High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of poor slump retention performance and large slump loss, and achieve the effects of excellent product performance, no slump loss, and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

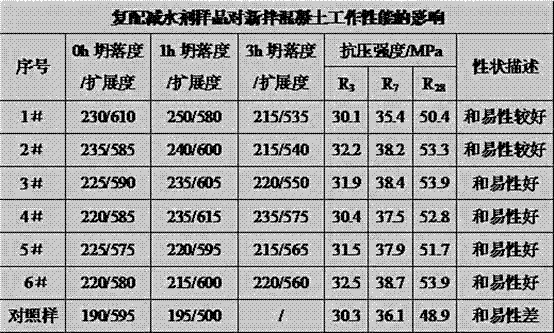

Examples

Embodiment 1

[0022] In a 500ml four-necked flask equipped with a thermometer, agitator and dropping funnel, add 100g of deionized water and 120g of prenol polyoxyethylene ether (polymerization degree n=54) in sequence, turn on nitrogen, heat in a water bath, and control the temperature When the temperature is about 40°C, stir while heating. After the isopentenol polyoxyethylene ether is melted, when the temperature is slowly raised to 60°C, add 2.84g of acrylamide, dropwise add 132g of an aqueous solution containing 5g of ammonium persulfate and 132g of an aqueous solution containing 78 g of a mixed aqueous solution of 28.6 g of hydroxyethyl methacrylate, 17.2 g of methacrylic acid, 0.3 g of mercaptoacetic acid, and 0.017 g of hydroquinone. The dropwise addition time of the mixed aqueous solution of hydroxyethyl methacrylate, methacrylic acid, thioglycolic acid and hydroquinone is 3.5 hours, and the dropwise addition time of the ammonium persulfate aqueous solution is 4 hours. Finally, coo...

Embodiment 2

[0024]In a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g of deionized water and 130g of allyl polyglycol ether (polymerization degree n=23) in sequence, turn on nitrogen, heat in a water bath, and control the temperature When the temperature is about 40°C, stir while heating. After the allyl polyglycol ether macromonomer melts, slowly raise the temperature to 60°C, add 3.62g of 2-acrylamido-2-methylpropanesulfonic acid Sodium was added dropwise to 135 g of an aqueous solution containing 5 g of ammonium persulfate and 86.5 g of a mixed aqueous solution containing 27.2 g of hydroxypropyl acrylate, 18.6 g of acrylic acid, 0.3 g of thioglycolic acid, and 0.022 g of phenothiazine. The dropwise addition time of the mixed aqueous solution of hydroxypropyl enoate, acrylic acid, thioglycolic acid and phenothiazine is 3.5 hours, the dropwise addition time of the ammonium persulfate aqueous solution is 4 hours, and the temperature is kept a...

Embodiment 3

[0026] In a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g of deionized water and 126g of prenol polyoxyethylene ether (polymerization degree n=54) in sequence, turn on nitrogen, heat in a water bath, and control the temperature 40°C, stir while heating, after the isopentenol polyoxyethylene ether macromonomer melts, slowly raise the temperature to 60°C, add 3.27g of acrylamide, dropwise add 4.6g of potassium persulfate 144 g of aqueous solution and 87.5 g of mixed aqueous solution containing 28.3 g of hydroxyethyl acrylate, 17.8 g of methacrylic acid, 0.35 g of sodium methacryl sulfonate, and 0.024 g of hydroquinone. The dripping time of the mixed aqueous solution of hydroxyethyl acrylate, methacrylic acid, sodium methacryl sulfonate and hydroquinone is 3.5 hours, the dropping time of potassium persulfate aqueous solution is 4 hours, and keep warm at 60°C after the dropping 3h. Finally, cool down, add alkali to neutralize, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com