Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179 results about "Iron disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mineral pyrite, or iron pyrite, also known as fool's gold, is an iron sulfide with the chemical formula FeS2 (iron(II) disulfide). Pyrite is considered the most common of the sulfide minerals.

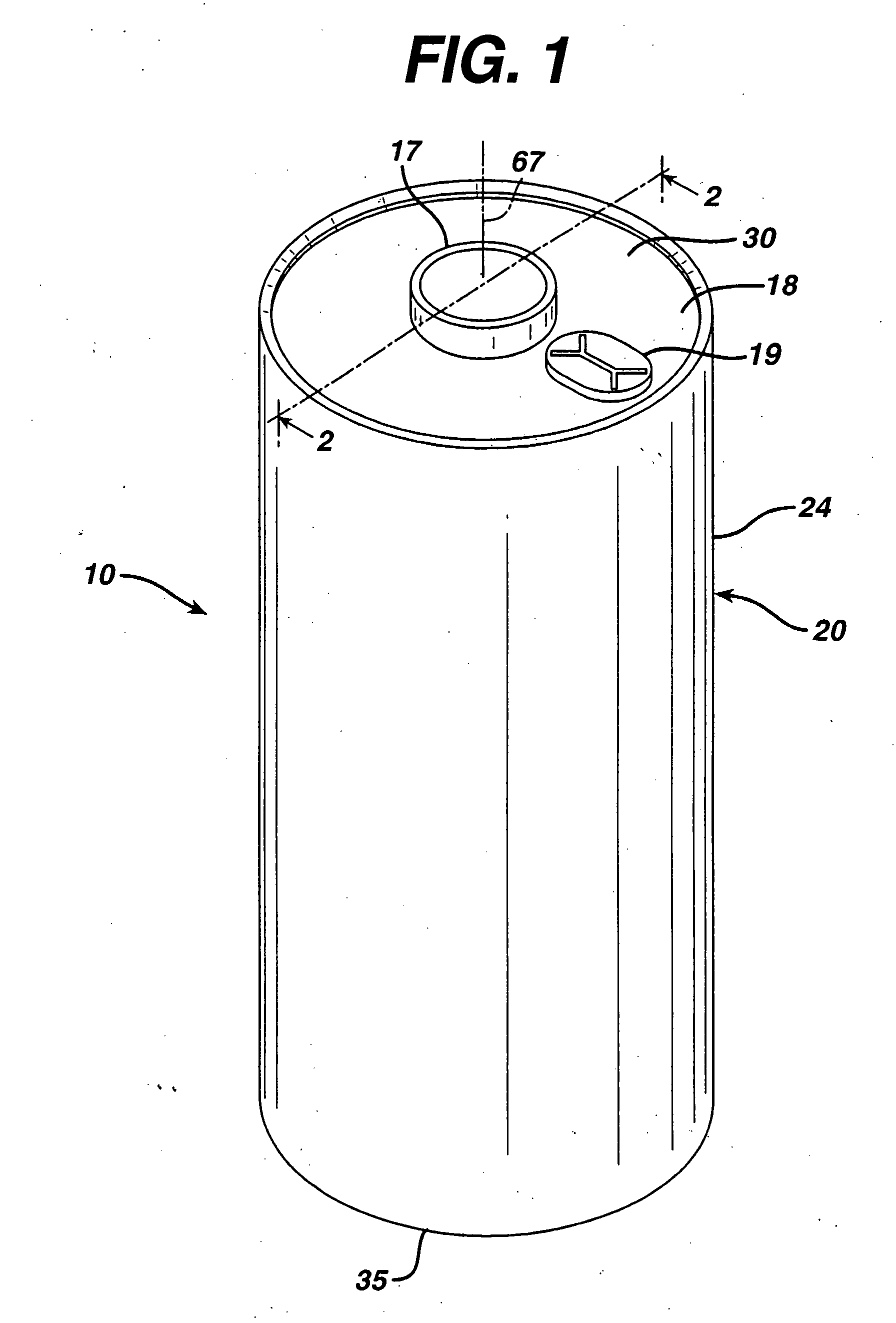

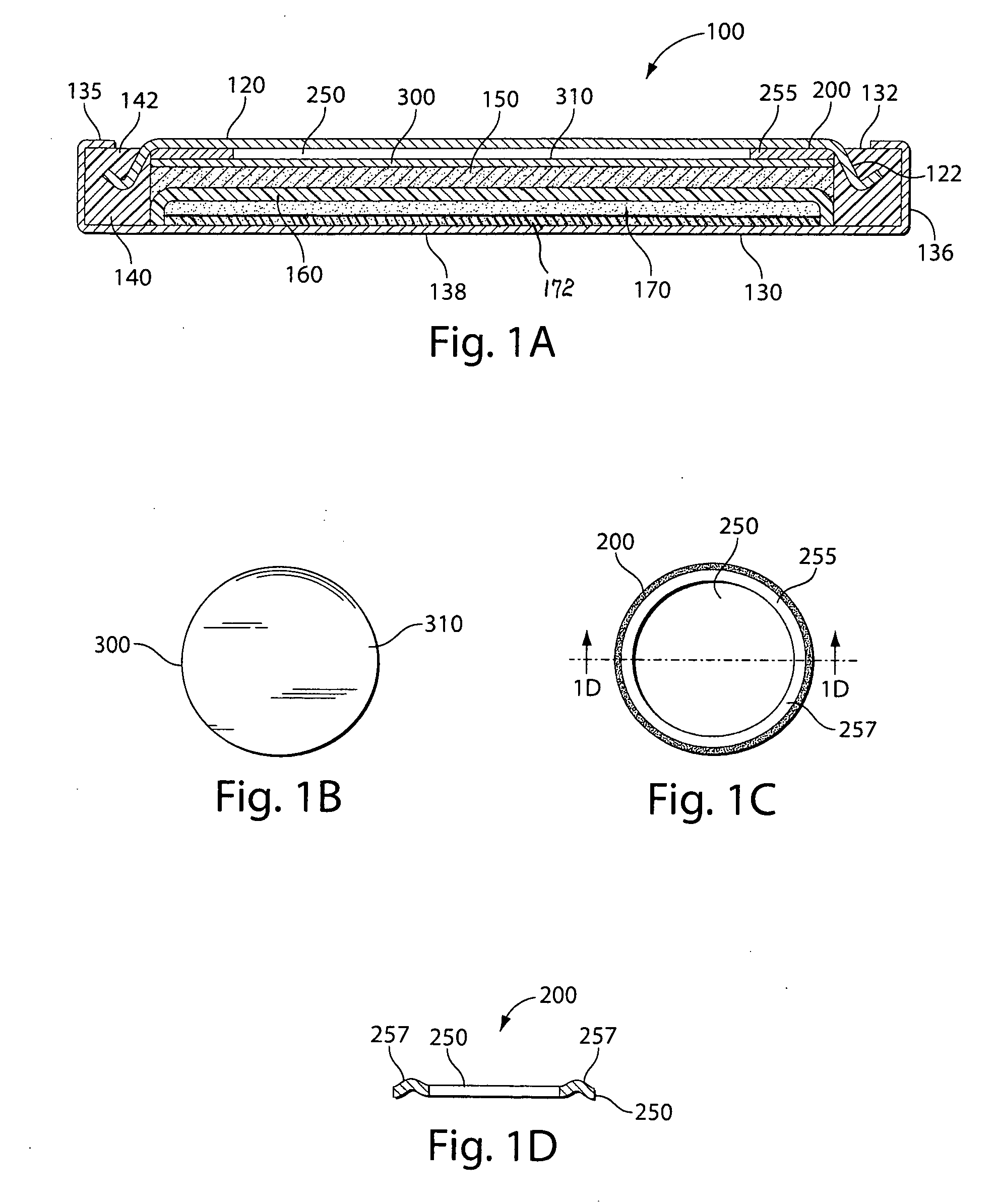

High discharge capacity lithium battery

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

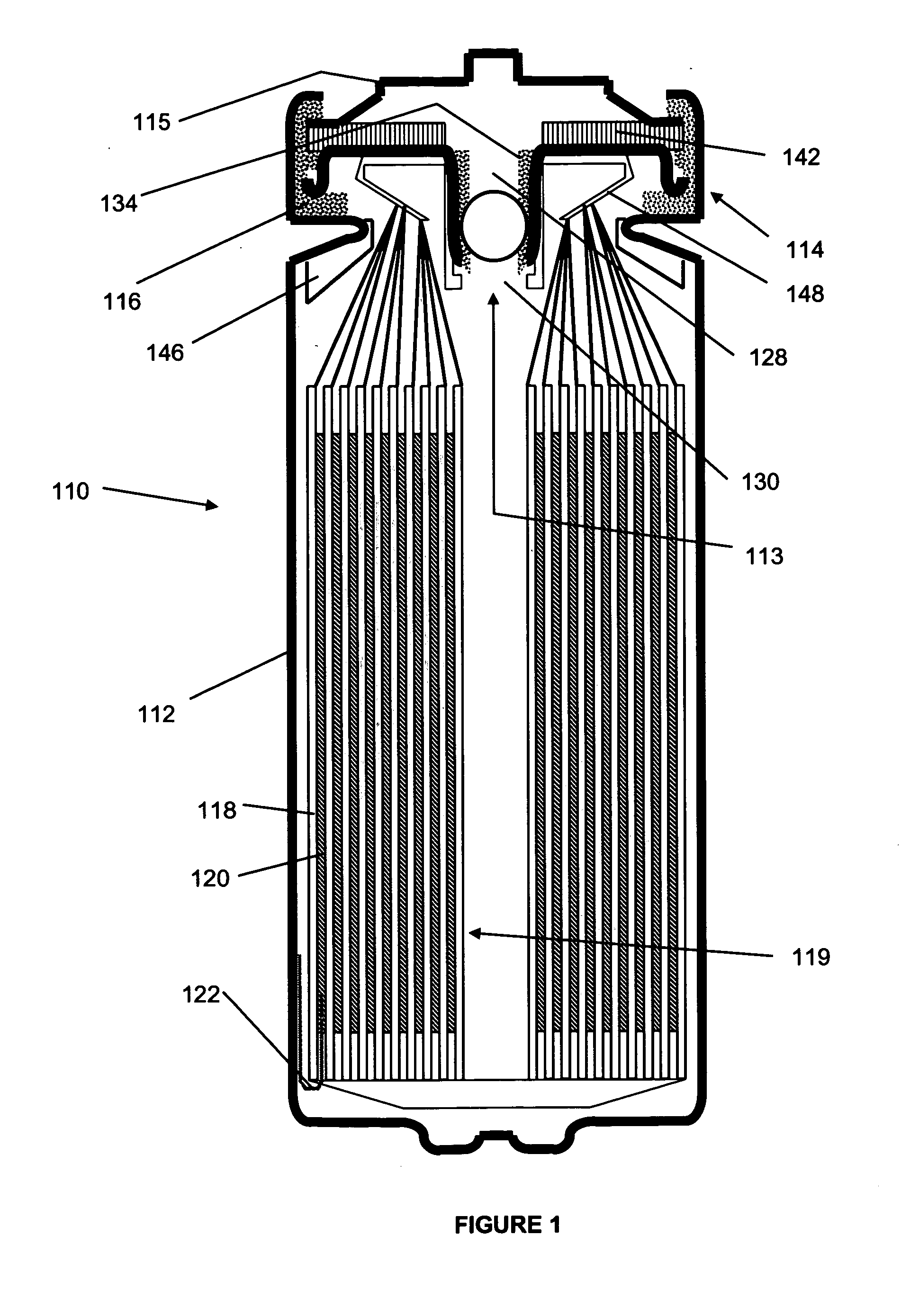

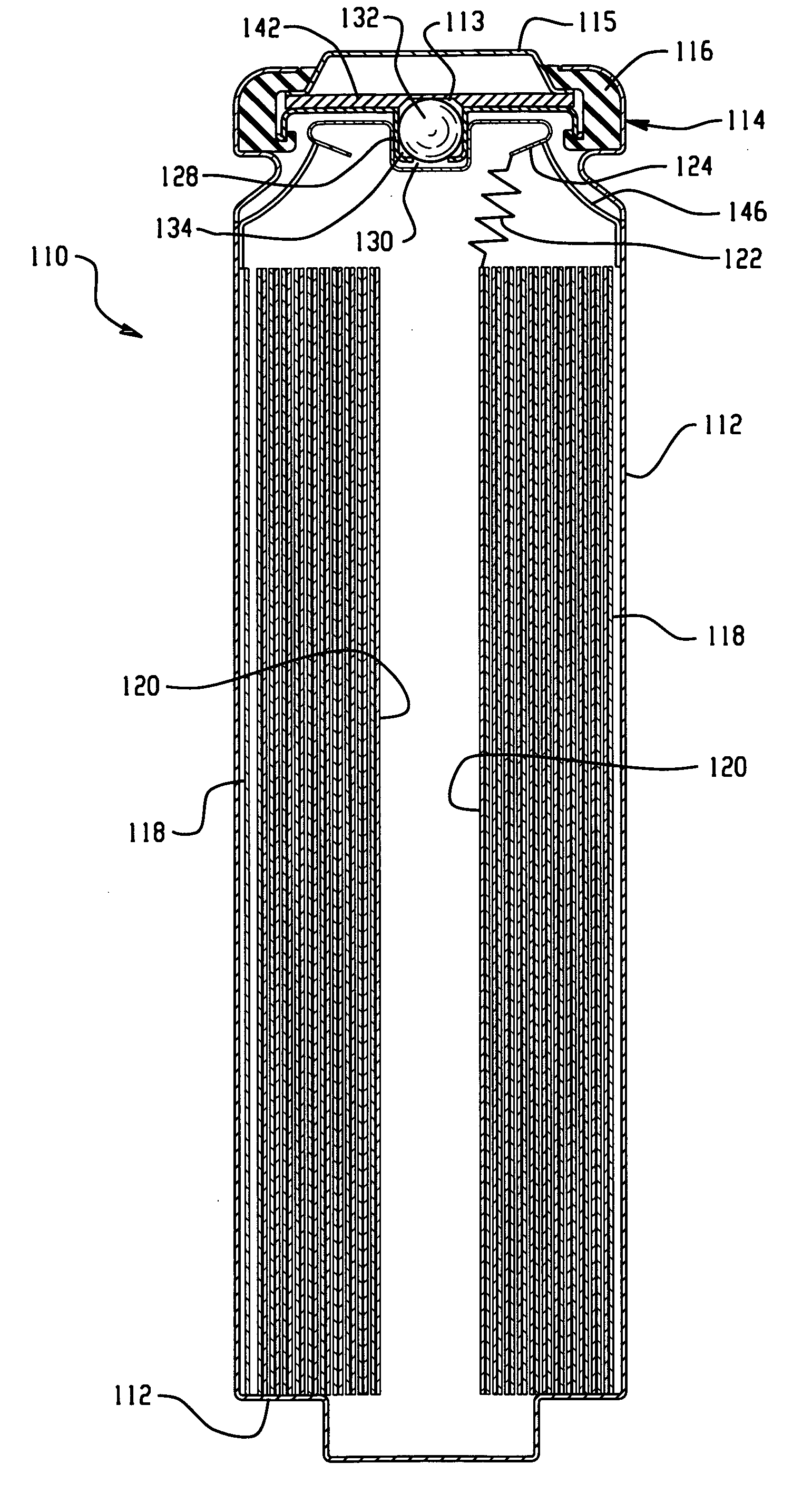

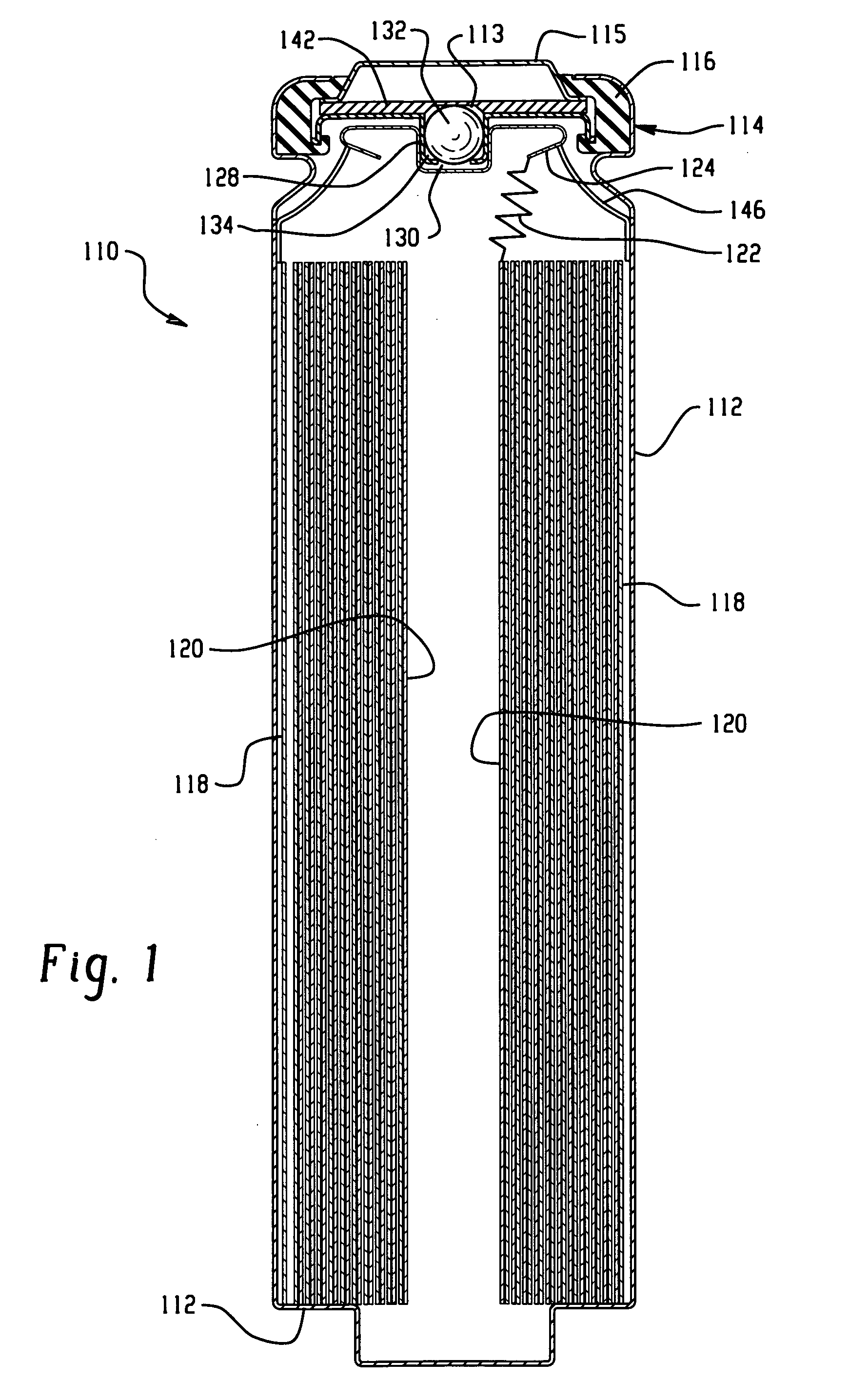

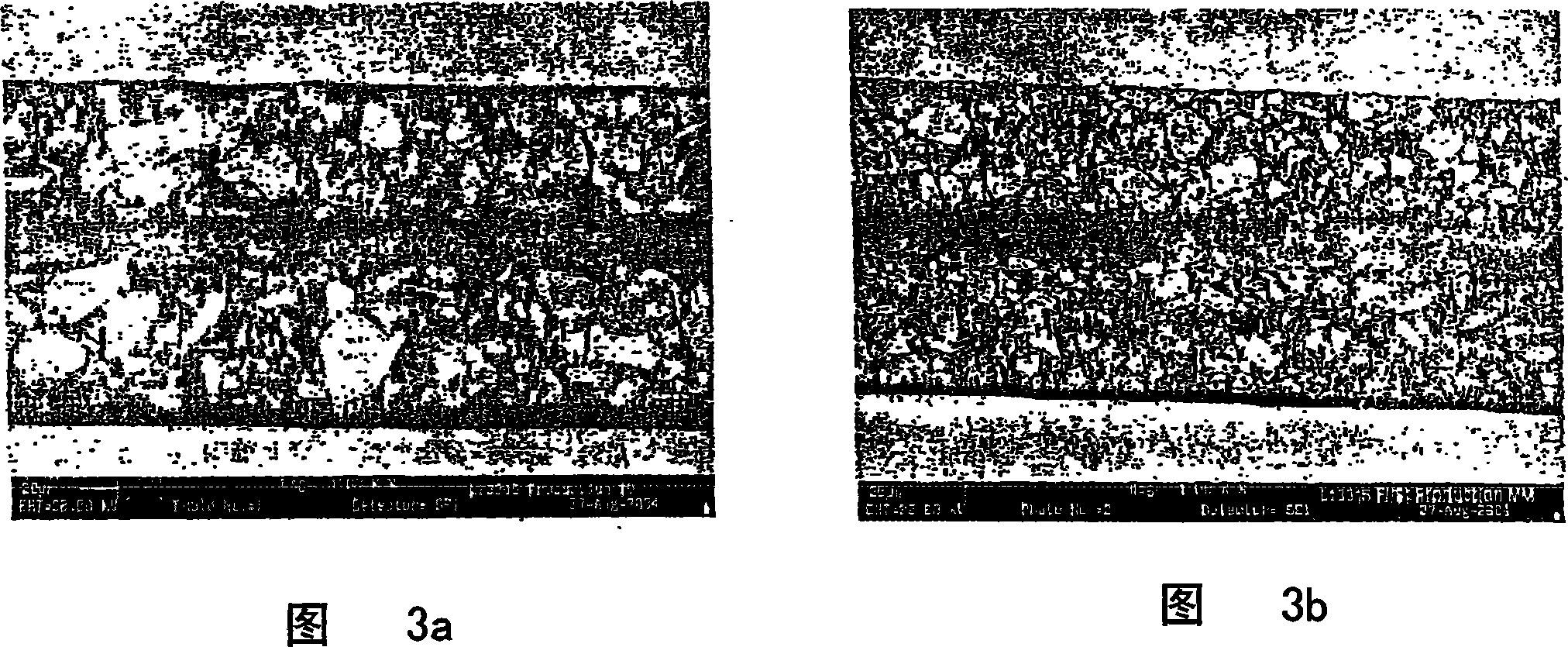

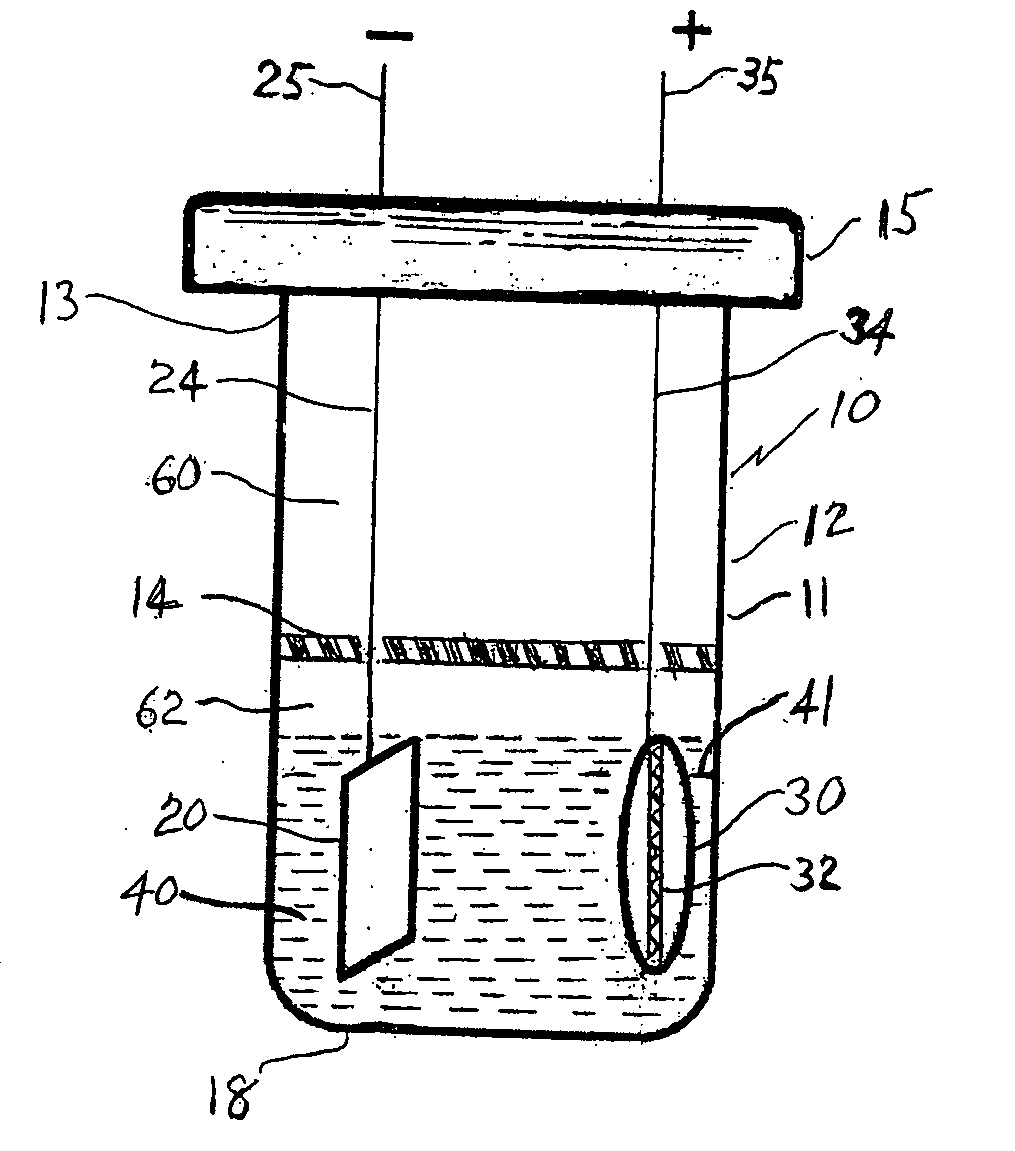

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

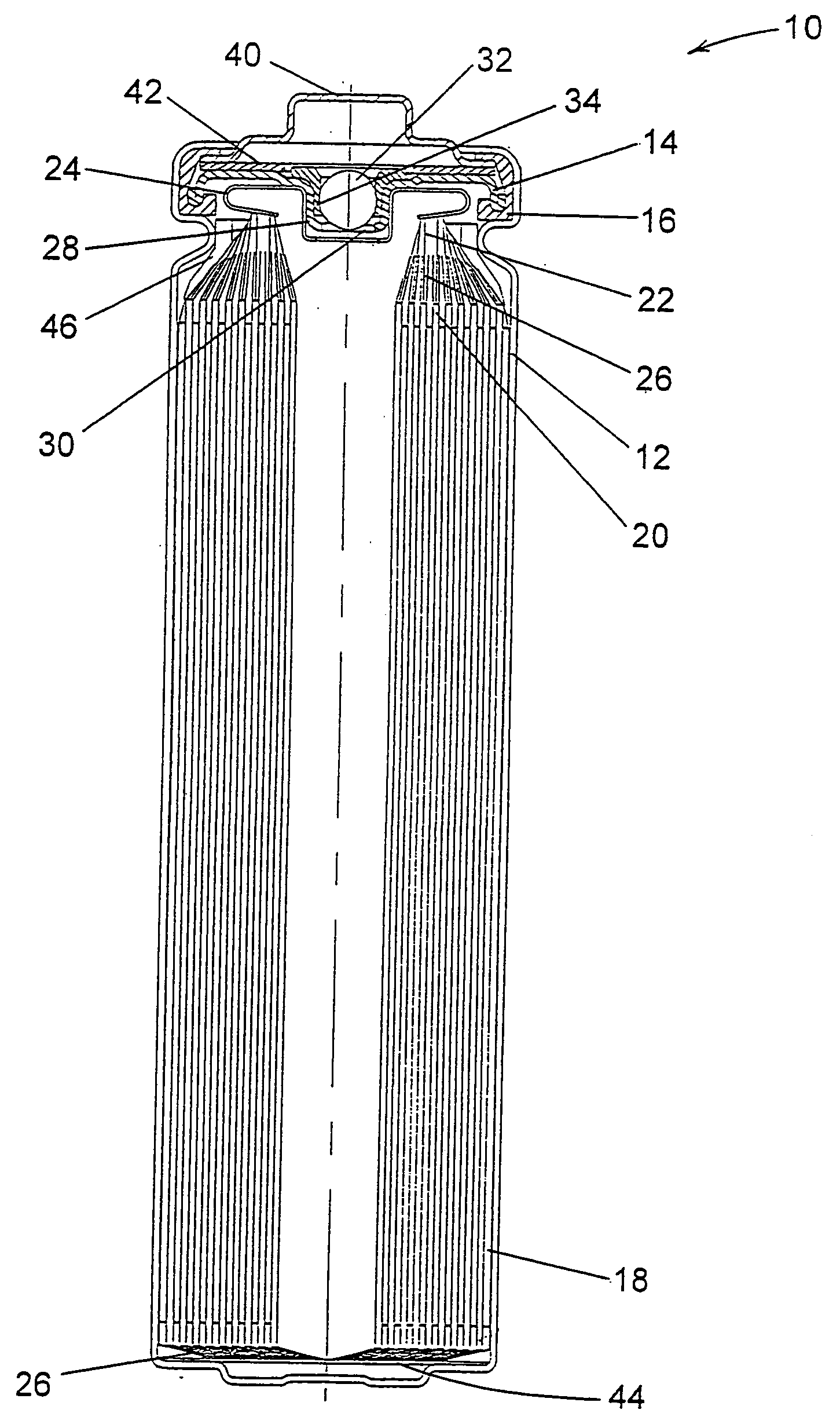

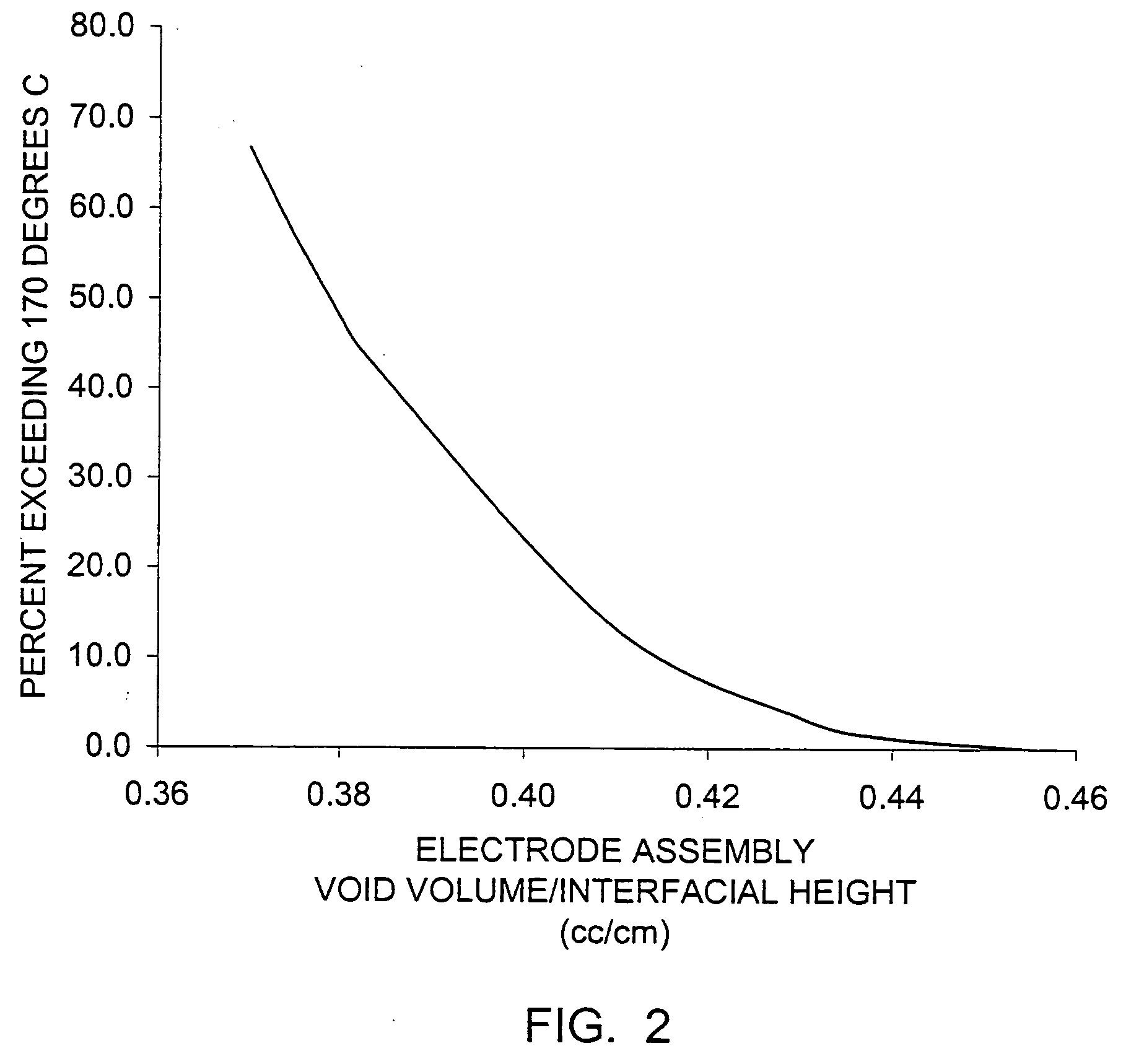

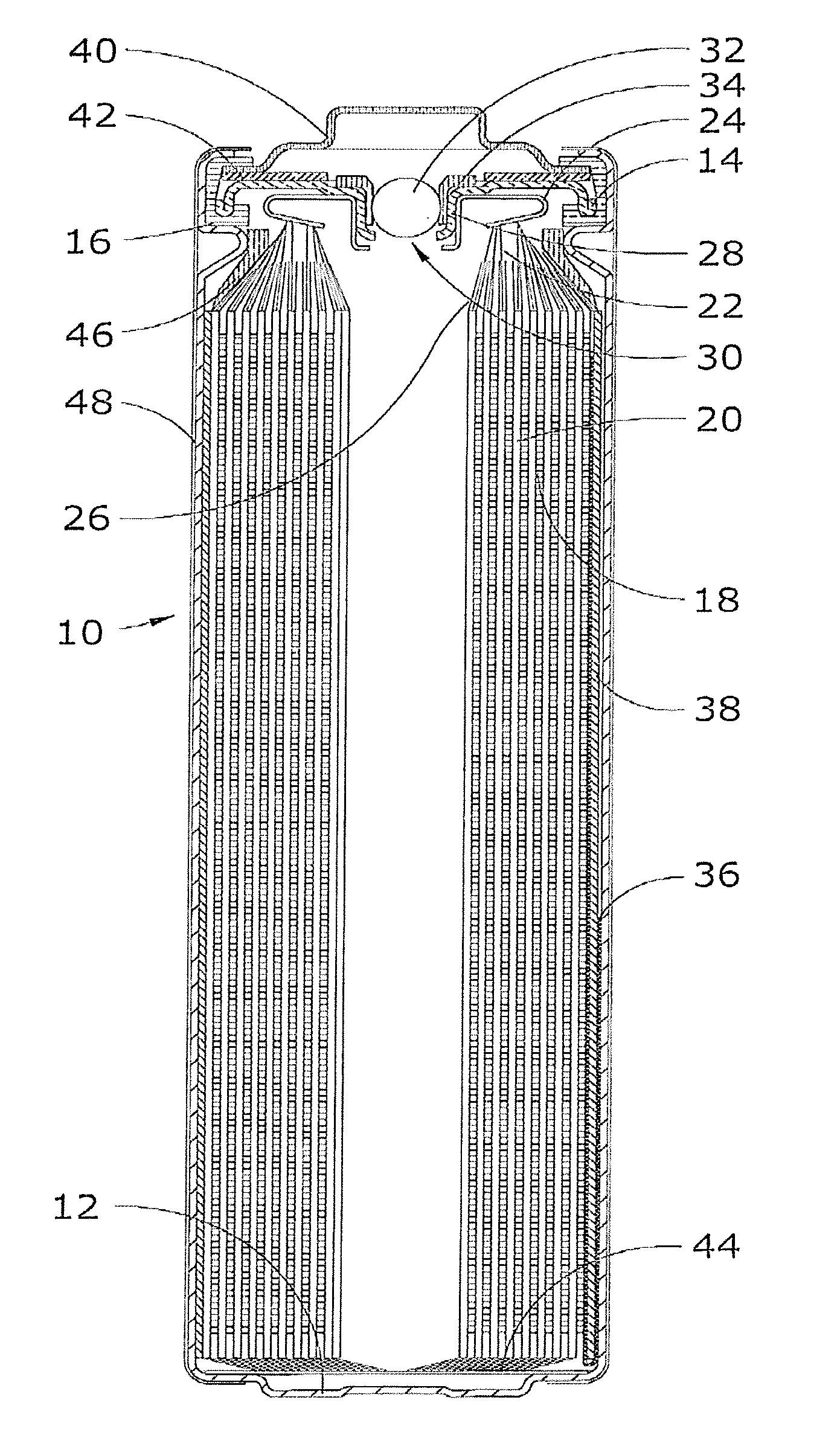

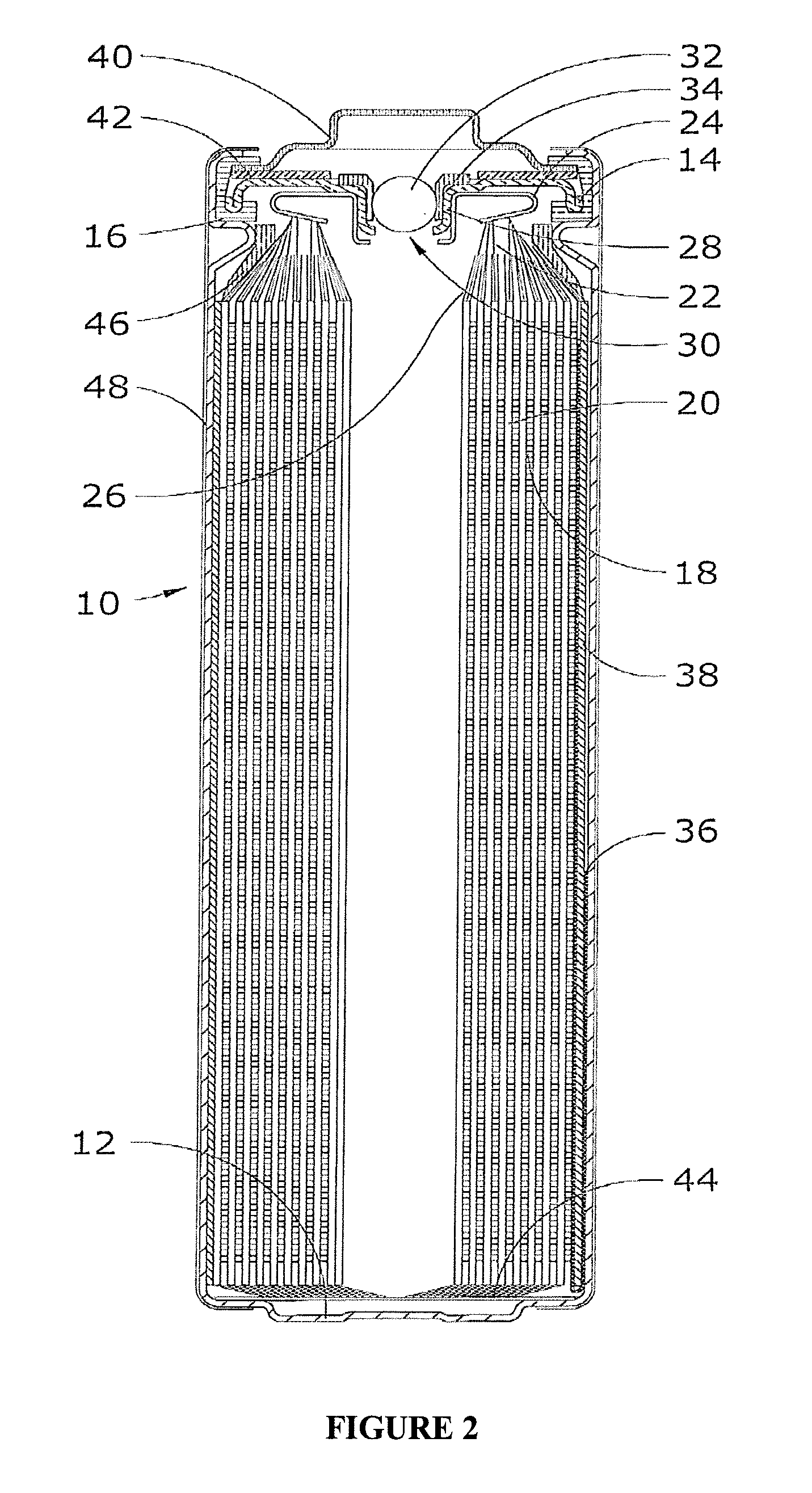

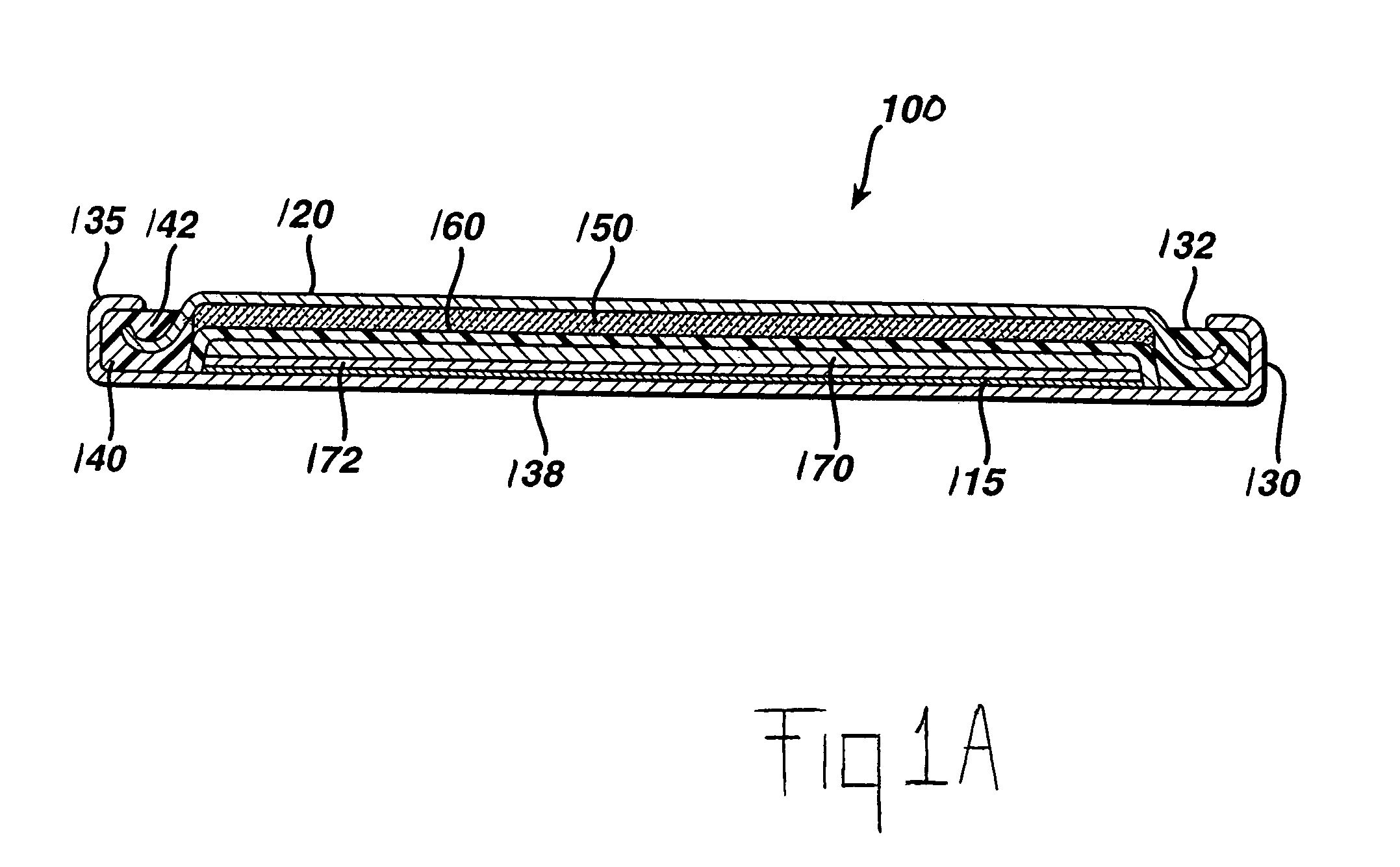

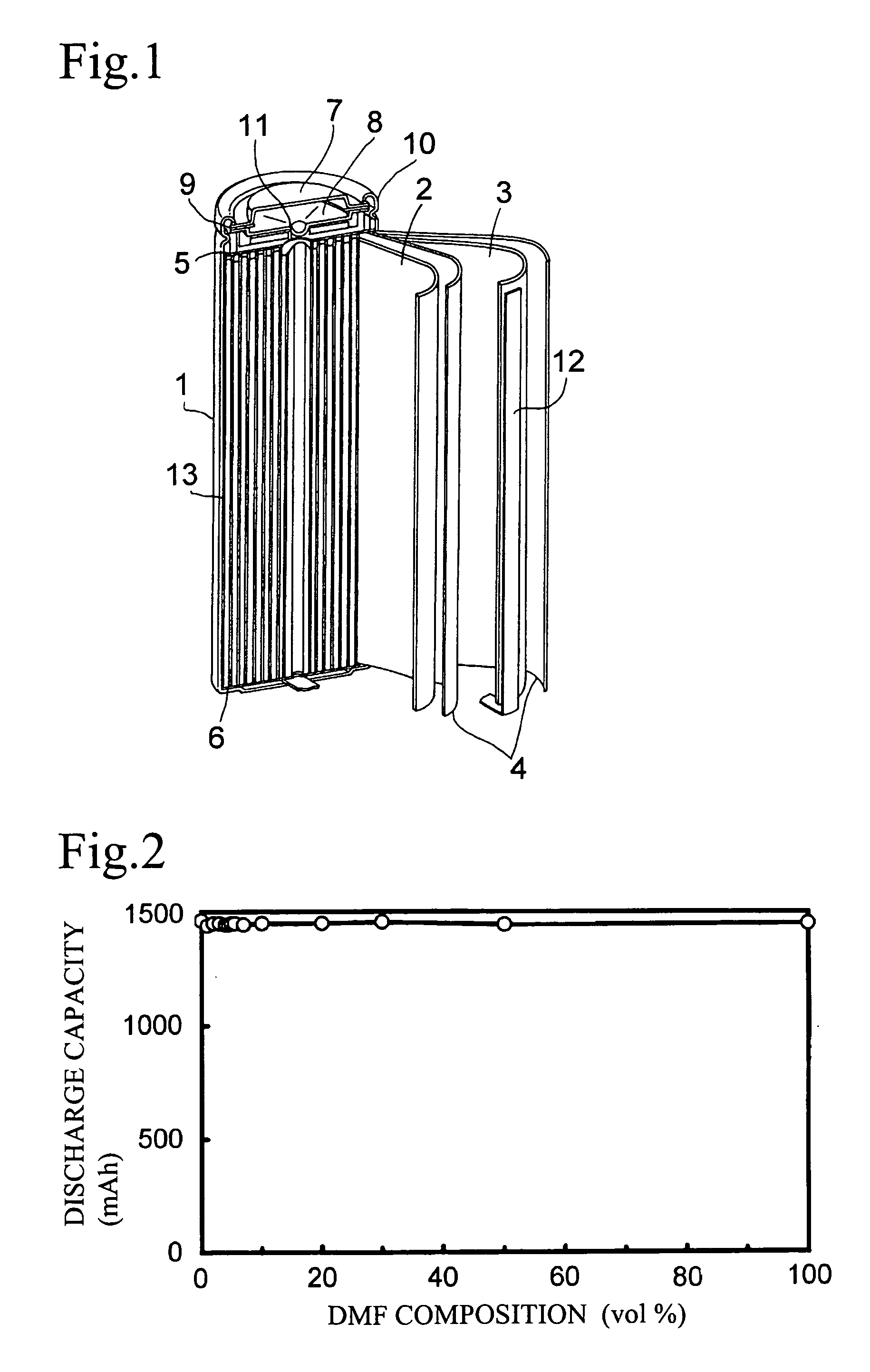

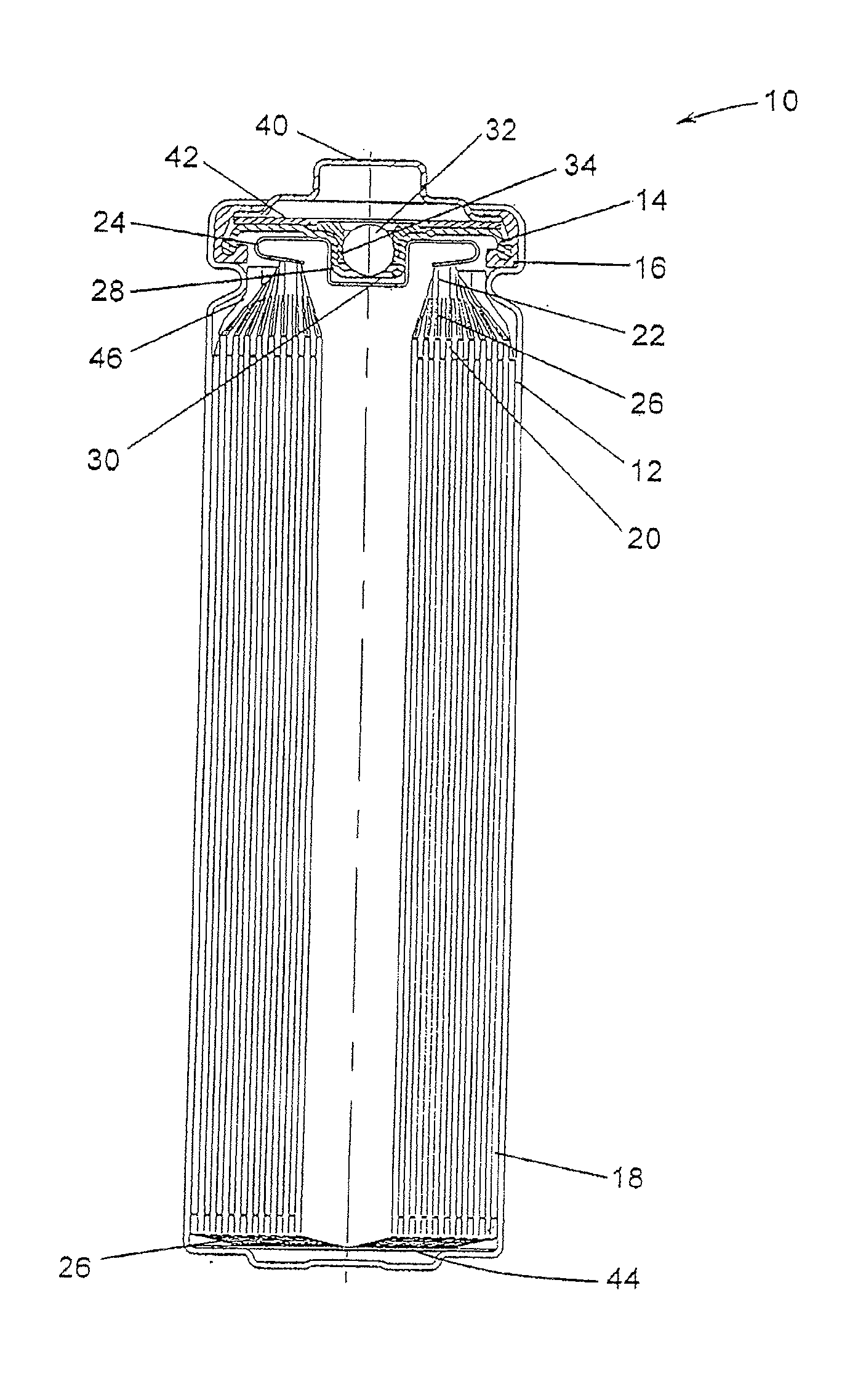

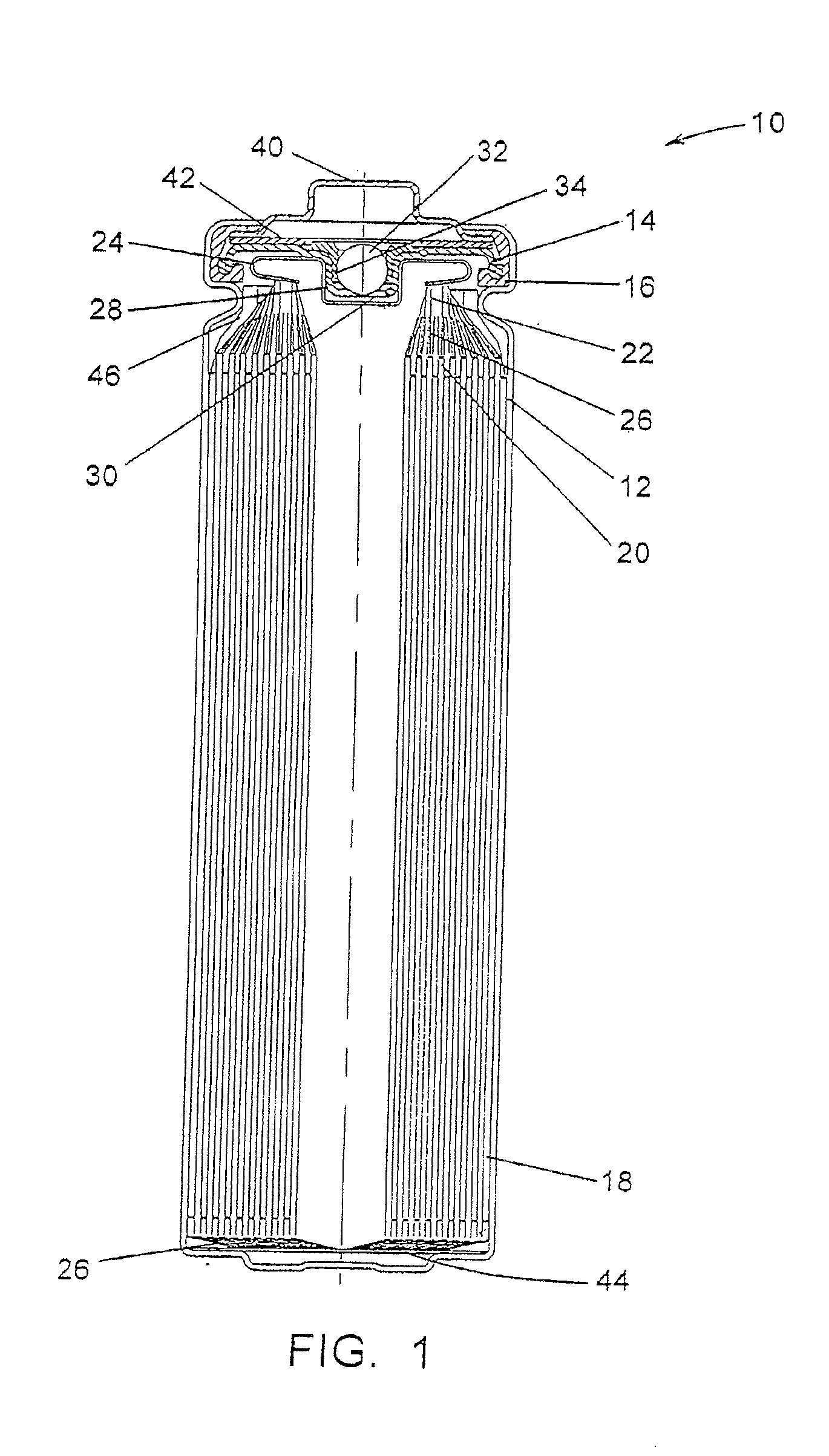

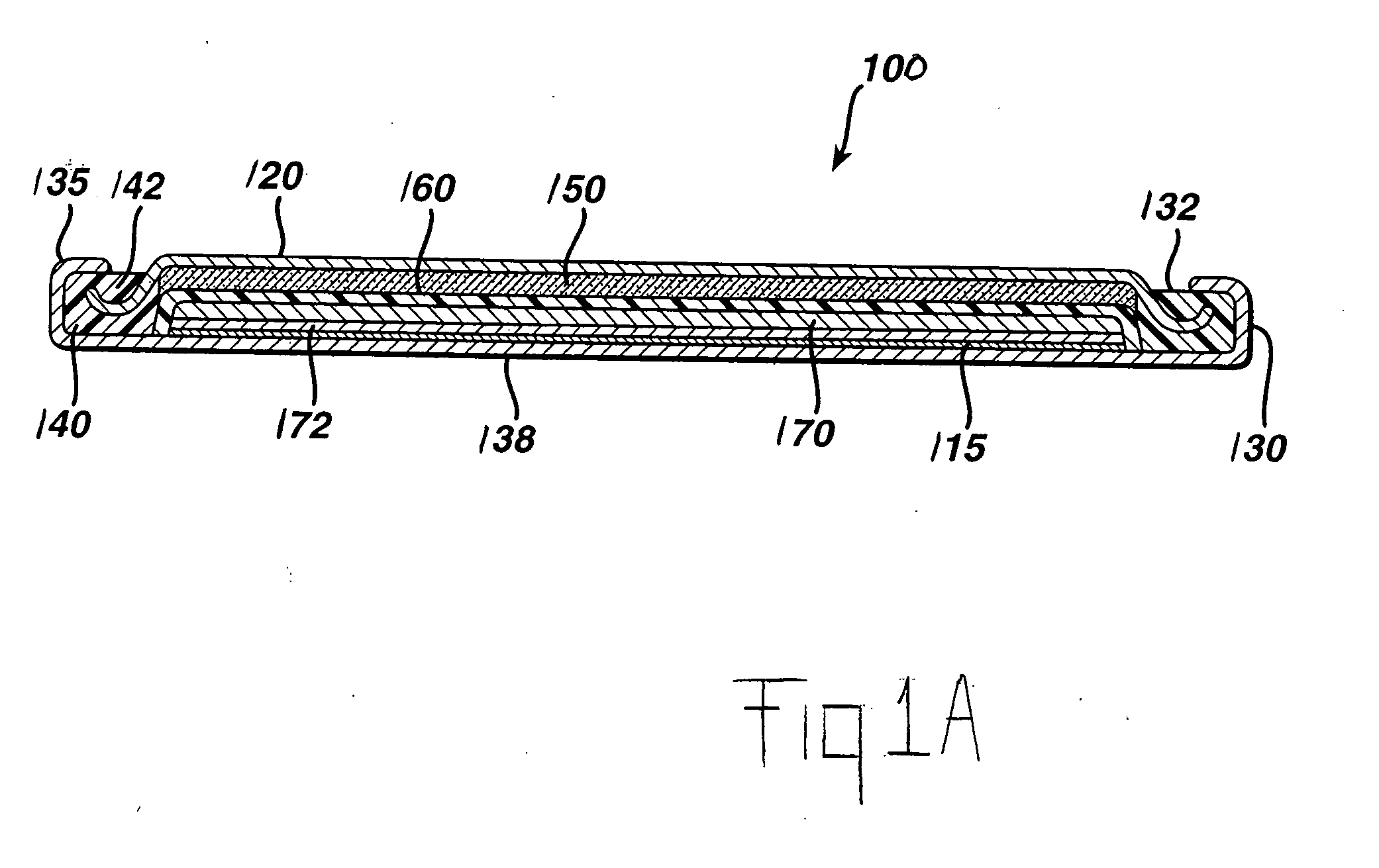

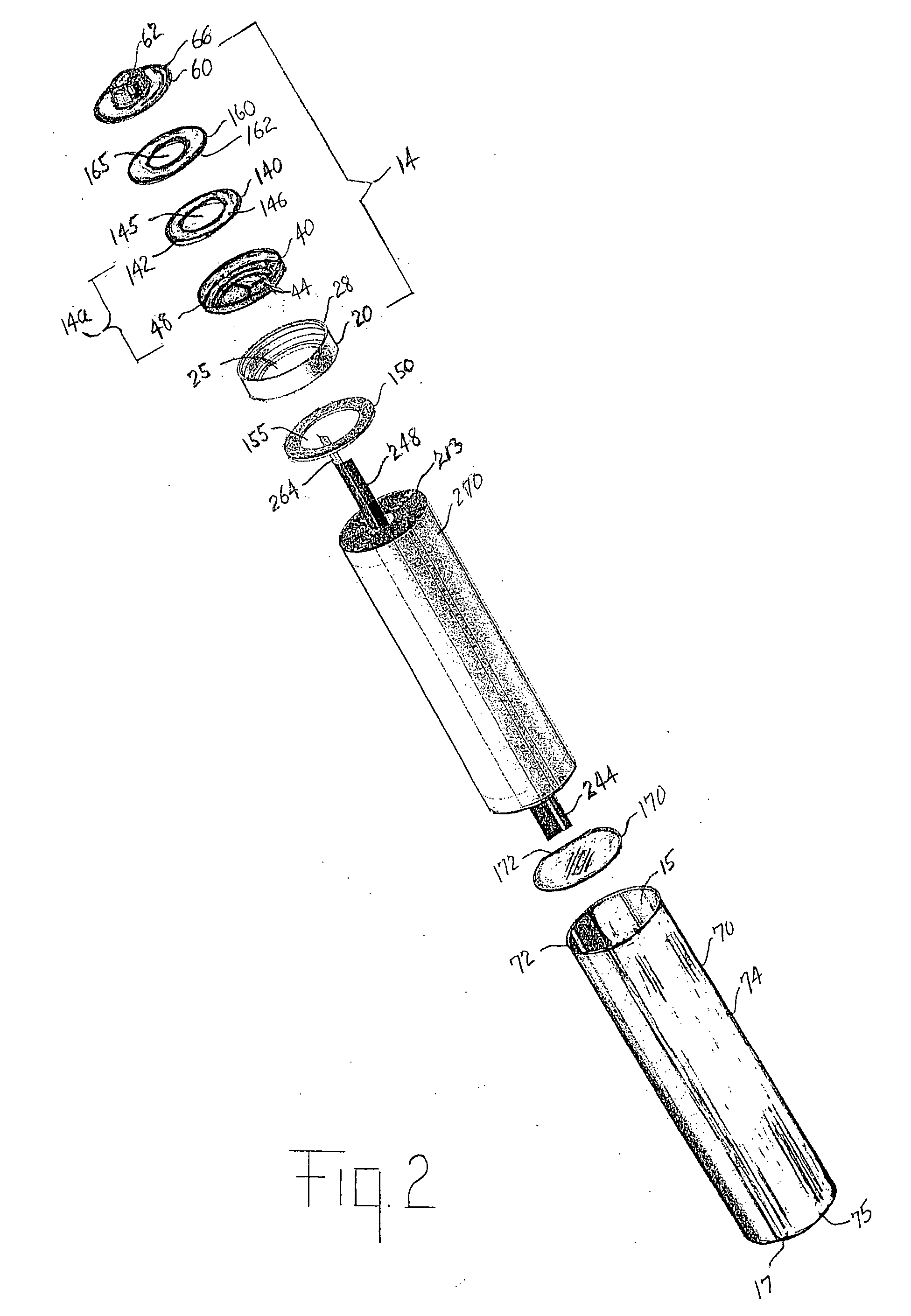

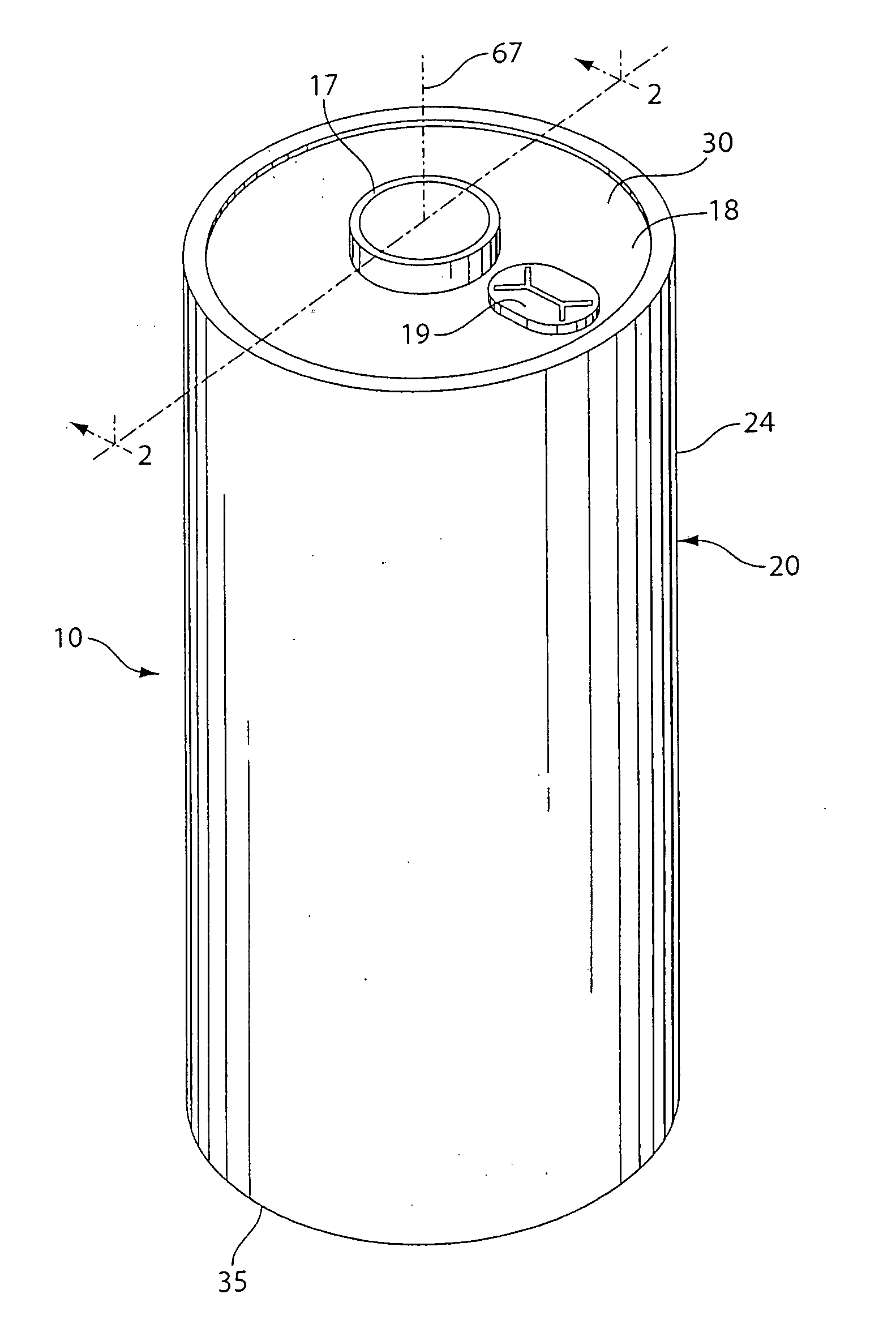

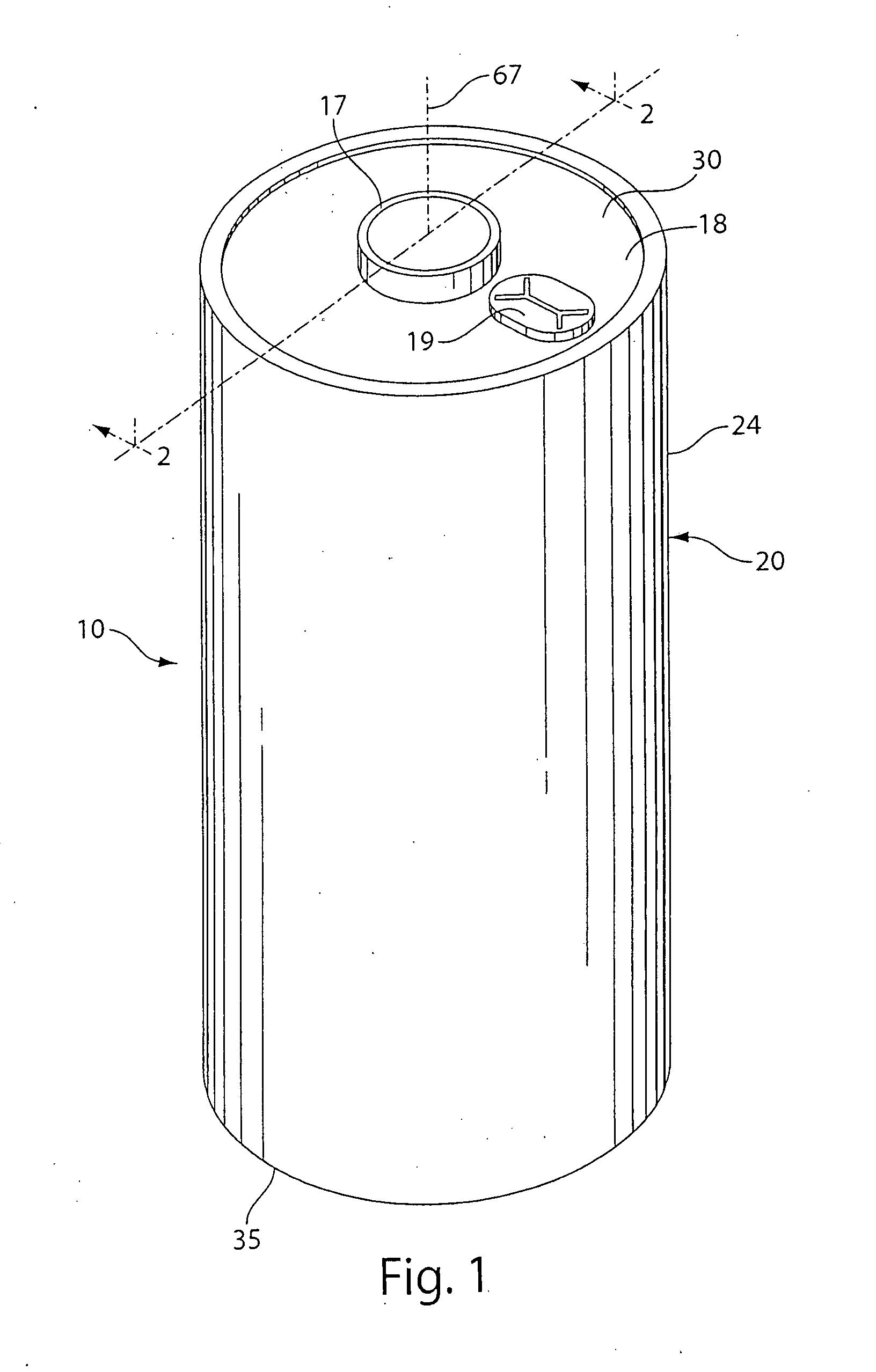

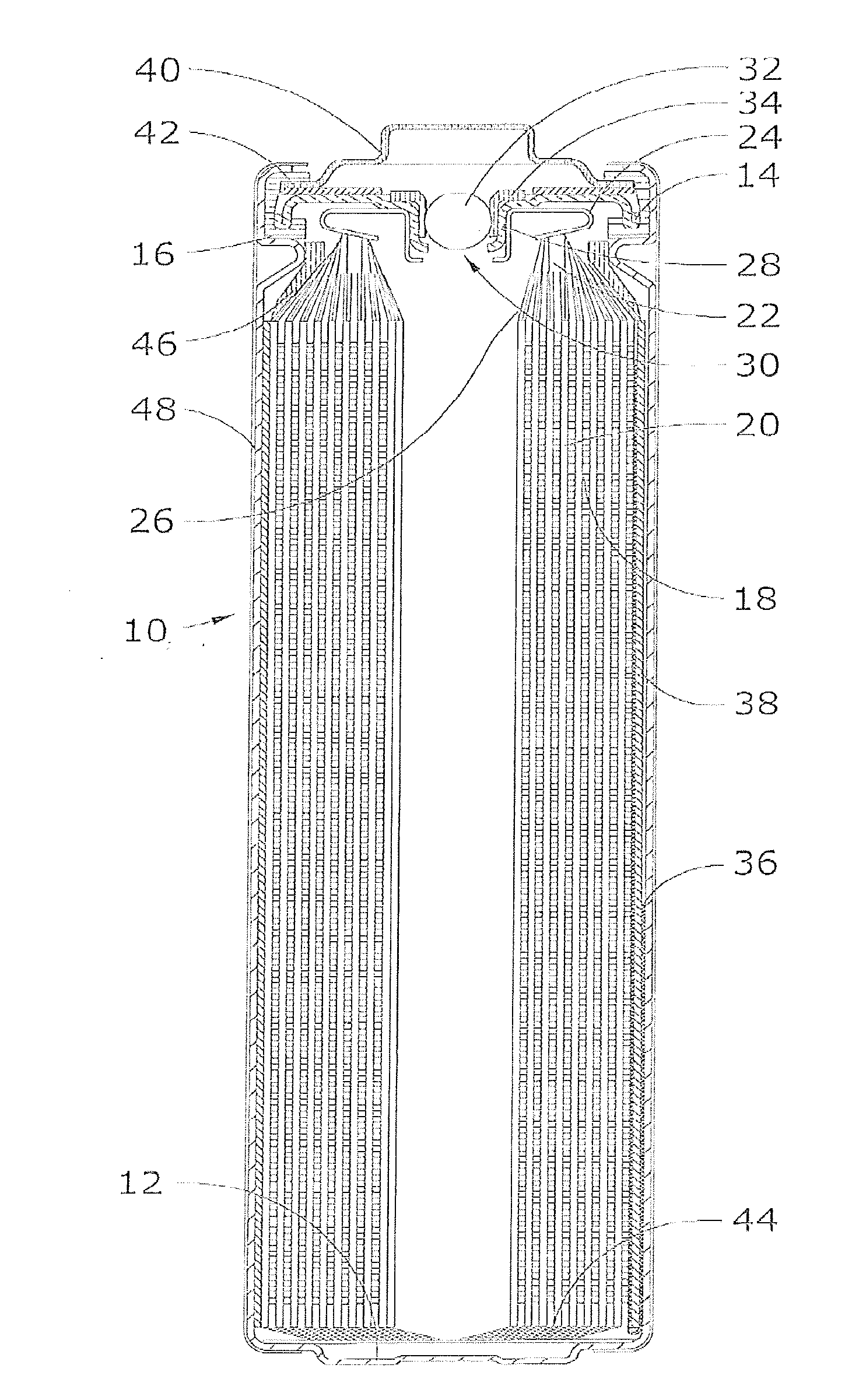

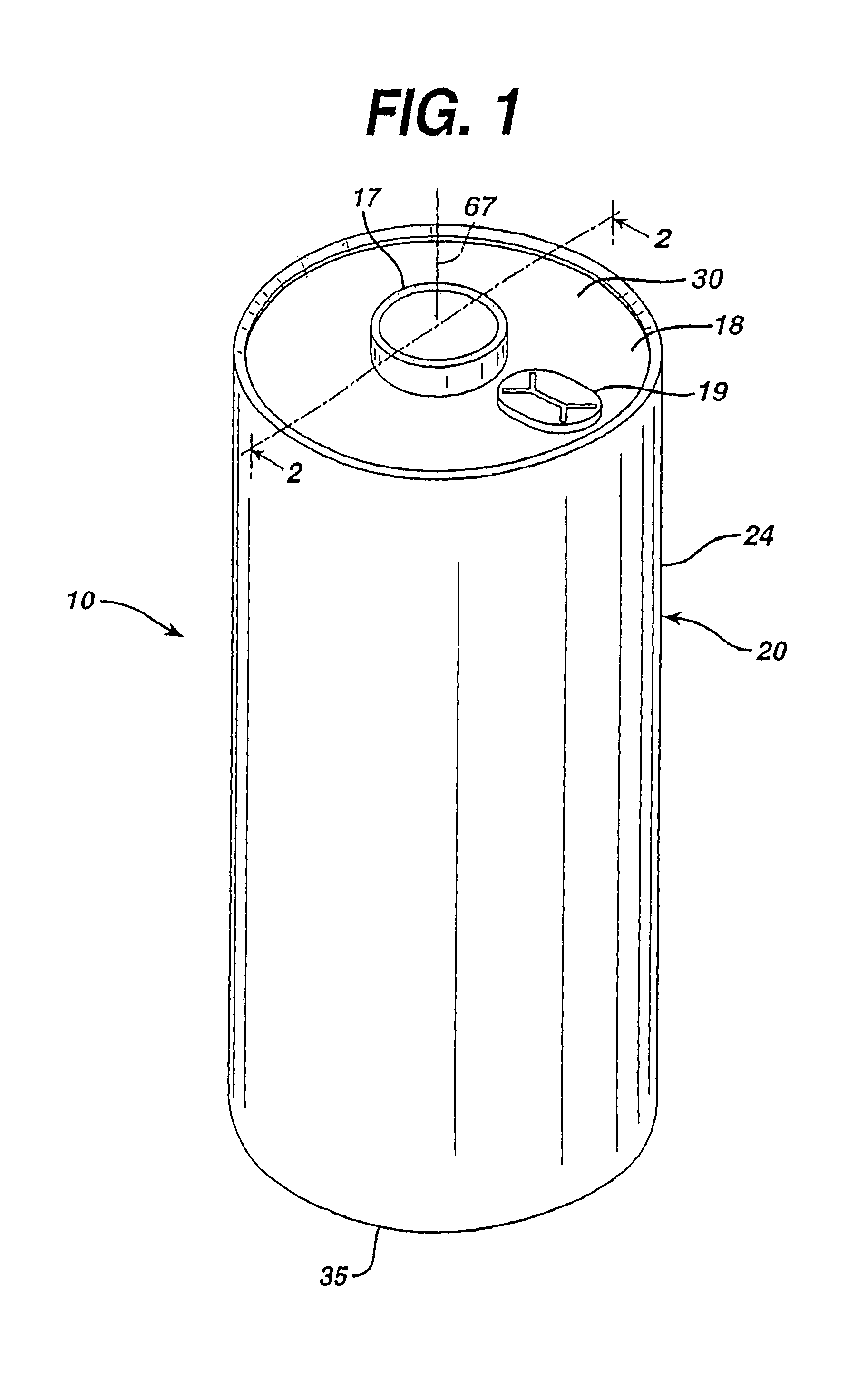

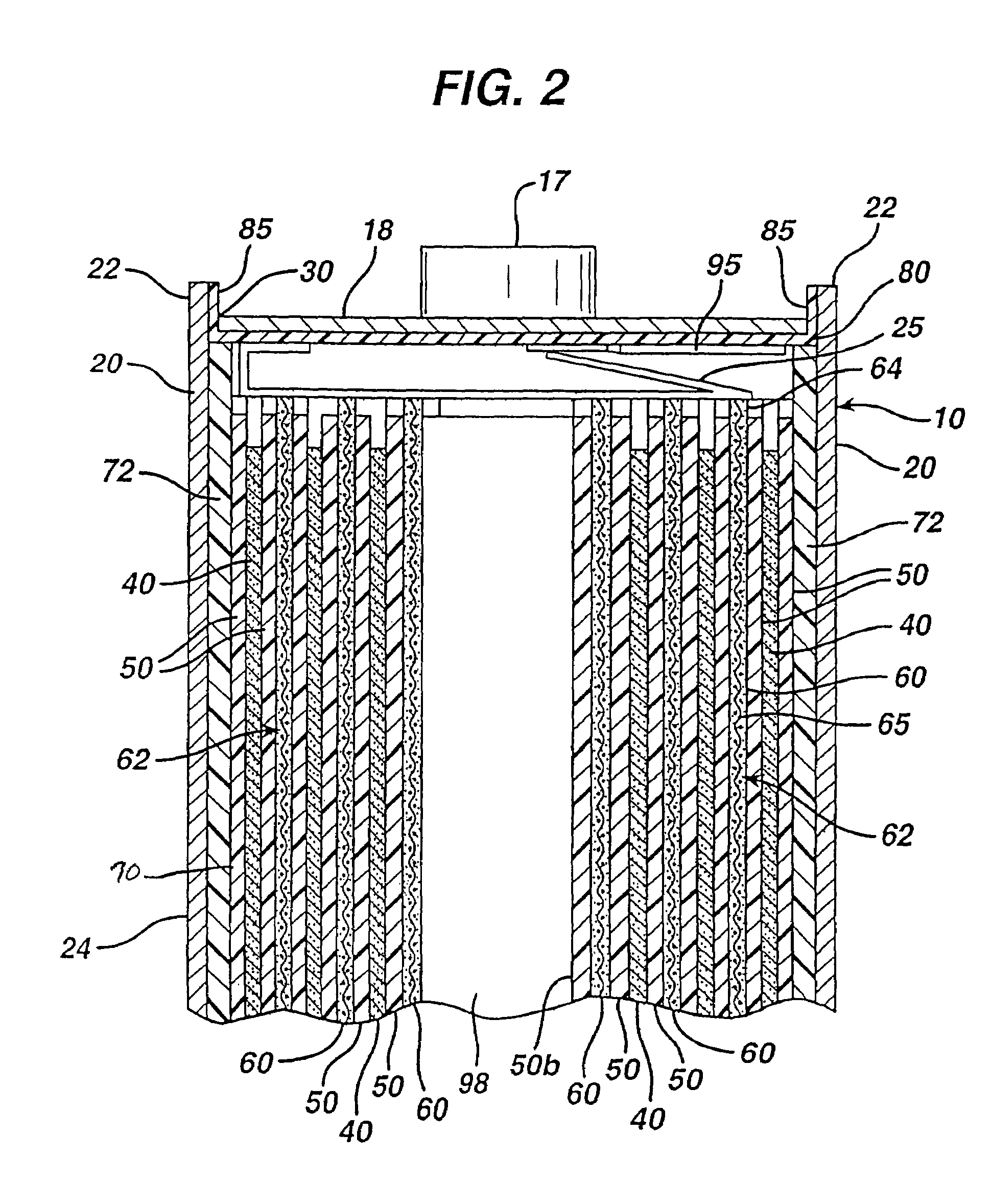

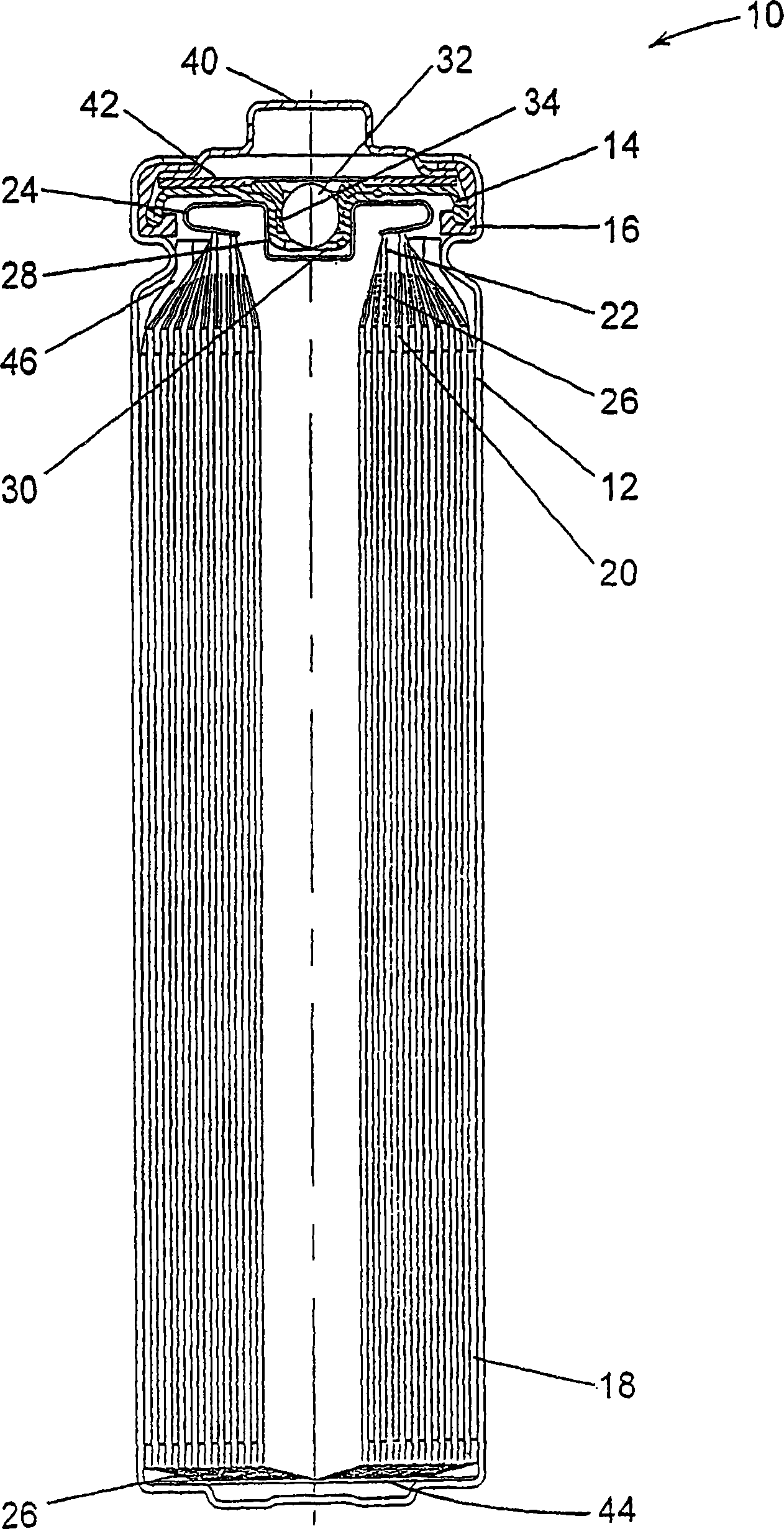

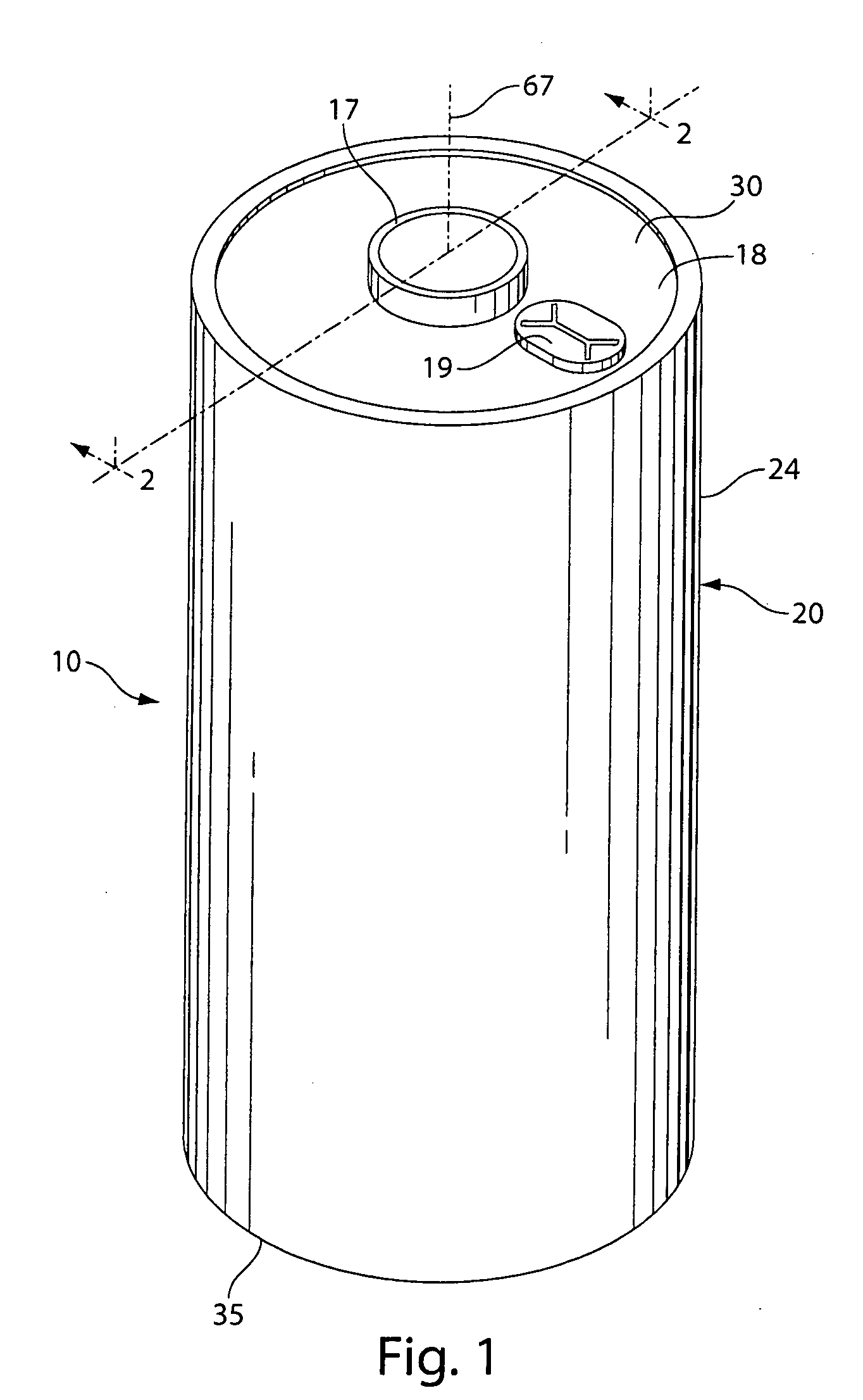

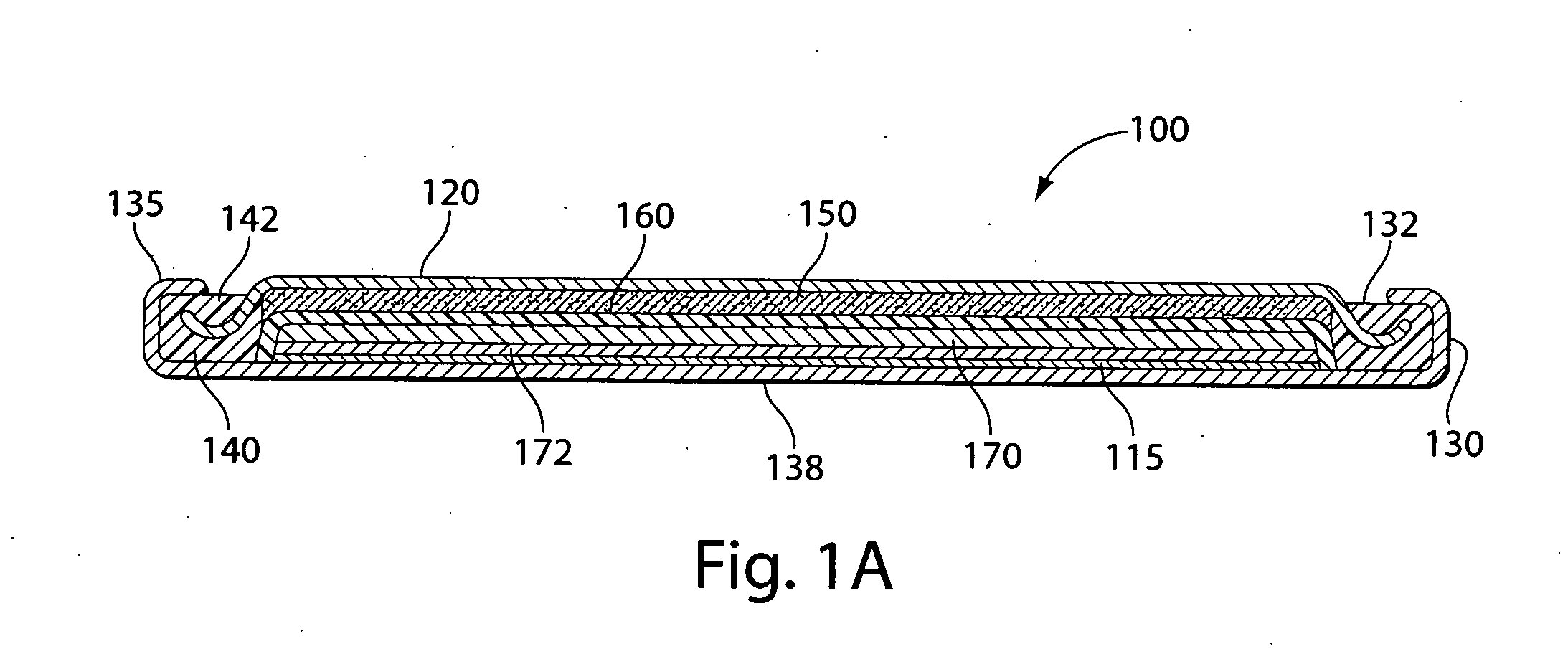

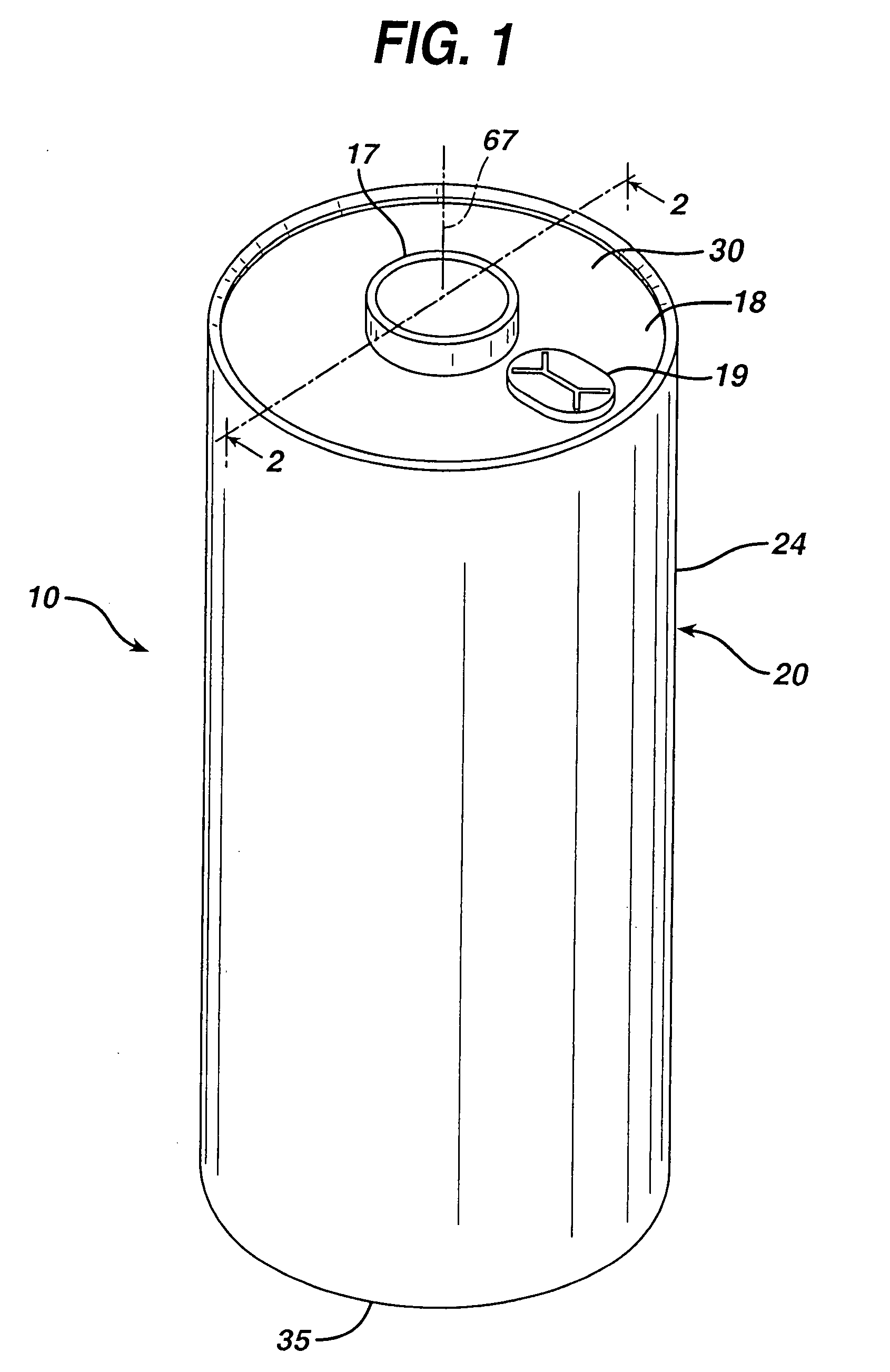

Lithium-iron disulfide cylindrical cell with modified positive electrode

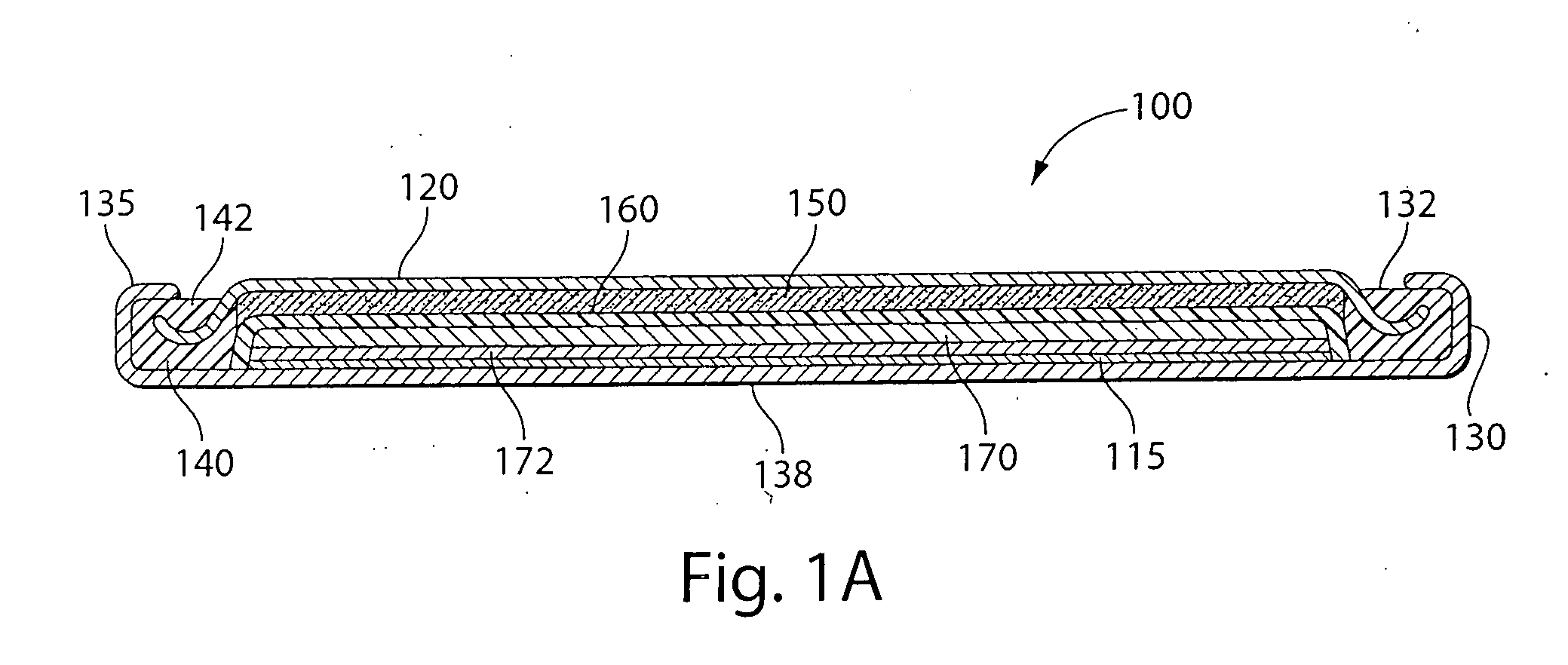

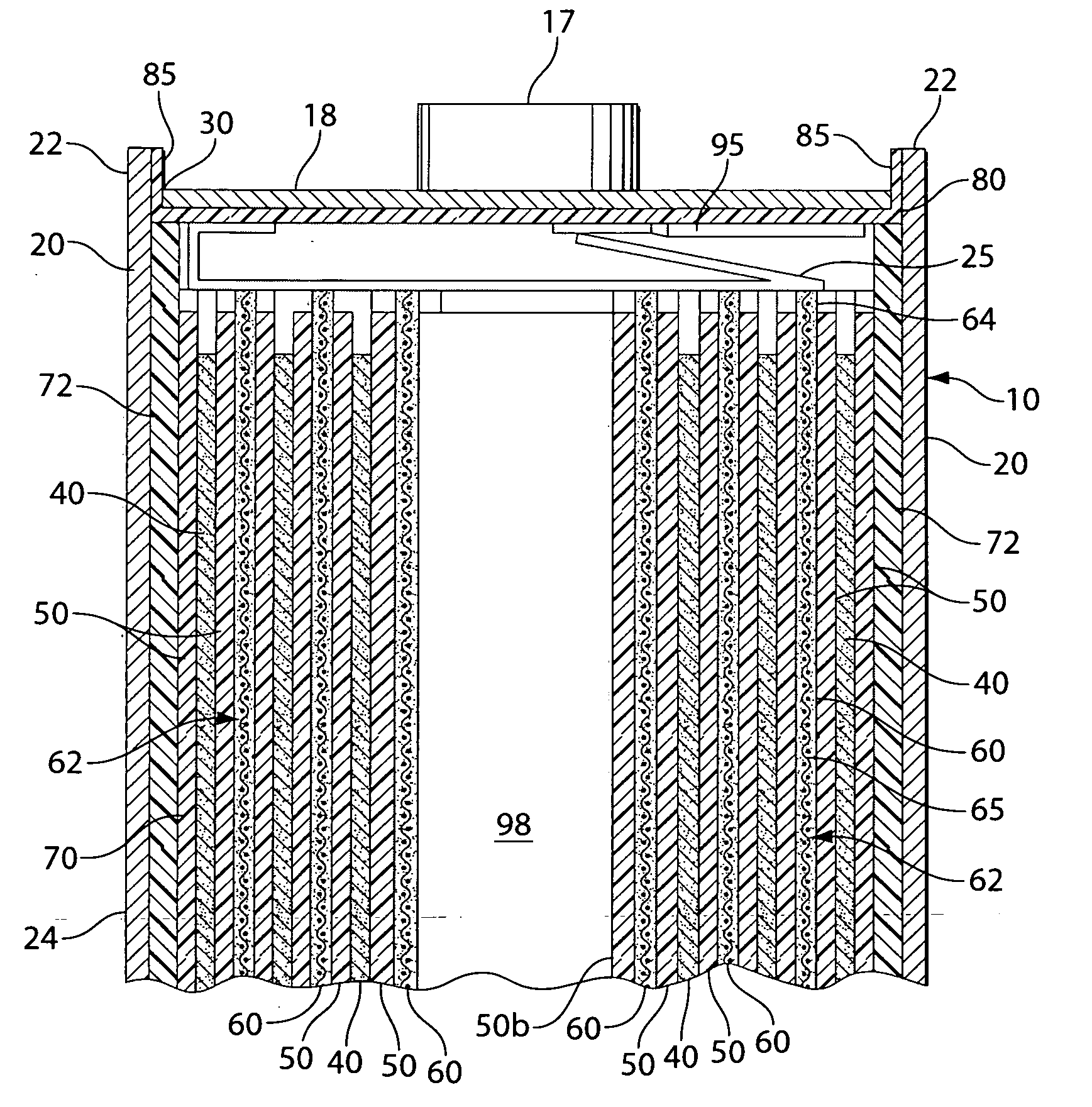

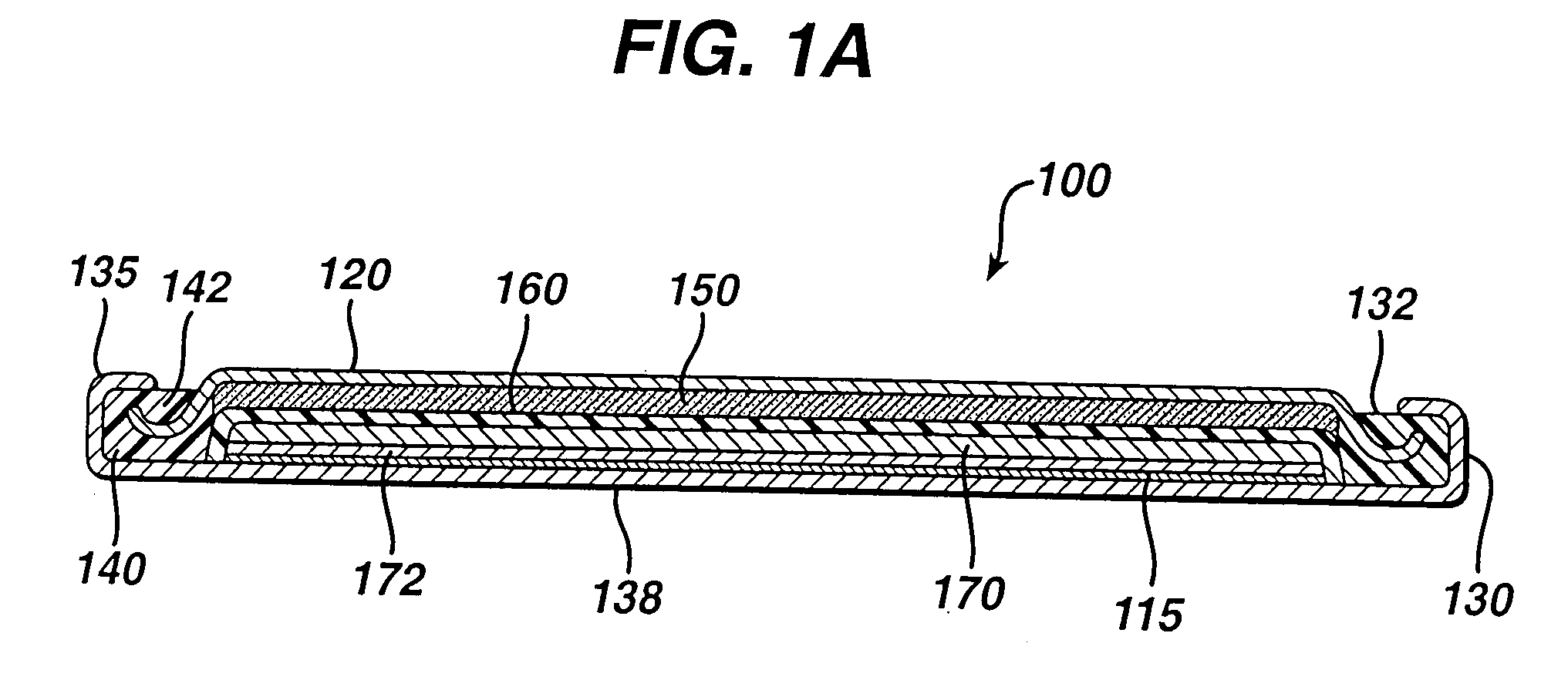

InactiveUS20080026293A1Improve battery performanceMaterial Utilization OptimizationFinal product manufactureElectrode carriers/collectorsEngineeringAlloy

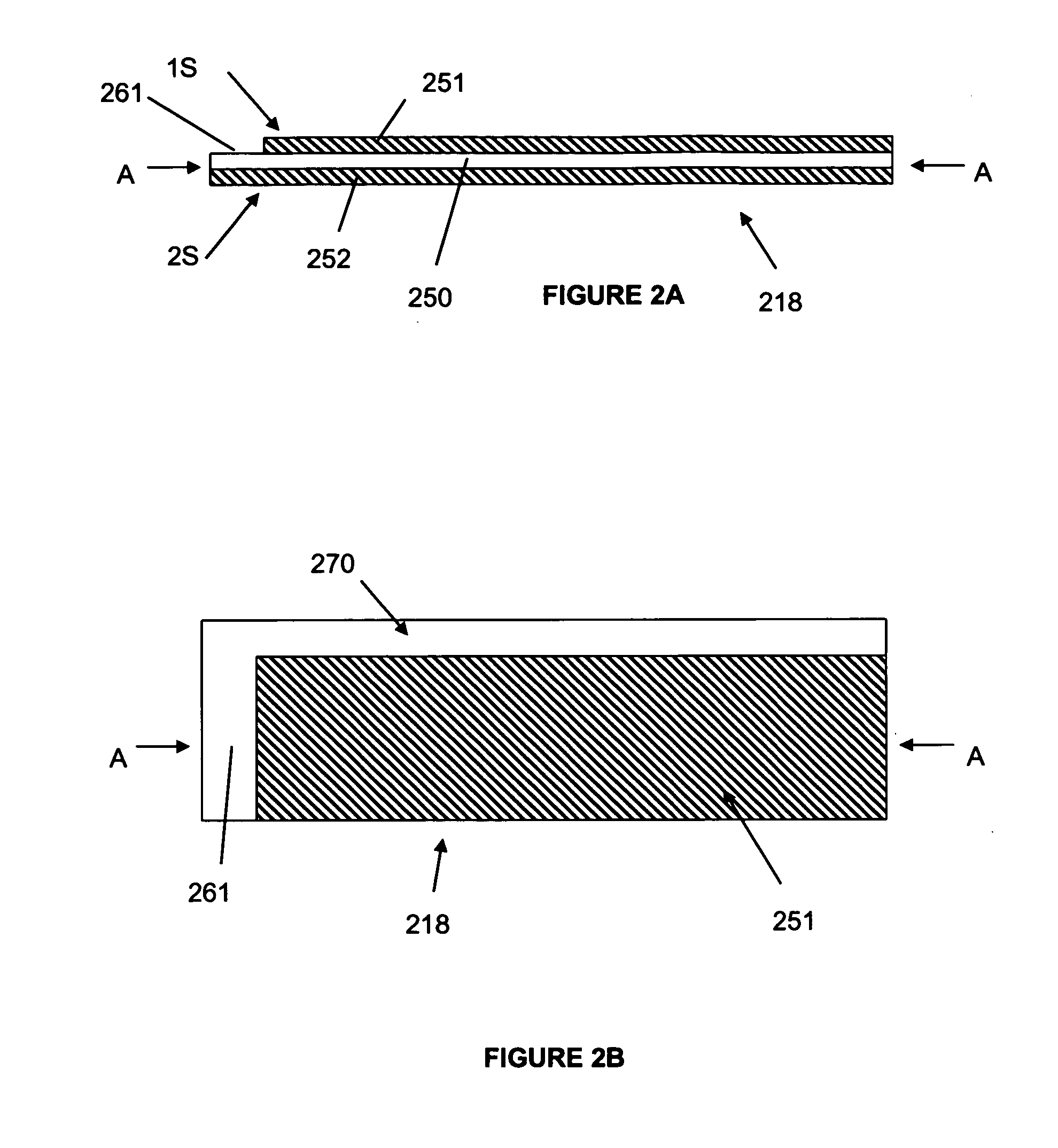

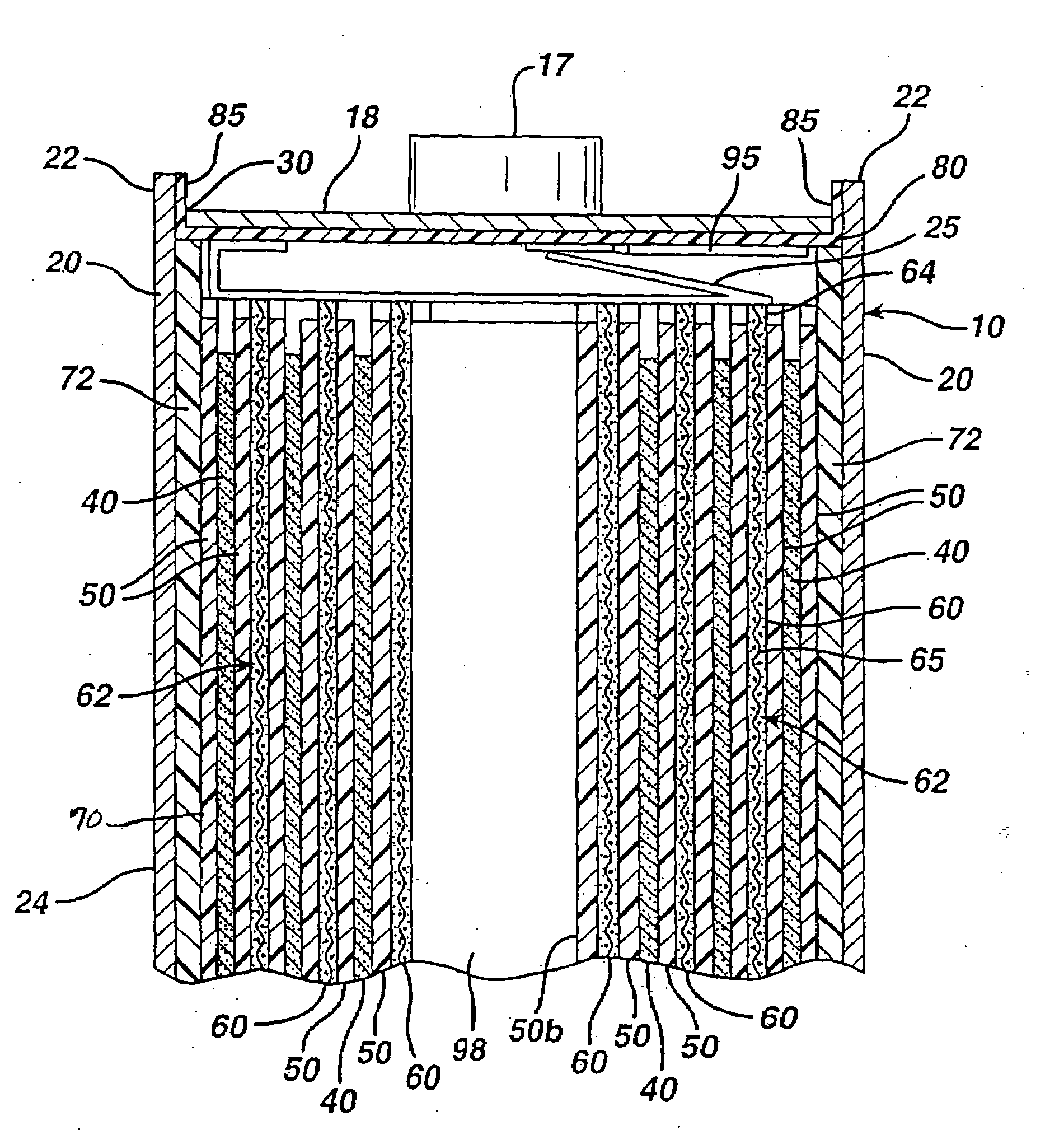

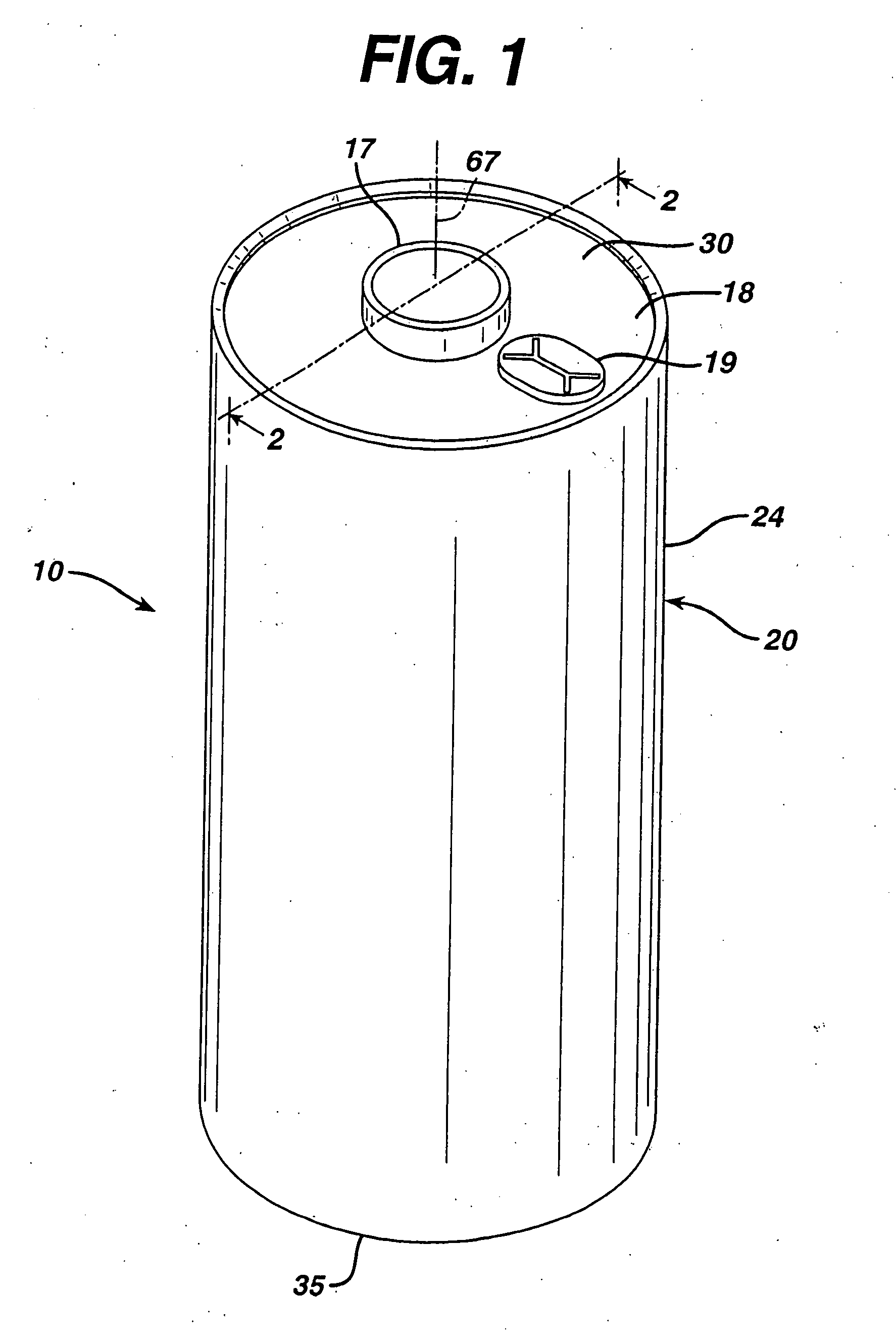

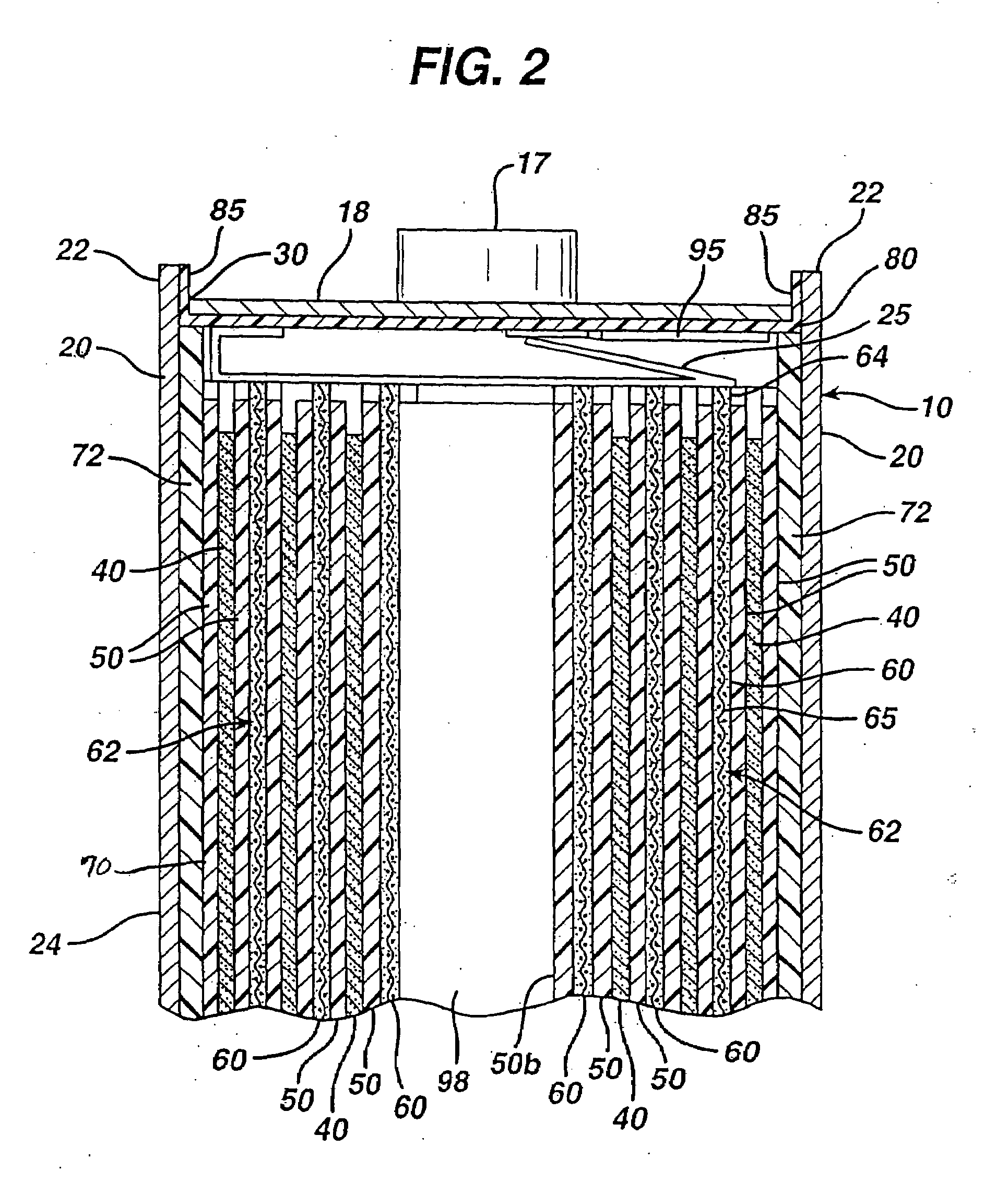

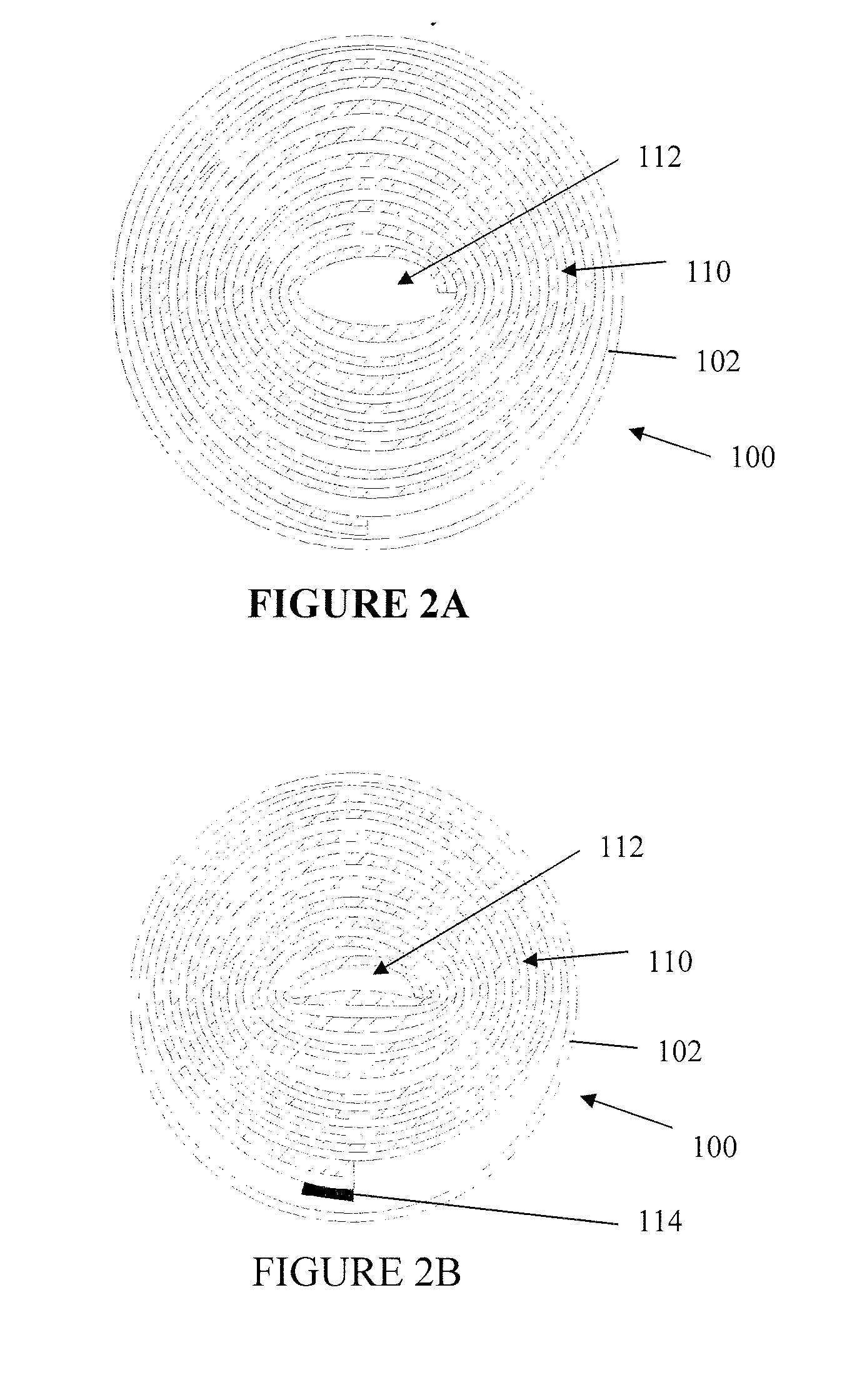

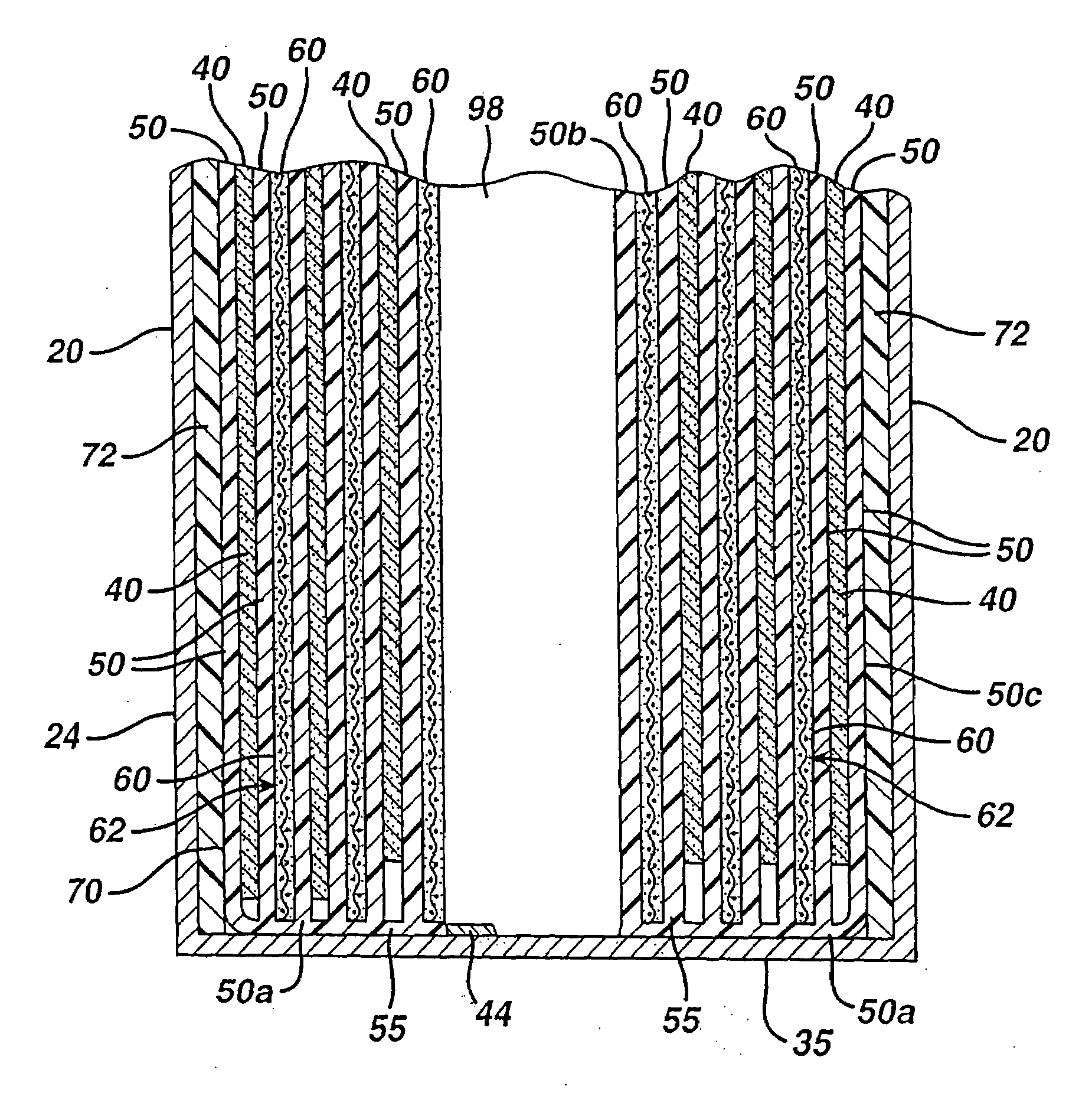

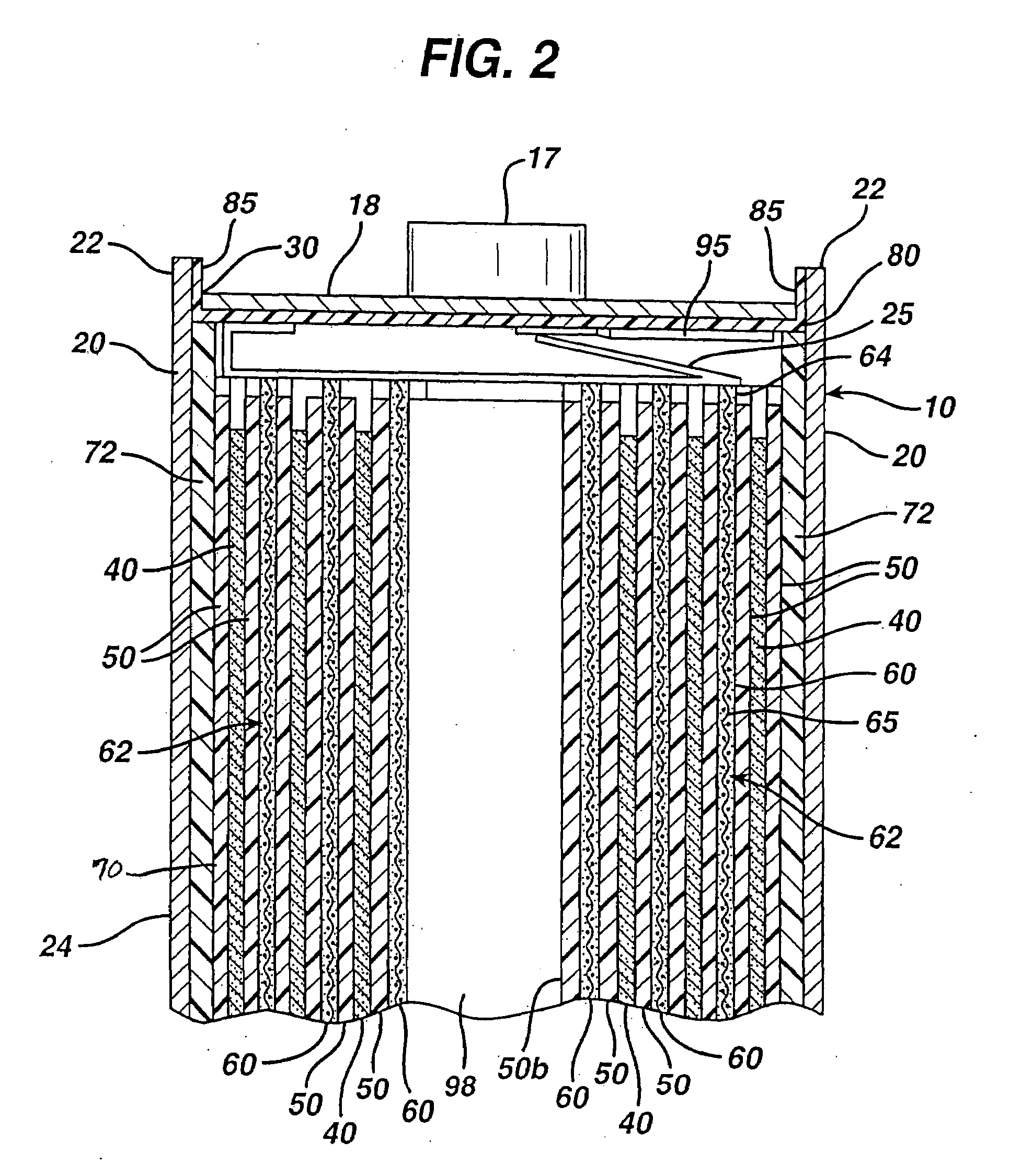

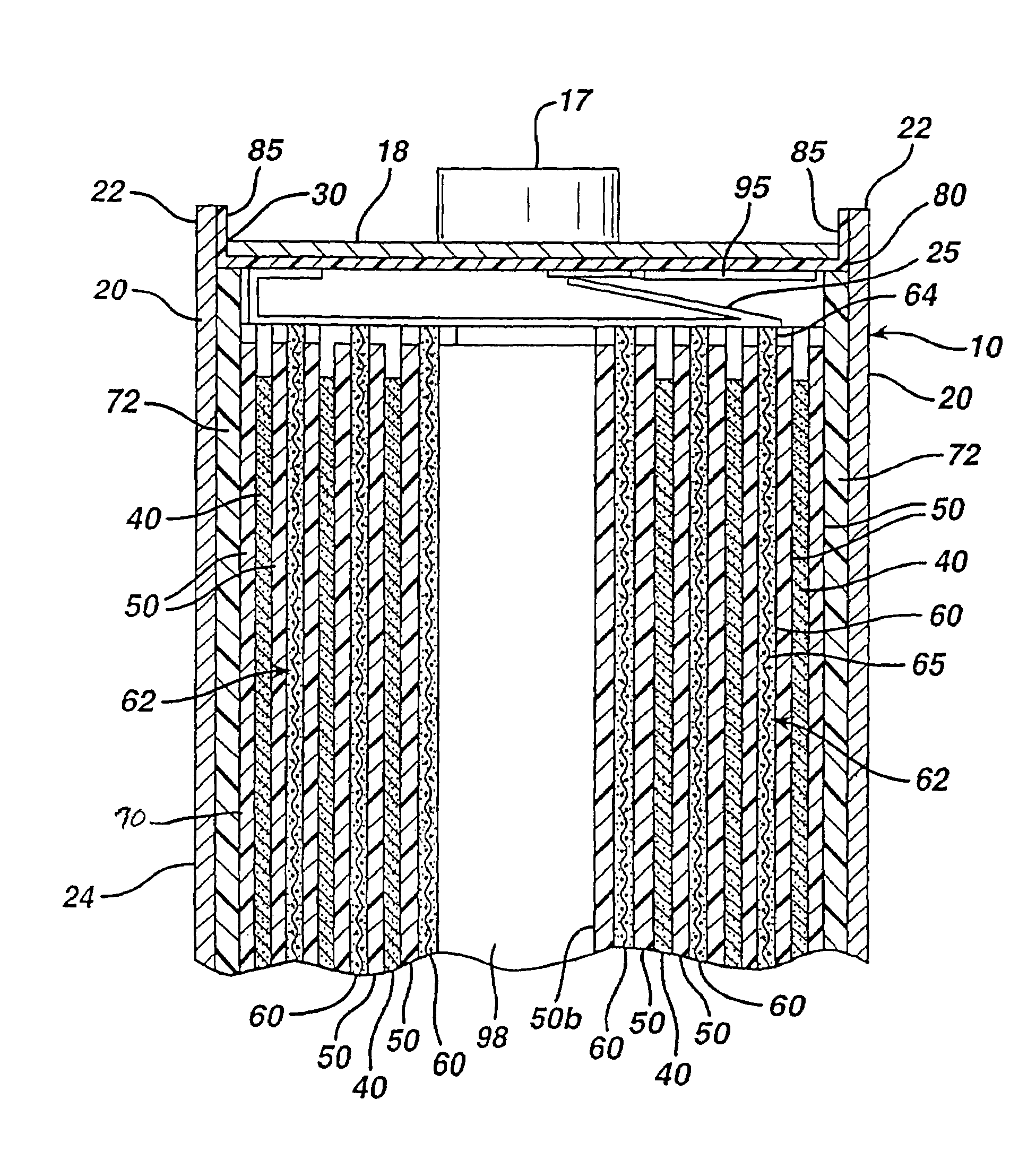

A primary electrochemical cell, and a method for making the same, relies upon a jellyroll electrode with a positive electrode material deposited on a conductive carrier having partially uncoated portion wherein electrochemically active material is coated on only one side of the carrier in order to achieve superior performance in comparison to a cell having no such uncoated portion. The partially uncoated portion is oriented along a longitudinal axis of the jellyroll. The positive electrode material is preferably iron disulfide, whereas the negative electrode comprises lithium or a lithium alloy.

Owner:EVEREADY BATTERY CO INC

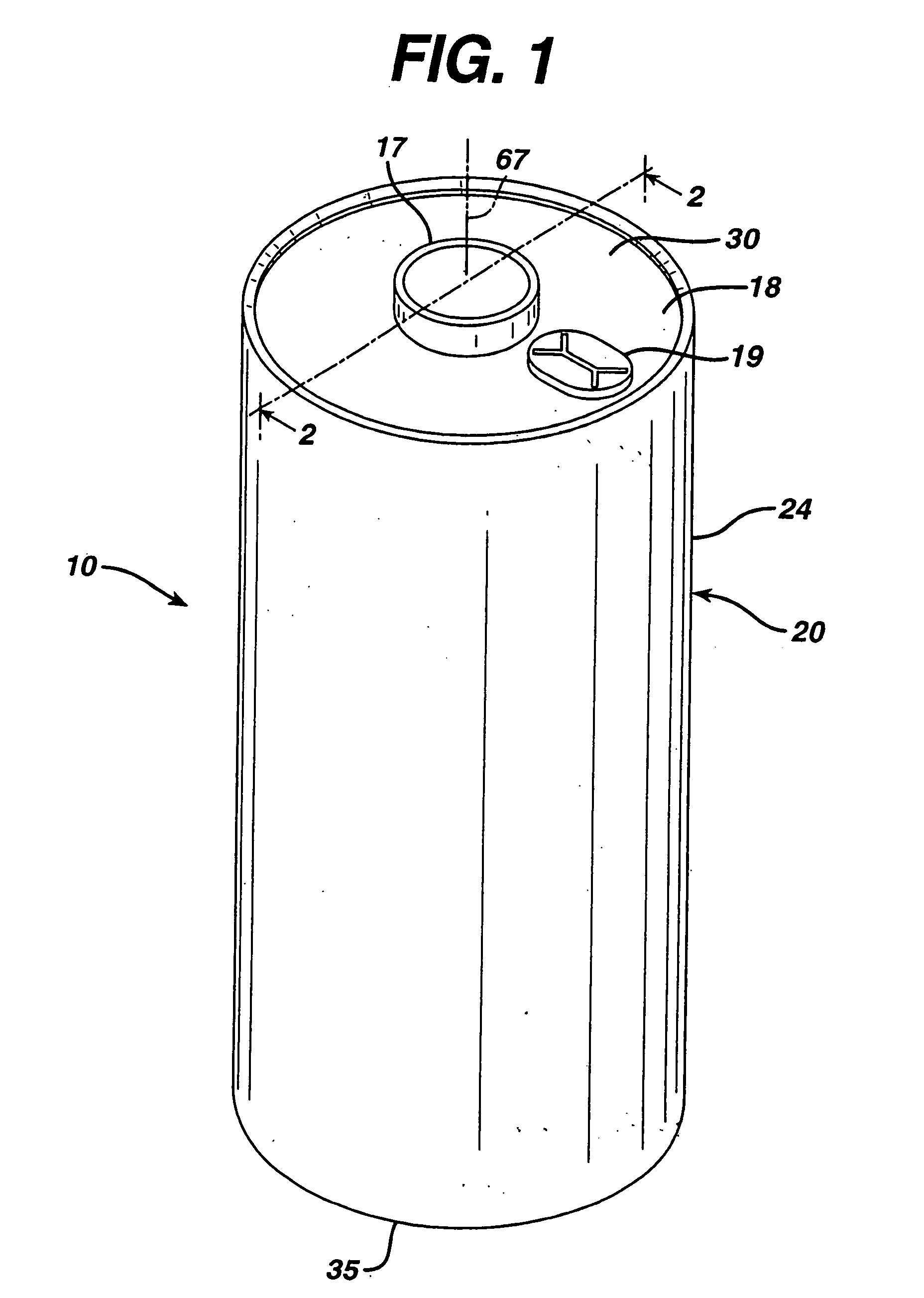

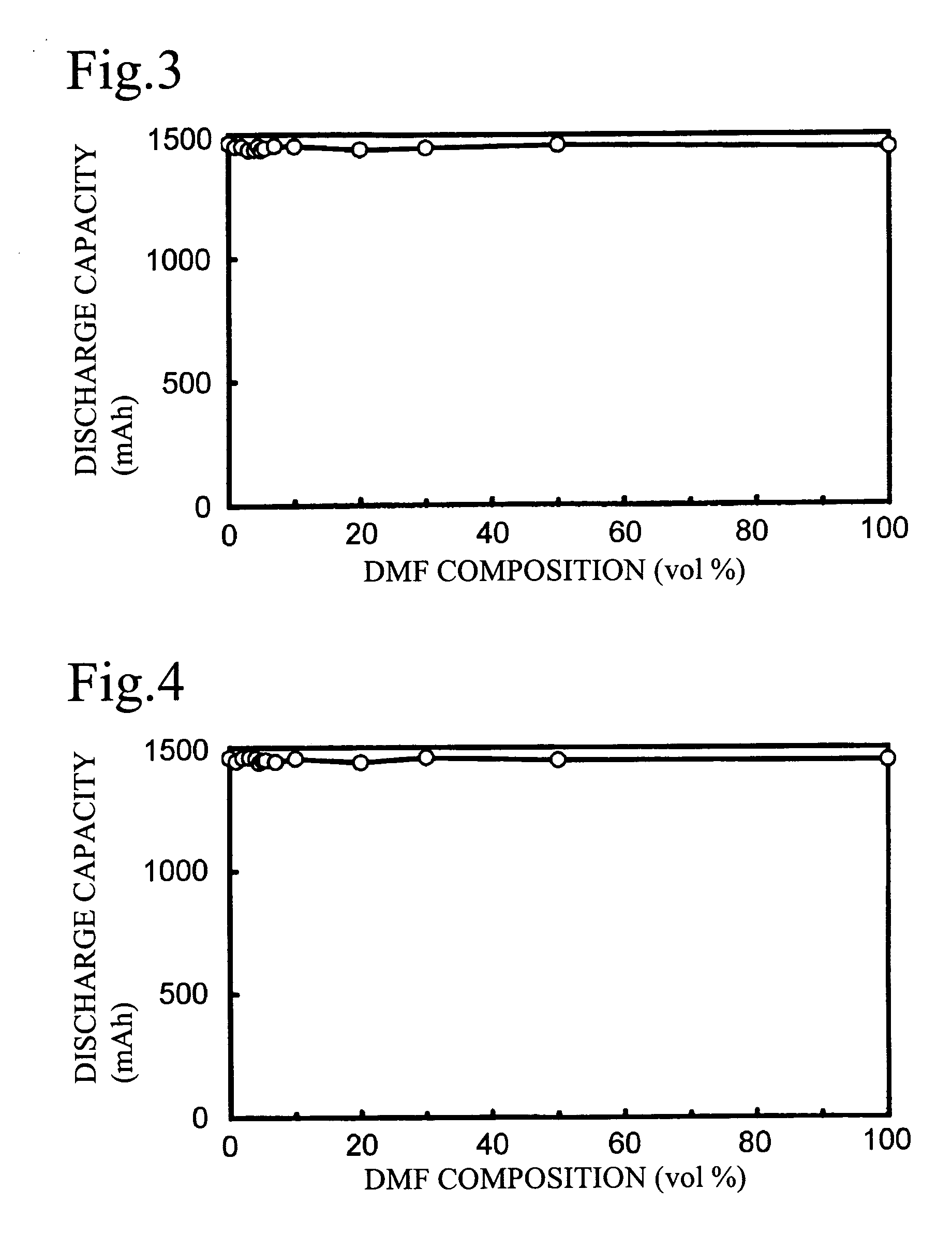

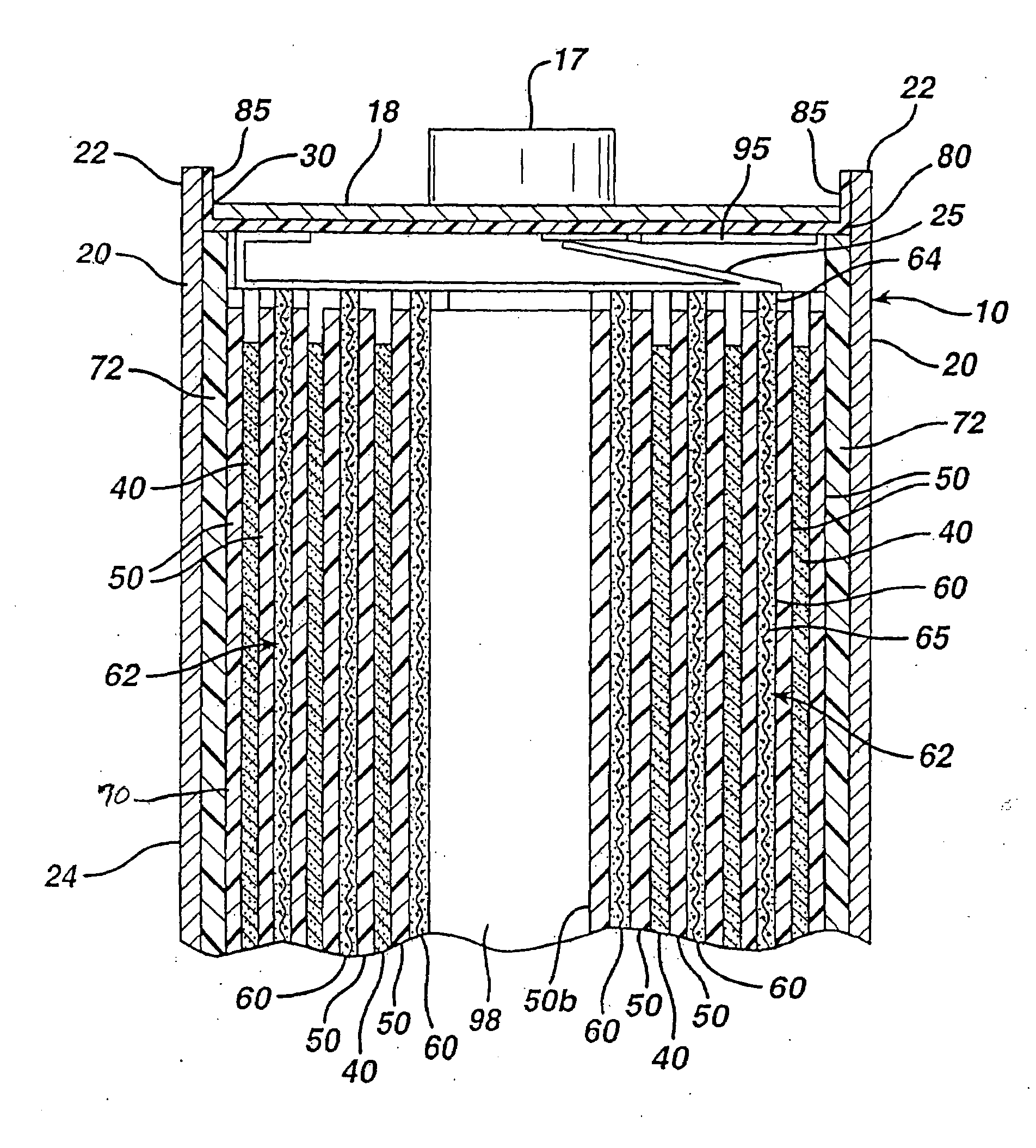

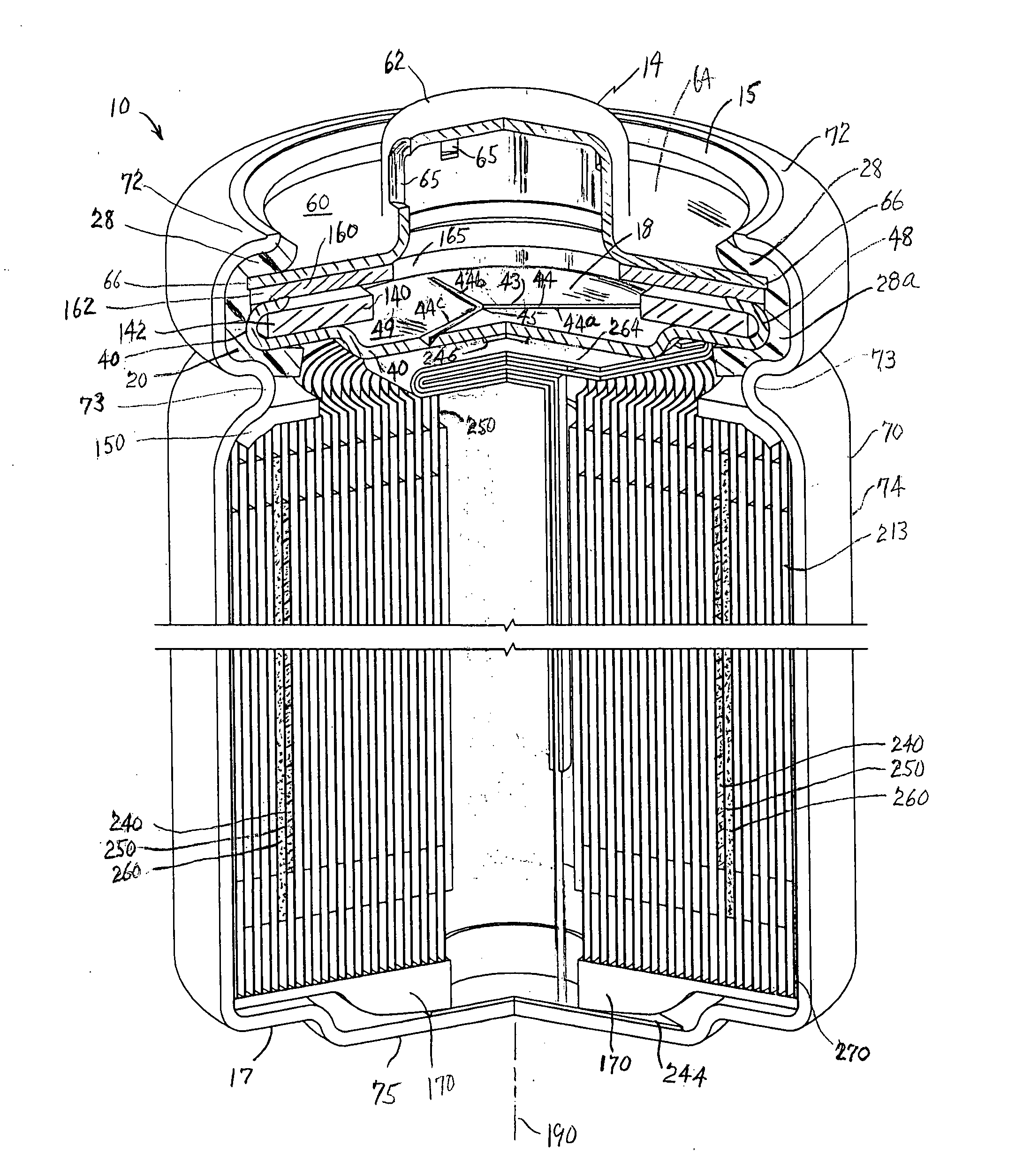

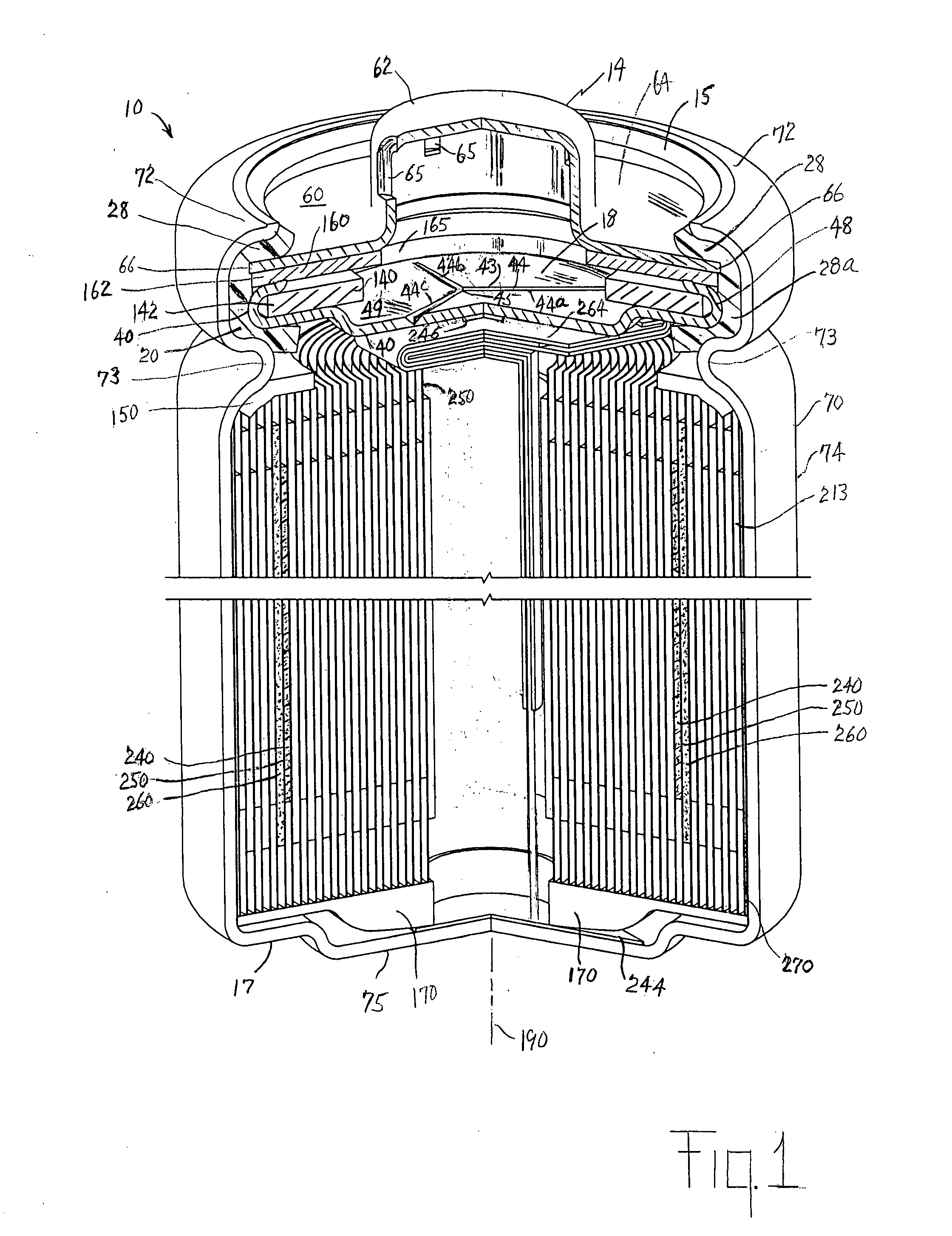

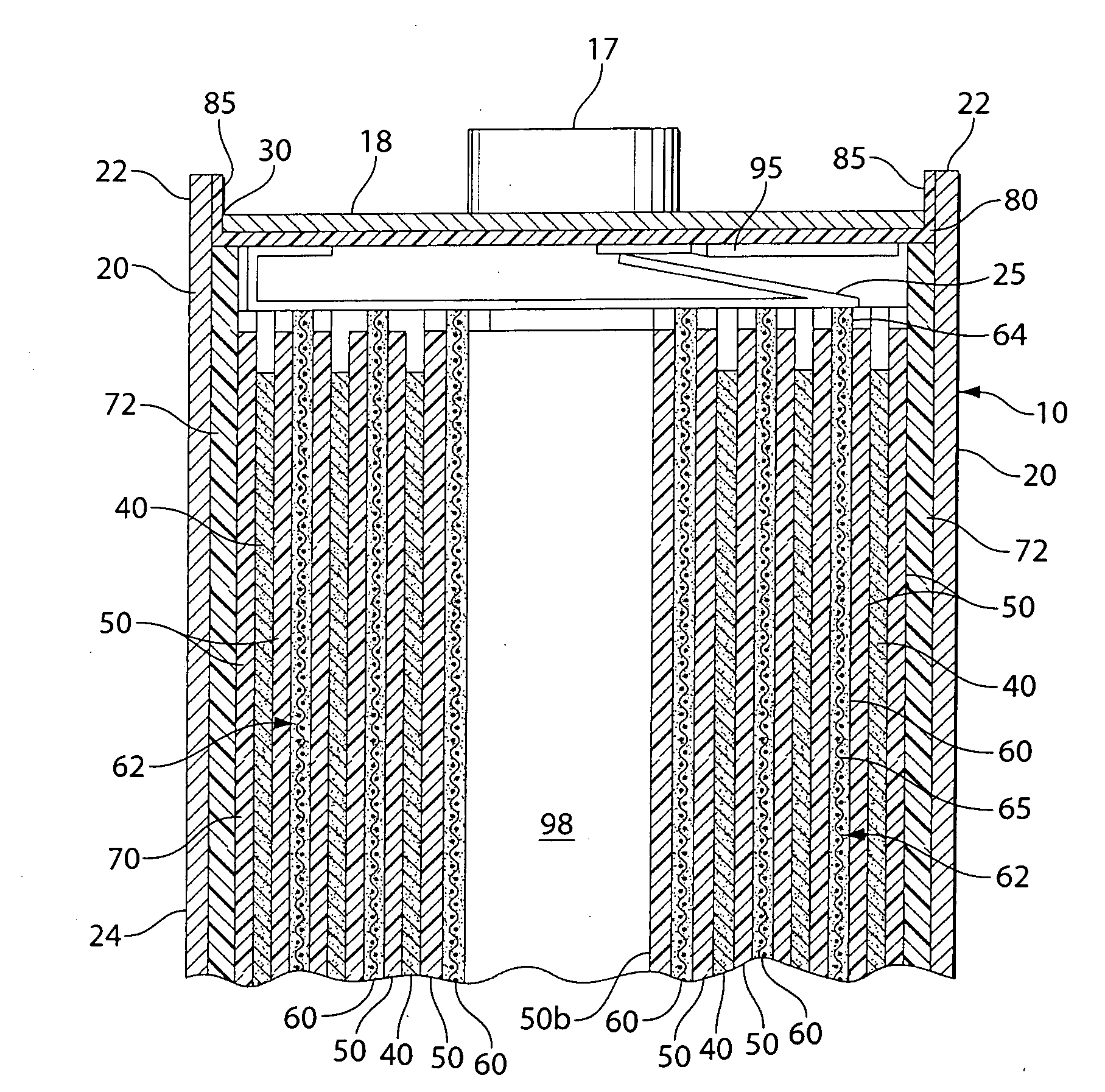

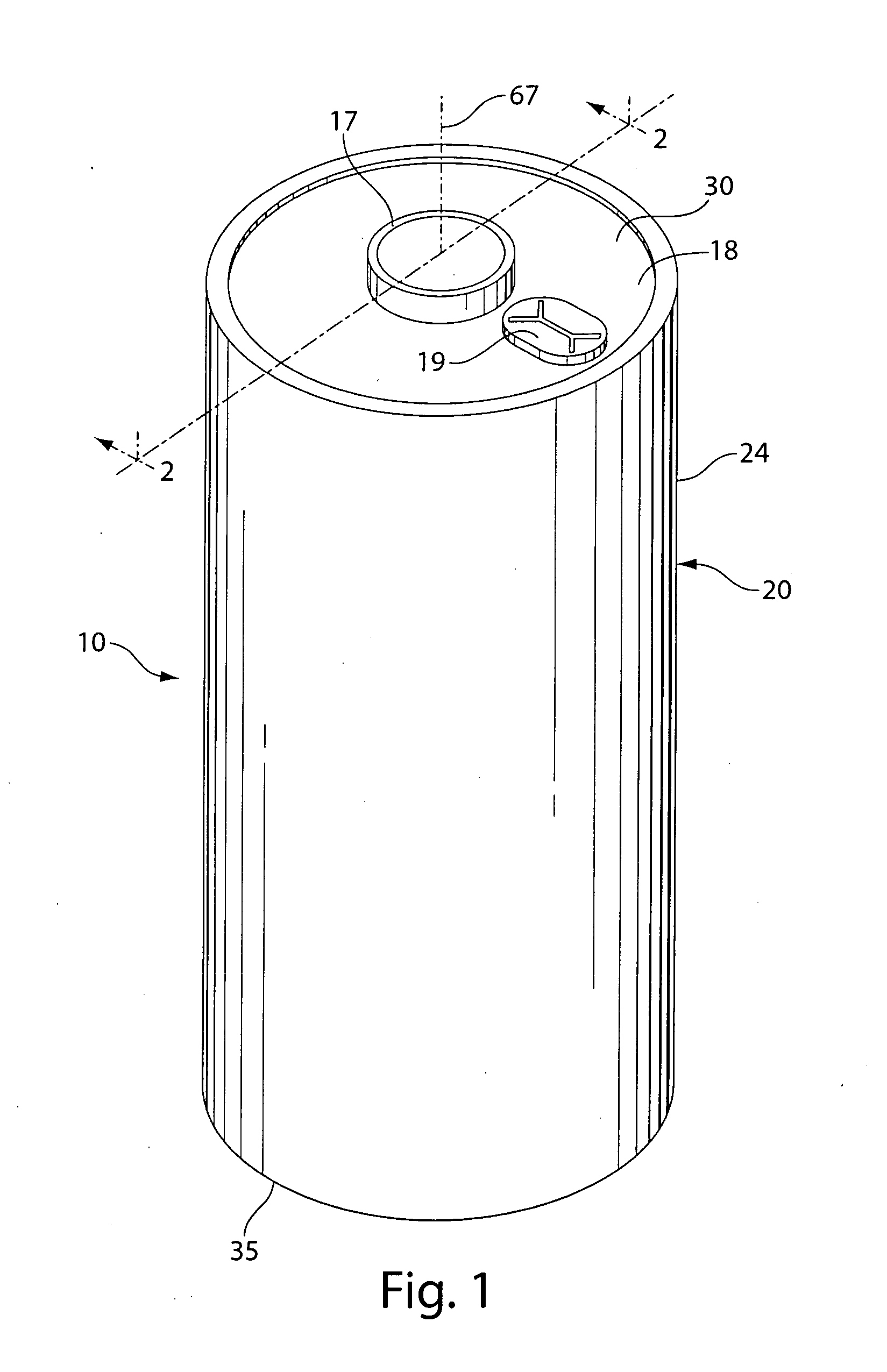

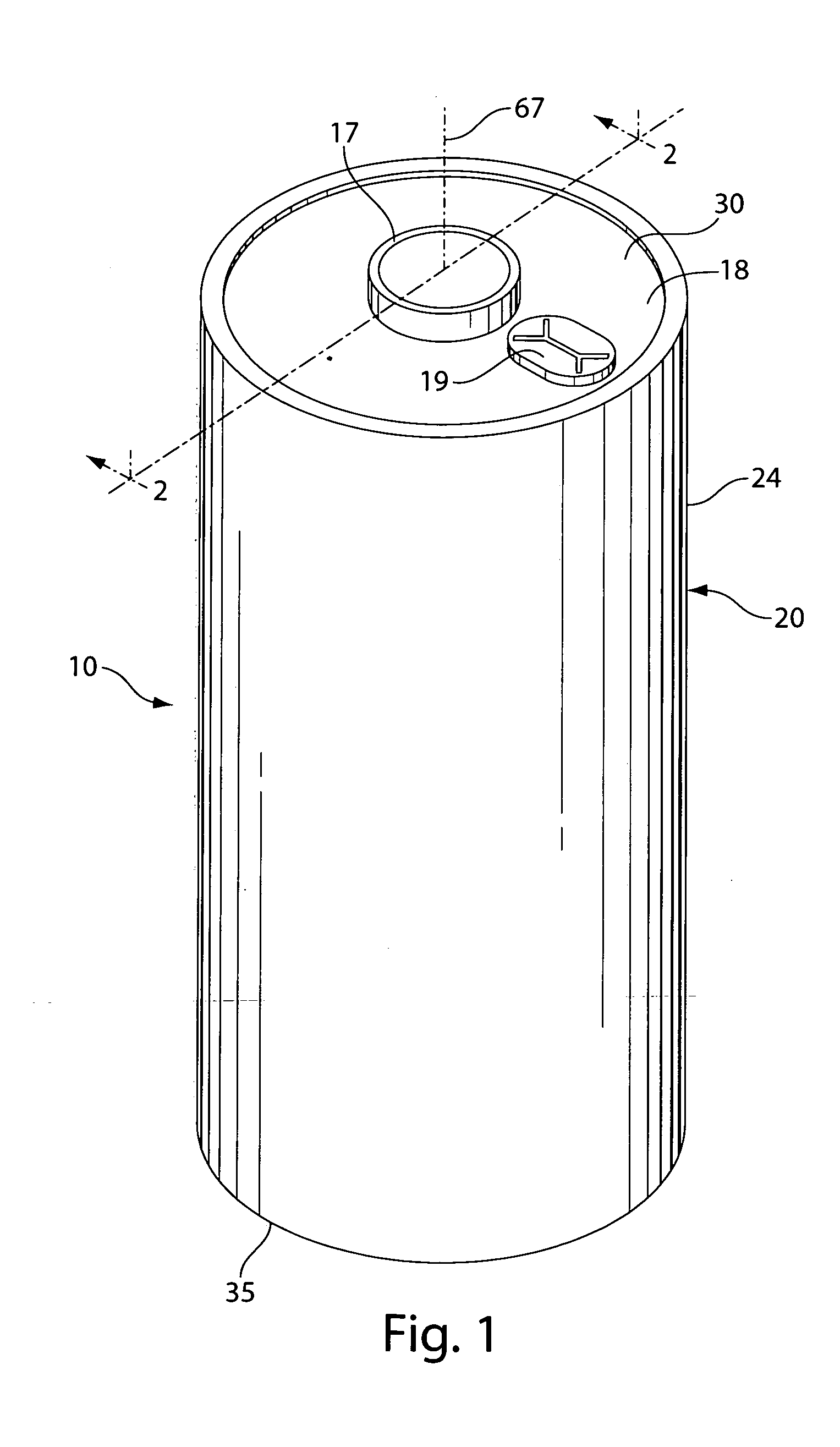

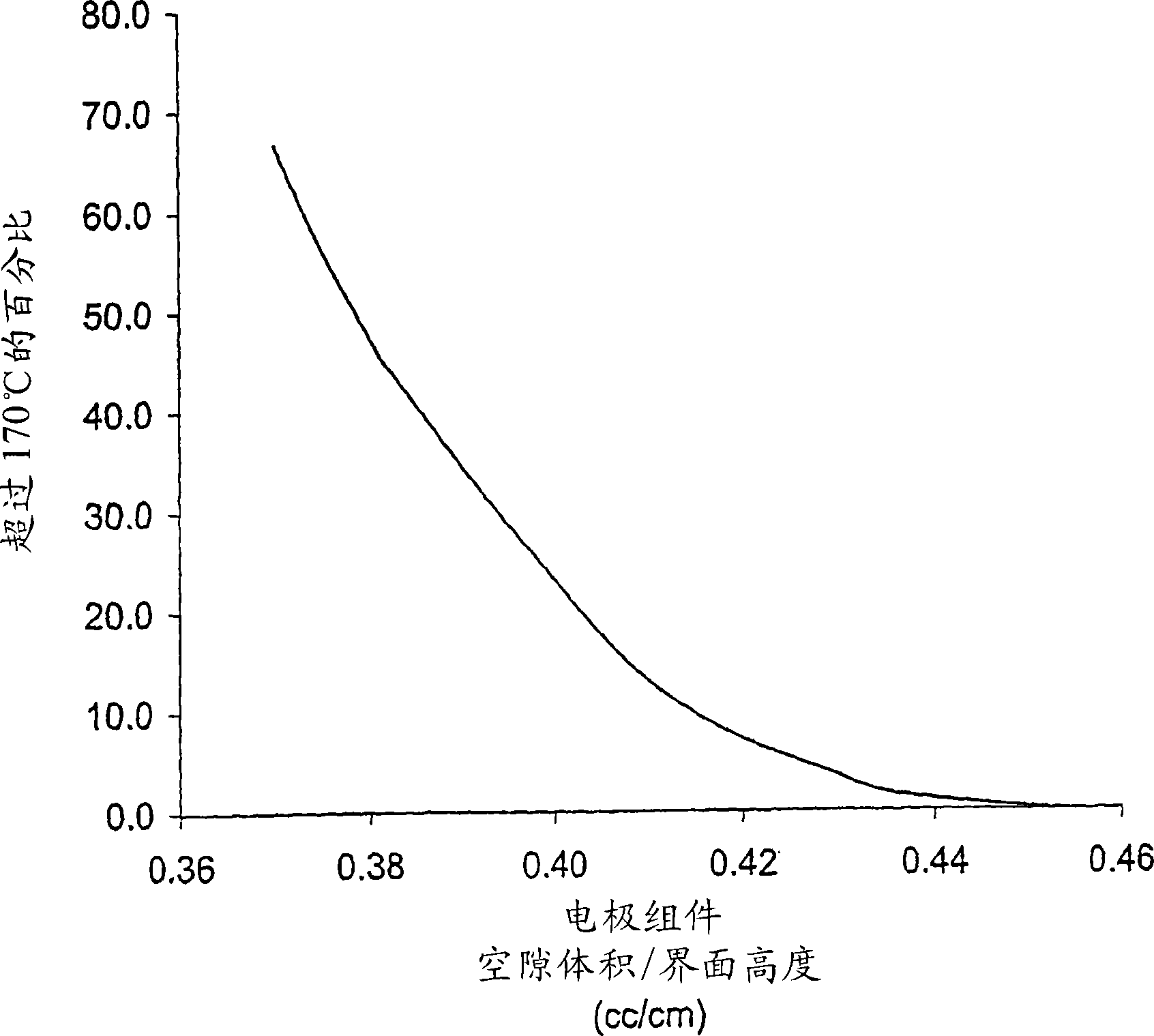

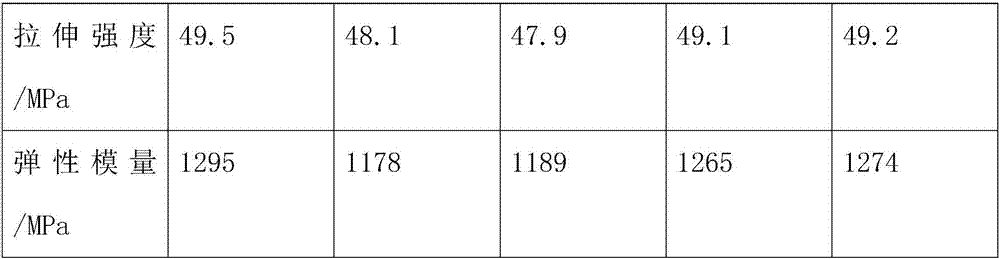

Electrochemical cell with positive container

InactiveUS20080026288A1Improve utilization efficiencyIncrease battery capacityFinal product manufactureElectrode carriers/collectorsSpiral woundEngineering

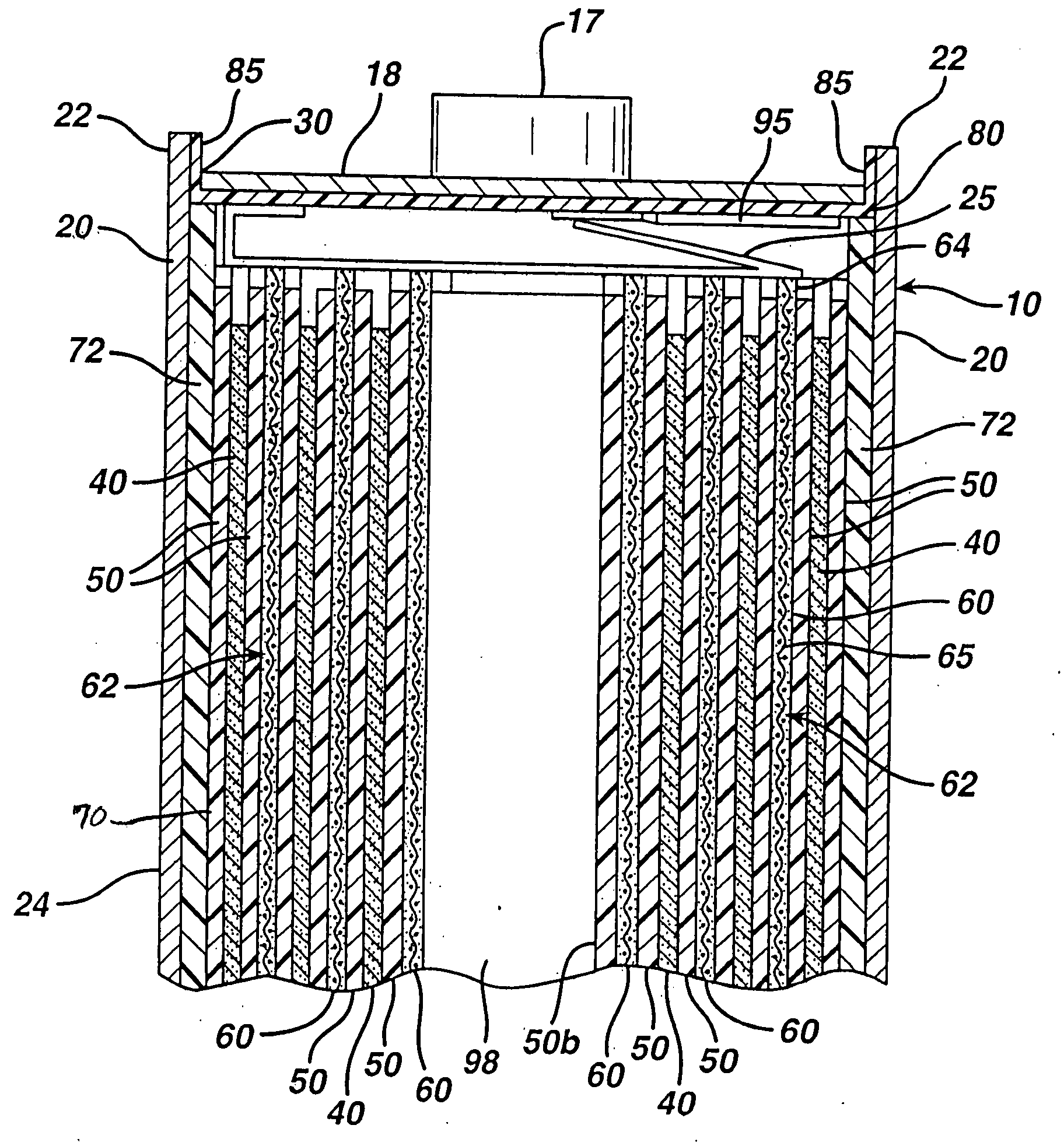

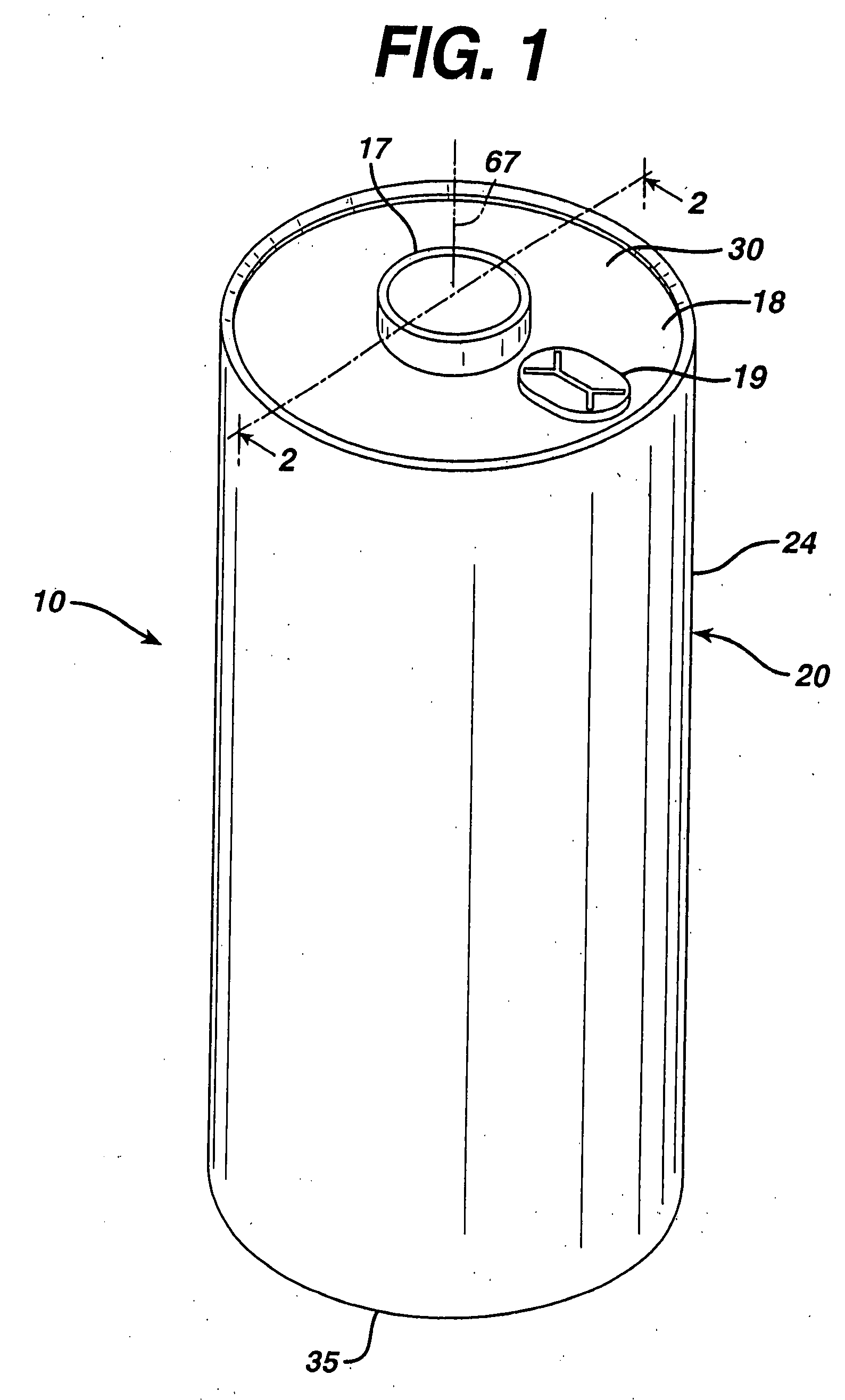

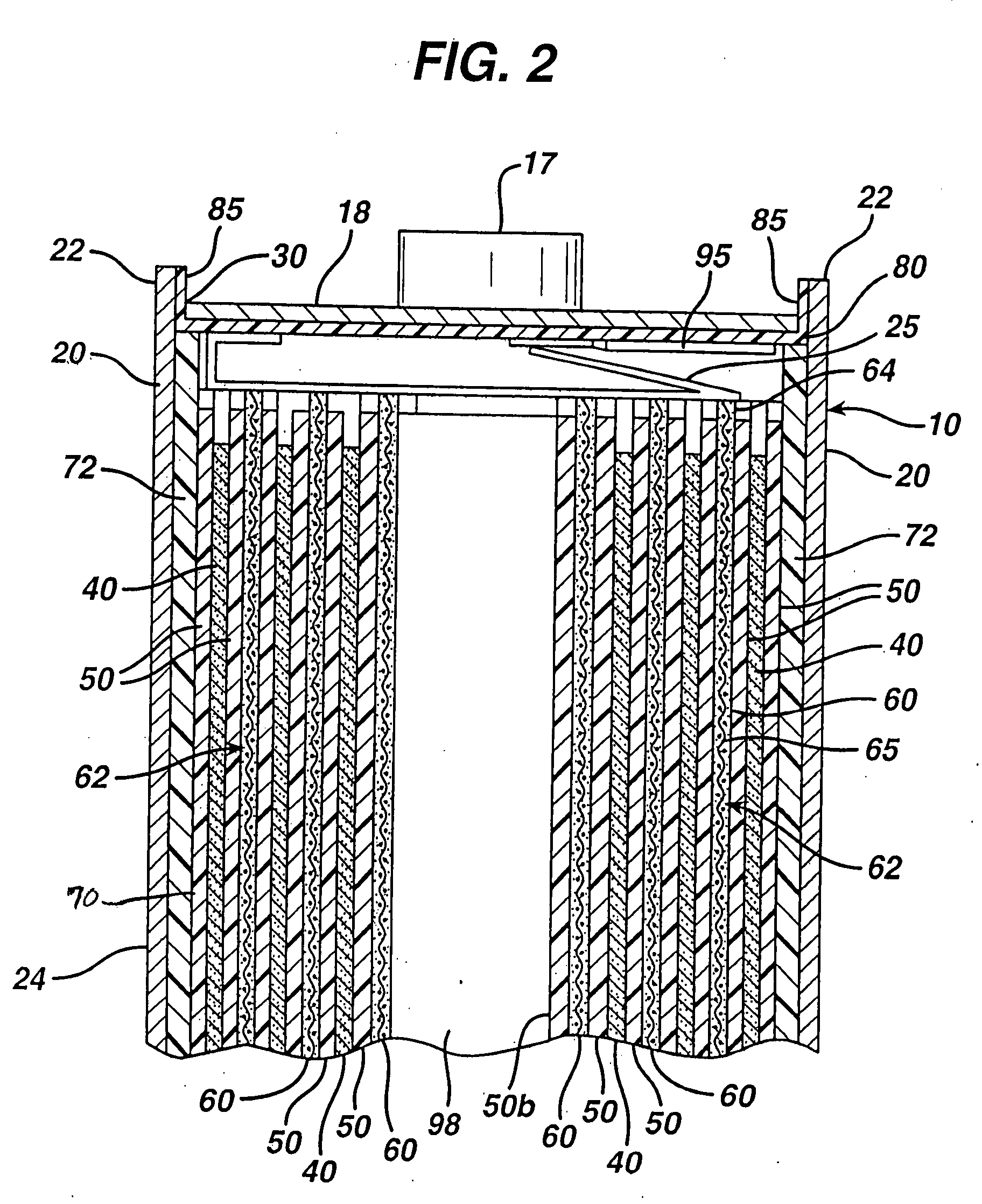

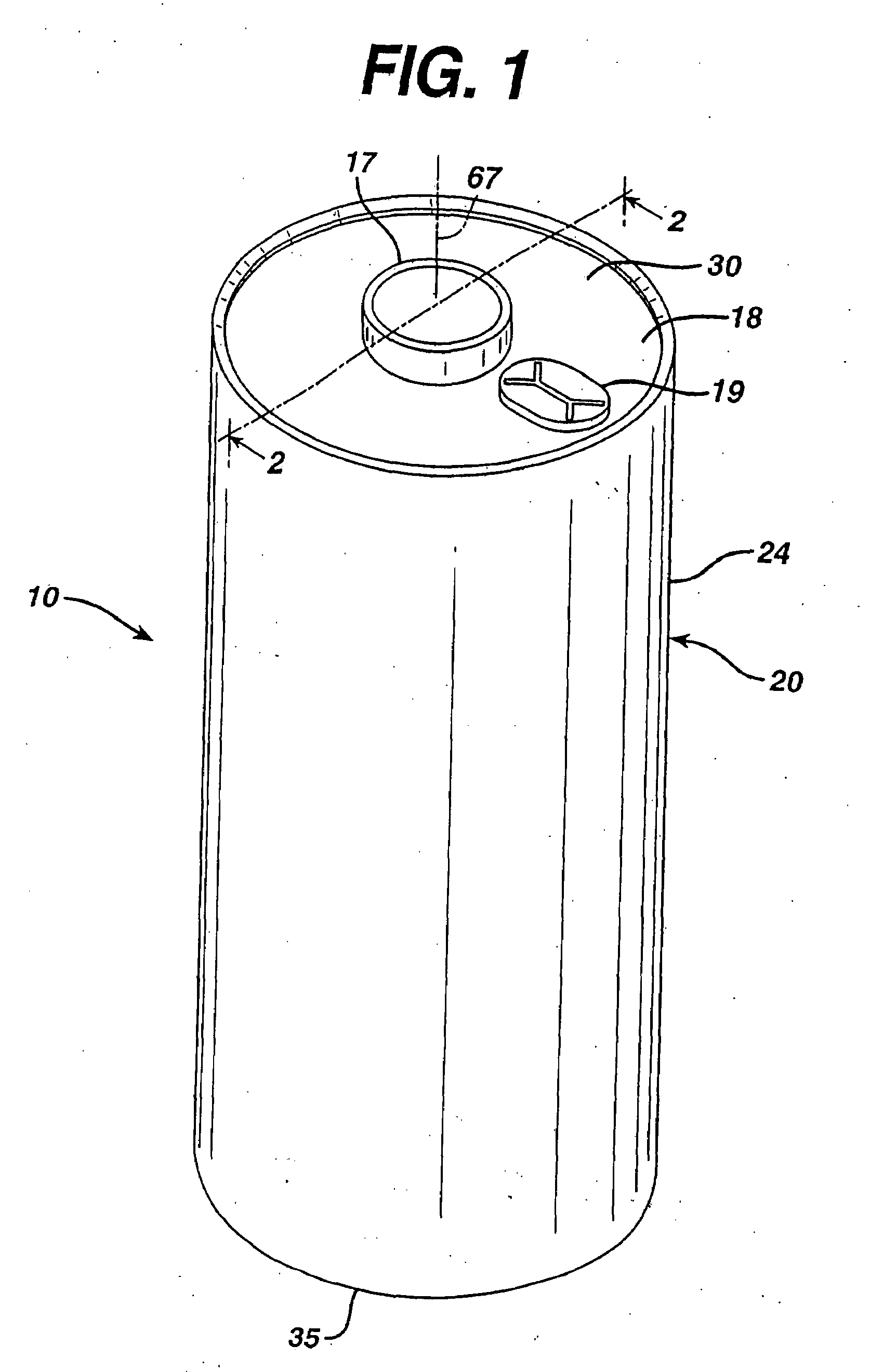

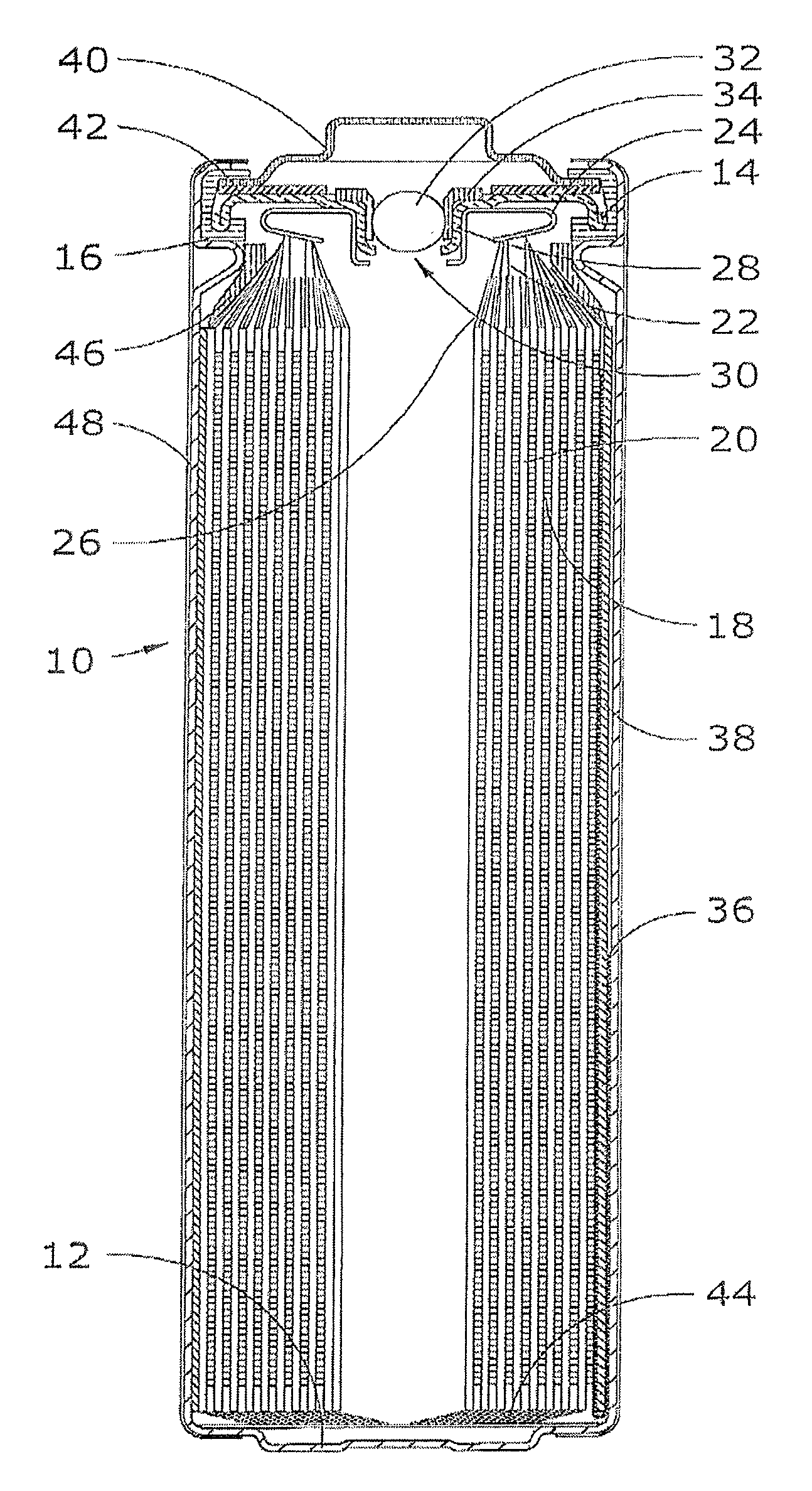

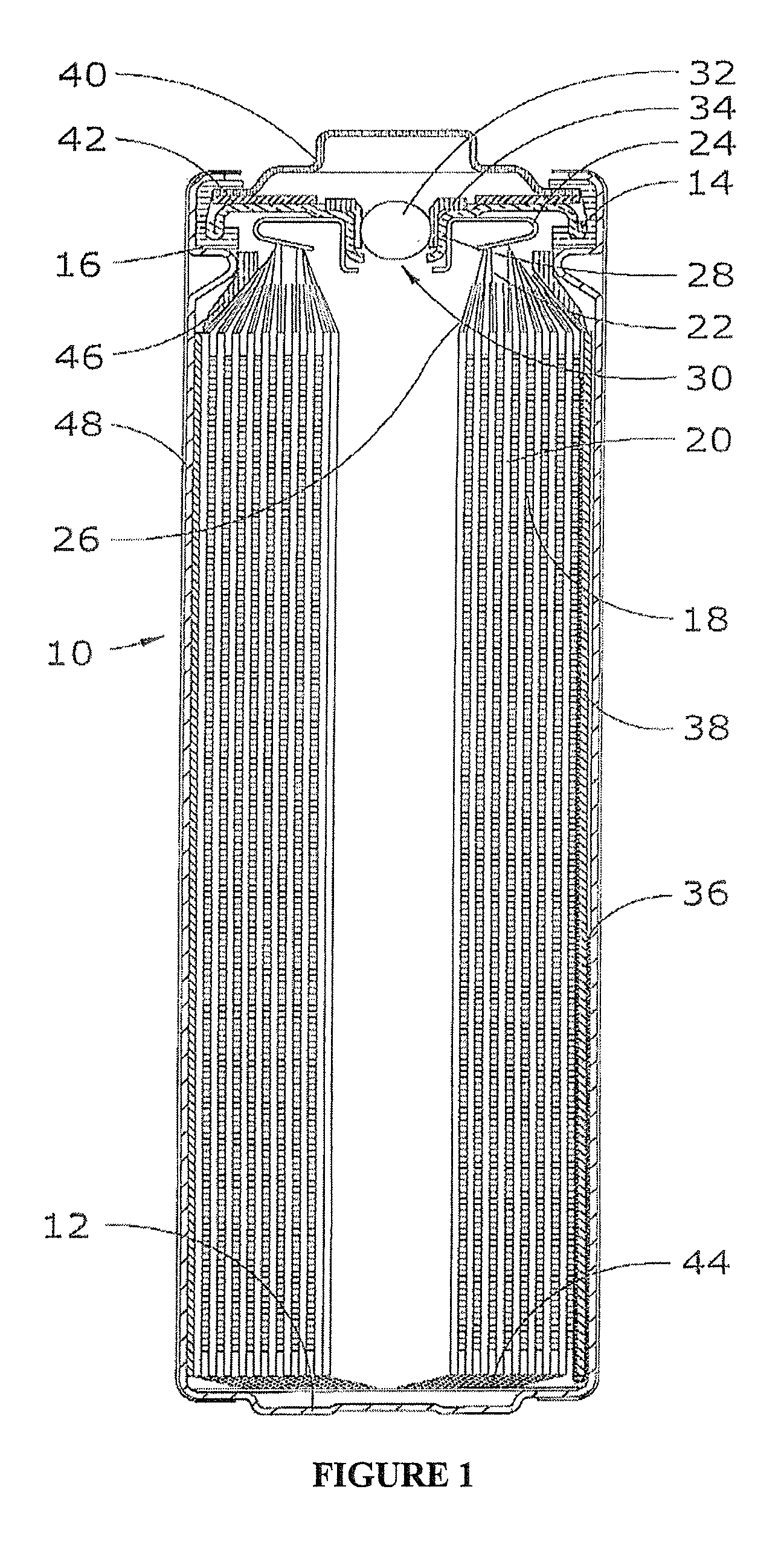

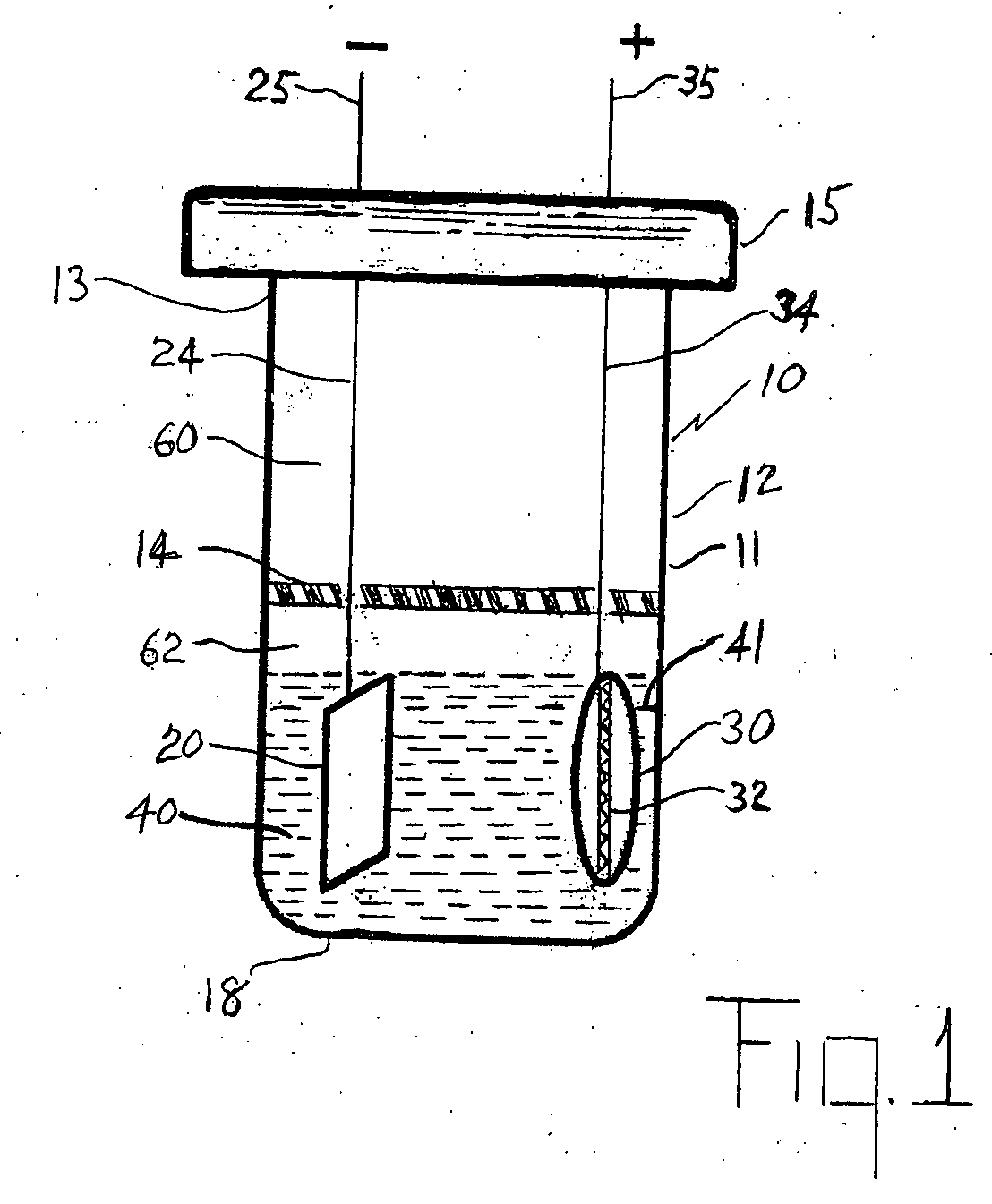

An electrochemical cell, particularly an electrochemical cell having a container with a positive polarity. In one embodiment, the cell is a primary cell that includes an electrode assembly having a lithium negative electrode and a positive electrode, preferably comprising iron disulfide. The cell is provided with a spiral wound electrode assembly with a portion of the positive electrode contacting the container. The positive electrode current collector contacts the container in one embodiment. The negative electrode includes an electrically conductive member that electrically contacts a cover of the cell and provides the cover with a negative polarity. In a preferred embodiment, the electrically conductive member makes pressure contact with a portion of the cell cover. A method of manufacturing such a cell is also provided.

Owner:EVEREADY BATTERY CO INC

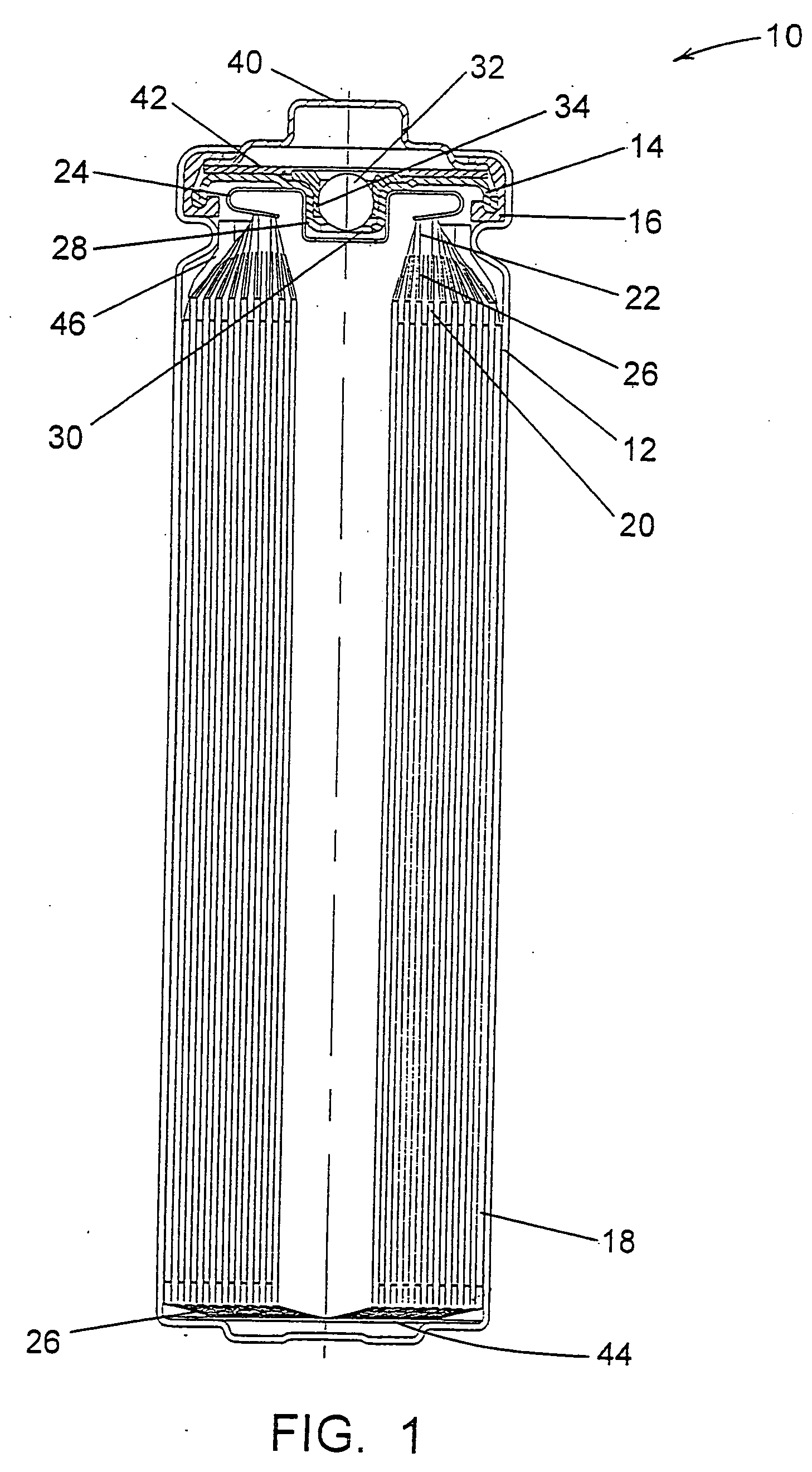

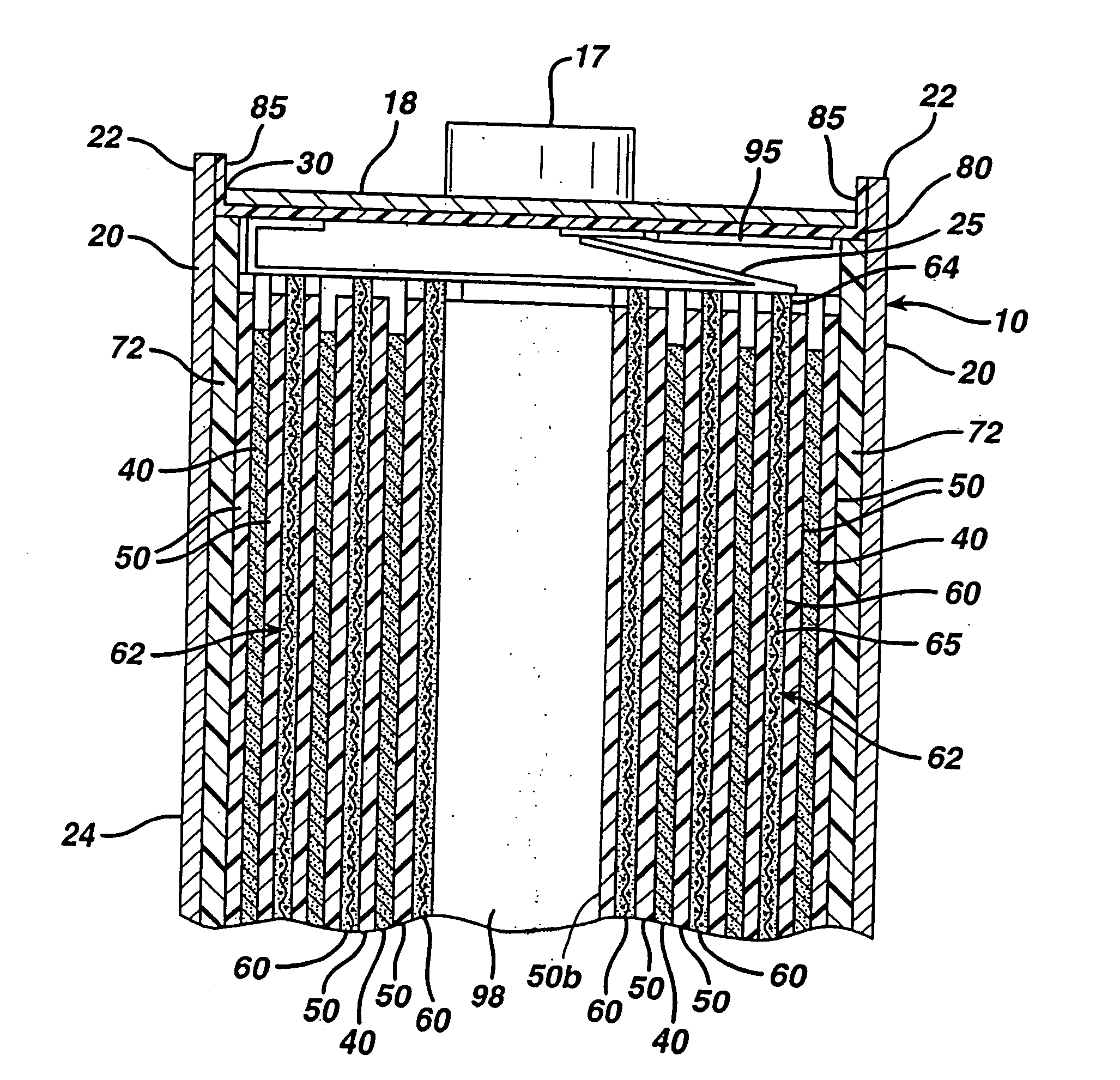

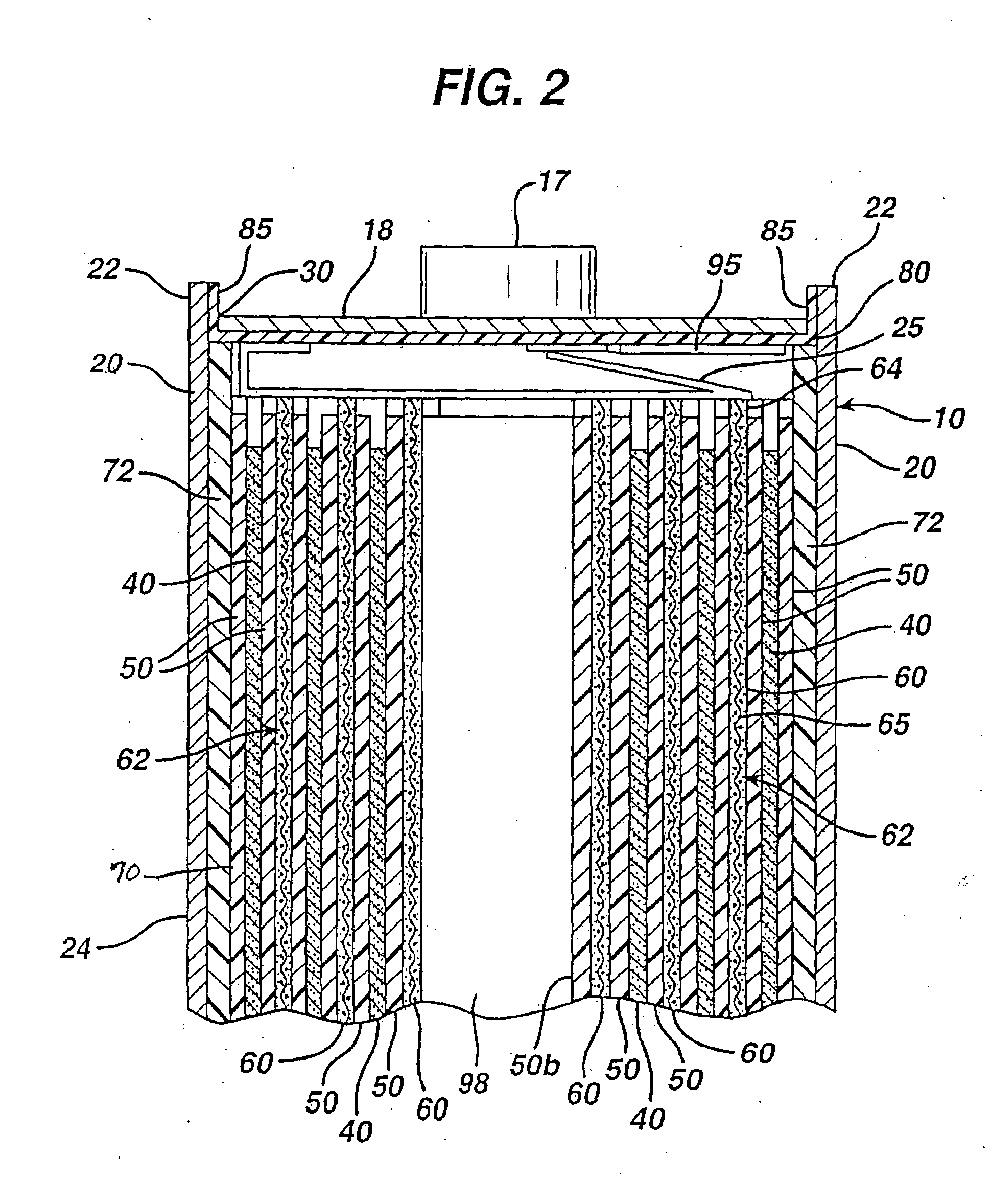

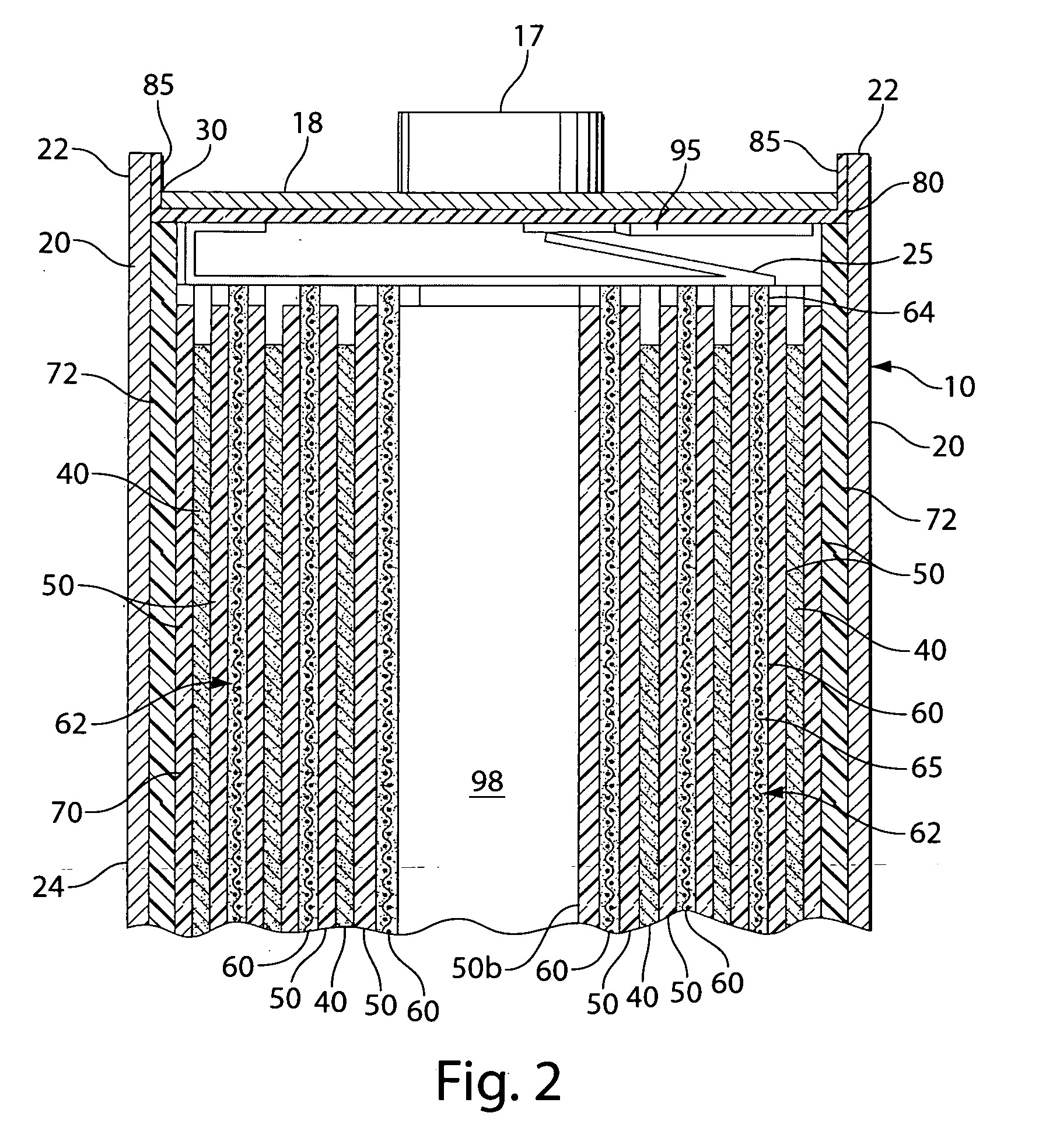

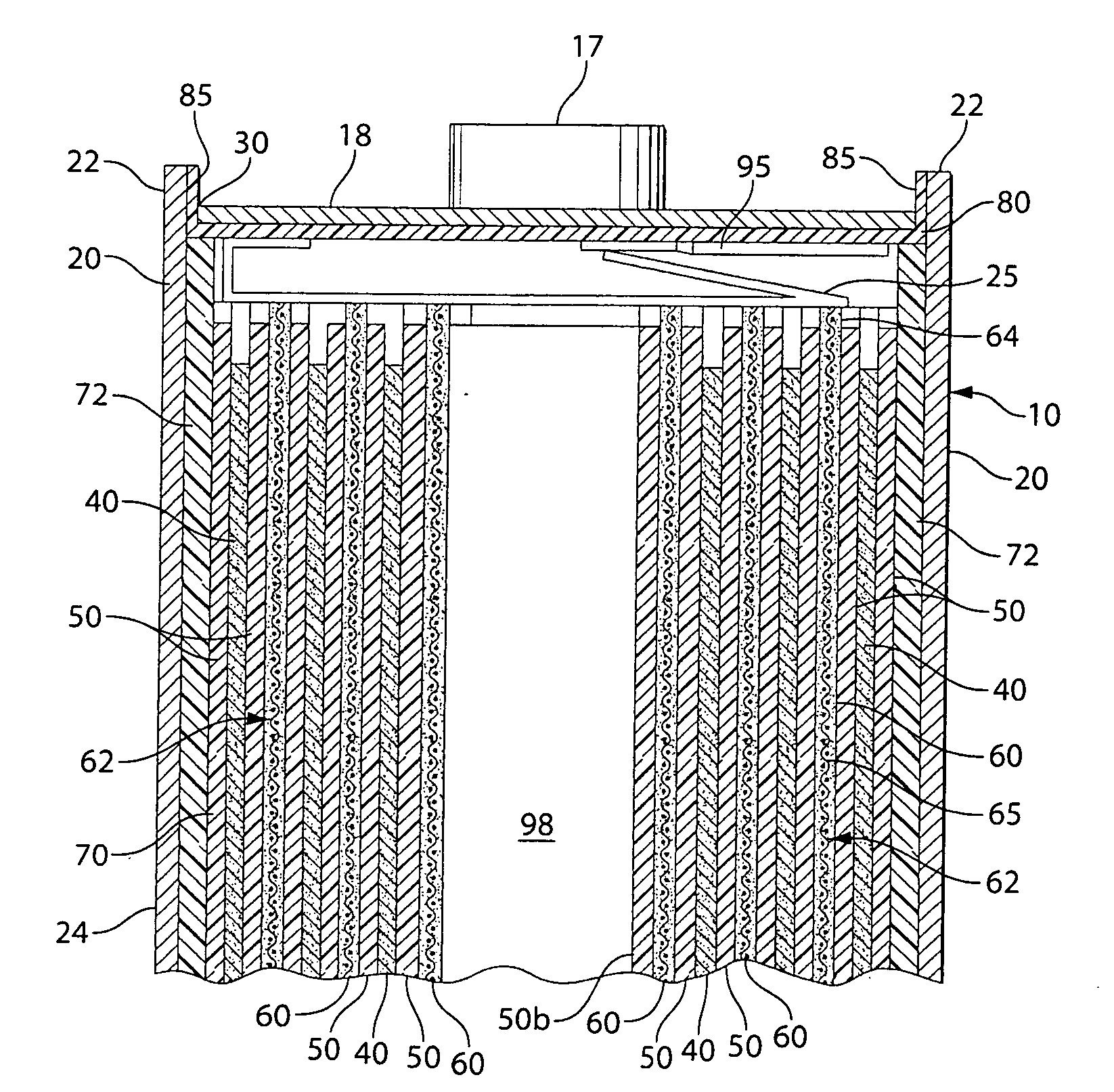

Lithium-Iron Disulfide Cell Design

ActiveUS20090104520A1Large capacityIncrease capacityCell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsCell designEngineering

Owner:ENERGIZER BRANDS

Lithium cell

InactiveUS20080057403A1Reduce degradationResolution problemOrganic electrolyte cellsElectrolytesPrimary cellSlurry

A primary cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in a nonaqueous solvent mixture which contains an alkyl ester, preferably an alkyl acetate. The electrolyte solvent may also include an organic cyclic carbonate. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:THE GILLETTE CO

Lithium-iron disulfide primary battery

InactiveUS20050095508A1Poor solvent powerSuppressing elevation of open circuit voltageOrganic electrolyte cellsActive material electrodesOrganic solventSolvent

There is provided a lithium-iron disulfide primary battery capable of suppressing the elevation of the open circuit voltage during the storage of battery. The lithium-iron disulfide primary battery has a positive electrode, which has iron disulfide as a cathode active material, including a cathode composition layer formed on a cathode current collector, a negative electrode including lithium as an anode active material, and an electrolytic solution including an electrolyte dissolved in an organic solvent. The organic solvent includes at least an alkylamide solvent. By this construction of the battery, the elevation of the open circuit voltage of the lithium-iron disulfide primary battery during the storage may be suppressed. Therefore, even after being stored for a long term, the lithium-iron disulfide primary battery can maintain compatibility with 1.5-V class primary batteries and the like.

Owner:SONY CORP

Lithium cell

ActiveUS20090186263A1Improve conductivityImprove the immunityCell electrodesOrganic electrolyte cellsElectrolysisPrimary cell

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in an organic solvent mixture. The electrolyte contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. The electrolyte may contain between about 200 and 2000, or between about 500 and 2000 parts by weight water per million parts by weight electrolyte. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

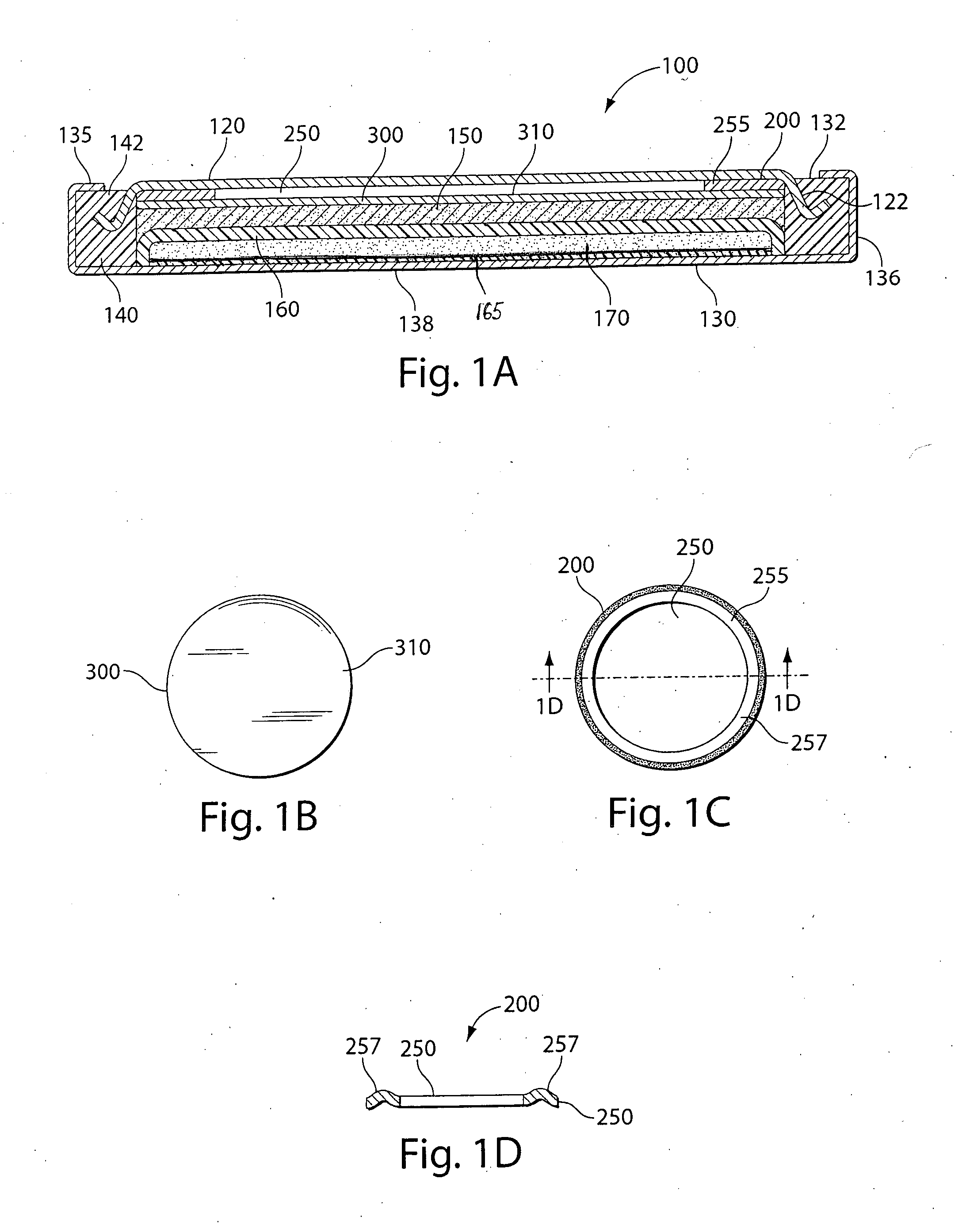

High Discharge Capacity Lithium Battery

ActiveUS20120021266A1Improve discharge performanceIncrease energy densityCell seperators/membranes/diaphragms/spacersCell electrodesHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:ENERGIZER BRANDS

Lithium cell

ActiveUS20090148756A1High affinityGood cohesive propertyElectrode rolling/calenderingSmall-sized cells cases/jacketsOrganic solventIron disulfide

A primary electrochemical cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The cell is balanced so that the anode is in theoretical capacity excess (mAmp-hrs) compared to the theoretical capacity of the cathode. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added. The electrolyte comprises a lithium salt dissolved in organic solvent.

Owner:DURACELL U S OPERATIONS

Lithium cell

ActiveUS20080003500A1Voltage delay is greatly reducedReduce probabilityOrganic electrolyte cellsSecondary cellsPrimary cellSlurry

A primary cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in a nonaqueous solvent mixture which contains an additive, preferably iodine, suppressing voltage delay. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

End cap seal assembly for a lithium cell

InactiveUS20080220316A1Improve conductivityReliable manufacturingCell electrodesOrganic electrolyte cellsEngineeringIron disulfide

An end cap assembly for a primary lithium cell is disclosed. The end cap has a principal application in closing and sealing a primary lithium cell having wound electrodes. The cell may typically have an anode comprising lithium and a cathode comprising iron disulfide (FeS2). The end cap assembly has a metal cathode contact cup therein having a closed end and opposing open end with integral side walls therebetween. The cathode contact cup is electrically connected to the cathode and is within the electrical pathway between the cathode and terminal end cap. The cathode contact cup has one or more grooves formed at the closed end thereof resulting in thinned or rupturable portions of remaining metal underlying said grooves. The thin or rupturable remaining metal portions are exposed directly to gas within the cell interior and are designed to rupture when gas within the cell builds to a predetermined level.

Owner:DURACELL U S OPERATIONS

Lithium cell with cathode including iron disulfide and iron sulfide

ActiveUS20090263727A1Improve discharge performanceImprove discharge efficiencyOrganic electrolyte cellsElectrolytesIron sulfideAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2), iron sulfide (FeS) and carbon particles. The electrolyte comprises a lithium salt dissolved in a solvent mixture. A cathode slurry is prepared comprising iron disulfide (FeS2) powder, iron sulfide (FeS) powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

Lithium cell

ActiveUS20090208849A1Reduce passive layer resistanceSlow build ratesPrimary cell maintainance/servicingElectrode carriers/collectorsSulfolaneAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt preferably lithium iodide (LiI) dissolved in an organic solvent mixture. The solvent mixture preferably comprises dioxolane, dimethoxyethane and sulfolane. The electrolyte typically contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

Method of preparing cathode containing Iron disulfide for a lithium cell

ActiveUS20090291366A1Improve discharge efficiencyUseful electrical energyFinal product manufactureOrganic electrolyte cellsPrimary cellAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) or a mixture of iron disulfide (FeS2) and iron sulfide (FeS) and conductive carbon particles. A cathode slurry is prepared comprising the FeS2 or FeS2 plus FeS powder, conductive carbon, binder, and a solvent. The binder is preferably a styrene-ethylene / butylene-styrene (SEBS) block copolymer. There is an advantage discovered in utilizing a hydronaphthalene solvent to form the cathode slurry. The preferred solvent is 1,2,3,4-tetrahydronaphthalene or decahydronaphthalene and mixtures thereof. The slurry mixture is coated onto a conductive substrate and the solvent evaporated leaving a dry cathode coating on the substrate. Higher drying temperature may be used resulting in a dry cathode coating which resists cracking. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

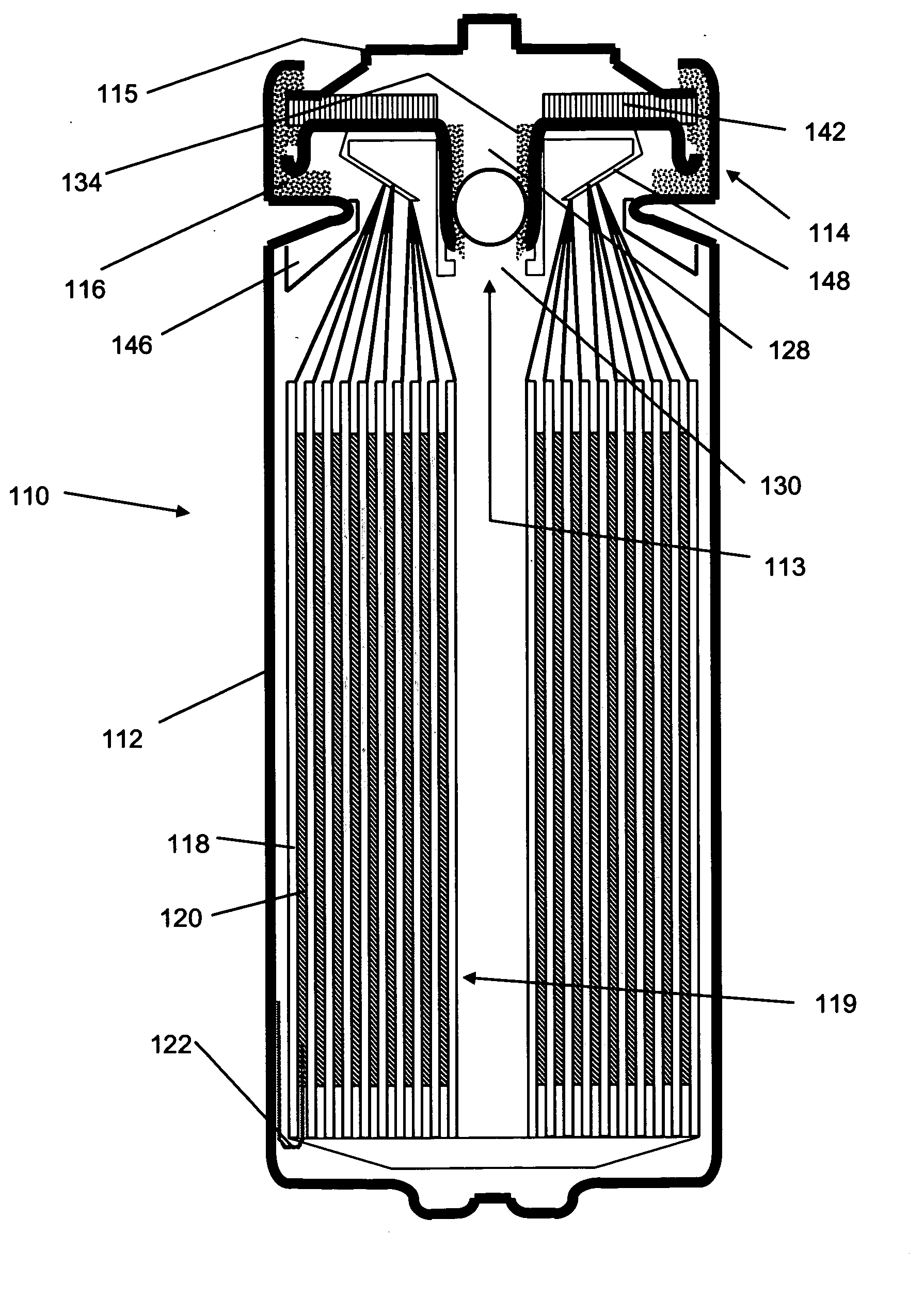

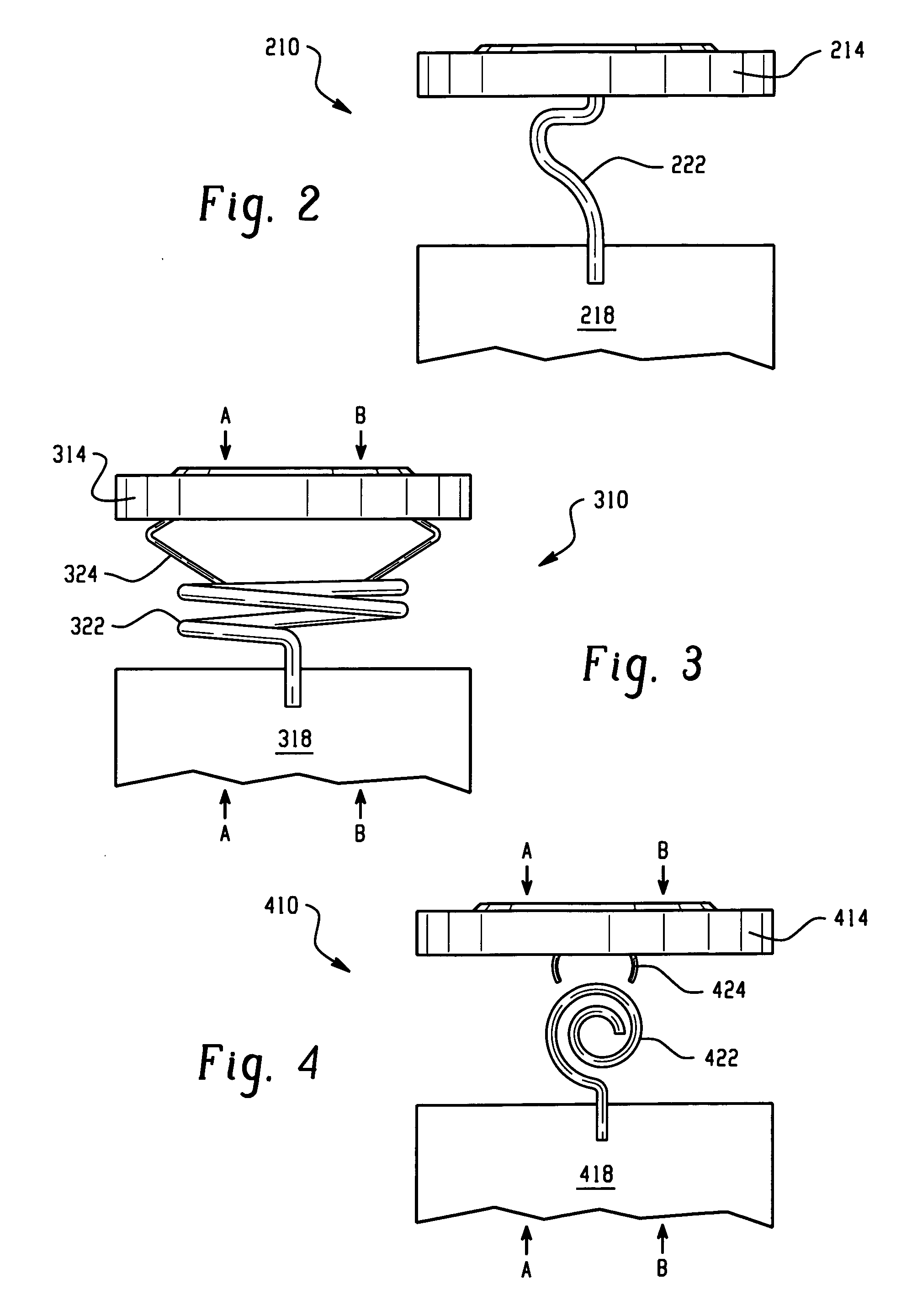

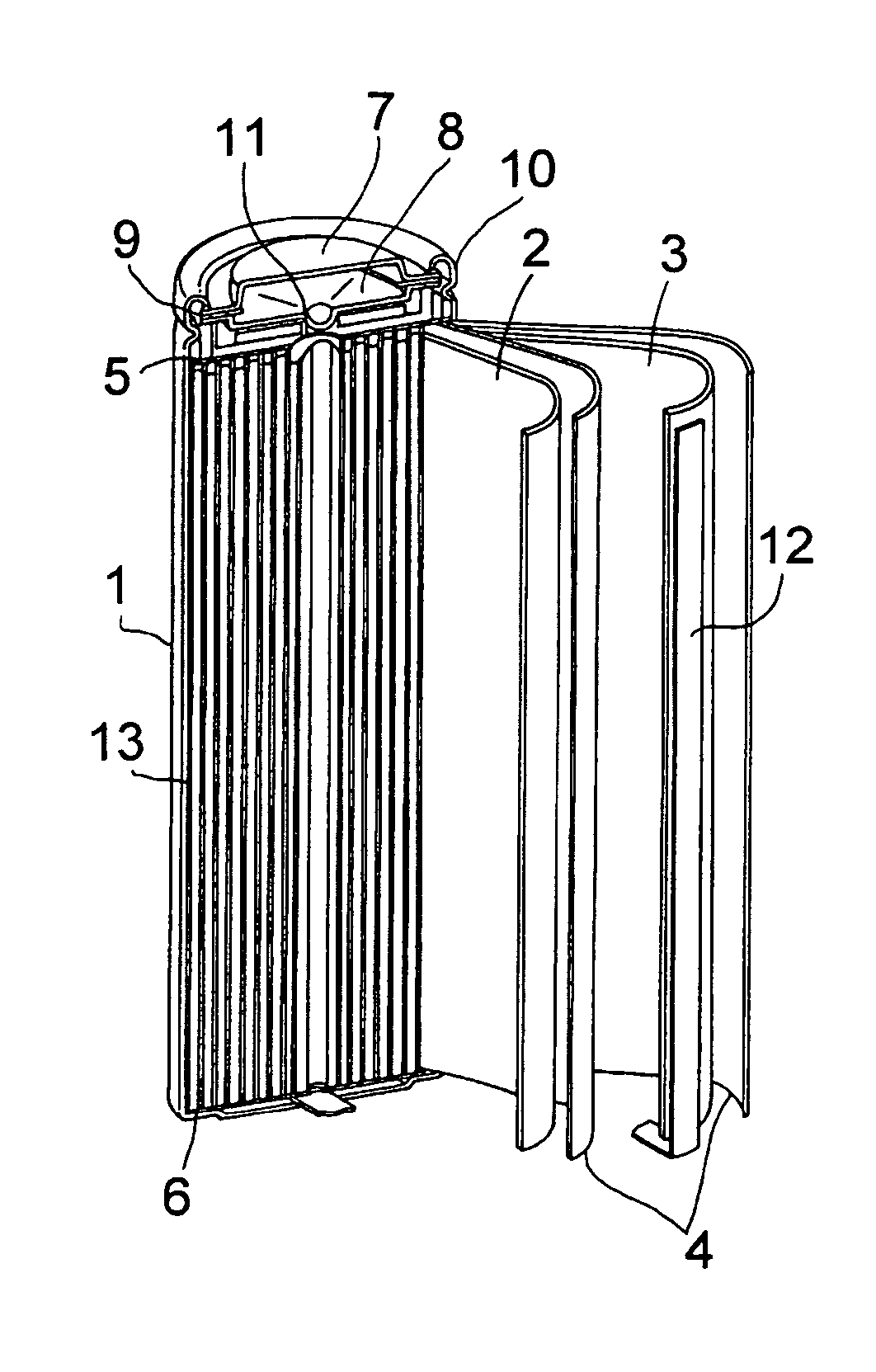

Lithium-Iron Disulfide Cell Design with Core Reinforcement

InactiveUS20100273036A1Relieve pressureFinal product manufactureSmall-sized cells cases/jacketsCell designElectrochemical cell

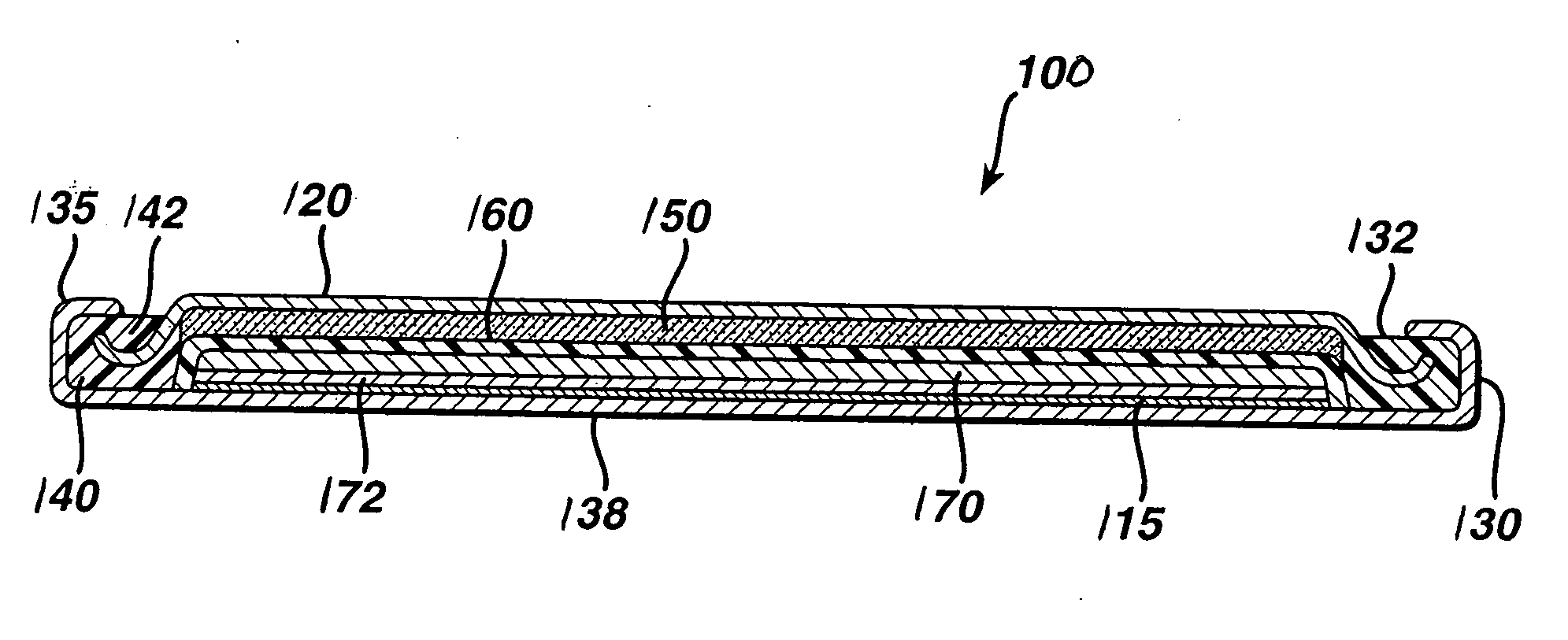

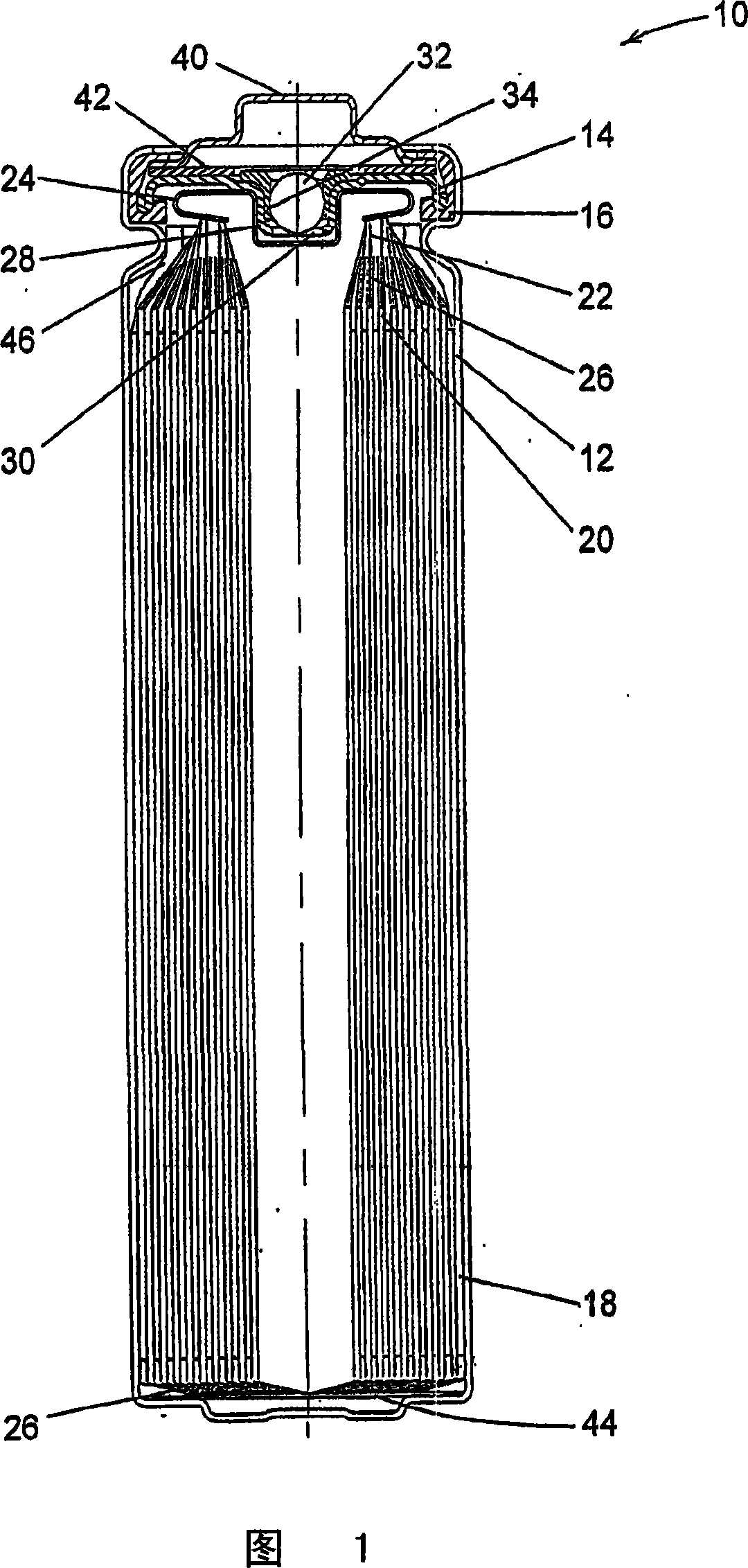

A electrochemical cell design, with particular applicability to lithium-iron disulfide batteries, is disclosed. The cell includes a spirally wound electrode assembly with a central core. The core causes uniform expansion within the cathode. The core may also collapse and / or possess a cross sectional shape that differs from the cross sectional shape of the cylindrical container which houses the electrode assembly.

Owner:EVEREADY BATTERY CO INC

Lithium cell cathode

InactiveUS20090074953A1Easy removal of contaminantReduce the amount of solutionElectrode thermal treatmentOrganic electrolyte cellsSlurryPrimary cell

A primary cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in a solvent mixture. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a substrate and solvent evaporated leaving a dry cathode coating on the substrate. The cathode coating is then baked at elevated temperatures in atmosphere under partial vacuum or in an atmosphere of nitrogen or inert gas. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:THE GILLETTE CO

Lithium cell cathode

ActiveUS20090070989A1Easy removal of contaminantSlow build ratesElectrode thermal treatmentFinal product manufactureAtmospheric airPrimary cell

Owner:DURACELL U S OPERATIONS

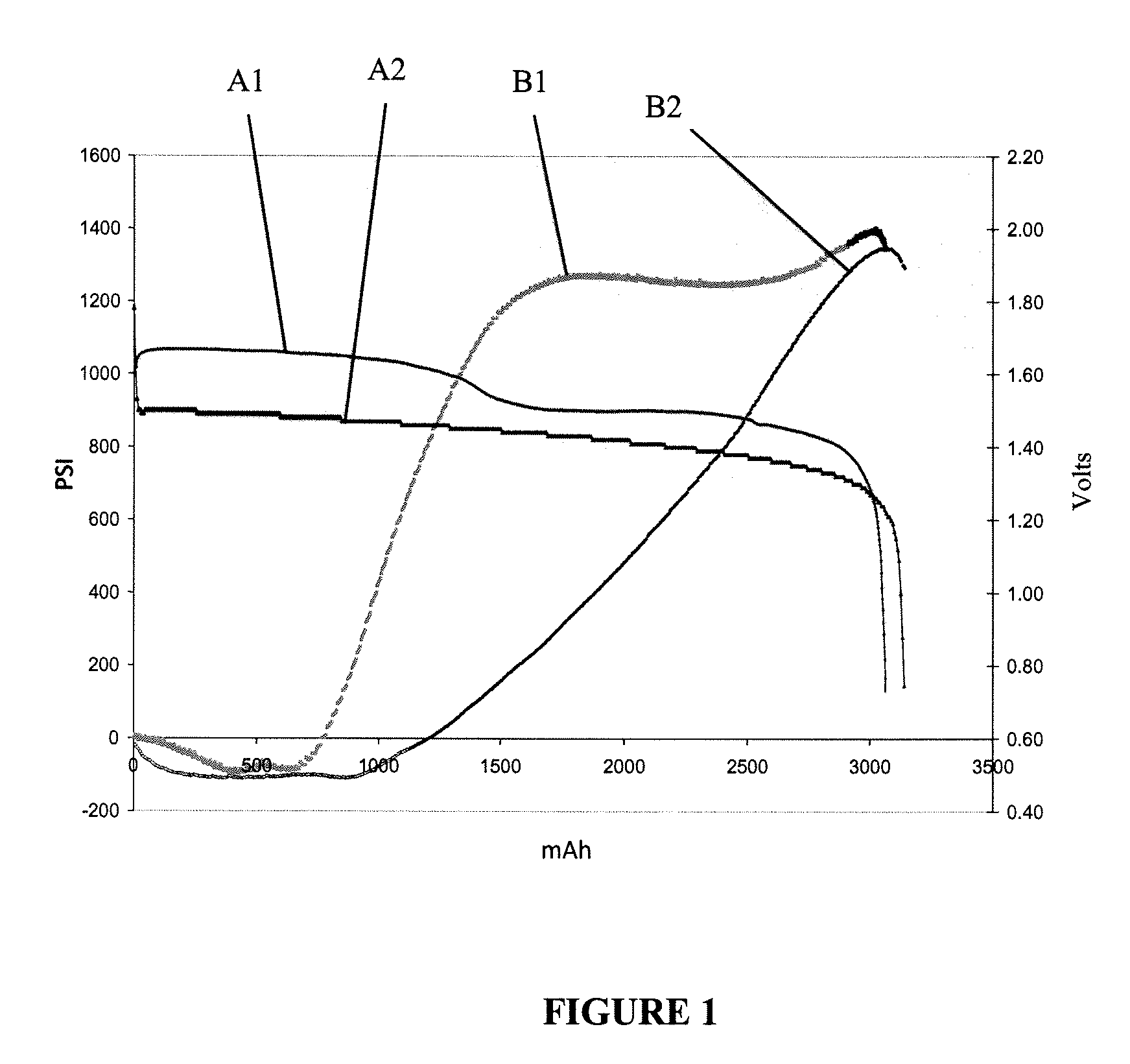

High discharge capacity lithium battery

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:ENERGIZER BRANDS

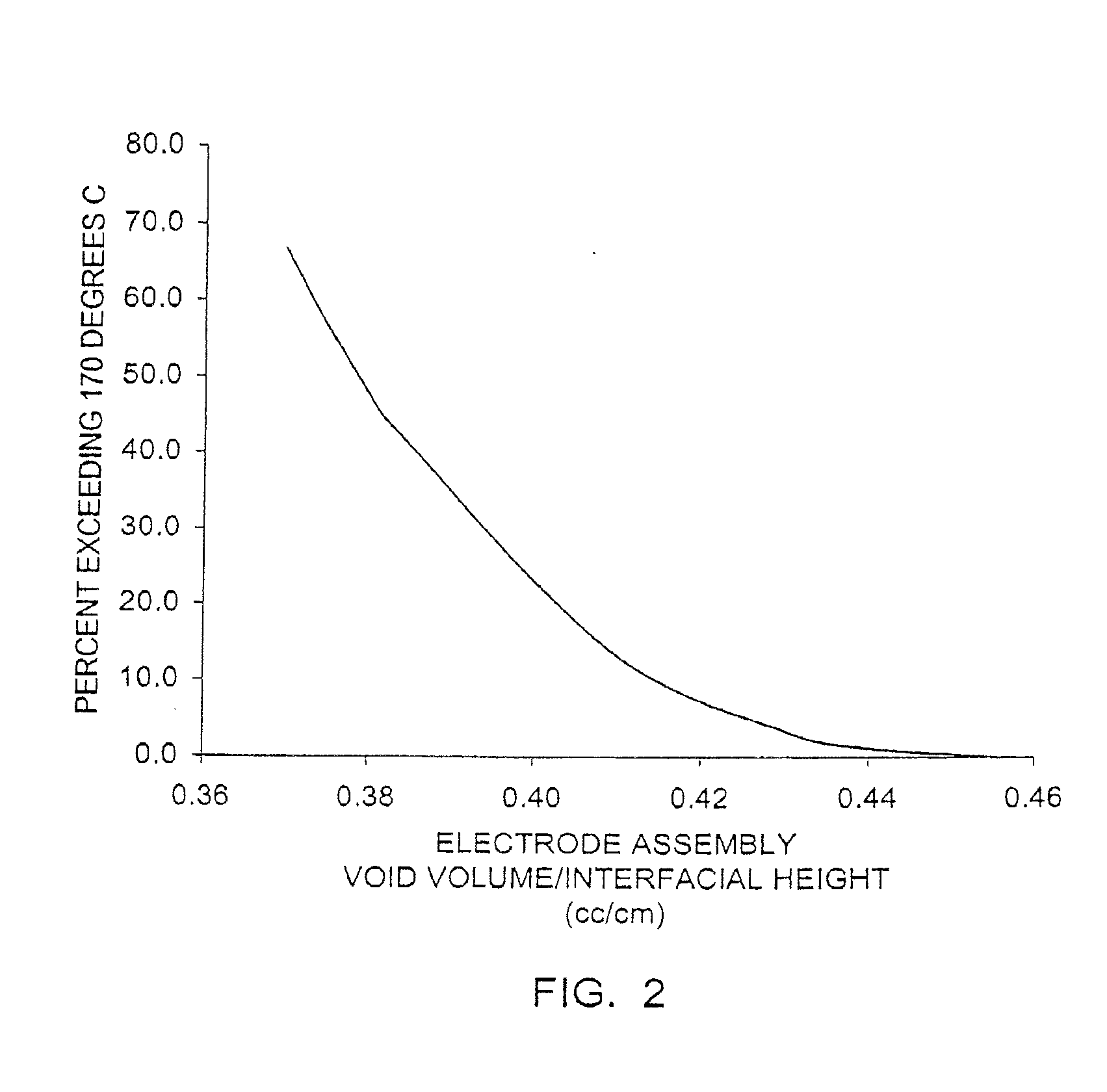

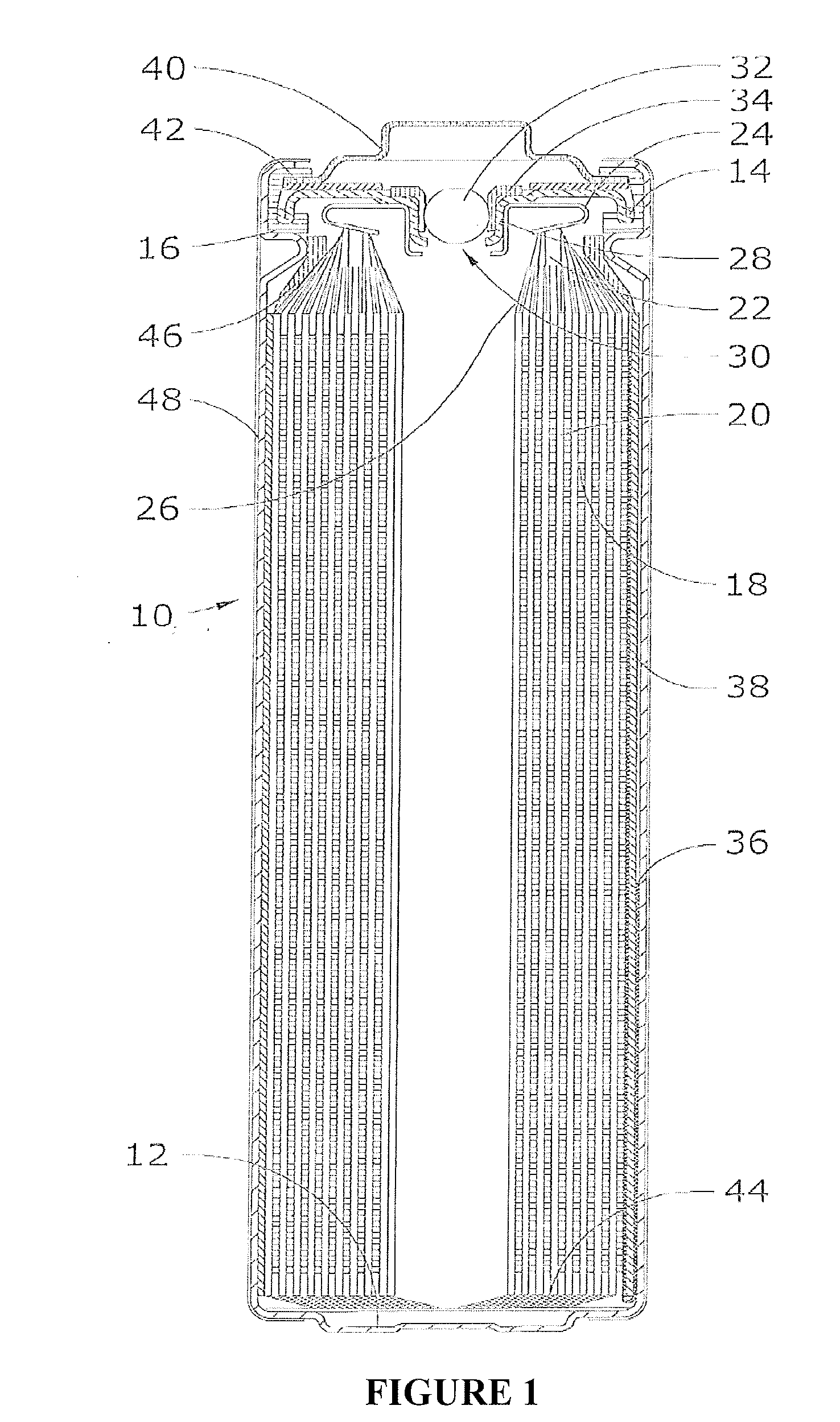

Lithium-Iron Disulfide Cell Design

ActiveUS20100310910A1MiniaturizationEasy to controlCell seperators/membranes/diaphragms/spacersFinal product manufactureCell designOptoelectronics

A lithium-iron disulfide electrochemical cell design is disclosed, relying on judicious selection of the electrolyte, a thicker lithium anode and a cathode with specific characteristics selected to cooperate with the electrolyte. The resulting cell has a reduced interfacial surface area between the anode and the cathode but, surprisingly, maintains excellent high drain rate capacity.

Owner:ENERGIZER BRANDS

Magnesium cell with improved electrolyte

ActiveUS20100310933A1Loss of capacityLoss of powerAlkaline accumulatorsElectrolytic capacitorsMagnesium salt1-Butyl-3-methylimidazolium hexafluorophosphate

An improved electrolyte for a cell having an anode comprising magnesium or magnesium alloy. The cell's cathode may desirably include iron disulfide (FeS2) as cathode active material. The improved electrolyte comprises a magnesium salt, preferably magnesium perchlorate dissolved in an organic solvent which preferably includes acetonitrile or mixture of tetrahydrofuran and propylene carbonate. The electrolyte includes an additive to retard the buildup of deleterious passivation coating on the magnesium anode surface, thereby enhancing cell performance. Such additive may preferably include 1-butyl-3-methylimidazolium tetrafluoroborate (BMIMBF4), 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6), lithium hexafluorophosphate (LiPF6), or aluminum chloride (AlCl3)

Owner:DURACELL U S OPERATIONS

Lithium cell

ActiveUS8465860B2Reduce chanceImprove conductivityCell electrodesOrganic electrolyte cellsElectrolysisPrimary cell

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in an organic solvent mixture. The electrolyte contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. The electrolyte may contain between about 200 and 2000, or between about 500 and 2000 parts by weight water per million parts by weight electrolyte. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS INC

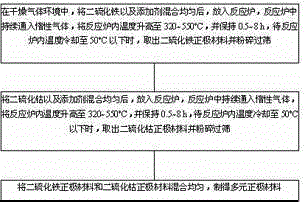

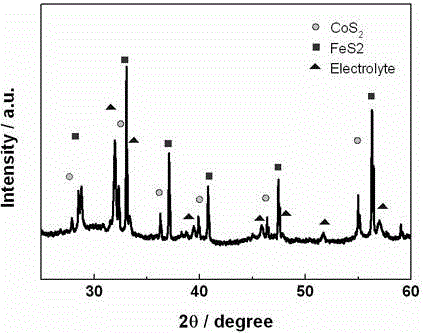

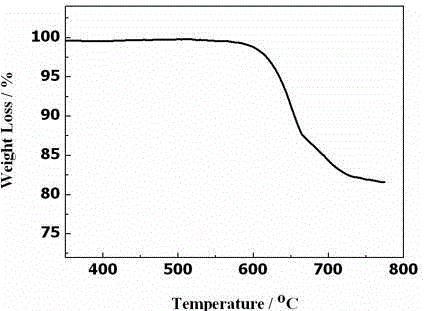

Preparation method of thermal battery positive electrode material, and thermal battery made of thermal battery positive electrode material

InactiveCN106207085ALower internal resistanceIncrease working voltagePrimary cell electrodesThermal BatteryIron disulfide

The invention discloses a preparation method of a thermal battery positive electrode material. The preparation method comprises the following steps: 1, mixing iron disulfide with additives in dry gas environment until the iron disulfide and the additives are uniform, putting the obtained mixture in a reaction furnace, continuously introducing an inert gas to the reaction furnace, rising the temperature in the reaction furnace to 320-550 DEG C, keeping the temperature for 0.5-8 h, taking out the obtained iron disulfide positive electrode material when the temperature in the reaction furnace decreases to 50 DEG C or below, crushing the iron disulfide positive electrode material, and sieving the crushed iron disulfide positive electrode material; 2, mixing cobalt sulfide with the additives until the cobalt sulfide and the additives are uniform, putting the obtained mixture in the reaction furnace, continuously introducing an inert gas to the reaction furnace, rising the temperature in the reaction furnace to 320-550 DEG C, keeping the temperature for 0.5-8 h, taking out the obtained iron disulfide positive electrode material when the temperature in the reaction furnace decreases to 50 DEG C or below, crushing the cobalt disulfide positive electrode material, and sieving the crushed cobalt disulfide positive electrode material; and 3, mixing the iron disulfide positive electrode material with the cobalt disulfide positive electrode material until the iron disulfide positive electrode material and the cobalt disulfide positive electrode material are uniform in order to prepare the polynary positive electrode material. The invention also discloses a thermal battery made of the positive electrode material.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

High discharge capacity lithium battery

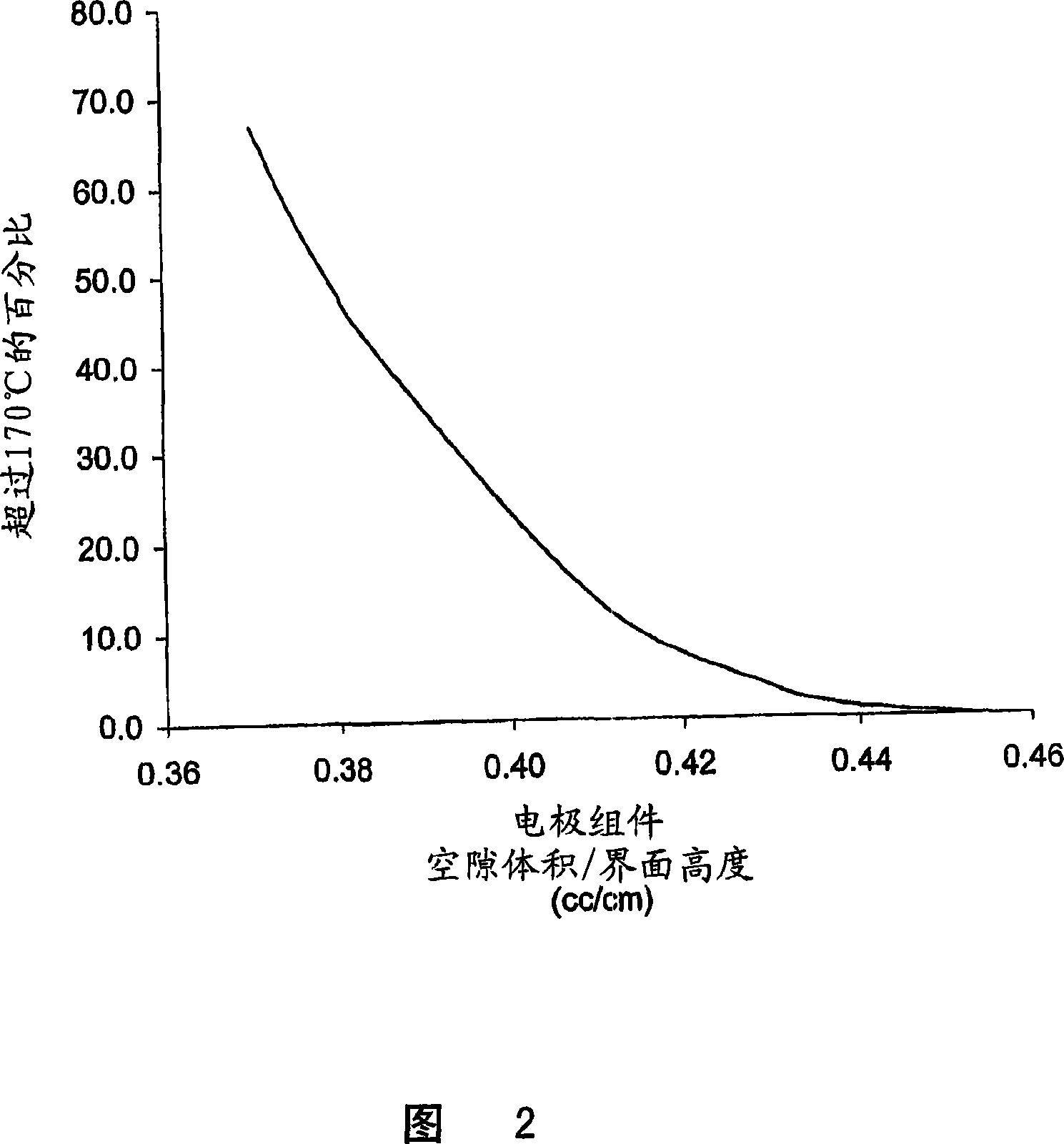

ActiveCN1883065ACell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsHigh concentrationHigh rate

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The positive electrode mixture containing the iron disulfide contains highly packed solid materials, with little space around the solid particles, to provide a high concentration of iron disulfide within the mixture. The separator is thin, to allow more space within the cell for active materials, yet strong enough to prevent short circuits between the positive and negative electrodes under abusive conditions, even when swelling of the cathode during cell discharge places additional stressed on the separator. As a result, the ratio of the interfacial capacity of the positive electrode to the electrode interfacial volume is high, as is the actual capacity on low rate / low power and high rate / high power discharge.

Owner:ENERGIZER BRANDS

Lithium cell with cathode containing iron disulfide

InactiveUS20090317725A1Improve electrochemical performanceLow viscosityOrganic electrolyte cellsPrimary cell electrodesSlurryPrimary cell

A primary cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt dissolved in a solvent mixture which contains 1,3-dioxolane and preferably 1,3-dimethyl-2-imidazolidinone. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:THE GILLETTE CO

Lithium cell with iron disulfide cathode

InactiveUS20100203370A1Advantage in cell performanceAdvantages in cell performanceCell electrodesOrganic electrolyte cellsLithium metalAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt preferably lithium iodide (LiI) dissolved in an organic solvent mixture. The solvent mixture preferably comprises dioxolane and dimethoxyethane. The electrolyte typically contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. The anode may be lithium metal or preferably is a lithium alloy. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:THE GILLETTE CO

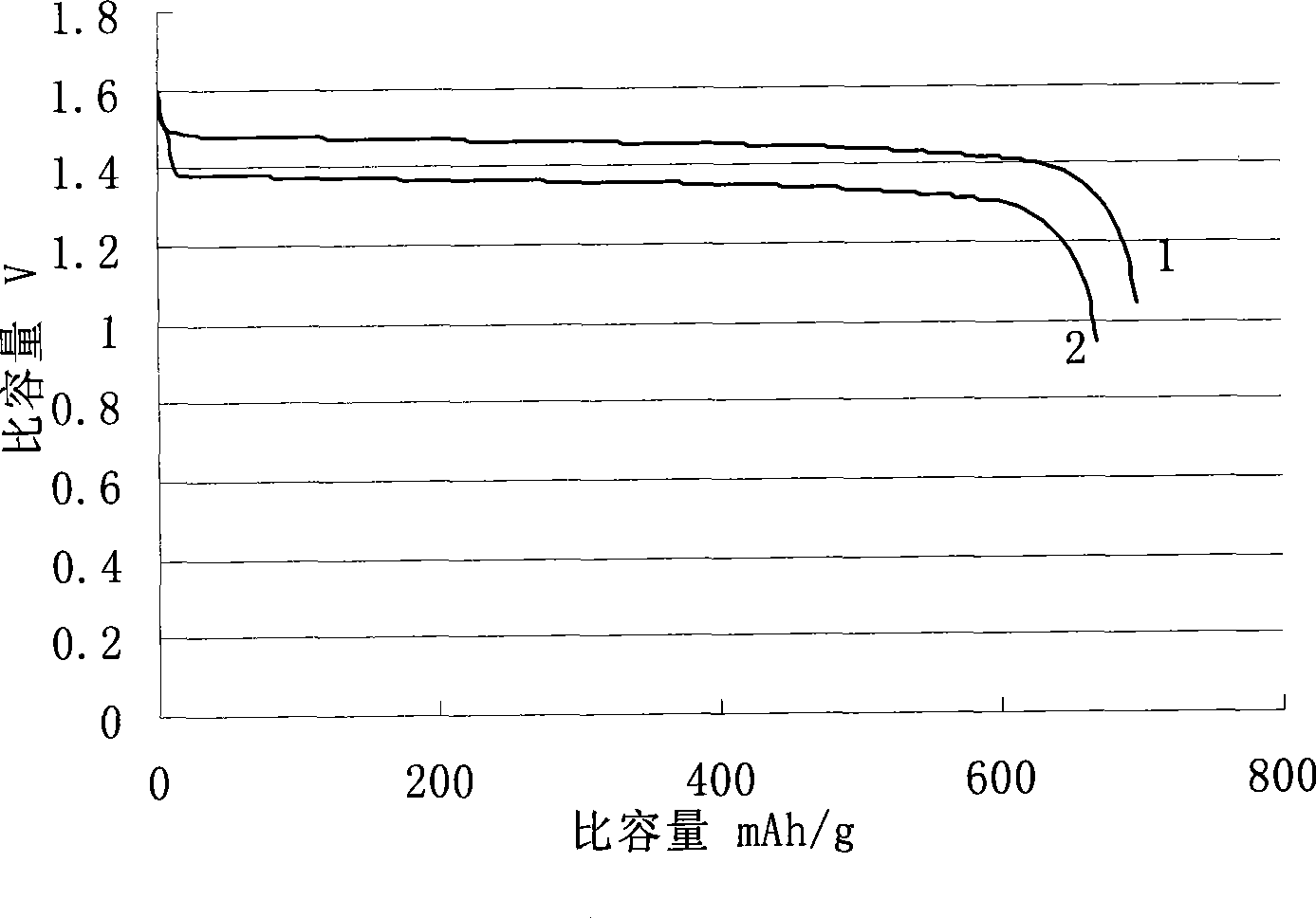

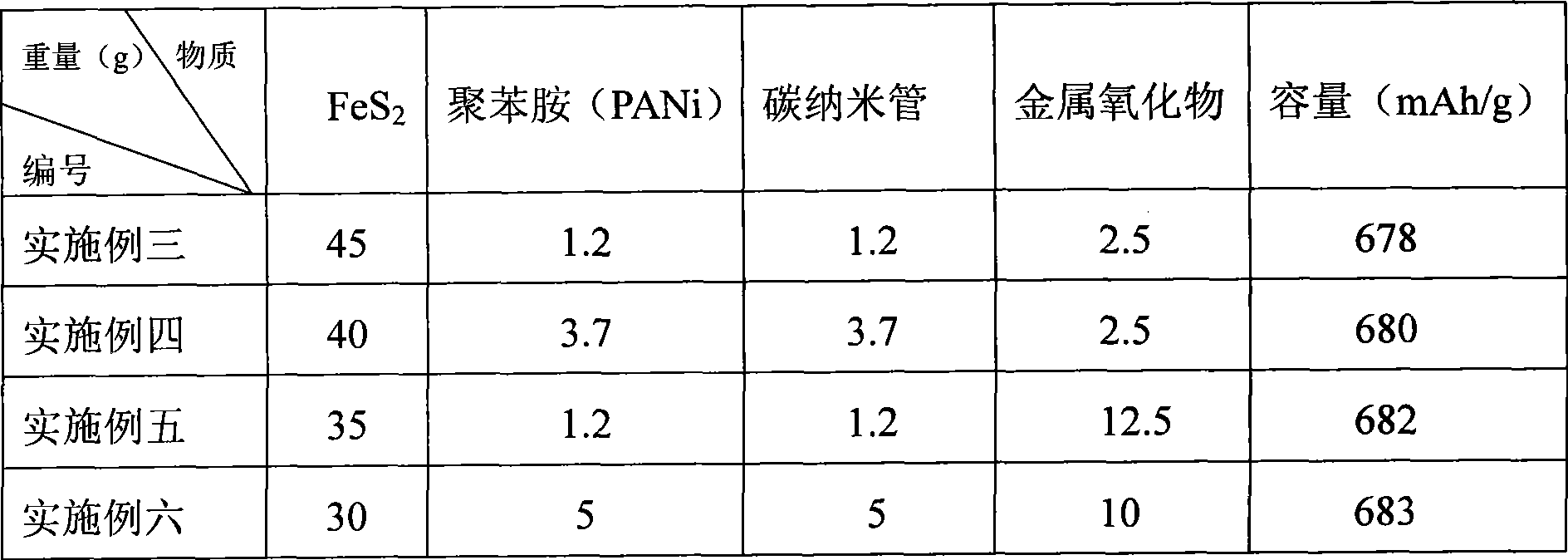

Lithium-iron disulfide anode materials and method for preparing same

InactiveCN1877887AImprove conductivityHigh voltage platformPrimary cell electrodesMetallurgyHigh energy

The invention discloses a preparing technology of high-energy Li-marcasite battery material, which comprises the following steps: covering conductivity and stable metal oxide on the surface of marcasite with composite conductive; setting the percentage of marcasite at 82-94 percent, conductive percentage at 4-10 percent and metal oxide percentage at 2-8 percent. The method reduces grain size of natural marcasite material through wetting ball grinding technology, which prepares the needed anode material.

Owner:TSINGHUA UNIV

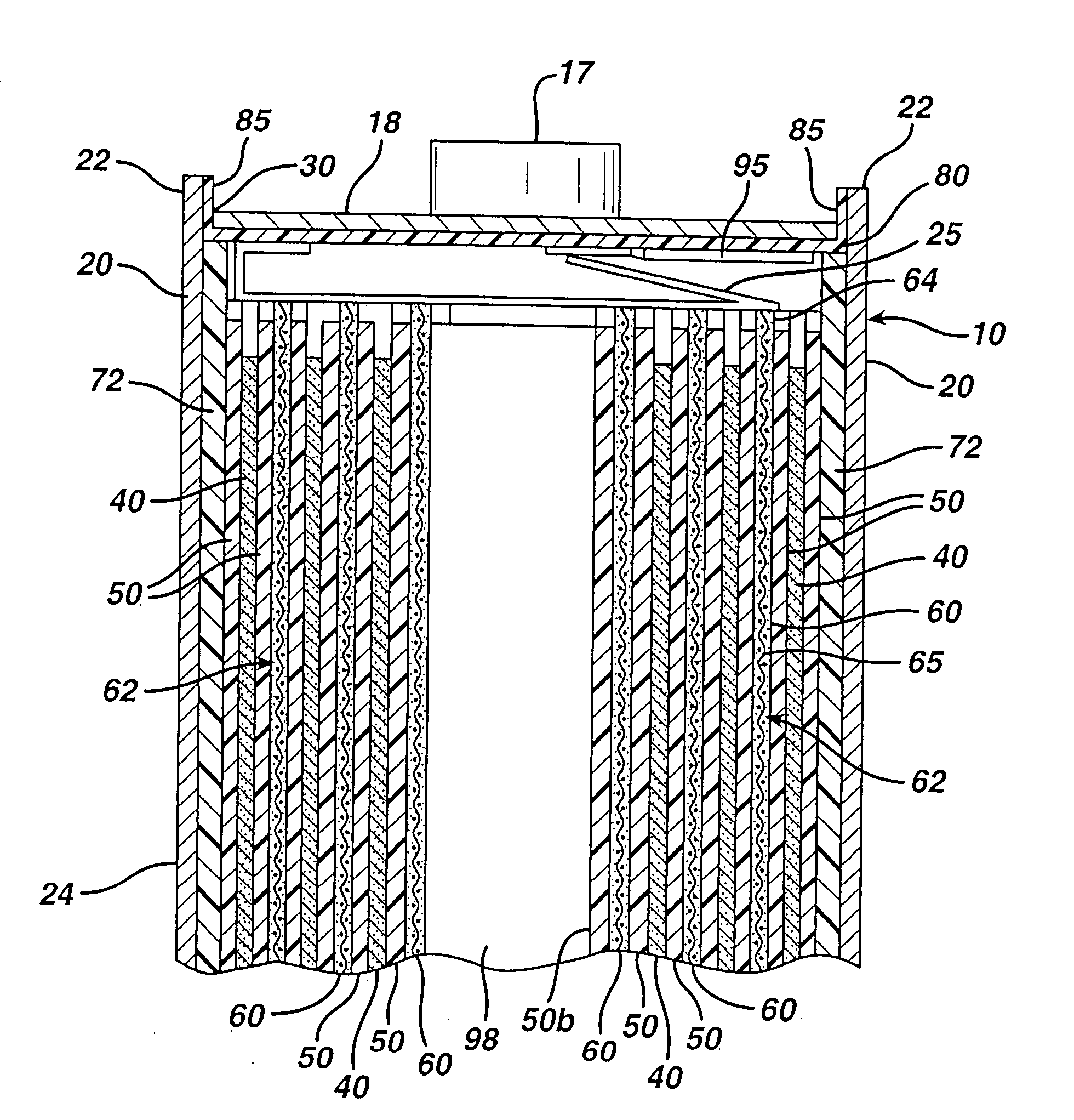

Resin-based high-strength wear-resistant grinding wheel material and preparation method thereof

InactiveCN107378803AWell mixedImprove performanceBonded abrasive wheelsGrinding devicesBoron nitrideIron disulfide

The invention discloses a resin-based high-strength wear-resistant grinding wheel material. The resin-based high-strength wear-resistant grinding wheel material is prepared from modified phenolic resin, epoxy resin, powder butadiene-acrylonitrile rubber, polyurethane elastomer, polyvinyl butyral, iron disulfide, copper powder, zinc oxide, graphite, hollow ceramic balls, corundum, carborundum, talcum powder, silicon carbide, aluminum oxide, boron oxide, boron nitride, chromic oxide, nanosilicon dioxide, a silane coupling agent, namely KH-550 and wear-resistant auxiliary agents. The invention further provides a preparation method of the resin-based high-strength wear-resistant grinding wheel material. The resin-based high-strength wear-resistant grinding wheel material is excellent in wear resistance, good in bonding performance and high in hardness; heat resistance and hardness of a resin grinding wheel are improved; cracks formed due to rigid grinding are reduced; heat is dissipated fast; a great amount of heat released in the cutting process of the grinding wheel can be dissipated fast and conveniently; and the effect that the cutting temperature is lowered is achieved.

Owner:安徽昌悌进出口贸易有限公司

Lithium cell

ActiveUS20080233467A1Improve battery performanceHigh voltage profilePrimary cell maintainance/servicingCell electrodesPrimary cellRest period

A primary cell having an anode comprising lithium and a cathode comprising iron disulfide (FeS2) and carbon particles. The cell can be in the configuration of a coin cell or the anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added. The electrolyte comprises a lithium salt dissolved in a nonaqueous solvent mixture which may include an organic cyclic carbonate such as ethylene carbonate and propylene carbon. The cell after assembly is subjected to a two step preconditioning (prediscahrge) protocol involving at least two distinct discharge steps having at lease one cycle of pulsed current drain in each step and at least one rest period (step rest) between said two steps, wherein said step rest period is carried out for a period of time at above ambient temperature. The preconditioning improves cell performance.

Owner:DURACELL U S OPERATIONS

Process for preparing FeS2 on monosilicon substrate by magnetically controlled sputter to Fe film

InactiveCN1387265AStandard stoichiometric compositionSimplify complex processesFinal product manufactureSemiconductor devicesIron disulfideVacuum pump

The present invention discloses a preparing method of iron disulfide for single crystal silicon substrate with iron coating synthesis of magnetic control sputtering. Two single crystal silicon slicesin bit vectors of 100 and 111 are used as the substrate of film carrier to deposit 25-150 nm thickness of pure iron coating by magnetic control sputtering, pure iron coating and the sublimation sulfur powder of requested mass enabling to create 80 KPa pressure is packed in quartz tube, after vacuum pumping the quartz tube is heated in a heating furnace to the temperature of 400-500 degree C with temperature rising rate of 3 degree C per minute for heat sulfurizing reaction for 10-20 hour, and then is cooled to the room temperature by the temp. drop rate of 2 degree C per minute.

Owner:ZHEJIANG UNIV

Anode material and anode plate of lithium-iron disulfide battery and method for preparing same

InactiveCN101521279ALower open circuit voltageHigh conductivityElectrode manufacturing processesActive material electrodesIron disulfideBattery cell

The invention discloses an anode material and an anode plate of a lithium-iron disulfide battery and a method for preparing the same, wherein the anode material comprises iron disulfide which is an iron disulfide nanometer crystal, and FeSO4, (NH2)2CS and S taken as reaction raw materials and PVP taken as a dispersing agent react under the acid or alkali condition to prepare the iron disulfide. The obtained iron disulfide is an N-shaped crystal, of which the purity is as high as 100 percent; compared with the iron disulfide used in the prior art, the iron disulfide of the invention can greatly reduce the open circuit voltage of the lithium-iron disulfide battery, make the voltage platform more stable, improve the conductive activity of the battery, improve the discharging performance of heavy current, improve the discharging depth of the battery and make the lithium-iron disulfide battery have higher actual values.

Owner:广州市天球实业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com