Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2686results about "Drill jigs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

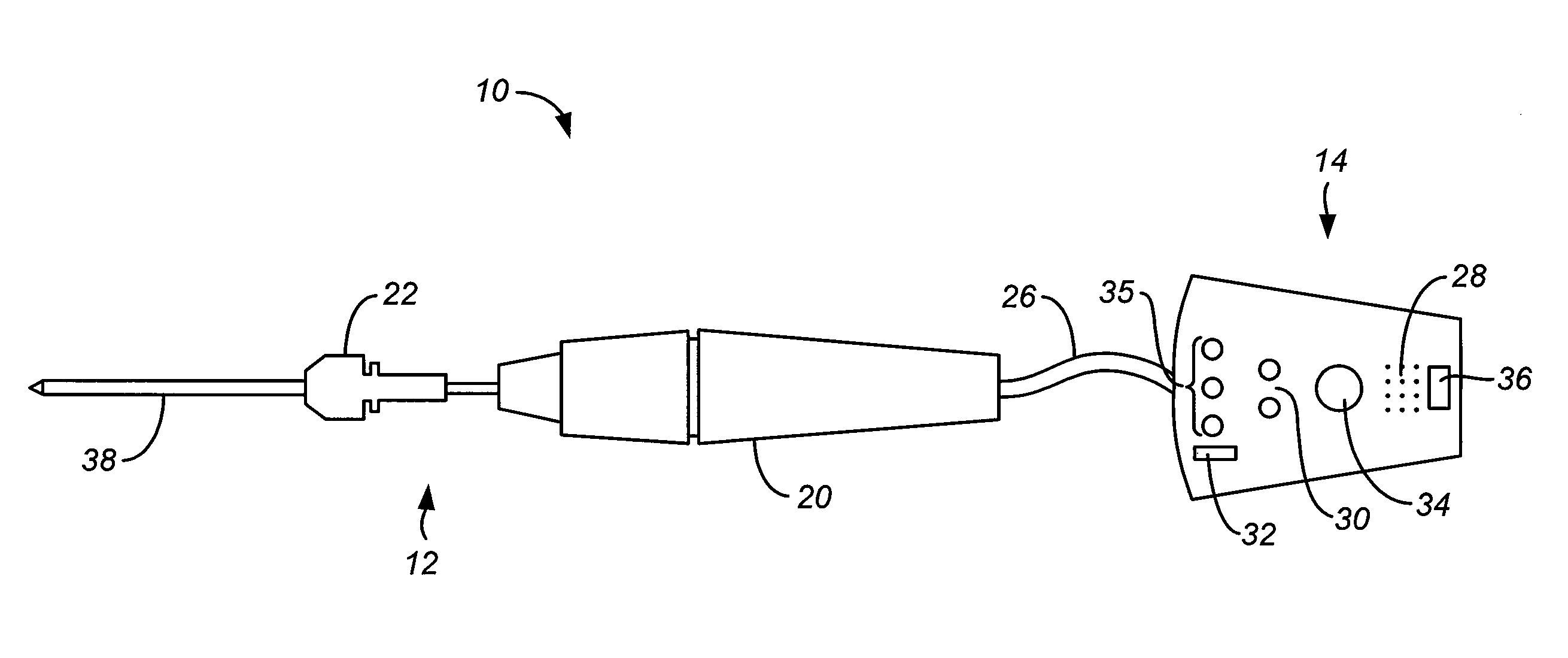

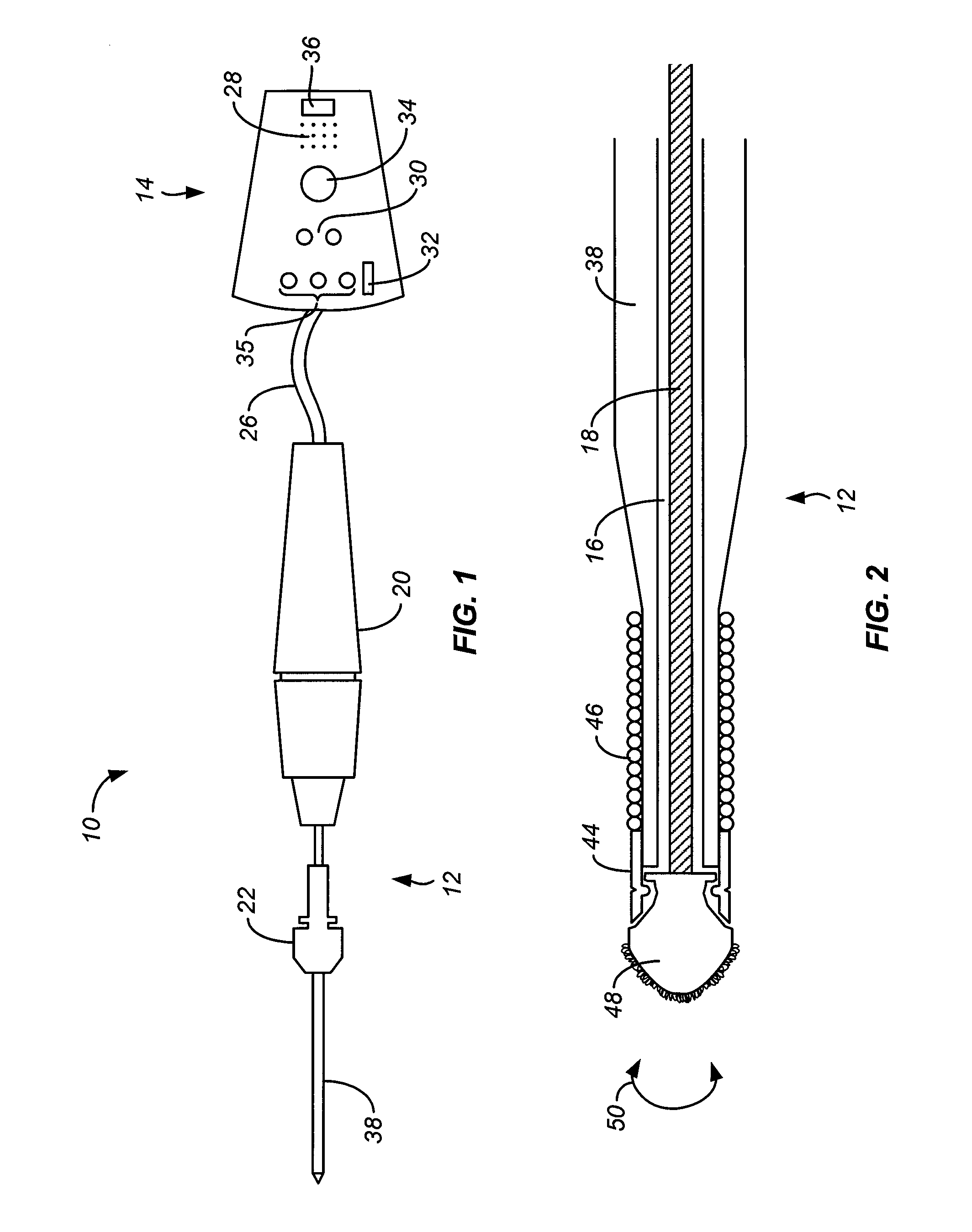

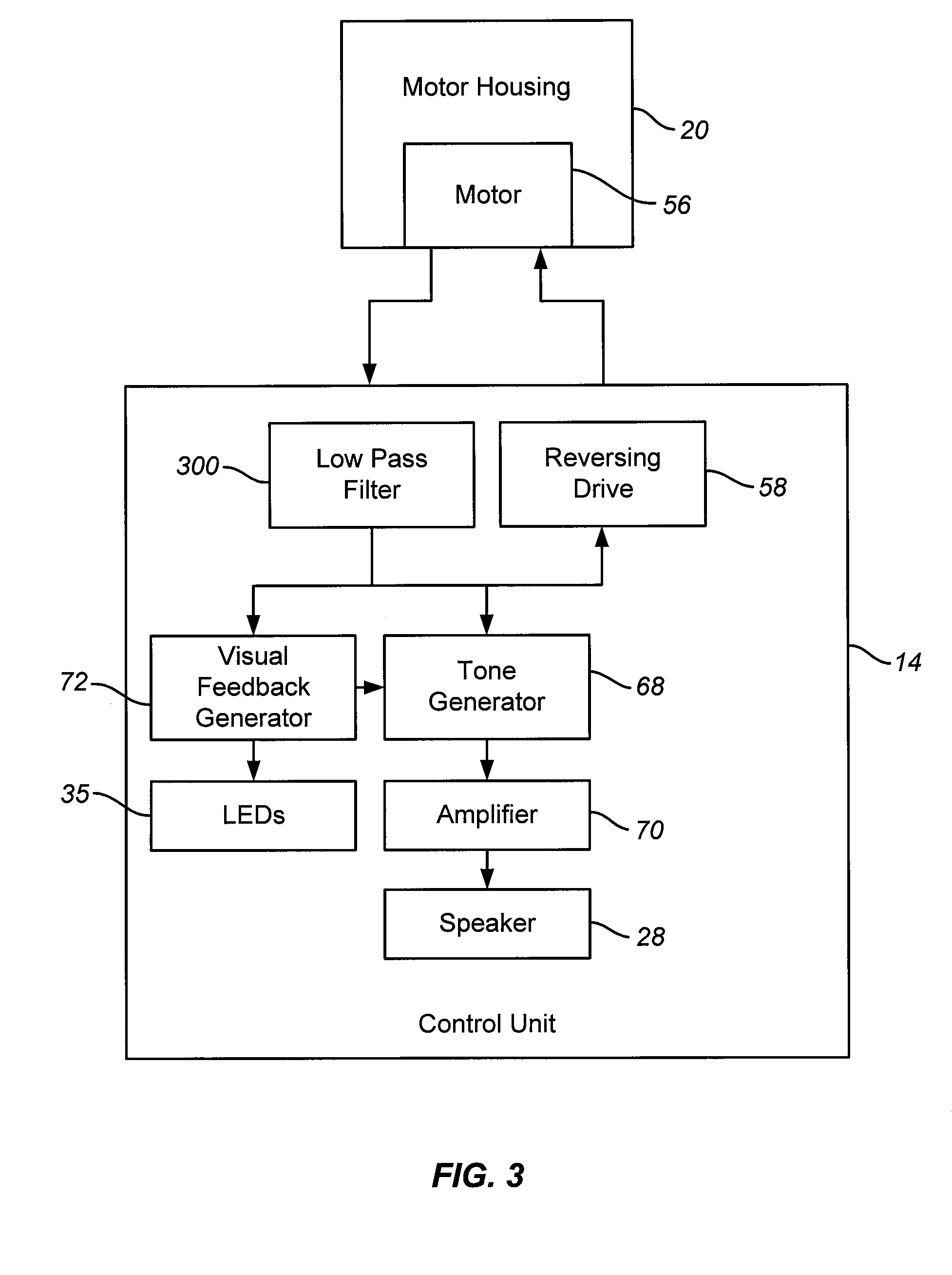

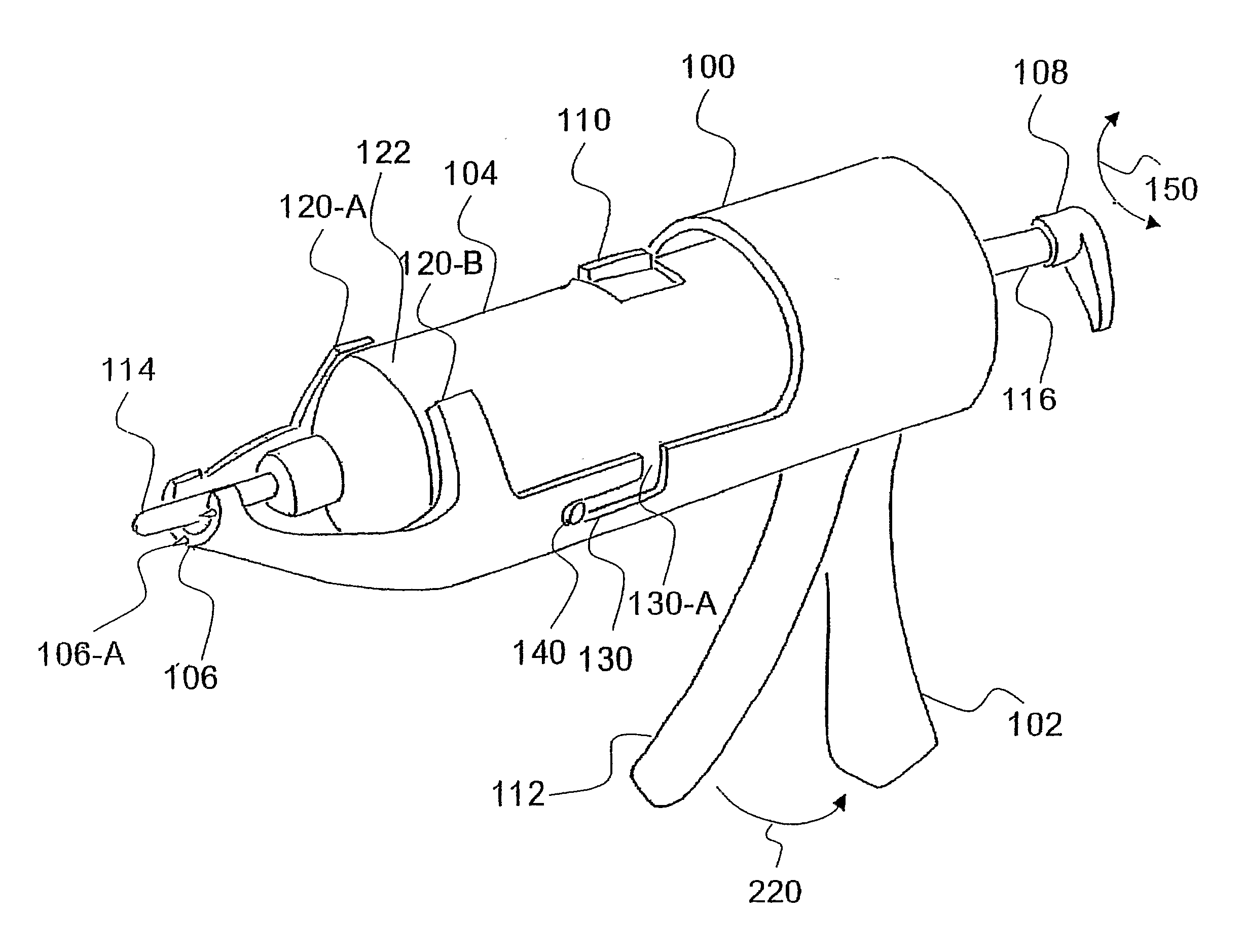

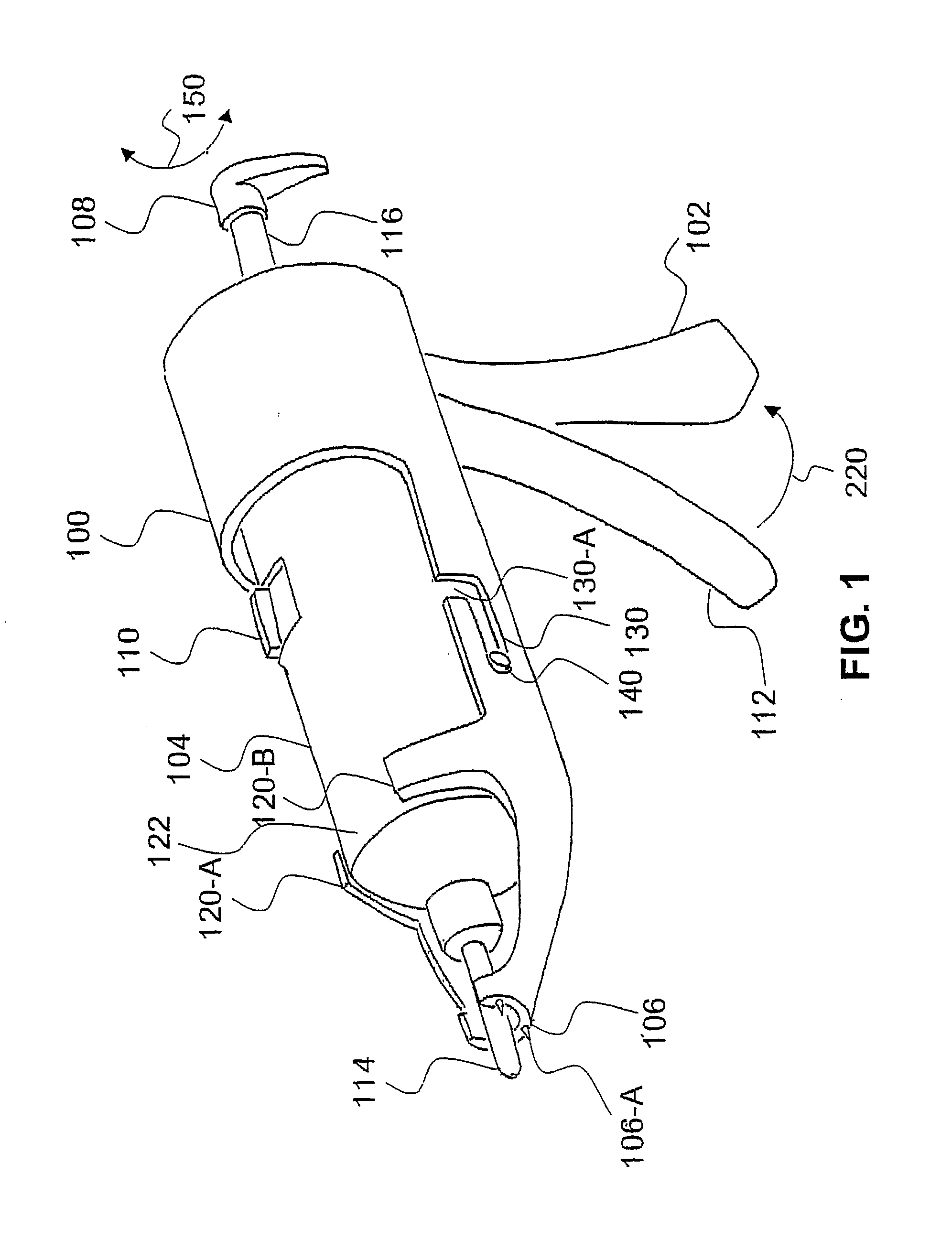

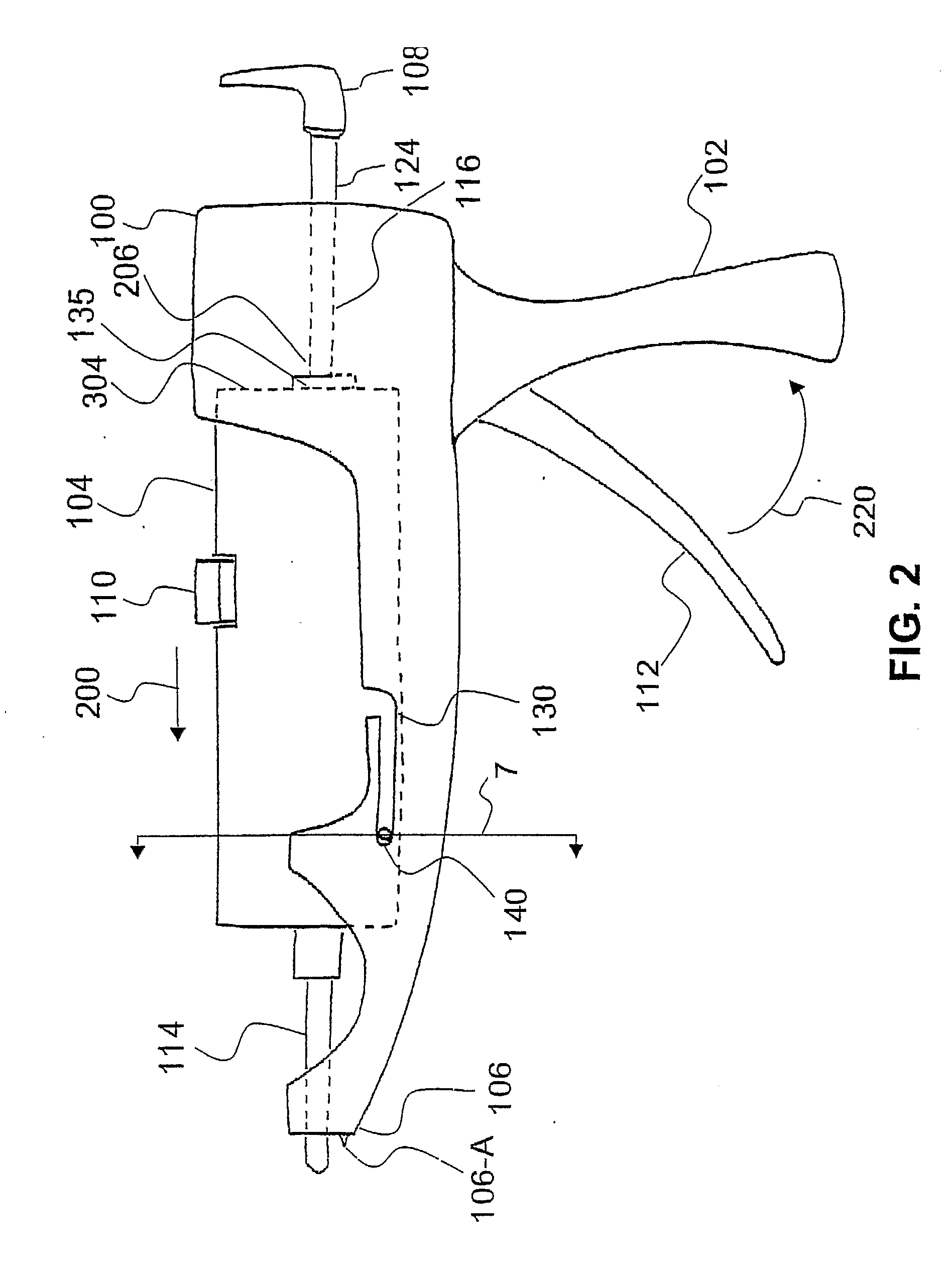

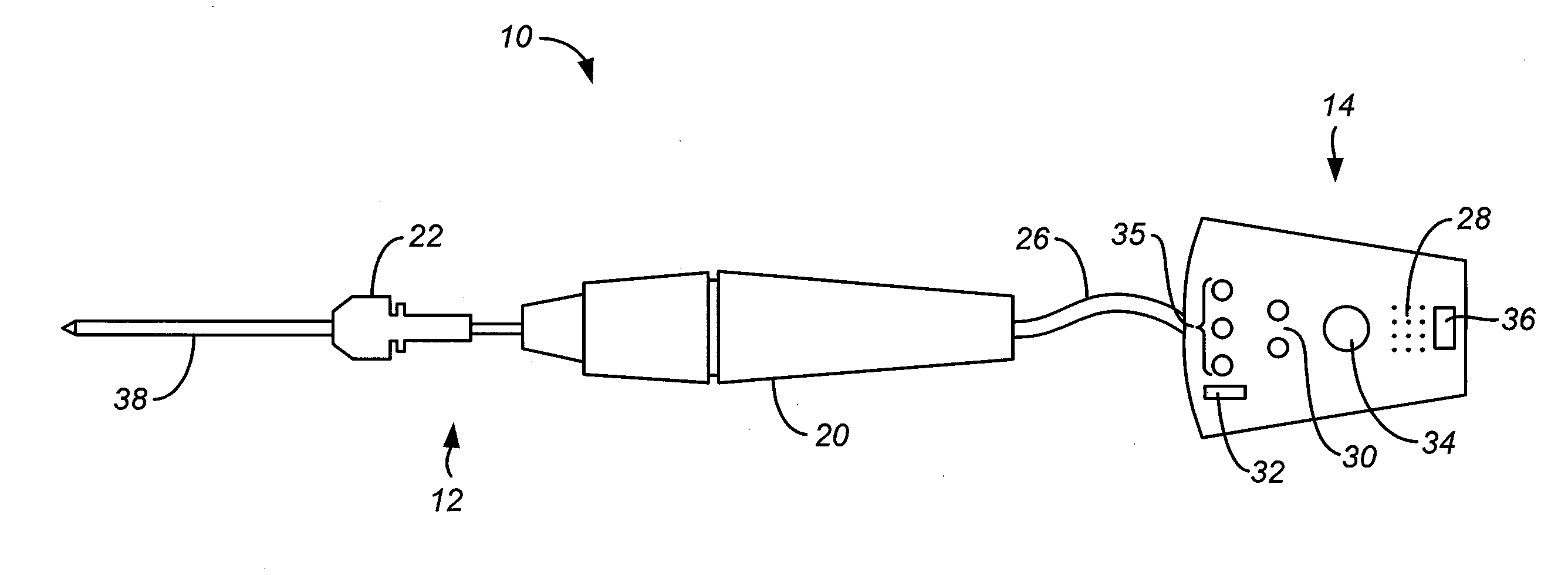

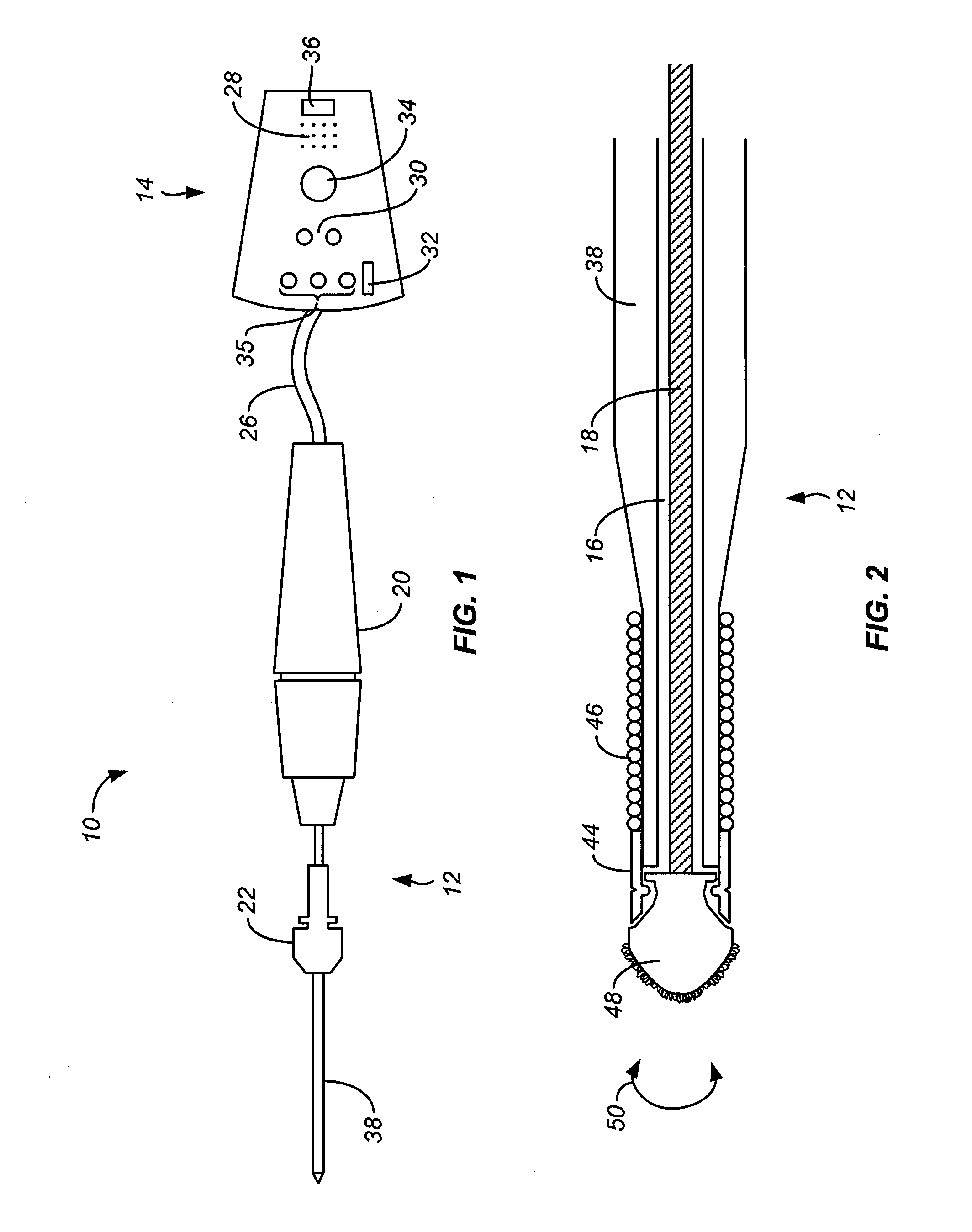

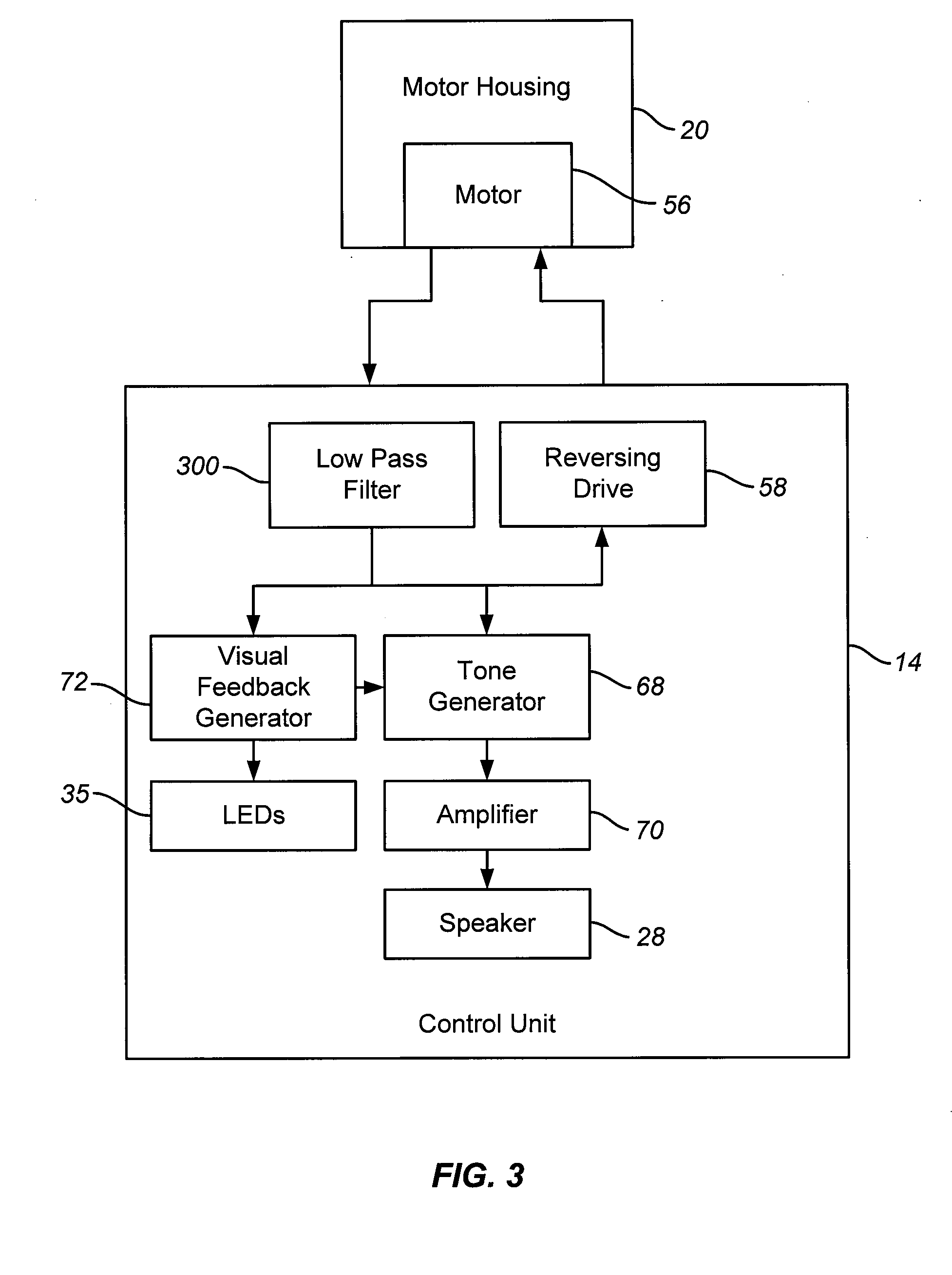

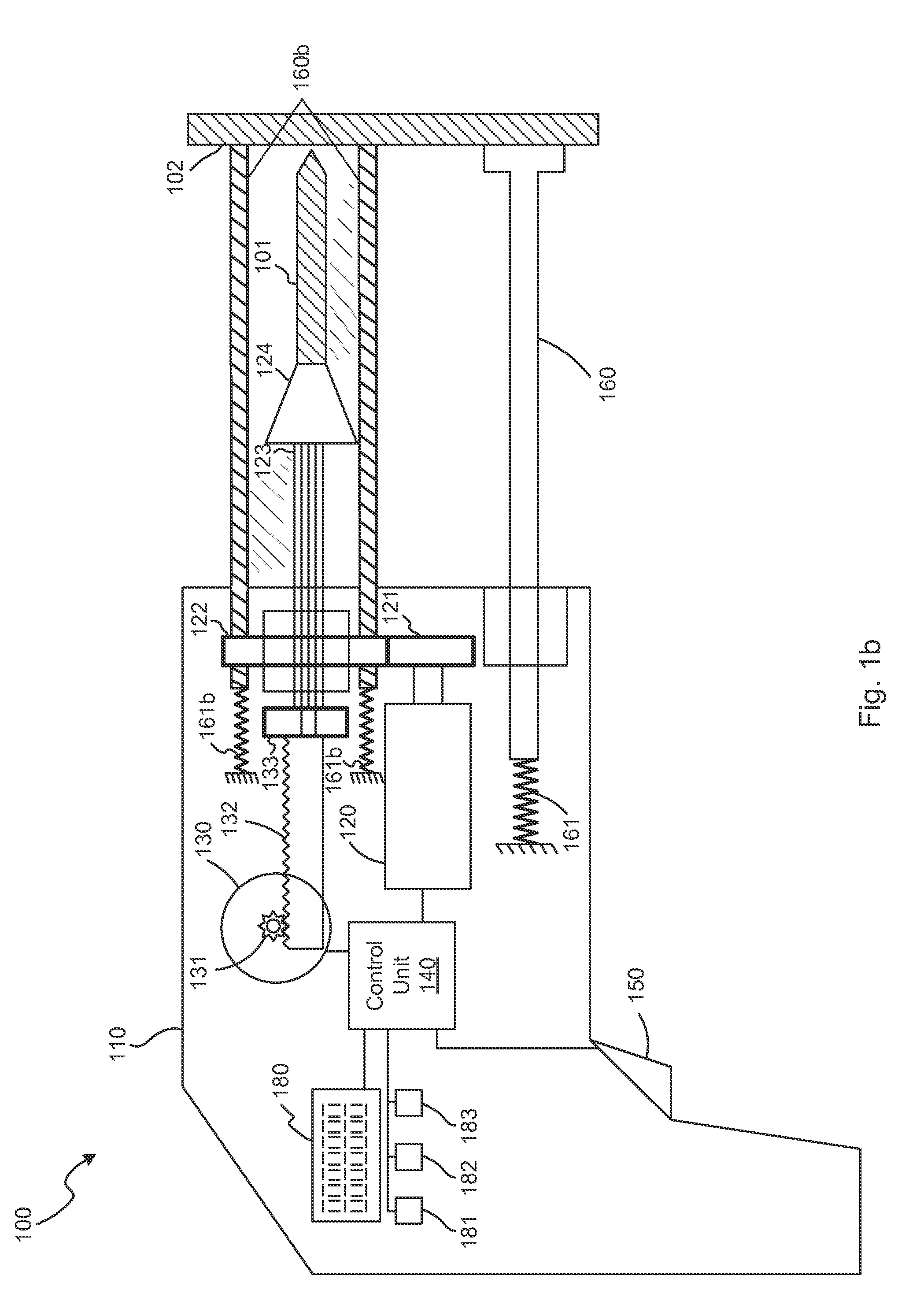

Method and system for reversibly controlled drilling of luminal occlusions

A luminal drilling system includes a drilling device and a control unit. The drilling device includes an elongate member having a drive shaft with a drill tip. The control unit includes a motor connectable to the drive shaft and control circuitry which rotationally oscillates the drive shaft with the direction of rotation automatically reversing whenever the load on the motor and / or drive shaft exceeds a threshold value.

Owner:BOSTON SCI SCIMED INC

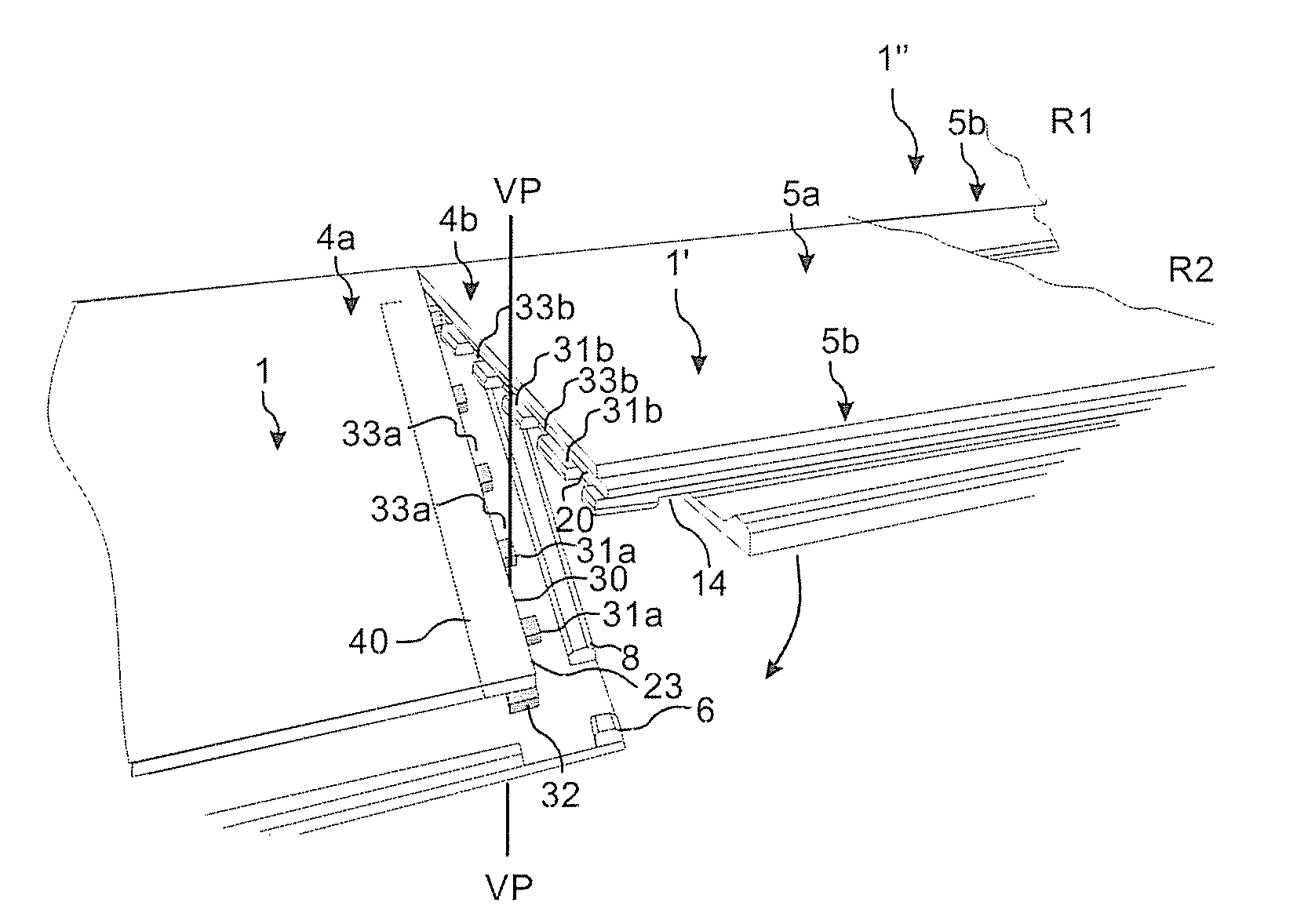

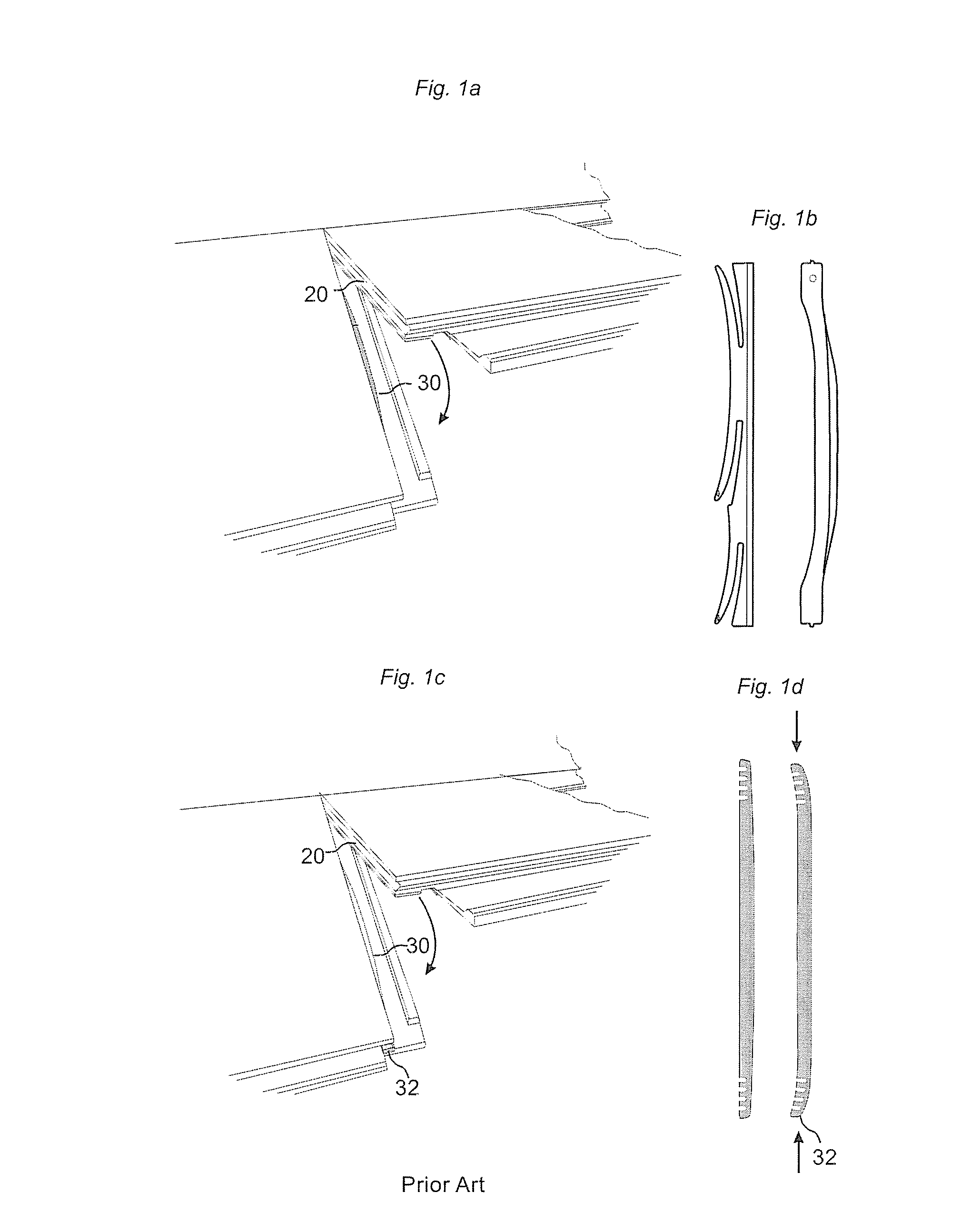

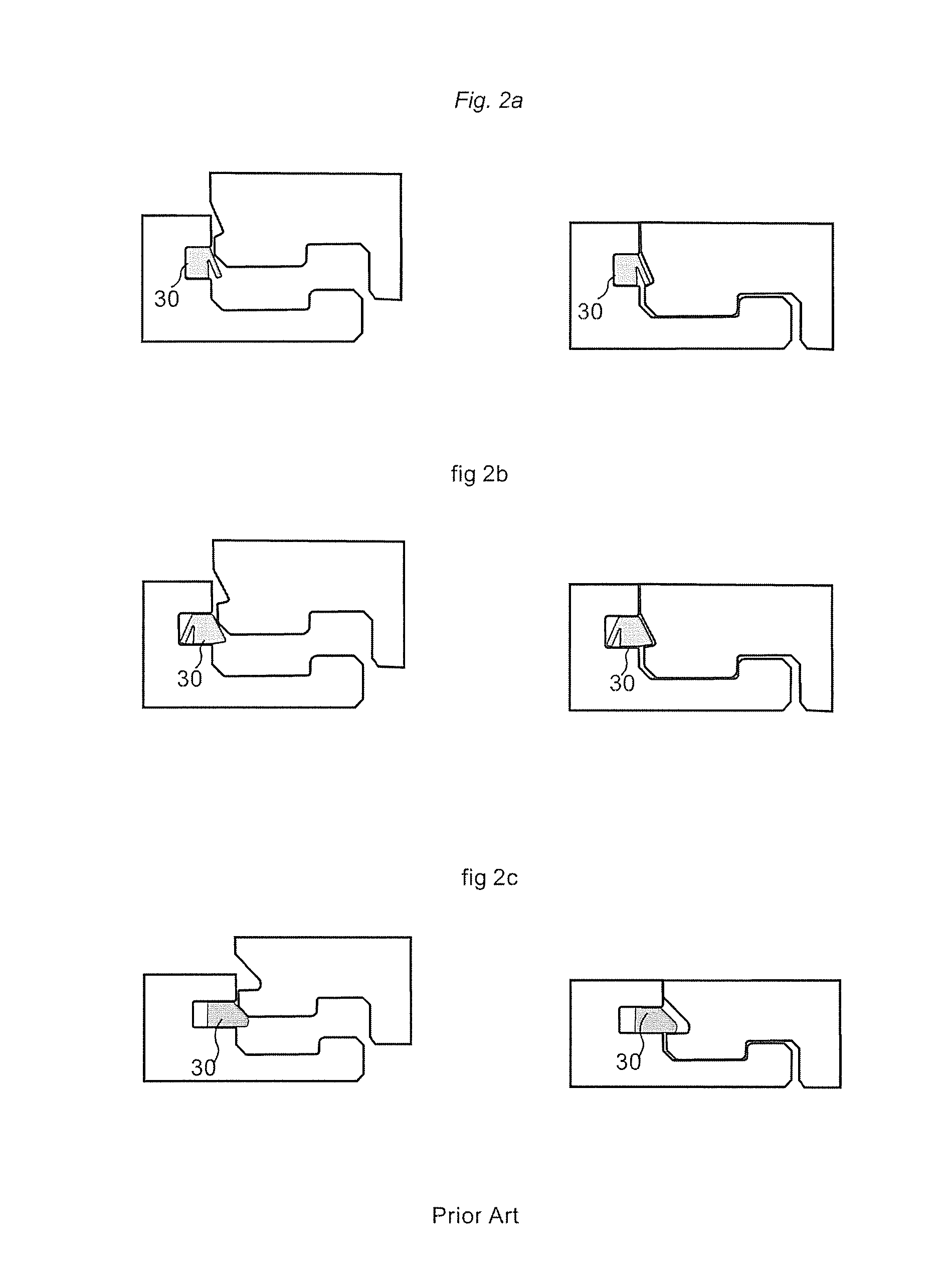

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Apparatus and method thereof for drilling holes in discrete controlled increments

InactiveUS20100034605A1Increased level of safety securityShorten the timeDrilling/boring measurement devicesThread cutting machinesBrain biopsyEngineering

An apparatus and method for forming a hole in material for non-medical and medical purposes such as a cranial burr hole for ventriculostomy and brain biopsy procedures. The apparatus includes a main unit upon which a drill unit is located. The drill unit includes a drill bit and an on / off switching means. The main unit includes a handle which is suitable for grasping, and an advancing mechanism including a release / engage mechanism, and an advancing lever and an optional on / off switch. The drill unit is advanced a predetermined distance relative to the main unit each time an advancing lever is pulled. In use, the apparatus is placed in a desired position upon the material to be drilled such a patient's skull and is stabilized by a stabilization platform, the apparatus is then turned on, and the advancing lever is pulled to advance the drill unit a predetermined distance relative to a longitudinal axis of the main unit with each pull of the advancing lever. The procedure is ended when the desired depth of penetration has been reached, or the material such as in the case of skull bone, has been completely penetrated.

Owner:CONCEPTUAL GRAY

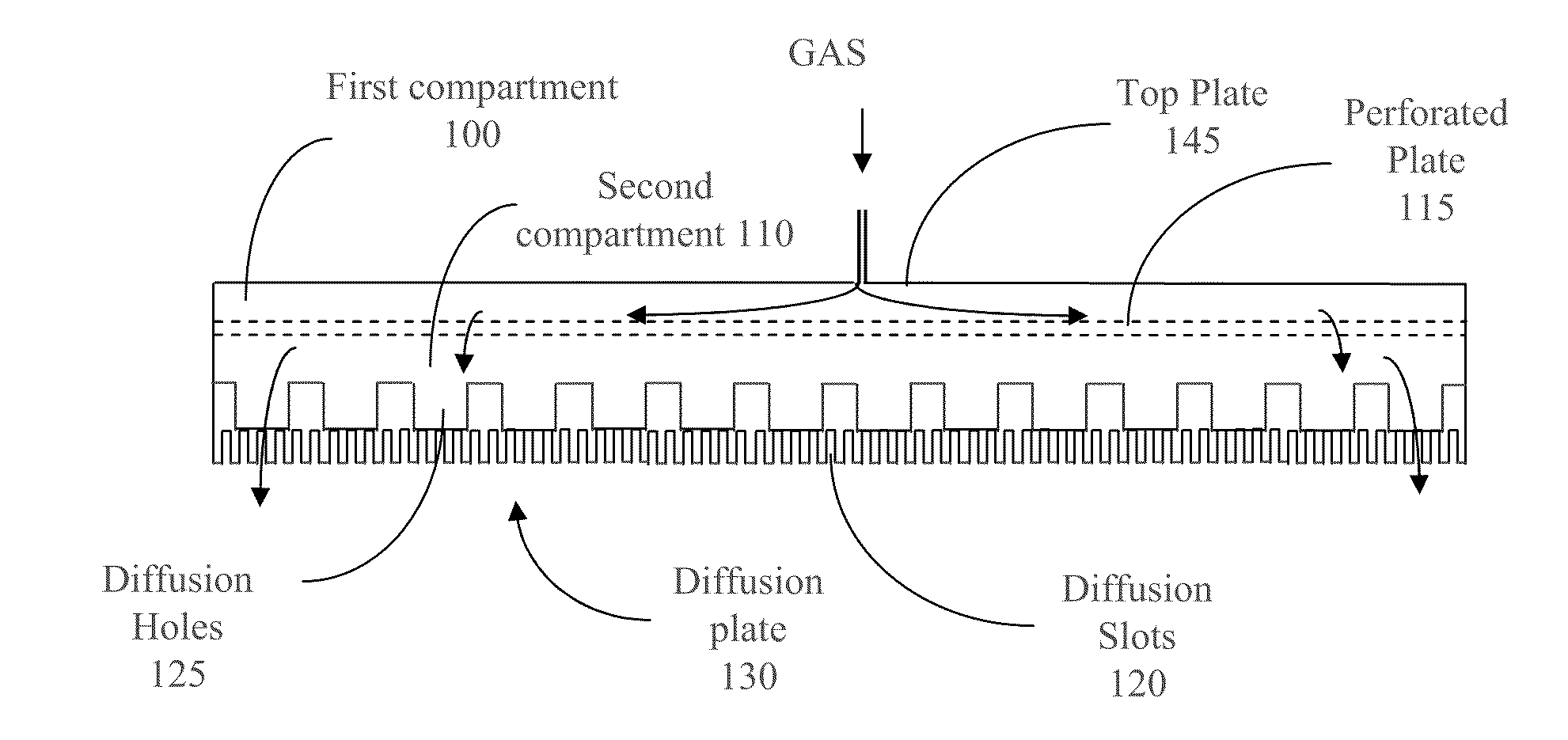

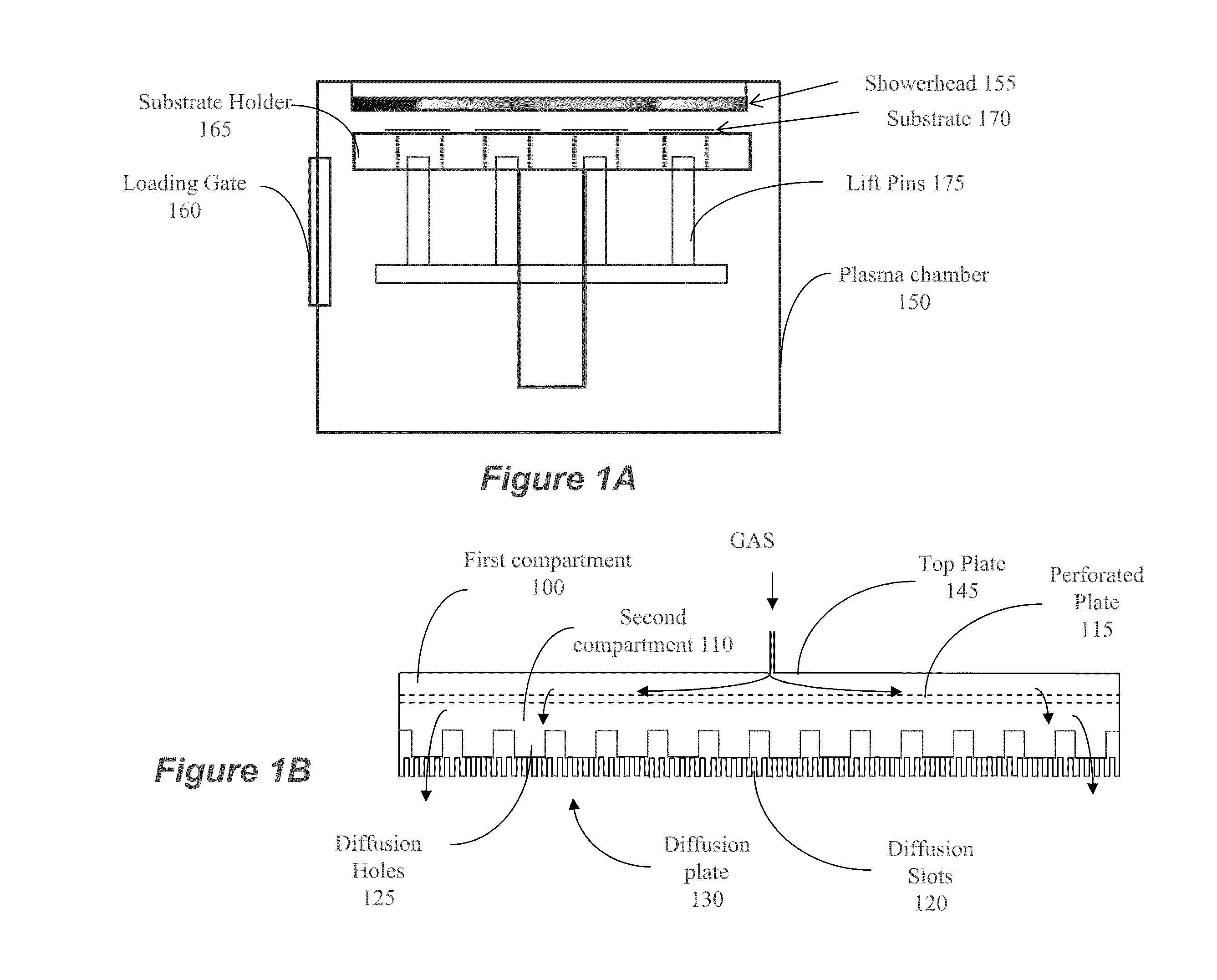

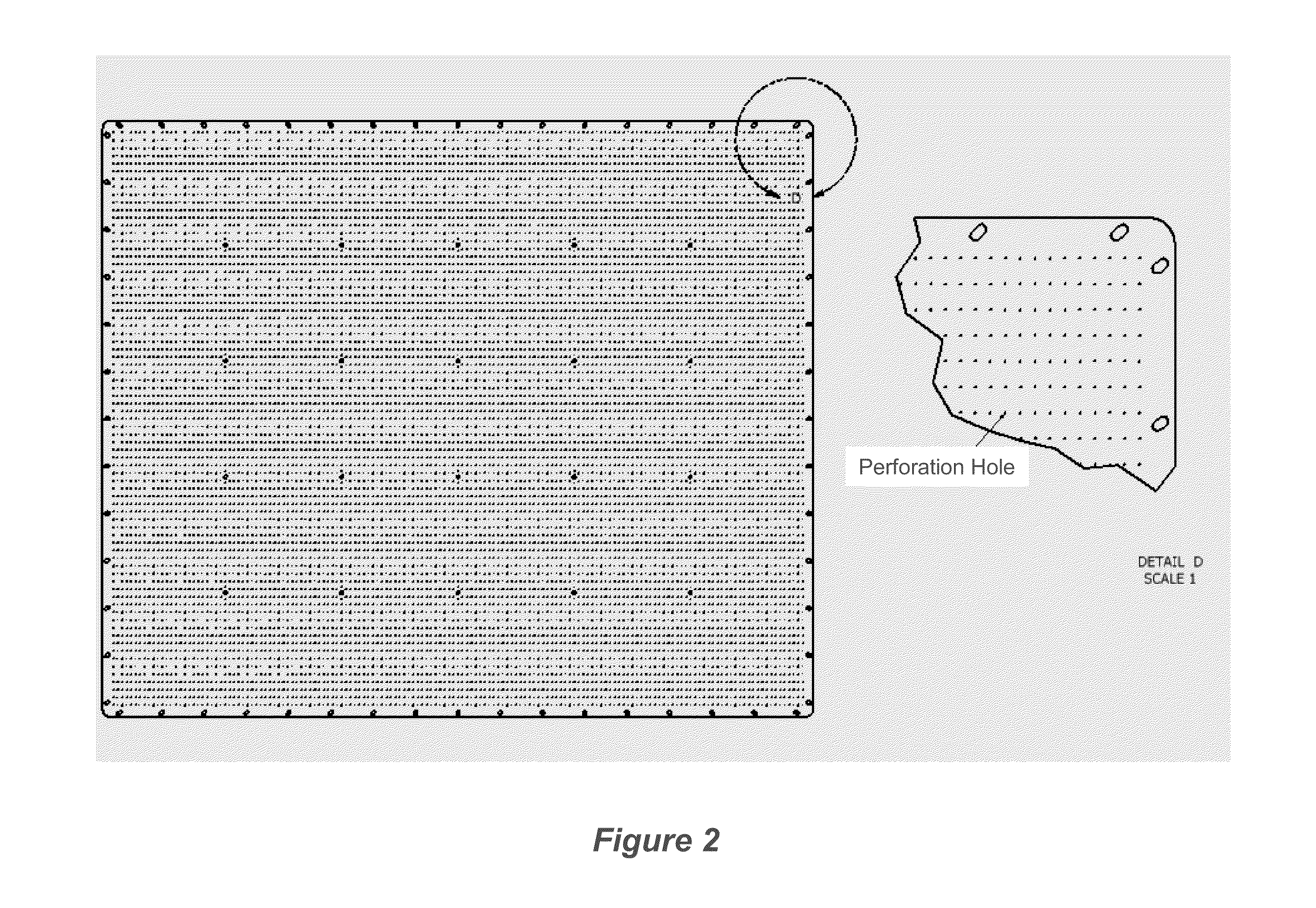

Showerhead assembly for plasma processing chamber

ActiveUS20110088847A1Easy and significantly less-expensive to manufactureImproved gas distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

A showerhead for a plasma process apparatus for processing substrates, comprising a showerhead body comprising a top plate and a bottom plate defining a cavity in between; a gas inlet formed in the top plate; a perforated plate positioned between the top plate and the bottom plate and dissecting the cavity into an upper gas compartment and a lower gas compartment; and, wherein the bottom plate comprises a plurality of elongated diffusion slots on its lower surface and a plurality of diffusion holes on its upper surface, each of the diffusion holes making fluid connection from the lower gas compartment to more than one of the diffusion slots.

Owner:KLA TENCOR TECH CORP

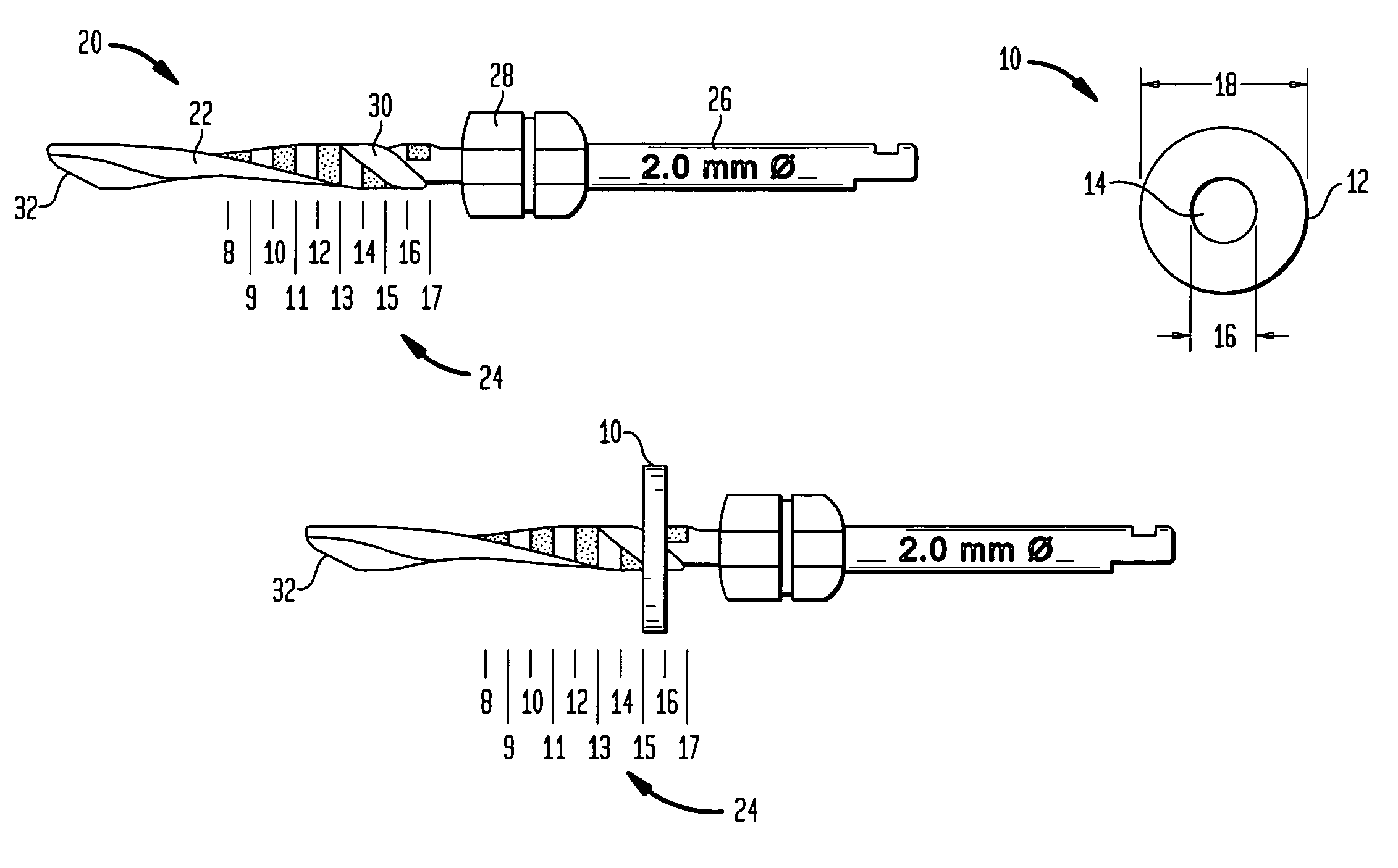

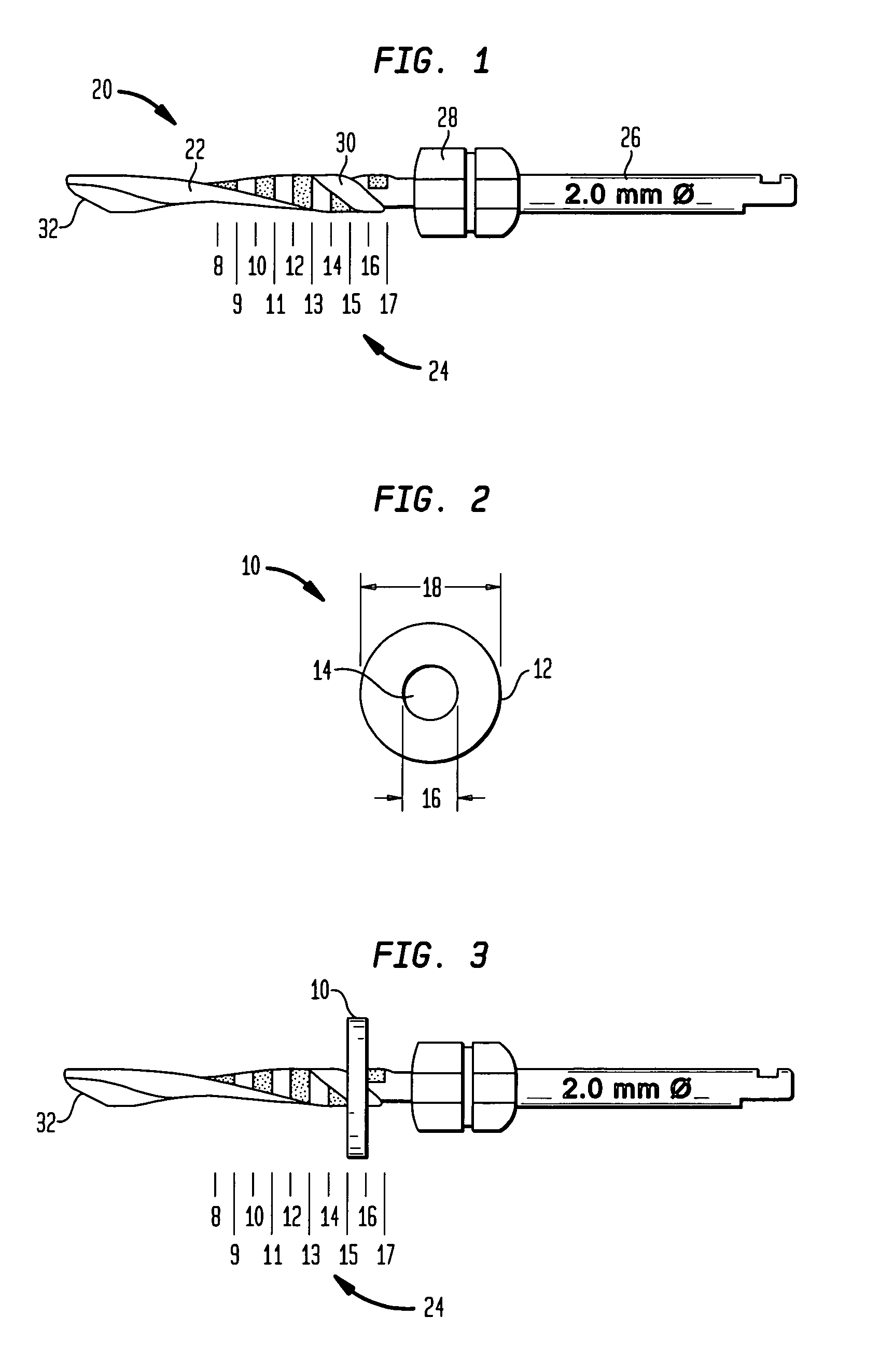

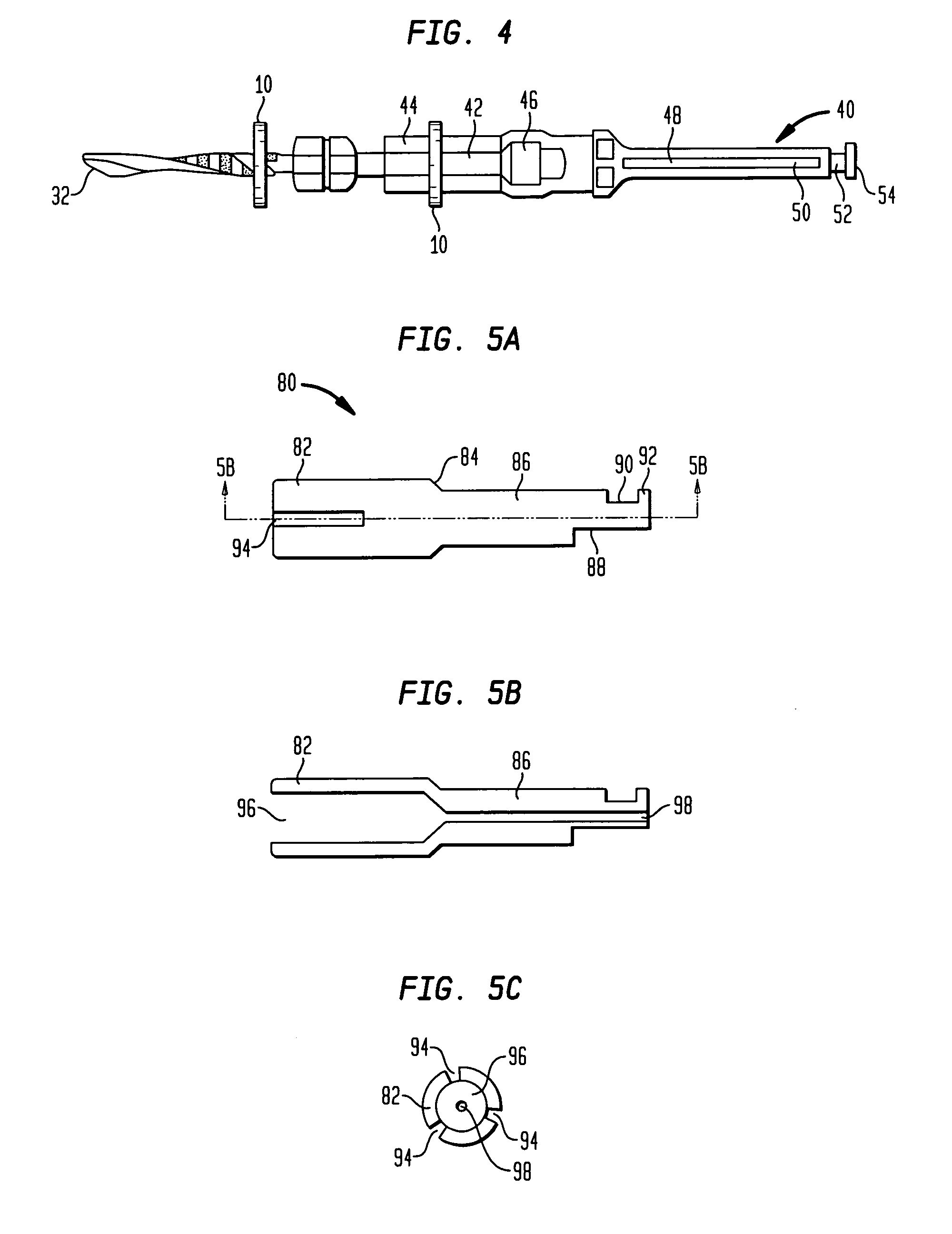

Drill measurement stops

InactiveUS7048477B2Easy to identifyReduce manufacturing costThread cutting toolsDental implantsEngineeringVisual perception

A depth stop for use with a drill bit comprises a tubular body having an opening therethrough. Used with a drill bit whose bit portion includes a cutting end, and a shank portion, the depth stop is frictionally positionable on the bit portion at a specified point from the cutting end, thereby indicating a specified depth. Depth stops are manufactured in different colors, each color corresponding to a specified range of drill bits that the depth stops will fit. The depth stops, manufactured from a sterilizable material, are intended for single use. The depth stop can be used with a drill bit and drill extender, where one or more depth stops provide multiple visual points of reference for the operator. The depth stops can be quickly mounted onto most any manufacturer's drill bits.

Owner:IDMS

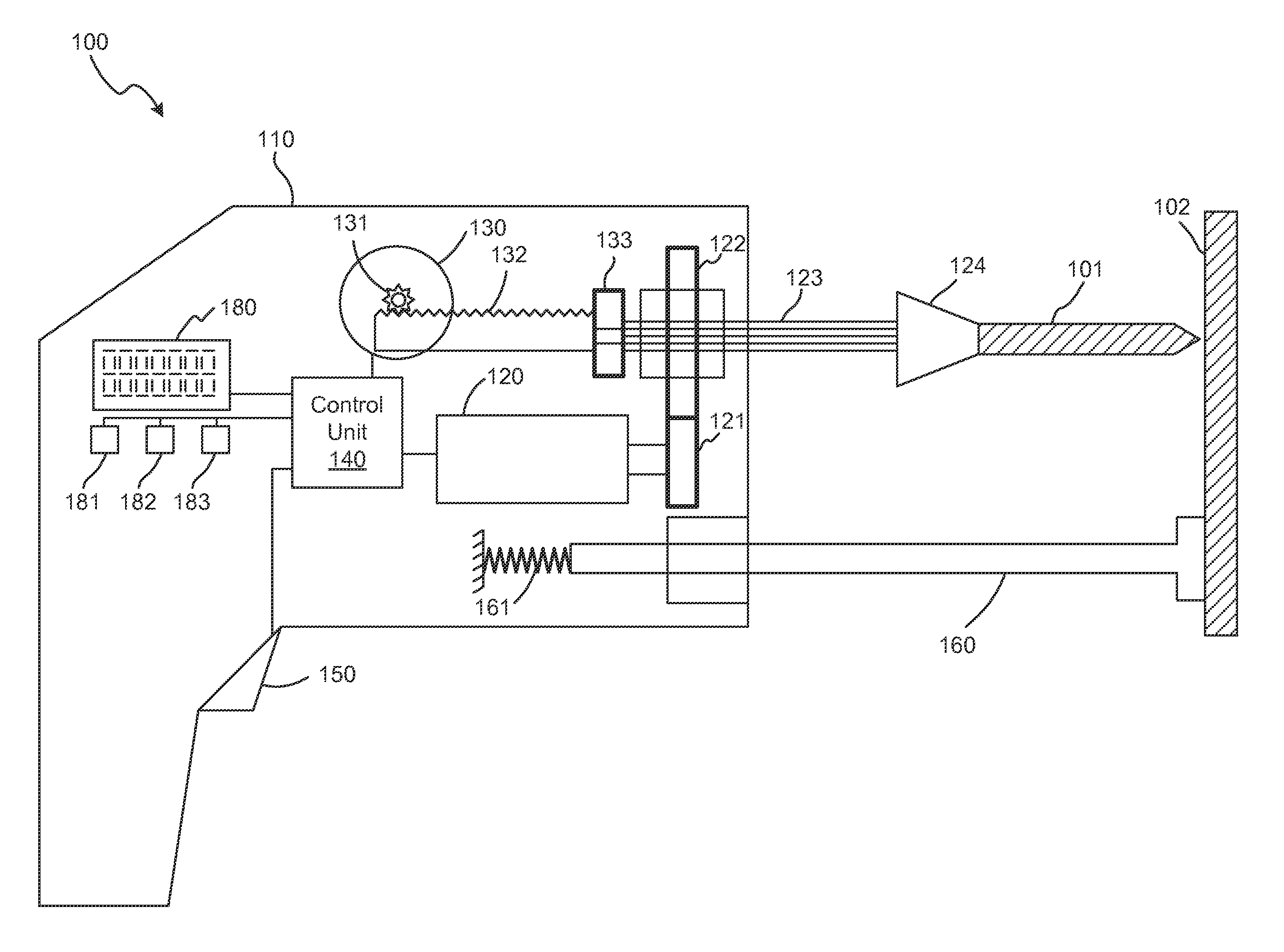

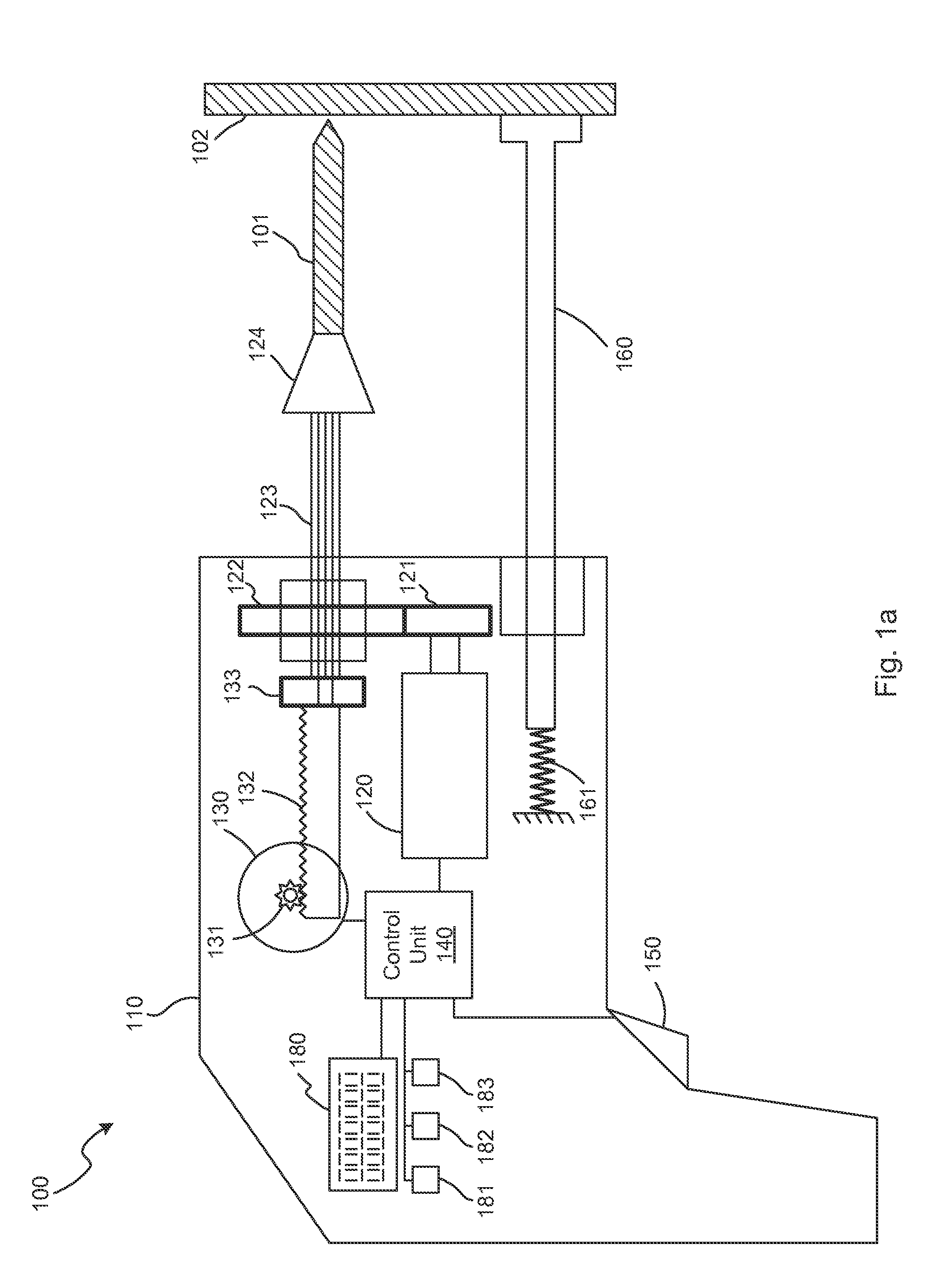

Method and system for reversibly controlled drilling of luminal occlusions

A luminal drilling system includes a drilling device and a control unit. The drilling device includes an elongate member having a drive shaft with a drill tip. The control unit includes a motor connectable to the drive shaft and control circuitry which rotationally oscillates the drive shaft with the direction of rotation automatically reversing whenever the load on the motor and / or drive shaft exceeds a threshold value.

Owner:BOSTON SCI SCIMED INC

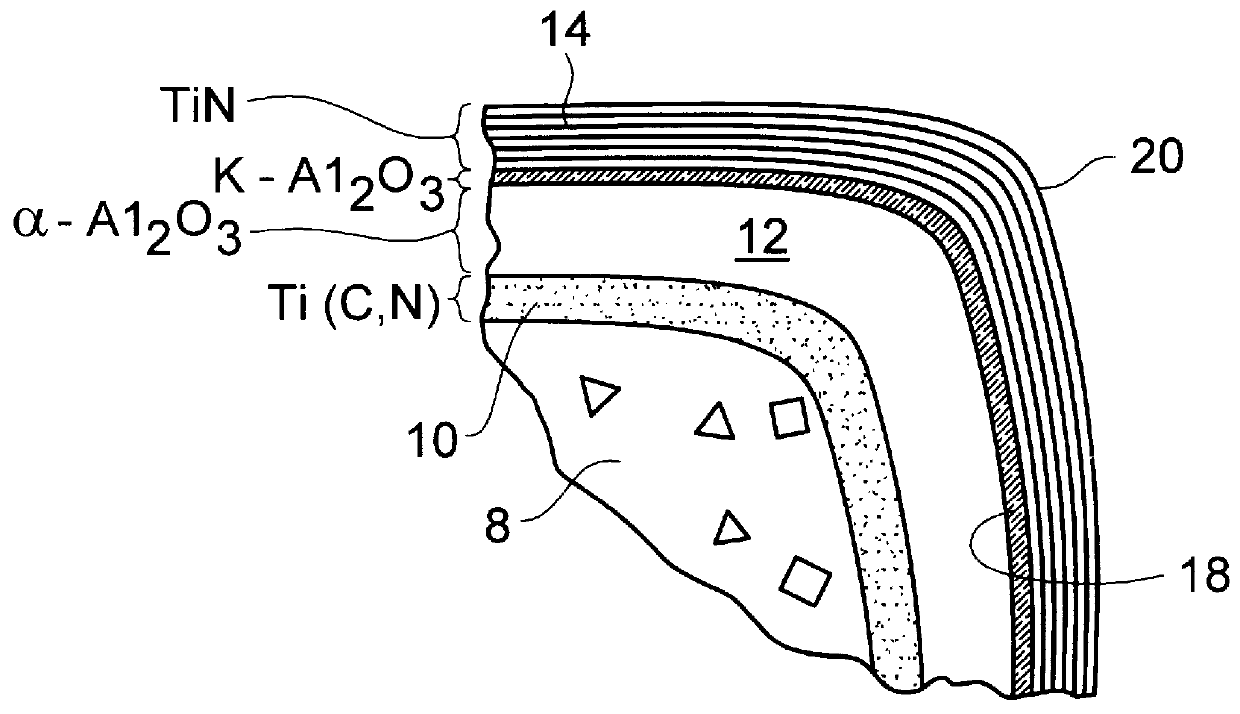

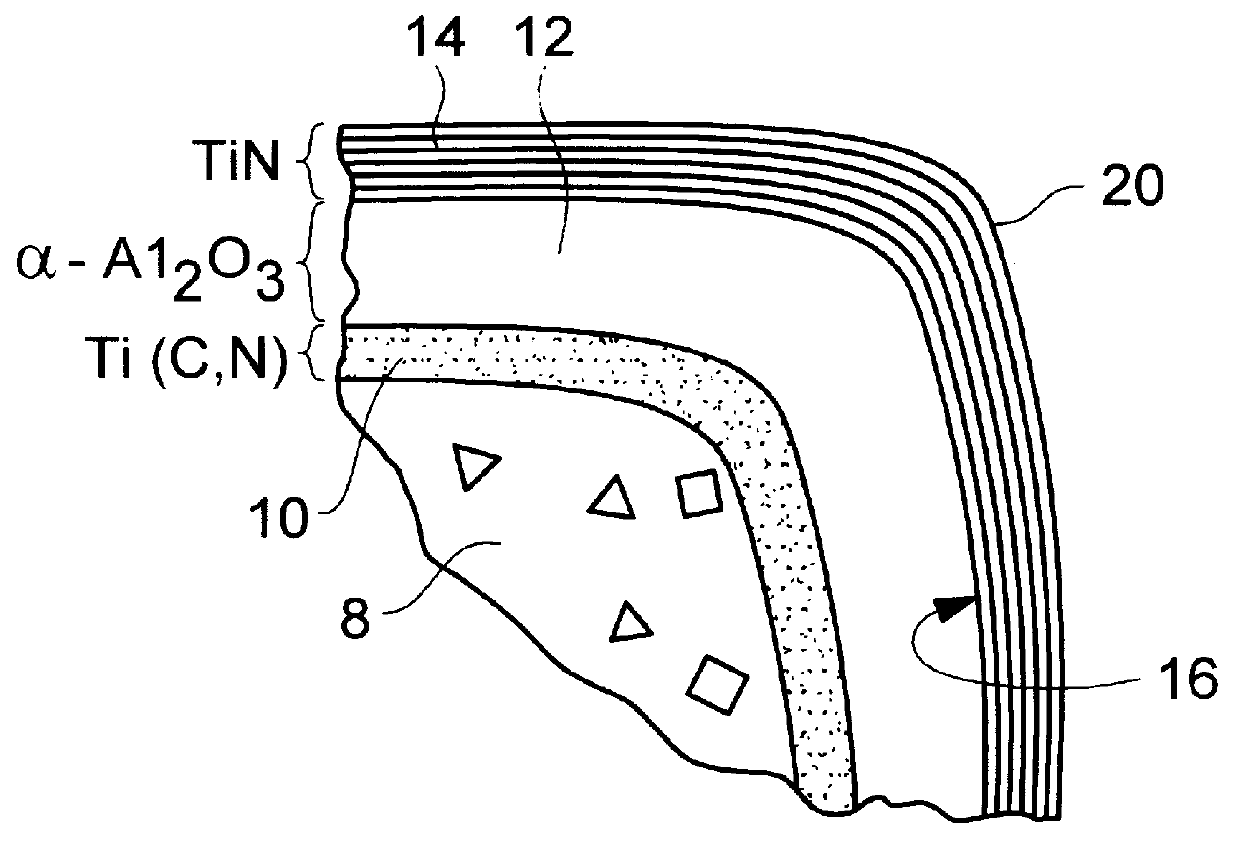

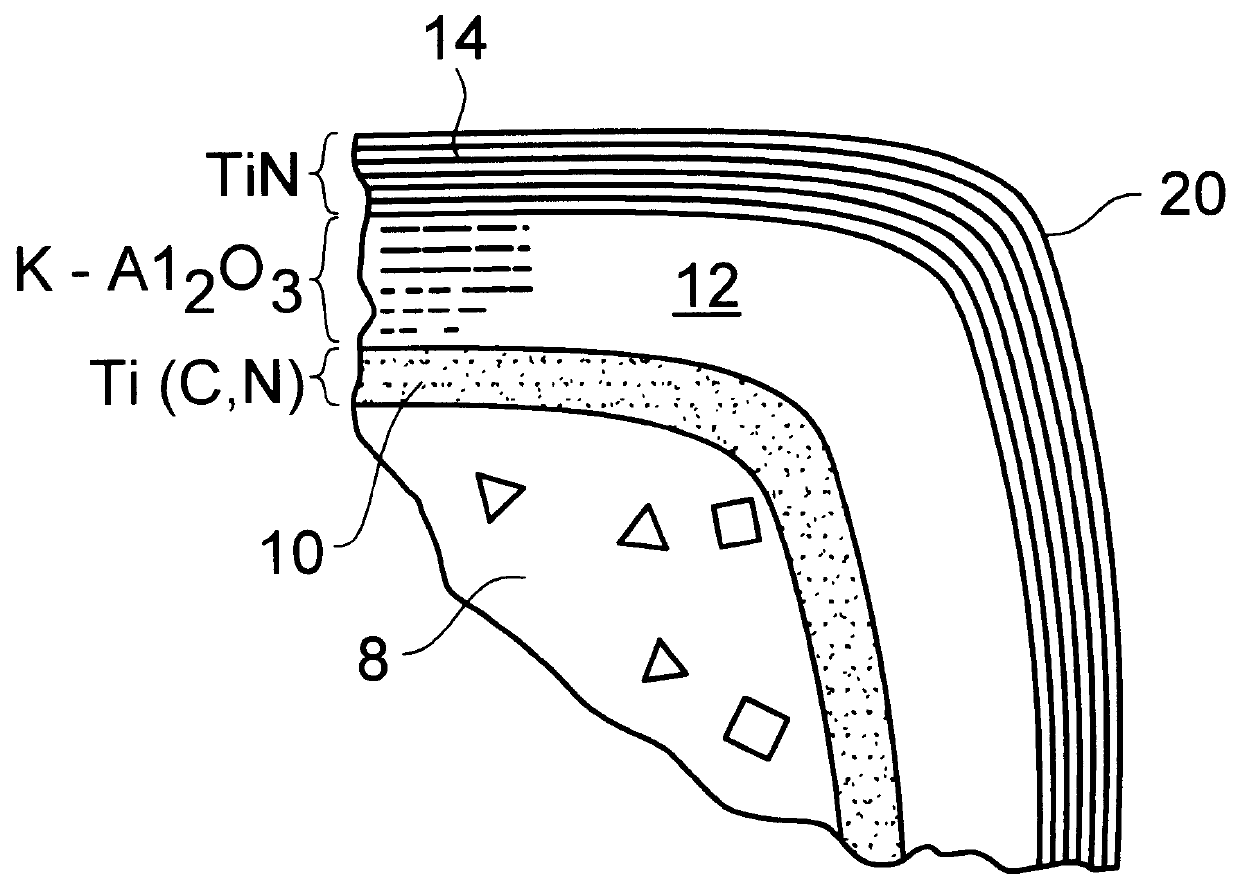

Cemented carbide body with high wear resistance and extra tough behavior

InactiveUS6015614AImprove wear resistanceExtra tough behaviorSynthetic resin layered productsTurning toolsWear resistantAlloy

There is provided an Al2O3-TiN coated cemented carbide insert intended for turning of steels and especially Ca-treated steels. The alumina layer is protected by an extra thick and multilayered coating of TiN. The TiN coating is wet blasted and, for this purpose, (Ti,Al)(C,O,N) bonded to the underlying Al2O3 layer which preferably consists of alpha -Al2O3. The extra tough behavior together with increased wear resistance can be obtained by optimizing the TiN layer thickness, structure and adhesion and wet blasting the said TiN coating. This invention is characterized by the fact that the coating layers are not missing at the cutting edge of the insert.

Owner:SECO TOOLS AB

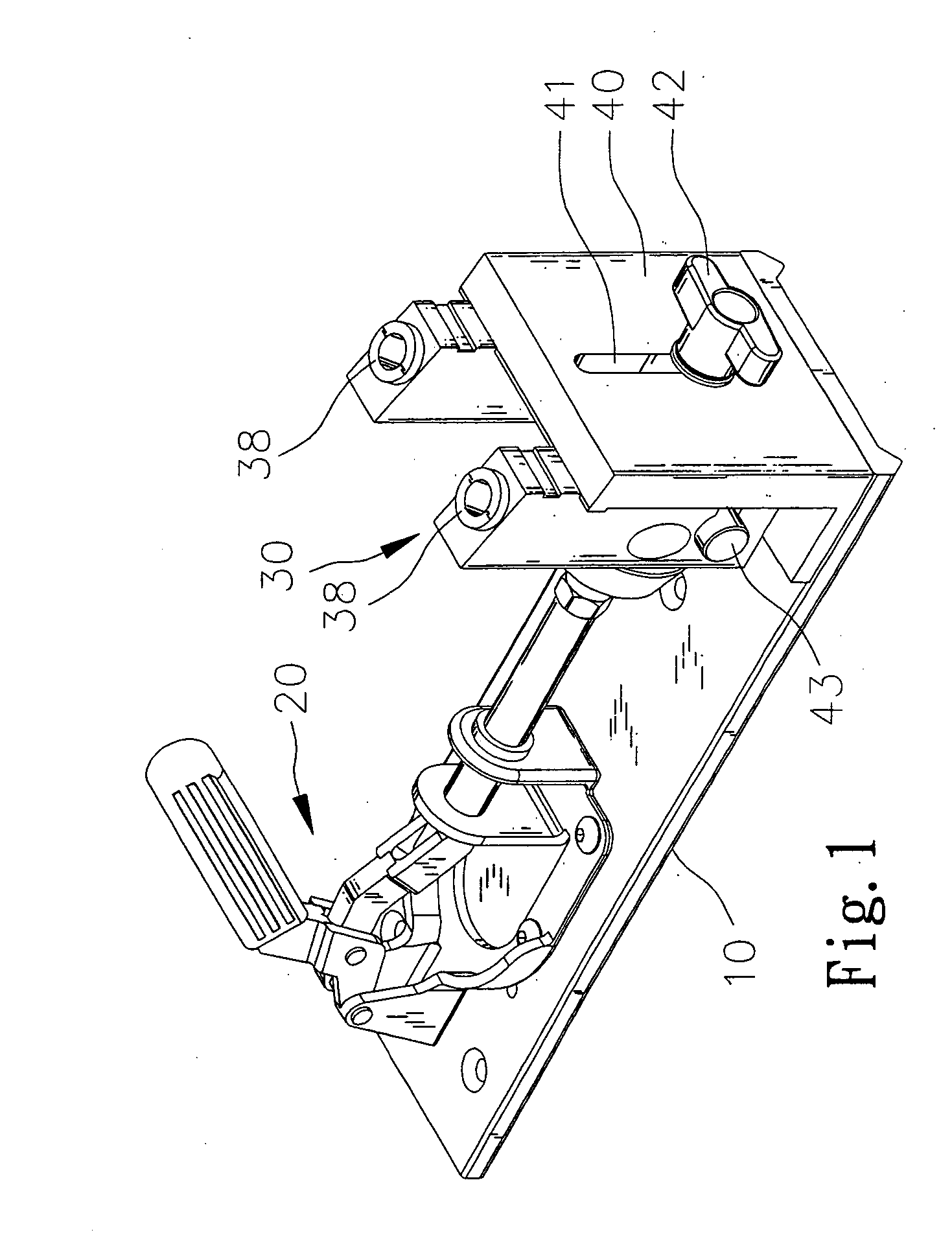

Pocket hole drilling machine

ActiveUS7374373B1Wear minimizationDrilling/boring measurement devicesThread cutting machinesEngineeringActuator

A pocket-hole drilling apparatus for drilling pocket-holes in a workpiece is disclosed. In one embodiment, an initiation switch actuates clamping the workpiece and the movement of a drilling module to cut a pocket-hole. The drilling module has a motor and a step-drill mounted thereon, which is slidably mounted on a guide module. The axis of the drilling module movement intersects work surface. In another embodiment, a movable fence provides the adjustability of pocket-hole depth. In yet another embodiment, two actuator tips are disposed in a fence to prevent the drilling of a pocket-hole through the sidewall of a workpiece. In still another embodiment, a short stroke clamping actuator is used to prevent human finger injury. In still another embodiment, a blower or an ejector pump is used to remove wood chips, wherein the blower is either attached to a drilling motor or to a separate blower motor; the ejector pump is mounted near the drill guide. In still another embodiment, two pocket-drills are slidably mounted on a block so as to drill two pocket-holes and to adjust pocket-hole spacing. In still another embodiment, a mounting structure is disposed either underneath or above the work surface to mount drilling module(s) so as to drill multiple pocket-holes into a wide workpiece at one setup. In still another embodiment, a drill guide forms a clearance for the cutting edges of the step-drill to minimize wear on the edges. In a further embodiment, an actuator provides both clamping and drilling movements, wherein the actuator is an electric motor or a hand lever.

Owner:KREG ENTERPRISES

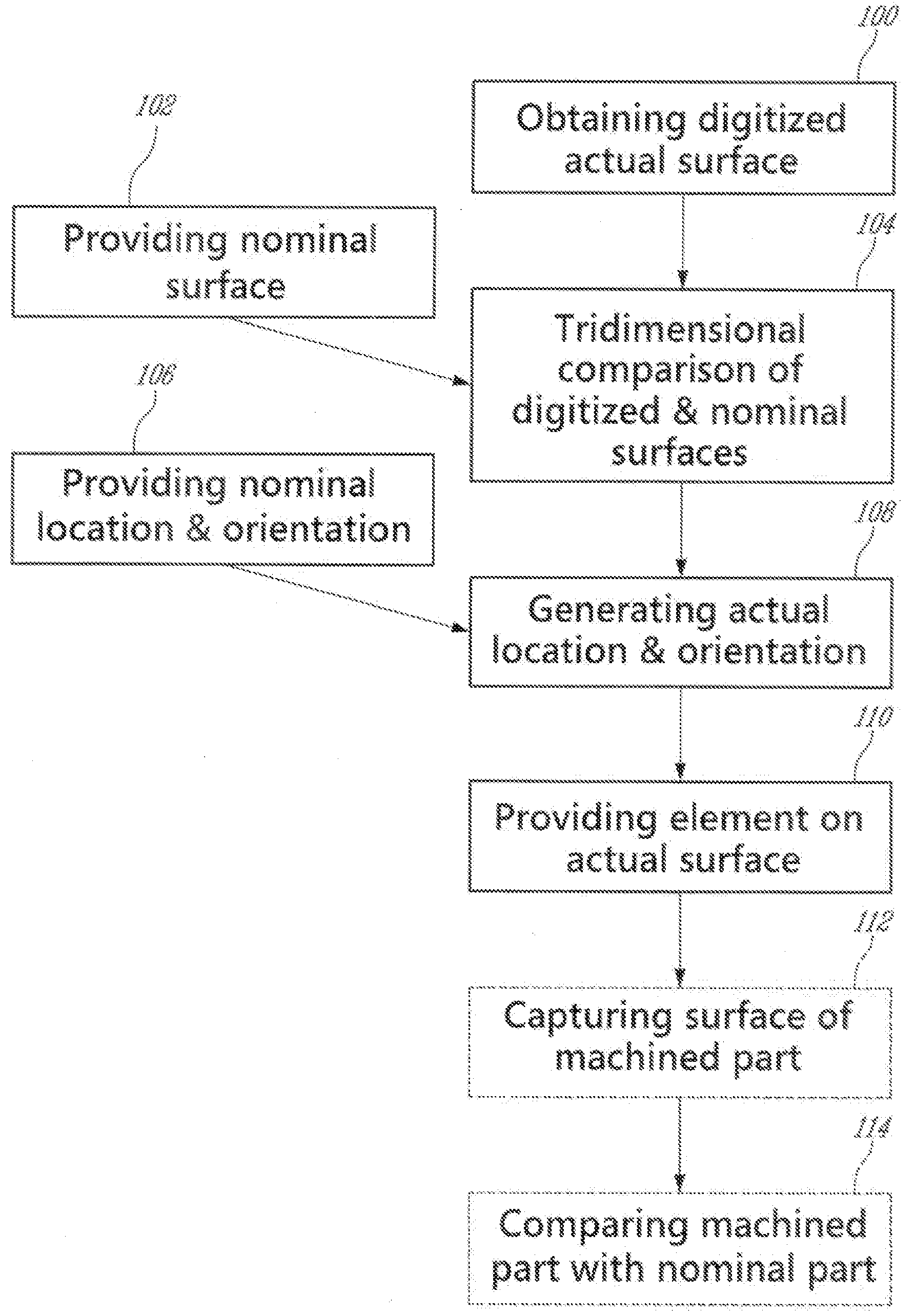

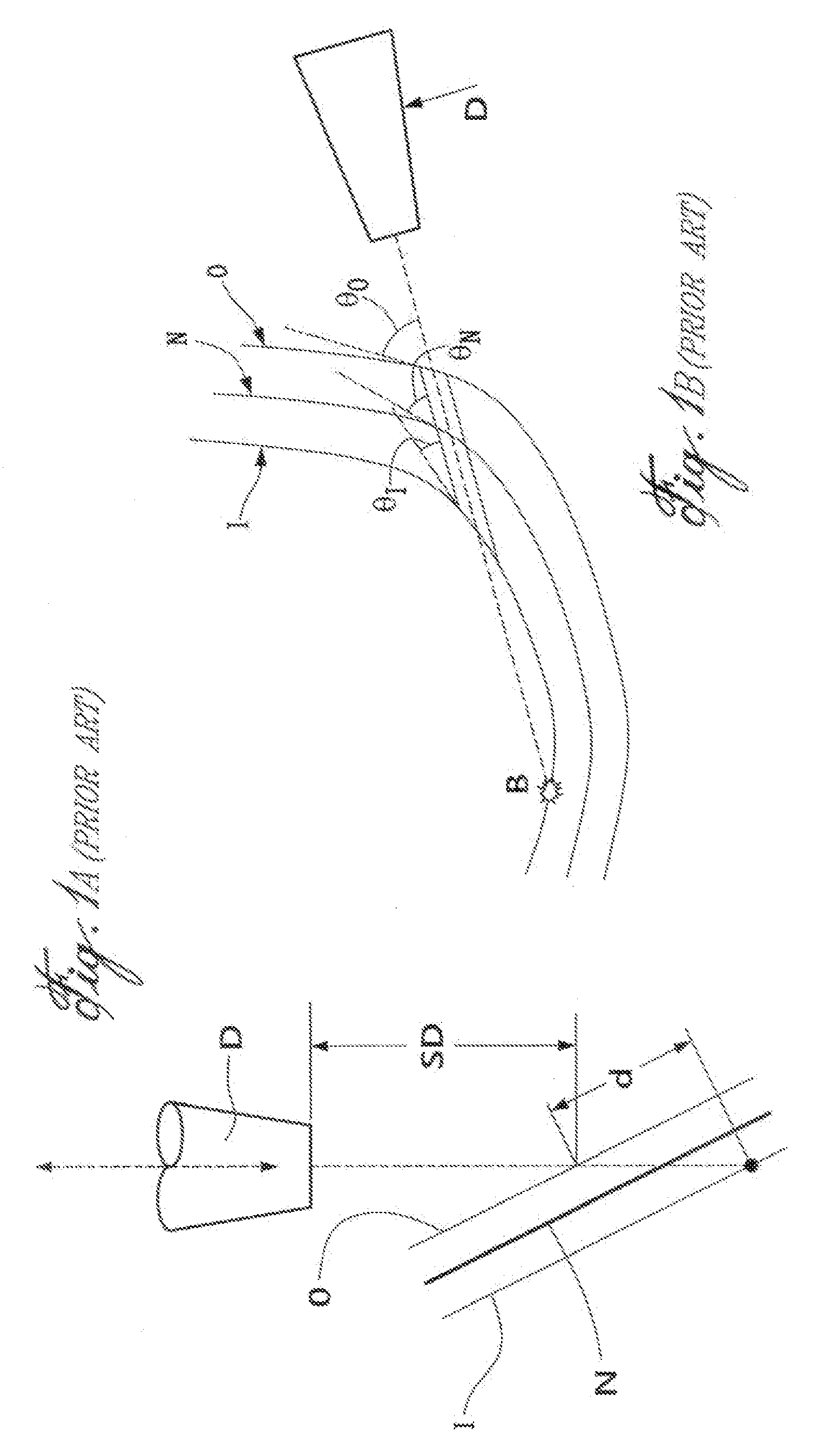

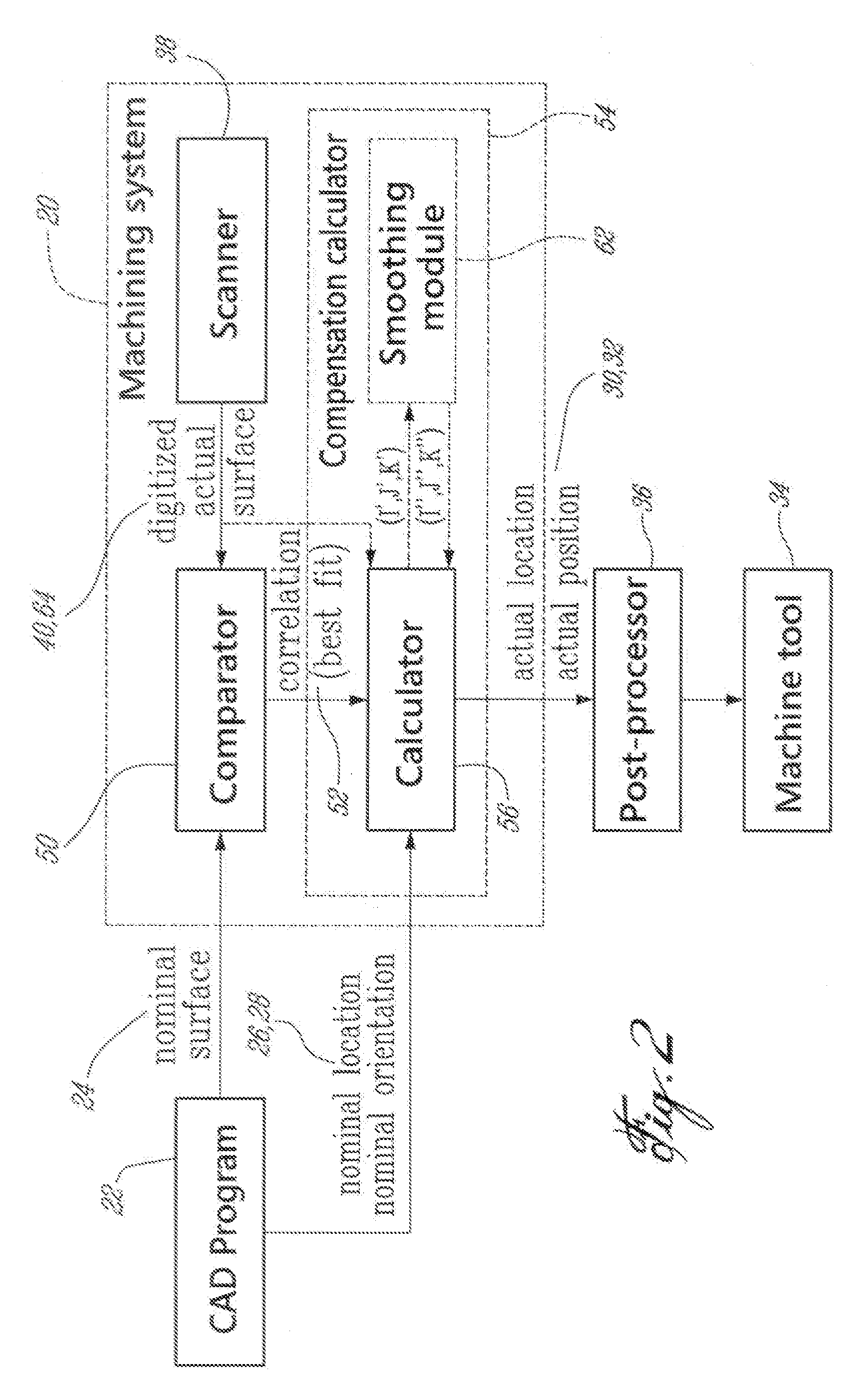

Method of making a part and related system

A system and method of making a part, including capturing an actual tridimensional surface of each part to obtain a corresponding digitized actual surface, performing a tridimensional comparison between the digitized actual surface of each part and a nominal tridimensional surface, generating an actual location and orientation of an operation to be performed based on the tridimensional comparison, and performing the operation on the part based on the generated actual location and orientation of the element.

Owner:PRATT & WHITNEY CANADA CORP

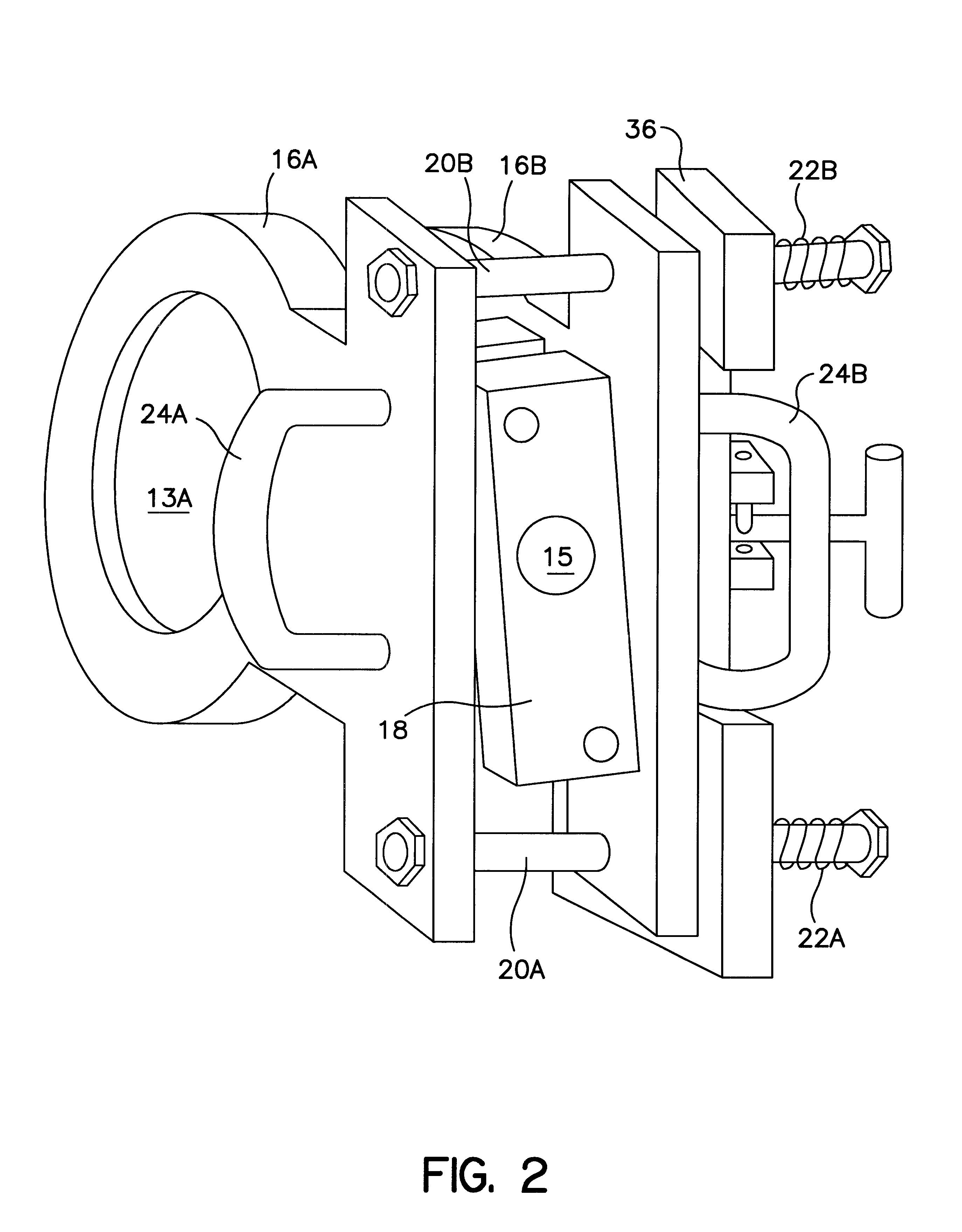

Bracket drill template

InactiveUS6193449B1Losing accuracySimple taskDrilling/boring measurement devicesThread cutting machinesRectangular apertureEngineering

A 3 sided bracket shaped template for accurately drilling door knob and lock holes in doors comprising a template plate a at right angle to a lock plate again at a right angle to a reverse plate. The template plate and reverse plate each contain rectangular apertures for drill passage, and the template plate further has zee bracket sleeves on the bottom and both sides of the rectangular aperture for slidably mounting removable plate guides each with different perpendicular cylindrical extension guide for drills of varying sizes. The lock plate also has a centered circular hole with a tubular drill guide perpendicular to the lock plate.

Owner:DIAZ ALBERTO

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

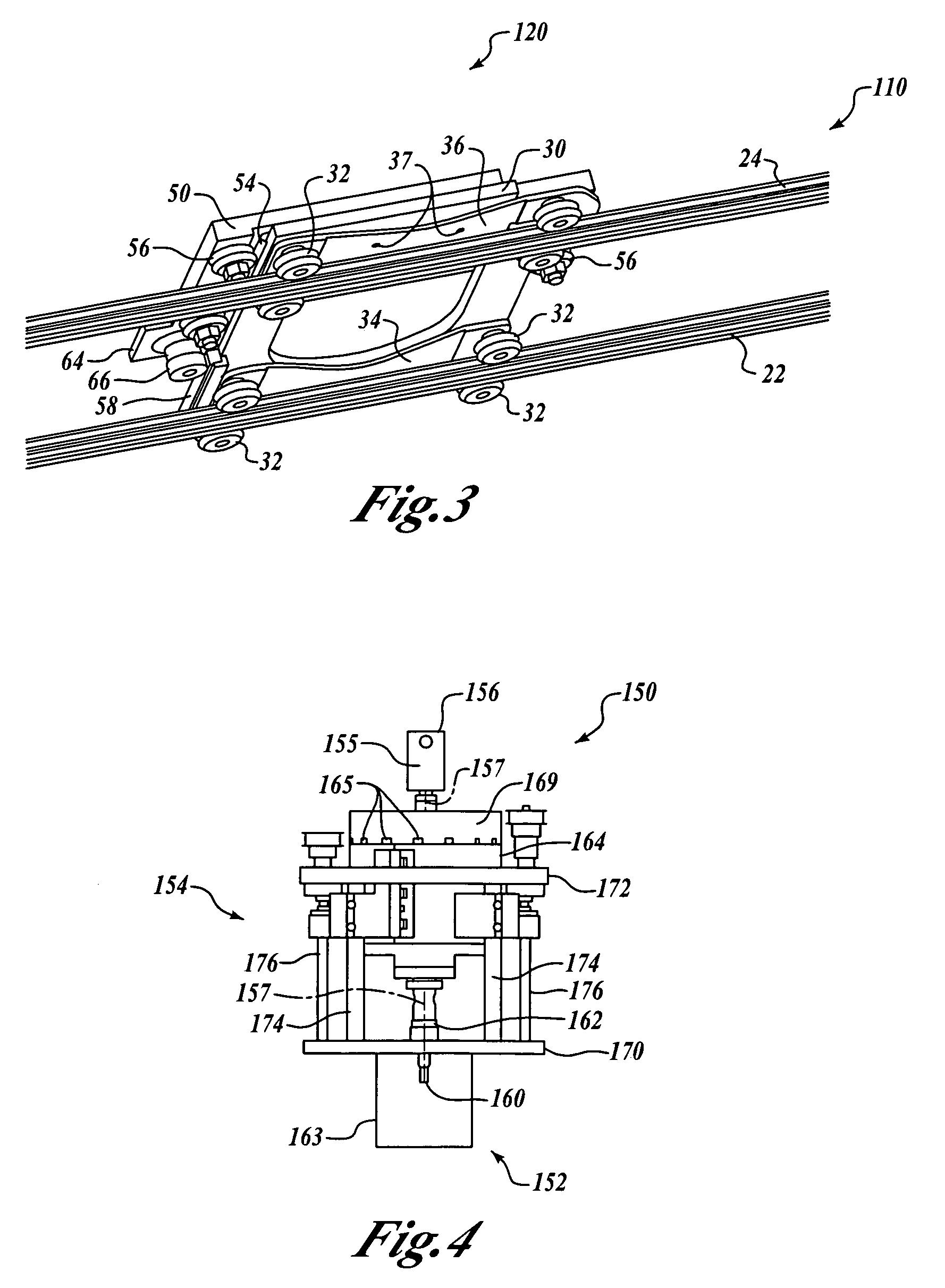

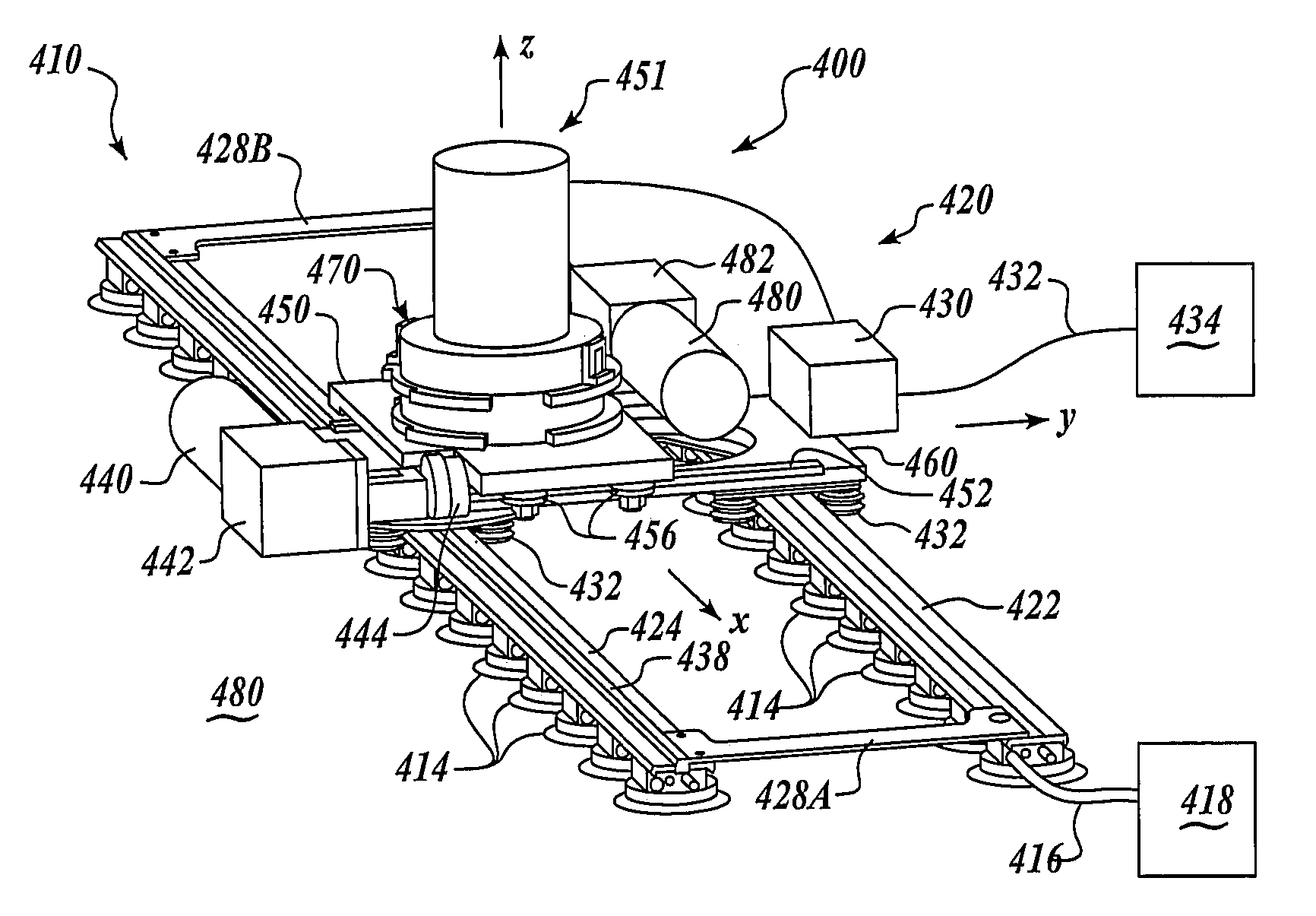

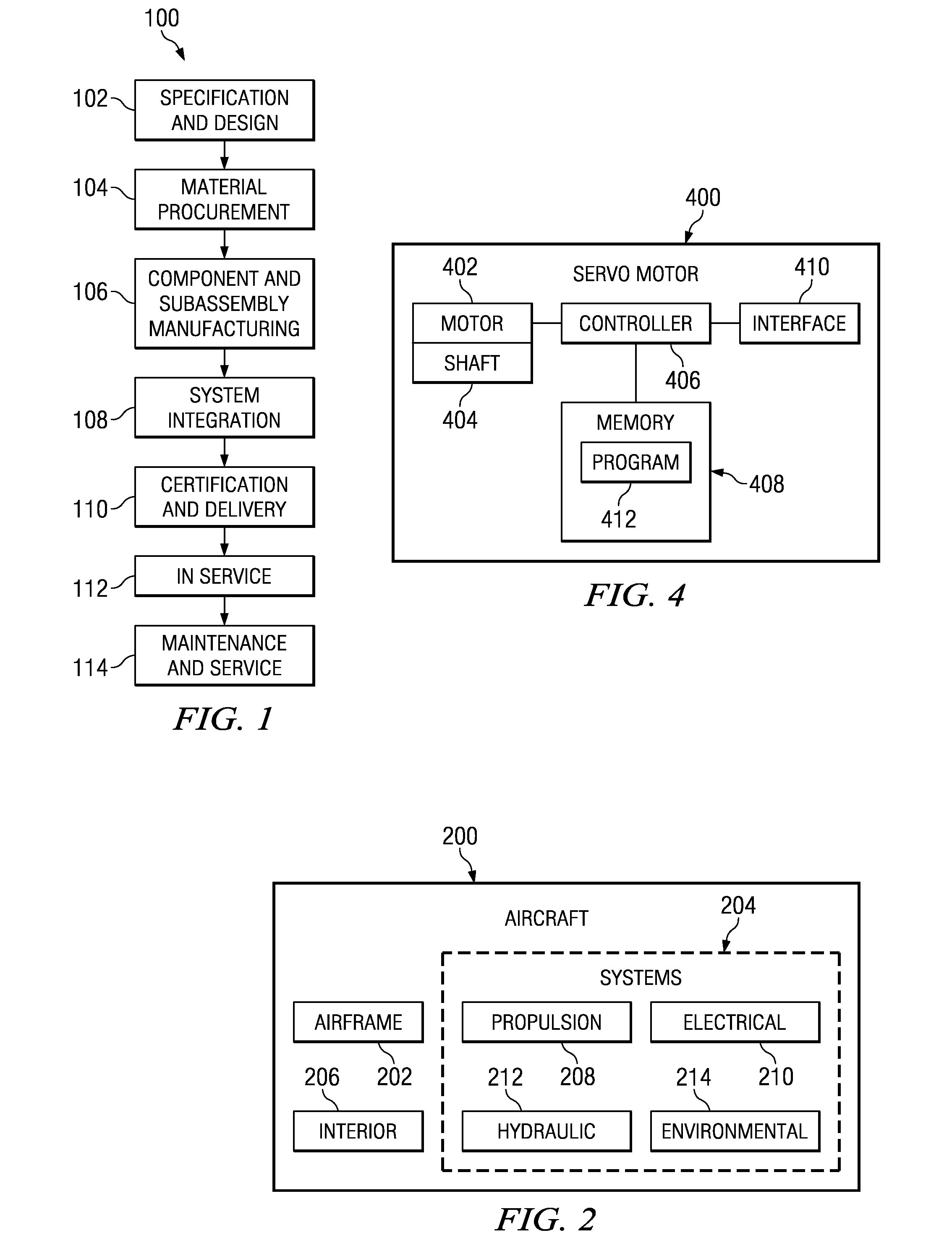

Apparatus and methods for servo-controlled manufacturing operations

ActiveUS7264426B2Improve accuracyImprove efficiencyAircraft componentsDrilling/boring measurement devicesMotor driveControl theory

Apparatus and methods for servo-controlled manufacturing operations are disclosed. In one embodiment, an apparatus includes a base member, a drive platform spaced apart from the base member by a separation distance, and a plurality of guide members extending between the drive platform and the base member. At least one of the drive platform and the base member are moveable along the guide members to increase or decrease the separation distance. The apparatus also includes a drive member operatively coupled between the drive platform and the base member, and a servo motor operatively coupled to the drive member. As the servo motor drives the drive member, the separation distance is varied. In an alternate embodiment, a manufacturing tool may be coupled to at least one of the drive platform and the base member.

Owner:THE BOEING CO

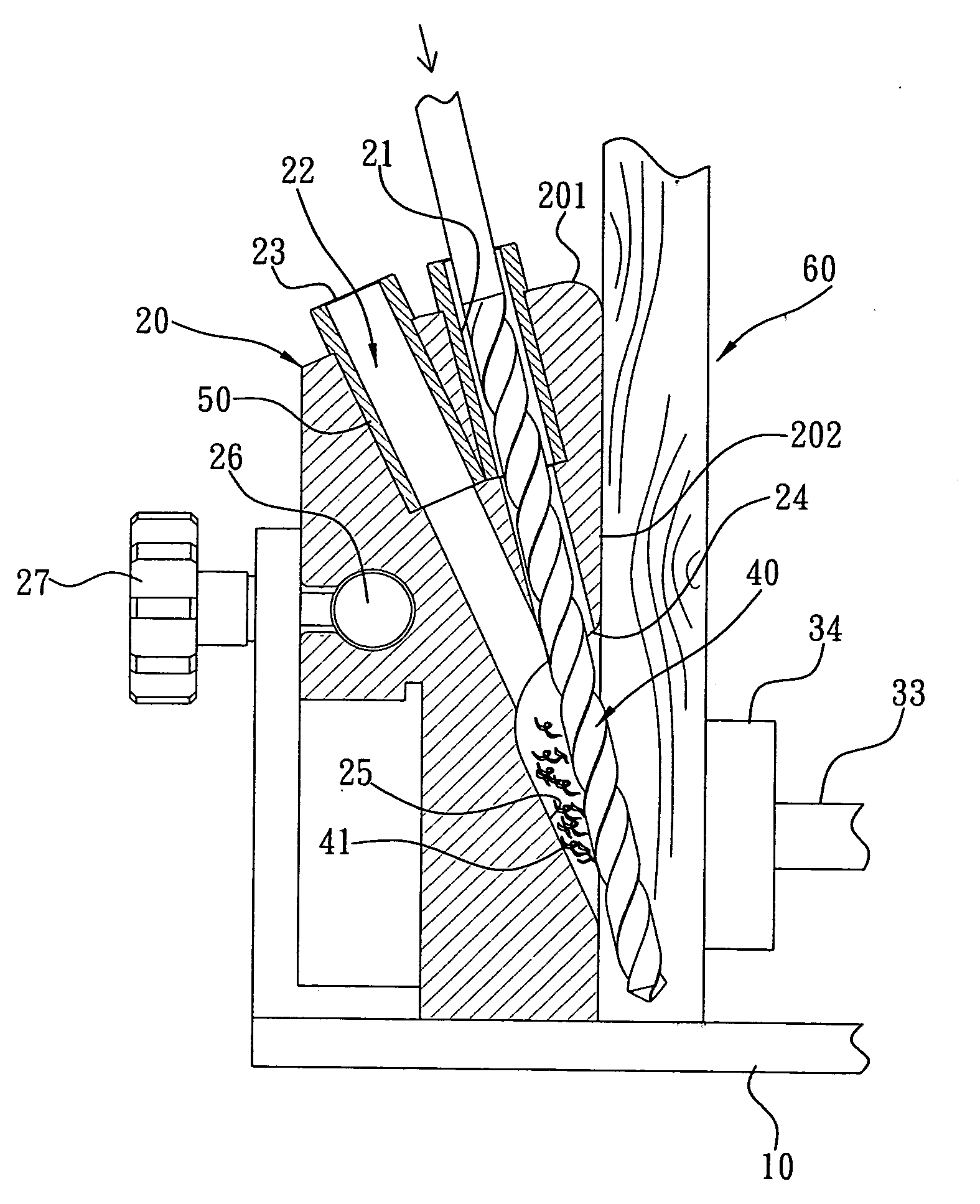

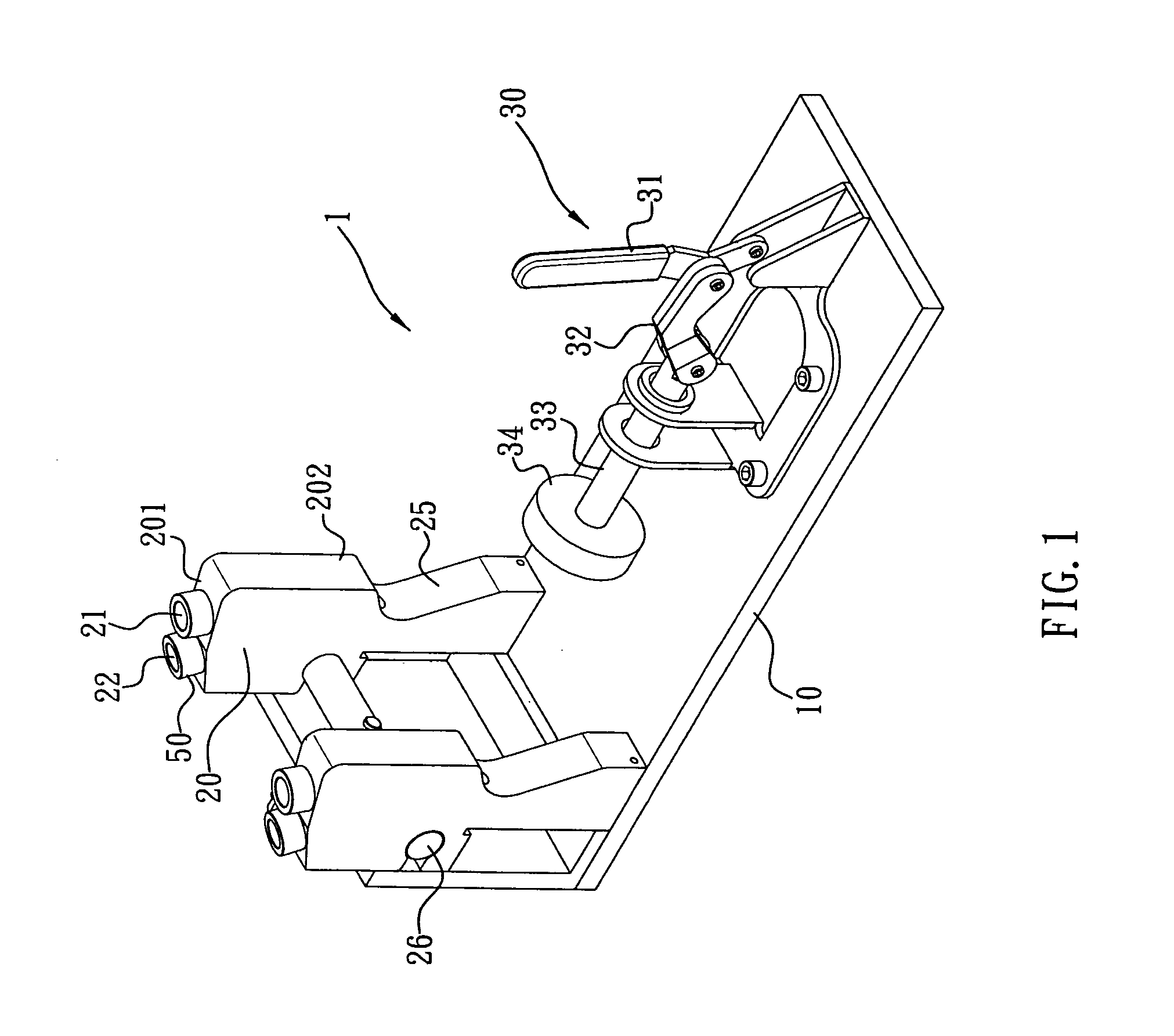

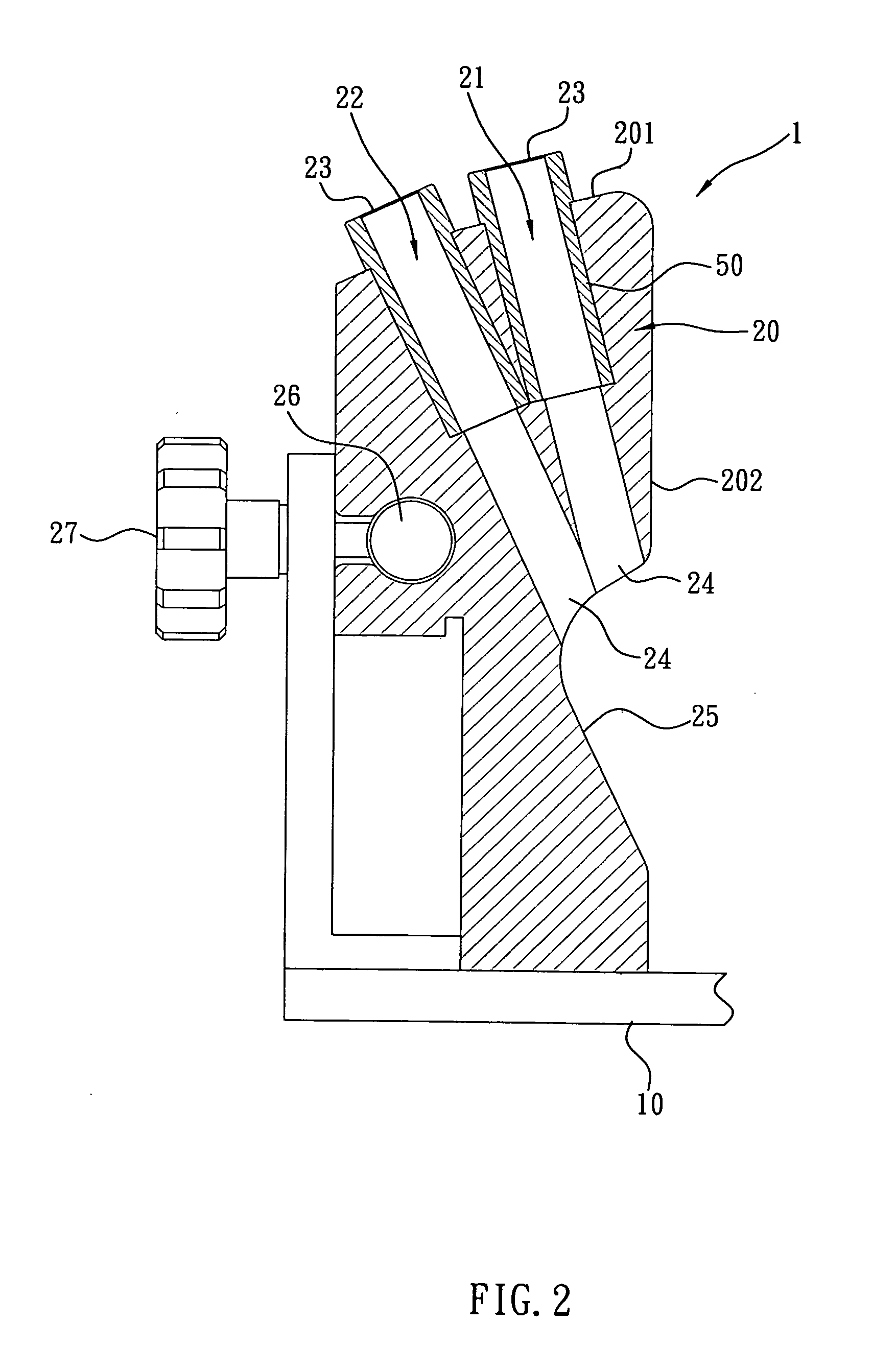

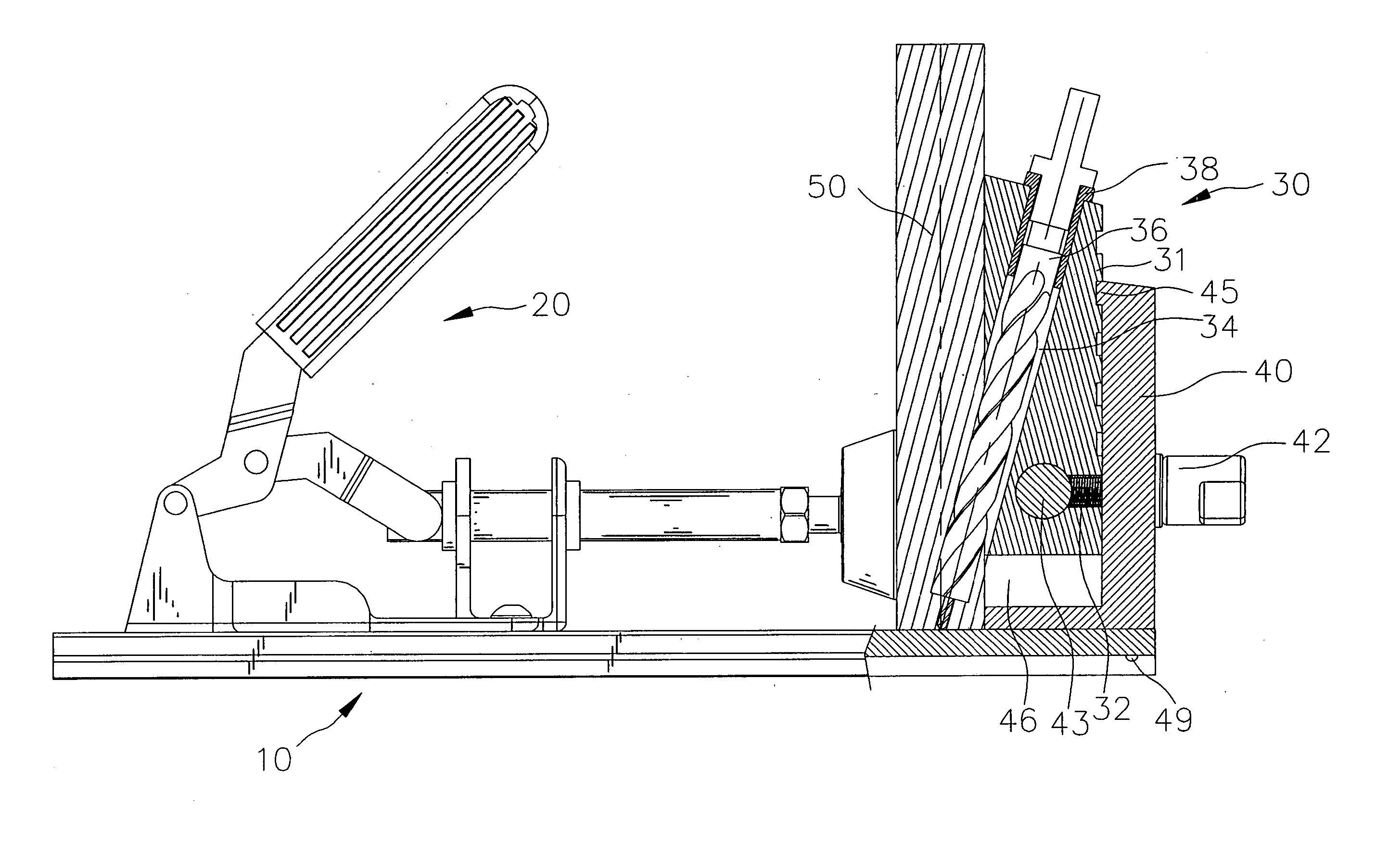

Inclined-hole drilling jig

InactiveUS20080075546A1Easy to disassembleSimple structureThread cutting machinesDrill jigsEngineeringDrill hole

An inclined-hole drilling jig primarily comprises a frame, at least one guide seat assembled thereon, and a workpiece positioner; wherein, the guide seats each have plural inclined guide channels to accommodate and orient a drill. The present invention is characterized by at least one first inclined guide channel and one second inclined guide channel of the guide seats with diverse inclinations, whereby, the guide seats can provide options for at least two diverse drilling inclinations to cater to users' various needs.

Owner:LIN TUNG CHUAN

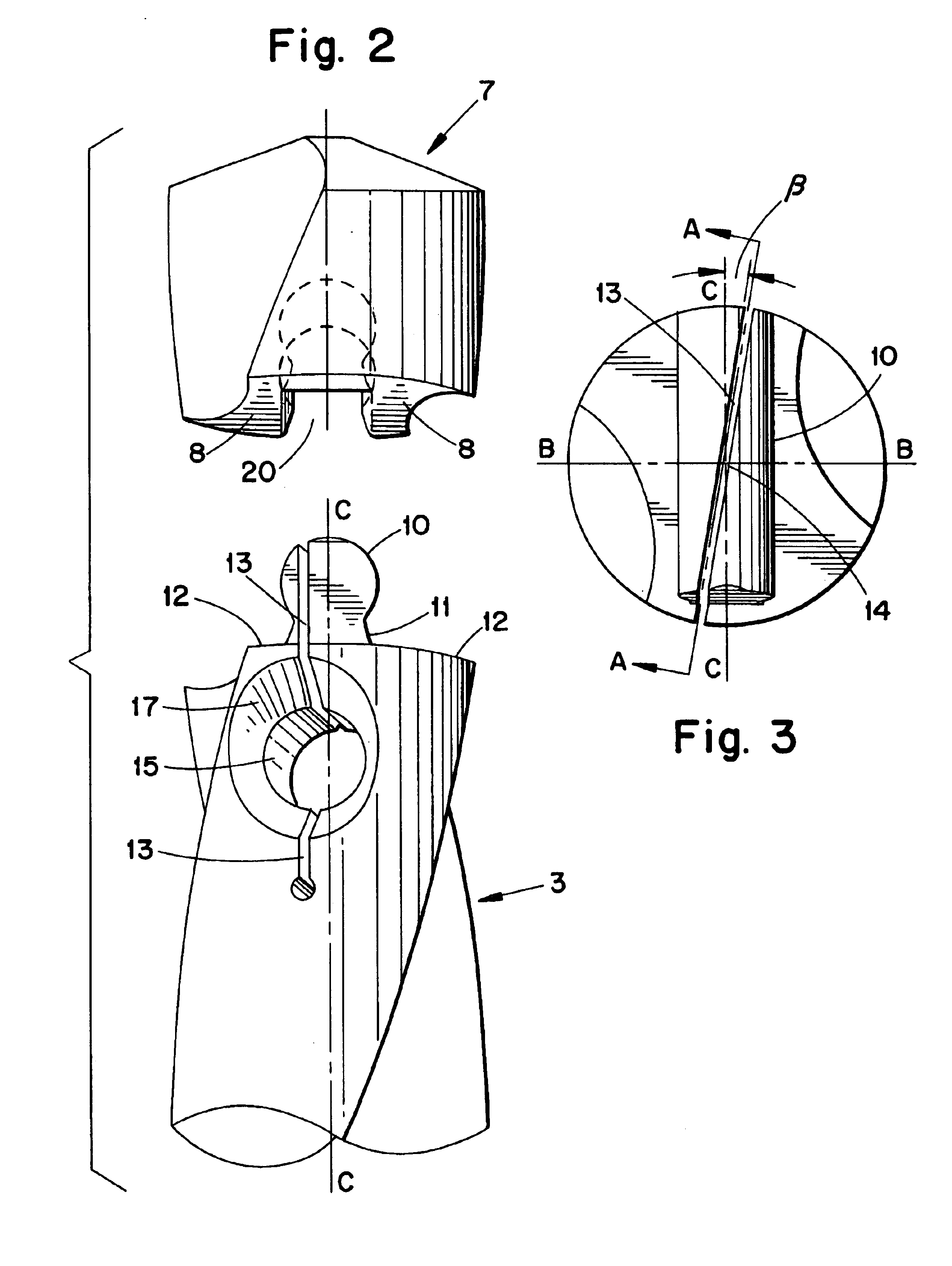

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

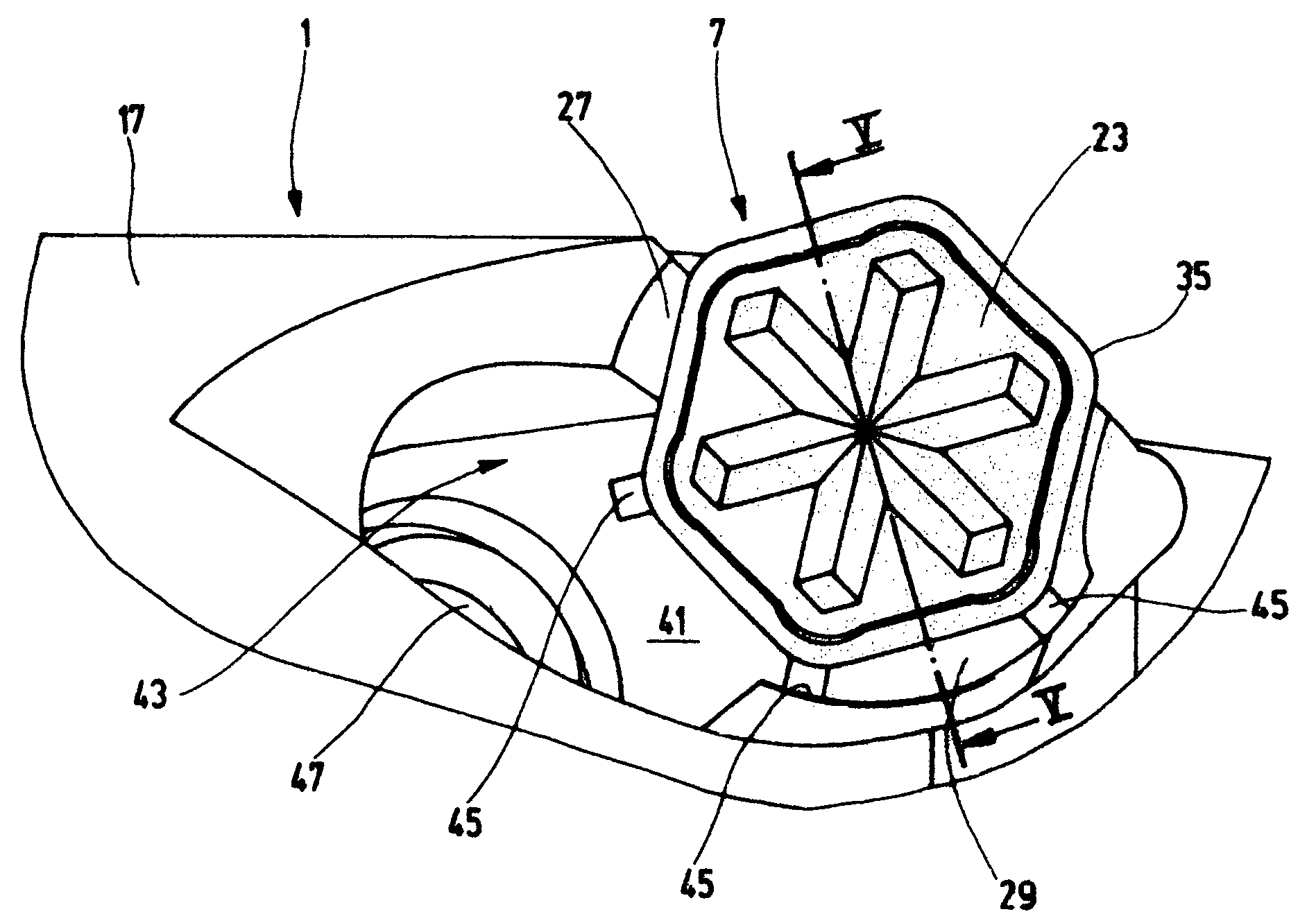

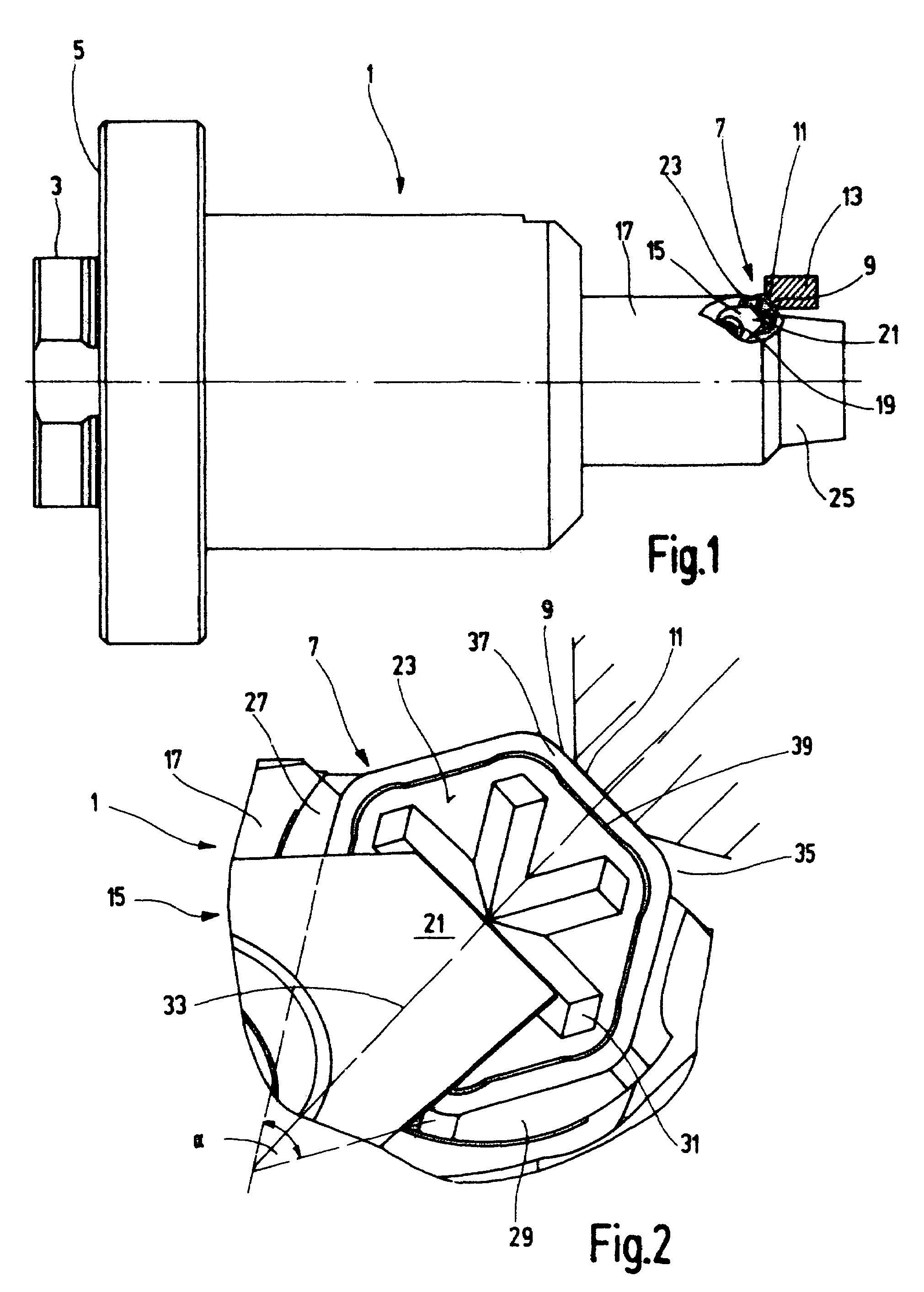

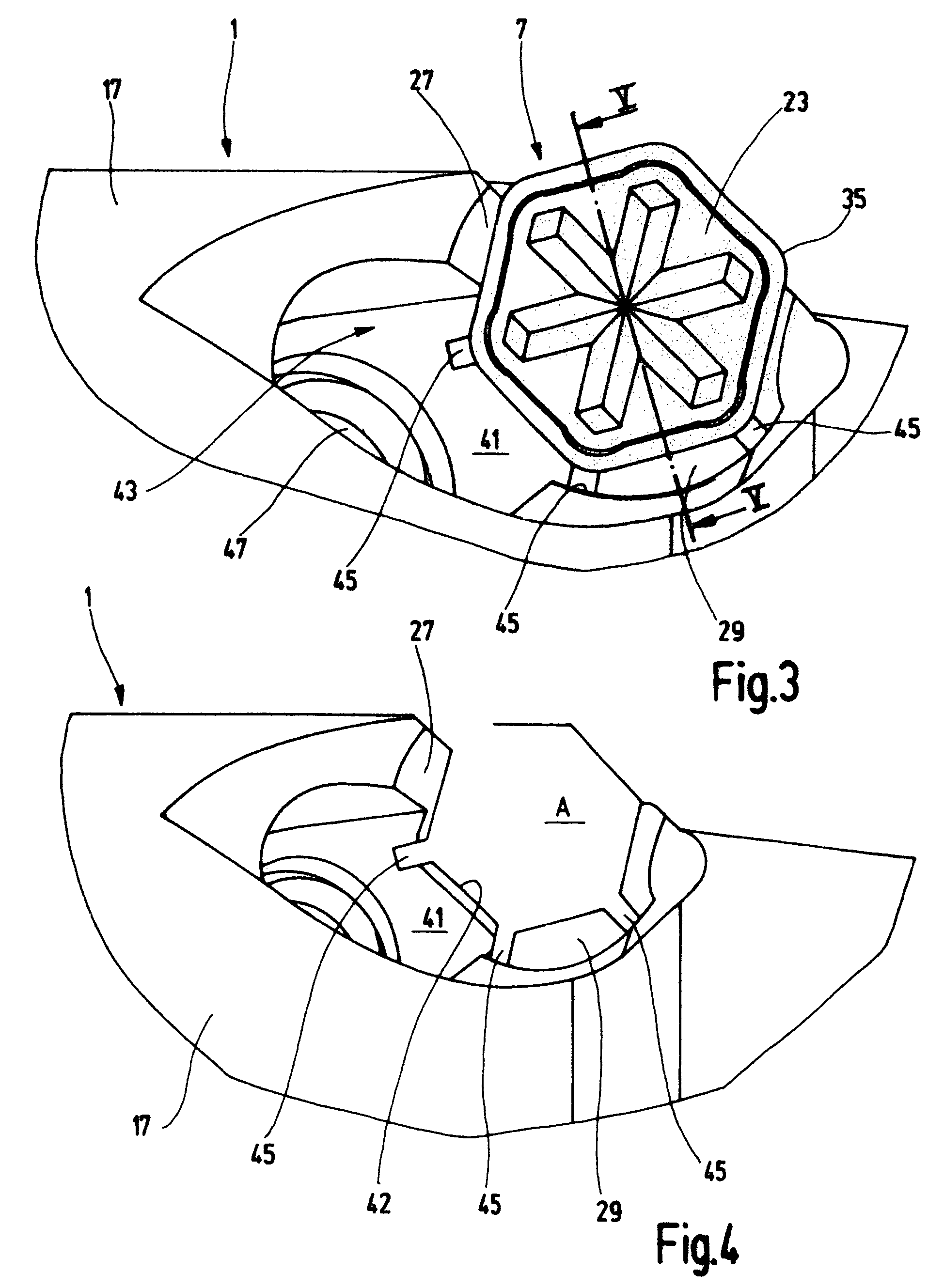

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

Wood-drilling apparatus

InactiveUS20050089381A1Drilling/boring measurement devicesThread cutting machinesDrill bitEngineering

A wood-drilling apparatus includes a table, a wall, at least one cylinder, a jig and at least one drill. The wall is installed on the table. The cylinder is vertically movably mounted on the wall. The cylinder defines an inclined passageway. The jig is installed on the table for pushing a workpiece against the cylinder. The drill is movably inserted in the inclined passageway for drilling the workpiece.

Owner:LIU HSU HSIU KWEI +1

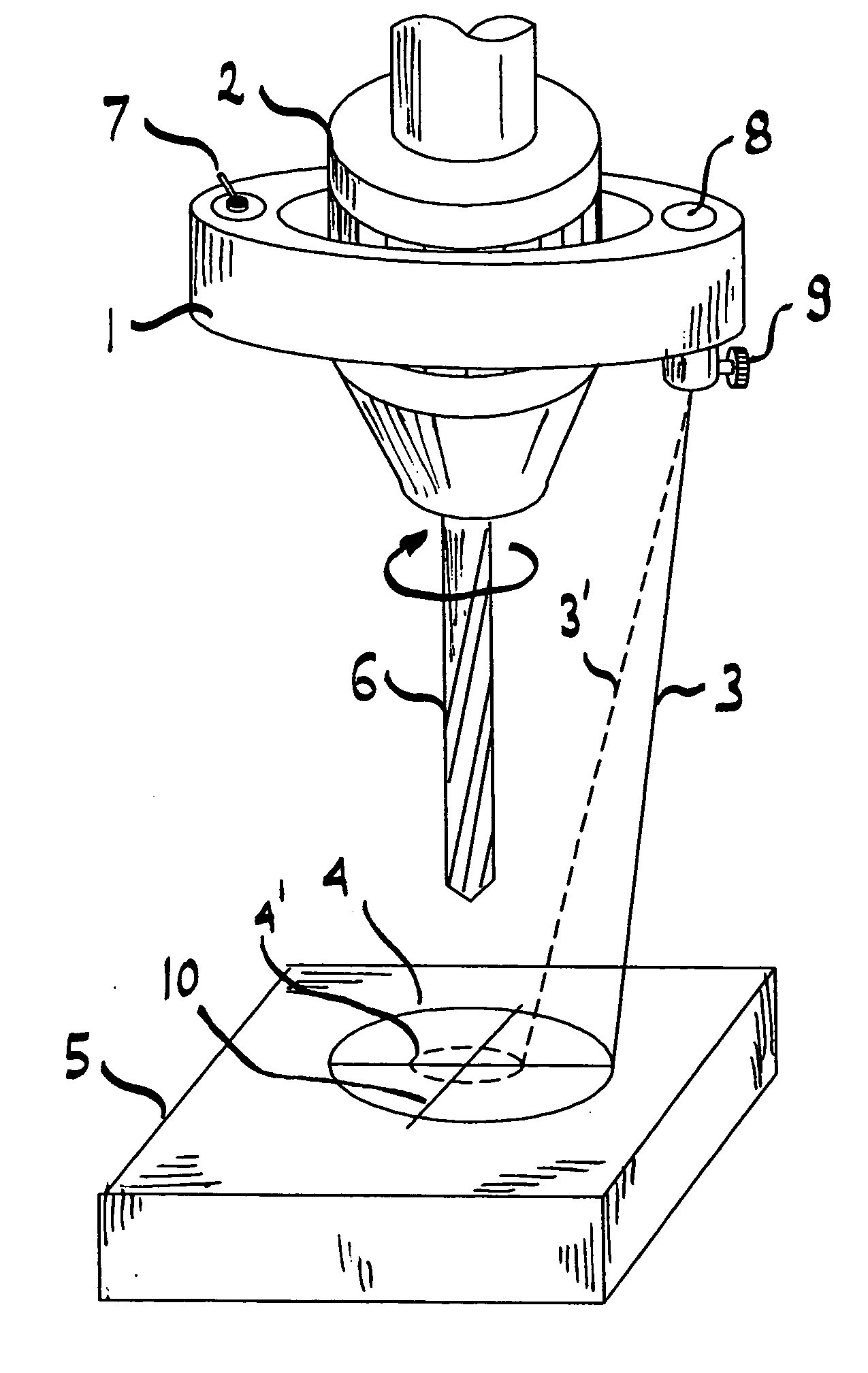

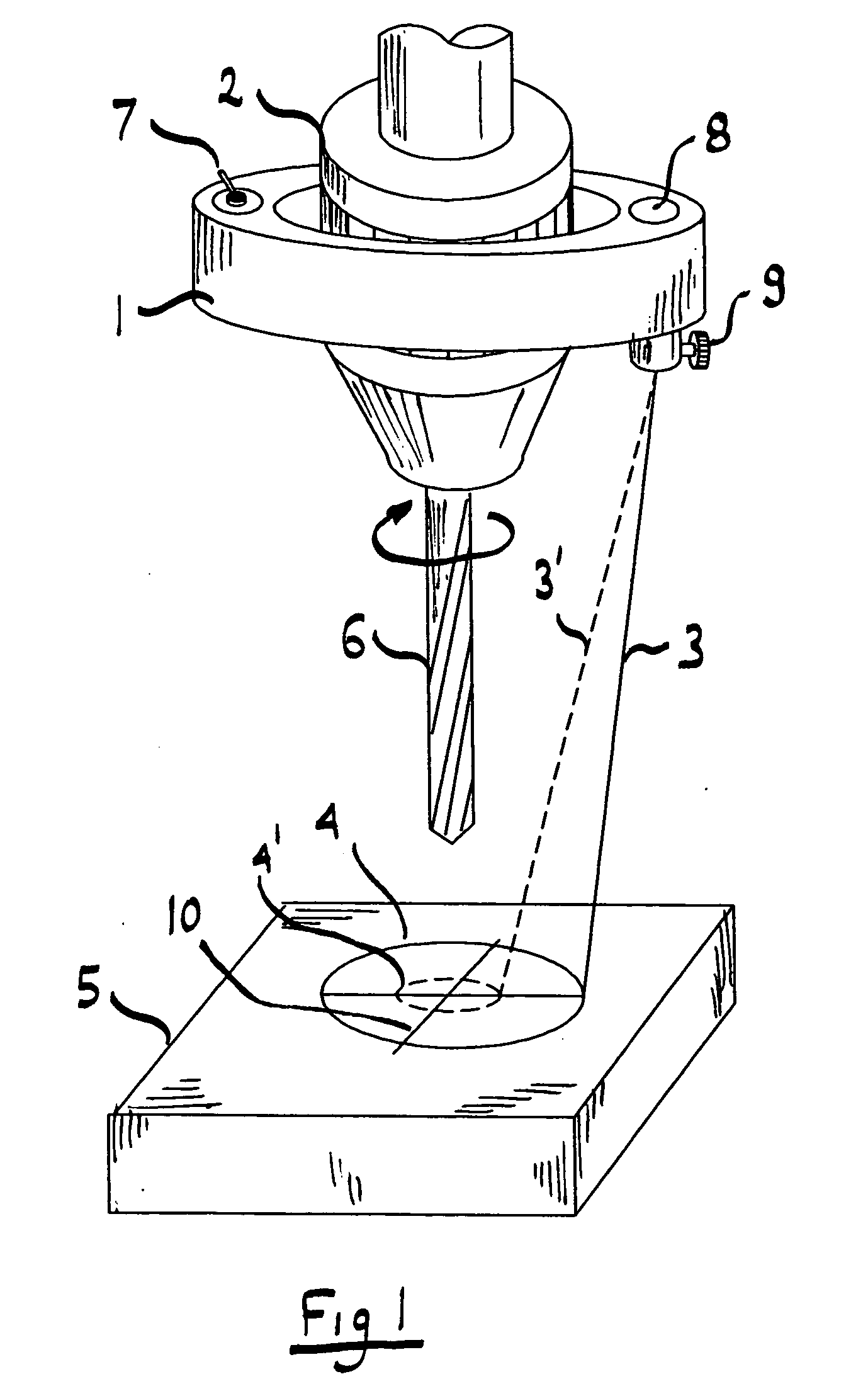

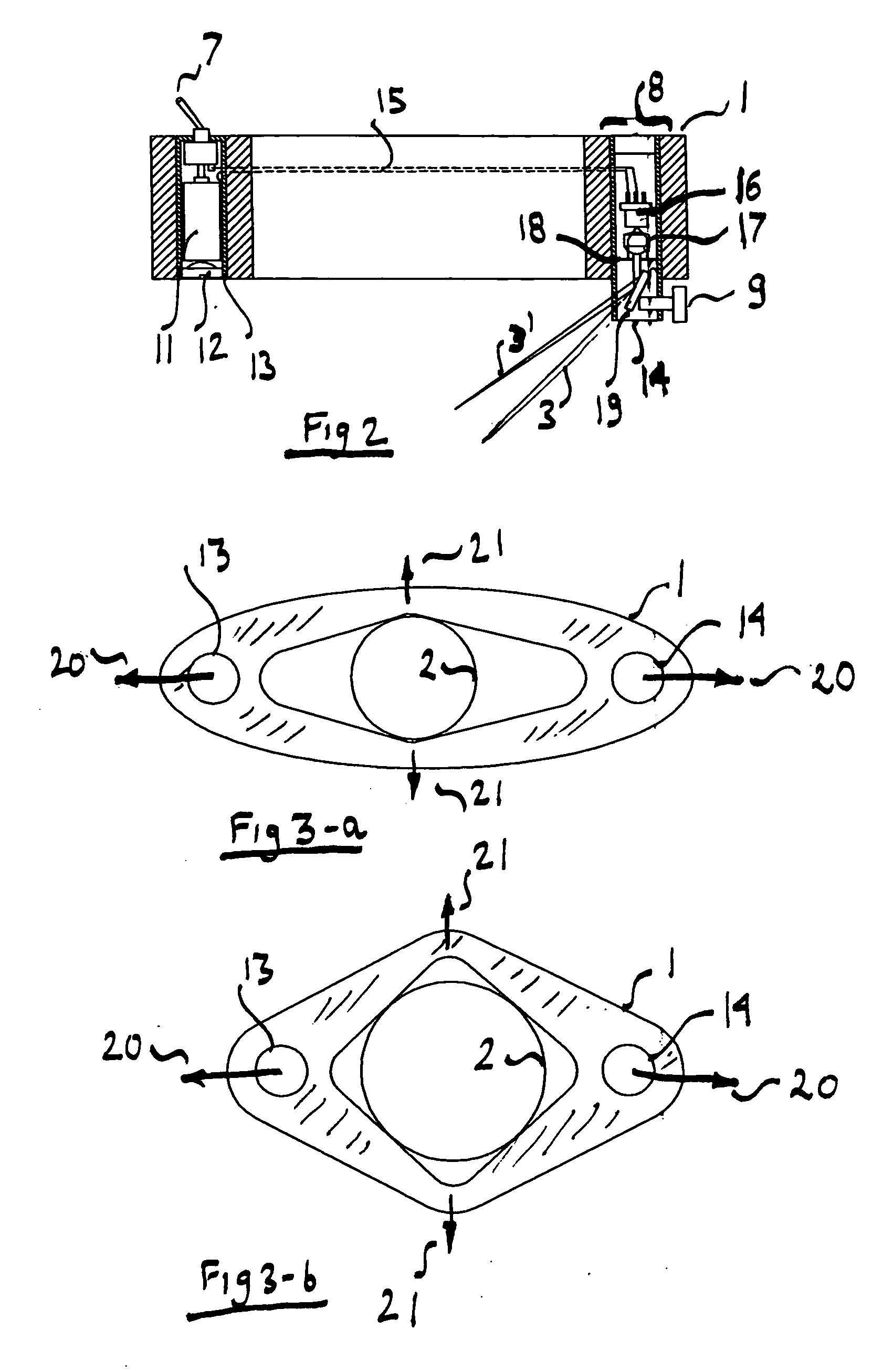

Laser centering jig

InactiveUS20070030486A1Drilling/boring measurement devicesThread cutting machinesEngineeringMachine tool

The invention relies on the visual persistence of the human eye to perceive a circle when a laser spot is rotated rapidly. A diode laser spot projector is temporarily attached to the spindle of a machine tool and projects a sharp spot on the work piece. As the spindle rotates, an image of a circle is formed which is perfectly centered with the axis of rotation of the spindle. The work piece is moved until the projected circle lines up with the desired location for machining. The size of the projected circle can be changed by adjusting the position of the laser beam or by changing the distance between the spindle and work piece. The jig can accommodate a wide range of chuck and collet diameters.

Owner:GELBART DANIEL

Drill assembly and method to reduce drill bit plunge

ActiveUS8511945B2Reduce plungeMaintain stiffnessDrilling/boring measurement devicesThread cutting machinesEngineeringDrill bit

A drill assembly and method for reducing plunge of a drill bit upon breaking through a workpiece. The drill assembly contains a motor to advance and retract the drill bit, the motor is controlled by a control unit in a feedback loop to achieve a desired stiffness. The control unit determines when the drill bit breaks through the workpiece and stops or retracts the movement of the drill bit.

Owner:QUANSER CONSULTING

Power assisted drill press

InactiveUS7108459B1Quick and easy securingEasily suppliedDrilling/boring measurement devicesThread cutting machinesEngineeringVariable pressure

A power assisted drill press having a feed cylinder fed by a variable pressure regulator which allows a user to controllably feed a bit and work material together while activating a drill motor to rotate the bit. An embodiment of the power assisted drill press utilizes a suction cup and venturi system for attachment of the press to a surface work material. The drill press uniquely allows a person to variably activate the feed cylinder and also activate the drill motor with a single hand.

Owner:MUELLER THOMAS L MUELLER TOD BEVERLY H & MUELLER JOSEPH E

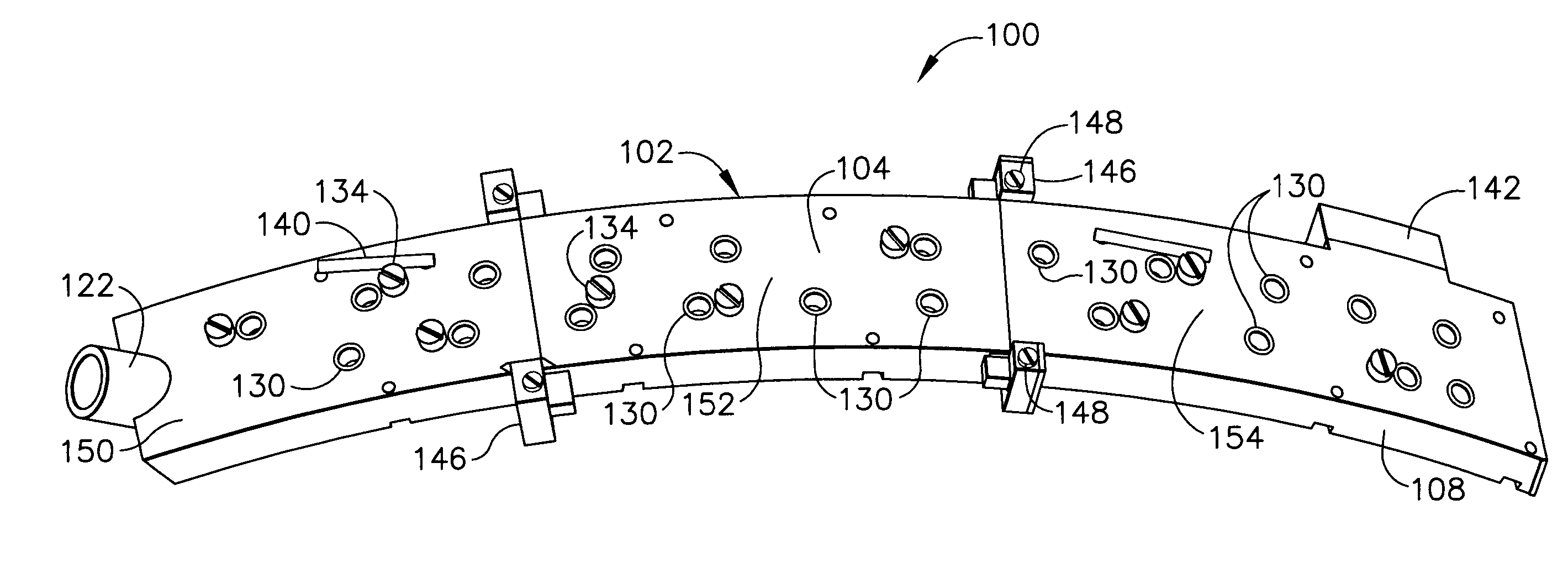

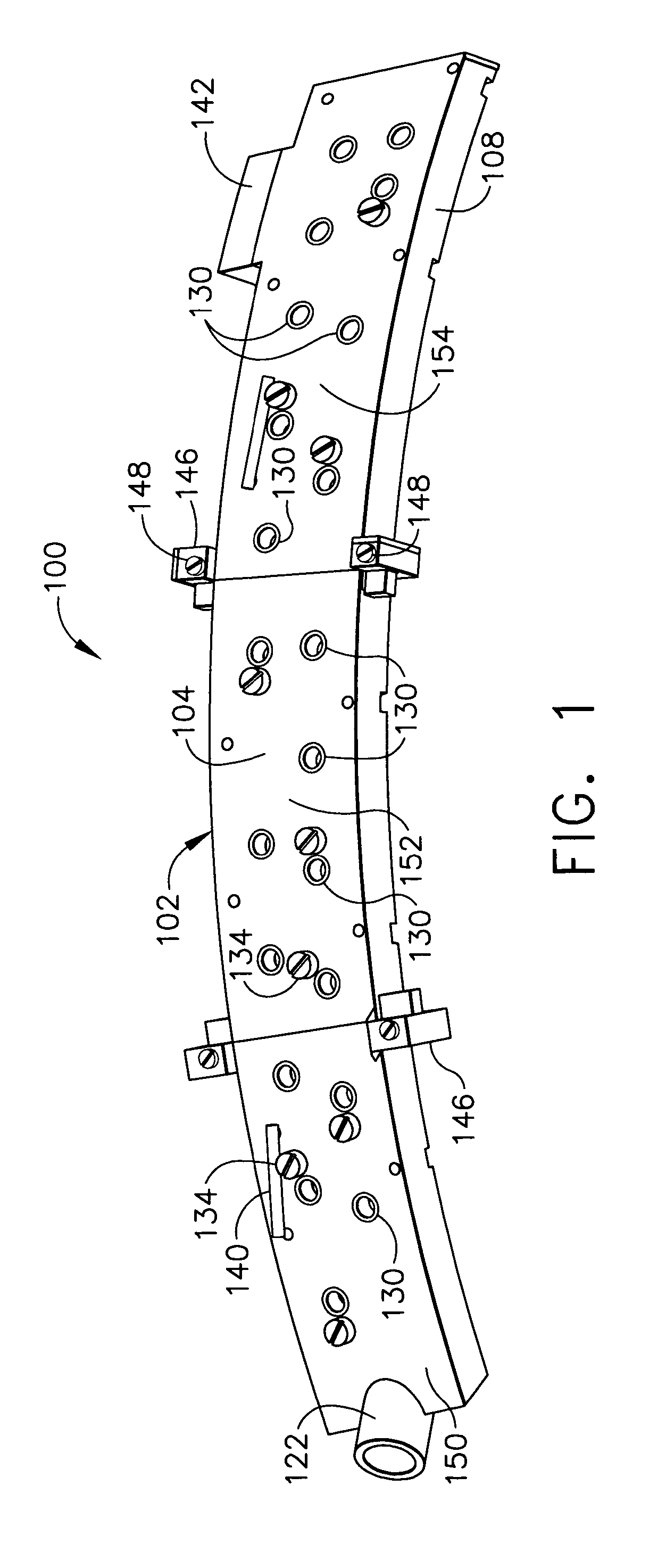

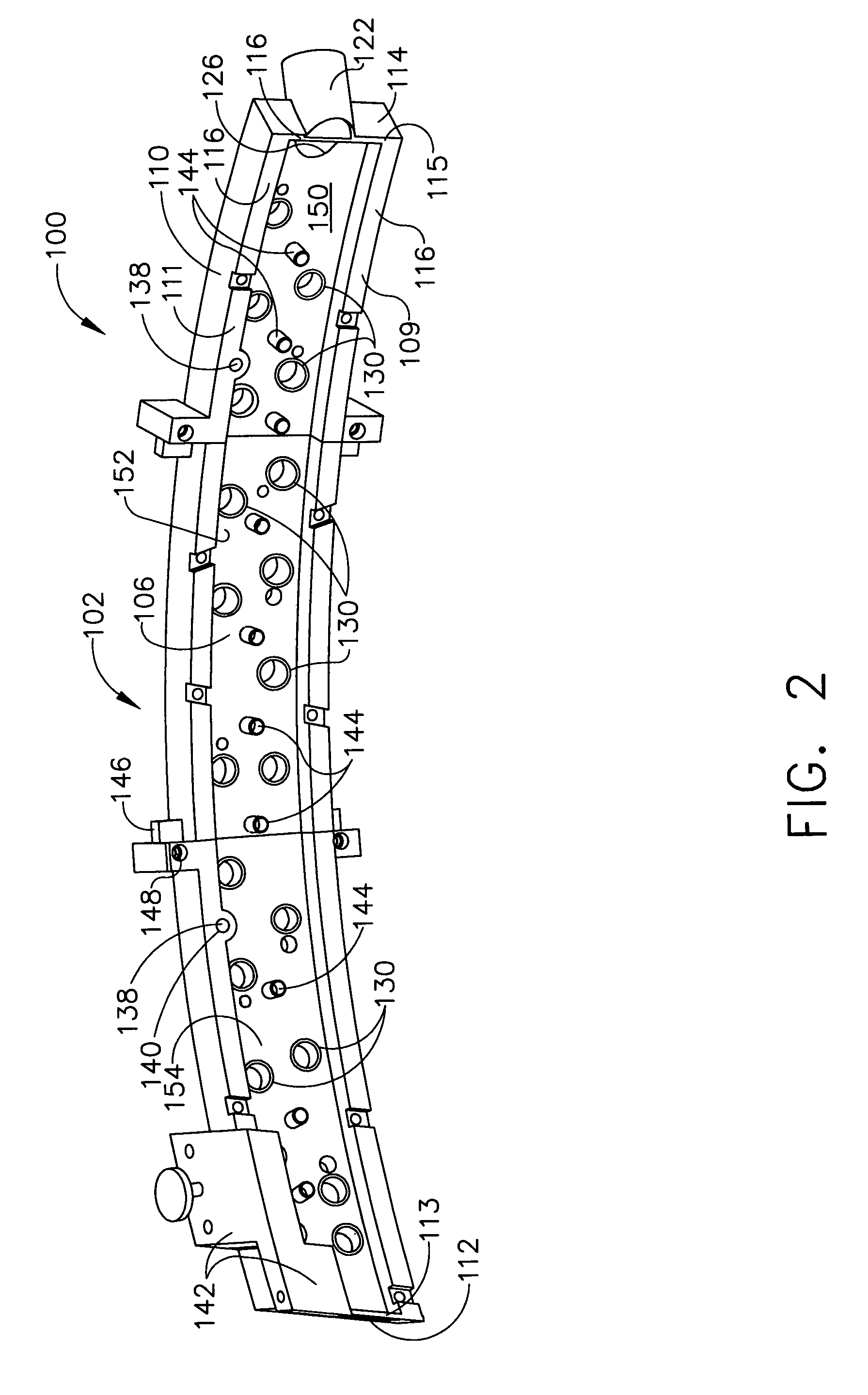

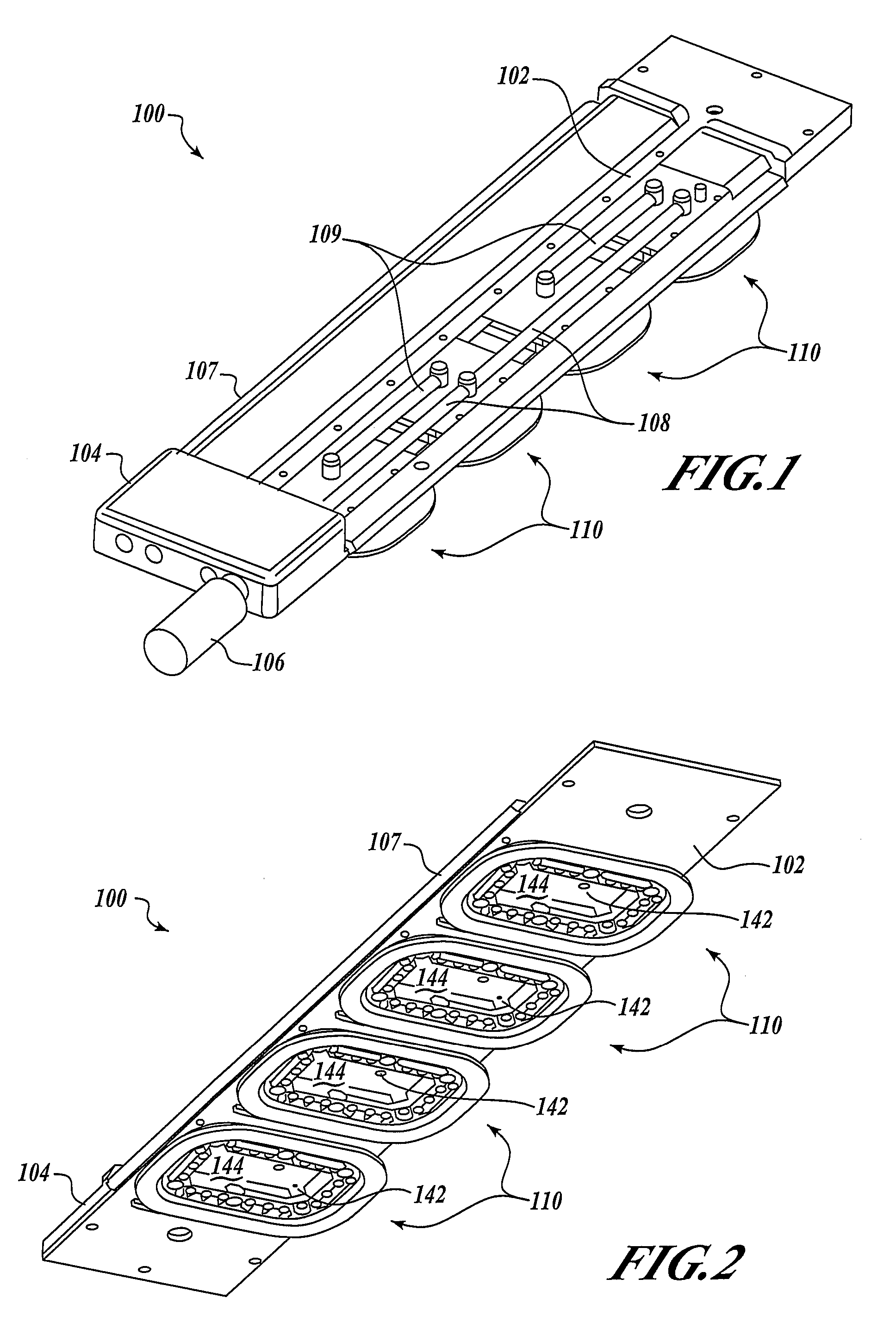

Drill template with integral vacuum attach

A drill template includes a vacuum housing with a skirt having a CAD-formed contact surface formed to an exact fit with a mold line surface of a structure. The drill template includes at least one drill guide bushing extending through the vacuum housing from a top surface to an interior surface of the vacuum housing; a vacuum port integral to the vacuum housing; and at least one index hole for positioning and aligning the vacuum housing on the structure. Index holes extend from the top surface through to the CAD-formed contact surface of the vacuum housing. A CAD-formed edge of part locator is formed according to a CAD solid model of the aircraft fuselage and fits to a precise location of the structure for precisely positioning the template on the structure. A vacuum port provides vacuum to the interior of the vacuum housing for removing drilling debris and dust.

Owner:THE BOEING CO

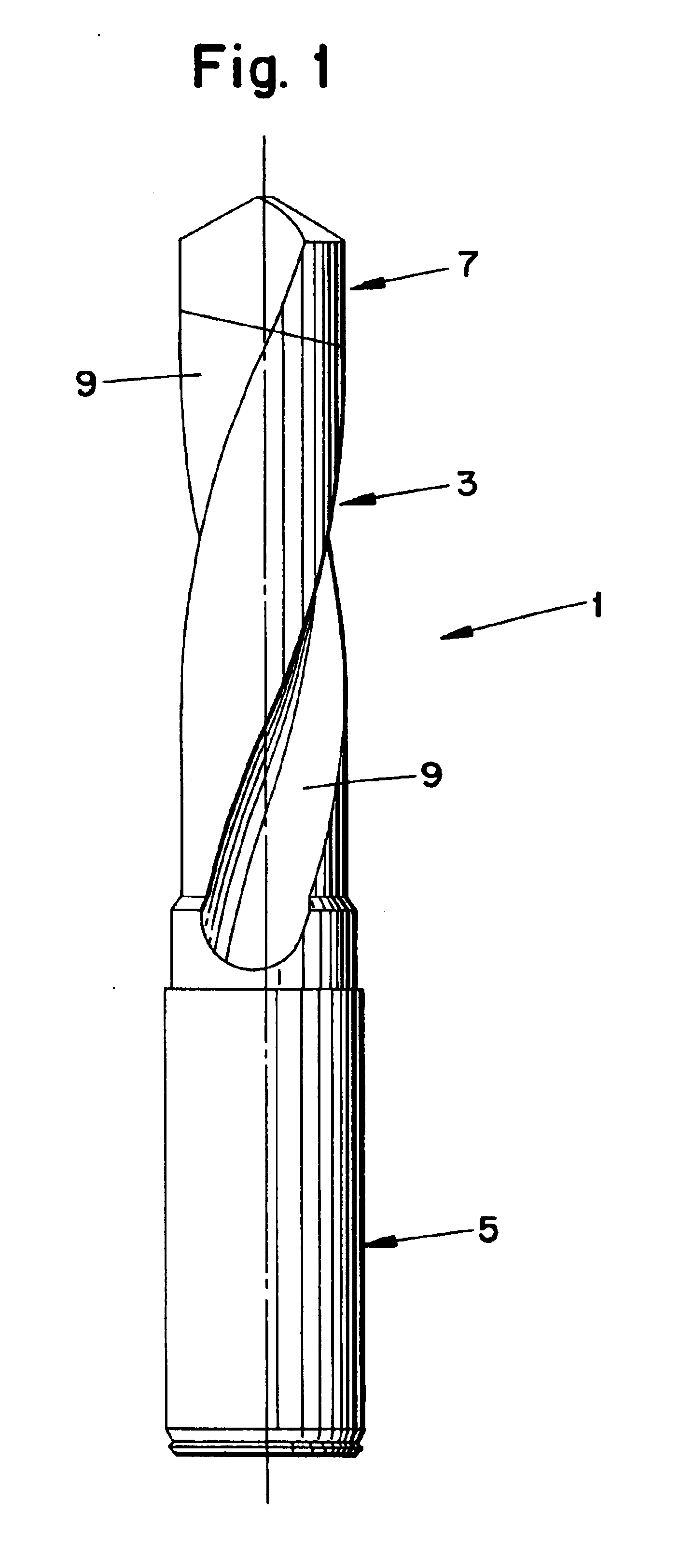

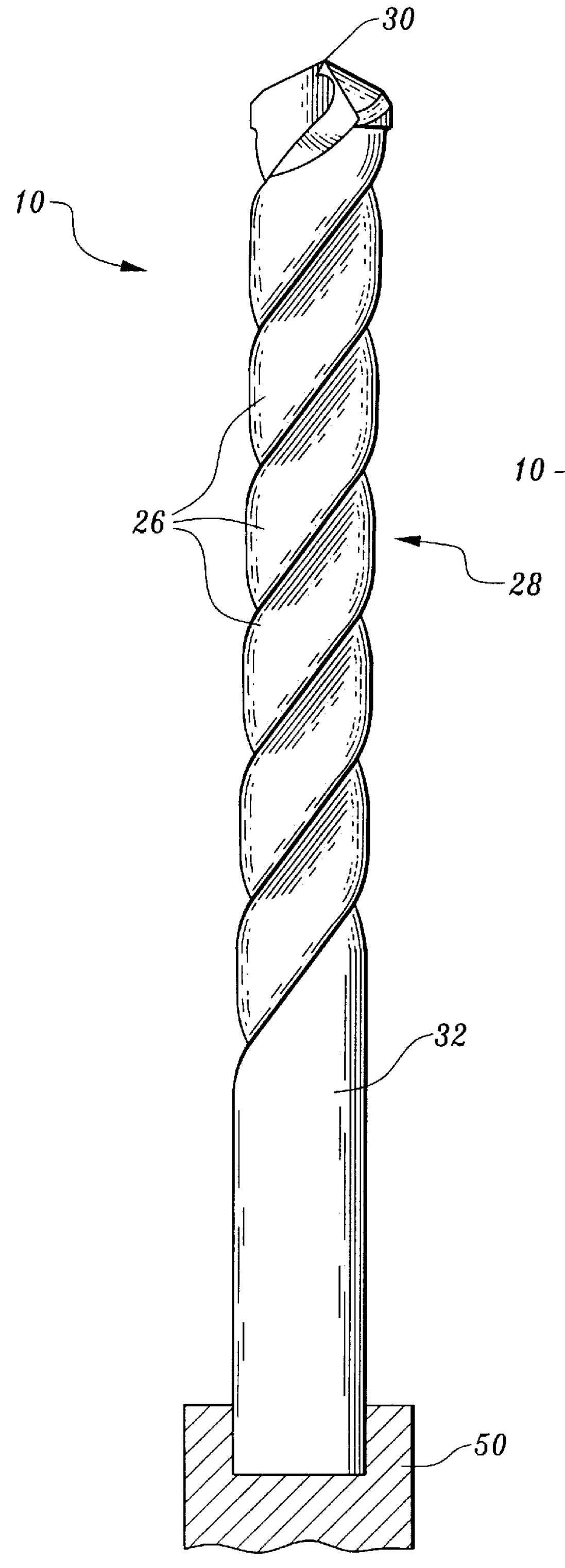

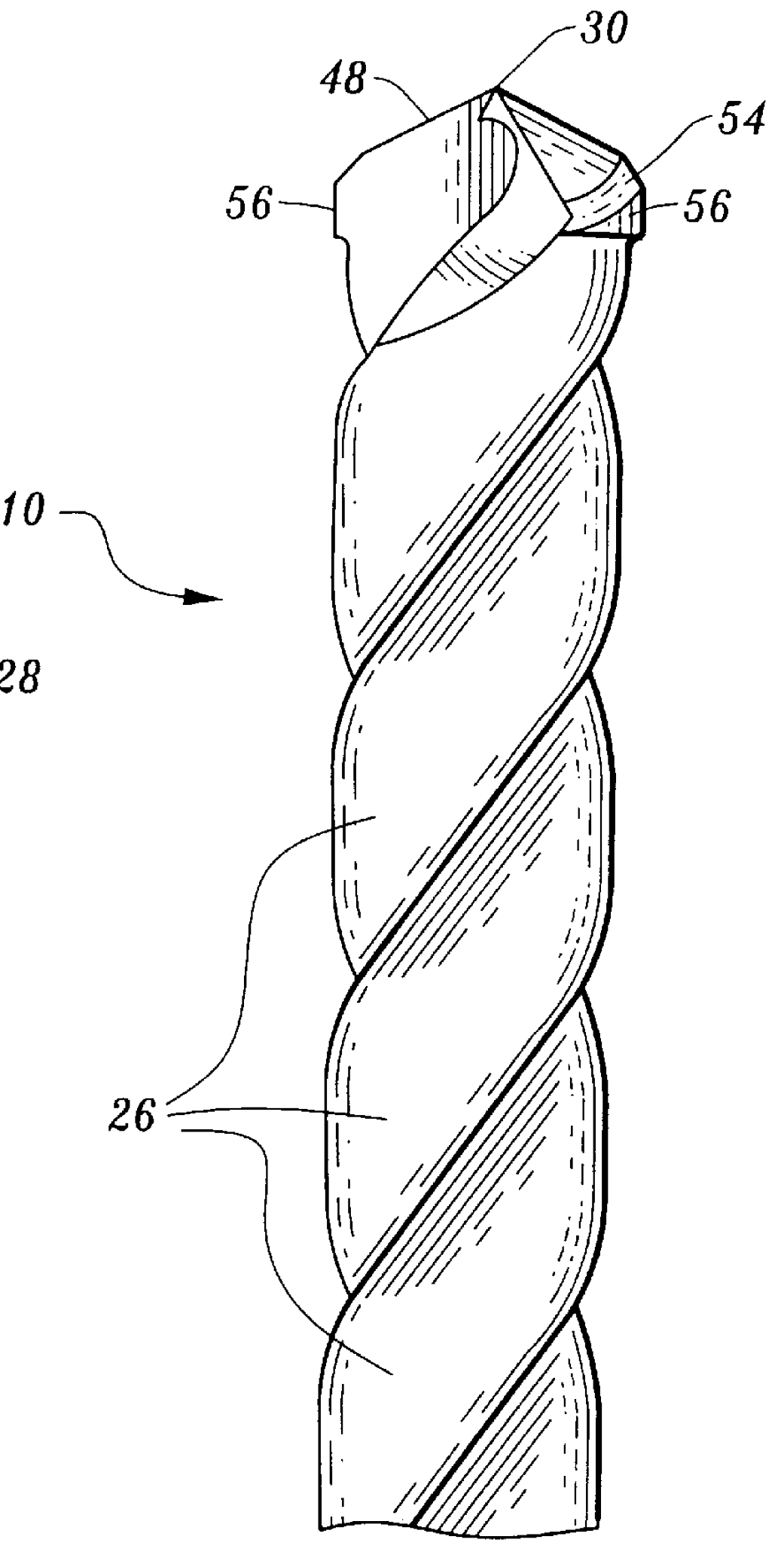

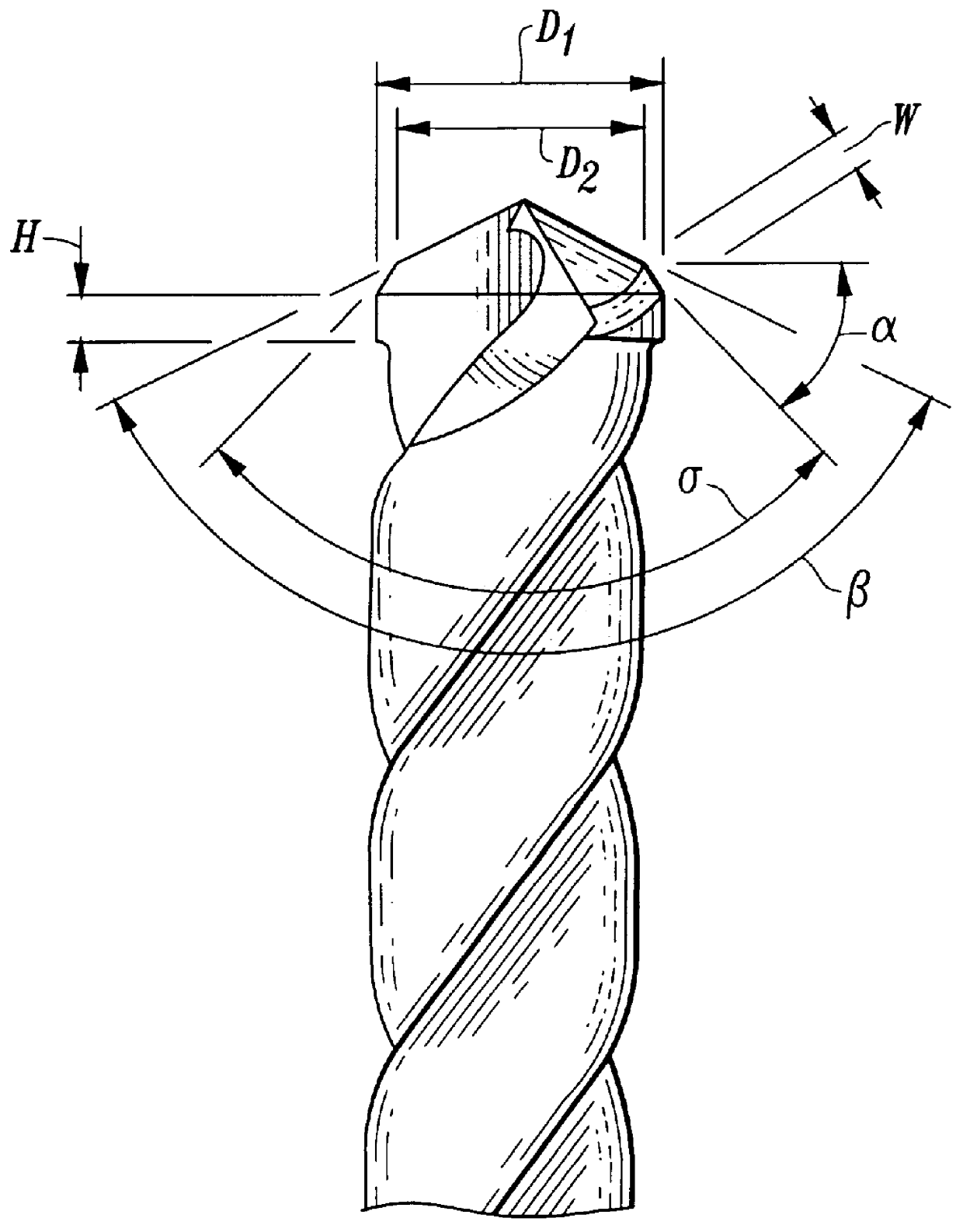

Precision drill bit

InactiveUS6126367AReduce frictionExtended bit lifeWood turning toolsTransportation and packagingHand heldDrill bit

Owner:LOCK N STITCH INC

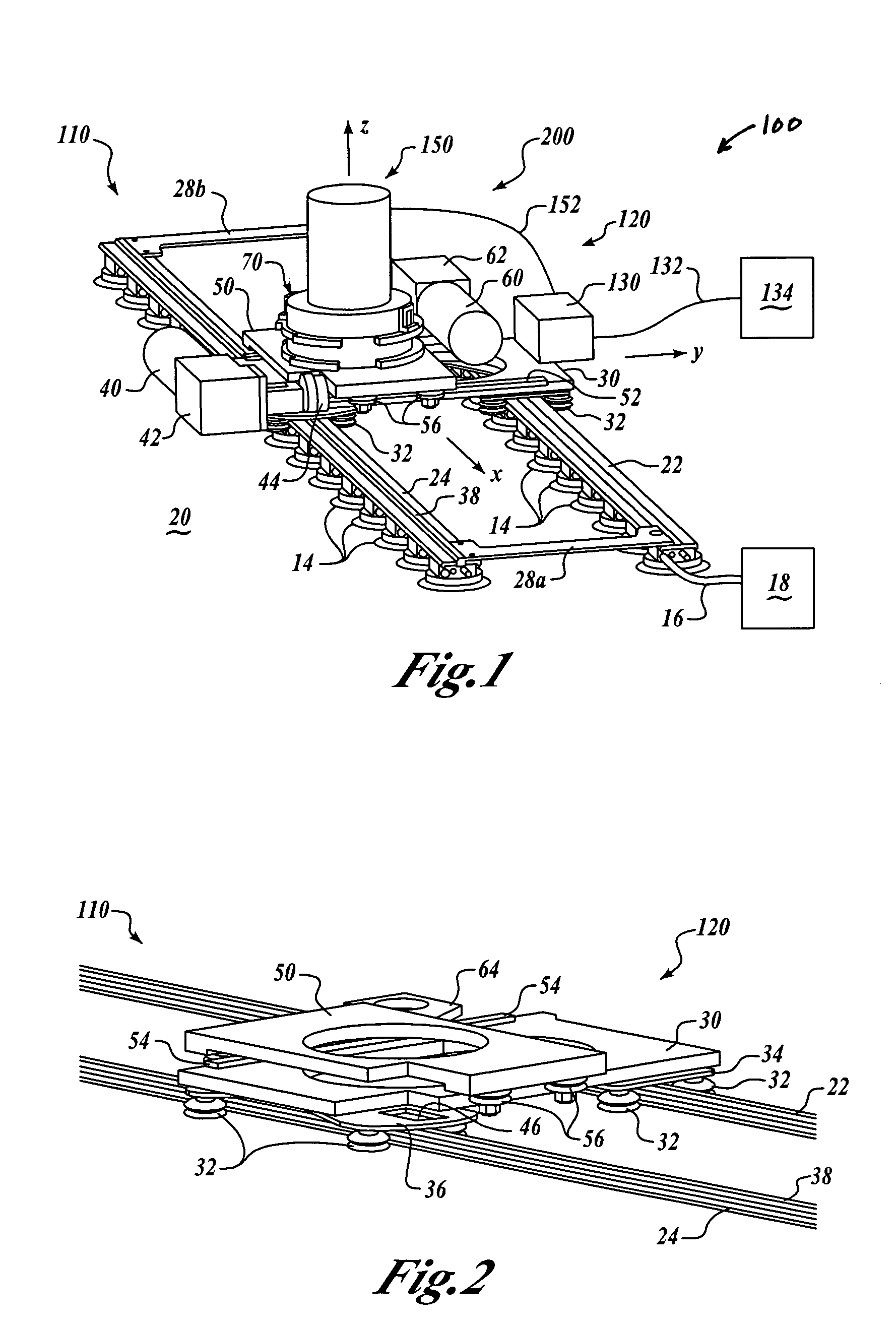

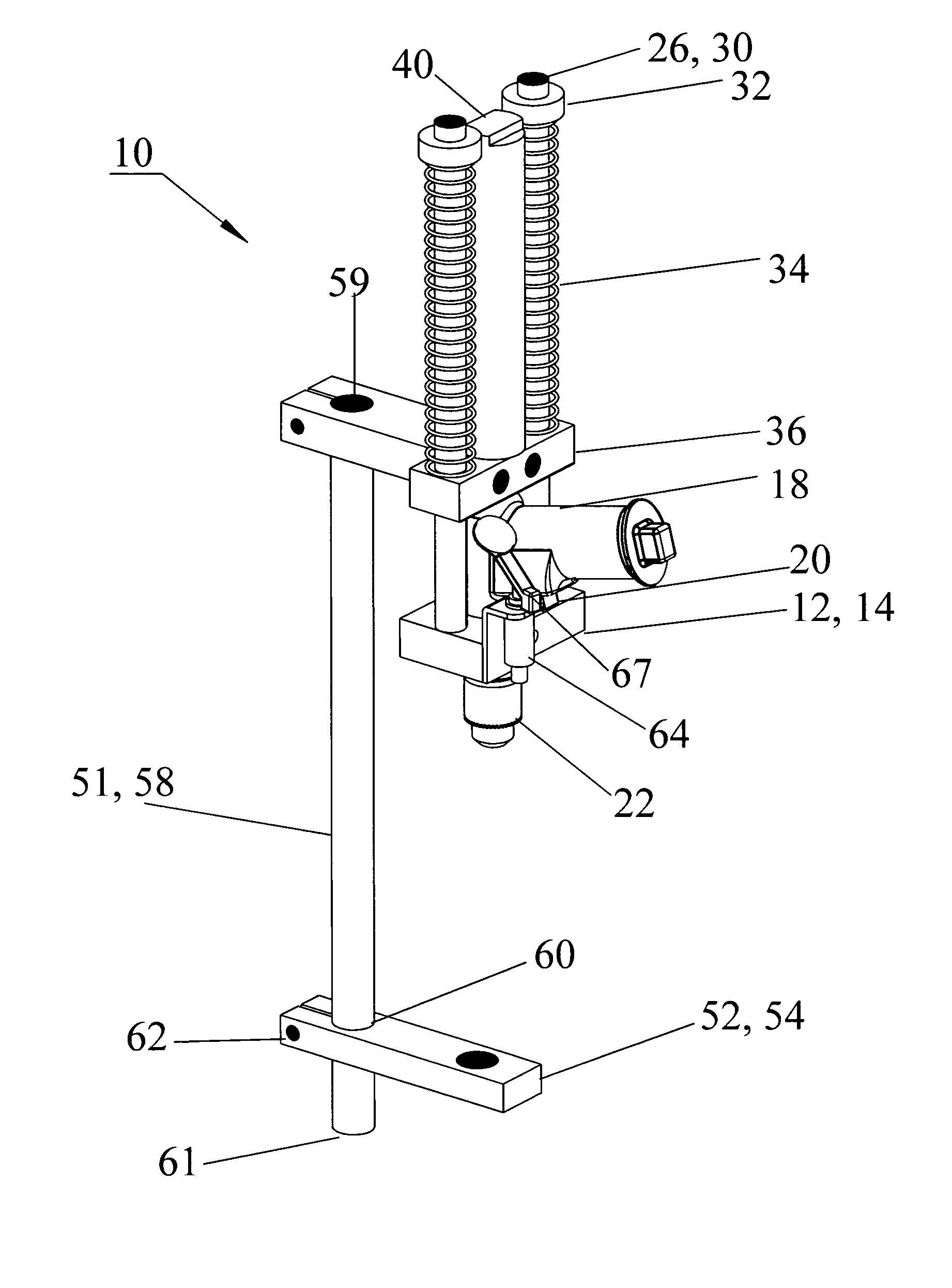

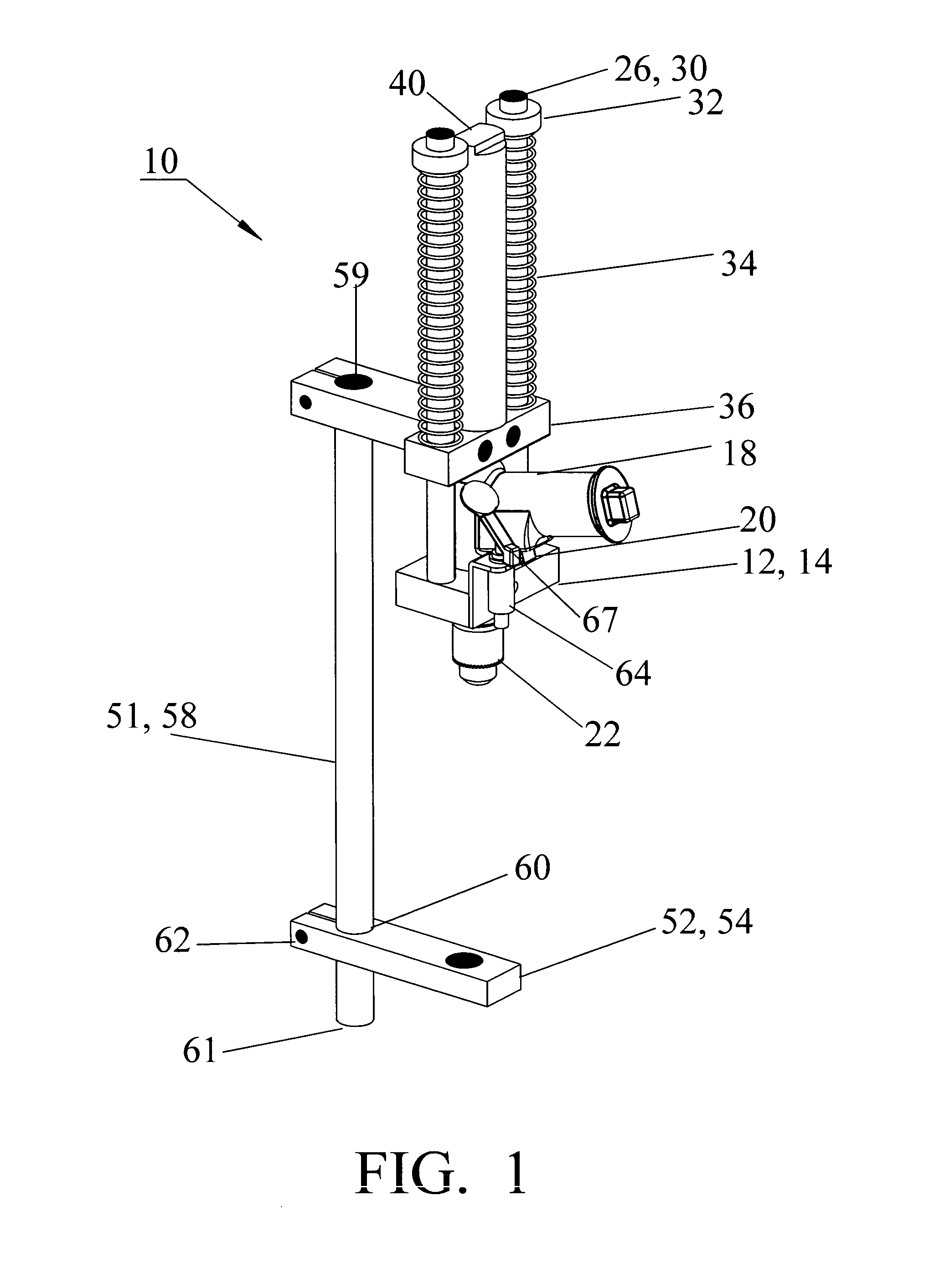

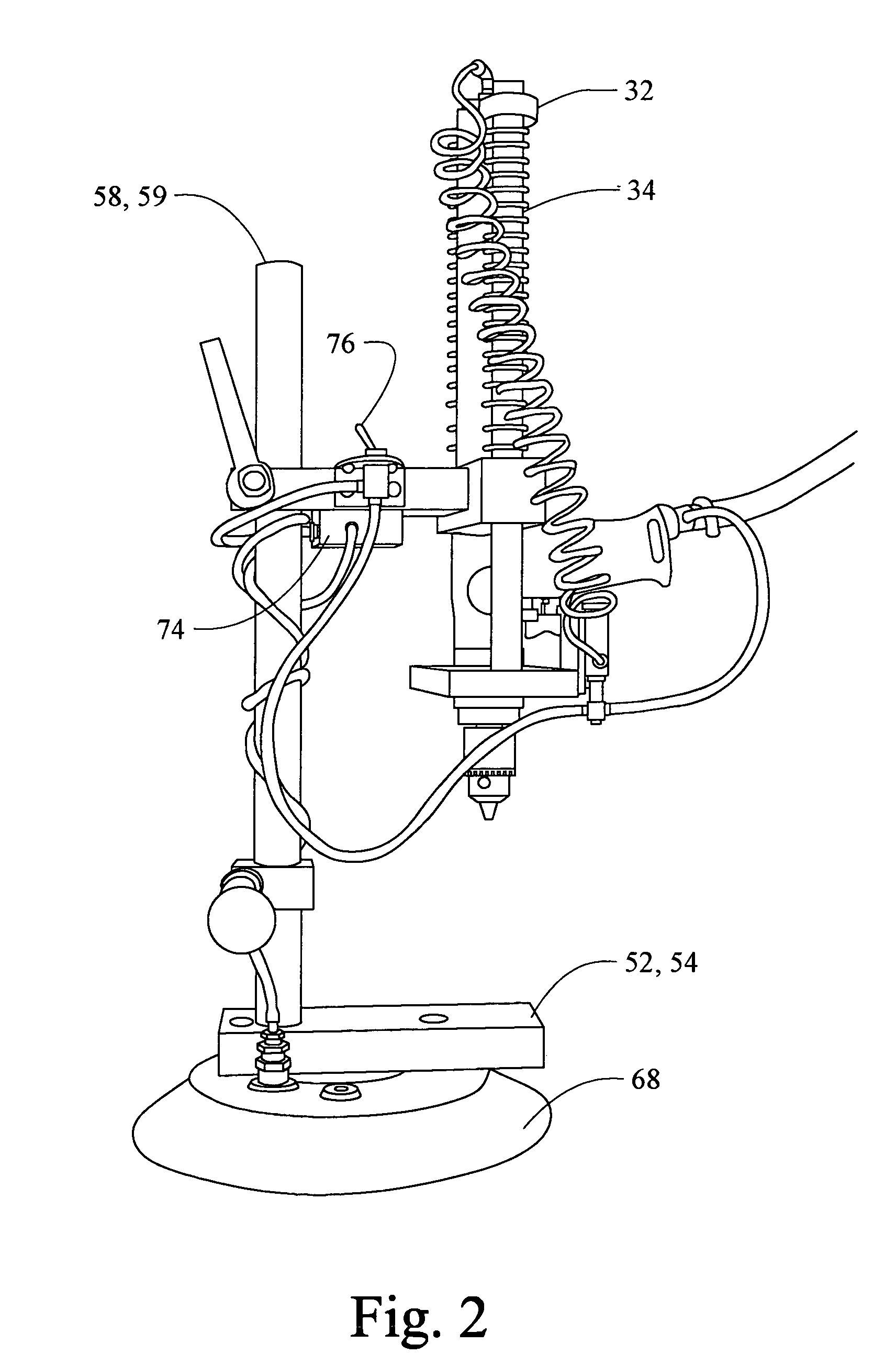

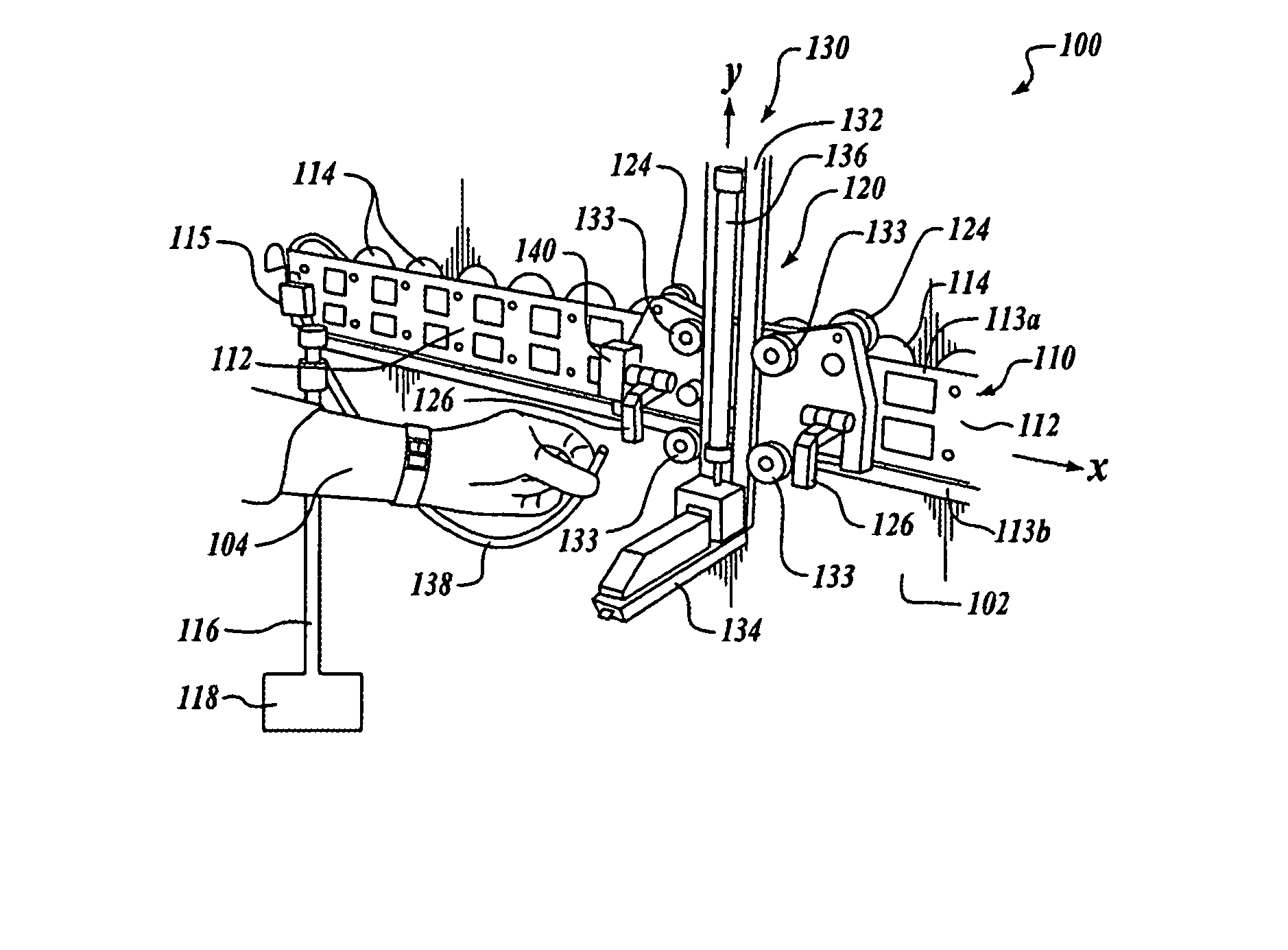

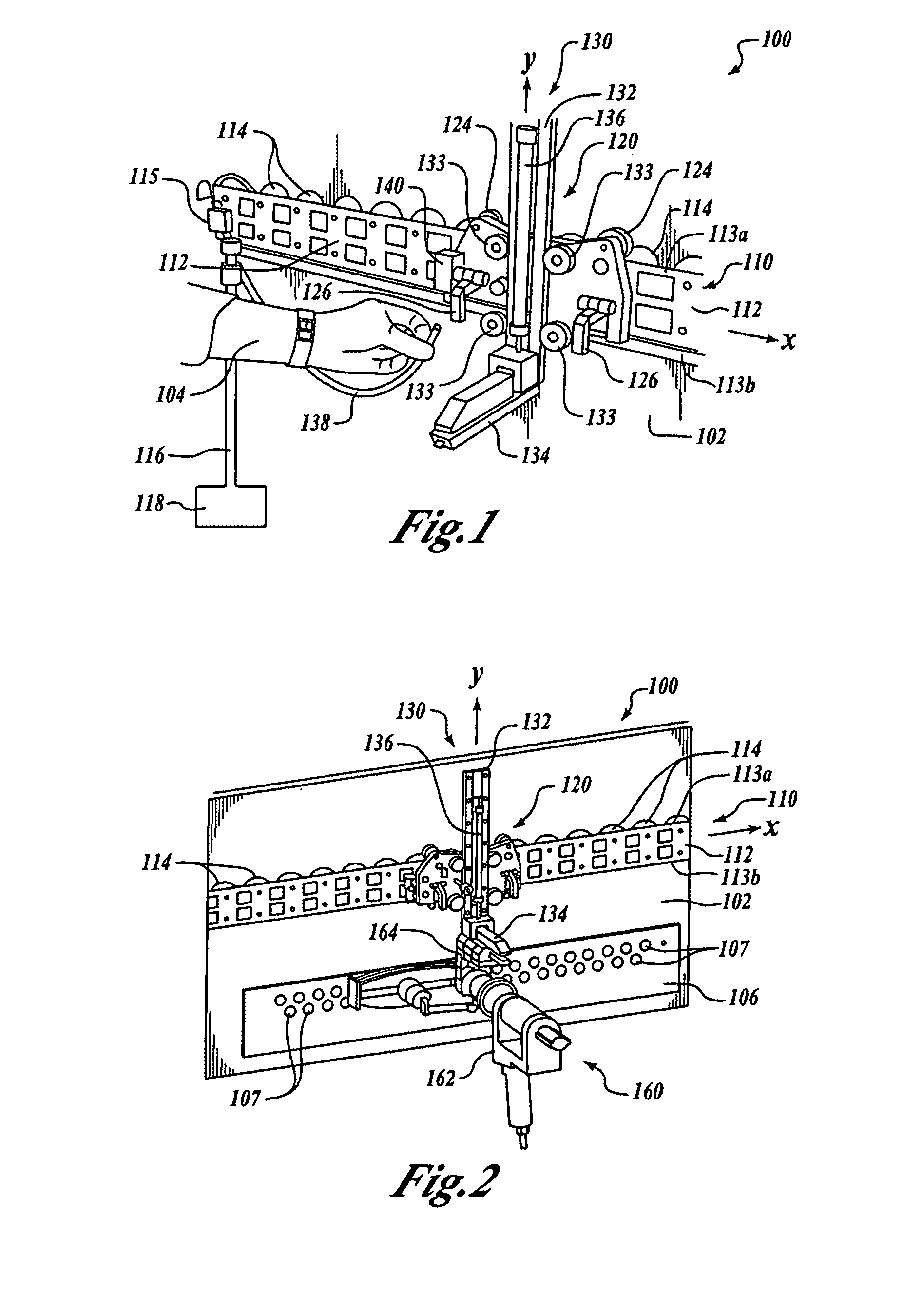

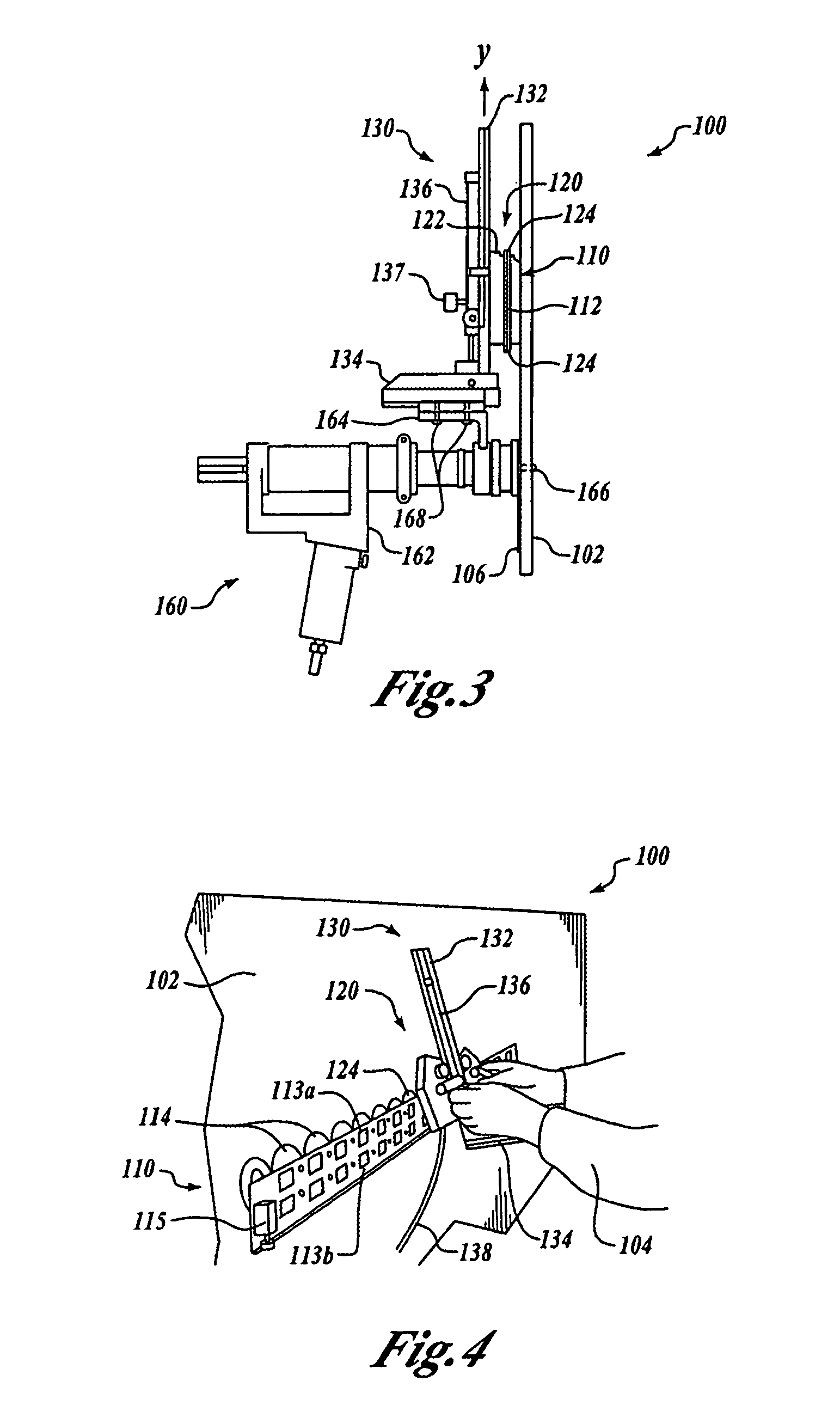

Methods and apparatus for counterbalance-assisted manufacturing operations

ActiveUS7273333B2Reduce the amount requiredImprove accuracyDrilling/boring measurement devicesThread cutting machinesGravitational forceEngineering

Methods and apparatus for counterbalanced manufacturing operations are disclosed. In one embodiment, an apparatus for supporting a tool relative to a surface of a workpiece includes a base adapted to be attached to the workpiece, a tool support coupled to the base, and a biasing device coupled to both the base and the tool support. The tool support is moveable relative to the base along a translation axis, and the biasing device is biasable along a biasing axis that is at least partially along the translation axis. The biasing device is adapted to at least partially counterbalance a force (e.g. a gravitational force) exerted on the tool support along the translation axis.

Owner:THE BOEING CO

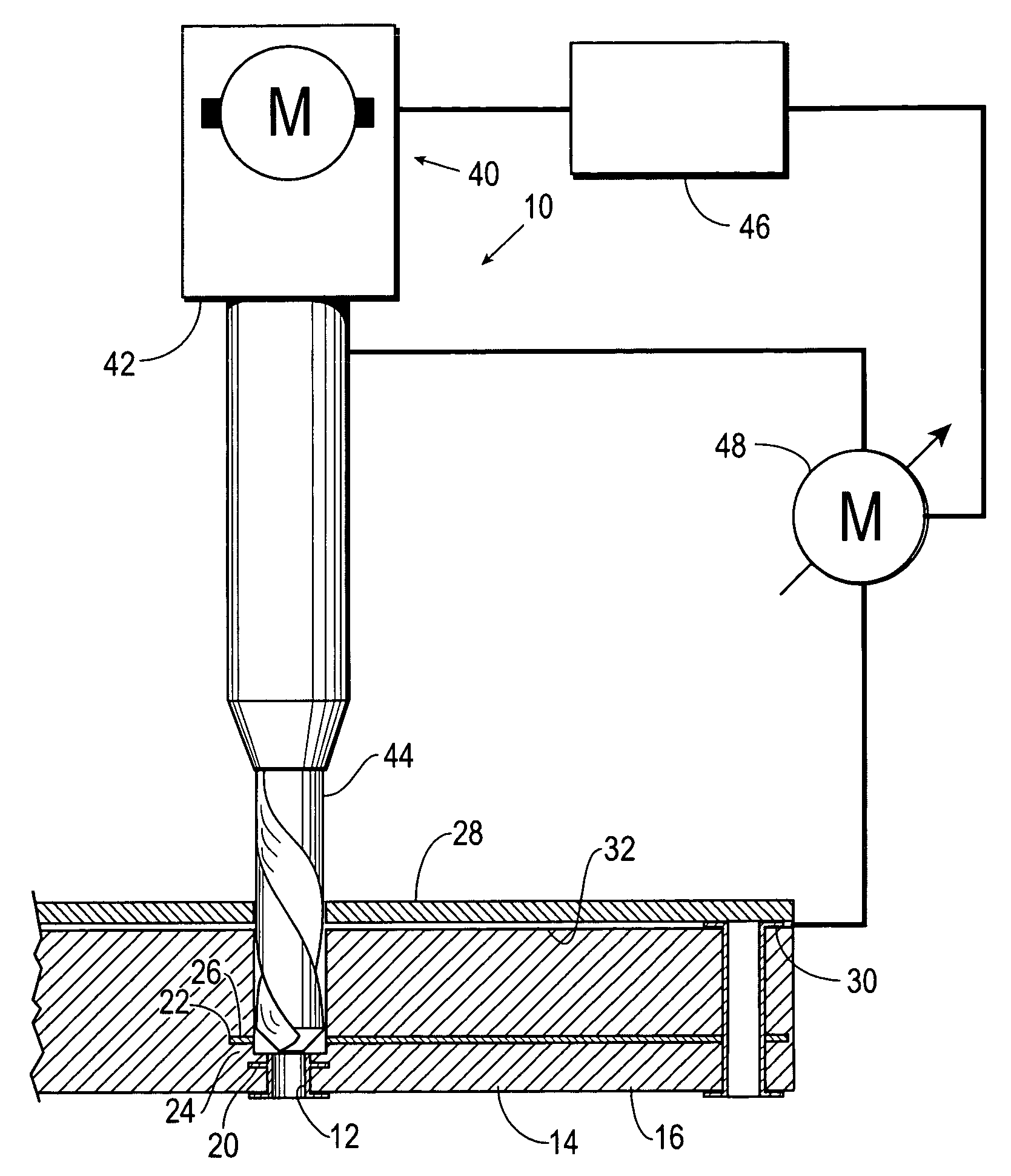

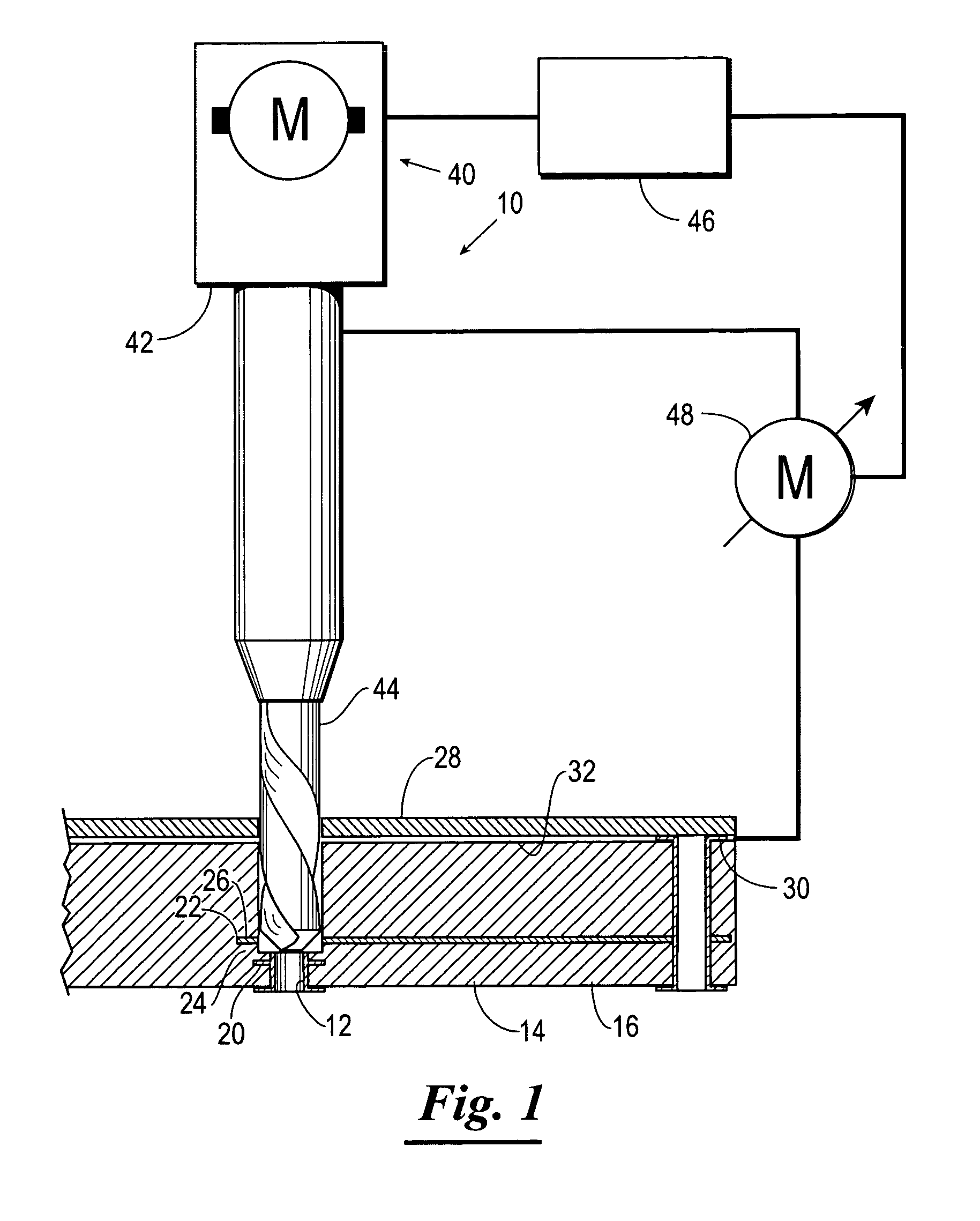

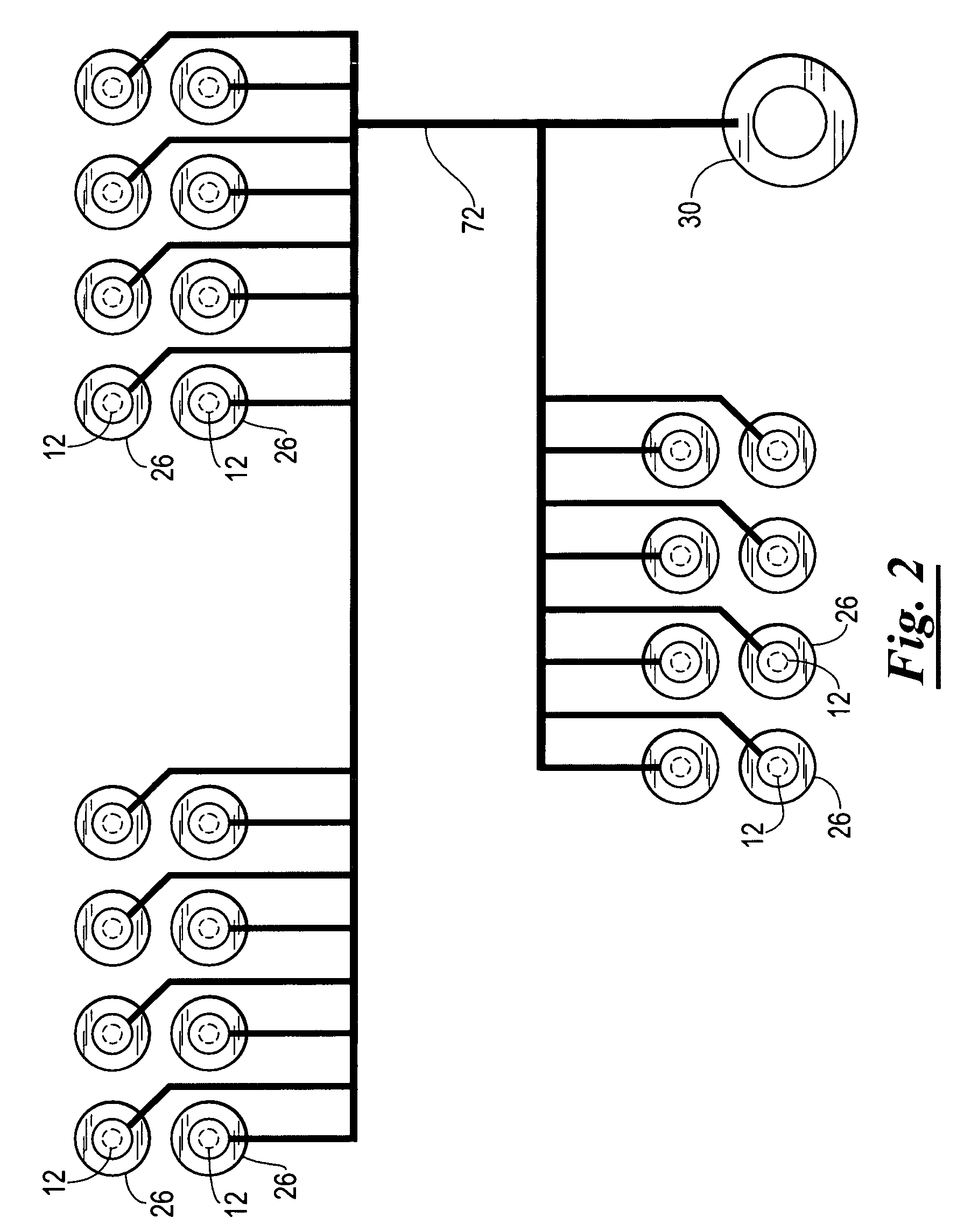

Closed loop backdrilling system

A multilayer circuit board is provided with at least one signal layer, at least one feedback layer, and at least one dielectric layer positioned between the signal layer and the feedback layer. The signal layer is connected to at least one plated hole. The feedback layer has a contact pad, which is positioned adjacent to the plated hole, but is electrically isolated from the plated hole. The contact pad is connected to a measurement unit. The dielectric layer is positioned between the signal layer and the contact pad of the feedback layer. A portion of the plated hole forms a stub portion, which extends a distance away from the signal layer and typically extends a distance away from the contact pad of the feedback layer. To remove the stub portion, a hole is bored or routed into the multilayer circuit board until electrical feedback is received by the measurement unit upon contact of a portion of the boring device with the contact pad. Upon receipt of the electrical feedback by the measurement unit, the boring device is retracted from the hole, and the hole formed by the boring device is filled with an epoxy, or other filler material.

Owner:VIASYST

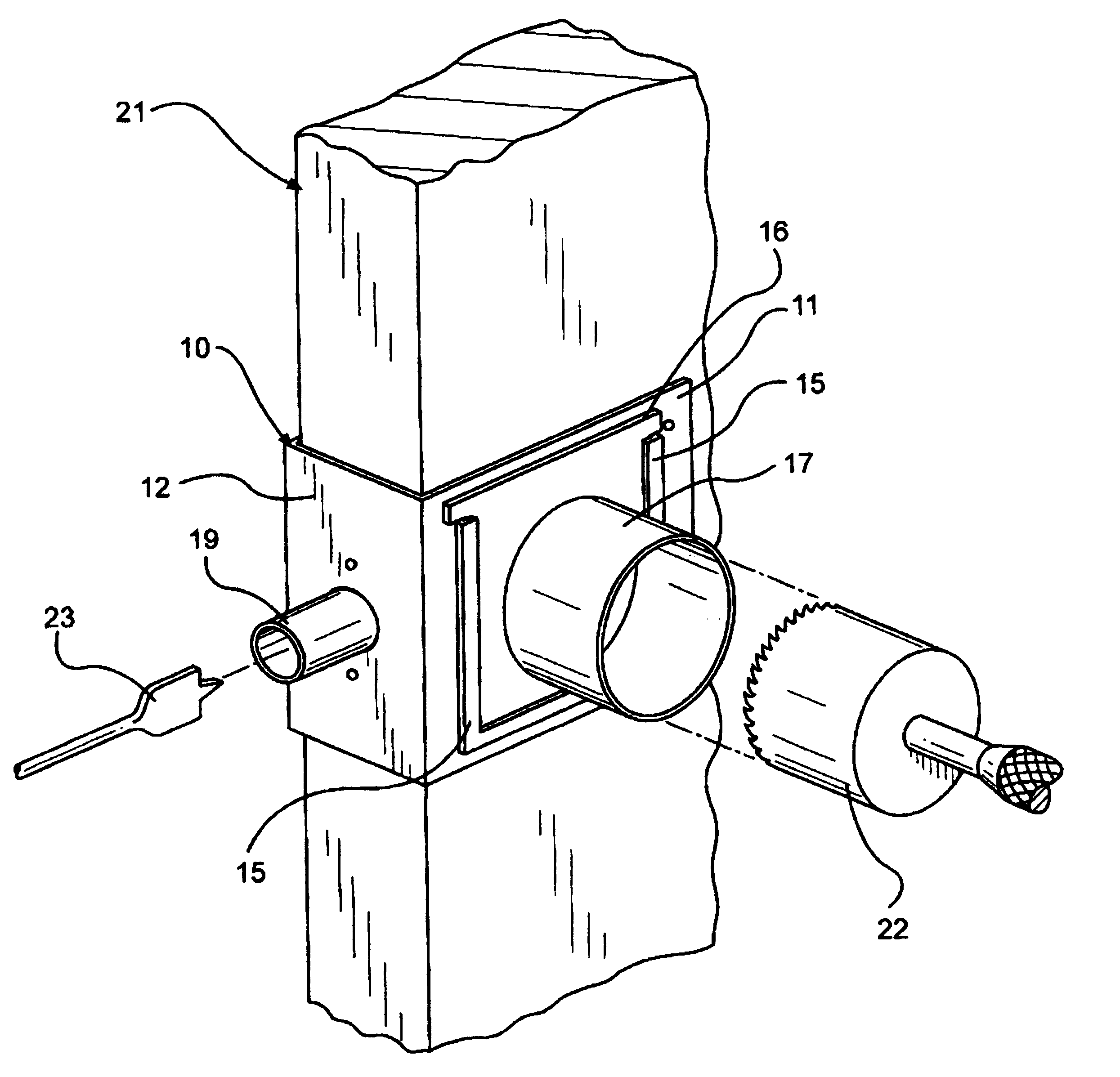

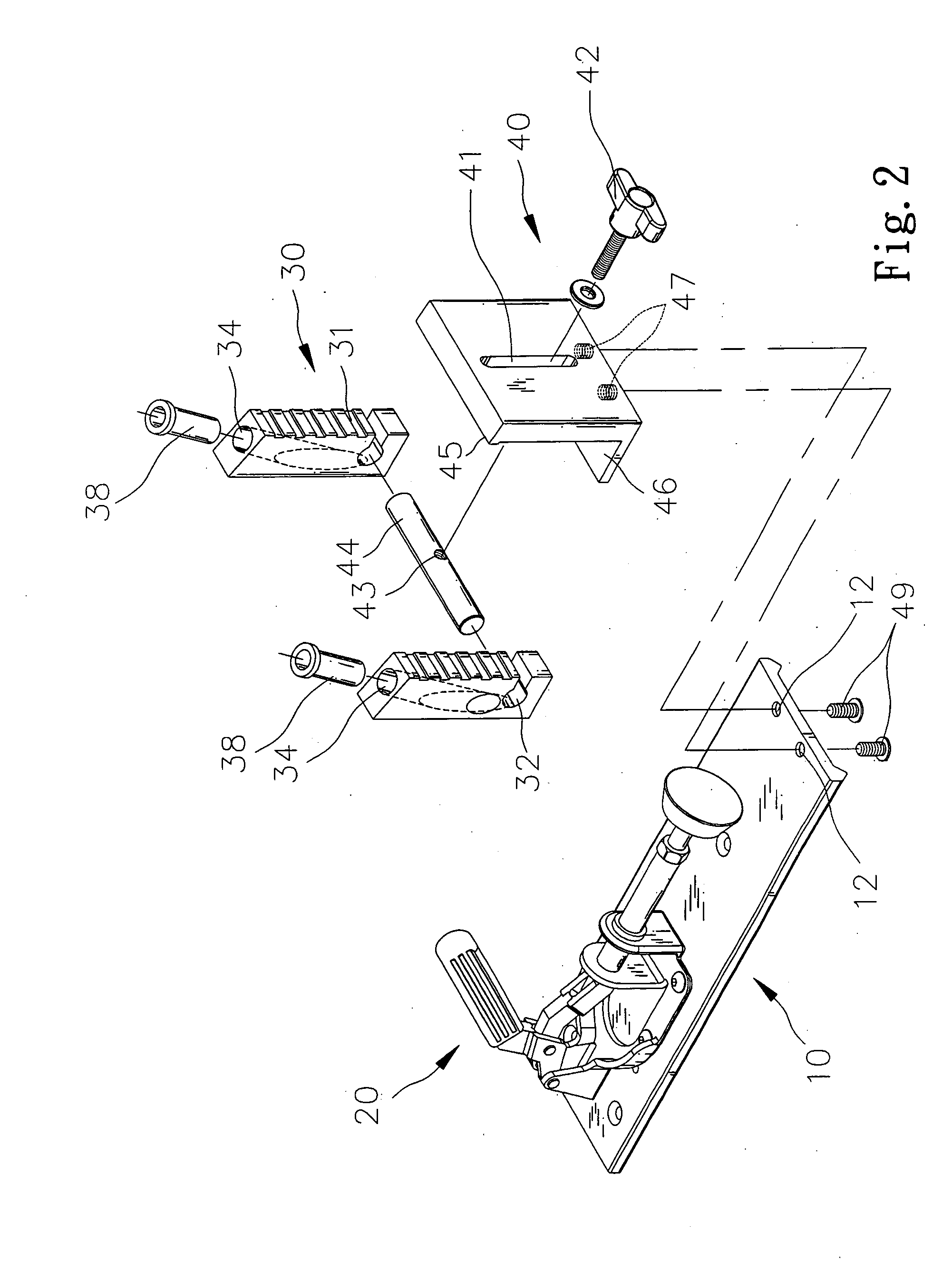

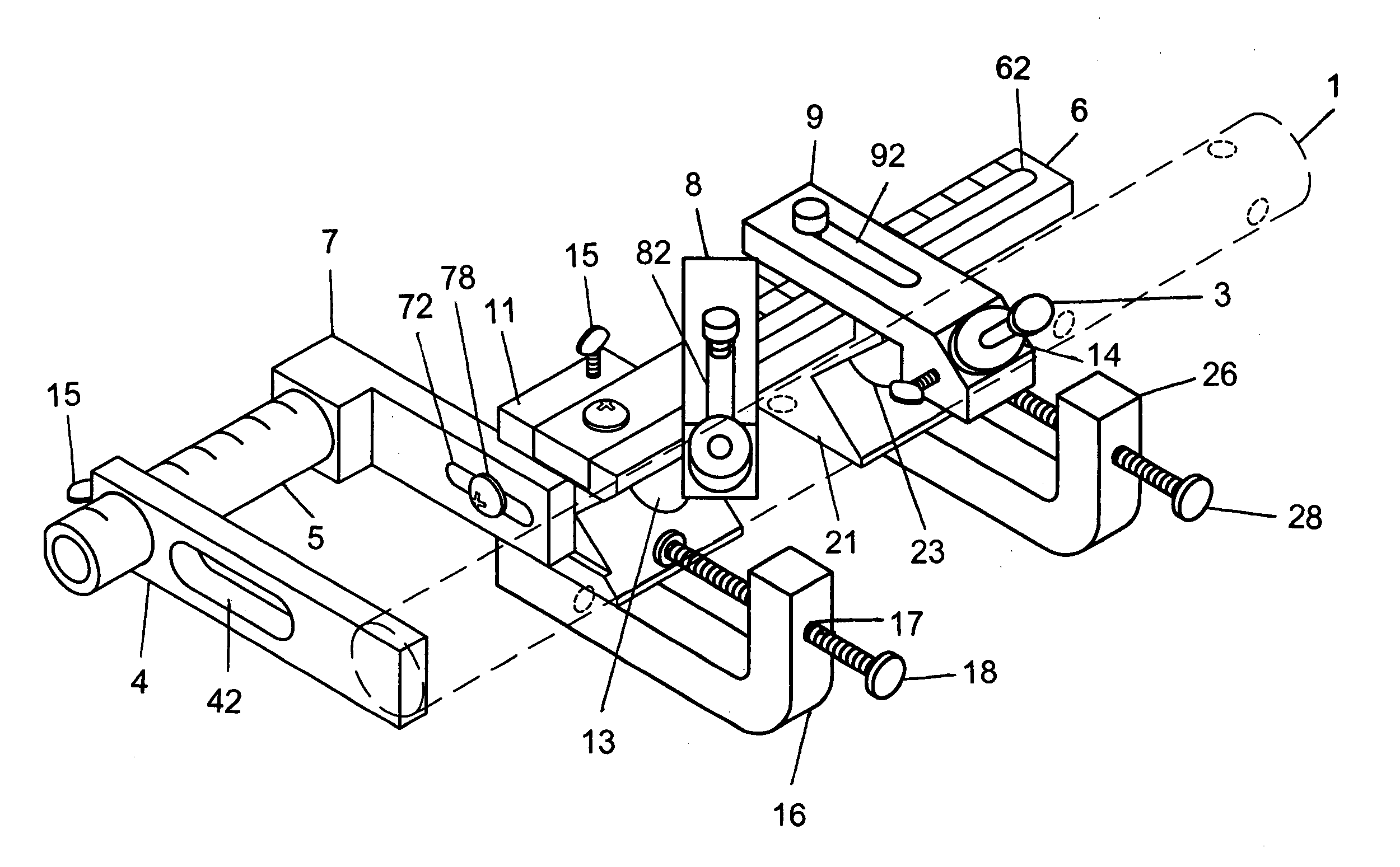

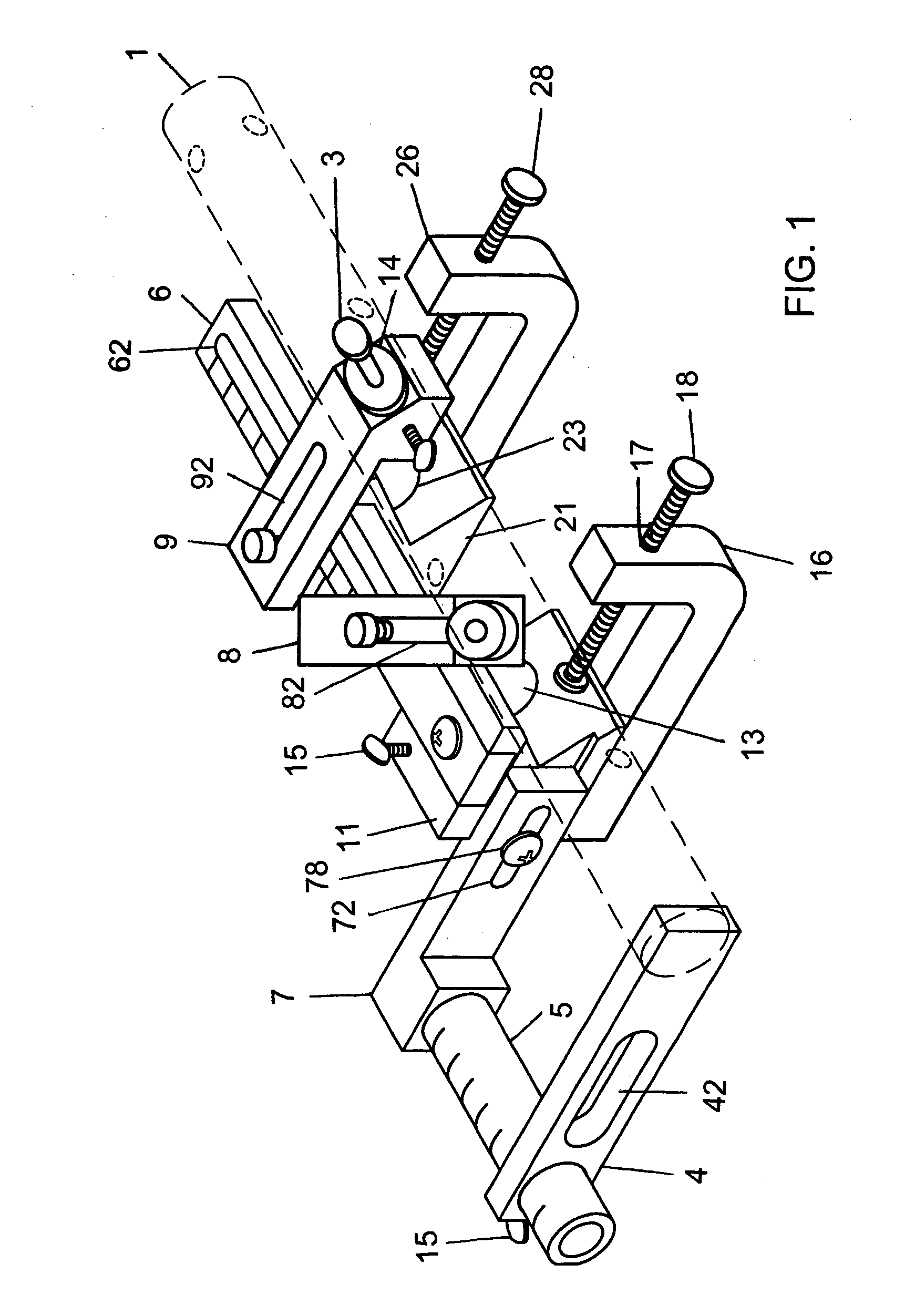

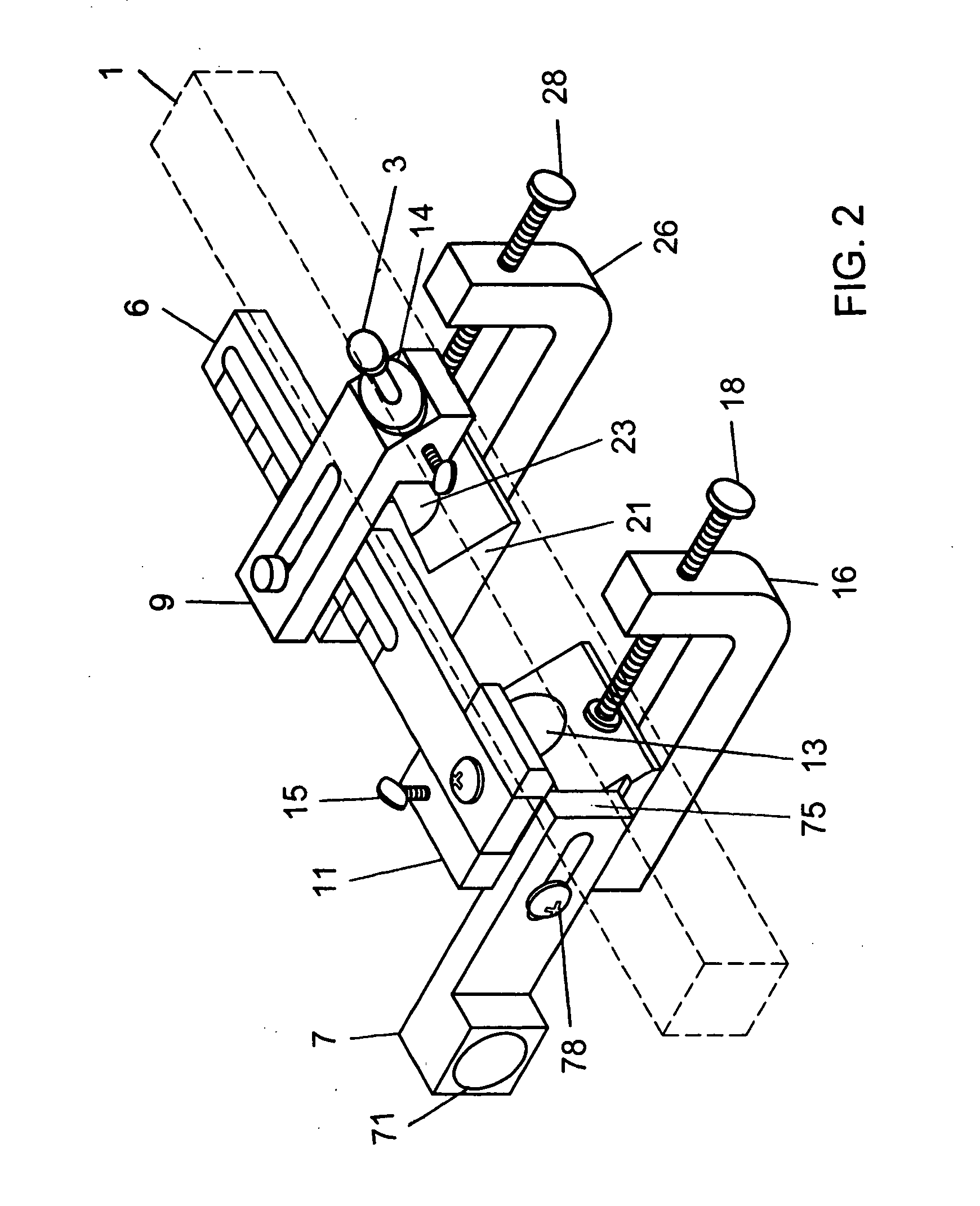

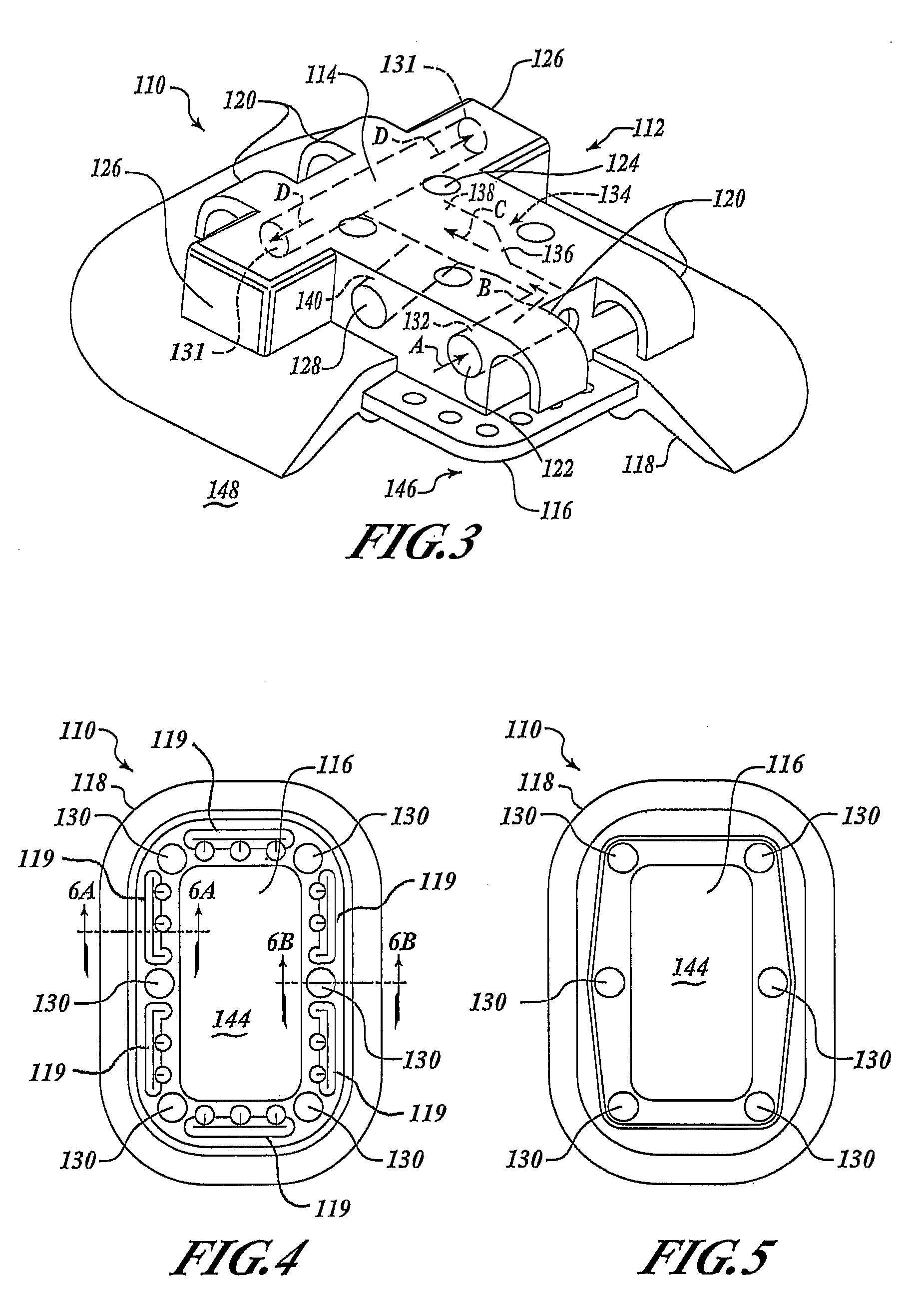

Fixturing device for drilling workpieces

InactiveUS20060233620A1Easy to manufactureEasy maintenanceThread cutting machinesDrill jigsEngineeringMechanical engineering

A fixturing device for holding a workpiece with a longitudinal axis is disclosed. The fixturing device includes a first v-block with holding surfaces that intersect each other at an intersection and form a v-shape. The first v-block has a hole formed therein with a center axis that is substantially perpendicular to the longitudinal axis of the workpiece and intersects the intersection of the holding surfaces. A clamping arm mounted to the first v-block for clamping the workpiece in the first v-block. A second v-block that is similar to the first v-block is also provided. A clamping arm is mounted to the second v-block for clamping the workpiece to the second v-block. A cross-member adjustably attaches the first v-block to the second v-block. At least one drill bushing is removably disposed in one of the hole in the first v-block and the hole in the second v-block.

Owner:HERRICK RICHARD

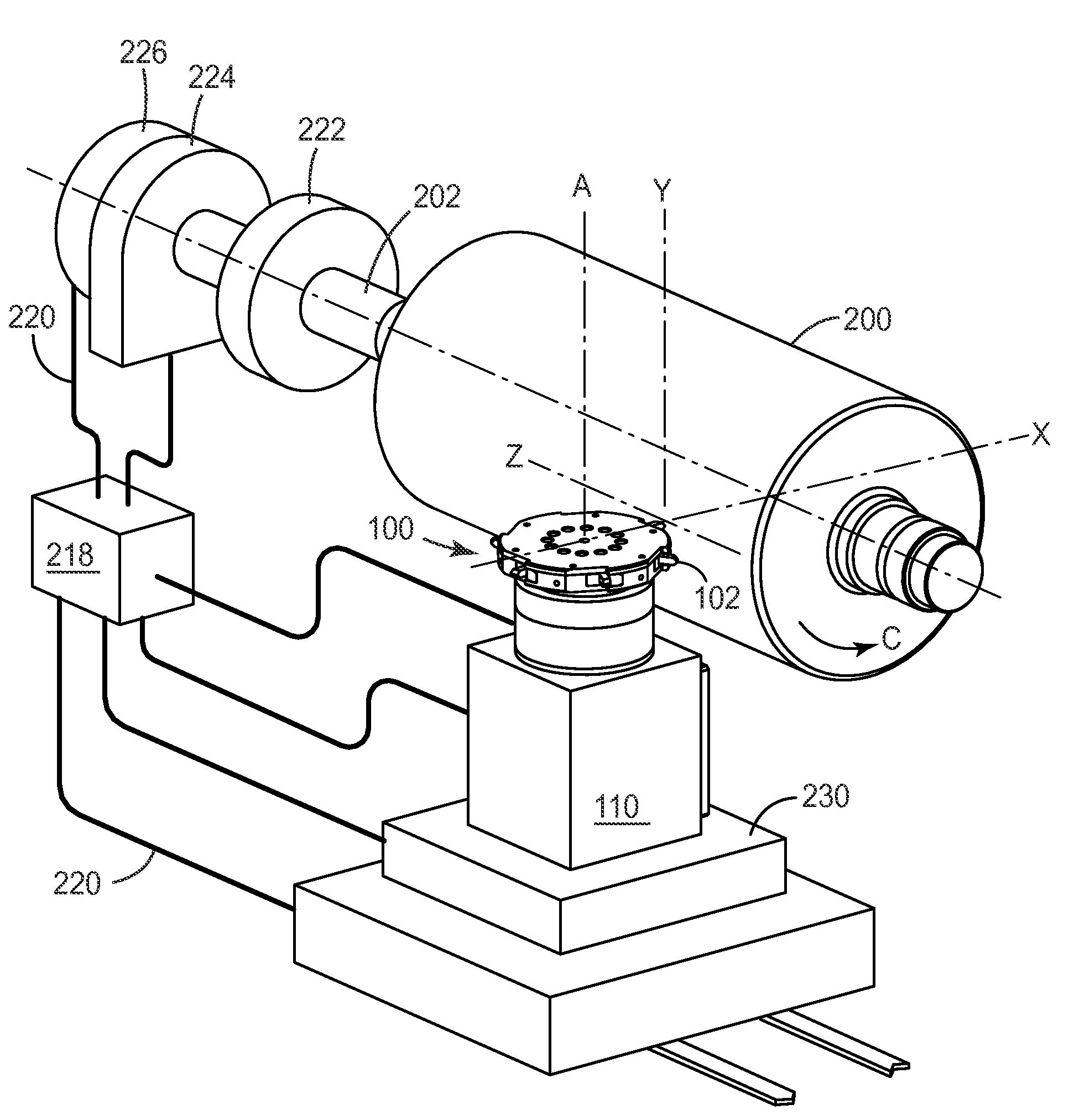

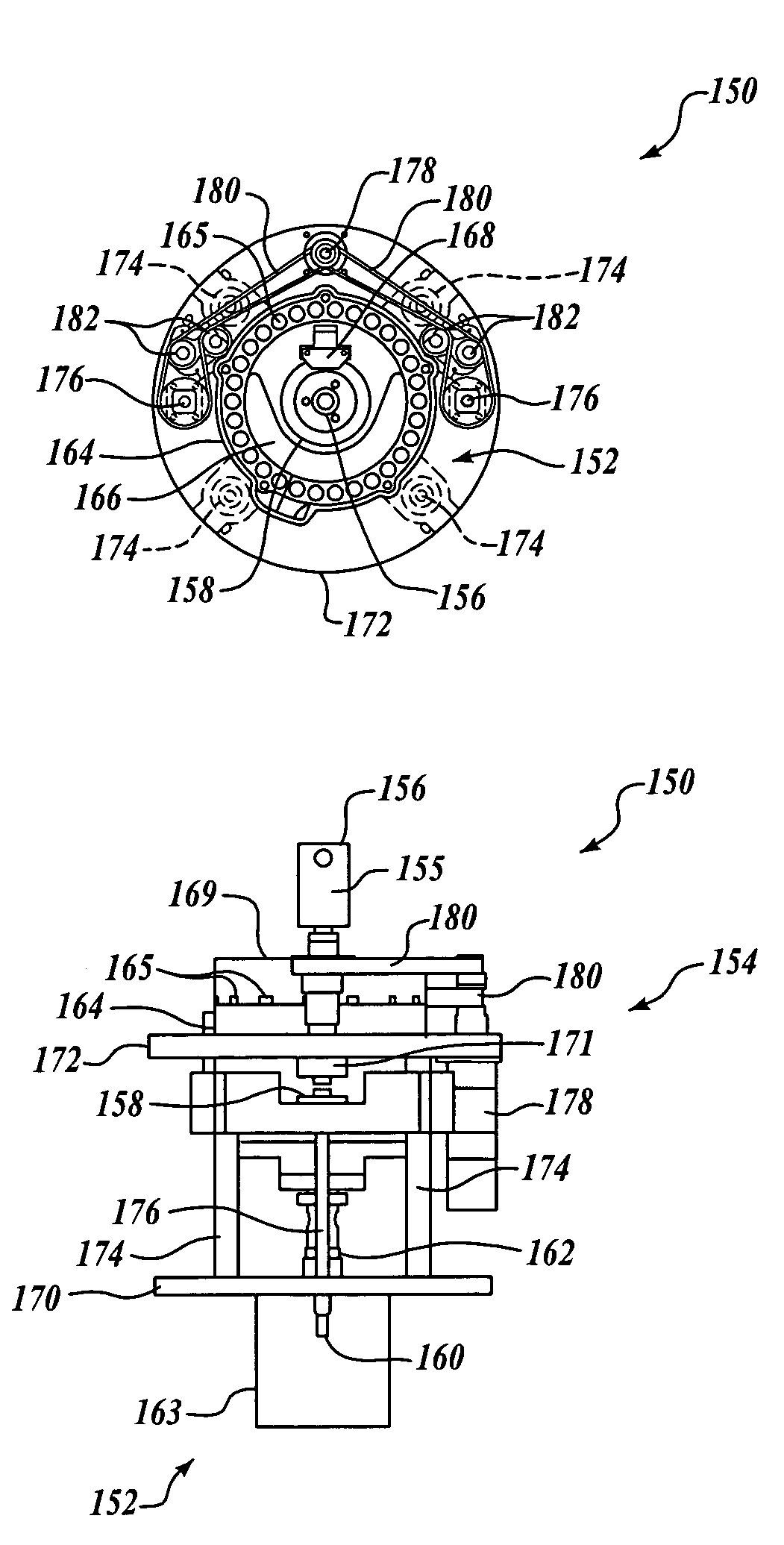

Apparatus and methods for manufacturing operations

ActiveUS7406758B2Improve efficiencyImprove throughputDrilling/boring measurement devicesThread cutting machinesEngineeringManufacturing operations

Apparatus and methods for manufacturing operations are disclosed. In one embodiment, a vacuum cup assembly includes a housing having a vacuum generator formed therein, and a compliant sealing member coupled to the housing. The vacuum generator is coupleable to a source of pressurized fluid and is adapted to generate a reduced pressure region. The sealing member forms an enclosable region in fluid communication with the reduced pressure region. In another embodiment, a method of performing a manufacturing operation includes installing a coordinating pin into an indexing hole, the coordinating pin including a quantum of indexing information. The quantum of indexing information is sensed, and a manufacturing operation is performed based at least partially on the quantum of indexing information.

Owner:THE BOEING CO

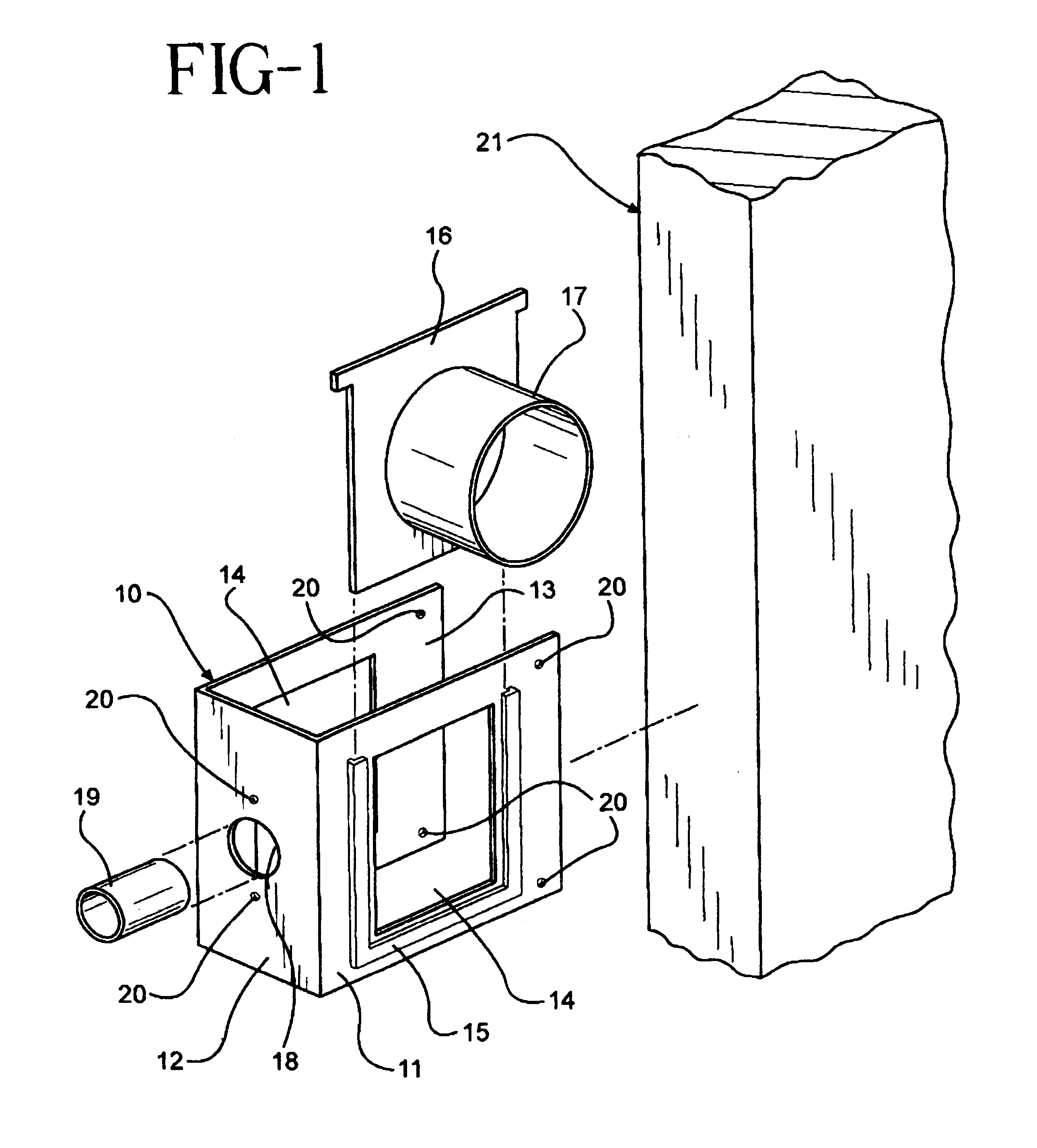

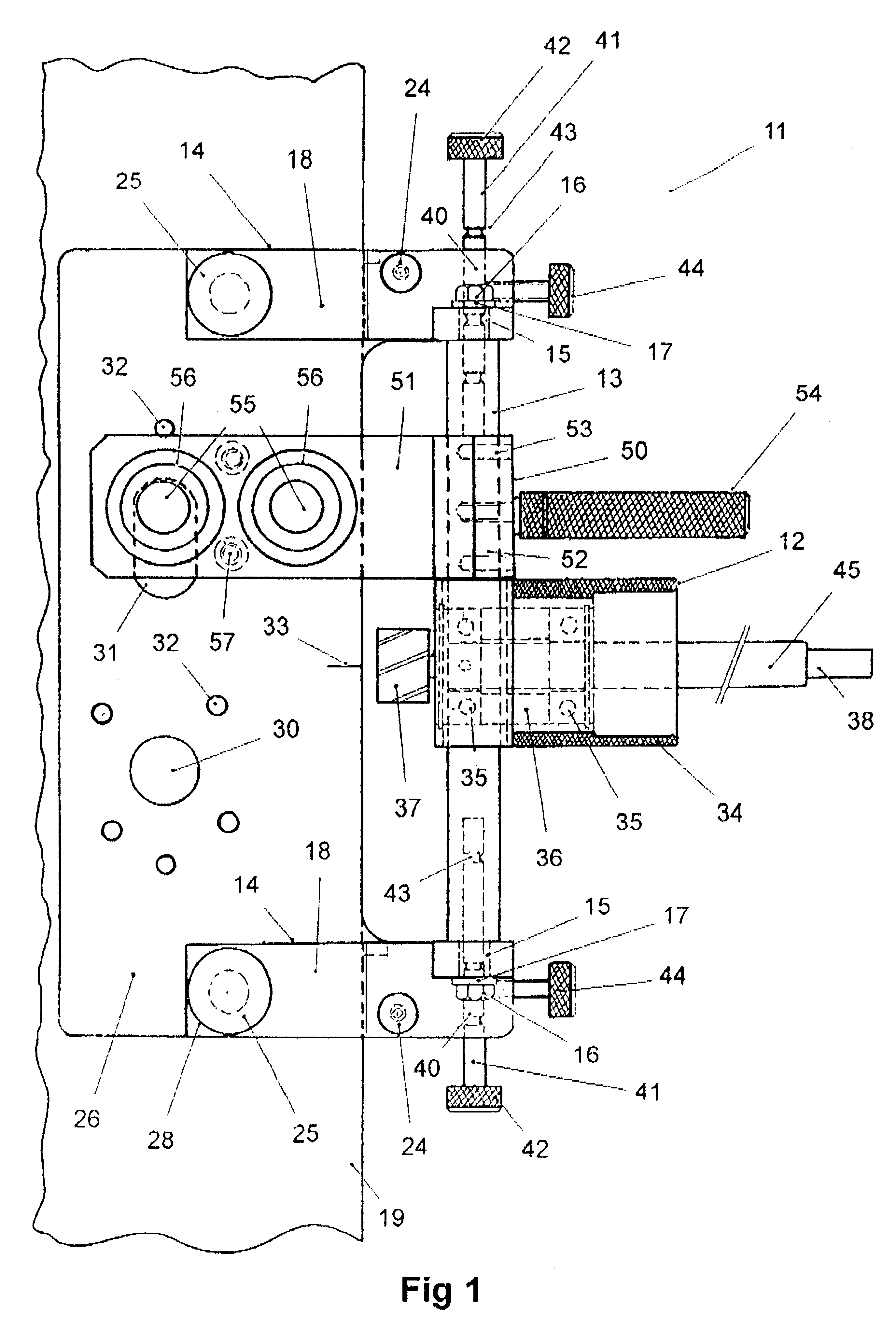

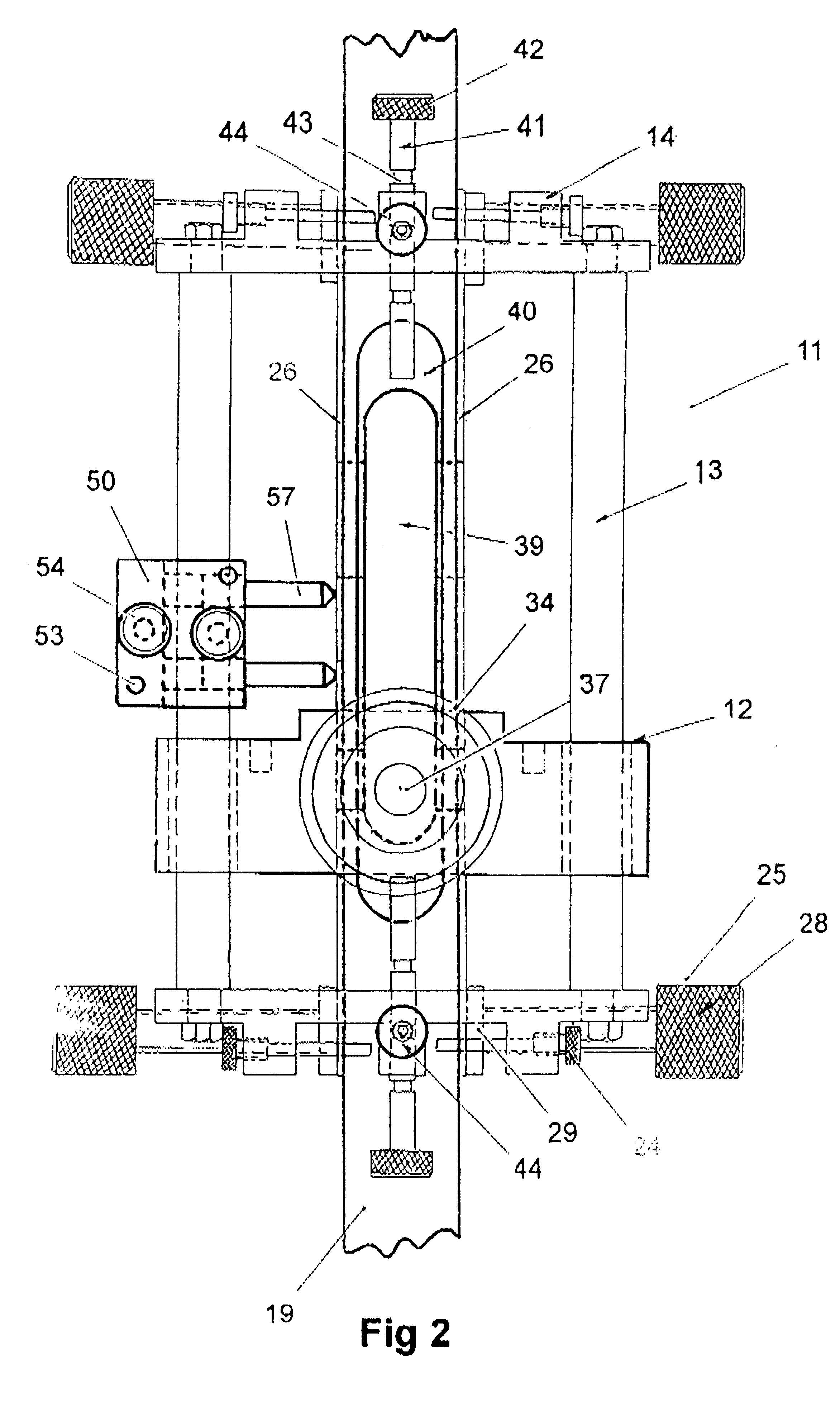

Jig for fitting locks to doors

InactiveUS6343632B1Eliminate damageEasy alignmentDrilling/boring measurement devicesThread cutting machinesLocking mechanismEngineering

A jig (11) for removable fitment along the edge of a door (19) which provides a suitable combination of guides and stops to allow the location and operation of suitable cutting tools such as drills or routers. The jig comprises a pair of parallel guide plates (26) the distance between which is adjustable for removable fitment to opposing surfaces of the door. Guide holes (30, 31, 32) are located in the guide plates through which a drill or other suitable tool may be inserted. The jig has guide means (12) associated therewith for allowing location of a suitable tool at the edge of the door for making a cylindrical hole or for machining a mortise therein for receiving the body of a mortise lock or a rebate for receiving the face plate of the lock mechanism. A guide block (50) to facilitate accurate drilling is also disclosed.

Owner:ZIVOJINOVIC ZARKO

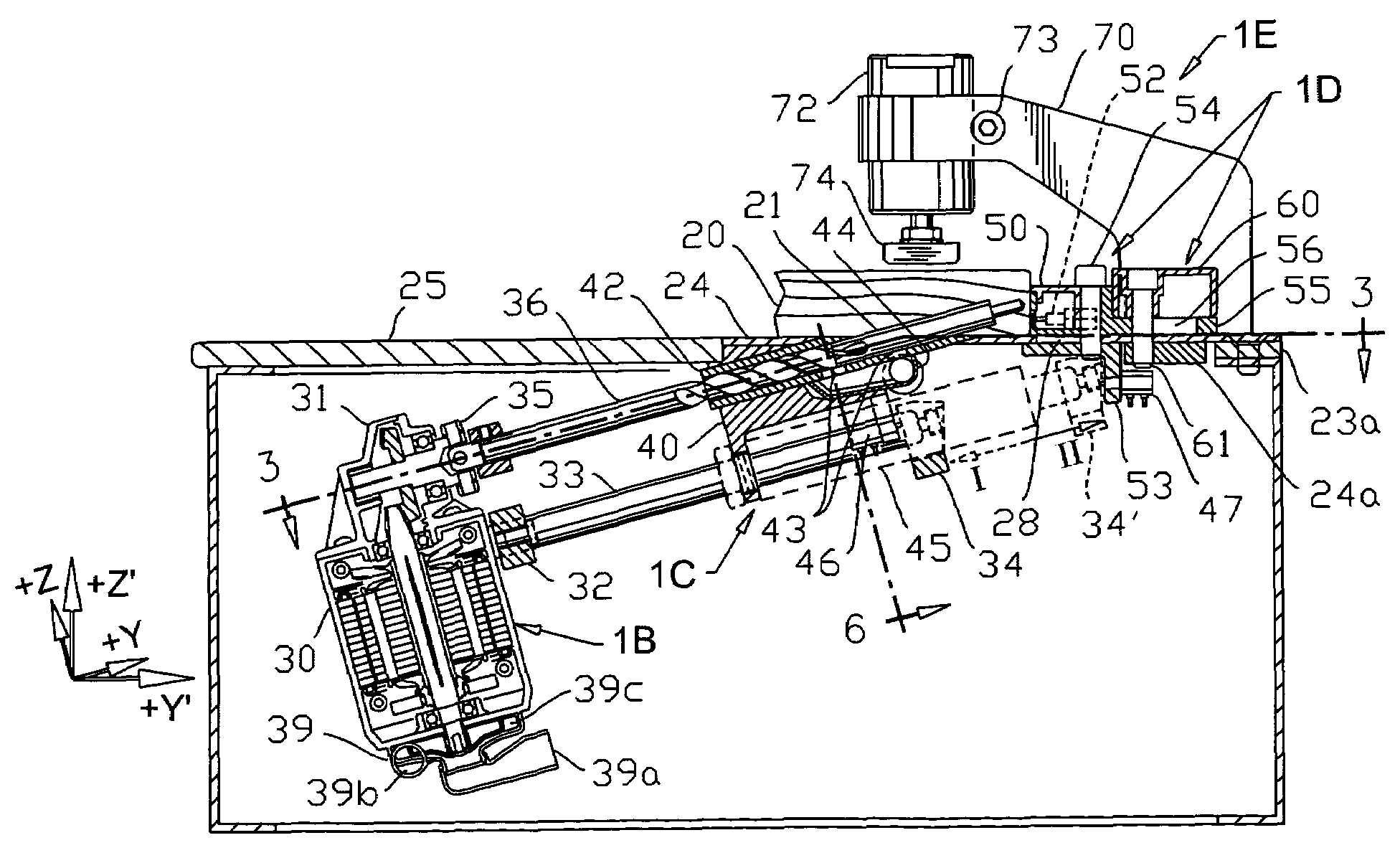

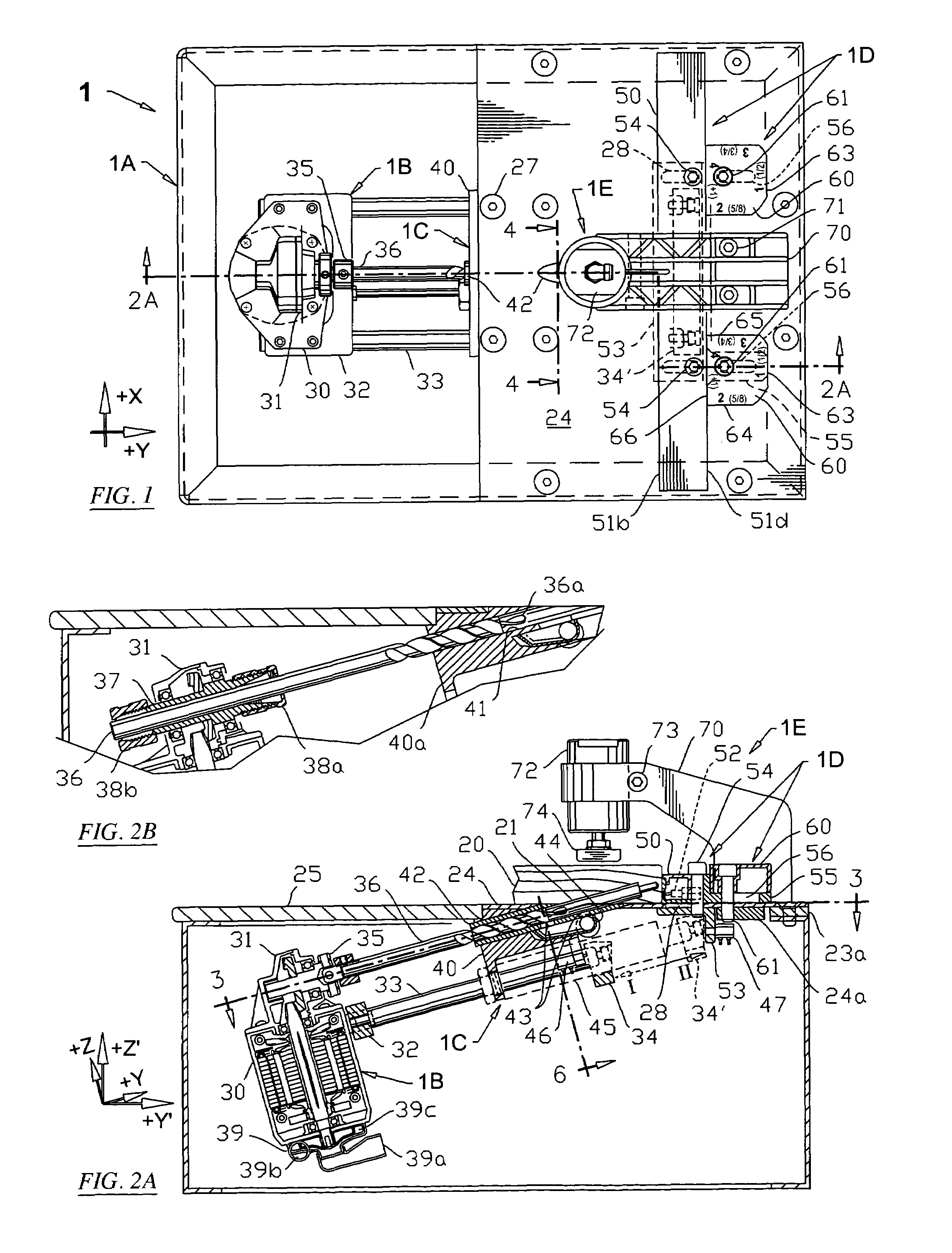

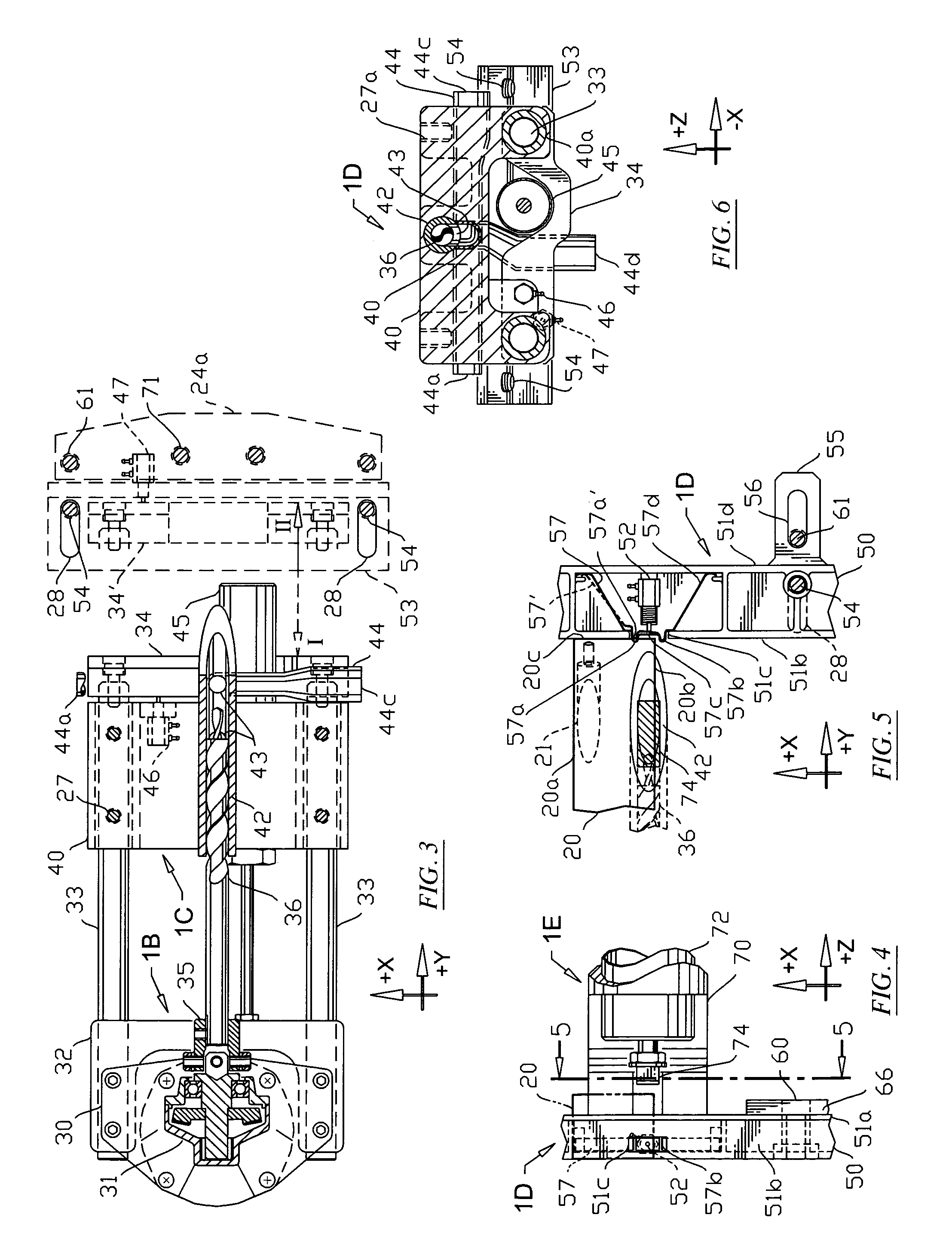

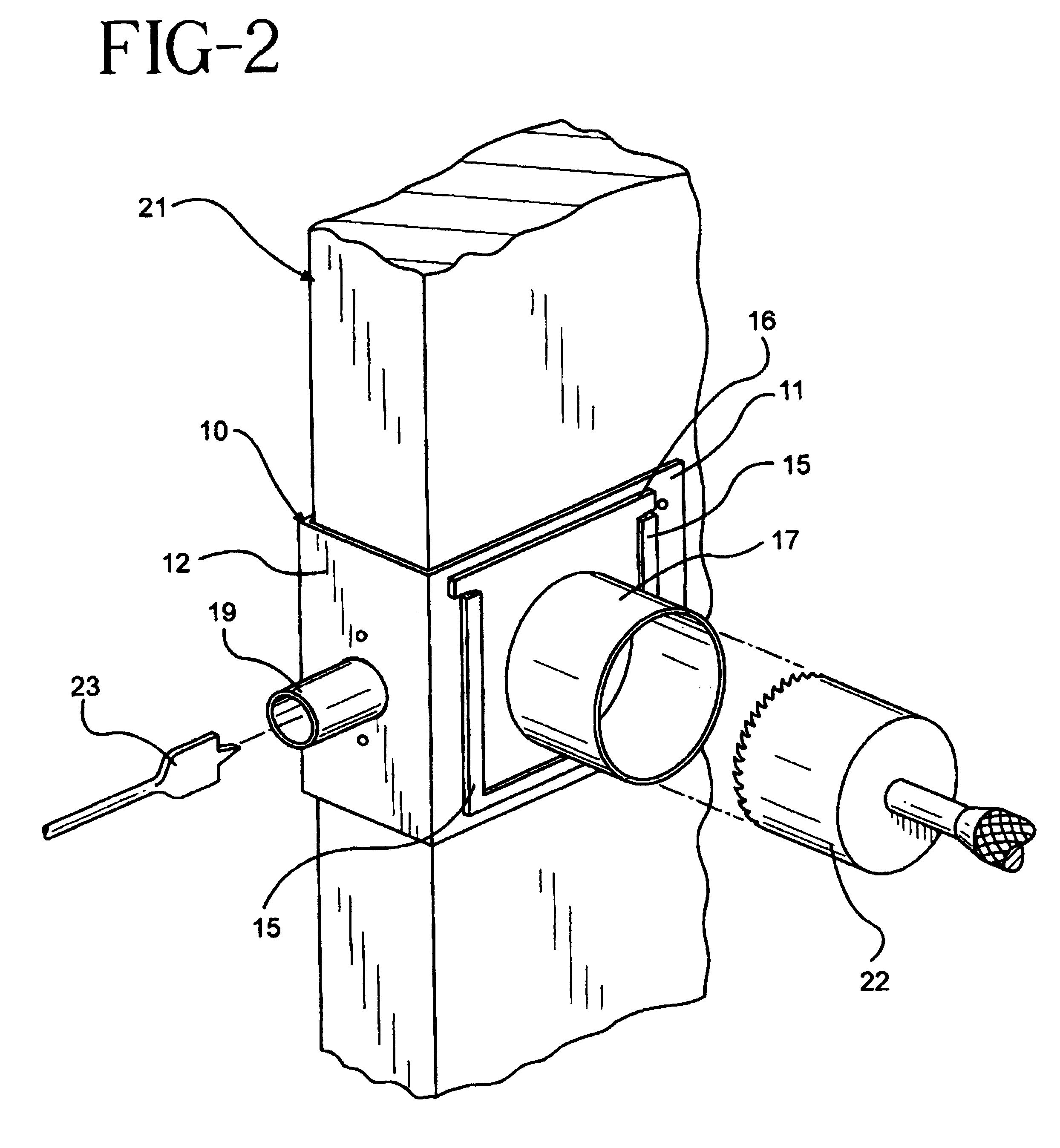

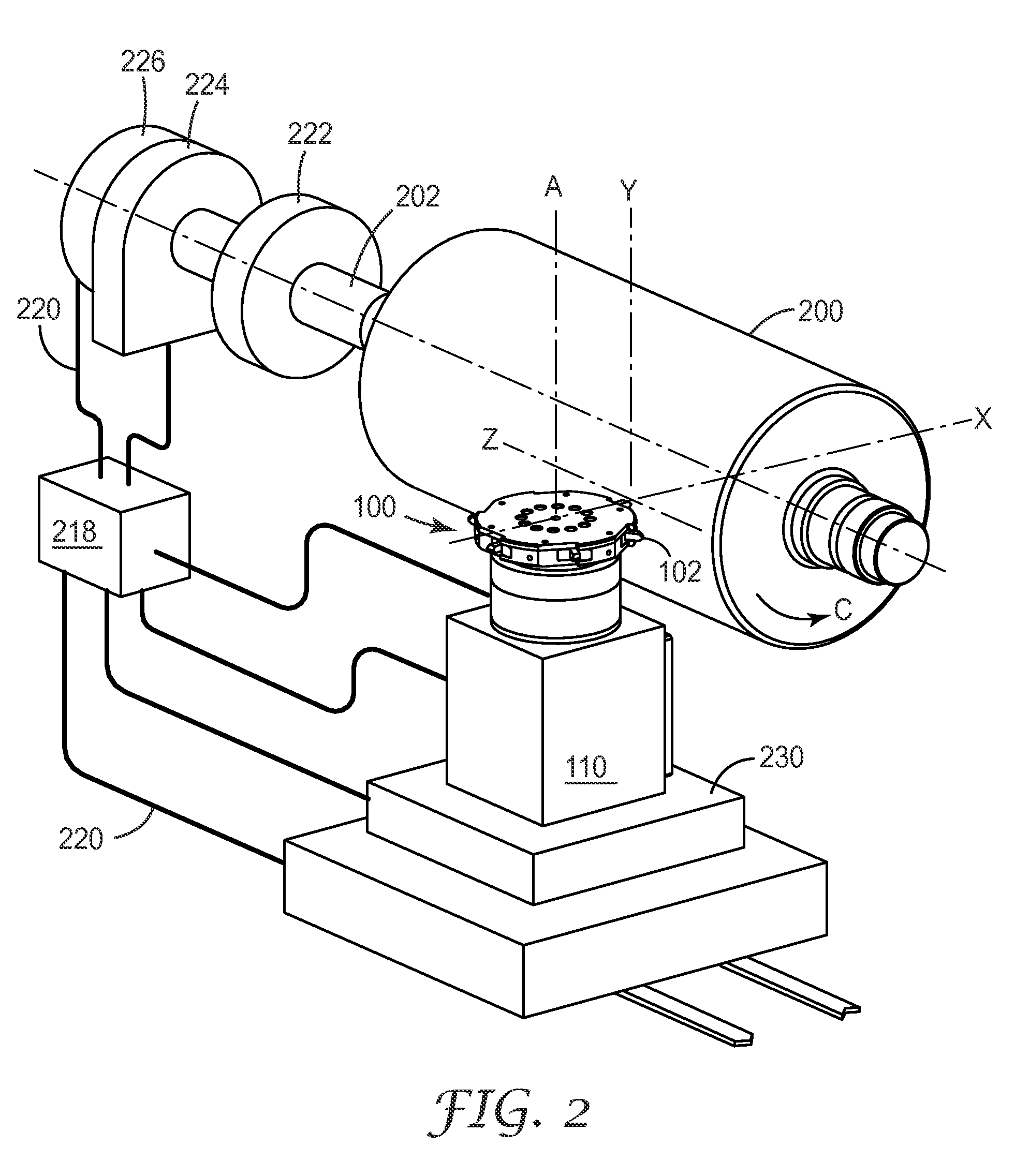

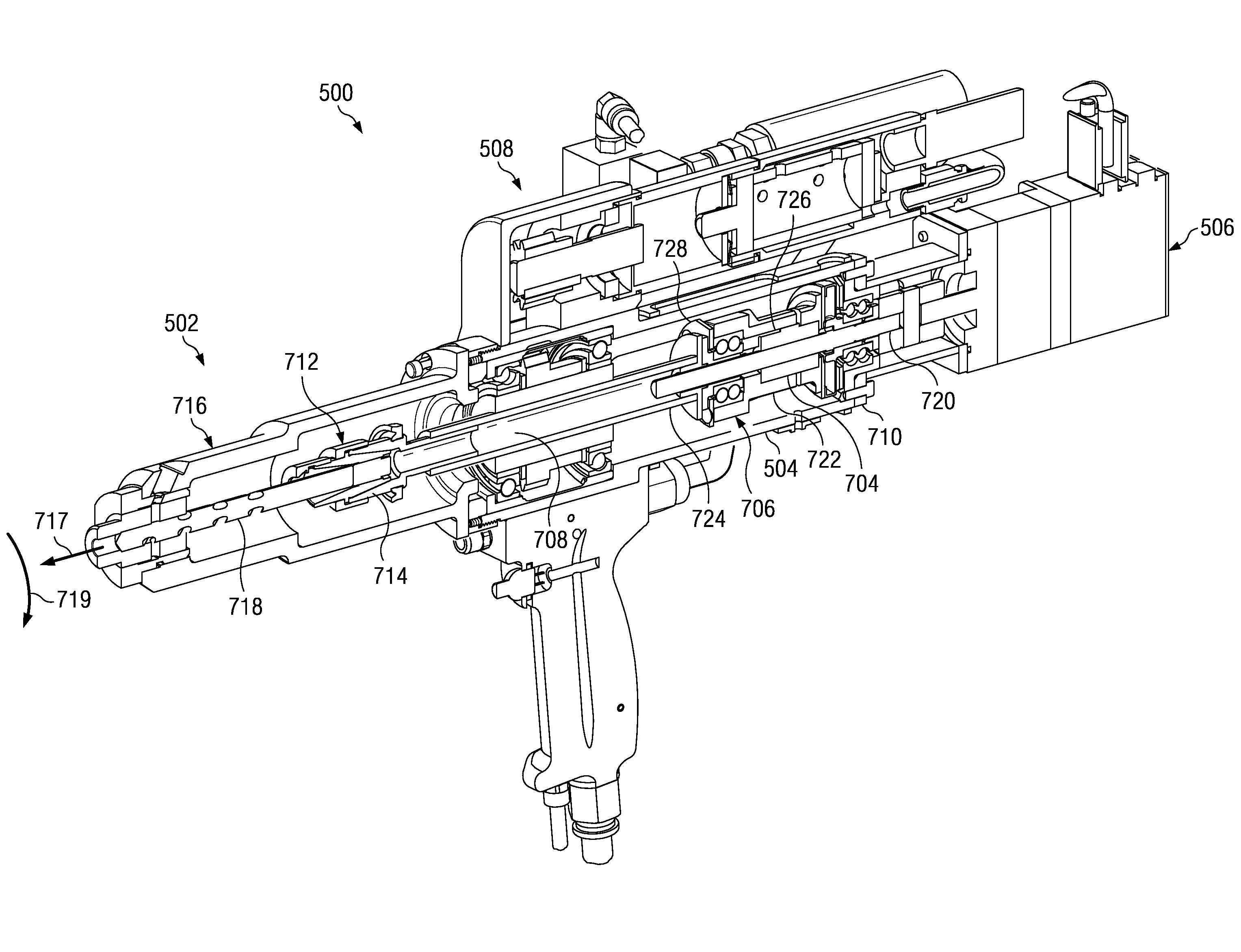

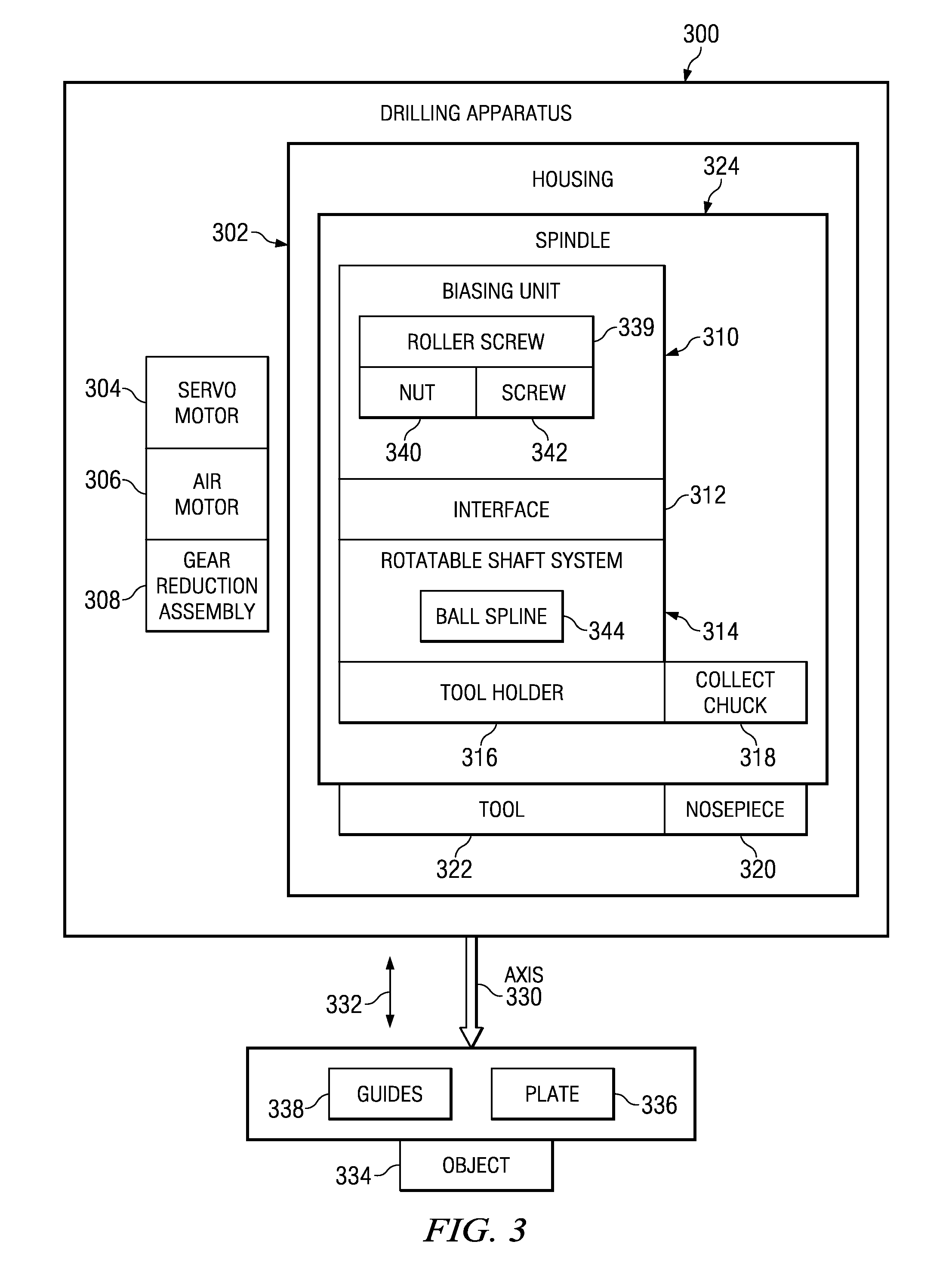

Method and apparatus for a spindle with servo feed control

A method and apparatus for a power feed drill. The power feed drill comprises a servo motor, a roller screw, a ball spline shaft, an air motor, and a collet chuck. The roller screw is rotatably mounted to the servo motor. The ball spline shaft has a first end connected to the roller screw, wherein rotation of the roller screw in a first direction moves the ball spline shaft in the first direction and wherein rotation of the roller screw in a second direction moves the ball spline shaft in an opposite direction to the first direction along an axis. The air motor is capable of transmitting rotation motion to the ball spline shaft to rotate around the axis. The collet chuck is fixably attached to a second end of the ball spline shaft, wherein the collet chuck is adapted to receive a tool.

Owner:THE BOEING CO

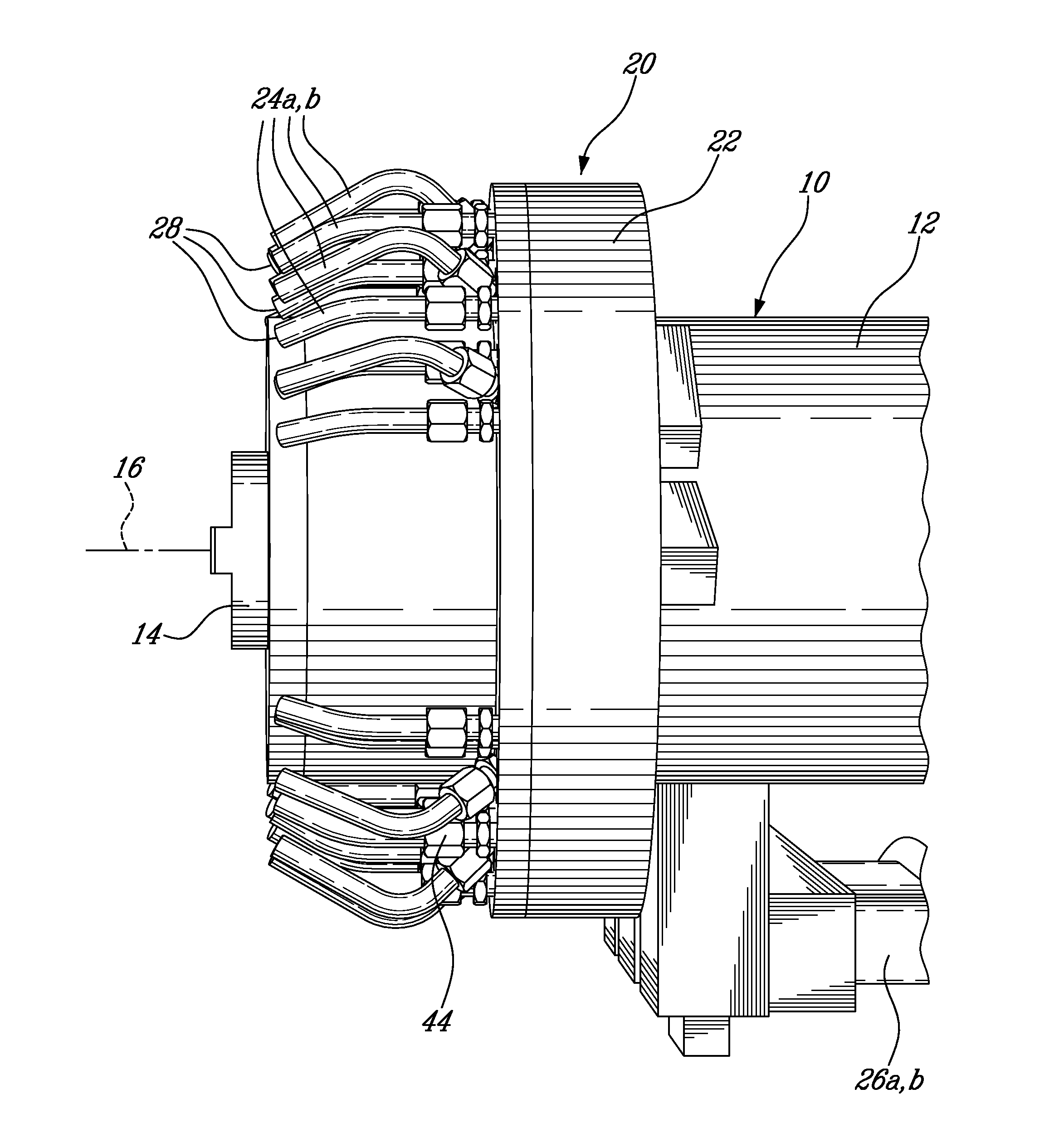

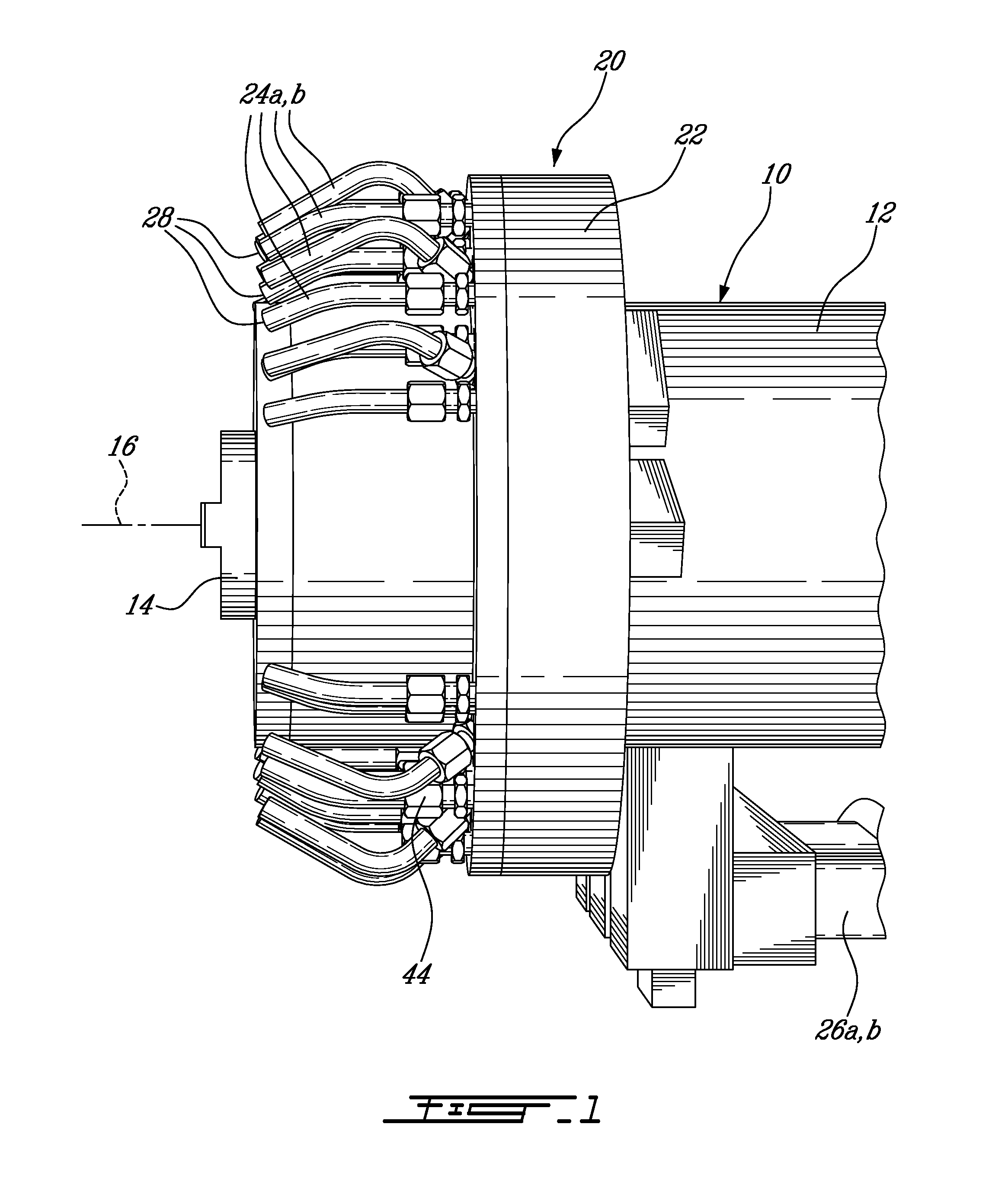

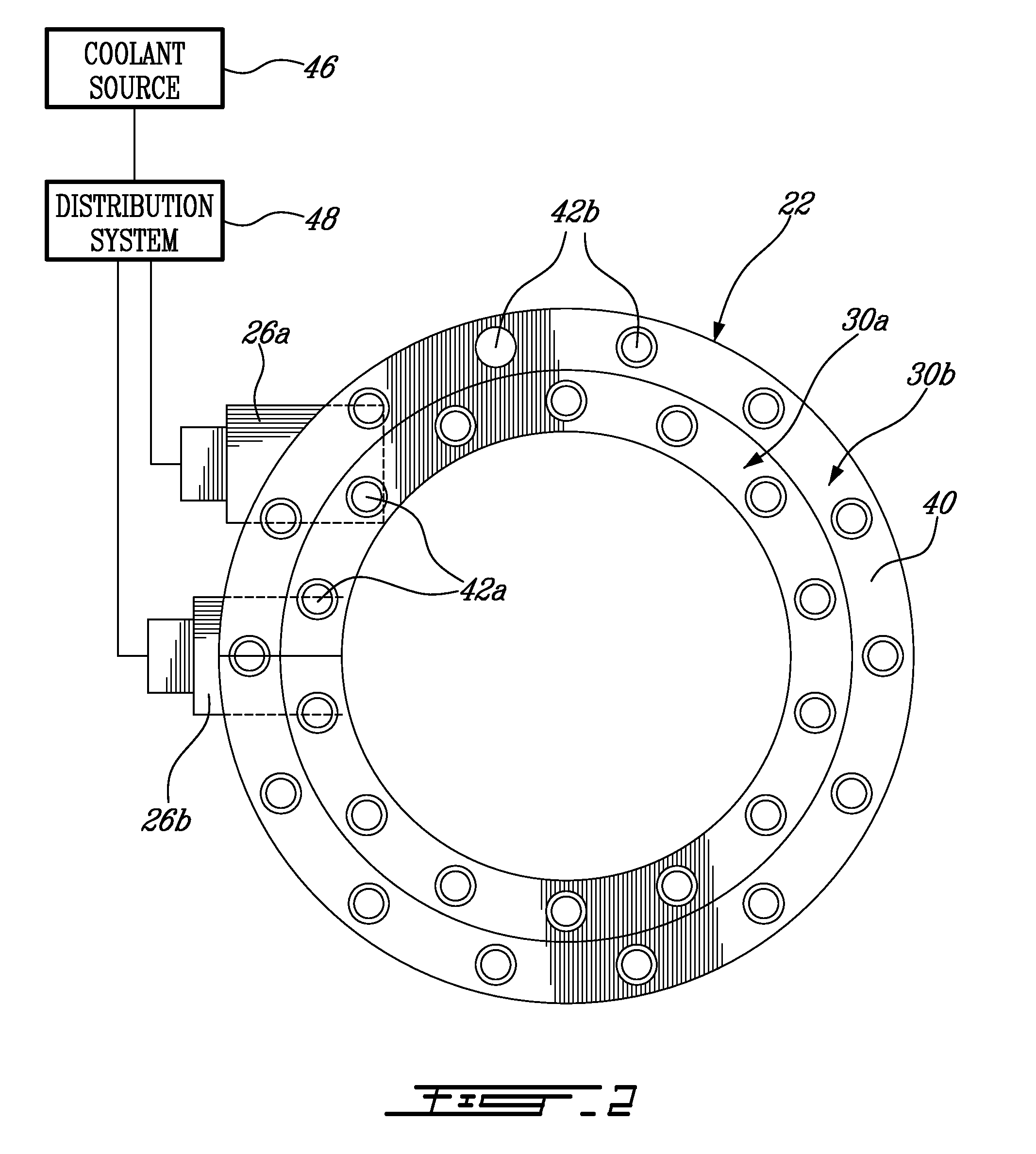

Multiple zone cooling apparatus

A cooling assembly for a machine tool including at least first and second nozzle rings mounted on the spindle housing, respectively defining first and second coolant conduits and respectively including first and second pluralities of nozzles in fluid communication with the respective conduit. Each first nozzle is oriented with an outlet thereof directed toward a first machining zone containing cutting edges of at last one tool having a first length. Each second nozzle is oriented with an outlet thereof directed toward a second machining zone different from the first machining zone and containing the cutting edges of at least one tool having a second length.

Owner:PRATT & WHITNEY CANADA CORP

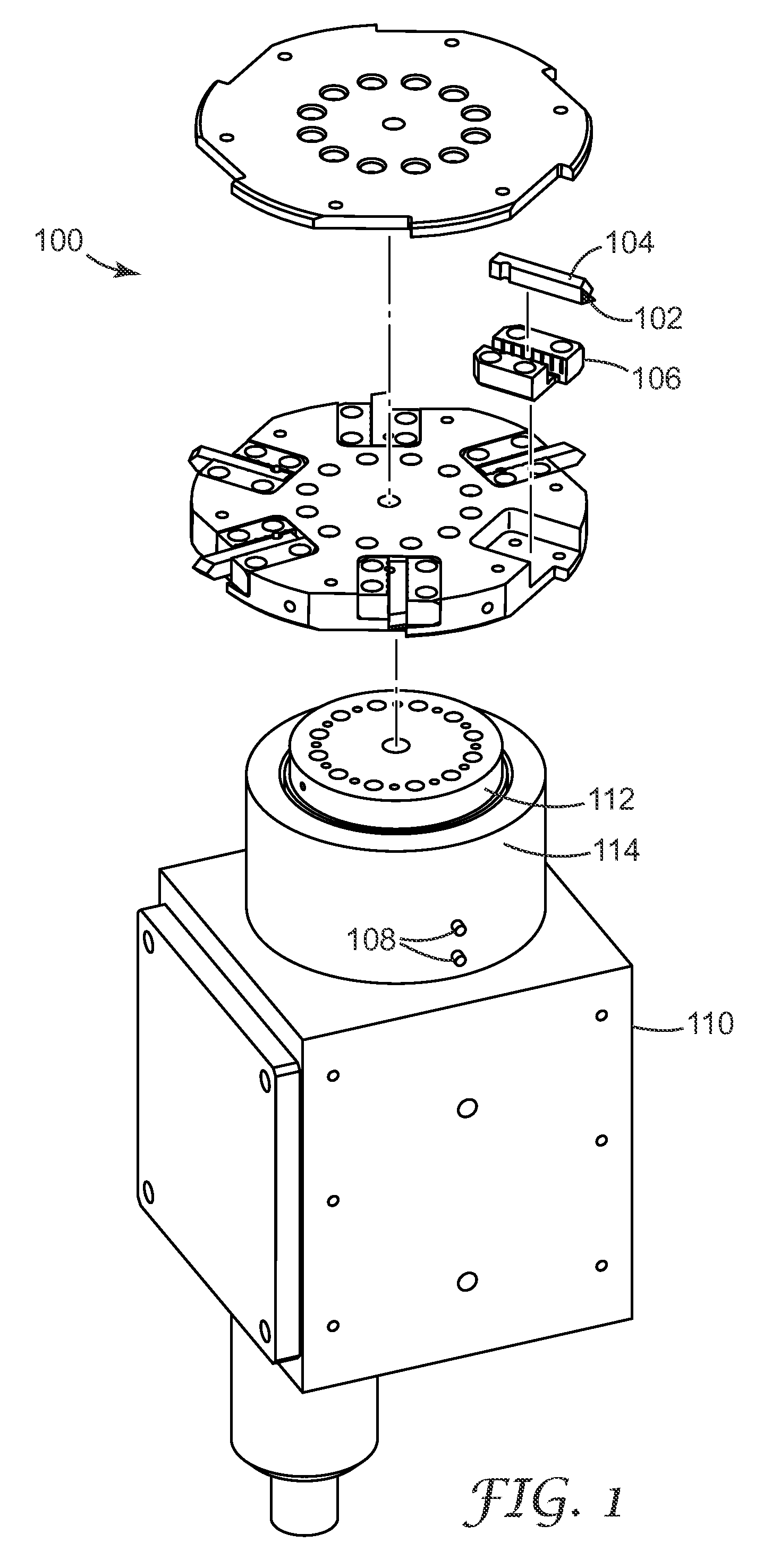

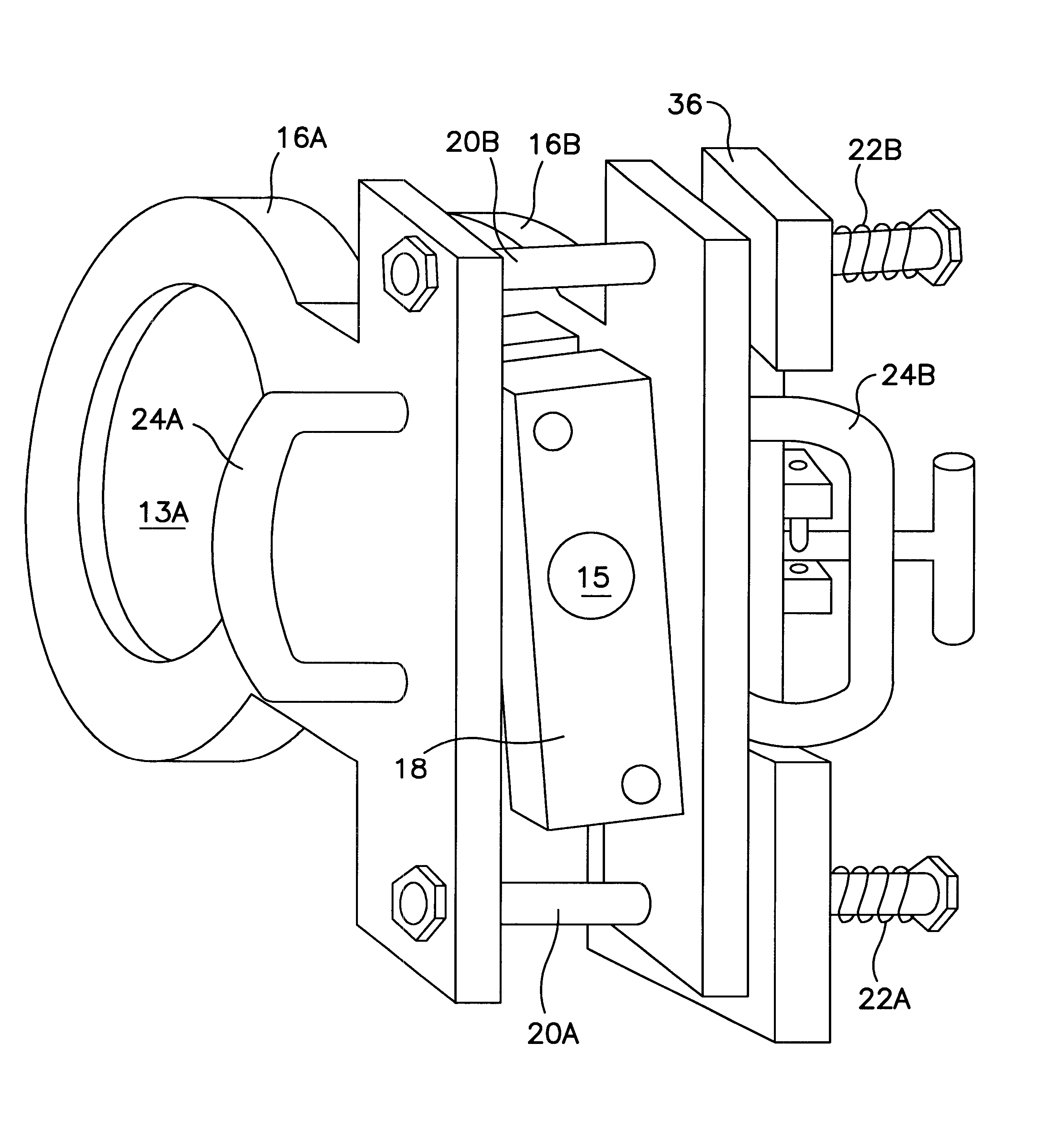

Tool jig for doors

A drill jig for a door comprising a pair of jaws that clamp onto the edge of a door. The clamp is first attached to the edge of the door by a spring load and then further secured by a cam which the workman turns to apply additional clamping force. A center block between the jaws has a guide hole for drilling the lock hole in the edge of the door. The centerline of the center block is perpendicular to the centerline of the knob hole and is positionable to permit location of the knob hole at either one of two locations depending on the style of the lock set. The center block is hingably attached to both jaws of the clamp such that guide hole for drilling the lock hole is always centered between the jaws.

Owner:FRIDMAN YEVGENY

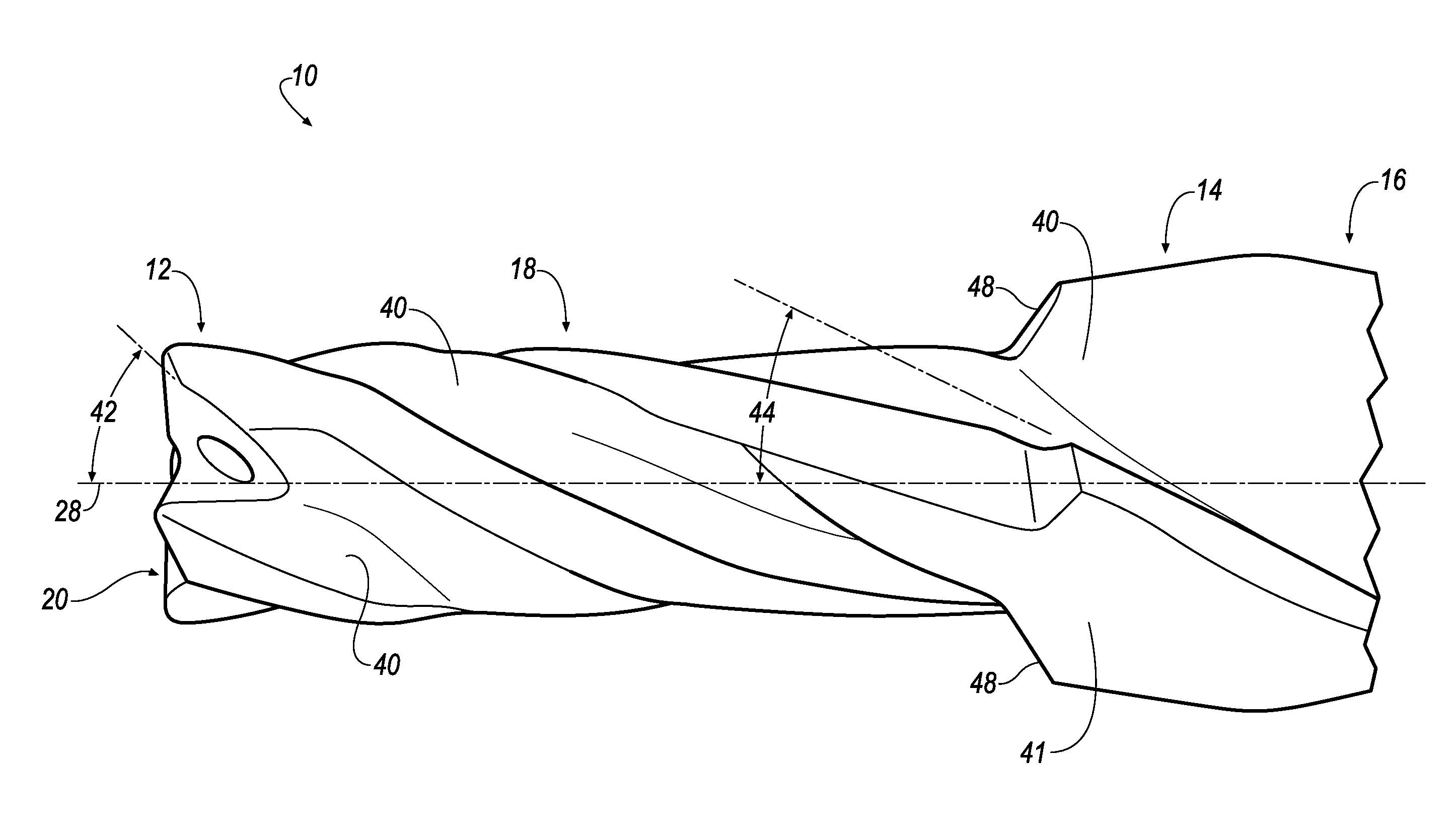

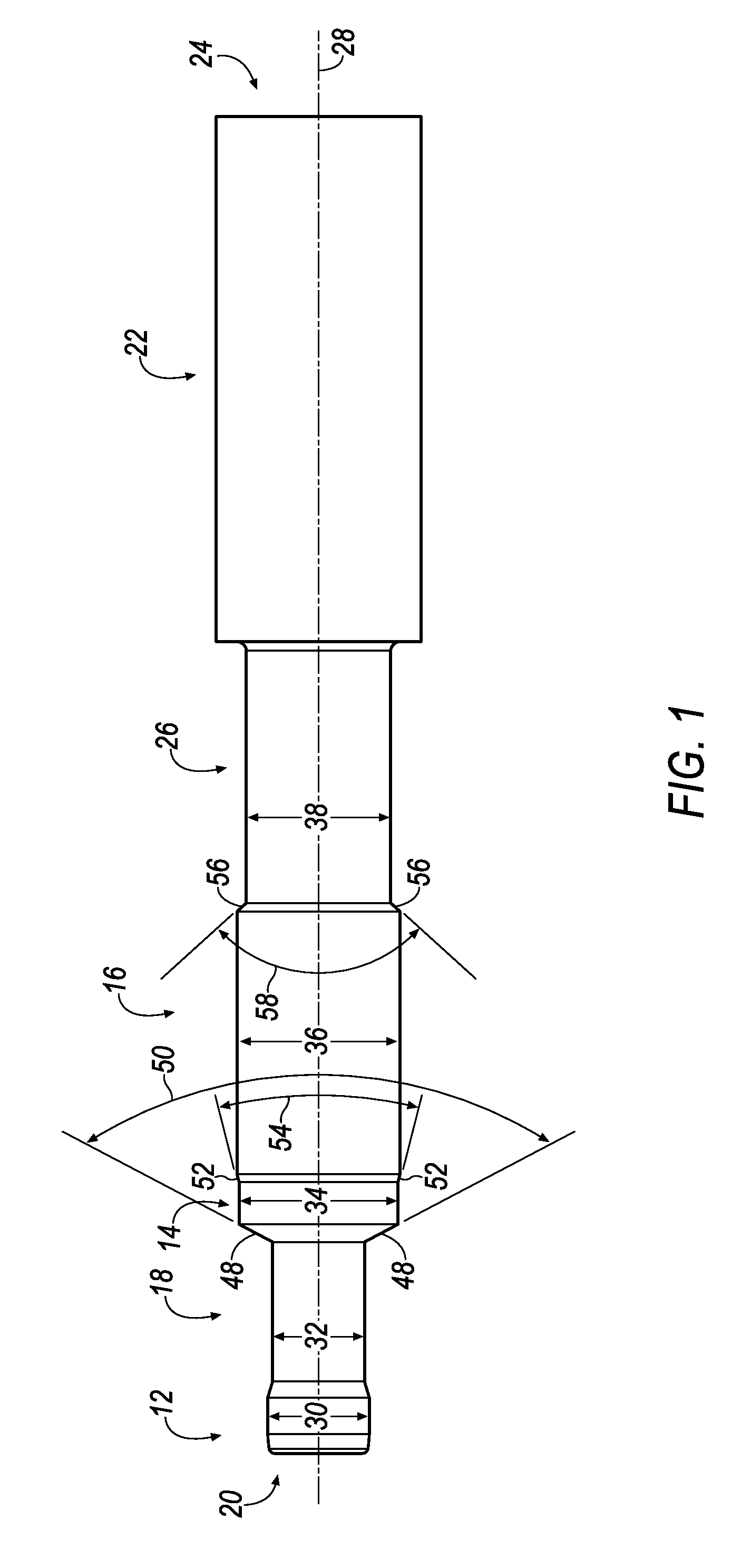

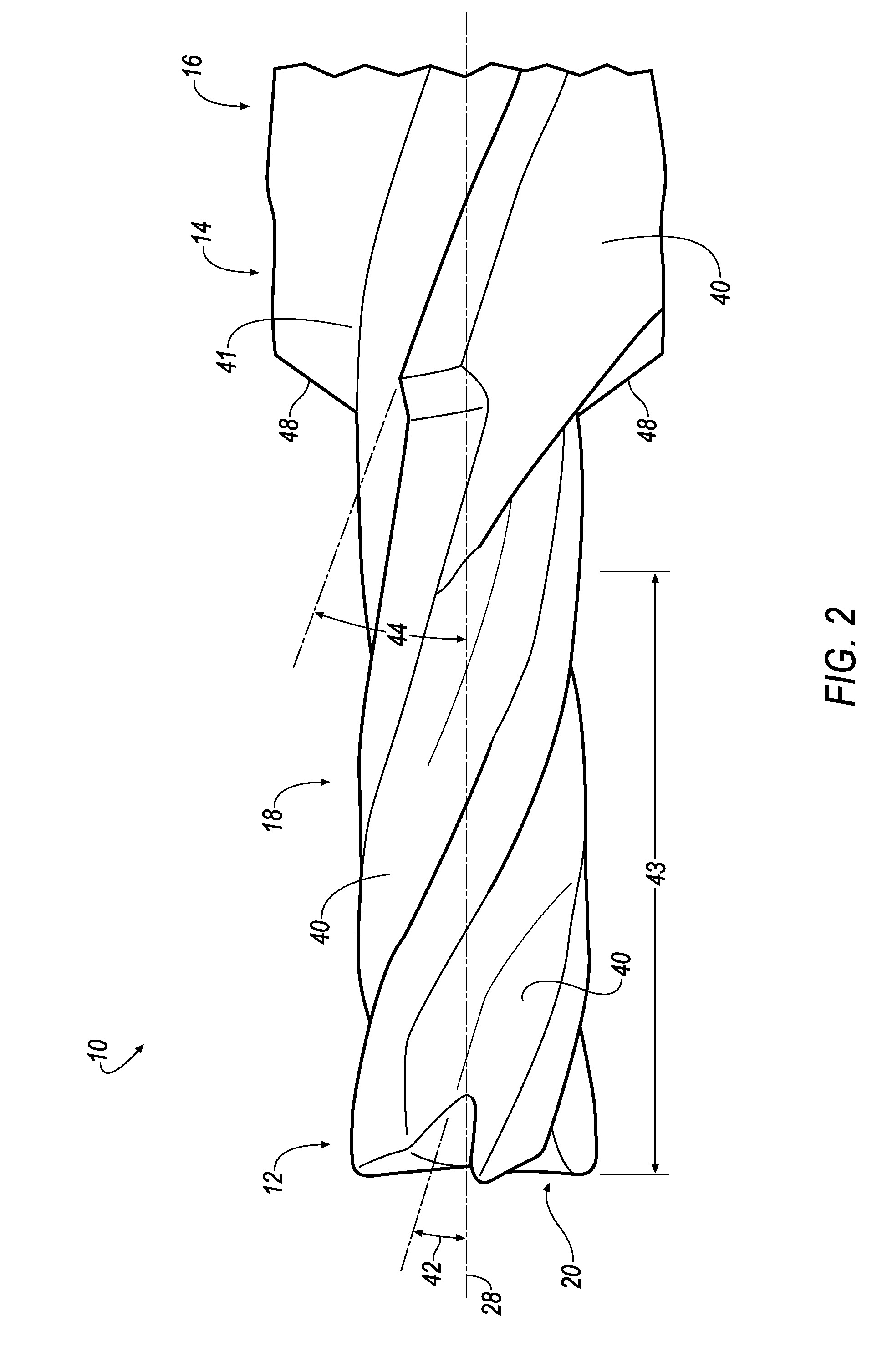

Combination end milling/drilling/reaming cutting tool

ActiveUS20120051863A1Improve fatigue lifeFaster cycle timeDrilling machinesMilling cuttersEngineeringMechanical engineering

A combination end milling / drilling / reaming cutting tool includes an end milling portion, a drilling portion, and a reaming portion. The cutting tool also includes a neck portion between the end milling portion and the drilling portion, and a clearance neck portion between a shank and the reaming portion. A method of machining a workpiece using the combination end milling / drilling / reaming cutting tool is also disclosed.

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com