Wear-resisting super-hydrophobic coating composition as well as preparation method and application thereof

A technology of super-hydrophobic coatings and compositions, applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of industrial application limitations and many steps, and achieve improved wear resistance and increased stability , enhance the binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

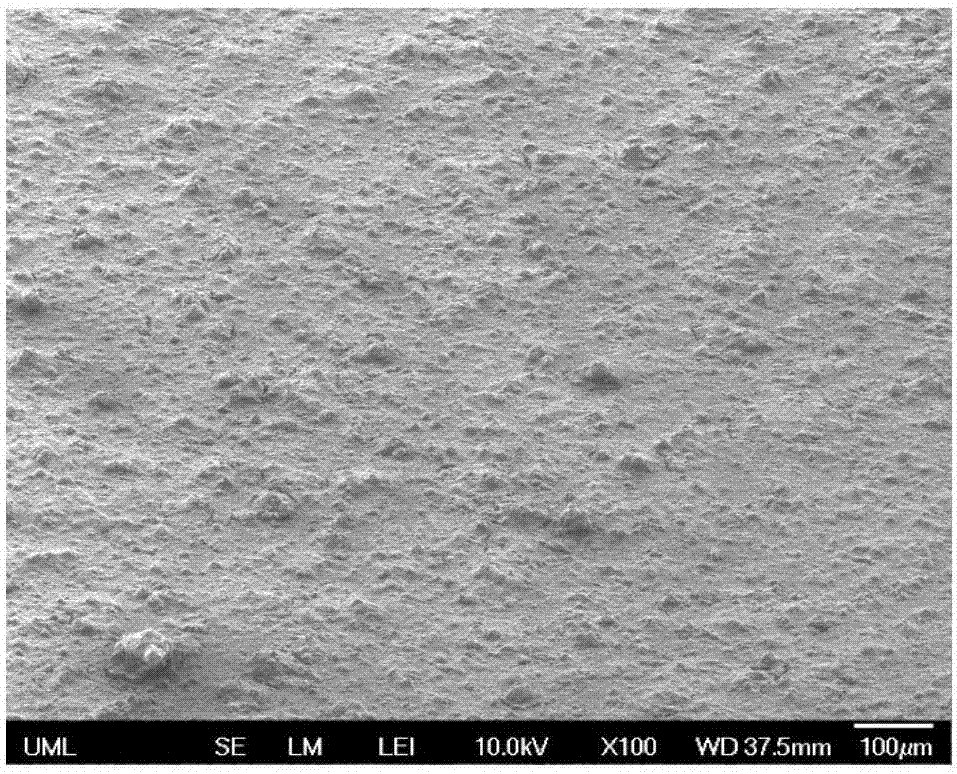

[0033] Preparation of nanomaterial dispersion: add 1.5g of hydrophobic fumed silica (R972) and 1.0g of perfluorooctyltriethoxysilane to 27.5g of isopropanol solution, and stir mechanically for 30 minutes to obtain nanomaterial dispersion ; The size of the micro-nano double rough structure is 0.03-3 microns.

[0034] Preparation of adhesive material dispersion: Add 6.0g of epoxy resin (EPO-TEK301) into 24.0g of acetone, and mechanically stir for 40 minutes to obtain the adhesive material dispersion;

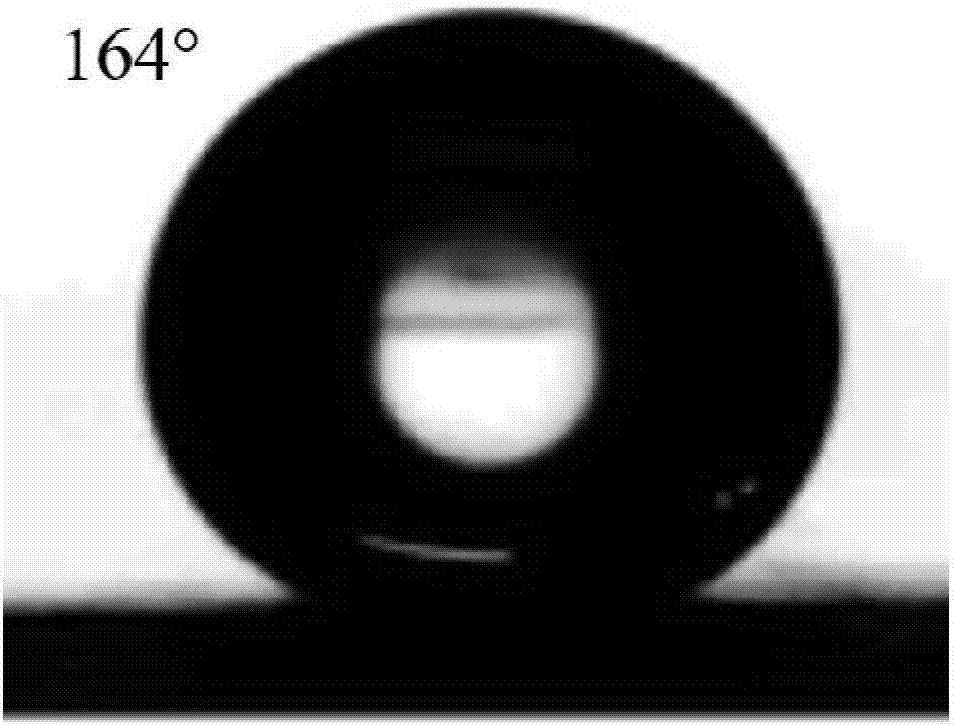

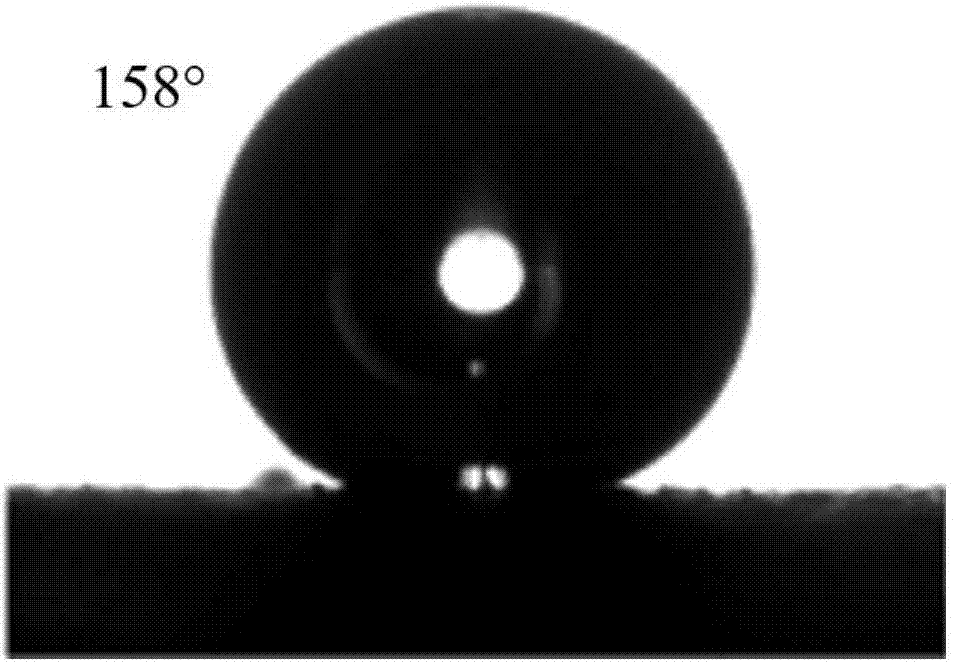

[0035] Application process: Mix the above nano-material dispersion and bonding material dispersion, stir mechanically for 20 minutes and mix evenly. The resulting mixed solution was sprayed 3 times over a clean glass plate at a distance of 20 cm and a speed of 8 cm / s through an air gun with a pressure of 40 psi, and then the glass plate was dried at room temperature for 1 hour and placed in an oven at 65 ° C. After curing for 2 hours, a superhydrophobic coating was finally obtain...

Embodiment 2

[0038] Preparation of nanomaterial dispersion: add 0.5g hydrophobic fumed silica (R972), 1.0g nano titanium dioxide (TTP-A10) and 1.0g hexadecyltrimethoxysilane to 27.5g ethanol solution, and mechanically stir for 30 minutes , that is to obtain the nano material dispersion; the size of the micro-nano double rough structure is 0.08-4 microns.

[0039] Preparation of adhesive material dispersion: Add 8.0g of polyurethane resin (KL-540E) into the mixed solution of 10.0g of acetone, 6.0g of ethyl acetate and 6.0g of dimethylformamide, and mechanically stir for 30 minutes to obtain the adhesive material dispersion liquid;

[0040] Application process: Mix the above nano-material dispersion and bonding material dispersion, stir mechanically for 20 minutes and mix evenly. Brush the obtained mixed solution on a clean iron sheet, and dry it in an oven at 120°C for 2 hours, and finally obtain a superhydrophobic coating on the surface of the iron sheet.

[0041]Test results: The surfac...

Embodiment 3

[0043] Preparation of nanomaterial dispersion: Add 2.5g of nano-polytetrafluoroethylene particles (3M-1600) and 1.5g of octyltrimethoxysilane to a mixed solution of 16.0g of acetone and 10.0g of ethanol, and stir mechanically for 20 minutes to obtain nanometer Material dispersion liquid; the size of the micronano double rough structure is 0.1-5 microns.

[0044] Preparation of the adhesive material dispersion: add 7.0 g of polyvinylidene fluoride (V203) to 23.0 g of dimethylformamide solution, and mechanically stir for 30 minutes to obtain the adhesive material dispersion;

[0045] Application process: Mix the above nano-material dispersion and bonding material dispersion, stir mechanically for 20 minutes and mix evenly. The obtained mixed solution was spin-coated on a clean aluminum sheet, and dried in an oven at 120°C for 2.5 hours, and finally a superhydrophobic coating was obtained on the surface of the aluminum sheet.

[0046] Test results: The surface of the coating has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com