Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

A technology of graft copolymer and amphoteric carboxylic acid, which is applied in the field of high water-reducing concrete superplasticizer and amphoteric carboxylic acid comb-shaped graft copolymer concrete superplasticizer, which can solve the problem of insufficient retention of dispersibility Good, can not meet the development of high-strength high-performance concrete with low water-binder ratio, and it is difficult to further improve the water-reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

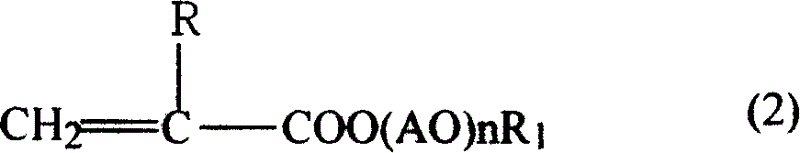

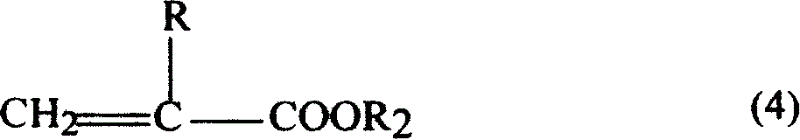

Method used

Image

Examples

Embodiment 1

[0083] Production Example 1 (synthesis of PCE-1)

[0084] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, a nitrogen inlet tube and a reflux condenser, add 200ml of deionized water, while stirring, purging the reaction vessel with nitrogen, and raising the temperature to 95°C, then 40g (A1) is mixed with 160g (B2) and 200 parts of water to make a mixed monomer aqueous solution, which is added dropwise to the reactor for 2 hours, and 80 parts of the initiator solution containing sodium persulfate is added dropwise at the same time. Adding time is about 4 hours. After the dropwise addition, keep warm for 2 hours, then add 20 parts of hydrogen peroxide initiator solution containing 35% concentration to the reaction bottle, keep warm for 2 hours, and cool to room temperature to obtain a brown color with a solid content of 30.2%. Transparent liquid with a pH of 3.5 and a molecular weight of 15,800 (PCE-1), the results are shown in Table 4.

Embodiment 2-9

[0085] Production Example 2-9 (Synthesis of PCE-2-9)

[0086] The PCE-2-9 of the present invention was prepared according to the steps of Example 1, but the specific monomer weight and type were changed, and the feeding was carried out according to the ratio described in Table 4. The test results are shown in Table 4.

[0087]

Embodiment 10

[0088] Production Example 10 (Synthesis of HP-1)

[0089] At room temperature, 58.8 parts by weight concentration of 8.5% soluble CNP-1 solution (Table 3) was added to 314.6 parts by weight concentration of 30.2% PCE-1 (Table 2), and the reaction was stirred at room temperature, and the viscosity began to increase. After stirring for 1 h, Add 1.5g of cross-linking agent F-1, stir at room temperature for 1 hour, the polymer solution becomes uniform, adjust the pH to 7.5 with 30% sodium hydroxide solution, and dilute with water to a concentration of slightly 20%, the copolymer is abbreviated as HP-1 (shown in Table 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com