Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

A high flame retardant, cable material technology, used in inorganic insulators, plastic/resin/wax insulators, organic insulators, etc., can solve the problem of low flame retardant efficiency, poor self-extinguishing effect of materials, and difficult to pass the VW-1 flame retardant test. requirements, etc., to overcome the effects of poor flame retardant performance, good shell formation and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

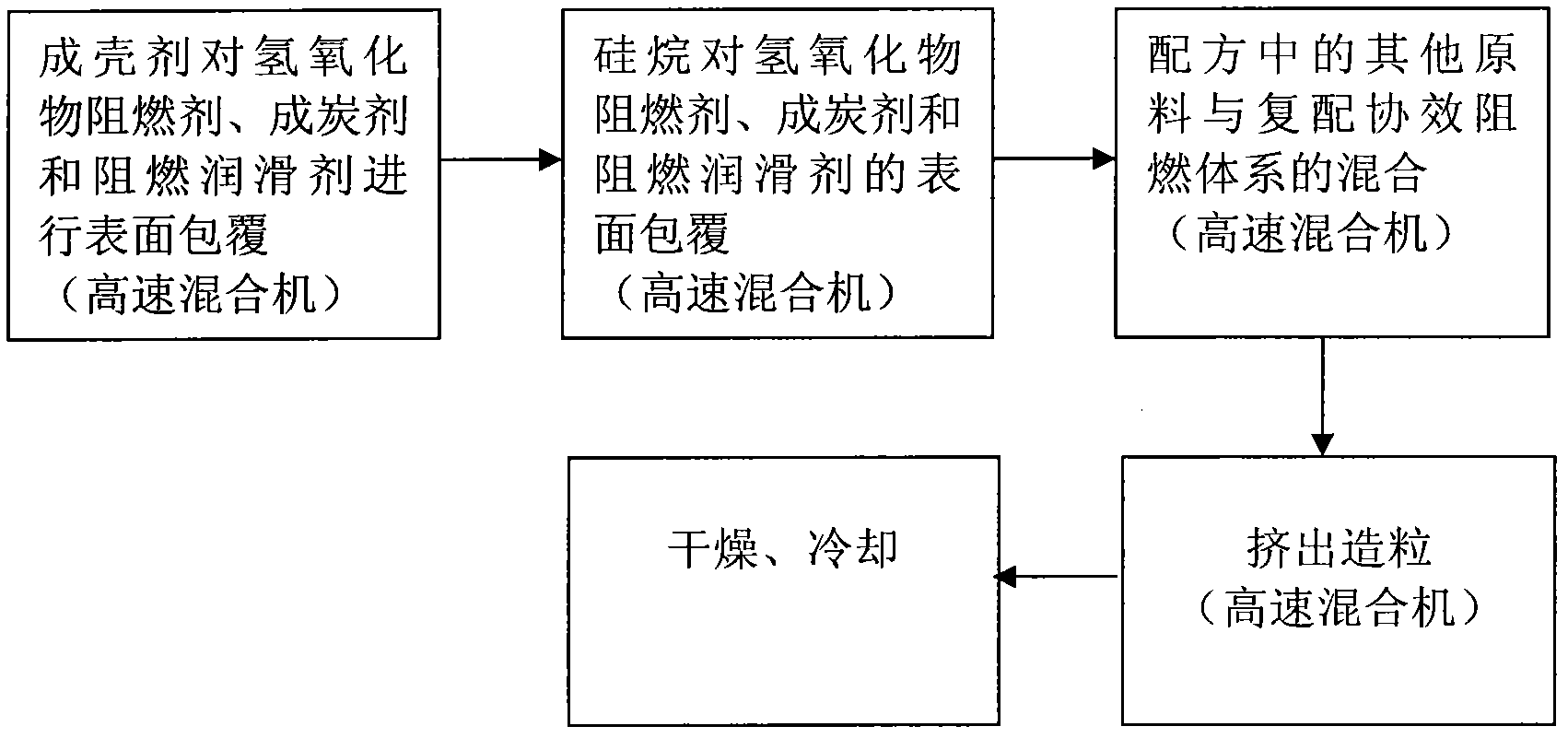

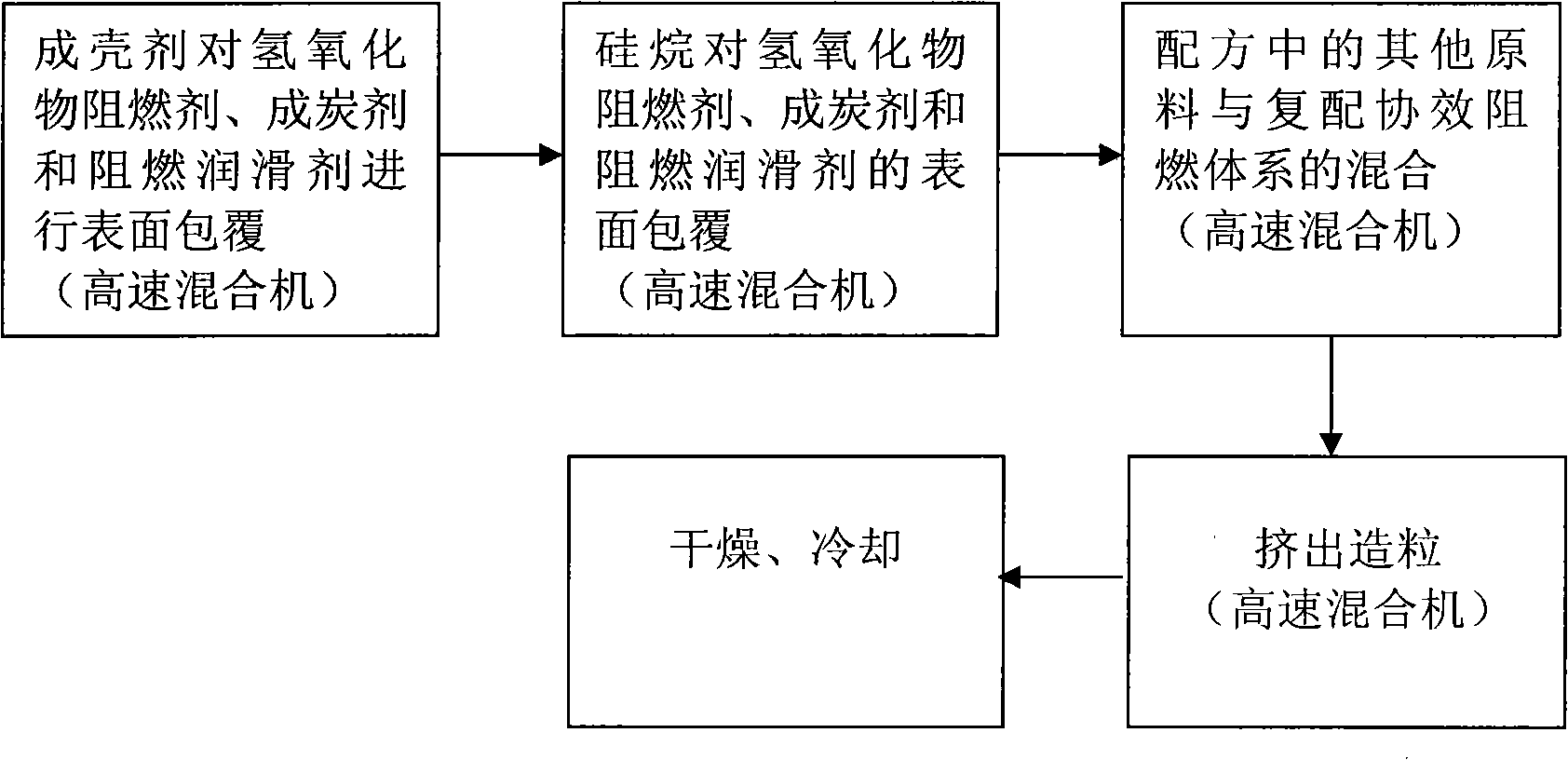

[0046] Referring to the accompanying drawings, the present invention also provides a method for preparing radiation crosslinked halogen-free high flame-retardant cable material, which includes the following steps:

[0047] A. Stir the hydroxide-based flame retardant, char-forming agent, and flame-retardant lubricant in a high-speed mixer for 2 minutes at high speed, then add the shell-forming agent and continue stirring at high speed to raise the temperature to above 100°C, so that the shell-forming agent can oxidize the hydrogen Flame retardants, char-forming agents and flame-retardant lubricants are used for surface coating.

[0048] B. Then add the silane coupling agent and stir for 5-8 minutes to perform secondary surface treatment.

[0049] C. Then add the initiator-ethanol solution, mix in a high-speed mixer for 4 to 6 minutes, and then discharge.

[0050] D. Use a mixing type twin-screw extruder with a temperature control device and a vacuum device to extrude and granu...

Embodiment 1

[0055] The name of each component of the cable material and the proportion of each component by weight are as follows:

[0056] EVA 80kg;

[0057] Maleic anhydride grafted polyethylene 20kg;

[0058] Magnesium hydroxide 75kg;

[0059] Zinc borate 20kg;

[0061] Melamine cyanurate 40kg;

[0062] Methyl silicone rubber 1kg;

[0063] Silane 1kg;

[0064] Cross-linking sensitizer TAIC 3kg;

[0065] Antioxidant 2kg;

[0066] Lubricant 2kg;

[0067] Initiator 0.2kg.

[0068] Preparation method of cable material: After stirring magnesium hydroxide, zinc borate, antimony trioxide and melamine cyanurate at high speed for 2 minutes, add methyl silicone rubber and continue high-speed stirring to raise the temperature to above 100°C, then add silane coupling agent Stir for 8 minutes, carry out secondary surface coating treatment, then add these components according to the weight parts of the above components, mix in a high-speed mixer for 5 minute...

Embodiment 2

[0073] The name of each component of the cable material and the proportion of each component by weight are as follows:

[0074] EVA 40kg;

[0075] POE 40kg;

[0076] Maleic anhydride grafted EVA 20kg;

[0077] Aluminum hydroxide 100kg;

[0078] Magnesium hydroxide 50kg;

[0079] Antimony trioxide 30kg;

[0080] Melamine 40kg;

[0081] Methyl silicone rubber 1kg;

[0082] Silane 2kg;

[0083] Cross-linking sensitizer TAIC 3kg;

[0084] Antioxidant 2kg;

[0085] Lubricant 2kg;

[0086] Initiator 0.4kg.

[0087] The preparation method of the cable material is the same as in Example 1.

[0088] The products prepared in this example were tested after being irradiated and cross-linked. The performance values are expressed as follows. The index values are the standard values that should be achieved according to the national regulations, and the typical values are the performance values of the products prepared in this example.

[0089] Experimental proj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com