Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1548 results about "Pentene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentenes are alkenes with chemical formula C₅H₁₀. Each contains one double bond within its molecular structure. There are a total of six different compounds in this class, differing from each other by whether the carbon atoms are attached linearly or in a branched structure, and whether the double bond has a cis or trans form.

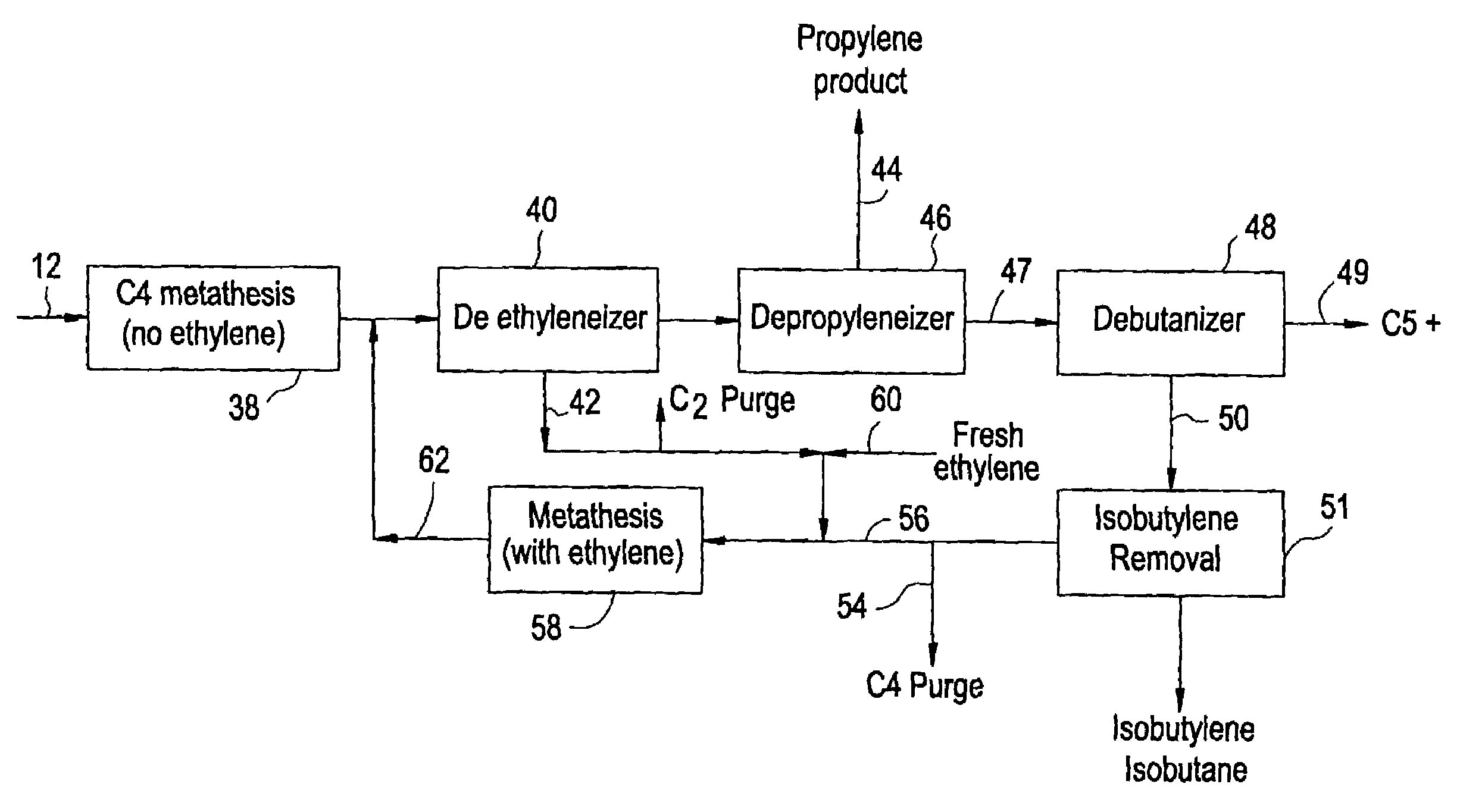

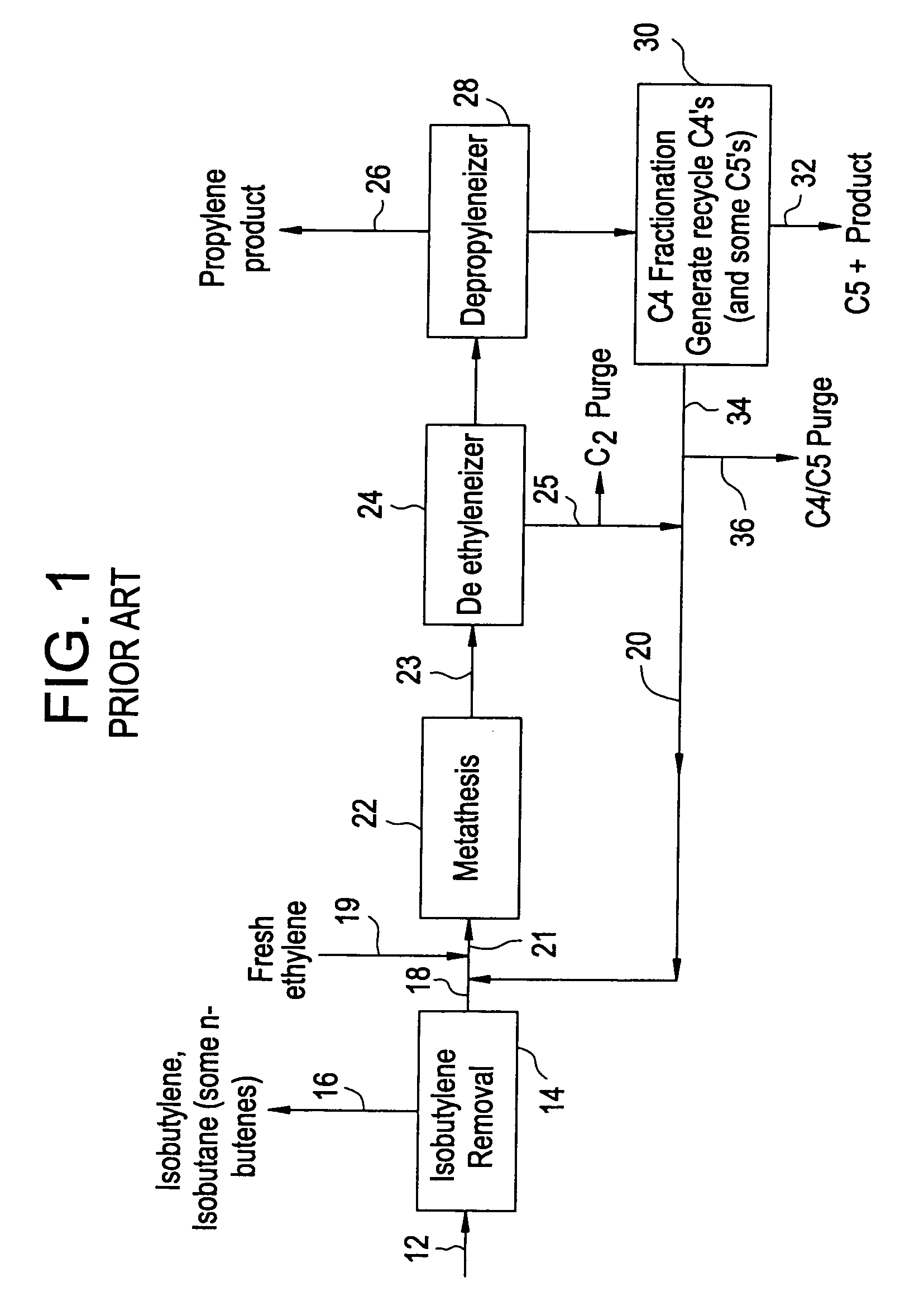

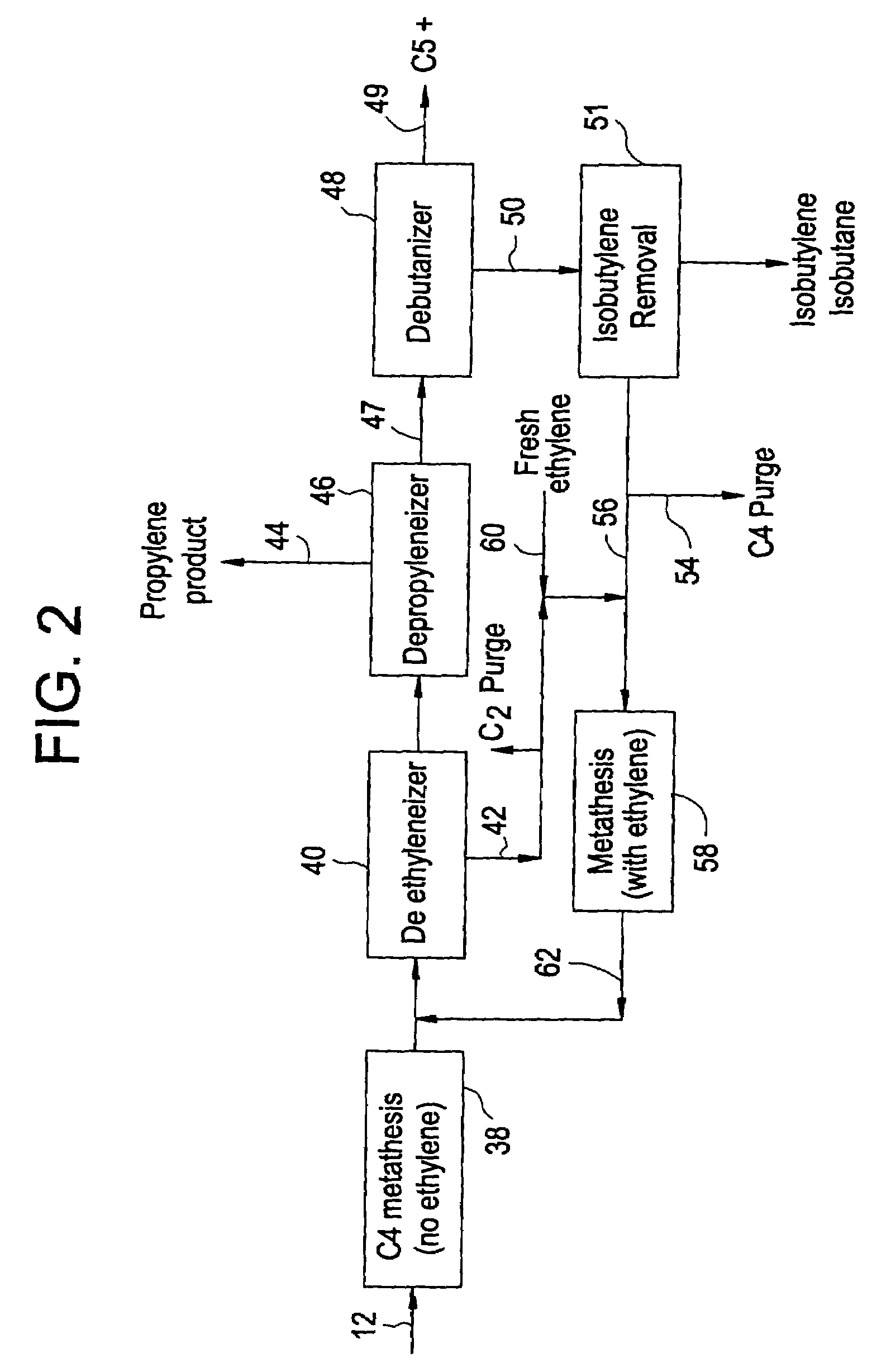

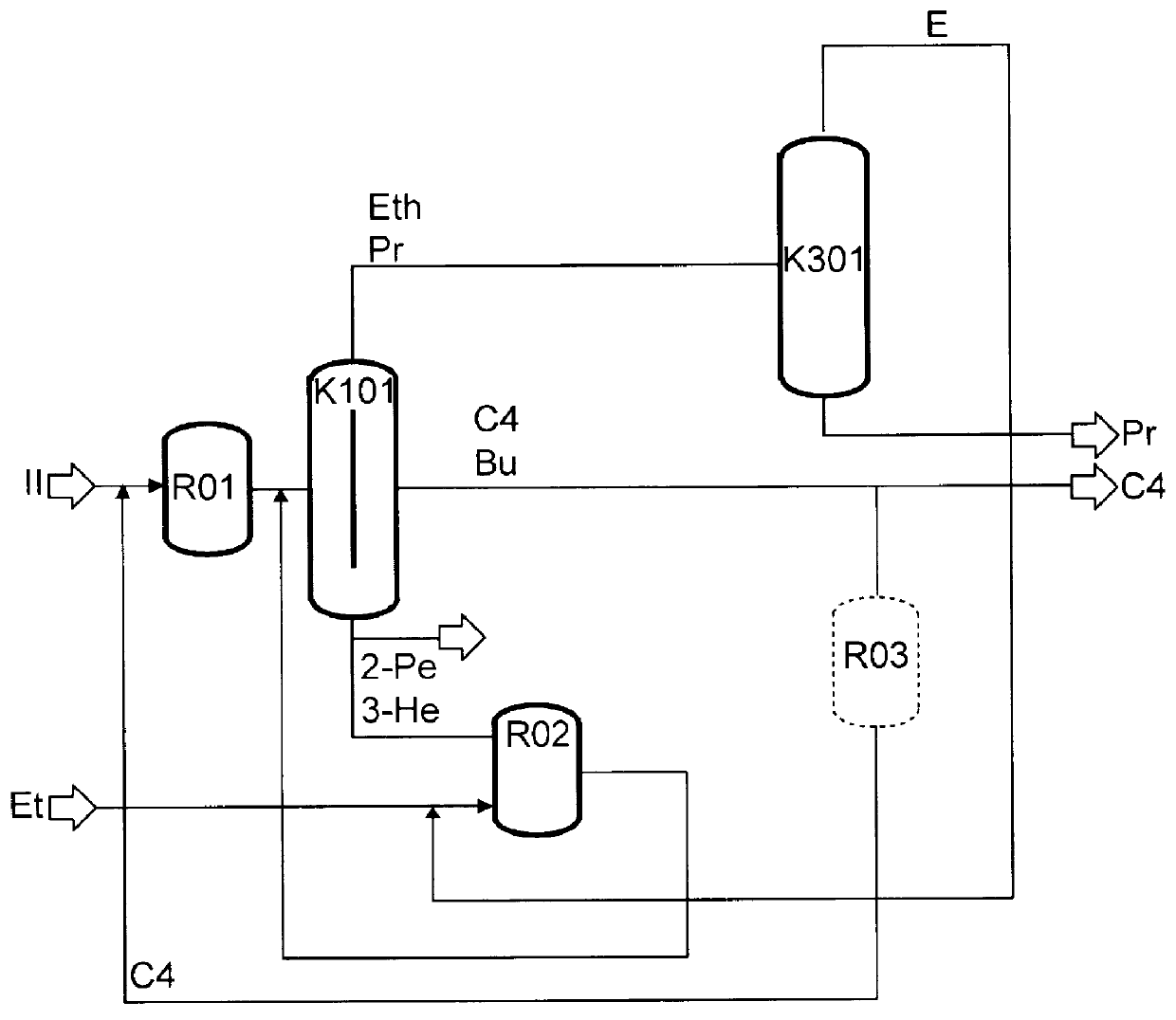

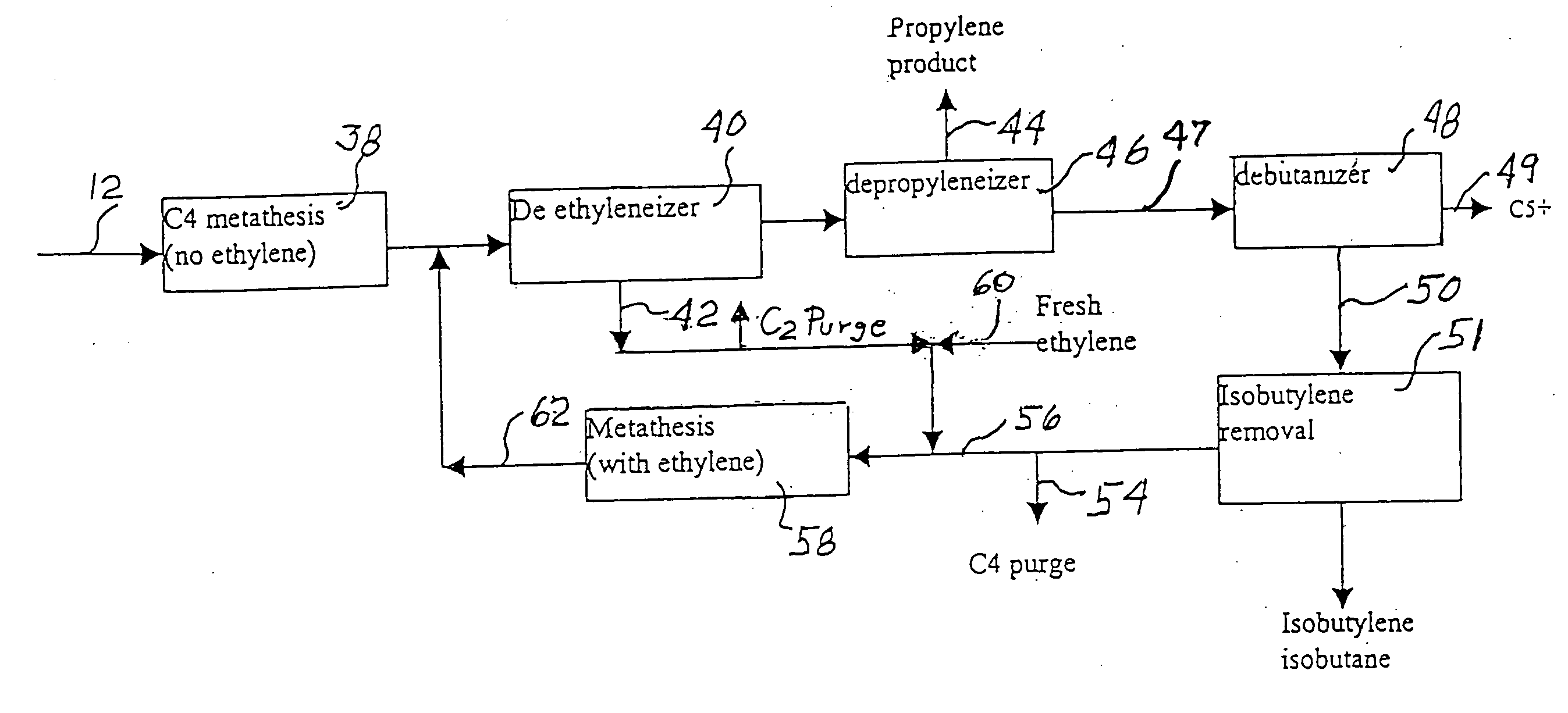

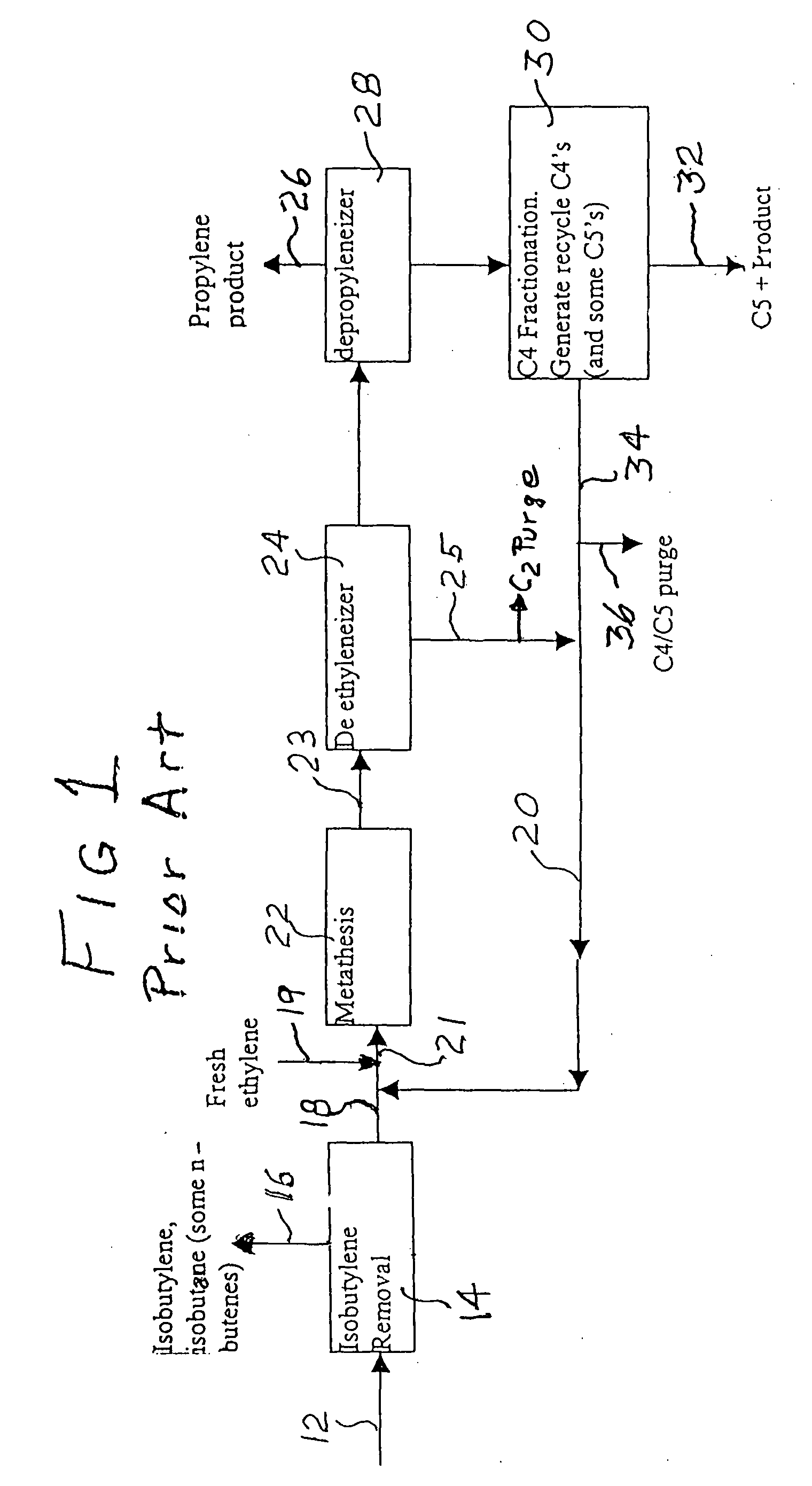

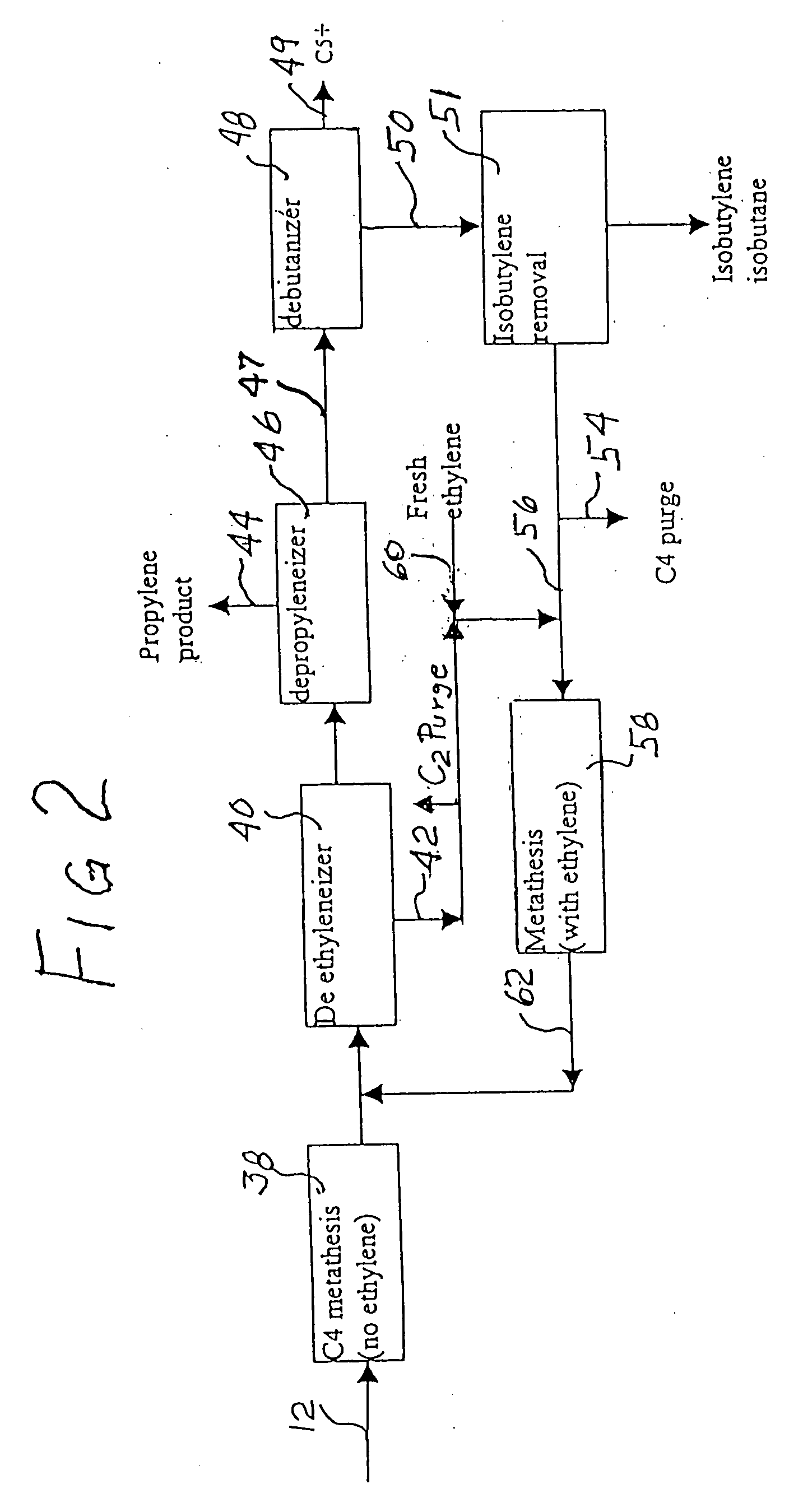

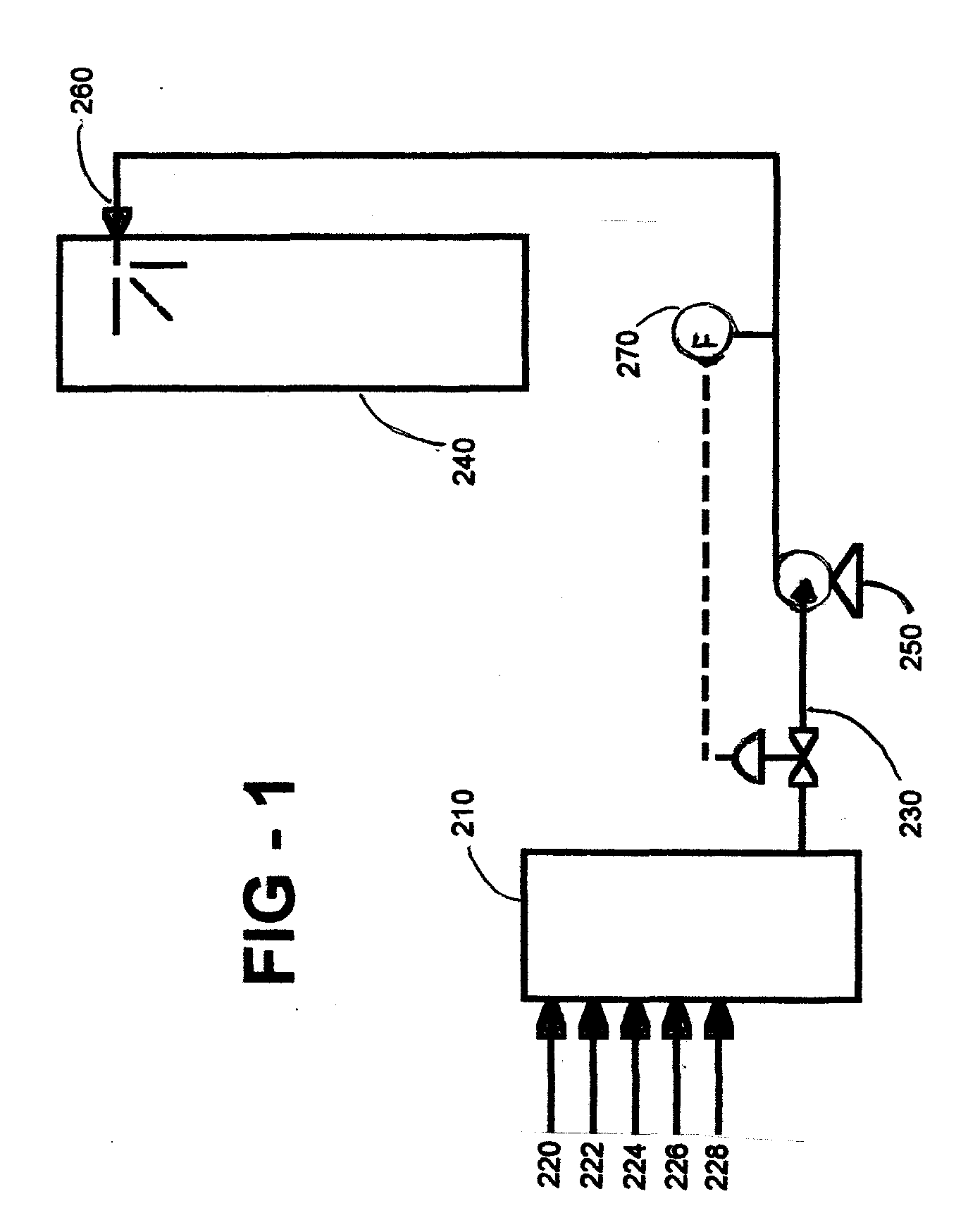

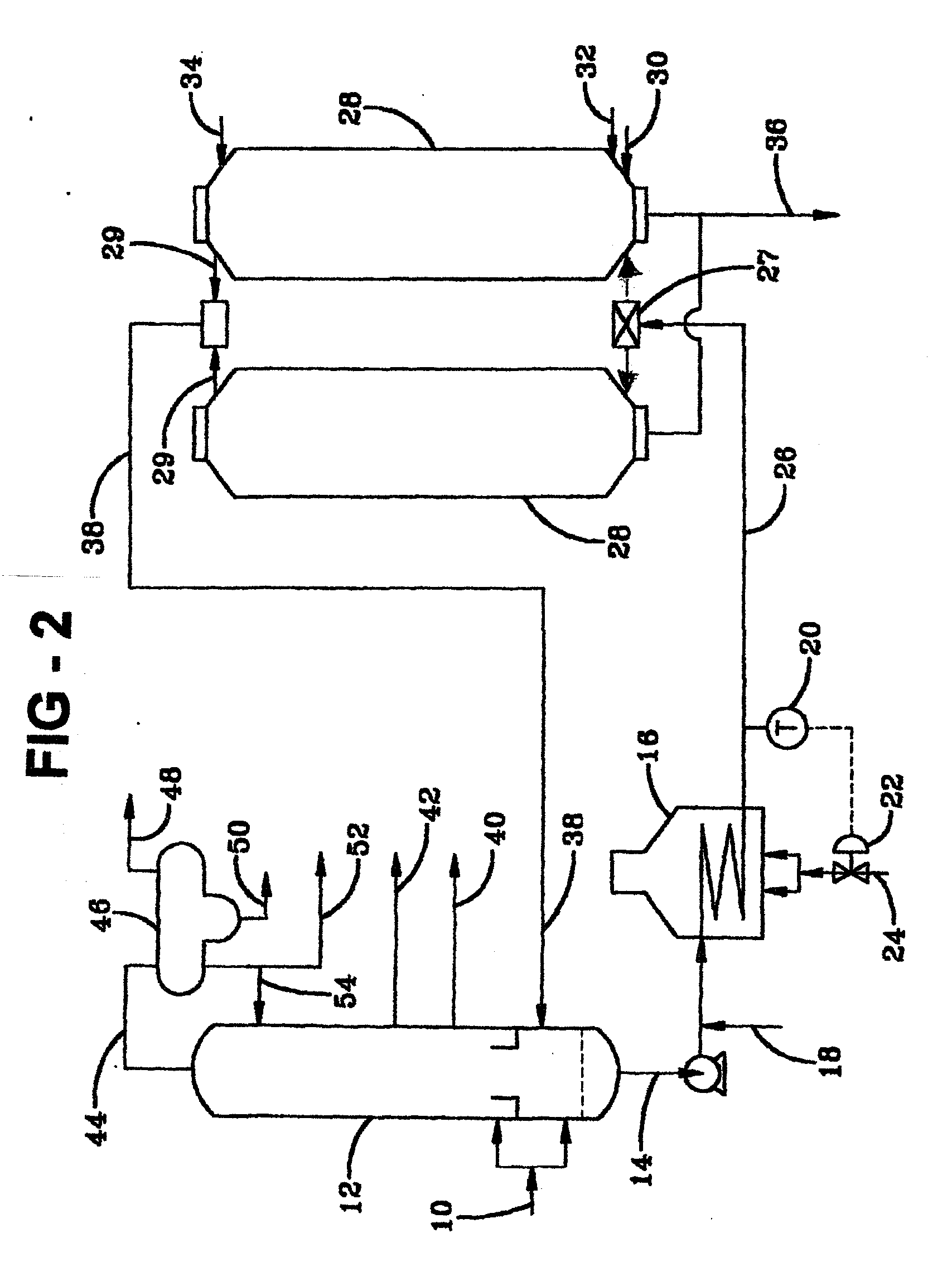

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

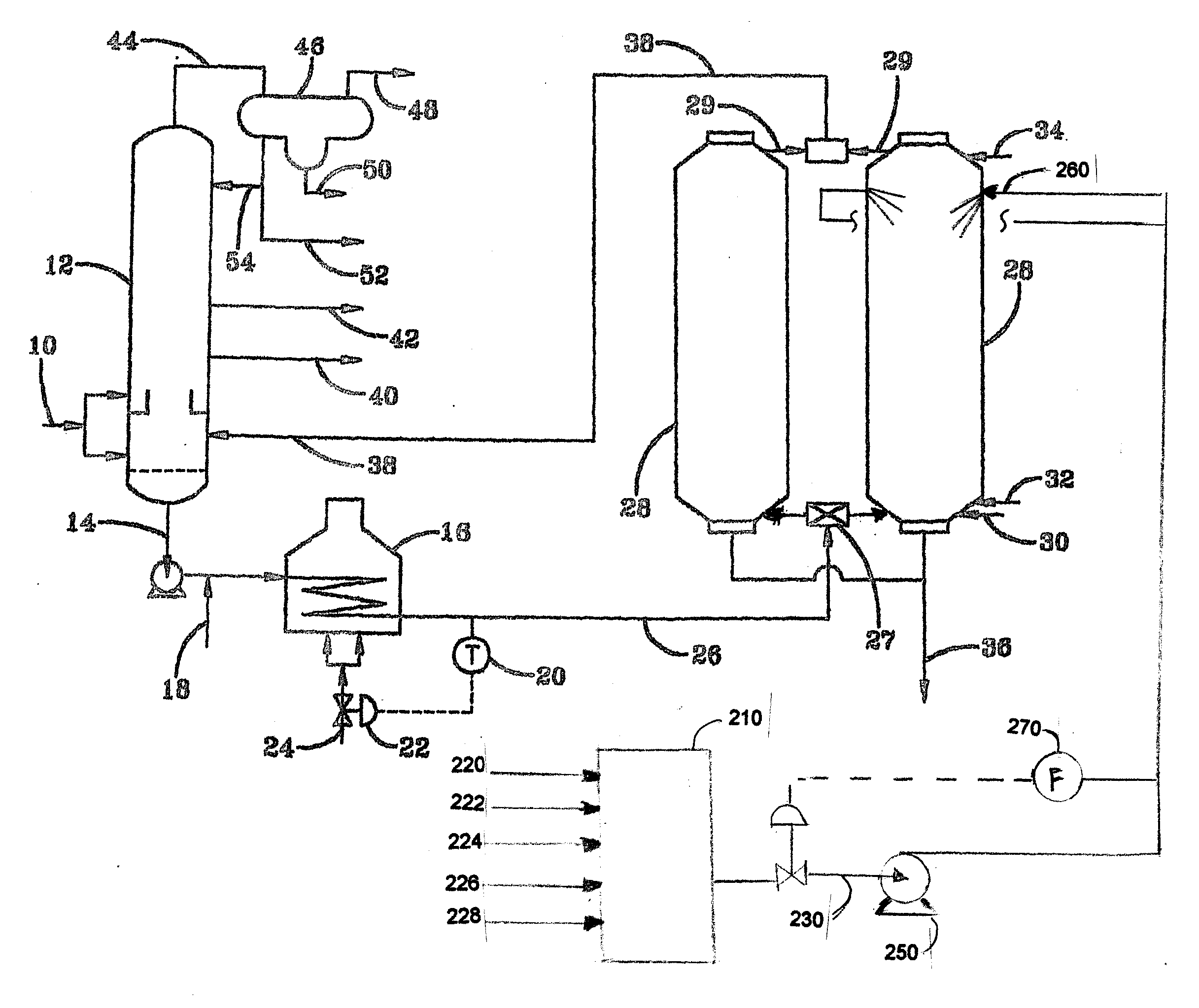

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

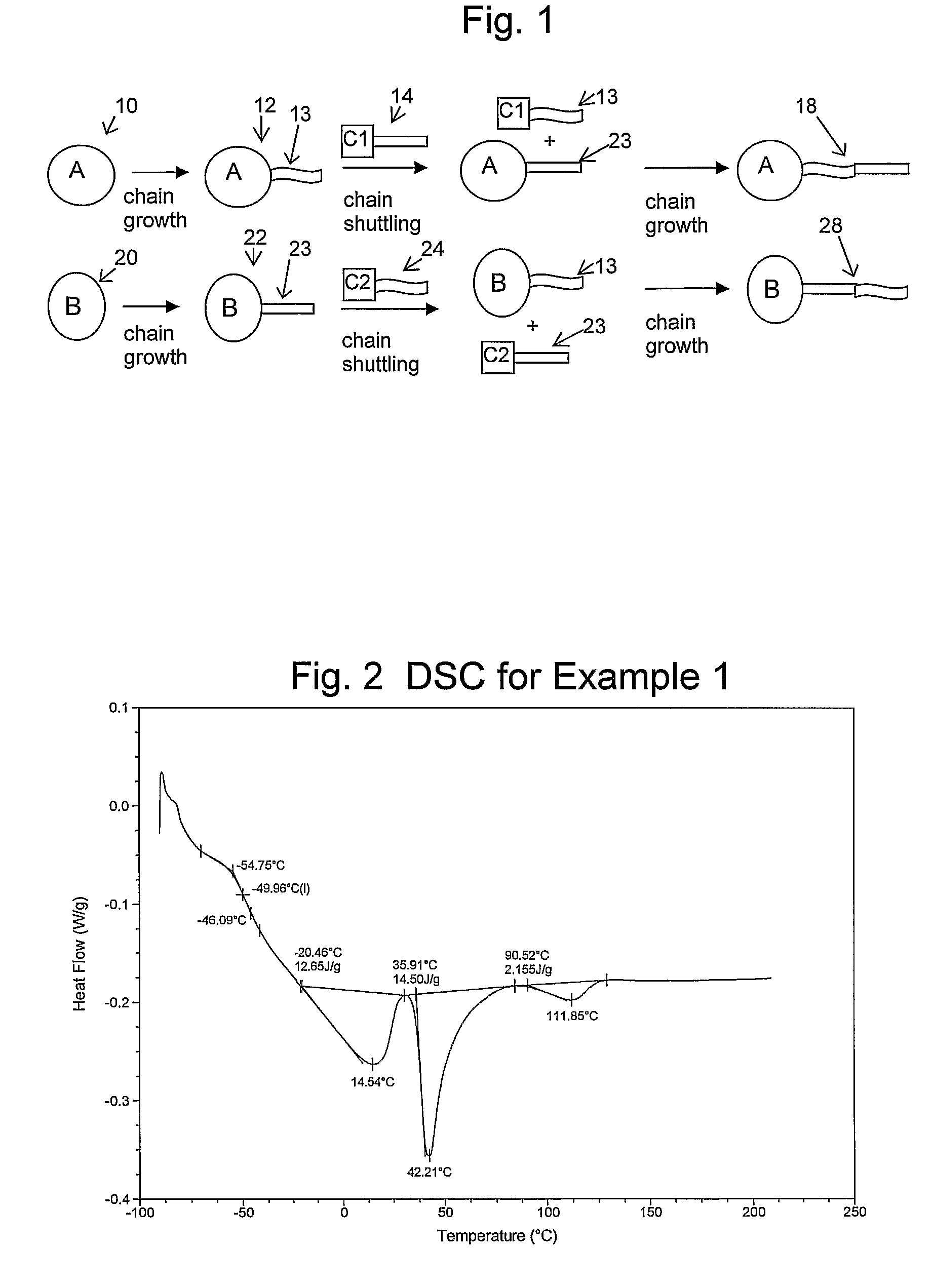

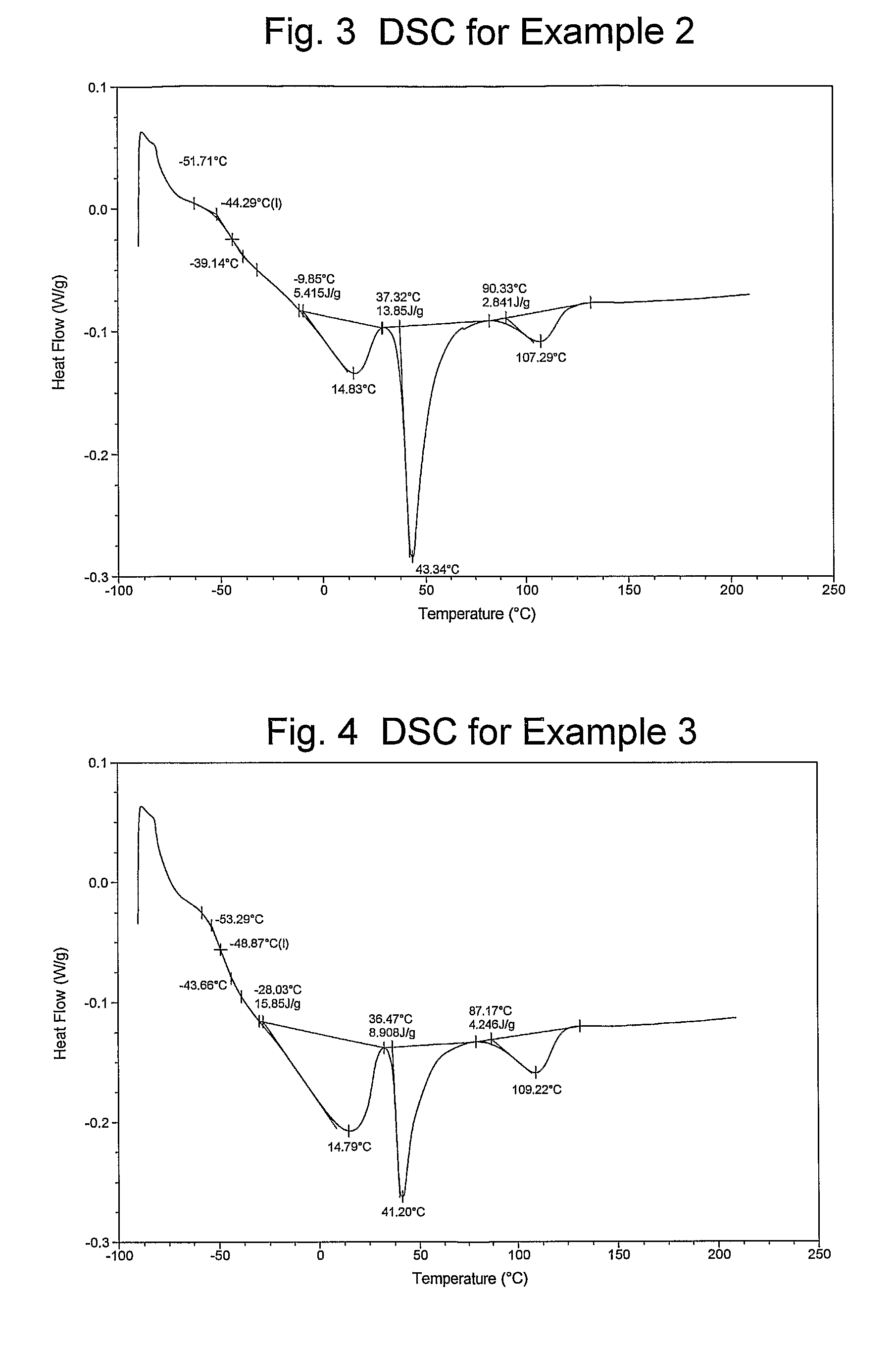

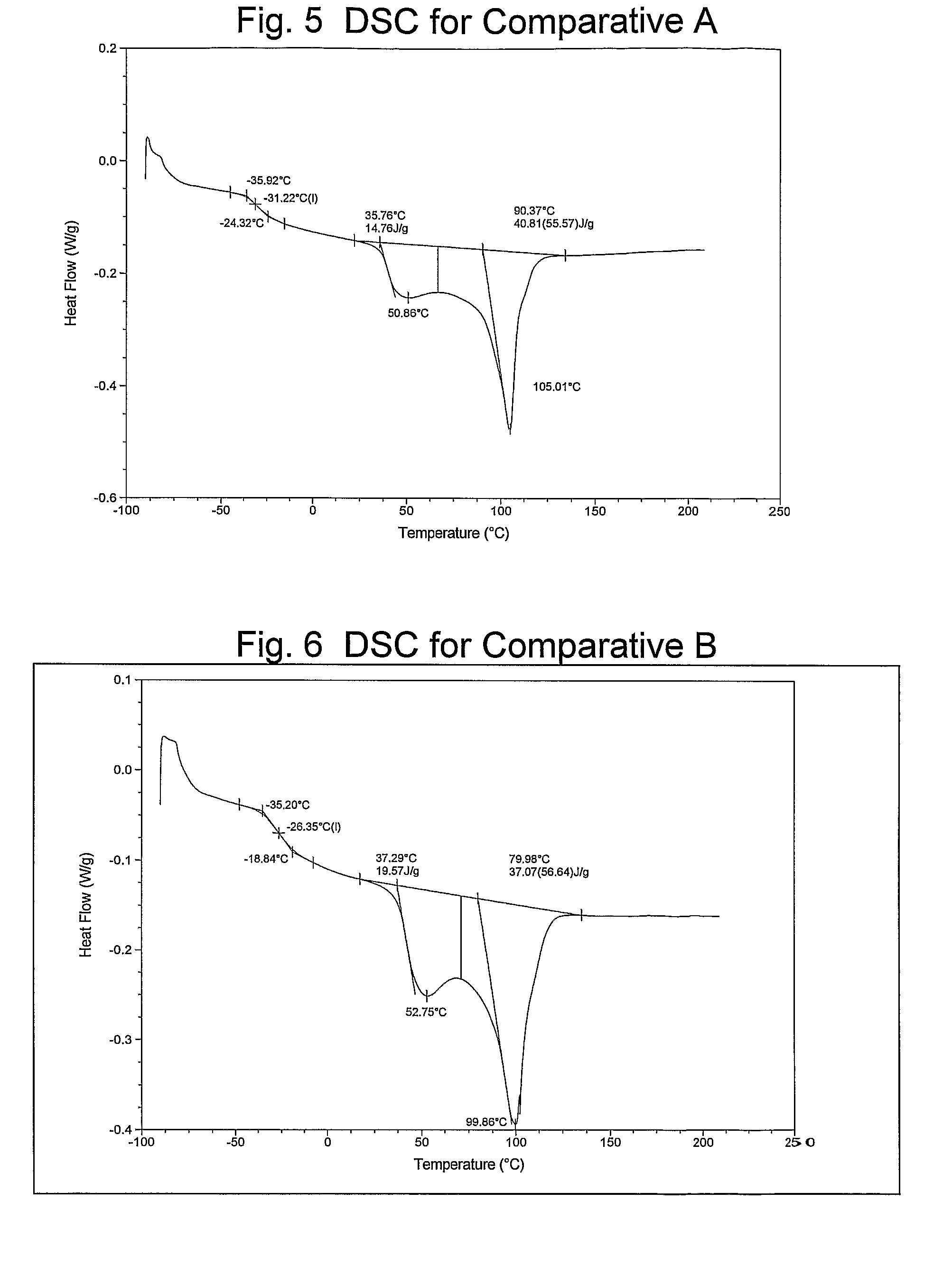

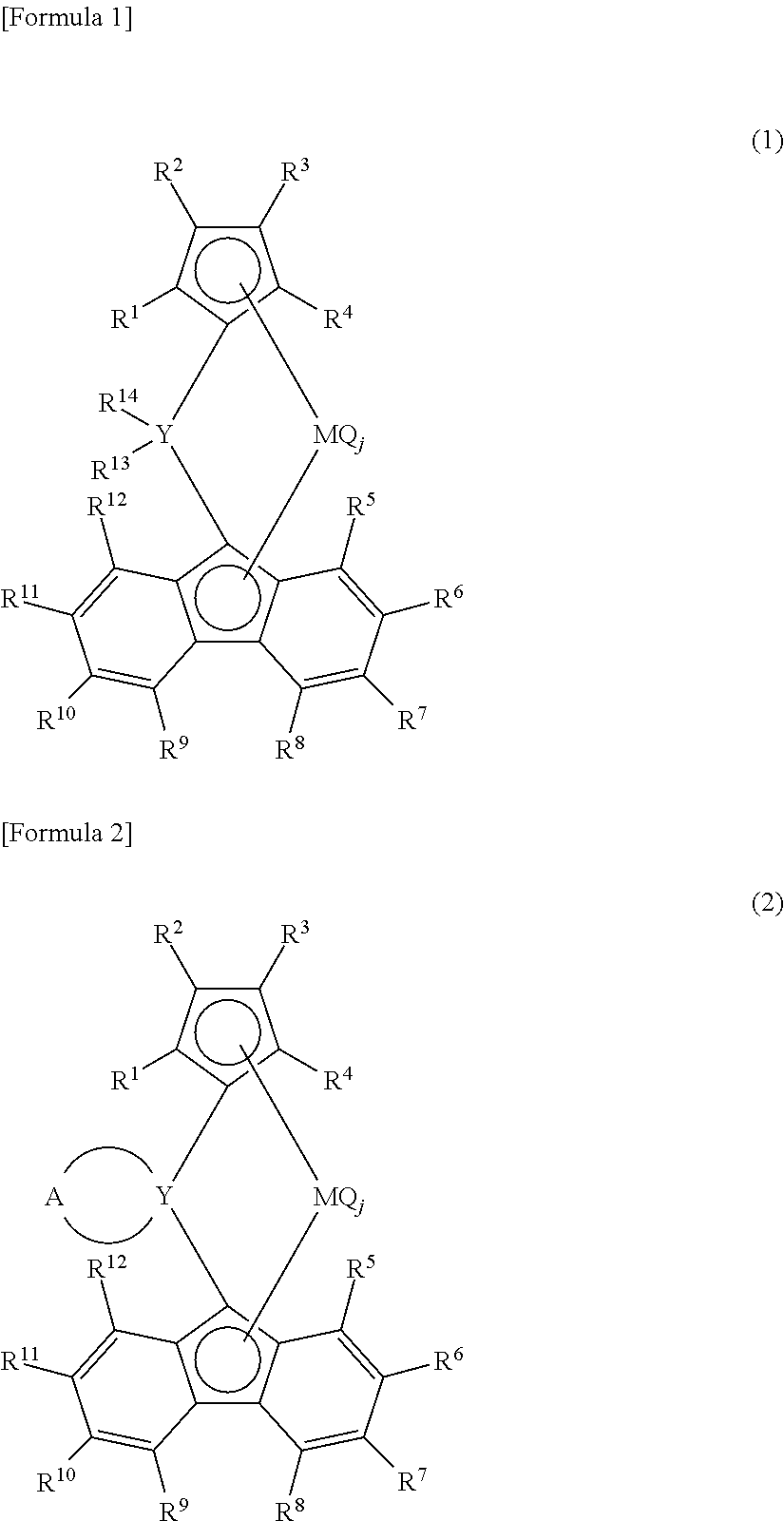

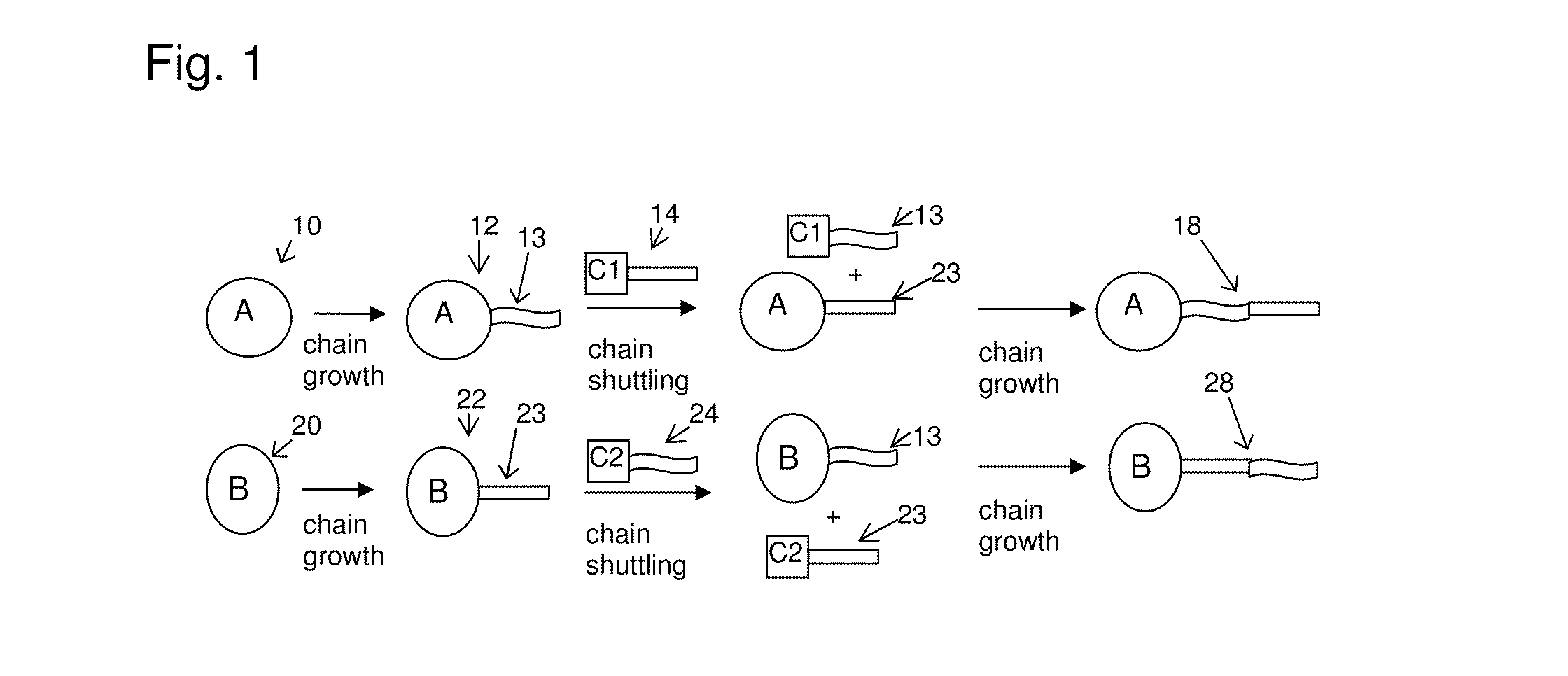

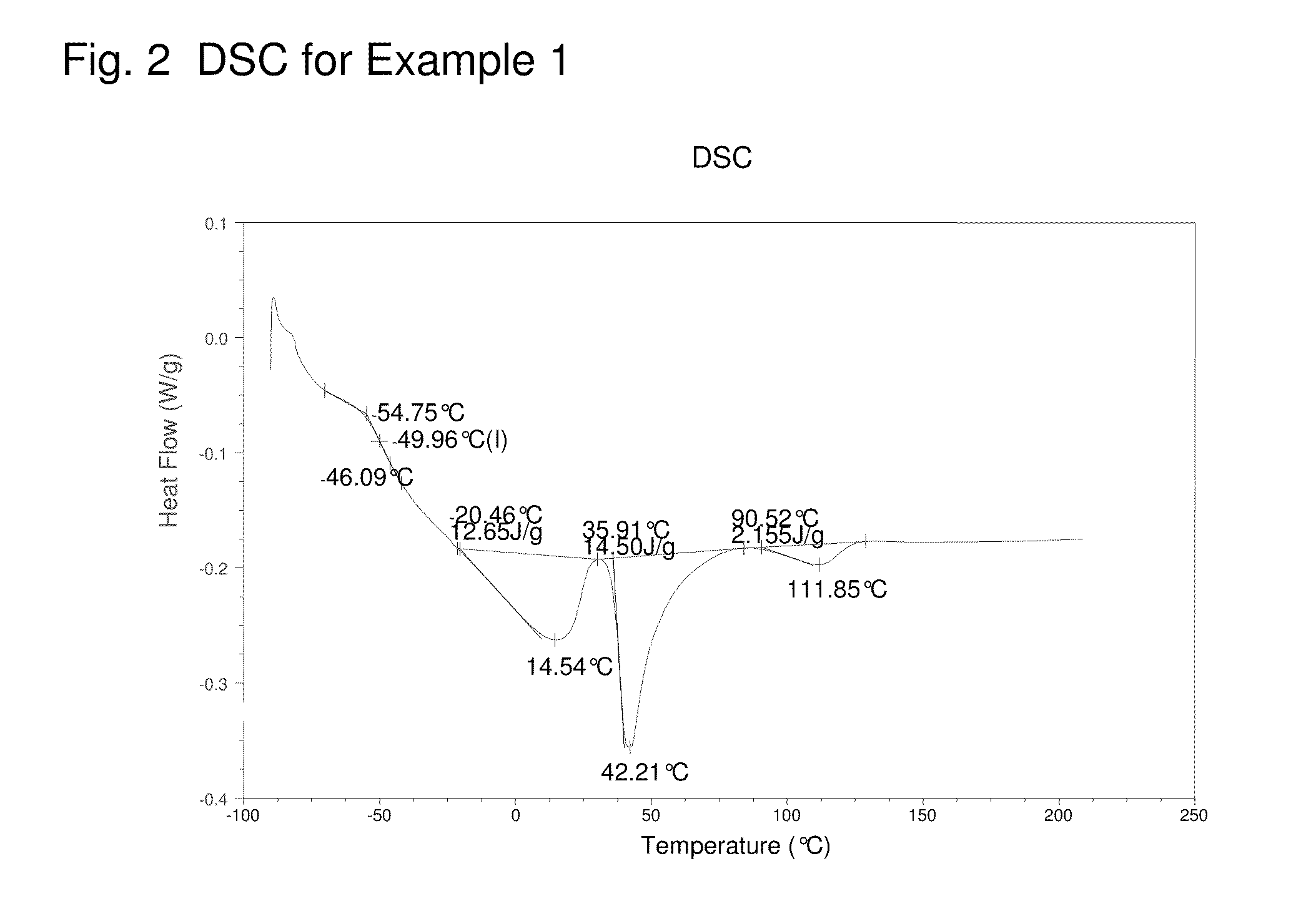

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

ActiveUS7951882B2Improve efficiencyWoven fabricsNon-woven fabricsOlefin polymerization4-Methyl-1-pentene

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

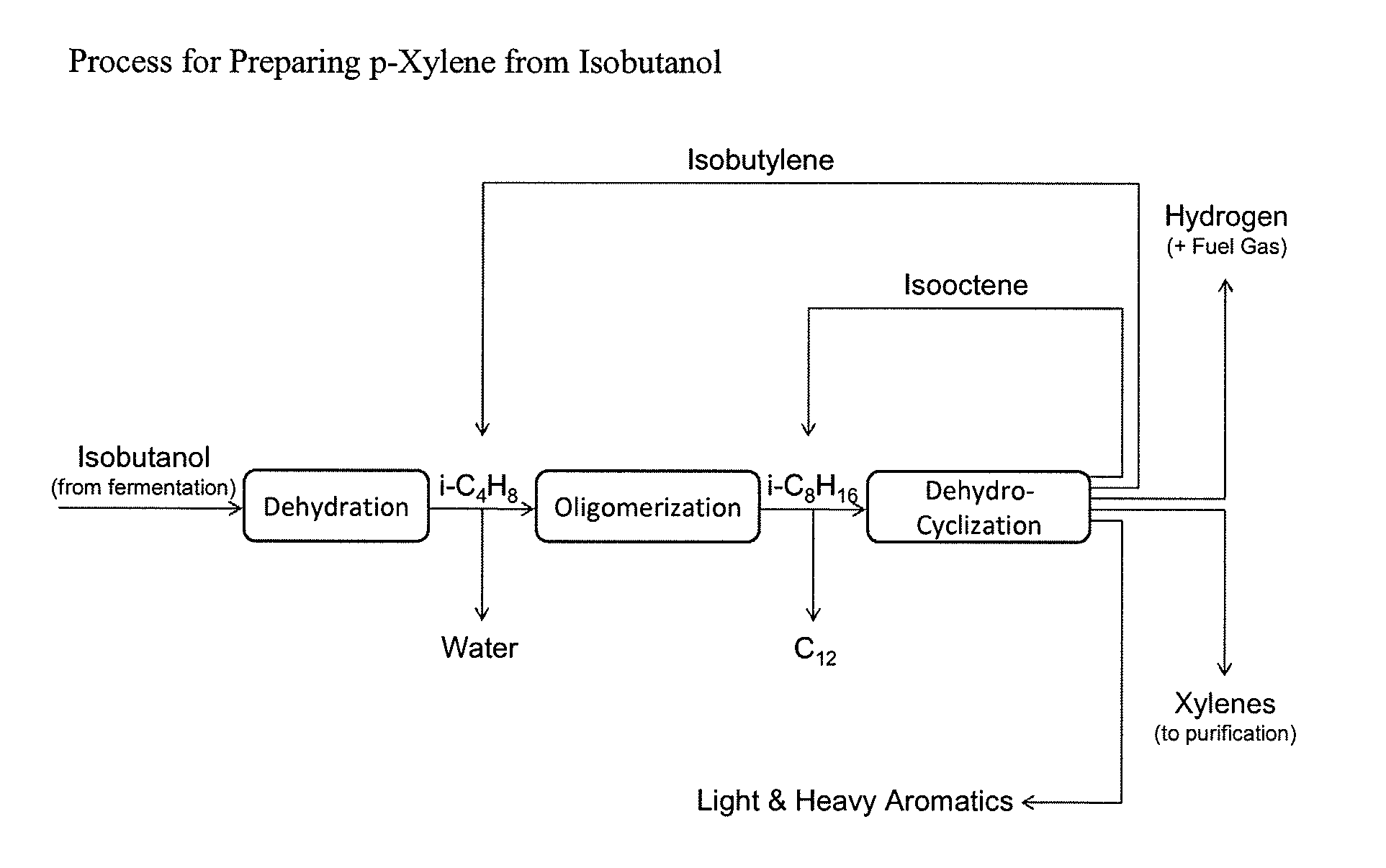

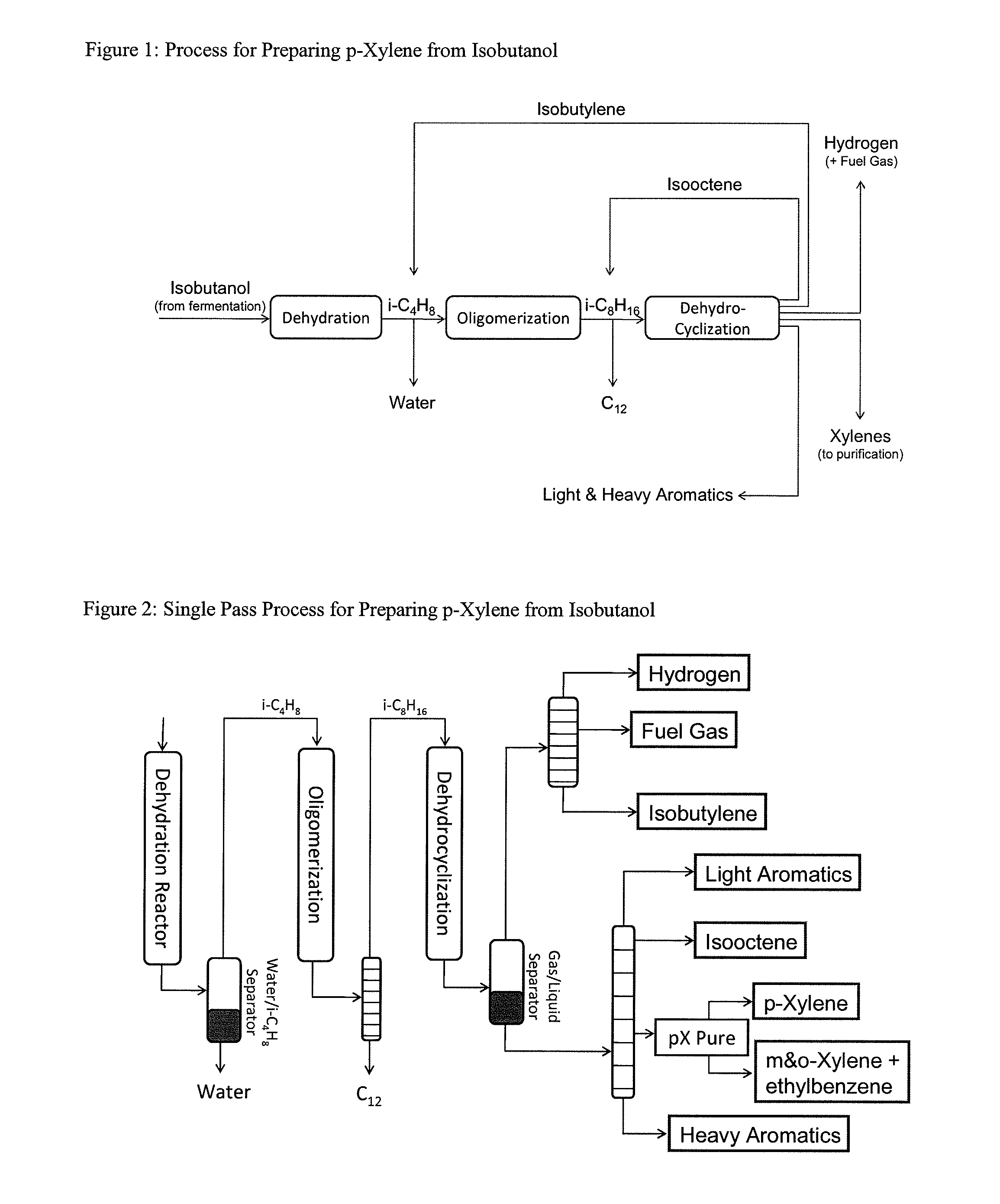

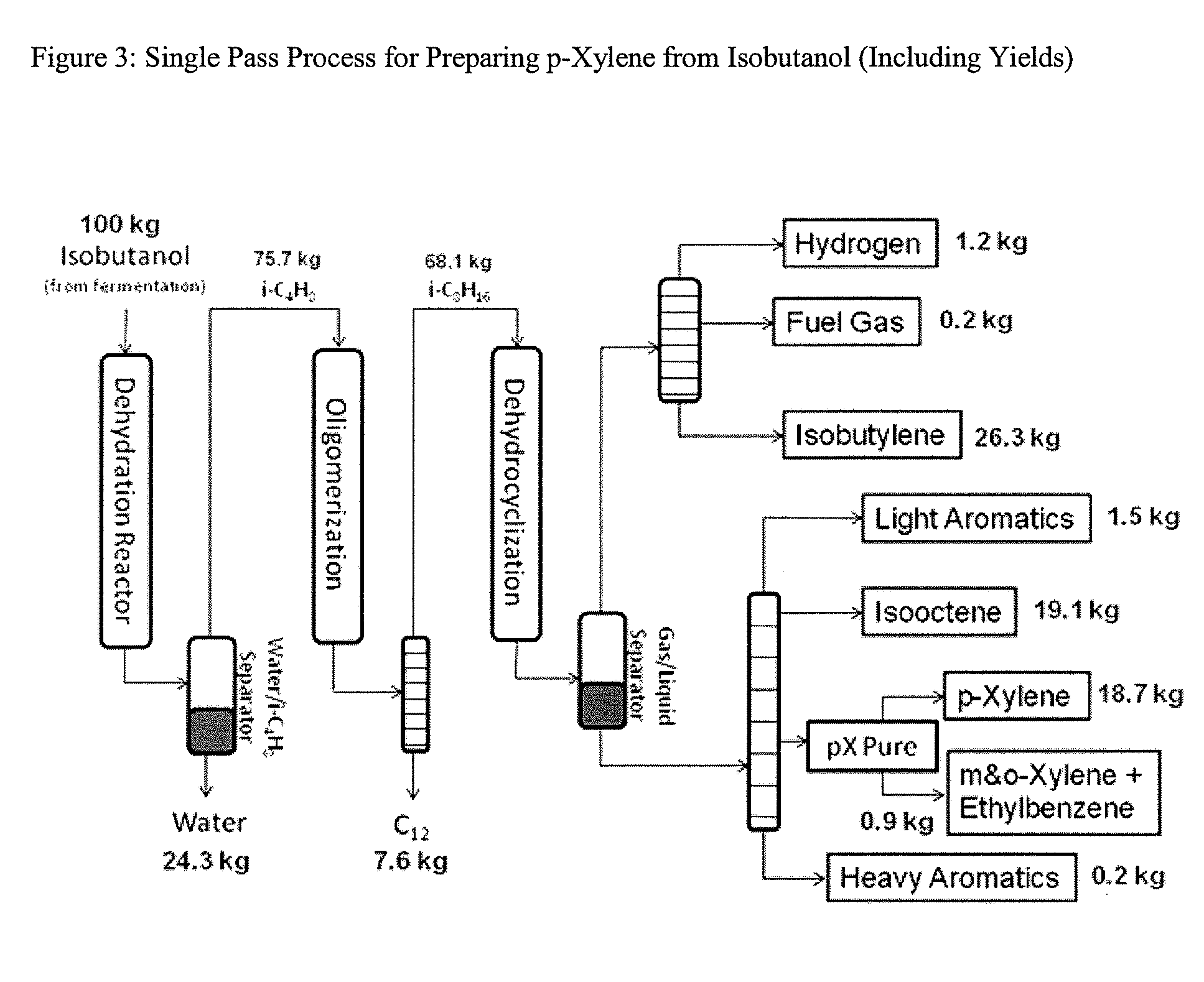

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

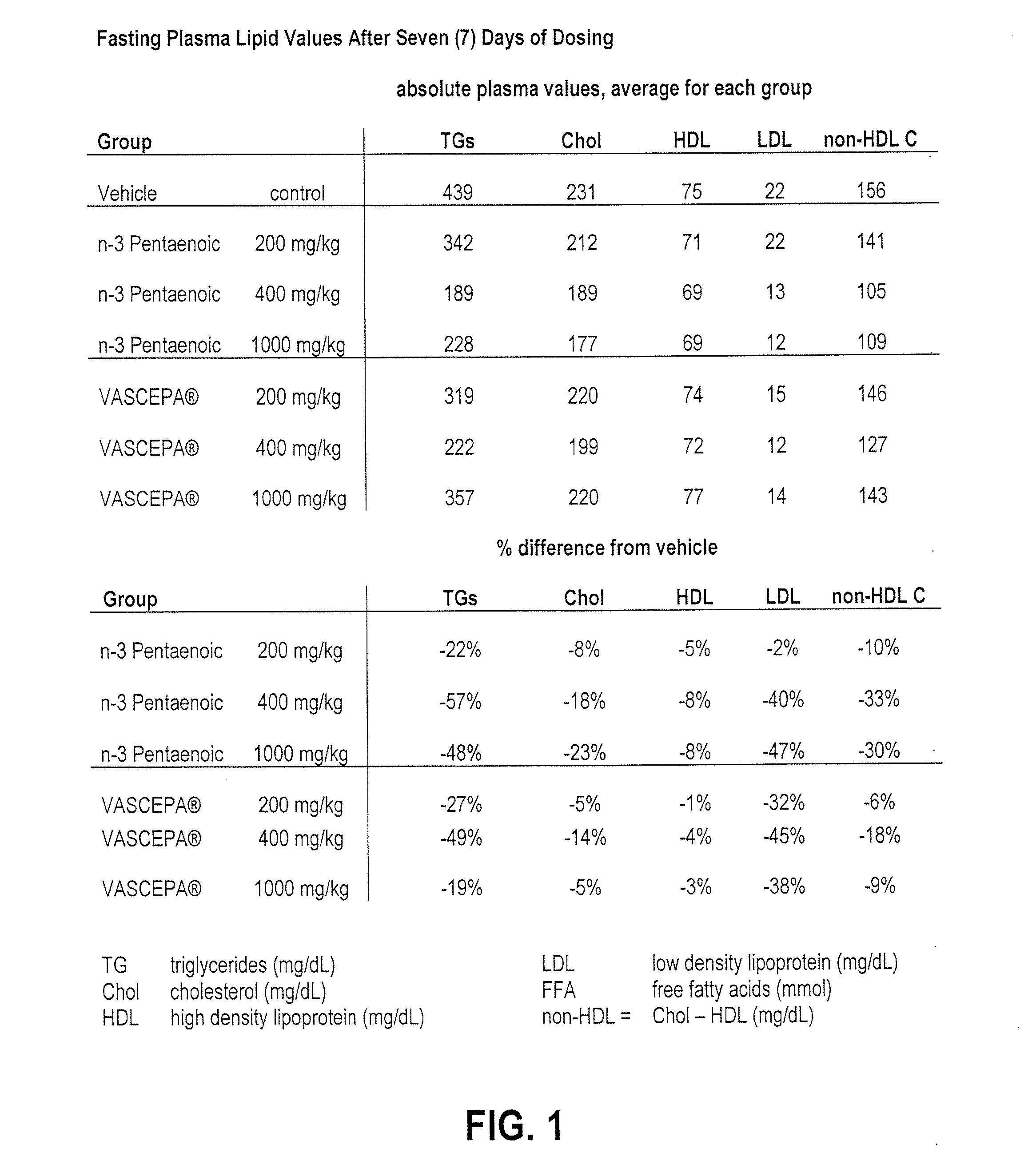

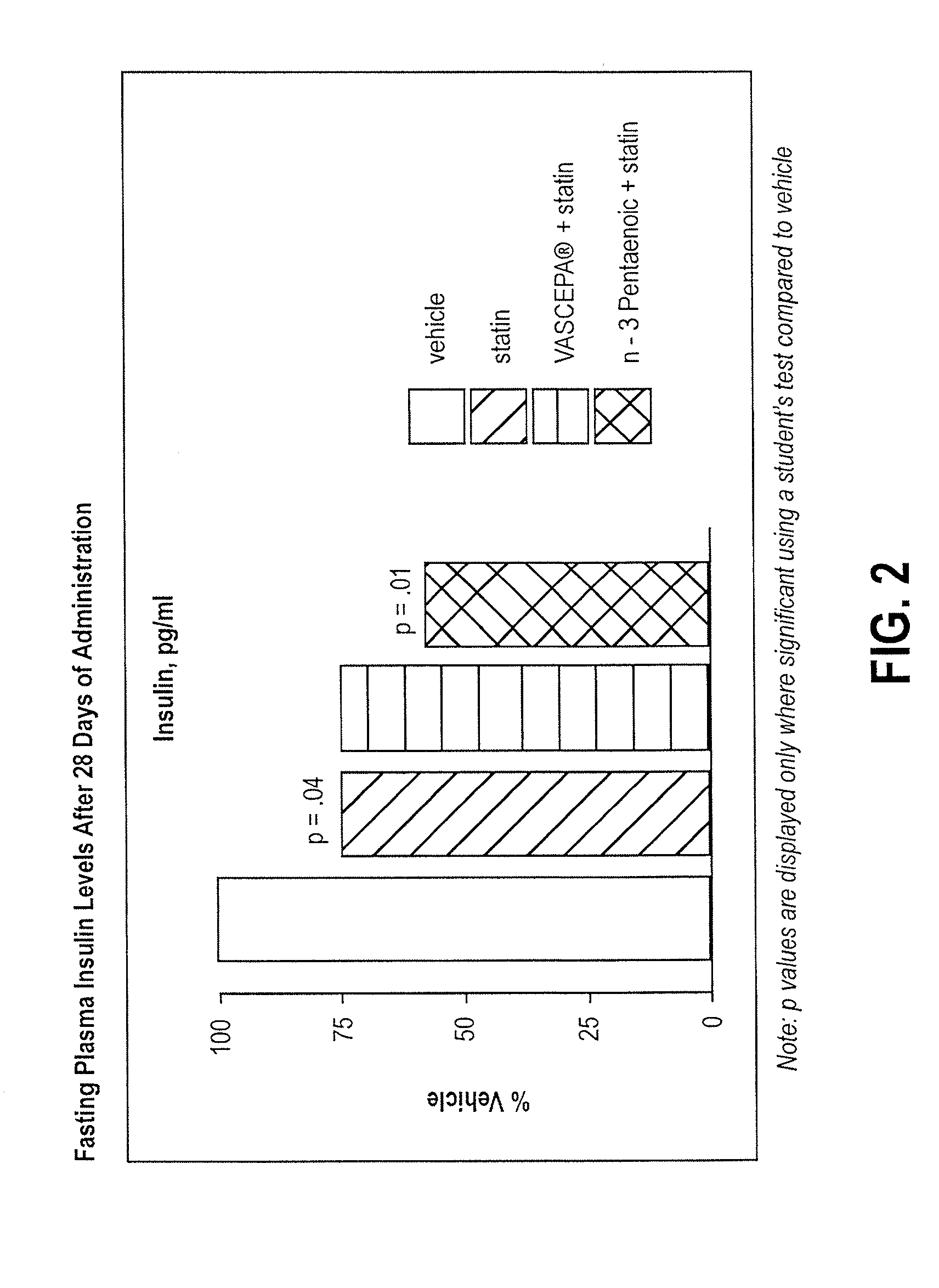

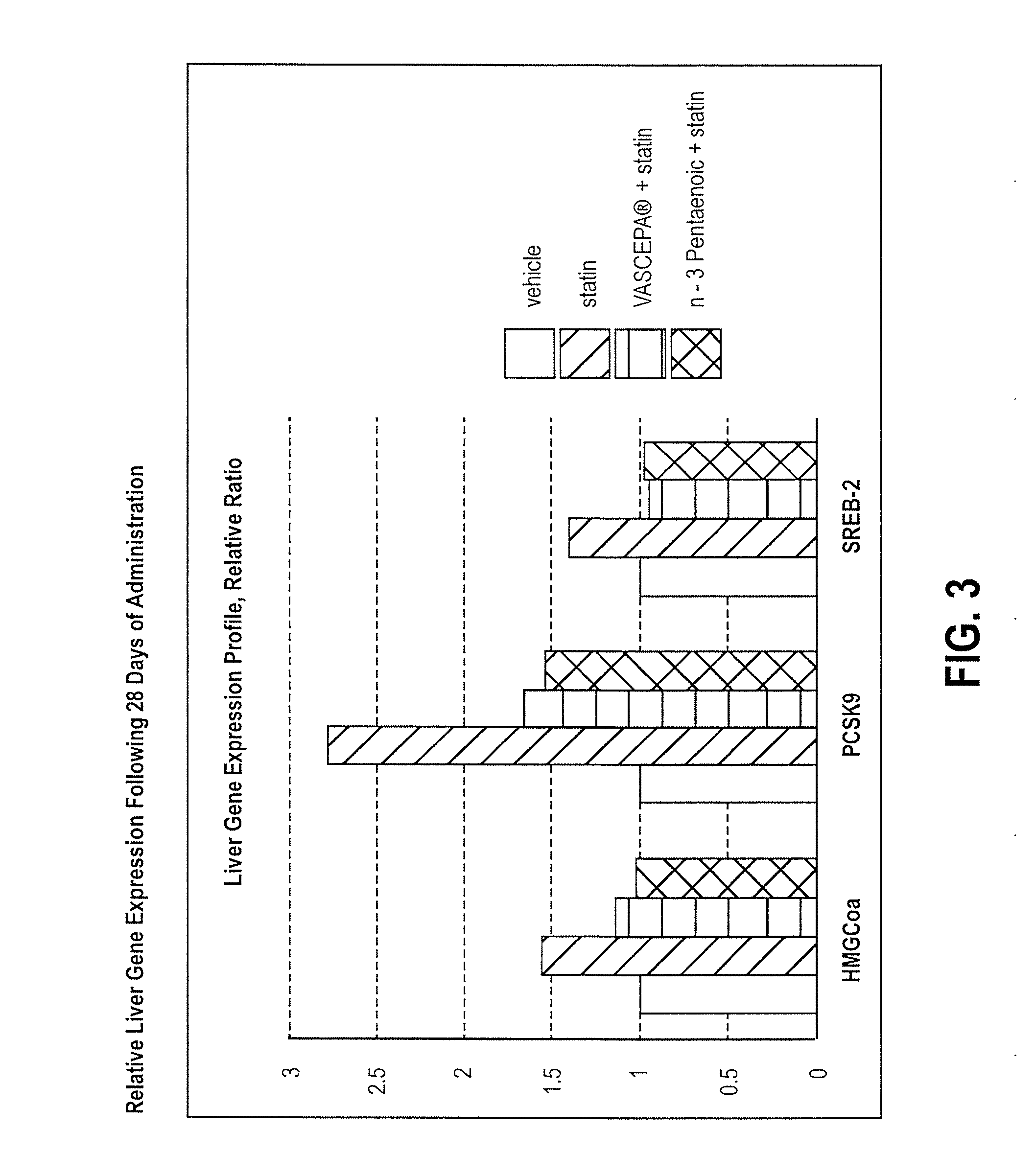

Omega-3 pentaenoic acid compositions and methods of use

Orally administrable composition comprising fatty acids, wherein at least 50% by weight of the fatty acids comprise omega-3-fatty acids, salts or derivatives thereof, wherein the omega-3 fatty acids comprise eicosapentaenoic acid (EPA; C20:5-n3), docosapentaenoic acid (DPA; C22:5-n3), and docosahexaenoic acid (DHA; C22:6-n3), wherein the ratio of DHA to EPA (DHA:EPA) is less than 1:20, and wherein the ratio of DHA to DPA (DHA:DPA) is less than 2:1 are provided. These compositions can be used for the treatment or prophylaxis of dyslipidemic, cardiovascular, CNS, inflammatory, and other diseases / conditions or risk factors therefore.

Owner:MATINAS BIOPHARMA

Hydrolytically-resistant boron-containing therapeutics and methods of use

Compositions and methods of use of borole derivatives, including benzoxaboroles, benzazaboroles and benzthiaboroles, as therapeutic agents for treatment of diseases caused by bacteria or viruses are disclosed, as well as methods for synthesis of said agents and compositions thereof.

Owner:ANACOR PHARMA LLC

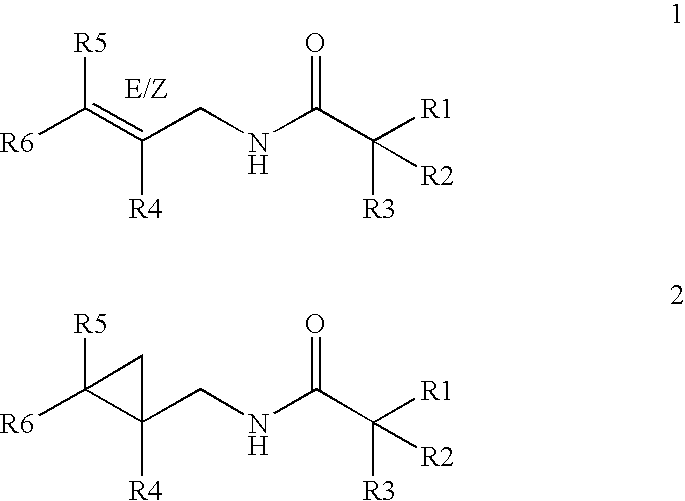

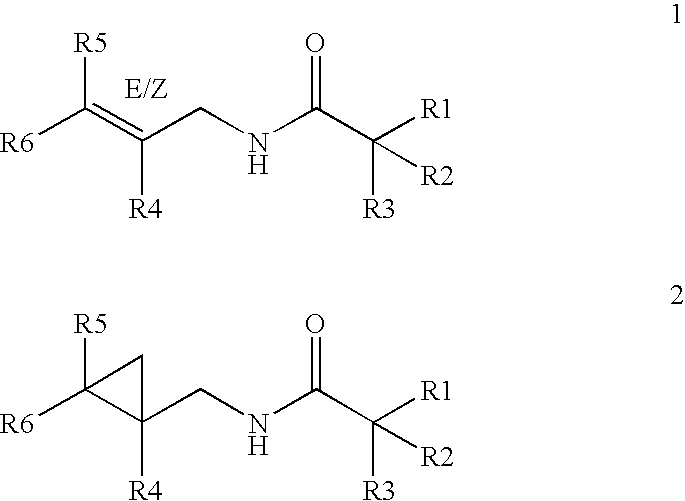

Saturated and unsaturated N-alkamides exhibiting taste and flavor enhancement effect in flavor compositions

ActiveUS20060057268A1Fatty acid chemical modificationOrganic compound preparationCyclopenteneEthyl group

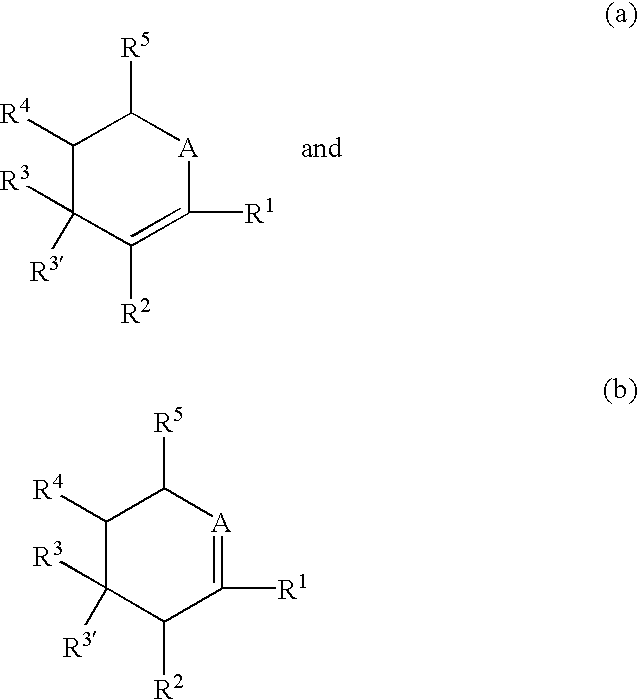

Saturated and unsaturated compounds having sweet, salt or umami taste enhancement qualities. The compounds have the structure: where R1═H or methyl; R2 is selected from the group consisting of H, C1-C4 alkyl, alkenyl and methylene; R3 is selected from the group consisting of H, C1-C8 straight or branched chain alkyl, alkenyl, dienalkyl or phenyl; or if R1═H, R2 and R3 taken together can represent cyclopropyl, cyclobutyl, cyclopentyl, cyclopentenyl, cyclohexyl, or cyclohexenyl; R4 is selected from the group consisting of H, methyl and ethyl; R5 is selected from the group consisting of H, methyl and ethyl; R6 is selected from the group consisting of H, C1-C9 straight or branched chain alkyl, alkenyl, alkyldienyl, acyclic or containing no more than one ring; with the proviso that in structure 1 when R4 is H or Me; and R5═H or methyl, R6 may be selected from the group described above or phenyl.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

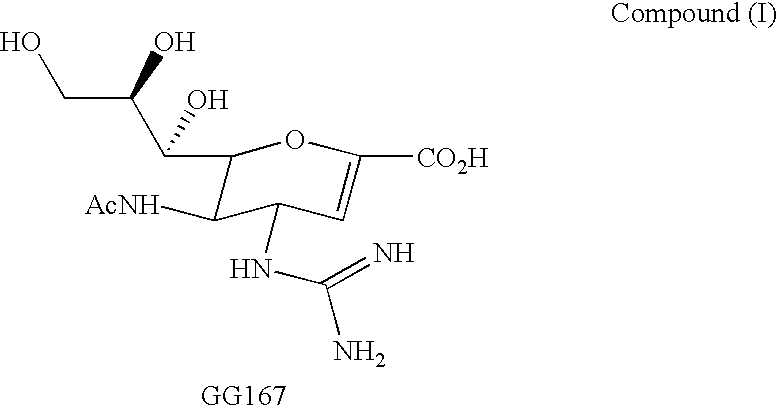

Cyclopentane and cyclopentene compounds and use for detecting influenza virus

New cyclopentane and cyclopentene compounds are provided along with their use in method for detecting influenza virus.

Owner:BIOCRYST PHARM INC

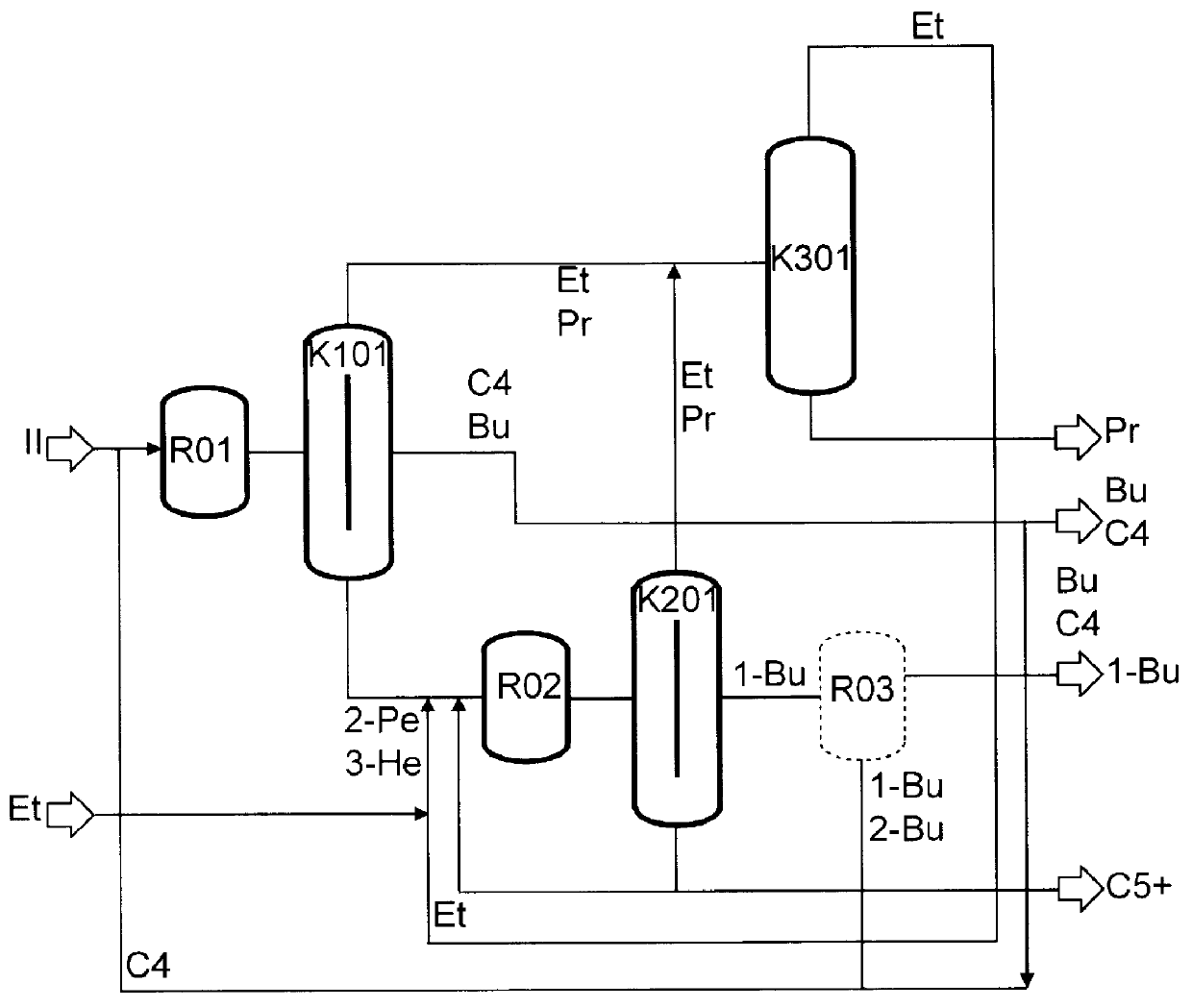

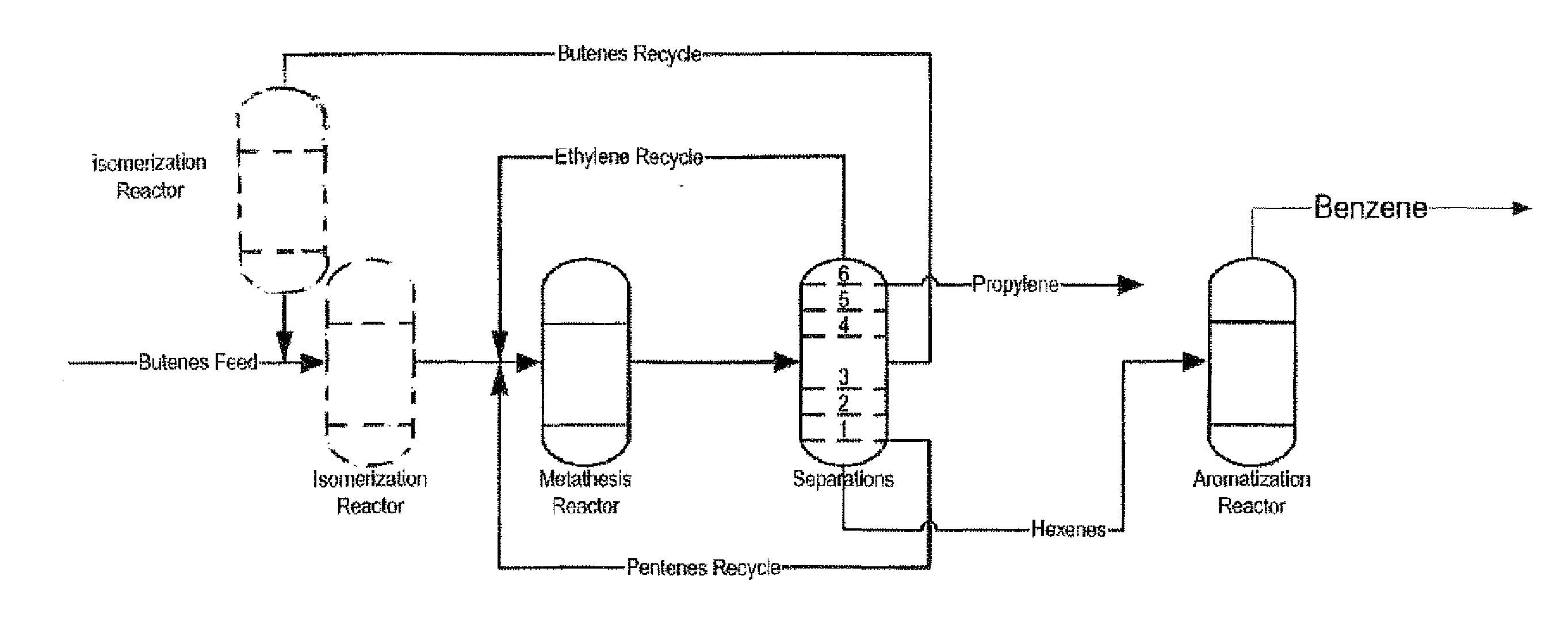

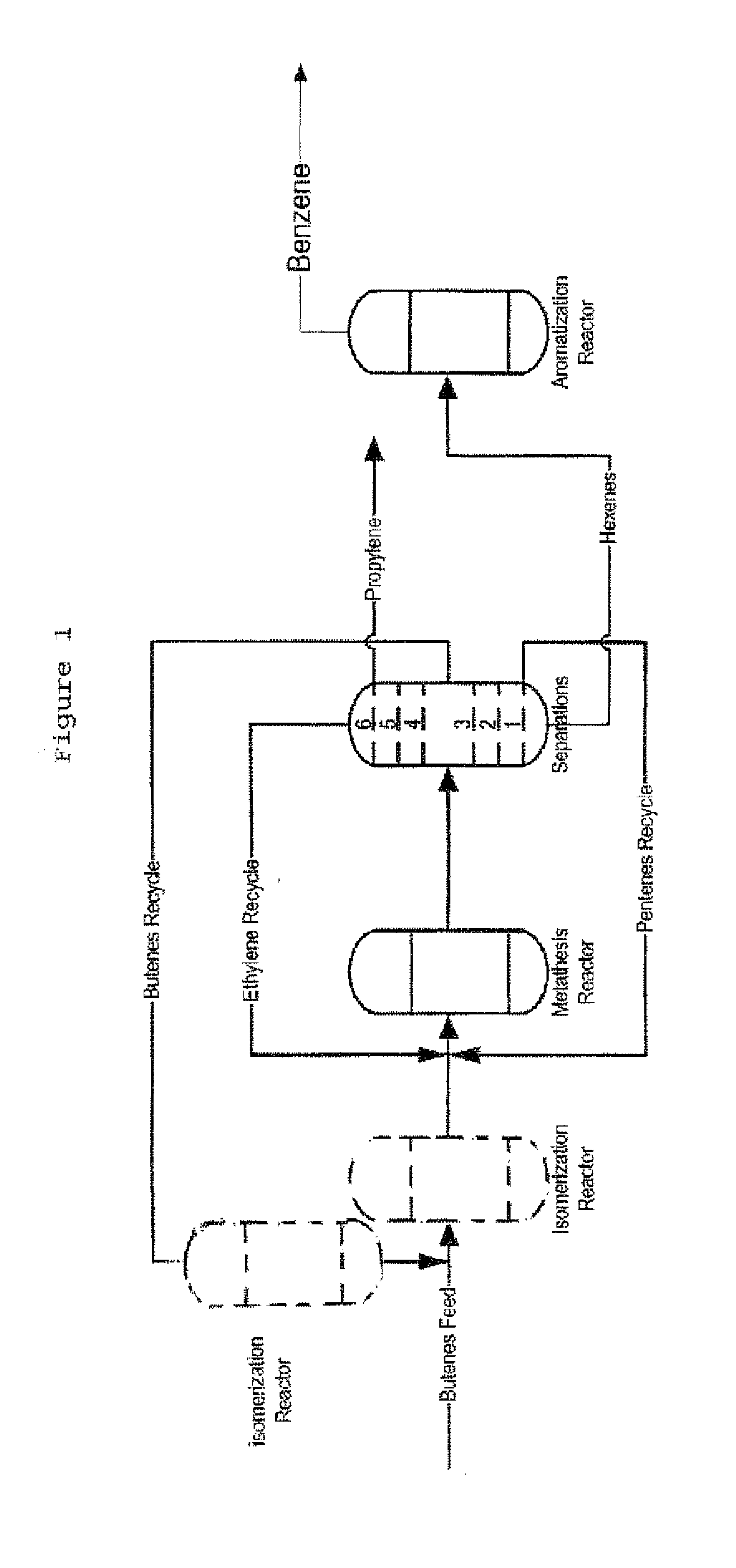

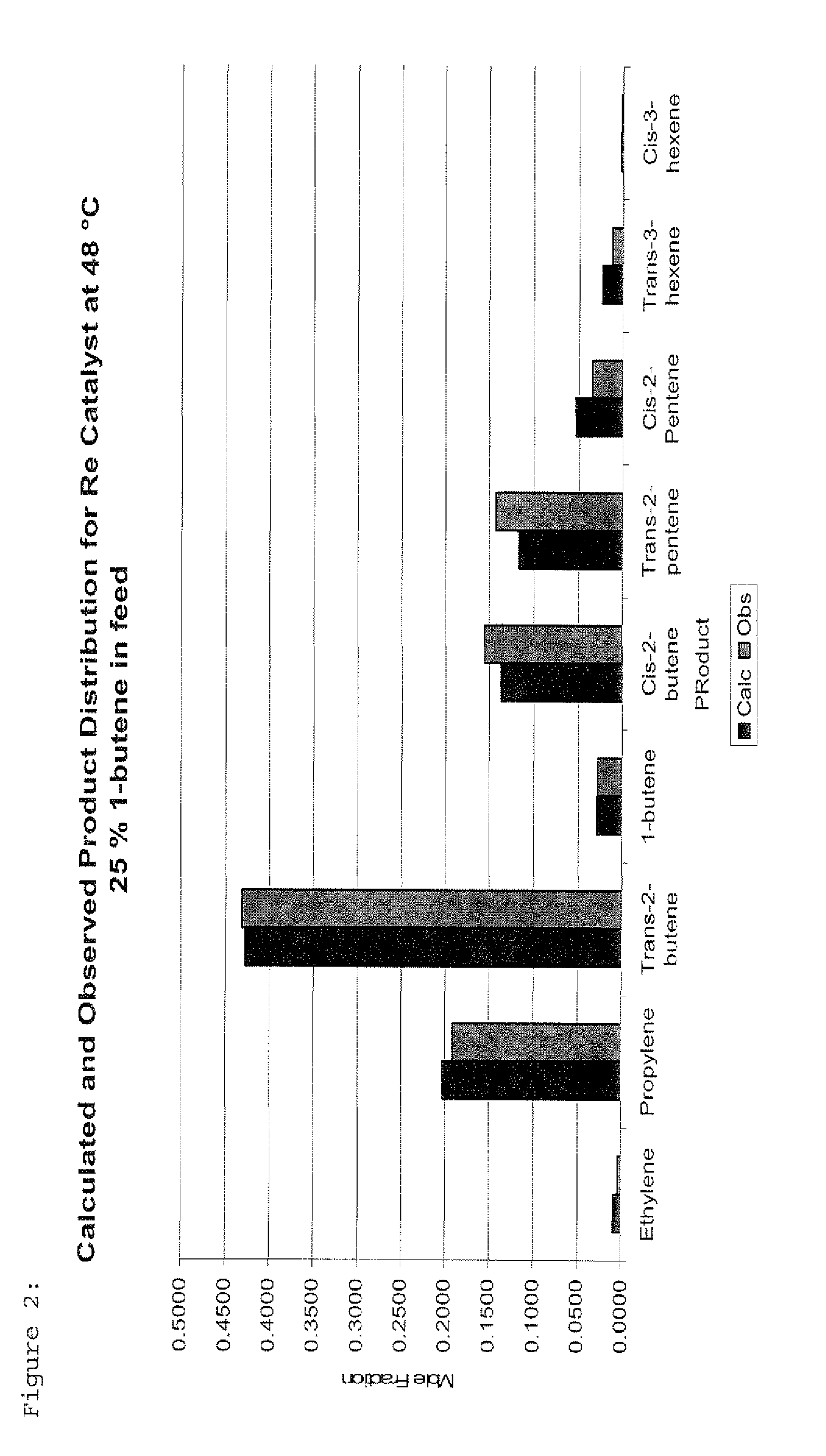

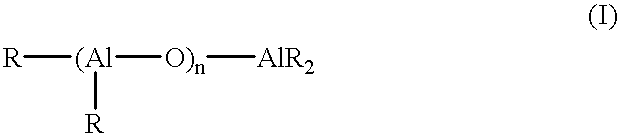

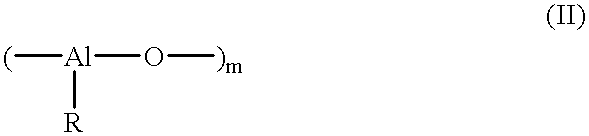

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

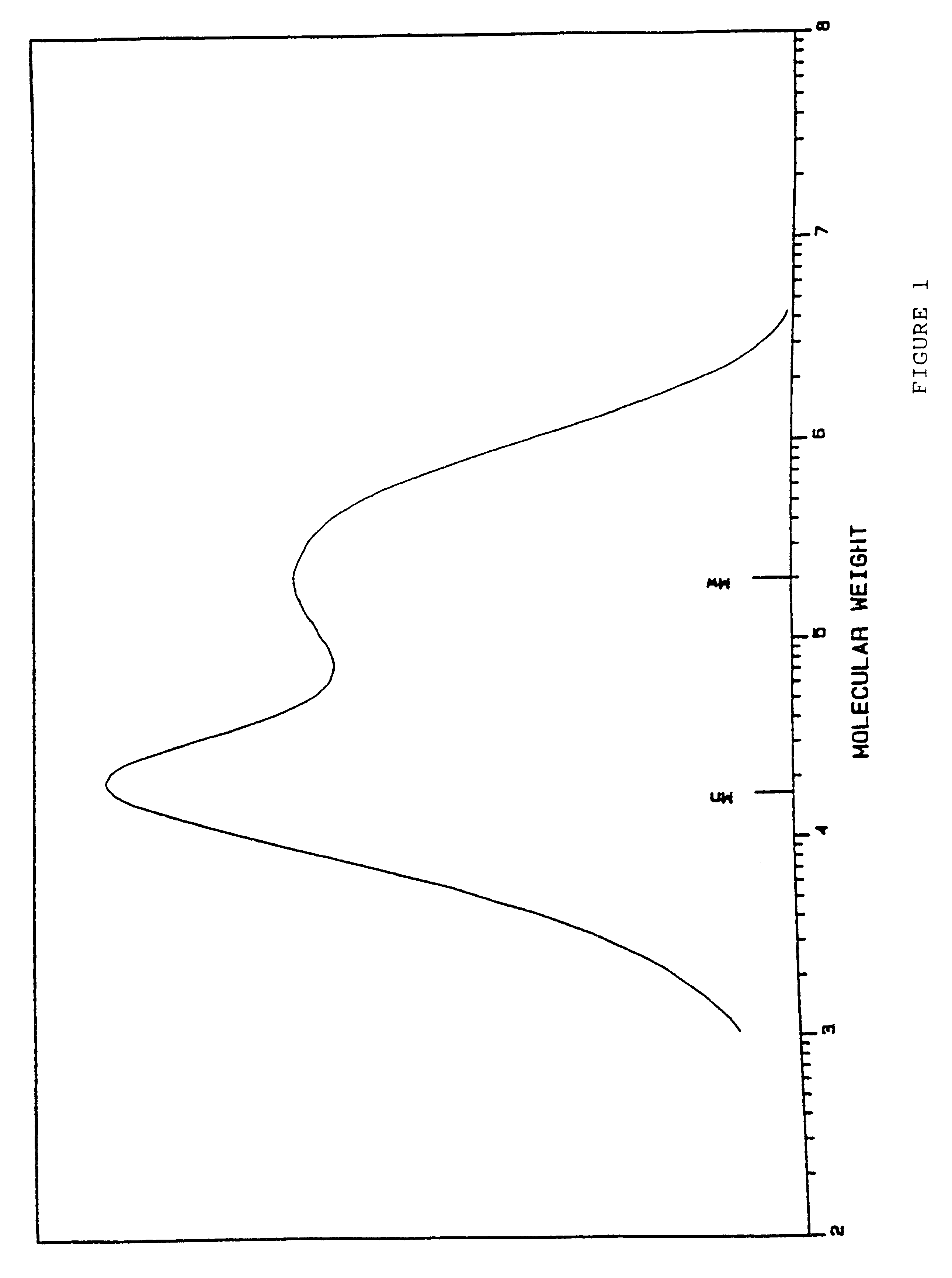

Process to produce bimodal polyolefins with metallocene catalysts using two reaction zones

A process for the preparation of polyolefins having a bi- or multimodal molecular weight distribution, the process comprising the steps of: (i) contacting an olefin monomer and a first co-reactant with a catalyst system in a first reaction zone under first polymerization conditions to produce a product comprising a first polyolefin having a first molecular weight distribution; and (ii) contacting an olefin monomer and a second co-reactant with a catalyst system in a second reaction zone under second polymerization conditions to produce a product comprising a second polyolefin having a second molecular weight distribution different from the first molecular weight distribution; wherein the first and second polyolefins are mixed together, wherein one of the co-reactants is hydrogen and the other is a comonomer selected from butene, methylpentene, hexene or octene, and wherein each catalyst system comprises (a) a metallocene catalyst component comprising a bis tetrahydroindenly compound of the general formula (IndH4)2R''MQ2 in which each Ind is the same or different and is indenyl or substituted indenyl, R'' is a bridge which comprises a C1-C4 alkylene radical, a dialkly mernamium or silicon or siloxane, or an alkyl phosphine or amine radical, which bridge is substitued or unsubstituted, M is a Group IV metal or vanadium and each Q is hydrocarbyl having 1 to 20 carbon atoms or halogen; and (b) a cocatalyst which activates the catalyst component.

Owner:FINA RES SA

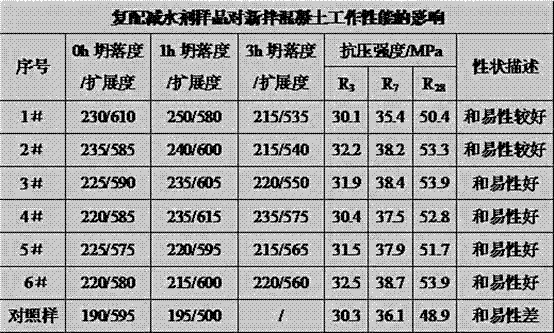

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

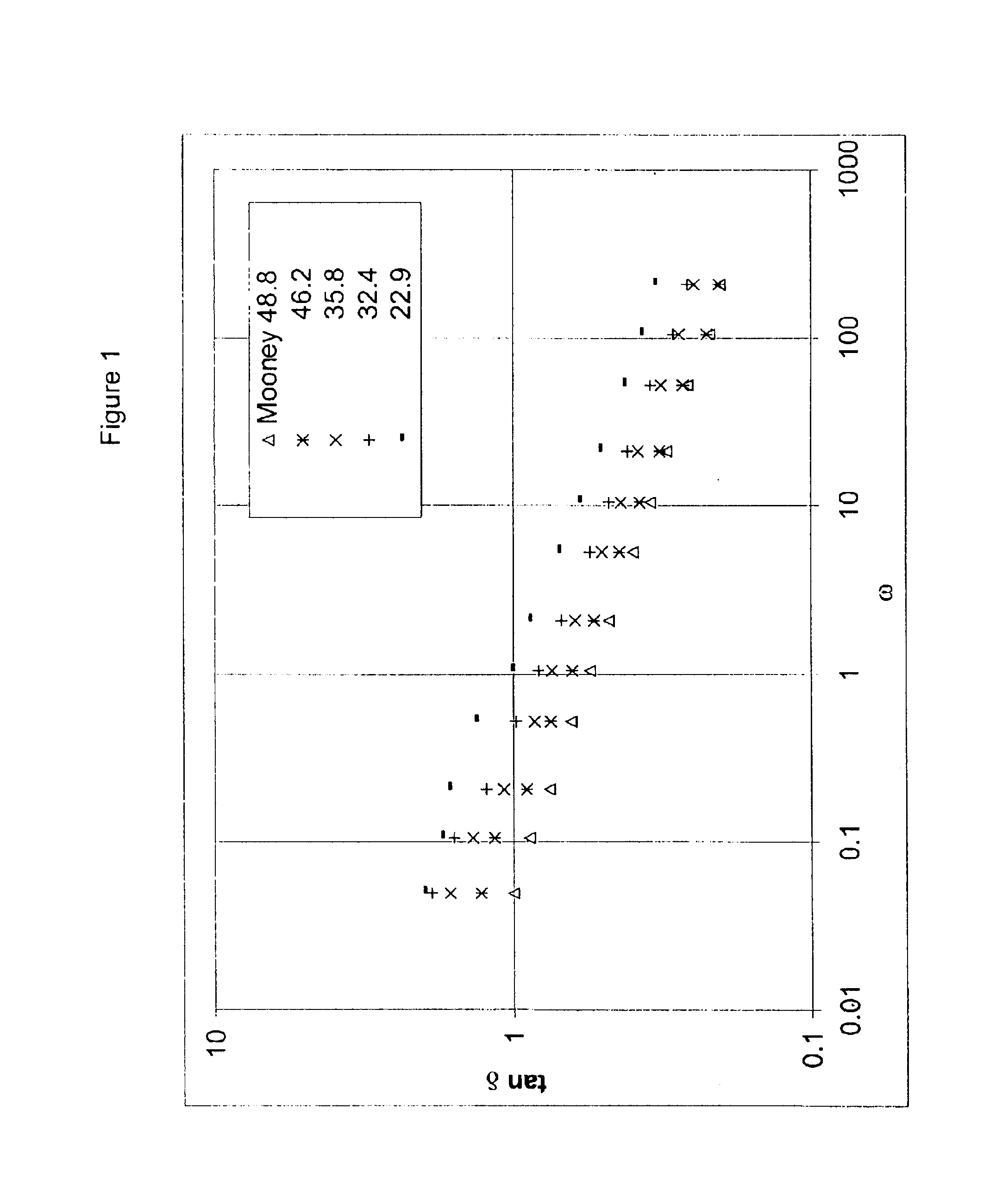

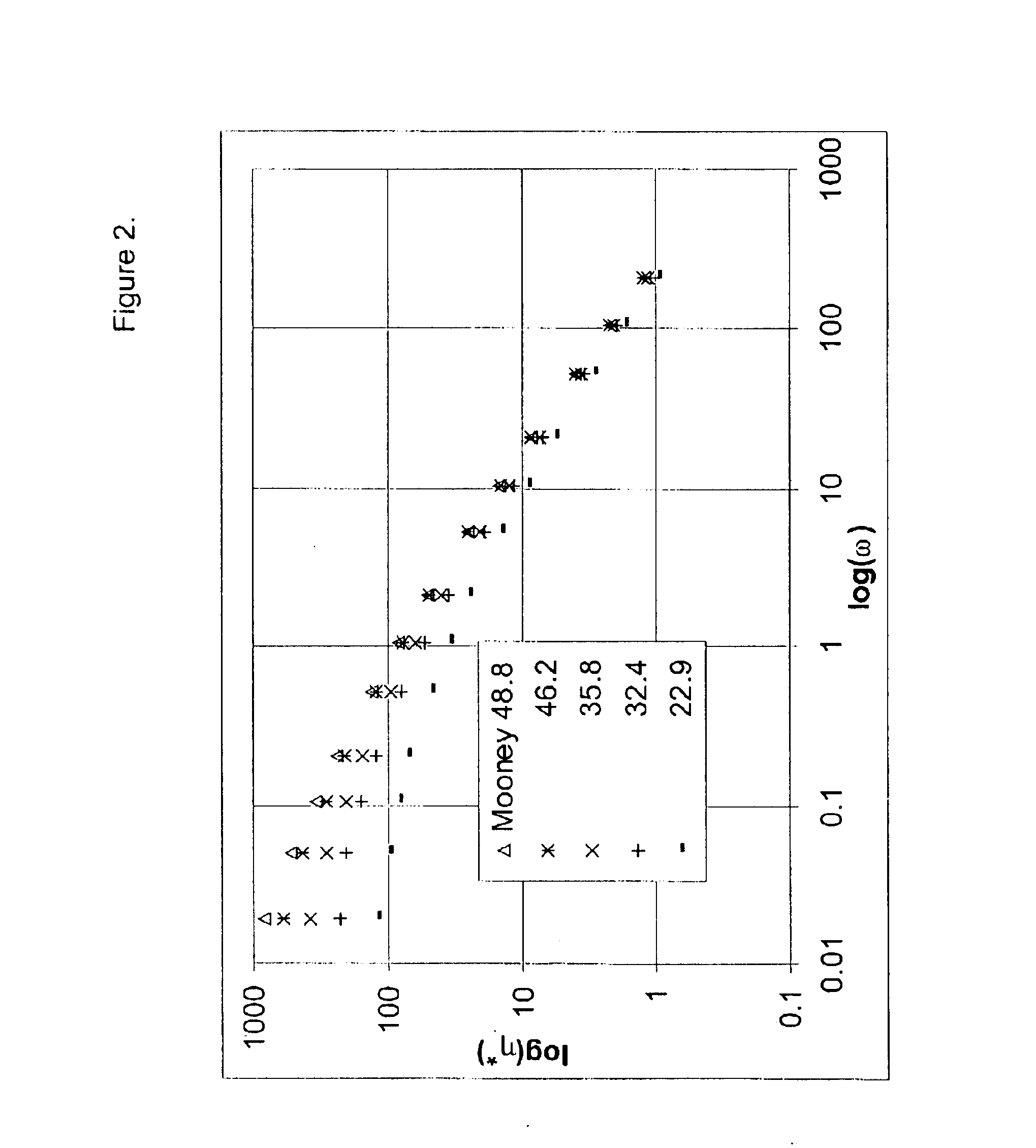

Processability butyl rubber and process for production thereof

A butyl polymer having improved processability is described, together with a process for production thereof. The butyl polymer derived from a reaction mixture which contains: (i) a monomer mixture comprising a C4 to C7 monoolefin monomer (preferably isobutylene) and a C4 to C14 multiolefin monomer (preferably isoprene); (ii) a multiolefin cross-linking agent (preferably divinyl benzene); and (iii) a chain transfer agent (preferably diisobutylene (2,2,4-trimethyl-1-pentene)). The subject butyl polymer has an improved balance of cold flow, filler dispersion, extrusion rate and die swell.

Owner:LANXESS LTD

Substituted cyslopentane and cyclopentene compounds useful as neuraminidase inhibitors

Owner:BIOCRYST PHARM INC

Base stocks and lubricant blends containing poly-alpha olefins

This disclosure relates to substantially atactic polymers of at least one of propylene, 1-butene or 1-pentene, processes for making such polymers and compositions including the polymers. The polymers may be used as lubricants or may be combined with low viscosity base stocks to form lubricants. The polymers may be made in the presence of a metallocene catalyst with a non-coordinating anion activator and optionally with hydrogen.

Owner:EXXON RES & ENG CO

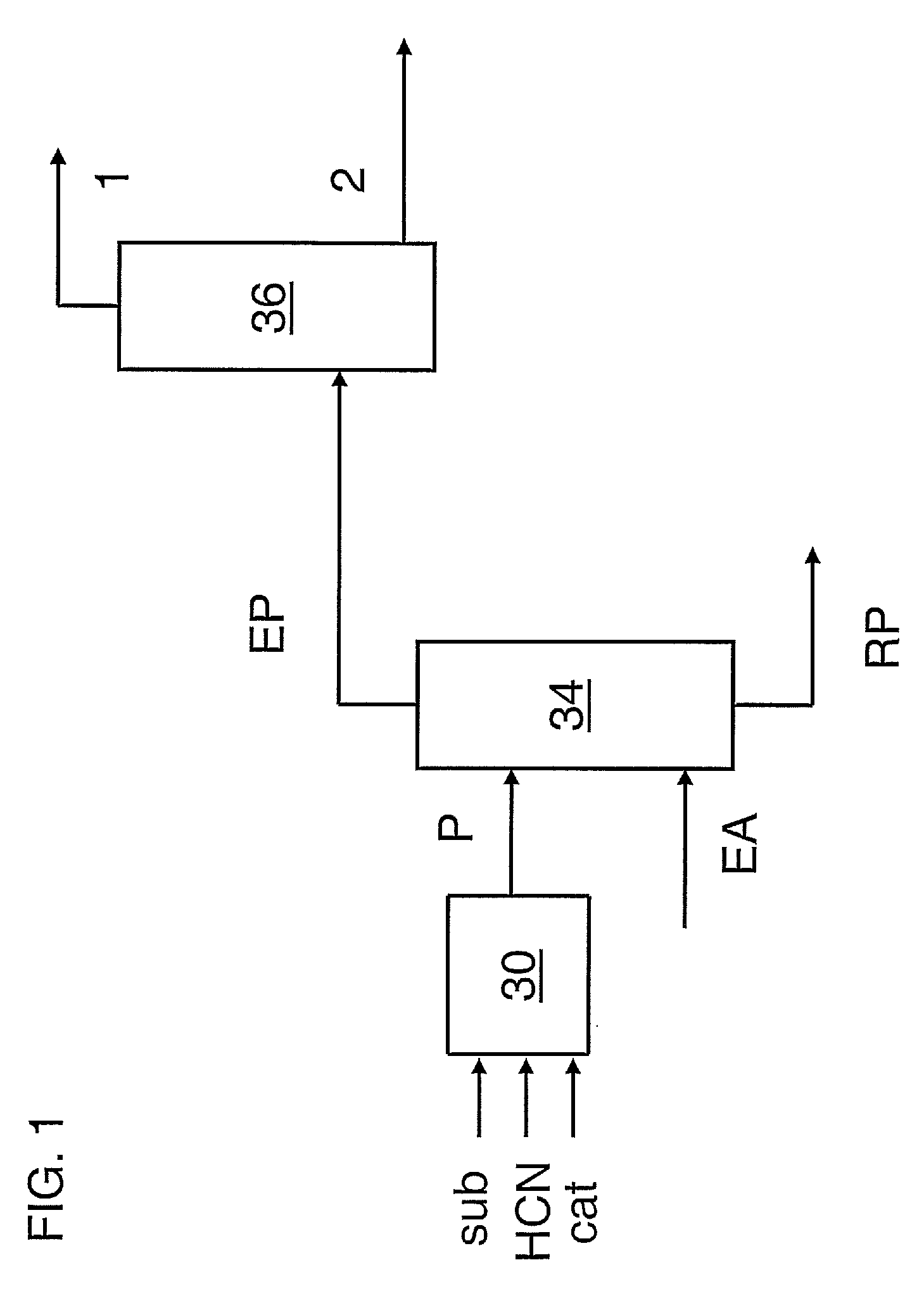

Hydrocyanation of pentenenitriles

ActiveUS20090182164A1Organic compound preparationPreparation by hydrogen cyanide additionHydrogenHydrocyanation

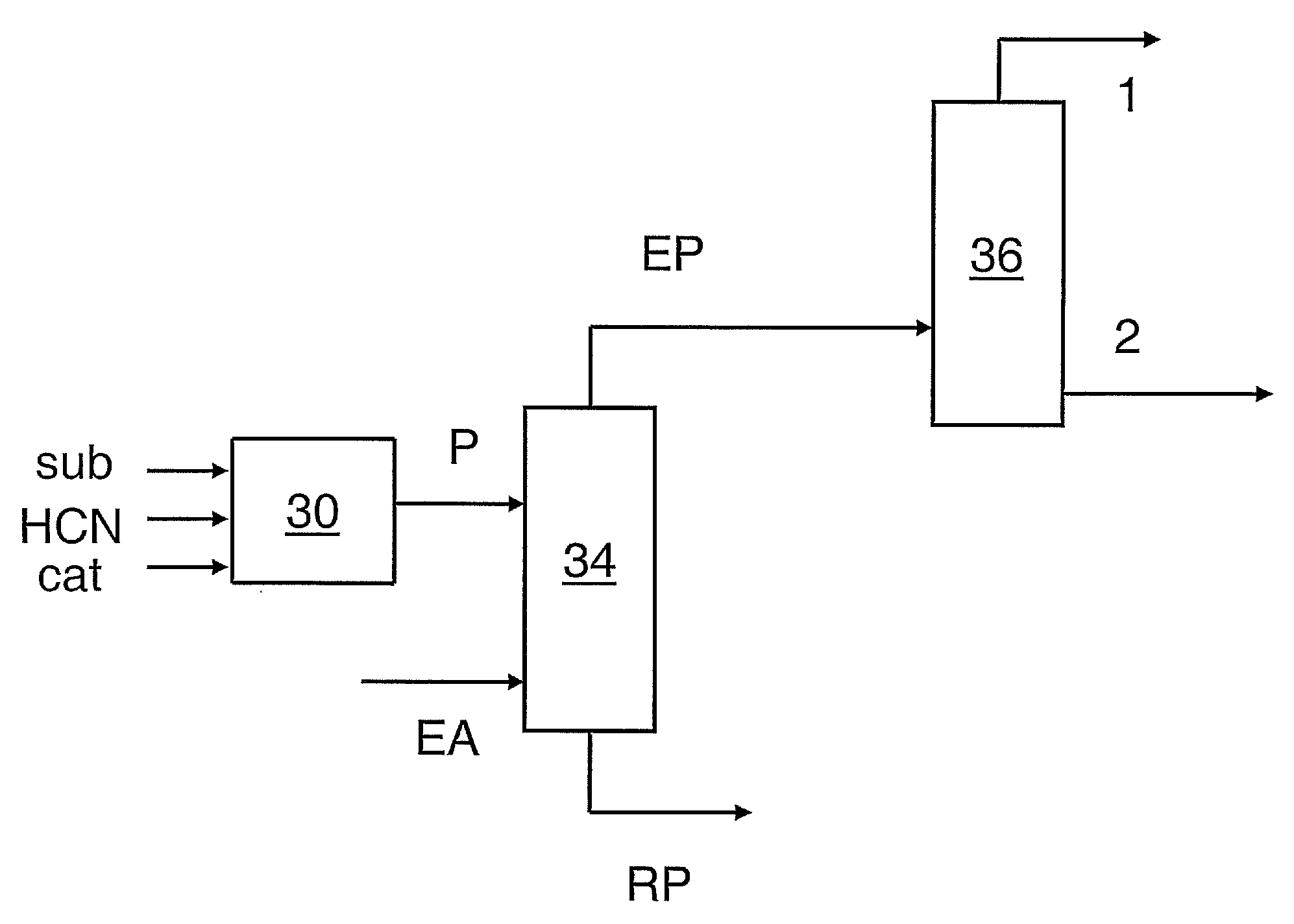

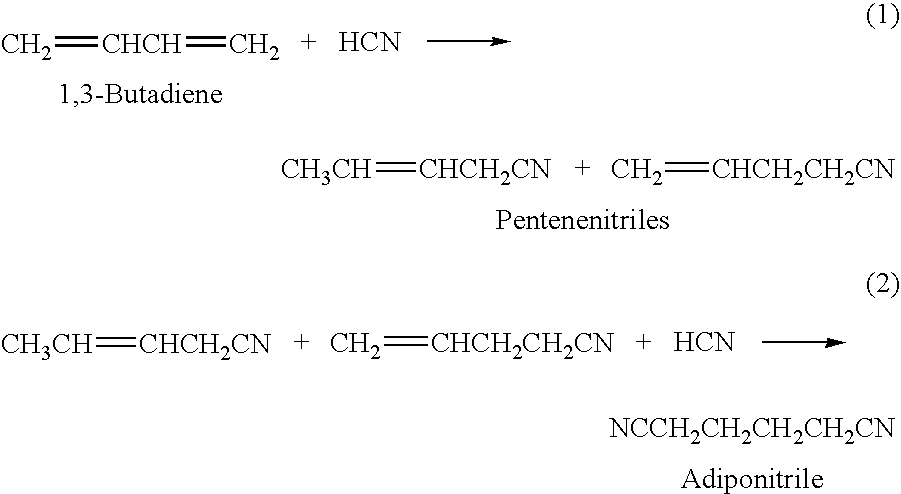

The invention provides a hydrocyanation process to produce adiponitrile and other dinitriles having six carbon atoms, in the presence of catalyst composition comprising a zero-valent nickel and at least one bidentate phosphorus-containing ligand wherein the bidentate phosphorus-containing ligand gives acceptable results according to at least one protocol of the 2-Pentenenitrile Hydrocyanation Test Method.

Owner:INV NYLON CHEM AMERICAS LLC

4-METHYL-1-PENTENE/a-OLEFIN COPOLYMER, COMPOSITION COMPRISING THE COPOLYMER AND 4-METHYL-1-PENTENE COPOLYMER COMPOSITION

ActiveUS20120220728A1Preferable in of flexibilityPreferable in of mechanical propertyPolymer scienceStress relaxation

The present invention provides a 4-methyl-1-pentene / α-olefin copolymer being excellent in lightness, stress absorption, stress relaxation, vibration damping properties, scratch resistance, abrasion resistance, toughness, mechanical properties and flexibility, having no stickiness during molding operation and being excellent in the balance among these properties; a composition comprising the polymer; and uses thereof. The 4-methyl-1-pentene / α-olefin copolymer (A) of the present invention satisfies specific requirements, and comprises 5 to 95 mol % of a structural unit (i) derived from 4-methyl-1-pentene, 5 to 95 mol % of a structural unit (ii) derived from at least one kind of α-olefin selected from α-olefins having 2 to 20 carbon atoms excluding 4-methyl-1-pentene and 0 to 10 mol % of a structural unit (iii) derived from a non-conjugated polyene, provided that the total of the structural units (i), (ii), and (iii) is 100 mol %.

Owner:MITSUI CHEM INC

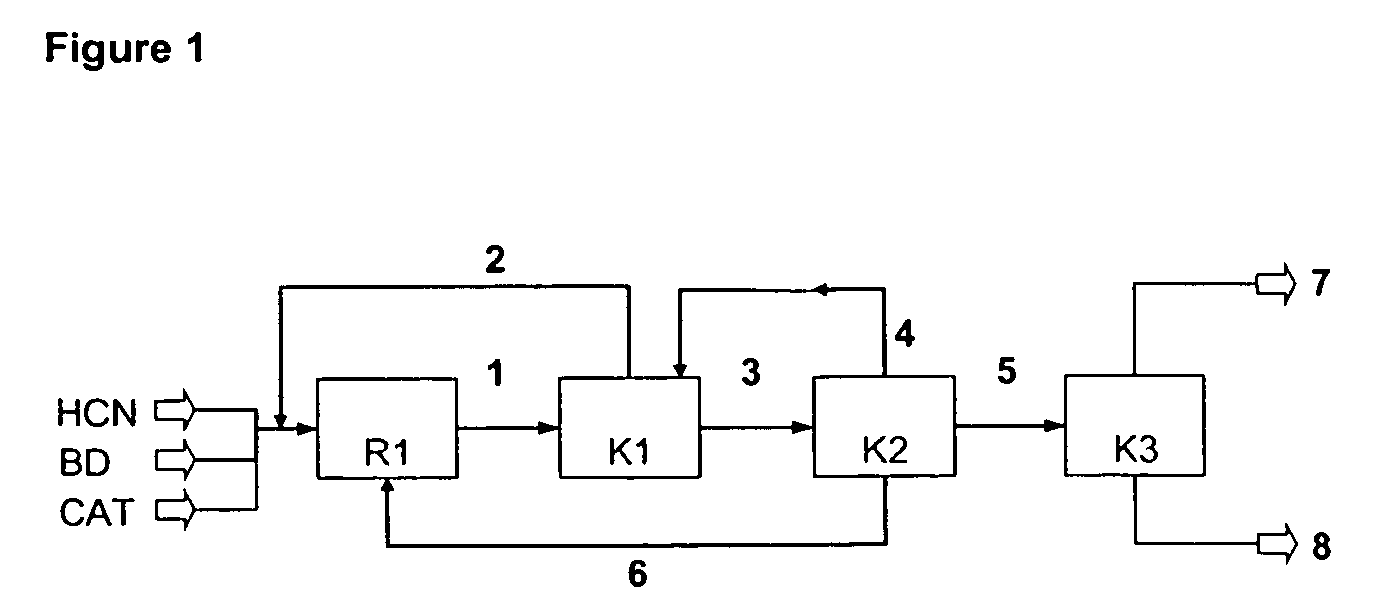

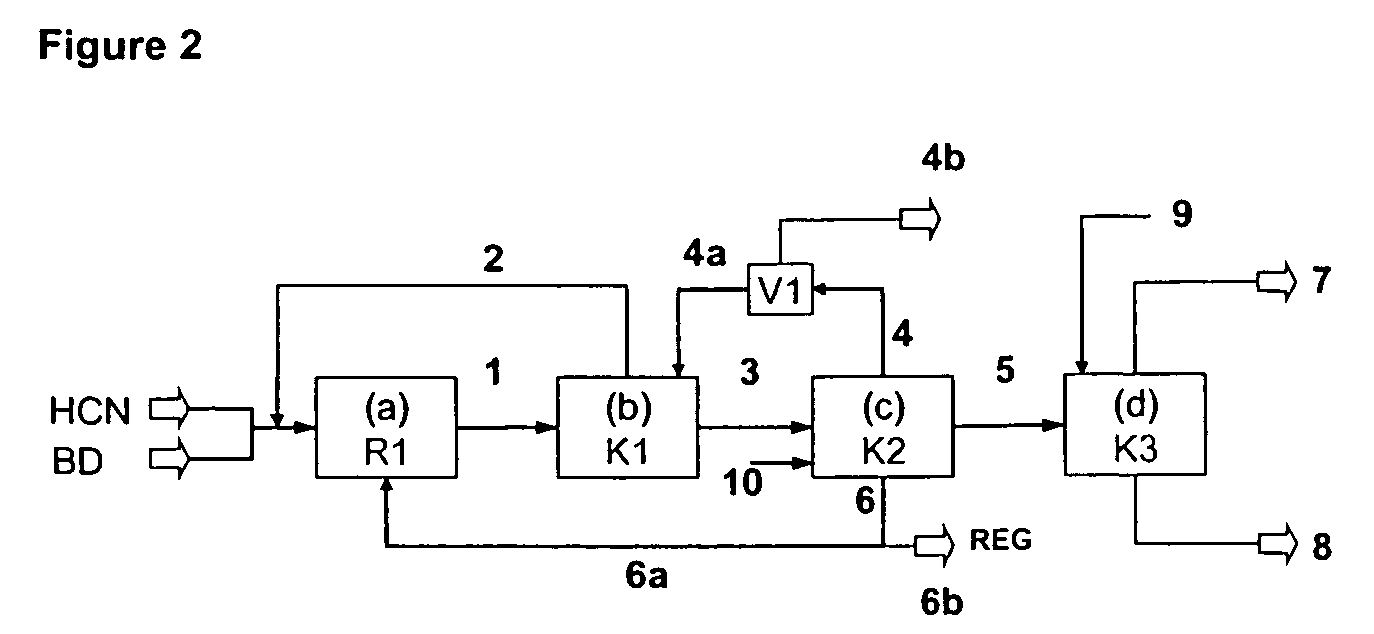

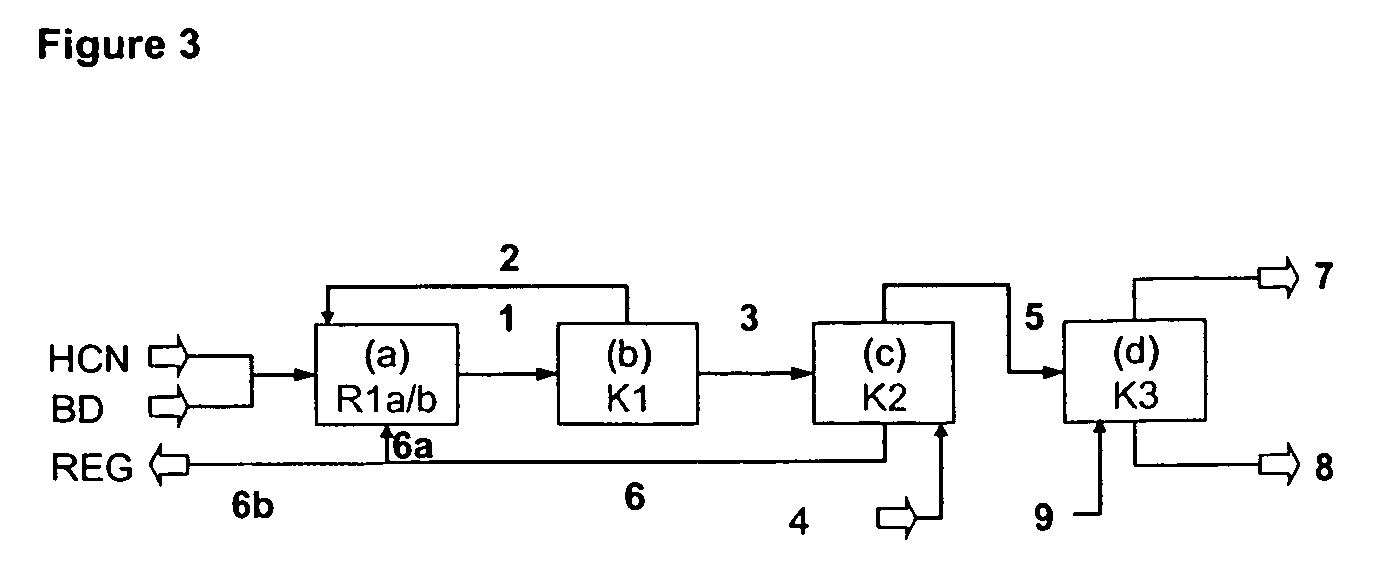

Method for producing 3-pentenenitrile

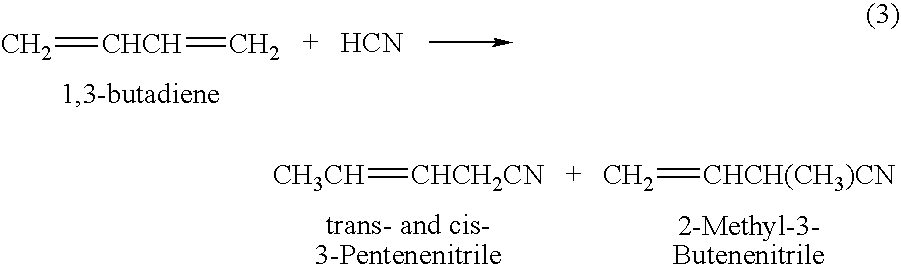

InactiveUS7541486B2Improve processing yieldReduce thermal stressOrganic compound preparationPreparation by hydrogen cyanide additionPtru catalystButadiene Dioxide

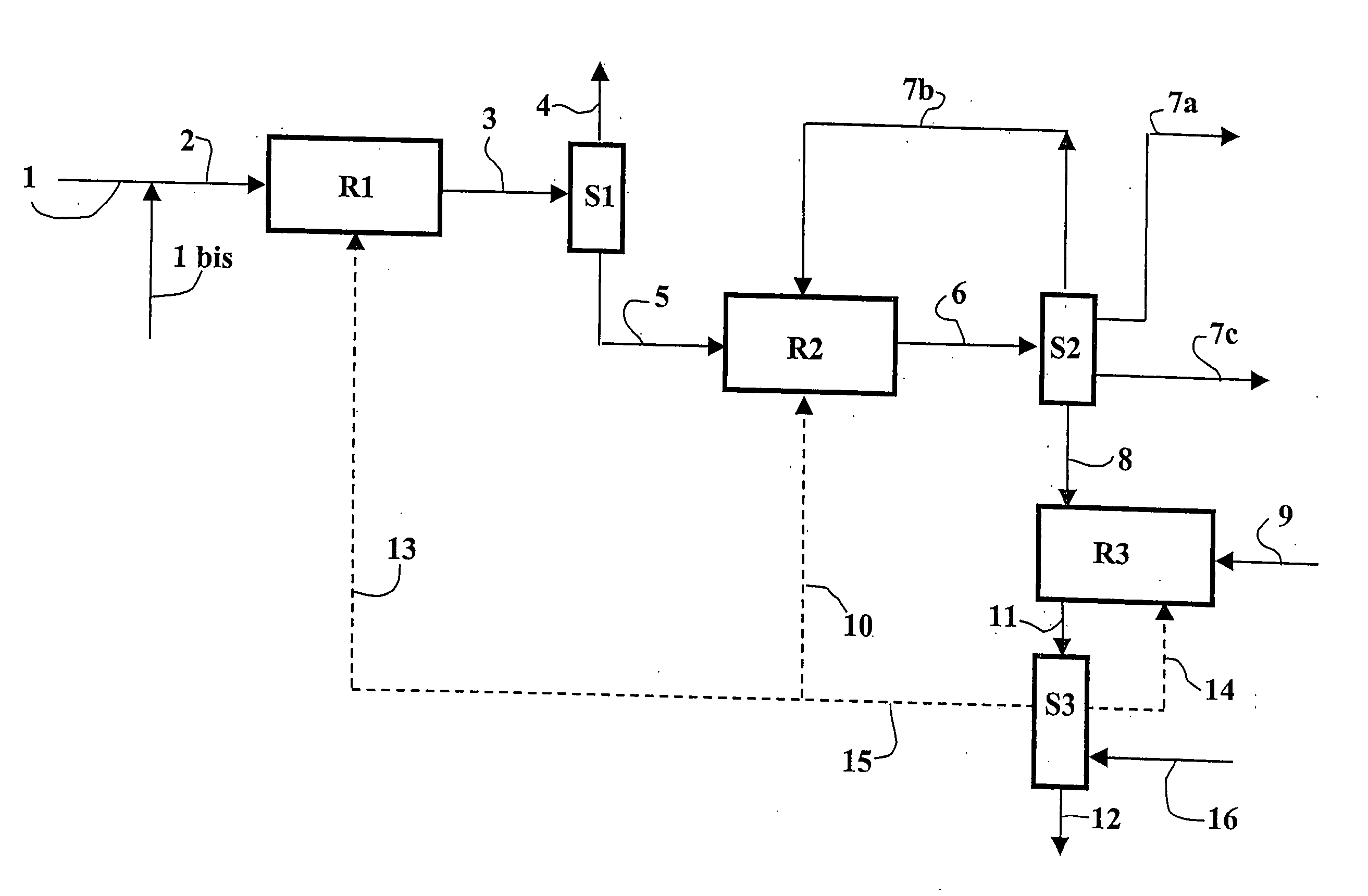

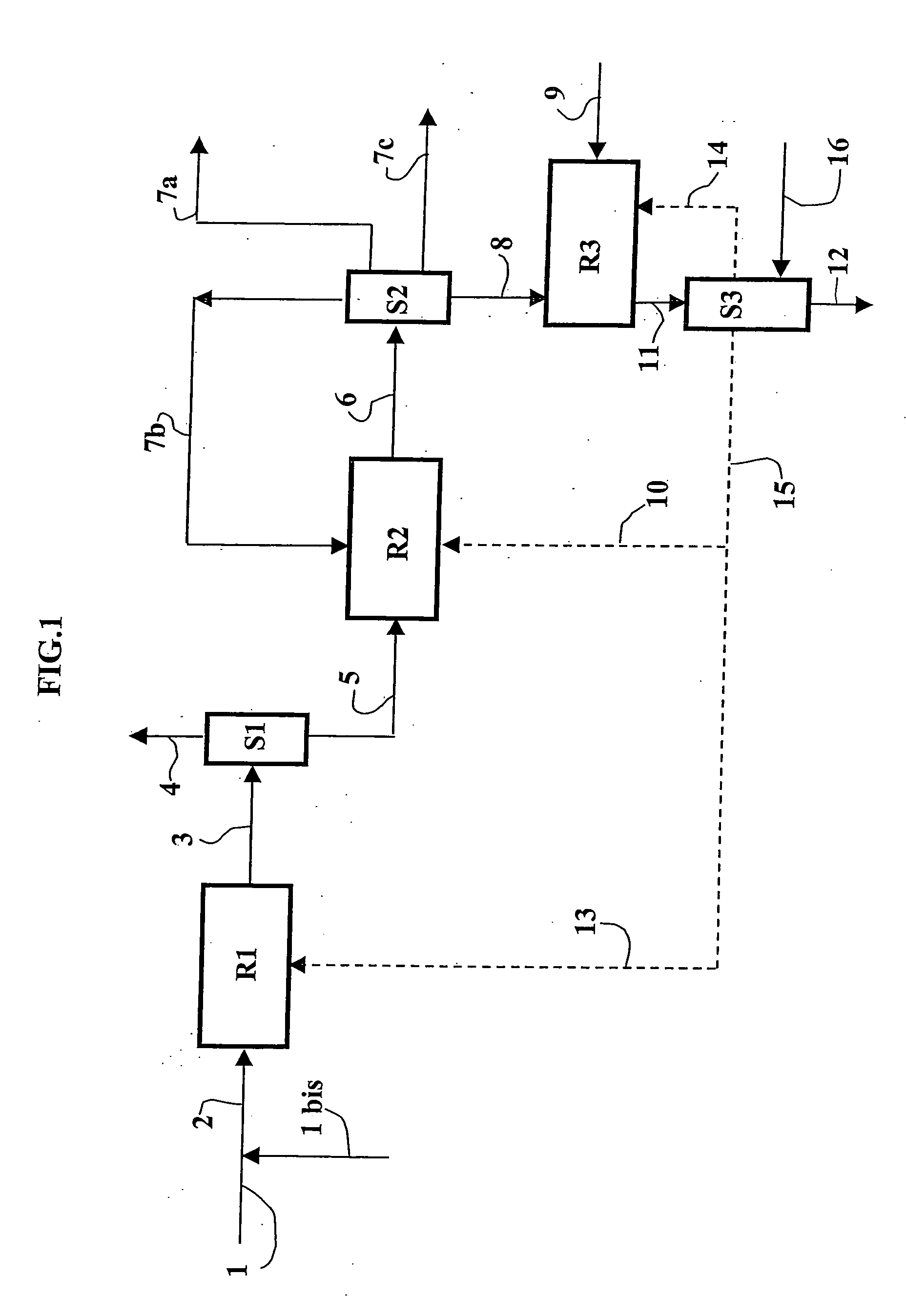

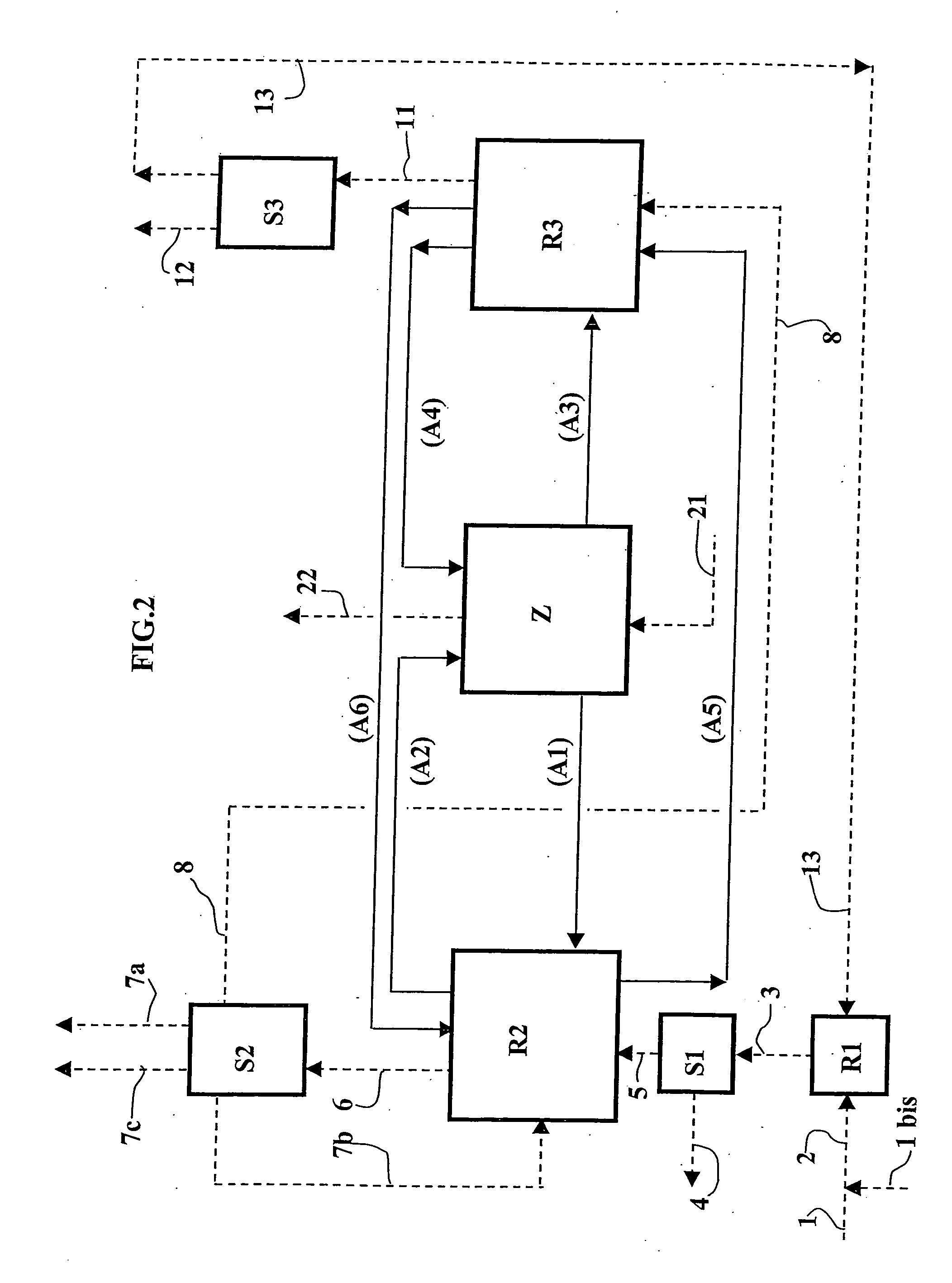

A process is described for preparing 3-pentenenitrile, characterized by the following process steps:(a) reacting 1,3-butadiene with hydrogen cyanide over at least one catalyst to obtain a stream 1 which comprises 3-pentenenitrile, 2-methyl-3-butenenitrile, the at least one catalyst and 1,3-butadiene,(b) distilling stream 1 in a column to obtain a high-1,3-butadiene stream 2 as the top product and a low-1,3-butadiene stream 3 as the bottom product which comprises 3-pentenenitrile, the at least one catalyst and 2-methyl-3-butenenitrile,(c) distilling stream 3 in a column to obtain a stream 4 as the top product which comprises 1,3-butadiene, a stream 5 which comprises 3-pentenenitrile and 2-methyl-3-butenenitrile at a side draw of the column, and a stream 6 as the bottom product which comprises the at least one catalyst,(d) distilling stream 5 to obtain a stream 7 as the top product which comprises 2-methyl-3-butenenitrile, and a stream 8 as the bottom product which comprises 3-pentenenitrile.

Owner:BASF AG

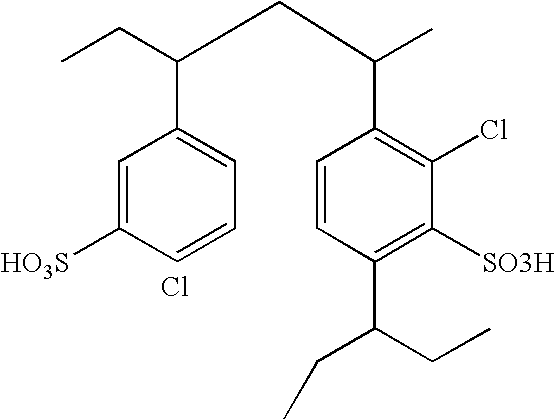

Methods, systems and catalysts for the hydration of olefins

InactiveUS20040236158A1Low compressibilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsButenePolymer science

The present invention provides a system, method and catalyst for olefin hydration. The method includes hydrating the olefin using a base treated, sulfonated, halogenated and acid regenerated thermally stable catalyst. In several variants, the olefin hydration comprises butene hydration, propene hydration, hydration of cyclohexene, propylene hydration, pentene hydration, hexene hydration, and heptene hydration. The present invention also provides a method of making a catalyst for olefin hydration, and provides alcohols manufactured by the catalyst(s), systems and methods described herein.

Owner:COLLIN JENNIFER REICHI +1

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

A process for preparing polymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, by contacting propylene, 4-methyl-1-pentene, or other C4-8 α-olefins and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining:(A) a first metal complex olefin polymerization catalyst,(B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and(C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Process for multistage conversion of a charge comprising olefins with four, five or more carbon atoms, with the aim of producing propylene

InactiveUS20050222475A1Improve propylene to ethylene ratioCatalytic crackingOrganic chemistry methodsButeneOligomer

The invention relates to a process for production of propylene in particular from a C4 and / or C5 cut from steam cracking and / or catalytic cracking, preferably comprising both butenes and pentenes, said process comprising at least one oligomerization stage, followed by a stage of catalytic cracking of the oligomers formed. Preliminary oligomerization, in particular of a wide fraction of the charge, makes it possible to optimize the yields, the conversion, and the selectivity for propylene, relative to direct cracking. It also makes it possible for cracking to be carried out in a fixed, moving, or fluidized bed, optionally with co-production of oligomers for uses other than the production of propylene.

Owner:INST FR DU PETROLE

Hydrocyanation process with reduced yield losses

ActiveUS20080015381A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionNitriteHydrogen

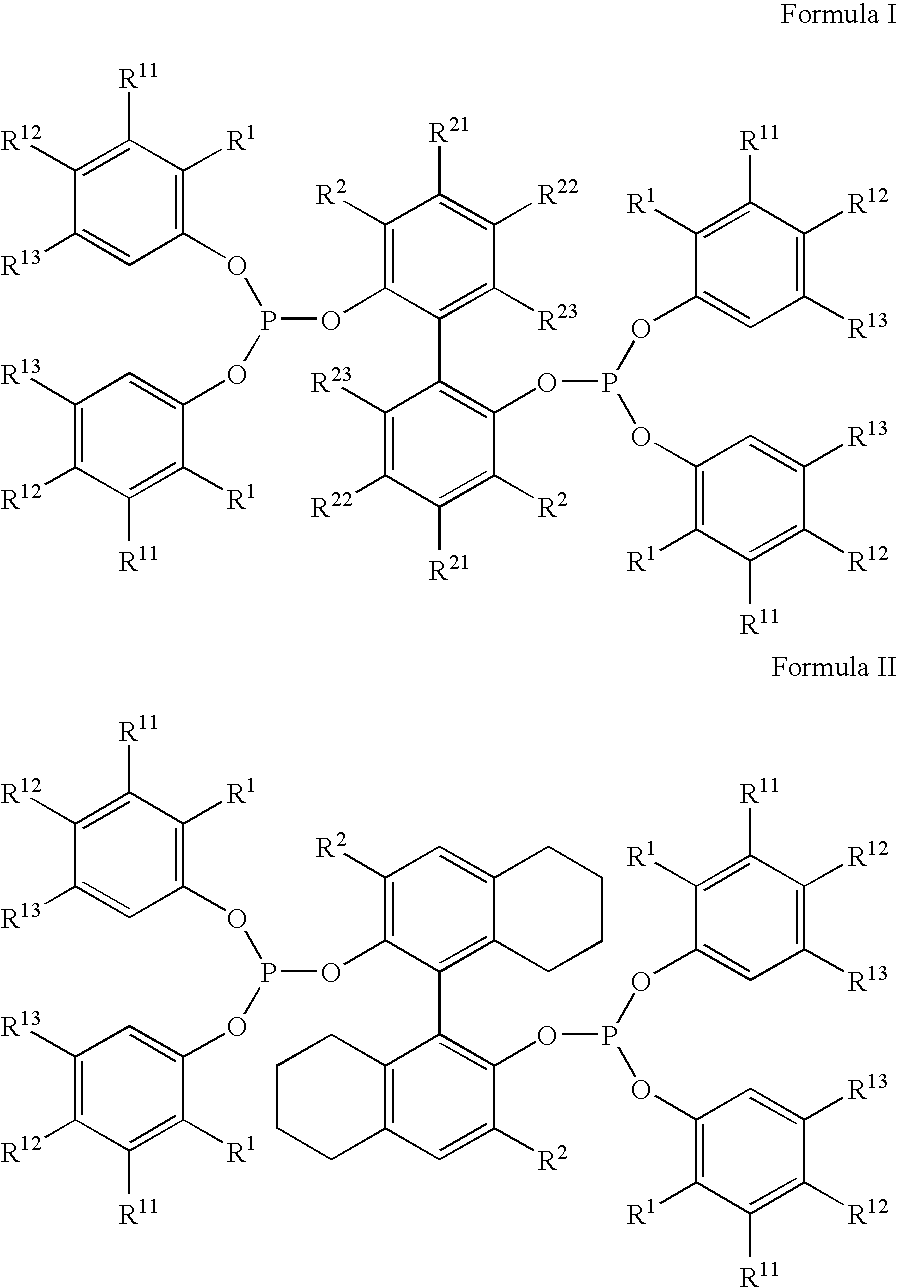

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitrites, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed)(molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one bidentate phosphite ligand; andwherein the bidentate phosphite ligand is selected from a member of the group represented by Formulas I and 11 as described herein.

Owner:INV NYLON CHEM AMERICAS LLC

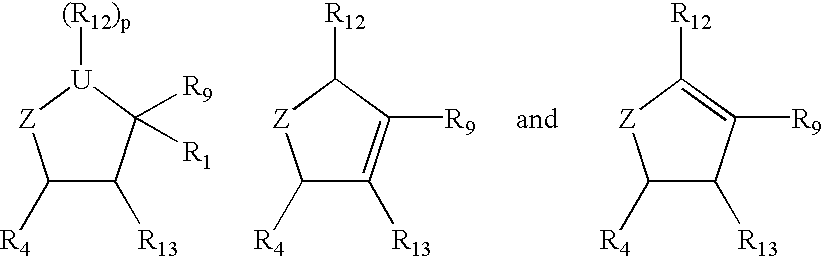

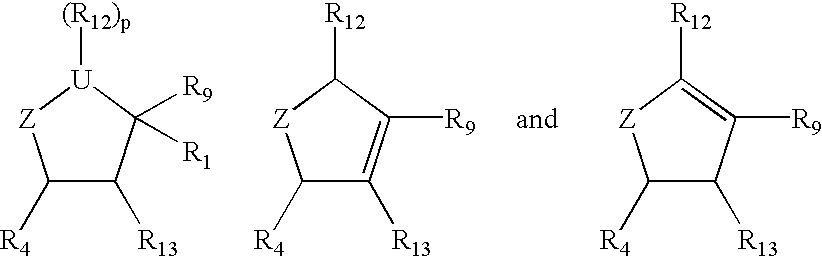

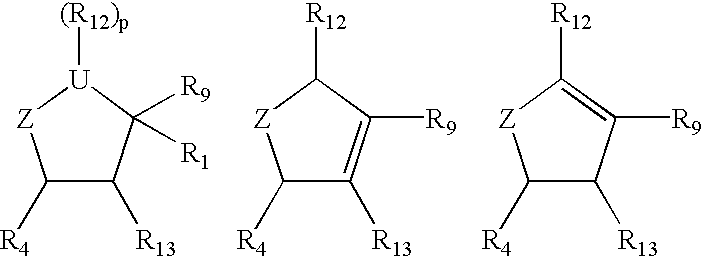

Substituted cyclopentane and cyclopentene compounds useful as neuraminidase inhibitors

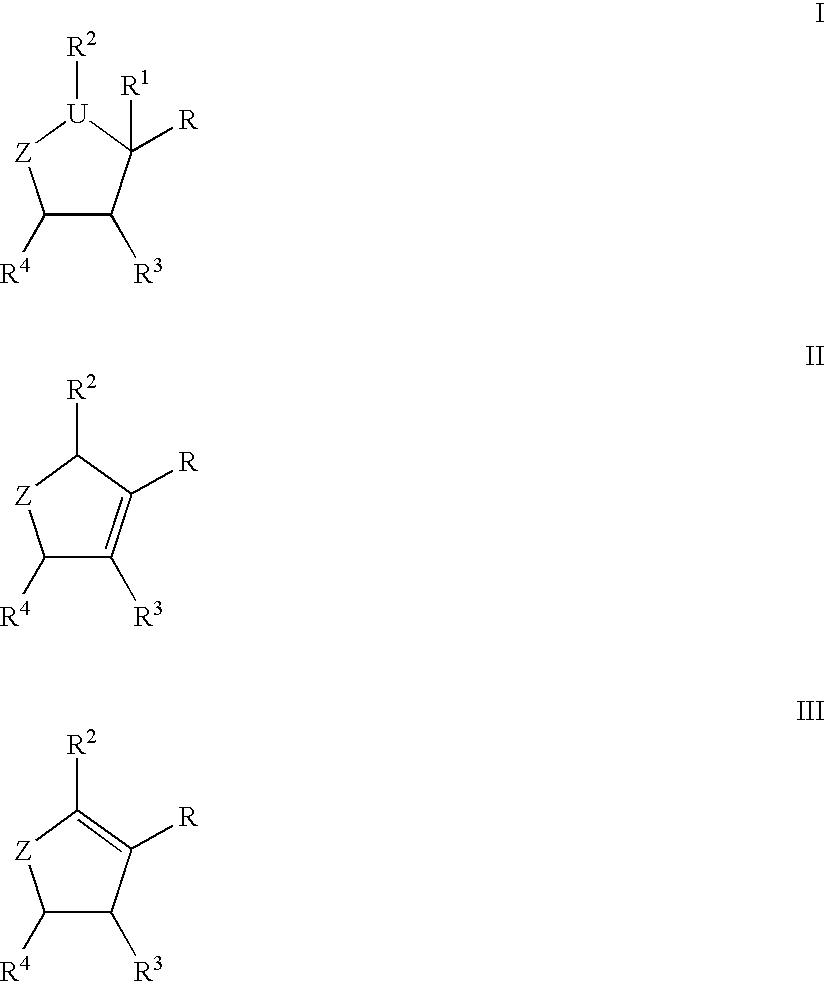

Compounds I-III wherein U is CH, O, or S; Z is mono- or di-substituted carbon; R is (CH2)nCO2H, (CH2)nSO3H, (CH2)nPO3H2, (CH2)nNO2, CH(SCH3)3, esters; R1 is H, hydroxyalkyl, aminoalkyl, alkoxyalkyl; RR1 is O; n is 0-4; R2, R3 is H, hydroxyalkyl, aminoalkyl, alkoxyalkyl, haloalkyl; R4 is (CH2)nOH, (CH2)nNH2, substituted alkyl were prepd. as neuraminidase inhibitors. Thus, (1R,3R,4R,1'S)-(-)-(1'-acetylamino-2 '-ethyl)butyl-4-(aminoimino)methylaminocyclopentan-1-carboxylic acid was prepd. and tested in vitro as neuraminidase inhibitor (IC50<1.mu.M).

Owner:BIOCRYST PHARM INC

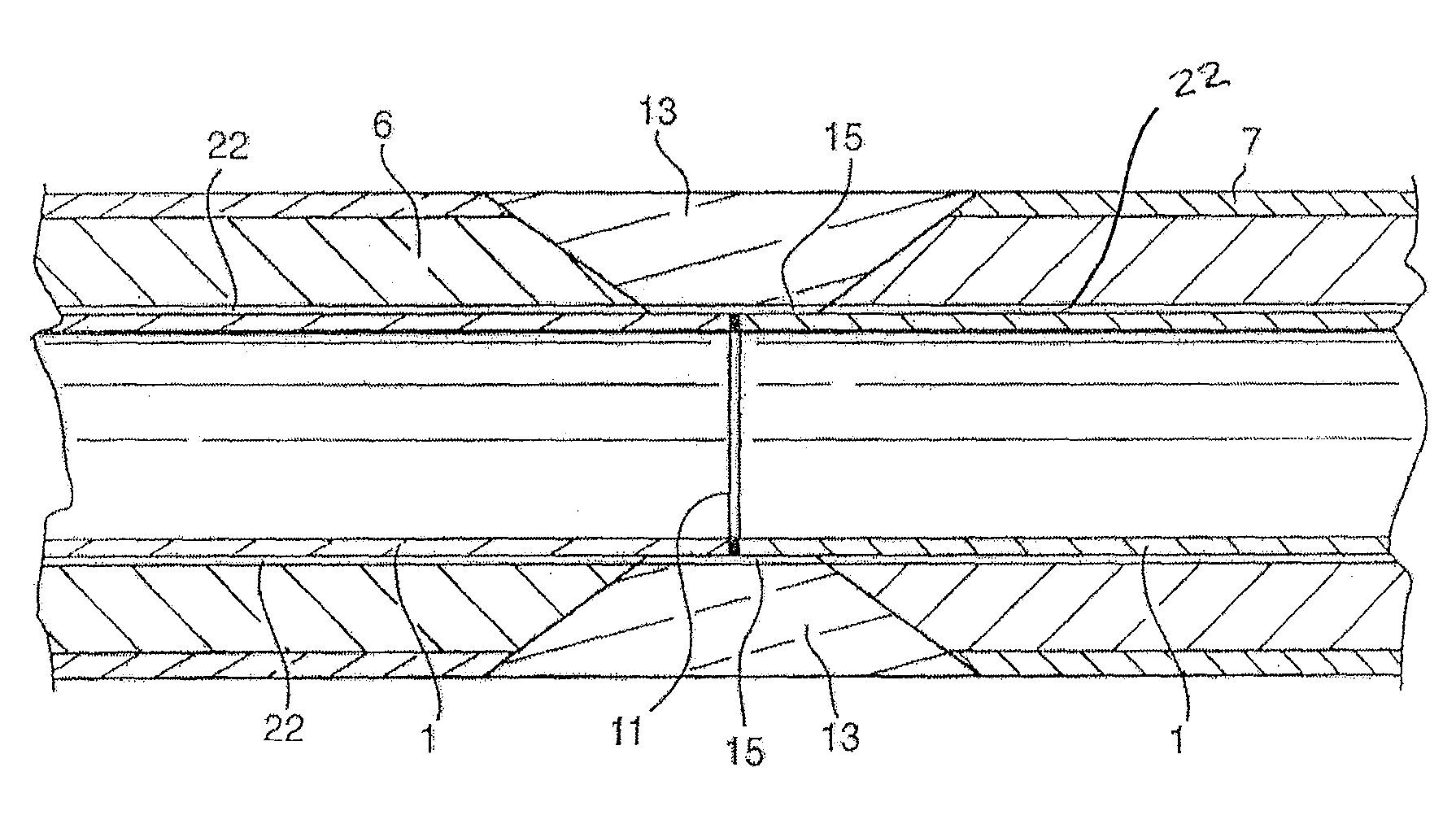

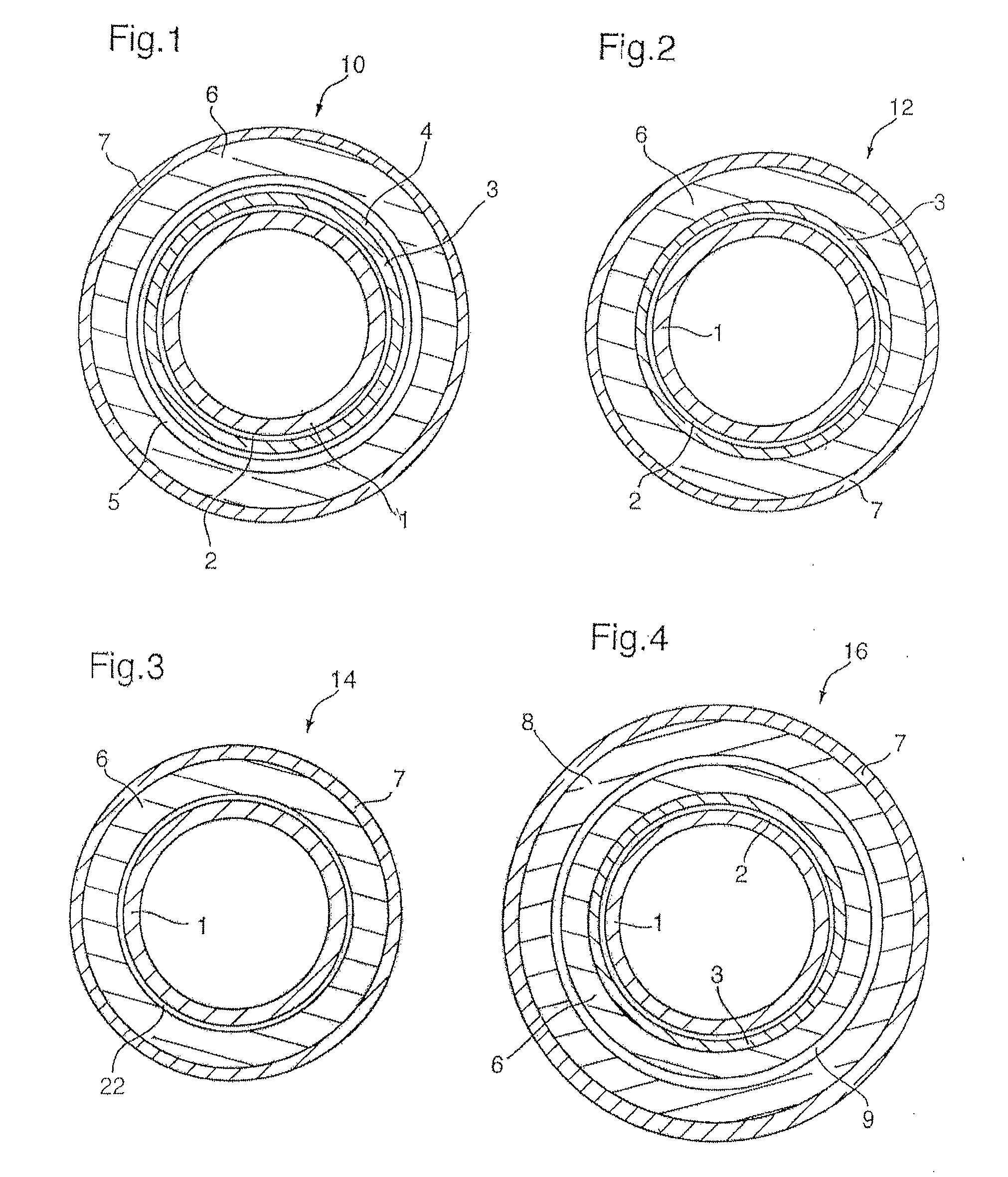

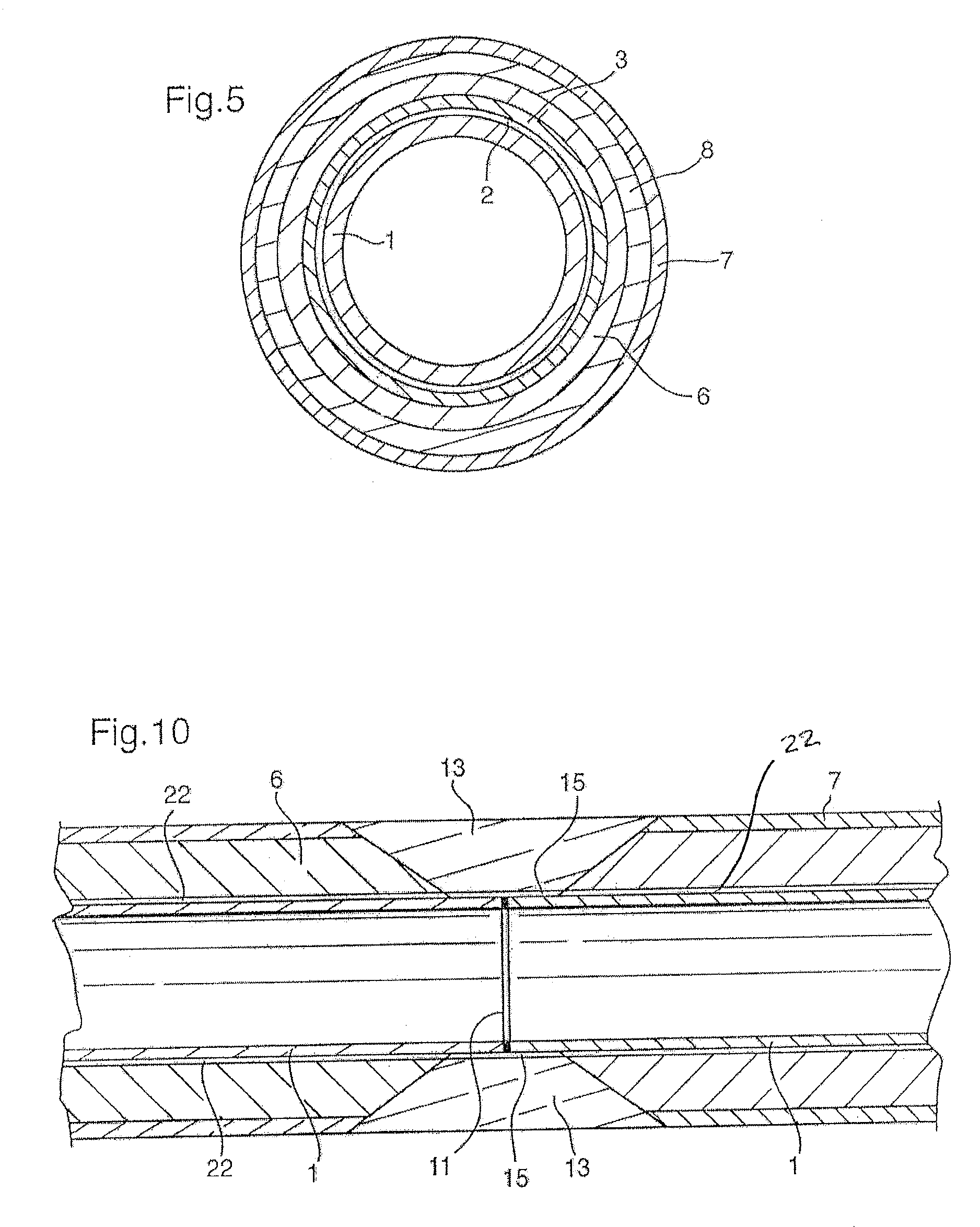

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

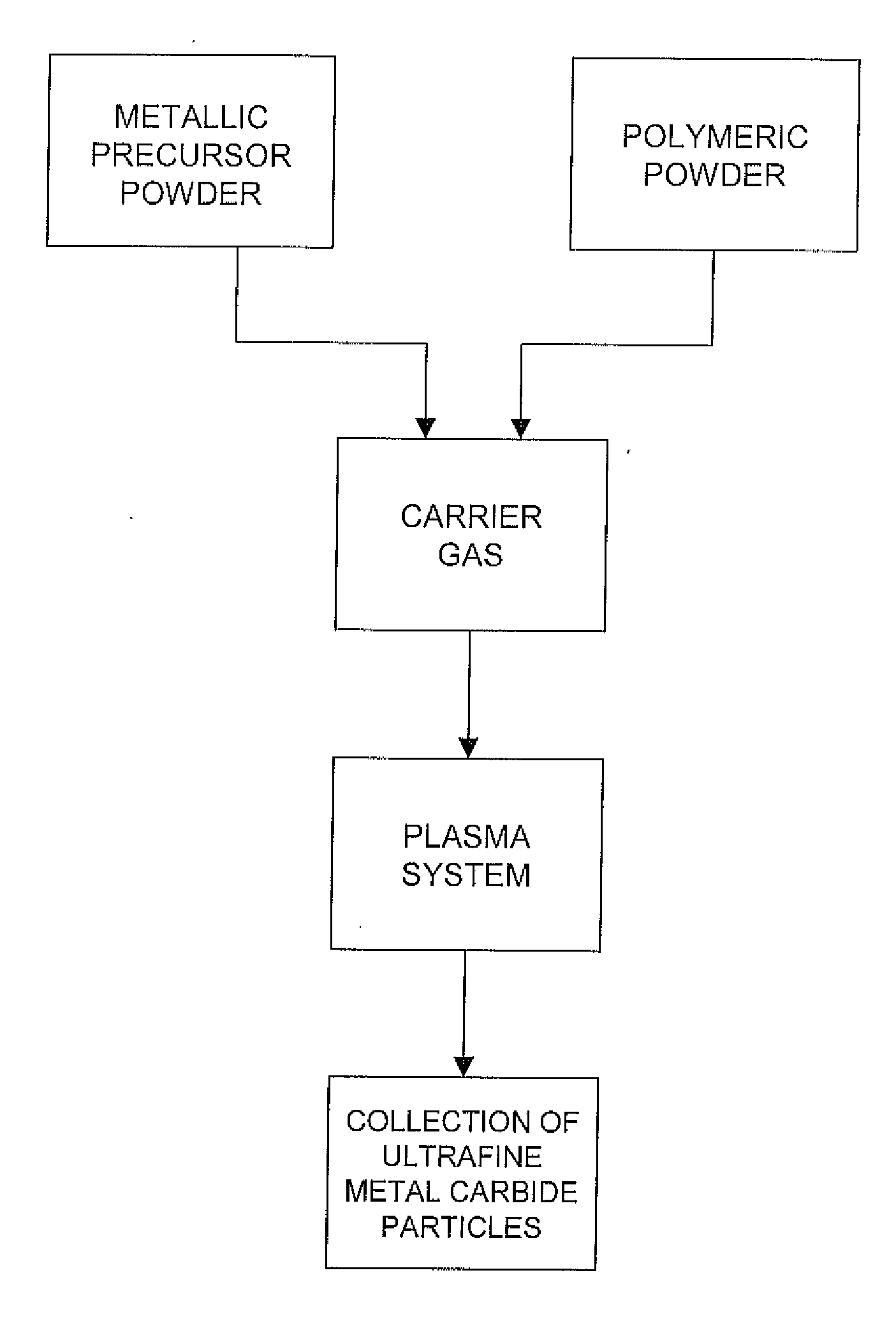

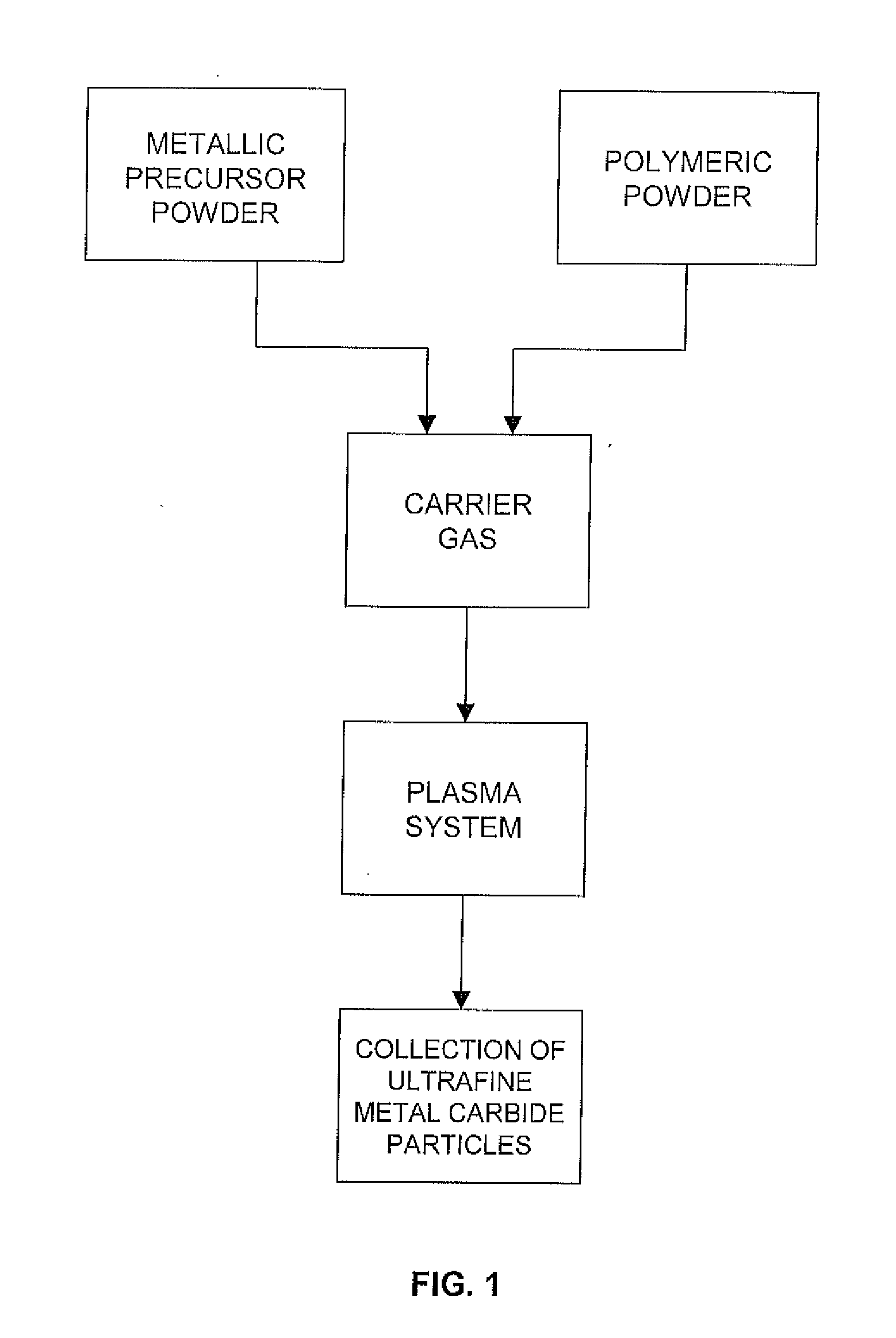

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

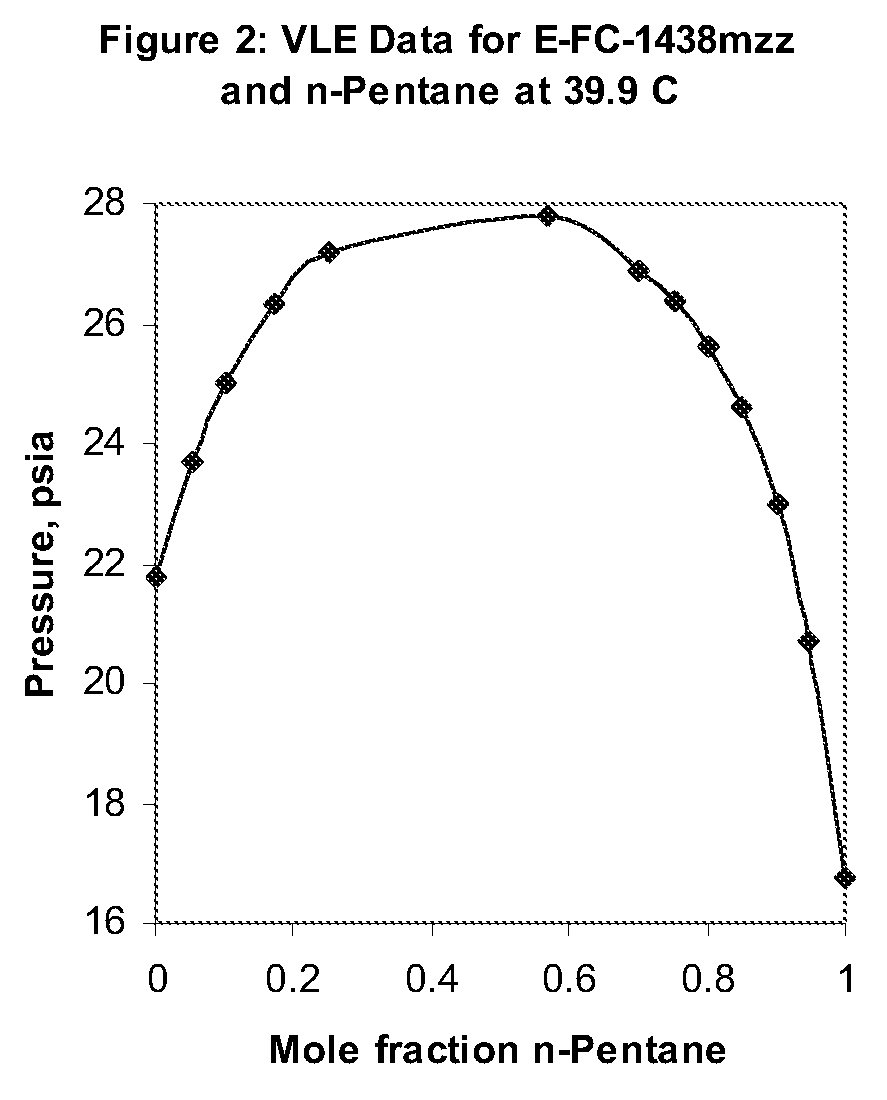

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

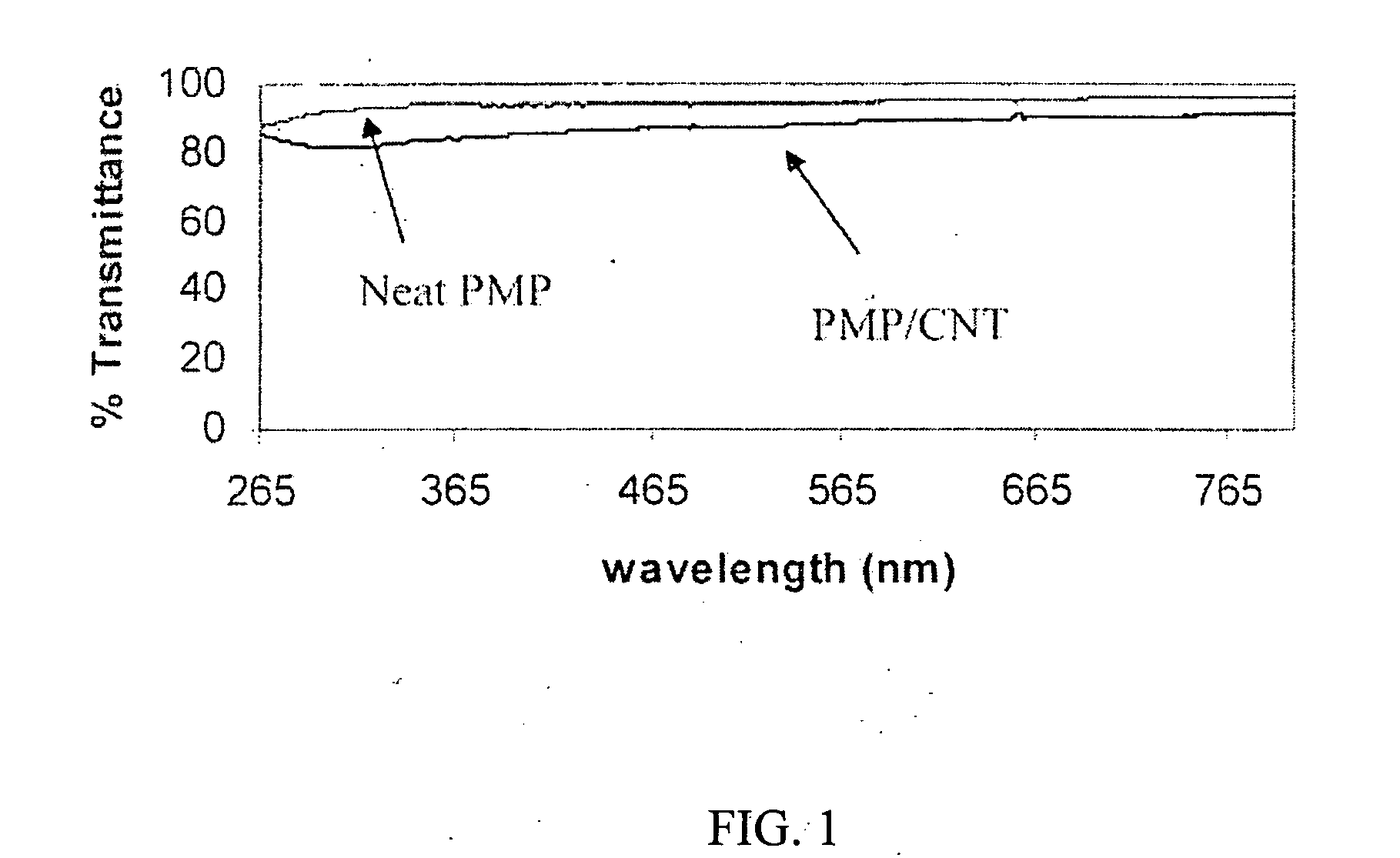

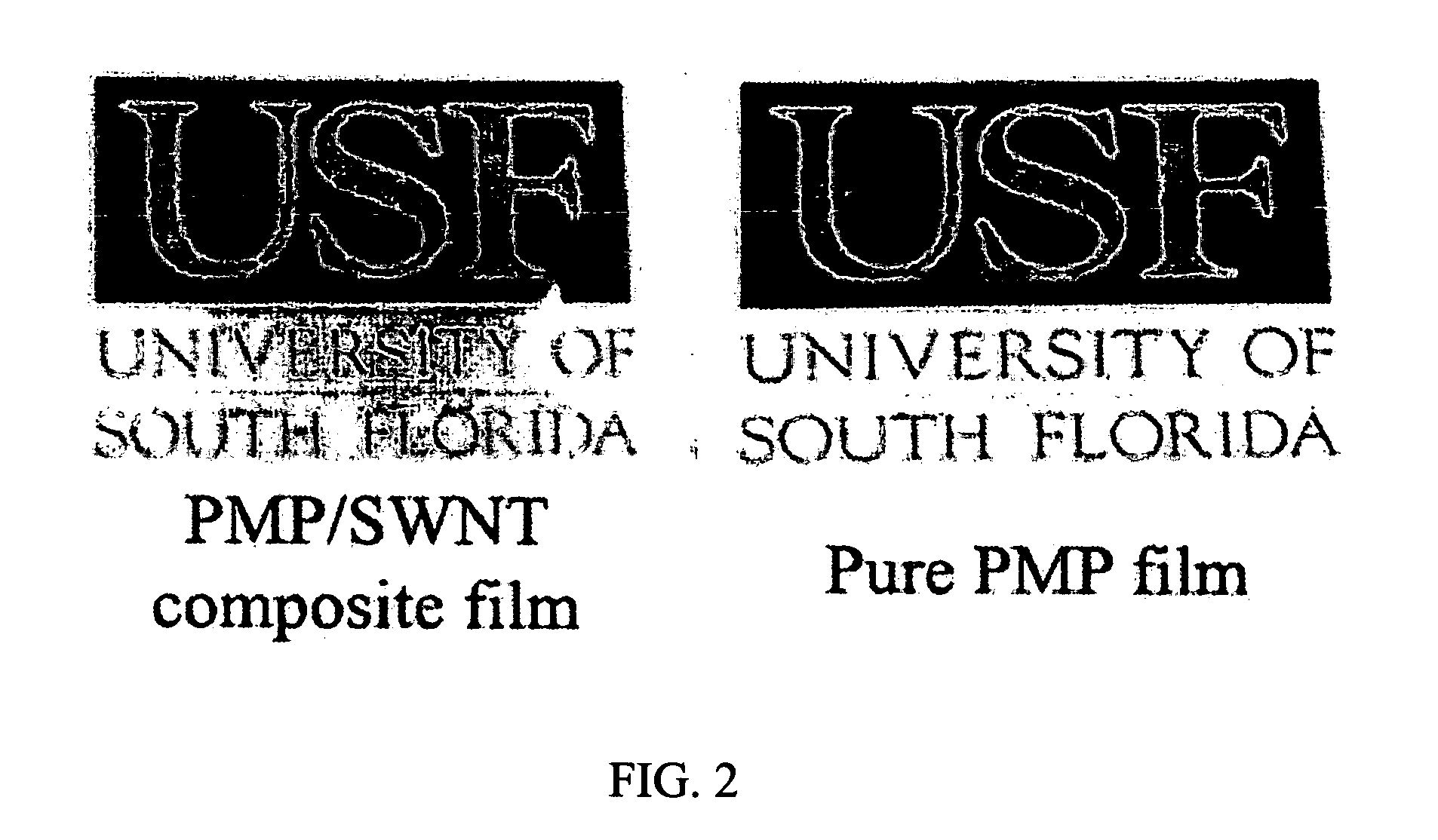

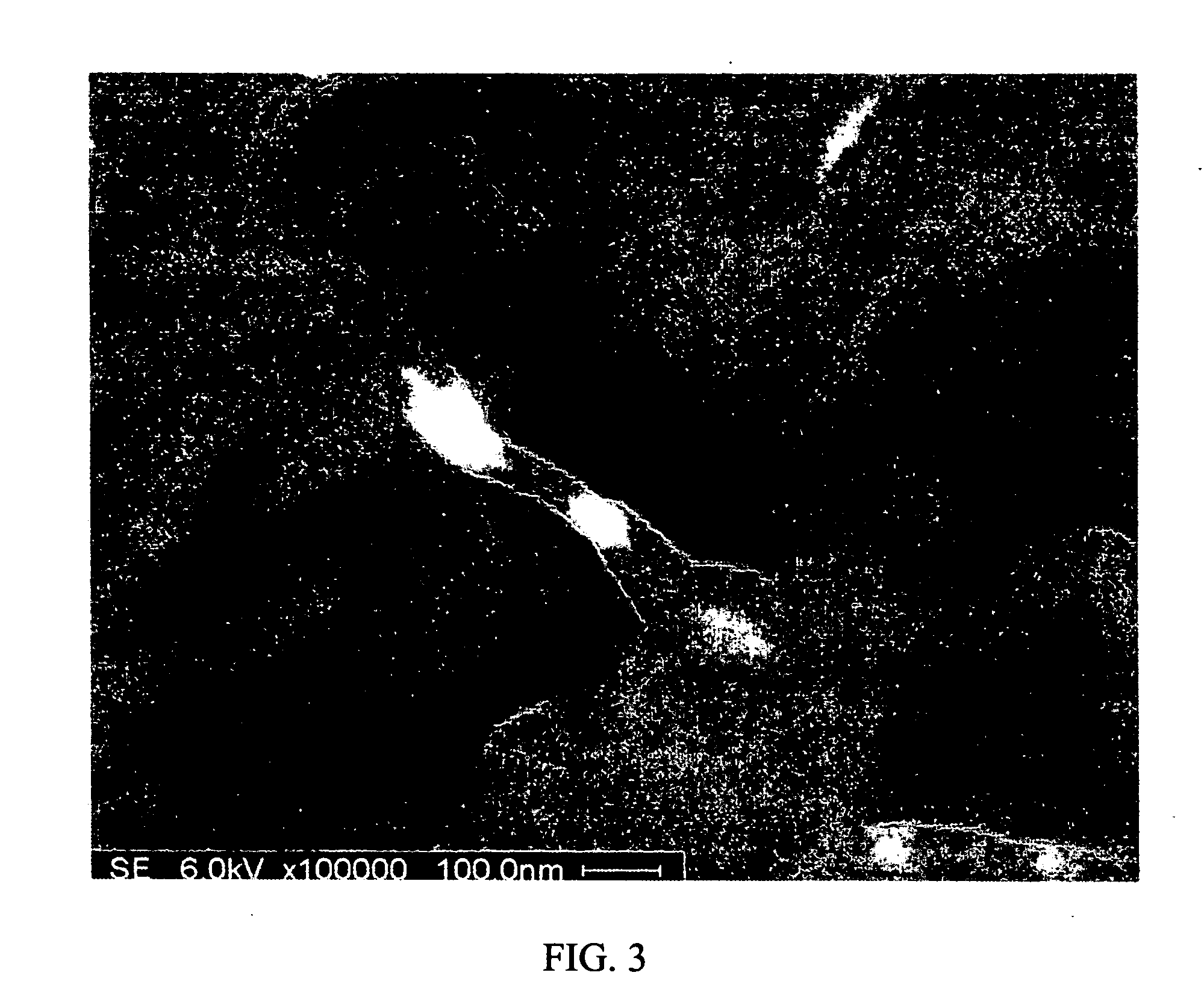

Polymer/carbon nanotube composites, methods of use and methods of synthesis thereof

InactiveUS20050245667A1Good optical performanceMaintain transparencyMaterial nanotechnologyElectric discharge heatingPolymer scienceOrganic dye

Novel transparent composites composed of single wall carbon nanotubes incorporated into the matrix of a polymer are utilized in services wherein the composites are exposed to ionizing radiation, including galactic cosmic radiation. Accordingly, the composites are useful in deep space applications like space vehicles, space stations, personal equipment as well as applications in the biomedical arts and atom splitting research. The composites can be modified with organic dyes containing at least one phenyl ring and the resulting doped composite is useful as a radiation detector. The preferred polymer is poly(4-methyl-1-pentene).

Owner:UNIV OF SOUTH FLORIDA

System and Method of Introducing an Additive with a Unique Catalyst to a Coking Process

InactiveUS20090209799A1High propensity to cokePromotes cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkyl transferNaphtha

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. Modifications of the catalysts in the additive improve performance for certain desired outcomes. One exemplary embodiment of the present invention uses the olefin production capabilities from newly developed catalysts to increase the production of light olefins (e.g. ethylene, propylenes, butylenes, pentenes) for alkylation process unit feed, the production of oxygenates, and petrochemical feedstocks, such as plastics manufacture. Another exemplary embodiment of the present invention is the use of the olefin production from newly developed catalysts to improve the coker naphtha quality. A third exemplary embodiment of the present invention uses the cracking characteristics of newly developed catalysts to optimize the production of light gas oils, naphtha, and gases from the coking process.

Owner:ETTER ROGER G +1

Processing C4 olefin streams for the maximum production of propylene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso-and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

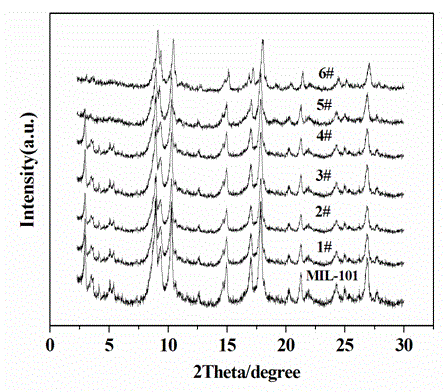

Metal-organic framework supported heteropoly acid catalyst for synthesizing glutaraldehyde and production method of metal-organic framework supported heteropoly acid catalyst

InactiveCN104437645AGood dispersionGood effectOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by oxidationCyclopentenePtru catalyst

The invention relates to a metal-organic framework supported heteropoly acid catalyst for synthesizing glutaraldehyde and a production method of the metal-organic framework supported heteropoly acid catalyst. The catalyst is prepared by a one-step synthesis method, namely a heteropoly acid component with catalytic oxidation activity is introduced into a duct of a metal-organic framework material UiO-66 in the process of synthesizing the metal-organic framework material UiO-66. The catalyst has the characteristics that the catalyst has a crystal framework structure, the active component is highly dispersed, and the heteropoly acid is over-high in load. The catalyst is applied to catalytic selective oxidation reaction of cyclopentene, so that the selectivity and the yield of the glutaraldehyde is greatly improved; the numerical value is much higher than the reported homogeneous catalysis level; and the metal-organic framework supported heteropoly acid catalyst has important industrial application value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com