Hydraulic shock absorber and damping force generator

A technology of hydraulic buffering and generating device, applied in gas-liquid shock absorbers, springs, shock absorbers, etc., can solve the problems of disordered damping force, difficult oil flow, and decreased responsiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

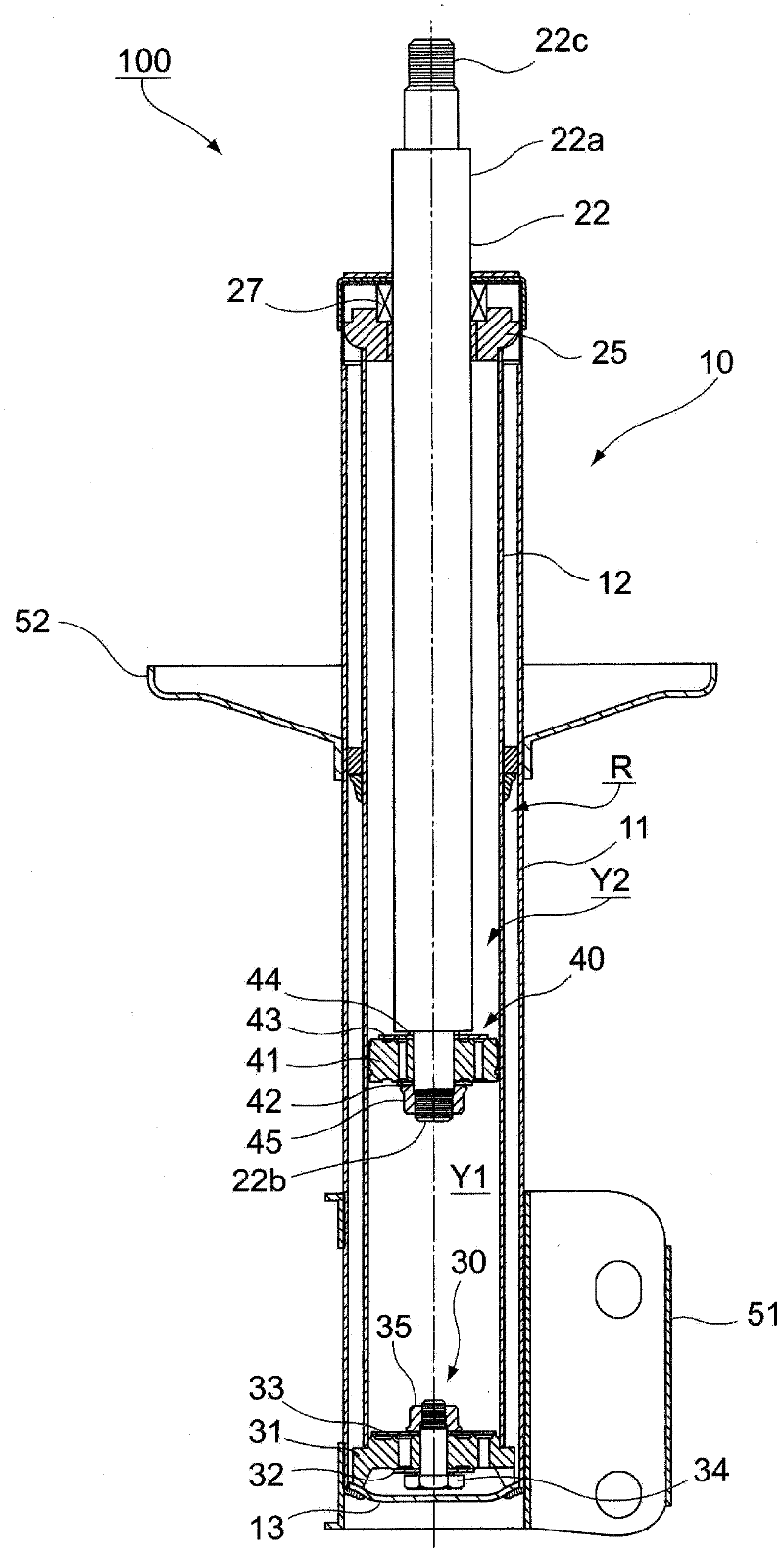

[0034] figure 1 It is a figure which shows the schematic structure of the hydraulic shock absorber 100 which concerns on an embodiment.

[0035] The hydraulic shock absorber 100 of the embodiment is a multi-cylinder hydraulic shock absorber constituting a part of a strut type suspension.

[0036] Such as figure 1 As shown, the hydraulic buffer device 100 is equipped with a hydraulic cylinder 10, and the hydraulic cylinder 10 has: a thin-walled cylindrical outer cylinder 11; a thin-walled cylindrical inner cylinder 12, which is accommodated in the outer cylinder 11; and a bottom cover 13, which is closed The cylinder centerline direction of the cylindrical outer cylinder 11 (in figure 1 One end of the middle is the up and down direction). Hereinafter, the cylindrical centerline direction of the outer cylinder 11 is simply referred to as "centerline directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com