Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Low in free phenols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

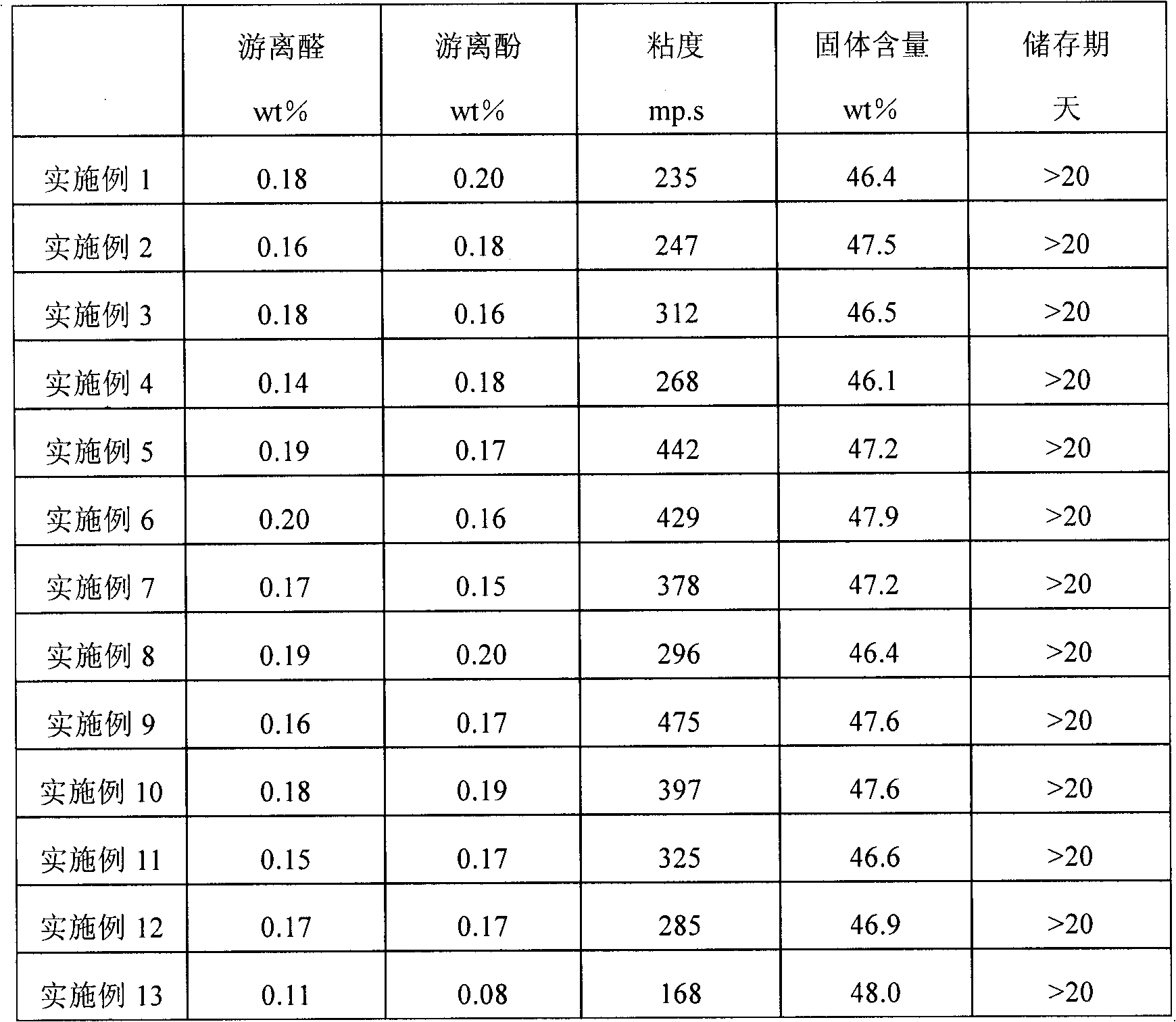

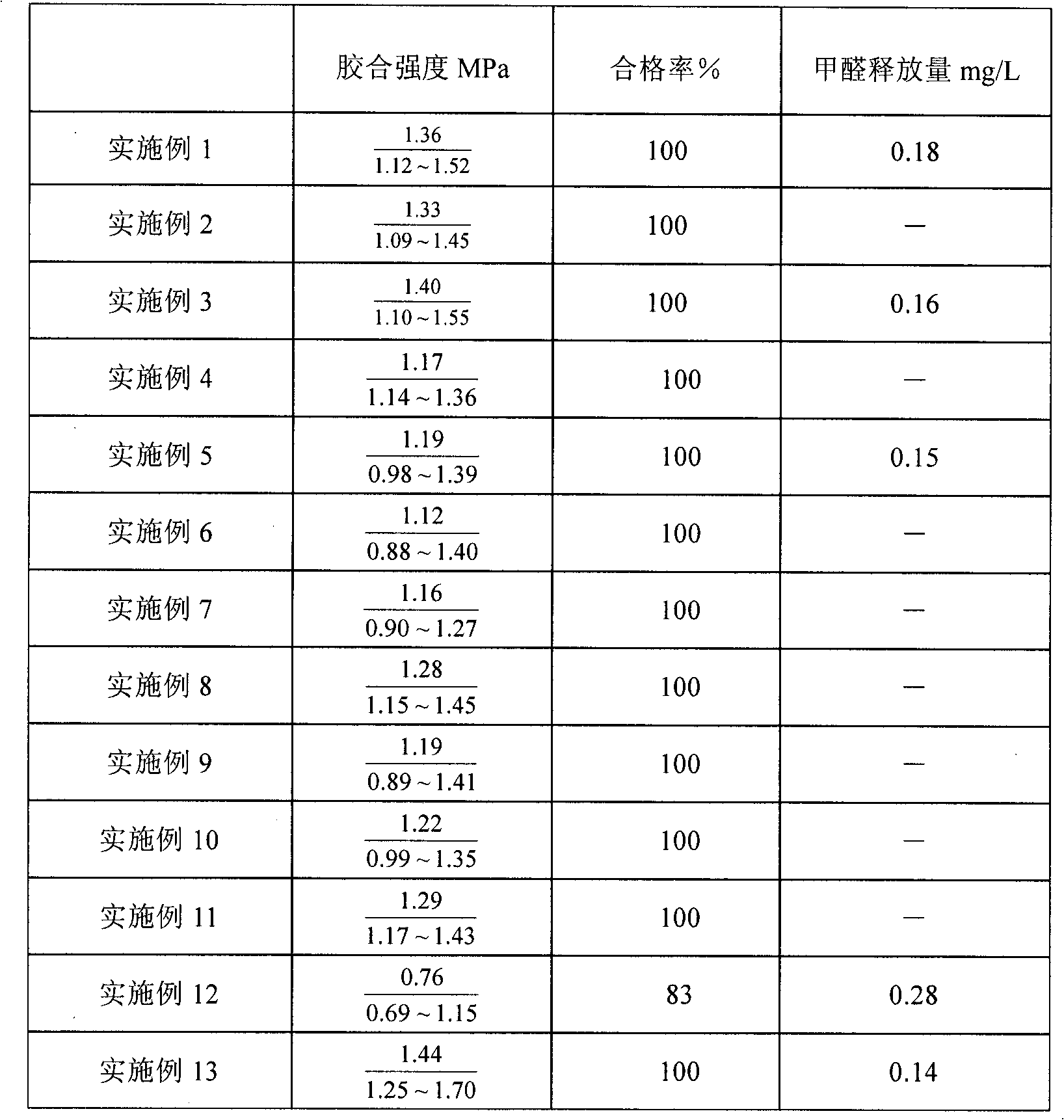

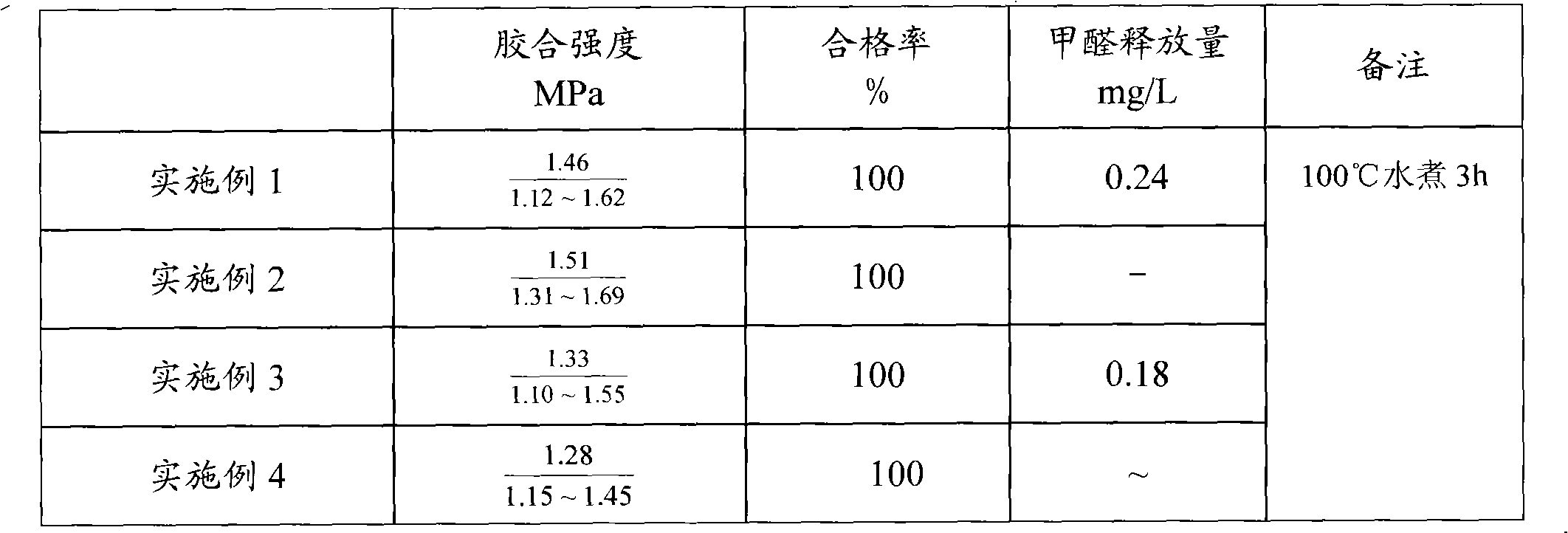

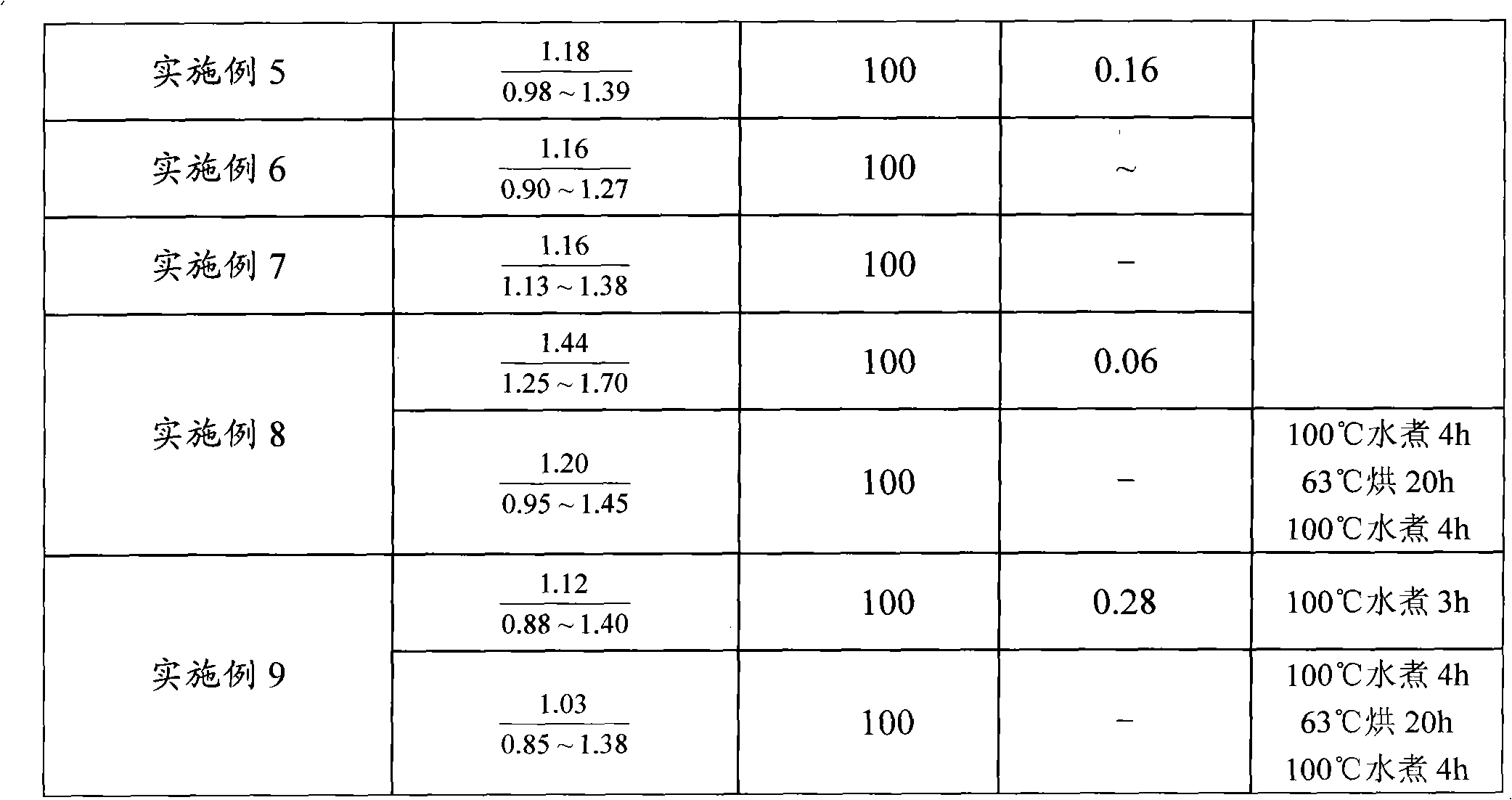

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522AOrderly and fast responseAdequate responseAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

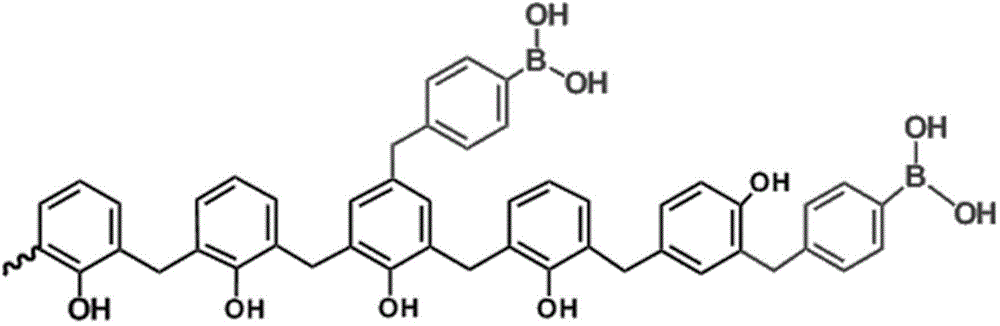

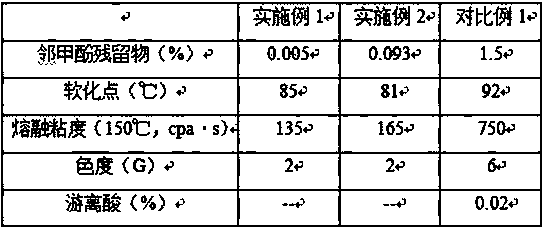

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Modified phenol formaldehyde resin and preparation method thereof

ActiveCN102757618AImprove toughnessHigh strengthAldehyde/ketone condensation polymer adhesivesToughnessPhenol formaldehyde resin

The invention discloses a modified phenol formaldehyde resin and a preparation method thereof, relating to the field of phenol formaldehyde resins. The preparation method comprises the following steps: reacting 100 parts of phenol, 10-200 parts of lignin and 1-20 parts of acidic catalyst at 80-200 DEG C for 2-8 hours to form a reaction liquid; regulating the temperature of the reaction liquid to 60-110 DEG C, adding 50-200 parts of formaldehyde and 2-20 parts of composite catalyst, and reacting for 1-5 hours to form a sticky matter; washing the sticky matter in 60-70 DEG C water 2-5 times, and dehydrating to obtain a lignin phenol formaldehyde resin; and pulverizing the lignin phenol formaldehyde resin to 200 meshes, and evenly mixing with 2-20 parts of powder nitrile-butadiene rubber to obtain the modified phenol formaldehyde resin. The free phenol content of the modified phenol formaldehyde resin is 2-5%, the thermal decomposition temperature is 400-490 DEG C, the toughness and strength are high, and the friction material prepared from the modified phenol formaldehyde resin has high adhesive property and frictional property.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

Dual catalyst system thermoplastic phenolic resin preparation method and application for preparing coated sand thereof

InactiveCN101619125AFast aggregationHigh yieldFoundry mouldsFoundry coresOrganic acidRoom temperature

A dual catalyst system thermoplastic phenolic resin preparation method comprises the steps of proportioning, refluxing and reacting, and drying; the raw materials comprises phenol or m-cresol and aldehydes compound, water, organic acid or inorganic acid and bivalent acetate in a molar ratio of 1:0.5-0.9:0-3.0:0.001-0.040:0.001-0.020; wherein, acetate is used as first catalyst and organic acid or inorganic acid is used as second catalyst in reaction process. The invention adopts phenolic aldehyde addition-condensation reaction in dual catalyst system to prepare the thermoplastic phenolic resin; the method has the advantage of rapid polymerization rate, high yield and low content of free phenols; the thermoplastic phenolic resin can be applied for preparing the coated sand and the prepared coated sand has higher hot tensile strength and tensile strength at room temperature.

Owner:SHAANXI NORMAL UNIV

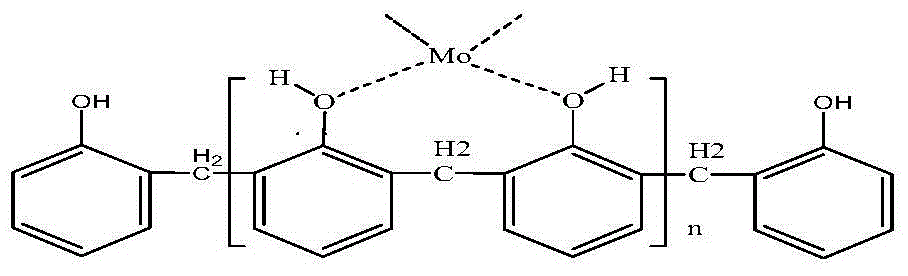

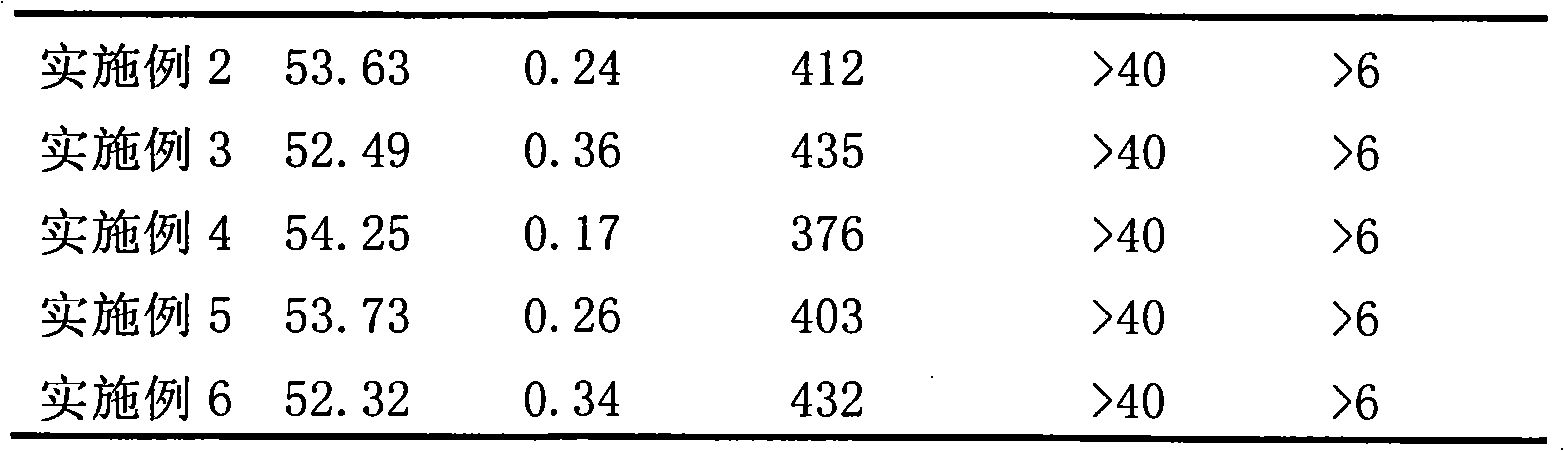

Fast-curing type high-temperature resistant binder and pre-coated sand thereof

ActiveCN104588569AFast aggregationLow in free phenolsFoundry mouldsFoundry coresRoom temperatureHigh intensity

The invention discloses a fast-curing type high-temperature resistant binder. The binder is molybdenum modified high o-phenolic resin, and the binder has a structure shown in the specification). The invention further discloses a pre-coated sand in which the molybdenum modified high o-phenolic resin is used as binder; with specially selected dehydrating agent, curing agent and lubricating agent, with optimized dosage, without adding functional auxiliaries like fire-resistant particles and accelerant, the curing speed of the pre-coated sand can be improved significantly, furthermore, the high-strength high-temperature bending strength of the fast-curing type high-temperature resistant pre-coated sand is equal to or greater than 6.0MPa, the normal-temperature tensile strength is 3.0MPa, the heat bending strength is equal to or greater than 3.0Mpa, the low tolerance is equal to or less than 18mL / g, and the radiating property is improved significantly. When the preparation method disclosed by the invention is utilized, the effect is more significant, i.e., the novel pre-coated sand with completely improved combination property is obtained by the improvement of the pre-coated sand raw materials and the method.

Owner:通辽市仁创铸造材料有限公司

Phenol-formaldehyde resin of lignin and biomass oil in use for moulding plastic material, and preparation method

This invention discloses a method for preparing lignin bio-oil phenolic resin used as molding material. The method comprises: mixing phenol, lignin bio-oil, aldehyde and acid catalyst to obtain a reaction system, adjusting the pH value of the reaction system to 1.0-3.0 by changing the addition amount of the acid catalyst, heating to 75-85 deg.C at 0.5-2 deg.C / min, ending heating, reacting (exothermic reaction), boiling when the temperature is increased to 95-106 deg.C, refluxing, keeping the temperature for 0.5-4.5 h, and vacuum-dehydrating to obtain lignin bio-oil phenolic resin. The method utilizes bio-oil obtained by rapid pyrolysis of lignin to replace phenol in preparing phenolic resin, and molding material with the same performance as that of pure phenolic resin. The method has such advantages as abundant and inexpensive raw material, and is environmentally friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Heat-resistant phenolic resin and application thereof in production of super-hard material resin mold

InactiveCN102153718ALow in free phenolsImprove liquidityBonded abrasive wheelsSuperhard materialHardness

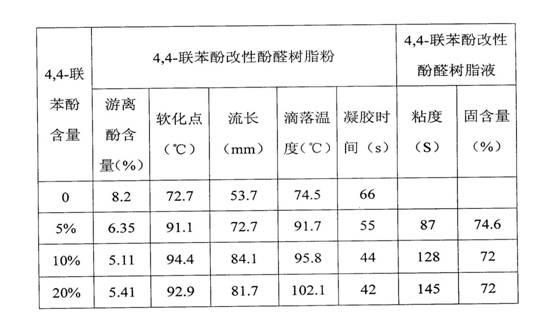

The invention relates to heat-resistant phenolic resin and the application thereof in the production of a super-hard material resin mold. The heat-resistant phenolic resin is characterized in that formaldehyde, phenol and 4,4-diphenol are used as monomers, and thermoplastic phenolic resin powder or thermosetting phenolic resin solution which is prepared by reaction in the presence of an acidic catalyst or alkaline catalyst can be used for producing a super-hard material resin mold according to the traditional process. A diamond resin mold produced from a modified resin bond has the advantages of high hardness, high strength and excellent abrasion resistance.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Production method of solid-thermosetting phenolic resin

The invention discloses a production method of a solid-thermosetting phenolic resin. The production method is characterized by comprising the following steps: mixing and evenly stirring phenol, a base catalyst and aldehyde which are respectively weighed, and heating for the reaction; after the reaction is finished, adding an acidic neutralizer for neutralization, and then adding a non-proton organic solvent; standing for layering the material into a lower-layer water phase, a middle-layer resin phase and an upper-layer solvent phase, separating out the lower-layer water phase and the upper-layer solvent phase, and retaining the middle resin phase; adding an alcohol or ketone organic solvent in the middle-layer resin phase; turning on a film evaporator, transporting the dissolved material to the film evaporator for vacuum dehydration; directly cooling and granulating the qualified resin and packaging; and recovering the solvents for repeated use. By the production method, the softening point of the resin is improved, evaporation efficiency is improved, energy consumption is reduced, and process time is shortened.

Owner:山东艾蒙特新材料有限公司

Automobile ceramic brake pad and manufacturing technology thereof

InactiveCN102936486AExtended service lifeReduce wear rateOther chemical processesFriction liningManufacturing technologyGraphite

The invention relates to the field of brake pad, and particularly relates to an automobile ceramic brake pad and a manufacturing technology thereof. The automobile ceramic brake pad is made from the following raw materials in parts by weight: 6-10 parts of phenolic resin, 12-18 parts of ceramic fiber, 8-12 parts of mineral fiber, 4-8 parts of zinc sulfide, 6-10 parts of nitrile-butadiene rubber phenol, 7-12 parts of artificial graphite, 4-6 parts of potassium titanate fiber, 6-12 parts of steel cotton fiber, 5-8 parts of red copper powder and 6-9 parts of barite. The invention provides an automobile ceramic brake pad and a manufacturing technology thereof, wherein the automobile ceramic brake pad is reasonable in component proportioning, simple in preparation technology and good in high-temperature stability, and has stable friction coefficient, long service life and high safety.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Liquefaction method of lignin for preparing thermoplastic phenolic resin

InactiveCN103554400ALow costSolve the problem of poor catalytic effect of weak acidEnzymatic hydrolysisHeteropoly acid

The invention discloses a liquefaction method of lignin for preparing a thermoplastic phenolic resin. The liquefaction method is as follows: mixing phenol, a heteropoly acid catalyst and enzymatic hydrolysis lignin, heating to 90-160 DEG C, and liquefying for 1-3 h to obtain a liquefied product. The invention provides an efficient method for preparing a phenolic compound used for substituting phenol by using enzymolysis lignin in abundant resource, and the method uses the a green heteropoly acid catalyst, which has no pollution to the environment. The enzymolysis lignin liquefaction product obtained by the invention can be used in the preparation of a lignin base thermoplastic phenolic resin.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

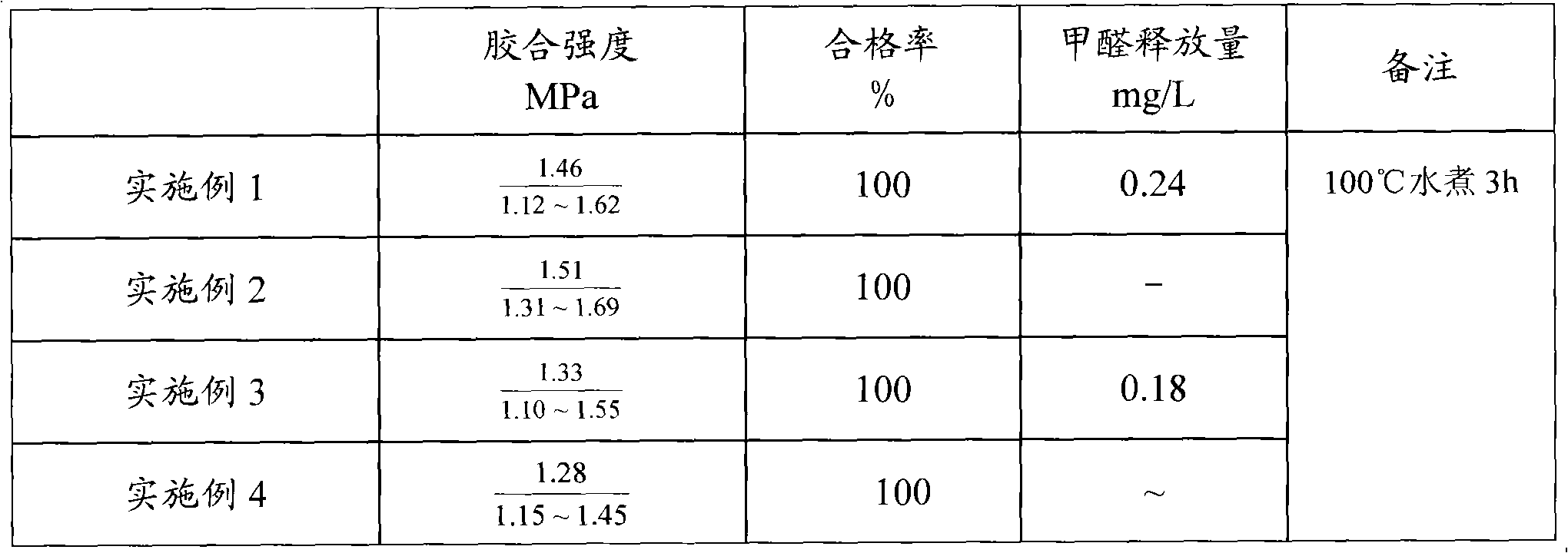

Preparation method of phenol-urea-formaldehyde resin adhesive for E0-grade outdoor plywood

InactiveCN102140156ALow in free phenolsIncrease dosageAldehyde/ketone condensation polymer adhesivesWood veneer joiningChemistryAlkali hydroxide

The invention discloses a preparation method of a phenol-urea-formaldehyde resin adhesive for E0-grade outdoor plywood. The preparation method comprises the following steps: step 1, mixing phenol, a formaldehyde solution and urea, adding a catalyst, and rising the temperature for reaction; step 2, adding the formaldehyde solution and urea which can also be added in the step 3 again, adding an alkali metal hydroxide solution for reaction; step 3, continuing to add the formaldehyde solution and the alkali metal hydroxide solution, if the urea is not added in the former step, adding the urea forreaction at the moment; and step 4, adding the urea and the alkali metal hydroxide solution for reaction until the viscosity is 1.5-2.0 seconds measured by a gardner-holdt tube reverse bubble measurement method, and then discharging. The adhesive-making process is mild in reaction and is easy to control, repeatability is good, and the storage life of the adhesive is more than 30 days. The strength of the plywood made of the adhesive meets the E0-grade requirement of I type plywood.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of bio oil-phenol-methanal copolycondensation resin wood adhesive

ActiveCN101974301AHigh mechanical strengthImprove waterproof performanceAldehyde/ketone condensation polymer adhesivesHydrocarbon oils treatmentAdhesiveAging resistance

The invention relates to a preparation method of a bio oil-phenol-methanal copolycondensation resin wood adhesive, belonging to the technical field of fine chemistry and high polymer materials, which comprises the following steps of filtering and refining bio oil to prepare the refined bio oil; adding sulfur and sodium hydroxide solution to the refined bio oil; stirring, heating and reacting to prepare the modified bio oil; and adding phenol and a catalyst to the modified bio oil to prepare the adhesive after reacting. In the method of the invention, the bio oil is taken as a substrate to synthesize the adhesive for wood, and the content of the bio oil is 50 to 60% of the total content of the adhesive. The prepared adhesive has the advantages of high mechanical strength, good waterproof performance and aging resistance, and can be used for preparing the products in high accessories of outdoor stage plywood, particle boards, fiberboards, layer base materials and the like. Moreover, thepreparation technology for pyrolyzing the bio oil wood adhesive is simple and fast, and the resins have the advantages of strong adhesion performance and long storage life.

Owner:BEIJING FORESTRY UNIVERSITY

Polyurethane grouting material for repairing roadbed-bottom culvert defects

InactiveCN105440651AGood curing instant efficiencyGood mechanical propertiesAntistatic agentPlasticizer

A polyurethane grouting material for repairing roadbed-bottom culvert defects comprises the following raw materials in parts by weight: 60-80 parts of a polyurethane prepolymer, 15-25 parts of modified phenolic resin, 1-10 parts of organic montmorillonite, 5-15 parts of a fire retardant, 2-3 parts of an antistatic agent, 5-30 parts of a plasticizer, 2-10 parts of a foam stabilizer, 0.05-1 part of a catalyst, and 10-35 parts of a solvent. The polyurethane grouting material for repairing roadbed-bottom culvert defects possesses good curing real-time efficiency and relatively high dimension stability, and also is excellent in mechanical properties and strong in engineering endurance.

Owner:ANHUI YOUTE HIGHWAY MAINTENANCE TECH CO LTD

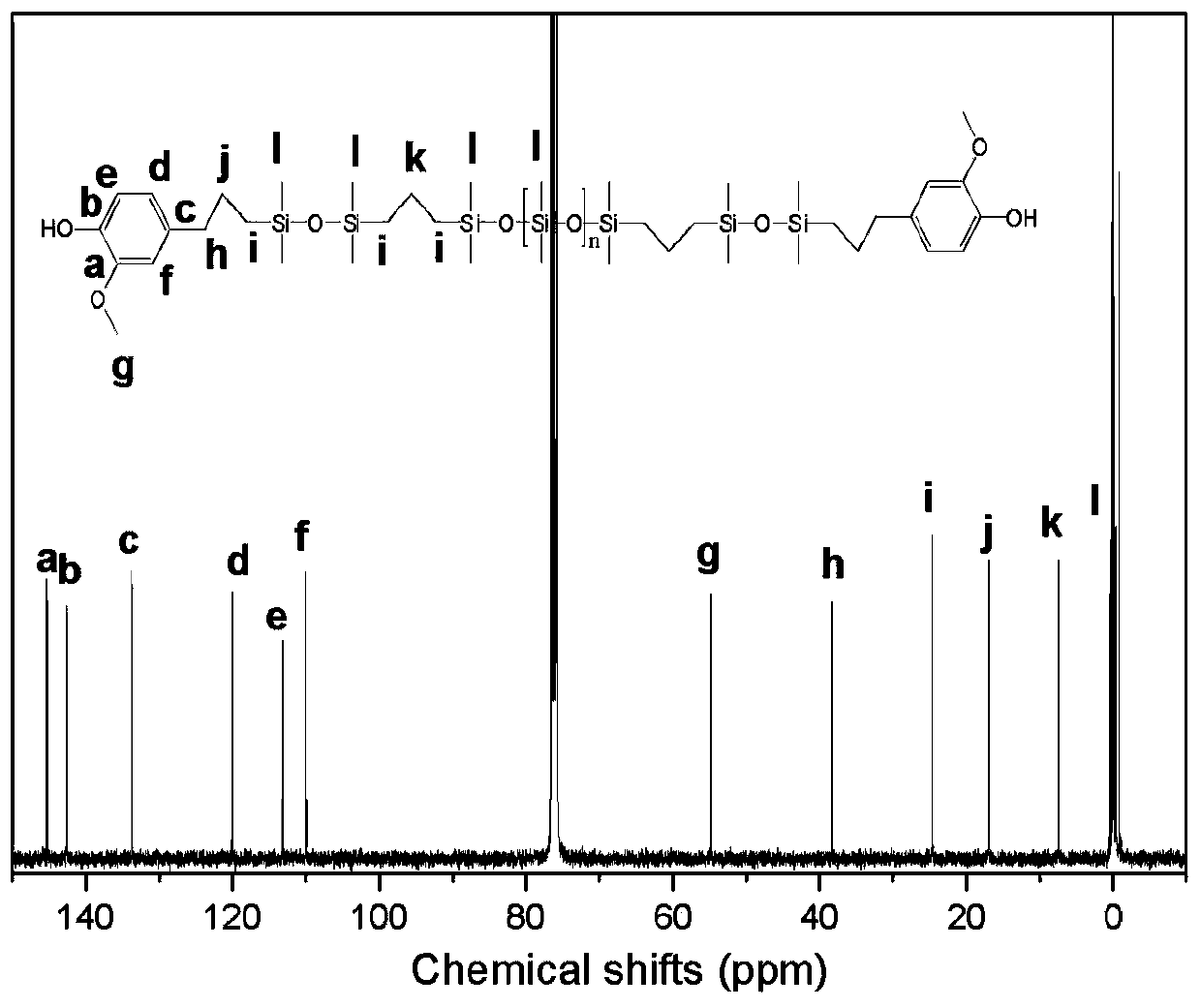

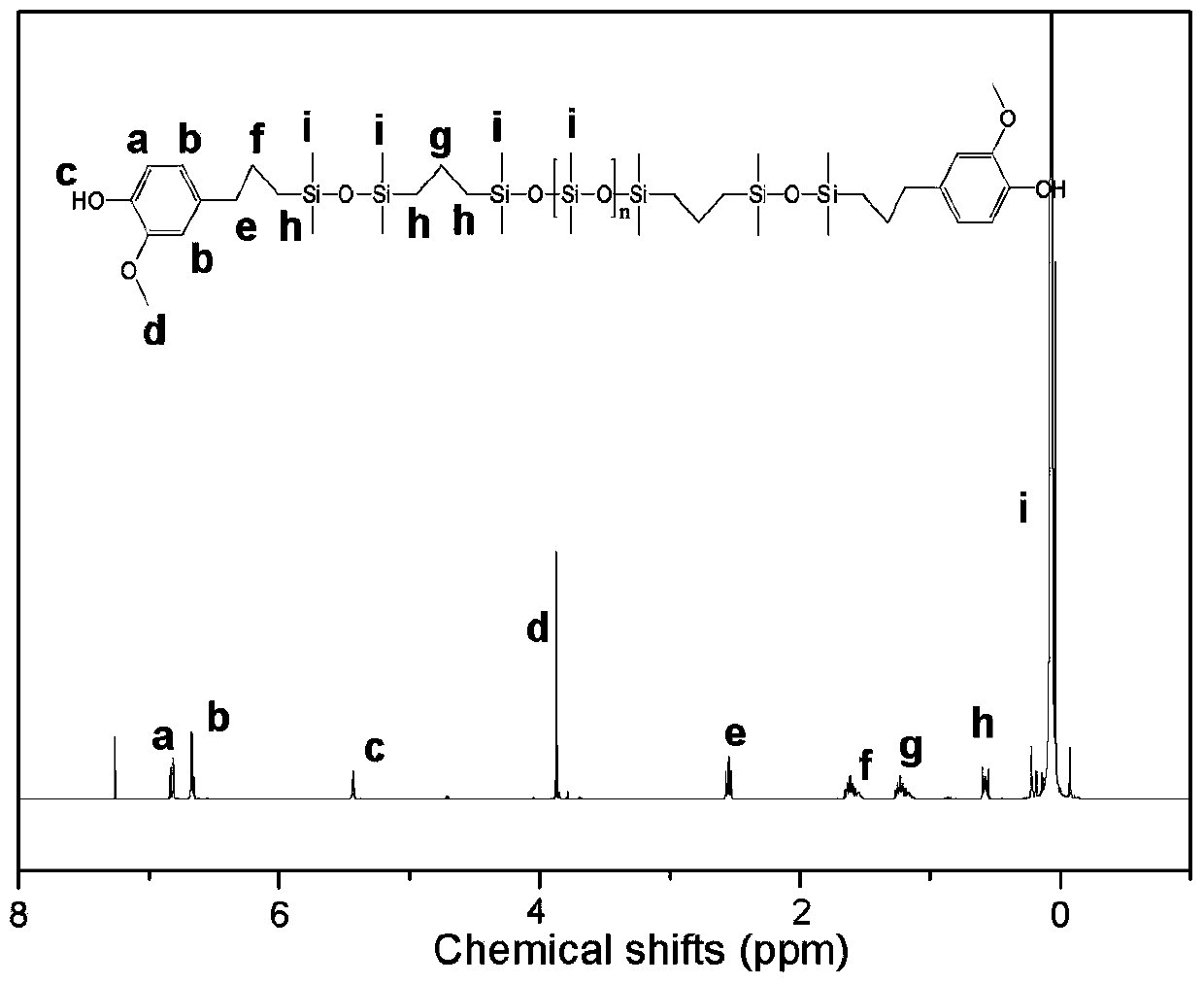

Phenol-terminated polysiloxane, preparation method thereof, and polysiloxane-polycarbonate copolymer

The invention discloses phenol-terminated polysiloxane, a preparation method thereof, and a polysiloxane-polycarbonate copolymer. The method includes the following steps: a) catalyzing a reaction of tetramethyldisiloxane and an allyl-containing phenolic compound by using a transition metal catalyst A to prepare phenol-modified hydrogen-containing silane having a phenol group at one end and a silicon-hydrogen bond at one end; b) performing separation by using reduced-pressure rectification to obtain phenol-modified hydrogen-containing silane with purity of >=99%; and c) catalyzing B by using atransition metal catalyst, performing a hydrosilylation reaction on the pure phenol-modified hydrogen-containing silane and polysiloxane with a vinyl end group to obtain the polysiloxane containing aphenol group at the end group. The content of the free allyl-containing phenol compound in the phenol-terminated polysiloxane is 100 ppm or less, the phenol group capping rate is 98% or more, and theresidual metal platinum content is <= 5 ppm. The phenol-terminated polysiloxane is used for preparing the modified polycarbonate, and the obtained polysiloxane-polycarbonate copolymer has a high polysiloxane content, and excellent heat resistance and yellowing resistance.

Owner:WANHUA CHEM GRP CO LTD +1

Method for producing environment-friendly high-performance novolac resin

The invention discloses a method for producing environment-friendly high-performance novolac resin, which is characterized by comprising the following steps: (1) according to weight ratio, weighing 100 portions of phenol, 30 to 70 portions of aldehyde and 1 portion of composite catalyst of organic phosphonic acid and divalent metal salts thereof; (2) mixing and stirring the phenol and the composite catalyst evenly; (3) heating the mixture to raise the temperature, adding the aldehyde when the temperature of the materials is between 50 and 100 DEG C, and when the temperature is raised to be between 80 and 110 DEG C, performing reaction for 0.5 to 4 hours; and (4) performing vacuum dehydration when the temperature is between 80 and 160 DEG C and the pressure is 0.08 MPa below zero, and simultaneously heating the materials by using 0.06MPa steam to obtain the environment-friendly high-performance novolac resin when the softening point of the materials reaches between 75 and 120 DEG C. The method effectively reduces the content of free phenols, improves the conversion rate of the phenol, and is advantageous for the health of production workers and environmental protection.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Preparation method of anti-damping resin grinding wheel

InactiveCN107520771AHigh bond strengthPromote interface integrationAbrasion apparatusGrinding devicesCarbon blackBonding strength

The invention provides a preparation method of an anti-damping resin grinding wheel. The preparation method of the anti-damping resin grinding wheel comprises 0.5-1.0 mass part of silane coupling agent, 8-12 mass parts of phenolic resin liquid, 50-80 mass parts of 46# plated white corundum, 20-40 mass parts of 54# plated white corundum, 0.5-1.0 mass part of carbon black, 8-12 mass parts of potassium fluoroaluminate, 3-5 mass parts of calcium sulfate whiskers, and 18-23 mass parts of modified phenolic resin powder. Plated white corundum abrasives are adopted; high-temperature coating layers are arranged on the surfaces of the abrasives; the coating layers facilitate improvement of the resin and abrasive interface bonding strength; silane coupling agent molecules contain reaction radicals chemically bonded with inorganic matter materials, and reaction radicals chemically bonded with organic matter materials; inorganic and organic interfaces are bonded to promote the interface fusion to improve the performances; secondly, the modified phenolic resins adopted in the method contain no radicals easy to oxidize in molecular structures compared with general phenolic resins; and the free phenol content in the method is low, so that the performance degradation of hardened resins can be effectively relieved.

Owner:珠海泰达砂轮有限公司

Preparation method of lignin modified phenolic resin for molding compound

The invention discloses a lignin modified phenolic resin for molding compound. The lignin modified phenolic resin can be prepared by the following method: mixing phenol, an acid catalyst and enzymolysis lignin, heating to 90 DEG C-160 DEG C, liquefying for 1-3 h, cooling to 70 DEG C, then adding formaldehyde into the reaction system, heating to 90-120 DEG C, reacting for 2-4 h, and carrying out vacuum distillation to obtain the lignin modified phenolic resin. The invention uses enzymolysis lignin in rich resource to partially substitute phenol to prepare phenolic resin, so as to obviously reduce cost. The lignin modified phenolic resin provided by the invention can be used for preparing molding compound, and has high mechanical properties, heat resistance and insulation.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Production method for electronic-grade phenolic resin

InactiveCN102181026AHigh purityLow impurity contentSemiconductor/solid-state device detailsSolid-state devicesEpoxyDistillation

The invention discloses a production method for electronic-grade phenolic resin. The production method includes the steps as follows: suctioning 10%-20% total amount of formaldehyde solution into a reaction kettle with a vacuum method, adding catalyst, stirring for 4-6 minutes, adding phenol, starting increasing temperature after charging materials, starting timing when the temperature achieves 70-100 DEG C, continuously dropping 65%-75% total amount of the formaldehyde solution within 1-2 hours, conducting temperature-insulation reaction for 1-10 hours after dropping is finished, then continuously and totally dropping the residual formaldehyde solution within 1-2 hours, and finishing reaction after conducting temperature-insulation reaction for 1-2 hours after dropping is finished. By adding formaldehyde solution in batches to react and by washing, vacuum dewatering, distillation, second vacuum dewatering and final refining, the electronic-grade phenolic resin with high purity can be prepared. The phenolic resin produced by the method is low in impurity content, free phenol content and volatile matter content, has good electrical property and can serve as a curing agent for 'epoxy moulding compounds for encapsulating semiconductor devices and integrated circuits'.

Owner:LIANYUNGANG ZHONGHE SCI & TECH +1

Phenolic resin glue containing potassium ion alkali compound and preparation method thereof

InactiveCN103865459AImprove flexural strengthHigh modulus of elasticityAldehyde/ketone condensation polymer adhesivesPotassium ionsSolvent

The invention relates to phenolic resin glue containing a potassium ion alkali compound and a preparation method thereof. The phenolic resin glue containing the potassium ion alkali compound comprises the following components in percentage by weight: 19-23.5wt% of phenol, 36.5-41.5% of industrial formaldehyde with weight concentration of 37%, 0.8-12wt% of potassium ion alkali compound, 0-12wt% of extender and the balance of solvent. The preparation method comprises the following processing steps: 1) taking the components; 2) preparing the potassium ion alkali compound into solution with the weight concentration of 30% or 50%; 3) starting a stirrer, placing phenol, potassium ion alkali compound, formaldehyde with the weight concentration of 37%, extender and solvent into a reaction vessel, performing reaction for 1-3 hours, cooling to the temperature below 40 DEG C, and discharging, so that the phenolic resin glue containing the potassium ion alkali compound is obtained, wherein solid content of the phenolic resin glue is 36.5-45wt%, and viscosity determined under the condition of coating four cups of the phenolic resin is 17-90 seconds. The phenolic resin glue containing the potassium ion alkali compound has the advantages that bonding strength is high, cost is low (phenol raw material amount is less), content of free phenol and free formaldehyde in the phenolic resin glue containing the potassium ion alkali compound is low, environmental performance is good, and the traditional phenolic resin glue can be replaced.

Owner:刘启明

Formula for ceramic brake pad and manufacturing technology of ceramic brake pad

InactiveCN102478091AReduce lossesHigh softening pointFriction liningManufacturing technologyAcrylonitrile

A formula for the ceramic brake pad and a manufacturing technology thereof relate to the brake pad. The formula comprises the following components in proportions: 7-9 parts of phenolic resin, 5 parts of butadiene-acrylonitrile rubber powder, 10-15 parts of ceramic fiber, 10-12 parts of mineral fiber, 4-6 parts of Kevlar fiber, 12-20 parts of potassium titanate whisker, 7-10 parts of synthetic graphite, 6-8 parts of zinc sulfide, 7-9 parts of red copper powder, 8-10 parts of white vermiculite and 6-10 parts of compound silicate whisker; the manufacturing method of the ceramic brake pad comprises the following steps: material preparation-material mixing-hot forming-thermal treatment-grinding-spraying; and the ceramic brake pad has the advantages of being free of noise and ash, having no corrosion on hubs, being long in service life and environment-friendly, and the like.

Owner:宋亚军

Lignin modified phenolic resin and preparing method thereof

InactiveCN106478906AHigh strengthIncreased swelling resistanceLignin derivativesSolid acidIon exchange

The invention relates to a lignin modified phenolic resin and a preparing method thereof, and belongs to the technical field of phenolic resin. The lignin modified phenolic resin is prepared from, by weight, 50-70 parts of lignin, 100-150 parts of phenol, 2-25 parts of an acidic hemicellulose liquid, 50-100 parts of alkaline hemicellulose liquid, 10-50 parts of soft water, 50-70 parts of phytate phosphorus resin, 1-15 parts of zeolite solid acid, 40-190 parts of formaldehyde, 2-20 parts of gel-type ion exchange resin and 1-15 parts of a nanometer composite catalyst. The preparing method includes the steps that the lignin, the phenol, the hemicellulose liquid, the soft water, the phytate phosphorus resin and the zeolite solid acid are added into a reaction kettle and reacted, then the formaldehyde and the nanometer composite catalyst are added, the mixture is washed, dried and smashed, then the gel-type ion exchange resin is added, and the lignin modified phenolic resin is obtained. The lignin modified phenolic resin is good in stability and low in production cost, and has the excellent size stability, forming processing performance and fire resistance.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Industrial production method of high-purity linear phenolic resin

The invention relates to the technical field of polymer synthesis of phenolic resin, in particular to a refinement process of linear phenolic resin. The process comprises the steps as follows: (1) putting phenol in a reactor, adding oxalic acid, heating the reactor to 80-100 DEG C, and dropwise adding formalin to the reactor; (2) after dropwise adding the formalin, keeping the temperature, and adding oxalic acid until the pH of the mixed solution in the reactor is 4-6; (3) adding a solvent to the reactor continuously; (4) transferring all materials in the reactor into an extraction kettle, adding water to the extraction kettle for extraction, and separating a water phase; (5) repeating washing operation in step (4) until the pH value of the materials is 6-7 to obtain a crude phenolic resinsolution; (6) transferring the crude phenolic resin solution into a dehydration kettle, and removing residual water under negative pressure; (7) coarsely removing the solvent and small-molecular impurities out of the phenolic resin by a multistage falling-film evaporator, and refining the phenolic resin by a multistage wiped-film evaporator group; (8) granulating the phenolic resin by a drum granulator to obtain a high-purity linear phenolic resin product.

Owner:SHANDONG TIANCHENG CHEM CO LTD

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522BAdequate responseTo achieve the purpose of modifying phenolic resinAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

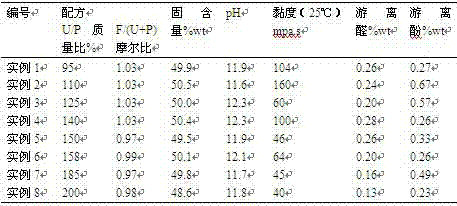

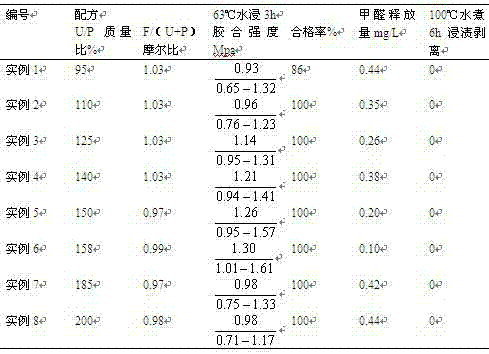

Preparation method of urea-phenol-formaldehyde resin adhesive used for E0 grade solid wood composite floorboard

InactiveCN102898605AReduce free phenolLow in free phenolsAldehyde/ketone condensation polymer adhesivesFlooringSolid woodDivalent metal ions

The invention discloses a preparation method of a urea-phenol-formaldehyde resin adhesive used for an E0 grade solid wood composite floorboard. In the first step, a formaldehyde solution, phenol and urea are mixed, an oxide or salt of divalent metal ion is added, or an alkali metal hydroxide is added, a heating reaction is carried out, wherein, the mol ratio of formaldehyde to the total amount of phenol and urea is 0.72-0.82; in the second step, the formaldehyde solution, urea and the alkali metal hydroxide are added, the mol ratio of formaldehyde to the total amount of phenol and urea is 1.03-1.13; in the third step, the formaldehyde solution and the alkali metal hydroxide are added, and the mol ratio of formaldehyde to the total amount of phenol and urea is 1.05-1.20; and in the fourth step, urea and the alkali metal hydroxide are added, and the final mol ratio of formaldehyde to the total amount of phenol and urea is 0.95-1.03, and a reaction is carried out until the viscosity can reach the requirement. The glue storage life is greater than 30 days. The plywood strength of the solid wood composite floorboard compacted by the glue accords with an II type plywood requirement.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Modified phenolic resin adhesive and preparation method and application thereof and preparation method of bamboo-wood composite board

ActiveCN108274555ALow in free phenolsInhibition releaseWood treatment detailsReed/straw treatmentWater contentPhenols

Owner:FUJIAN HEQIZU FORESTRY SCI & TECH CO LTD +1

Thermosetting glass fiber reinforced phenolic aldehyde composite material for injection and preparation method thereof

The invention discloses a thermosetting glass fiber reinforced phenolic composite material for injection and a preparation method thereof. The composite material is prepared from the following raw materials: phenolic resin, glass fibers, superfine aluminum hydroxide, mica powder, zinc stearate, a silane coupling agent, polyvinyl acetal modified thermosetting phenolic resin and the like. The thermosetting glass fiber reinforced phenolic aldehyde composite material for injection can be formed by utilizing injection molding and mould pressing processes, the injection molding manufacturability is good, the surface of a formed part is flat and smooth, continuous production can be realized through the injection molding, the efficiency is improved, and the comprehensive yield of products is high; injection molding of the material can be operated mechanically in the whole process, operators are reduced, labor intensity is reduced, and production efficiency is improved; and parts prepared from the material are high in curing speed and high in production efficiency, and have good technical economy.

Owner:SHANDONG NORTH MODERN CHEM IND

Modified thermoplastic phenolic resin adhesive used in automobile brake pad and preparation method thereof

The invention provides a modified thermoplastic phenolic resin adhesive used in automobile brake pads and a preparation method thereof. The adhesive is prepared from following components, by weight: 100 parts of phenols, 73-80 parts of aldehydes, 0.05-0.08 parts of acids, 1-7 parts of nano organic modified montmorillonite, 2-4 parts of D-glucose and 1-7 parts of dialdehydes. The preparation method comprises following steps: (A) adding the nano organic modified montmorillonite and the acid into a reaction container according to ratio and stirring the mixture for 30 min at 50-60 DEG C; (B) increasing the temperature to 90-100 DEG C, adding 73-80 parts of aldehydes to the reaction liquid within 60-90 min, and continuously performing the reaction with temperature maintained for 30-60 min; (C) adding 2-4 parts of D-glucose to the reaction liquid, and performing a reaction for 10-20 min at 90-100 DEG C; (D) adding 1-7 parts of dialdehydes to the reaction liquid,, and performing a reaction at 90-100 DEG C for 25-40 min; and (E) starting a vacuum pump to control the pressure in the reaction container to be -0.08 MPa, and performing dehydration for 5 h to prepare the modified thermoplastic phenolic resin adhesive. The method increases the heat resistance and toughness of phenolic resin and reduces the contents of free phenols and volatiles in the resin.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Halide-containing brake material and preparation method and application thereof

ActiveCN110778629AImprove thermal conductivityNo crackOther chemical processesDomestic articlesCarbon fibersKaolin clay

The invention relates to a halide-containing brake material and a preparation method and application thereof, and belongs to the technical field of brake materials. The preparation method comprises the following steps: adding aromatic alcohol phenolic resin, butadiene rubber, feldspar powder, argil, kaolin, calcined petroleum coke powder and halide into a mixer according to a proportion, mixing and stirring for 20-25min, then adding carbon fibers, potassium titanate whiskers and magnesium borate whiskers according to a proportion, and mixing and stirring for 12-18min until the mixture is uniform to obtain the halide-containing brake material; and placing a steel backing and the brake material into a mold for compression molding, placing the mold into an oven for heating and curing after demolding, and finally machining to obtain an automobile brake pad or a rail transit vehicle brake pad. The friction material of the automobile brake pad and the rail transit vehicle brake pad is particularly suitable for a brake disc with a dual material being aluminum alloy, the porosity of a microporous material is large, the hardness is low, and damage to the brake disc is reduced. The microporous material and the aluminum alloy brake disc are high in heat dissipation speed, the working temperature of a friction pair can be reduced, and the friction pair can bear larger load.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

Phenol-polyaldehyde prepolymer modified environment-friendly phenolic resin and preparation method thereof

ActiveCN103265674ALow in free phenolsReduce internal stressAldehyde/ketone condensation polymer adhesivesPrepolymerFree phenol

The invention relates to a phenol-polyaldehyde prepolymer modified environment-friendly phenolic resin and a preparation method thereof. The phenolic resin in the method is prepared from phenol, formaldehyde and a phenol-polyaldehyde prepolymer through catalytic synthesis. The preparation method comprises the following steps: synthesizing the phenol-polyaldehyde prepolymer from a polyaldehyde monomer and phenol at a certain temperature in the presence of a catalyst; and introducing the phenol-polyaldehyde prepolymer into a phenolic resin system. The introduction of the phenol-polyaldehyde prepolymer increases the aldehyde equivalent in the system, and can effectively decrease the free phenol content in the resin; and the replacement of part of the formaldehyde with the polyaldehyde can effectively decrease the free formaldehyde content in the resin. Besides, the long-chain structure of the phenol-polyaldehyde prepolymer can enhance the flexibility of the phenolic resin and reduce the internal stress in the curing process, so that a pressed sheet has favorable adhesion strength and can meet the requirements for Class I waterproof plywood. The phenolic resin prepared by the invention has the advantages of low free phenol / free aldehyde content, simple process and the like, and is applicable to the field of production of functional environment-friendly artificial boards.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com