Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1838 results about "Generatrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a generatrix (/dʒɛnəˈreɪtrɪks/) or generator is a point, curve or surface that, when moved along a given path, generates a new shape. The path directing the motion of the generatrix motion is called a directrix.

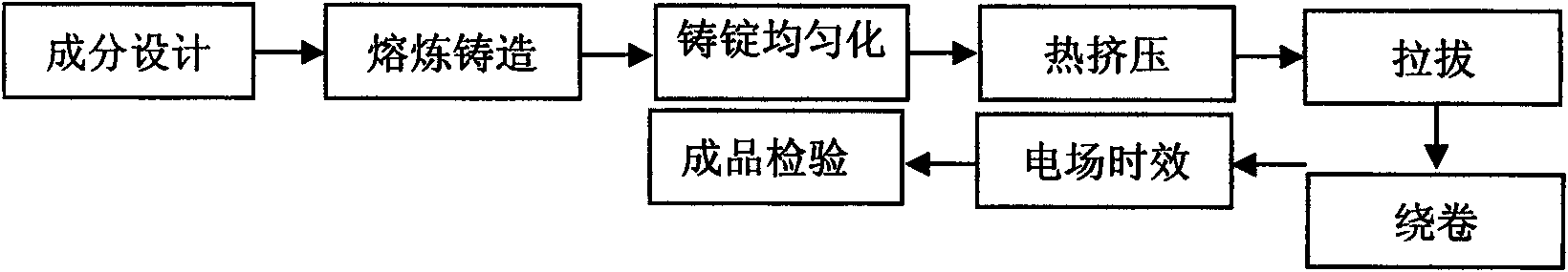

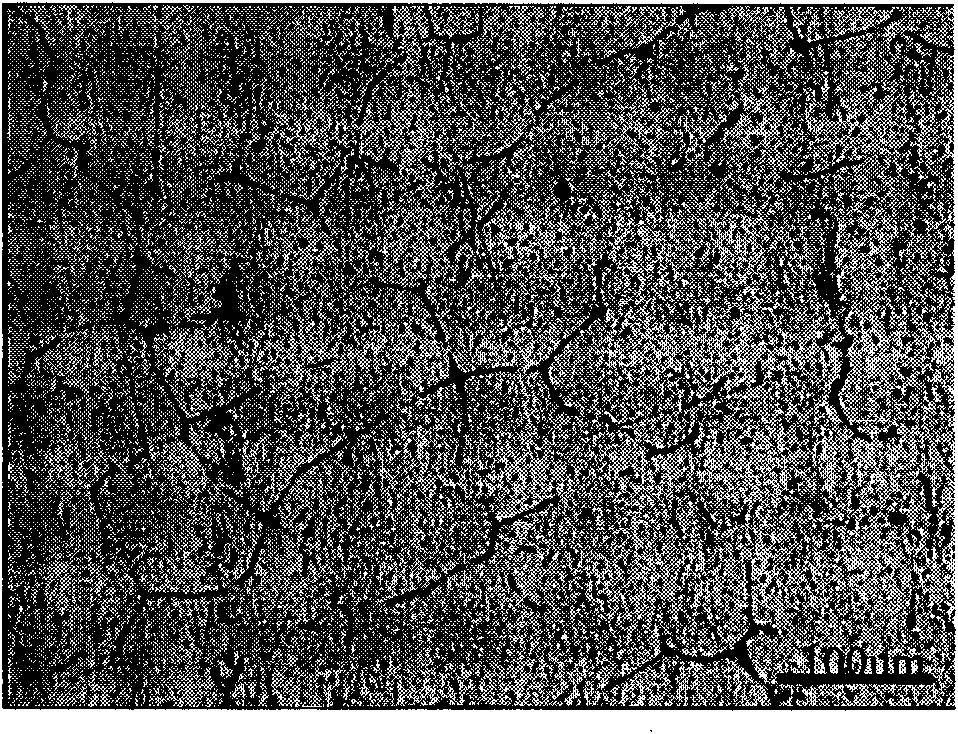

Aluminum alloy lead with lanthanon yttric and preparation method thereof

ActiveCN101587757AImprove conductivityHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthTime effect

The invention discloses an aluminum alloy lead with lanthanon yttric and preparation method thereof. The specific component and weight percentage of the invention are Si0.5%-0.7%, Mg0.6%-0.9%, Fe 0.1%-0.2%, Y 0.2%-0.8%, Al residue. The preparation method is following: preparing the elements according to the alloy design to prepare aluminum alloy wire material via melting, casting, homogenization, extrusion and wire drawing, preparing the cables via winding to obtain the aluminum alloy lead with great intensity and conduction via the electric field time effect heat treatment. The aluminum alloy lead with high intensity of the invention adds the lanthanon yttric to purify the melting body and reduce the silicon quantity in the alloy further enhance the conductive rate of the melting on the one hand; on another hand to thin the crystal grain and enhance intensity of the alloy wire; the generatrix intending intensity is 260MPa and the conductive rate can achieve 57% IACS.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

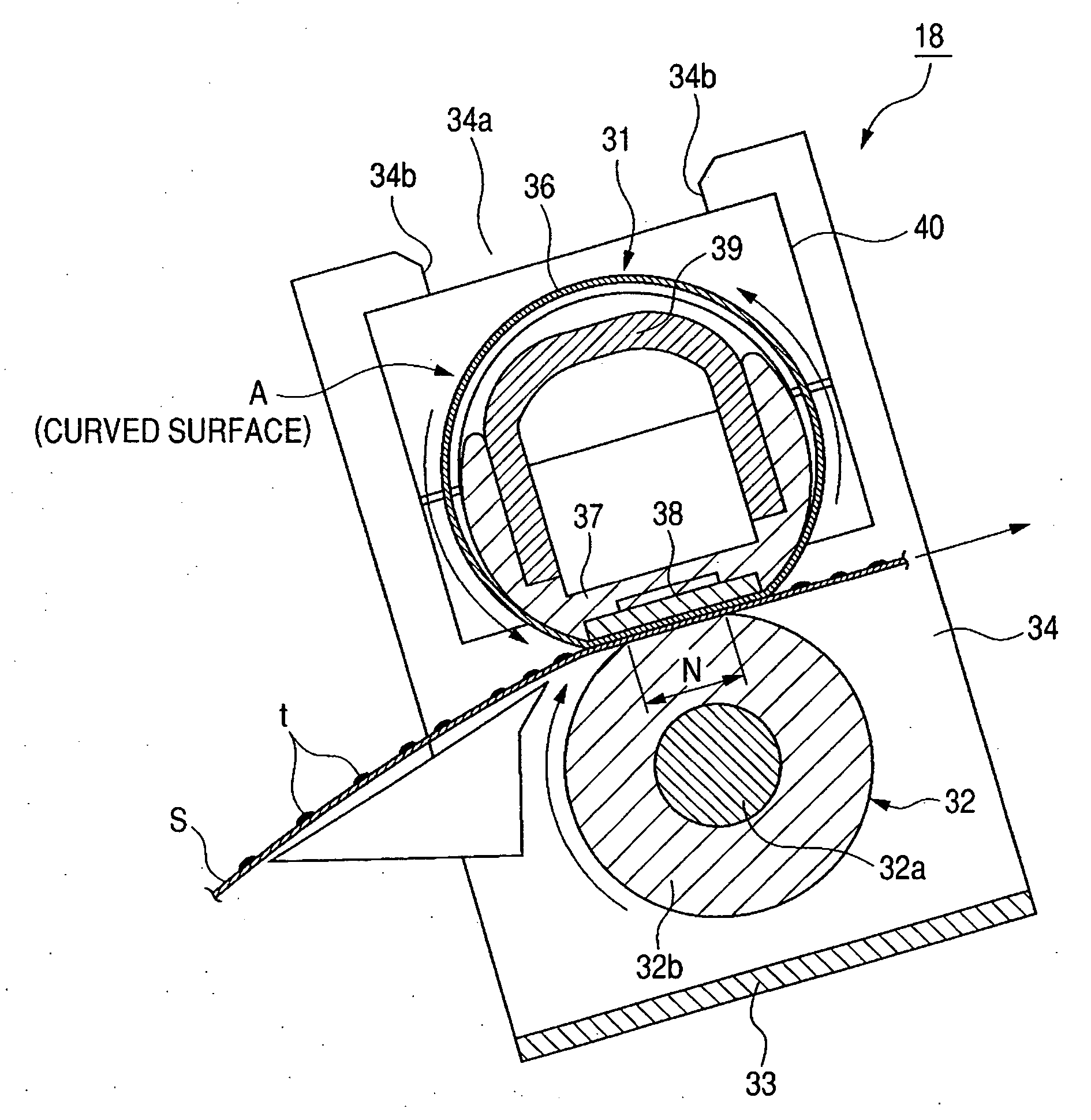

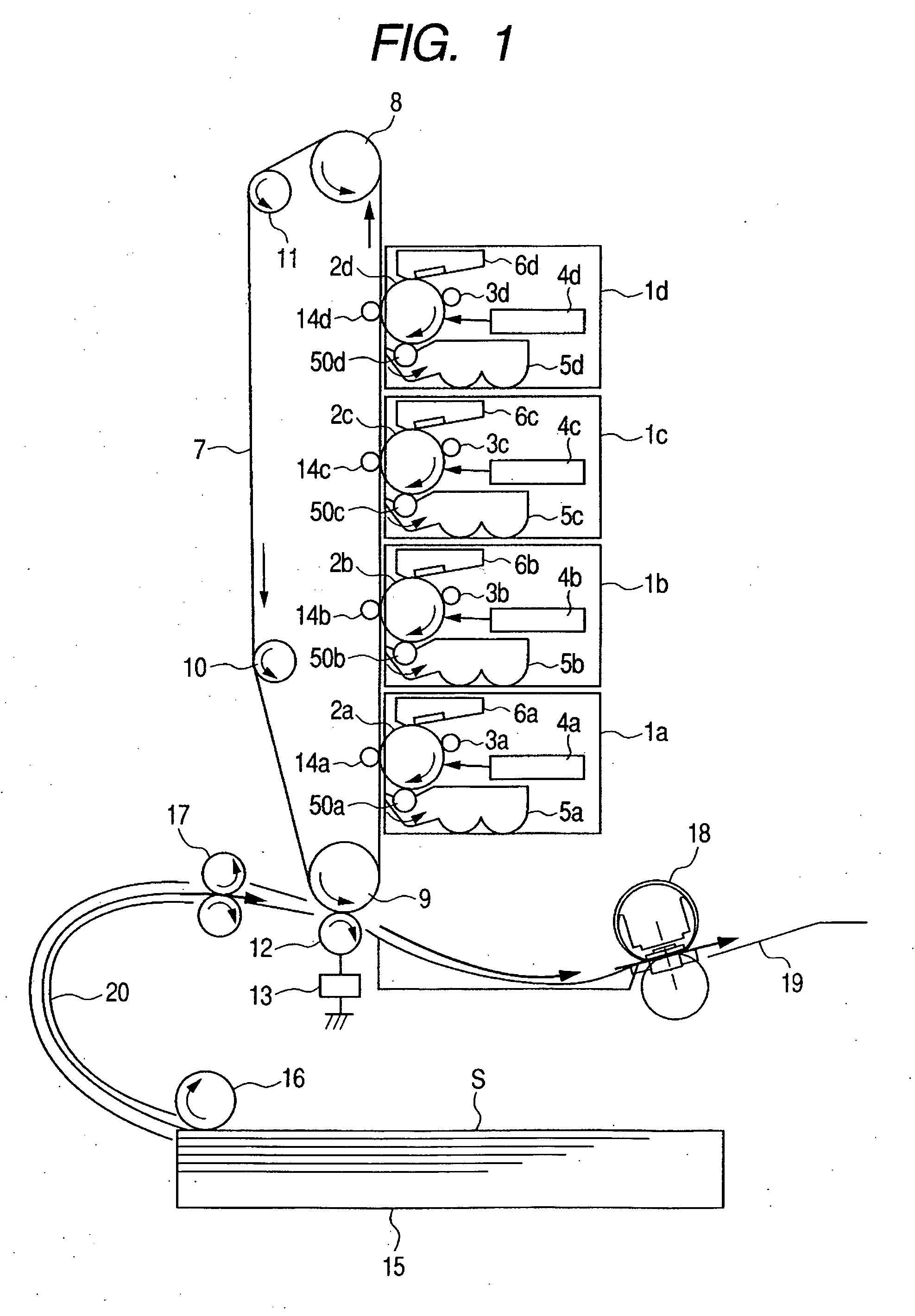

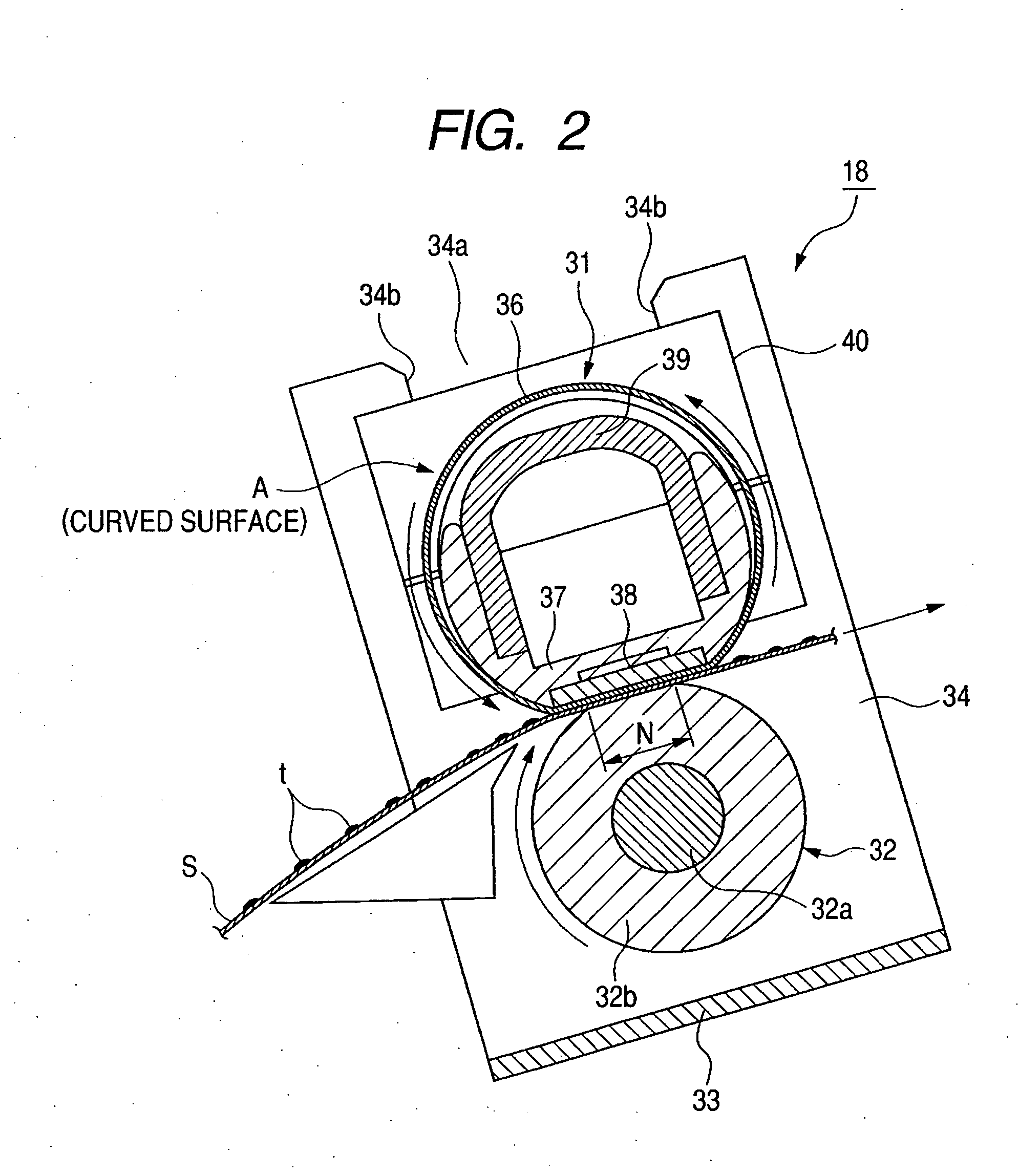

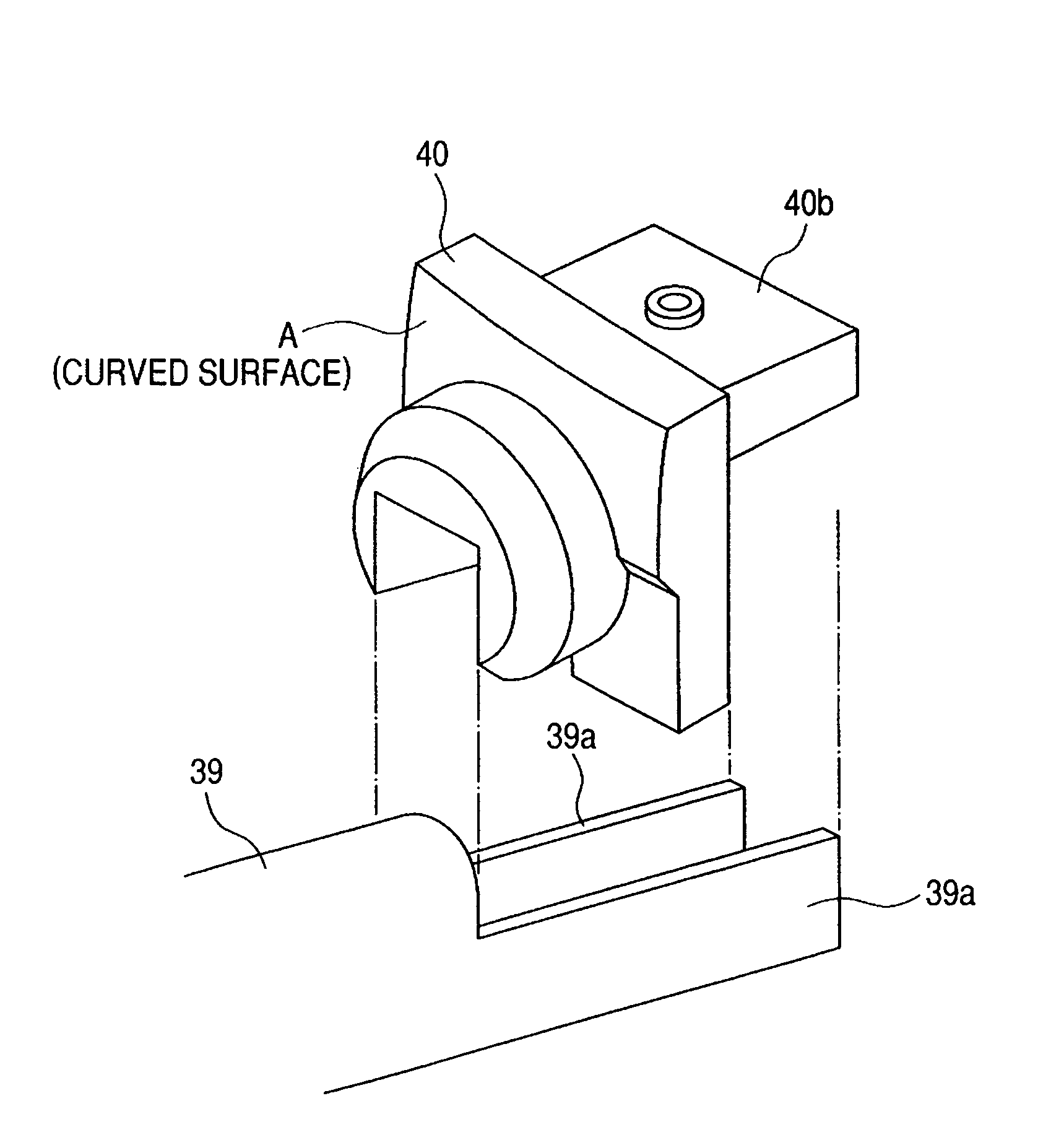

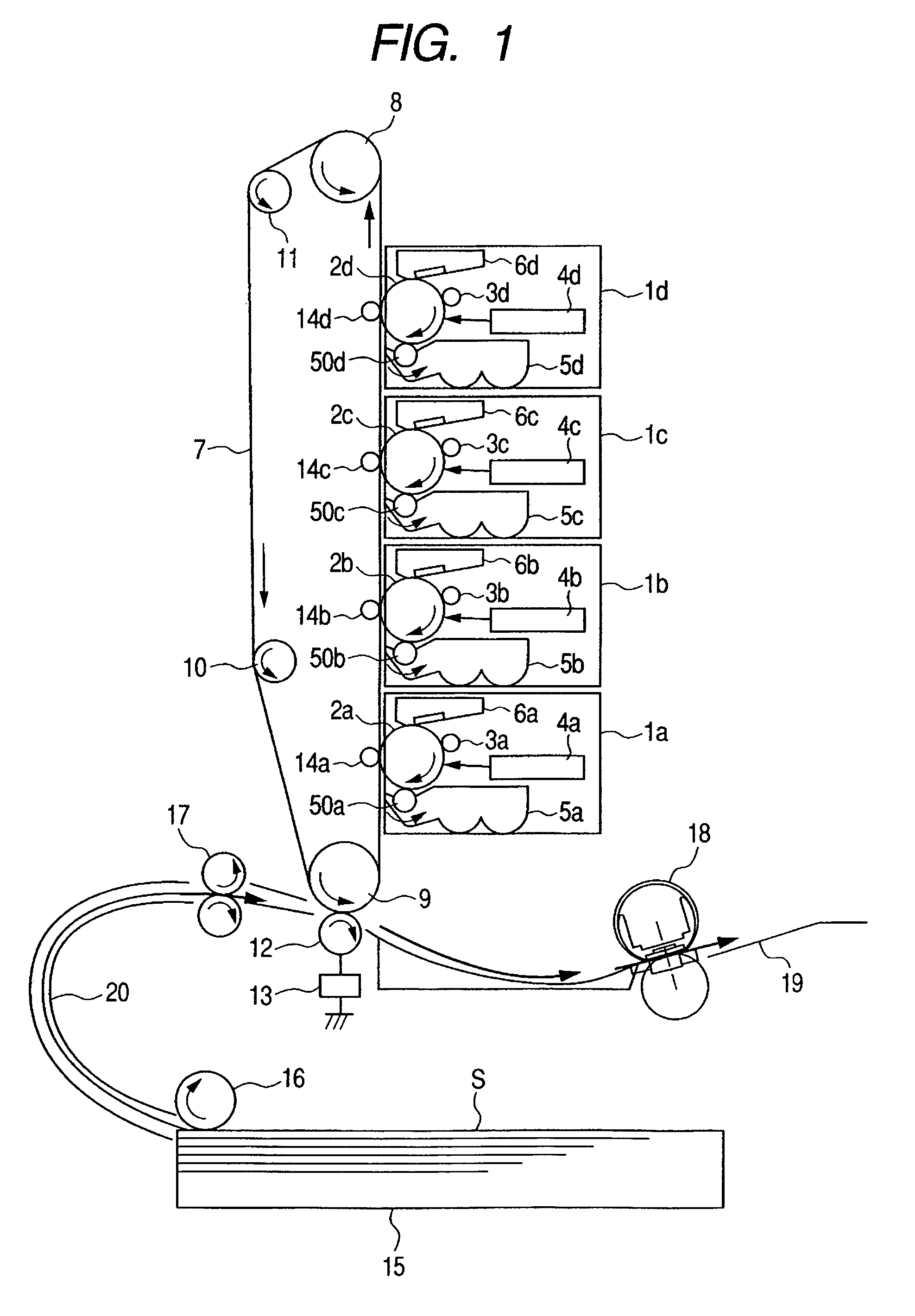

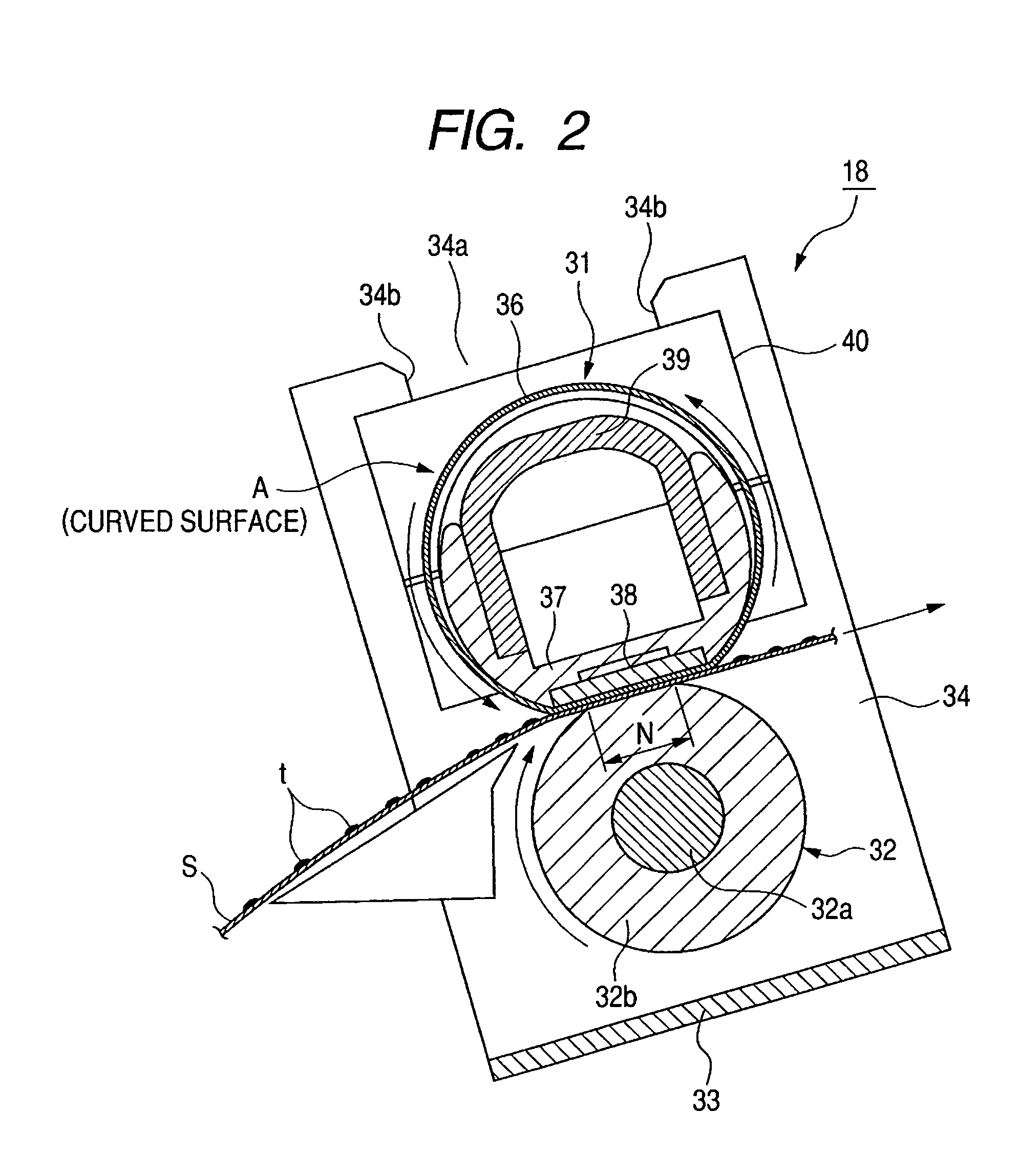

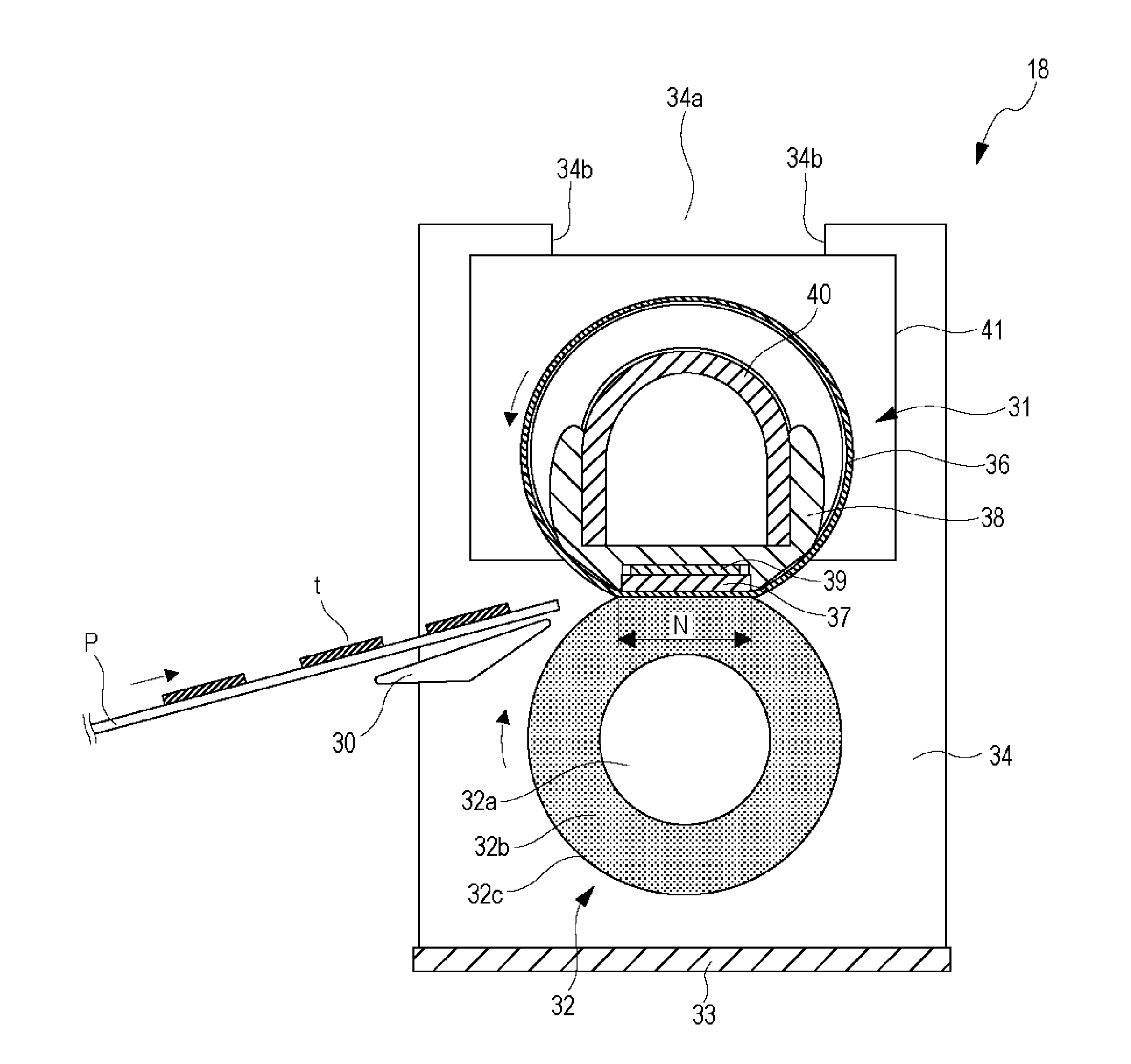

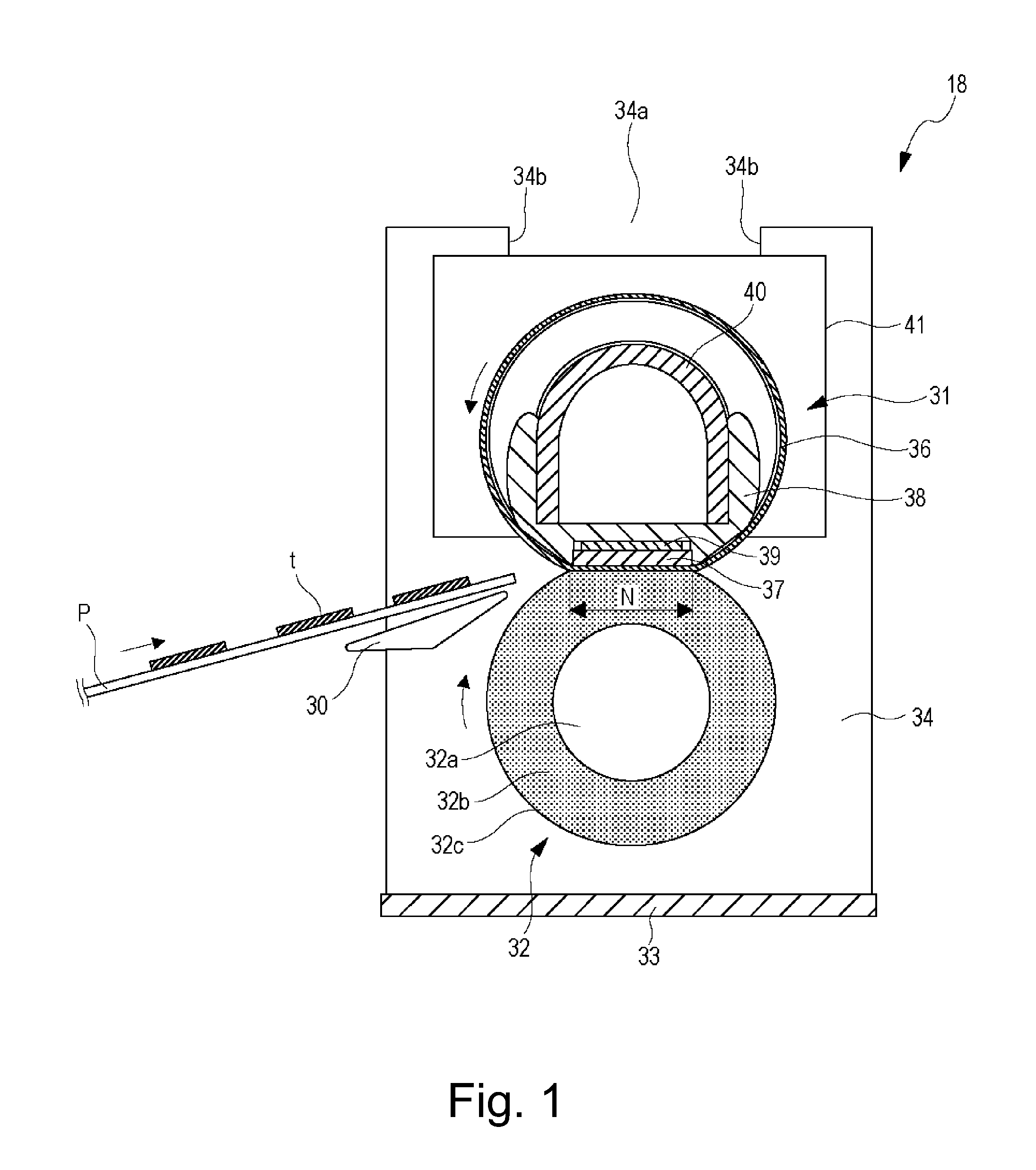

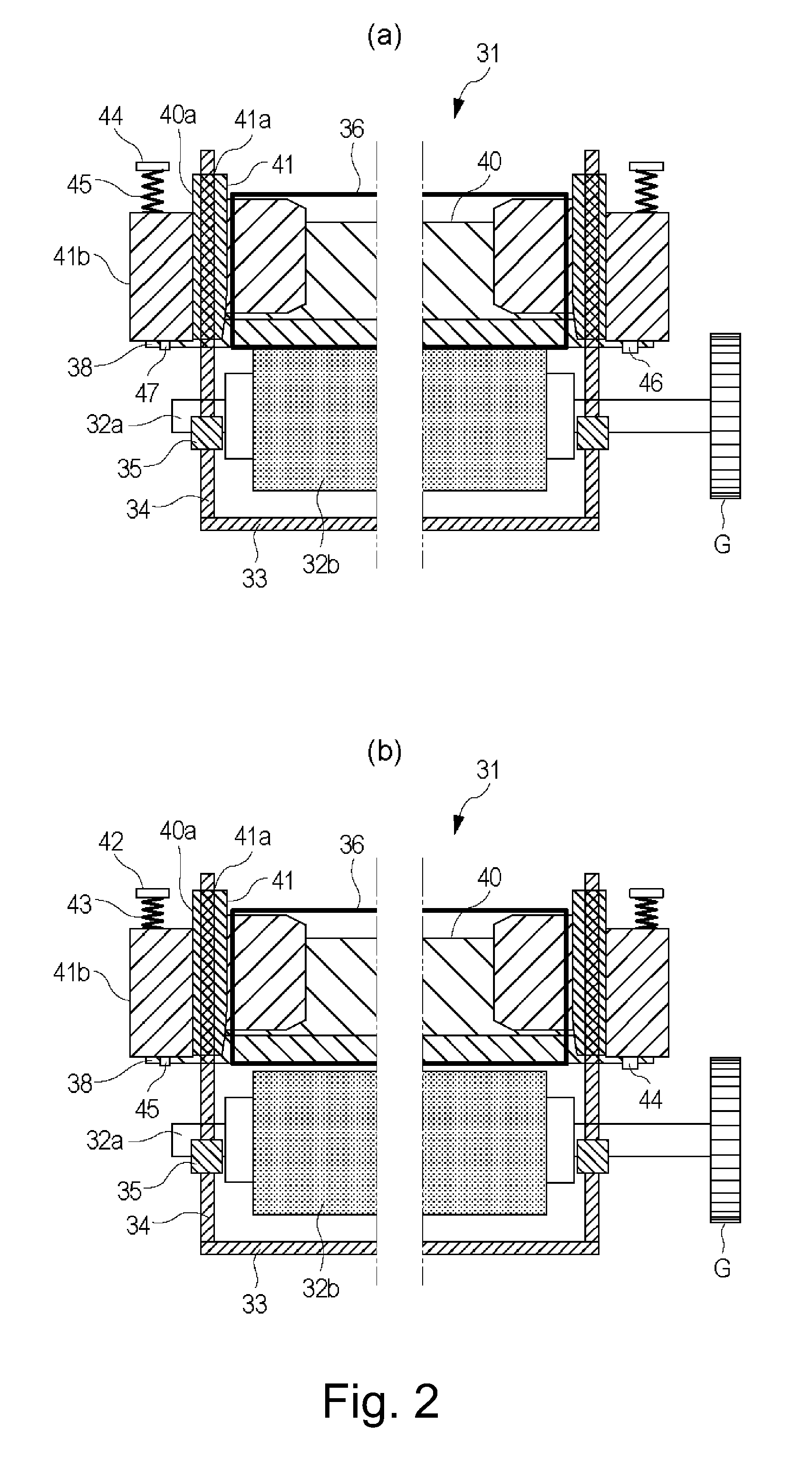

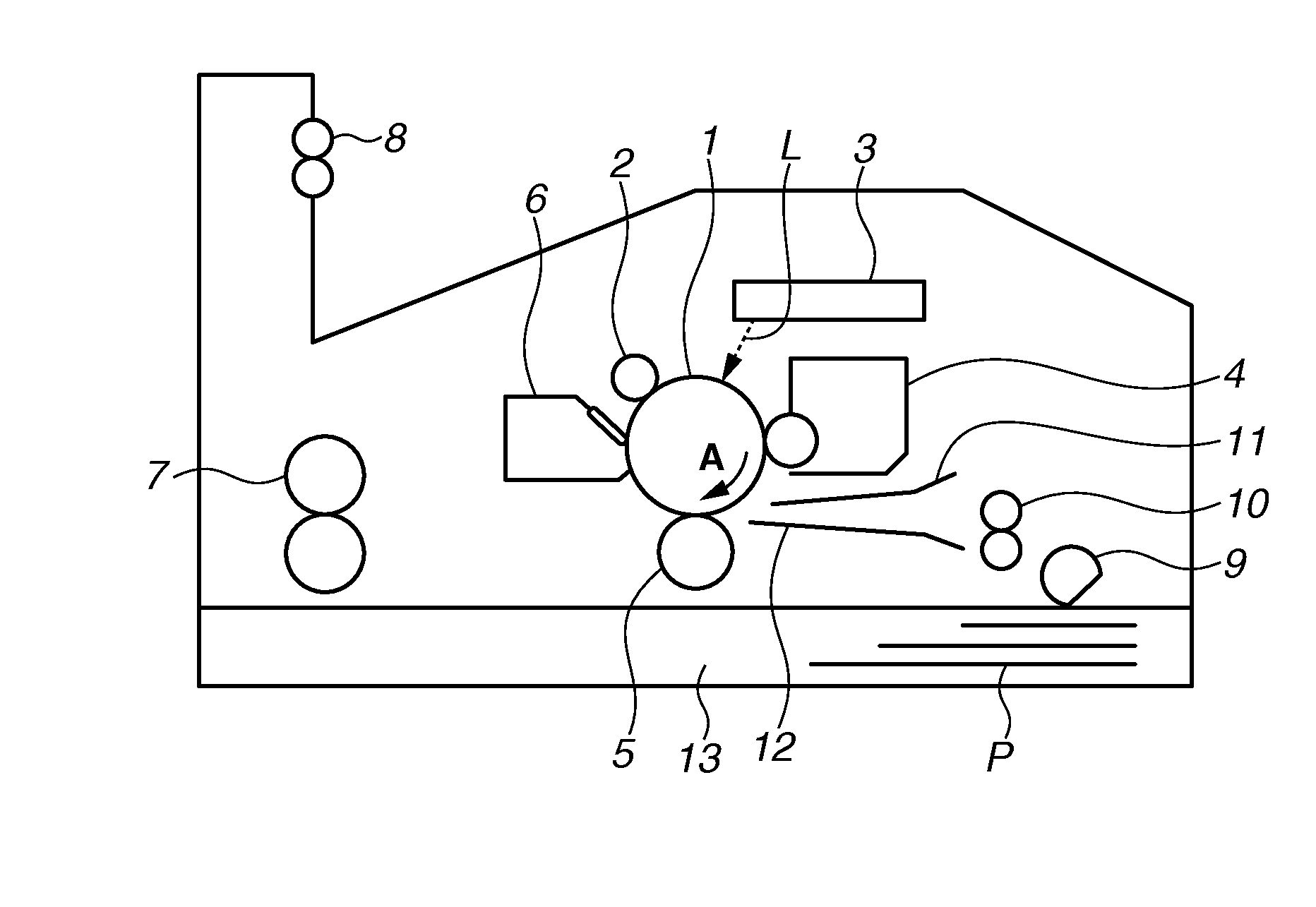

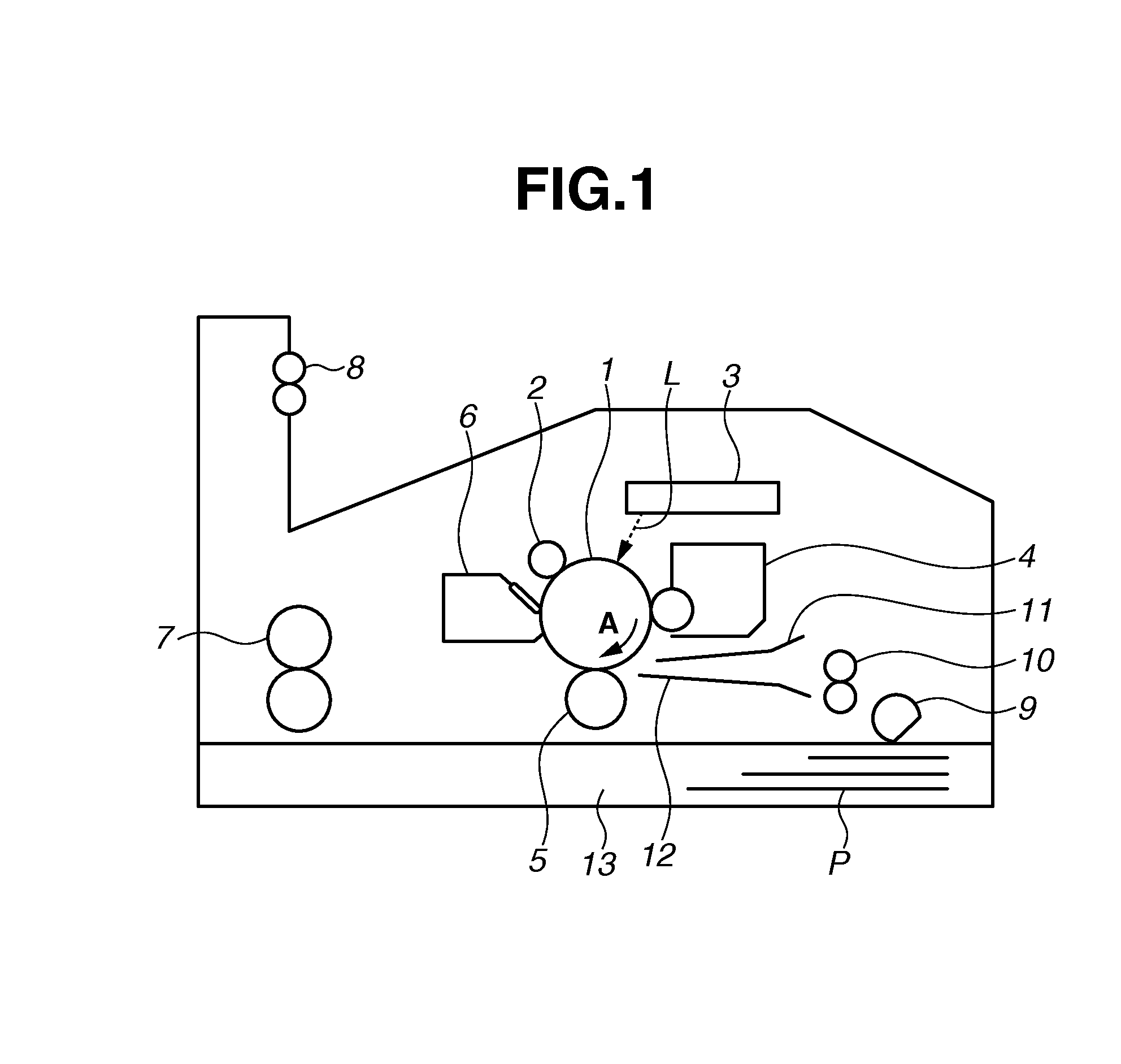

Image heating apparatus using flexible sleeve

ActiveUS20060233575A1Preventing deterioration of durabilityIncreased durabilityElectrographic process apparatusEdge surfaceEngineering

The image heating apparatus includes a flexible sleeve, a sliding member for sliding on the inner periphery of the sleeve, a back-up member for forming a nip portion together with the sliding member through the sleeve, wherein a recording material for bearing an image is heated while being held and conveyed by the nip portion and a regulation member set by facing the edge surface of the sleeve in the generatrix direction to regulate the movement of the sleeve in the generatrix direction, the regulation surface having a regulation surface with which the edge surface of the sleeve contacts when the sleeve moves in the generatrix direction, wherein the regulation surface of the regulation member has a curved-surface area in which a line when the regulation surface is cut at a virtual plane almost parallel with the nip portion is a curved line expanede toward the edge surface of the sleeve. Thereby, an image heating apparatus is provided which is able to restrain deterioration of the durability of the flexible sleeve.

Owner:CANON KK

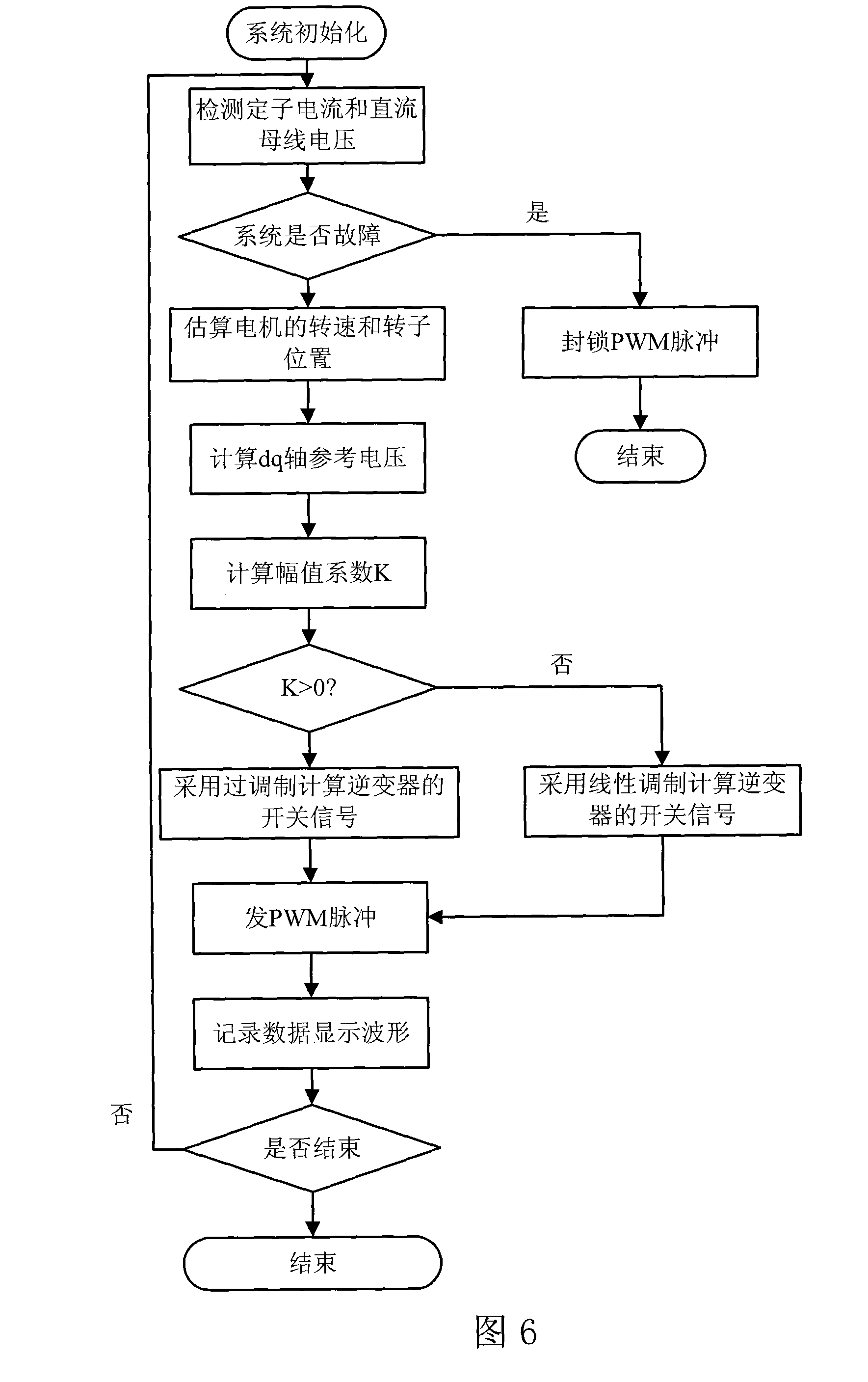

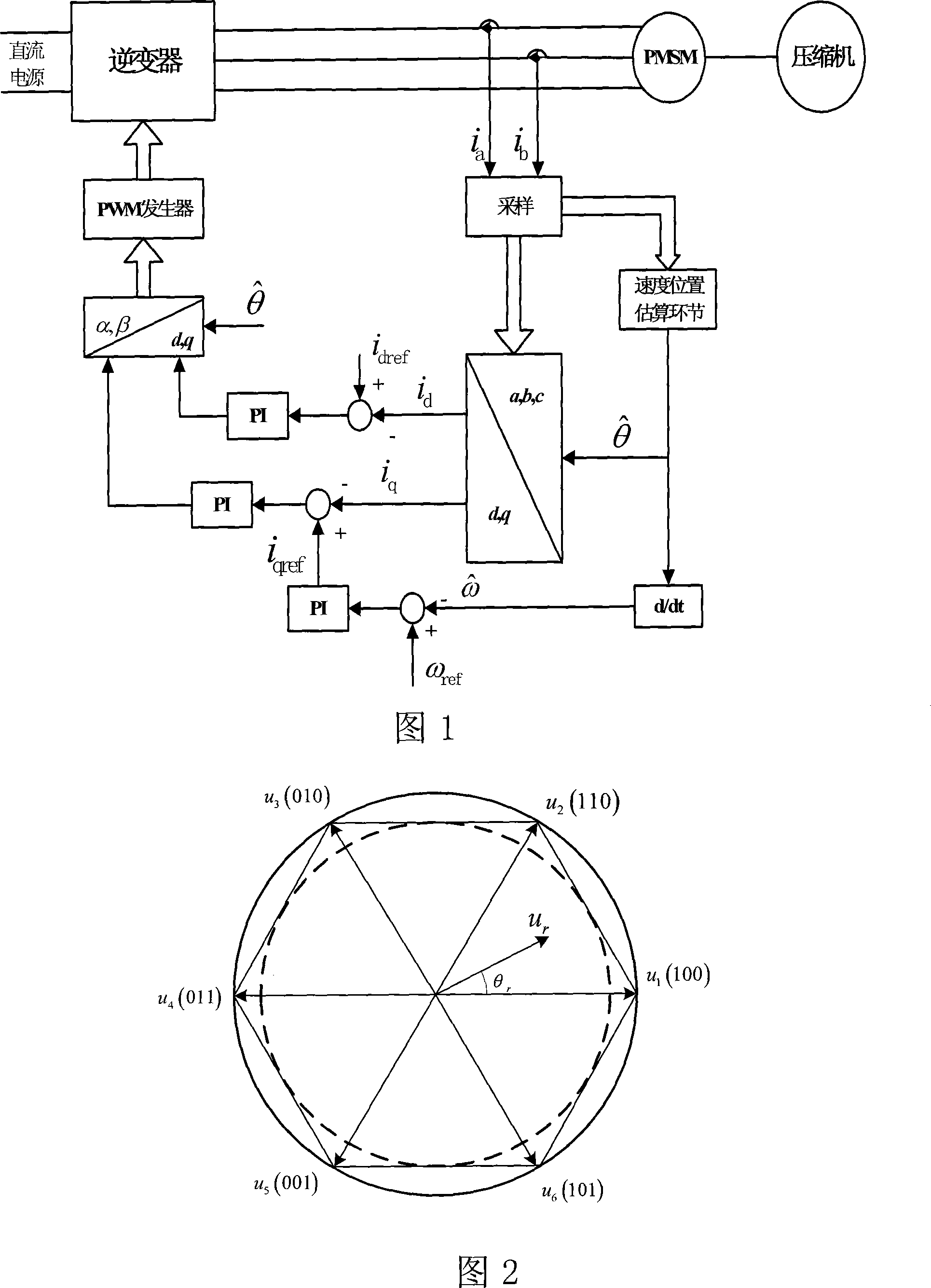

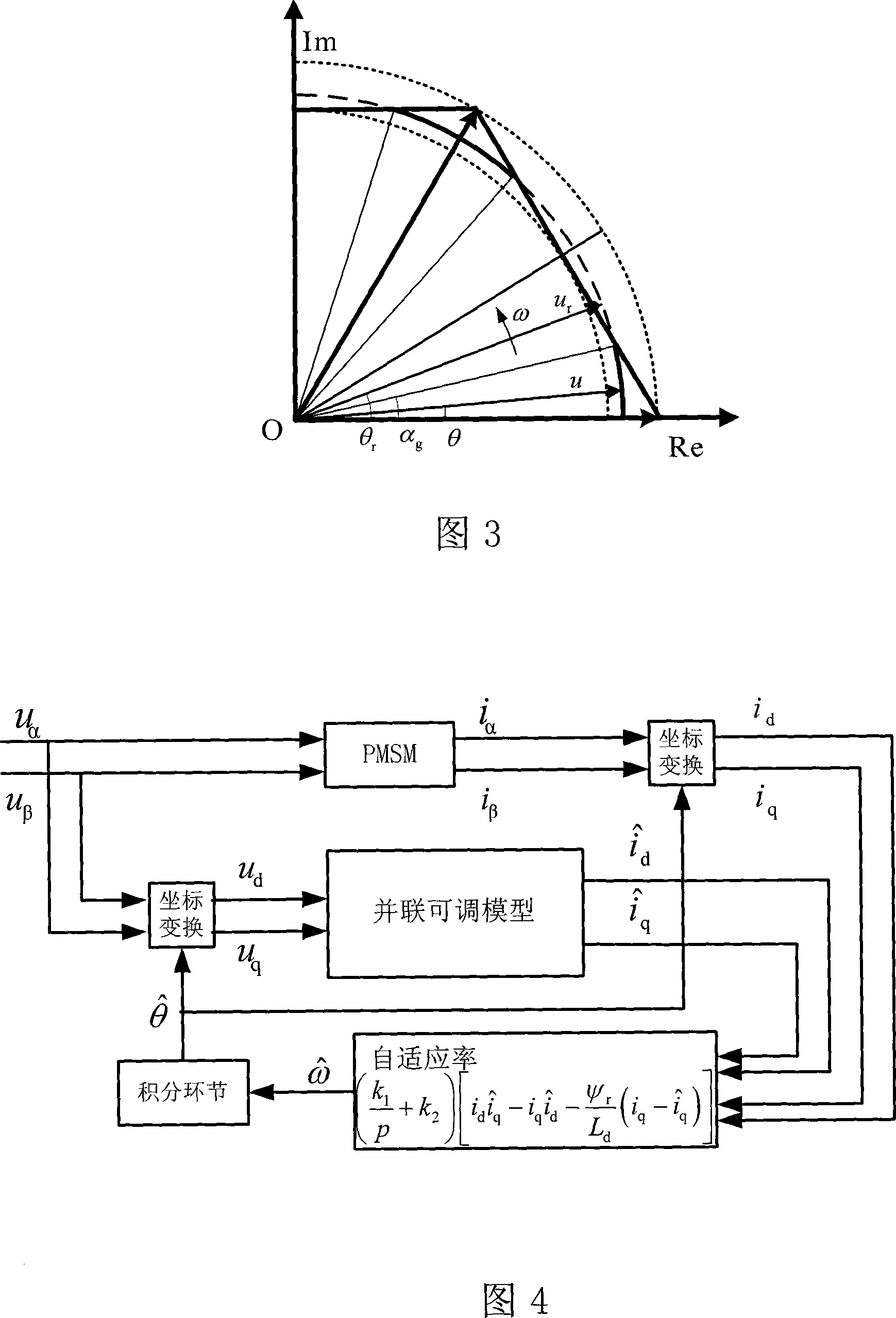

Permanent magnetism synchronous electric machine - compressor system high speed operation control method

InactiveCN101252336AImprove voltage utilizationAC motor controlVector control systemsPhase currentsSynchronous motor

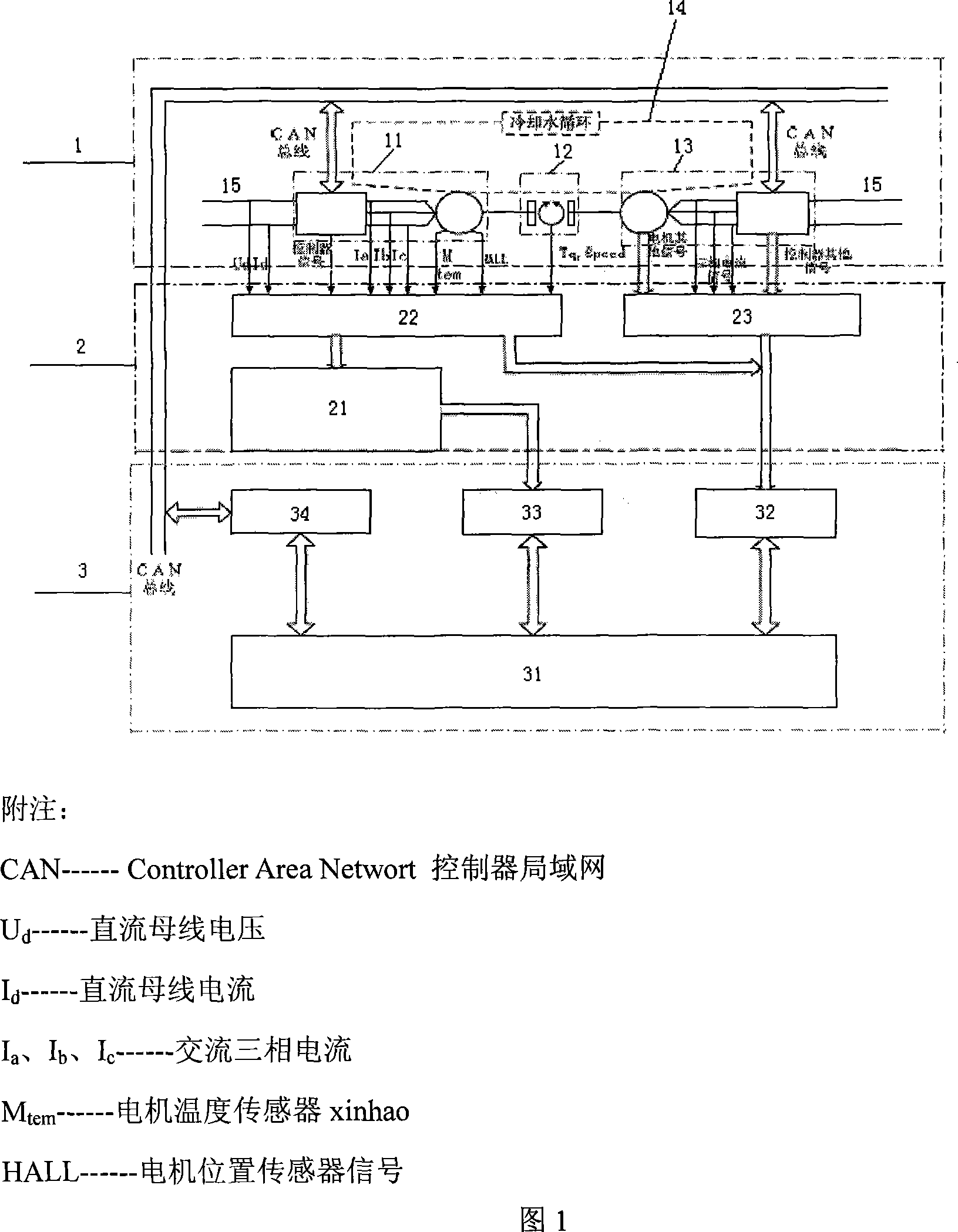

Disclosed is a high-speed control method for a permanent magnet synchronous motor-compressor system, including the following steps: initial design is carried out; a motor is detected through DSP, including detecting the two-phase current of the stator of the motor, the voltage Udc of a DC generatrix; the voltage of a d-p shaft is calculated; faults of overcurrent, overpressure and undervoltage are detected; if any fault exists, the PWM pulse signals are blocked and then the control program is paused; if no fault exists, the following steps will be carried out; the rotating speed of the motor and the position of the rotor are identified in the process of speed-position estimation; the current and the voltage of the reference d-q shaft of the motor are calculated; switching signals of an inverter are acquired through haplotype over-modulation; the data are recorded and waveforms are displayed; judgment of whether to pause the control program is carried out; if not, the second step is carried out again; if yes, the control program will be paused. The control method applies haplotype over-modulation method into the permanent magnet synchronous motor-compressor system, realizing sensorless over-modulation to the synchronous motor-compressor vector control system.

Owner:TSINGHUA UNIV

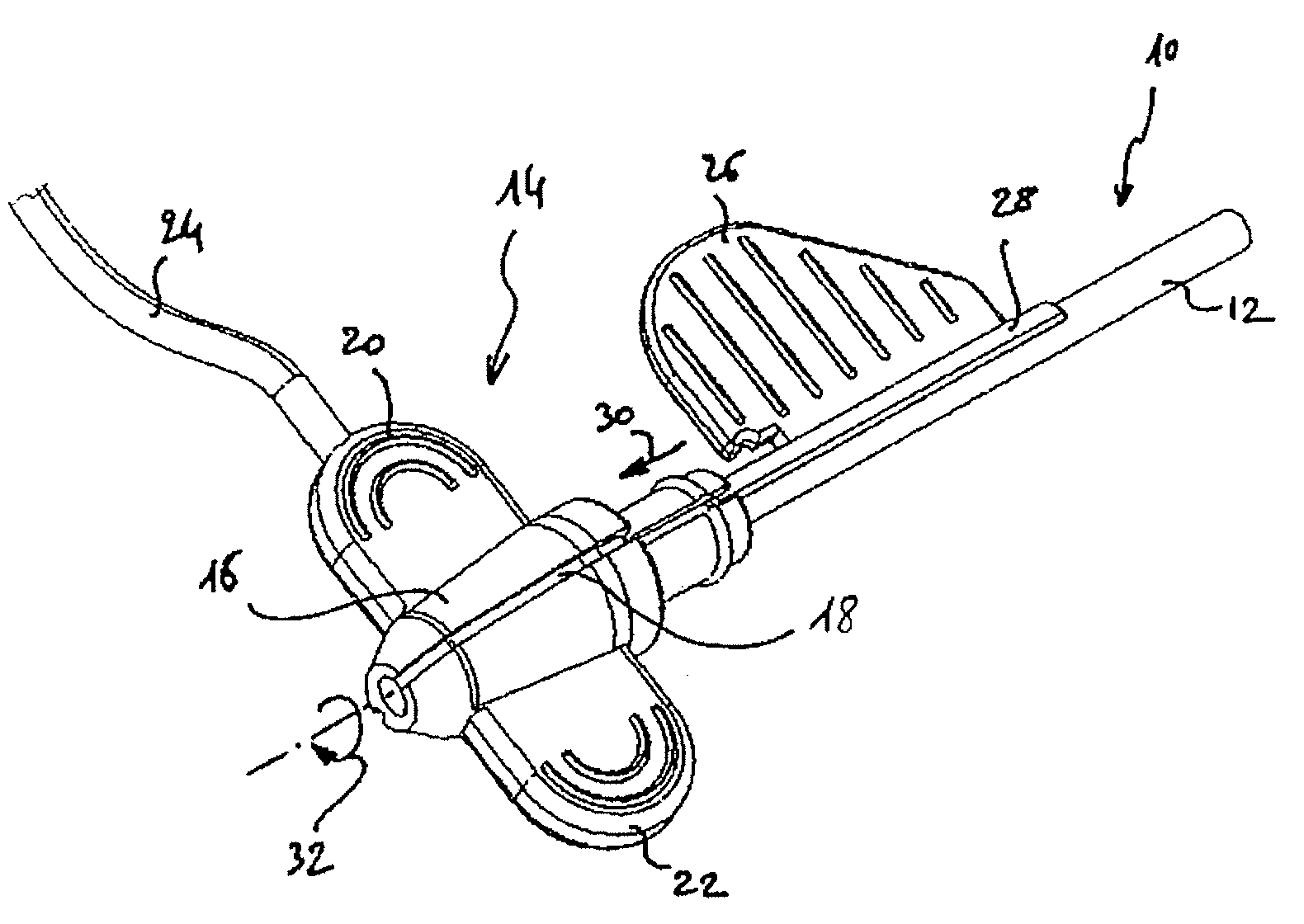

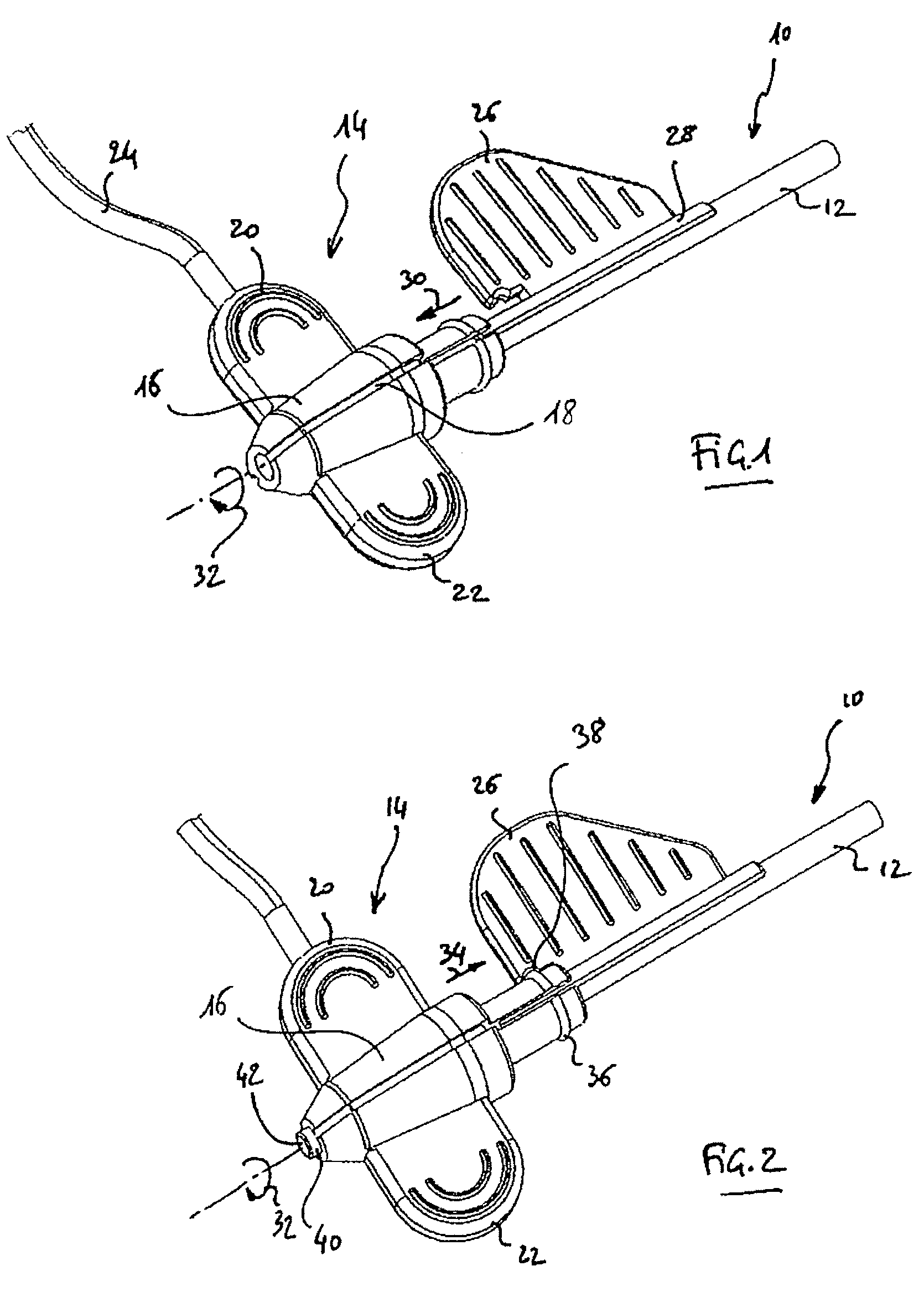

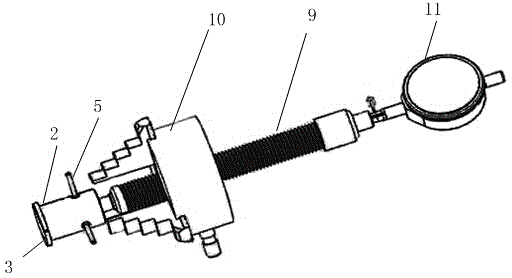

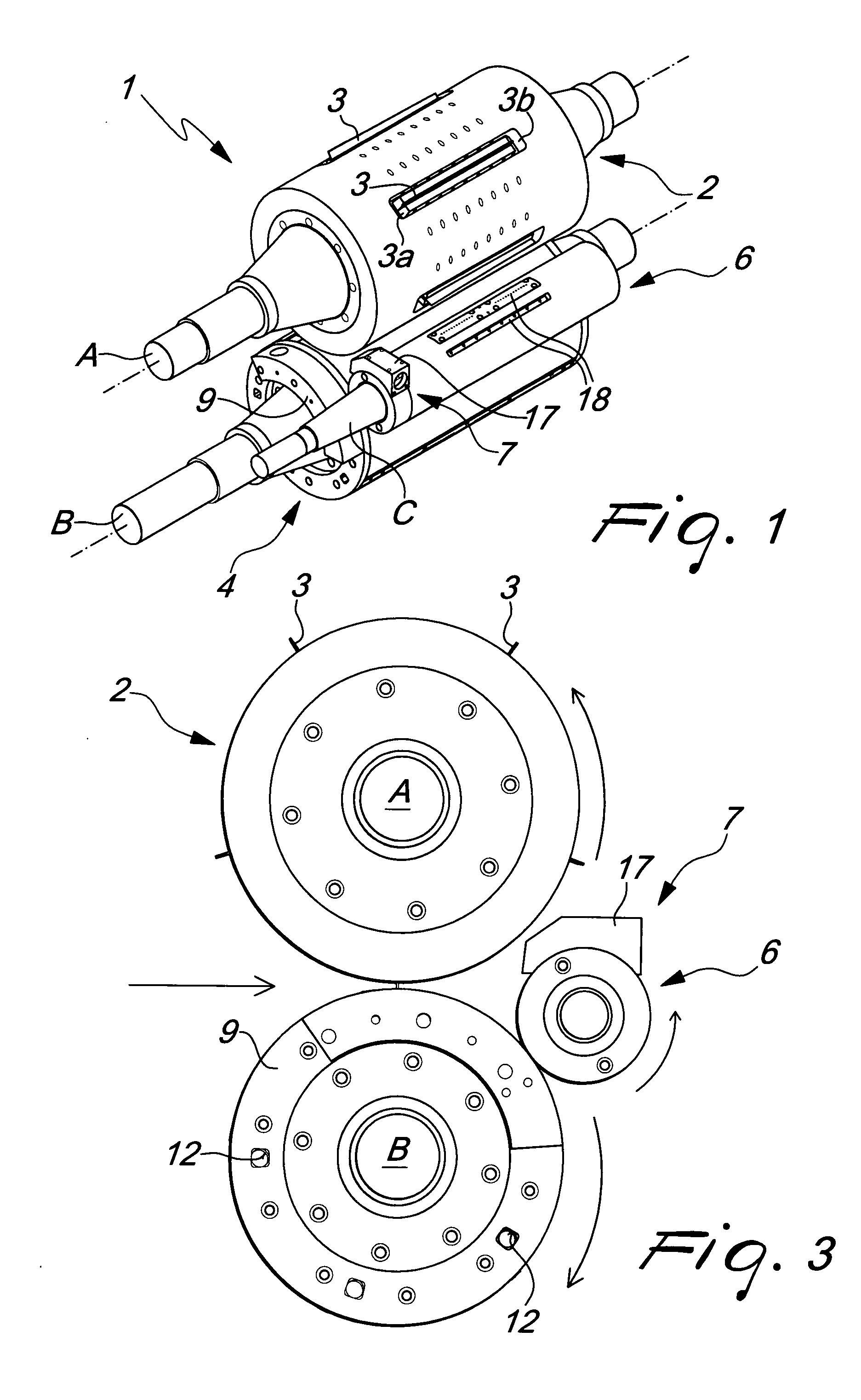

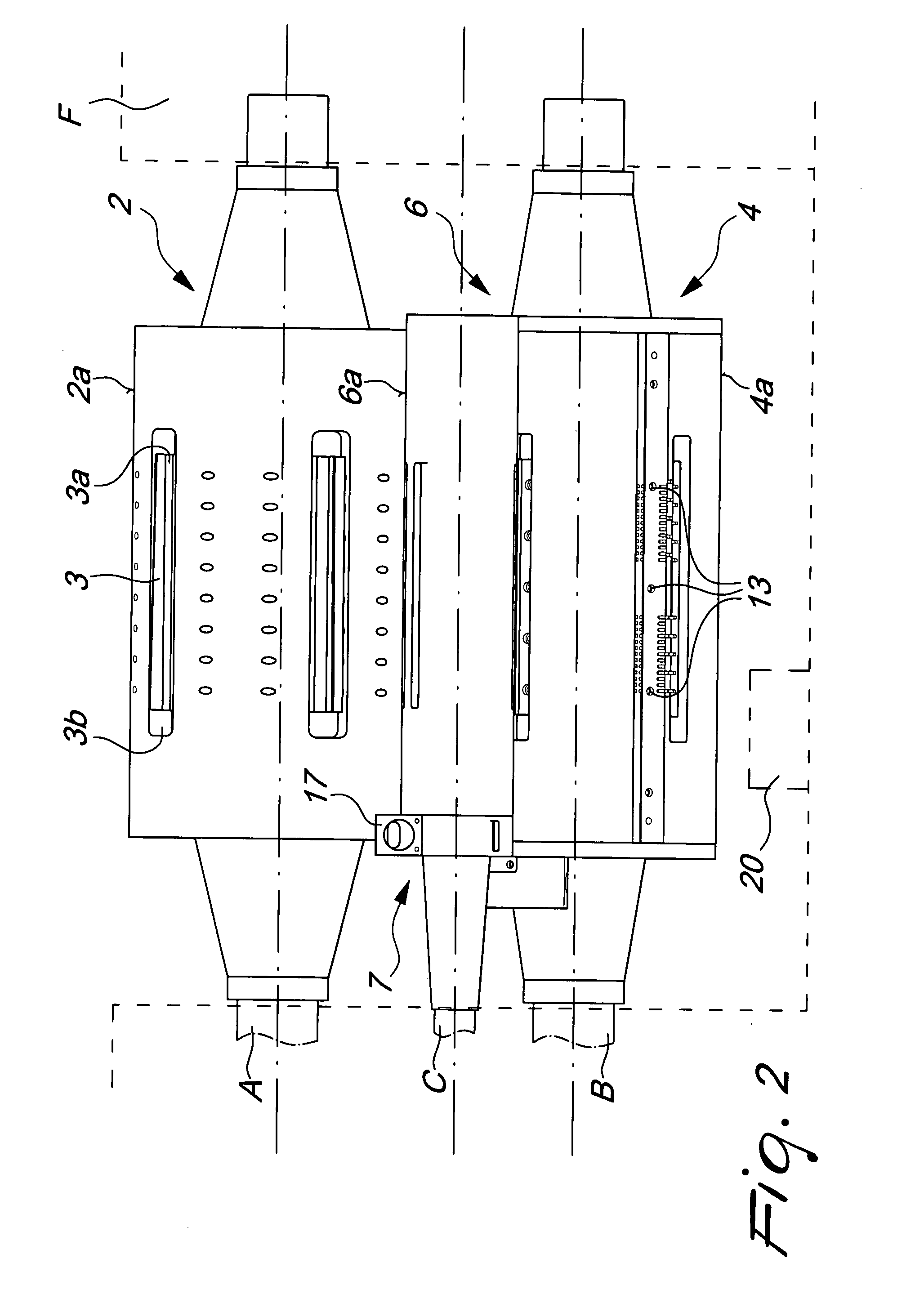

Toolkit for implanting an intracorporeal lead such as for cardiac pacing or sensing

ActiveUS8142446B2Reduce riskRisk minimizationElectrotherapyInfusion syringesExtreme positionAtrial pacing

A toolkit for implanting an intracorporal lead, preferably a cardiac sensing / pacing lead. This toolkit includes a guide-catheter (10), having a sheath (12) with an internal lumen (42) opened at its distal and proximal ends, and cuttable along a generatrix in order to allow extracting of the guide-catheter after use. A hemostatic valve (14) is mounted at the proximal end (40) of the guide-catheter, for selectively filling, or not, the internal lumen of the guide-catheter at its input end. The valve is frangible in at least two parts, each dissociable from the guide-catheter at both sides around a median axial plane. The valve comprising a mobile element sliding on the guide-catheter between two extreme positions, with an opened position where the proximal end (40) of the guide-catheter (10) freely emerges out of the valve so as to allow access to said internal lumen, and a closed position where this proximal end of the guide-catheter is filled in a tight manner.

Owner:SORIN CRM

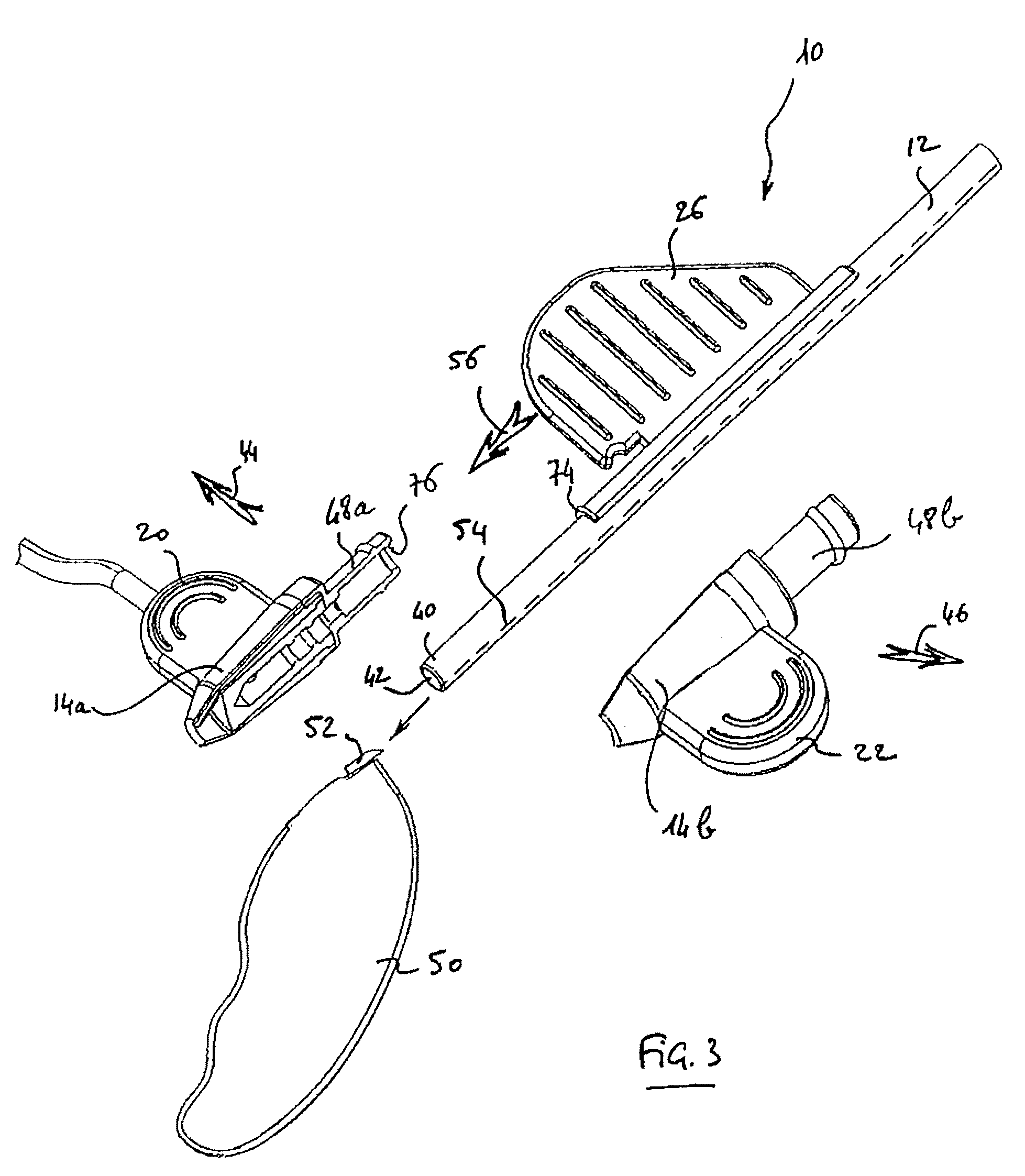

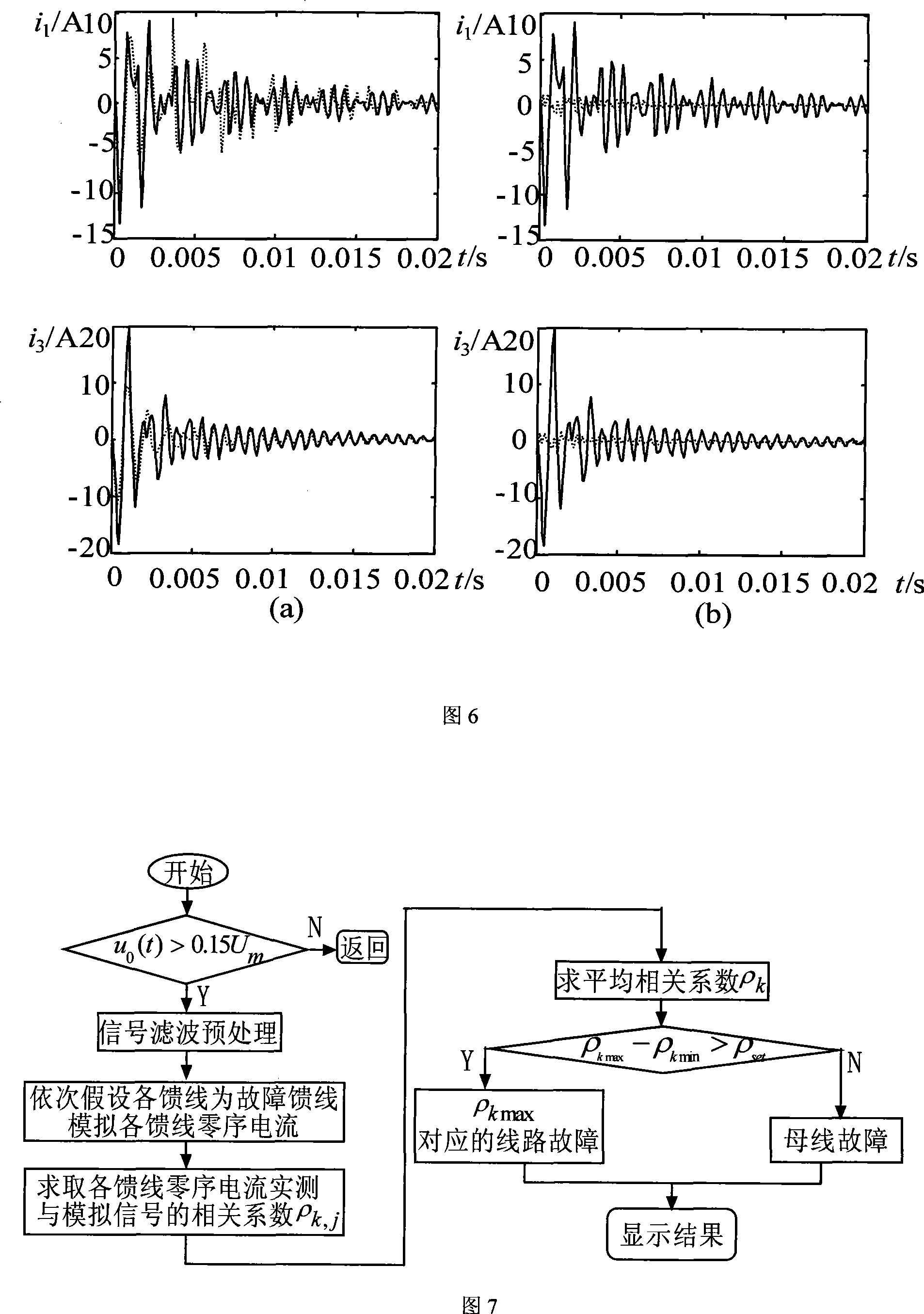

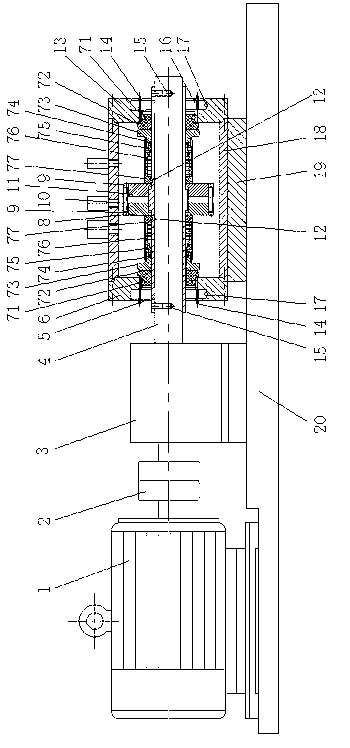

Failure line selection method of small current ground system by using simulation after zero mode current measure

InactiveCN101242097AOvercome the influence of small fault transient currentRealize correct line selectionEmergency protective circuit arrangementsCapacitanceEngineering

The invention provides a fault route-selecting method by using small current grounding system simulated by measured zero-mode current. The method includes following steps: when a generatrix zero-mode voltage instantaneous value is over the limit, a fault route-selecting is started and recorded immediately; zero-phase shift digital wave filter is used to obtain a high-frequency transient weight of each feed line zero-mode current; orderly the feed line is supposed to be fault feed line, the rest of the high-frequency transient weight of the feed line zero-mode current is quantificationally solved by using the measured simulative method according to the supposed high-frequency transient weight of the feed line zero-mode current and each feed line zero-order distributing capacitance parameter; the actual-measured wave shape and simulative wave shape of the high-frequency transient weight of the feed line zero-mode current are analyzed and a average relative coefficient of the actual-measured wave shape and simulative wave shape of the high-frequency transient weight of the feed line zero-mode current are solved, the route-selecting criterion is formed to achieve the fault route selection. The principle analysis and simulation indicate that route selection of this method is accurate and reliable.

Owner:KUNMING UNIV OF SCI & TECH

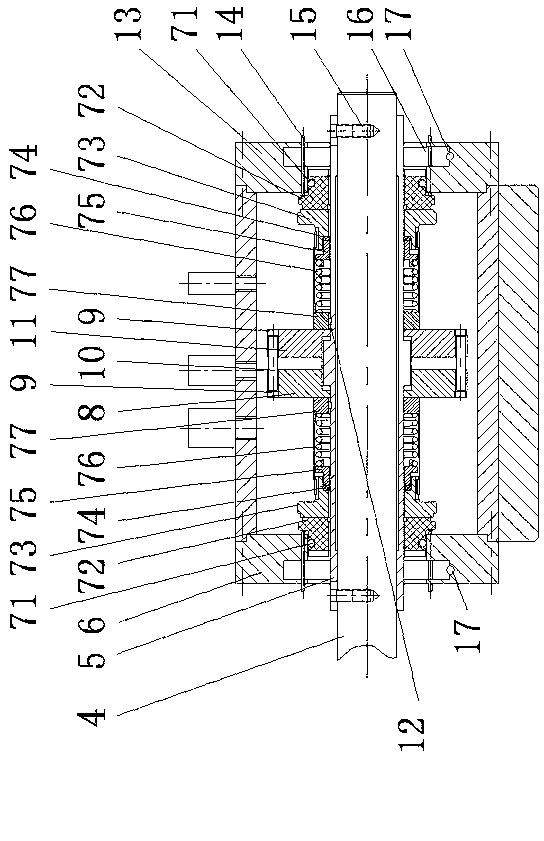

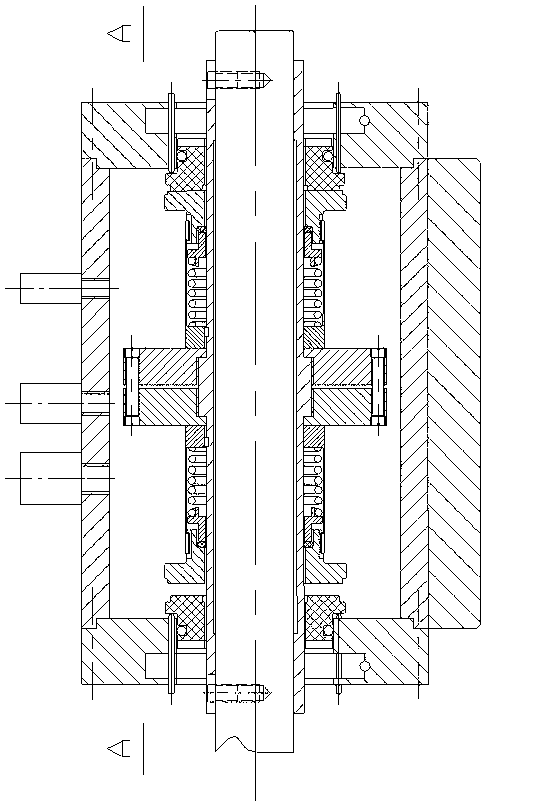

Mechanical seal performance testing device

ActiveCN103267613AAvoid axial forceRealize automatic adjustmentMeasurement of fluid loss/gain rateWork measurementFriction torqueAxial force

Provided is a mechanical seal performance testing device. The mechanical seal performance testing device comprises a main shaft, a working cavity with end caps at two ends, and two sets of mechanical seals to be tested. A shaft sleeve and the main shaft are in clearance fit and penetrate through the end caps at the two ends of the working cavity together. U-shaped openings on the same generatrix are arranged in two ends, extending out of the end caps, of the shaft sleeve, and a transmission pin is arranged on a portion, corresponding to the U-shaped openings, of the main shaft; two sections of threads which are equal in thread pitch and opposite in screwing direction are arranged in the middle of the shaft sleeve, and movable ring bases in the two mechanical seals to be tested are arranged on the back sides of two nuts screwed on the threads respectively; the movable ring bases and the shaft sleeve slide in the axial direction and are located and connected in the circumferential direction; a radial force sensor used for measuring end face friction torque indirectly is arranged on the transmission pin, and an axial force sensor used for measuring end face specific pressure is arranged between the back side of a static ring and the end cap of the working cavity; the end cap is provided with an annular ring which is concentric with a center hole, and therefore a leakage cavity used for collecting leakage amount is formed. The mechanical seal performance testing device is suitable for mechanical seal performance tests of various pressure working conditions and various size series, including performance tests of high-pressure and large-diameter mechanical sealing.

Owner:NANJING FORESTRY UNIV

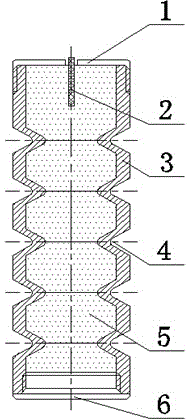

Non-Pneumatic Elastic Wheel

ActiveUS20100307653A1Improve staminaIncrease resistanceNon-inflatable tyresNon-metallic wheel bodyFiberResin matrix

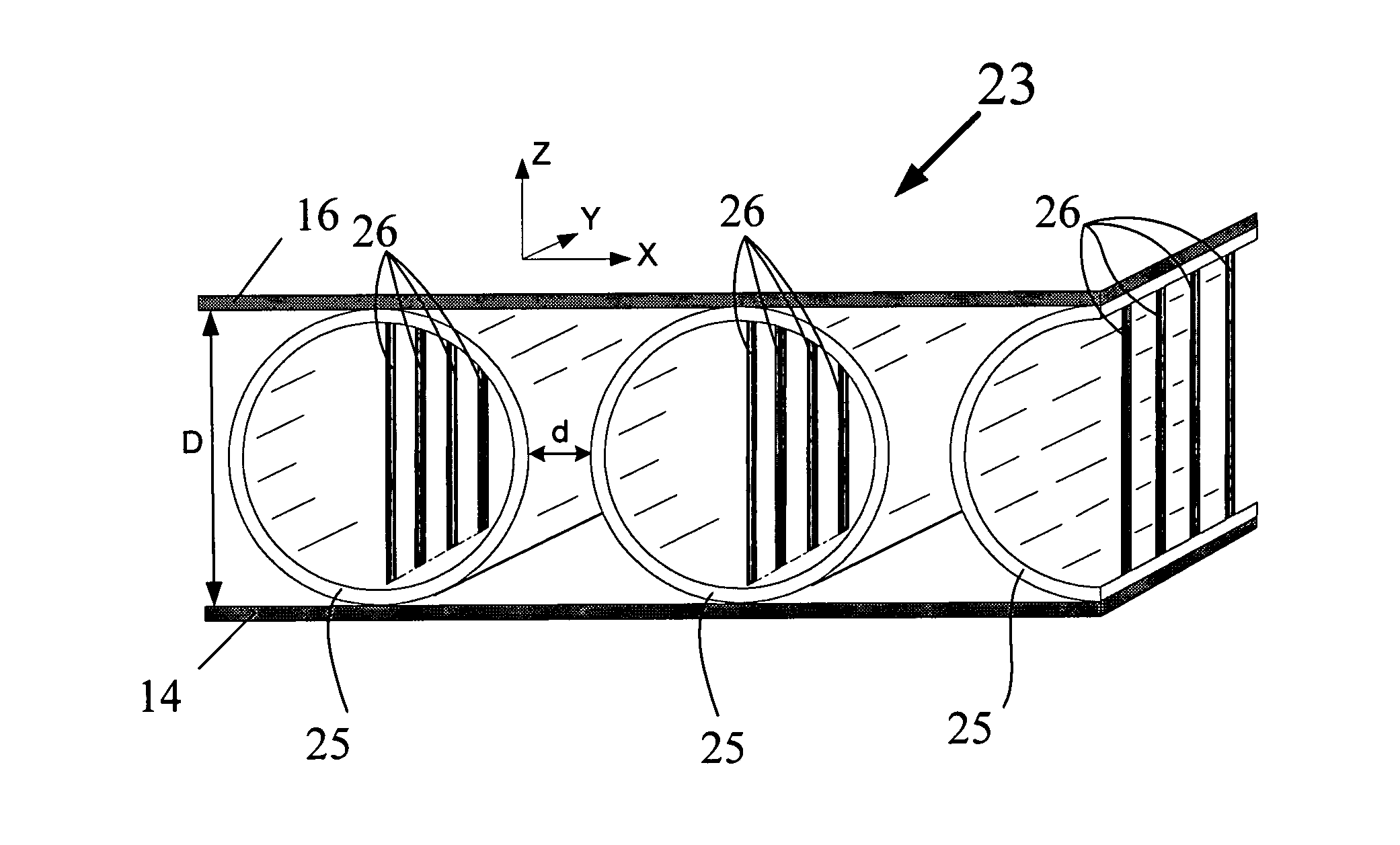

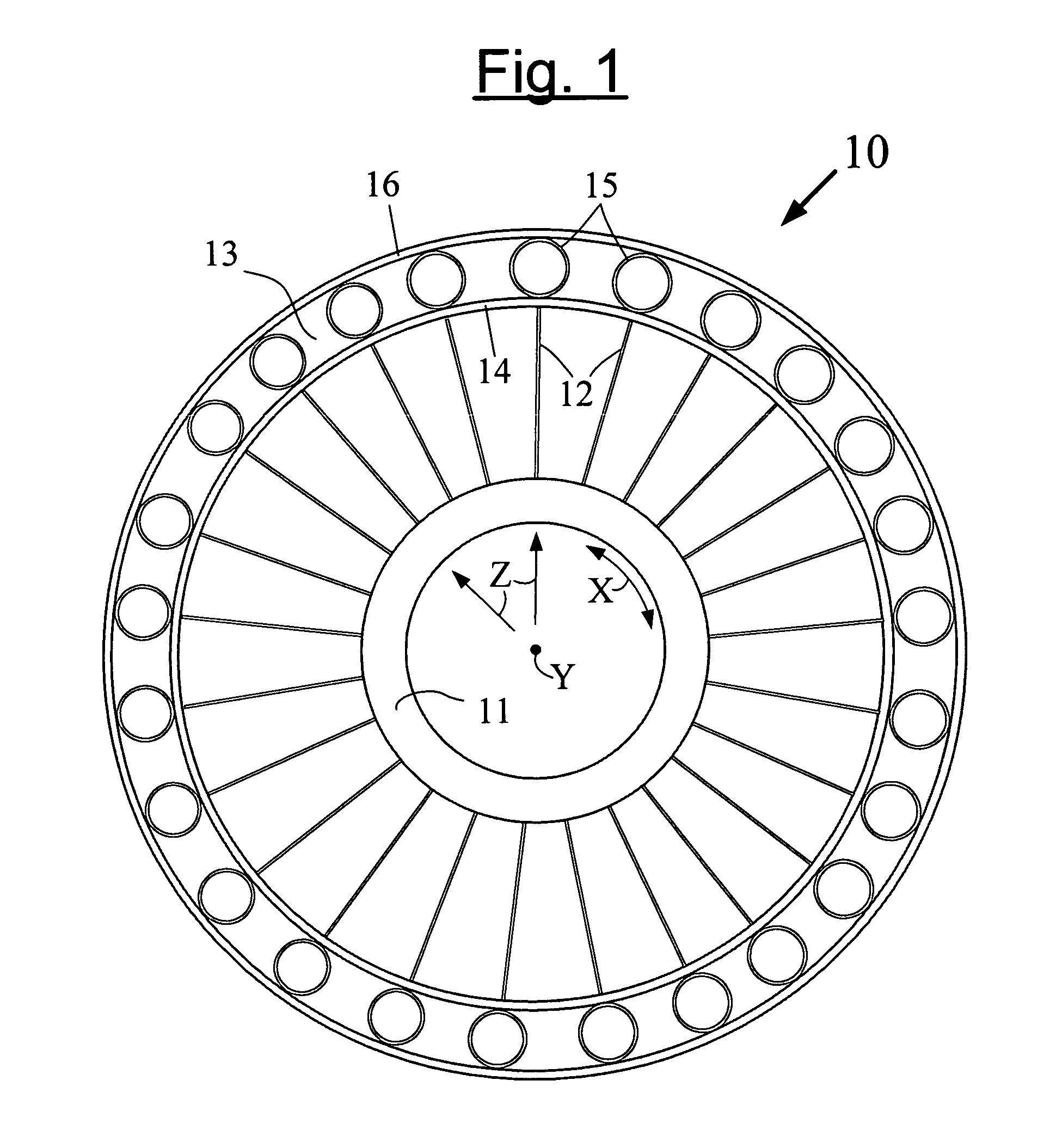

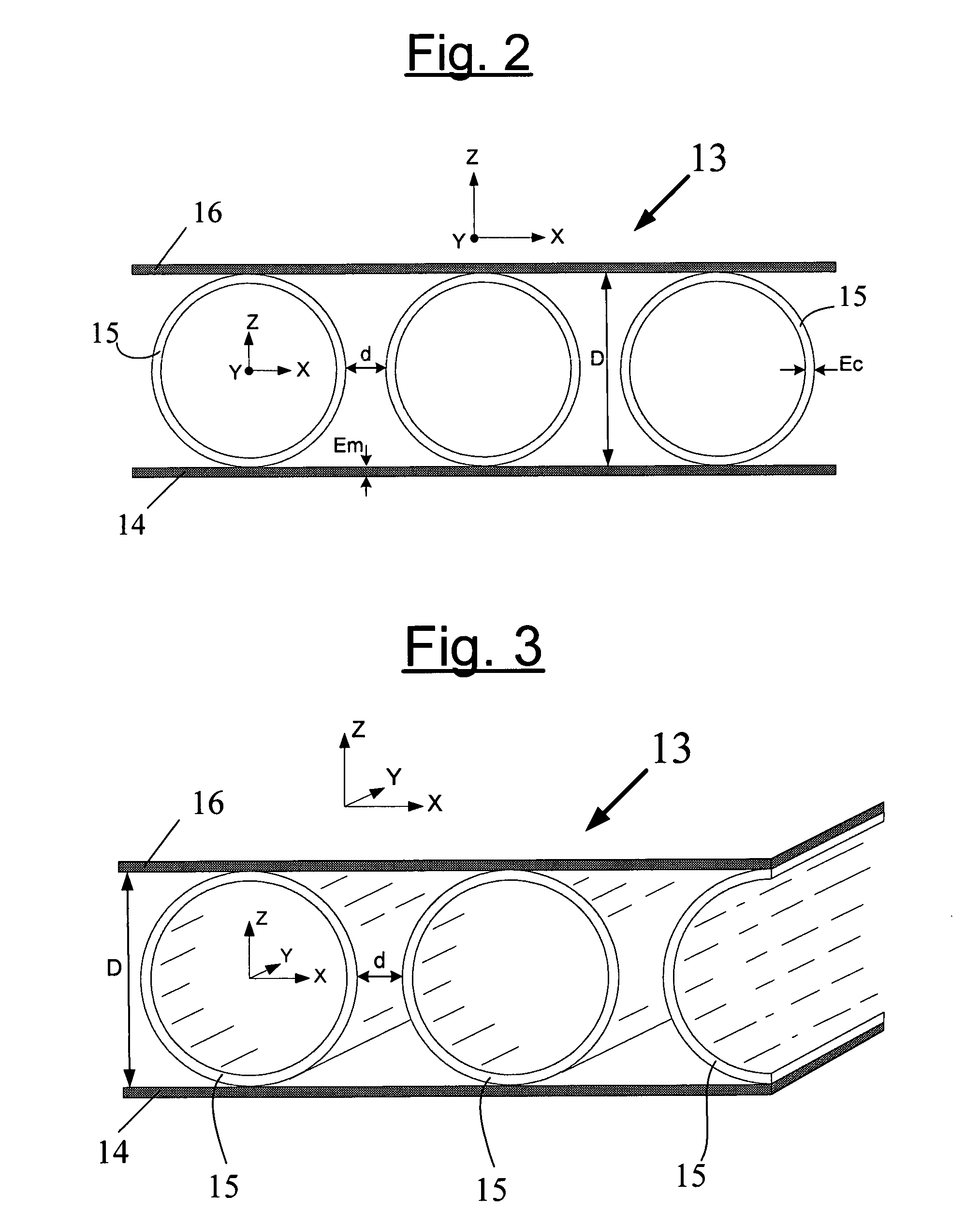

Non-pneumatic resilient wheel (10), that is supported structurally and defines three perpendicular directions, circumferential (X), axial (Y) and radial (Z), this wheel comprising: a hub (11); an annular band referred to as a shear band (13) comprising at least one inner circumferential membrane (14) and one outer circumferential membrane (16) that are oriented in the circumferential direction X; and a plurality of support elements (12) that connect the hub (11) to the inner circumferential membrane (14)U. The two membranes (14, 16) are connected to one another by means of a series, that extends in the circumferential direction (X), of cylinders (15) referred to as connection cylinders, said connection cylinders (15) being non-touching in the circumferential direction X and having their generatrix oriented in the axial direction Y. The connection cylinders (15) are composite cylinders comprising fibres embedded in a resin matrix.

Owner:MICHELIN RECH & TECH SA +1

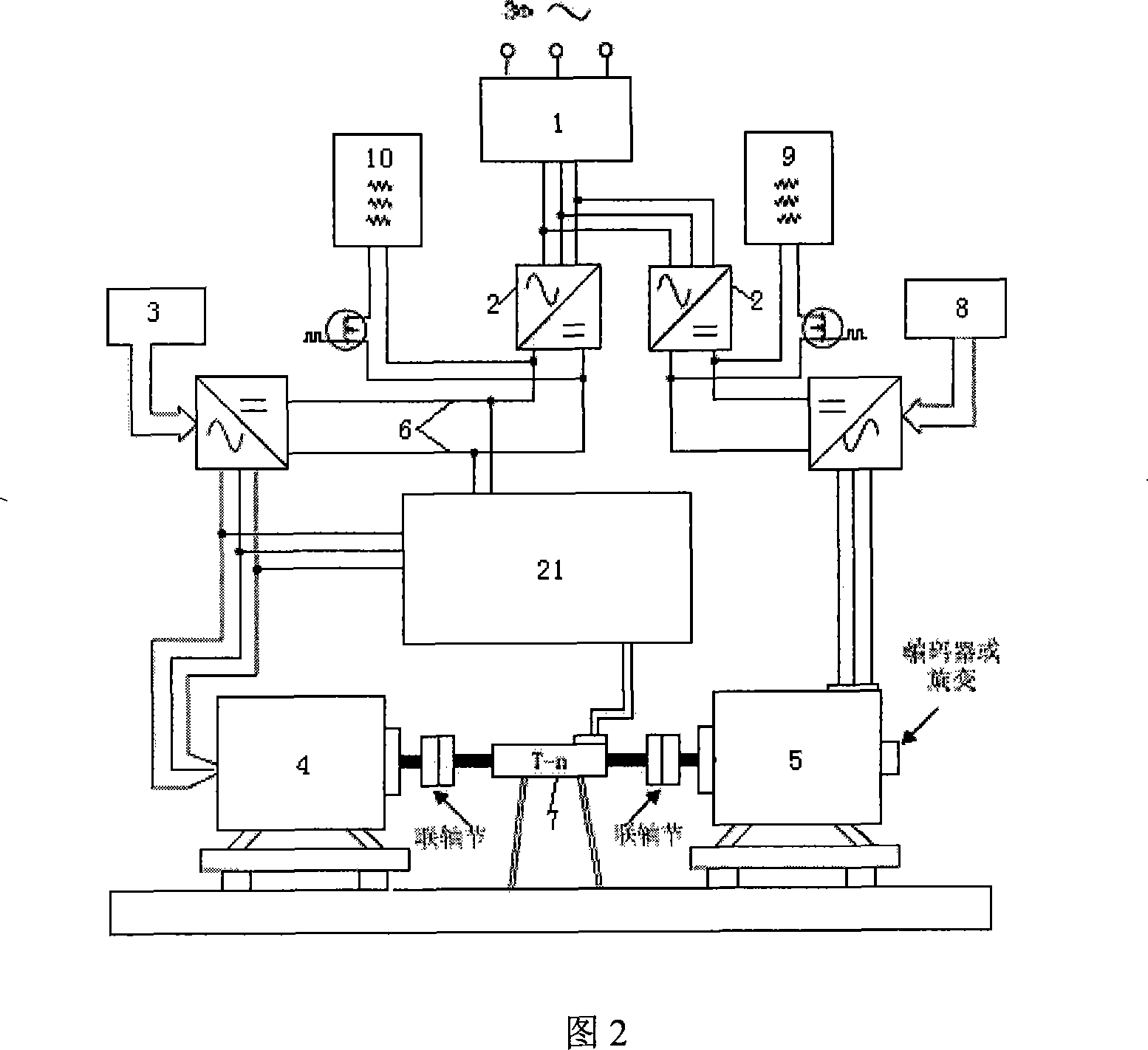

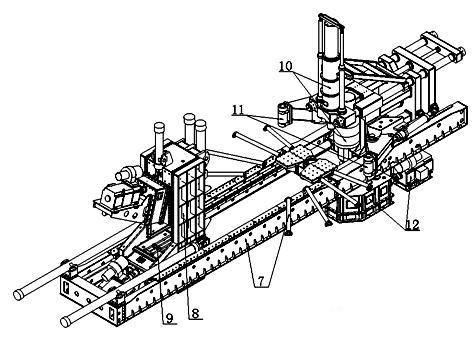

Hybrid power automobile drive electric motor test bench and test method

ActiveCN101241168AWide voltage rangeReduce lossVehicle testingDynamo-electric machine testingSkin complexionMotor testing

The present invention relates to test table for driving motor of hybrid electric vehicle to finish capability test of driving motor of hybrid electric vehicle and debugging function of control software. The table system has simple structure, convenient operation and maintains and high test precision. When the grades of motor and load voltage are identical, the system can work parallel with DC generatrix and feed back energy, the energy lose is less, the power supply need to provide system loss energy is about 10% to 20%, the cost is reduced greatly and the requirement of capacity of power supply is little. When the grades of motor and load voltage aren't identical, two complexions are happened, when motor is as driver, energy is applied to load resistance box by dynamometer system or power supply; when the motor is as generator, the energy is applied to load resistance box by power supply.

Owner:CHERY AUTOMOBILE CO LTD

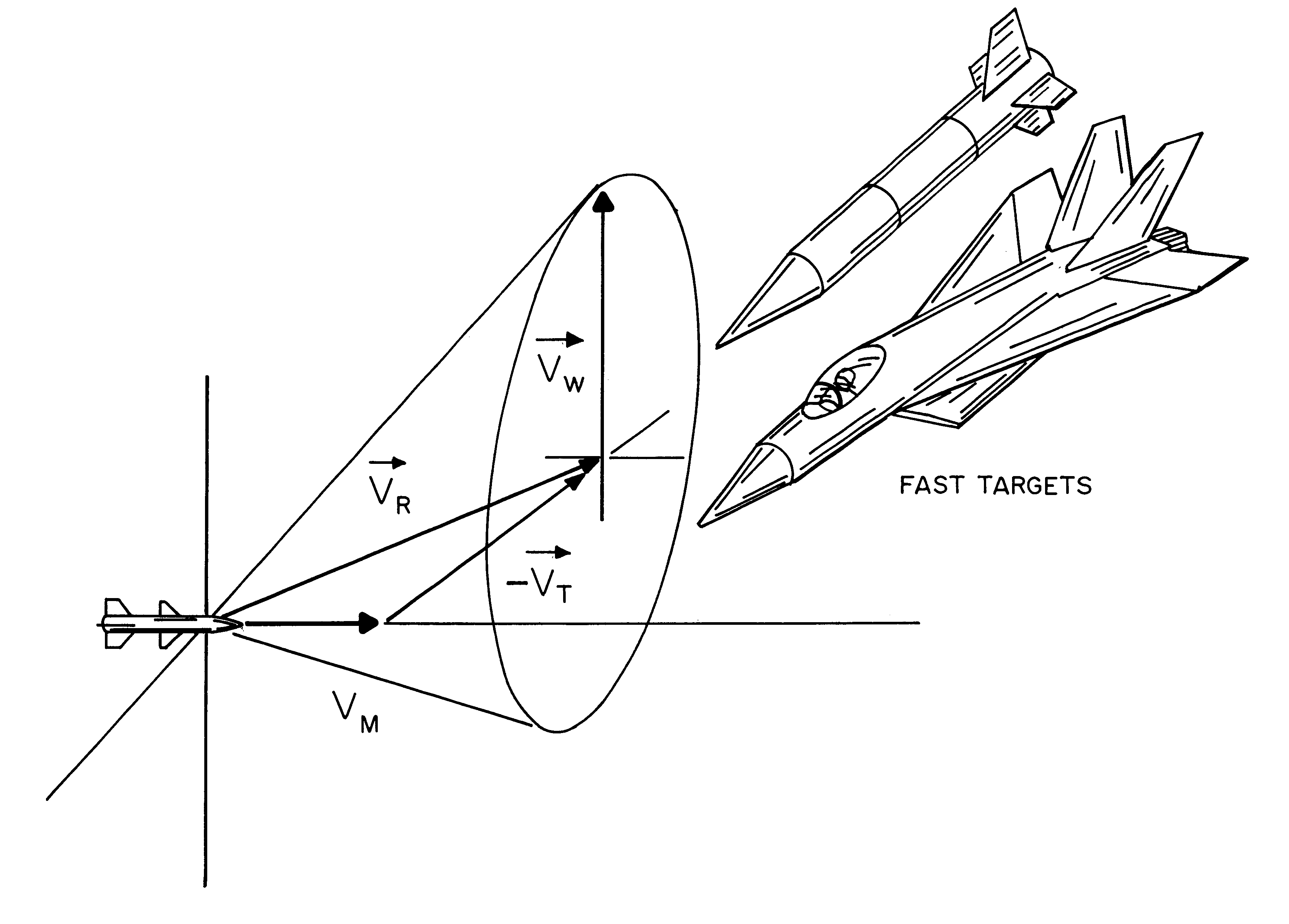

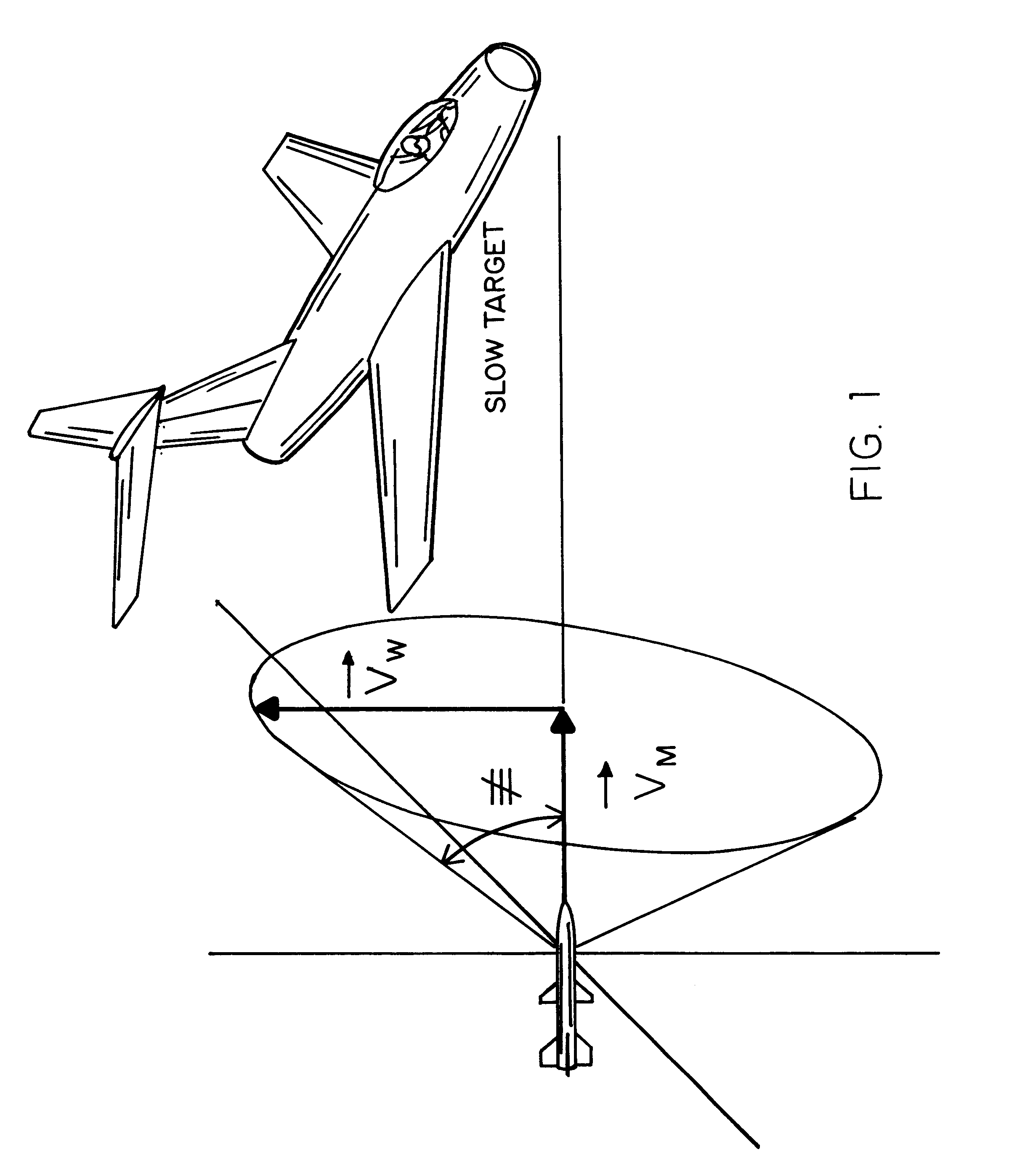

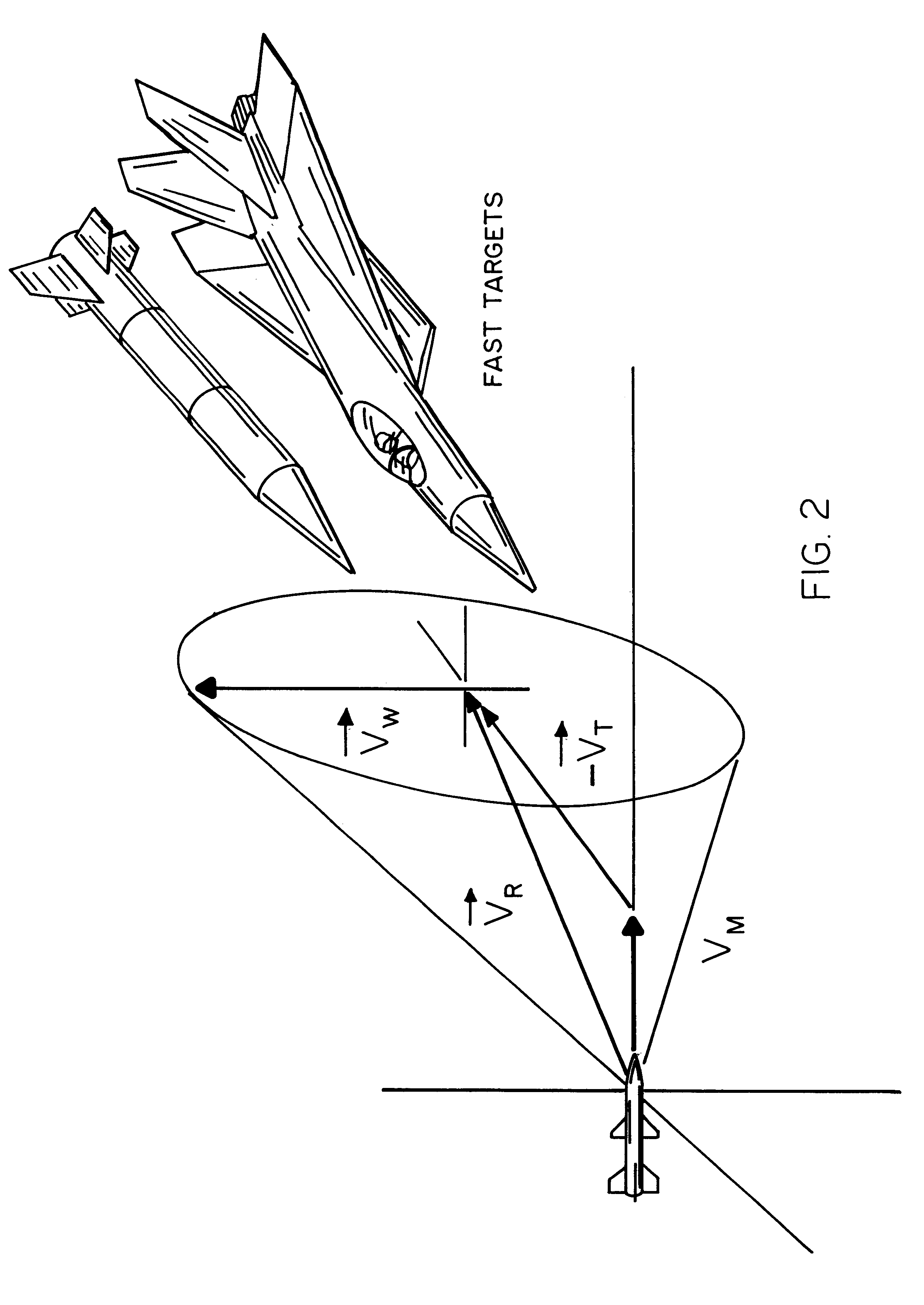

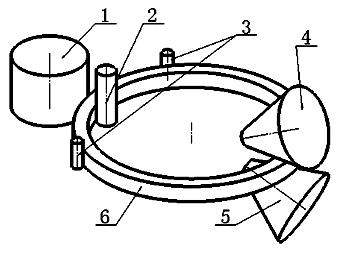

Imaging-infrared skewed-cone fuze

A fuzing system for non-spinning or substantially non-spinning weapons is implemented by means of wide angle optics providing at least forward-hemisphere coverage, an array of infrared detectors and a microprocessor for image and data processing, aim-point selection, directional-warhead aiming and skewed-cone fuzing. The skewed-cone fuzing has a generatrix which is the vector sum of missile velocity, warhead velocity and the negative of target velocity.

Owner:NORTHROP GRUMMAN SYST CORP

Dodging special-shaped lens used for shaping semiconductor laser leams, dodging laser source and optical system

The invention provides a dodging special-shaped lens used for shaping semiconductor laser leams. The lens comprises an entrance face receiving laser injection and an exit face allowing laser ejection, the entrance face which is a half-cylindrical curved surface and the exit face which is an aspheric surface are arranged oppositely, and the distance between two ends of a generatrix of the aspheric surface is larger than that of the half-cylindrical surface, so that lasers injected through the entrance face are enabled to be wholly injected onto the exit face. The dodging special-shaped lens is simple in structure, easy for batch processing, low in cost and especially capable of well realizing adjusting of divergence angles of laser beams output by semiconductor lasers of various wavelengths and homogenized adjusting of Gaussian curve distribution of light energy output by lasers, and utilization rate of laser energy is improved while good dodging and aberration-eliminating performances are provided.

Owner:XIAN HUANIC OPTOELECTRONICS CORP

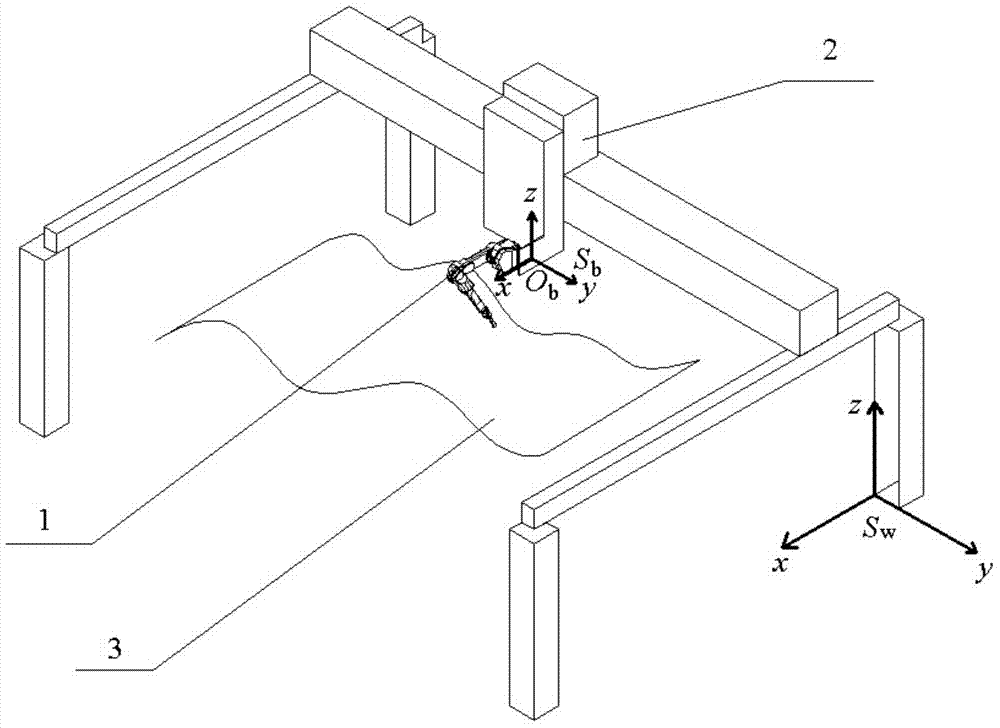

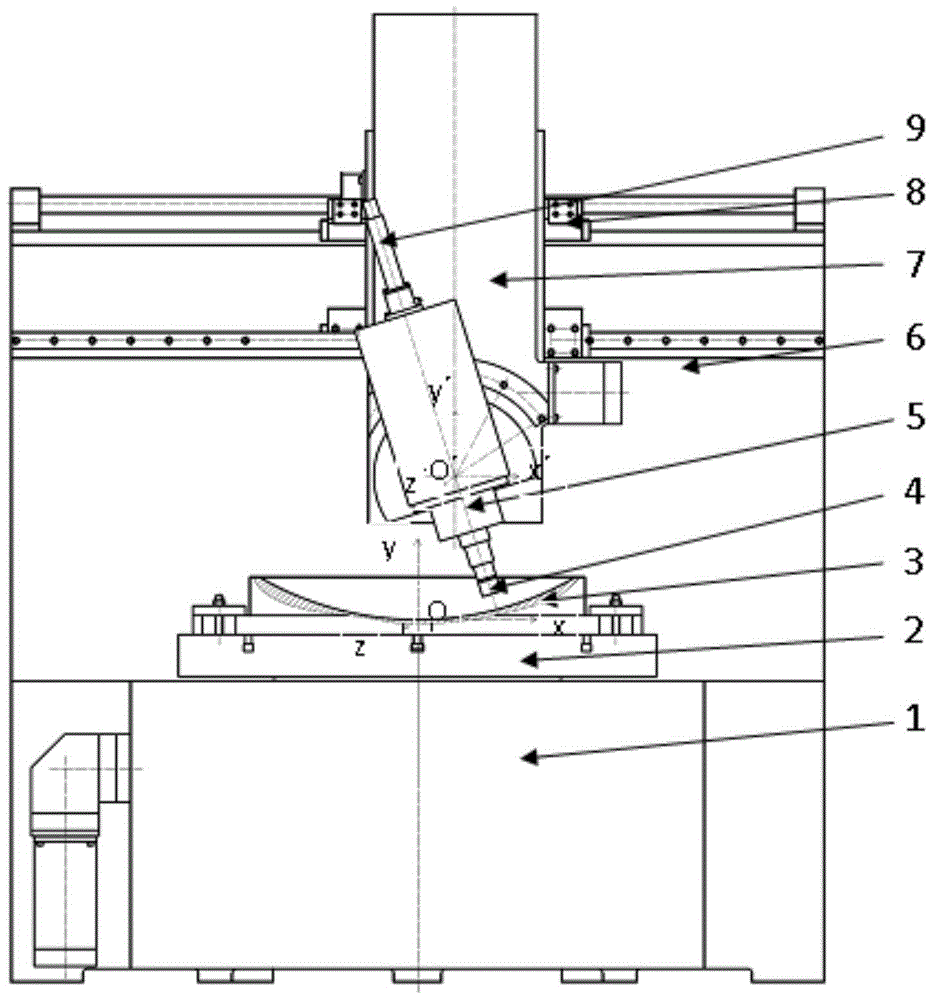

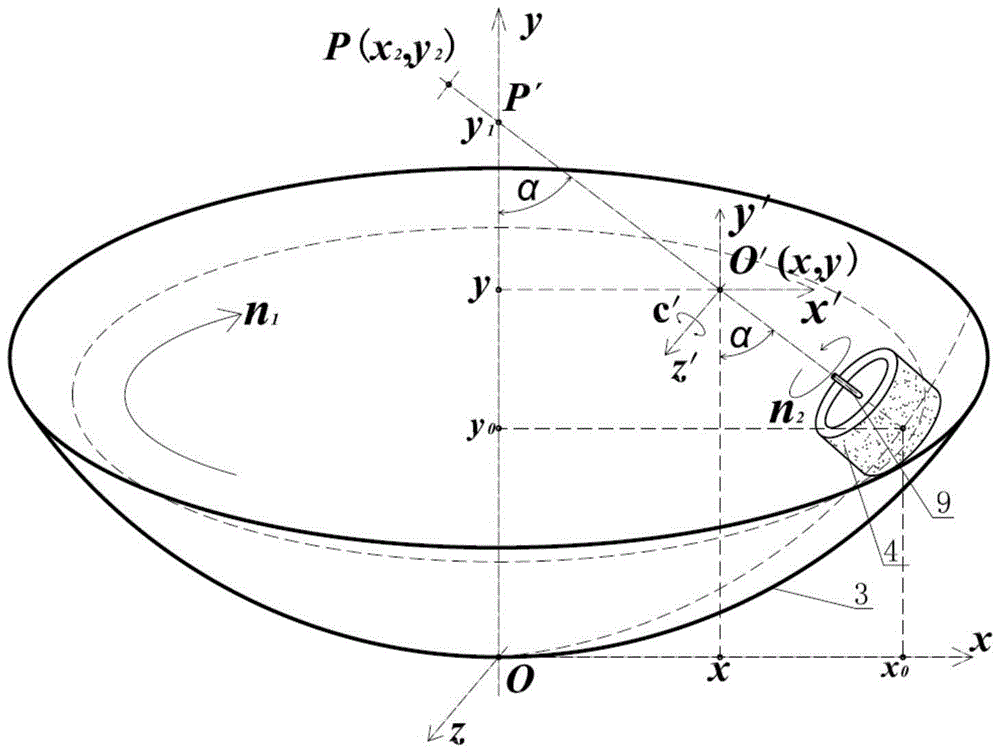

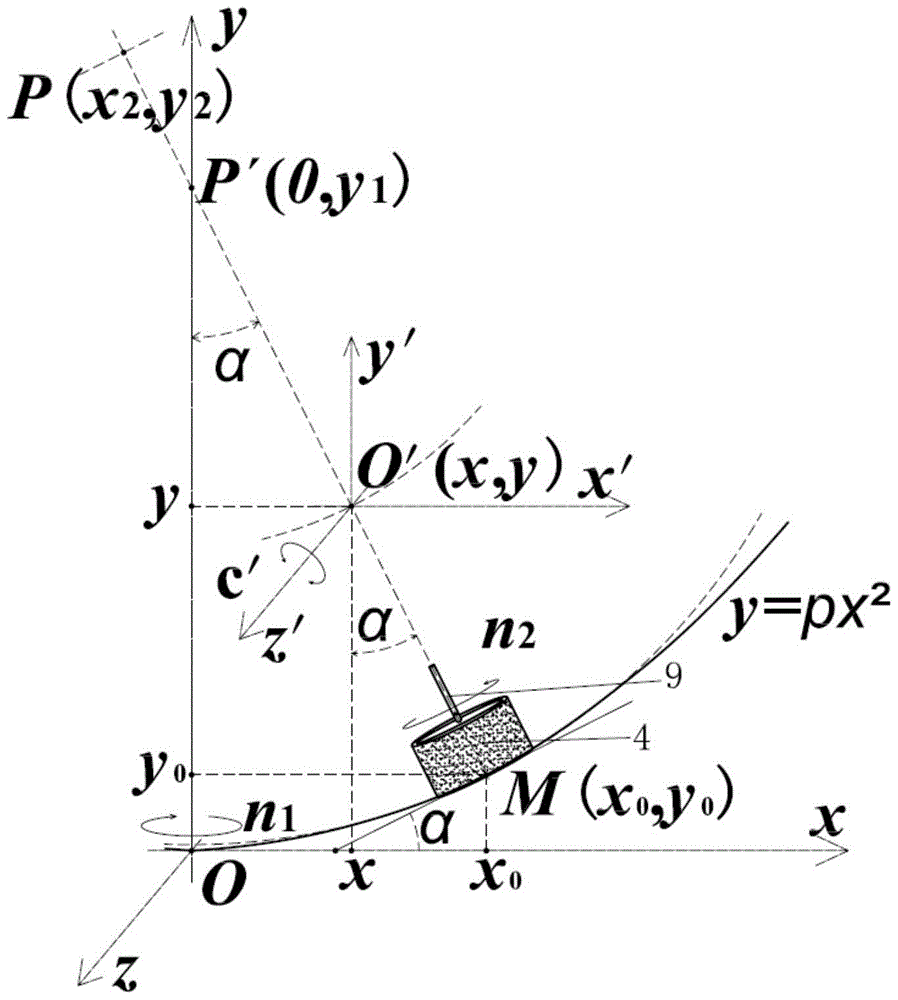

Painting robot position planning method for large-scale free-form surface

ActiveCN104331542AImprove efficiencyHigh degree of automationSpecial data processing applicationsFree formAngular velocity

The invention discloses a painting robot position planning method for a large-scale free-form surface and relates to the technical field of robot painting. According to the method, firstly, a spray gun track planning method is adopted to complete blocking of the large-scale free-form surface and planning of a spray gun track; then on a specified position search cone generatrix, a point in a working space of a painting robot and a three-dimensional moving platform is selected and a joint angle and a joint angular velocity in the painting motion are solved out by utilizing the robotics principle so as to carry out feasibility checking on the point; next, collision interference check is carried out by utilizing a motion simulation function of three-dimensional shaping software; finally, all feasible positions corresponding to free-form surface blocks are found. The painting robot position planning method for the large-scale free-form surface can implement batch position planning on a plurality of free-form surface blocks in the large-scale free-form surface and has a high calculating speed and a high automation degree.

Owner:清研同创机器人(天津)有限公司

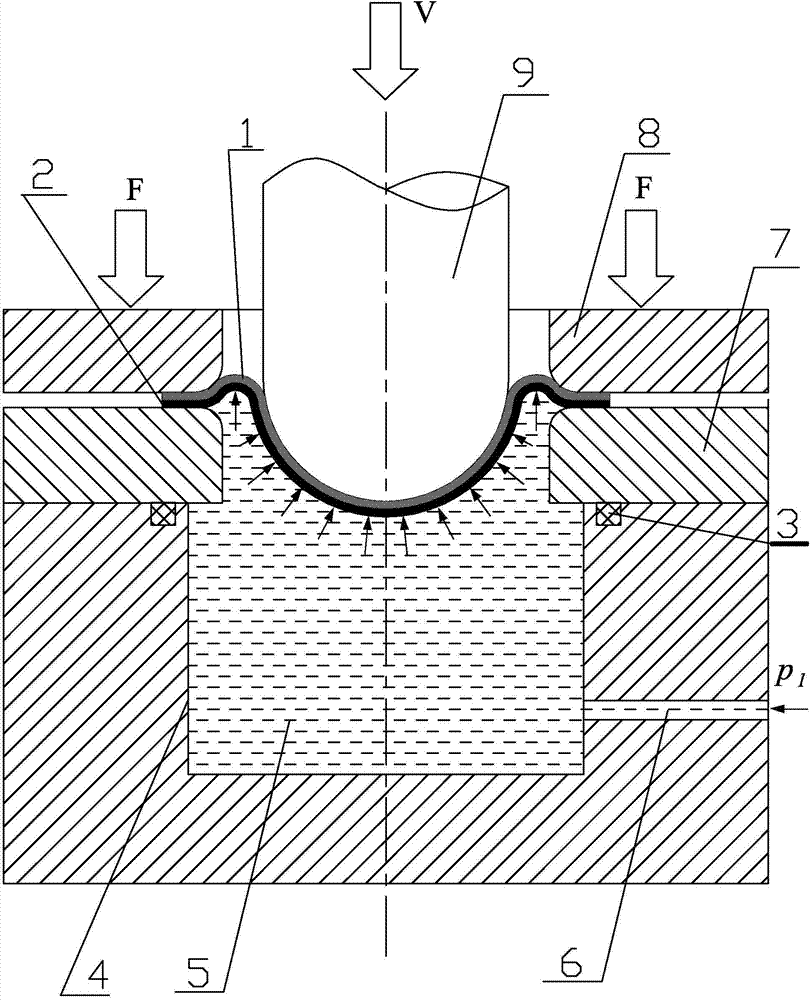

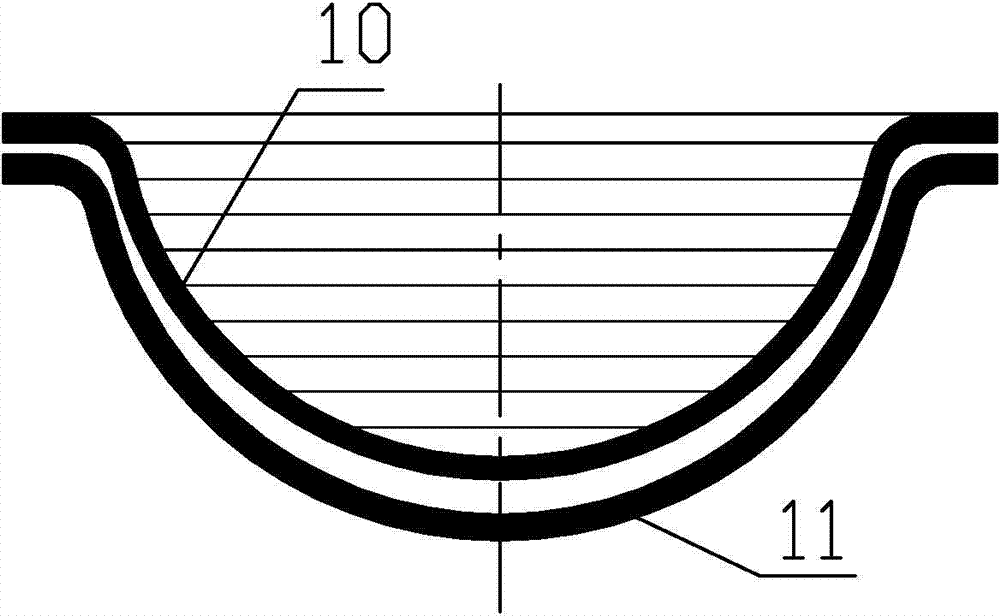

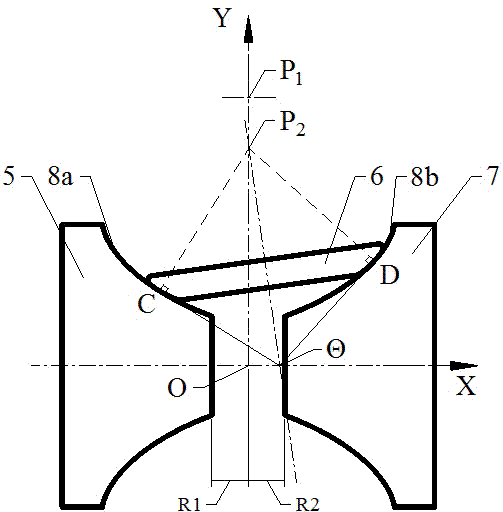

Hydro-mechanical deep drawing forming method capable of improving surface precision of large-scale thin-wall curved-surface part

The invention discloses a hydro-mechanical deep drawing forming method capable of improving surface precision of a large-scale thin-wall curved-surface part, and relates to hydro-mechanical deep drawing forming methods. The problems that the curved-surface part is prone to be locally wrinkled and the surface precision is affected in the deep drawing process are solved. Concentric circles with certain distances are carved in the upper surface of an auxiliary forming sheet, the auxiliary forming sheet and a target forming sheet are stacked on a female die, and deep drawing forming is carried out on the auxiliary forming sheet and the target forming sheet. A gap generated by resilience of the auxiliary forming sheet and resilience of the target forming sheet is utilized for separating a deep drawing piece. The diameters and the thicknesses of the concentric circles of the deep drawing piece of the auxiliary forming sheet are measured. Normal inside offsetting is carried out on a molded surface generatrix of an initial deep drawing male die at the corresponding position. Fitting is carried out on an offset point, and the surface generatrix considering deformation and thinning of the auxiliary forming sheet can be obtained. According to the fitted surface generatrix, the initial deep drawing male die is finished, and an ideal deep drawing male die surface is obtained. Deep drawing forming and separation of the auxiliary forming sheet and the target forming sheet are carried out again, and the large-scale thin-wall curved-surface part with improved surface precision can be obtained.

Owner:抚顺三方机械制造有限公司

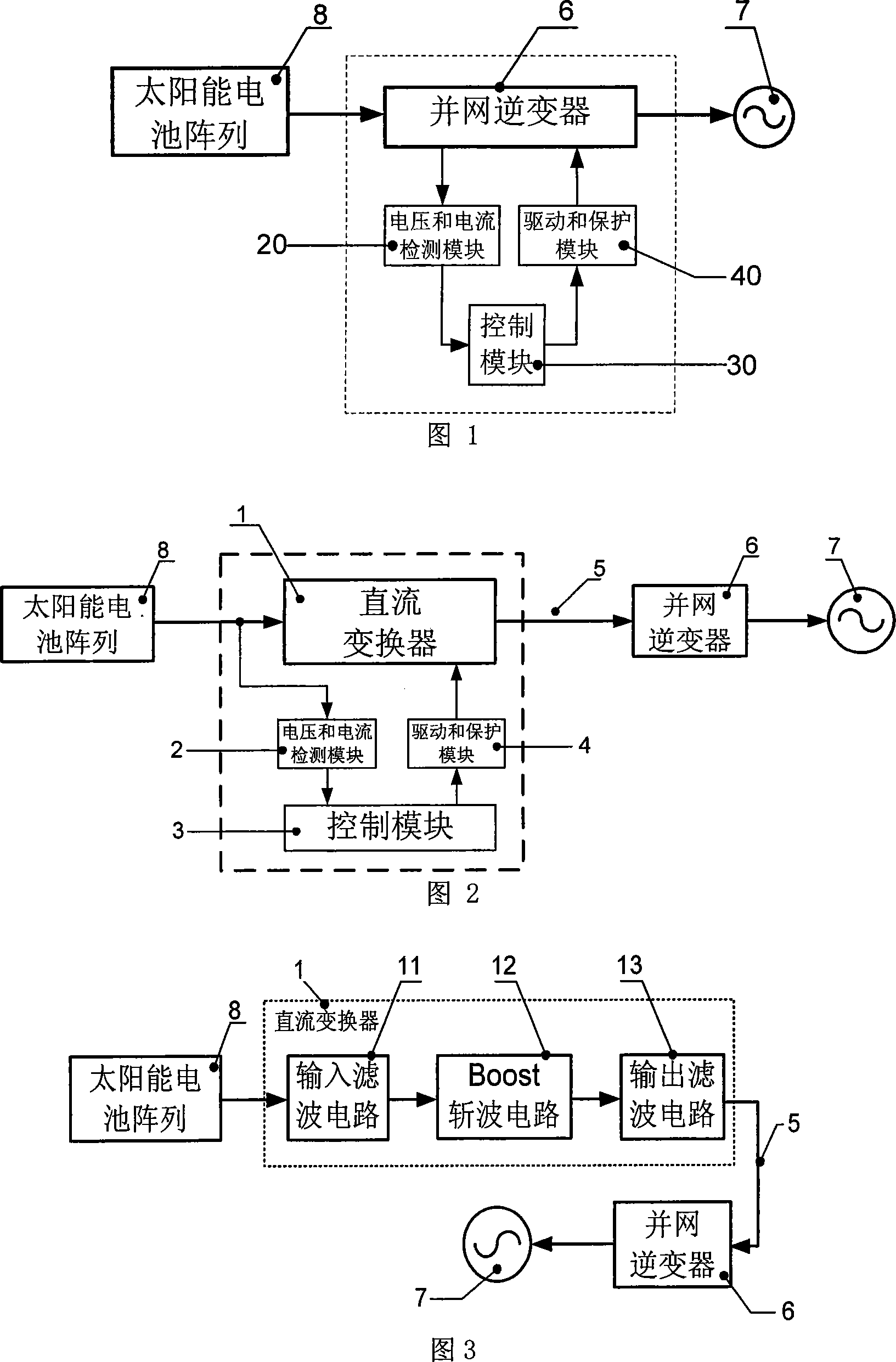

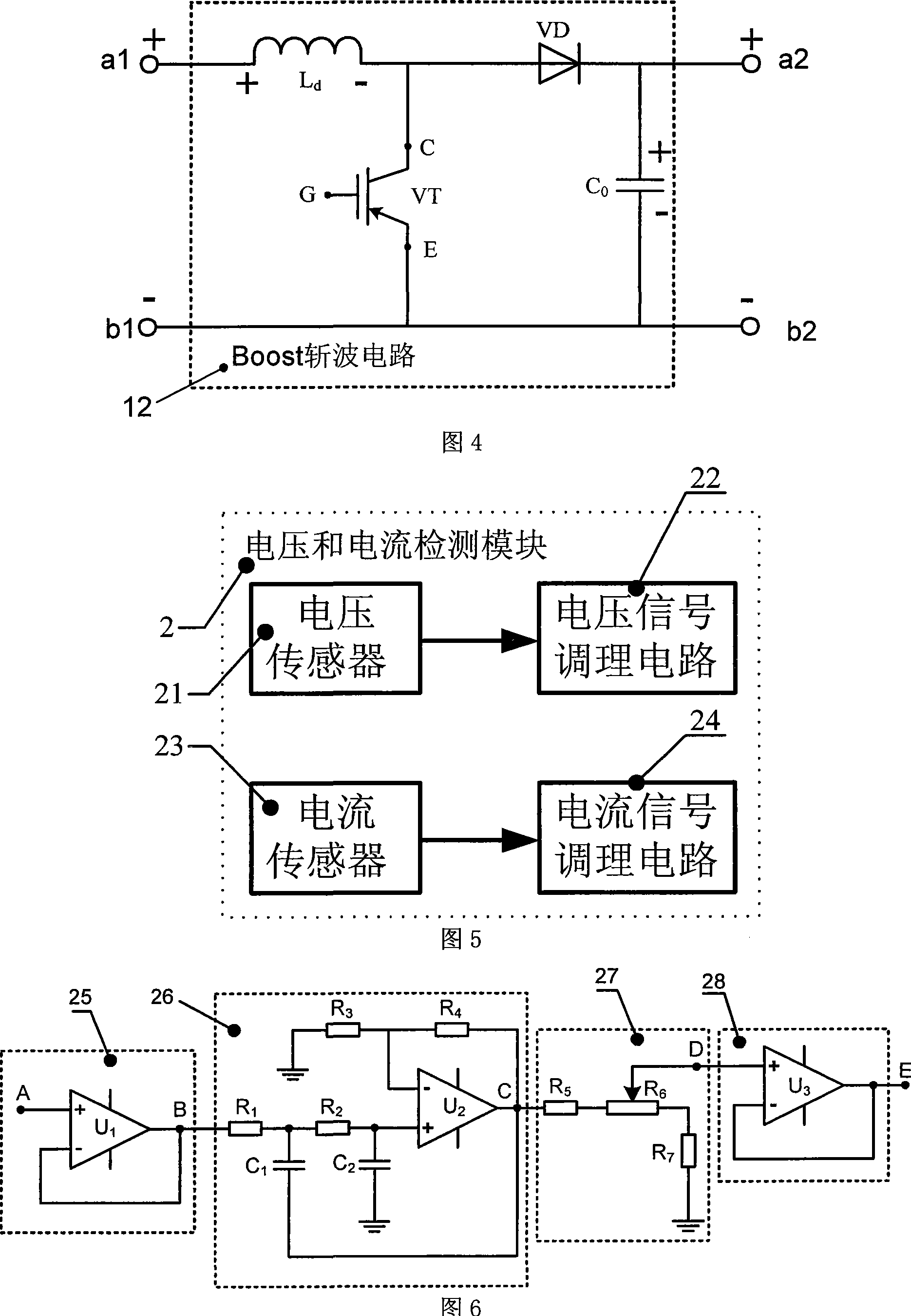

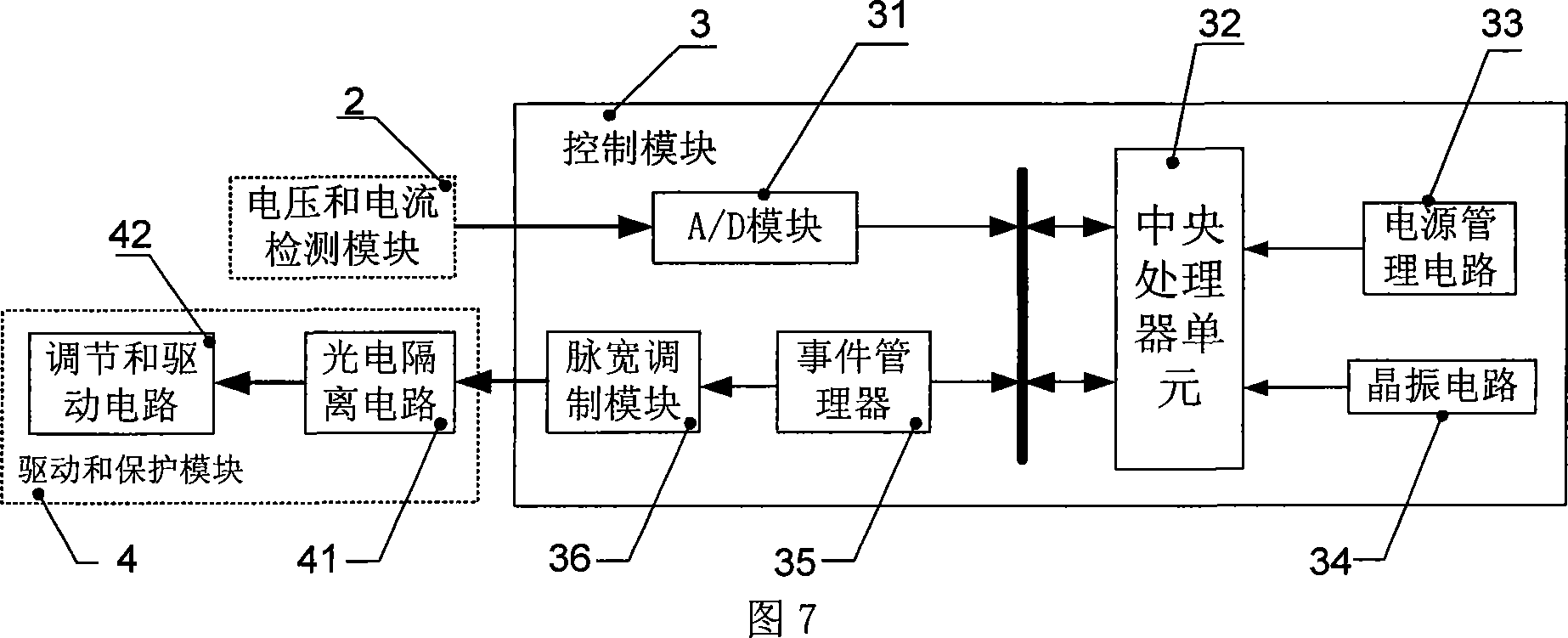

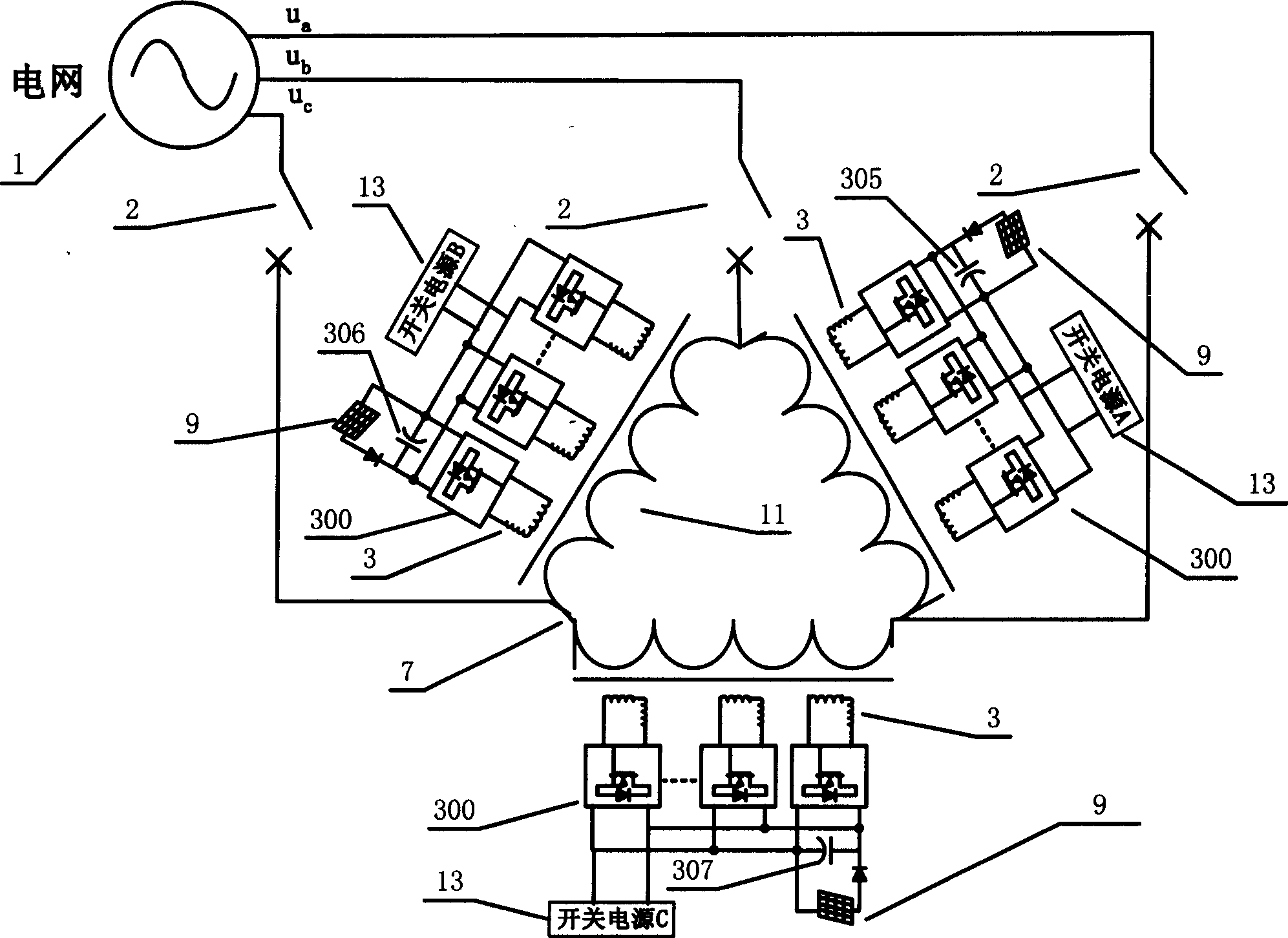

Photovoltaic power generation tracking controller based on digital signal processor

InactiveCN101227090ALow costReduce difficultyDc-dc conversionDc source parallel operationDigital signal processingEngineering

The invention discloses a photovoltaic power-generating maximal power tracking controlling device which is on the basis of digital signal processing device, the device comprises a direct current converter, a voltage and electric current detecting module, a controlling module and a driving and protecting module, wherein the input end of the direct current converter is connected with the output end of a solar battery array, the output end is connected with the input end of a grid-connected inverter through a direct current generatrix, the grid-connected inverter is connected with an electric net, the input end of the voltage and electric current detecting module is connected with the output end of the voltage and electric current detecting module, the output end of the voltage and electric current detecting module is connected with the input end of the controlling module, the output end the controlling module is connected with the input end of the driving and protecting module, and the output end of the driving and protecting module is connected with a grid electrode G of a isolated-gate bipolar field effect transistor of the direct current converter. The invention has the advantages of low cost, which is easy to popularize and use, reduces the difficulty of the system controlling realization, and increases controlling effect. The installation of the invention is flexible, maintenance is convenient, and the influence of a single branch road fault can be reduced in maximum limit.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

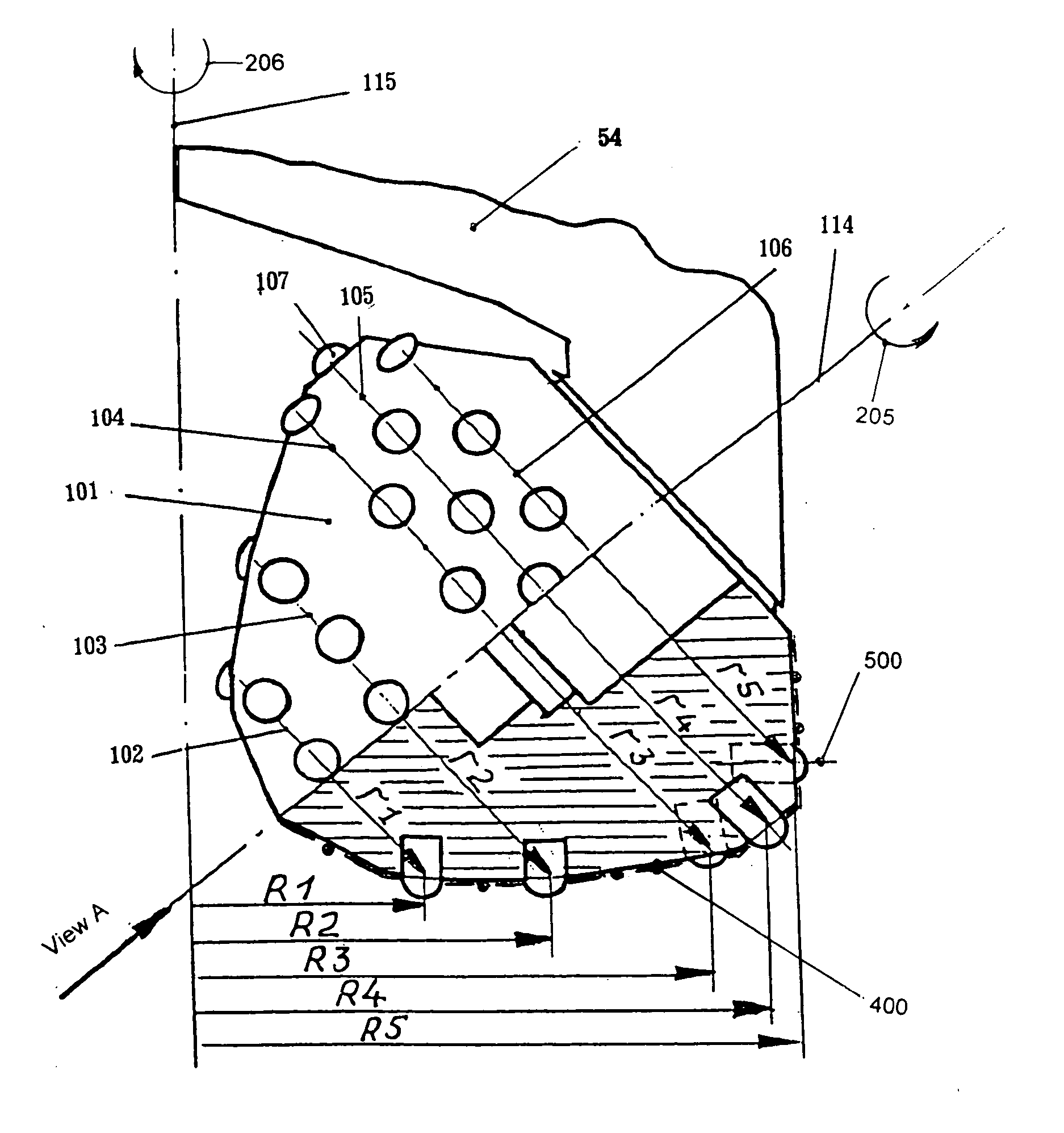

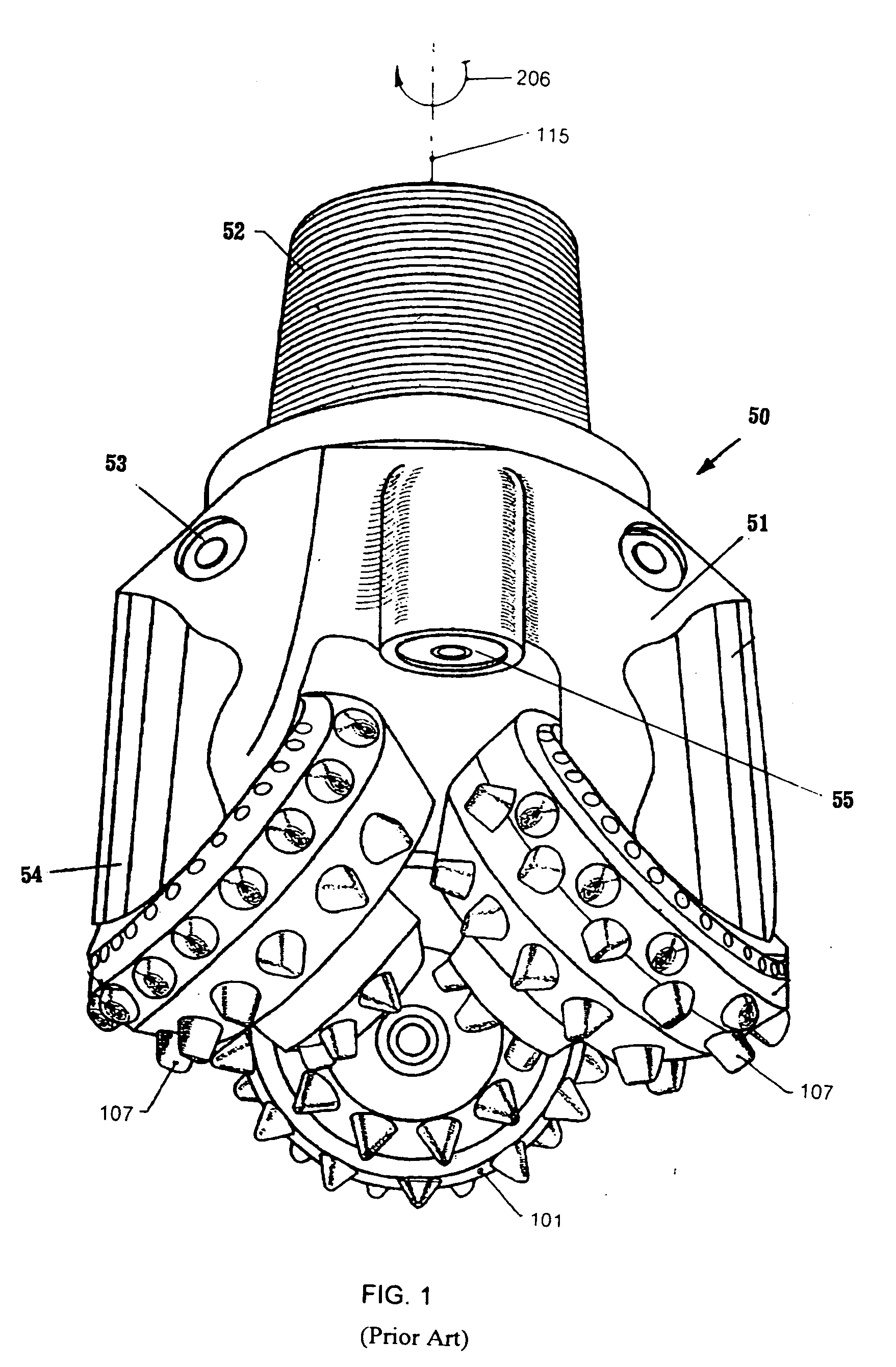

Anti-tracking earth boring bit with selected varied pitch for overbreak optimization and vibration reduction

InactiveUS20050167161A1Reduce in quantityIncreased durabilityDrill bitsCutting machinesResonanceAbsolute difference

An earth boring drill bit is constructed having rotatable cutter for forming a borehole in earth. At least one circumferential row of cutting elements is optimized to create overbreak of rock and eliminate tracking, wherein selected pitches have mathematically determined pairs and the absolute difference between the selected pitch and its pair is greater than 10% of the difference between maximum and minimum pitch for that circumferential row. Furthermore, cutting elements are placed along pre-selected generatrices with deviation from said generatrices, which is less than half the maximum pitch of circumferential rows occupied by said cutting element. The present invention eliminates tracking and reduces detrimental axial resonance frequency vibration while reducing cutting element count, including tungsten-carbide inserts, as compared to conventional roller cutter drill bits used for oil, gas and shot hole drilling wells and simultaneously increases footage drilled, drilling speed, and durability.

Owner:AARON ANNA VICTORVNA +1

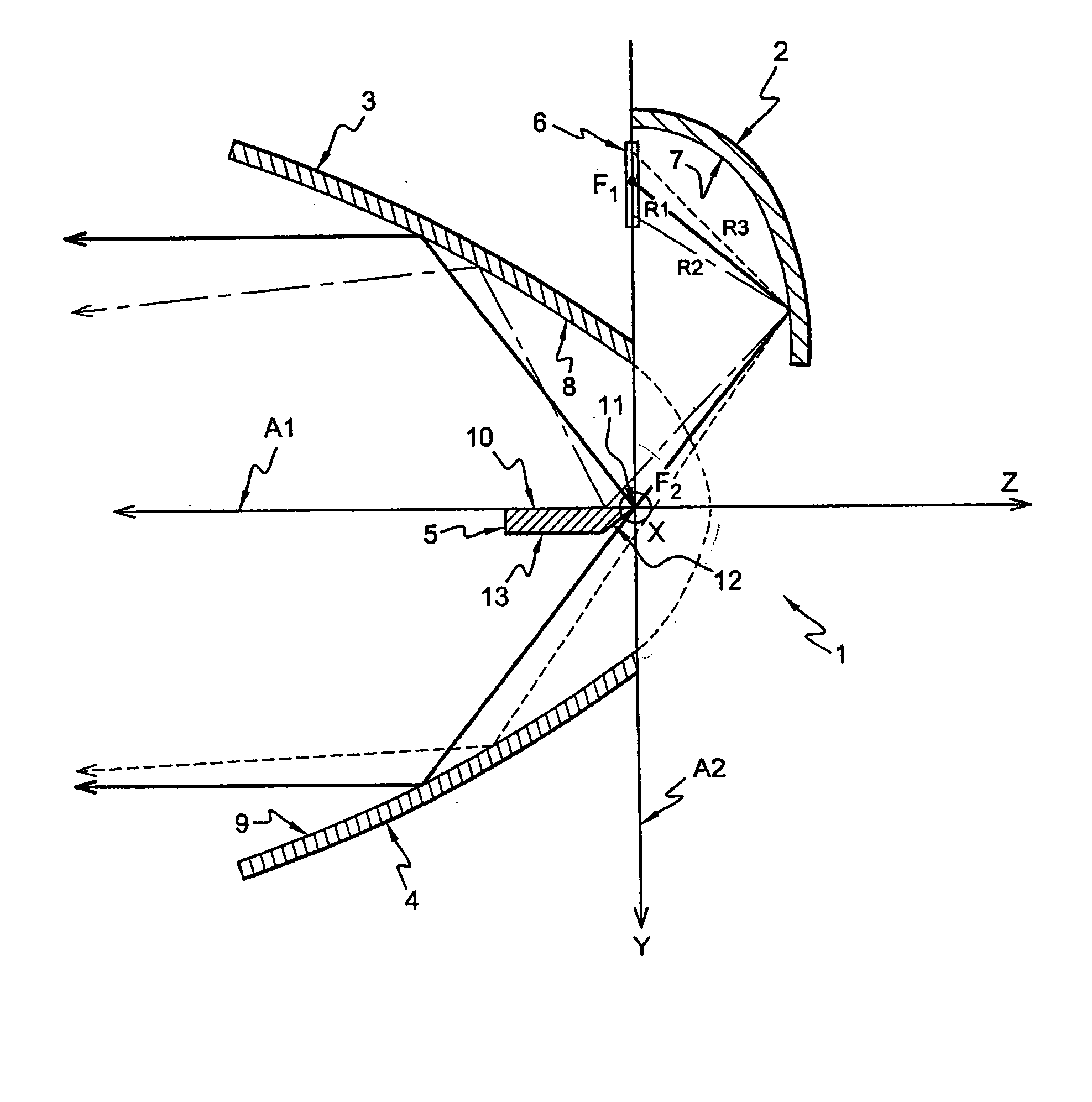

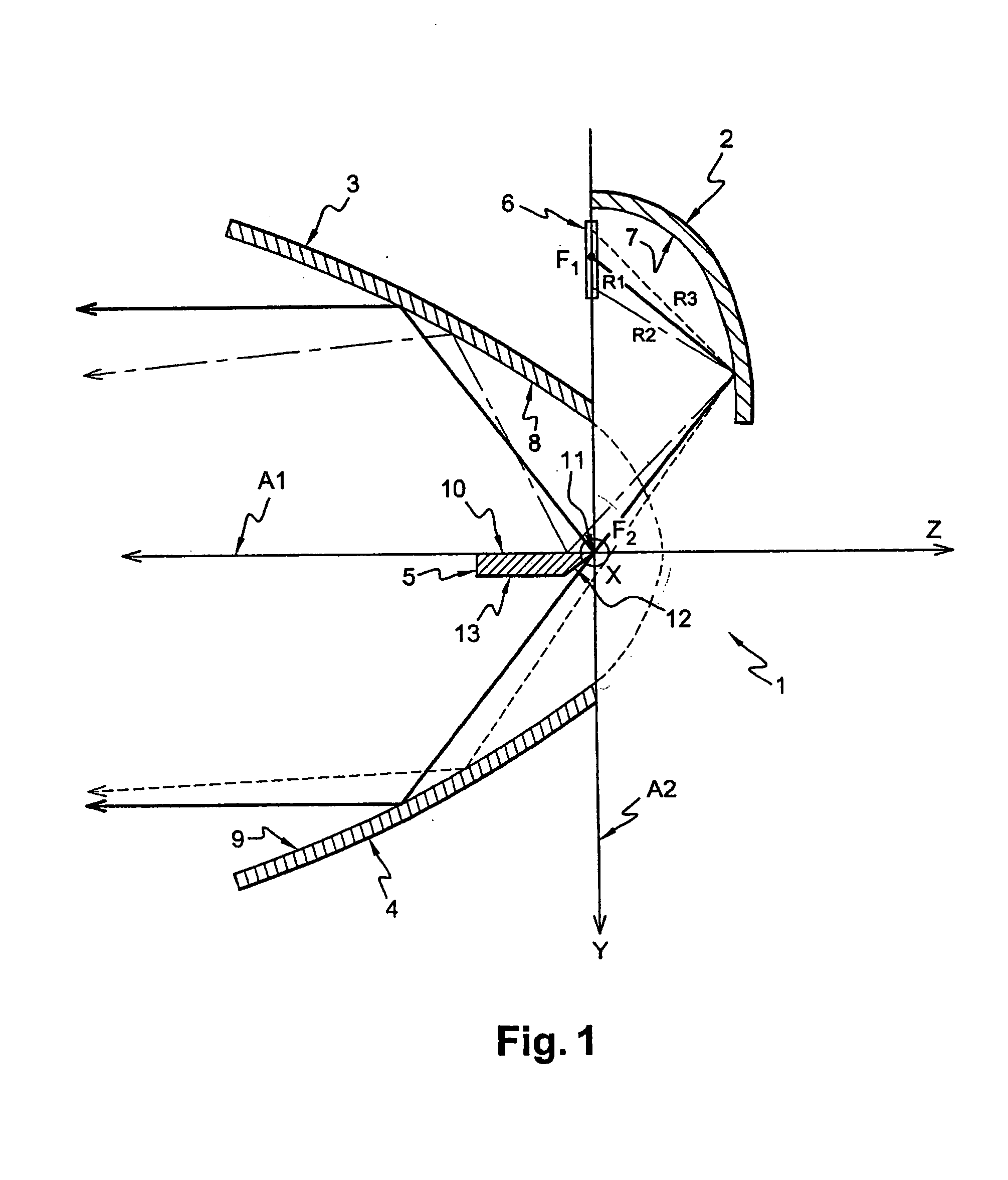

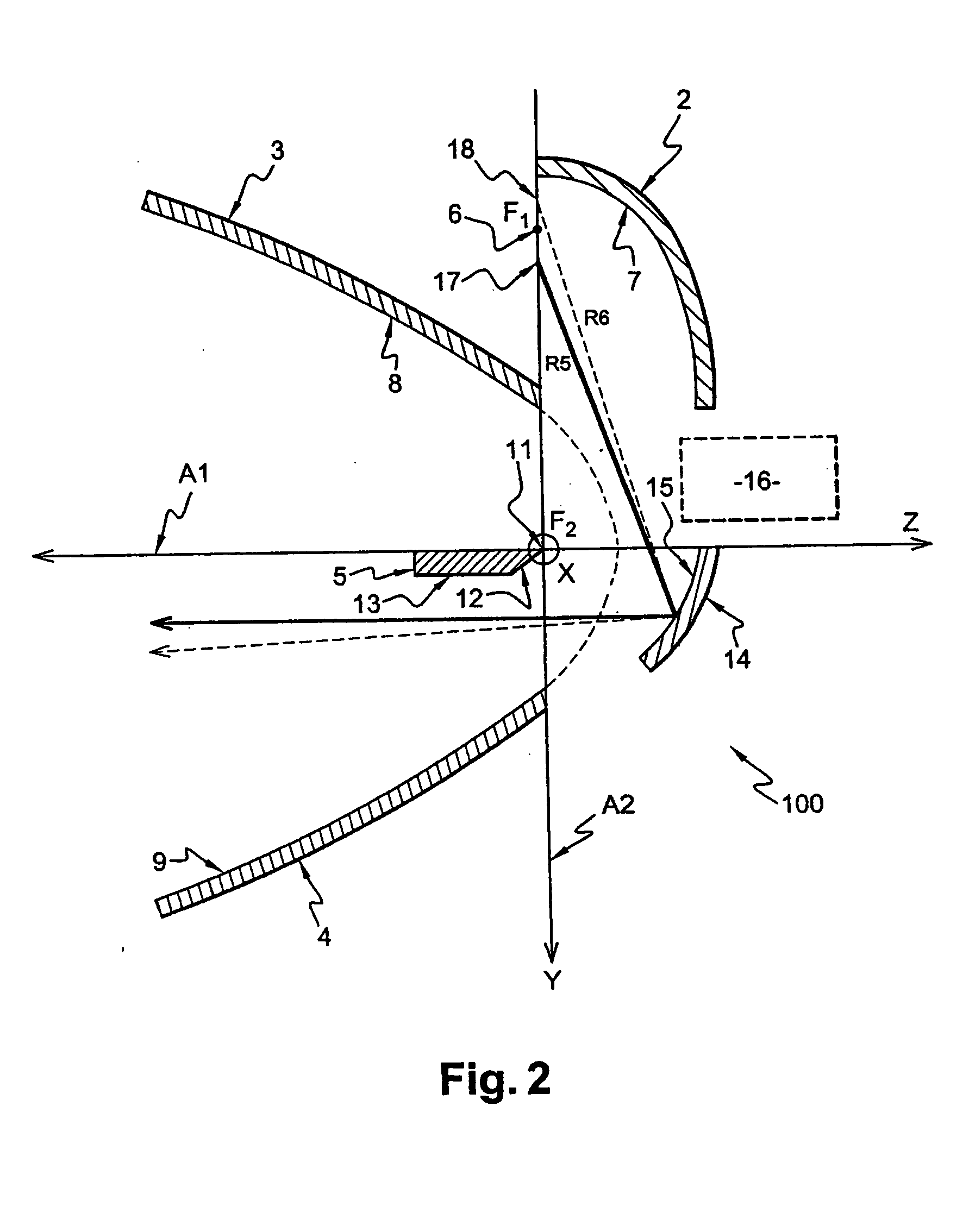

Lighting module for a vehicle headlight

InactiveUS20050094402A1Reduce the amount of lightEliminate useVehicle headlampsLighting support devicesOptical axisLight beam

The present invention relates to a lighting module for a vehicle headlight which produces a lighting beam of the type having a cut-off, and which is particularly well adapted for use with light emitting diodes. The module has a first reflector which includes an elliptical surface for reflecting light rays and having an elliptical generatrix, together with at least one first light source which is arranged in the vicinity of the first focus of the said first reflector. The module also includes: a second reflector, for producing a first portion of the cut-off beam and having an optical axis, which passes through the second focus of the first reflector and at right angles to the optical axis of the said first reflector; a third reflector producing a second portion of the cut-off beam and having an optical axis passing through the second focus of the said first reflector and at right angles to the optical axis of the said first reflector; and a fourth reflector or bender, which is arranged between the said second reflector and the said third reflector. The bender has an edge referred to as a cut-off edge, which is arranged close to the said focus of the said first reflector, in such a way as to form the cut-off in the lighting beam, together with a reflective top face which contains the said optical axes of the second and third reflectors respectively.

Owner:VALEO VISION SA

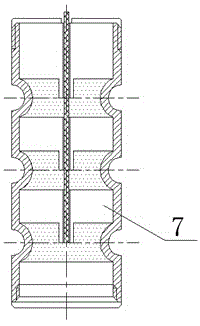

Case circular discontinuous energy concentrating jet flow cracker

InactiveCN103983153AHas energy-gathering effectSpeed up meltingFluid removalBlastingExplosive AgentsEngineering

The invention belongs to the technical field of engineering blasting and ammunition engineering. A circular discontinuous energy concentrating jet flow cracker comprises a round tube-shaped case, an end cover and a detonating unit; explosives are mounted inside the cavity the round tube-shaped case; the detonating unit is leaded out of the case through a hole formed in the end cover; the outer round surface of the round tube-shaped case is provided with circular grooves which are parallel to one another, and the circular grooves are in a conical or semicircular shape and form circular protrusions in the corresponding shape on the inner wall surface of the cavity of the round tube-shaped case; the width of the circular grooves is 1 / 2-1 / 5 as much as the outer diameter of the case, the length of the generatrix of the conical cross sections or the diameter of the semicircular cross sections of the circular grooves is 1-7 times larger than the thickness of the wall of the case, the apex angle of the conical cross sections is 40-120 degrees, and the distance between the central axises of every two neighboring circular grooves is 1.5-40 times as large as the width of the circular grooves. The circular discontinuous energy concentrating jet flow cracker impacts a target at a high speed through the high-temperature, high-pressure and energy-concentrated discontinuous jet flows which are generated by the case, is simple in structure, convenient to machine and use, small in amounts of explosives used in a single blasting, low in vibration, low in production cost and capable of ensuring the safety and meeting various usage requirements.

Owner:UNIV OF SCI & TECH OF CHINA

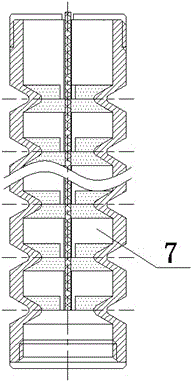

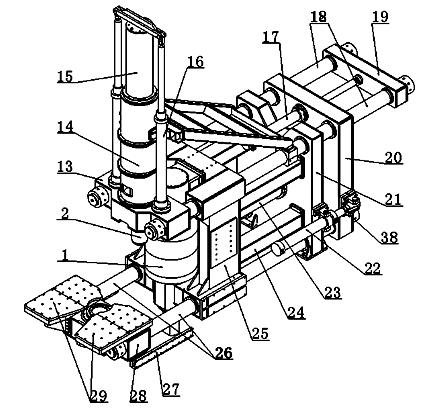

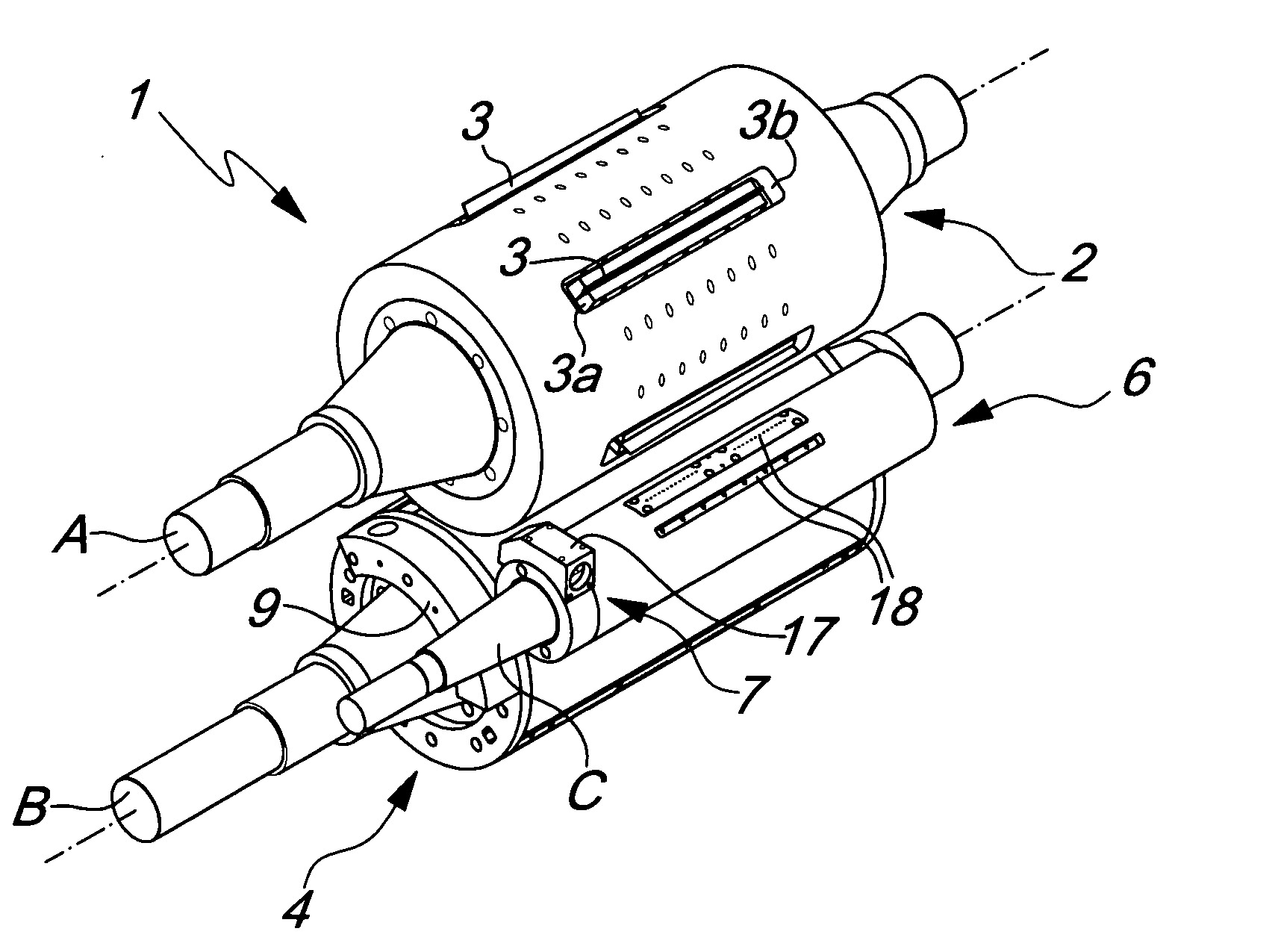

Large radial-axial ring rolling machine

Disclosed is a large radial-axial ring rolling machine. A radial rolling portion is provided with an up-drawing core roller shaft mechanism and a four-post vertical double-acting mechanism, and an axial rolling portion overcomes space limitations and is provided with a lower conical roller driving motor in a forward direction. A slider of the radial rolling portion comprises four guide posts, a fixed frame, a movable frame and the like, all parts are simple in structure, regular in appearance, easy in machining and convenient in assembly, and respective action of vertical support of a core roller is ensured, namely the technical conception of vertical double acting is realized. By the aid of the large radial-axial ring rolling machine, blanks and finished products can horizontally enter and exit the machine, difficulty in feeding and discharging is reduced, a production line can be formed to realize automated feeding and discharging, and the problem of bottleneck in improvement of working efficiency is solved. As the axial rolling portion is provided with the lower conical roller driving motor in the forward direction, assembly difficulty in mounting the high-power motor is greatly reduced, lubricating conditions of a rotating component are greatly improved when the motor works, and the service life of the motor is prolonged. By the aid of the motor mounted in the forward direction, the size of the machine below a horizontal plane of a generatrix on a lower conical roller is reduced, so that the pit depth of a foundation of the portion is decreased.

Owner:JINAN CASTING FORGING MACHINERY INST

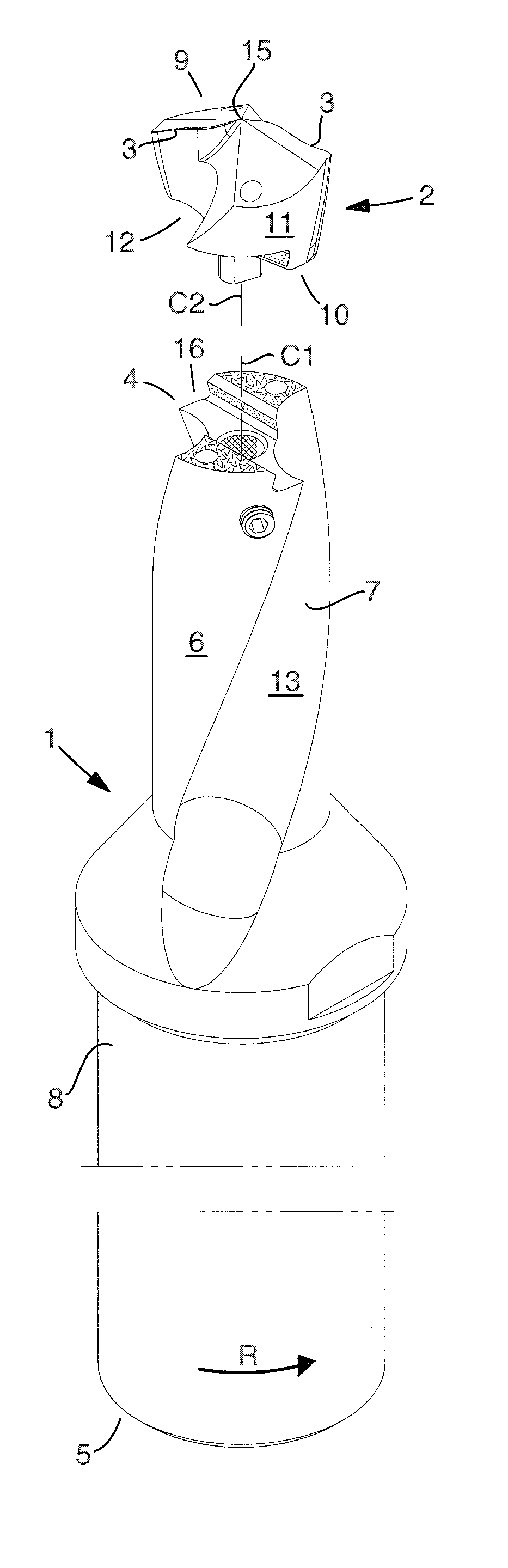

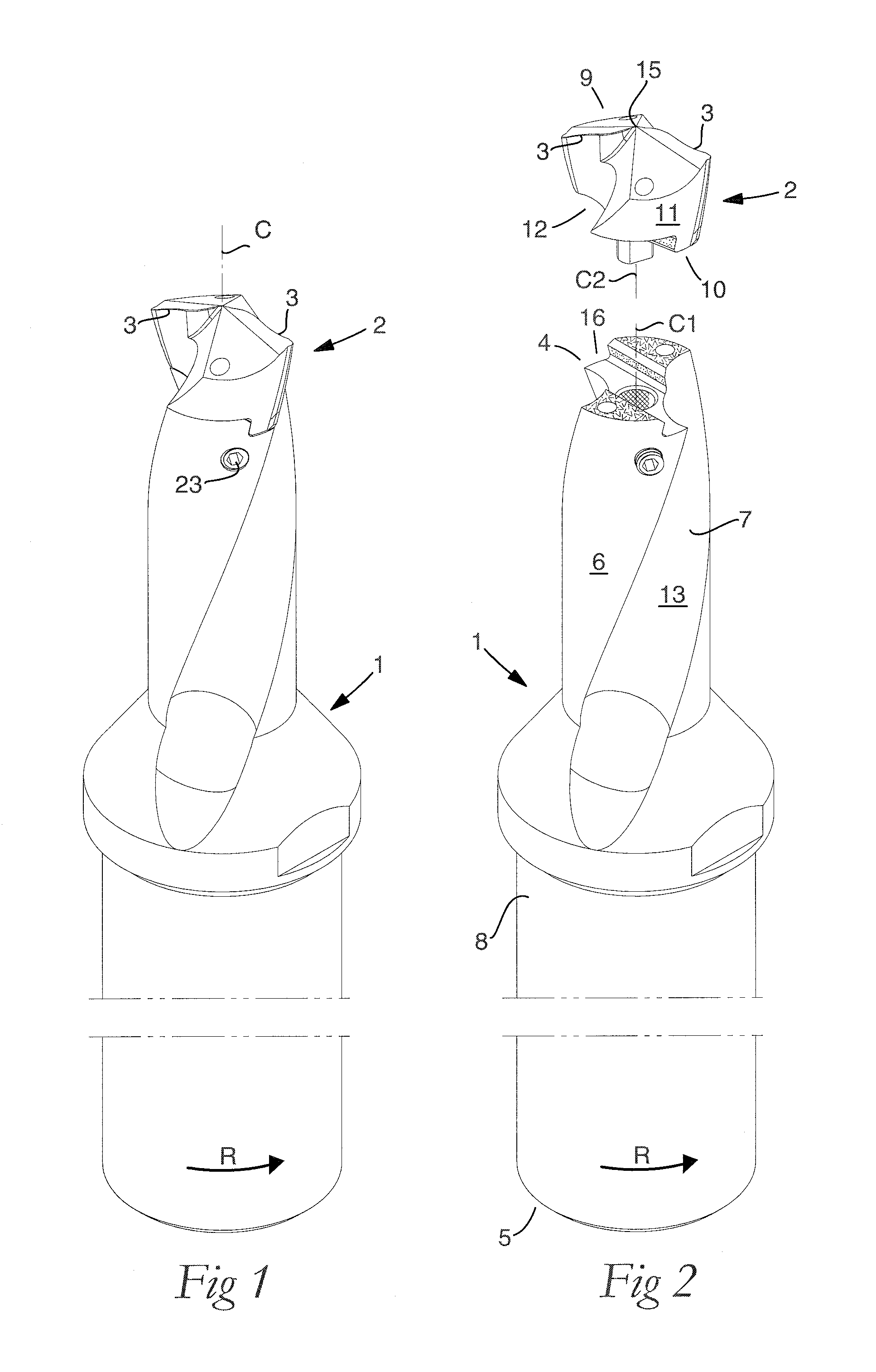

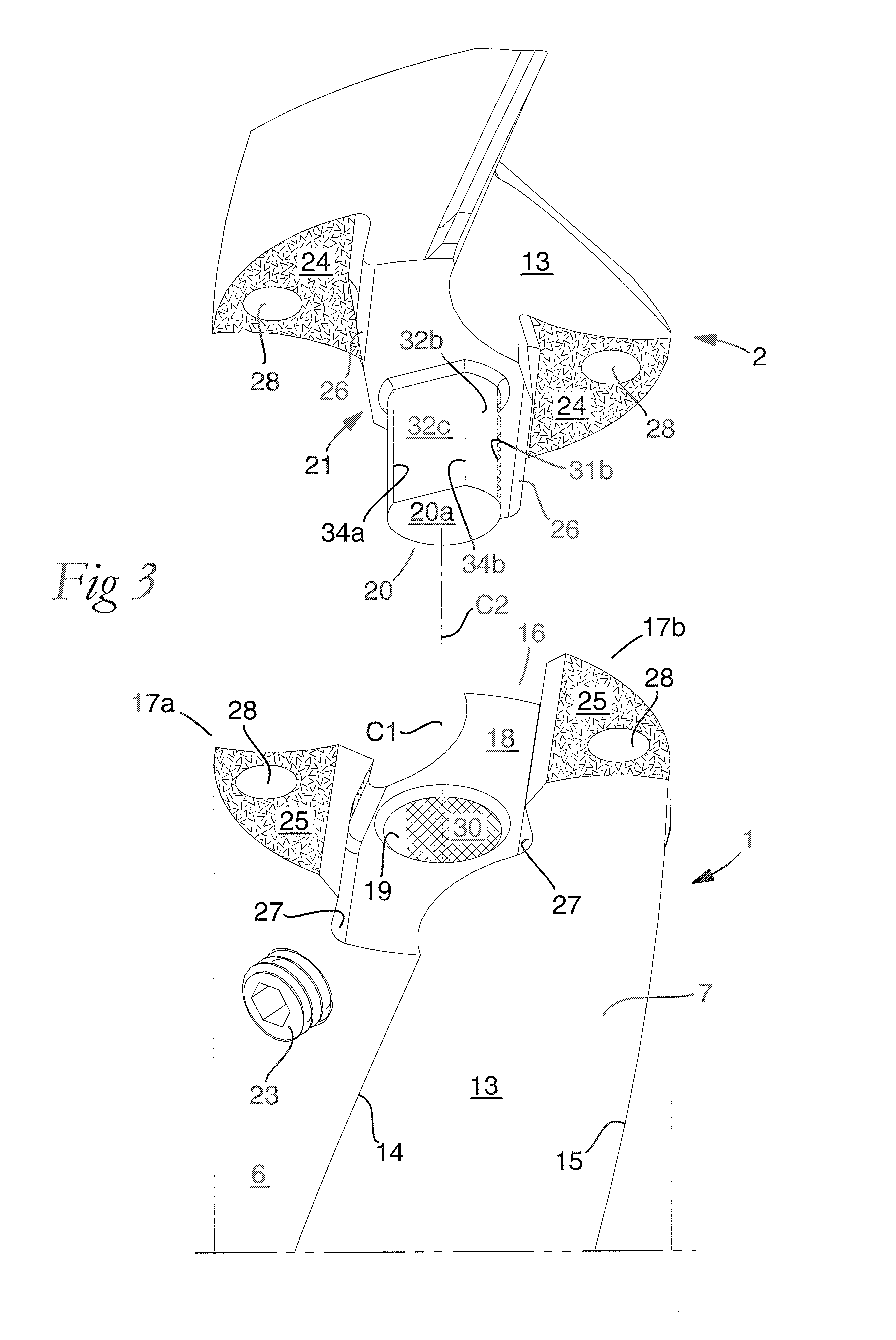

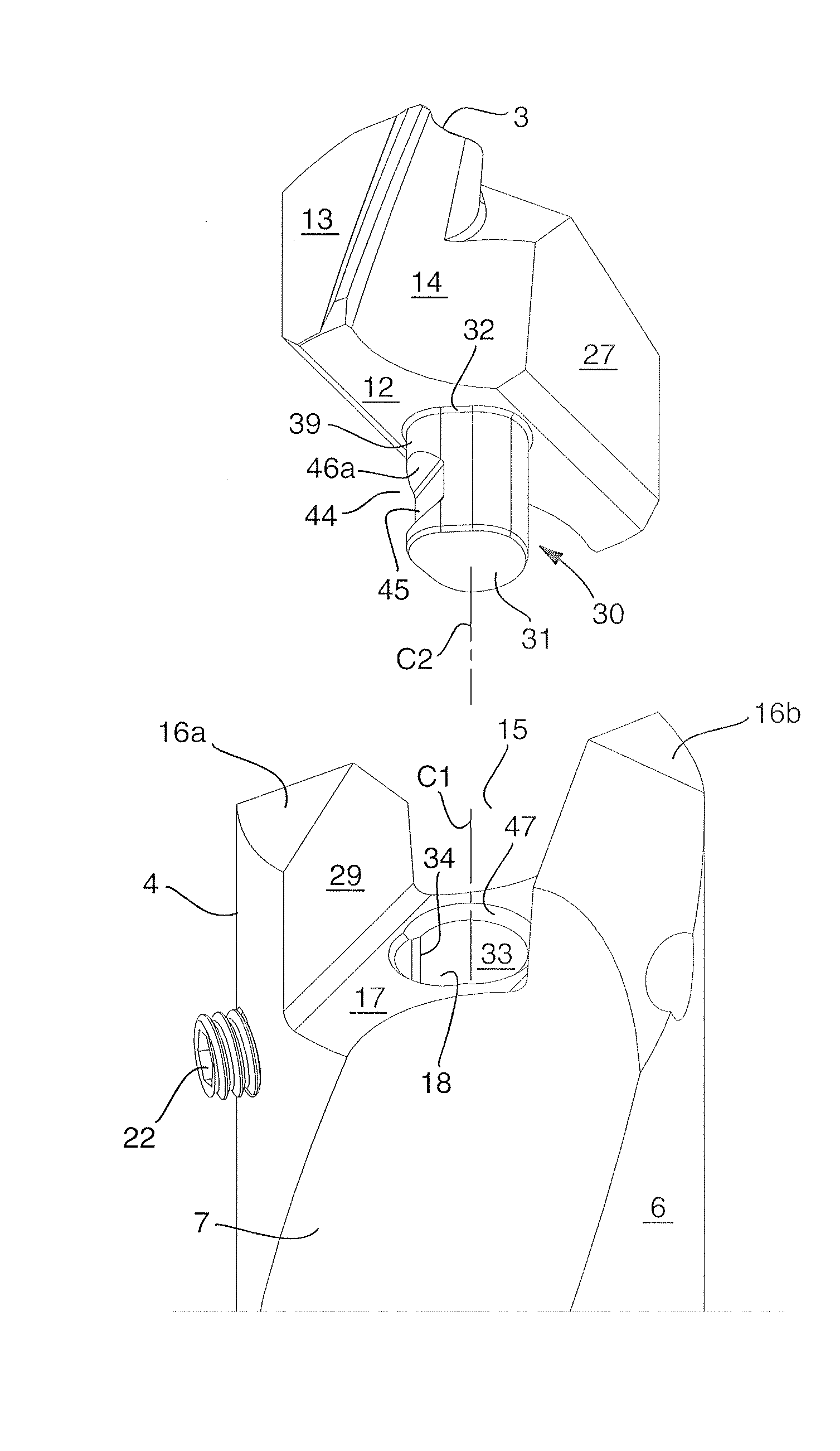

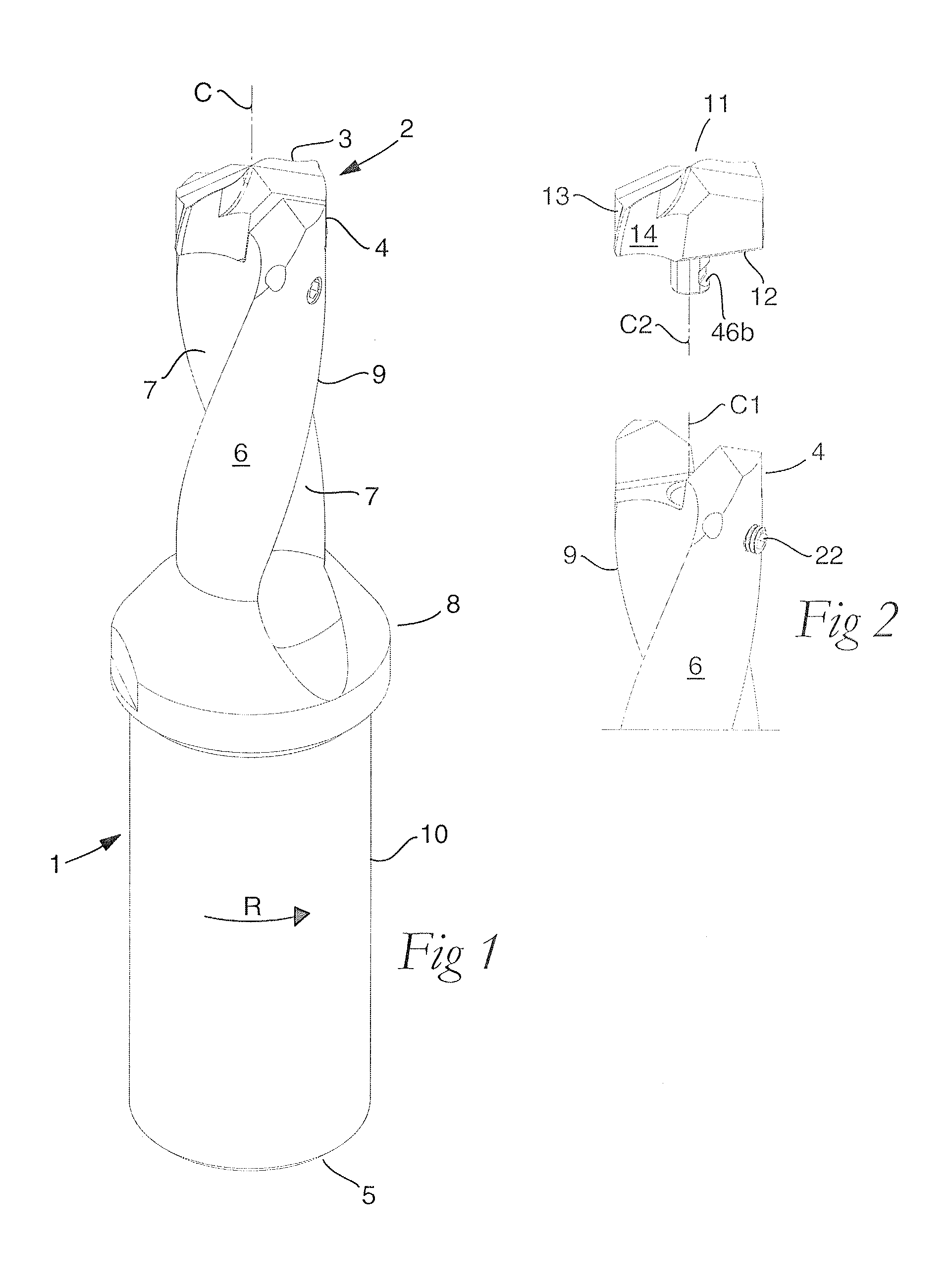

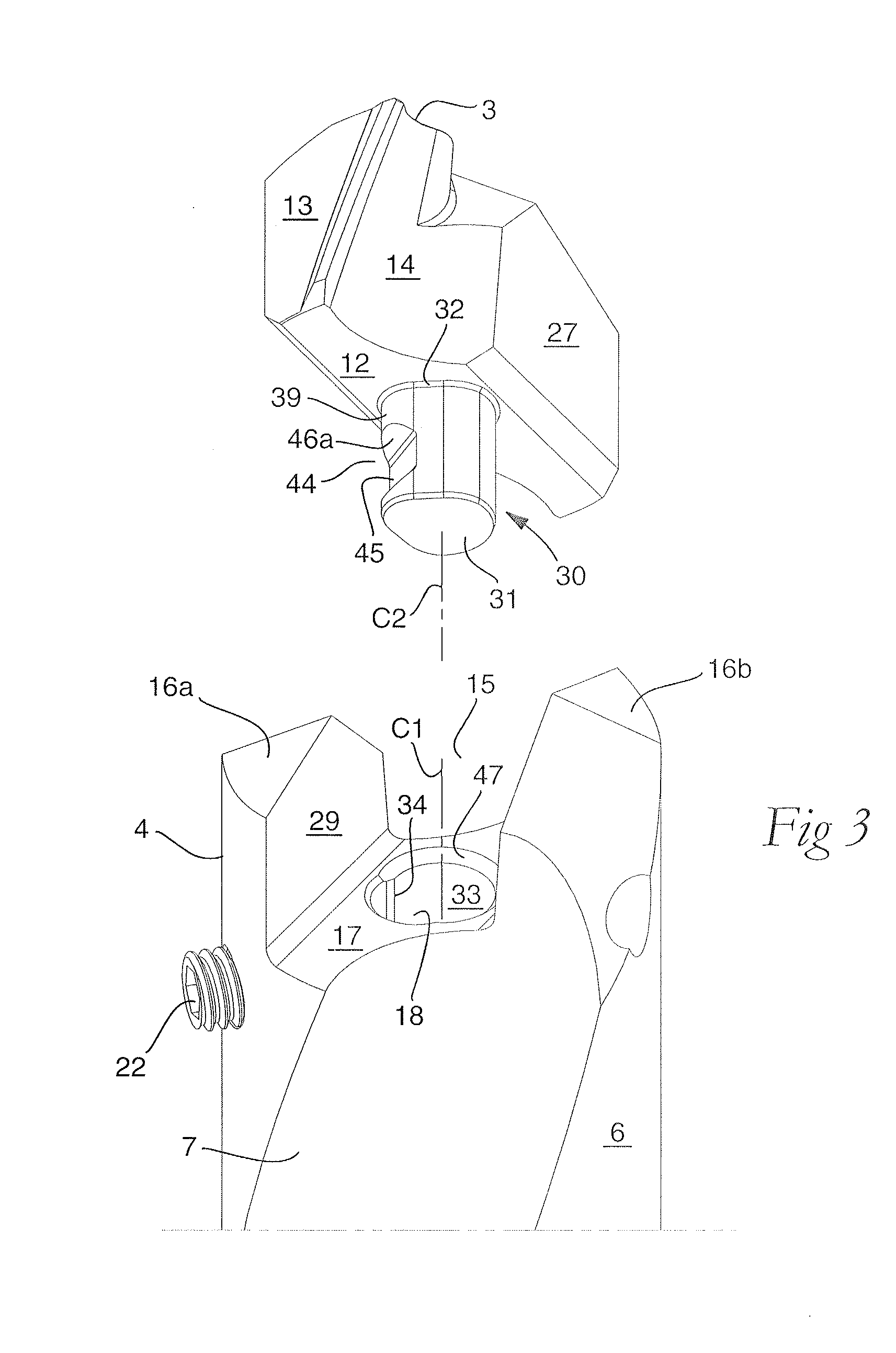

Rotatable tool for chip removing machining as well as a loose top therefor

A rotatable tool for chip removing machining, including a basic body having front and rear ends between which a first center axis (C1) extends around which the basic body is rotatable, and a loose top having front and rear ends between which a second center axis (C2) extends. The front end of the basic body includes a jaw which is delimited by two torque-transferring drivers and an intermediate bottom in which a part of the loose top is receivable, and a center hole that mouths in the bottom of the jaw and has a hole wall which extends axially inside the basic body and in which a threaded hole mouths for a screw to co-operate with a centering pin that protrudes axially rearward from the loose top, the centering pin being insertable into the center hole. The centering pin has a cross-sectional area that is less than a cross-sectional area of the center hole. The centering pin includes two diametrically opposed surfaces, a first one of the surfaces forming a contact surface that extends tangentially between two axially running boundary generatrices which are situated along an imaginary circumscribed circle (S1), the center of which coincides with the center axis (C2) of the loose top, and between which an arc angle (α) is less than 180°. The contact surface, via the boundary generatrices, transforms into a second one of the surfaces that is spaced-apart inwardly from the circumscribed circle (S1).

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Image heating apparatus using flexible sleeve

An image heating apparatus includes a flexible sleeve, a sliding member for sliding on the inner periphery of the sleeve, and a back-up member for forming a nip portion together with the sliding member through the sleeve. A recording material for bearing an image is heated while being held and conveyed by the nip portion, and a regulation member is set by facing the edge surface of the sleeve in the generatrix direction to regulate the movement of the sleeve in the generatrix direction, the regulation member having a regulation surface with which the edge surface of the sleeve contacts when the sleeve moves in the generatrix direction. The regulation surface of the regulation member has a curved-surface area in which a line when the regulation surface is cut at a virtual plane almost parallel with the nip portion is a curved line expanded toward the edge surface of the sleeve. Thereby, an image heating apparatus is provided which is able to restrain deterioration of the durability of the flexible sleeve.

Owner:CANON KK

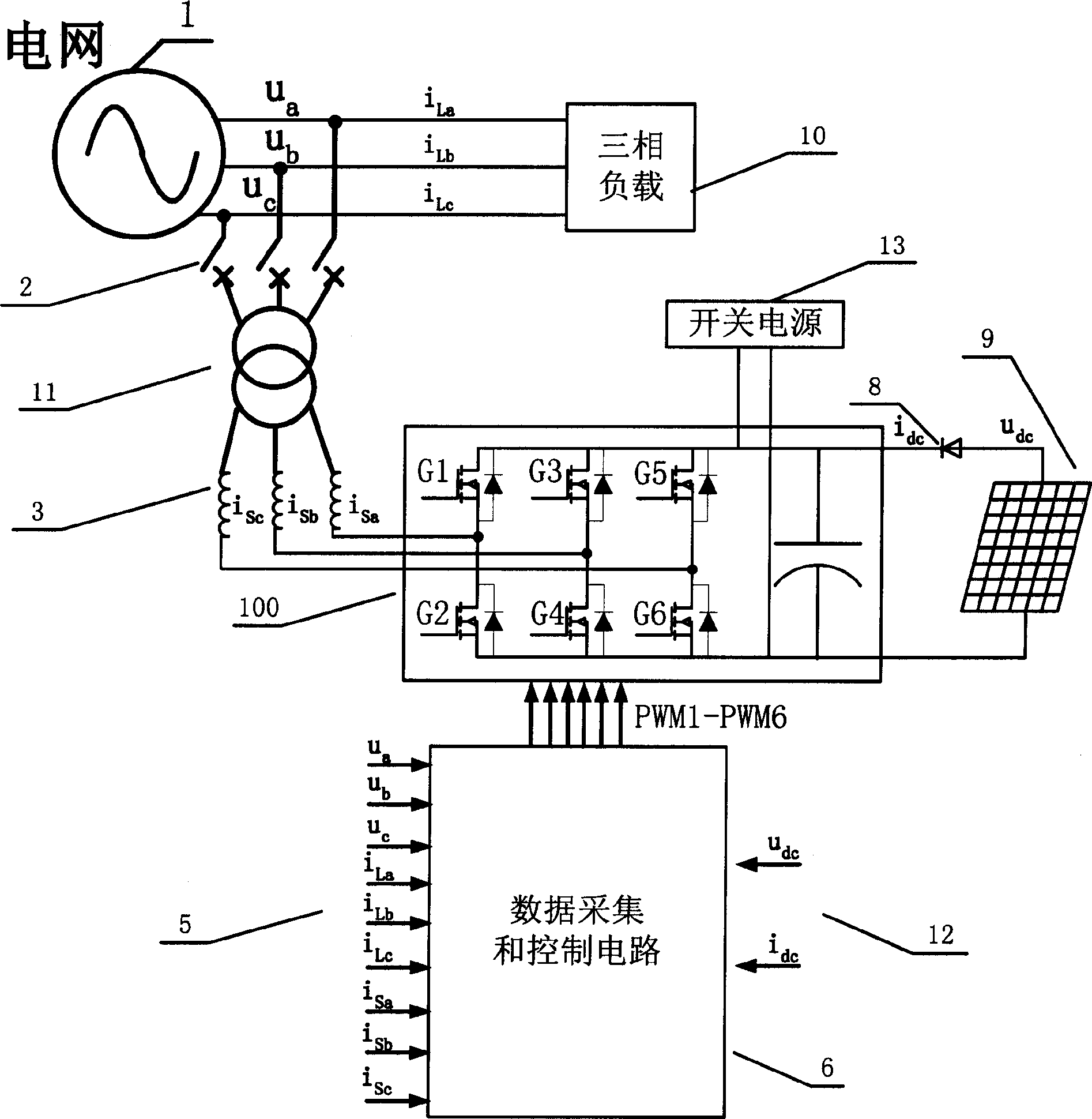

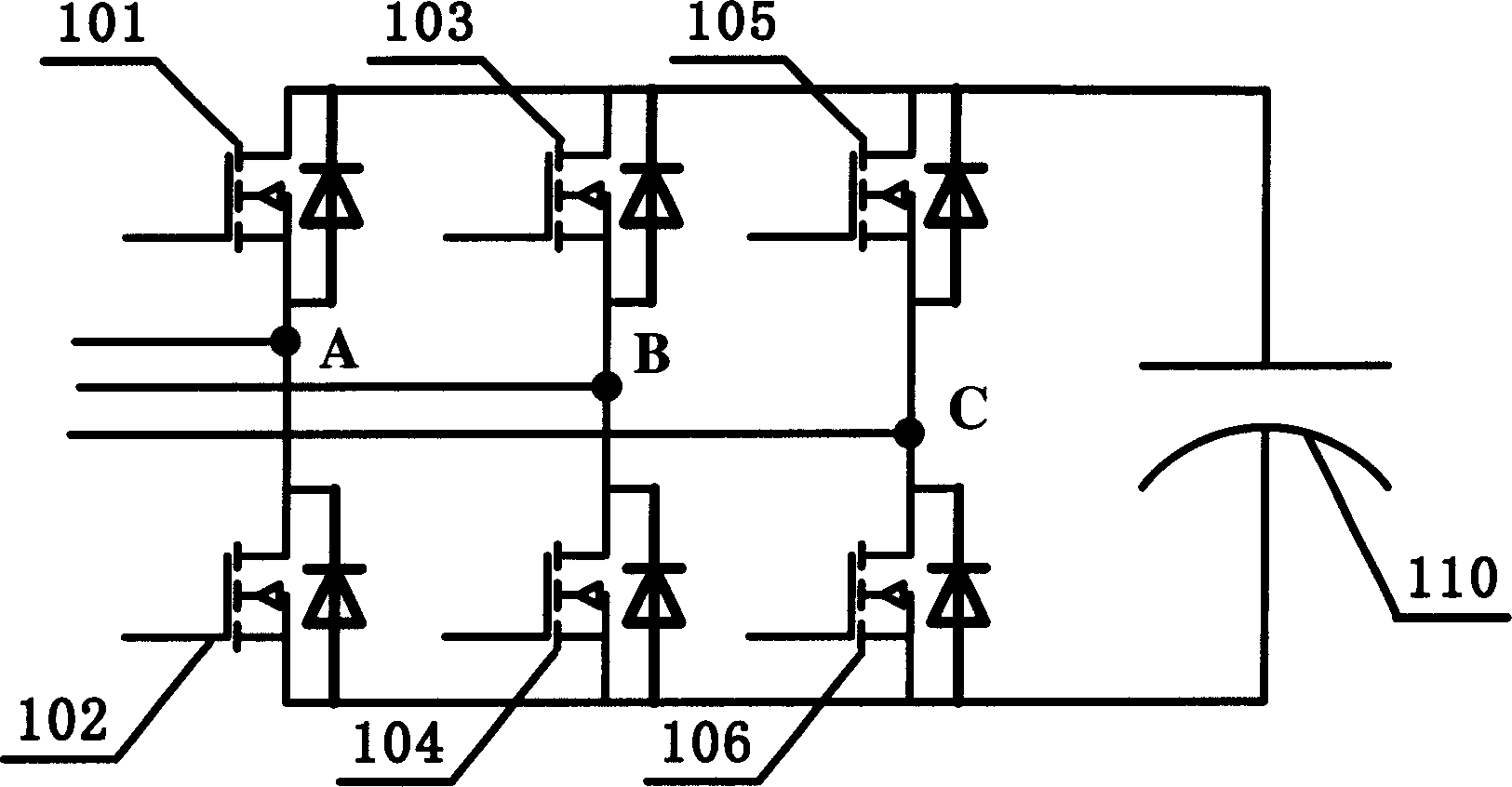

Photovoltaic parallel network device having reactive and harmonic compensation function

InactiveCN1658465APhotovoltaic energy generationDc-ac conversion without reversalCapacitanceThree level

A three-phase photovoltaic interconnected device having both reaction and harmonic compensation function, and belongs to the field of multi-functional photovoltaic interconnected device technology. The characteristic is: the main power circuit of this device is composed of the photovoltaic array, the interconnected inverter and interconnected filter sensor. The structure of the inverter has many kinds of patterns, such as the two level structure, the three level structure, the three-phase generatrix capacitance separated chain structure with transformation, the three-phase union capacitance chain structure with transformation and the chain structure without transformation. This device can emit the power to the electric net, and can in time compensate the reaction and harmonic wave of the current in the net. This invention increases the utilization ratio of the solar battery board of photovoltaic electricity generation, and meanwhile it solves the problem of the working method of the photovoltaic system in the bad lighting conditions, that is, the system will not be left unused and compensate the harmonic wave and reaction of the electric net.

Owner:TSINGHUA UNIV

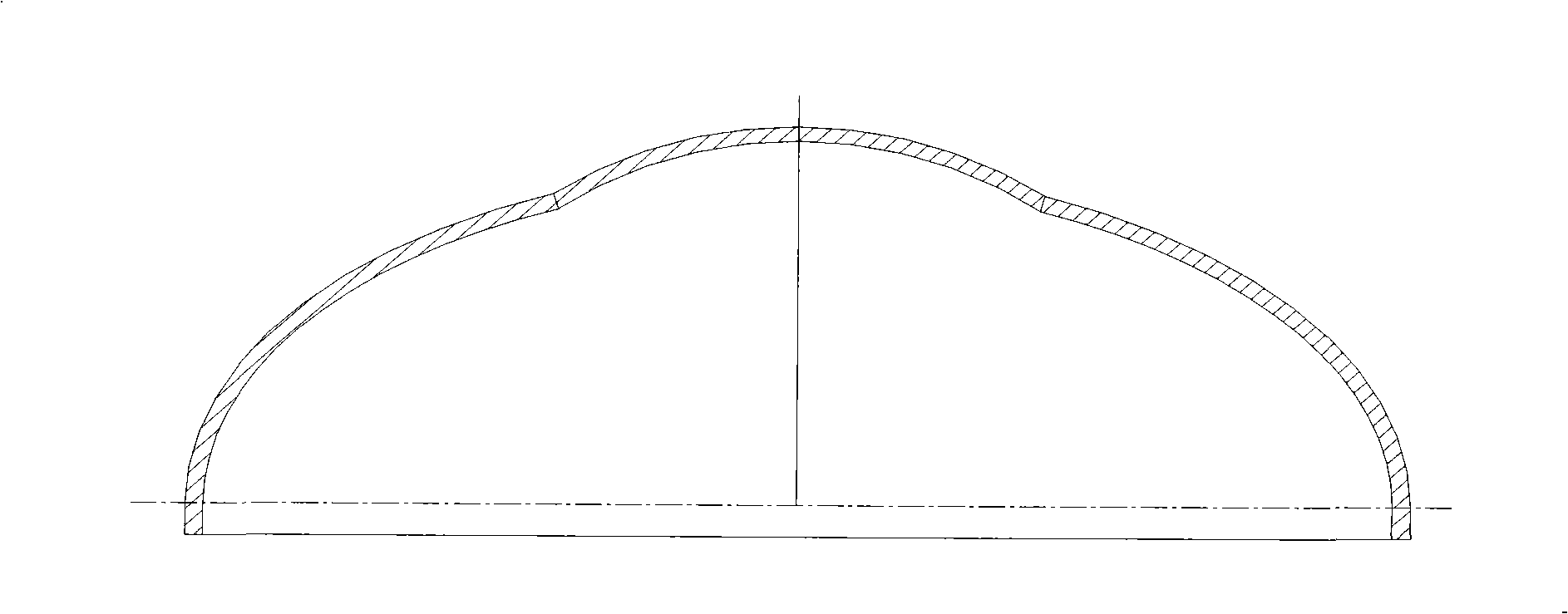

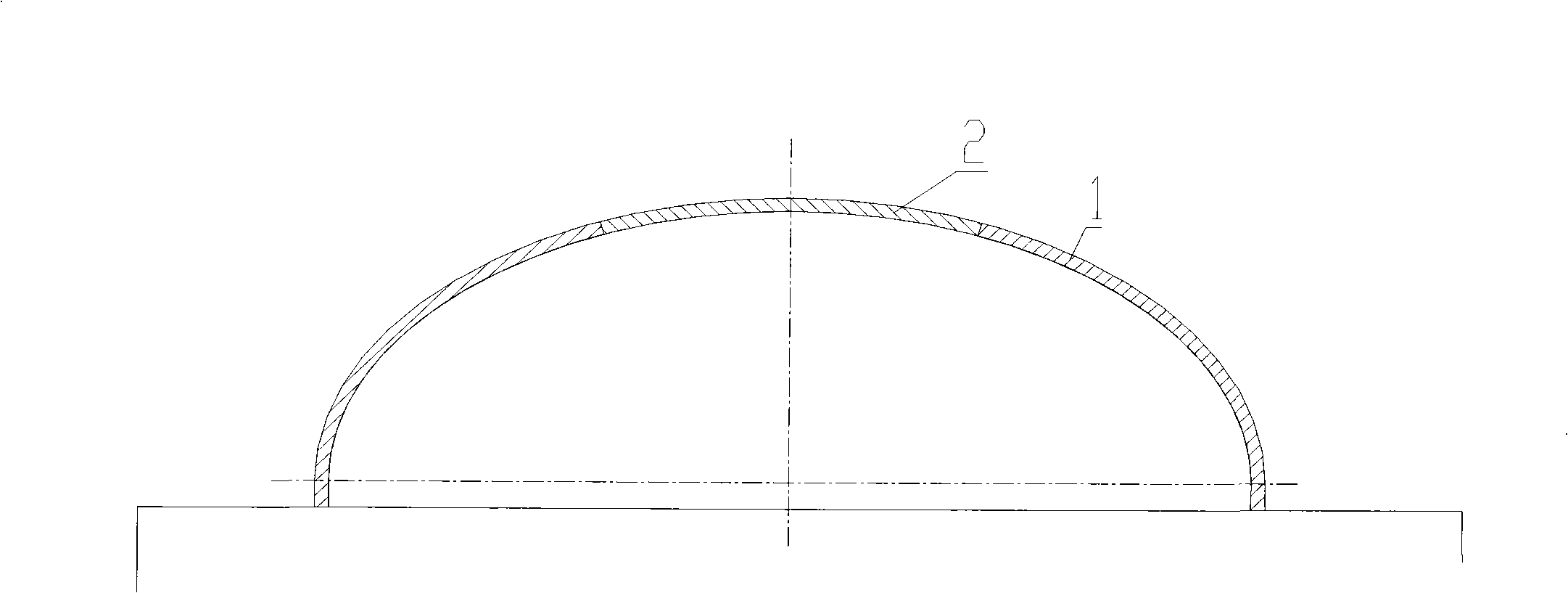

Processing welding technique of large closing end

ActiveCN101332555AEliminate shape mutationsPressure vesselsOther workshop equipmentEngineeringMachining

The invention discloses a machining and welding process of a large sealed head. The machining and welding process comprises the following steps: 1) a lobe die is machined; 2) a lobe is punched for forming; 3) a welding groove of the lobe is made, assembled and welded; and a smooth curve is drawn between the lobe generatrix and the sealed head vertex after assembling and welding; a machining die of a top round plate is made according to the smooth curve, and the top round plate is formed by pressing the machining die; the welding groove is machined; the top round plate and the lobe are welded. The machining and welding process of the large sealed head has simple operating steps, and can eliminate the deformation near a butt seam, and the sealed head welded by the machining and welding process has nice appearance and good stress.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

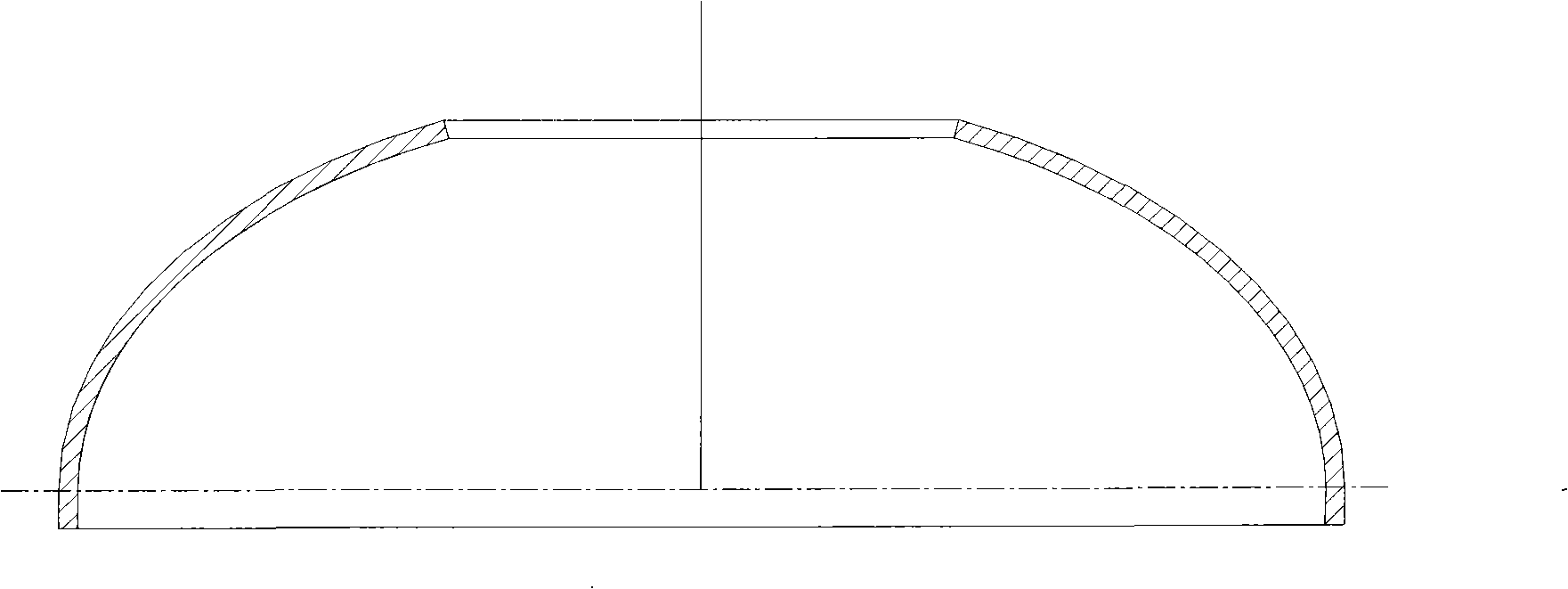

Precise grinding method for large-caliber axisymmetric aspheric surfaces

InactiveCN105014503AAvoid Principle ErrorsGuaranteed motion accuracyGrinding feed controlLensHyperboloidEngineering

A ground workpiece, a grinding wheel main shaft and a grinding wheel grinding tool are involved in a precise grinding method for large-caliber axisymmetric aspheric surfaces. The ground workpiece is fixedly arranged on a rotating working table. The top face of the ground workpiece is an aspheric surface. The grinding wheel main shaft is arranged on a y-axis feed slide base connected with an x-axis feed slide base. The grinding wheel grinding tool is fixed to the grinding wheel main shaft. The precise grinding method is characterized in that the rotating central line of the grinding wheel main shaft is controlled by a three-axis linkage control model to coincide with the normal of a grinding point on the generatrix of the aspheric surface all the time so that principle errors caused by grinding feed movement tracks can be avoided and the movement precision can be ensured; The aspheric surface is ground through the end face of the grinding wheel grinding tool so that the grinding ratio can be increased; and meanwhile, loss of the grinding wheel grinding tool is compensated for through a real-time detection method so that the grinding efficiency can be improved. A movement mechanism is simple, the grinding efficiency is improved, the grinding accuracy is ensured, and the precise grinding method can be suitable for grinding paraboloids of revolution, hyperboloids of revolution, ellipsoids of revolution and other large axisymmetric aspheric surfaces.

Owner:SHANGHAI JIAO TONG UNIV +1

Rotatable tool for chip removing machining as well as a loose top and a basic body therefor

ActiveUS20110236145A1Strong and robustTool workpiece connectionTransportation and packagingEngineeringFront and back ends

A rotatable tool for chip removing machining, including a basic body having front and rear ends between which there extends a first geometrical center axis (C1) around which the basic body is rotatable in a predetermined direction of rotation, and a loose top having front and rear ends between which a second geometrical center axis (C2) extends. The front end of the basic body includes a jaw, which is delimited by two drivers and an intermediate bottom and in which a part of the loose top is received. A centering pin protrudes axially rearward from the loose top and is inserted in an axial center hole, which mouths in the bottom of the jaw and in which a threaded hole mouths for a screw co-operating with the center pin. The center hole includes a cylindrical support surface, which is concentric with the center axis (C1) of the basic body and against which the centering pin of the loose top is pressed by the screw. The centering pin of the loose top includes first and second diametrically opposed, external surfaces, each having an axial extension and a peripheral extension, the first external surface forming a contact surface that is pressed against the support surface of the center hole and extends tangentially between two axially extending boundary generatrices, which are situated along an imaginary circumscribed circle (S2) having a center (MP2) coinciding with the center axis (C2) of the loose top, and between which an arc angle (β) is less than 180°, the second external surface forming a clearance surface that lacks contact with the inside of the center hole as a consequence of the cross-sectional area of the centering pin being smaller than the cross-sectional area of the center hole. The circumscribed circle (S2) has a radius (r2) that is equally great as the radius (r1) of an inscribed circle (S1) along the cylindrical support surface of the center hole. A greatest radial distance (RD2) between the center axis (C2) of the loose top and a point on the clearance surface of the centering pin is greater than the radius (r2) of the circumscribed circle (S2) but smaller than a corresponding distance (RD1) between the center axis (C1) of the basic body and a clearance surface situated in the center hole and opposite the support surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

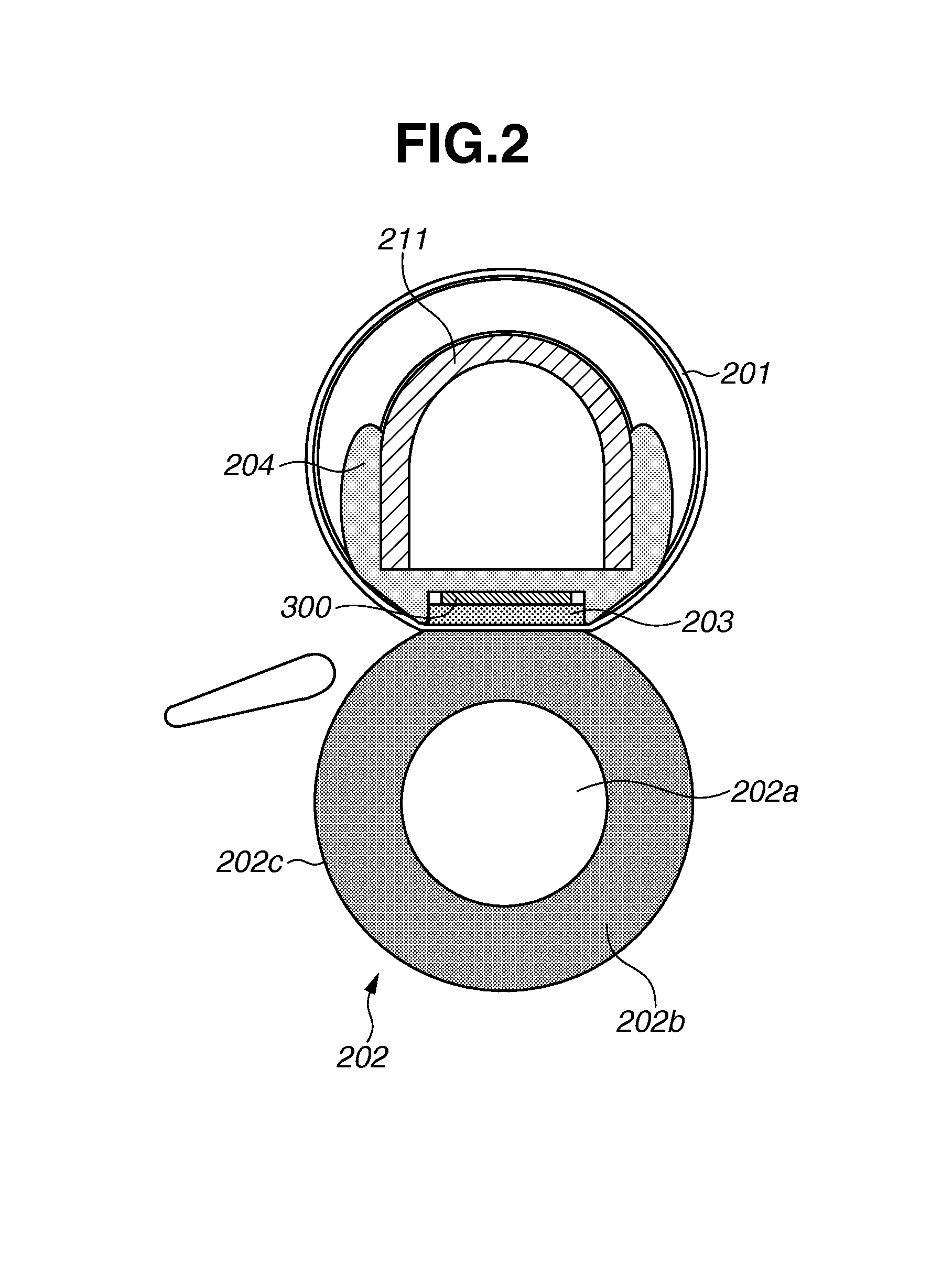

Fixing device

A fixing device includes a cylindrical film, a planar heater, a heat conduction member, a supporting member, a limiting member for limiting heater end portions with respect to a generatrix direction of the film so as to prevent the end portions from moving in a heater thickness direction relative to the supporting member, and a pressing member. A fixing device state is switchable between a first state in which a press-contact force in the nip is enough to fix the toner image and a second state in which the press-contact force in the nip is smaller than the press-contact force in the first state. A surface where the supporting member opposes the heat conduction member has a shape such that with respect to the generatrix direction, a central portion of the film is projected toward the pressing member than an end portion of the film.

Owner:CANON KK

Spin-free stepless transmission unit

The invention discloses a spin-free stepless transmission unit and aims to provide a spin-free stepless transmission unit which can avoid loss of spin efficiency in certain range of gear ratio. The spin-free stepless transmission unit comprises a spin-free input cone disc (5), a spin-free output cone disc (7) and a spin-free idler wheel (6) which are pressed and in contact by means of clamping force; power is transmitted by traction; speed regulation is realized by swinging the idler wheel by a certain angle; generatrices of rotating curved surfaces of the spin-free input cone disc (5) and the spin-free output cone disc (7) are a logarithmic curve. In a speed regulation process, the rotating axes of the spin-free input cone disc (5), the spin-free output cone disc (7) and the spin-free idler wheel (6) of the spin-free stepless transmission unit and a common tangent of contact points are intersected at one point. The spin-free stepless transmission unit is used for replacing stepless transmission units in various annular stepless transmissions.

Owner:SICHUAN UNIV

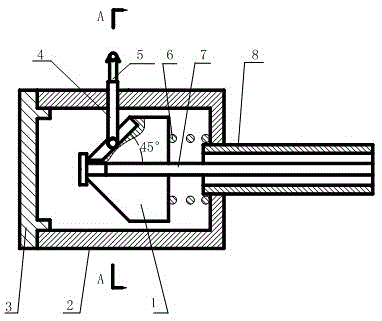

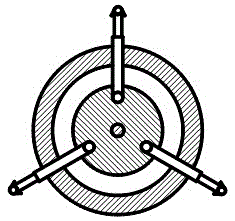

Depth aperture internal diameter measurement device

ActiveCN105547106AGuaranteed backingGuaranteed measurement accuracyMechanical diameter measurementsMeasurement deviceCircular cone

The invention discloses a depth aperture internal diameter measurement device, comprising a tapered block, a sleeve, three measurement rods, a spring, a push rod, a sleeve rod, a thread sleeve rod, a three-claw chuck and an internal diameter dial indicator. The conical surface of the tapered block is uniformly provided with three sliding grooves which are formed along the generatrix direction of the tapered block; the included angle between each sliding groove and the axis of the tapered block is 45 degree; the wall of the sleeve is provided with three through holes which are uniformly distributed along the circumference; three measurement rods pass through the through hole in the wall of the sleeve; and one end of the measurement rod is clamped inside a sliding groove. In the invention, the included angle between the sliding groove and the axis of the tapered block is 45 degrees and the displacement of the measurement rod along the radial direction is turned into an axial direction, which avoids the intermediate transfer between the levers in the traditional measurement, has more accurate measurement and can measure the maximum and minimum diameter of any cross section.

Owner:NANJING COLLEGE OF INFORMATION TECH

Fixing apparatus

A fixing apparatus for fixing a toner image to a recording material includes a cylindrical film, a heater configured to make contact with the film, the heater including a substrate and a heat generation resistor formed on the substrate, and a heat conduction member configured to make contact with a surface of the heater opposite to a surface thereof being in contact with the film, the heat conduction member having a higher thermal conductivity than that of the substrate, and being divided into parts in a generatrix direction of the film. The toner image formed on the recording material is fixed on the recording material by using heat of the film, and one of the parts of the heat conduction member is configured to make contact with the heater continuously from a center to an end of a heat generation region of the heater in the generatrix direction.

Owner:CANON KK

Cutting and folding assembly for products such as tissues, napkins and the like

InactiveUS20080176729A1Avoid separationAccurate configurationMechanical working/deformationFolding thin materialsPressure generationSuction stress

A cutting and folding assembly for sheet products of the multiple-ply type, comprising at least one rotatably supported first roller with cutting blades for cutting the continuous ribbon substantially transversely, associated with a rotary actuation; at least one rotatably supported second roller, associated with a rotary actuation, the second roller provided with a first retention suction for the products cut; and at least one third rotatably supported folding roller, that has a rotary actuation and a second retention suction for cut products, the first, second and third rollers having parallel axes and being in contact along respective generatrices, the second roller being provided with a pressure generation element for generating pressure on the back of the products to keep their plies in contact with the third roller during the formation of the transverse fold.

Owner:S TECH CO LTD

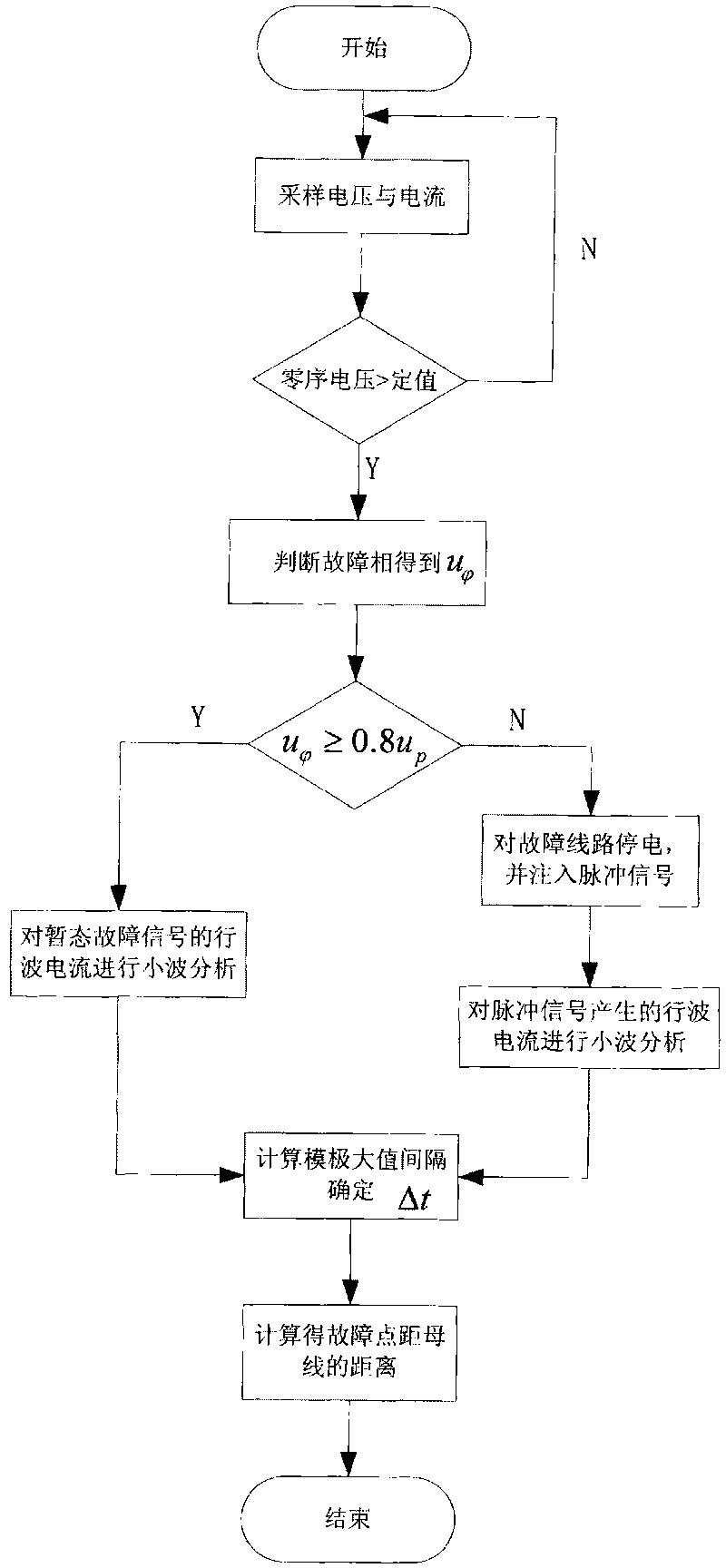

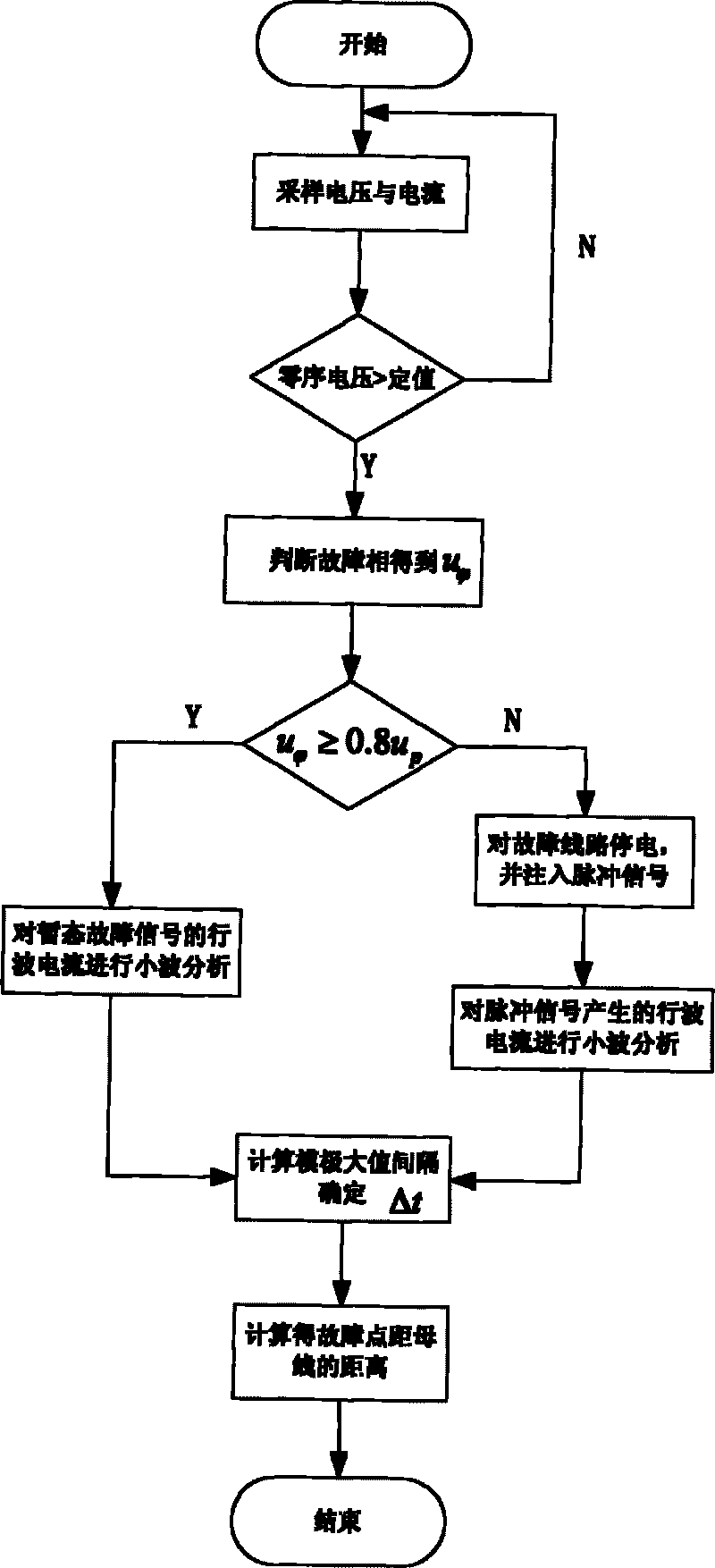

Method for locating single-phase grounding fault by adopting transient state travelling wave and injection method

InactiveCN101706547AImprove accuracyOvercome the shortcomings that easily cause inaccurate positioningFault location by pulse reflection methodsTransient statePower grid

The invention relates to a method for locating a single-phase grounding fault by adopting a transient state travelling wave and an injection method, which is suitable for locating a single-phase grounding fault of a low-current grounding system. The method solves the defects of a single fault locating method, thereby improving the fault locating accuracy. The method comprises the following steps of: (1) sampling a zero sequence voltage, and calculating and judging whether the zero sequence voltage exceeds a setting threshold value or not; if the zero sequence voltage exceeds the setting threshold value, showing that an electricity grid has a single-phase grounding fault, and then executing the following steps; (2) judging a fault phase according to the voltage change law in a system single-phase fault, then obtaining a phase voltage at the fault moment, and comparing the obtained phase voltage with 0.8up, wherein up is a system phase voltage peak value; (3) if the wavelet analysis is carried out on a transient state travelling wave signal, determining the time delta t for the travelling wave to go to and fro between a fault point and a generatrix once, thereby calculating the distance from the fault point to the generatrix; (4) and if a fault circuit is selected, cutting the power of the fault circuit, injecting a pulse signal to the fault signal, carrying out wavelet transform, detecting the reflected wave of the fault point, thereby obtaining delta t, and then calculating the distance from the fault point to the generatrix.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com