Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169 results about "Liquid aluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metalier’s aluminium liquid metal is a low-density metal. It is noted for its ability to slow corrosion. It is this quality, as well as its beauty and availability, that makes aluminium such a popular joinery choice for modern architecture. Use Metalier’s aluminium liquid metal to complement other aluminium features.

Medium strength aluminium alloy wire with conductivity of 60% IACS, and preparation method thereof

ActiveCN103820685AHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureRare-earth elementManufacturing technology

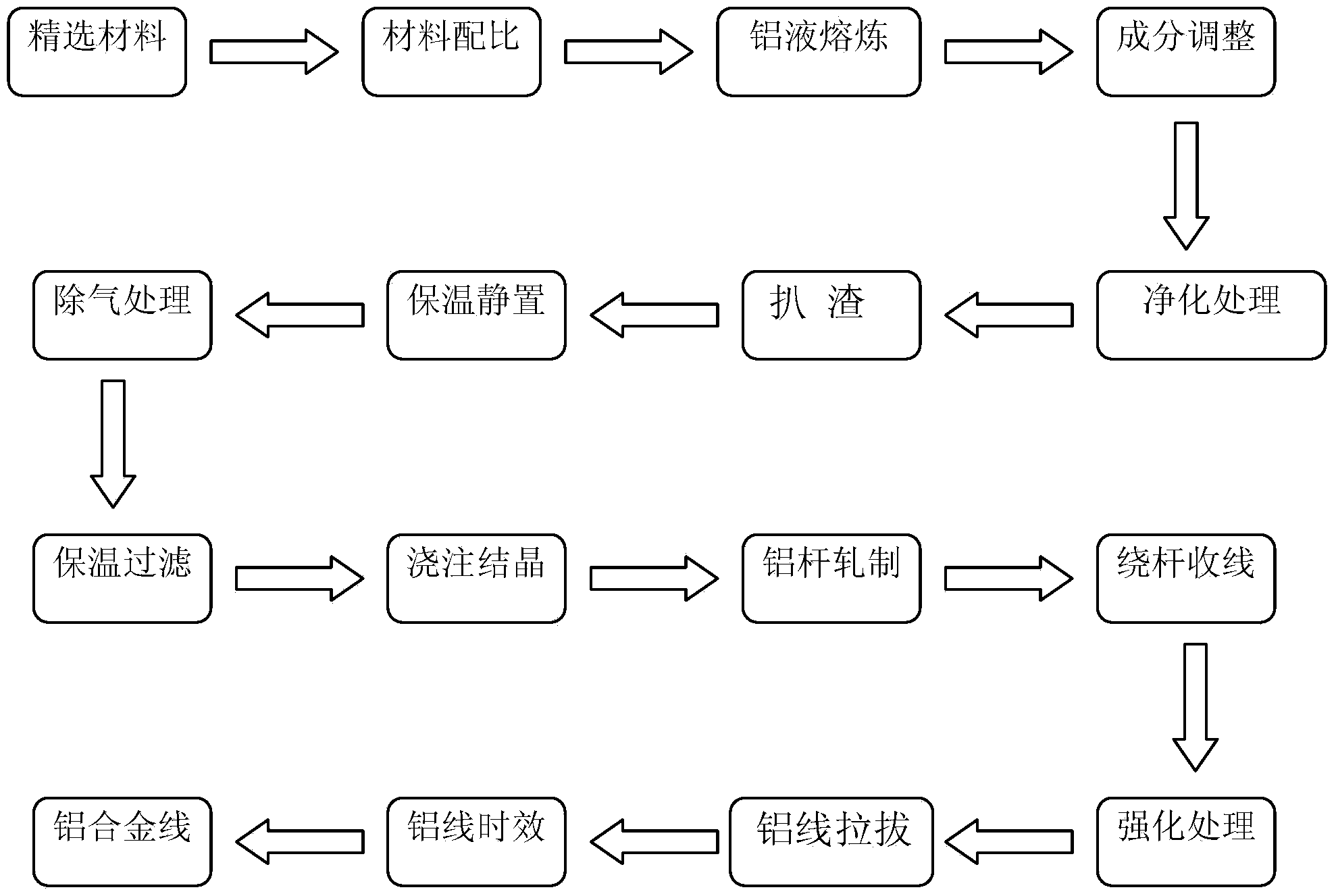

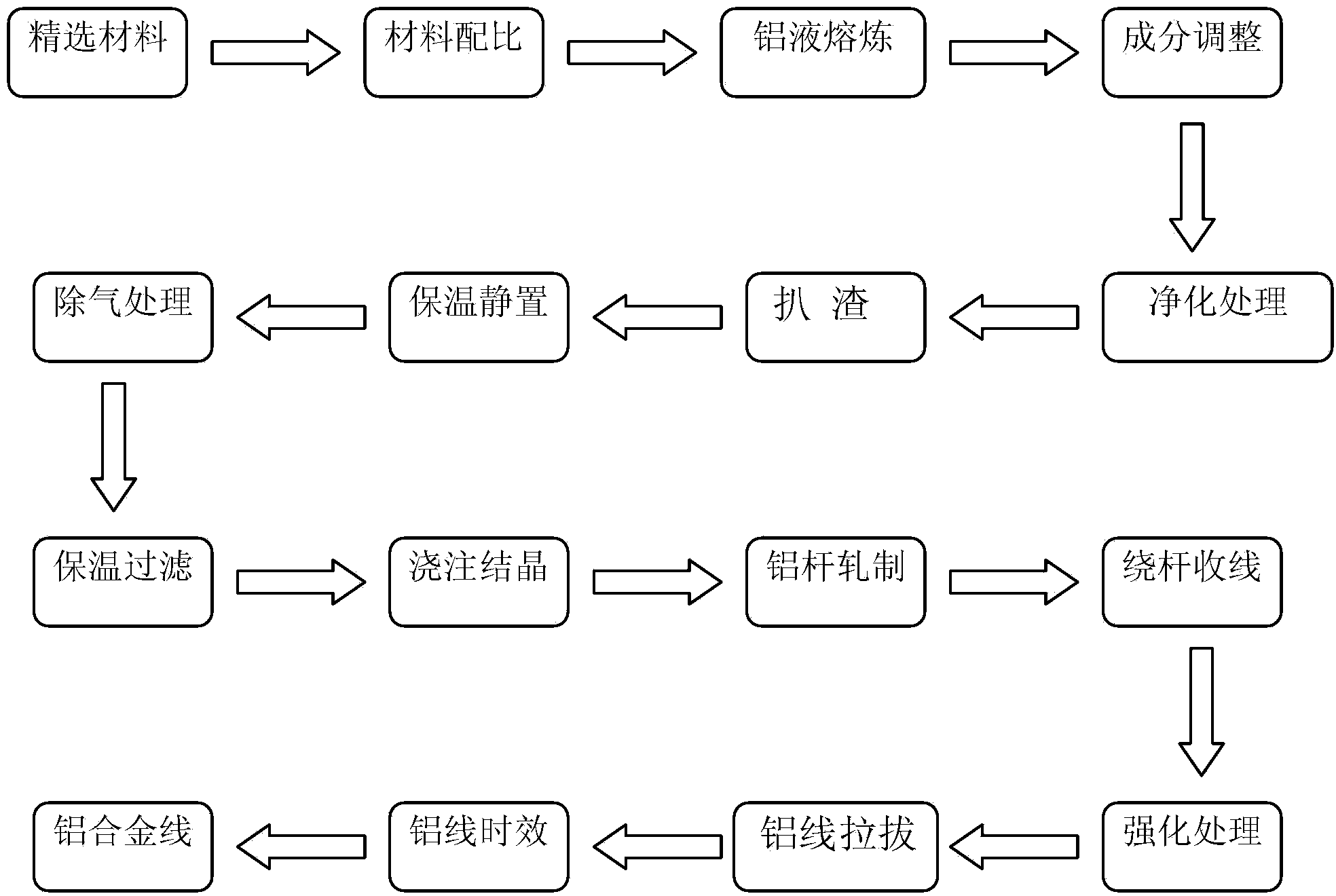

The invention relates to a medium strength aluminium alloy wire with conductivity of 60% IACS, and a preparation method thereof, and belongs to the field of alloy manufacturing technology. The alloy elements comprise, by weight, 0.16%-0.22% of iron, 0.24%-0.30% of silicon, 0.40%-0.48% of magnesium, 0.01%-0.02% of boron and 0.08%-0.15% of a rare earth element, with the balance being aluminium. The medium strength aluminium alloy wire with a product conductivity higher than or equal to 60% IACS and tensile strength higher than or equal to 230 MPa is obtained by processes of selecting materials, smelting liquid aluminium, adjusting liquid aluminium ingredients, carrying out purifying treatment, deslagging, standing with heat preservation, degassing, filtering with heat preservation, casting and crystallizing, rolling an aluminum rod, drawing and aging. The wire and cable produced by using the aluminium alloy can be erected continuously by a conventional construction process. In a circuit operation process, circuit loss can be reduced; construction fee can be reduced; and the medium strength aluminium alloy has significant economic benefits and social benefits.

Owner:WUXI HUANENG ELECTRIC CABLE

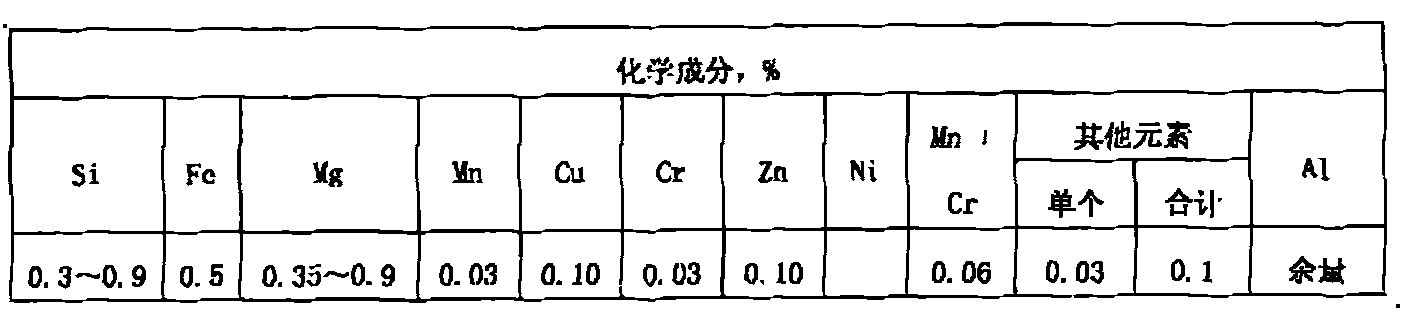

High strength alloy round aluminium rod and production method thereof

ActiveCN101956103AChange the way of beingChange speedMetal rolling arrangementsNitrogenHigh intensity

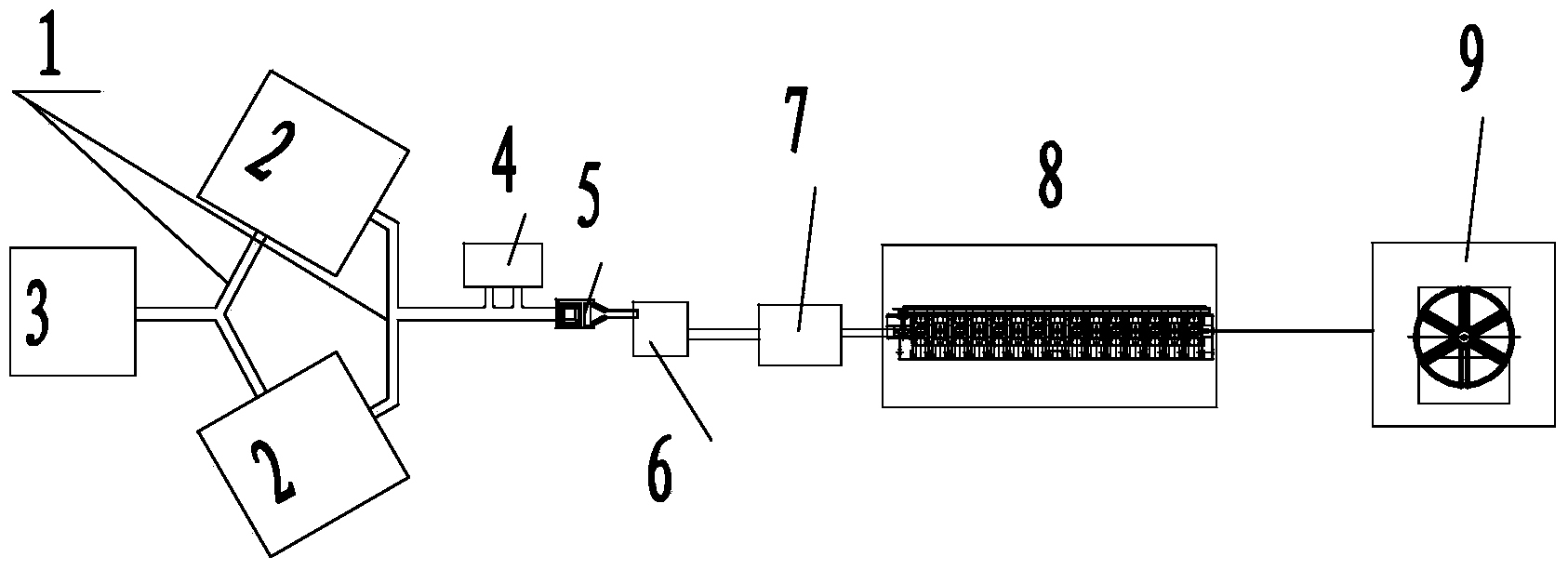

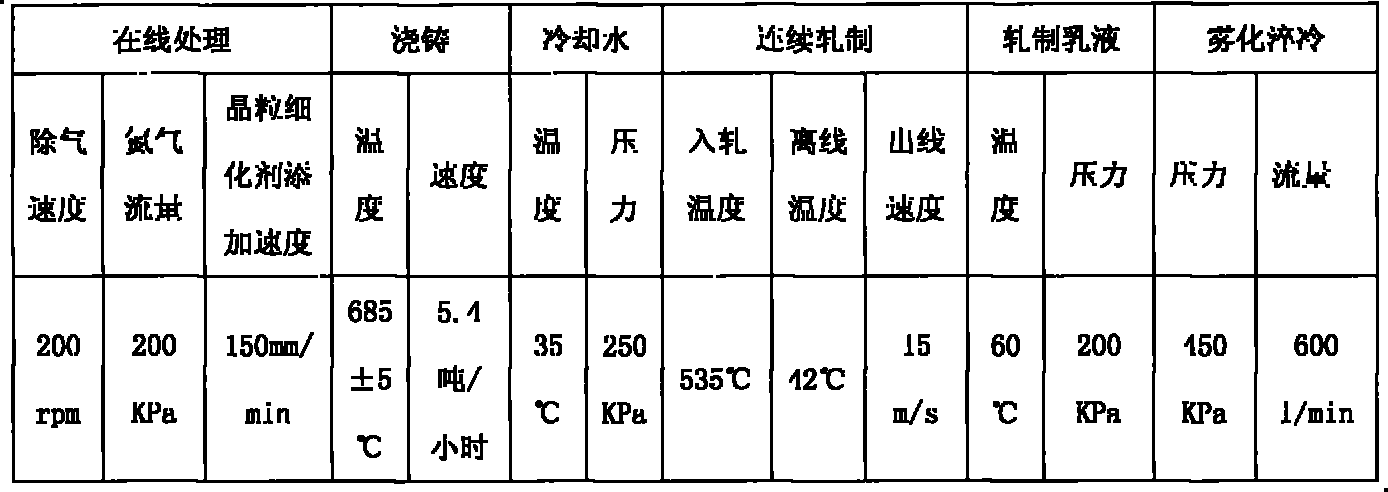

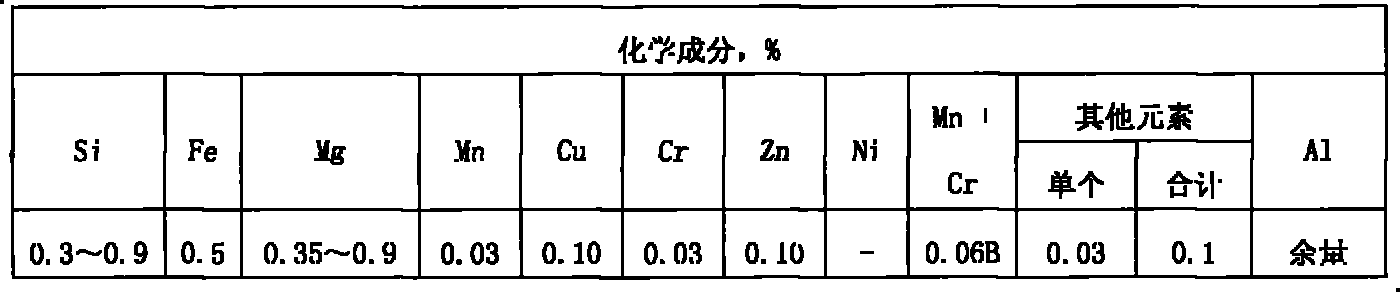

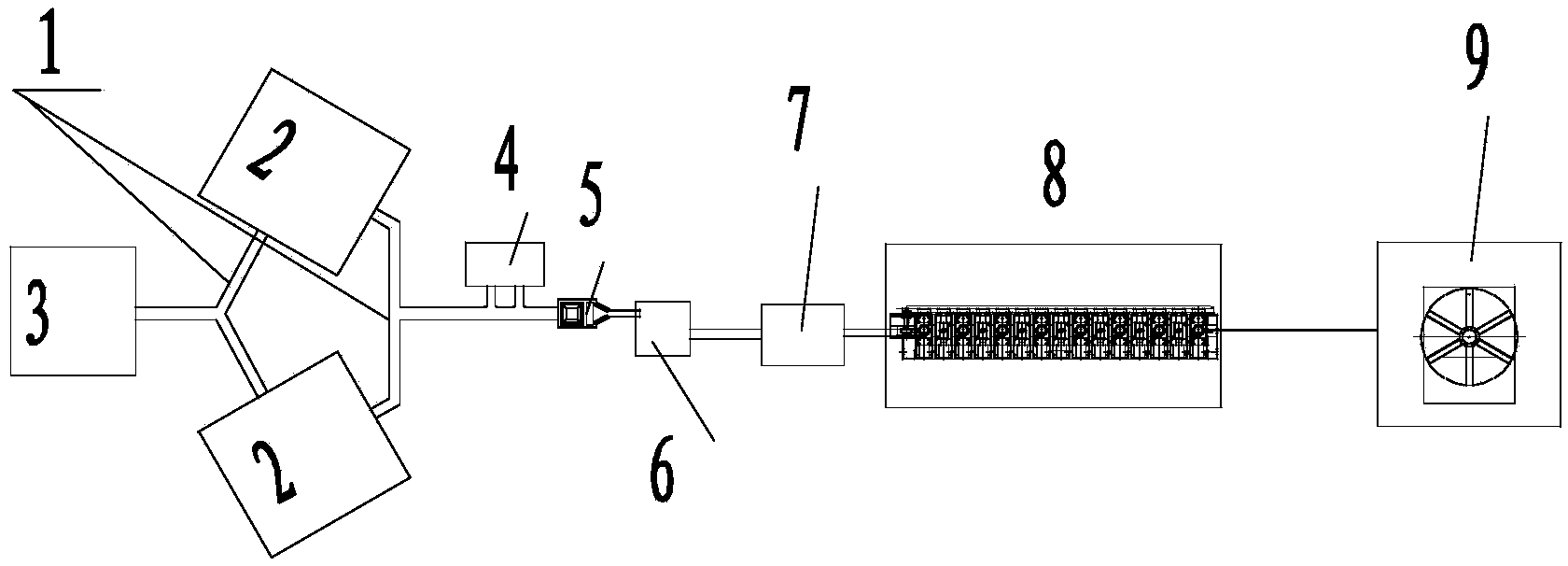

The invention provides a high strength alloy round aluminium rod and a production method thereof. Liquid aluminium with the content of more than 99.5% is added into a smelting furnace, the temperature is controlled to be 760-800 DEG C; silicon and magnesium and iron chelating agent are added, wherein the content of Si is controlled to be less than or equal to 0.6%, the content of Mg is controlled to be 0.3-0.9%, and the content of Fe is controlled to be less than or equal to 0.3%; aluminium melt is prepared, nitrogen is utilized to blow powder refining agent into the solution for refining, the usage amount of refining agent is 1.2kg / ton, and the pressure of nitrogen which is led in is 0.05-0.4MPa, thus obtaining aluminium melt with higher purity; and continuous casting and tandem rolling are carried out on aluminium melt subject to standing, before casting, Al-Ti-B rod is added in a chute at the speed of 150mm / min, so as to carry out online grain refinement treatment on the aluminium melt; and the rolled wire is subject to solid solution strengthening by virtue of an atomization quenching channel. Compared with common pure aluminium electrician round aluminium rod, the Al-Si-Mg alloy round aluminium rod of the invention has the advantages that: tensile strength is improved by 56.5%, the maximum can reach 64.6%; corresponding elongation is increased by 200%, the maximum can reach 228%; and resistivity is increased by only 28%.

Owner:YUNNAN ALUMINUM

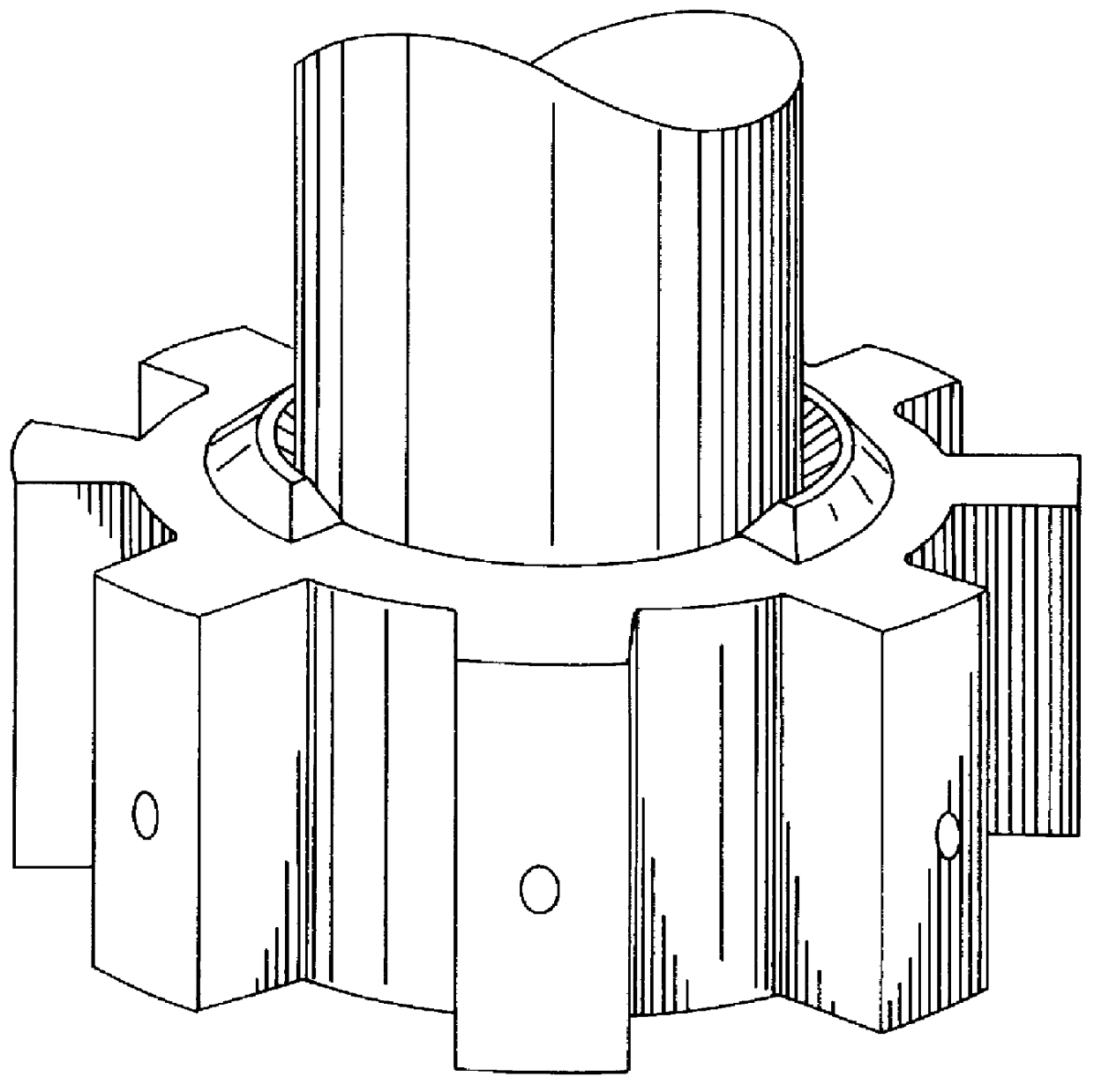

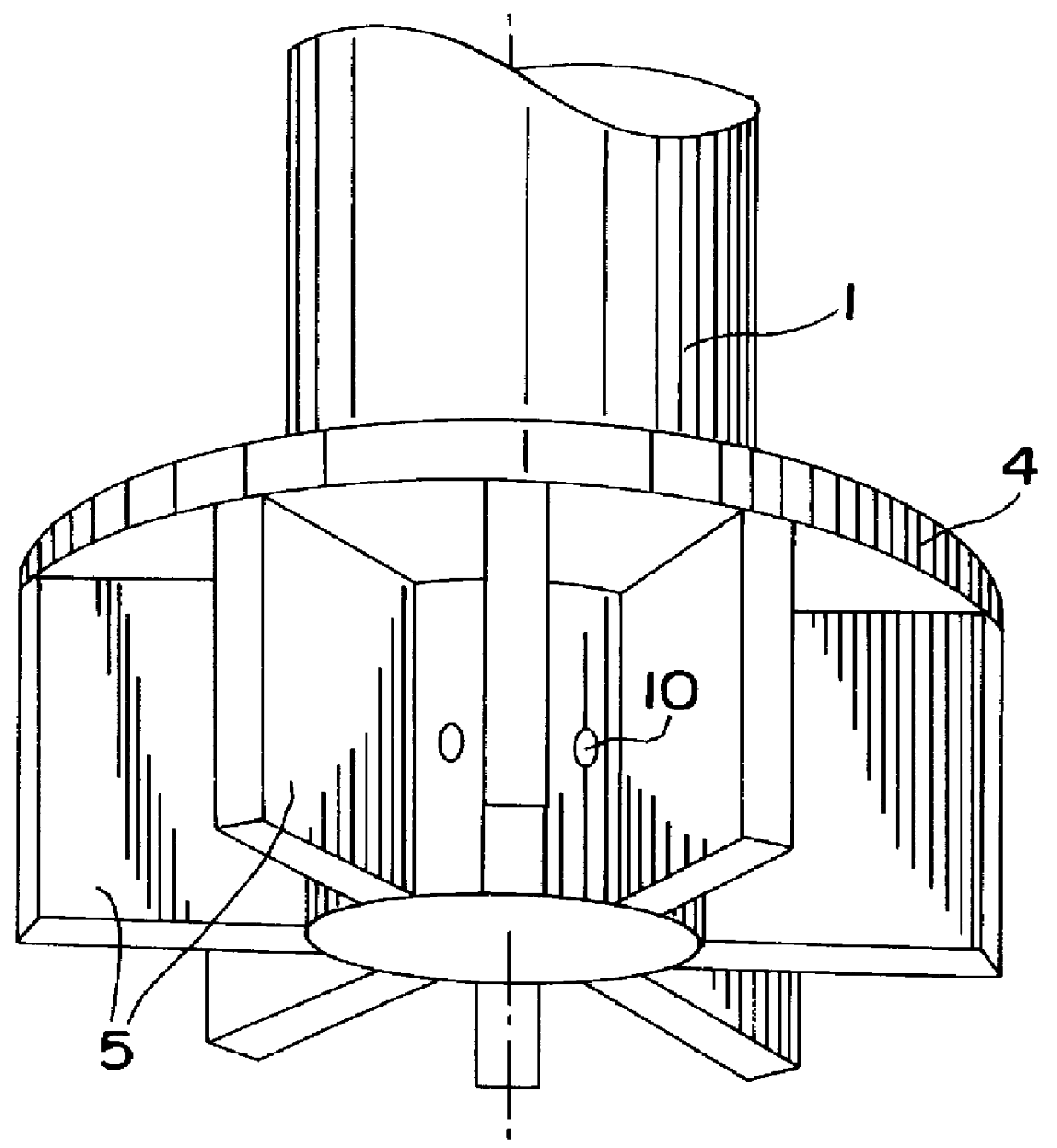

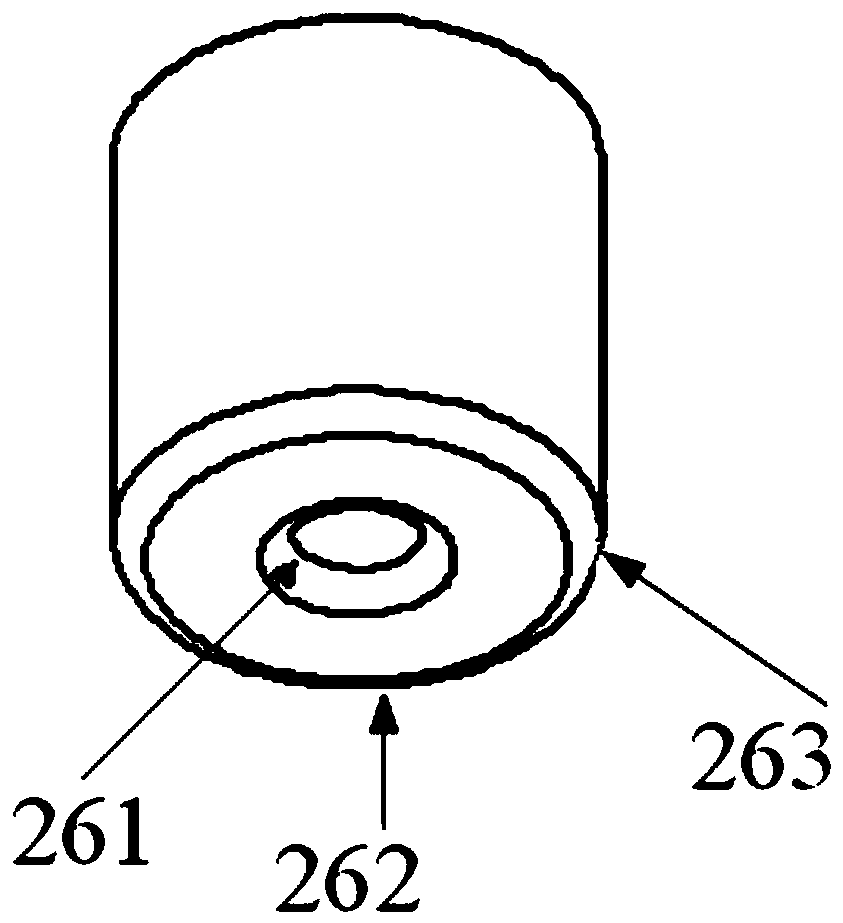

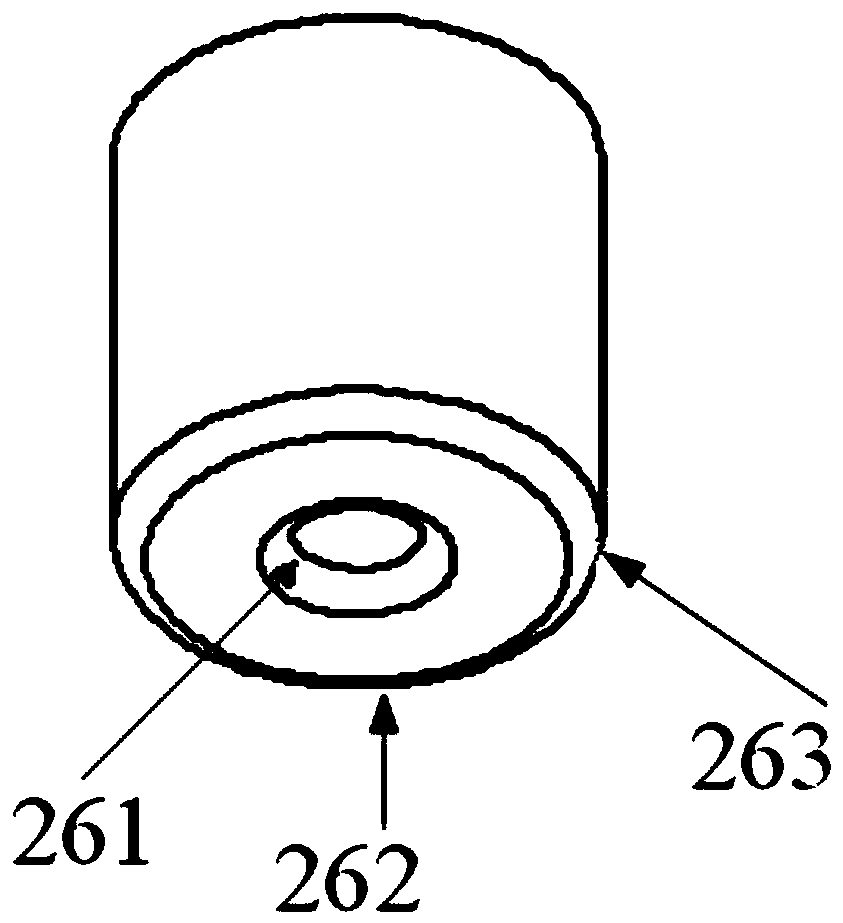

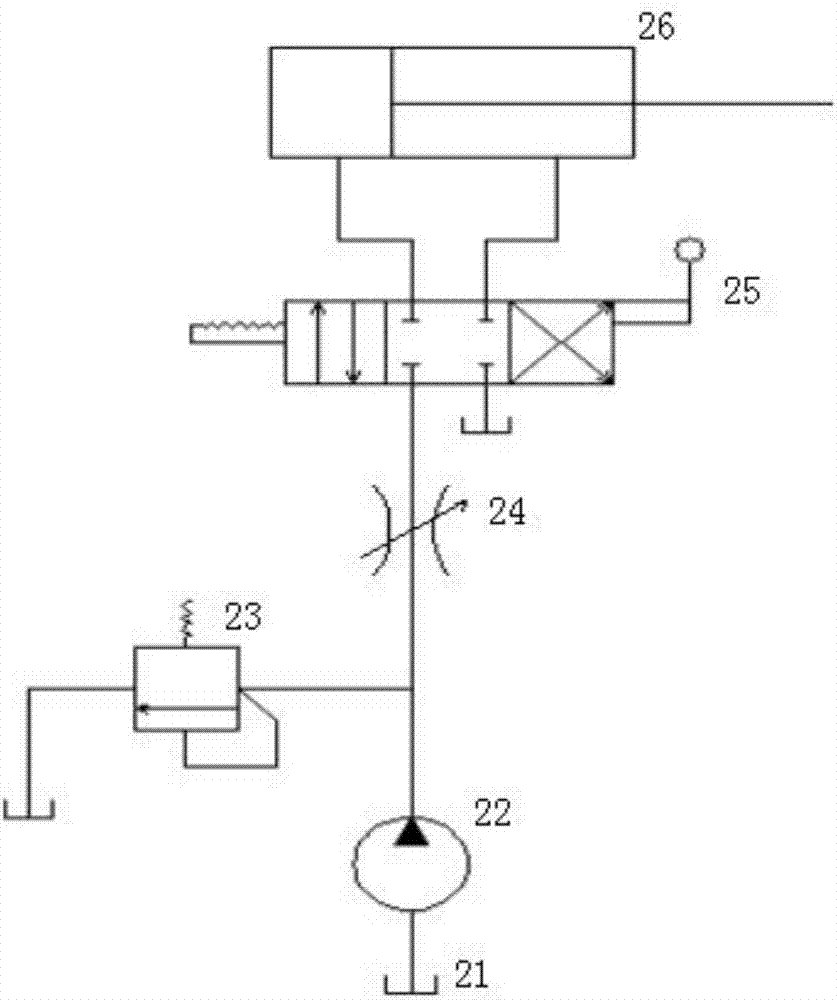

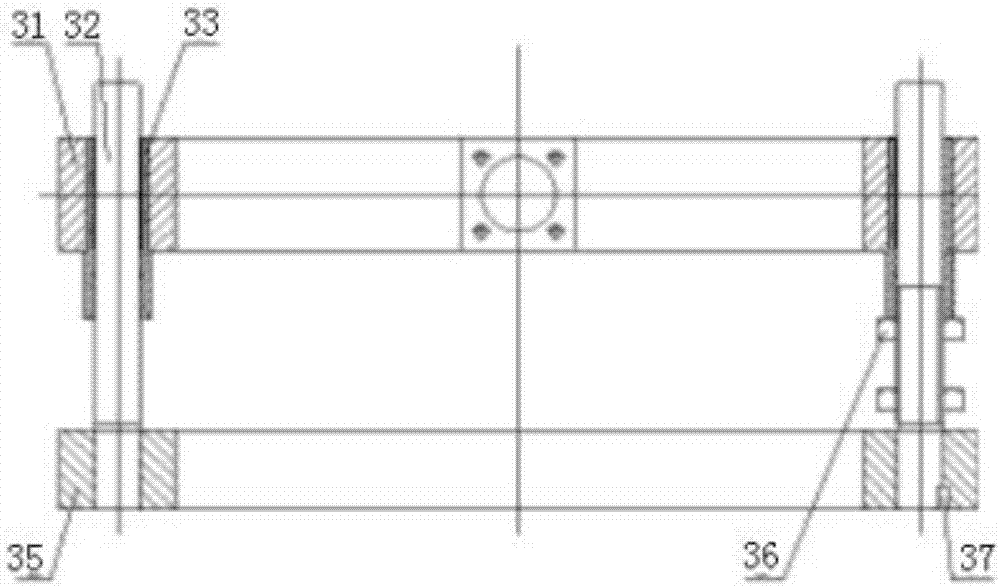

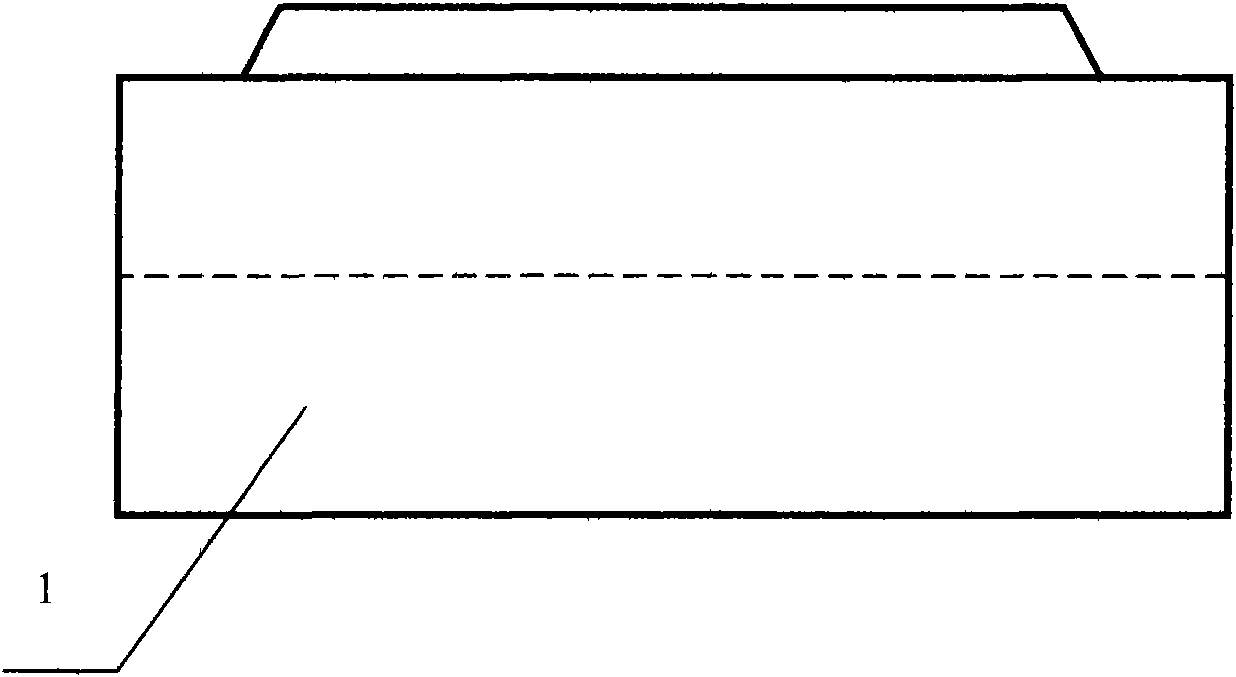

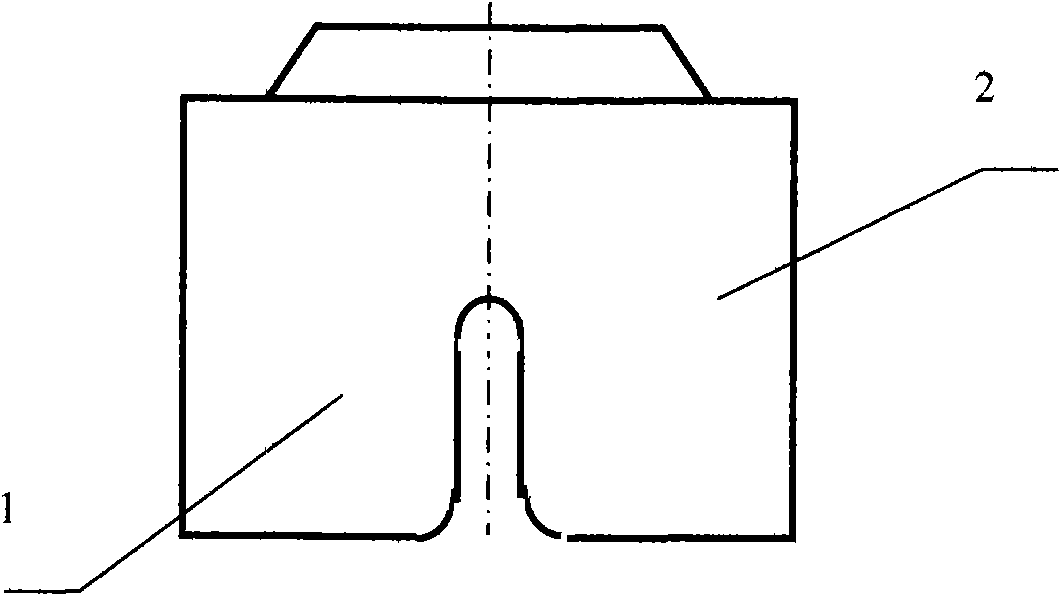

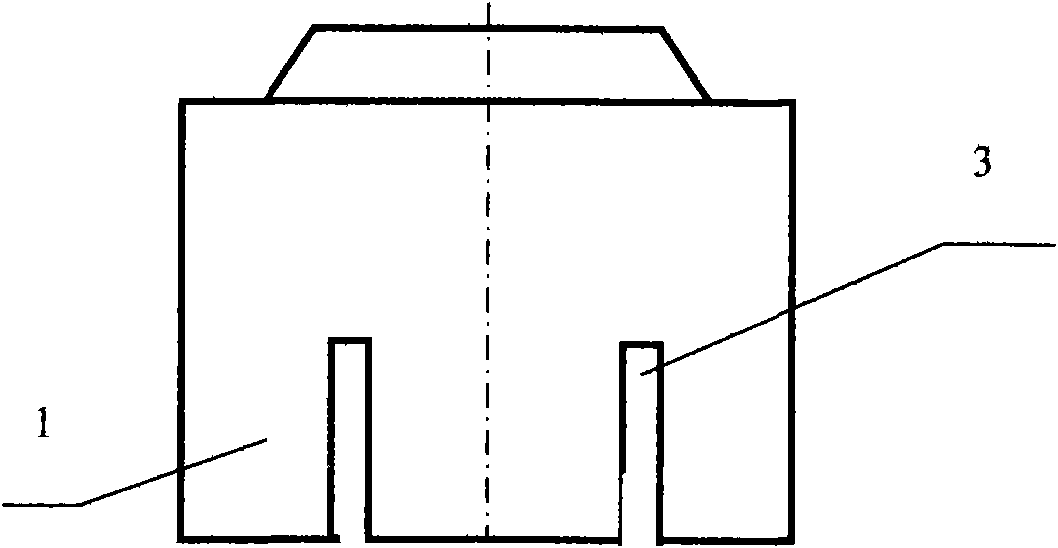

Rotary gas dispersion device for treating a liquid aluminium bath

InactiveUS6060013AHigh blade lift ratioDifficult to manufactureMechanical apparatusStirring devicesEngineeringLiquid aluminium

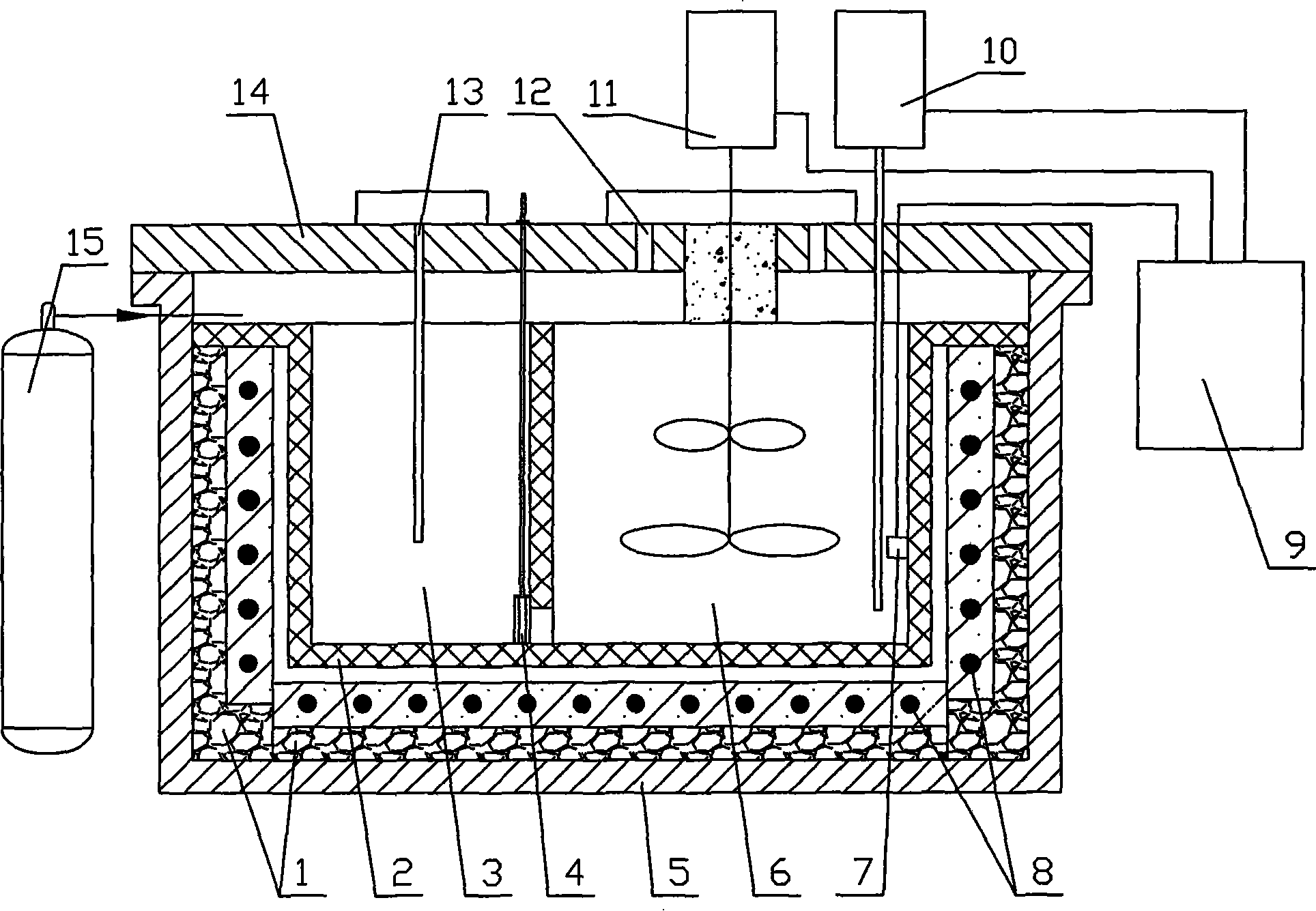

PCT No. PCT / FR97 / 01367 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Jul. 23, 1997 PCT Pub. No. WO98 / 05915 PCT Pub. Date Feb. 12, 1998A rotary gas dispersion device for use in a liquid aluminium treatment vessel is disclosed. The device is useful for reducing surface disturbance, splashing and vortices while maintaining the effectiveness of the treatment. Said device includes a rotor (1) consisting of a set of blades (5) and a substantially flat disc (4) thereabove. Gas is injected through the central hub and side ports (10) between the blades. The ratio of the outer diameter of the rotor to the diameter of the central hub thereof is of 1.5-4.

Owner:NOVELIS INC

Preparation method of ultrahigh-purity and superfine aluminium oxide powder

The invention relates to a preparation method of ultrahigh-purity and superfine alumina powder. The preparation method comprises the following process steps of: (1) injecting a high-purity aluminium sheet, isopropanol and a catalyst into a synthetic reaction tower to generate gaseous aluminium isopropoxide; cooling gaseous aluminium isopropoxide into liquid aluminium isopropoxide by virtue of a condenser; (2) injecting liquid aluminium isopropoxide into a reduced pressure distillation purification tank for evaporating to form steam, injecting the steam to a material receiving tank to become liquid ultrahigh-purity aluminium isopropoxide; (3) adding ultrahigh-purity aluminium isopropoxide into a vacuum stirring and drying machine, injecting high-purity water, and carrying out hydrolysis reaction under the circulating water cooling condition, so as to obtain ultrahigh-purity aluminium hydroxide and isopropanol aqueous solution; and drying in a vacuum stirring and drying machine; and (4) placing ultrahigh-purity aluminium hydroxide powder into a corundum crucible, and calcining in an electrically pushed slab kiln until the aluminium hydroxide powder is changed into alpha-Al2O3 powder, thus preparation is completed.

Owner:DALIAN HILAND PHOTOELECTRIC MATERIAL

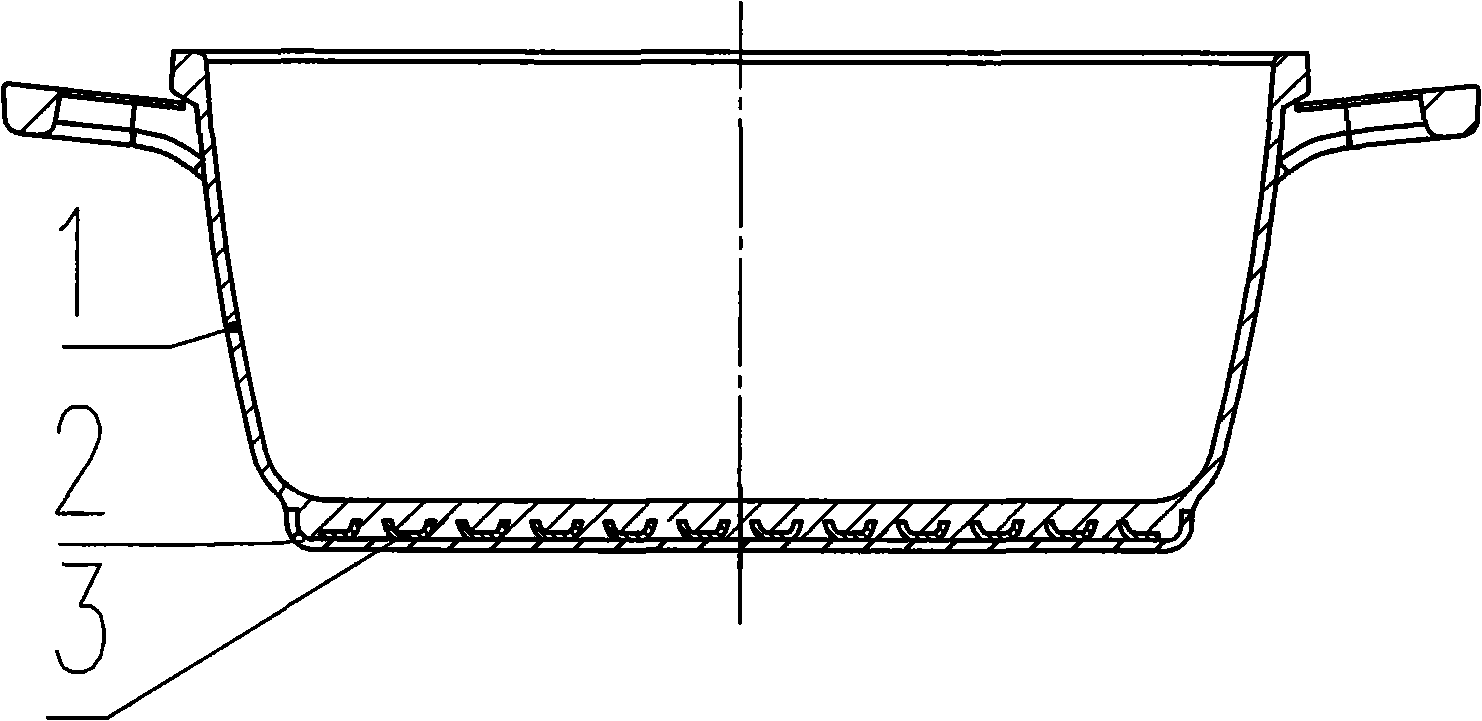

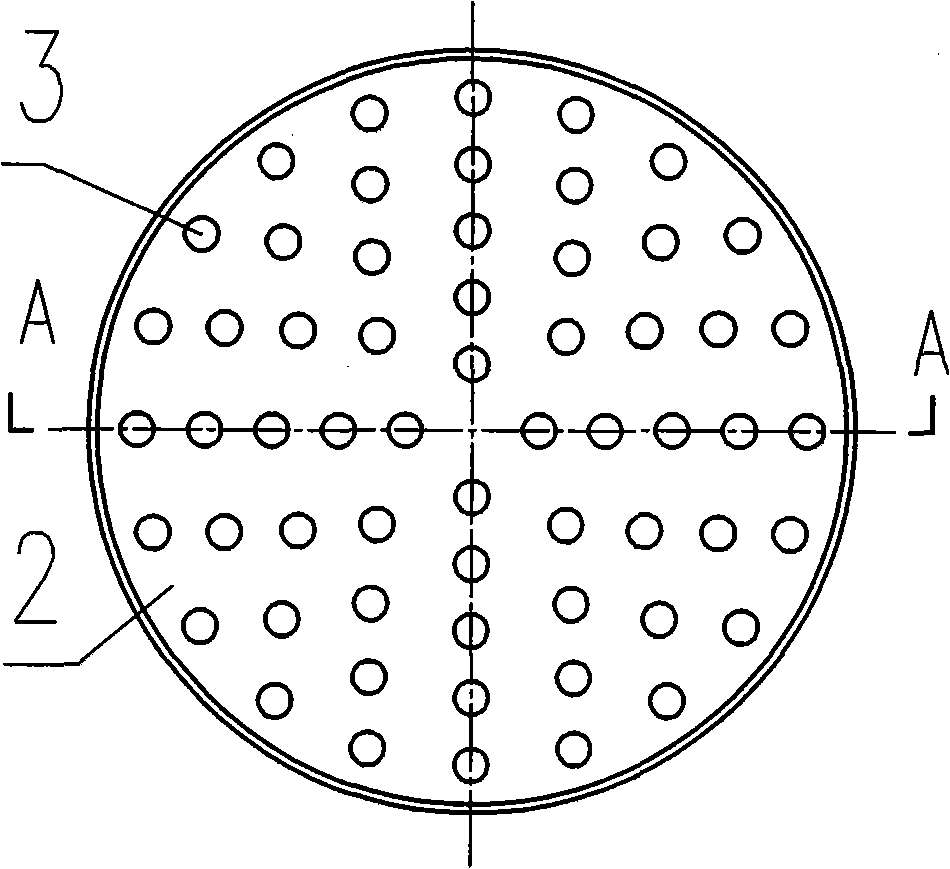

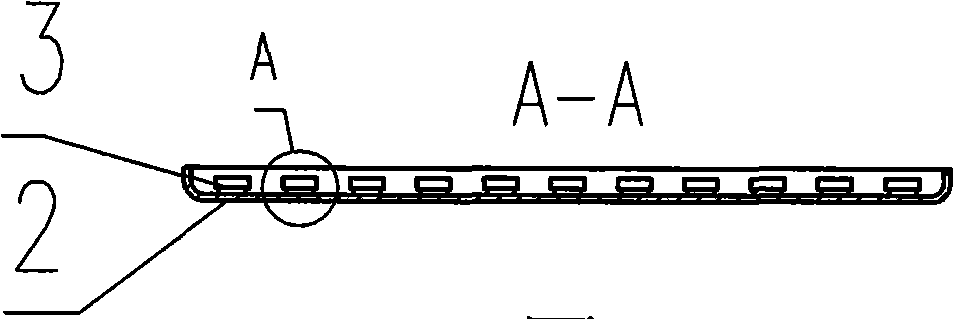

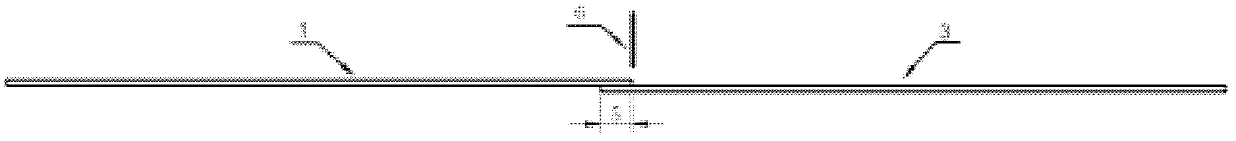

Press-casting multi-bottom pan and press-casting forming manufacturing process

ActiveCN101278801AHigh thermal fatigue stabilityHigh thermal efficiencyCooking-vessel materialsMolten stateInjection pressure

The invention relates to a die-casting composite bottom pan, including an aluminum alloy pan body and a stainless iron composite bottom sheet. The invention is mainly characterized in that the stainless iron composite bottom sheet is provided with a plurality of clip pieces; the edge of the stainless iron composite bottom sheet is provided with a flange coating the lower peripheral of the pan body; the lower part of the aluminum alloy pan body and the stainless iron composite bottom sheet are cast into a whole body by a die-cast machine. The invention also relates to a die-cast manufacturing technique of the die-casting composite bottom pan. The manufacturing technique includes the following procedures: (1) the composite bottom sheet is manufactured: the stainless iron composite bottom sheet is stamped for forming and the clip piece is welded on the stainless iron composite bottom sheet; (2) the stainless iron composite bottom sheet is placed: the stainless iron composite bottom sheet is placed into a die mold setting cavity; (3) die casting: after matching the die, the die-cast machine fills the liquid aluminum alloy in the melting state with 600 to 700 DEG C temperature and 20 to 80MPa injection pressure ratio into the setting cavity at the injection speed of 20 to 60m / s, the filling time is 0.02 to 0.07s, and after the setting cavity is full of the aluminum liquid, the pan body and the stainless iron composite bottom sheet are cast into a whole body by the die-cast machine; (4) surface treatment: after the die-casting pan is cooled, flash edges of the pan body are removed, and then the pan body is sandblast and sprayed, thus manufacturing the die-casting composite bottom pan. The invention is a cook applicable to electromagnetic stove with the advantages of stable connection with the composite bottom sheet, high heat efficiency, good heat and fatigue resistance, simple manufacturing technique and high rate of finished products, etc.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

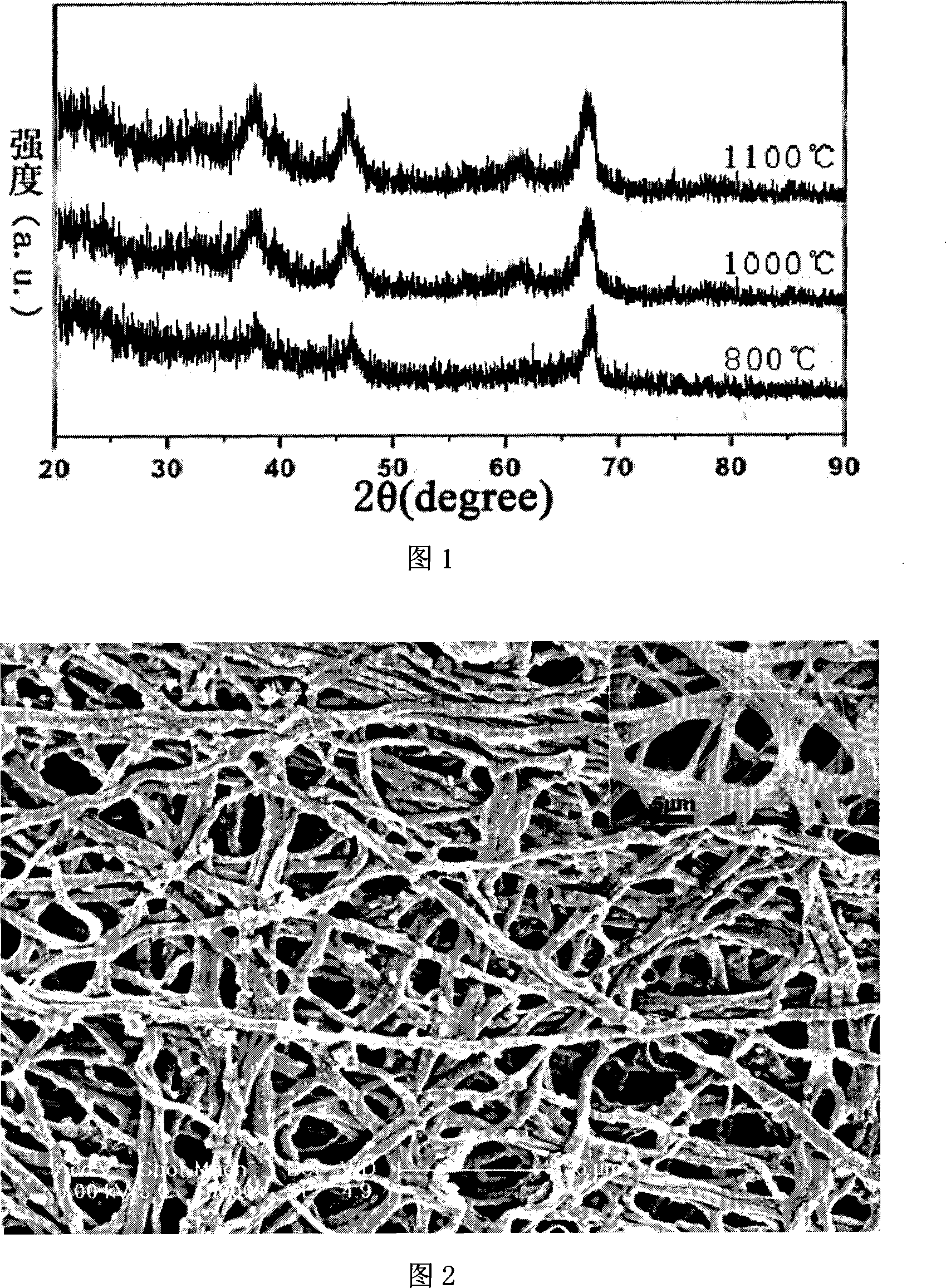

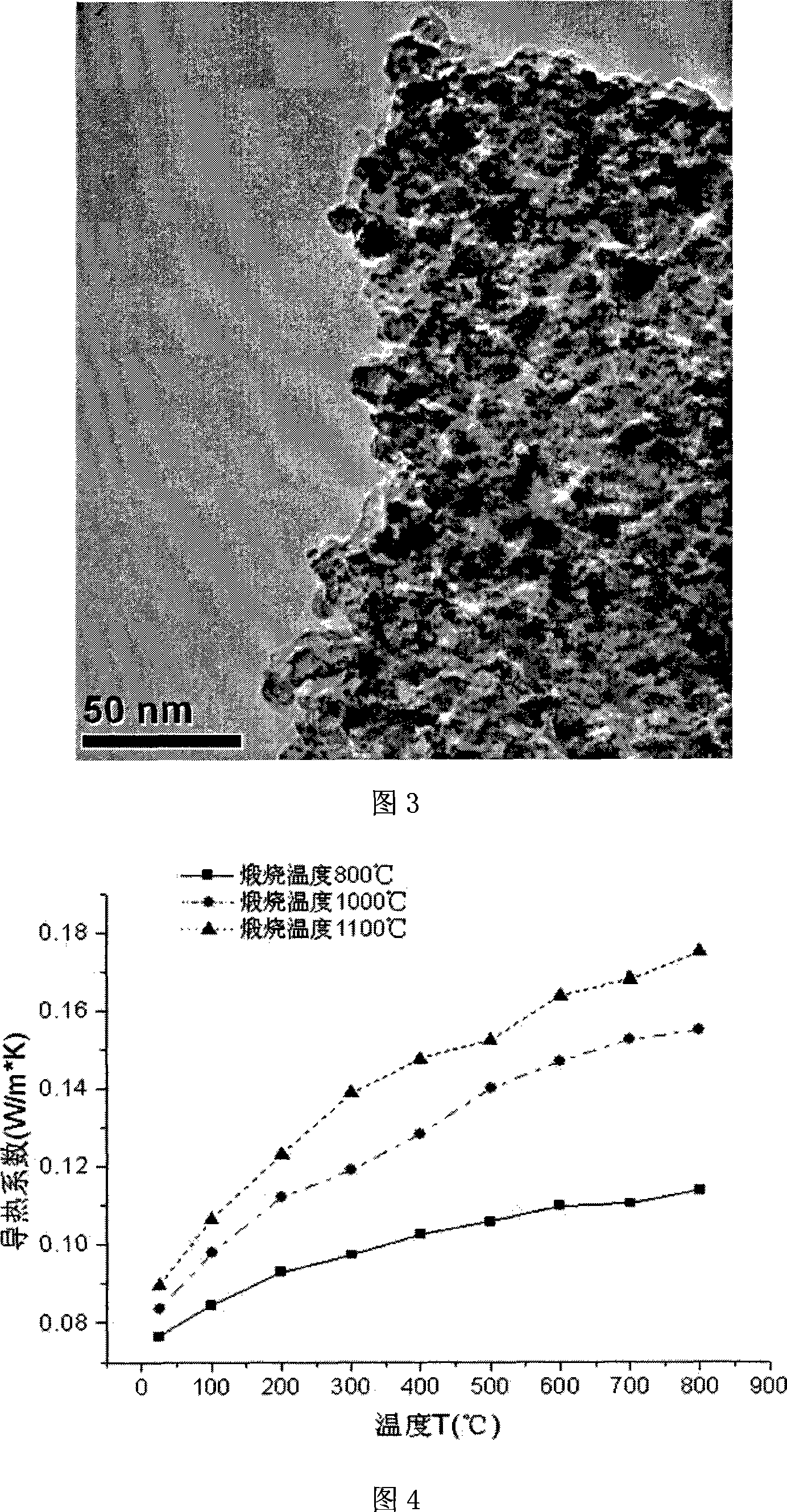

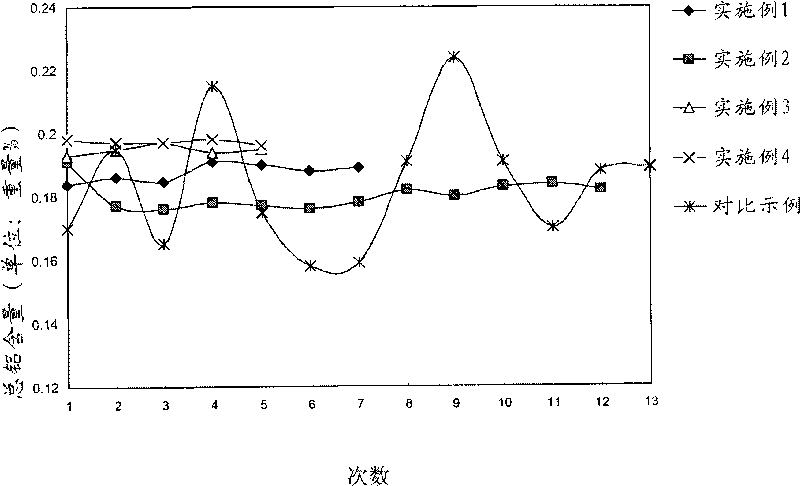

Method for preparing classifying porous aluminum oxide nano heat insulating material

InactiveCN101100307AReduce heat transferSmall coefficient of thermal expansionNanostructure manufactureChemical industryCeramic sinteringEGG SHELL MEMBRANE

This invention relates to the production of classified porous alumina nanometer thermal insulating material, based-on biological templet synthesis technique, by using waste egg shell membrane as raw material. First, the membrane is pretreated by separation and washing, followed by dipping in prodromal liquid aluminium salt solution, then oxidized burnt, forming alumina nanometer material in situ under the effect of biological templet. This invention has advantages of: simple process, low cost, being able to control the granule size and aperture dimension by regulating the burning temperature and speed of stepping-up temperature. The product has advantages of small heat conductivity, low expansion coefficient, well property of anti-heat shock, able to be used in field of metallurgical industry, ceramic furnace as excellent heat insulation refractory.

Owner:SHANGHAI JIAO TONG UNIV

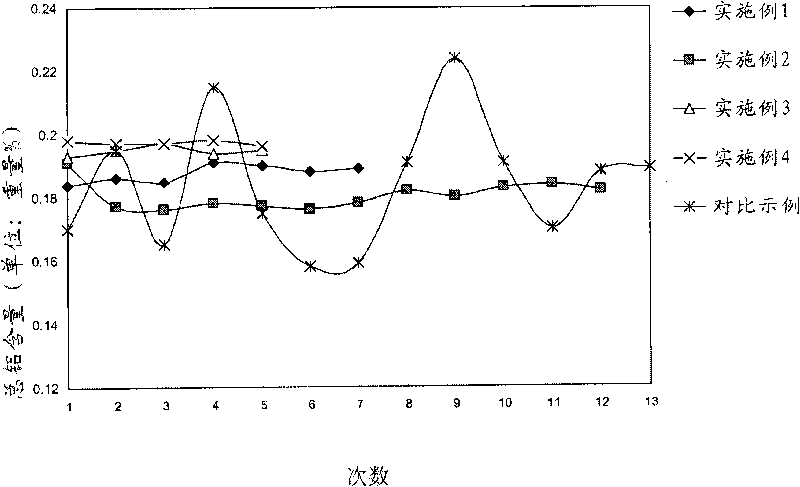

Continuous hot dip galvanizing zinc liquid aluminium content adjusting method

InactiveCN101717906AGood coating performanceImprove performanceHot-dipping/immersion processesIngotLiquid aluminium

The invention provides a continuous hot dip galvanizing zinc liquid aluminium content adjusting method. In the continuous hot dip galvanizing technical process, the total Al content in zinc liquid is detected, and the steps are carried out: if the total Al content is less than or equal to 0.185%(weight), a main zinc ingot (1) metal is added; if the total Al content is more than 0.185%(weight) and less than or equal to 0.190%(weight), the main zinc ingot (1) and a main zinc ingot (2) are added based on the weight ratio of 1:4; if the total Al content is more than 0.190%(weight) and less than or equal to 0.195%(weight), the main zinc ingot (1) and the main zinc ingot (2) are added based on the weight ratio of 1:8; if the total Al content is more than 0.195%(weight) and less than 0.22%(weight), the main zinc ingot (2) is added; if the total Al content is more than or equal to 0.22%(weight), a pure zinc ingot and the main zinc ingot (2) are added based on the weight ratio of 1:4; and in the adding process, the unchanged zinc liquid level is taken as reference.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

Medium strength aluminium alloy wire with conductivity of 55% IACS, and preparation method thereof

ActiveCN103820686APromote precipitationPromote spheroidizationMetal/alloy conductorsCable/conductor manufactureManufacturing technologyAdditive ingredient

The invention relates to a medium strength aluminium alloy wire with conductivity of 55% IACS, and a preparation method thereof, and belongs to the field of alloy manufacturing technology. The alloy elements comprise, by weight, 0.16%-0.22% of iron, 0.48%-0.54% of silicon, 0.62%-0.67% of magnesium, 0.01%-0.02% of boron and 0.02%-0.05% of ytterbium, with the balance being aluminium. The medium strength aluminium alloy wire with a product conductivity higher than or equal to 55% IACS and tensile strength higher than or equal to 315 MPa is obtained by processes of selecting materials, smelting liquid aluminium, adjusting liquid aluminium ingredients, carrying out purifying treatment, deslagging, standing with heat preservation, degassing, filtering with heat preservation, casting and crystallizing, rolling an aluminum rod, drawing and aging. The wire and cable produced by using the aluminium alloy can be erected continuously by a conventional construction process. In a circuit operation process, circuit loss can be reduced; construction fee can be reduced; and enormous economic benefits and social benefits can be brought about for power transmission and transformation industries.

Owner:WUXI HUANENG ELECTRIC CABLE

Alumina anode steel claw protection ring and method for producing the same

The invention discloses an aluminum oxide anode steel paw protection ring and the production process, wherein the ring is made from 20-100% of aluminum oxide and right amount of binder through mixing, forming and hardening by the conventional methods.

Owner:邹建明 +1

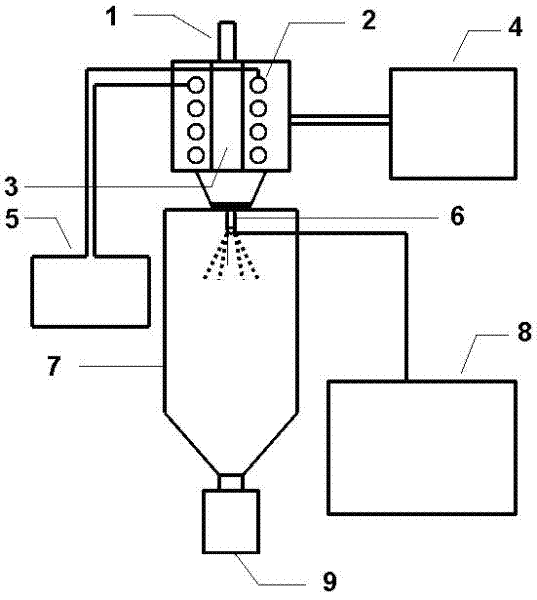

Technique of preparing novel grain reinforced aluminum base composite material and special equipment thereof

InactiveCN101195876AImprove wear resistanceImprove wettabilityAluminum matrix compositesPre treatment

The invention discloses a preparation process and the special equipment thereof for novel grain intensifying aluminum radical composite material. The melting and mixing process of the preparation method are performed in a body-connected sealing equipment, the aluminum matrix alloy is added through a charging opening of a melting pool, after the aluminum matrix alloy is melted, a valve at the bottom part of the melting pool is opened, the melted liquid state aluminum matrix alloy directly flows into the mixing pool, when the liquid level of the mixing pool reaches the defined height, the valve is closed, the pretreated SiC is added through a charging opening at the top part of the mixing pool, a charging rod adopting an aluminum casing as covering material is adopted when material is charged, as the aluminum casing of the charging rod is melted, the SiC is melted in the aluminum matrix alloy, then the material is sent into the die assembly through a discharging pump, and directly made into billet material or a product. In the invention, the melting and the mixing are effectively combined, the system of melting pool and mixing pool is simplified, the structure is simple, the controlling is simple, the cost is reasonably reduced, the content of the silicon carbide grain in the aluminum radical composite material of the product is stable and uniformly distributed, and the whole performance of the aluminum radical composite material is enhanced.

Owner:汪喜和

Preparation method for titanium-aluminium alloy

The invention relates to a preparation method for titanium-aluminium alloy, belongs to the field of alloys and aims to solve the technical problem of providing the preparation method for the titanium-aluminium alloy. The preparation method comprises the following steps: titanium serves as an anode and liquid aluminium serves as a cathode and then titanium and liquid aluminium are electrolyzed in a fused salt electrolyte to prepare the titanium-aluminium alloy, wherein the fused salt electrolyte comprises the main body fused salt NaCl-KCl and soluble titanium salt; the mass ratio of the NaCl-KCl to the soluble titanium salt in the fused salt electrolyte is 100 to 1-10; the weight of the soluble titanium salt is measured by the weight of titanium. According to the preparation method for the titanium-aluminium alloy, as liquid aluminium is adopted to serve as the cathode and is alloyed in a smelting state, the alloyed titanium aluminium alloy sinks at the bottom of a crucible and is easy to separate; the obtained titanium-aluminium alloy products are spongy and easy to wash, the impurity content is less and the follow-up processing is facilitated.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for producing aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis

The invention provides a method for producing an aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis. In an electrolytic furnace, aluminium is taken as a cathode, a cathode sleeve is sheathed thereon, graphite is taken as an anode, an electrolyte system is formed from LiCl and KCl, wherein, the weight ratio of LiCl: KCl is equal to 45: 55, the electrolysistemperature is 380-450 DEG C, the self-consumption cathode method is adopted for carrying out electrolysis, the current density of the cathode is 1-3.0A / cm<2>, the current density of the anode is 0.5A / cm<2>, the cell voltage is 4.1-5.6V, LiCl is supplemented during the electrolysis process for leading the mixing ratio of LiCl: KCl of the electrolyte to be in the vicinity of an eutectic point, theliquid aluminium-lithium alloy with high lithium content is deposited in the vicinity of the cathode in a molten salt electrolytic cell by 1-4 hours of electrolysis, and the solid aluminium-lithium alloy is prepared by solidification. The method can obtain the liquid aluminium-lithium alloy with evenly distributed alloy components at low temperature. The method can avoid the defects of burning loss of lithium during the doping process and the like, simultaneously save energy consumption of doping, mixing and melting process, avoid cracking of the cathode and uneven components, and avoid the defects of burning loss of the lithium caused by higher temperature and volatilization loss of LiCl.

Owner:HARBIN ENG UNIV

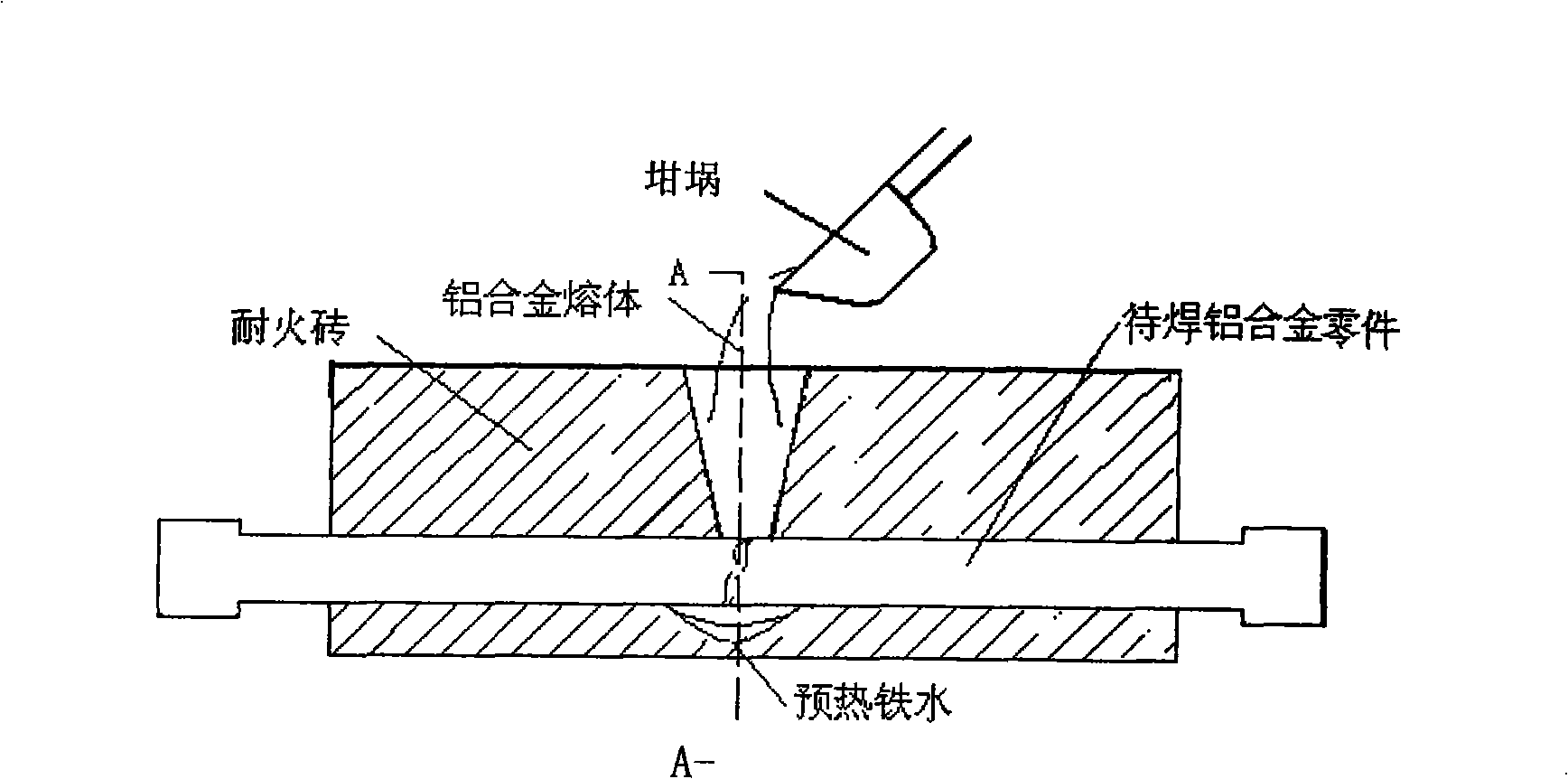

Aluminothermy welding method of aluminium alloy

InactiveCN101347868AEasy to carryImprove performanceAlumino-thermic welding apparatusCrucibleWeld seam

The invention relates to a thermit welding method of aluminium alloy, which comprises the following steps: preparing a thermit welding agent; placing the thermit welding agent in a crucible; embedding a TiC igniter into the thermit welding agent; exposing a part; igniting the exposed part; igniting the thermit welding agent in the crucible for thermit reaction; placing the solid aluminium alloy into the surface of reactants in the crucible immediately after the reaction is finished; using the residual heat to melt the solid aluminium alloy and obtaining the liquid aluminium alloy melt; preheating fractures of the aluminium alloy parts to be welded to the temperature of 390-410 DEG C when the former step is carried out; directly casting the aluminium alloy melt to the position of the fracture of the processed aluminium alloy parts; carrying out the densification processing by striking and extruding the welding seam when the metal to be seamed is just solidified and realizing the welding; and clearing weld flash by hands when the temperature is high. The thermit welding method of the invention is applicable to emergent and fast welding and repairing of aluminium alloy armor plates and aluminium alloy parts of armored equipment in battlefields and is also applicable to emergent welding and repairing of aluminium alloy parts of civilian vehicles or other machines in field working.

Owner:江阴东大新材料研究院

Preparation method of aluminum-boron alloy powder and aluminum-boron slurry of crystalline silicon cell

InactiveCN102368411AImprove photoelectric conversion efficiencyReduced series resistanceNon-conductive material with dispersed conductive materialMetal/alloy conductorsBack surface fieldPhysical chemistry

The invention relates to a preparation method of an aluminum-boron alloy powder and aluminum-boron slurry of a crystalline silicon cell. The preparation method comprises the following special implementation steps of: carrying out reduction reaction and gas atomization on a boron compound in molten liquid aluminum to prepare the aluminum-boron alloy; and mixing 72-82% of aluminum-boron alloy powder by mass, 0.1-10% of inorganic glass adhesion agent by mass, 15-25% of organic adhesion agent by mass and 1-5% of additive to prepare the aluminum-boron slurry. In a back surface field of the crystalline silicon cell which is prepared from the aluminum-boron slurry in the invention, a p-type doping concentration is one order of magnitude more than the p-type doping concentration of the back surface field prepared from the normal aluminum slurry at the same temperature, so that the inactivation effect on the back surface of the crystalline silicon cell is more excellent; and meanwhile, serial-connection resistance of the cell is reduced so that the photoelectric conversion efficiency of the solar cell is improved.

Owner:NANCHANG UNIV

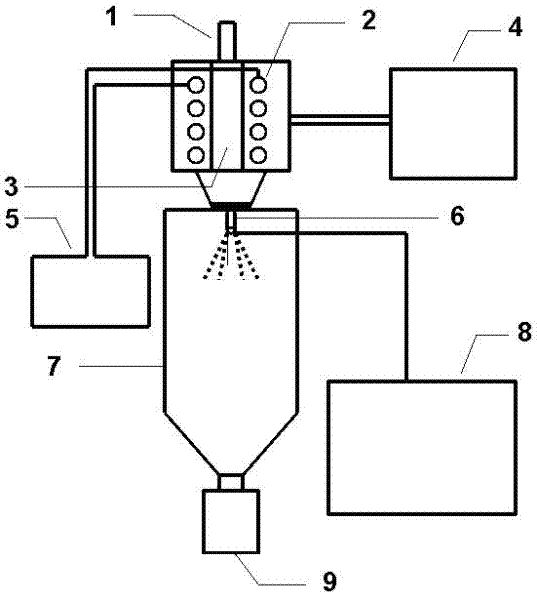

Method of producing aluminium polychloride using aluminium hydroxide mud

InactiveCN1948156ATo achieve the purpose of comprehensive utilizationImprove hygieneAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The present invention relates to a method for producing aluminium polychloride by utilizing aluminium hydroxide sludge. Said method includes the following steps: firstly, adding dilute hydrochloric acid or waste hydrochloric acid into reaction tank, then adding aluminium hydroxide sludge, stirring to make reaction and dissolvation, adding calcium aluminate powder and adding additive, make continuous reaction and dissolvation, heat-insulating, making natural precipitation to obtain supernatant fluid, said supernatant fluid is liquid aluminium polychloride; making the liquid aluminium polychloride be fed into a high-level tank and added into a pool under the drying drum, making the drying drum be contacted with said liquid aluminium polychloride, and making the liquid aluminium polychloride be adsorbed on the surface of said drum, utilizing scraper blade in the front of said drum to scrape off said absorbed liquid aluminium polychloride from the drum so as to obtain the solid aluminium polychloride.

Owner:童益

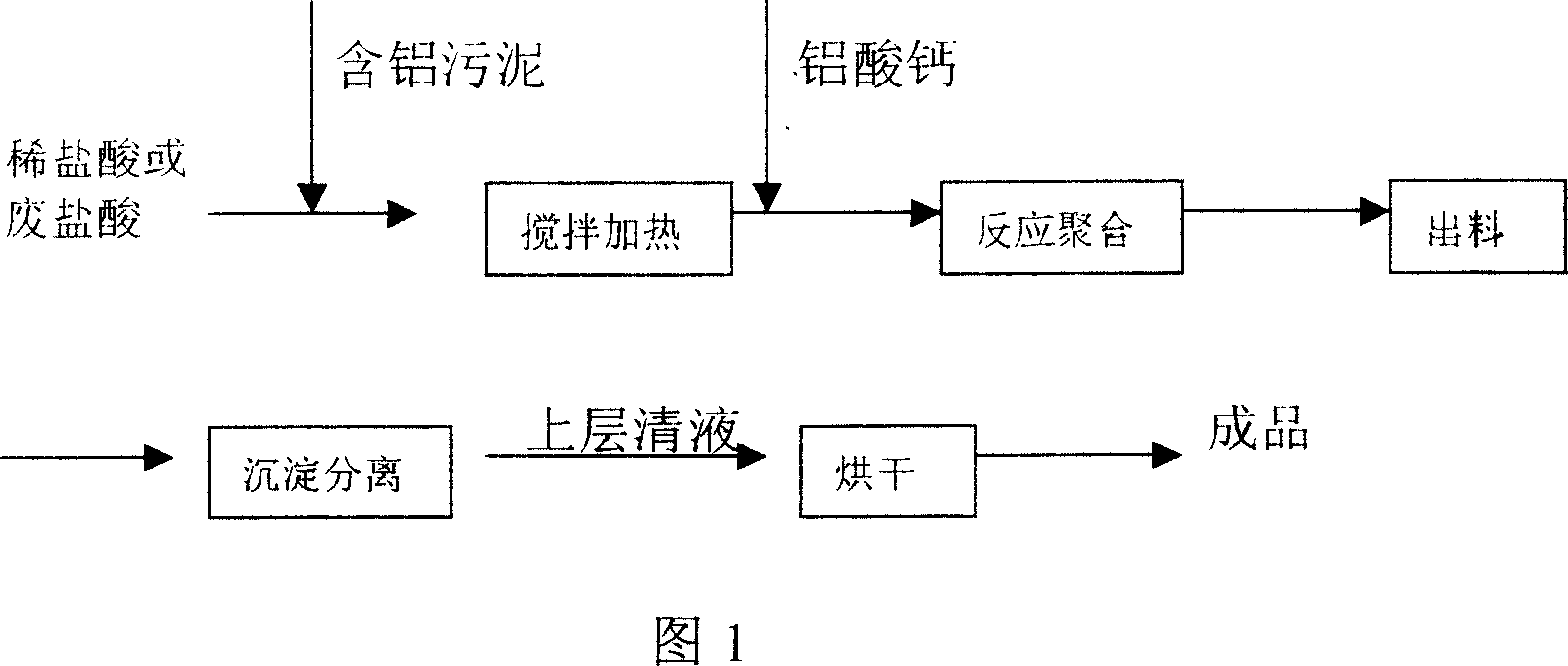

Aluminum-ion secondary battery employing nickel-sulfur compound as positive electrode and preparation technology of aluminum-ion secondary battery

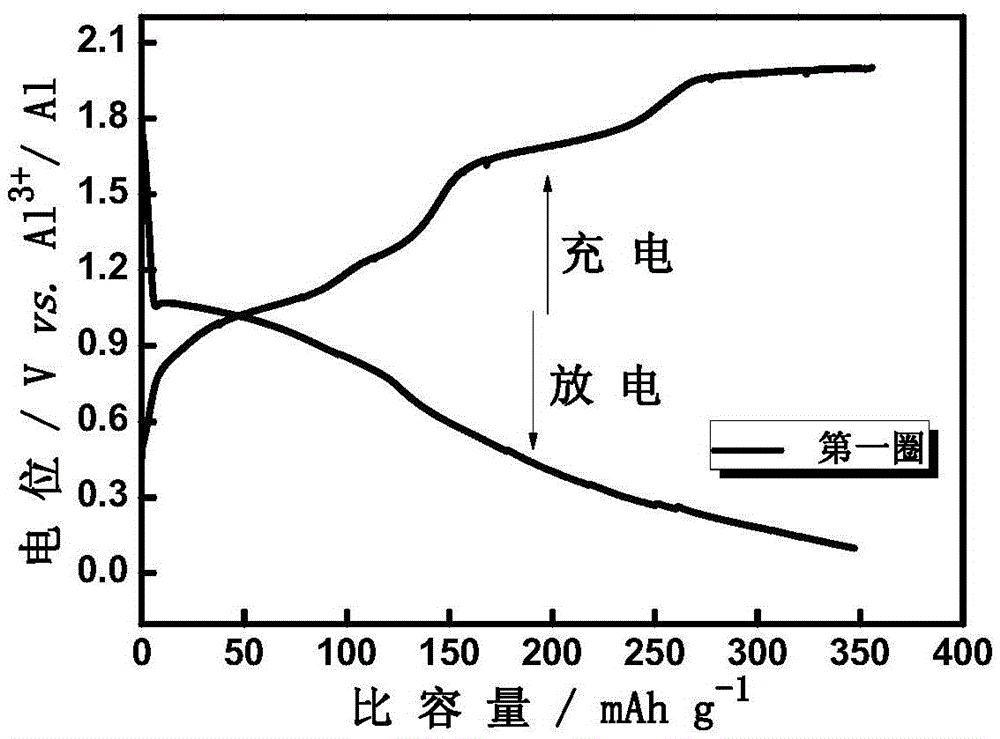

InactiveCN105633371ARich reservesLow priceNon-aqueous electrolyte accumulatorsCell electrodesLarge capacityAluminum Ion

The invention belongs to the technical field of batteries, and particularly relates to an aluminum-ion secondary battery employing a nickel-sulfur compound as a positive electrode and a preparation technology of the aluminum-ion secondary battery. The aluminum-ion secondary battery can be widely applied to the fields of electronic industry, communication industry and the like, and can also be applied to a power battery for an electric automobile. The aluminum-ion secondary battery comprises a positive electrode, a negative electrode, a diaphragm material, a liquid aluminum-ion electrolyte and an electrolytic tank device, wherein a positive active material is the nickel-sulfur compound; the negative electrode is metal aluminum or aluminum-containing alloy; the liquid aluminum-ion electrolyte is a non-aqueous solution electrolyte containing Al<3+> ions; and the positive electrode, the negative electrode and the electrolyte of the battery and the like are coated by an insulated soft package or are assembled by a tubular container. The aluminum-ion secondary battery provided by the invention can be repeatedly charged and discharged and has the advantages of high capacity, high charge-discharge efficiency, good cycling stability and excellent charge-discharge characteristics; the first discharge specific capacity can reach 350mAhg<-1>; and the discharge platform can reach 1.1V vs.Al<3+ / >Al.

Owner:BEIJING ALUMINUM ENERGY S&T +2

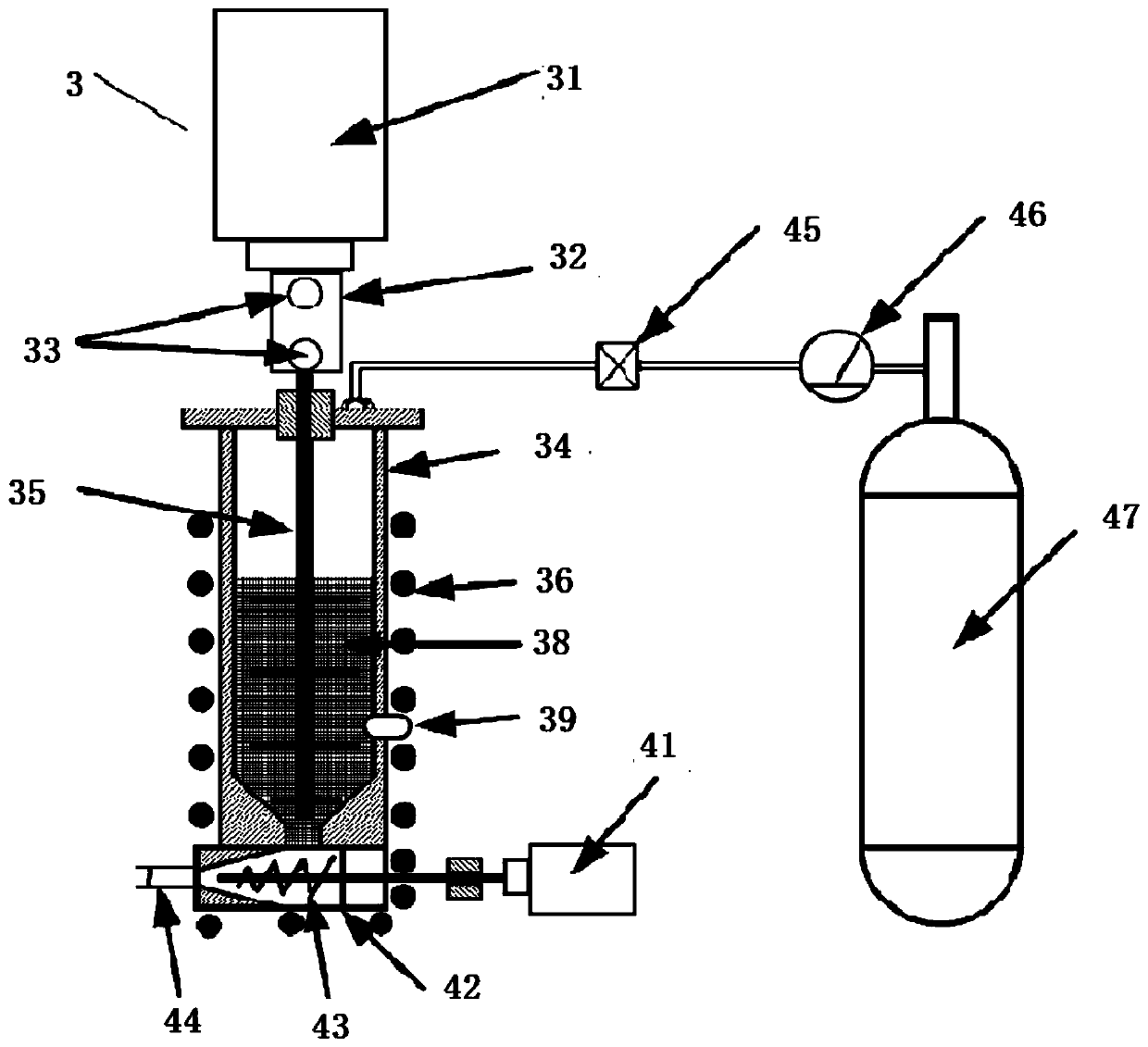

3D printing device used for preparing aluminum matrix composite and printing method thereof

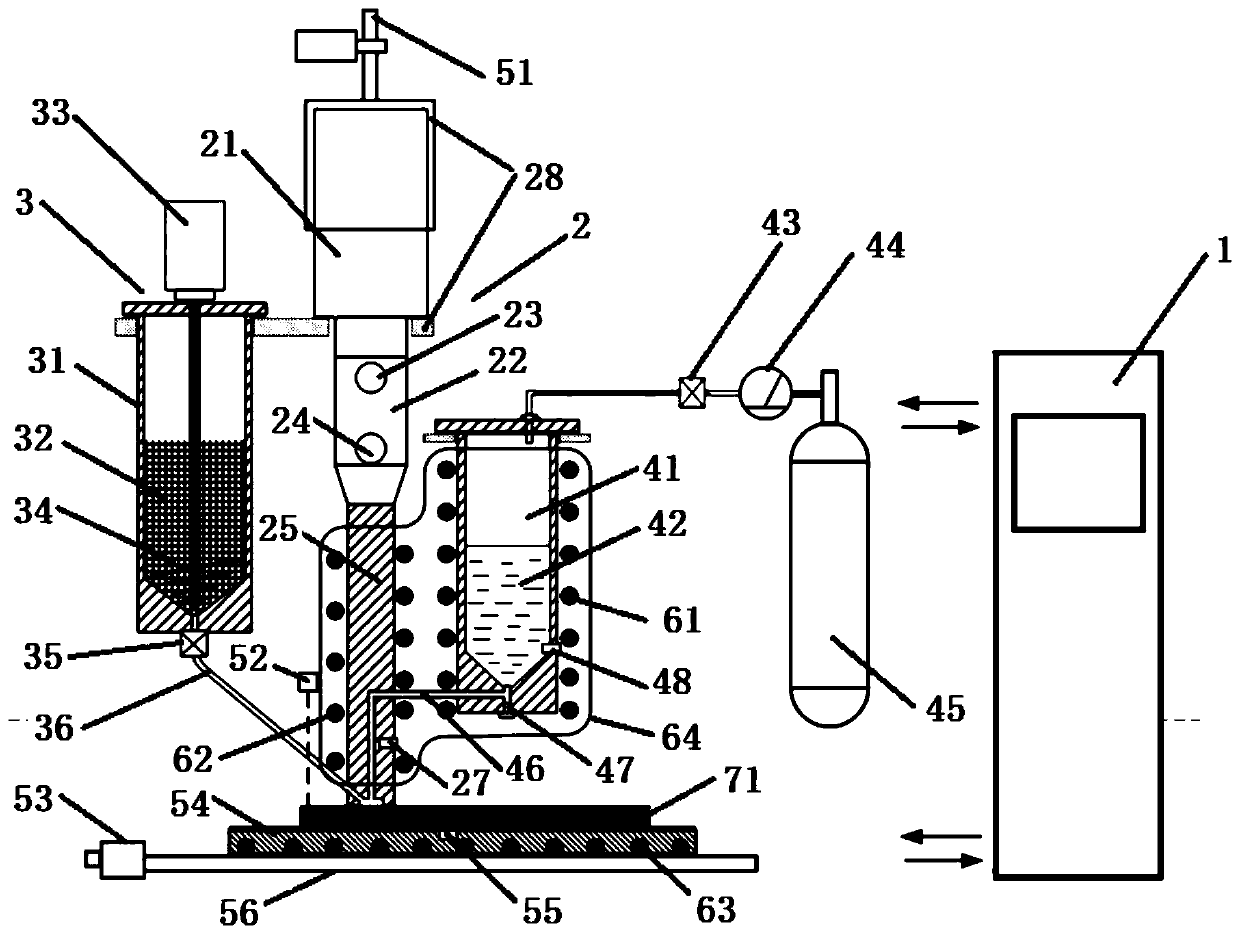

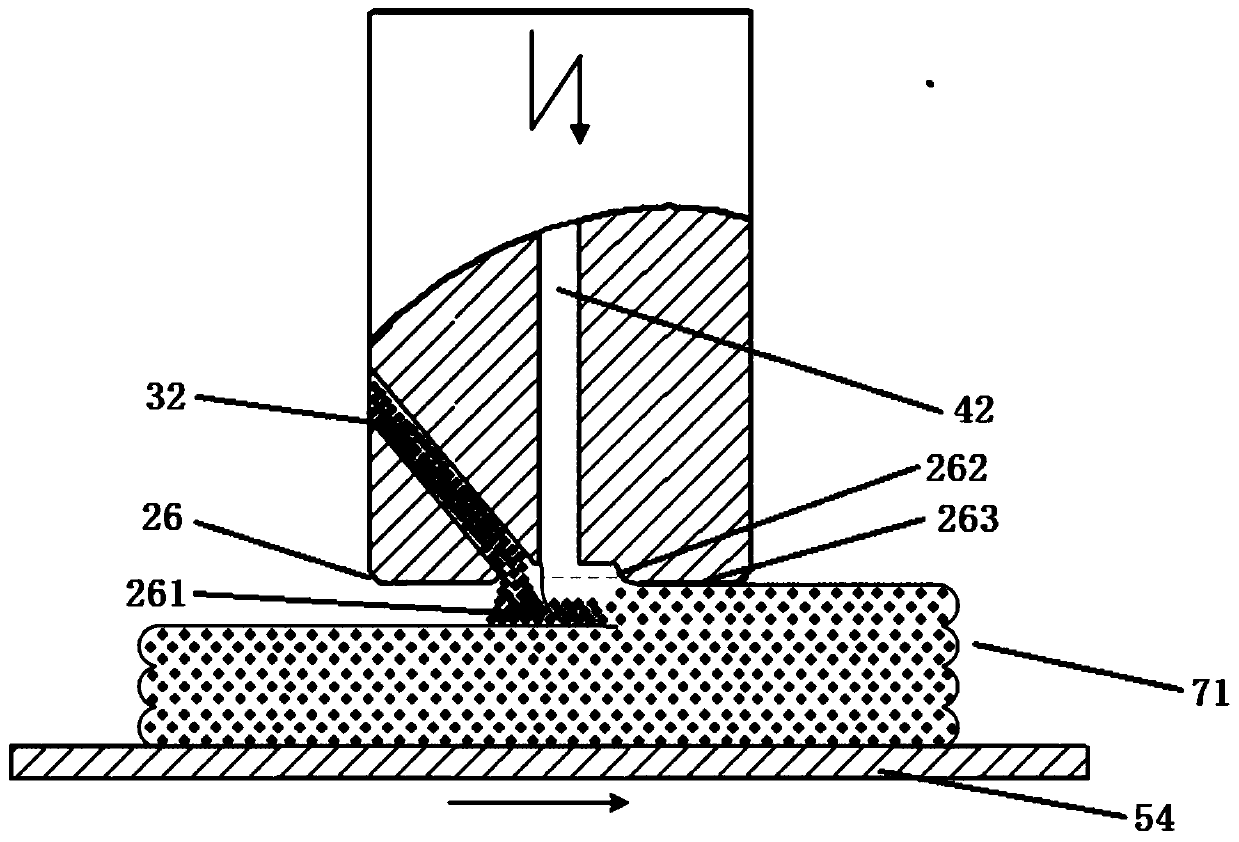

ActiveCN110899705AQuality assuranceAvoid the problem of uneven distribution of reinforcing particlesAdditive manufacturing apparatusLight reflectionRapid prototyping

The invention relates to a 3D printing device used for preparing aluminum matrix composite and a printing method thereof, and relates to 3D printing devices and printing methods. The 3D printing device used for preparing aluminum matrix composite and the printing method thereof aims to solve the problems that the cost of 3D printing is high, the difficulty of laser 3D printing technology is increased due to the high light reflection performance of the aluminum alloy; and the distribution of reinforcing particles are uneven when selective laser printing layer by layer. According to the 3D printing device used for preparing aluminum matrix composite and the printing method thereof, ceramic particles and liquid aluminum alloy melt are adopted as rapid forming materials and are respectively stored in two storage tanks, the powder flow is controlled through adjusting the rotating speed of a screw rod, the gas pressure is adjusted, so that the feeding and stopping of the aluminum alloy meltand the feeding amount are controlled, the ceramic particles and the liquid aluminum alloy melt are transported to a place to be printed through a feeding pipe and an ultrasonic pole nozzle, the liquid aluminum alloy melt infiltrates into the gap of the ceramic particles under the ultrasonic action and then seeps out to contact with the surface to be printed, and a connection is formed. The 3D printing device used for preparing aluminum matrix composite and the printing method thereof is used for the preparation of aluminum matrix composite reinforced by the ceramic particles.

Owner:HARBIN INST OF TECH

Formed material blended feed type aluminum matrix composite 3D printing device and printing method

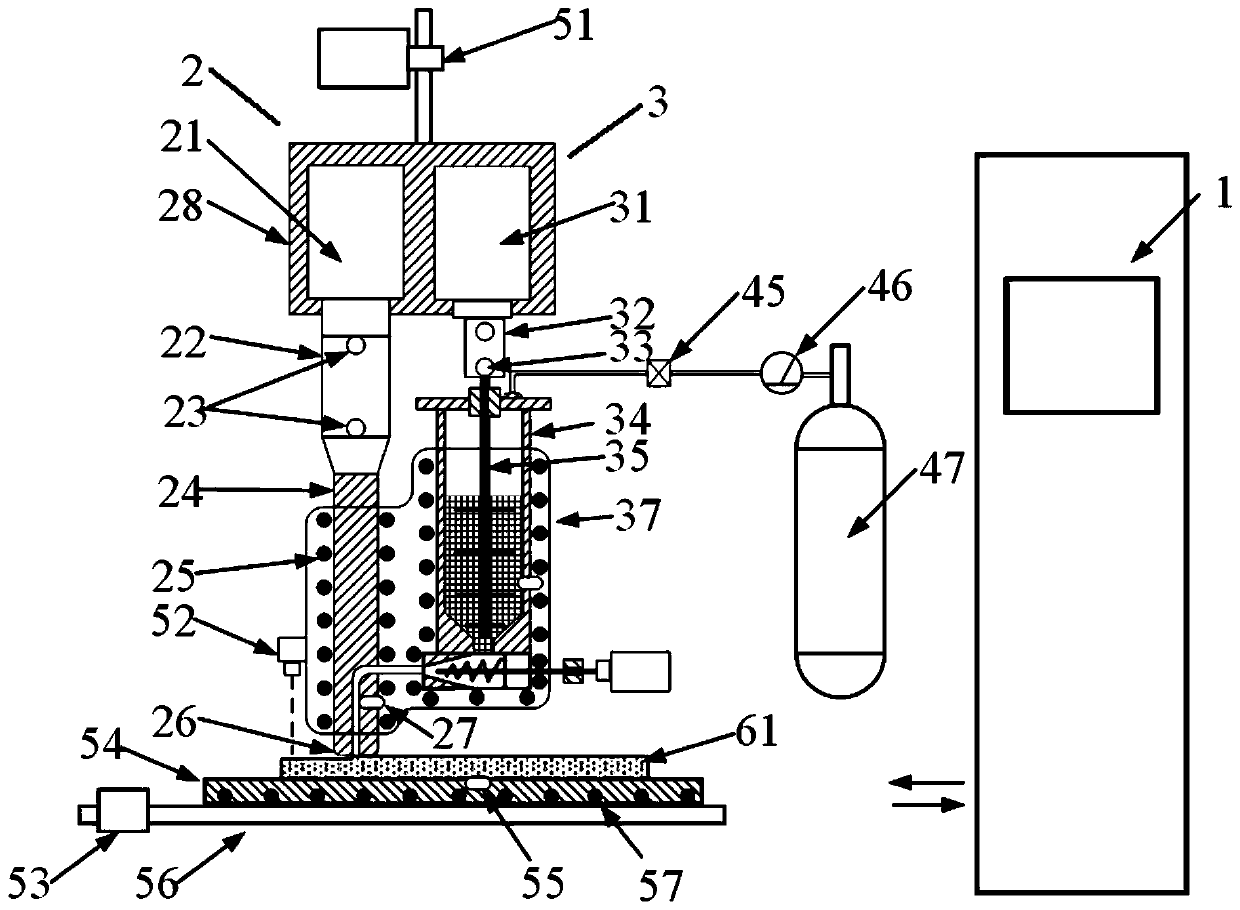

ActiveCN110919001AAchieve wettingAchieve associativityAdditive manufacturing apparatus3d printSurface oxidation

The invention relates to a 3D printing device and printing method, and discloses a formed material blended feed type aluminum matrix composite 3D printing device and a printing method. The problems that due to oxide films on the surfaces of metal powder, wetting and combining of ceramic and the metal powder are poor, the difficulty of the laser 3D printing technology is large, and distribution ofreinforced particles is not uniform during laser selective layer-by-layer printing are solved. A mixture of ceramic particles and liquid aluminum alloy met is adopted as a formed material, the formedmaterial is assembled in a storage tank provided with an ultrasonic stirring device, and the ceramic particles in the mixture is distributed uniformly under the action of a mace-shaped ultrasonic toolhead; and the mixture is extruded into a conveying pipe through a pushing device, the rotating speed of a screw rod is adjusted to control feeding and stop and the feeding quantity of the mixture, the mixture is conveyed to the to-be-printed place through an ultrasonic polar nozzle, and the liquid aluminum alloy melt and the ceramic particles are wetted and combined under the ultrasonic action and are in contact on the to-be-printed surface to be connected. The device and the method are used for aluminum matrix composite printing.

Owner:HARBIN INST OF TECH

Aluminum electrolytic tank calcining method

An aluminum electrolytic tank baking method relates to the technology method for electrolytic preparation of the metal aluminum with alumina as raw material, especially a novel electrolytic tank current-carrying baking method in the process of electrolytic preparation. The preparing process comprises: pouring the molten liquid aluminium into the novel electrolytic tank, covering the liquid aluminum with the cryolite, and current-carrying baking until the voltage is down to 1.5-2.0V from 3V naturally, characterized by : when the tank voltage is less than 2.0V, employing the gradually lifting anode method for improving the voltage, keeping the voltage of 2.0-2.1V, improving the voltage to 3V again at the 24 hours before starting, and finishing the electrolytic tank baking when the temperature reaches 850-900 DEG C.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

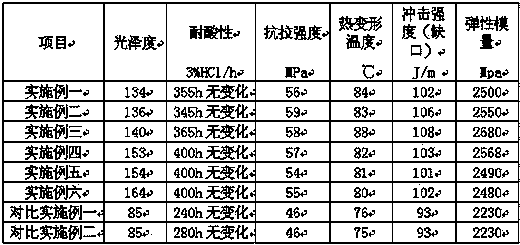

Method for modifying aluminium profile for buildings

InactiveCN103820776AStable internal performanceImprove performanceMetallic material coating processesSodium sulfateMaterials science

The invention relates to modification of aluminium profiles and in particular relates to a method for modifying an aluminium profile for buildings. The method comprises the steps of smelting aluminium ingots into molten aluminium, adding mixed powder of zirconium-coated titanium dioxide and zirconium-coated silicon dioxide, maintaining the materials at a melting temperature for 3-5 hours, pouring the materials into a mold with a temperature above 600 DEG C under the pressure of 1.1-1.5MPa, and cooling and insulating so as to obtain the aluminium profile through demolding; preparing a modifying agent from 20-40 parts of sodium fluoride, 30-60 parts of ammonium bifluoride, 10-20 parts of potassium permanganate, 40-50 parts of potassium chromate, 15-25 parts of zinc phosphate, 8-18 parts of sodium nitrate, 5-12 parts of praseodymium chloride, 10-16 parts of ethylenediamine tetraacetic acid, 7-14 parts of malic acid, 8-12 parts of sodium dodecyl benzene sulfate, 6-13 parts of nickel sulfate, 15-25 parts of triethanolamine, 5-10 parts of reducing agents containing alkali metals, 7-13 parts of chlorinated polypropylene or polyolefin substrate adhesion promoter and 500-900 parts of water by weight, and controlling the pH value to be 3-4, thus obtaining the modifying agent; dipping and drying twice to obtain a modified aluminium profile. The prepared aluminium profile is bright and soft, has excellent corrosion resistance and is safe and environment-friendly.

Owner:MERLAN INT GRP H K

Cylinder device and manufacturing method thereof

ActiveCN103437896AReduce axial sizeMiniaturizationCylinder headsCylindersWear resistantMiniaturization

The invention relates to a cylinder device manufacturing method, which comprises the steps of a) prefabricating a ceramic cylinder liner with a porous structure; b) sintering or depositing a wear-resistant alloy layer on the inner surface of the ceramic cylinder liner; c) casting molten aluminum on the outer surface of the ceramic cylinder liner to form a cylinder body. The embodiment of the invention additionally provides a cylinder device which is manufactured by adopting the cylinder device manufacturing method. The cylinder device comprises the ceramic cylinder liner with the porous structure, the wear-resistant layer which is formed on the inner surface of the ceramic cylinder liner, and the cylinder body which is formed on the outer surface of the ceramic cylinder liner and is made of cast aluminum, wherein wear-resistant alloy which seeps inwards from the inner surface of the ceramic cylinder liner and the molten aluminum which seeps inwards from the outer surface of the ceramic cylinder liner are mutually interlaced in the ceramic cylinder liner. The cylinder device provided by the embodiment of the invention can be manufactured to be very thin, the axial dimension of an engine can be reduced, the miniaturization of the engine is facilitated and the manufacturing cost is lower.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Preparation method, product, and applications of aluminum oxide-coated lithium cobalt oxide material

ActiveCN104485440AReduce processing stepsAvoid Particle Morphology EffectsElectrode manufacturing processesSecondary cellsInlet valveLiquid aluminium

The invention discloses a preparation method of an aluminum oxide-coated lithium cobalt oxide material. The preparation method comprises following steps: (1) lithium cobalt oxide powder is delivered into a blender; (2) aluminum oxide powder is uniformly mixed with carbon powder at a molar ratio of 1:0.5-2, compact is obtained via compacting, the compact is delivered into a vacuum furnace communicated with the blender, and vacuumizing is performed; (3) the vacuum furnace is subjected to heating processing; (4) gaseous aluminium (II) oxide is delivered into the blender for stirring, and a pipe arranged between the vacuum furnace and the blender is blocked, so that the surface of the preloaded lithium cobalt oxide powder is uniformly coated after condensation of gaseous aluminium (II) oxide; and (5) an air inlet valve of the blender is open, air is delivered into the blender, liquid aluminium (II) oxide is changed into solid aluminium oxide, and the surface of the lithium cobalt oxide powder is uniformly coated so as to obtain the aluminum oxide-coated lithium cobalt oxide material. The invention also discloses the material prepared via the preparation method, and applications of the material in preparation of cathodes of lithium ion batteries of 4.5V or more.

Owner:东莞市鸿德电池有限公司

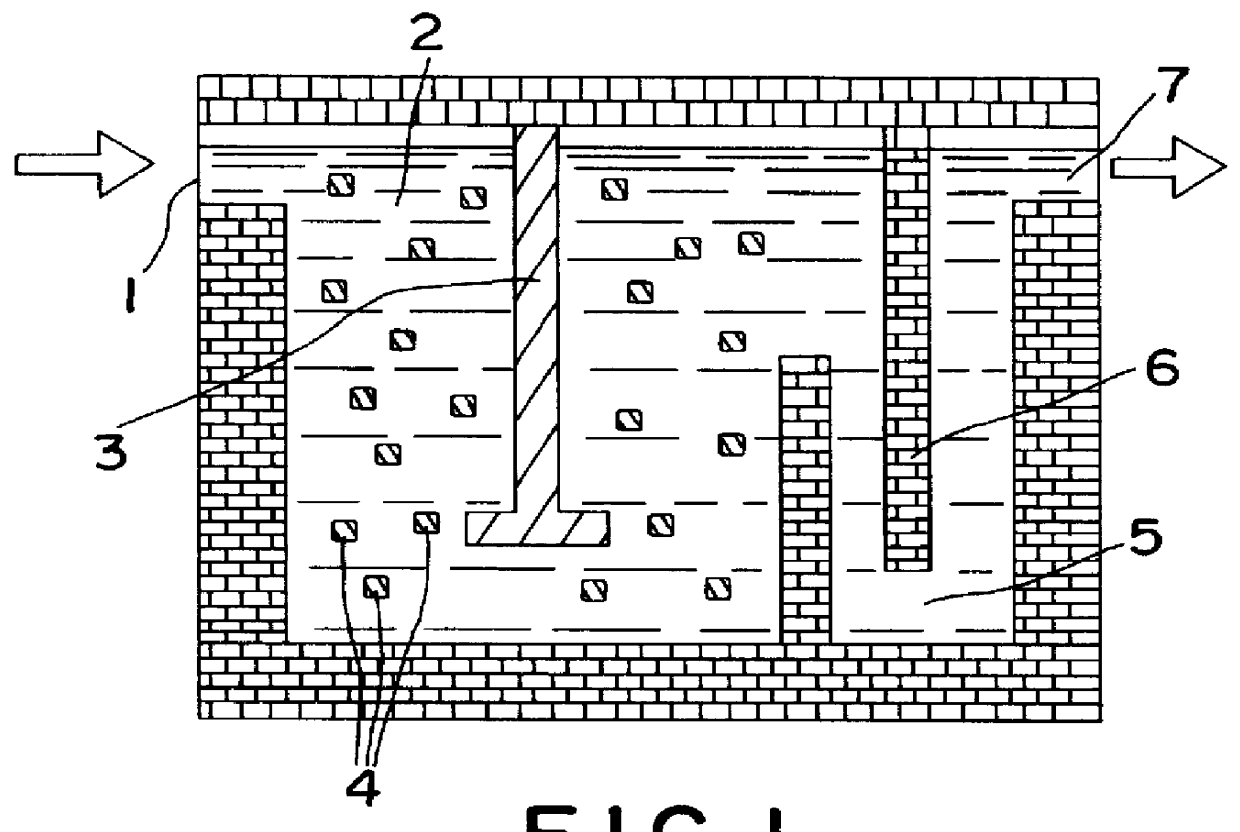

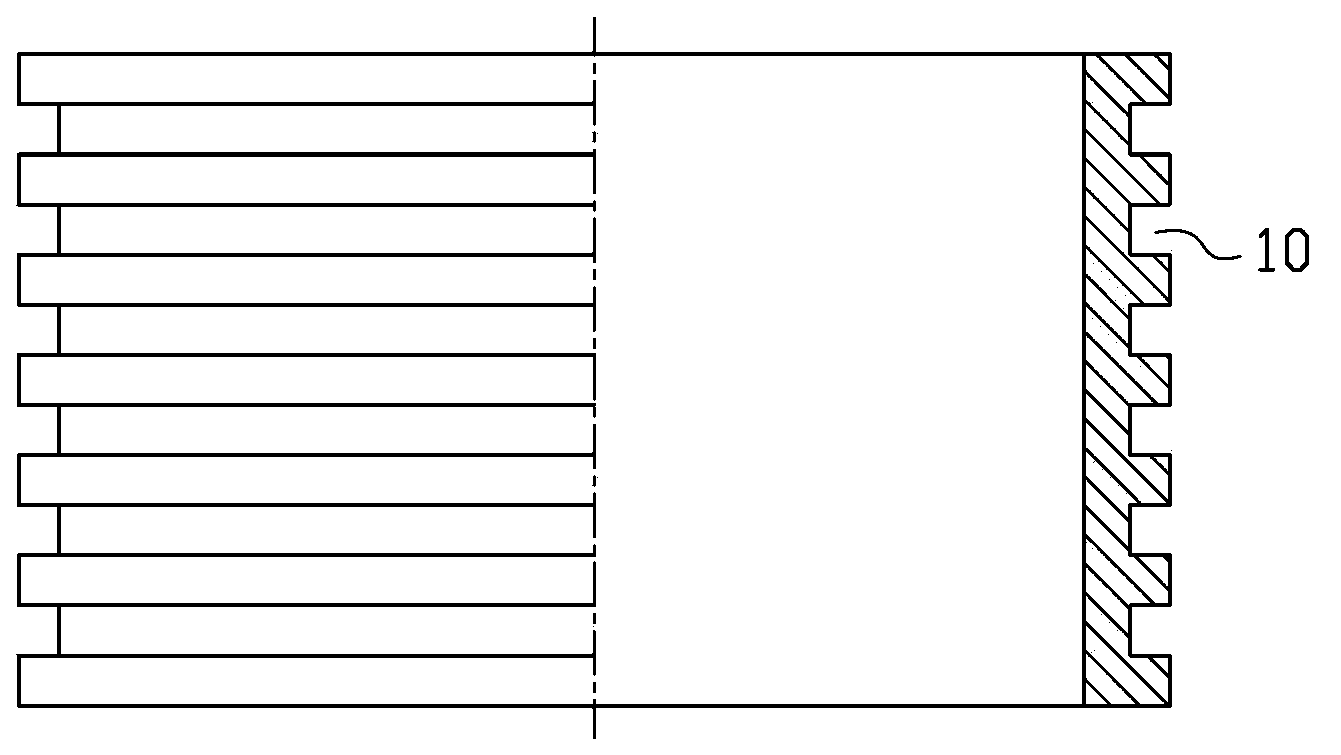

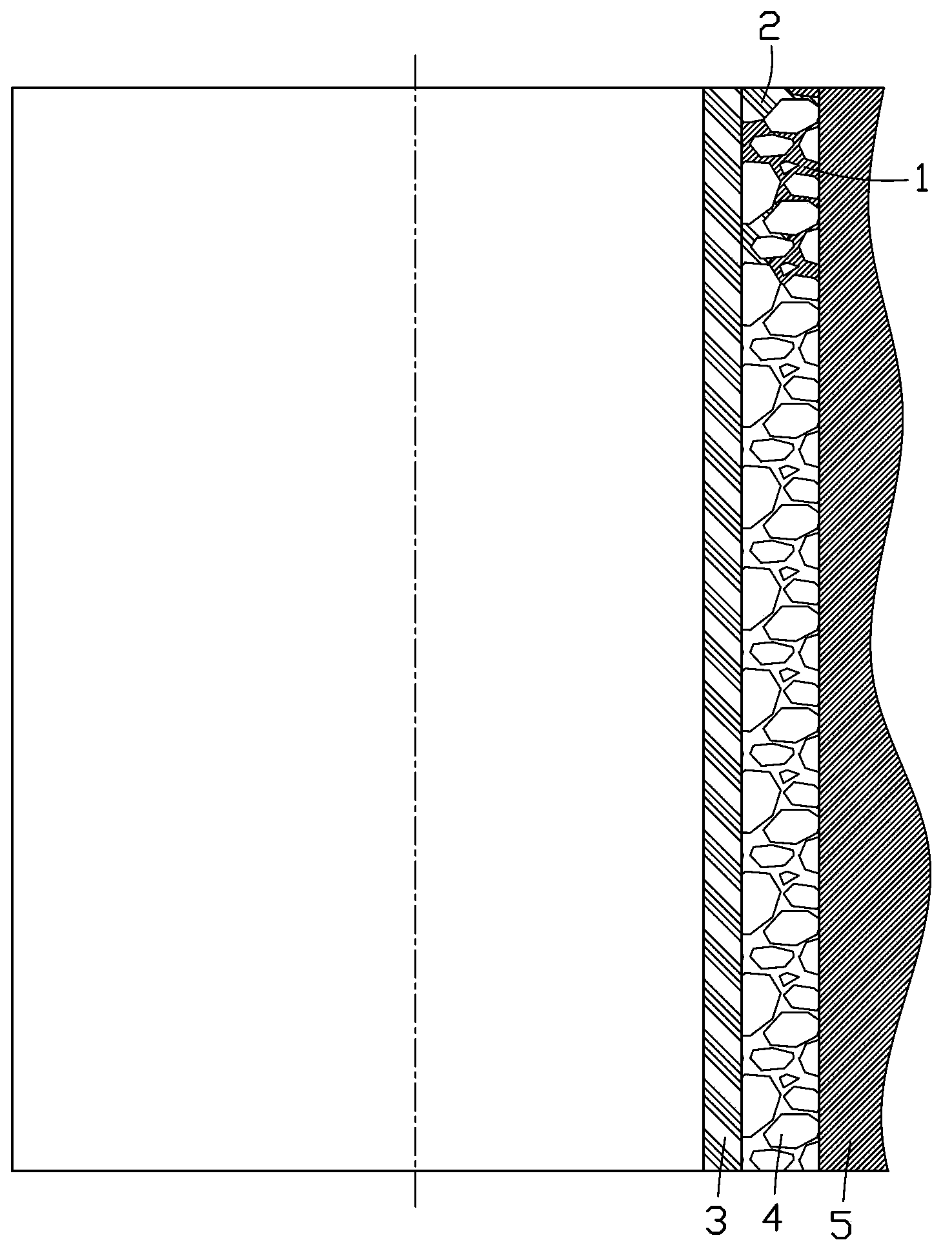

Cathode current collector for a hall-heroult cell

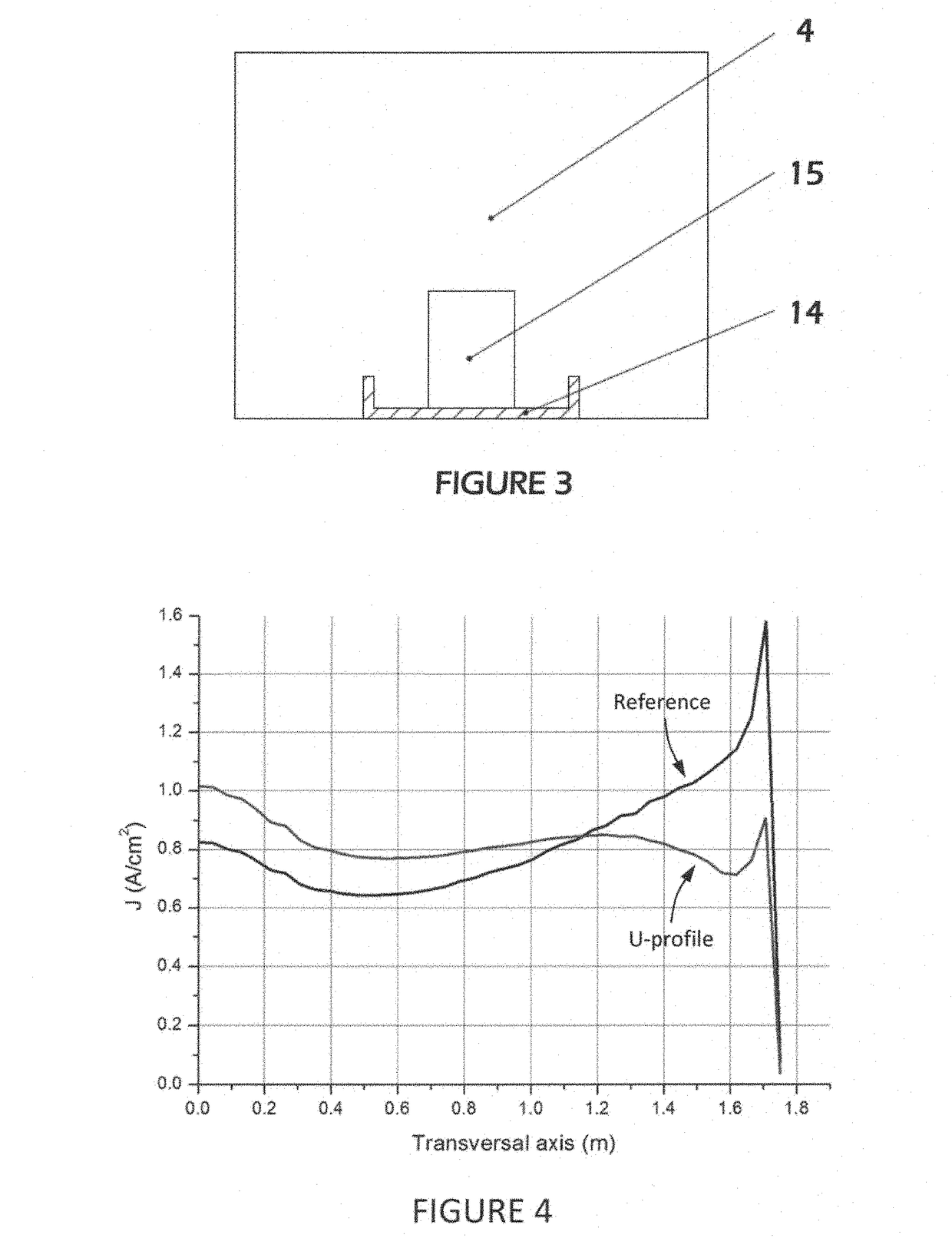

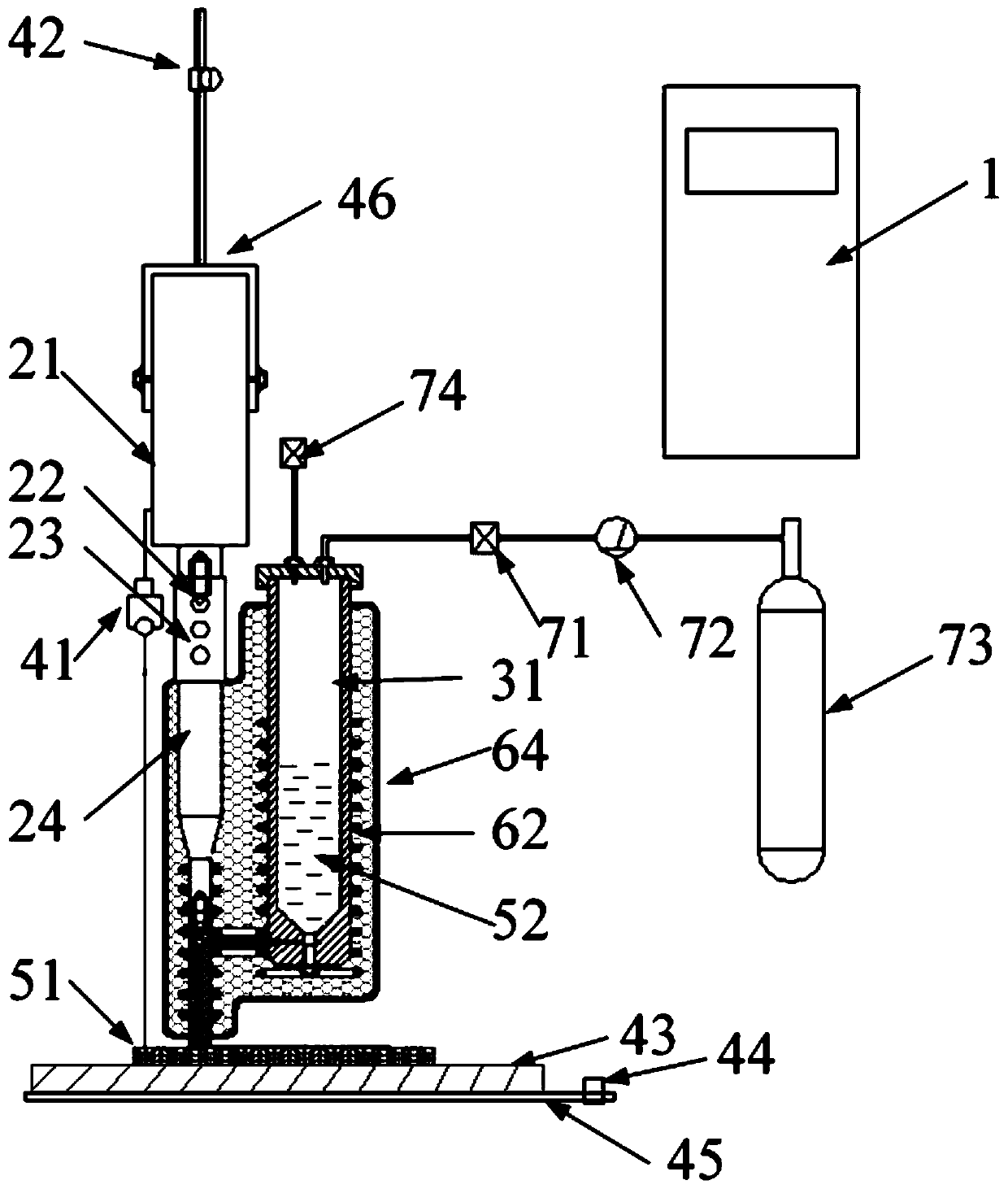

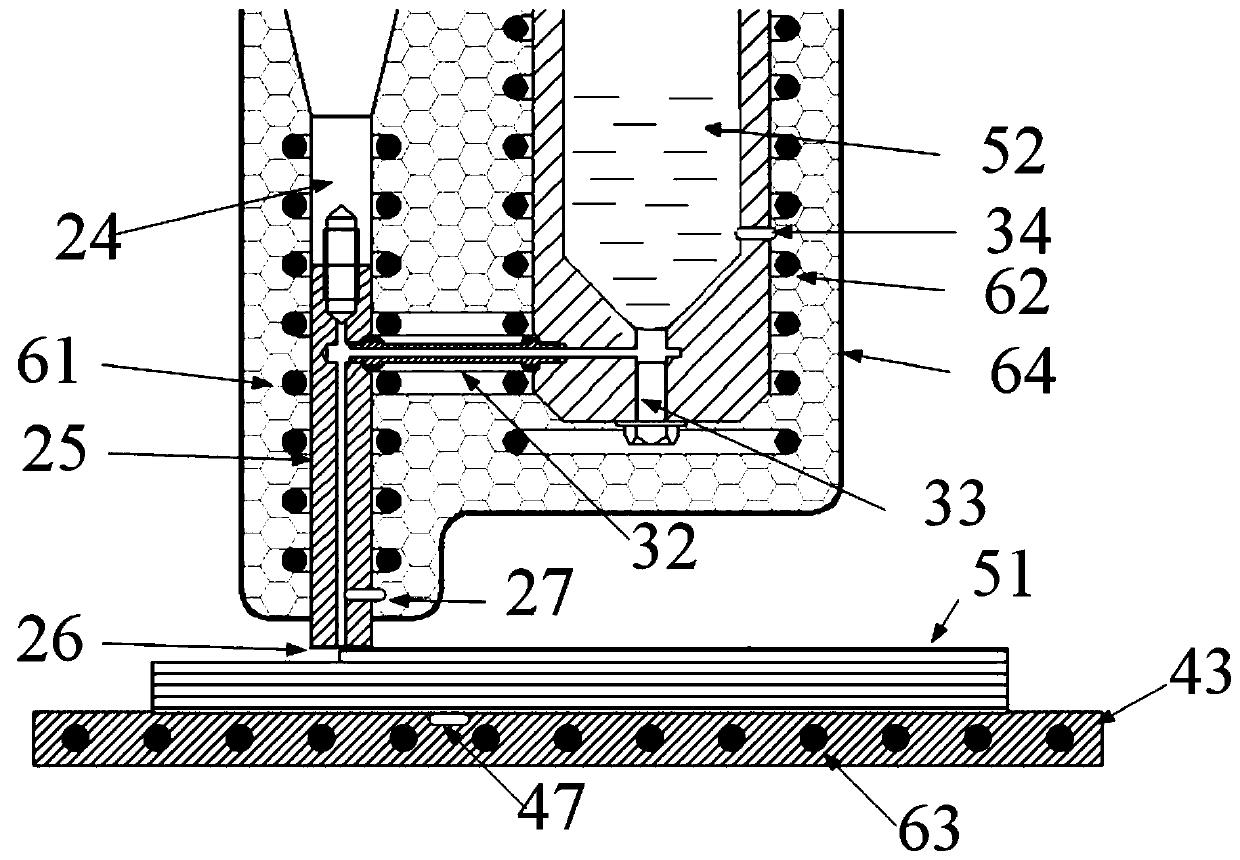

The invention relates to an electrolytic cell (1) for the production of aluminium (2) including collector bars structure modifications (13,14,15,16) under the cathode (4), namely a copper collector bar held in a U-shaped profile or directly embedded into the cathode. This leads to an optimized current distribution in the liquid aluminium metal (2) and / or inside the carbon cathode allowing for operating the cell at lower voltage. The lower voltage results from either a lower anode to cathode distance (ACD), and / or to lower voltage drop inside the carbon cathode from liquid metal to the end of the collector bar.

Owner:NOVALUM SA

Production process of aluminium sulfate by using aluminum ores

InactiveCN102145909AShorten the production cycleSave manpower and material resourcesAluminium sulfatesChemical reactionEvaporation

The invention discloses a production process of aluminium sulfate by using aluminum ores. The method comprises the following steps: a) adding aluminum ore powder paste and concentrated sulfuric acid in a reaction kettle to perform a chemical reaction; b) discharging the obtained solid-liquid mixture to a thinning tank to dilute and cool; c) conveying the solid-liquid mixture in a filter press to perform filter pressing and obtain an aluminium sulfate solution; d) performing acid-base neutralization on the aluminium sulfate solution to obtain a liquid aluminium sulfate product; e) heating the aluminium sulfate solution to evaporate; and f) delivering the evaporated aluminium sulfate solution to a crystallizing steel band, and performing air blowing and water cooling to obtain solid aluminium sulfate. The method has the following advantages: the existing sedimentation method is not adopted, and the solid-liquid mixture is subjected to filter pressing to obtain the liquid aluminium sulfate product, the product has low moisture so that a lot of heat energy can be saved during evaporation and the cost can be reduced; the production time is half an hour, thus the production cycle can be shortened, labor can be saved and the efficiency can be high; the filter pressing of the solid-liquid mixture can be directly performed to obtain an aluminium sulfate solution; and the aluminium sulfate solution is not evaporated and is directly delivered to the crystallizing steel band to prepare the solid aluminium sulfate through air blowing and water cooling.

Owner:周广强

Method for preparing liquid aluminium sulphate

InactiveCN1843926ARich sourcesReduce manufacturing costAluminium sulfatesAluminium sulfateLiquid state

The invention discloses a method for preparing liquid aluminum sulfate, comprising following steps: putting waste sulfuric acid into reactor; regulating its concentration with water; adding aluminum ash gradually for reaction, the temperature for reaction is controlled between 50 Deg.C to 90 Deg. C; adding decolourant to remove color if necessary; filtering and getting liquid aluminum sulfate. The production cost is low.

Owner:朱炳金

Aluminum alloy ultrasonic-assisted 3D printing device and printing method thereof

ActiveCN110814350AImprove mechanical propertiesHigh precisionAdditive manufacturing apparatus3d printMetallic materials

The invention discloses an aluminum alloy ultrasonic-assisted 3D printing device and a printing method thereof, and relates to a 3D printing device and a printing method. The problems that according to an existing ultrasonic-assisted liquid bimetal direct 3D printing device and method, the effect of promoting wetting and combining of liquid metal by ultrasonic waves cannot be achieved, and in addition, metal materials consistent in property cannot be advantageously obtained are solved. Powdery or block-shaped pure aluminum or aluminum alloy metal is used as a raw material to be put in a storage tank, after the raw material is heated to be melted, certain gas pressure is applied, the liquid metal is made to flow towards a nozzle through gas extrusion force, and after the liquid metal flowsout of the nozzle, an oxidation film on the surface of liquid aluminum and an oxidation film on the surface of a previous layer of aluminum or substrate aluminum are broken to achieve micro melting connection. According to the method, the temperature which is 20-100 DEG C higher than the melting point of a to-be-printed metal material is selected as the printing temperature, the preheating temperature of a substrate is 50-200 DEG C lower than the melting point of the metal material, and the printing speed is 5-20 cm / min. The aluminum alloy ultrasonic-assisted 3D printing device and the printing method thereof are used for aluminum alloy printing.

Owner:HARBIN INST OF TECH

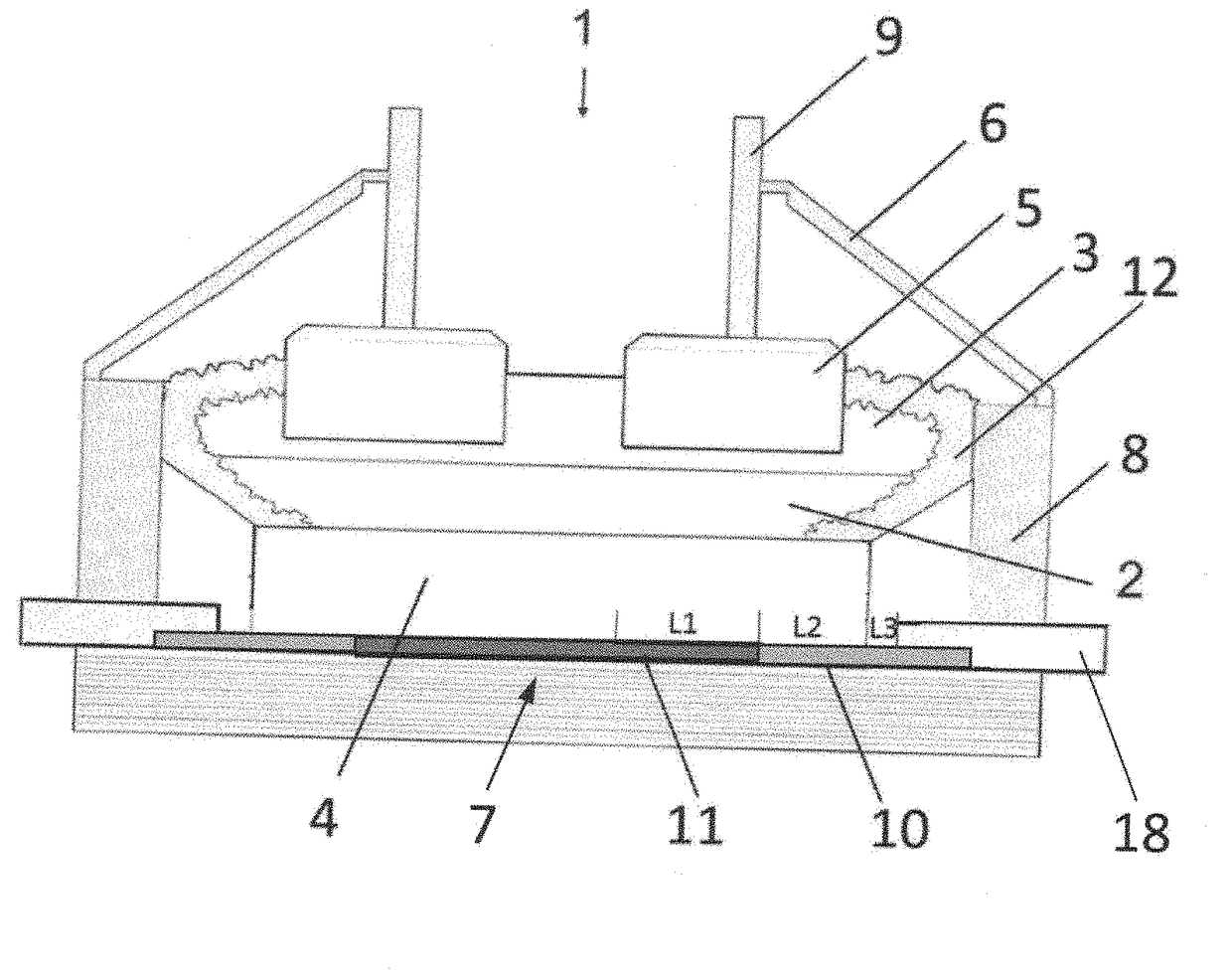

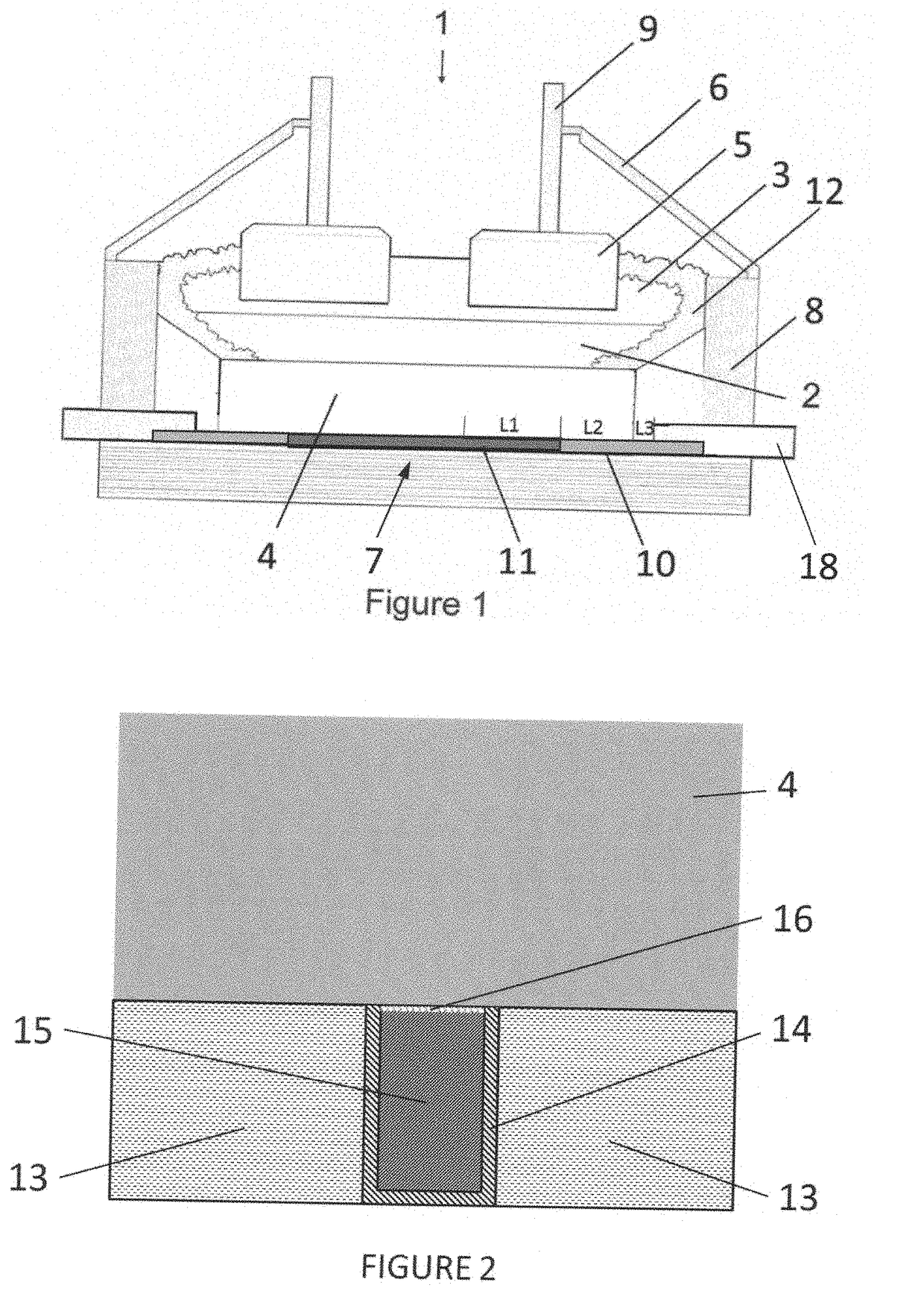

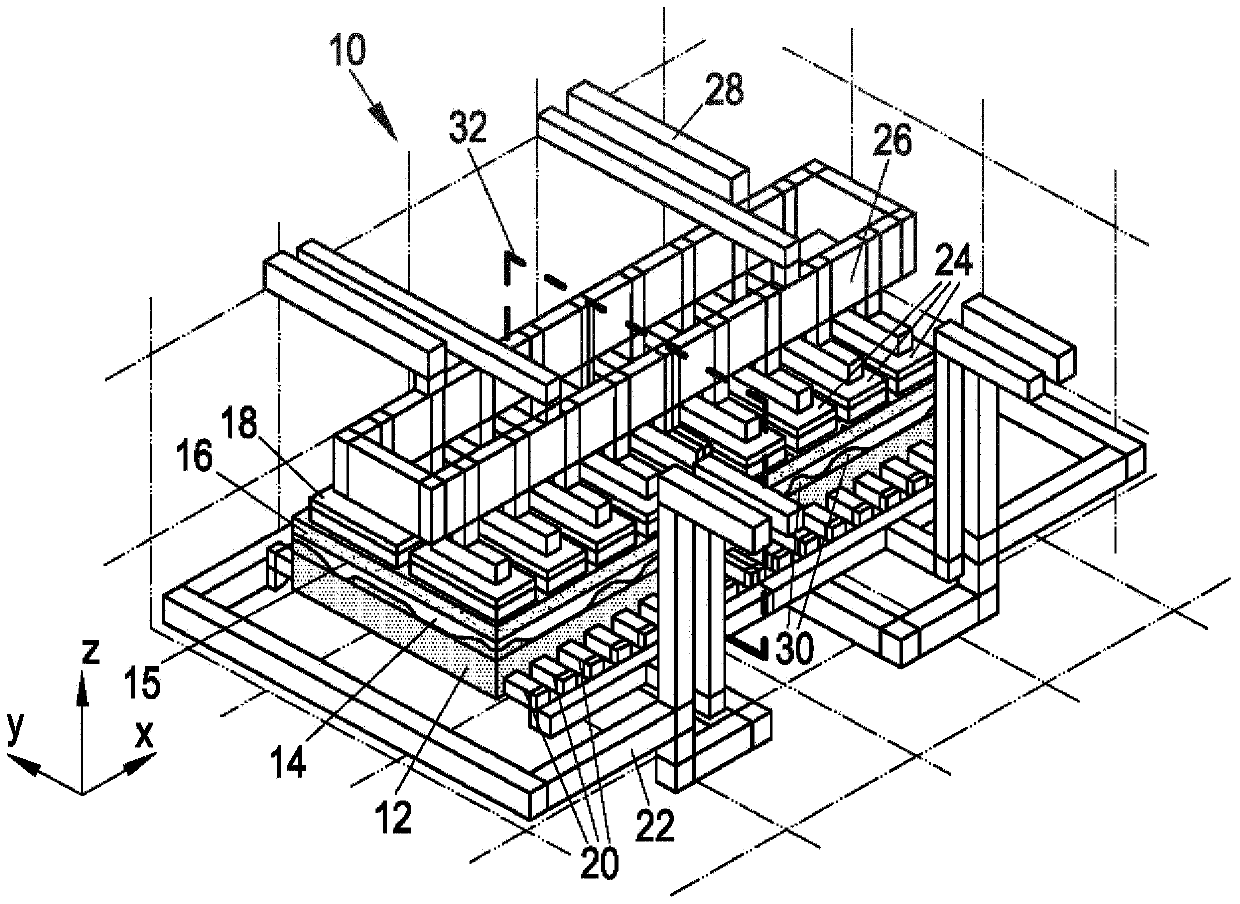

Electrolysis cell and cathode with irregular surface profiling

InactiveCN103635610AUniform fluctuations form the potential distributionPotential distribution with less volatilityCellsElectrolysisWave form

The present invention relates to an electrolysis cell, in particular for the production of aluminium, comprising a cathode, a layer of liquid aluminium on the top side of the cathode, a melt layer on top of the layer of liquid aluminium, and an anode above the melt layer, wherein the cathode has, on the top side thereof, a surface profiling formed from two or more elevations, wherein the surface profiling of the cathode is configured and arranged such that in each case one elevation is provided at at least two of the twenty points on the surface of the top side of the cathode which are arranged in each case vertically below those regions of the boundary between the layer of liquid aluminium and the melt layer at which the peaks with the twenty highest maximum values are present in the reference wave forming potential distribution at the boundary, wherein a reference wave forming potential is defined as the wave forming potential which is present at a point in the boundary between the layer of liquid aluminium and the melt layer during the operation of the electrolysis cell with, instead of the cathode with surface profiling, a reference cathode without surface profiling but of otherwise identical configuration to the cathode with surface profiling.

Owner:SGL CARBON SE

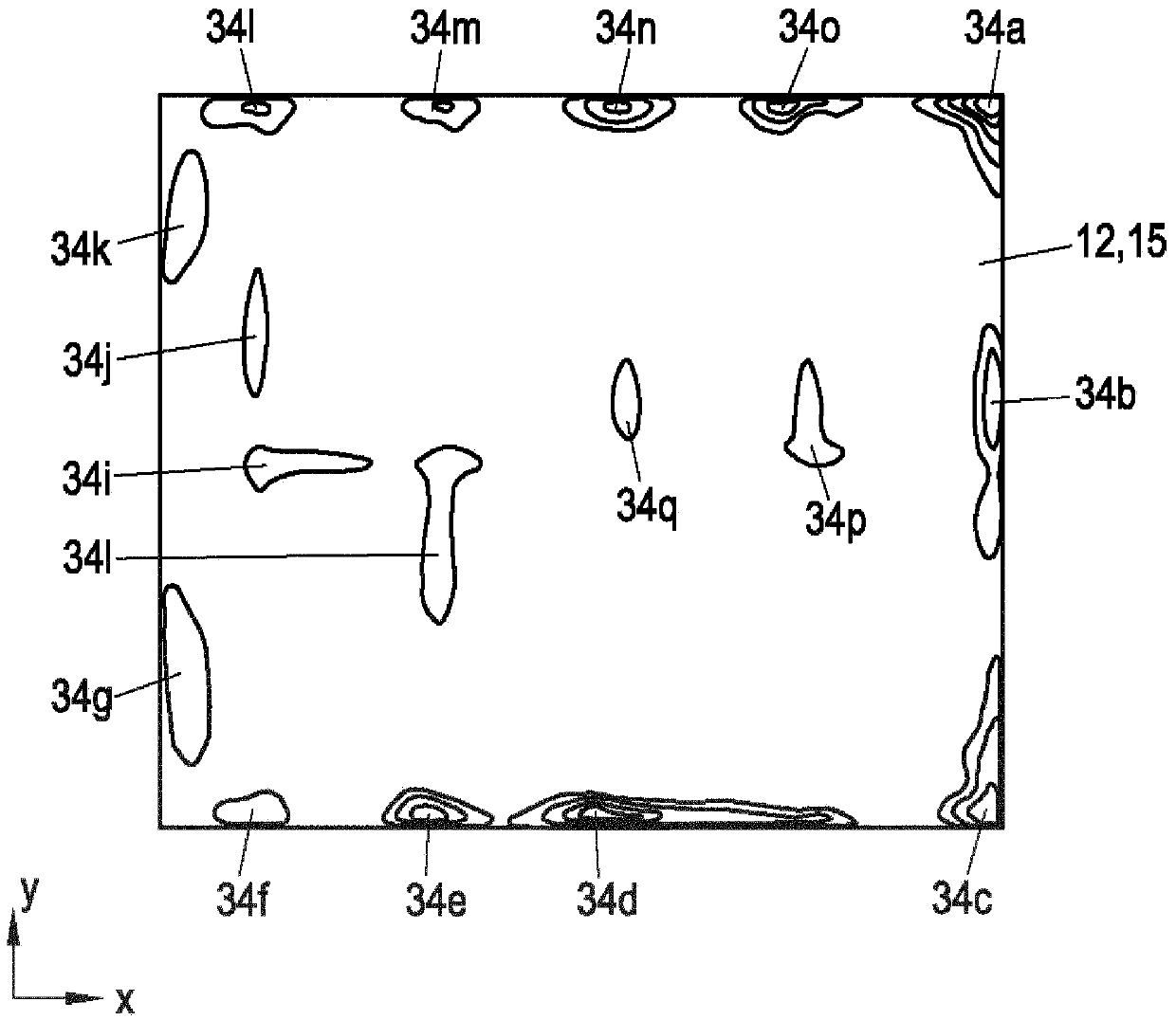

Integrated die forging forming technology

The invention relates to an integrated die forging forming technology. The integrated die forging forming technology comprises the steps that an aluminum matrix composite material is prepared; and metal which is molten into a liquid phase is poured into a cavity containing the liquid aluminum matrix composite material, cylinders with perpendicular axes of a T-shaped part are filled with the liquid molten metal, liquid filling is performed under the first pressure, the pressure of a punch is less than or equal to the pressure of a hydraulic piston which presses on a left sliding block and a right sliding block, the loading speed of the punch is 15 mm / s, the pressure is kept for 20 s after the punch is loaded, the punch is continuously loaded at the second pressure after the aluminum matrix composite material is solidified so that a solidified metal part can push the left sliding block and the right sliding block to move outwards, after the left sliding block and the right sliding block reach set positions, punch loading is stopped, and two cylindrical parts with axes horizontally unequal in diameter are formed through plastic deformation, wherein the first pressure is less than the second pressure.

Owner:ZHONGBEI UNIV

Anode carbon block with centre joint groove

The invention relates to an anode carbon block with a centre joint groove. In the invention, the centre joint groove with the width more than 20mm is formed upwards at the bottom of the anode carbon block along the length centre line of the anode carbon block so as to replace two narrow grooves of the existing general carbon block. The anode carbon block with the centre joint groove has the advantages that in the process of roasting, the gas exhausting passage can be shortened, a smoke volatile substance generated in the carbon block is easy to exhaust, and the porosity is reduced, so that the interior of the carbon block is roasted and heated evenly, the stress is balance, the carbon block has less possibility of cracking, and the yield and quality of the anode carbon product are improved; and after the carbon block is roasted, the roasted coke particles in the groove of the carbon block are easy to clean, the pollution of the roasted coke particles to the electrolyte and liquid aluminium in the process of electrolyzation is reduced, and the heat-conducting property of the carbon block is improved, thereby being beneficial for CO gas in the aluminium electrolysis to separate out and achieve the purpose of saving the current drain of the aluminium electrolysis.

Owner:高德金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com