Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252results about How to "Improve rolling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

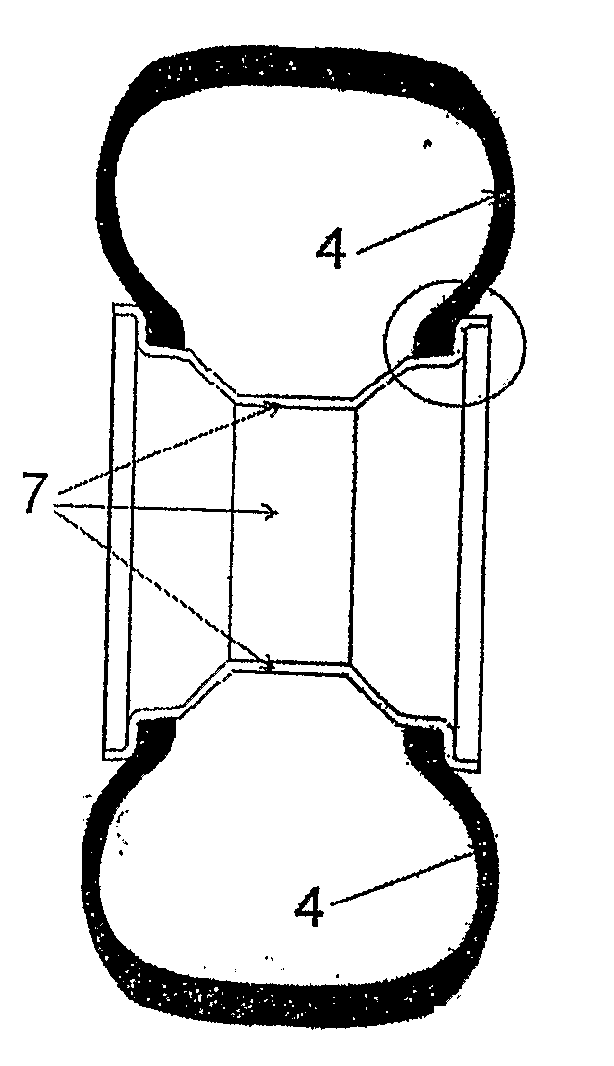

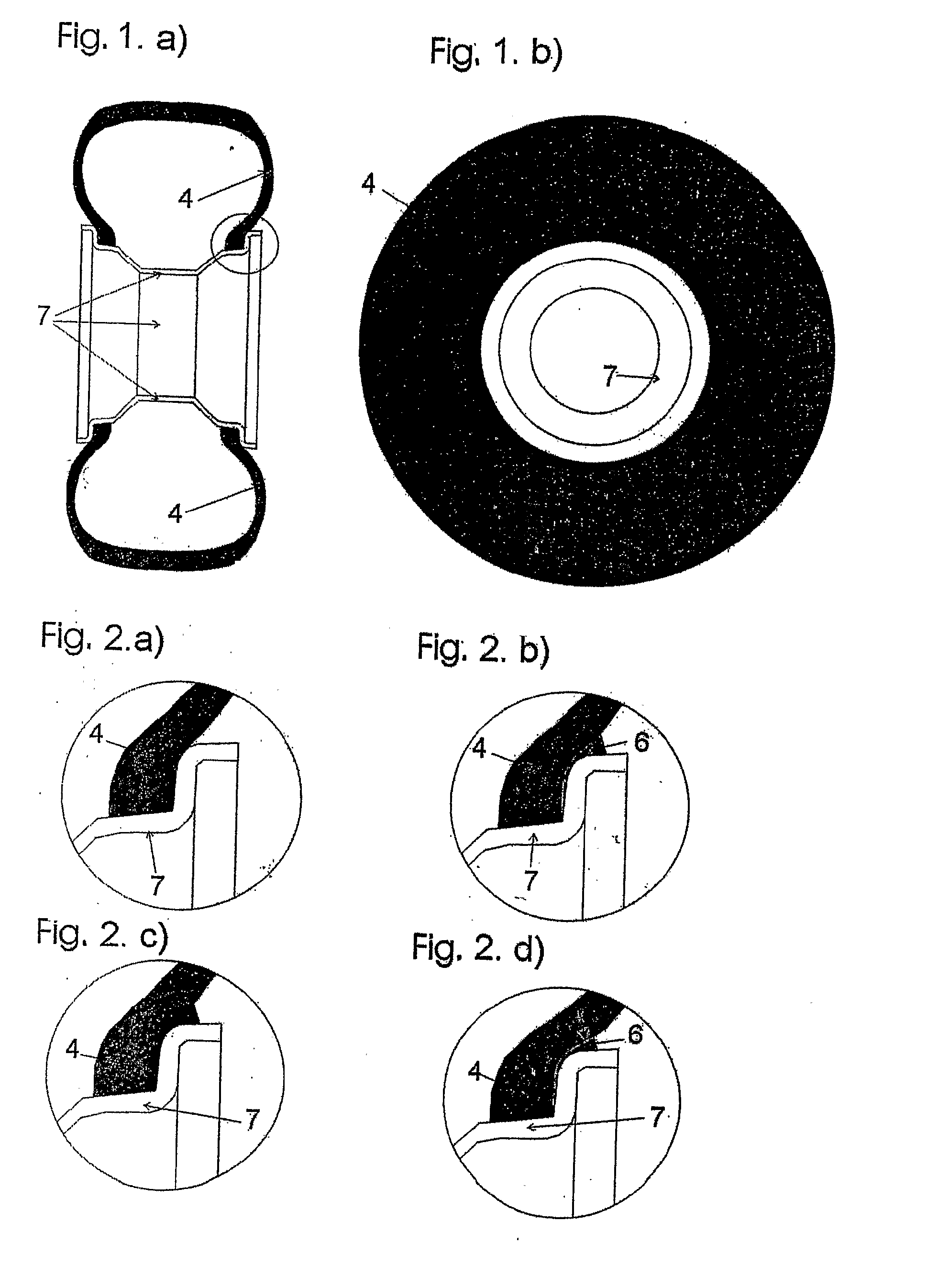

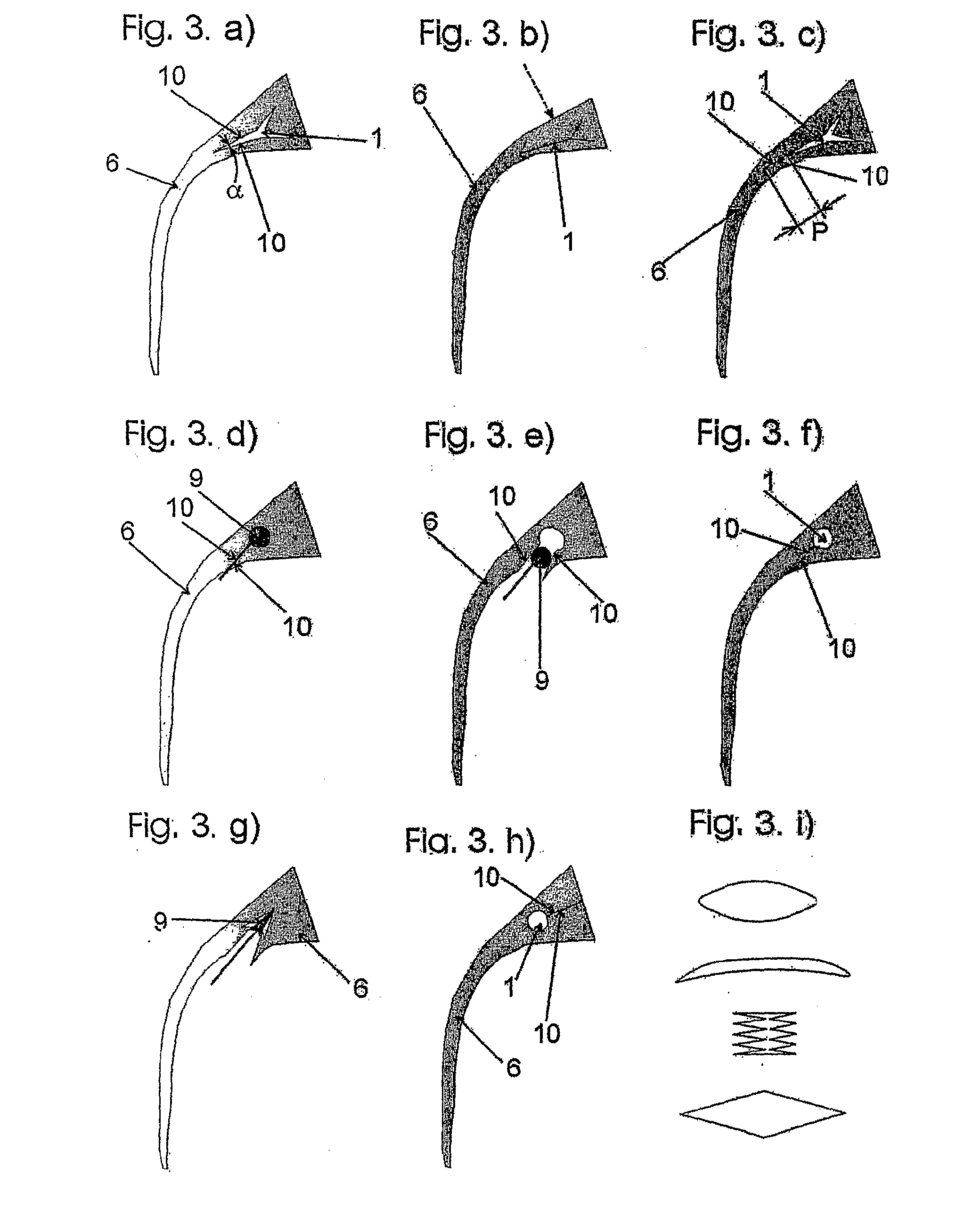

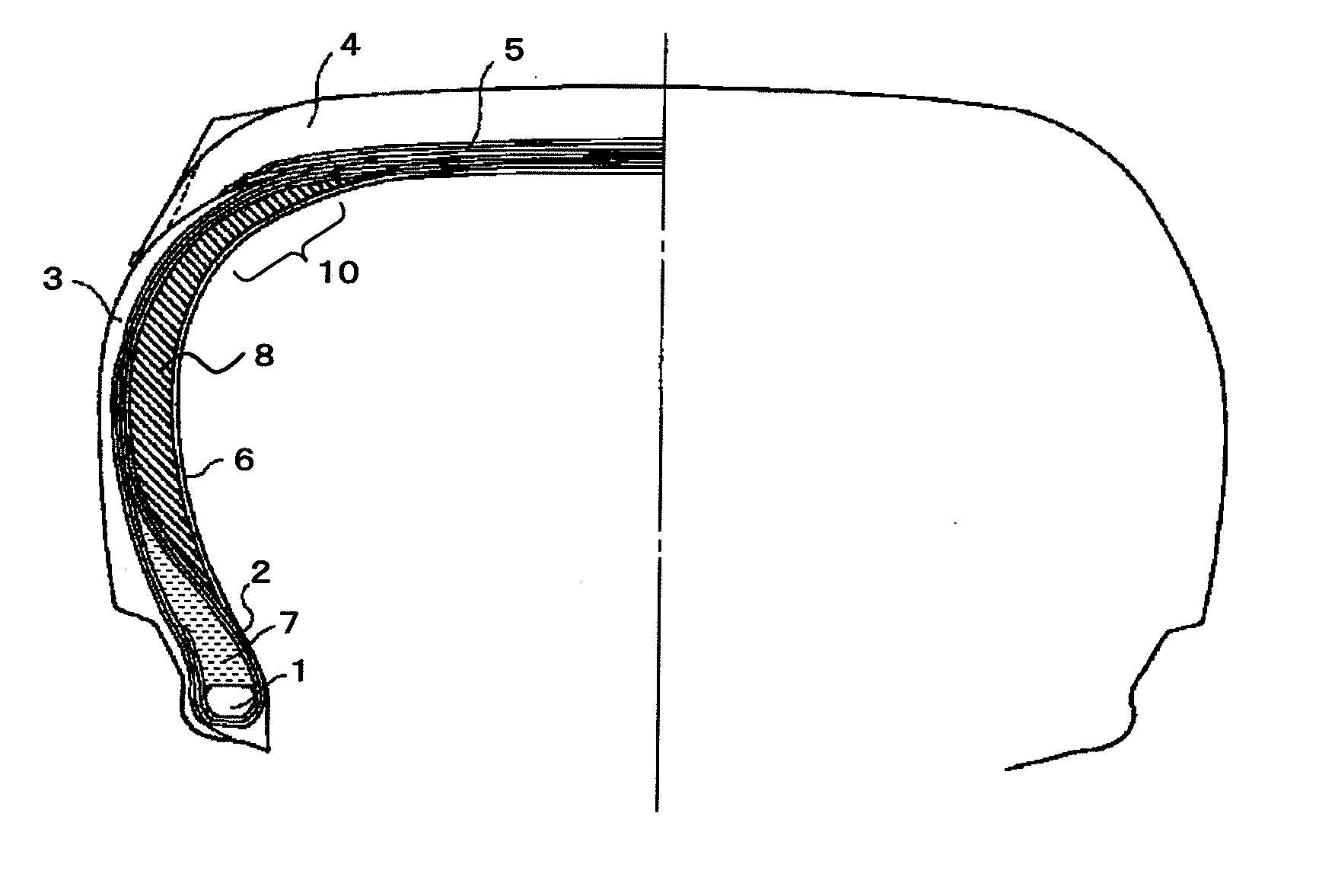

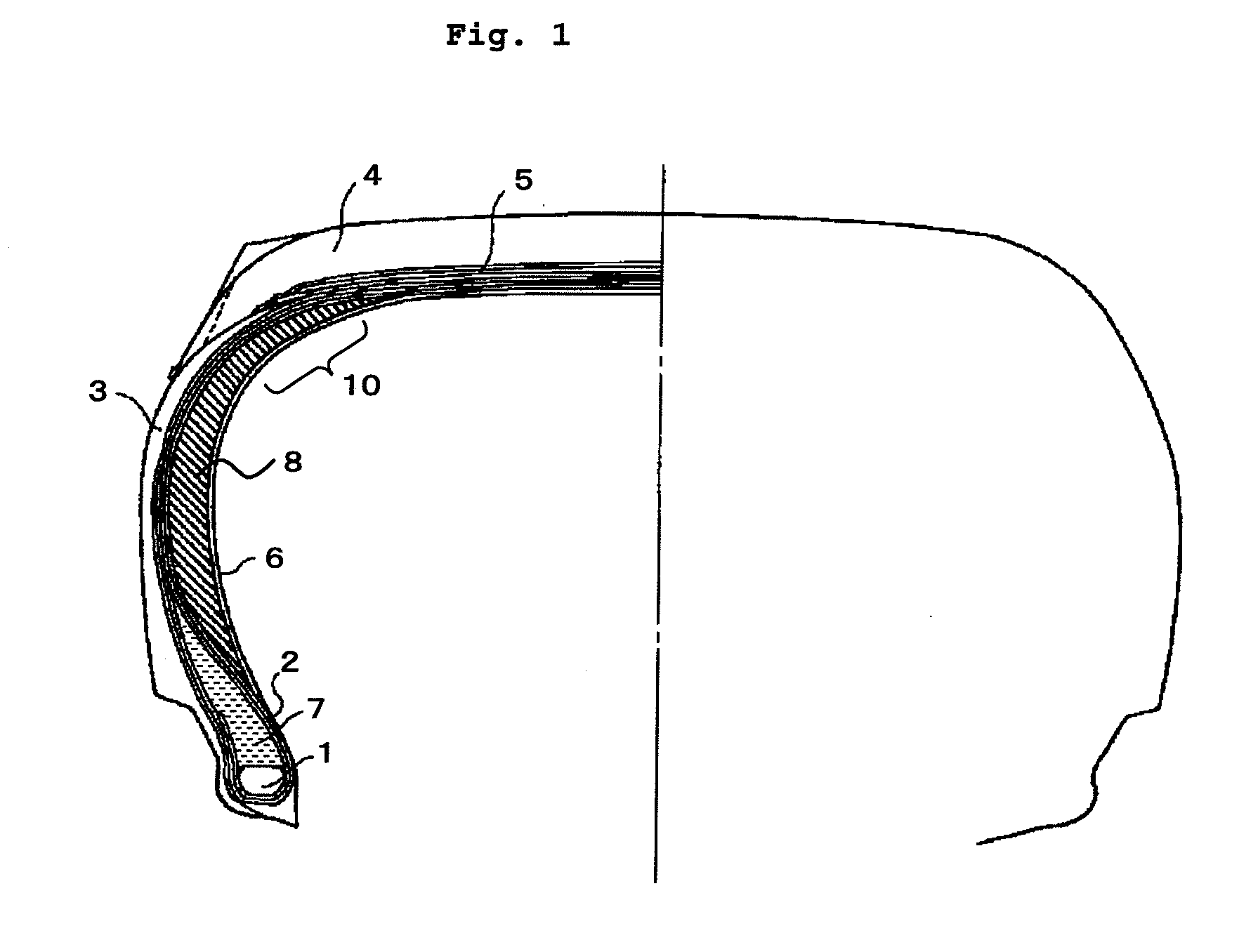

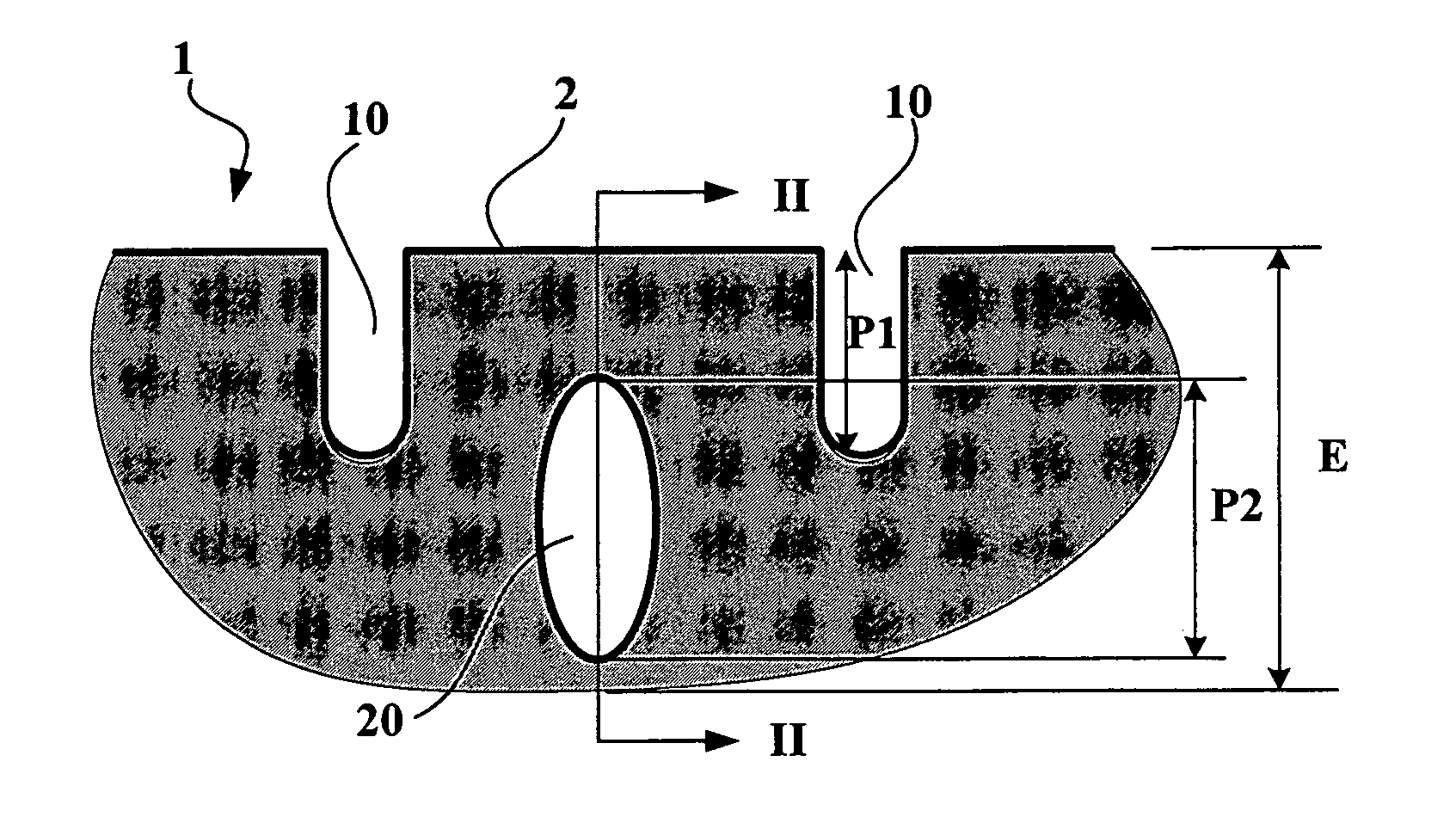

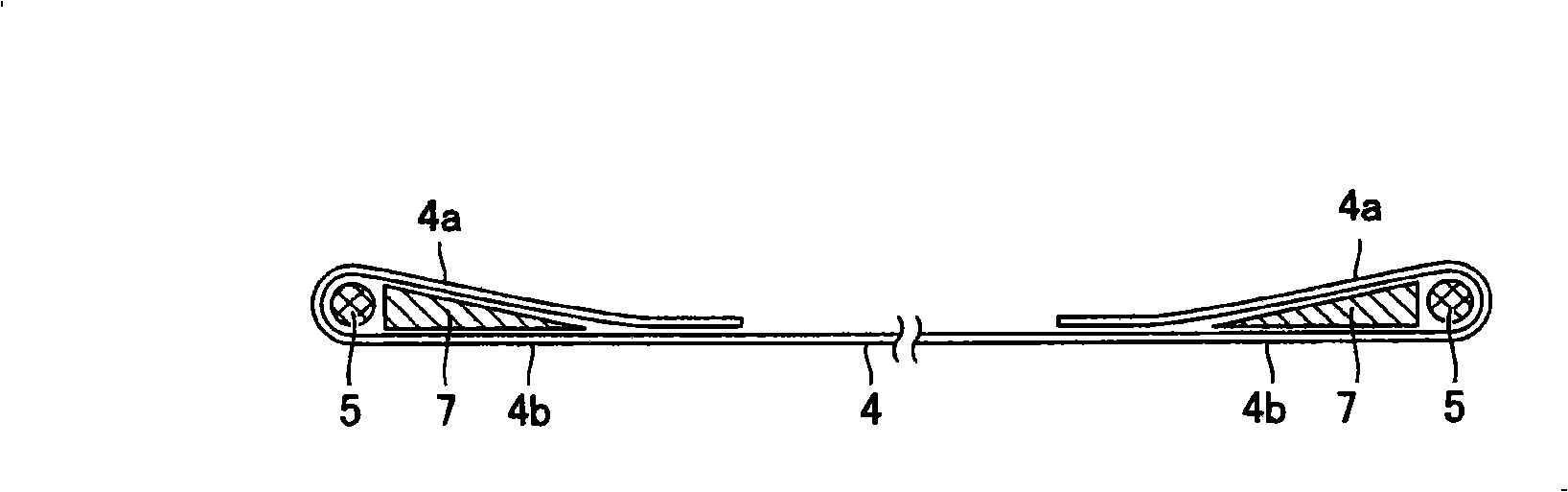

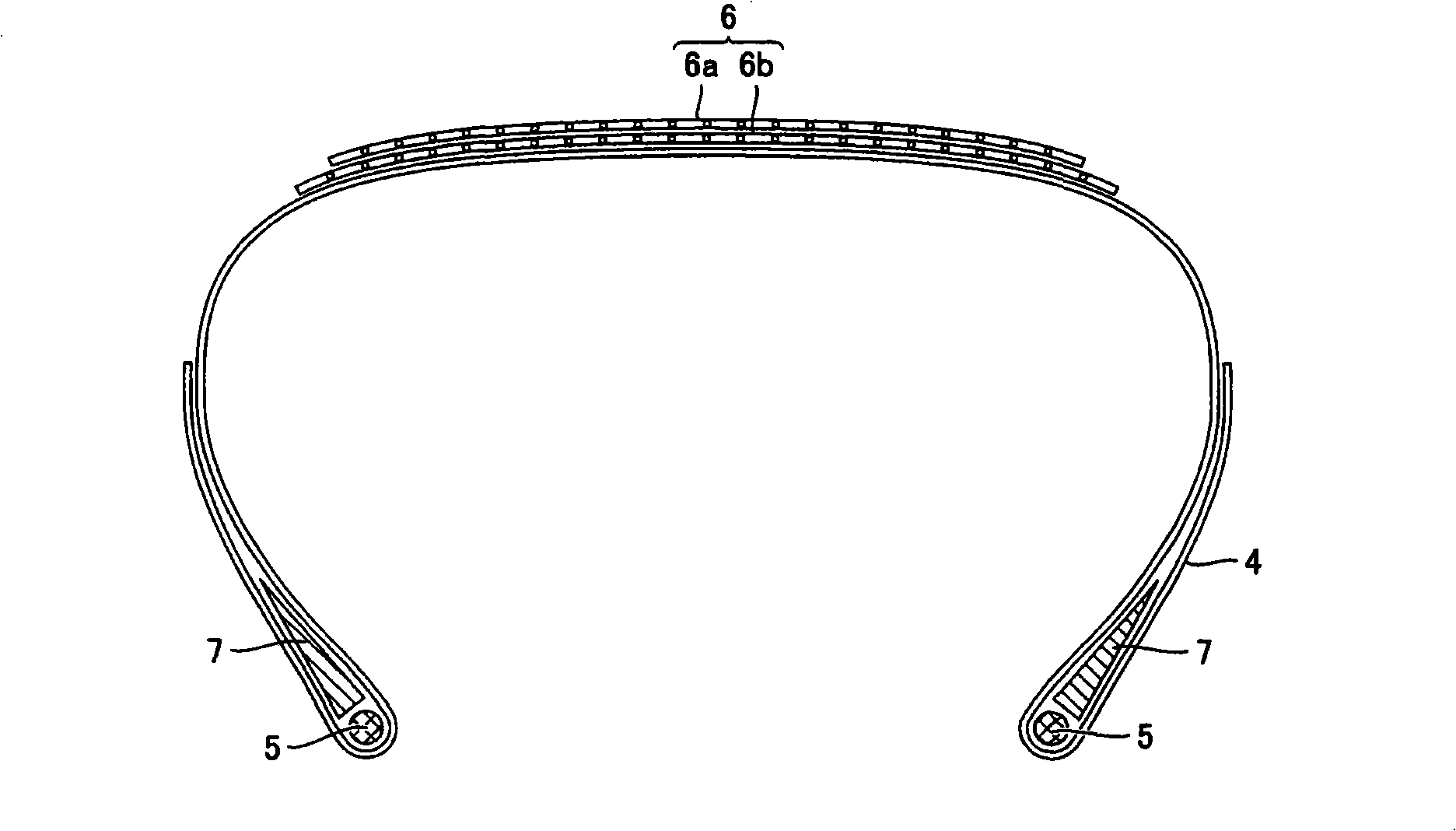

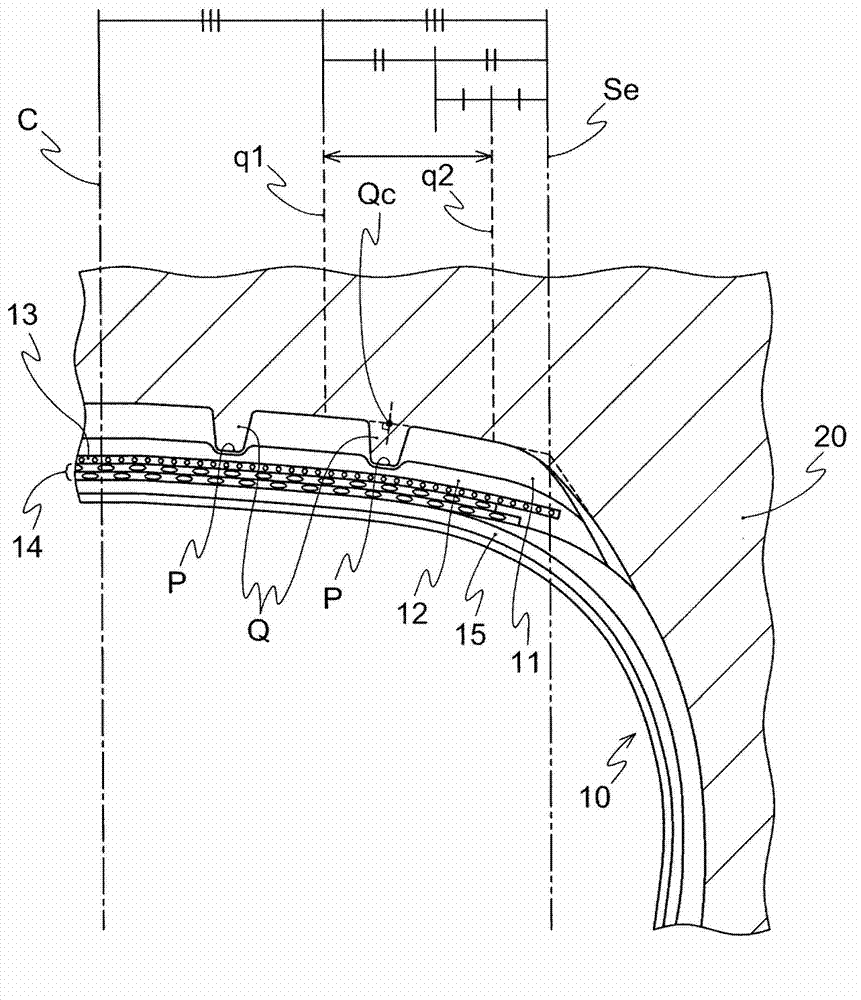

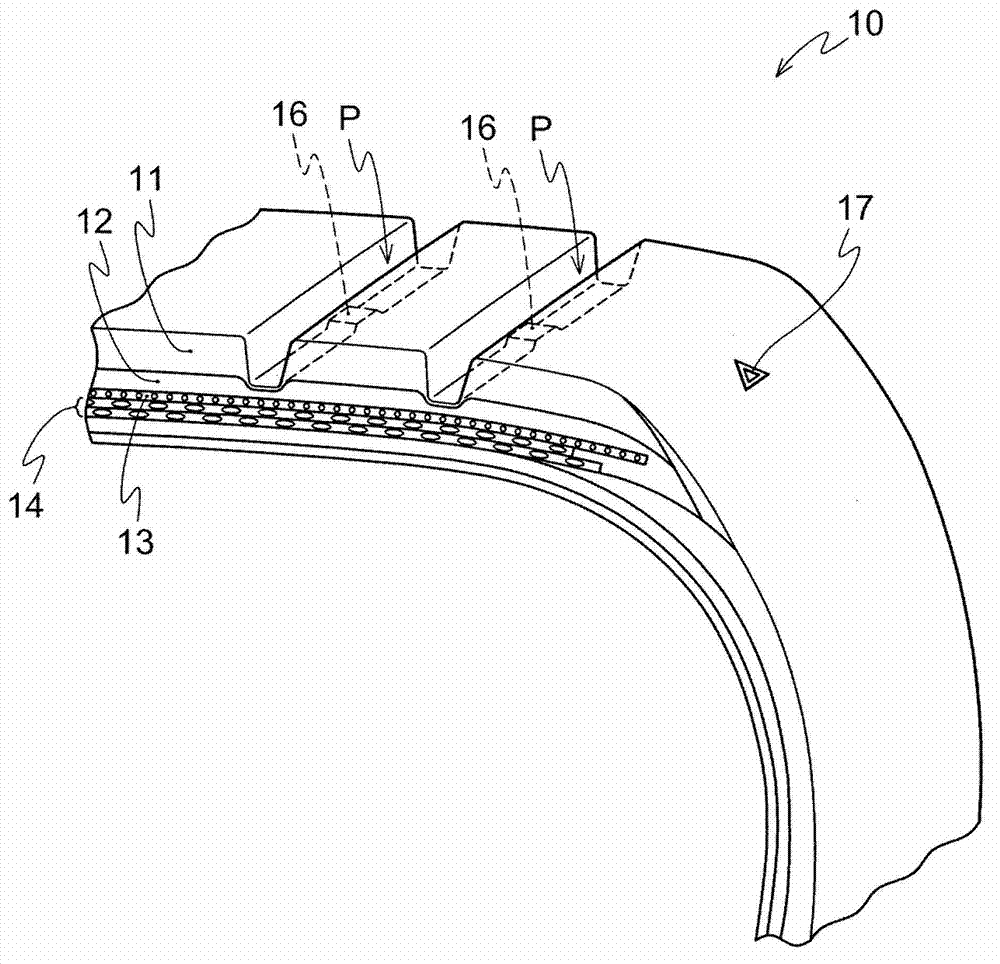

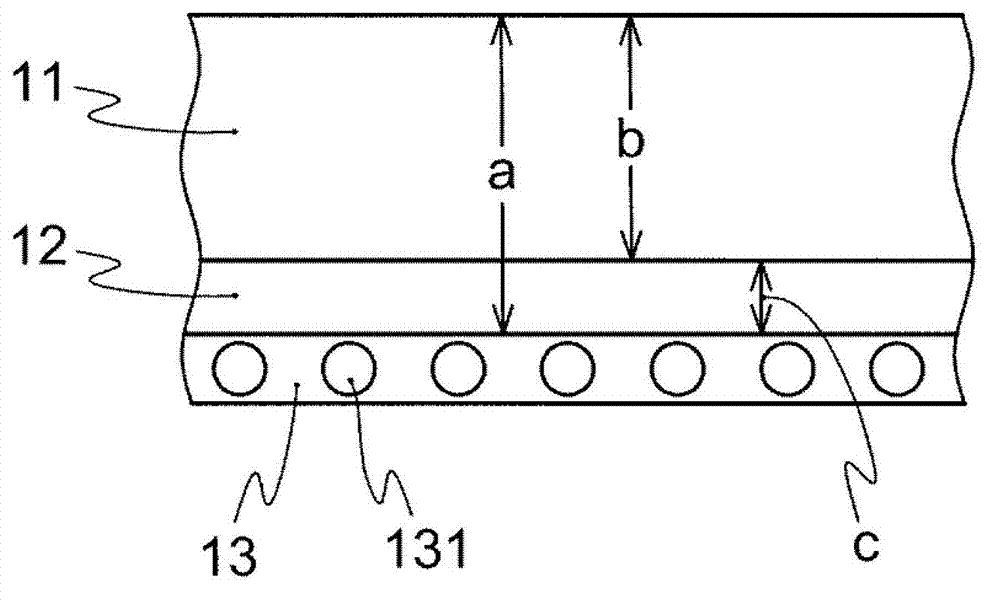

Chamber of a peristaltic pump for tire pressure adjustment

InactiveUS20090294006A1Effective shapingReduced service lifeTyresTyre beadsTire beadPeristaltic pump

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:CODA INNOVATIONS SRO

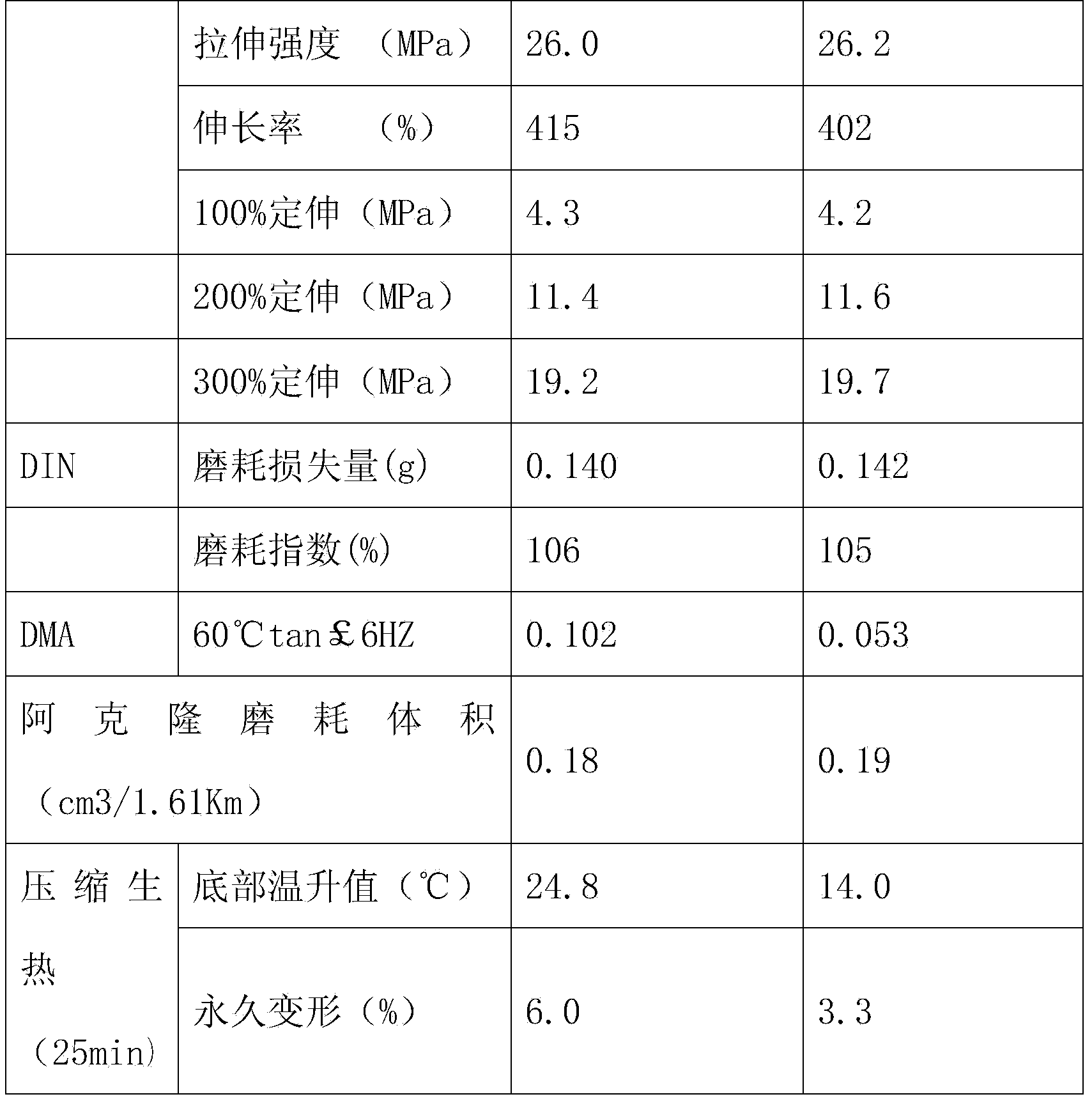

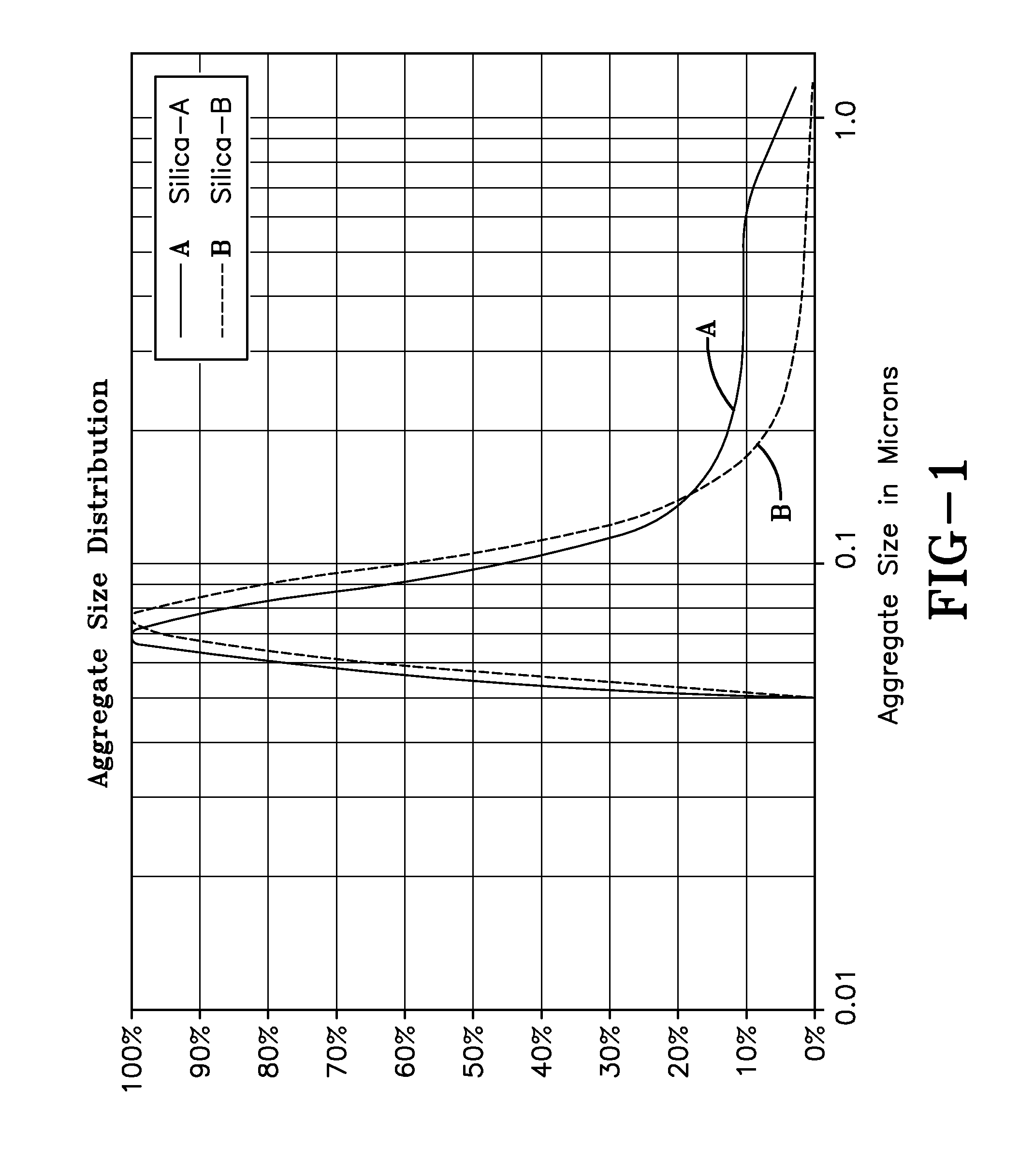

Tire compositions and components containing free-flowing filler compositions

ActiveUS20080161475A1Better wear characteristicsImprove rolling resistanceSpecial tyresSulfur containingOrganic chemistry

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

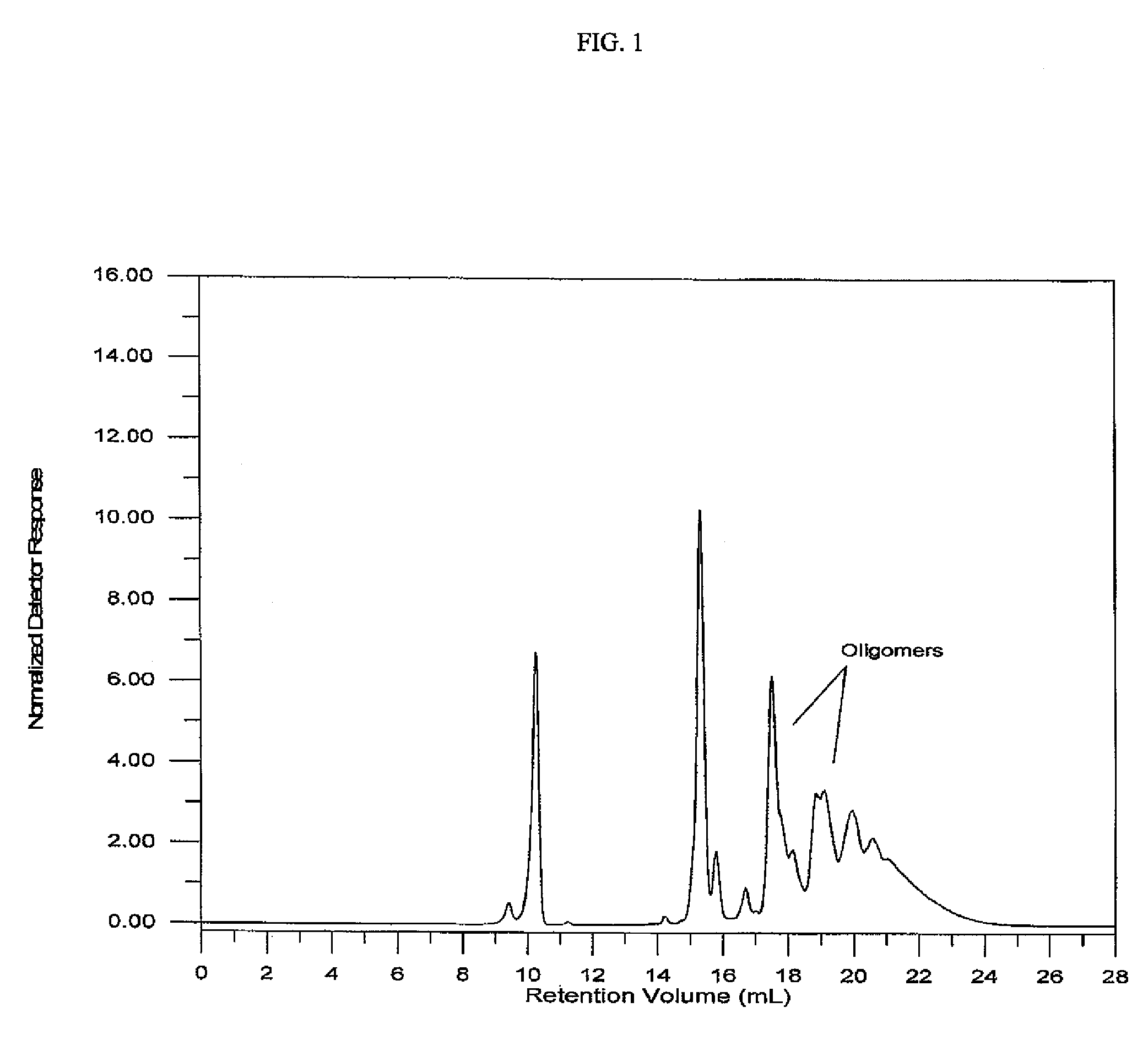

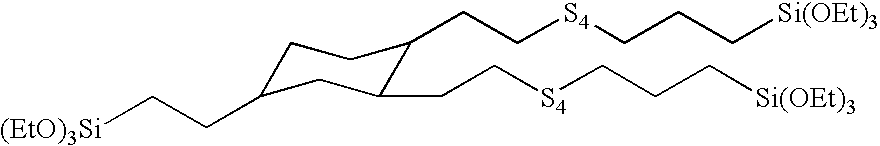

Tire compositions and components containing free-flowing filler compositions

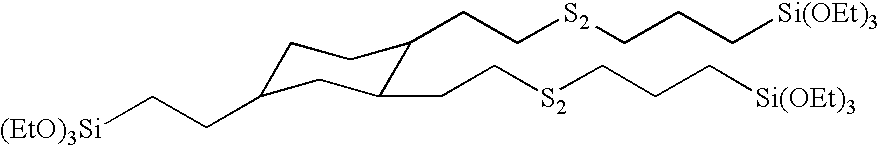

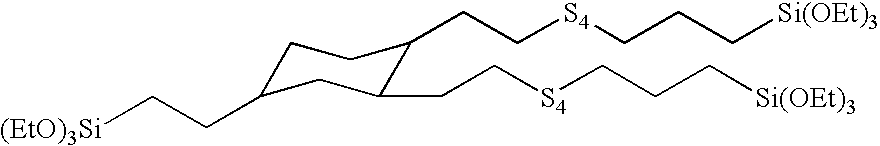

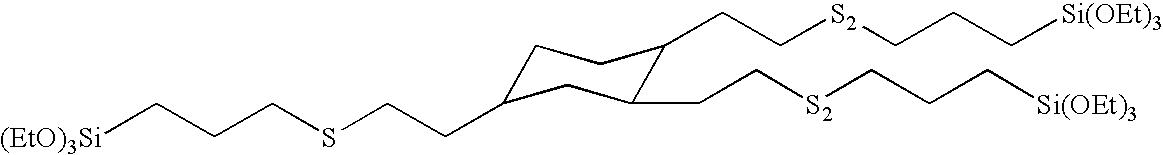

ActiveUS20080161460A1Better wear characteristicsImprove rolling resistanceSpecial tyresPolysulfideOrganic chemistry

Free-flowing filler compositions containing silated cyclic core polysulfide coupling agents, and rubber and tire compositions containing the filler compositions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Tire compositions and components containing free-flowing filler compositions

ActiveUS7968635B2Better wear characteristicsImprove rolling resistanceSpecial tyresPolysulfideOrganic chemistry

Free-flowing filler compositions containing silated cyclic core polysulfide coupling agents, and rubber and tire compositions containing the filler compositions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Tire compositions and components containing free-flowing filler compositions

ActiveUS7968633B2Better wear characteristicsImprove rolling resistanceSpecial tyresOrganic chemistrySulfur containing

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

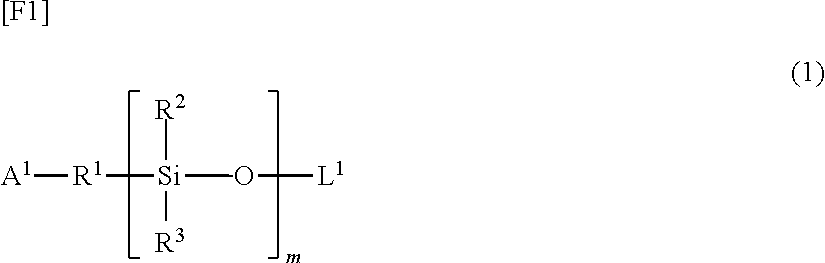

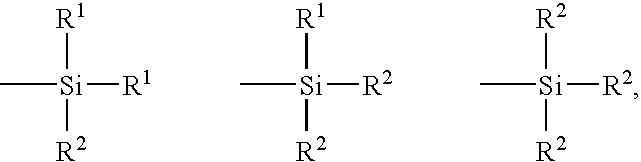

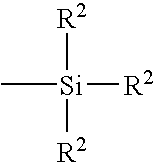

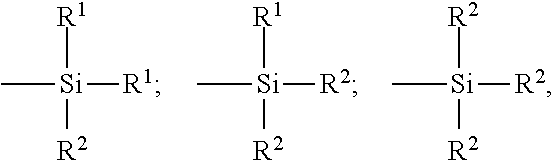

Method for producing modified conjugated diene polymer/copolymer, modified conjugated diene polymer/copolymer, and rubber composition and tier using the same

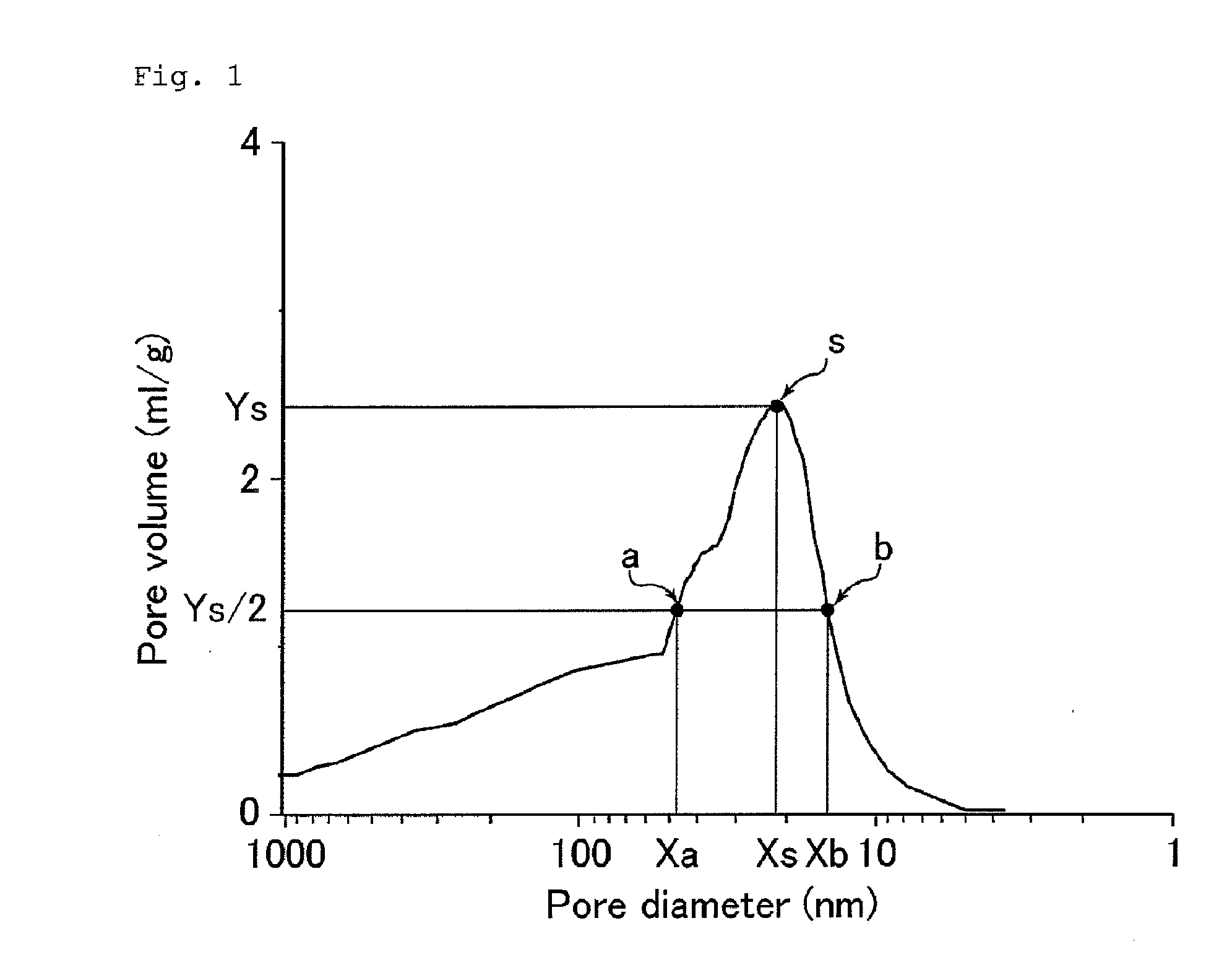

ActiveUS20110146877A1Increased durabilityImprove rolling resistanceSpecial tyresPneumatic tyre reinforcementsSilane compoundsPolymer science

The invention provides a method for producing a modified conjugated diene (co)polymer, the method including comprising: a modification reaction step including causing an organic silane compound to react with a conjugated diene (co)polymer having an active site at the active site, the organic silane compound having a characteristic group for forming a silanol group through hydrolysis and, in the vicinity of the characteristic group, (i) a functional group which binds the organic silane compound to the conjugated diene (co)polymer via addition to or substitution at the active site and which promotes reaction between the silanol group and a reinforcing filler after the addition or substitution reaction, or (ii) a functional group which promotes reaction between the silanol group and a reinforcing filler, and a hydrolyzation step performed after the modification reaction step; a modified conjugated diene (co)polymer having, at a molecular end of the conjugated diene (co)polymer, a silanol group, and a functional group in the vicinity of the silanol group, the functional group accelerating reaction between the silanol group and the reinforcing filler; a rubber composition containing the (co)polymer and carbon black having specific characteristics; and a tire formed from the rubber composition.

Owner:BRIDGESTONE CORP

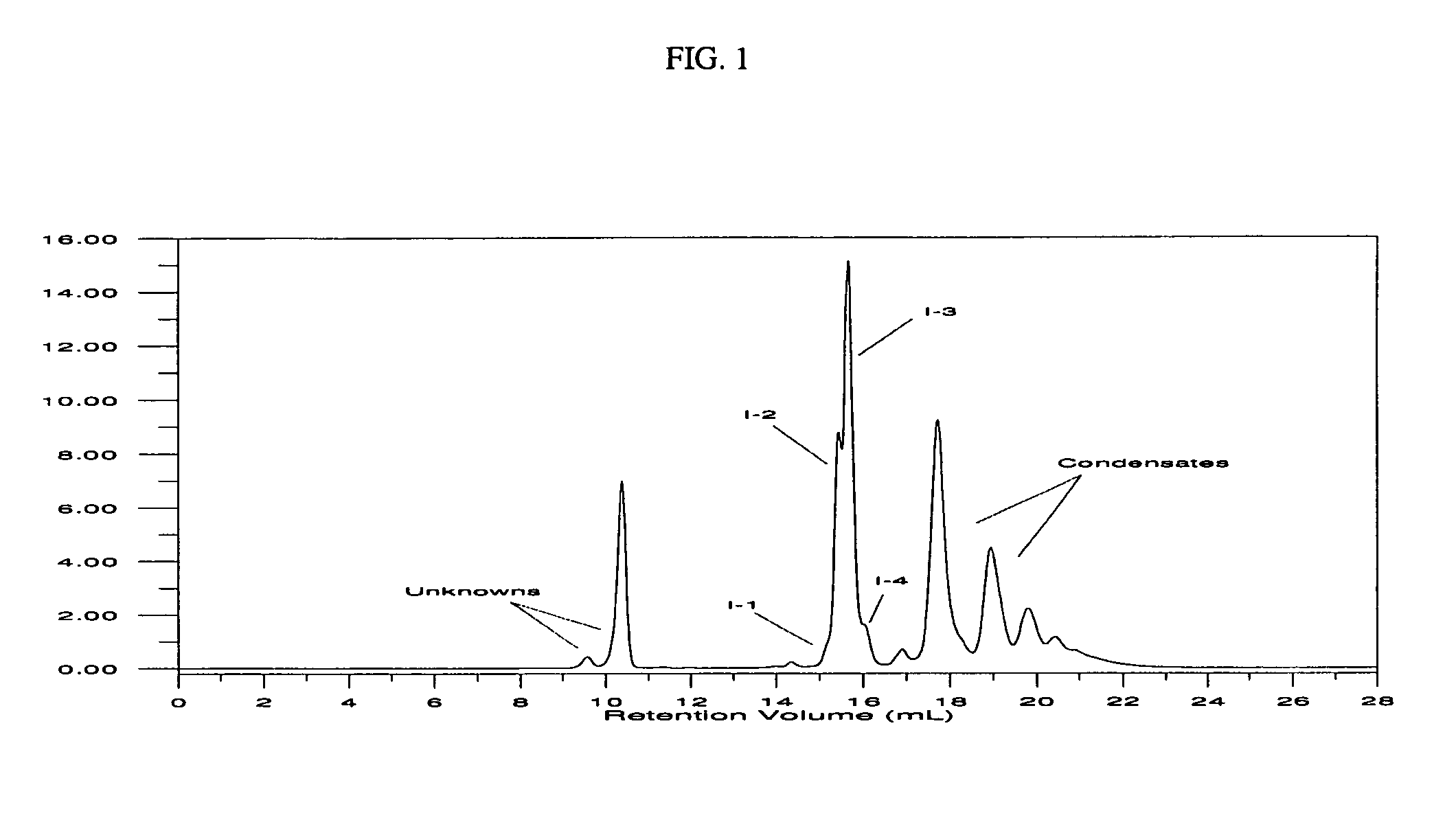

Non-random styrene-butadiene rubber

InactiveUS7064171B1Exceptionally beneficial performance characteristicBalanced combinationSpecial tyresTyre tread bands/patternsPolymer scienceGlass transition

The present invention reveals a tire having a tread that is comprised of (1) 30 phr to 80 phr of a non-random styrene-butadiene rubber comprised of polymer chains that are derived from styrene and 1,3-butadiene, wherein from about 10 weight percent to about 50 weight percent of the repeat units in the styrene-butadiene rubber are derived from styrene, wherein from about 60 weight percent to about 90 weight percent of the repeat units in the styrene-butadiene rubber are derived from 1,3-butadiene, wherein from about 30 weight percent to about 50 weight percent of the styrene repeat units are in sequences containing 5 to 20 styrene repeat units, wherein the bound styrene content found in the first half of the polymer chains differs from the bound styrene content found in the second half of the polymer chains by at least 5 weight percent, wherein the styrene-butadiene rubber has a 1,2-vinyl content which is within the range of about 8 percent to about 20 percent, wherein the styrene-butadiene rubber has a number average molecular weight which is within the range of 200,000 to 475,000, and wherein the styrene-butadiene rubber has a glass transition temperature which is within the range of −82° C. to −50° C. and (2) 20 phr to 70 phr of polybutadiene. The tire tread formulation can optionally contain silica and lignin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber Mixture

InactiveUS20130102714A1Mitigates the conflict of objectivesImprove rolling resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

A rubber mixture, in particular for vehicle pneumatic tires, straps, belts and hoses. The rubber mixture includes the following constituents: at least one synthetic diene rubber; at least one carbon black; at least one silane; and, at least one amphophilic compound. The rubber mixture ameliorates the target conflict between rolling resistance and wet grip.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Method for preparing white carbon black modified by silane coupling agent

InactiveUS20130131357A1Easy to operateImprove efficiencyPigmenting treatmentMaterial nanotechnologyHydrophobic silicaSolvent

The invention relates to a method for preparing silica modified by a silane coupling agent. The method comprises the following steps: preparing a kind of coupling agent sol solution by mixing the solvent, water, catalyst and coupling agent; uniformly dispersing silica into the sol solution by means of ultrasonic dispersion or shear dispersion to achieve a turbid solution with uniform dispersion and ideal particle size; and then stirring the turbid solution at a constant speed to make the coupling agent sol reacting with silica to prepare highly hydrophobic silica modified by the coupling agent through controlling the temperature and reaction time. The coupling agent sol solution is obtained by a sol-gel process and silica is uniformly dispersed in the coupling agent sol solution through combined action of various dynamic means to ensure the sufficient reaction between silica and coupling agent, thus to obtain silica modified by the coupling agent.

Owner:BEIJING UNIV OF CHEM TECH

Tire with a Tread Comprising an SNBR Elastomer

InactiveUS20110263750A1Improve gripImprove rolling resistanceSpecial tyresTyre tread bands/patternsPlasticizerNitrile

Owner:MICHELIN RECH & TECH SA +1

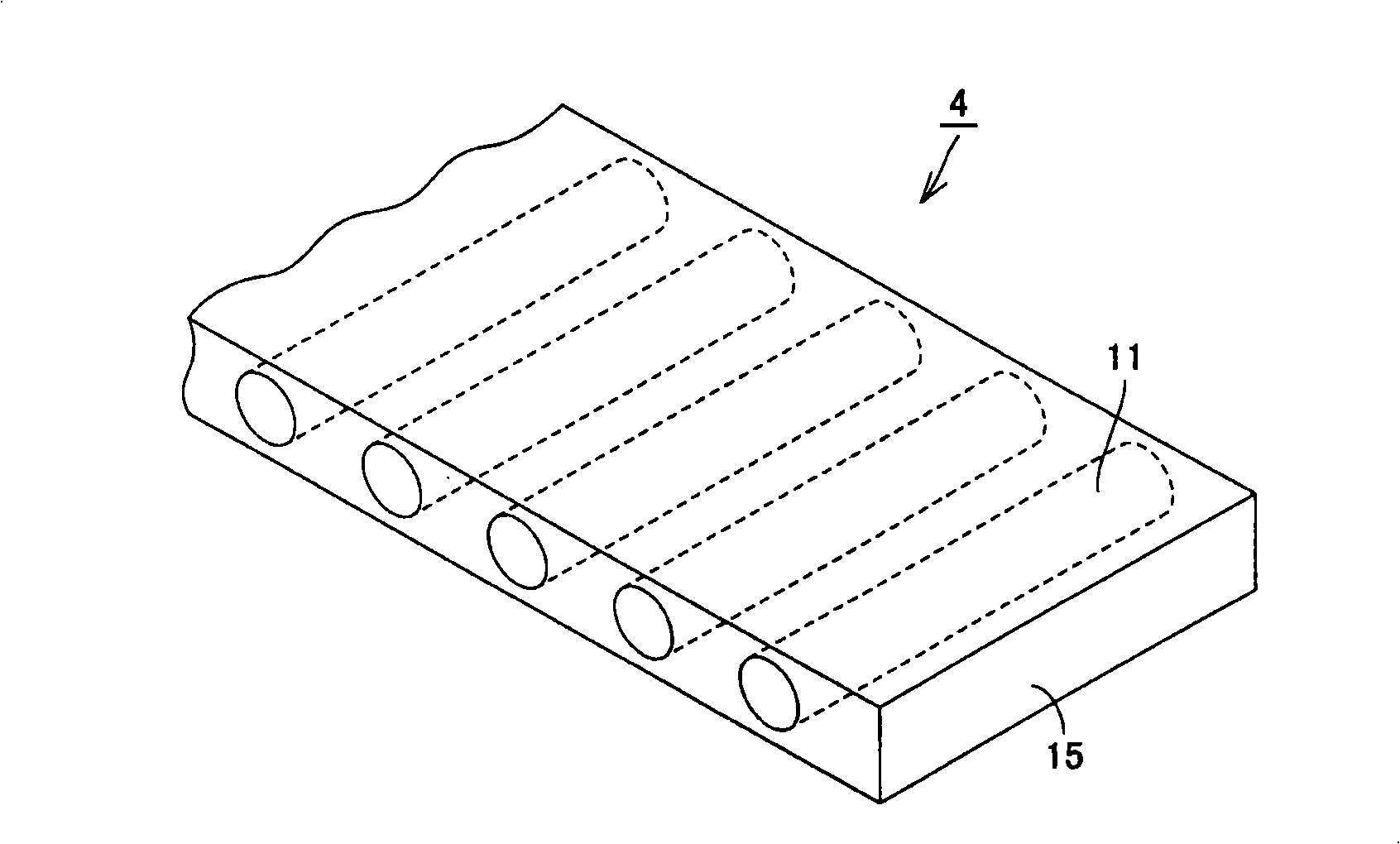

Wear-adaptable running tread

InactiveUS20050081972A1Reducing and even preventing appearanceAdapting the rigidity levels of the treadTyresTyre tread bands/patternsEngineeringRoad surface

A tread of a total thickness E for tires, comprising, when new: a running surface intended to be in contact with the roadway during travel; a plurality of first cutouts of a depth of less than the thickness of the tread and defining tread pattern elements of a height less than the total thickness of the tread; a plurality of cavities subjacent the running surface when new and extending over an average length L, each of these cavities being intended to form at least one new groove or incision after partial wear of the tread; each cavity delimited by the rubber of the tread having an upper generatrix beneath the running surface when new; this tread being characterized in that, for each cavity, the upper generatrix follows an undulating profile having a series of recesses and elevations, the amplitude of these recesses and elevations being at least 10% of the depth of the new grooves or incisions created.

Owner:MICHELIN RECH & TECH SA

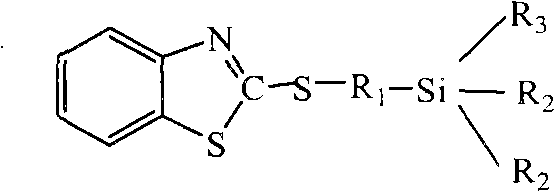

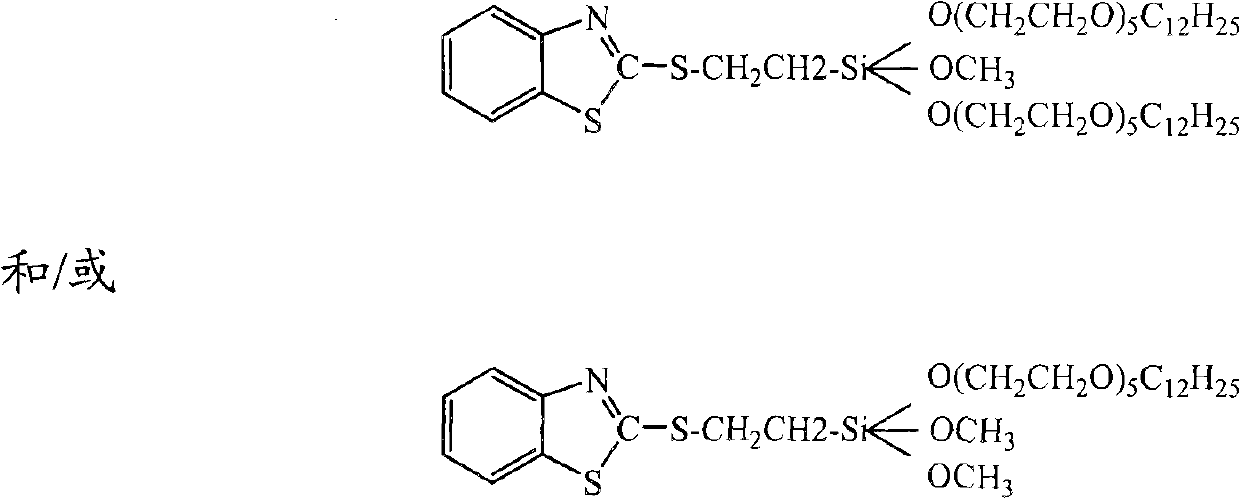

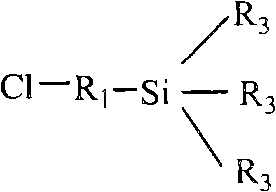

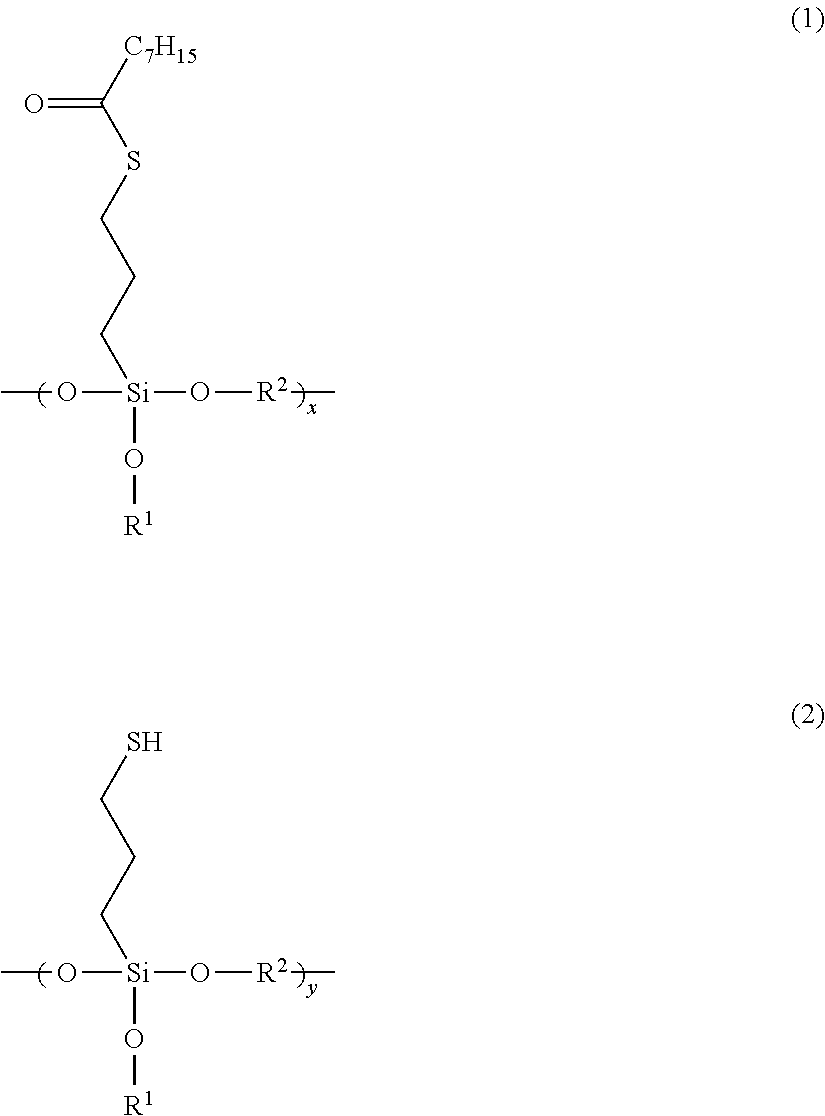

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Tire rubber composition and pneumatic tire

InactiveUS20110136961A1Improve wet grip performanceImprove balanceSpecial tyresRolling resistance optimizationPolymer scienceSilicon dioxide

It is an object of the present invention to provide a tire rubber composition excellent in performances such as silica dispersibility and processability. The present invention relates to a tire rubber composition, comprising: a rubber component that contains an epoxidized natural rubber; silica; and a silane coupling agent, wherein the amount of the epoxidized natural rubber in 100% by mass of the rubber component is 15% by mass or more, the silica has a CTAB specific surface area of 180 m2 / g or more and a BET specific surface area of 185 m2 / g or more, and the silane coupling agent contains a mercapto group.

Owner:SUMITOMO RUBBER IND LTD

Tire with silica reinforced tread

InactiveUS6022922AImprove roll resistanceImprove wet skid resistanceTyresSpecial tyresPolymer scienceSilicon dioxide

The invention relates to a tire with a tread which is reinforced with a quantitative amount of silica, including a silica coupler, where the tread rubbers are of a blend comprised of styrene / isoprene / butadiene terpolymer rubber and cis 1,4-polybutadiene rubber or styrene / isoprene / butadiene terpolymer rubber, cis 1,4-polybutadiene rubber and isoprene / butadiene copolymer rubber. Optionally, the rubber blend can contain a minor amount of cis 1,4-polyisoprene natural rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

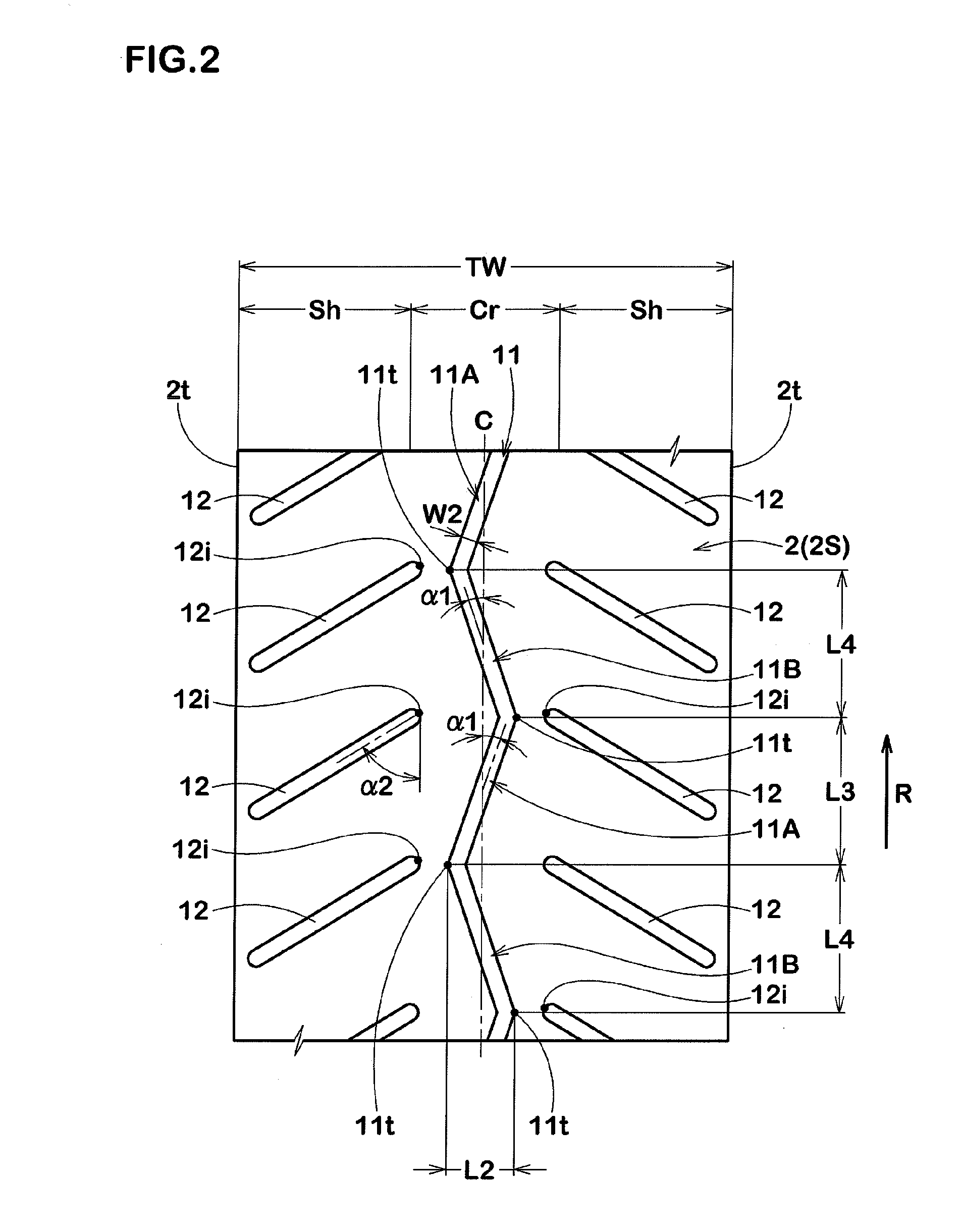

Motorcycle tire

InactiveUS20110132509A1Reduce roll resistanceSacrificing steering stability and ride comfortMotorcycle tyresTyre tread bands/patternsMotorcycle tyreEngineering

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tire, tire member and tire

InactiveCN101333308ACurb usageIncreased durabilitySpecial tyresRolling resistance optimizationPolymer scienceSilicon dioxide

A rubber composition for a tire comprising a rubber component containing at least one of a natural rubber and an epoxidized natural rubber, not less than 15 parts by mass of silica based on 100 parts by mass of the rubber component, and not less than 0.5 part by mass of calcium stearate based on 100 parts by mass of the rubber component, a tire member made using the rubber composition for a tire, and a tire made using the tire member.

Owner:SUMITOMO RUBBER IND LTD

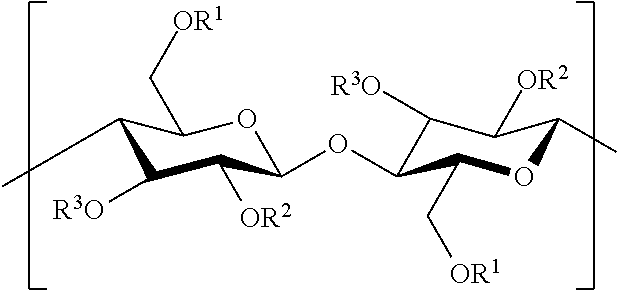

Elastomeric compositions comprising cellulose ester additives

An elastomeric composition is provided comprising at least one elastomer, at least one cellulose ester additive, at least one methylene acceptor, at least one methylene donor, and optionally, at least one filler; wherein the cellulose ester additive comprises at least one cellulose ester. The cellulose ester additive can also comprise at least one compatibilizer and / or plasticizer.

Owner:EASTMAN CHEM CO

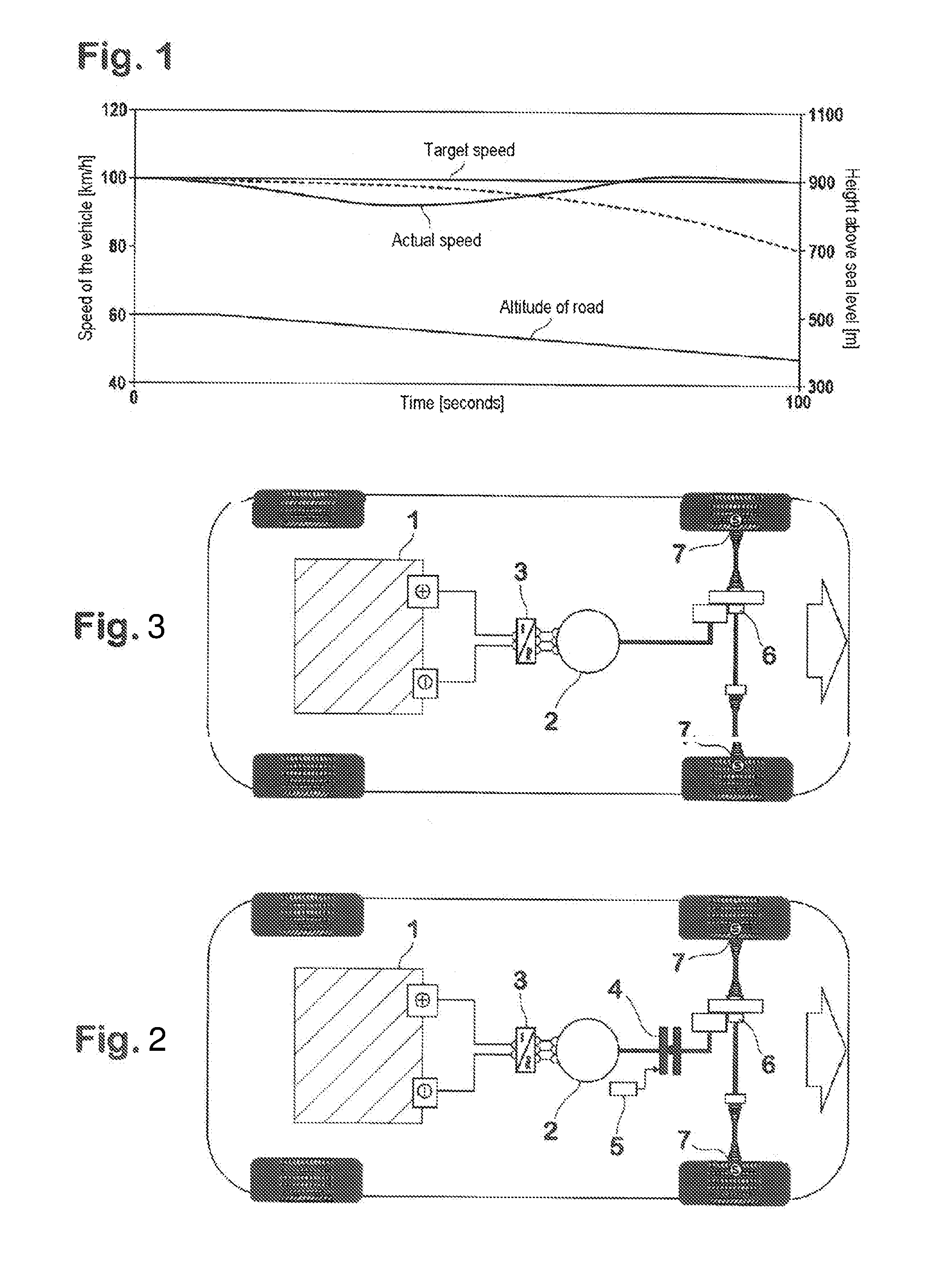

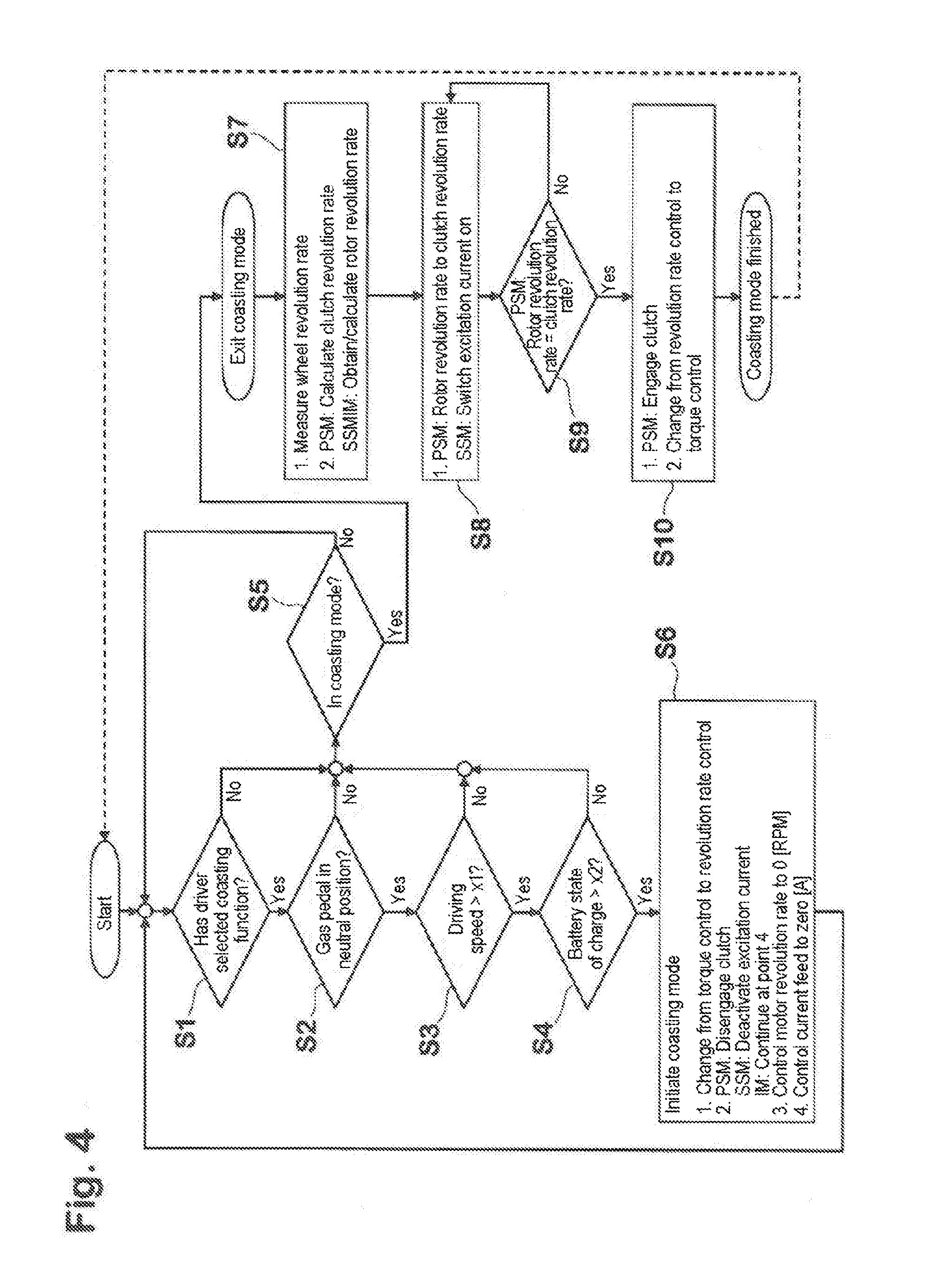

Electric motor vehicle and operating method for an electric motor vehicle

ActiveUS20160303996A1Long-term useImprove rolling resistanceSpeed controllerOperating modesCurrent velocityElectric machine

The disclosure concerns an operating method for an electric motor vehicle with at least one electrical machine as the traction motor and with an operating element for preselecting a coasting function, wherein, if the coasting function is preselected by the driver, under predetermined conditions the operating mode is automatically changed into a coasting mode, in which neither a drive torque nor a drag torque is exerted on the wheels of the vehicle. According to the disclosure, the predetermined conditions include the conditions that the gas pedal is in a neutral position and that the current speed of the vehicle is at or is greater than a preset value. Under the predetermined conditions the operating mode is automatically changed into the coasting mode by bringing the drive train of the vehicle into a state in which the at least one electrical machine is consuming no electrical energy.

Owner:FORD GLOBAL TECH LLC

Carriage for a conveyor, in particular for a gravity conveyor, conveying system, and method for operating a conveying system

ActiveUS20180215547A1Improve rolling resistanceRestrict movementConveyorsRollersDelivery systemElectrical and Electronics engineering

A carriage for a conveyor comprising a carriage body which is configured for embracing a running rail and which comprises a first and a second leg which are connected by a connection portion, wherein the first leg has first rollers which are attached to the internal side of the first leg, and the second leg has second rollers which are attached to the internal side of the second leg, and the connection portion has third rollers which are attached to the internal side of the connection portion, it is provided according to the invention that the first and the second rollers are vertically disposed, and the third rollers are horizontally disposed.

Owner:FERAG AG

Rubber composition for tread and pneumatic tire

InactiveUS20110082234A1Improve rolling resistanceWell-balanced mannerSpecial tyresRolling resistance optimizationCrack resistanceRolling resistance

The present invention has its object to provide a rubber composition for a tread which can prevent reversion and can also achieve environmental performance (excellent rolling resistance, response to depletion of oil resources, attention to CO2 emission), wet grip performance, dry grip performance, handling stability, and durability (abrasion resistance, crack resistance) in a well-balanced manner. The present invention also aims to provide a pneumatic tire using the rubber composition for the tread thereof. The rubber composition for a tread includes a rubber component containing 35% by mass or more of an epoxidized natural rubber; and a white filler, wherein a total sulfur content is less than 1.75% by mass, and a crosslink density is 7.0×10−5 mol / cm3 or more.

Owner:SUMITOMO RUBBER IND LTD

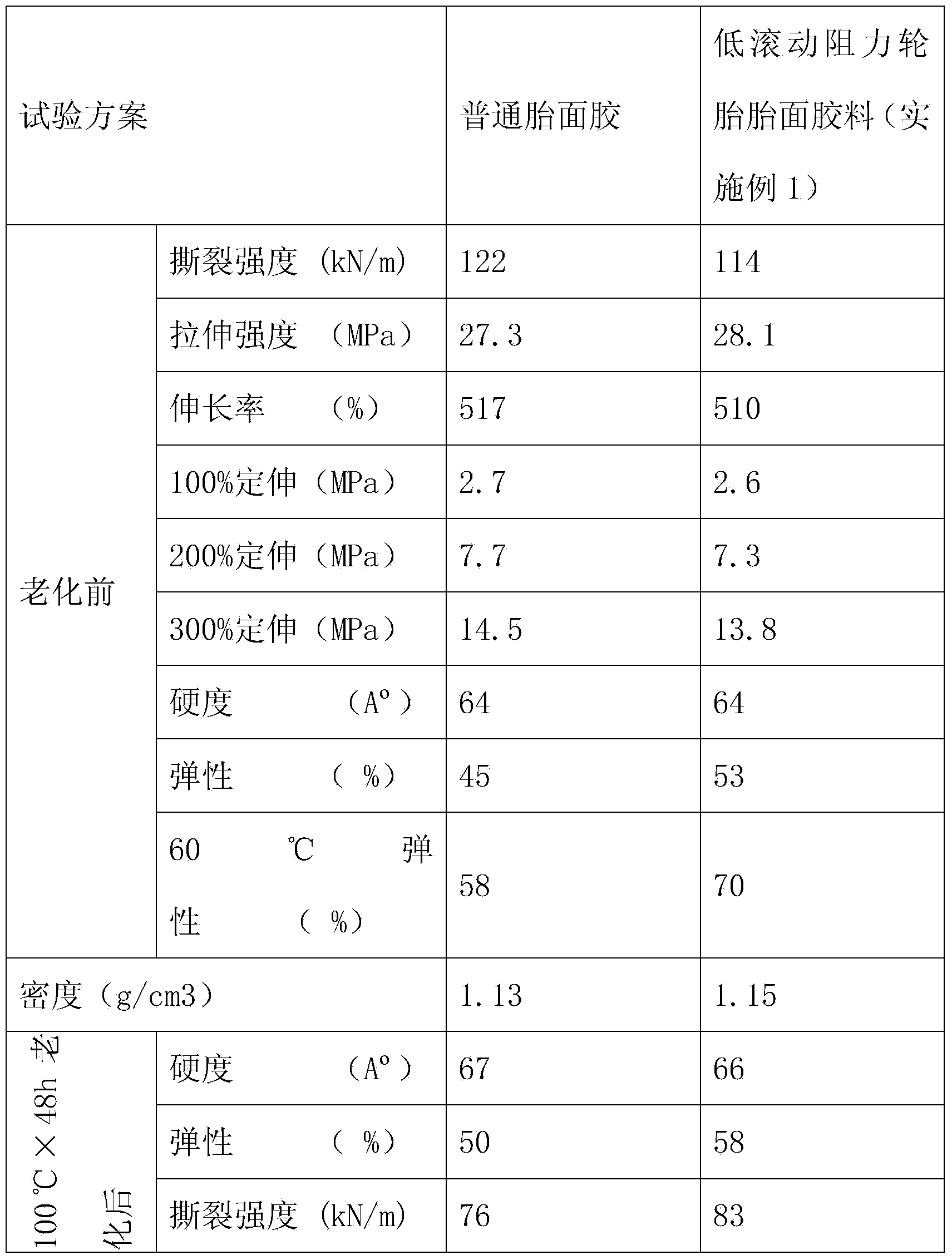

Tire tread mix with low rolling resistance

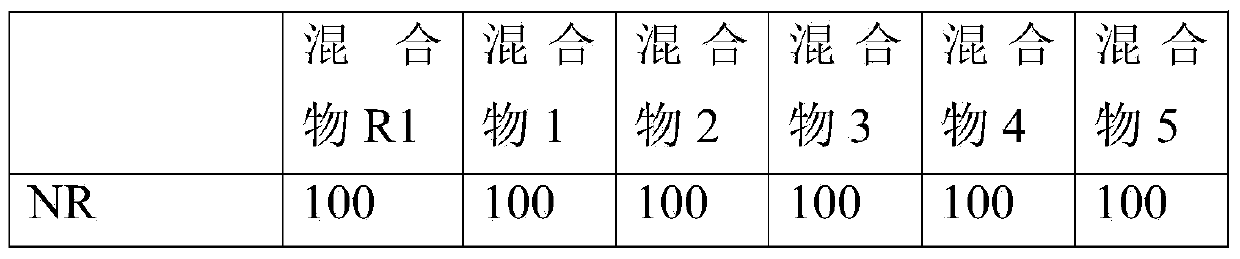

ActiveCN103408807AImprove rolling resistanceReduce Paine EffectSpecial tyresRolling resistance optimizationRolling resistanceSulfur

The invention relates to tire tread mix with low rolling resistance. The tire tread mix with low rolling resistance has the advantages that carbon black serving as a tread filler of a conventional tire is partially substituted by white carbon black, meanwhile, a right amount of silane coupling agent is added for chemically modifying the white carbon black, so that the Payne effect and loss angle tangent tan delta at a high temperature of the mix can be effectively reduced, further the rolling resistance of a tire is improved, the effects of reduction of oil consumption and exhaust emission and environmental friendliness are achieved, and therefore, by adopting the tire tread mix with low rolling resistance, about 50% of tread lag performance and about 20% of rolling resistance of the tire can be reduced, thus more than 30% of fuel is saved. The tire tread mix with low rolling resistance comprises the following comments in parts by weight according to a formula: 70-90 parts of natural rubber, 10-30 parts of cis-butadiene rubber, 5-30 parts of carbon black, 30-50 parts of white carbon black, 5-10 parts of coupling agent, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 3-6 parts of antiager, 1-2 parts of sulfur, 1.0-2.0 parts of promoter and 0.1-0.3 part of scortch retarder CTP.

Owner:SAILUN GRP CO LTD

Rubber composite for car radial tire treads

ActiveCN103435873AImprove wet skid resistanceImprove rolling resistanceRolling resistance optimizationElastomerRolling resistance

The invention discloses a rubber composite applied to car radial tire treads. The rubber composite comprises the following substances of (i) dialkene elastomer; (ii) more than 30 phr of inorganic reinforcing filler; (iii) 2-15 phr of a coupling agent; (iv) 0-20phr of a plasticizer; and (v) 2-20 phr of resin, wherein phr represents the weight parts of all materials accounting for 100 parts by weight of dialkene elastomer. When the tire tread comprising the rubber composite is in use, the tire tread has excellent slip resistance and rolling resistance, and the tires are endowed with the balance of wetland grip, rolling resistance and wear resistance.

Owner:QINGDAO HAIJIA AJUVANTS

Tire with tread intended for both on and off-the-road service

InactiveUS20160200899A1Increase valueLess internal heat generationSpecial tyresEngineeringHeavy duty

This invention relates to heavy duty pneumatic rubber tires with treads intended for mixed service use on diverse surfaces and to rubber compositions for such tire tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with component of rubber composition comprised of silica reinforcement and emulsion polymerization derived terpolymer rubber of diene/vinyl aromatic compound which contains pendant hydroxyl groups

InactiveUS20020173560A1Enhance elastomer reinforcing effectEnhances rubber reinforcement aspectSpecial tyresElastomerPolymer science

This invention relates to a tire having at least one component of a silica reinforced rubber composition comprised of an emulsion polymerization derived terpolymer rubber which contain pendant hydroxyl groups, particularly derived from diene hydrocarbon and vinyl aromatic compound monomers, particularly a hydroxyalkyl methacrylate. Preferably the hydroxyalkyl methacrylate is a hydroxypropyl methacrylate (HPMA). Preferably at least one additional elastomer is blended with the terpolymer rubber. The rubber composition is prepared by blending a coupling agent therewith subsequent to the addition said silica reinforcement. Said tire component may be, for example, a tire tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

Masterbatch, Rubber Composition, And Pneumatic Tire

InactiveCN103205039AImprove rolling resistanceImprove handling stabilitySpecial tyresTyre tread bands/patternsMasterbatchPolymer science

The present invention aims to provide a masterbatch which enables microfibrillated plant fibers to be well dispersed in a rubber composition so that they can provide reinforcement equal to or greater than that by conventional fillers; a rubber composition containing the masterbatch; and a pneumatic tire produced using the rubber composition. The present invention relates to a masterbatch containing a modified natural rubber with a phosphorus content of 200 ppm or less, and microfibrillated plant fibers. Preferably, the microfibrillated plant fibers in a primary form have an average fiber diameter of 4 nm to 10 [mu]m and an average fiber length of 100 nm to 200 [mu]m.

Owner:SUMITOMO RUBBER IND LTD

Roll for a papermaking machine

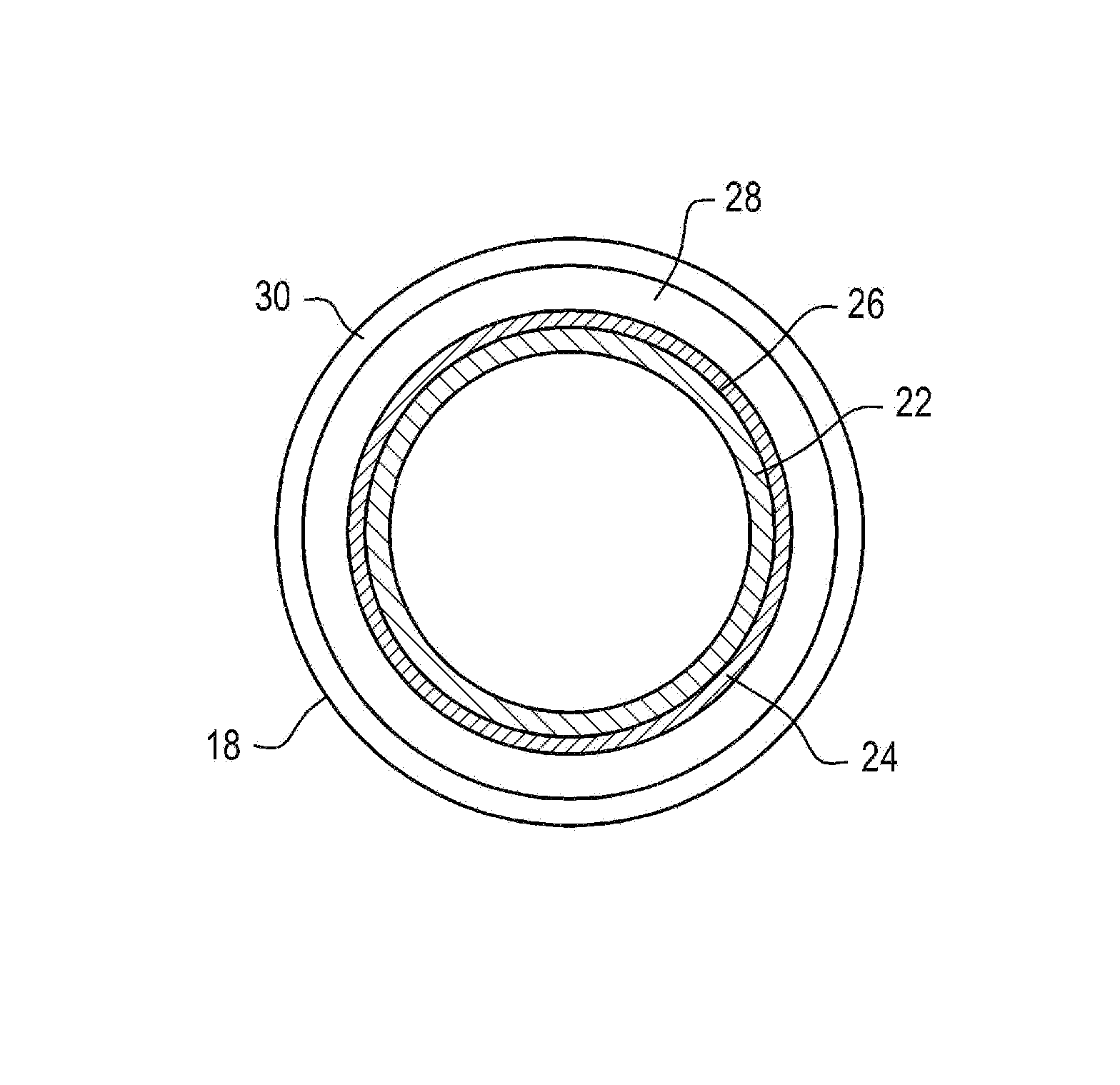

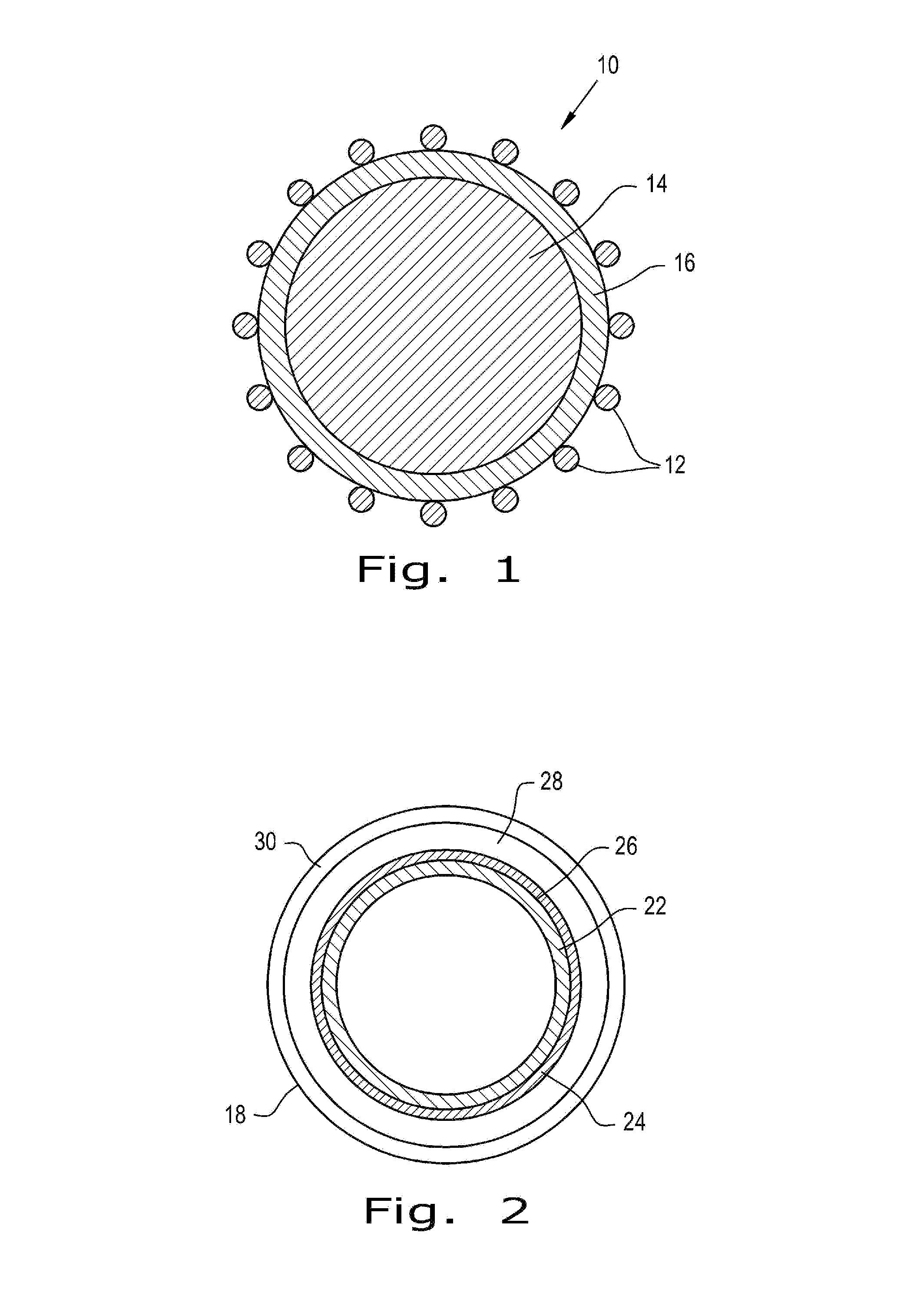

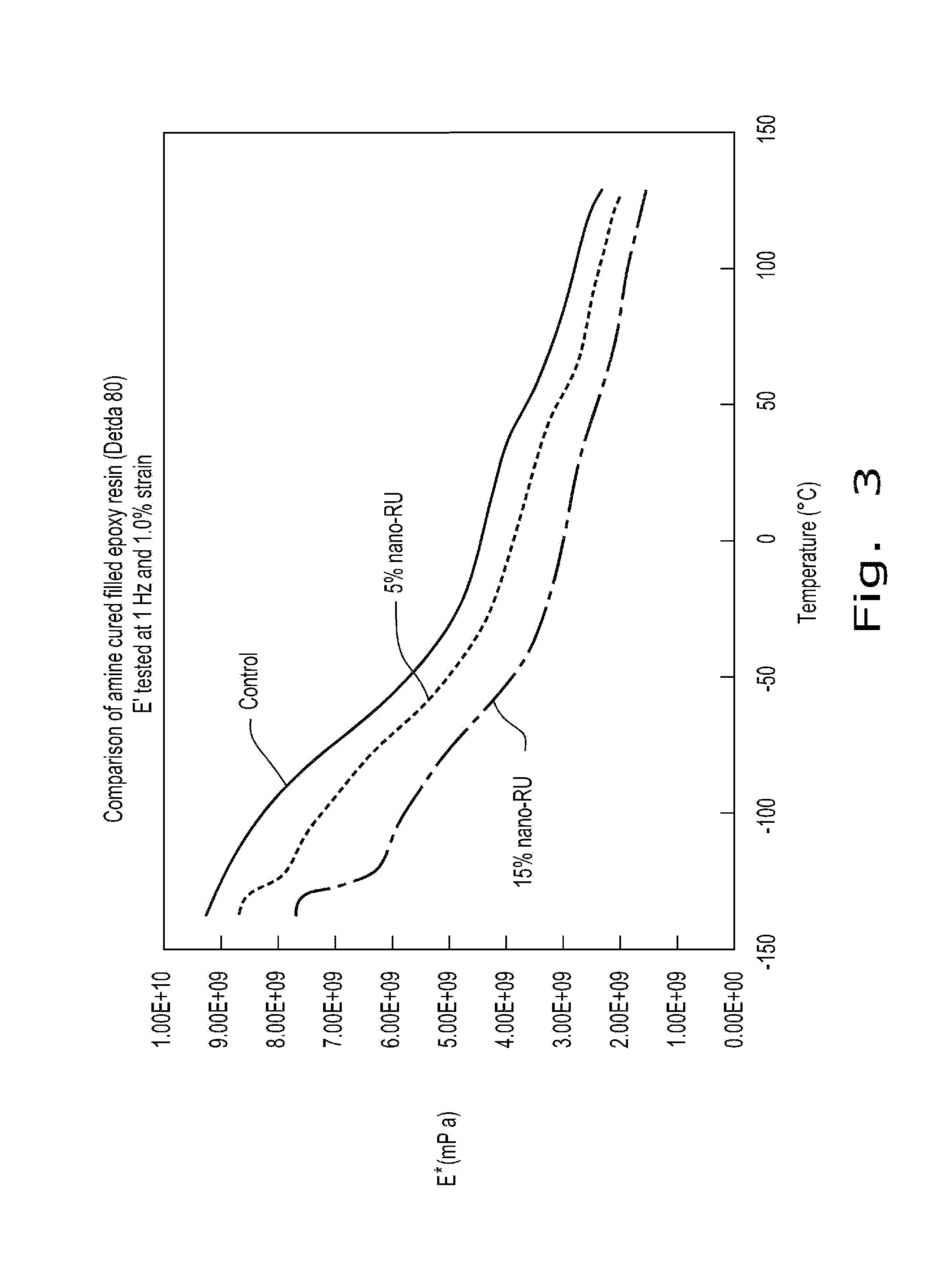

InactiveUS20130312926A1Improve performanceImprove surface qualityPretreated surfacesCalendersElastomerPolymer science

A roll for use in a papermaking machine has a circumferential surface formed of a polymeric material including a plurality of chemically reactive elastomer nano-particles and a resin. The polymeric material has a glassy transition temperature that is substantially the same as a glassy transition temperature of the resin alone.

Owner:VOITH PATENT GMBH

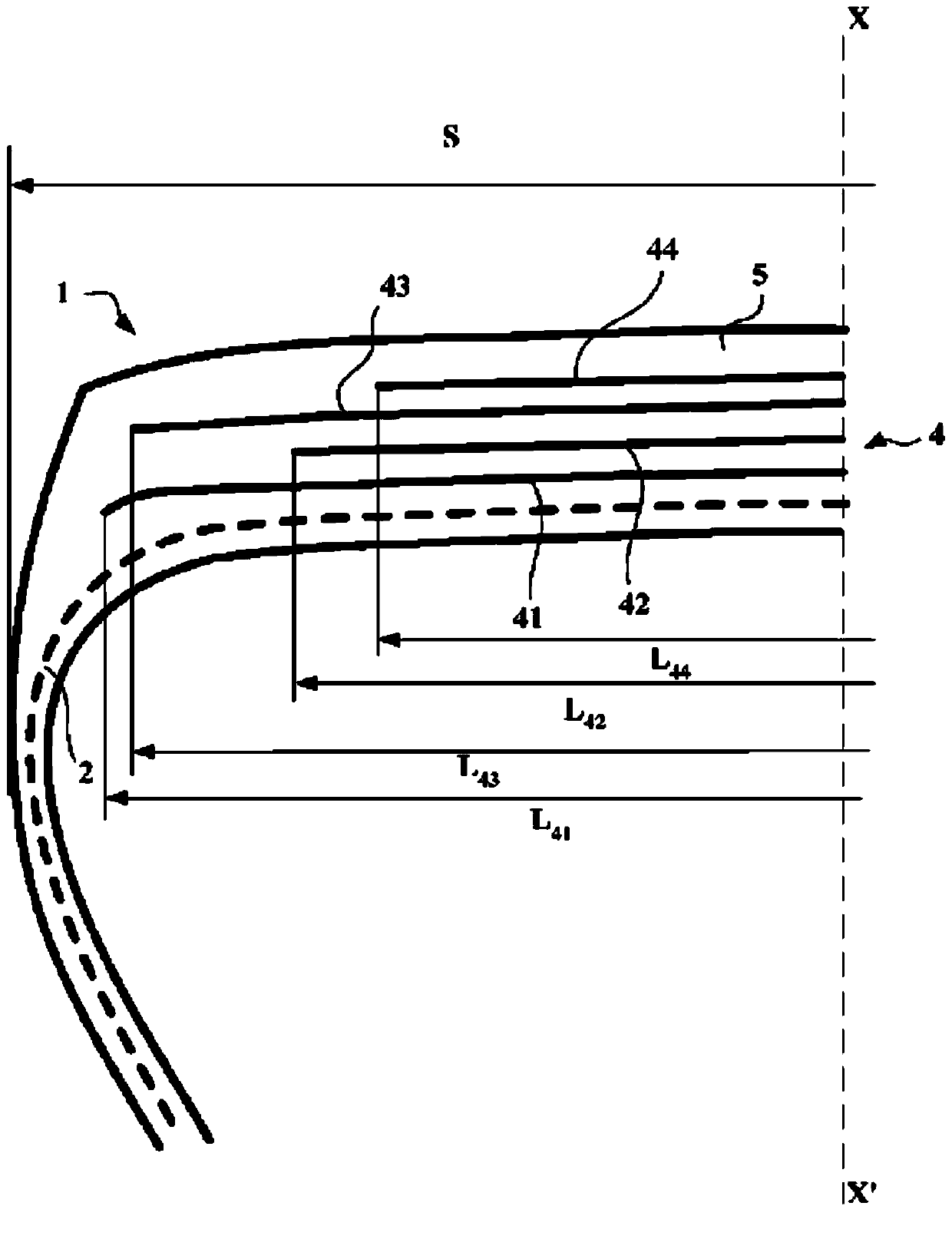

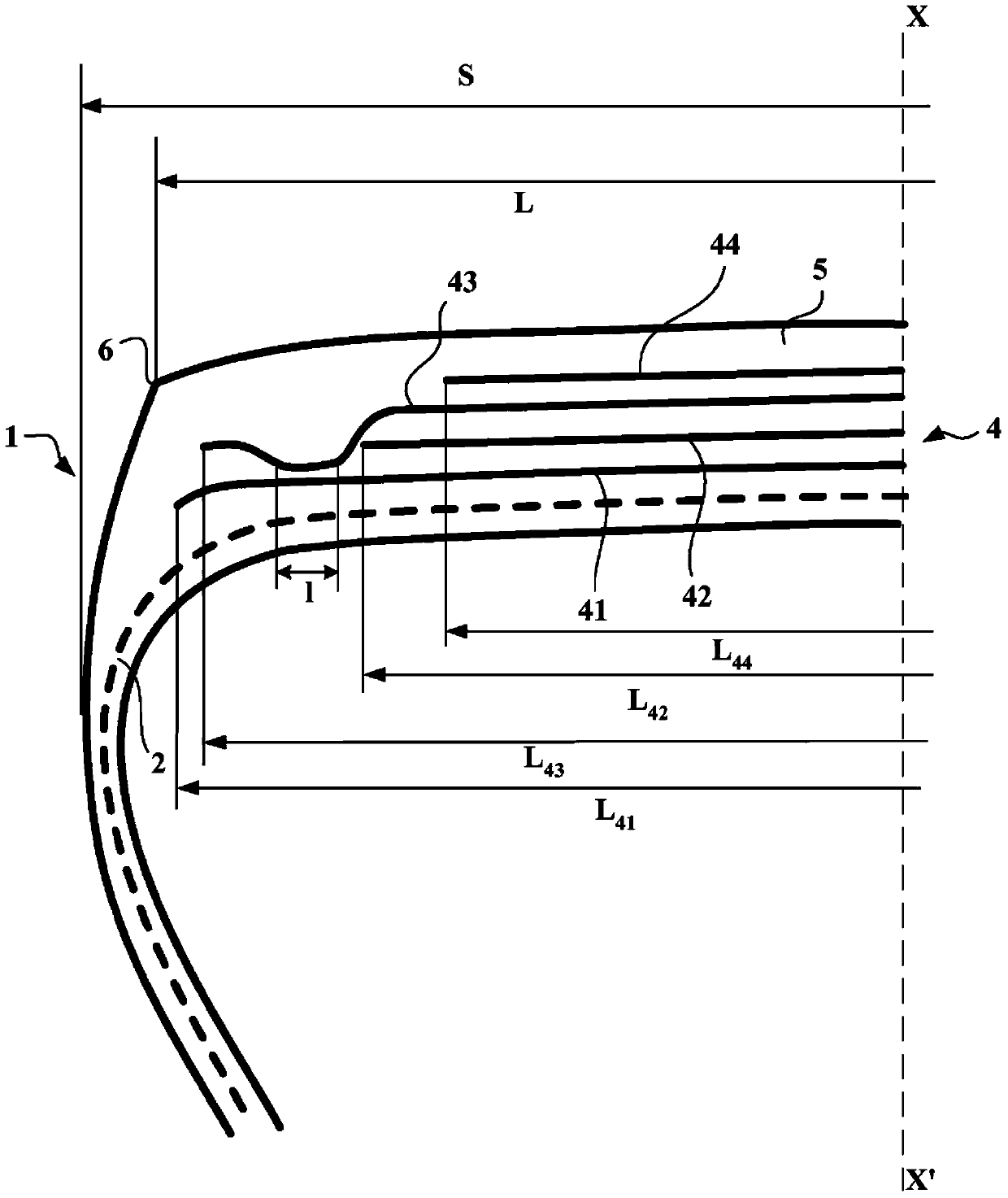

Tyre comprising a layer of circumferential reinforcing elements

ActiveCN103874587ALow modulus of elasticityReduce compressionHeavy duty tyresHeavy duty vehicleTensile strainEngineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

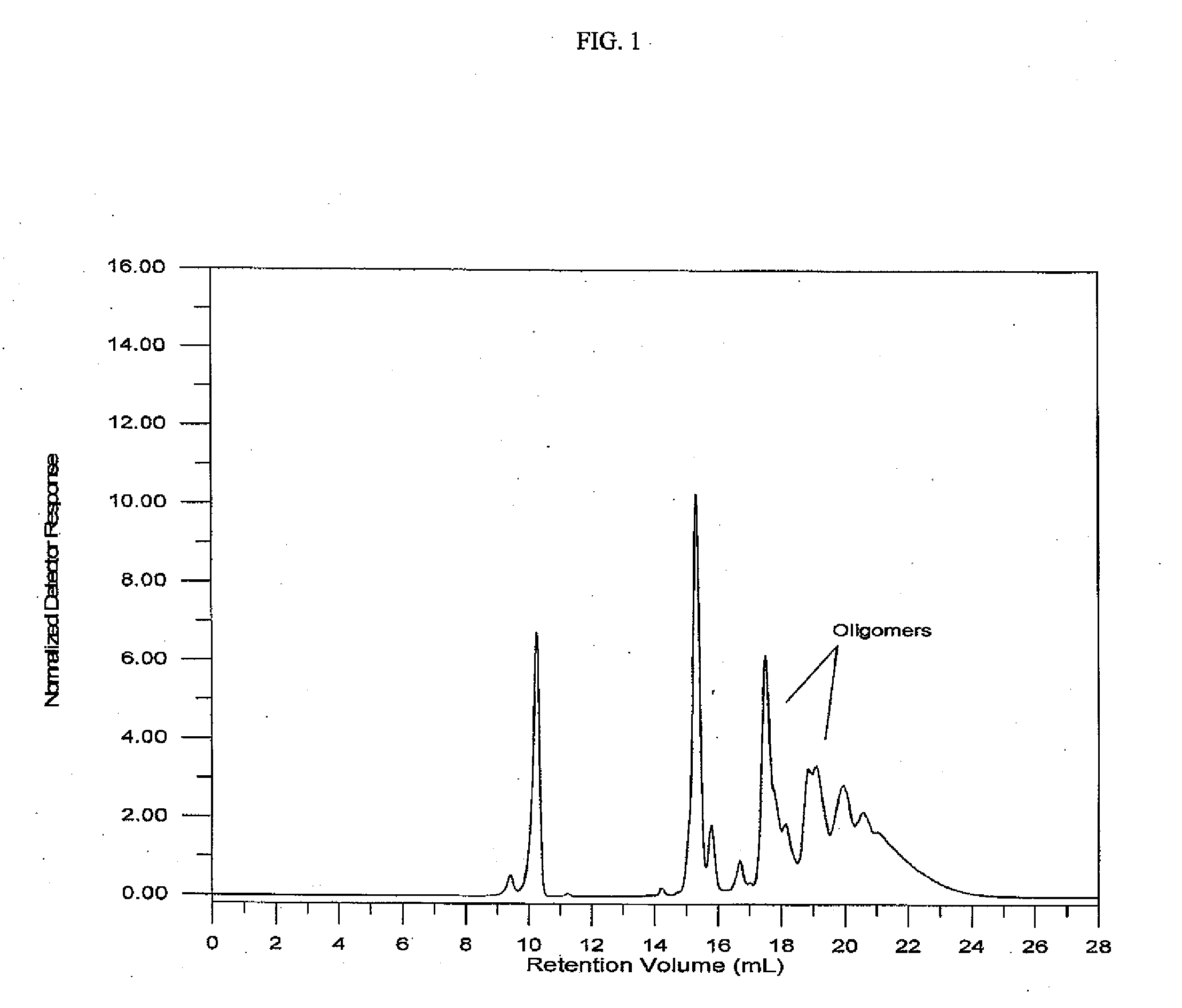

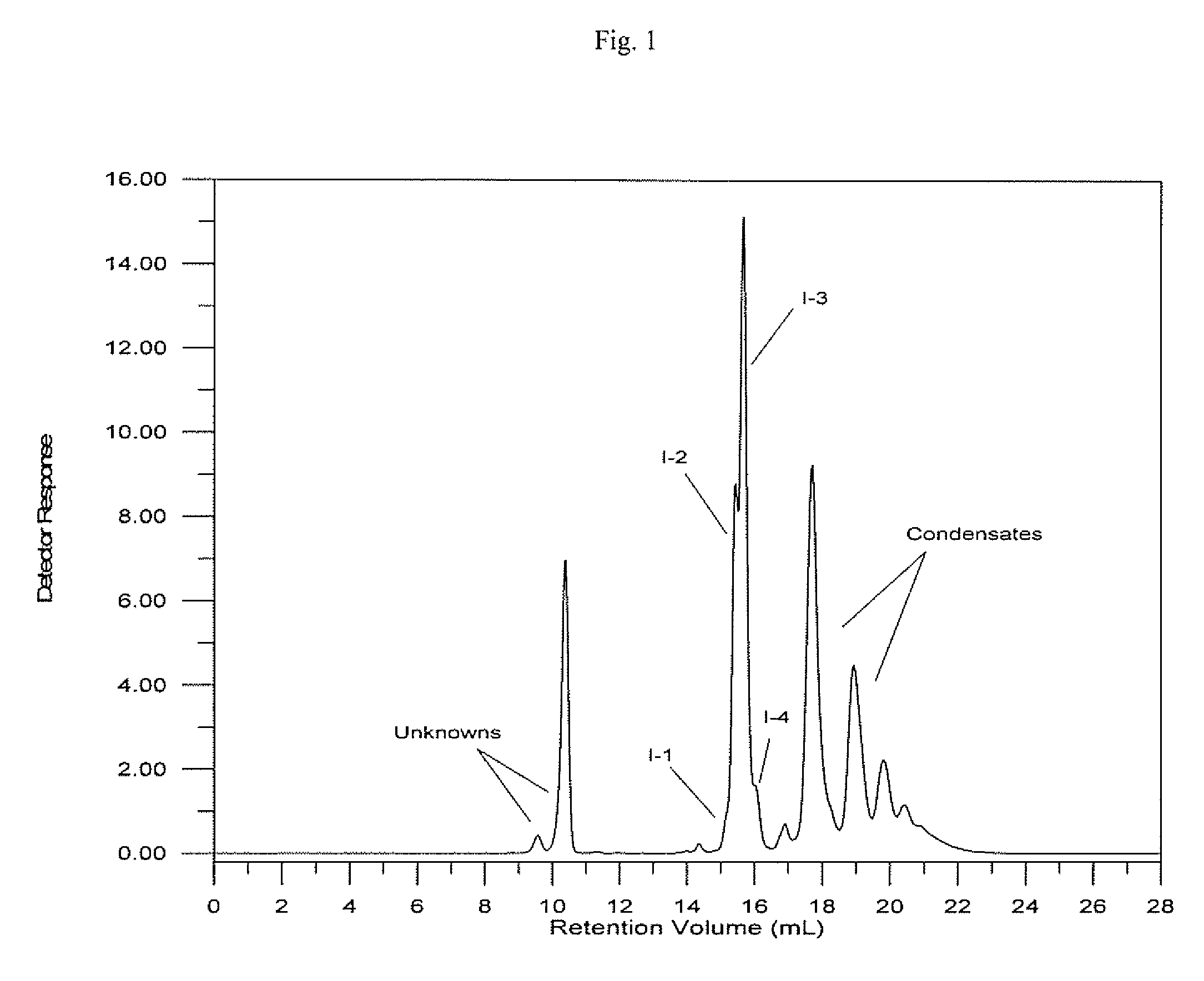

Free-flowing filler composition and rubber composition containing same

ActiveUS7737202B2Easy to wearImprove rolling resistanceSpecial tyresSolid ballsPolysulfidePolymer chemistry

This invention relates to novel free-flowing filler compositions containing silated cyclic core polysulfide coupling agents, and to a rubber containing the filler composition.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Inflatable tire

ActiveCN103242578AImprove rolling resistanceImprove wetting performanceSpecial tyresRolling resistance optimizationLanding performanceRolling resistance

The object of the invention is to provide an inflatable tire with good rolling resistance, wet land performance and wear-resistance, wherein the generation of groove cracks on the surface of the tire is inhibited. The inflatable tire is an inflatable tire with a surface, and the surface comprises a drive surface and a base part. The drive surface is prepared by a rubber combination for the drive surface, and the rubber combination comprises a preset amount of silicon dioxide that has a 70-300m2 / g BET specific surface area, a preset amount of carbon black and / or inorganic filler, and 0.5-5 parts in weight of release agent, wherein the release agent comprises at least one of a group that consists of fee fatty acid metal salt, fatty acid amides and amide ester. The base part is prepared by a rubber combination for the base part, and based on the weight parts, the rubber combination comprises a preset amount of carbon black and / or silicon dioxide that has a 70-300m2 / g BET specific surface area.

Owner:SUMITOMO RUBBER IND LTD

Tire sidewall rubber combination comprising 1,2-syndiotactic polybutadiene

InactiveCN104311908AReduce driving noiseImprove rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of rubber, in particular to a tire sidewall rubber combination comprising 1,2-syndiotactic polybutadiene. 100 weight parts of rubber components serve as the standard, and the combination further includes, by weight, 35-65 parts of carbon black, 5-25 parts of environmentally-friendly aromatic oil, 1.0-5.0 parts of tackifying resin, 1.0-4.0 parts of zinc oxide, 0.5-2.5 parts of stearic acid, 1.5-3.5 parts of sulphur and 0.5-3.0 parts of accelerant. The rubber components include, by weight, 5-50 parts of polybutadiene rubber, 5-45 parts of 1,2 syndiotactic polybutadiene and 35-55 parts of natural rubber. According to the tire sidewall rubber combination comprising the 1,2-syndiotactic polybutadiene, the tire running noise is effectively lowered, the driving comfort is improved, the rolling resistance of a tire is relieved, the physical and mechanical performances of tires made of the tire sidewall rubber combination are basically identical with those of common tires, and the advantages of the wet land griping force and the dry land controllability of the tires are maintained.

Owner:TRIANGLE TIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com