A kind of air film type core body and its sealing method for on-line sealing of boiler flue in power plant

A boiler flue and gas film technology, which is applied in the field of online plugging of the boiler flue gas film core and its plugging in power plants, can solve the problems of difficult operation and high risk of operation for operators, and achieve easy transportation and cost saving , Personnel safety, convenience and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

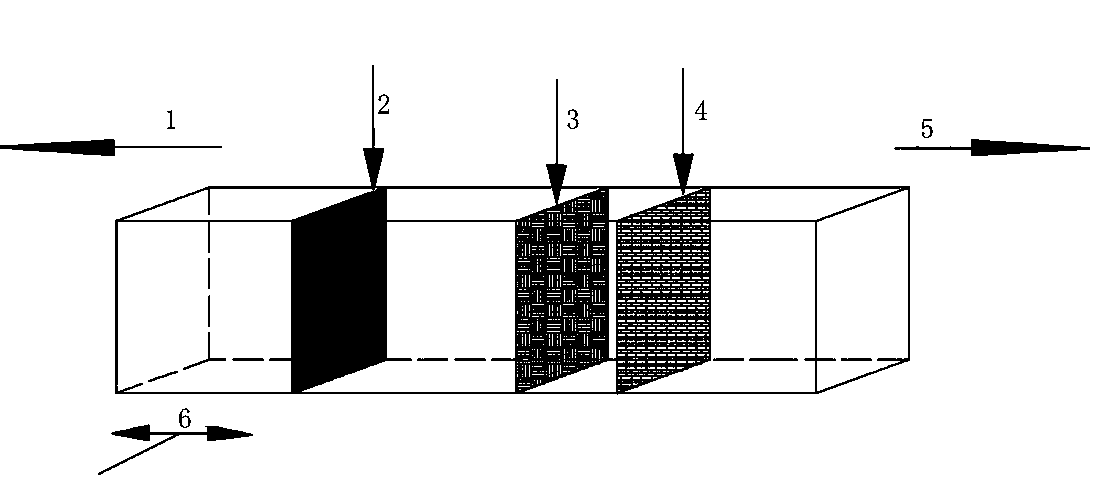

[0014] Such as figure 1 Shown is the overall structure diagram of the original construction plan. At present, during the construction of the main chimney 5, the flue gas is discharged through the temporary chimney 1. In order to prevent the flue gas 6 from entering the flue of the main chimney, the baffle door 2 must be closed, and the baffle door 2 will have air leakage. It is necessary to reduce the load or shut down the operator. Install smoke-blocking steel plates 3 and smoke-blocking brick walls 4 into the flue to block. But there will be great risks, such as long construction period and cumbersome procedures, too many potential dangers to personnel, and high economic costs.

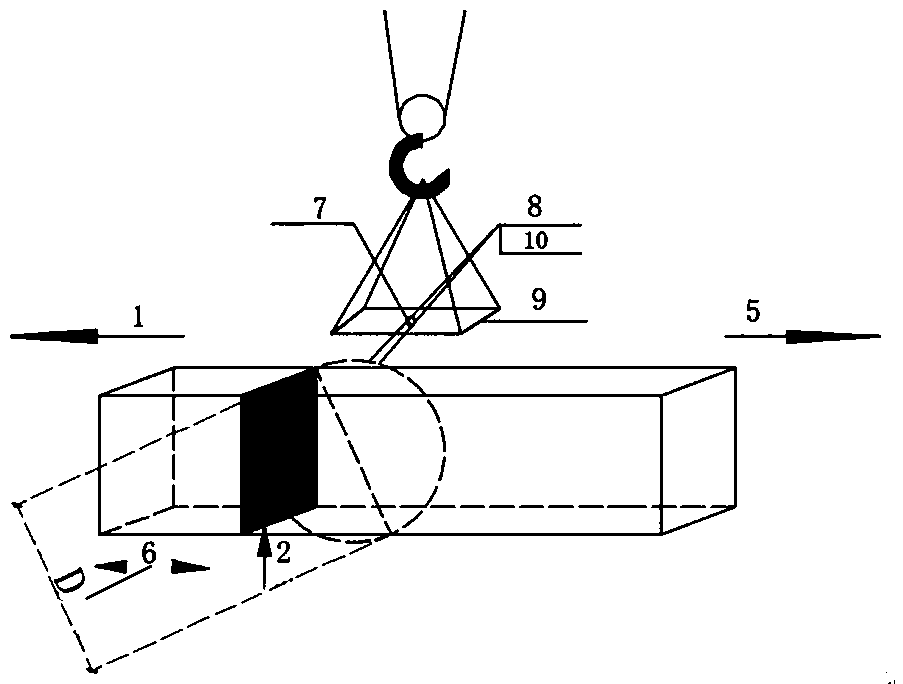

[0015] Such as figure 2 Shown is the construction drawing of the air film core body installation. An air film type core body for online sealing of boiler flue in a power plant. The air film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com