Medium strength aluminium alloy wire with conductivity of 60% IACS, and preparation method thereof

A medium-strength aluminum alloy and aluminum alloy wire technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, circuits, etc., can solve the problems of large power loss in transmission lines, conductivity is only 57%, and high heat treatment temperature. Effects of reducing line loss, reducing secondary dendrite spacing, and improving strength and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

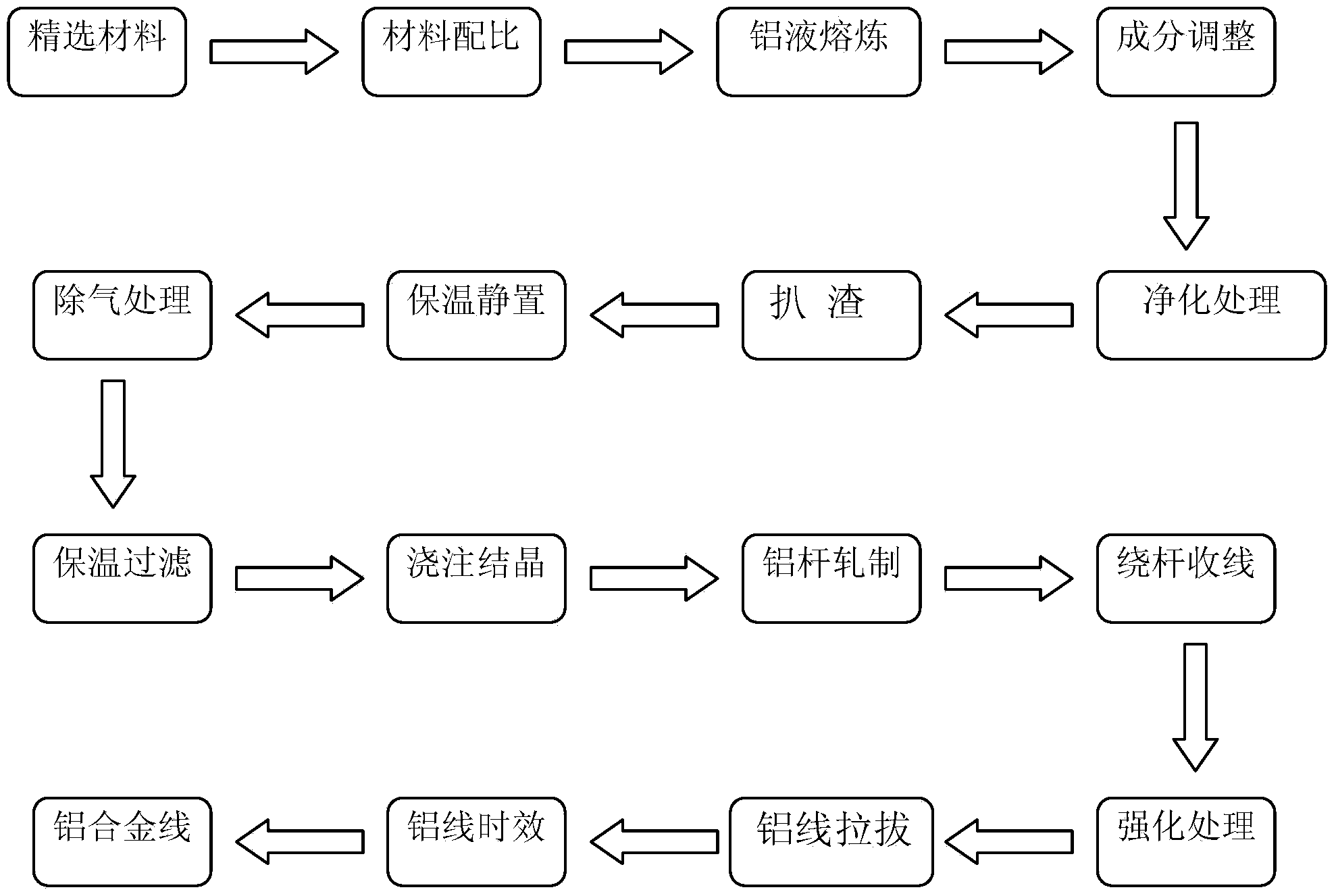

Method used

Image

Examples

Embodiment 1

[0048] A 60% IACS medium-strength aluminum alloy wire with a conductivity of 60%. The formula ratio by weight percentage is as follows: iron 0.16%, silicon 0.24%, magnesium 0.40%, boron 0.01%, rare earth elements 0.08%, and the rest is aluminum.

[0049] The rare earth elements are mainly cerium and lanthanum, in which cerium is 0.036%-0.085%, lanthanum is 0.023%-0.052%, and the amount is other mixed rare earth elements.

[0050] Conductivity 60% IACS medium-strength aluminum alloy wire, the steps are as follows:

[0051] (1) Material selection: by weight percentage:

[0052] a. Aluminum ingot: select 7 tons of Al99.60 aluminum ingot, Si-0.14%; Fe 0.18%; Cu 0.009%; Ti+Mn+Cr+V≤0.02%; other impurity content≤0.03%; the rest is aluminum ;

[0053] b. Aluminum-iron alloy: aluminum-iron alloy 10kg, Fe 5%; Si 0.17%; Cu 0.006%; Ti+Mn+Cr+V 0.025%; other impurities content ≤0.03%; the rest is aluminum;

[0054] c. Aluminum-silicon alloy: 105kg of aluminum-silicon alloy, Si 10%; Fe 0.18%; Cu 0.004...

Embodiment 2

[0079] An IACS medium-strength aluminum alloy wire with a conductivity of 60%. The formula ratio is as follows in terms of weight percentage: iron 0.22%, silicon 0.30%, magnesium 0.48%, boron 0.02%, rare earth element 0.15%, and the rest is aluminum.

[0080] The rare earth elements are mainly cerium and lanthanum, in which cerium is 0.036%-0.085%, lanthanum is 0.023%-0.052%, and the amount is other mixed rare earth elements.

[0081] Conductivity 60% IACS medium-strength aluminum alloy wire, the steps are as follows:

[0082] (1) Material selection: by weight percentage:

[0083] a. Aluminum ingots: 7 tons of Al99.70 aluminum ingots. The molten aluminum made from aluminum ingots guarantees Si 0.08%; Fe 0.15%; Cu 0.002%; Ti+Mn+Cr+V 0.015%; other impurities Content ≤0.03%; the rest is aluminum;

[0084] b. Aluminum-iron alloy: Aluminum-iron alloy 5kg, Fe 5%; Si 0.17%; Cu 0.006%; Ti+Mn+Cr+V 0.023%; other impurities content ≤0.03%; the rest is aluminum;

[0085] c. Aluminum-silicon alloy: ...

Embodiment 3

[0110] An IACS medium-strength aluminum alloy wire with a conductivity of 60%. The formula ratio is as follows in terms of weight percentage: iron 0.19%, silicon 0.27%, magnesium 0.44%, boron 0.015%, rare earth element 0.1%, and the rest is aluminum.

[0111] The rare earth elements are mainly cerium and lanthanum, of which cerium is 0.036%-0.085%, lanthanum is 0.023%-0.052%, and the rest are other rare earth elements.

[0112] Conductivity 60% IACS medium-strength aluminum alloy wire, the steps are as follows:

[0113] (1) Material selection: by weight percentage:

[0114] a. Aluminum ingots: the molten aluminum made by smelting aluminum ingots ensures that Si≤0.16%; Fe≤0.22%; Cu≤0.01%; Ti+Mn+Cr+V≤0.02%; other impurities content ≤0.03%; the rest Is aluminum

[0115] b. Aluminum-iron alloy: Fe 5%; Si≤0.2%; Cu≤0.1%; Ti+Mn+Cr+V≤0.1%; other impurity content ≤0.03%; the rest is aluminum;

[0116] c. Aluminum-silicon alloy: Si 10%; Fe≤0.2%; Cu≤0.1%; Ti+Mn+Cr+V≤0.1%; other impurity content ≤0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com