Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126 results about "Wood production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lumber and wood products are created in the wood industry from the trunks and branches of trees through a series of steps, as follows.

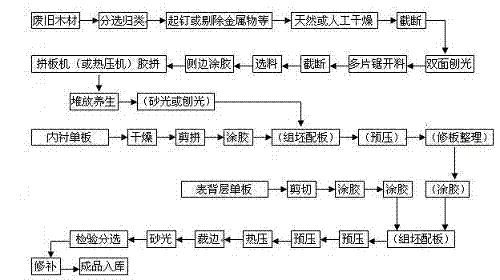

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

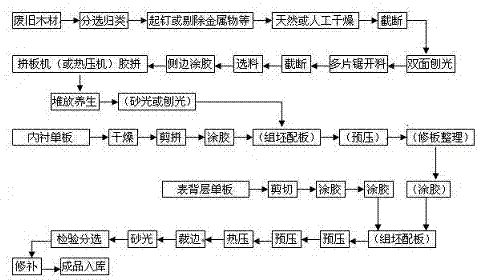

Flora and method for producing Chinese eaglewood wood on Aquilaria senensis (Lour.) Gilg by bottle interpolation method

The invention belongs to the field of manually planted Aquilaria senensis (Lour.) Gilg and relates to a microbial flora preparation for producing Chinese eaglewood wood and a matched bottle interpolation method. Eight endophytic strains of the Chinese eaglewood wood such as colored Botryodiplodia theobromae Pat are extracted and separated from natural Chinese eaglewood wood tissues, and are respectively disinfected and purified to obtain liquid flora preparations with Chinese eaglewood wood production capacity, and the obtained liquid flora preparations jointly act on the Aquilaria senensis (Lour.) Gilg. Meanwhile, the conventional matched infusion method is improvement on the bottle interpolation method; and by the ingenious bottle interpolation method, the disadvantages that a complete set of infusion apparatus is depended and the dripping speed is required to be constantly observed and adjusted in the conventional method are overcome. By the method, a microbial inoculum can be manually immersed into calluses of healthy Aquilaria senensis (Lour.) Gilg in batches and penetrate and infect protoxylem to promote a micro-circulation system in the protoxylem to secrete resin and produce the Chinese eaglewood wood in an abnormal metabolism mechanism.

Owner:唐显

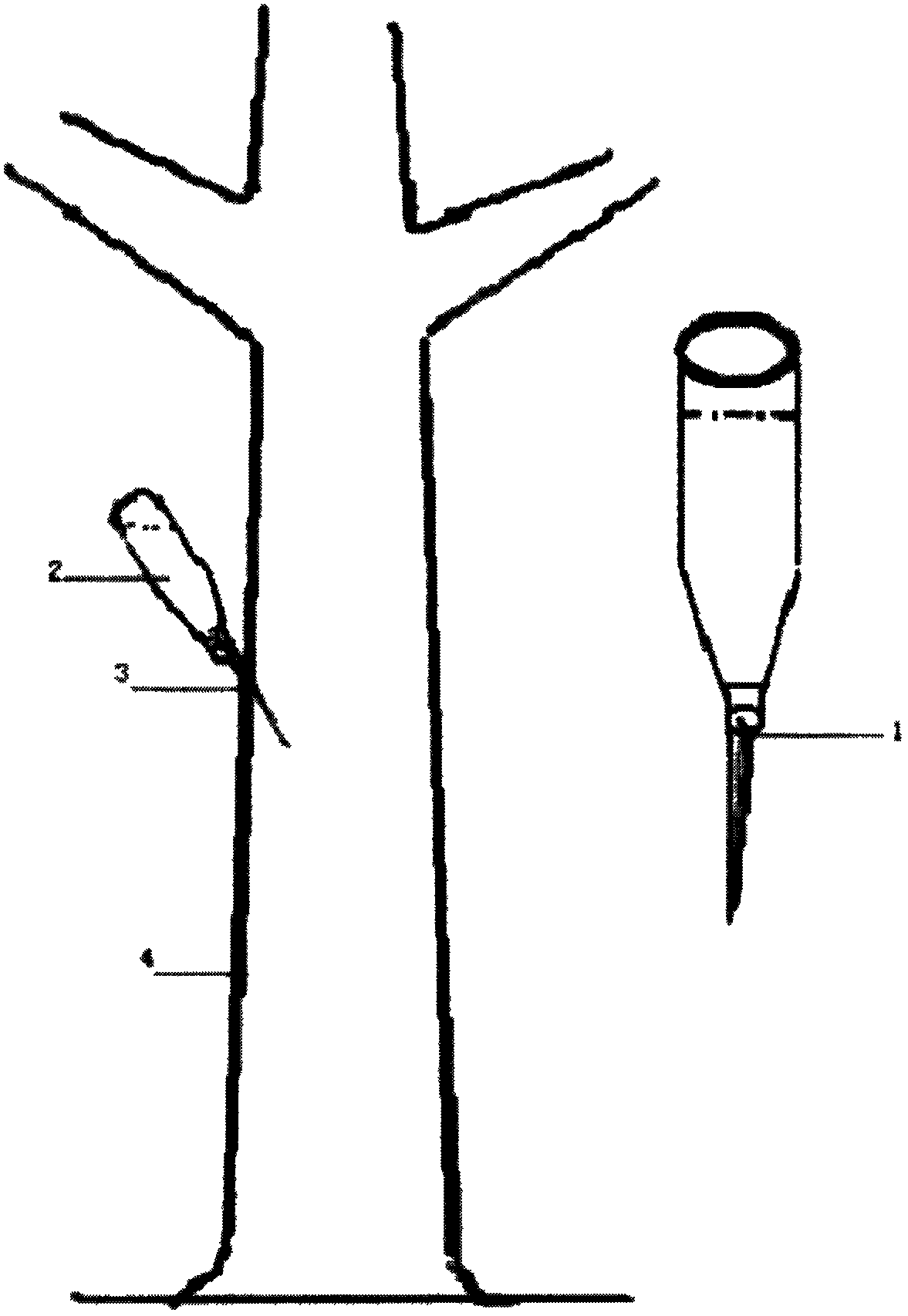

Raw material selection of straw board and producing technique thereof

InactiveCN101264624ALow costHigh strengthFlat articlesDomestic articlesUltimate tensile strengthSawdust

The invention relates to a raw material selection method and a manufacturing process of a straw board, belonging to the technical field of non-wood plant straw board, which is characterized in that a new raw material formulation and the manufacturing process are provided, in which wheat straw, reed, rice hull and sawdust are utilized to substitute for wood, so as to produce non-wood board. The raw material formulation and manufacturing process are aimed at eliminating the defects in the prior manufacturing process of non-wood plant straw board, and the manufacturing process comprises the following steps: raw material treatment, dehydration, raw material proportioning, glue applying and mixing, veneering treatment and laying, blank pavement and shaping, heating and pressurizing, and cutting edges. The straw board thus produced has the advantages of low costs, and high strength.

Owner:刘金忠

Method for producing recombination module wood from secondary processing wood

InactiveCN101284389AUnique textureImprove textureWood compressionWood treatment detailsCrack resistanceEngineering

The invention discloses a method of recombined module wood production by using secondary processing wood such as peeling board or reconstituted decoration lumber scrap. The method includes the steps of: vapor treating at a high temperature or digesting in oxydol and caustic soda, drying, gumming, further drying after being gummed, trimming, compression moulding, consolidating at a high temperature and obtaining the recombined module wood; the density of the obtained wood reaches 0.8-1.2kg / cm<3>, and the obtained wood has unique texture, fine texture and superior performance, and no need for treatments of insect prevention, mold prevention, corrosion resistance and cracking prevention. The obtained wood can be directly applied to fields of flooring, furnishing, building, etc., and is characterized by cracking resistance, deformation resistance and so on. The method has simple procedure, makes good use of the waste and greatly saves the forest resource by producing module wood with the waste secondary processing wood, thus, being an ideal substitute of the log.

Owner:浙江仕强竹业有限公司

Carbonized wood production process

InactiveCN103009451AHigh degree of carbonationReduce carbonizationWood charring/burningCarbonizationHardness

The invention relates to a carbonized wood production process, which comprises the following steps of: 1) cutting and flattening wood; 2) conducting flame jet carbonization treatment to the surface of the wood by using a flame jet device; and 3) grinding the surface of the carbonized wood and removing the carbonized part on the surface of the wood. The flame jet device comprises an oxygen cylinder and a jet gun. By using the characteristics that the texture of the wood is loose and soft and the hardness is different, and by using the oxygen jet gun to jet flames onto the surface of the wood, the carbonization degree of the loose and soft part is high, the carbonization degree of the hard part is low and the surface of the wood has stereoscopic natural textures after grinding. The carbonized wood production process has the advantages of simple carbonization method, easiness in operation, simple equipment and low use cost.

Owner:SHANGHAI TAIYI ENTERPRISE

Real wood grain generation technique ecologic floor production technique

The invention discloses a production process of ecological floors produced with an especially natural wood production technology, adopts high density fiber boards as the substrate material and includes the following steps of: 10 days of curing; cutting the material into small pieces to form floor blanks and 7 days of curing; groove opening and 7 days of curing; spraying waterproof paint at a naked part of the groove; coating an oily adhesive agent, two shaded priming paints, two ink printing patterns and finally a top coating on the back; 24 days of curing; coating an oily adhesive agent and a transparent putty on the front face; making 240 meshes of sanding, and varnishing two shaded priming paints, two ink printing patterns and a wear resistant priming paint on the front face; varnishing a sanding priming paint , making 320 meshes of sanding and varnishing a wear resistant priming paint on the front face; varnishing a sanding priming paint, making 320 meshes of sanding, varnishing an additive color priming paint, rolling a top coating, spraying a top coating and finally rolling and coating a scratching resistant top coating on the front face; packaging after all paints are dried and 7 days of curing. The production process protects the environment, saves materials with real and beautiful surface effects; and the floors can not easily deform and each performance is excellent.

Owner:ZHEJIANG CHANX WOOD

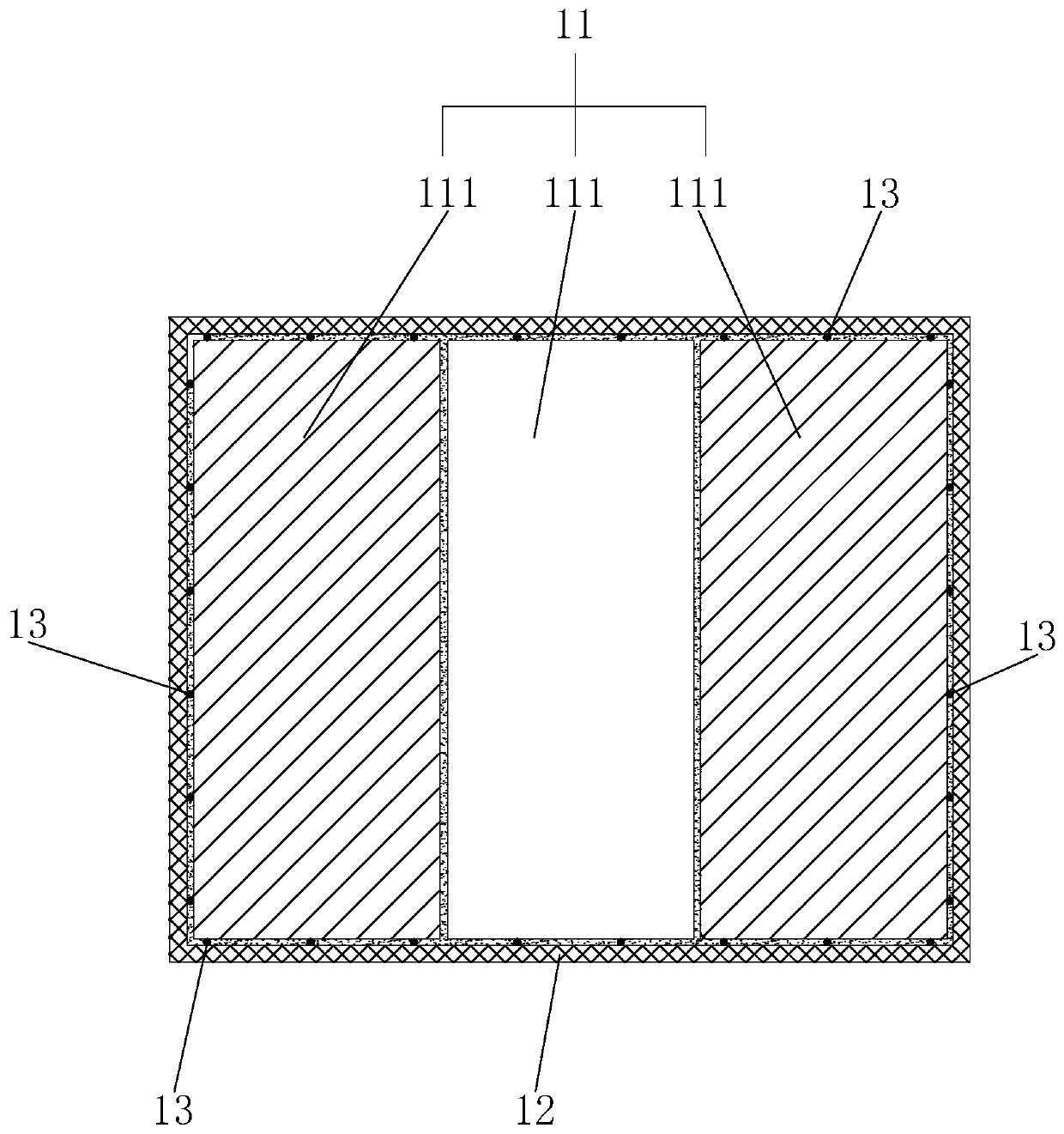

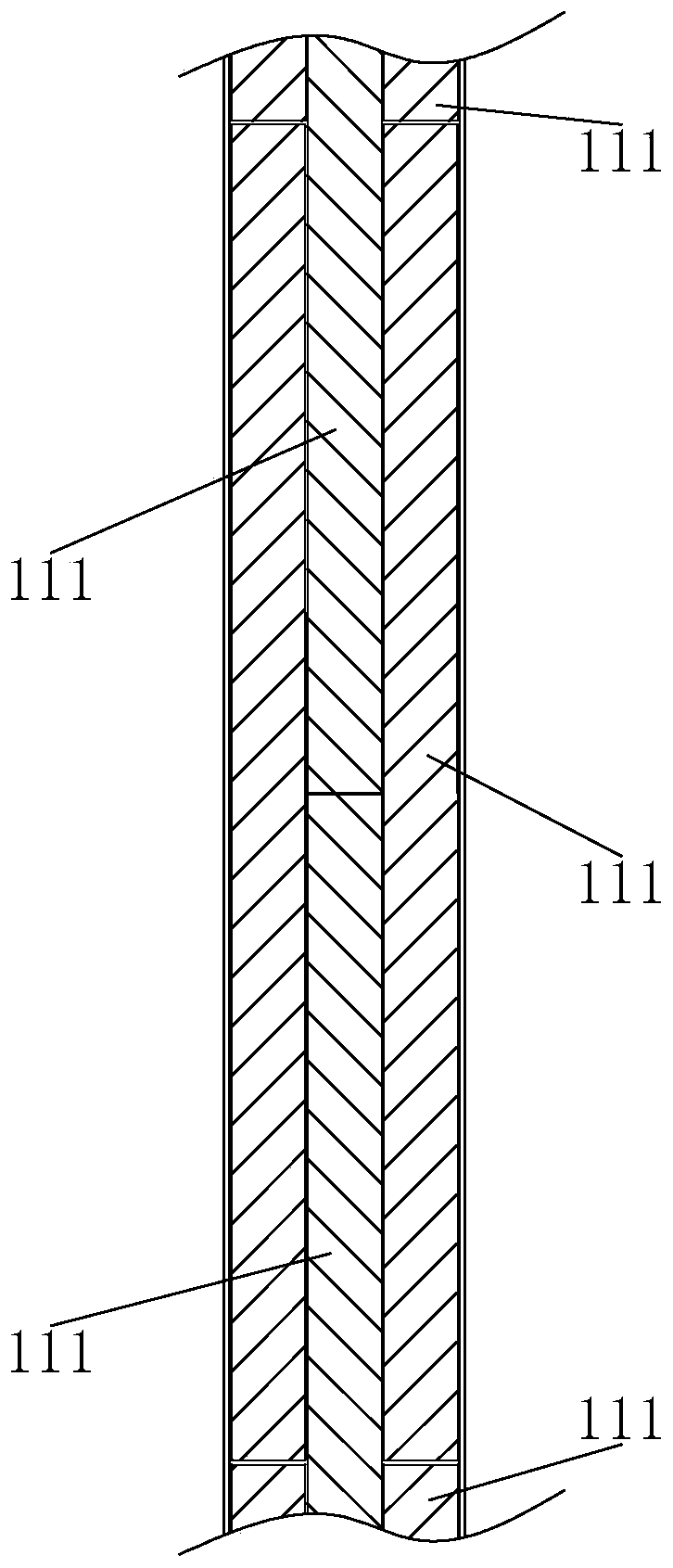

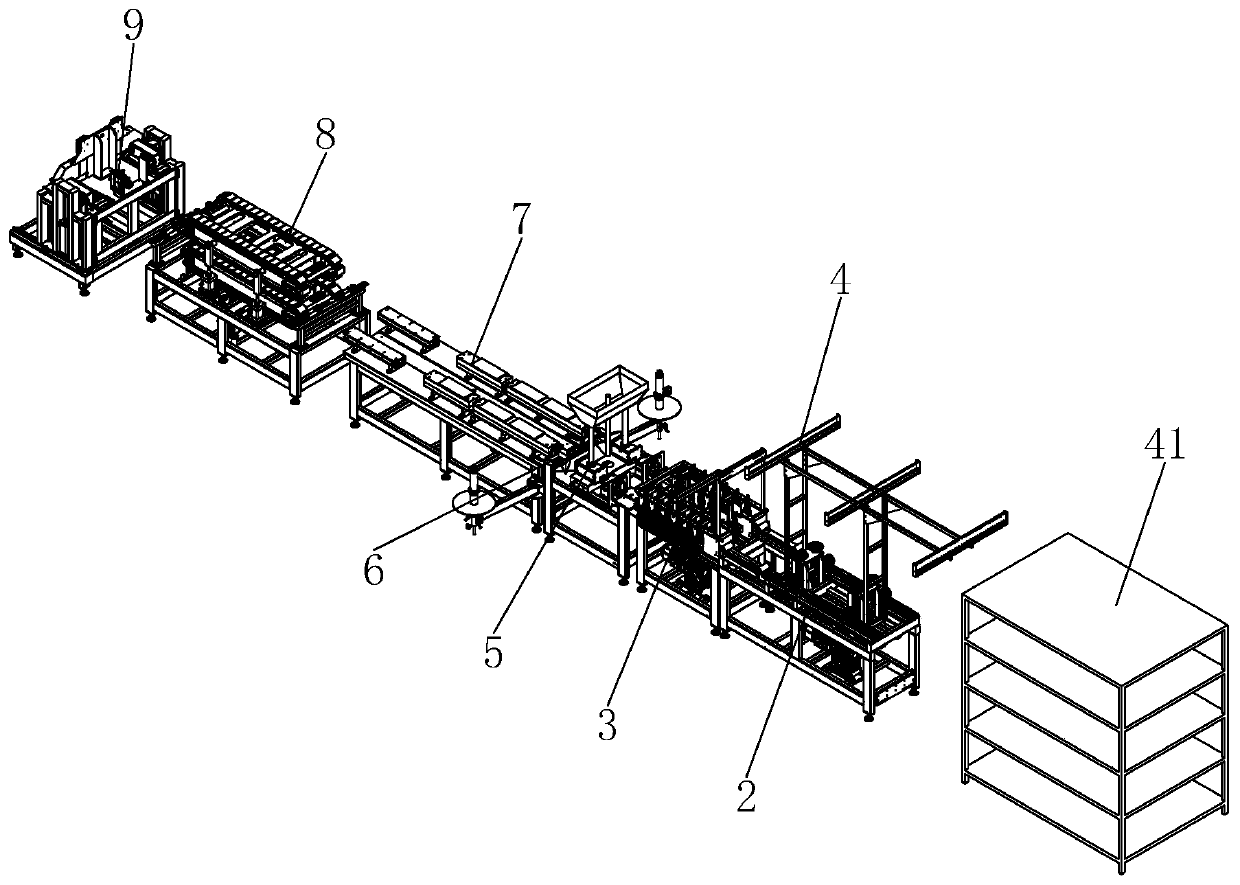

Composite square wood and production line thereof

PendingCN110067385AProne to the problem of rising and openingInhibit swellingOther plywood/veneer working apparatusWood veneer joiningProduction lineGlass fiber

The invention discloses a composite square wood which comprises a square wood body, wherein the square wood body comprises a plurality of closely overlapped wood strips, the mutually spliced wood strips are arranged in the same length direction, the ends of every two adjacent overlapped wood strips are not aligned, the wood strips are bonded by glue, and glass fiber cloth is bonded and wrapped onthe peripheral side surface of the square wood body. The composite square wood has the following advantages and effects that the wood strips in the square wood body are closely overlapped, and duringthe overlapping process, the ends of every two adjacent overlapped wood strips are not aligned, and when the wood strips are overlapped, the wood strips in a plurality of length directions are distributed in a staggered mode, so that the purpose of unlimited square wood length is achieved; meanwhile, the strength of the composite square wood can be improved through glue between the square bodies and the glass fiber cloth wrapped on the surface of the square wood body in a bonding mode. The invention further discloses a composite square wood production line for producing the composite square wood.

Owner:浙江衡昶科技有限公司

Biomass granular fuel and processing method thereof

The invention discloses a biomass granular fuel. Raw materials comprises the following components in proportions by weight: 4 to 6 parts of shaving, 12 to 18 parts of wood chip, 0.1 to 0.4 part of swelling agent and 0.1 to 0.4 part of flame accelerator, wherein the water content of the shaving is 4 to 6 percent; the wood chip is a mixture of a wood chip of which the water content is 25 to 35 percent and a wood chip of which the water content is 8 to 10 percent according to a weight ratio of 1 to 2. The invention also provides a processing method of the biomass granular fuel. The processing method comprises pulverization, primary mixing, secondary mixing, tertiary mixing and granulation. The biomass granular fuel which is provided by the invention and is processed by utilizing the production waste of a timber is more convenient to use and transport; the resource utilization rate is improved; the heat value of the biomass granular fuel can reach 4500 to 4700 kilocalories per kilogram; a liquid fuel is added into the raw materials in a spraying manner as the flame accelerator; sodium hydrogen carbonate and ammonium hydrogen carbonate are used as the swelling agent; the combustion performance of the biomass granular fuel is further improved; according to the biomass granular fuel and the processing method thereof, the raw materials are subjected to the primary mixing and the secondary mixing; the uniform distribution of moisture is facilitated; the flame accelerator is atomized and sprayed into a secondary mixture; the uniform distribution of the flame accelerator is promoted.

Owner:玉溪加宝生物能源有限公司

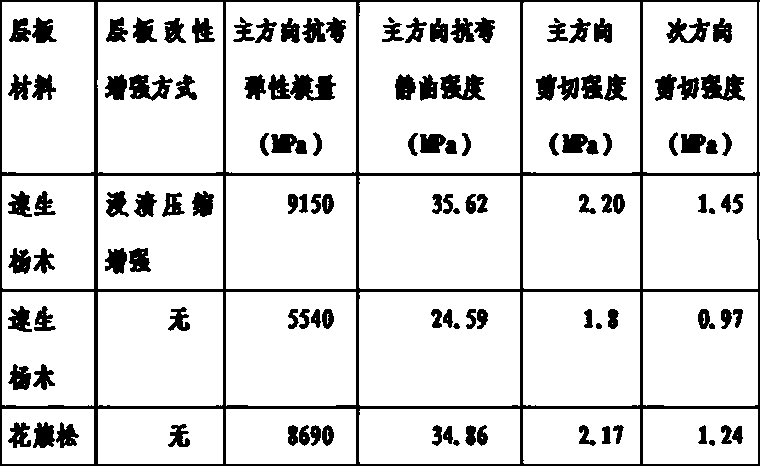

Processing method of crosswise laminated plate

InactiveCN103433982AImprove performanceExpand the scope of useWood veneer joiningVacuum pumpingWood production

The invention relates to a processing method of a crosswise laminated plate, which comprises the steps of laminate preparation, compound modifier preparation, surface layer laminate modification and reinforcement, laminate finger jointing, laminate-plate gluing, assembling, pressing and post-processing. A surface layer laminate modification and reinforcement process comprises the steps of putting surface layer laminates into a closed pressure tank for vacuum pumping treatment and then performing compression for reinforcement to the treated laminates; and an assembling and pressing process comprises the steps of putting the modified and reinforced laminates on a surface layer, assembling the laminates in a manner that the texture directions of adjacent laminates are mutually perpendicular, putting the assembled laminates into a press for cold pressing and applying lateral pressure at the same time. The processing method has the advantages that not only can fast growing wood at home be used for producing crosswise laminated plates, but also the performance of the produced crosswise laminated plates is excellent, the main mechanical property indexes of the products can reach and exceed the property indexes of similar domestic and overseas products, the products are endowed with multiple functions such as flame retarding and antibacterial functions, the utilization scope of the fast growing wood is expanded, and the development of domestic wood structure buildings towards safe and high-quality high-rise buildings is promoted.

Owner:NANJING FORESTRY UNIV

Composite phenolic glue composition and application method thereof

InactiveCN103361013ALow in free phenolsReduce the amount of glue appliedNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberPolymer science

The invention relates to a composite phenolic glue composition which comprises thermosetting phenolic resin, bark powder, illite, pyrophyllite, muscovite, anion powder, halloysite, calcite, carbon fiber, shell powder and water. When a certain amount of larch bark powder, which contains abundant tannin and lignin, is added into a phenolic resin glue in due time, the larch bark powder can perform the functions of substituting equal amount of glue, saving the glue and lowering the free phenols and aldehydes, and can also enhance the quality of the artificial board and prevent the artificial board from cracking. The bark is a wood production leftover, and is a pure natural nontoxic biomass material; and thus, when the bark is substituted for part of the phenolic glue, the artificial board production technique, including gluing, hot pressing and the like, is not changed, the inspection proves that the produced artificial board satisfies the national standard, and the release amounts of phenols and aldehydes can be greatly lowered.

Owner:周广胜

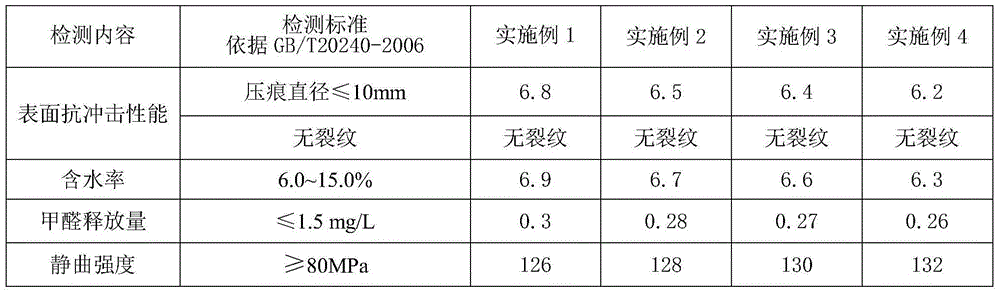

Furniture reconsolidated bamboo preparation method

ActiveCN104960069APromote carbonizationThere will be no cracking, etc.Reed/straw treatmentFlat articlesWater contentWood production

The invention relates to the technical field of furniture bamboo wood production and particularly relates to a furniture reconsolidated bamboo preparation method. The preparation method includes the steps of sectioning, bamboo chip preparing, rolling, binding, carbonization, cooling, impregnation, primary drying, secondary drying, compression and forming, so that a reconsolidated bamboo finished product can be prepared. The reconsolidated bamboo produced by the preparation method can be widely applied to various pieces of furniture, is small in surface impression diameter, less in formaldehyde release amount, large in static bending intensity, low in water content, and not easy to crack or deform, and has the advantages of excellent shock resistance, greening and environmental protection, good elasticity, and anticorrosion and mothproofing. The development and research of the reconsolidated bamboo can alleviate resource shortage and perform the advantage of bamboo wood resources, and moreover, improve the utilization value and added value of bamboo wood and can meet the needs of furniture market environmental protection.

Owner:官宝瑛

Artificial fish bait made by composite material and production method thereof

The invention relates to a composite artificial false fishing lure, and relative production. Wherein, said composite is formed by polycarbonate resin, polyethylene resin, acrylic nitrile- butadiene-styrene rein, added with silica dioxide nanometer powder; mixing and adding additive, injection molding, removing mould, cooling and shaping. The invention is lighter than wood production, with better flexibility and corrosion resistance, while it will not be degraded in long time service.

Owner:南京鸿耕展金属有限公司

Nano alumina-containing modified wood production method

InactiveCN104859011AHigh surface hardnessEfficient processingWood treatment detailsPretreatment apparatusPolyethylene glycolNano al2o3

The invention discloses a nano alumina-containing modified wood production method including five steps of wood pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post drying treatment, the wood modification agent comprises nano alumina, polyethylene glycol (peg), aluminum and titanium compound coupling agent OL-AT1618, distilled water, sodium octaborate, diammonium phosphate, boric acid, carbendazim, dodecyl dimethyl benzyl ammonium chloride, sodium dodecyl benzene sulfonate and silicon sol, and the particle size of the nano alumina is in the 1-100 nm range. The beneficial effect is that the nano alumina-containing modified wood has the advantages of simple process, high efficiency, environmental protection, strong permeability, stable performance, even composite and the like, and the surface hardness, smoothness, wear resistance, cold and hot fatigue, fracture toughness, good processing properties, dimension stability, anti-corrosion flame retardant properties and the like of the treated wood are improved obviously.

Owner:王玉燕

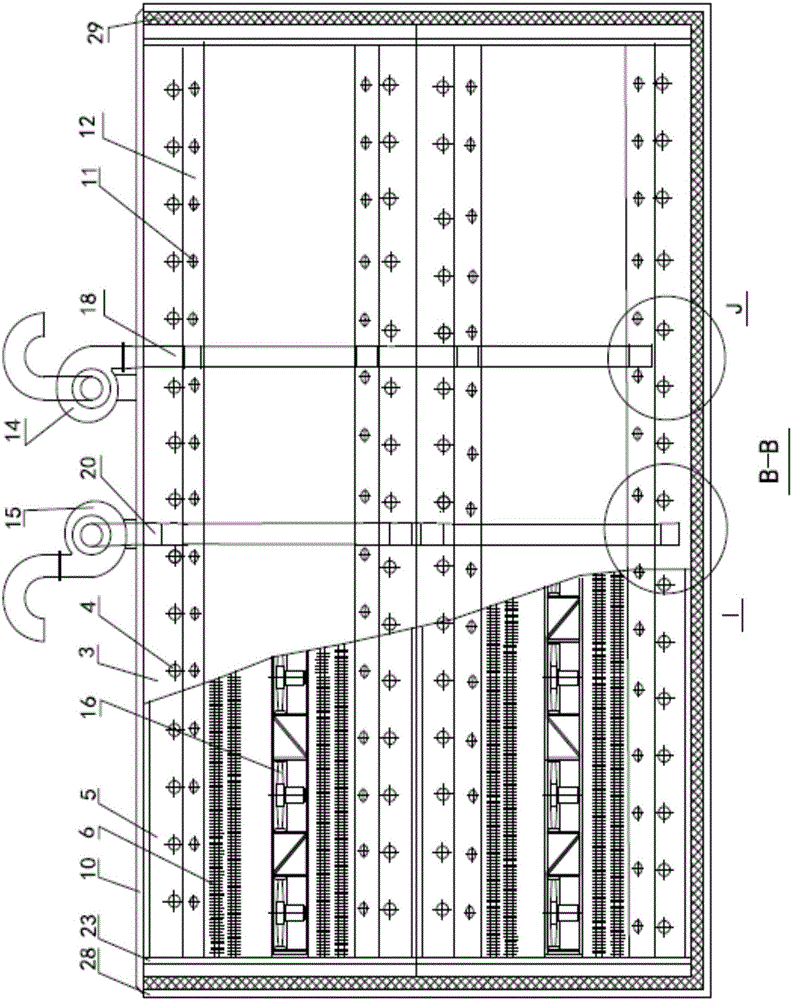

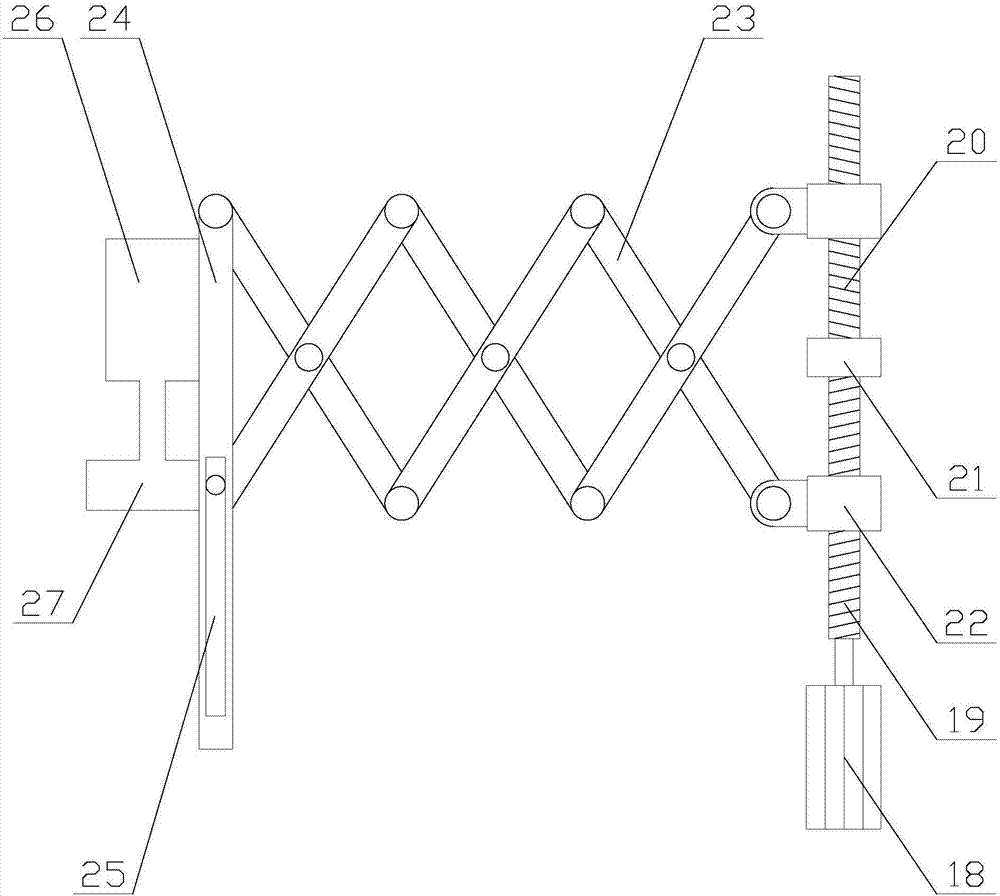

Side draught fan type cabin wood drying device and drying method

ActiveCN106288671AMeet the needs of dry productionPollution compensationDrying solid materials with heatAuxillariesWood productionMachining

The invention relates to a wood drying device and drying method, in particular to a side draught fan type cabin wood drying device and drying method. In order to solve the problems that an existing wood drying production device and method waste energy, pollute environment and prolong the wood production machining period, imported wood has the large medical inspection and insect removing workloads, and an existing wood transportation ship cannot achieve the function of wood drying in the remote transportation way, the device comprises a cabin, a cabin-interior equipment bearing frame, a drying device humidity adjusting air exchange system, a wood drying medium forced circulating system, a heat exchanger system, a drying medium state monitoring sensor system and a dried wood water containing rate monitoring sensor system. The method comprises the steps of wood stacking, cabin cover closing, wood drying, drying degree detection of the wood, and drying medium state adjusting according to a detection result. The device and method are used for drying and insect removal treatment in the wood transportation process.

Owner:BEIJING WUZHOUMU INT IND CO LTD

Plastic-wood production equipment with quantitative matching and dehumidifying functions

The invention relates to plastic-wood production equipment with quantitative matching and dehumidifying functions. The plastic-wood production equipment comprises a shell and two charging hoppers, wherein a processing chamber, two baffle plates and two quantitating mechanisms are arranged in the shell; two collecting pipes, two grid plates and two dehumidifying mechanisms are arranged in the processing chamber; and each quantitating mechanism comprises a fixed plate, a support block, a first motor, a drive gear, a drive plate, two driven gears, two connecting shafts, two half gears, two racksand two limiting elements. According to the plastic-wood production equipment with the quantitative matching and dehumidifying functions, raw materials are quantitatively added through the quantitating mechanisms, so that the matching of the raw materials is ensured, the quality of plastic wood is improved, and the practicability of the plastic-wood production equipment is higher; and a dehydrating agent is sprayed through a dehumidifying mechanism, moisture in the processing chamber is removed, and the influence of a humid environment on the plastic wood is reduced, so that a mechanical property of the plastic wood is improved, and the market competitiveness of the plastic-wood production equipment is improved.

Owner:德化利鑫新材料科技有限公司

Laminated wood production process

InactiveCN102463609ASave raw materialsQuality improvementWood veneer joiningEconomic benefitsWood production

The invention discloses a laminated wood production process, which belongs to the technical field of board processing. The specific method is as follows: blank processing, board drying, board processing, board choice and cutting, tooth milling, glue application, finger-jointing, edge planing, board assembly, sanding and post-processing. The laminated wood production process has the advantages that: not only can a great deal of raw material be saved, but also the quality of the product can be increased, the percent of pass reaches 98.9 percent, and thereby the economic benefit is increased.

Owner:王殿营

Special multifunction filler for wood production and its blending process

InactiveCN1478842AGood preloading effectSolve the problem of instant viscosity change curve synchronizationMacromolecular adhesive additivesOxalateIon exchange

A multifunctional filler dedicated for woodworking industry is prepared from Ca-base bentone, sodium carbonate, wood powder or strew-stalk powder, melamine, adipic acid, urea and oxalic acid through mixing 60-80% of Ca-base bentone with sodium carbonate, grinding, laying aside for at least 3 days, drying, grinding by 120 meshes, and mixing with others by high-speed shearing and stirring. Its advantages are high quality of plywood and low cost.

Owner:SHANGHAI YINGXIANG IND

Process method for producing medium density fiber board by utilizing waste wood

InactiveCN103419265AUniform thicknessFlat surfaceFlat articlesDomestic articlesFiberPulp and paper industry

The invention relates to a process method for producing a medium density fiber board by utilizing waste wood. Used raw materials adopt worthless branches and residuums generated by wood processing, such as scantlings, battens, waste veneers and log cores; in the sizing process in the process of producing the fiber board, FM-1 urea resin is used; and the process flow for producing the fiber board comprises the steps of chipping the raw materials, screening, pulping, sizing, drying, paving, pre-pressing, carrying out hot pressing, cooling the board, trimming edges, sanding and forming. Due to adoption of the technical scheme, the waste wood raw materials can be sufficiently utilized and the high-quality medium density fiber board with uniform thickness and smooth surface is produced.

Owner:ZUNYI HAIFENG WOOD CO LTD

Method for modifying timber through biotechnology and optoelectronic technology

A method for modifying wood by biologic and photoelectric techniques features that the biologic enzyme preparation is used to remove xylose from wood. said biologic enzyme preparation is prepared from cellulose, alpha-amylase, neutral proteinase, beta-amylase, xylanase, beta-glucanase, pectinase and neutral lipase. The modified wood can be used for music instrument.

Owner:李书

Cutting device for wood production and processing

ActiveCN108044724AThickness is easy to controlThickness and adjustmentProfiling/shaping machinesEngineeringWood production

The invention discloses a cutting device for wood production and processing. The cutting device comprises a moving seat, an upper end of the moving seat is provided with a working table, a cavity is opened in the working table, and the cavity is provided with a first threaded rod horizontally, a supporting plate is arranged on the first threaded rod, the supporting plate is rotatably connected with the first threaded rod, a placing plate is arranged on the right side of the supporting plate, a first motor is arranged on the upper end of the placing plate, and the first threaded rod is connected with the driving end of the first motor, and the lower end of the placing plate is provided with a bracket, the first threaded rod is symmetrically sleeved with moving blocks, and each moving blockis screwed with the first threaded rod, a first limit rod is arranged in the cavity horizontally. The cutting device has a stable structure, a simple operation, a scientific and reasonable design, a short production period, low production cost, is easy to control the thickness of wood cutting, easy to adjust the height of a cutter, easy to move, save a lot of time and energy of workers, and is worth promoting.

Owner:惠州合雅木业有限公司

Nano silicon dioxide modified wood production method

InactiveCN104858950AExcellent surface hardnessGood dimensional stabilityWood treatment detailsPressure impregnationEnvironmental resistanceTreatment effect

The invention discloses a nano silicon dioxide modified wood production method including five steps of pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post-drying treatment, wherein the wood modification agent comprises nano silicon dioxide, fatty alcohol polyoxyethylene ether, distilled water, trimethyl borate, dodecyl dimethyl benzyl ammonium chloride, N-(2-benzimidazole)-methyl carbamate, and imidacloprid. The beneficial effect is that the nano silicon dioxide modified wood production method has the advantages of simple treatment process, easy operation, low cost, good treatment effect, no toxicity, environmental friendliness and the like, the treated wood has no obvious appearance change, and wood dimensional stability, density, surface hardness, bending strength and bending elastic modulus, good processing properties, wear resistance, anti-corrosion flame retardant properties are greatly increased.

Owner:王玉燕

Anticorrosive wood production method

InactiveCN104858964ASimple processEfficient treatment processBiocideWood treatment detailsBronopolMethyl carbamate

The invention discloses an anticorrosive wood production method including five steps of wood pretreatment, preservative preparation, preservative liquid preparation, dipping treatment and post-drying treatment, a preservative comprises polyethylene glycol (peg), bronopol, 4, 5-dichloro-N-octyl-4-isothiazoline-3-one, imidacloprid, 2-chloro-5-hydroxy meta-xylene, dithiocyano-methane, dodecyl dimethyl benzyl ammonium chloride and N-(2-benzimidazole)-methyl carbamate and fatty alcohol polyvinyl chloride (PVC) ether. The beneficial effects are that the anticorrosive wood production method has the advantages of simple process, high efficiency, and easy operation, and the like, the processed wood maintains the original features, meanwhile has excellent anti-corrosion, mouldproof, insect-resistant, antibacterial and other effects, and is good in environmental protection property, stable in performance, and durable.

Owner:王玉燕

Novel carbonized wood production method

InactiveCN105479572AImprove thermal stabilityGood dispersionWood treatment detailsPressure impregnationWater vaporCarbonization

Owner:GUILIN RONGTONG TECH CO LTD

Composite urea-formaldehyde glue composition and application method thereof

InactiveCN103361015AReduce the amount of glue appliedReduce manufacturing costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberPolymer science

The invention relates to a composite urea-formaldehyde glue composition and an application method thereof. The composition comprises urea-formaldehyde resin, bark powder, illite, pyrophyllite, muscovite, anion powder, halloysite, calcite, carbon fiber, shell powder and water. When a certain amount of larch bark powder, which contains abundant tannin and lignin, is added into a urea-formaldehyde resin glue in due time, the larch bark powder can perform the functions of substituting equal amount of glue, saving the glue and lowering the free phenols and aldehydes, and can also enhance the quality of the artificial board and prevent the artificial board from cracking. The bark is a wood production leftover, and is a pure natural nontoxic biomass material; and thus, when the bark is substituted for part of the urea-formaldehyde glue, the artificial board production technique, including gluing, hot pressing and the like, is not changed, the inspection proves that the produced artificial board satisfies the national standard, and the release amount of residual aldehydes can be greatly lowered.

Owner:呼伦贝尔林拓科技有限责任公司

Large-section plastic-wood cutting machine

ActiveCN104227757ASuitable for useSimple structureMetal working apparatusCircular discTransmission belt

The invention discloses a large-section plastic-wood cutting machine. The large-section plastic-wood cutting machine comprises a frame, an operation table is arranged on the frame, a saw table is arranged at one end of the frame and fixed onto a saw table support, and a disk saw is arranged in the middle of the saw table and driven by a motor; the motor is fixed to the bottom of the saw table support and connected with the disk saw through a transmission belt; the saw table support is provided with a collection device below the disk saw; the operation table is connected onto the frame through a sliding device. By means of the operation table, to-be-cut plastic-wood is placed on a cutting table, the cutting table is pushed to horizontally move along the frame through the sliding device, and one end, contacting with the disk saw, of the to-be-cut plastic-wood is cut by the disk saw. In order to prevent particles generated during cutting from polluting the environment, the collection device is arranged below the disk saw, and plastic-wood particles generated during cutting can be recycled for plastic-wood production after being collected by the collection device, so that material utilization rate is increased.

Owner:BINZHOU SUNSHIEN WPC

Nano titanium dioxide modified wood production method

InactiveCN104859010AImprove flame retardant performanceImprove anti-corrosionRadiation/waves wood treatmentWood treatment detailsWood productionFatty alcohol

The invention discloses a nano titanium dioxide modified wood production method, including five steps of wood pretreatment, wood modification agent preparation, wood modification liquid preparation, dipping treatment and post-drying treatment; and a wood modification agent comprises nano titanium dioxide, silica sol, fatty alcohol polyoxyethylene ether, distilled water, sodium octoborate, carbendazim, tetra hydroxmethyl sulfate, dodecyl dimethyl benzyl ammonium chloride, diammonium phosphate, boric acid and ammonium molybdate. The beneficial effects are that the nano titanium dioxide modified wood production method has the advantages of simple treatment process, easy operation, environmental friendliness, low cost, and the like, by use of the nano titanium dioxide for modification, the nano titanium dioxide modified wood has broad spectrum, high efficient and durable antibacterial effect, and the corrosion resistance, flame resistance, surface hardness, wear resistance, bending resistance, bend elastic modulus, processing good properties, dimension stability, water resistance, discoloration resistance and the like of the processed wood are greatly improved.

Owner:王玉燕

A method for planting pickled mustard with high yield

InactiveCN102293120ANormal growth does not affectAvoid destructionClimate change adaptationFertilising methodsWoodlotBolting

The invention discloses a high-yield planting method of mustards in established Italian poplar forests. The method is characterized by comprising the following steps: (1) selecting Sichuan and Zhejiang mosaic mustard varieties which have the characteristics of good lump shape, obliquely upward leaf, late bolting, strong cold resistance, harmful bacterium resistance, high yield and high quality; (2) clearing up forest lands; (3) carrying out tillage-free planting; (4) carrying out drought prevention and fertilization; and (5) timely harvesting. In the method disclosed by the invention, the resources such as precious lands and sunshine and the like in established forests are fully used so as to vigorously develop green mustards, which both ensures that the quality of forest trees and the wood production rate are high, and ensures that the quality of mustards, the yield of mustards and the forest farm benefit are high, thereby enriching the social wealth, increasing the earnings of farmers, consolidating the forestation effect, and speeding up the forest and ecological development speed.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Cross-laminated sheet processing method

InactiveCN103433982BImprove performanceSafe Tall Building DevelopmentWood layered productsFinger jointEngineering

The processing method of the interlaced laminated board of the present invention includes laminate preparation, compound modifier configuration, surface layer laminate modification and enhancement, laminate finger joint, laminate sizing, billet assembly, pressing, and post-processing. The modification and strengthening process of the surface laminates includes putting the surface laminates into a closed pressure tank for vacuum treatment, and then compressing and strengthening the treated laminates; The surface layer is assembled in such a way that the grain directions of adjacent laminates are perpendicular to each other. After the blanks are assembled, they are put into a press for cold pressing and forming, and at the same time, lateral pressure is applied. The method of the present invention can not only use domestic fast-growing wood to produce cross-laminated boards, but also produce cross-laminated boards with excellent performance, the main mechanical performance index of the product can reach and exceed the performance index of similar products at home and abroad, and at the same time endow it with flame retardancy and antibacterial The versatility of the wood expands the utilization range of fast-growing wood, and promotes the development of domestic wood structure buildings to safe and high-quality high-rise buildings.

Owner:NANJING FORESTRY UNIV

Termite-Proofing Agent and Its Application Method

InactiveUS20080015168A1High degreeLow toxicityBiocidePhosphorous compound active ingredientsOrganic solventTree trunk

The present invention is a composition comprising a neonicotinoid-based compound having a high degree of insecticide activity, an organic solvent and a surfactant. The present invention is also a method that allows the obtaining of lumber that does not require termite-proofing treatment following production of lumber by injecting this composition into a tree trunk and allowing the chemical to circulate and disperse within the tree trunk.

Owner:LANXESS DEUTDCHLAND GMBH

Filmmaking and assembly method and pressing process of tobacco stalk laminated plate

InactiveCN101607409AHigh strengthEasy to apply glueCane mechanical workingOsier rod peelingManufacturing cost reductionPlant stalk

The invention relates to a filmmaking and assembly method and a pressing process of a tobacco stalk laminated plate, which belong to the production industry of non-wood plant stalk plates, in particular to a filmmaking and assembly method and a pressing process of the tobacco stalk laminated plate, which are used for producing a man-made plate by using tobacco stalks as raw materials to replace wood. Aiming at various defects existing in the production process and the technical formulation of the non-wood plant stalk man-made plates, the invention designs a tobacco stalk filmmaking method and an assembly paving method as well as a pressing process. The invention can effectively improve the plate strength, simplifies the production procedure, and lowers the manufacture cost; and the specific procedure can be detailed in the description.

Owner:刘金忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com