Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Consistent and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

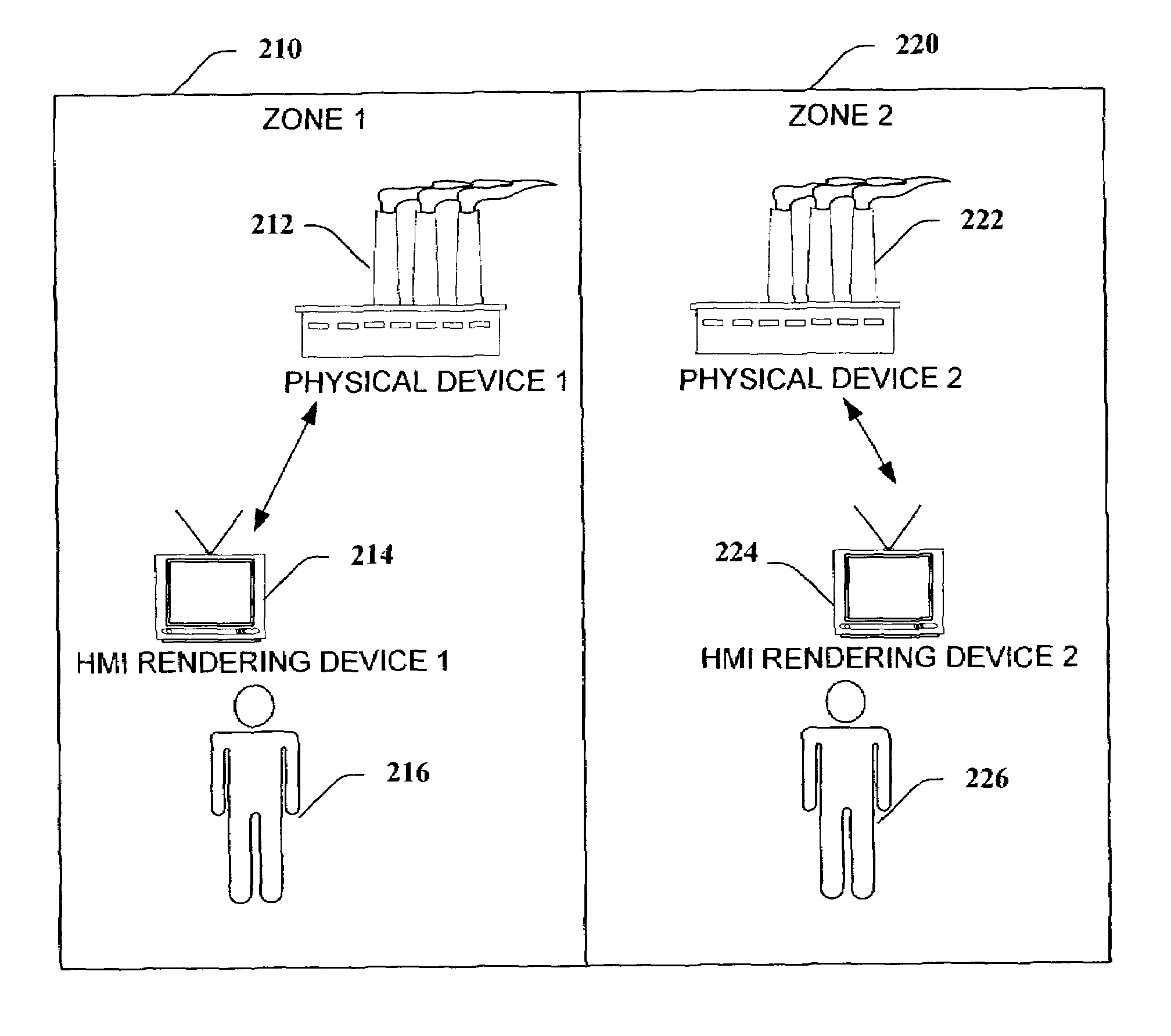

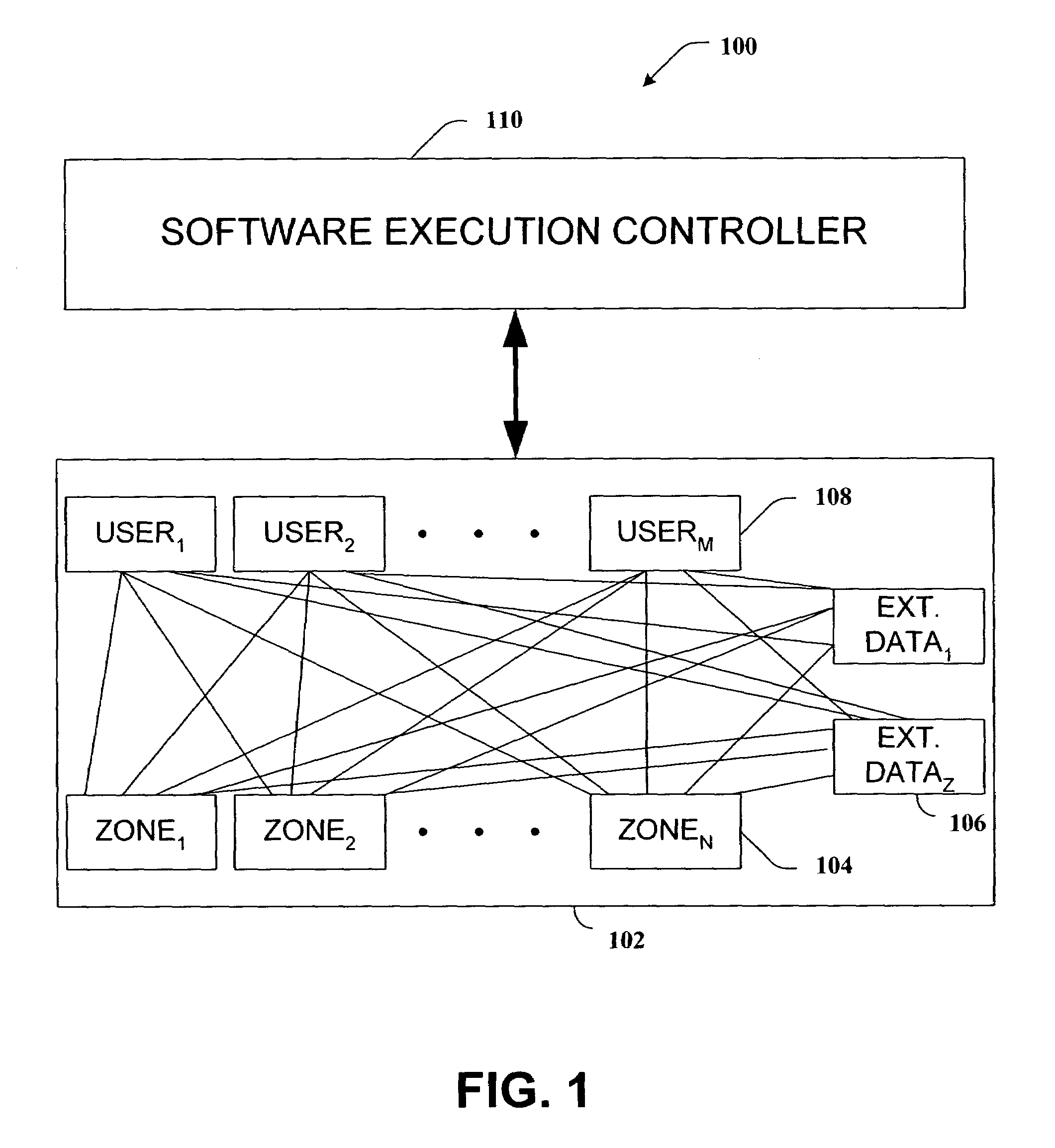

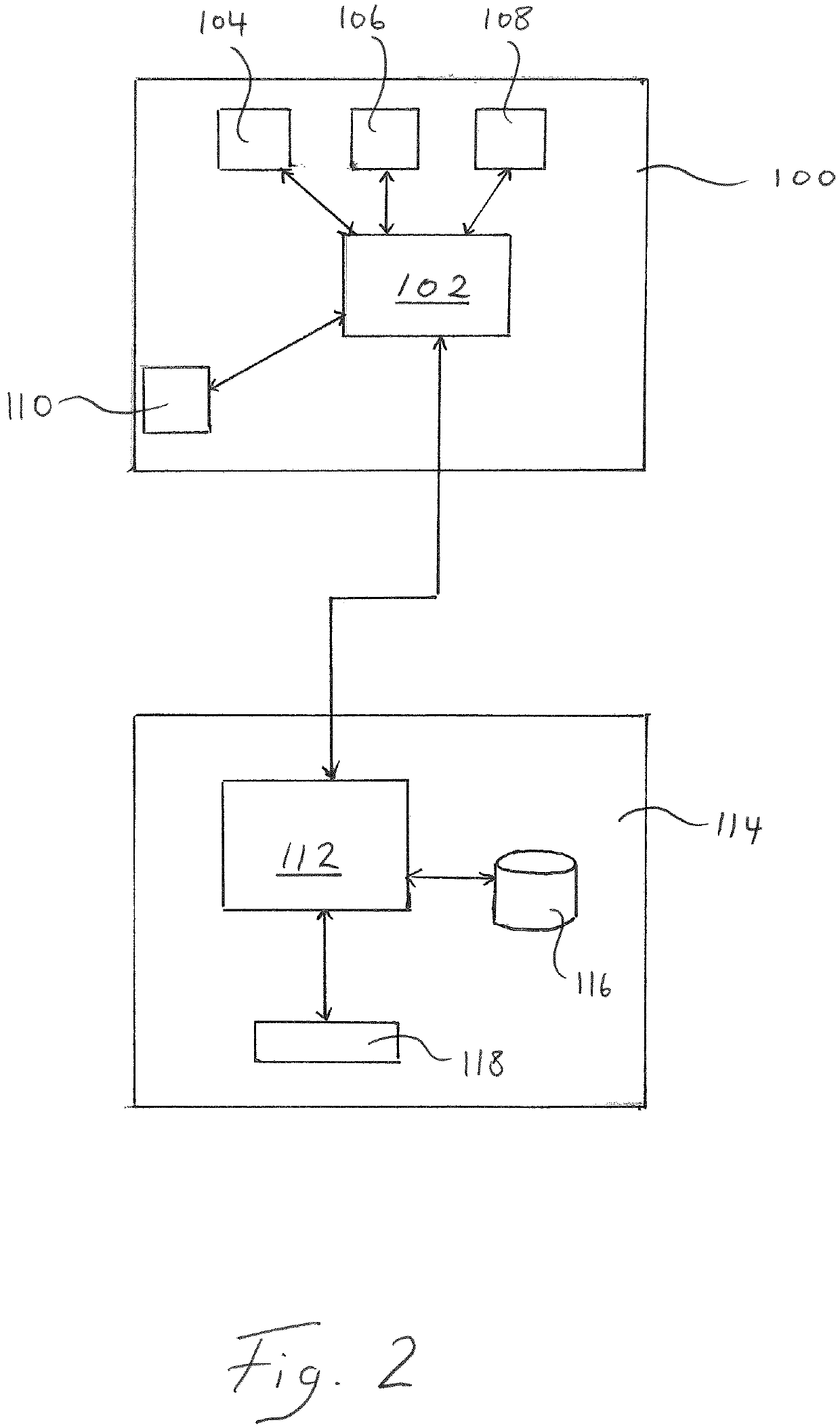

Location-based execution of software/HMI

ActiveUS7194446B1Consistent and reliableFacilitate HMI renderingProgramme controlDigital computer detailsHuman–machine interfaceAutomation

A system and / or method that configures a HMI based at least upon a current state of parameters and a predefined protocol. A processing component queries an industrial automation environment receiving a current state of parameters relating to a human machine interface (HMI). A rendering component automatically configures the HMI to function in accordance with a predefined protocol.

Owner:ROCKWELL SOFTWARE

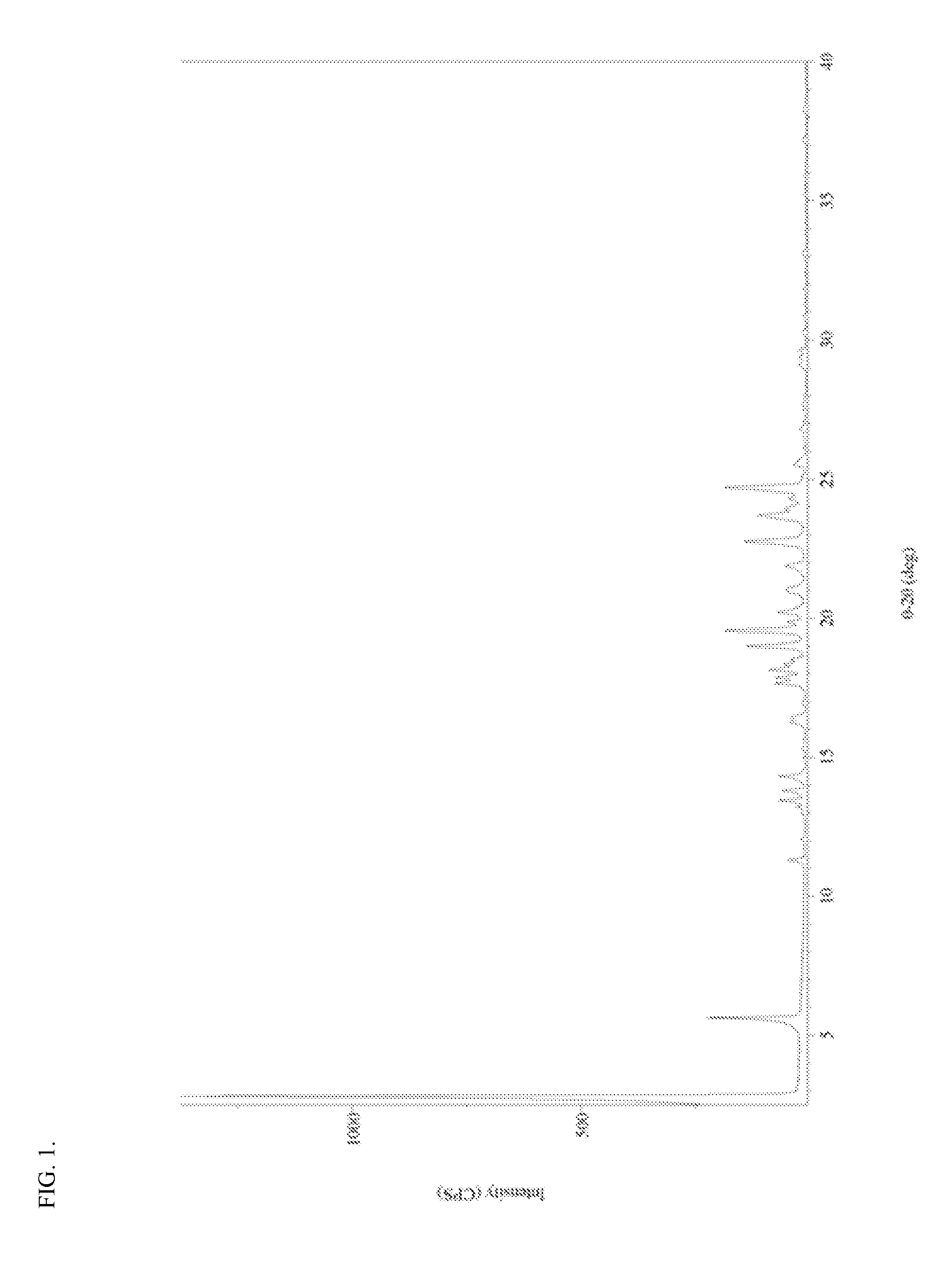

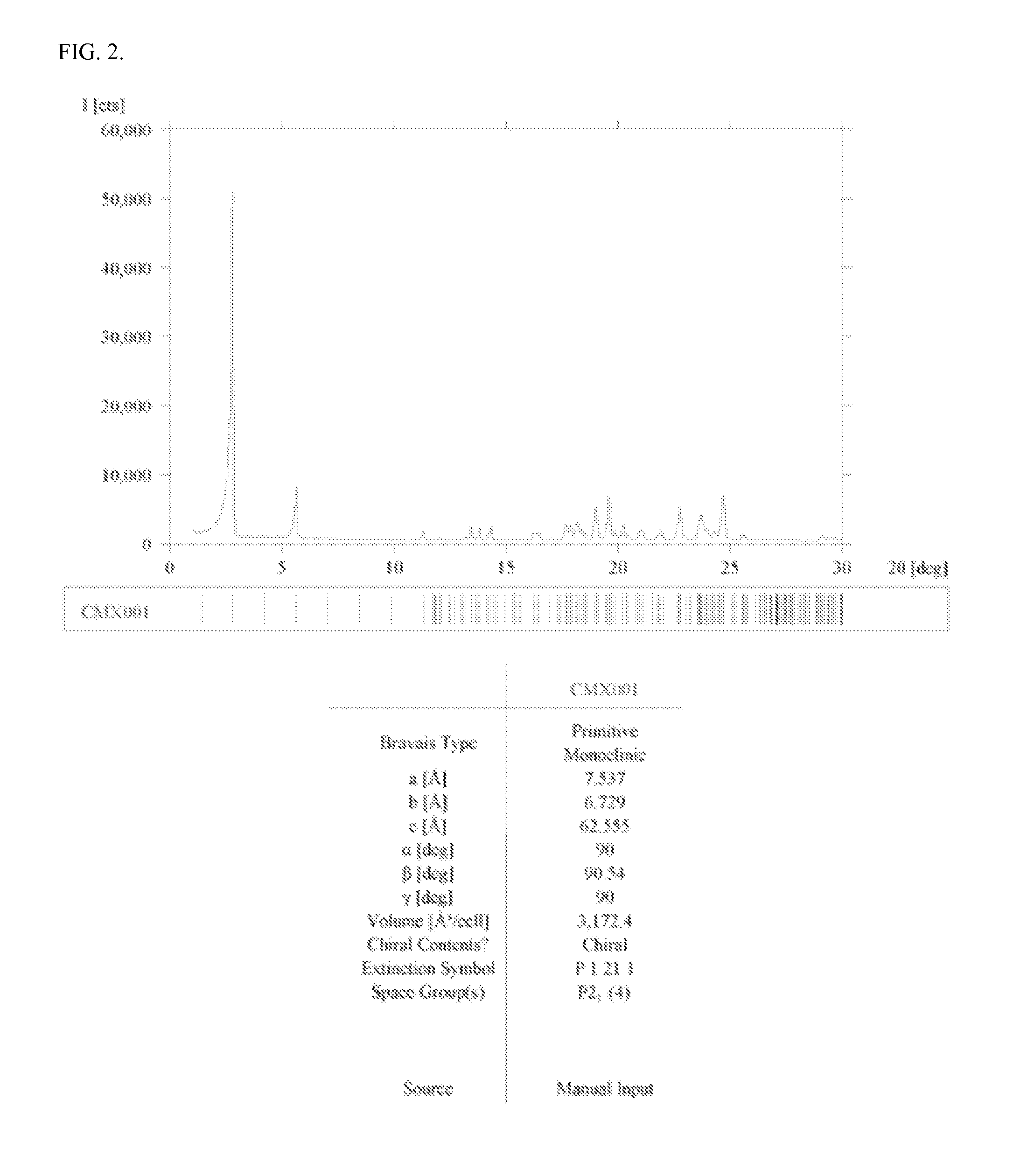

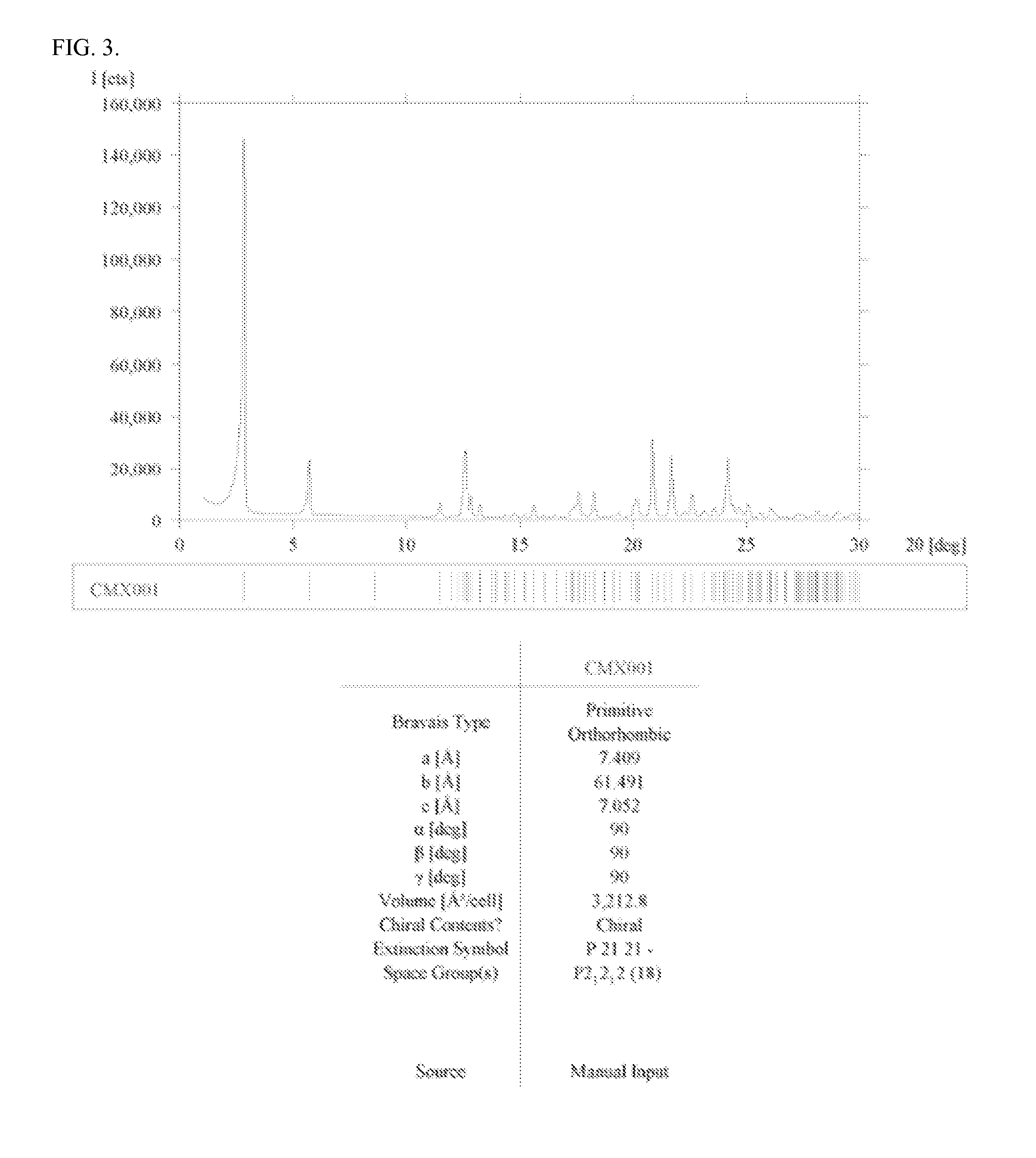

Morphic forms of hexadecyloxypropyl-phosphonate esters and methods of synthesis thereof

ActiveUS8962829B1Effort is complicatedConsistent and reliableOrganic active ingredientsOrganic chemistry methodsMedicinal chemistryPhosphonate

The disclosure describes methods of synthesis of phosphonate ester compounds. The methods according to the disclosure allow for large-scale preparation of phosphonate ester compounds having high purity and stability. Also disclosed are morphic forms of phosphonate ester compounds.

Owner:EMERGENT BIODEFENSE OPERATIONS LANSING LLC

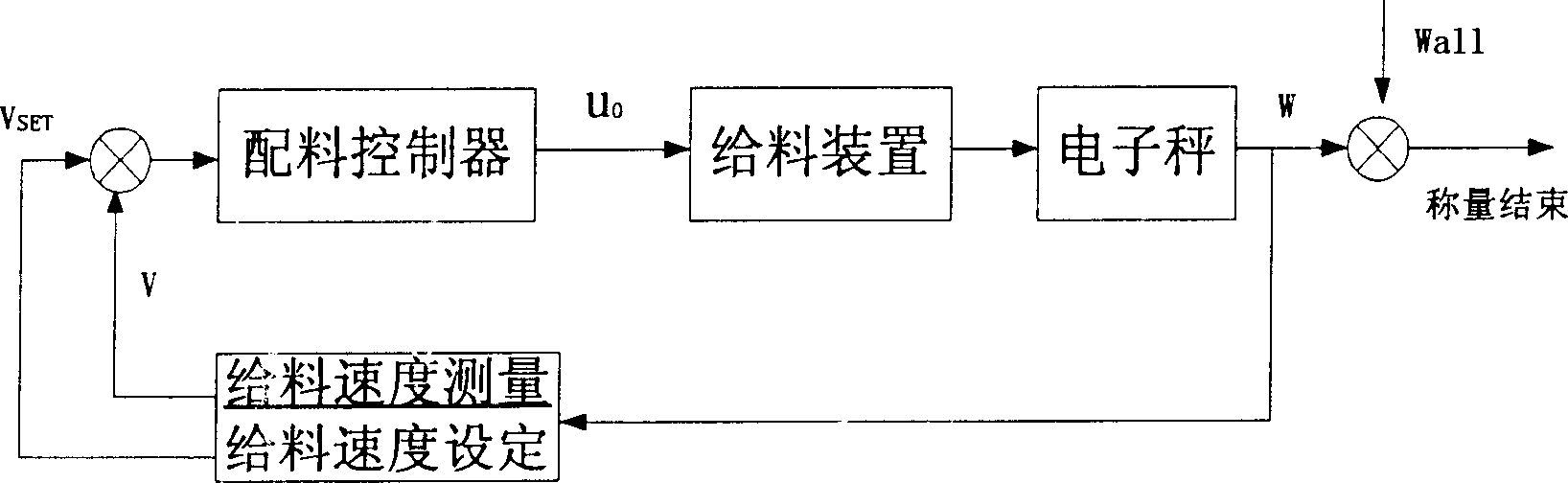

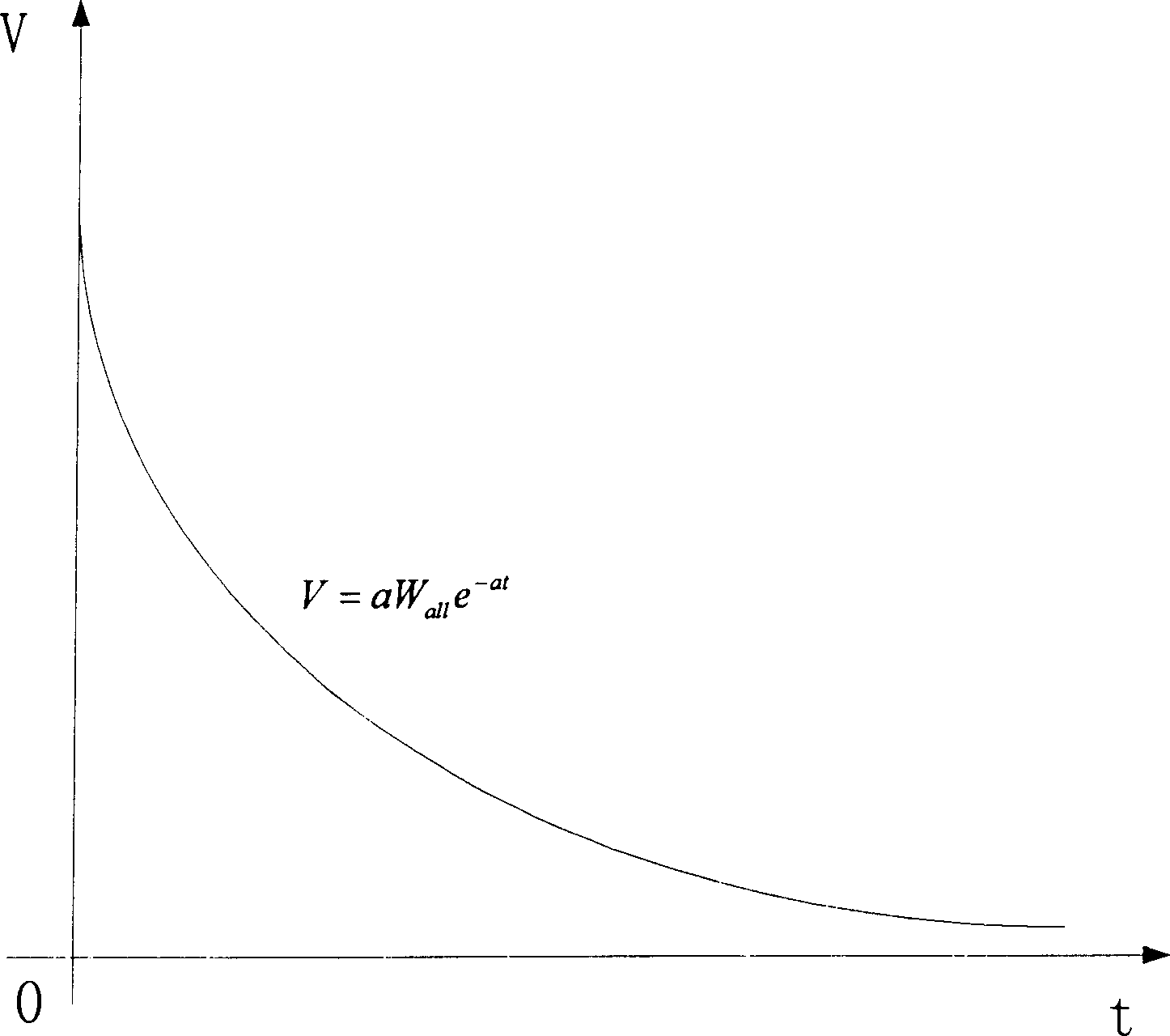

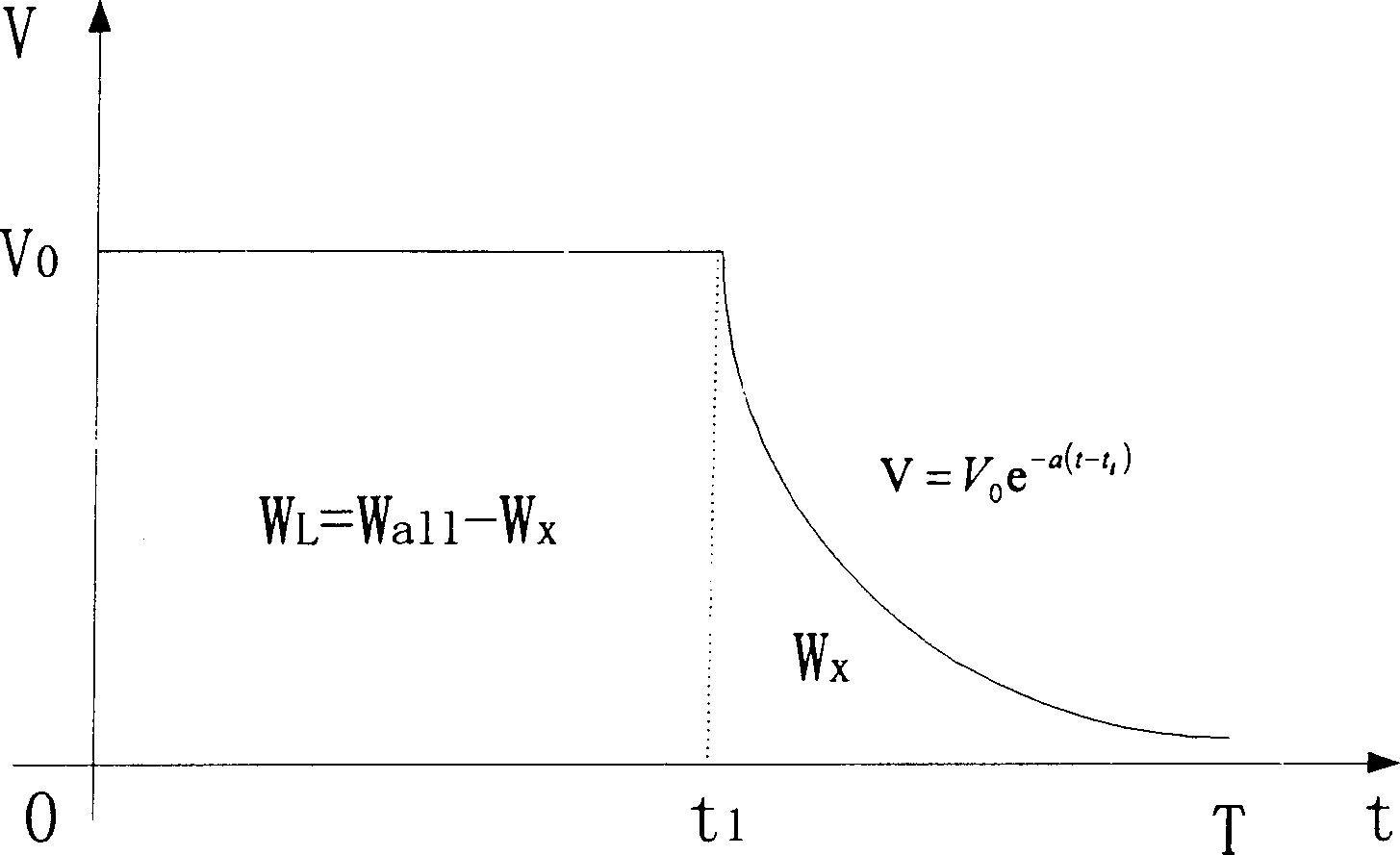

On-line weighing dispensing method based on feed speed control

ActiveCN1707379AConsistent and reliableAvoid the influence of human factorsRatio controlAutomatic controlEngineering

The on-line weighing and compounding method based on material feeding speed control is one kind of automatically controlled stepless speed regulating material compounding method for in-situ production, and can realize high precision weighing of complicated materials and improve production process control. The on-line weighing and compounding method determines the material feeding speed V through determining speed decrease index alpha and initial material feeding speed V0, and determines the material accumulation W through combining with the speed converting time t, so as to set and control the change of the material feeding speed V based on known weighed material Wall, control the weighing time T, and ensure the real-time weighed material W reaching to the known weighed material Wall at most.

Owner:MESNAC

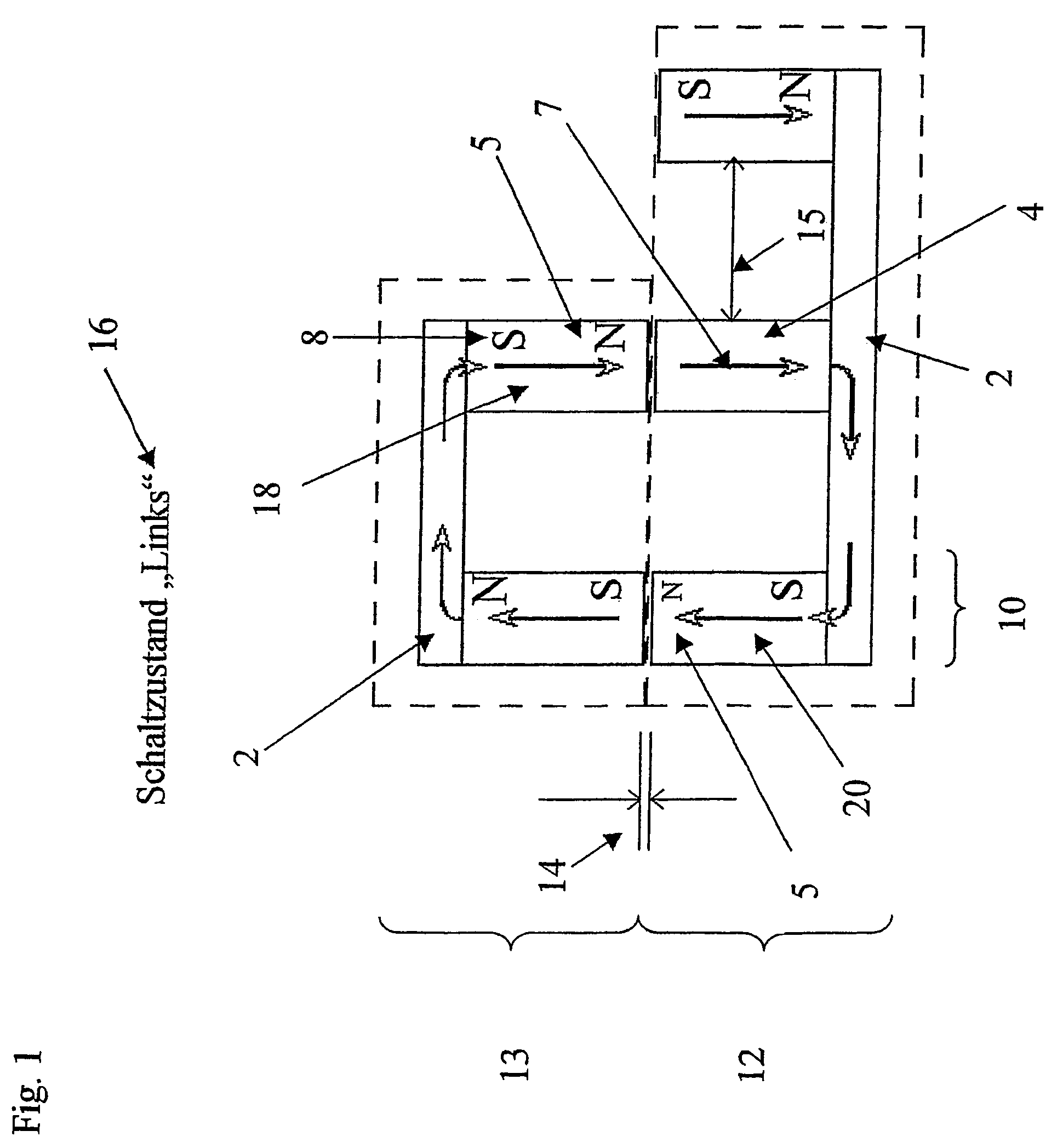

Switching unit having a locking function for a tool

InactiveUS7619499B2Switch is robustAvoid disadvantagesElectromagnets without armaturesContact mechanismsIndustrial toolEngineering

Owner:BOSCH REXROTH AG

Winder apparatus with transfer brush roll

ActiveUS20050211818A1Highly consistent and reliable web-transferCheap manufacturingFilament handlingWebs handlingEngineeringConductor Coil

A winder apparatus for winding webs of material into rolls includes a conveyor, and a winding turret with a plurality of rotatably driven winding spindles thereon. The winding turret indexes the winding spindles relative to the apparatus conveyor, with each spindle moved to a transfer position wherein a web of material is transferred from the conveyor onto the spindle to initiate roll formation. A rotatably driven transfer brush assembly is positionable in operative association with the conveyor and the spindle in the winding position to facilitate efficient and consistent transfer of a web from the conveyor onto the spindle for roll formation.

Owner:HUDSON-SHARP MACHINE COMPANY

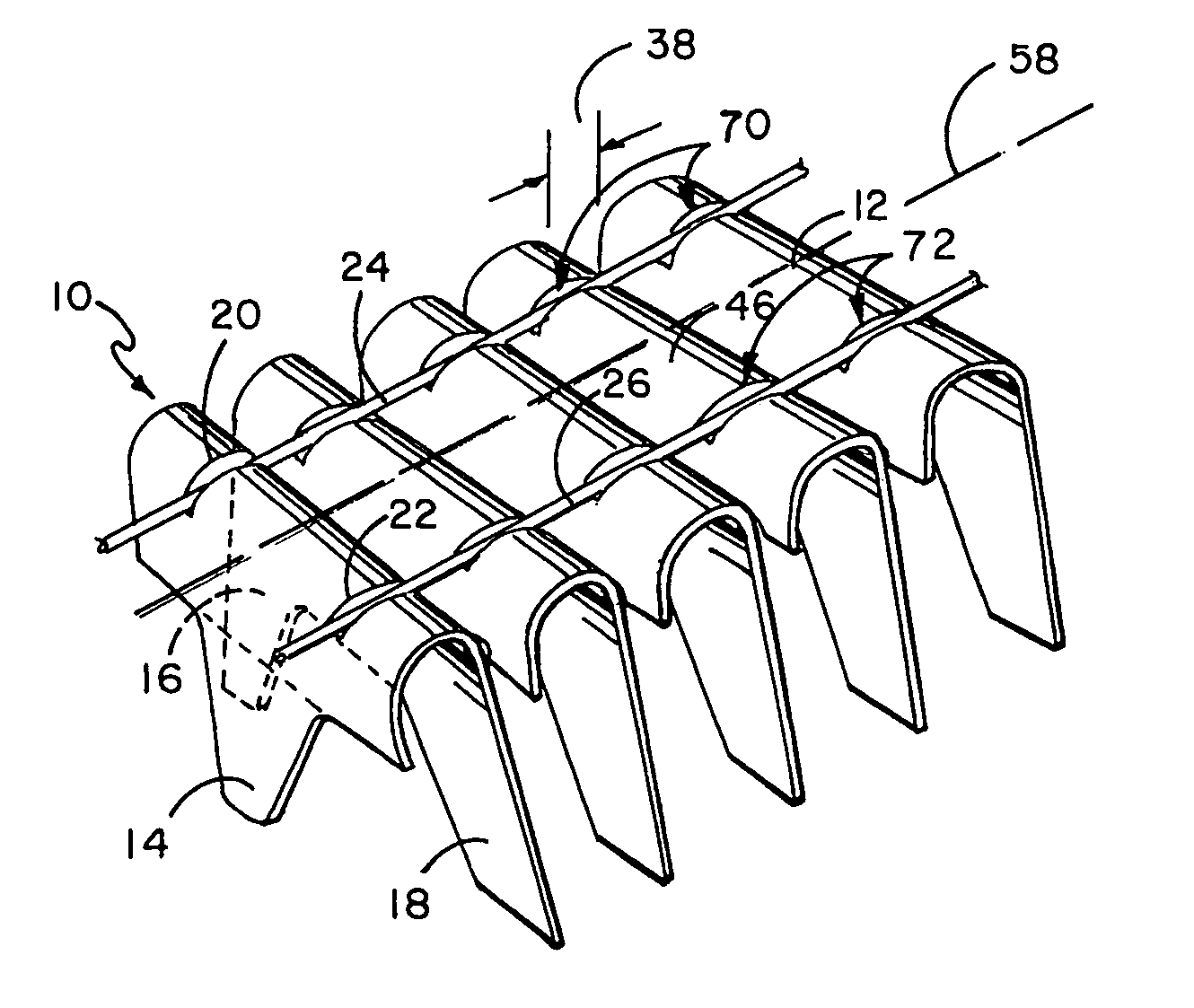

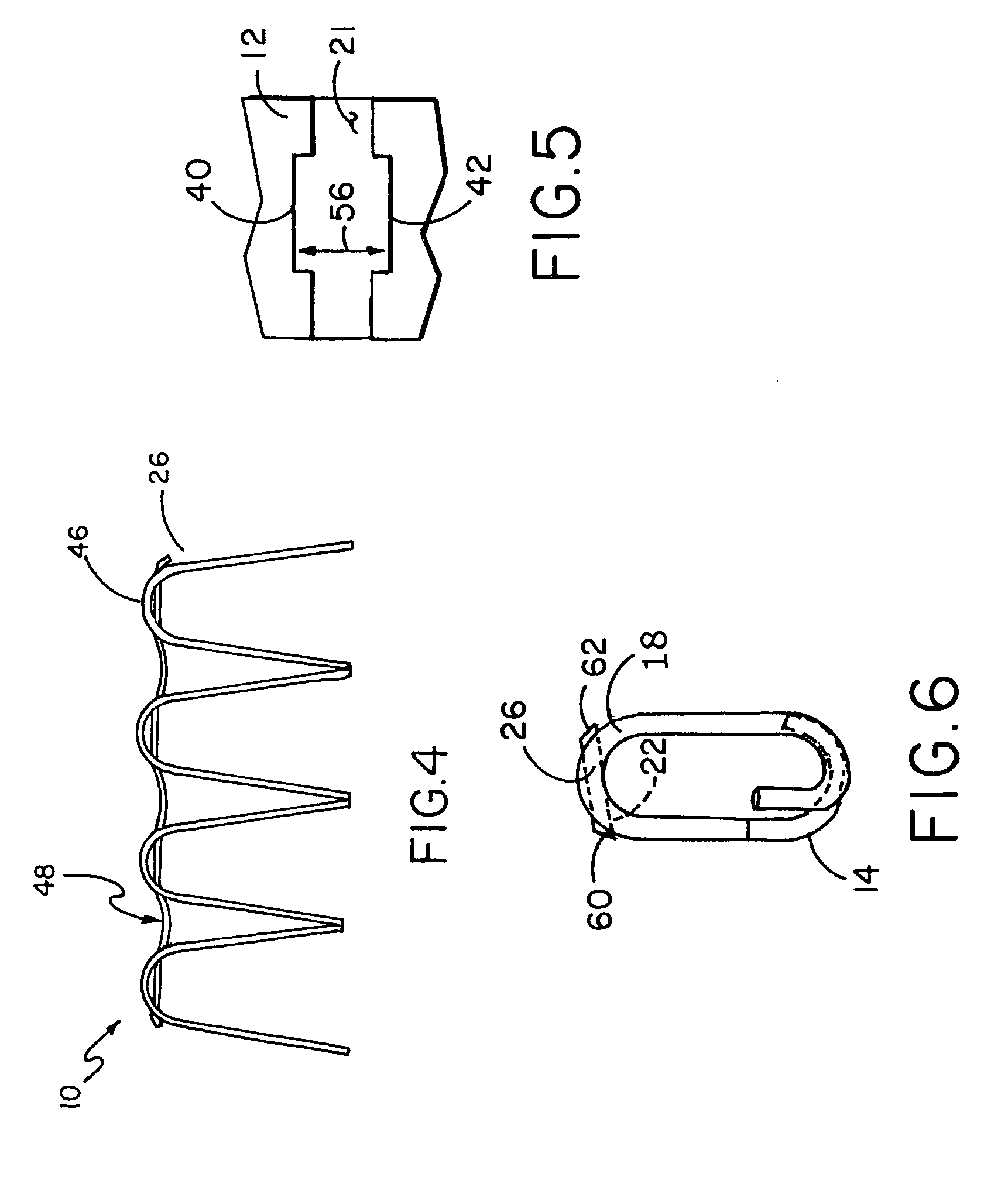

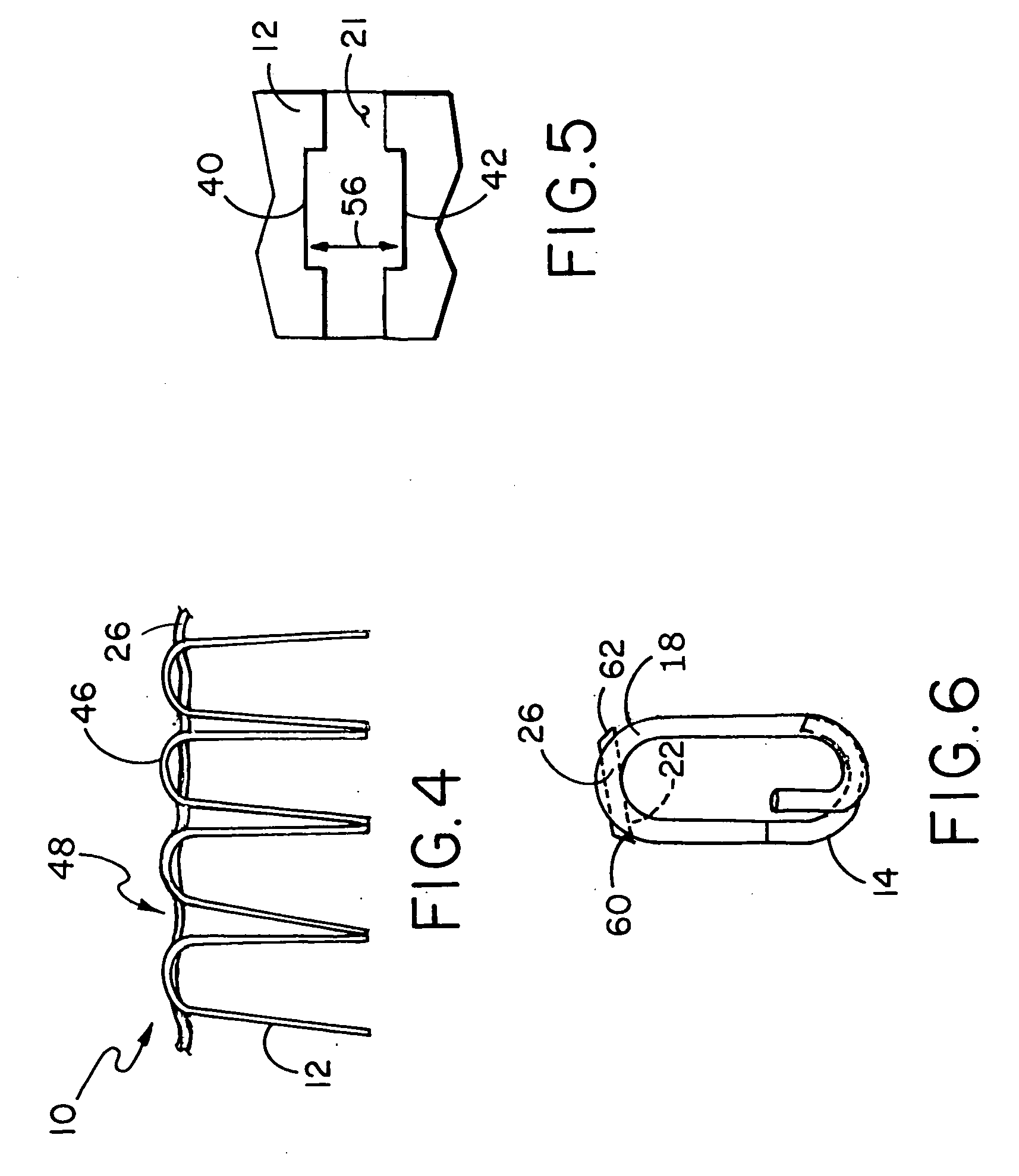

U-clip assembly and method

InactiveUS7882948B2Easy to pinchGenerally smooth exteriorSnap fastenersMetal-working apparatusMechanical engineeringSoft metal

A structure and method for forming a U-clip assembly made of a plurality of U-clips arrayed in a continuous abutting relation, each U-clip having first and second slots defined in its crown portion with first and second soft metal wires positioned, respectively, in such first and second slots, such soft metal wire forming a shallow U shape between adjacent crown portions, such first and second soft metal wires being compressed within their slots to expand within such slots for contacting and urging against the sides and bottom of each slot and being retained therein, such soft metal wire and its shallow U shape between adjacent crown portions allowing the U-clip assembly to maintain a non-curved shape and to be substantially flat in configuration.

Owner:WEST ROBERT J

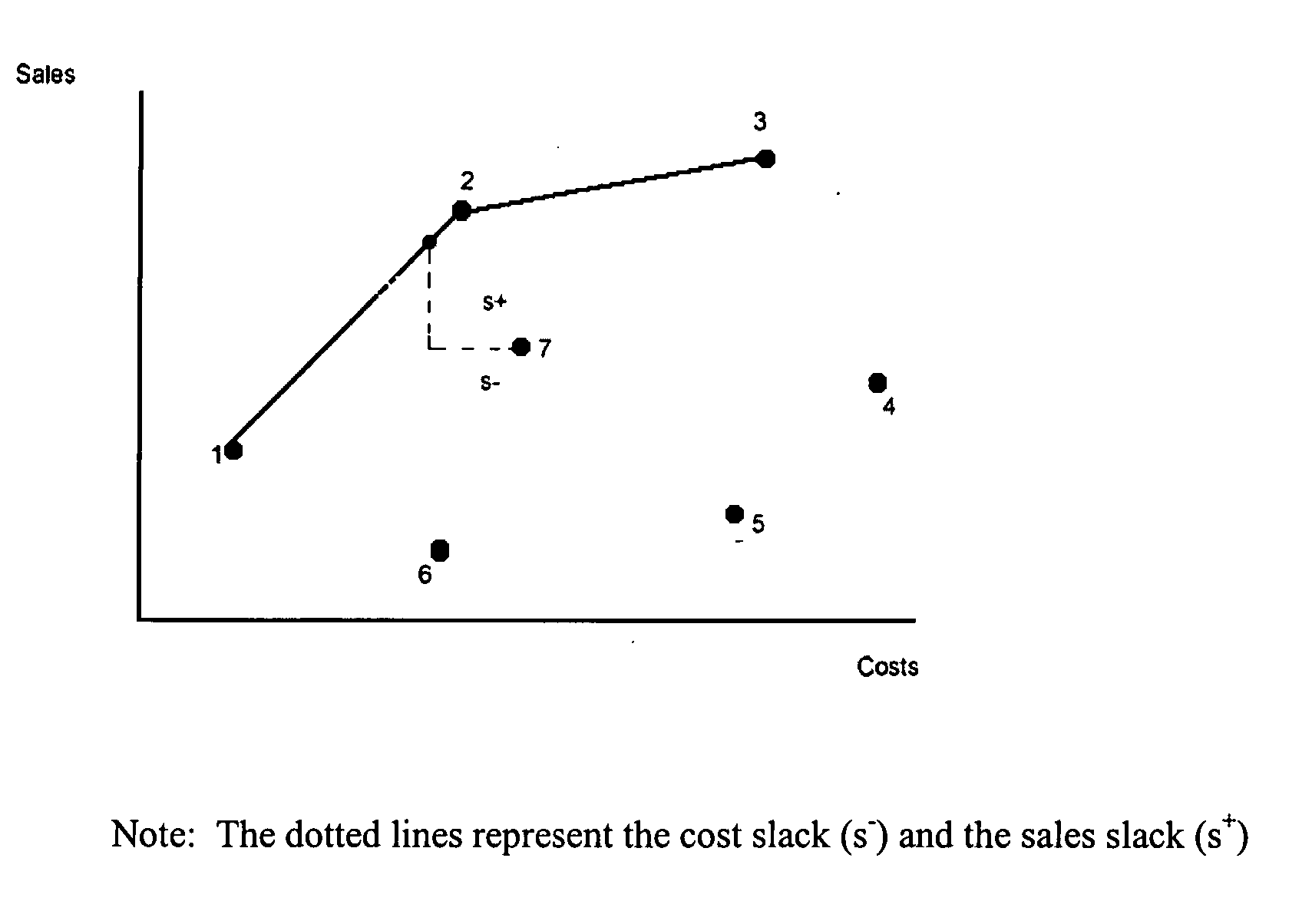

Application of data envelopment analysis in auditing

InactiveUS20050288980A1Consistent and reliableFinanceSpecial data processing applicationsRevenue efficiencyAnalysis tools

A data processing procedure DEA (Data Envelopment Analysis) is described as an analytical tool in an audit engagement. DEA receives data inputs from financial statements of a plurality of clients, constructs efficiency frontiers and evaluates relative income efficiencies. DEA can be used in the overall review stage to detect any anomalies and to assess the reasonableness of financial statements. Application of DEA can significantly minimize errors in an audit judgment by providing accurate and reliable benchmarks and red flags at a reasonable low cost

Owner:FEROZ EHSAN H +2

Semiconductor switch pulse discharge module

InactiveUS20050128656A1Consistent and reliableDc-dc conversionPulse generation by energy-accumulating elementElectricityTypes of capacitor

A capacitor-type pulse discharge apparatus for generating an electric current pulse through an electrical load, comprises an electrical power source and at least one pulse discharge switch module. The pulse discharge switch module includes a capacitor for storing an electrical energy, a semiconductor high-power switch and a semiconductor low-power switch connected to the same terminal of the capacitor. The high-power switch has an input connected in series to the capacitor for allowing the stored electrical energy to be transferred from the capacitor to the load, and the low-power switch has an input connected in series to the capacitor for allowing charging supply from the electrical power source to charge the capacitor.

Owner:DANA CORP

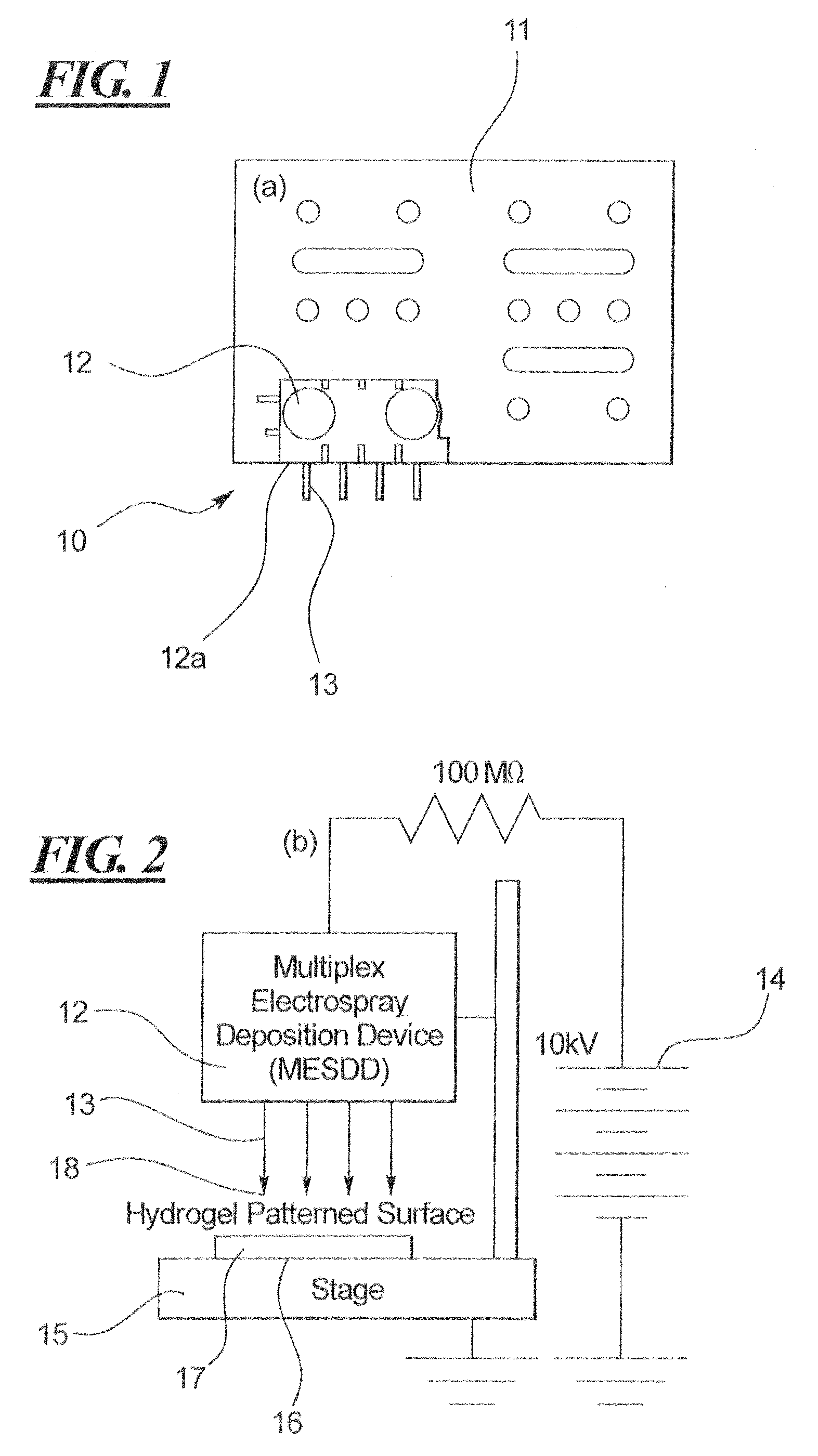

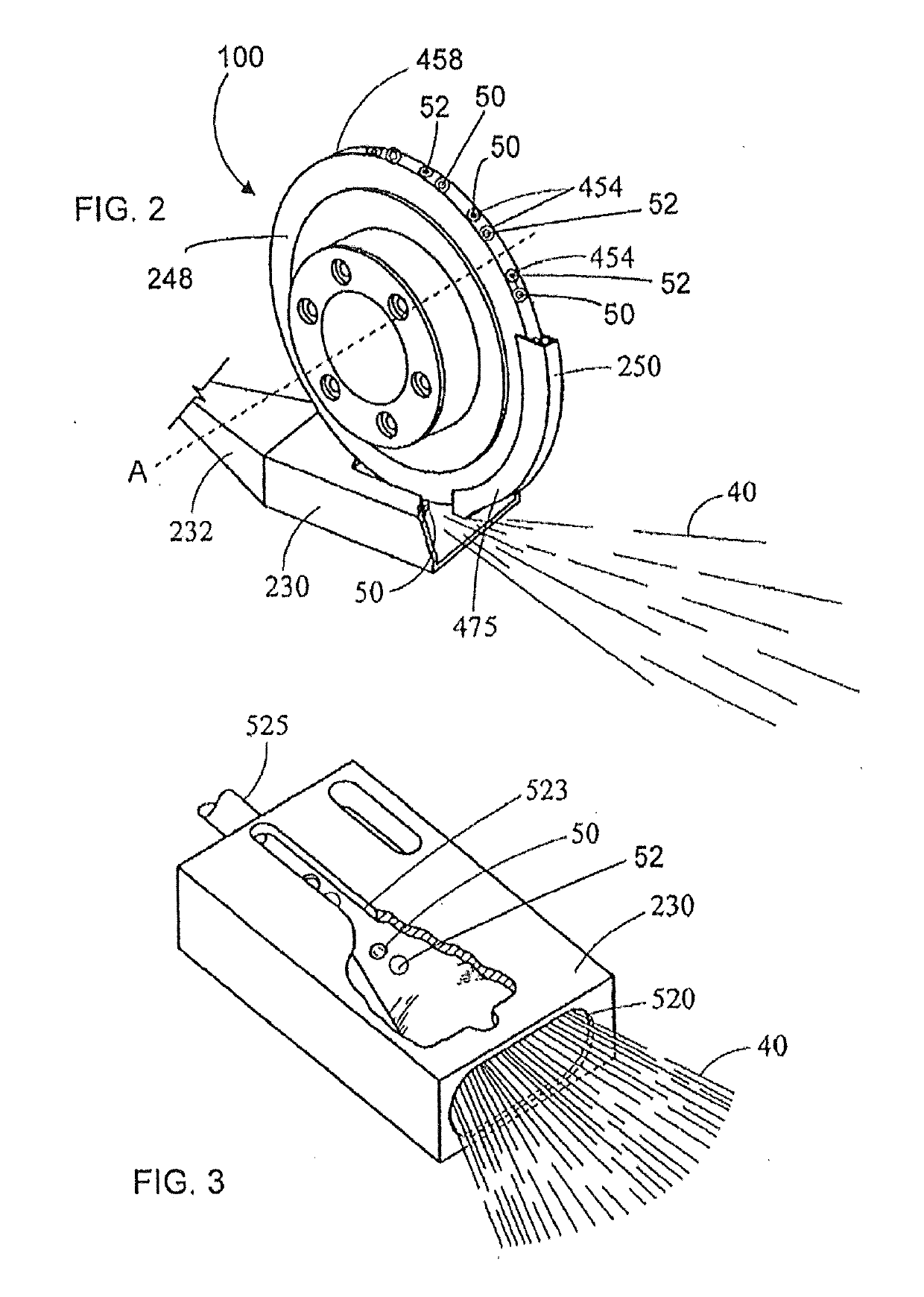

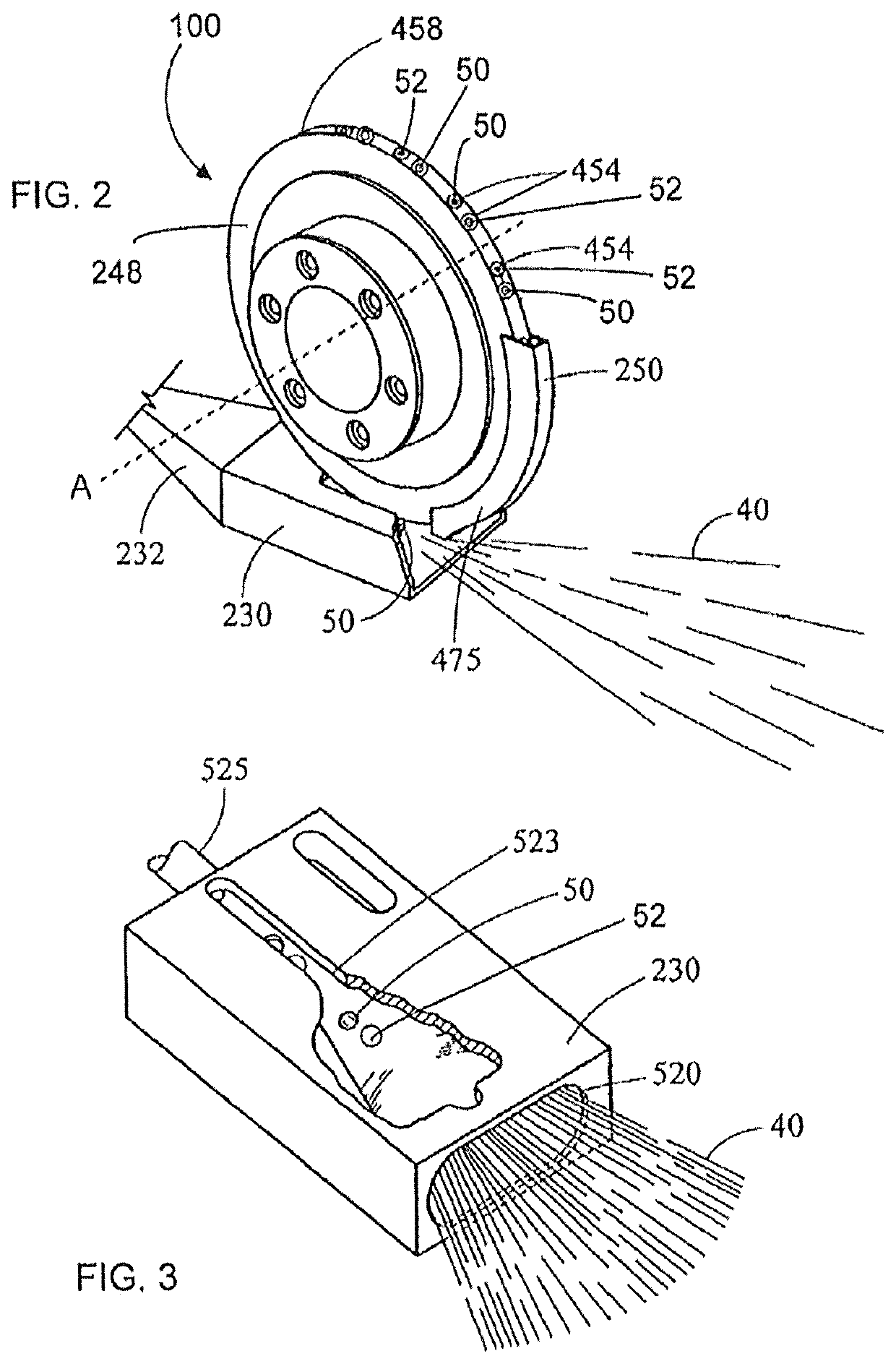

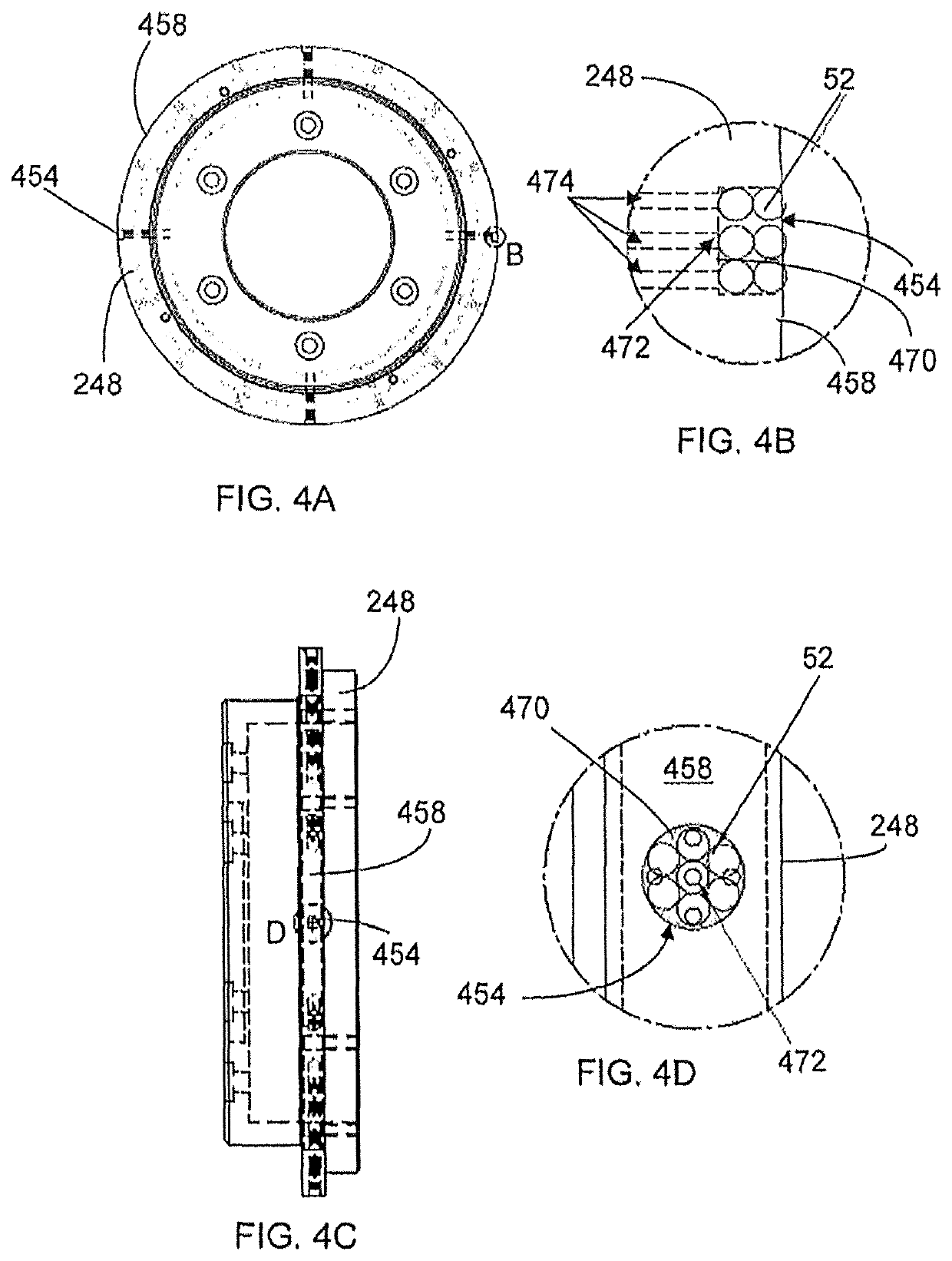

Multiplexed electrospray deposition method

ActiveUS8293337B2Consistent and reliableImprove efficiencyLiquid spraying plantsPretreated surfacesPotential differenceMicrofabrication

Multiplexed electrospray deposition apparatus capable of delivering picoliter volumes of one or more substances is disclosed. The apparatus may include a unitary planar dispenser etched from a silicon wafer through microfabrication or micromachining technology. The apparatus may be used as a deposition tool for making protein microarrays in a noncontact mode. Upon application of potential difference in the range of 7-9 kV, the substances may be dispensed directly, not through a collimating mask, onto a substrate with microhydrogel features functionalized with an anchoring agent.

Owner:CORNELL UNIVERSITY

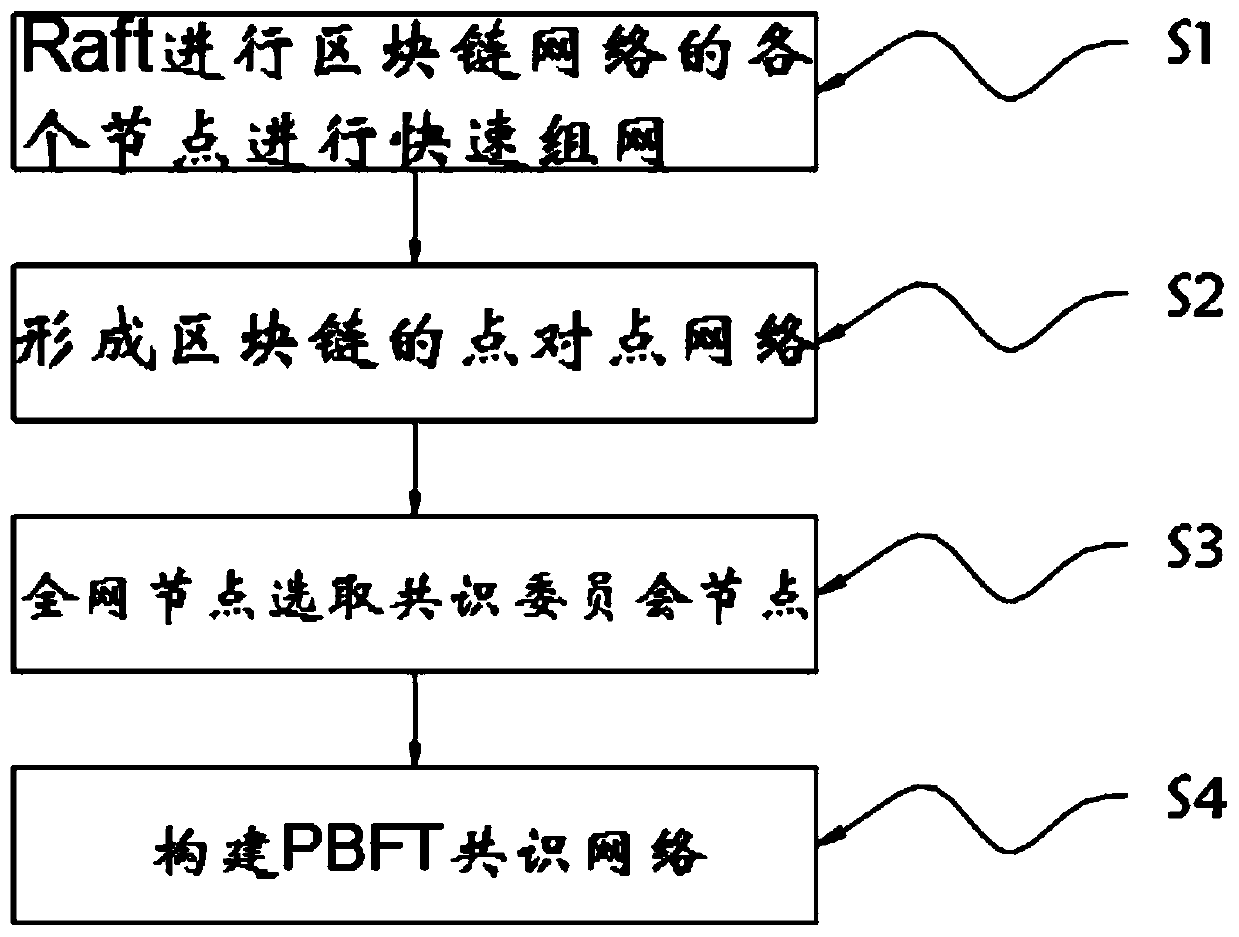

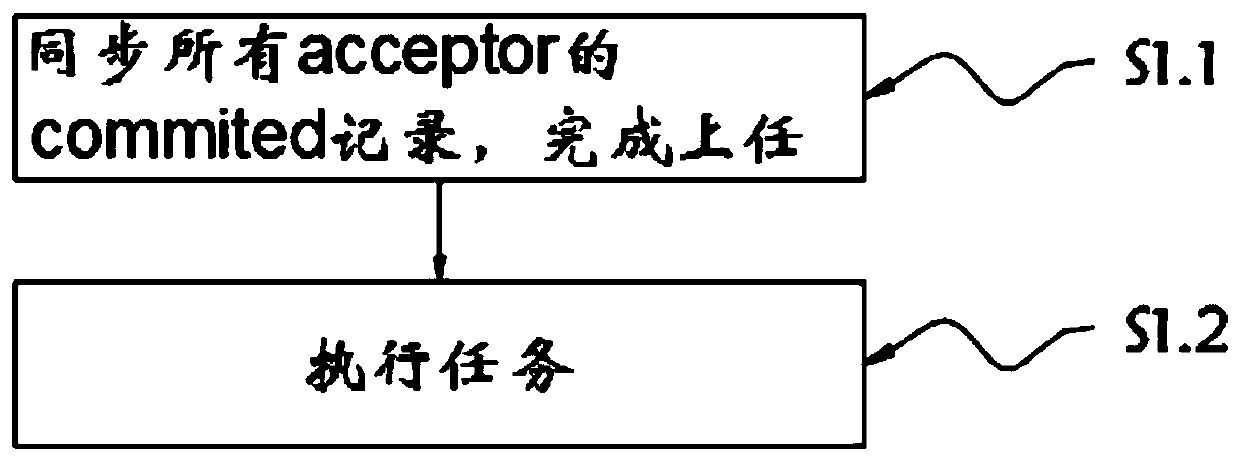

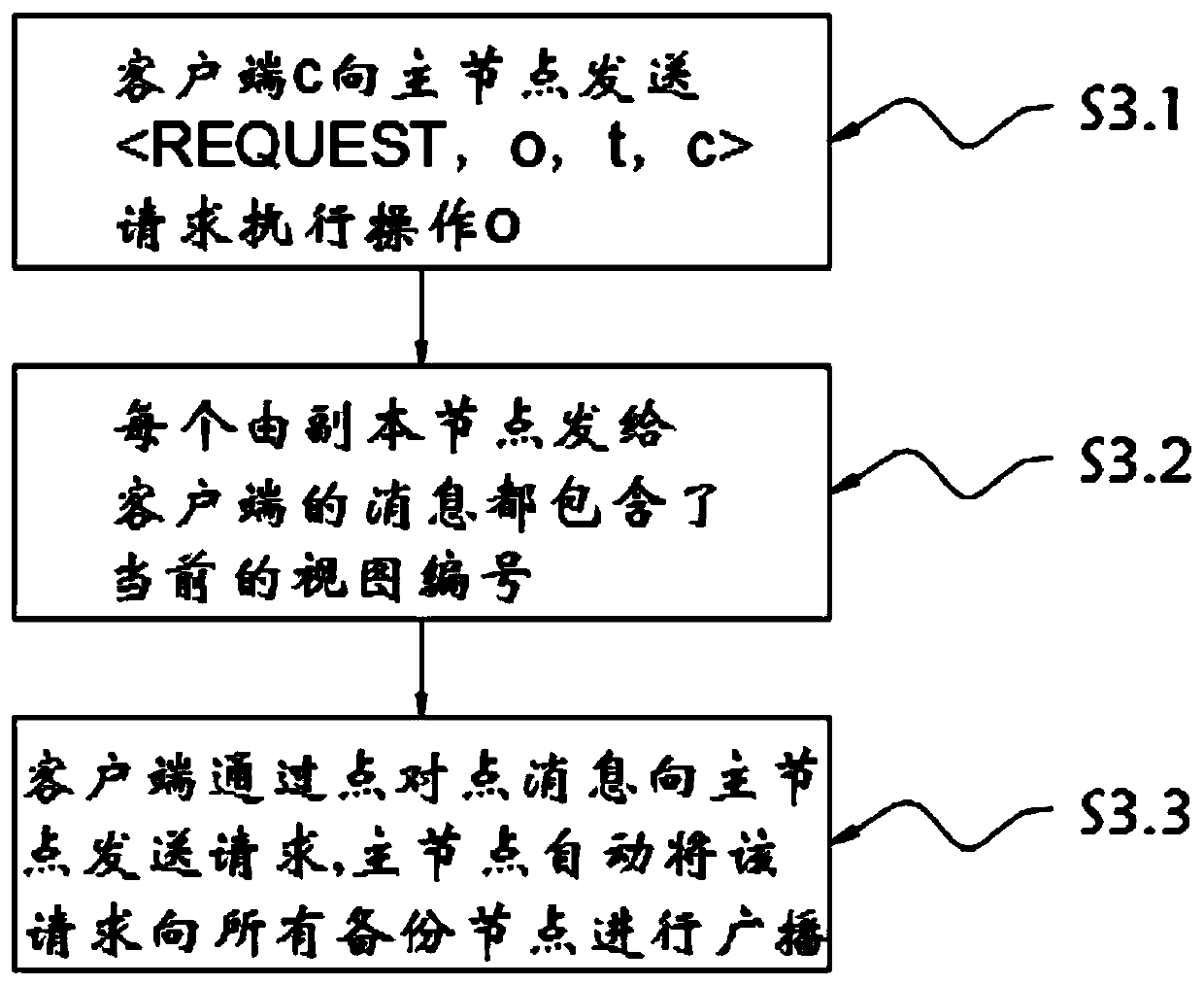

Hybrid consensus network algorithm and system of block chain Raft + PBFT

InactiveCN111464349AReduce pullingTake office quicklyData switching networksSecuring communicationPaxosStochastic algorithms

The invention relates to the technical field of block chains, in particular to a hybrid consensus network algorithm of block chain Raft + PBFT. The method comprises the following steps: selecting a host from paxos, synchronizing commid records of all acceptors, and completing the above steps; obtaining pass of the followers by commid, and completing a task; enabling a client c to send (REQUEST, o,t, c) a request to perform an operation o to the master node; wherein each message sent to the client by the replica node comprises a current view number; and enabling a main node to automatically broadcast the request to all backup nodes. Rapid networking is carried out on each node of a block chain network by adopting Raft to form a point-to-point network of a block chain, consensus committee nodes are selected from nodes of the whole network by adopting a random algorithm, a PBFT consensus network is constructed, relatively reliable consistency is ensured, and a consensus mechanism is formed.

Owner:NANJING ZHONGCHENG BLOCK CHAIN RES INST CO LTD

Holder with V-knife blade for bi-directional rupture disc assembly

ActiveUS20060157107A1Consistent and reliableEliminate the problemLarge containersEqualizing valvesEngineeringKnife blades

This invention relates to a cylindrical holder member for a bi-directional bulged rupture disc. The support body of the holder has a rim that supports the rupture disc with the concave surface of the disc facing the holder. The support body is provided with a unitary one-piece, centrally creased cutting element that is of generally V-shaped configuration in plan view. The cutting element has a pair of elongated converging leg components with each leg component being connected to and supported by the interior wall surface of the holder body, with each leg component having an arcuate cutting edge. The cutting edges of the leg components merge at the crease in the cutting element to define a central cutting edge peak section. The cutting element is positioned in the holder with the cutting edge peak section extending beyond the rim of the support body into the concave area of the disc. The V-shaped cutting element functions to provide for a fuller and more rapid opening of the disc upon reversal and engagement with the cutting element as compared with prior reverse buckling disc three-knife blade cutter units. The invention has especial utility in food, beverage, and pharmaceutical applications requiring sanitary pressure relief rupture disc structure.

Owner:FIKE CORP

Lignocellulosic biomass fermentation process co-product fuel for cement kiln

A fuel made from co-products derived from a lignocellulosic biomass fermentation process is used to fuel a cement production process. Filter cake and syrup co-products are mixed and dried, then burned in a cement kiln to create the temperatures needed for cement production.

Owner:SUSTAINABLE TECH CORP

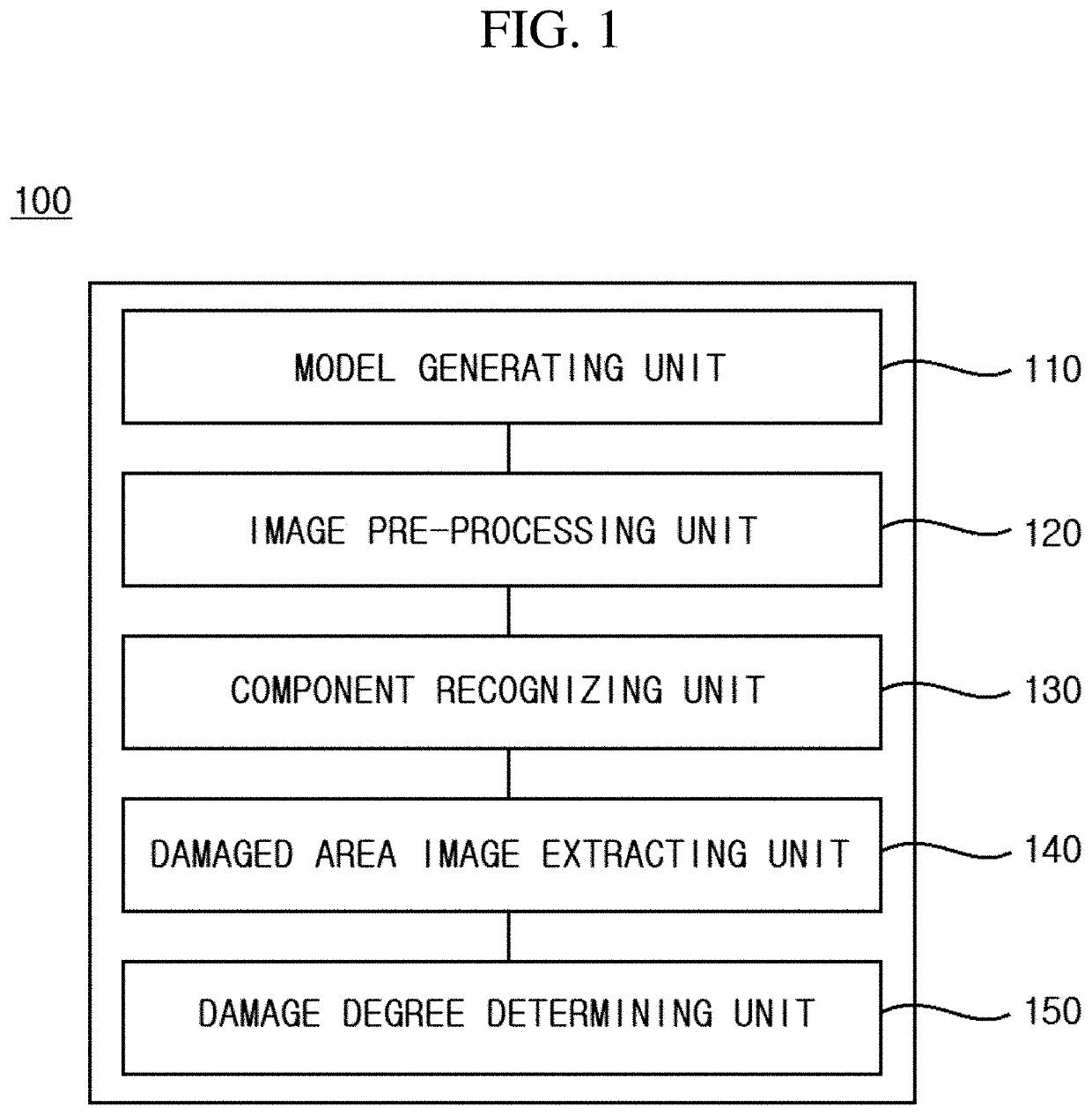

Deep learning-based system and method for automatically determining degree of damage to each area of vehicle

PendingUS20210327042A1Quick exportConsistent and reliableImage enhancementData processing applicationsPattern recognitionLearning based

The present invention relates to a deep-learning based system and method of automatically determining a degree of damage to each area of a vehicle, which is capable of quickly calculating a consistent and reliable quote for vehicle repair by analyzing an image of a vehicle in an accident by using a deep learning-based Mark R-CNN framework and then extracting a component image corresponding to a damaged part, and automatically determining the degree of damage in the extracted component image based on a pre-trained model.

Owner:AGILESODA INC

Automobile forward lighting combined lamp

ActiveCN103697390AEasy to replaceEasy to produceProtective devices for lightingOptical signallingEngineeringLight fixture

The invention relates to an automobile forward lighting combined lamp. The automobile forward lighting combined lamp consists of a lamp housing (2), a functional single lamp (1), a decorative cover (3) and an external dimming assembly, wherein the functional single lamp (1) is arranged on the lamp housing (2) through the external dimming assembly. The automobile forward lighting combined lamp is characterized in that the lamp housing (2) and the functional signal lamp (1) are installed by locking the functional single lamp (1) in a functional single lamp mounting hole (2-1) in the lamp housing (2) through the external dimming assembly, a tail lamp wire of the functional single lamp (1) penetrates through a functional single lamp outgoing wire hole (2-2) in the lamp housing (2), and then the decorative cover (3) is installed in a decorative cover mounting hole (2-4) in the lamp housing (2), so that limiting ribs (1-2) on the upper side and the lower side of the decorative cover (3) are used for limiting the lamp housing (2) in the X-axis direction and the Z-axis direction. According to the automobile forward lighting combined lamp, a lamp bulb is convenient to replace, the mounting connection is firm, and the universality is high.

Owner:JIANGSU WENGUANG VEHICLE ACCESSORIES

Holder with V-knife blade for bi-directional rupture disc assembly

InactiveUS8038024B2Consistent and reliableEliminate the problemLarge containersEqualizing valvesEngineeringKnife blades

Owner:FIKE CORP

Multiplexed Electrospray Deposition Apparatus

ActiveUS20090317558A1Consistent and reliableImprove efficiencyLiquid spraying plantsPretreated surfacesMicrofabricationChemistry

Multiplexed electrospray deposition apparatus capable of delivering picoliter volumes of one or more substances is disclosed. The apparatus may include a unitary planar dispenser etched from a silicon wafer through microfabrication or micromachining technology. The apparatus may be used as a deposition tool for making protein microarrays in a noncontact mode. Upon application of potential difference in the range of 7-9 kV, the substances may be dispensed directly, not through a collimating mask, onto a substrate with microhydrogel features functionalized with an anchoring agent.

Owner:CORNELL UNIVERSITY

Winder apparatus with transfer brush roll

ActiveUS7108219B2Consistent and reliableEasy dischargeFilament handlingWebs handlingEngineeringConductor Coil

A winder apparatus for winding webs of material into rolls includes a conveyor, and a winding turret with a plurality of rotatably driven winding spindles thereon. The winding turret indexes the winding spindles relative to the apparatus conveyor, with each spindle moved to a transfer position wherein a web of material is transferred from the conveyor onto the spindle to initiate roll formation. A rotatably driven transfer brush assembly is positionable in operative association with the conveyor and the spindle in the winding position to facilitate efficient and consistent transfer of a web from the conveyor onto the spindle for roll formation.

Owner:HUDSON-SHARP MACHINE COMPANY

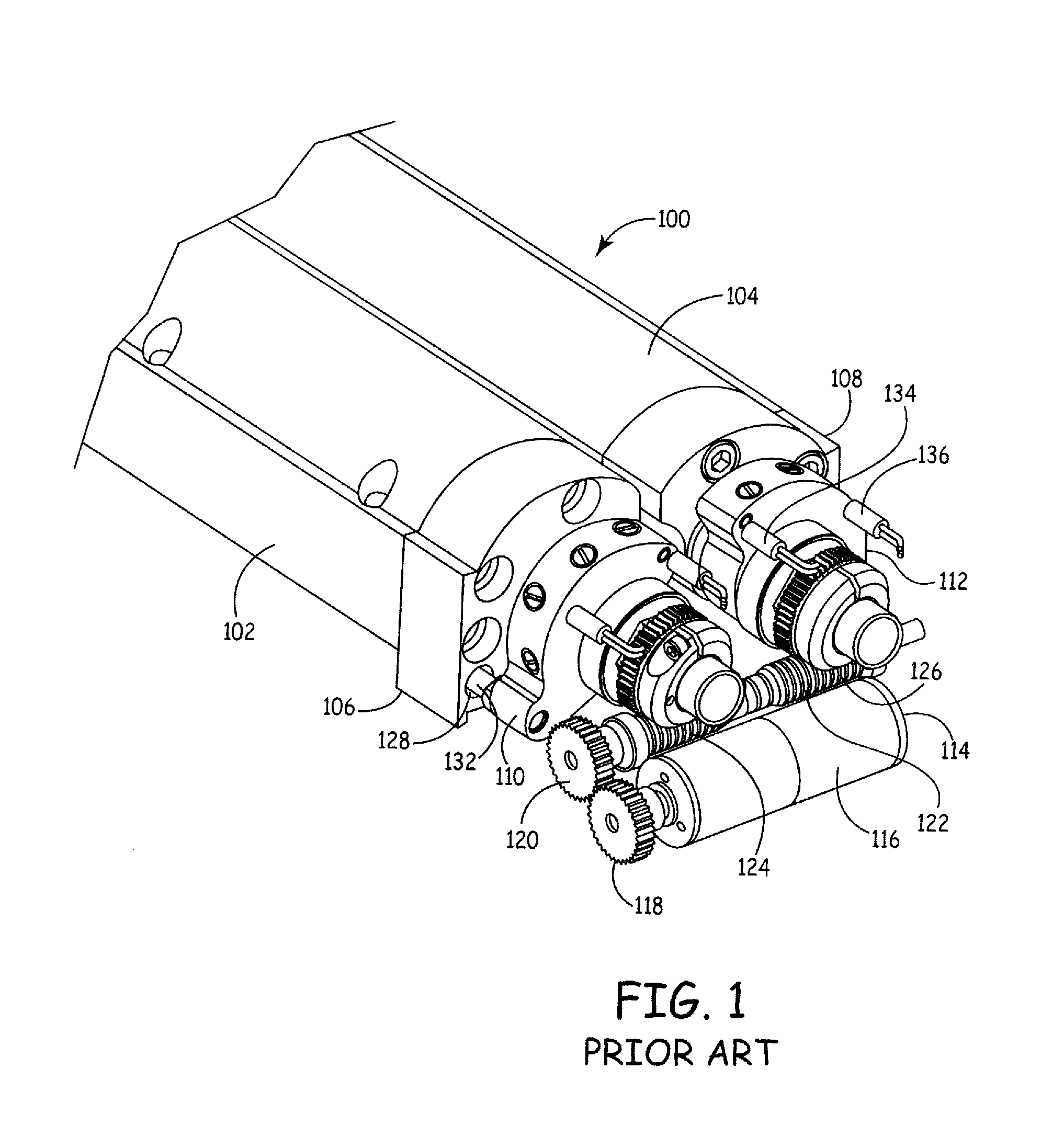

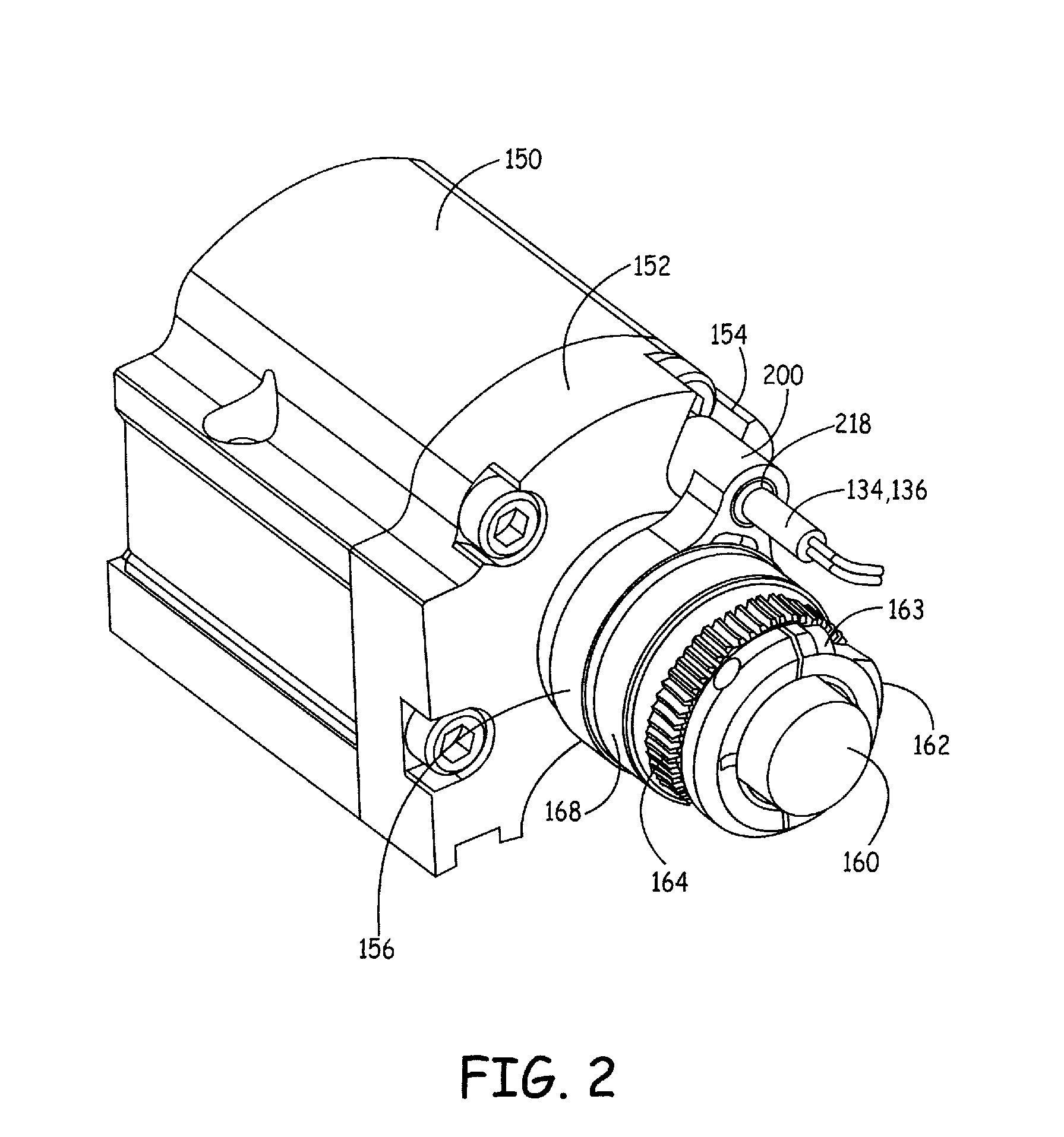

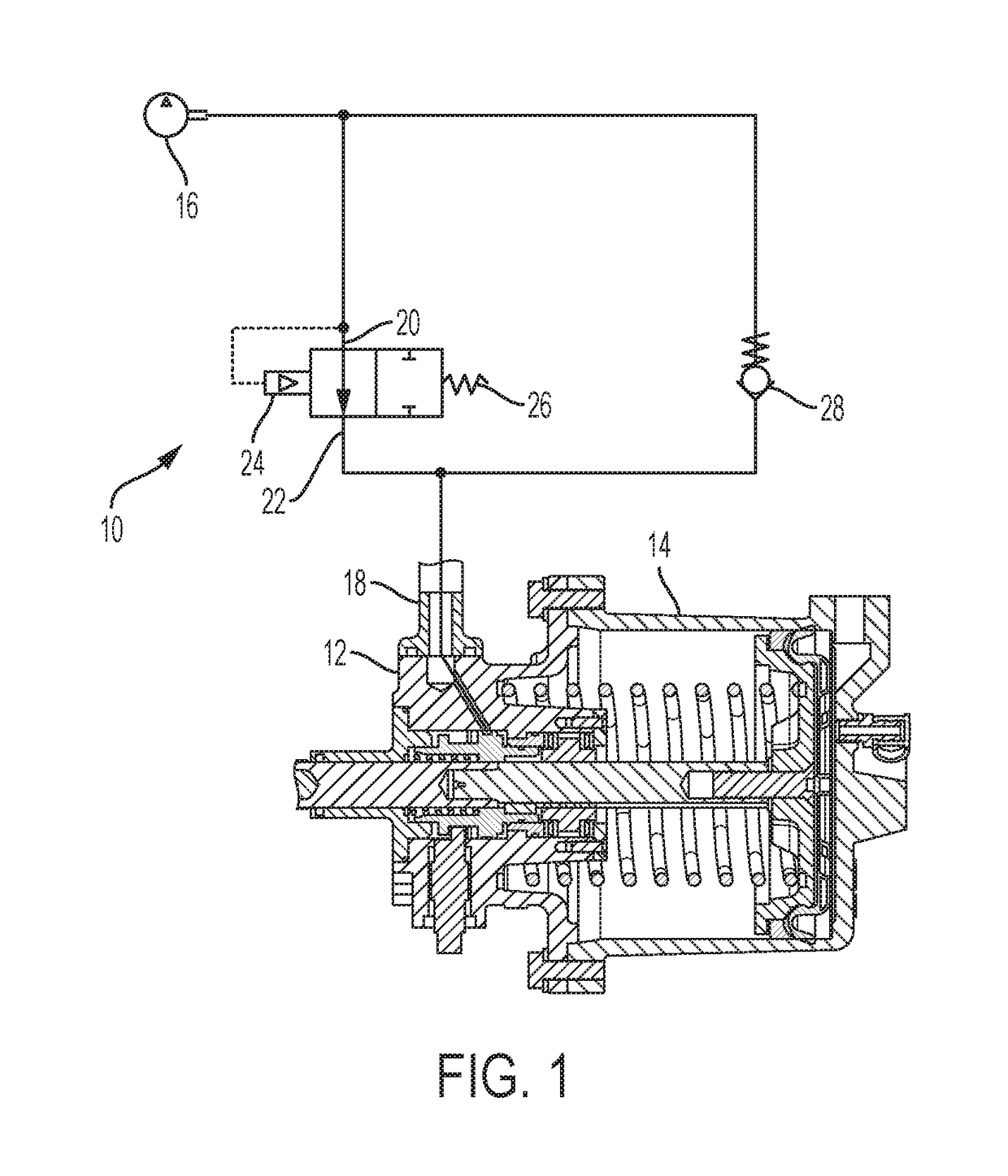

Shutter clutch

ActiveUS20100018825A1Easy to overrideEasy to removeMechanical actuated clutchesSlip couplingDetentEngineering

A clutch assembly for a UV module shutter, comprises a shutter shaft, a shutter drive arm, a clutch plate, at least one ball, a clutch thrust washer, and a spring assembly. The shutter shaft has a flange, the flange having a plurality of radially positioned flange detents. The shutter drive arm includes a drive pin, a drive arm cavity, and a receiver slot opening into the drive arm cavity, the drive pin disposable in a drive slot of a shutter end cap. The clutch plate may be disposed in the clutch plate cavity, may have a tab disposed in the receiver slot and a plurality of clutch plate detents. Each of the ball(s) may extend from one of the flange detents and may be partially disposable in one of the clutch plate detents. The spring assembly may exert a bias against the clutch plate and the thrust washer. The shutter shaft may extend through the shutter drive arm, the clutch plate, and the clutch thrust washer.

Owner:AIR MOTION SYST

U-clip assembly and method

InactiveUS20090223026A1Low melting temperaturePrevent electrolysisSnap fastenersMetal-working apparatusEngineeringMechanical engineering

A structure and method for forming a U-clip assembly made of a plurality of U-clips arrayed in a continuous abutting relation, each U-clip having first and second slots defined in its crown portion with first and second soft metal wires positioned, respectively, in such first and second slots, such soft metal wire forming a shallow U shape between adjacent crown portions, such first and second soft metal wires being compressed within their slots to expand within such slots for contacting and urging against the sides and bottom of each slot and being retained therein, such soft metal wire and its shallow U shape between adjacent crown portions allowing the U-clip assembly to maintain a non-curved shape and to be substantially flat in configuration.

Owner:WEST ROBERT J

Model training method and system for automatically determining damage level of each of vehicle parts on basis of deep learning

PendingUS20210327040A1Consistent and reliableQuick exportImage enhancementData processing applicationsAlgorithmAccidents vehicle

The present invention relates to a method and a system for training a model for automatically determining the degree of damage for each vehicle area based on deep learning, which generate a model capable of quickly calculating a consistent and reliable vehicle repair quote by learning so as to automatically extract a picture in which it is possible to determine the degree of damage among accident vehicle pictures by using the Mask R-CNN framework and the Inception V4 network structure based on deep learning, and learning the degree of damage for each type of damage.

Owner:AGILESODA INC

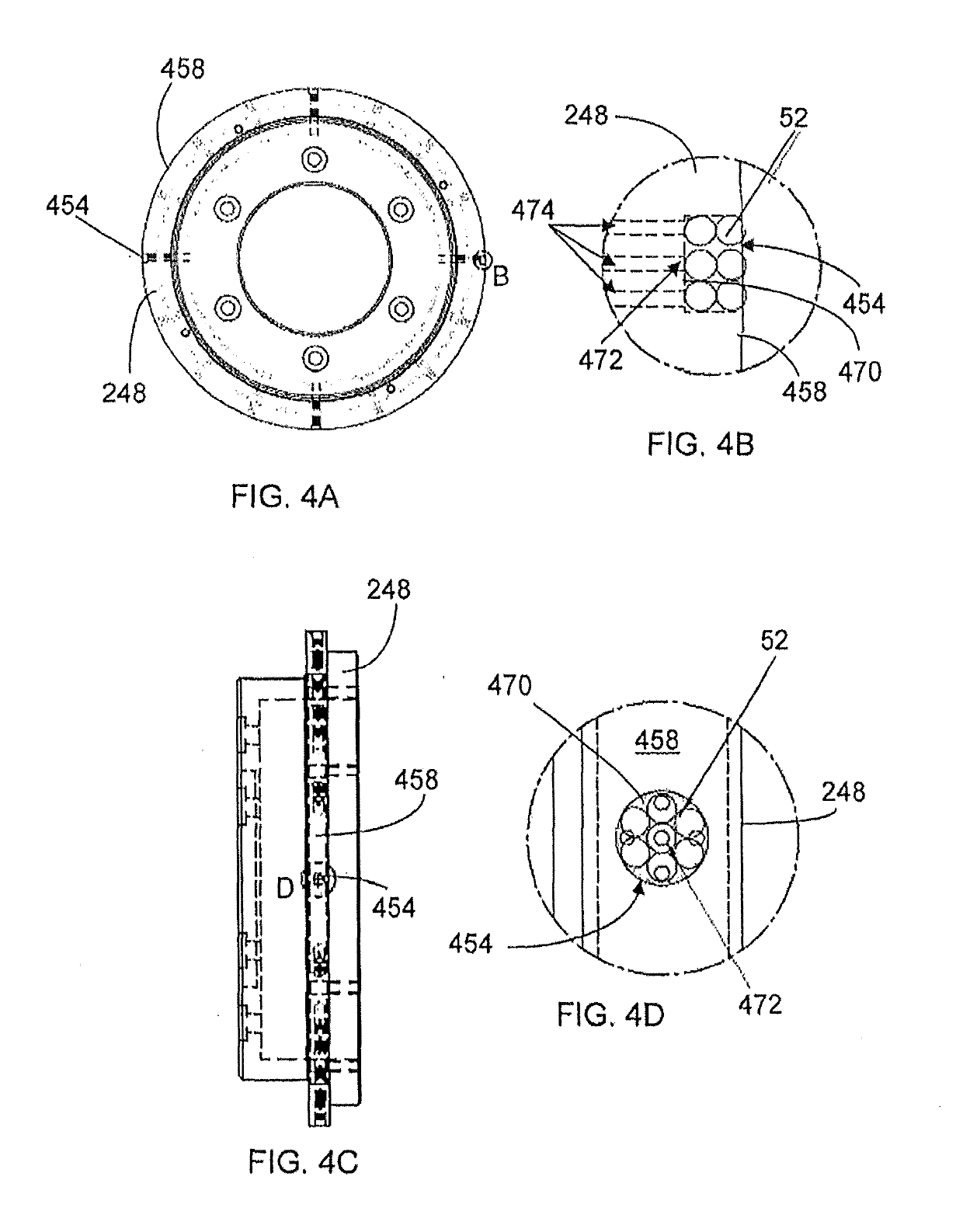

Cigarette filter object insertion apparatus and associated method

ActiveUS20190307163A1Reducing and eliminating defectConsistent and reliableTobacco smoke filtersEngineeringFilter material

An apparatus and method for forming a rod member used to manufacture cigarette filter elements, involve an insertion device for inserting objects into and along the rod member formed from a continuous filter material supply. The insertion device includes an insertion member adjacent to the filter material supply and defining a series of receptacles about a periphery thereof. The insertion member rotates in a first rotational direction to receive the objects in the receptacles at a first rotational position and to insert the objects from the receptacles into the rod member at a second rotational position. A cleaning element is adjacent to the insertion member between the second and first rotational positions in the first rotational direction, and engages each of the receptacles upon rotation of the insertion member between the second and first rotational positions to remove residual material from the receptacles prior to the first rotational position.

Owner:R J REYNOLDS TOBACCO COMPANY

Shutter clutch

ActiveUS7922591B2Easy to overrideEasy to removeRadiation pyrometryMechanical actuated clutchesFlangeClutch

A clutch assembly for a UV module shutter, comprises a shutter shaft, a shutter drive arm, a clutch plate, at least one ball, a clutch thrust washer, and a spring assembly. The shutter shaft has a flange, the flange having a plurality of radially positioned flange detents. The shutter drive arm includes a drive pin, a drive arm cavity, and a receiver slot opening into the drive arm cavity, the drive pin disposable in a drive slot of a shutter end cap. The clutch plate may be disposed in the clutch plate cavity, may have a tab disposed in the receiver slot and a plurality of clutch plate detents. Each of the ball(s) may extend from one of the flange detents and may be partially disposable in one of the clutch plate detents. The spring assembly may exert a bias against the clutch plate and the thrust washer. The shutter shaft may extend through the shutter drive arm, the clutch plate, and the clutch thrust washer.

Owner:AIR MOTION SYST

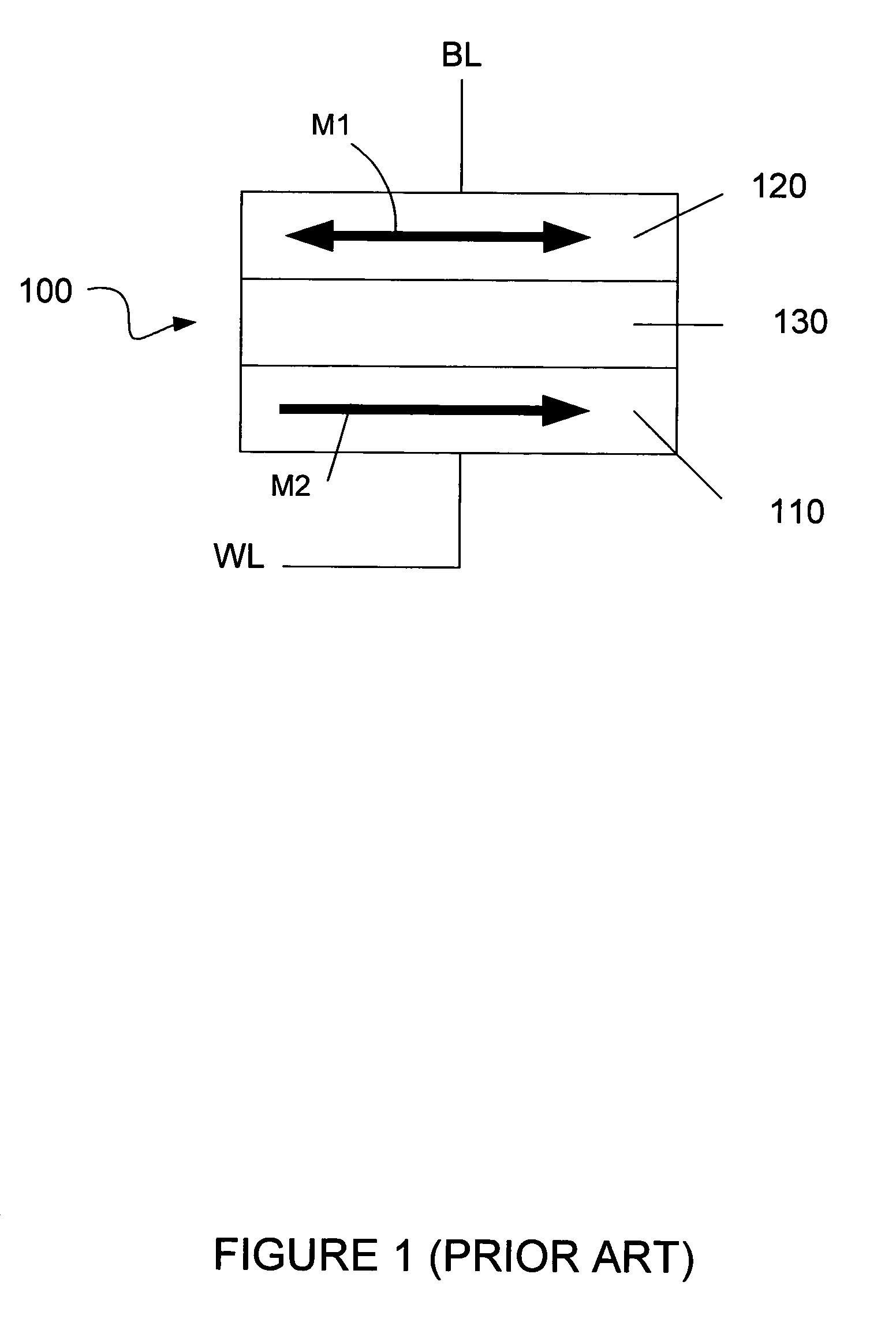

Selecting a magnetic memory cell write current

ActiveUS20050117412A1Minimizes half-select errorConsistent and reliable magnetic memory cell writingSolid-state devicesSemiconductor/solid-state device manufacturingWrite currentStorage cell

The invention includes an apparatus and method for selecting a desirable magnitude of a magnetic memory cell write current. The method includes determining a minimal magnitude of write current for writing to the magnetic memory cell, determining a maximal magnitude of write current for writing to the magnetic memory cell, and calculating the selected magnitude of magnetic memory cell write current based on the minimal magnitude of write current and the maximal magnitude of write current.

Owner:SAMSUNG ELECTRONICS CO LTD

Control system for automatic parking brake of rail vehicle

ActiveUS20180222465A1Consistent and reliableServometer circuitsApplication and release valvesControl systemEngineering

A control valve for an automatic parking brake having an inlet for coupling to a source a brake pipe pressure, an outlet for coupling to a control inlet of the automatic parking brake and a pilot for coupling to the source of brake pipe pressure. The control valve is moveable between a first position where the inlet is in communication with the outlet and a second position where the inlet and the outlet are isolated from each other in response to a predetermined amount of brake pipe pressure at the pilot. The control valve includes a spring biasing the control valve into the first position.

Owner:NEW YORK AIR BRAKE CORP

Cigarette filter object insertion apparatus and associated method

ActiveUS11388927B2Reducing and eliminating defectConsistent and reliableTobacco smoke filtersEngineeringFilter material

Owner:R J REYNOLDS TOBACCO COMPANY

Breath sampling device and method

ActiveUS11298046B2Maximize displacementConsistent and reliableRespiratory organ evaluationSensorsMedicineEngineering

Disclosed is apparatus for collecting a breath sample from a human subject, the apparatus comprising at least a mask portion which, in use, is positioned over the subject's mouth and nostrils so as to collect breath exhaled from the subject, the apparatus further comprising movement detection means for detecting movement of the mask portion, and an alarm signal generator, which alarm signal generator generates an alarm signal if the subject's head is outside a predetermined range of acceptable orientations during collection of a breath sample, but only after the subject's head has been outside the predetermined range of acceptable orientations for a defined or measurable period of time.

Owner:OWLSTONE MEDICAL LTD

Selecting a magnetic memory cell write current

ActiveUS20050117409A1Minimizes half-select errorConsistent and reliable magnetic memory cell writingSolid-state devicesSemiconductor/solid-state device manufacturingWrite currentStorage cell

The invention includes an apparatus and method for selecting a desirable magnitude of a magnetic memory cell write current. The method includes determining a minimal magnitude of write current for writing to the magnetic memory cell, determining a maximal magnitude of write current for writing to the magnetic memory cell, and calculating the selected magnitude of magnetic memory cell write current based on the minimal magnitude of write current and the maximal magnitude of write current.

Owner:SAMSUNG ELECTRONICS CO LTD

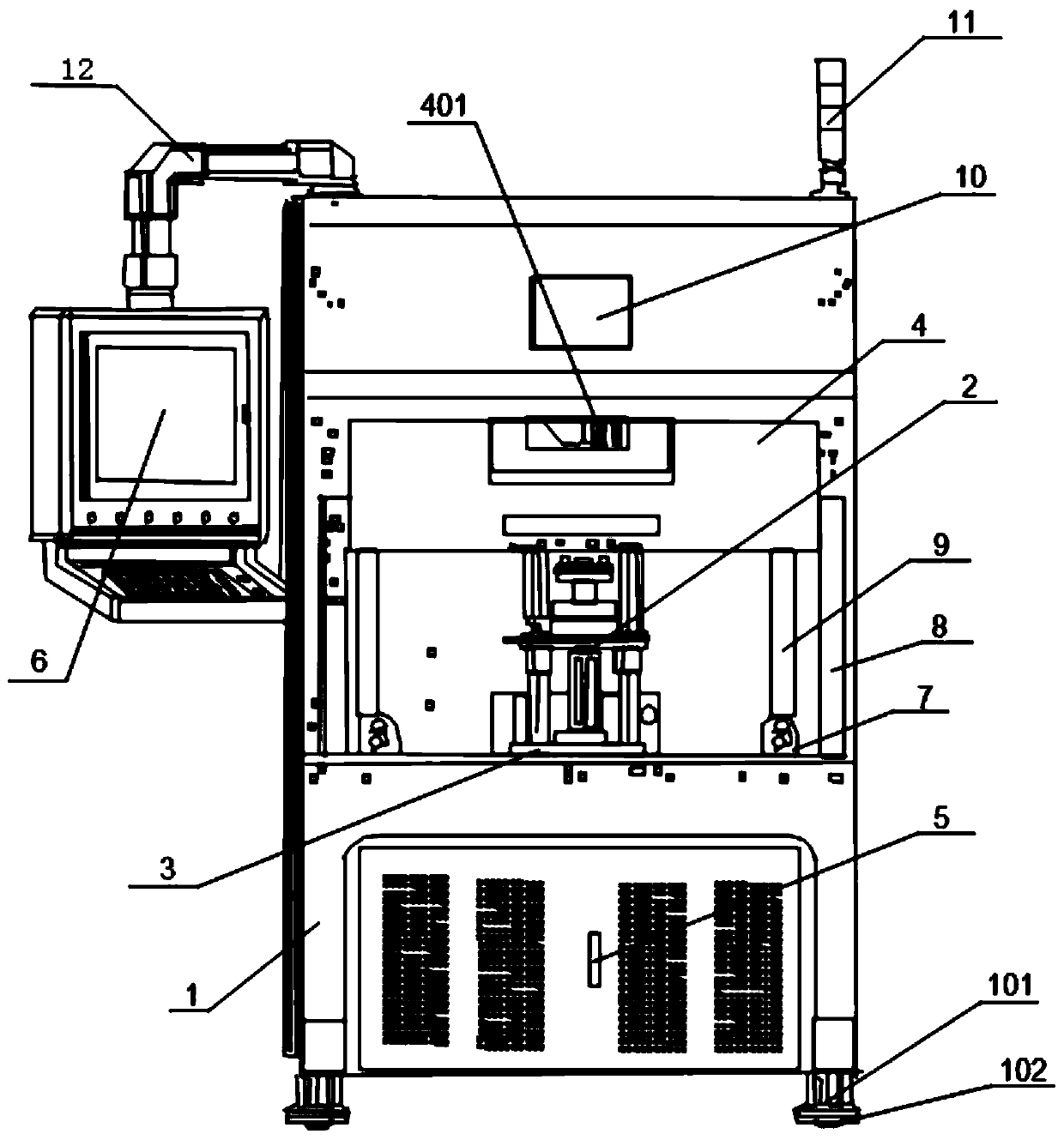

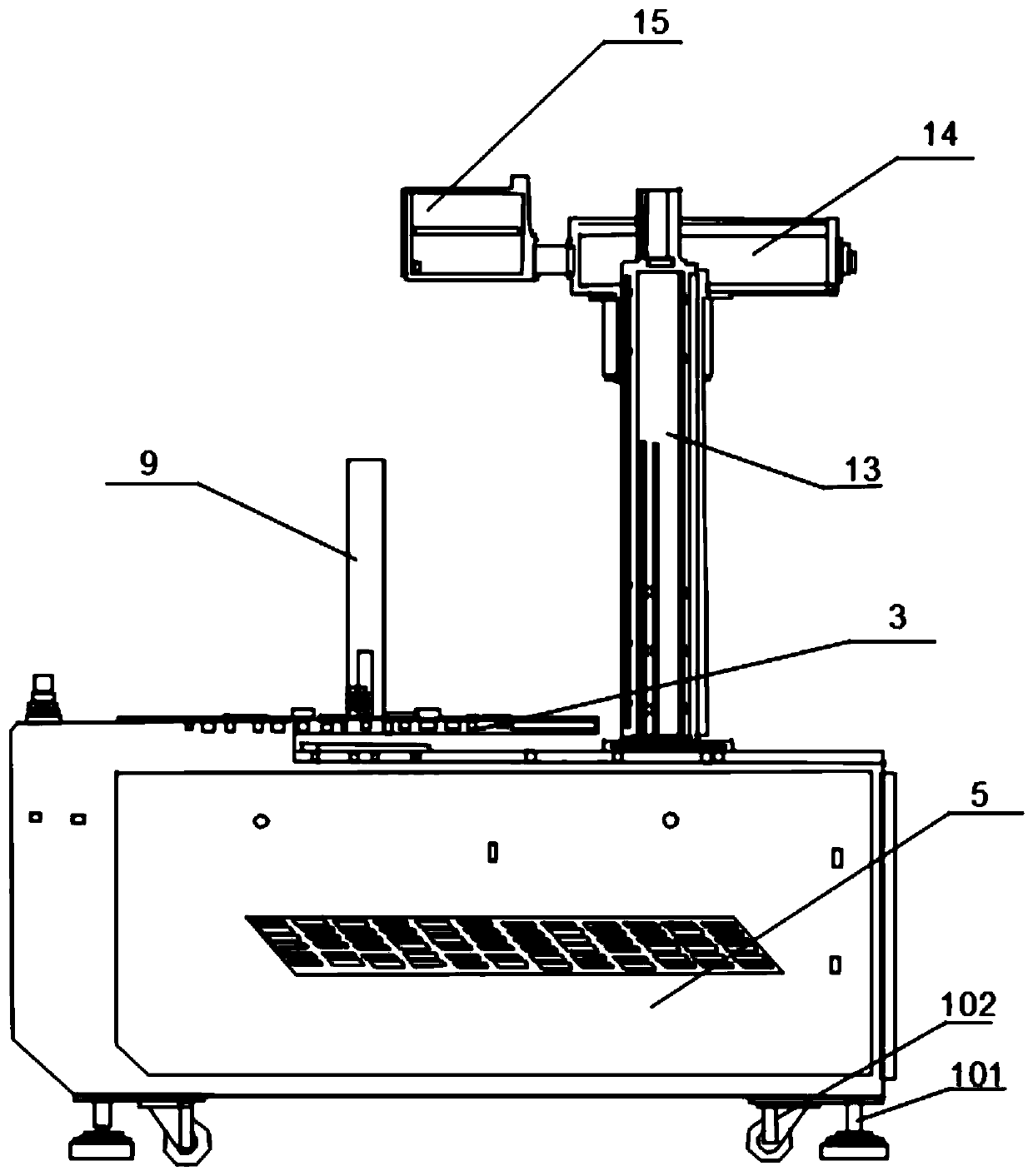

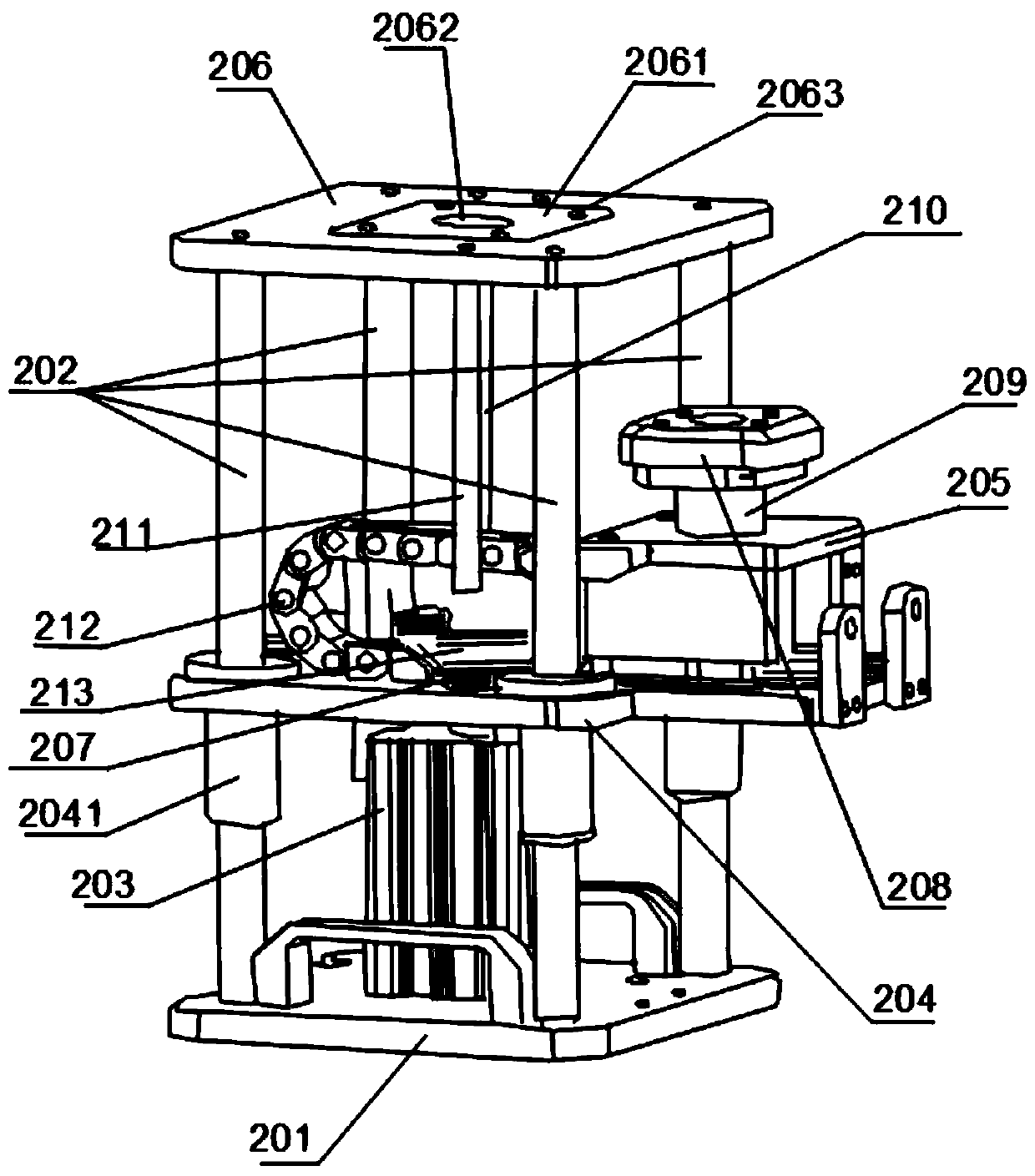

High-precision penetration control laser plastic welding equipment and working method thereof

ActiveCN110667124AMeeting Diversity RequirementsMeet welding precision requirements and traceability analysis controlPhysicsLaser soldering

The invention discloses high-precision penetration control laser plastic welding equipment and a working method thereof, and relates to the technical field of laser welding. The equipment comprises aframe body, a lower electrical cabinet and an upper computer, wherein a pressure closed loop clamping and pressing mechanism is fixedly mounted on the upper surface of a double-station turntable. Thepressure closed loop clamping and pressing mechanism comprises a mounting base, a centering and balancing stand column, a pressing cover plate, a bearing plate, a first precision electric cylinder, asliding table, a supporting column, a self-selecting model, a second precision electric cylinder and a numerical display welding penetration measuring ruler. A PLC control system man-machine interfaceconnected with the upper computer is arranged above the frame body. The method can reliably ensure finished-product consistency, can adaptively and actively perform adaptive welding speed and displacement exploration, pre-welding and penetration presetting on different types of workpieces to be machined, the diversity requirements of plastic laser welding are met better, the welding precision requirement is met better and traceability analysis and control functions are achieved.

Owner:上海三束实业有限公司

Selecting a magnetic memory cell write current

ActiveUS6937504B2Error minimizationConsistent and reliableSolid-state devicesSemiconductor/solid-state device manufacturingComputer architectureMagnetic memory

The invention includes an apparatus and method for selecting a desirable magnitude of a magnetic memory cell write current. The method includes determining a minimal magnitude of write current for writing to the magnetic memory cell, determining a maximal magnitude of write current for writing to the magnetic memory cell, and calculating the selected magnitude of magnetic memory cell write current based on the minimal magnitude of write current and the maximal magnitude of write current.

Owner:SAMSUNG ELECTRONICS CO LTD

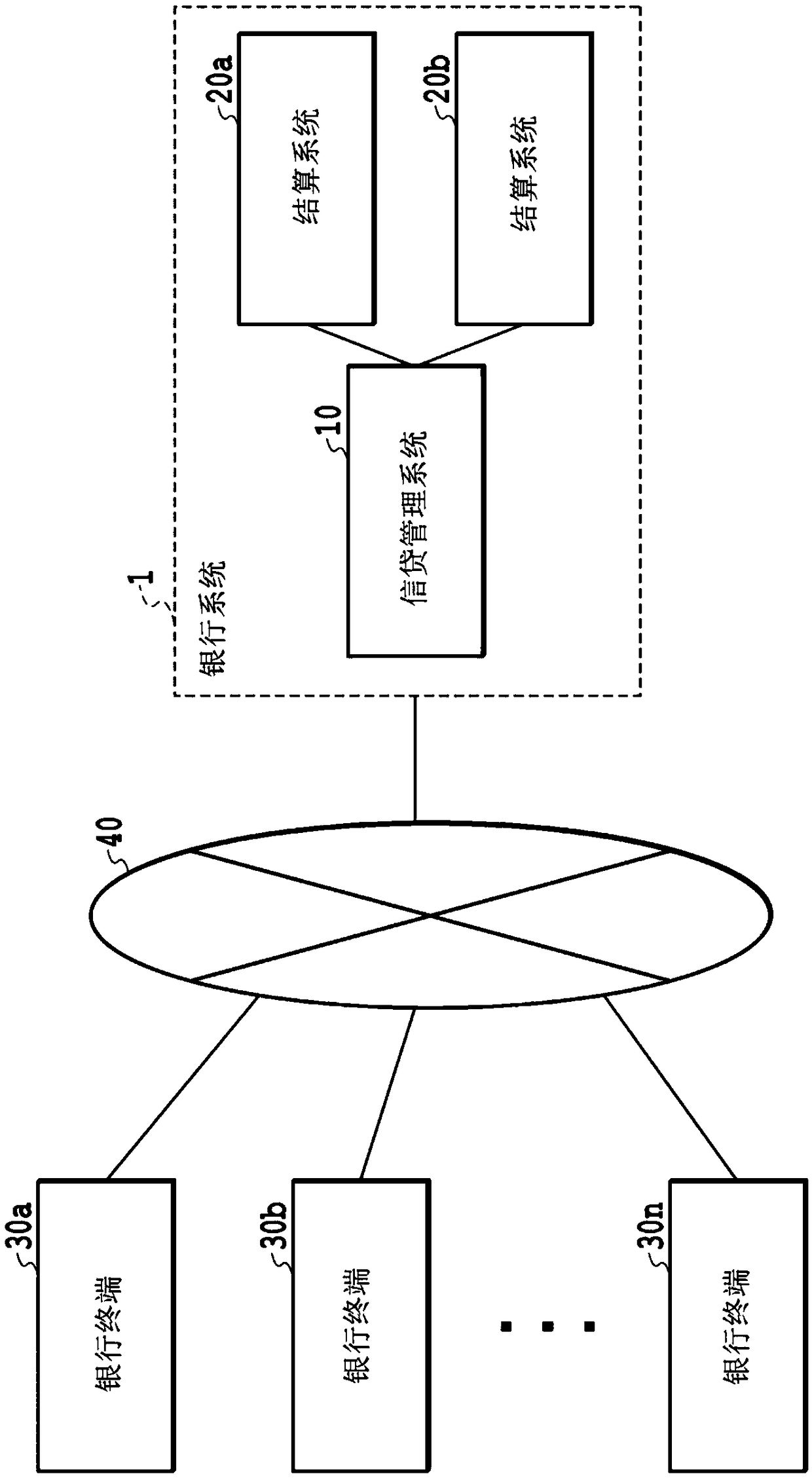

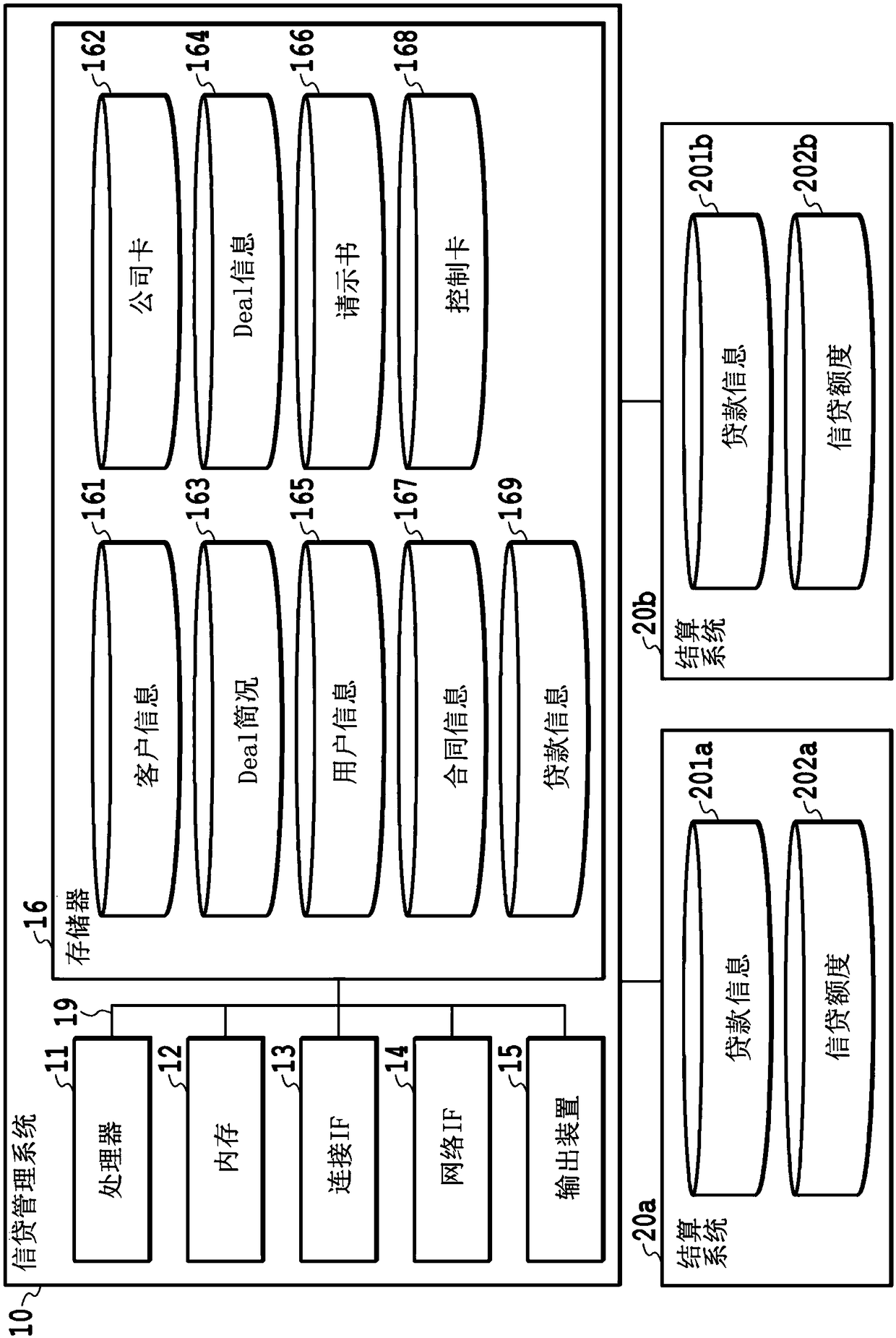

Banking system and method executed by banking system

Provided is a banking system for ensuring the consistency of credit information that is to be registered to an accounting system on the basis of conditions for approval in a request for approval and the fulfillment state of conditions needed for loan execution. In response to approval of request-for-approval data, the banking system receives deal information associated with the request-for-approval data and first facility information generated on the basis of status information of a control card. Second facility information based on the received first facility information is stored. The banking system determines whether facility data that is to be registered to credit facilities is consistent with the detail information of facilities stored in second facility information, and determines whether the status information of a control card stored in the second facility information is appropriate. The facility data is registered to credit facilities in response to an affirmative determination result.

Owner:SUMITOMO MITSUI BANKING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com