Resin-based high-strength wear-resistant grinding wheel material and preparation method thereof

A high-strength, resin-based technology used in abrasives, bonded grinding wheels, grinding/polishing equipment, etc., can solve problems such as poor strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

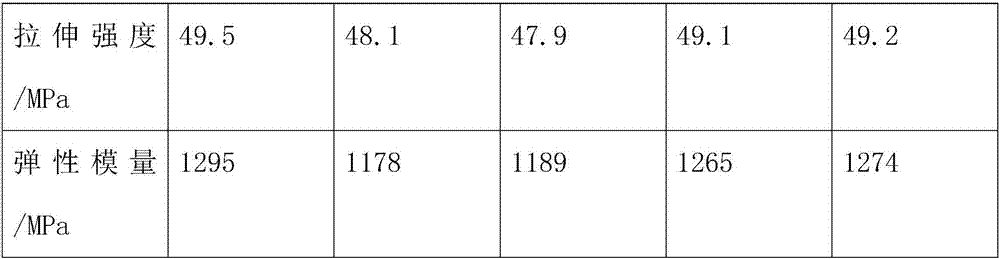

Embodiment 1

[0015] A kind of resin-based high-strength wear-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 45 parts of modified phenolic resin, 10 parts of epoxy resin, 6 parts of powdered nitrile rubber, 5 parts of polyurethane elastomer, polyethylene 4.5 parts of alcohol butyral, 3.5 parts of iron disulfide, 6 parts of copper powder, 6 parts of zinc oxide, 3.5 parts of graphite, 2.5 parts of hollow ceramic ball, 4.5 parts of corundum, 3 parts of corundum, 4.5 parts of talcum powder, 6 parts of silicon carbide , 4.5 parts of alumina, 4.5 parts of boron oxide, 3.5 parts of boron nitride, 3 parts of chromium trioxide, 2.5 parts of nano silicon dioxide, 6 parts of silane coupling agent KH-550, 4.5 parts of wear-resistant additive.

[0016] The modified phenolic resin was prepared according to the following process: 20 parts by weight of nano-montmorillonite, 6 parts of multi-walled carbon nanotubes and 3.5 parts of dichloroethane were ...

Embodiment 2

[0020] A resin-based high-strength wear-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 40 parts of modified phenolic resin, 15 parts of epoxy resin, 4 parts of powdered nitrile rubber, 6 parts of polyurethane elastomer, polyethylene 3 parts of alcohol butyral, 5 parts of iron disulfide, 4 parts of copper powder, 9 parts of zinc oxide, 2 parts of graphite, 4 parts of hollow ceramic ball, 3 parts of corundum, 5 parts of corundum, 3 parts of talcum powder, 8 parts of silicon carbide , 1 part of alumina, 6 parts of boron oxide, 2 parts of boron nitride, 4 parts of chromium trioxide, 1 part of nano-silica, 8 parts of silane coupling agent KH-550, and 3 parts of wear-resistant additive.

[0021] The modified phenolic resin was prepared according to the following process: 15 parts by weight of nano-montmorillonite, 8 parts of multi-walled carbon nanotubes and 2 parts of dichloroethane were uniformly mixed, ultrasonically treat...

Embodiment 3

[0025] A resin-based high-strength wear-resistant grinding wheel material proposed by the present invention, its raw materials include by weight: 50 parts of modified phenolic resin, 5 parts of epoxy resin, 8 parts of powdered nitrile rubber, 4 parts of polyurethane elastomer, polyethylene 6 parts of alcohol butyral, 2 parts of iron disulfide, 8 parts of copper powder, 3 parts of zinc oxide, 5 parts of graphite, 1 part of hollow ceramic ball, 6 parts of corundum, 1 part of corundum, 6 parts of talcum powder, 4 parts of silicon carbide , 8 parts of alumina, 3 parts of boron oxide, 5 parts of boron nitride, 2 parts of chromium trioxide, 4 parts of nano-silica, 4 parts of silane coupling agent KH-550, and 6 parts of wear-resistant additive.

[0026] The modified phenolic resin was prepared according to the following process: 25 parts by weight of nano-montmorillonite, 4 parts of multi-walled carbon nanotubes and 5 parts of dichloroethane were evenly mixed, ultrasonically treated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com