Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2313results about How to "Improve fatigue life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

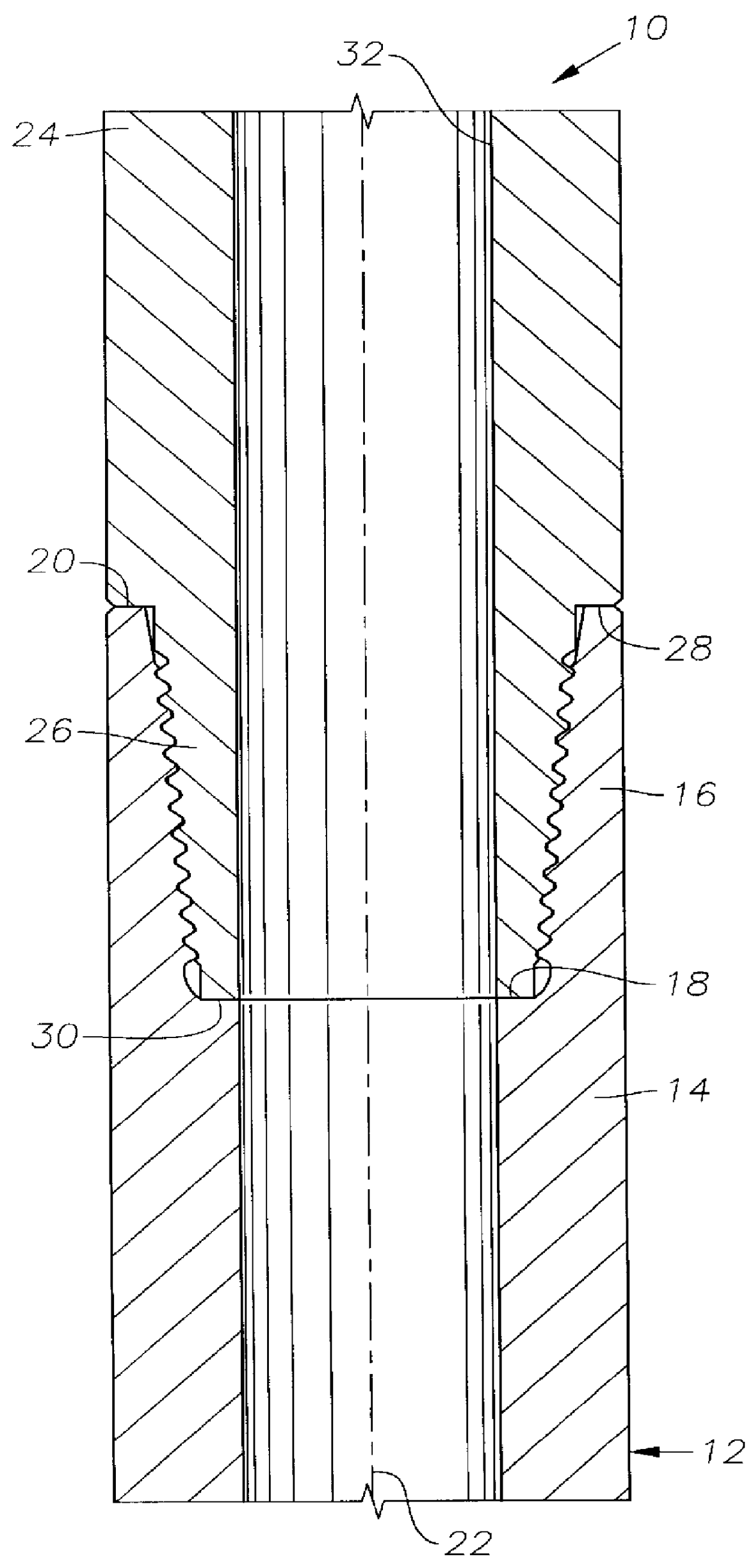

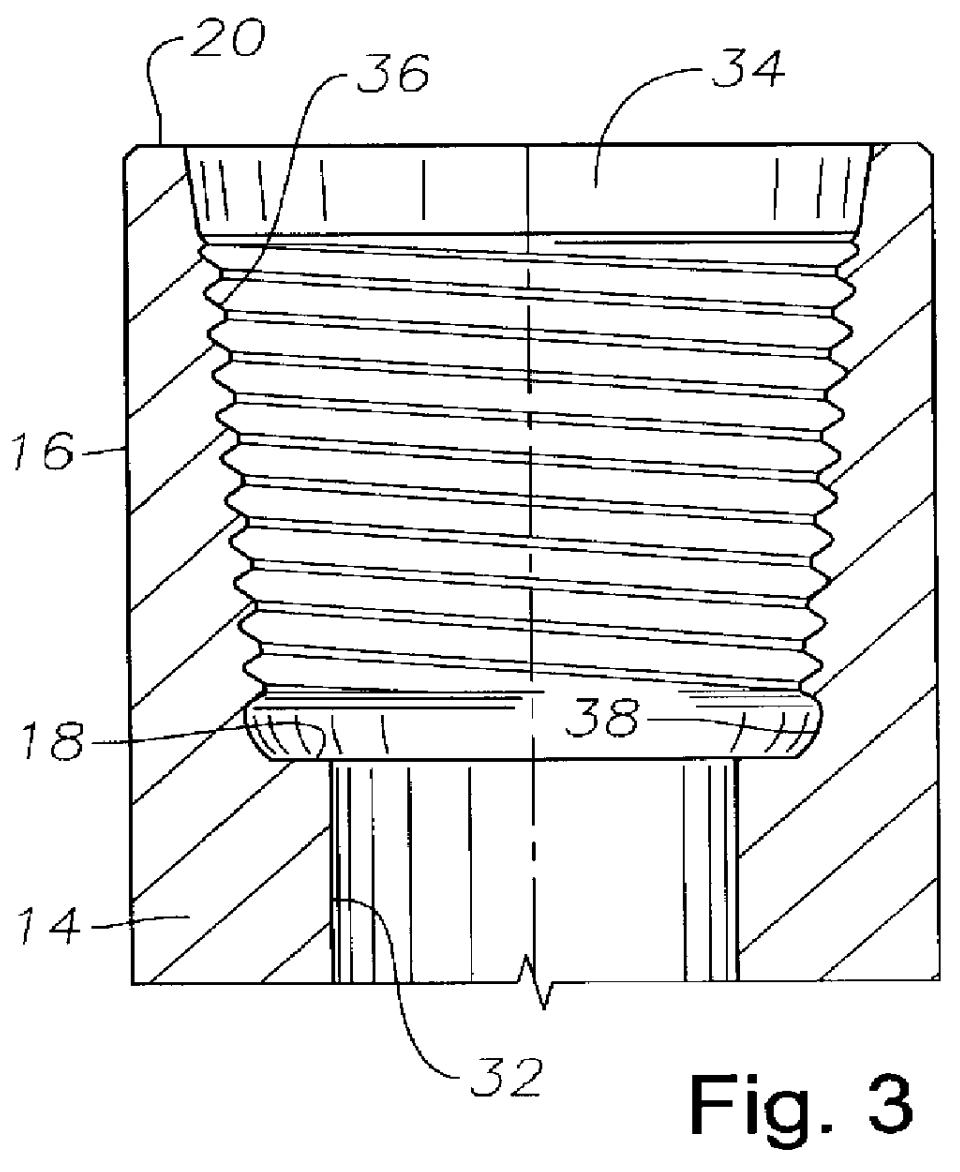

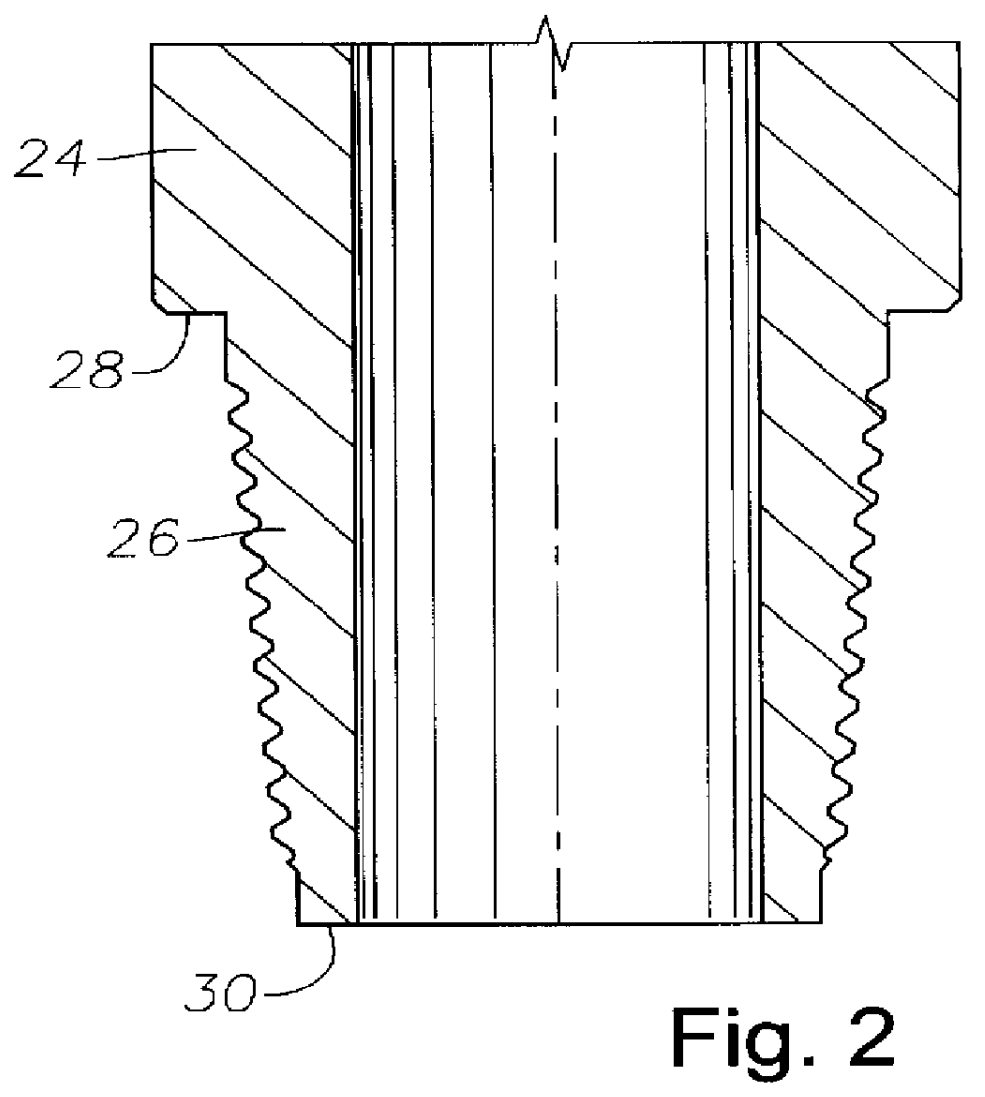

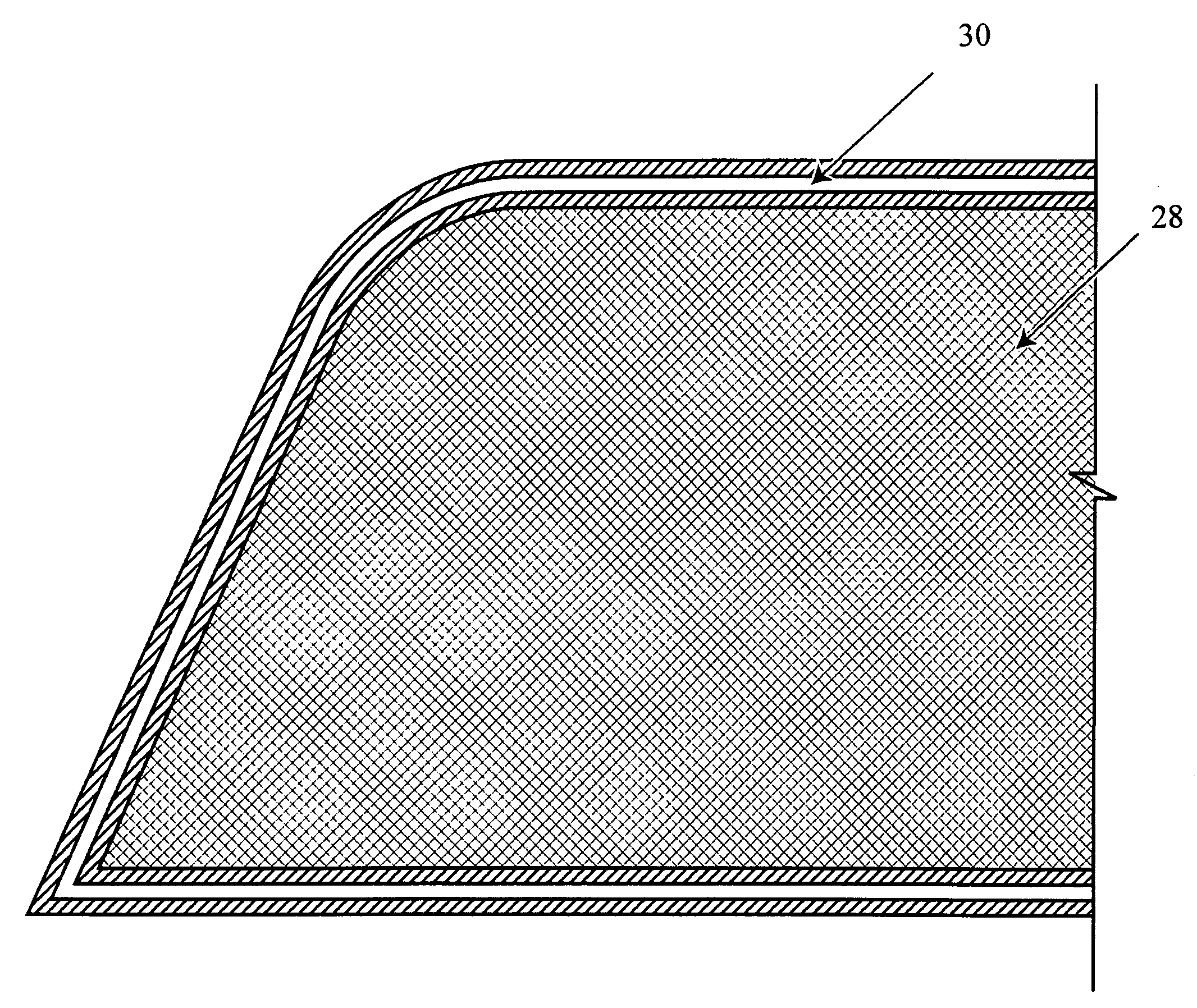

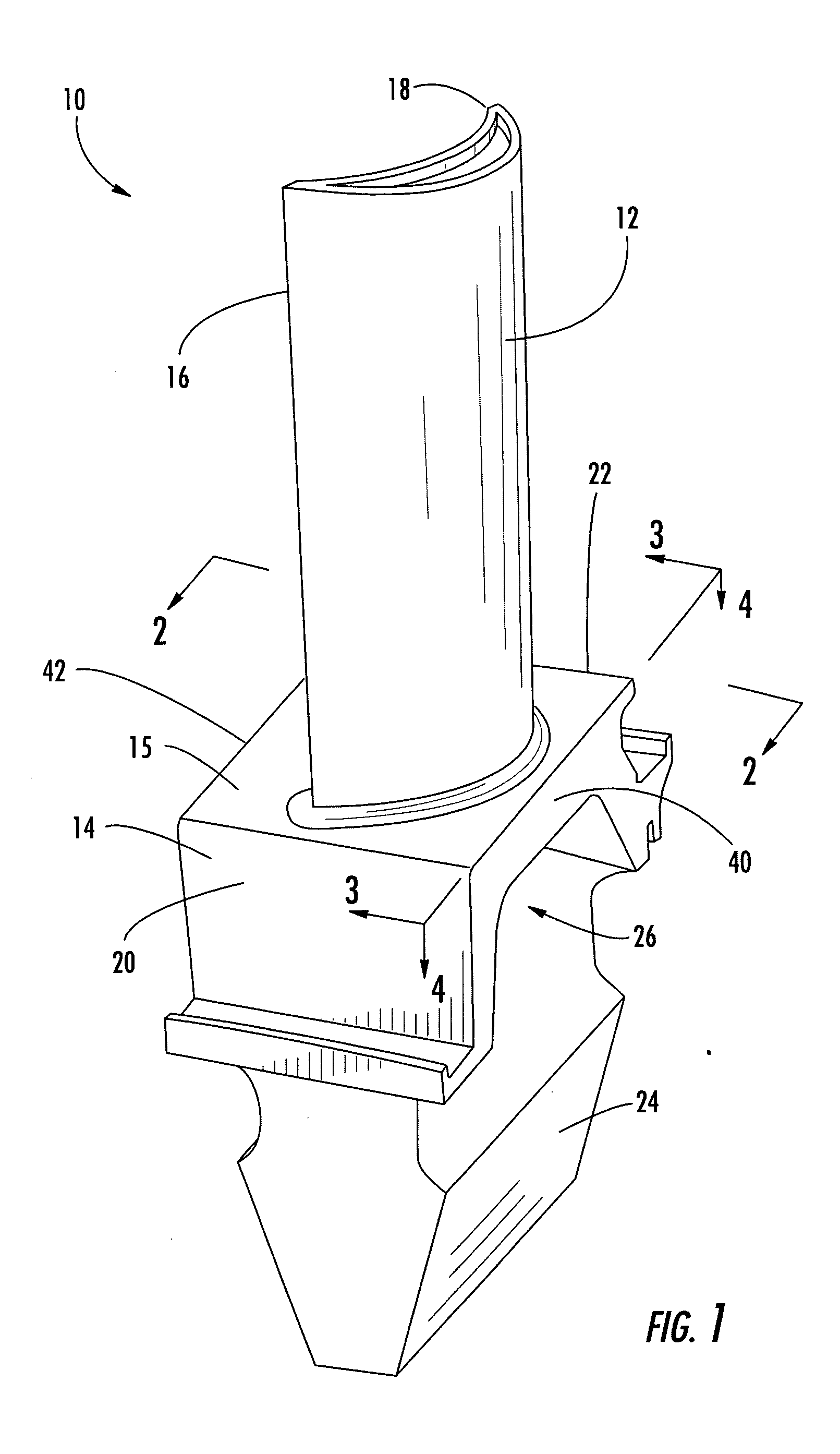

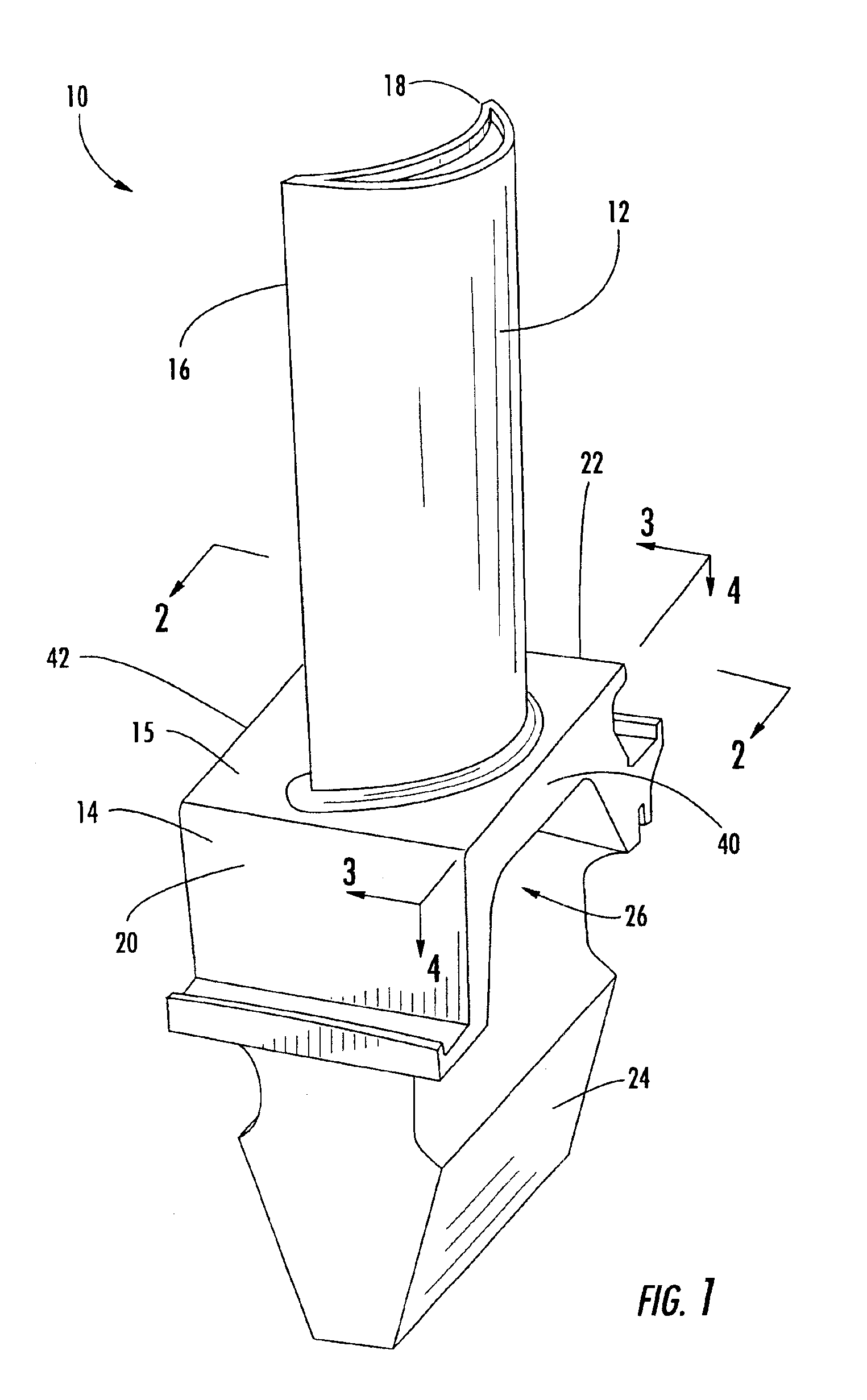

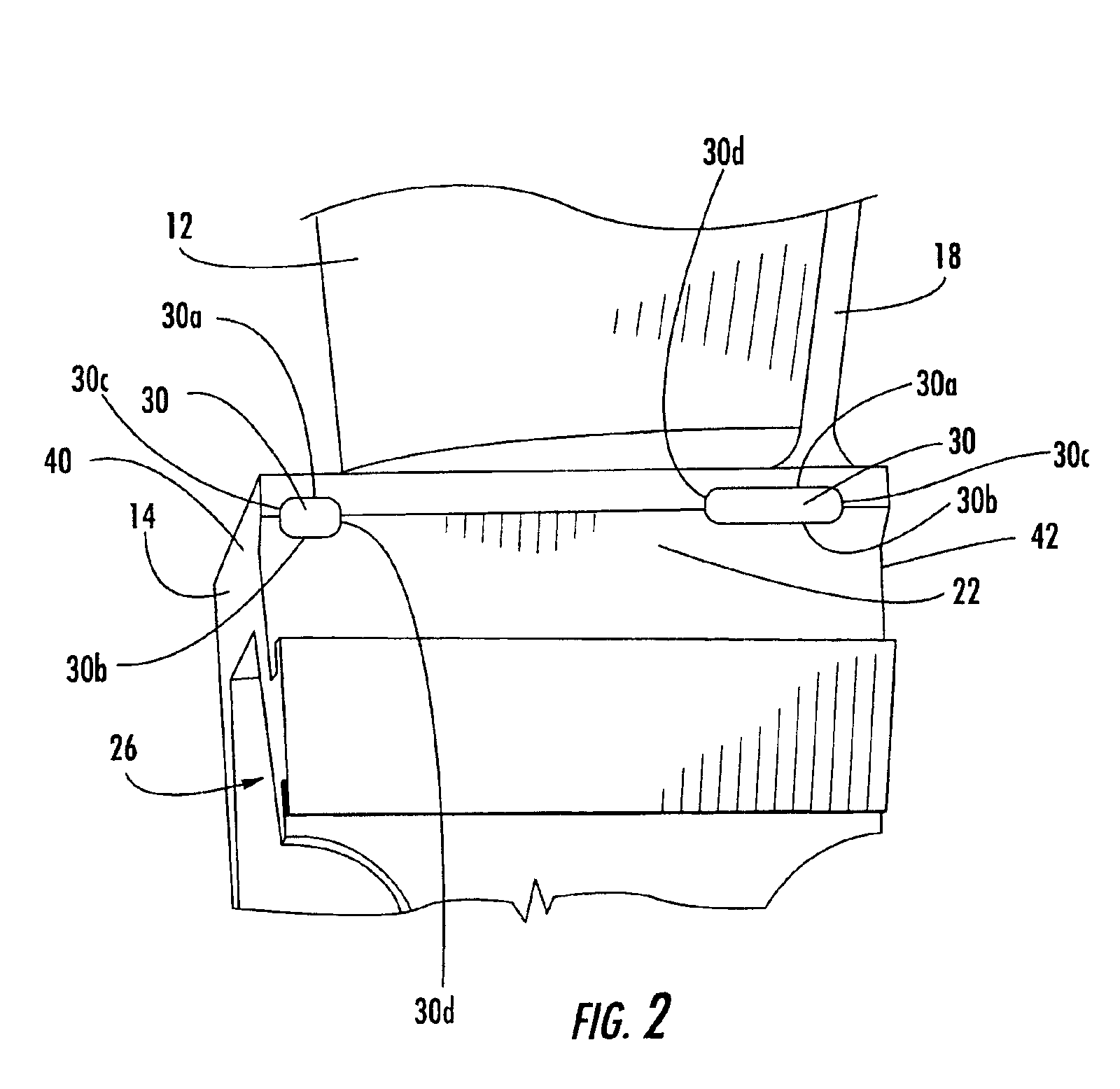

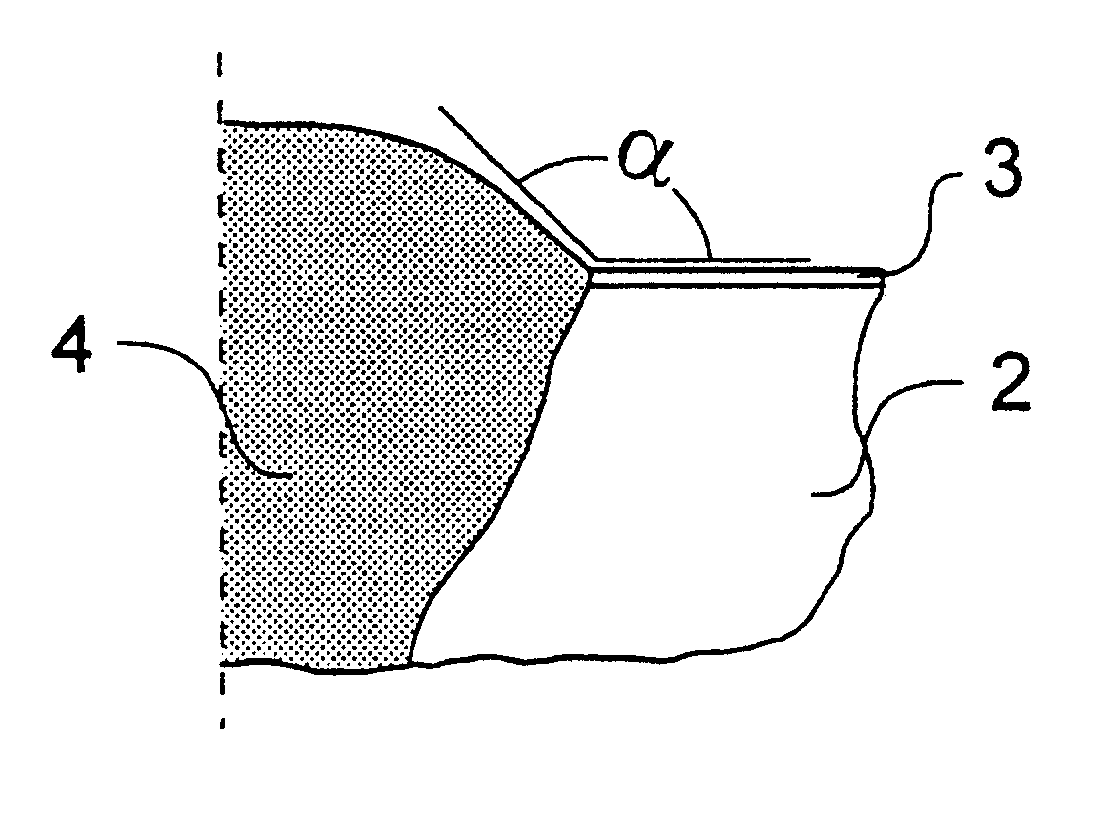

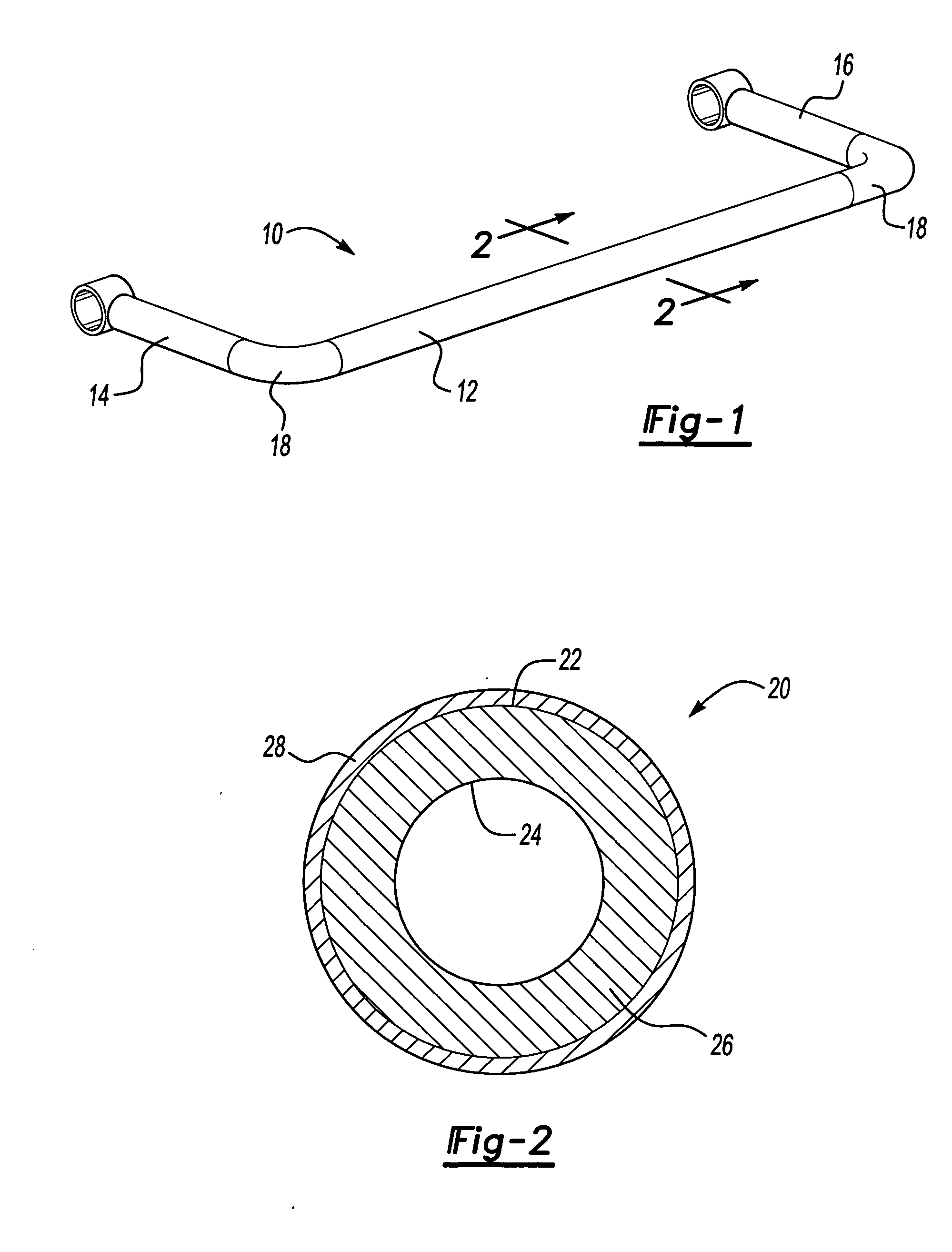

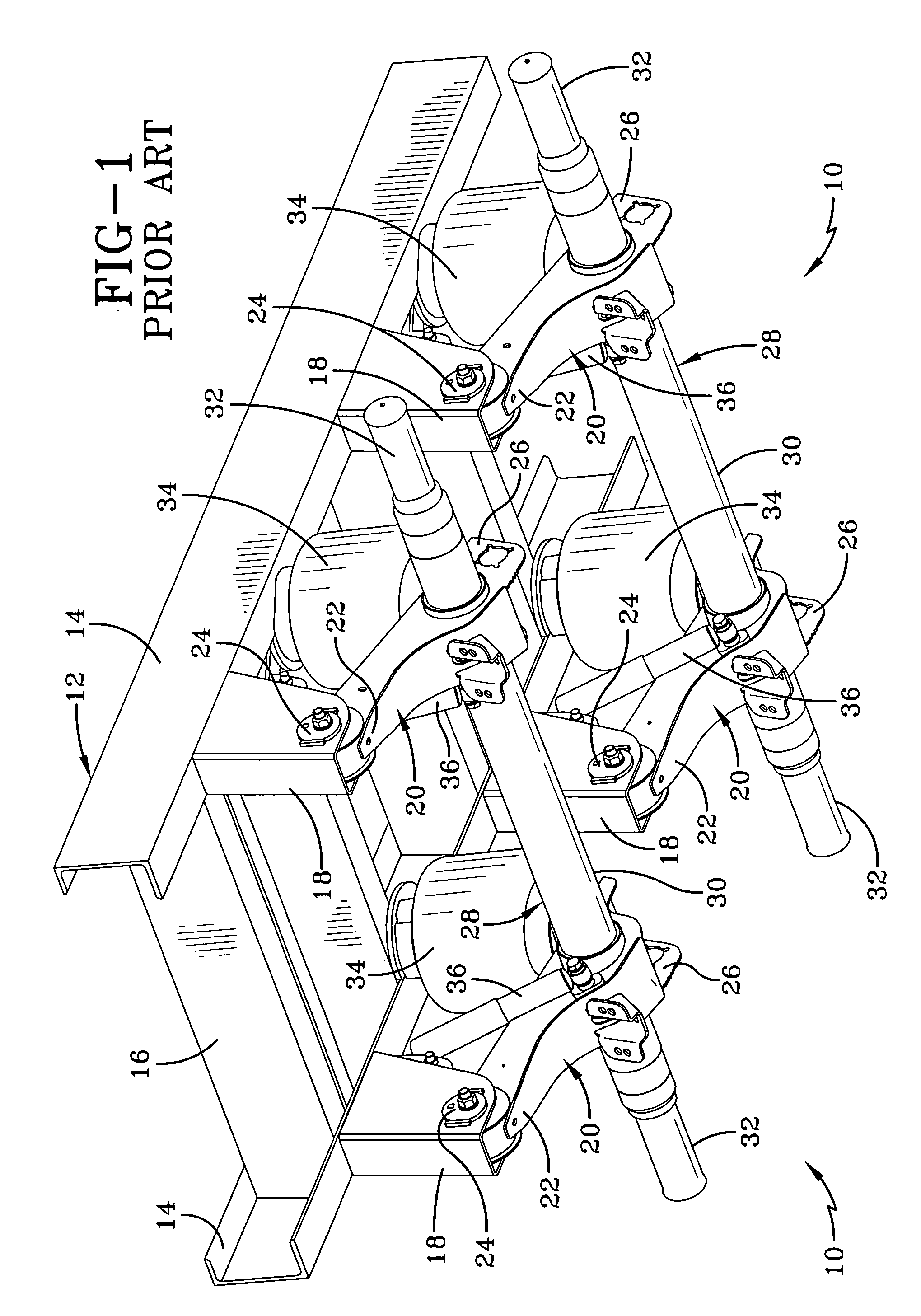

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

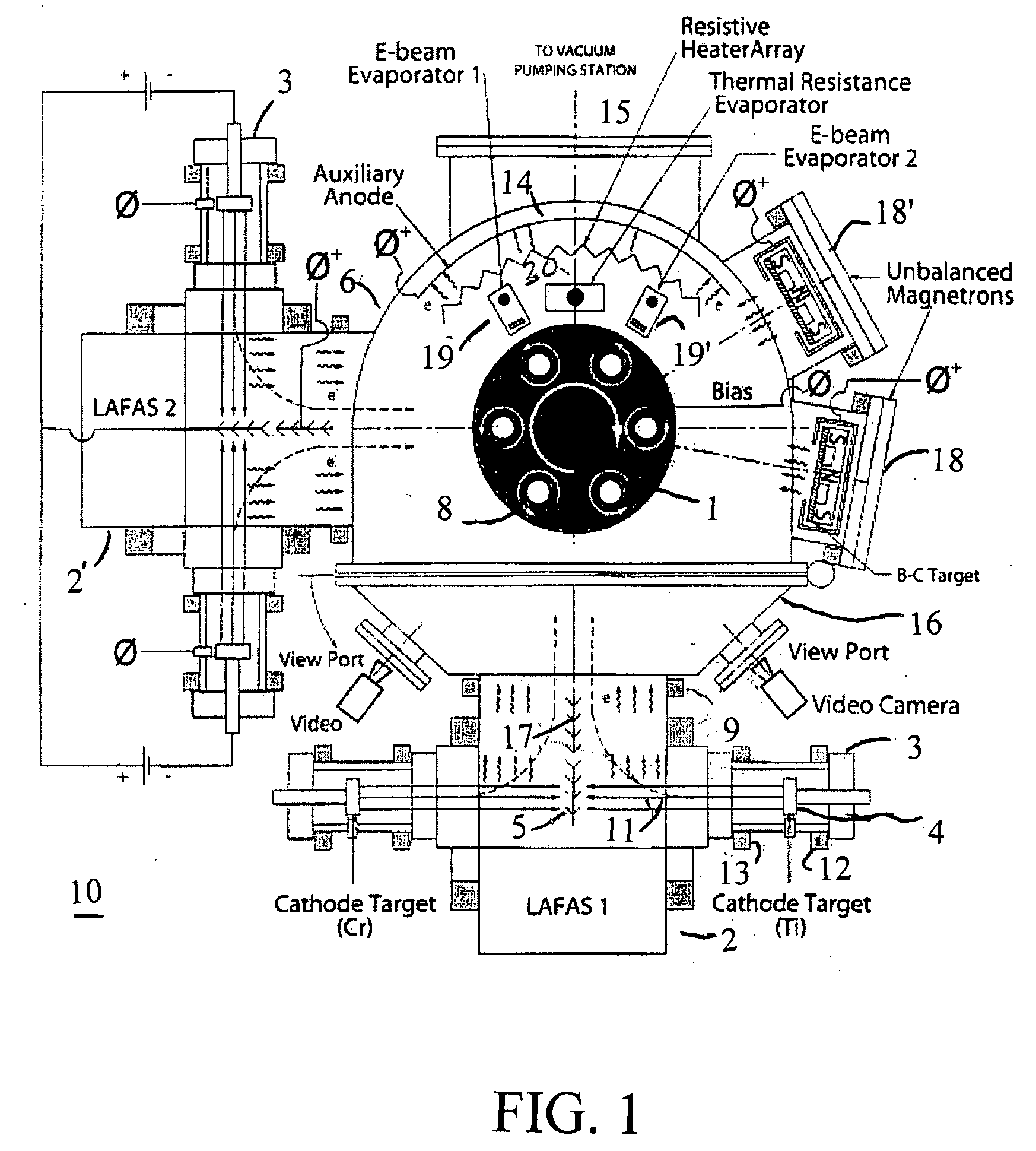

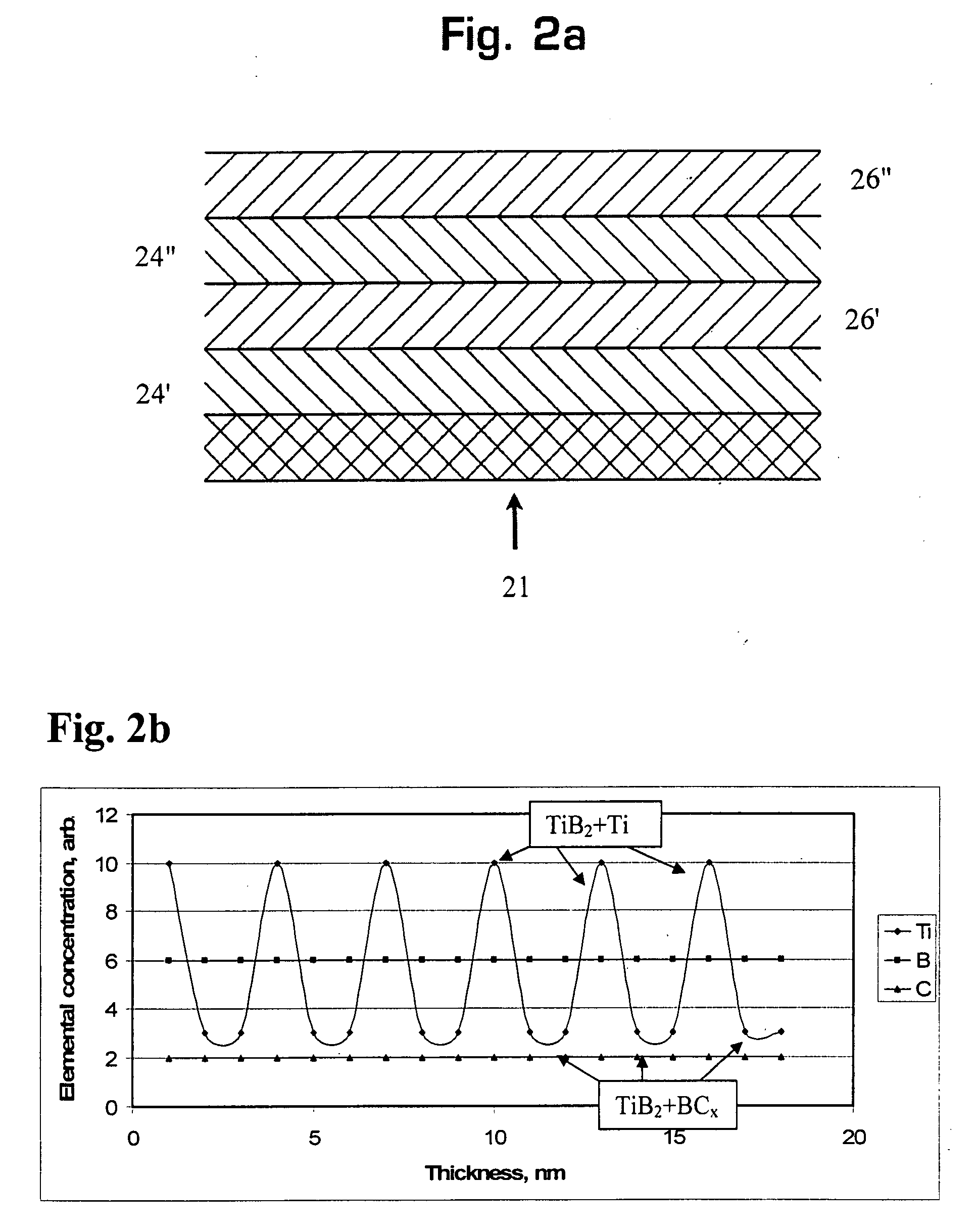

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

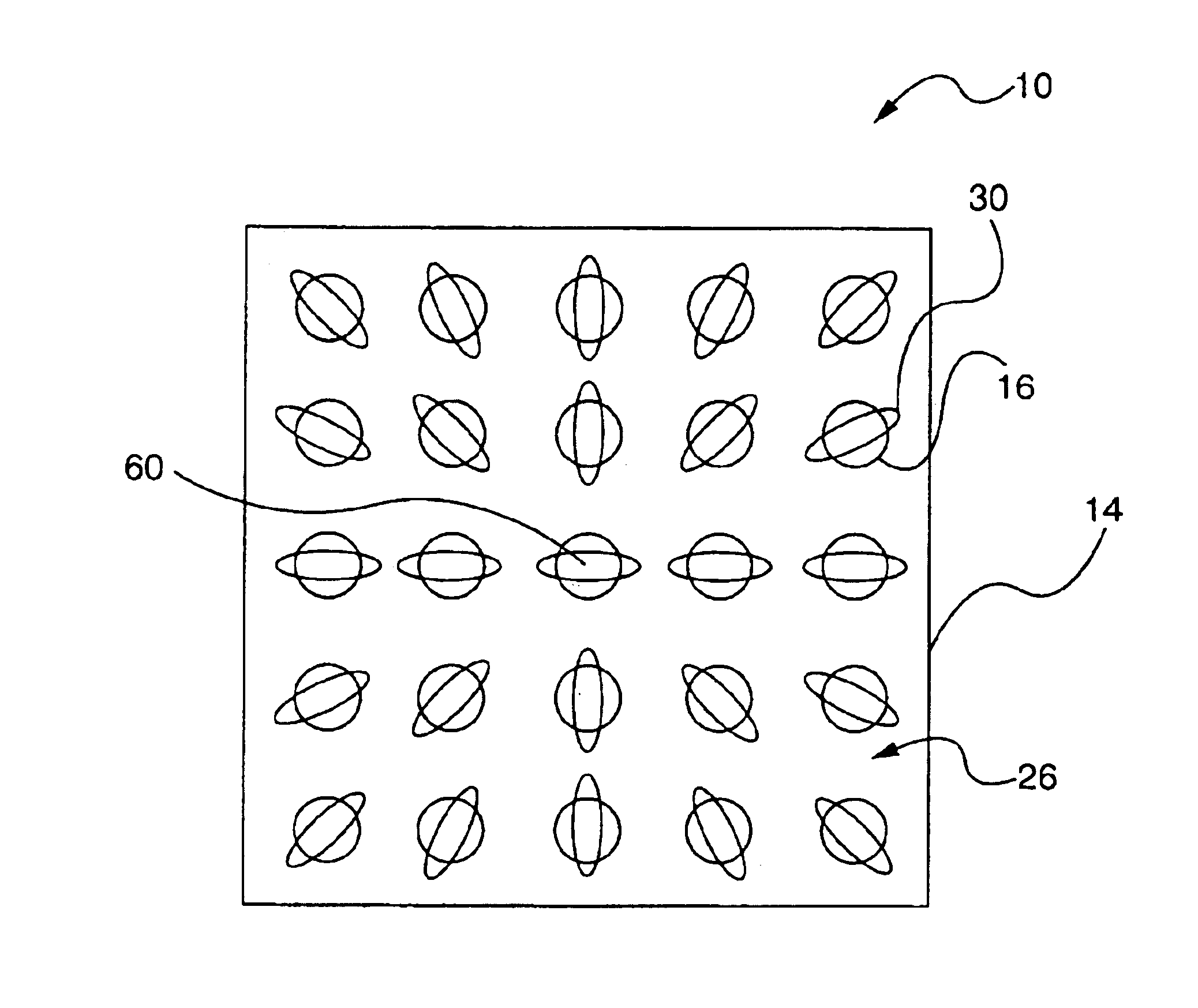

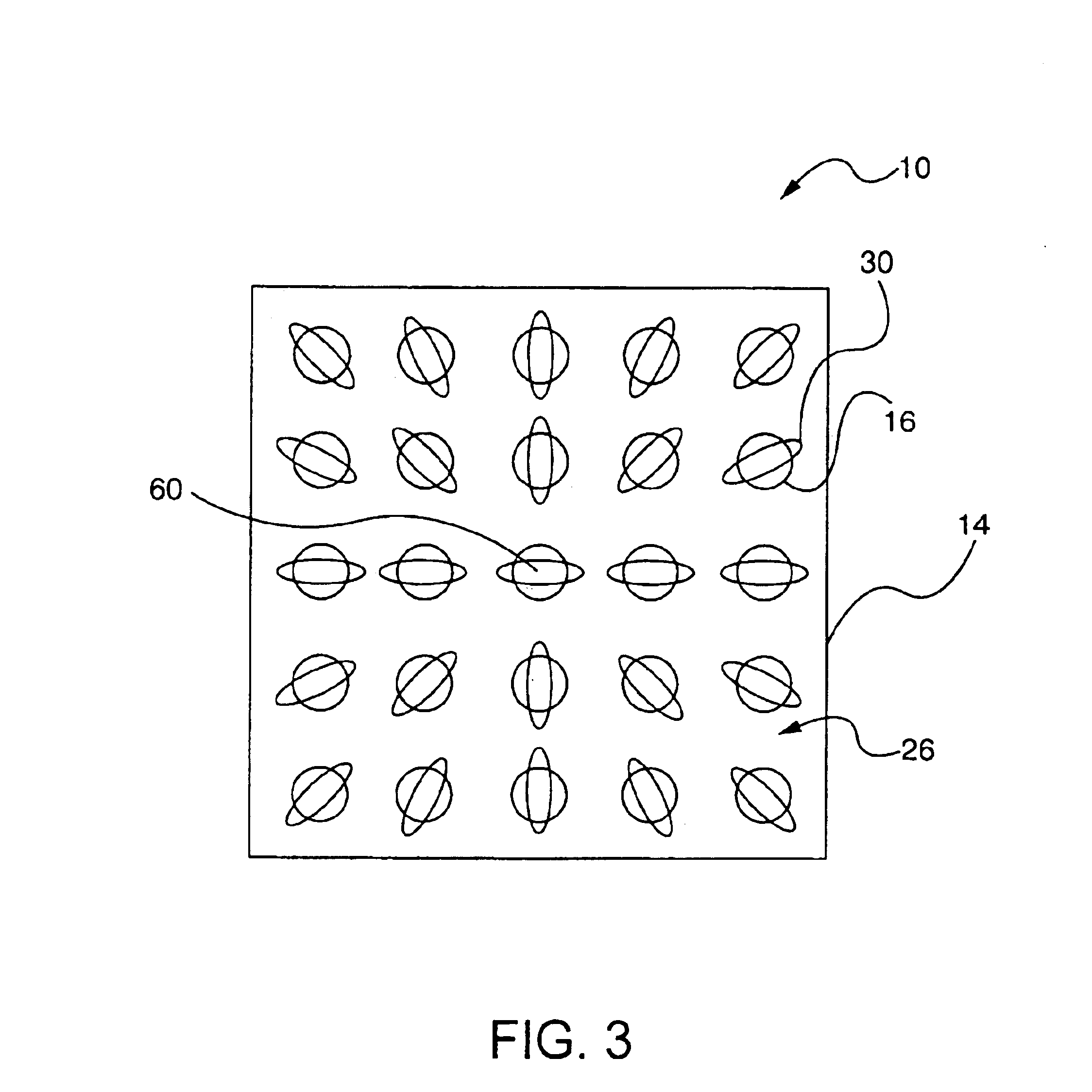

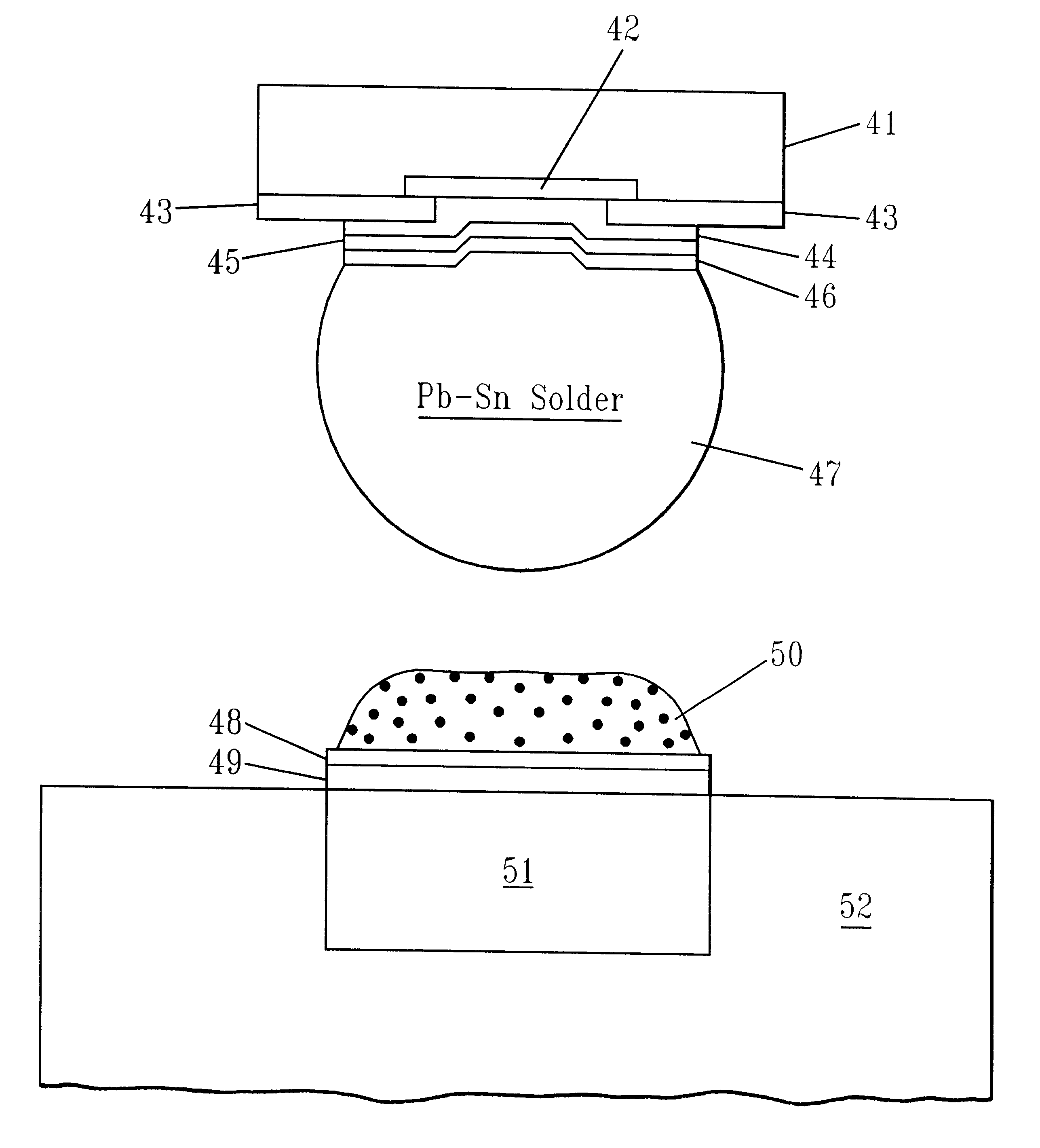

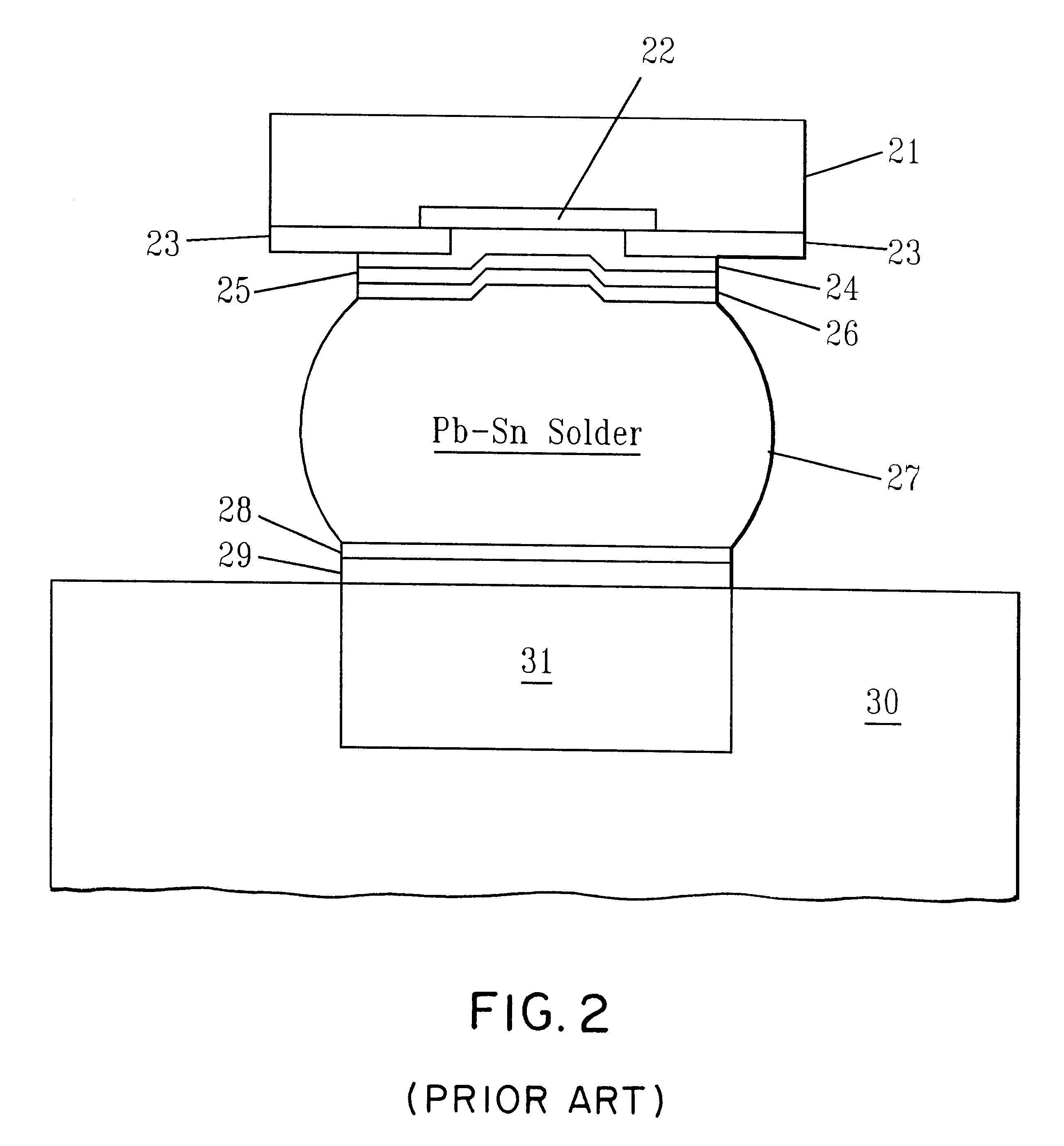

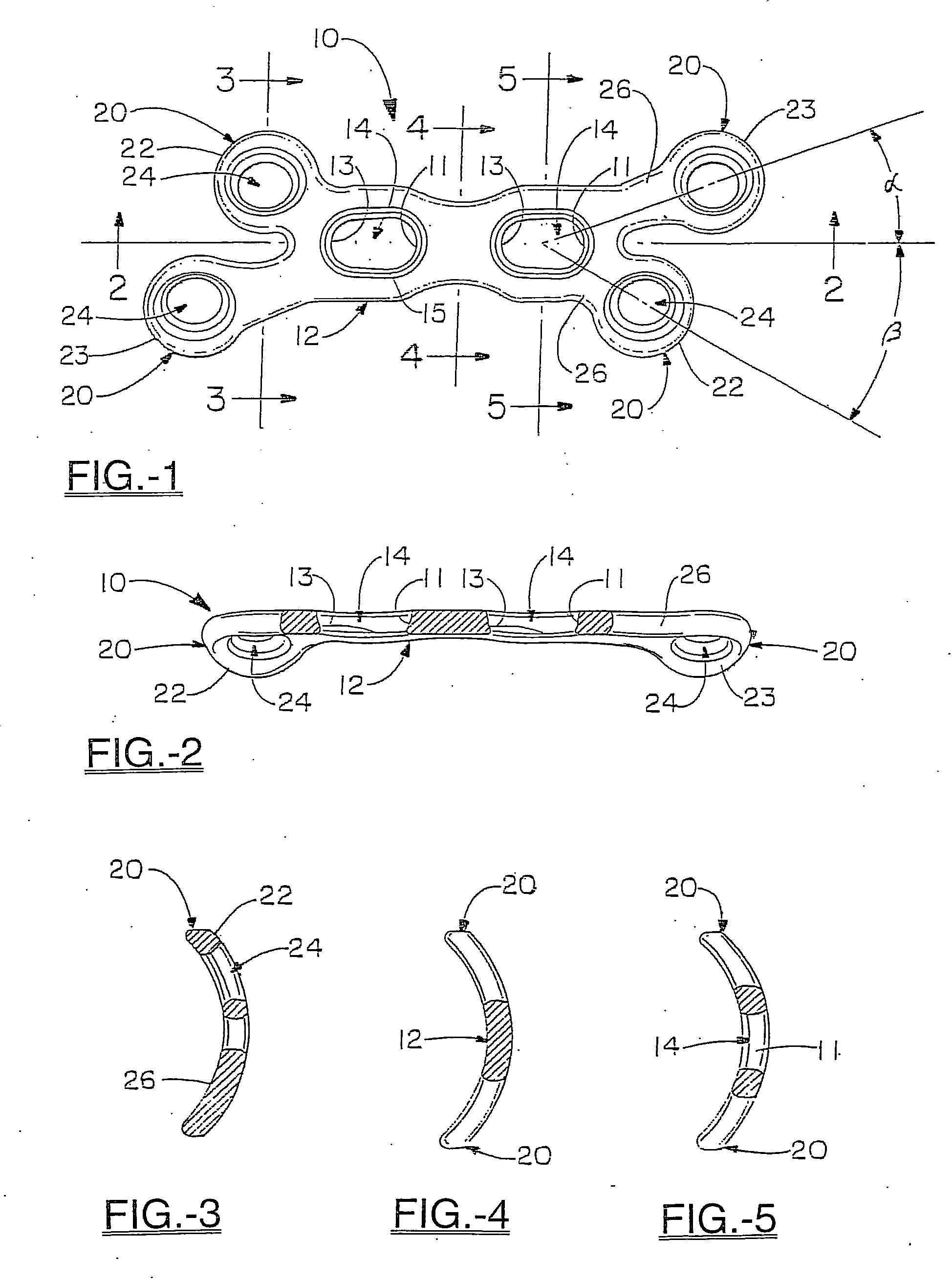

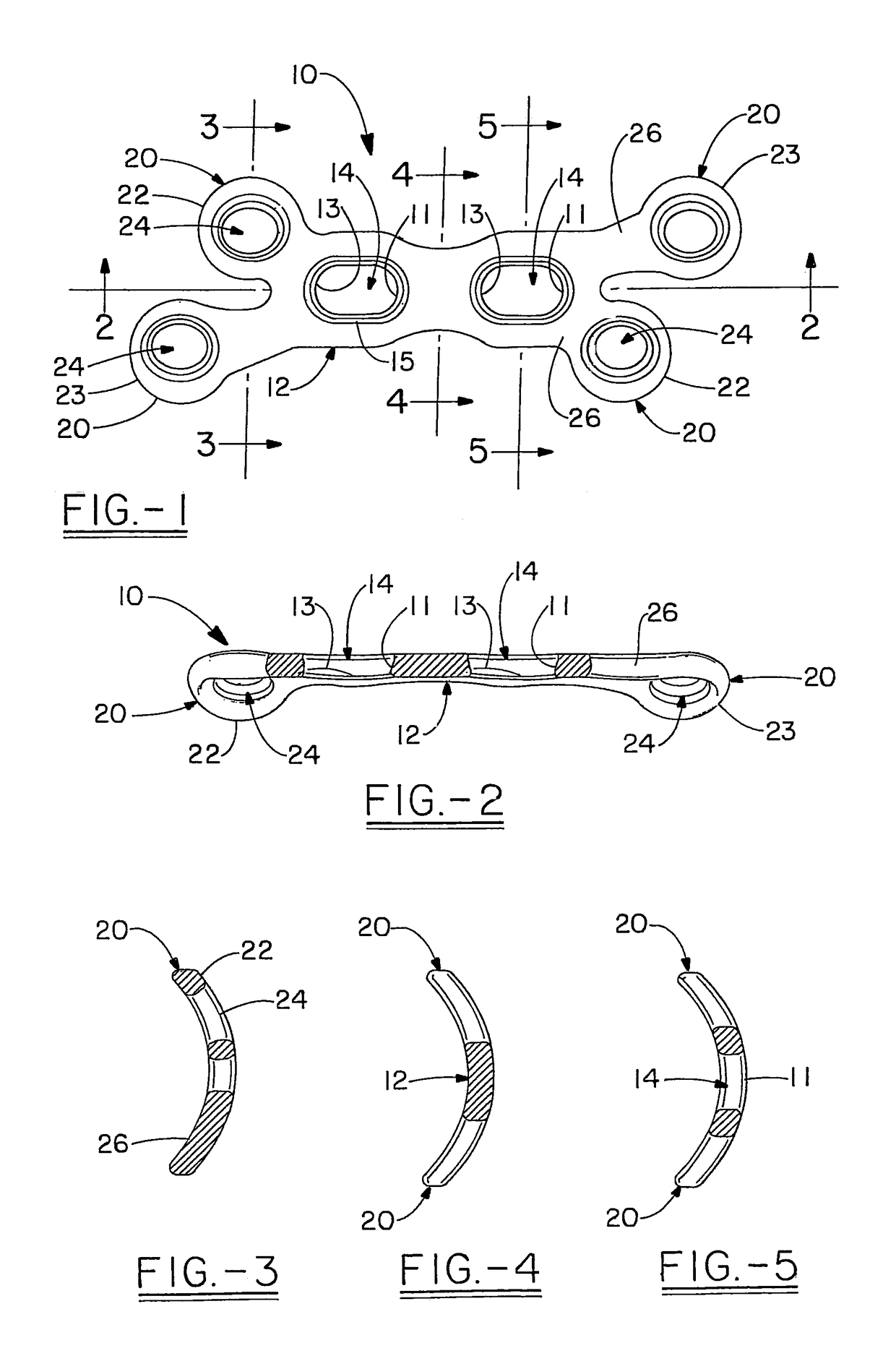

Partially captured oriented interconnections for BGA packages and a method of forming the interconnections

InactiveUS6913948B2Improve fatigue lifeEnhanced pad adhesionPrinted circuit assemblingSemiconductor/solid-state device detailsIncreased fatigueEngineering

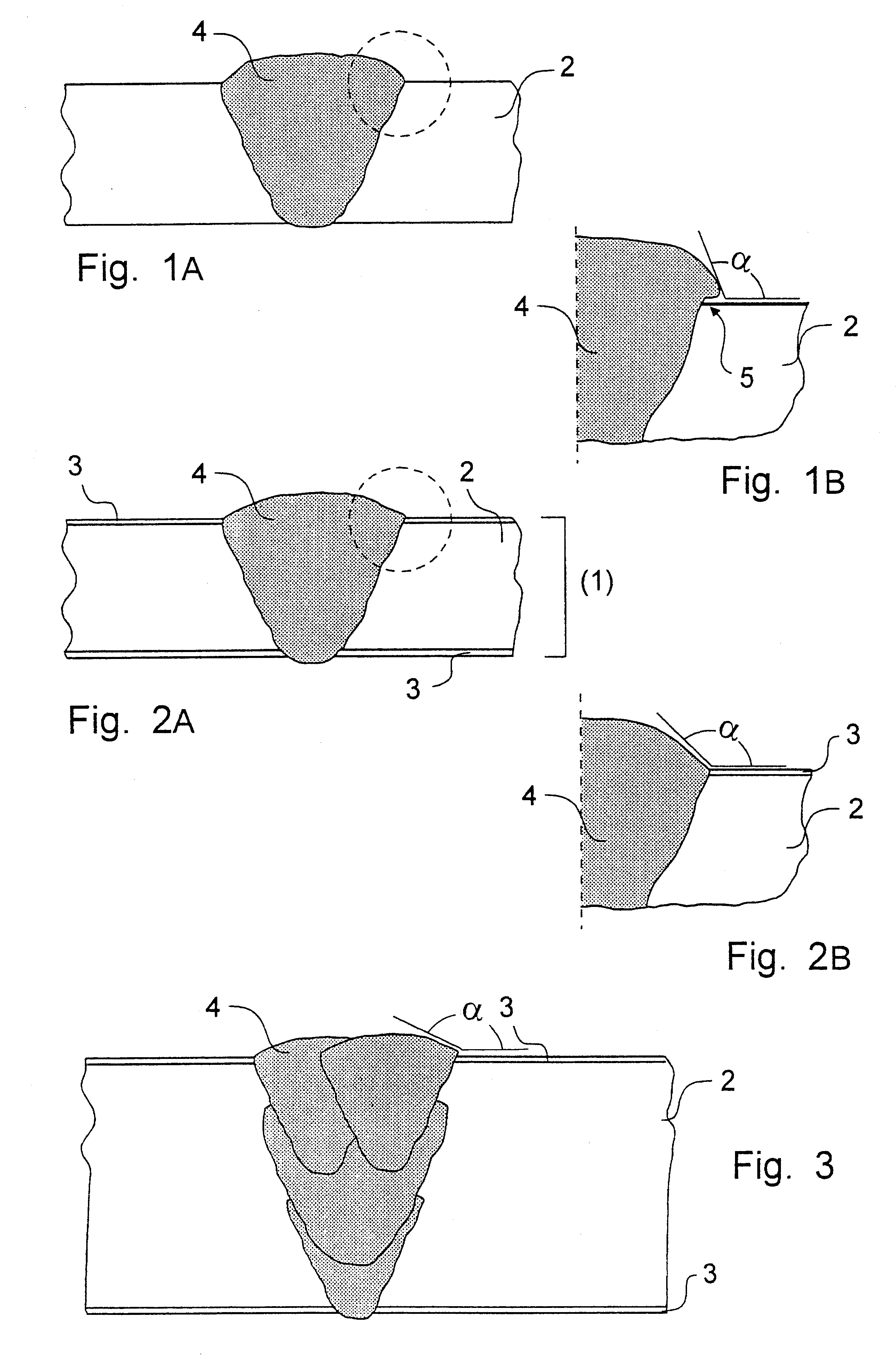

A Ball Grid Array package having an increased fatigue life and improved conductive pad adhesion strength, as well as providing sufficient wiring space within the package, is disclosed. In particular, solder joints having a combination of mask-defined and pad-defined solder joint profiles are formed using a mask having non-circular elongated openings. The non-circular elongated openings of the mask have a major axis and a minor axis, such that the dimension of the openings along the major axis is greater than the diameter of the conductive pads, and the dimension of the openings along the minor axis is less than the diameter of the conductive pads. In addition, the major axis of the openings within the mask are selectively oriented in the direction of highest stress for each solder joint within the package, while providing ample wiring space therein.

Owner:IBM CORP

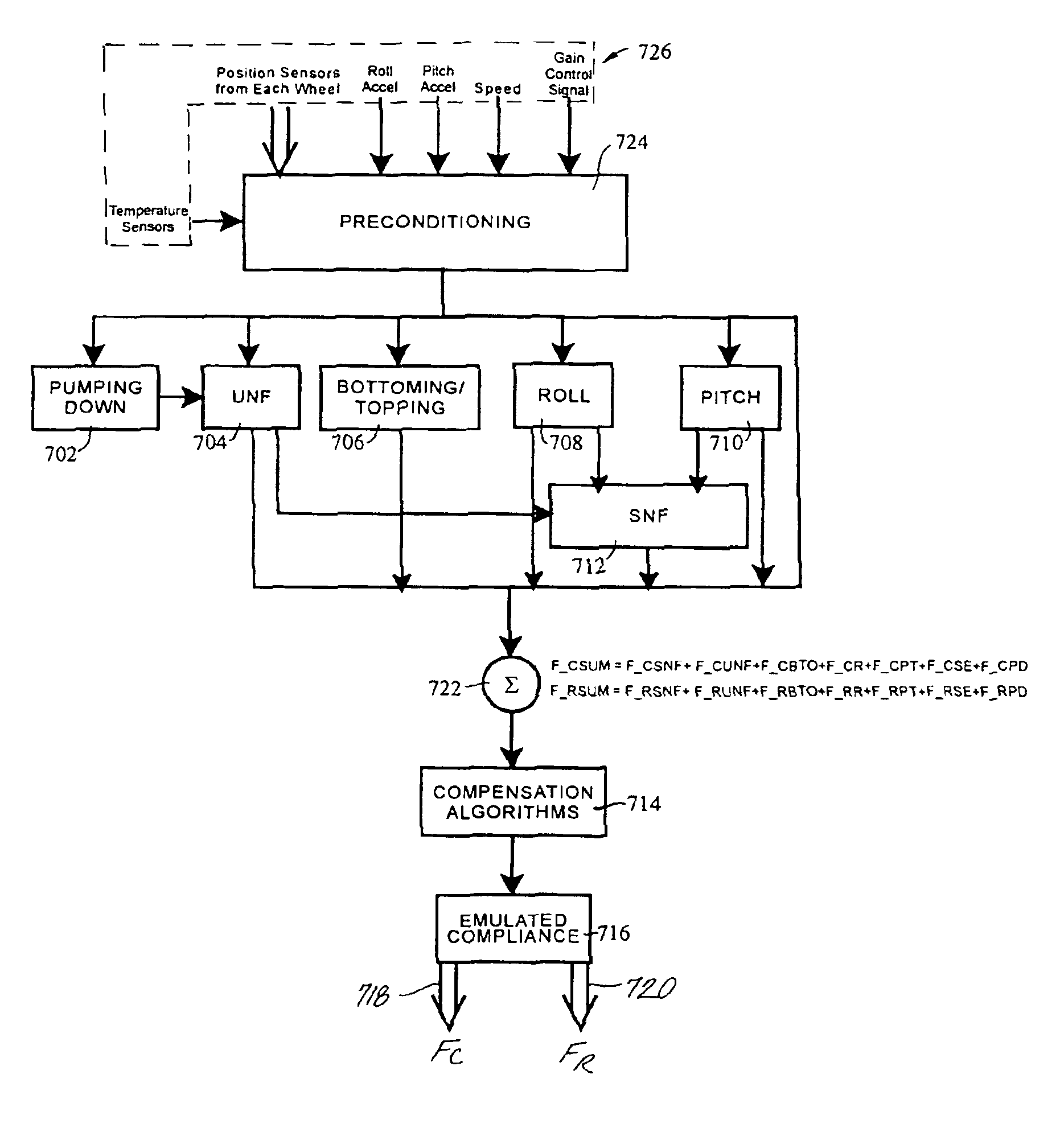

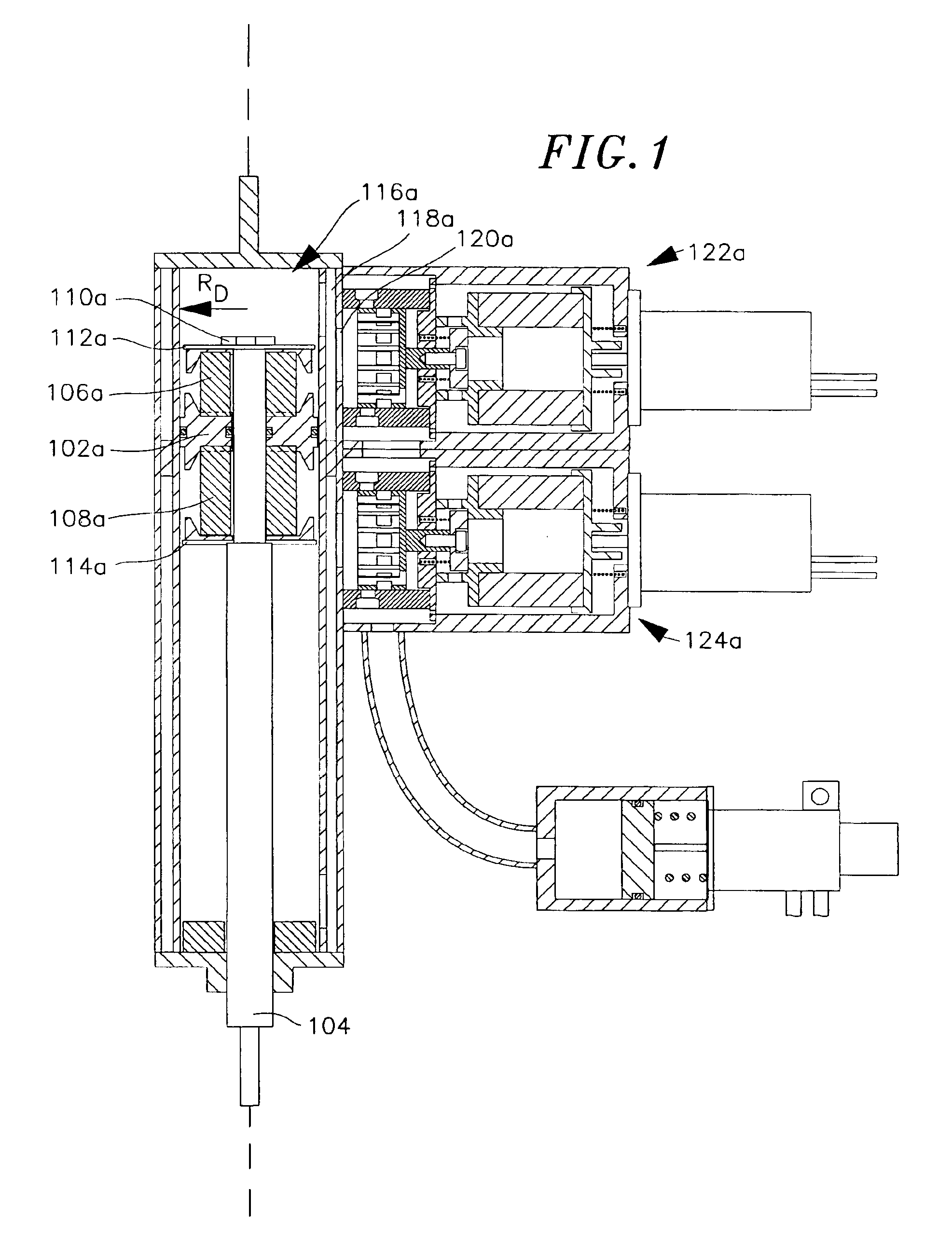

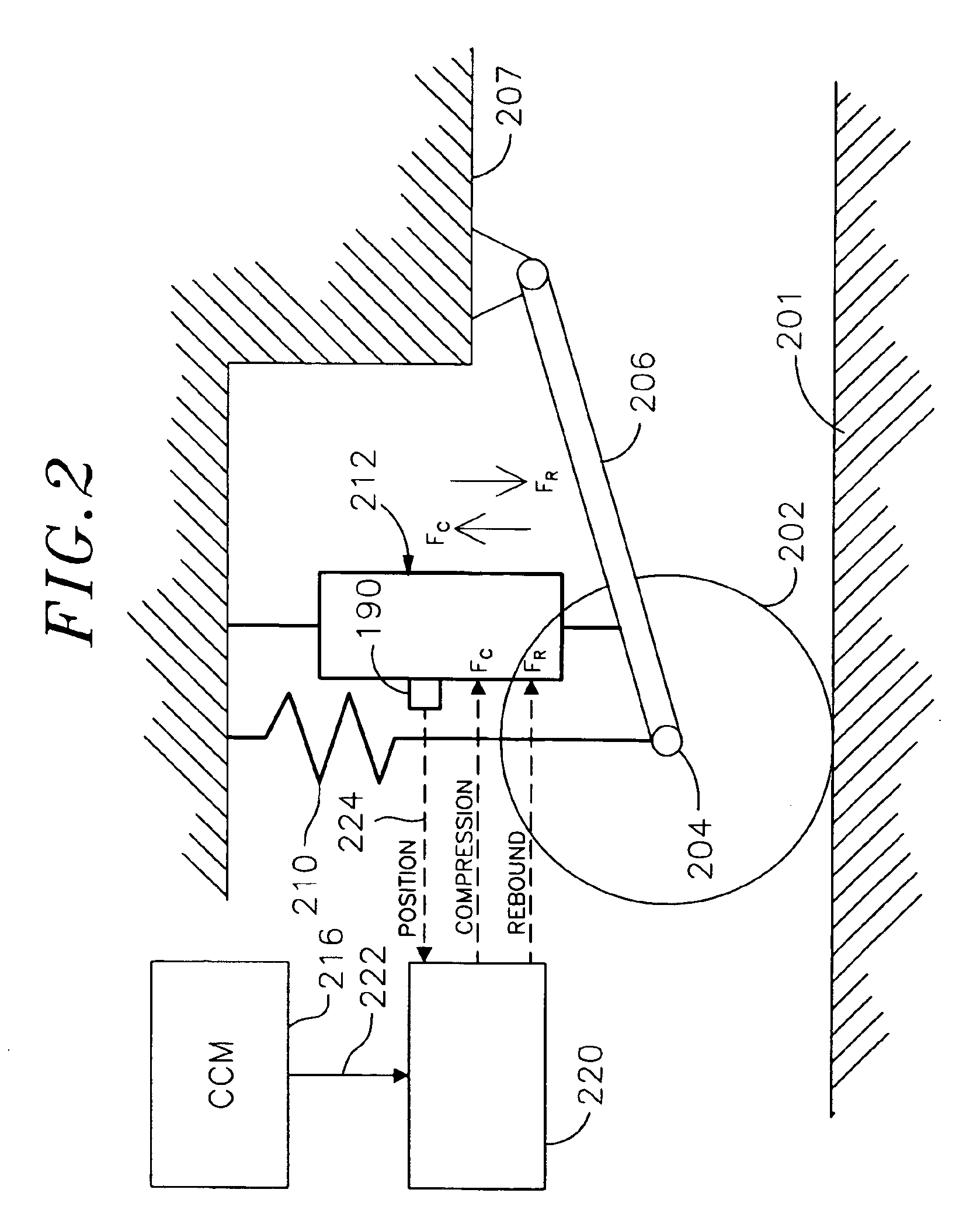

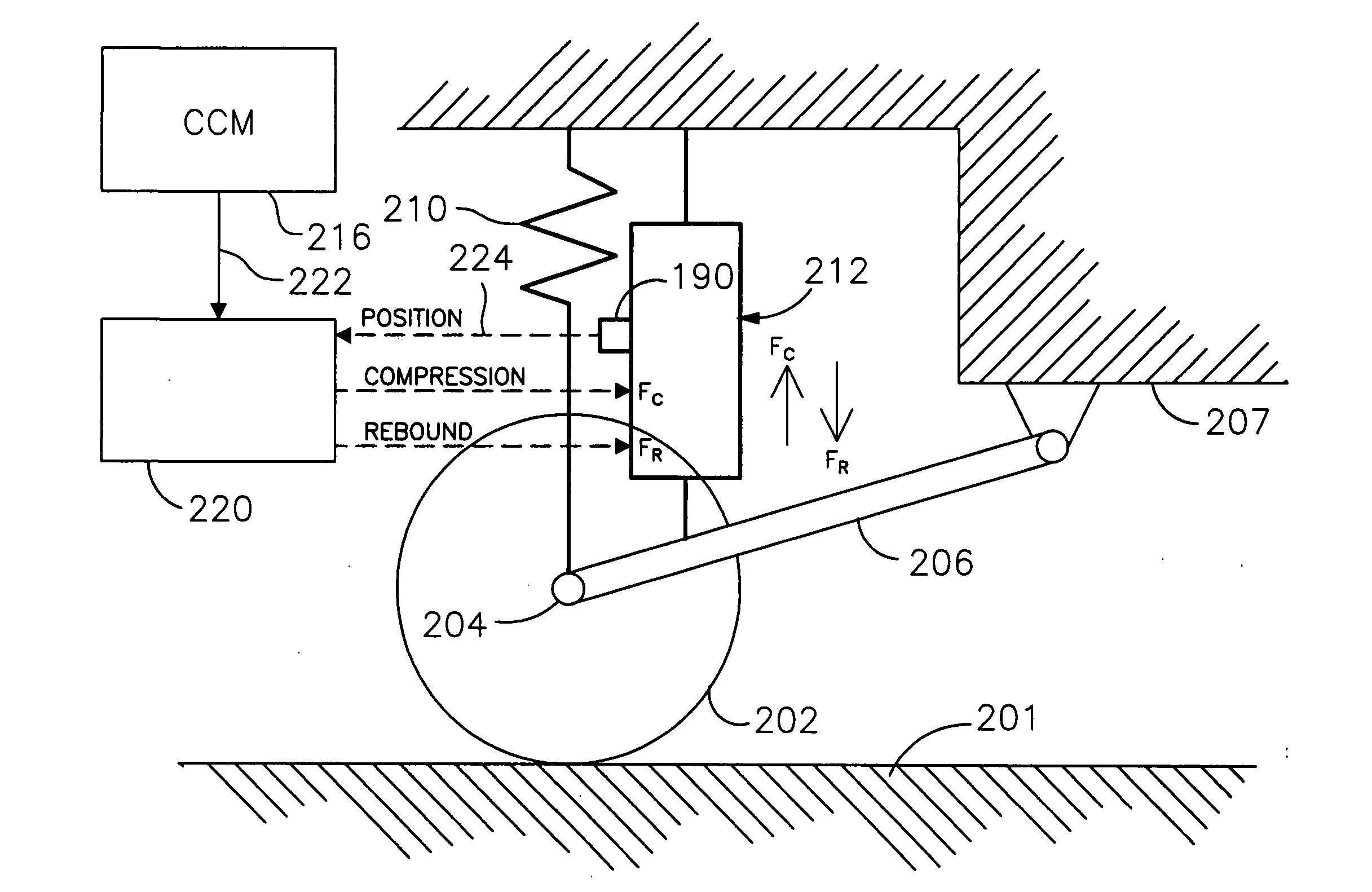

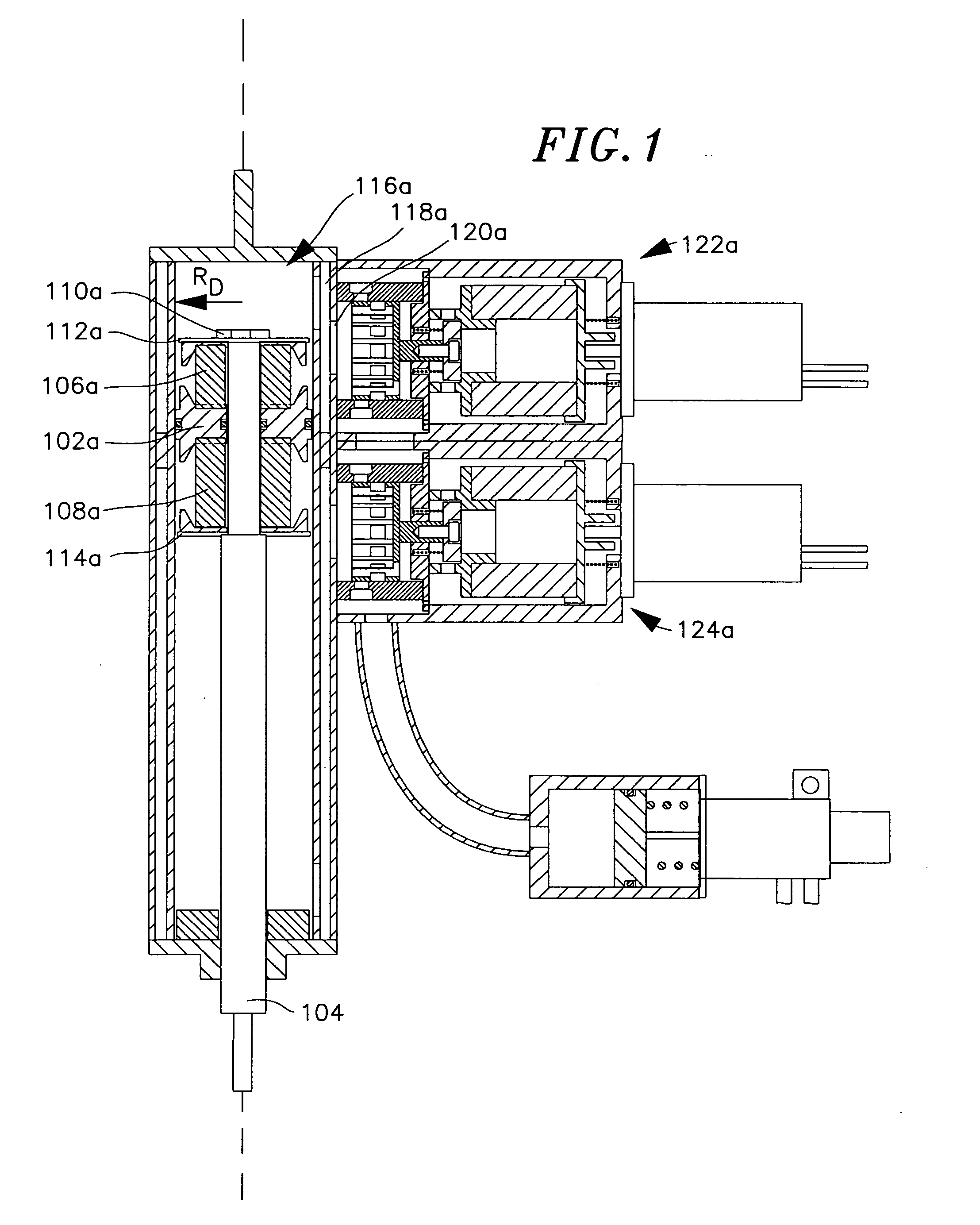

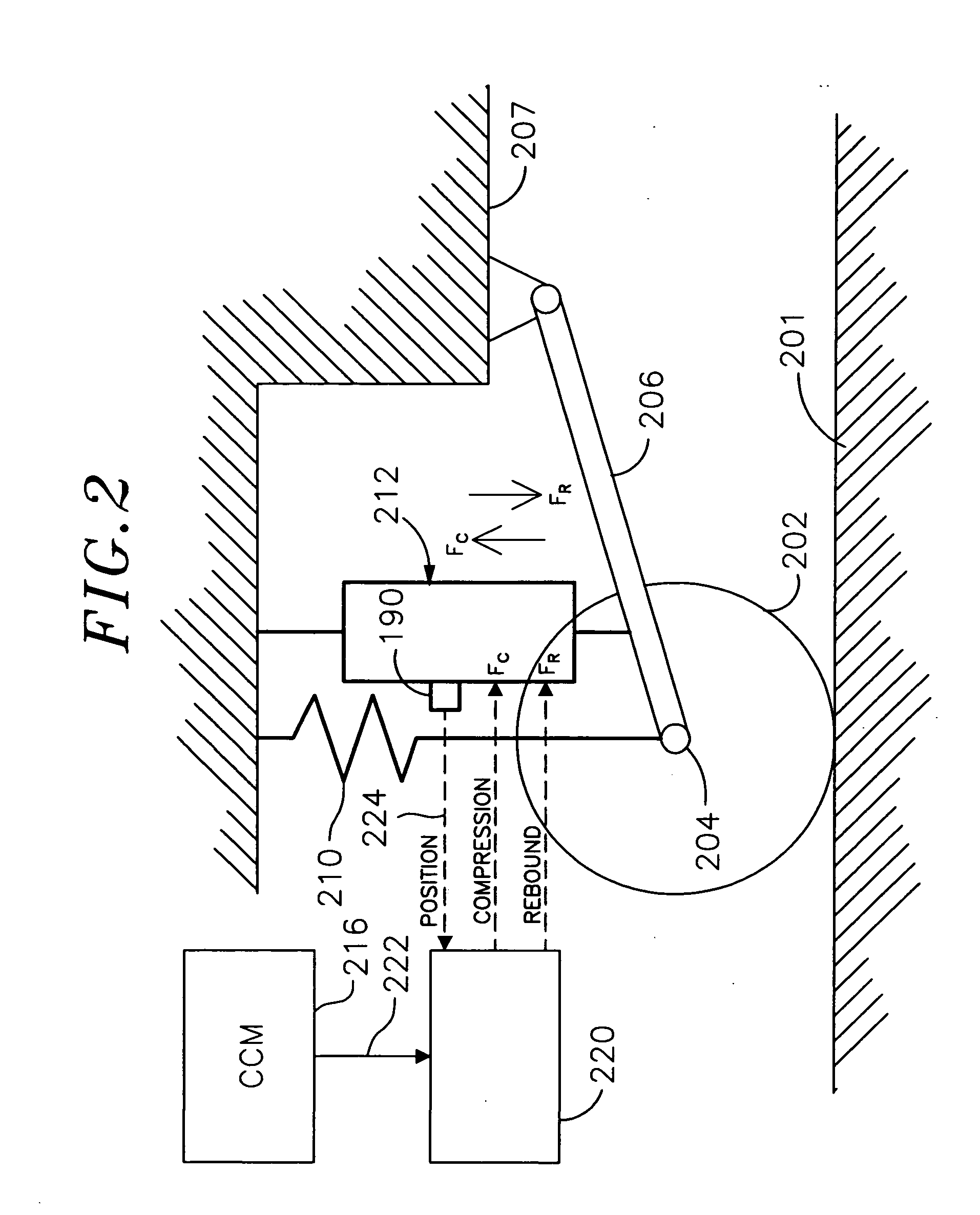

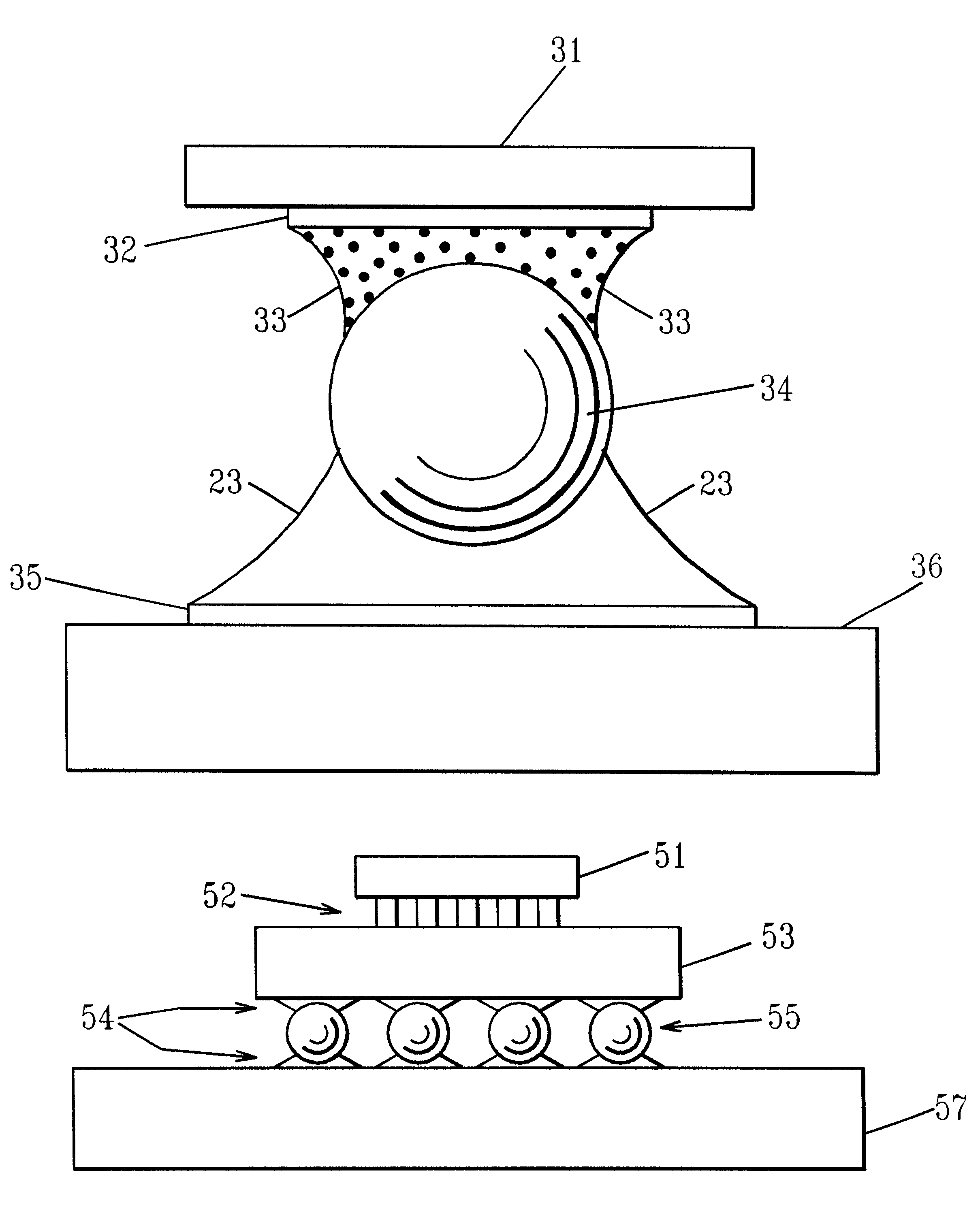

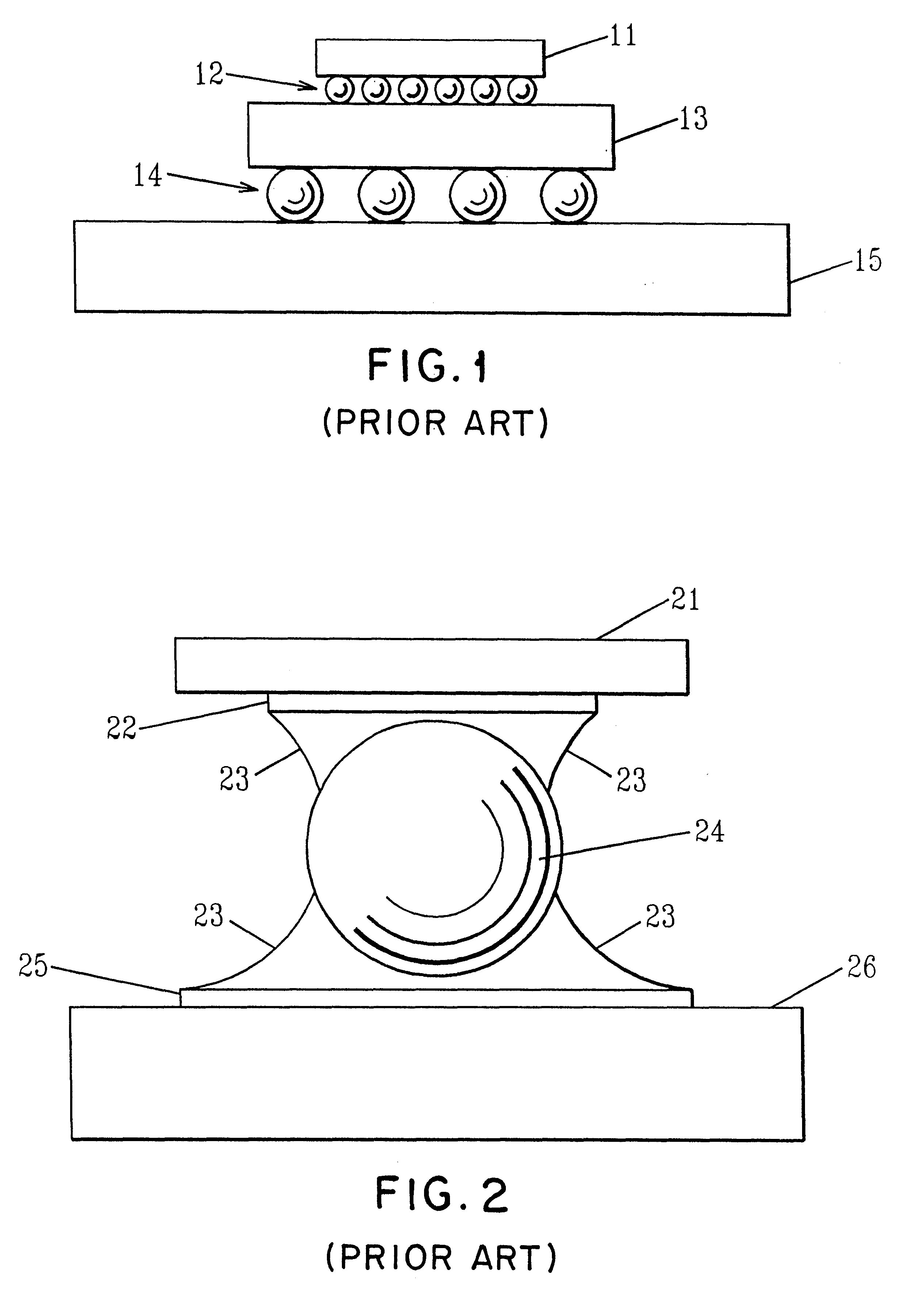

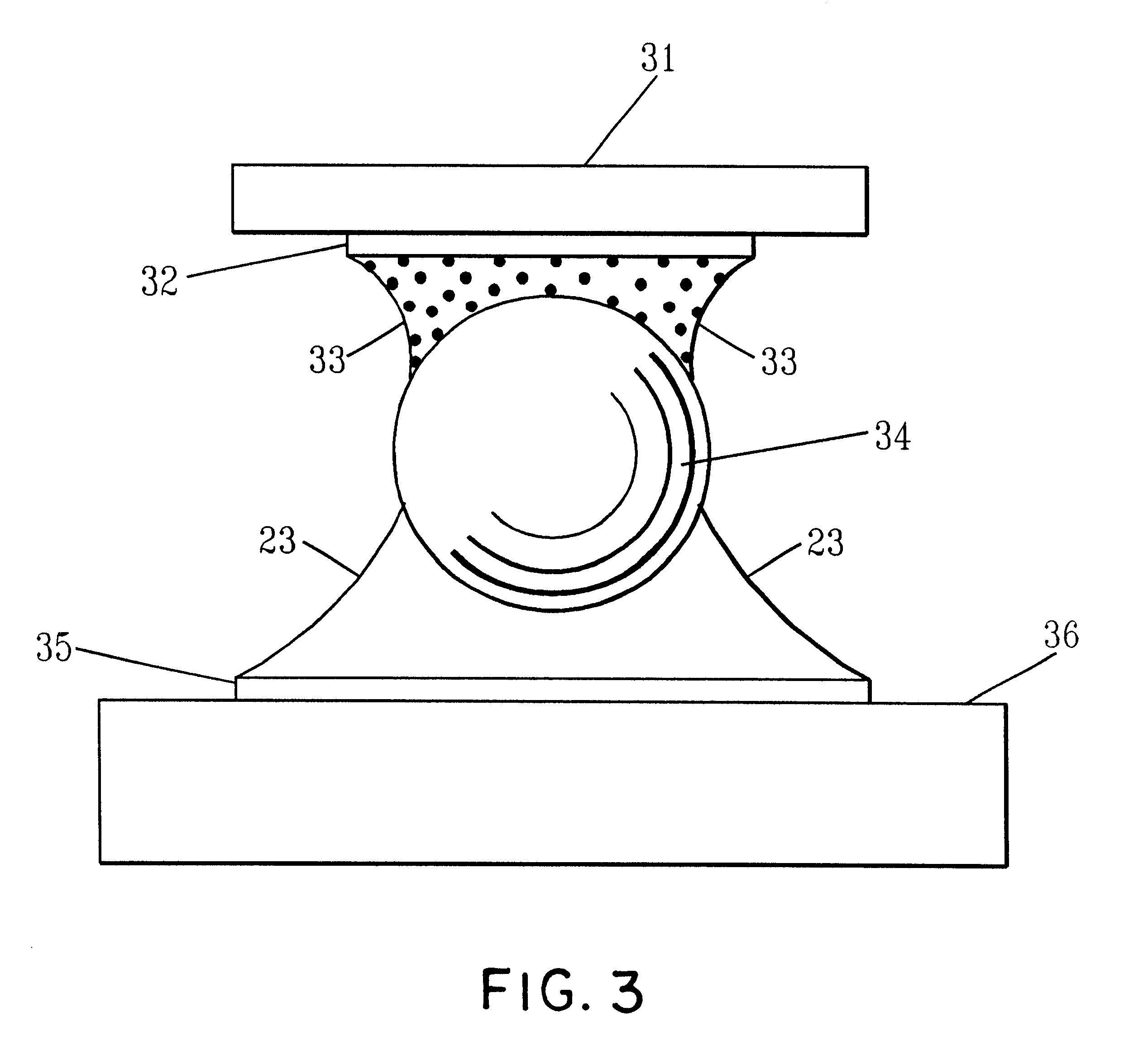

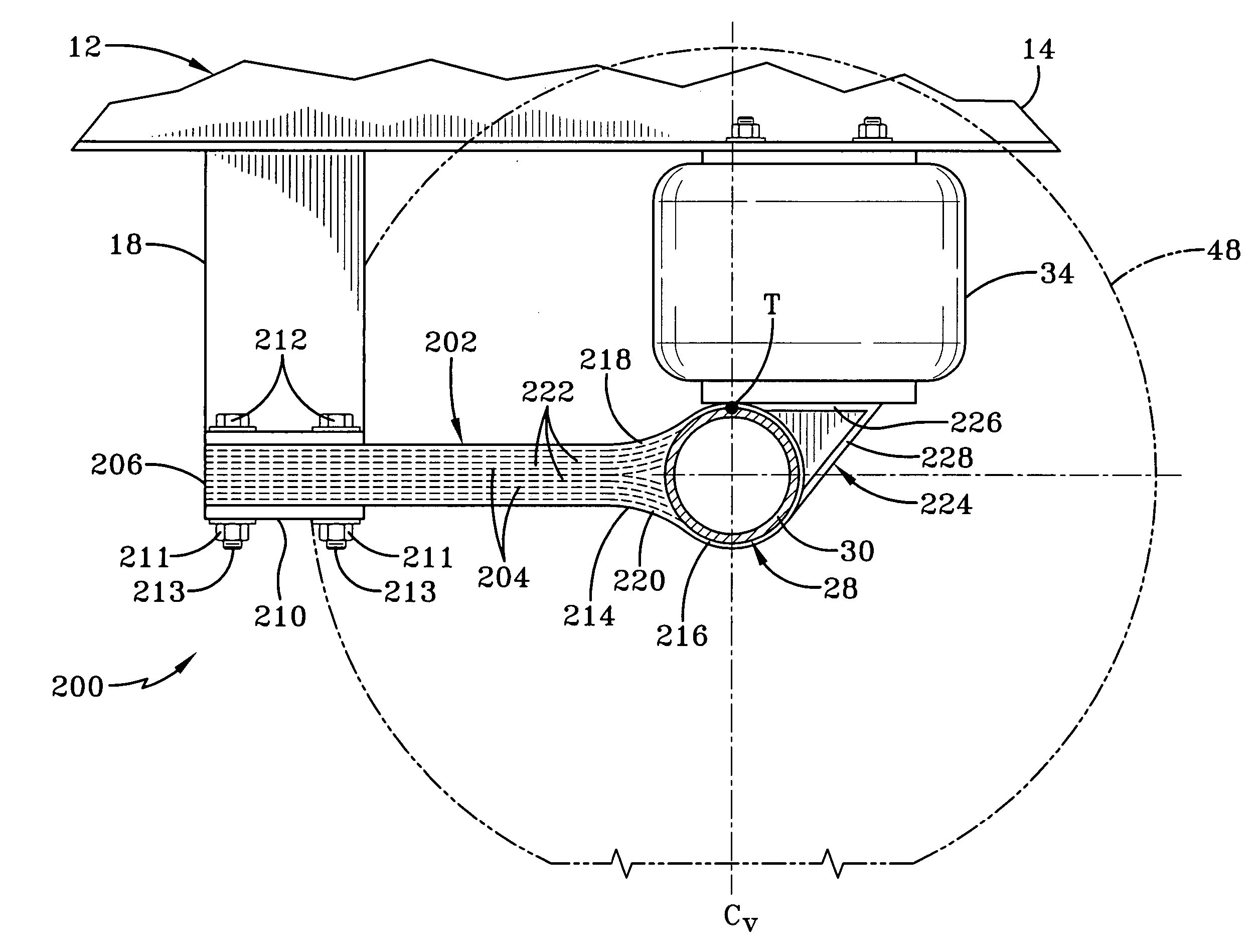

Enhanced computer optimized adaptive suspension system and method

InactiveUS7076351B2Minimizing body motionIncrease fluid pressureAuxillary drivesFunctional valve typesComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:WICKA JOHN D +1

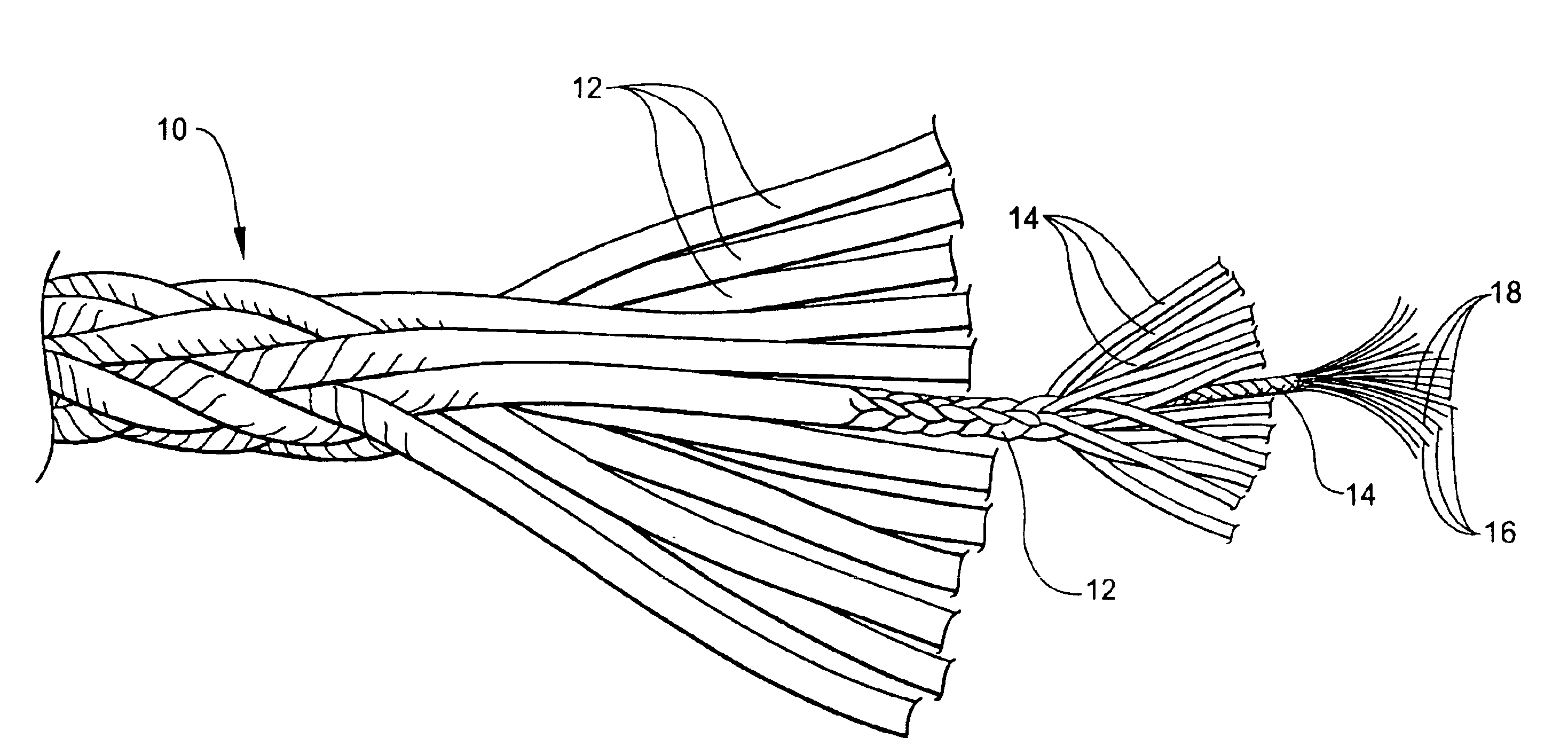

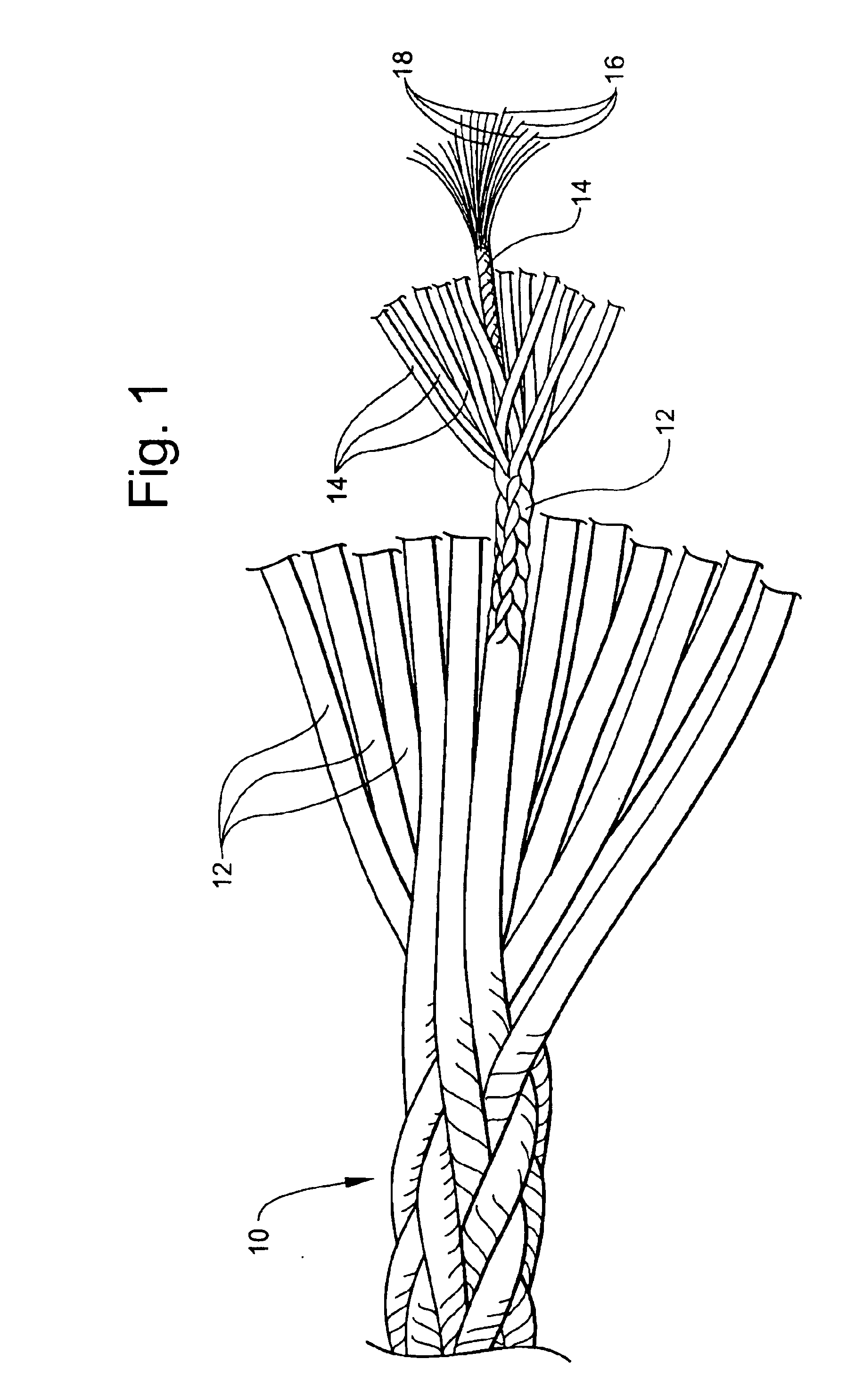

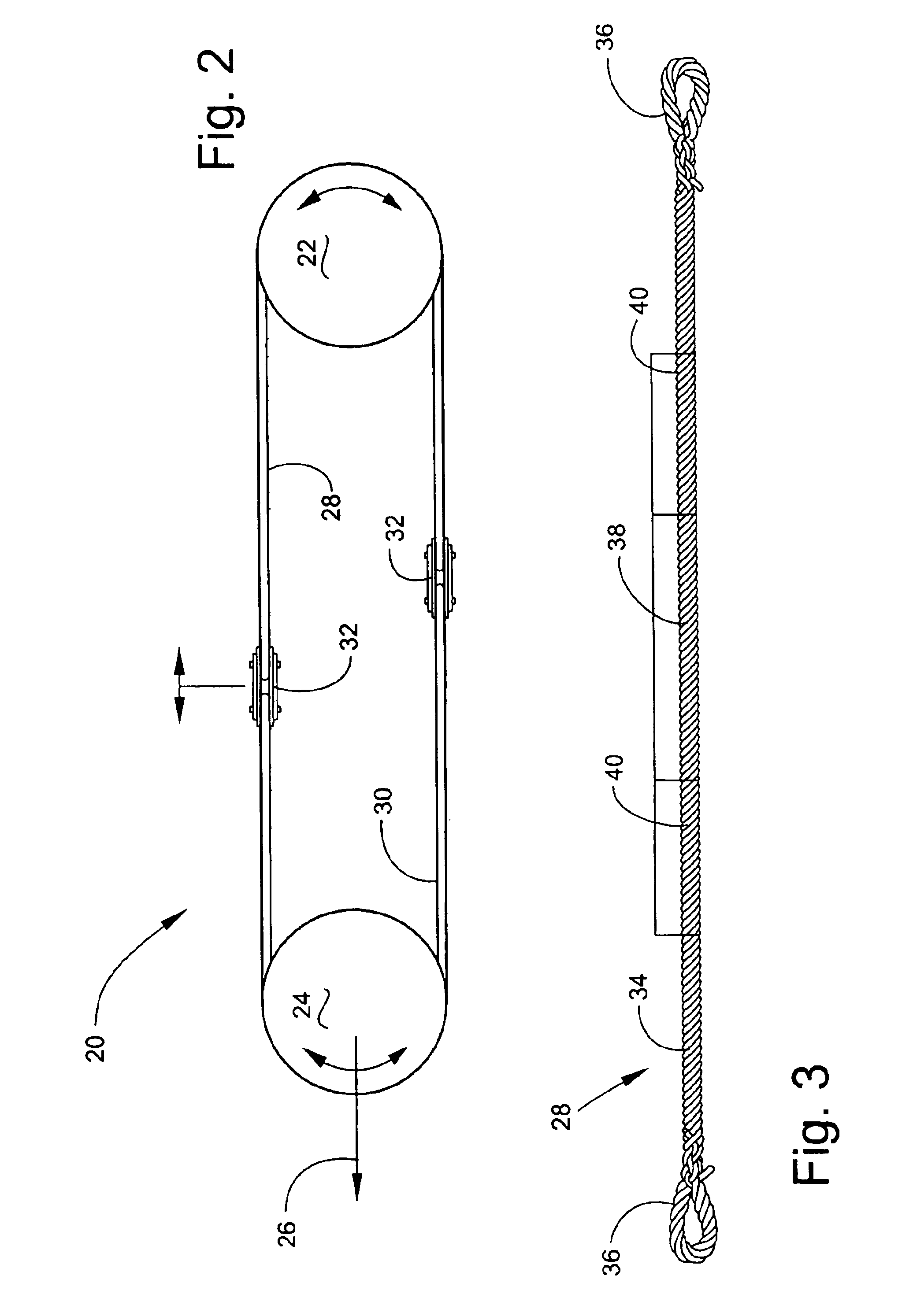

Rope for heavy lifting applications

A large diameter rope having improved fatigue life on a sheave, pulley, or drum is disclosed. This rope includes a blend of HMPE filaments and liquid crystal polymer filaments selected from the group of lyotropic polymer filaments and thermotropic polymer filaments. The rope may be constructed as a braided rope, a wire-lay rope, or a parallel core rope.

Owner:CORTLAND IND LLC +1

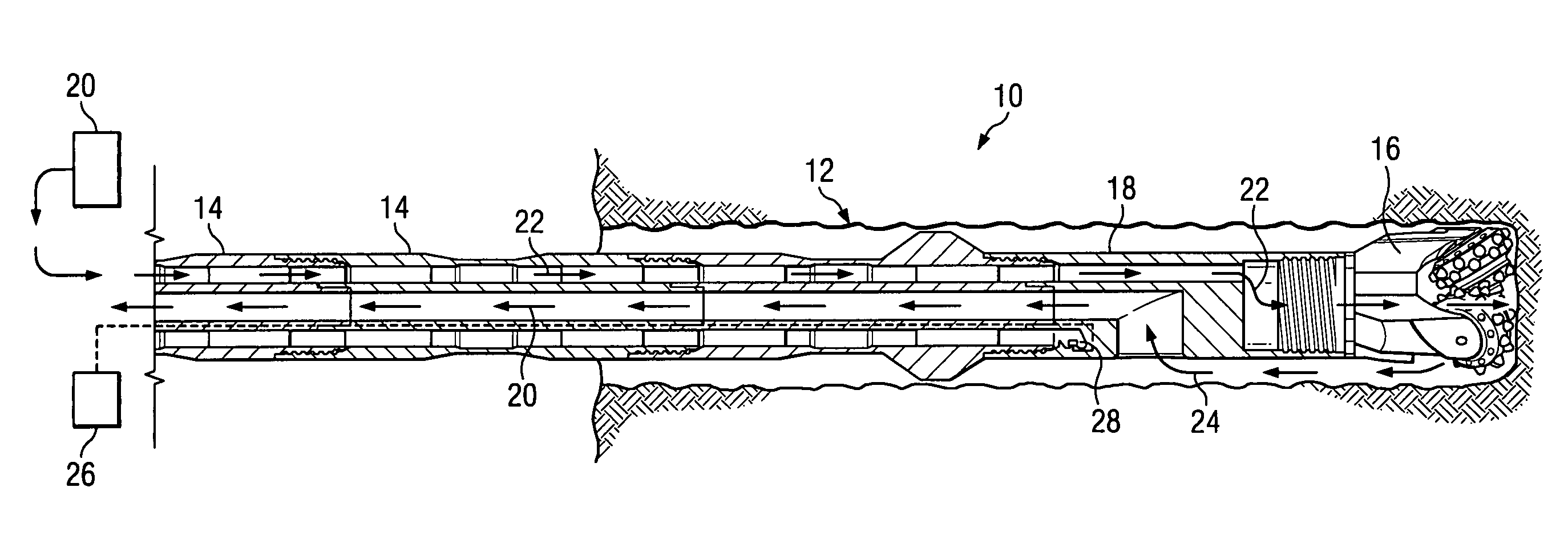

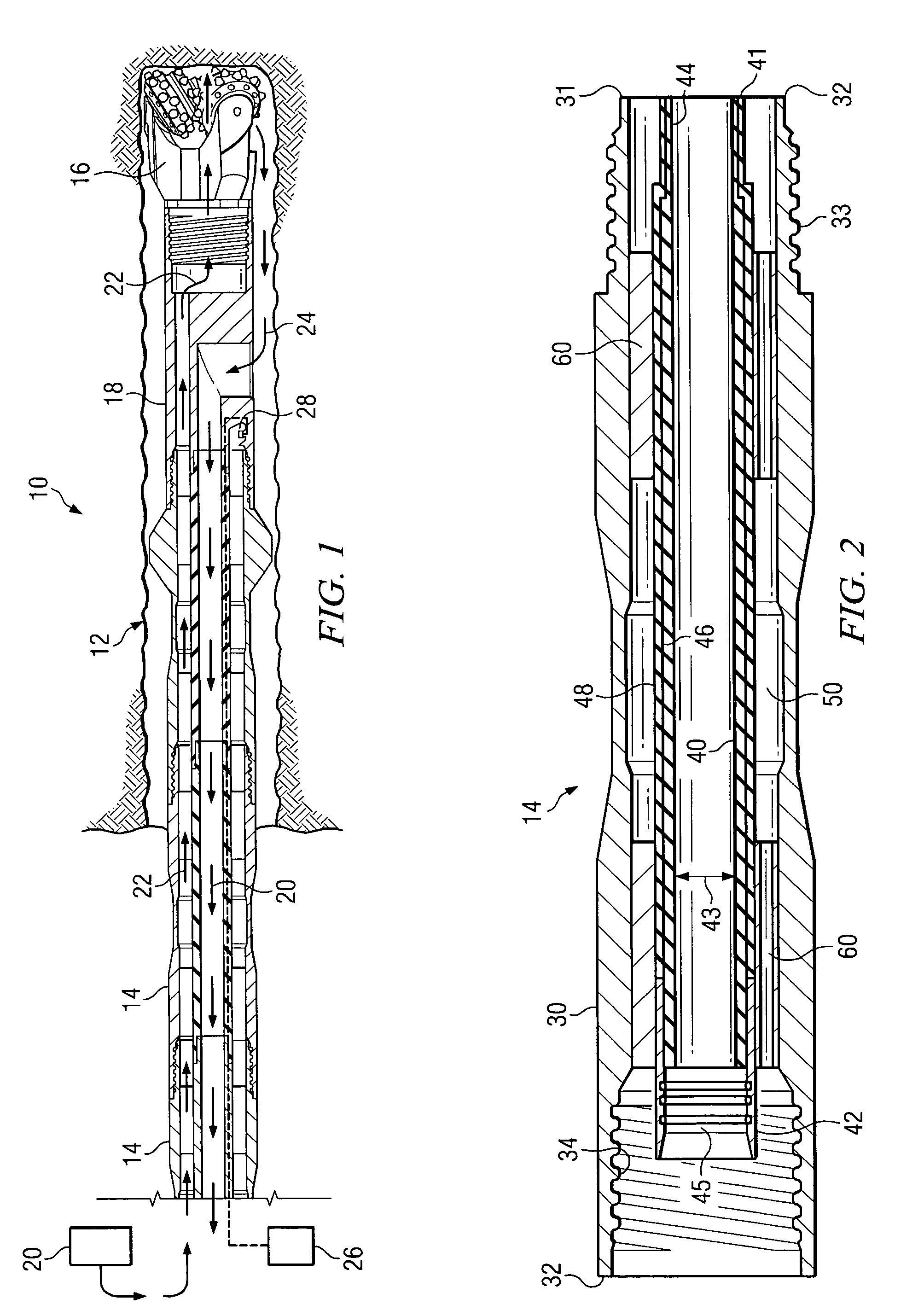

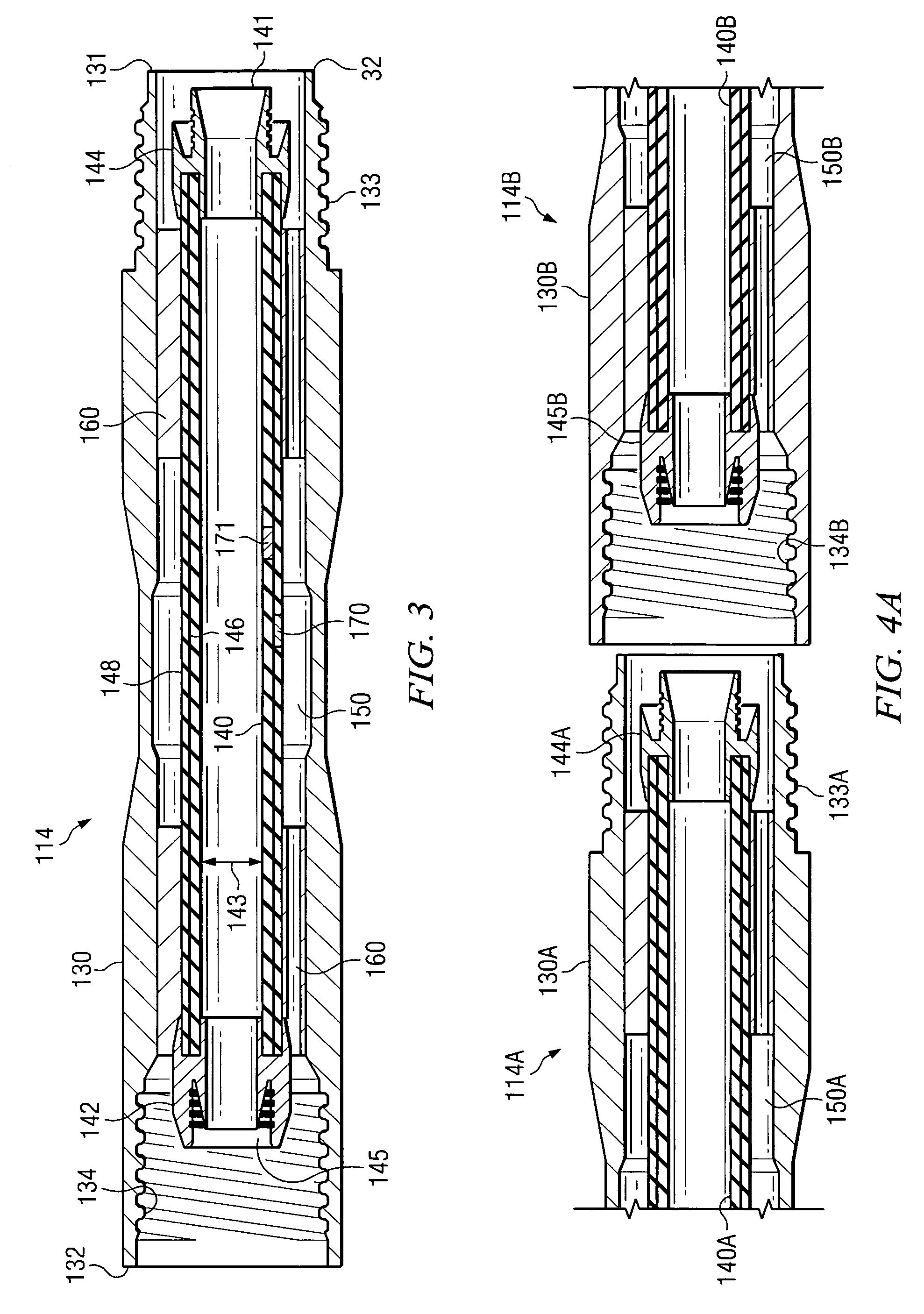

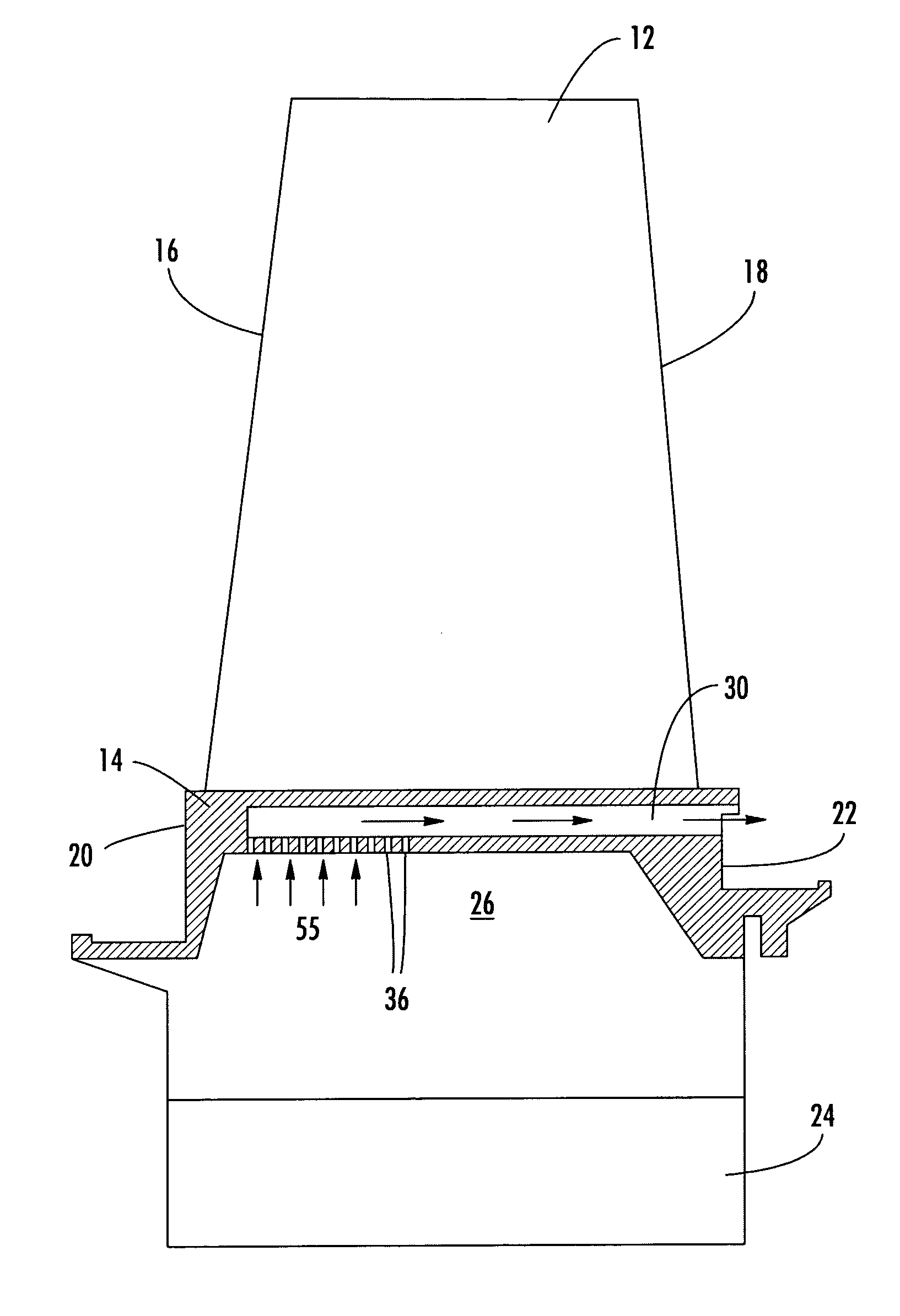

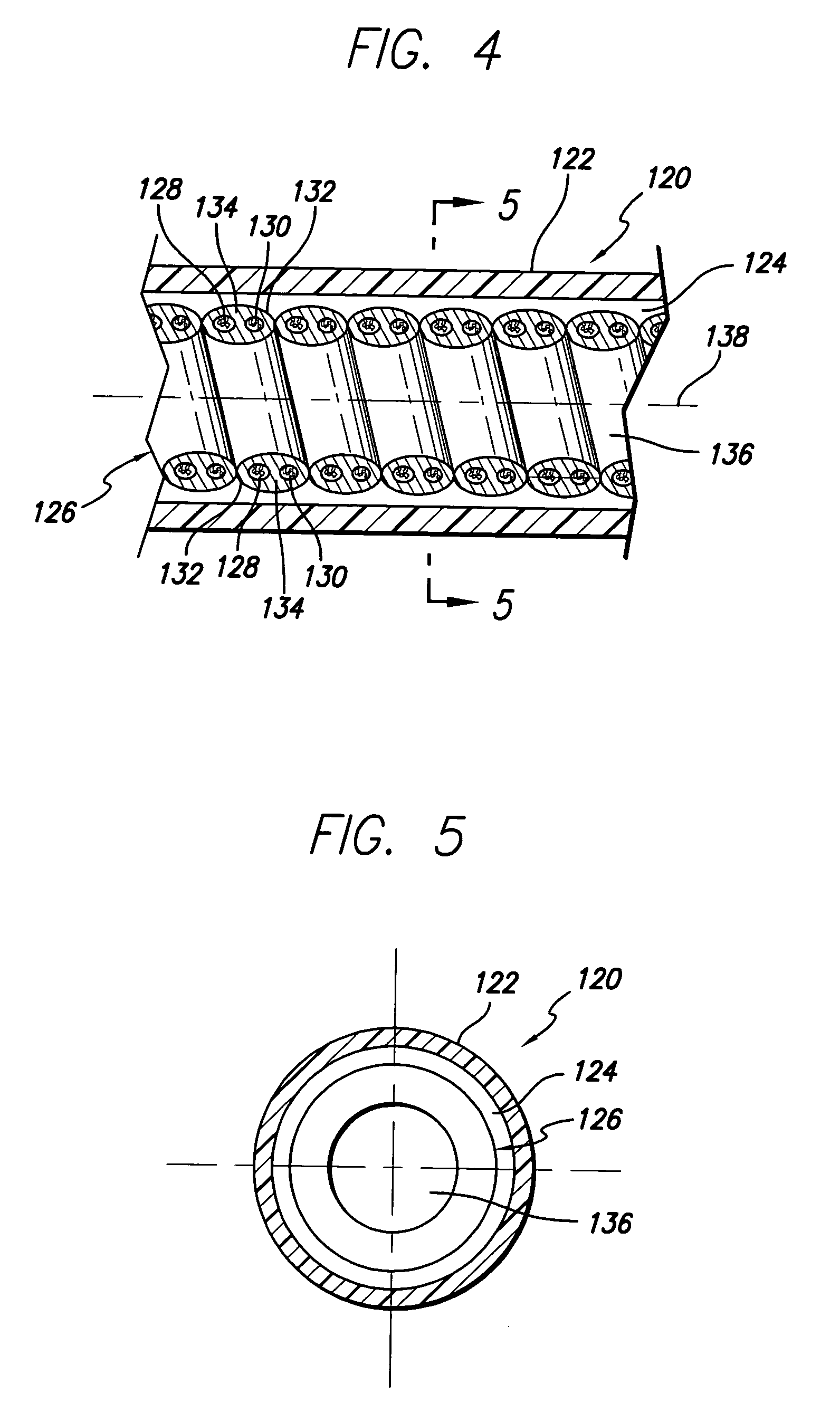

Dual wall drill string assembly

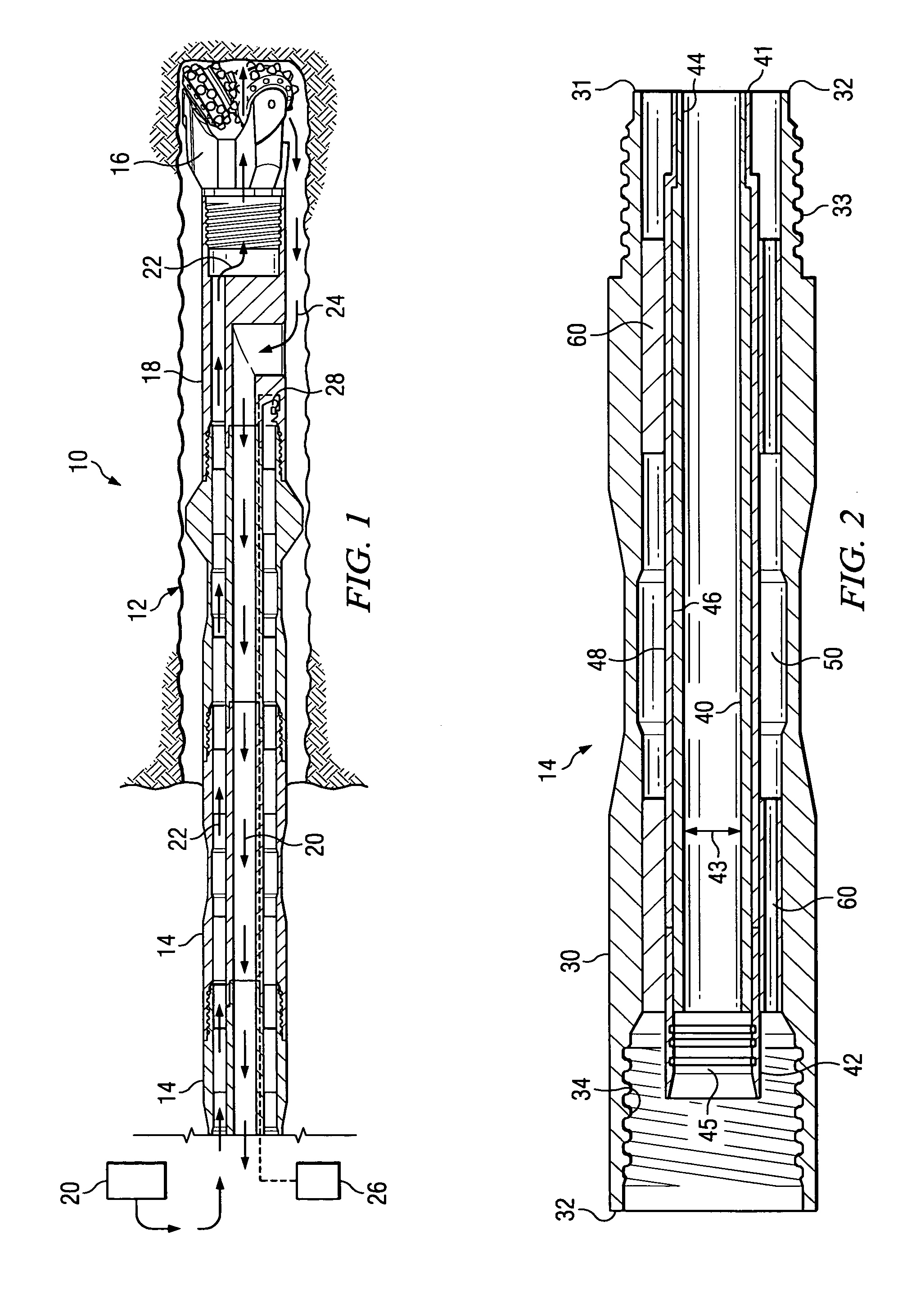

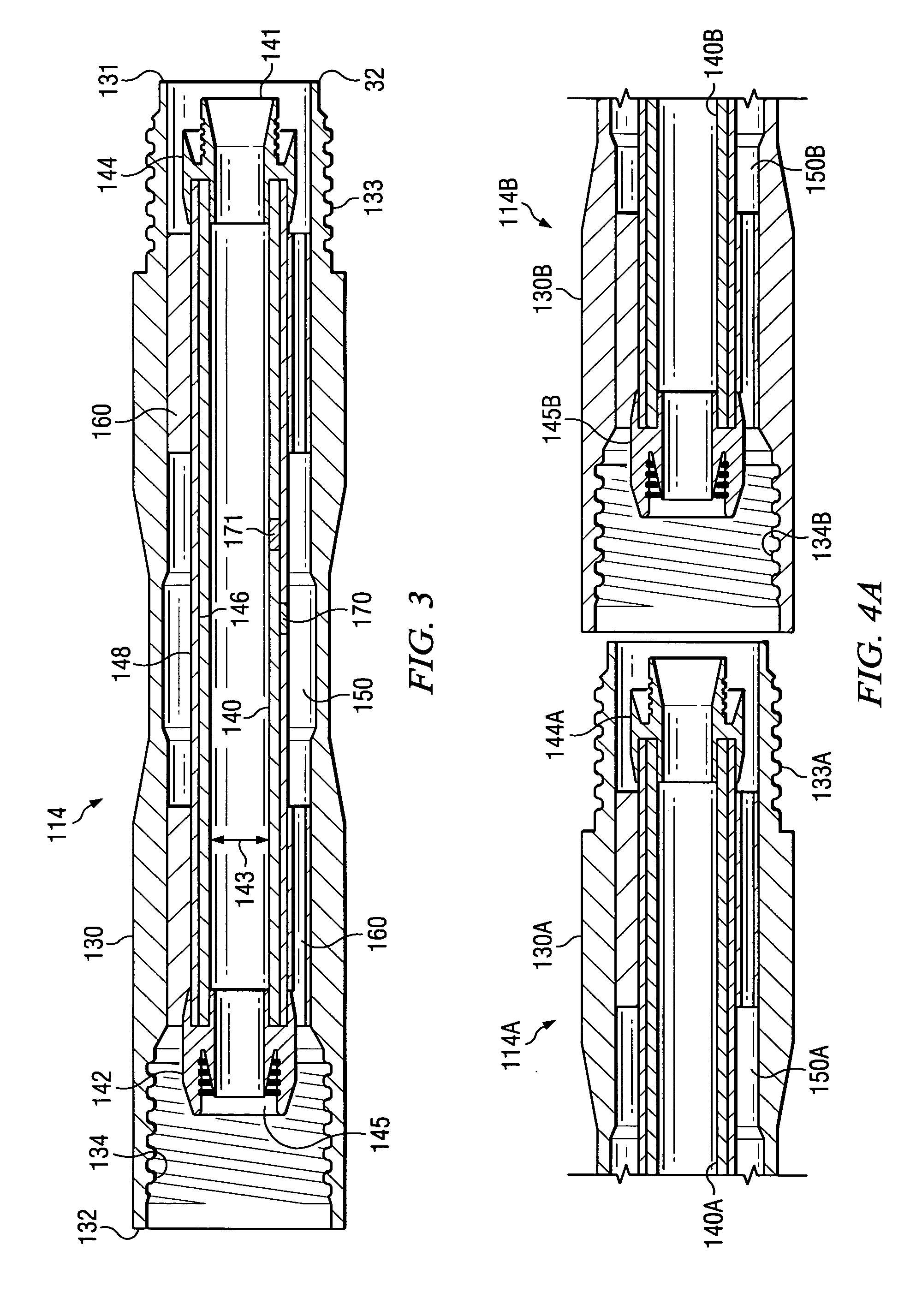

ActiveUS20050103527A1Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingEngineering

A coil tubing or jointed dual wall drill string assembly for subsurface drilling. The drill string assembly includes a metallic outer tube having an outer tube first end and an outer tube second end opposite the outer tube first end. The assembly also includes a flexible, substantially non-metallic inner tube that is substantially enclosed within and generally coaxially aligned with the outer tube. The flexible, substantially non-metallic inner tube has an inner tube first end, an inner tube second end opposite the inner tube first end, and an inner tube inner diameter. The inner tube and the outer tube define an annular channel therebetween. The drill string assembly also includes a means for conveying fluid through the annular channel toward the inner tube first end. The annular channel is adapted to convey drilling fluid under pressure toward the inner tube first end and the inner tube is adapted to convey cuttings toward the inner tube second end.

Owner:AMERICAN AUGERS +1

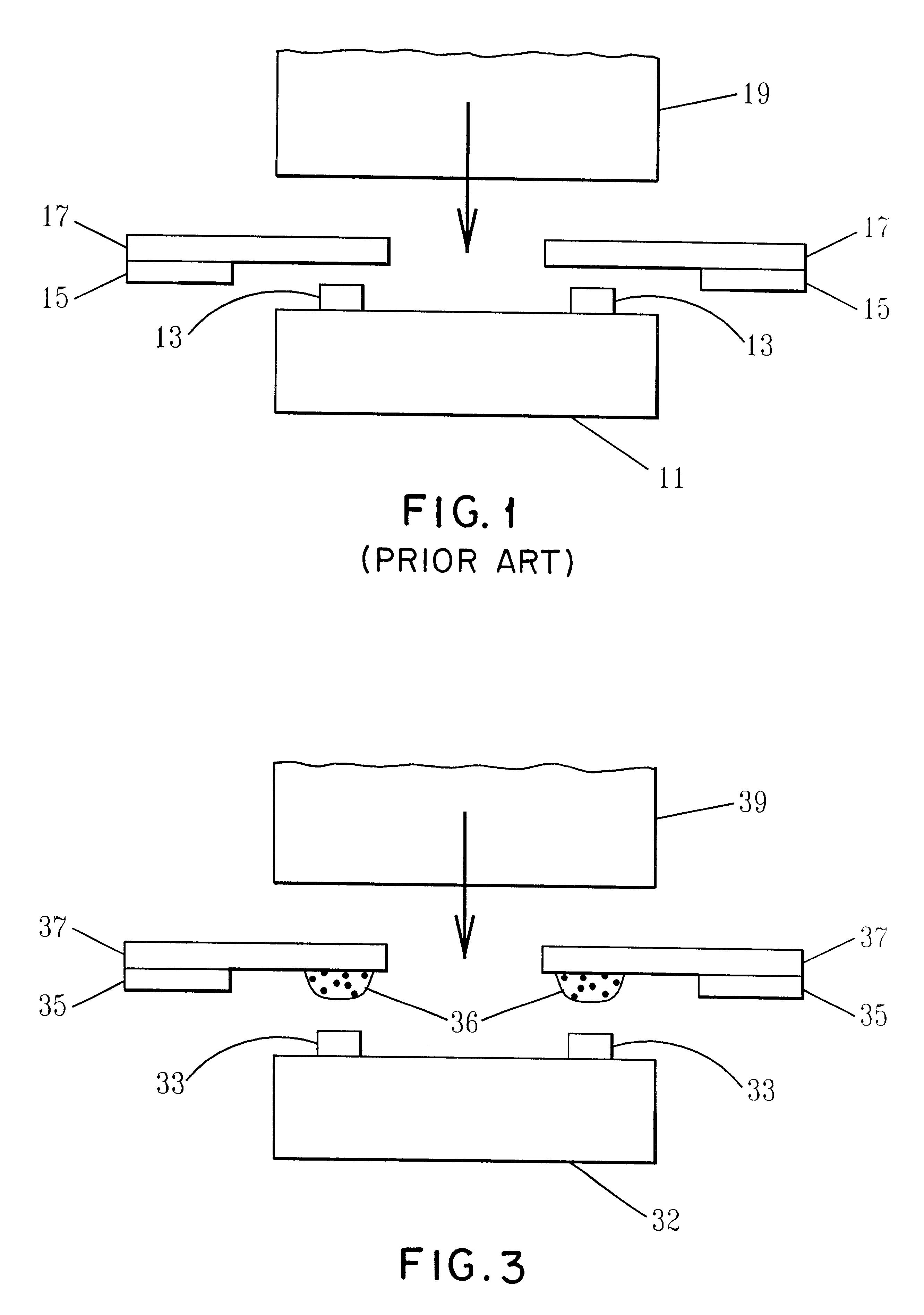

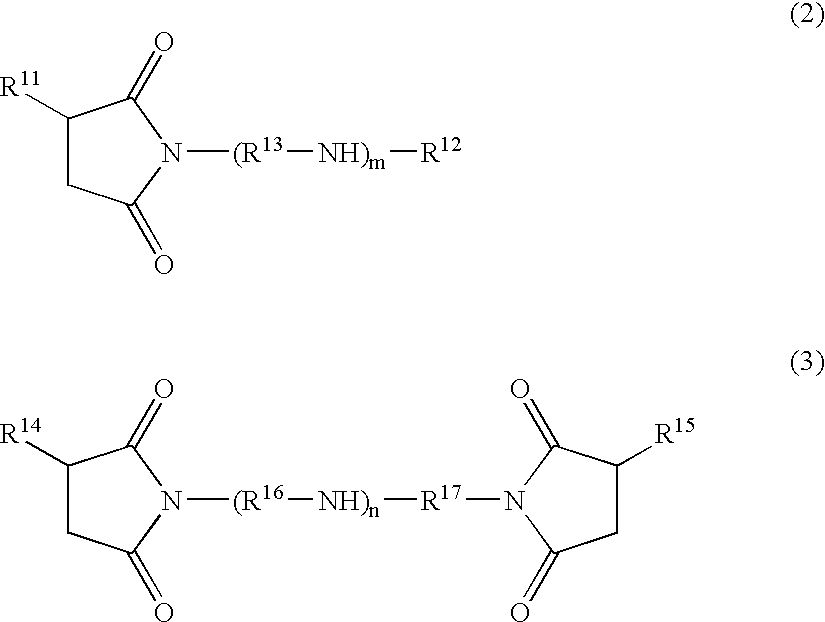

Structure employing electrically conductive adhesives

InactiveUS6337522B1Stable TAB joint structureImprove fatigue lifePrinted circuit assemblingLayered productsInterfacial reactionActive-matrix liquid-crystal display

A new interconnection scheme is disclosed for a tape automated bonding (TAB) package, a flip chip package and an active matrix liquid crystal display (AMLCD) panel, where an electrically conducting adhesive is used to form an electrical interconnection between an active electronic device and its components. The electrically conducting adhesive can be a mixture comprising a polymer resin, a no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating which provides a metallurgical bond between the conducting particles as well as to the substrates. The advantages of using the electrically conducting adhesives include reduction in bonding pressure and / or bonding temperature, control of interfacial reactions, promotion of stable metallurgical bonds, enhanced reliability of the joints, and others.

Owner:AU OPTRONICS CORP

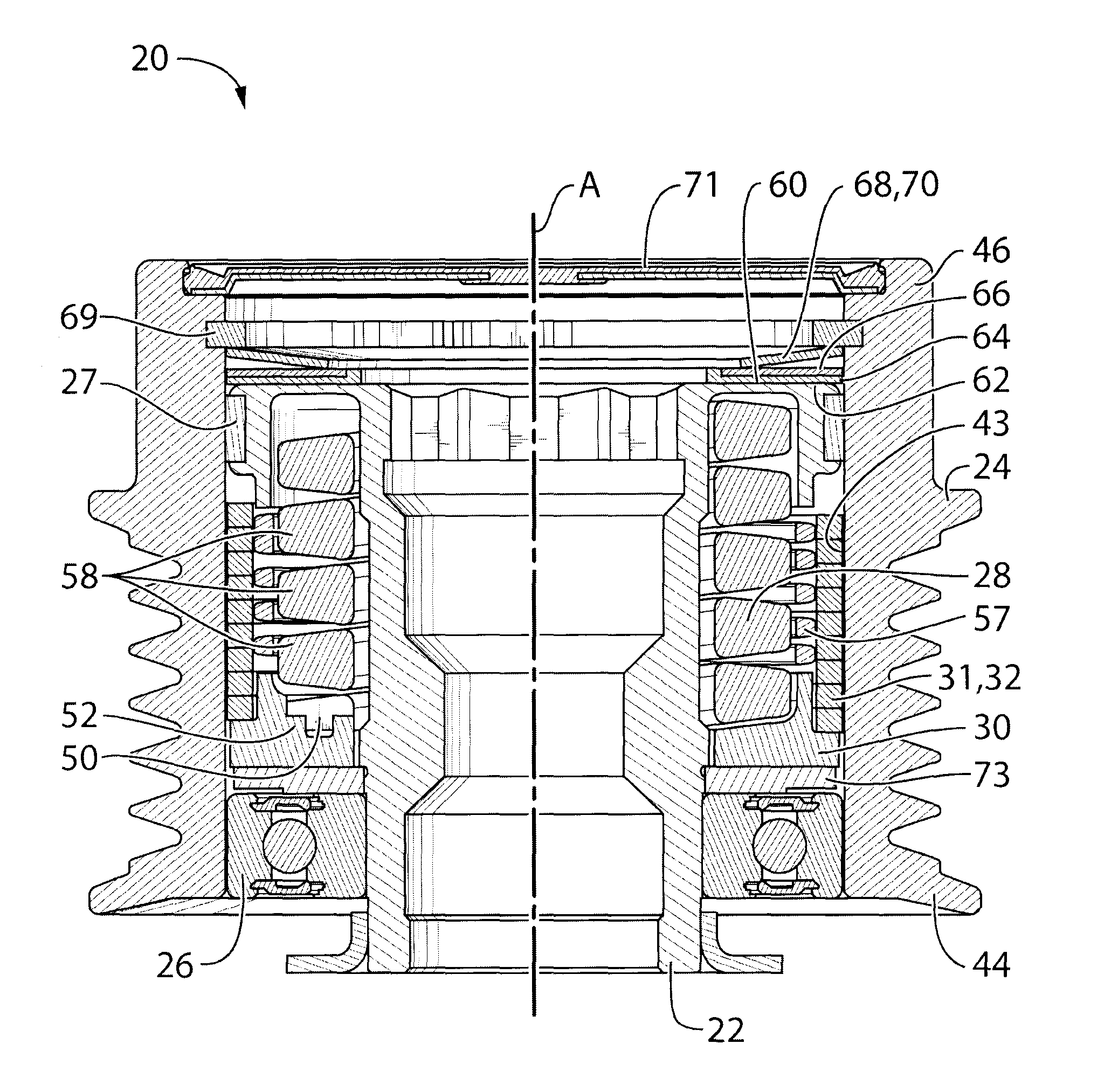

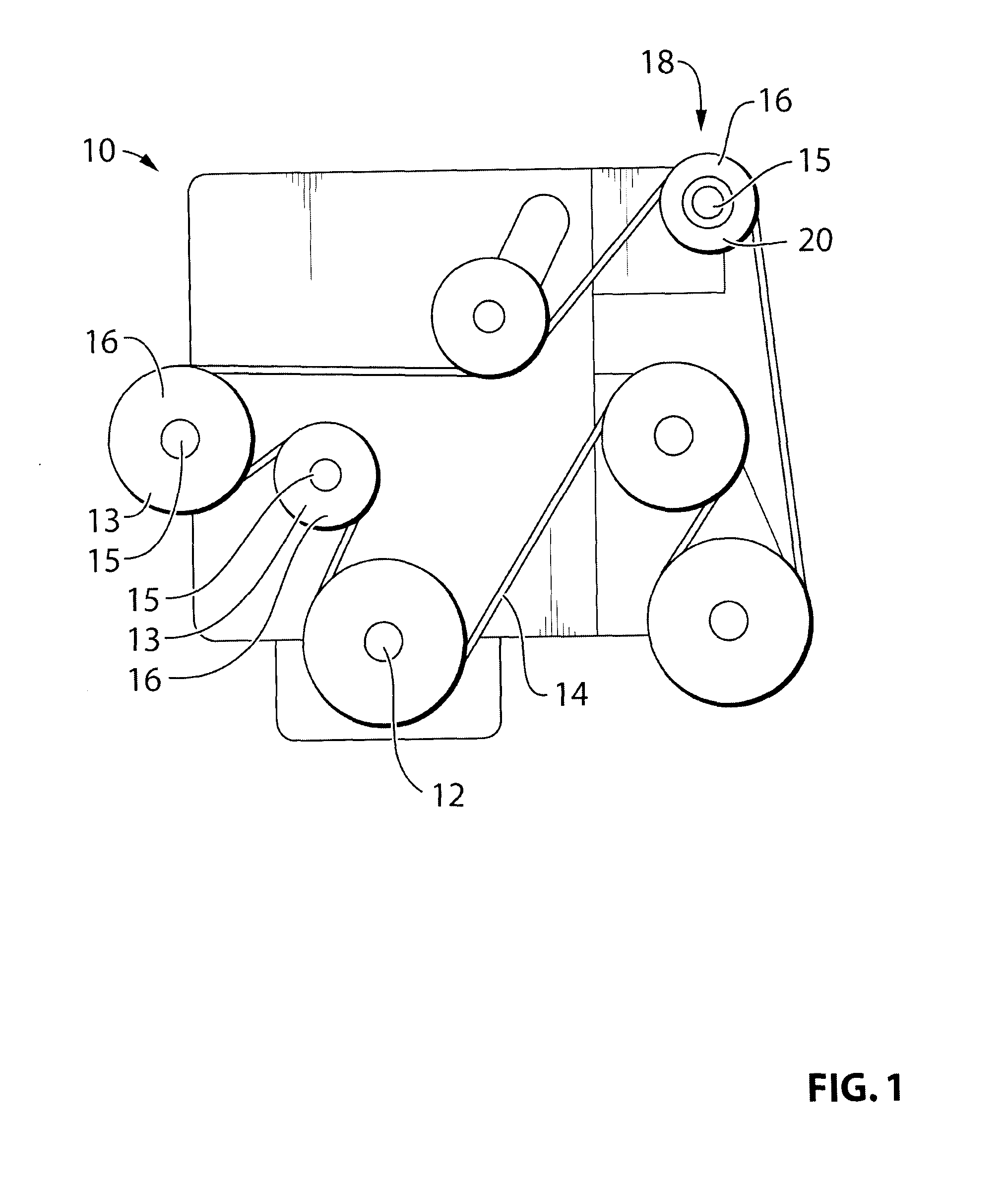

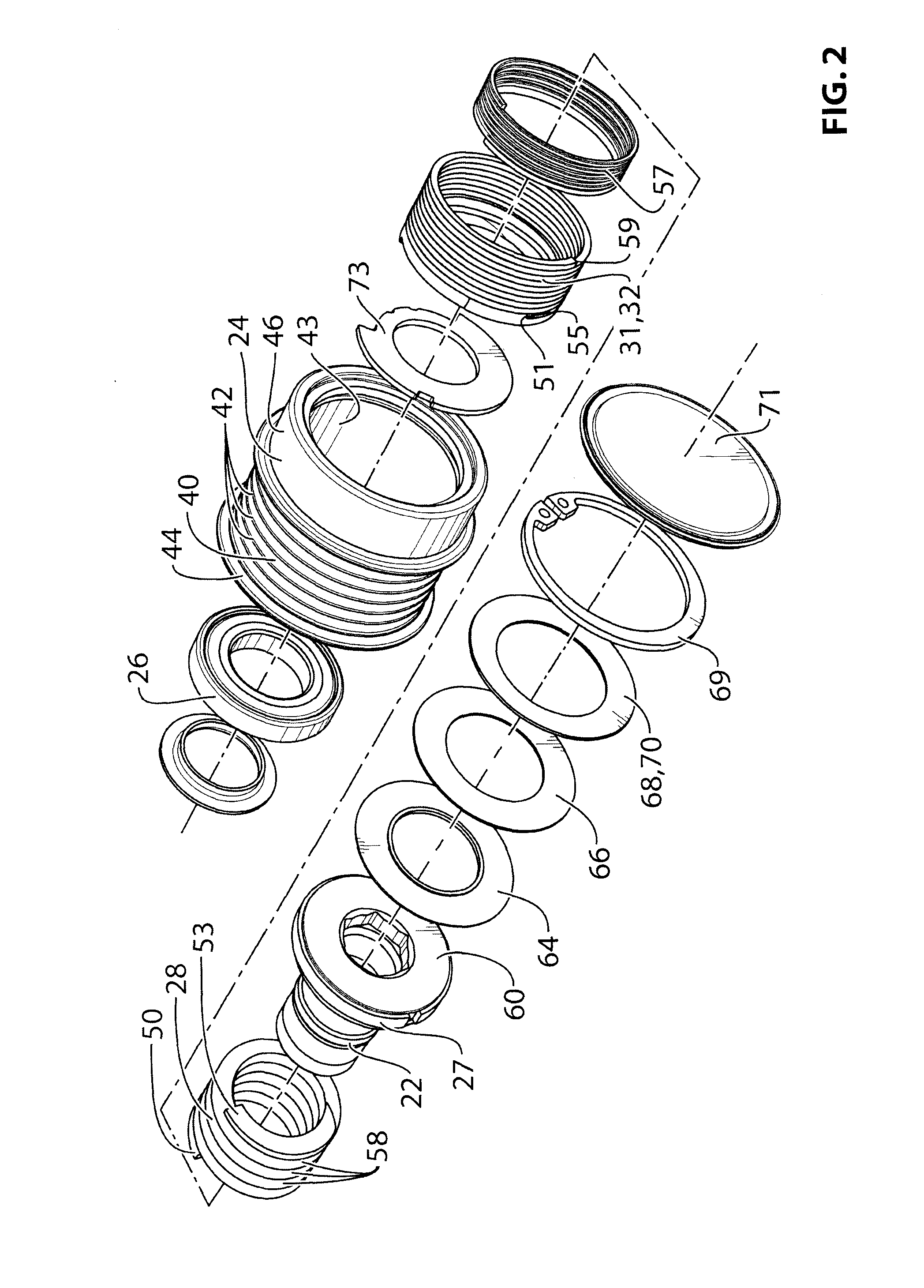

Enhanced computer optimized adaptive suspension system and method

InactiveUS20050098401A1Minimizing body motionIncrease fluid pressureOperating means/releasing devices for valvesSpringsComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:GREAT NORTHERN TECH

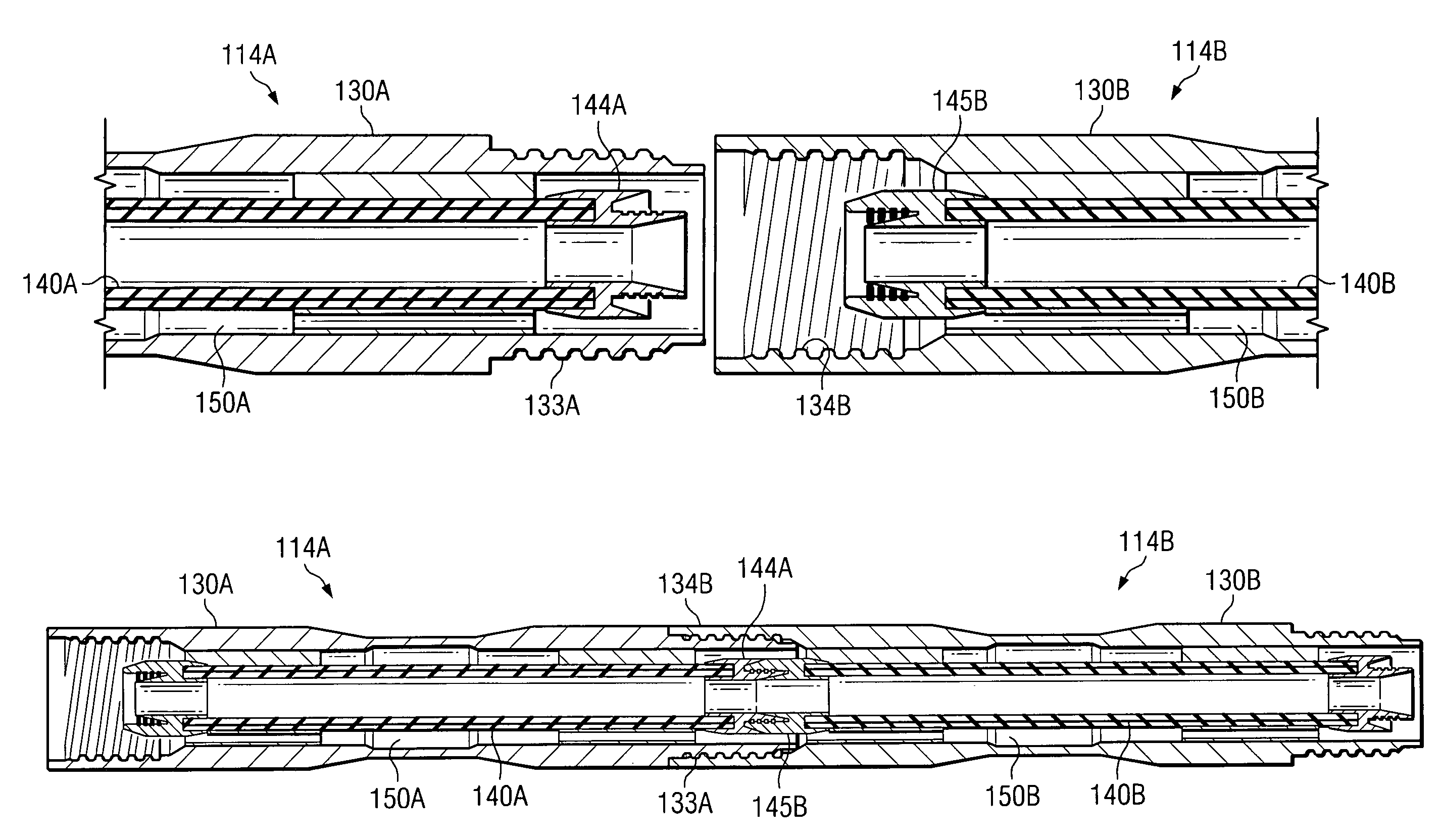

Dual wall drill string assembly

InactiveUS7152700B2Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingDrilling fluid

Owner:AMERICAN AUGERS +1

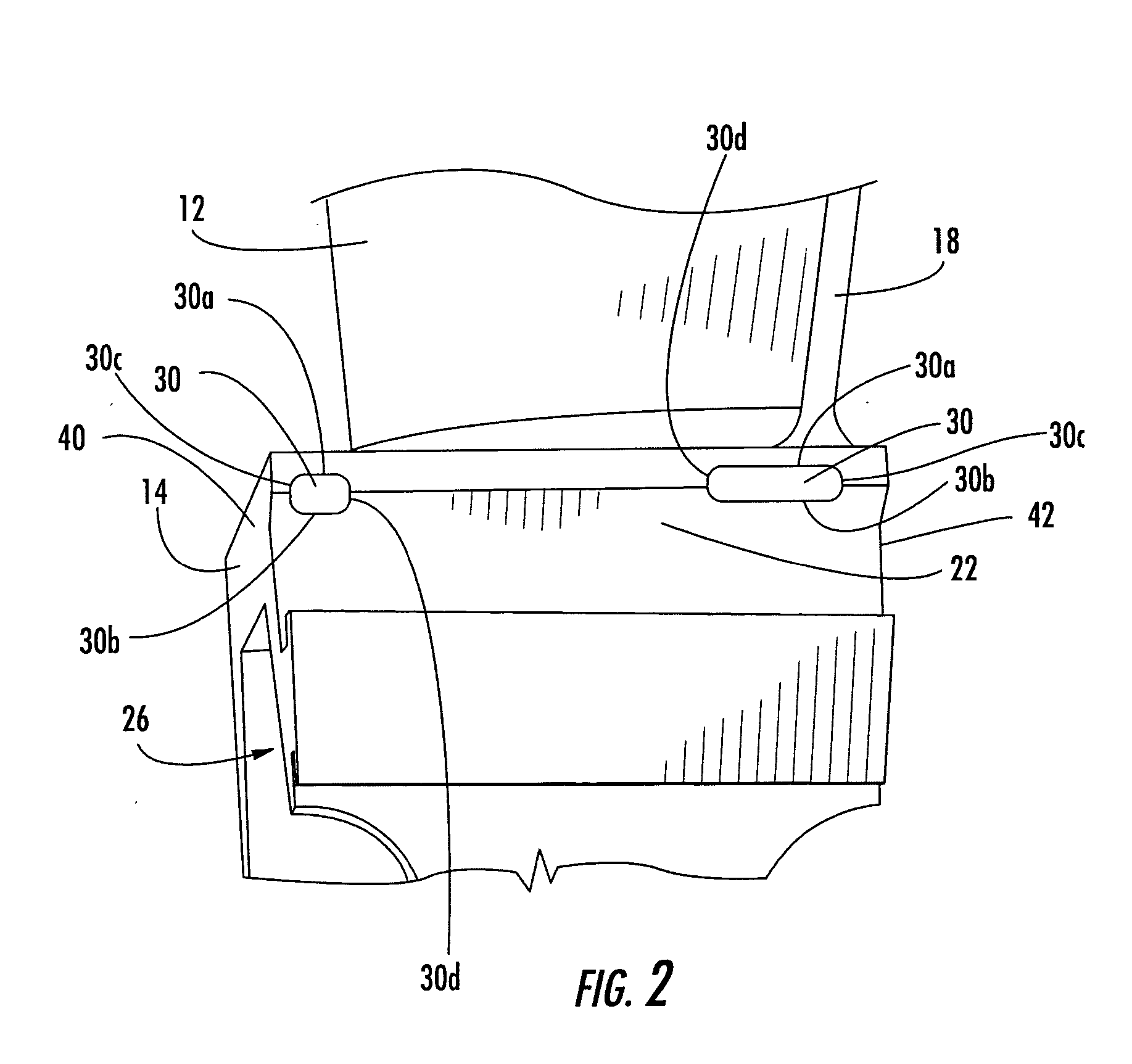

Turbine blade platform cooling system

ActiveUS20050058545A1Improve fatigue lifeFacilitate flow of coolantPump componentsRotary propellersLeading edgeTurbine blade

Aspects of the invention relate to a cooling system for a blade platform that can provide cooling to and reduce stress on the platform. Aspects of the invention relate to including one or more channels in the blade platform such that the channels extend from the trailing edge face of the platform toward, but terminate prior to, the leading edge face of the platform. The channels can be generally oval or oblong in conformation. Extending between the hollow shank and the channels can be a plurality of cooling holes. During engine operation, coolant is supplied to the shank of the blade assembly. Because the pressure at the shank is greater than the pressure at the trailing edge of the platform, coolant flow is induced through the cooling holes and into the channels. After flowing through the channels, the coolant can be dumped at the trailing edge.

Owner:SIEMENS ENERGY INC

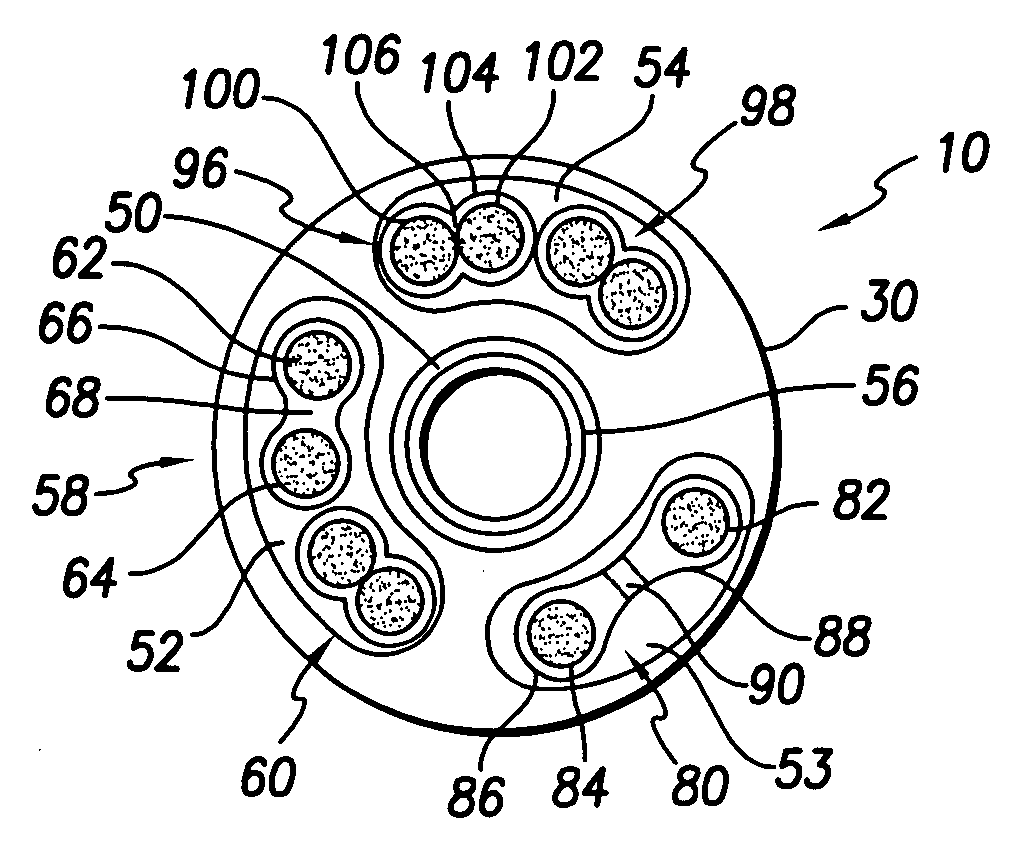

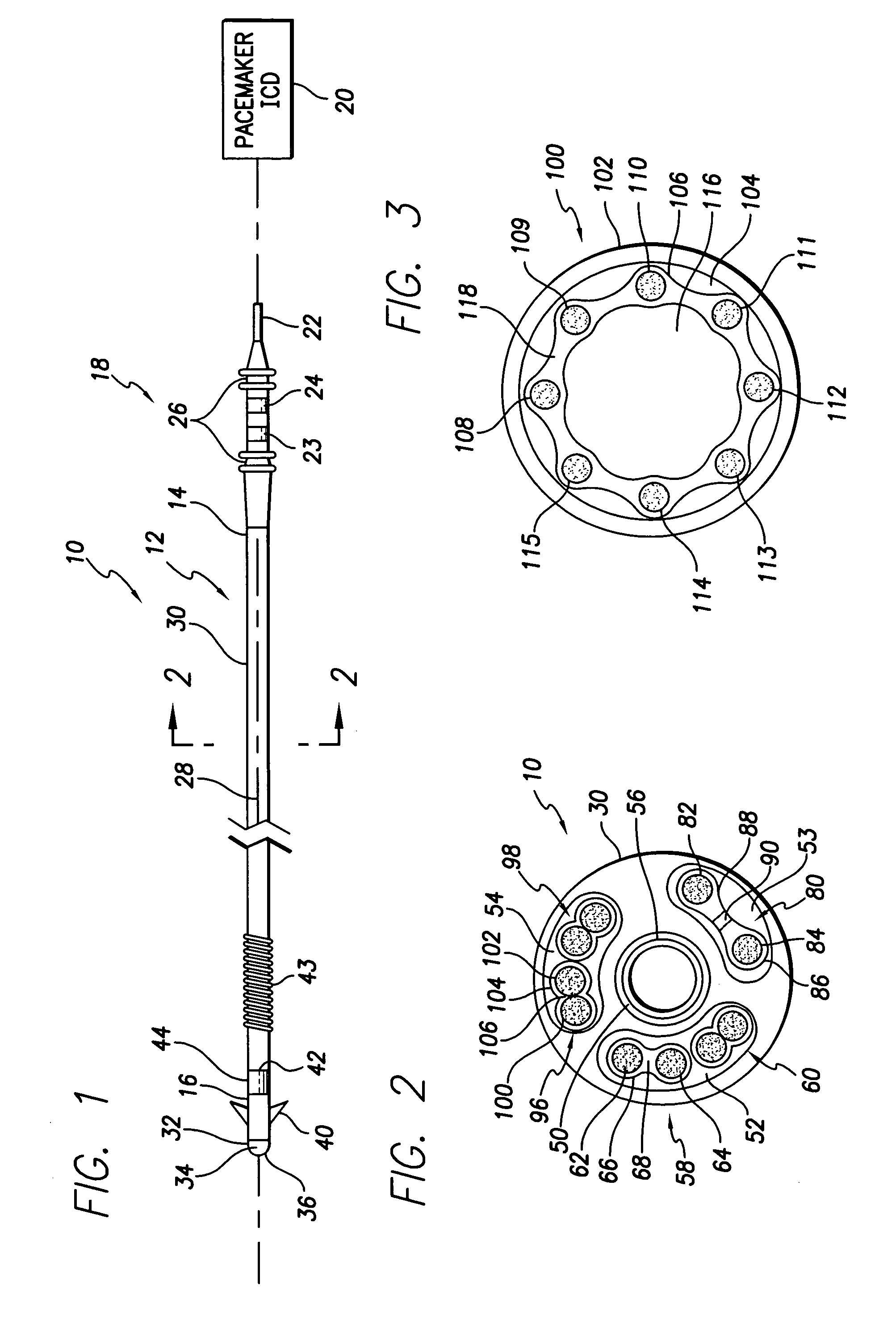

Implantable medical lead having multiple, jointly insulated electrical conductors

InactiveUS6925334B1Improve fatigue lifeIncrease flexibilityTransvascular endocardial electrodesDiagnostic recording/measuringElectricityElectrical conductor

An implantable lead for transmitting electrical signals between a proximal end and a distal end comprises an elongated lead body defining a longitudinally-extending lumen, and a plurality of individual electrical conductors contained in the lumen of the lead body and extending between the proximal and distal ends, the plurality of individual conductors sharing a common insulating coating. Each of the plurality of individual electrical conductors preferably comprises a braided, multifilar cable conductor. In one embodiment, the common insulating coating electrically isolates the plurality of conductors from each other, and may include a bridging portion extending between individual conductors.The plurality of electrical conductors and the common insulating coating comprise a conductor assembly that may have a helical configuration defining a longitudinally-extending passageway for receiving a stylet, guide wire, or the like, for placement of the distal end of the lead. Alternatively, the conductor assembly may have a tubular configuration, the plurality of individual conductors being embedded therein in spaced-apart, parallel relationship or along a generally helical path along the length of the lead body for greater lead flexibility.

Owner:PACESETTER INC

Decoupler with tuned damping and methods associated therewith

ActiveUS20130217524A1Reduce torsional vibrationImprove fatigue lifeAuxillary drivesRotating vibration suppressionEngineeringDamping torque

In an aspect, the invention relates to a decoupler that is positionable between a shaft (eg. for an alternator) and an endless power transmitting element (eg. a belt) on an engine. The decoupler includes a hub that mounts to the shaft, and a pulley that engages the endless power transmitting element, an isolation spring between the hub and the shaft. The decoupler provides at least a selected damping torque between the hub and the pulley.

Owner:LITENS AUTOMOTIVE INC

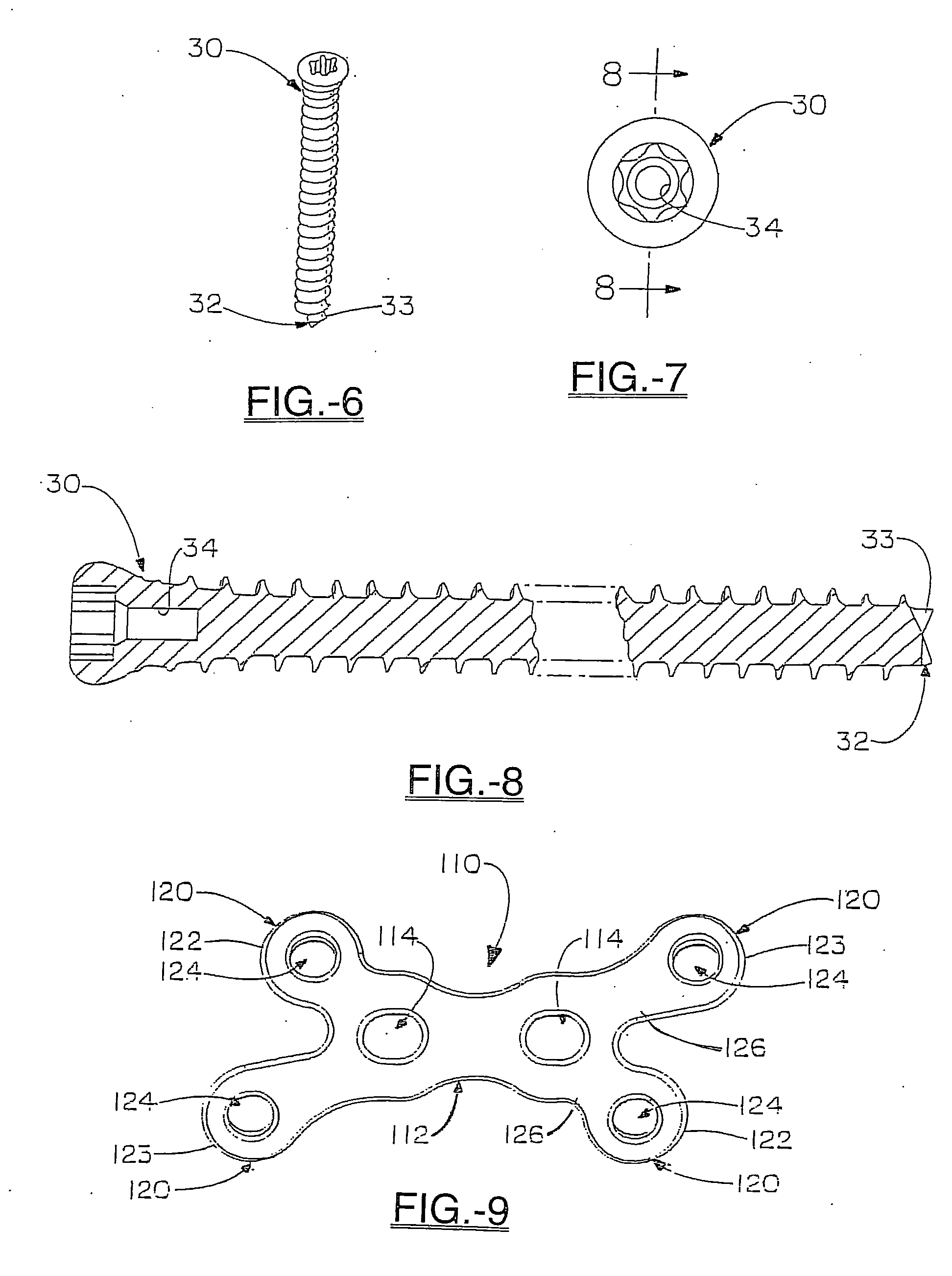

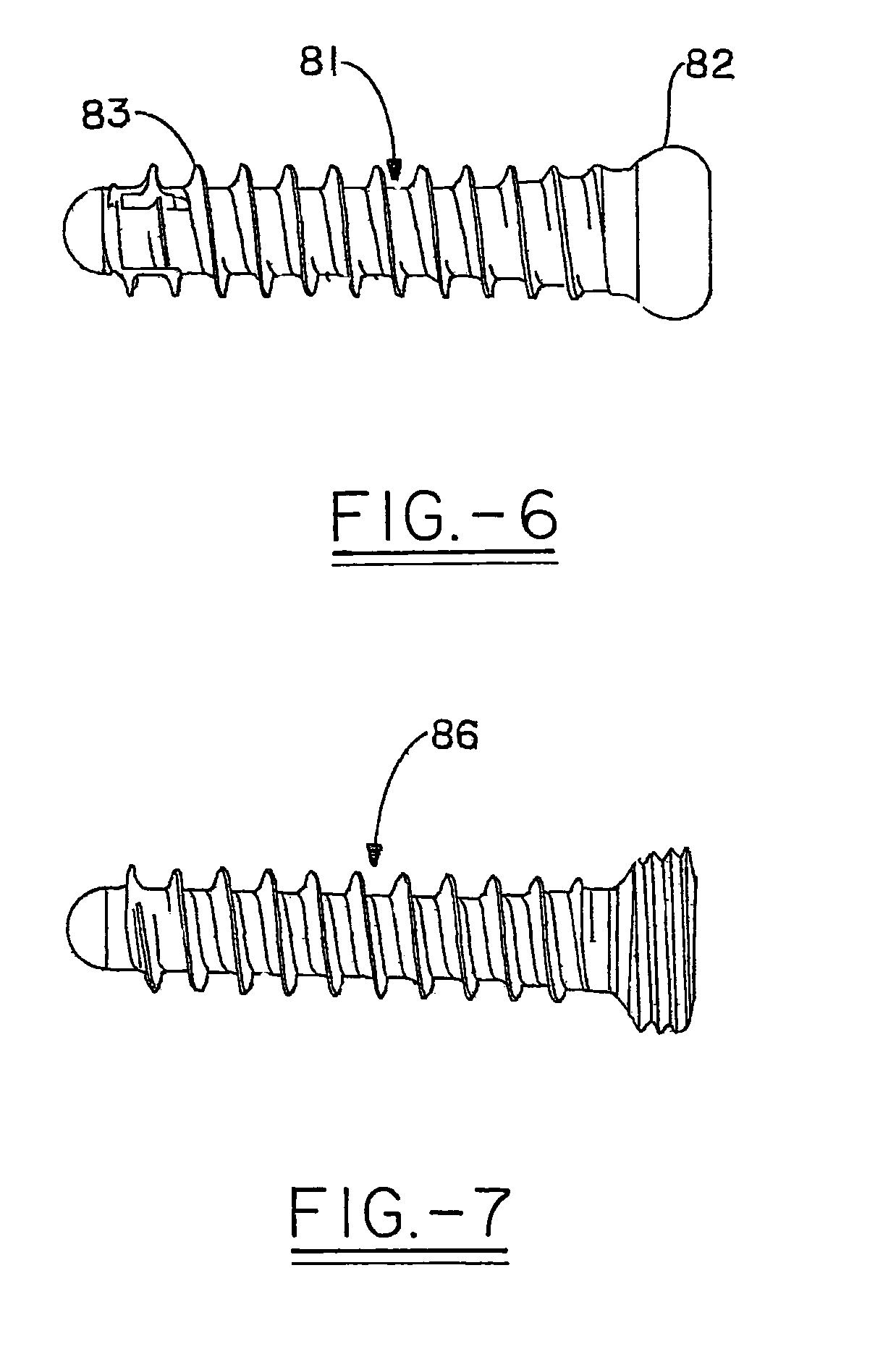

Orthopedic plate

ActiveUS20060200145A1Increased pull-out strengthAvoid confictJoint implantsBone platesSmall patellaeBone tissue

The present invention relates to an orthopedic plate and screw system and instruments for surgical fixation of a small bone or bones including specifically the small bones of the spine. The plate facilitates three dimensional contouring to provide for a variety of applications and to accommodate individual variation in bone shape. The plate has a modified x shape including a central trunk portion including one or more screw holes along a longitudinal axis and a set of divergent upper and an oppositely extending set of divergent lower arms, each arm including screw holes which are placed at a radially equal distance but which diverging asymmetrically from the longitudinal axis relative to its paired upper or lower mate. The screws of the system are self-starting, self-tapping screws including the option of partial or full cannulation. In a further embodiment, the plate is intended for use through the length of the spine.

Owner:ORTHOHELIX SURGICAL DESIGNS

Turbine blade platform cooling system

InactiveUS6945749B2Improve fatigue lifeReduce structural stiffnessPump componentsBlade accessoriesLeading edgeTurbine blade

Aspects of the invention relate to a cooling system for a blade platform that can provide cooling to and reduce stress on the platform. Aspects of the invention relate to including one or more channels in the blade platform such that the channels extend from the trailing edge face of the platform toward, but terminate prior to, the leading edge face of the platform. The channels can be generally oval or oblong in conformation. Extending between the hollow shank and the channels can be a plurality of cooling holes. During engine operation, coolant is supplied to the shank of the blade assembly. Because the pressure at the shank is greater than the pressure at the trailing edge of the platform, coolant flow is induced through the cooling holes and into the channels. After flowing through the channels, the coolant can be dumped at the trailing edge.

Owner:SIEMENS ENERGY INC

Orthopedic plate for use in fibula repair

ActiveUS8118848B2Increased pull-out strengthRoom for improvementJoint implantsBone platesEngineeringIliac screw

The present invention relates to an orthopedic plate for use in repair of a fibula. The plate has a Y-shaped profile which has the contour of a spoon where the bowl includes a terminal pair of arms that form differing angles and lengths relative to the trunk portion of the plate. The arms include locking screw holes where the screws converge toward each other, but do not impinge so as to provide-multiplanar fixation.

Owner:WRIGHT MEDICAL TECH

Lubricating oil composition for transmission

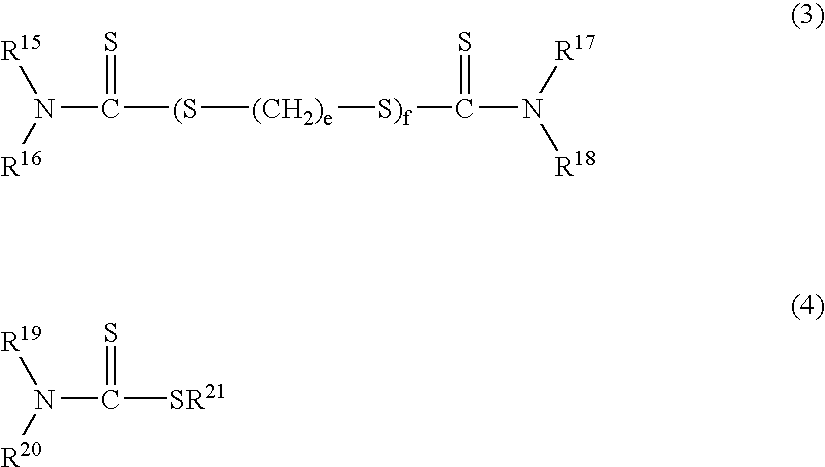

ActiveUS20070191239A1Improve fatigue lifeExcellent Low Temperature ViscosityOrganic chemistryAdditivesMeth-Viscosity index

Lubricating oil compositions for transmissions comprises (A) a lubricating base oil with a kinematic viscosity at 100° C. adjusted to 1.5 to 6 mm2 / s, composed of (A1) a lubricating base oil with a kinematic viscosity at 100° C. of 1.5 mm2 / s or higher and lower than 7 mm2 / s or (Al) the lubricating oil and (A2) a lubricating base oil with a kinematic viscosity at 100° C of 7 to 50 mm2 / s, blended with (B) a poly(meth)acrylate-based additive, so that the composition has a kinematic viscosity at 100° C. of 3 to 8 mm2 / s and a viscosity index of 95 to 200, (A) and (B) fulfill a specific requirement. The compositions achieve long fatigue life though having low viscosity.

Owner:NIPPON OIL CORP

Weldable aluminum product and welded structure comprising such a product

InactiveUS6337147B1Smooth transitionReduce the amount requiredElectric discharge heatingArc welding apparatusUltimate tensile strengthAluminium alloy

Improved shape and strength of the weld in a welded structure are obtained by use of a weldable aluminum product comprising a structural component which is a sheet, a plate or an extruded body and is made of an aluminum alloy containing not more than 1.5 wt % Zn. This component has, adhered on at least one side, a cladding layer made of an AA7xxx-series alloy having a corrosion potential lower than that of the alloy of the structural component. The alloy of the structural component is preferably an AA5xxx-series alloy containing Mg in the range 2 to 6 wt %.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Structure, materials, and applications of ball grid array interconnections

InactiveUS6297559B1Increase in sizeStable structurePrinted circuit assemblingFinal product manufacturePolymer resinSolder ball

A new interconnection scheme of a ball grid array (BGA) module is disclosed where a solder ball is connected to the BGA module by use of an electrically conducting adhesive The electrically conducting adhesive can be a mixture comprising a polymer resin, no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating and others. The solder balls in a BGA module can also be connected to a printed circuit board by use of another electrically conductive adhesive which can be joined at a lower temperature than the first joining to the BGA module. Additionally, an electrically conducting adhesive can be formed into electrically conducting adhesive bumps which interconnect an integrated circuit device to the BGA module.

Owner:IBM CORP

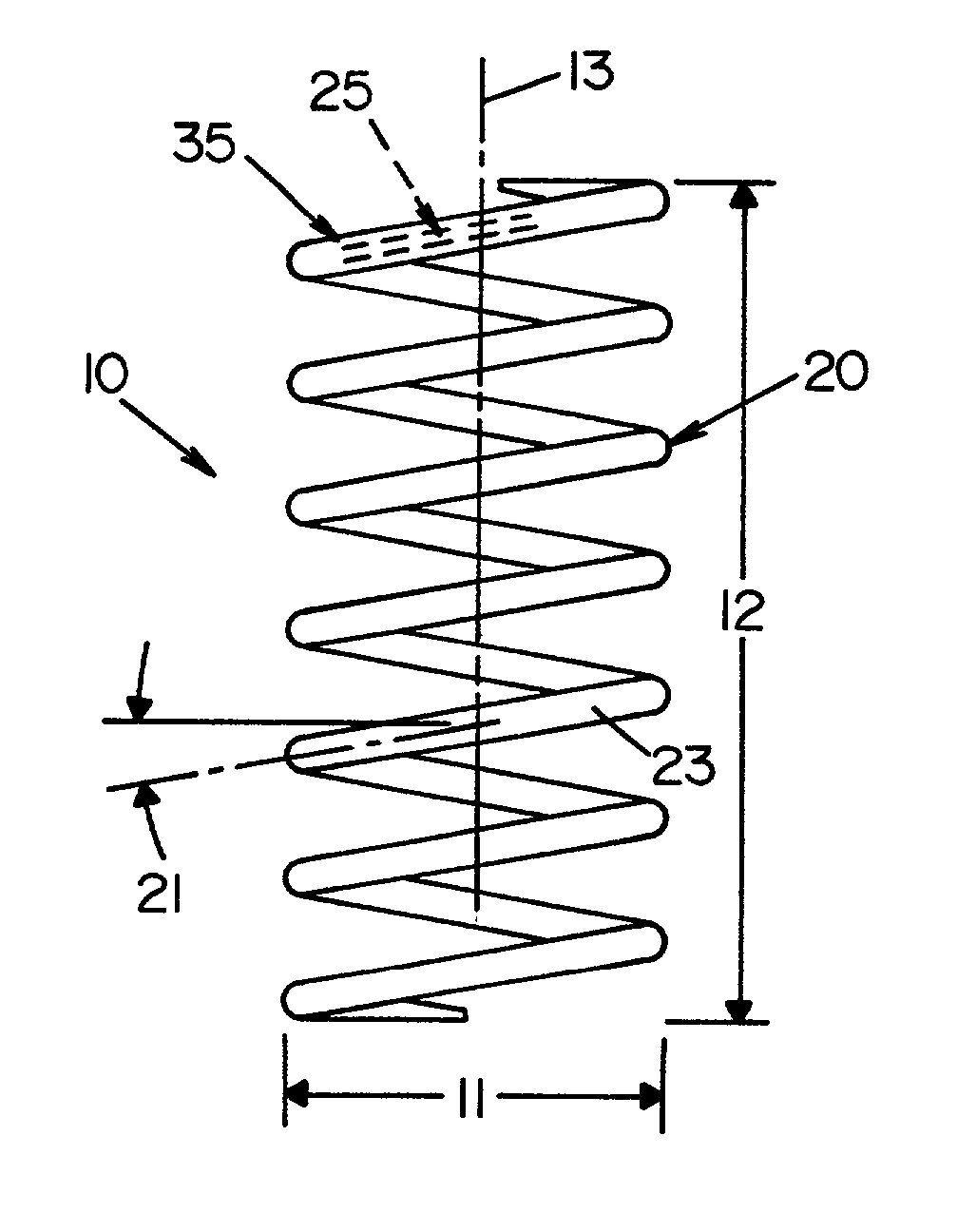

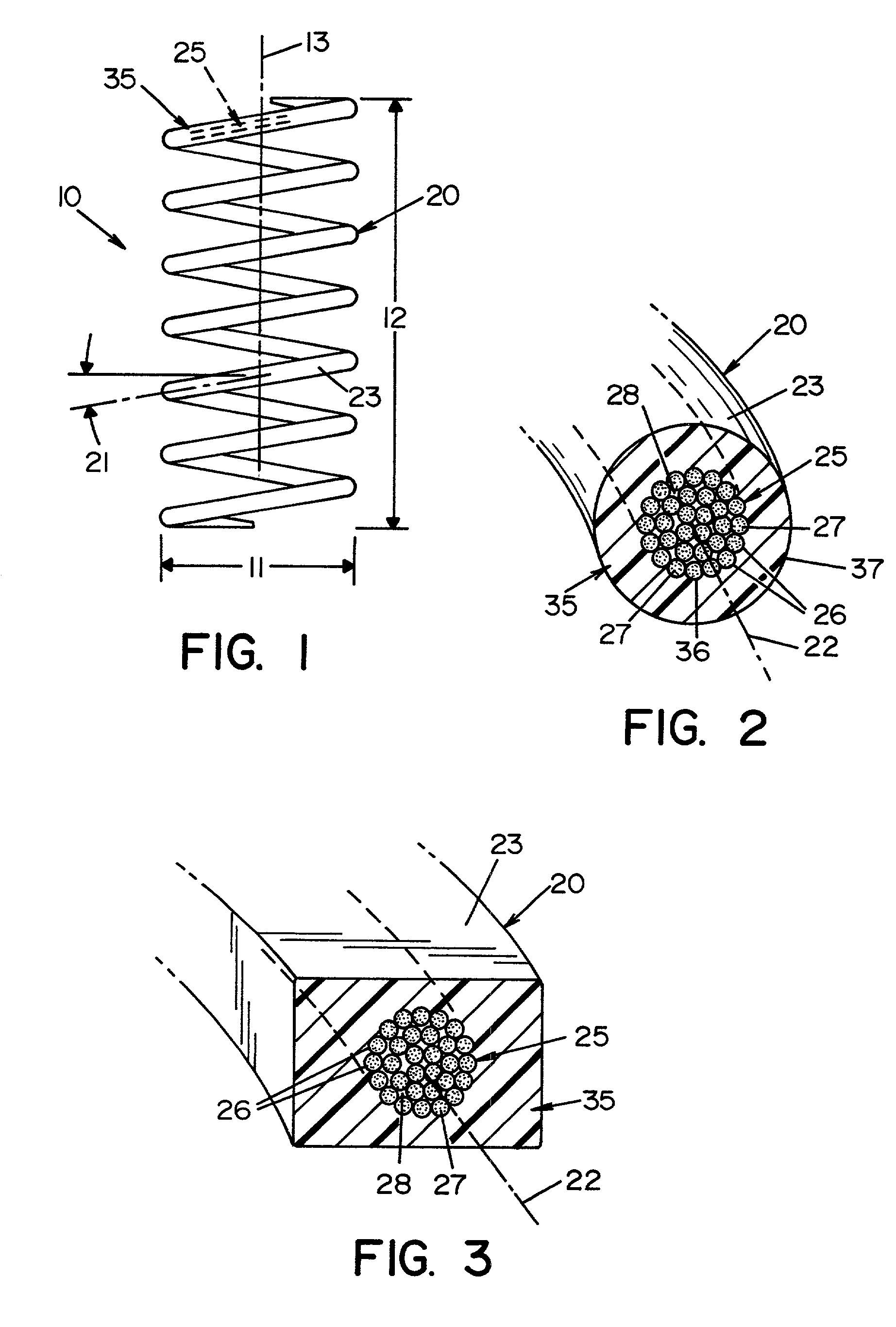

Fiber-reinforced composite springs

InactiveUS20020190451A1Predictable load versus deformation behaviorImprove fatigue lifeDomestic articlesShock absorbersCoil springFiber-reinforced composite

A fiber-reinforced composite spring comprising a coiled spring wire that comprises a fiber-reinforced core having longitudinal axis, where the core comprises core-reinforcing fiber tows that are twisted about the longitudinal axis of the core, and an outer layer surrounding the fiber-reinforced core, where the outer layer comprises a resin that is devoid of fiber tows.

Owner:THE UNIVERSITY OF AKRON

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

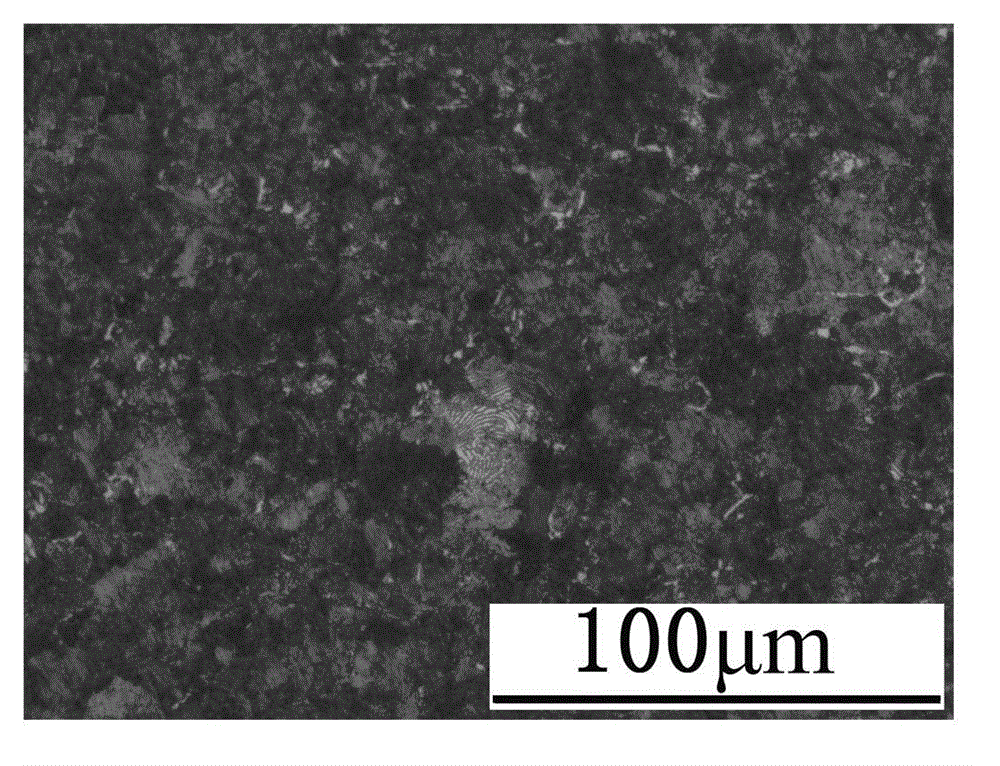

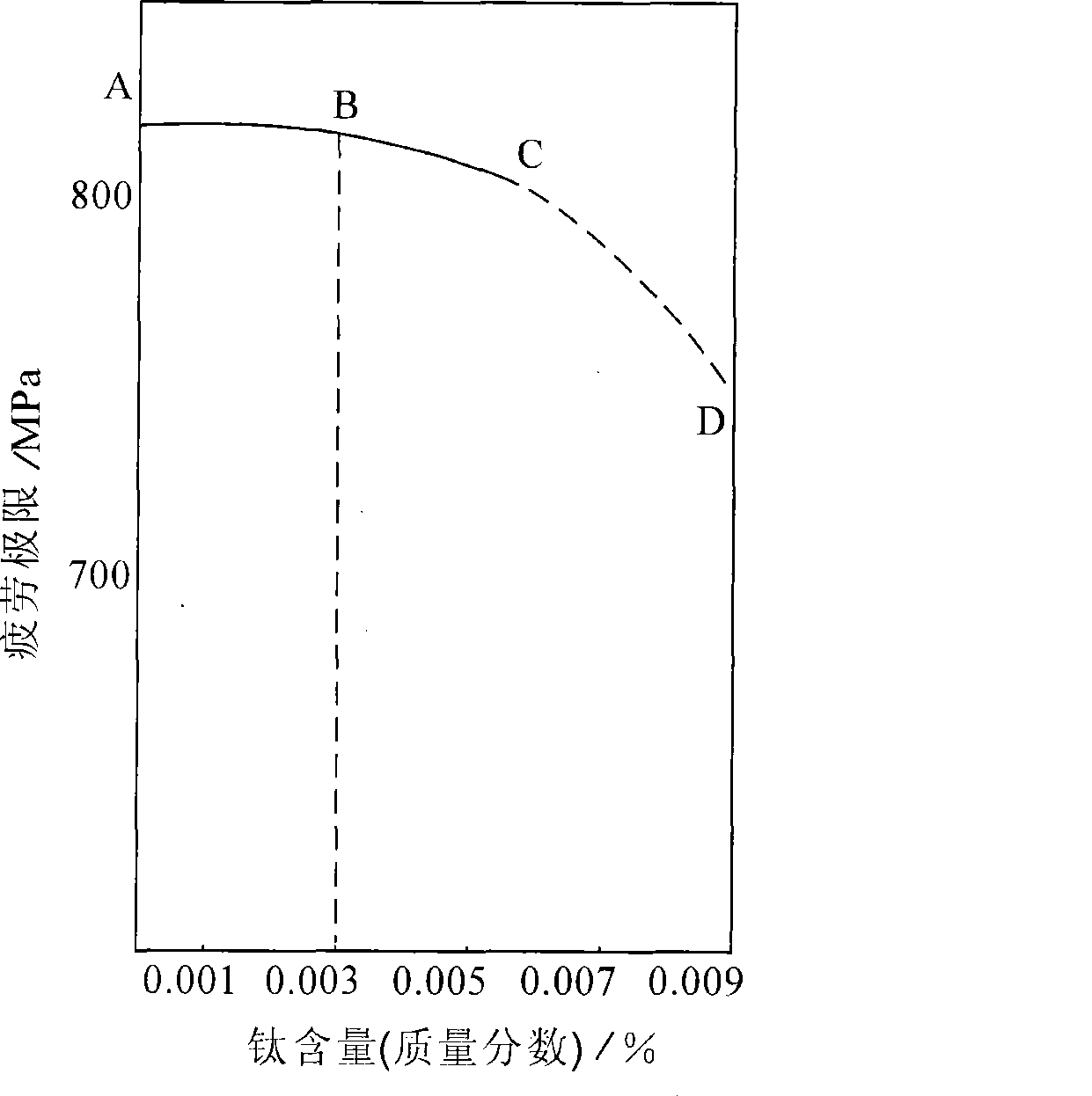

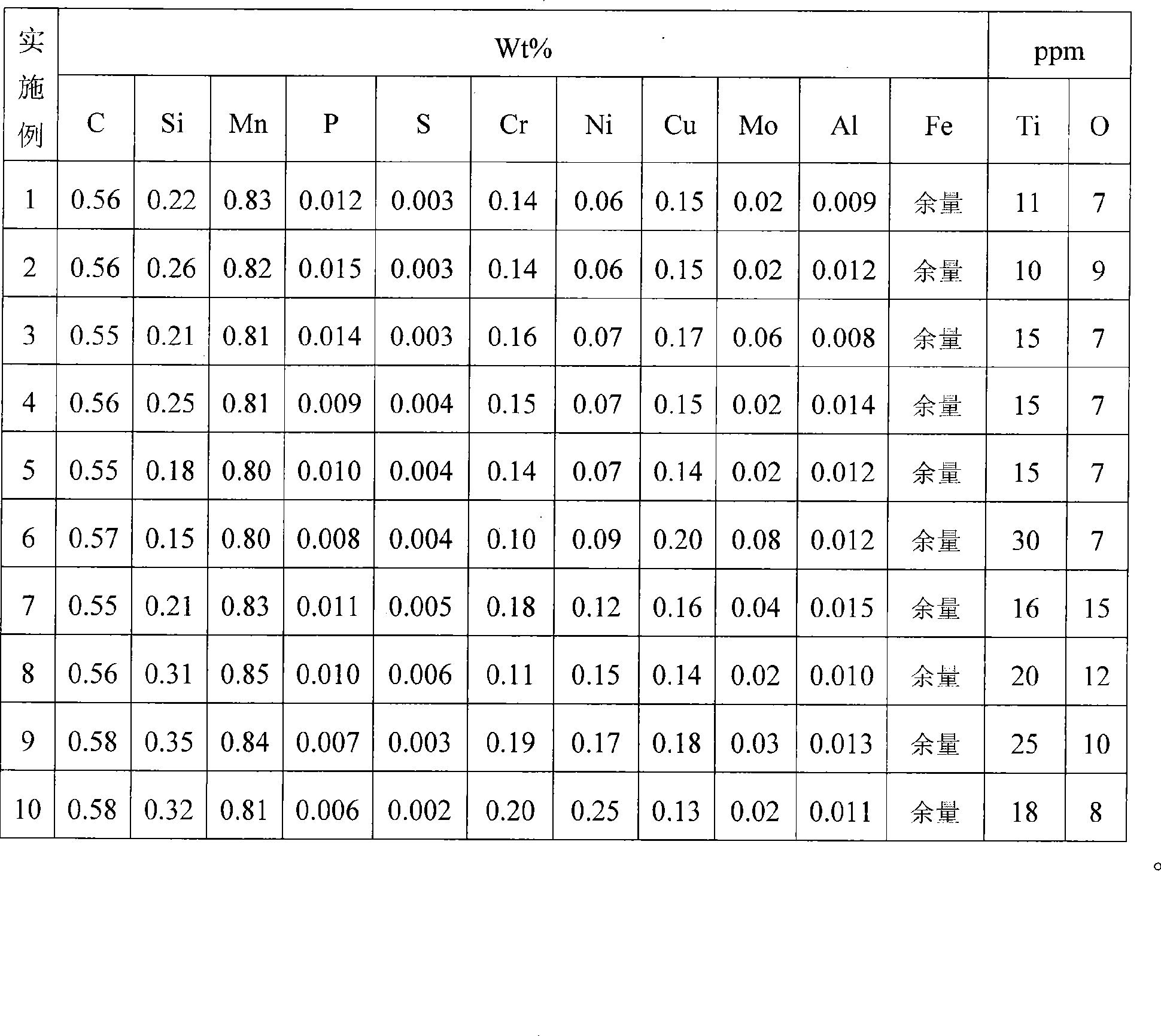

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

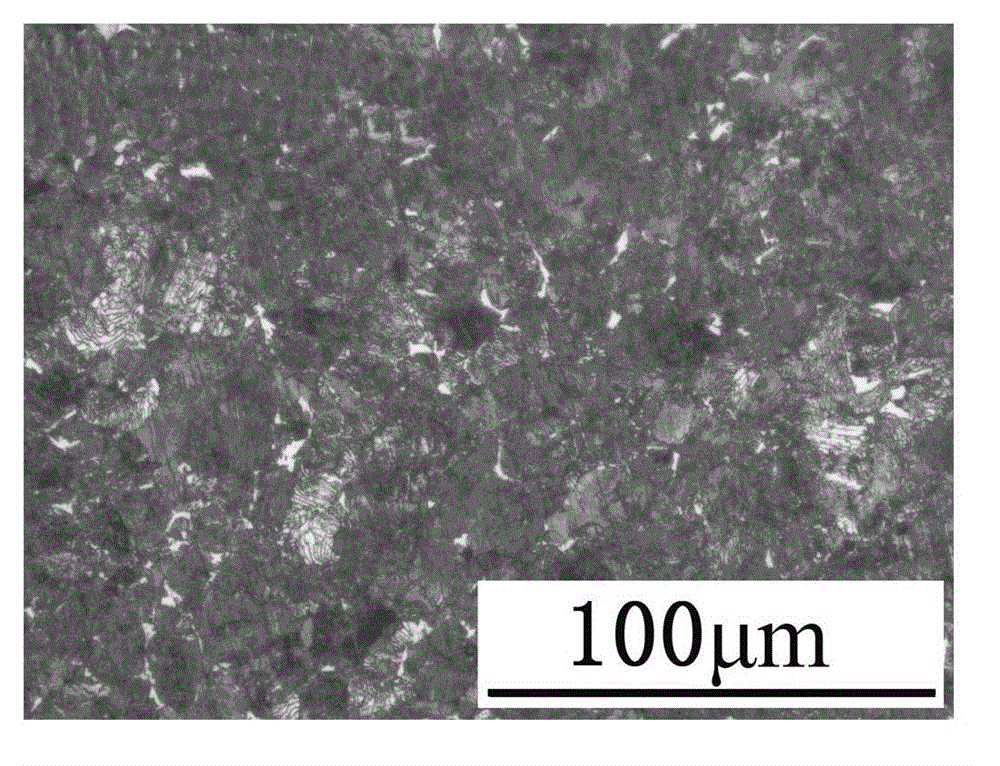

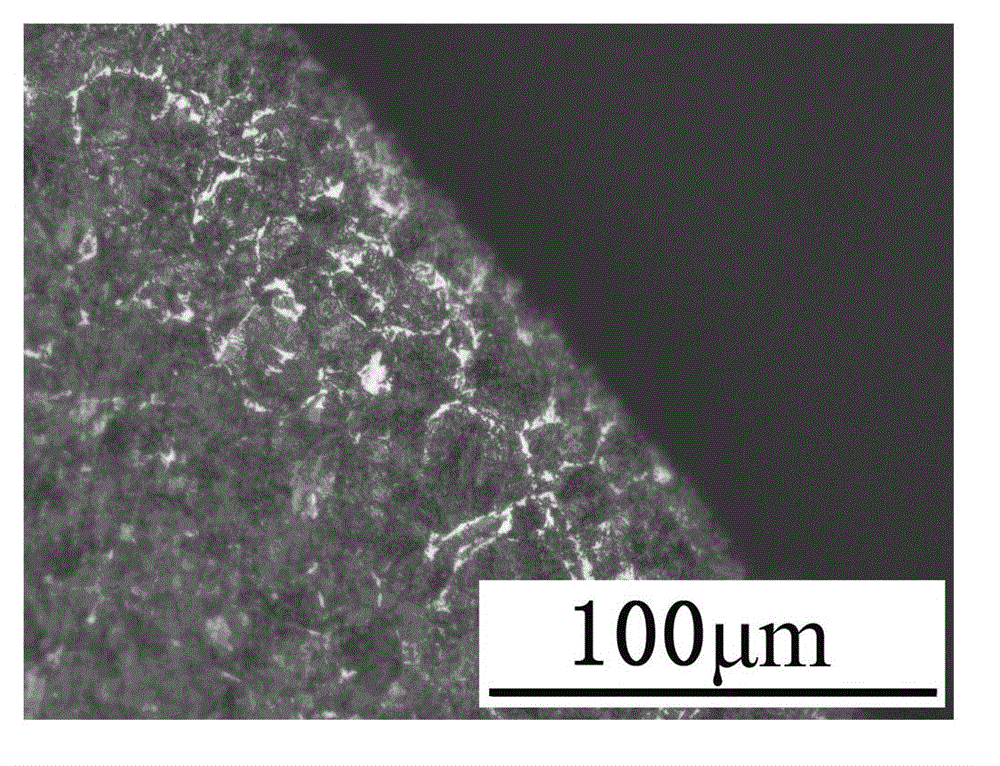

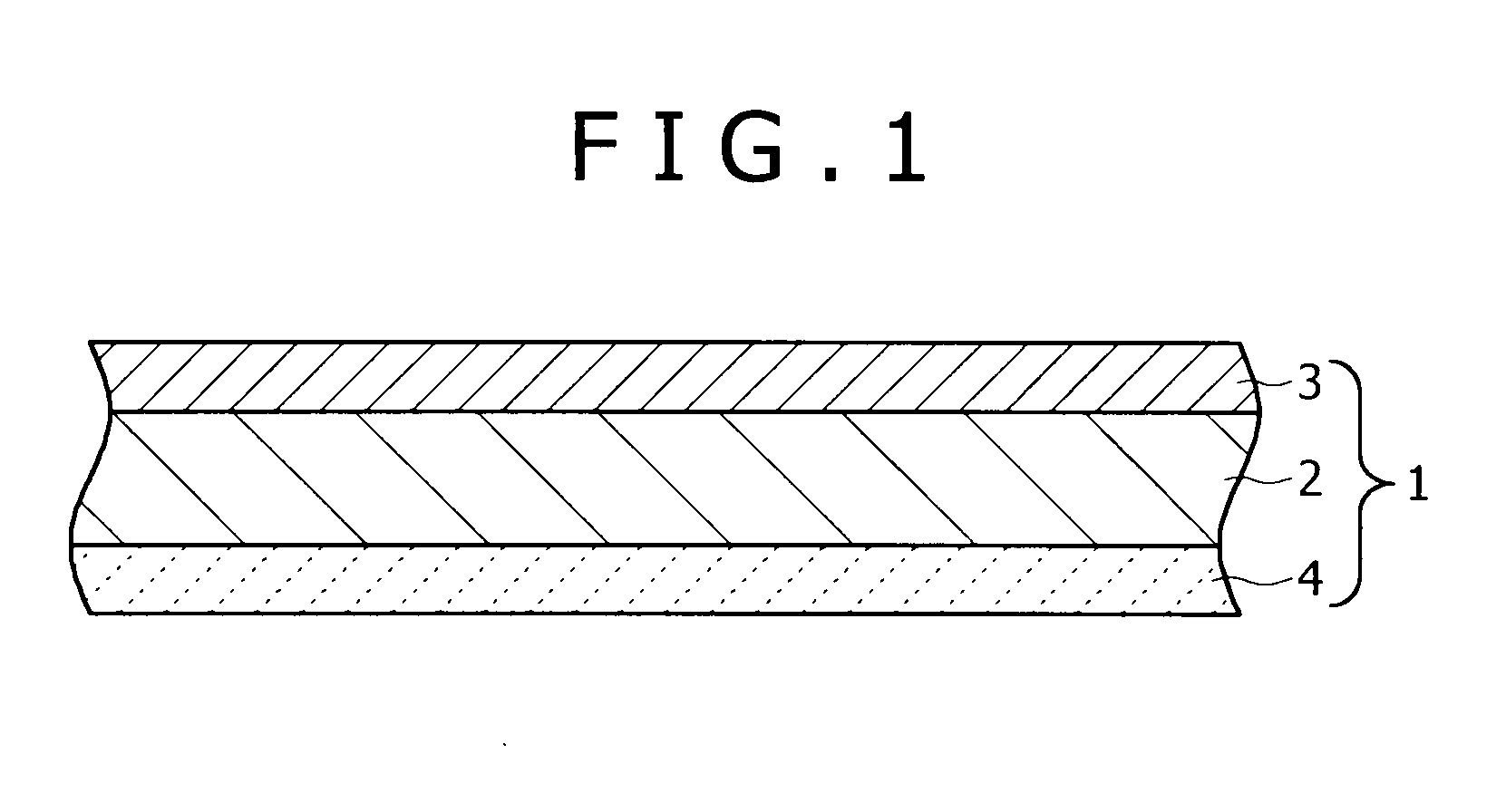

Aluminum alloy clad sheet for a heat exchanger and its production method

ActiveUS20090165901A1High elongationGood formabilityWelding/cutting media/materialsThin material handlingUltimate tensile strengthImpurity

Disclosed herein is an aluminum alloy clad sheet for a heat exchanger including a core layer, a sacrificial layer formed on one surface of the core layer, and a filler layer including an Al—Si based alloy formed on the other surface of the core layer. The core layer includes a predetermined amount of Si, Cu, Mn, Ti, and Mg, the remainder including Al and inevitable impurities, and the sacrificial layer includes a predetermined amount of Si, Mn, and Zn, the remainder including Al and inevitable impurities. The core layer has a crystal grain size after the brazing heat treatment at 595° C. for 3 minutes of at least 50 μm and less than 300 μm. The filler layer and the sacrificial layer are defined for their thickness, and the number of intermetallic compounds in the core layer is also defined to a predetermined range. By such constitution, the aluminum alloy clad sheet has improved fatigue life and post-braze strength, high corrosion resistance, and excellent erosion resistance and brazeability.

Owner:KOBE STEEL LTD

Lubricating oil composition for transmissions

InactiveUS20060135378A1Low viscosityImprove fatigue lifeAdditivesBase-materialsHydrogenOxidation stability

A lubricating oil composition for transmissions comprises a lubricating base oil comprising (A) a lubricating base oil so adjusted to have a kinematic viscosity at 100° C. of from 1.5 to 5 mm2 / s and a % CN of from 10 to 60 (B) a mineral lubricating base oil having a kinematic viscosity at 100° C. of from 10 to 50 mm2 / s and a sulfur content of from 0.3 to 1 percent by mass and (C) a synthetic oil composed of carbon and hydrogen and having a number average molecular weight of from 2,000 to 20,000, in respective specific amounts and (D) an extreme pressure additive of from 0.05 to 2 percent by mass, based on the total amount of the composition, of comprising a phosphorus-based extreme pressure additive, a sulfur-based extreme pressure additive and / or a phosphorus-sulfur-based extreme pressure additive, wherein in the composition, the phosphorus content (P) is from 0.01 to 0.05 percent by mass, the total sulfur content (S) is from 0.05 to 0.3 percent by mass, and the P / S ratio is from 0.10 to 0.40. The lubricating oil composition has both excellent fuel economy performance and satisfactory durability for gears and bearings and furthermore excellent low temperature viscosity and oxidation stability.

Owner:NIPPON OIL CORP

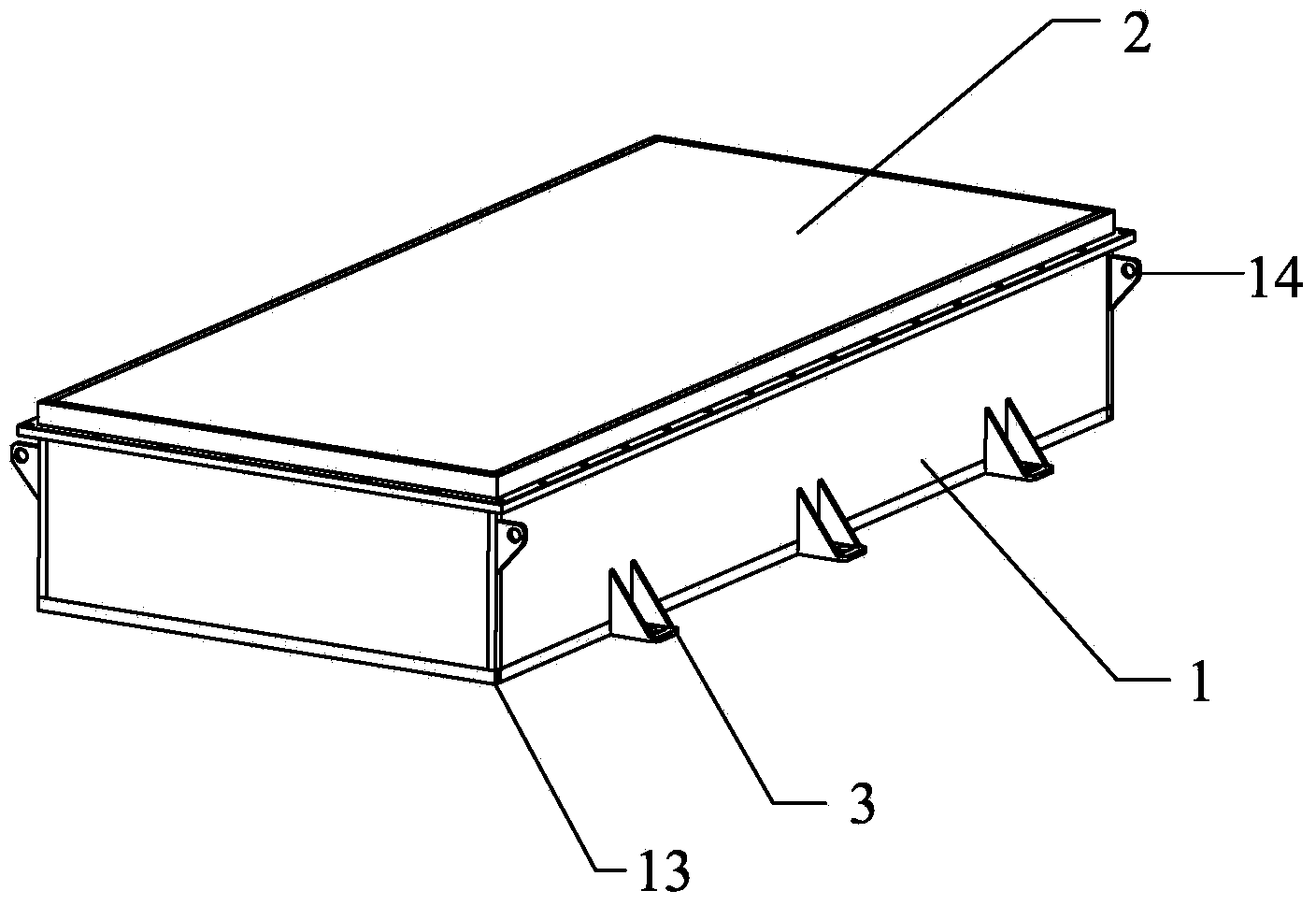

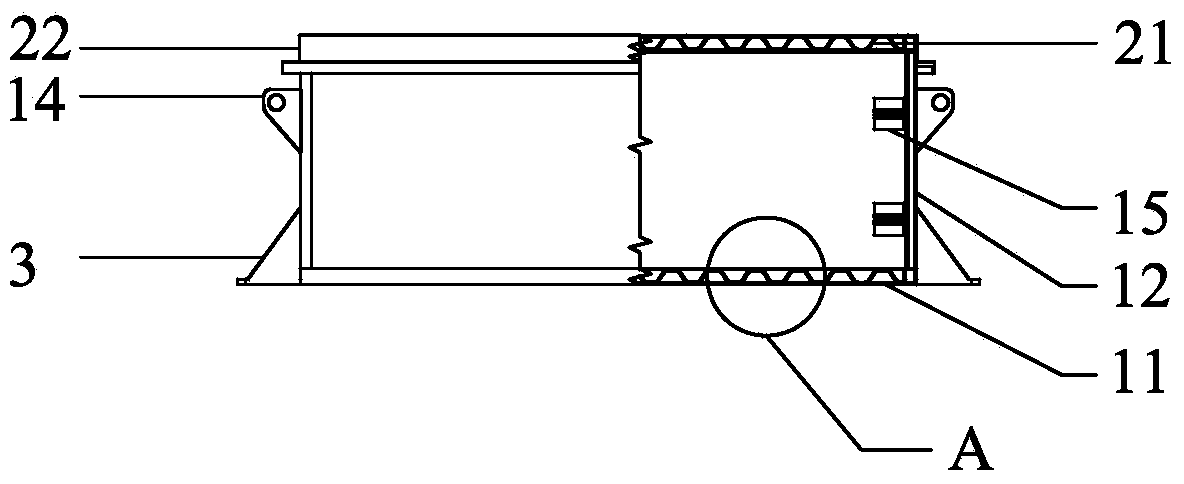

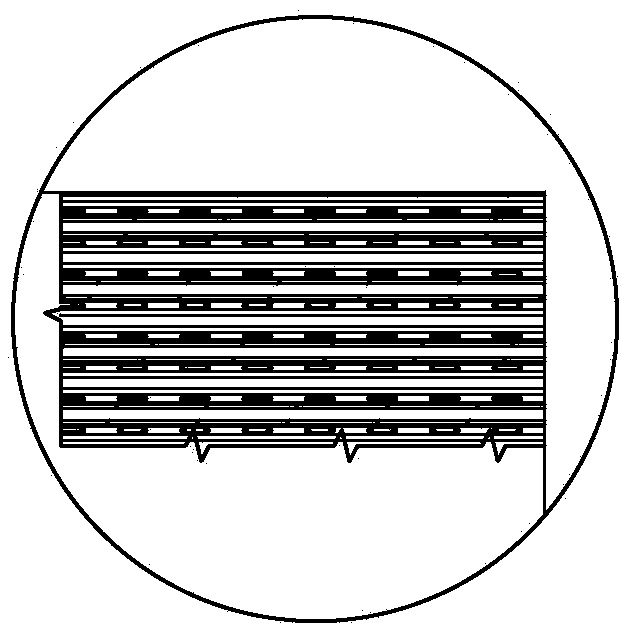

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

Stabilizer bar

InactiveUS20060243355A1Reduce manufacturing costHigh hardnessFurnace typesInterconnection systemsTemperingClassical mechanics

A tubular stabilizer bar for a vehicle suspension is formed from an as-quenched steel material that is not subjected to a tempering process, and which has a hardness of at least 40 Rockwell C. The stabilizer bar includes an ultimate tensile strength that is greater than 200 ksi with a ratio of yield strength to ultimate tensile strength that is no more than 0.9. The stabilizer bar is significantly harder and has significantly improved fatigue life without compromising ductility, when compared with prior designs.

Owner:MERITOR SUSPENSION SYST U S

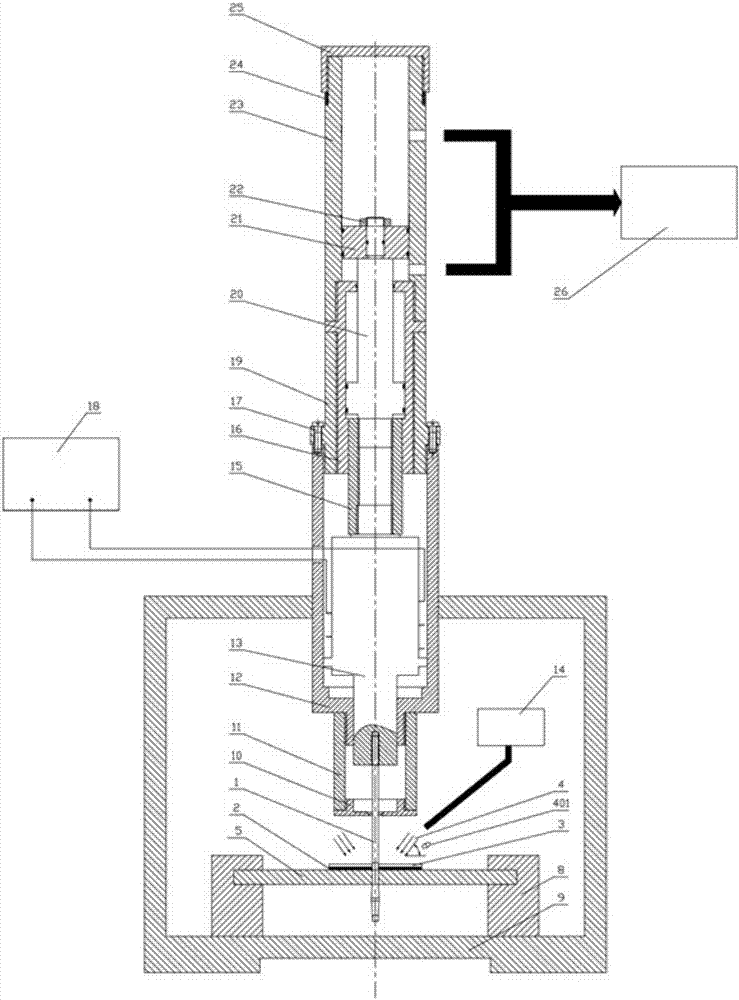

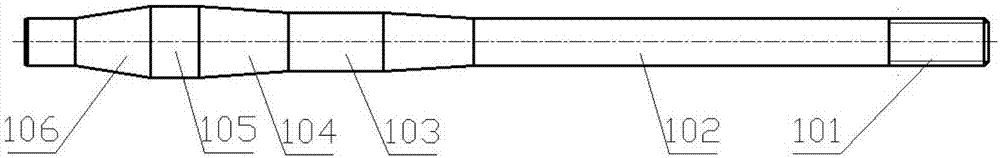

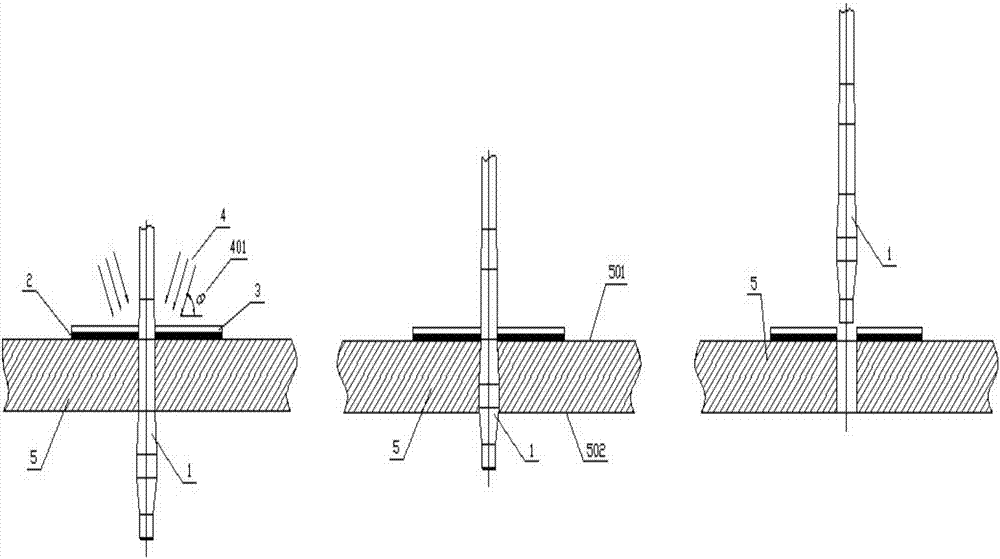

Laser shock and supersonic vibration extrusion co-strengthening device and method

ActiveCN107254581AImprove fatigue resistanceSmooth inner surfaceLaser beam welding apparatusShock waveUltrasonic vibration

The invention provides a laser shock and supersonic vibration extrusion co-strengthening device and method. The device comprises a laser assembly, a vibration assembly, a hydraulic assembly and a connecting assembly. The method comprises steps as follows: a hole formed on sheet metal is strengthened while laser shock strengthening and supersonic vibration extrusion strengthening are adopted, a mandrel forms clearance fit with the hole to constrain the hole, so that distortion of hole and a hole angle when the laser shock is performed on the outer surface of a workpiece is prevented, and the strengthening effect of the hole wall is improved; when the laser shock is performed on the outer surface of the sheet metal, supersonic vibration is applied to the mandrel in the hole, three-dimensional pressure stress distribution is formed nearby the hole wall at certain depth under the interaction produced by laser shock waves and power ultrasound at certain frequency, amplitude and modal, and higher anti-fatigue performance and smoother inner surface of the hole are obtained. With the adoption of the device and the method, defects of a traditional strengthening technology are overcome, and the problem that the hole is strengthened through either single laser shock or single supersonic vibration extrusion is solved.

Owner:JIANGSU UNIV

Rolling method controlling network carbide precipitation of large-section GCr15 bearing steel

The invention discloses a rolling method controlling network carbide precipitation of large-section GCr15 bearing steel. According to the method, GCr15 continuous casting billet serves as raw materials; and the following working procedures of heating, decaling, rough rolling, intermediate rolling, pre-finish-rolling, first time of water penetrating cooling, finish rolling of a rod reducing and sizing mill, second time of water penetrating cooling, cooling of a cooling bed and final obtaining of finished product rods are sequentially included. By means of the method, the level of the obtained network carbide of the large-section GCr15 bearing steel is reduced to be smaller than or equal to level 2 from the original level larger than or equal to level 3, the comprehensive mechanical performance of high-carbon-chromium bearing steel is improved, the service life of a bearing is prolonged, besides, the production cost is reduced, and the market competitiveness of the bearing steel is improved.

Owner:DAYE SPECIAL STEEL CO LTD

Heavy-duty vehicle axle/suspension system

InactiveUS20060244234A1Cost efficientImprove fatigue lifeInterconnection systemsResilient suspensionsVehicle frameEngineering

An axle / suspension system for a heavy-duty vehicle, in which the vehicle includes a frame that extends in a longitudinal direction relative to the vehicle. The axle / suspension system is attached to the vehicle frame via at least one hanger and includes at least one beam, which includes a first end and a second end. The first end of the beam is connected to the hanger, and the second end of the beam immovably captures an axle, which extends in a transverse direction relative to the vehicle. The beam is formed of a composite material and has a substantially constant cross section in the transverse direction to provide sufficient strength to control roll forces encountered by the vehicle during operation.

Owner:HENDRICKSON USA L L C

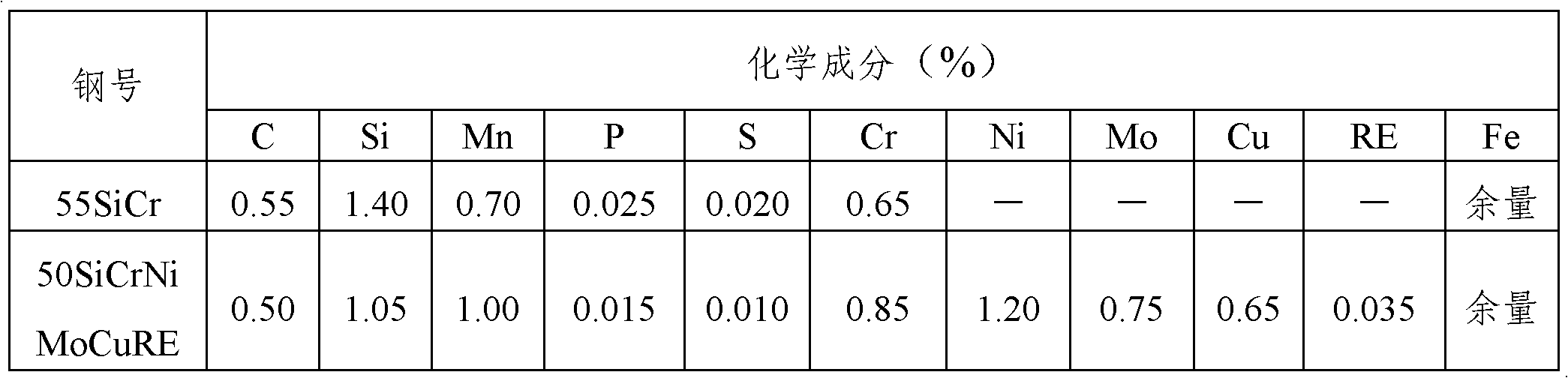

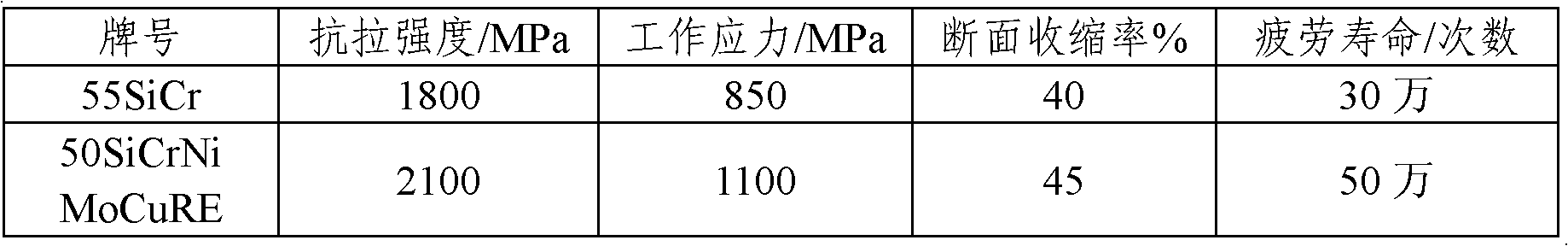

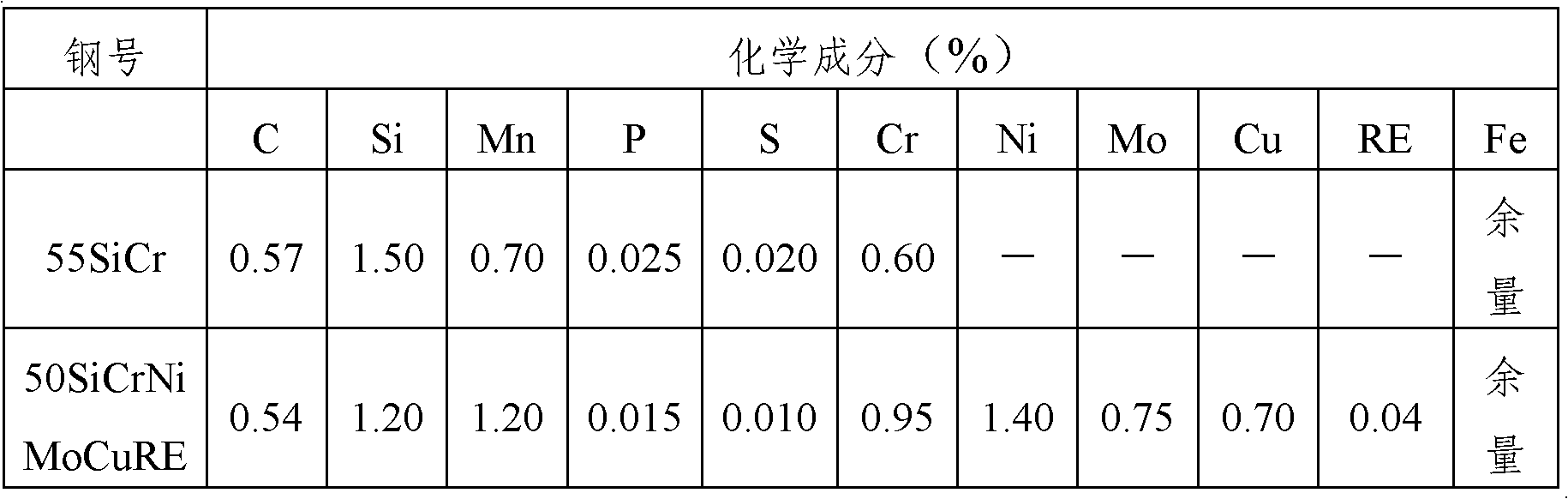

Spring steel used for automobile suspension as well as preparation method and application thereof

ActiveCN102634735AHigh tensile strengthIncrease work stressProcess efficiency improvementChemical compositionSpring steel

The invention provides a spring steel used for an automobile suspension. the spring steel comprises the following ingredients in percentage by weight: 0.46-0.56% of C, 0.90-1.20% of Si, 0.80-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.70-1.0% of Cr, 0.90-1.50% of Ni, 0.60-0.90% of Mo, 0.50-0.80% of Cu, 0.02-0.07% of RE and the balance of Fe and inevitable impurities. The invention also provides a preparation method for the spring steel and a method for preparing a spring steel wire by using the spring steel. According to the invention, the chemical components of the spring steel are reasonably designed, and the smelting rolling and steel wire preparation method and the auxiliary material adding method and proportion are improved. Compared with the existing 55SiCr steel, the tensile strength of the spring steel disclosed by the invention is improved by 400MPa, the working stress is improved by 200MPa, and the fatigue life is improved by 200 thousand times.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

Structure, materials, and methods for socketable ball grid

InactiveUS6300164B1Improve fatigue lifeReduce failurePrinted circuit assemblingFinal product manufacturePolymer resinAdhesive

A socketable ball grid array structure is disclosed which comprises mechanically rigid (compared to solder alloys) balls coated with noble contact metals joined to the chip carrier terminals by means of a novel electrically conducting adhesive. Because of the nature of the filler that includes conducting particles with a fusible coating and the appropriate selection of the polymer resin used in the adhesive, the balls are attached to the module in a compliant and resilient manner while leaving the majority of the bottom surface of the balls pristine. The array of balls can therefore be plugged into mating sockets in a printed circuit board forming a demountable contact. This facilitates easy removal of the socketable BGA from a board for repair or upgrade purposes as well as allows ease of plugging and unplugging of these BGA's into test and burn-in boards.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com