Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2646 results about "Dynamometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

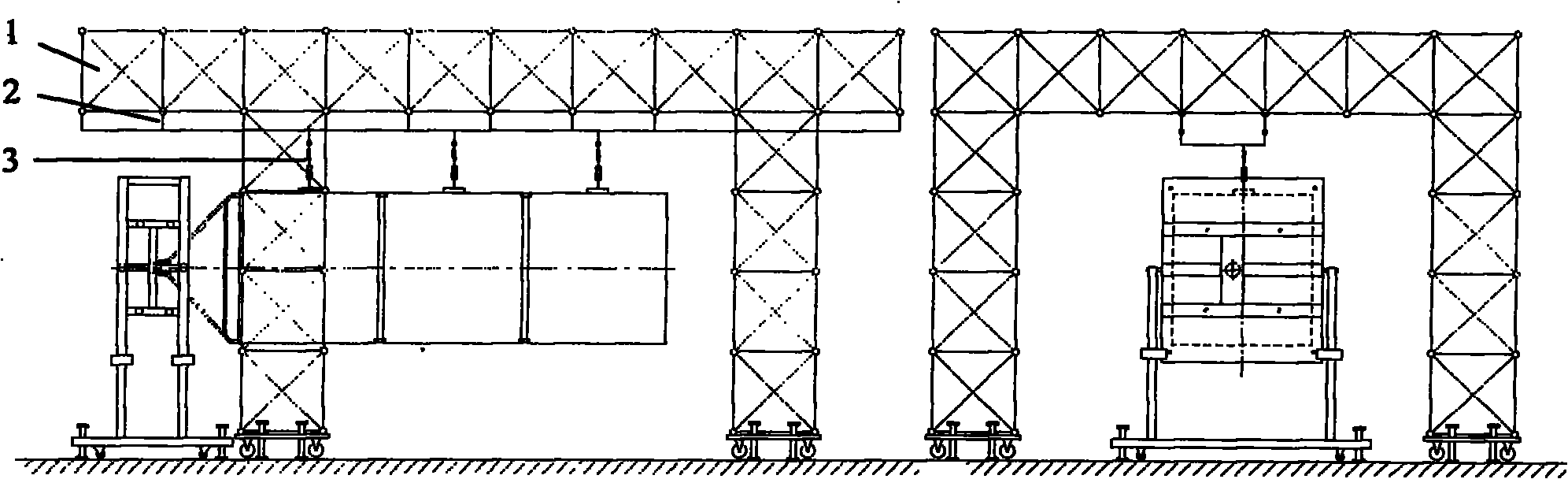

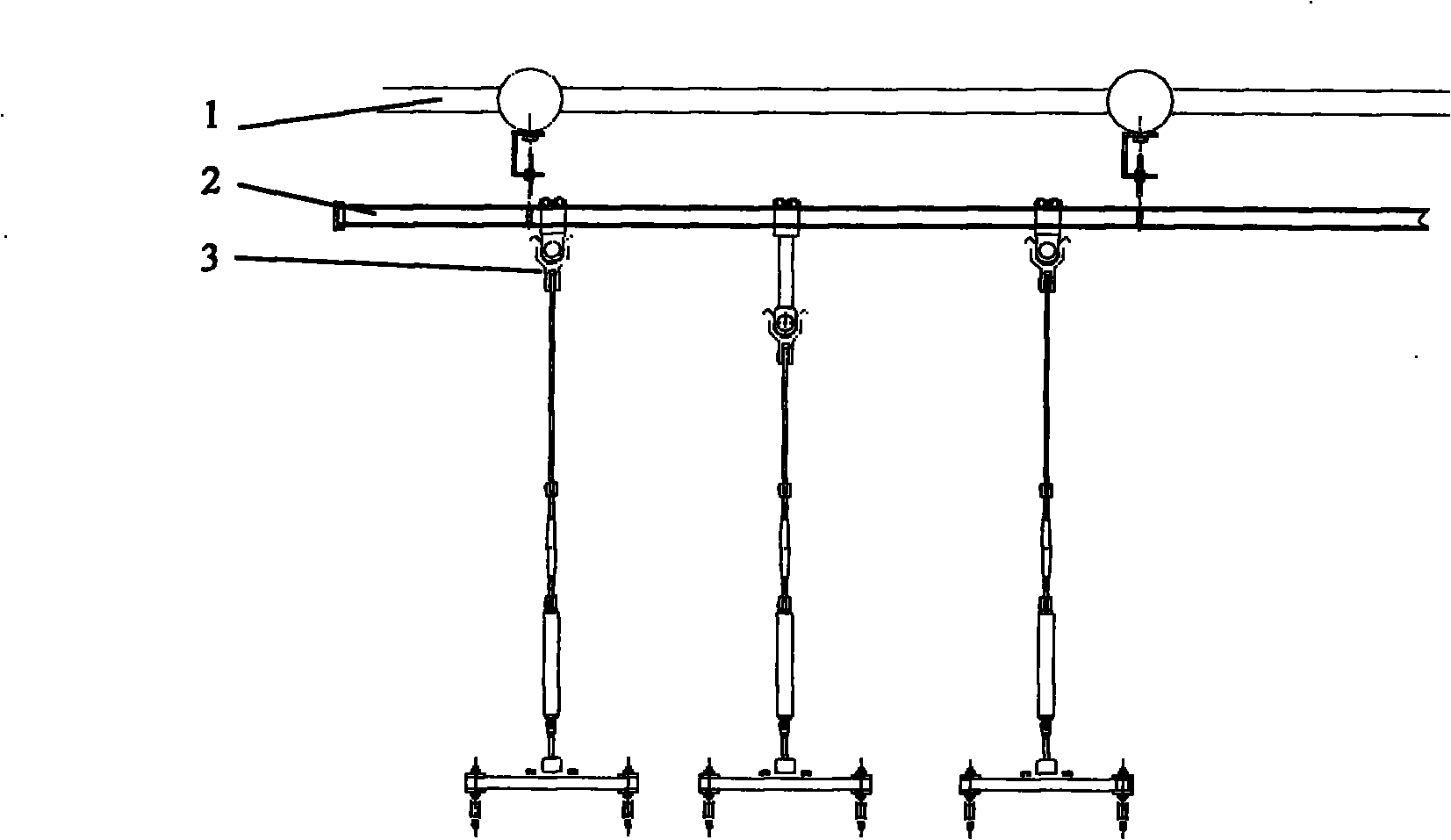

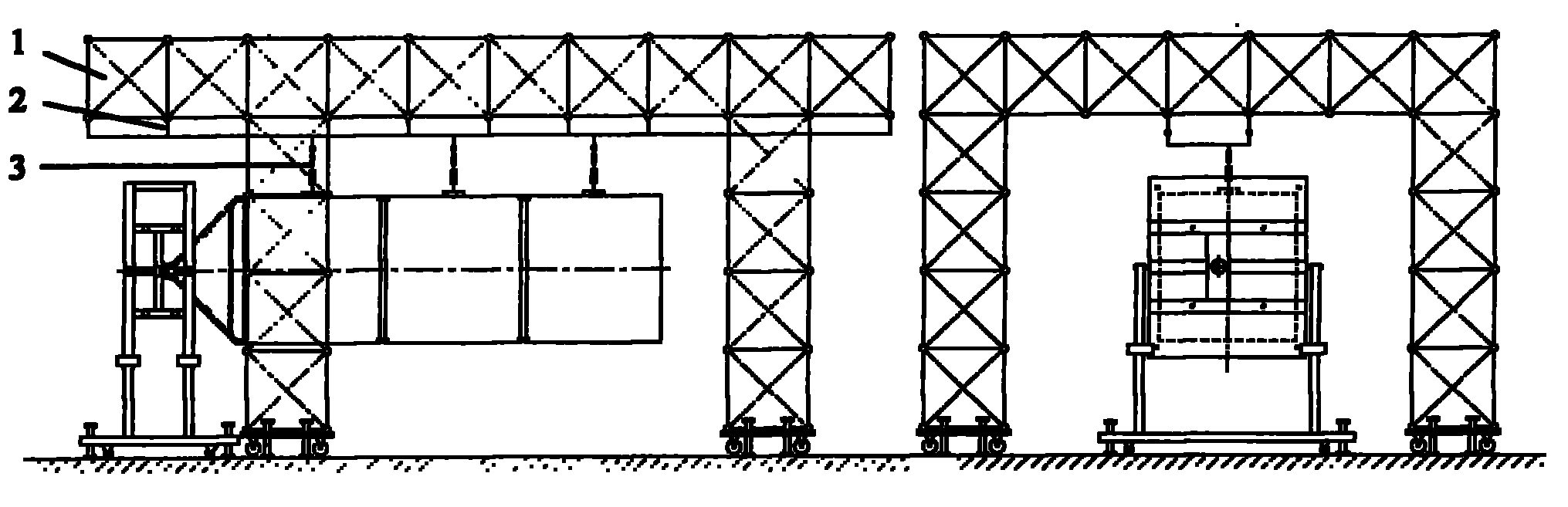

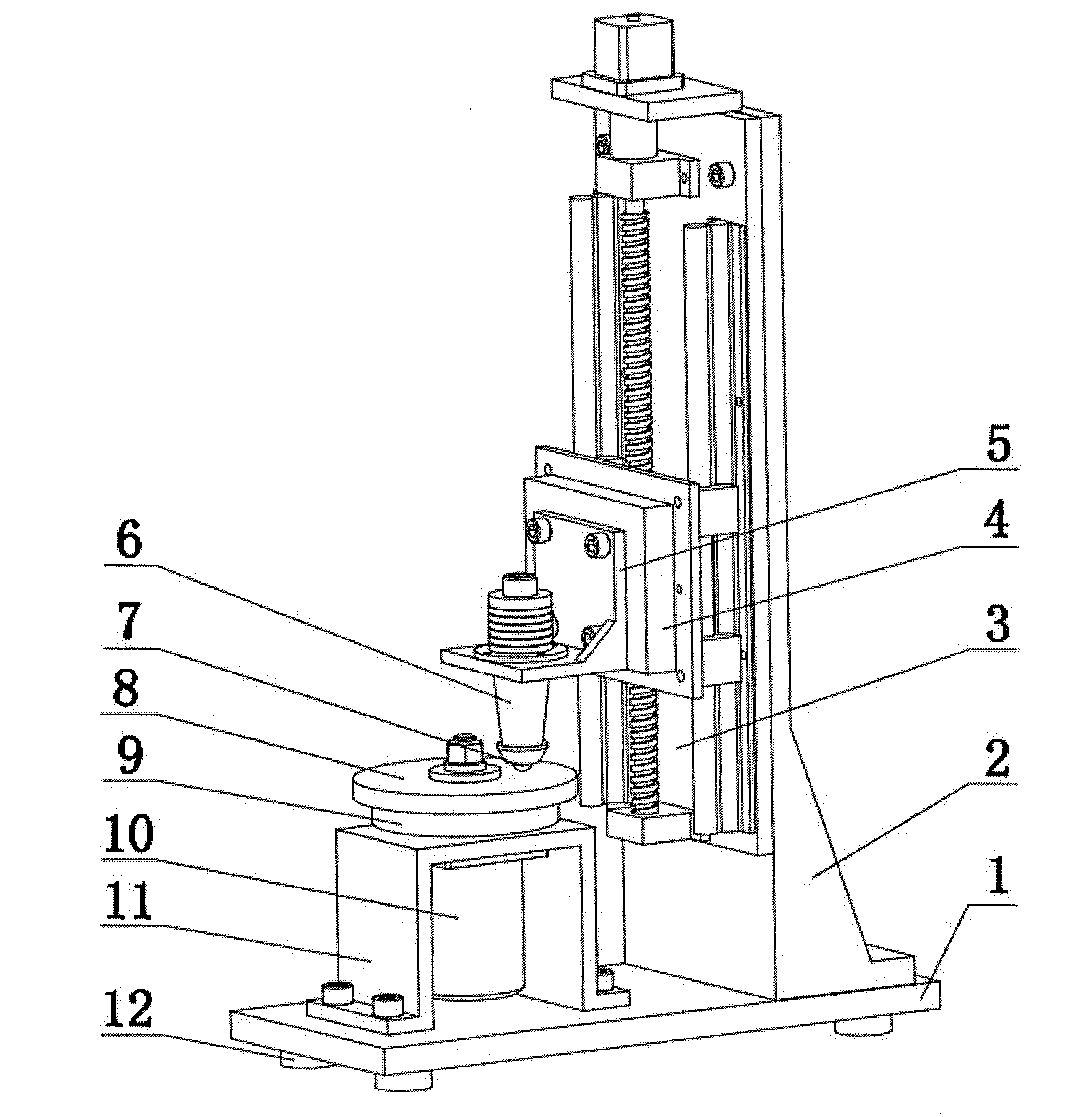

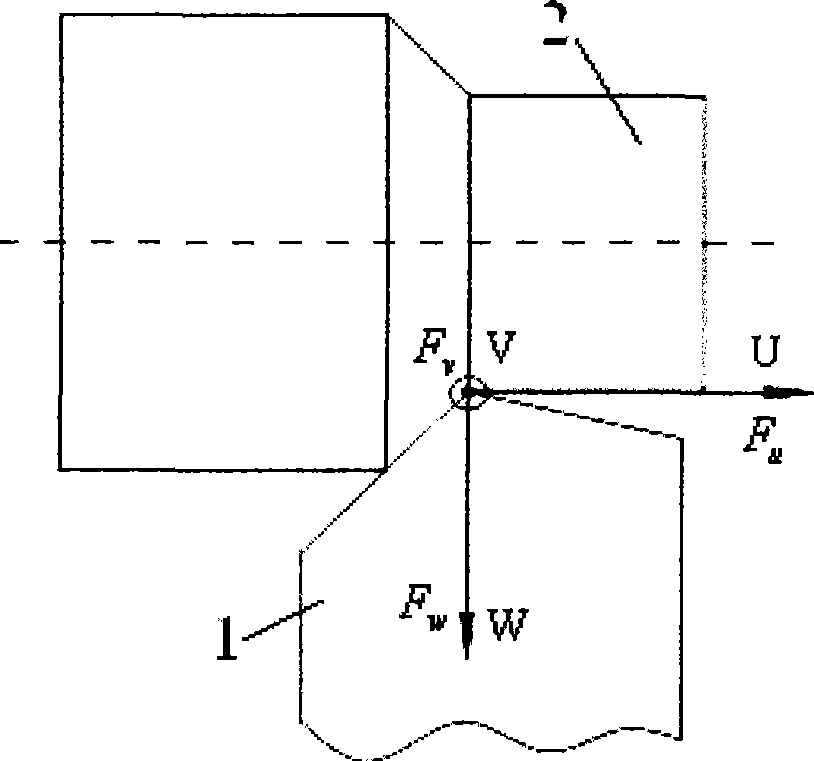

Zero-gravity suspension type deployment test device

ActiveCN102145755AThe overall structure is simple and reliableFlexible moving processCosmonautic condition simulationsSupporting systemEngineering

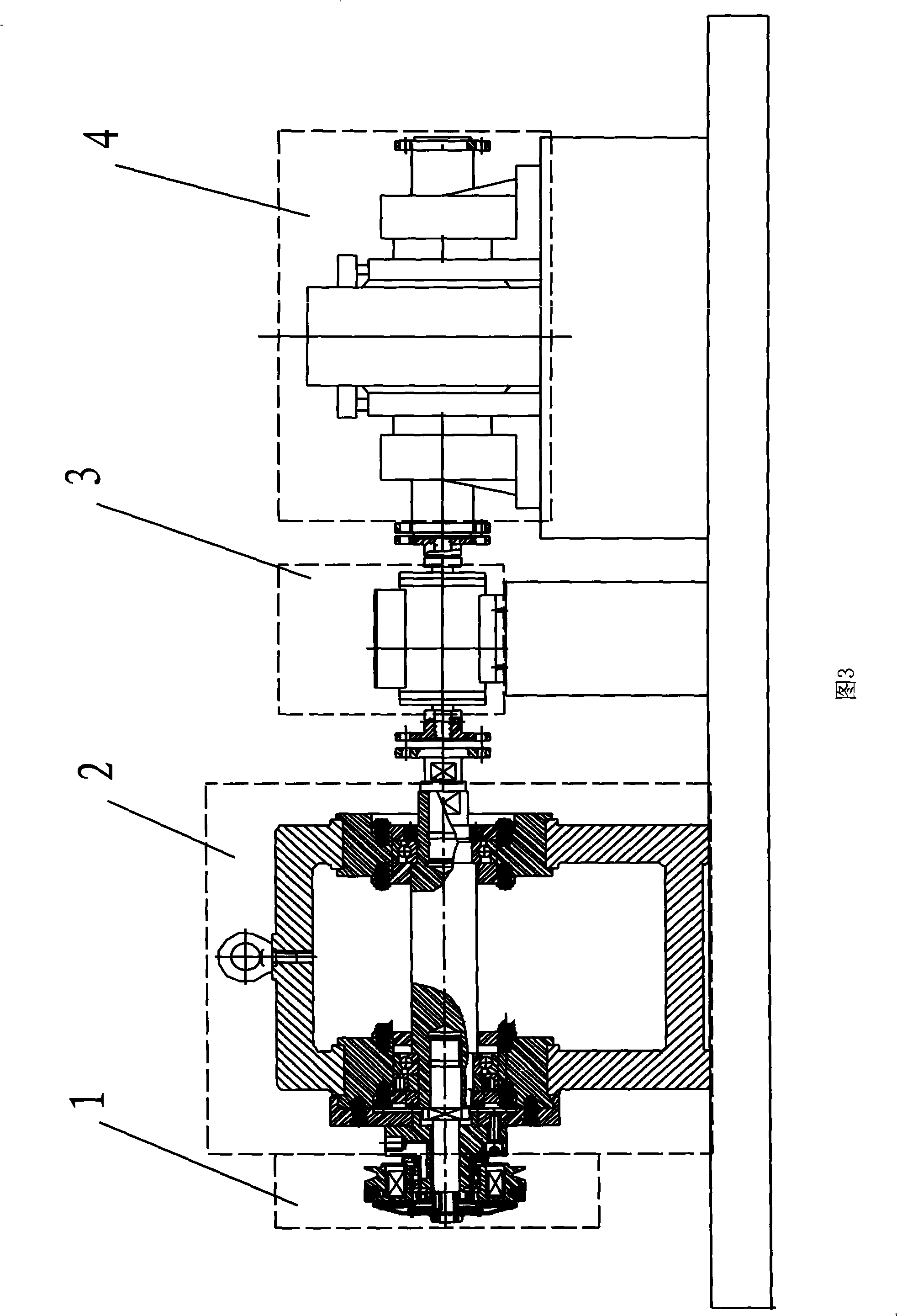

The invention relates to a solar cell array and antenna deployment test device for spacecraft such as a satellite and the like, and provides a zero-gravity suspension type deployment test device which overcomes the shortcomings of the air-floating deployment test device in the prior art and solves the problem existing in simulation of the zero-gravity state of the environment orbit of the solar cell array and antenna of the satellite in the ground gravity environment. The zero-gravity suspension type deployment test device is characterized by comprising a support system [1], a guide rail system [2] and a hanging system [3]. The support system [1] comprises four upright frames and a horizontal frame. The guide rail system [2] comprises two longitudinal guide rails, multiple transverse guide rails and a guide rail hanger. The guide rail system [2] is mounted below the horizontal frame. The hanging system [3] comprises a rolling bearing frame, a tubular dynamometer and a connecting piece. Through the invention, the problems existing in simulation of the zero-gravity state of the environment orbit of the solar cell array and antenna of the satellite in the ground gravity environment and the like are solved, and beneficial effects of simple structure, convenience in use, strong adaptability and the like are obtained.

Owner:SHANGHAI SATELLITE ENG INST

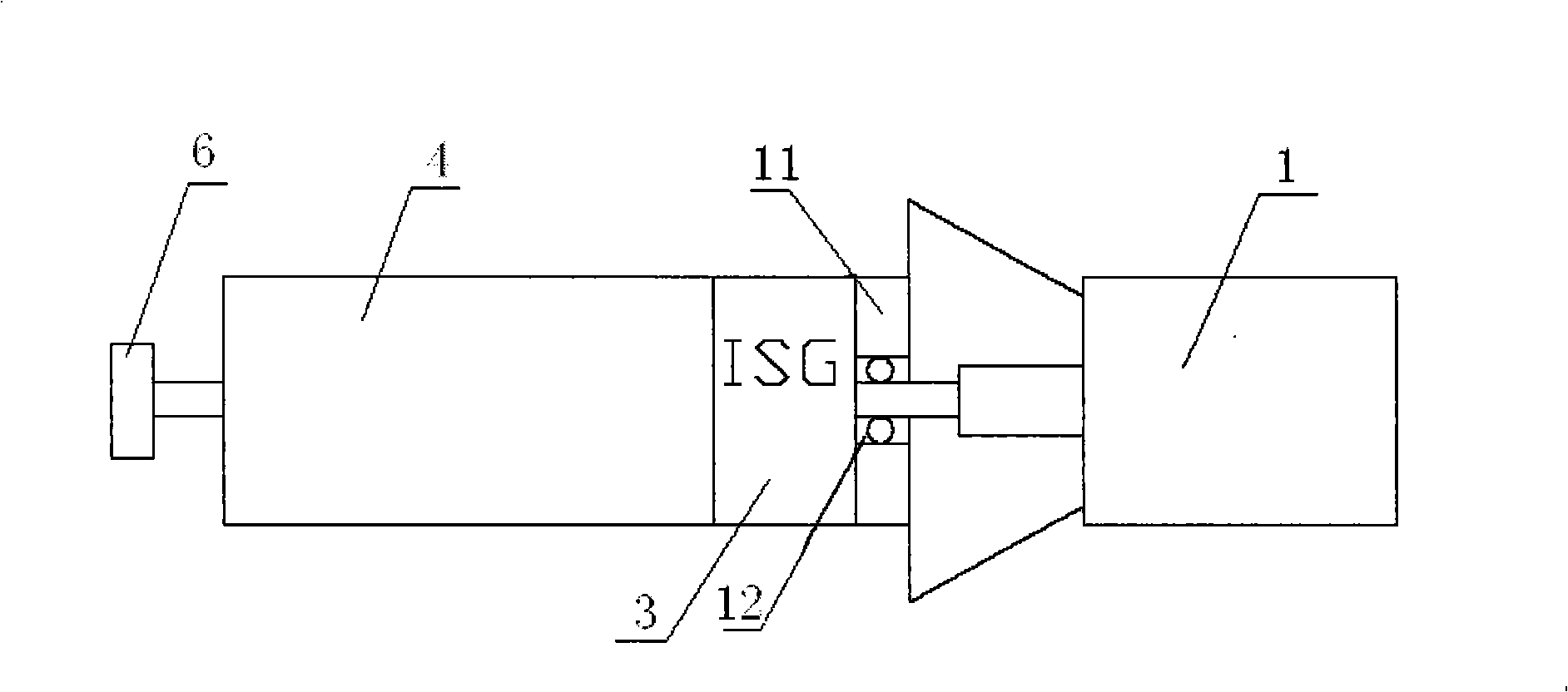

Hybrid power assembly performance matching test bench

The invention discloses a hybrid power assembly performance matching test bench which comprises an engine, a clutch, a speed changer, an engine controller ECU, a power generating / motor-driven integrated motor ISG, a motor controller IPU, a power battery pack, a battery management system ECU, a vehicle controller HCU, a DC converter DC / DC, a shift mechanism, a clutch pedal, a brake pedal, an accelerator pedal, two dynamometers, a bench control system and a rapid control prototype dSPACE. The test bench has the advantages that the entire vehicle state is simulated on an engine test bench, the main parts of the hybrid power system, the power battery pack, the BCU, the HCU, the IPU and the DC / DC are arranged by simulating the entire vehicle state, the sturcture is compact, the testing programis simple, the performance matching of the hybrid power assembly can be easily realized on the test bench, and NEDC and other condition tests can be conducted by simulating the entire vehicle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

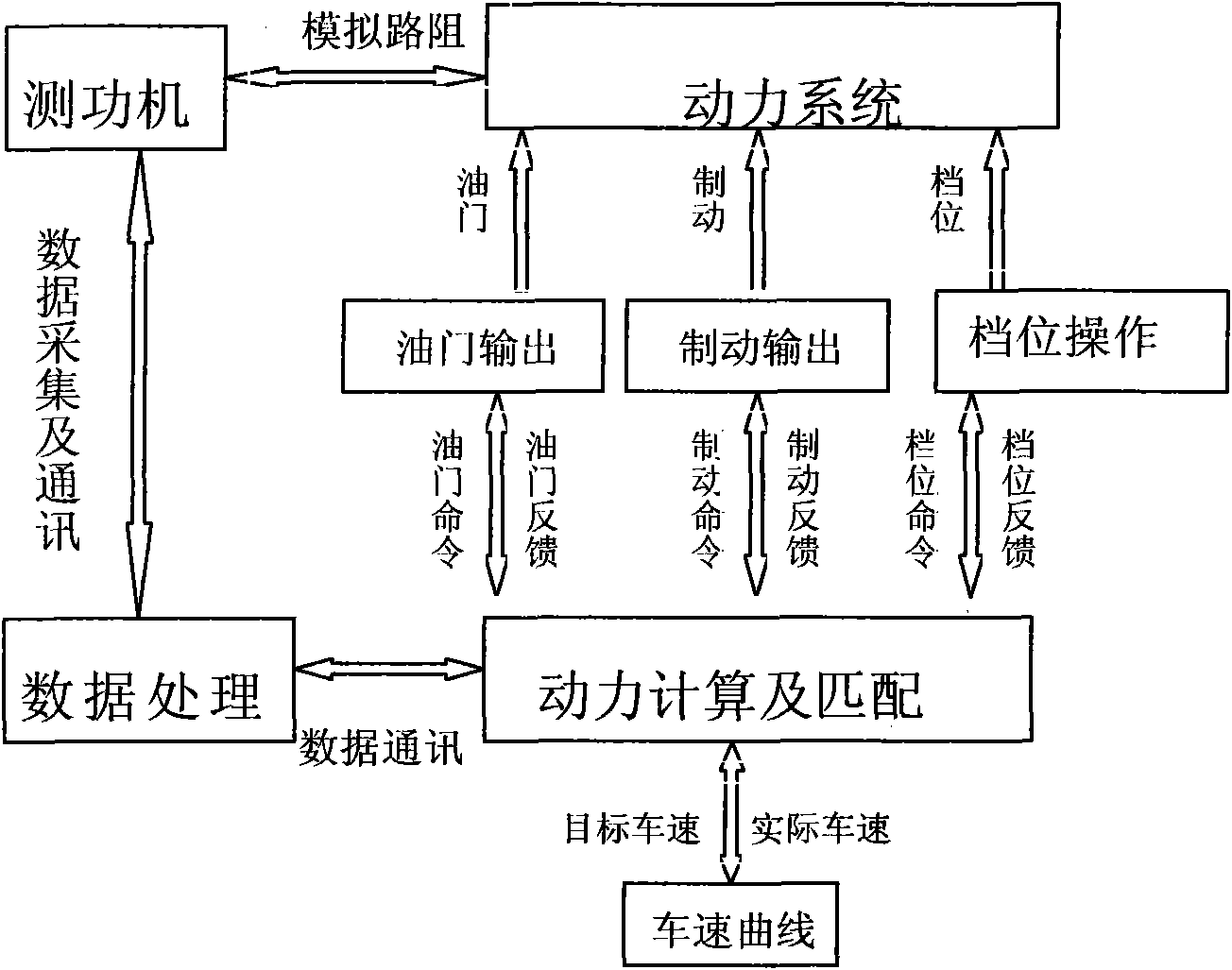

Driving simulation test method for test bench of power system of electric automobile

ActiveCN101916519AEasy and flexible operationLow costCosmonautic condition simulationsSimulatorsComputer moduleDynamometer

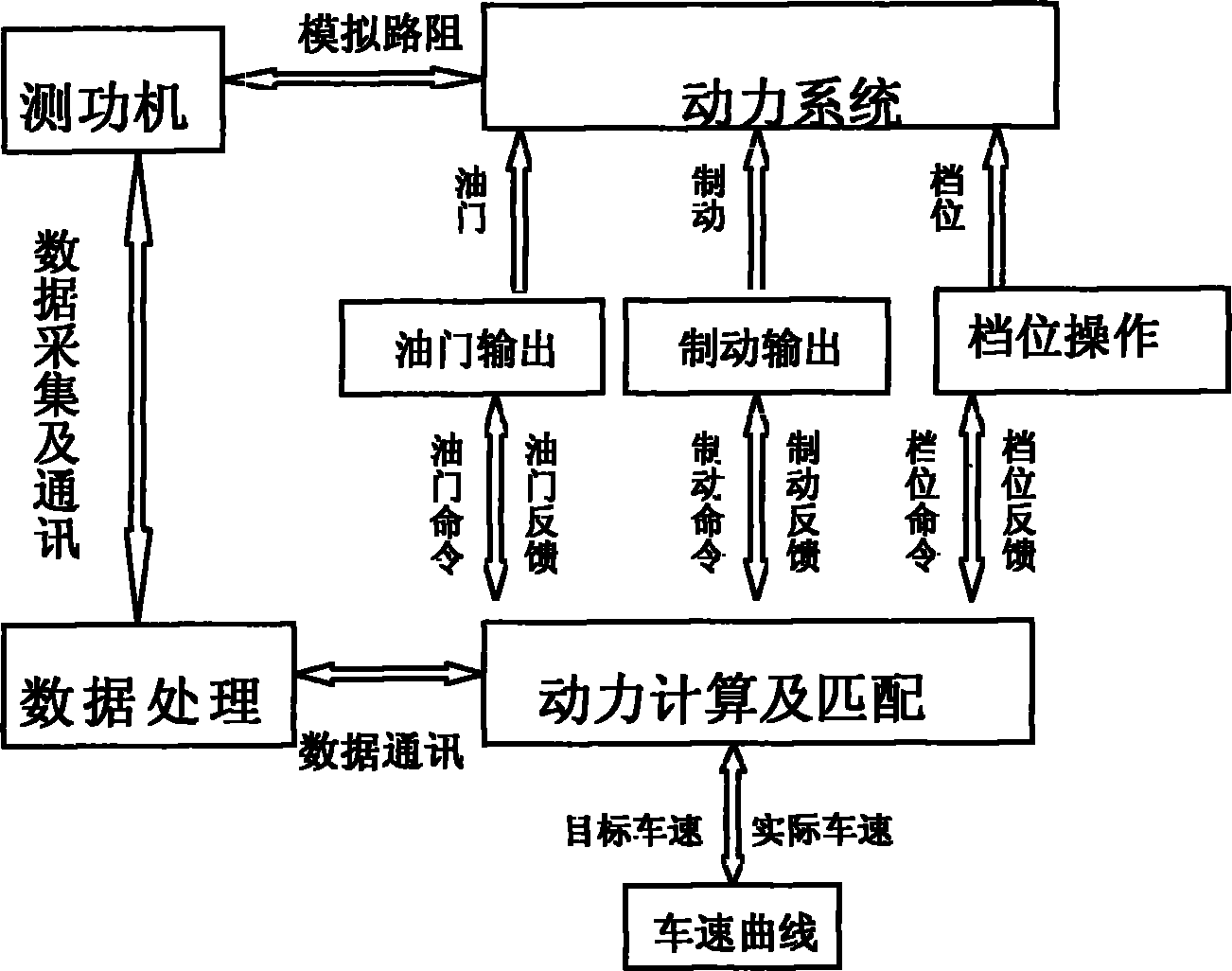

The invention relates to a driving simulation test method in the field of a power system of an electric automobile. In the method, a speed curve part, a power calculating and matching part, a data processing part, a dynamometer, a vehicle road impedance realization part, an accelerator output part, a brake output part, a shift operation part and the power system are combined, and the corresponding functional modules are integrated; by setting target speed-time parameters, technical parameters of different vehicles and the like and calculating and matching the power of the whole vehicle, different commands such as rotating speed, torque, accelerator, brake, clutch, shift and the like at different speeds are obtained, and components on a test bench of the power system of the electric automobile perform corresponding actions so as to complete driving simulation tests under different predetermined road conditions and different vehicle models; and analysis can be performed according to the acquired and recorded related data after the tests are finished so as to obtain the related performance analysis report of the power system and complete the driver driving simulation test on the test bench of the power system of the electric automobile.

Owner:CHANGSHA CRRC INTELLIGENT CONTROL & NEW ENERGY TECH CO LTD

Dynamic load simulating device and method for automobile power system test

InactiveCN102305715AAvoid Differential ValuesImprove dynamic stabilityMachine gearing/transmission testingEngine testingRolling resistanceDynamometer

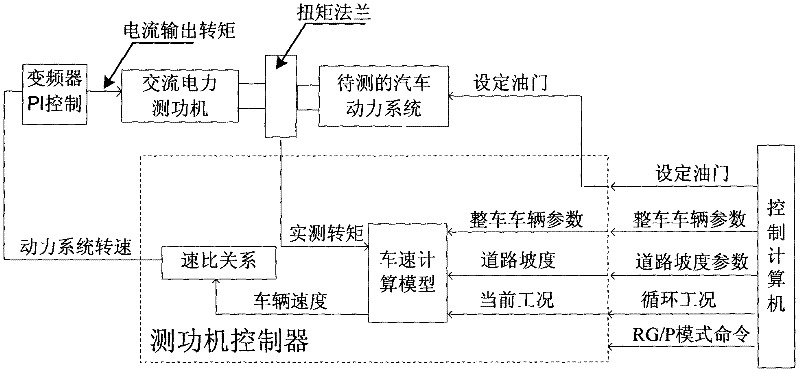

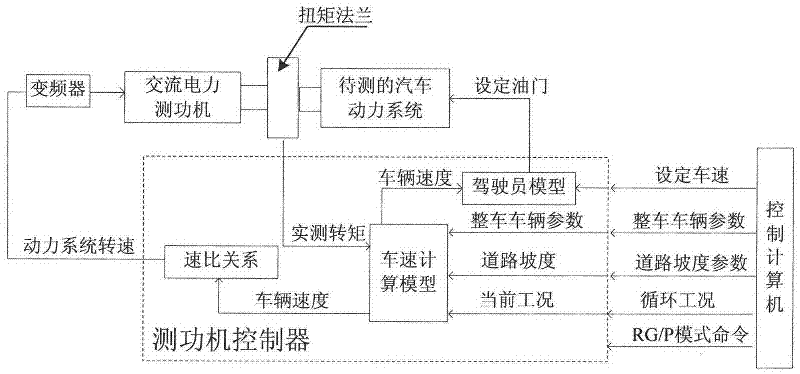

The invention relates to a dynamic load simulating device and a dynamic load simulating method for an automobile power system test, and belongs to the technical field of vehicle power system tests. The dynamic load simulating device comprises a control computer, a dynamometer controller, a frequency converter, an alternating current (AC) power dynamometer and a torque flange with a controller. A virtual automobile model-based control algorithm is adopted, a virtual automobile model is driven by an actual measurement torque, and the simulation of the rolling resistance, wind resistance and the inertia resistance of a vehicle is realized under the conditions of not calculating angular acceleration of the dynamometer. The dynamic load simulating device and the dynamic load simulating method have high stability and high simulation precision, are favorable for shortening the development cycle of an automobile power system and providing convenient test environment for the development of the power system. A process that the vehicle acceleration is acquired by differentiating the rotation speed of the automobile power system is avoided in the calculation process, and a phenomenon that accurate differential values are difficult to acquire due to relatively large noise caused by the process of differentiating the rotation speed is prevented.

Owner:TSINGHUA UNIV

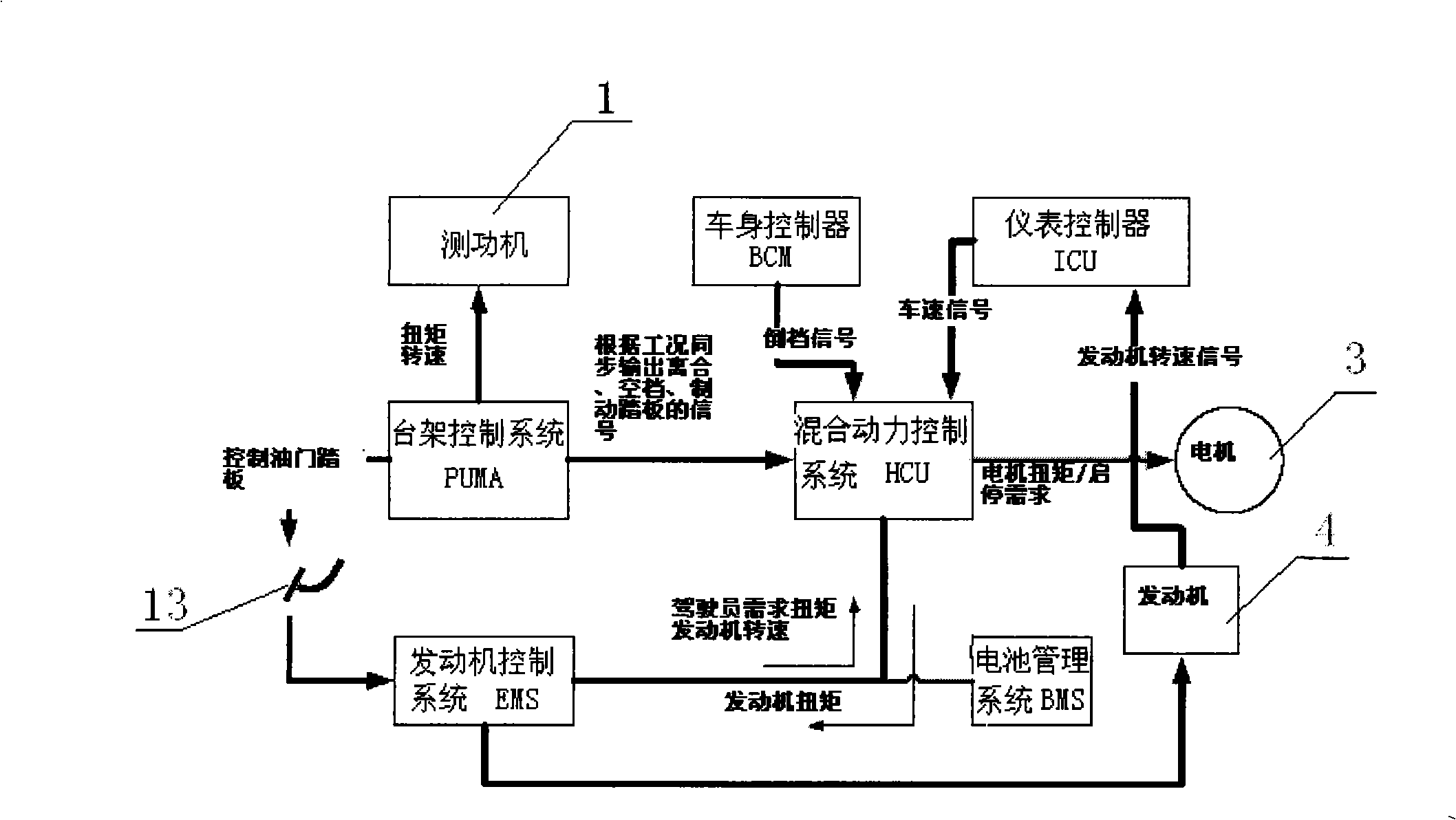

Hybrid power automobile dynamic force assembly durable test stand and test method

ActiveCN101261189AVerify validityVerify reliabilityVehicle testingEngine testingControl signalDynamometer

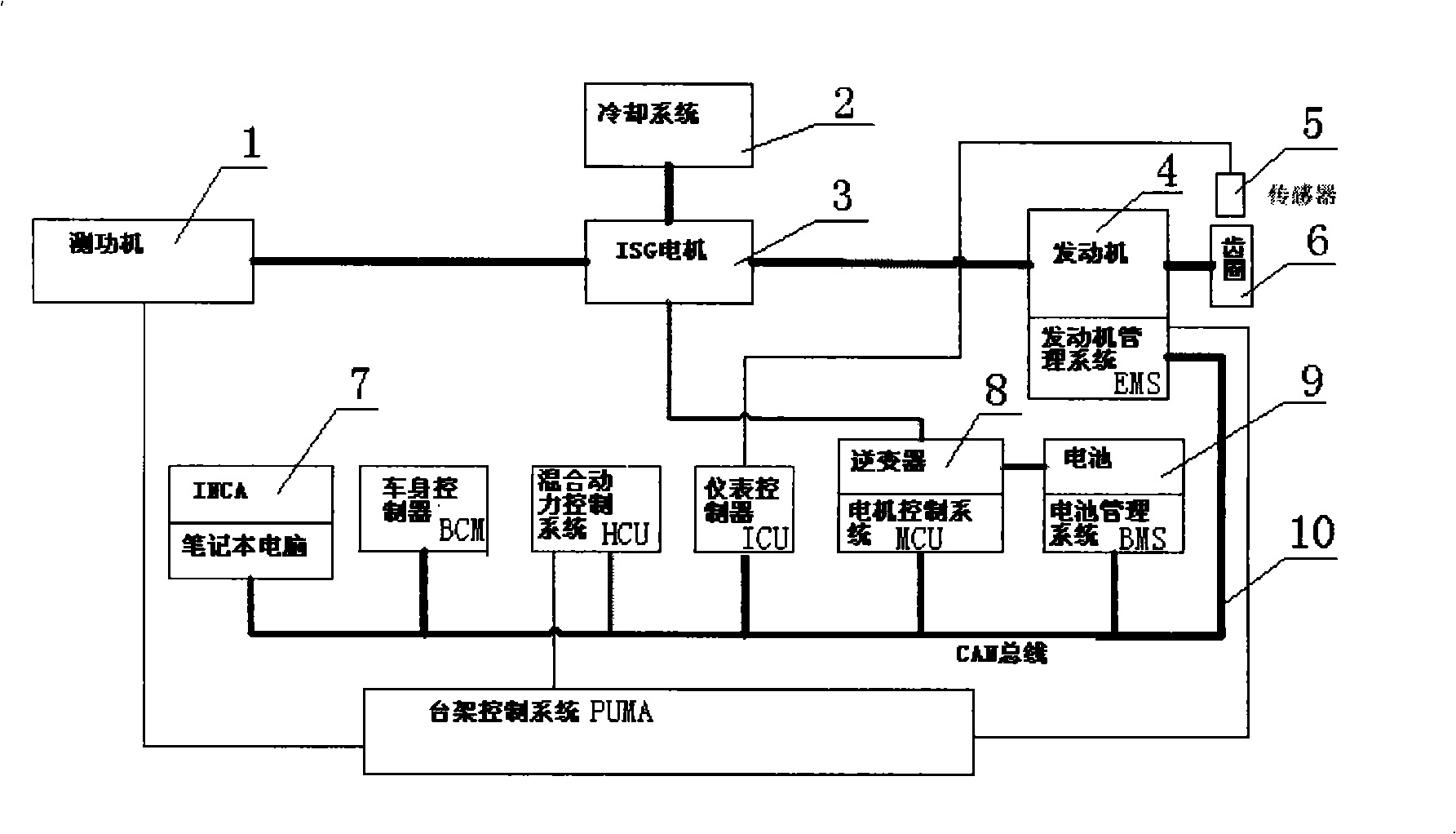

The invention discloses a hybrid electric vehicle power assembly durability testing frame and a testing method. A dynamometer is connected with an engine and a tooth ring through an ISG motor which is electrically connected with an inverter; a rotation speed sensor which is arranged at the external side of the tooth ring is connected with an instrument controller; a frame control system respectively emits test control signals to a hybrid electric control system, an engine management system and a dynamometer; the hybrid electric control system receives external signals and initiates the requirements of starting or stopping and torque to the engine management system and the motor control system according to a self-control strategy. The frame control system (PUMA) controls the operation of the dynamometer by a pre-arranged speed curve and a torque curve, thus leading the engine to run under the working conditions defined in advance. The distribution of motor torque and engine torque and the auxiliary driving torque of the motor are controlled by the hybrid electric control system according to the rotation speed of the engine and the torque requirement.

Owner:CHERY AUTOMOBILE CO LTD

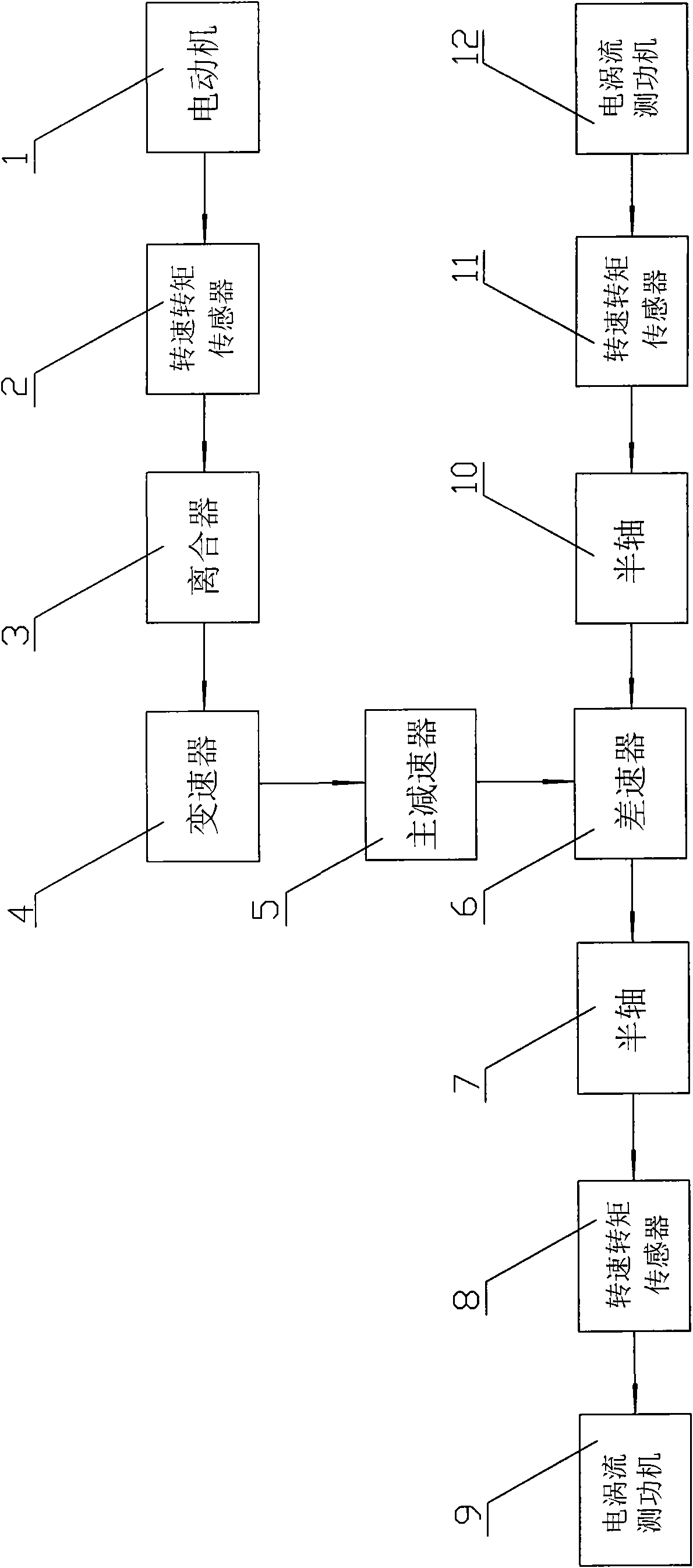

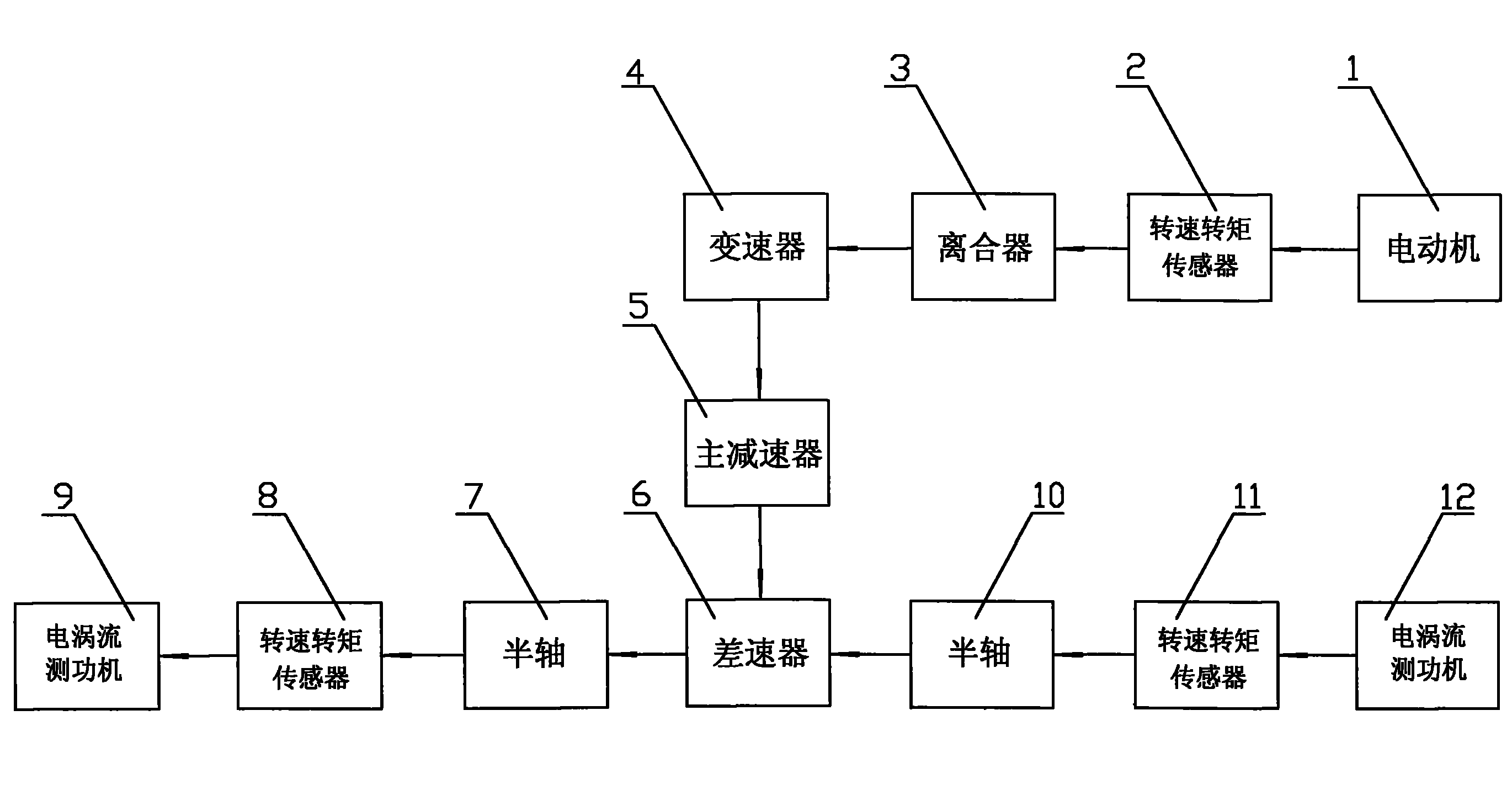

Test method of automobile transmission system efficiency

InactiveCN101846585ASimple test methodFast dynamic responseVehicle testingMachine gearing/transmission testingDynamometerEngineering

The invention relates to a test method of automobile transmission system efficiency, which comprises the following steps: a variable frequency and variable speed motor is connected with an automobile transmission system through a revolution speed and torque sensor; two eddy current dynamometers are respectively connected with two half shafts of the automobile transmission system through the revolution speed and torque sensor; a speed variator of the automobile transmission system is positioned at a certain shift; the target rotation speed of the two half shafts under the rotation speed of a certain variable frequency and variable speed motor is determined according to the transmission ratio; the variable frequency and variable speed motor is started, the eddy current dynamometers load the two half shafts respectively so that the two half shafts can reach the target rotation speed, and then the product of the sum of the torque of the two half shafts and the rotation speed of the half shafts is the output power of the automobile transmission system; and the output power and the product of the torque and the rotation speed of the variable frequency and variable speed motor are compared to obtain the transmission efficiency of the automobile transmission system. The test method is simple, and has quick dynamic response and high testing precision.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

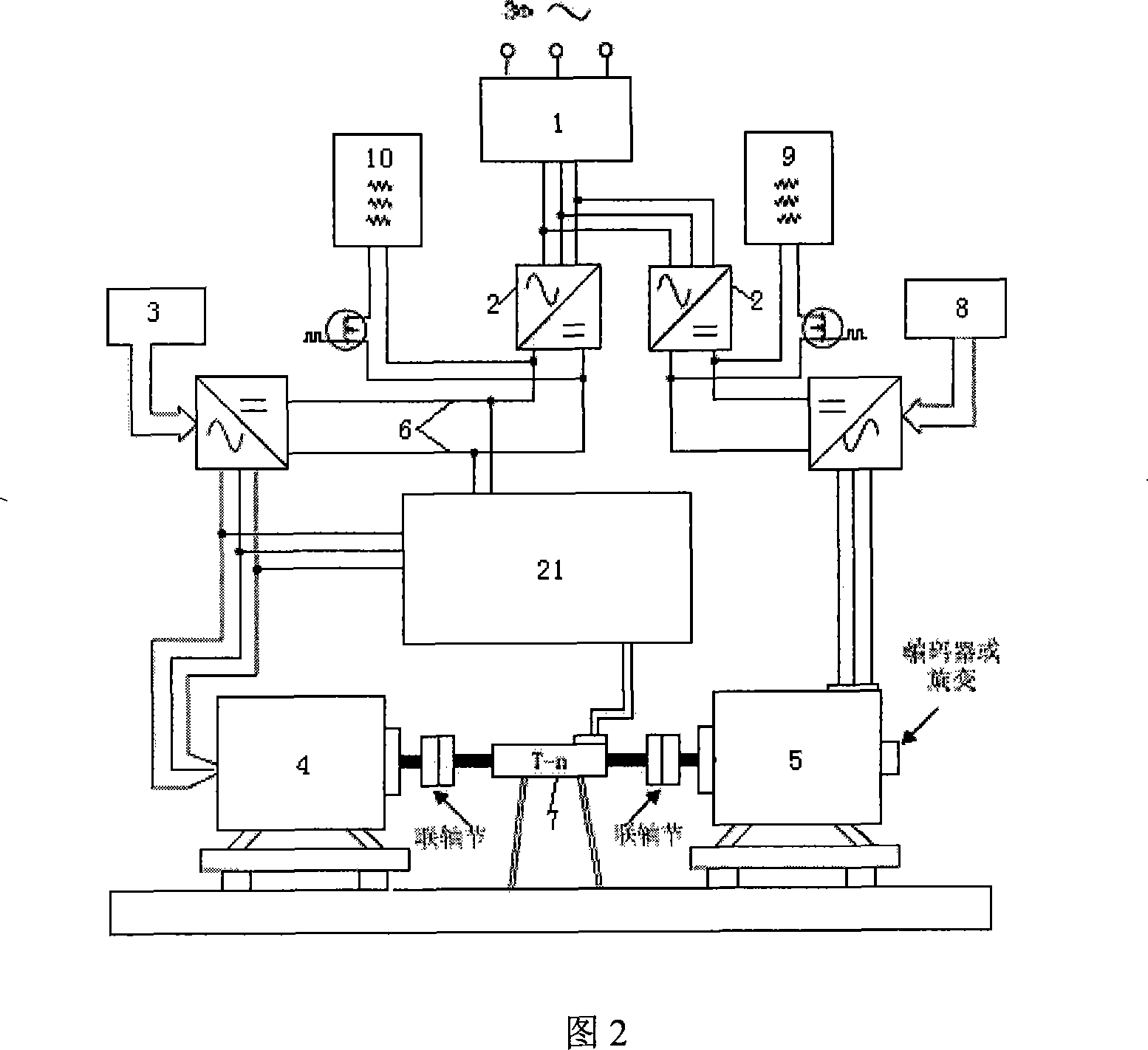

Hybrid power automobile drive electric motor test bench and test method

ActiveCN101241168AWide voltage rangeReduce lossVehicle testingDynamo-electric machine testingSkin complexionMotor testing

The present invention relates to test table for driving motor of hybrid electric vehicle to finish capability test of driving motor of hybrid electric vehicle and debugging function of control software. The table system has simple structure, convenient operation and maintains and high test precision. When the grades of motor and load voltage are identical, the system can work parallel with DC generatrix and feed back energy, the energy lose is less, the power supply need to provide system loss energy is about 10% to 20%, the cost is reduced greatly and the requirement of capacity of power supply is little. When the grades of motor and load voltage aren't identical, two complexions are happened, when motor is as driver, energy is applied to load resistance box by dynamometer system or power supply; when the motor is as generator, the energy is applied to load resistance box by power supply.

Owner:CHERY AUTOMOBILE CO LTD

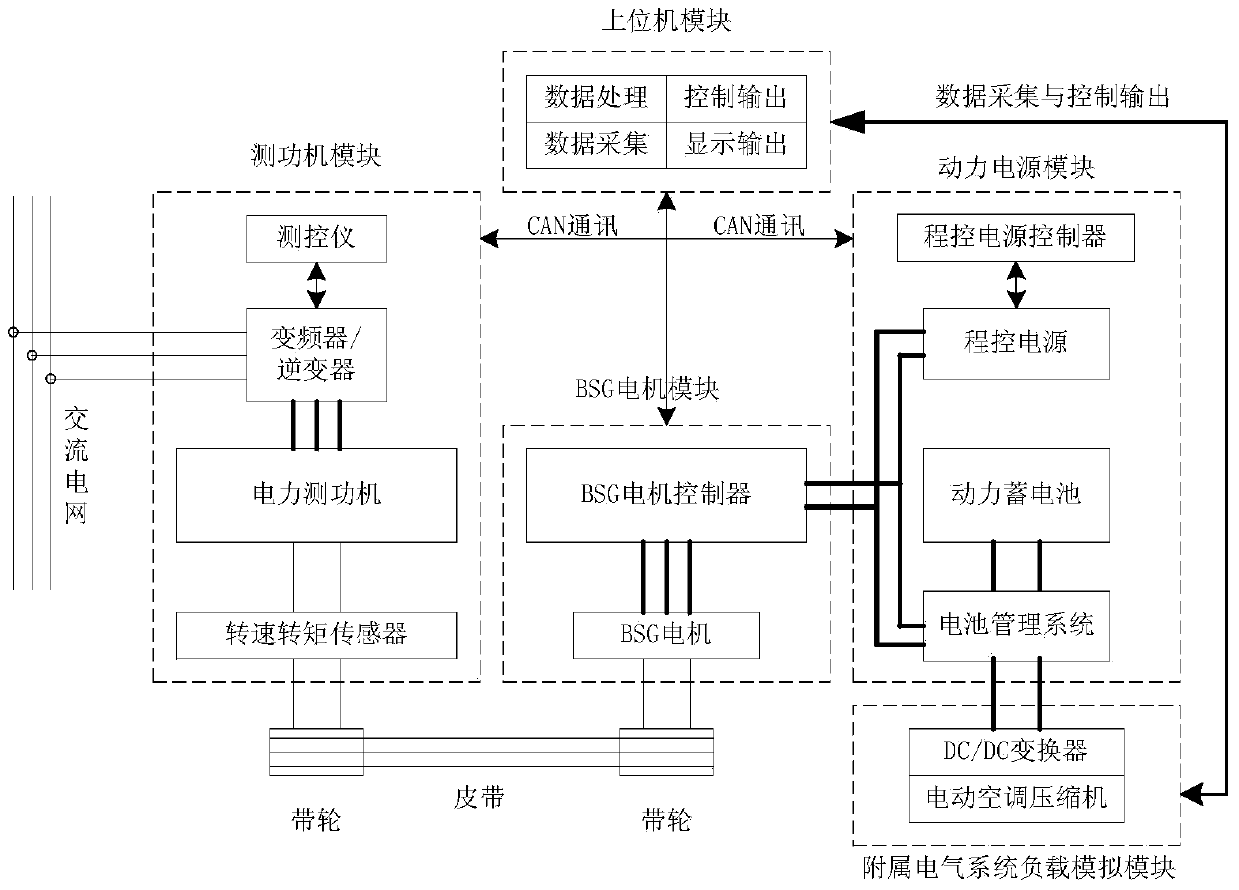

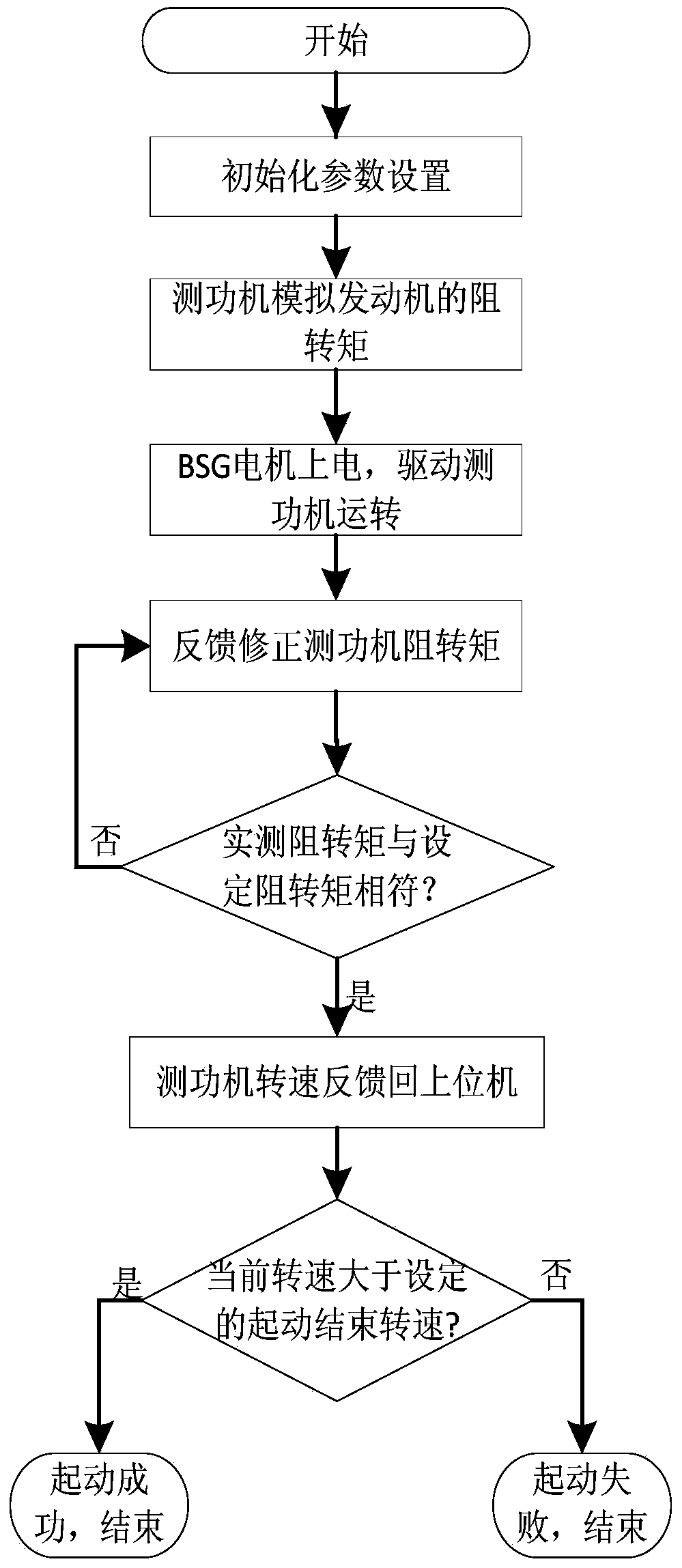

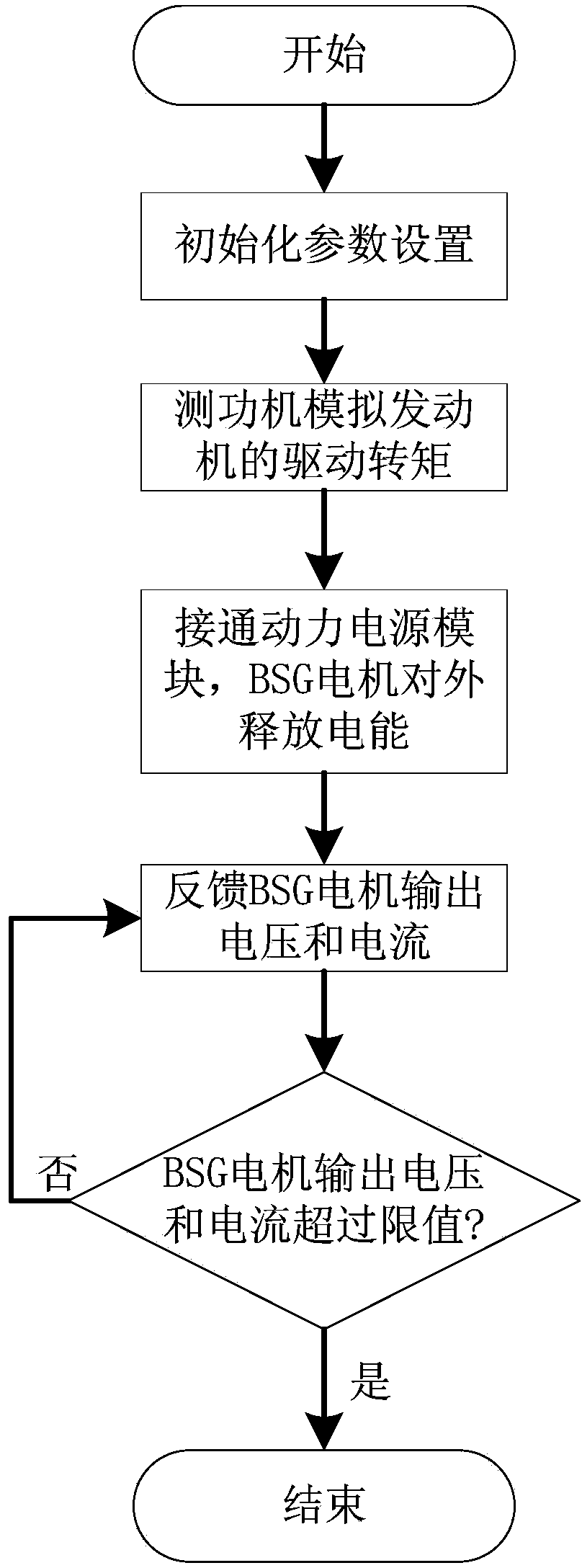

Testing system and method for electric part of power system for weak hybrid electric vehicle

ActiveCN103809120AFull trial testShorten the test cycleElectric testing/monitoringDynamo-electric machine testingElectrical batteryDynamometer

The invention discloses a testing system and a method for electric part of power system for weak hybrid electric vehicle, and the system comprises a BSG motor module provided with a BSG motor and a BSG motor controller; a dynamometer module provided with a dynamometer, a measuring and control instrument and a torque and speed sensor, and a transducer or an inverter; a power module provided with a power storage battery, a battery management system, a program control power supply and a program control power supply controller; an auxiliary electric system load simulation module provided with a DC / DC convertor and an auxiliary electric system load; an upper computer module. The method adopts the half object simulation principle, the dynamometer simulates the engine for doing test to the BSG motor module and does the service life test for the electric part of weak hybrid power system at different working conditions that the BSG motor starts the engine, the engine drives the BSG motor for generating, regenerative braking, idle parking while the battery drives the load, the system and method can reduce the test cost, shorten the test period for vehicle performance and raise the developing speed for product.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

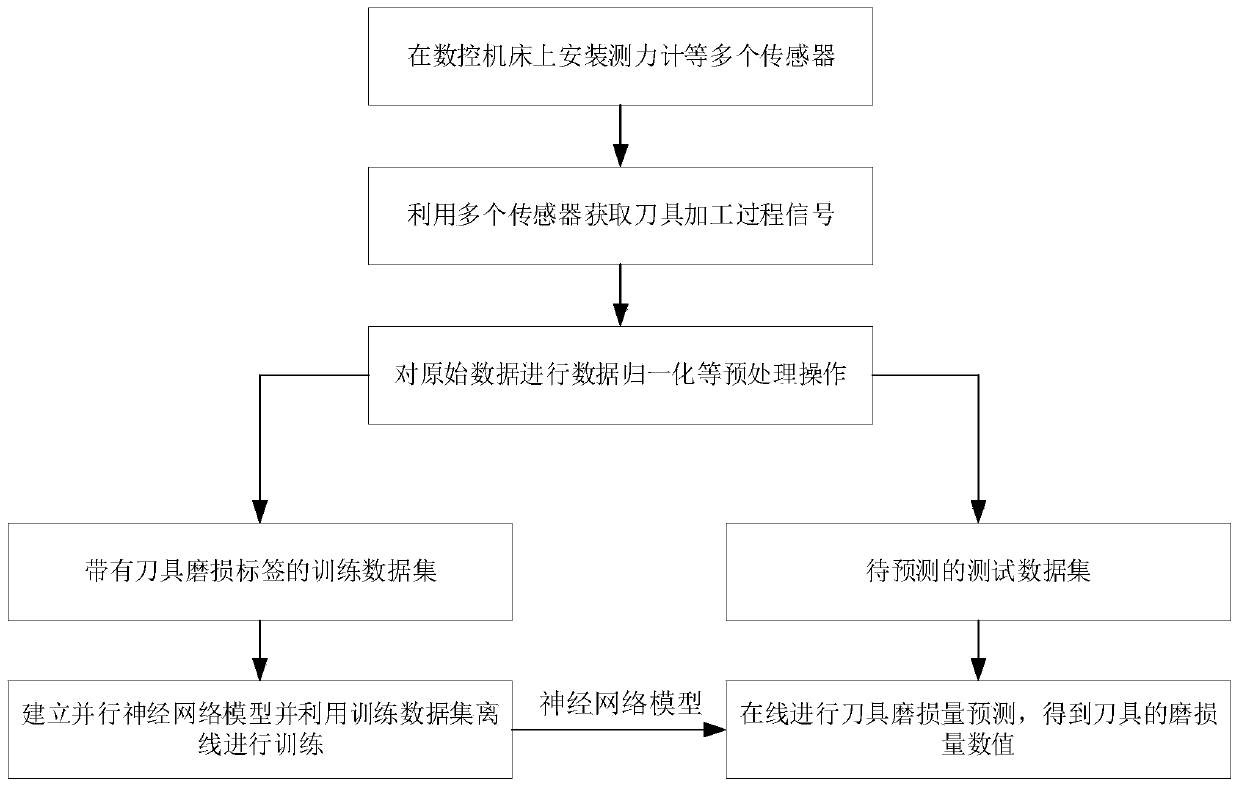

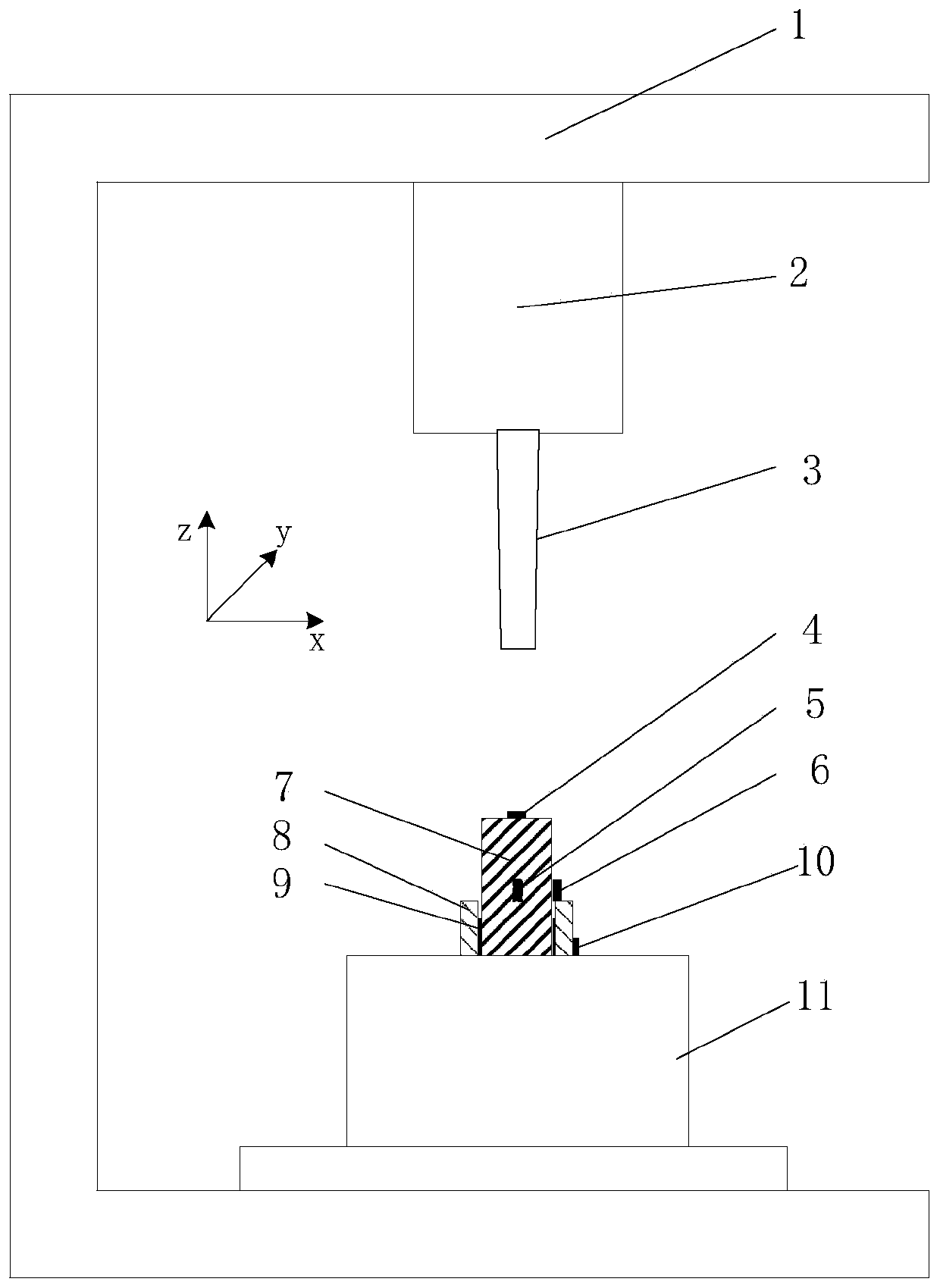

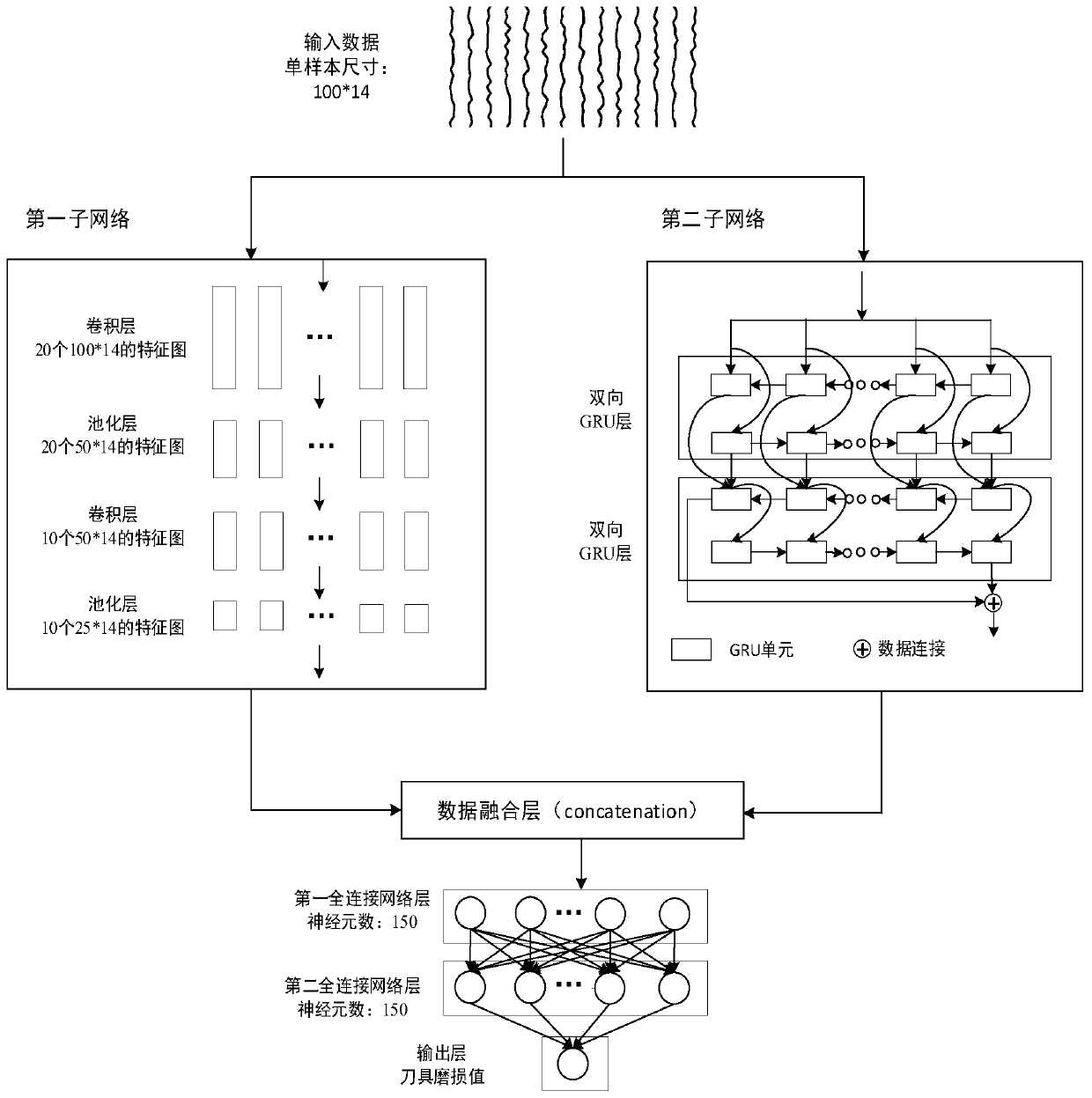

Tool wear condition prediction method of numerical control machine tool based on parallel deep neural network

ActiveCN109822399AStrong feature extraction abilityEffective mining of time series featuresMeasurement/indication equipmentsNumerical controlEngineering

The invention discloses a tool wear condition prediction method of a numerical control machine tool based on a parallel deep neural network. A dynamometer, an acceleration sensor and an acoustic sensor are installed on a workbench and a fixture of the numerical control machine tool; a milling experiment is conducted, the cutting force and vibration and acoustic signals of a milling process are collected so as to obtain multisensor data, and the wear capacity of a tool is collected; pretreatment is performed so as to obtain training data and to-be-tested data; a parallel deep neural network model is established; the treated training data and the label of the wear capacity of the tool are input into an offline training model in the parallel deep neural network model; and the to-be-tested multisensor data are introduced into the trained model so as to predict the wear capacity of the tool in real time and on line. According to the method, the implied characteristics during tool processingof the numerical control machine tool are fully mined, and the wear capacity of the tool can be predicted in real time. The method has the advantage of wide applicability and can be widely applied tovarious numerical control machine tools.

Owner:ZHEJIANG UNIV

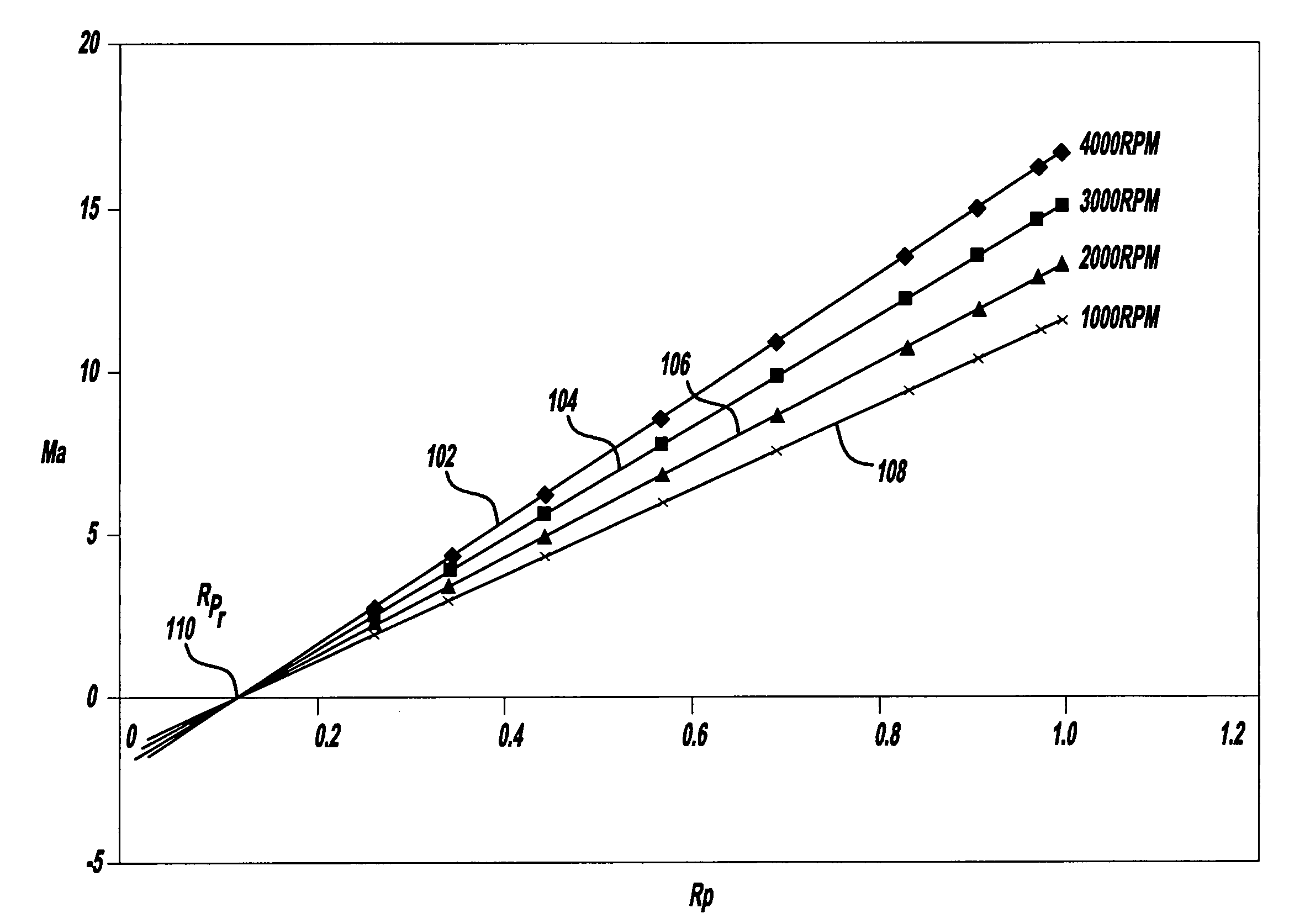

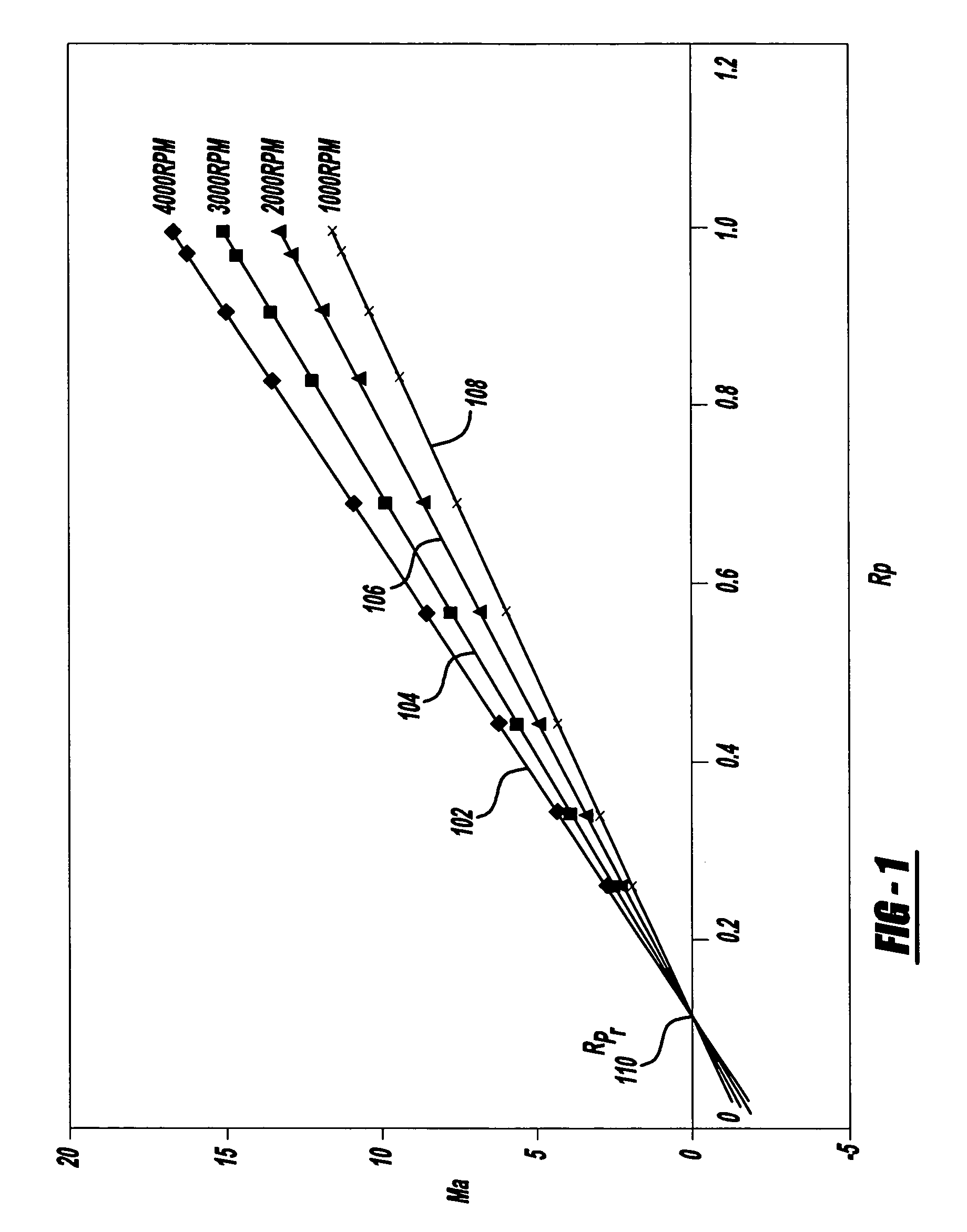

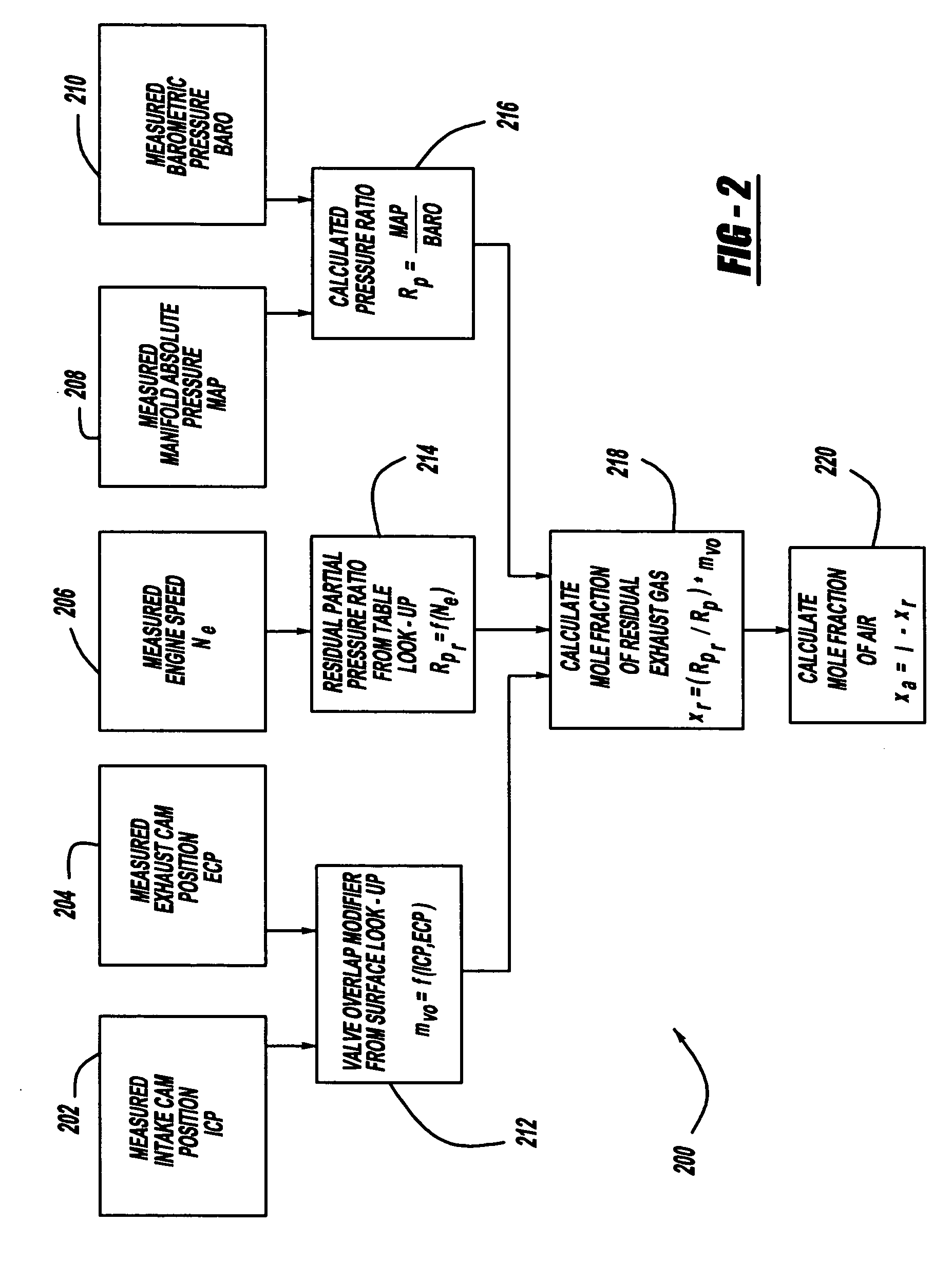

Method for controlling an operating condition of a vehicle engine

A residual ratio factor characterizing the amount of residual exhaust gas left in a selected cylinder at the end of a piston intake stroke is determined from tabular and surface models based on previously gathered dynamometer data from a test vehicle at various engine speeds. The residual ratio factor is then used to calculate the mole fractions of air and residual exhaust gas in the selected cylinder, which, in turn, are used to determine mass airflow at an engine intake port at the end of the intake stroke. The mass airflow can then be used to derive further models for determining an engine operating parameter, such as fuel / air ratio, required for achieving at preselected vehicle operating condition.

Owner:FCA US

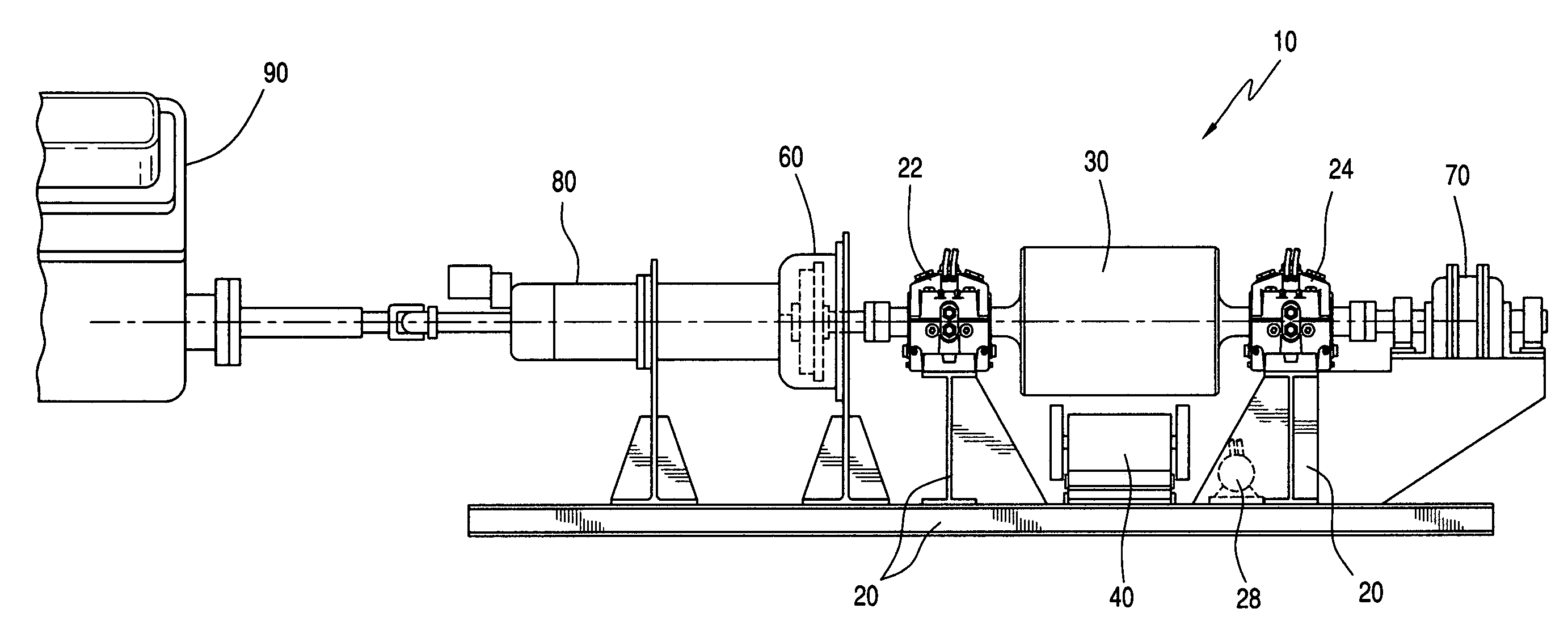

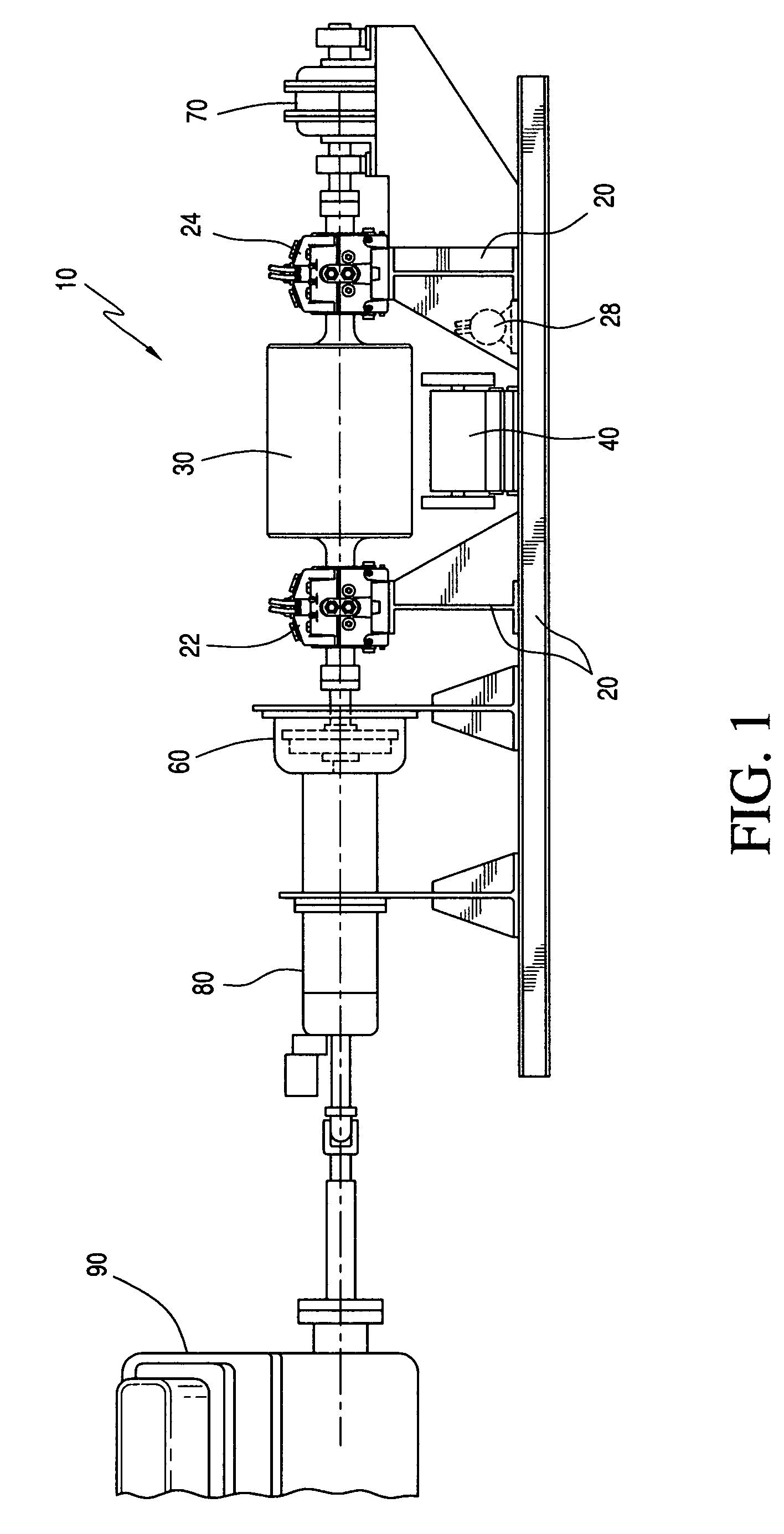

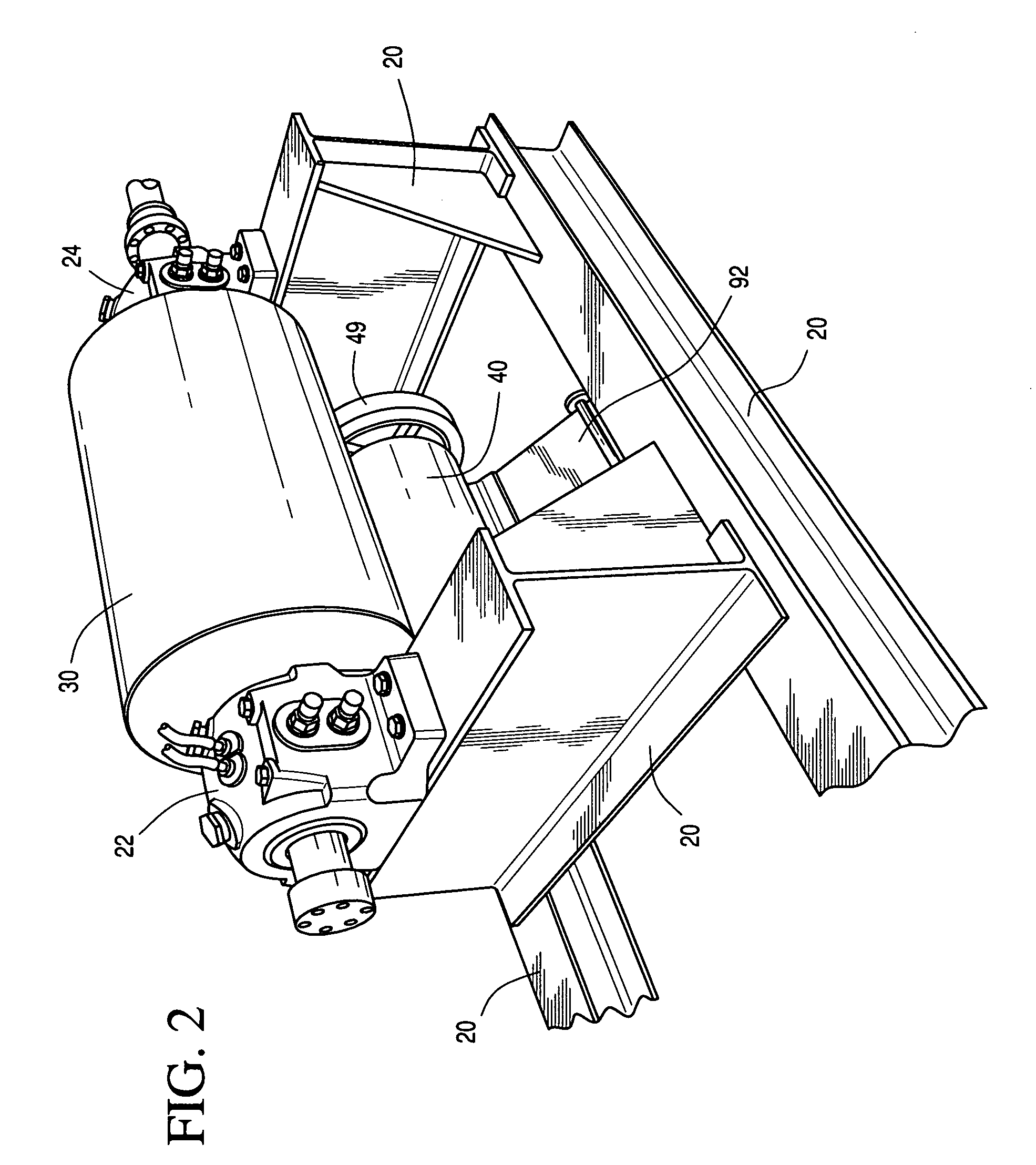

Dynamometer

A dynamometer comprises a frame, an inertial flywheel, and a starter motor. The inertial flywheel is supported by the frame and the starter motor is movably mounted to the frame so as to be selectively engageable with the inertial flywheel. Means is provided for coupling an engine to be tested to the apparatus. The flywheel is brought up to speed by means of the starter motor and then coupled to the engine, which has been separately brought up to speed, via a clutch. The flywheel is supported by the frame in pressurized oil sleeve bearings.

Owner:VICKIO JR LOUIS P +2

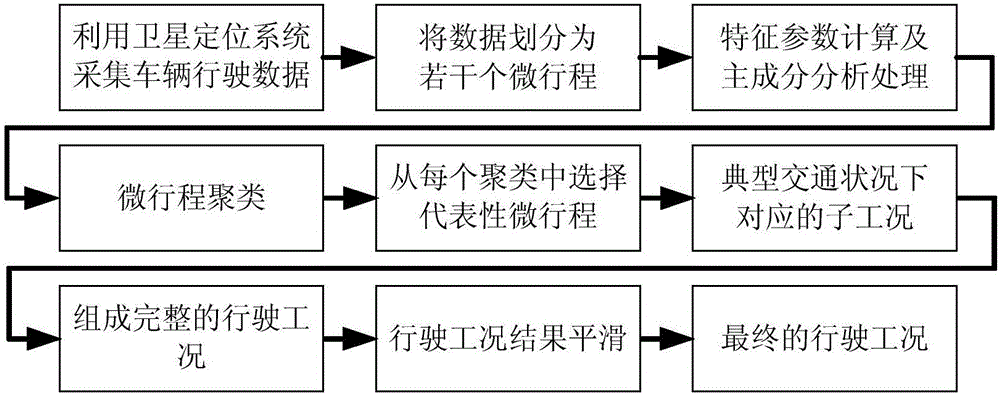

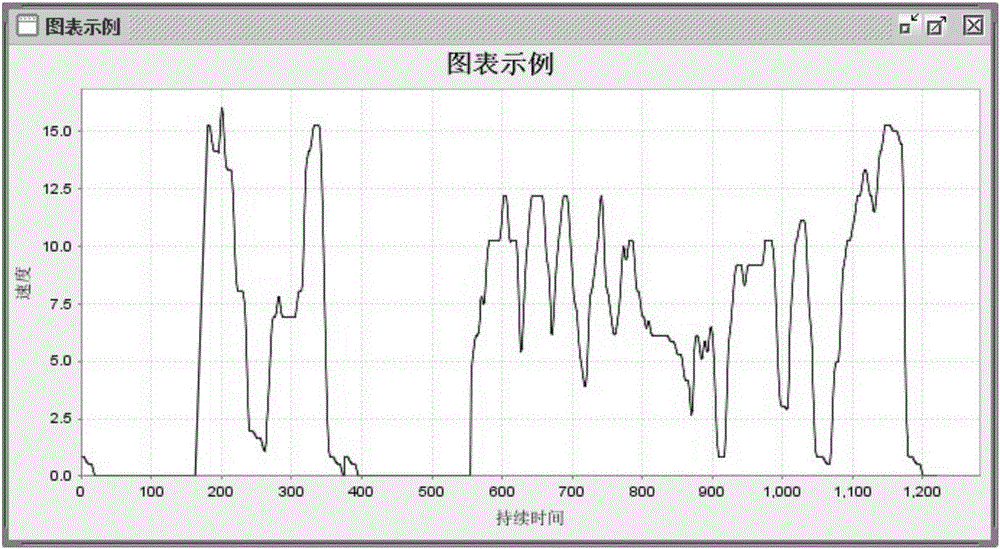

Vehicle driving condition establishment method combining principal component analysis with fuzzy c-mean clustering

InactiveCN106203856AStrong representativeEasy to follow testsCharacter and pattern recognitionResourcesVehicle dynamicsSmoothing kernel

The invention discloses a vehicle driving condition establishment method combining principal component analysis with fuzzy c-mean clustering. The method comprises the steps of extracting satellite positioning data of each road traffic condition in a vehicle dynamic monitoring system of a road transport enterprise, and calculating and dividing the data into small sections of micro-strokes; and performing calculation of characteristic parameters such as an average speed, an idle time proportion and the like for each micro-stroke, obtaining a matrix of a sample quantity (row) X the characteristic parameters (column), adopting mean normalization and principal component analysis for matrix data, selecting preorder principal components which meet the conditions that the cumulative contribution rate of characteristic values of the principal components is greater than 85% and the principal components can comprehensively reflect all the characteristic parameters, performing fuzzy c-mean clustering analysis on scores of the principal components, and clustering the micro-strokes into different groups, namely, screening sub-conditions. An initial synthesis condition is smoothed by adopting a filter with a double-weighted smoothing kernel function. According to the method, existing satellite positioning data is fully utilized; compliance testing is easily carried out on a dynamometer; relatively high universality is achieved; and the research cost of vehicle driving condition establishment is reduced.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

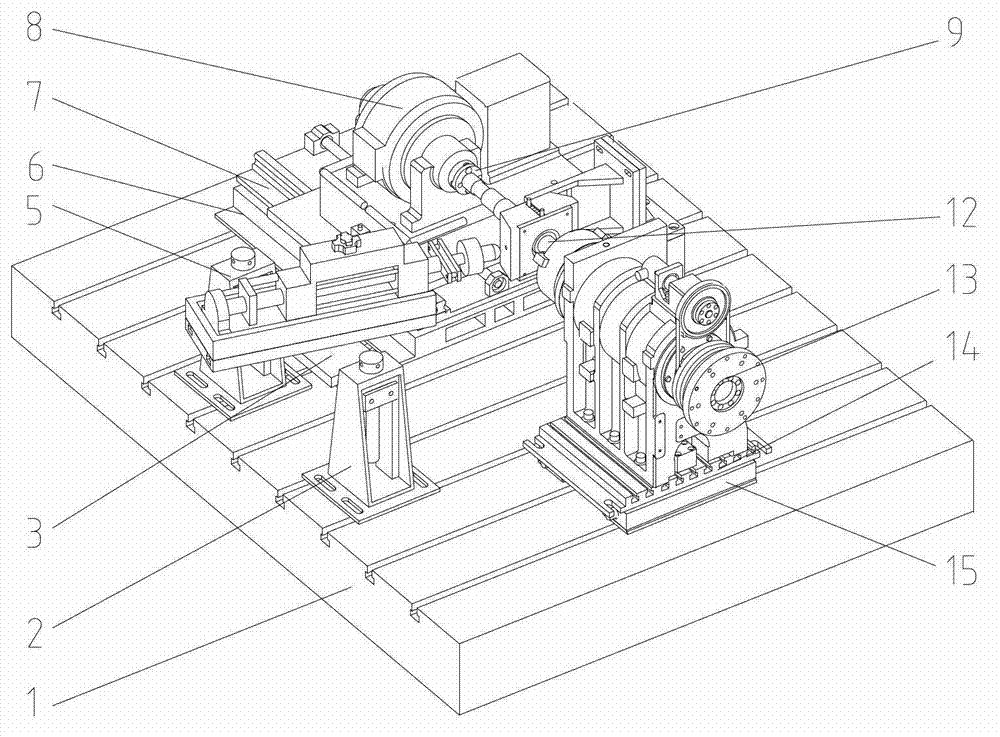

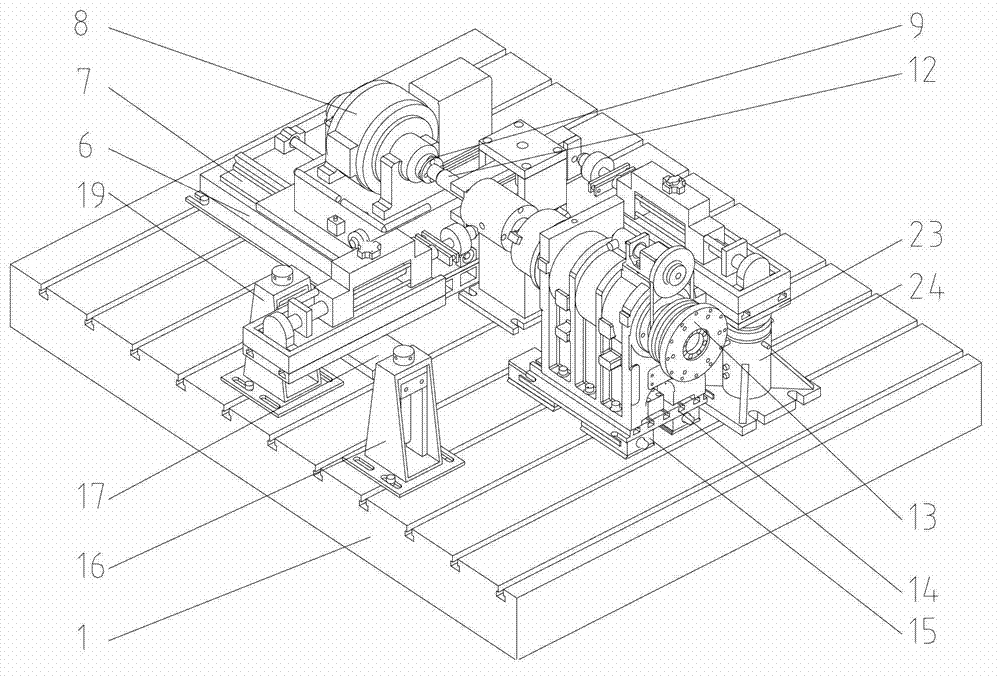

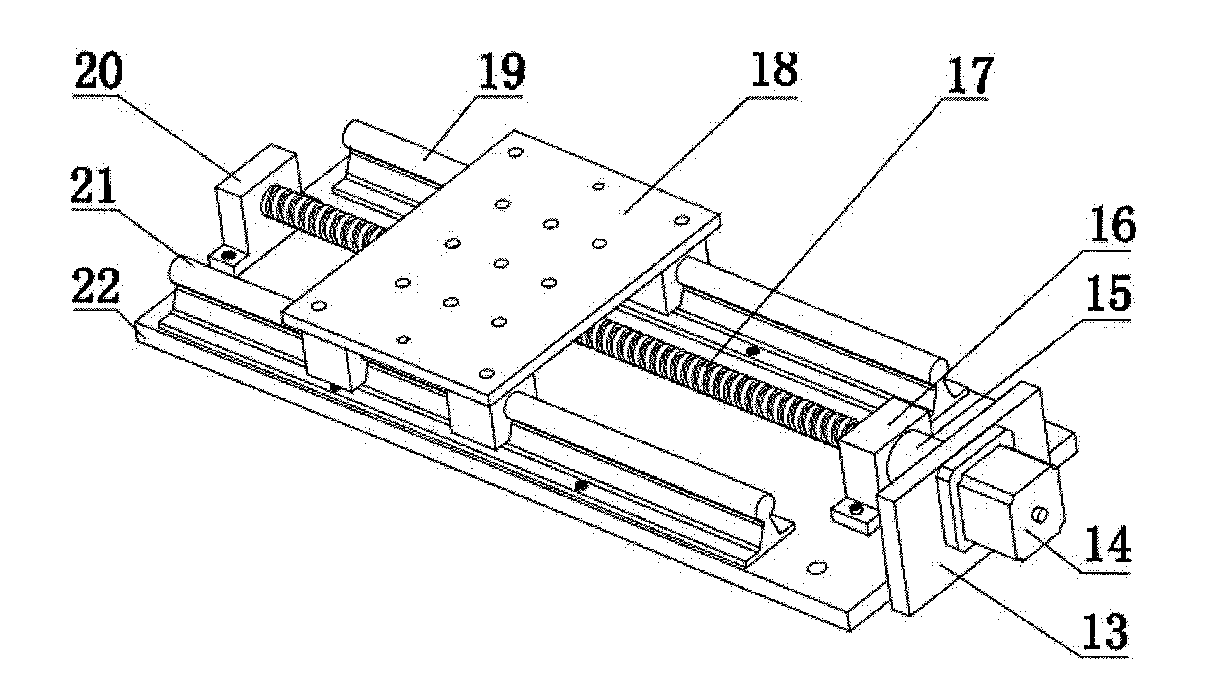

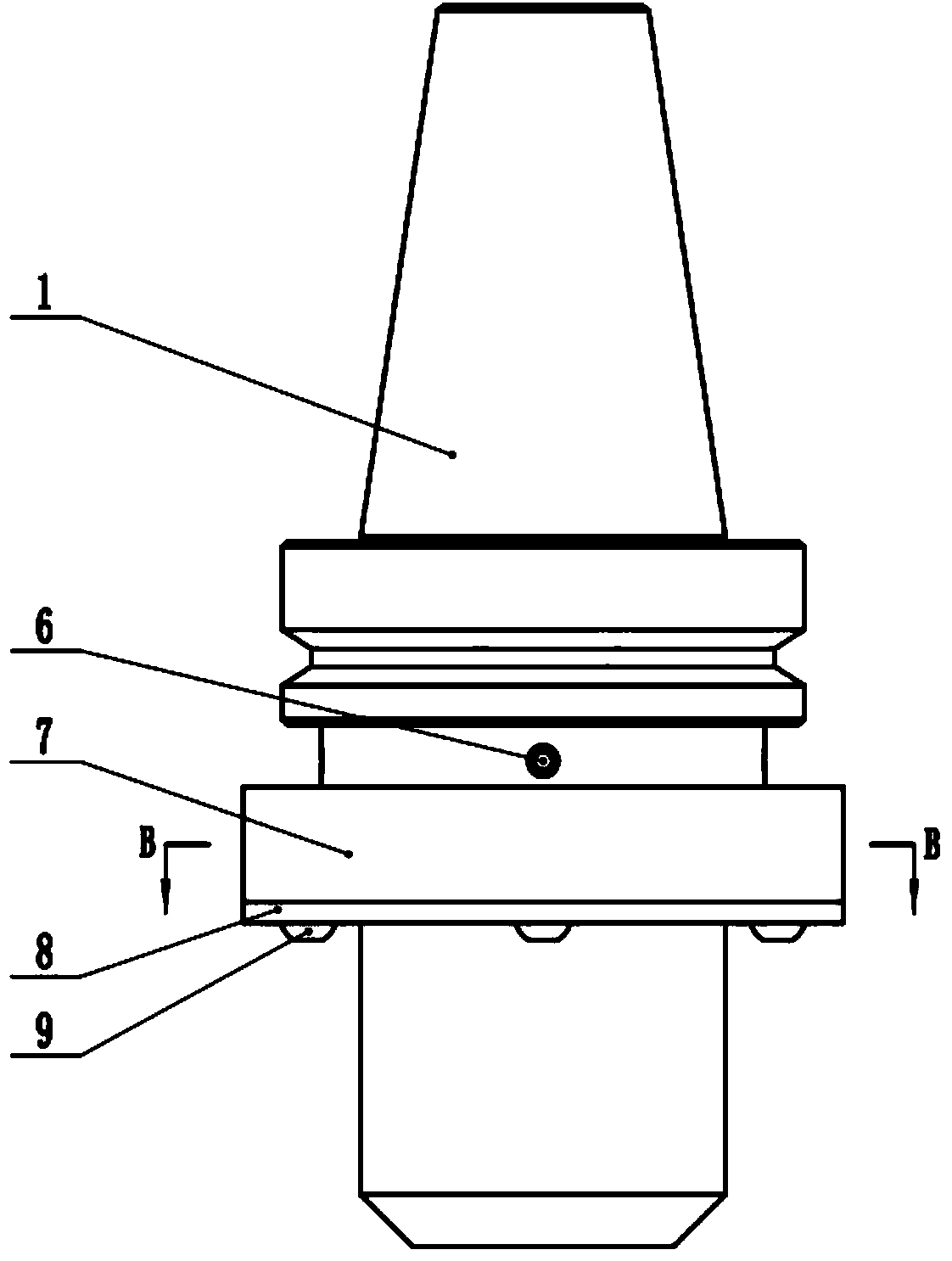

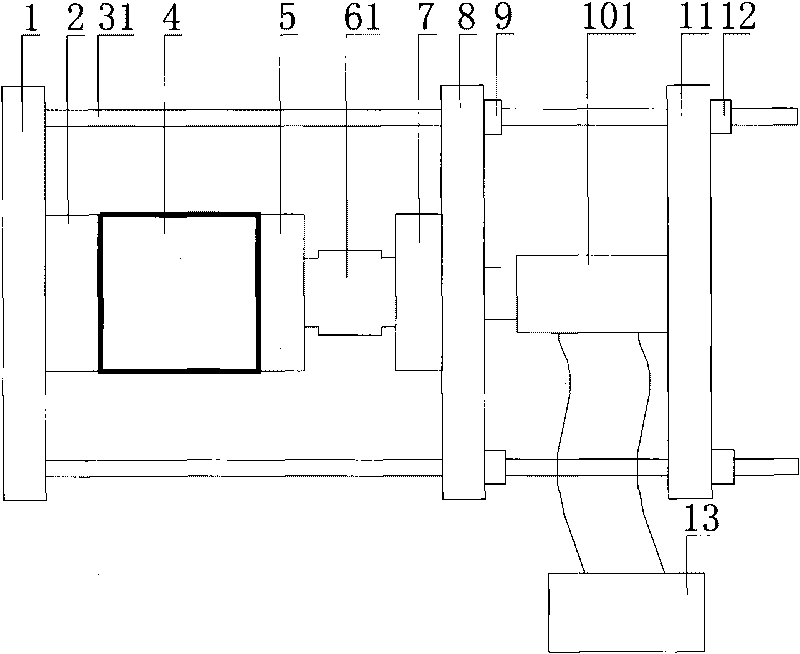

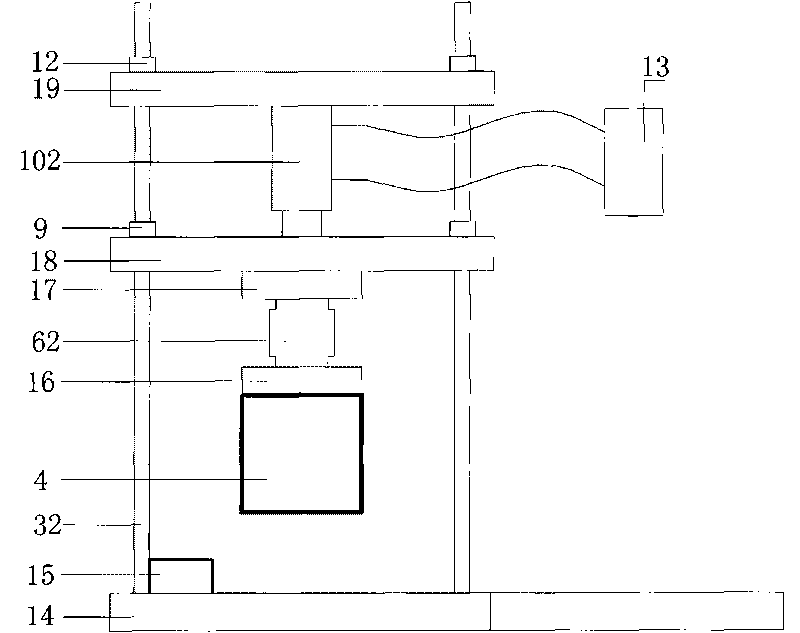

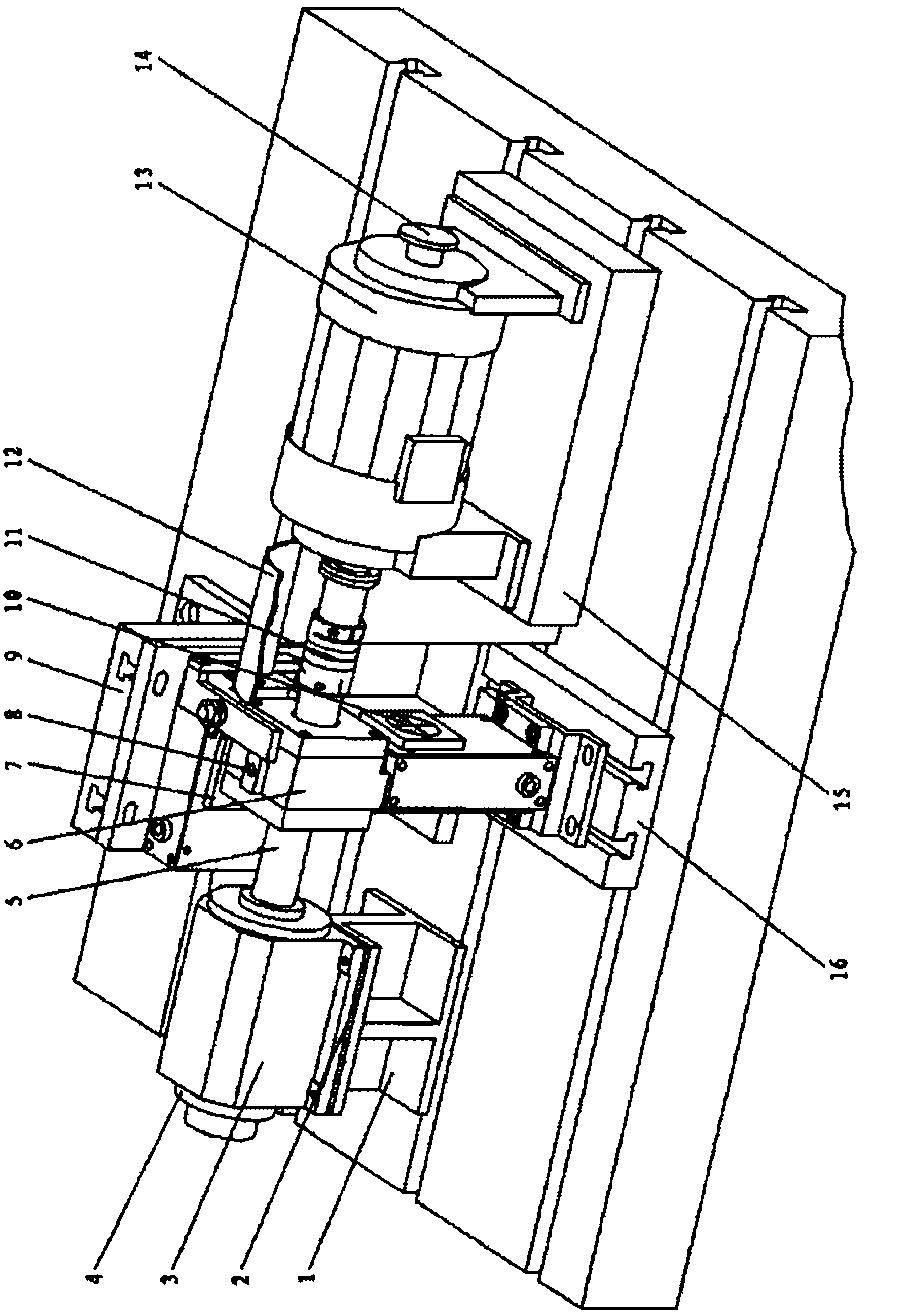

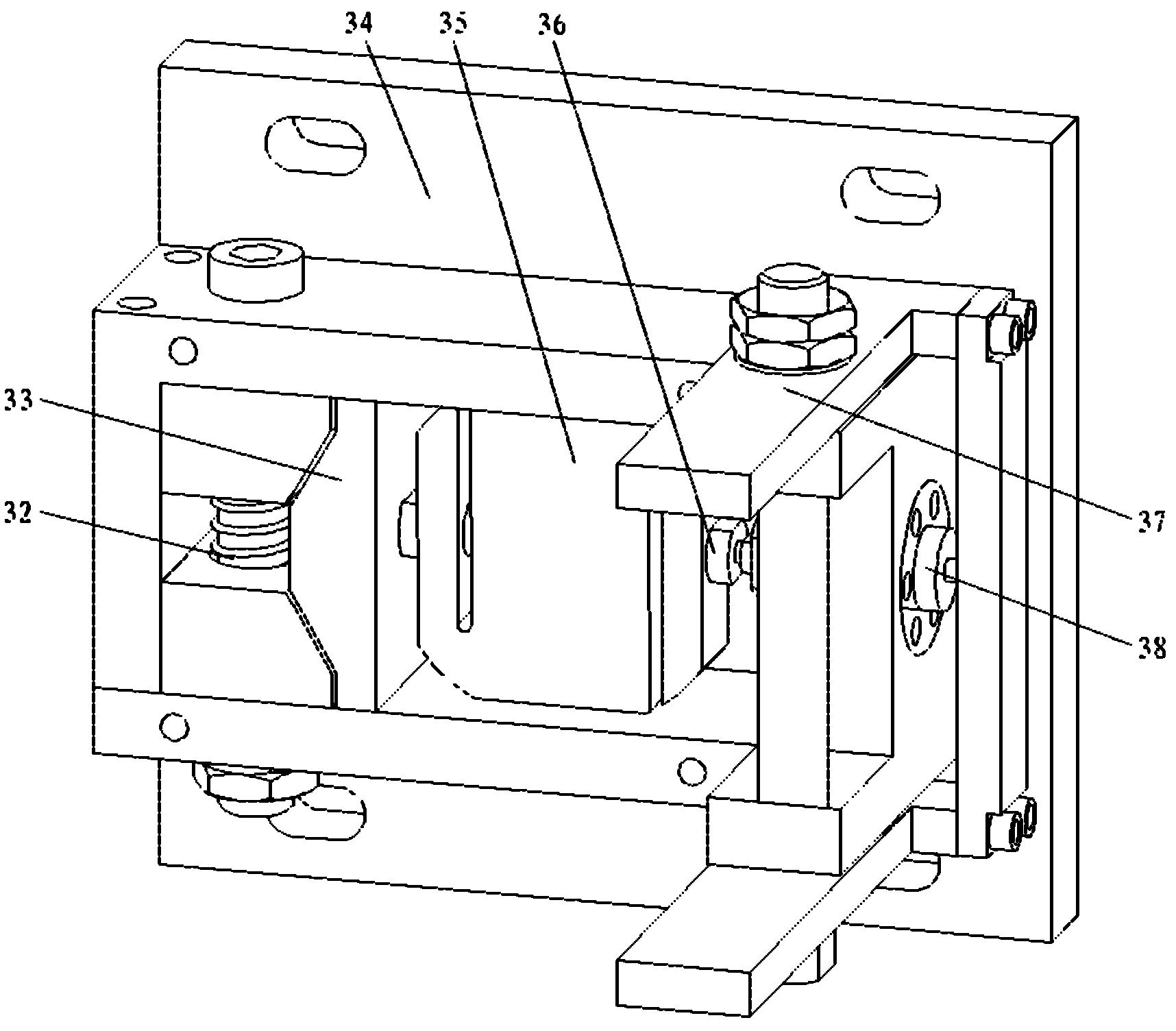

Machine tool spindle reliability test bed based on mixed loading of electro-hydraulic servo and dynamometer

ActiveCN102889983ATrigger failureExposure to failureMachine part testingElectro hydraulicAxial force

The invention relates to a test device of a machine tool spindle, in particular to a machine tool spindle reliability test bed based on mixed loading of electro-hydraulic servo and a dynamometer, and aims to solve the problem that the conventional machine tool spindle reliability test device cannot truly simulate dynamic cutting force loading, static cutting force loading and cutting torque loading. The machine tool spindle reliability test bed mainly comprises a machine tool spindle supporting part, a torque loading part and a cutting force loading part, wherein the machine tool spindle supporting part is formed by combining a spindle box base plate (14) and an iron gasket (15); the torque loading part consists of a loading rod (12), an elastic diaphragm coupler (9) and the dynamometer (8), which are coaxially assembled; and the cutting force loading part employs two loading modes, namely a cutting resultant force loading mode and a cutting axial force and radial force separated loading mode. By performing reliability test for simulating true working conditions on the tested machine tool spindle, the failure of a product is stimulated and exposed, and practical basic data are provided for reliability growth and evaluation of the product.

Owner:JILIN UNIV

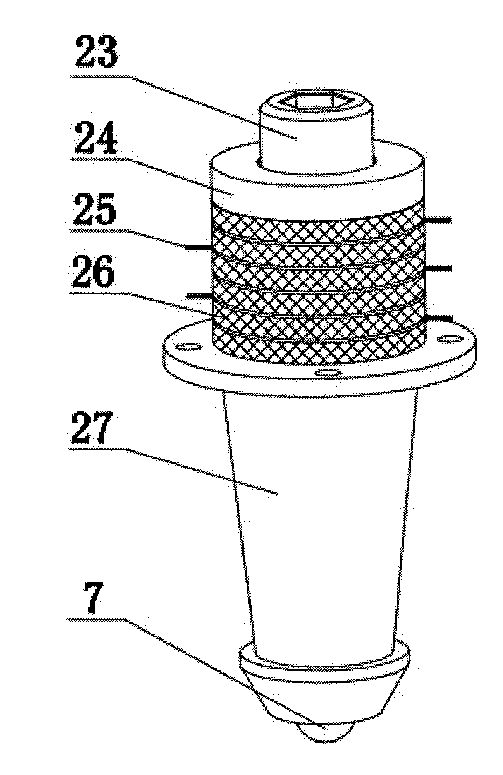

Spherical contact type friction characteristic testing device under ultrasonic vibration

InactiveCN103278411APrecise control of test parametersHigh degree of automationUsing mechanical meansInvestigating abrasion/wear resistanceRotary stageVibration amplitude

The invention discloses a spherical contact type friction characteristic testing device under ultrasonic vibration. The device consists of a main movement unit, a loading unit and a dynamometer unit, wherein the torque output by a step motor is converted into axial pressure of a sliding table through a lead screw nut pair of a trapezoidal screw, and an upper sample and a lower sample which are arranged at the bottom of a piezoelectric micromachined ultrasonic transducer are contacted with each other, and certain pressure is applied to the lower sample; when the piezoelectric micromachined ultrasonic transducer is connected with an ultrasonic power supply, the upper sample produces ultrasonic frequency vibration with micron-grade amplitude in the horizontal direction or the vertical direction, the lower sample rotates together with a rotating platform and forms a friction pair with the upper sample, so that the friction characteristic of the spherical contact under ultrasonic vibration can be tested. The device can be used for accurately controlling the testing parameters, is high in degree of automation, and can be used for performing spherical contact friction experiments of various types of friction materials under different ultrasonic vibration frequencies and vibration amplitudes.

Owner:JILIN UNIV

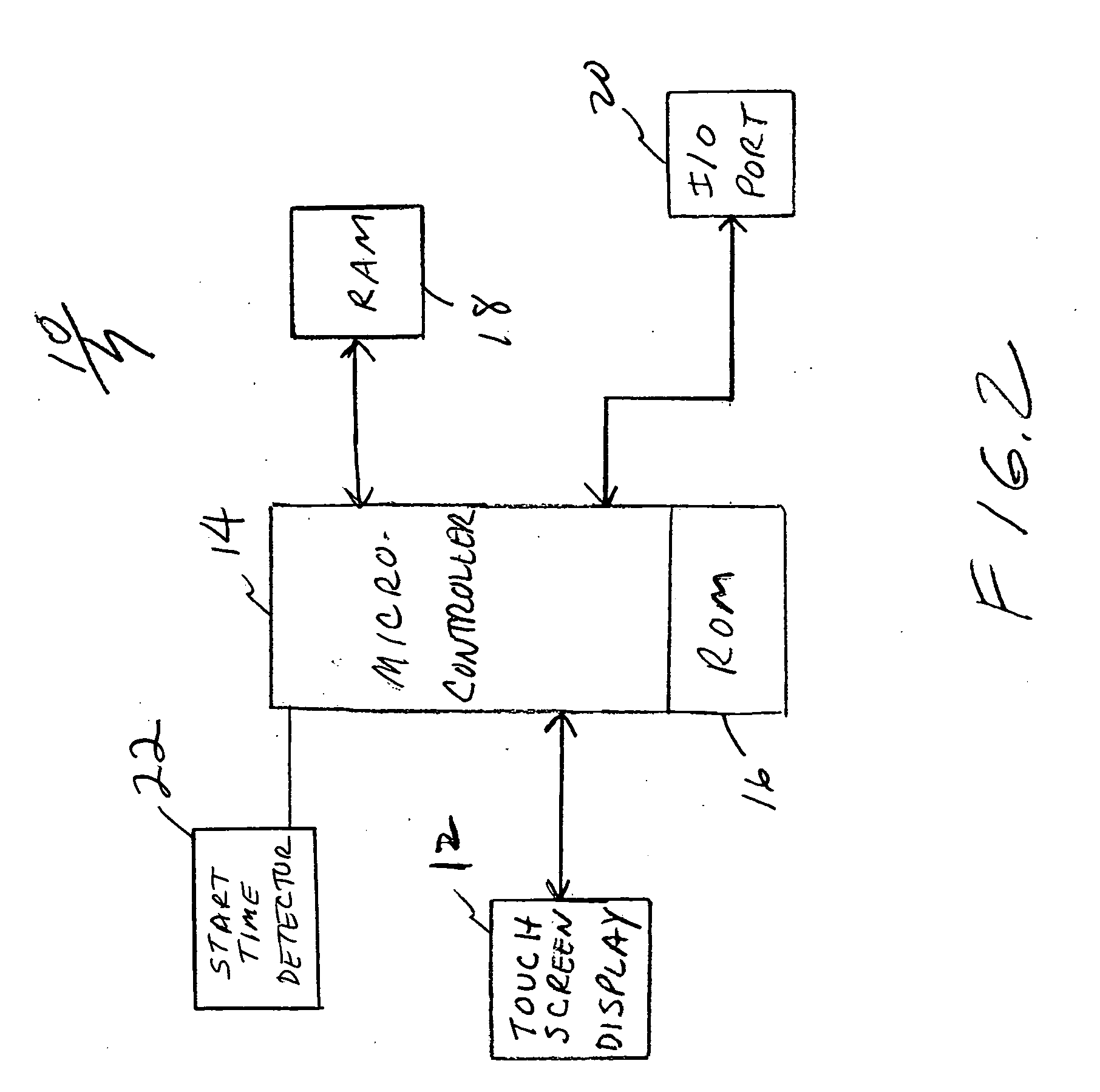

Programmable automotive computer system

ActiveUS20060106510A1Easy data entryEasy to useVehicle testingRegistering/indicating working of vehiclesMonitor modeEngineering

A device and corresponding method for enabling a user to accurately control, monitor, and evaluate performance of a vehicle. The system includes a portable programmable computer device that a user can readily install by plugging it into a diagnostic connector port of the vehicle for providing the controlling, monitoring, and evaluating functions. The present invention enables a user to perform performance tuning of the engine, provides dynamometer type functions such as horsepower and torque measurements, and provides a virtual drag strip function for accurately measuring acceleration data. According to an alternative embodiment, a monitor mode is provided for enabling the user to monitor selected characteristics of the vehicle and a diagnostics mode is provided for providing for the identification and display of diagnostic trouble codes (DTCs) with informative text descriptions. The present invention also enables the clearing of selected DTCs without requiring expensive customized equipment for that purpose.

Owner:HYPERTECH

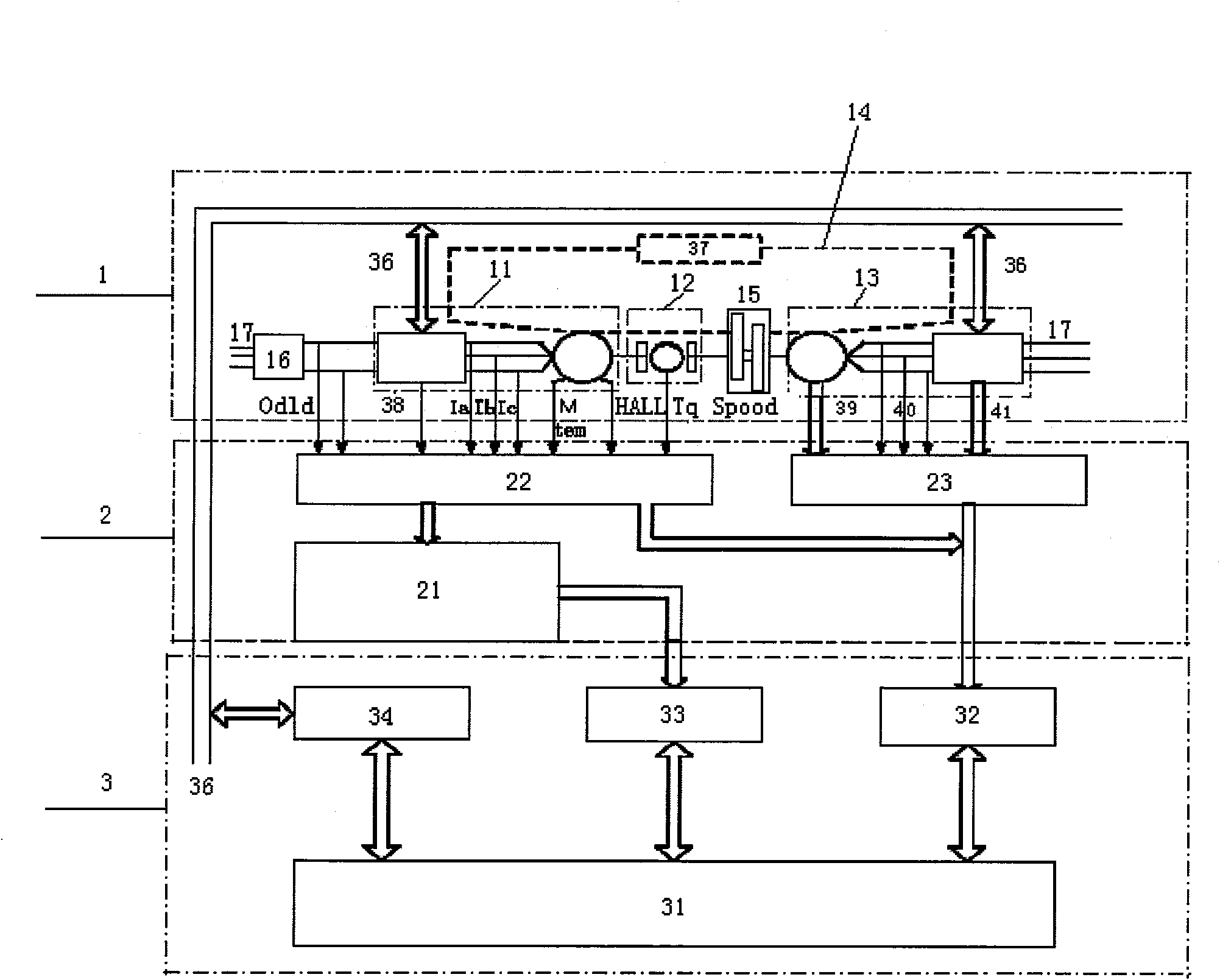

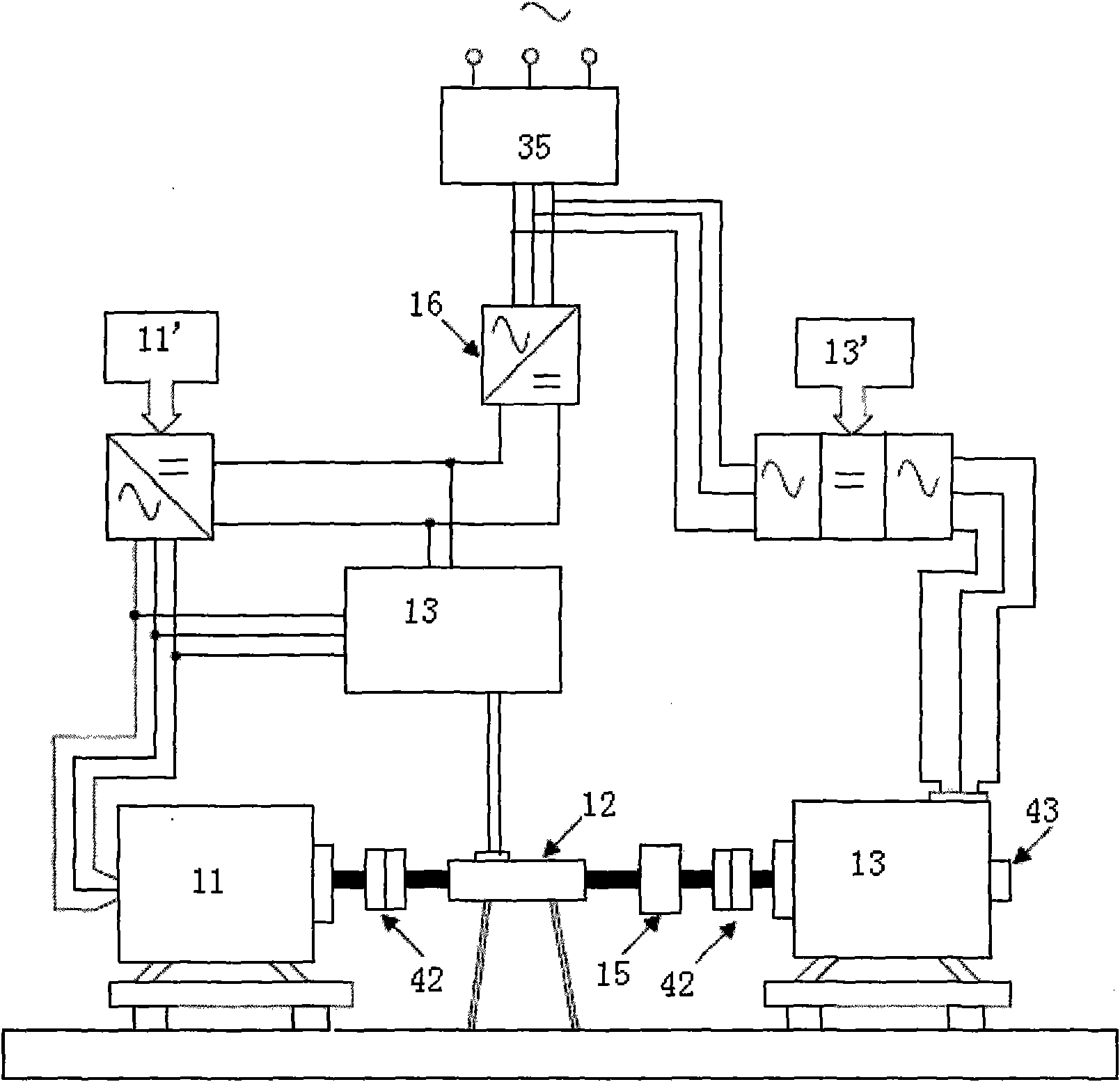

Test stand system of electric automobile driving motor

ActiveCN101650410AImprove test accuracyImprove system efficiencyVehicle testingDynamo-electric machine testingReduction driveDynamometer

The invention relates to a test stand system of an electric automobile driving motor, which comprises a dynamometer system and a measured motor system, a speed reducer is installed between the dynamometer system and the measured motor system and used for adjusting the rotary speed of the measured motor in the measured motor system, the electricity of the dynamometer and the measured motor is respectively supplied by two sets of power supplies, a stand motor is arranged in a feedback electric network at an alternating current end, the measured motor can have a wider voltage range, and the standsystem has high efficiency and can carry out hardware-in-loop test for electric automobile power assemblies.

Owner:SHANGHAI SICAR VEHICLE TECH DEV

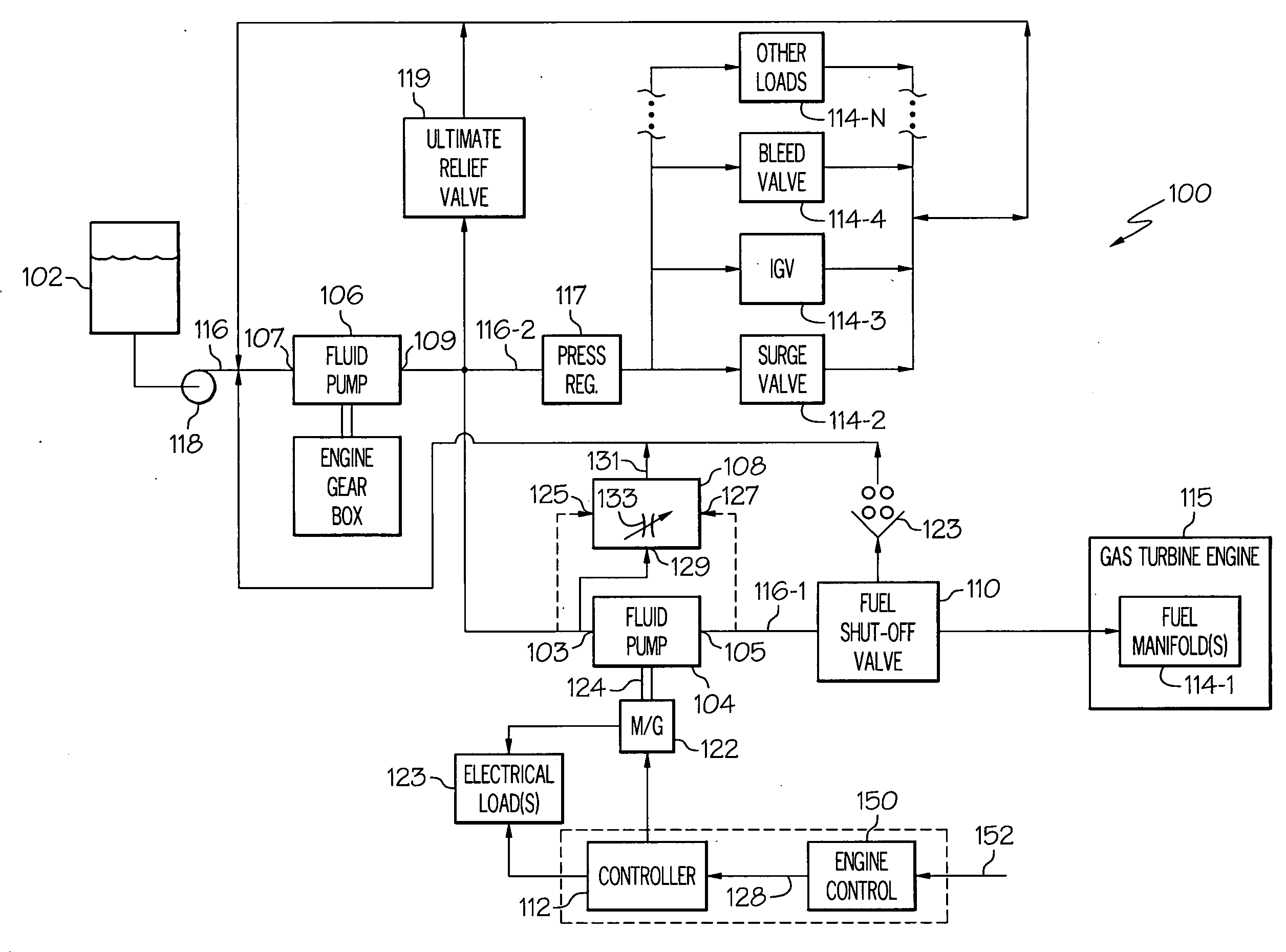

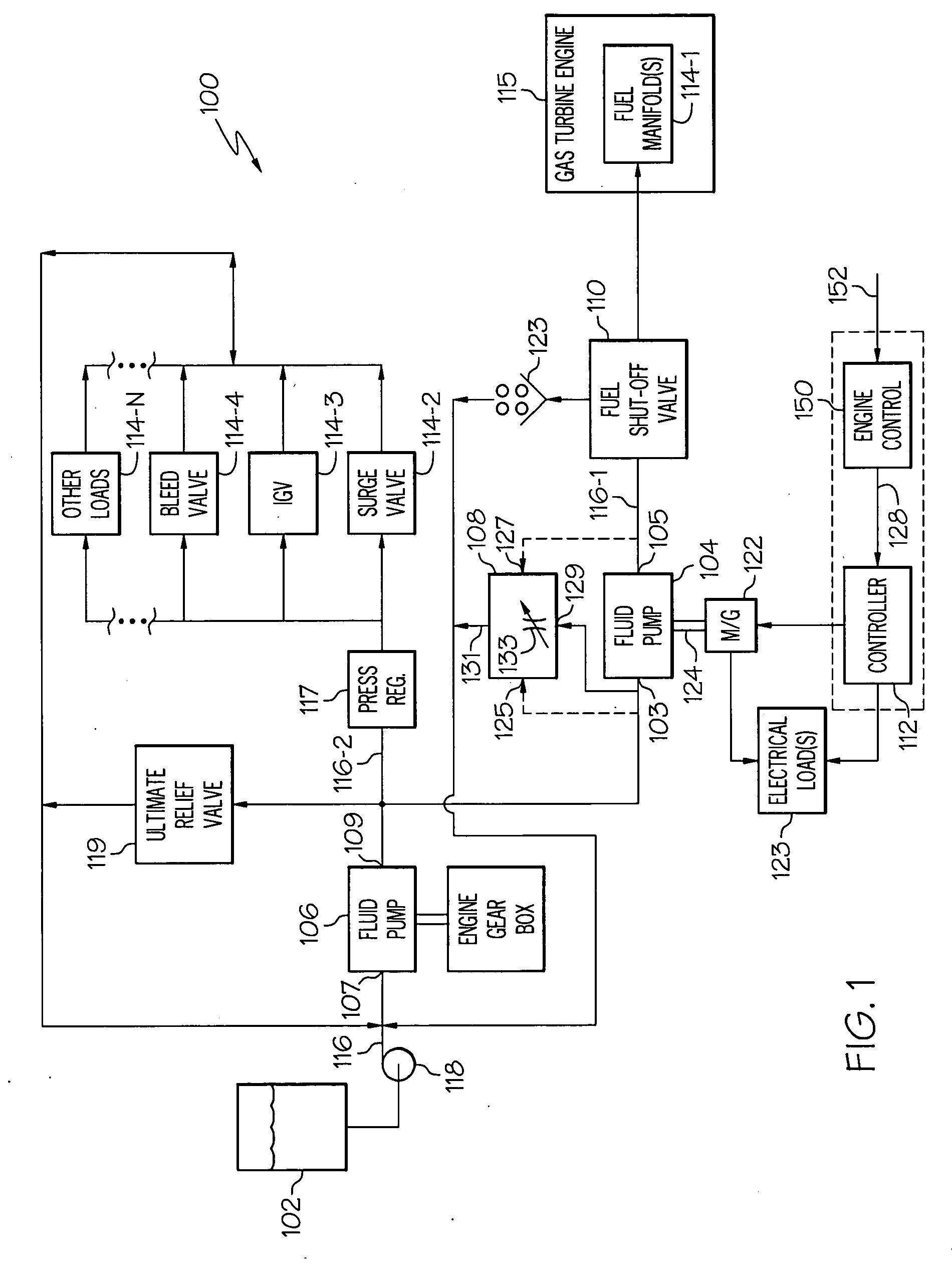

Electric power generating turbine engine fuel supply system

A turbine engine fuel supply system includes a priority flow line, a plurality of secondary fuel loads, a fluid-powered metering pump, a mechanically-driven fuel pump, and an electric machine. The fluid-powered metering pump, upon receiving fuel at its fuel inlet, rotates at a rotational speed, discharges the fuel from its fuel outlet at a flow rate dependent on the rotational speed, and supplies a first drive torque. The mechanically-driven fuel pump receives a second drive torque and, in response, draws fuel into its fuel inlet and discharges the fuel from its outlet to the fluid-powered metering pump fuel inlet to drive the fluid-powered metering fuel pump. The electric machine receives the first drive torque from the fluid-powered metering pump and generates electrical power.

Owner:HONEYWELL INT INC

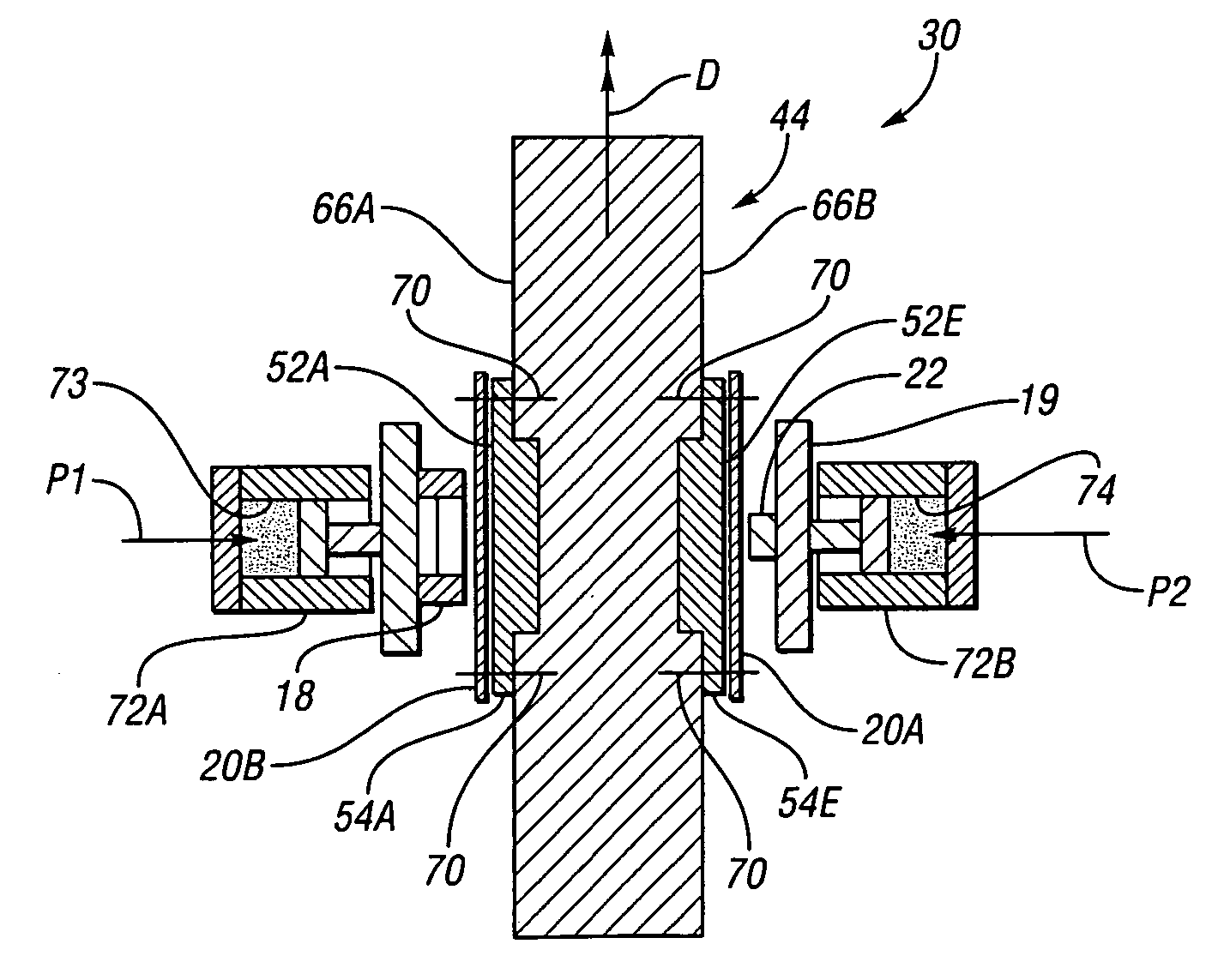

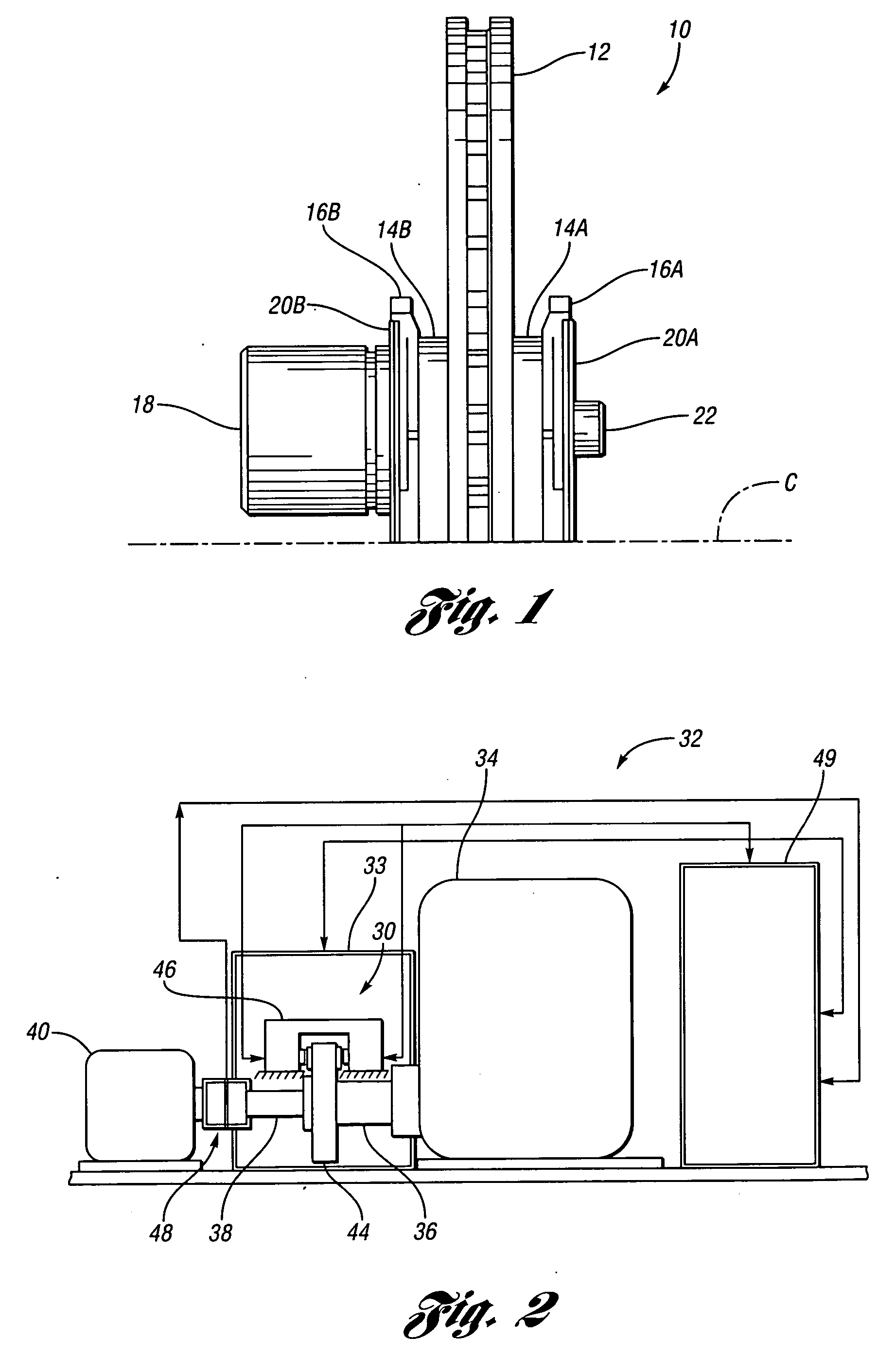

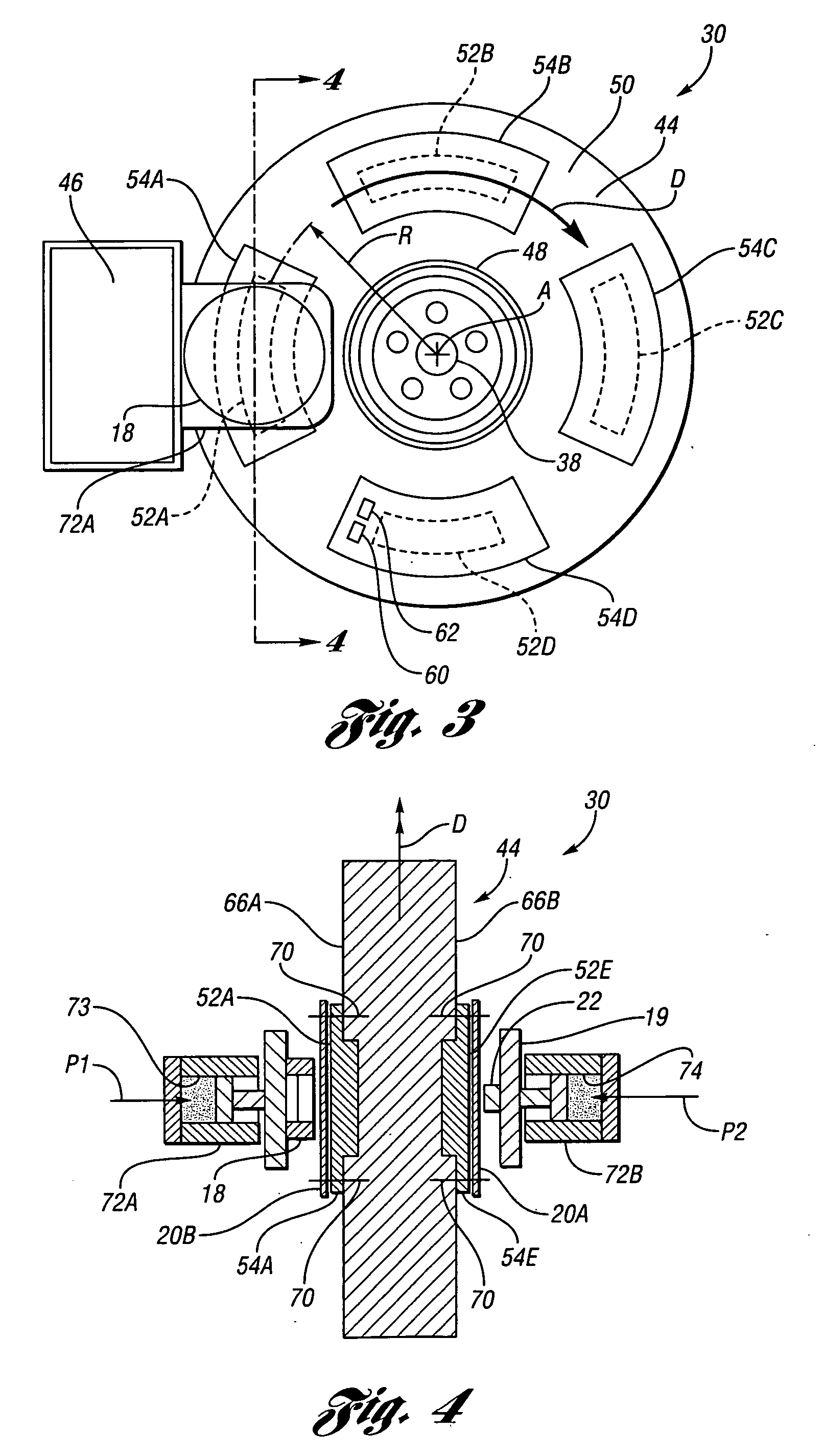

Test apparatus and method of measuring surface friction of a brake pad insulator material and method of use of a brake dynamometer

ActiveUS20070068220A1Easy to measureEasy to testUsing mechanical meansInvestigating abrasion/wear resistanceDynamometerEngineering

A test apparatus for measuring surface friction of a damping material such as brake pad insulator material includes a rotor configured to support the damping material for rotation therewith, an actuator pressurizable to apply axially-inward force to the damping material and a stator configured to support the actuator. A sensor determines the force applied to the actuator and a torque cell is axially aligned with the rotor for measuring torque of the rotor in relation to force applied to the damping material. The calculation of surface friction of the damping material is possible based on the measured load and torque. A method of measuring surface friction of a brake pad insulator material as well as a method using a brake dynamometer is also presented.

Owner:WOLVERINE ADVANCED MATERIALS

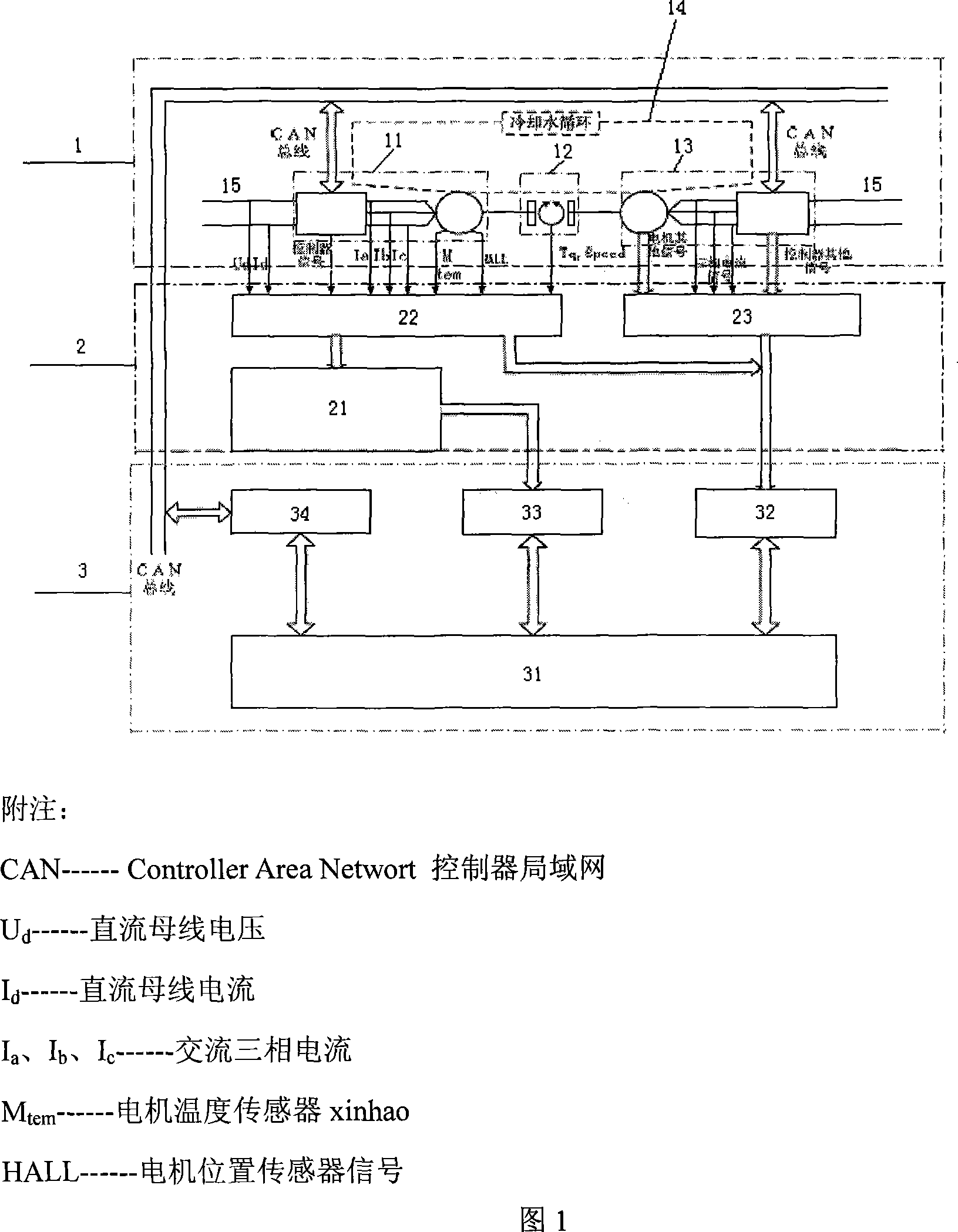

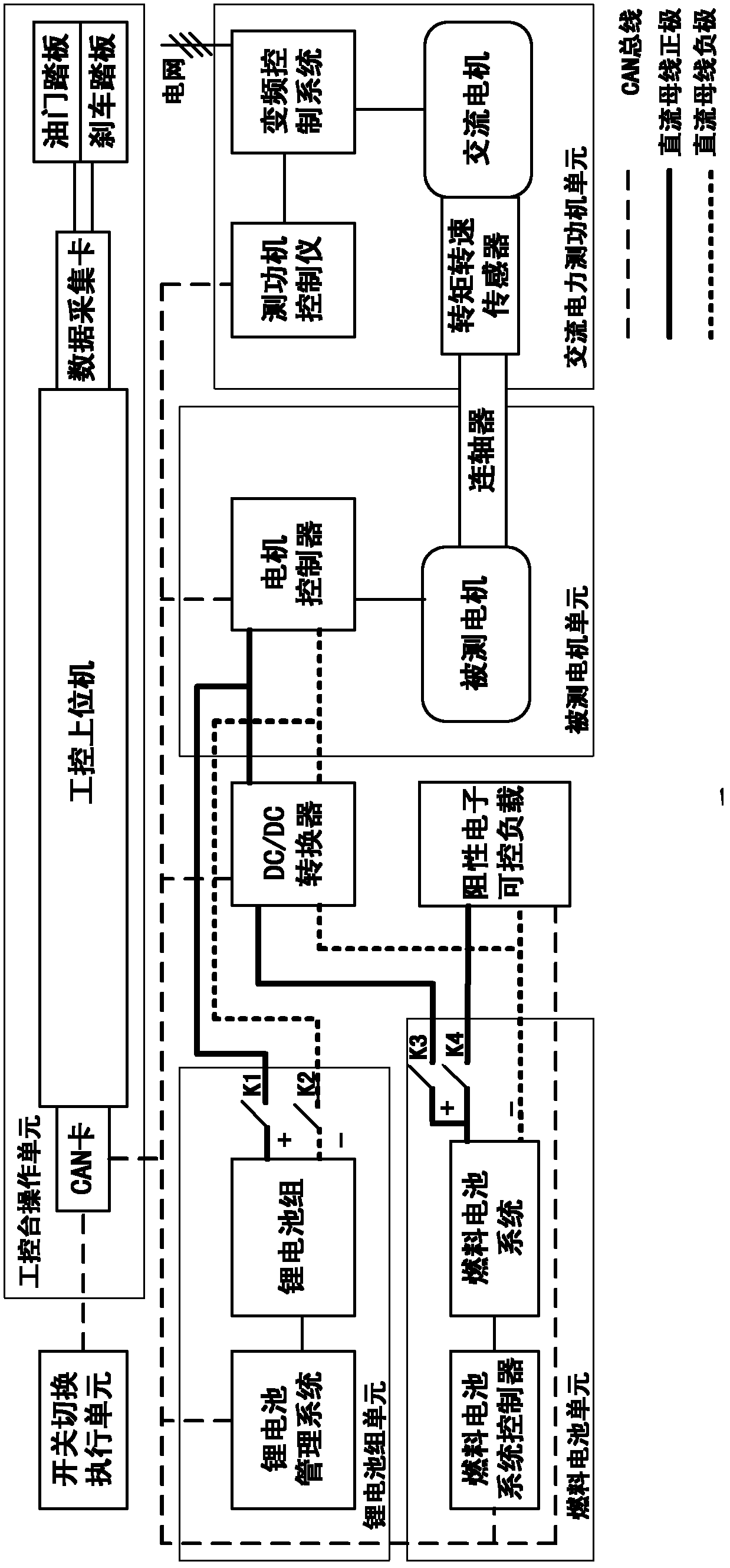

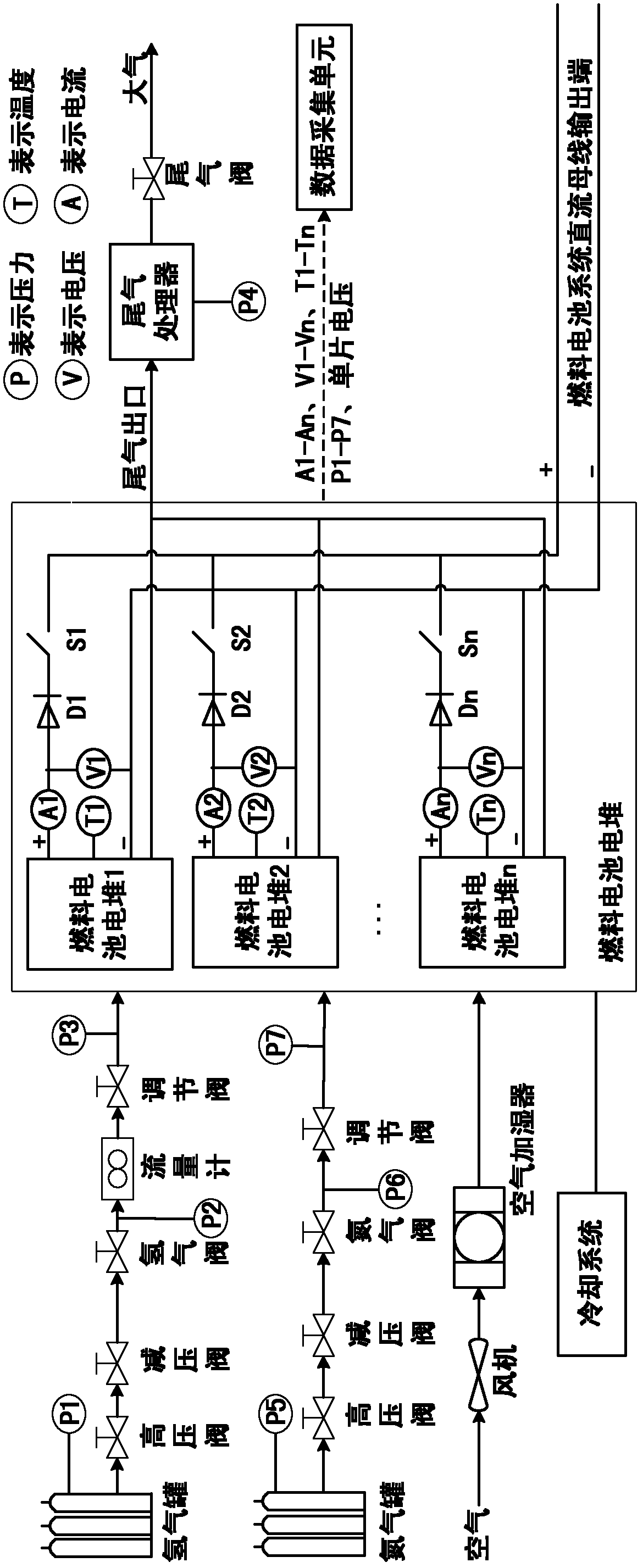

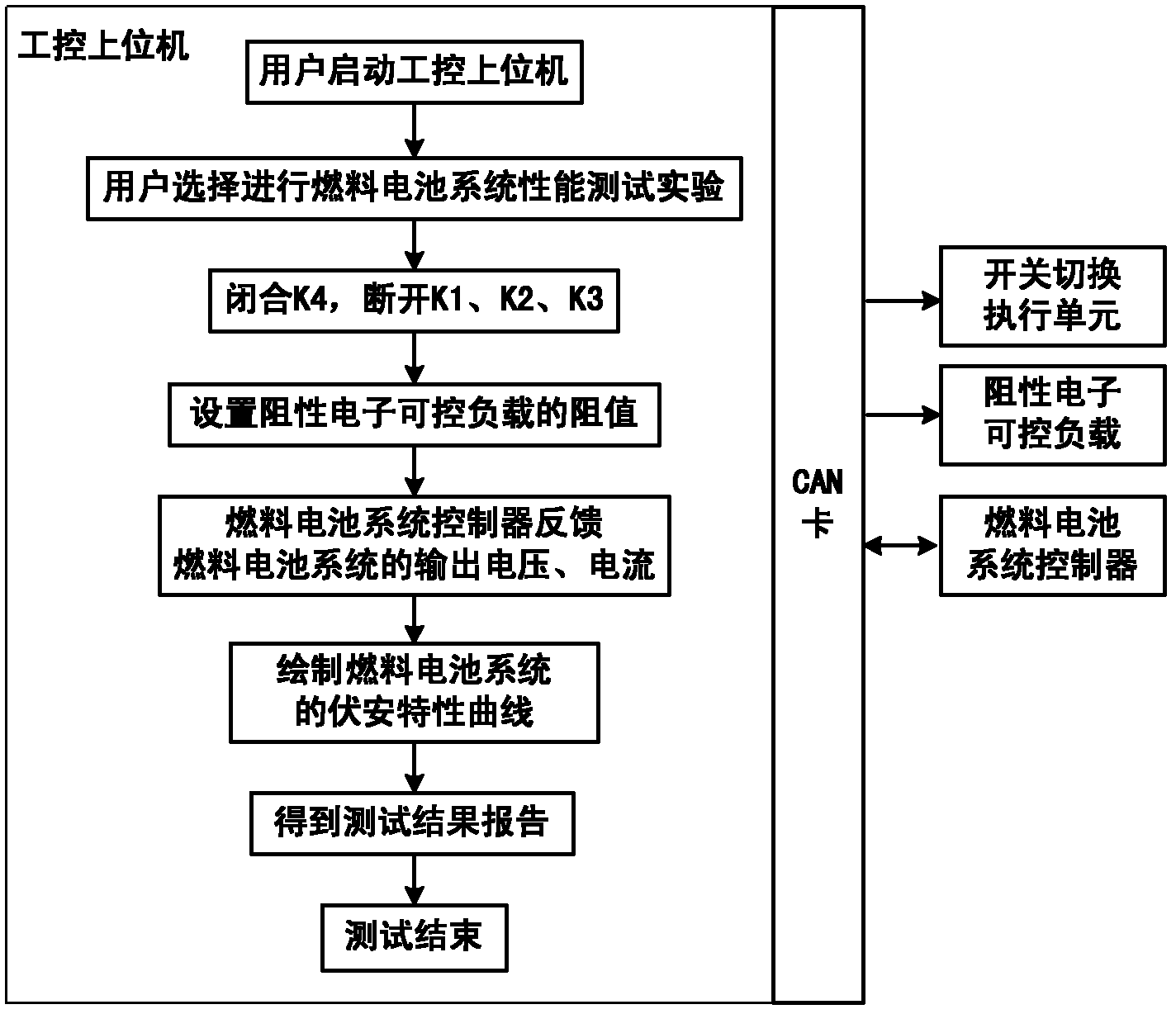

Comprehensive test platform and method for dynamic system of fuel cell hybrid electric vehicle

ActiveCN102494898AEasy to operateImprove maintainabilityInternal-combustion engine testingDynamo-electric machine testingArea networkData acquisition

The invention discloses a comprehensive test platform and a comprehensive test method for a dynamic system of a fuel cell hybrid electric vehicle. The platform comprises an industrial control console operation unit, a lithium cell pack unit, a fuel cell unit, a direct-current / direct-current (DC / DC) converter, a tested motor unit, an alternating-current power dynamometer unit, a switching execution unit and a resistive electronic controllable load, wherein the industrial control console operation unit communicates with all the other units through a data acquisition card, a controller area network (CAN) card and a CAN bus, and simulates to manage the whole comprehensive test platform. According to the comprehensive test platform and the comprehensive test method, comprehensive test functions of testing the performance of a fuel cell system, a lithium cell pack and a tested motor and managing the energy of the dynamic system is realized.

Owner:WUHAN UNIV OF TECH

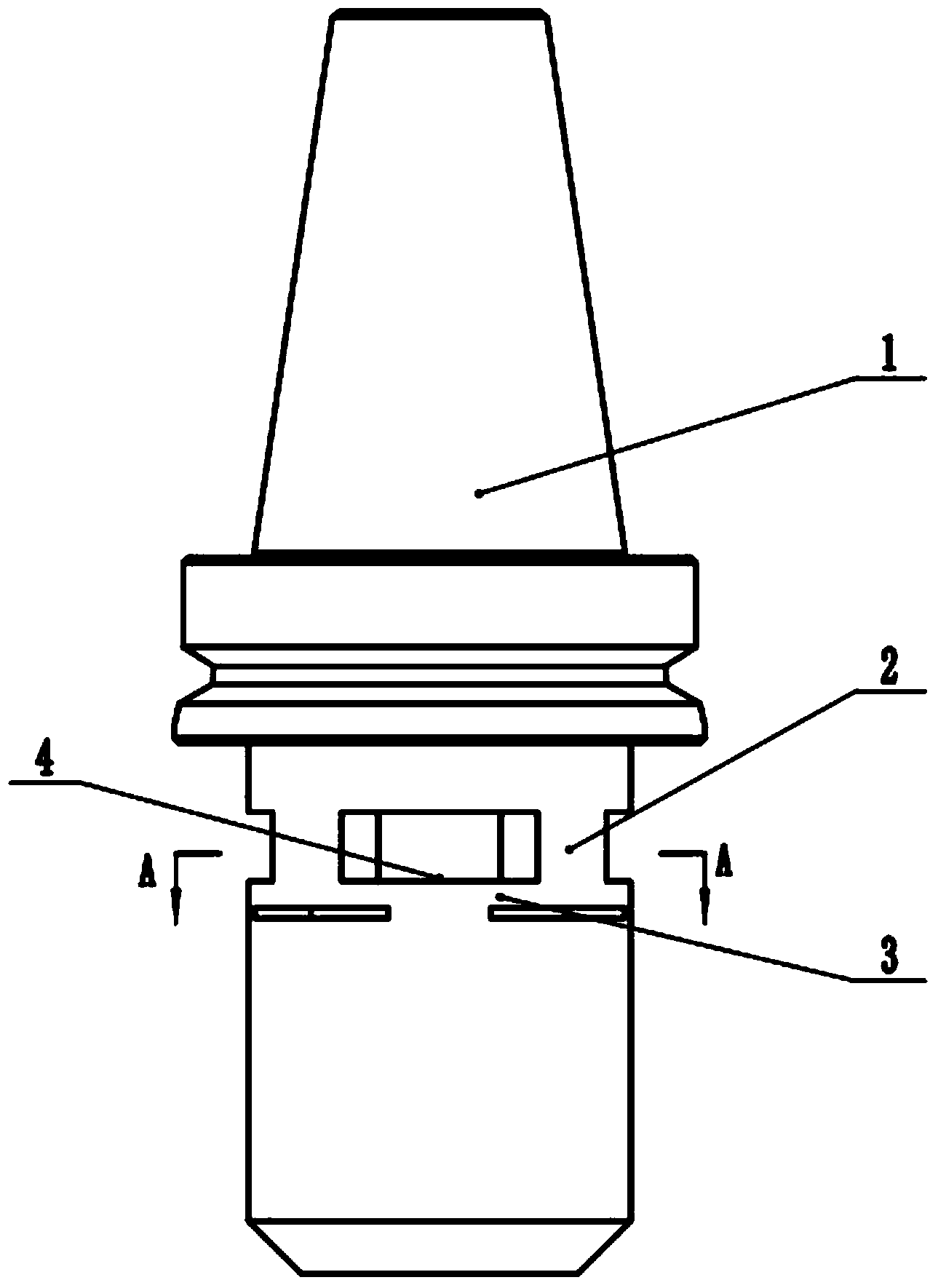

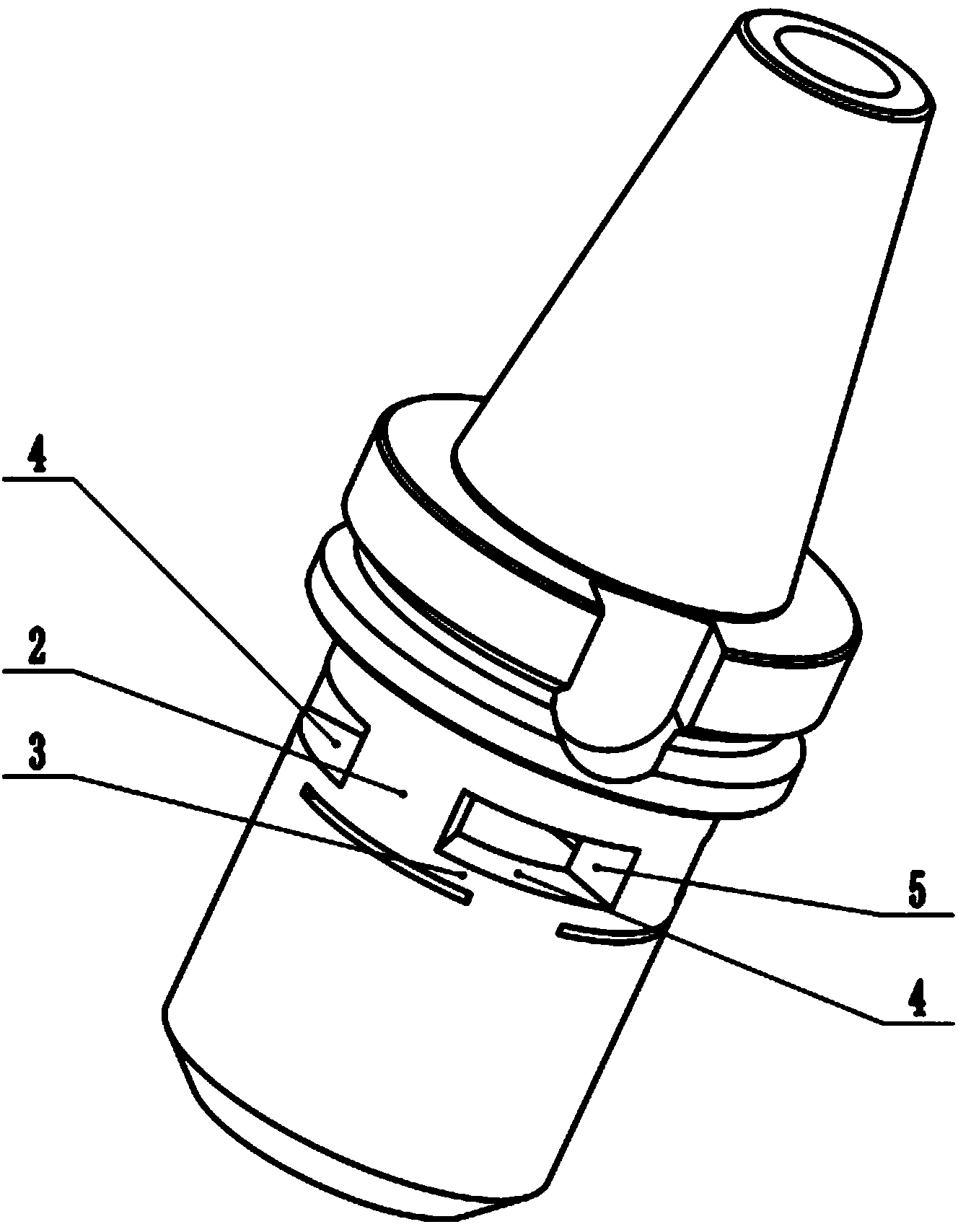

Capacitive intelligent knife handle system for detection of four-dimensional cutting force

ActiveCN104139322ADoes not affect installationDoes not affect normal useMeasurement/indication equipmentsMetal working apparatusRobot handComputer module

The invention discloses a capacitive intelligent knife handle system for detection of a four-dimensional cutting force. The capacitive intelligent knife handle system mainly comprises a standard knife handle, a capacitive displacement sensor, a lithium battery, a capacitive sensor detection circuit, a signal preprocessing and collecting unit, a signal wireless transmitting module, an outer packaging ring, a sealing cover and a fixing block, wherein a deformation rib structure is formed through grooving at a cylinder part of the lower end of the standard knife handle, the four-dimensional cutting force is computed by utilizing the deformation of a deformation rib, and the deformation is measured by the capacitive displacement sensor. The capacitive intelligent knife handle system for the detection of the four-dimensional cutting force, disclosed by the invention, has the advantages that the structure change of an original knife handle is smaller, the installation and the use of a knife and the catching of a mechanical hand are not influenced, the capacitive intelligent knife handle system has the advantages that the structure is simple, the applicability is strong and the like, the accuracy of detecting the deformation of the deformation rib by utilizing a high-accuracy capacitive micro displacement sensor is higher than the accuracy of detecting the deformation of the deformation rib by utilizing a strain type dynamometer, and the dynamic performance is better.

Owner:HARBIN INST OF TECH

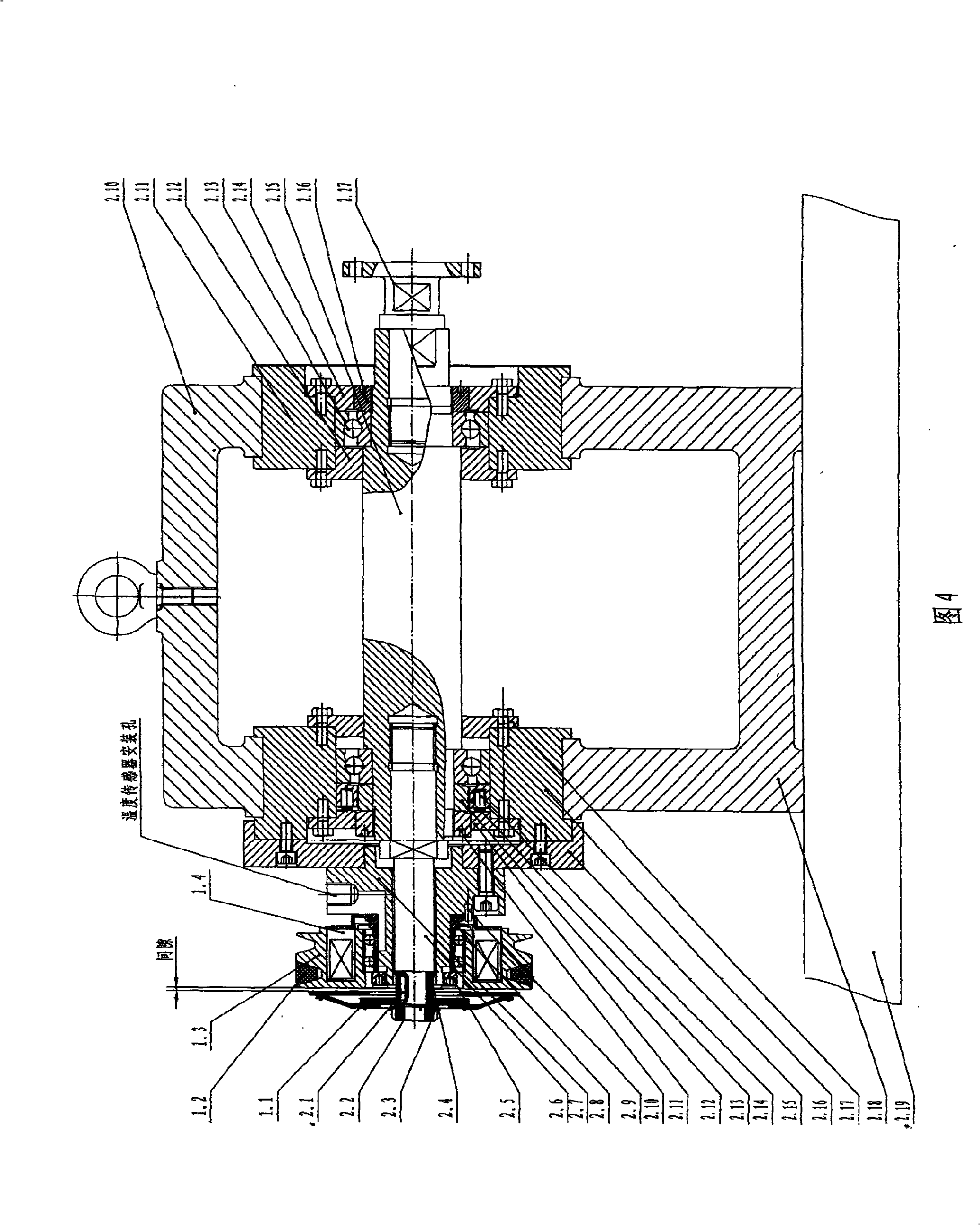

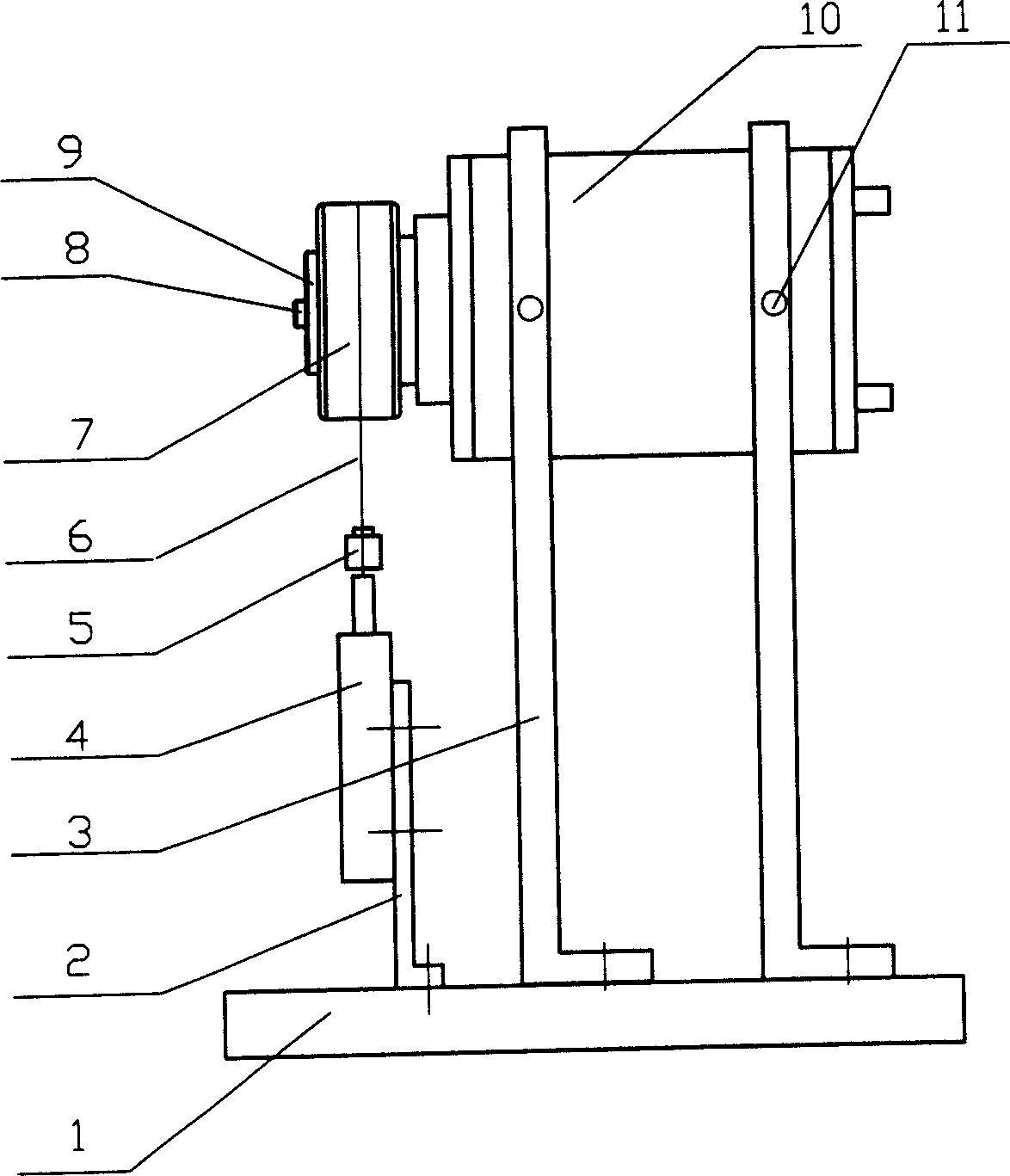

Electromagnetic clutch dynamic torque automatic test method and apparatus of automobile air conditioner compressor

InactiveCN101303259AStrong simulationEasy to detectWork measurementTorque measurementElectromagnetic clutchFrequency conversion

The present invention provides an automatic test method and apparatus for vehicle air conditioner compressor electromagnetic clutch dynamic torsional moment, comprising a mainly supporting component (2), a torque revolution speed transducer (3), an electric eddy current dynamometer (4) and an electrical control system, wherein the electromagnetic clutch (1) is installed on the left end of the supporting component to form a cantilever structure, and is driven to rotate through a belt pulley of the electromagnetic clutch driven by a frequency conversion motor; the right end of the supporting component is linked with the torque revolution speed transducer and the electric eddy current dynamometer separately by a coupling, the torque revolution speed transducer and the electric eddy current dynamometer are both installed on each seat to ensure the axiality to be consistent with the supporting component main shaft. The automatic test method and apparatus can simulate air conditioner electromagnetic clutch actual use condition factually, test dynamic parameter variation regularity with the existing of revolution speed spectrum and torque loading spectrum, observe and research dynamic procedure in full, and provide science foundation for evaluating performance, lifetime and reliability thereof.

Owner:LUOYANG BEARING SCI & TECH CO LTD

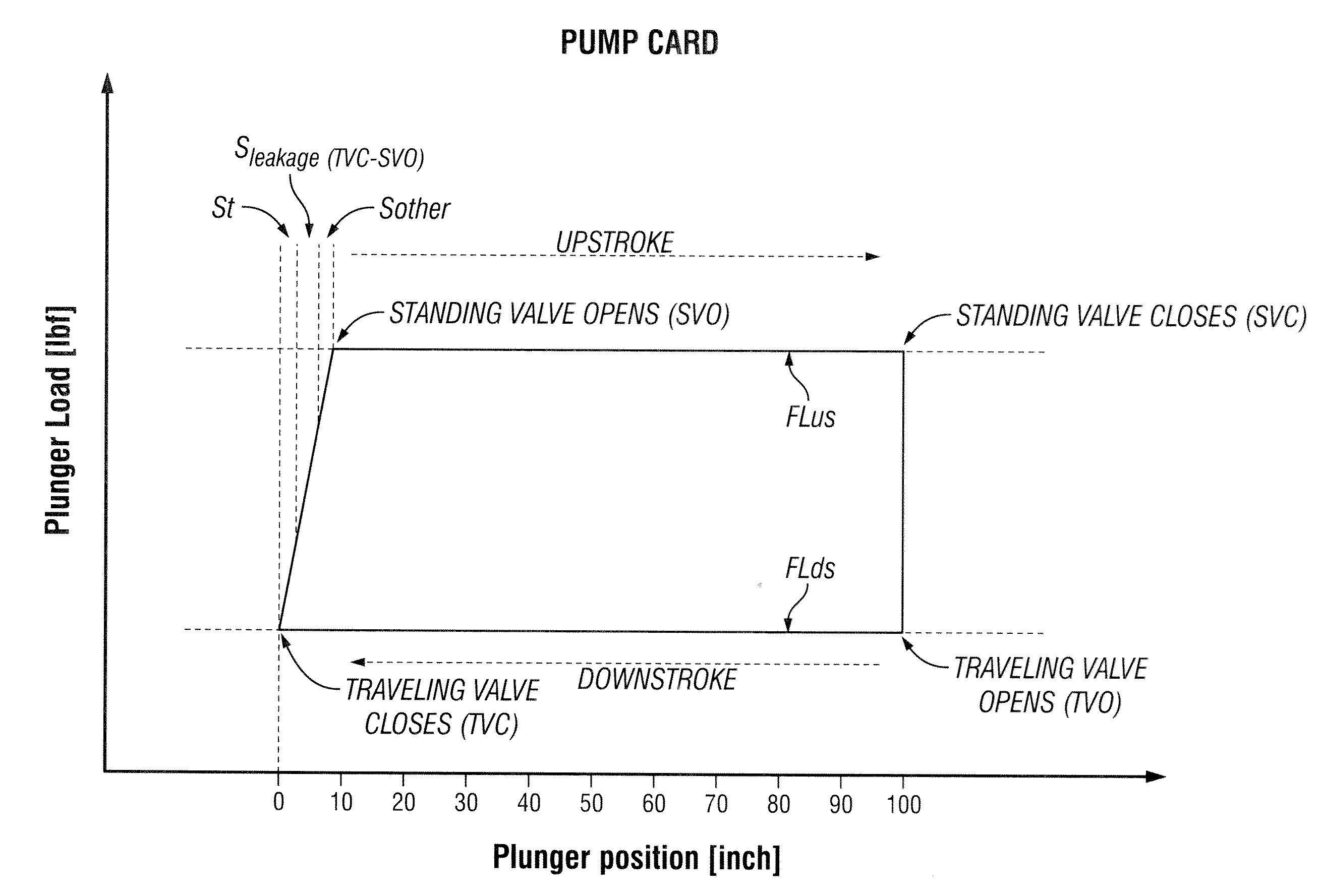

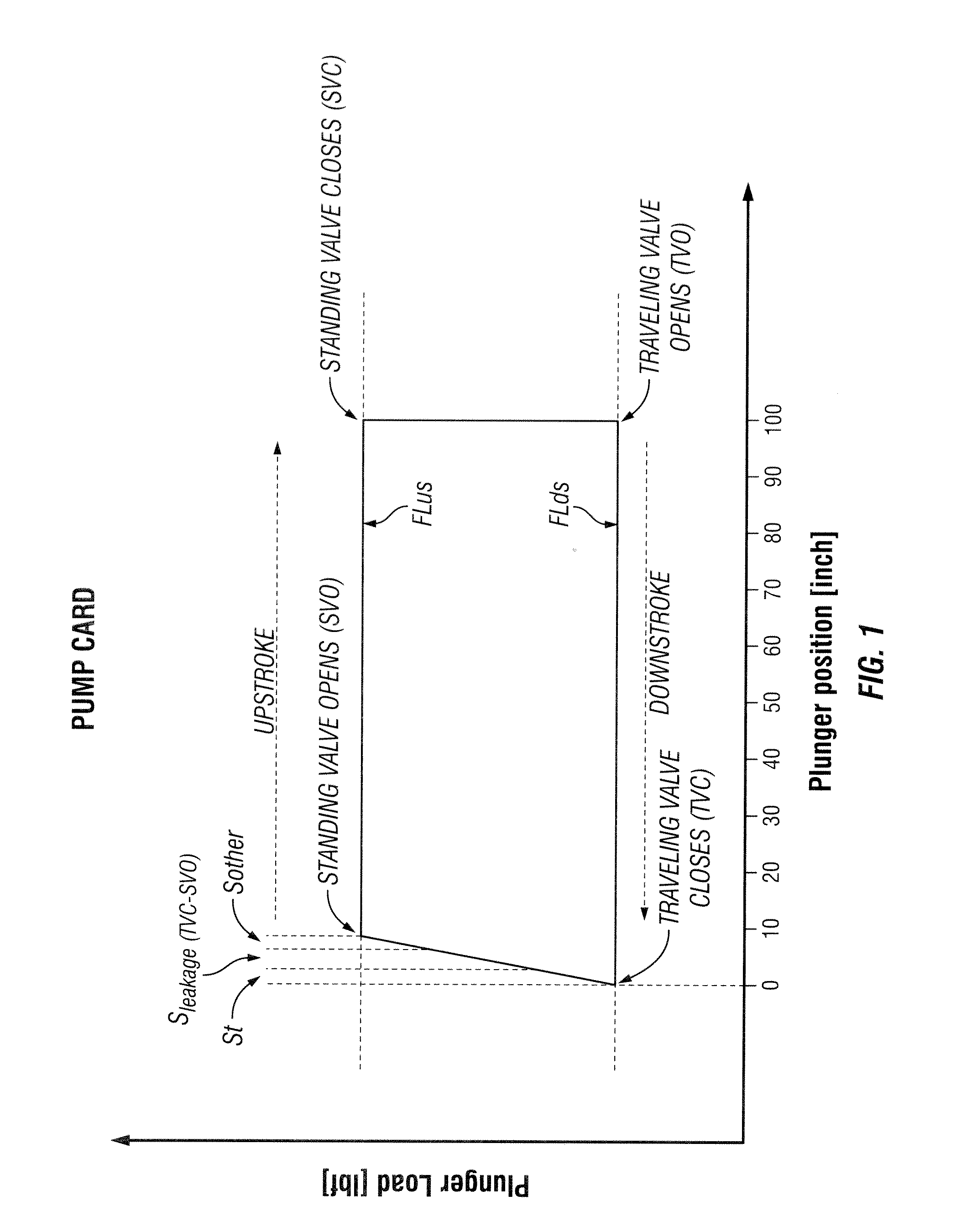

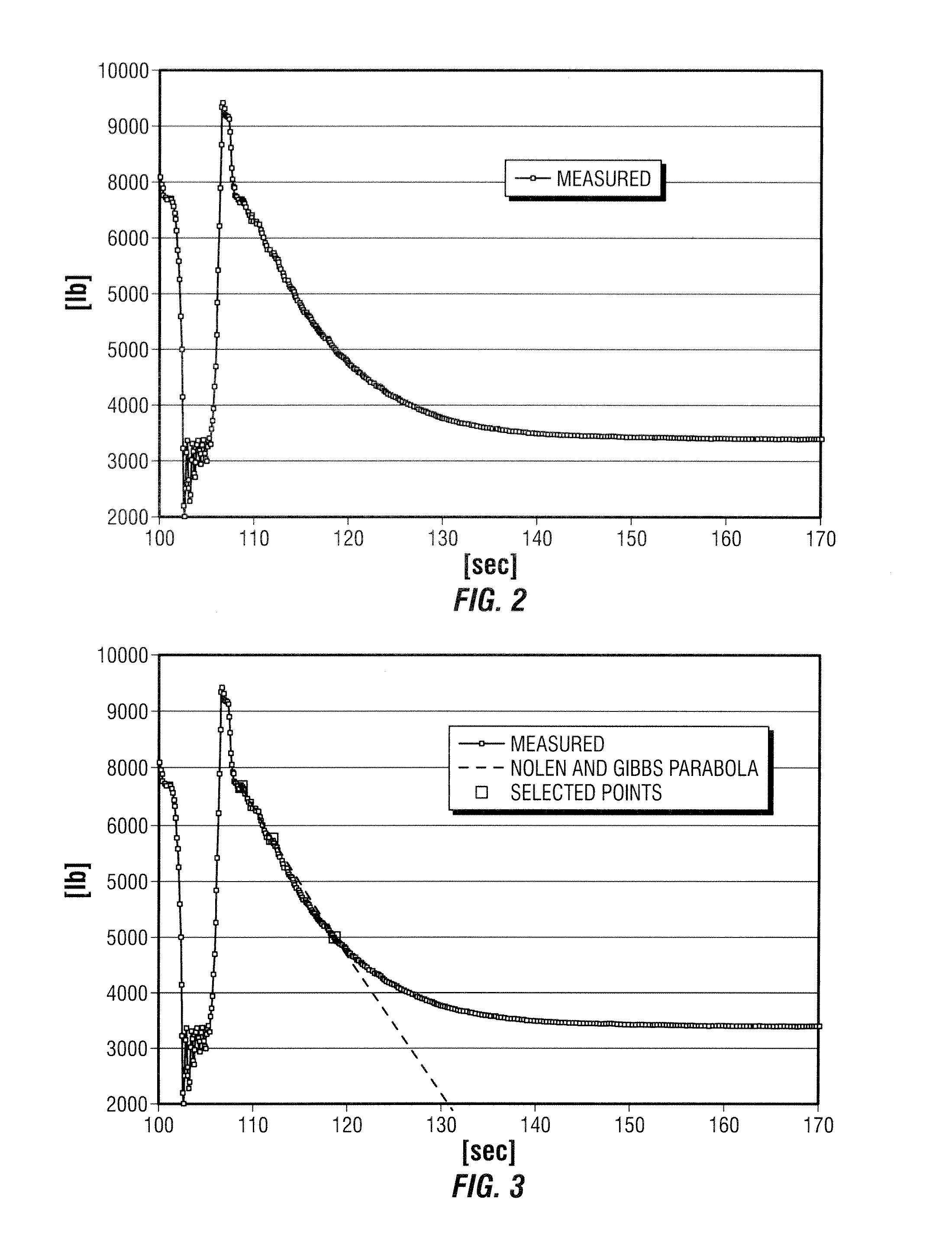

Methods for measuring leakage rate and inferring production rate of an oilfield downhole pump

ActiveUS20130024138A1Improve accuracyAccurately determineSurveyConstructionsProduction rateEngineering

Methods for measuring the leakage rate of a downhole pump using either measured axial load information from the drive rod string or using measured production data. The invention is for methods of applying the leakage rate to a downhole dynamometer card, for a reciprocating rod pump, for determining well production.

Owner:RAVDOS HLDG INC

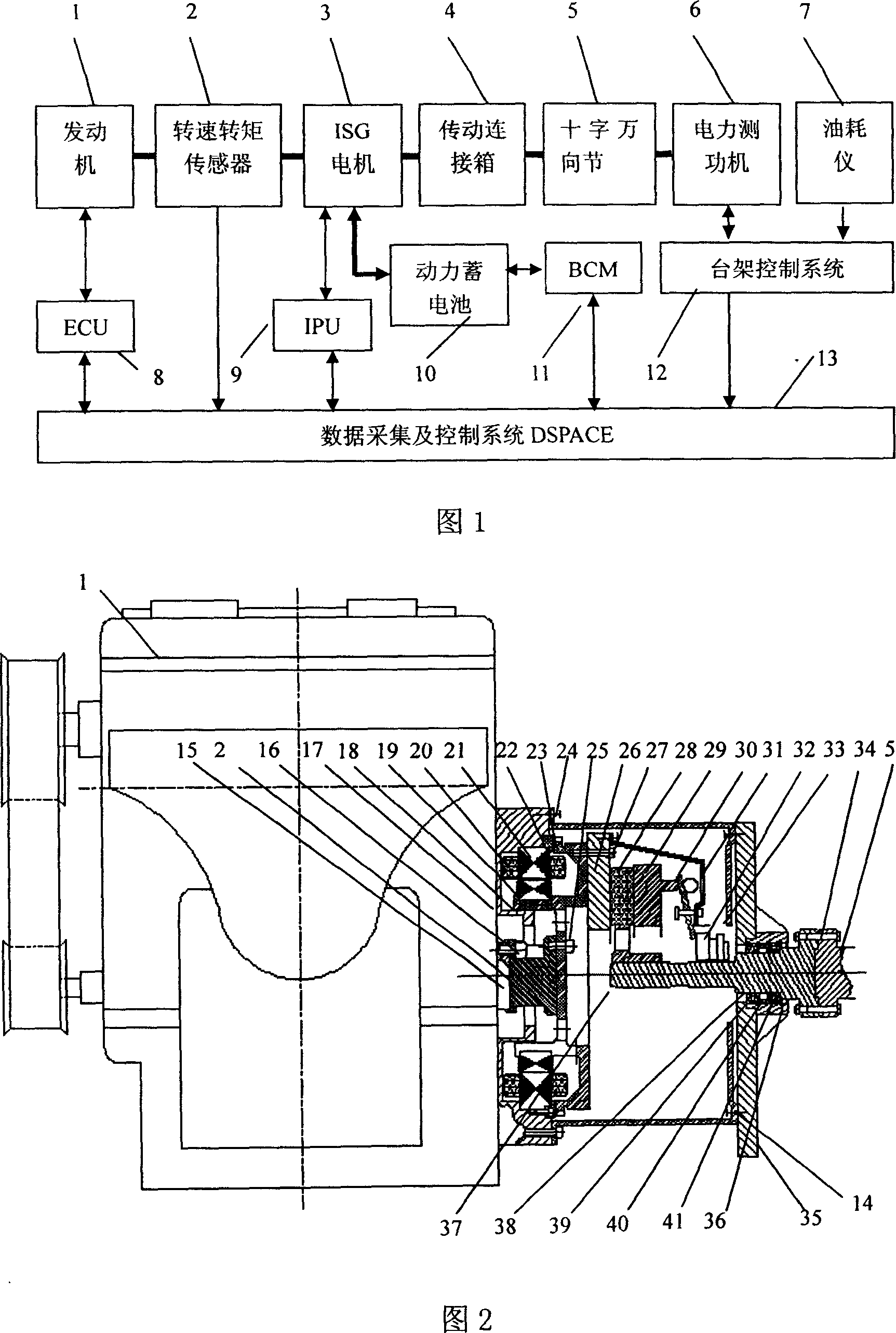

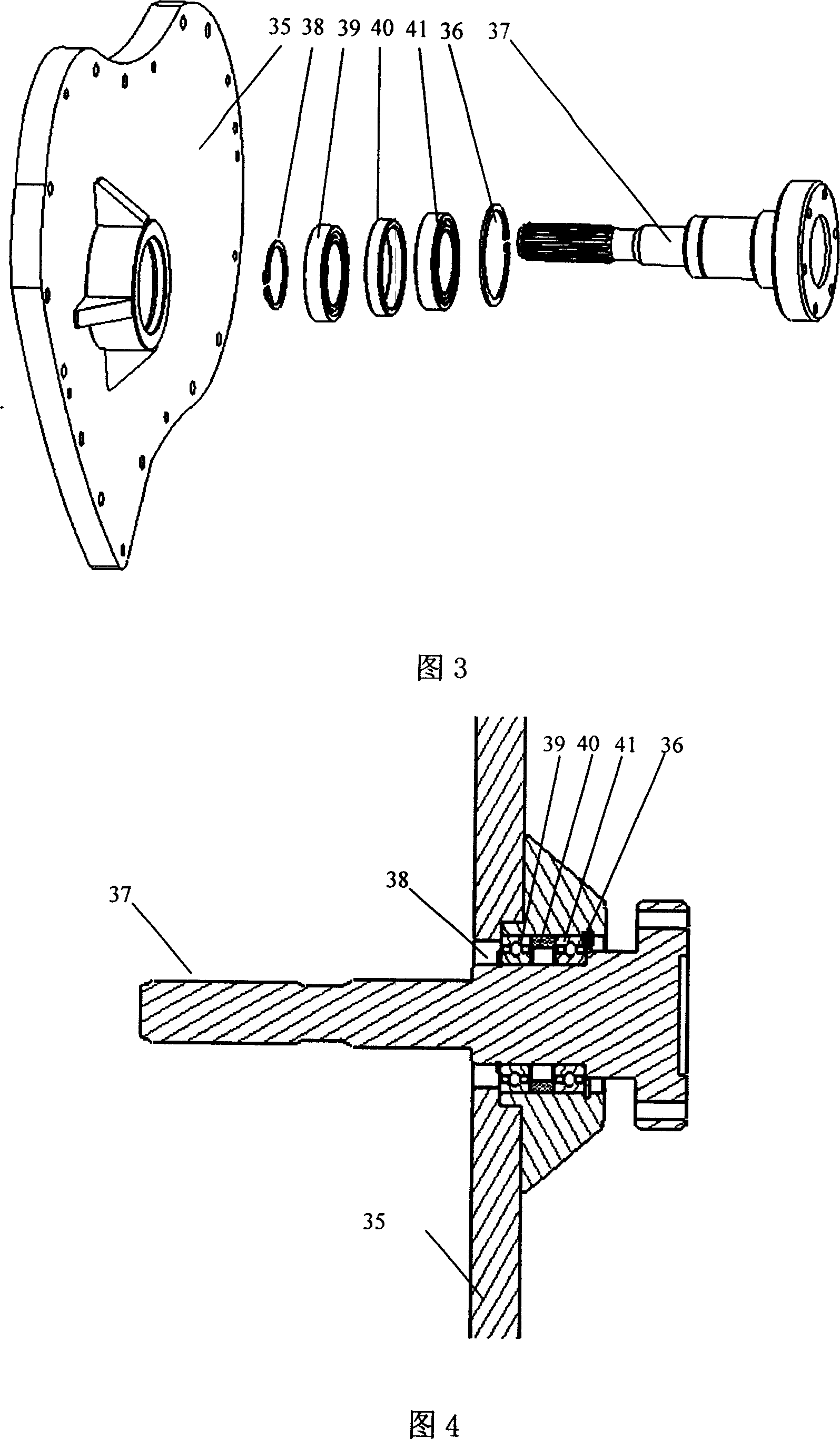

Test bench for performance of hybrid power vehicle transmission system

InactiveCN101013063AImprove support conditionsReduce torque fluctuationVehicle testingElectric signal transmission systemsMotor speedDynamometer

A hybrid driven vehicle transmission system performance test platform includes engine, speed torque sensor, ISG motor, transmission link support box, cross universal joint, electricity dynamometer, fuel consumption meter, control system, and others. The speed torque sensor is installed between the engine and the ISG motor, and the ISG stator connects to the clutch, and the transmission link support box and ISG motor stator are installed together to the engine installation surface; in the transmission link support box installs the transmission shaft, and the spline of the transmission shaft connects with the spline in the clutch friction chip, and the flange end of the transmission shaft connecting with the cross universal joint, the cross universal joint connecting with the power dynamometer. The invention integrates engine, motor and control system, increasing the speed and torque sensor and the transmission link support box, reducing the torque fluctuation in the transfer process, and it can respectively control the engine, motor speed and torque, and measure the parameters of system fuel consumption, battery voltage, current, charge state, and others.

Owner:CHONGQING UNIV +1

Loading device for testing permeability of concrete chloride ions and test method

InactiveCN101718671ASolve permeabilitySimple structurePermeability/surface area analysisDynamometerEngineering

The invention discloses a loading device for testing the permeability of concrete chloride ions, which comprises a longitudinal loading system and a lateral loading system, wherein the longitudinal loading system comprises a longitudinal bearing steel plate, an 'L'-shaped positioning piece, a lateral high-strength transmission screw, a longitudinal steel base plate, a longitudinal dynamometer, a longitudinal ball seat, a longitudinal loading steel plate, a longitudinal hydraulic jack, a longitudinal fixing steel plate and the like; and the lateral loading system comprises a lateral bearing steel plate, an 'L'-shaped test piece block, a longitudinal high-strength transmission screw, a lateral steel base plate, a lateral dynamometer, a lateral ball seat, a lateral loading steel plate, a lateral hydraulic jack, a lateral fixing steel plate and the like. The invention also relates to a test method for testing the permeability of the concrete chloride ions by utilizing the loading device. The loading device and the test method solve the problems that the conventional device for testing the permeability of the concrete chloride ions cannot load tested pieces, cannot simulate the actual load condition of the conventional concrete and cannot measure the permeability of the concrete chloride ions under the condition of pressure load.

Owner:HOHAI UNIV +1

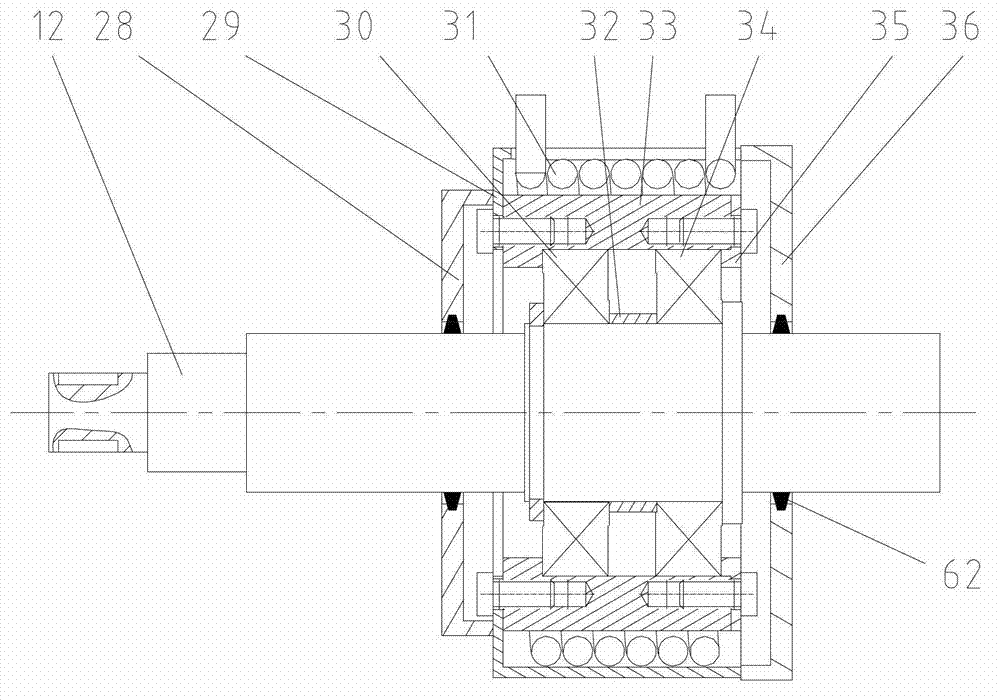

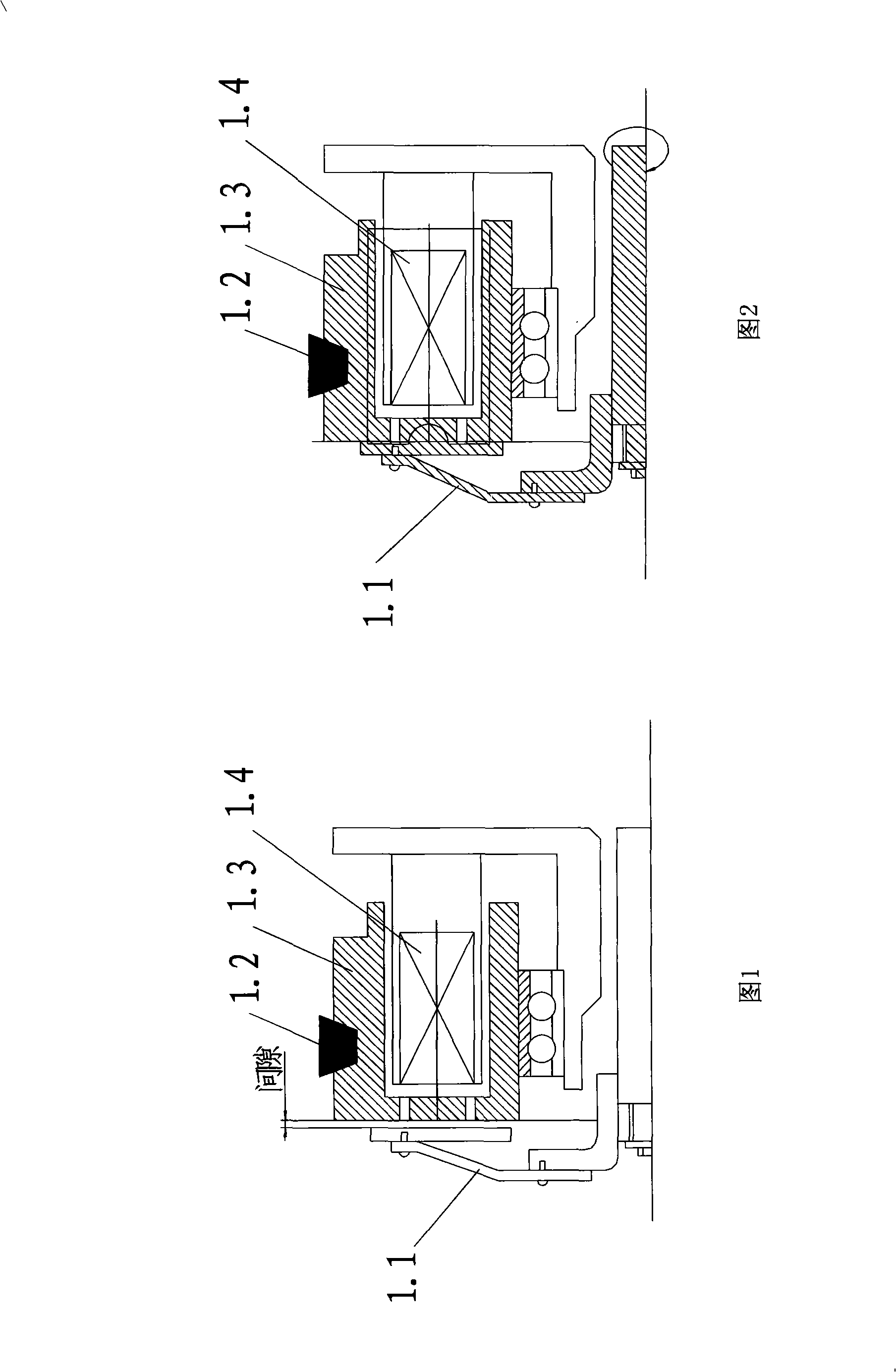

Dynamic loading device for high-speed motorized spindle

ActiveCN102426097ARestoration of different types of stress situationsHigh vibration frequencyMachine gearing/transmission testingCouplingDynamometer

The invention discloses a dynamic loading device for a high-speed motorized spindle. The device comprises a supporting part and a loading part, wherein the supporting part comprises a spindle base, an axial loading bracket, a radial loading base plate and a dynamometer base. The spindle base comprises a spindle base plate, an adjusting base plate and a clamping mechanism. The loading part comprises a radial loading mechanism, an axial loading mechanism, a torque loading mechanism, a loading rod and a bearing unit. The torque loading mechanism comprises a power dynamometer and a high-speed spring tube coupling. The adjusting base plate and the clamping mechanism are overlapped on the spindle base plate and are fixedly connected with each other; the power dynamometer is fixed on the dynamometer base and is connected with the right end of the loading rod through the high-speed spring tube coupling; the left end of the loading rod is connected with the right end of a detected high-speed motorized spindle which is arranged in the clamping mechanism. The bearing unit is sleeved on the loading rod; the radial loading mechanism is arranged on the radial loading base plate and is positioned just below the bearing unit; and one end of the axial loading mechanism is arranged on the axial loading bracket, and the other end of the axial loading mechanism is in contact connection with the bearing unit.

Owner:JILIN UNIV

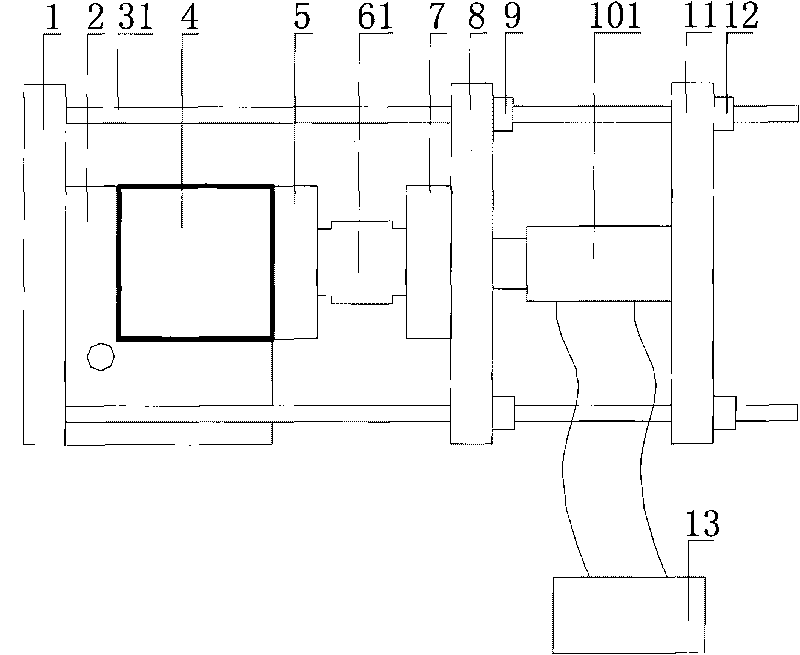

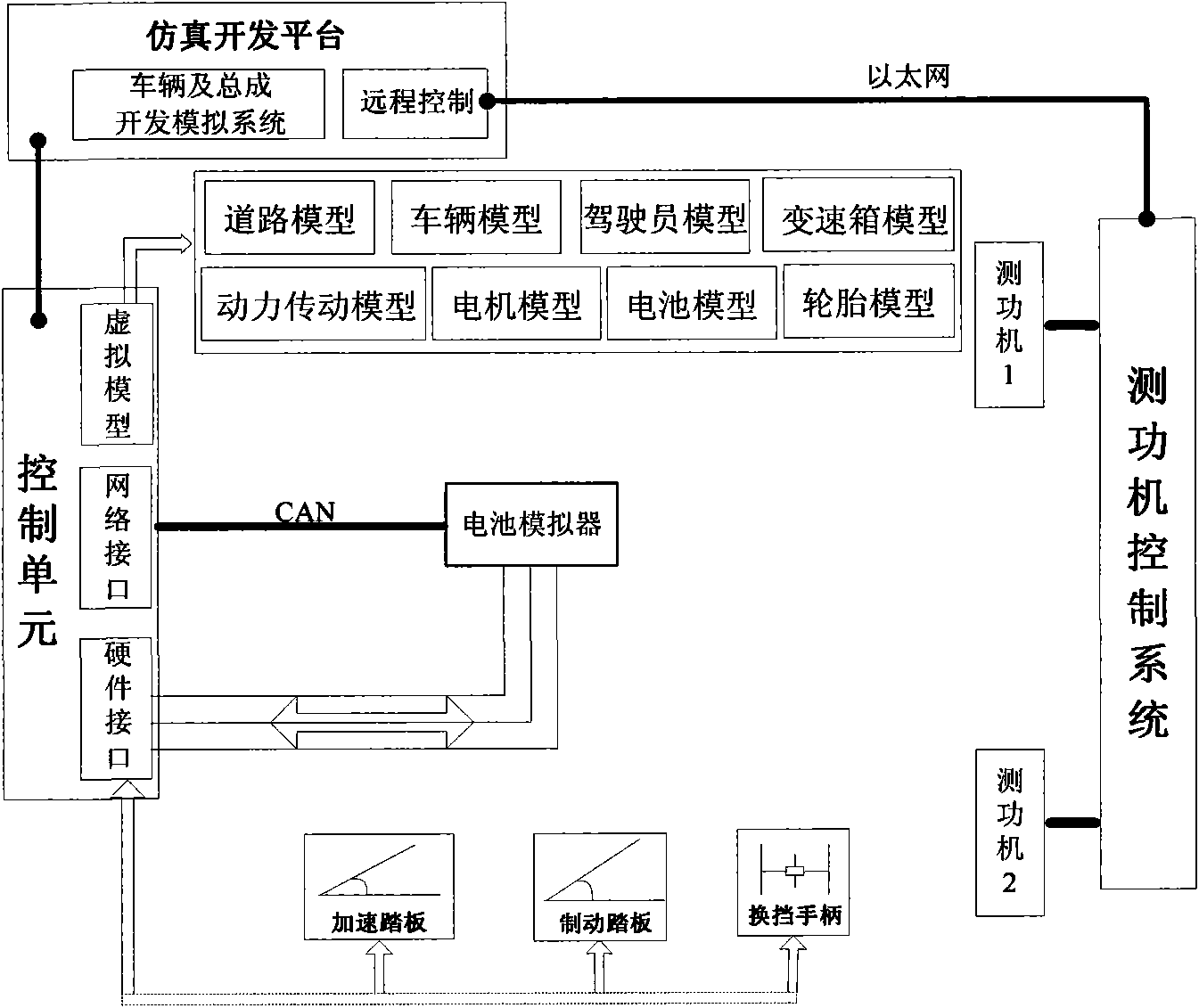

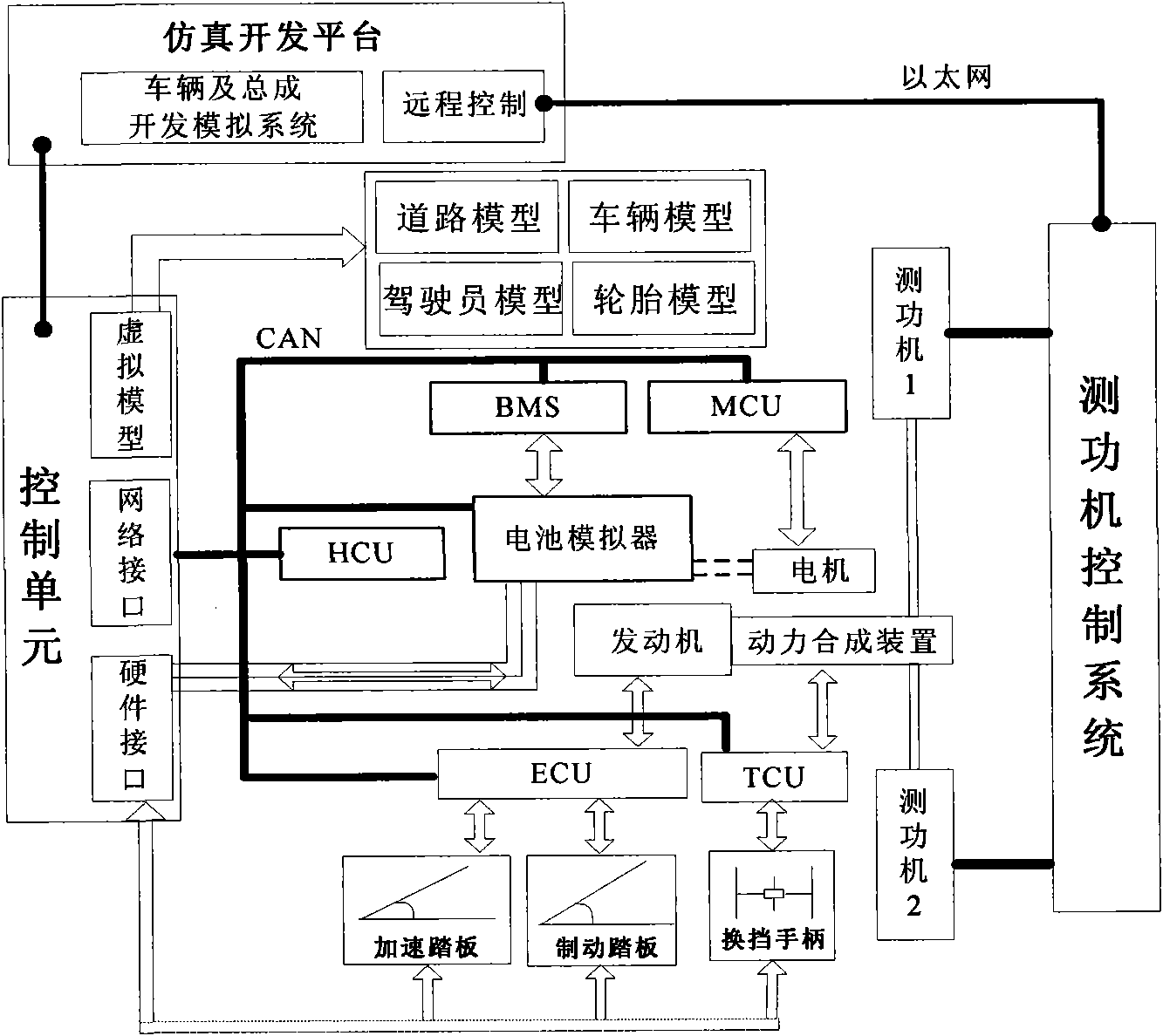

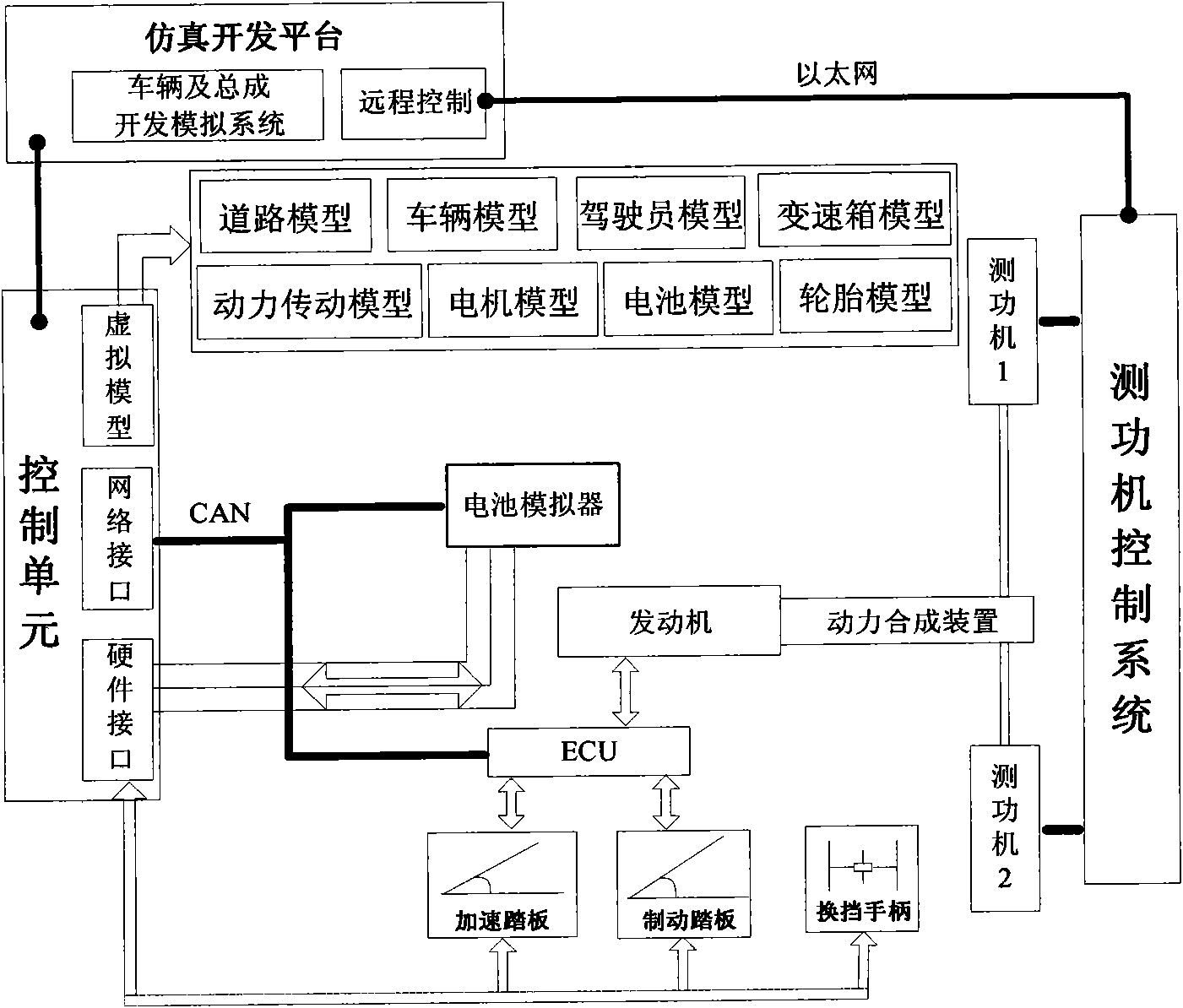

Hybrid assembly test bed system of passenger vehicle

InactiveCN102466568AReduce development costsReduce development riskVehicle testingHybrid carArea network

The invention relates to a hybrid assembly test bed system of a passenger vehicle and belongs to the technical field of hybrid assembly test of passenger vehicles. A dynamometer control system is respectively connected with a dynamometer 1 and a dynamometer 2; the dynamometer control system is connected with a simulation development platform through Ethernet; a control unit is connected with the simulation development platform; the network interface of the control unit is connected with a battery simulator through a CAN (controller area network) bus; the hardware interface of the control unit is connected with an accelerator pedal, a brake pedal and a shift knob, and the control unit is internally provided with a virtual model; and the simulation development platform comprises a vehicle and assembly development simulation system and a remote controller. According to the invention, a systemic solution and a verification method are provided for hybrid car development, the entire car development cycle is shortened, and the entire car development cost is lowered, thus the system is innovation in the field of new energy source test equipment.

Owner:FAW GROUP

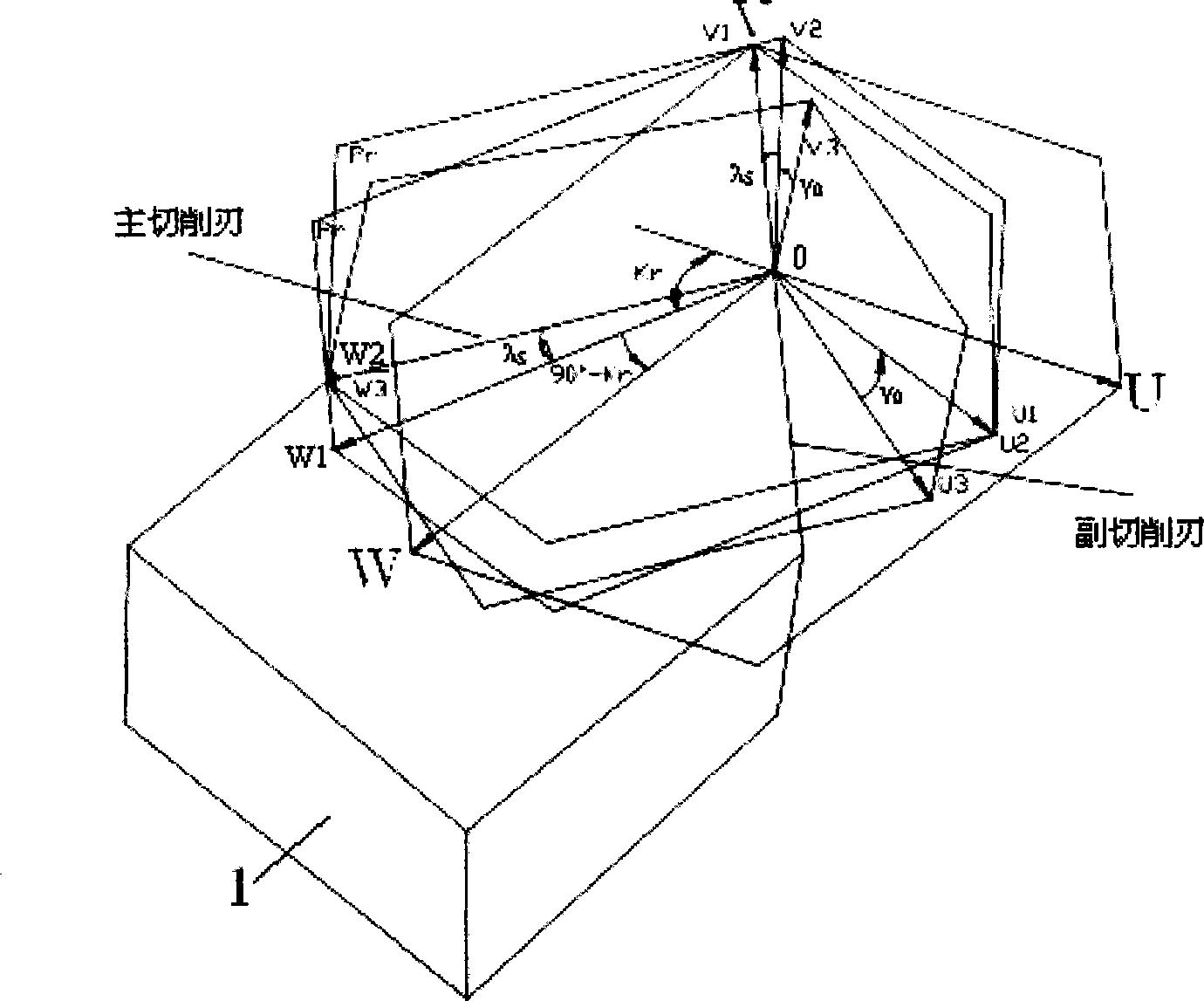

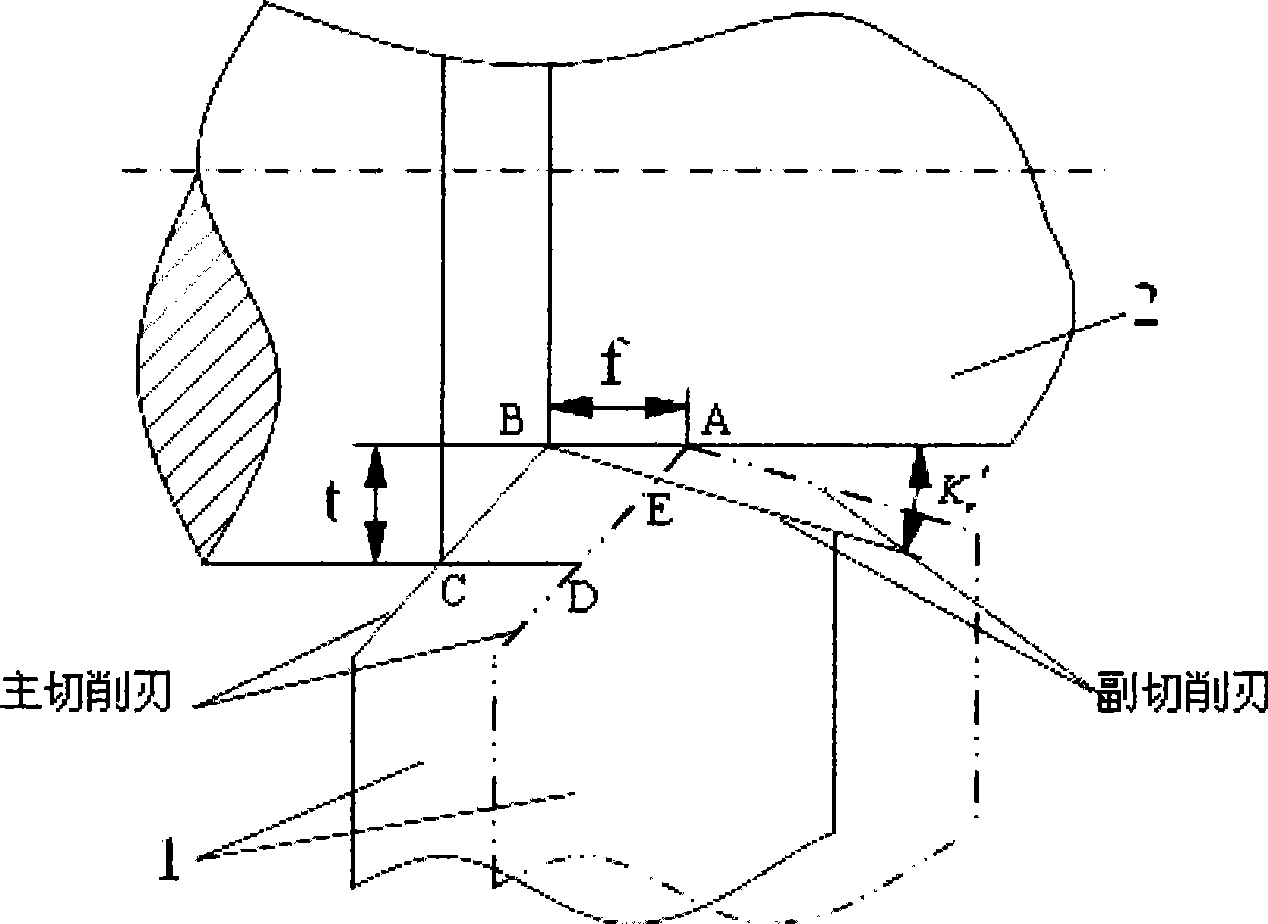

Turning force prediction method based on cutting-tool angle and cutting amount parametric variation

InactiveCN101412196AMeasurement/indication equipmentsMeasurement of force componentsEngineeringCutting force model

The invention discloses a method for predicting a turning force based on cutter angle and parameter variation of cutting data. The method comprises the following steps: using a dynamometer to measure a cutting force distributed along a coordinate axis of a coordinate system in one-time turning, calculating a three-way turning force coefficient of the cutting force in a converted coordinate system through converting the coordinate system, and calculating and obtaining the predicted turning force according to the factor of the cutting force, so as to achieve prediction of a three-way turning force for processing work pieces made from the same material and having the same heat treating state under the same cutting and lubricating conditions of the cutters made from the same material at any cutter angle parameter and cutting data parameter. The method for predicting the turning force needs little workload for cutting experiments, and the obtained cutting force models have wider application application, have predicting precision meeting actual demand, and are convenient to popularize and apply.

Owner:XIAN UNIV OF TECH

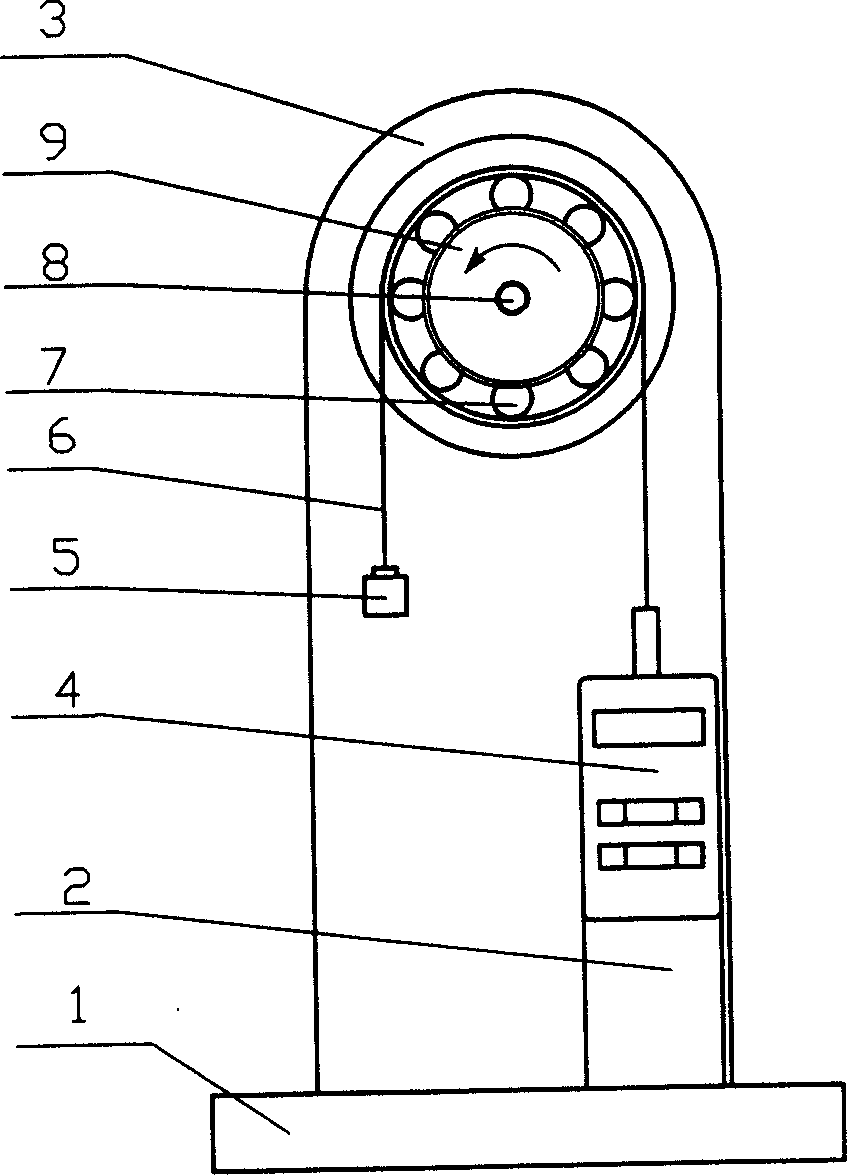

Measuring for friction torque of bearing under micro-loading at different rotation rate and measuring apparatus therefor

ActiveCN1865878AThe principle is simpleSimple structureMachine bearings testingWork measurementObservational errorFriction torque

The disclosed measuring apparatus and method for frictional moment comprise: the target bearing with diameter as D is suspended a segment nylon wire with ends connected to weight and dynamometer respectively, when bearing static, the show value on dynamometer as A1 balances to the weight; if rotating toward one direction by some rate, the show value increases to A2, and the formula M=(A2-A1) .D / 2 can express the corresponding frictional moment. This invention is reliable, simple, and well practical.

Owner:CIXING GROUP

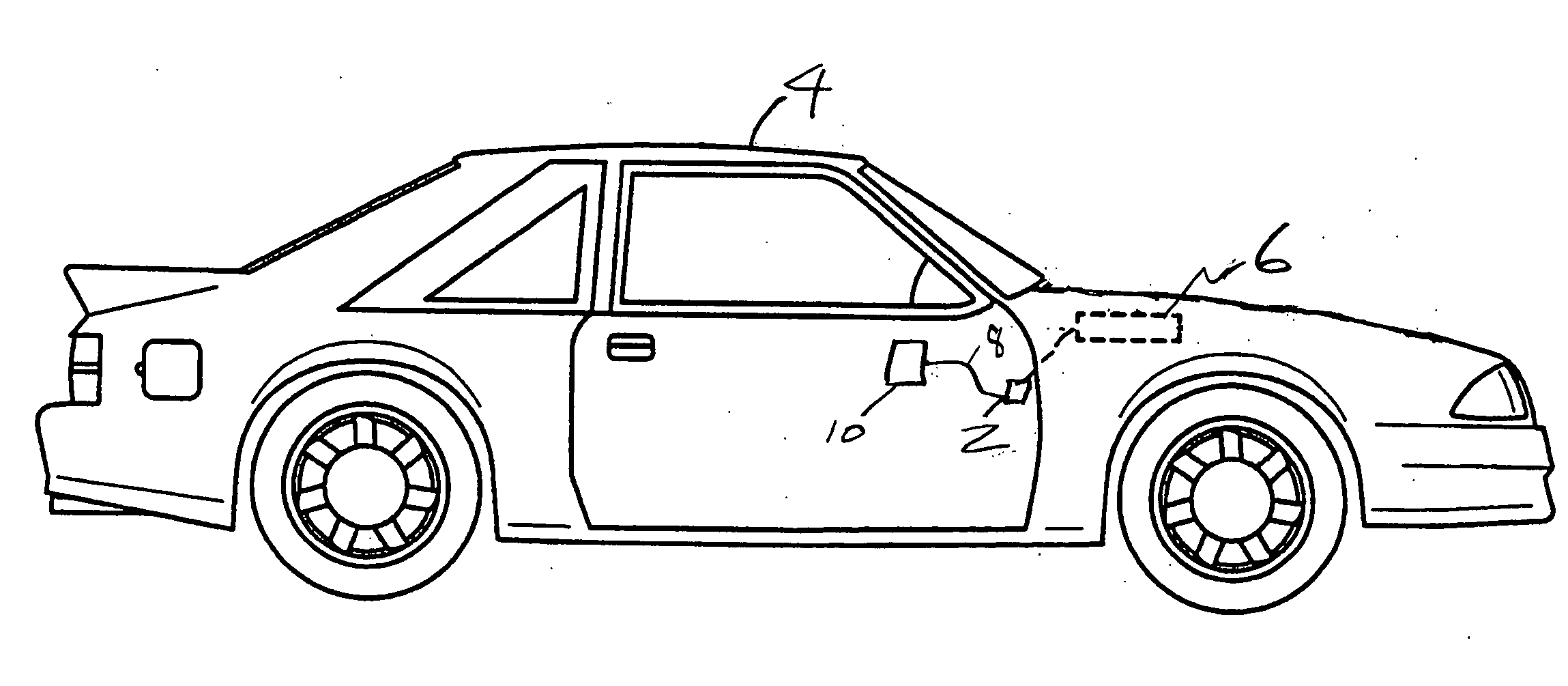

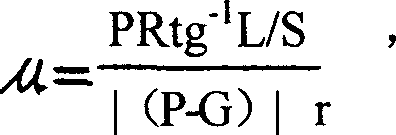

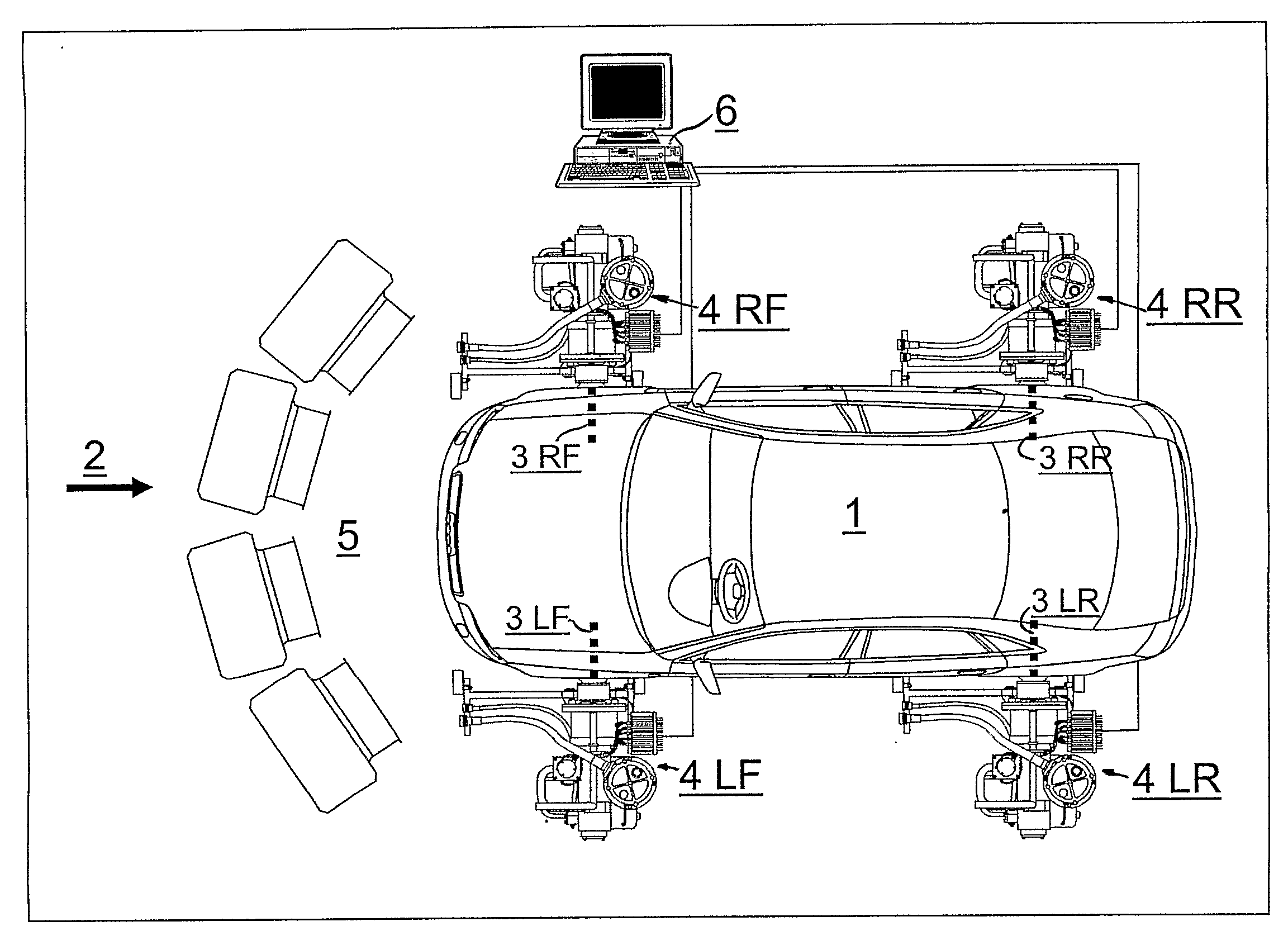

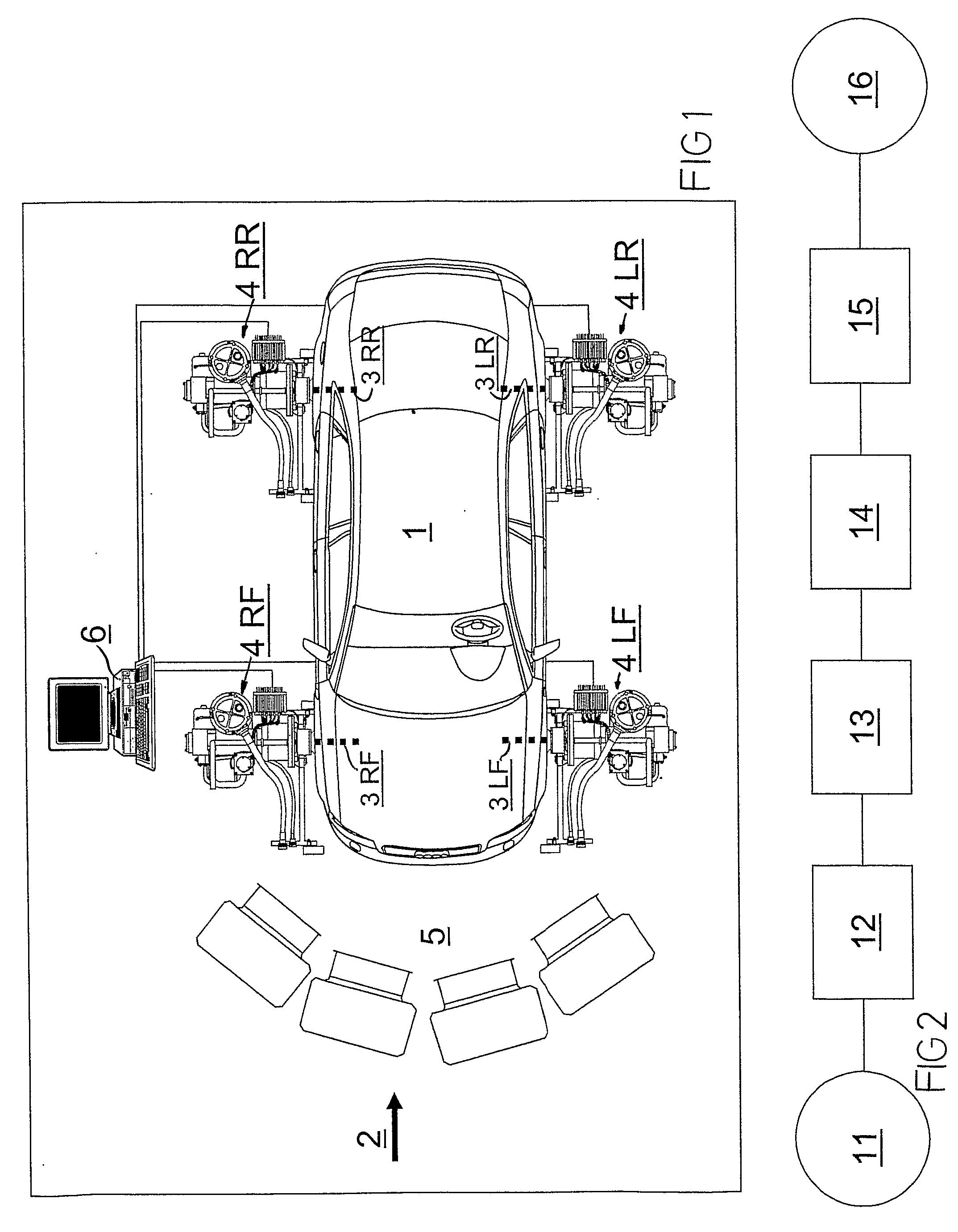

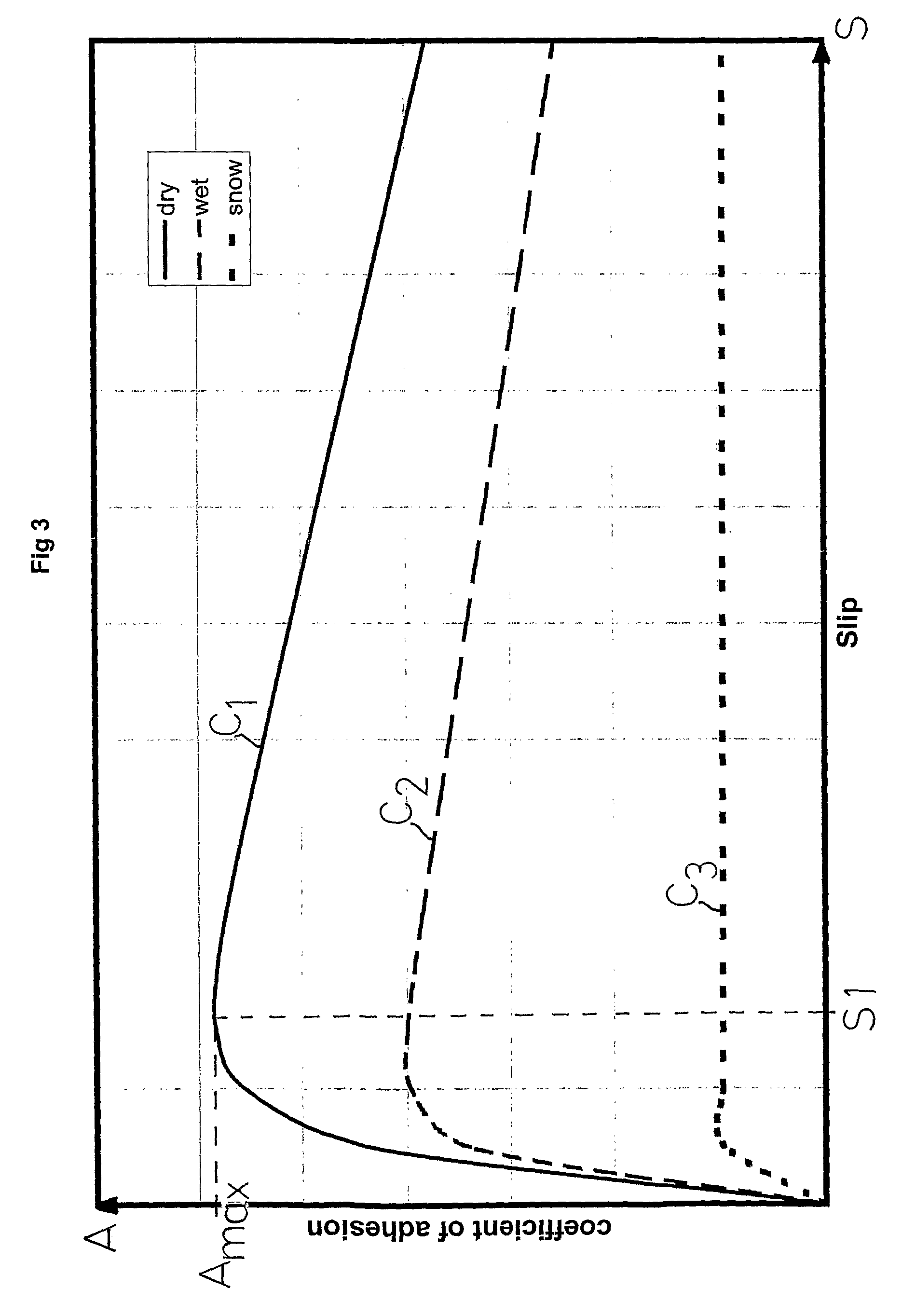

Method and device for dynamometer testing of a motor vehicle and Vehicle components

ActiveUS20090126510A1Increase flexibilityPrevent overloadVehicle testingWork measurementBrake torqueDynamometer

A method and a device for dynamometer testing of a motor vehicle (1), having a front end and a rear end and a right side and a left side, as seen in a driving direction, and / or vehicle components, by measuring torque and rotational speed on drive shafts (3LF, 3RF, 3LR, 3RR) of the vehicle, wherein a braking torque is applied to each one of said shafts by individual hydraulic dynamometer test units by throttling hydraulic fluid flows, and wherein said braking torque is adjustable for each individual one of said drive shafts (3LF, 3RF, 3LR, 3RR) such that a resulting individual rotational speed for that shaft corresponds to a virtual vehicle speed when driving the motor vehicle on a road, compensated with a slip value.

Owner:ROTOTEST INT

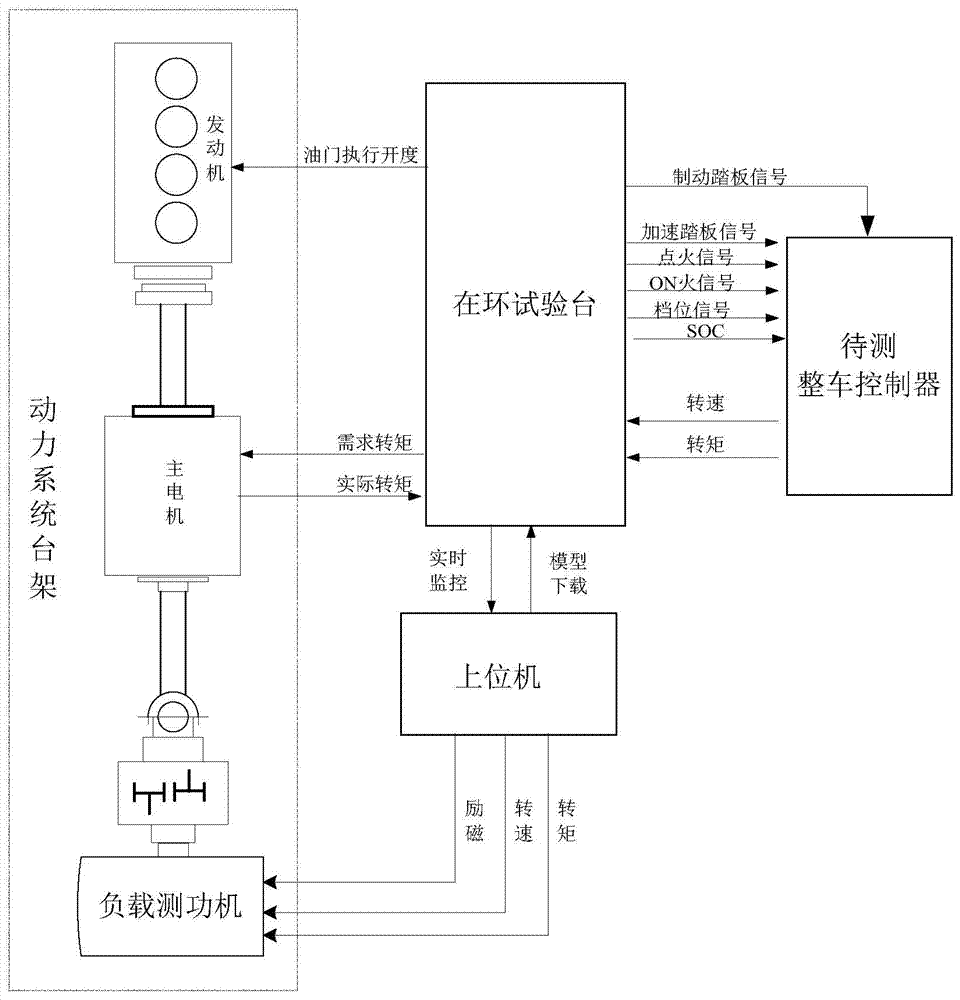

In-loop simulation test system and test method for vehicle management system

ActiveCN104298123AImprove performanceQuality improvementSimulator controlElectric machinerySoftware development

The invention discloses an in-loop simulation test system and test method for a vehicle management system. The test system comprises a hybrid power system stand and an in-loop test bench for being in communication connection with a vehicle management system to be tested. The hybrid power system stand comprises an engine and a main motor which are mutually connected as well as a load dynamometer which is connected with the main motor. By enabling an actual hybrid power drive system to be combined with a conventional hardware-in-loop simulation system, the vehicle management system to be tested is allowed to be in a real vehicle power drive system in a simulation manner, thereby improving vehicle management system software development quality and precision, reducing real vehicle road test times, reducing development time and cost, and reducing road test process risk; meanwhile, vehicle power performance test can be achieved; and through matching optimization of the power system, the whole performance of the vehicle is improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com