Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

713results about How to "Reduce inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition with docosapentaenoic acid

InactiveUS20090054329A1Stimulate barrier integrityImproving barrier integrityBiocidePeptide/protein ingredientsEPA - Eicosapentaenoic acidBarrier integrity

This invention concerns a method for stimulating barrier integrity in a subject by administering to a subject a composition comprising docosapentaenoic acid (22:5 n3; DPA). Also the invention concerns a composition comprising DPA and eicosapentaenoic acid (EPA).

Owner:NUTRICIA

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

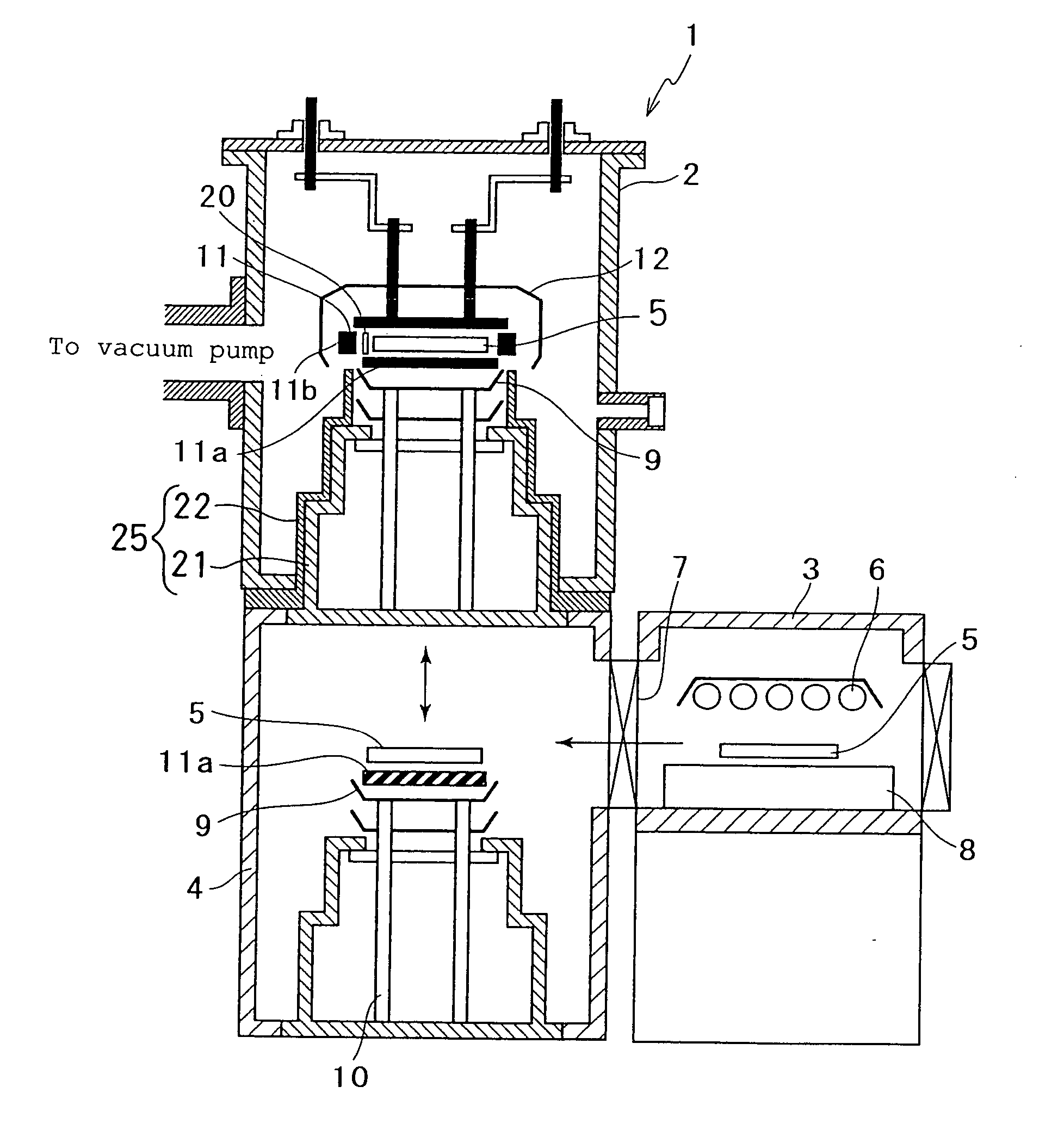

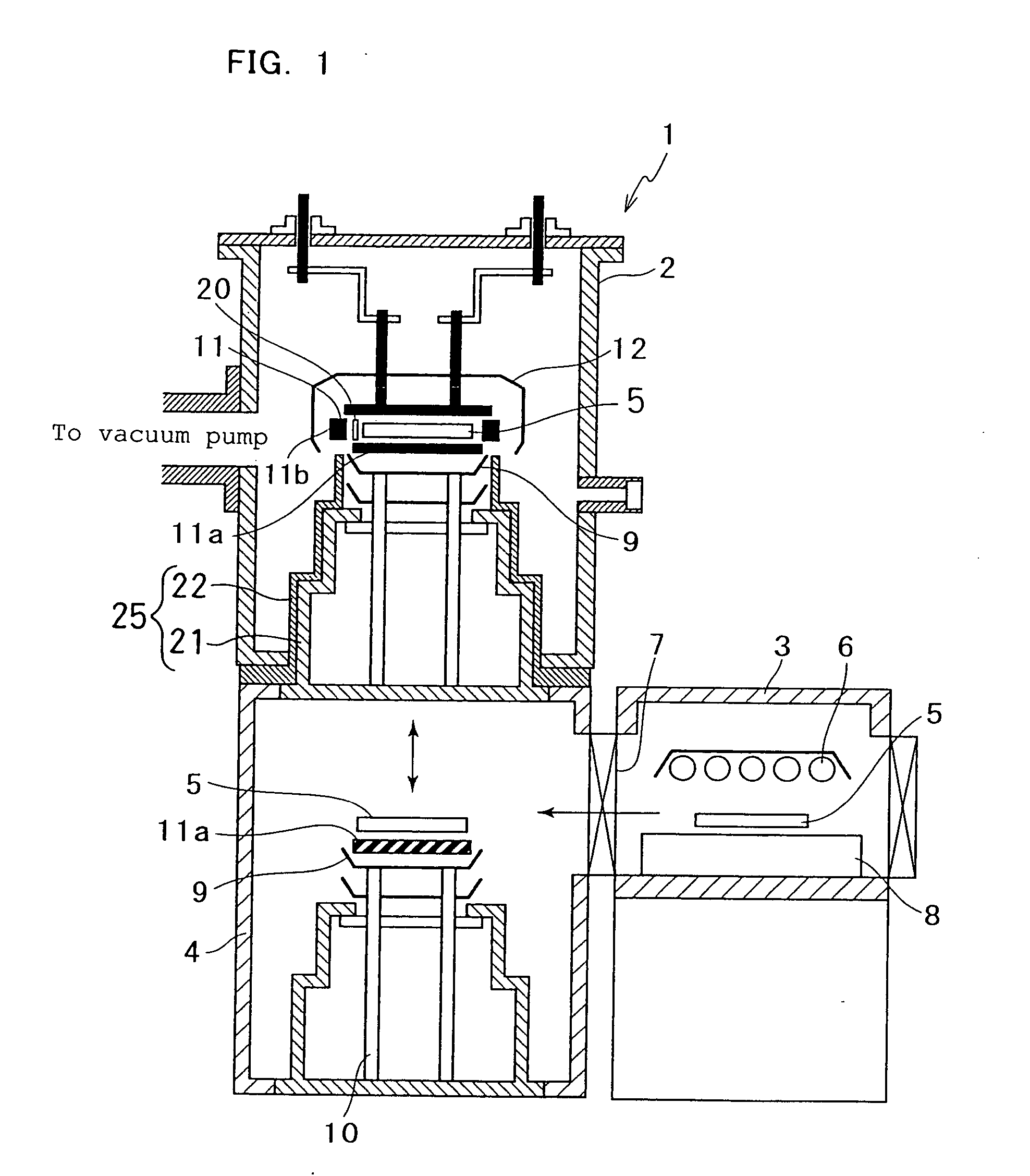

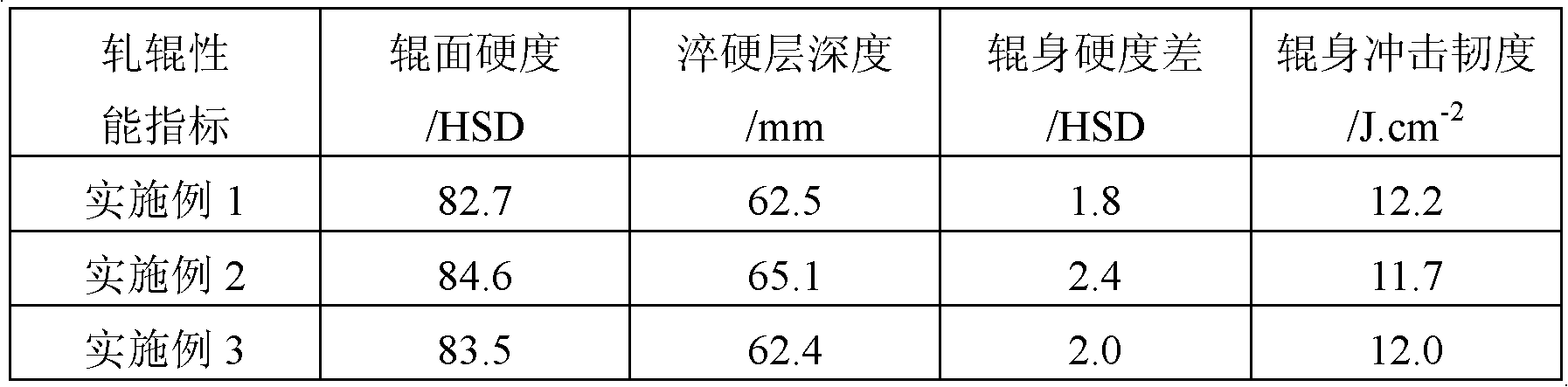

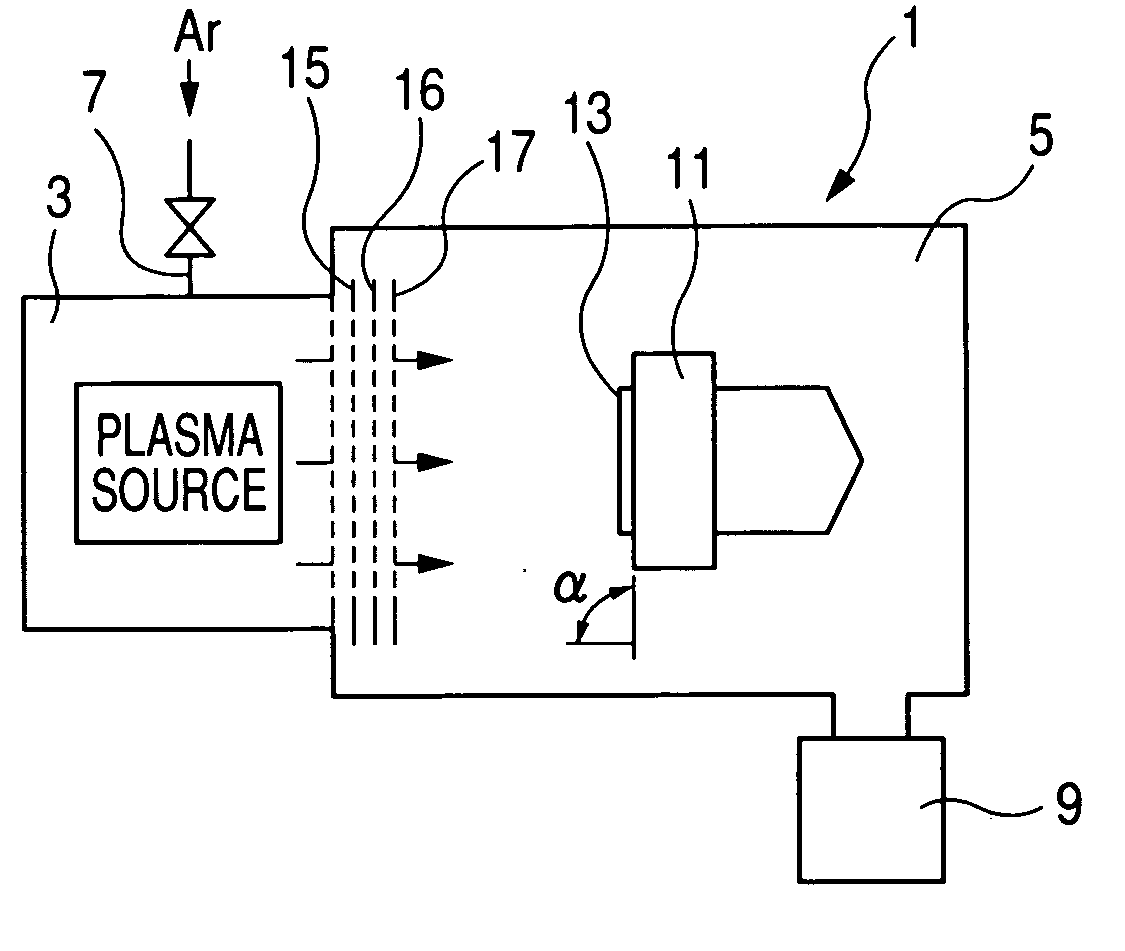

Method of heat treatment and heat treatment apparatus

InactiveUS20060249073A1No longer performedEfficient productionPolycrystalline material growthAfter-treatment detailsSeed crystalEquipment use

The present invention is a method suitable for heat treatment, or a heat treatment method for growing single crystal silicon carbide by a liquid phase epitaxial method, wherein a monocrystal silicon carbide substrate as a seed crystal and a polycrystal silicon carbide substrate are piled up, placed inside a closed container, and subjected to high-temperature heat treatment, by which very thin metallic silicon melt layer is interposed between the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate during heat treatment, and single crystal silicon carbide is liquid-phase epitaxially grown on the monocrystal silicon carbide substrate. The closed container is in advance heated to a temperature exceeding approximately 800° C. in an preheating chamber kept at a pressure of approximately 10−5 Pa or lower, the closed container is reduced in pressure to approximately 10−5 Pa or lower, and the container is transported and placed in the heat chamber, which is in advance heated to a prescribed temperature in a range from approximately 1400° C. to 2300° C., in a vacuum at a pressure of approximately 10−2 Pa or lower or in an inert gas atmosphere at a prescribed reduced pressure, by which the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate are heated in a short time to a prescribed temperature in a range from approximately 1400° C. to 2300° C. to produce single crystal silicon carbide which is free of fine grain boundaries and approximately 1 / cm2 or lower in density of micropipe defects on the surface. Further, the present invention is heat treatment equipment used in carrying out the heat treatment method.

Owner:THE NEW IND RES ORG

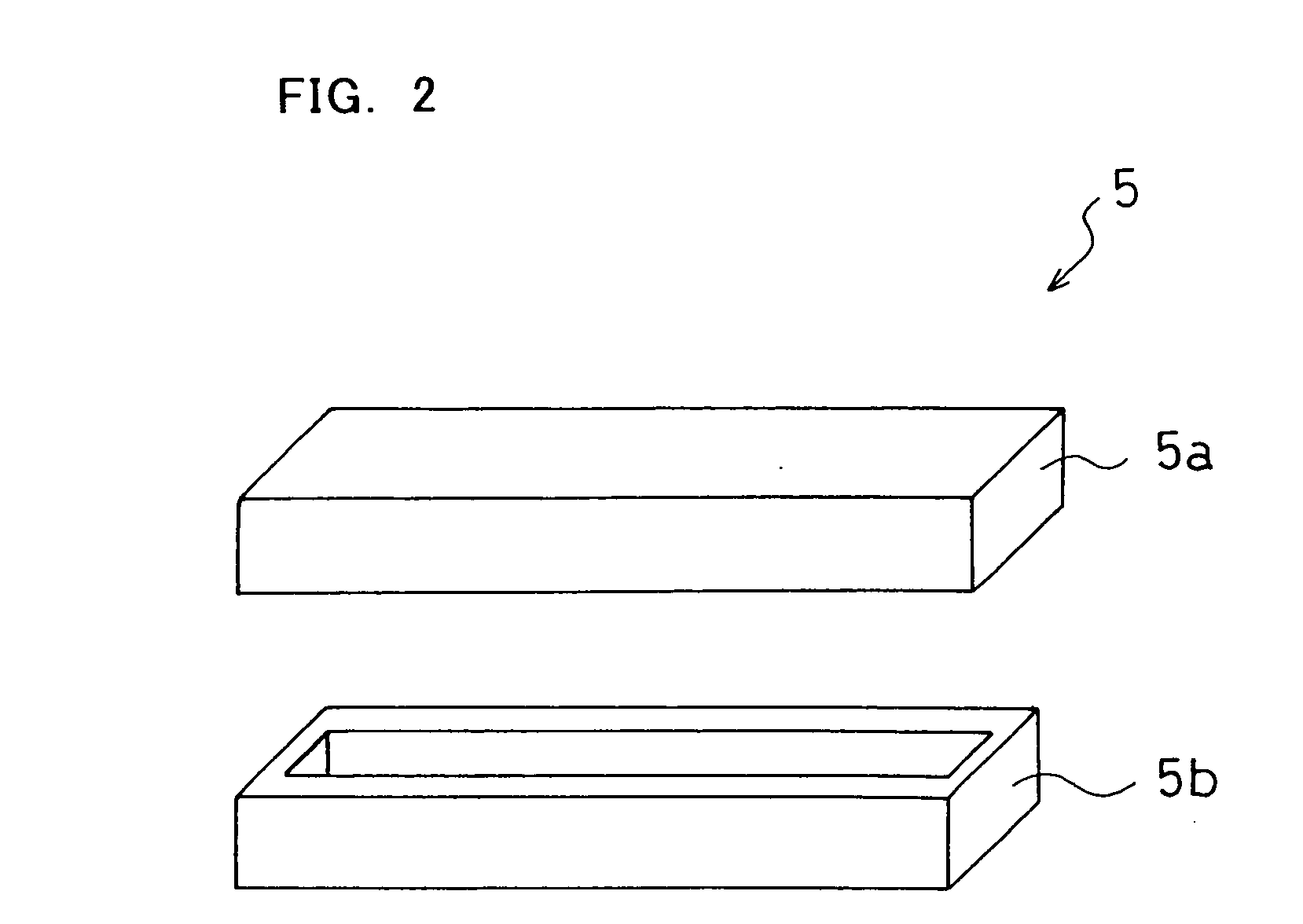

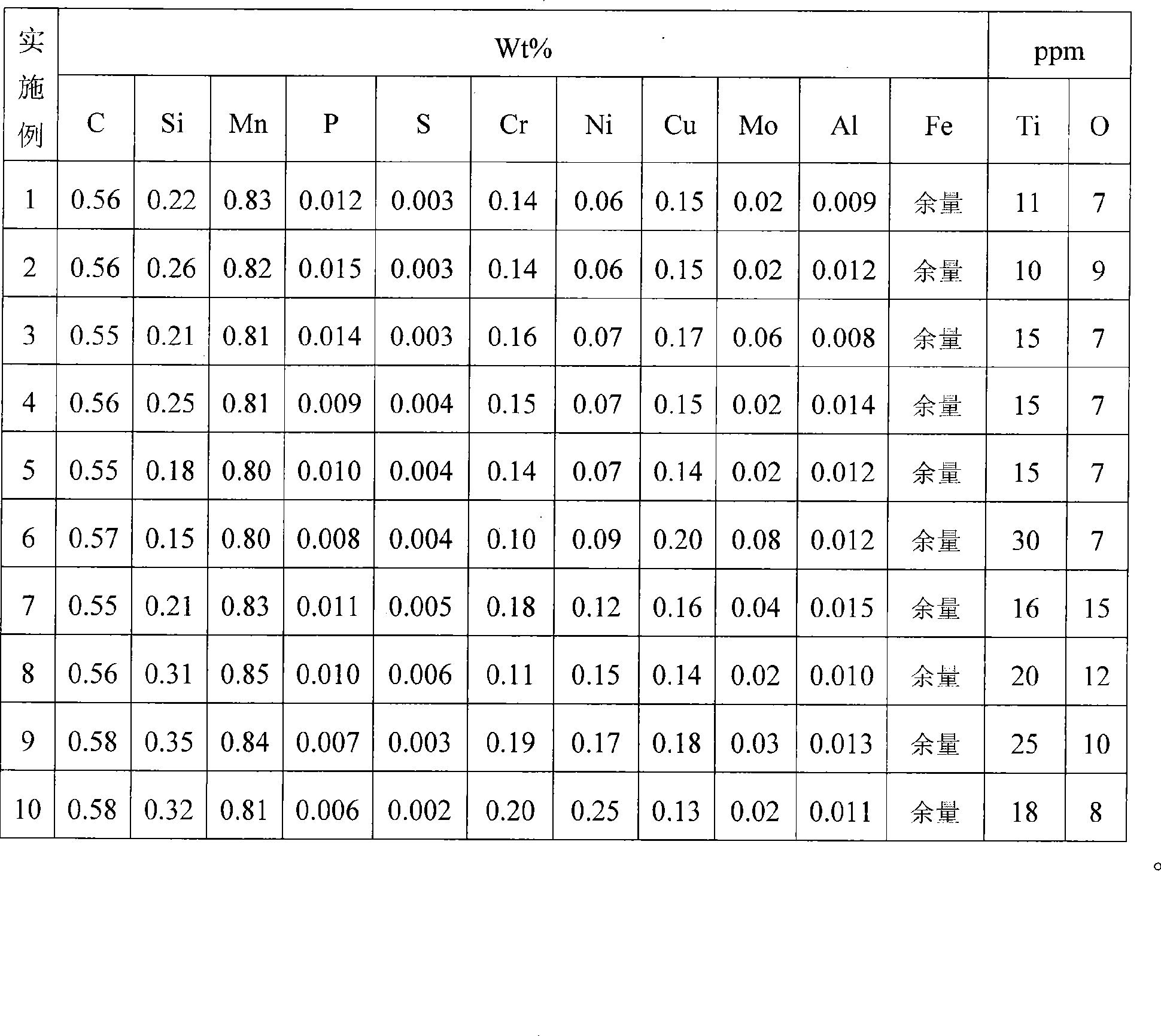

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

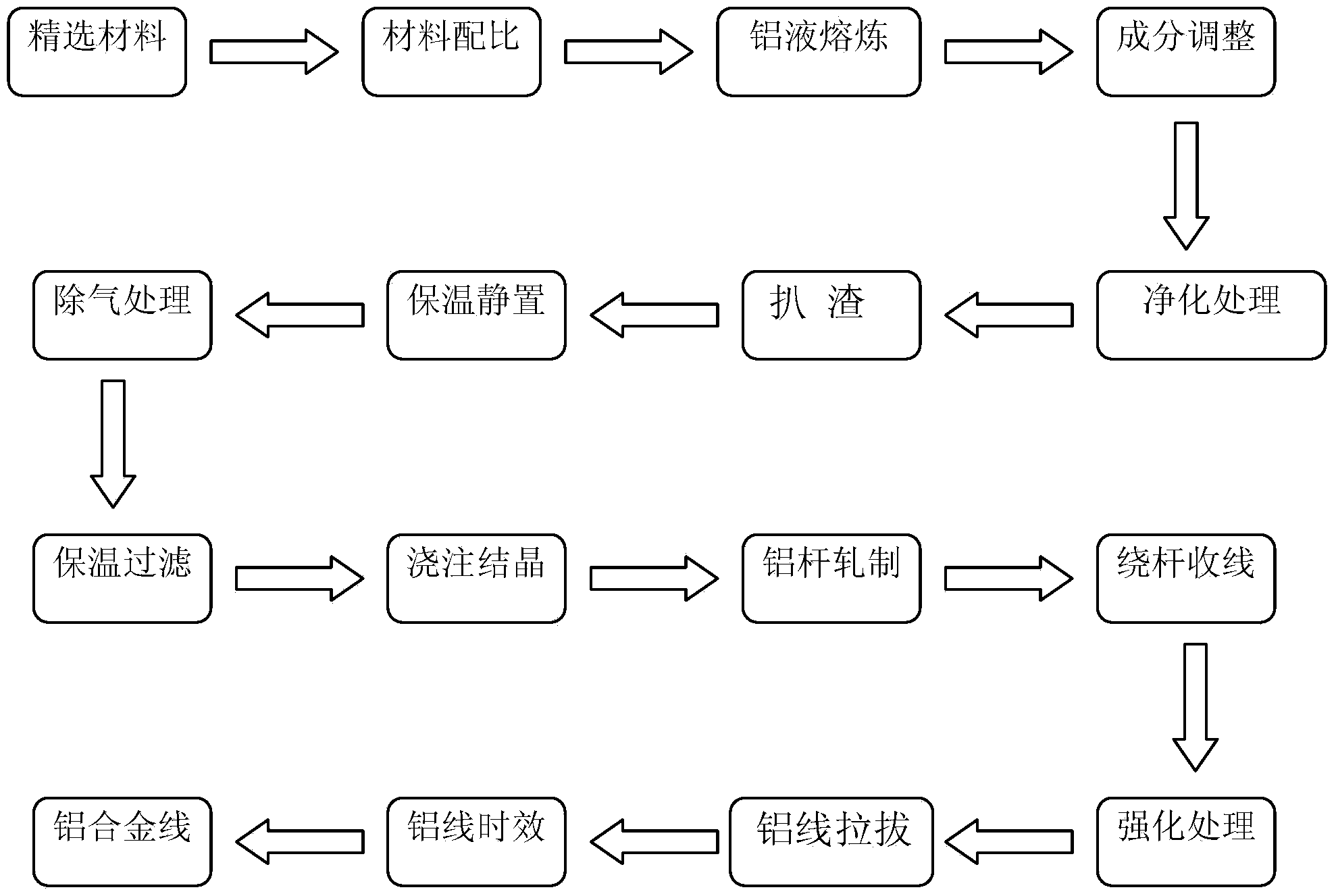

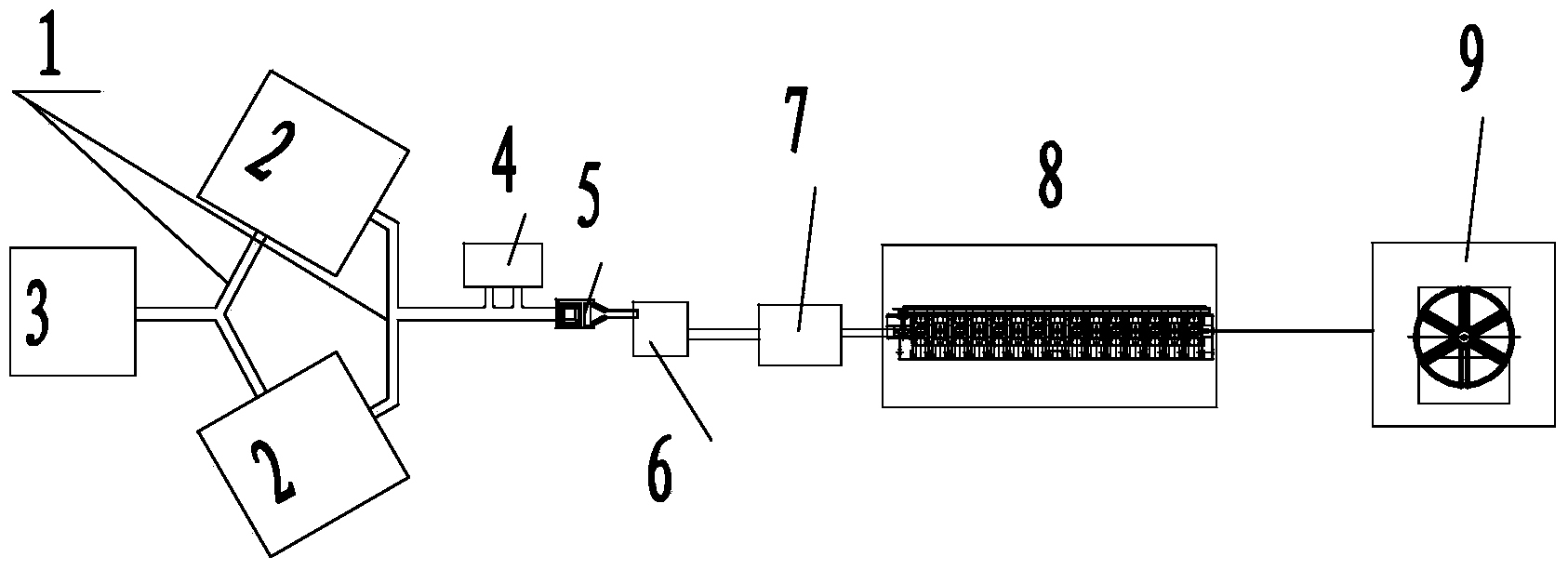

Medium strength aluminium alloy wire with conductivity of 60% IACS, and preparation method thereof

ActiveCN103820685AHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureRare-earth elementManufacturing technology

The invention relates to a medium strength aluminium alloy wire with conductivity of 60% IACS, and a preparation method thereof, and belongs to the field of alloy manufacturing technology. The alloy elements comprise, by weight, 0.16%-0.22% of iron, 0.24%-0.30% of silicon, 0.40%-0.48% of magnesium, 0.01%-0.02% of boron and 0.08%-0.15% of a rare earth element, with the balance being aluminium. The medium strength aluminium alloy wire with a product conductivity higher than or equal to 60% IACS and tensile strength higher than or equal to 230 MPa is obtained by processes of selecting materials, smelting liquid aluminium, adjusting liquid aluminium ingredients, carrying out purifying treatment, deslagging, standing with heat preservation, degassing, filtering with heat preservation, casting and crystallizing, rolling an aluminum rod, drawing and aging. The wire and cable produced by using the aluminium alloy can be erected continuously by a conventional construction process. In a circuit operation process, circuit loss can be reduced; construction fee can be reduced; and the medium strength aluminium alloy has significant economic benefits and social benefits.

Owner:WUXI HUANENG ELECTRIC CABLE

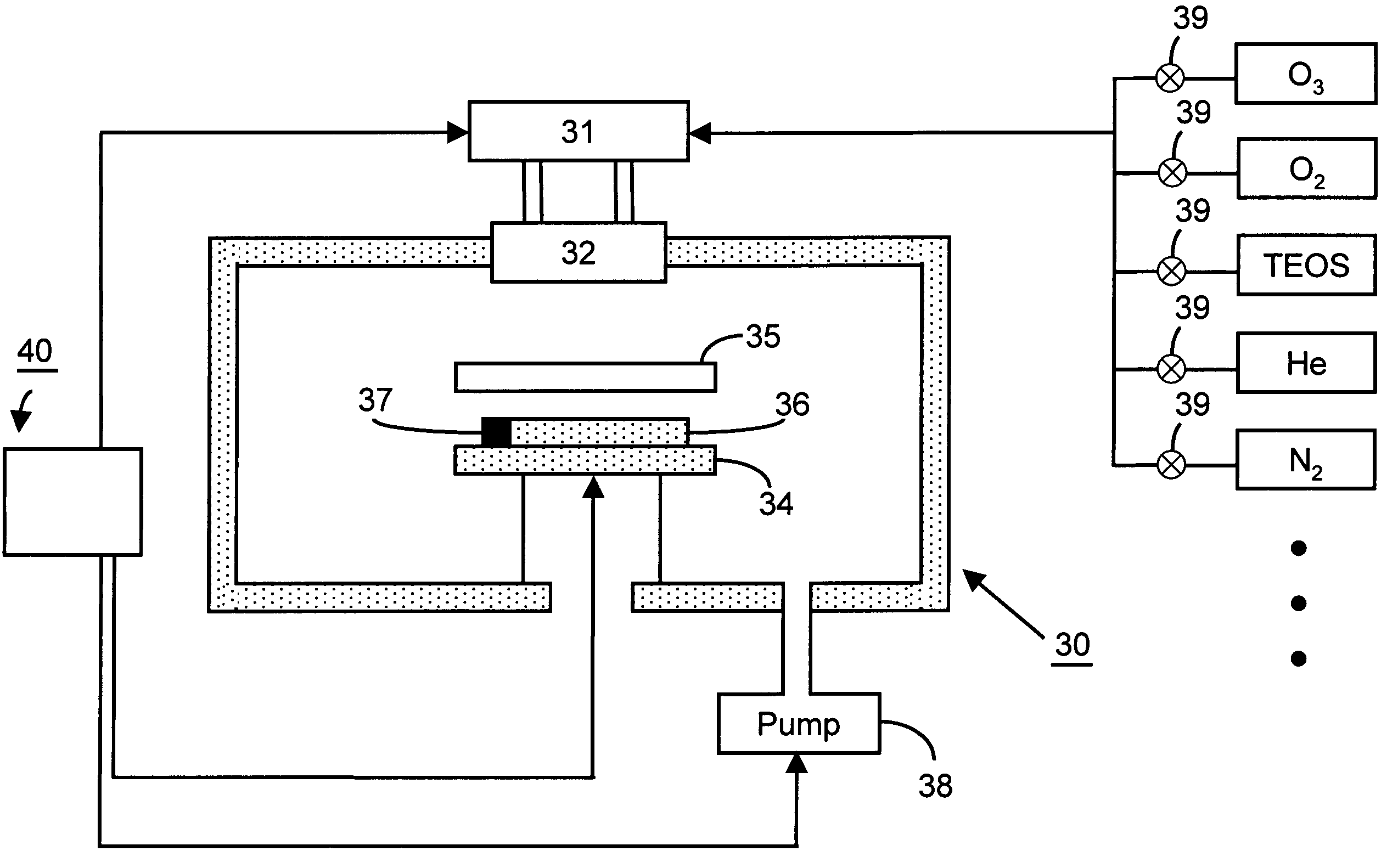

Crack and residue free conformal deposited silicon oxide with predictable and uniform etching characteristics

ActiveUS20050106318A1Pressure is easy to controlReduce inclusionsDecorative surface effectsVacuum evaporation coatingCrazingDecomposition

A silicon oxide layer is formed by oxidation or decomposition of a silicon precursor gas in an oxygen-rich environment followed by annealing. The silicon oxide layer may be formed with slightly compressive stress to yield, following annealing, an oxide layer having very low stress. The silicon oxide layer thus formed is readily etched without resulting residue using HF-vapor.

Owner:ROBERT BOSCH GMBH

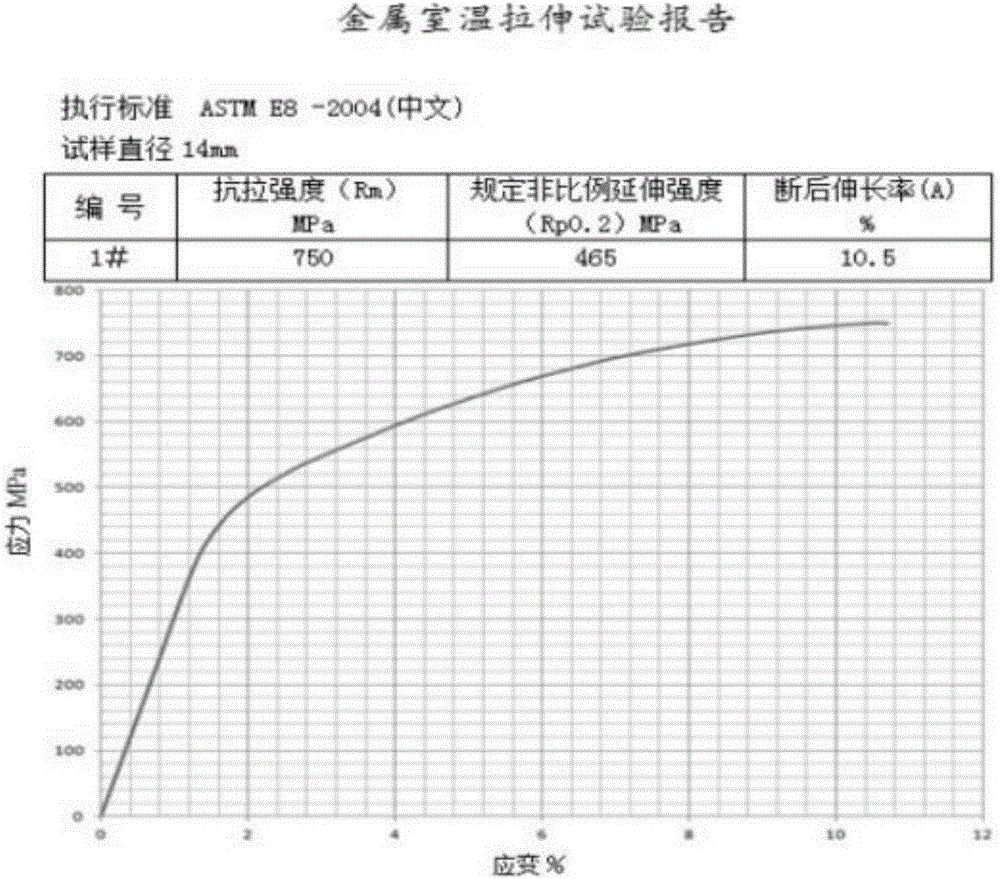

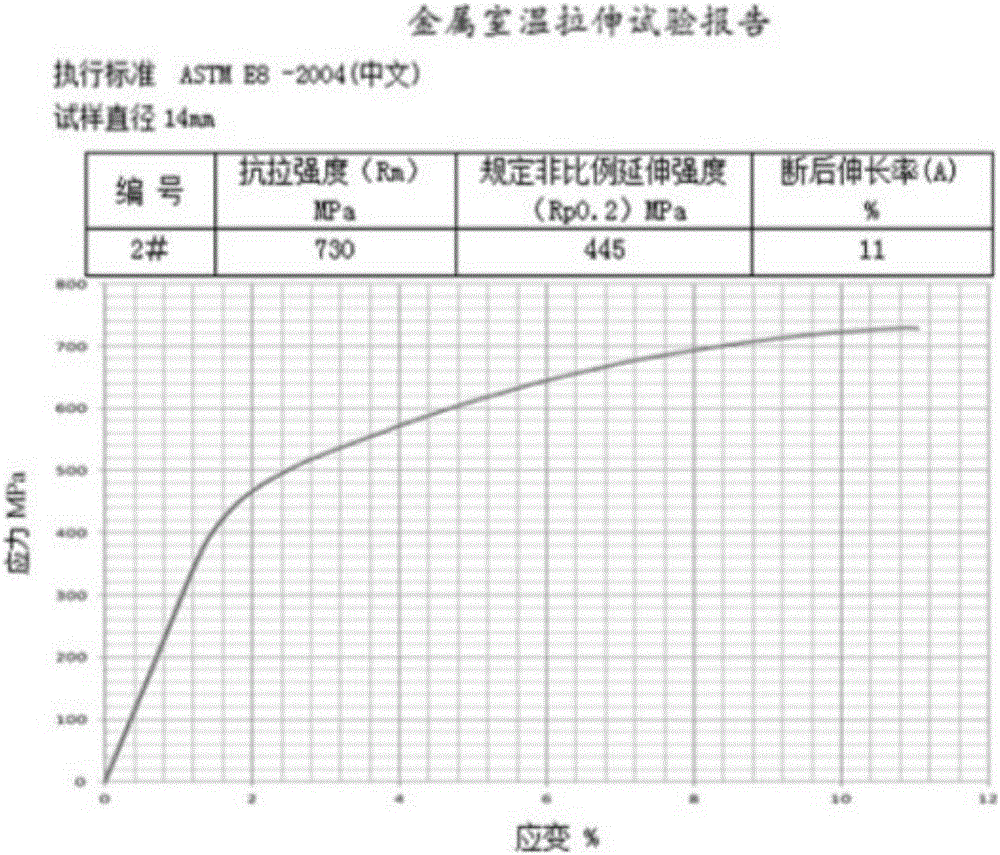

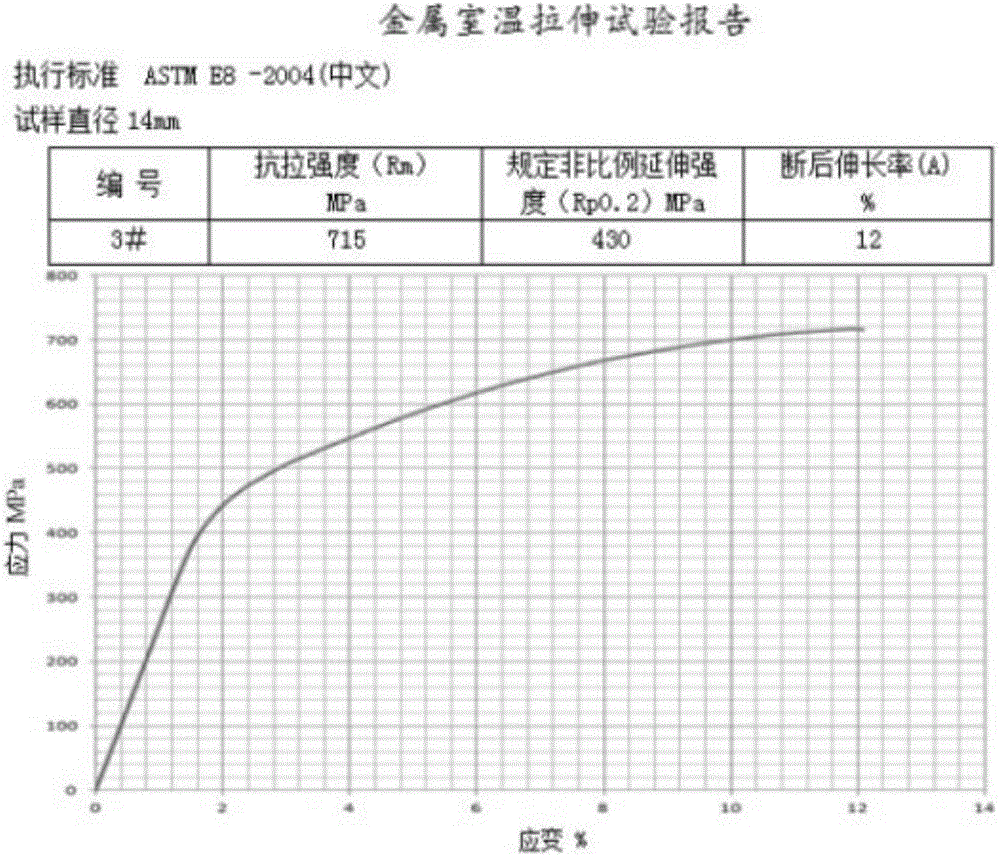

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

Cu-Mn Alloy Sputtering Target and Semiconductor Wiring

InactiveUS20100013096A1Functional deteriorationStrong oxidizing powerCellsSemiconductor/solid-state device detailsSelf-diffusionDeposition process

Proposed is a Cu—Mn alloy sputtering target, wherein the Mn content is 0.05 to 20 wt %, the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce is 500 wtppm or less, and the remainder is Cu and unavoidable impurities. Specifically, provided are a copper alloy wiring for semiconductor application, a sputtering target for forming this wiring, and a manufacturing method of a copper alloy wiring for semiconductor application. The copper alloy wiring itself for semiconductor application is equipped with a self-diffusion suppression function for effectively preventing the contamination around the wiring caused by the diffusion of active Cu, improving electromigration (EM) resistance, corrosion resistance and the like, enabling and facilitating the arbitrary formation of a barrier layer, and simplifying the deposition process of the copper alloy wiring for semiconductor application.

Owner:JX NIPPON MINING& METALS CORP

Method for preparing nanometer tungsten combined powder by collosoling, spraying and desiccating and hot reducing

The invention relates to a powder preparation process, especially for preparing a nano composite powder, which belongs to the field of powder metallurgical technique. The preparation process is characterized by: weighing the different metal salts in proportion for preparing a salt solution and a mixed salt solution; adding a few acid or alkali for controlling the pH value in a range of less than 4 or more than 10, adding 0.1% to 5% of surfactant, spray drying at the temperature of between 300 C. and 350 C. for preparing the nano oxide composite powder or composite salt powder precursor; obtaining the nano tungsten base composite powder by first reduction at 400 C. to 600 C. and second reduction at 650 C. to 1000 C. . The nano tungsten base composite powder prepared by the process has superfine granularity, uniform distribution, high purity, and good sintering activity.

Owner:CENT SOUTH UNIV

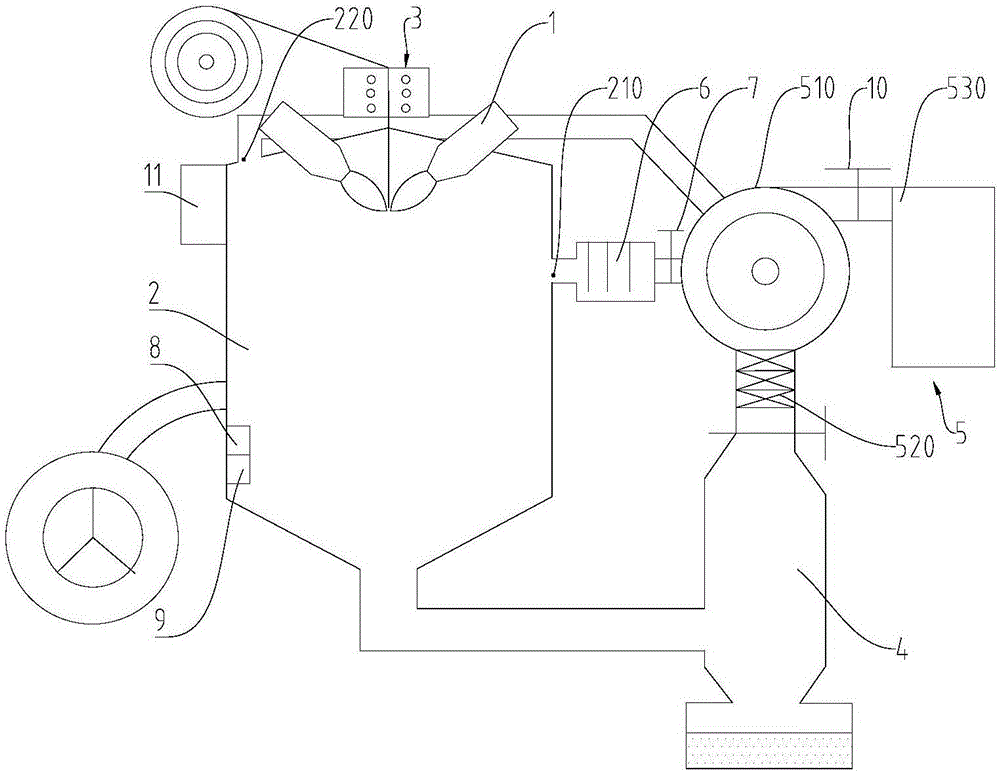

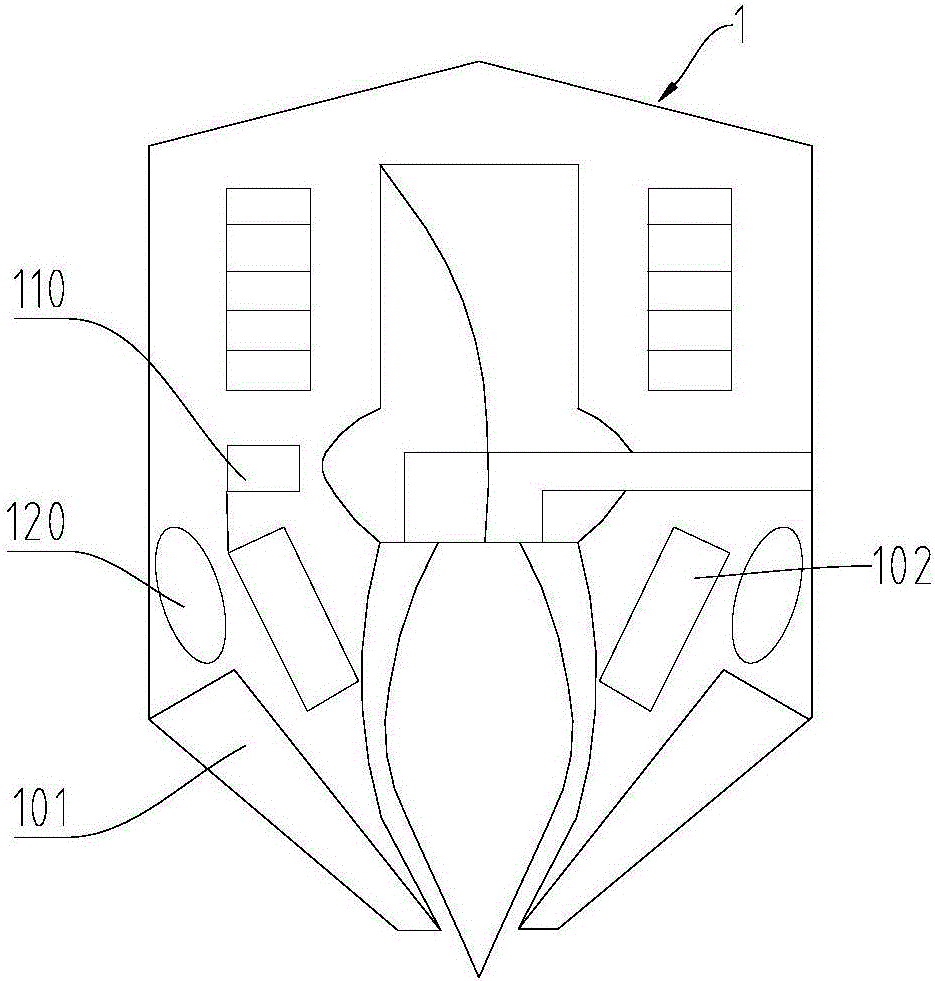

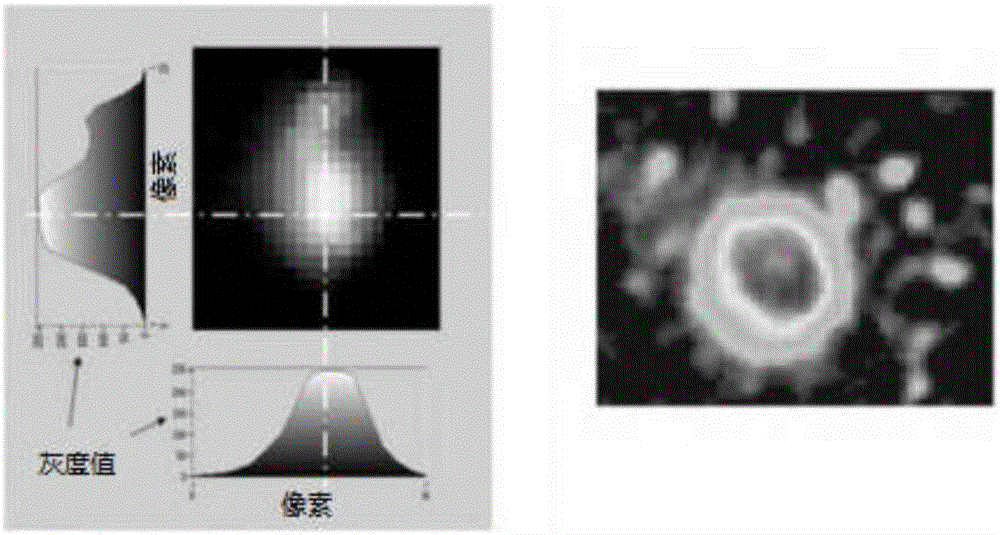

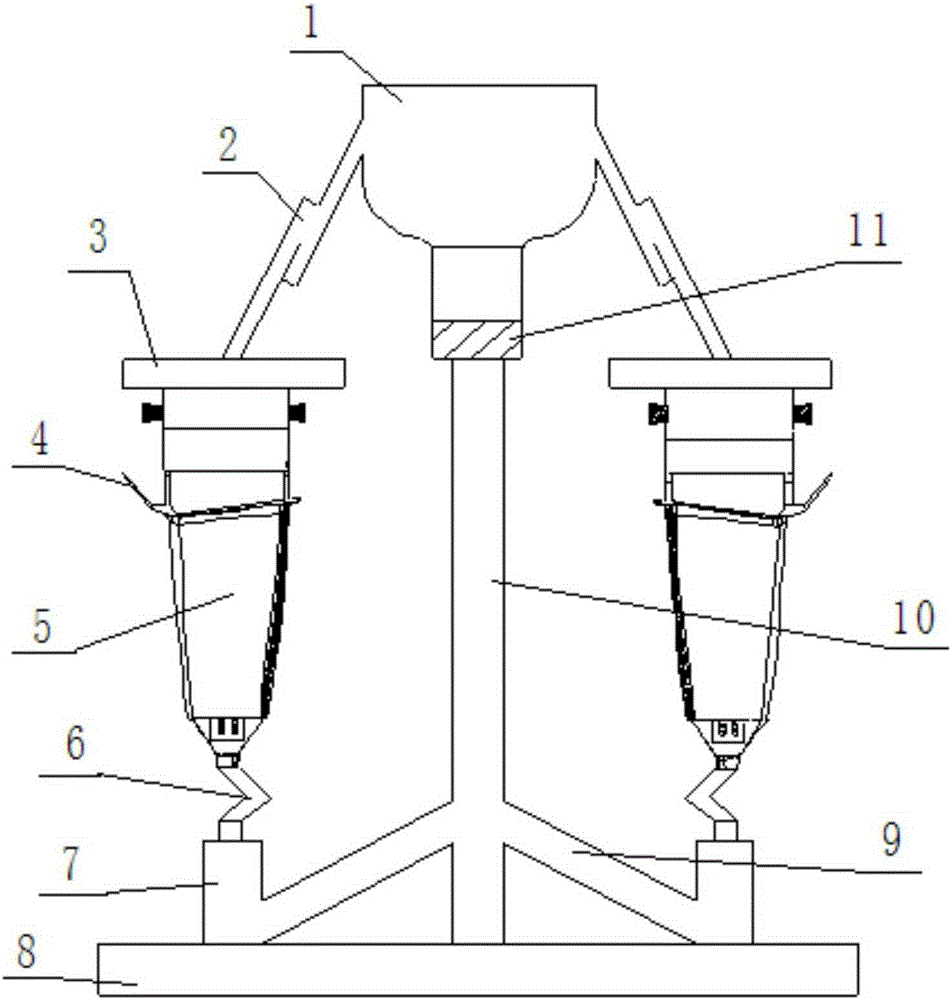

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

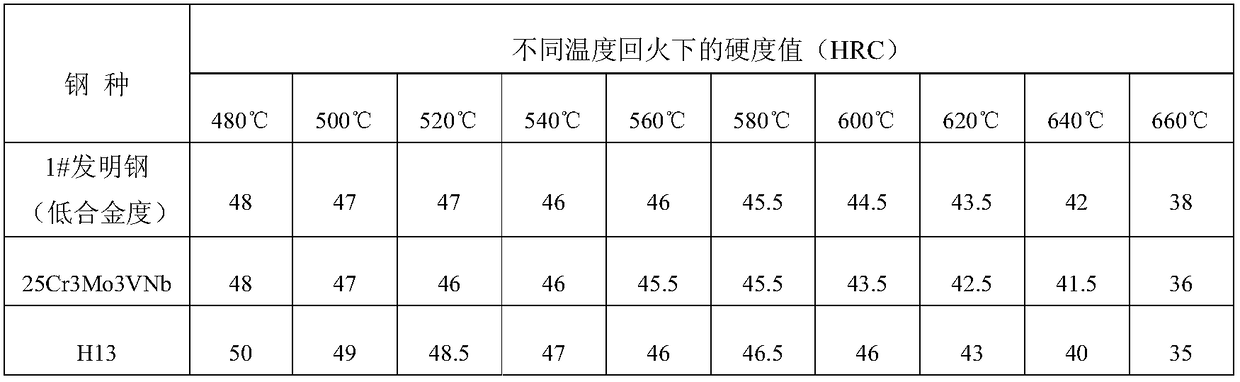

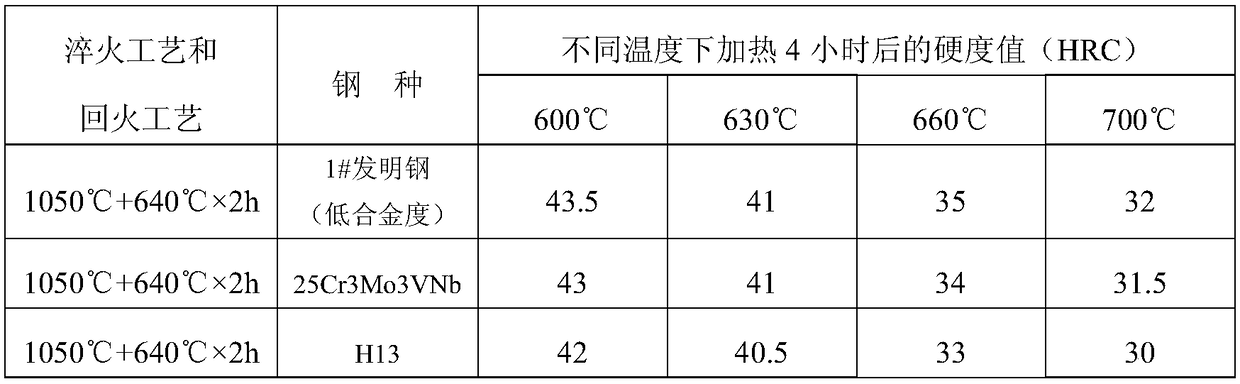

High-temperature, high-strength and low-carbon hot work die steel and preparation method thereof

The invention discloses hot work die steel capable of being used for a long term at the working condition of 600-700 DEG C and belongs to the field of material and preparation. The hot work die steelcomprises the following components in percentage by mass: 0.12-0.30 of C, equal to or less than 0.5 of Si, equal to or less than 0.5 of Mn, 1.0-3.0 of Cr, 1.5-2.5 of Mo, 0.3-1.2 of W, 0.5-1.6 of Ni, 0.2-1.0 of V, 0.03-0.15% of Nb, equal to or less than 0.05 of N, equal to or less than 0.03 of S, equal to or less than 0.03 of P, equal to or less than 3.5 of (Mo+W), equal to or less than 1.0 of (Nb+V) and the balance of Fe and unavoidable impurity elements. According to the hot work die steel, low carbon is adopted to form lath martensite so as to obtain high tenacity at room temperature and lowtemperature; through alloying of Cr, W, Mo, V, Nb and the like and the thermal deformation optimization and thermal treatment technology, solution strengthening is improved and MC and M2C type carbide still keeping stability at 600-700 DEG C is formed so as to obtain high temperature strength and thermal stability of the material. Compared with the commonly used hot work die steel at present including H13, 25Cr3Mo3NiNbZr and the like, the high temperature strength at 700 DEG C of the hot work die steel is improved by 50-100%, the tempering thermal stability is improved by 50-100%, the problemabout hot work die steel used at 600-700 DEG C is better solved, and the hot work die steel has longer service life at 600 DEG C and below.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing tungsten-copper composite material with fine grain

The invention relates to the field of powder metallurgy technology characterized in that, forming the powder with 200 MPa-500 MPa and feeding into sintering furnace, elevating the temperature to 400-700 deg. C. at the speed of 5-20 deg. C per minutes, heat preserving for 15-120 mins, elevating the temperature to sintering temperature of 1150-1350 deg. C. at the speed of 20-60 deg. C per minutes, heat preserving for 30-120 mins.

Owner:CENT SOUTH UNIV

Bright corrosion resisting zinc-iron alloy plating process

The invention discloses a bright corrosion resisting zinc-iron alloy plating process which comprises the step of adding complexing agent and ferrous ion to zincate zincification solution. Zinc-iron alloy plating bath comprises 6-12g / L of ZnO, 90-150 g / L of NaOH, 20-50 mL / L of trolamine, 5-13g / L of FeSO4.7H2O, 2-8mL / L of DE, 0.5-1g / L of ethylenediamine tetracetic acid, 0.02-0.1 g / L of vanillina, 0.02-0.1 g / L of dodecyl sodium sulfate and 1-2 g / L of Zn powder. The process can reach the cathode current efficiency of 90 percent, is easy to control the alloy component and can obtain bright zinc-iron alloy plating containing 17-20 percent of iron; in addition, electrochemistry and salt-spray fog corrosion results show that the bright zinc-iron alloy plating has better corrosion resistance than pure zinc plating chromating, and the bright zinc-iron alloy plating has better protection property and decoration performance.

Owner:SOUTH CHINA UNIV OF TECH

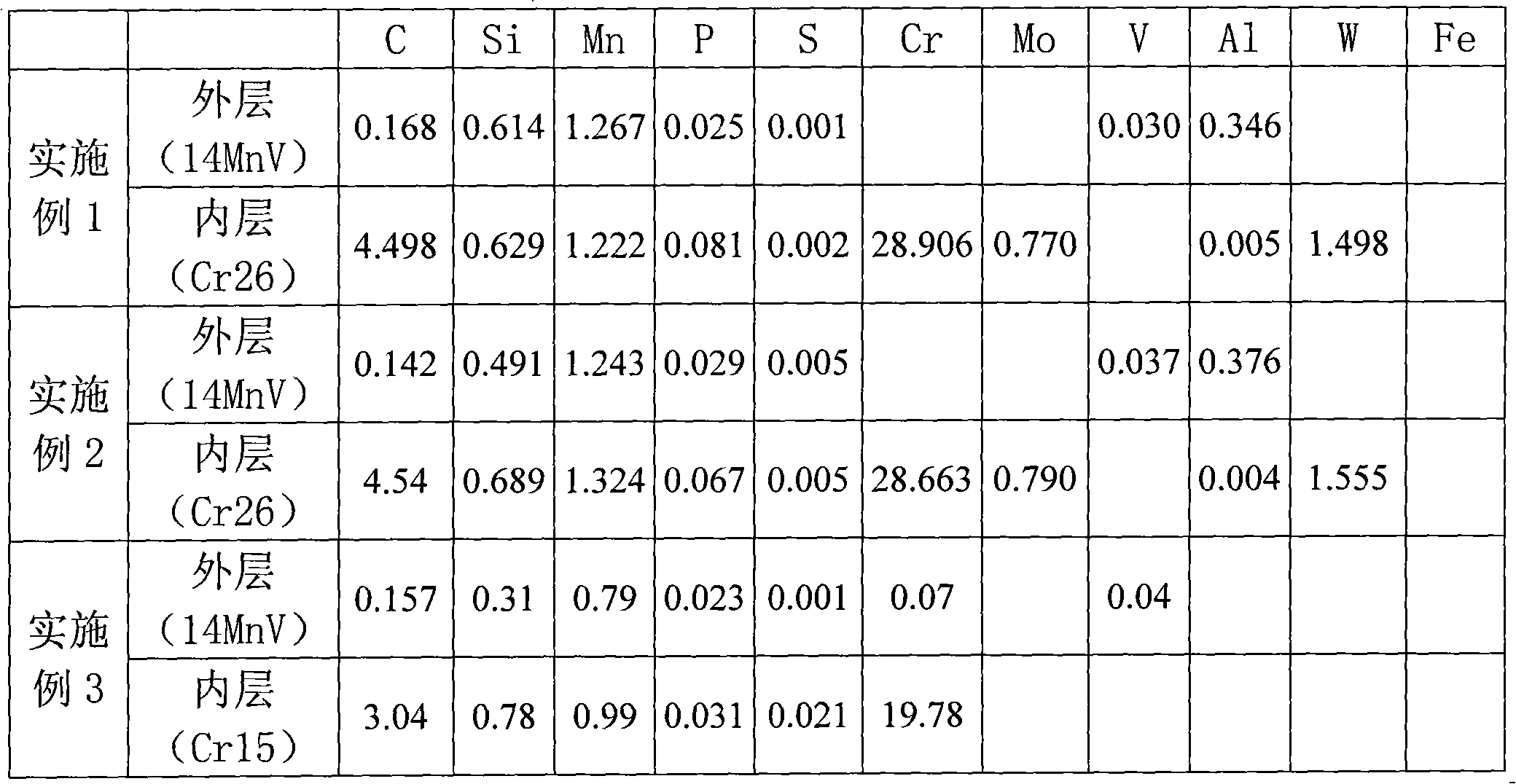

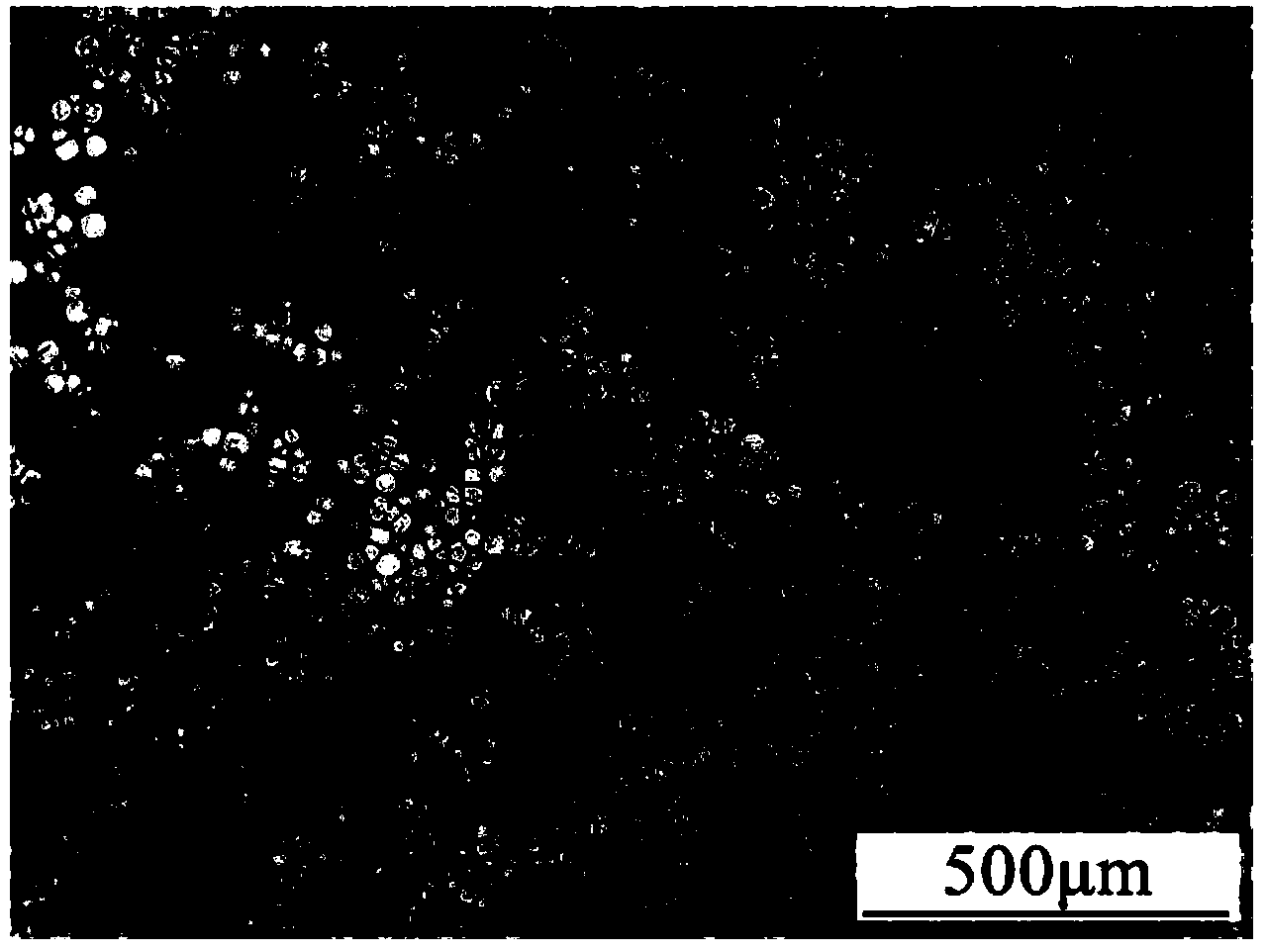

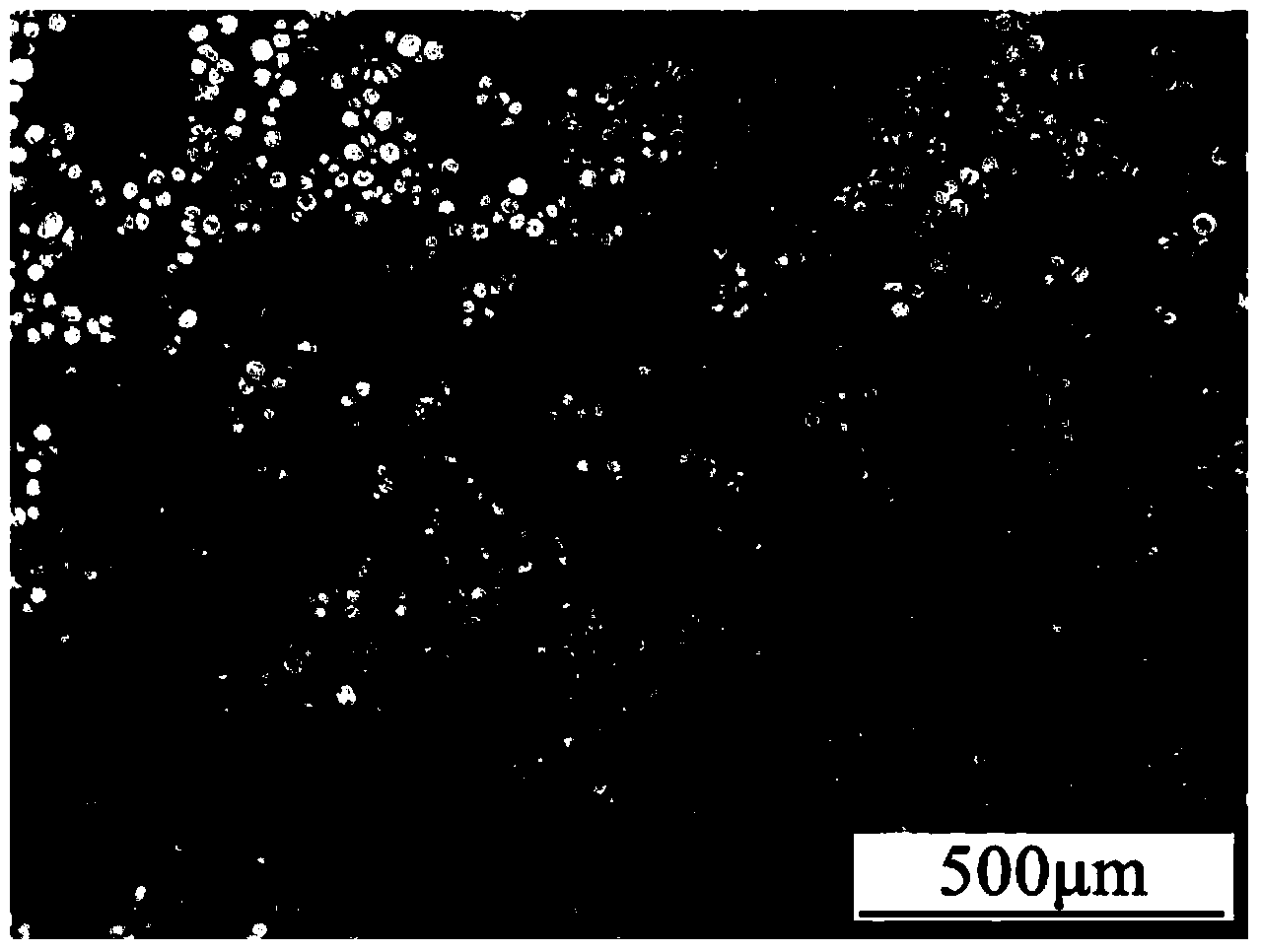

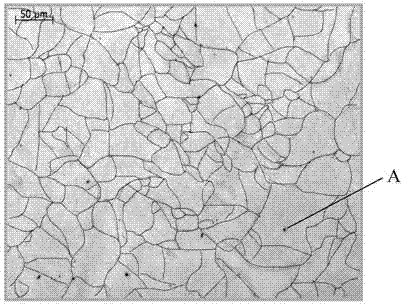

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube die after being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention also discloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method can be metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Preparation method of semisolid slurry of rare earth magnesium alloy

The invention discloses a preparation method of a semisolid slurry of a rare earth magnesium alloy. According to the guiding principle of promoting grain nucleation and inhibiting grain growth, pure aluminium is added into rare earth magnesium alloy melt, and a lot of fine dispersed Al2RE intermetallic compound particles which are generated by an in-situ reaction provide nuclei of heterogeneous nucleation for primary alpha-Mg so as to promote grain nucleation; and after the melt is transferred to a tundish, considering stability of a solid-liquid interface during the solidification process, the growth of a primary phase is delayed by reasonable control of cooling conditions in different stages of solidification so as to realize the effect of inhibiting grain growth. The invention provides a low-cost agitation-free green semisolid slurry preparation method. In comparison with a traditional semisolid slurry preparation technology, efficiency of the preparation method is improved greatly and cost is reduced remarkably. By the preparation method, a high-quality rheological slurry is provided for follow-up rheoforming of rare earth magnesium alloy, such as rheo-die casting, rheological squeeze casting and the like. The preparation method has a wide application prospect in rheoforming of a magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

Smelting method of ultra-low oxygen pure steel

The invention relates to the field of smelting and specifically relates to a smelting method of ultra-low oxygen pure steel. A vacuum electric furnace or a vacuum induction furnace is adopted for smelting and vacuum pouring, and the vacuum degree is required to be 0.05-100Pa; after a metal charge is molten, a vacuum state is kept, molten metal is boiled for 5-30min, the oxygen content is reduced by vacuum carbon-oxygen reaction, and no deoxidizer or deoxidization alloy is added. The standing is performed for 20-30min after alloying, and the molten metal is boiled for 5-30min in the vacuum state. When the oxygen content is below 10ppm, 0.5-3kg / t of Si-Ca-Al-Mg-RE composite deoxidizer is added, the standing is performed for 1-10min after adding, then vacuum pouring is performed, and then the pure steel with the total oxygen content of below 4ppm can be obtained. The invention aims at solving the problems that existing steel ingots and cast blanks have more internal inclusions with relatively large sizes, the purity is not high and the channel segregation is serious. Simultaneously, by adopting a rare earth composite additive to perform modification treatment on the inclusions in the steel, the sizes of the inclusions are reduced, and the number of the inclusions in the steel is reduced, thus a new effective way is provided for pure smelting of molten steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

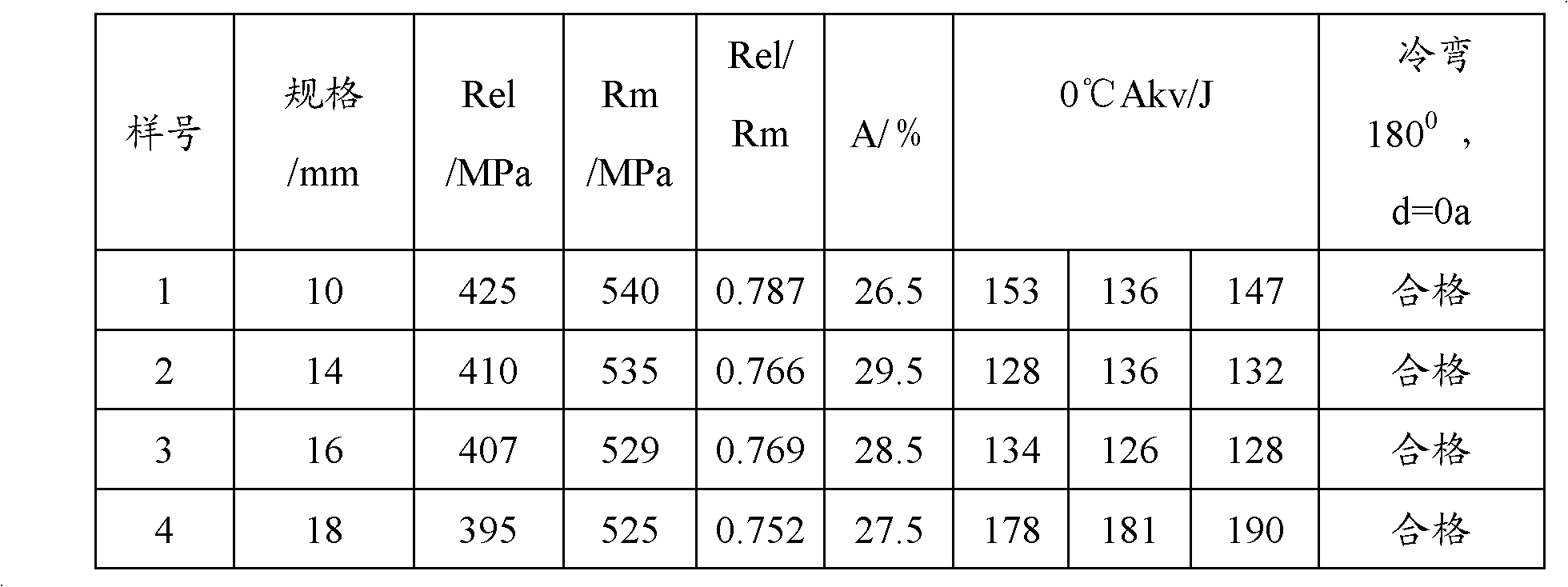

Steel plate for automobile axle housing and production method thereof

Steel plates for automobile axle housings, the percentage by weight is C0.1~0.18%, Si≤0.5%, Mn1.2~1.6%, Ti0.01-0.06%, Nb0.01-0.04%, P:≤0.025%, S: ≤0.015% and the rest are Fe and impurities. The steel plate production method: casting molten steel smelted in a converter that meets the chemical composition requirements into a slab, according to the percentages of Ti, Fe and Nb, adding TiFe after LF refining treatment to create white slag, and adding NbFe in the converter process or LF refining; Put the slab into the furnace to heat and keep it warm; the starting temperature of rough rolling is 1080-1120°C, the starting temperature of finish rolling is 910-950°C, the temperature of finishing rolling is 830-870°C, three times of continuous rolling after finishing rolling, rolling The reduction rate of the last three passes is not less than 11%, 8%, and 6%; the shear temperature is 150-300°C. In order to improve the mechanical performance index and cold forming performance of the steel plate.

Owner:LIUZHOU IRON & STEEL

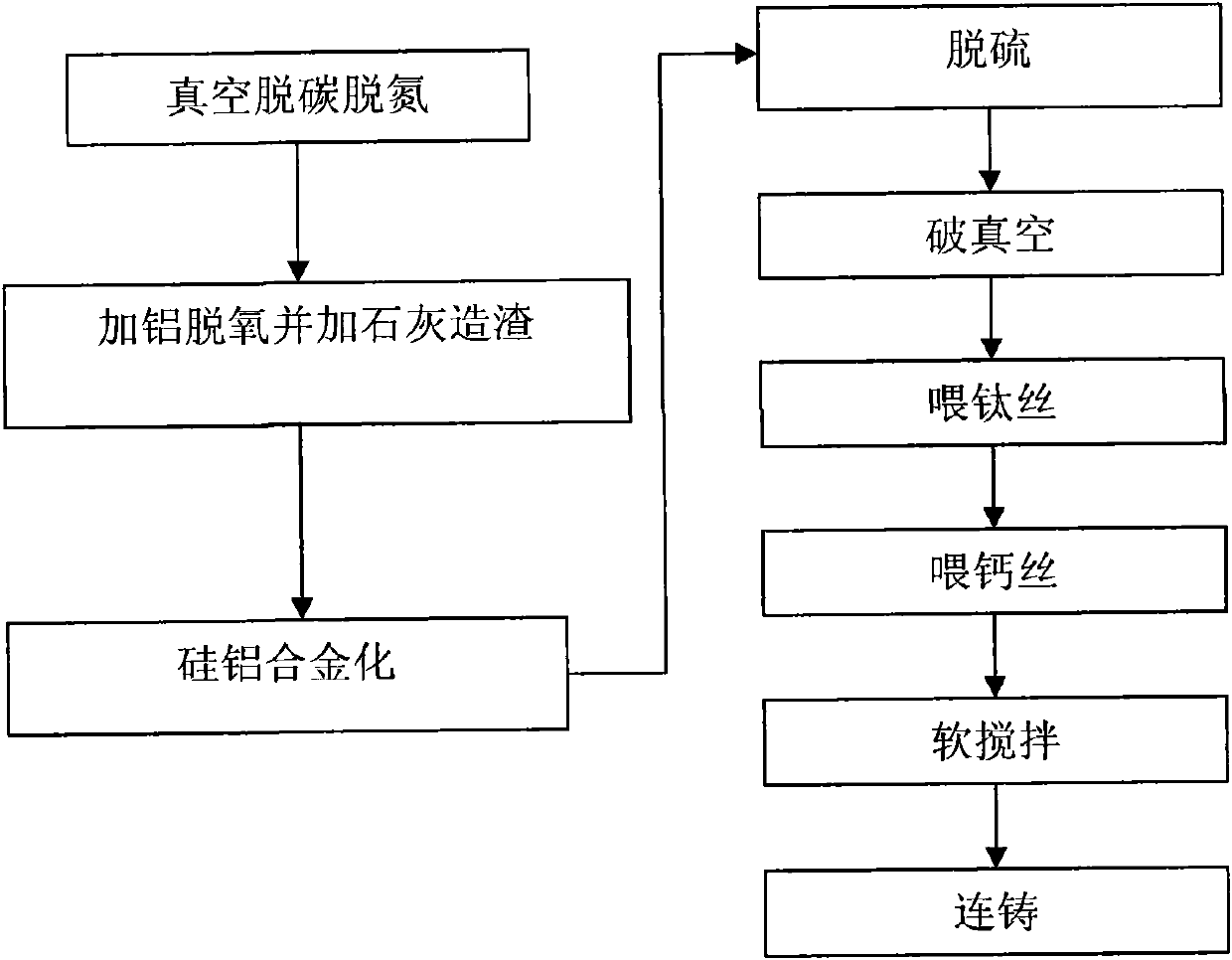

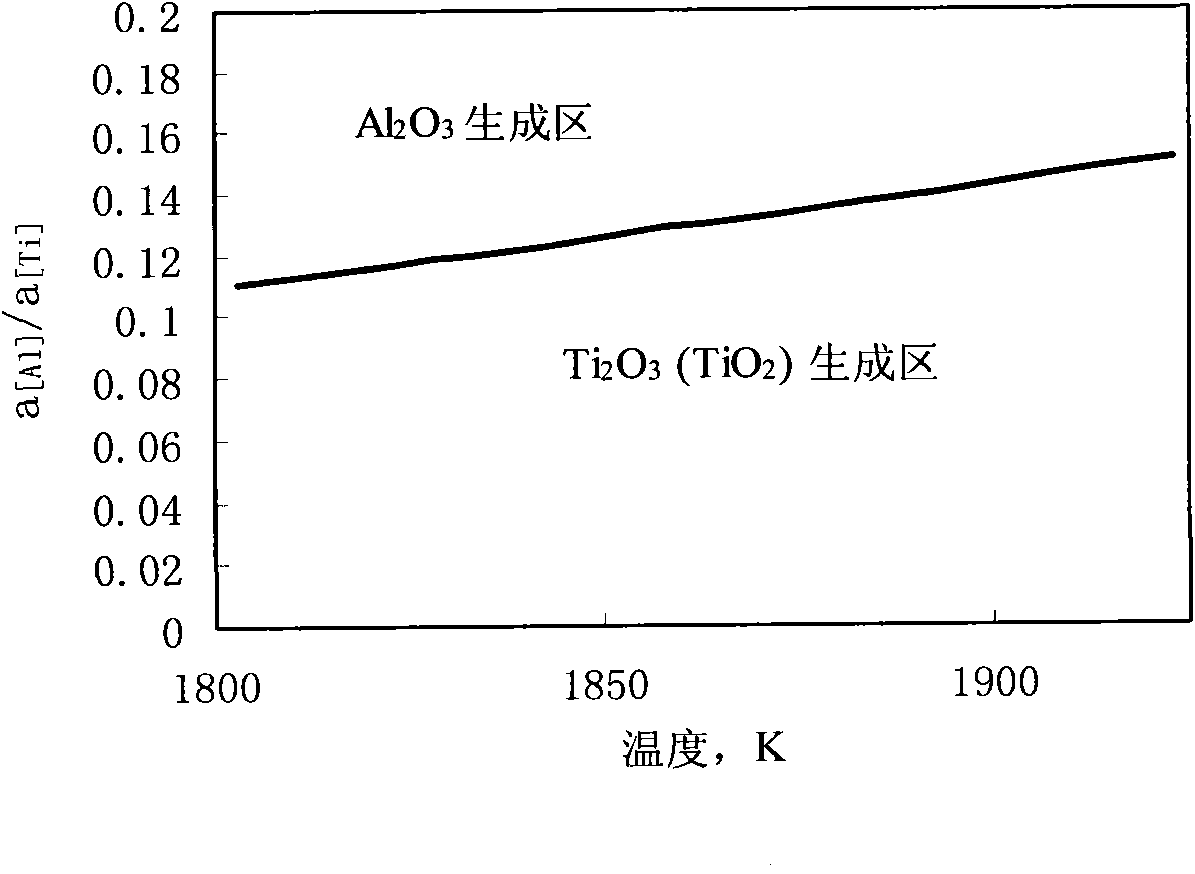

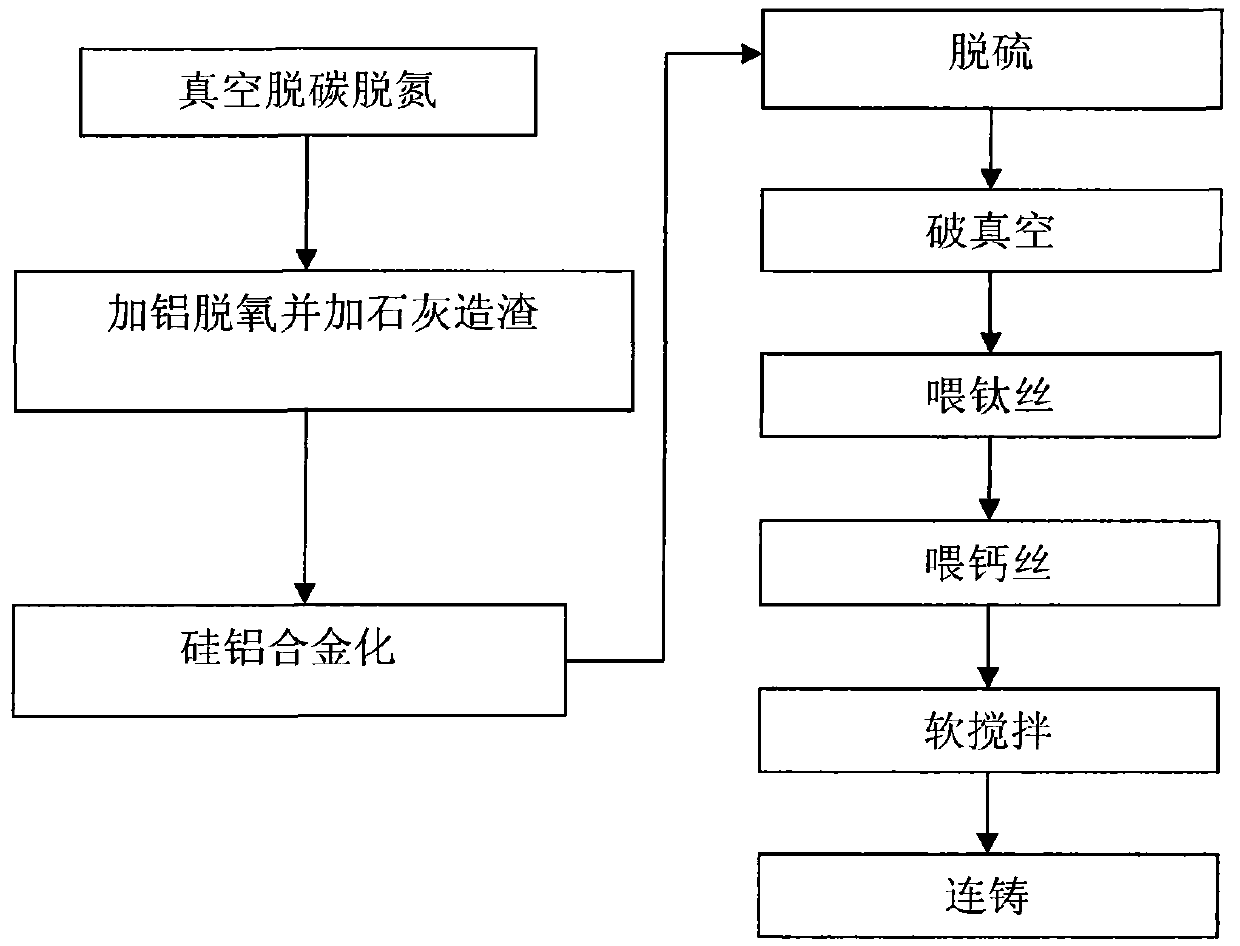

Production method of ultralow-oxygen titanium-containing ferrite stainless steel

The invention discloses a production method of ultralow-oxygen titanium-containing ferrite stainless steel, which comprises the following steps: 1) preparing molten ferrite stainless steel under a vacuum condition in a vacuum oxygen blowing decarburization furnace, wherein the carbon mass percentage content and nitrogen mass percentage content in the molten ferrite stainless steel are both less than 0.01 percent; 2) performing deoxidization, namely adding 6 to 12 kilograms of aluminum block or grains into each ton of steel and adding 10 to 28 kilograms of active lime into each ton of steel; 3) alloying silicon and aluminum, namely adding 2 to 9 kilograms of silicoferrite which contains 70 to 80 percent of silicon into each ton of steel and adding 0 to 1 kilogram of aluminum blocks or grains into each ton of steel, wherein the aluminum content is 0.02 to 0.1 percent; 4) performing desulphurization; (5) breaking vacuum; 6) softly stirring; 7) feeding titanium wires; 8) feeding silicon and calcium wires, wherein the calcium content is 5 to 30ppm; 9) softly stirring; and 10) continuously casting. The method can be used for producing ultralow-oxygen titanium-containing ferrite stainless steel, prevent or inhibit forming magnesia alumina spinel which are harmful impurities in a production process, improve product quality, prevent the water gap of tundish from being blocked in a continuous casting process and guarantee smooth production.

Owner:BAOSHAN IRON & STEEL CO LTD

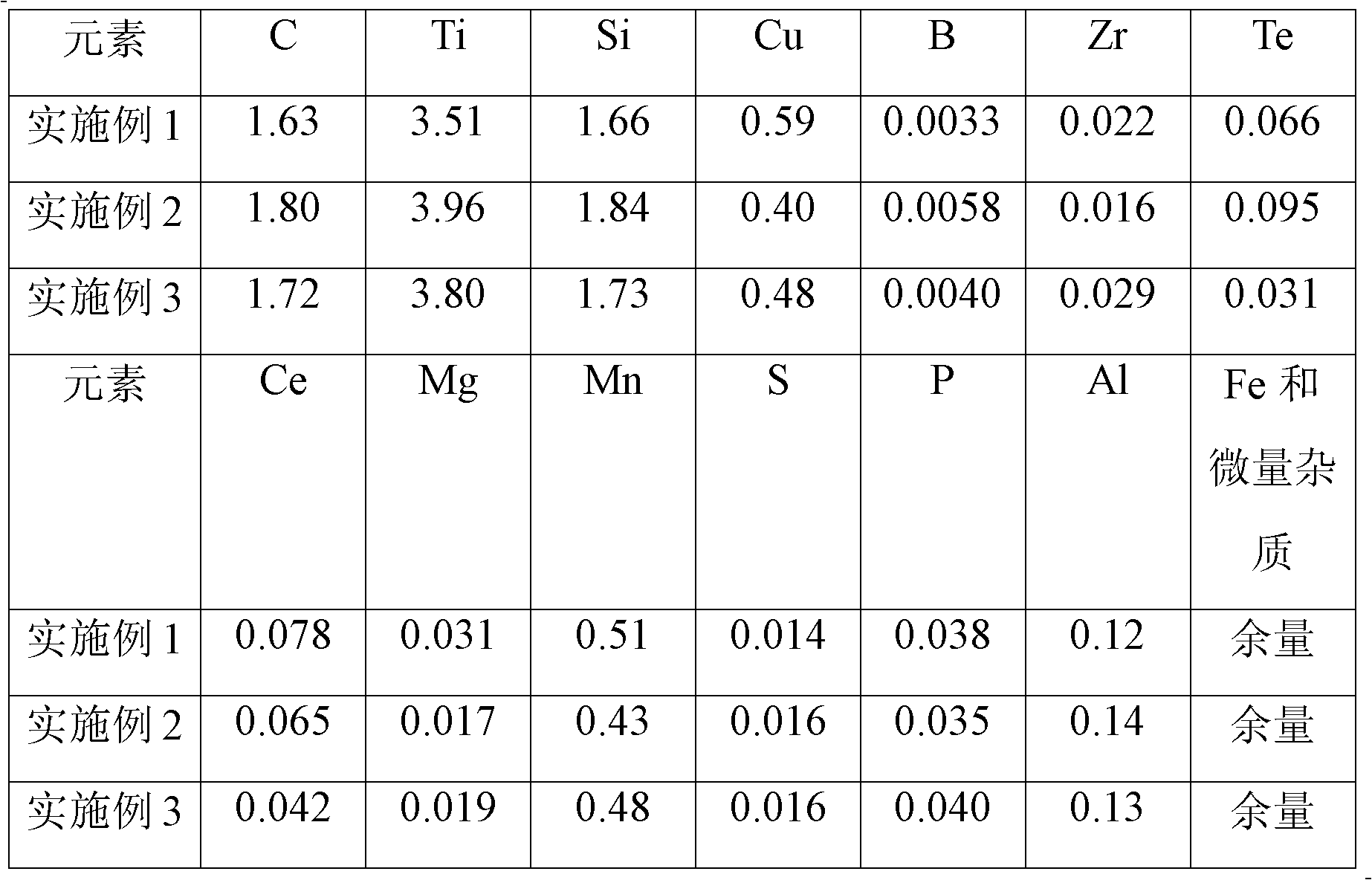

Abrasion resistant cast steel and preparation method thereof

InactiveCN102383066ASimple production processLow costProcess efficiency improvementElectric furnaceUltimate tensile strengthWear resistance

The invention discloses abrasion resistant cast steel and a preparation method thereof and belongs to the technical field of casting. The abrasion resistant cast steel comprises the following chemical constituents of: 1.60 to 1.80 of C, 3.5 to 4.0 of Ti, 1.65 to 1.85 of Si, less than 0.8 of Mn, 0.4 to 0.6 of Cu, 0.003 to 0.006 of B, 0.015 to 0.030 of Zr, 0.03 to 0.10 of Te, 0.04 to 0.08 of Ce, 0.015 to 0.040 of Mg, 0.12 to 0.15 of Al, less than 0.04 of S, less than 0.05 of P and the balance of Fe and unavoidable micro impurities, wherein the total of the chemical constituents is 100; and C %=0.25*Ti %+(0.70 to 0.85). The abrasion resistant cast steel can be produced by using an electric furnace and is treated by isothermal quenching; due to high-hardness TiC particles and an austenite-bainite base body which are contained in the abrasion resistant cast steel, the abrasion resistant cast steel has the characteristics of high strength, high hardness, high flexibility, high abrasion resistant and the like; and the service life of an abrasion resistant part can be prolonged obviously.

Owner:SHANDONG HUIFENG CASTING TECH

Resource-saving boron-containing high-speed steel composite roll and preparation method thereof

InactiveCN102107215ASave resourcesImprove purityRollsMetal rolling arrangementsResource savingFerrosilicon

The invention discloses a resource-saving boron-containing high-speed steel composite roll and a manufacturing method thereof, wherein the composite roll provided by the invention is prepared through centrifuging compound casting of an outer layer part and a roll core part. The outer layer comprises the following raw materials in percentage by weight: 35% of alloy scrap iron of high-speed steel roll, 20-25% of alloy scrap iron of high-chromium iron roll, 15-20% of alloy scrap iron of high nickel-chromium infinite chilled cast iron roll, 4-8% of tungsten dreg-iron alloy, 1.0-1.5% of ferroboron, 1.0-1.2% of low-carbon ferromanganese, 0.15-0.25% of ferrotitanium, 0.2-0.3% of yttrium-base heavy-tombarthite antaciron, 0.25-0.30% of nitrogenized ferrochrome, 0.2-0.3% of magnesium-aluminum-calcium alloy, and the balance of low-carbon waste steel sheet. The roll core is spheroidal graphite cast iron. The composite roll has the advantages of good comprehensive mechanical property and abrasive resistance, is manufactured by utilized roll processing dregs as main raw material, has the characteristics of resource conservation, low cost and the like, and has good economic and social benefits in popularization and application.

Owner:BEIJING UNIV OF TECH

Ion beam irradiation apparatus and insulating spacer for the same

InactiveUS20050211926A1Reduce the amount requiredIncrease profitElectric arc lampsIon beam tubesAtomic physicsMesh grid

The frequency of replacement of an insulating spacer disposed between grids of an ion beam irradiation apparatus is to be reduced. In addition, the intervals of the multiple grids in the ion beam irradiation apparatus are to be kept constant. To achieve these objects, in a so-called insulating spacer provided for maintaining insulation between the grids, a groove portion having a bottom onto which sputtered materials are hard to adhere is provided on the central portion of the side surface of the insulating spacer all along its circumference.

Owner:TDK CORPARATION

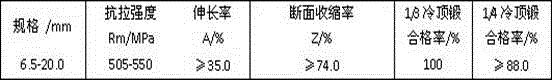

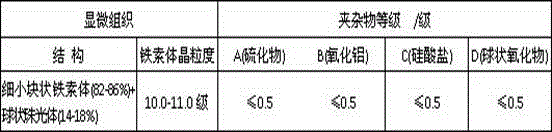

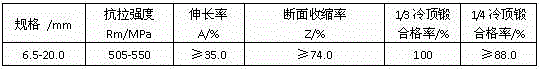

Steel wire rod for high-strength boron-contained and annealing-free fastening piece and preparation method thereof

The invention discloses a steel wire rod for a high-strength boron-contained and annealing-free fastening piece and a preparation method thereof. The steel wire rod for the high-strength boron-contained and annealing-free fastening piece comprises the following chemical components in percentage by weight: 0.20-0.24 wt% of C, Si not more than 0.04 wt%, 0.50-0.70 wt% of Mn, 0.25-0.35 wt% of Cr, 0.035-0.055 wt% of Ti, 0.035-0.055 wt% of Als, 0.0045-0.0060 wt% of B, S not more than 0.004 wt%, P not more than 0.012 wt%, O not more than 0.0015 wt%, H not more than 0.00015 wt%, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of molten iron pretreatment desulfurization, molten steel smelting, deoxidation alloying, molten steel LF furnace refining, molten steel VD furnace vacuum refining, molten steel pouring, steel blank heating and controlled rolling and controlled cooling. The steel wire rod for high-strength boron-contained and annealing-free fastening piece is high in cleanness, few in inclusions, excellent in hardenability, proper in strength and hardness and excellent in ductility and toughness and cold heading and upsetting deformation capacity, can directly form a 10.9-grade high-level standard part through cold heading without needing spheroidizing annealing, reduces the processing procedures and the steel consumption, and reduces the production cost.

Owner:WUKUN STEEL

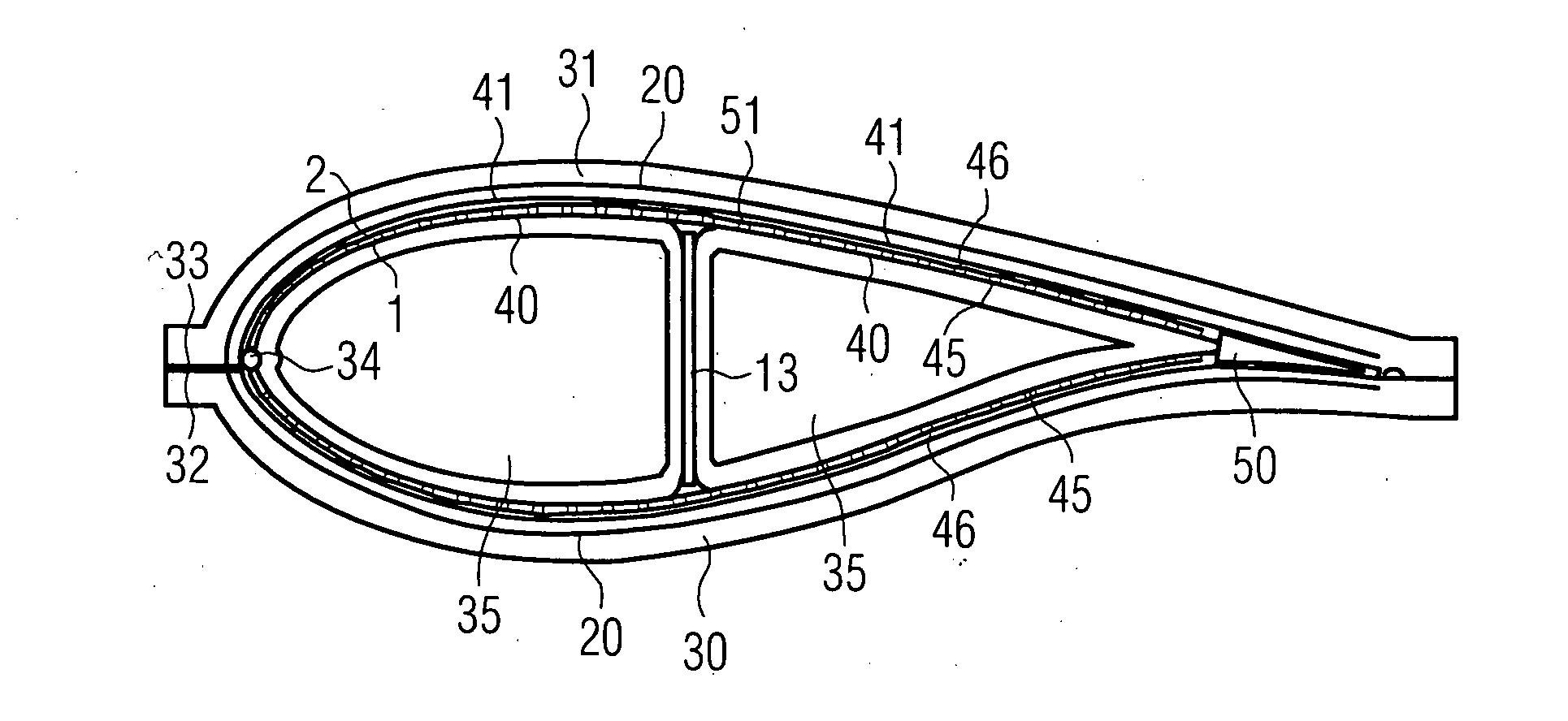

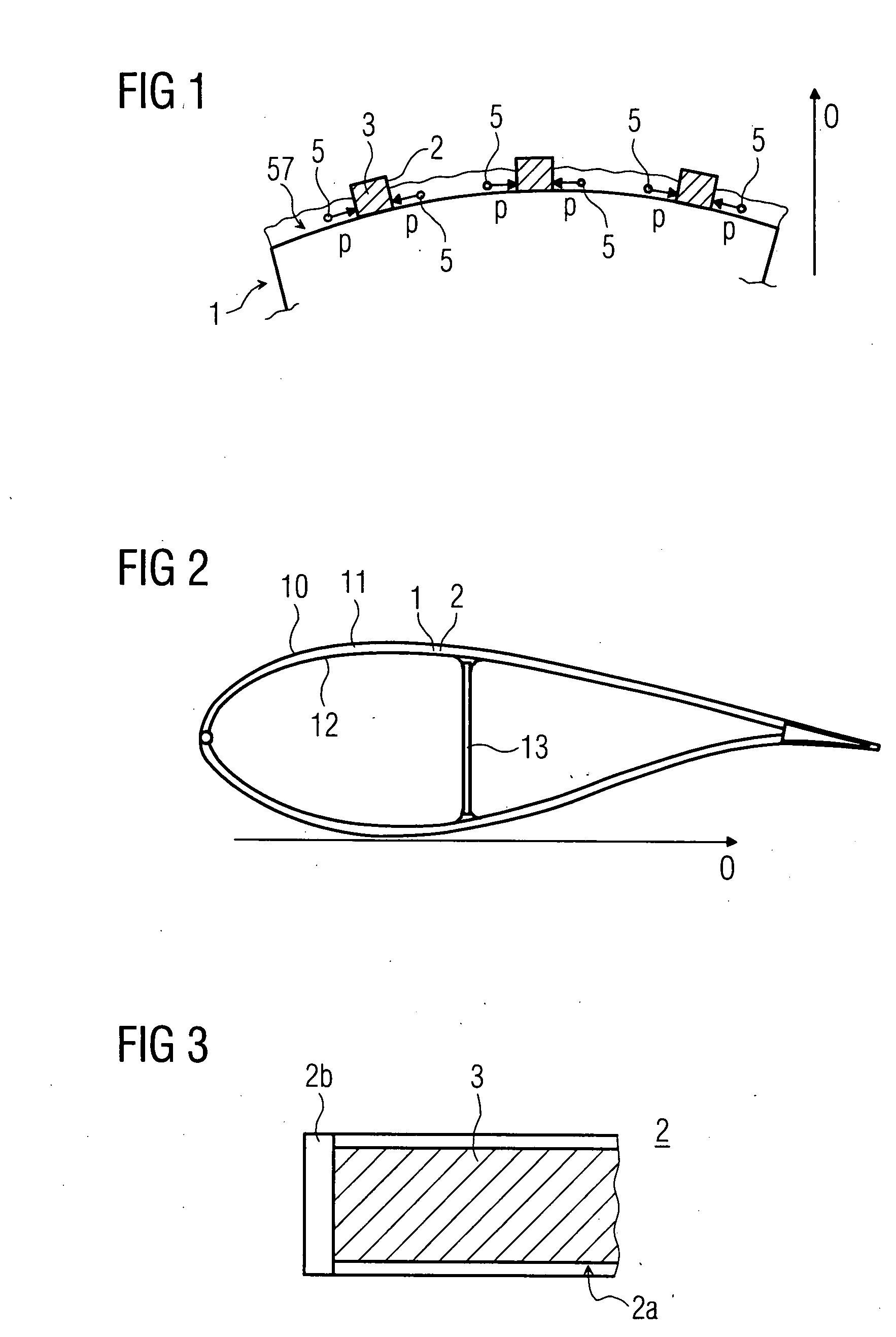

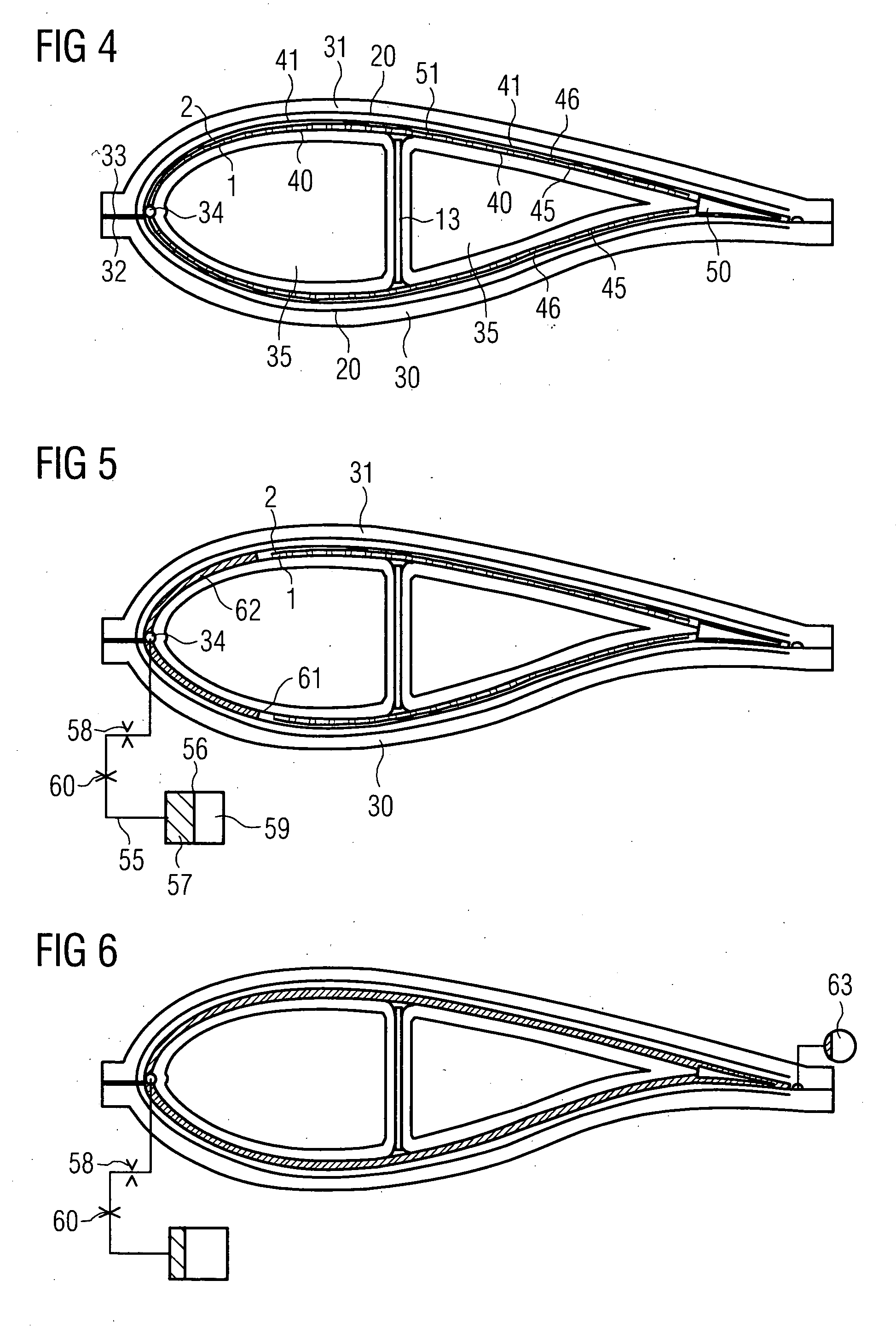

Method for casting a component and a component comprising at least partly of fibre-reinforced plastic laminate

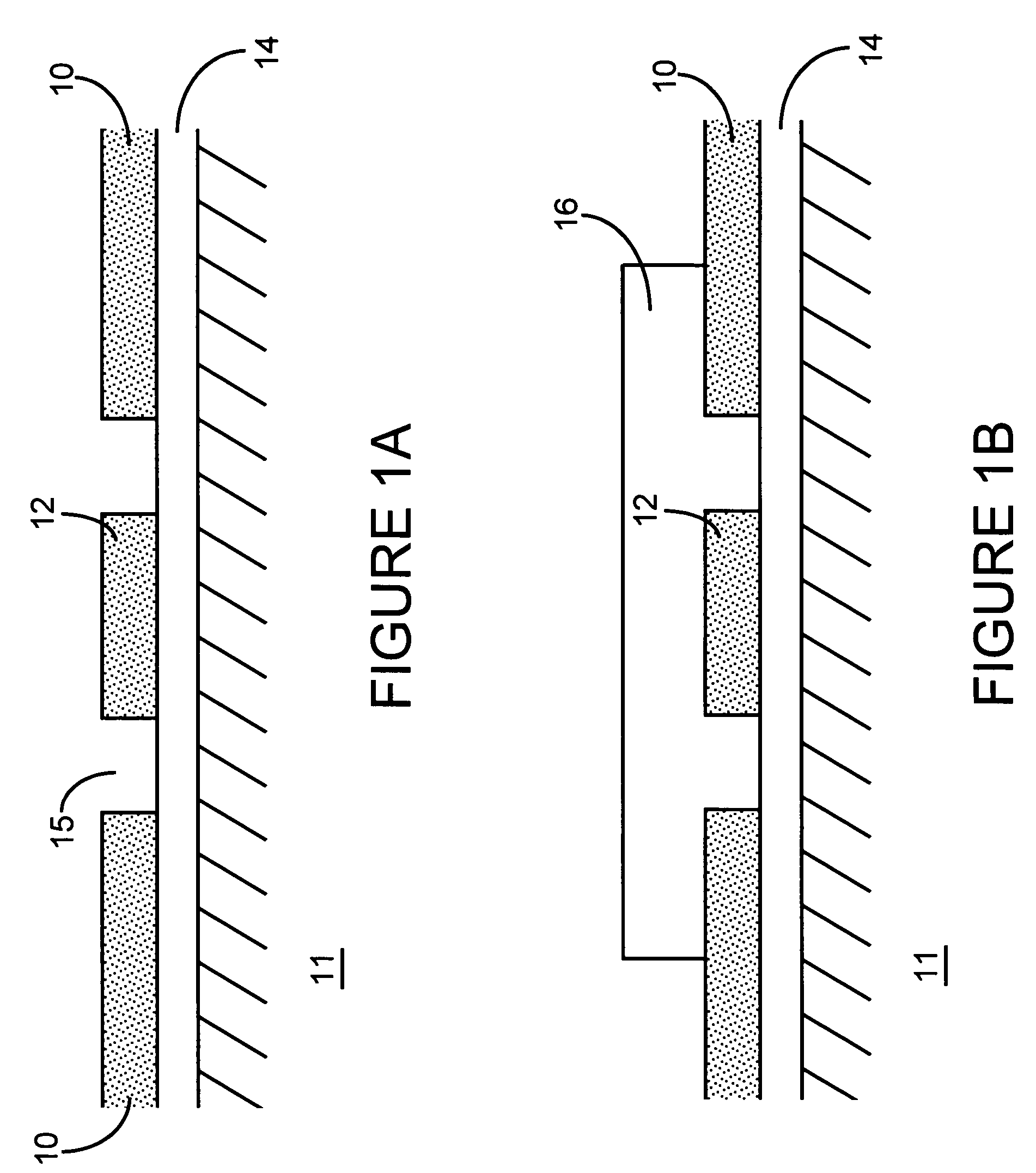

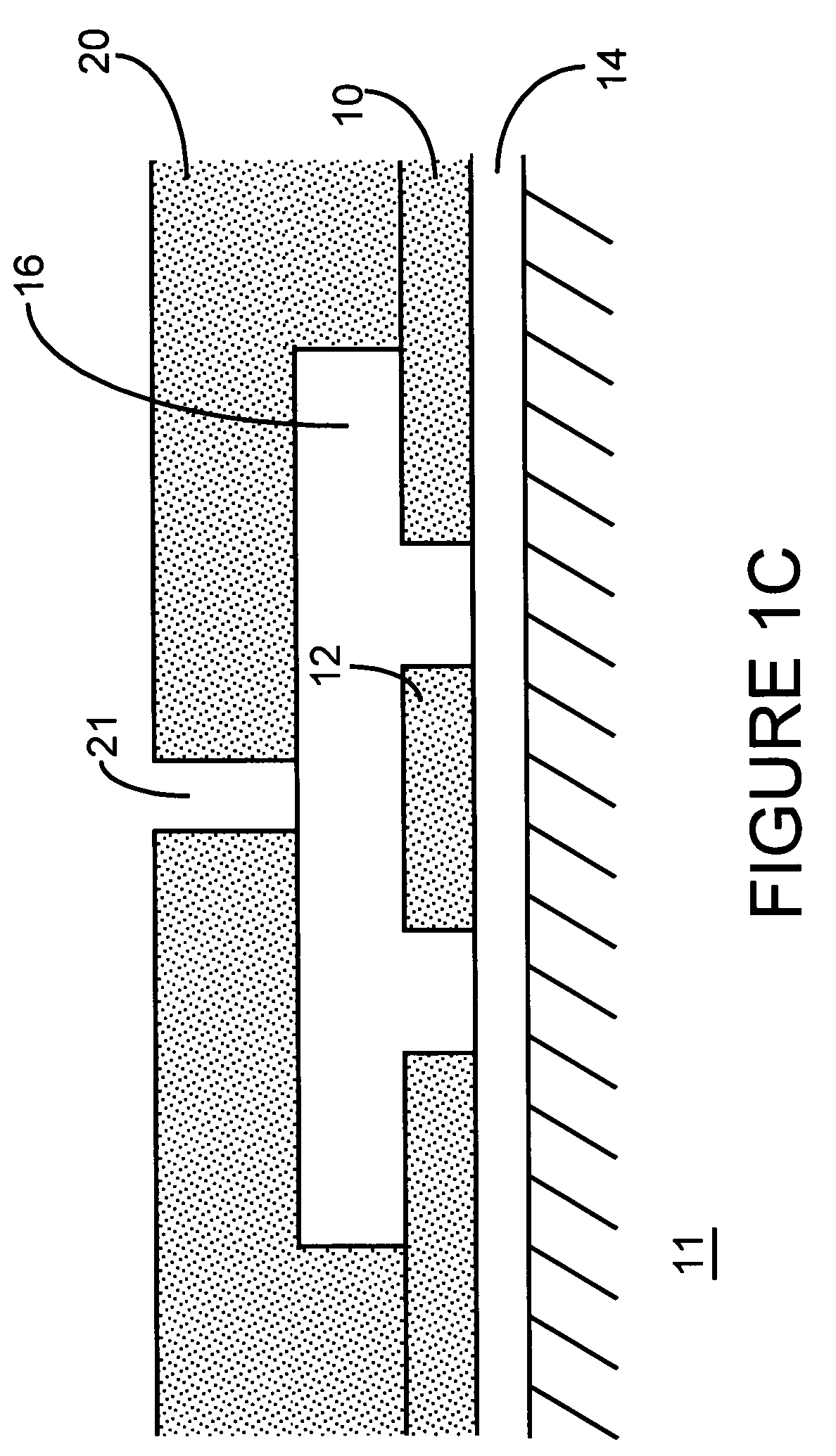

ActiveUS20070274835A1Reduces and eliminates riskReduce inclusionsSynthetic resin layered productsReaction enginesSemipermeable membraneGas passing

There is described a method for casting a component comprising at least partly of fibre-reinforced plastic laminate by which the fibre-reinforcement is arranged in a casting mould, wherein at least one venting duct is placed, wherein said fibre-reinforcement and said venting duct are at least partly wetted by the plastic during the casting process in such a way that venting is achieved through said venting duct, and wherein the surface of the venting duct is at least partially made with a semi-permeable membrane that allows the passage of gases but does not allow or only slowly allows the passage of plastics. Furthermore there is described a component comprising at least partly of fibre-reinforced plastic laminate, wherein the plastic laminate inside comprises of one or more venting ducts, wherein the surface of a venting duct is at least partially made with a semi-permeable membrane that allows the passage of gases but does not allow or only slowly allows the passage of plastics.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

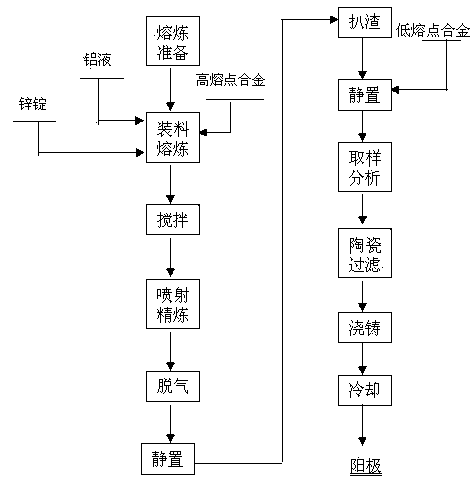

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

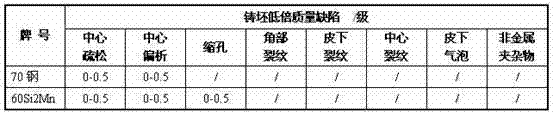

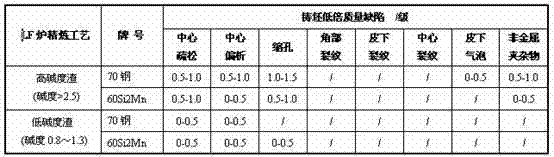

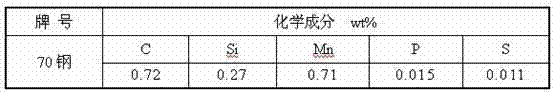

Ladle furnace low alkalinity slag refining process

The invention provides ladle furnace low alkalinity slag refining process. According to the process, bottom blowing of argon to ladles is carried out in the whole course of steel making and tapping, and ferrosilicon, silicon-calcium-barium and high carbon ferromanganese are sequentially added into the ladles for deoxidation and alloying; under the condition that argon flow is 30 to 50 NL / min, argon is blown to the liquid steel for two to three minutes, electrodes are inserted to melt slag, and the slag is modified; the liquid steel is heated to a temperature of 1580 to 1600 DEG C, and alkalinity of the slag is controlled to be 0.8 to 1.3; under the condition that argon flow is 20 to 30 NL / min, argon is blown to the liquid steel for 25 to 30 minutes, and components of the slag are controlled. Therefore, compound inclusion particles with a low melting point and good plastic deformation are formed in the liquid steel and float upward rapidly, which is beneficial for effective removal of inclusions in the liquid steel, thereby substantially improving cleanliness of the liquid steel, obviously enhancing quality of billets, enabling defects of billets like looseness, cracks, segregationand non-metallic inclusions to be greatly reduced, the content of micro inclusions, especially inclusions of B type oxides and D type oxides, in steel products to be substantially reduced and the steel products to meet subsequent processing requirements of 70 high carbon steel wires and 60 Si2Mn spring steel.

Owner:WUKUN STEEL

Magnesium alloy hub manufacture

A technology for manufacturing the Mg-alloy wheel hub includes such steps as preparing Mg alloy by additional use of RE element (0.5-2.0 wt.%) as part of its raw materials, smelting while adding the Mg-alloy coveriong agent prepared from MgCl2, CaF2, KCl, BaCl2 and MgO and the refining agent prepared from NaCl and KCl, preparing mould, spraying on inner surface of mould, casting, heat treating and surface treating. Its advantages are high strength, precision and surface finishing quality, high vibration damping effect, and saving oil.

Owner:重庆镁业科技股份有限公司

High-Purity Copper or High-Purity Copper Alloy Sputtering Target, Process for Manufacturing the Sputtering Target, and High-Purity Copper or High-Purity Copper Alloy Sputtered Film

ActiveUS20110163447A1High resistanceReduce percent defectCellsSemiconductor/solid-state device detailsSputteringNon-metallic inclusions

Provided is a high-purity copper or high-purity copper alloy sputtering target of which the purity is 6N or higher and in which the content of the respective components of P, S, O and C is 1 ppm or less, wherein the number of nonmetal inclusions having a particle size of 0.5 μm or more and 20 μm or less is 30,000 inclusions / g or less. As a result of using high-purity copper or high-purity copper alloy from which harmful inclusions of P, S, C and O system have been reduced as the raw material and controlling the existence form of nonmetal inclusions, the present invention addresses a reduction in the percent defect of wirings of semiconductor device formed by sputtering a high-purity copper target so as to ensure favorable repeatability.

Owner:JX NIPPON MINING & METALS CO LTD

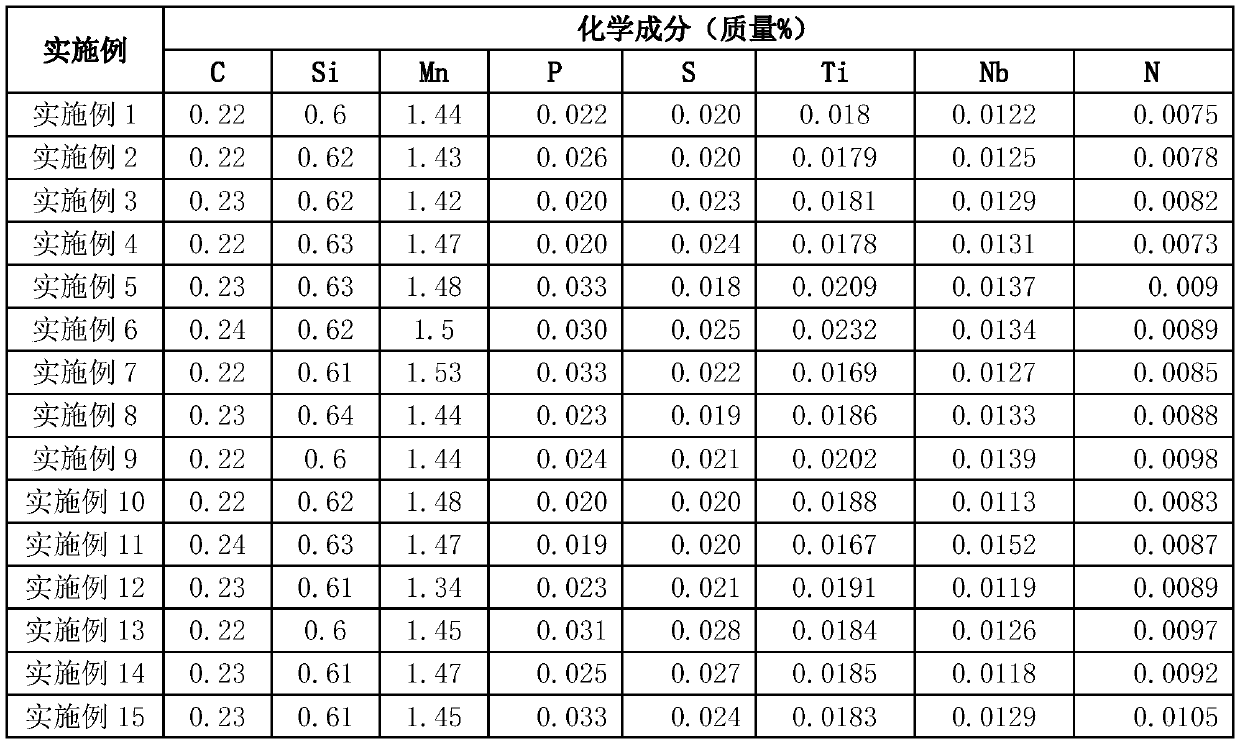

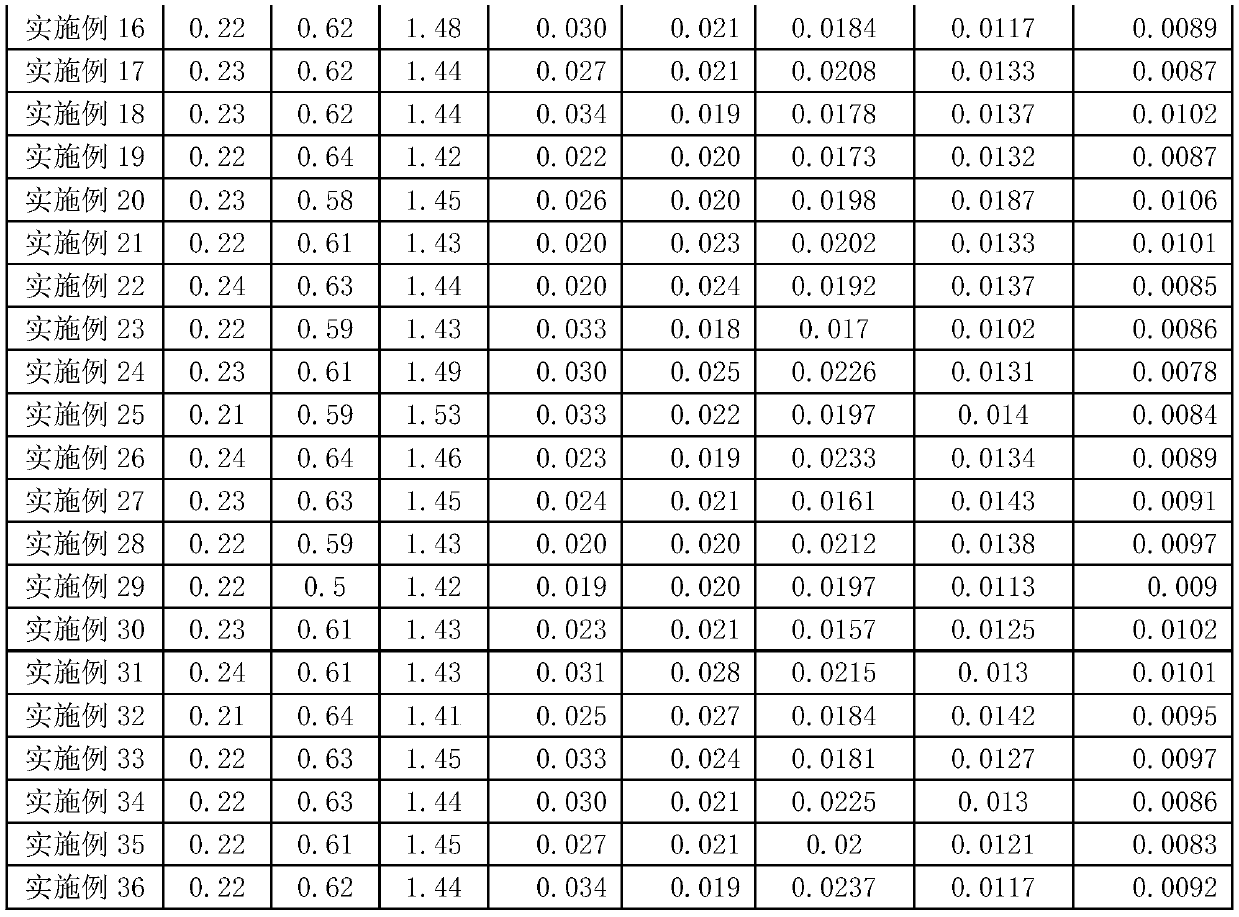

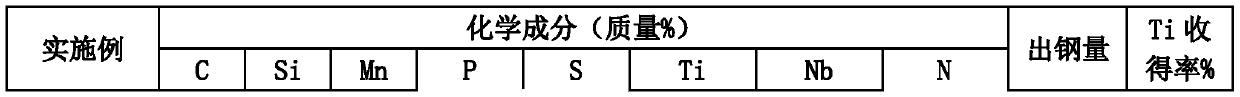

Niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and production method thereof

The invention provides a niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and a production method thereof, and belongs to the technical field of iron and steelsmelting. The niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar comprises, by mass, 0.21-0.25% of C, 0.50-0.65% of Si, 1.40-1.55% of Mn, not greater than 0.045% of P, not greater than 0.045% of S, 0.015-0.025% of Ti, 0.010-0.020% of Nb, 0.0070-0.0110% of N, and the balance Fe and other impurities. In the production method, ferrosilicon, silicomanganese anda carburant are added at the time of 1 / 4 tapping, and all alloys are added at the time of 3 / 4 tapping; the titanium-nitrogen alloy is added at an argon blowing station, and the argon blowing time is greater than or equal to 6 minutes; and high-casting-speed casting powder is adopted for continuous casting, a billet is heated, rolled and fed onto a cooling bed, and finally, the finished product isobtained. According to the niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and the production method thereof, by adding the titanium-nitrogen alloy at the molten steel exposure positon of the argon blowing station, the titanium yield is increased; by reducing the influence of the niobium and titanium content on the quality of the high-casting-speed continuous casting billet, the titanium inclusion in steel is reduced, and the castability of molten steel meets requirements; and by adopting the high-casting-speed continuous casting powder, the cast billet quality is improved.

Owner:YANGCHUN NEW STEEL CO LTD

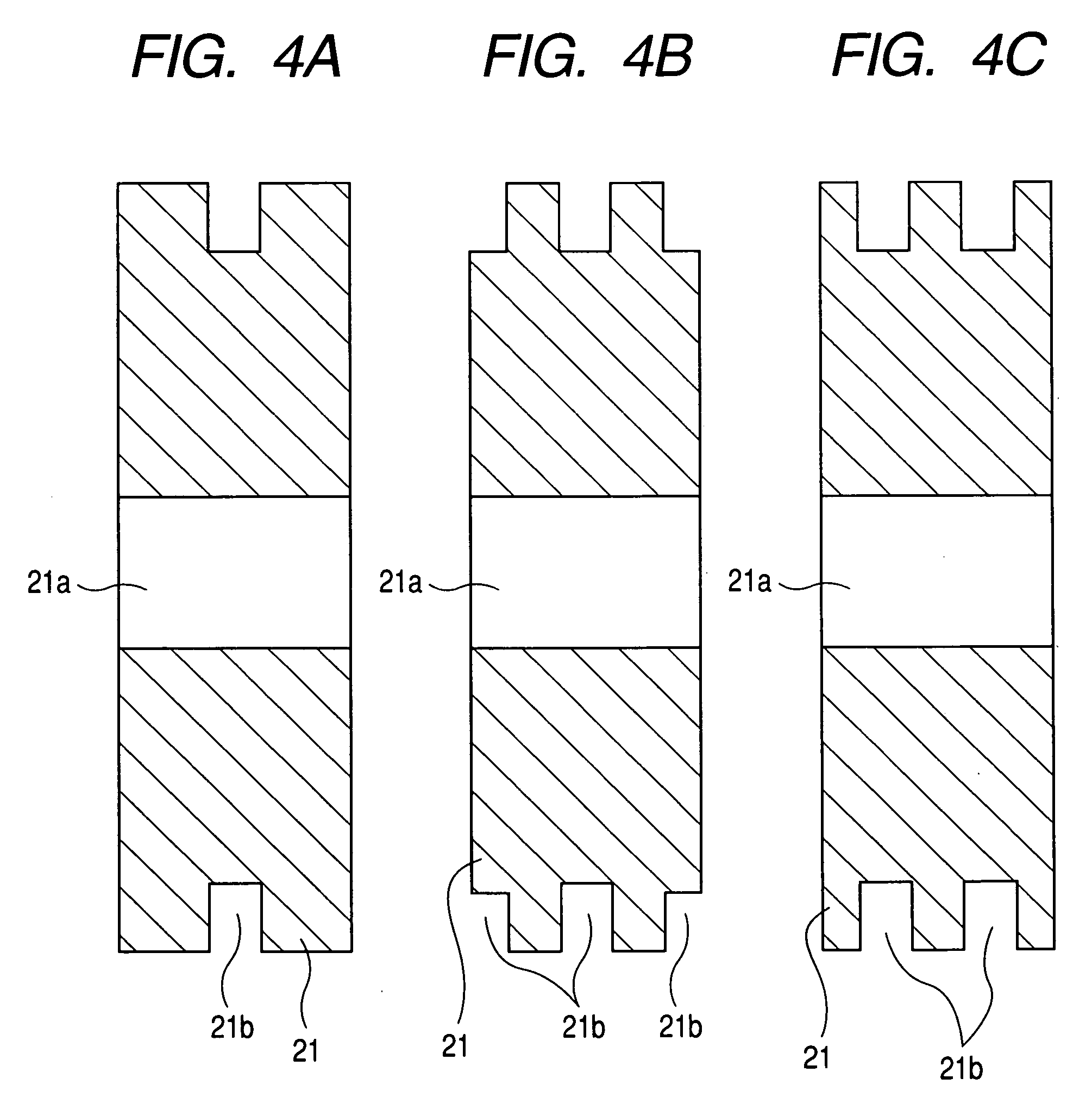

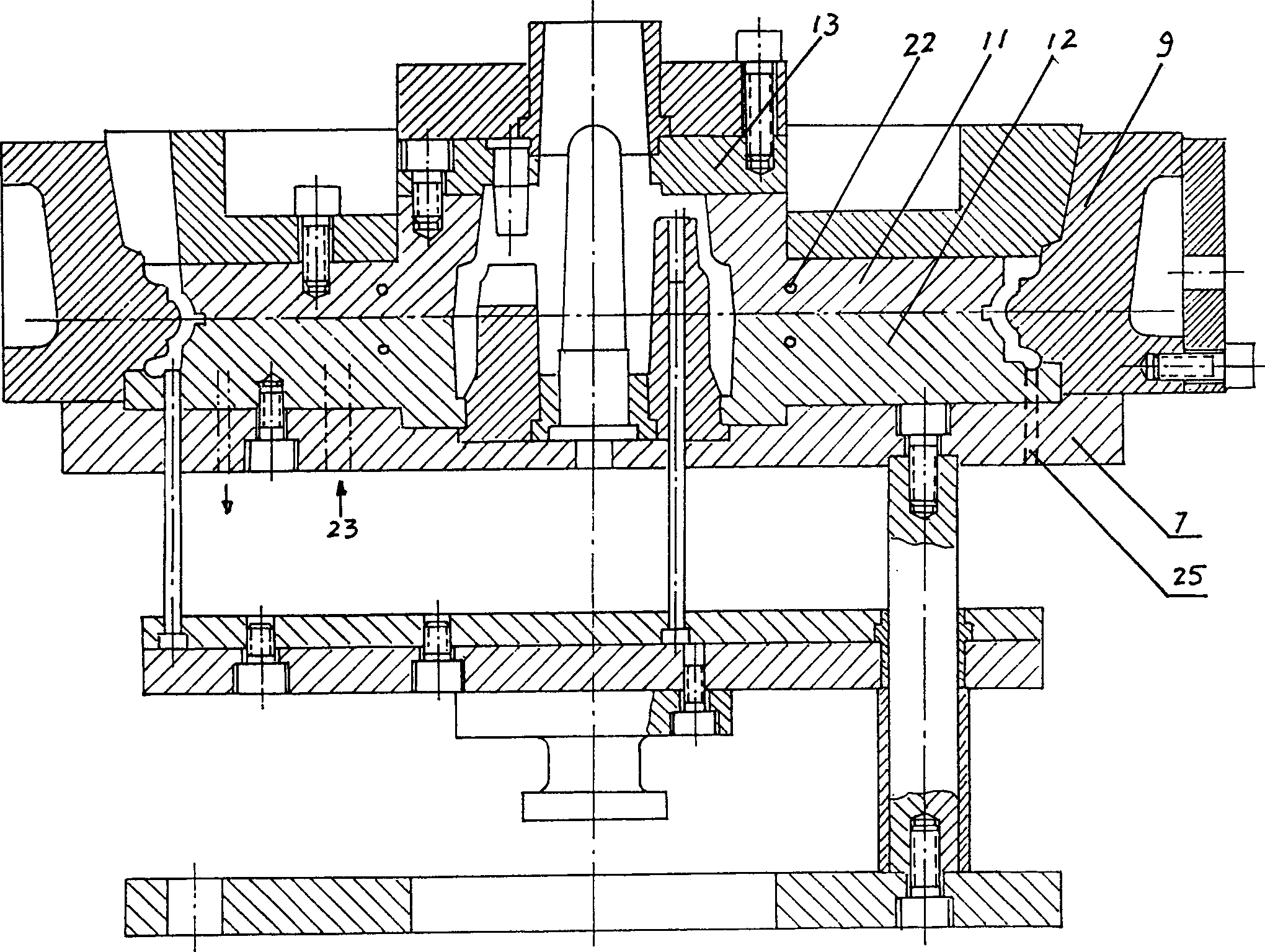

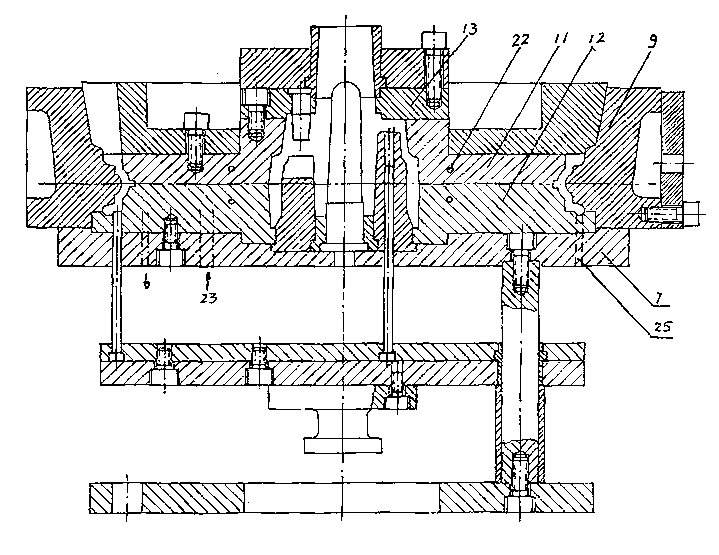

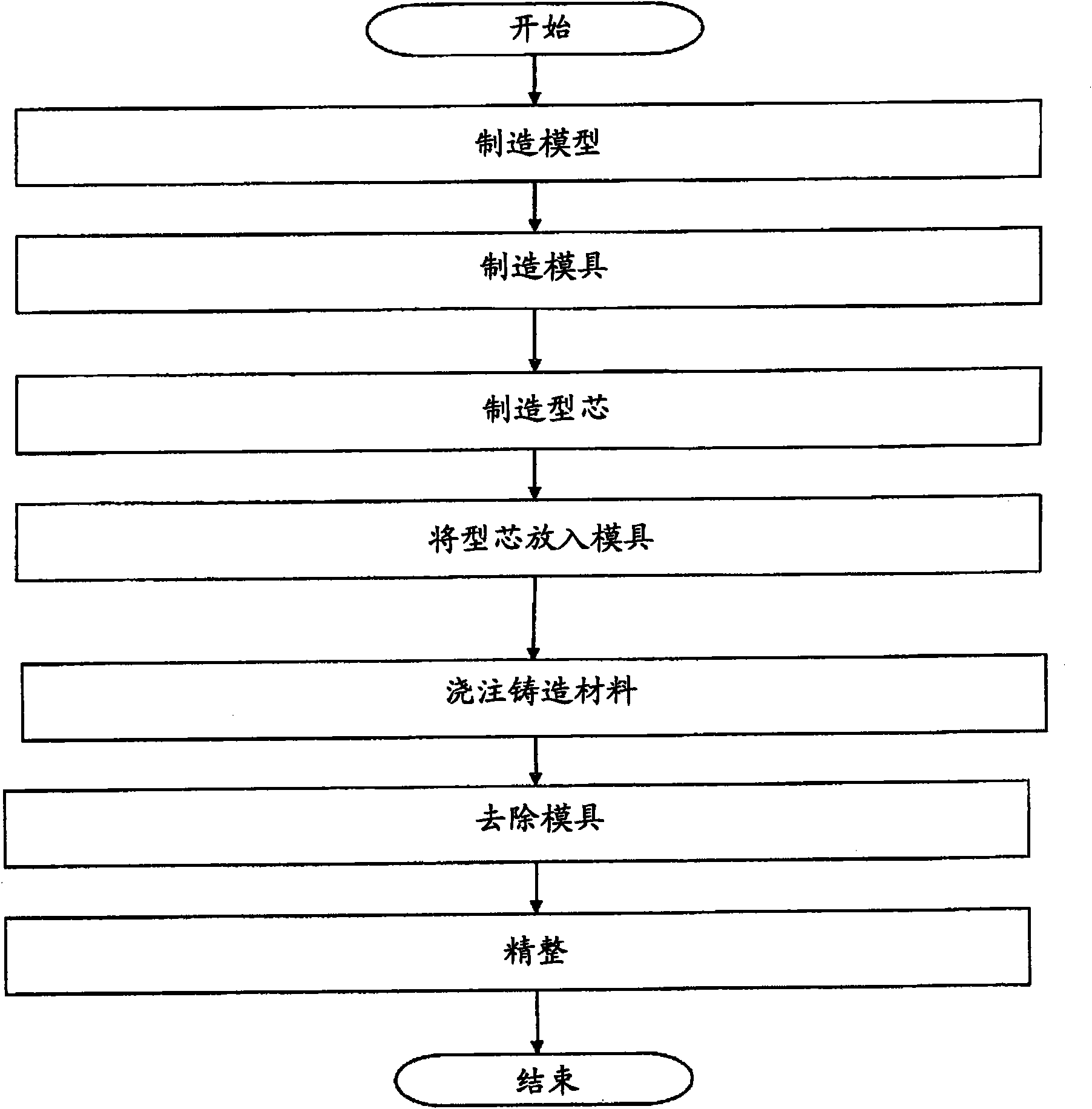

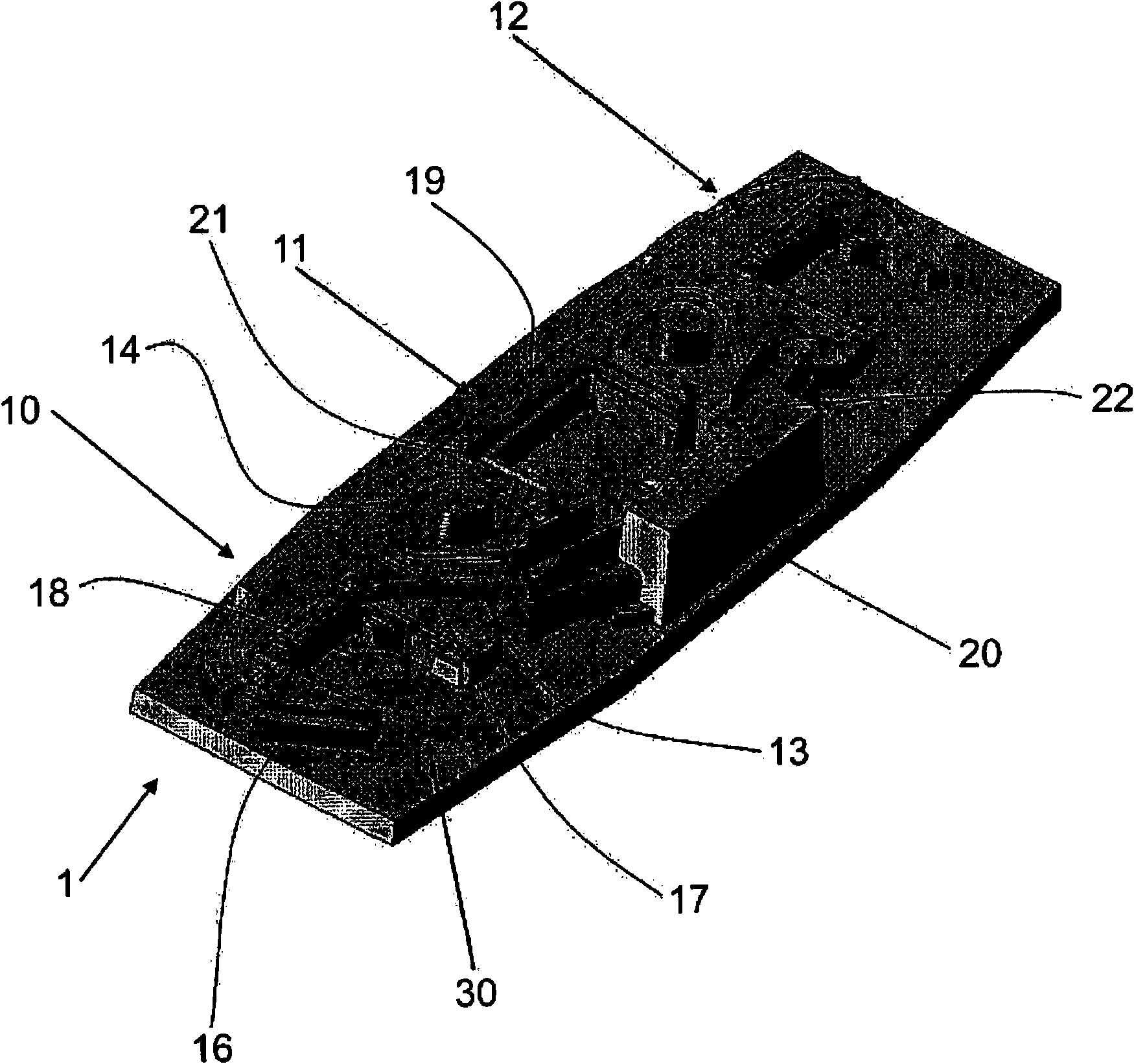

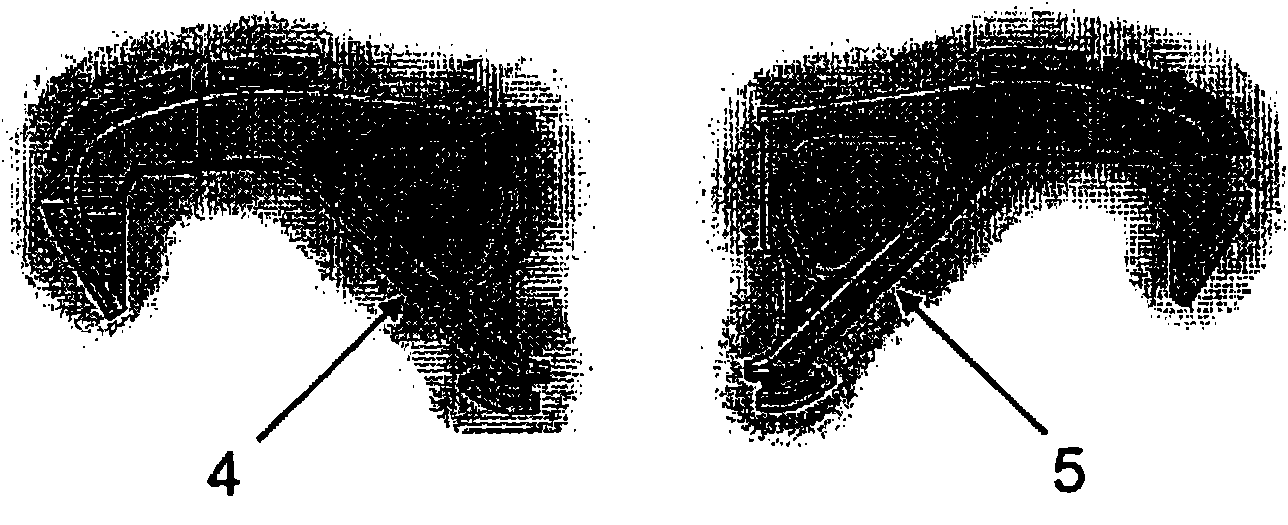

Casting process of a truck sideframe, casting model, railway car truck sideframe, railway car truck and railway car

The present invention refers to a casting process for a railway truck sideframe comprising the stages of: (i) manufacture of the model; (ii) manufacture of the mold; (iii) manufacture of the cores; (iv) placement of the cores into the mold; (v) pouring of the casting material; (vi)removing mold and (vii) finishing. The cores of the bases and the central section of the truck sideframe are eliminated in this process. The present invention also refers to a casting model (1 ), comprising a first sideframe section (10) connected by a central section (11 ) to a second sideframe section (12). The sideframe sections (10 and 12) have a base (30), with their respective space (18) in their free extremities, and a central section (11) has a central space (21). The cavity formation elements positioned in the base (18) and central (21 ) spaces are eliminated in the casting model of the present invention (1 ), so that the central and base cores are not required in the casting process. The housing (23) avoids the placement of the core of the brake guide (9) in the mold. Finally, the present invention describes a railway car truck sideframe whose principal characteristic is the fact that it is produced in accordance with the casting process of the present invention.

Owner:AMSTED MAXION FUNDICAO E EQUIPAMENTOS FERROVIARIOS

Pouring system for hollow single crystal blade

The invention discloses a pouring system for a hollow single crystal blade. The pouring system comprises a pouring cup, rectangular feeding blocks, blade wax pieces, crystal guide sections, a disc and a sprue. The sprue and the crystal guide sections are perpendicularly mounted on the disc. The upper end of the sprue is communicated with the pouring cup through a ceramic filter net. The lower end of the sprue is communicated with the crystal guide sections through ingates. The crystal guide sections are communicated with the lower ends of the blade wax pieces through spiral crystallizers. The upper ends of the blade wax pieces are communicated with the rectangular feeding blocks. The rectangular feeding blocks are communicated with the upper portion of the pouring cup through slag collecting gas vents. Feeding heads are further arranged at the upper ends of the blade wax pieces. The pouring system is reasonable in structure, the probability of inclusions, loosening, mixed crystals, a high-angle boundary, a low-angle boundary, zebra crystals and a crystal orientation deviation scrap rate of the single crystal blade is reduced, the product percent of pass is greatly increased, economic losses are reduced, the developing cycle is shortened, on time delivery of the blade is ensured, and the pouring system can be widely applied and popularized in the technical field of melted module precise casting.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com