Dual catalyst system thermoplastic phenolic resin preparation method and application for preparing coated sand thereof

A phenolic resin and thermoplastic technology, which is applied in the field of preparation of thermoplastic phenolic resin for high-strength coated sand, can solve problems such as high softening point, slow polymerization speed, and increased gas generation, and achieve thermal tensile strength and normal temperature tensile strength High strength, low free phenol content, fast polymerization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

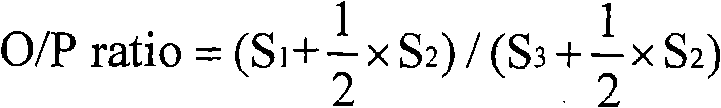

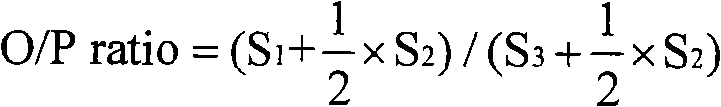

Image

Examples

Embodiment 1

[0026] Taking 1 mole of raw material phenol for preparing thermoplastic phenolic resin as an example, other raw materials used and their proportioning and preparation methods are as follows:

[0027] 1. Ingredients

[0028] Take 94g of phenol, 19.52g of paraformaldehyde, 31.5g of water, 0.36g of oxalic acid, and 0.88g of zinc acetate, put them in a reaction kettle, and stir evenly, that is, the molar ratio of phenol to paraformaldehyde, water, oxalic acid, and zinc acetate is 1 : 0.65: 1.75: 0.004: 0.004, paraformaldehyde is a low molecular weight paraformaldehyde with a degree of polymerization of 8-100.

[0029] 2. Reflux reaction

[0030] The reactant was heated to 120° C. under stirring, and reacted at constant temperature for 4 hours.

[0031] 3. Vacuum drying

[0032] After the reaction, put the resultant into a vacuum oven with a vacuum degree of -0.07MPa, continue stirring and heating to 180° C. and vacuum dry for 4 hours to prepare a thermoplastic phenolic resin. ...

Embodiment 2

[0042] Taking 1 mole of raw material phenol for preparing thermoplastic phenolic resin as an example, other raw materials used and their proportioning and preparation methods are as follows:

[0043] In batching step 1, take 94g of phenol, 15.02g of paraformaldehyde, 0.09g of oxalic acid, and 0.22g of zinc acetate, place them in a reaction kettle, and stir evenly, that is, the molar ratio of phenol to paraformaldehyde, water, oxalic acid, and zinc acetate 1:0.50:0:0.001:0.001, paraformaldehyde is a low molecular weight paraformaldehyde with a degree of polymerization of 8-100. Other steps are the same as in Example 1 to prepare a thermoplastic phenolic resin.

Embodiment 3

[0045] Taking 1 mole of raw material phenol for preparing thermoplastic phenolic resin as an example, other raw materials used and their proportioning and preparation methods are as follows:

[0046] In batching step 1, take 94g of phenol, 27.03g of paraformaldehyde, 54.0g of water, 3.6g of oxalic acid, and 4.4g of zinc acetate, put them in the reaction kettle, stir evenly, that is, phenol and paraformaldehyde, water, oxalic acid, acetic acid The molar ratio of zinc is 1:0.90:3.0:0.04:0.02, and the paraformaldehyde is a low molecular weight paraformaldehyde with a polymerization degree of 8-100. The other steps are the same as in Example 1 to prepare a thermoplastic phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com