Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3372 results about "Degree of polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The degree of polymerization, or DP, is the number of monomeric units in a macromolecule or polymer or oligomer molecule. For a homopolymer, there is only one type of monomeric unit and the number-average degree of polymerization is given by DPₙ≡Xₙ=Mₙ/M₀, where Mₙ is the number-average molecular weight and M₀ is the molecular weight of the monomer unit. For most industrial purposes, degrees of polymerization in the thousands or tens of thousands are desired.

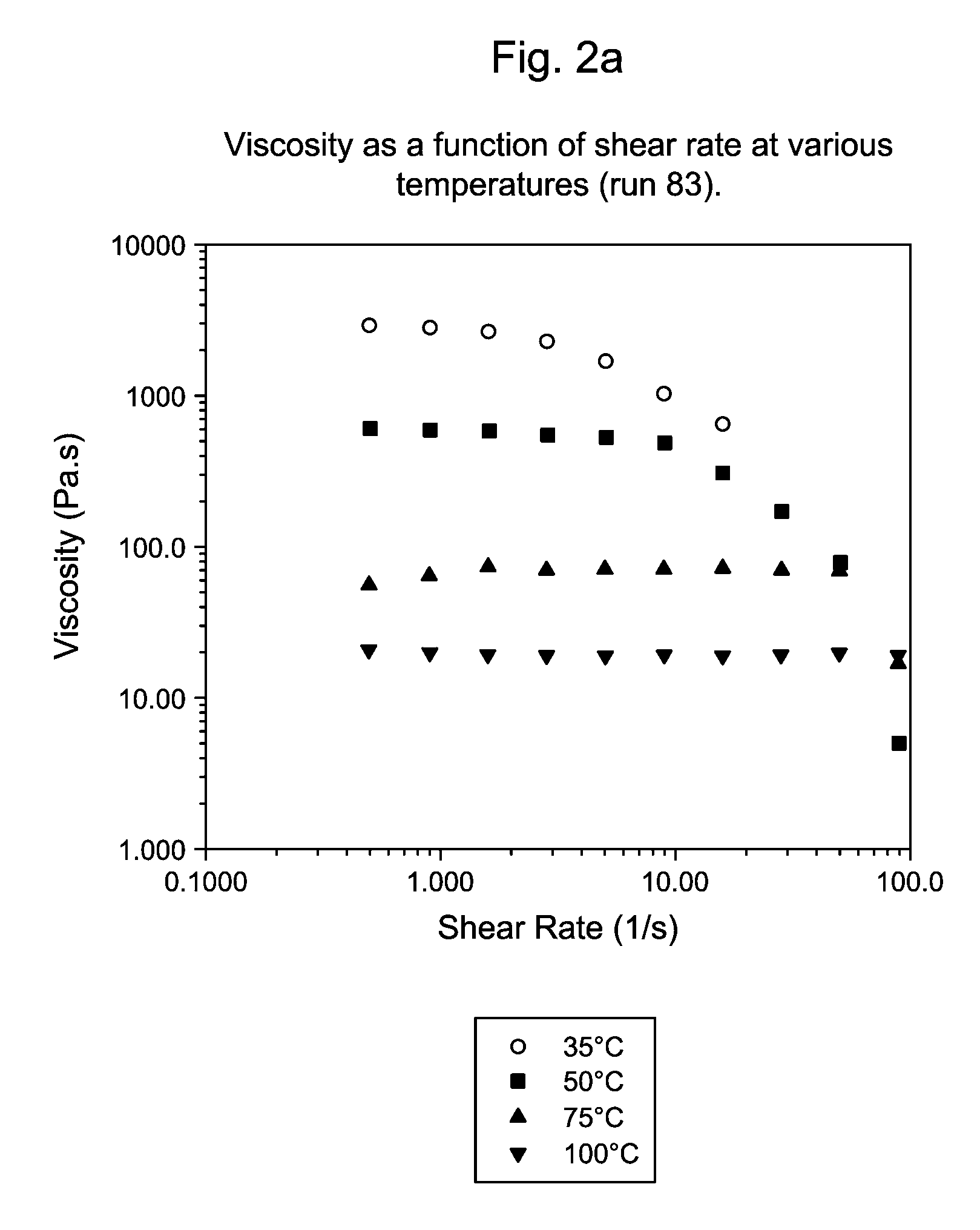

Method and materials for hydraulic fracturing of wells

InactiveUS6949491B2Increase effective viscosityRestrict pressure lossFluid removalFlushingFracturing fluidCarrier fluid

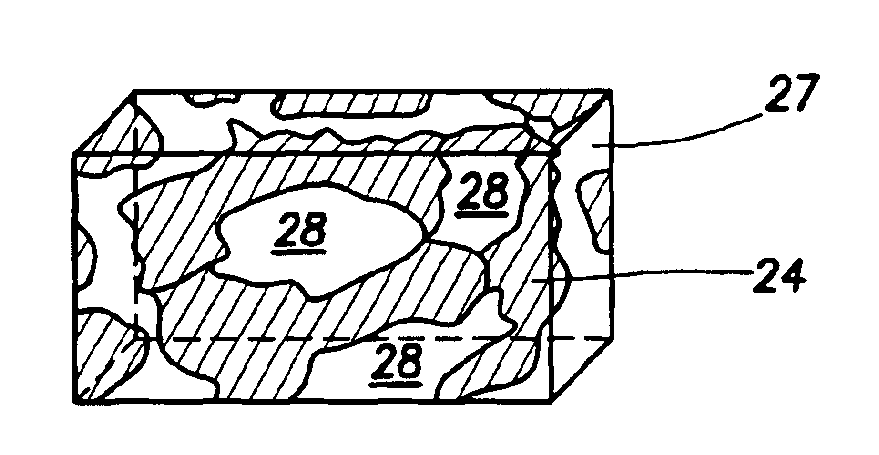

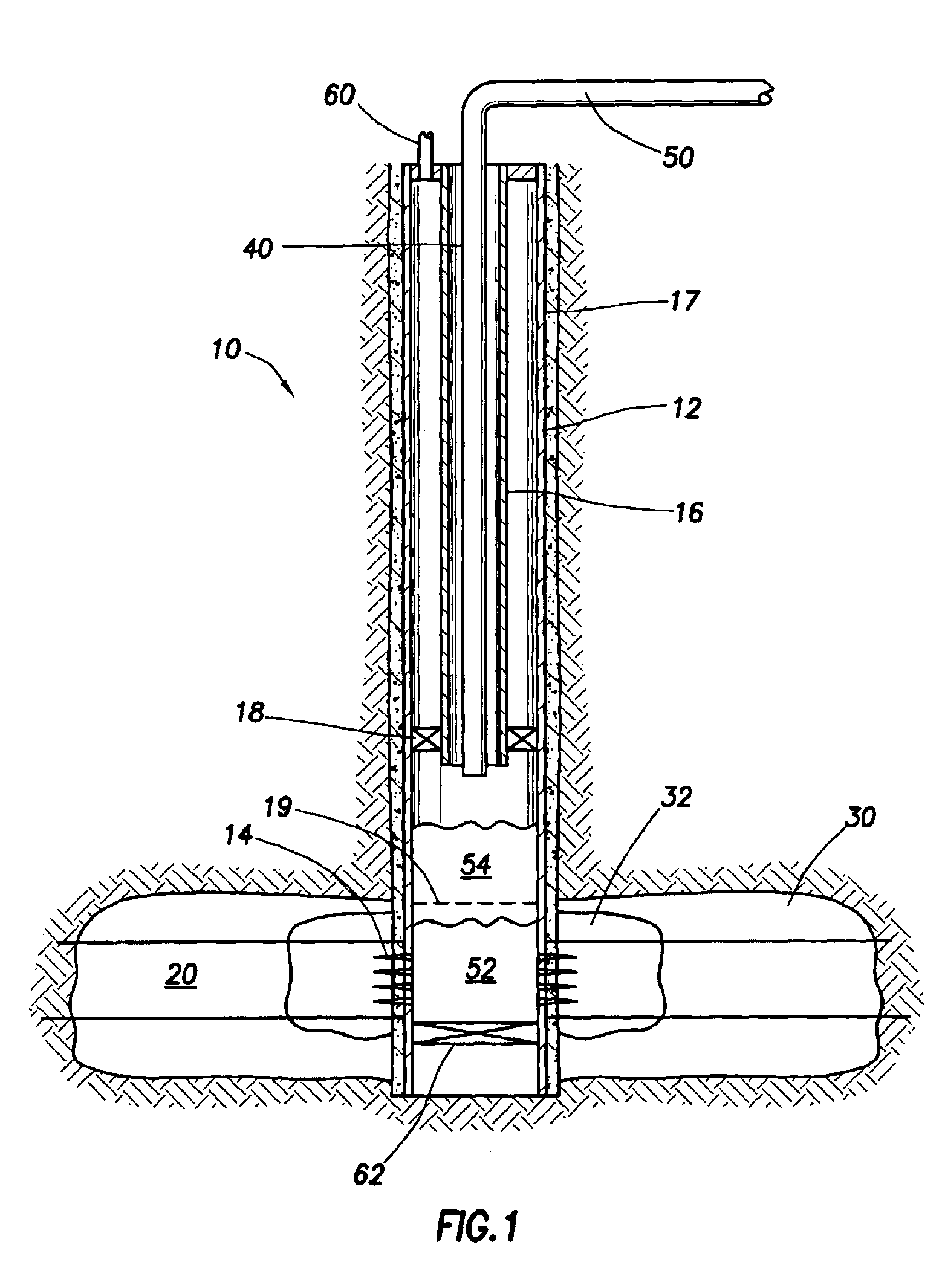

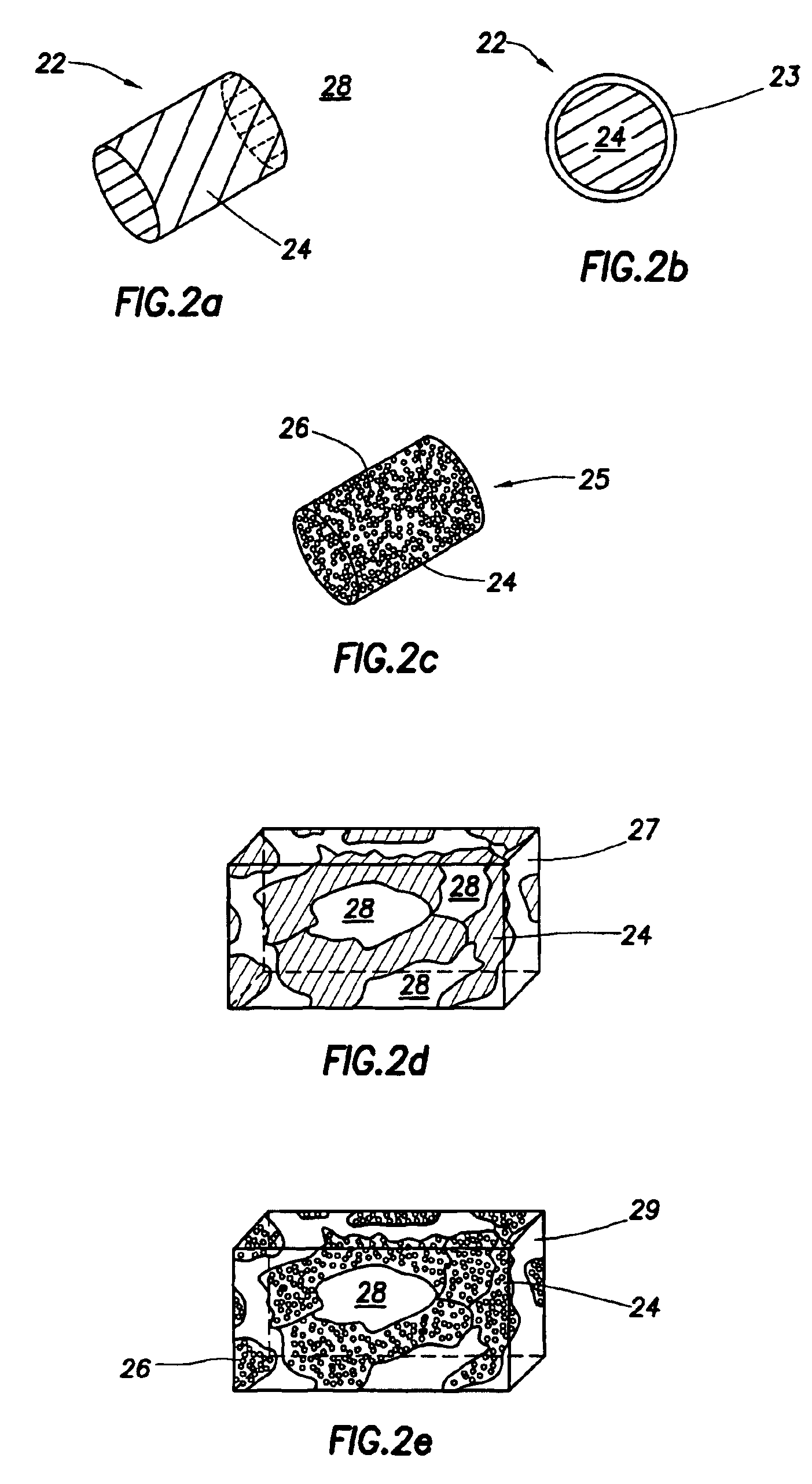

Hydraulic fracturing of wells by injecting a degradable polymer phase as a fracturing fluid is provided. Composition and degree of polymerization of the degradable polymer and the selection of additives may be varied to adjust the viscosity, degradation time and other properties of the fracturing fluid. Viscous degradable fluid or pellets of degradable polymer may be placed in a wellbore as an internal phase in a low viscosity carrier fluid. A polymer-continuous liquid phase may be formed at a selected location in the wellbore, usually near perforations, before the polymer phase is pressured into a formation to form a hydraulic fracture.

Owner:ENERPOL LLC

Production of polytrimethylene ether glycol and copolymers thereof

A process for the manufacture of polytrimethylene ether glycol comprising the steps of: (a) providing (1) 1,3-propanediol reactant selected from the group consisting of 1,3-propanediol and / or oligomers or prepolymers of 1,3-propanediol having a degree of polymerization of 2-9 and mixtures thereof, and (2) a polycondensation catalyst; and (b) polycondensing the 1,3-propanediol reactant to form a polytrimethylene ether glycol at less than one atmosphere pressure, and the product of the process. In addition, polytrimethylene ether glycol has a number average molecular weight greater than 1,500, an APHA color of less than 120, an unsaturation of less than 20 meq / kg, and a content of cyclic ether oligomers of less than 2%.

Owner:DUPONT IND BIOSCIENCES USA LLC

Stable probiotic microsphere compositions and their methods of preparation

The invention relates to viable and stable probiotic formulations for intestinal targeting made of microspheres comprising each a core of one or more probiotic bacteria, microcrystallline cellulose with a degree of polymerization from 165-365 and mean diameter from 45 to 180 μm, a disintegrant and a stabilizer, the core being coated with a non-enteric coating and further coated with an enteric coating. Each probiotic microsphere has a residual moisture level of less than 5% and a water activity (aw) between 0.1 and 0.5. Such a probiotic microsphere shows no reduction in viable bacteria after one hour in simulated gastric fluid. The present invention also relates to the process of preparing such formulation.

Owner:CANACURE CORP

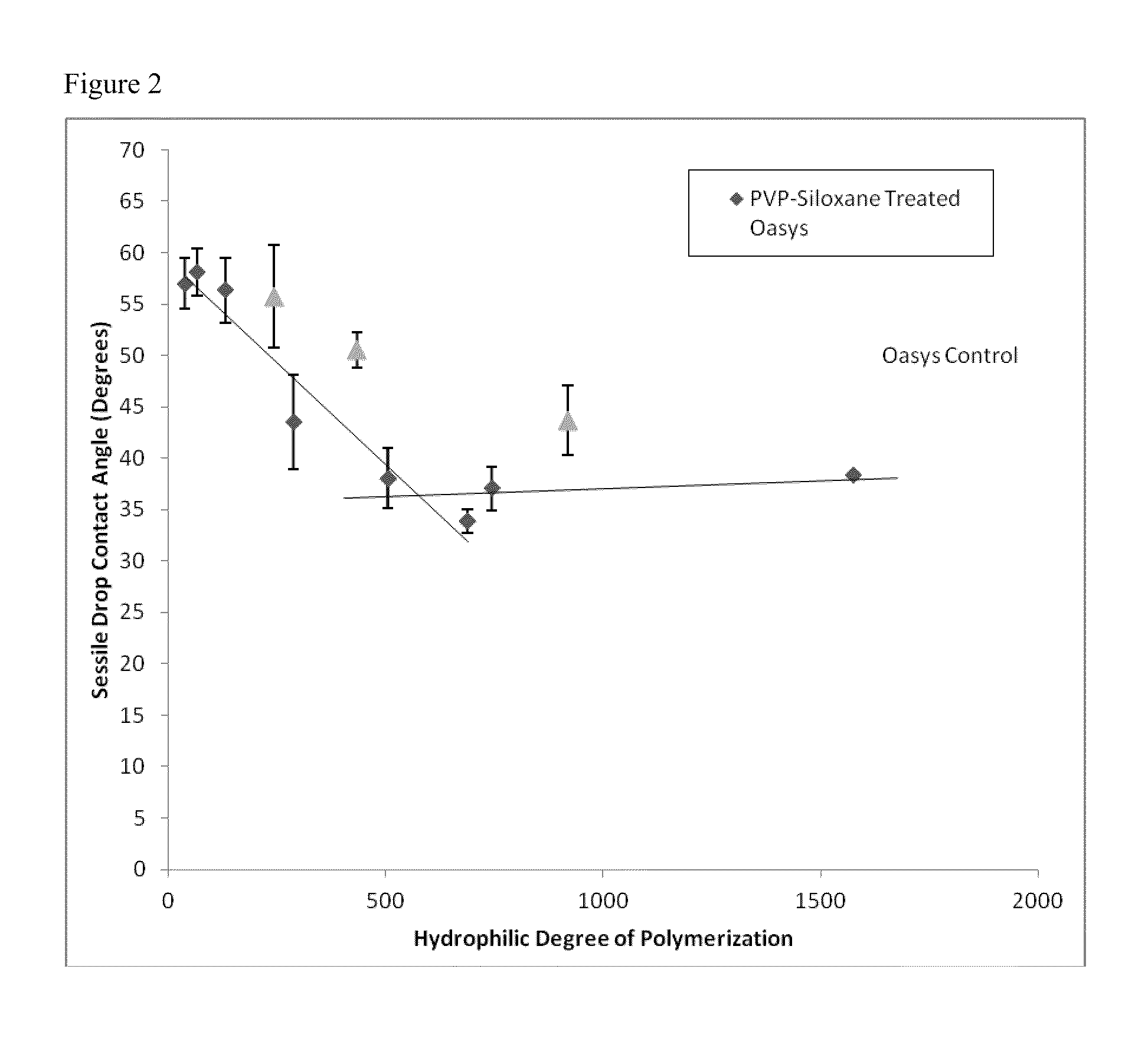

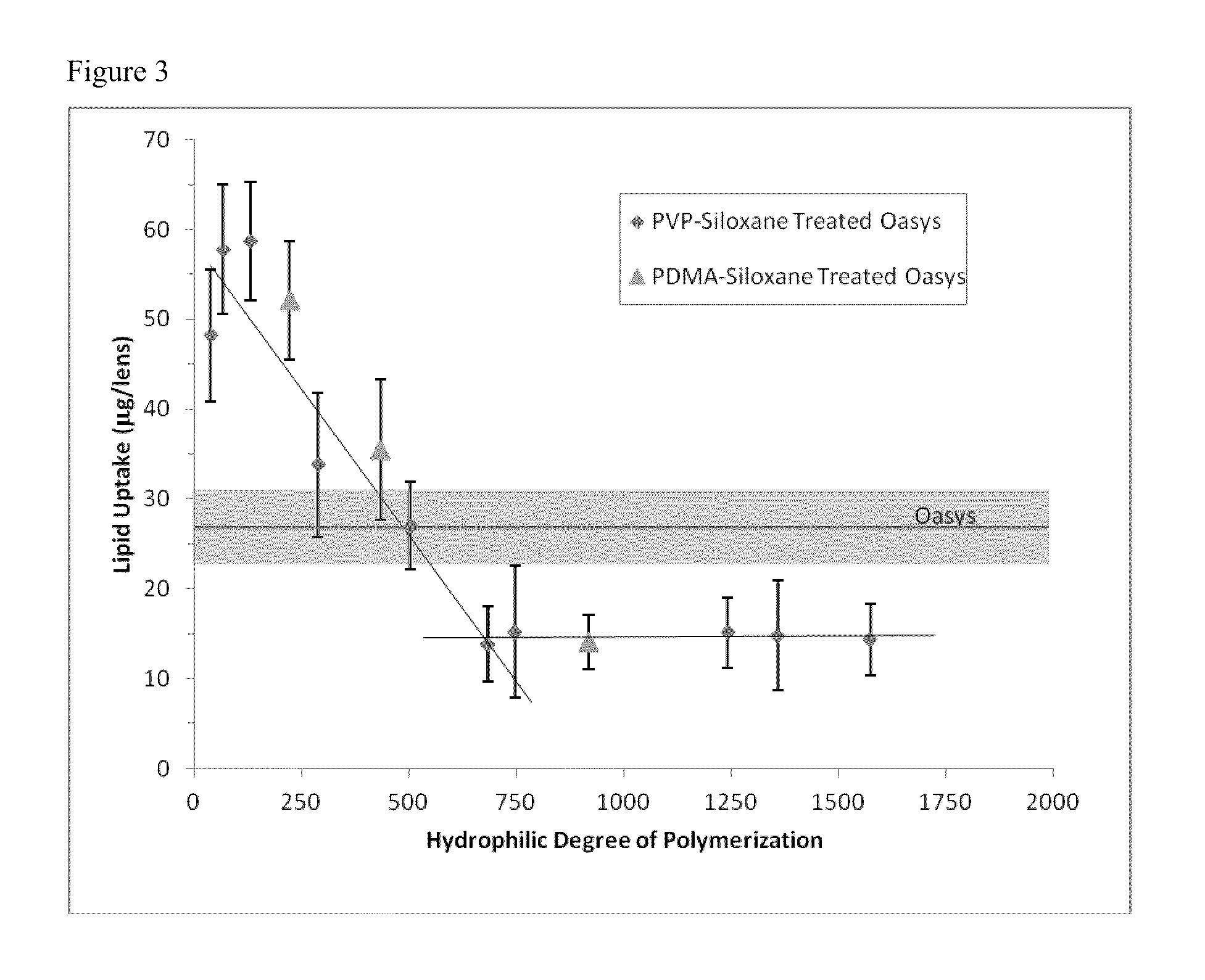

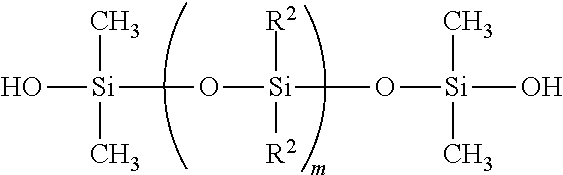

Non-reactive, hydrophilic polymers having terminal siloxanes and methods for making and using the same

ActiveUS20110275734A1Increase concentrationHigh polydispersitiesOptical partsOptical elementsHydrophilic polymersBackbone chain

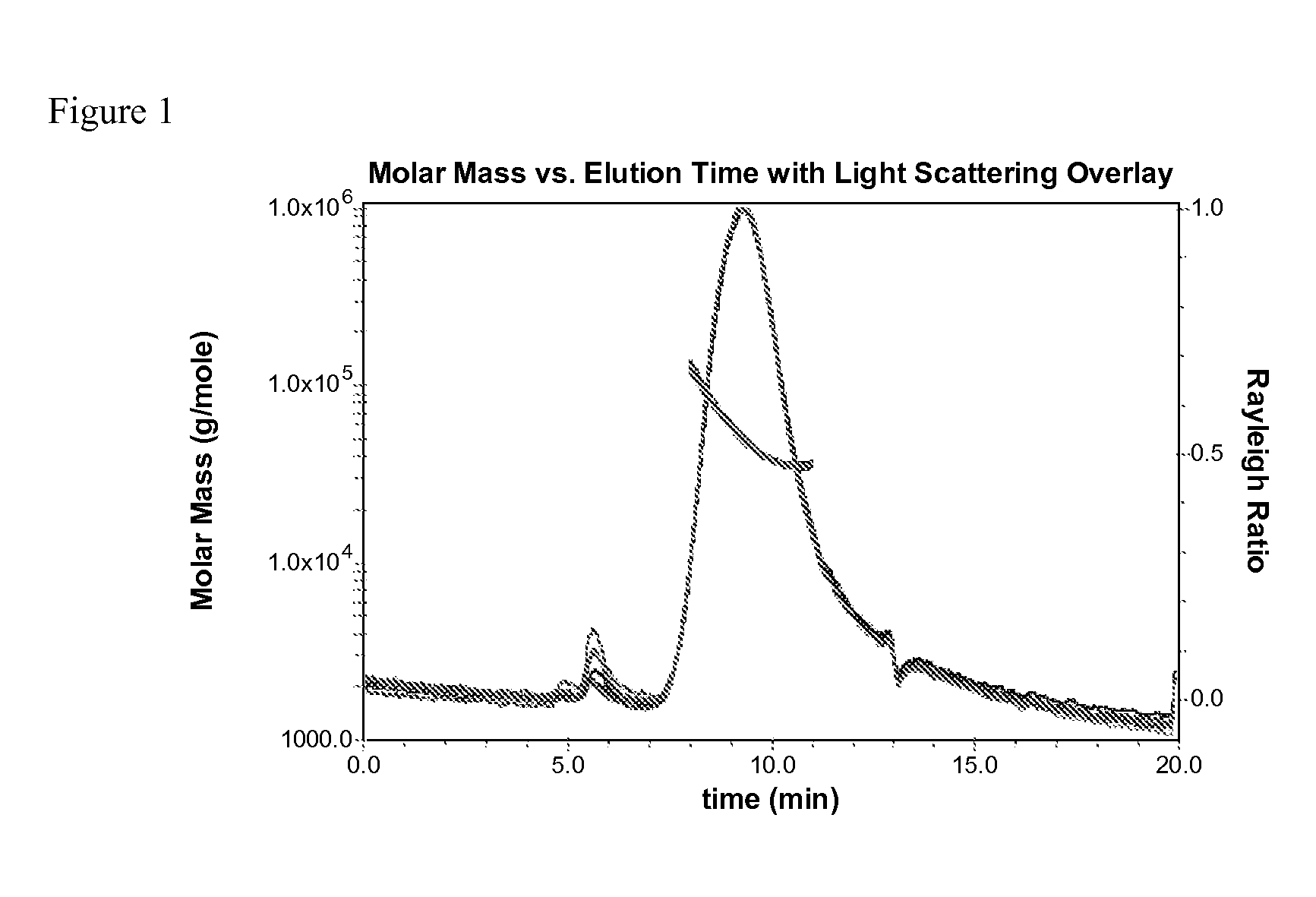

The present invention relates to compositions comprising at least one stable, near-monodisperse, non-reactive hydrophilic polymer comprising in said polymer's backbone, a hydrophilic segment having a degree of polymerization of about 10 to about 1000, and a linear silicone segment at least one terminal end of said non-reactive hydrophilic polymer, wherein said silicone segment comprises between about 6 and about 200 siloxy units, and said non-reactive hydrophilic polymer is associated, via the linear silicone block with a silicone hydrogel. The non-reactive hydrophilic polymers may be incorporated into the formulation from which the silicone hydrogel is made or may be contacted with the silicone hydrogel post formation.

Owner:JOHNSON & JOHNSON VISION CARE INC

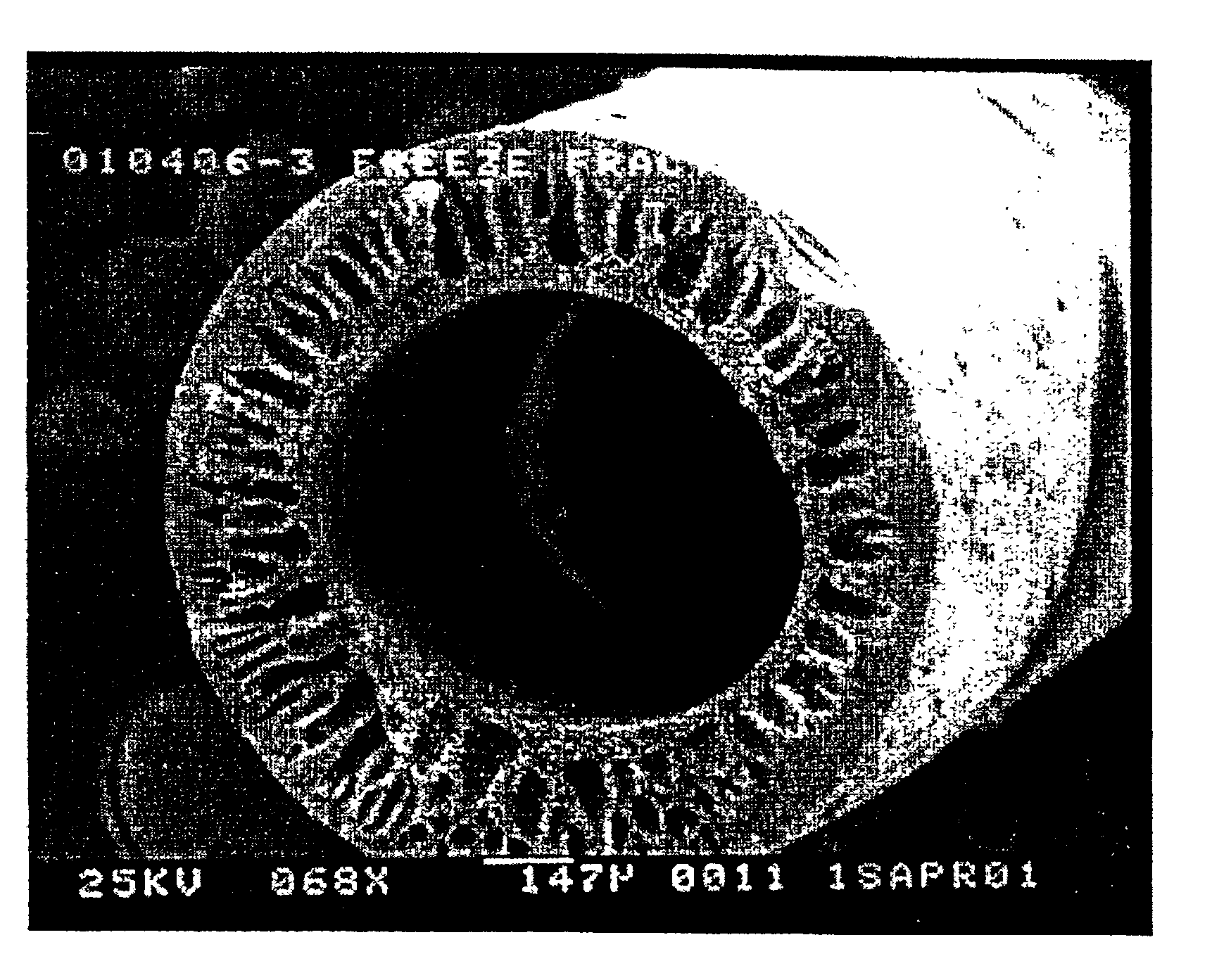

Hollow fiber microfiltration membranes and a method of making these membranes

InactiveUS6890435B2Narrow pore size distributionHigh mechanical strengthSemi-permeable membranesMembranesFiberHollow fibre membrane

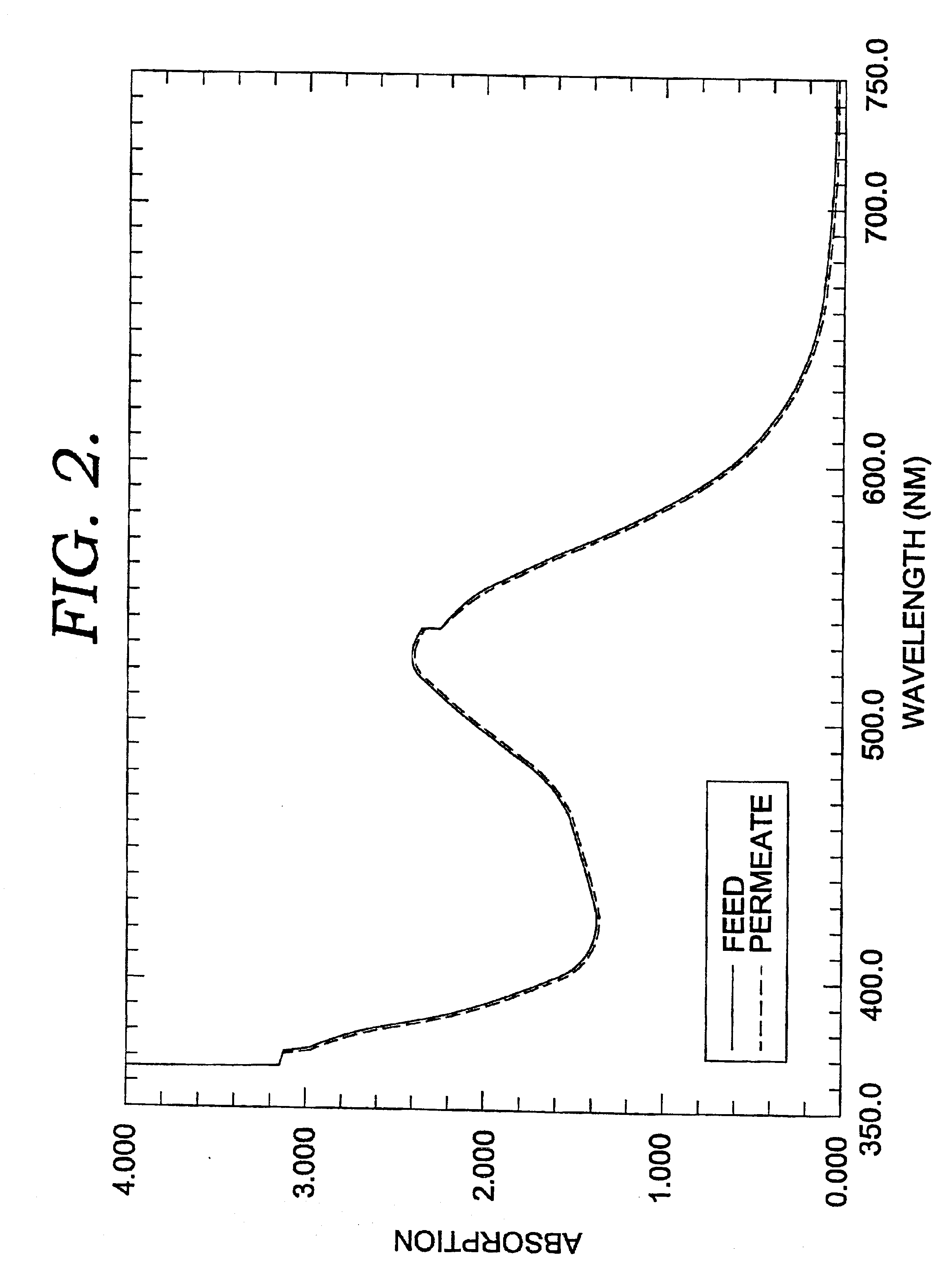

A hollow fiber microfiltration (MF) membrane is provided. The casting solution used to make this membrane includes a fiber-forming polymer having a degree of polymerization greater than about 1000, a water-soluble polymer, an anhydride with about 2 to 12 carbon atoms, and a solvent. The membrane is formed by mixing and heating these components to form a viscous dope and then extruding the dope through an annular orifice to form a hollow fiber MF membrane. The hollow fiber membrane is then fed through a coagulation bath and two leaching baths. The membrane is especially useful for filtering liquids, such as wine and juice, so as to remove bacteria, gel, and solid particles from the liquids.

Owner:KOCH MEMBRANE SYST

High aspect ratio cellulose nanofilaments and method for their production

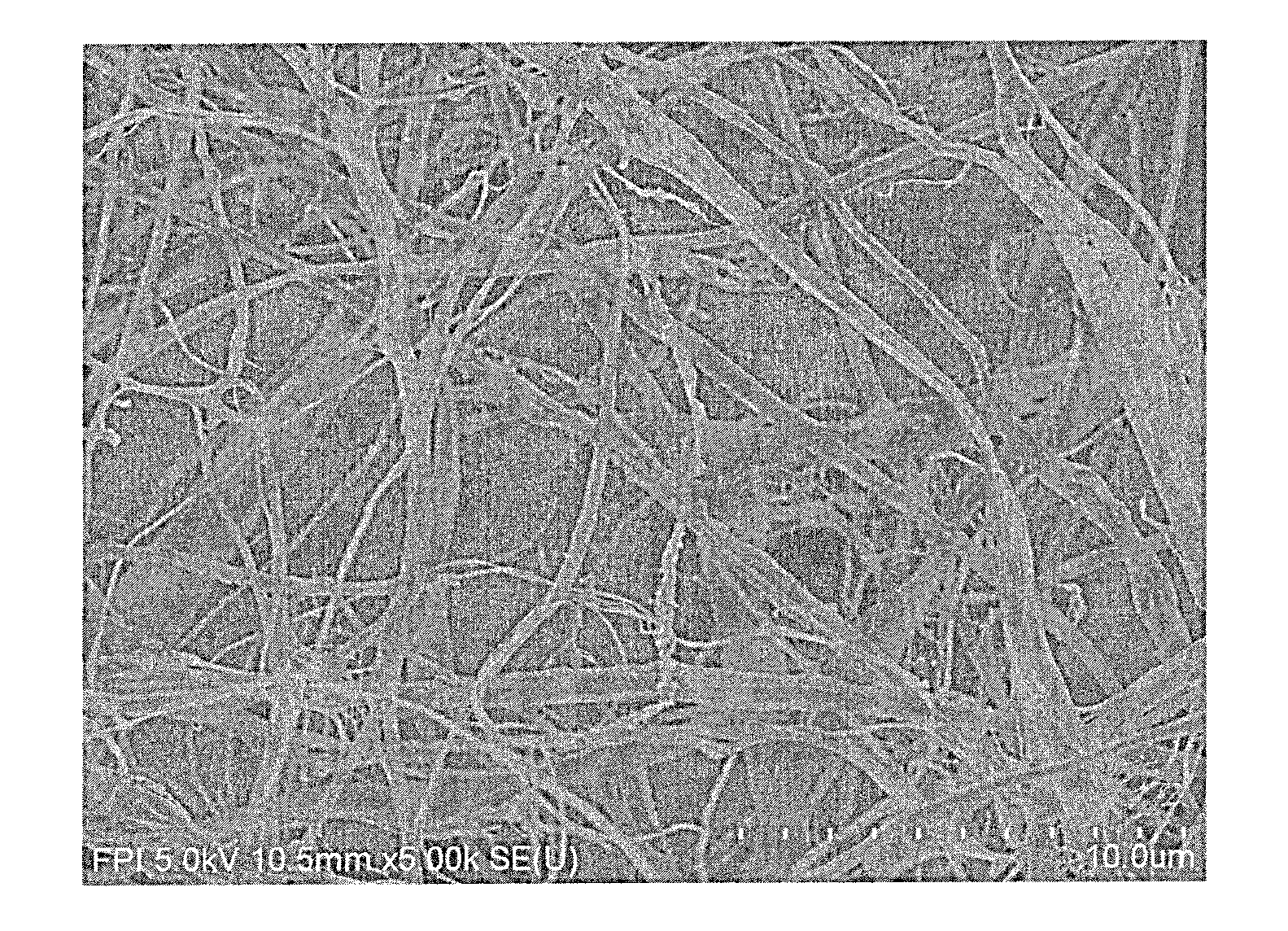

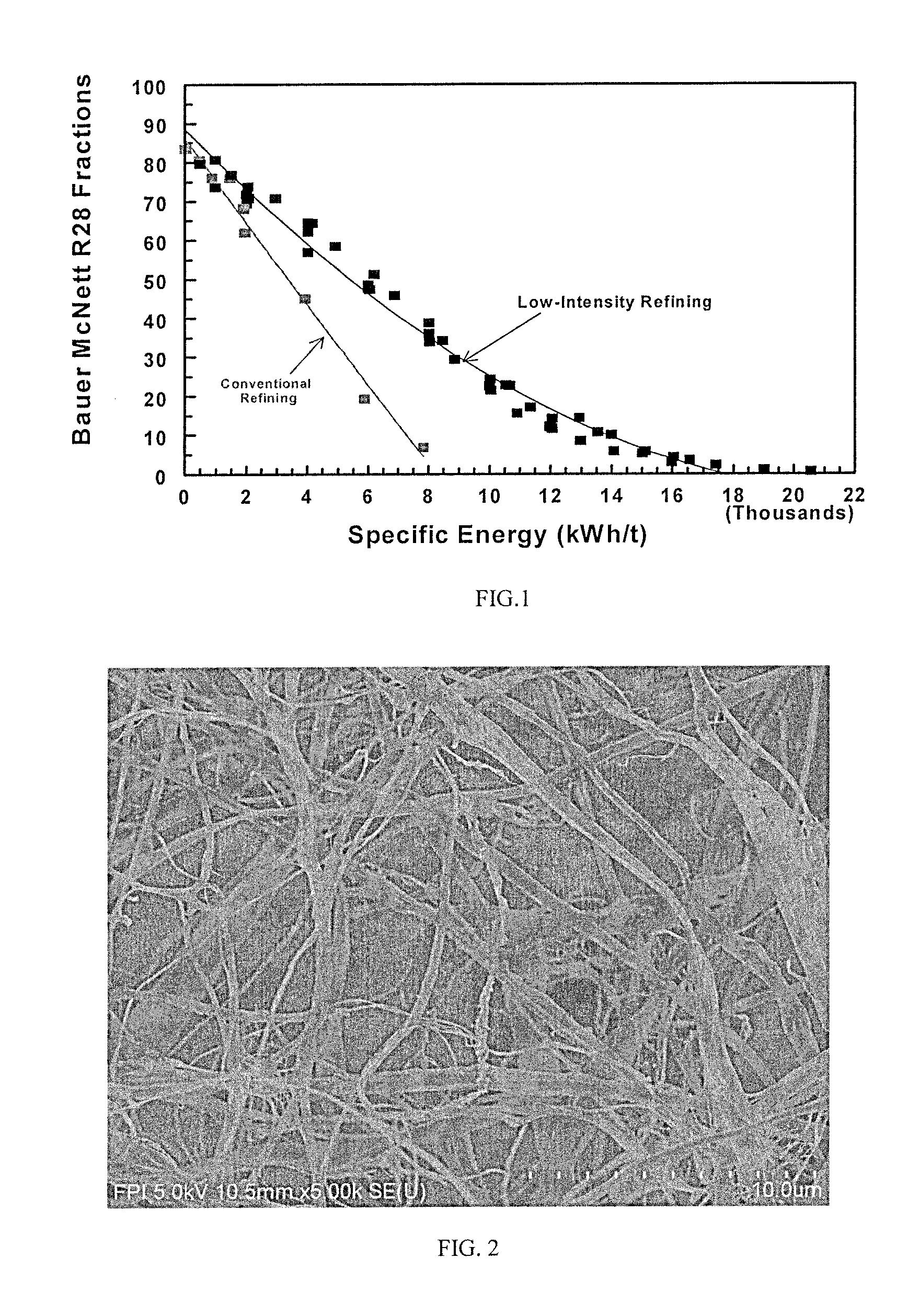

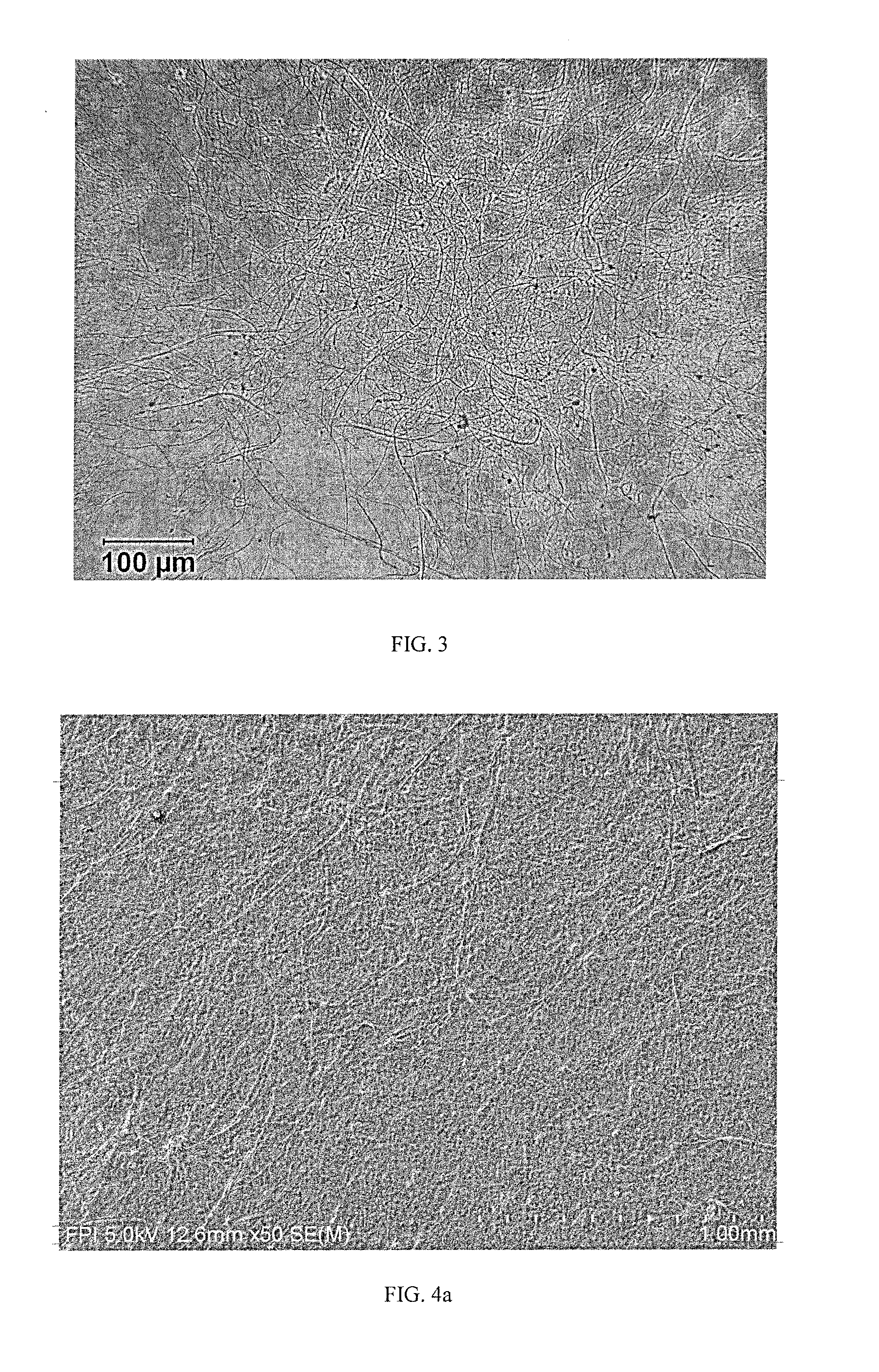

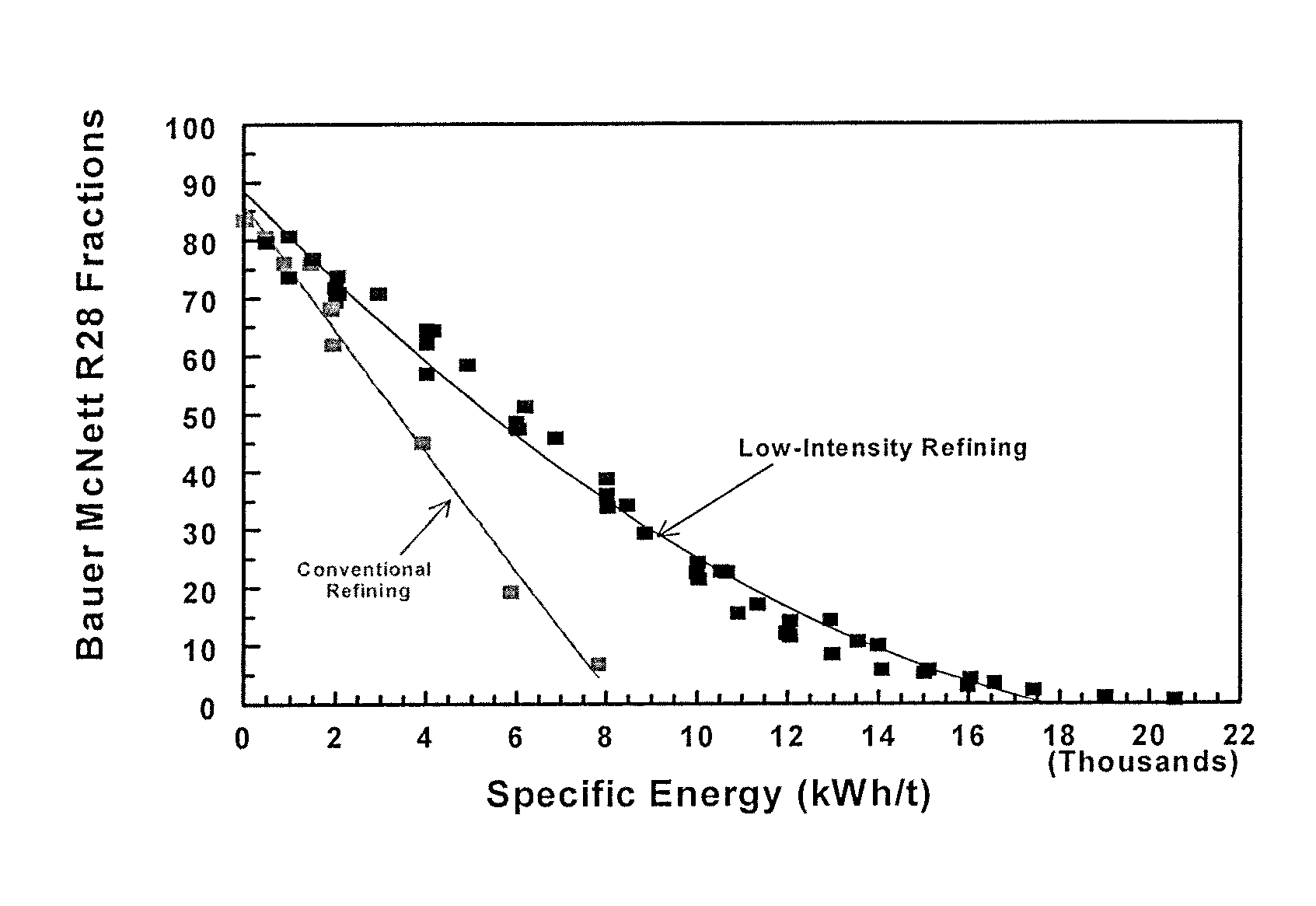

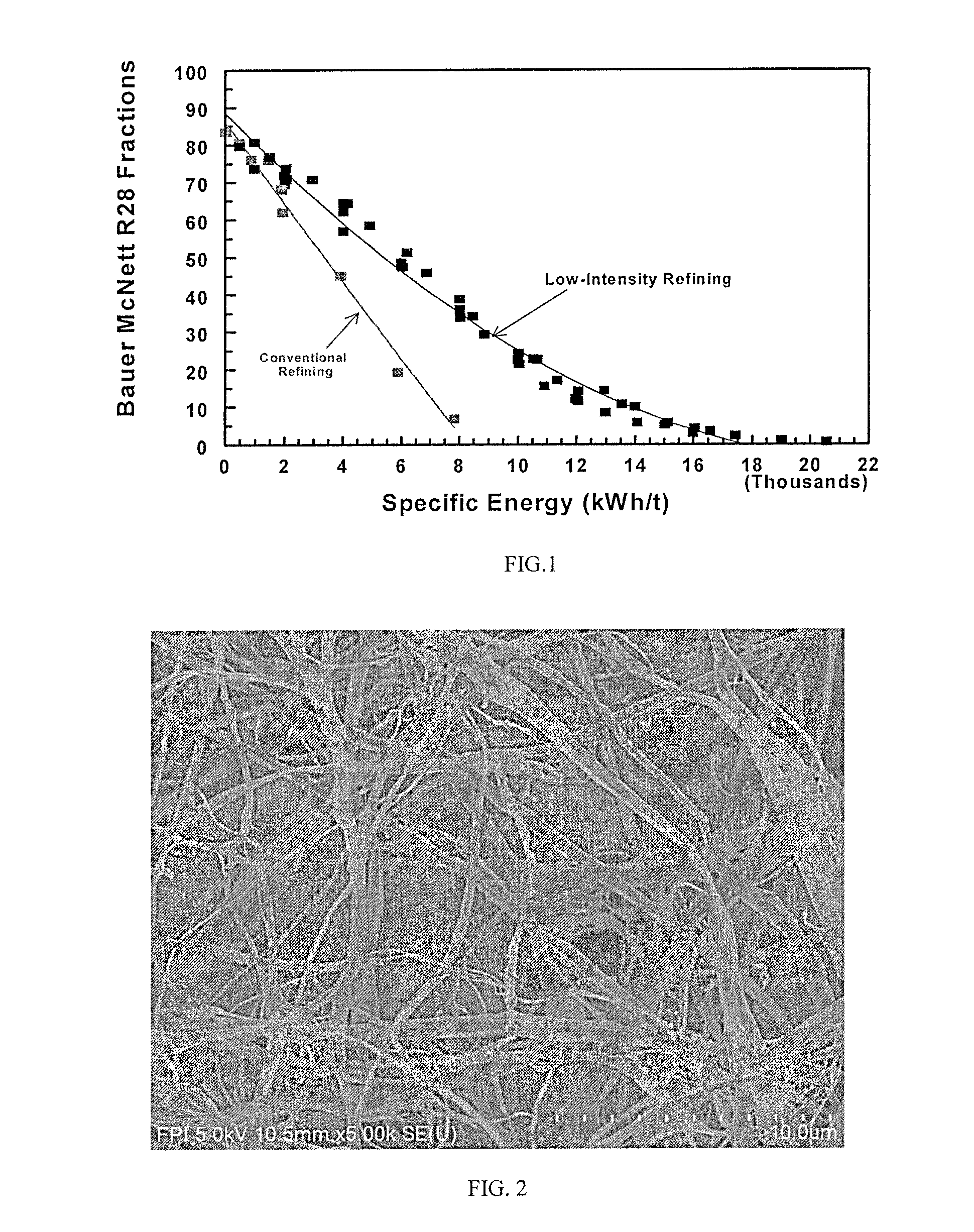

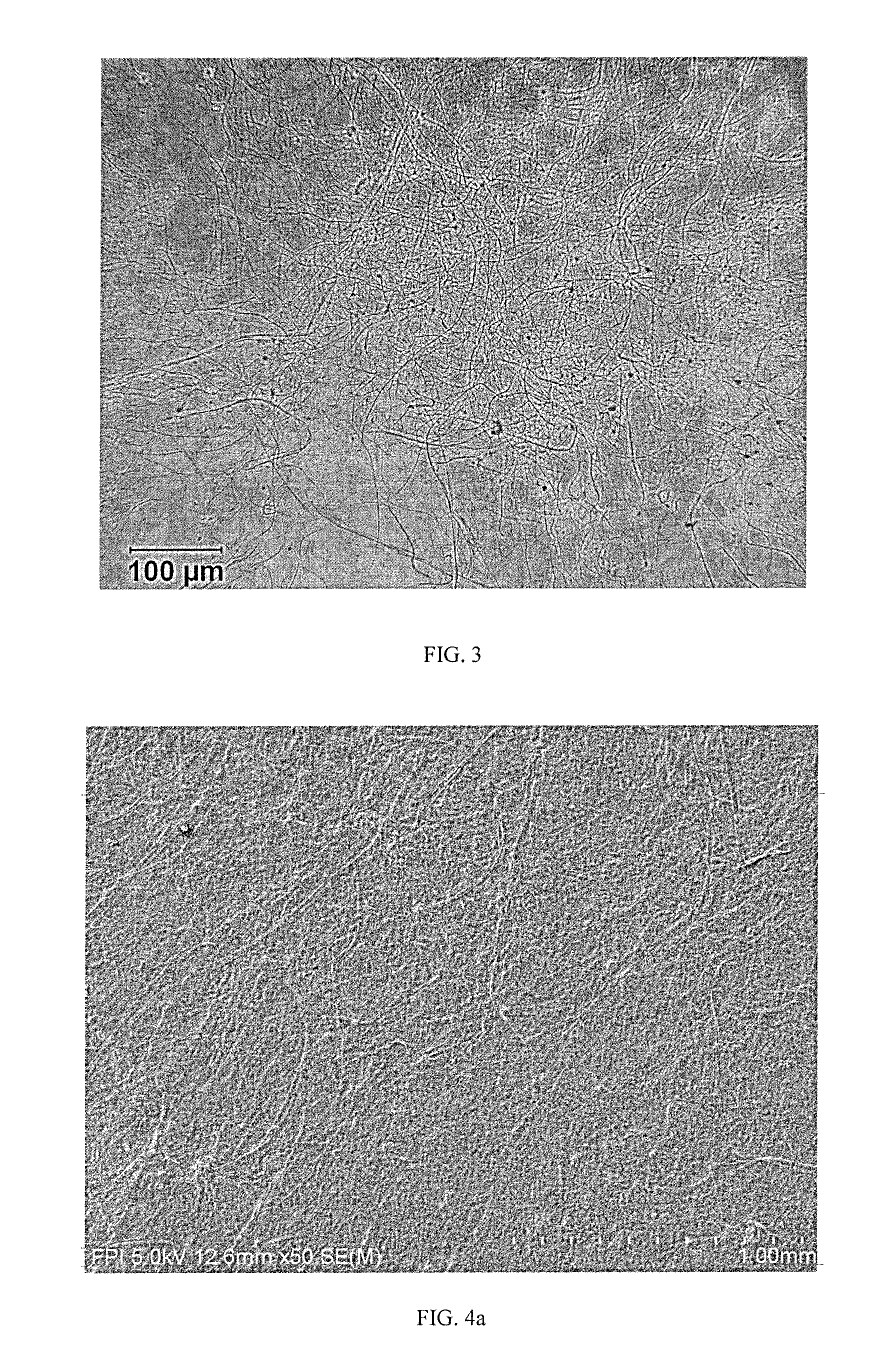

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

Organ model

ActiveUS20120045743A1Suitable for operationSuitable for useSynthetic resin layered productsPretreated surfacesSilica particleSurface layer

A material for forming an organ model containing an aqueous gel, which comprises polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole, and silica particles; a method for producing a material for forming an organ model, comprising cooling an aqueous polyvinyl alcohol solution which contains polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole and silica particles, to a temperature of −10° C. or lower, and thawing the resulting formed aqueous gel; and an organ model at least provided with a surface layer comprising the material for forming an organ model. Thus, it is possible to provide: an organ model which has a hydrophilic property similar to an organ of a human body, gives such an incision feel that an incised portion spreads just similar to a living human organ and, therefore can be appropriately used in, for example, exercising surgical procedures; a material for forming an organ model appropriately usable for the organ model; and a method for producing the same.

Owner:YUUGENGAISHA SEIWADENTAL

Prepn process of active defoaming agent composition

The present invention is one kind of active defoaming composition suitable for eliminating harmful foams under high temperature and strong alkaline condition in high efficiency, and may be used in washing paper pulp, treating metal surface and other fields. The active defoaming composition is prepared with organic siloxane, silicone resin, inorganic oxide particle, hydrophobic treating agent, catalyst and other material. The preparation process includes the following steps: 1. mixing organic siloxane, silicone resin and catalyst, and heating the mixture to 80-200 deg.c for controllable polymerization; 2. adding inorganic oxide particle and hydrophobic treating agent; and 3. further heating to reaction at 80-200 deg.c temperature and 0.01-0.08 MPa vacuum for 2-10 hr, and cooling to room temperature to obtain white polymer as the active defoaming composition.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Water-soluble film and package using the same

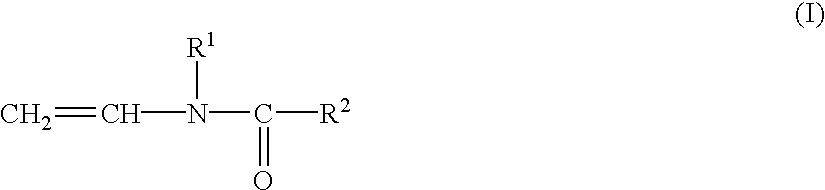

InactiveUS6956070B2Improve solubilityGood chemical resistanceOrganic detergent compounding agentsSynthetic resin layered productsVinyl AmidePolyvinyl alcohol

The present invention provides a water-soluble film which comprises a modified polyvinyl alcohol containing an N-vinylamide monomer unit in an amount of 1 to 10 mole percent, and a carboxyl group and a lactone group in a total amount of 0.020 to 4.0 mole percent in the molecule, and having a degree of polymerization of 300 to 3000, and a degree of hydrolysis of 75 to 99.5 mole percent. Further, the present invention provides a package obtained by packaging an acidic substance, a chlorine-containing compound, or the like using the water-soluble film.

Owner:KURARAY CO LTD

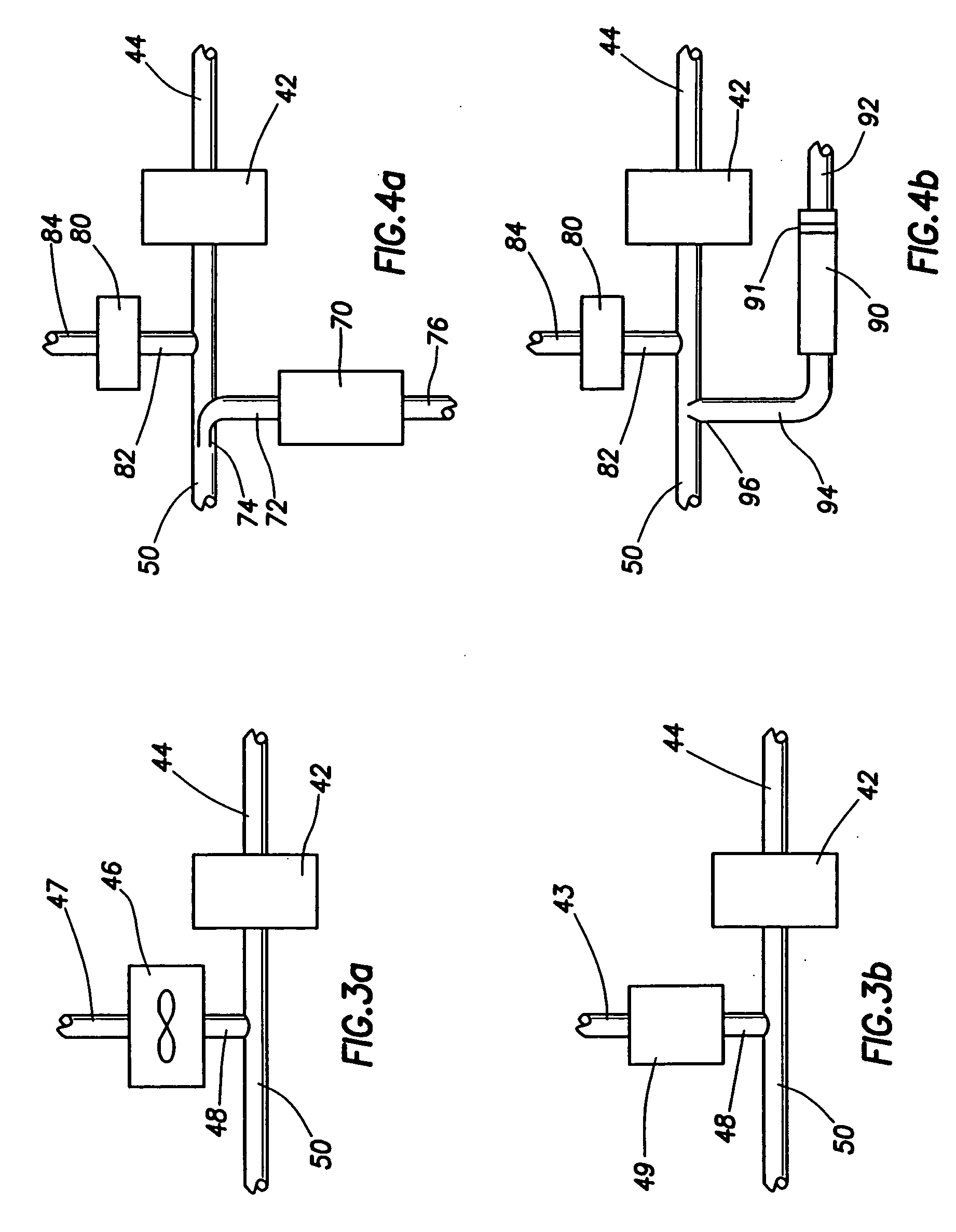

Method and materials for hydraulic fracturing of wells

InactiveUS20050272613A1High viscosityPreventing overflushing of proppantFluid removalFlushingFracturing fluidHydraulic fracturing

Hydraulic fracturing of wells by injecting a degradable polymer phase as a fracturing fluid is provided. Composition and degree of polymerization of the degradable polymer and the selection of additives may be varied to adjust the viscosity, degradation time and other properties of the fracturing fluid. Viscous degradable fluid or pellets of degradable polymer may be placed in a wellbore as an internal phase in a low viscosity carrier fluid. A polymer-continuous liquid phase may be formed at a selected location in the wellbore, usually near perforations, before the polymer phase is pressured into a formation to form a hydraulic fracture.

Owner:ENERPOL LLC

Method for producing polyether polyol

The object of the present invention is to provide a method for producing a polyether polyol which is little colored and has a high degree of polymerization in high yield by a dehydration-condensation of a polyol. In the present invention, a dehydration-condensation reaction is carried out in the presence of a catalyst composed of an acid and a base.

Owner:MITSUBISHI CHEM CORP

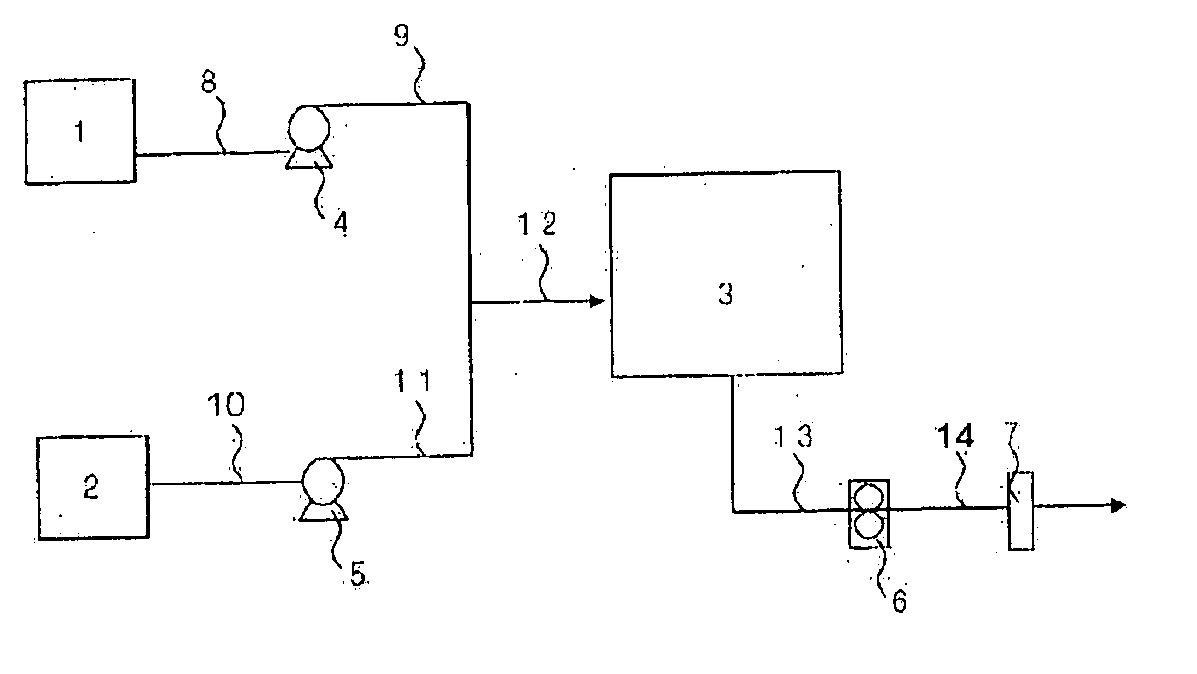

Method for Preparing Adhesive Acrylic Ester Polymer Syrup

InactiveUS20070299226A1Improve performanceThe polymerization process is stableEster polymer adhesivesContinuous reactorProduction rate

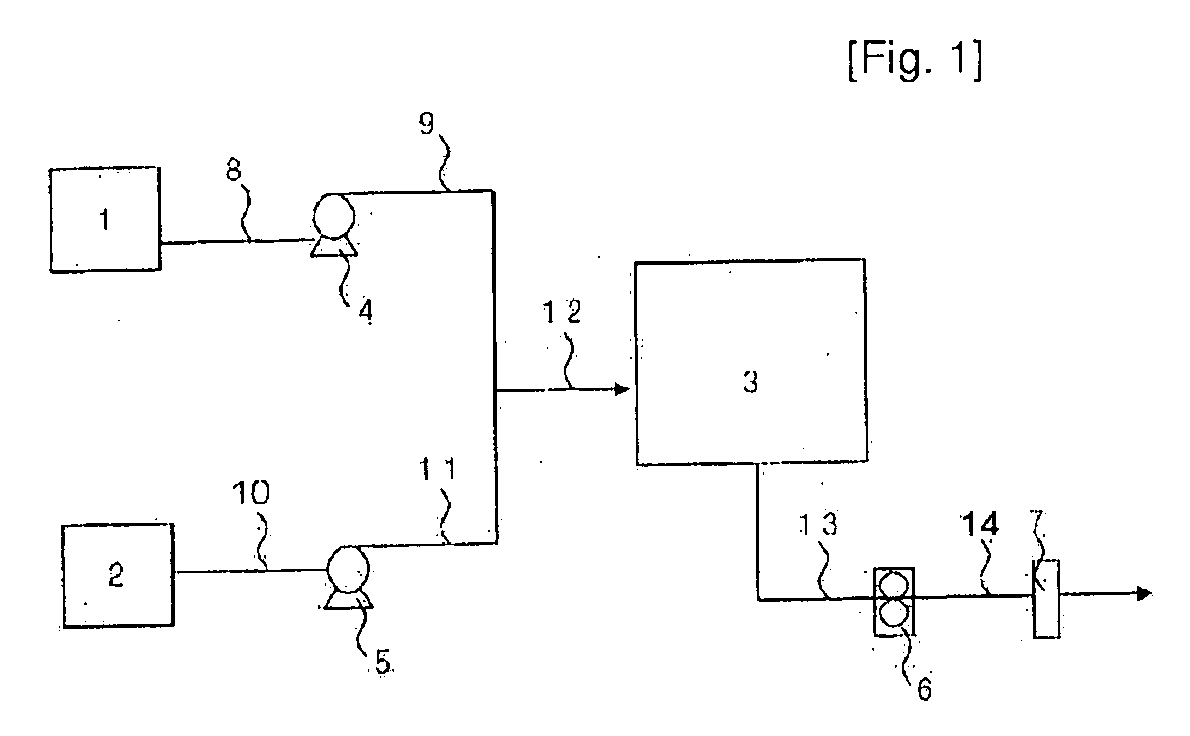

The present invention relates to a method for preparing an acrylic ester polymer syrup by bulk polymerization, and more particularly, to a method for preparing an acrylic ester polymer syrup, which comprises the steps of: supplying a monomer solution and an initiator solution to a monomer solution reservoir and an initiator solution reservoir, respectively; supplying the monomer solution and the initiator solution to a complete-mixing type continuous reactor, while maintaining the dissolved oxygen in the monomer solution reservoir and the initiator solution reservoir at 0.0001 to 3 ppm, separately or after mixing prior to the supply; and performing bulk polymerization continuously while maintaining the solution mixture supplied to the continuous reactor at 70 to 150 ° C. and 1 to 10 atm, with a mean residence time of 30 to 240 minutes. In accordance with the present invention, an acrylic ester polymer syrup can be obtained with a degree of polymerization of 20 to 70% at a low polymerization temperature, even with a small amount of initiator. Productivity can be improved by reducing reaction time with the use of an initiator having a short half-life and polymerization can be performed very stably and continuously without gelation.

Owner:LG CHEM LTD

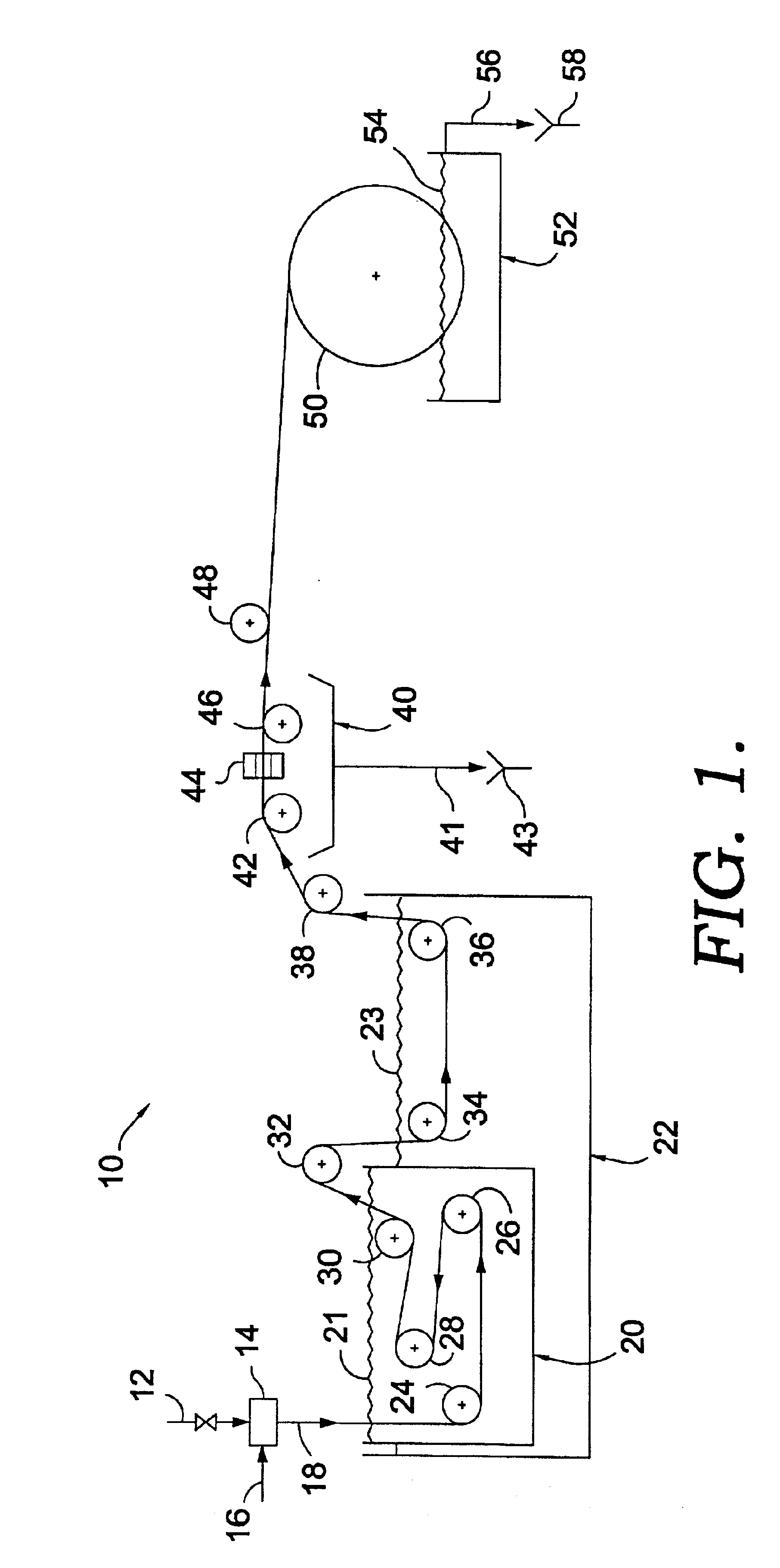

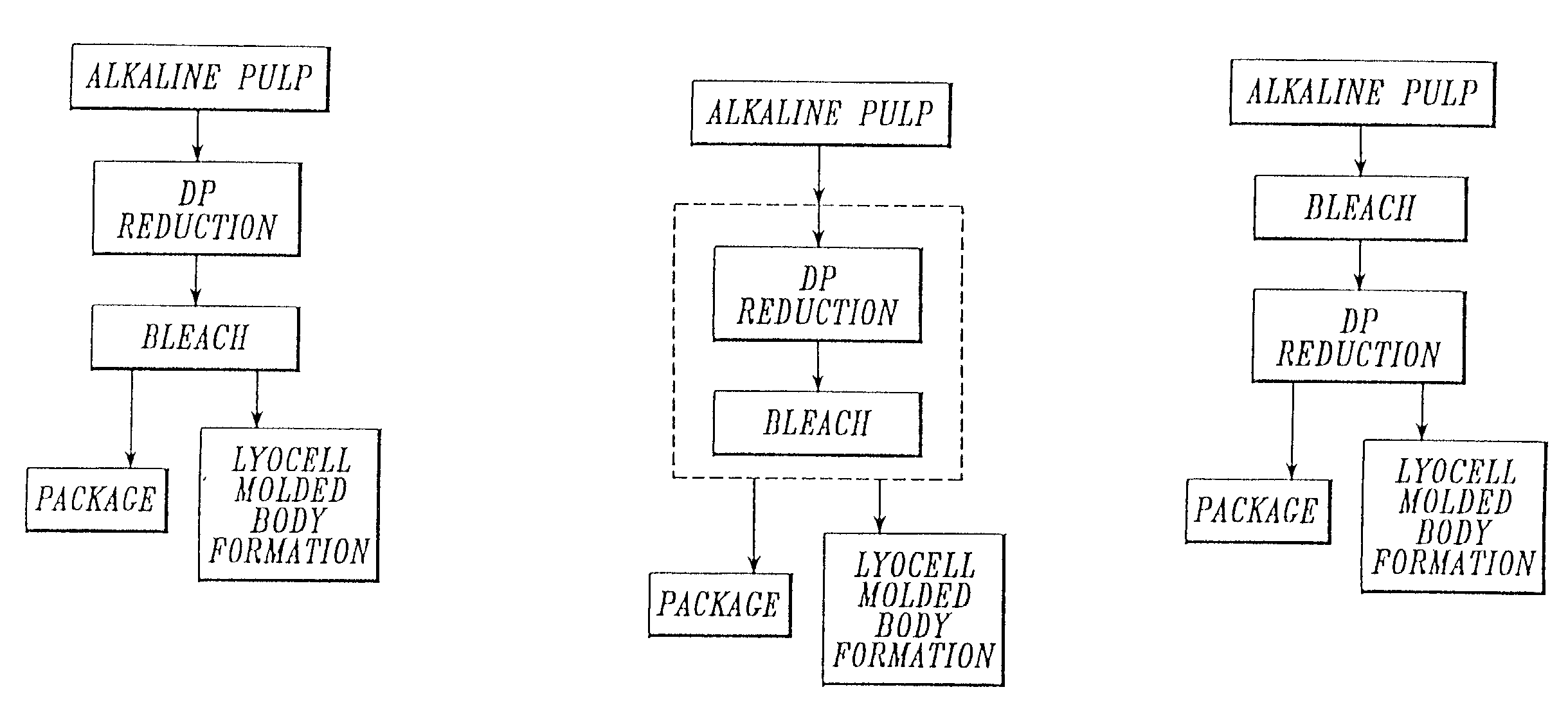

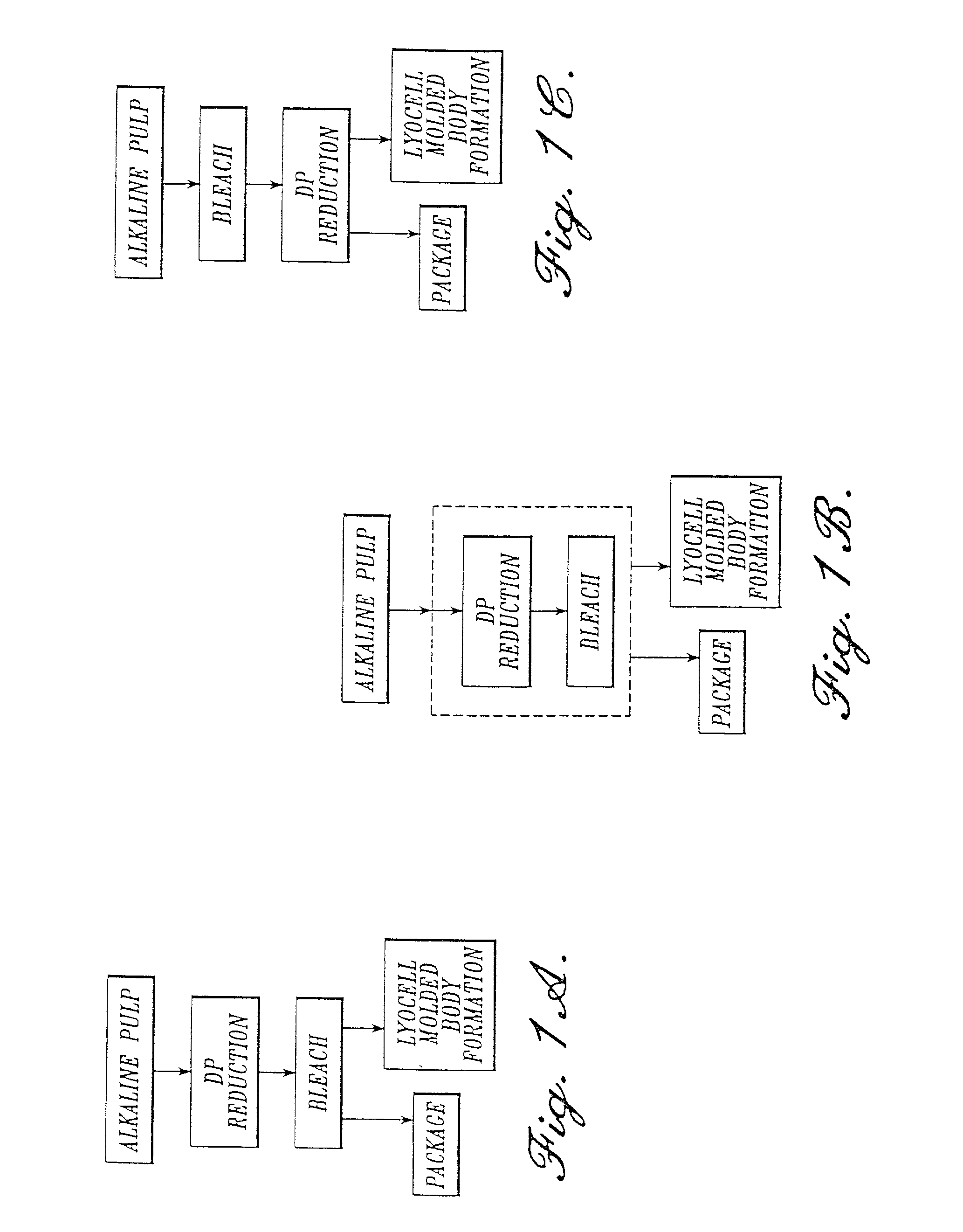

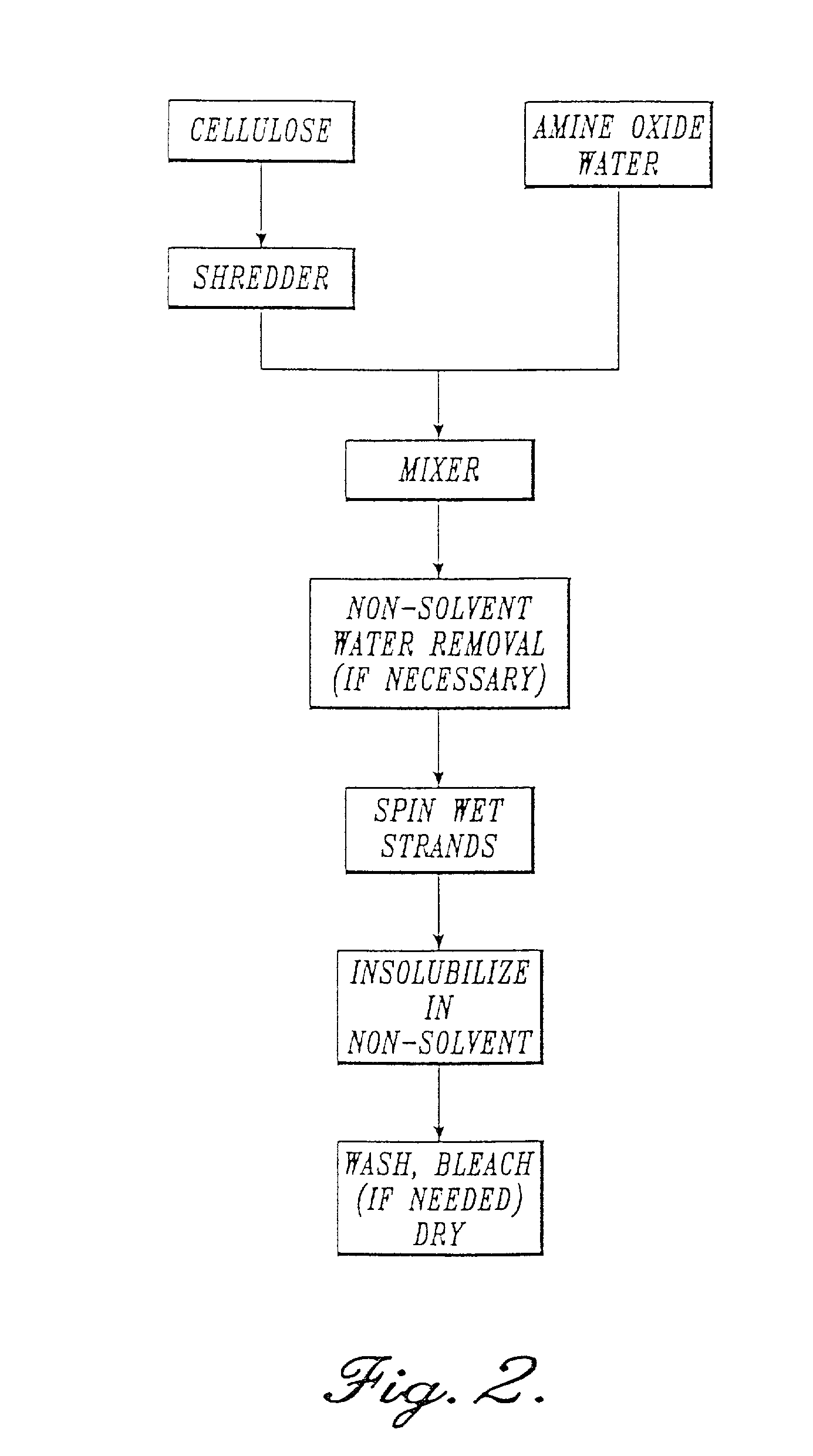

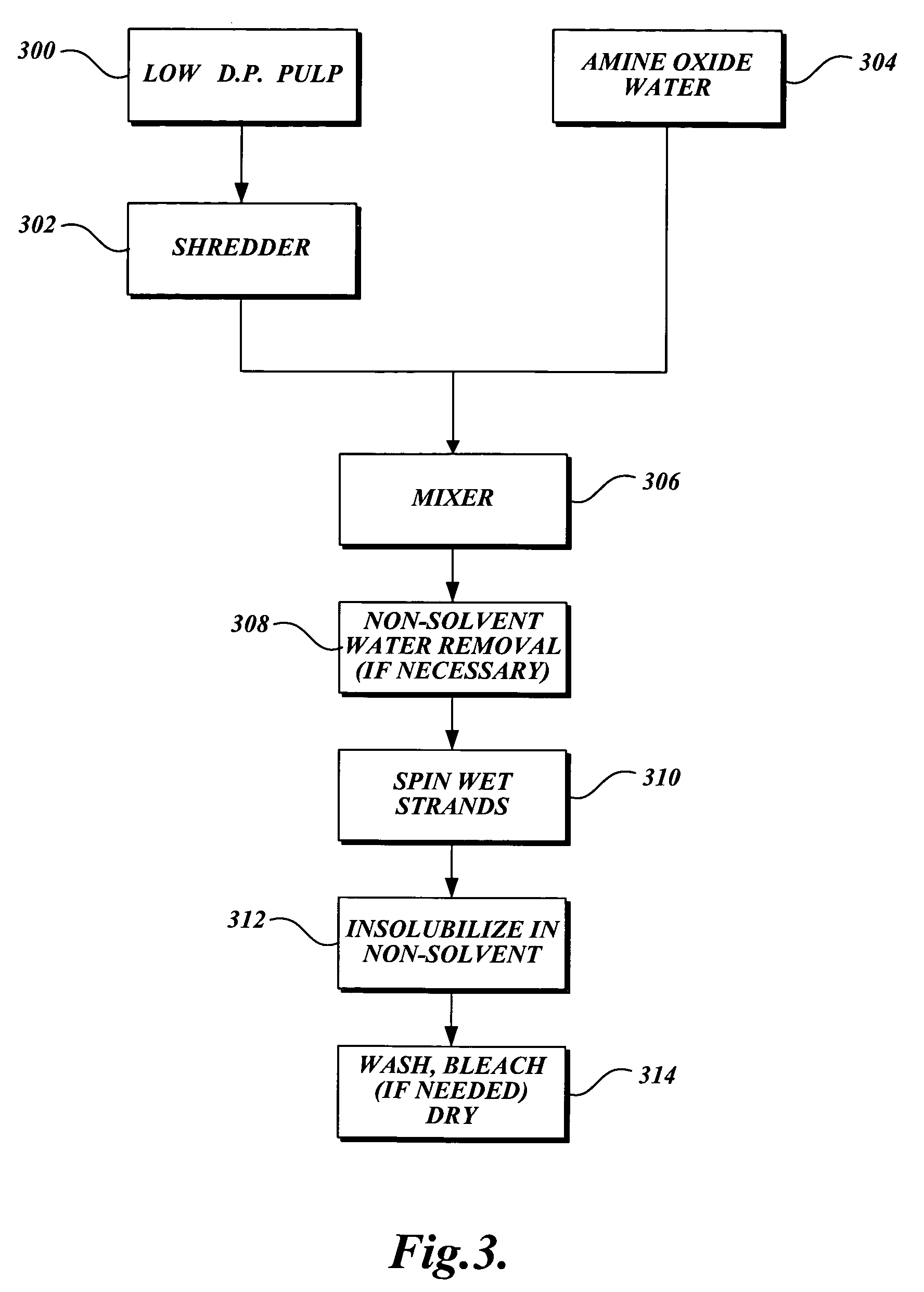

Process for making lyocell fiber from sawdust pulp

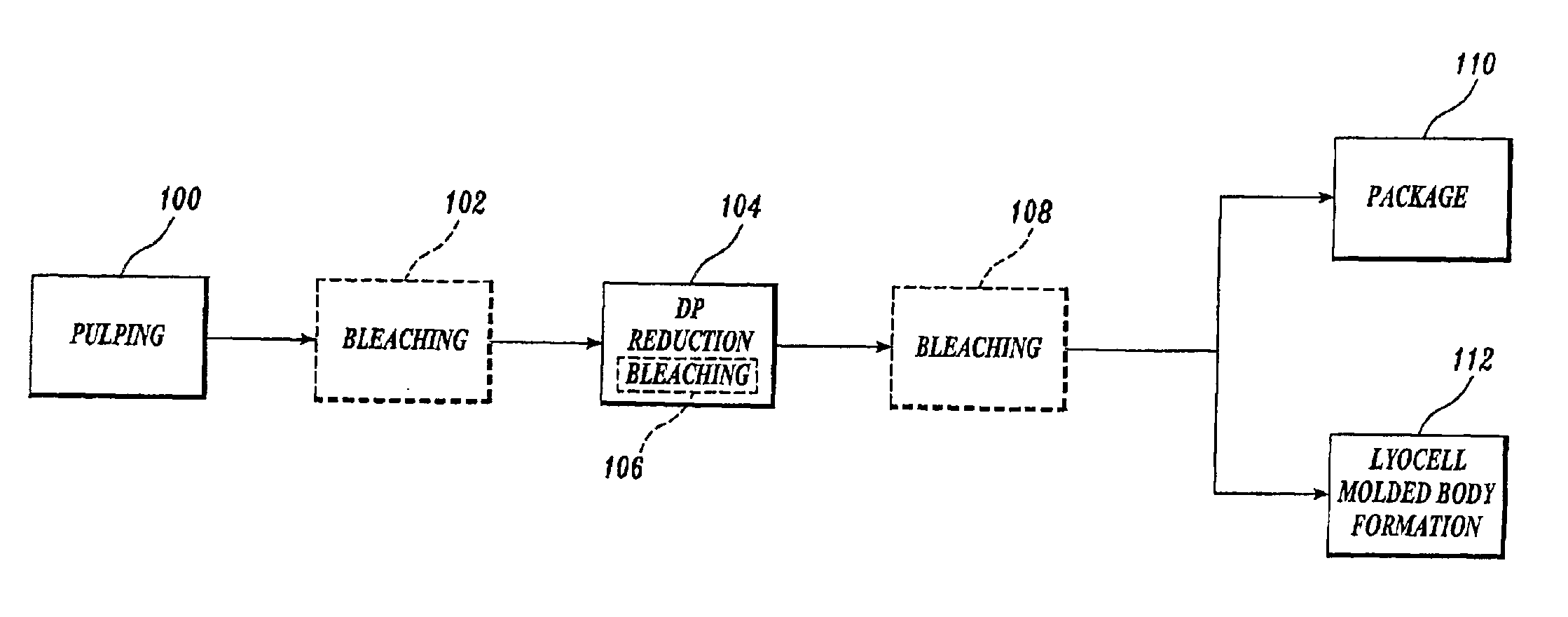

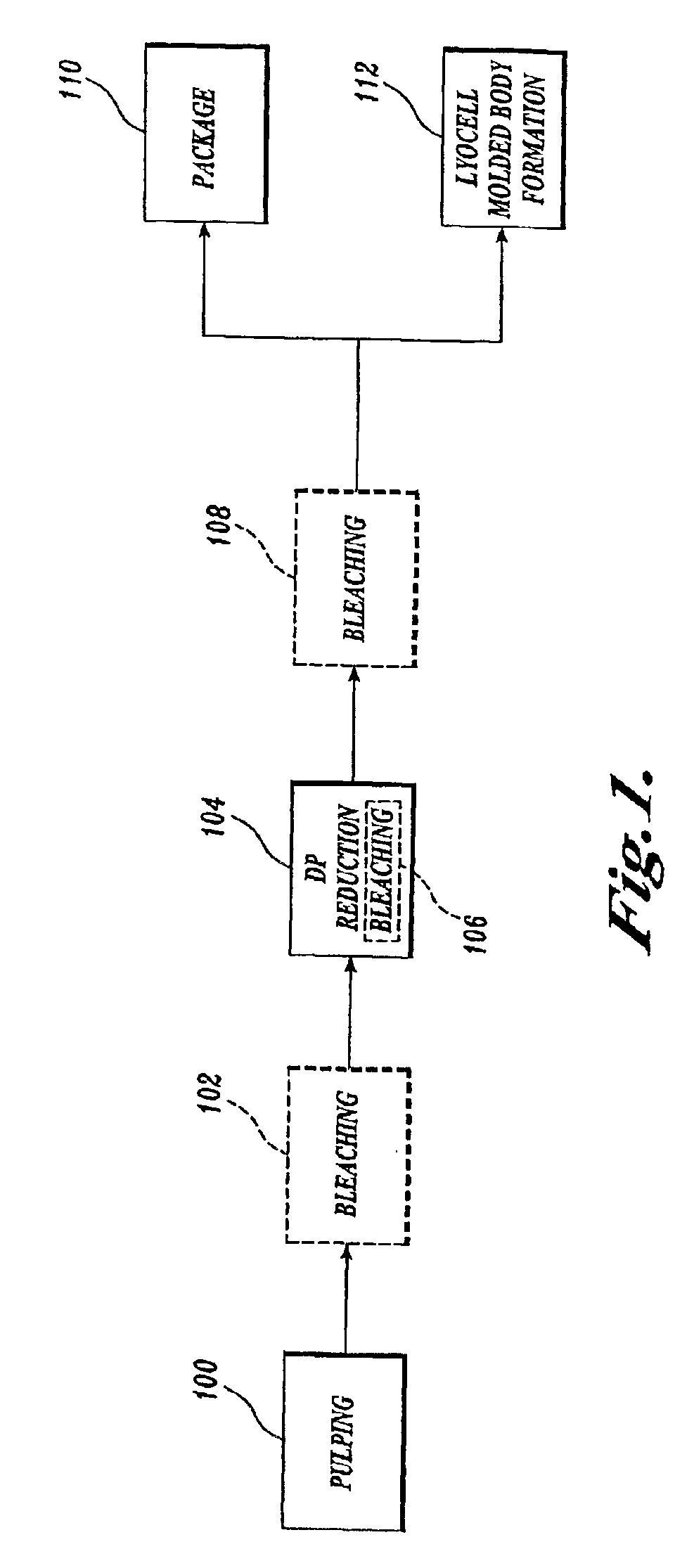

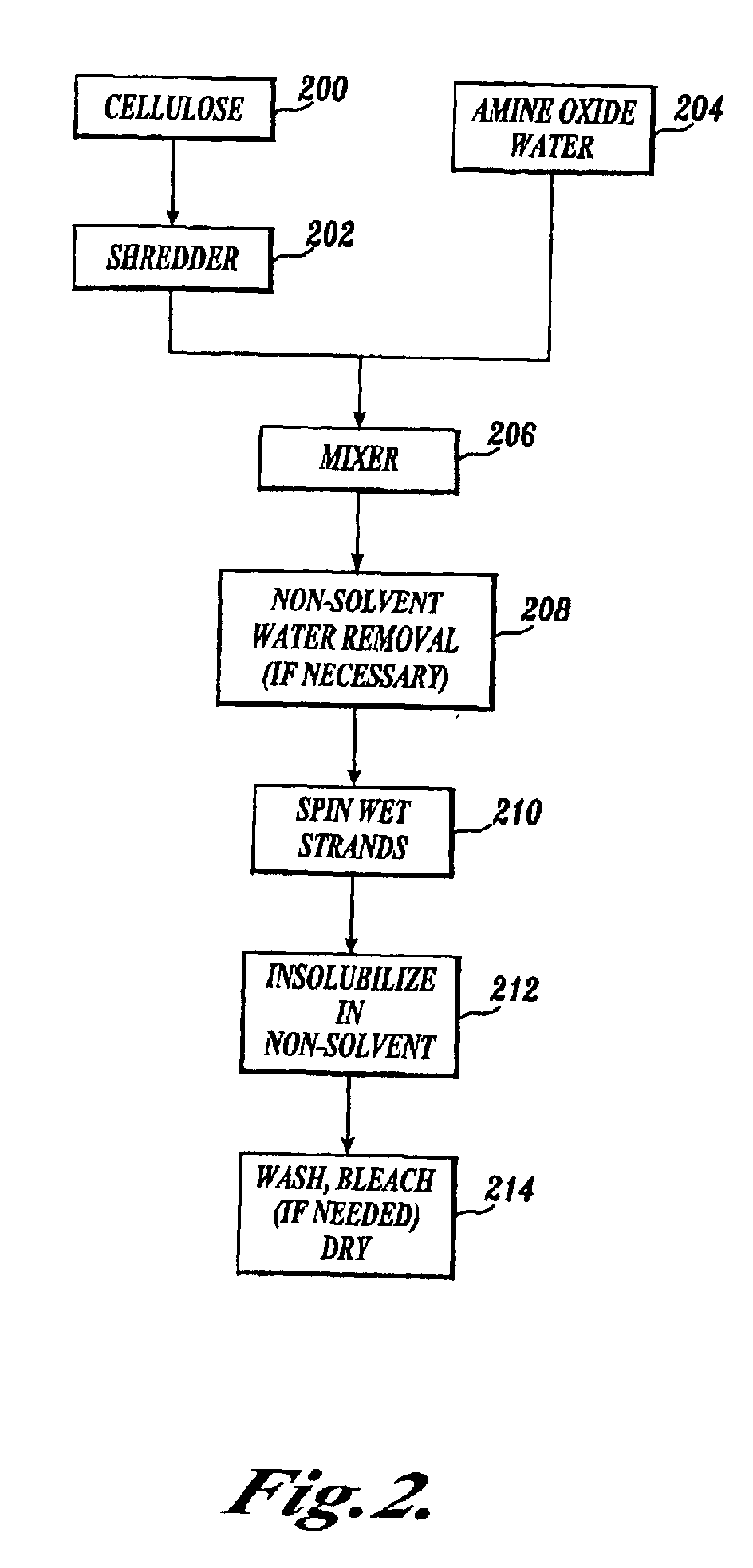

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

Process for making a composition for conversion to lyocell fiber from an alkaline pulp having low average degree of polymerization values

InactiveUS7083704B2Reducing hemicellulose contentIncreasing copper numberPulp properties modificationMonocomponent cellulose artificial filamentHemicelluloseLyocell

The present invention provides compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization (D.P.) and a narrow molecular weight distribution. Further, the present invention provides processes for making compositions, useful for making lyocell fibers, by contacting an alkaline pulp having a high hemicellulose content of at least about 7% with an oxidant sufficient to reduce the average degree of polymerization to about 200 to 1100 without substantially reducing the hemicellulose content or increasing the copper number of the pulp.

Owner:INT PAPER CO

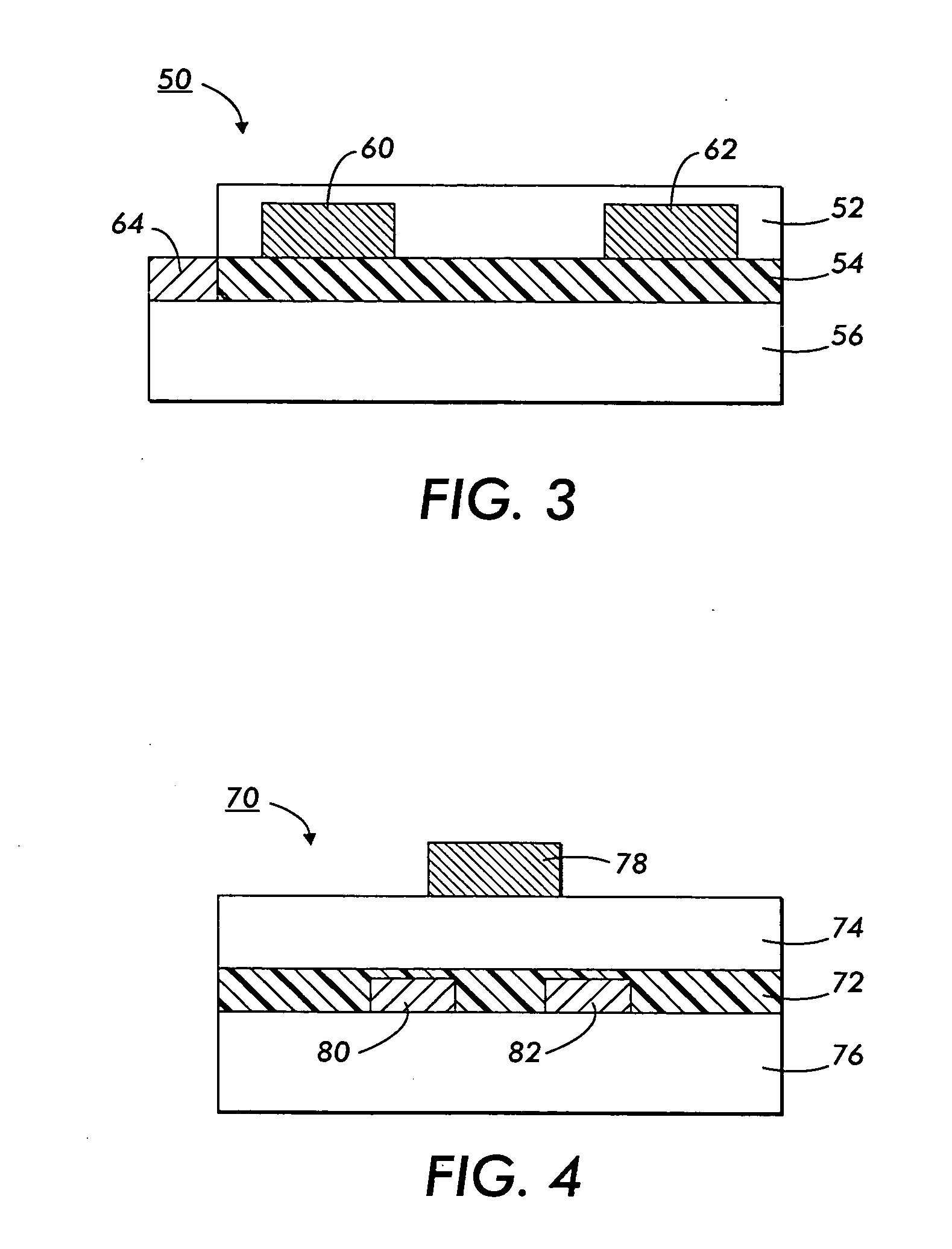

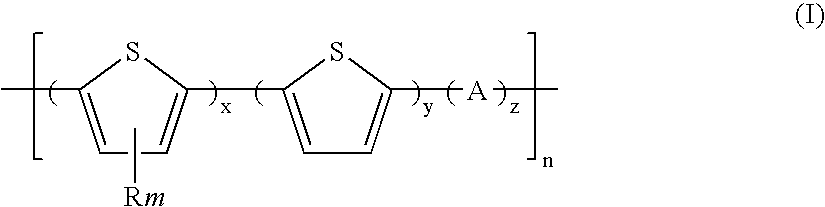

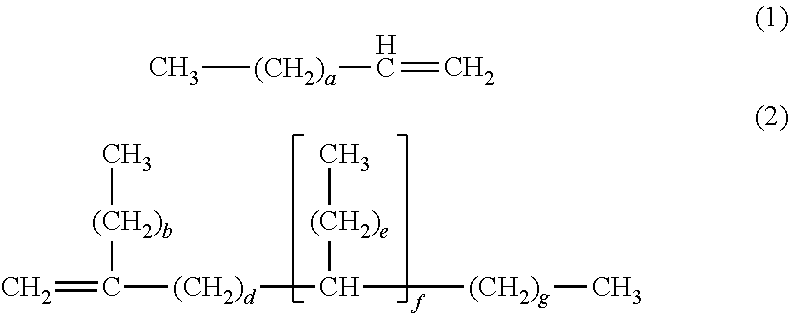

Polythiophenes and electronic devices generated therefrom

InactiveUS20050017311A1Improve stabilityImprove molecular structureTransistorSolid-state devicesPolymer scienceSide chain

An electronic device containing a polythiophene wherein R represents a side chain, m represents the number of R substituents; A is a divalent linkage; x, y and z represent, respectively, the number of Rm substituted thienylenes, unsubstituted thienylenes, and divalent linkages A, respectively, in the monomer segment subject to z being 0 or 1, and n represents the number of repeating monomer segments in the polymer or the degree of polymerization.

Owner:XEROX CORP

Biodegradable medical adhesive, and preparation method and purpose thereof

ActiveCN103083718AIncrease the degree of cross-linkingHigh hardnessSurgical adhesivesNitrile polymer adhesivesBackbone chainCross linker

The invention relates to a novel medical adhesive which can be subjected to crosslinking copolymerization and which has good biodegradability. A polymer substrate of the adhesive comprises both single alpha-cyanoacrylate and double alpha-diol cyanoacrylate monomer molecules. Olefinic bonds in single alpha-cyanoacrylate structure can be subjected to polymerization under a trace-amount anionic condition. The double alpha-diol cyanoacrylate in the polymer substrate can serve as a crosslinking agent, such that crosslinking copolymerization of the system can be carried out. Chain growth occurs with a three-dimensional multi-point polymerization manner. A gelling speed is fast, and linear polymerization degree of double-bond polymerization is low. A meshed main chain of the solid 3D-body high polymer obtained by polymerization has degradation sites. Degradation product path is clear, and the degradation product can be absorbed. The medical adhesive can be used in wound bonding, bleeding stopping at massive trauma, visceral and soft tissue wound closure, and the like. In addition, the medical adhesive has a potential purpose to be developed into a tissue engineering material.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A +1

Leaf fertilizer composition comprising sodium alginate oligosaccharide and application of leaf fertilizer composition

ActiveCN103011968AWide variety of sourcesLow priceOrganic fertilisersLiquid fertilisersManganeseUronic acid

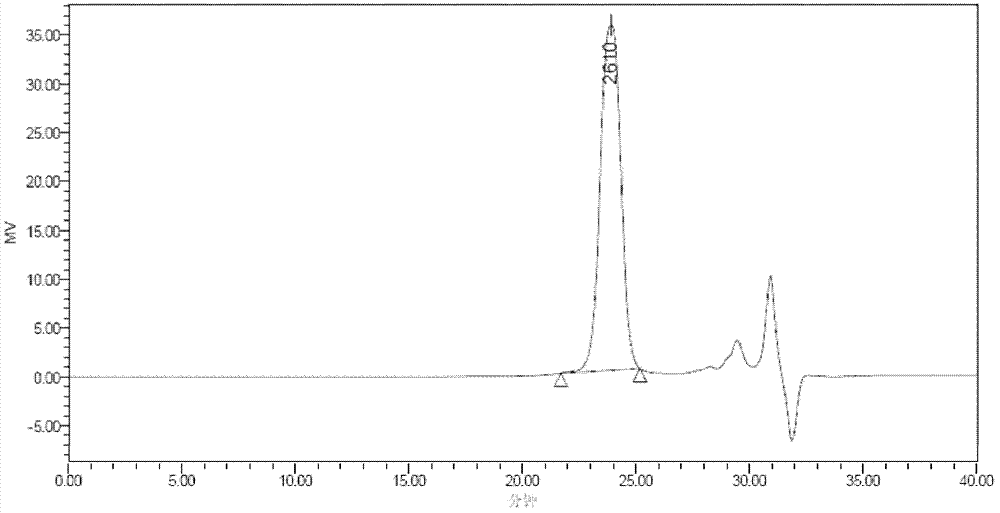

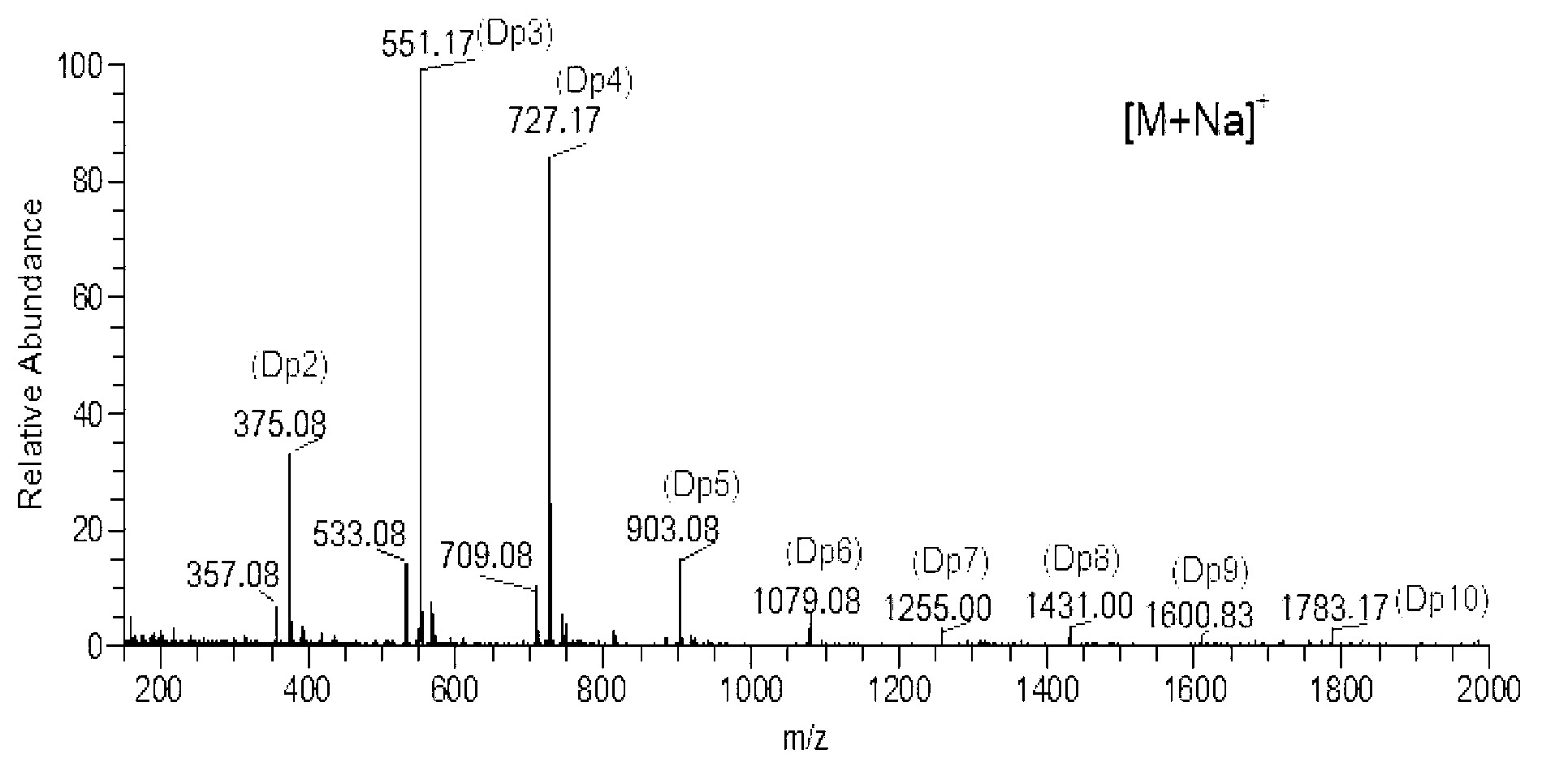

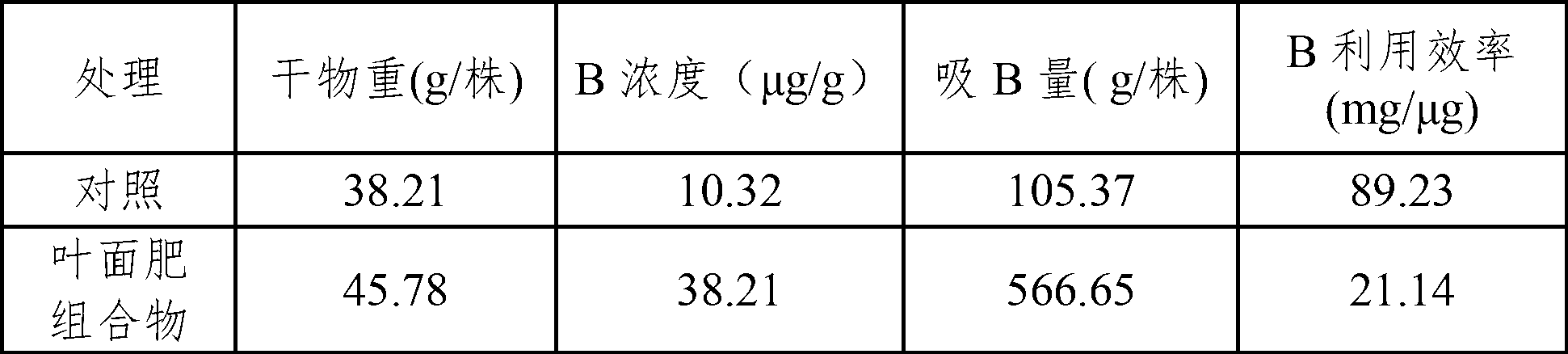

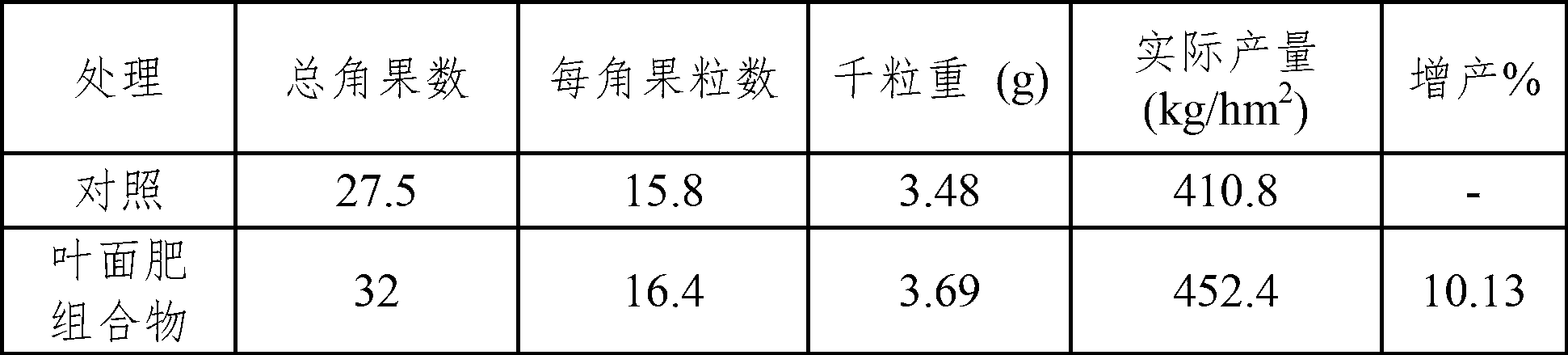

The invention discloses a leaf fertilizer composition comprising sodium alginate oligosaccharide, which is characterized in that the composition comprises sodium alginate oligosaccharide, amino acid and microelements that can promote plant growth significantly, wherein sodium alginate oligosaccharide is also known as sodium alginate, sea-tangle glue and algin, is natural polysaccharide carbohydrate extracted from sea tangle, and is a copolymer comprising a-L-mannuronic acid (M), b-D-guluronic acid (G) connected with a-L-mannuronic acid (M) by 1,4-glycosidic bond, and different GGGMMM fragments; a molecular formula is (C6H7O6Na)n; the degree of polymerization is 2-10; the uronic acid constitution M / G is equal to 7:3; the uronic acid content is greater than 90%, and is 2-3% of the total content; the content of a microelement leaf fertilizer is 2-20%; and the microelement leaf fertilizer comprises at least two of sulfur, boron, ferrum, manganese, copper, zinc and molybdenum. The composition is mainly applicable to industrial crops, fruit and vegetable crops, grain crops, economic trees, flowers, lawns and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-strength film laminates having layers of plasticizer-containing polyvinyl (N)acetal and plasticizer-containing polyvinyl (ISO)acetal

ActiveUS8597792B2Improve mechanical propertiesGood compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerization of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

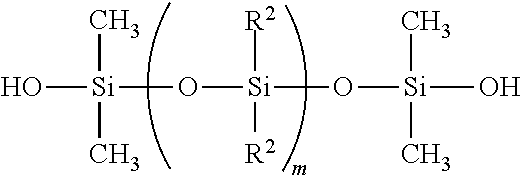

Release modifier and release coating organopolysiloxane composition

ActiveUS8933177B2Heavy release propertyLow viscosityLayered productsSkin careAlkoxy groupSilicone coating

To provide a release modifier which provides a heavy release force to a cured release layer of silicone coating composition. The release modifier comprises an organopolysiloxane resin-organopolysiloxane condensation reaction product that is obtained by the condensation reaction of (a1) 100 weight parts of MQ-type organopolysiloxane resin in which the molar ratio of the M unit to the Q unit is 0.6 to 1.0 and the content of the hydroxyl group or alkoxy group is 0.3 to 2.0 weight % with (a2) 20 to 150 weight parts of chain-form diorganopolysiloxane that has an average degree of polymerization of 100 to 1000 and at least one hydroxyl group or alkoxy group; this organopolysiloxane resin-organopolysiloxane condensation reaction product preferably has a prescribed hydroxyl group content.

Owner:DOW TORAY CO LTD

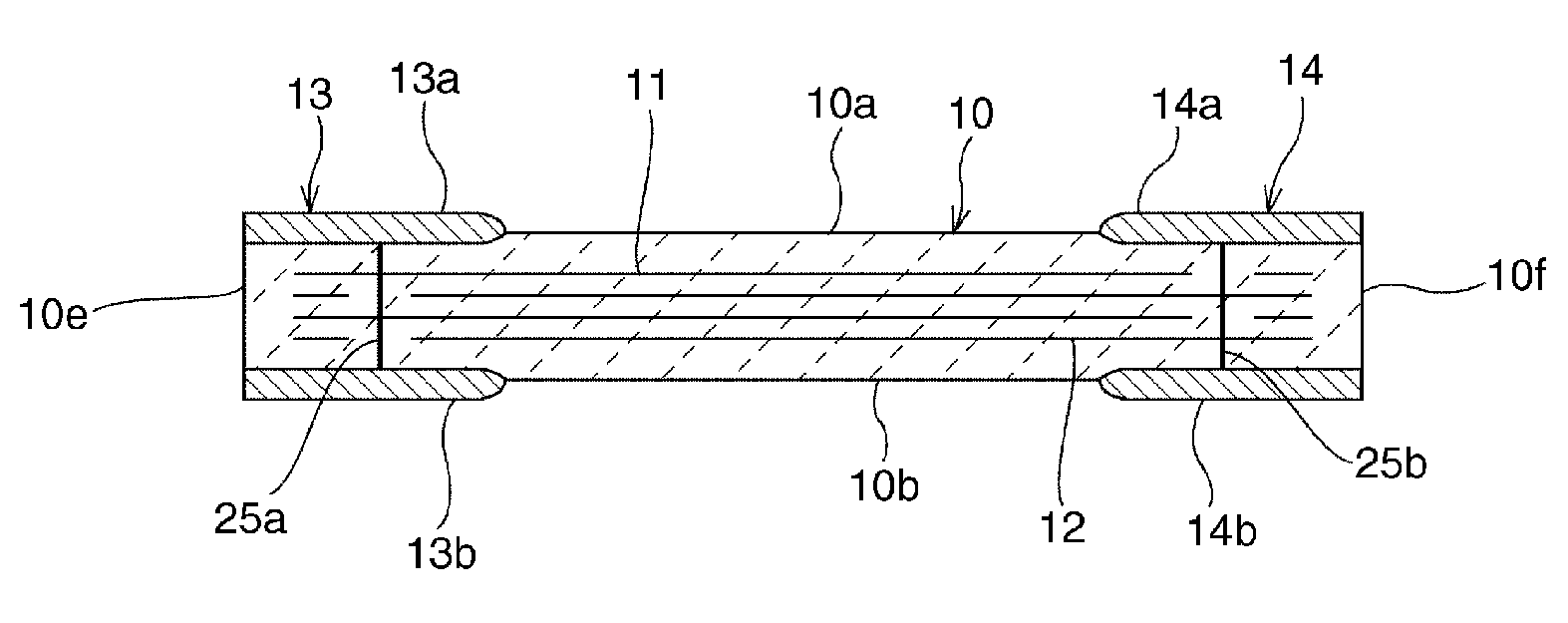

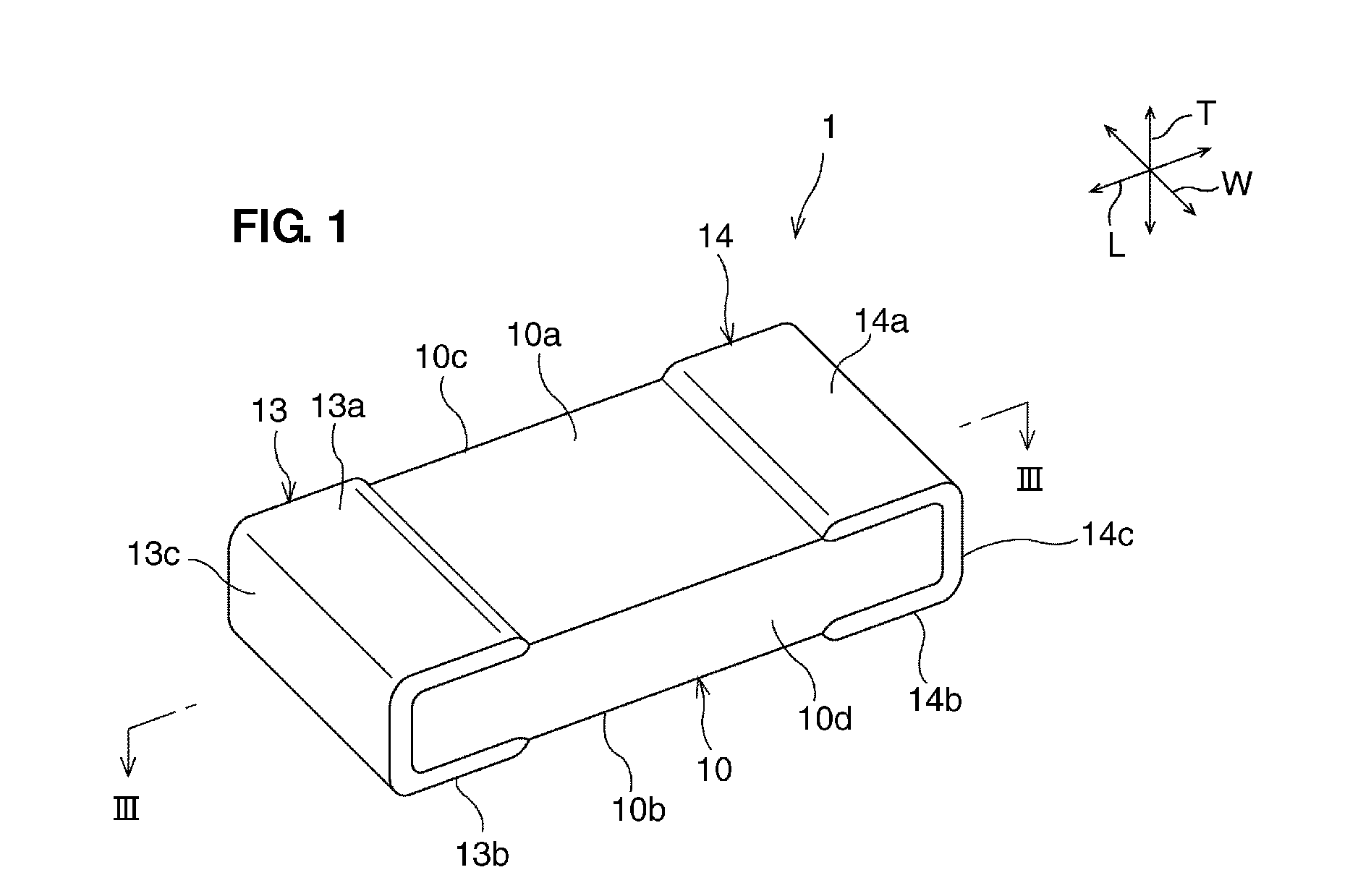

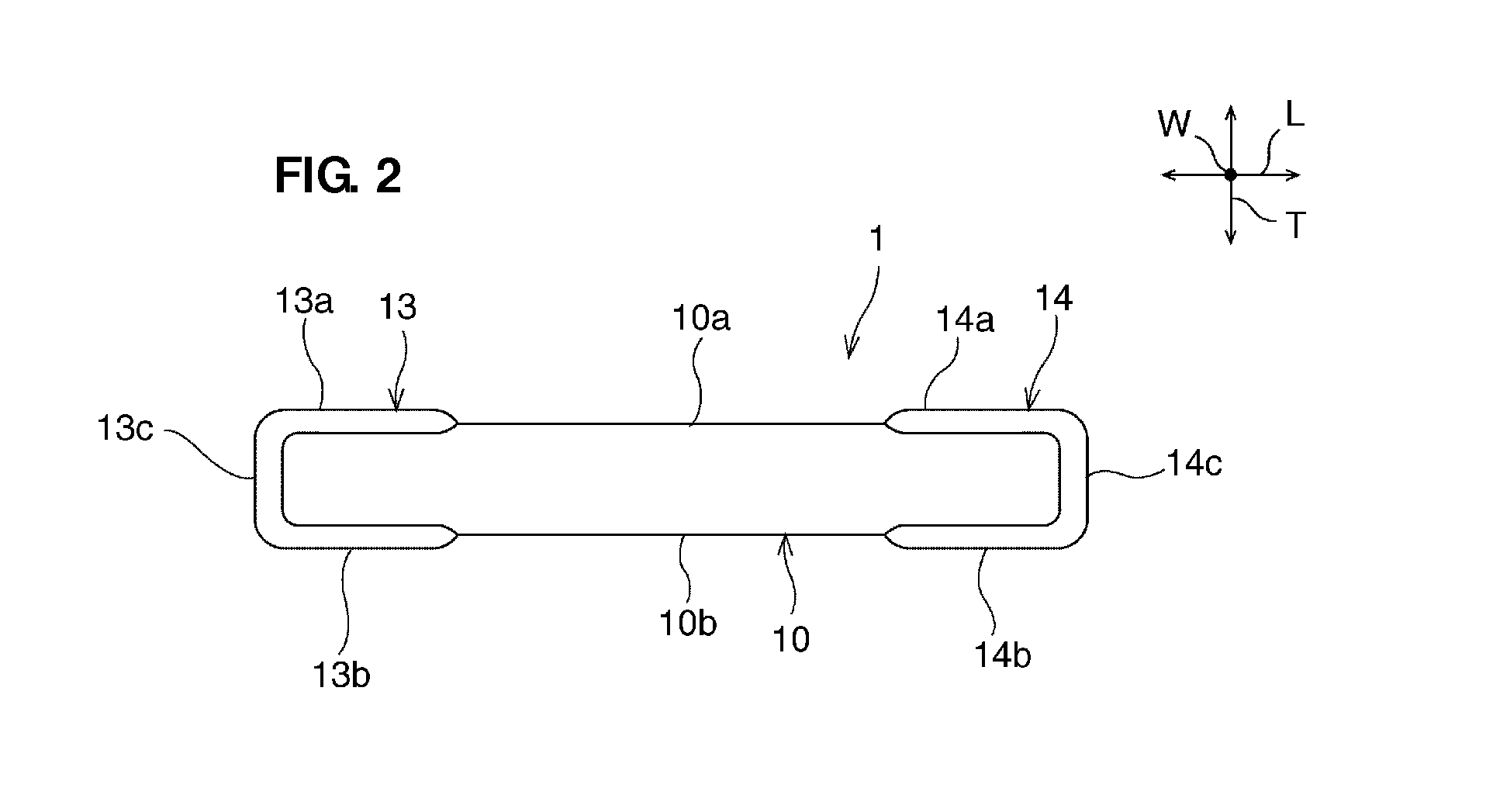

Method of manufacturing ceramic electronic component, ceramic electronic component, and wiring board

ActiveUS20120018205A1Minimize changesCharacteristic is prevented and minimizedResistor terminals/electrodesFinal product manufactureConductive pasteMetallurgy

A method of manufacturing a ceramic electronic component prevents variations in characteristics even when the ceramic electronic component is embedded in a wiring board. Ceramic green sheets containing an organic binder having a degree of polymerization in a range from about 1000 to about 1500 are prepared. A first conductive paste layer is formed on a surface of each of the ceramic green sheets. The ceramic green sheets are laminated to form a raw ceramic laminated body. A second conductive paste layer is formed on a surface of the raw ceramic laminated body. The raw ceramic laminated body formed with the second conductive paste layer is fired.

Owner:MURATA MFG CO LTD

Silicone-Based Releasable Adhesive Composition, Sheet-Form Substrate Having Releasable Adhesive Layer Formed By Curing This Composition, And Use Of Such A Protective Film Or Fixing Sheet

InactiveUS20120328863A1Easy to controlEasy to disassembleSynthetic resin layered productsOrganic non-macromolecular adhesivePolymer scienceAlkoxy group

Problem: To provide a silicone-based releasable adhesive composition that is capable of easily controlling peeling force of a releasable adhesive layer by the composition, and whereby the silicone-based releasable adhesive composition has excellent attachment characteristics and releasability characteristics. A further object is to provide a sheet-form substrate and a releasable adhesive sheet that have a releasable adhesive layer formed by curing this composition.Resolution Means: The silicone-based releasable adhesive composition includes an organopolysiloxane resin-organopolysiloxane condensation reaction product obtained by condensation reaction between (a1) 100 weight parts of an MQ type organopolysiloxane resin containing hydroxyl groups or alkoxy groups in a range of 0.3 to 2.0 weight % and having an M unit to Q unit molar ratio of 0.6 to 1.0, and (a2) 20 to 150 weight parts of a chain-like diorganopolysiloxane having an average degree of polymerization of 100 to 1,000 and having at least one hydroxyl group or alkoxy group, wherein the organopolysiloxane resin-organopolysiloxane condensation reaction product preferably includes a certain hydroxyl group content.

Owner:DOW CORNING TORAY CO LTD

Interlayer film for laminated glass and laminated glass

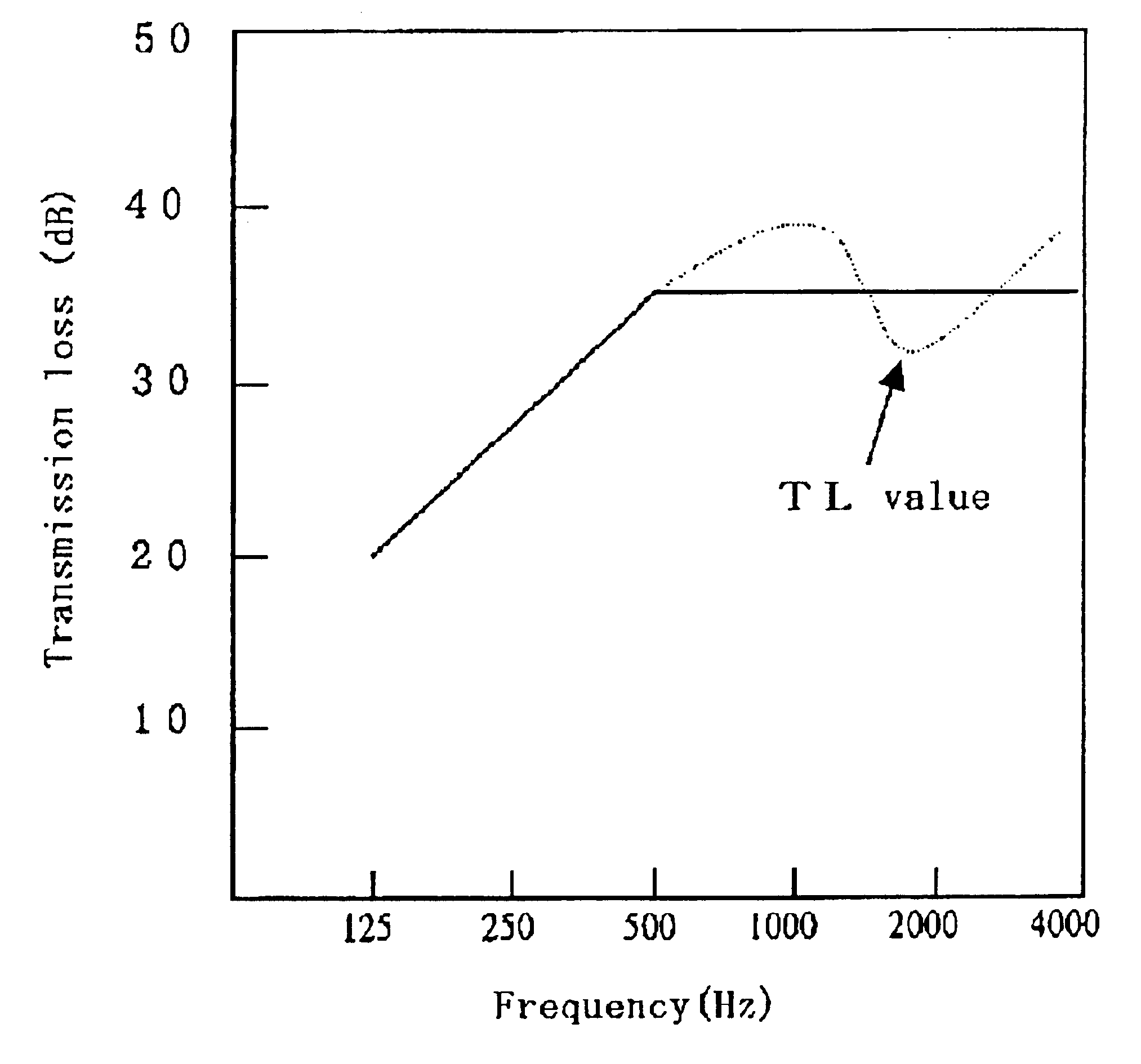

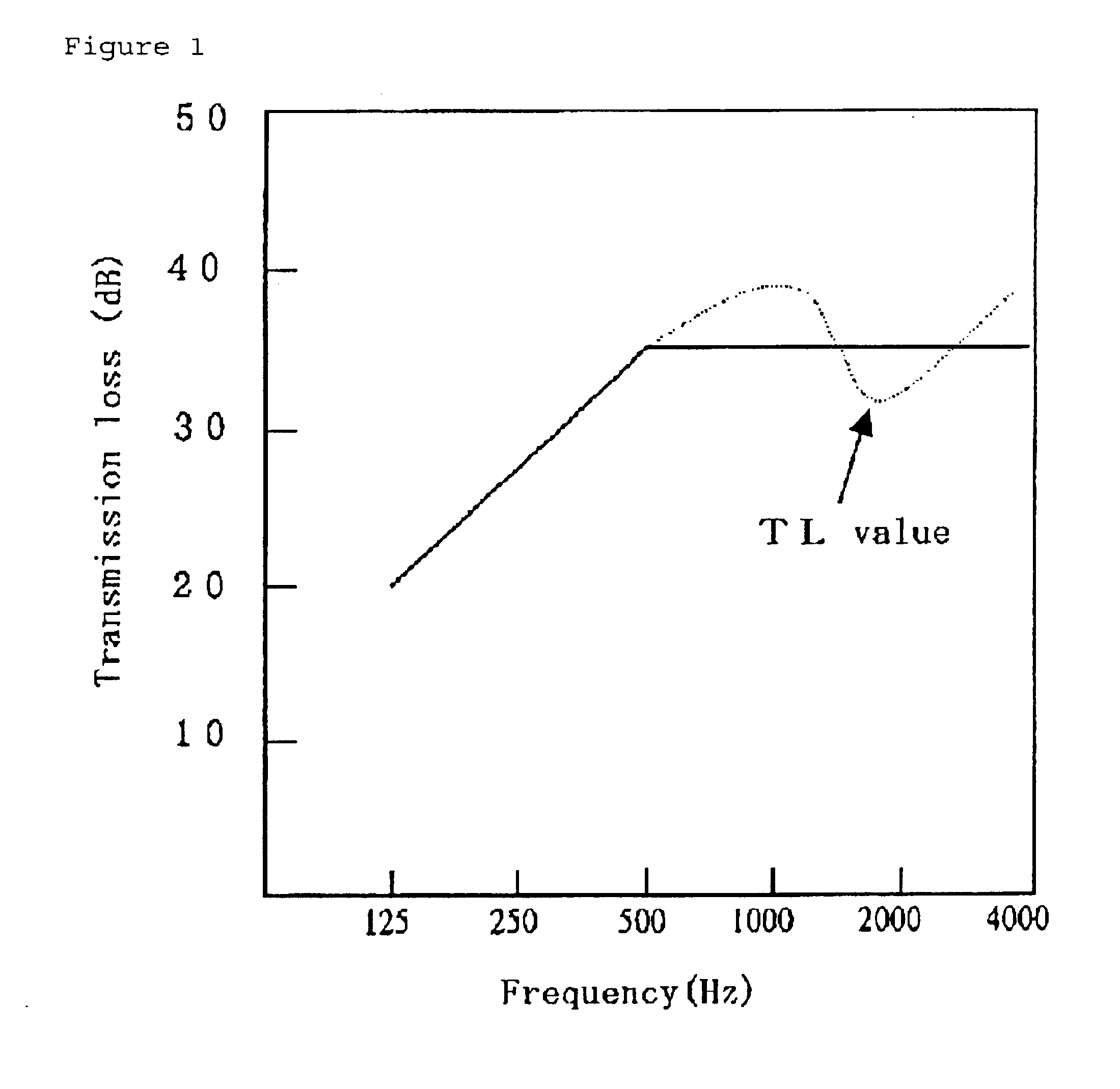

InactiveUS6903152B2Non-fibrous pulp additionFibre treatmentUltrasound attenuationDynamic viscoelasticity

The invention provides an interlayer film for a laminated glass and a laminated glass,which are protected against a slump in TL value through attenuation of said coincidence effect and adapted to display an outstanding sound insulation performance over a broad temperature range.An interlayer film for a laminated glass comprising a plasticizer and a polyacetal resin,which is a blend of a polyacetal resin having an average polymerization degree of 1,000 to 3,000 and a polyacetal resin having an average polymerization degree of 3,000 to 5,000, andwhich has an acetalization degree of 60 to 85 mol % and an acetyl group content of 8 to 30 mol %.An interlayer film for a laminated glasswhich shows a temperature dependence of loss tangentin which the lowest-temperature side maximum of loss tangent appears at 30° C. or lower when examined for dynamic viscoelasticity.

Owner:SEKISUI CHEM CO LTD

Single functional branched polyethylene glycol containing degradable radical, preparation method and biorelevant substance of single functional branched polyethylene glycol

ActiveCN104725628ASolve the problem of activity decline or even disappearIncrease exposurePharmaceutical non-active ingredientsPolyethylene glycolEnzyme

The invention discloses single functional branched polyethylene glycol (formula 1 in the specification) containing a degradable radical, a preparation method and a modified biorelevant substance of single functional branched polyethylene glycol (formula 2 in the specification), wherein U is a trivalent branched radical; n1, n2 and n3 are degree of polymerization of PEG chains; three PEG chains are respectively and independently polydisperse or monodisperse; A1 and A2 are C1-20 alkyl; L1, L2, L3 and Z1 are linking radicals; q1 is 0 or 1; R01 is a functional radical or of protected form; D is residue of the biorelevant substance; L4 is a linking group formed after R01 reacts with the biorelevant substance; and the part other than R01 of formula (1) contains at least one radical degradable under the condition of light, heat, enzyme, oxidoreduction, acidity or alkality. The medicine modified by the single functional branched polyethylene glycol containing the degradable radical can be degraded under specified conditions to release highly active medicine molecules, so that the activity and efficacy of the medicine are improved.

Owner:XIAMEN SINOPEG BIOTECH

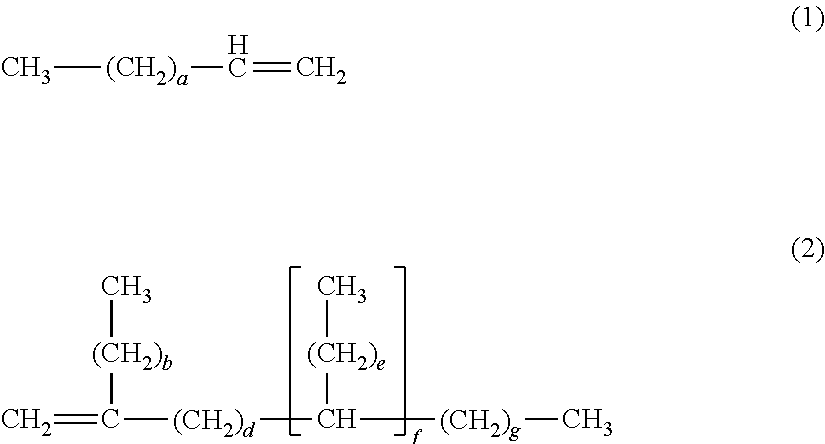

Vinyl-Terminated Macromonomer Oligomerization

Vinyl-terminated macromonomer oligomerization, namely, a process to produce polymacromonomers comprising contacting a vinyl-terminated macromonomer with a catalyst system capable of oligomerizing vinyl-terminated macromonomer, in the presence of an aluminum containing compound, a zinc containing compound, or a combination thereof, under polymerization conditions to produce a polymacromonomer, and polymacromonomers produced thereby. Also, polymacromonomers having a degree of polymerization greater than 10, a glass transition temperature Tg of less than 60° C., and an Mn of greater than or equal to about 5000 Da.

Owner:EXXONMOBIL CHEM PAT INC

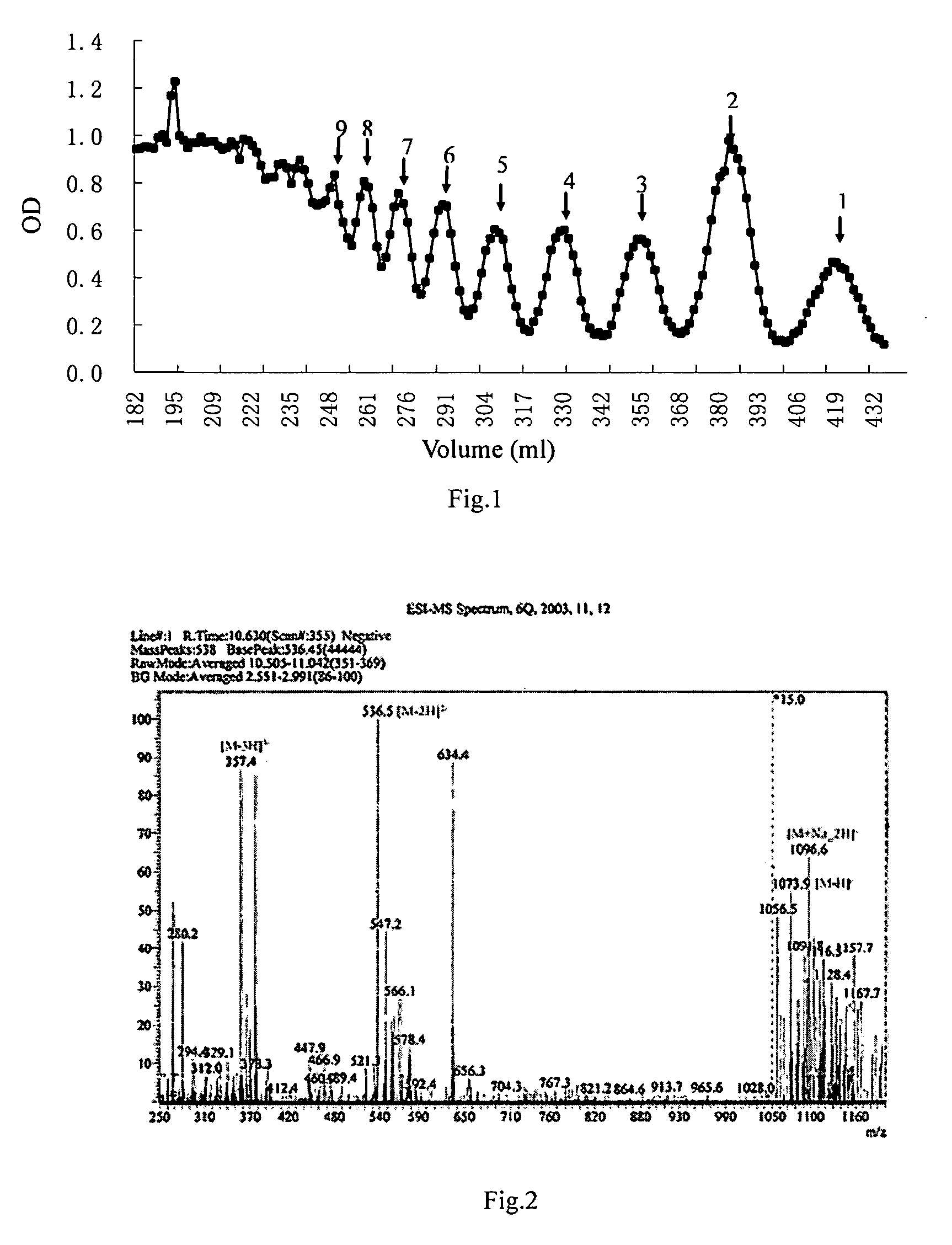

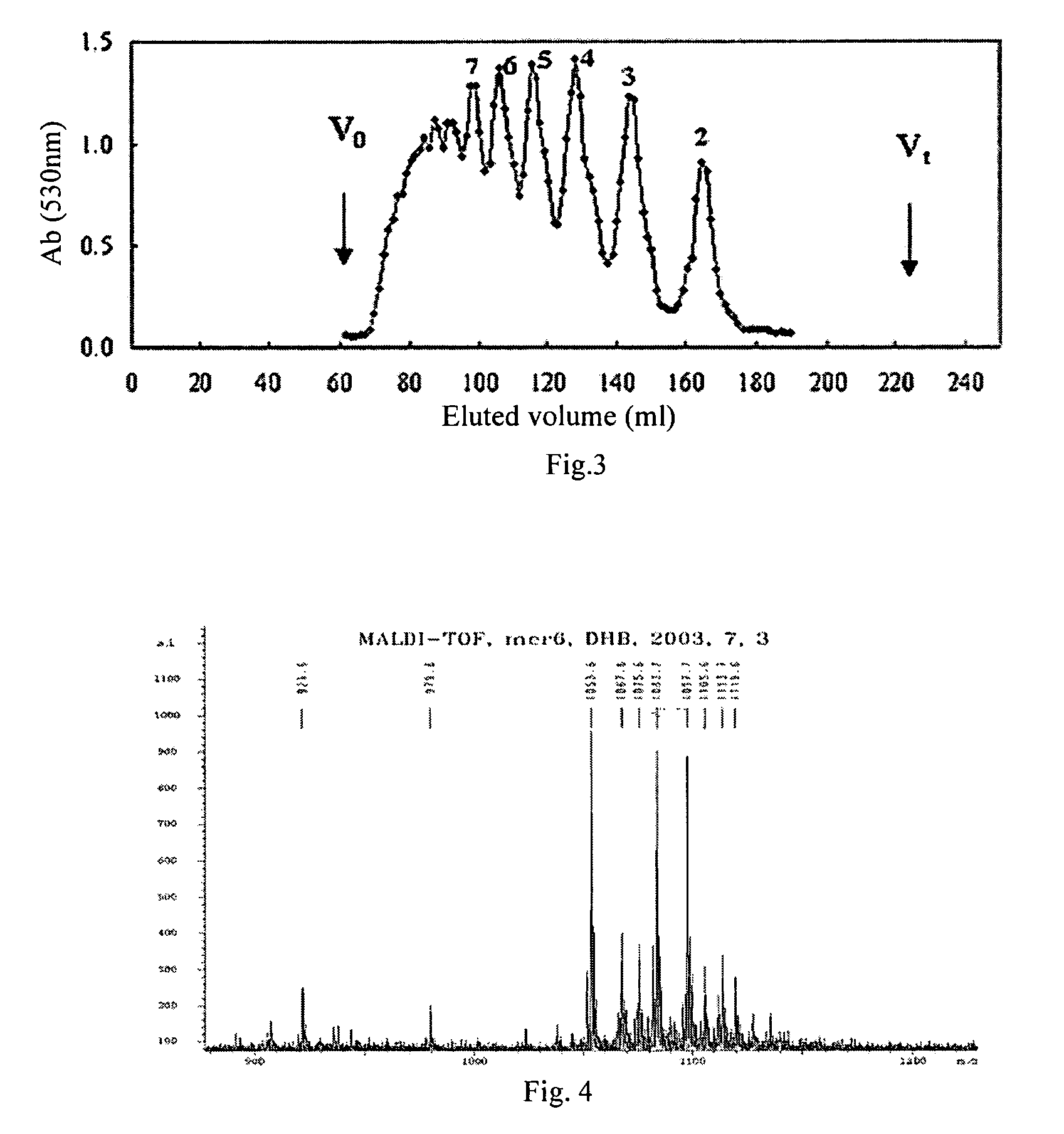

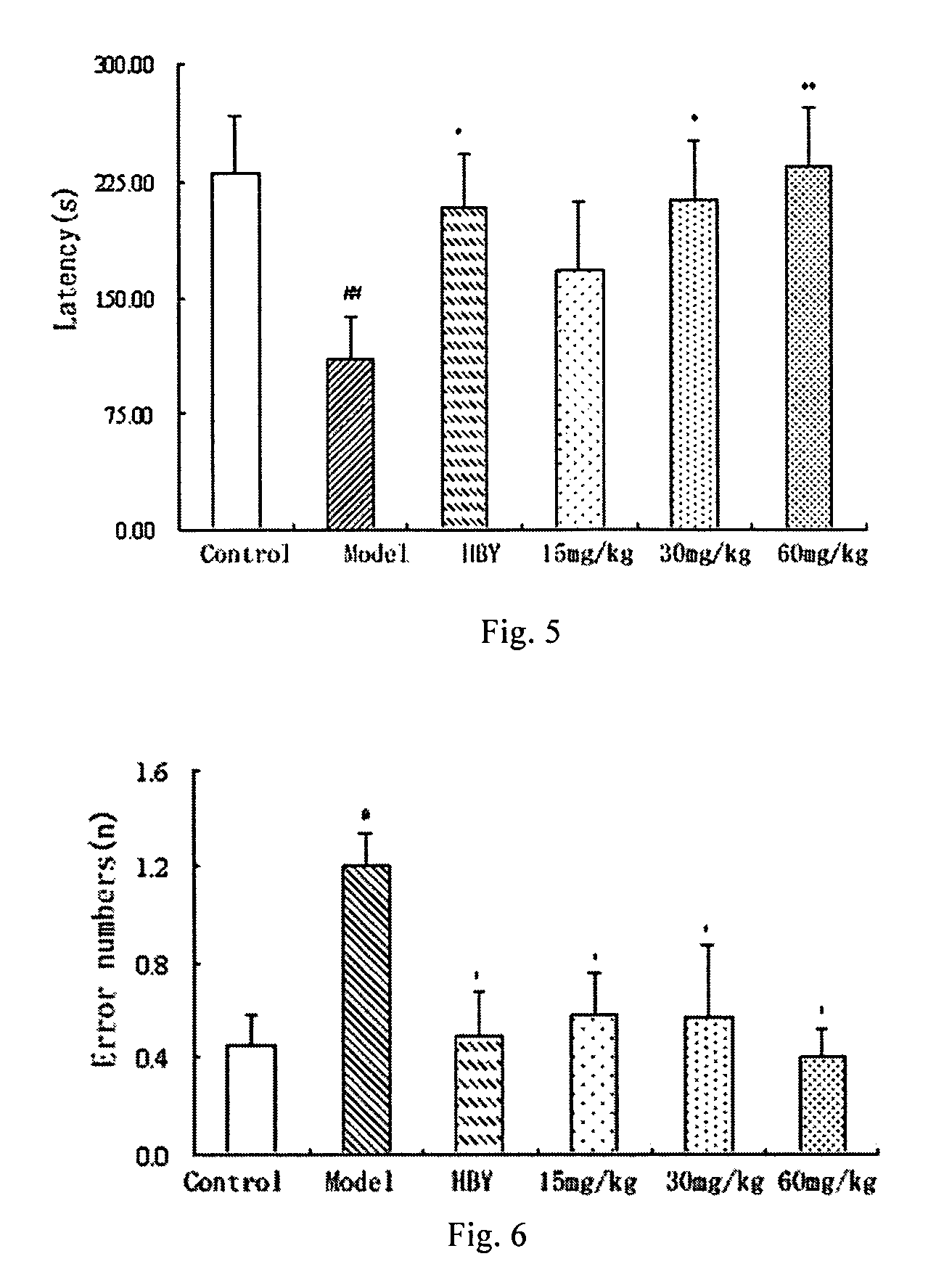

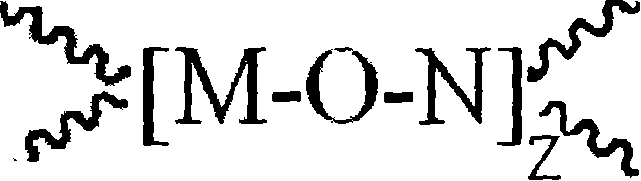

Algin oligosaccharides and the derivatives thereof as well as the manufacture and the use of the same

The present invention provides an alginate oligosaccharide and its derivatives with the degree of polymerization ranging from 2 to 22. The alginate oligosaccharide is composed of β-D-mannuronic acid linked by 1,4 glycosidic bonds. The derivatives with the reduced terminal in position 1 of carboxyl radical can be prepared by oxidative degradation. The present invention also provides a process for preparing the alginate oligosaccharide and its derivatives, which includes the procedures that an alginate solution is reacted for 2 to 6 h in an autoclave at pH 2-6 and the temperature of 100-120° C., and pH is adjusted to 7 after the reaction is stopped, after which the resultant oligosaccharide is oxidized in the presence of an oxidant to obtain an oxidative degradation product. The alginate oligosaccharide and its derivatives of the invention can be used in the manufacture of a medicament for the prophylaxis and treatment of AD and diabetes.

Owner:OCEAN UNIV OF CHINA

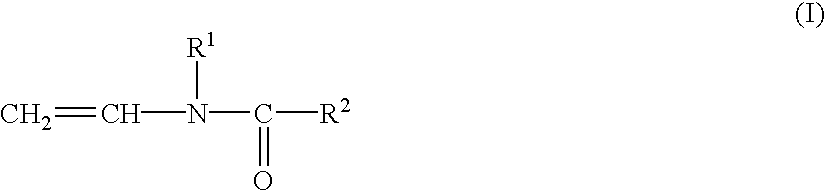

Microgel with nanometer grade sensitivity of temperature and PH value and preparation method thereof

InactiveCN101037494AWith temperatureHas dual pH sensitive propertiesPharmaceutical non-active ingredientsEmulsion polymerizationDrug carrier

The invention relates to a temperature and pH valve sensitive nano microgel and a preparation method thereof. Structure formula of the microgel and copolymer thereof is shown above, wherein temperature sensitive monomer M is amide group containing compound, pH sensitive monomer N is carboxyl group containing compound, crosslinking agent O is acryloyl group containing compound, and mole ratio of amount of the three groups is 50-90 to 40-5 to 10-5. Degree of polymerization Z is 10-500. The method of preparing the microgel under condition of adding no emulsifier includes: employing specific dropping technique and nonsoap emulsion polymerization method, composing reactant water solution by M, N, O and water solvent according proportion, timed adding the reactant water solution to initiator water solution drop by drop, after ruleless copolymerizing and purifying, obtaining the double sensitive nano microgel with equal particle diameter of 40-300 nm and high stability. The microgel is easy to store, convenient for use and widely be used for medicament carrier and coating field. Advantages of the preparing method are: range of applicability is wide, technique is simple, and preparation can be large-scale production.

Owner:DONGHUA UNIV

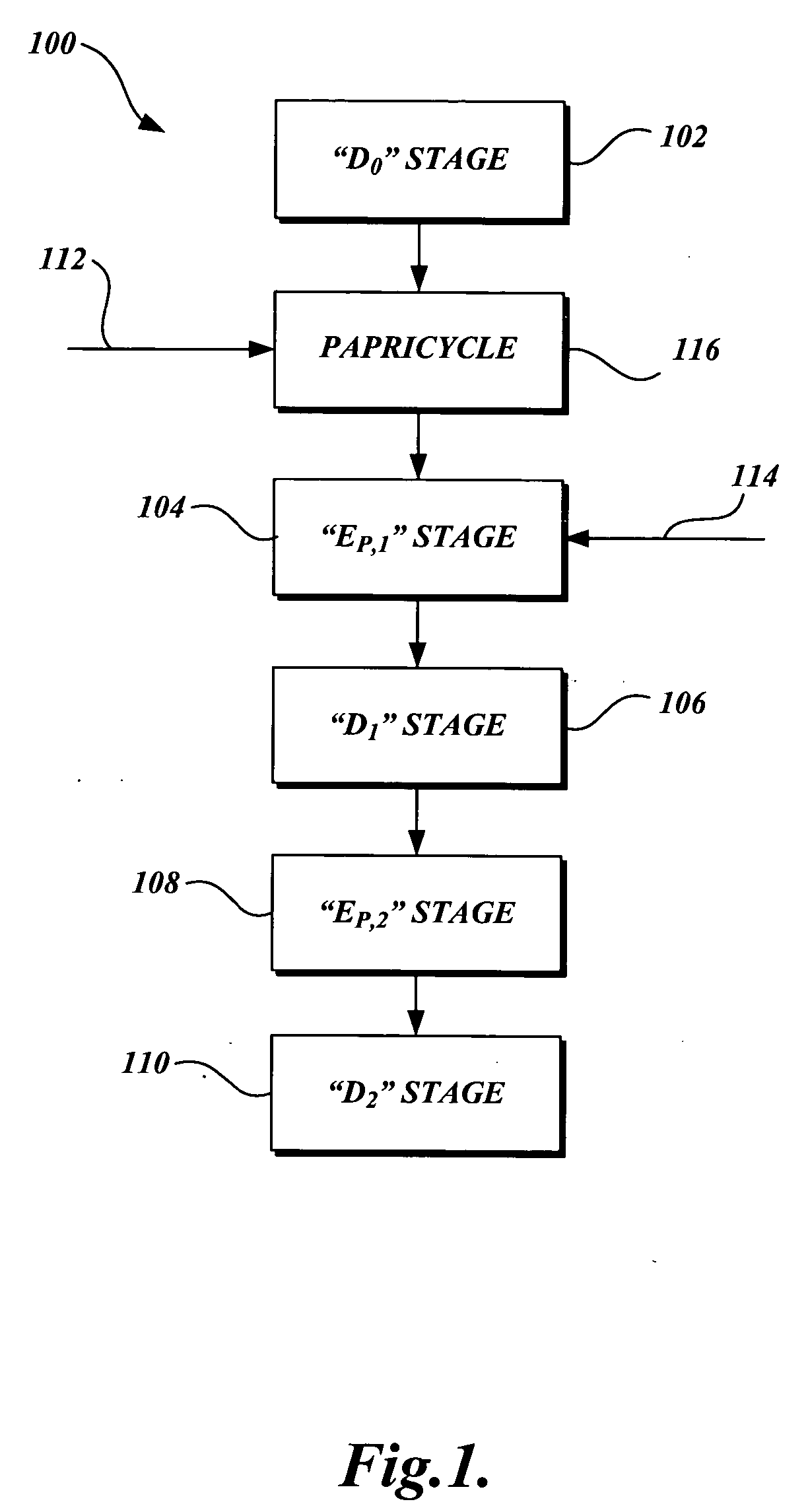

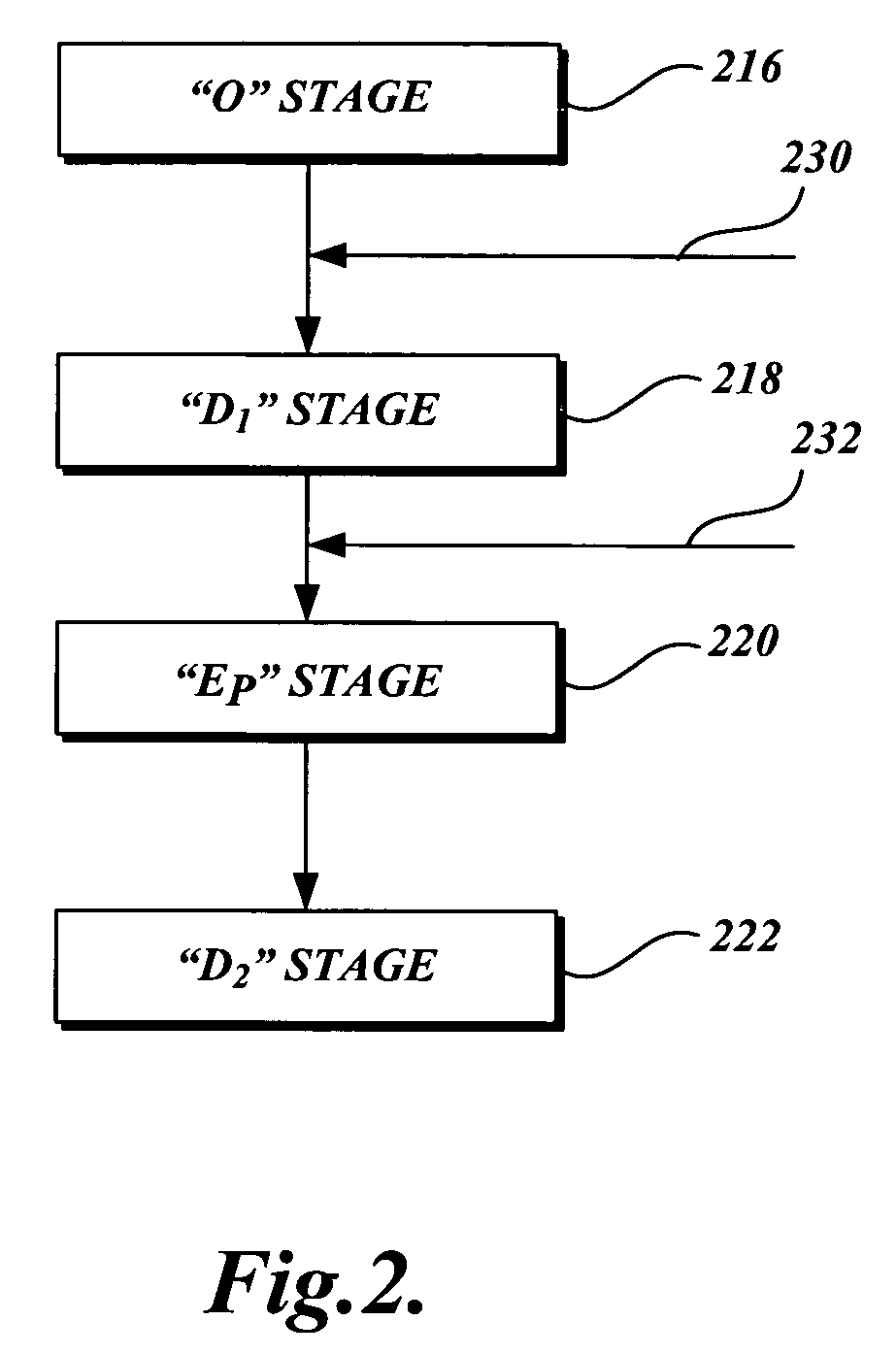

Low pH treatment of pulp in a bleach sequence to produce pulp having low D.P. and low copper number for use in lyocell manufacture

InactiveUS20060070711A1Reduce the degree of polymerizationIncreasing copper numberPulp properties modificationLayered productsBleachPulp mill

A high pH and a low pH process for reducing the degree of polymerization of a pulp having a hemicellulose content of at least 7%. The high pH is greater than 8, and the low pH process is 2 to 8. The high pH process reduces the degree of polymerization without substantially increasing the copper number. The low pH process requires a subsequent treatment with alkali to reduce the copper number of the pulp to less than 2. The process can be practiced in pulp mills with a bleaching sequence having one or more E or D stages. At the end of the bleach sequence, a pulp having a degree of polymerization of 200 to 1100, a copper number of less than 2, and a hemicellulose content of at least 7% is provided. The pulp can be used to make lyocell fibers.

Owner:WEYERHAEUSER NR CO

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS9051684B2Improve consistencyImprove scalabilityFinely-divided cellulose conservationReed/straw treatmentMicrometerPaperboard

Owner:FPINNOVATIONS INC

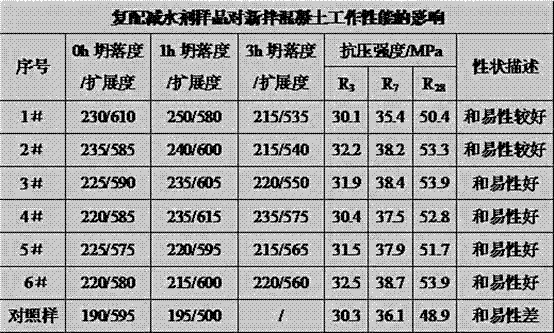

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Super-wide environmental-friendly decorative film material and preparation technology thereof

ActiveCN103059473ASolve the problem of strong odor at the beginning of useGuaranteed flatnessFlat articlesEnvironmental resistanceHazardous substance

The invention relates to a super-wide environmental-friendly decorative film material and a preparation technology thereof. The super-wide environmental-friendly decorative film material is prepared from high degree-of-polymerization PVC (Polyvinyl Chloride) resin powder, a environmental-friendly plasticizer, a stabilizer, a fire retardant, an internal lubricant and a mildew preventive serving as main raw materials by adopting working procedures such as material sieving, material blending, high-speed mixing, smelting, crude refining, refining, extrusion and filtrating, rolling, embossing, cooling and shaping, trimming, reeling and the like. The super-wide environmental-friendly decorative film material solves the problem that a general plastic decorative film has strong peculiar smell when coming into use, does not contain harmful substances such as phthalate, lead and cadmium, and is environmental-friendly, suitable for use in rooms and harmless to human bodies. Mountain and water streaks are prevented from occurring in the product so that the product has excellent appearance smoothness; due to addition of high-quality mildew preventive, the problem that the product goes moldy after being used for a long time is avoided; and in addition, the width of the product can reach 5 meters so that the product is suitable for use in specific occasions.

Owner:浙江明士达股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com