Apparatus for duplicating usage parameters written in memory of industrial tool

A technology for operating parameters and memory, applied in static memory, read-only memory, information storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] 7.1 General principles

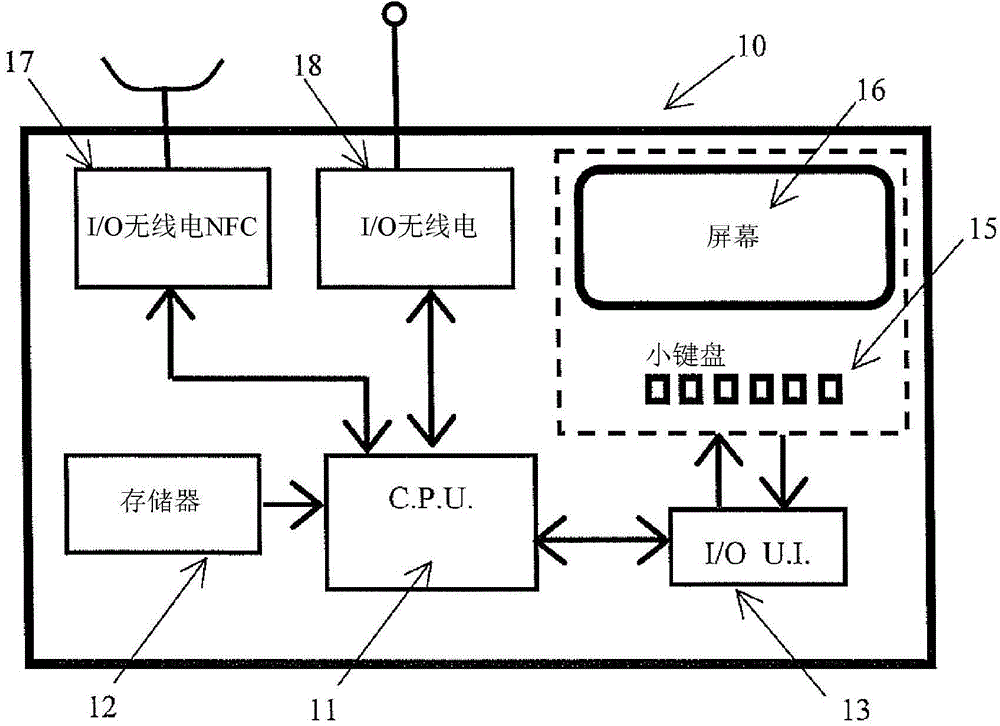

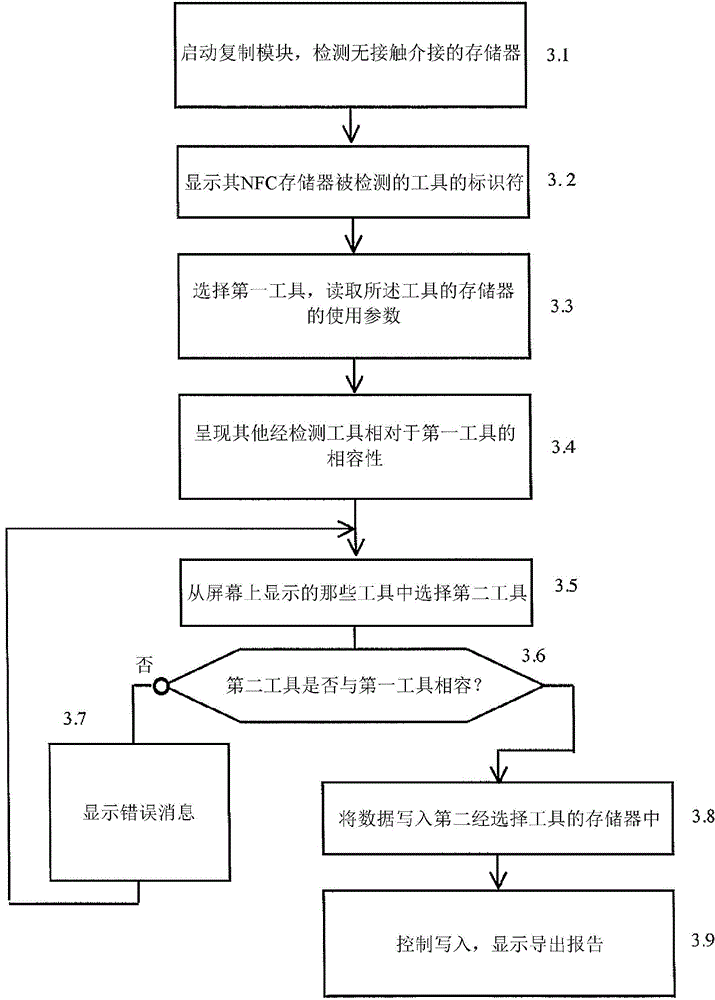

[0056]The invention relates to a device for duplicating readable data of a memory integrated in a portable tool, which is accessible in read and write mode via a wireless link when said tool is in its environment memory, and the memory incorporated into the tool need not be powered by an energy source other than that provided by the replicating device. At least a portion of the data of the memory defines operating parameters of the portable tool. The device comprises, inter alia: means for identifying at least two tools, the first tool having a memory whose operating parameters must be copied into the memory of the second tool; reading this in the memory of the first portable tool means for operating parameters of the portable tool; and means for writing the operating parameters read in the memory of the first tool to the memory of the second portable tool.

[0057] 7.2 Description of the preferred device implemented

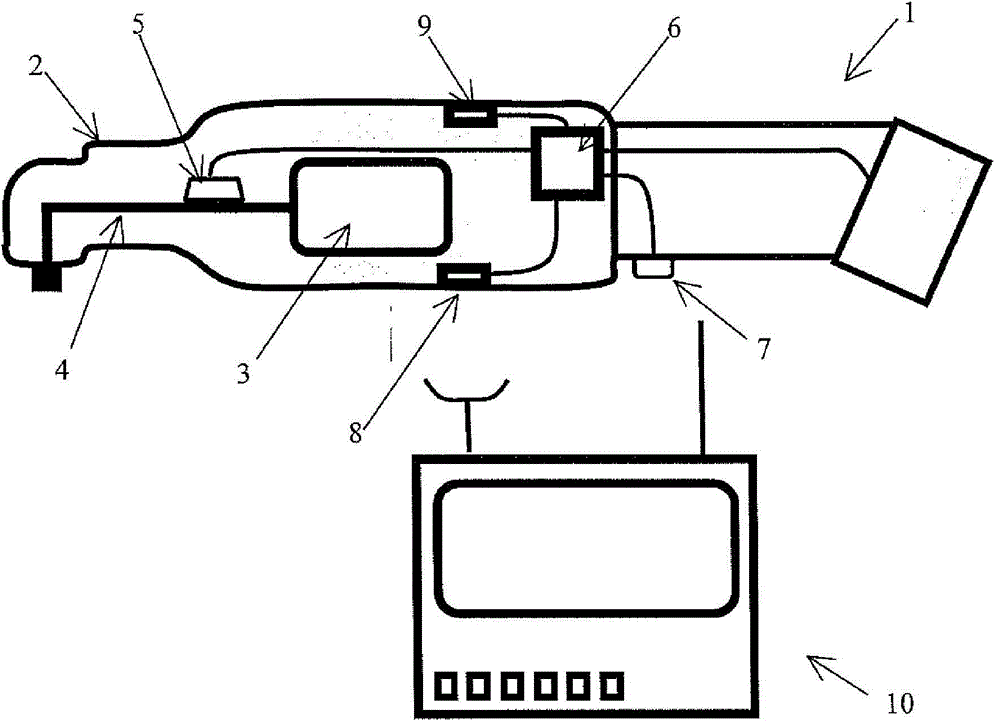

[0058] An electric scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com