Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

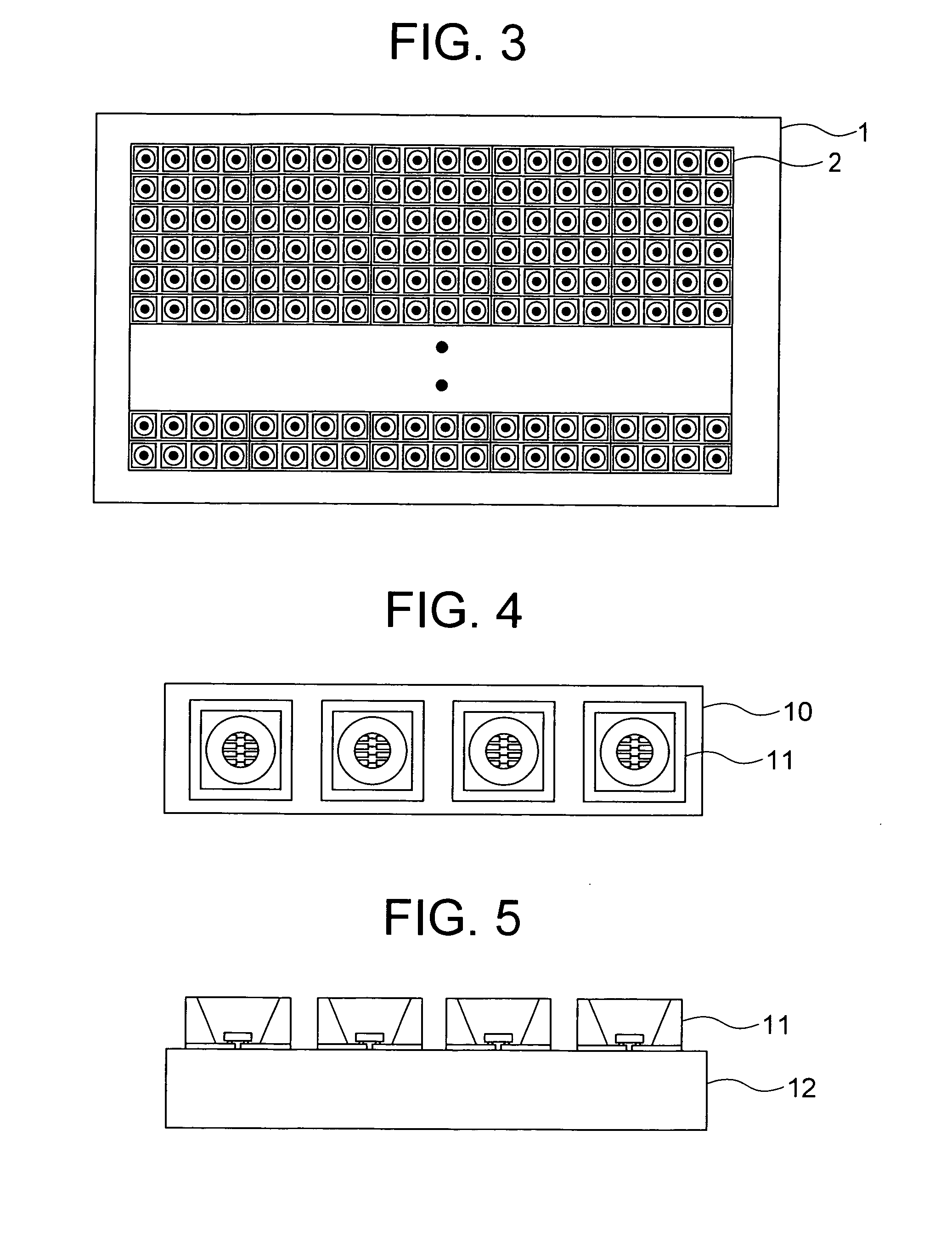

1783results about How to "Improve processing yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

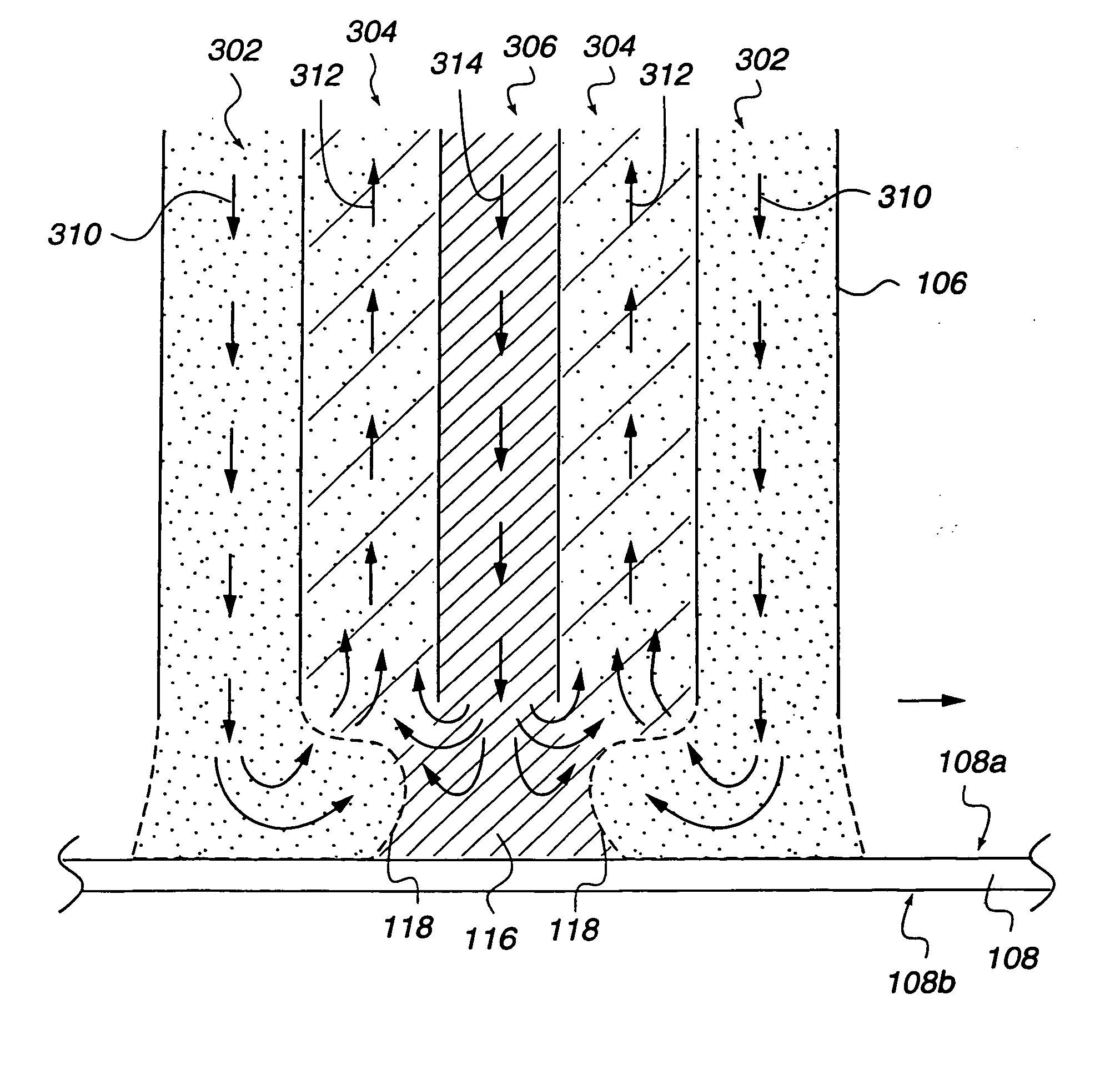

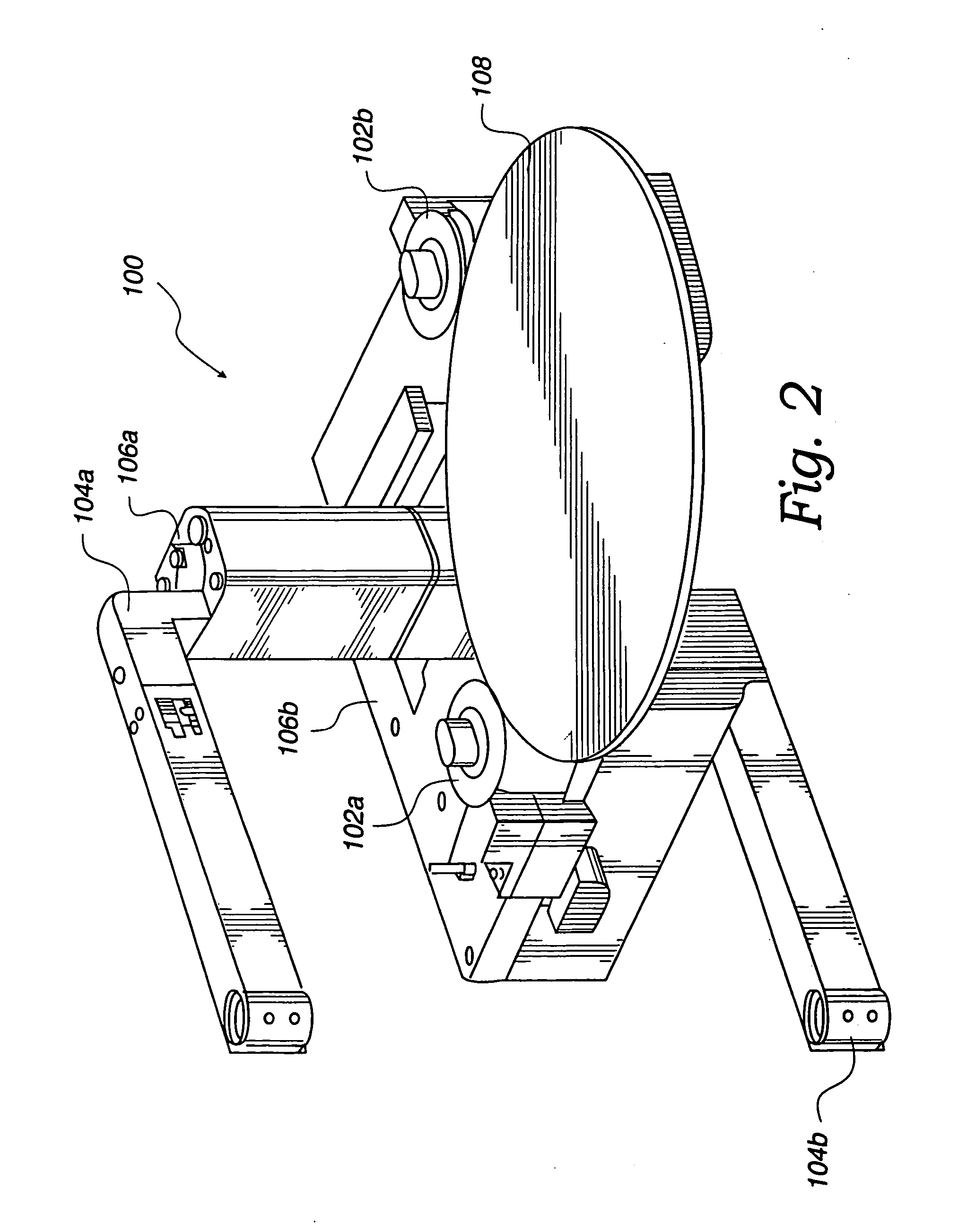

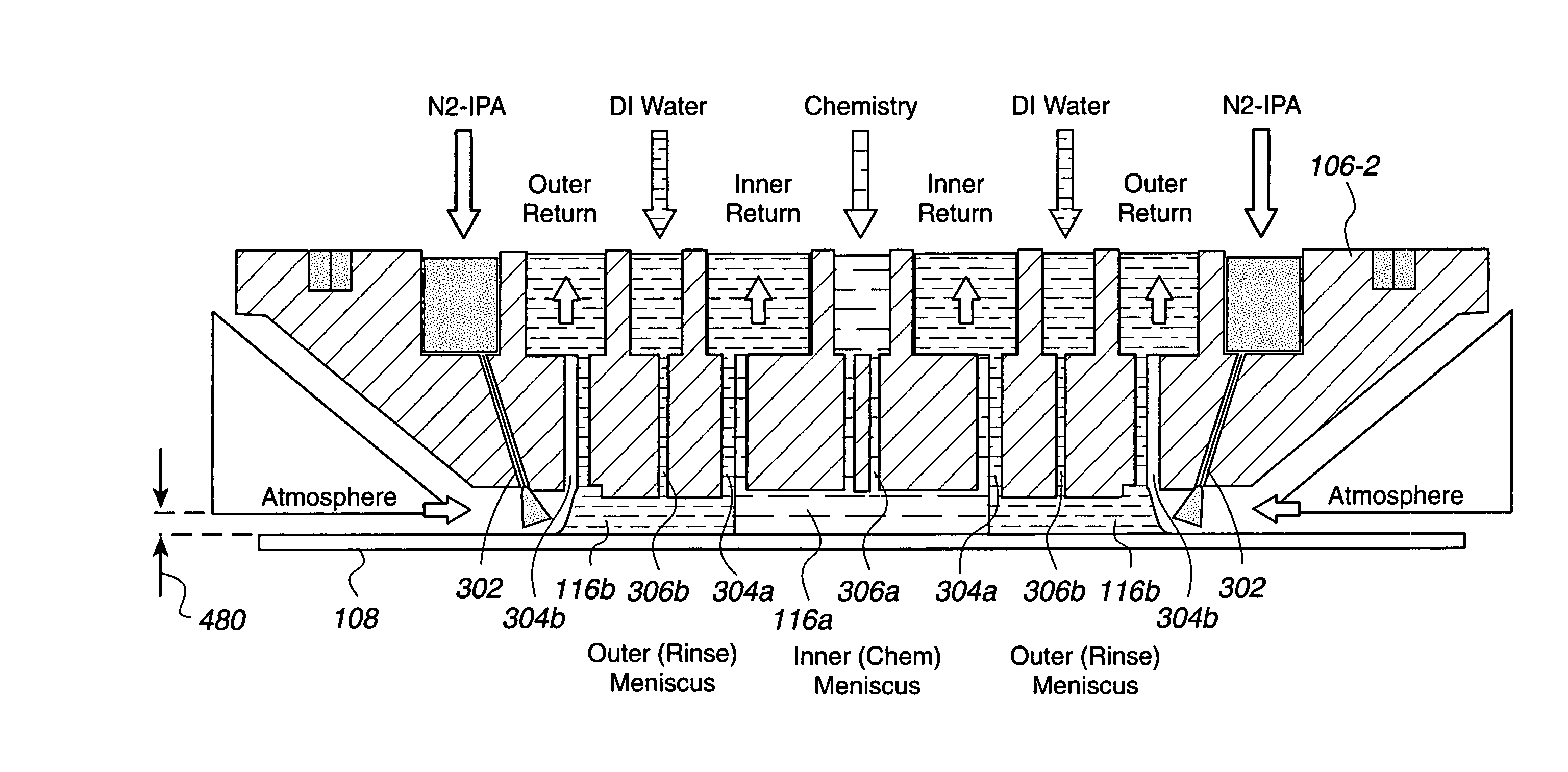

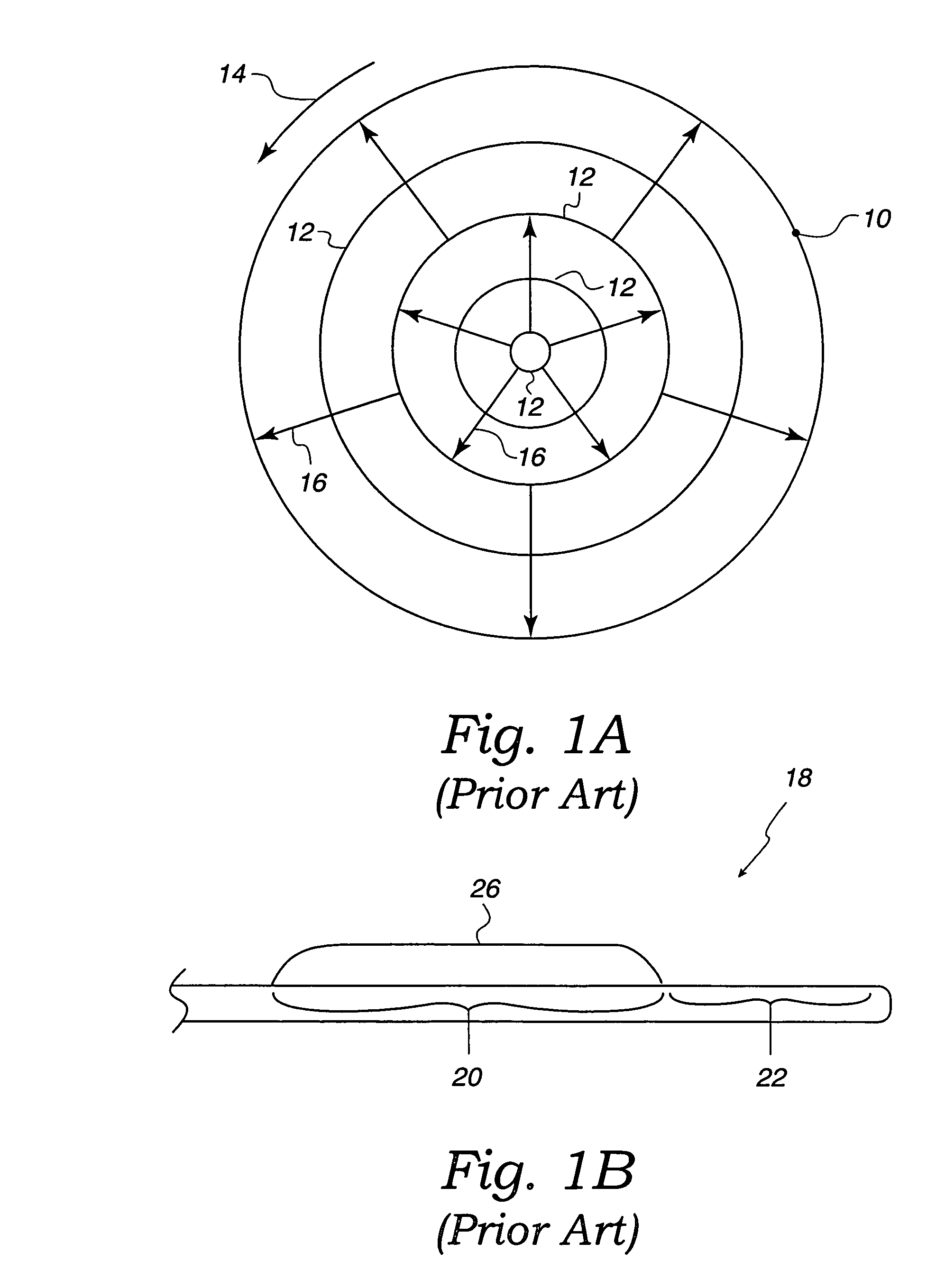

Apparatus and method for utilizing a meniscus in substrate processing

InactiveUS20050217703A1Process environment can be powerfully controlled and managedMore processedLiquid surface applicatorsSemiconductor/solid-state device manufacturingActive agentEngineering

An apparatus for processing a substrate is provided which includes a proximity head proximate to a surface of the substrate when in operation. The apparatus also includes an opening on a surface of the proximity head to a cavity defined in the proximity head where the cavity delivers an active agent to the surface of the substrate through the opening. The apparatus further includes a plurality of conduits on the surface of the proximity head that generates a fluid meniscus on the surface of the substrate surrounding the opening.

Owner:LAM RES CORP

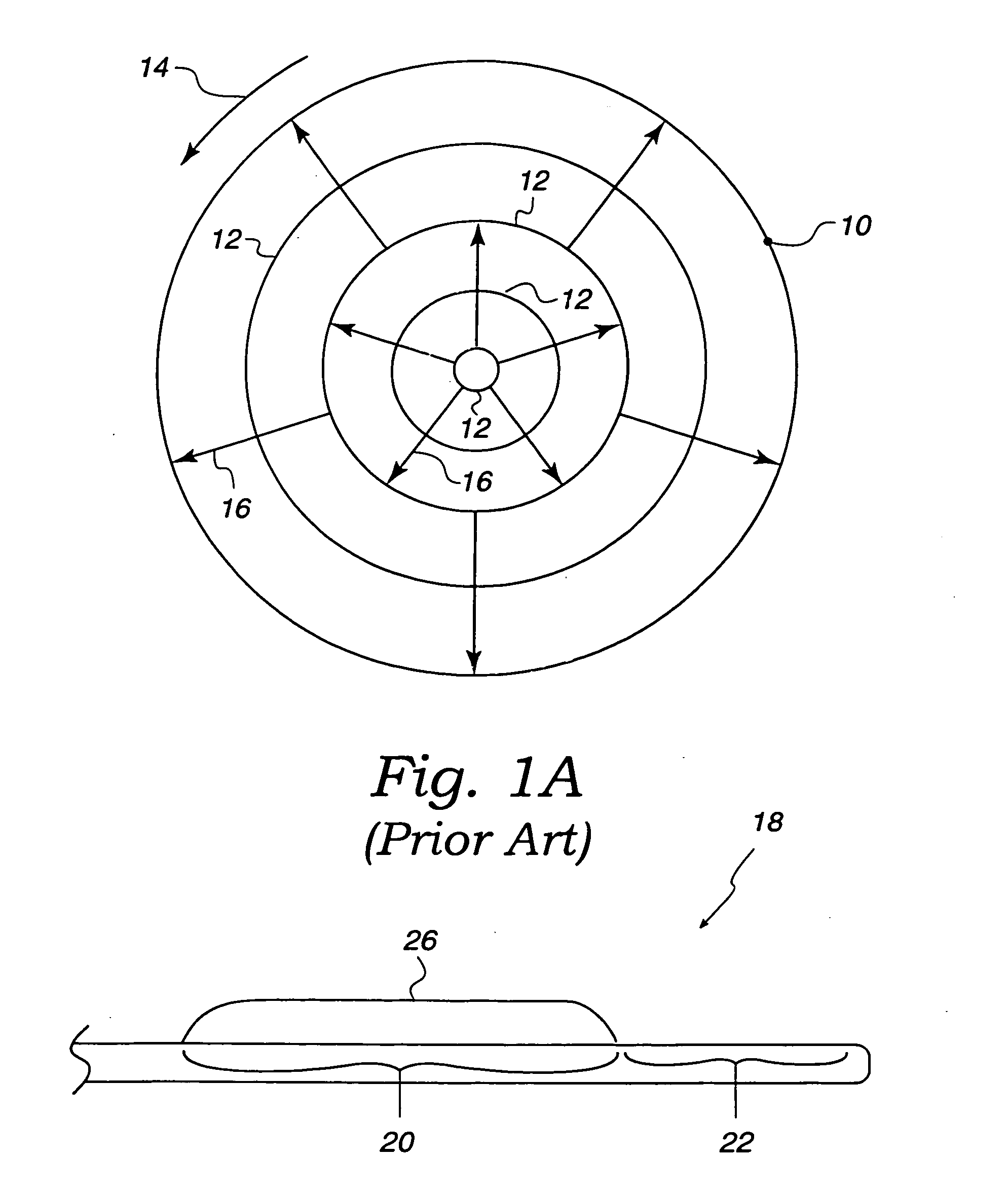

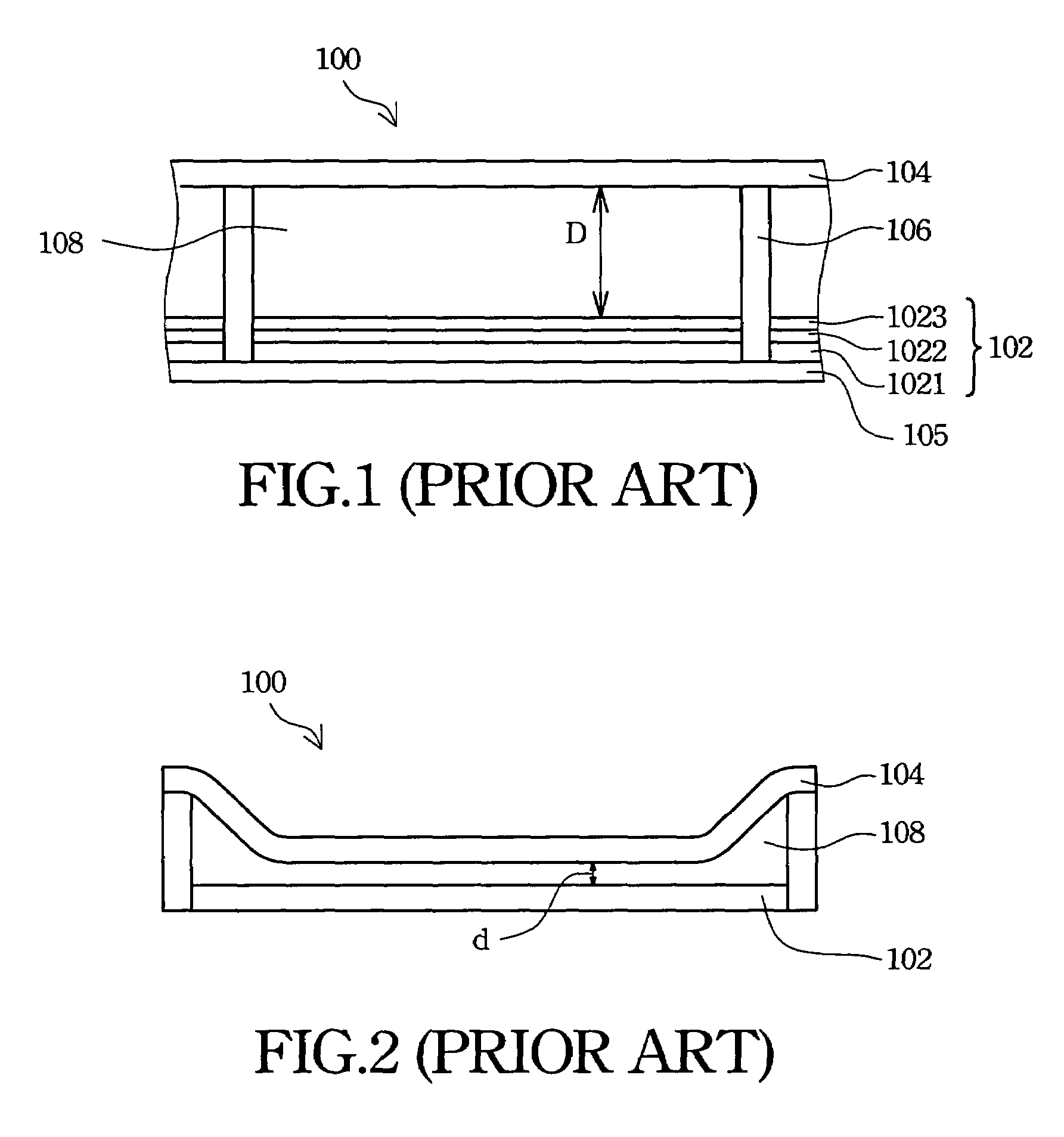

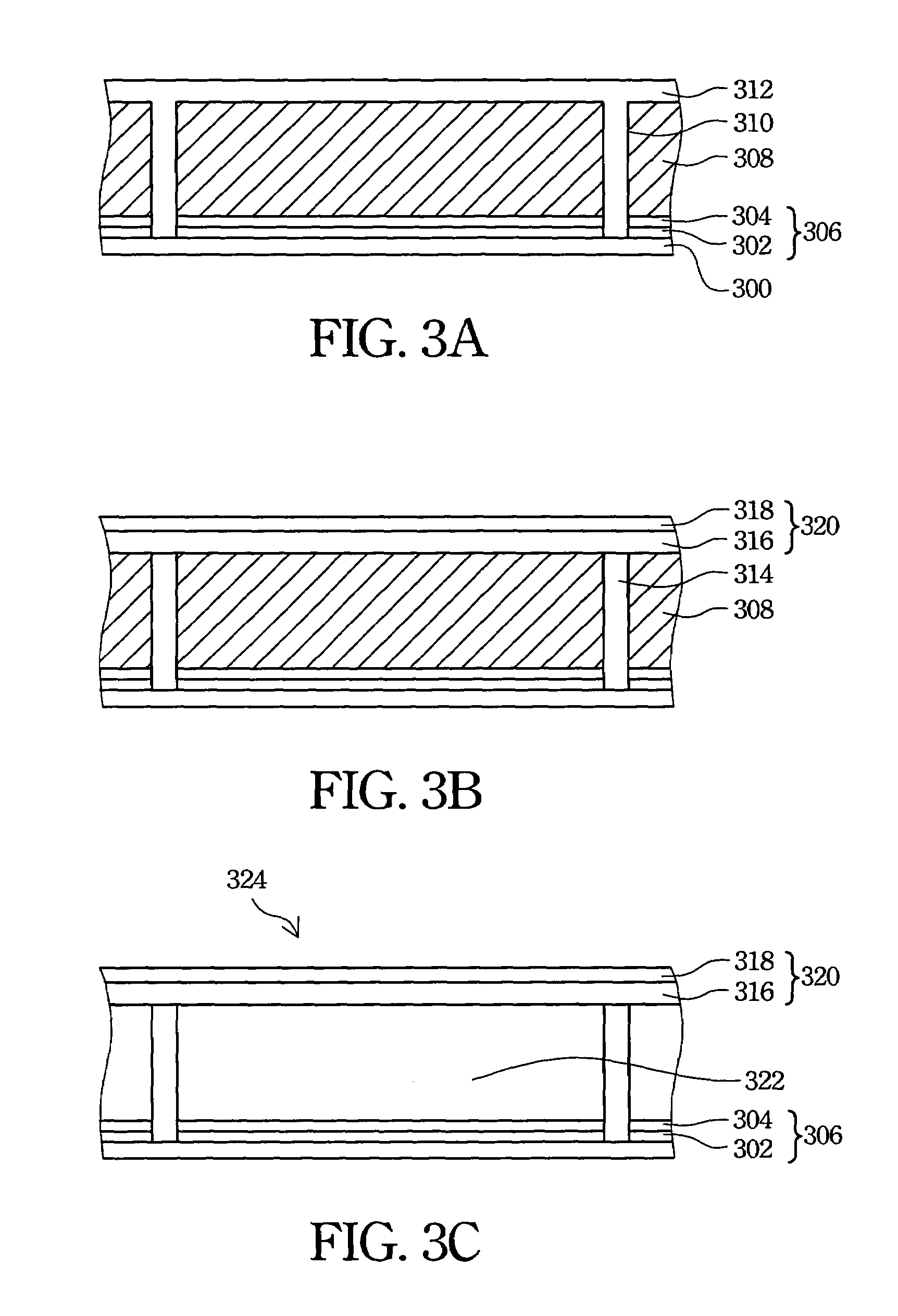

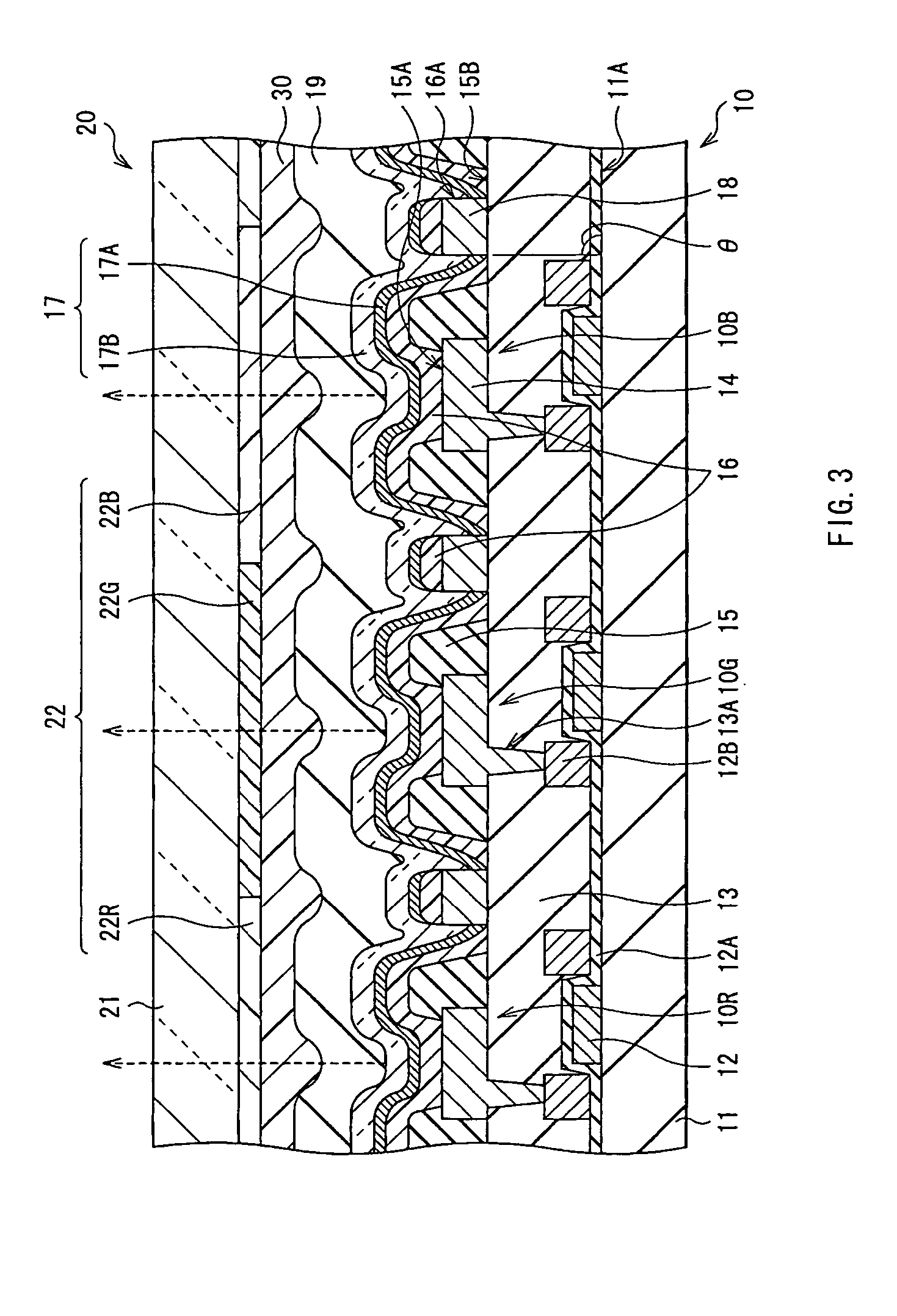

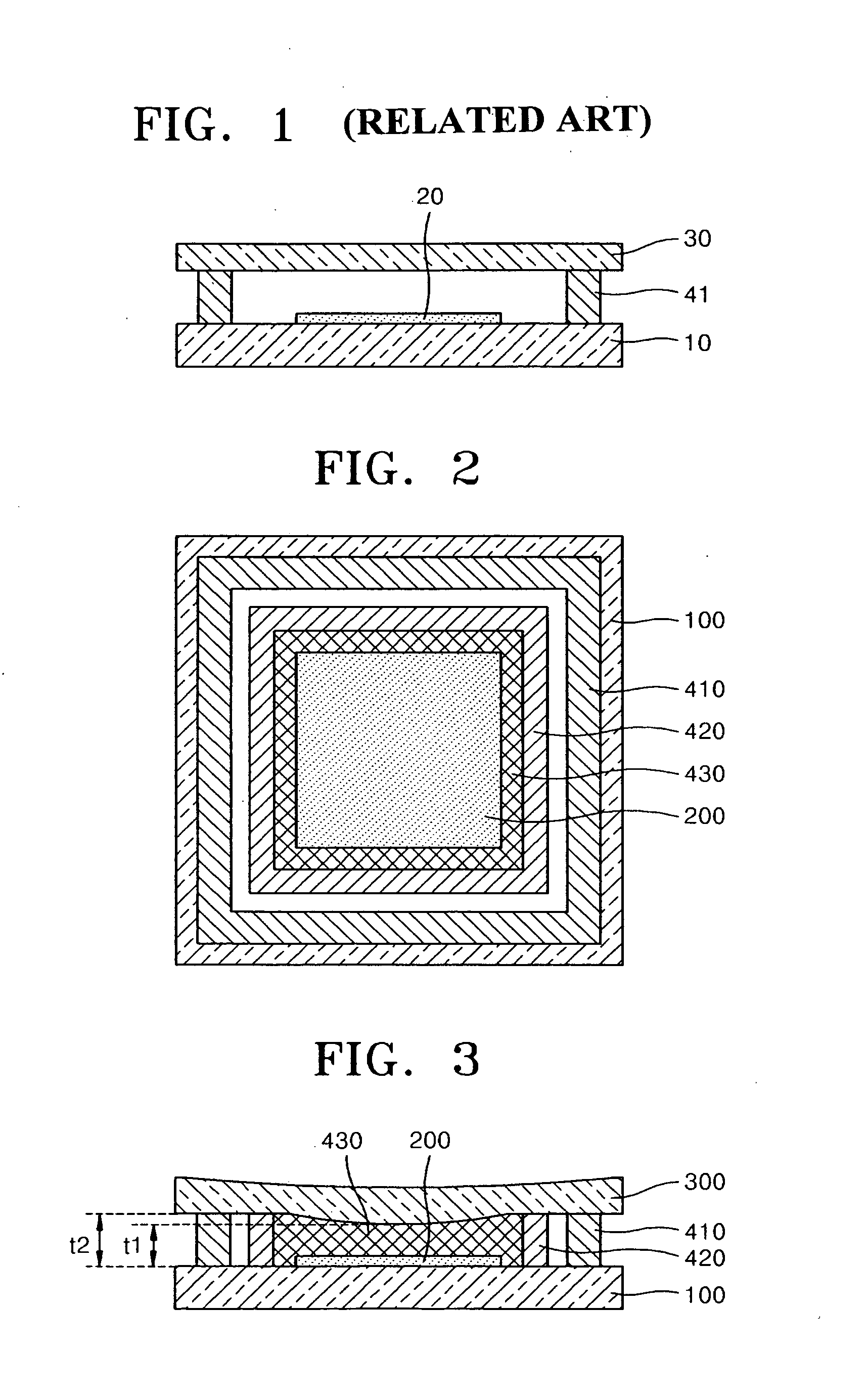

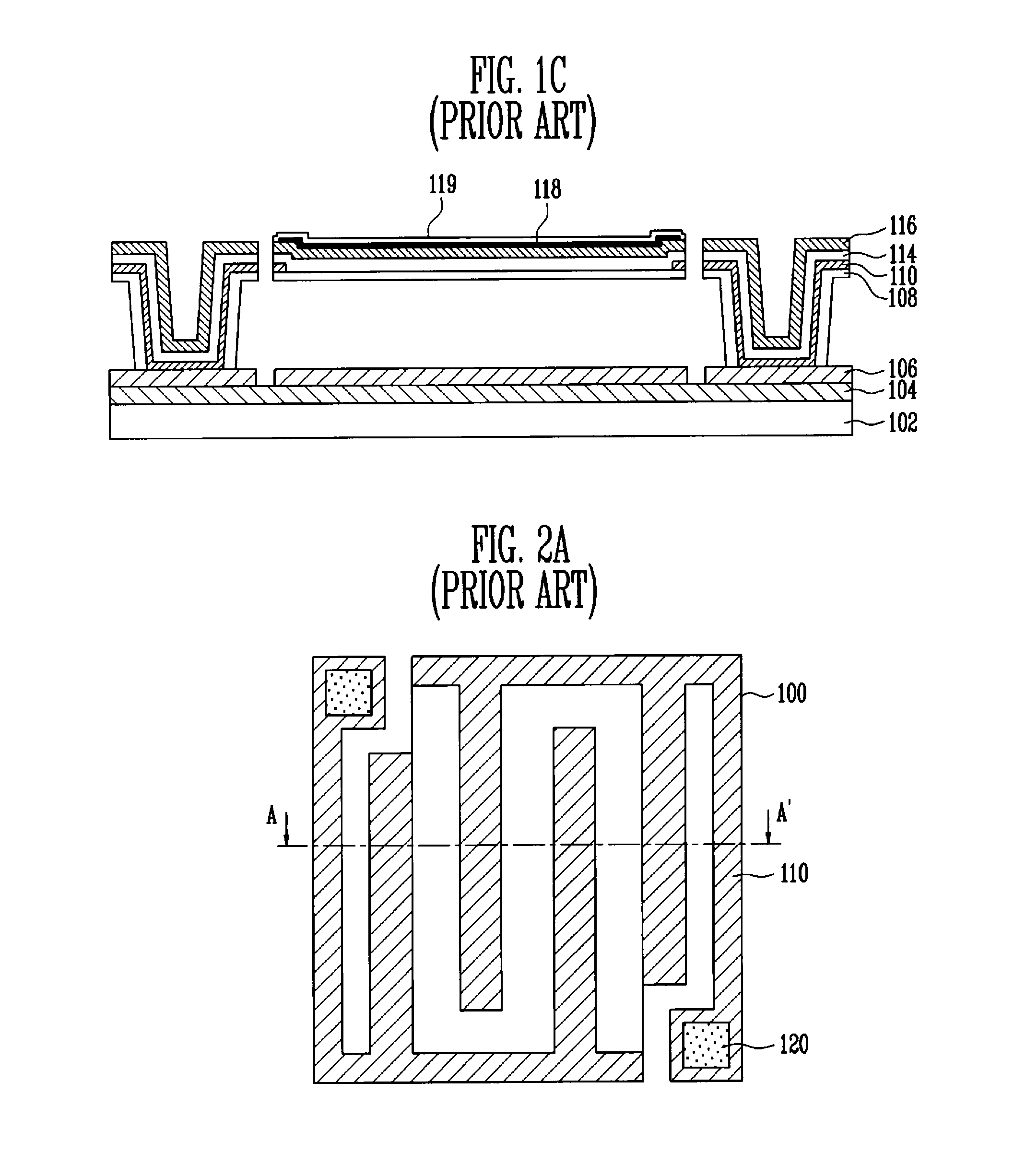

Structure of an optical interference display unit

InactiveUS6958847B2Avoid pollutionIncreased process complexityTelevision system detailsColor television detailsLight reflectionReflective layer

Owner:SNAPTRACK

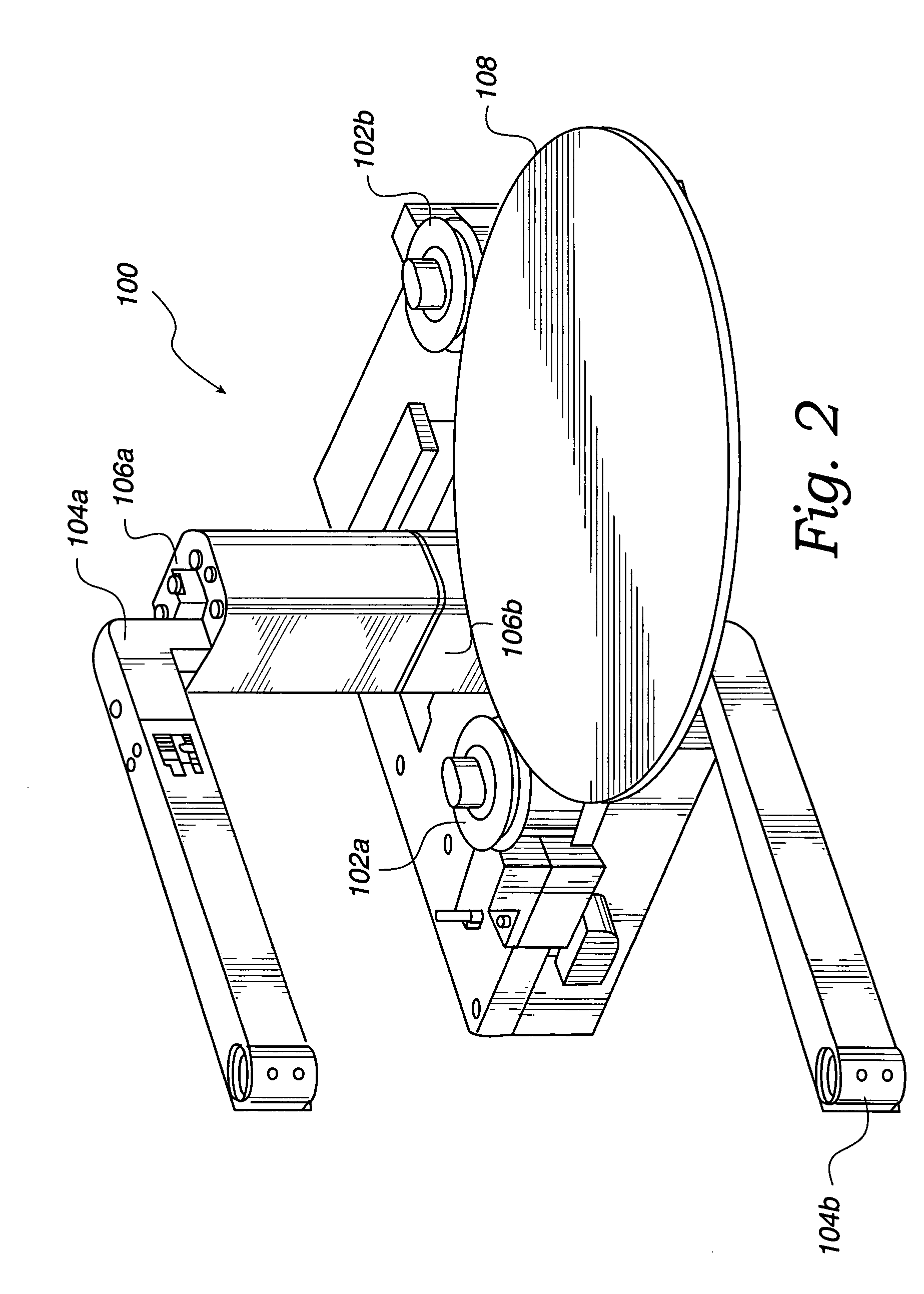

Plasma Processing Apparatus

InactiveUS20080236751A1Improve process yieldUniformity of processElectric discharge tubesSemiconductor/solid-state device manufacturingCircumferential ringsPlasma processing

A plasma processing apparatus wherein a layer structure consisting of plural layers formed in stack one upon another on a semiconductor wafer placed on the sample holder located in the process chamber, is etched with plasma generated in the process chamber by supplying high frequency power to the electrode disposed in the sample holder, the apparatus comprising a ring-shaped electrode disposed above the electrode and around the periphery of the top portion of the sample holder, an outer circumferential ring of dielectric material disposed above the ring-shaped electrode and opposite to the plasma, and a power source for supplying power at different values to the ring-shaped electrode depending on the sorts of layers of the layer structure.

Owner:HITACHI HIGH-TECH CORP

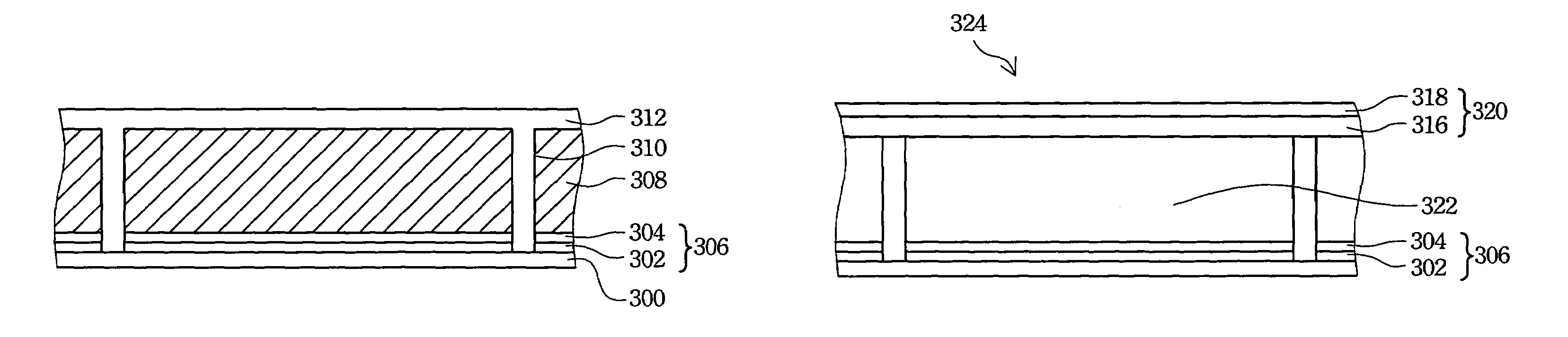

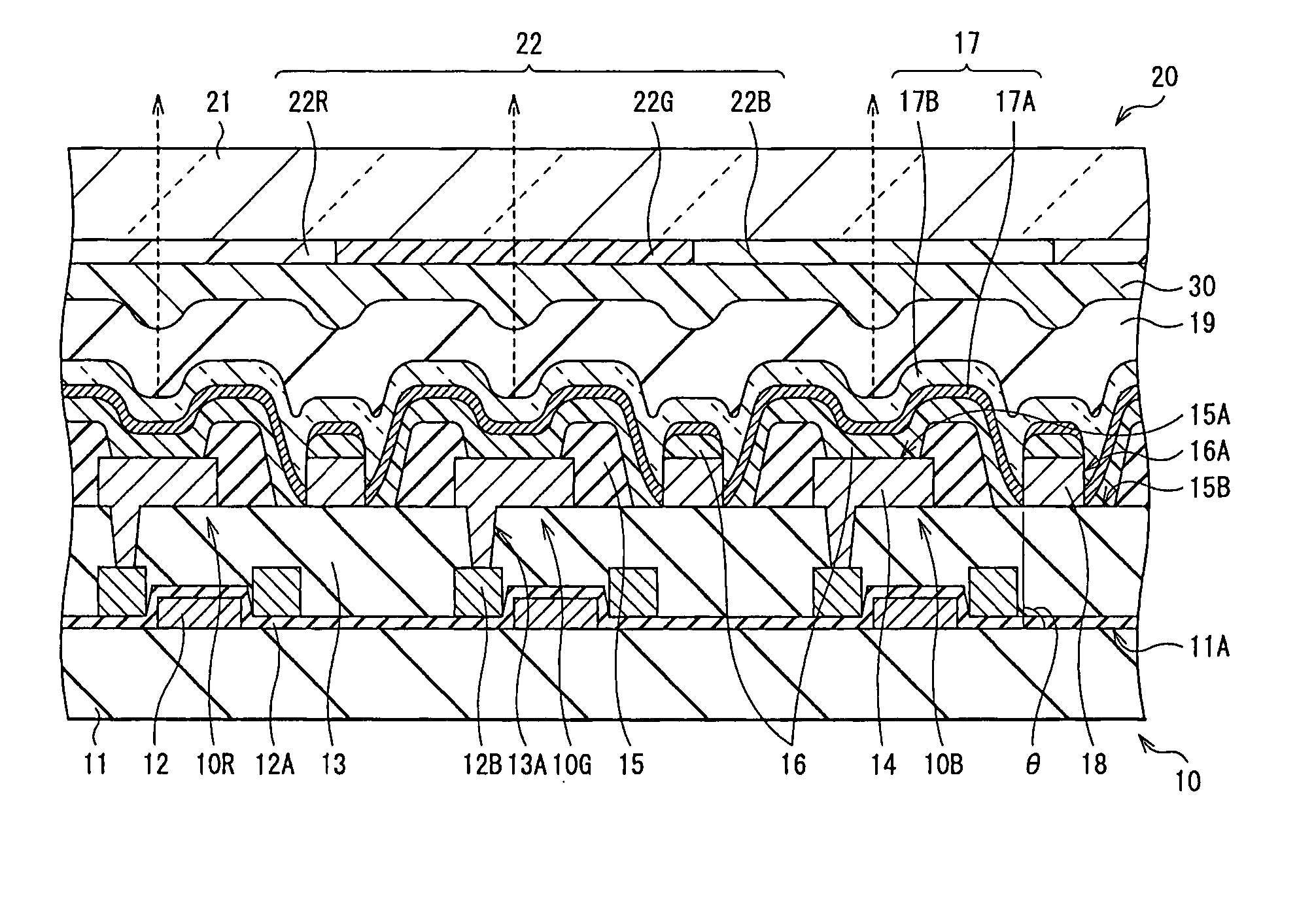

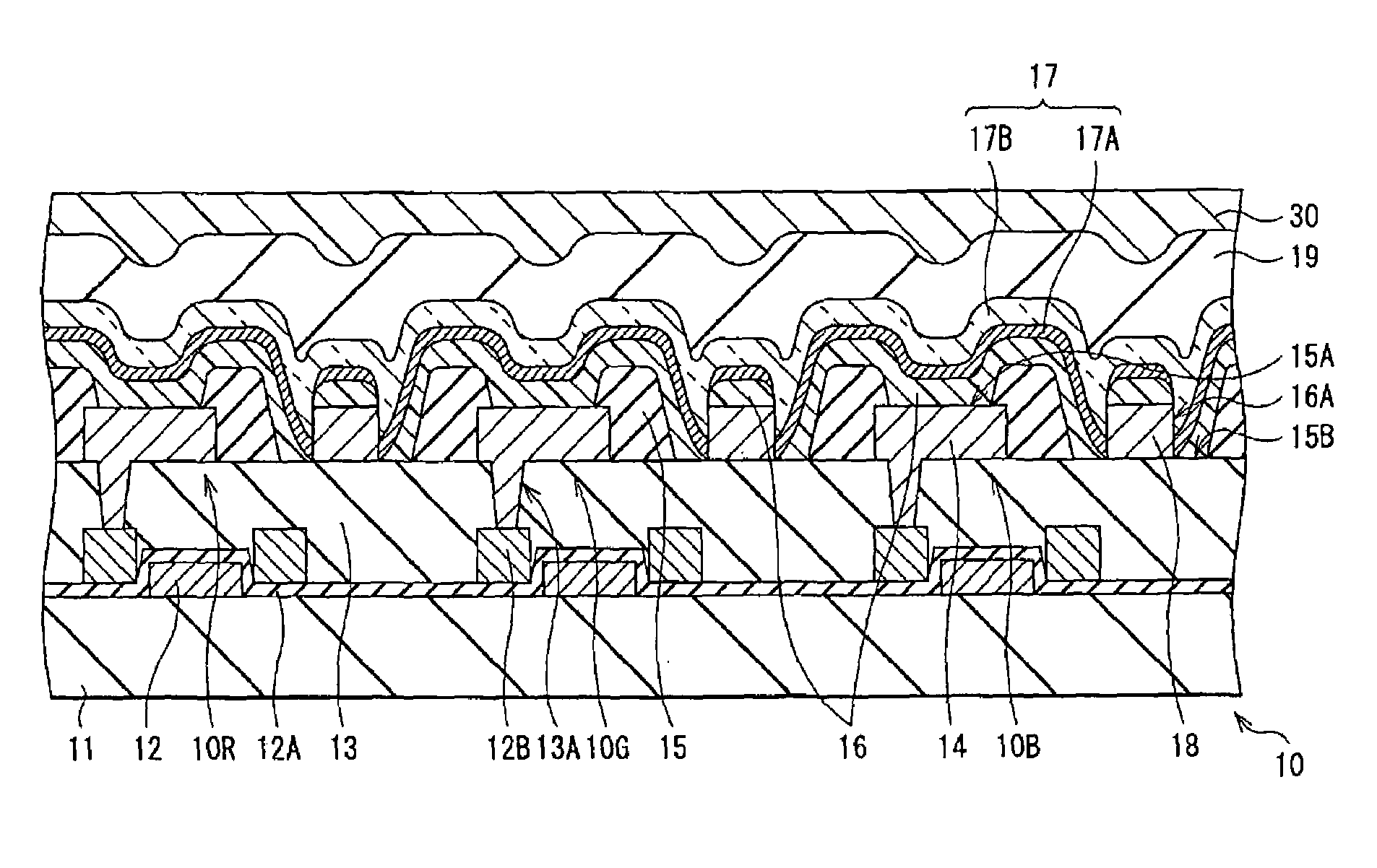

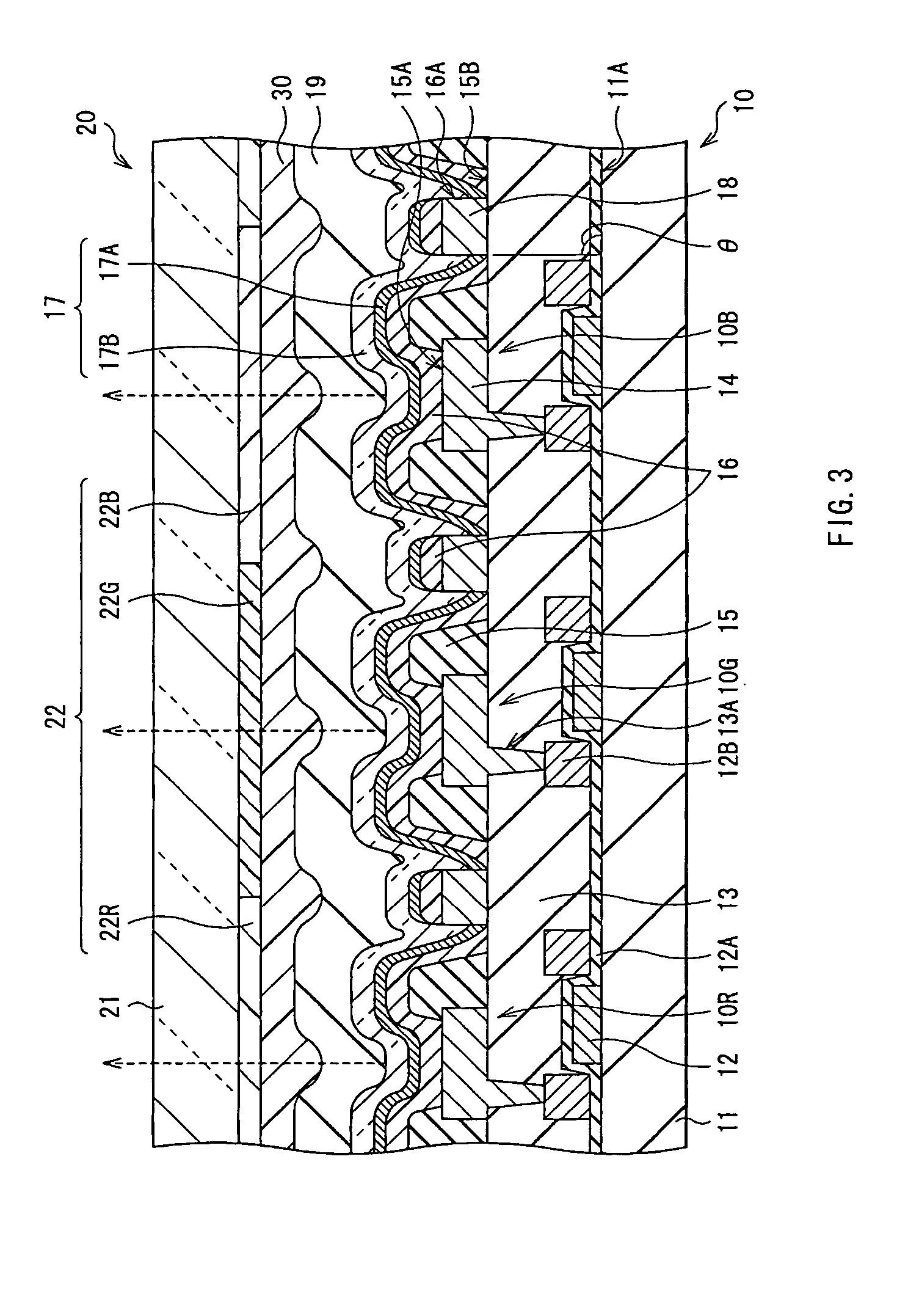

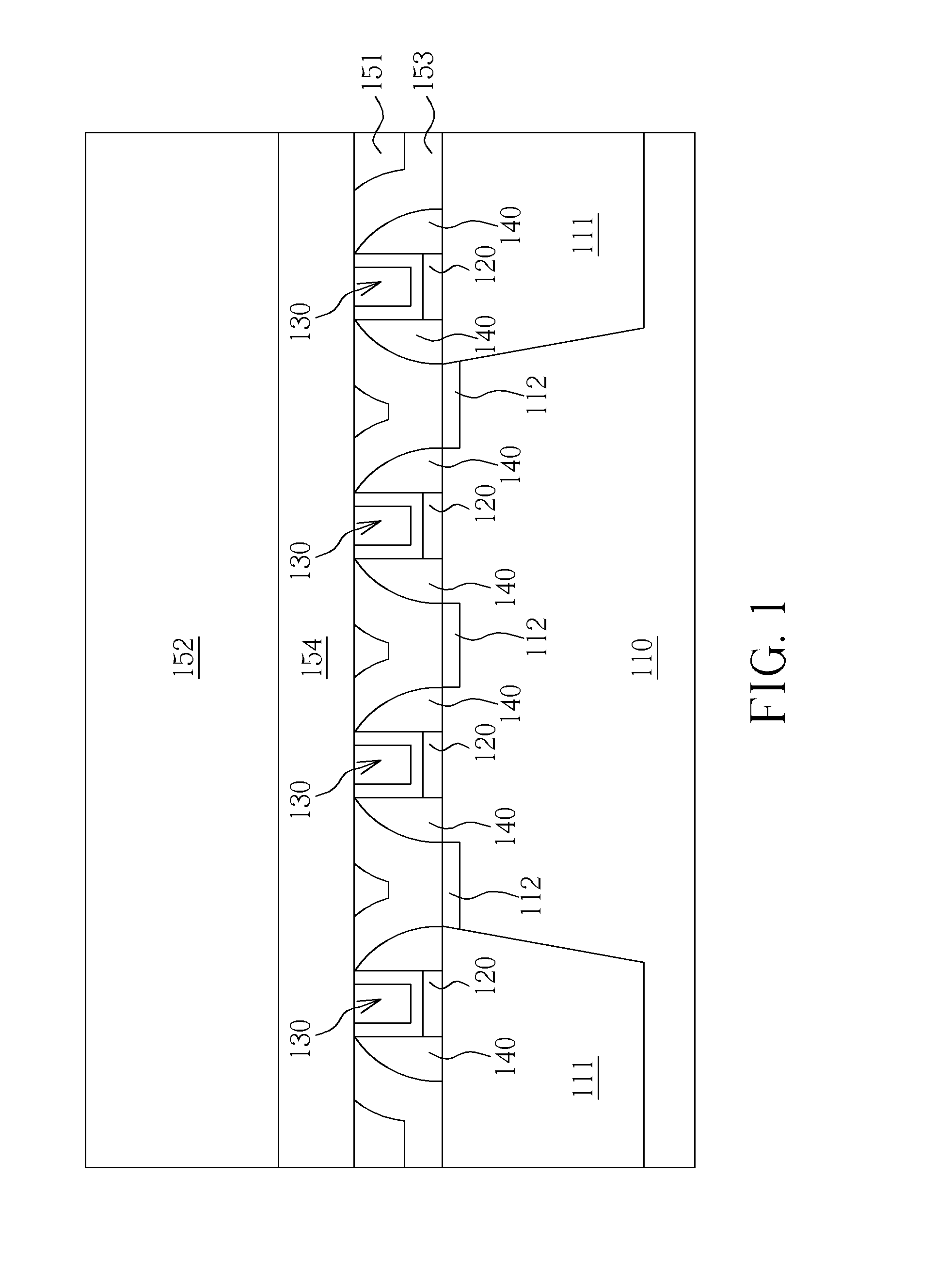

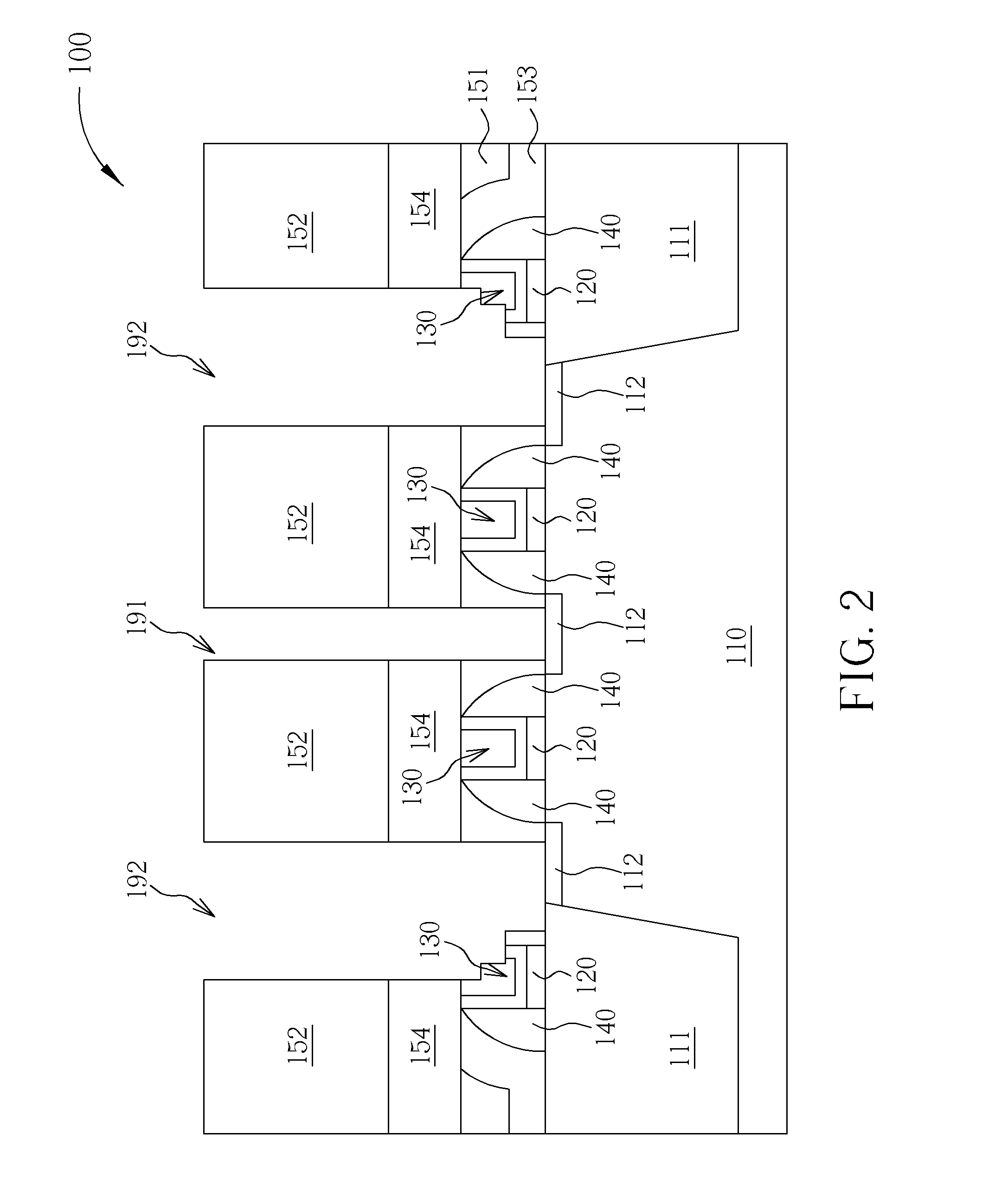

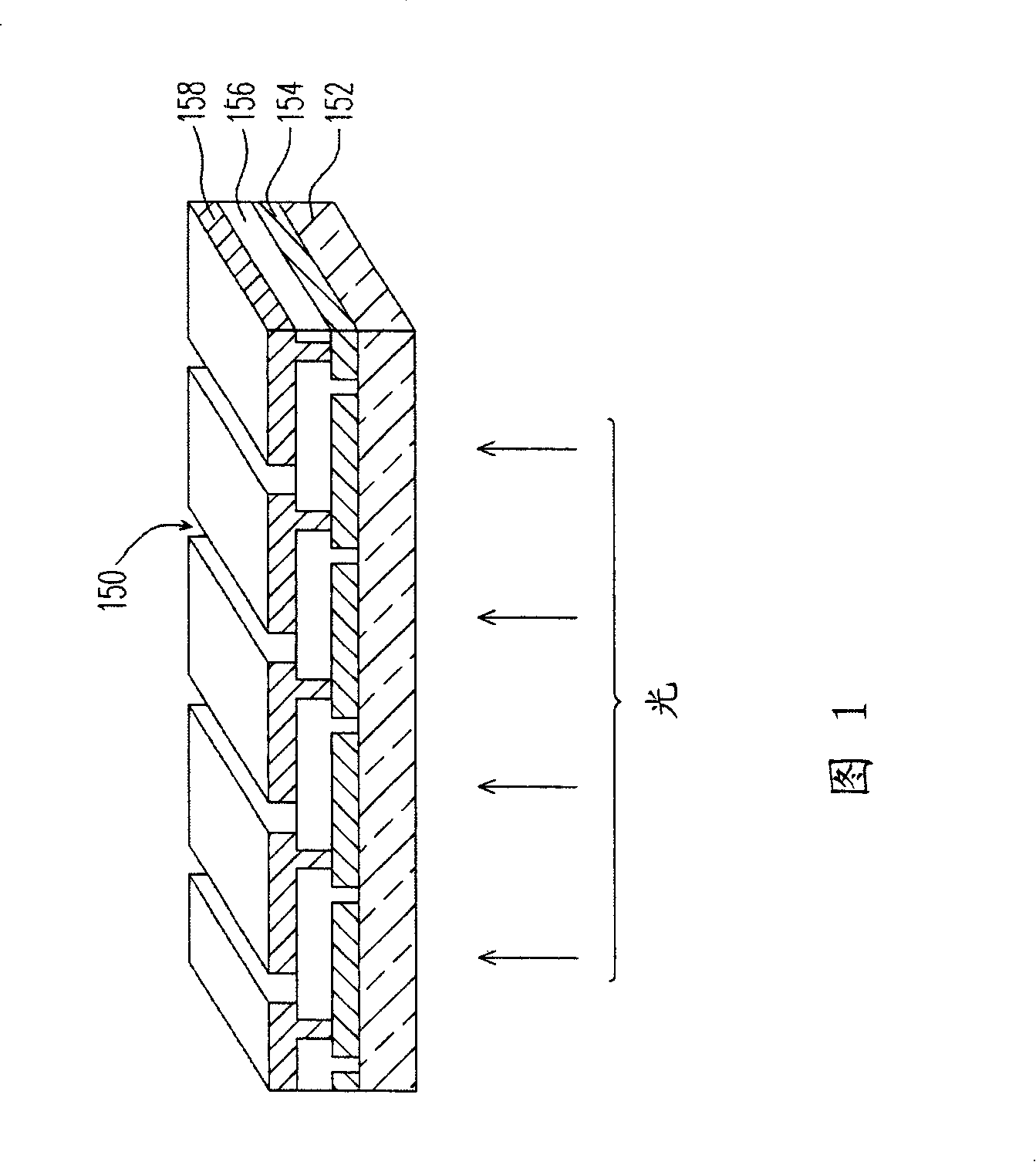

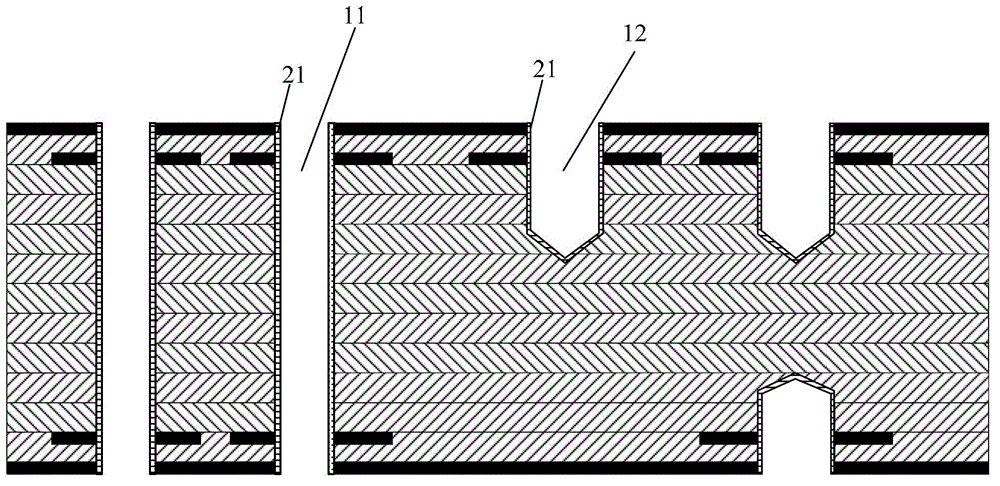

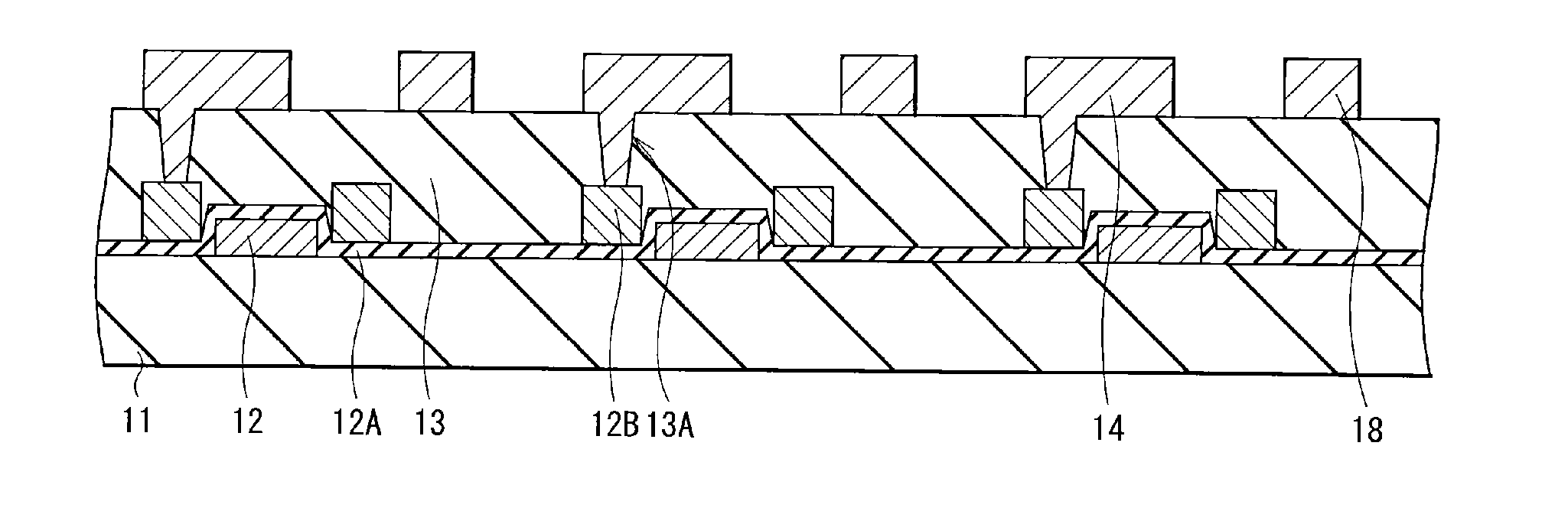

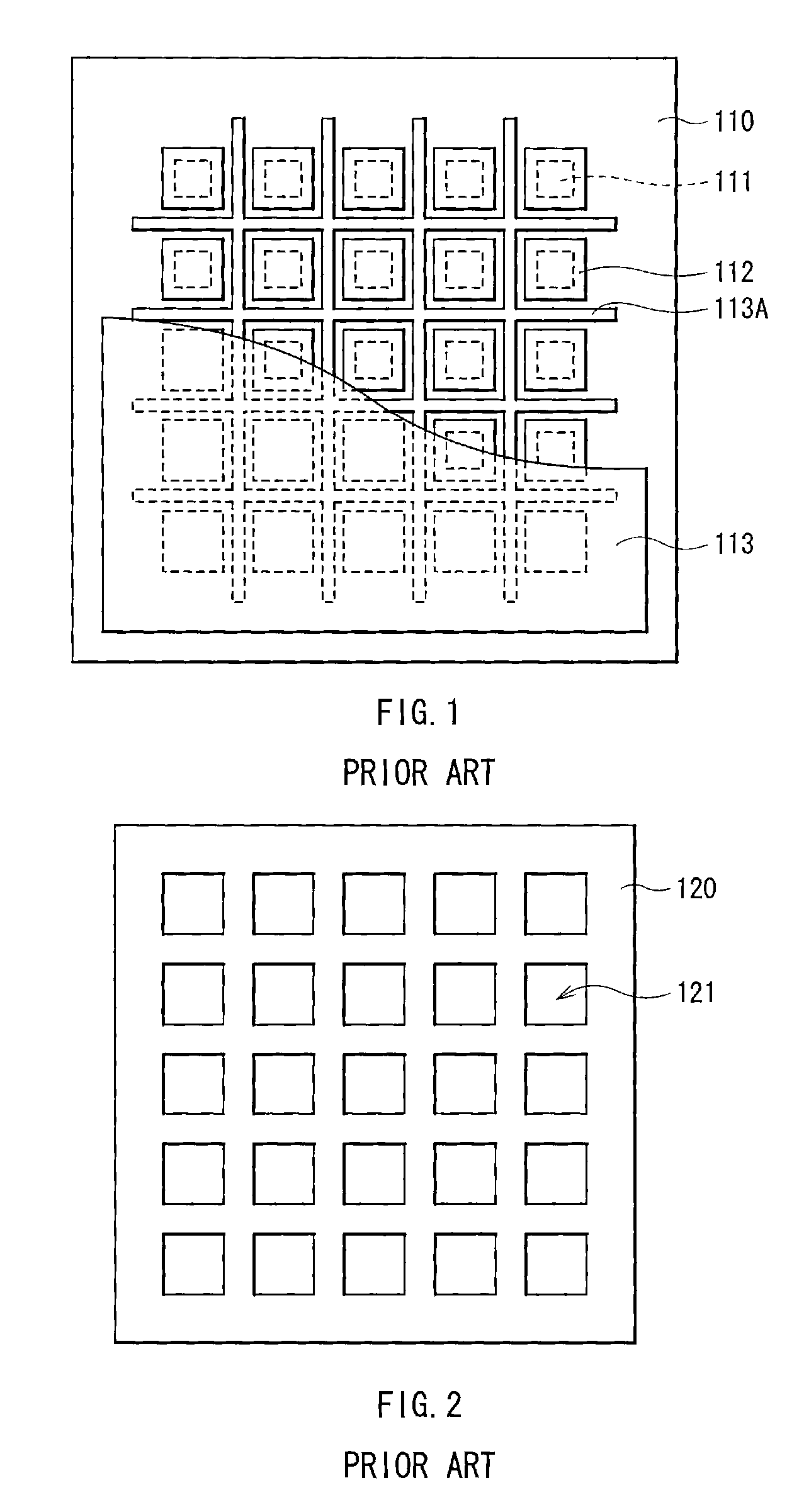

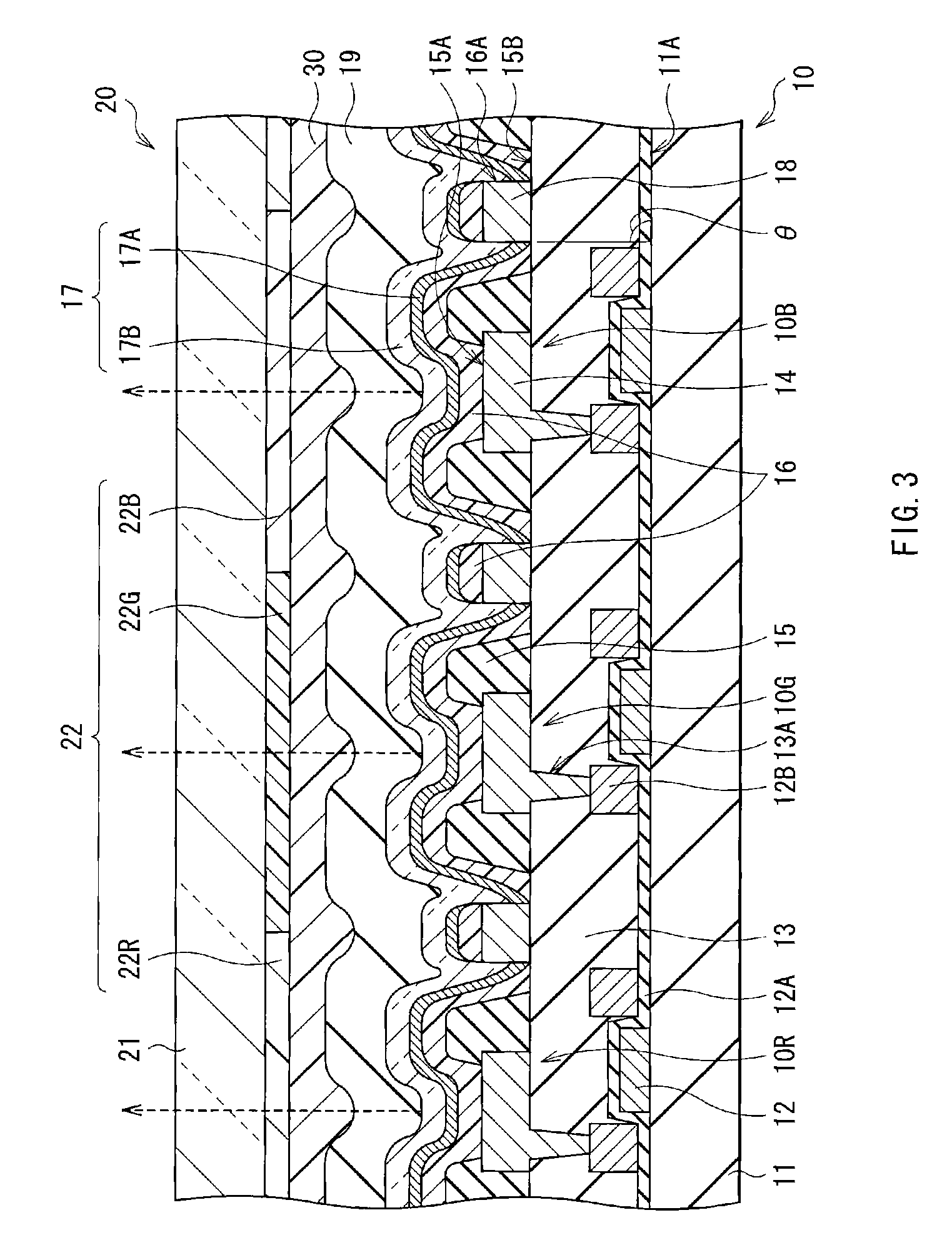

Organic light emitting device, manufacturing method thereof, and display unit

InactiveUS20050077816A1Inhibition of variationImprove display qualityVacuum tubesDischarge tube luminescnet screensOrganic light emitting deviceOrganic layer

The invention provides an organic light emitting device which can electrically connect an auxiliary wiring and a second electrode without using a mask for pixel coating, a manufacturing method thereof, and a display unit. In organic light emitting devices, for example, a first electrode as an anode, an insulating film, an organic layer including a light emitting layer, and a second electrode as a cathode are layered in this order from a substrate side. The organic layer has a break part on a side face of an auxiliary wiring. The auxiliary wiring and the second electrode are electrically connected through this break part.

Owner:THOMSON LICENSING SA

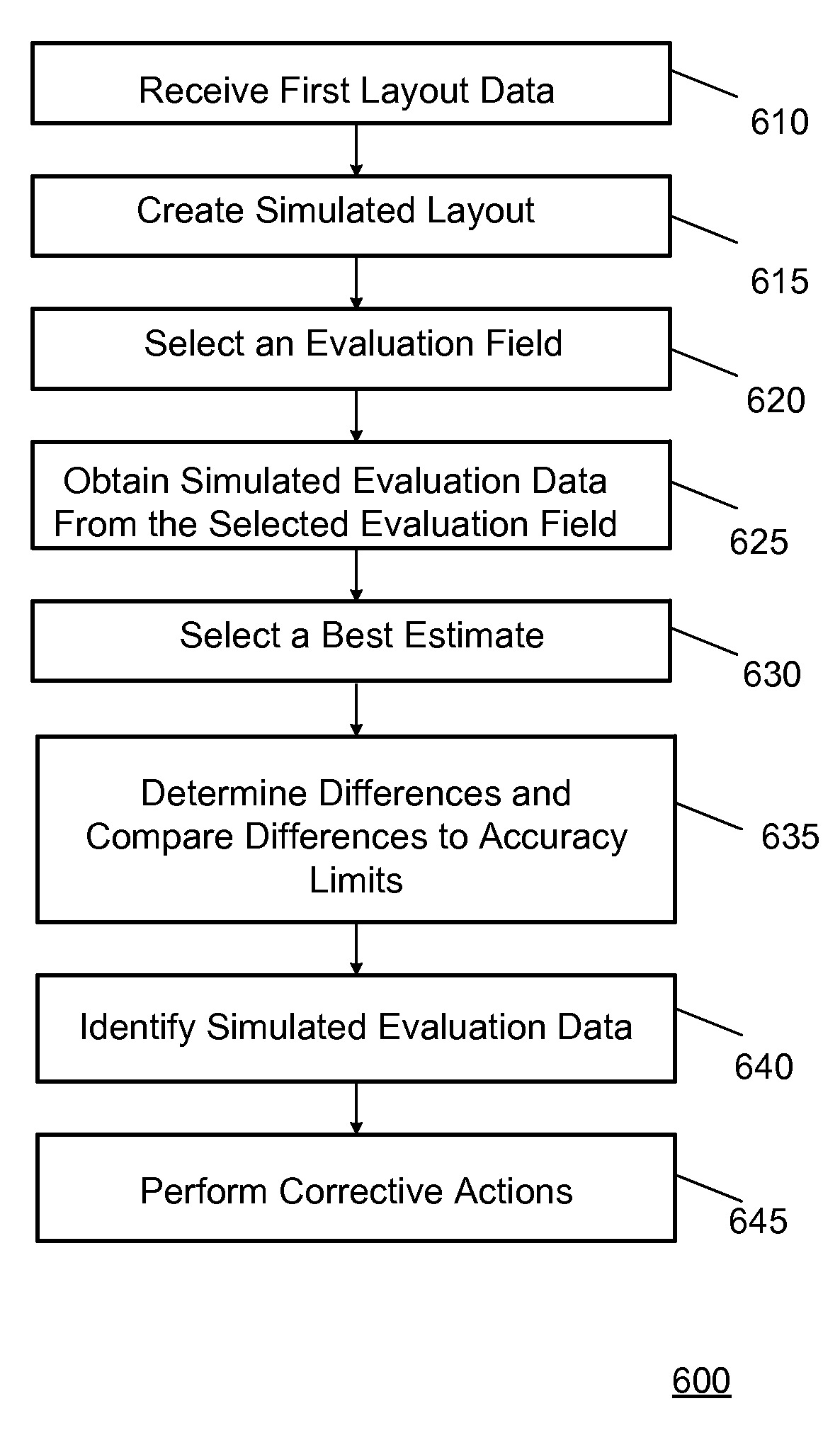

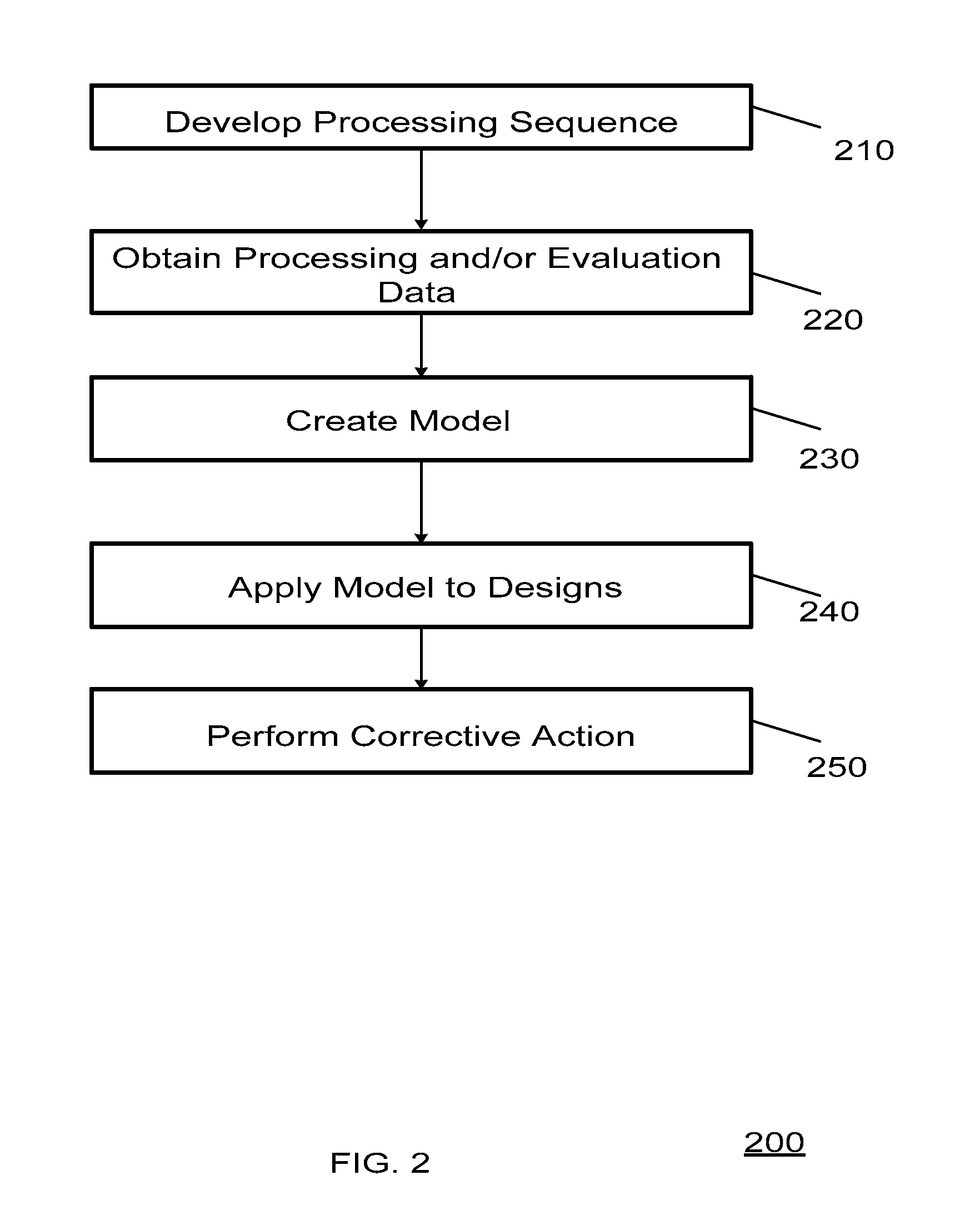

Enhanced Process Yield Using a Hot-Spot Library

InactiveUS20090144691A1Improve processing yieldSemiconductor/solid-state device testing/measurementSolid-state devicesChemistry

Owner:TOKYO ELECTRON LTD

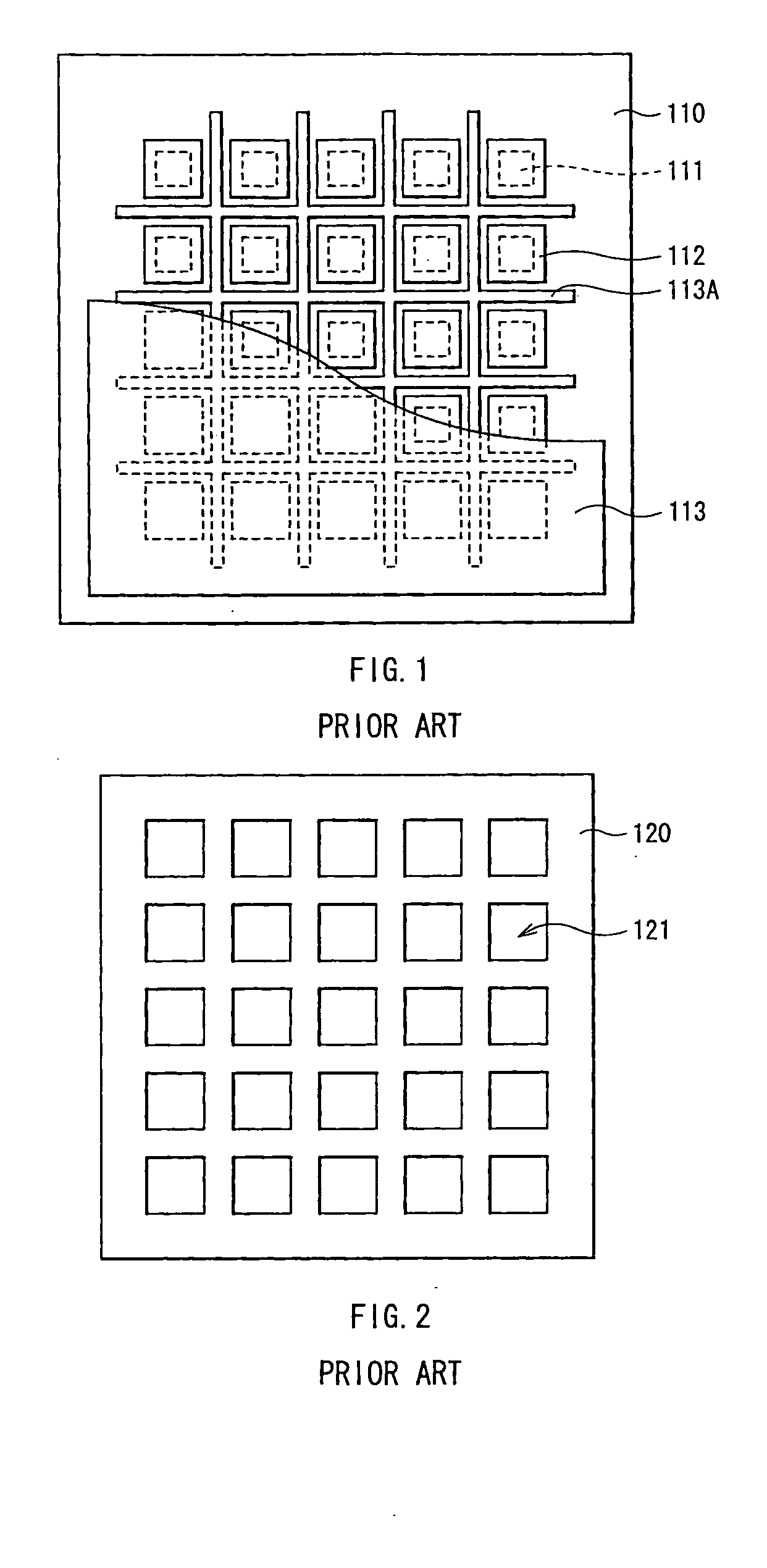

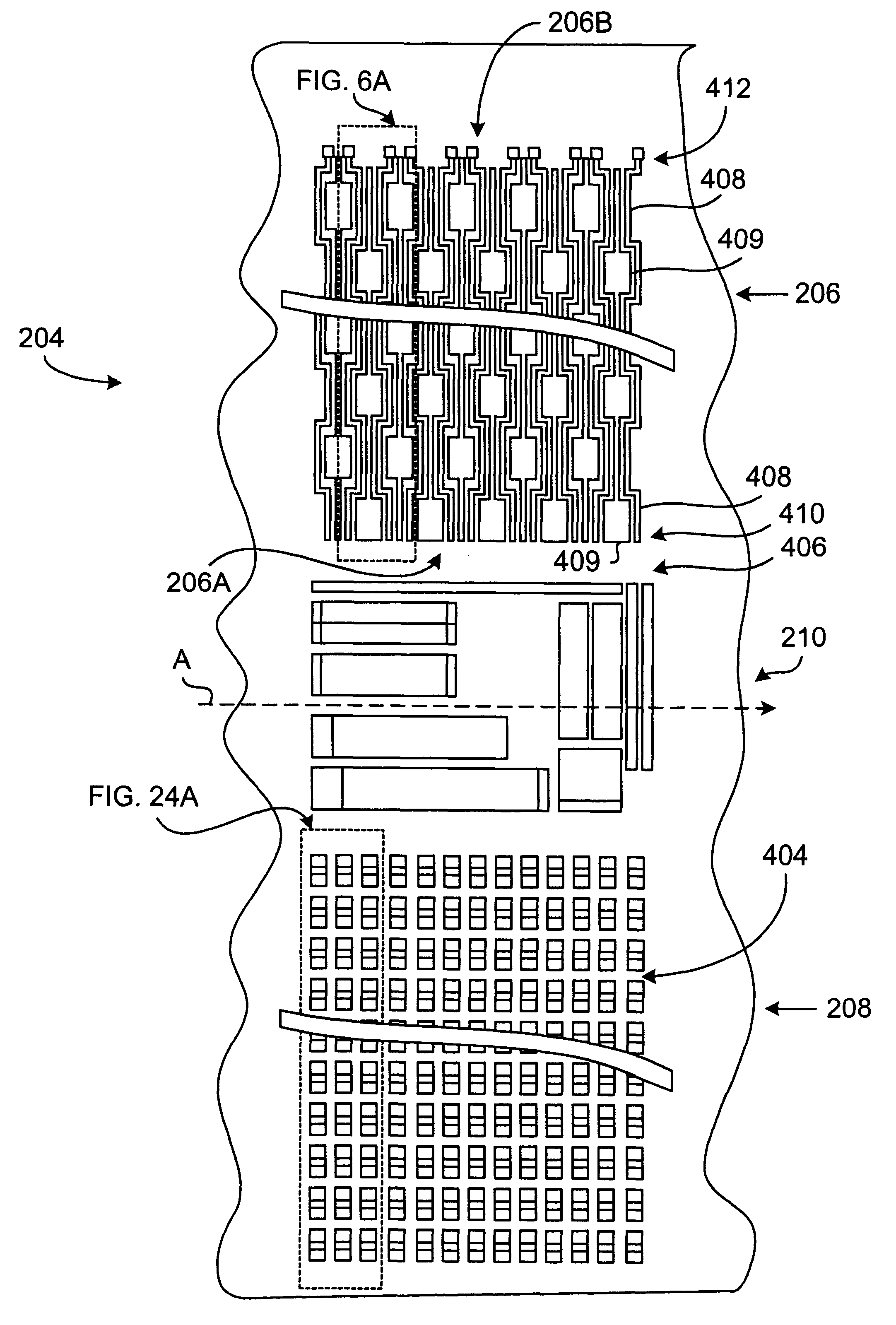

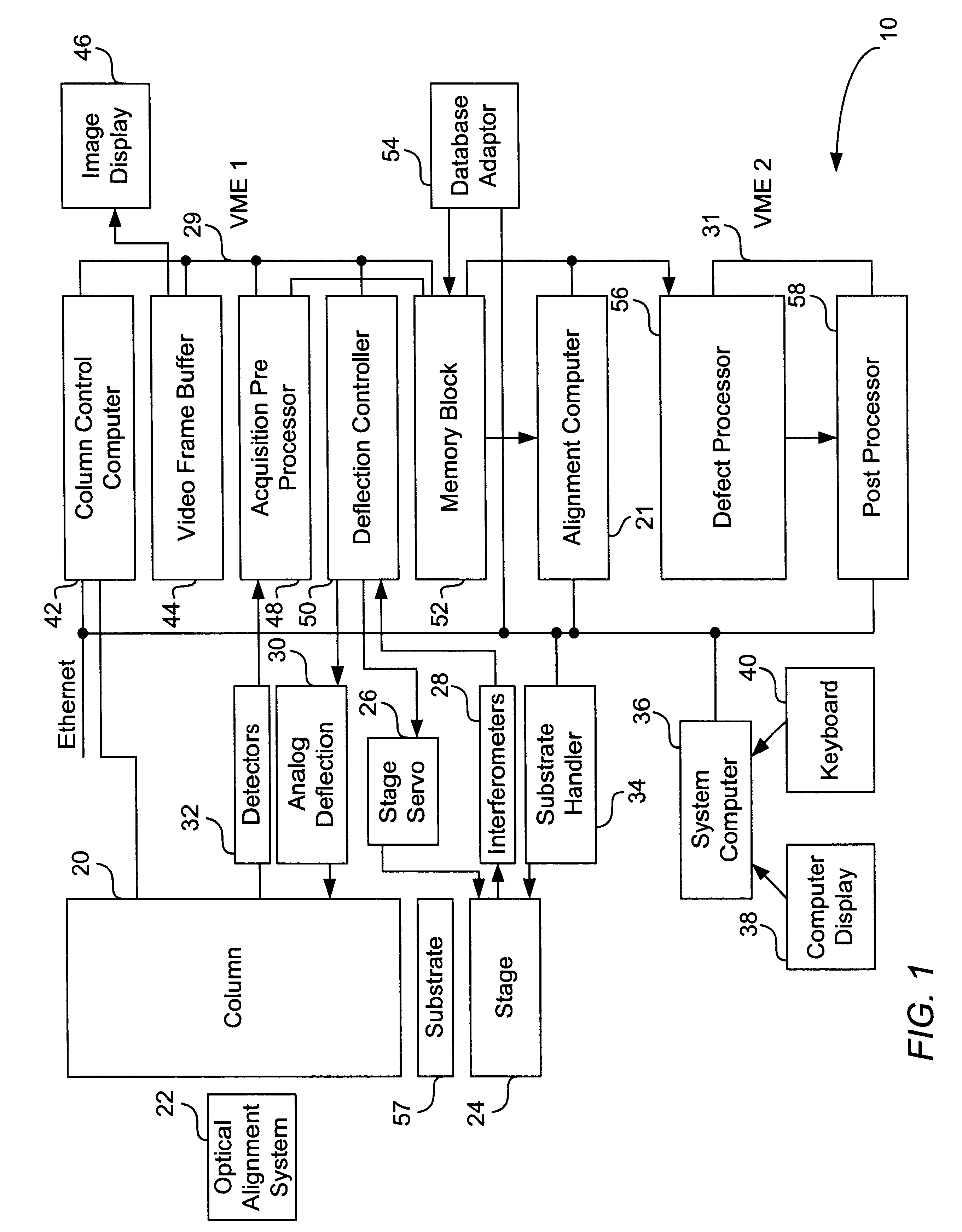

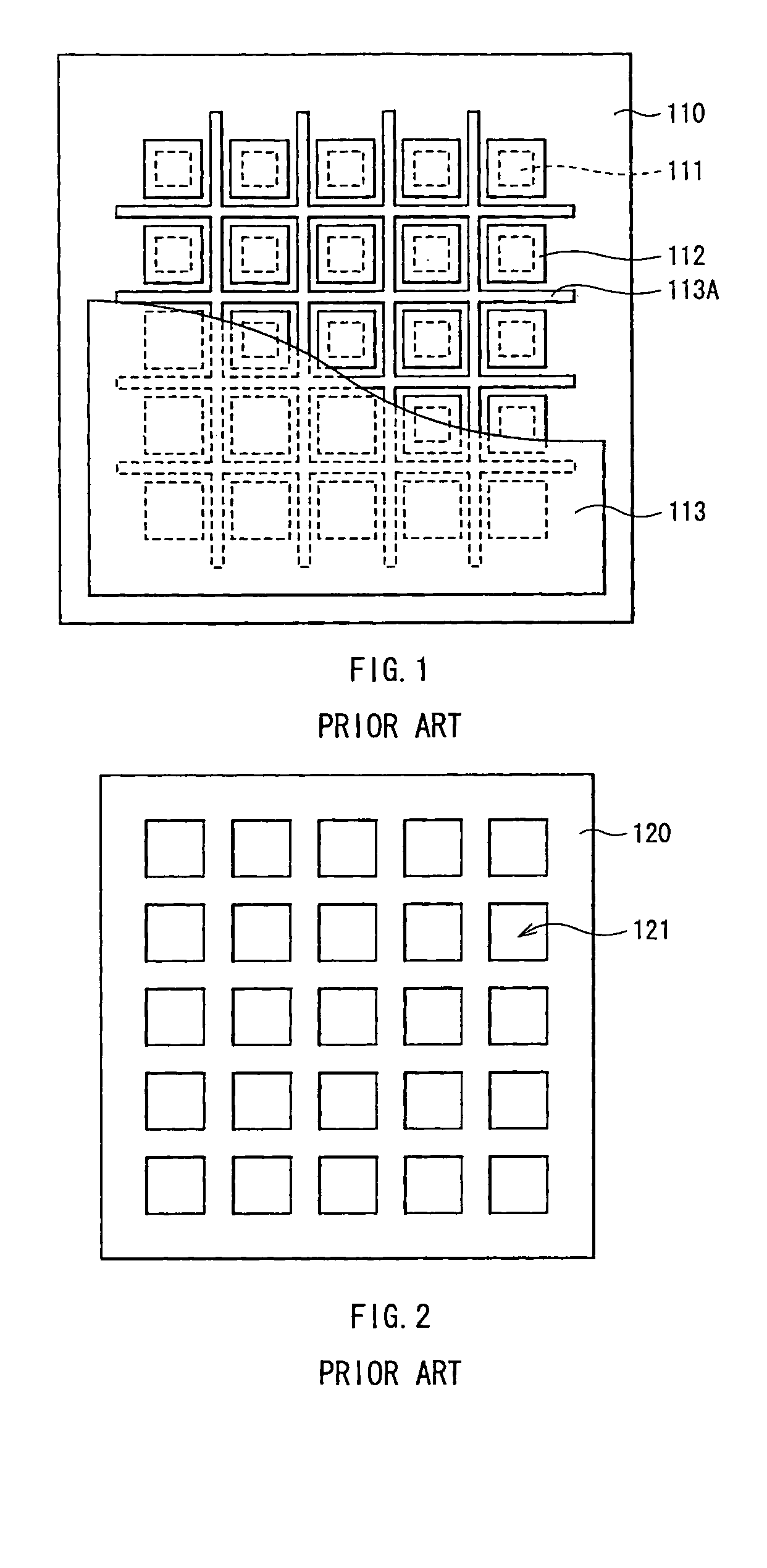

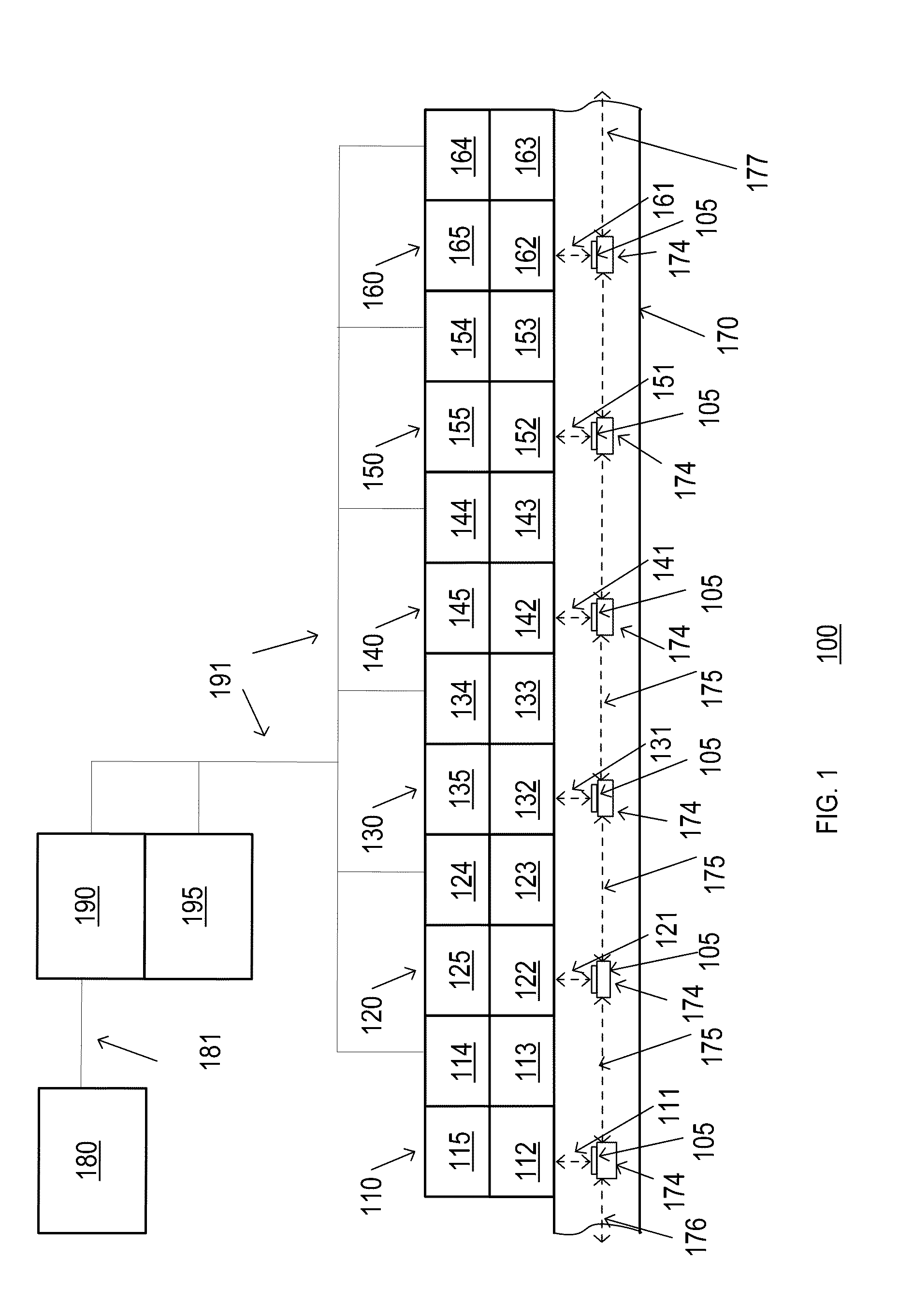

Test structures and methods for inspection of semiconductor integrated circuits

InactiveUS6528818B1Easily dry-etchedEasy to processSemiconductor/solid-state device testing/measurementElectric discharge tubesSemiconductor chipIntegrated circuit

Disclosed is a semiconductor die having a scanning area. The semiconductor die includes a first plurality of test structures wherein each of the test structures in the first plurality of test structures is located entirely within the scanning area. The semiconductor die further includes a second plurality of test structures wherein each of the test structures in the first plurality of test structures is located only partially within the scanning area. The test structures are arranged so that a scan of the scanning area results in detection of defects outside of the scanning area.

Owner:KLA TEMCOR

Organic light emitting device, manufacturing method thereof, and display unit

InactiveUS7173373B2Inhibition of variationImprove display qualityDischarge tube luminescnet screensStatic indicating devicesOrganic light emitting deviceOrganic layer

The invention provides an organic light emitting device which can electrically connect an auxiliary wiring and a second electrode without using a mask for pixel coating, a manufacturing method thereof, and a display unit. In organic light emitting devices, for example, a first electrode as an anode, an insulating film, an organic layer including a light emitting layer, and a second electrode as a cathode are layered in this order from a substrate side. The organic layer has a break part on a side face of an auxiliary wiring. The auxiliary wiring and the second electrode are electrically connected through this break part.

Owner:THOMSON LICENSING SA

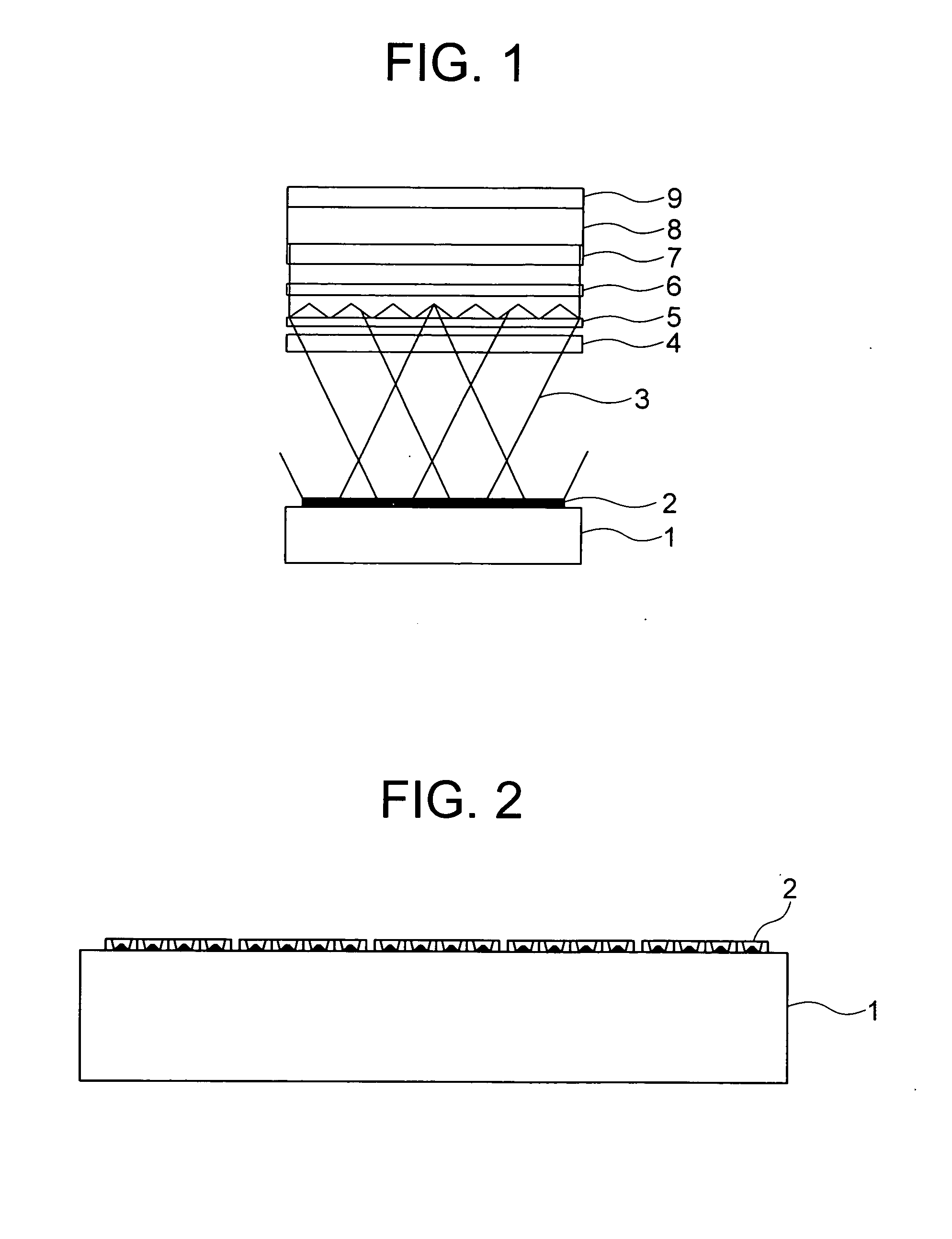

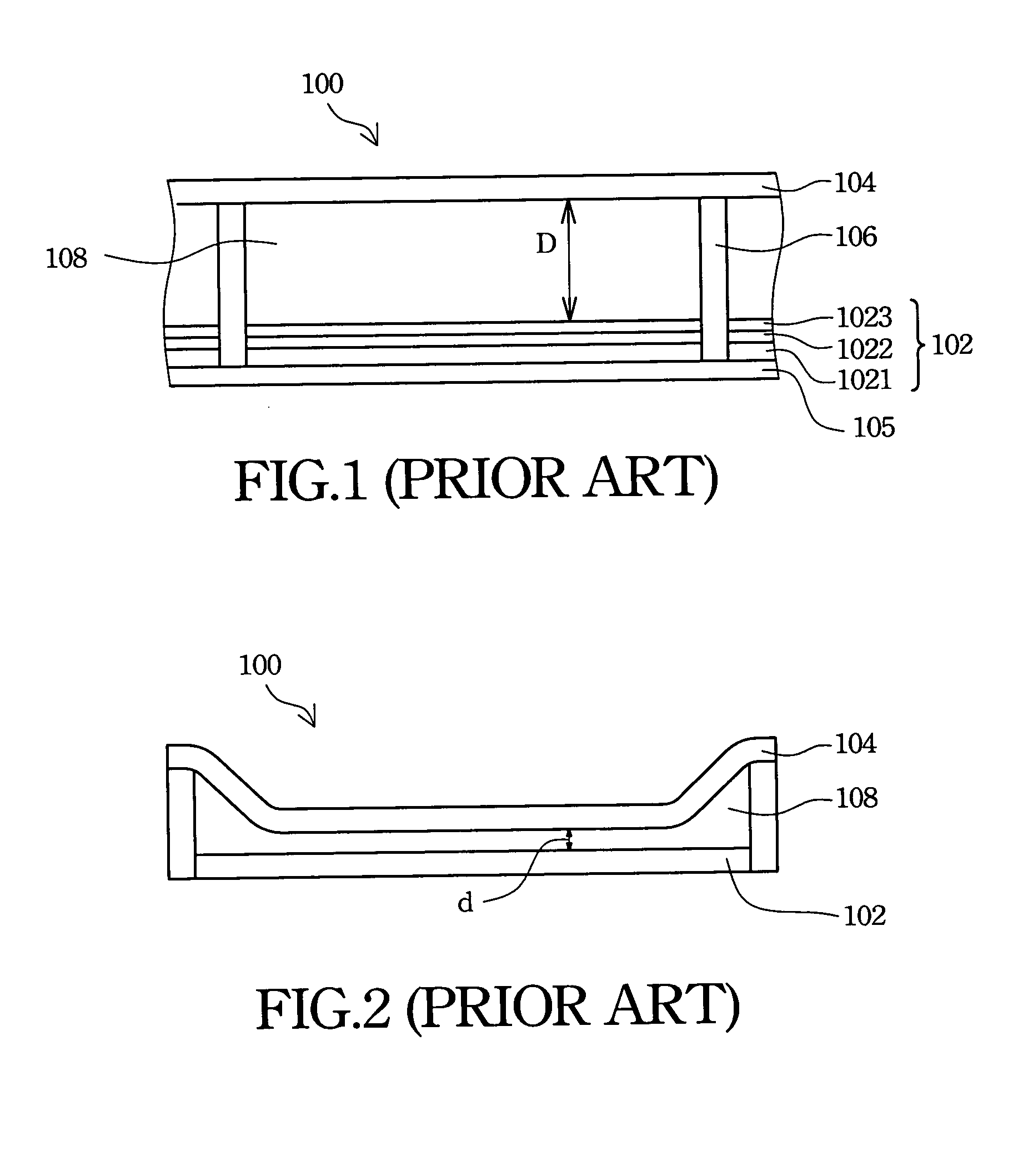

Liquid crystal display apparatus

ActiveUS20070085944A1Increase brightnessIncrease in sizeSolid-state devicesNon-linear opticsCold cathodeEngineering

A cold-cathode tube has hitherto been used as a backlight for supplying illumination to a liquid crystal television but recently, light emitting diode pieces have been used for a backlight of a large-size liquid crystal television. For the purpose of improving the emission efficiency, flip chip mounting of the light emitting diode piece is advantageous but the mounting yield is restricted by the piece size, electrode structure and wire pattern structure, facing situations having difficulties in realizing simplified mounting and reduction of costs of members. In a liquid crystal display apparatus having a liquid crystal panel, an optical system and a light source, the light source includes a light emitting element structure having positive and negative electrodes, at least one of them being plural, and wires mounted to the positive and negative electrodes through flip chip mounting by making electrical correspondence to individual regions of the positive and negative electrodes.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

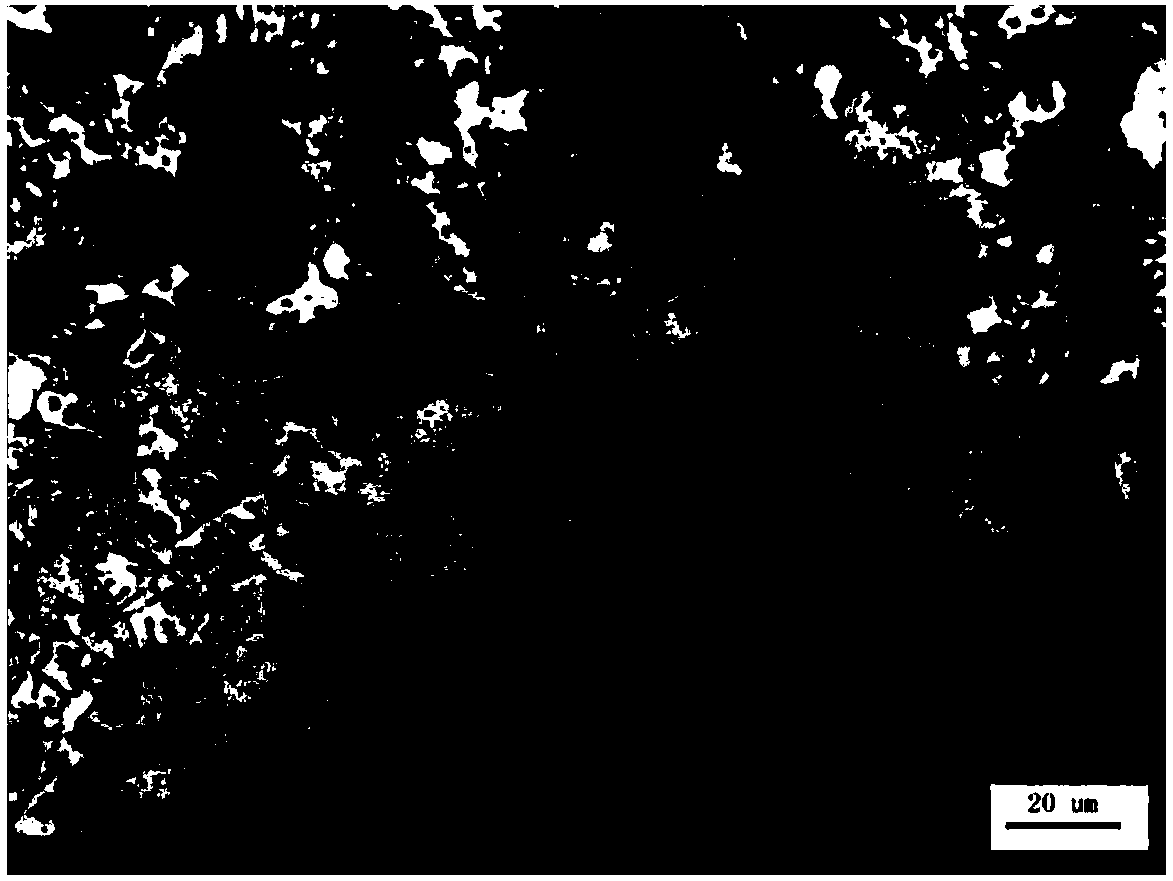

Polyimide porous membrane and lithium ion battery comprising same

ActiveCN101665580AUniform hole diameter distributionImprove breathabilitySecondary cellsCell component detailsBenzoic acidChlorinated paraffins

The invention discloses a polyimide porous membrane and a lithium ion battery comprising the same. The polyimide porous membrane is prepared by the following method, and the method comprises the following steps: forming a polyamic acid membrane by using the mixture of a mixture containing polyamic acid, pore-forming substance and solvent, and subjecting the polyamic acid membrane to amidation at the temperature higher than the decomposing temperature of the pore-forming substance, wherein the solvent is a solvent which dissolves the polyamic acid but slightly dissolves or does not dissolve thepore-forming substance; and the pore-forming substance may be one or combination of benzoic acid polyol ester, phthalic acid dialkyl ester, polyprotic acid alkyl ester, phenyl alkysulfonate, chlorinated paraffin and epoxidized soybean oil. The service life and the processing yield of the lithium ion battery made of the polyimide porous membrane serving as a battery membrane are improved. Moreover, the polyimide porous membrane also has higher thermal stability, and greatly improves the safety performance of the battery.

Owner:BYD CO LTD

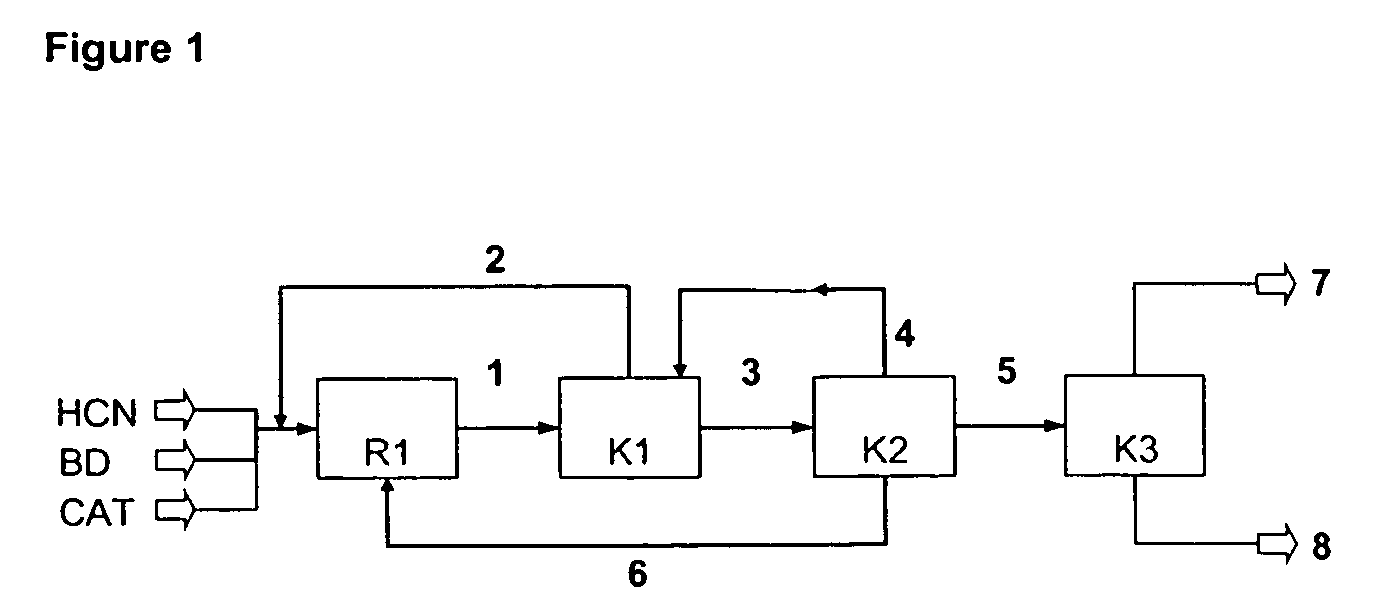

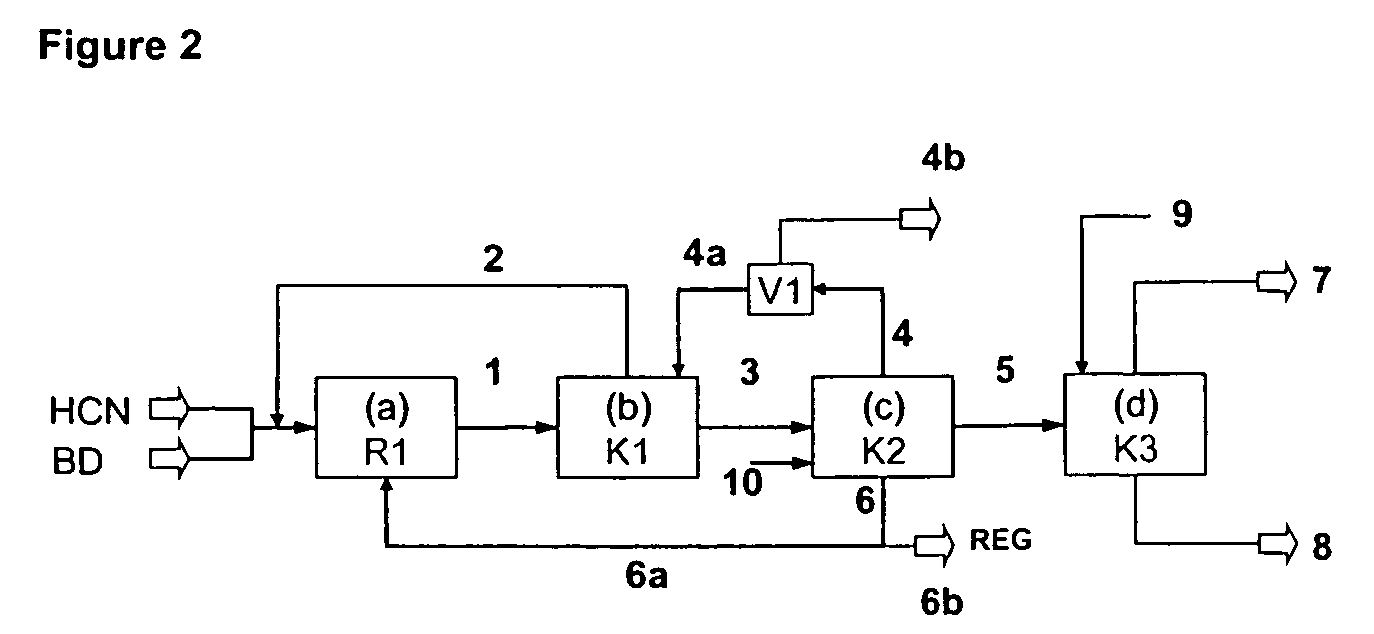

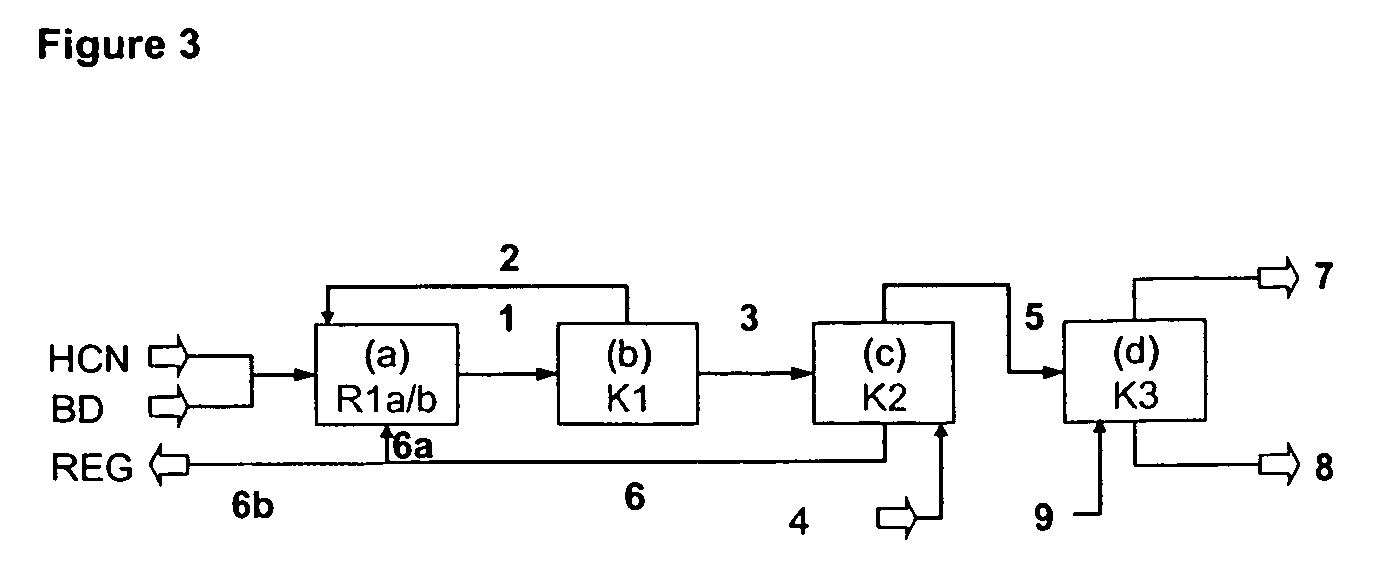

Method for producing 3-pentenenitrile

InactiveUS7541486B2Improve processing yieldReduce thermal stressOrganic compound preparationPreparation by hydrogen cyanide additionPtru catalystButadiene Dioxide

A process is described for preparing 3-pentenenitrile, characterized by the following process steps:(a) reacting 1,3-butadiene with hydrogen cyanide over at least one catalyst to obtain a stream 1 which comprises 3-pentenenitrile, 2-methyl-3-butenenitrile, the at least one catalyst and 1,3-butadiene,(b) distilling stream 1 in a column to obtain a high-1,3-butadiene stream 2 as the top product and a low-1,3-butadiene stream 3 as the bottom product which comprises 3-pentenenitrile, the at least one catalyst and 2-methyl-3-butenenitrile,(c) distilling stream 3 in a column to obtain a stream 4 as the top product which comprises 1,3-butadiene, a stream 5 which comprises 3-pentenenitrile and 2-methyl-3-butenenitrile at a side draw of the column, and a stream 6 as the bottom product which comprises the at least one catalyst,(d) distilling stream 5 to obtain a stream 7 as the top product which comprises 2-methyl-3-butenenitrile, and a stream 8 as the bottom product which comprises 3-pentenenitrile.

Owner:BASF AG

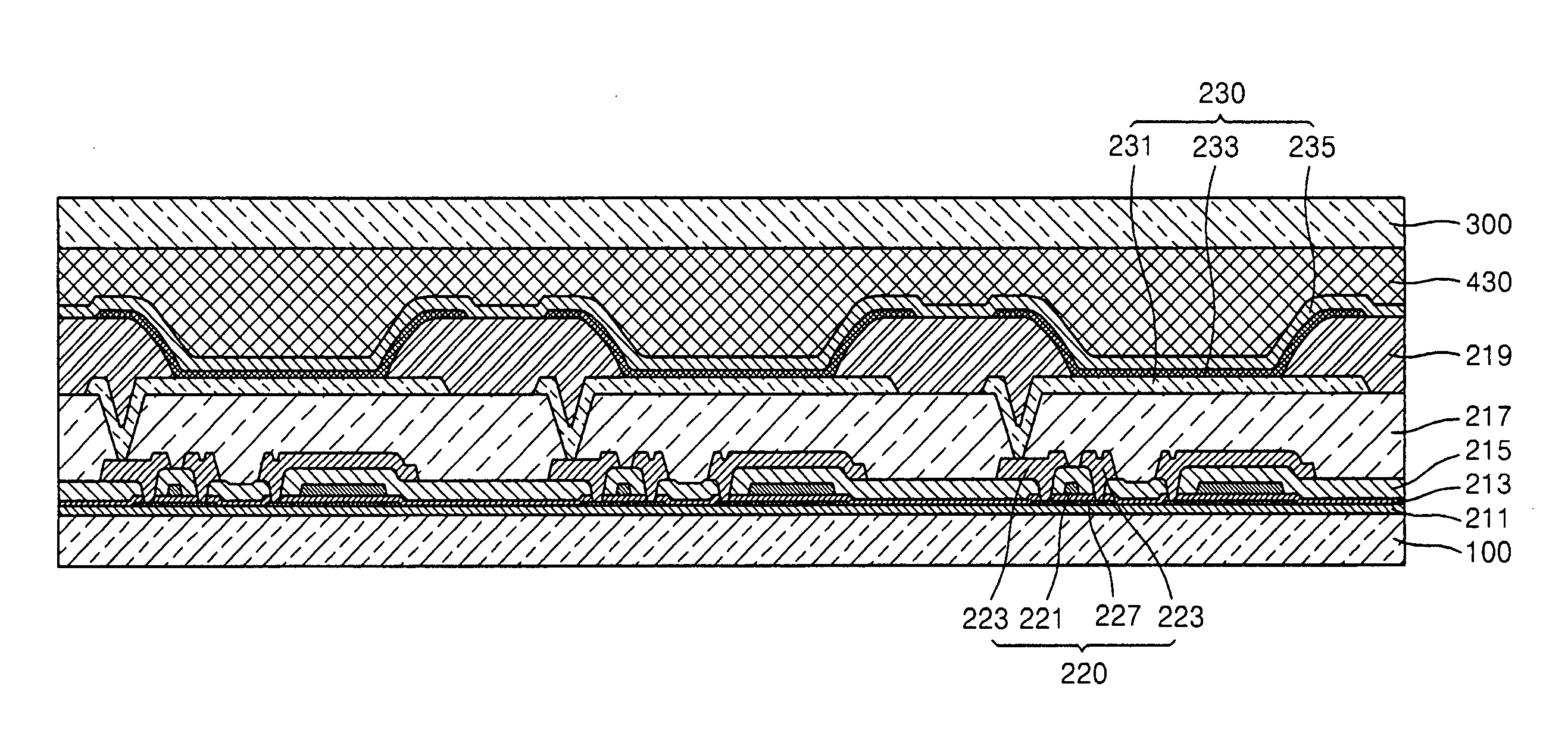

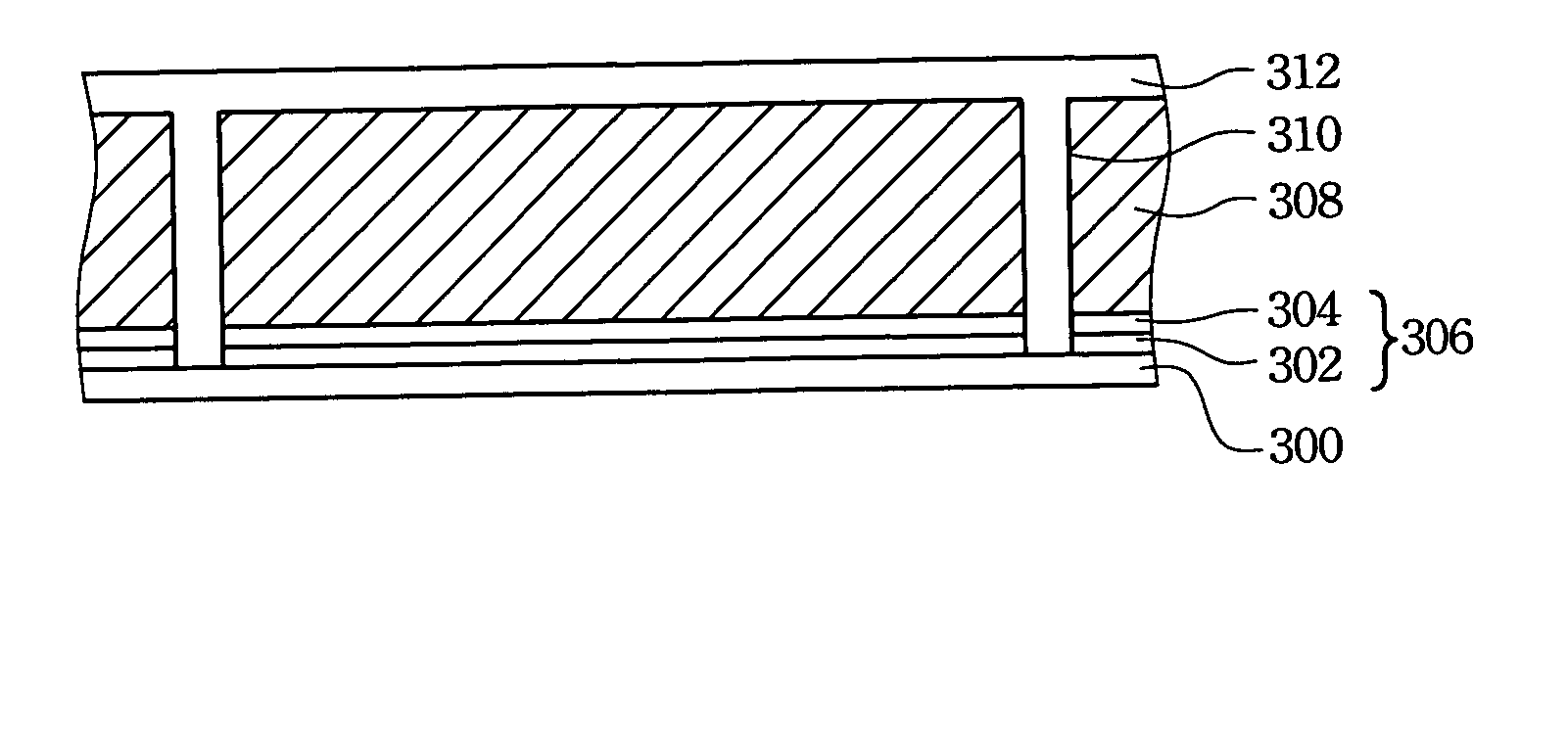

Organic light emitting display device and method of manufacturing thereof

ActiveUS20090195147A1Increase manufacturing process yieldEliminate bubblingDischarge tube luminescnet screensFinal product manufactureDisplay deviceOptoelectronics

Provided are an organic light-emitting display device and a manufacturing method of the organic light emitting display device. The organic light-emitting display device includes: a substrate; a display unit formed on the substrate; an encapsulation substrate formed above the display unit; a first sealant bonding the substrate and the encapsulation substrate; a filler formed between the substrate and the encapsulation substrate; and a second sealant interposed between the first sealant and the filler so as to separate the filler from the first sealant, wherein a distance of a portion of the substrate and the encapsulation substrate is smaller than that of other portions of the substrate and the encapsulation substrate. Accordingly, penetration of impurities, such as oxygen or water, from the outside into the organic light emitting display device is prevented.

Owner:SAMSUNG DISPLAY CO LTD

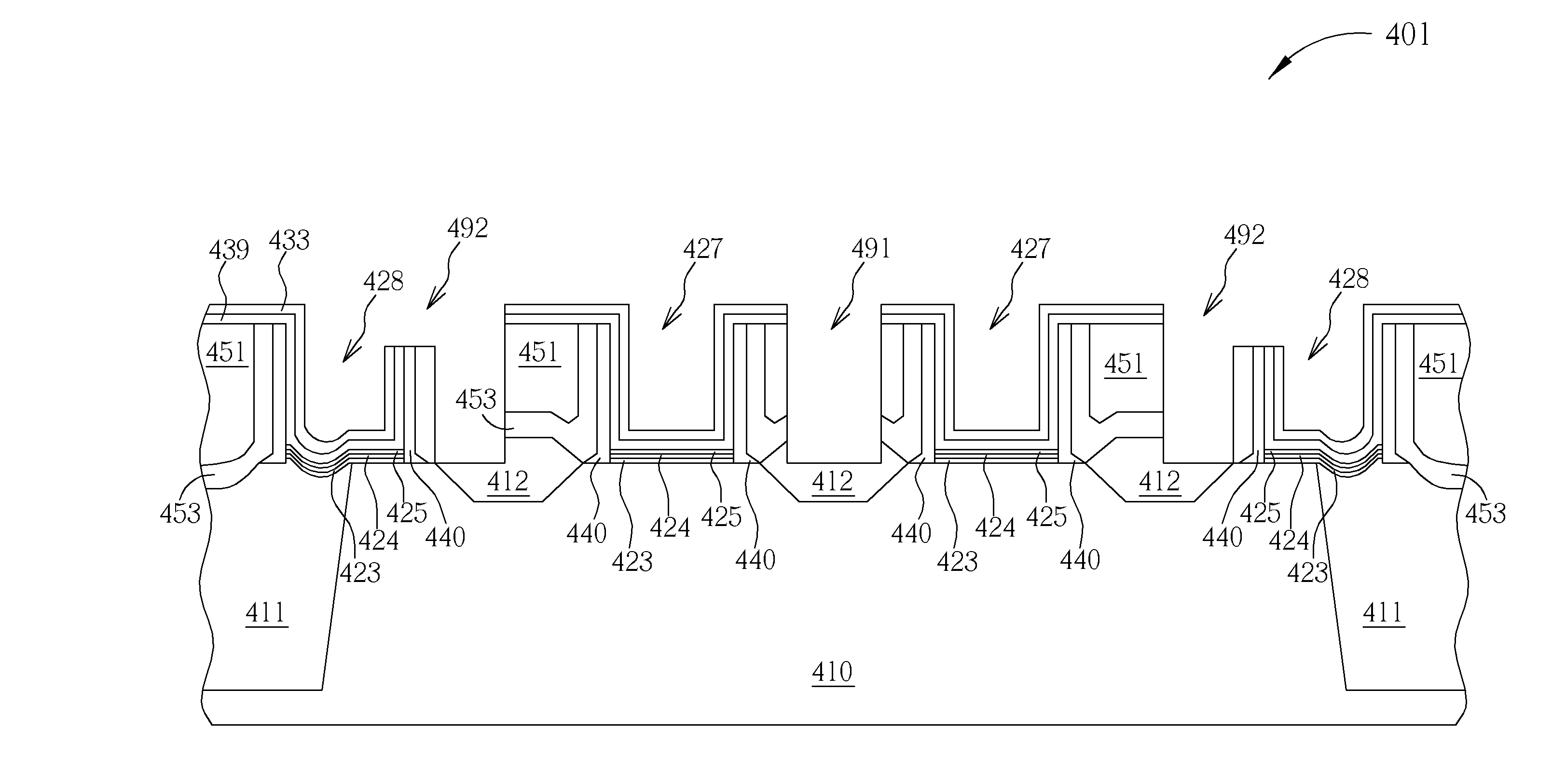

Semiconductor device and manufacturing method thereof

InactiveUS20130062701A1Improve device qualityImprove processing yieldTransistorSemiconductor/solid-state device detailsInter layerDielectric layer

A manufacturing method of a semiconductor device includes the following steps. First, a substrate is provided. At least one sacrificial gate structure is formed on the substrate, at least one diffusion region is formed in the substrate at each of two sides of the sacrificial gate structure, and a first inter-layer dielectric layer is formed to cover the diffusion region. A gate recess is then formed in the sacrificial gate structure. A first diffusion contact hole is then formed in the first inter-layer dielectric layer and at least partially exposes the diffusion region. A metal layer is subsequently formed in the gate recess and the first diffusion contact hole.

Owner:UNITED MICROELECTRONICS CORP

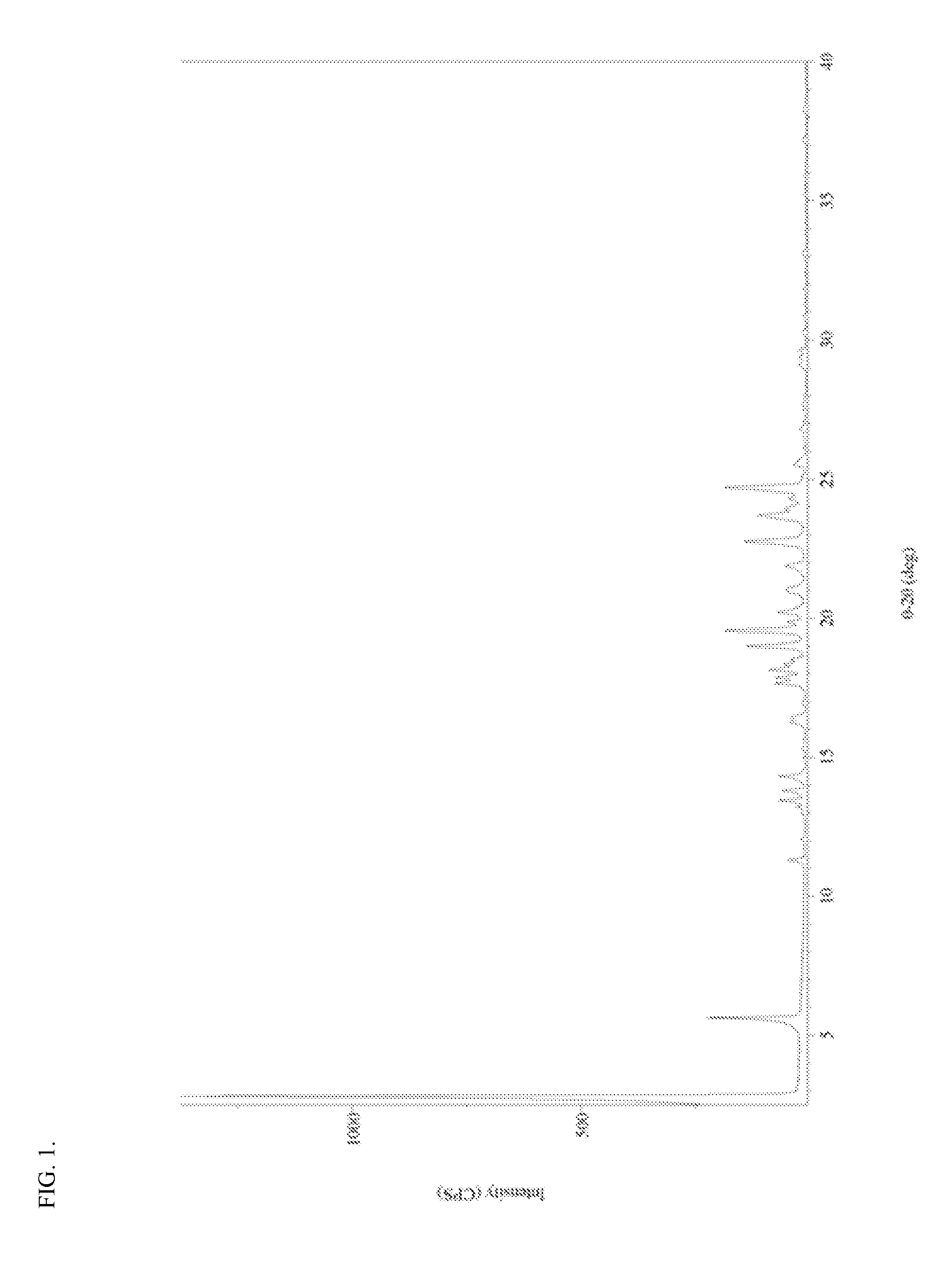

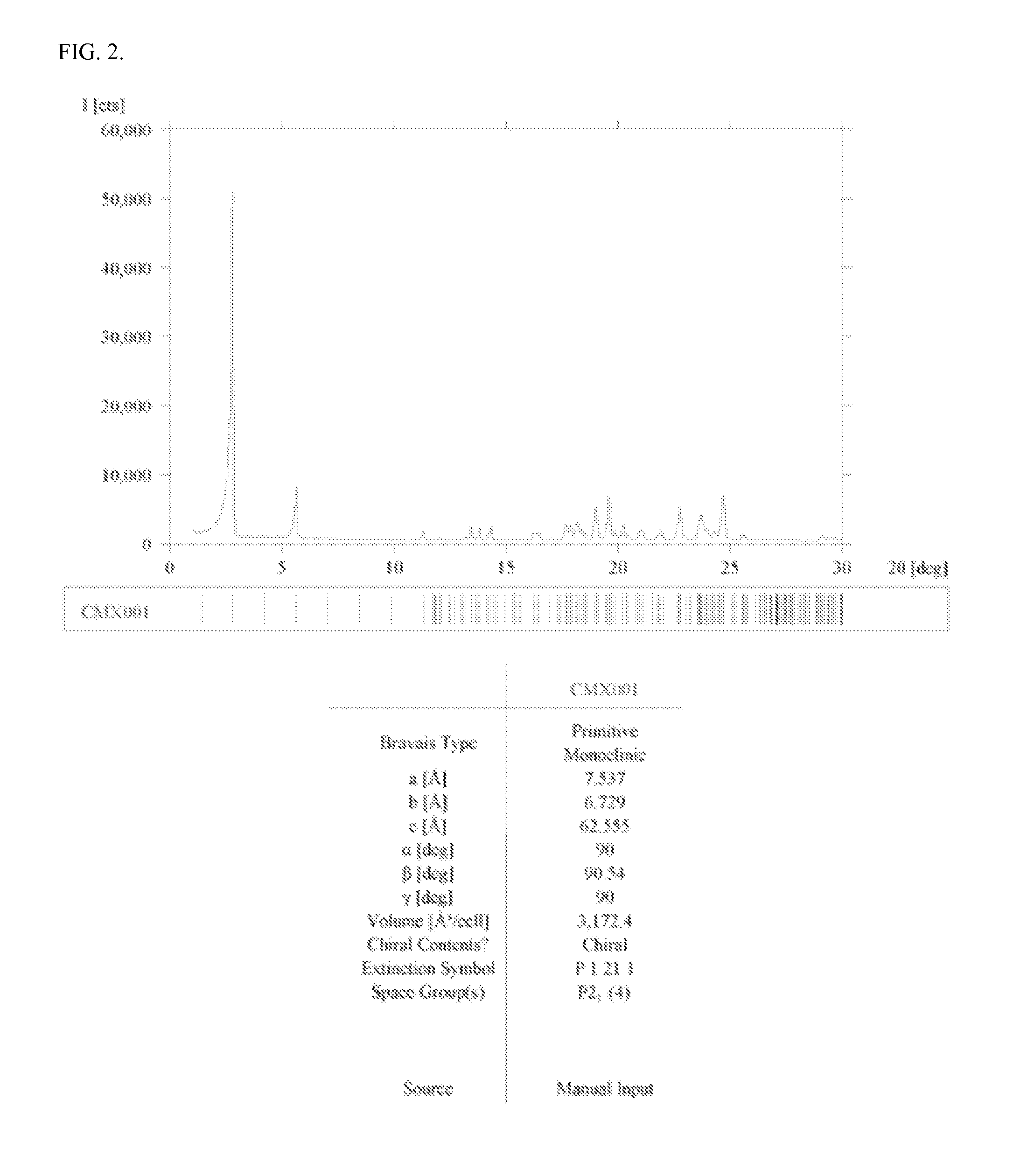

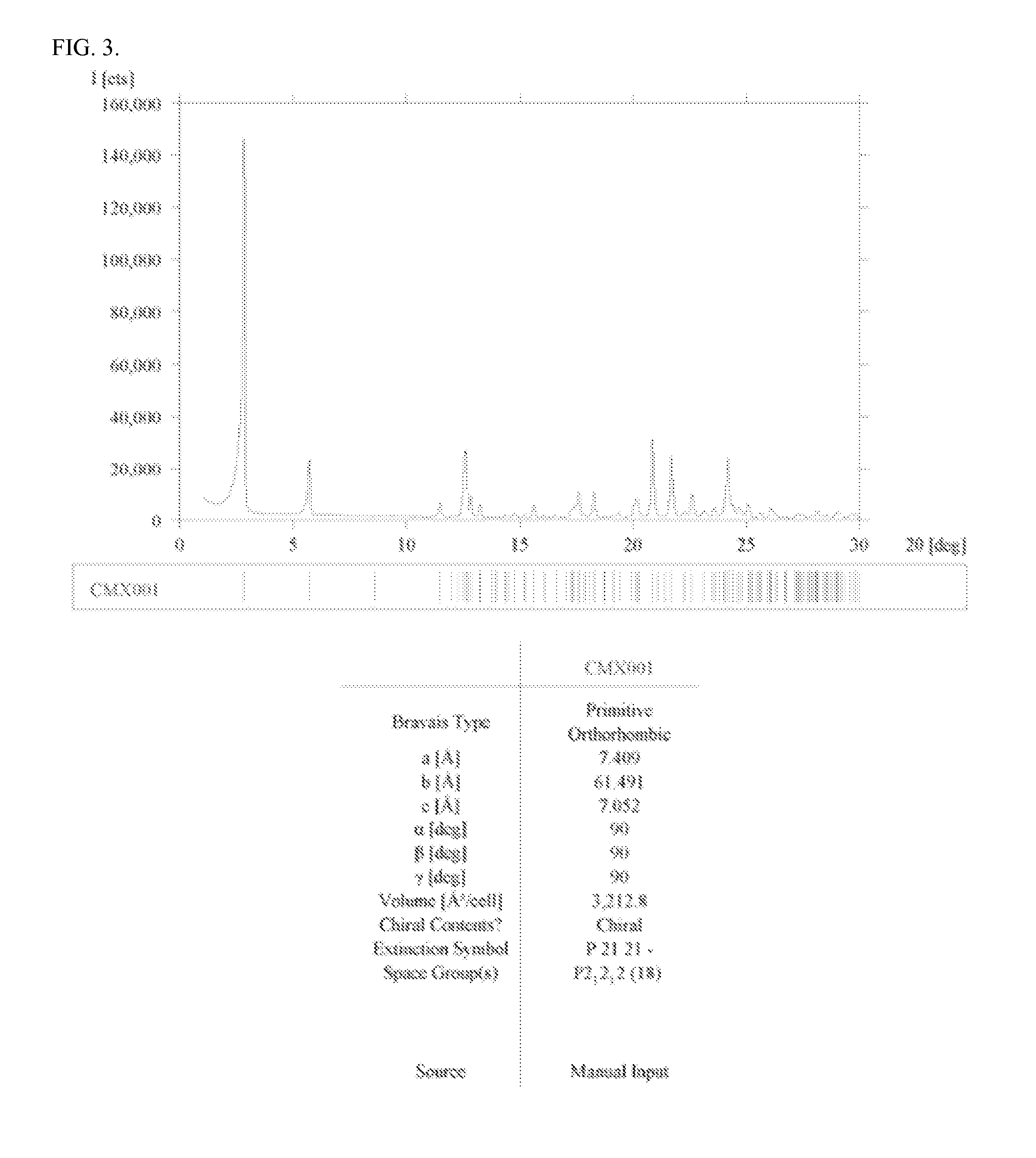

Morphic forms of hexadecyloxypropyl-phosphonate esters and methods of synthesis thereof

ActiveUS8962829B1Effort is complicatedConsistent and reliableOrganic active ingredientsOrganic chemistry methodsMedicinal chemistryPhosphonate

The disclosure describes methods of synthesis of phosphonate ester compounds. The methods according to the disclosure allow for large-scale preparation of phosphonate ester compounds having high purity and stability. Also disclosed are morphic forms of phosphonate ester compounds.

Owner:EMERGENT BIODEFENSE OPERATIONS LANSING LLC

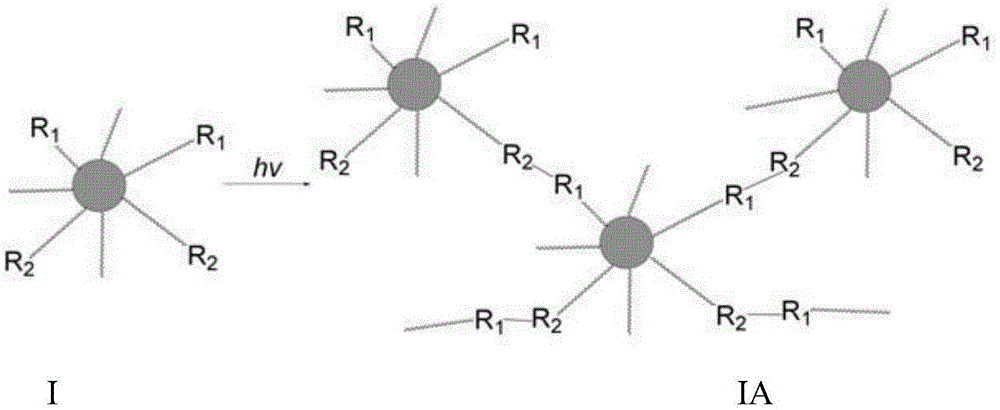

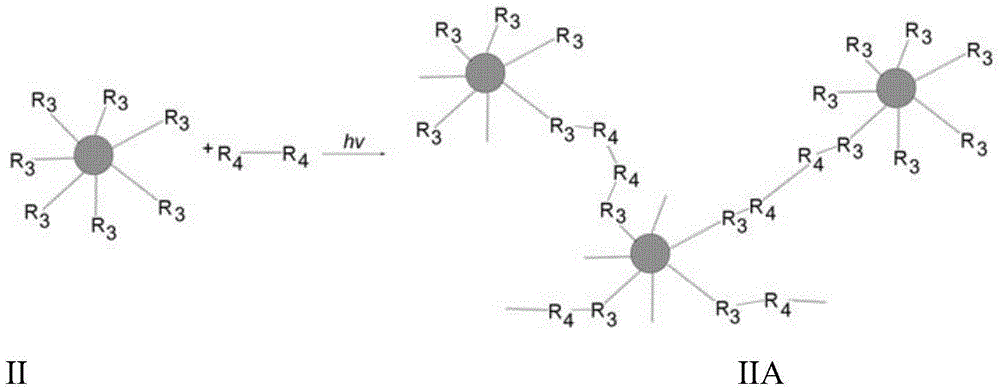

Cross-linkable quantum dot and preparation method thereof, array substrate and preparation method of array substrate

ActiveCN105552241AIncrease usageImprove processing yieldSolid-state devicesSemiconductor/solid-state device manufacturingCross-linkQuantum dot

The invention provides a cross-linkable quantum dot (QD) and a preparation method thereof, an array substrate prepared by the cross-linkable quantum dot (QD) and the preparation method of the array substrate. The surface of the cross-linkable quantum dot is provided with a group pair R1 and R2 which can react to form a cross-linked network, or the surface of the cross-linkable quantum dot is provided with a group R3 which can be cross-linked by a cross-linking agent to form the cross-linked network.

Owner:BOE TECH GRP CO LTD

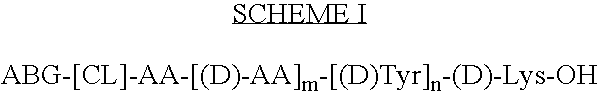

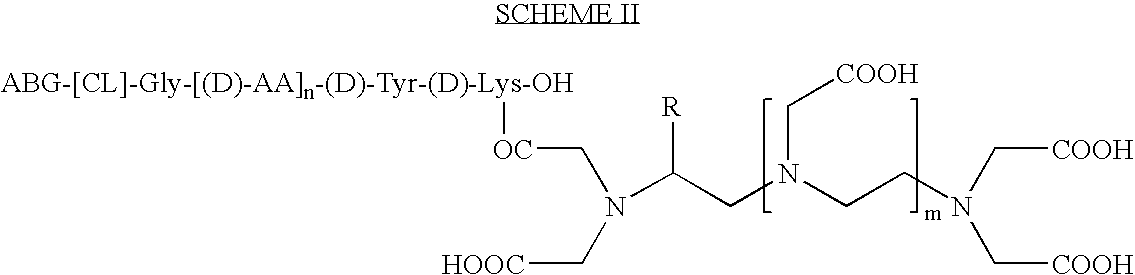

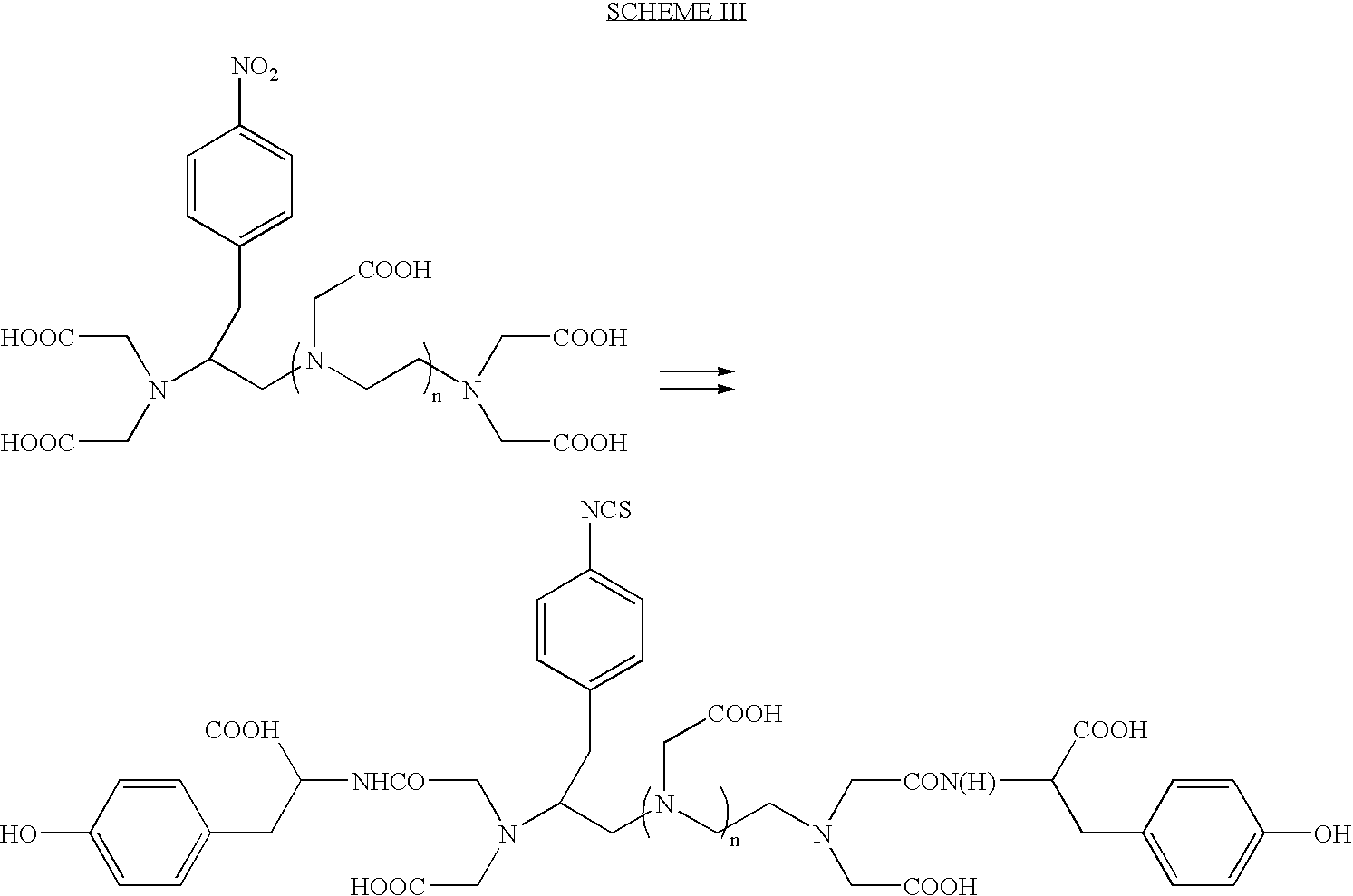

Stable radioiodine conjugates and methods of their synthesis

InactiveUS7147856B2Low efficiencyAggregate formationPeptide/protein ingredientsRadioactive preparation carriersCarbohydrate structureSynthesis methods

Methods are described for conjugating radioiodinated peptides or carbohydrate structures to proteins with improved yields and qualities of conjugates. In one method, specially designed radioiodinated bifunctional peptides containing nonmetabolizable amide bonds are coupled to antibodies. In a second method, radioiodinated nonmetabolizable bifunctional peptides, which also contain aminopolycarboxylates, are coupled to antibodies. In a third method, radioiodinated bifunctional aminopolycarboxylates are coupled to antibodies. In a fourth method, a hydrazide-appended antibody is coupled to a radioiodinated carbohydrate or a thiolated antibody is coupled to a hydrazide-appended and radioiodinated carbohydrate. In a fifth method a monoderivatized cyanuric chloride is used to conjugate thiolated antibody. Radioiodinated residualizing antibody conjugates made by these methods are particularly stable in vivo and are suitable for radioimmunodetection and radioimmunotherapy.

Owner:IMMUNOMEDICS INC

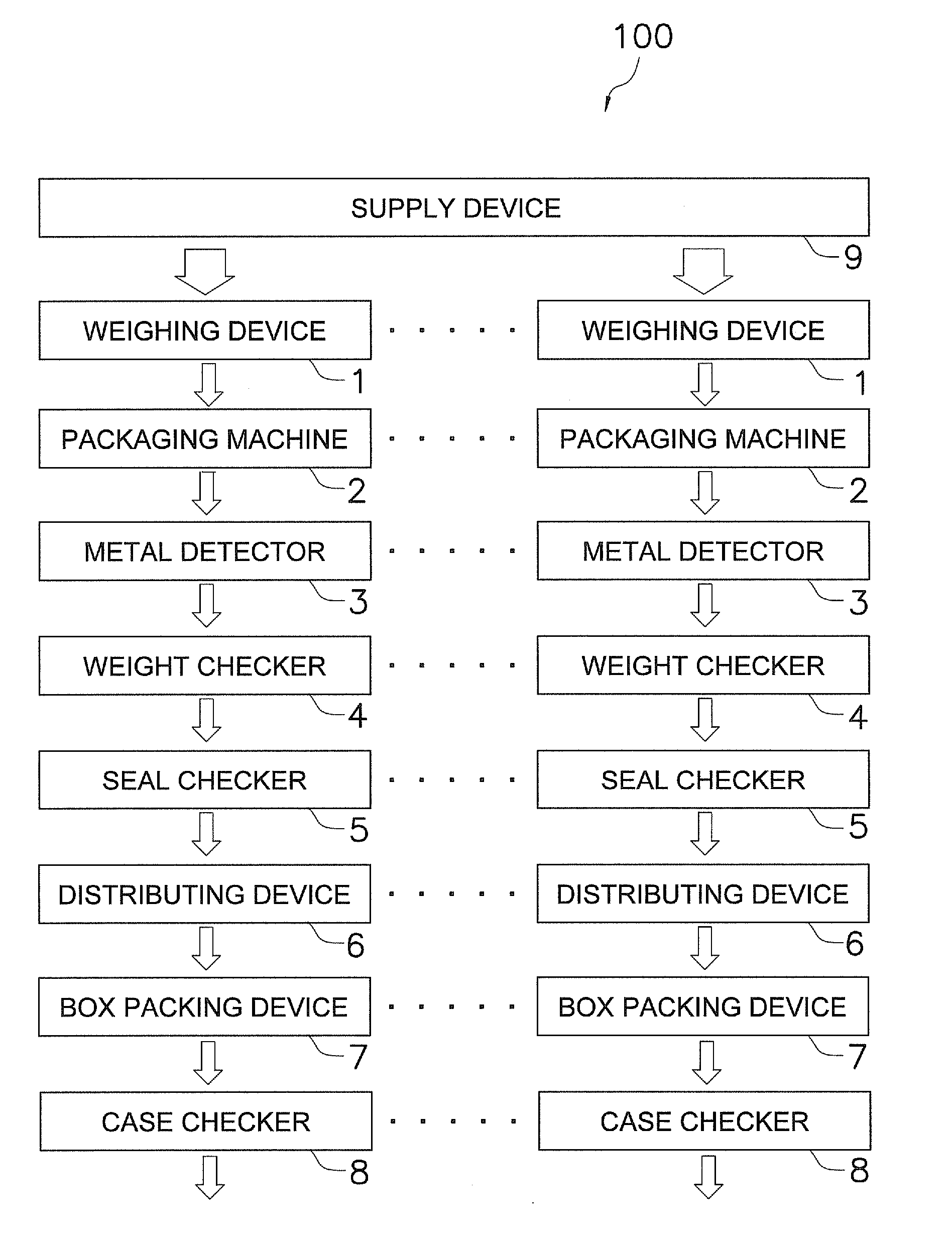

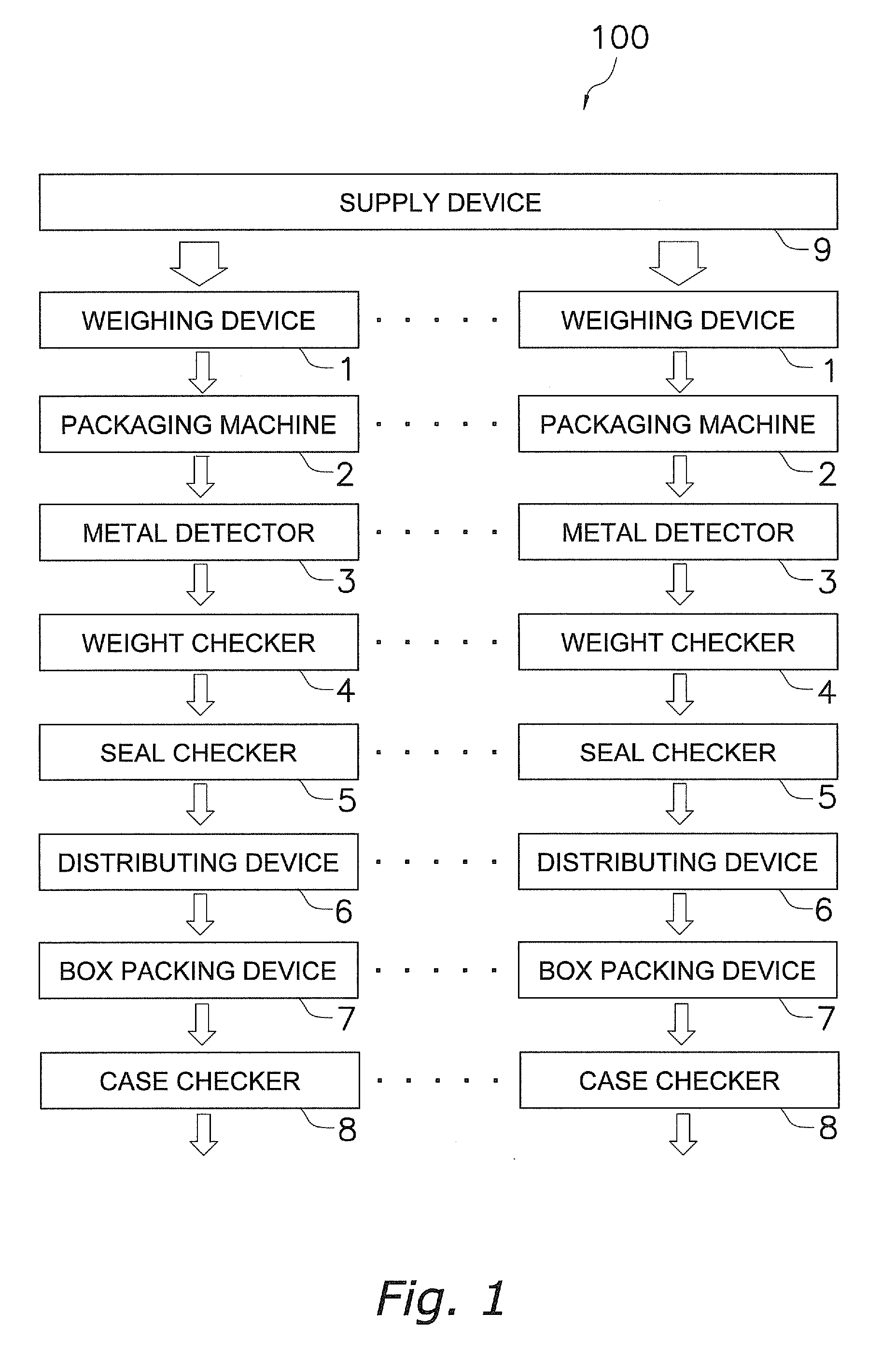

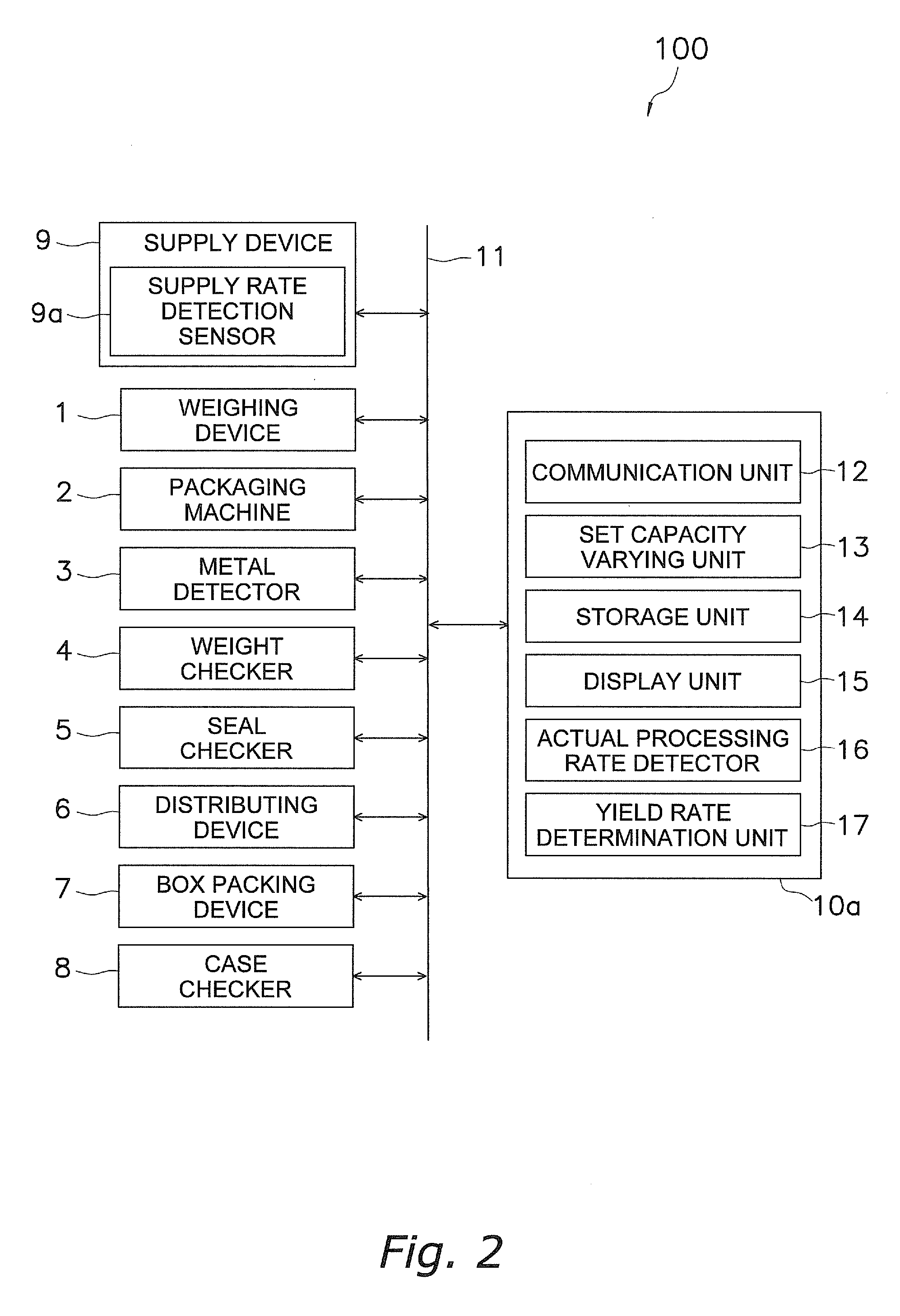

Production system

InactiveUS20060231295A1Easy to operateImprove processing yieldProgramme controlPackaging cigaretteProduction lineControl system

A production system is provided in which high production efficiency can be maintained in the entire production line even in cases in which there is a lack of uniformity in the rates at which the articles are actually supplied from a supply unit; the weighing unit, packaging unit, quality inspection unit, or other constituent device has stopped operating; or other problems have occurred. In this production system, a centralized control system controls the set capacities of devices that constitute a production line including a weighing device, a bagging machine, and other devices disposed downstream, so that the capacities are varied on the basis of the detection results of a supply rate detection sensor of a supply device, that is, on the basis of the actual rates of supply from the supply device to the weighing device.

Owner:ISHIDA CO LTD

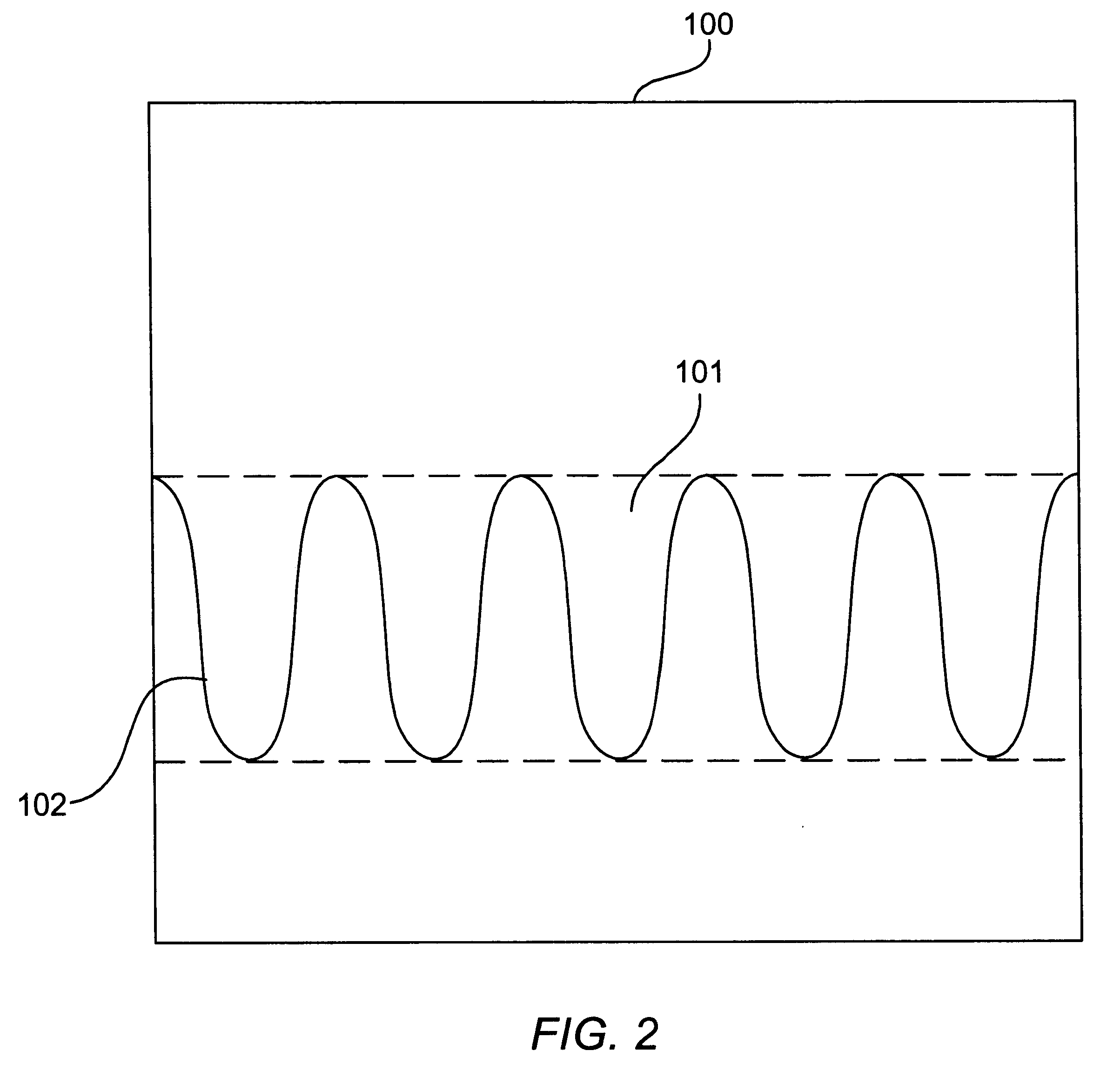

Apparatus and method for utilizing a meniscus in substrate processing

InactiveUS7093375B2Process environment can be powerfully controlled and managedMore processedLiquid surface applicatorsDrying gas arrangementsActive agentEngineering

An apparatus for processing a substrate is provided which includes a proximity head proximate to a surface of the substrate when in operation. The apparatus also includes an opening on a surface of the proximity head to a cavity defined in the proximity head where the cavity delivers an active agent to the surface of the substrate through the opening. The apparatus further includes a plurality of conduits on the surface of the proximity head that generates a fluid meniscus on the surface of the substrate surrounding the opening.

Owner:LAM RES CORP

Structure of an optical interference display unit

InactiveUS20050157364A1Good uniformity and qualityIncrease mechanical stressTelevision system detailsColor television detailsLight reflectionReflective layer

An optical interference display unit, at least comprises a light-incidence electrode and a light-reflection electrode located on a transparent substrate. The light-incidence electrode at least comprises a transparent conductive layer and a dielectric layer. The light-reflection electrode at least comprises an absorption layer and a reflective layer.

Owner:SNAPTRACK

Touch control type display panel, colorful color filter and its production method

ActiveCN101320107AThe process steps are simpleImprove processing yieldStatic indicating devicesNon-linear opticsEngineeringLight filter

The invention discloses a touch-sensitive type display panel, a colored filter and a making method thereof. The touch-sensitive type colored filter comprise a base plate, a black matrix, a colored filter layer and a second electrode layer; wherein, the black matrix is arranged on the base plate to define a plurality of secondary pixel regions; the black matrix comprises a first electrode layer, and the first electrode layer is provided with a plurality of openings which correspond to the secondary pixel regions; the colored filter layer comprises a plurality of colored filtering units, and the colored filtering units are respectively arranged in the secondary pixel regions; the second electrode layer is arranged on the base plate, and the second electrode layer comprises a plurality of sub-patterns; wherein, the sub-patterns respectively correspond to the secondary pixel regions. The invention also provides the making method of the touch-sensitive type filter and the display panel to which the touch-sensitive type colored filter is applied.

Owner:AU OPTRONICS CORP

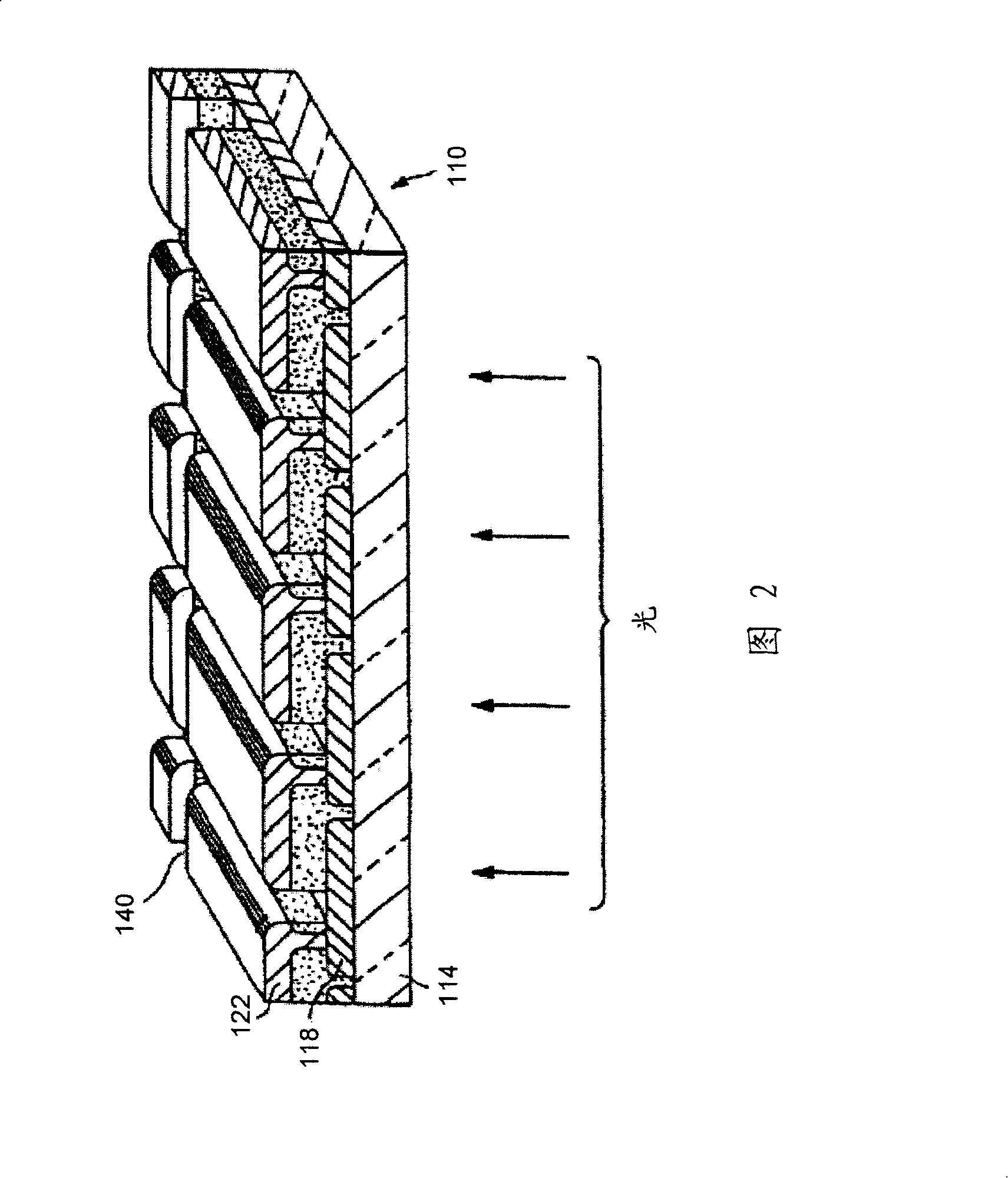

Translucent type thin-film solar cell module and manufacturing method thereof

InactiveCN101232058AHigh light transmittanceImprove processing yieldFinal product manufacturePhotovoltaic energy generationOptical transmittanceEngineering

The invention provides a transparent thin-film solar battery module and manufacture method thereof. The manufacture method forms openings in two directions in a transparent eletrode material layer, thus avoiding a negative influence on the process yield rate due to the problem of short circuit caused by the laser cutting process at a high temperature. Additionally, the transparent thin-film solar battery module has the openings exposing a transparent substrate without covered transparent electrodes, thus improving the light transmittance of the battery.

Owner:IND TECH RES INST

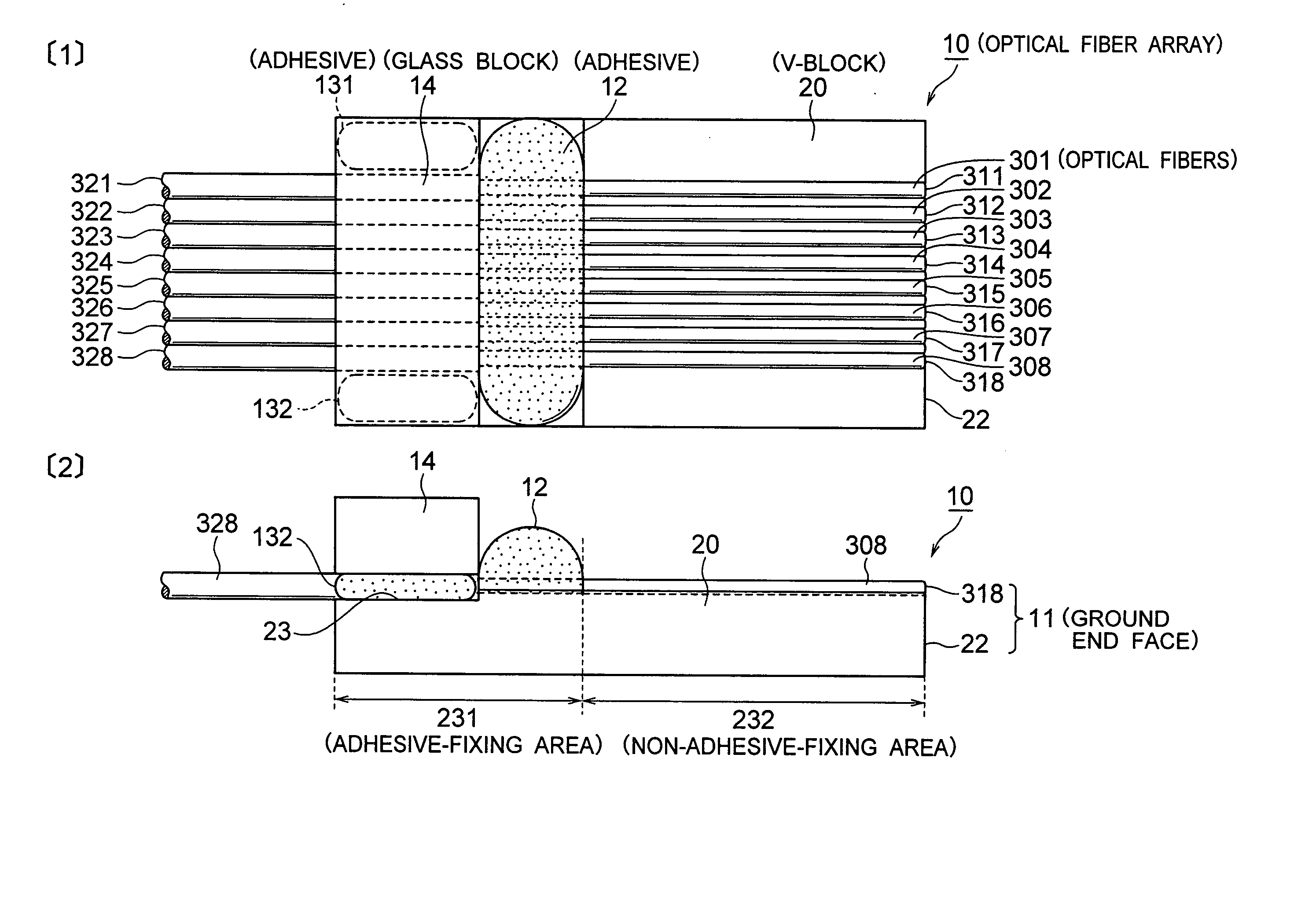

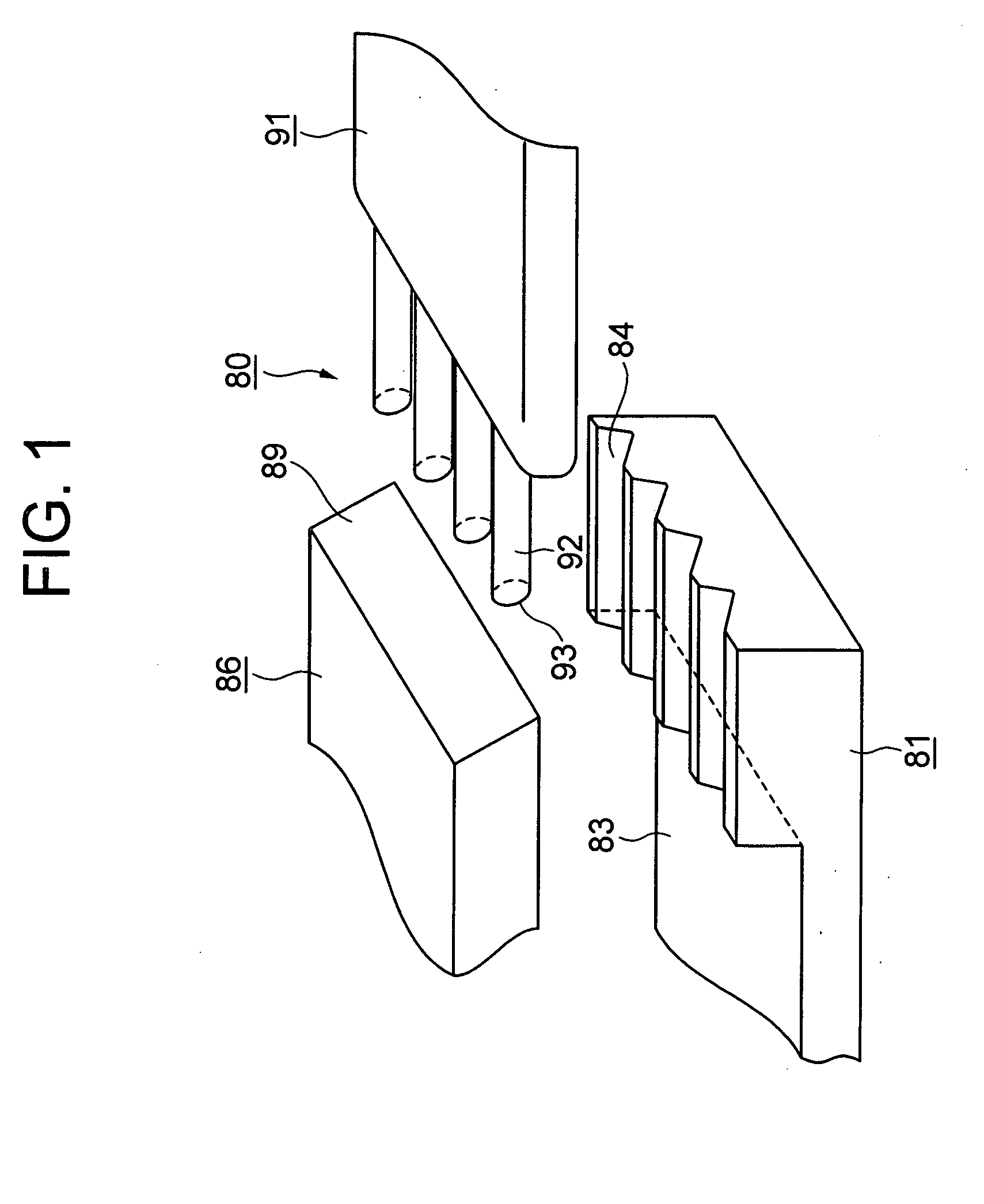

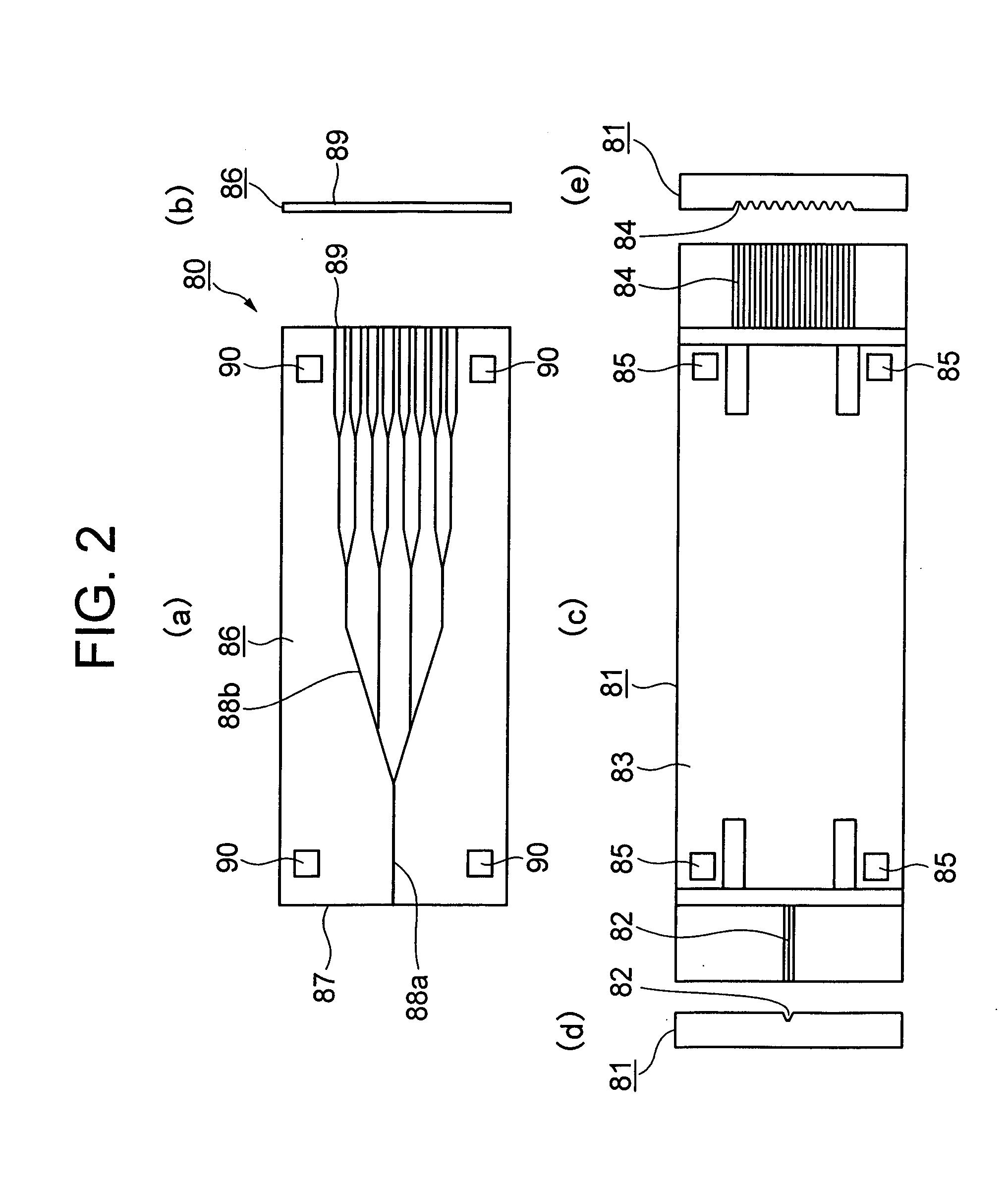

Optical fiber component, optical waveguide module, and manufacturing method

InactiveUS20050254770A1Increasing alignment precisionIncreasing optical fiber strengthCoupling light guidesWaveguideOptical fiber cable

Owner:NEC CORP

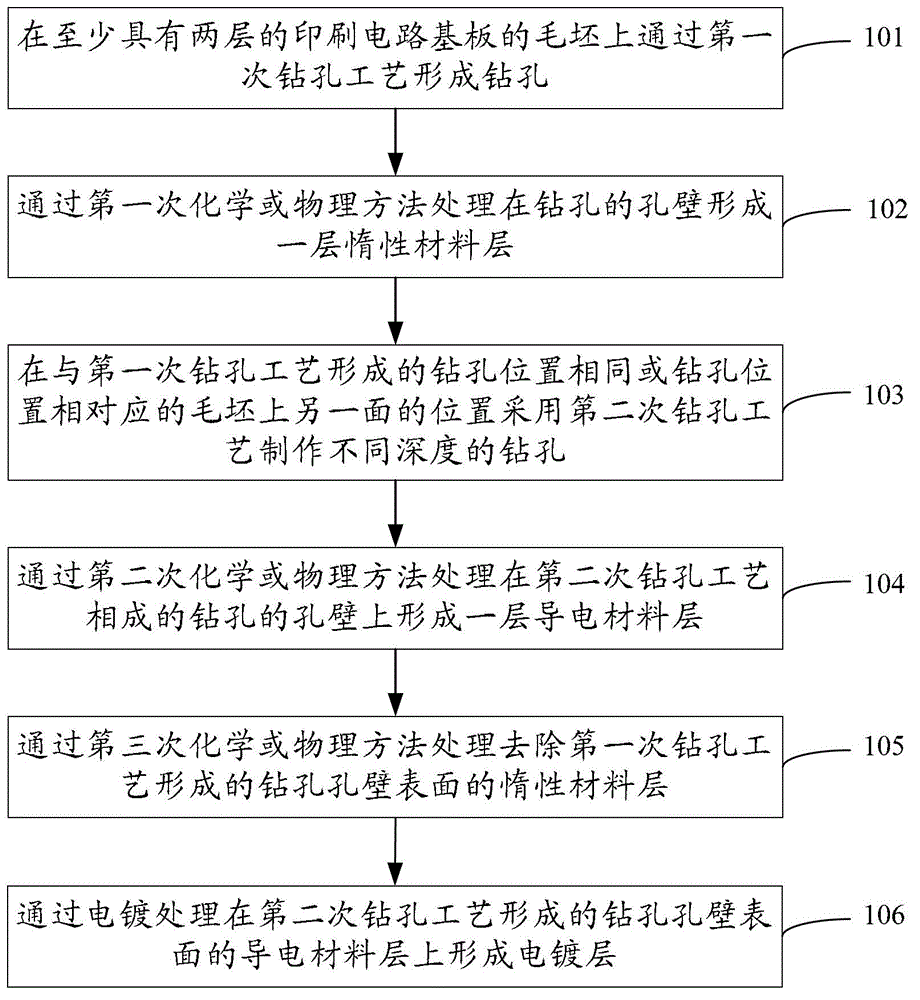

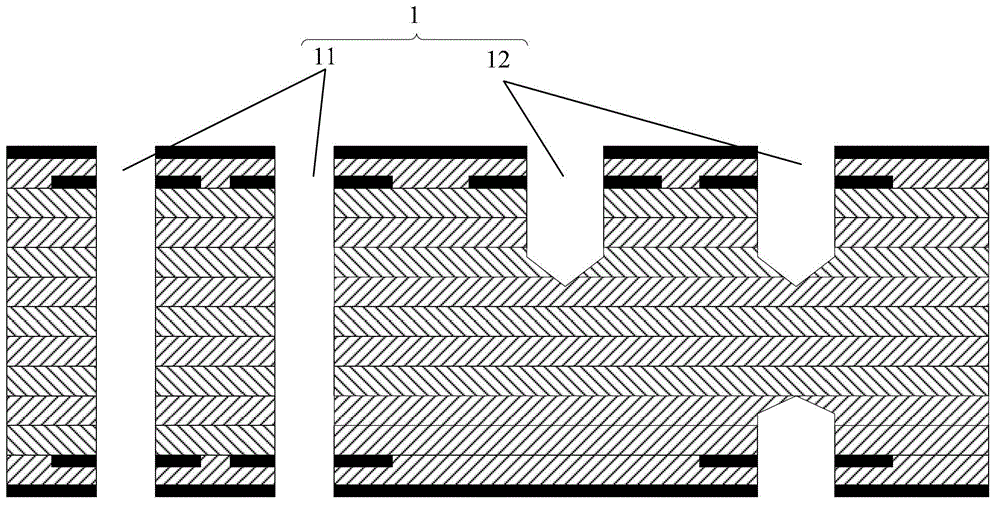

Through hole structure, printed circuit board, and manufacture method of through hole structure

ActiveCN102946695AReduce manufacturing difficultyImprove processing efficiencyElectrical connection printed elementsPrinted element electric connection formationEngineeringPrinted circuit board

The embodiment of the invention provides a through hole structure, a printed circuit board and a manufacture method of the through hole structure, and relates to the field of printed circuit boards. According to the invention, the density of an outgoing line is increased, the transmission capacity of a signal is increased, the manufacture difficulty is lowered, and the product reliability is improved. The through hole structure is surrounded by hole walls and comprises at least two through hole parts which are formed through division along the axial direction of the through hole structure and at least one step part which is formed through division along the axial direction, wherein the at least two through hole parts are surrounded by the hole walls, the at least one step part is surrounded by the hole walls, each step part of the at least one step part is located between two adjacent through hole parts of the at least two through hole parts and is connected with the two adjacent through hole parts; and the hole walls of the at least two through hole parts and the hole walls of the at least one step part at least comprise one insulated hole wall and one metalized hole wall. The example of the invention is applied to manufacturing the printed circuit board.

Owner:XFUSION DIGITAL TECH CO LTD

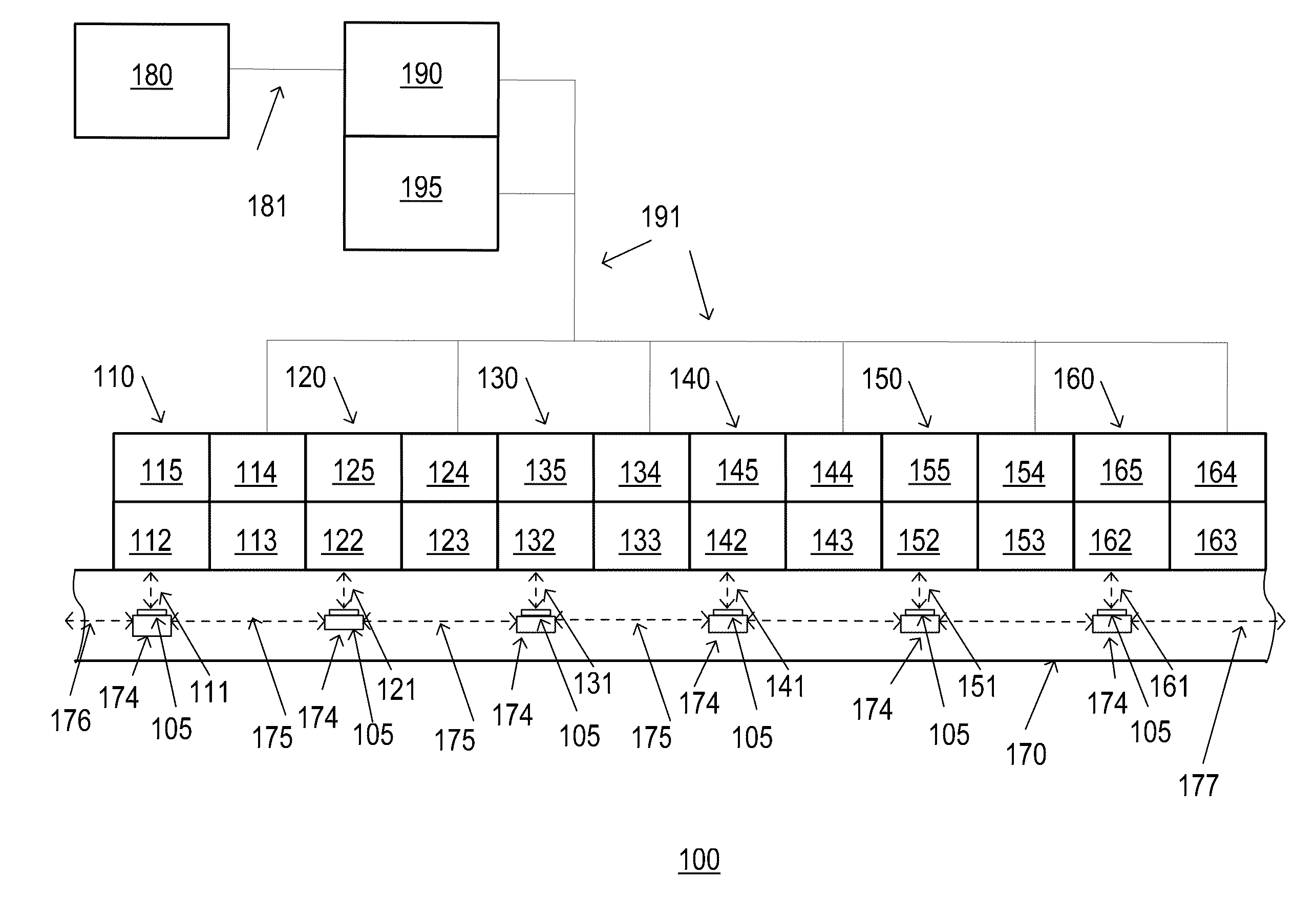

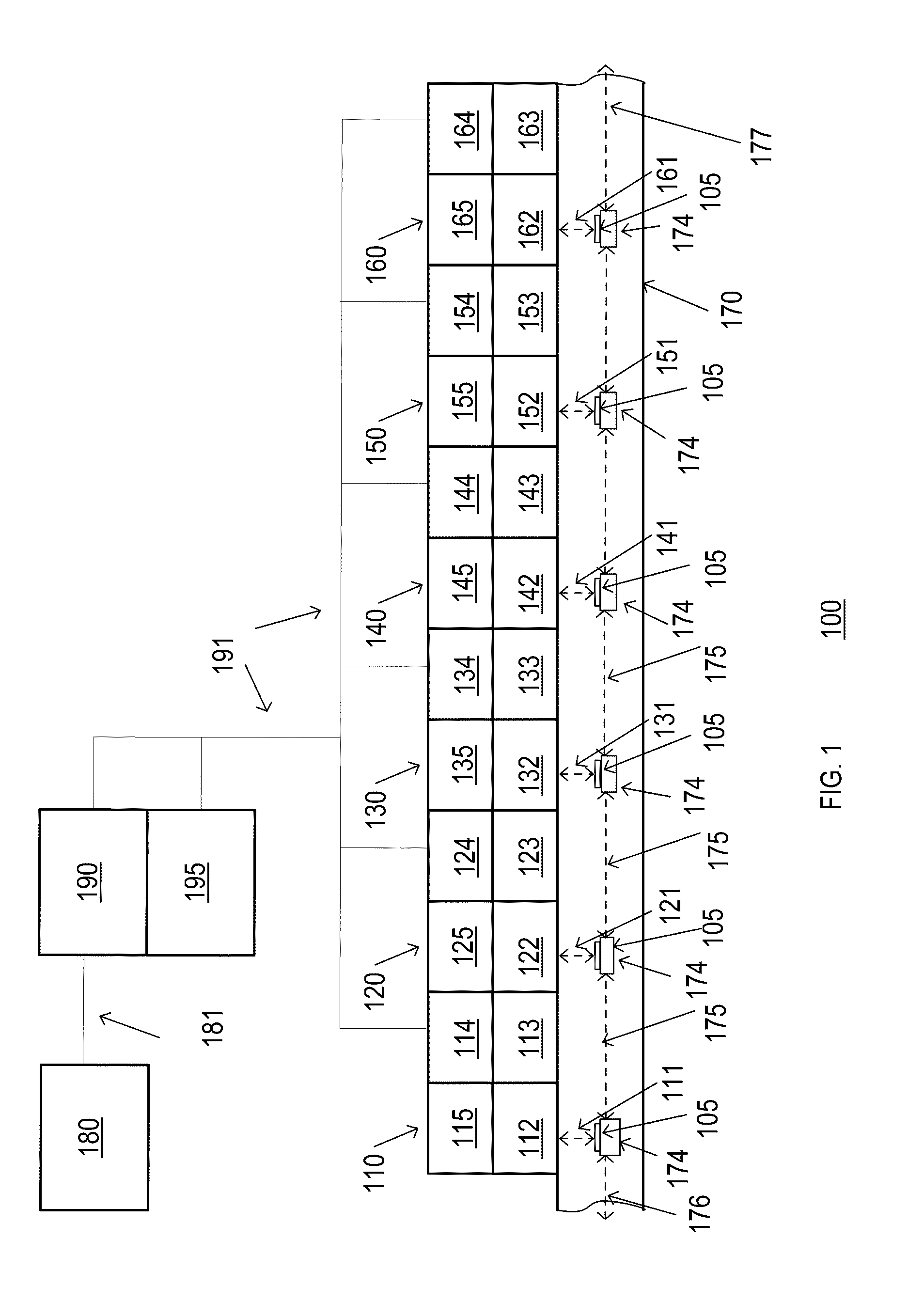

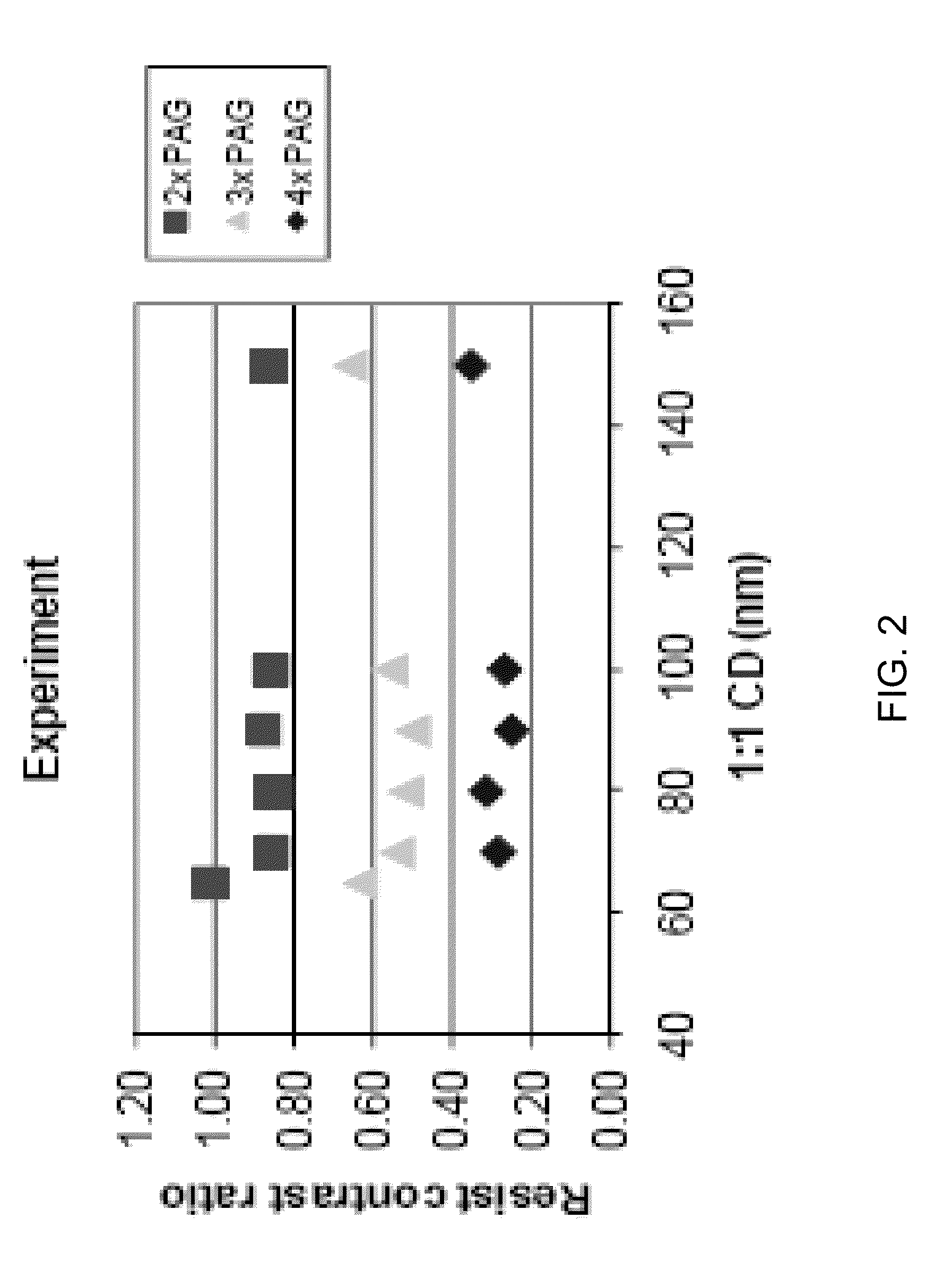

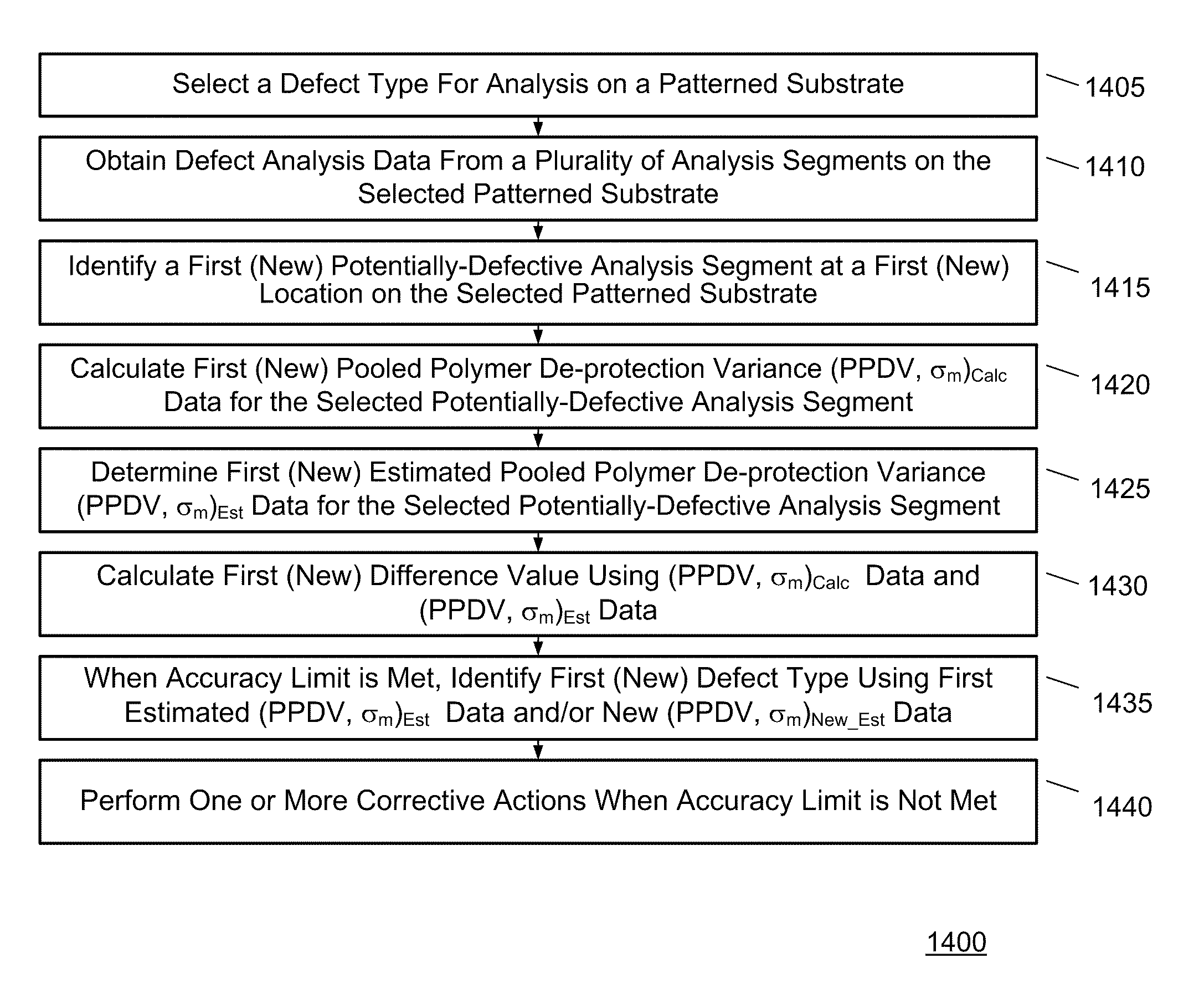

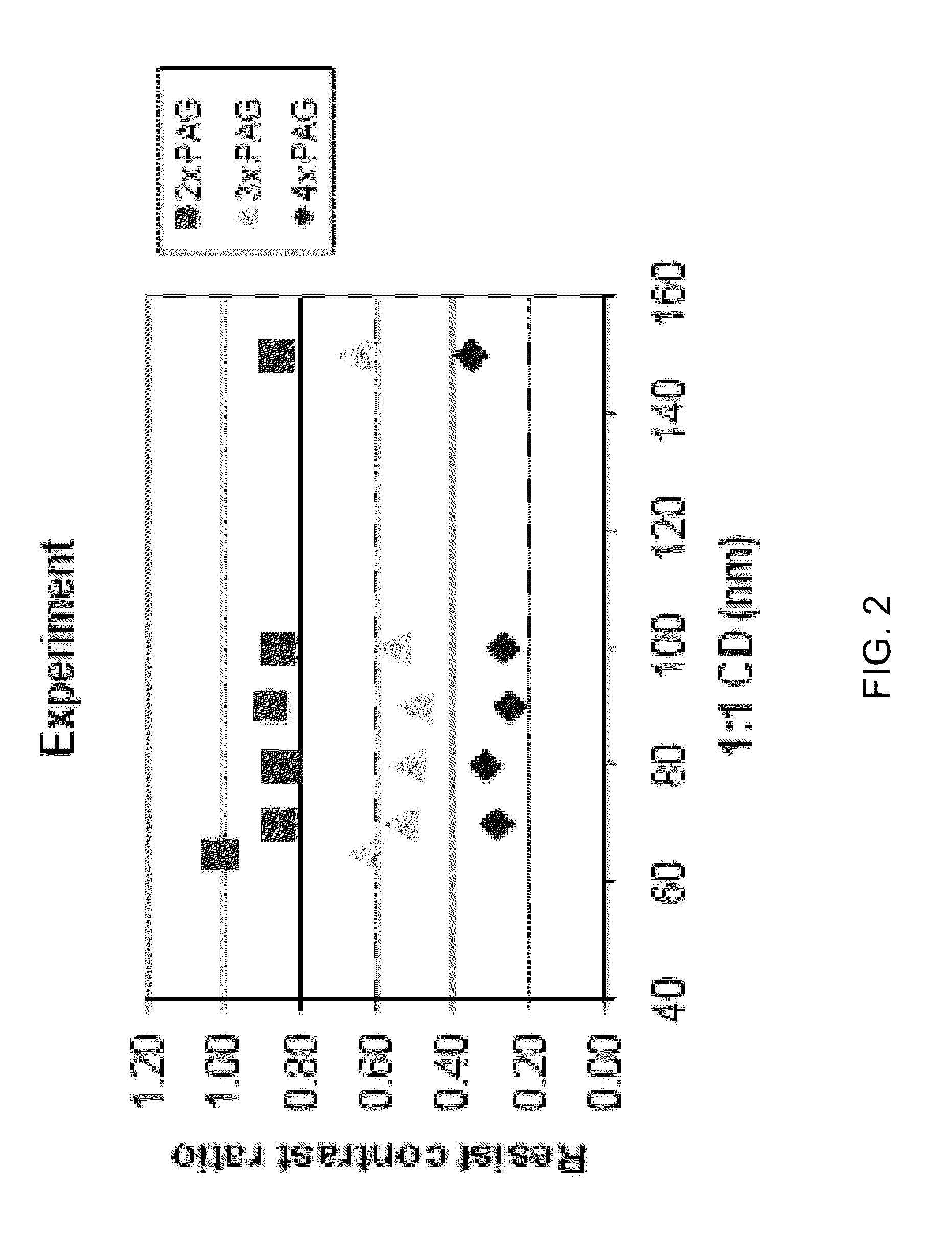

Simplified Micro-Bridging and Roughness Analysis

InactiveUS20110239167A1Improve processing yieldSimple calculationSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceData treatmentComputer science

The invention provides apparatus and methods for processing substrates using pooled statistically based variance data. The statistically based variance data can include Pooled Polymer De-protection Variance (PPDV) data that can be used to determine micro-bridging defect data, LER defect data, and LWR defect data.

Owner:TOKYO ELECTRON LTD

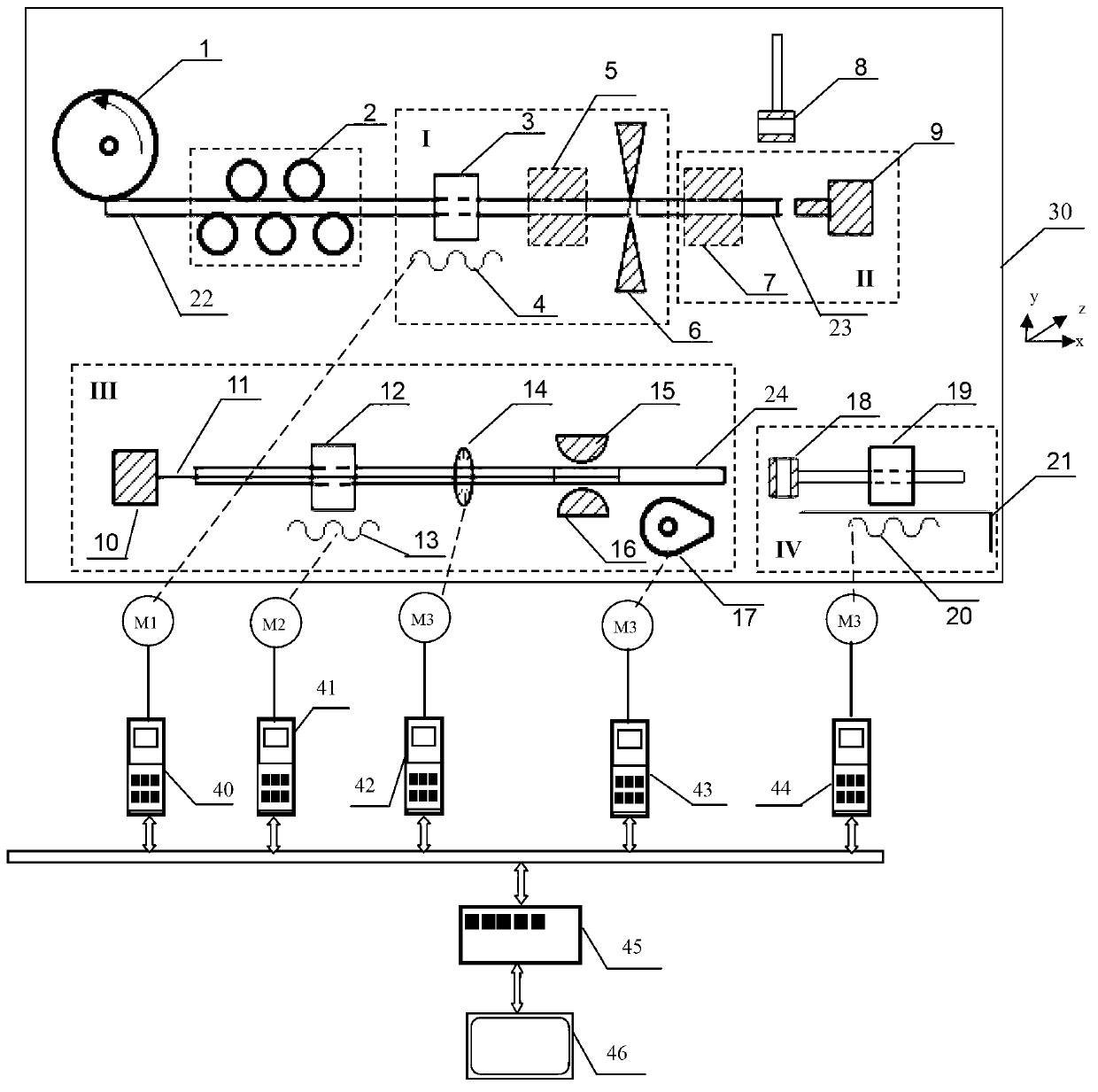

Method for optimization of pipe integrated numerical control machining process

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

Simplified micro-bridging and roughness analysis

InactiveUS8108805B2Simple calculationImprove processing yieldSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceComputer sciencePolymer

The invention provides apparatus and methods for processing substrates using pooled statistically based variance data. The statistically based variance data can include Pooled Polymer De-protection Variance (PPDV) data that can be used to determine micro-bridging defect data, LER defect data, and LWR defect data.

Owner:TOKYO ELECTRON LTD

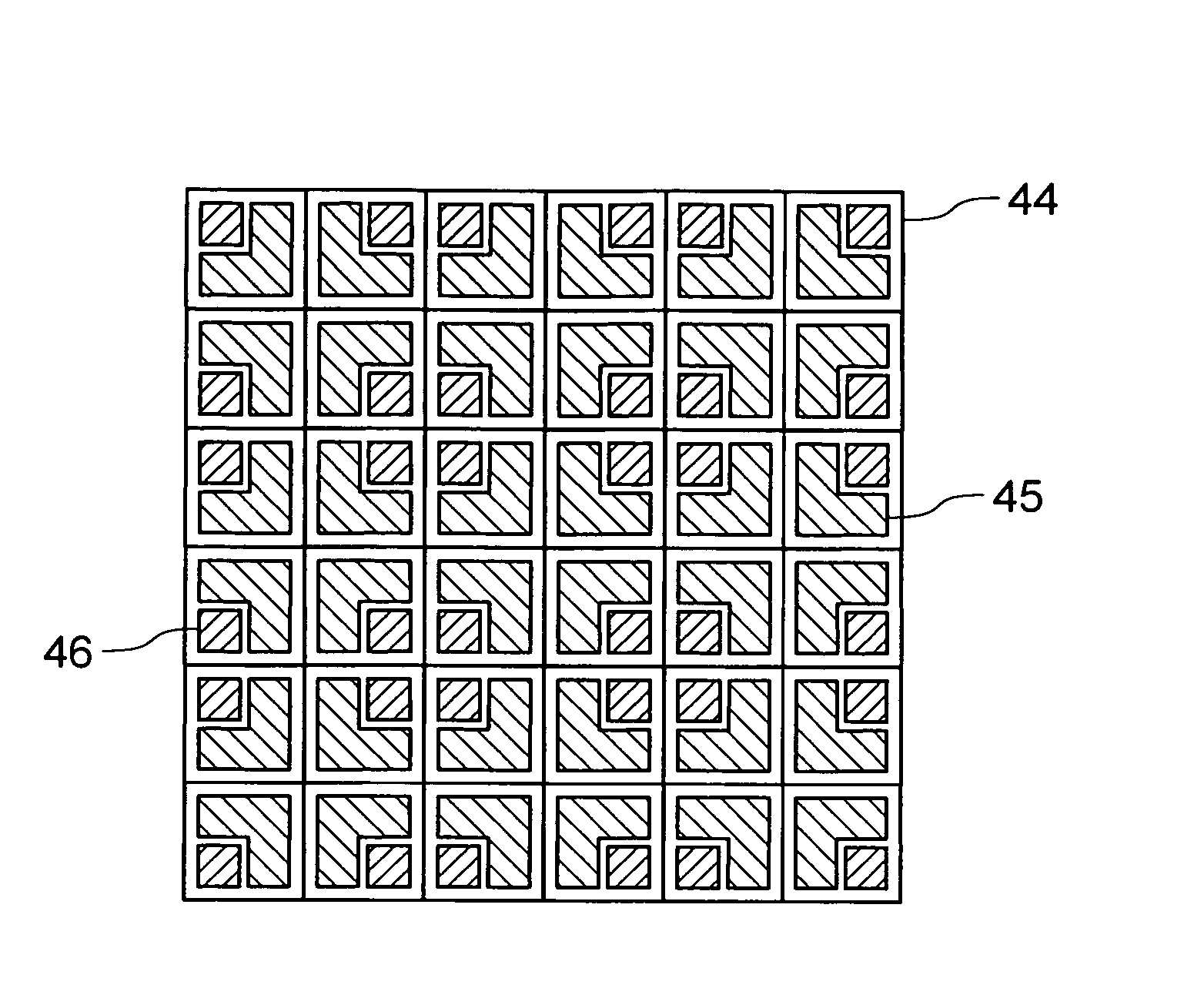

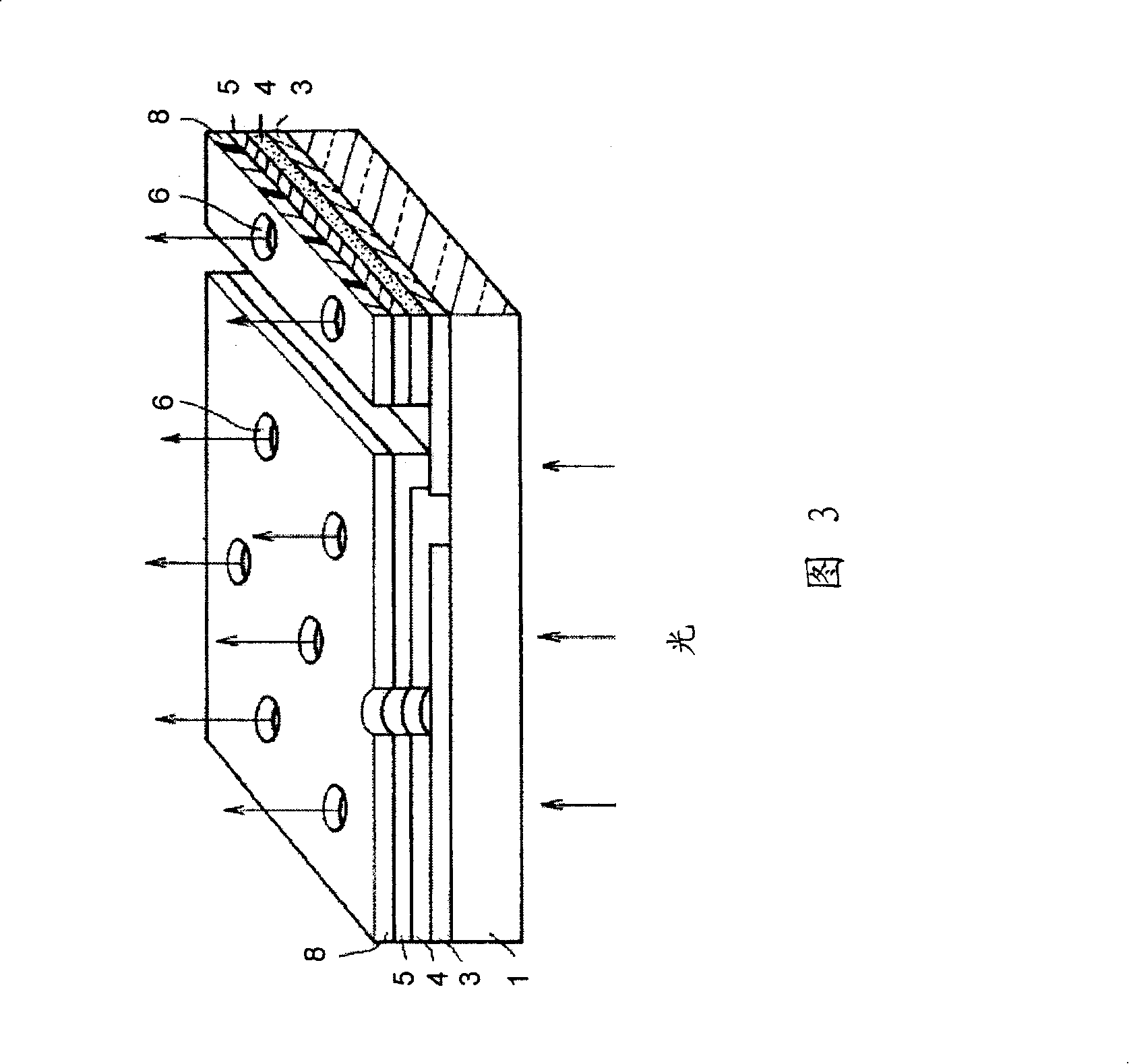

Bolometer structure, infrared detection pixel employing bolometer structure, and method of fabricating infrared detection pixel

InactiveUS20100148067A1Improve processing yieldImprove responsivityMaterial analysis by optical meansPyrometry using electric radation detectorsResponsivityReadout integrated circuit

Provided are a bolometer structure, an infrared detection pixel employing the bolometer structure, and a method of fabricating the infrared detection pixel.The infrared detection pixel includes a substrate including a read-out integrated circuit (ROIC) and on which a reflection layer for reflecting infrared light is stacked, a bolometer structure formed to be spaced apart from the substrate and including a temperature-sensitive resistive layer, a first metal layer formed in a pattern on one surface of the temperature-sensitive resistive layer, a second metal layer formed in a pattern complementary to the pattern of the first metal layer on the other surface of the temperature-sensitive resistive layer in order to complementarily absorb infrared light, and an insulating layer formed between the temperature-sensitive resistive layer and the first metal layer, and a metal pad receiving a change in resistance of the temperature-sensitive resistive layer according to infrared light absorbed by the first metal layer and the second metal layer from the second metal layer, and transferring the change in resistance to the ROIC.Thus, it is possible to improve responsivity, and implement a simple bolometer structure robust against stress. Consequently, process yield can be improved, and the volume, weight, price, etc., of application products can be reduced by reducing the volume of a bolometer structure.

Owner:ELECTRONICS & TELECOMM RES INST

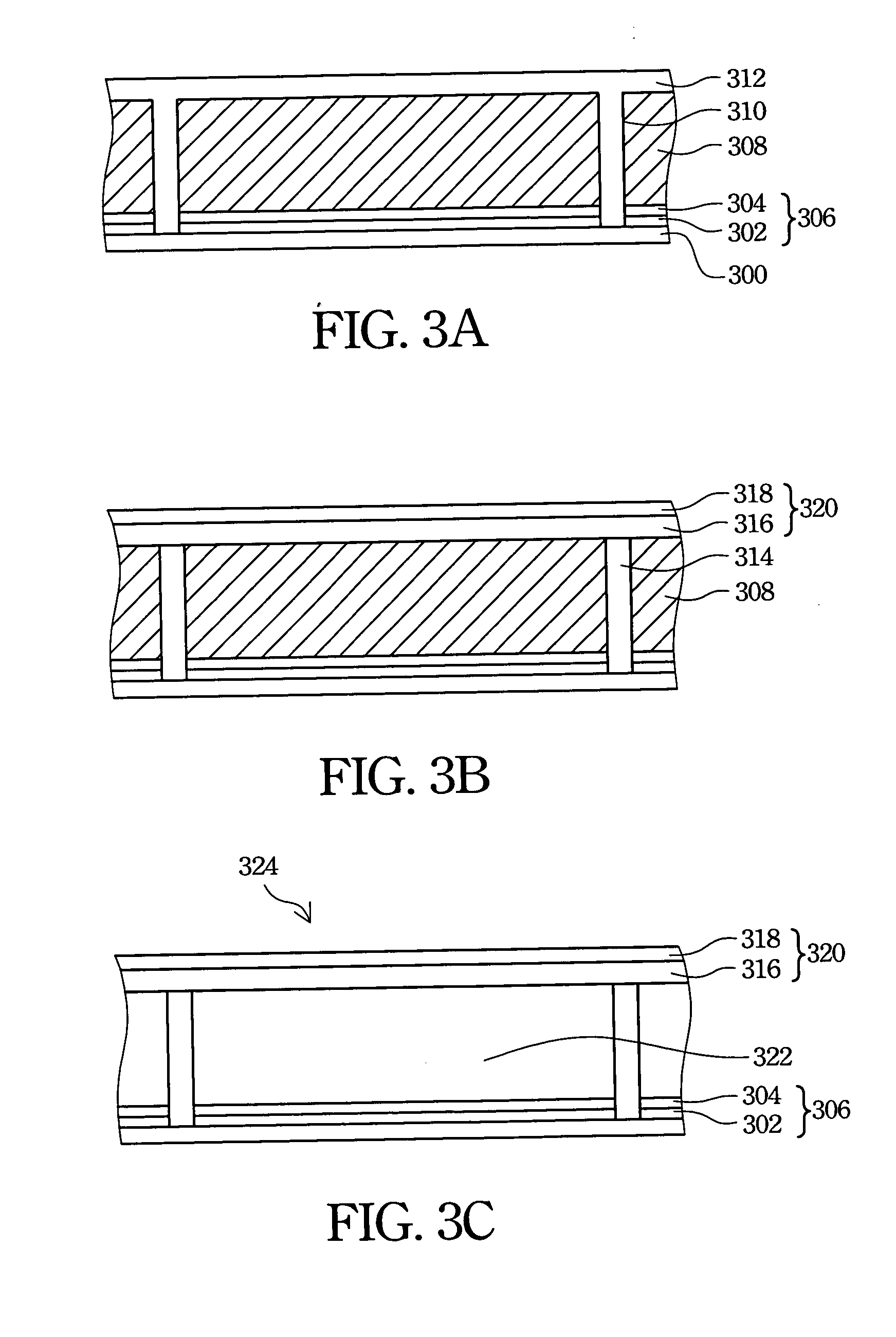

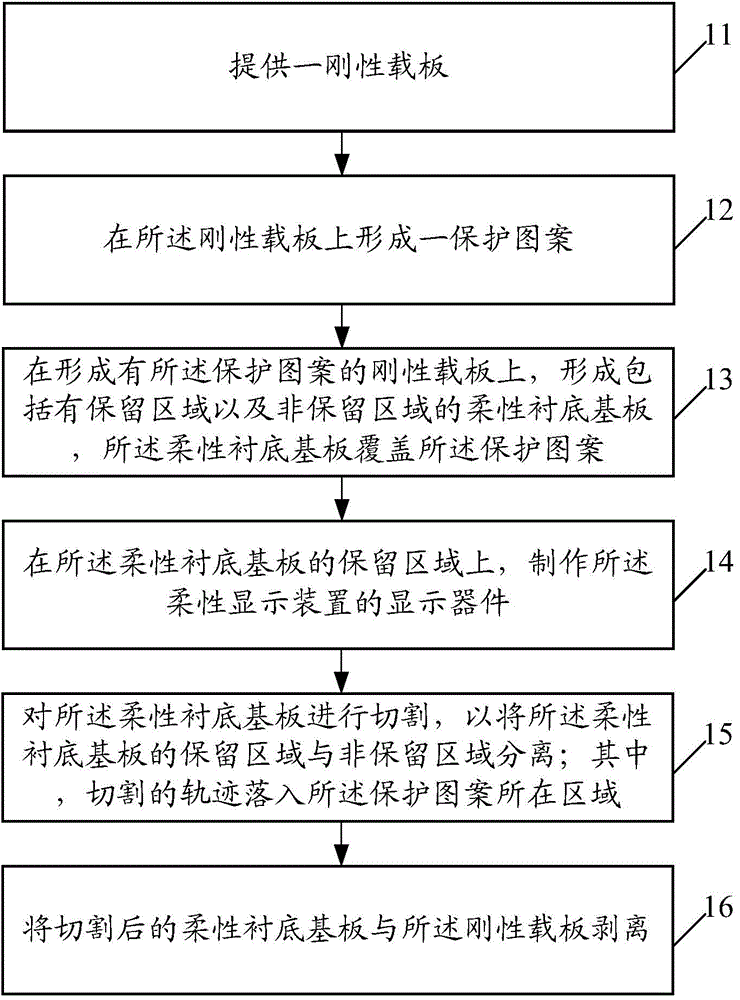

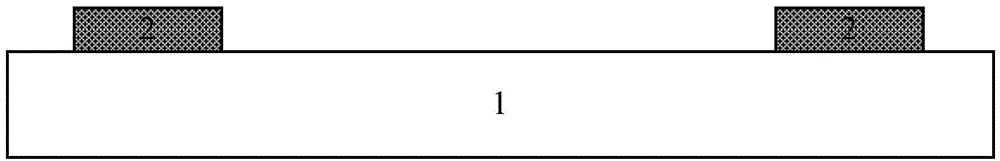

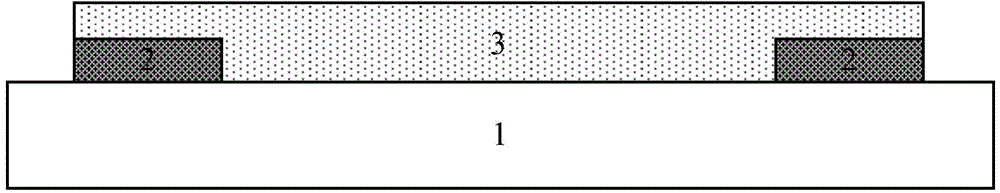

Flexible display device and fabricating method thereof

ActiveCN104821294AAvoid damageInfluence productionSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention provides a flexible display device and a fabricating method thereof and relates to the fabricating field of a display. The fabricating method comprises: providing a rigid carrier plate; forming a protective pattern on the rigid carrier plate; forming a flexible supporting base substrate, which comprises a reserved area and a non-reserved area and covers the protective pattern, on the rigid carrier plate where the protective pattern is formed; fabricating a display device of the flexible display device on the reserved area of the flexible supporting base substrate; cutting the flexible supporting base substrate to separate the reserved area of the flexible supporting base substrate from the non-reserved area; enabling a cutting trajectory to fall into an area where the protective pattern is located; and stripping the flexible supporting base substrate, after being cut, off the rigid carrier plate. According to the scheme of the invention, the protective pattern is disposed on the cutting trajectory corresponding to the rigid carrier plate, the rigid carrier plate is prevented from damage, which is caused by cutting, through the protective pattern, and then subsequent fabricating of the flexible display device is prevented from being influenced after the rigid carrier plate is cracked.

Owner:BOE TECH GRP CO LTD

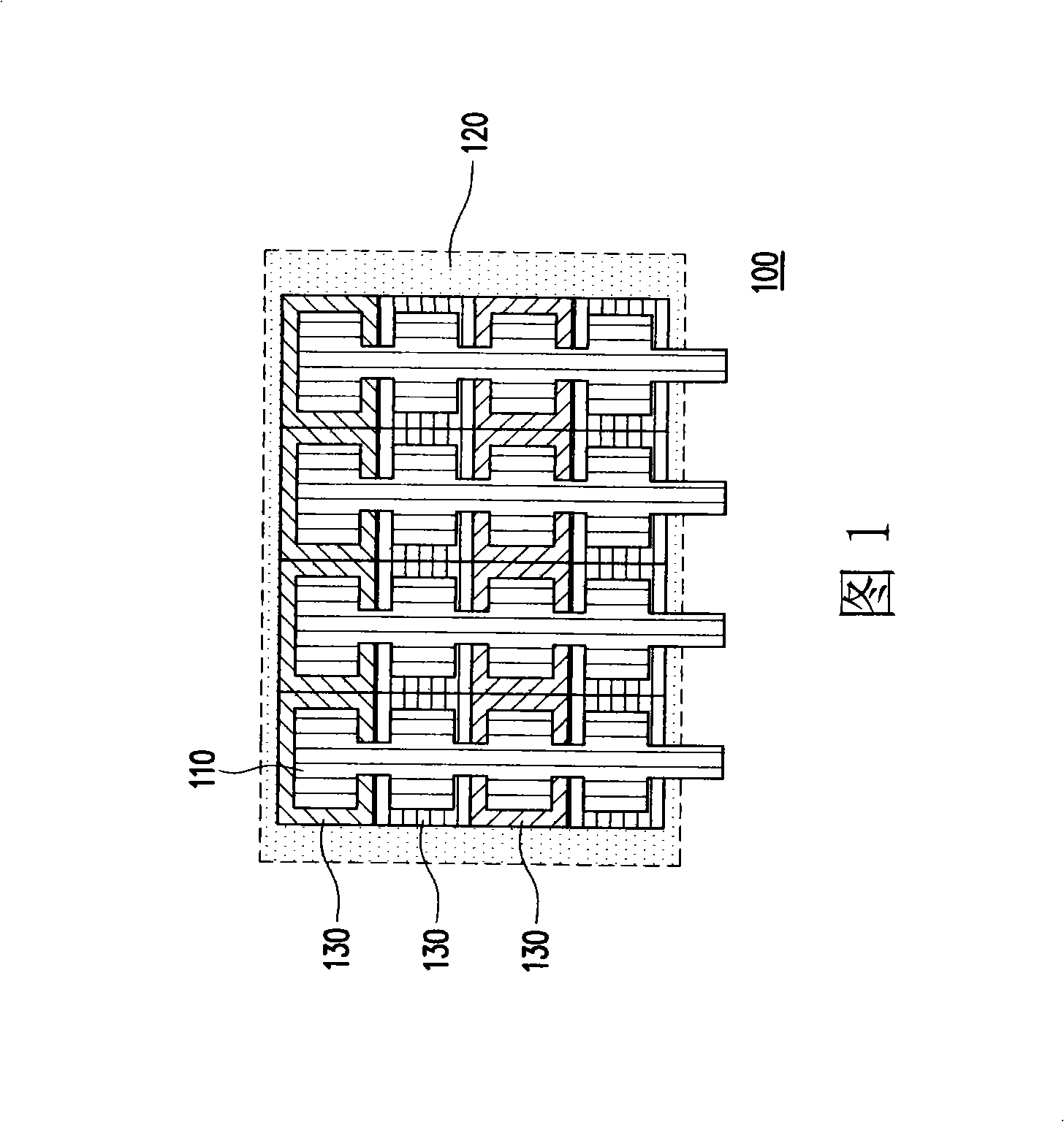

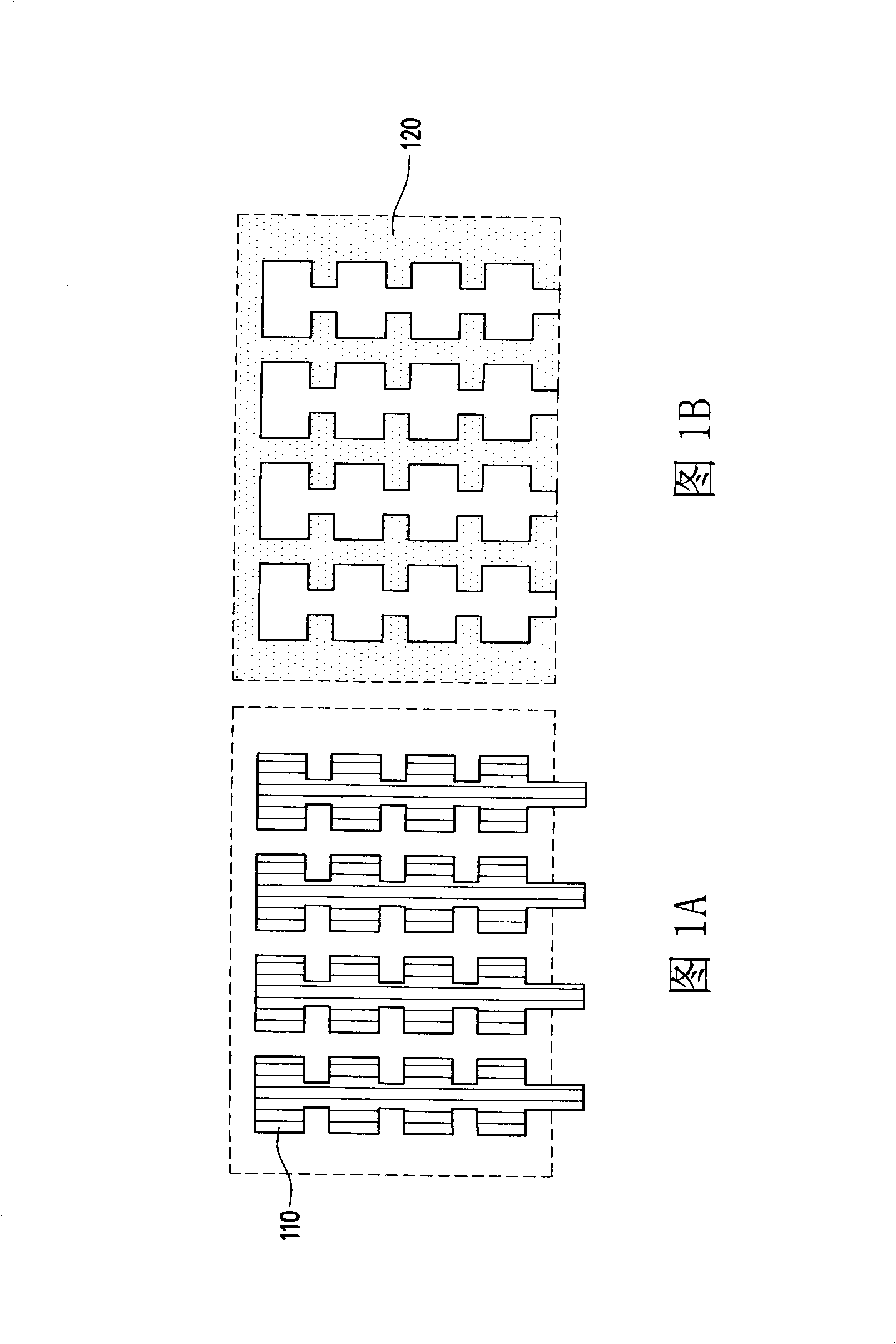

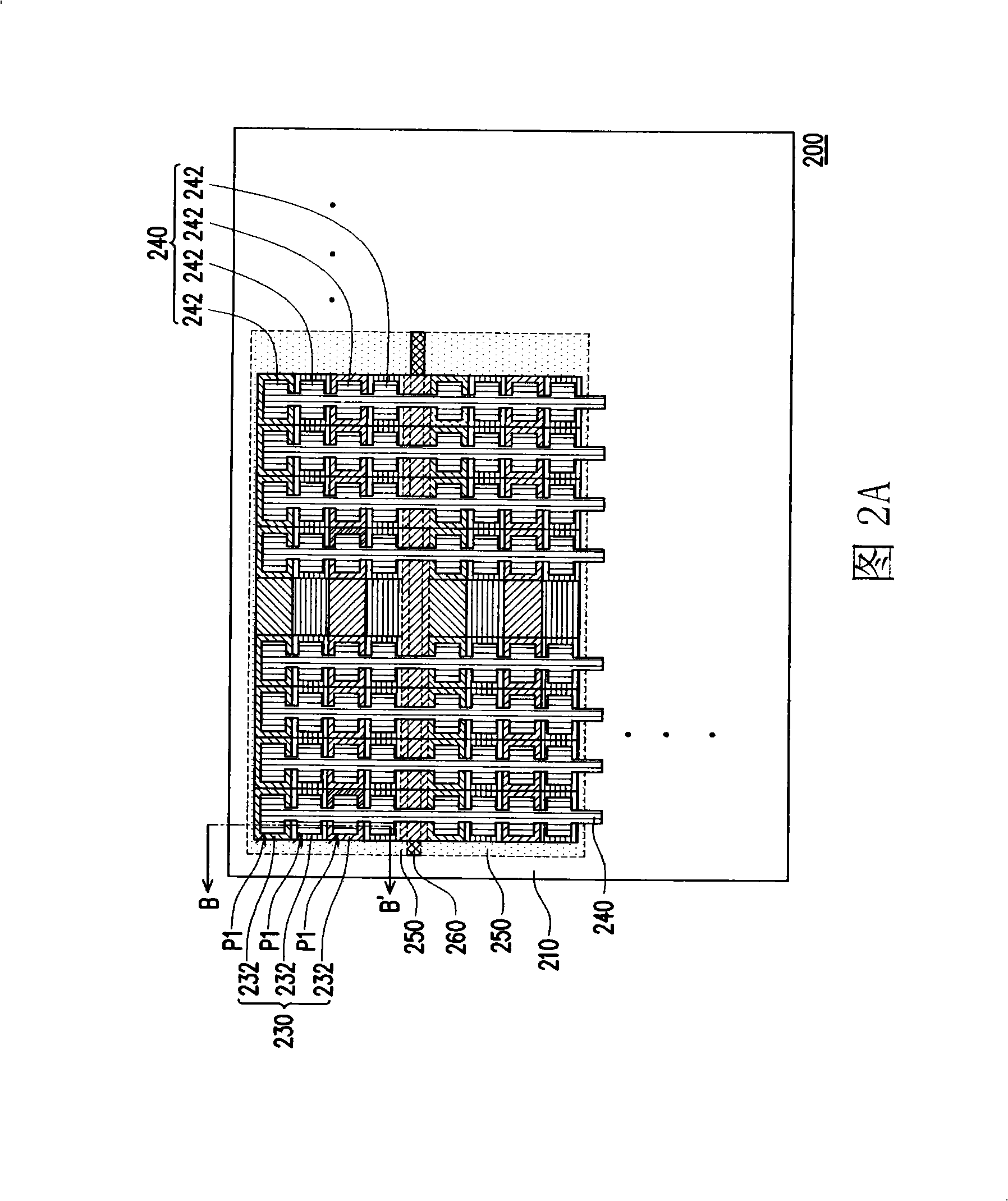

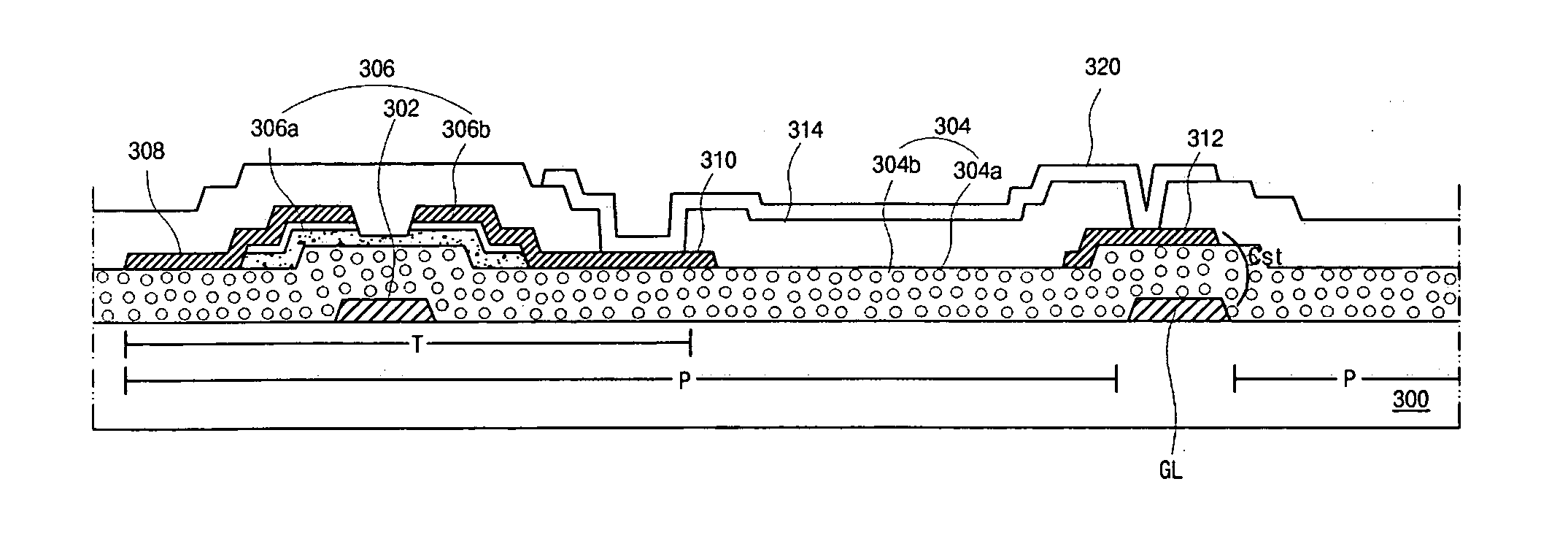

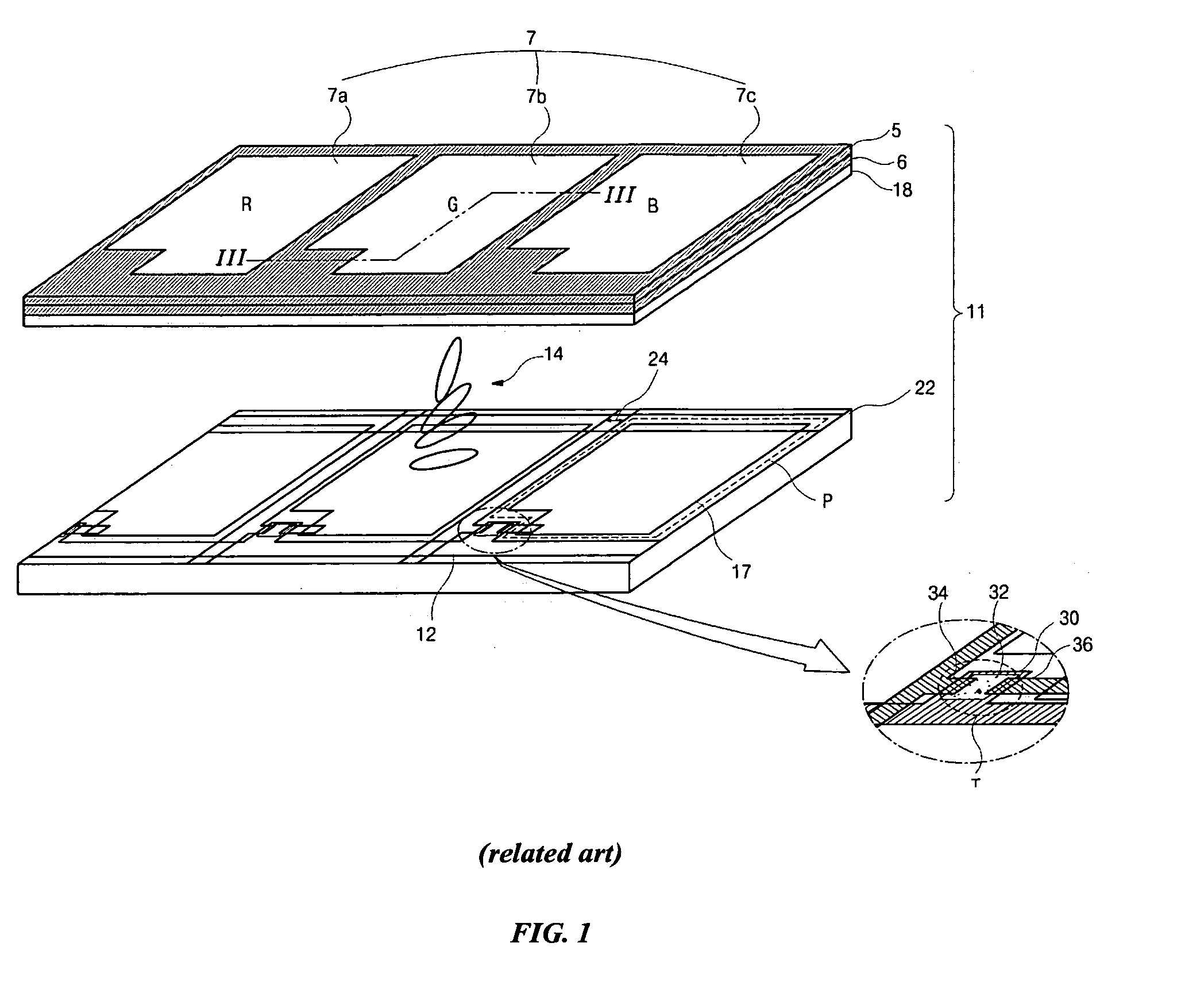

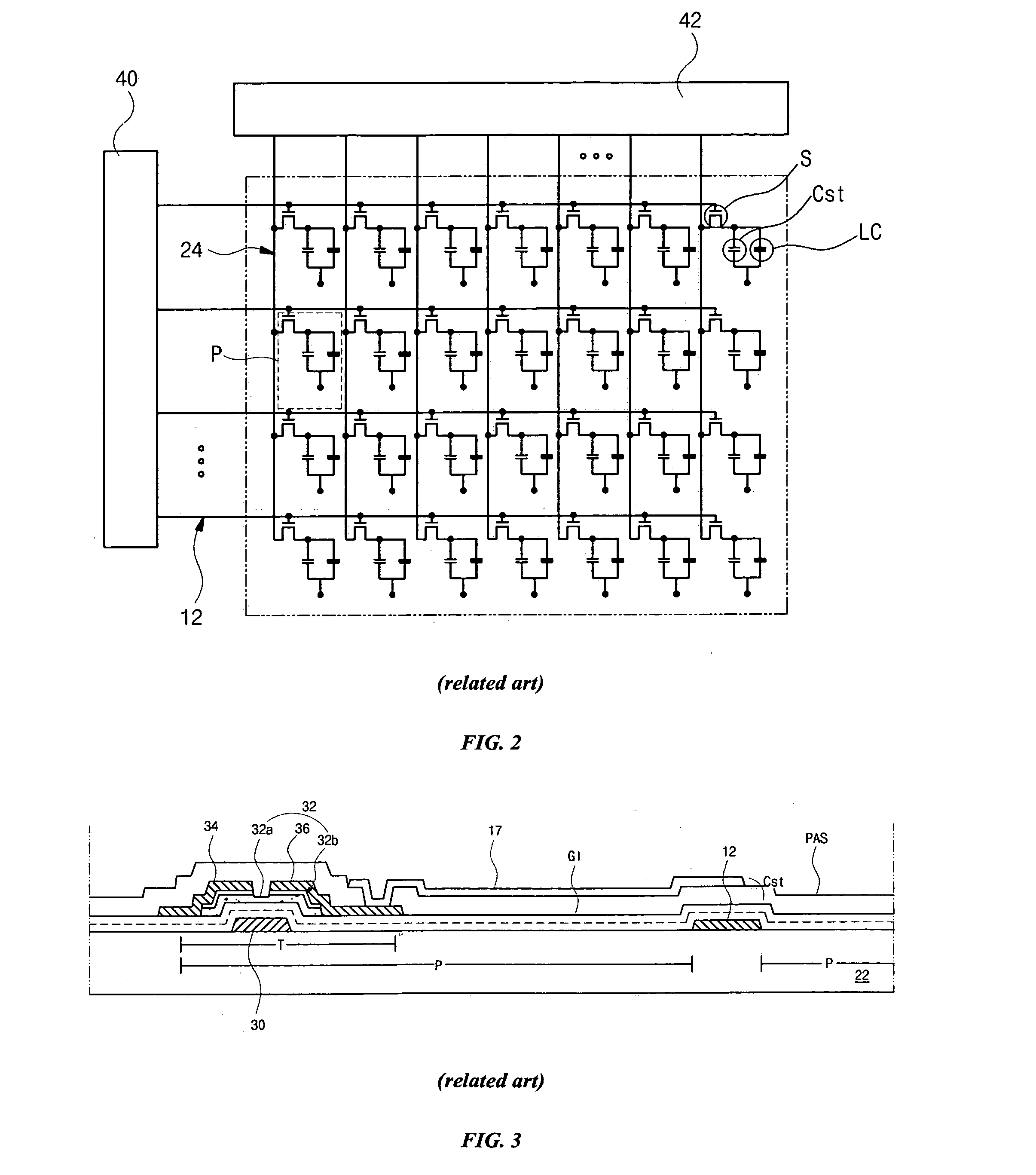

Array substrate for liquid crystal display device and method of fabricating the same

InactiveUS20070236623A1Enhance layeringImprove processing yieldNanoopticsNon-linear opticsLiquid-crystal displayOrganic matrix

An array substrate for a liquid crystal display device, including: a substrate; a gate electrode on the substrate; and a gate insulating layer including an organic matrix of an organic material and an additive that increases a dielectric constant of the gate insulating layer.

Owner:LG DISPLAY CO LTD

Steel with excellent processing performance for gardening tool and production method thereof

The invention discloses steel with excellent processing performances for a gardening tool and a production method thereof. The steel comprises the following components of, by weight, 0.45%-0.65% of C,0.1%-0.40% of Si, 0.5%-1.5% of Mn, 0.1%-0.5% of Cr, 0.02%-0.05% of Al, less than or equal to 0.4% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that deoxidation is carried out by adopting Al, and time of argon blowing in tundish is larger than or equal to 10 minutes, the casting superheat degree is less than or equal to 25 DEG C, the thickness of a casting blank is 130-200 mm; charing temperature of the casting blank is larger than or equal to 500 DEG C; heating temperature is 1100-1200 DEG C, the temperature is kept for 2-5 hours, the rolling speed is 5-15 m per second, rolling start temperature is larger than or equal to 1080 DEG C, and rolling finish temperature is larger than or equal to 920 DEG C; and the cold speed is less than or equal to 20 DEG C per second, the casting blank is coiled at the temperature of 650-730 DEG C, then is put into a slow cooling pit for heat preservation and slow cooling for more than or equal to 48 hours, is cooled to below 200 DEG C, and then is air-cooled to the room temperature. According to steel with the excellent processing performances for the gardening tool and the production method thereof, the steel plate has excellent formability and wear resistance.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com