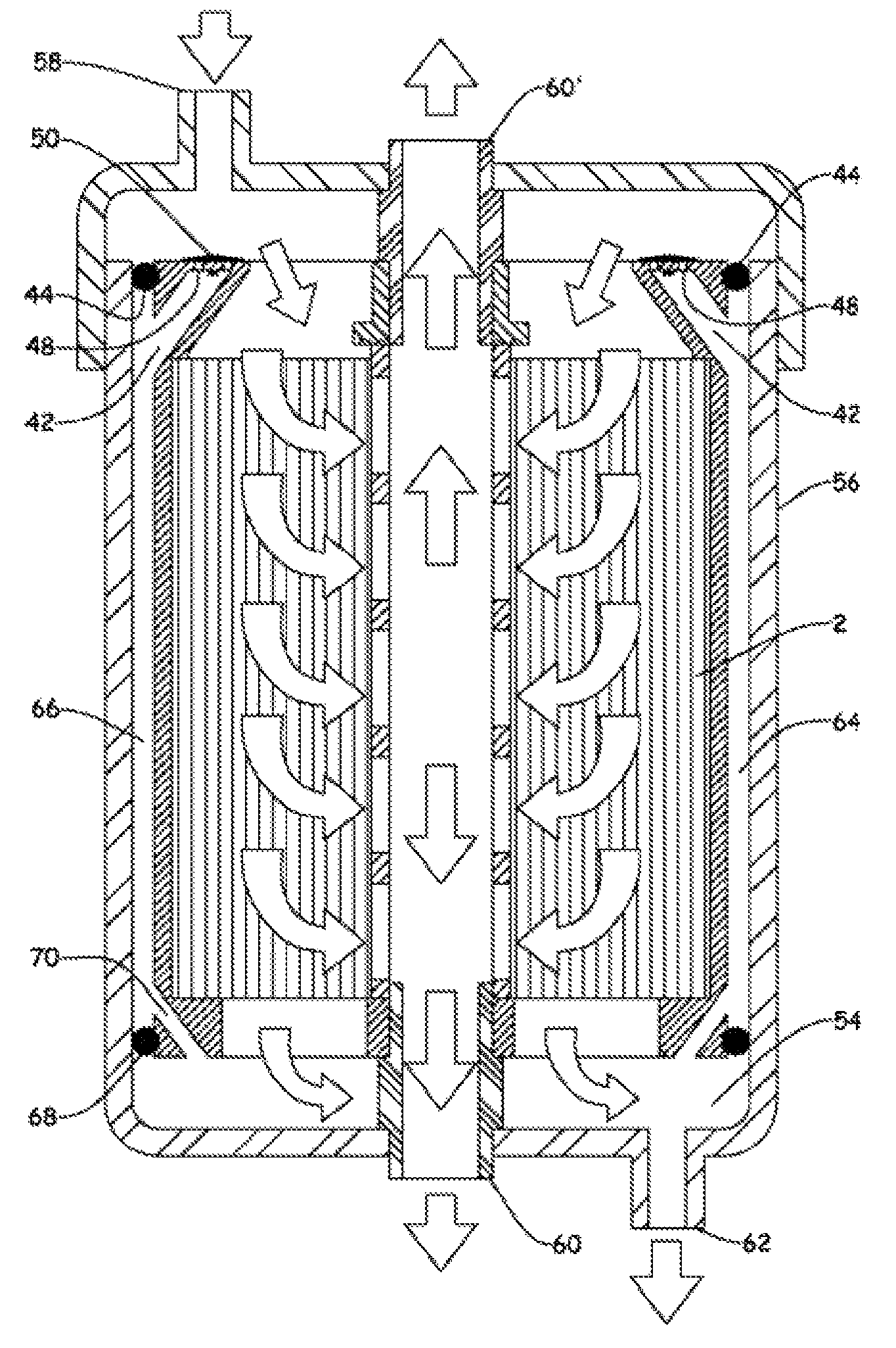

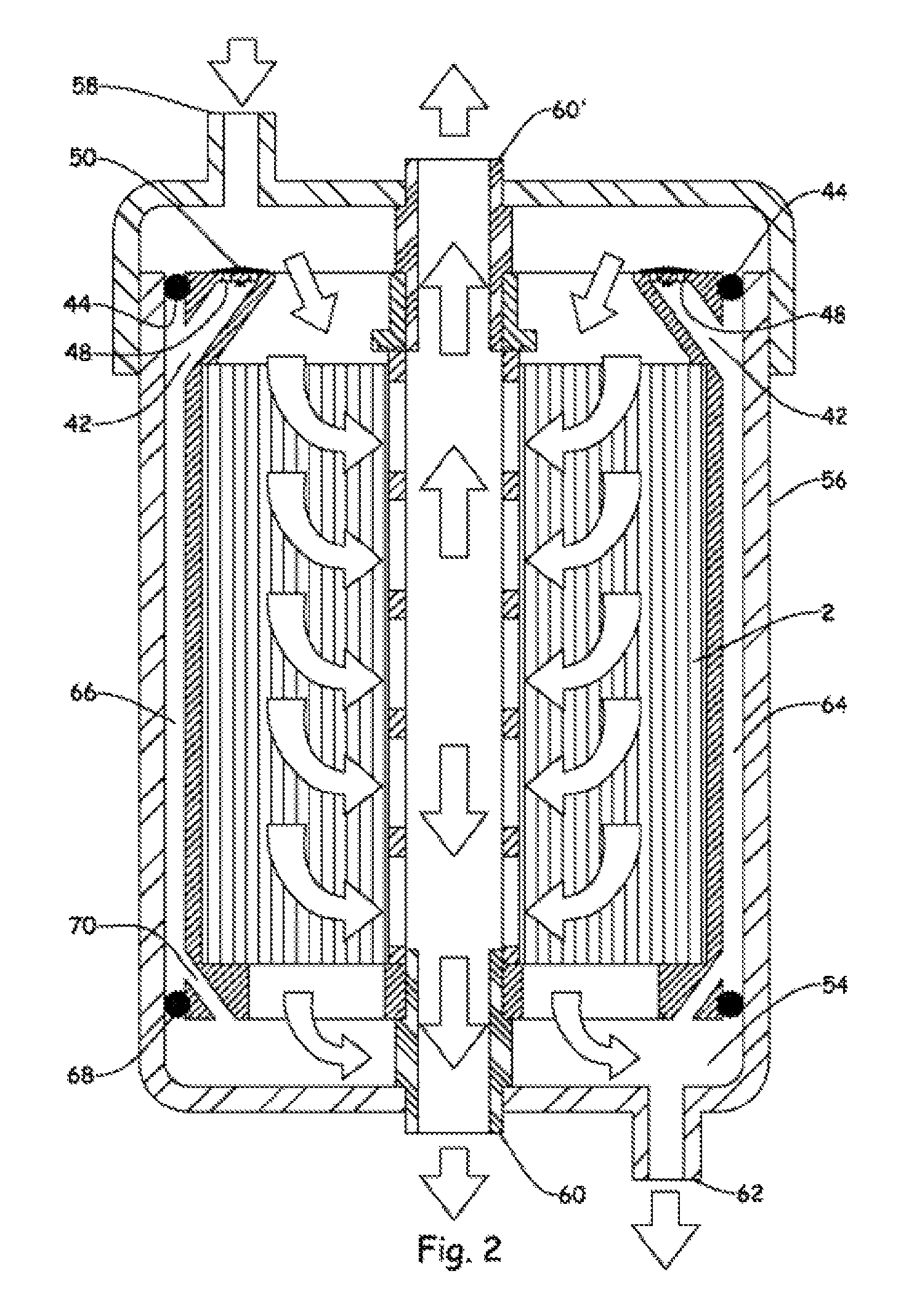

InactiveUS6391200B2Improve distributionProlong lifeCombination devicesSemi-permeable membranesFilter mediaSpiral wound

A spiral wound filter element is disclosed which includes alternating layers of filter medium and diffusion medium wrapped about a cylindrical core defining a central axis of the filter element. The alternating layers extend from a radially innermost layer of the filter element to a radially outermost layer of the filter element, the diffusion medium is defined by a continuous lengthwise sheet of mesh material, and the filter medium is defined by at least one sheet of filter material arranged along the length of the continuous sheet of mesh material. The alternating layers of filter medium and diffusion medium define three distinct radially disposed layered filtering sections surrounding the cylindrical core, and include a first filtering section having radially outer prequalifying layers, a second filtering section having middle prequalifying layers and a third filtering section having radially inner qualifying layers. The radially outer prequalifying layers and the middle prequalifying layers define about two-thirds of the radial distance from the radially outermost layer of the filter element to the radially innermost layer of the filter element.

Owner:3M INNOVATIVE PROPERTIES CO

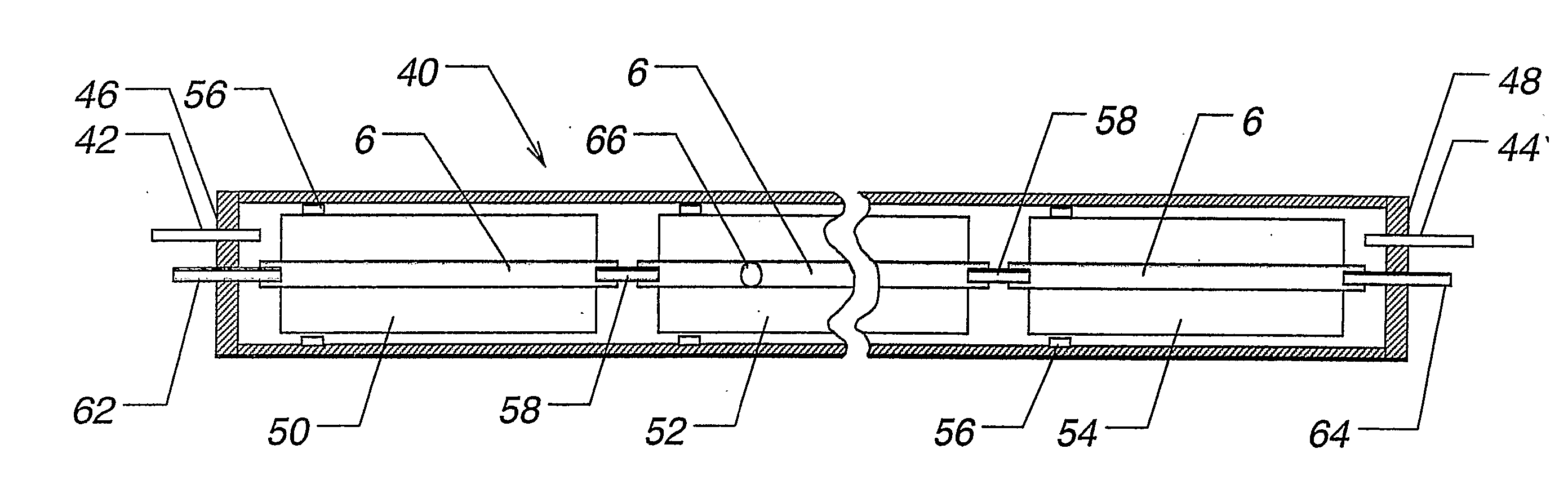

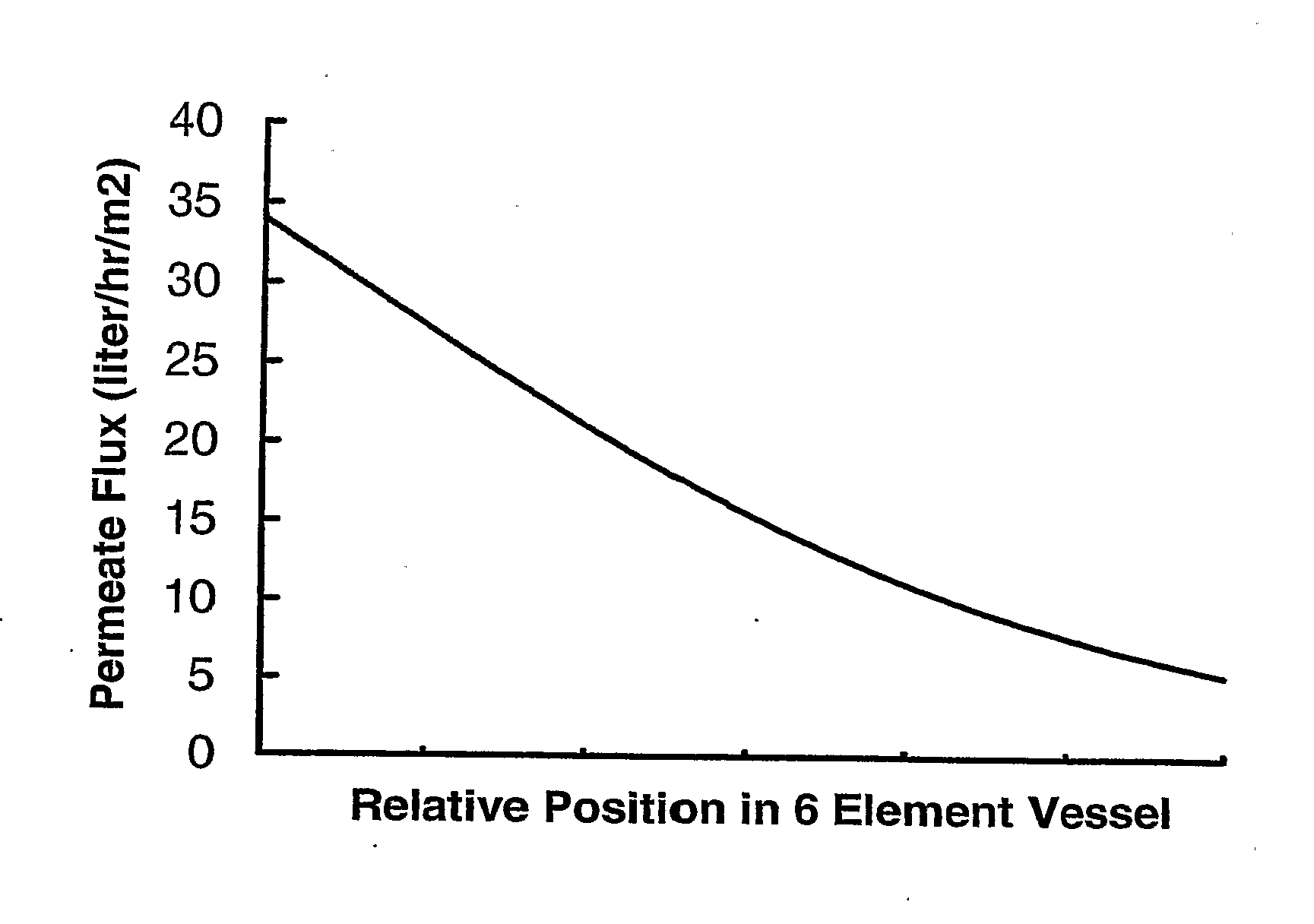

Apparatus for Treating Solutions of High Osmotic Strength

InactiveUS20070272628A1Improves pressure vesselUniform flux distributionGeneral water supply conservationSeawater treatmentFiltrationReverse osmosis

The present invention pertains to an apparatus and method for treating a solution of high osmotic strength, especially seawater and solutions of greater than 20 bar osmotic pressure, by passing the solution through a vessel containing spiral wound reverse osmosis or nanofiltration elements. The vessel contains at least three elements in series and at least two of these elements have standard specific fluxed that differ by at least 50%. The invention allows a more even flux distribution within a filtration system to be obtained, and it may advantageously be combined with variations en element construction and feed spacers.

Owner:MICKOLS WILLIAM EDWARD +4

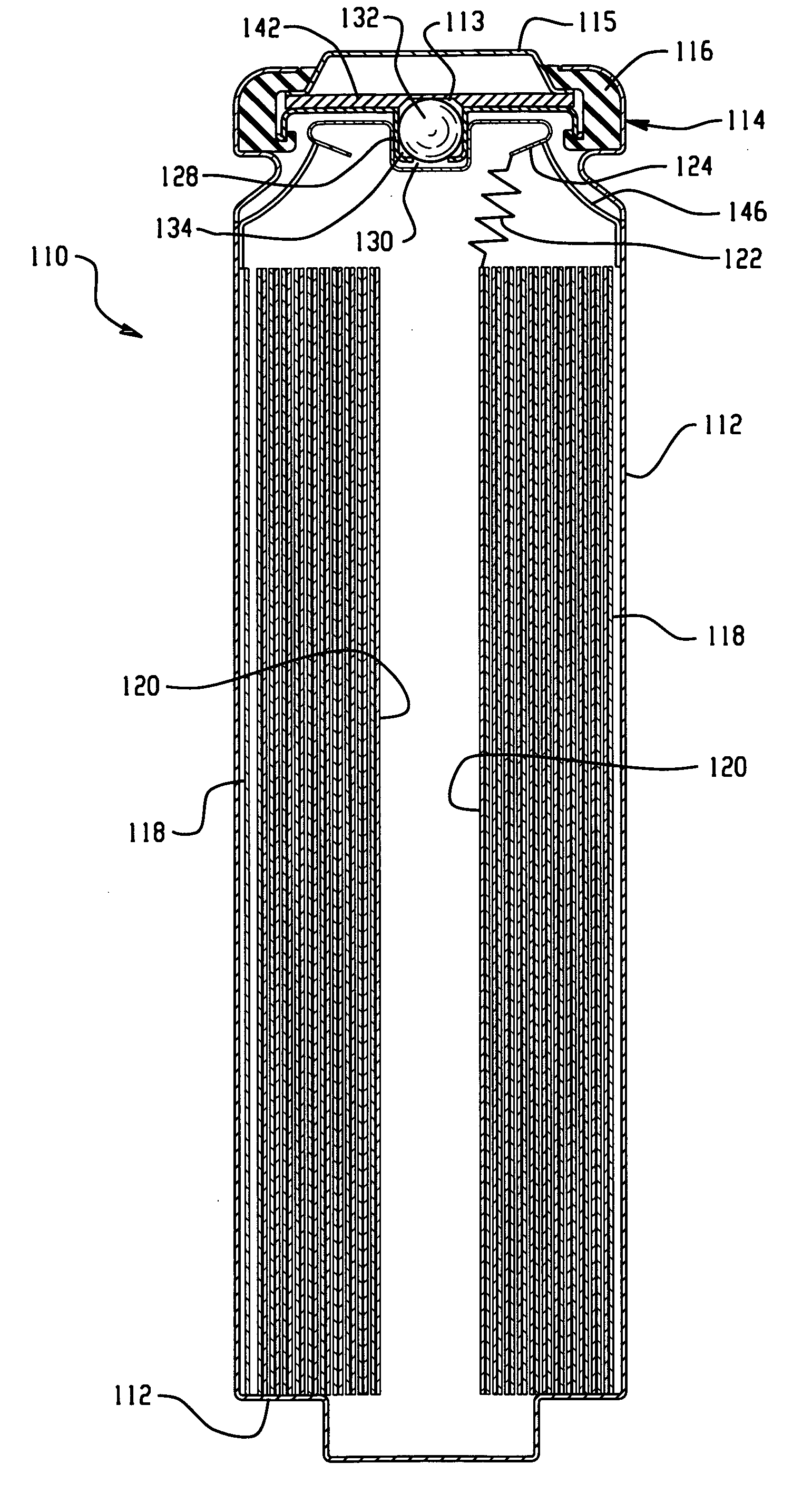

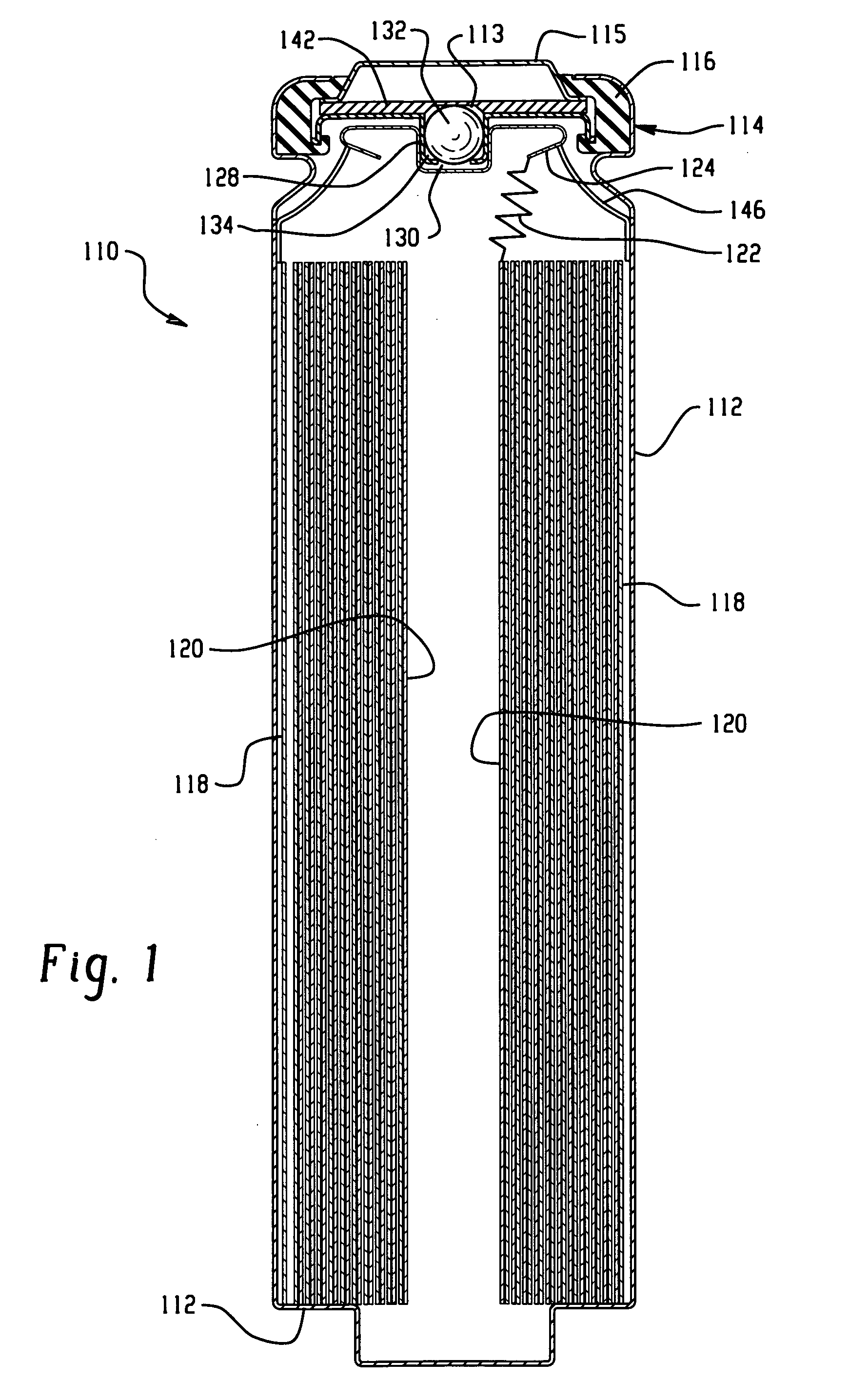

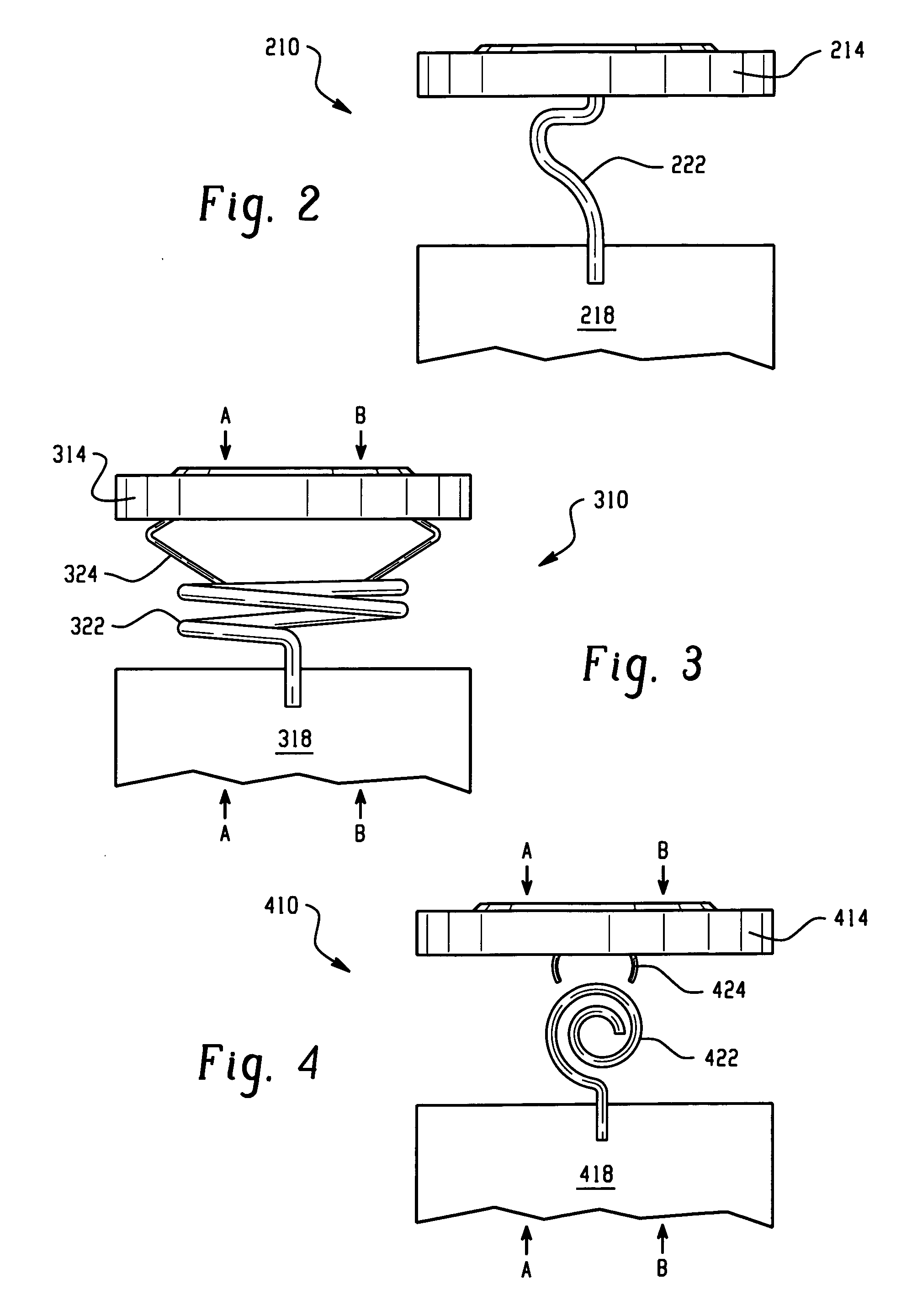

Electrochemical cell with positive container

InactiveUS20080026288A1Improve utilization efficiencyIncrease battery capacityFinal product manufactureElectrode carriers/collectorsSpiral woundEngineering

An electrochemical cell, particularly an electrochemical cell having a container with a positive polarity. In one embodiment, the cell is a primary cell that includes an electrode assembly having a lithium negative electrode and a positive electrode, preferably comprising iron disulfide. The cell is provided with a spiral wound electrode assembly with a portion of the positive electrode contacting the container. The positive electrode current collector contacts the container in one embodiment. The negative electrode includes an electrically conductive member that electrically contacts a cover of the cell and provides the cover with a negative polarity. In a preferred embodiment, the electrically conductive member makes pressure contact with a portion of the cell cover. A method of manufacturing such a cell is also provided.

Owner:EVEREADY BATTERY CO INC

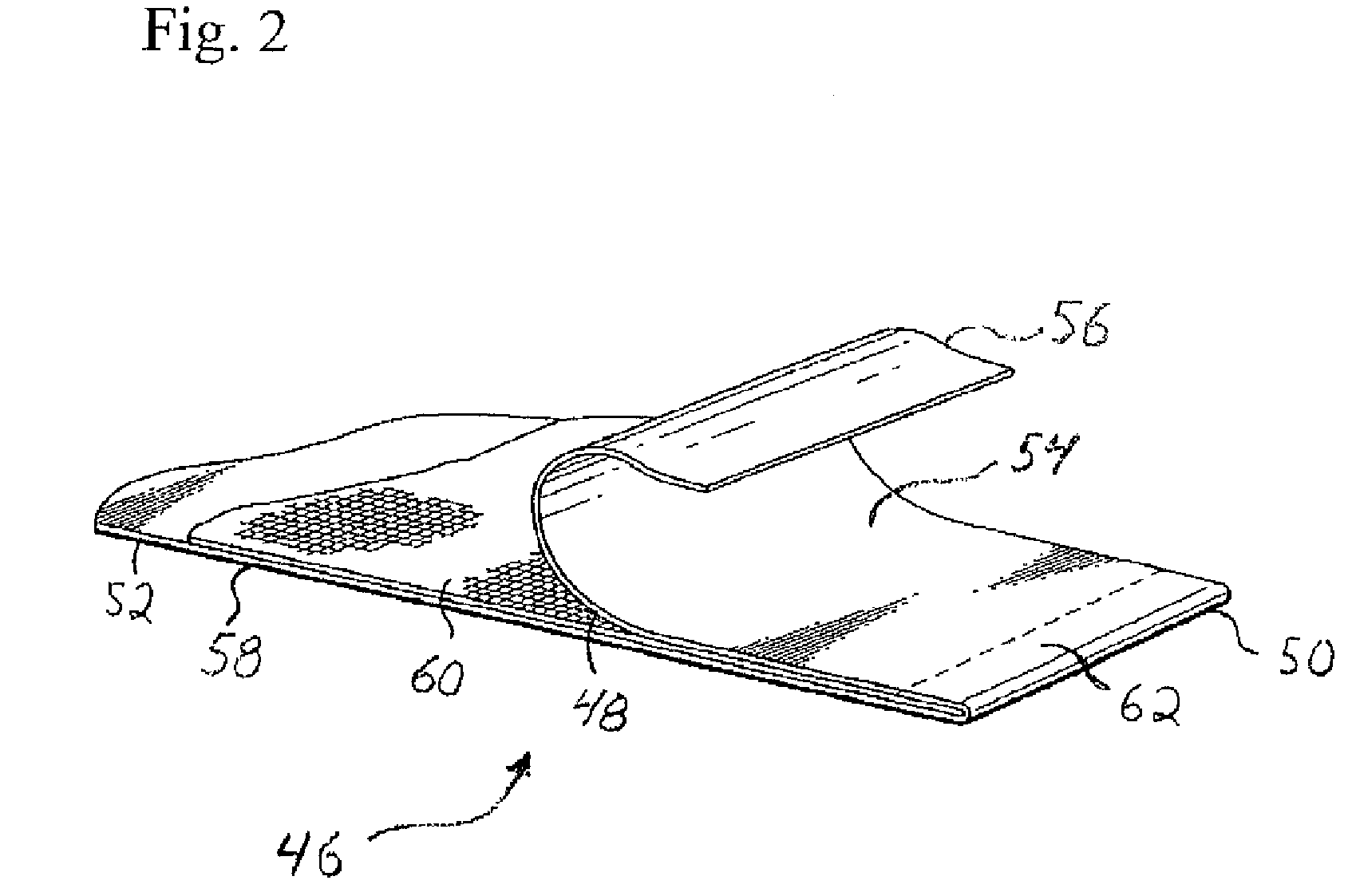

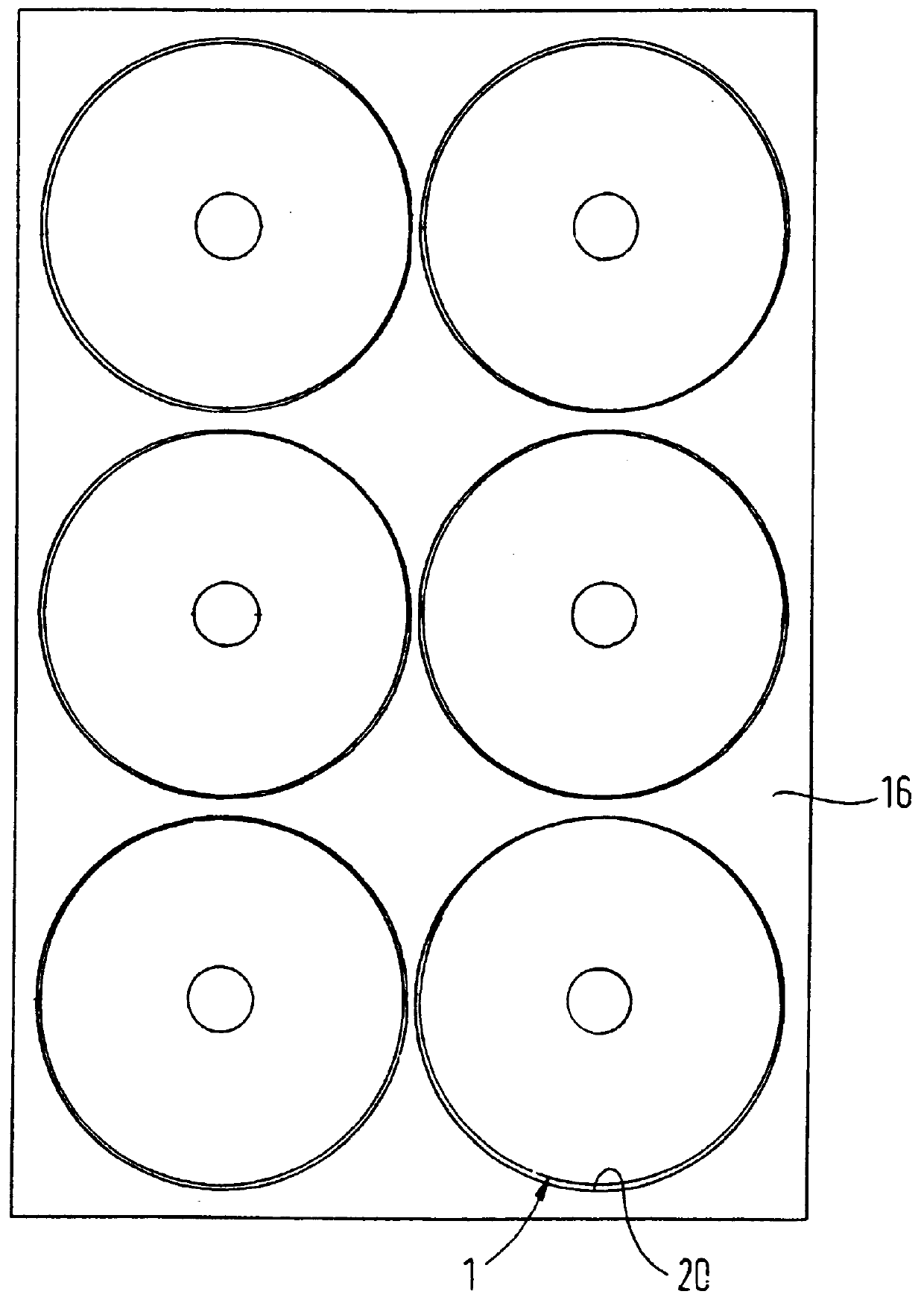

Membrane leaf packet with reinforced fold

The present invention is directed toward membrane leaf packets, spiral wound modules and methods for making and using the same. The subject leaf packet comprises a membrane sheet folded upon itself and reinforced with sealant and tape along at least a portion of the fold on the back side of the membrane sheet.

Owner:DOW GLOBAL TECH LLC

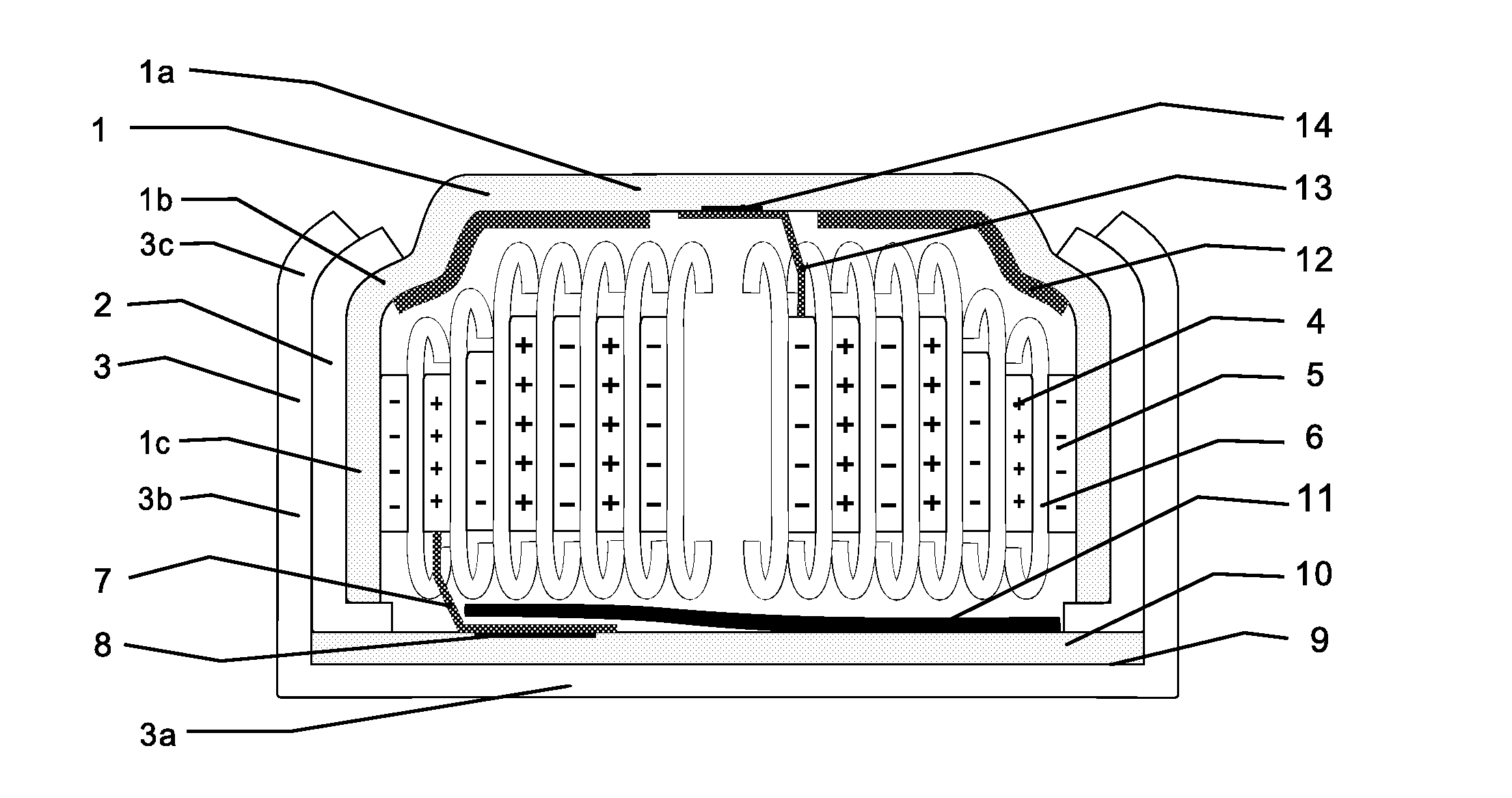

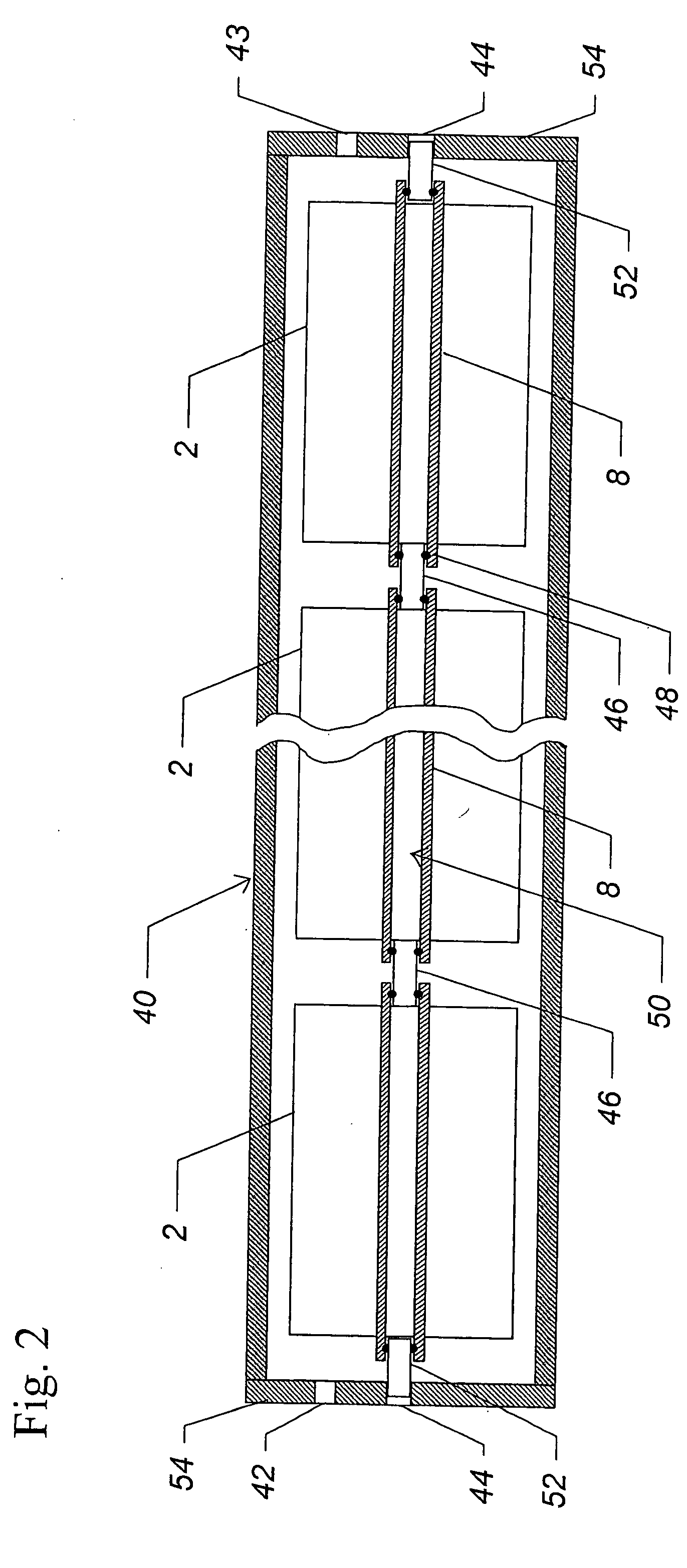

Rechargeable lithium ion button cell battery

ActiveUS20110091753A1Reliable contactEasy to weldCell electrodesFinal product manufactureButton batteryHigh energy

A rechargeable lithium ion button cell battery having a sealed housing comprises an inner casing and an outer casing, both casings have at least one flat area as top or bottom of the battery, and a round or oval side wall vertically formed to the flat area. Said side walls are single wall not folded double walls. An insulation gasket is positioned between said side walls, and the outer casing opening is mechanically crimped to complete the seal of the battery. Inside the sealed housing the anode & cathode electrodes are spiral wound with separator to be a round or oval roll. Said roll axis is vertical to the said flat areas of the casings. The two electrodes are tapered in width and comprise current collectors of metal foils coated with lithium-intercalating active materials, leaving small area of uncoated metal foils as welding tabs for connecting to the casings. The tabs are welded to the casings respectively, or for the tab of the electrode which connecting to outer casing, welded to an aluminum flake first and said flake is pressed on the outer casing by said gasket. Two insulation washers could be applied to inner side of the casings to prevent short circuit. Such battery has high energy density, low impedance, high reliability and long cycle life.

Owner:WANG FANG +1

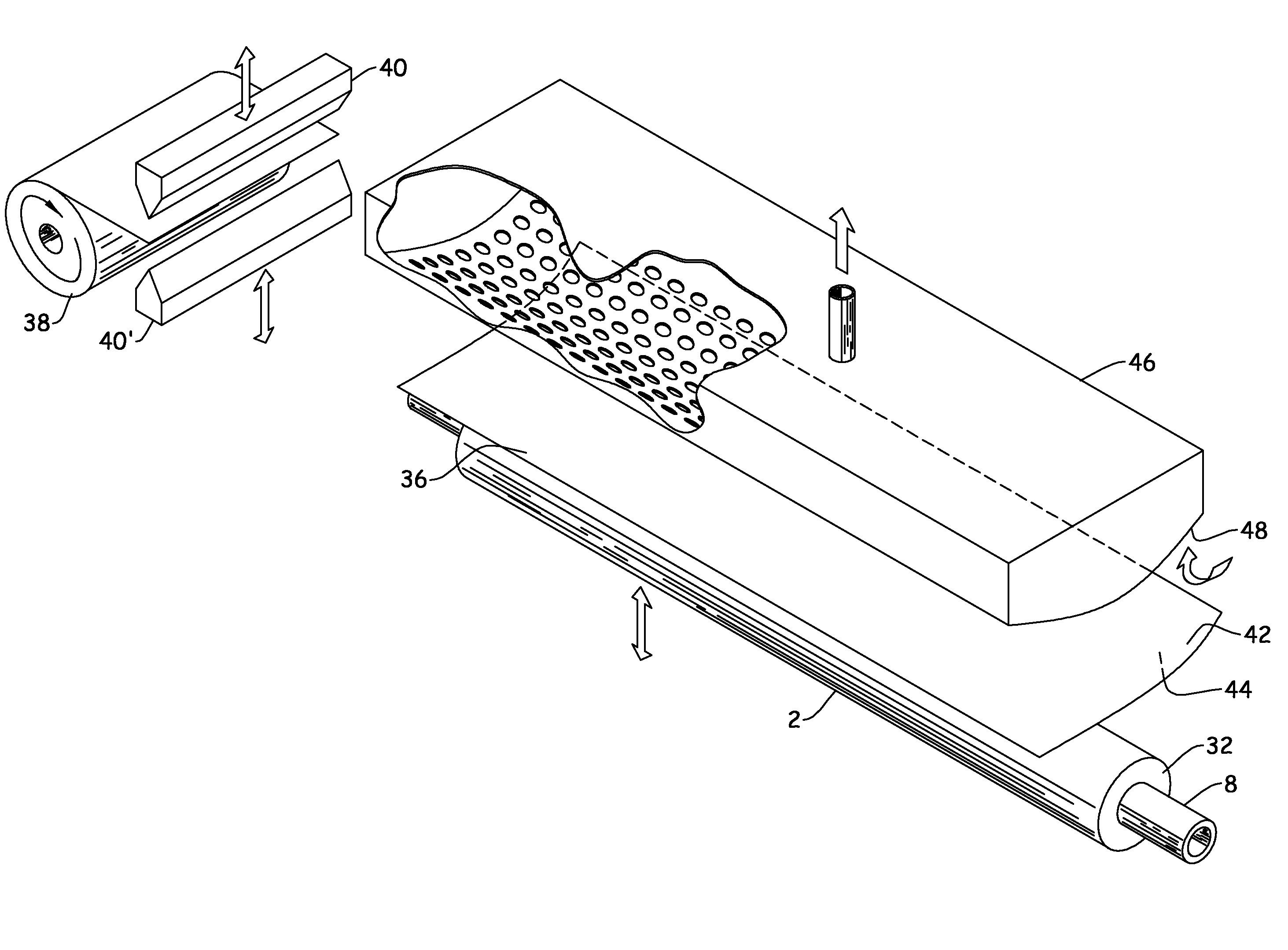

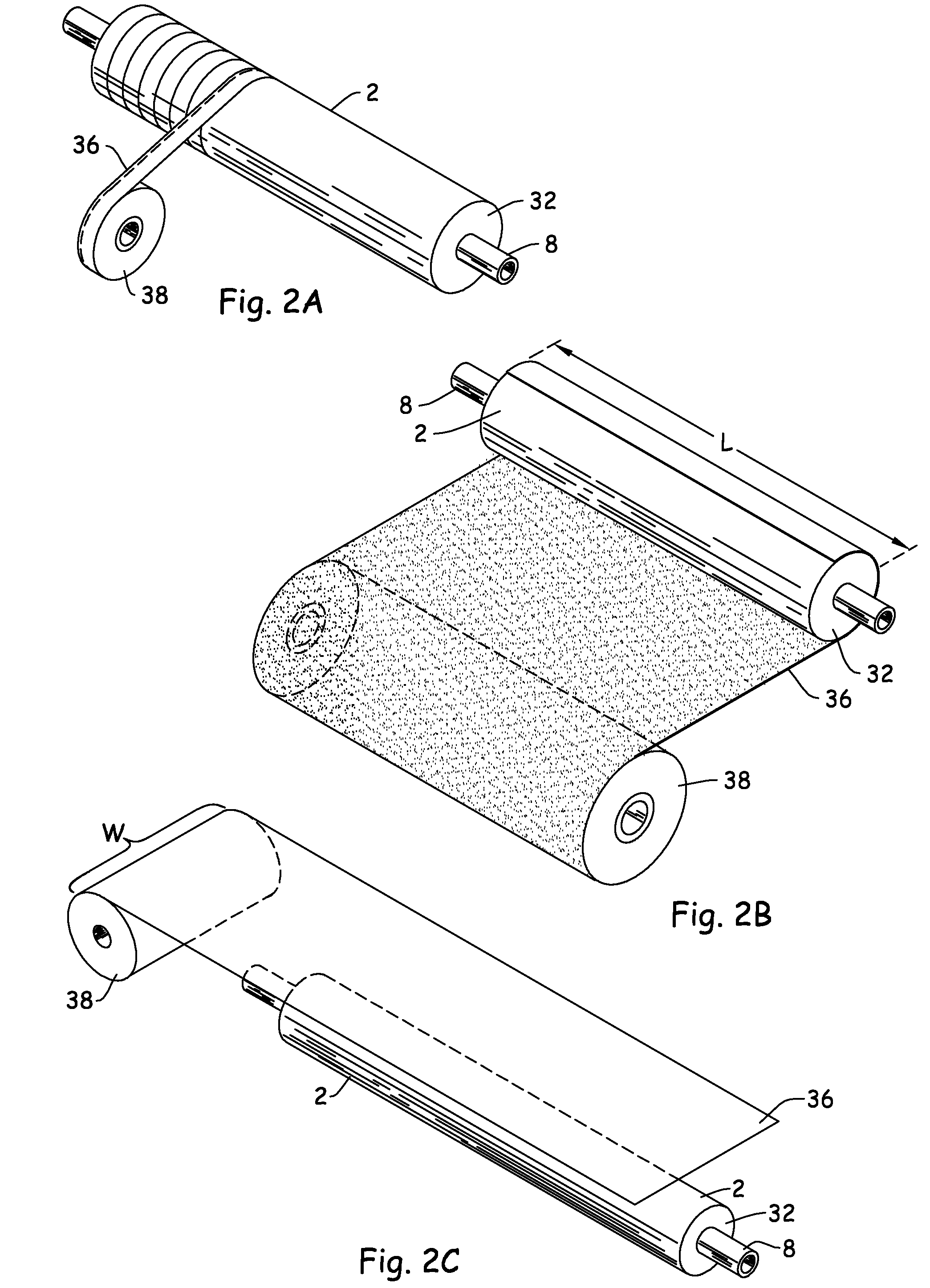

Method for applying tape layer to outer periphery of spiral wound module

Means and methods for applying a tape layer from a roll to the outer periphery of a spiral wound module. In preferred embodiments the length of the tape coincides with the length of the module.

Owner:DOW GLOBAL TECH LLC

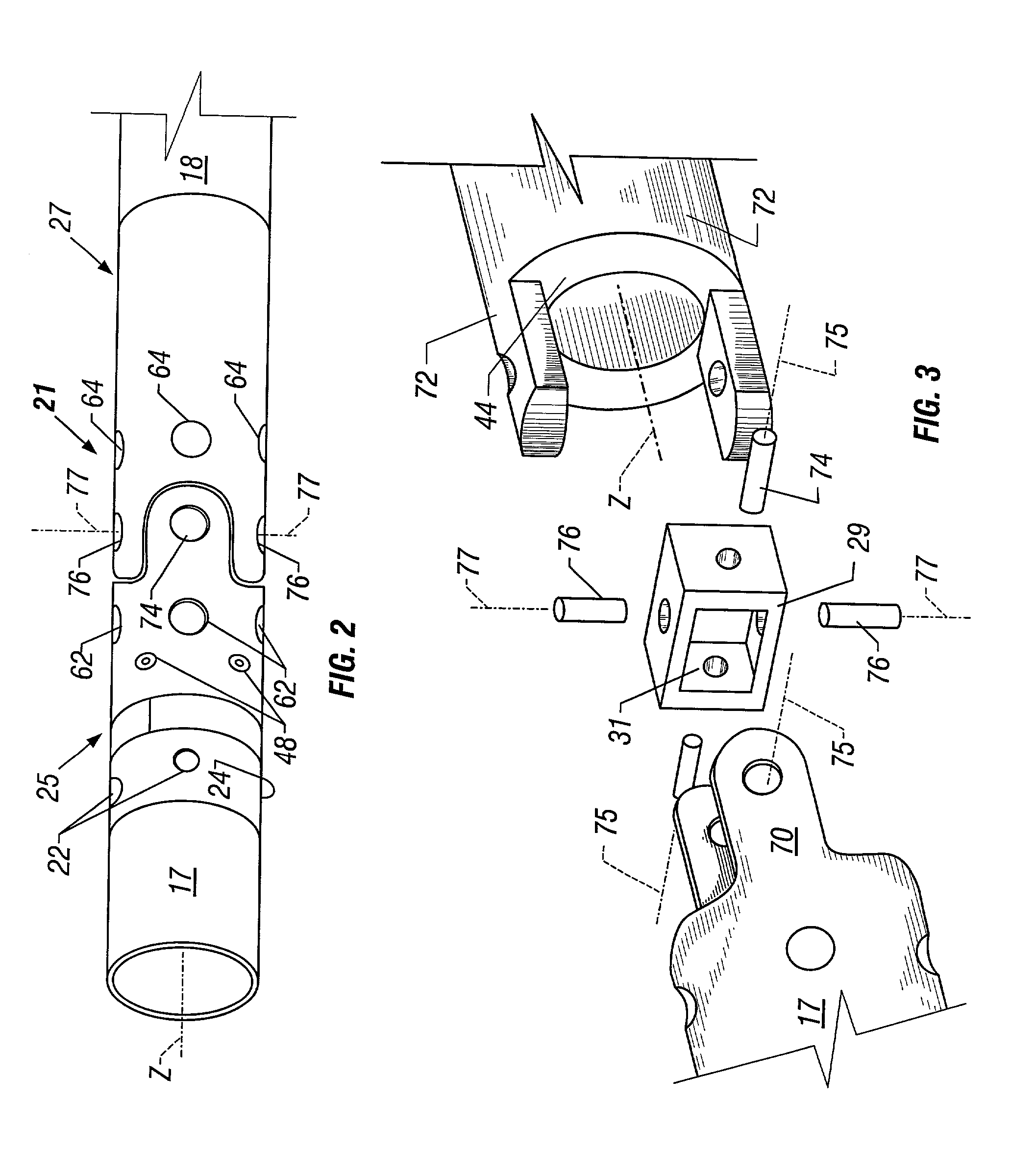

Flexible joint for well logging instruments

InactiveUS20020129945A1Easy to separateEasy to disconnectSurveyDrilling rodsWell loggingUniversal joint

A universal joint between adjacent, electrically connected instrument housings for downhole well operations allow the connected housings to bend longitudinally as required to traverse an arced section of a well bore but does not permit relative elongation or twisting about the longitudinal axis of the housings. I one embodiment, a fluid impermeable open passage space at atmospheric pressure surrounds electrical signal carriers linking the instrument circuitry within the two housings. The passage is constructed as a high-pressure flexible bellows or as a braided or spiral wound high-pressure fluid hose. In another embodiment, a fluid impermeable sheath surrounds the signal carriers and encapsulates the signal carriers by a resilient solid. The articulation structure comprises a Cardan-type of universal joint wherein two fingers project longitudinally from the end of each of the housings. The fingers are meshed and pivotally joined to respective spindles projecting radially from the open center of a ring spyder. The protective bellows, hose or resilient compound filled sheath is secured at opposite ends to bore plugs in the respective instrument housings. Between the instrument housings, the hose, bellows or filled sheath passes through the open center of the spyder ring.

Owner:BAKER HUGHES INC

Spiral-wound liquid membrane module for separation of fluids and gases

InactiveUS20060131235A1Lower energy requirementsEfficient separationMembranesSolid sorbent liquid separationChemical physicsSpiral wound

The present invention is a filtering and chemical separation device that performs the operations of solvent extraction and pervaporation in a single piece of equipment, configured as a spiral-wound membrane module, and provides for the replenishment of the solvent in the supported liquid membrane while the module continues in operation. It provides a solution to the problem of separating miscible compounds efficiently and with low energy requirements.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

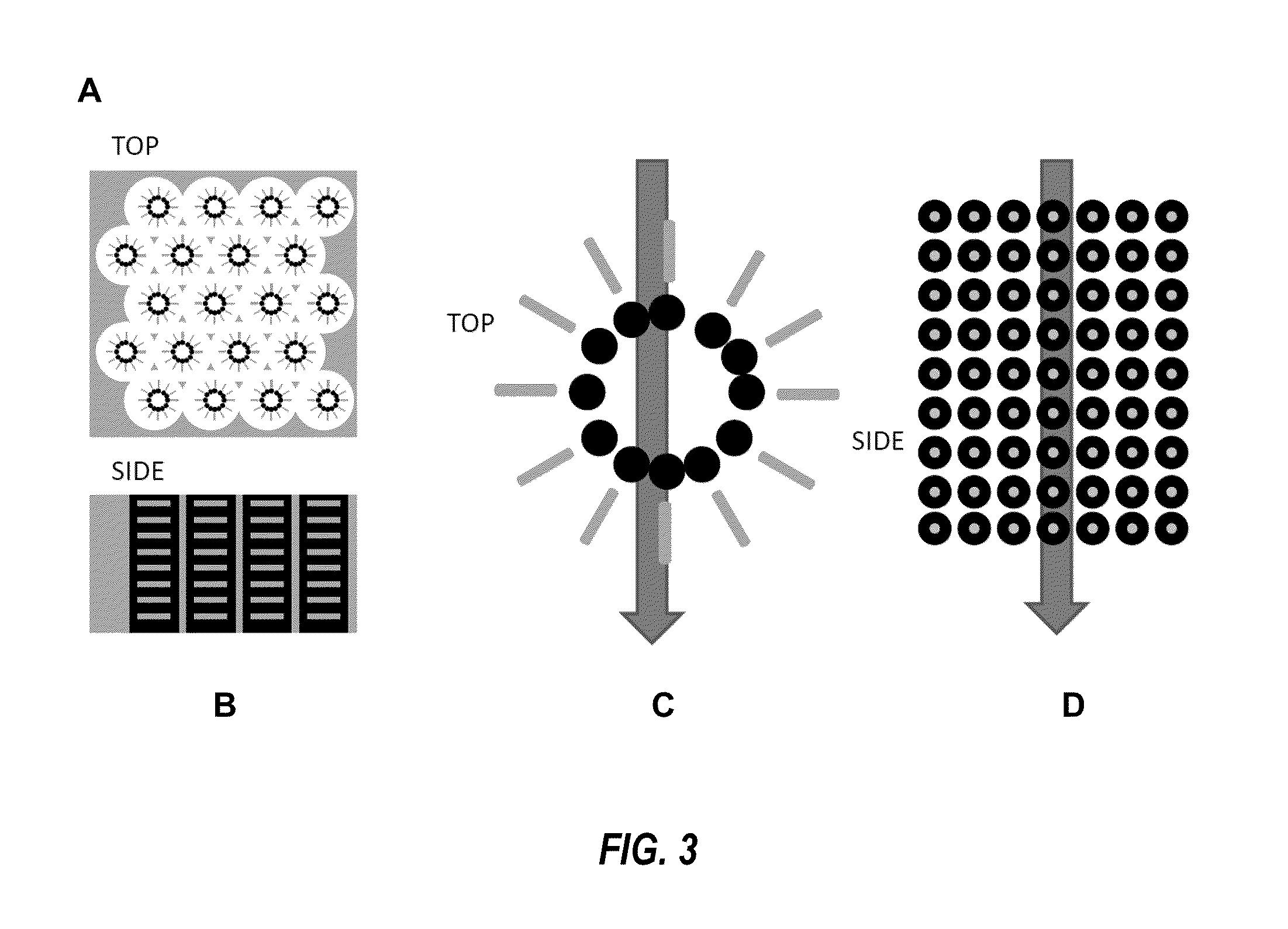

Self-Assembled Surfactant Structures

ActiveUS20110284456A1Small apertureSolid electrolytesSemi-permeable membranesEvaporationSpiral wound

Stabilized surfactant-based membranes and methods of manufacture thereof. Membranes comprising a stabilized surfactant mesostructure on a porous support may be used for various separations, including reverse osmosis and forward osmosis. The membranes are stabilized after evaporation of solvents; in some embodiments no removal of the surfactant is required. The surfactant solution may or may not comprise a hydrophilic compound such as an acid or base. The surface of the porous support is preferably modified prior to formation of the stabilized surfactant mesostructure. The membrane is sufficiently stable to be utilized in commercial separations devices such as spiral wound modules.

Owner:ZNANO LLC +1

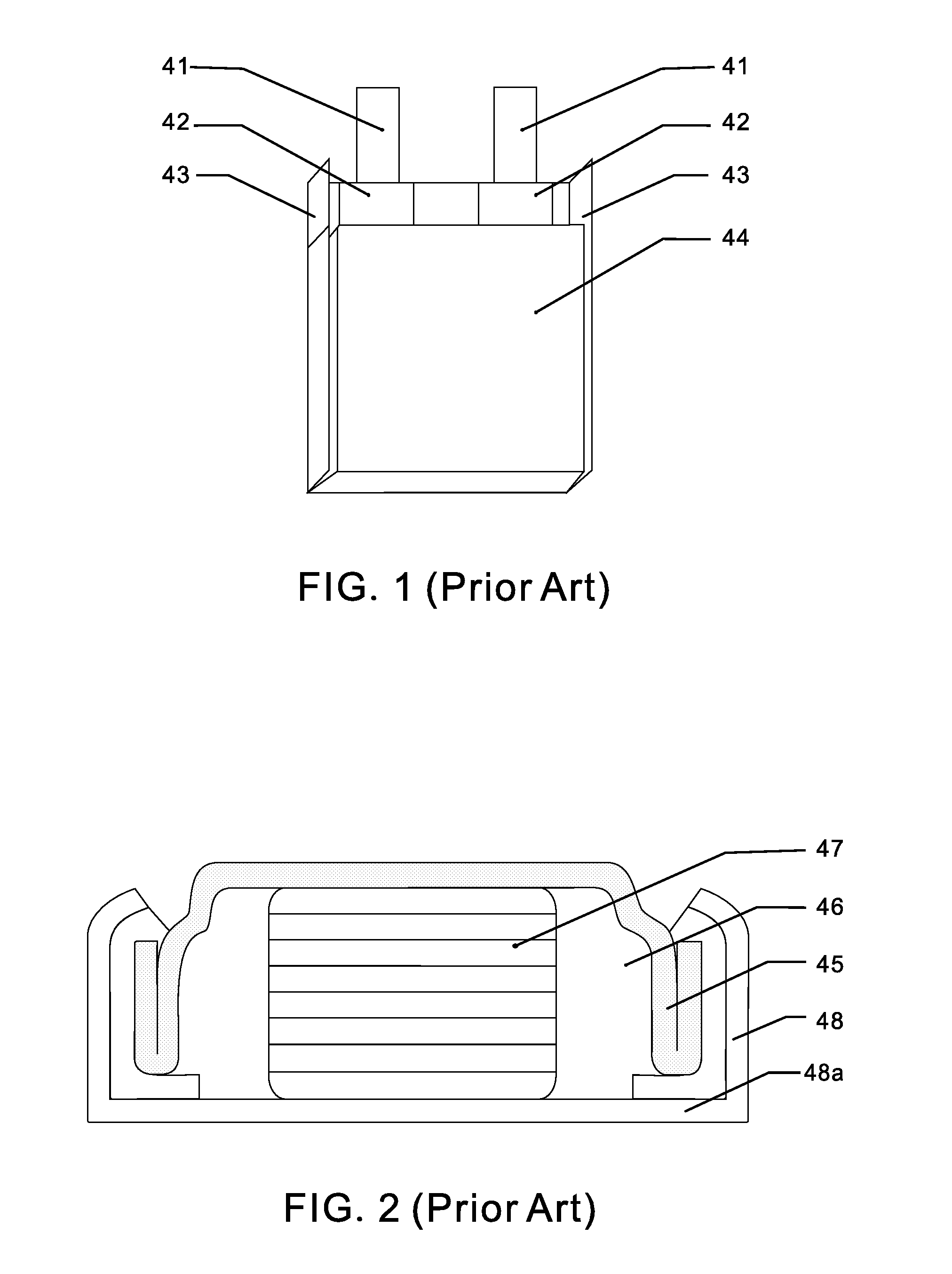

Sealed cell having a multilayer case

InactiveUS6146785AHigh mechanical strengthIncrease costPrimary cell to battery groupingFinal product manufactureSpiral woundEngineering

The invention provides a sealed organic-electrolyte cell. A spiral-wound group of electrodes have at least one alternation of negative electrode, separator and positive electrode. The cell has an enclosure made up of a cover and an end wall interconnected in a sealed manner by a side case surrounding the group. Each cover and end wall has a respective current outlet terminal and a central core around which the electrode group is spiral-wound, with an end wall and the cover being fixed to the ends thereof. The case surrounding the group is made of a combined metal-and-plastics multilayer material of a thickness that is smaller than 0.5 mm. The invention also provides a module of such cells and a battery that has at least one such module. The battery is suitable for use as the battery of an electric vehicle.

Owner:ALCATEL LUCENT SAS

Spiral wound filtration membrane cartridge with chevron seal

InactiveUS7208088B2Reduced tightnessEasy to replaceUltrafiltrationReverse osmosisFiltration membraneSpiral wound

A spiral wound filtration cartridge construction is provided which includes a cartridge positioned within a solid outer cylinder which, in turn is positioned within a solid outer cylinder which, in turn is positioned within a solid housing. Fluid flows within the space between the outer cylinder and housing is controlled by a ring and flexible chevron construction. The chevron construction includes outer peripheral holes, the sizes and number of which are set to determine by-pass flow.

Owner:MILLIPORE CORP

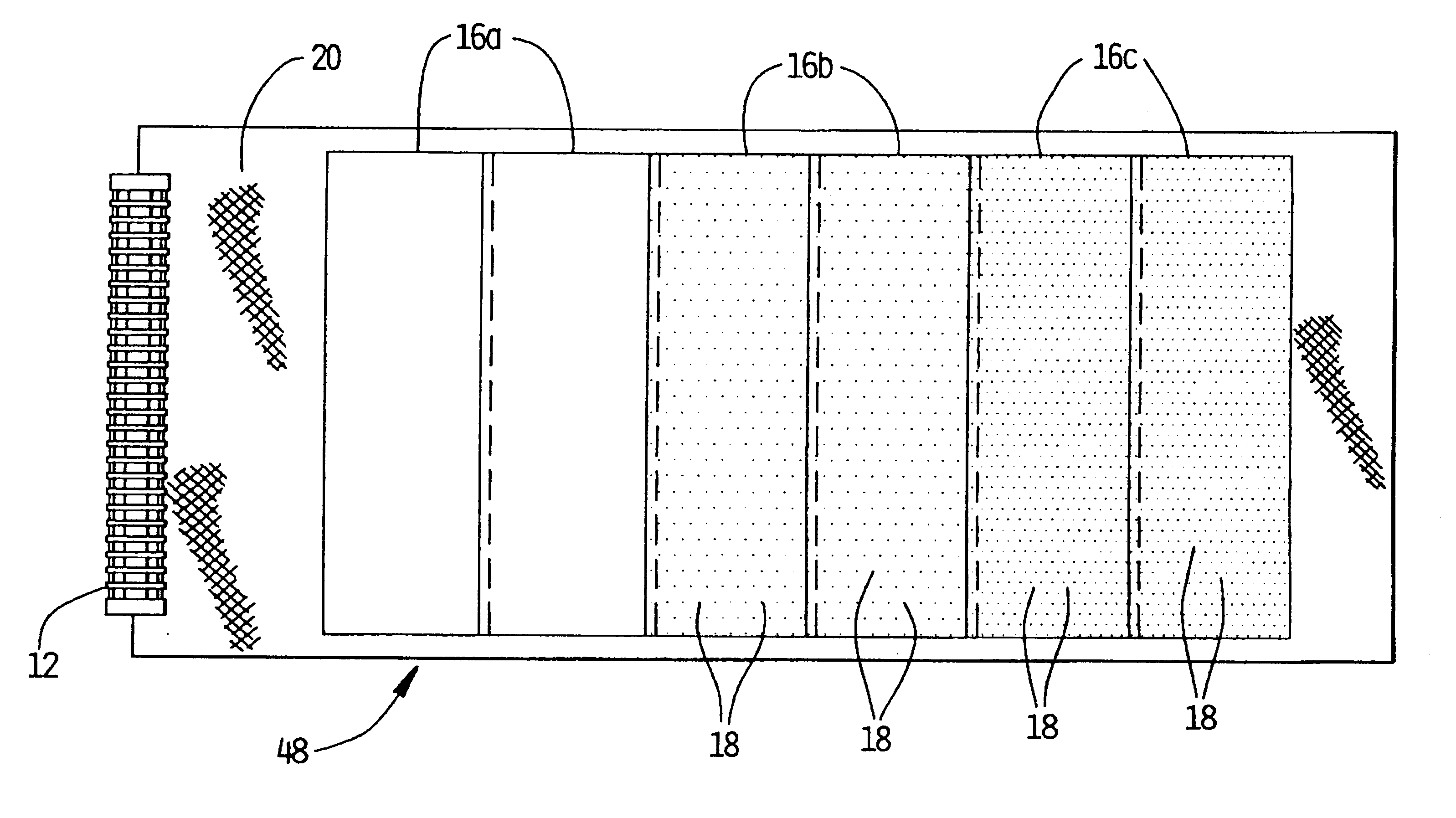

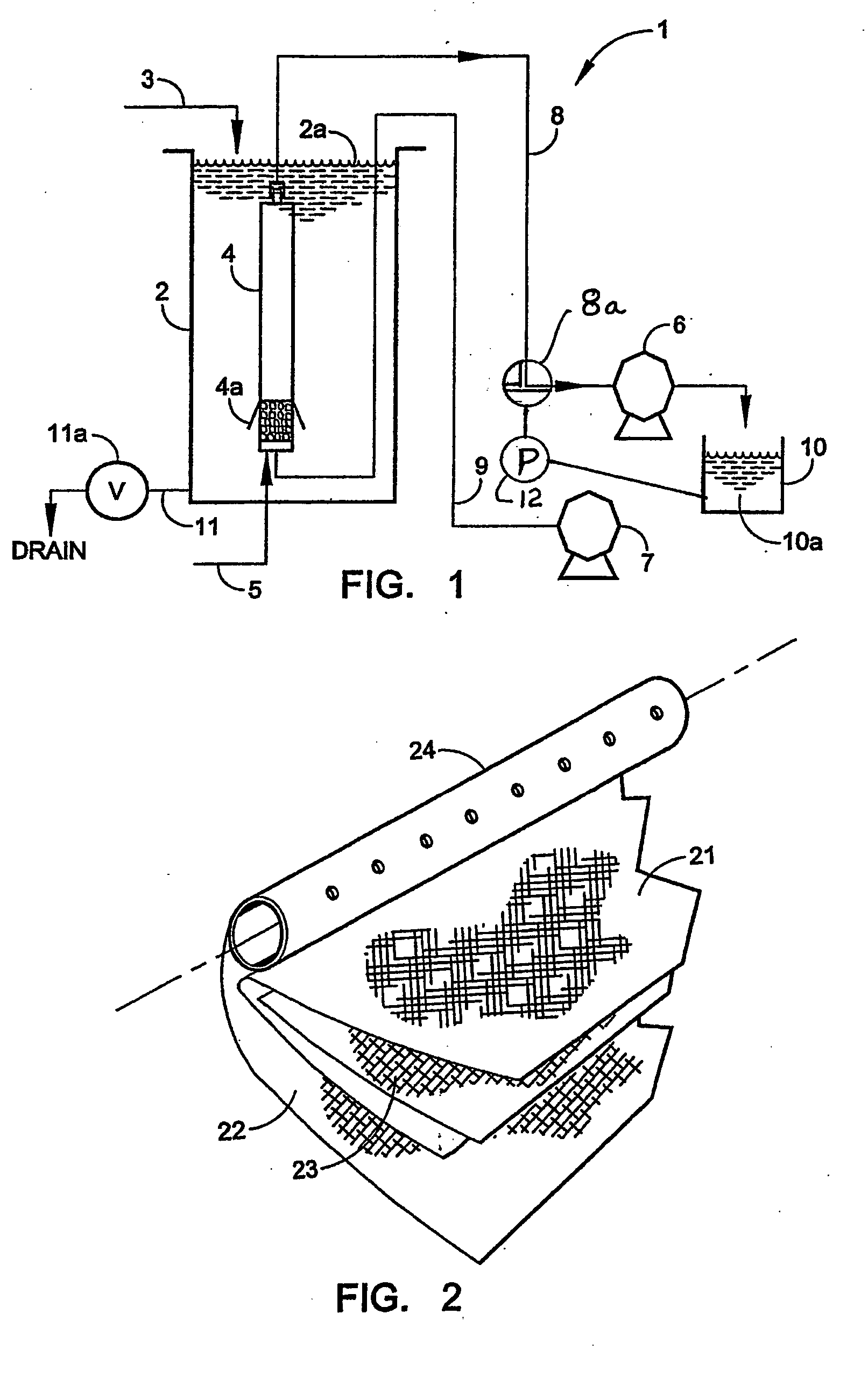

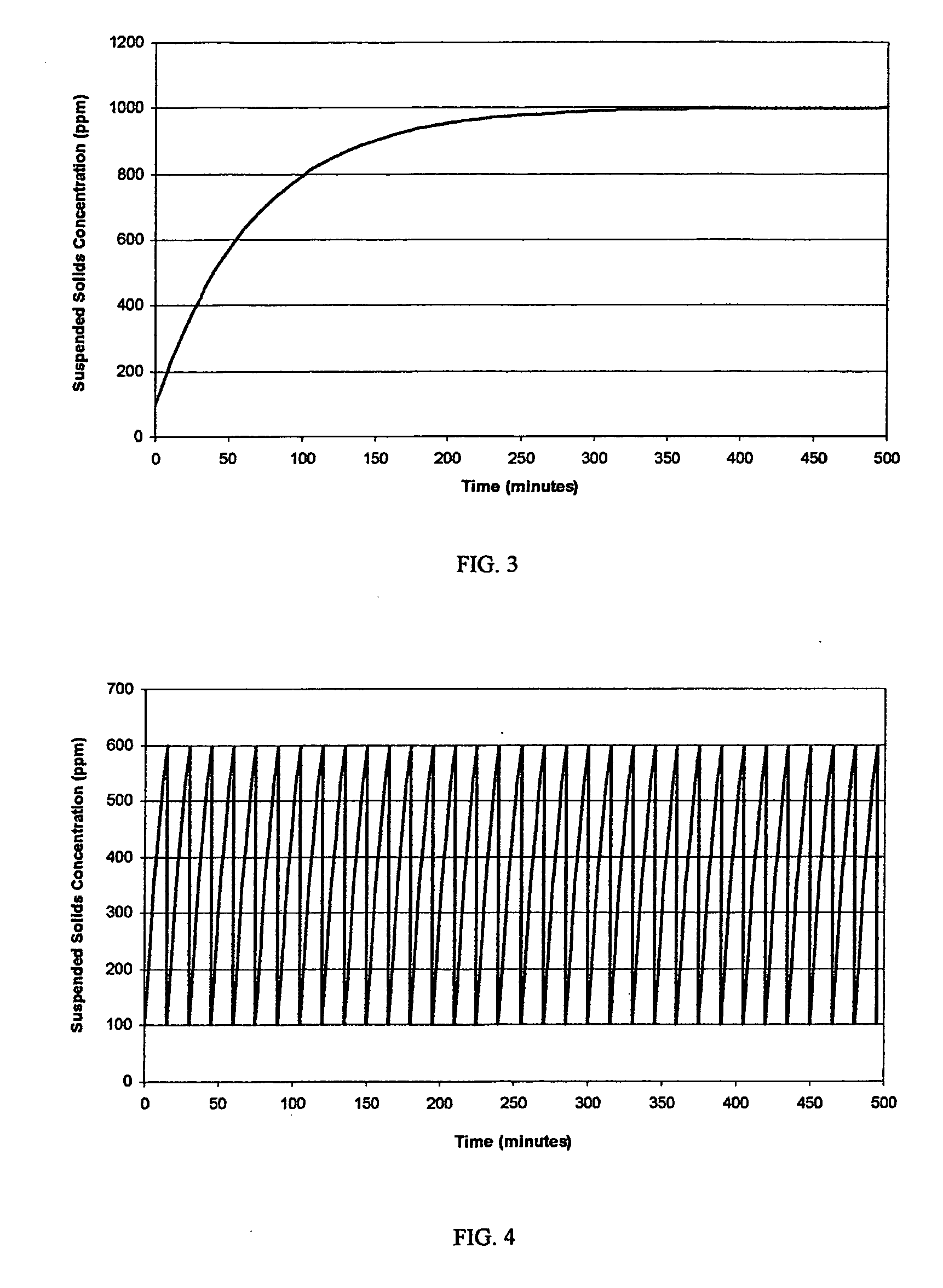

Low pressure filtration

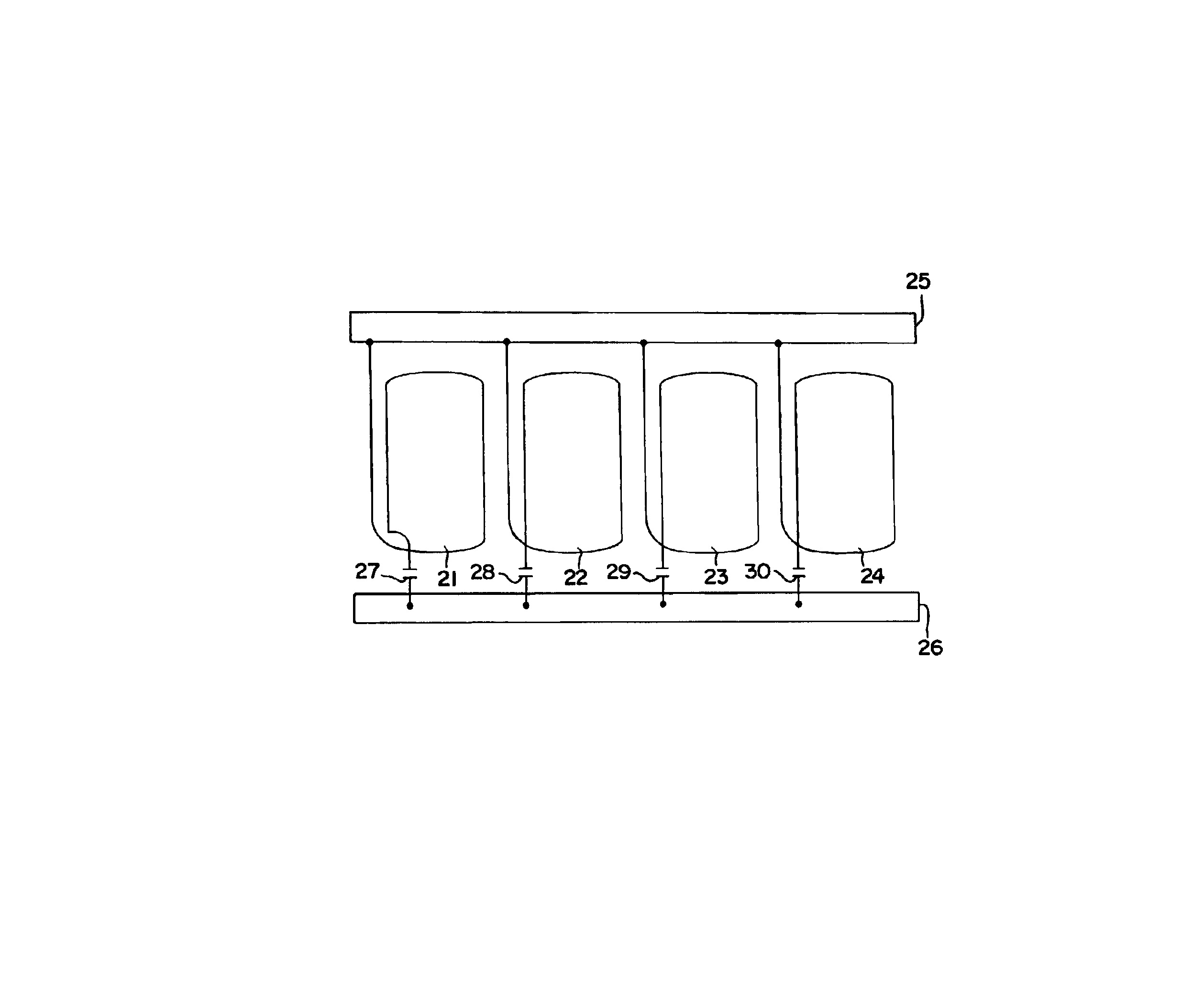

ActiveUS20070131614A1Produced economicallyReduce energy consumptionMembranesUltrafiltrationFiltrationStreamflow

High flow, low-pressure ultrafiltration or microfiltration spiral wound membrane cartridges are used in filtration of liquid feedstocks having high suspended solids. Applications may utilize either vacuum or pumping for transmembrane drive pressure (TMP), and gas may optionally be bubbled up through the cartridges with certain feedstocks. Water permeate flux rates as high as 90 gallons per square foot per day (gfd) can be obtained at TMPs below 5 pounds per square inch. By locating each spiral wound cartridge in its own casing and supplying liquid feedstock to an open lower end of the casing, as opposed to submerging such cartridges in a tank filled with feedstock, overall low pressure performance is greatly improved. High permeate flow can be maintained for long periods of time between shutdowns for intensive cleaning. TMP is gradually increased to maintain a substantially constant rate of permeate discharge until a target is reached, indicative of solids accumulation on the membrane surface to an undesirable extent; then backflushing is effected for a short time. Discarding the hold-up volume of feedstock in the cartridge, the backflushing fluid and dislodged solids, allows production to be promptly resumed with fresh feedstock at performance at near original levels.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

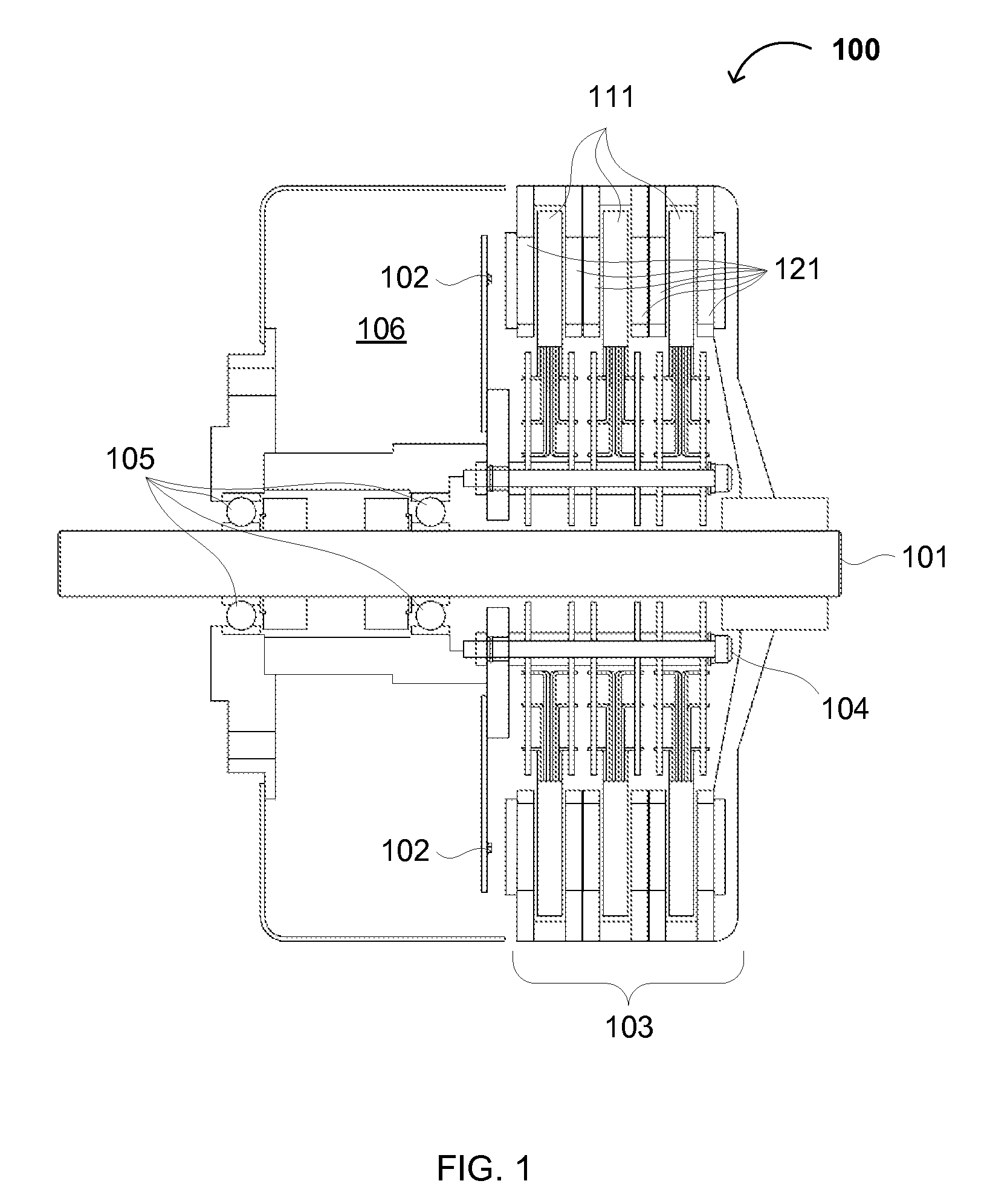

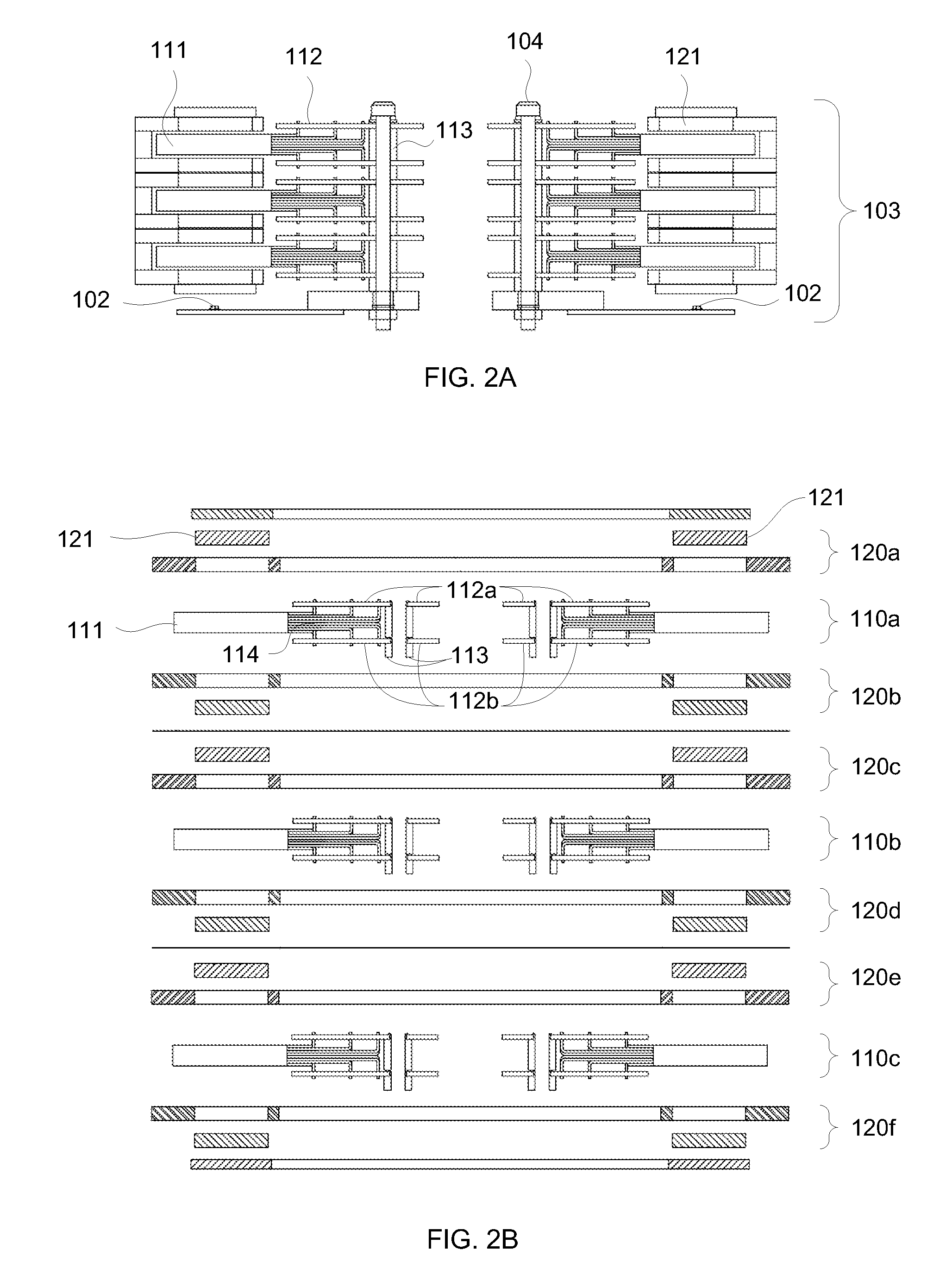

Apparatus for axial magnetic field electric motor

InactiveUS7573173B1Readily apparentMagnetic circuit rotating partsAsynchronous induction motorsIn planeSpiral wound

Apparatuses, circuits, and methods for driving an axial field electric motor, and systems using the same. The electric motor generally comprises a fixed magnet assembly having a plurality of fixed magnets arranged circularly around a shaft, a coil assembly including a plurality of coil layers, and a controller configured to provide each of a plurality of drive signals to one of the coil layers. Each of the drive signals generally has a different phase (e.g., each drive signal may pulse and / or oscillate with different phase offsets). The fixed magnets generally have north-south axes parallel to the shaft (e.g., the magnetic field is axial to the shaft). Each of the coil layers generally comprises a plurality of electromagnetic coils arranged circularly around the shaft in plane that is substantially perpendicular to the shaft. Each of the electromagnetic coils comprises a conductive spiral wound in the plane of the coil layer. Each coil layer is mechanically coupled to another of the coil layers in the coil assembly. Electric motors according to the present invention are advantageously efficient and lightweight and provide for coil assemblies that can be stacked for additional torque.

Owner:AXIMET TECH

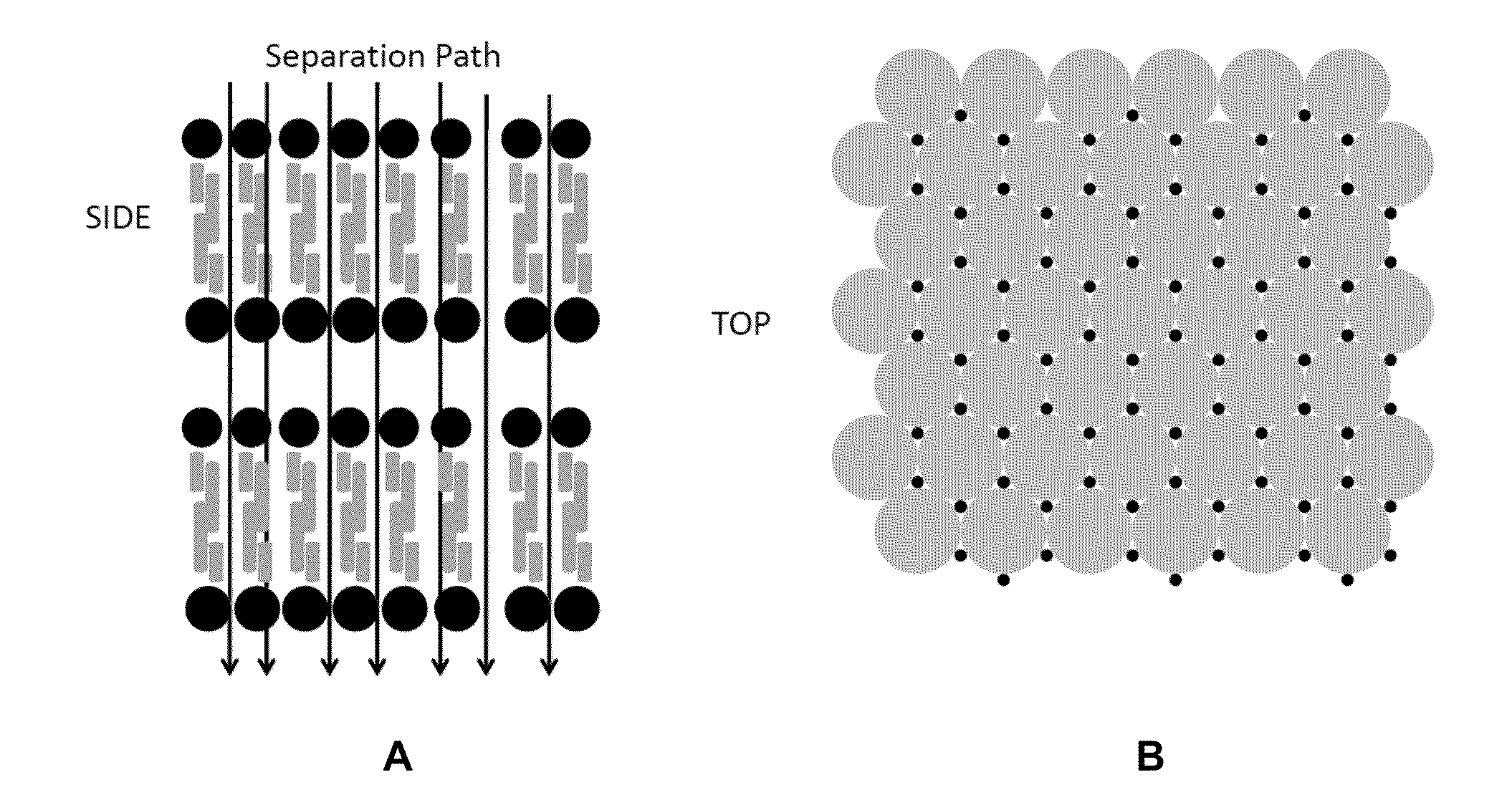

Improved Spiral Wound Element Construction

InactiveUS20160008763A1Paper/cardboard wound articlesLoose filtering material filtersFiltrationMembrane surface

Embodiments of the present invention provide replacement of conventional separate feed spacer mesh with features placed, deposited or integrated on or into either the porous permeate carrier, the inactive side of the membrane sheet, or select portions of the membrane surface. Spiral-wound membrane filtration elements well known in the art consist of a laminated structure comprised of a membrane sheet sealed to or around a porous permeate carrier which creates a path for removal of the fluid passing through the membrane to a central tube, while this laminated structure is wrapped spirally around the central tube and spaced from itself with a porous feed spacer to allow axial flow of the fluid through the element.

Owner:AQUA MEMBRANES

Method for Testing Separation Modules

InactiveUS20080105038A1High sensitivityEnhanced signalMembranesSemi-permeable membranesFiltrationSpiral wound

New methods and apparatus are described for assessing the integrity of a separation module or filtration system. A principle embodiment concerns use of a transient pulse of challenge species to probe a spiral wound module. The resulting time-dependent concentration of challenge species in the permeate is detected, recorded, and compared to a reference. An apparatus is further claimed for detecting permeate conductivity at multiple points within the permeate collection tube of a spiral wound module. Also disclosed is a process whereby the permeate stream from a filtration system is concentration by a high recovery membrane apparatus prior to measurement of challenge species concentration.

Owner:DOW GLOBAL TECH LLC

Cross-flow filtration apparatus with biocidal feed spacer

InactiveUS20090314713A1Reduce the amount requiredReduce amount of biofoulingMembranesSemi-permeable membranesSpiral woundCross-flow filtration

A cross-flow filtration apparatus is provided. The cross-flow filter is a spiral wound filter that includes a semi-permeable membrane wrapped around a perforated central tube. The semi-permeable membrane includes a feed spacer and a membrane. The feed spacer is a biocidal feed spacer with a biocidal agent impregnated within the feed spacer to prevent biofouling of the feed spacer and the membrane.

Owner:HYDRANAUTICS

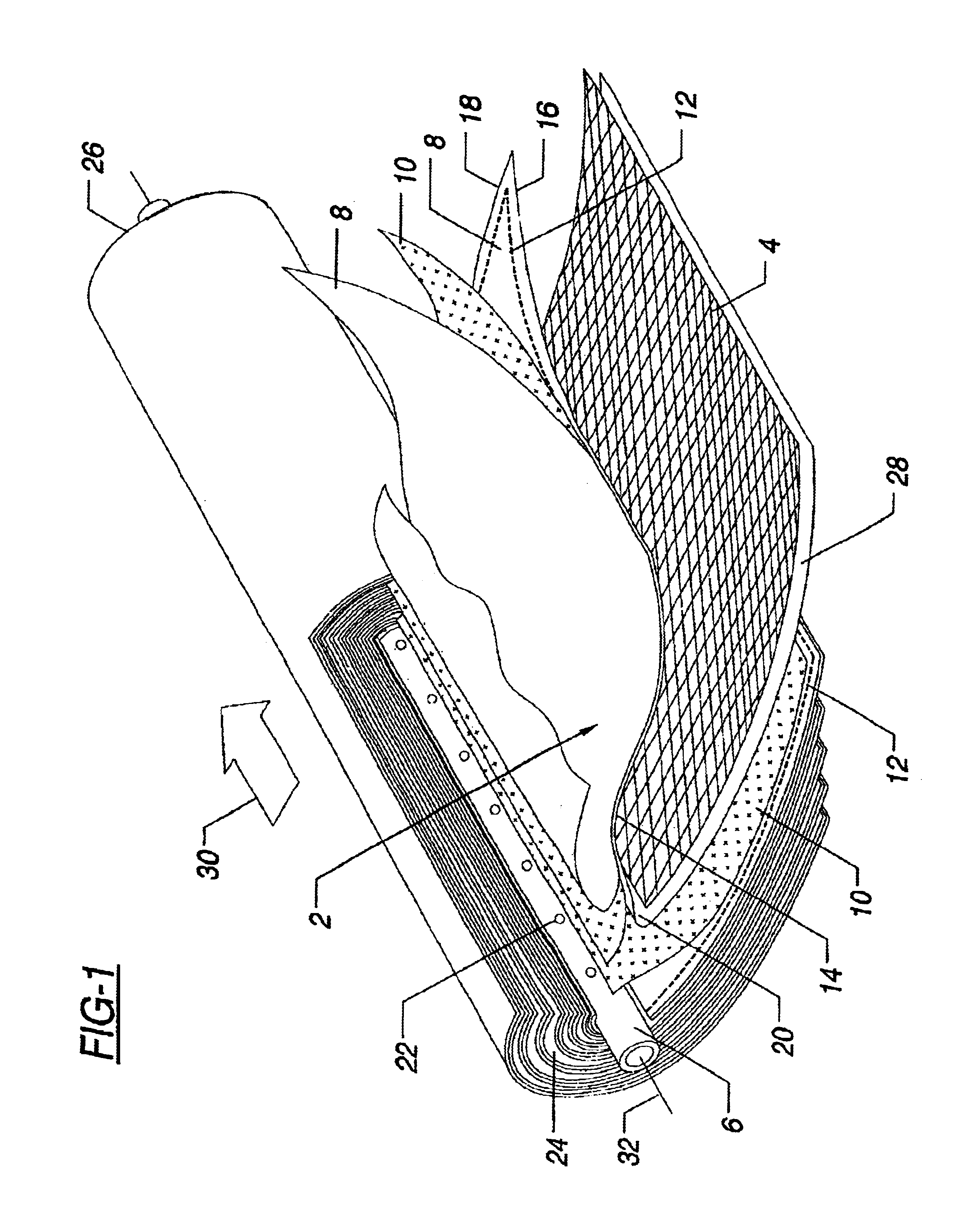

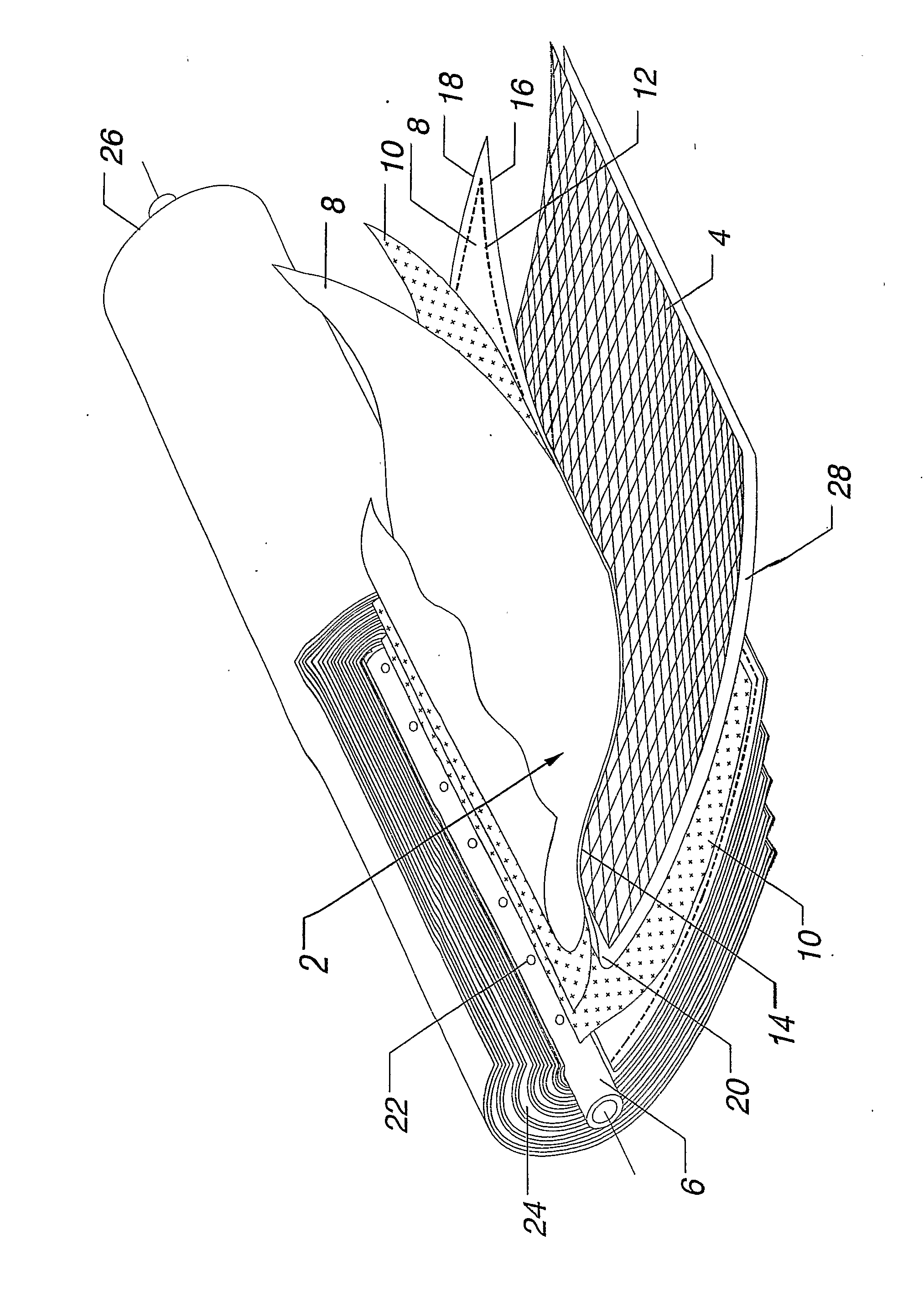

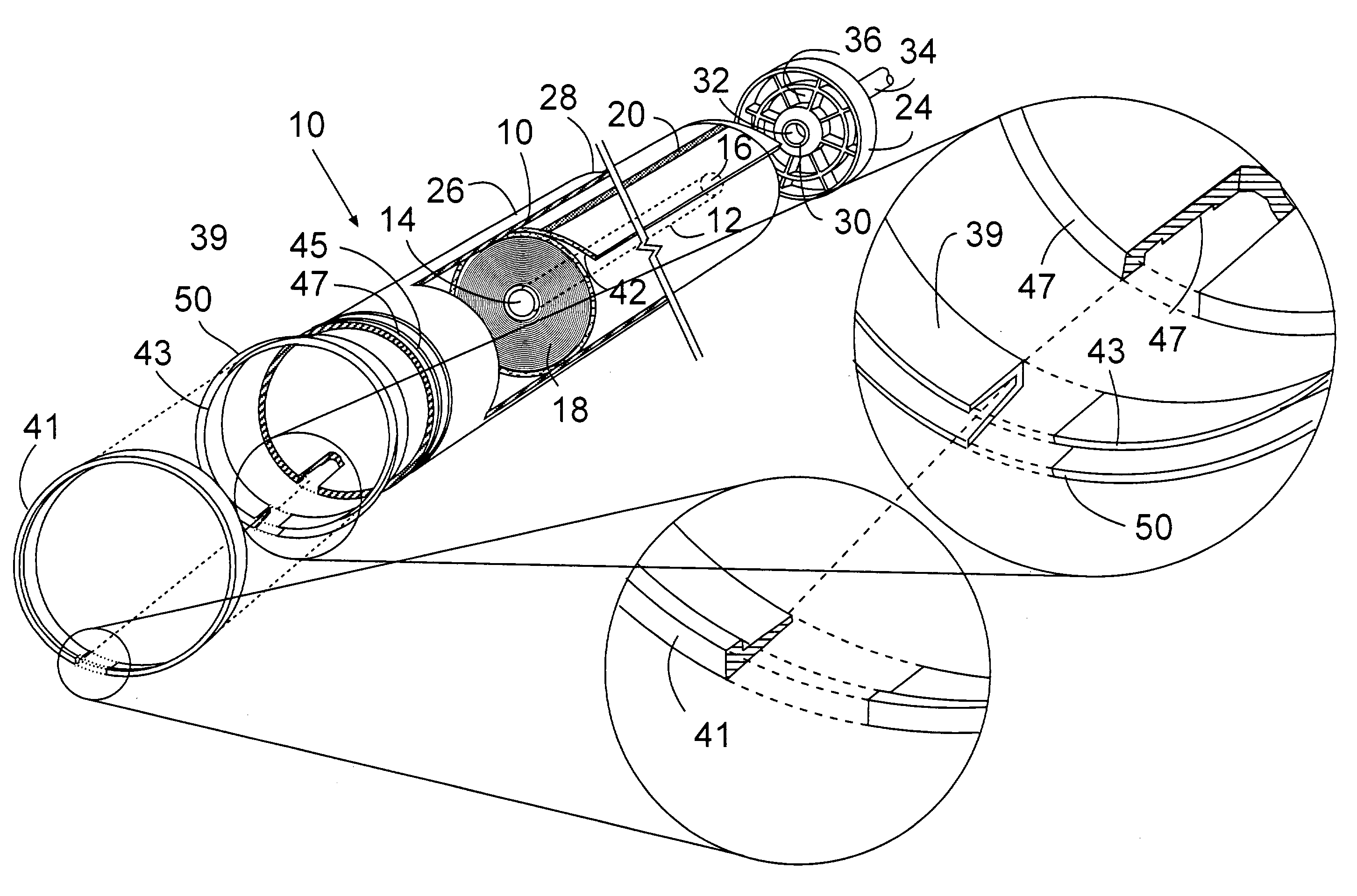

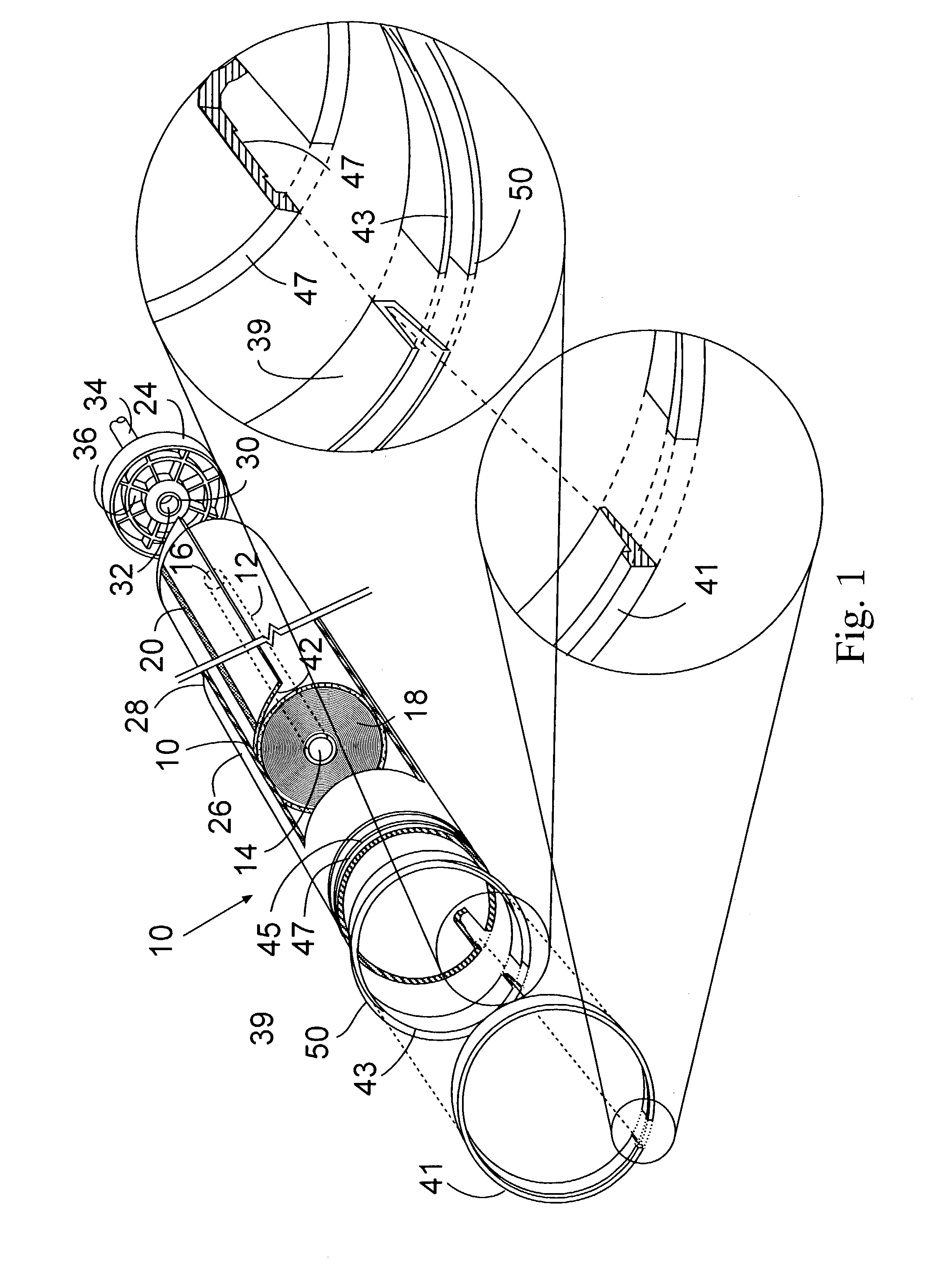

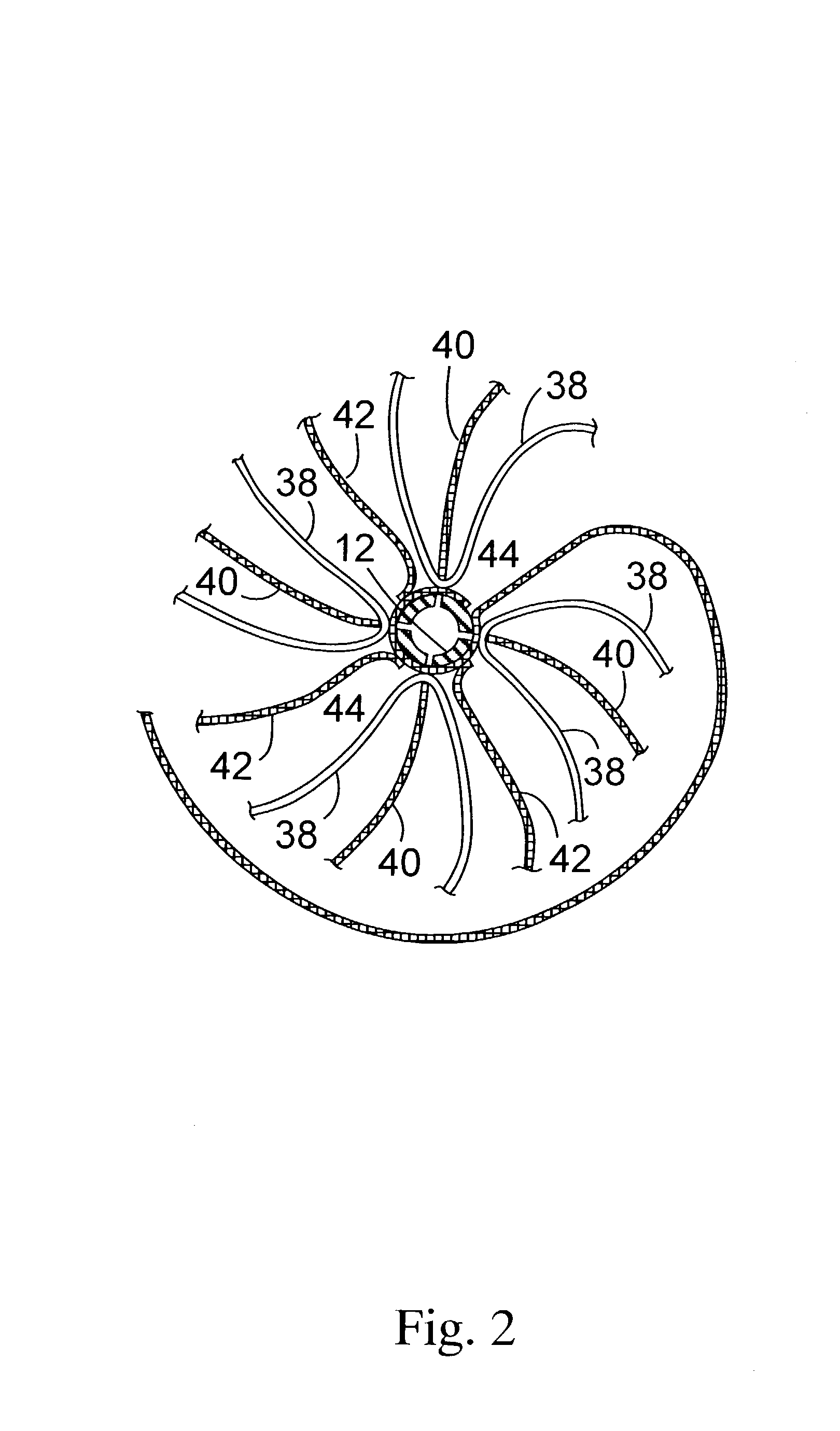

Blister protection for spiral wound elements

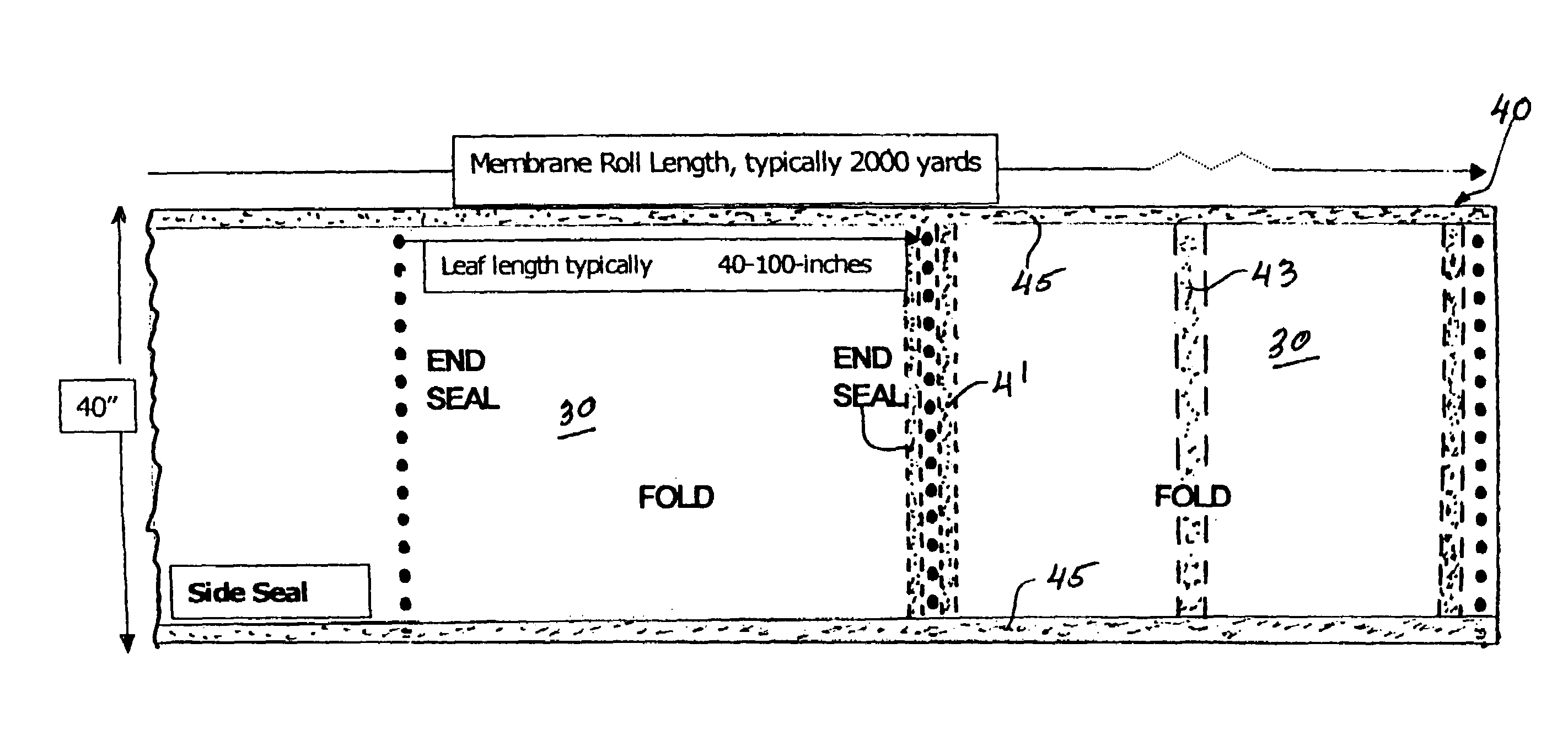

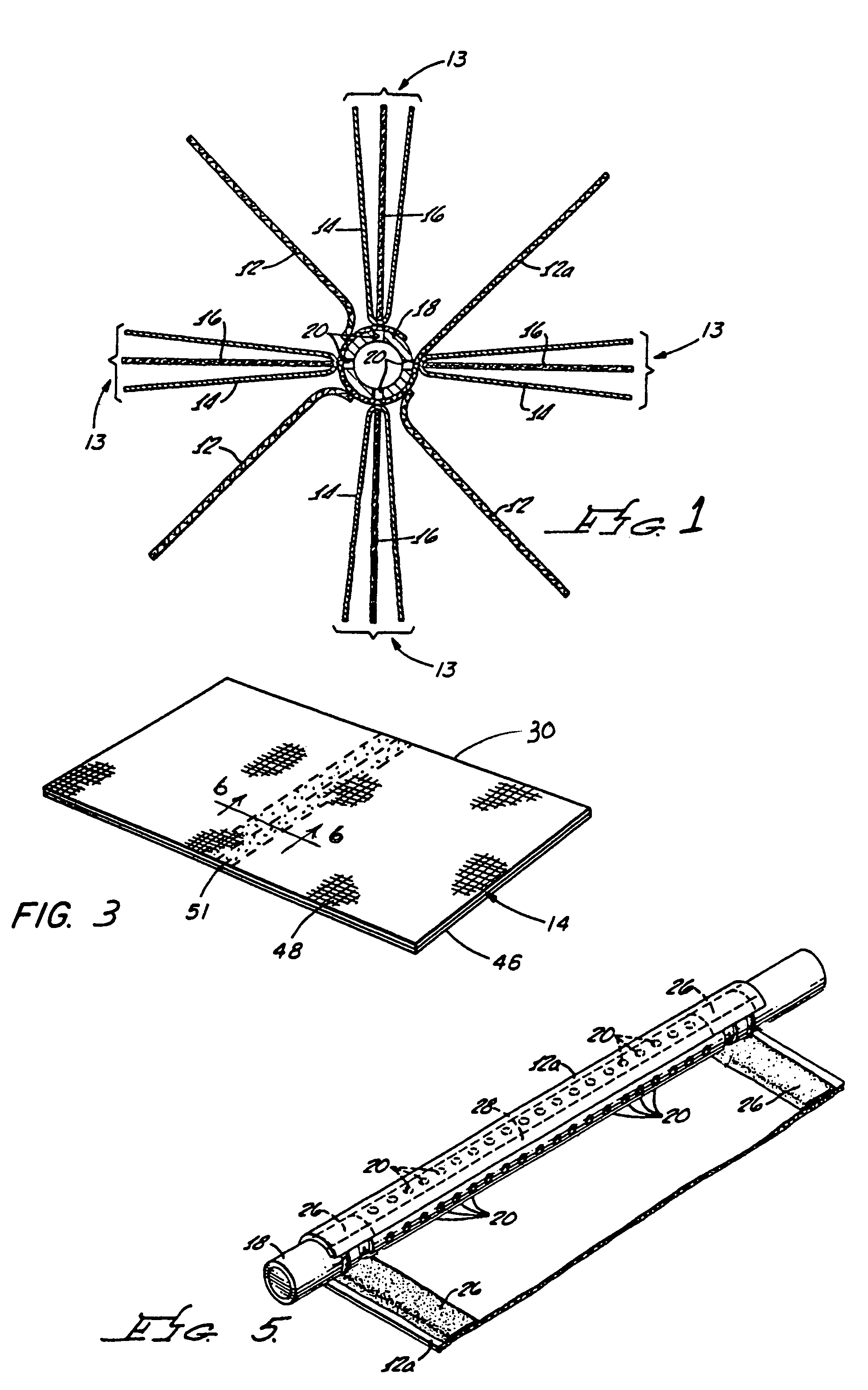

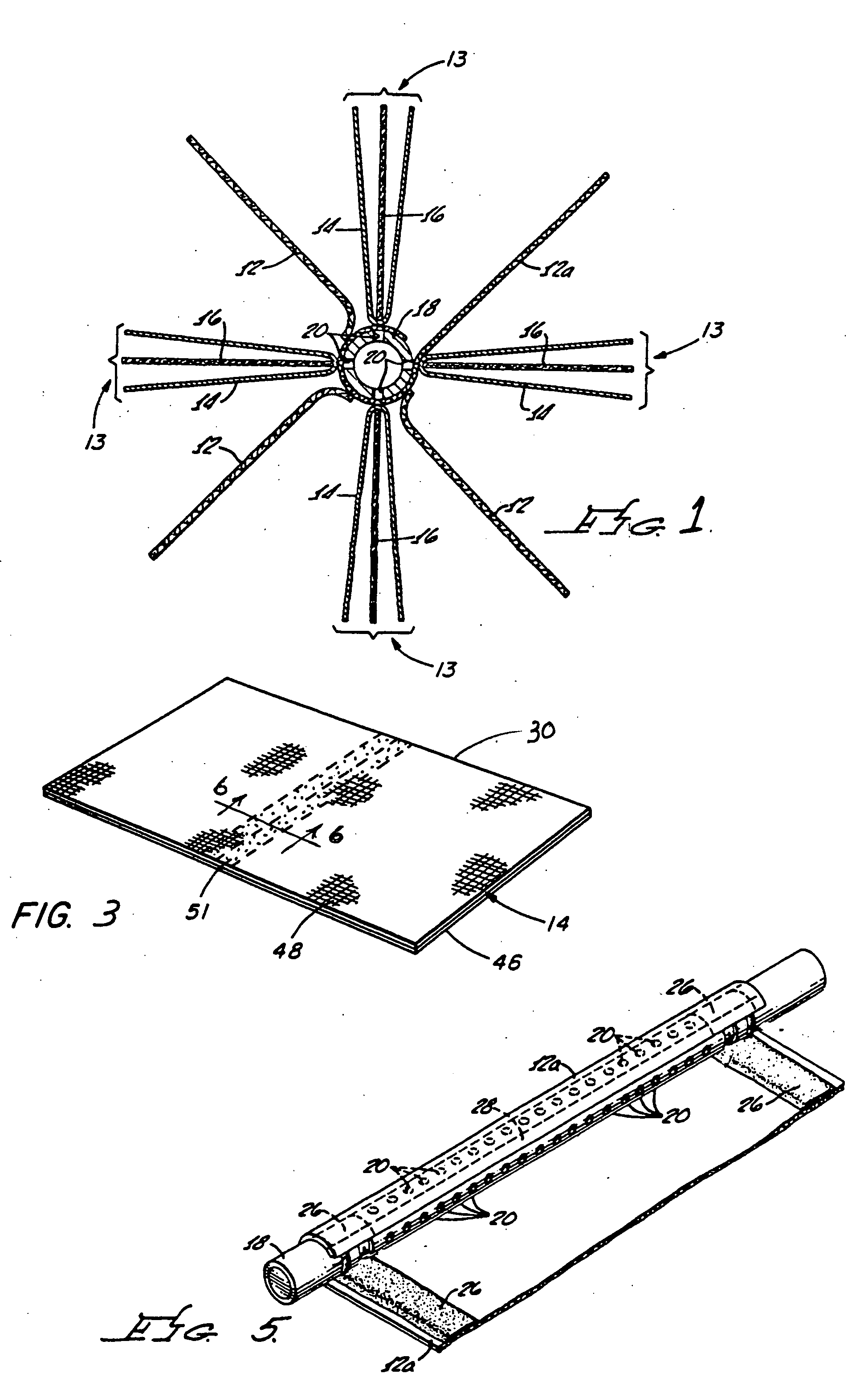

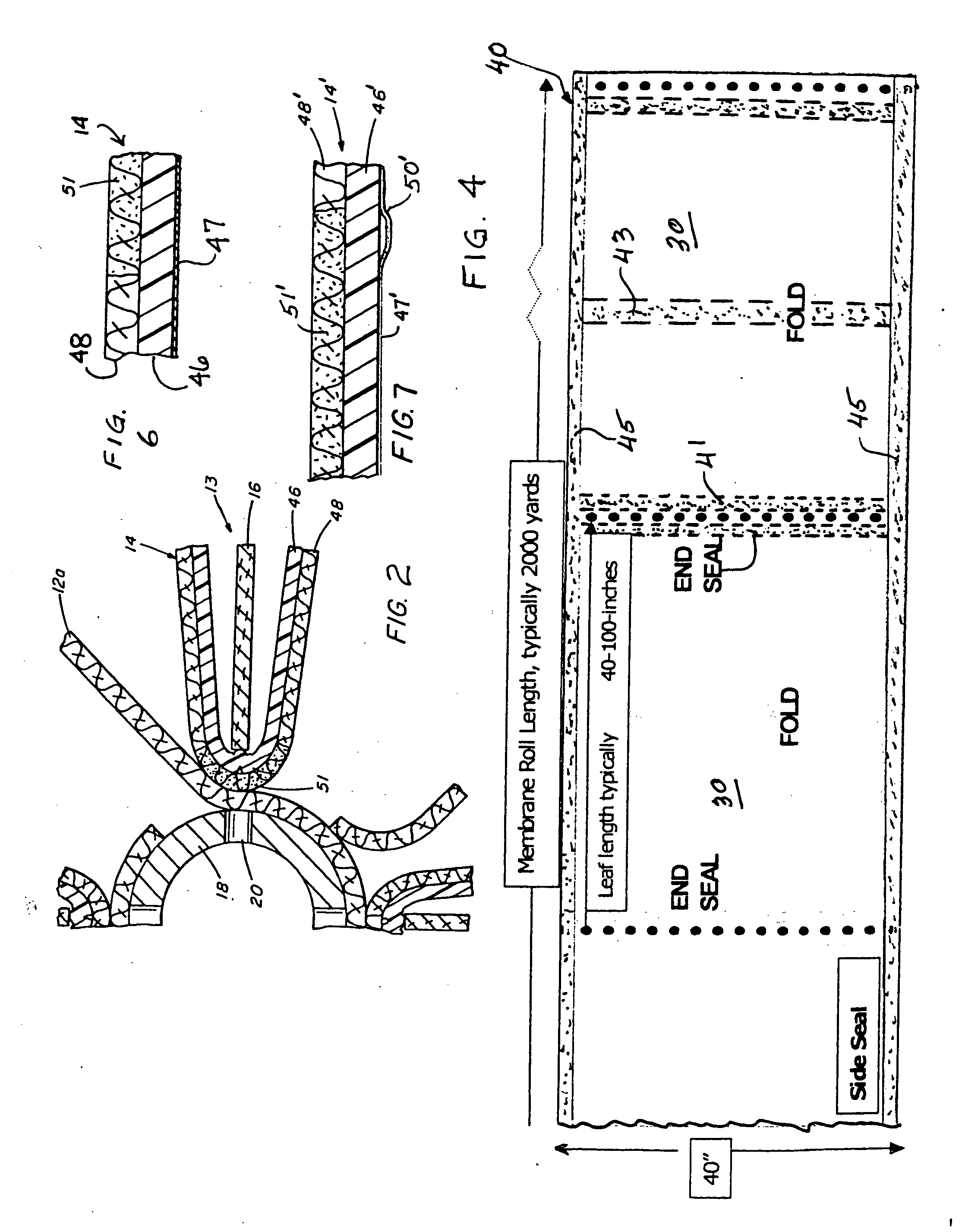

InactiveUS7303675B2Preventing osmotic blisteringInherently resistant to osmotic blisteringSynthetic resin layered productsLaminationOsmotic blisteringSemipermeable membrane

A method for preventing osmotic blistering in spirally-wound elements of semipermeable membrane sheet material (14) by applying an effective coating of a sealant (41, 43, 45) to the upstream surface of such membrane material in regions where such potential for blistering exists and thereby preventing the permeation of liquid into the surface of the semipermeable membrane in these regions.

Owner:GE OSMONICS INC

Blister protection for spiral wound elements

InactiveUS20050121380A1Preventing osmotic blisteringPrevent leakageEngine sealsSynthetic resin layered productsOsmotic blisteringSemipermeable membrane

A method for preventing osmotic blistering in spirally-wound elements of semipermeable membrane sheet material (14) by applying an effective coating of a sealant (41, 43, 45) to the upstream surface of such membrane material in regions where such potential for blistering exists and thereby preventing the permeation of liquid into the surface of the semipermeable membrane in these regions.

Owner:GE OSMONICS INC

Spiral wound element and seal assembly

InactiveUS8778182B2Quickly and easily flushed of airImprove energy consumptionMembranesSemi-permeable membranesSpiral woundVALVE PORT

A spiral wound element and a seal assembly comprising: a ring-shaped seal disposed about a portion of an outer periphery of the element, a secondary pathway and a valve that selectively permits fluid flow through the secondary pathway.

Owner:DOW GLOBAL TECH LLC

NMR probe having an inner quadrature detection coil combined with a spiral wound outer coil for irradiation

InactiveUS6876200B2Minimal mutual inductanceImprove reliability and power efficiency and sensitivityElectric/magnetic detectionMeasurements using magnetic resonanceClose couplingSaddle coil

A high resolution NMR probe having two or more resonators, an inner resonator which is closely coupled to a sample and is used to stimulate and receive a response from one nuclear species, and an outer resonator to induce transitions in another nuclear species, wherein the resonators may be provided with cooling capability and may be made of superconducting material, and wherein the inner resonator may be a saddle coil or a birdcage coil with capability of being tuned, and wherein the outer resonator may be one or more spiral wound saddle coil.

Owner:AGILENT TECH INC

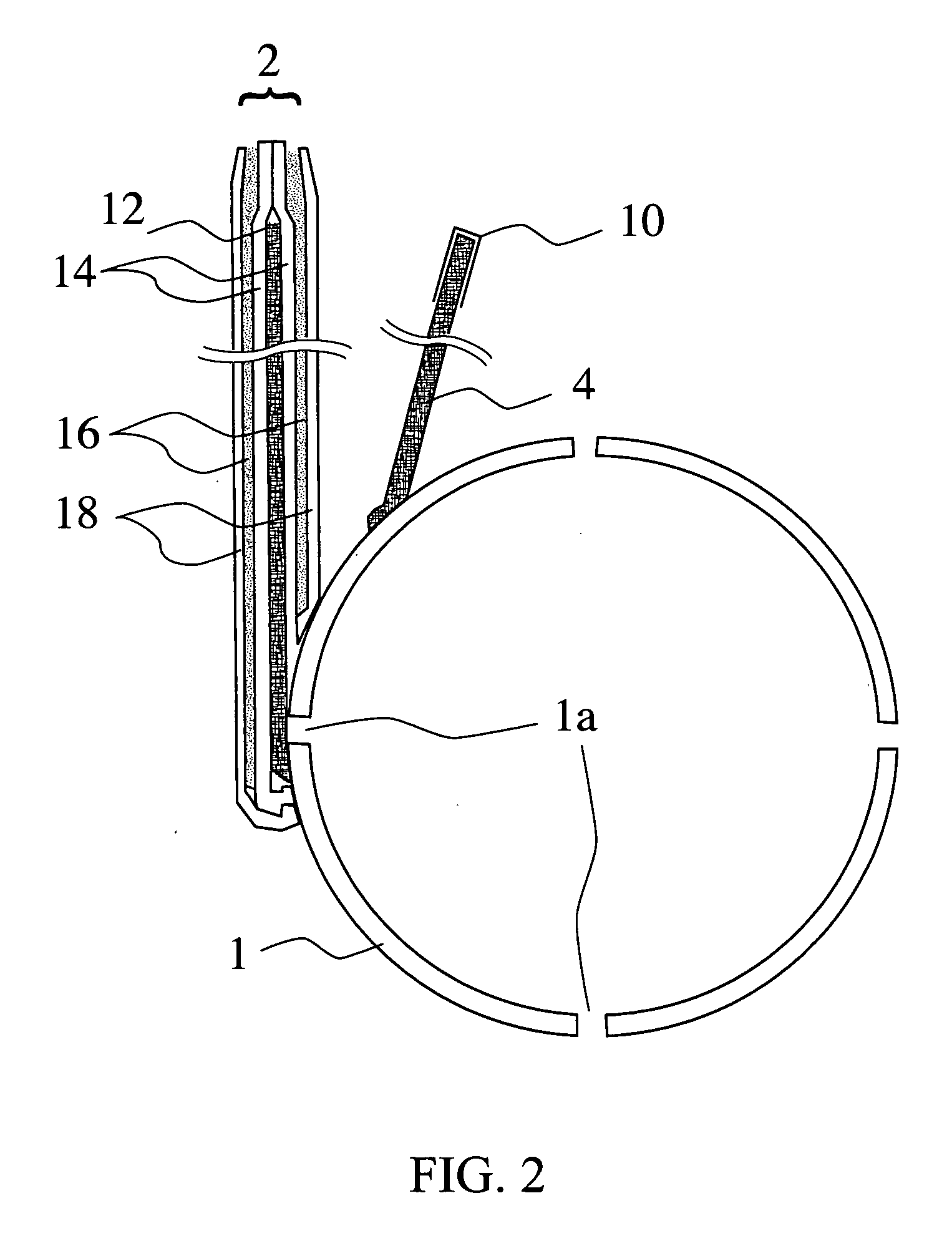

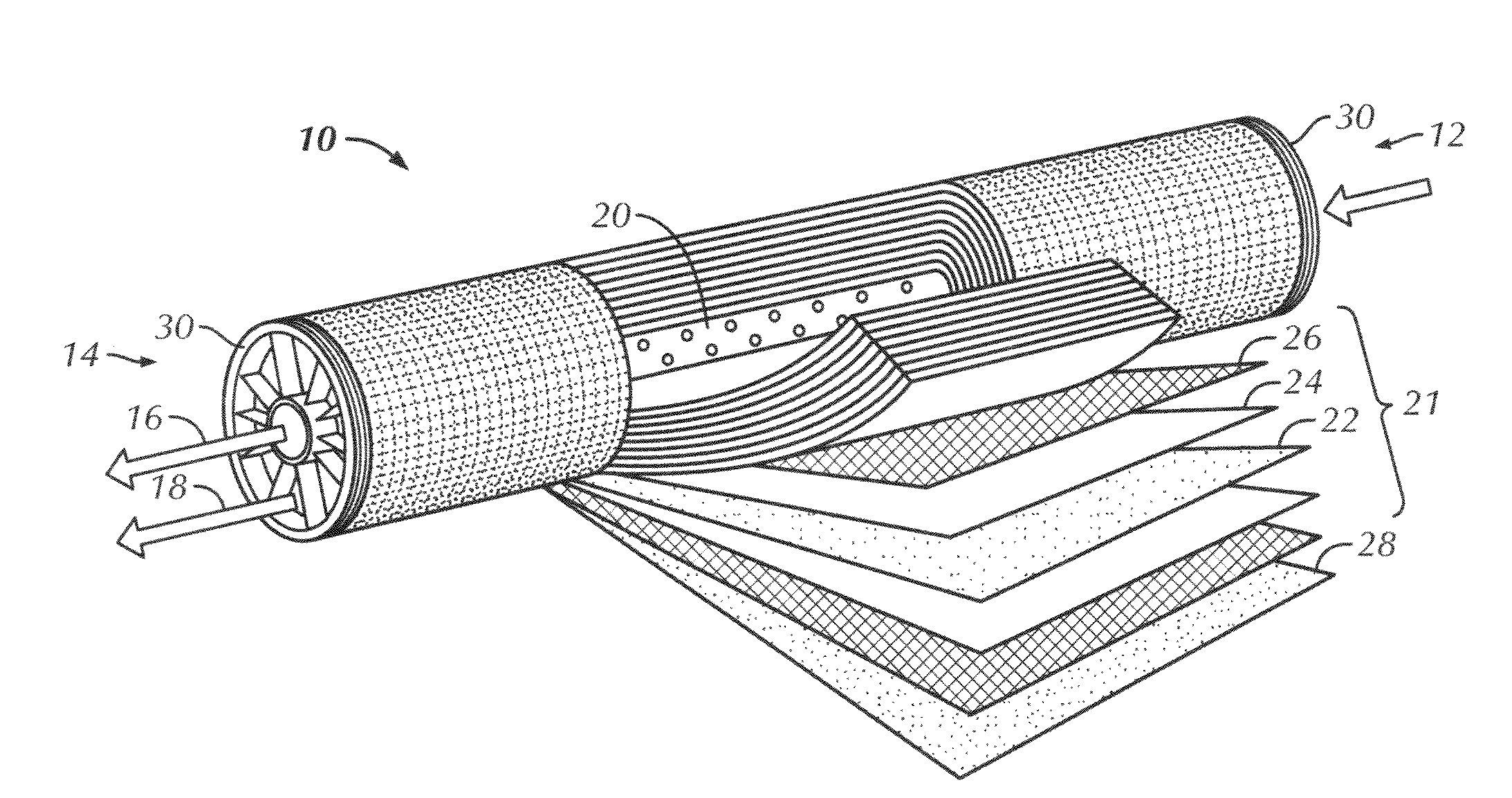

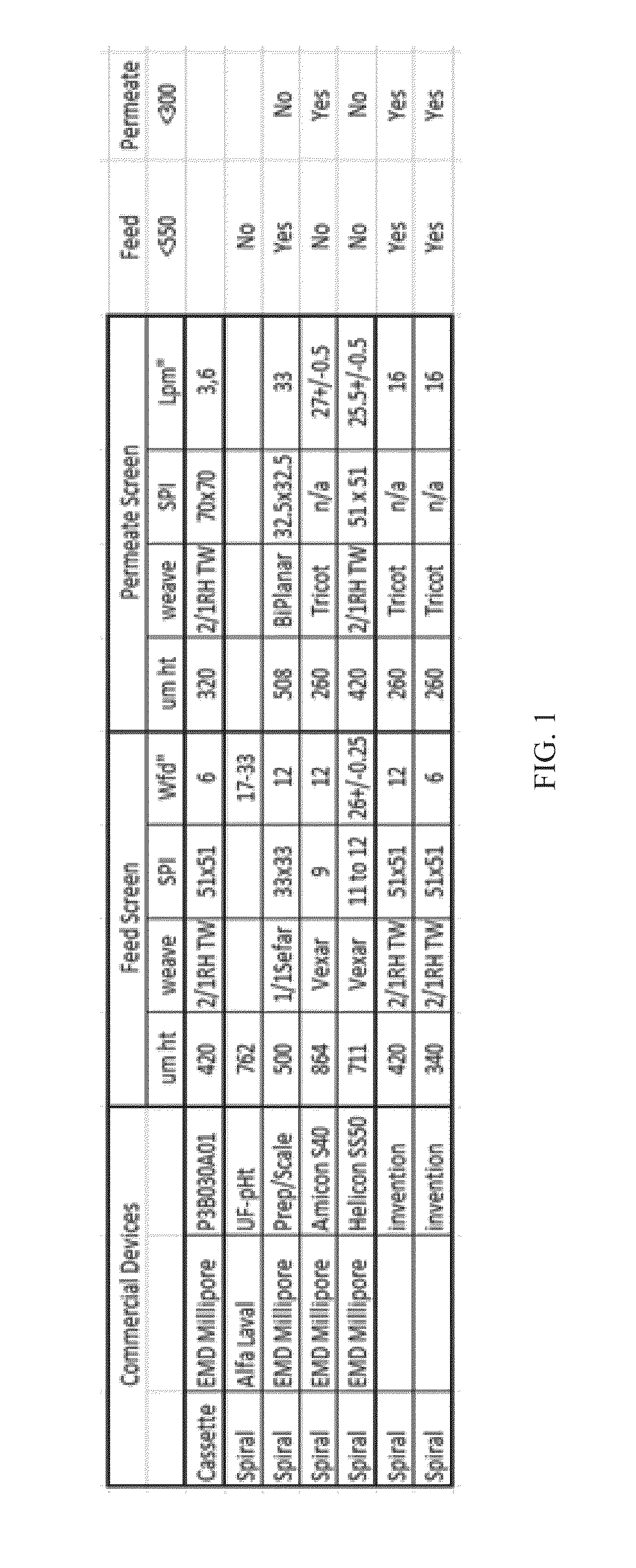

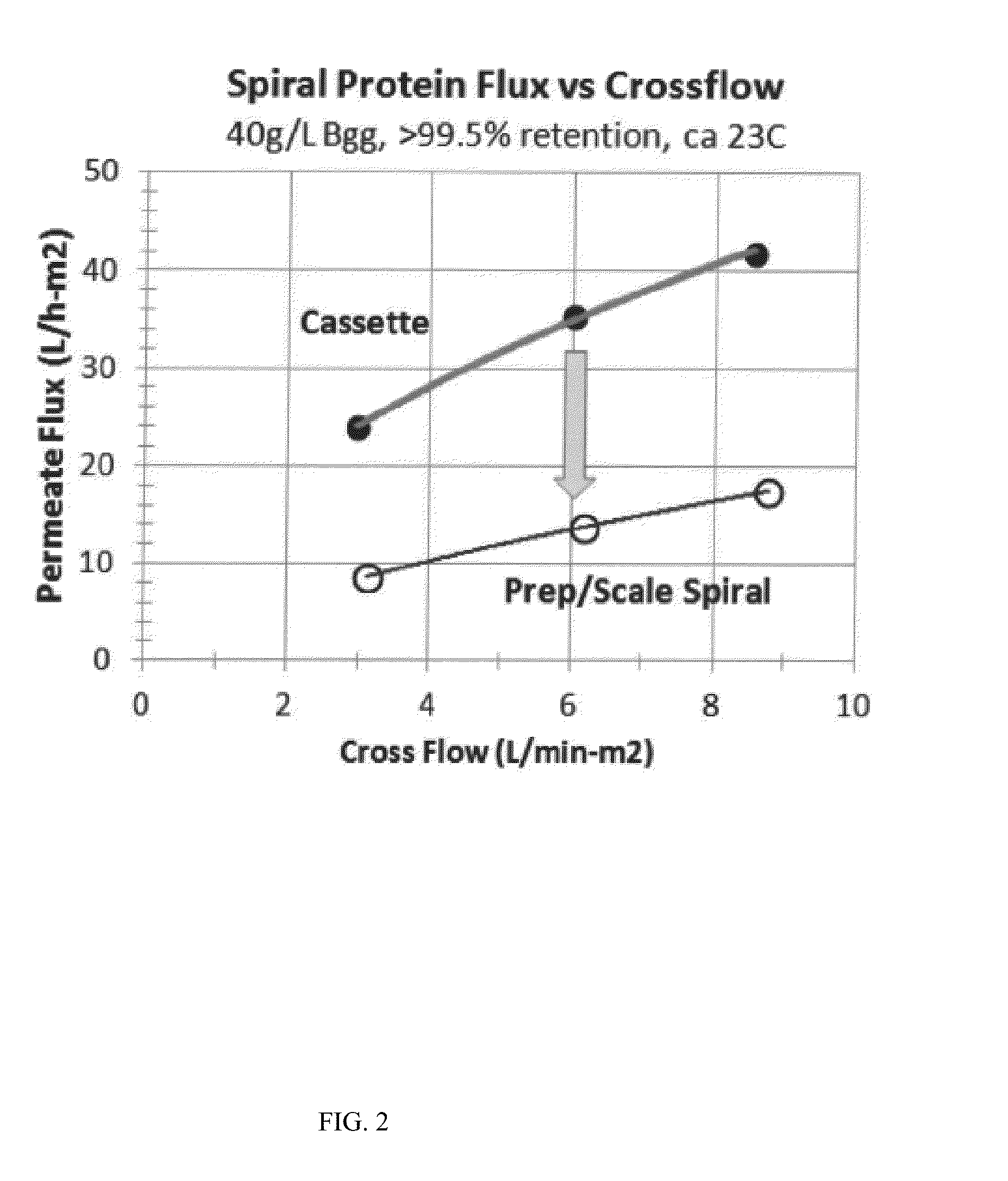

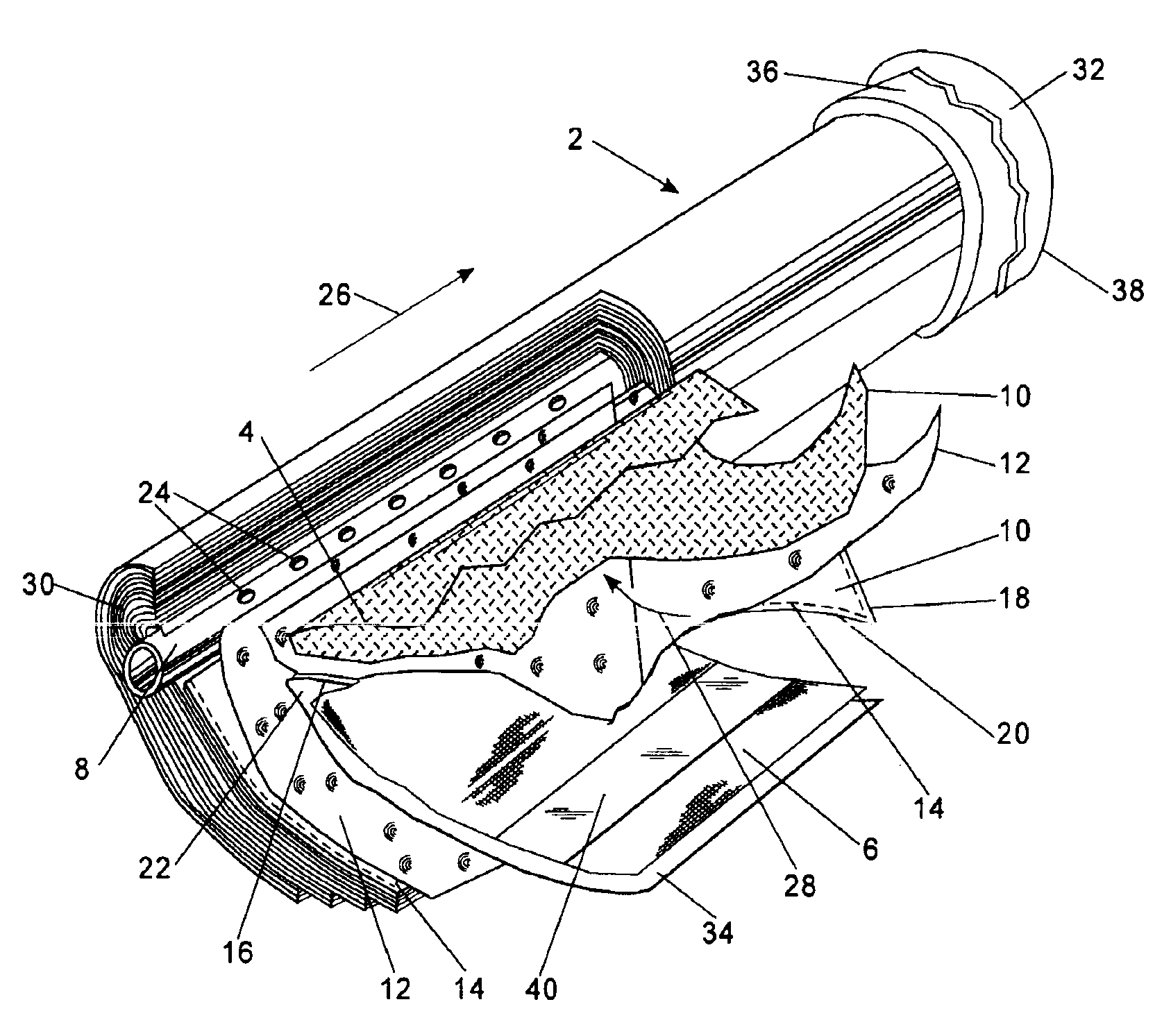

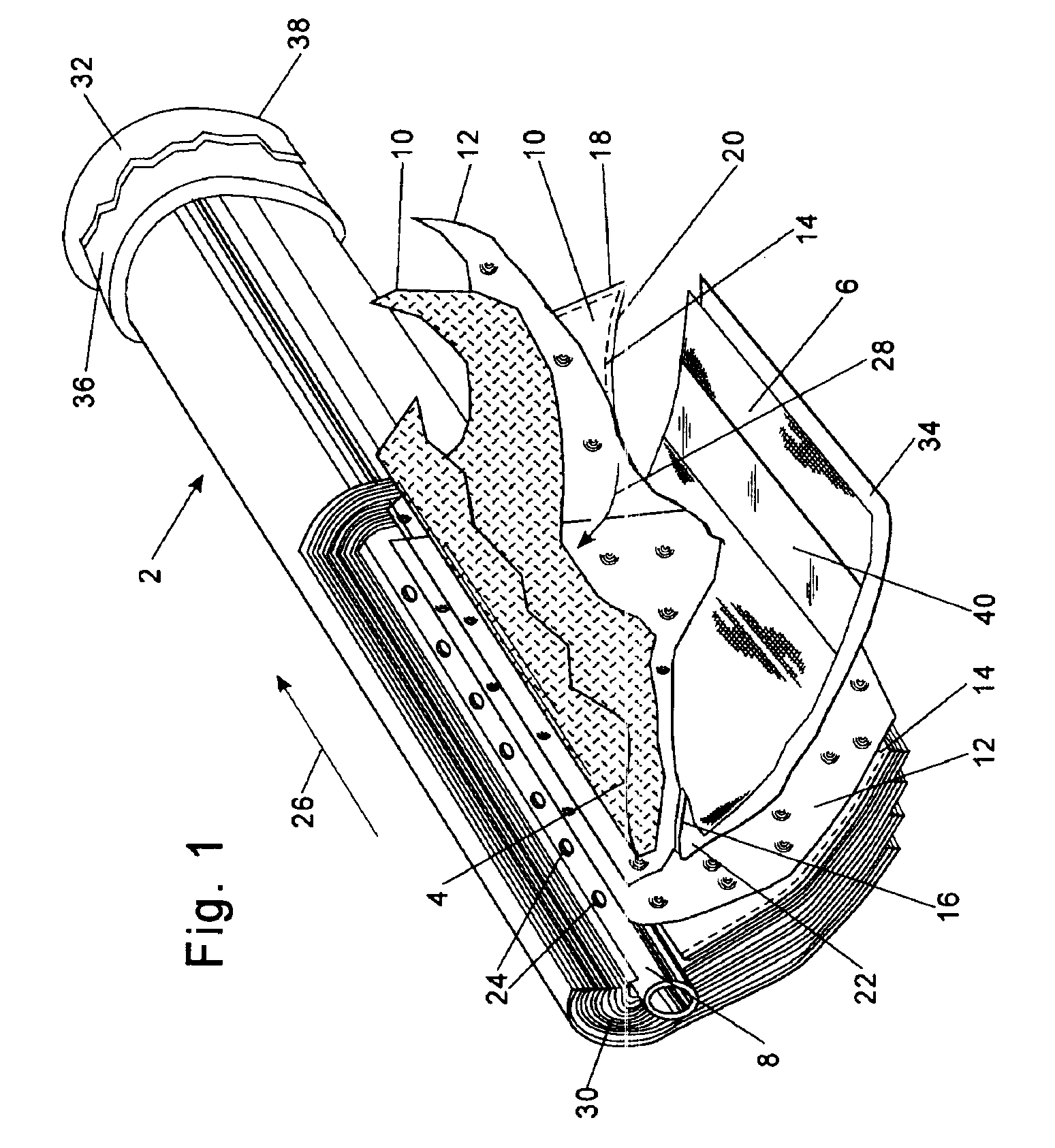

Compact spiral-wound filter elements, modules and systems

ActiveUS20150375173A1Increased feed channel pressure dropEasy to mergeUltrafiltrationReverse osmosisFiltrationSpiral wound

The present invention provides compact spiral-wound filter elements having cassette-like performance. The invention further provides filtration systems (e.g., TFF systems) and processes (e.g., SPTFF processes) employing compact spiral-wound filter elements having cassette-like performance.

Owner:MILLIPORE CORP

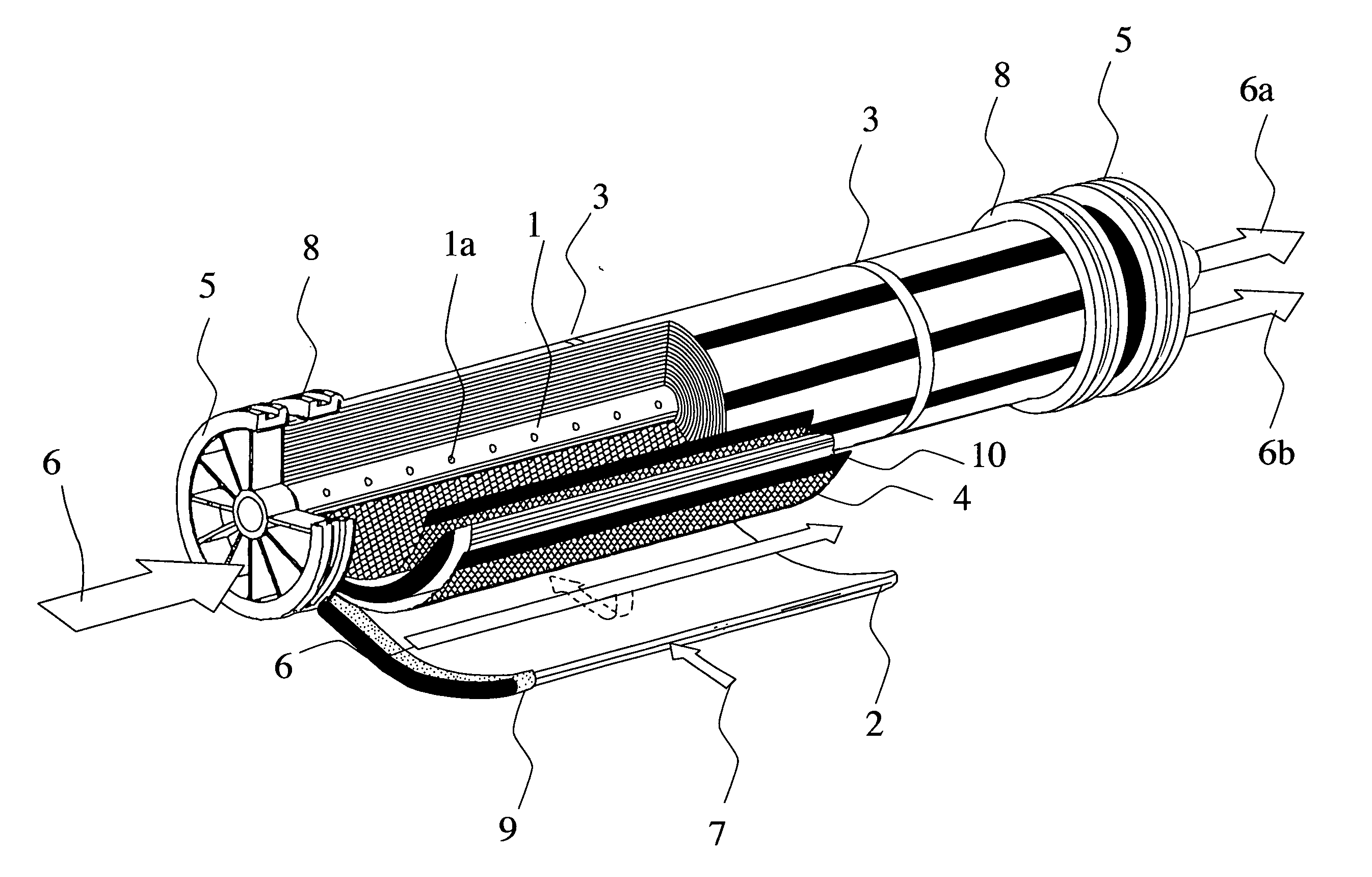

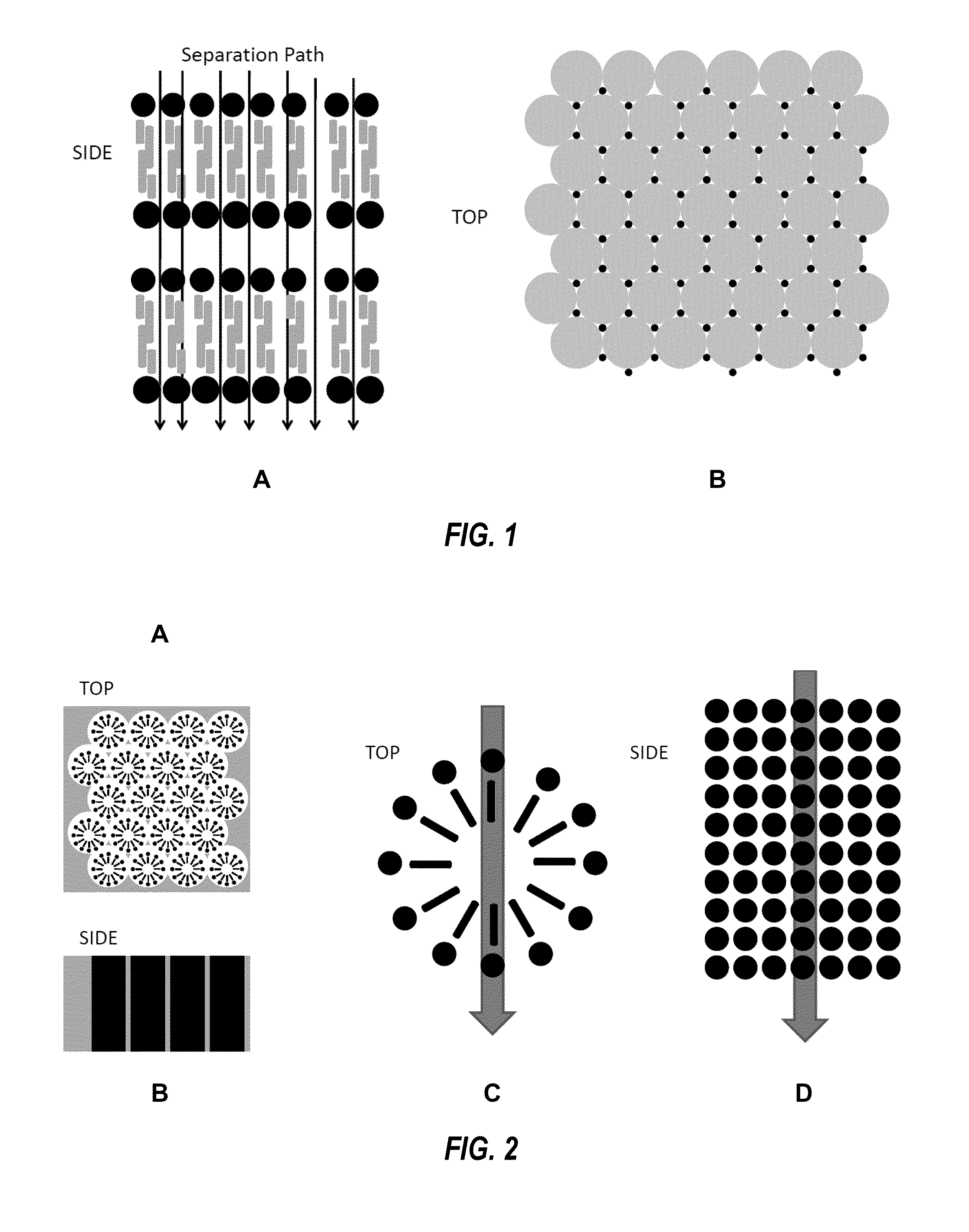

Use of acoustic signals for measuring membrane fouling in spiral wound modules

ActiveUS8210042B2Vibration measurement in solidsVibration measurement in fluidMembrane foulingTransducer

A spiral wound module assembly comprising: a permeate collection tube, at least one membrane envelope wound about the permeate collection tube, an outer module housing, and at least one acoustic transducer located adjacent to the permeate collection tube. Several embodiments are disclosed including a stand-alone probe adapted for insertion into the permeate collection tube. In several other embodiments, one or more transducers are secured to the inner surface of the permeate collection tube. The invention further includes a method of measuring membrane fouling within a spiral wound module comprising the steps of: a) transmitting an acoustic signal from a location adjacent to the permeate collection tube; b) receiving an echo signal resulting from the transmitted acoustic signal reflecting from an interface within the module; c) providing a reference signal corresponding to a known state of membrane fouling; d) comparing the echo signal to the reference signal; and e) determining a state of membrane fouling based upon the comparison of the echo signal and reference signal.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com