Stabilizer bar

a stabilizer bar and tube technology, applied in the field of tube stabilizer bars, can solve the problems of reducing the fatigue life of components, overall hardness, ultimate tensile strength, and brittleness, and achieve the effects of reducing manufacturing costs, increasing hardness, and improving fatigue li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

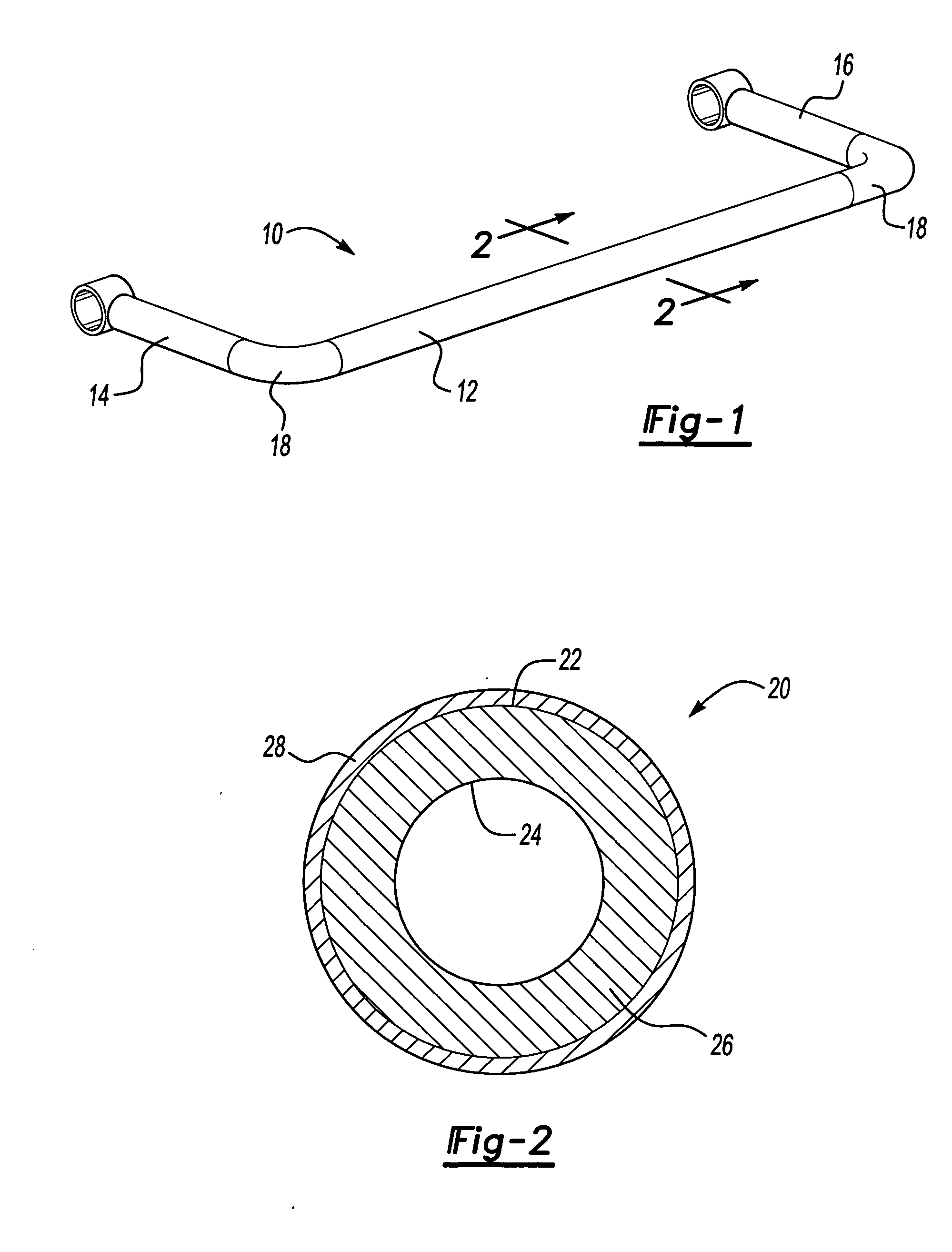

[0012] A stabilizer bar is shown generally at 10 in FIG. 1. The stabilizer bar 10 is formed to have a U-shape with a center portion 12 and first and second transversely extending legs 14, 16. Radiused bends 18 transition from the center portion 12 to the first and second transversely extending legs 14, 16. The first and second transversely extending legs 14, 16 are each attached to a suspension trailing arm or lower control arm (not shown) as known.

[0013] The stabilizer bar 10 includes a tubular body 20 (see FIG. 2). The tubular body 20 includes an outer surface 22 and an inner surface 24 that are spaced apart to define a wall thickness 26. Wall thickness 26 can vary as needed to provide desired vehicle roll resistance.

[0014] The subject invention provides a stabilizer bar 10 that is made from a lower carbon content steel material that is subjected to a heat treating process that does not include tempering. Any type of lower carbon content steel can be used. Typically, a lower car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| elongation property | aaaaa | aaaaa |

| elongation property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com