Electromagnetic clutch dynamic torque automatic test method and apparatus of automobile air conditioner compressor

An electromagnetic clutch, automatic test technology, applied in the direction of measuring devices, instruments, torque measurement, etc., can solve the problems of limiting the development speed of the automobile industry, no relevant reports, and inability to truly simulate the working conditions of electromagnetic clutches. Improve the level of automatic measurement and control, the effect of fast response and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

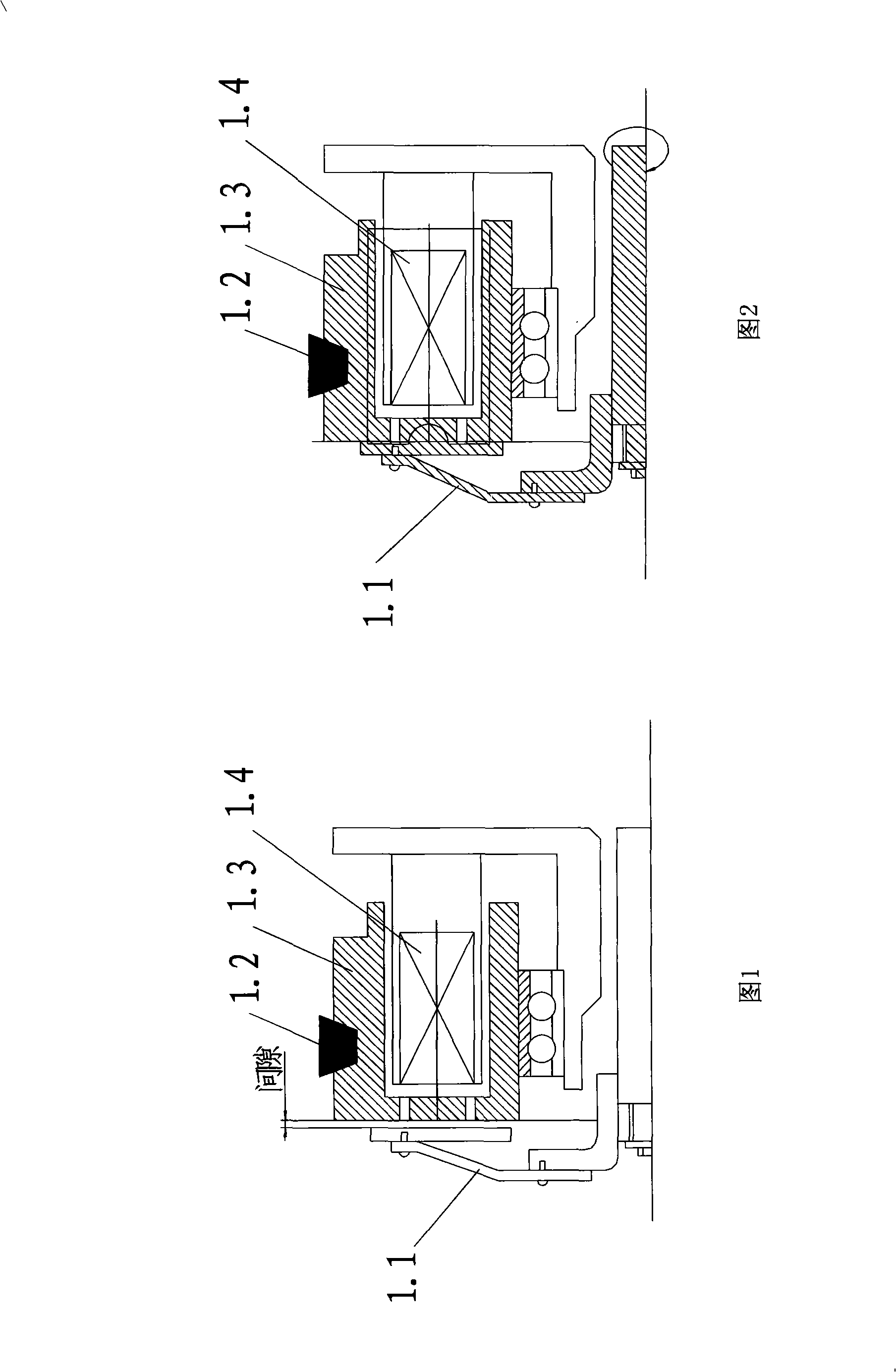

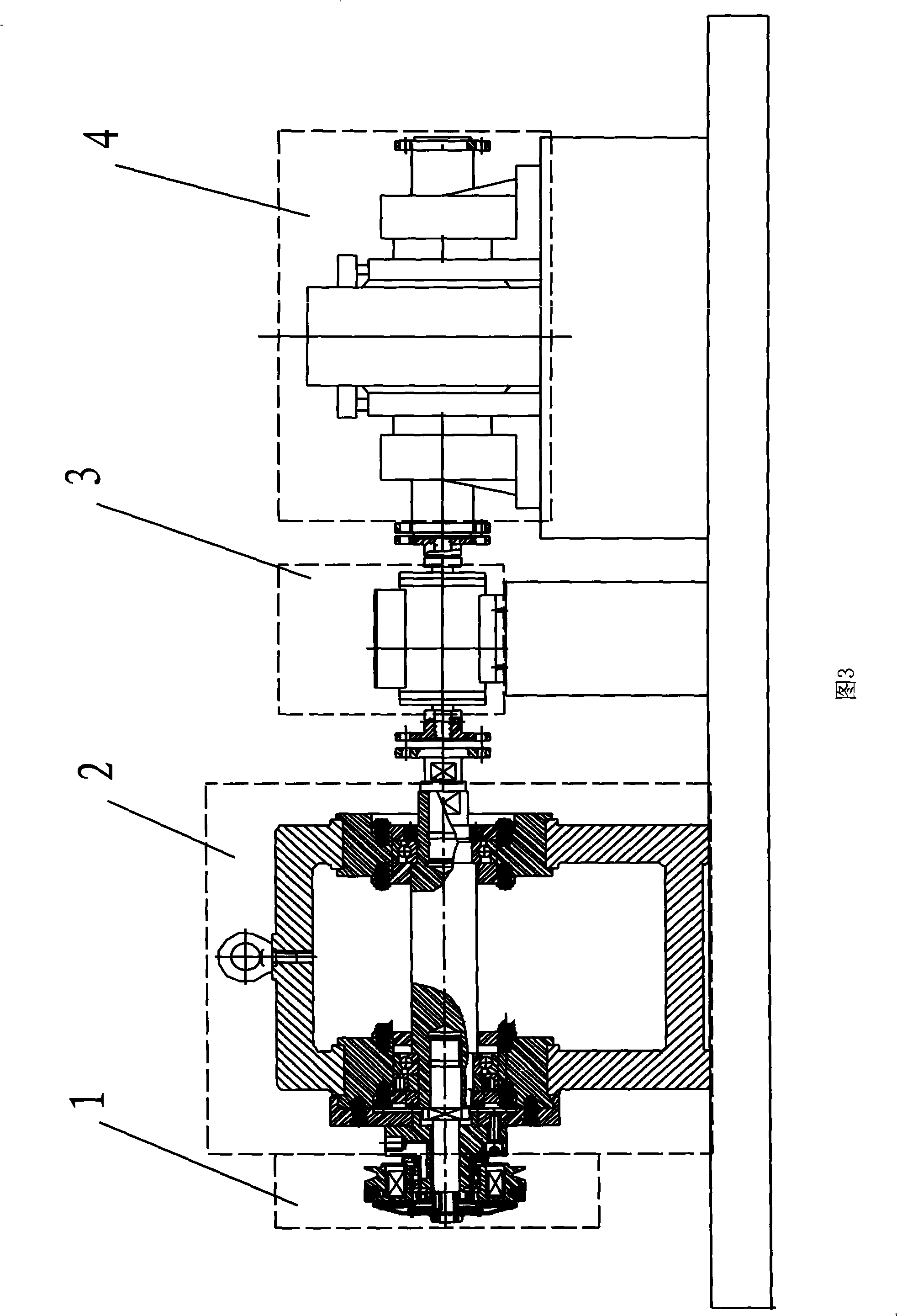

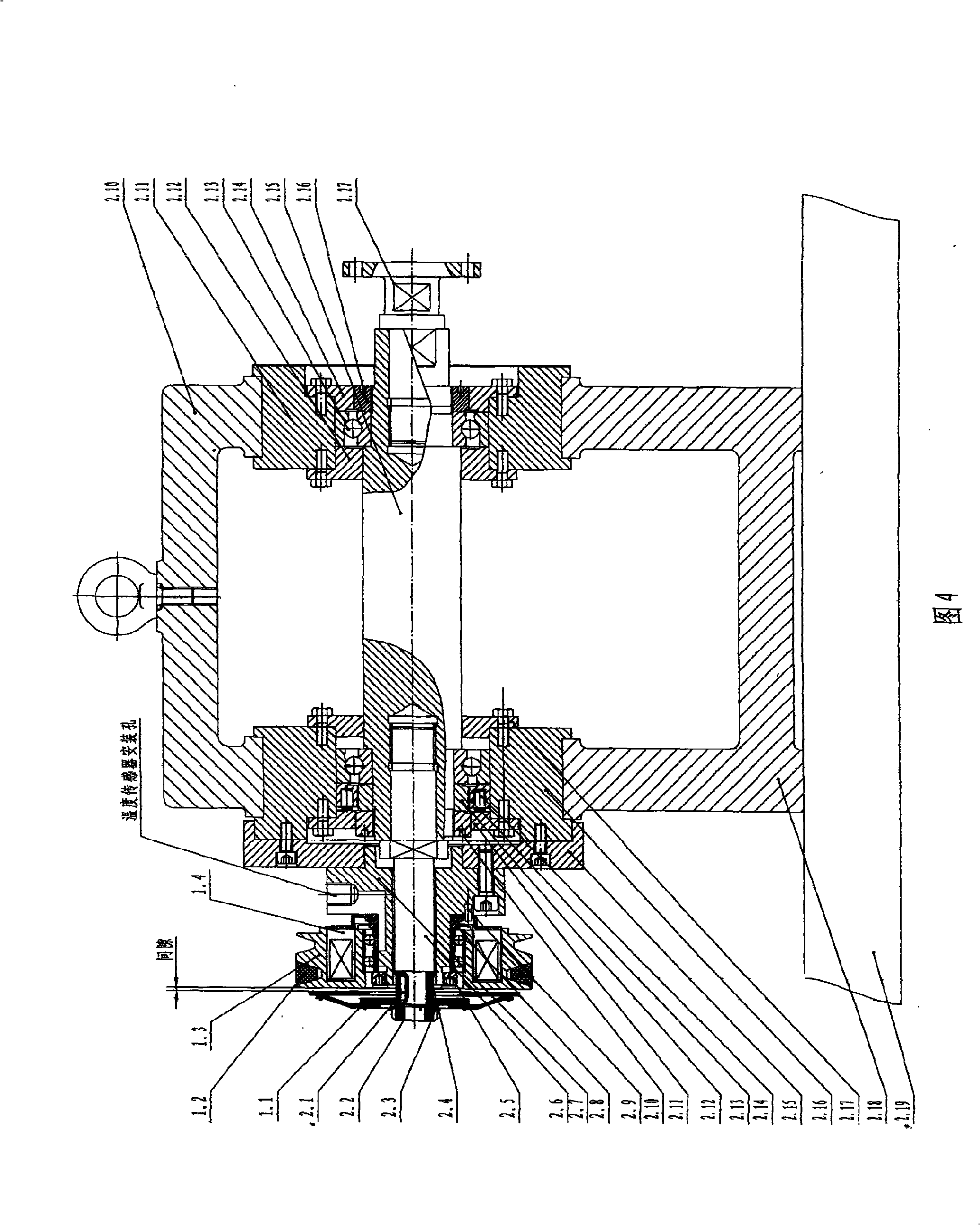

[0028]As shown in Figures 3 and 4: the automatic test device for the dynamic torque of the electromagnetic clutch of the automobile air-conditioning compressor of the present invention, the automatic test device is mainly composed of a support assembly (2), a torque speed sensor (3), an eddy current dynamometer ( 4) It is composed of an electrical control system, wherein the electromagnetic clutch (1) is designed and installed on the left end of the support assembly (2) to form a cantilever structure, and the pulley of the electromagnetic clutch (1) is driven by the variable frequency motor to rotate; the support assembly (2) The right end of the motor is connected to the torque and speed sensor (3) and the eddy current dynamometer (4) respectively through the coupling. The torque and speed sensor (3) and the eddy current dynamometer (4) are placed on their respective bases to ensure that Its coaxiality is consistent with the main shaft of the support assembly (2). The upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com