Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Industrial tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

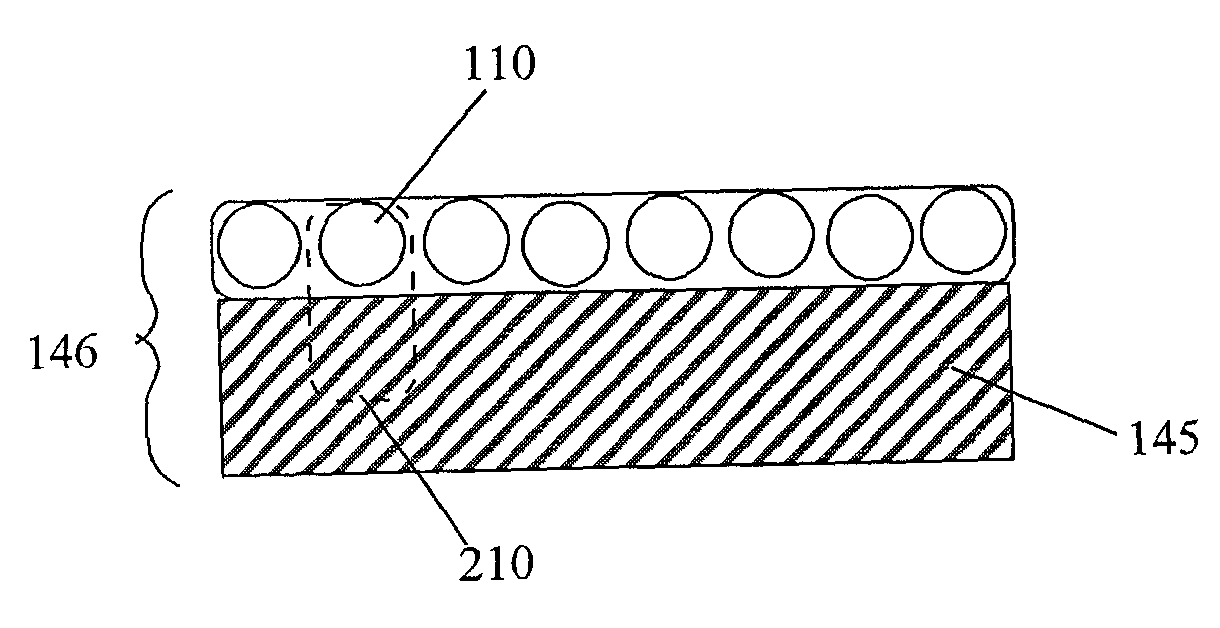

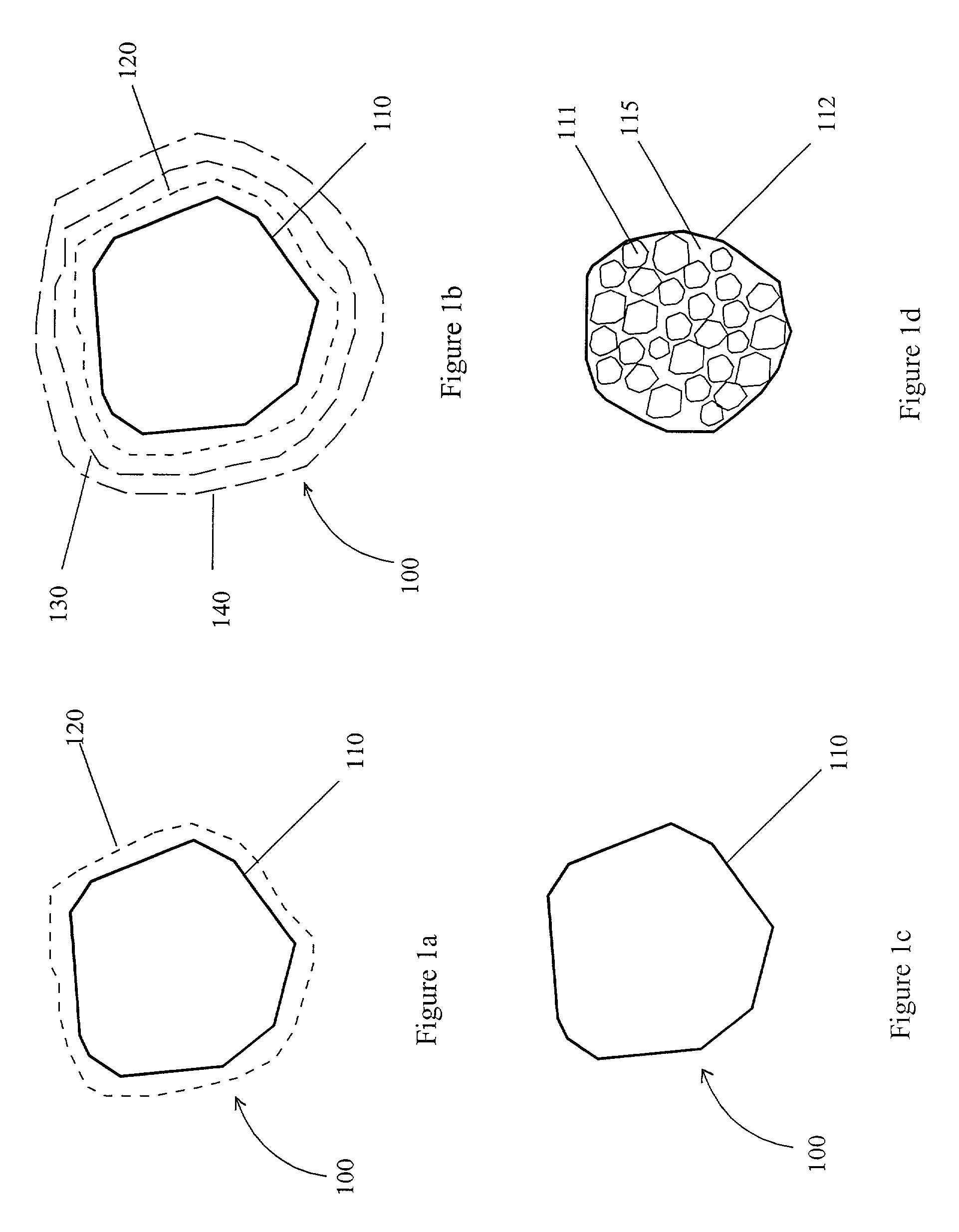

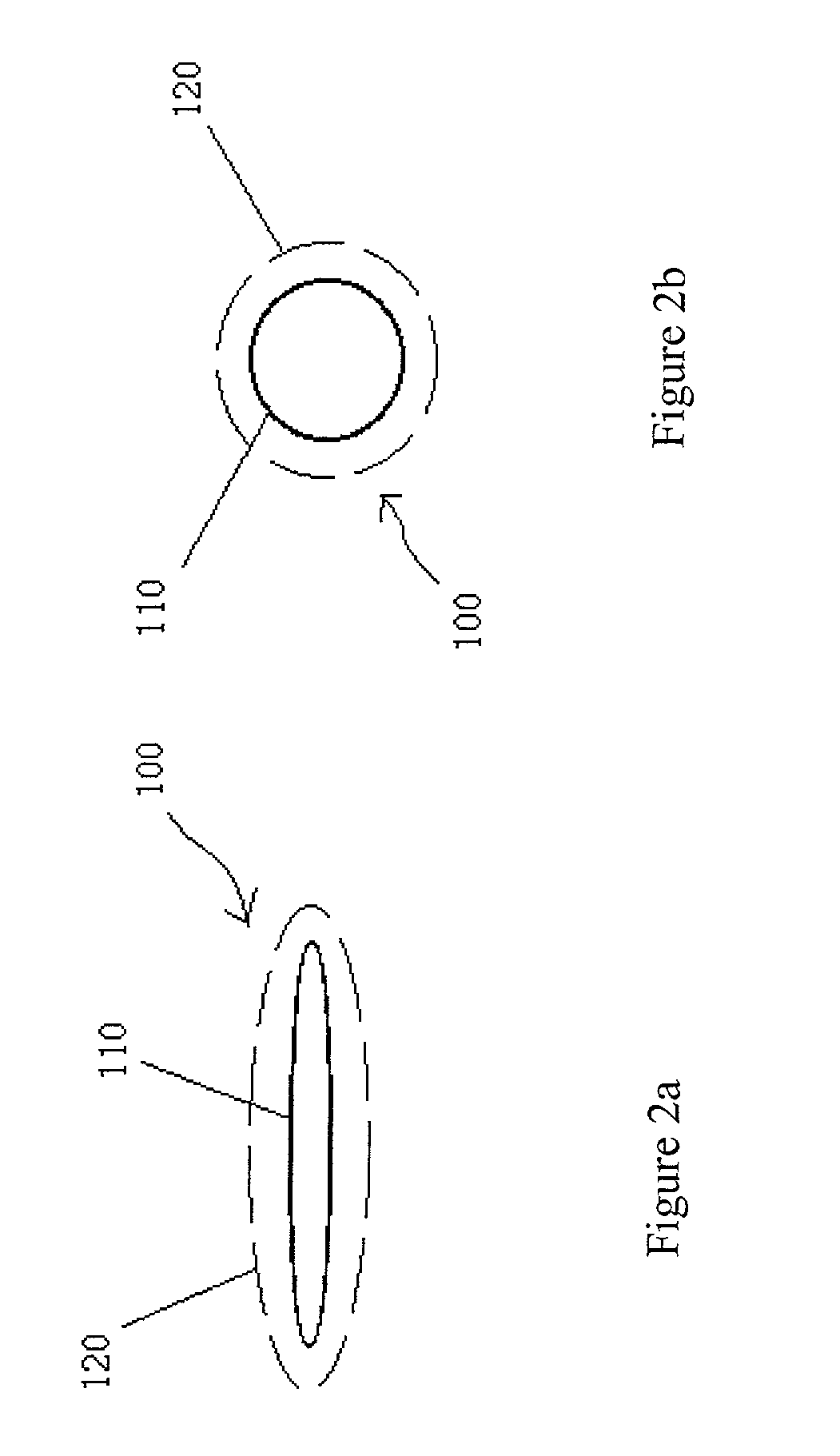

Self-grown monopoly compact grit

InactiveUS6616725B2Strong and more resilientProduced cost-effectivelyPigmenting treatmentOther chemical processesBoron nitrideSolvent

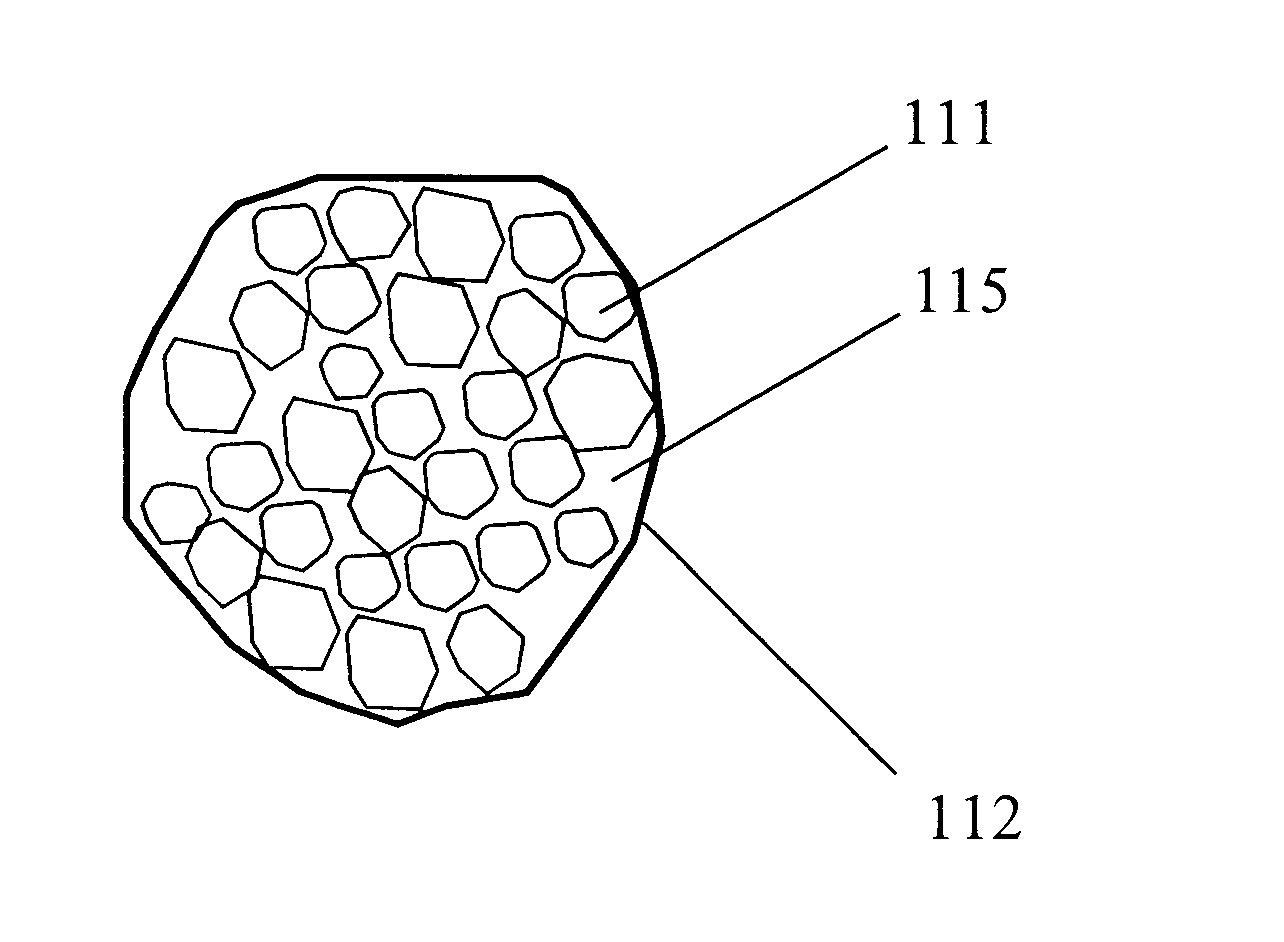

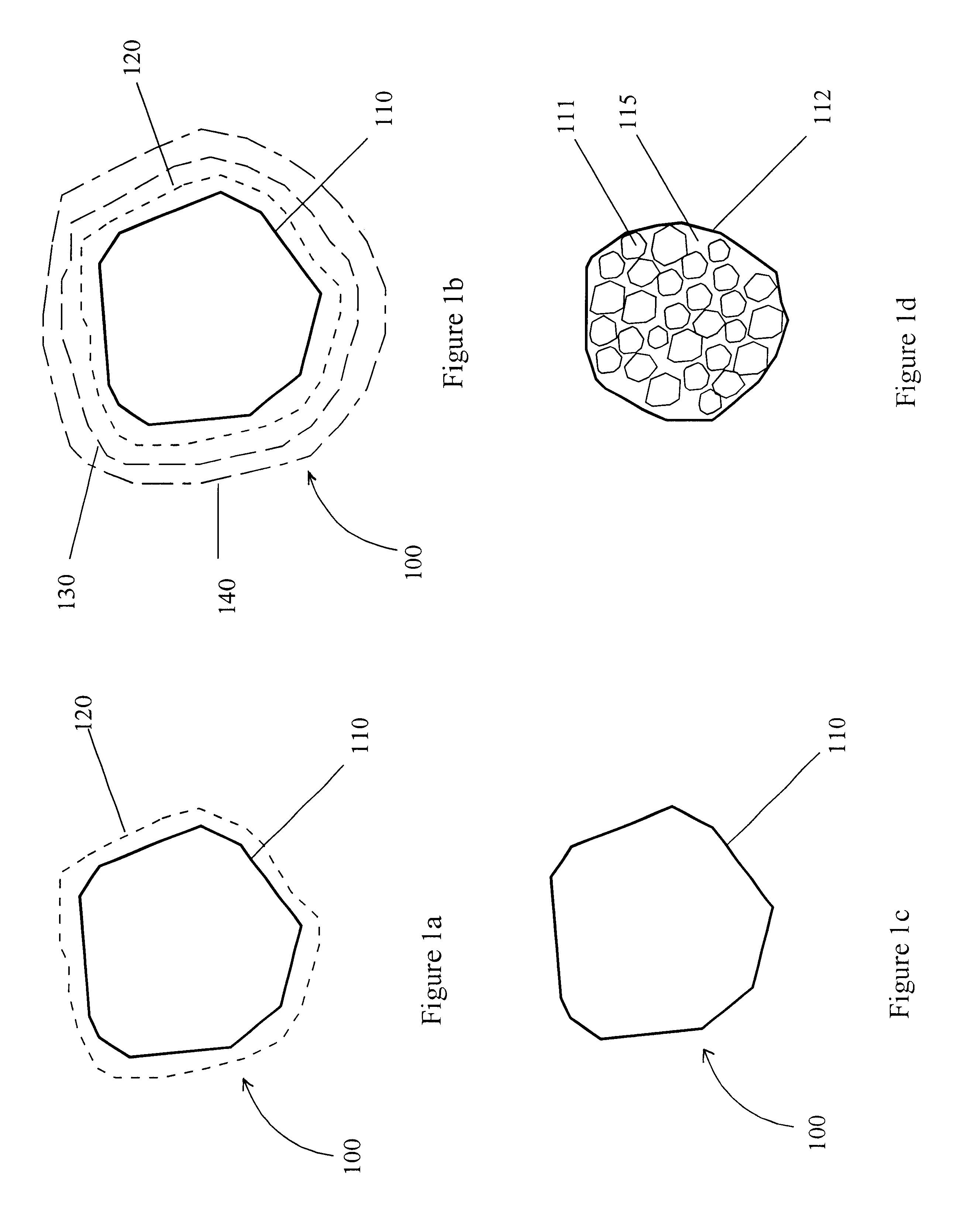

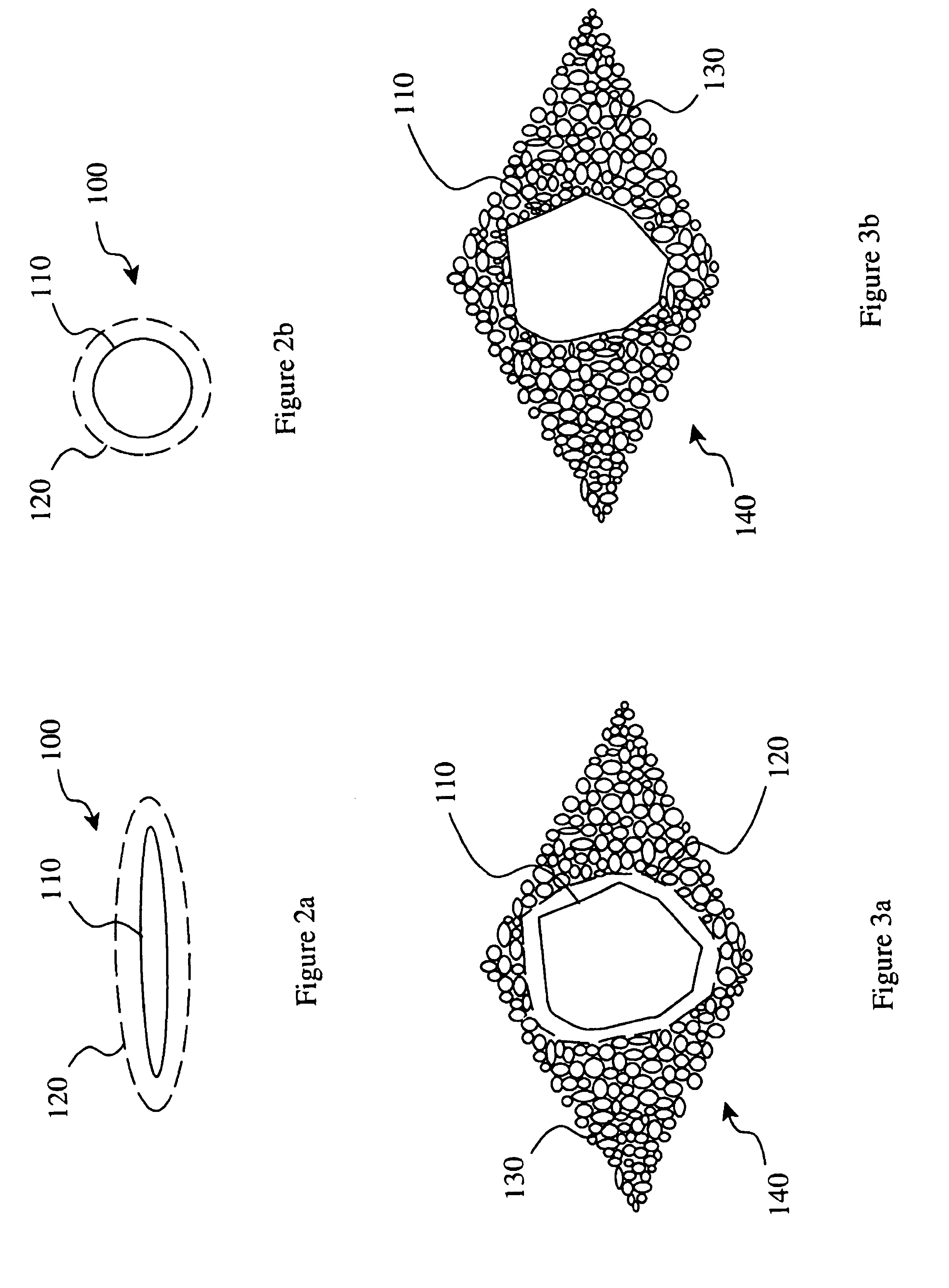

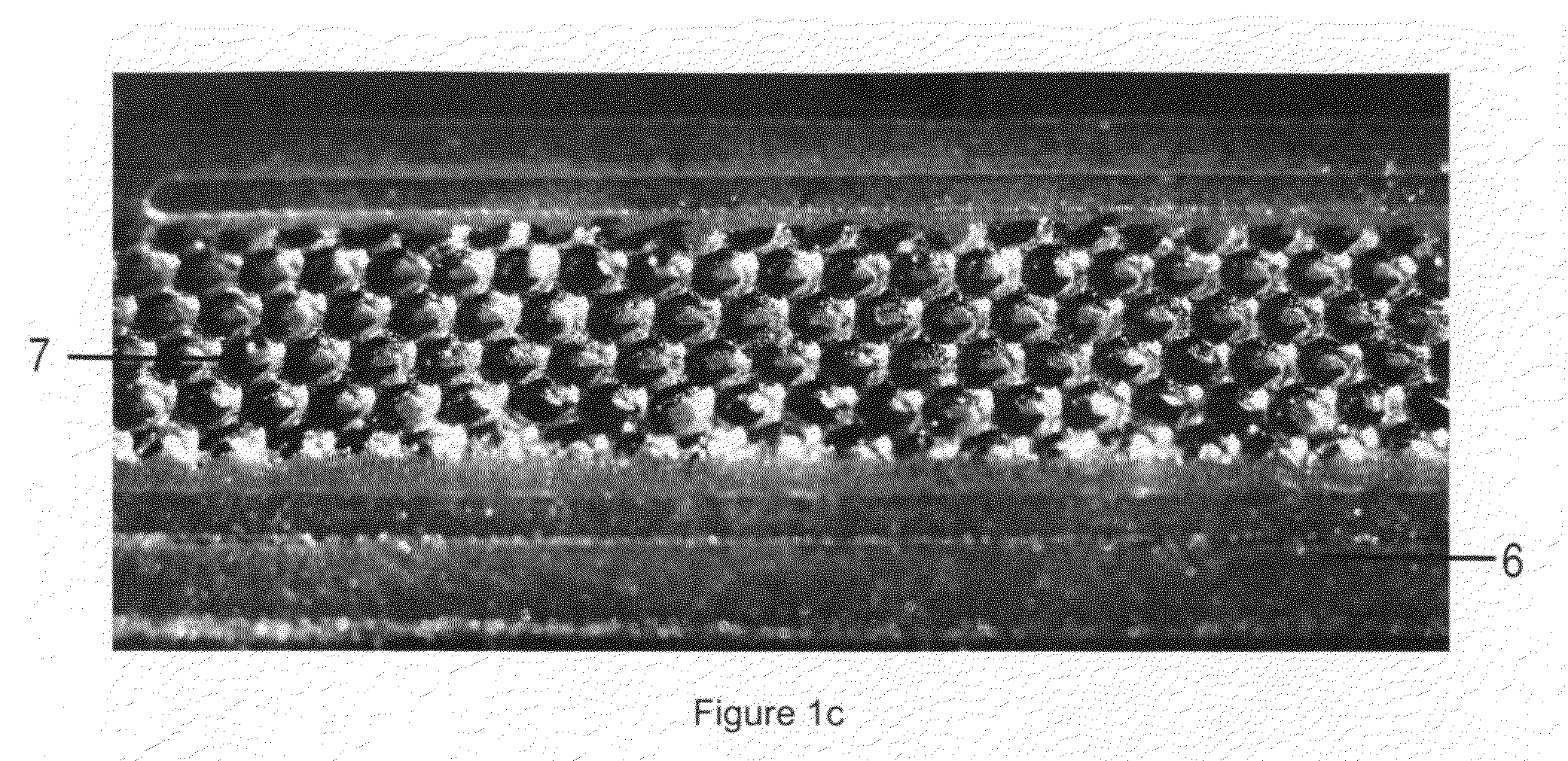

A self-grown monopoly compact grit and high pressure, high temperature process for preparing the same. The high pressure, high temperature sintered / synthesized monopoly compact grit is used in various industrial tools such as saw blades, grinding wheels, cutting tools and drill bits. Further, the monopoly compact grit of the present invention is produced from a seed of a mono-crystal of diamond or cubic boron nitride surrounded by either a self-grown crystal layer or an integrally bonded poly-crystalline sintered compact layer. The self-grown crystal layer is a new grown crystal structure where the seed crystal grows into a new phase through a normal diamond or cubic boron nitride synthesis process in the presence of a catalyst metal solvent. The compact layer is composed of about 50 to about 90 volume percent of diamond or cubic boron nitride, a typical binder material, which is a catalyst for crystal-to-crystal bonding, and a cementing agent which is a binding agent capable of forming stable carbide and nitride bonds.

Owner:CHO HYUN SAM +2

Chrome coated surfaces and deposition methods therefor

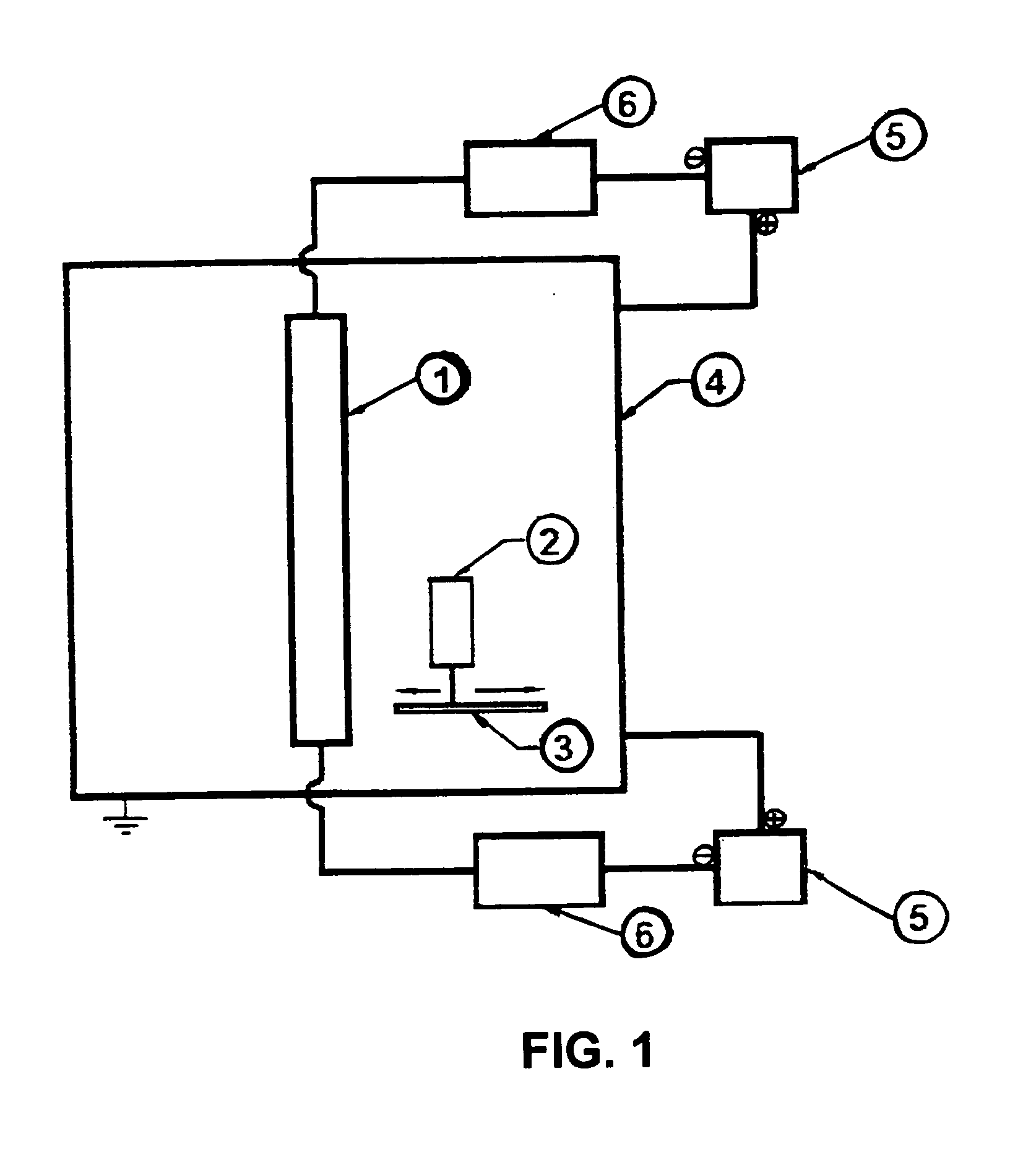

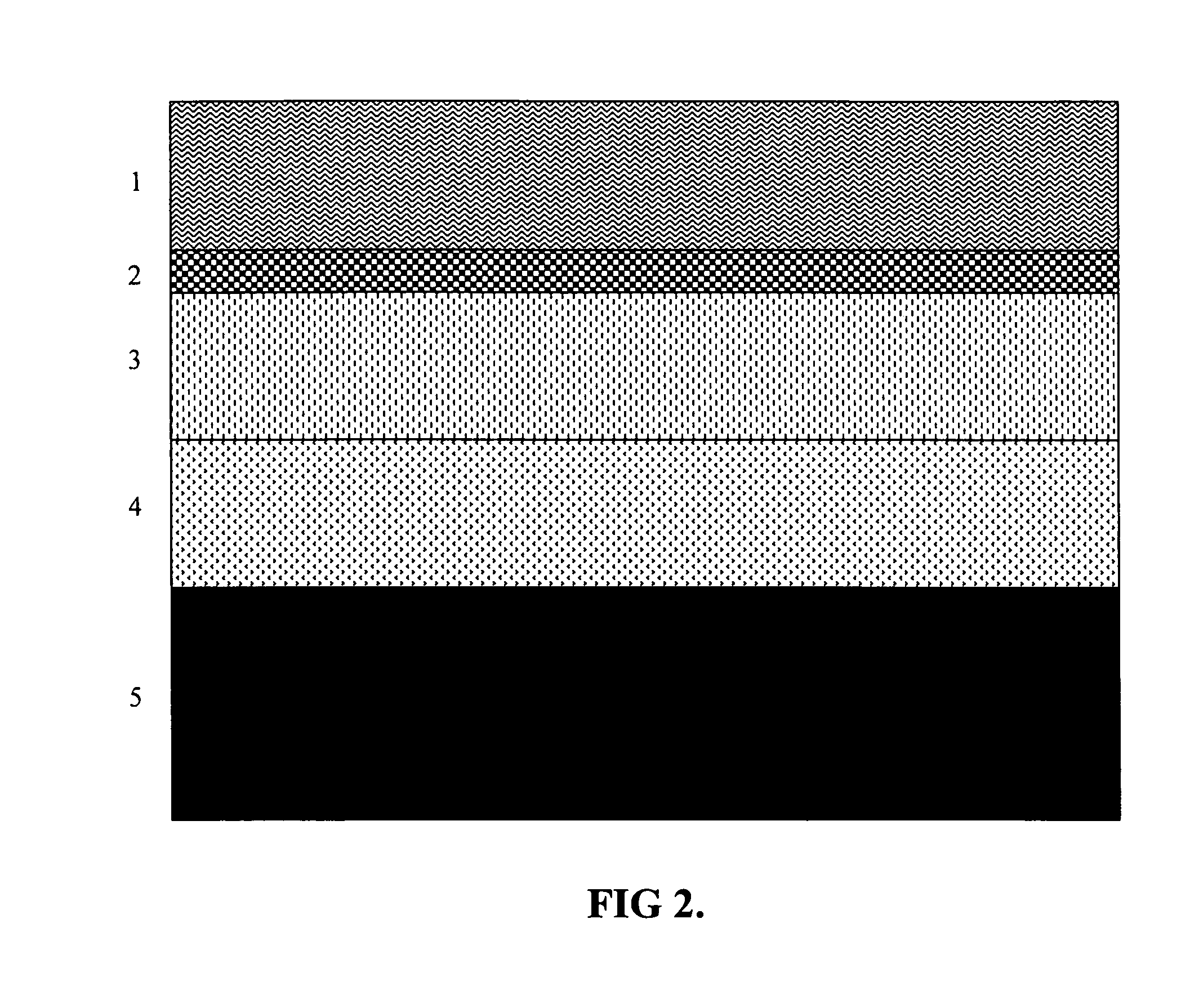

InactiveUS20070207310A1Method is time-consume and expensiveQuality improvementVacuum evaporation coatingPretreated surfacesPlatinumMetal coating

A plasma vapor deposition method for producing highly reflective and adherent metal or metal alloy decorative coatings on articles such as automotive fixtures is described. The improved coatings are particularly applicable to chrome based coatings on automobile fixtures and accessories, including wheels, hubcaps, bumpers and door handles. The method also provides plated metal coatings such as gold, platinum and silver for jewelry and industrial tools.

Owner:METASCAPE

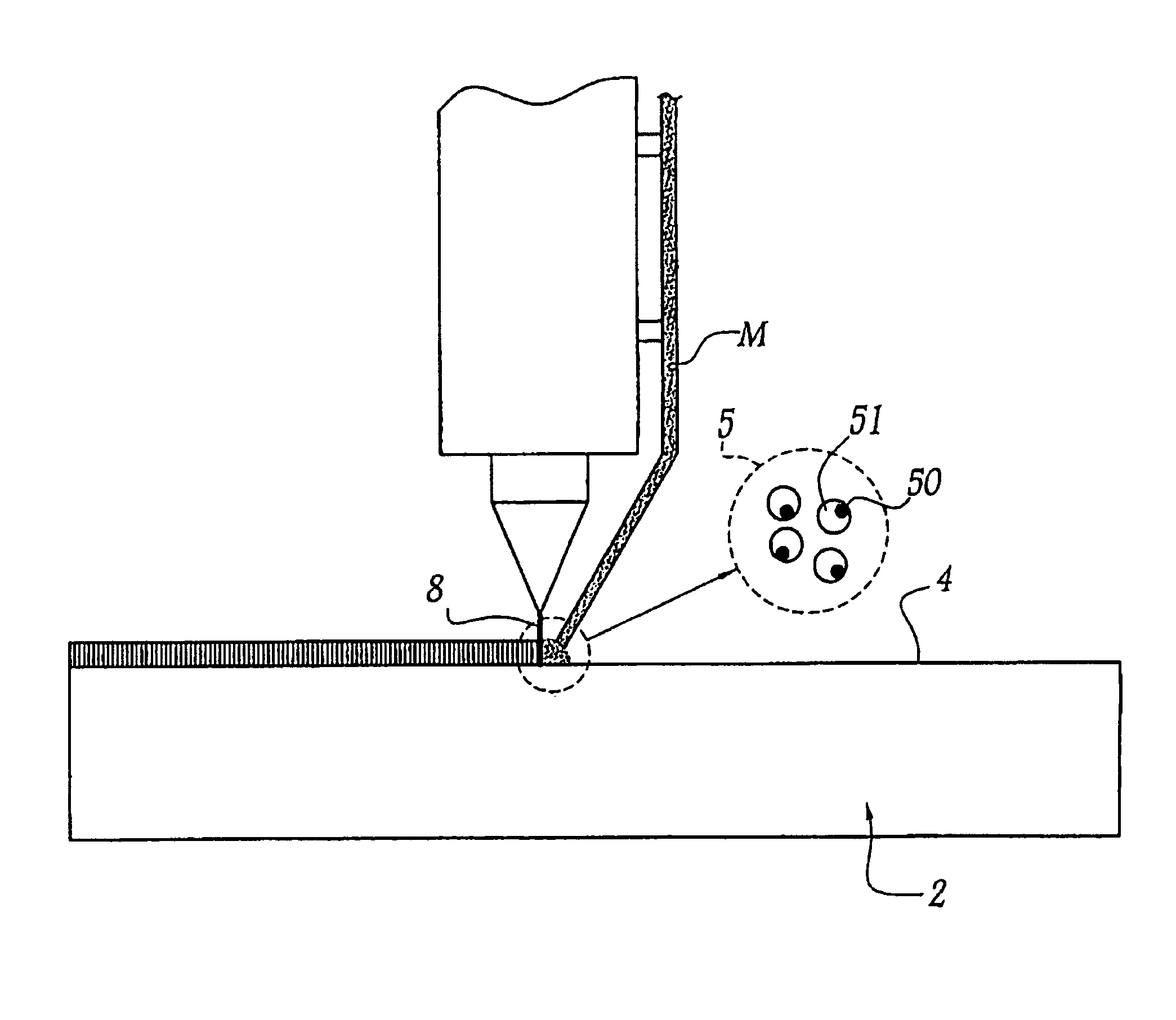

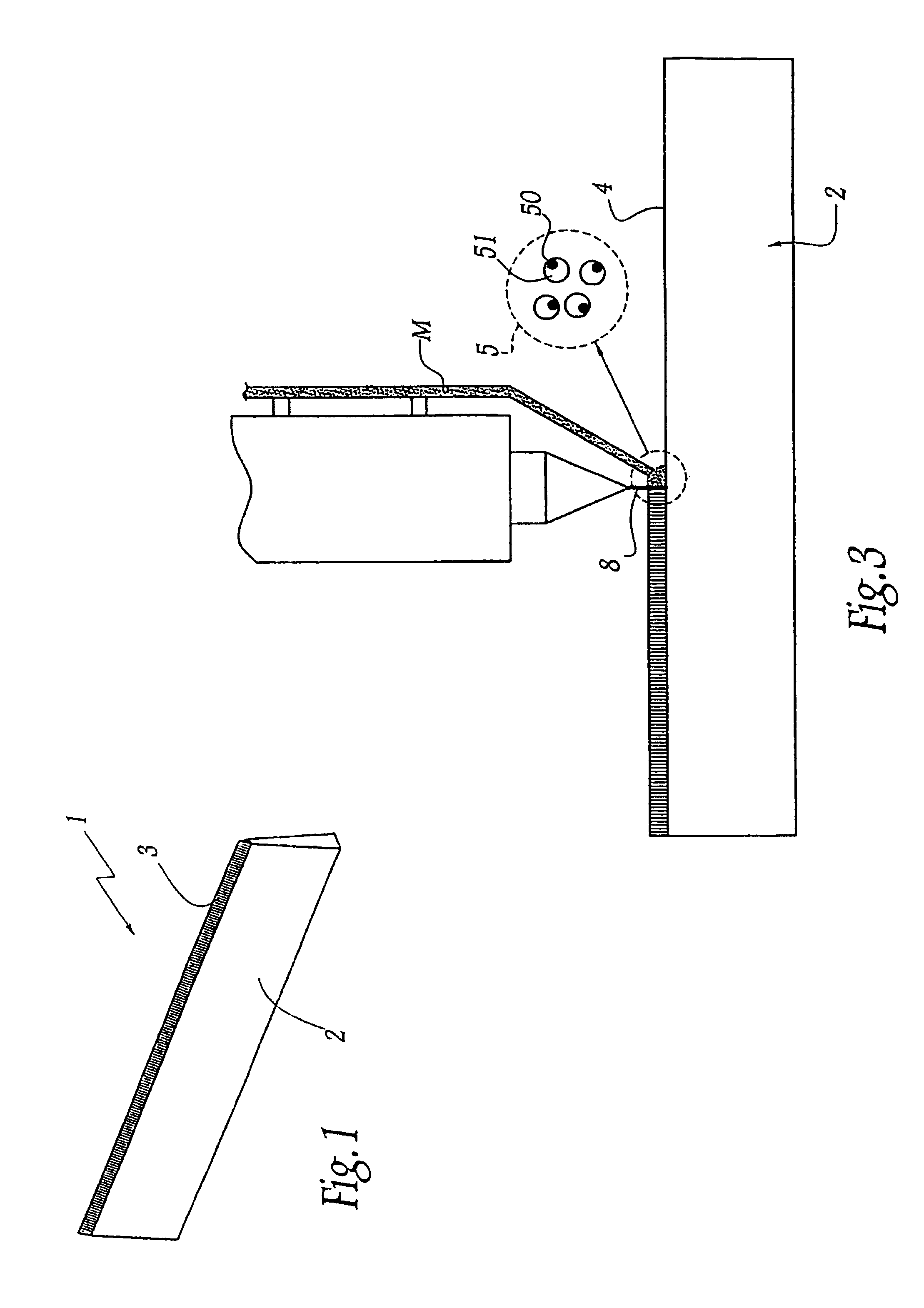

Method of producing a cutting blade and cutting blade thus produced

ActiveUS8096221B2High degreeQuality improvementMetal sawing devicesMetal sawing tool makingIndustrial toolAlloy

A method of fabricating a blade for a cutting tool, in particular for a knife, a pair of scissors, a saw, a household appliance, or indeed an industrial tool, the blade being made of steel or an alloy of stainless steel with a cutting edge extending over a portion of its periphery. The cutting tool fitted with a blade presents great resistance to wear of the cutting edge of the blade.

Owner:SOC DEXPL TARRERIAS BONJEAN

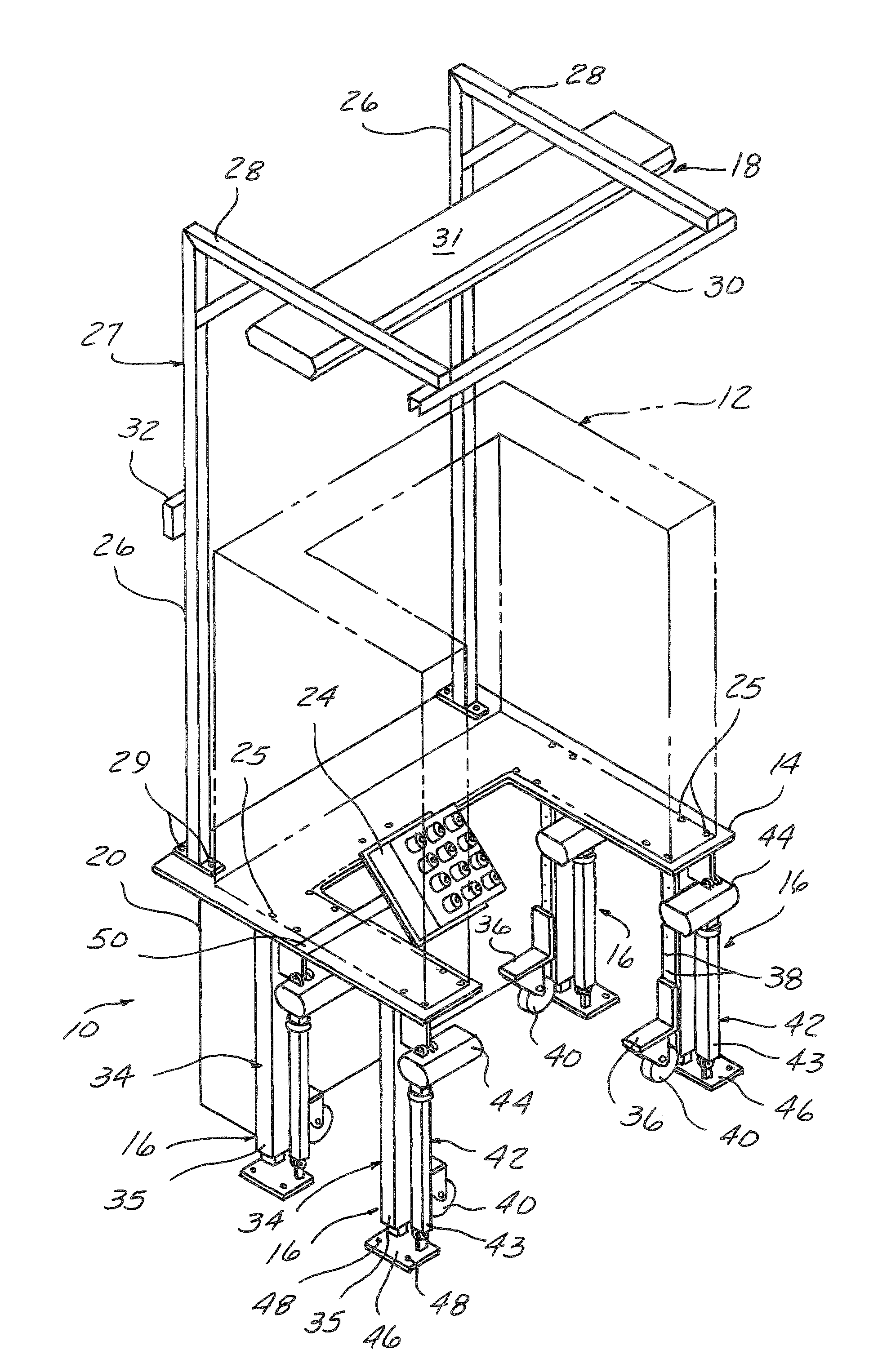

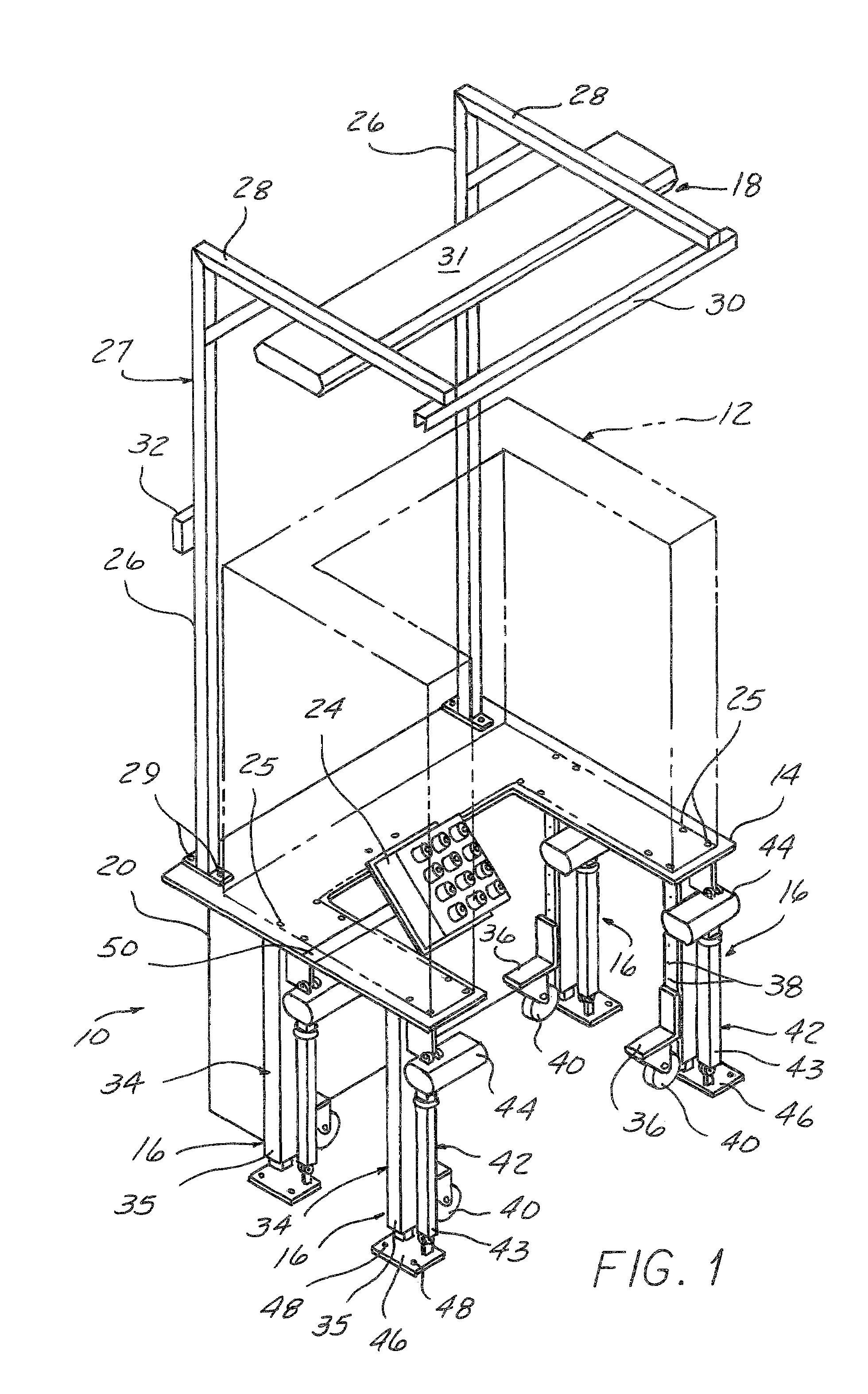

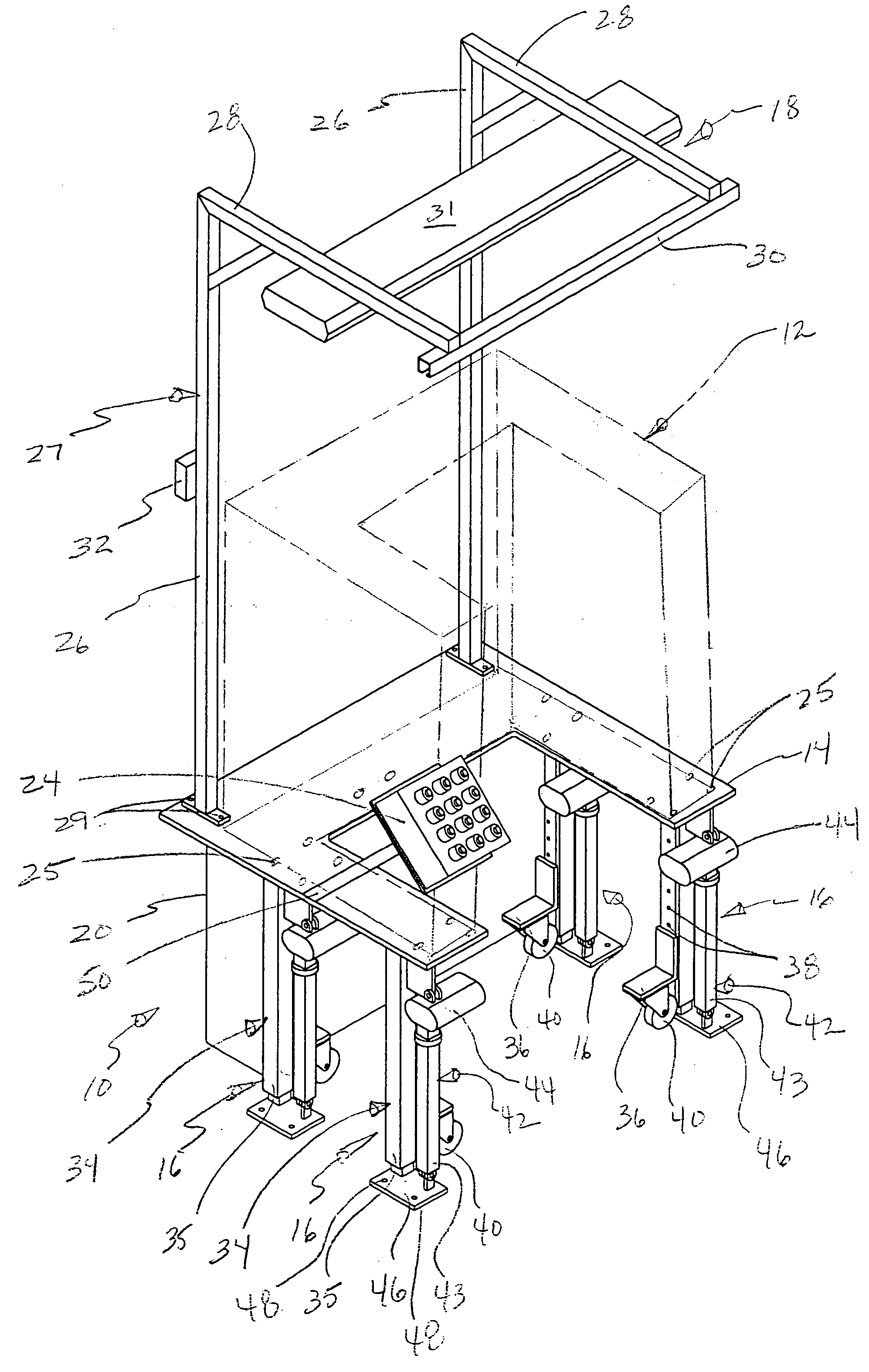

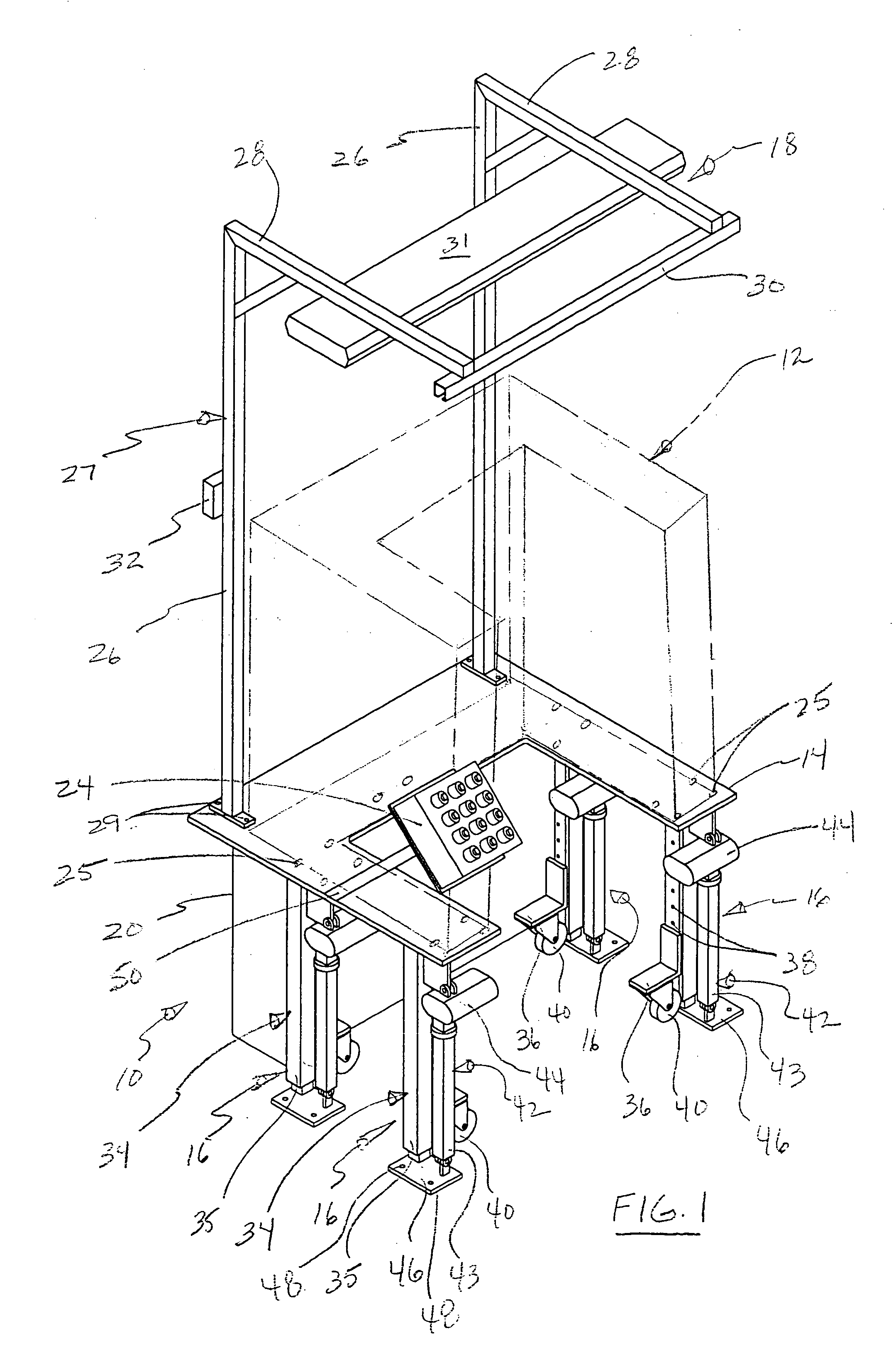

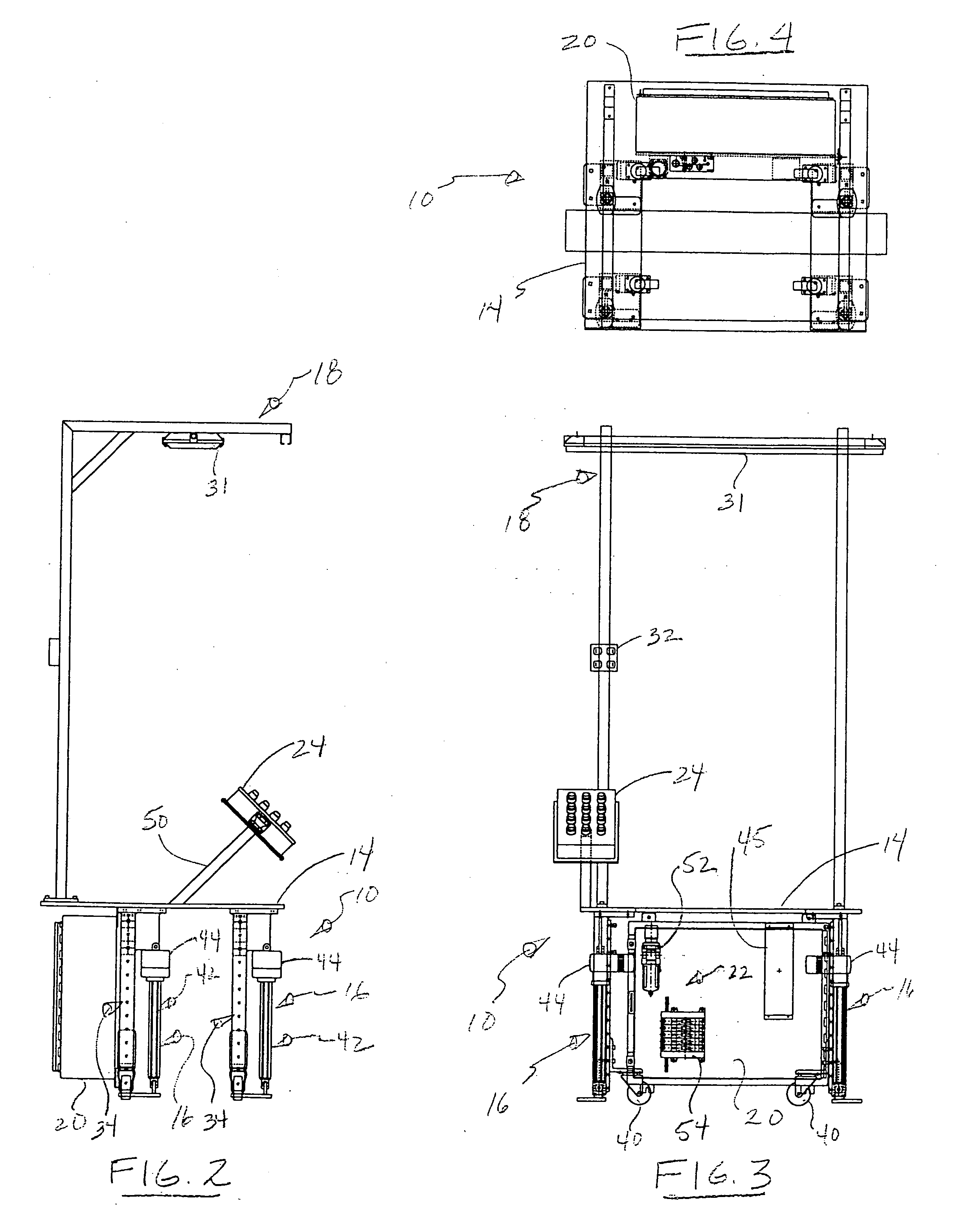

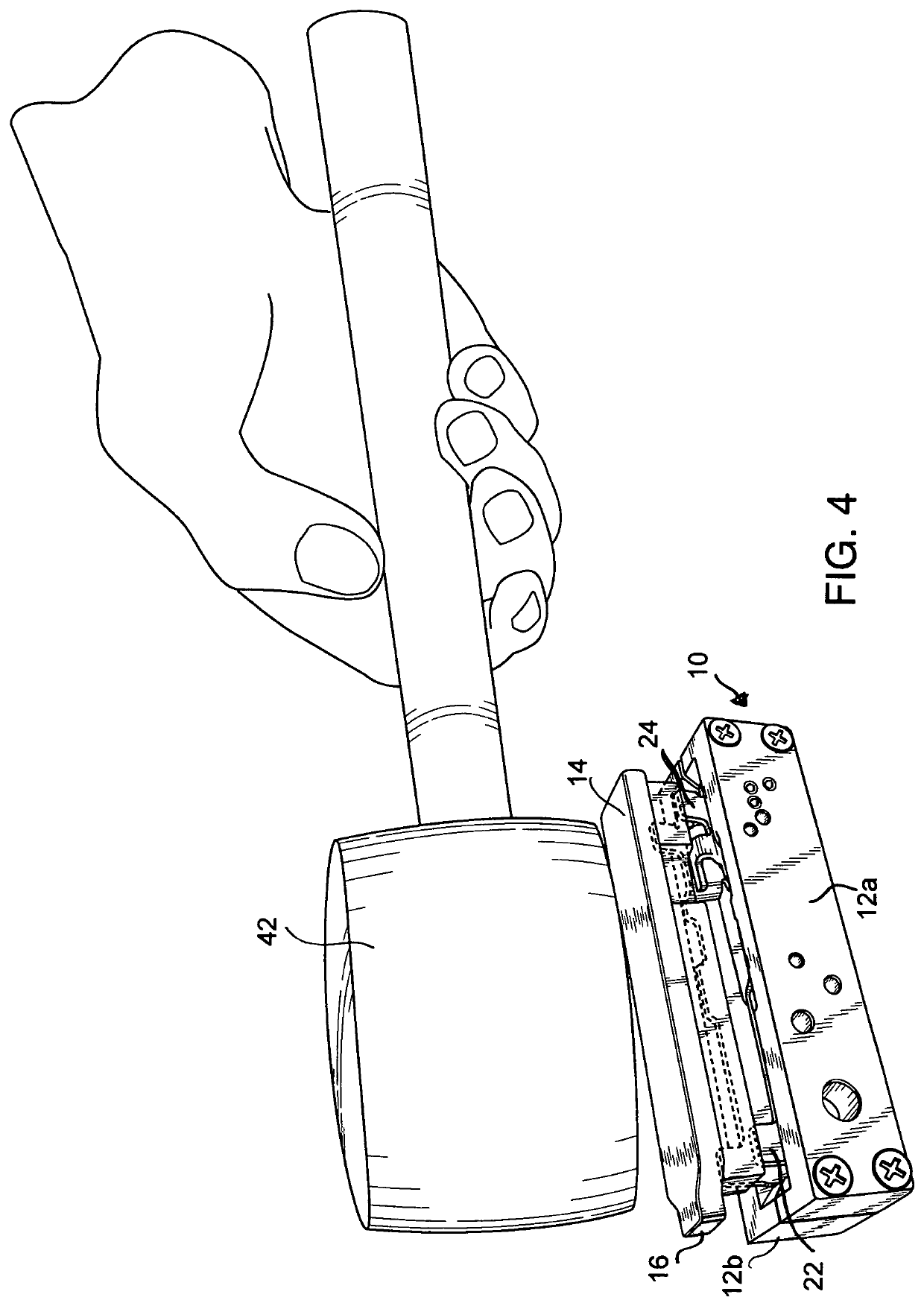

Modular base for industrial tools

Owner:LABOR AIDING SYST

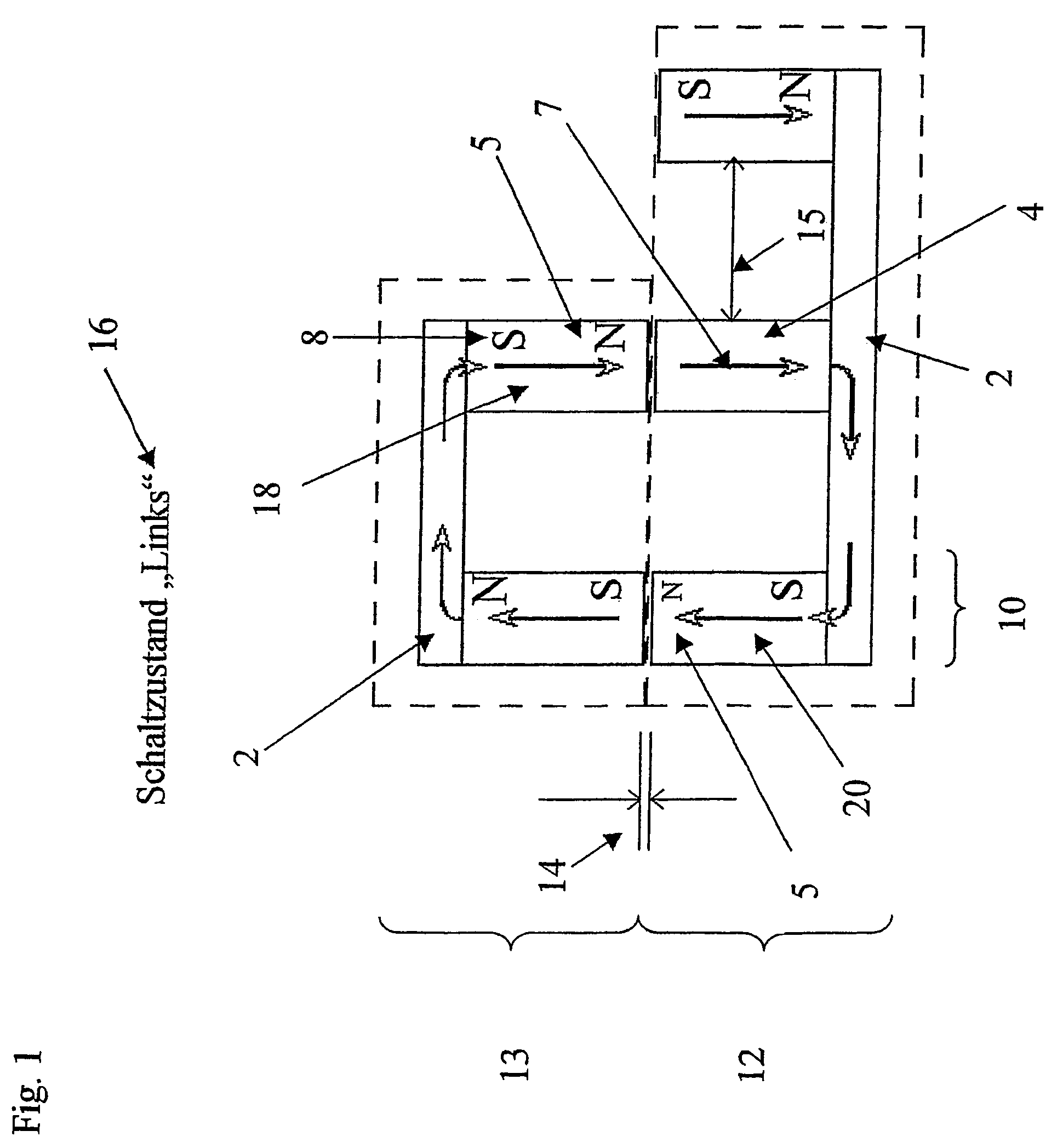

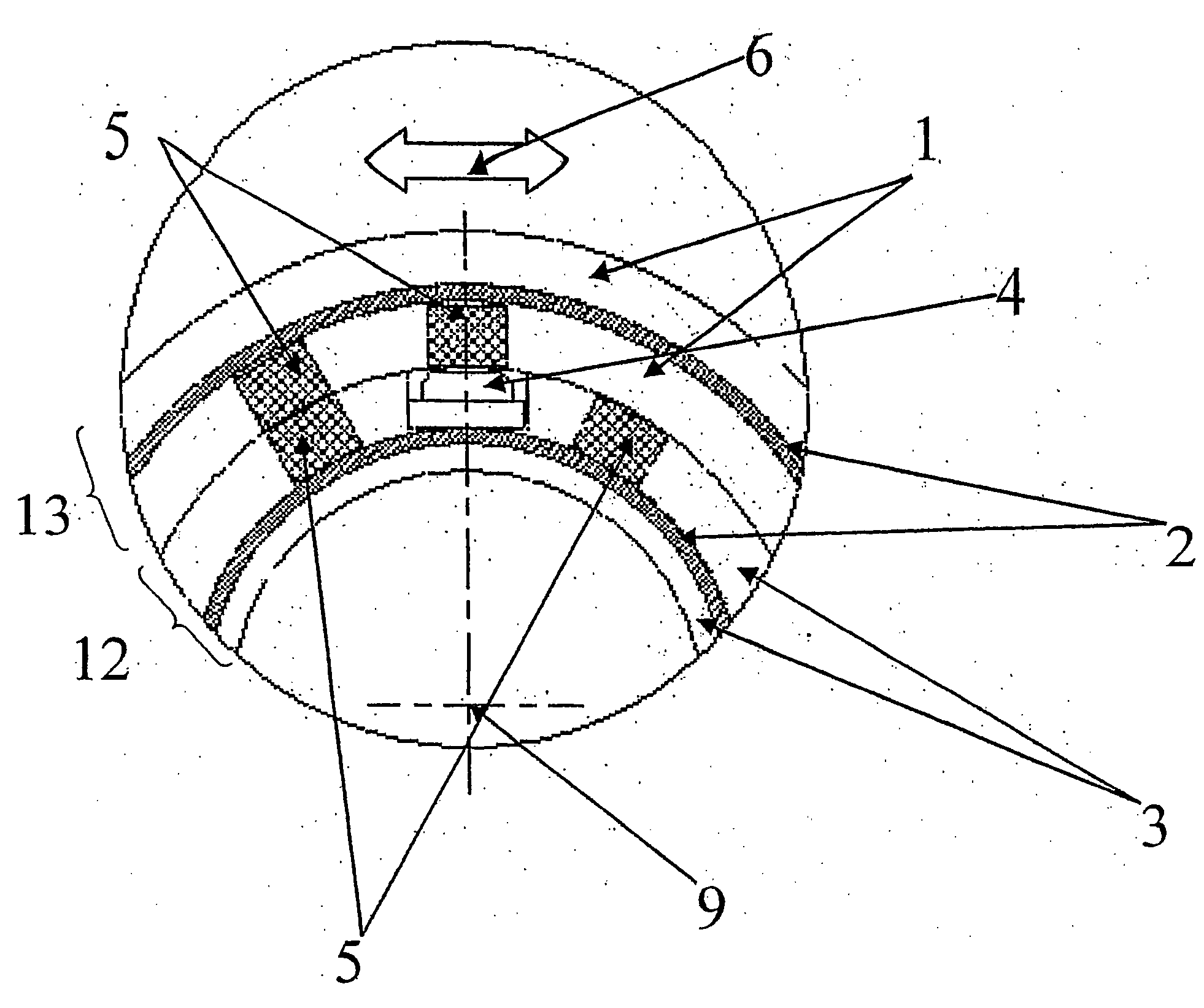

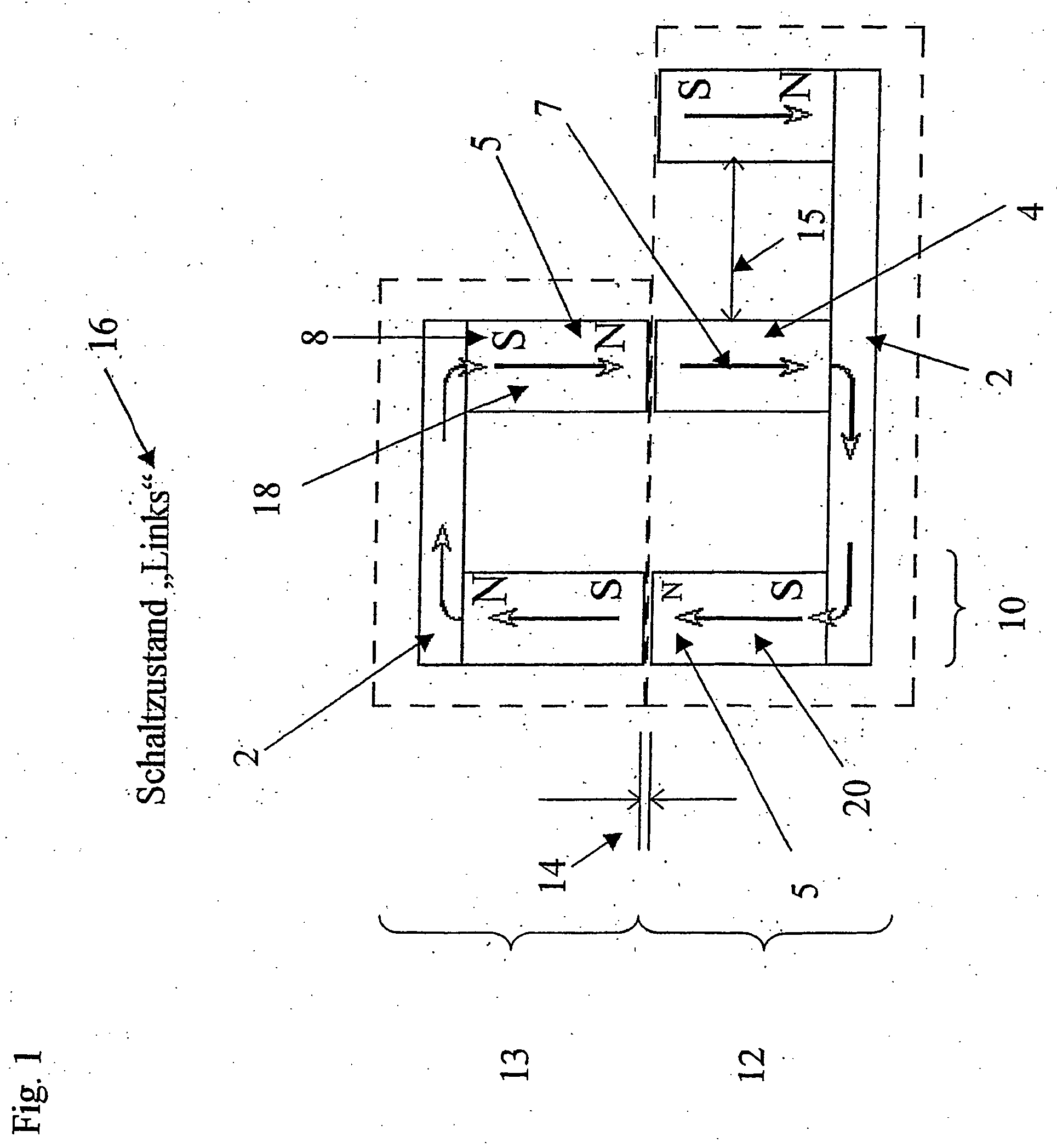

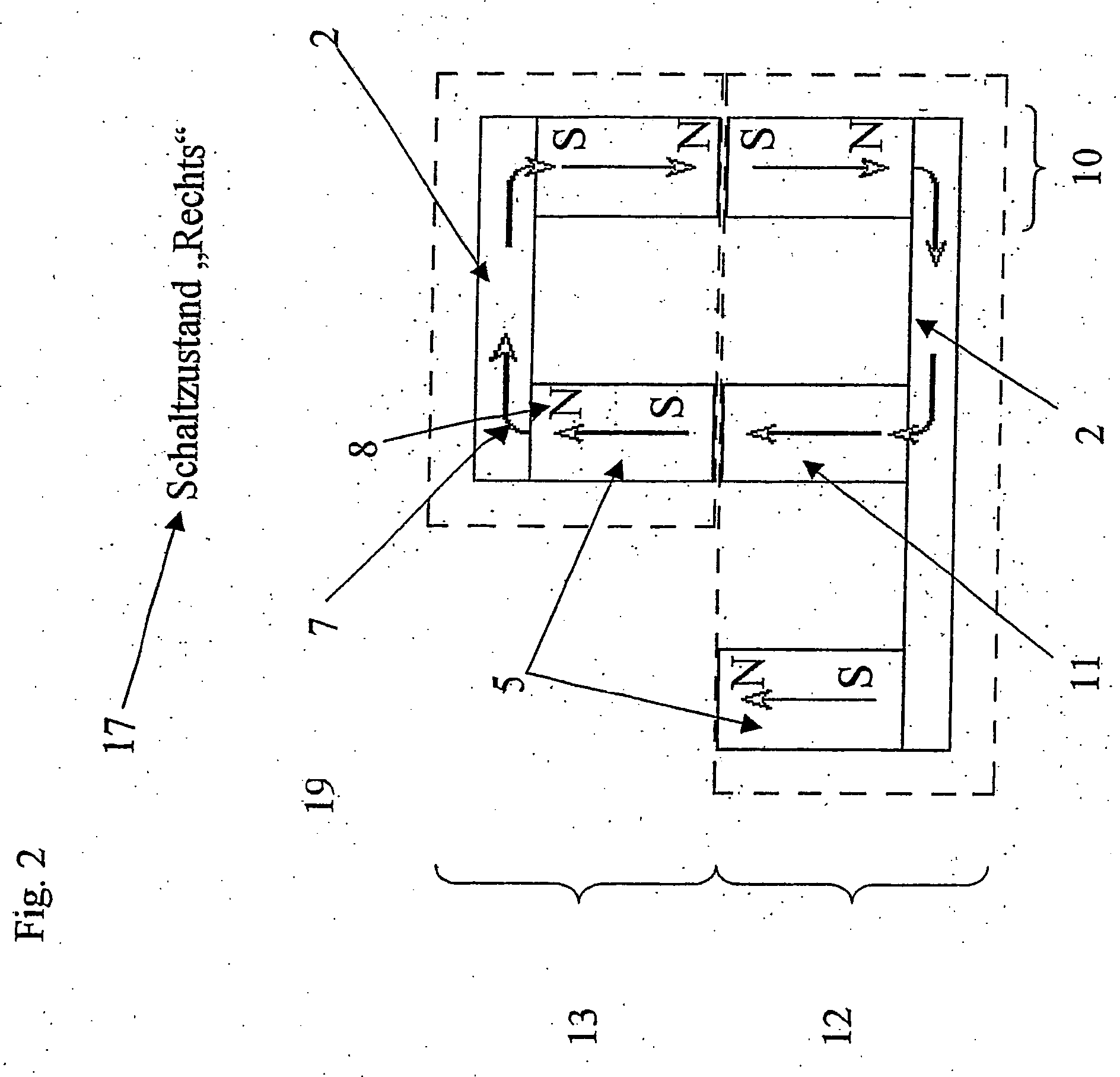

Switching unit having a locking function for a tool

InactiveUS7619499B2Switch is robustAvoid disadvantagesElectromagnets without armaturesContact mechanismsIndustrial toolEngineering

Owner:BOSCH REXROTH AG

Self-grown monopoly compact grit

InactiveUS20030044613A1Few defectIncrease valueUltra-high pressure processesMetal-working apparatusBoron nitrideSolvent

A self-grown monopoly compact grit and high pressure, high temperature process for preparing the same. The high pressure, high temperature sintered / synthesized monopoly compact grit is used in various industrial tools such as saw blades, grinding wheels, cutting tools and drill bits. Further, the monopoly compact grit of the present invention is produced from a seed of a mono-crystal of diamond or cubic boron nitride surrounded by either a self-grown crystal layer or an integrally bonded poly-crystalline sintered compact layer. The self-grown crystal layer is a new grown crystal structure where the seed crystal grows into a new phase through a normal diamond or cubic boron nitride synthesis process in the presence of a catalyst metal solvent. The compact layer is composed of about 50 to about 90 volume percent of diamond or cubic boron nitride, a typical binder material, which is a catalyst for crystal-to-crystal bonding, and a cementing agent which is a binding agent capable of forming stable carbide and nitride bonds.

Owner:CHO HYUN SAM +2

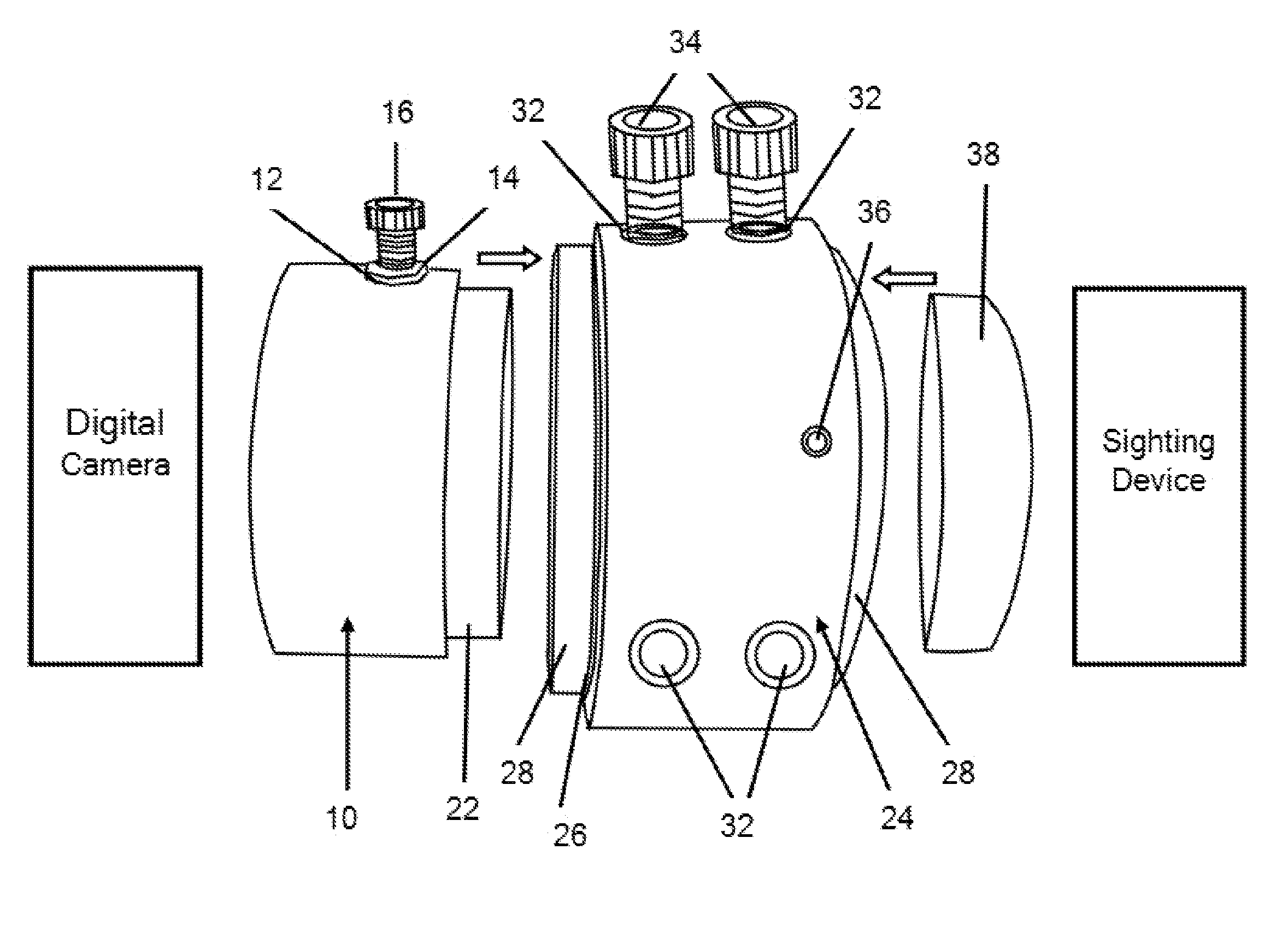

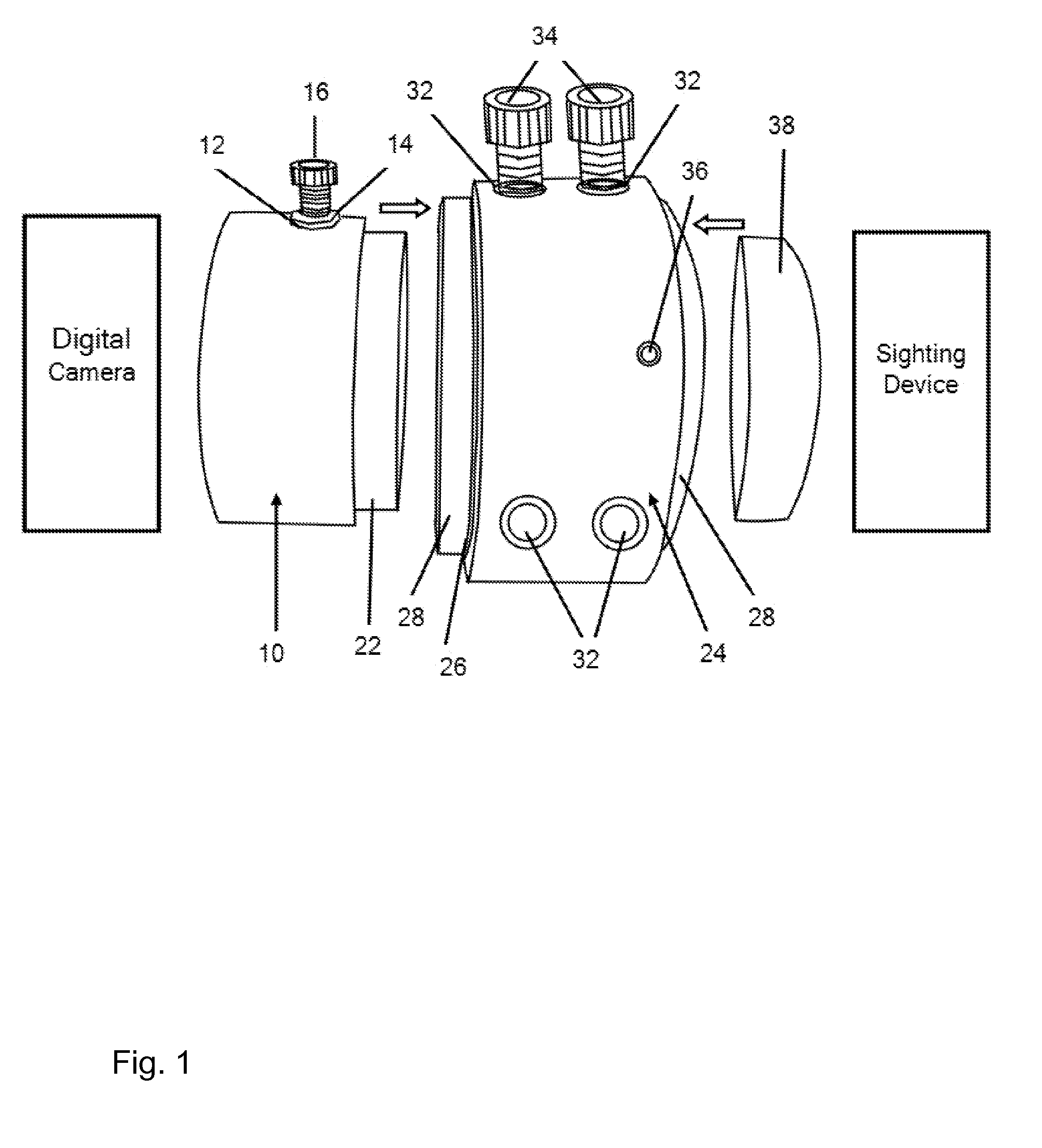

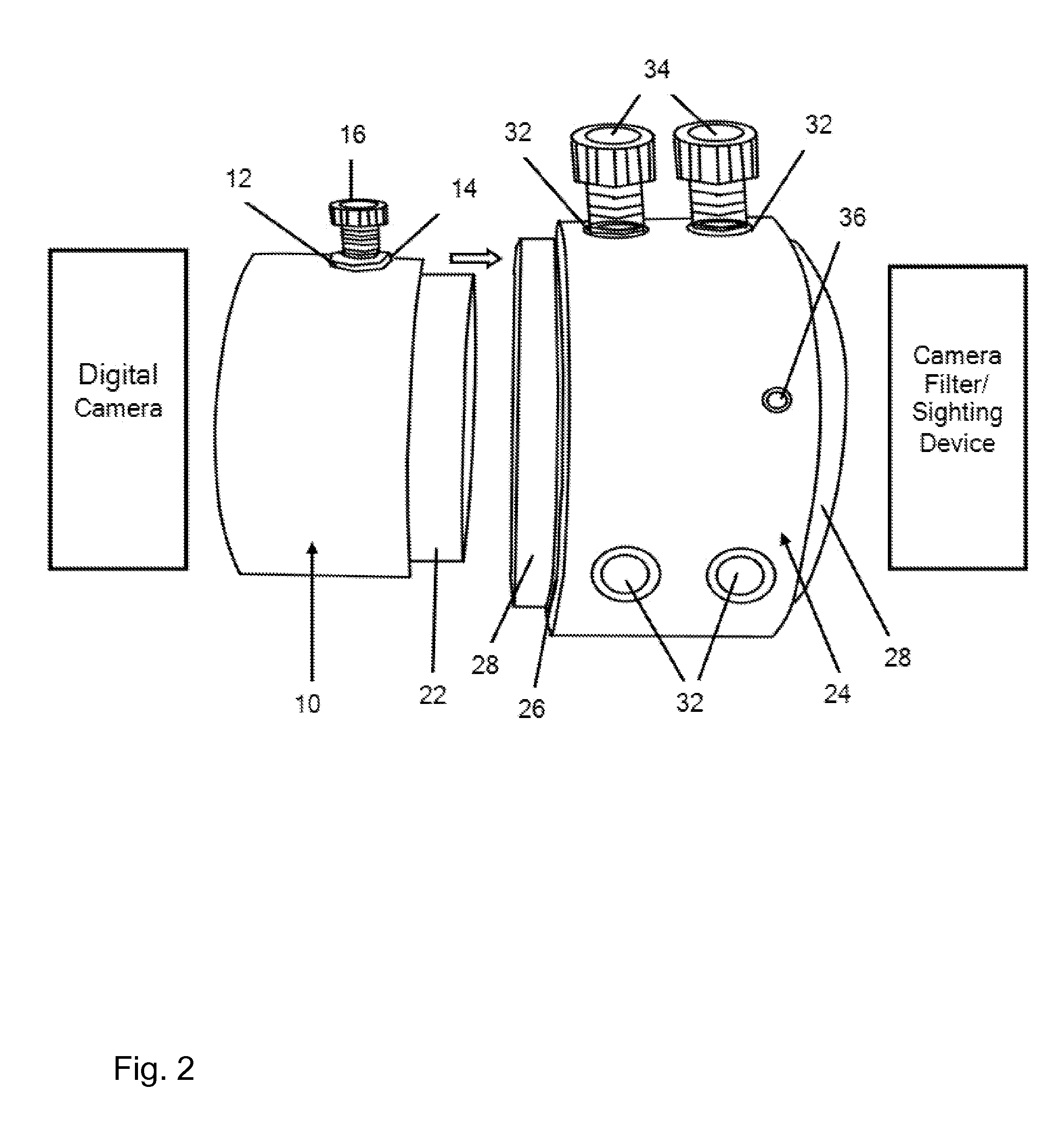

Digital Camera Lens Guard and Use Extender

InactiveUS20150077626A1Increase capacityMinimize damageTelevision system detailsColor television detailsCamera lensEyepiece

A digital camera lens guard and use extender to: extend the picture-taking capacities of the digital camera by using different camera filters; enable the digital camera to take pictures of the images formed at the eyepiece of a sighting device; protect the camera lens from dust, moisture, and contaminations; make the digital camera usable as an industrial tool; allow the digital camera to be used in photographing activities such as surveillance, sports, past times, research, astronomy; and maintain the original functions of the digital camera.

Owner:LIQUE ROY

Modular base for industrial tools

A modular base for industrial machinery that allows fixturing and tooling of an industrial machine to be replaced without having to realize the cost of having to rebuild and / or replace the surrounding equipment. The present invention provides a mounting table adaptable to be releasably connected to the industrial machine. A plurality of telescopically adjustable legs are connected to the mounting table to provide a height adjustment to the mounting table. The legs have a plurality of rollers connected thereto for rollably supporting the mounting table. A plurality of mounting platforms are also connected to the legs and adaptable to be releasably fixtured to a foundation. A light fixture is connected to and extends from the mounting table and is adaptable to cast light on the industrial machine. A programmable controller is coupled to the mounting table and is adaptable to be releasably coupled to and in communication with the industrial machine. A pneumatic controller is coupled to the mounting table and is adaptable to communicate with the industrial machine. A control panel is coupled to and in communication with the programmable controller and is adaptable to manipulate the industrial machine.

Owner:LABOR AIDING SYST

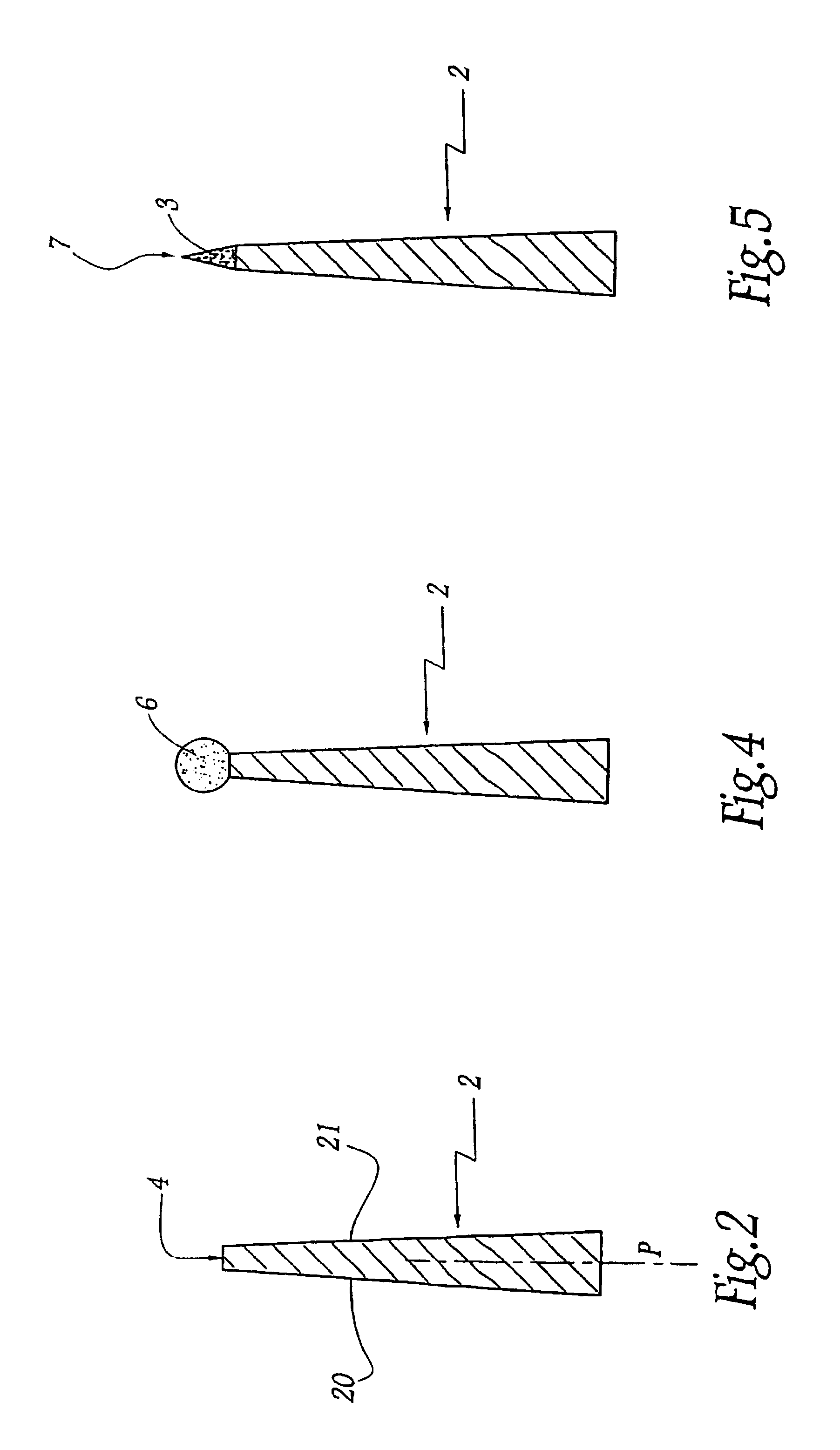

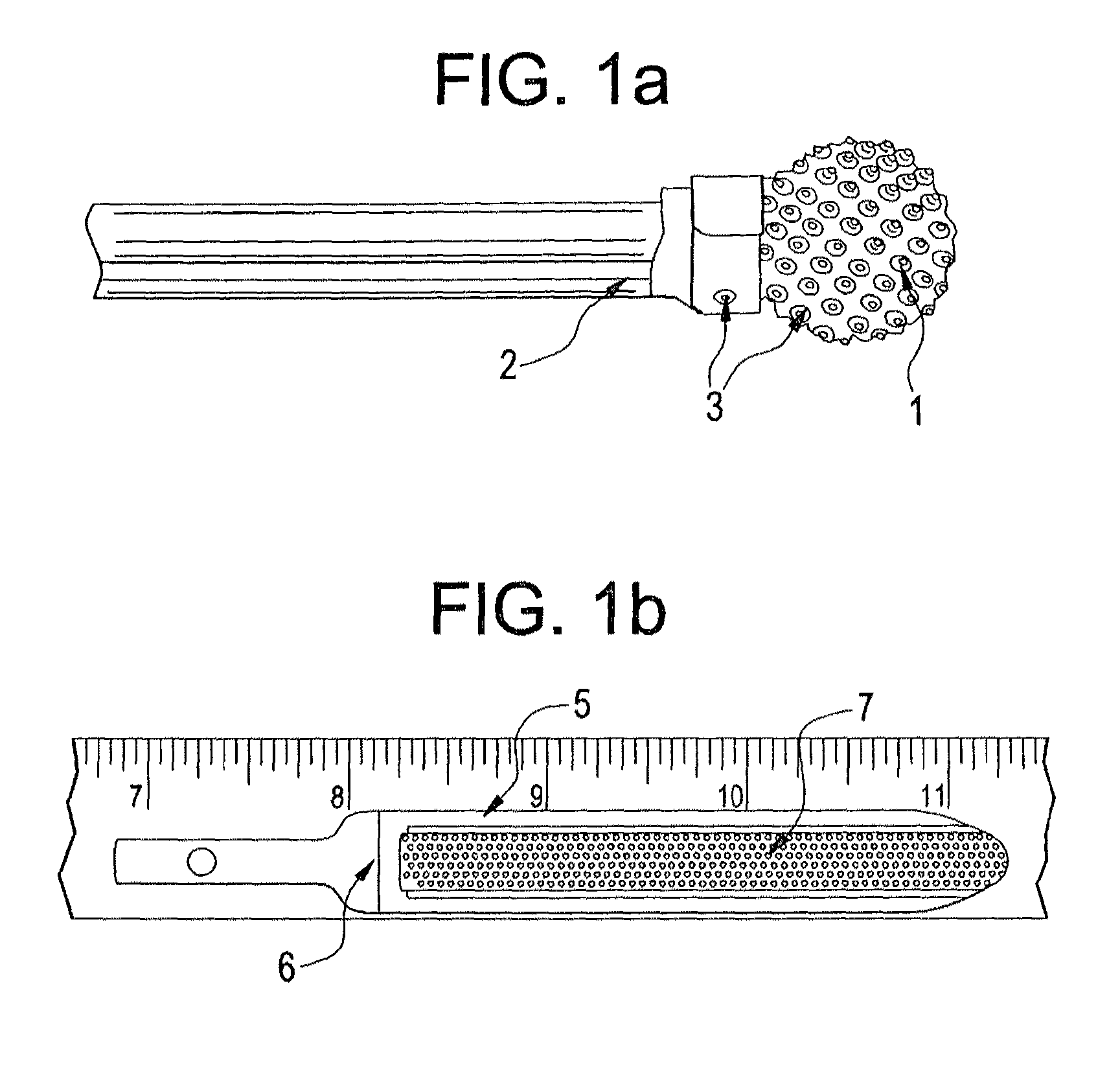

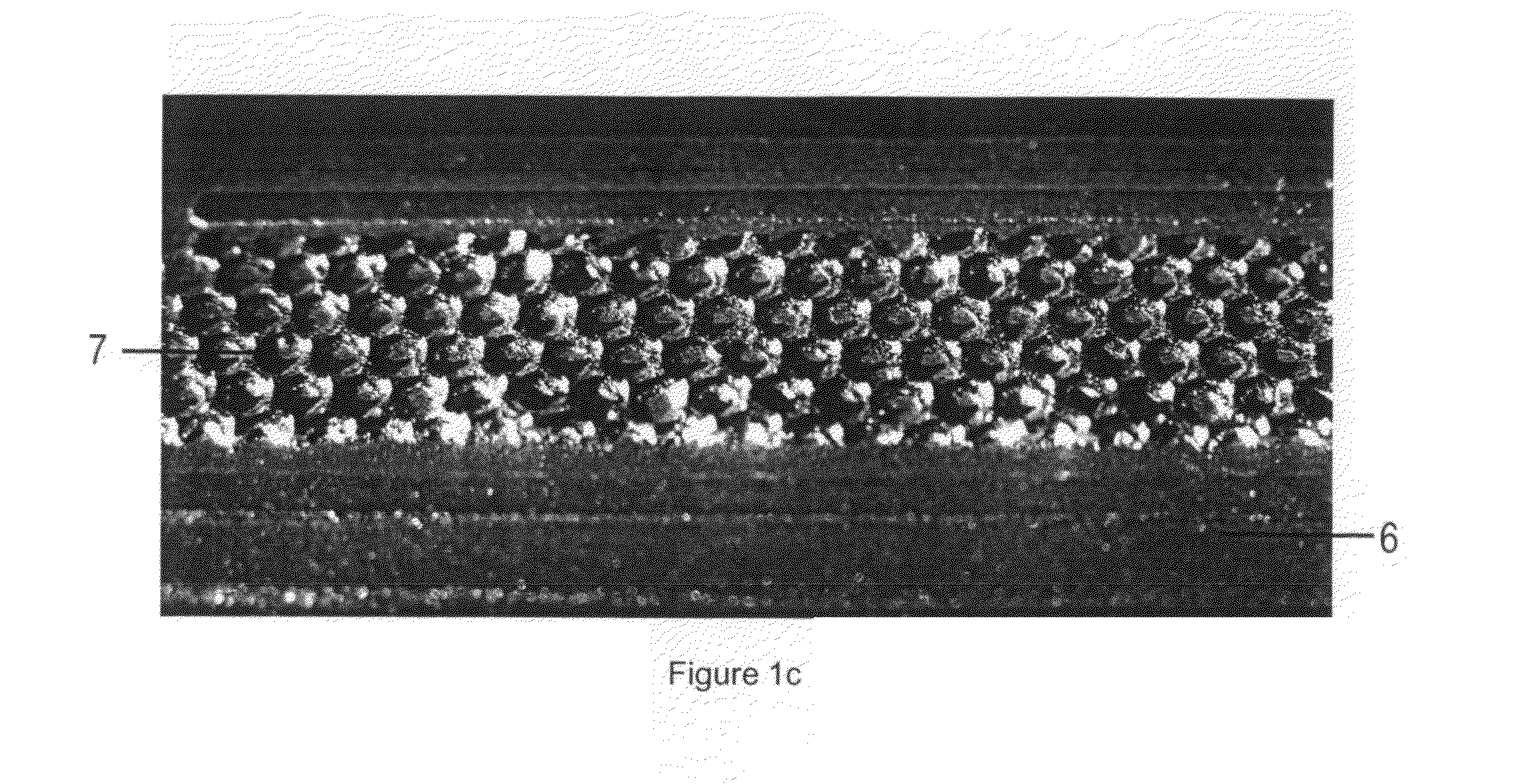

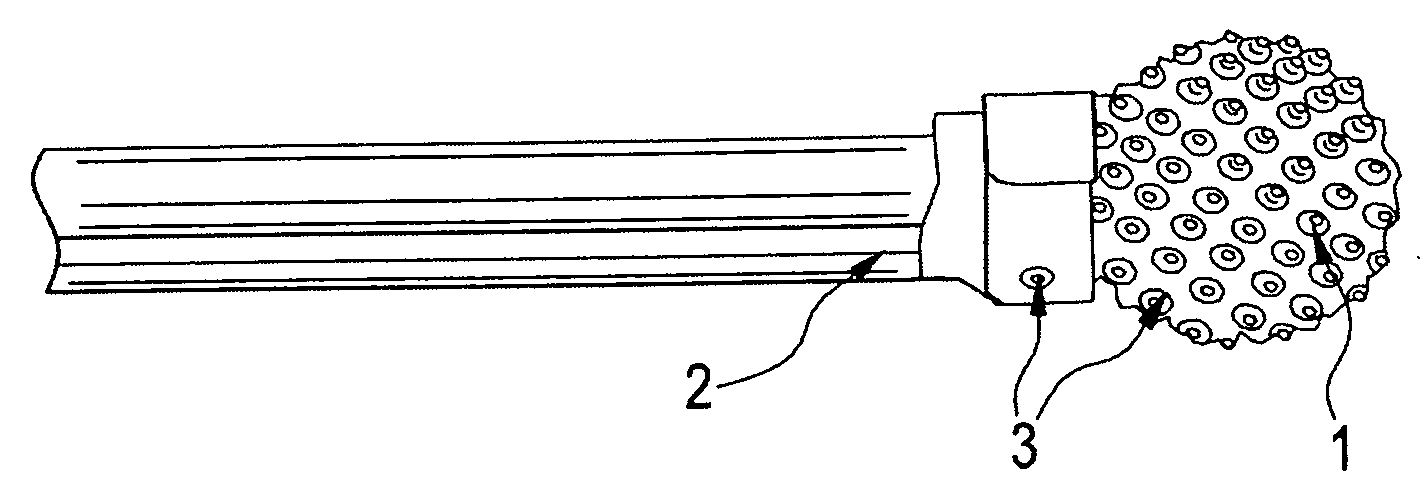

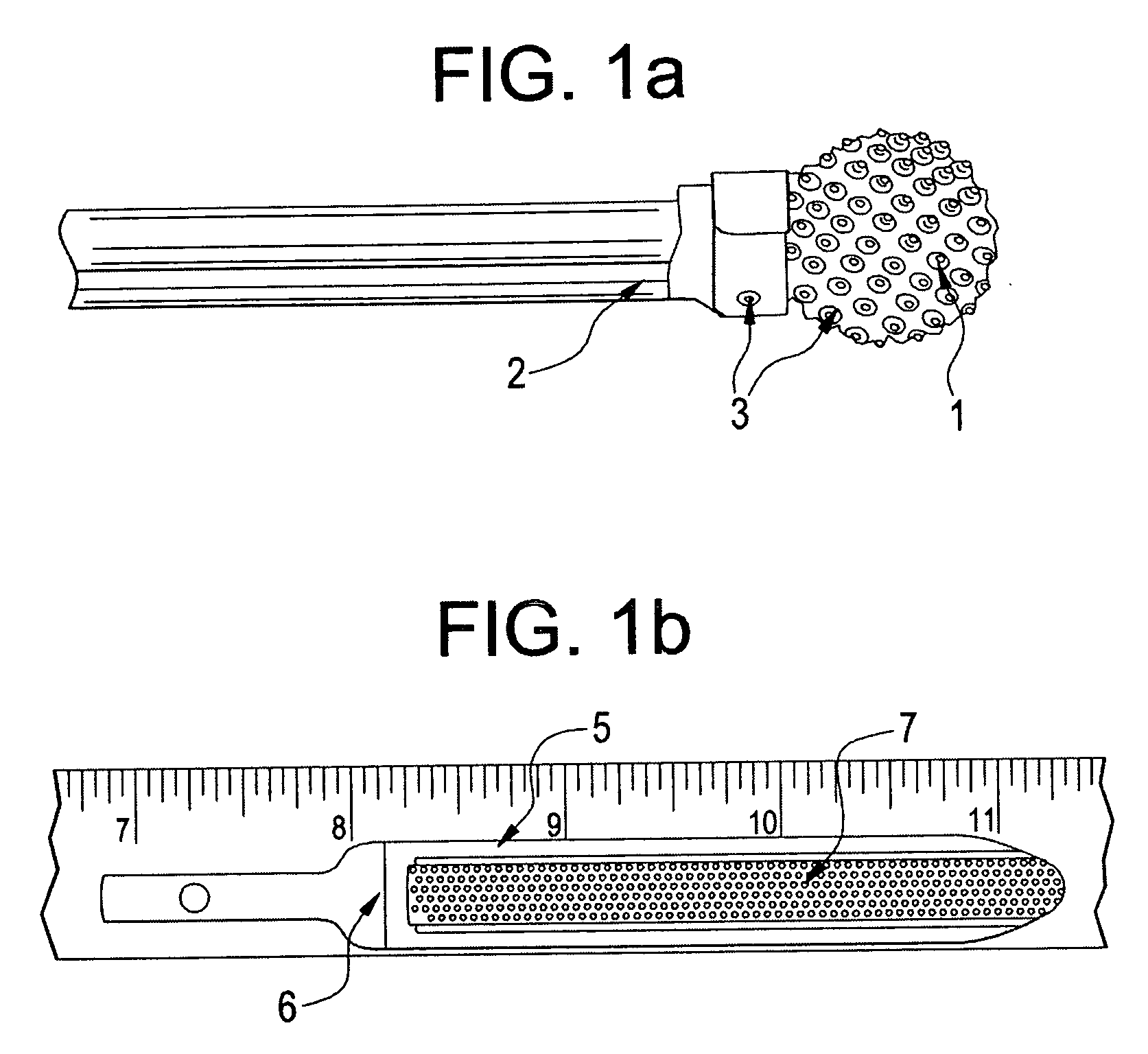

Advanced burr, applique for a burr and method of fabricating

InactiveUS8246620B2Improve the lubrication effectIncrease resistanceJoint implantsEndoscopic cutting instrumentsIndustrial toolMaterial removal

An abrading device including an advanced burr and appliqué for a burr and a new process for making cutting tools for fine material removal applications such as in bone and tissue surgeries. An appliqué sheet is first engineered by CAD with an abrading surface having cutting facets. The appliqué is attached to a surface of a tool blank and then metallurgically bonded and coated by the BRAZOL® or Co—P process. The tool blank has a proximal shank attachable to a driver and a distal surface to which the appliqué is affixed. Since each facet is attached to surrounding facets and then strongly bonded to the tool, the facets do not dislodge when used to abrade a surface of an object. The BRAZOL® or Co—P coating imparts excellent wear resistance and lubricity to the cutting facets. This results in excellent operational and material removal characteristics. This approach to making surgical and fine industrial tools offers engineered flexibility in design rather than process dependent designs.

Owner:HOLKO KENNETH +1

Switching unit having a locking function for a tool

InactiveUS20070108029A1Avoid disadvantagesSwitch is robustElectromagnets without armaturesContact mechanismsIndustrial toolElectrical and Electronics engineering

Owner:BOSCH REXROTH AG

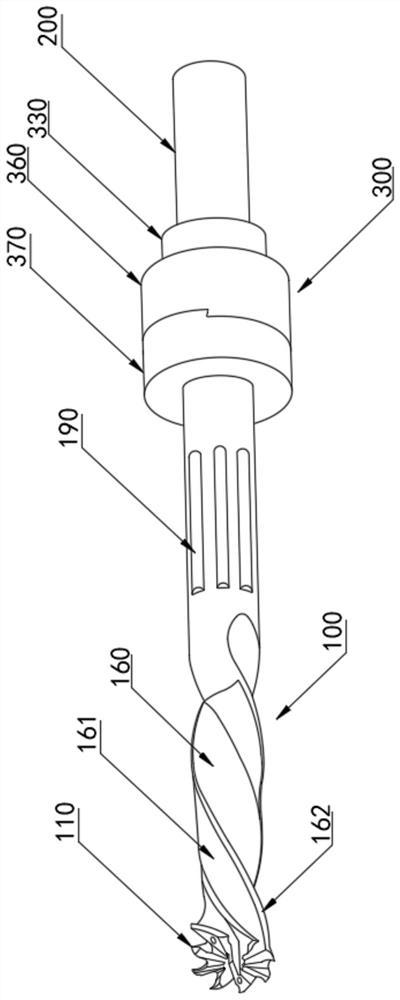

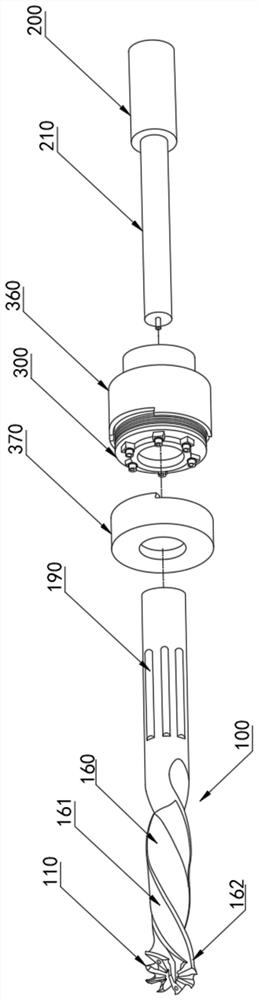

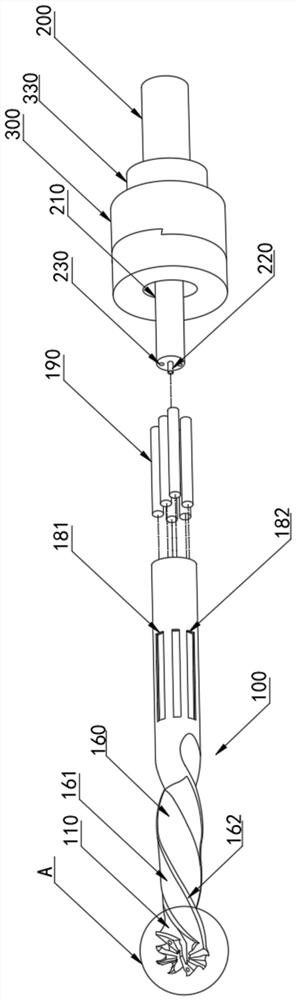

Staggered edge drill reamer for composite hole machining

ActiveCN112453509AReduce speedProcessableTransportation and packagingReaming toolsIndustrial toolMetal machining

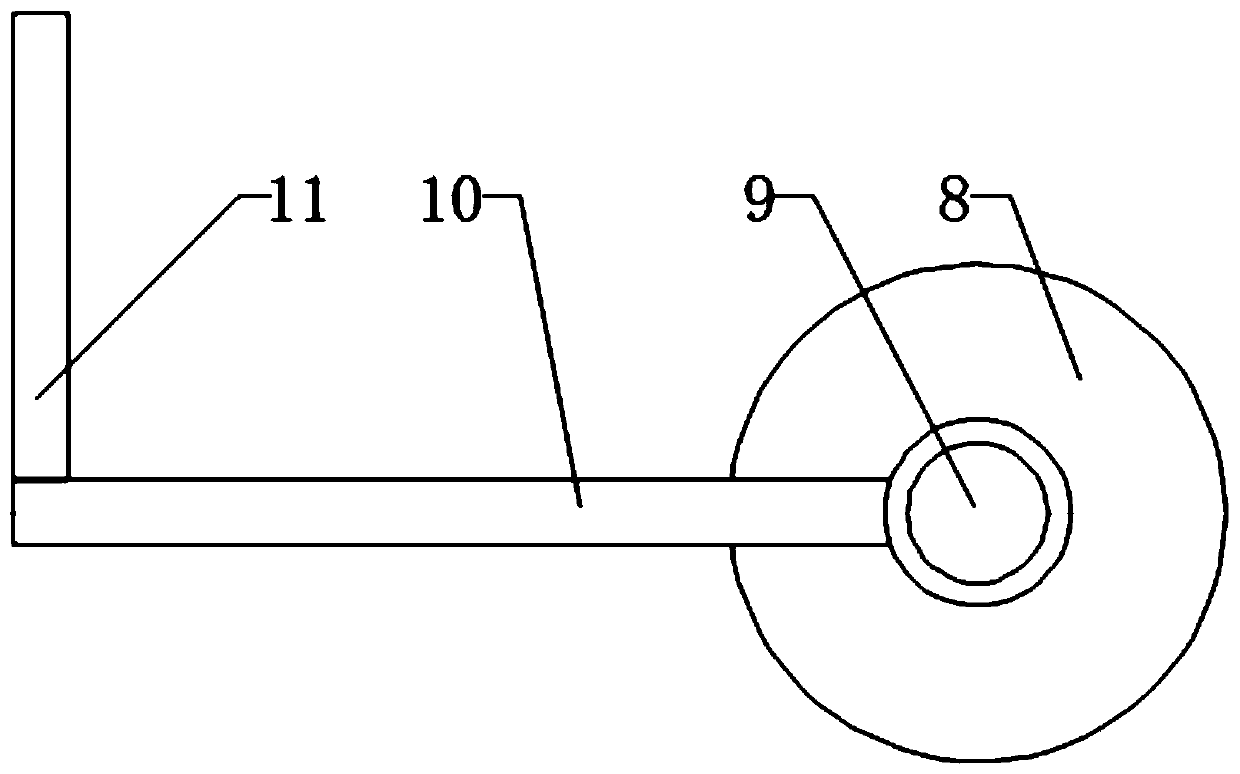

The invention belongs to the technical field of industrial tools, and particularly relates to a staggered edge drill reamer for composite hole machining. The staggered edge drill reamer comprises a drill rod, a tail handle and an adjusting device. According to the technical scheme, the adjusting device is arranged at the right end of the drill rod, and comprises a shell I, and a parallel bearing is fixedly mounted on the left side of the shell I; a shell II is fixedly installed on the left side of the parallel bearing, and a spacing ring is fixedly installed on the right side of the shell I; and the tail handle is fixedly installed on the right side of the spacing ring, and a mandrel is fixedly arranged on the left side of the tail handle, and installed on the inner walls of the shell I and the shell II. The invention has the beneficial effects that chips generated on a metal processing surface through ab auxiliary cutting edge and an arc edge are guided to a chip guide groove througha chip dividing groove, and the chips of a main cutting edge are guided to a chip groove through the chip guide groove; a roller is attached to the metal surface in the hole, and the metal surface inthe hole is rolled through the roller, so that the protrusion part of the surface is pressed into the concave part; and the smooth surface is machined in the hole, and the super mirror machining and polishing effects are achieved.

Owner:河源市蓝海米克模具刀具有限公司

Advanced burr, applique for a burr and method of fabricating

InactiveUS20100152738A1Improve the lubrication effectImprove wear resistanceJoint implantsEndoscopic cutting instrumentsSurgical operationIndustrial tool

An abrading device consists of an advanced burr and appliqué for a burr and a new process for making cutting tools for fine material removal applications such as in bone and tissue surgeries. An appliqué sheet is first engineered by CAD with an abrading surface having cutting facets. The appliqué is attached to a surface of a tool blank and then metallurgically bonded and coated by the BRAZOL® or Co—P process. The tool blank has a proximal shank attachable to a driver and a distal surface to which the appliqué is affixed. Since each facet is attached to surrounding facets and then strongly bonded to the tool, the facets do not dislodge when used to abrade a surface of an object. The BRAZOL® or Co—P coating imparts excellent wear resistance and lubricity to the cutting facets. This results in excellent operational and material removal characteristics. This approach to making surgical and fine industrial tools offers engineered flexibility in design rather than process dependent designs.

Owner:HOLKO KENNETH +1

Grinding device for improving sharpness of milling cutter

InactiveCN110216532AImprove sharpnessExtended service lifeMilling cuttersGrinding/polishing safety devicesIndustrial toolMilling cutter

The invention discloses a grinding device for improving sharpness of a milling cutter, and belongs to the field of industrial tools. The grinding device for improving the sharpness of the milling cutter comprises a bottom plate, wherein the bottom plate is used as a mounting platform of the grinding device. A milling cutter synchronous rotator is arranged at one end of the bottom plate, a top endmechanism is arranged on the top surface of the milling cutter synchronous rotator, and a standard milling cutter and a milling cutter to be milled are arranged on the side surface of the milling cutter synchronous rotator. According to the grinding device for improving the sharpness of the milling cutter, through the real-time comparison of the standard milling cutter, the grinding precision of the milling cutter to be milled is improved; an air outlet is formed in one side of the milling cutter to be milled and used for blowing away grinding scraps, wherein the air outlet is connected to thetop end mechanism, a scrap collecting box is arranged at the air outlet pointing position of the air outlet and is used for collecting the grinding scraps, and the scrap collecting box is fixed on the bottom plate; an air cylinder mounting plate is fixedly arranged on the side face of the top end mechanism, so that reasonable grinding can be realized, thus improving the sharpness of the wearing and blunt milling cutter, prolonging the service life of the milling cutter and reducing the waste of industrial cutters.

Owner:SUZHOU MAIKAFU IND TECH CO LTD

Internal surface treating method of hole before tapping on aluminumdiematerial, internal surface of hole processed casting structure, and industrial tool of internal surface improvement

InactiveUS20060042070A1Prevent pressure leaksImproves internal surfaceMetal rolling stand detailsMetal working apparatusIndustrial toolNonferrous metal

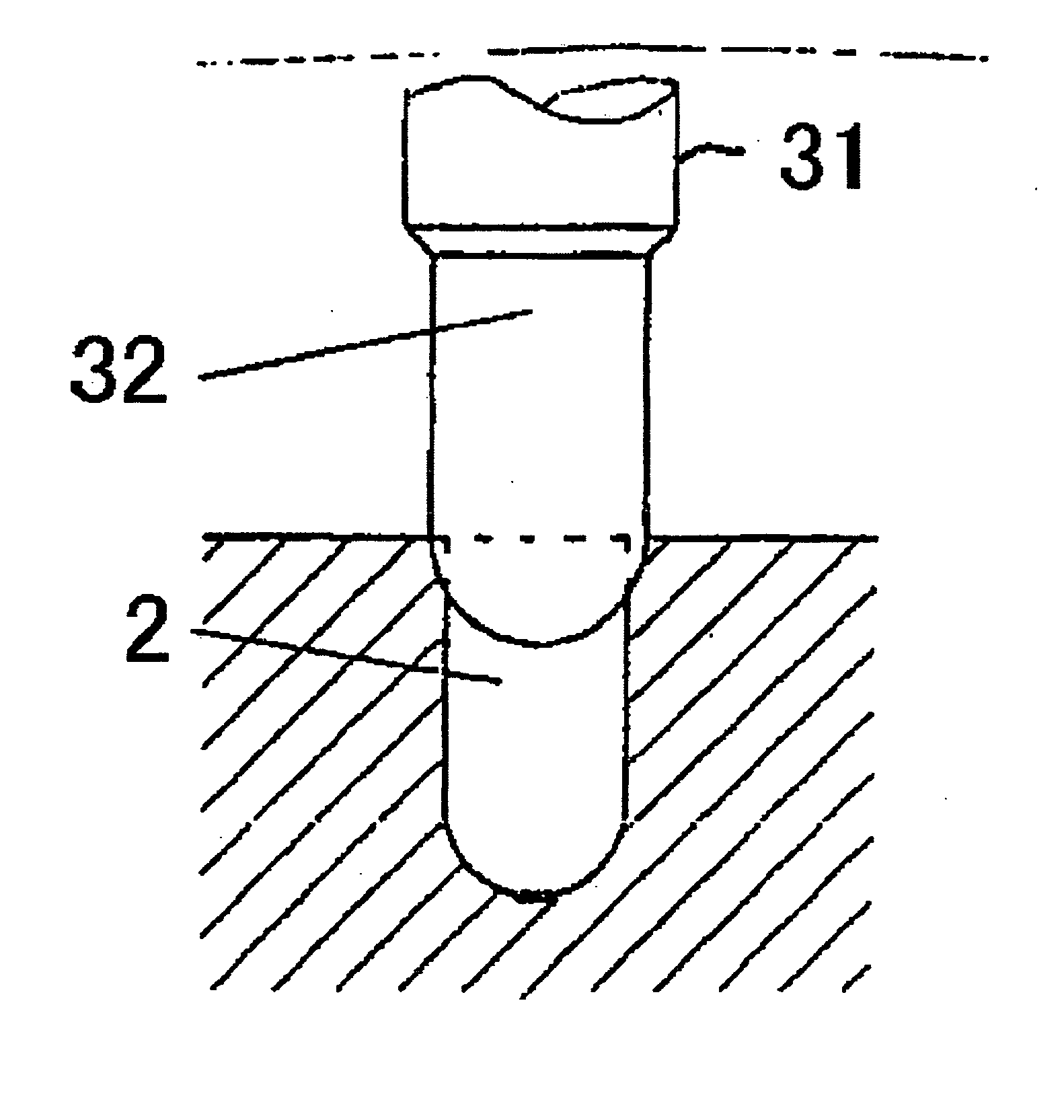

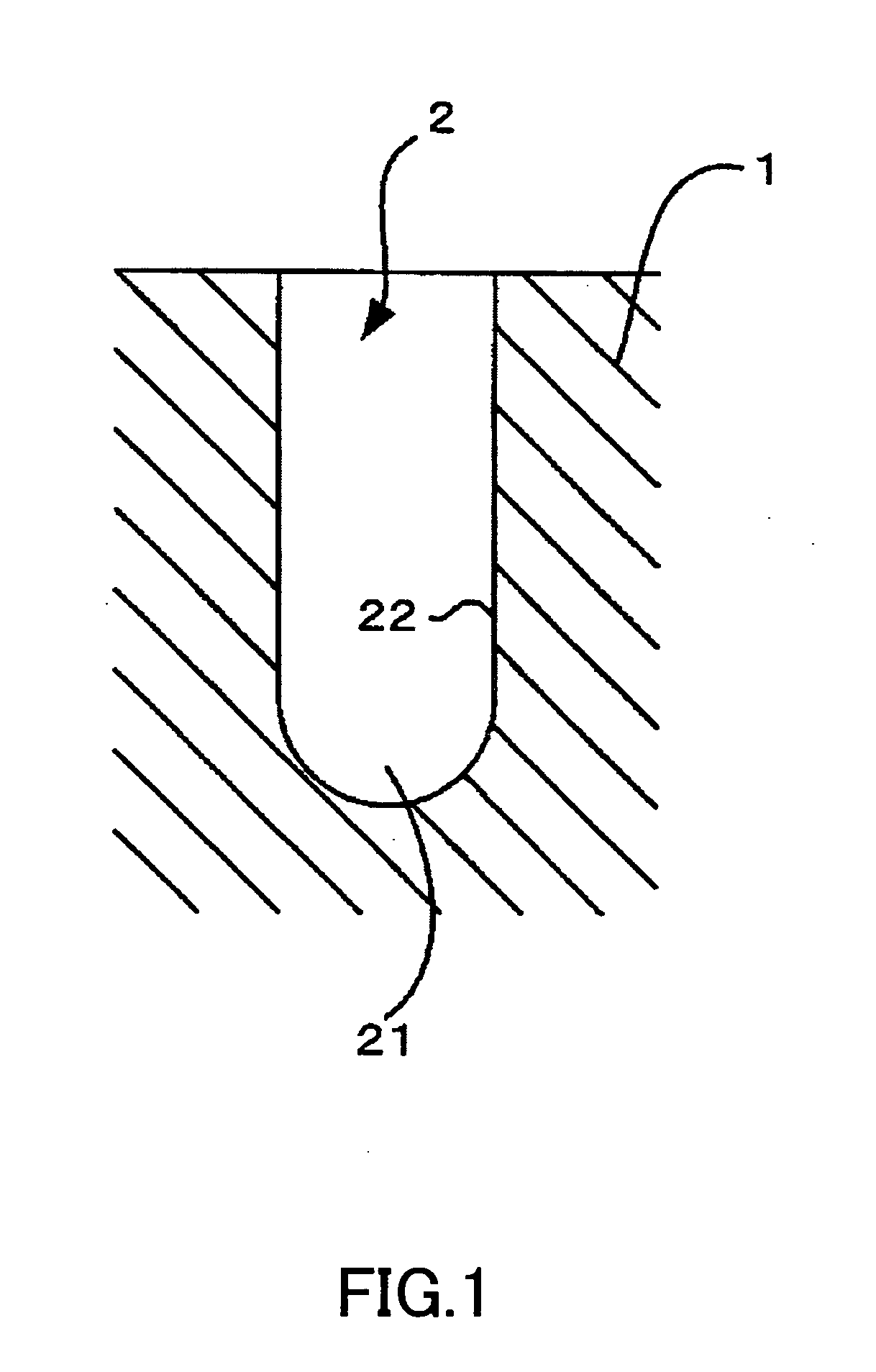

The present invention provides a improvement method of an internal surface of a hole of a casting in which an internal surface of a hole formed in a casting made of nonferrous metal is processed at high speed without excessively heating the same, thereby splitting and eliminating casting nests which are peculiar to the casting, and metal structure is reformed so that fluid does not leak from the casting nests formed in the casting, and to provide a casting structure whose hole internal surface of is improved, and a processing tool of the internal surface. A tool having a cross section area greater than that of a hole formed in the casting is sent and press-fitted into the hole while rotating the tool, friction heat is generated between a surface of the tool and the internal surface of the hole and then, the tool is pulled out from the hole in a state in which the rotation of the tool is maintained, thereby reforming a metal structure of the internal surface to form a reformed layer.

Owner:FULL CHU CORP

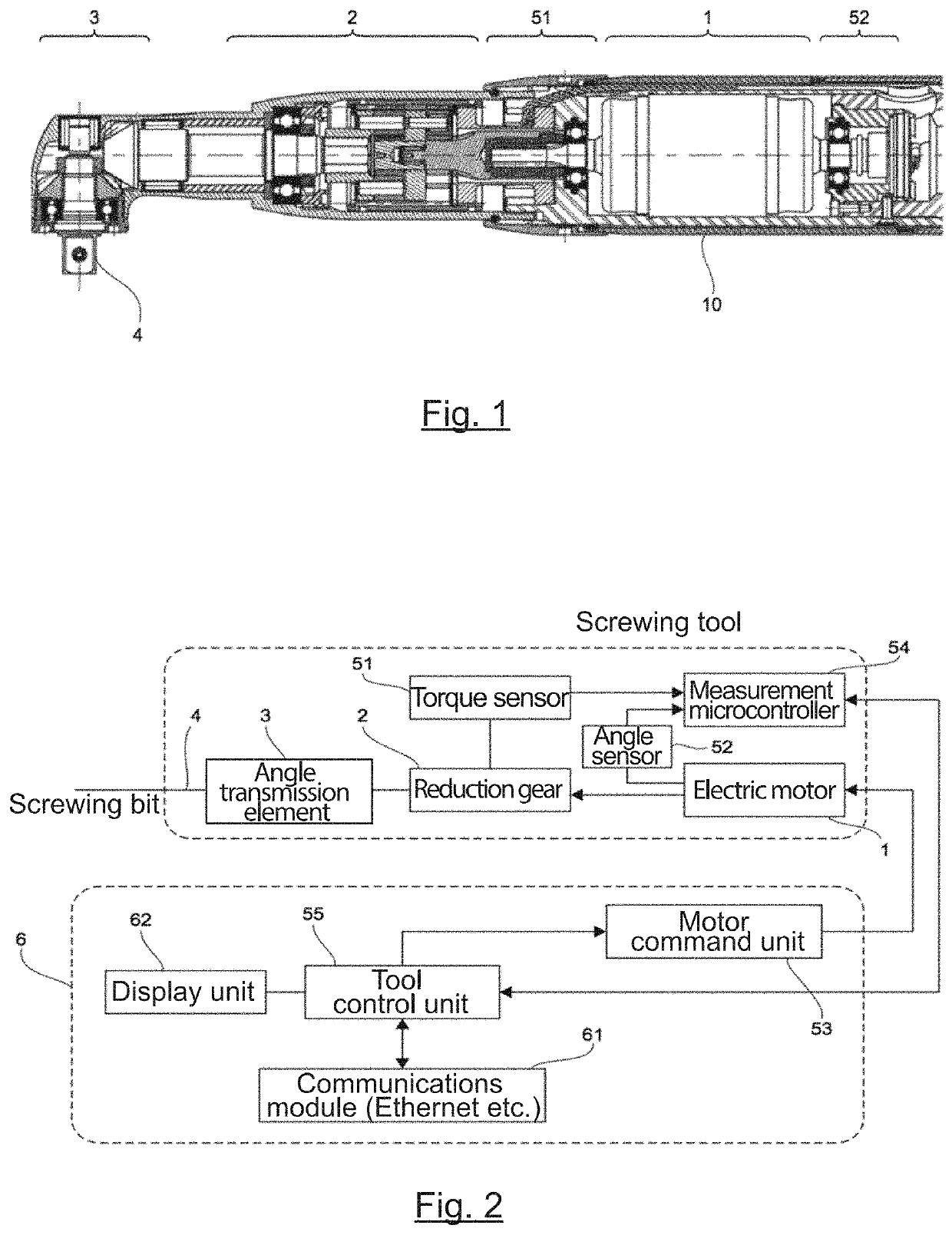

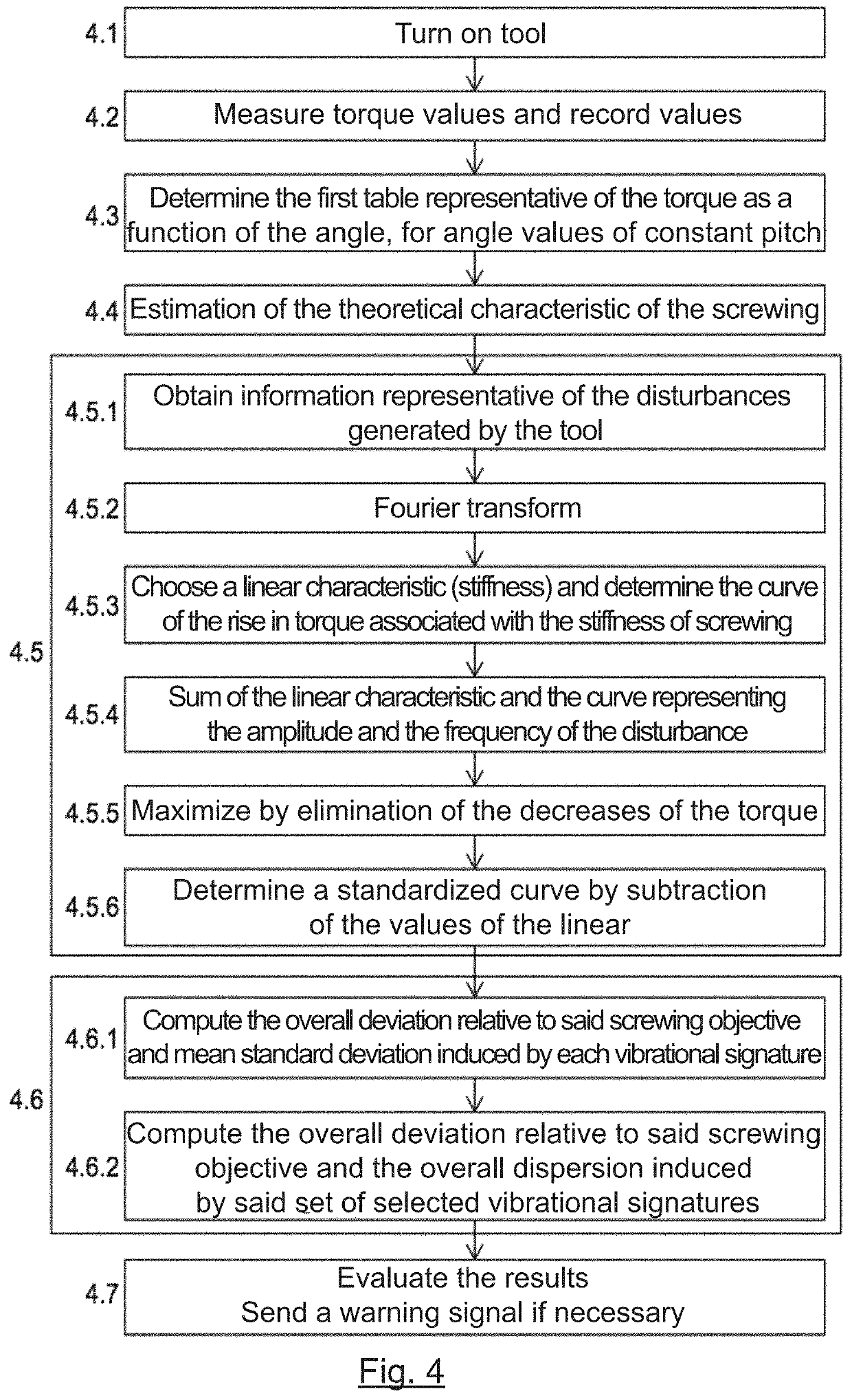

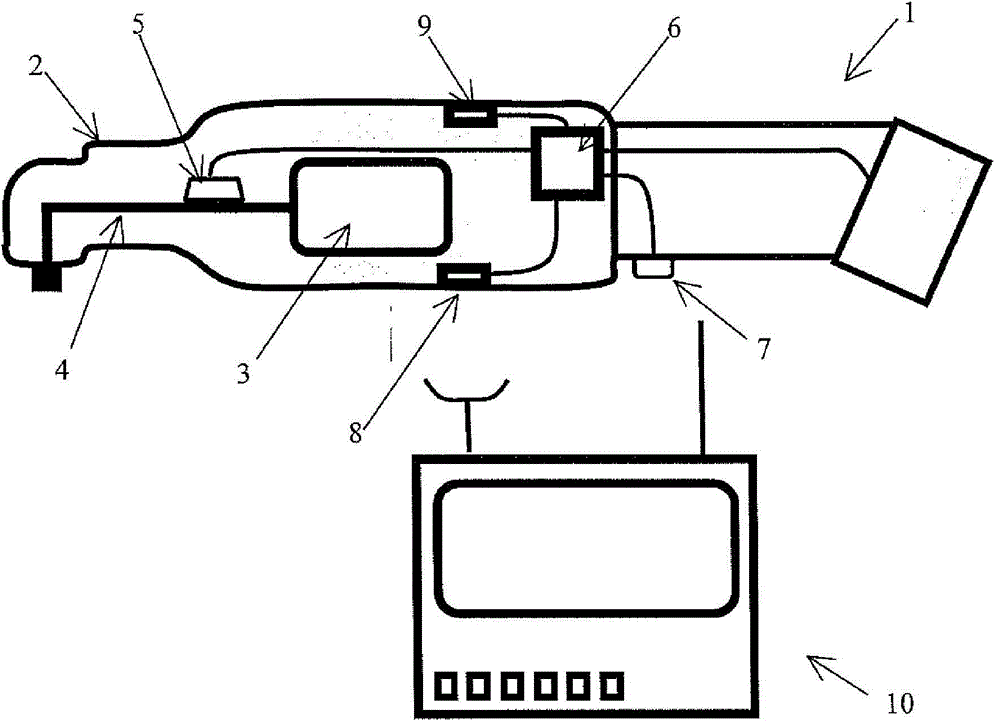

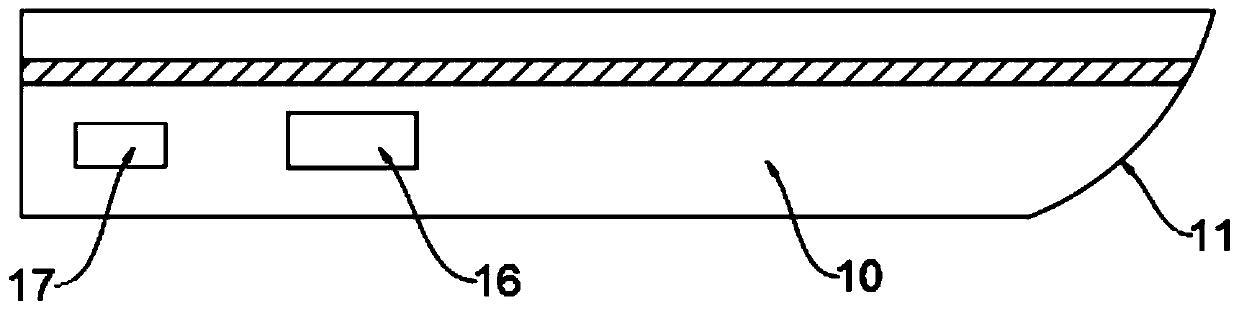

Method of Assistance in the Maintenance of an Industrial Tool, Corresponding Tool and System and Program Implementing the Method

PendingUS20210199416A1Easy to detectEasy to operateImage enhancementImage analysisIndustrial toolShortest distance

A method for assisting maintenance of an industrial tool (e.g., a screw driver or drill), implementing rotationally mobile components. The method includes: obtaining measurement data representing an angle and / or a torque during use of the tool; analyzing the measurement data to determine quality data representing possible disturbances induced for each of a set of controlled components, delivering a tool signature; storing the signature in a memory associated with the tool, and readable contactlessly at short distances; remotely reading the signature in the memory, by a terminal; identifying a component requiring action, based on the signature; obtaining, through the terminal, an intervention to be carried out, comprising 3D information on the tool; taking an image of the tool, by a camera on the terminal; displaying a representation in augmented reality, by using the image and the 3D pieces of information, identifying a defective component and / or maintenance operations to be performed.

Owner:ETAB GEORRENAULT

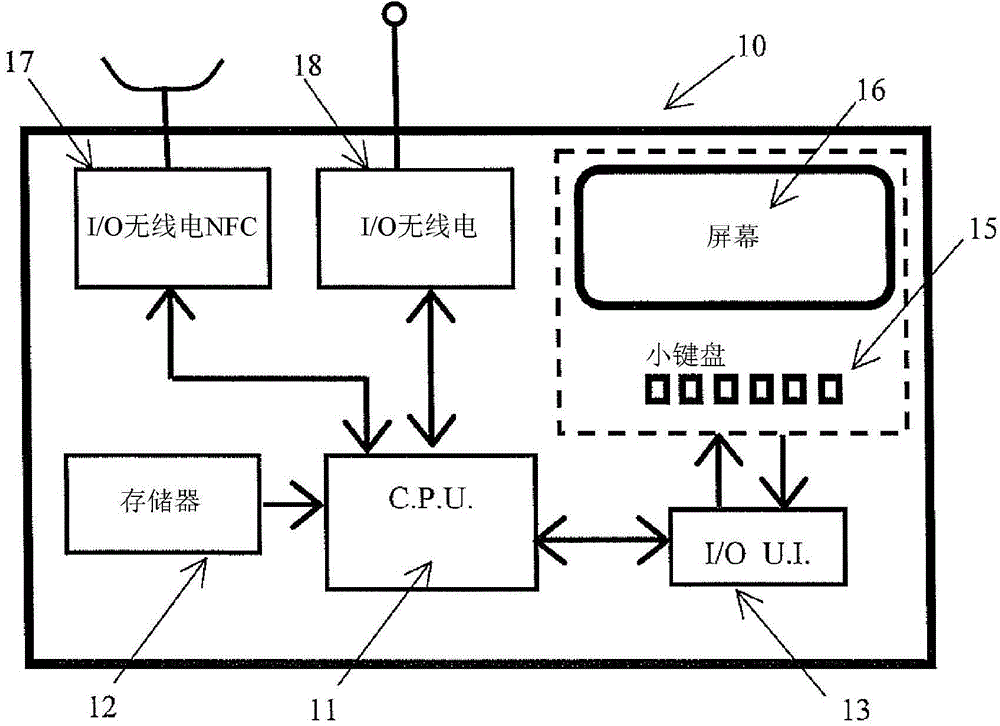

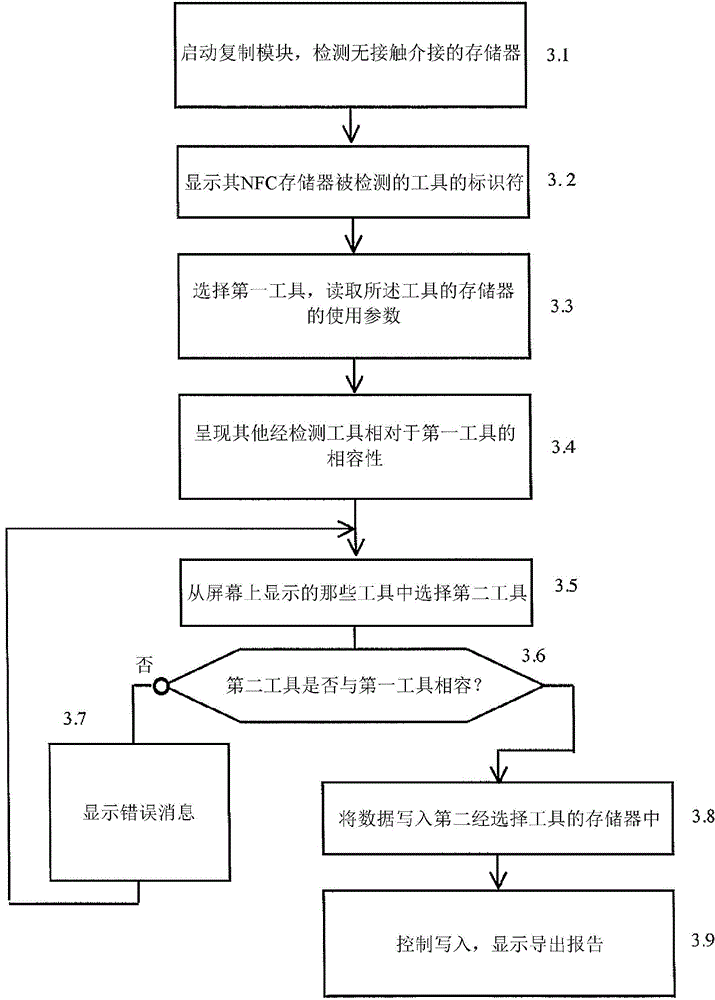

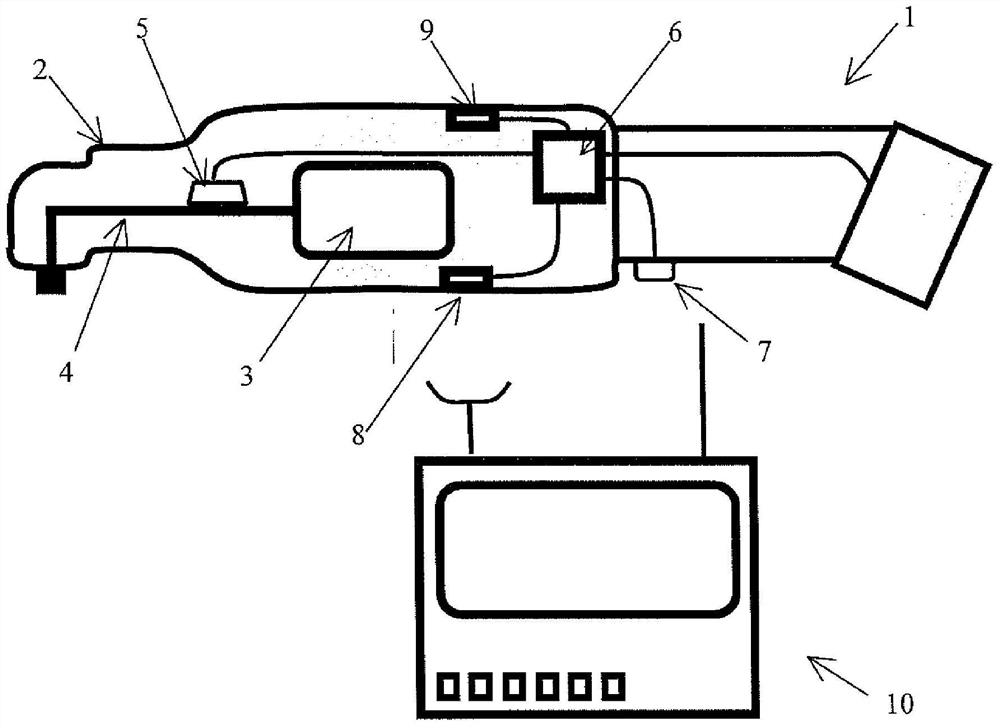

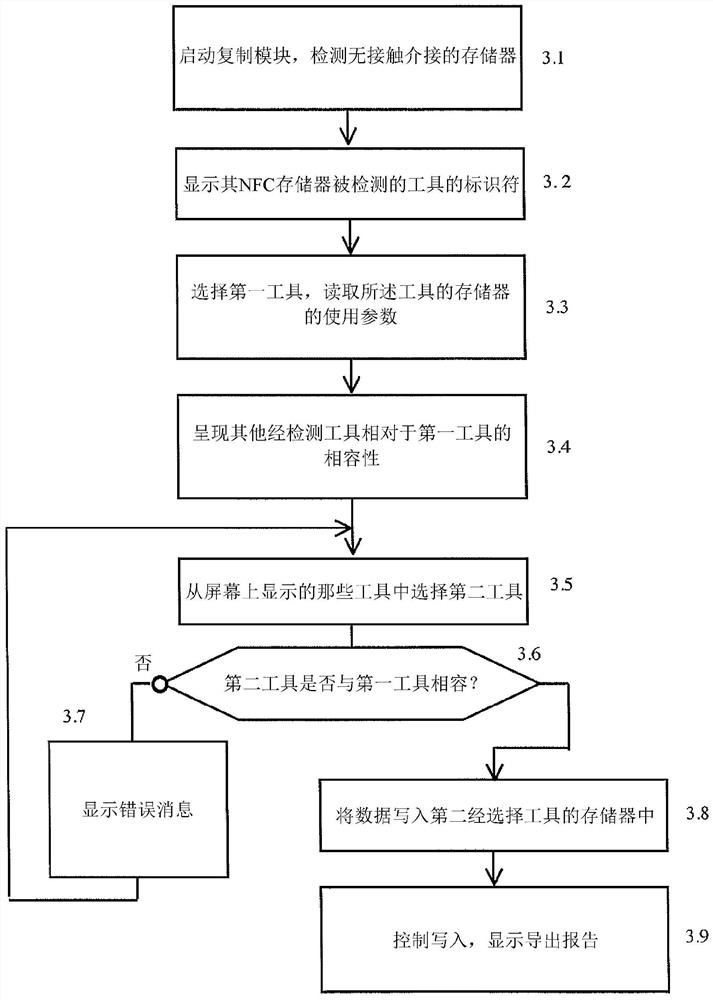

Apparatus for duplicating usage parameters written in memory of industrial tool

The presen invention relates to an apparatus for duplicating usage parameters written in a memory of an industrial tool. When the tool is located in the environment thereof, and the apparatus can access the memory om a reading and write-in mode by means of a wireless link. At least one portion of the data of the memory defines the usage parameters of the portable tool. The apparatus particularly comprises a member for identifying the portable tool, wherein a memory of a first tool has usage parameters to be copied to a memory of a second tool; a member for reading the usage parameters of the first portable tool in the memory of the first portable tool; and a member for writting the usage parameters read from the memory of the first tool into the memory of the second portable tool. In this way, the industrial tool broken down can be easily and rapidly replaced by another tool operating normally.

Owner:ETAB GEORRENAULT

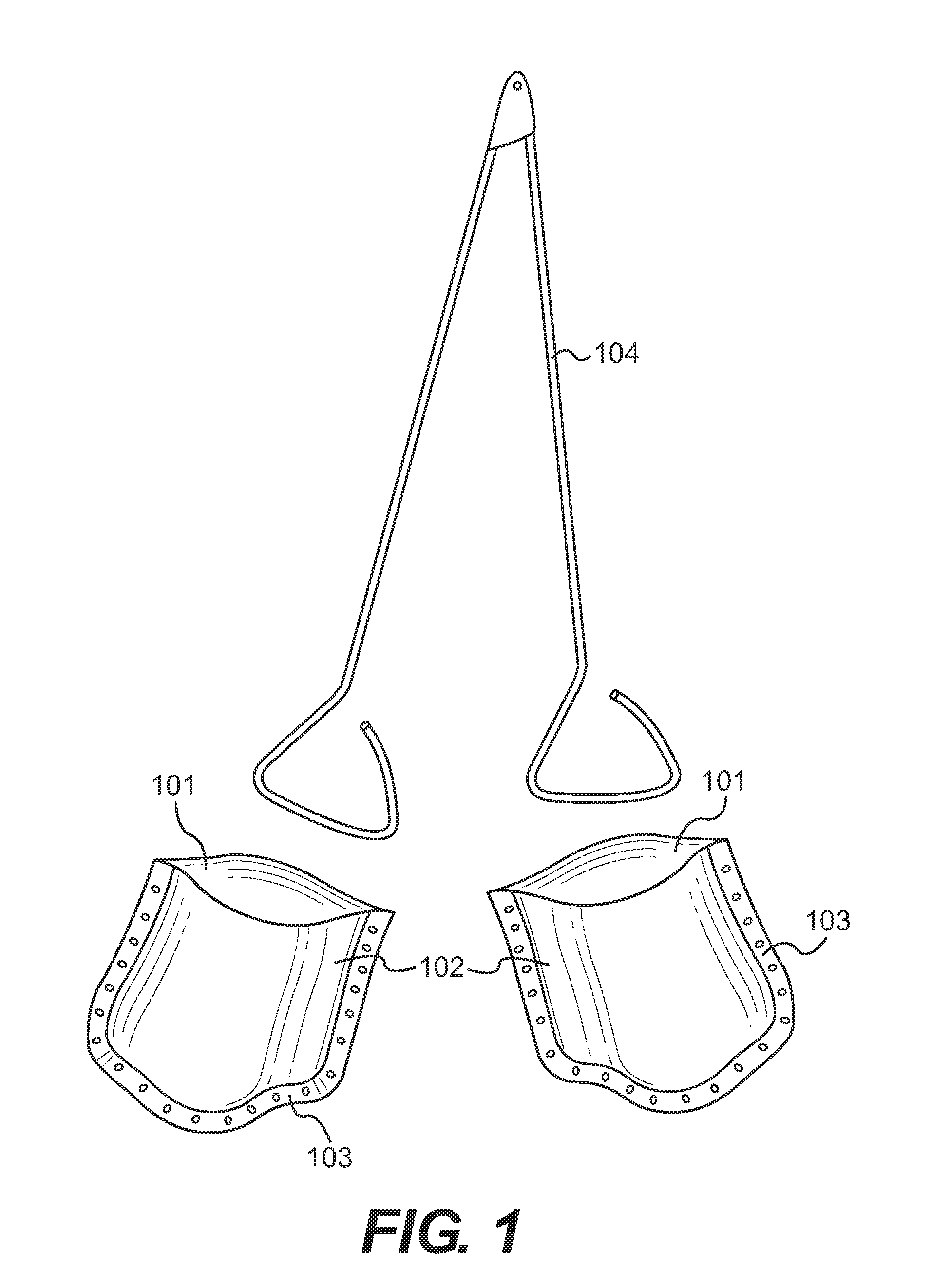

Means and Method to Protect Items From Contamination

InactiveUS20090014345A1Effective controlEffectively maneuverOther accessoriesContainer/bottle contructionIndustrial toolProtection KIT

A protective sleeve used to cover and isolate tools such as cooking utensils, medical tools, industrial tools and the like from contaminants. The sleeve comprises an interior portion, an exterior portion, and an exterior trim and is comprised of a malleable material so that it may be crimped and secured to the end of any utensil or tool. The sleeve, being malleable, may also be shaped to supplement the utensil or tool. For example, a sleeve over a spatula could be shaped with lipped edges so as to allow the spatula to more easily hold and maneuver foods. An example of a use of the protective sleeve is to protect foods from cross-contamination of harmful bacteria that may be present on raw or undercooked meats.

Owner:CAINES CLYNTON

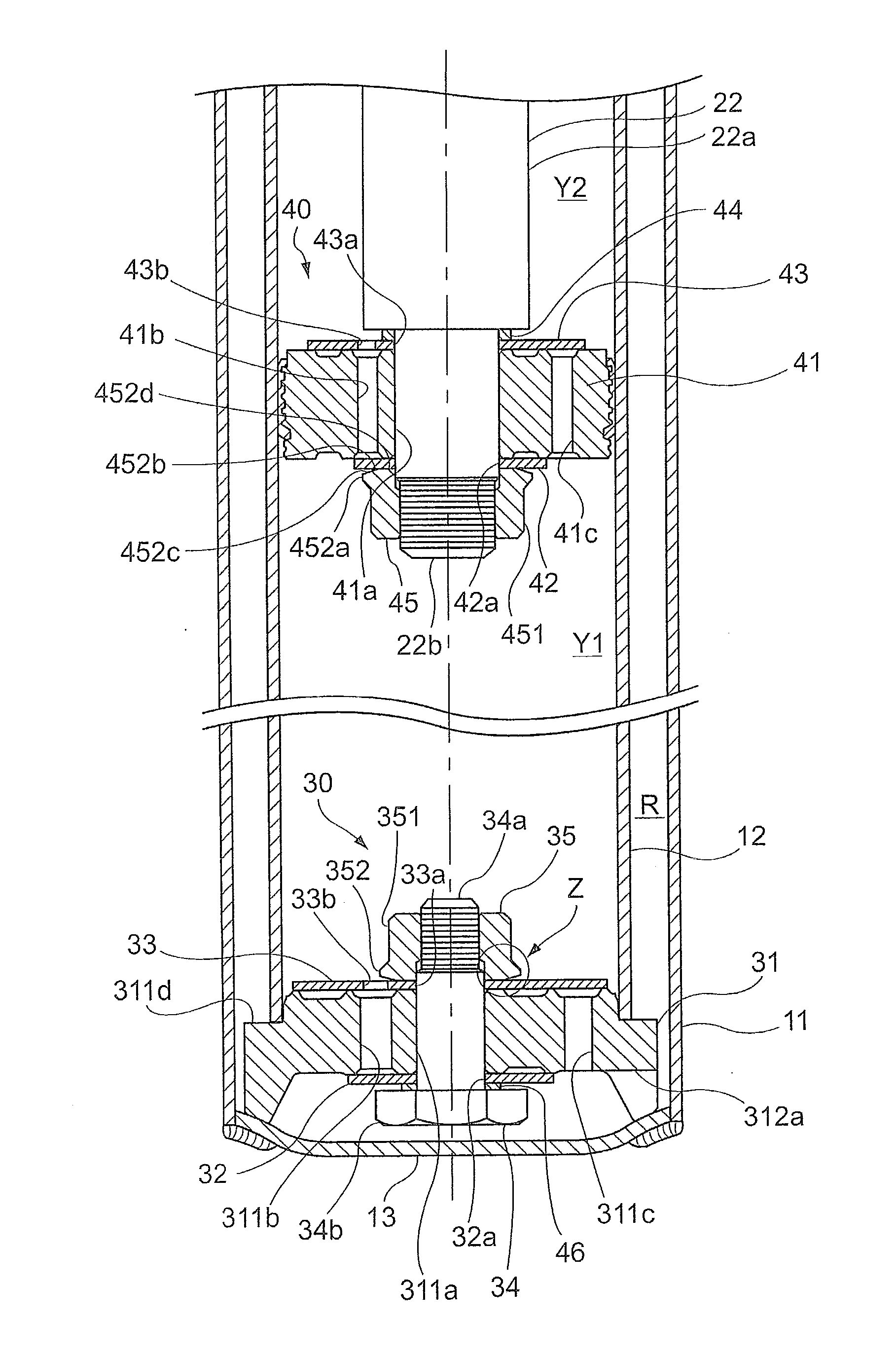

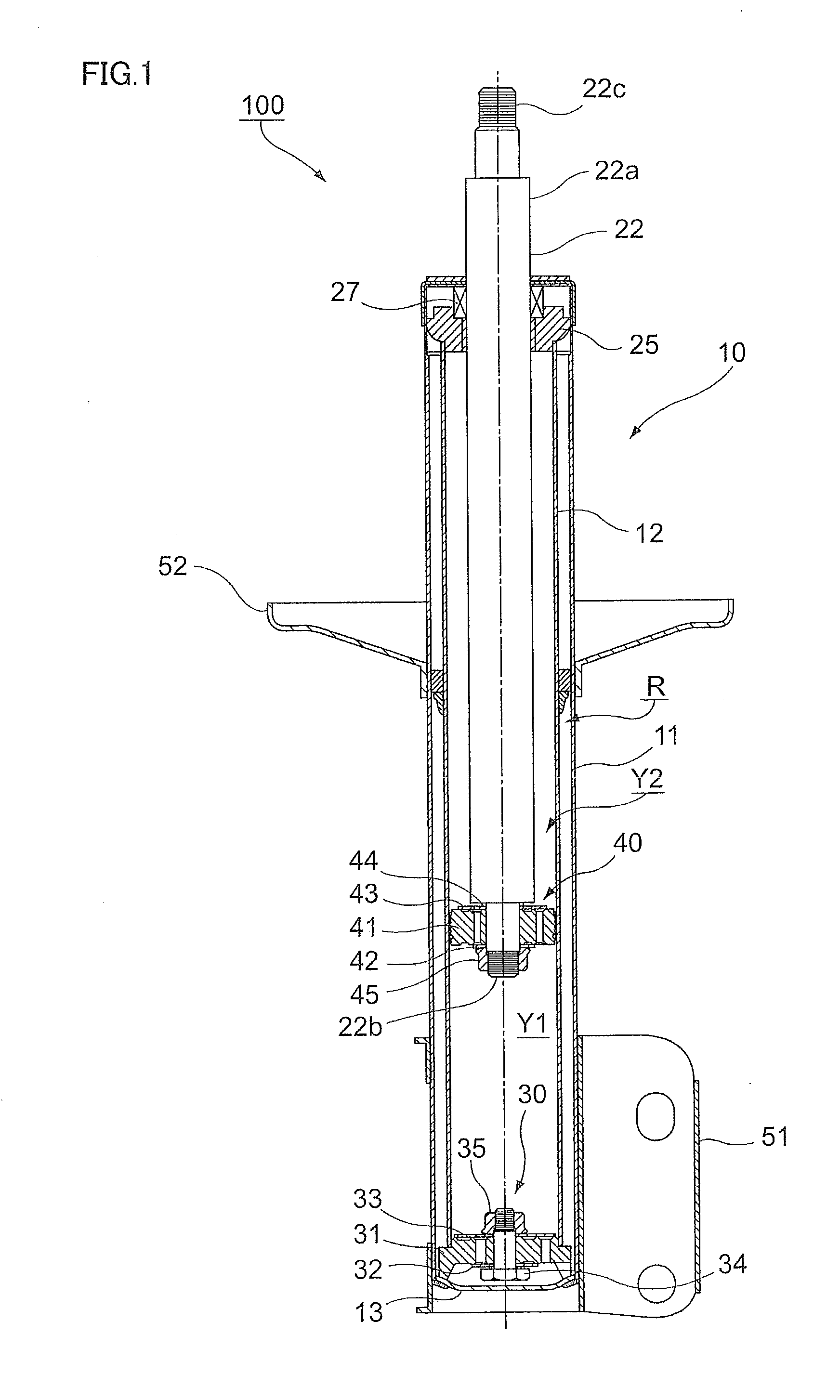

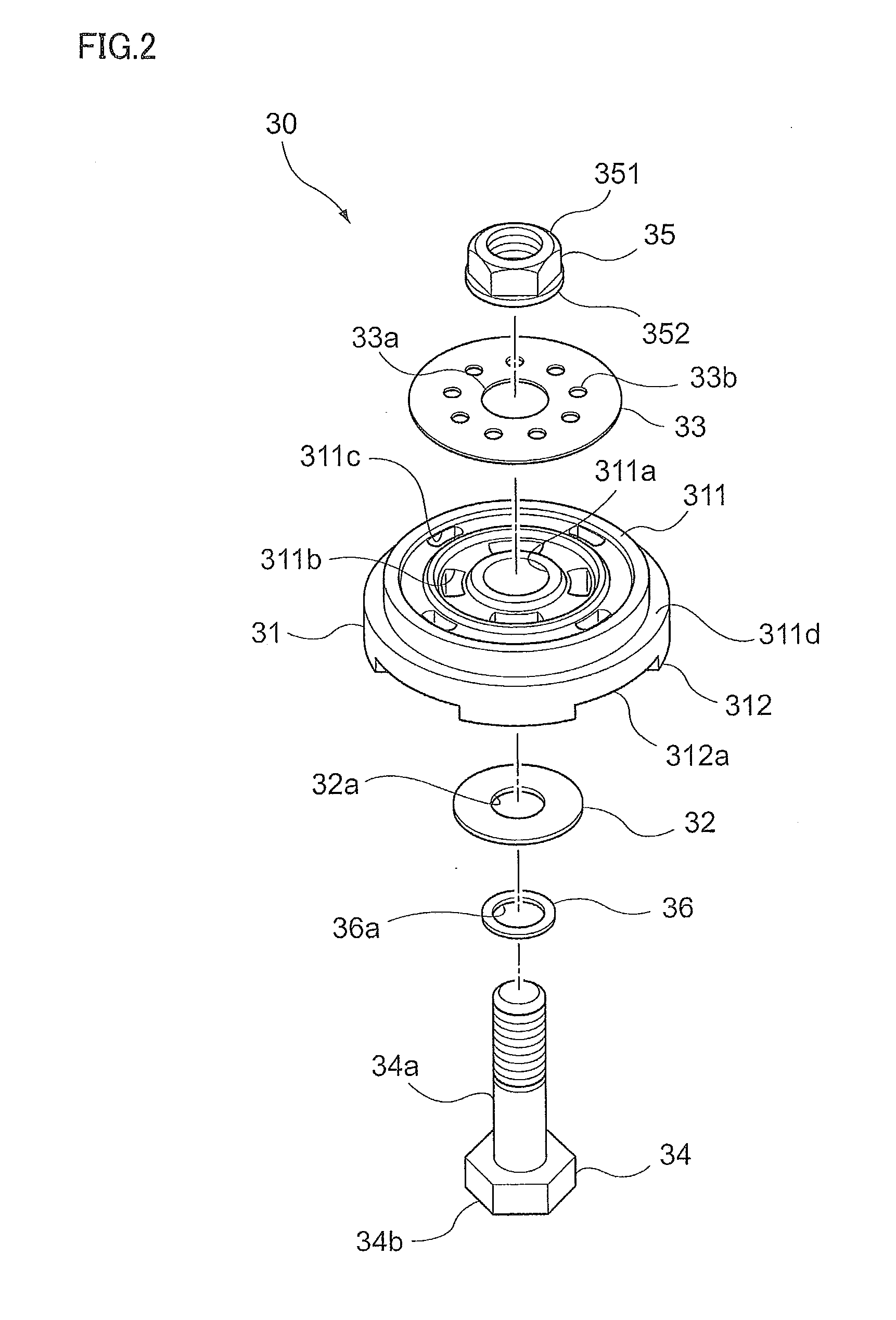

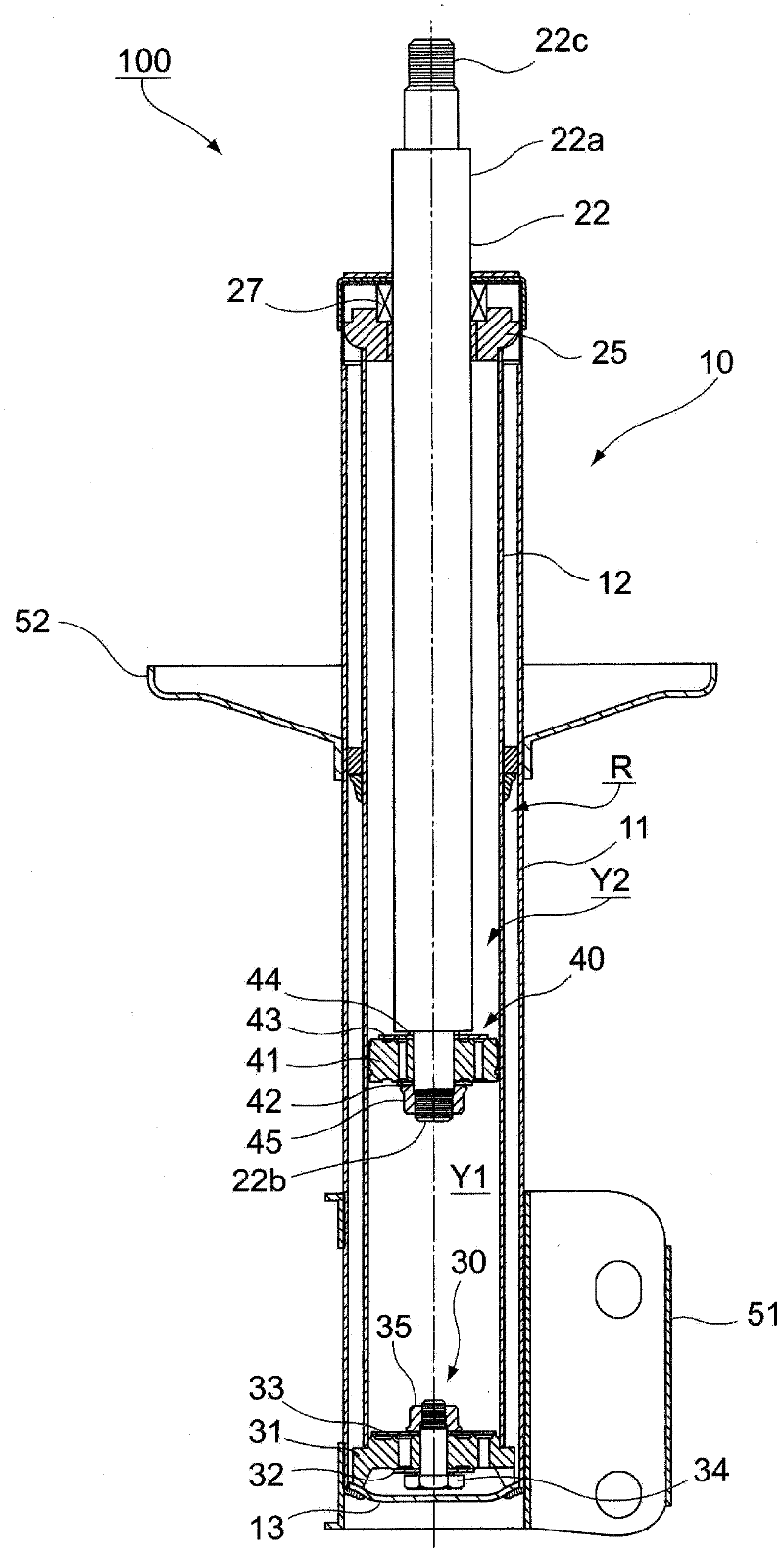

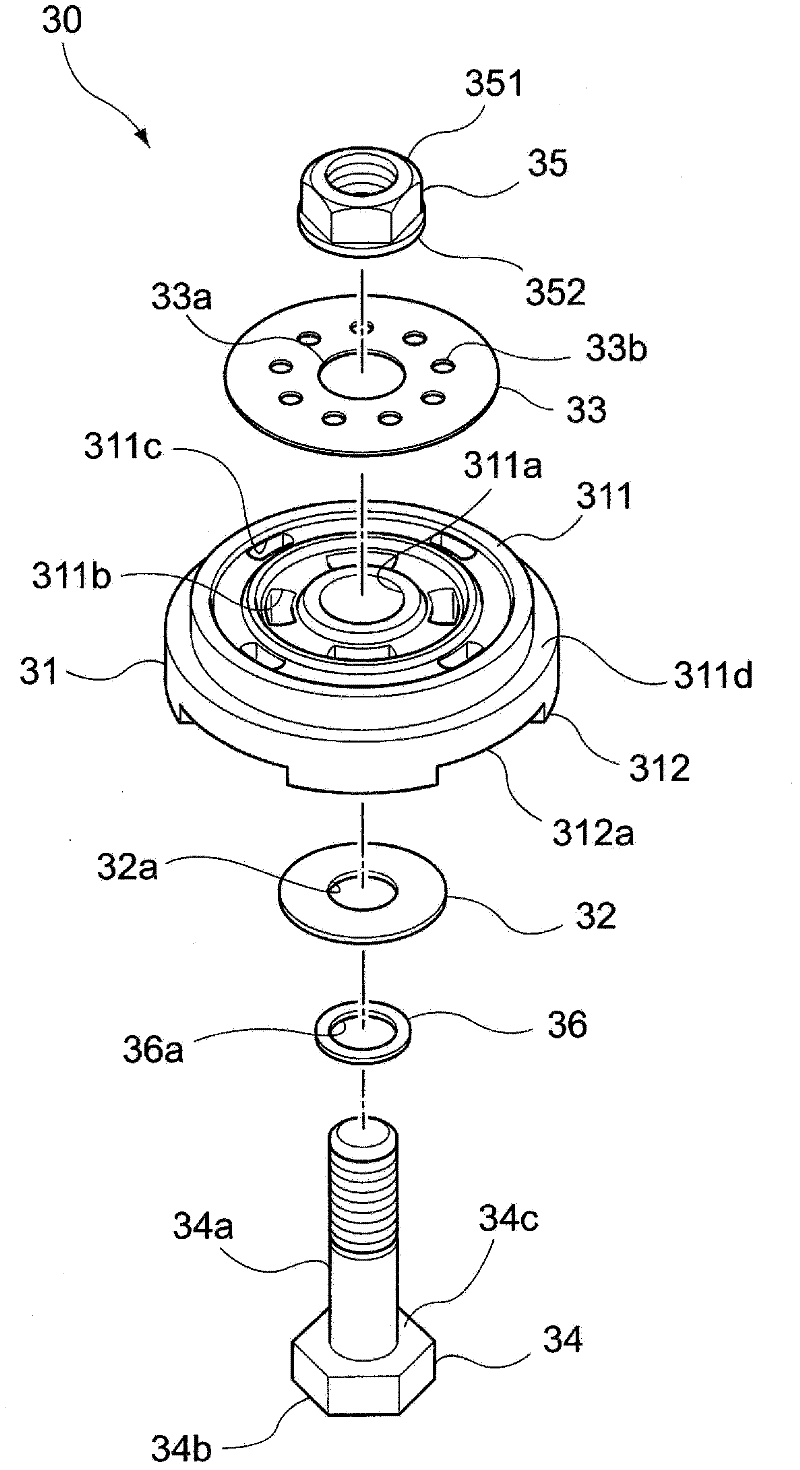

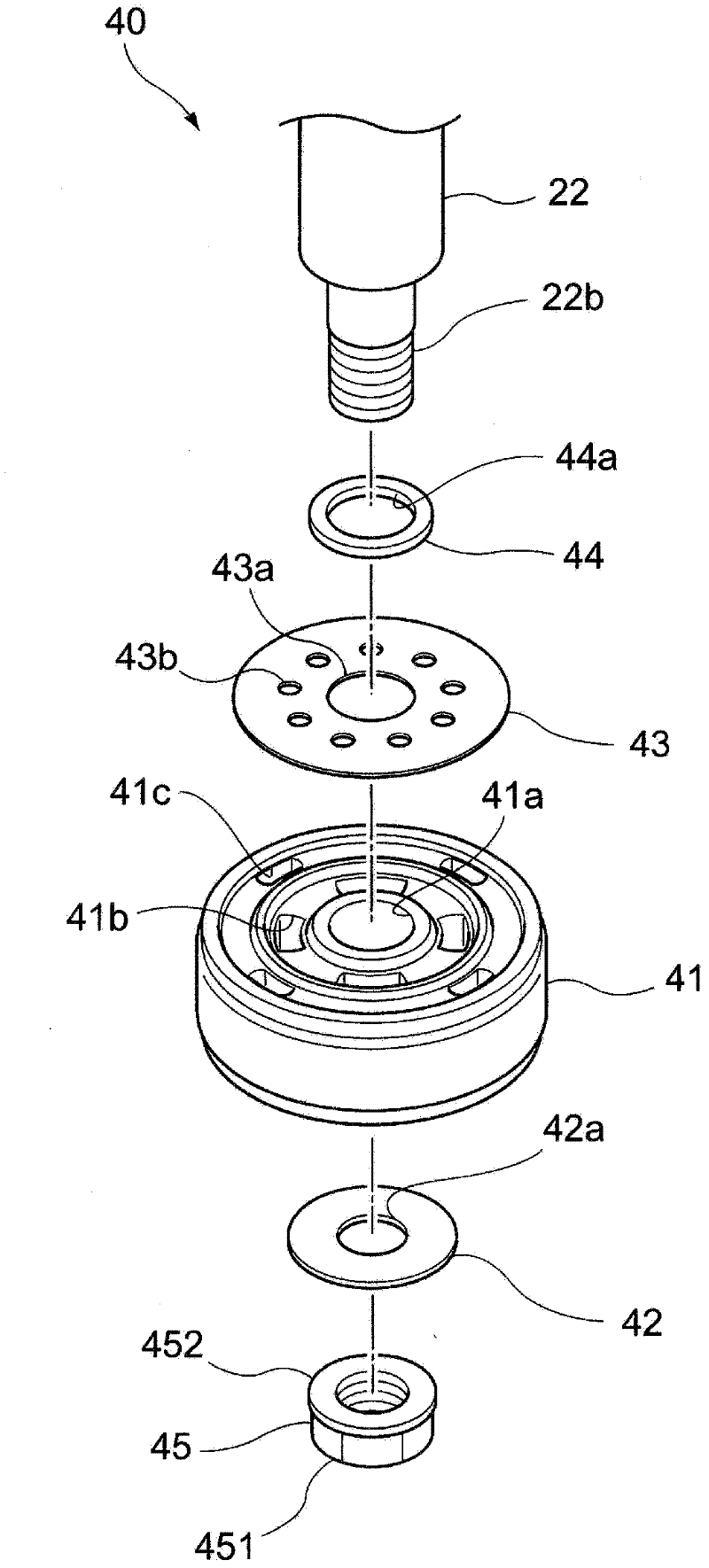

Hydraulic shock absorber and damping force generator

InactiveUS20120199429A1Reduce in quantityEasy to assembleSpringsLiquid based dampersIndustrial toolHydraulic shock

A hydraulic shock absorber includes: a dividing member dividing a closed space and having a communicating passage for communicating divided spaces; a valve covering an open end of the communicating passage; a bolt penetrating through the dividing member and the valve; and a nut fastening the dividing member and the valve together with the bolt. The bolt or the nut has a head fitted with an industrial tool, and a base end arranged on a valve side beyond the head to contact with the valve and including an extending part extending outside an outer shape of the head in a radial direction, a facing part of the base end facing the valve comes into contact with the valve at a position inside an outermost end of the extending part in the radial direction, and an outer region outside a contact part does not come into contact with the valve.

Owner:SHOWA CORP

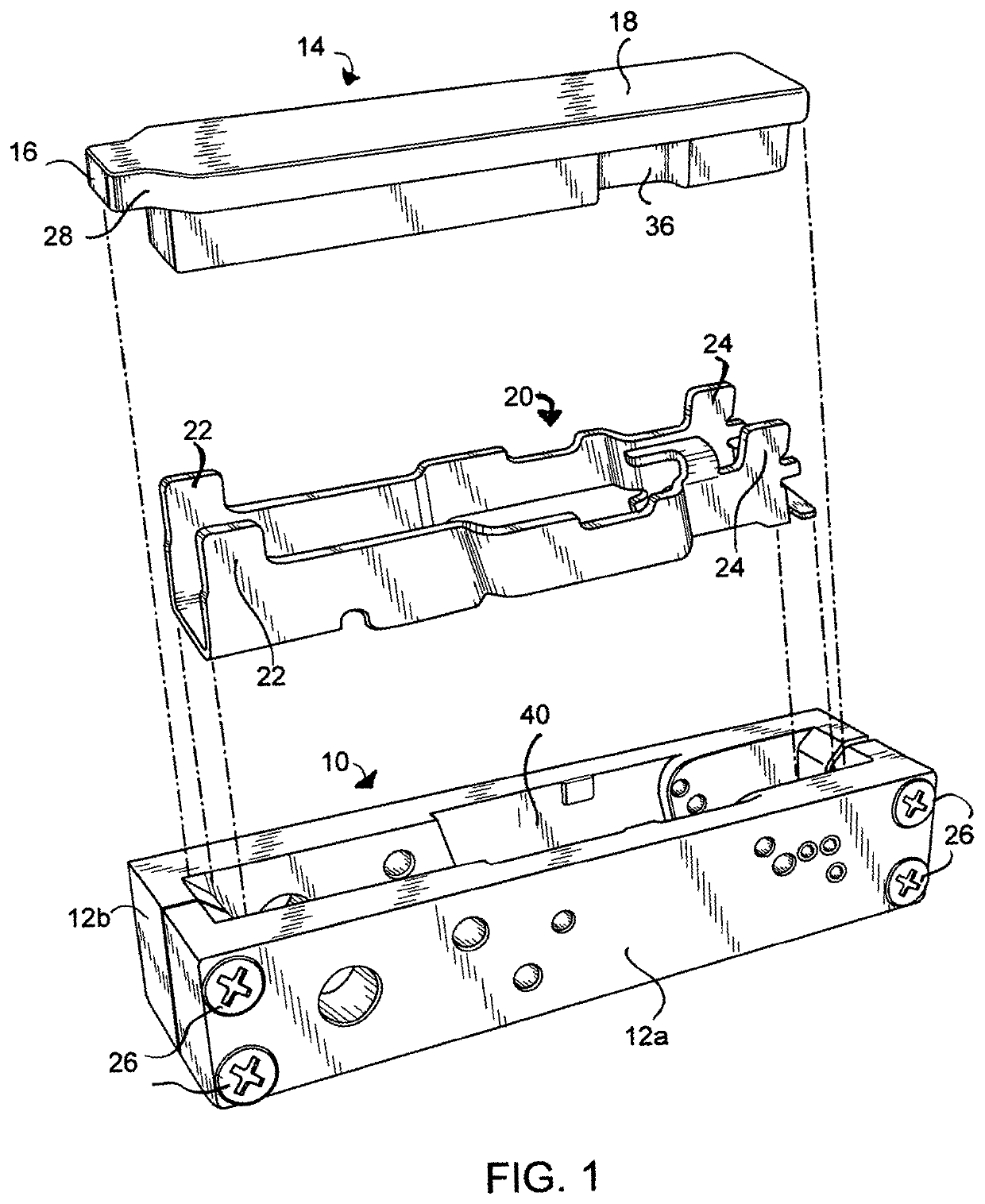

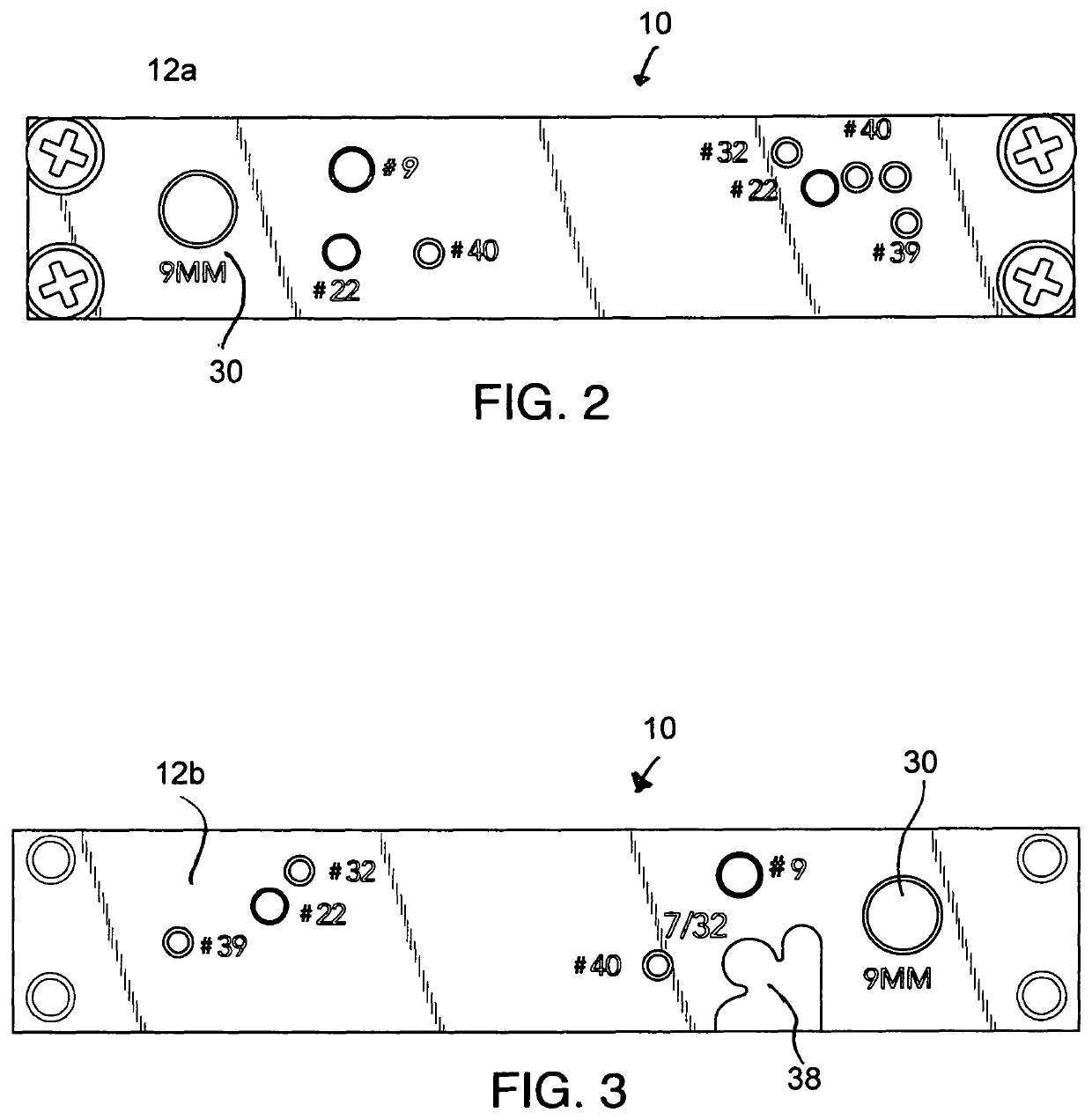

Tool jig and method of use

ActiveUS11117199B1Good adhesionMore preciseBreech mechanismsDrill jigsIndustrial toolProcess engineering

A custom-made tool used to control the location and / or movement of parts to be worked to complete an unfinished metal structure into a completed firearm receiver. The tool is a two-part jig fashioned especially for building a handgun receiver from a pre-shaped metal works without the need for other industrial tools or apparatus. Using only commonly available tools in most home work shops, the disclosed jig facilitates producing a firearm receiver from an unfinished metal structure. This disclosure also teaches a method for creating a completed pistol receiver from an unfinished metal structure using the invention.

Owner:VINROE JORDAN J

Hydraulic shock absorber and damping force generator

A hydraulic shock absorber includes: a dividing member dividing a closed space and having a communicating passage for communicating divided spaces; a valve covering an open end of the communicating passage; a bolt penetrating through the dividing member and the valve; and a nut fastening the dividing member and the valve together with the bolt. The bolt or the nut has a head fitted with an industrial tool, and a base end arranged on a valve side beyond the head to contact with the valve and including an extending part extending outside an outer shape of the head in a radial direction, a facing part of the base end facing the valve comes into contact with the valve at a position inside an outermost end of the extending part in the radial direction, and an outer region outside a contact part does not come into contact with the valve.

Owner:SHOWA CORP

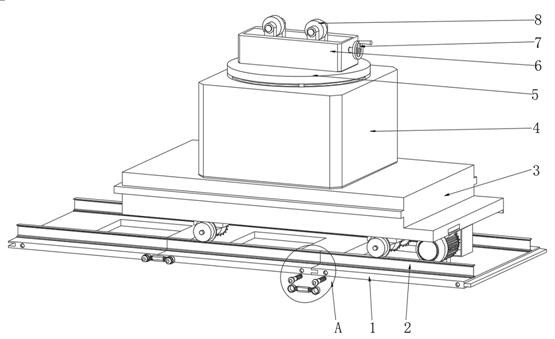

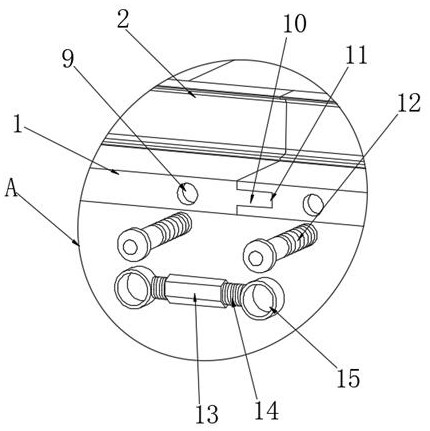

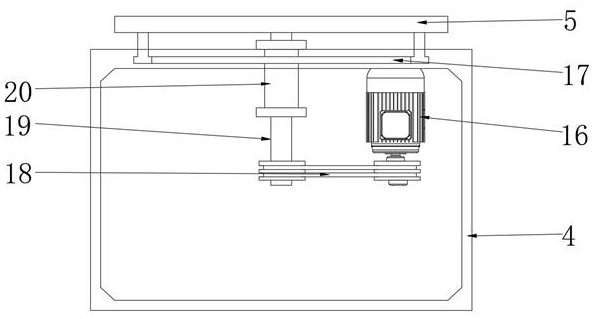

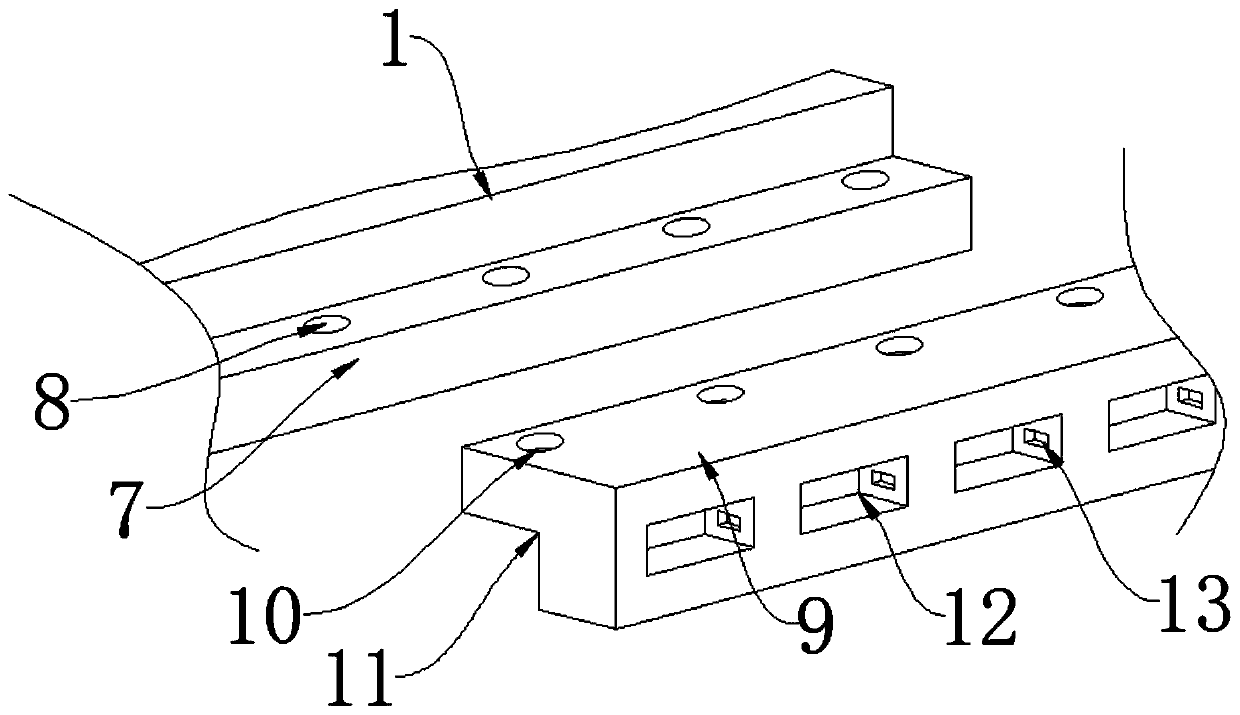

Rail trolley for industrial tool conveyance and rail

InactiveCN112249626AEasy to assemble and useEasy to disassemble and recycleMechanical conveyorsIndustrial toolElectric machinery

The invention relates to the technical field of industrial conveyance, and discloses a rail trolley for industrial tool conveyance and a rail. Guide rail plate frames are connected through locking mechanisms, I-shaped guide rails are symmetrically fixed to the upper sides of the guide rail plate frames, a rail trolley mechanism is clamped on the upper sides of the I-shaped guide rails, a supporting seat is fixed to the upper side of the rail trolley mechanism, the supporting seat is combined with a rotating disc in a clamped manner through a limiting clamping groove, and a supporting and adjusting mechanism is fixed to the upper side of the rotating disc. Through matching and combination between packaging clamping blocks and packaging clamping grooves, under locking connection of the locking mechanisms, the work personnel can conveniently assemble the guide rails for use, and meanwhile, after use, the work personnel can conveniently disassemble and recycle the guide rails; and in the use process of the rail trolley, a rotating motor drives the rotating disc to rotate, under the adjusting and supporting of the supporting and adjusting mechanism, the work personnel can conveniently adjust the direction and the spacing distance of roller supports.

Owner:松阳县景鸿设计工作室

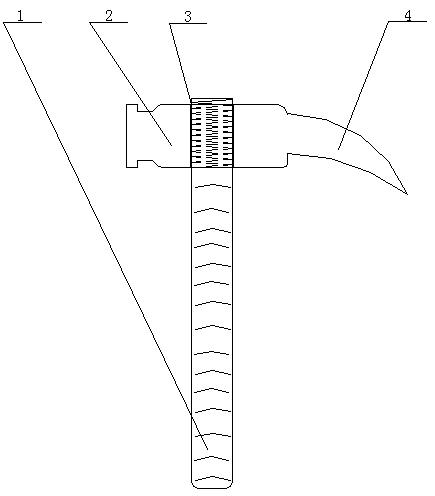

Novel claw hammer

InactiveCN102975173AEnhance the effect of nailingSimple structureHand hammersIndustrial toolBiochemical engineering

The invention relates to the technical field of industrial tools, in particular to a novel claw hammer. The novel claw hammer comprises a hammer handle (1), a hammer body (2), a hammer body central hole (3) and a claw port (4), wherein the hammer body central hole (3) is arranged in the middle of the hammer body (2), the hammer handle (1) is in threaded connection with the hammer body center hole (3), and the claw port (4) is arranged at one end of the hammer body (2). The novel claw hammer is simple in structure, can enhance the effect of nail removing, and is more convenient and rapid to use.

Owner:朱忠如

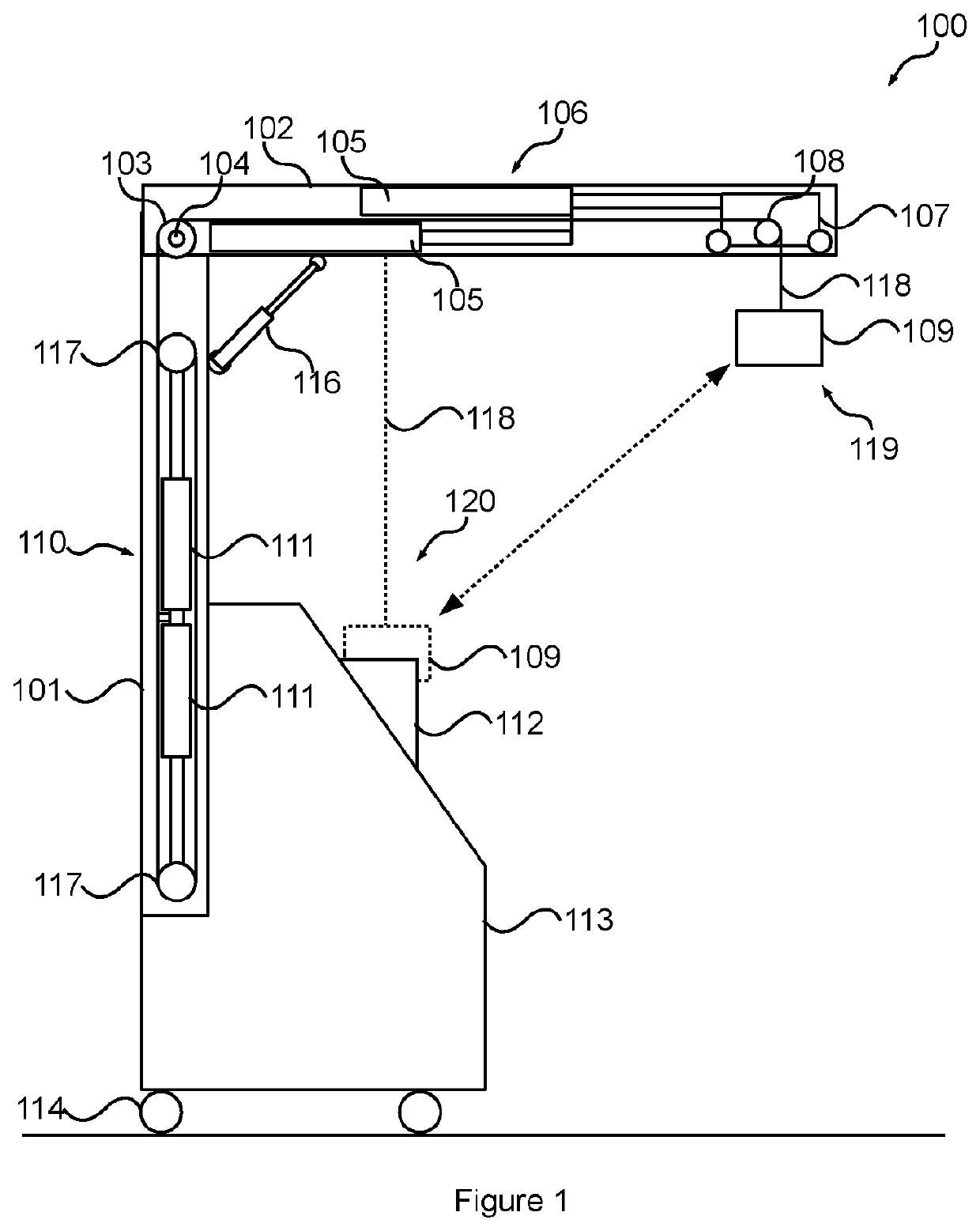

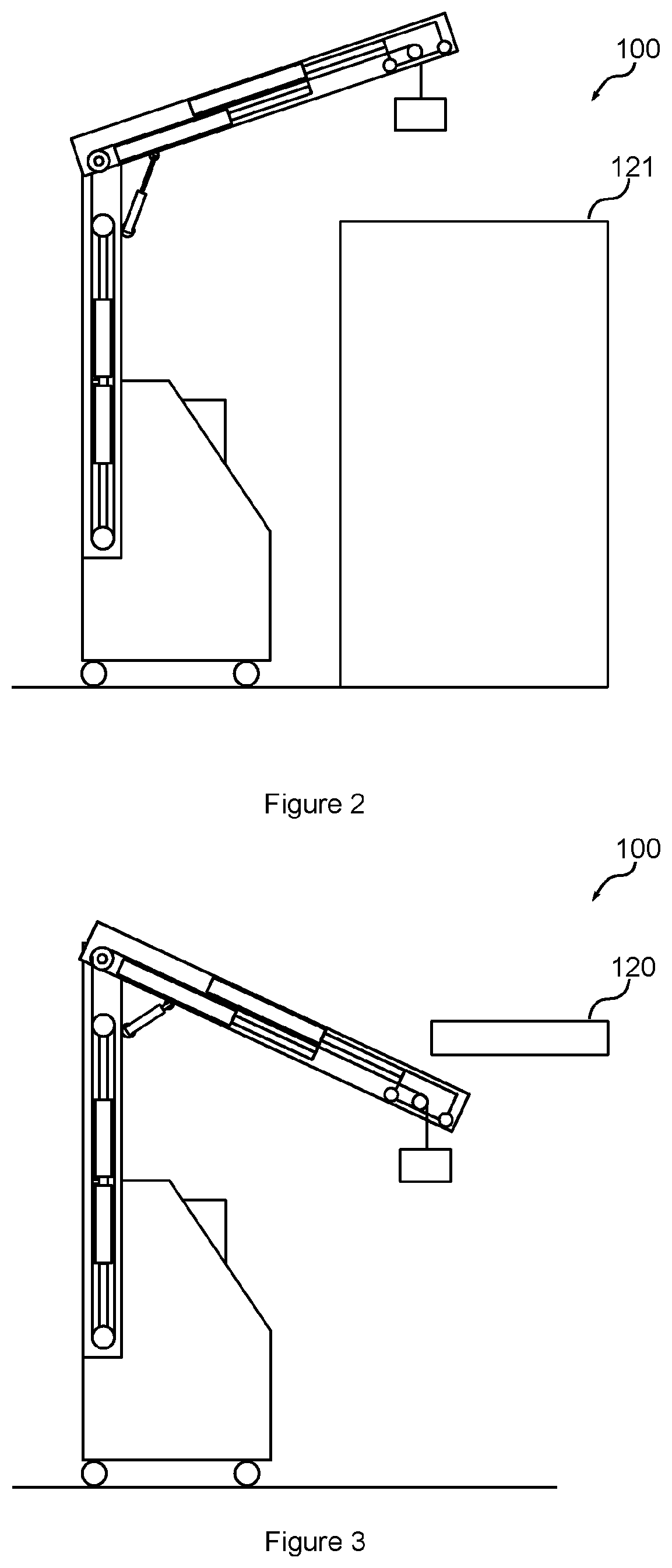

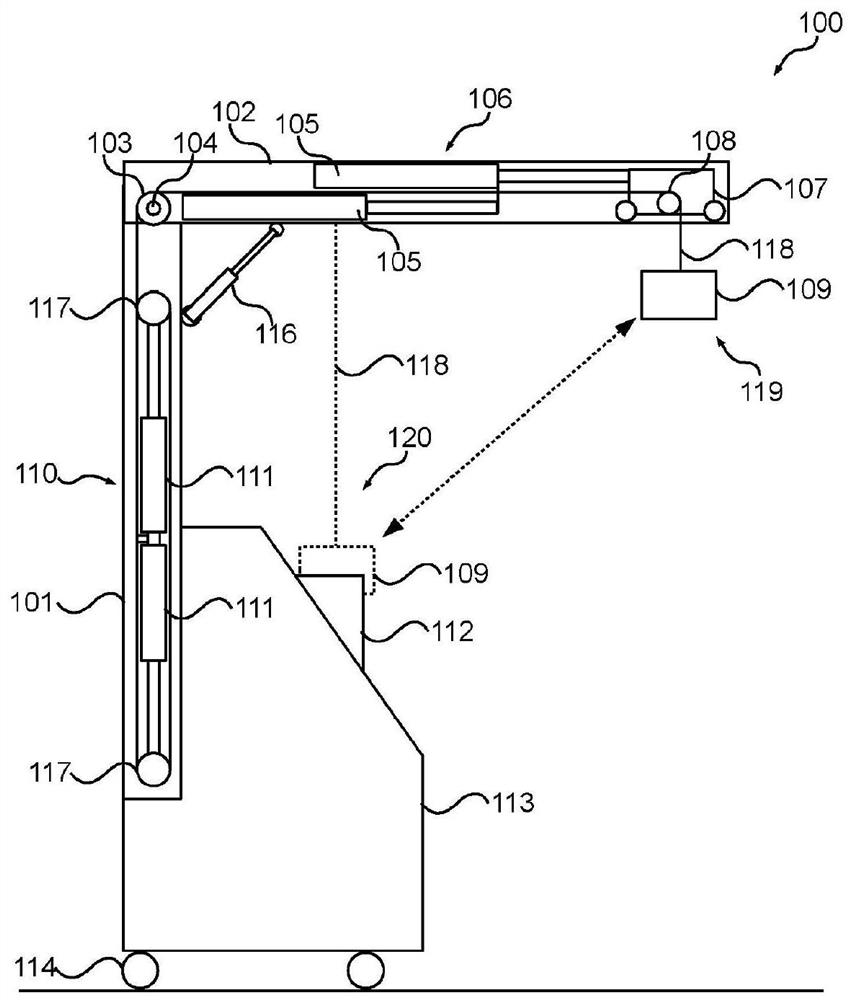

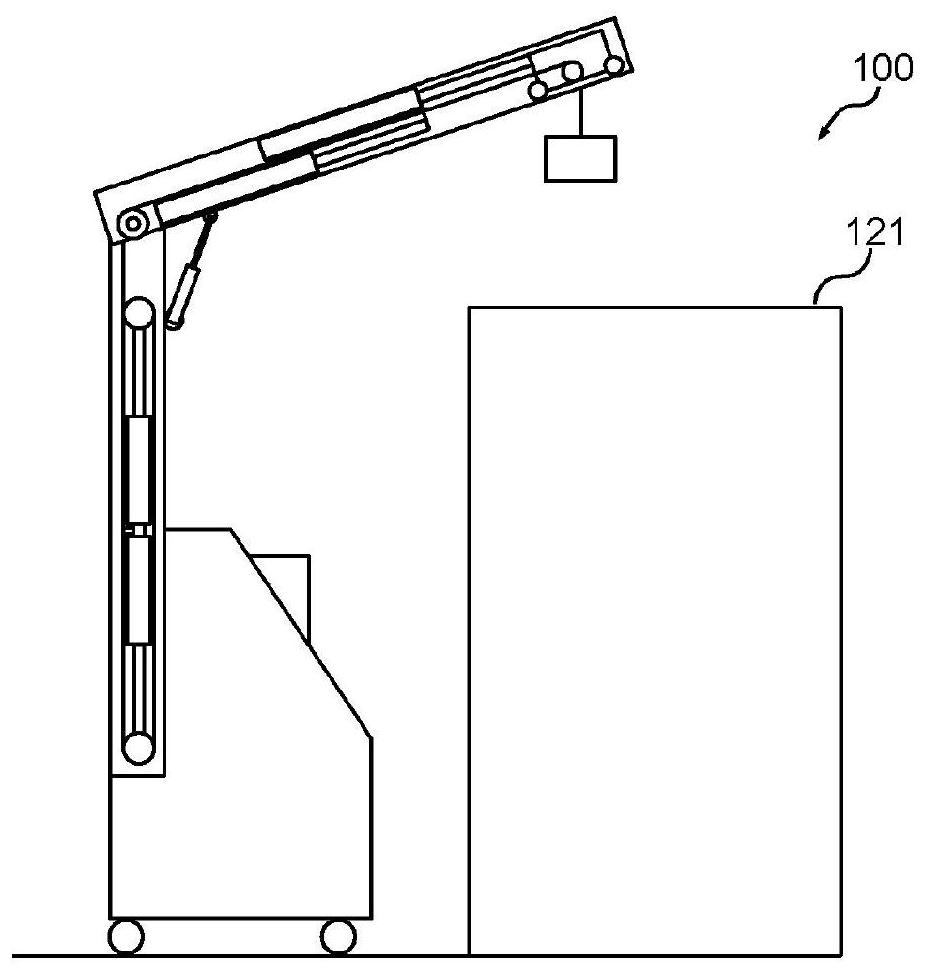

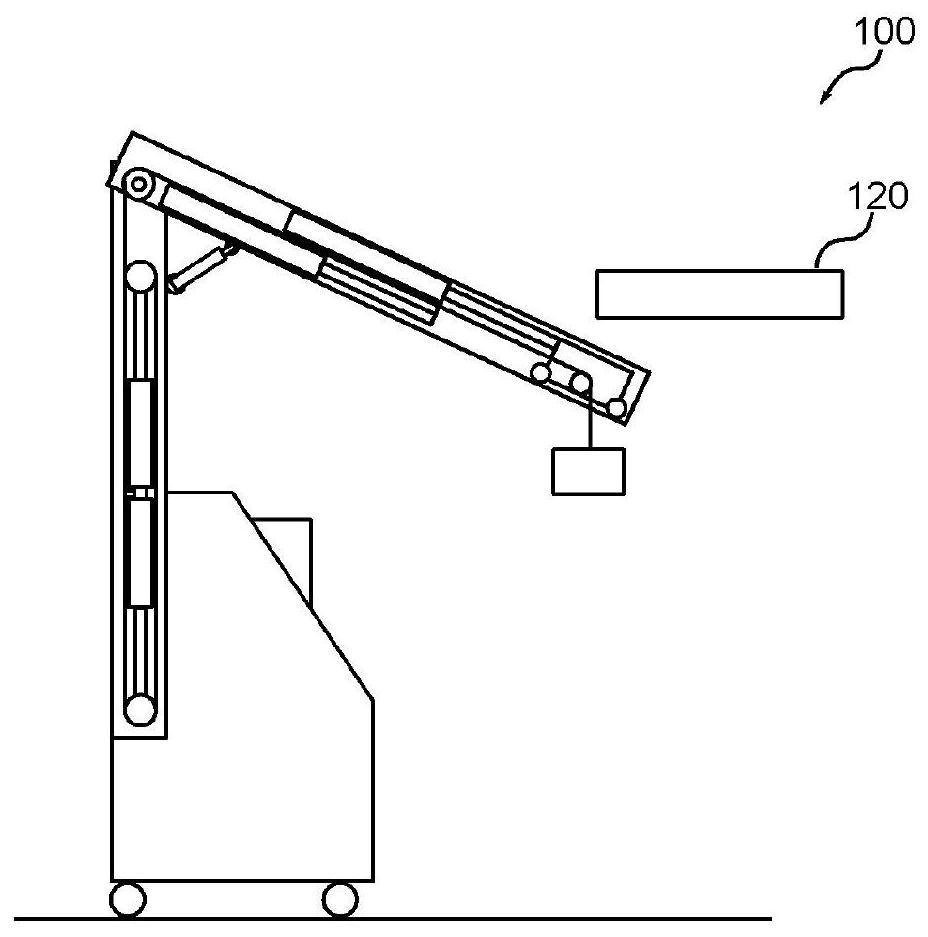

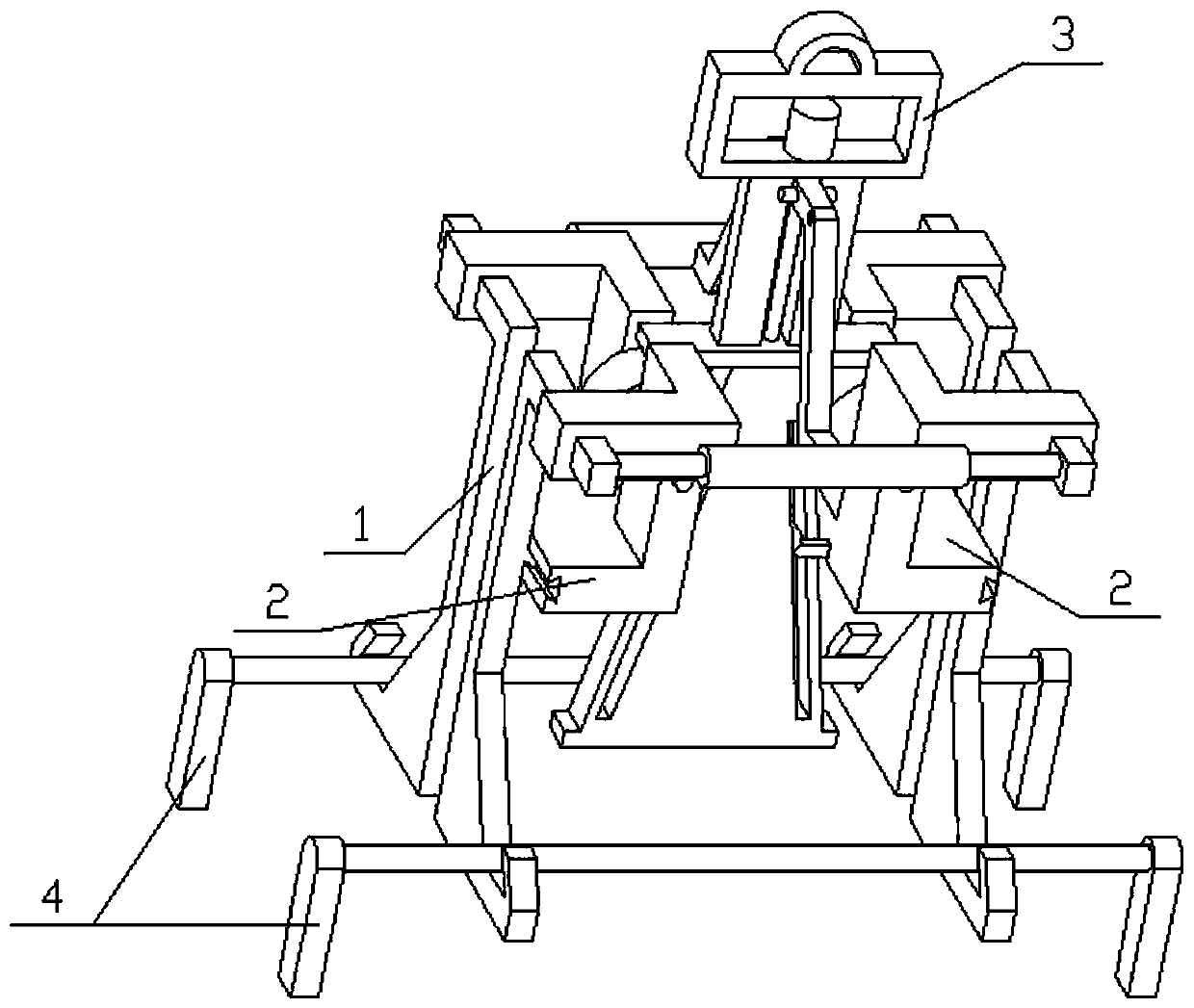

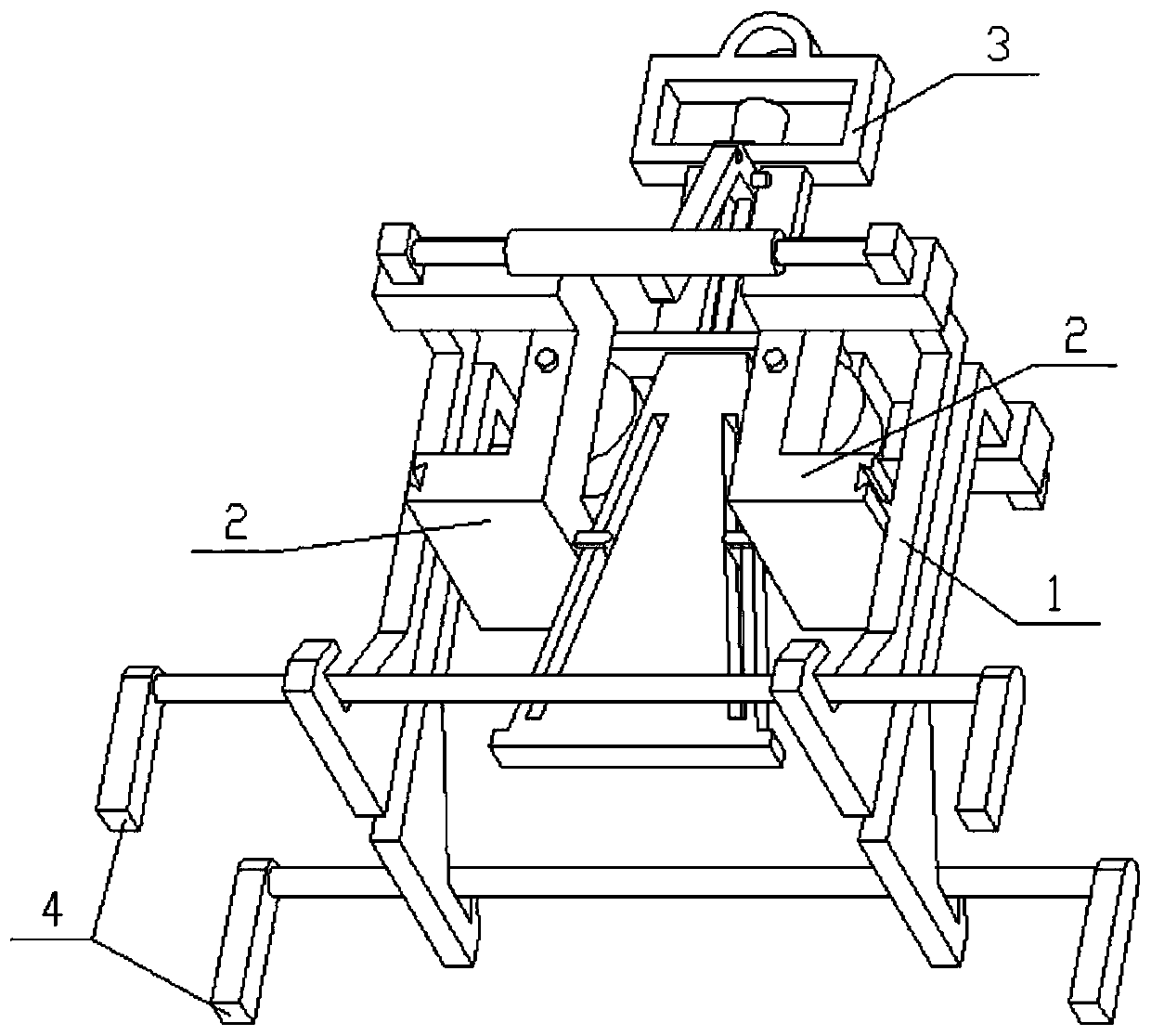

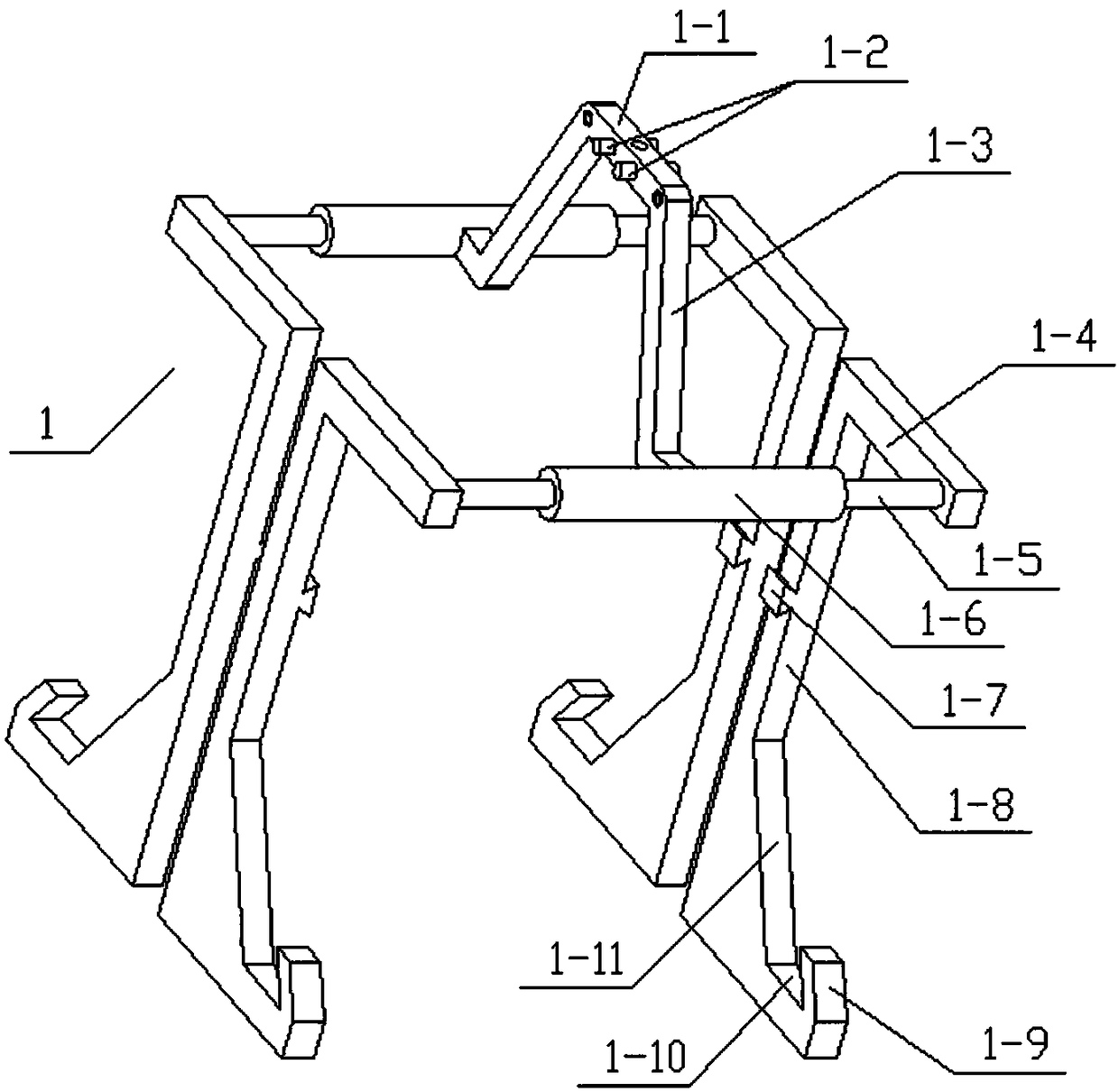

A weight balancing gantry

PendingUS20220126411A1Easy to placeReduce positioningResistance electrode holdersWelding/cutting auxillary devicesBogieIndustrial tool

A weight balancing gantry has a tower having a fixed length radial arm pivotally coupled from a pivot point at an upper end of the tower. An angle strut acts between the tower and the radial arm across the pivot point. A pivot point pulley is located at the upper end of the tower and a weight balancing mechanism located at the tower. A bogey runs along the radial arm and has a bogey pulley. A positioning mechanism at the radial arm has at least one controlled cylinder for positioning and holding the bogey along to the radial arm. A cable runs from the weight balancing mechanism, up across the pivot point pulley and over the bogey pulley to attach to an industrial tool.

Owner:CUSCHIERI CLEM

A weight balancing gantry

PendingCN113613834AWelding/cutting auxillary devicesPortable liftingIndustrial toolBalancing machine

Owner:克莱姆库什埃利

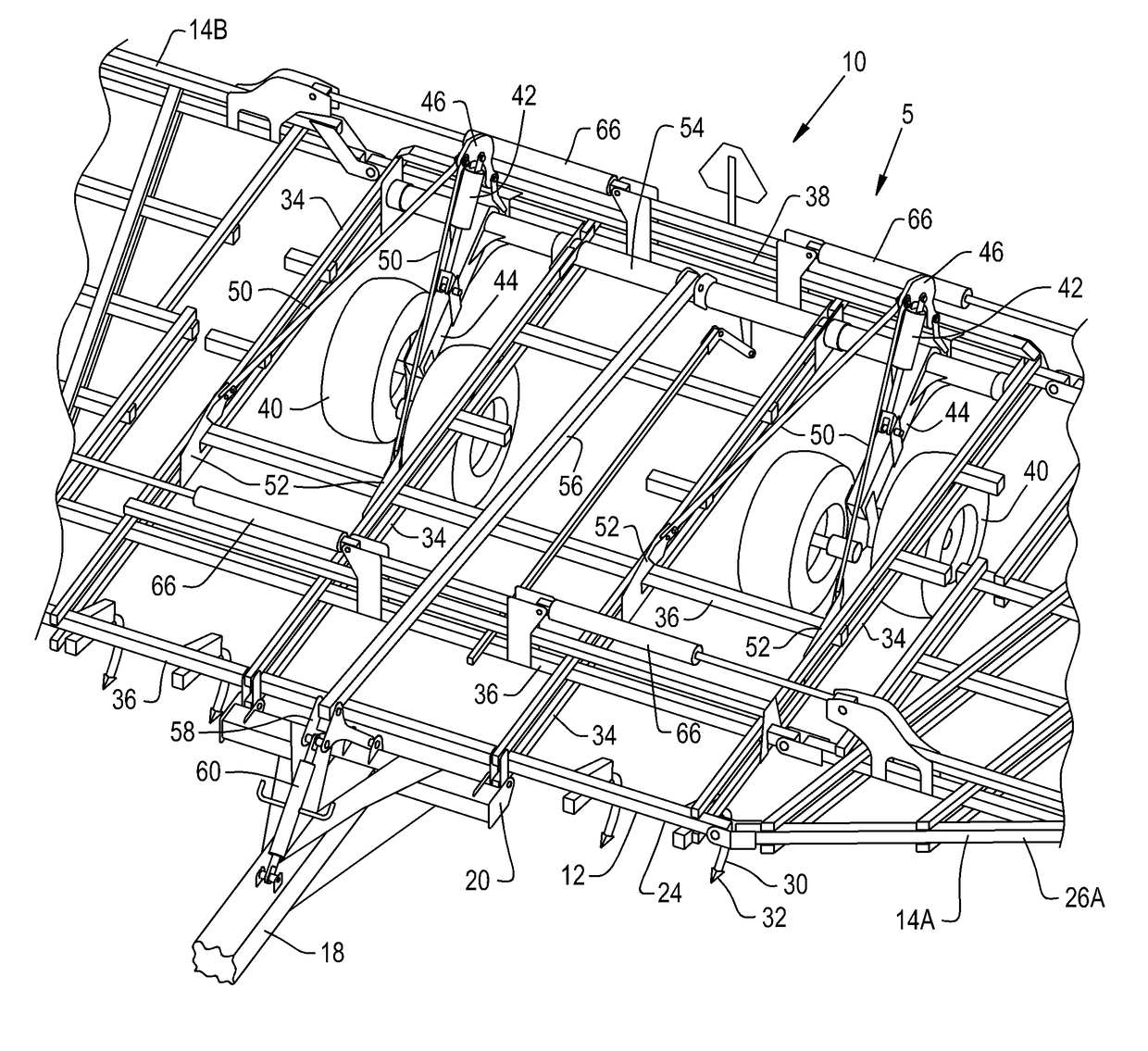

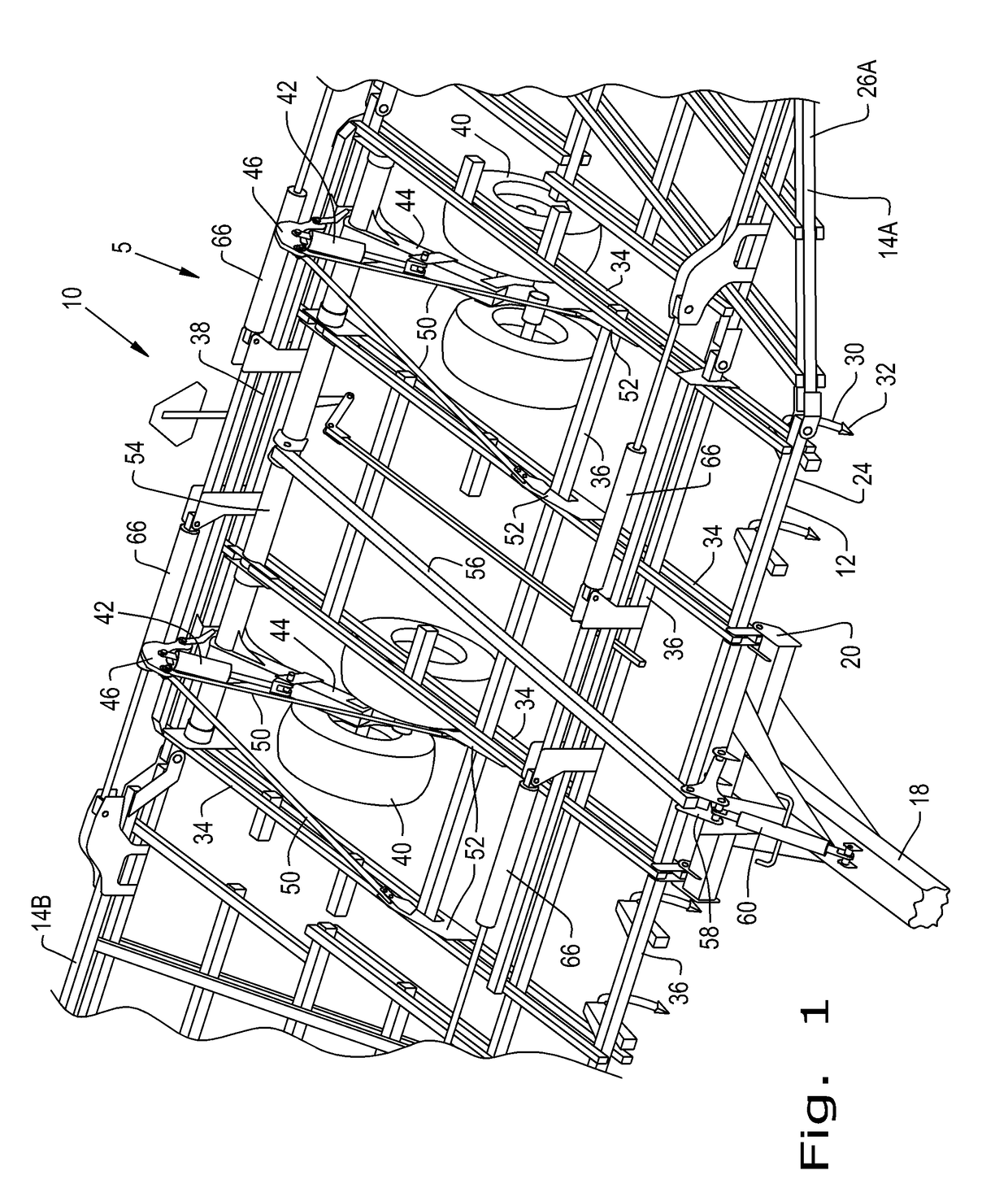

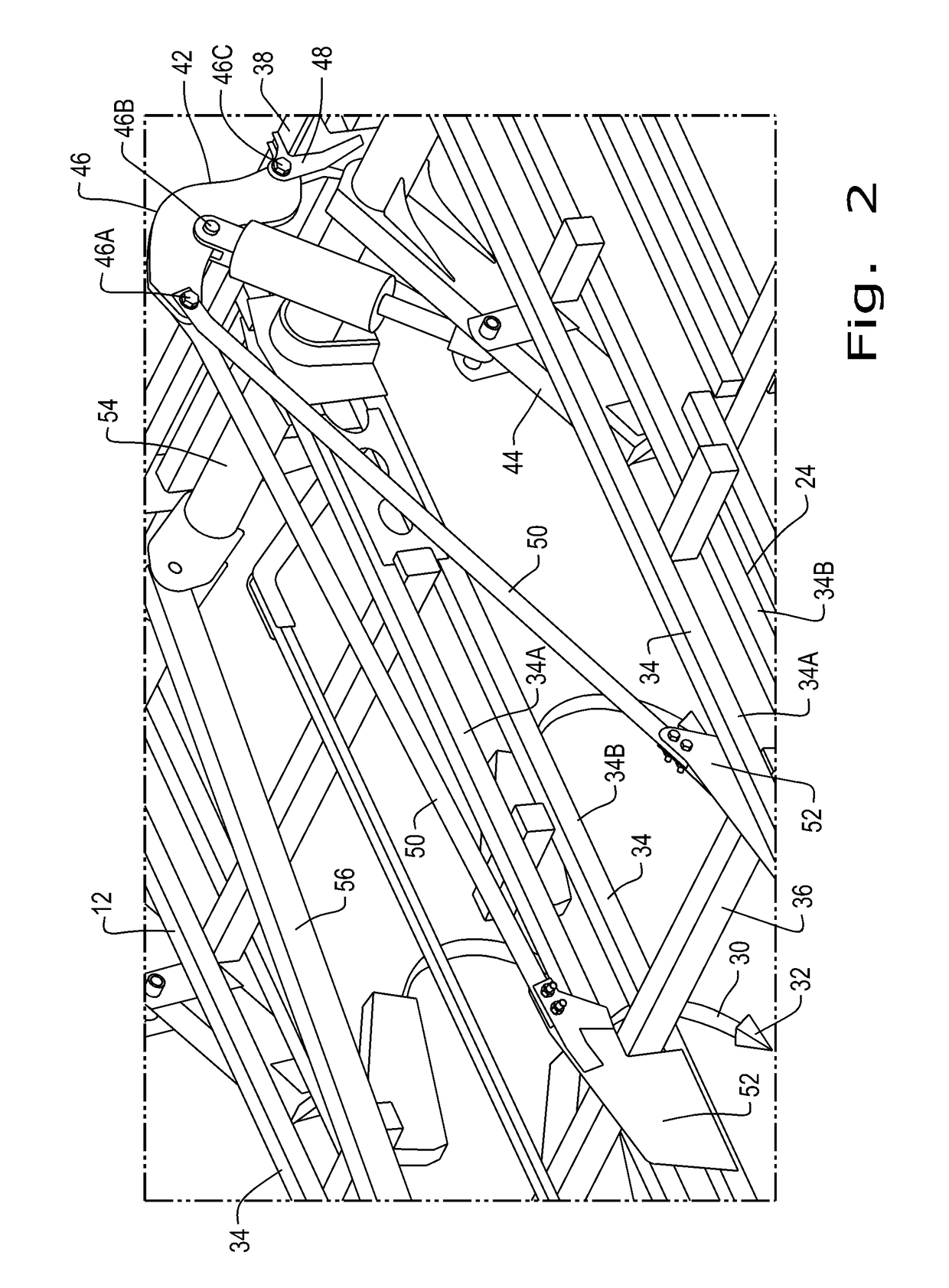

Transport load spreading device

ActiveUS20170318730A1Apply evenlyIncrease loadAgricultural machinesHarrowsIndustrial toolEngineering

Owner:BLUE LEAF I P

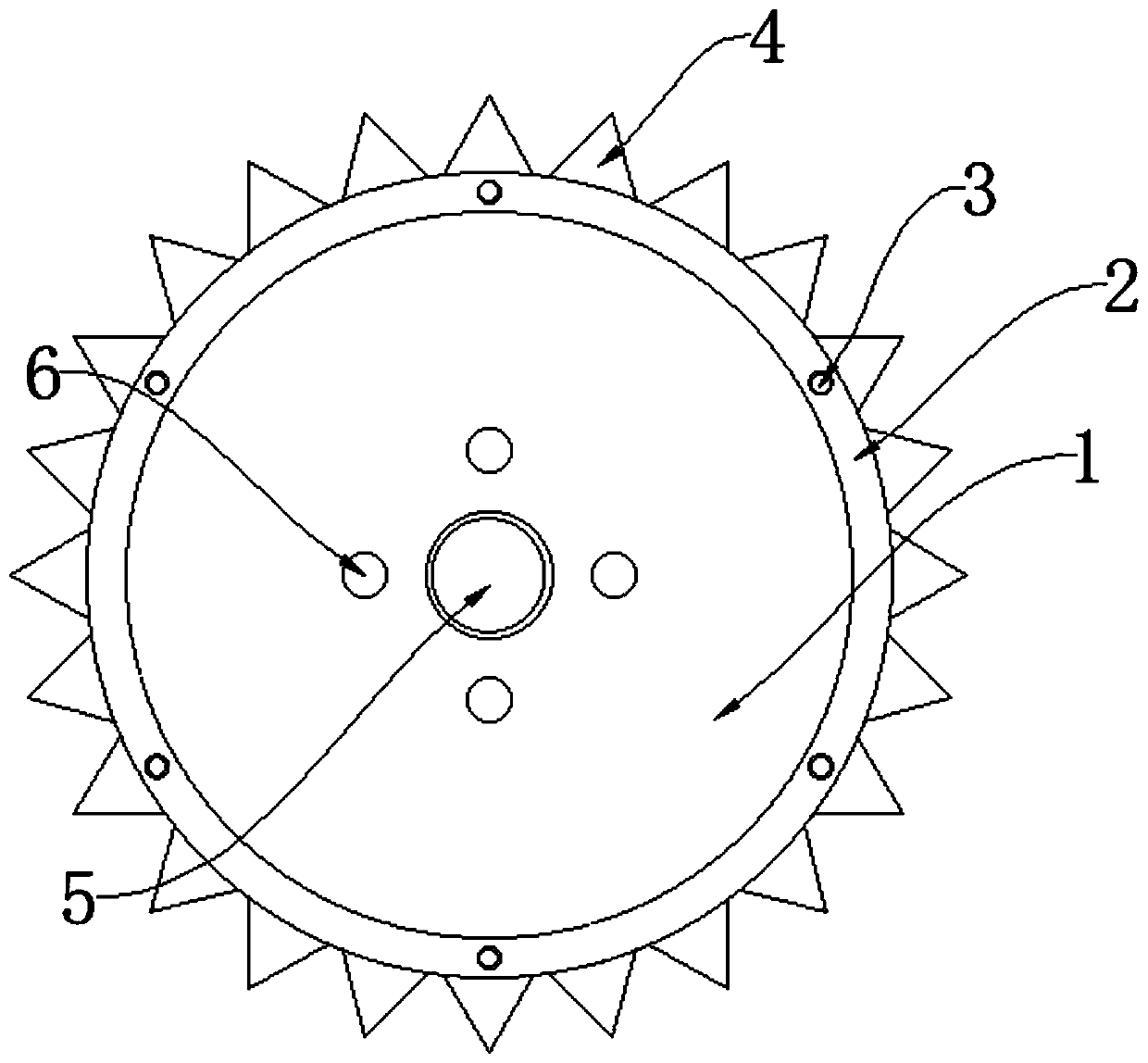

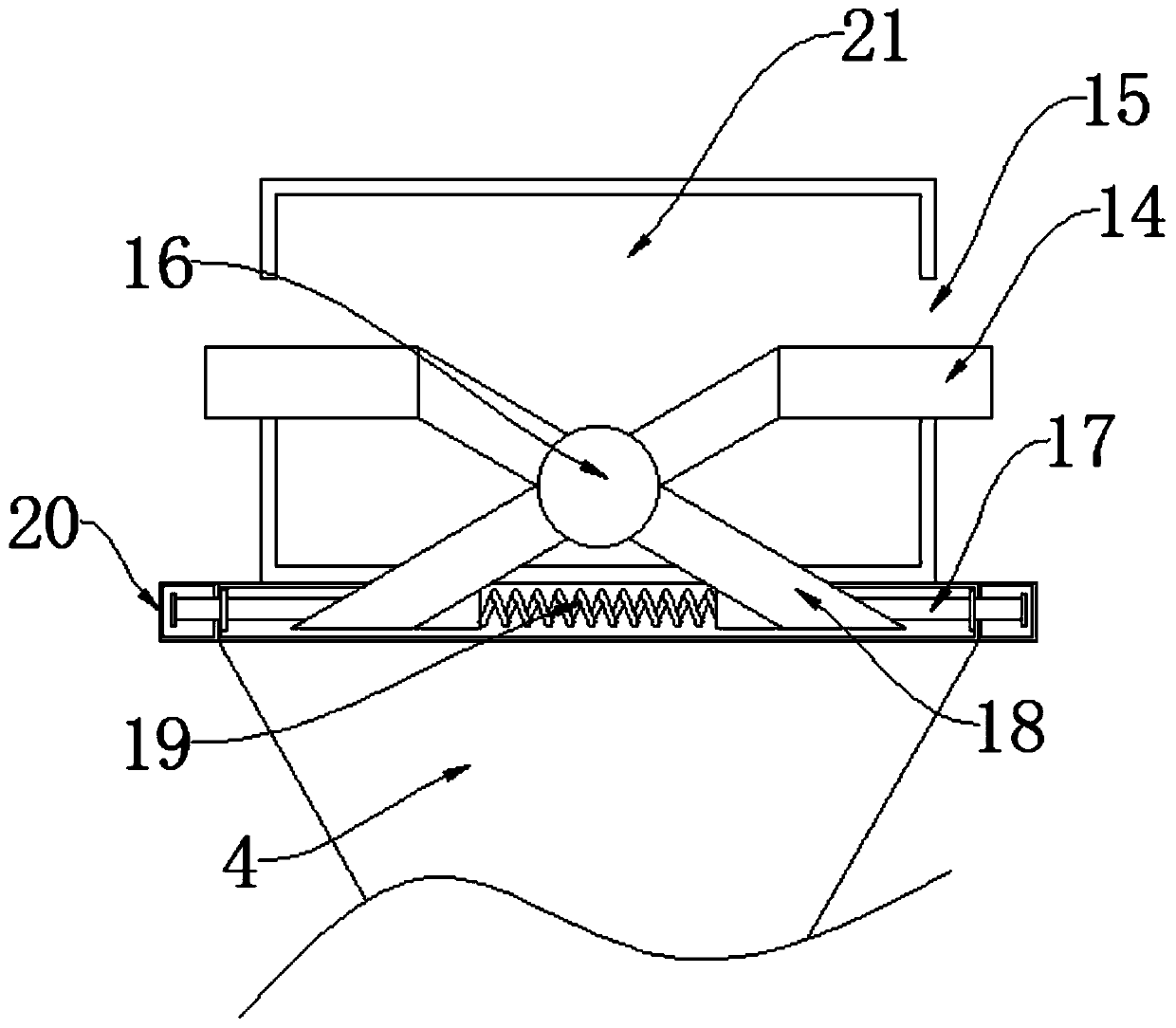

High-strength industrial tool

InactiveCN110181300ASolve the problems of inconvenient replacement and insufficient performanceIncrease flexibilityPositioning apparatusMetal-working holdersIndustrial toolUsability

The invention discloses a high-strength industrial tool, and relates to the technical field of industrial tools. By adoption of the high-strength industrial tool, the problems that an existing industrial tool is poor in overall convenience and flexibility, a tool bit cannot be replaced conveniently, and the usability is imperfect are solved. A tool fixing mechanism is mounted outside a tool mounting disc and is rotatably connected with the tool mounting disc through fixing double-headed bolts. A tool body is mounted outside the tool fixing mechanism. A main installation fixing hole is formed in the middle of the tool mounting disc. Auxiliary stabilizing holes are formed in one side of the main installation fixing hole. A fixing lug is arranged in the tool fixing mechanism. A fixing throughhole is formed in the fixing lug. A tool installation fixing block is arranged in the tool fixing mechanism. Auxiliary fixing through holes are formed in the upper end of the tool installation fixingblock.

Owner:SUZHOU MAIKAFU IND TECH CO LTD

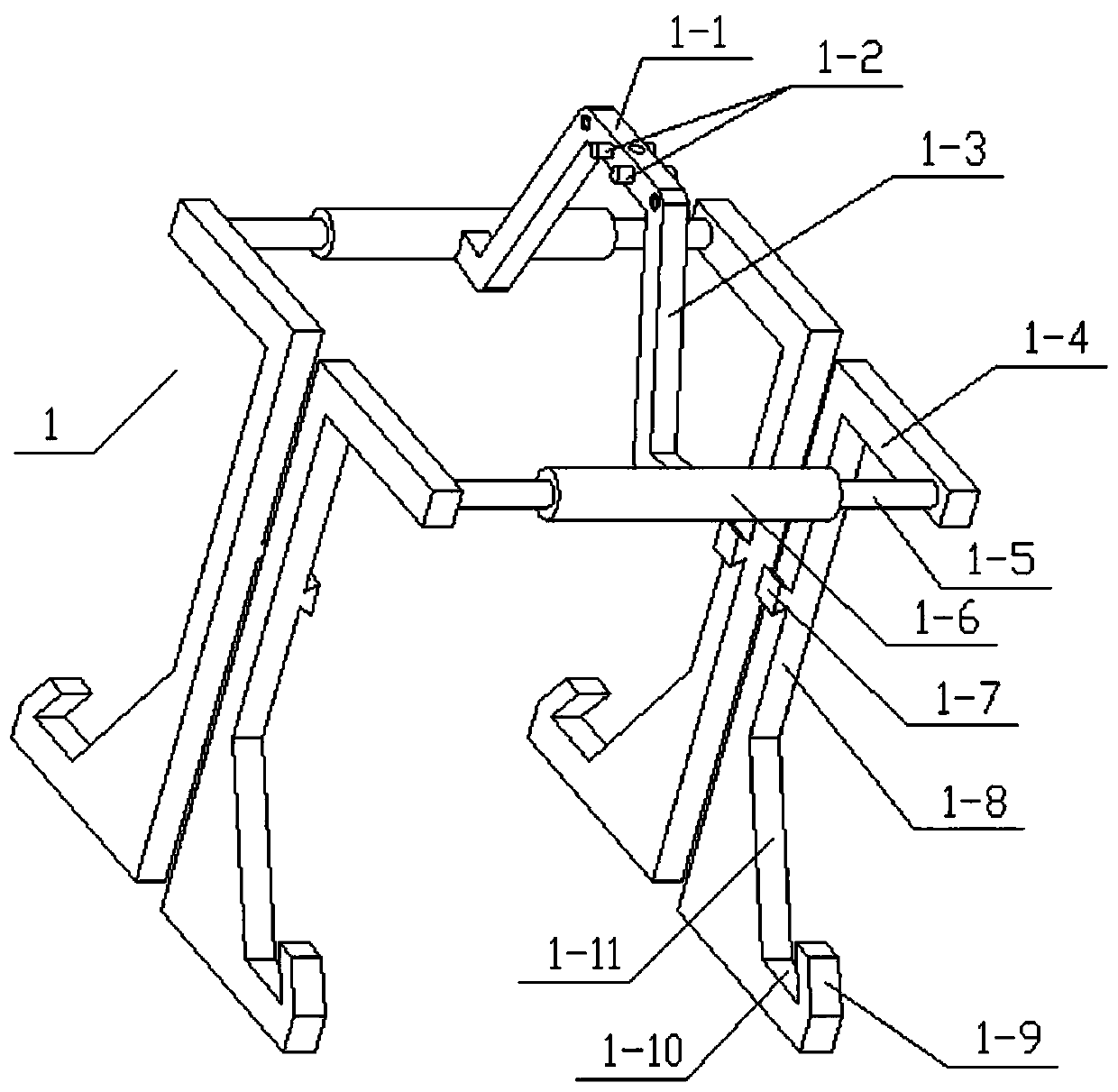

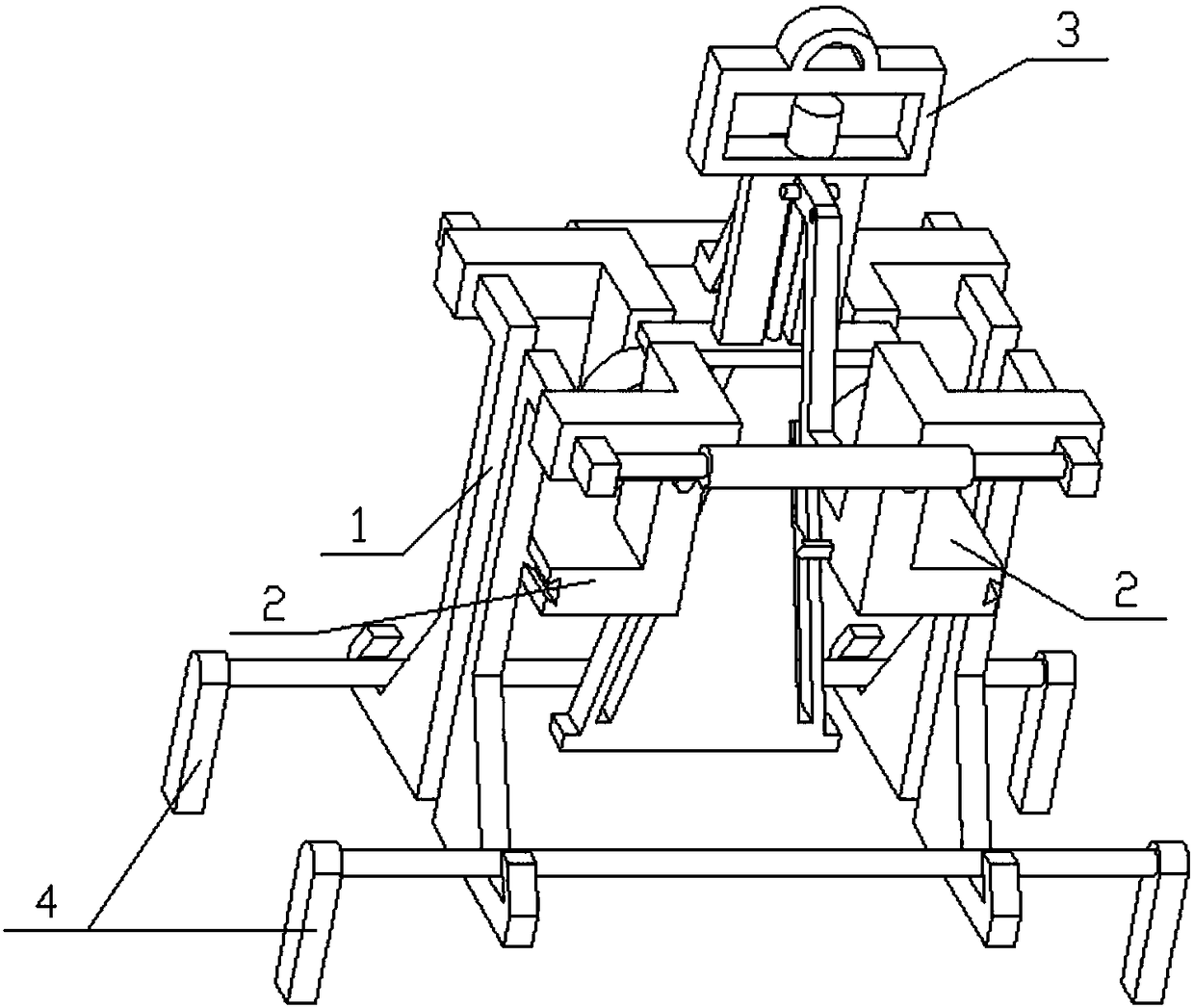

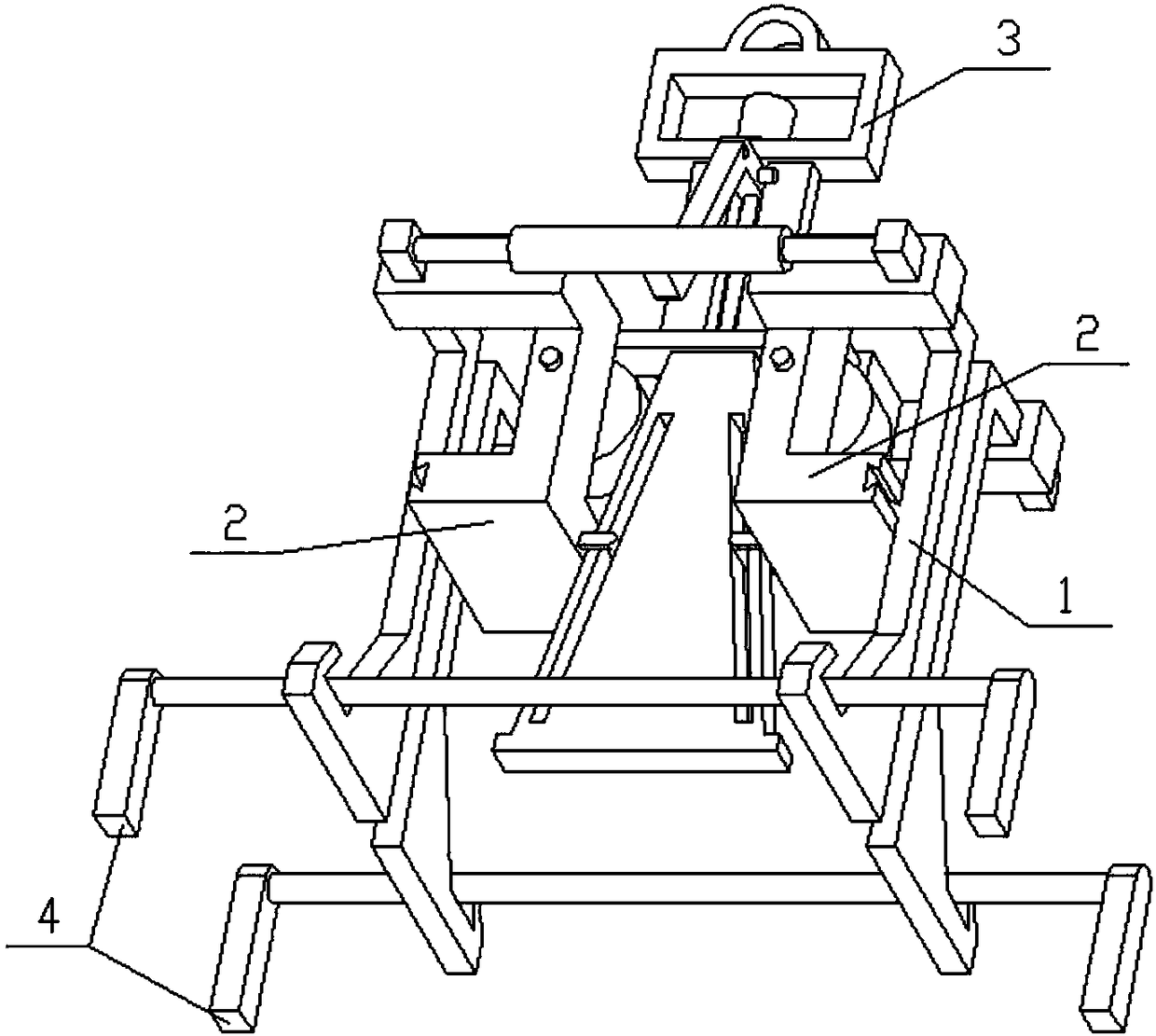

Folding industrial container hoisting device

The invention relates to an industrial tool and in particular to a folding industrial container hoisting device. While a rectangular frame is upwards pulled through a hoist, two L-shaped hanging brackets at the left end and two L-shaped hanging brackets at the right end are automatically outwards expanded, and two L-shaped hanging brackets at the front end and two L-shaped hanging brackets at therear end are outwards expanded too, so a container is hoisted by the four L-shaped hanging brackets. A middle position of a middle cross rod is provided with a threaded hole in a vertical direction. The middle end of the middle cross rod is fixedly connected with two limiting columns. The front and rear ends of the middle cross rod are hinged and connected with inclined connecting rods. The lowerends of the two inclined connecting rods are fixedly connected with hollow cylinders. The left and right ends of the two hollow cylinders are slidably connected with inserting columns. An extension spring is welded between the two inserting columns at the front end, and an extension spring is welded between the two inserting columns at the rear end. The two extension springs are positioned in thetwo hollow cylinders. The outer ends of the four inserting columns are fixedly connected with upper cross slide bars.

Owner:王仁锋

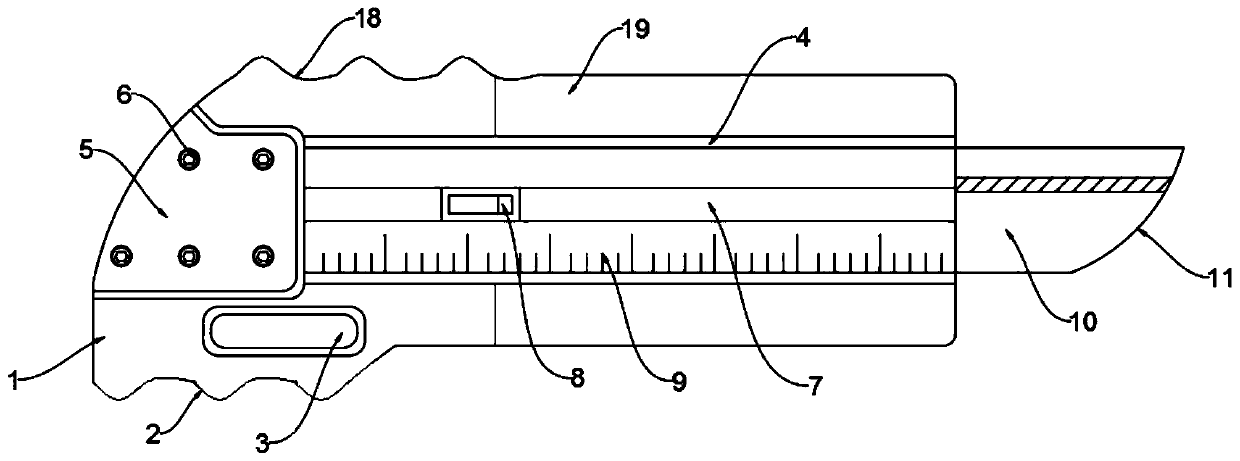

Industrial tool allowing blade to be conveniently replaced

InactiveCN110202617AThe process is simple and convenientSolve the problem that the whole process of replacing the blade is very cumbersomeMetal working apparatusIndustrial toolLocking mechanism

The invention discloses an industrial tool allowing a blade to be conveniently replaced, and relates to the technical field of industrial tools. The problems that the whole blade replacing process ofan existing industrial tool allowing a blade to be conveniently replaced is very tedious, and the moving range of a locking part is narrow are solved. A tool body is arranged at one end of a tool holder, the upper end of the tool holder is provided with a second hand shank grain, the lower end of the tool holder is provided with a first hand shank grain, and a holding hole is formed above the first hand shank grain; the blade is arranged between two sliding grooves, the outer surface of the blade is provided with scale lines, a guiding groove is formed above the scale lines, and a pushing block is arranged at the front end of the guiding groove; a cutting edge is arranged at one end of the blade; and a pressing ring is arranged on the front end face of each locking mechanism, a limiting ring is arranged on one side of each pressing ring, and elastic connecting parts are arranged between each pressing ring and the corresponding limiting ring.

Owner:SUZHOU MAIKAFU IND TECH CO LTD

Device for duplicating operating parameters recorded in the memory of an industrial tool

The presen invention relates to an apparatus for duplicating usage parameters written in a memory of an industrial tool. When the tool is located in the environment thereof, and the apparatus can access the memory om a reading and write-in mode by means of a wireless link. At least one portion of the data of the memory defines the usage parameters of the portable tool. The apparatus particularly comprises a member for identifying the portable tool, wherein a memory of a first tool has usage parameters to be copied to a memory of a second tool; a member for reading the usage parameters of the first portable tool in the memory of the first portable tool; and a member for writting the usage parameters read from the memory of the first tool into the memory of the second portable tool. In this way, the industrial tool broken down can be easily and rapidly replaced by another tool operating normally.

Owner:ETAB GEORRENAULT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com