Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27333 results about "Silane coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

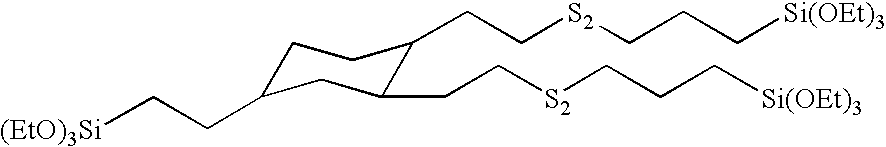

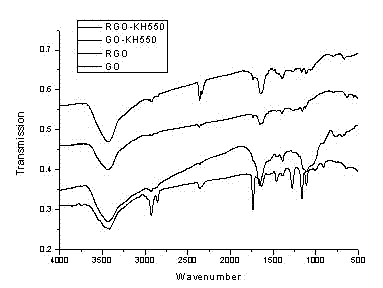

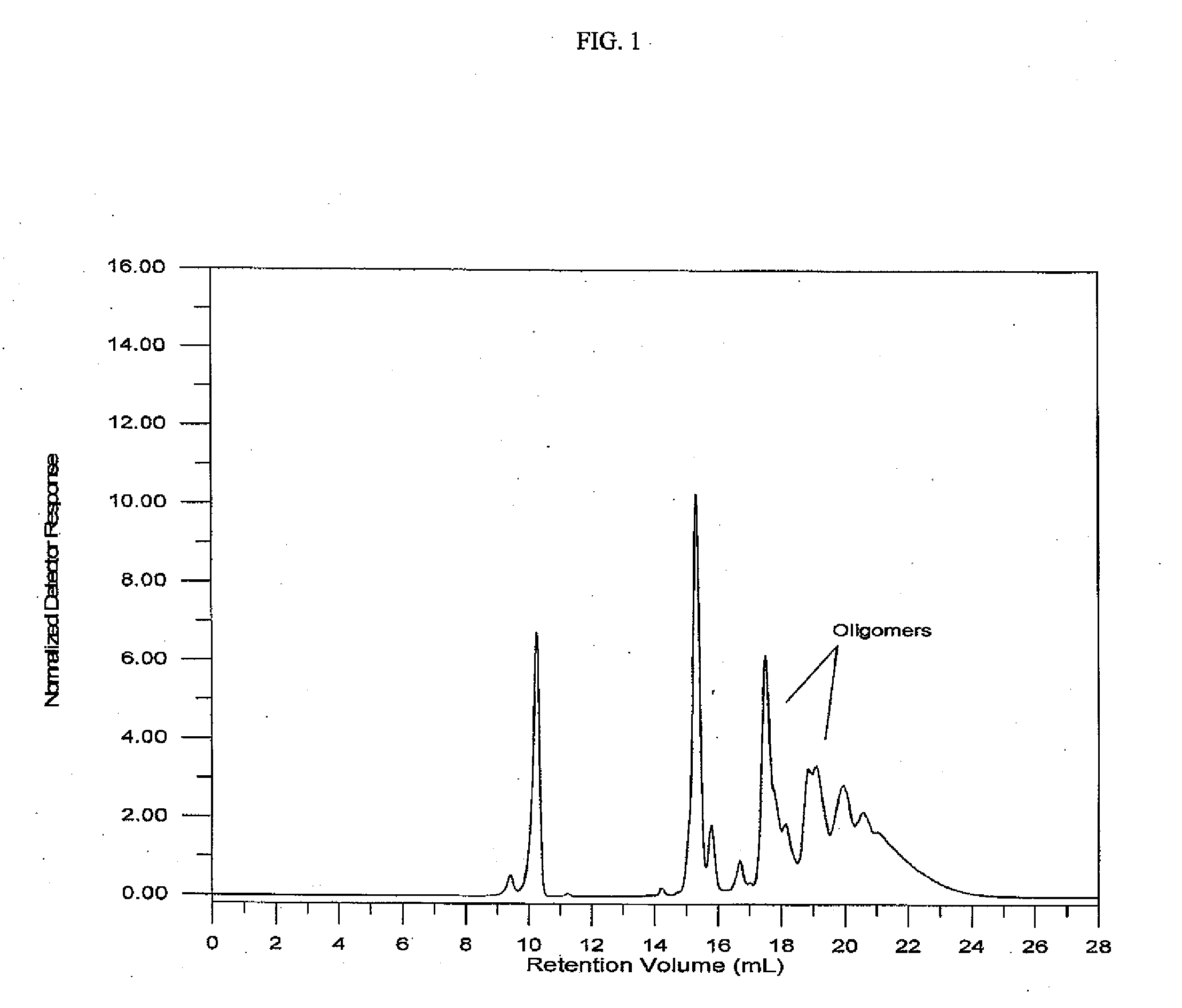

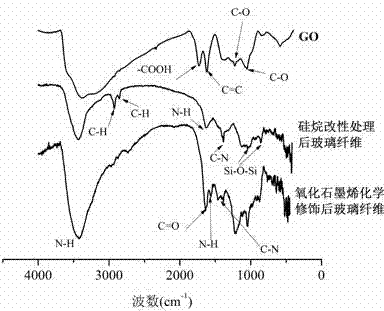

Silane coupling agents are a very common reactive primers used to promote adhesion between metal or glass and polymeric adhesives,28 shown in Fig.

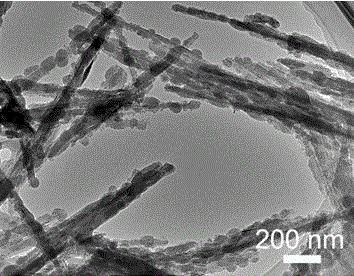

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

Dental adhesive kit

A kit for dental adhesive comprising a radical polymerizable monomer having an acid group in the molecule, a photosensitizer and / or a peroxide, a water-soluble organic solvent, an organic sulfinic acid and / or a salt thereof or a barbituric acid and / or a derivative thereof, and water. The kit may further comprises a radical polymerizable monomer which has no acid group and is insoluble or hardly soluble in water, an amine compound, a silane coupling agent and a 1,3,5-triazine-2,4-dithion derivative. By using this kit, the adhesive composition can be applied directly to a dentine without conducting a pretreatment.

Owner:SUN MEDICAL

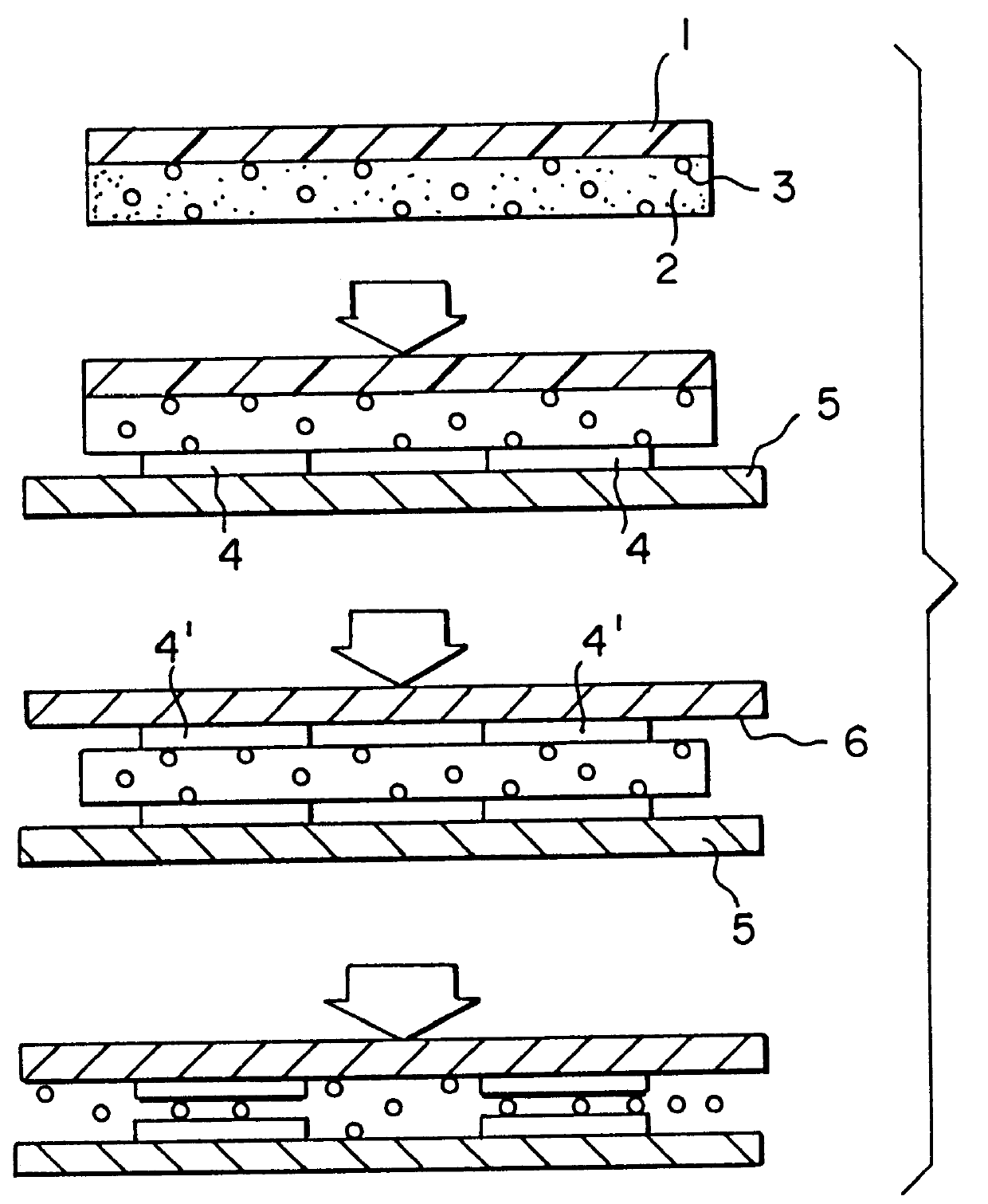

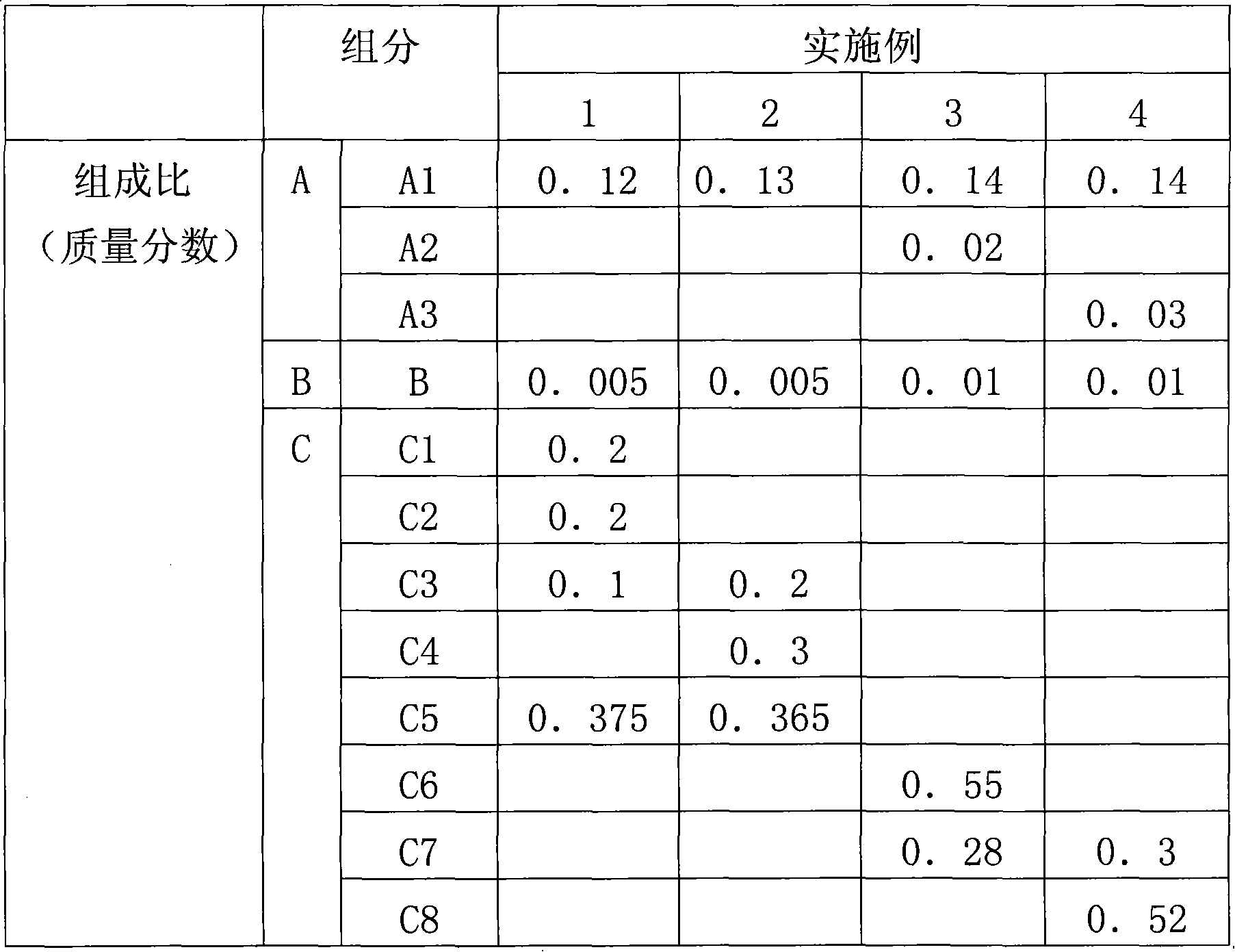

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

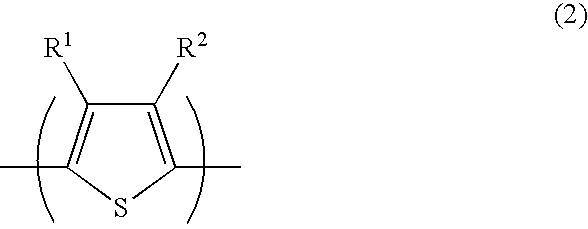

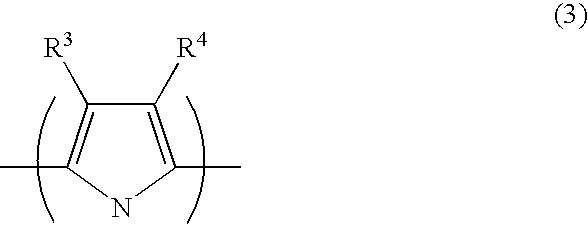

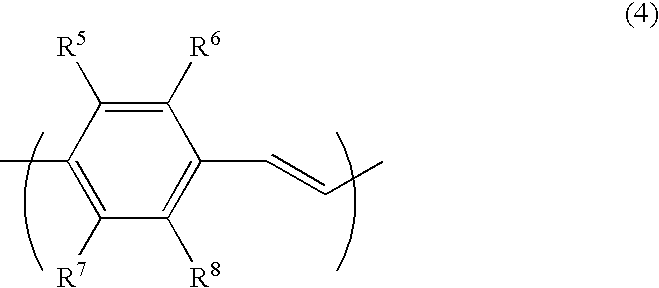

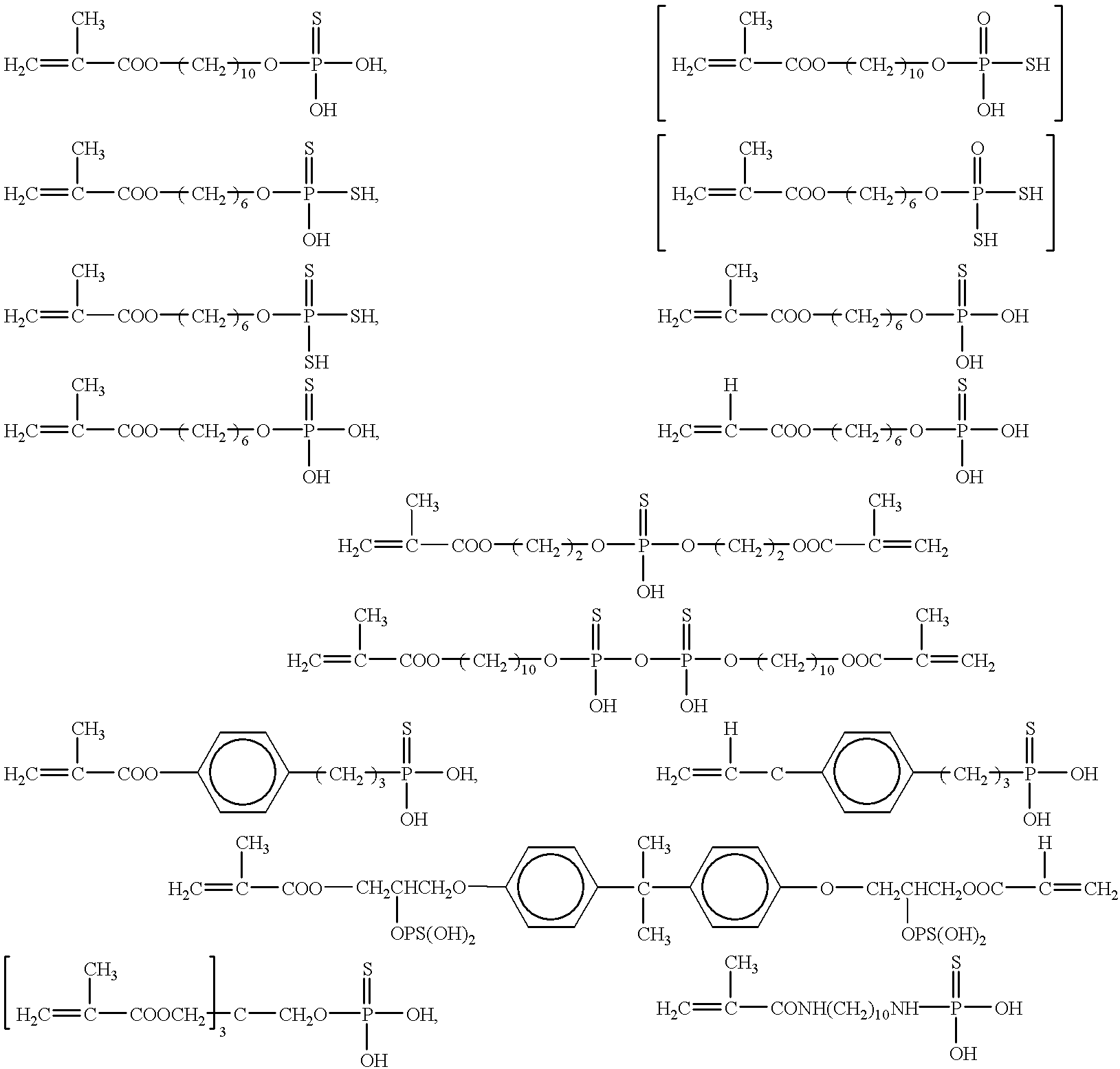

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

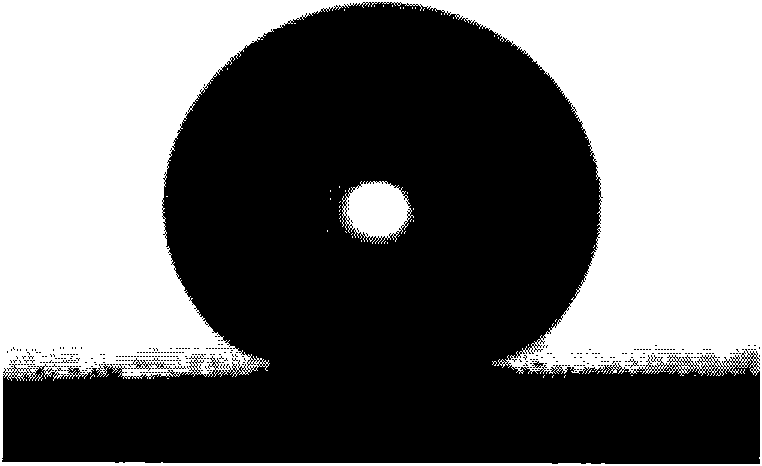

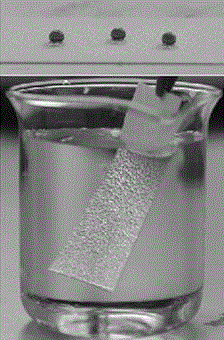

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

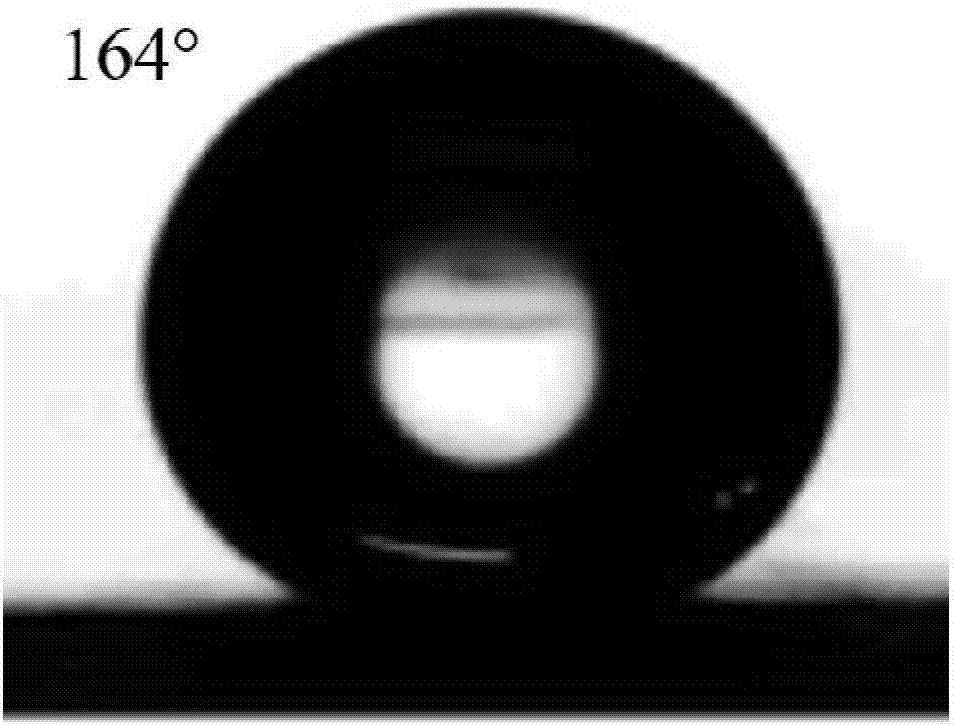

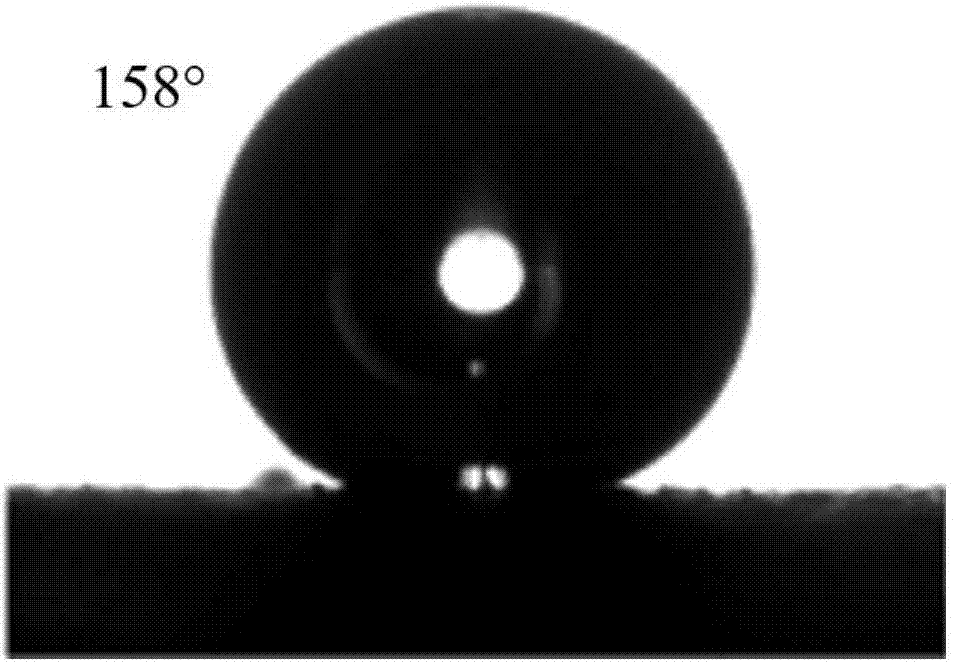

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

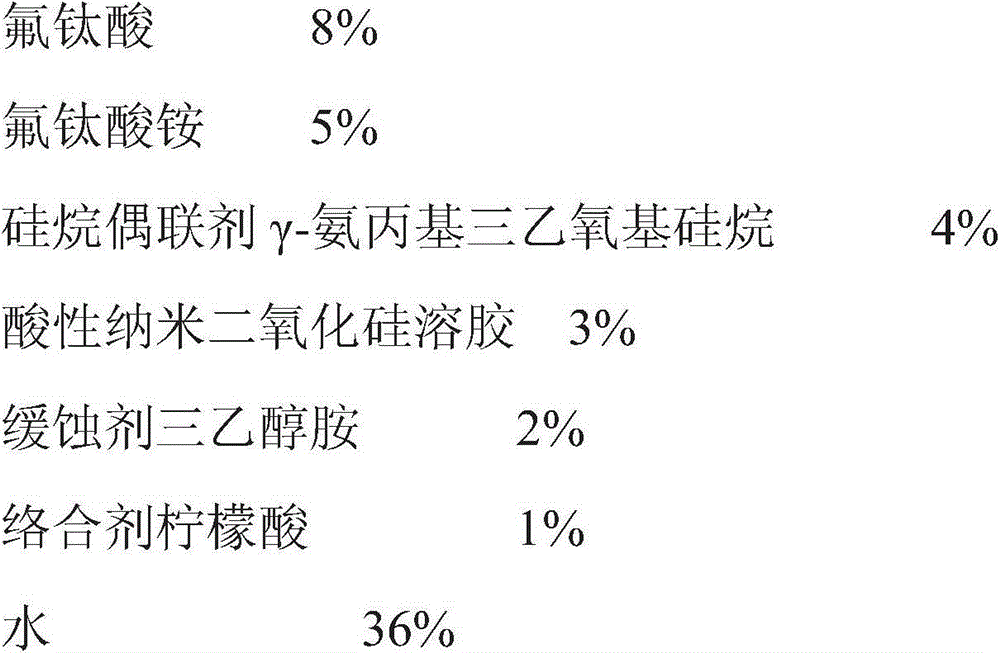

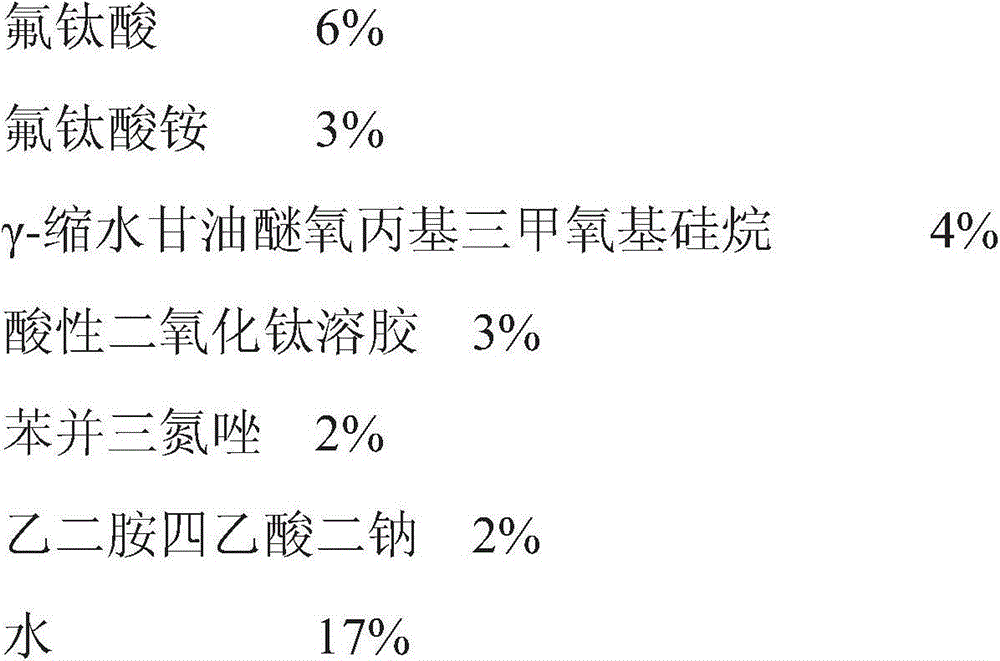

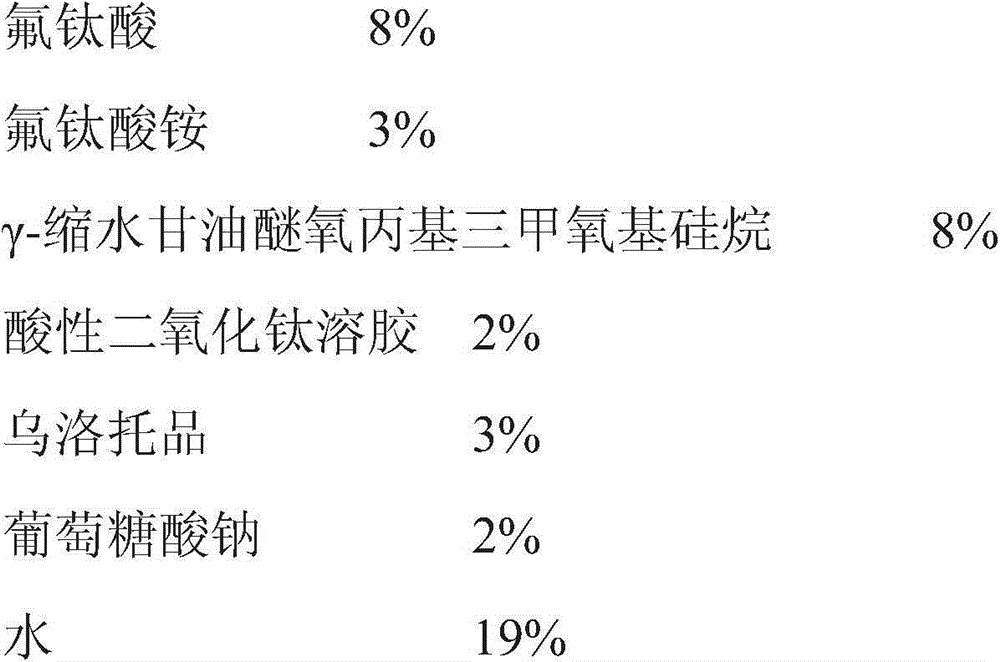

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

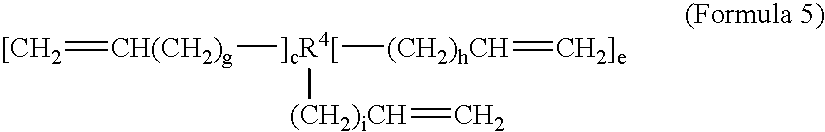

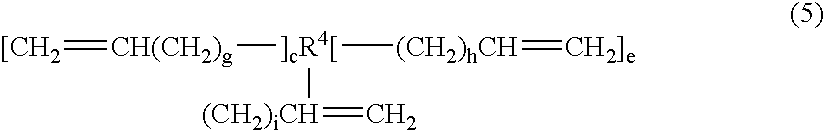

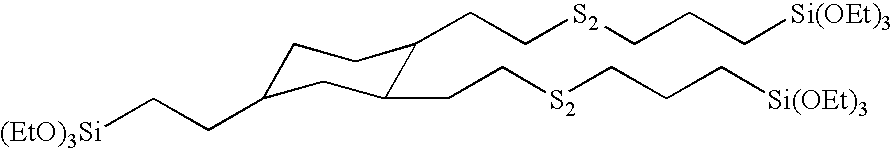

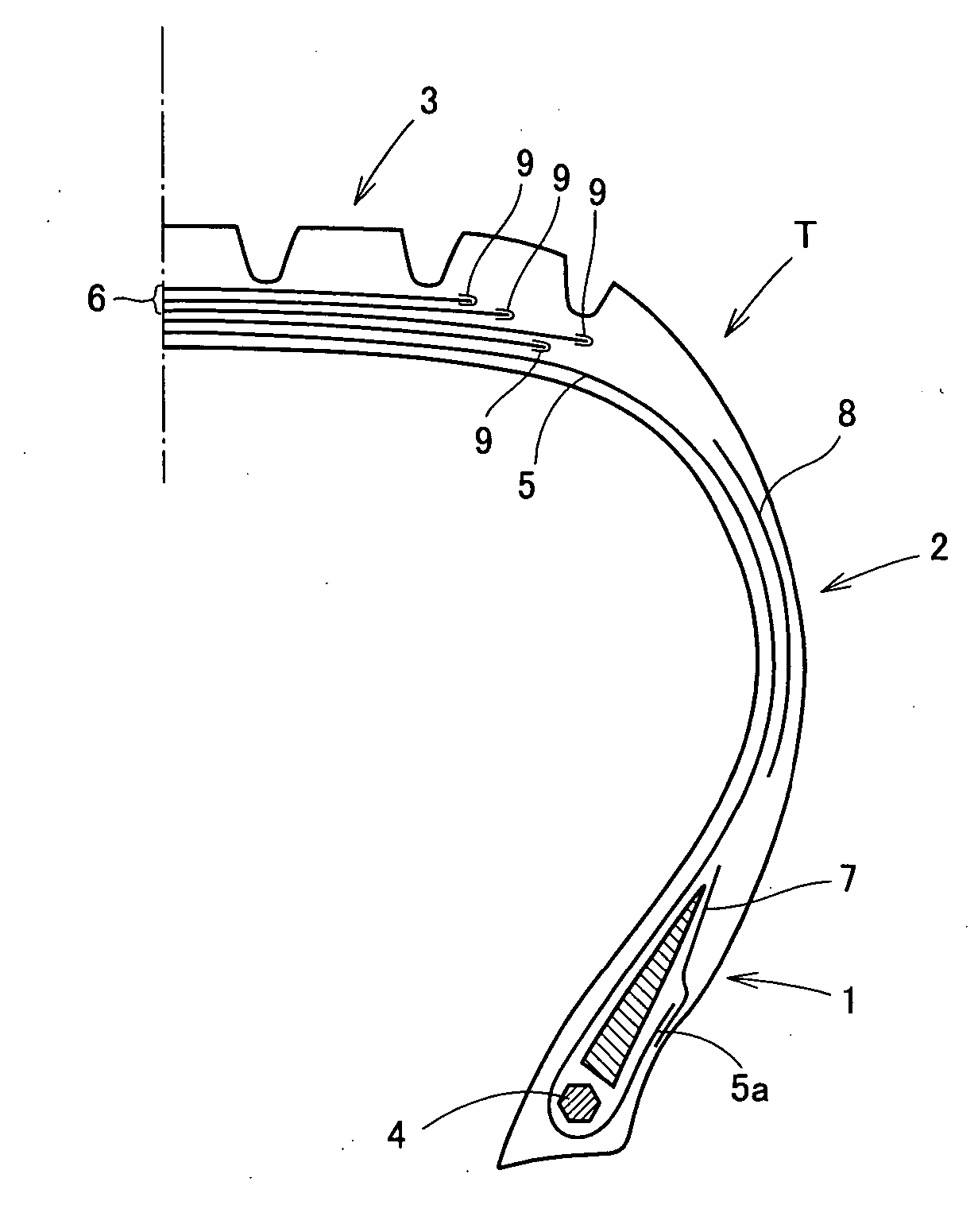

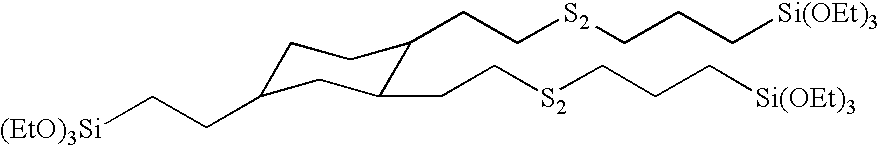

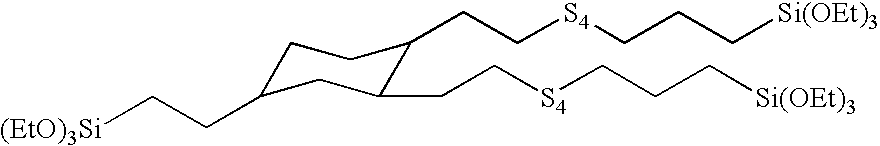

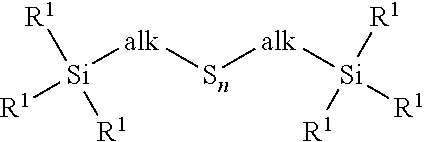

Silated core polysulfides, their preparation and use in filled elastomer compositions

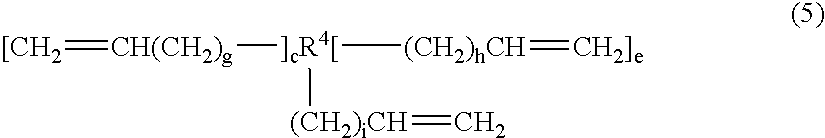

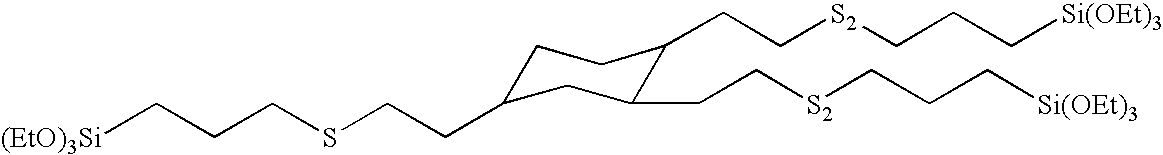

ActiveUS20080161477A1Good dispersion of fillerImprove productivityGroup 4/14 element organic compoundsSpecial tyresElastomerSilanes

This invention relates to novel sulfur-containing silane coupling agents, and organic polymers containing carbon-carbon double bonds. These novel silanes can be carried on organic and inorganic fillers. The invention also relates to articles of manufacture, particularly tires, made from the elastomer compositions described herein.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

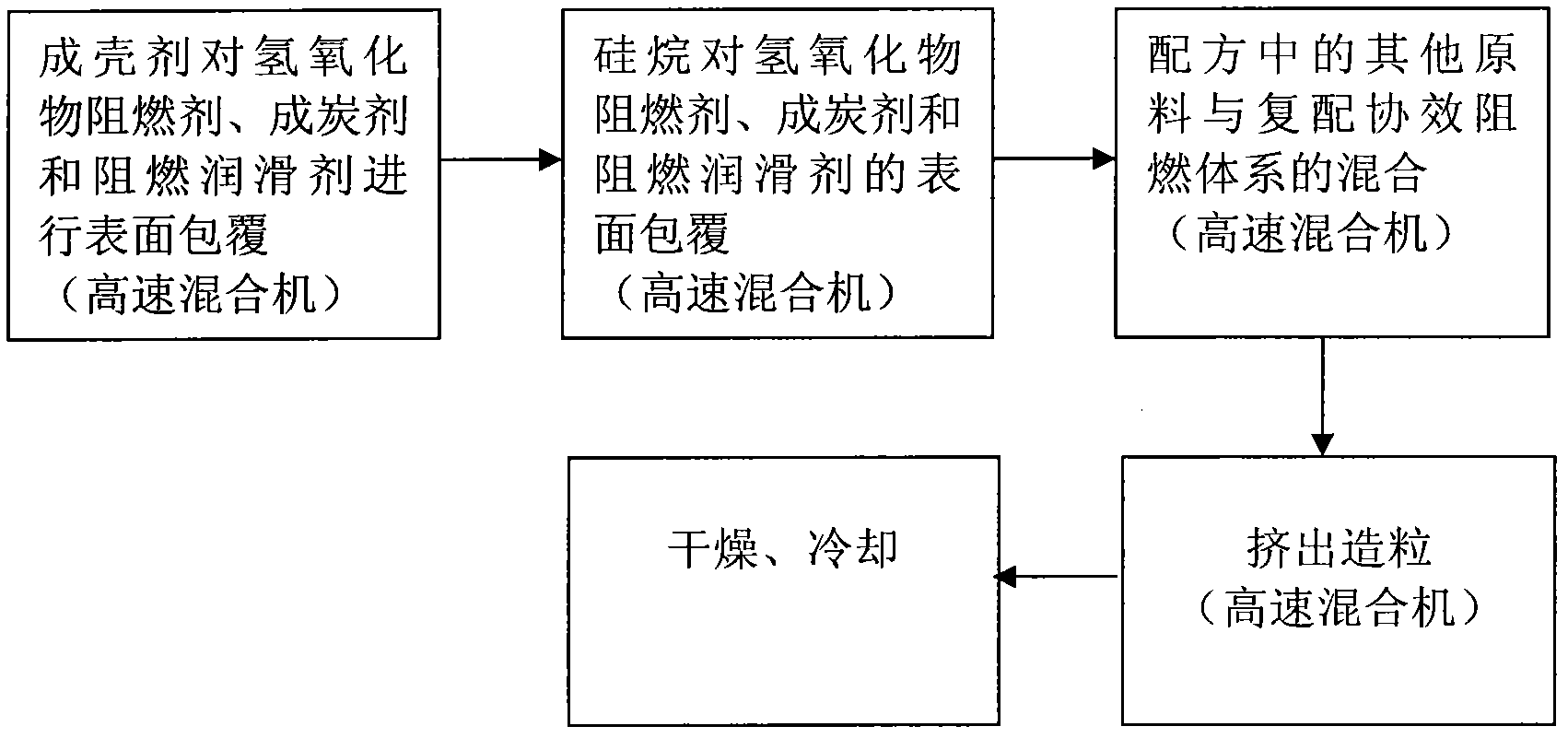

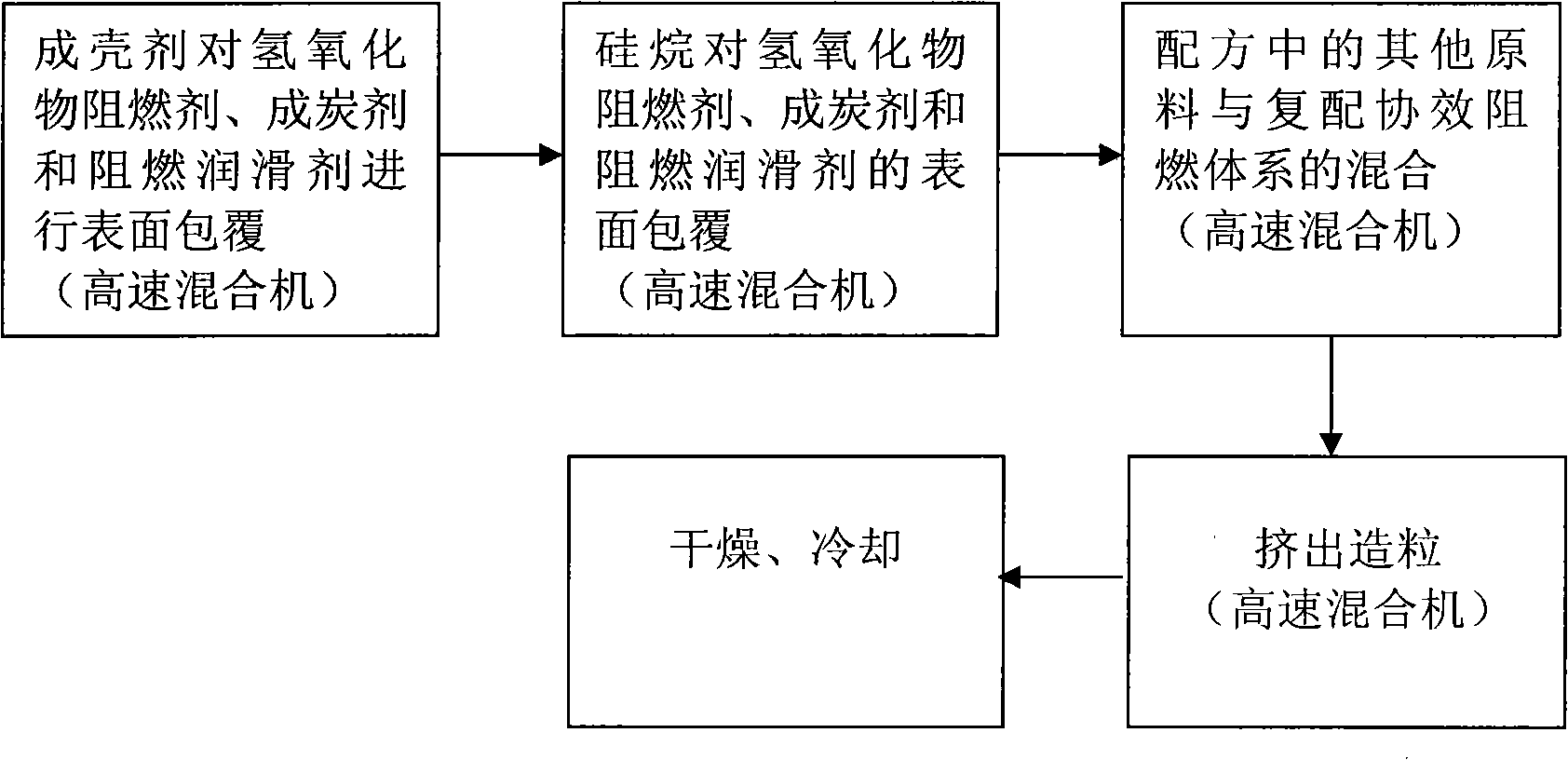

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

Preparation method of silica aerogel aqueous heat-insulating coating

InactiveCN102719129ADoes not require surface hydrophobic modificationWon't collapseCoatingsSilicon compoundsMicrosphereAlkoxy group

The invention discloses a preparation method of a silica aerogel aqueous heat-insulating coating, and is characterized in that: prepared SiO2 microspheres are hydrophobic inside and hydrophilic outside; and the aerogel microspheres can be added into an aqueous coating carrier to prepare a good heat-insulating material. The main preparation method comprises the following steps of: before drying the prepared wet gel microspheres, performing surface modification by using an organic silane or an organic chlorosilane, so that the prepared wet gel microspheres are hydrophobic by grafting a large number of alkoxy groups or alkyl groups on the surfaces thereof, or directly preparing the hydrophobic wet gel microspheres; performing surface modification on the microspheres by using a hydrophilic silane coupling agent, and drying to obtain the SiO2 microspheres which are hydrophobic inside and hydrophilic outside; and adding the prepared microspheres into an aqueous coating for preparing the aqueous heat-insulating coating.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

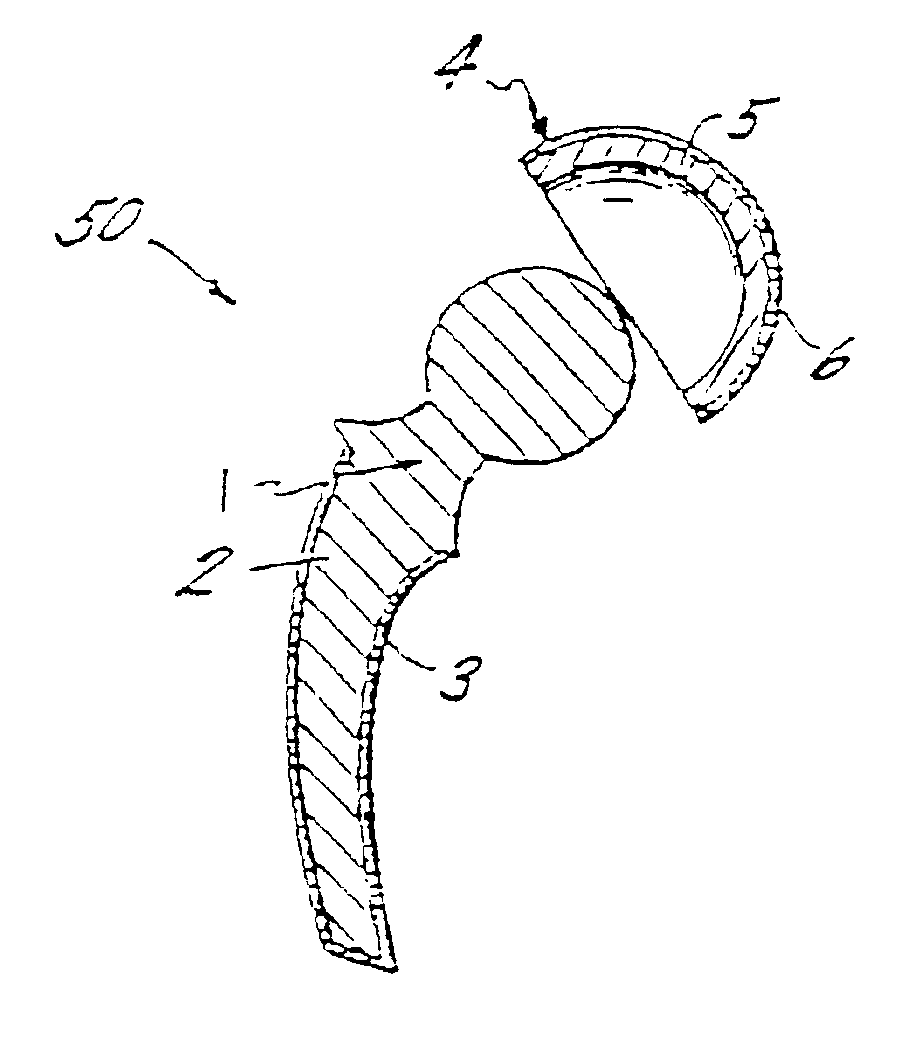

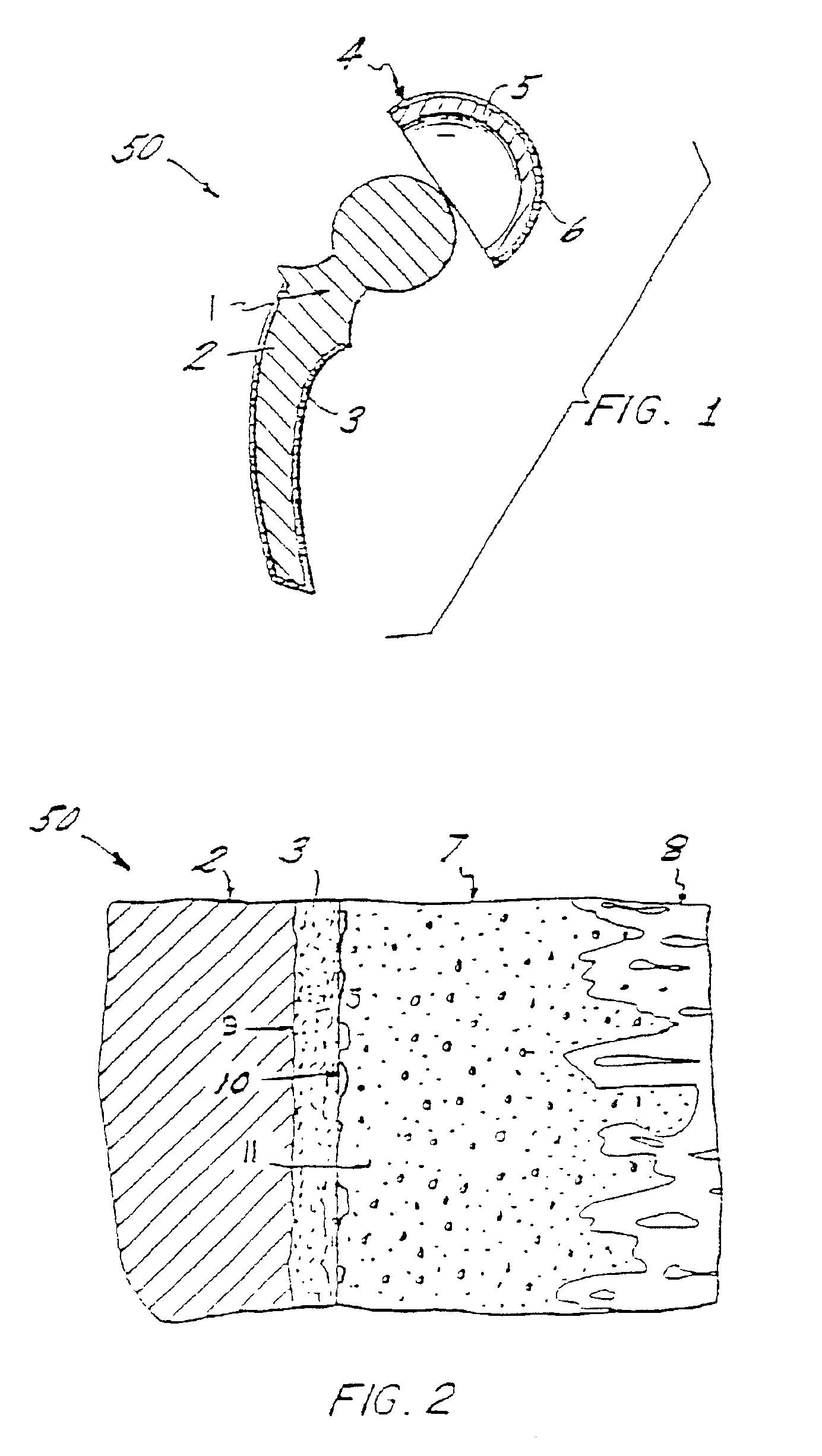

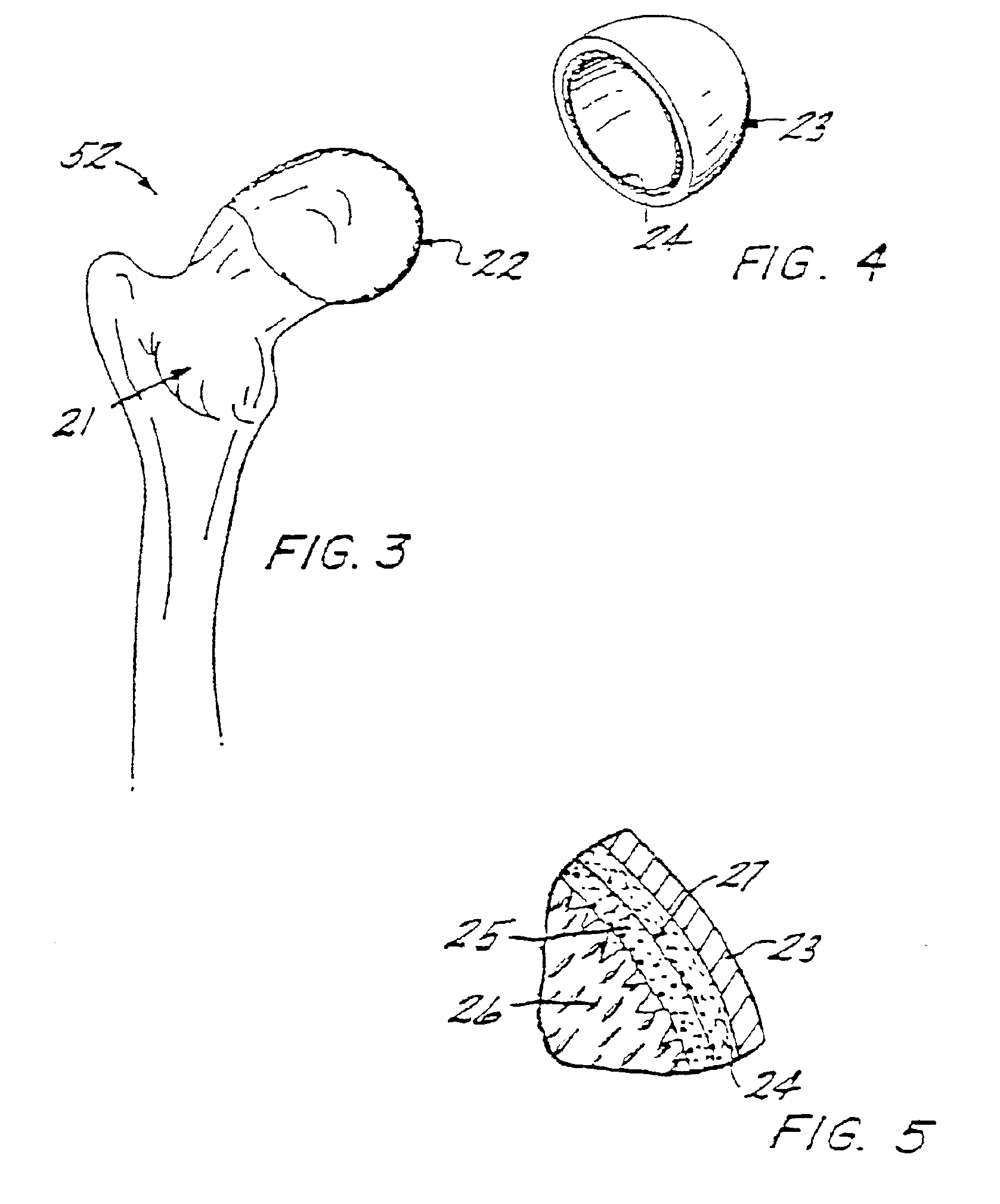

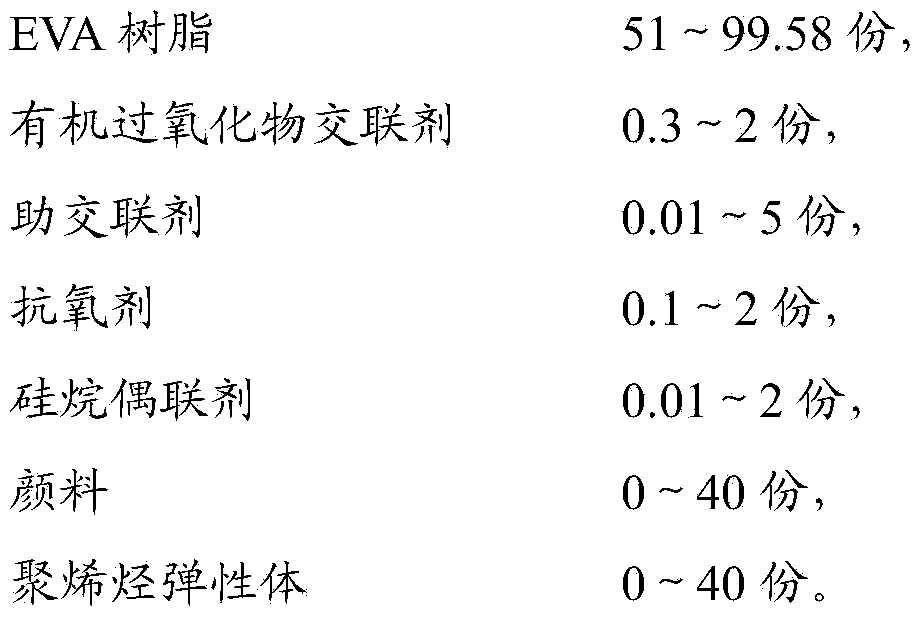

Bone connective prosthesis and method of forming same

InactiveUS6984236B2Improve cohesionImprove adhesionImpression capsBone implant2-methylpropene(Hydroxyethyl)methacrylate

The above-discussed and other problems and deficiencies of the prior art are overcome or alleviated by the improved bone connective prosthesis and method of forming the same of the present invention, comprising the addition of at least one biocompatible metal coupling agent to a prosthetic element, and then adding the biocompatible copolymerizer 2-hydroxyethyl methacrylate (“HEMA”) to the PMMA film and / or cement in an amount effective to enhance the cohesion between the prosthetic and the bone cement. In general, a PMMA / HEMA film is applied to the prosthetic element in the presence of a silane coupling agent by dipping, painting, spraying, etc.

Owner:FARO TECH INC

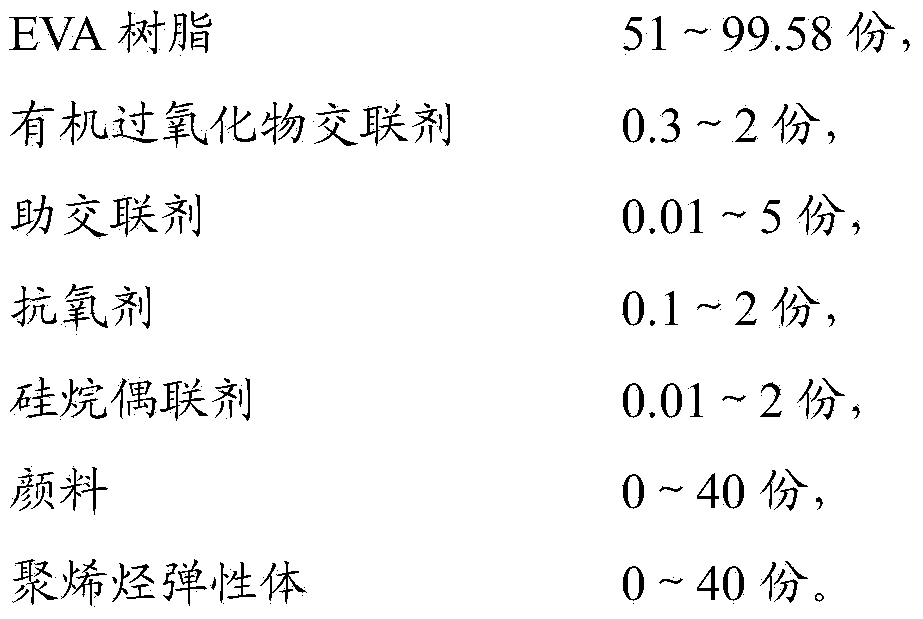

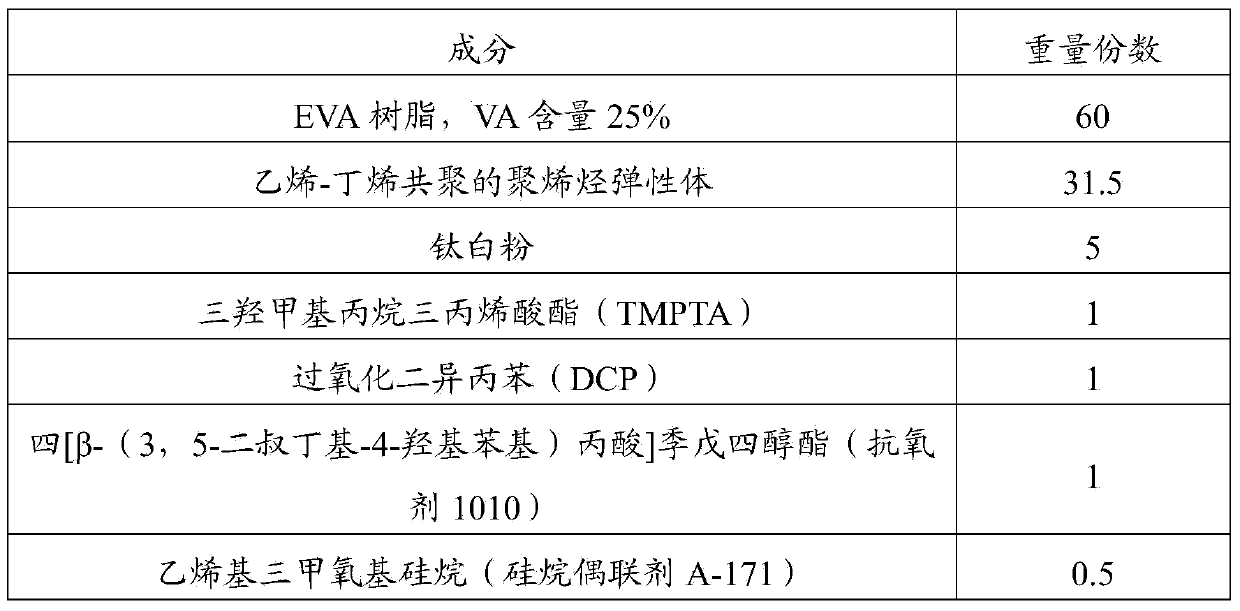

Radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film and preparation method thereof

ActiveCN103804774AGood dimensional stabilityImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyolefin

The invention discloses a radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film which comprises the following components in parts by weight: 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer. The invention also discloses a preparation method of the radiation pre-crosslinked EVA resin film, which comprises the steps of sufficiently mixing 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer, and adding into an extruder; extruding and forming a film through a T-shaped flat mould; rolling and radiating to obtain the radiation pre-crosslinked EVA resin film. Since the film is partially crosslinked before use, the dimensional stability and heat resistance of the film are remarkably improved, thus the film is suitable for large-scale popularization and application.

Owner:SHANGHAI HIUV NEW MATERIALS

Waterborne room-temperature self-curing inorganic zinc rich coating

ActiveCN102146225AStrong adhesionHigh modulusAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceMaterials science

The invention discloses waterborne room-temperature self-curing inorganic zinc rich coating. The coating is prepared by uniformly mixing a prepared base stock and powder in a mass ratio of 1:1.5-3.5, wherein the process of preparing the base stock comprises the following steps of: adding 5 to 10 parts of water into alkali metal silicates solution with the mode number of 2.5 to 3.7 and stirring the mixture at low speed; then adding silica sol drops with the grain diameter of 7 to 20nm and the solid content of 25 to 32 percent, dripping 1 to 10 parts of silane coupling agent and adding 0.5 to 2parts of stabilizing agent; and filtering out precipitates to obtain the transparent base stock. The inorganic zinc rich coating has high drying speed and good early-period waterproofness and can resist to washing with certain pressure after being dried for 20 minutes, has good salt spray corrosion resistance due to the adoption of multiple anticorrosion mechanisms and can resist to the high temperature of 400 DEG C. Meanwhile, the constructability of the conventional waterborne inorganic zinc rich coating is greatly improved; and the corrosion resistance year limit can reach over 15 years. The paint is prepared at normal temperature under normal pressure and has low production cost. The environmental protection requirement is met.

Owner:SOUTH CHINA UNIV OF TECH +1

Tire compositions and components containing silated cyclic core polysulfides

Sulfur-containing silane coupling agents, and organic polymers containing carbon-carbon double bonds. These silanes can be carried on organic and inorganic fillers. The invention also relates to tire compositions and articles of manufacture, particularly tires, made from the elastomer compositions described herein.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

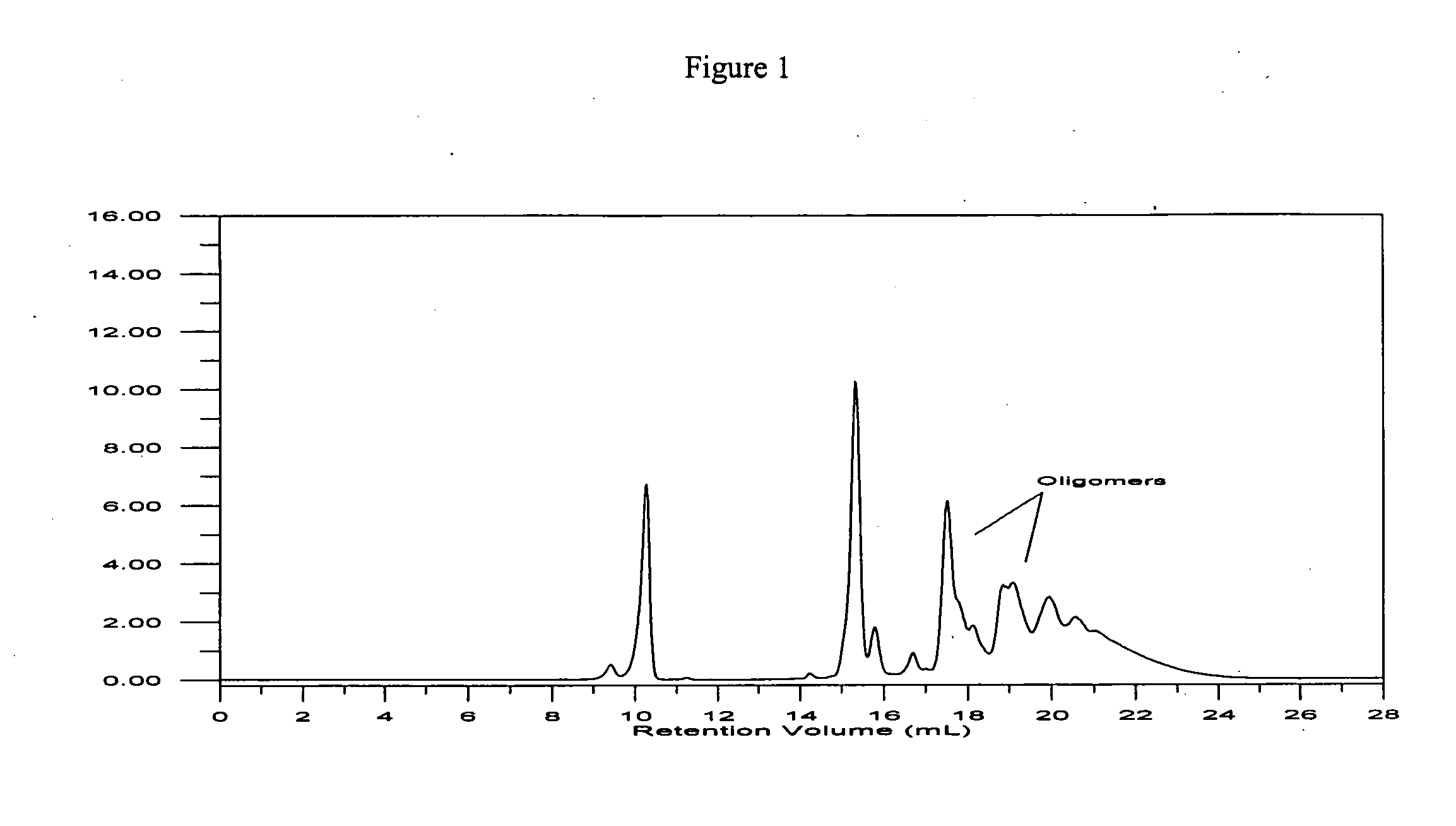

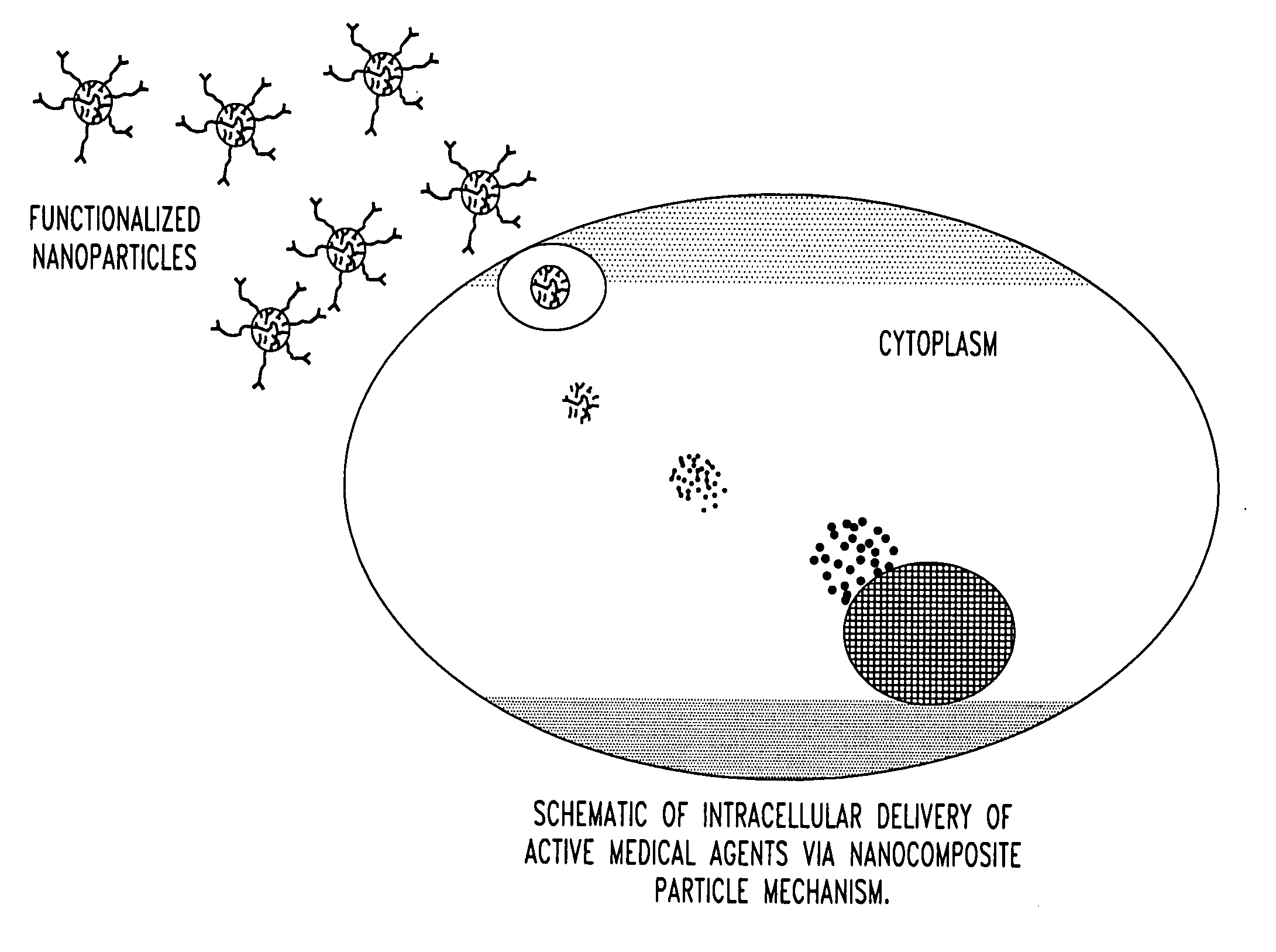

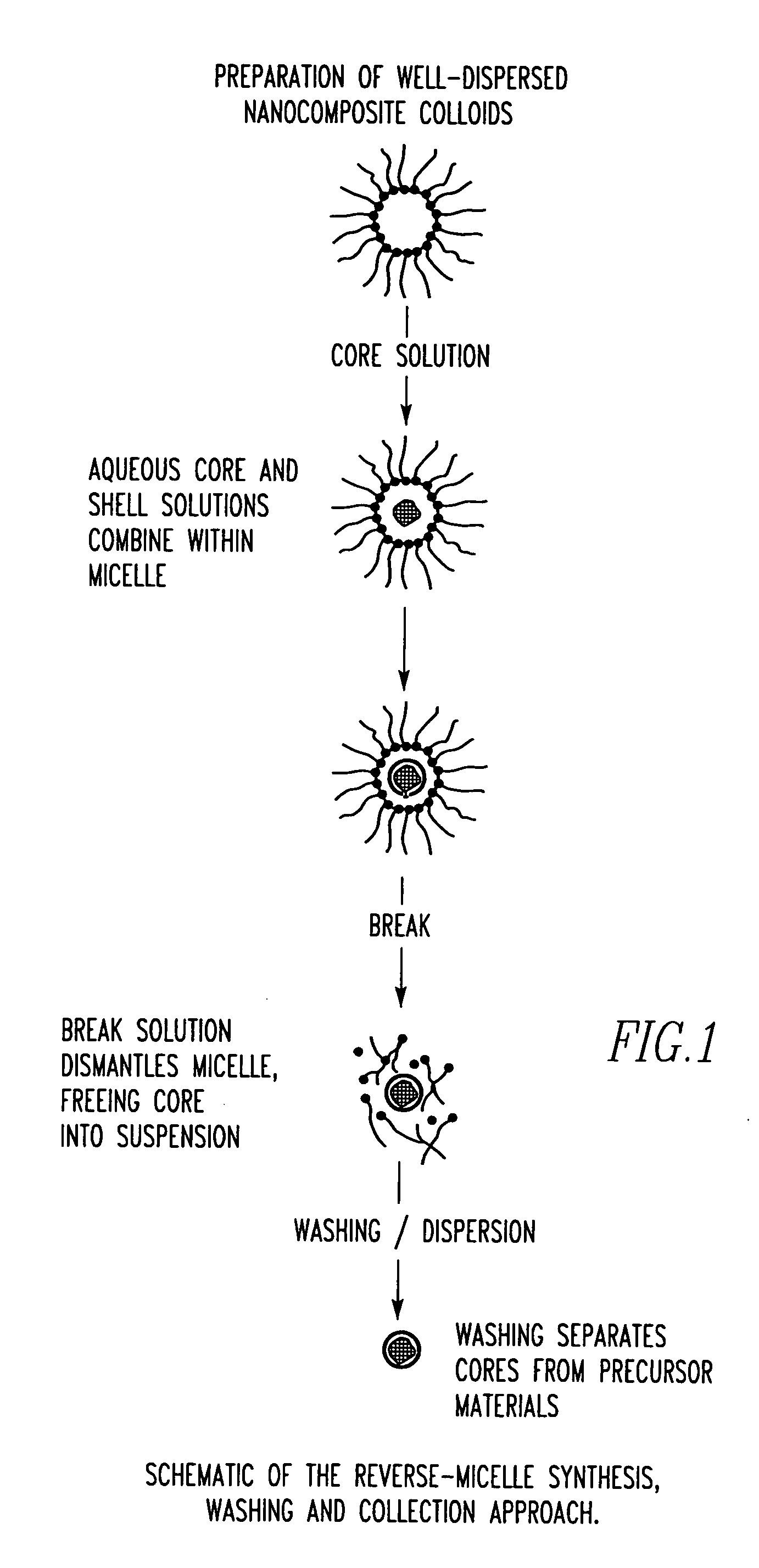

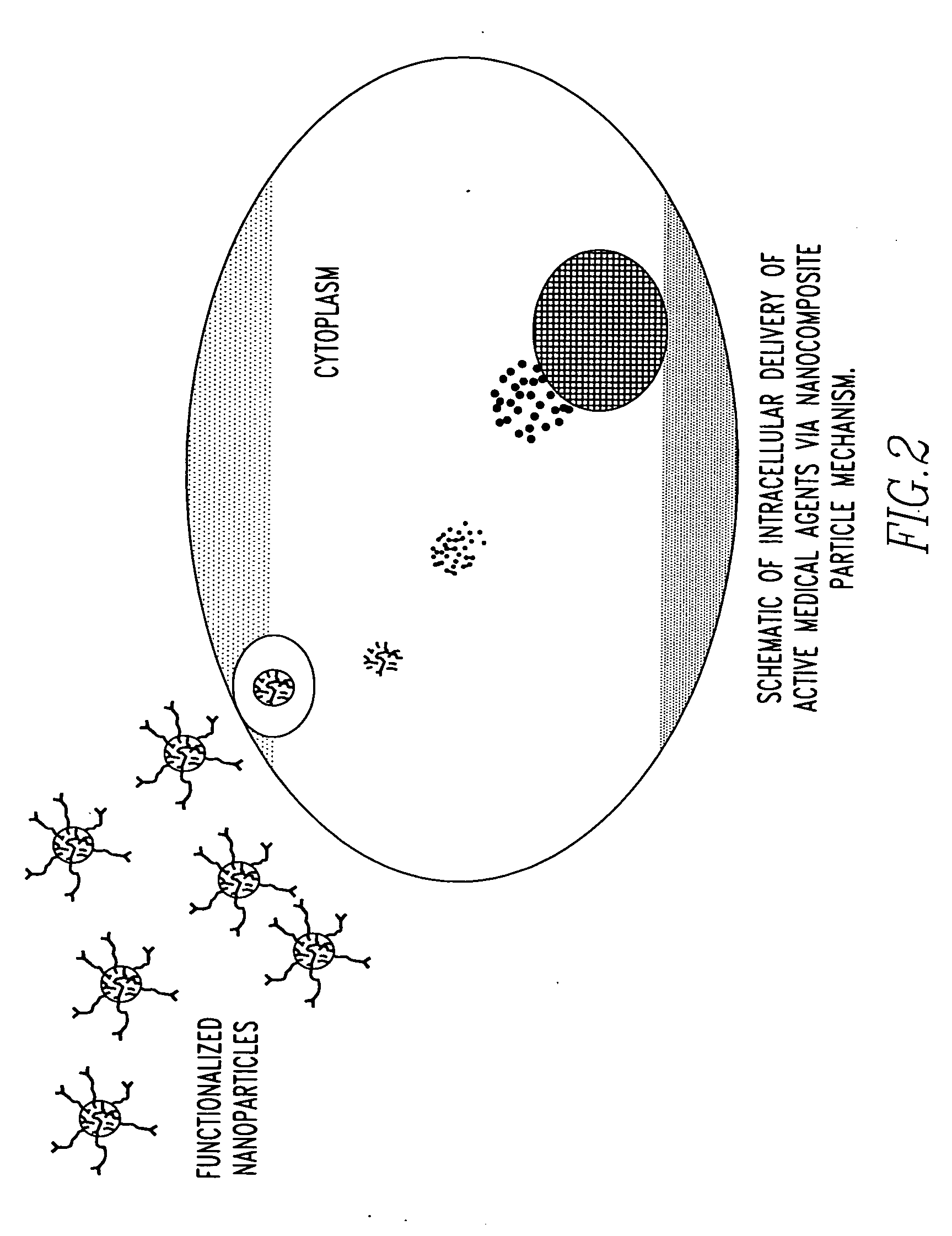

Unagglomerated core/shell nanocomposite particles

ActiveUS20050281884A1Improve stabilityPromote absorptionPowder deliveryMaterial nanotechnologyAlcoholMicroemulsion

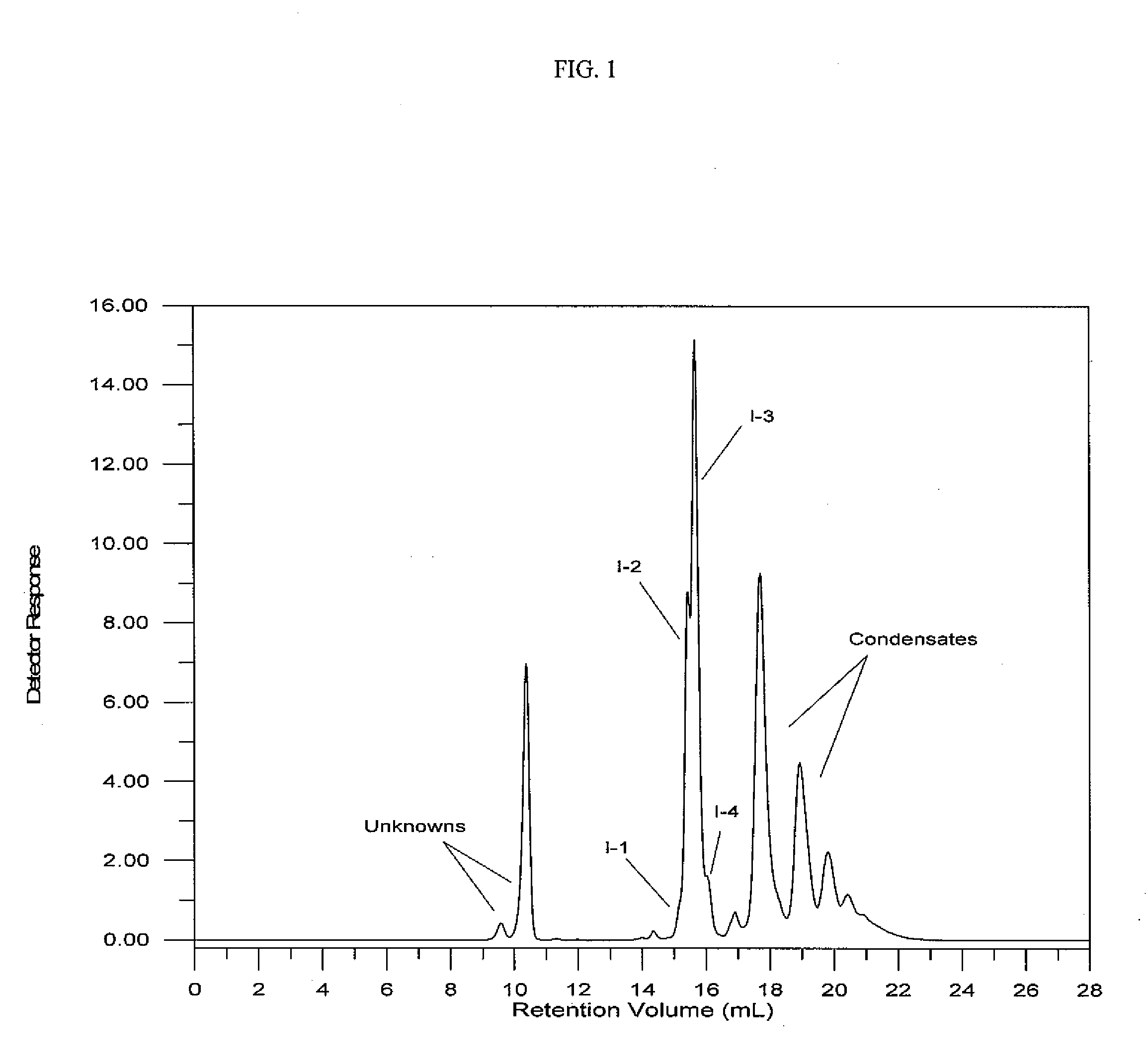

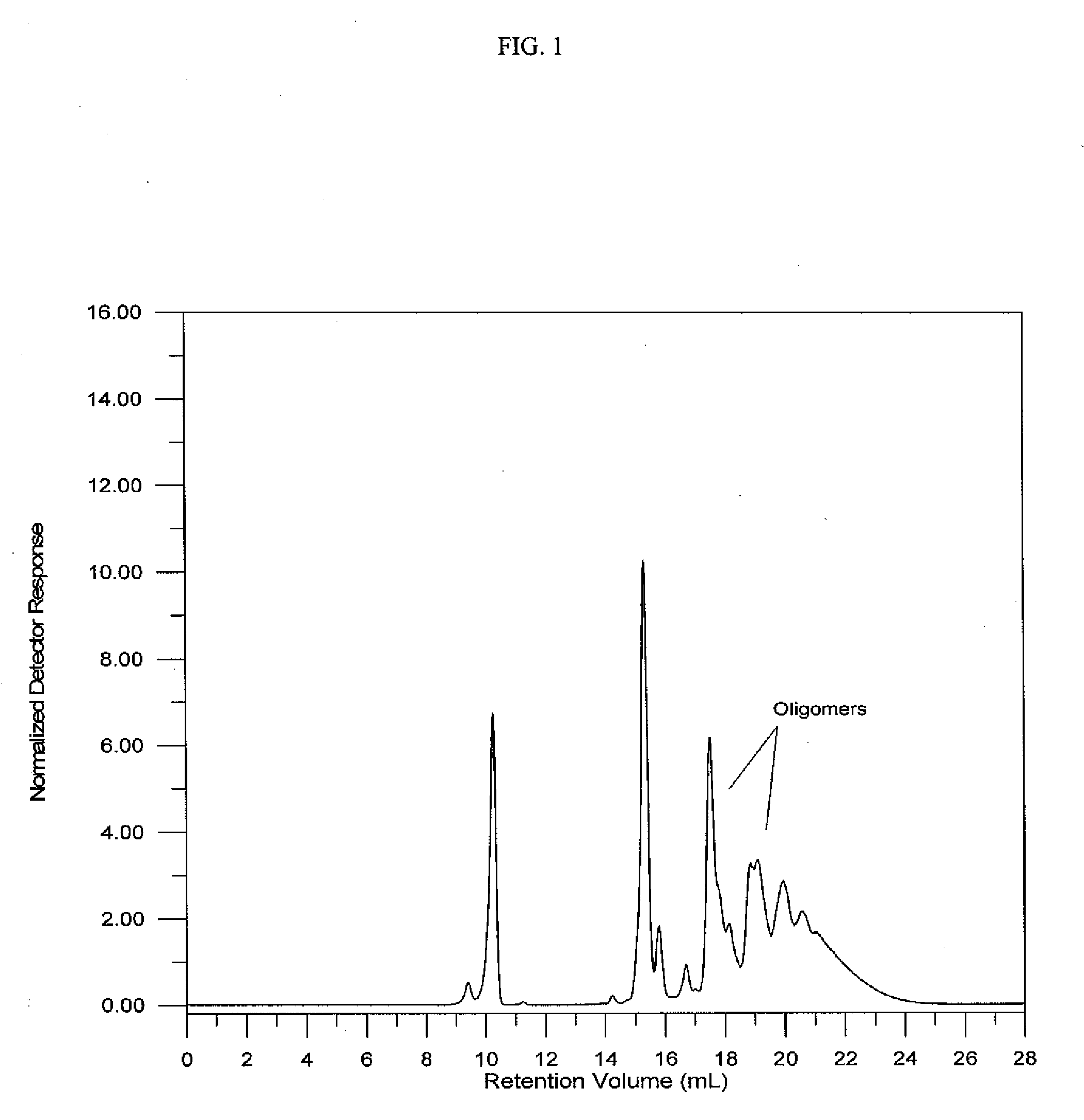

The present invention provides a method for the synthesis of unagglomerated, highly dispersed, stable core / shell nanocomposite particles comprised of preparing a reverse micelle microemulsion that contains nanocomposite particles, treating the microemulsion with a silane coupling agent, breaking the microemulsion to form a suspension of the nanocomposite particles by adding an acid / alcohol solution to the microemulsion that maintains the suspension of nanocomposite particles at a pH of between about 6 and 7, and simultaneously washing and dispersing the suspension of nanocomposite particles, preferably with a size exclusion HPLC system modified to ensure unagglomeration of the nanocomposite particles. The primary particle size of the nanocomposite particles can range in diameter from between about 1 to 100 nm, preferably from between about 10 to 50 nm, more preferably about 10 to 20 nm, and most preferably about 20 nm.

Owner:PENN STATE RES FOUND

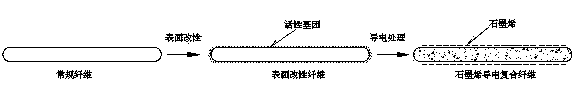

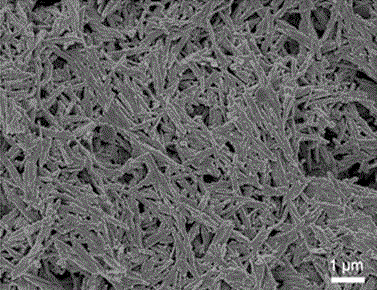

Preparation method of graphene electroconductive composite fiber

The invention provides a preparation method of a graphene electroconductive composite fiber. The method is characterized by comprising the following procedures: in a textile fiber surface modification procedure, a textile fiber is soaked into a silane coupling agent KH560 solution with the concentration of 1-30 percent for 2-3 hours and then is put into an oven of 50-65 DEG C to be dried to prepare the surfactant modified textile fiber; in a graphene dispersion system preparation procedure, graphene is prepared from an oxidized graphene aqueous solution prepared by means of a Hummer's method in a chemical reduction method, and a uniform and stable graphene dispersion system with the concentration of 0.1-5 percent is prepared under the function of a dispersing agent; in a graphene composite fiber preparation procedure, the modified textile fiber is soaked in the graphene dispersion system for 2-3 hours and then put into the oven of 50-65 DEG C to be dried to obtain the graphene electroconductive composite fiber. The preparation method is simple and reasonable in process, easy to operate, high in yield, high in reduction degree and high in conductivity and anti-radiation performance; the using amount of graphene is less and the dispersion system is uniform and stable.

Owner:QINGDAO UNIV

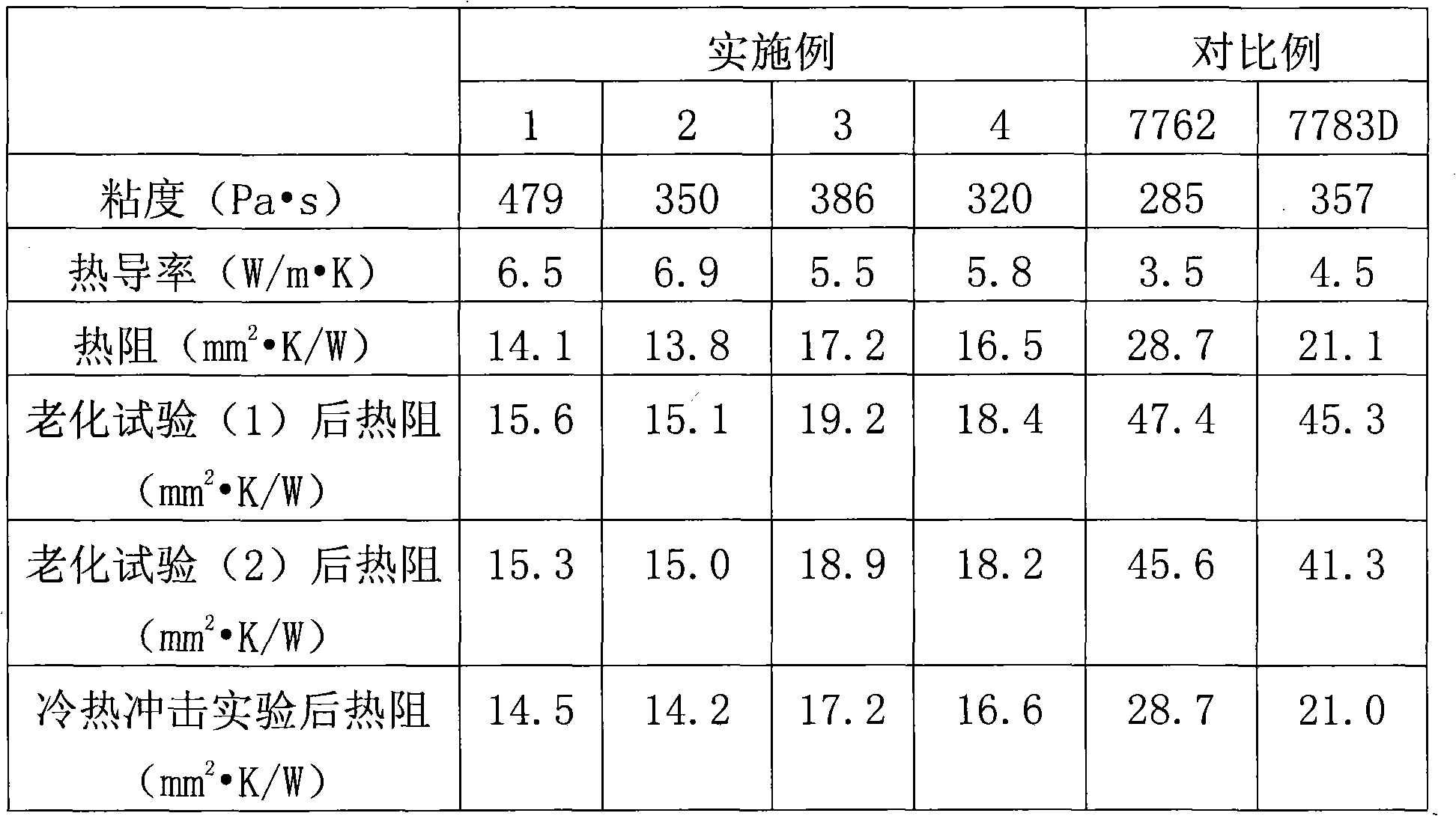

Heat conductive silicone grease composition

ActiveCN101294067AReduce dispersionReduce coupling effectHeat-exchange elementsHeat conductingCoupling

The invention discloses a heat-conducting silicone grease composition which mainly consists of organic silicone oil, a silicane coupling agent and heat-conducting powder, wherein the silicane coupling agent covers the surface of the heat-conducting powder; the heat-conducting powder is prepared from powders with larger, intermediate and small diameters; and the concerned metal powder is subjected to heat treatment to form an oxide film on the surface of the metal powder. The heat-conducting silicone grease composition has high heat conductivity and good fluidity; secondarily, the heat-conducting silicone grease composition has high temperature resistance and can keep good heat conductivity and fluidity at 250 DEG C; additionally, the heat-conducting silicone grease composition requires no refrigeration and has the advantages of simplified storage and operation flows and high reliability.

Owner:SHENZHEN BORNSUN INDAL

Tire compositions and components containing silated core polysulfides

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

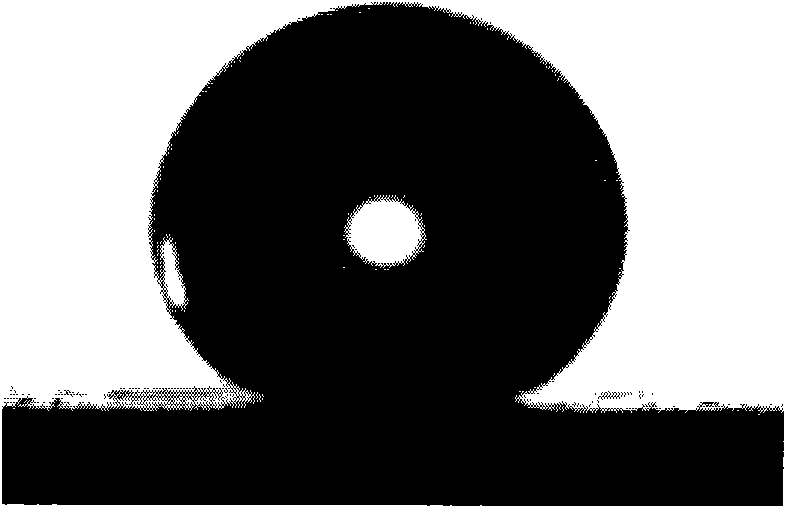

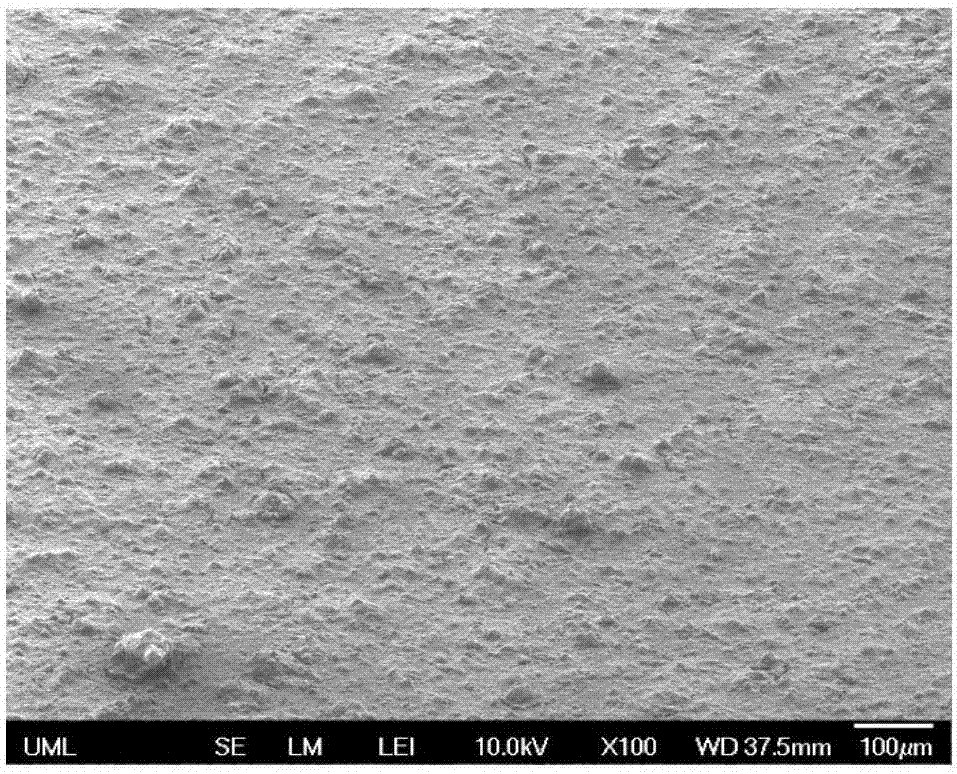

Preparation method of aqueous super-hydrophobic/super-hydrophobic and oileophobic coating

InactiveCN106811114AExcellent superhydrophobicityExcellent super amphiphobic propertiesAntifouling/underwater paintsPaints with biocidesNanoparticles dispersionSolvent

The invention discloses a preparation method of a water-based super-hydrophobic or super-amphiphobic coating. Nano-particles are ultrasonically dispersed into water, the pH of the solution is adjusted to obtain a nano-particle dispersion; The silane coupling agent is hydrolyzed under stirring to obtain an organosilane polymer / nanoparticle composite suspension; and then applied to the surface of the base material by spraying or dipping to obtain a water-based superhydrophobic / superamphiphobic coating. The present invention successfully prepares a water-based super-hydrophobic or super-amphiphobic coating with excellent performance without using any additives (organic solvent, surfactant and water-based solvent), and has many advantages such as water-based environmental protection, low price and excellent performance. , It has broader application prospects in the fields of self-cleaning surface, anti-corrosion coating, oil pollution prevention and oil transportation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Wear-resisting super-hydrophobic coating composition as well as preparation method and application thereof

InactiveCN107987675AImprove protectionLong-term effective superhydrophobic propertiesLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoNanoparticle

The invention relates to a wear-resisting super-hydrophobic coating composition as well as a preparation method and application thereof. The composition is prepared from a nano-material dispersion solution and a binding material dispersion solution. The nano-material dispersion solution is prepared by mixing a nanoparticle material, a hydrophobic silane coupling agent and a volatile solvent, wherein nanoparticles form a rough structure with a micro-nano dual scale through a mutual effect of the nanoparticles and the structure is dispersed in the solution of the hydrophobic silane coupling agent; the hydrophobic silane coupling agent has one or more groups and covalent bond connection is formed by the hydrophobic silane coupling agent and the micro-nano dual rough structure; meanwhile, thewear-resisting super-hydrophobic coating composition at least contains one hydrophobic group. A super-hydrophobic coating layer formed by the super-hydrophobic coating composition keeps a long-term effective super-hydrophobic property; the coating composition adopts a binding material so that the binding force between a super-hydrophobic structure and a matrix is enhanced and the protection effectof the coating layer is enhanced; a processing technology of the super-hydrophobic coating layer is simple and convenient and large-area construction is facilitated.

Owner:杭州纳微生物化学有限公司

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

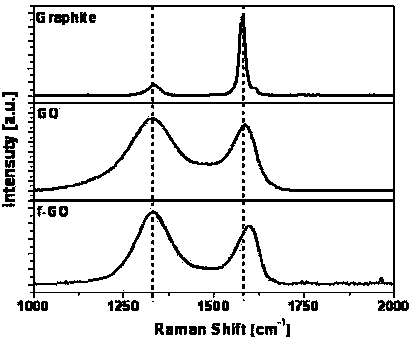

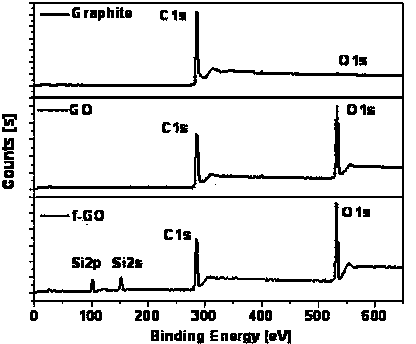

Method for preparing graphene modified by silane coupling agent

The invention discloses a method for preparing graphene modified by a silane coupling agent. The method includes adding graphite oxide and the silane coupling agent into reaction solvent, controlling the temperature to range from 0 DEG C to 90 DEG C, realizing stirred reaction for 0.1 to 72 hours and obtaining graphite oxide grafted with the silane coupling agent; adding the graphite oxide grafted with the silane coupling agent into reduction solvent, adding a reducer into the reduction agent, controlling the temperature to range from 0 DEG C to 90 DEG C, realizing stirred reduction reaction for 0.1 to 72 hours and obtaining graphene liquor grafted with the silane coupling agent; and treating the graphene liquor grafted with the silane coupling agent and then obtaining solid graphene powder modified by the silane coupling agent. The mass ratio of the graphite oxide and the silane coupling agent is 1:0.1-5. The technological method is simple and speedy, requirements on reaction conditions are low, a process is easy to control, and the graphene modified by the silane coupling agent can be obtained without catalysts or multi-step complicated reaction. The graphene is fine in polymer compatibility and simple in preparation and can be widely applied to fields of preparation of graphene modified polymers and novel electrochemical electrodes and novel optical and conductive materials, raw materials are easily available, and a product has good dispersibility in partial organic solvent.

Owner:NANJING UNIV

Pneumatic tire and method of producing the same

InactiveUS20060102269A1Increased durabilityReduce rolling resistanceSpecial tyresPneumatic tyre reinforcementsRolling resistanceCobalt salt

There is provided a pneumatic tire capable of achieving both reduced rolling resistance and enhanced durability and a method of producing the same. The pneumatic tire includes a reinforcement layer, formed of a steel cord coated with coating rubber, including at least one of a carcass, a bead reinforcement layer, a side reinforcement layer and a belt, with said coating rubber formed of a rubber compound containing 100 parts by mass of diene rubber, 30 to 80 parts by mass of silica having a nitrogen surface area of at least 70 m2 / g and at most 150 m2 / g, 1 to 15 parts by mass of a silane coupling agent, and organic acid cobalt salt. Preferably the steel cord has a cut edge of a breaker coated with an edge strip of rubber.

Owner:SUMITOMO RUBBER IND LTD

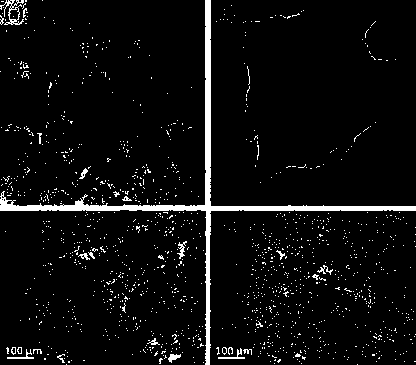

Preparation method of functionalized graphene oxide/epoxy resin nanocomposite

The invention relates to the technical field of polymer-based nanocomposites, and provides a preparation method of a functionalized graphene oxide / epoxy resin nanocomposite in order to effectively solve the problems of dispersion and interface of graphene in epoxy resin. The method comprises the steps of performing ultrasonic treatment on the silane coupling agent modified graphene oxide (f-GO) for 20-40 minutes, and dispersing in an organic solvent; adding epoxy resin, and mixing to obtain master batch; removing the organic solvent under a vacuum condition; adding a curing agent and mixing; performing high-temperature curing to obtain the functionalized graphene oxide / epoxy resin nanocomposite. The graphene oxide / epoxy resin nanocomposite prepared by the method provided by the invention can effectively improve the mechanical and thermal properties of epoxy resin, including strength, rigidity, toughness and thermal stability.

Owner:HANGZHOU NORMAL UNIVERSITY

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

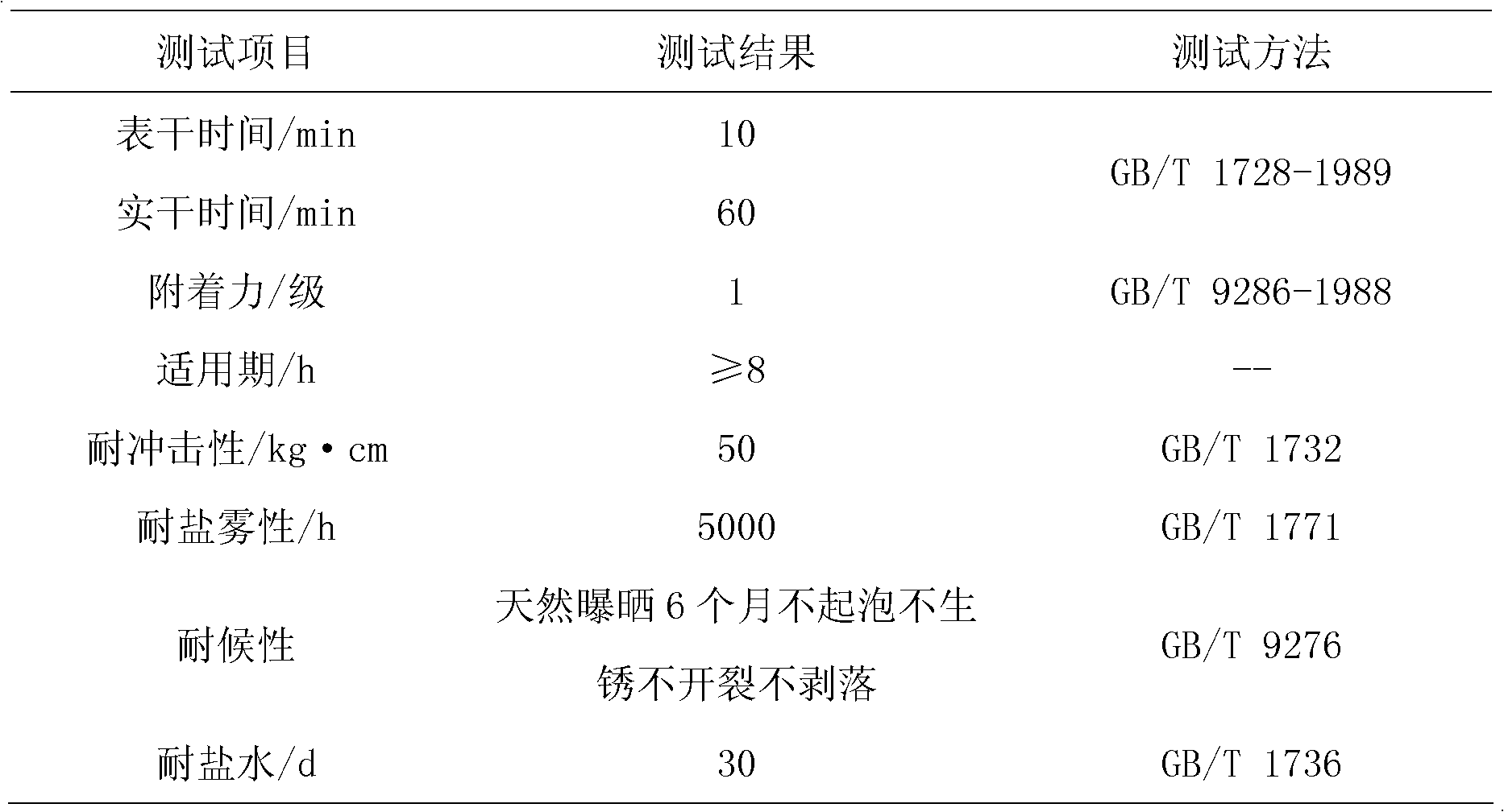

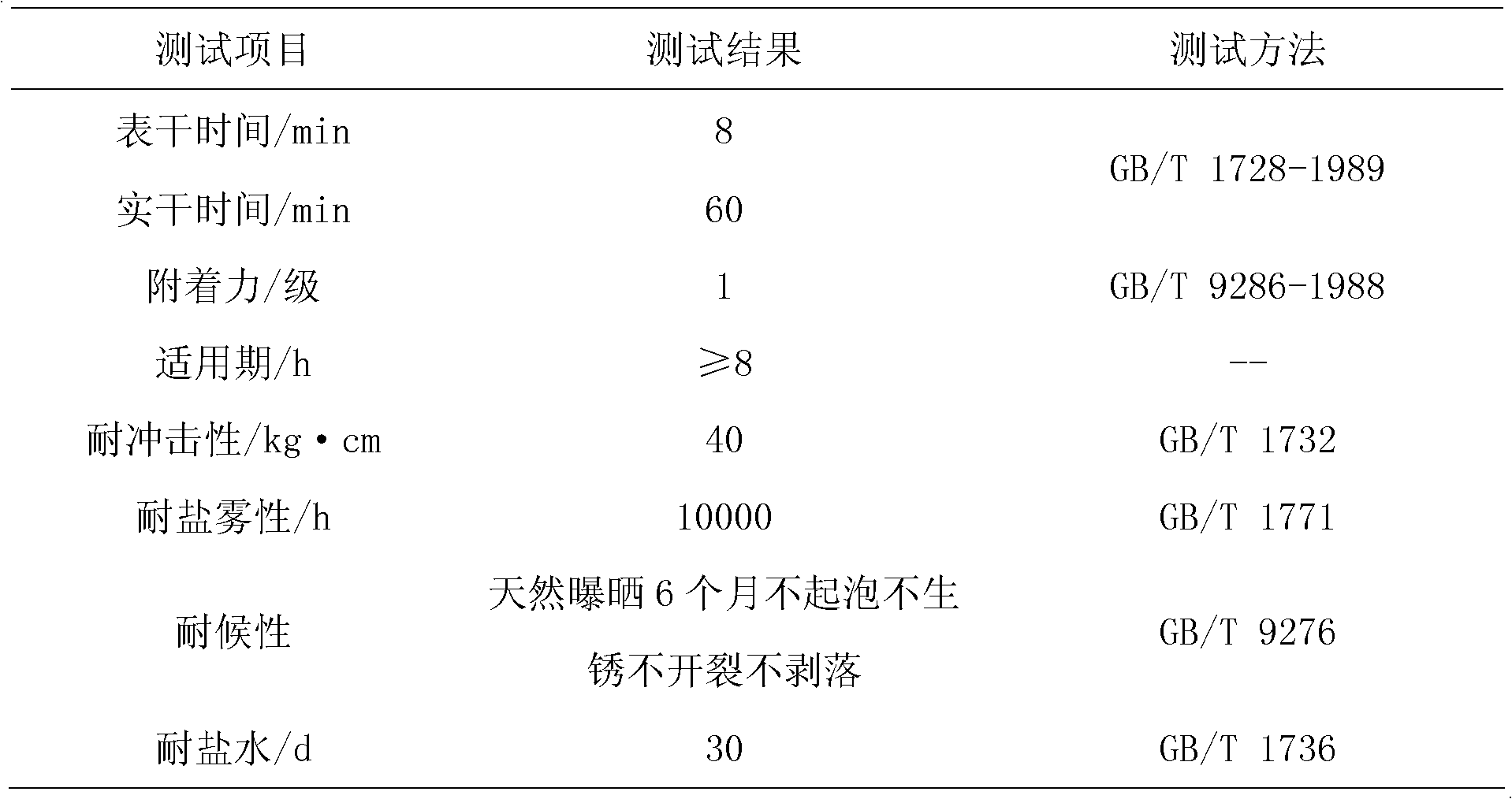

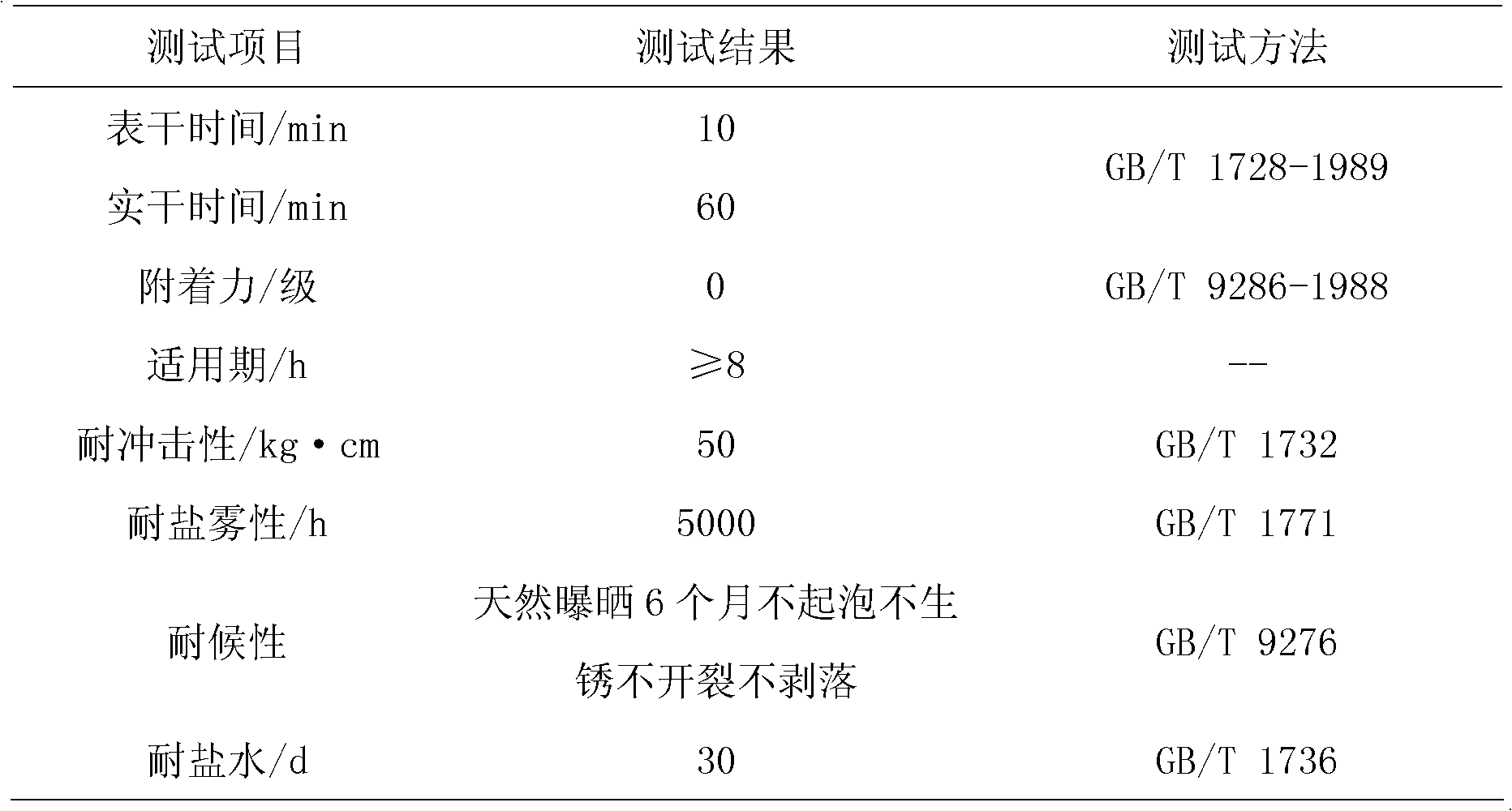

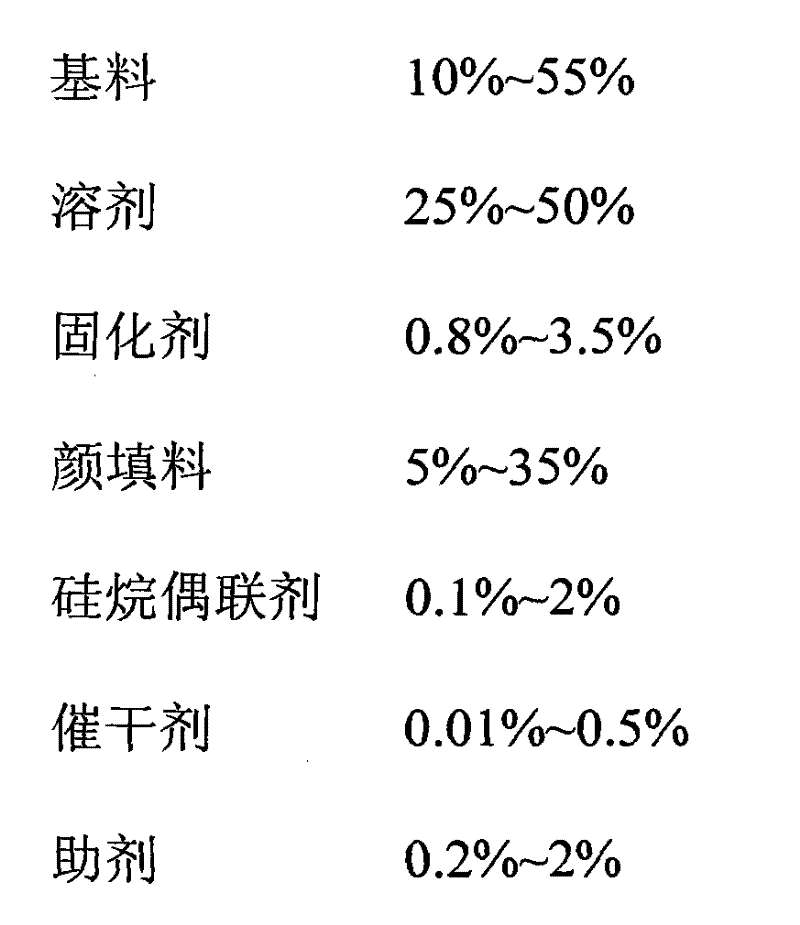

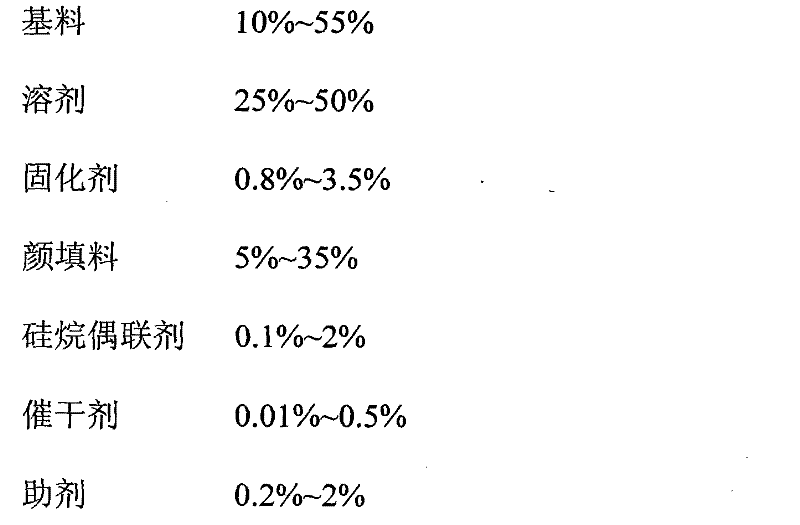

anti-corrosion coating

InactiveCN102260450AStrong adhesionEasy constructionAlkali metal silicate coatingsAnti-corrosive paintsMetal coatingSolvent

The invention belongs to the field of metal coatings, and in particular relates to a coating that can be used at high temperatures and is corrosion-resistant; the technical problem to be solved by the invention is to provide a coating that still has strong mechanical strength, strong adhesion, Corroded paint; in order to solve the above problems, the technical solution provided by the present invention is: a high-temperature anti-corrosion paint, including base material, solvent, curing agent, pigment and filler, silane coupling agent, drier, auxiliary agent; the present invention The beneficial effect is that: it has good adhesion, impact resistance and mechanical strength, the thickness of the coating film is 50 μm, the coating can withstand the temperature of 600 ° C, and has good corrosion resistance.

Owner:SNTO TECH GRP

Tire compositions and components containing free-flowing filler compositions

ActiveUS20080161475A1Better wear characteristicsImprove rolling resistanceSpecial tyresSulfur containingOrganic chemistry

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Processes for making silane, hydrophobated silica, silica masterbatch and rubber products

ActiveUS20100022684A1Excellent scorch safetyNo lossPigmenting treatmentSilicon organic compoundsPolymer scienceHydrophobic silica

The present invention provides a process for making silica-filled rubber masterbatch using silica hydrophobated with a trimethoxy silane coupling agent that is soluble in an alcohol-water solution containing at least about 70 wt % water. One embodiment uses a mixture of trimethoxy silanes, one or more of which react with rubber to bond the silica to the rubber, and one or more of which do not react with rubber, but do hydrophobate the silica. Hydrophobated silica is mixed with latex polymer and incorporated into rubber during coagulation of the latex, which is preferably coagulated with calcium chloride. The present invention further provides a process for making the trimethoxy silane coupling agents. Preferred trimethoxy silane coupling agents include bis-(3-trimethoxysilylpropyl)-disulfide and bis-(3-trimethoxysilylpropyl)-tetrasulfide. Rubber products, particularly tires, compounded with the inventive silica masterbatch can be processed for a long time before scorching because the silica masterbatch provides a long scorch time.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

Method for chemically modifying inorganic filler with graphene oxide, product and application

InactiveCN103788413AImprove adhesionHigh mechanical strengthPigment treatment with organosilicon compoundsPigment physical treatmentEpoxySilanes

The invention discloses a method for chemically modifying inorganic filler with graphene oxide and a product. The method comprises the following steps: performing surface hydroxylation treatment and silane coupling agent treatment on the inorganic filler; maintaining the pH of a graphene oxide solution at 5.8-6.0 with an MES buffer solution; sequentially adding EDC and NHS, and performing ultrasonic treatment for 1-3 hours; adding the treated inorganic filler, and performing an amidation reaction at room temperature; and after the reaction, filtering, washing and drying to obtain the graphene oxide modified inorganic filler. The invention also discloses a method for preparing an inorganic filler / epoxy resin composite by use of the product. The process flow of the method disclosed by the invention is simple and environmentally friendly; the GO is connected to the surface of the inorganic filler by a chemical modification process, and the firm covalent bond combination between the GO and inorganic particles is generated, so that the interface adhesiveness and mechanical strength between the inorganic filler and the polymer are enhanced, and a new idea is provided to the modification of an inorganic filler surface and the preparation of a high-performance composite.

Owner:UNIV OF JINAN

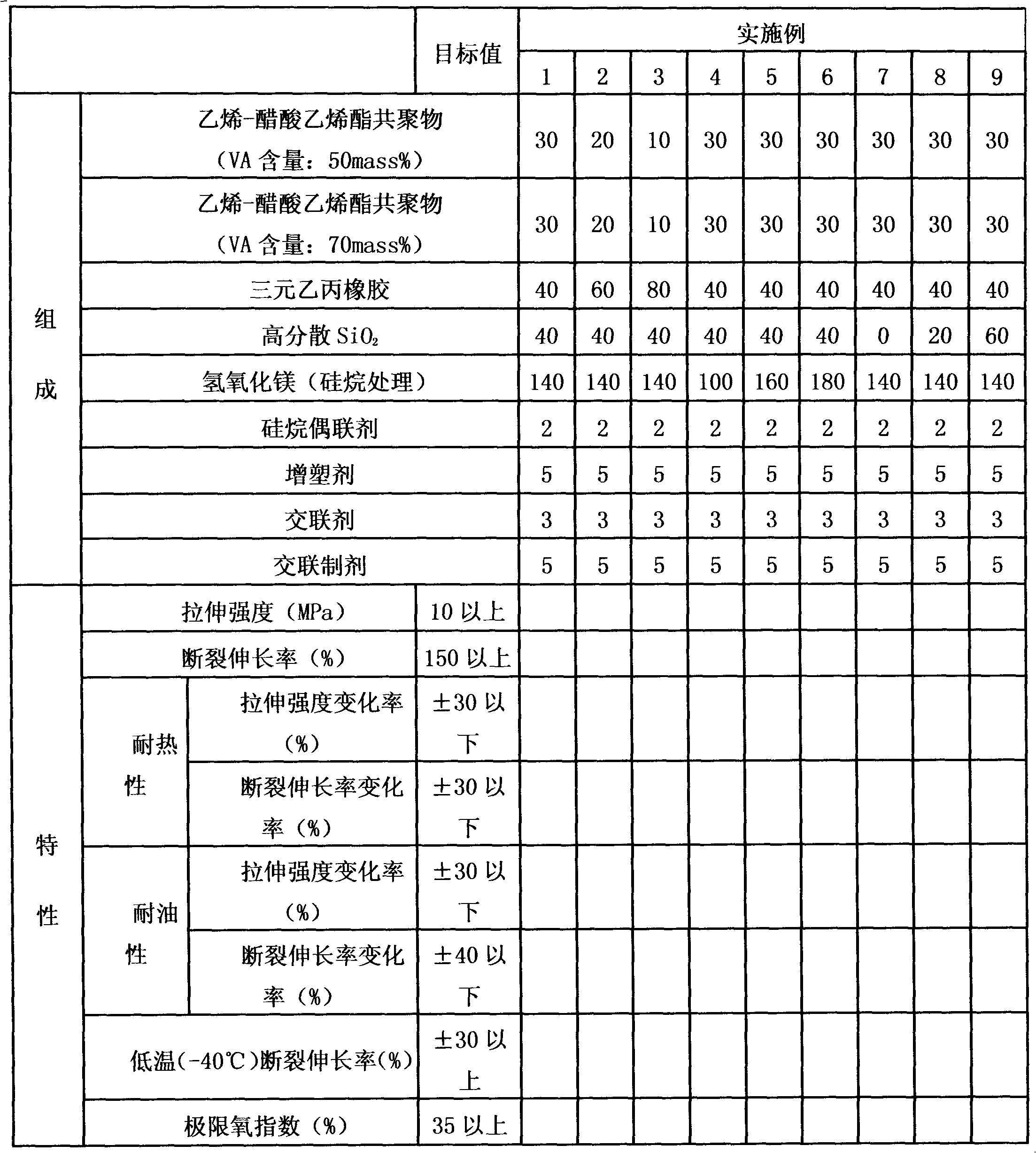

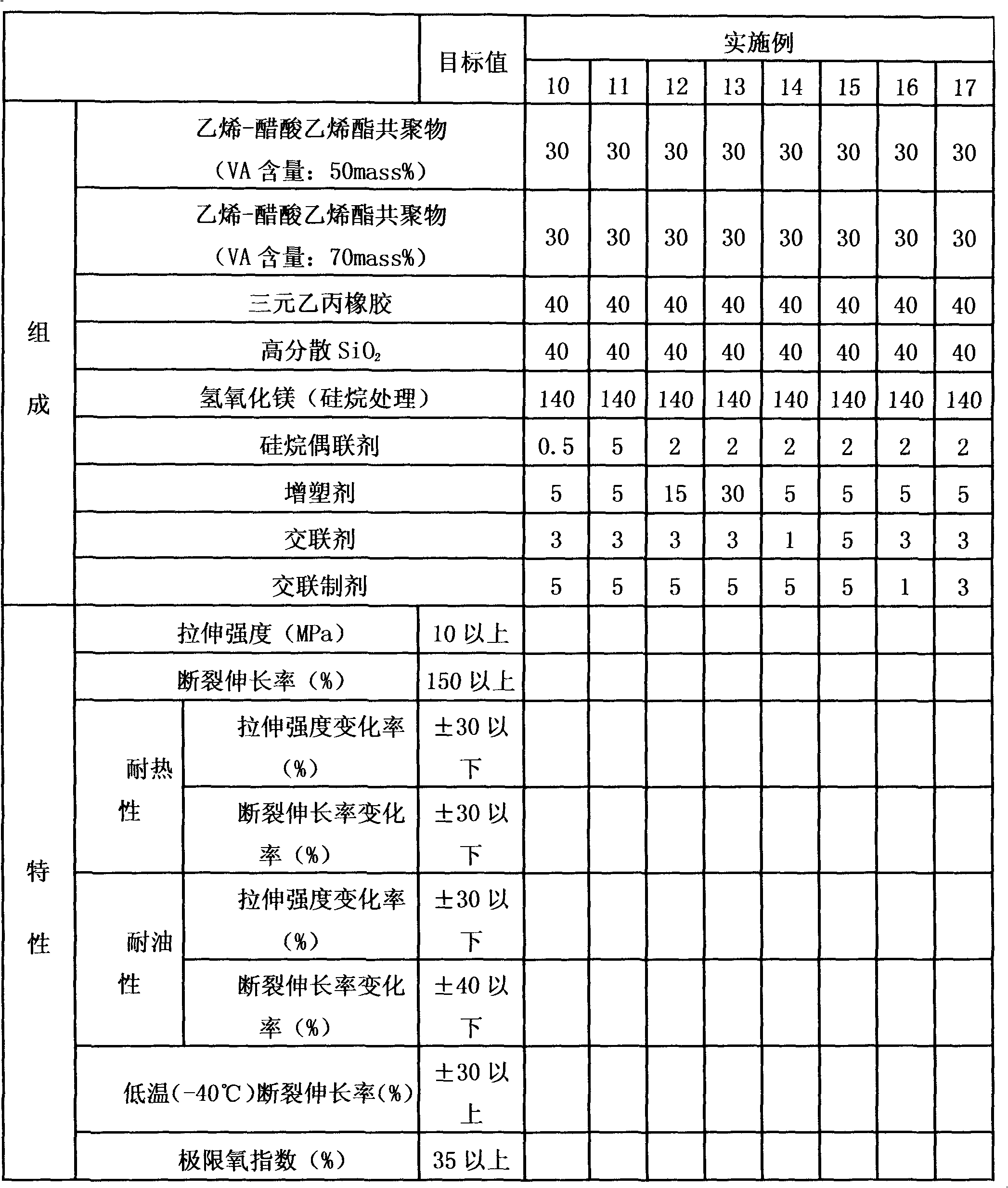

Halogen-free flame-retardant cable sheath material for railway locomotive and manufacturing method for halogen-free flame-retardant cable sheath material

InactiveCN102382358AImprove toleranceImprove low temperature resistanceInsulated cablesInsulated conductorsPlasticizerEngineering

The invention discloses a halogen-free flame-retardant cable sheath material for a railway locomotive and a manufacturing method for the halogen-free flame-retardant cable sheath material. The halogen-free flame-retardant cable sheath material comprises 100 weight parts of rubber, 100 to 180 weight parts of metal hydroxide serving as a flame retardant, 0 to 60 weight parts of carbon black or white carbon black serving as a reinforcing agent, 0.5 to 5 weight parts of silane coupling agent, 5 to 30 weight parts of plasticizer, 1 to 5 weight parts of crosslinking agent and 1 to 5 weight parts of crosslinking aid. The halogen-free flame-retardant cable sheath material is prepared by a blending technology. The sheath material has excellent flame retardancy, oil resistance and low-temperature resistance, is suitable for cable sheaths of railway locomotives, and can meet the requirement of halogen-free flame-retardant cables for locomotives.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com