Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Duralumin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Duralumin (also called duraluminum, duraluminium, duralum, dural(l)ium, or dural) is a trade name for one of the earliest types of age-hardenable aluminium alloys. Its use as a trade name is obsolete, and today the term mainly refers to aluminium–copper alloys, designated as the 2000 series by the International Alloy Designation System (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

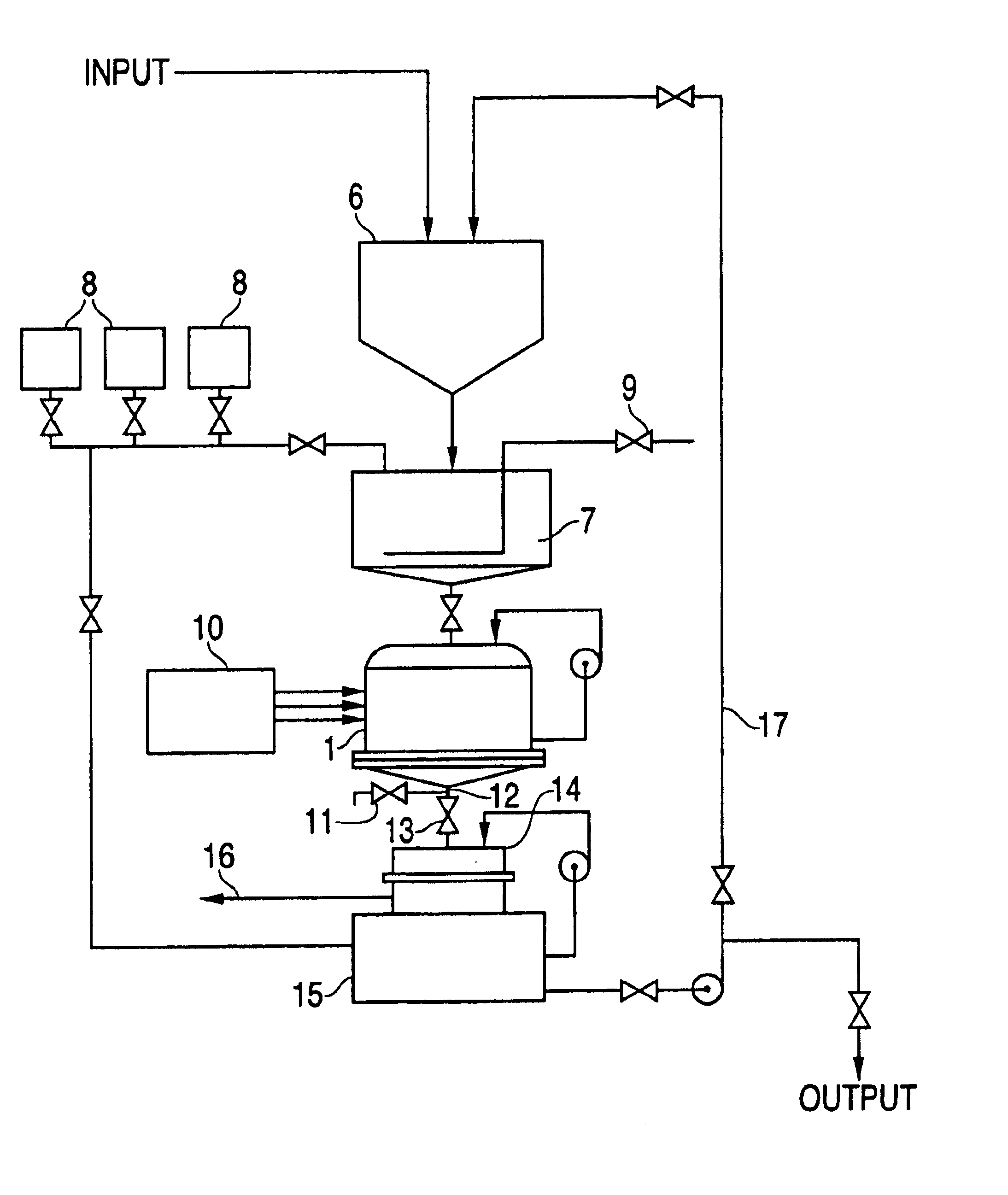

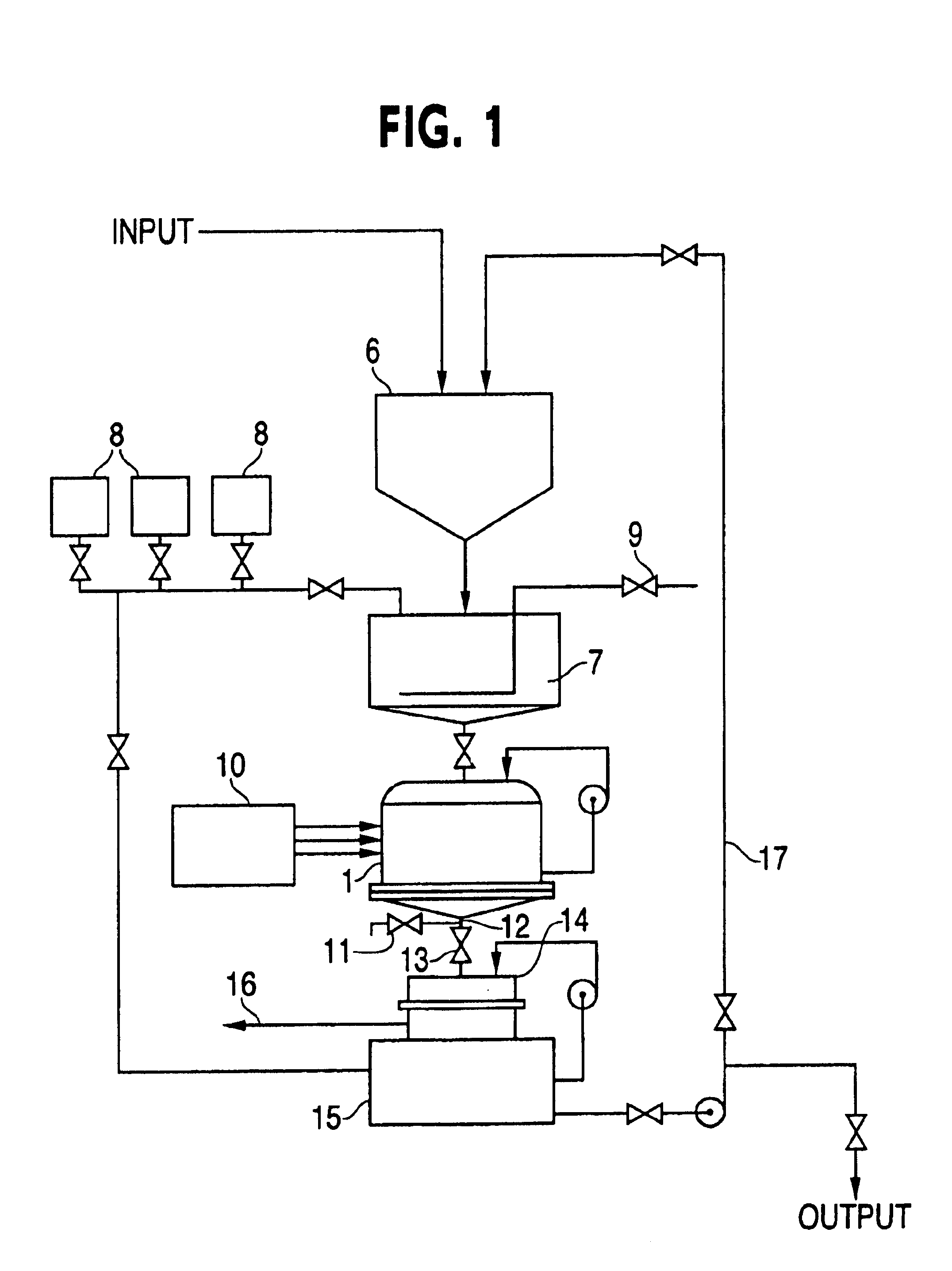

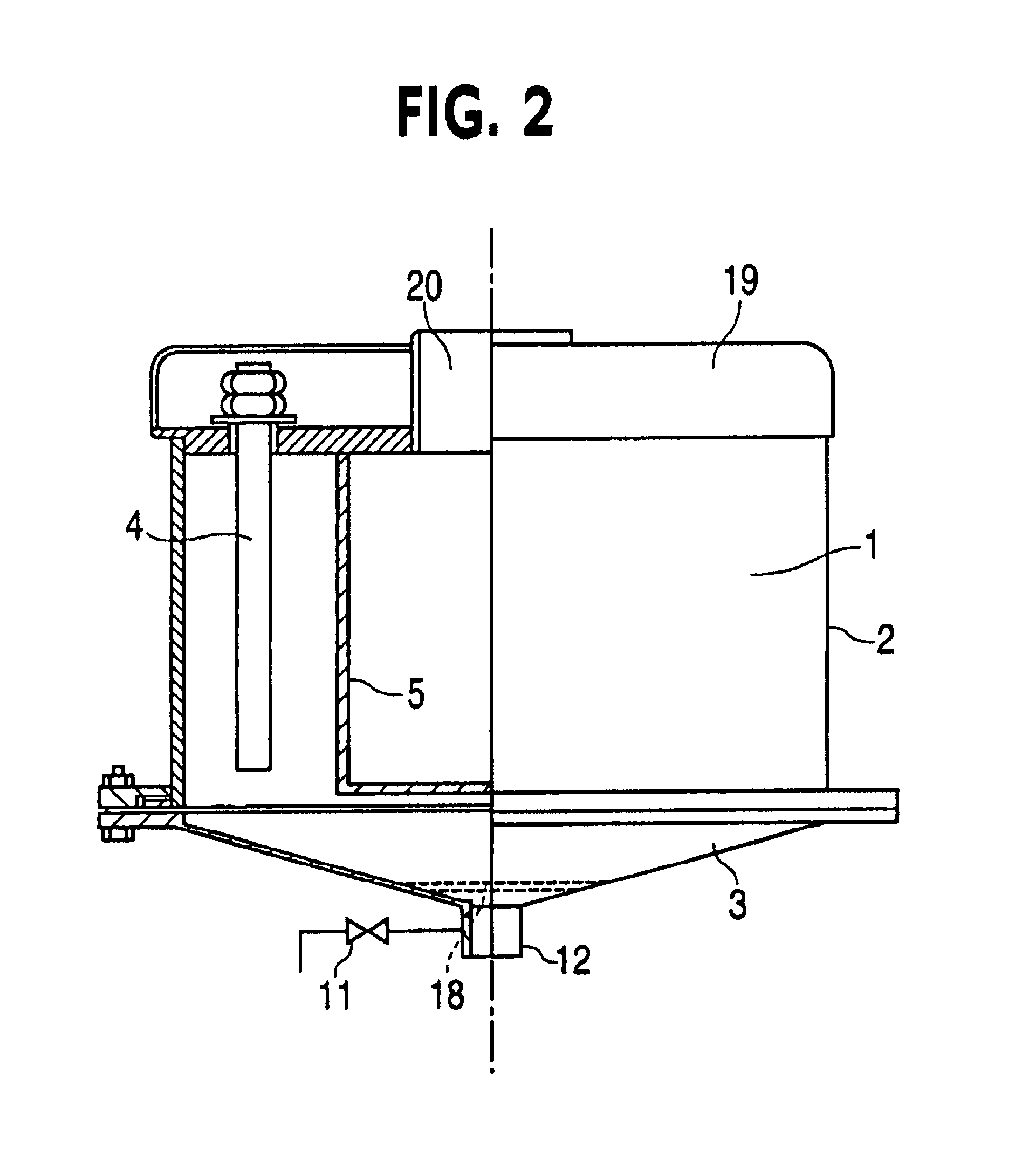

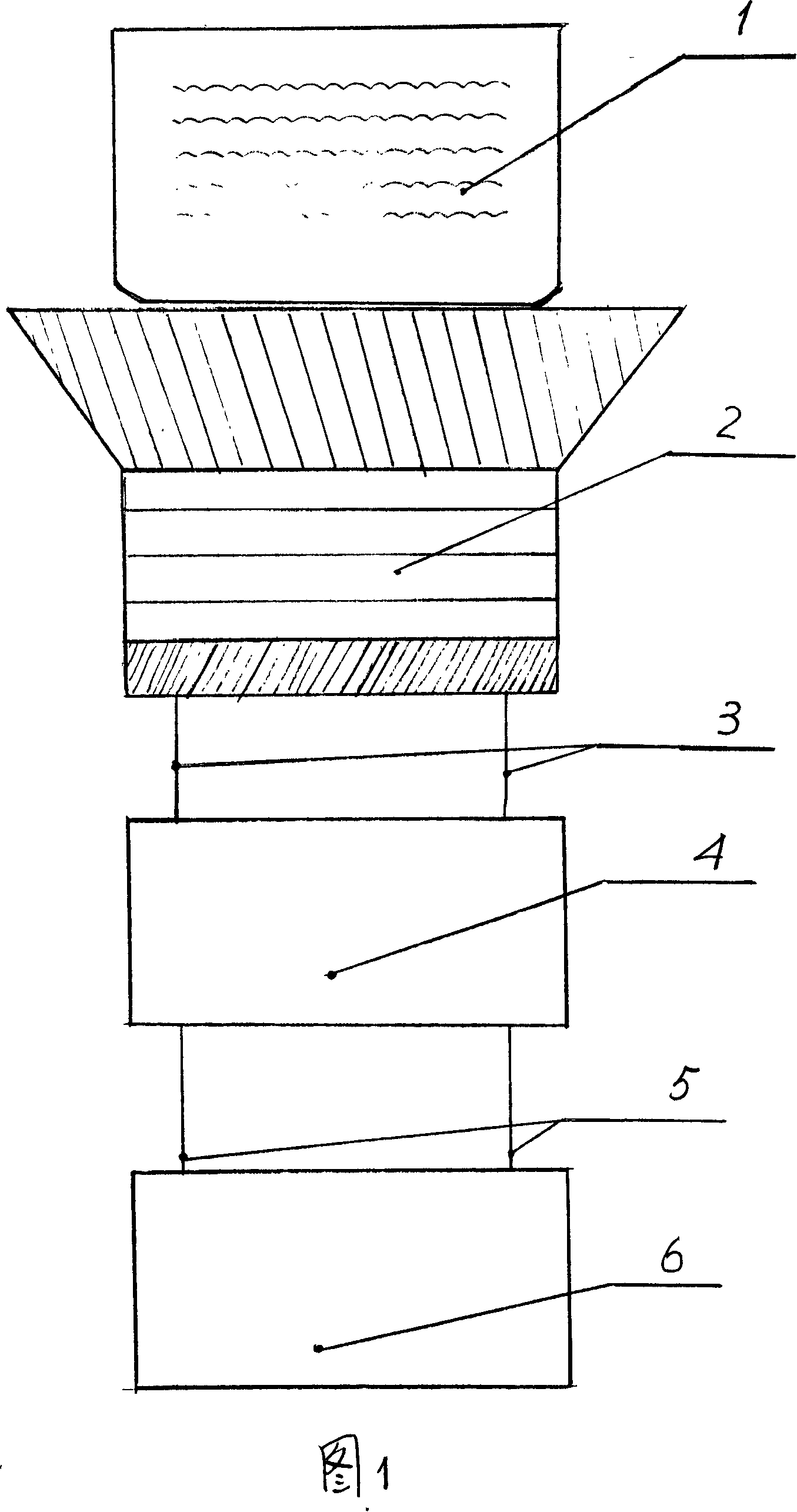

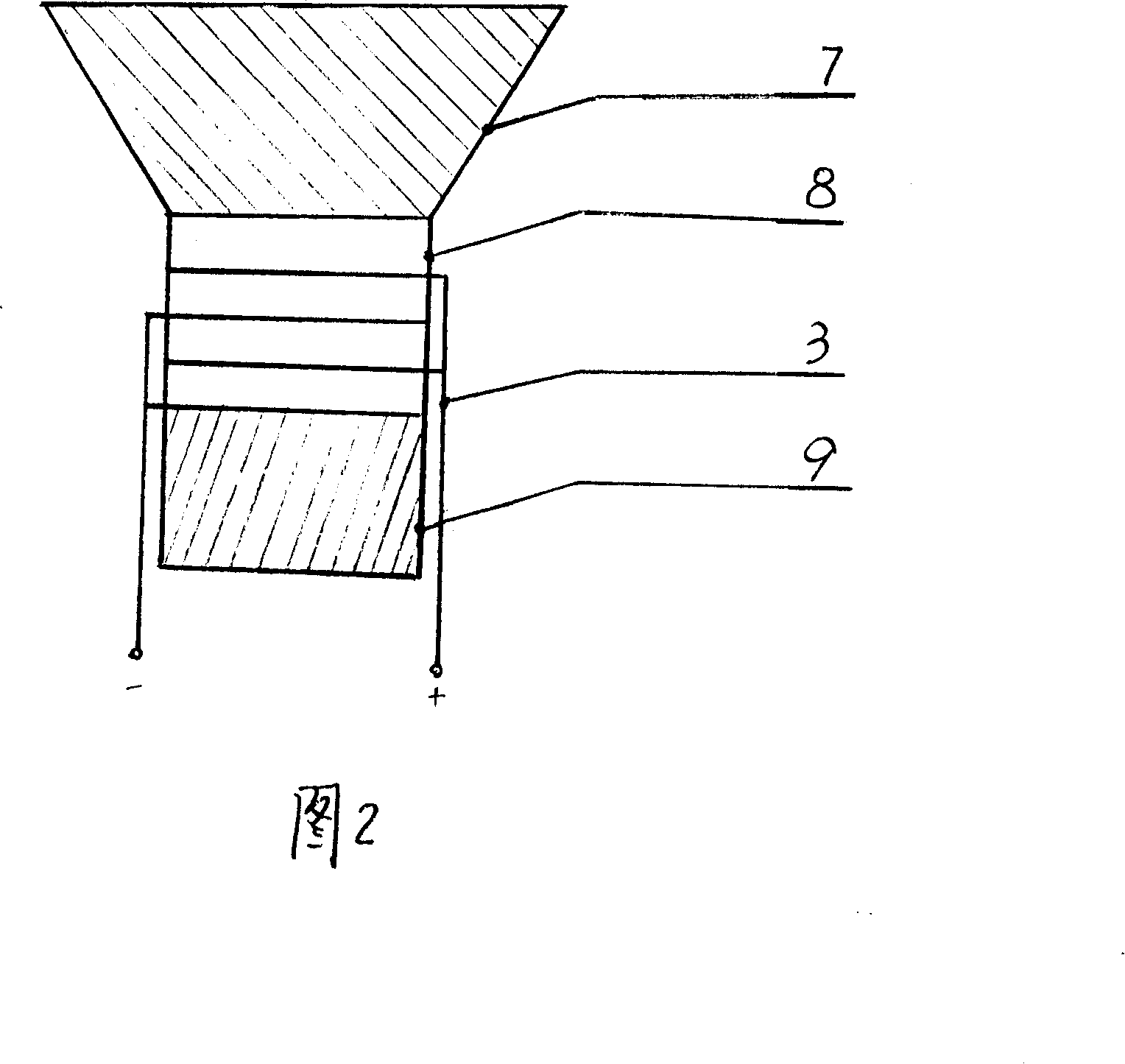

Method and device for electroextraction of heavy metals from technological solutions and wastewater

InactiveUS6887368B2Reduced heavy metal levelLess energy consumptionFrom normal temperature solutionsLiquid separation by electricityConductive materialsMaterials science

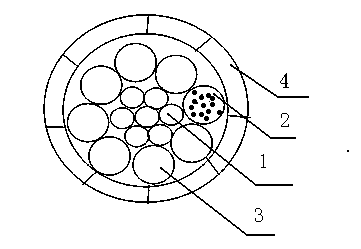

The basic principles of the method for heavy metals electroextraction from technological solutions and wastewater includes pretreating to remove Chromium-6 and high concentrations of heavy metals and periodically treating in a six-electrode bipolar cylindrical electroreactor made of non-conducting material to achieve lower accepted levels of impurities. Six cylindrical steel electrodes form two triode stacks and are fed with three-phase alternating current of commercial frequency (50-60 Hz), which can be pulsed. Each phase of the three-phase current is connected to three electrodes of one triode stack or in parallel to two triode stacks. The parallel connection of three-phase current to two triode stacks is performed so that the same phase of the three phase current is connected in parallel with each two opposite electrodes of six electrodes located along the periphery, or with two adjacent electrodes. A bipolar stationary aluminum electrode is situated in the inter-electrode space. In one of the embodiments, the bipolar electrode is made of a perforated heat-resistant plastic container filled with secondary aluminum and duralumin scrap. In another embodiment, the bipolar electrode of aluminum or duralumin scrap may be made without a perforated container and is placed in the inter-electrode space as a bulk scrap. In this case, to prevent shorts, each of six steel electrodes is placed in isolated perforated plastic shell with holes of 5 mm in diameter. Non-ferrous metals are extracted in a form of ferrite-chromites, and aluminates as well as hydroxyl salts deposited in the inter-electrode space without electrolysis deposits on electrodes. Deposits are separated from solution by known methods of filtration.

Owner:URAL PROCESS ENG +2

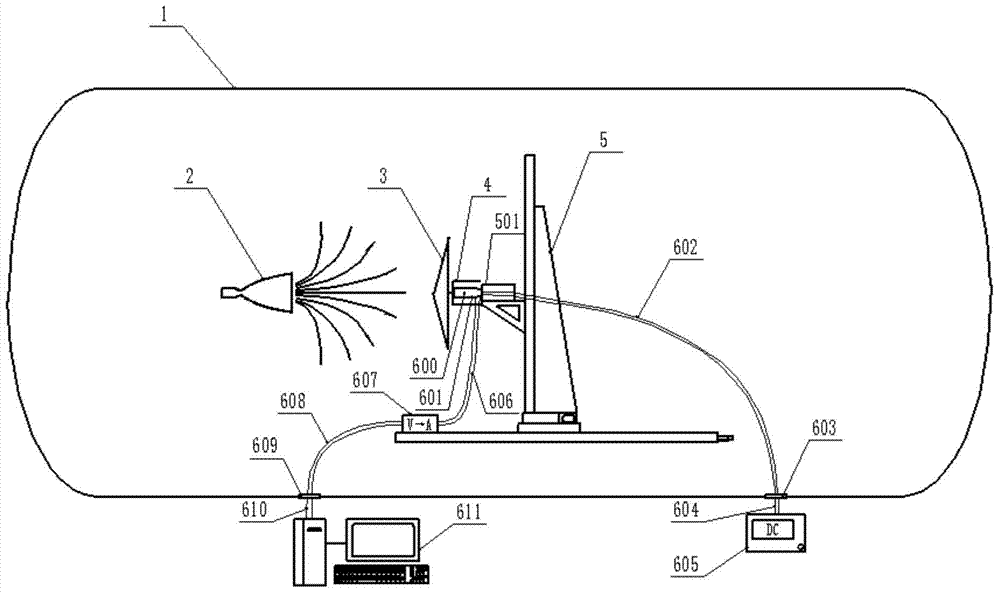

Vacuum plume aerodynamic force measuring system and method

The invention discloses a vacuum plume aerodynamic force measuring system and method. The vacuum plume aerodynamic force measuring system comprises a vacuum chamber, an engine, a force measuring model, a plume protection cover, a displacement mechanism, a mounting base and a six-component balance force measuring system. According to the vacuum plume aerodynamic force measuring system and method, a small-range six-component balance is used as a force measuring element for directly measuring vacuum plume aerodynamic force, so that a measurement result is more accurate; according to the characteristics of high speed and high temperature of engine vacuum plumes, duralumin is used as a material for designing the force measuring model and the plume protection cover, so that the force measuring model and the six-component balance are prevented from being damaged; the displacement mechanism is used for driving the six-component balance and the force measuring model to scan a plume field, and aerodynamic force measurement can be conducted at multiple positions under multiple working conditions in one close-cabin experiment. The vacuum plume aerodynamic force measuring method comprises the following steps that the six-component balance is calibrated, a six-component balance working formula is calculated, experimental equipment is installed, the experiment is conducted, and data are processed.

Owner:BEIHANG UNIV

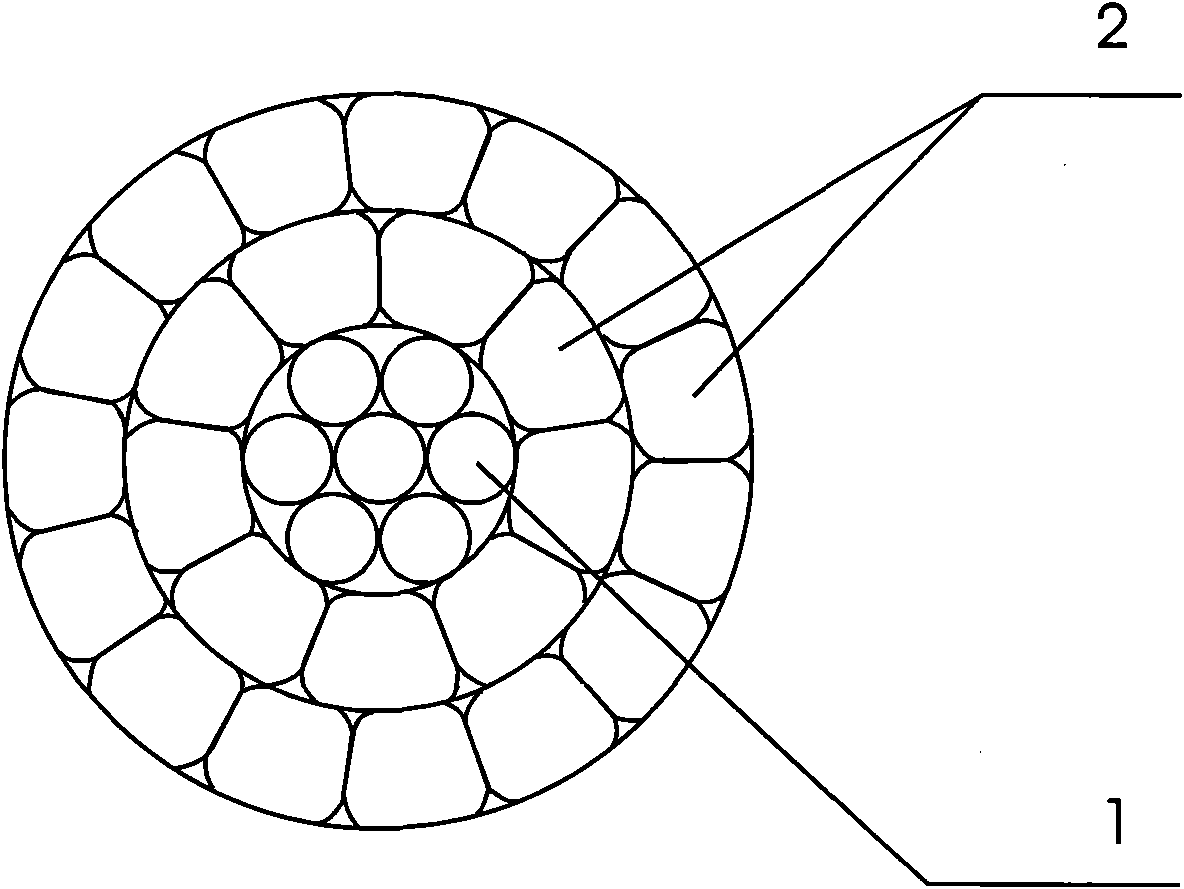

High-conductivity rare earth duralumin monofilament material for overhead conductors

ActiveCN104946936AImprove conductivityImprove mechanical propertiesMetal/alloy conductorsRare earthDuralumin

The invention discloses a high-conductivity rare earth duralumin monofilament material for overhead conductors. The high-conductivity rare earth duralumin monofilament material comprises 0.002-0.05% of B, 0.02-0.20% of Er, 0.02-0.20% of Y, 0-0.060% of Si, 0-0.140% of Fe, 0.01% or less of V+Ti+Cr+Mn, and the balance of Al and inevitable impurity elements. The conductivity of the duralumin monofilament material prepared through adding a tiny amount of alloyage elements and optimally controlling the components of alloy is greater than 63.0% IACS, the tensile strength is greater than 165MPa, and the normal temperature mechanical properties and electrical performances can meet high-conductivity duralumin conductor requirements, so the high-conductivity rare earth duralumin monofilament material can be used in the field of overhead conductors in the electric power industry in order to meet energy saving and consumption reduction demands.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +5

Preparation method of cast aluminum alloy film coat

InactiveCN101781763AGood compatibilityImprove corrosion resistanceMetallic material coating processesDuraluminFluorine containing

The invention relates to a preparation method of a cast aluminum alloy film coat, which is characterized by cleaning a cast aluminum alloy component firstly, performing chromate oxidation treatment secondly, and then preparing a film sealing coat of fluorine containing acrylicester on a chromate oxide film. Construction methods such as brushing or spraying is used for the invention, the methods are flexible and simple and has high maneuverability; the invention can be applied in the protective treatment for cast aluminum alloy of ZL102, ZL104, ZL107, ZL112, ZL114 and the like, and is particularly suitable for treatment of the cast aluminum alloy component used in the ocean environment; and the invention is also suitable for the protective treatment of other aluminum alloy materials or components, such as treatment of duralumin, super duralumin, wrought aluminum and rust-proof aluminum alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

High-conductivity anti-icing lead and production method thereof

InactiveCN101625911AImprove conductivityIncrease ampacityNon-insulated conductorsCable/conductor manufactureDuraluminCentral layer

The invention discloses a high-conductivity anti-icing lead and a production method thereof, aiming at improving the conductivity and anti-icing ability of cables. The high-conductivity anti-icing lead is provided with a steel strand core; the periphery of the steel strand is concentrically coated with annealed aluminum wires; the cross section of the annealed aluminum wire is in a roofing shape; and short edges are tightly arranged into a coating layer inward. The method comprises the steps of controlling a roofing duralumin mongline, annealing and concentrically stranding. Compared with the prior art, the invention has a conductivity of 63 percent IACS, can greatly reduce power consumption of lines compared with ordinary steel core aluminum wires and improves the conductivity by over 3.3 percent; the roofing annealed aluminum wire has compact structure and little clearance between the aluminum wire strands, is unlikely to be condensed on the surface of the lead during snowing and freezing rain, has an operational temperature 30 DEG C higher than the ordinary steel core aluminum wires and has enough de-icing ability; besides, the steel wires in the central layer are less likely to be polluted by rain or corrosion environment and the lead has longer service life.

Owner:广东吉青电缆实业有限公司

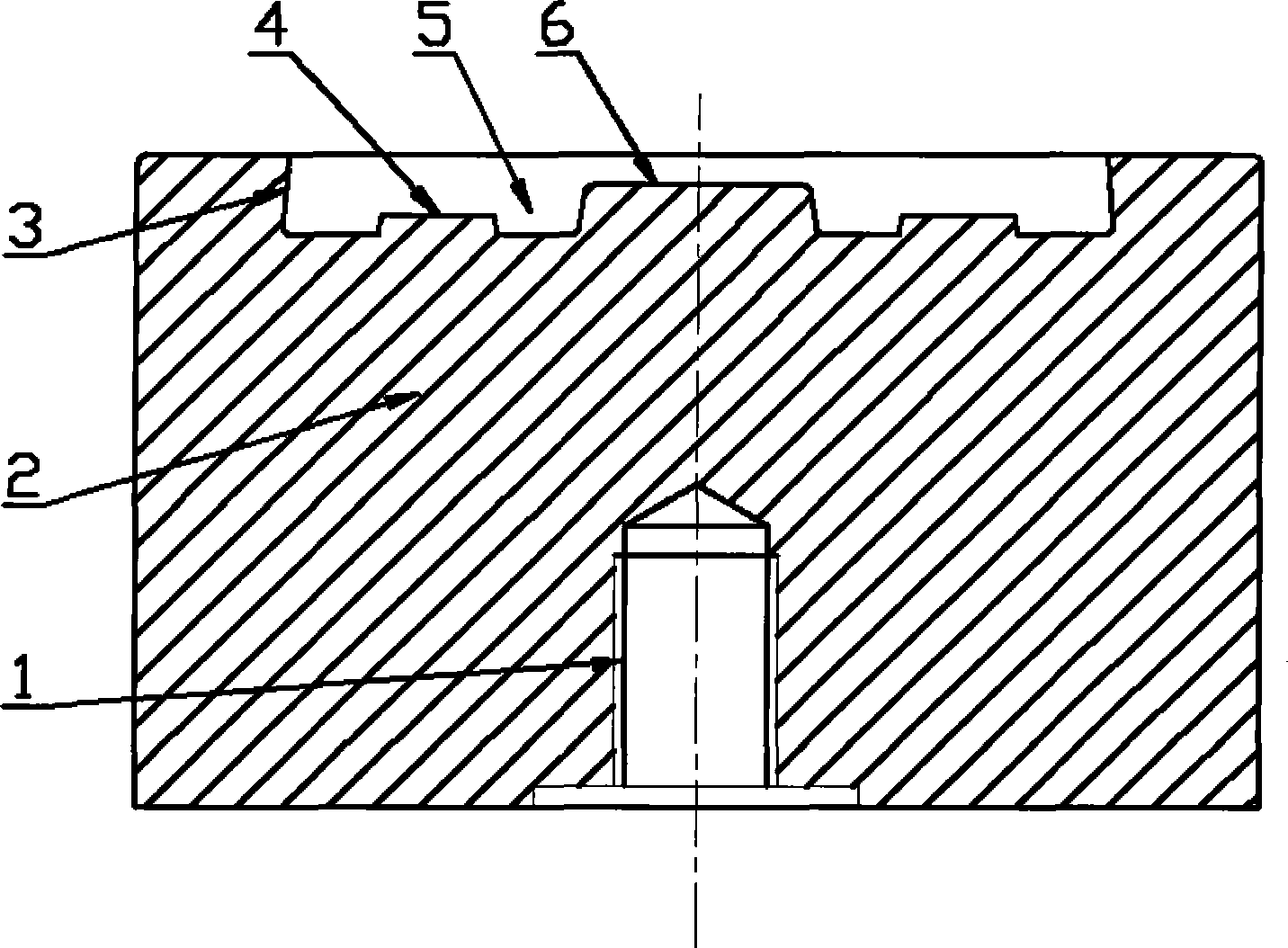

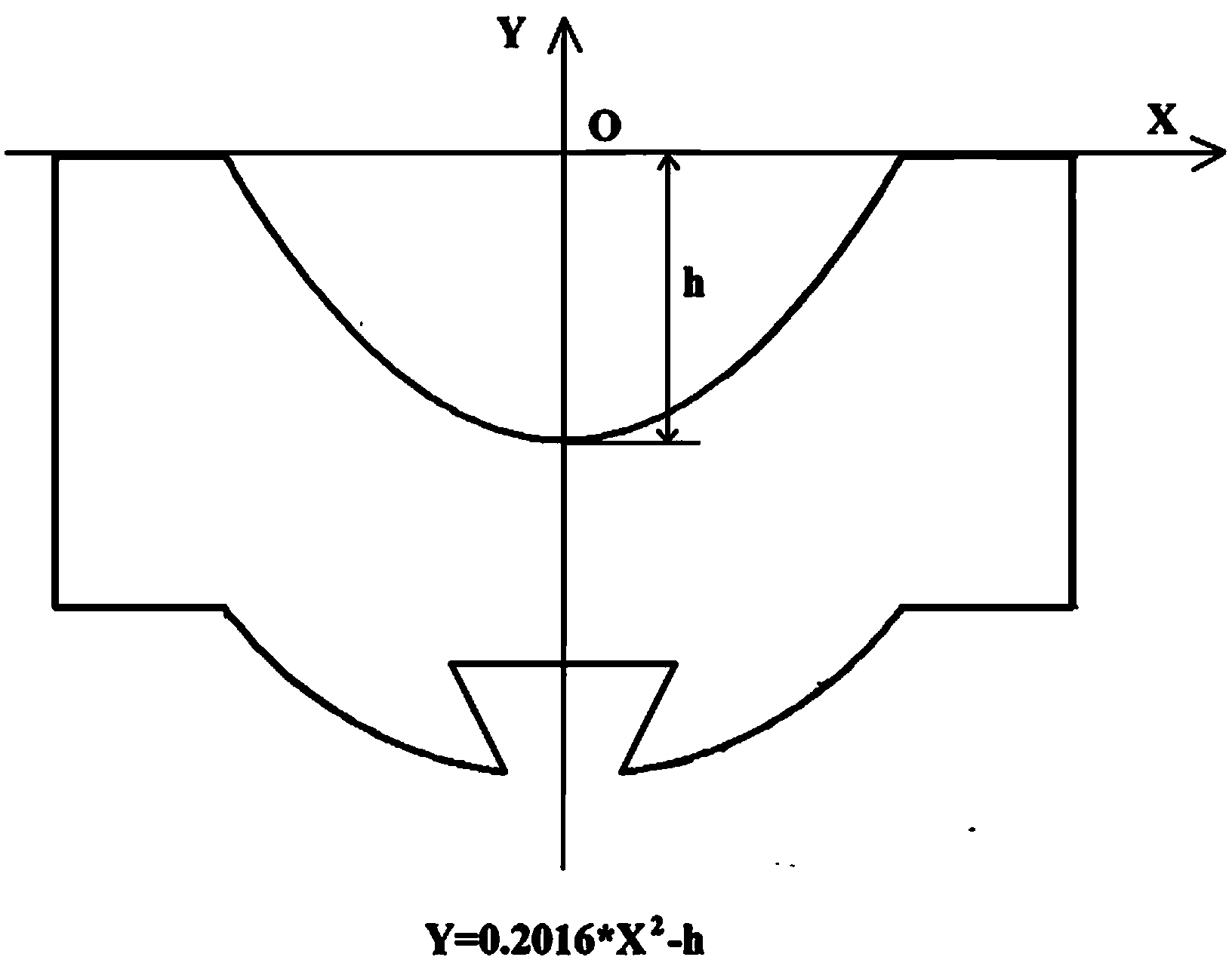

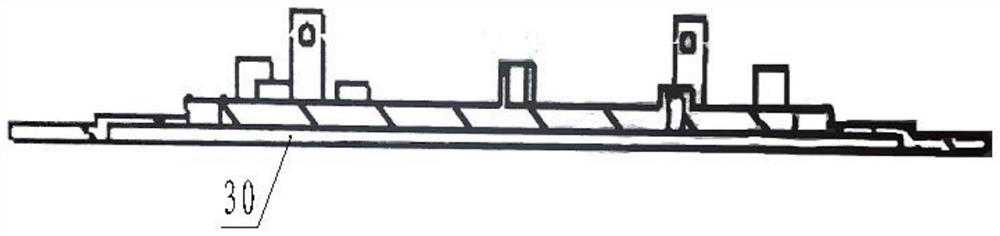

Starter head for semi-continuous casting the hard aluminum alloy billet

The invention provides a dummy bar head used for semi-continuous casting of duralumin round ingot; the material of the dummy bar head is steel and the mainbody thereof is a dummy bar body; the upper part of the dummy bar body is provided with a chamber; the circumferential surface of the chamber is a negative conical surface with the taper ranging from -2 DEG to -10 DEG; the bottom surface of the chamber is provided with a central convex platform and a ring-shaped convex platform; the circumferential surface of the central convex platform and the ring-shaped convex platform is a conical surface with the taper ranging from 1 DEG to 30 DEG; the bottom of the dummy bar body is provided with a connecting thread; the dummy bar body is fixed on a supporting platform by the connecting thread; the negative conical surface of the circumference of the upper chamber of the dummy bar body is used for improving the adhesion force of ingot casting and dummy bar head in the initial stage of the casting and is beneficial to demoulding after the semi-continuous casting is finished; the ring-shaped convex platform and the central convex platform in the chamber increase the homogenization of bottom cooling of the ingot casting in the initial stage of the semi-continuous casting, prevent the bottom crack of the ingot casting, support and stabilize the ingot casting; the dummy bar head has simple structure, convenient installation and usage, long service life and is applicable to the semi-continuous casting of duralumin round ingot.

Owner:苏州有色金属研究院有限公司

Low-cost 63% IACS high-conductivity duralumin conductor and manufacturing method thereof

ActiveCN105950893AImprove conductivityLow costNon-insulated conductorsConductive materialDuraluminRare earth

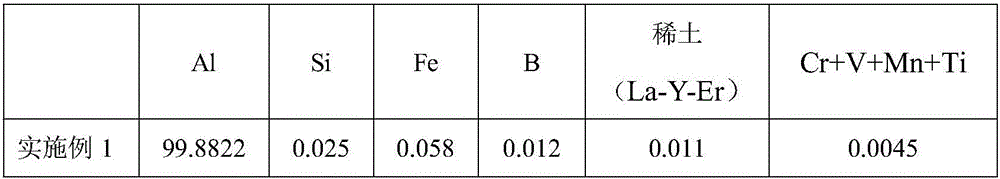

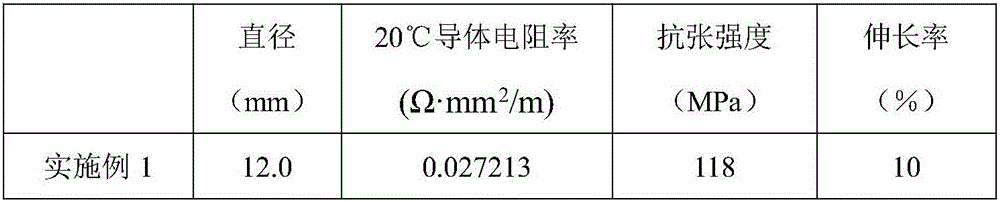

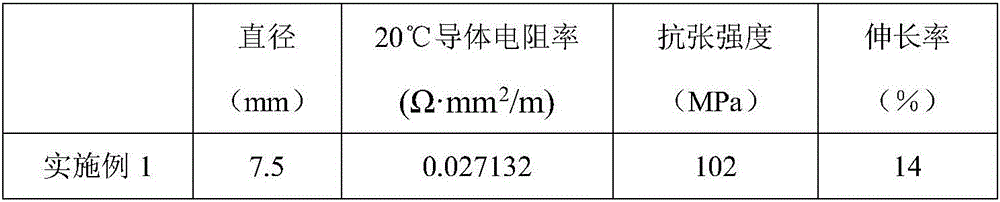

The invention discloses a low-cost 63% IACS high-conductivity duralumin conductor and a manufacturing method thereof. The method comprises the steps that firstly, electrician aluminum is smelted, wherein a 99.90% high-purity aluminum ingot is selected; secondly, rare earth treatment and boronizing treatment are conducted on molten aluminum, all elements in the molten aluminum comprise, by mass percent, smaller than or equal to 0.03 wt% of Si, smaller than or equal to 0.06 wt% of Fe, smaller than or equal to 0.005 wt% of (Cr+V+Mn+Ti), 0.01 wt%-0.03 wt% of B, 0.01 wt%-0.03 wt% of rare earth and larger than or equal to 99.88 wt% of Al, and the rare earth includes La, Y and Er; thirdly, the molten aluminum in the second step is continuously cast and rolled, an aluminum rod is produced, the aluminum rod with the diameter phi of 7.5 mm is extruded through an aluminum extruder, and aluminum wires of various shapes and specifications are formed through cold drawing and drawing; and fourthly, the aluminum wires are stranded to form the aluminum conductor according to the design requirement, wherein the tensile strength of the aluminum conductor is larger than or equal to 168 MPa, and the conductor resistance rate is smaller than or equal to 0.027350 omega.mm<2> / m at the temperature of 20 DEG C. The duralumin conductor has excellent electric conduction performance, the cost of the conductor is reduced by 15%-25%, and the economic efficiency of a circuit is further improved.

Owner:FAR EAST CABLE +3

Aluminum alloy chemical-milling solution and milling method using same

The invention discloses an aluminum alloy chemical-milling solution and a milling method using the same. The milling method comprises the following steps of preparing the milling solution by utilizing right amounts of analytically pure NaOH, Na2S, triethanolamine, ethylenediamine tetraacetic acid, Na2S2O3, technical pure Al and deionized water; then, putting a pretreated duralumin or duralumin alloy into the solution, and performing milling treatment at a right temperature and a right stirring speed; and after reaching a milling depth, taking out a test-piece, checking a roughness of the surface of the aluminum alloy after suffering from the milling, and calculating a milling speed. The milling solution designed through the technical solution not only is applicable to a milling process of the duralumin or duralumin alloy, but also has the advantages of high milling speed and less surface roughness, and process parameters can be convenient to control.

Owner:TIANJIN UNIV

Novel hard aluminium alloy bar material hot-extrusion mold

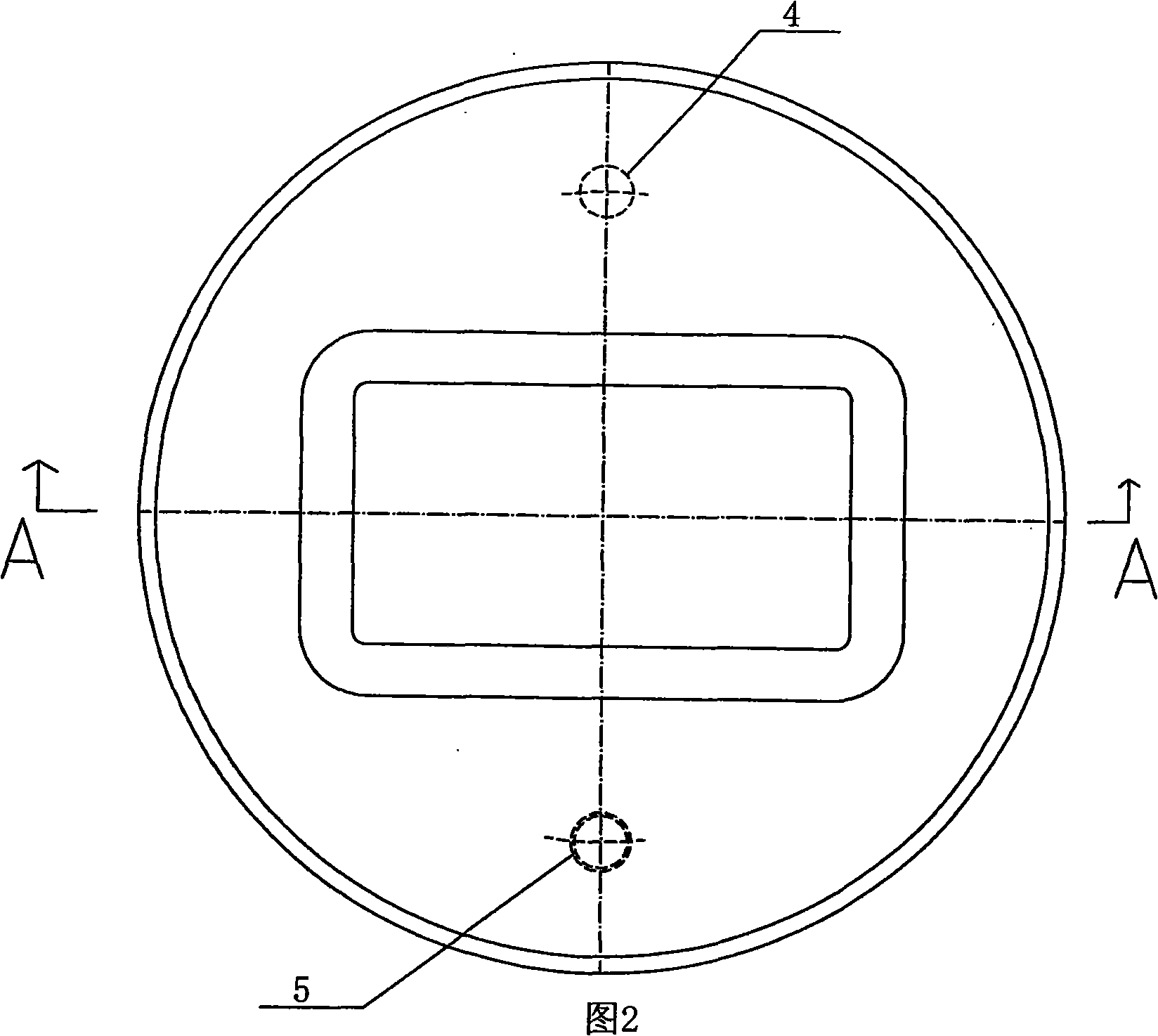

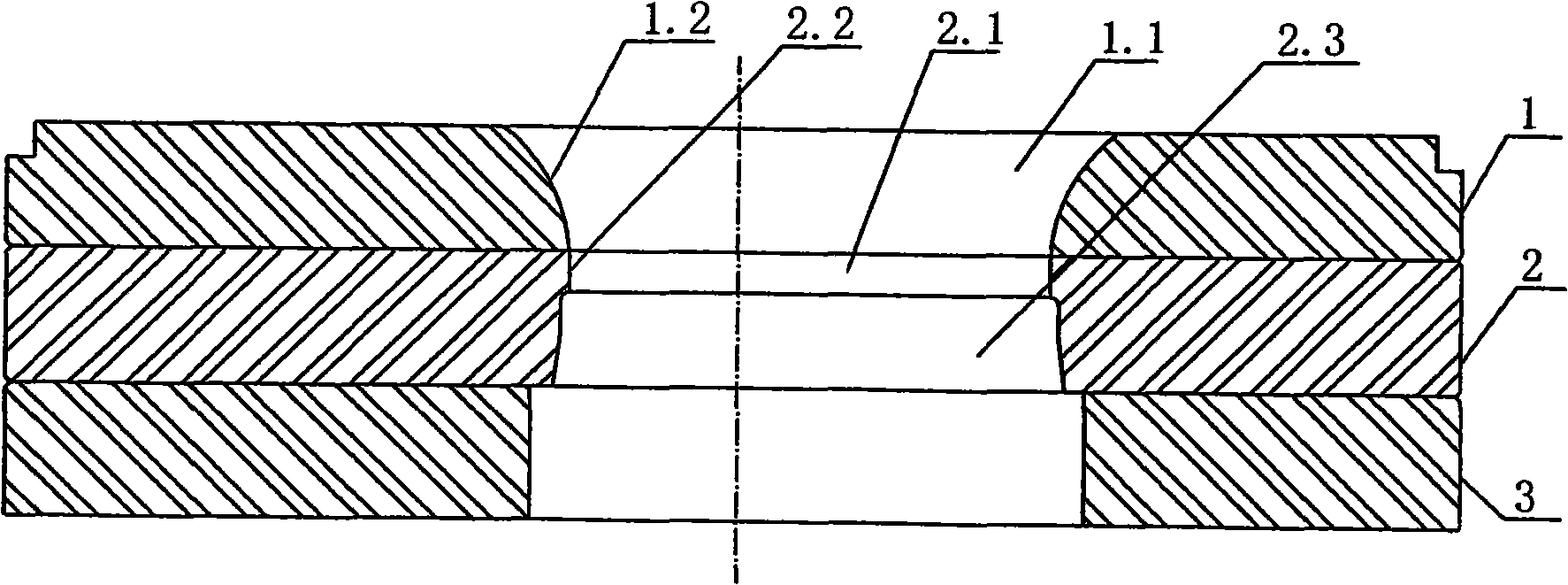

The invention relates to a novel duralumin alloy bar material hot extrusion die which is mainly used for the hot extrusion of the duralumin alloy bar materials in the fields of modern war industry, aviation and space, and automobile industry. The die comprises a pattern die (2) and a die cushion (3) and is characterized in that a preposed guide die (1) is additionally arranged before the pattern die (2); a front feeding soldering chamber (1.1) of the preposed guide die (1) and a pattern cavity working belt (2.2) of the pattern die (2) are smoothly transited by a circular arc (1.2); the height of the front feeding soldering chamber (1.1) of the preposed guide die (1) is 40-50mm. The die can eliminate the condensed trail of the existing duralumin alloy bar material.

Owner:JIANGYIN GIANSUN MOLD

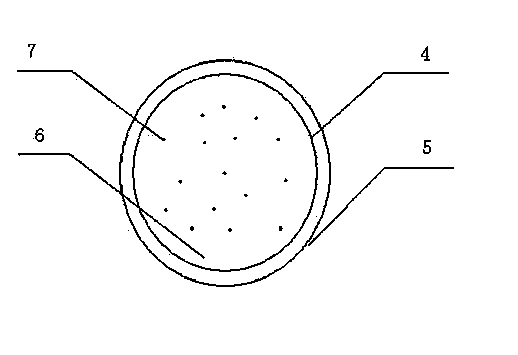

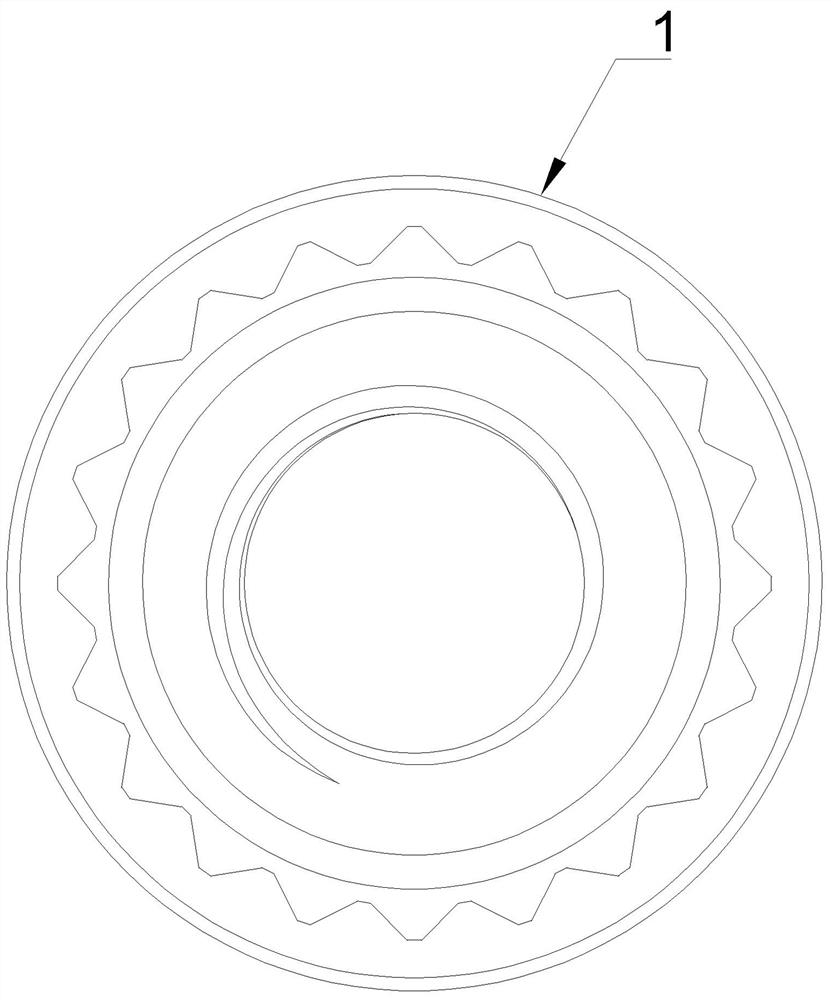

Duralumin/silicon carbide extreme ultraviolet multilayer reflector and manufacturing method for the same

InactiveCN102520470ASimple interfaceReduce manufacturing costMirrorsVacuum evaporation coatingManufacturing technologyDuralumin

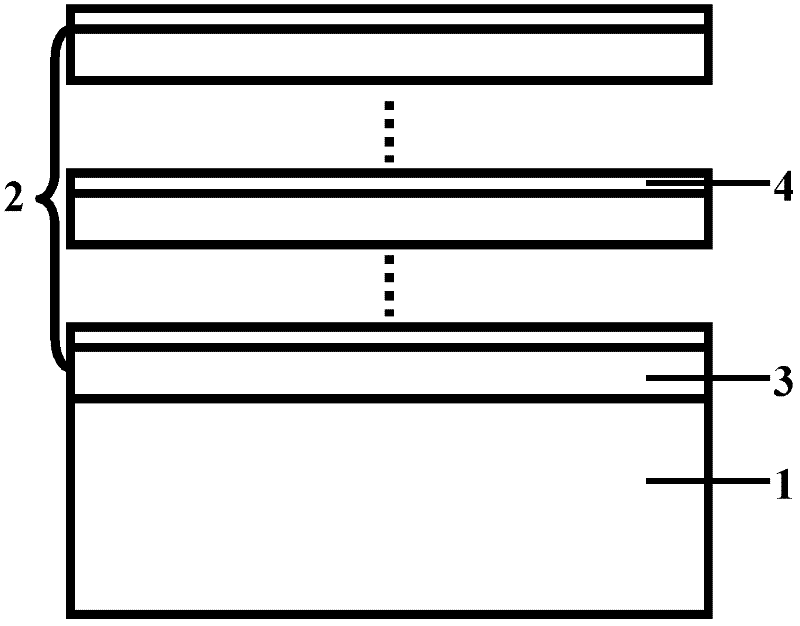

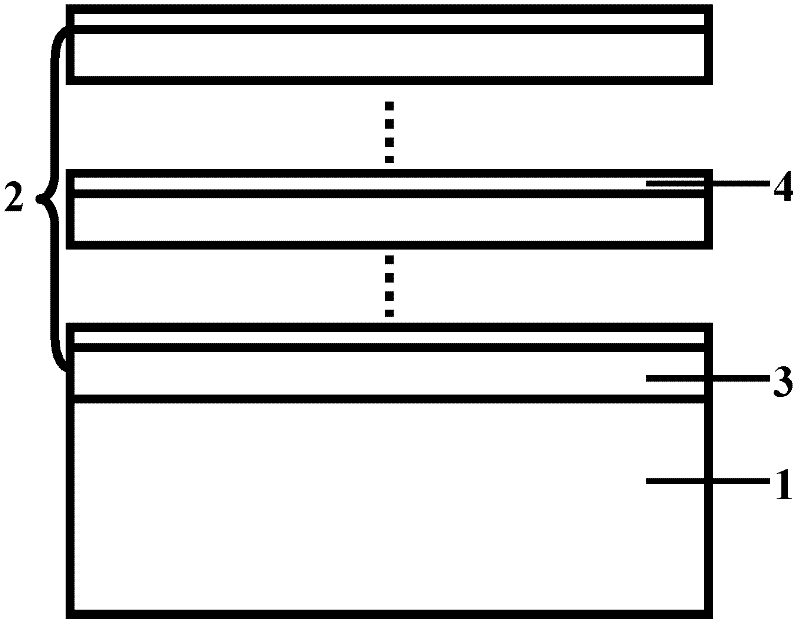

The invention belongs to the technical field of precision optical component manufacturing, and discloses a duralumin / silicon carbide extreme ultraviolet multilayer reflector and a manufacturing method for the same. The reflector of the invention comprises a substrate (1) and a duralumin / silicon carbide periodic multilayer film (2), wherein duralumin thin film layers (3) and silicon carbide thin film layers (4) are alternatively deposited on the surface of the substrate (1). The reflector manufacturing method of the invention comprises the following steps of: firstly, washing the substrate (1), and then, plating the duralumin / silicon carbide periodic multilayer film (2) on the substrate (1). The reflector of the invention overcomes the defects, such as larger interface roughness and higher mutual penetration between film layer materials, of the conventional aluminum / silicon carbide multilayer film, reduces the difficulty in the manufacturing technology and reduces the price of metal materials by 2 orders of magnitude; and the novel duralumin / silicon carbide extreme ultraviolet multilayer reflector has the advantages of good film-forming quality, easy manufacturing process, cheap price, excellent optical performance meeting the needs, and the like, thereby being more suitable for realizing industrialization of such products.

Owner:TONGJI UNIV

Duralumin conductor material with 63% IACS and preparation method thereof

ActiveCN105671372AImprove yieldImprove performanceConductive materialMetal/alloy conductorsMetallurgyAdditive ingredient

The invention relates to a duralumin conductor material with the 63% IACS and a preparation method thereof. According to the high-conductivity duralumin conductor material, an industrial pure aluminum ingot is molten, the ingredients such as Si, Fe and B are adjusted, and refining treatment is carried out to obtain molten aluminum with the required ingredients; then the molten aluminum is poured to form an ingot, then the aluminum ingot is subjected to hot rolling to form a rod, and the aluminum rod is subjected to iron separation treatment; according to the iron separation treatment process, heat preservation is carried out for 1 h to 3 h at the temperature of 300 DEG C to 350 DEG C; and finally, the aluminum rod obtained after iron separation treatment is drawn to form a wire, the total deformation of drawing is controlled to be larger than or equal to 90%, and the duralumin conductor material with the conductivity larger than or equal to 63% IACS and the tensile strength larger than or equal to 160 MPa is prepared. The existing state of Fe is a high-iron phase and an iron-rich phase. The duralumin conductor material is stable in performance and high in yield, and the requirement for raw materials is loosened, so that the duralumin conductor material is low in price. Due to the fact that the conductivity of the duralumin conductor material with the 63% IACS is high, the loss of a transmission line is reduced, and the duralumin conductor material with the 63% IACS is especially suitable for long-distance overhead transmission lines.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

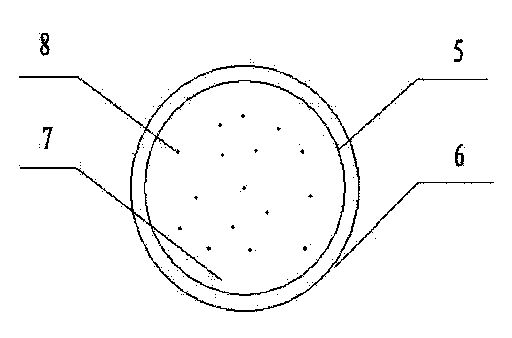

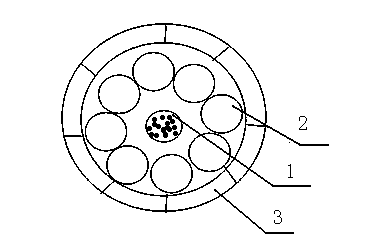

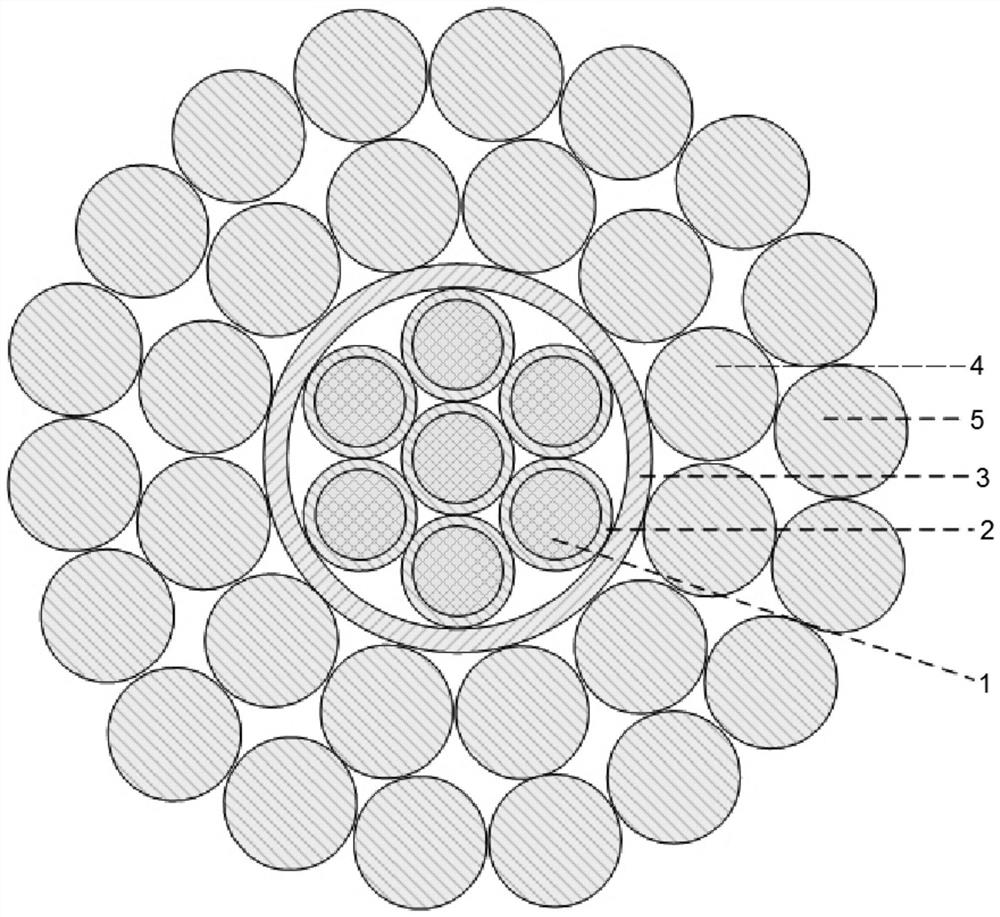

Low-swinging carbon fiber photoelectric composite overhead conductor

The invention relates to a low-swinging carbon fiber photoelectric composite overhead conductor which is characterized by sequentially comprising a carbon fiber strength bearing part, a stainless steel optical unit, a photoelectric composite structure composed of duralumin round wires and a duralumin molded line outer layer from inside to outside. Spiral surrounding stripes are arranged on the outer contour of the duralumin molded line outer layer. Compared with the prior art, the low-swinging carbon fiber photoelectric composite overhead conductor has the advantages of being good in softening performance and improving tensile strength. Meanwhile, the spiral surrounding stripes are arranged on the outer contour of the duralumin molded line outer layer, and therefore reduction of swinging of the overhead conductor is facilitated.

Owner:HENAN KOSEN CABLE

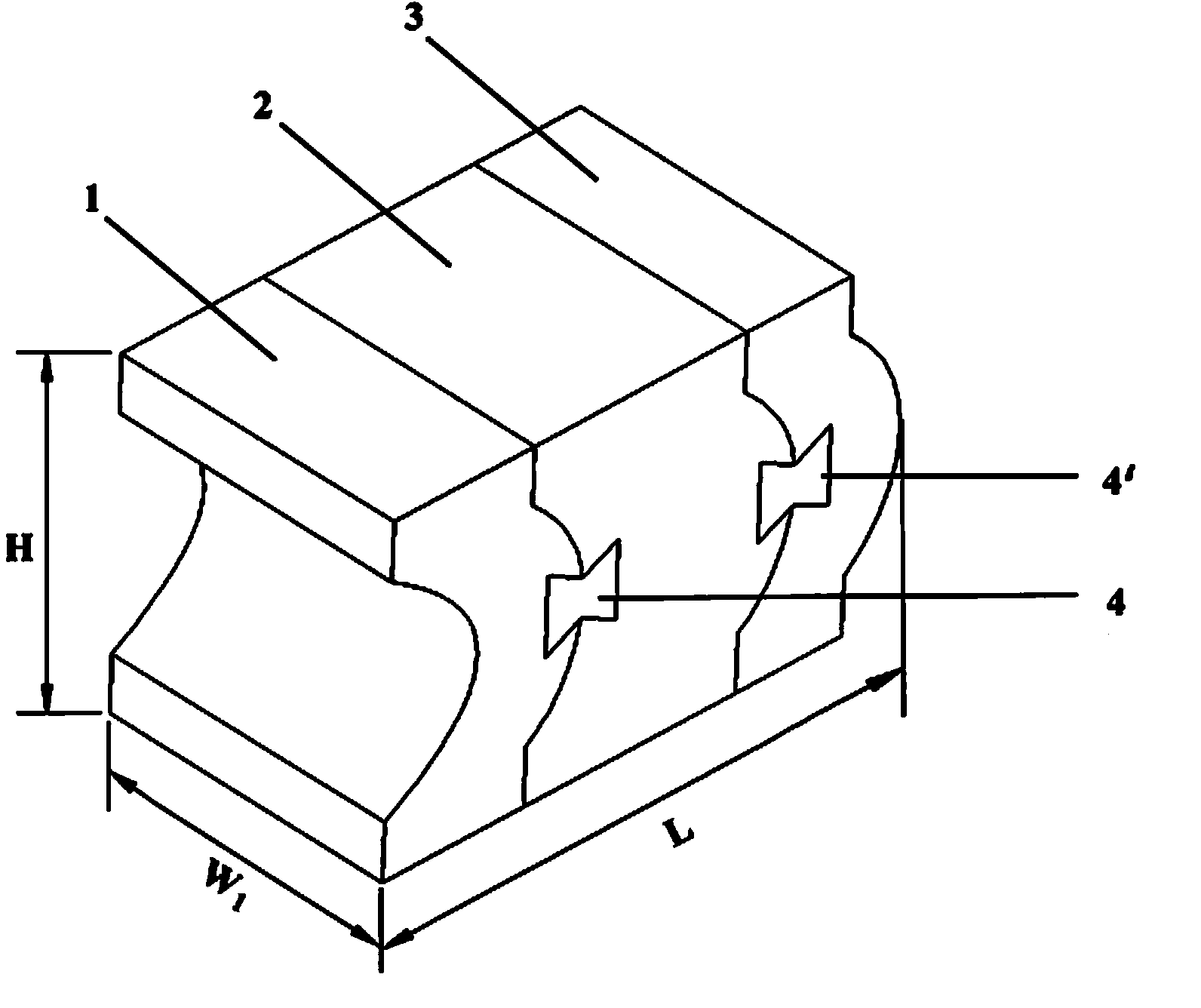

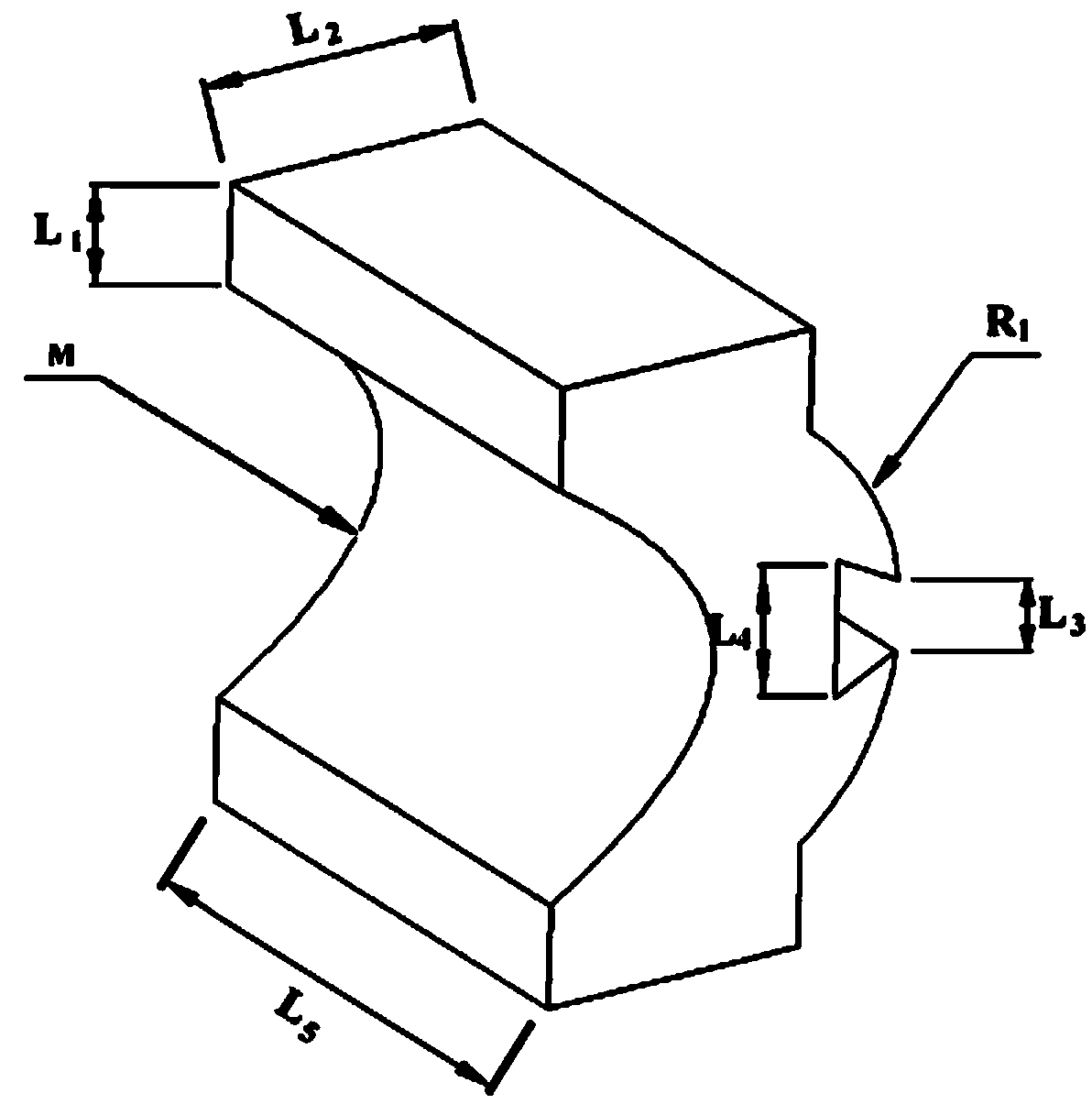

Combined metal solid armature for electromagnetic emission and manufacturing method thereof

ActiveCN104240974AImprove anti-ablation performanceImprove the ability to resist electromagnetic forceContact materialsInterference fitDuralumin

The invention discloses a combined metal solid armature for electromagnetic emission and a manufacturing method thereof. The combined metal solid armature is formed by combining a pure copper block (3), a pure aluminum block (2) and a commercial pure titanium block (6) into a whole in an interference fit mode through duralumin double-dovetail-groove connecting keys I and II (4 and 4'), wherein the pure copper block (3), the pure aluminum block (2) and the commercial pure titanium block (6) are similar in shape, the proportion of the contact area between the pure copper block (3) and an electromagnetic emission track to the contact area between the pure aluminum block (2) and the electromagnetic emission track to the contact area between the commercial pure titanium block (6) and the electromagnetic emission track is 1:2:1.3, and the conductivity of the pure copper block (3), the conductivity of the pure aluminum block (2) and the conductivity of the commercial pure titanium block (6) are gradually increased. The combined metal solid armature is a C type armature. According to the combined metal solid armature, by the adoption of the segmentation and combination technology, gradient distribution of the conductivity is ingeniously achieved, and the problem that the gradient change of the conductivity of a homogenous material can not be achieved easily or a material with the gradient change of the conductivity can not be prepared easily is solved. Due to the fact that the conductivity is decreased gradually and the strength is improved gradually from the front section to the rear section, redistribution of currents is facilitated, the phenomenon that the currents are excessively accumulated at the single tail portion is relieved, and the thermal ablation resistance and the electromagnetic force resistance of the solid armature are improved.

Owner:YANSHAN UNIV

Low-swinging carbon fiber composite core photoelectric composite overhead conductor

The invention relates to a low-swinging carbon fiber composite core photoelectric composite overhead conductor which sequentially comprises a stainless steel optical unit, a carbon fiber composite core and a duralumin molded line outer layer from inside to outside. The stainless steel optical unit is composed of a plurality of optical fibers which are arranged in a stainless steel protection pipe. The carbon fiber composite core is a high-strength conductive composite material composed of epoxy resin, nanometer expanded graphite with the expansion multiple more than 100 and reinforcing carbon fibers. Spiral surrounding stripes are arranged on the outer contour of the duralumin molded line outer layer. Compared with the prior art, the low-swinging carbon fiber composite core photoelectric composite overhead conductor has the advantages of being good in softening performance and improving tensile strength. Meanwhile, the spiral surrounding stripes are arranged on the outer contour of the duralumin molded line outer layer, and therefore reduction of swinging of the overhead conductor is facilitated.

Owner:HENAN KOSEN CABLE

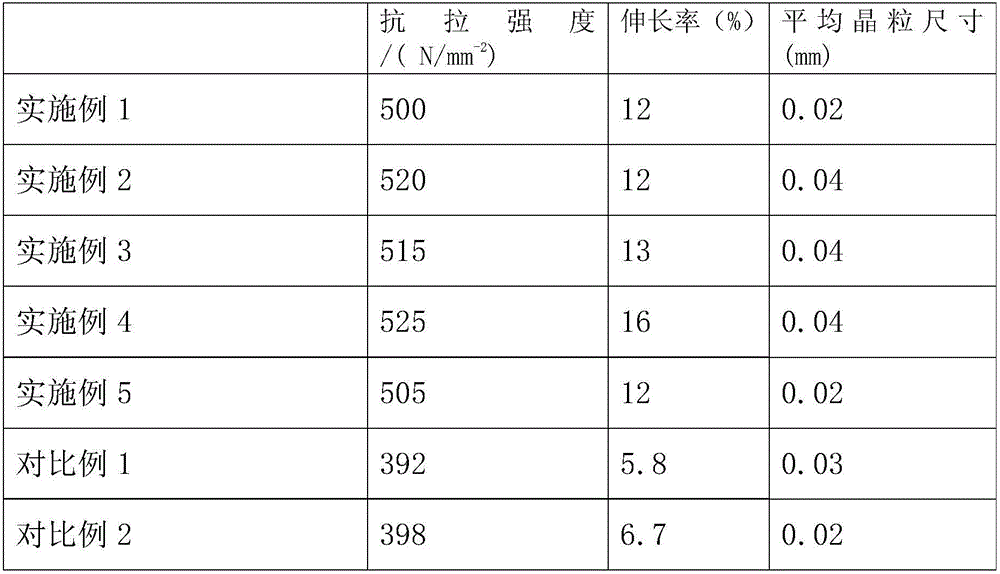

A kind of production technology of environment-friendly high-toughness duralumin alloy profile

ActiveCN104975213BReduce production processShorten the production cycleDuraluminUltimate tensile strength

The invention discloses an environment-friendly high-toughness hard aluminum alloy profile production process. The production process comprises burdening and smelting; the burdening is performed for the following component in percentage by mass: 5-5.5% of Cu, 2-4.5% of Fe, 0.1-0.3% of Mn, 0.5-3% of Mg, 1.1-1.5% of Zn, 0.1-1% of Si, 0.1% of Ni, 0.2% of Ti, and the balance of Al; the smelting is performed for 6-8 h under high temperature to obtain aluminum alloy molten liquid; and then, the horizontal continuous casting, the continuous extrusion and the three-stage ageing heat treatment are performed. The process shortens the alloy production process and period without needing the homogenization and the preheating treatment, and totally accords with the production requirements of energy conservation and greenness of a short-flow process; and a prepared aluminum alloy profile has excellent toughness and tensile strength, and can satisfy the gradually increasing high-end demands.

Owner:浙江米皇新材股份有限公司

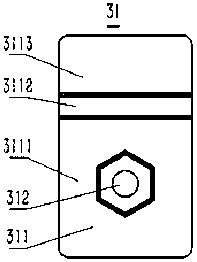

Duralumin pole piece and battery module

PendingCN108054332AImprove structural strengthReduce strainFinal product manufactureMultimode batteriesDuraluminPole piece

The invention relates to a duralumin pole piece and a battery module. The duralumin pole piece includes total output pole pieces, double-row duralumin pole pieces and a single-row duralumin pole piece. Each total output pole piece includes a rectangular duralumin pole piece and an embossed teeth equipped hexagonal head screw that are combined together by a pressure riveting process, and is used for electric connection with a post terminal serving as a total output pole of the battery module. Each double-row duralumin pole piece is an H-shaped structure composed of one connecting part and two welding parts, and is used for electrically connecting a plurality of post terminals of two adjacent columns of batteries in the battery module. The single-row duralumin pole piece is used for used forelectric connection of other post terminals except the total output pole in the outermost two columns of battery post terminals in the battery module. The rectangular duralumin pole pieces, the single-row duralumin pole piece and the double-row duralumin pole pieces are all coated with wiredrawing surfaces. The battery module consists of a battery pack, packing straps and a duralumin pole piece,and the duralumin pole piece and the battery pack adopt laser welding. The duralumin pole piece and the battery module provided by the invention have the advantages of high production efficiency, lowproduction cost, simple and convenient welding, and high welding reliability.

Owner:江西安驰新能源科技有限公司

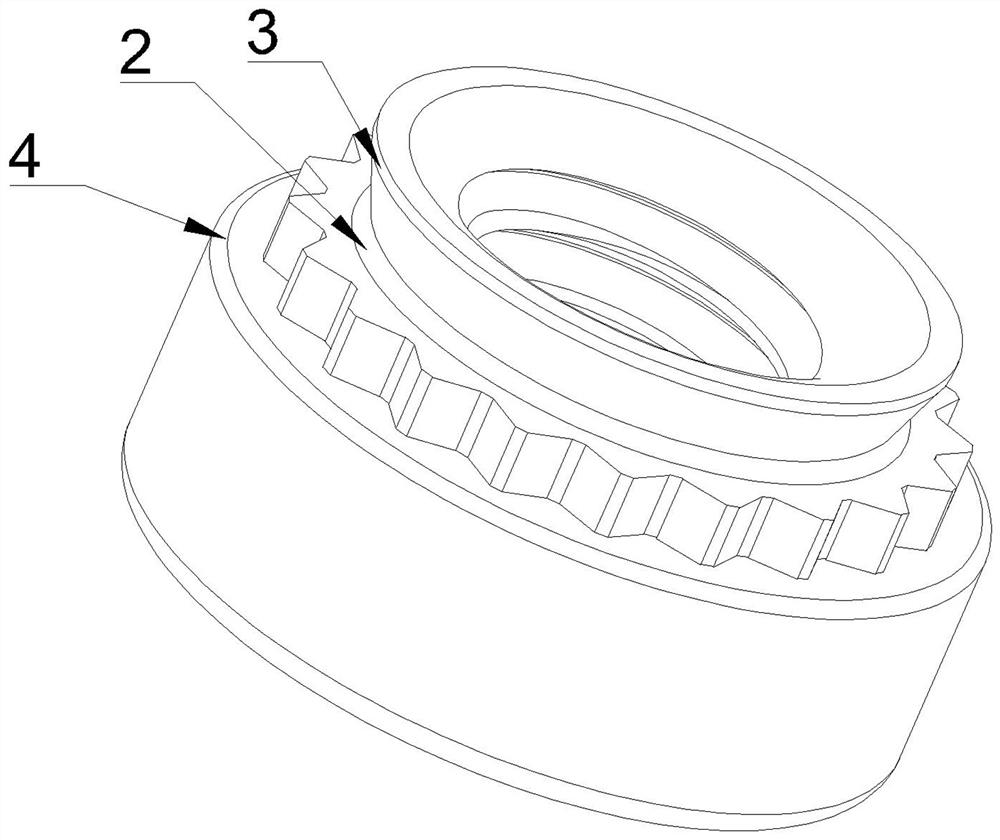

High-strength aluminum rivet nut device and machining method thereof

PendingCN111761307ASimple structureWide thickness rangeNutsPositioning apparatusThermal dilatationPunching

The invention discloses a high-strength aluminum rivet nut device and a machining method thereof. According to key points of the technical scheme, the machining method comprises the following steps: 1, a raw material is selected, specifically, a 7-series or 2-series high-strength duralumin alloy in a T6 aging state is selected; 2, warm heading is conducted, specifically, warm-heading machining isconducted on a multi-station cold header, the processes comprise cutting, shaping, flat heading, heading, forward and reverse composite extrusion, punching and the like, warm heading adopts resistancefor heating and enables the temperature of the material to be kept at 200 DEG C-400 DEG C, and the production speed is 50 pieces / min-200 pieces / min; 3, tapping is conducted; and 4, cleaning is conducted for rust prevention. According to the aluminum rivet nut device, the defects during application of a steel rivet nut device to an aluminum plate are avoided in the aspects of potential corrosion,thermal expansion and light weight, and meanwhile the high-strength aluminum alloy is selected so that the requirement for the application strength can be met.

Owner:ZHEJIANG HUAYUAN AUTOMOBILE PARTS

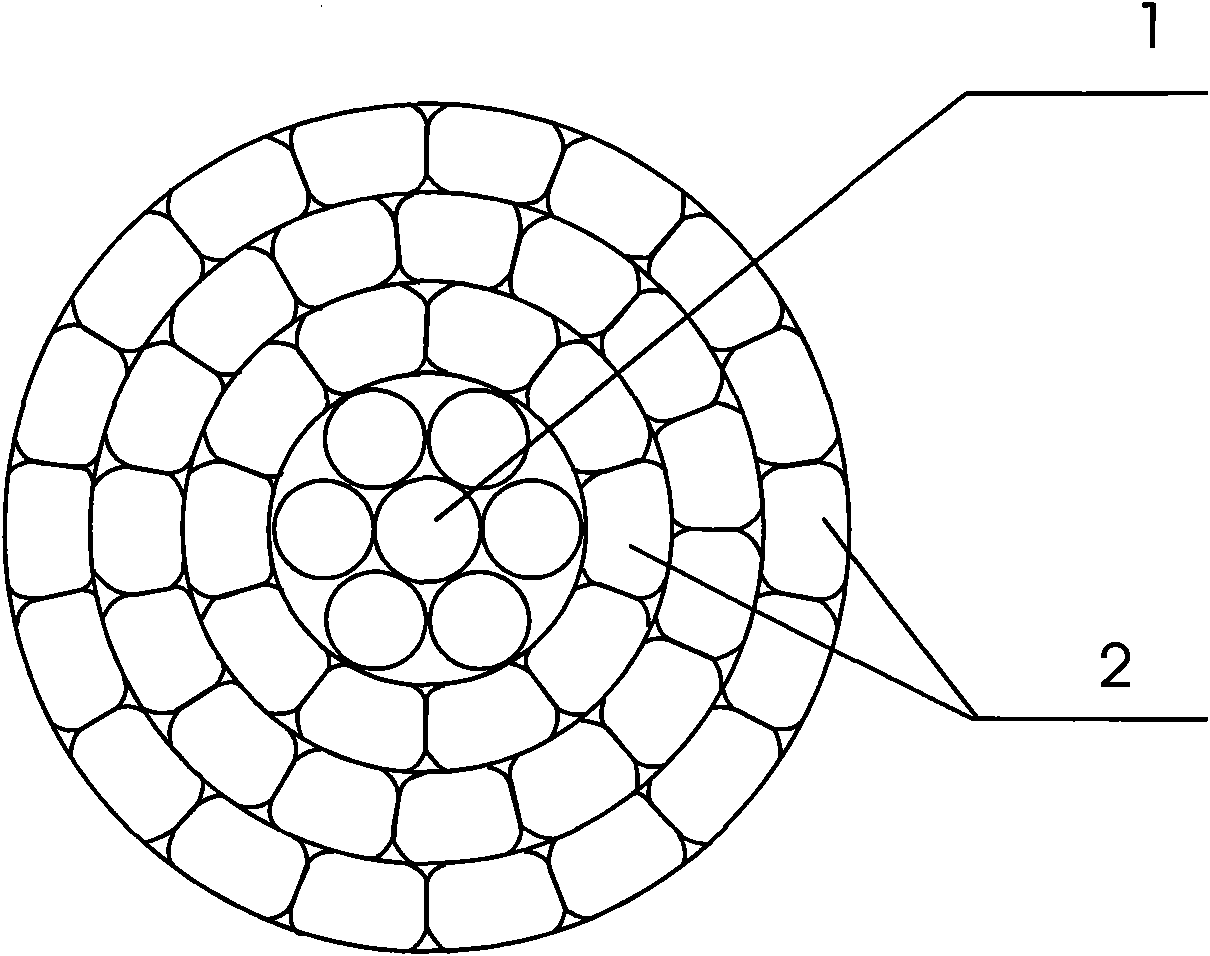

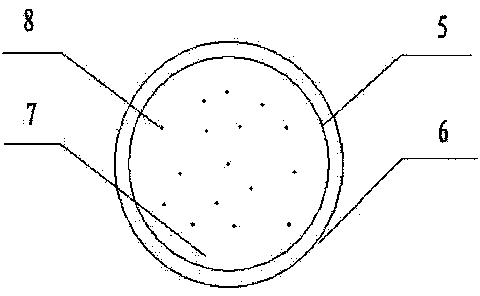

Stranded aluminum-clad composite core wire

PendingCN112366024ASolving Corrosion ProblemsImprove bending resistanceAuxillary non-insulated conductorsDuraluminFiber-reinforced composite

The invention provides a stranded aluminum-clad composite core wire which comprises fiber reinforced composite material cores, an aluminum coating layer, a duralumin layer and an aluminum wire layer,the outer surfaces of the fiber reinforced composite material cores are coated with the aluminum coating layer, all the fiber reinforced composite material cores are coated with the duralumin layer, and the duralumin layer is coated with the aluminum wire layer. The fiber reinforced composite material cores adopts a twisting type, the structure is relatively stable, the stress is uniform, the added aluminum coating layer can prevent external media such as water from corroding the internal fiber reinforced composite material cores, the overall tensile strength can be improved, and in the process of conducting wire connection, a steel pipe can be directly crimped outside the duralumin layer, so that the bending resistance and the corrosion resistance of the wire cores are improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Processing technique of high-conductivity duralumin wire

ActiveCN103413631AGood effectGuaranteed conductivityManufacturing wire harnessesElectricityDuralumin

The invention belongs to the technical field of electrical equipment, and particularly relates to a processing technique of a high-conductivity duralumin wire. The processing technique comprises the step of controlling elements of an original duralumin rod, the step of controlling the diameter of the original duralumin rod, the step of controlling drawing passes, the step of controlling deformation of each drawing pass and the step of controlling outlet speed of a finished wire. The processing technique can be implemented based on existing production conditions, and needed extra expense and cost are low. In terms of the technique, the duralumin wire can be produced by adopting the technique as long as technological parameters are appropriately changed on an original device, the implementation is technically easy, and the processing technique is convenient to implement and operate. In terms of the effect on the conductivity of the wire, the electric conductivity of the duralumin wire can exceed 62.0%, and the effect is very obvious. According to the processing technique, line losses and energy consumption brought by long-distance electricity transmission can be reduced, economic benefits of power generation enterprises are obviously improved, and the cost of electricity transmission is obviously reduced. Energy can be largely saved, and environmental protection is facilitated.

Owner:STATE GRID CORP OF CHINA +3

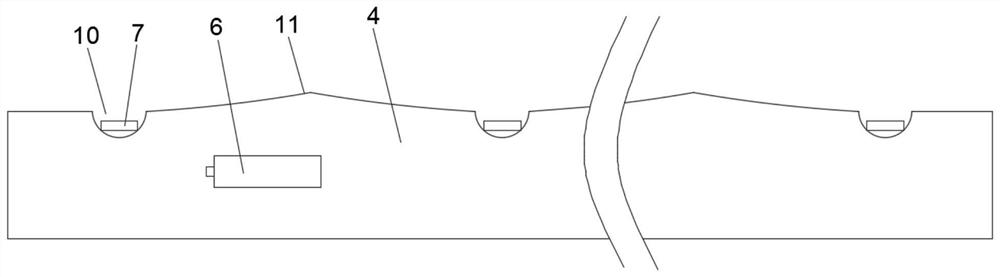

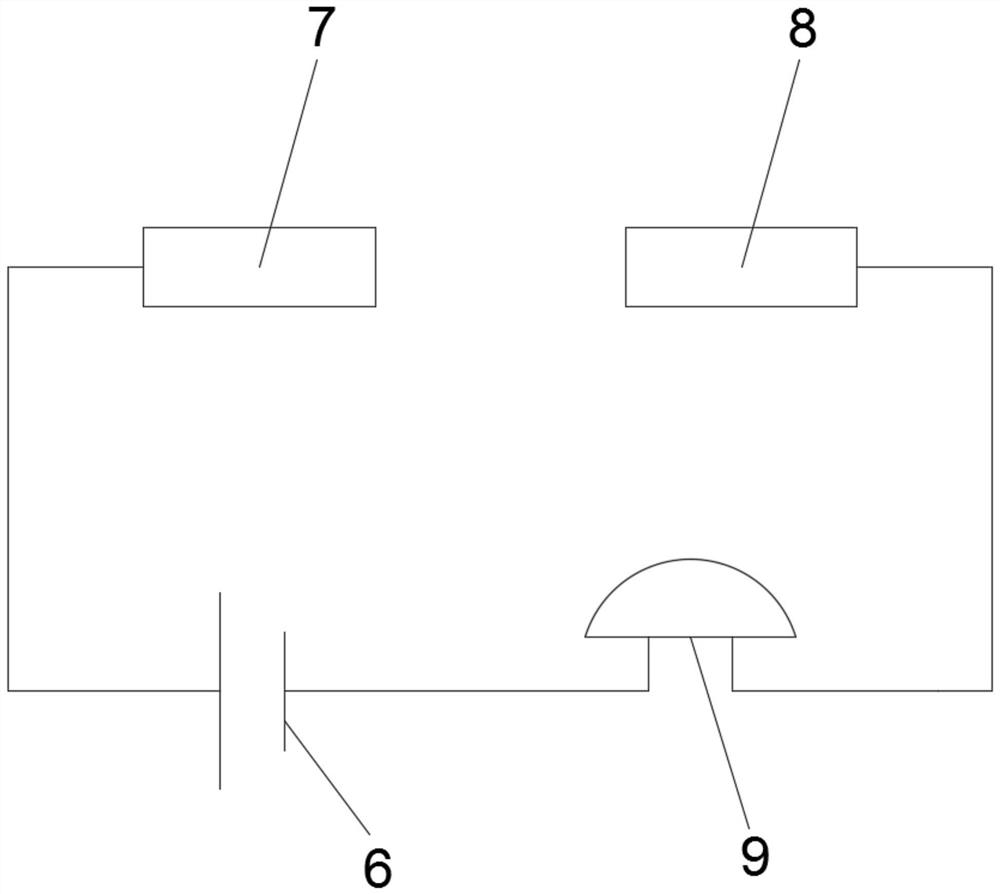

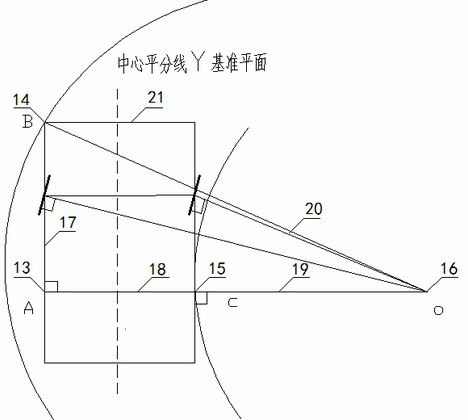

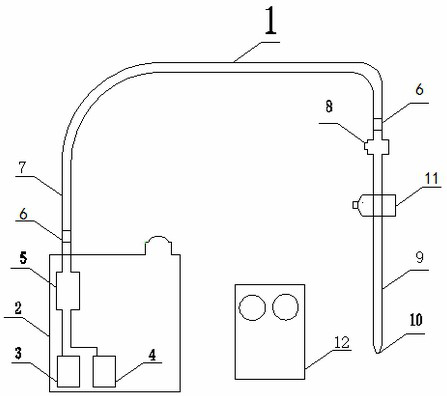

Rapid detection method for automobile passage circle with pressure-regulating liquid spraying device

ActiveCN112557050ASolve the difficulty of trackingWide adaptabilityVehicle testingRight triangleDuralumin

The invention relates to an automobile passage circle rapid detection method with a pressure regulating liquid spraying device. The method comprises the steps of preparation before detection, field actual measurement and data analysis. During preparation before measurement, a pressure regulating liquid spraying device is installed, and measuring points are preset according to the structure of a detected vehicle (21) and a right triangle: a rear axle center outer measuring point A (13), an outermost side front measuring point B (14) and a rear axle center inner measuring point C (15). The pressure regulating liquid spraying device is provided with a first pump (3), a second pump (4) and a pressure regulating valve (8), the inner diameter of a spraying pipe (9) is a high duralumin pipe of 10+ / - 0.5 mm, and the diameter of a nozzle (10) is 3 + / - 0.2 mm. During field actual measurement, the detected vehicle (21) is positioned and arranged, the liquid spraying device is started, liquid issprayed at a low position to form a track, and data are measured according to preset measuring points. During data analysis, the turning radius of the front point of the outer side of the detected vehicle (21) is calculated through right-angled triangle layout, and the vehicle channel circle trafficability of the detected vehicle (21) is judged. The method has the advantages of being simple, convenient to operate, good in repeatability of the detection process and wide in detected vehicle types.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

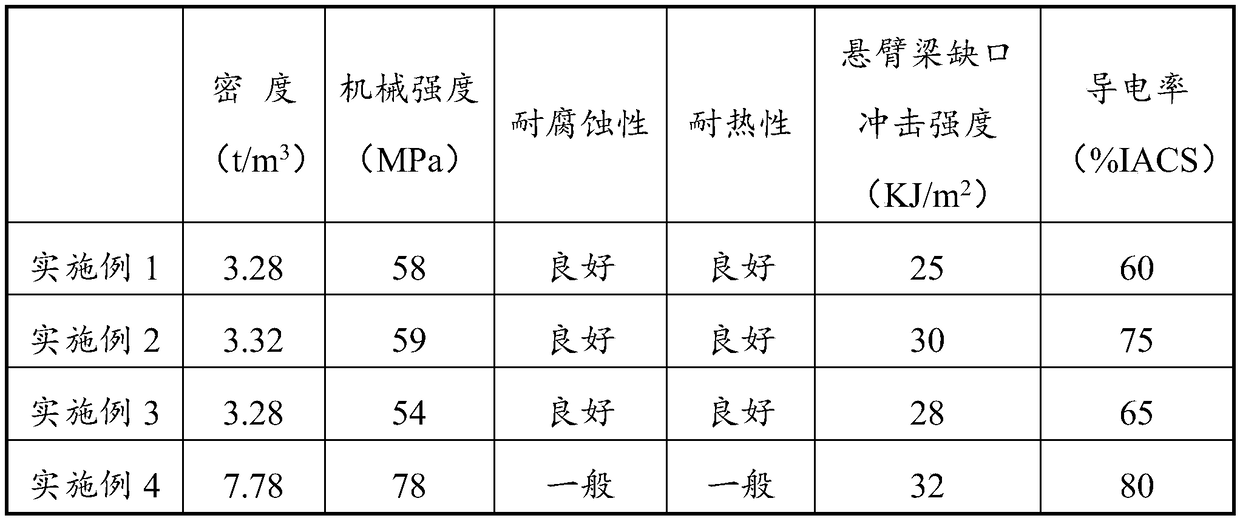

Production method of cylindrical and tubular mechanical part

The invention relates to a production method of a cylindrical and tubular mechanical part. The production method comprises the steps that reduced iron powder is marked as the raw material A, and a mixture of liquid unsaturated polyester resin and a liquid curing agent is marked as the raw material B; the raw material B is poured into the raw material A, stirring and uniform mixing are performed, then mixing and milling are performed, and an obtained mixture is loaded into a steel capsule with the inner wall and outer wall each coated with a layer of a lubricating agent; the steel capsule is subjected to vacuumizing treatment for 5-30 min under the pressure of minus 0.01-minus 0.015 MPa; then the steel capsule is pushed into a die of a metal extrusion press, isostatic cool pressing is performed, and a tubular or cylindrical blank is obtained; and after the obtained blank is subjected to primary curing, cutting and dividing and deep curing, the mechanical part product is obtained. The mechanical part produced through the production method is low in weight, the density is 1.8-3.5 t / m<3> which is 2-4 times smaller than the density of steel, the strength of the mechanical part is not lower and is higher than those of structural steel, duralumin, fir and the like, and the mechanical part can completely replace part of cast blanks.

Owner:唐竹胜

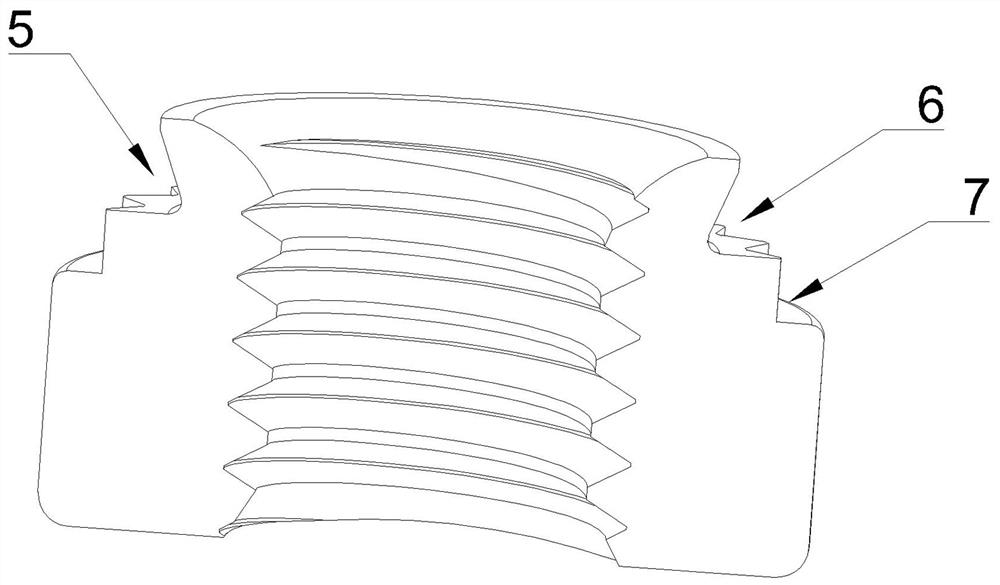

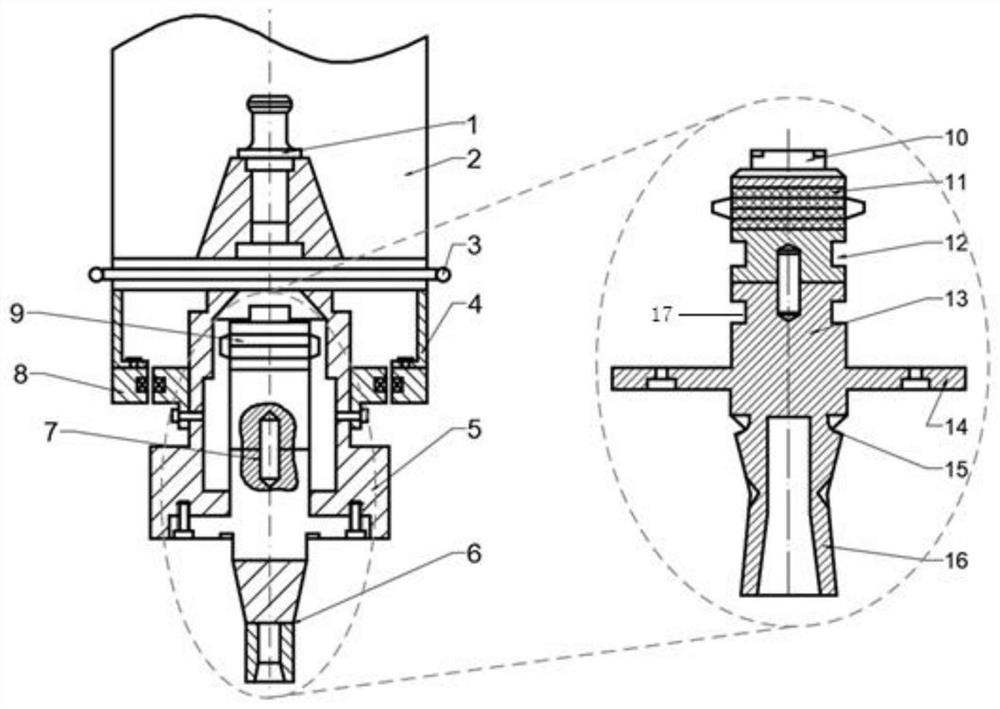

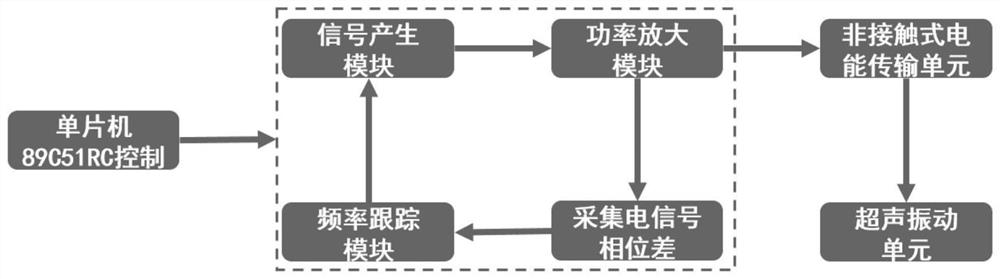

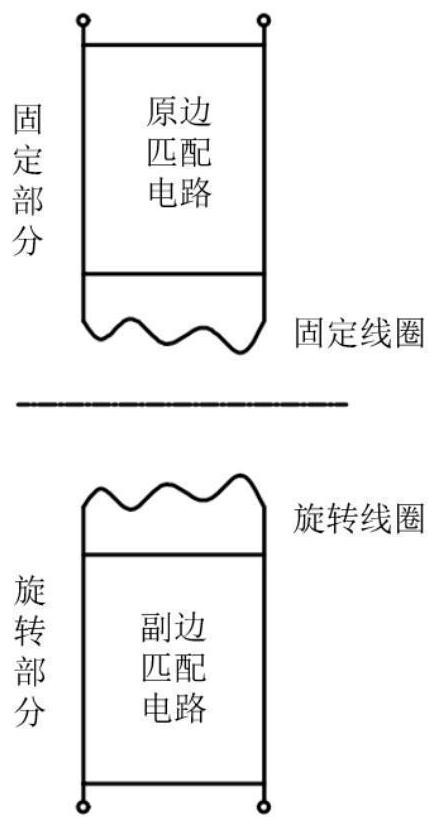

Ultrasonic vibration device and design method

The invention discloses an ultrasonic vibration device and a design method. The problems of large cutting force, high cutting temperature, low machining precision and the like of difficult-to-machine materials such as composite materials, hard alloy and the like during machining are solved. Anultrasonic vibration auxiliary drilling and milling device is designed, a rear cover plate, piezoelectric ceramics and a front cover plate of a piezoelectric transducer are respectively made of 45 steel, PZT-8 and duralumin materials, so that good piezoelectric conversion characteristics and axial displacement output are achieved; and an ultrasonic amplitude-change pole is designed into a conical transition type composite amplitude-change pole, and the tail end of the amplitude-change pole is designed into a groove type, so that the large amplification factor is achieved, and the resonant frequency can be corrected by adjusting counterweight liquid in the groove.

Owner:安徽天航机电有限公司

Large-capacity non-heat treated high-conductivity aluminum alloy conductive material

ActiveCN102363849BImprove heat resistanceHigh strengthMetal/alloy conductorsConductive materialsYttrium

The invention discloses a large-capacity non-heat treated high-conductivity aluminum alloy conductive material belonging to the technical field of electric wire and cable conductive materials. The aluminum alloy conductive material is mainly composed of the four following elements: aluminum, erbium, yttrium and ferrum, and the mass percent of each element is as follows: the mass percent of the erbium is 0.21-0.30%, the mass percent of the yttrium is 0.26-0.30%, the mass percent of the ferrum is 0.15-0.25%, the mass percent of the impurity silicon is not more than 0.06%, the sum of the mass percent of the impurities including chromium, manganese, vanadium and titanium is not more than 0.012%, and the rest is aluminum. The aluminum alloy conductive material provided by the invention has the tensile strength of more than 160 MPa, the elongation of more than 2.0% and the conductivity of more than 61% IACS. On the aspects of normal temperature mechanics performance and electrical properties, the aluminum alloy conductive material is as good as the duralumin conductive material, even better, and on the aspect of heat resistance, the aluminum alloy conductive material meets the heat resistance requirement of the heat-resisting aluminum alloy conductive material, in comparison with the 60% IACS heat-resisting aluminum alloy conductor, the aluminum alloy conductive material can reduce line loss by 1.5% and get obvious economic benefits.

Owner:WETOWN ELECTRIC GRP CO LTD

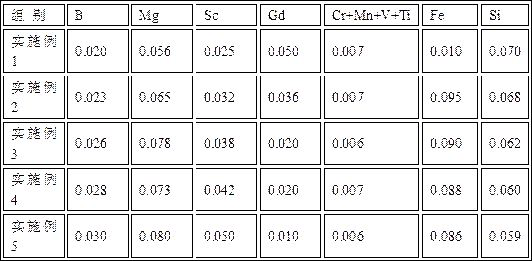

High-conductivity corrosion-resistant aluminum alloy monofilament for overhead conductor and preparation method of high-conductivity corrosion-resistant aluminum alloy monofilament

The invention discloses a high-conductivity corrosion-resistant aluminum alloy monofilament for an overhead conductor and a preparation method of the high-conductivity corrosion-resistant aluminum alloy monofilament. The high-conductivity corrosion-resistant aluminum alloy monofilament comprises the following components in percentage by mass: 0.005 to 0.03 percent of B, 0.005 to 0.10 percent of Mg, 0.005 to 0.05 percent of Sc, 0.005 to 0.05 percent of Gd, less than or equal to 0.07 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.007 percent of (V+Ti+Cr+Mn) and the balance of aluminum and inevitable impurities. Al with the purity of 99.85% is adopted as a raw material, on the basis that impurity elements are strictly purified and controlled by adding a proper amount of B element for boronizing treatment, trace Mg, Sc and Gd alloying elements are added, a duralumin monofilament which is high in electric conductivity, resistant to corrosion, low in cost and small in power transmission loss can be prepared, so that the electric energy transmission efficiency and safe operation level of an overhead transmission line are improved, and the transmission line loss and operation maintenance cost are reduced.

Owner:JIANGSU ELECTRIC POWER CO +2

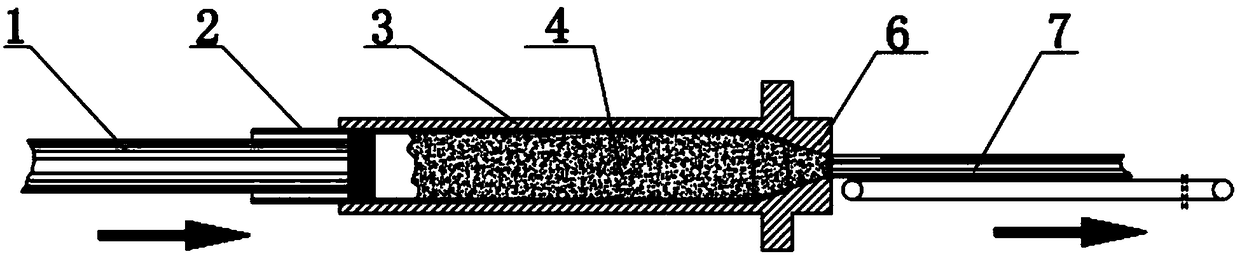

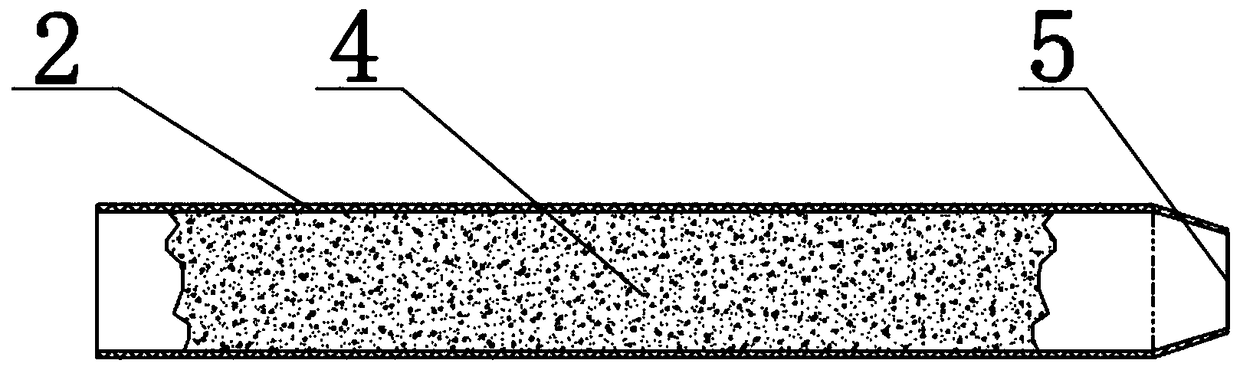

Composite bar energy converter cleaning machine

InactiveCN101138764ASimple structureWide operating frequency rangeMechanical vibrations separationCleaning using liquidsCavitationAcoustic energy

A compound bar transducer cleaning machine belongs to cleaning machinery. The compound bar transducer is provided with a vessel for holding liquid. The compound bar transducer and a power amplifier are connected by a conductor. The power amplifier and a signal source are connected by the conductor. The compound bar transducer consists of a duralumin front cover plate, a piezoelectric ceramics heap and a steel back cover plate. The conductor is connected with a positive electric contact and a negative electric contact of the piezoelectric ceramics heap. The utility model is able to turn electric energy into acoustic energy, thus, producing cavitation effect in water to finish clean-out operation. The utility model has advantages of simple structure, broad range of working frequency, wide application and good operation, which is especially suitable for washing the parts with gaps that are difficult to clean.

Owner:童晖

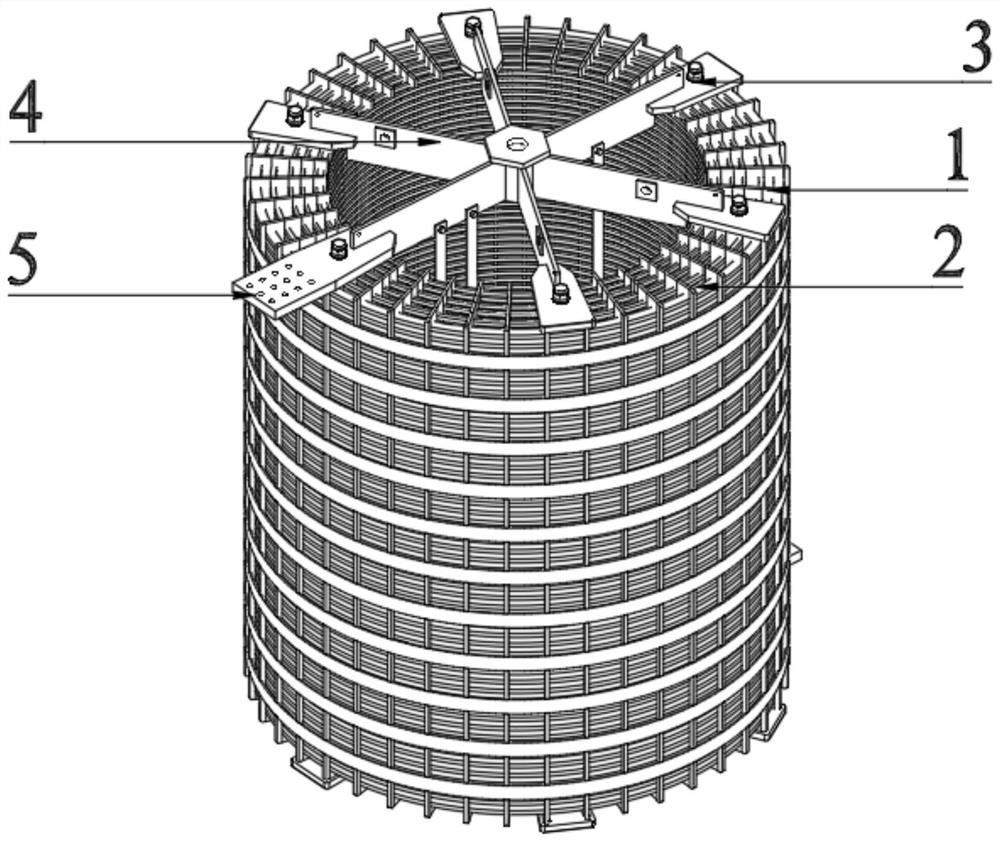

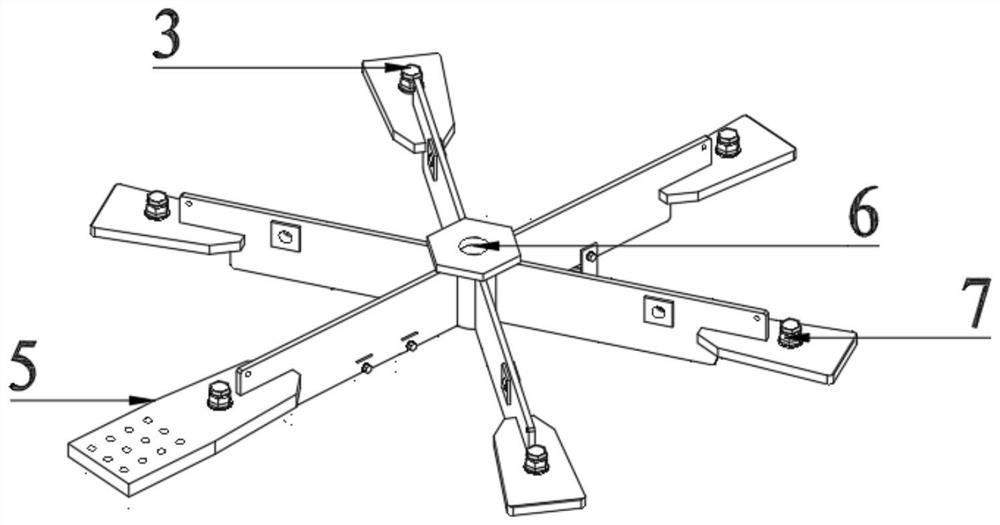

Open type current limiting reactor and manufacturing method thereof

PendingCN114582605AReduce typesLowered species,Transformers/reacts mounting/support/suspensionTransformers/inductances coolingDuraluminMechanical engineering

The invention discloses an open type current limiting reactor which comprises a winding and a coil clamping device. The winding comprises a plurality of insulating plates and coils, and a plurality of clamping grooves for accommodating the coils are uniformly formed in the insulating plates; the coil is a bare hard aluminum flat wire, the bare hard aluminum flat wire is horizontally wound on the clamping groove of the insulating plate in the circumferential direction, and the winding is connected with the coil clamping device so as to clamp and fix the winding; the coil clamping device comprises an upper star-shaped frame, a lower star-shaped frame and an insulating pull rod, the upper star-shaped frame is installed at the upper end of the coil, the lower star-shaped frame is installed at the lower end of the coil, the upper star-shaped frame is connected with the lower star-shaped frame through the insulating pull rod, and incoming and outgoing lines of the reactor are led out through the upper star-shaped frame. The bare duralumin flat wire is not wrapped by an insulating film, so that the problem of breakdown of the insulating film in operation of a product does not need to be worried about; and as the product is fixed by adopting the zigzag insulating plate, the heat dissipation area is increased, and the heat dissipation capability of the air-core reactor is enhanced. The invention further discloses a manufacturing method of the open type current limiting reactor.

Owner:SHANDONG HADA ELECTRIC

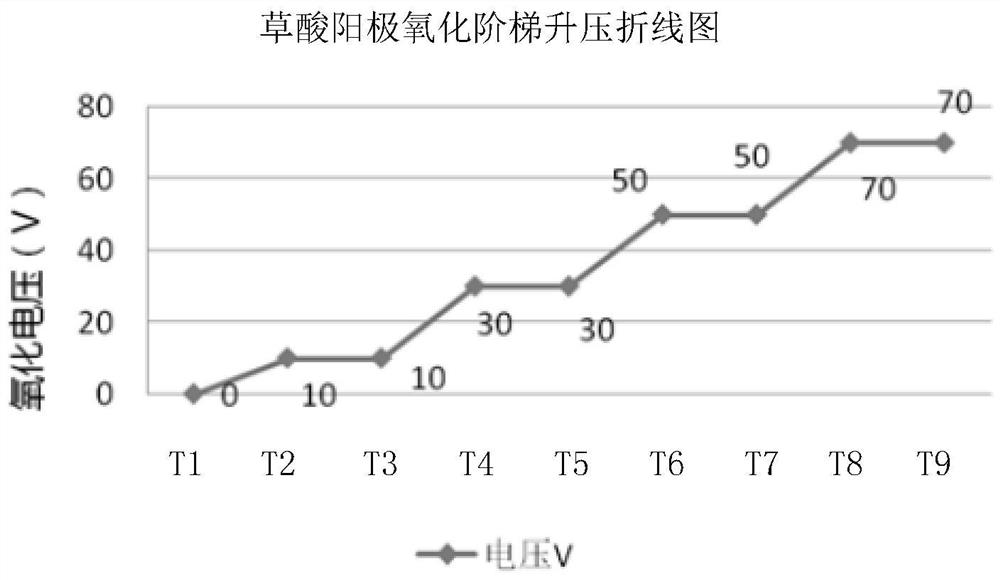

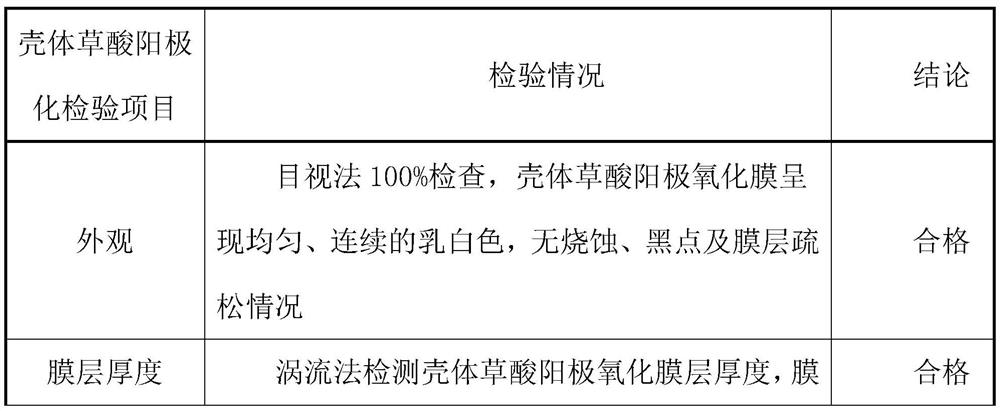

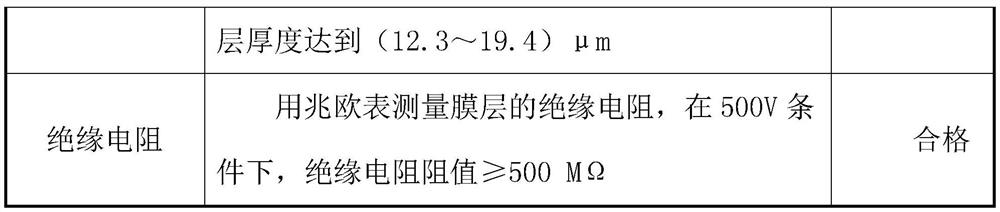

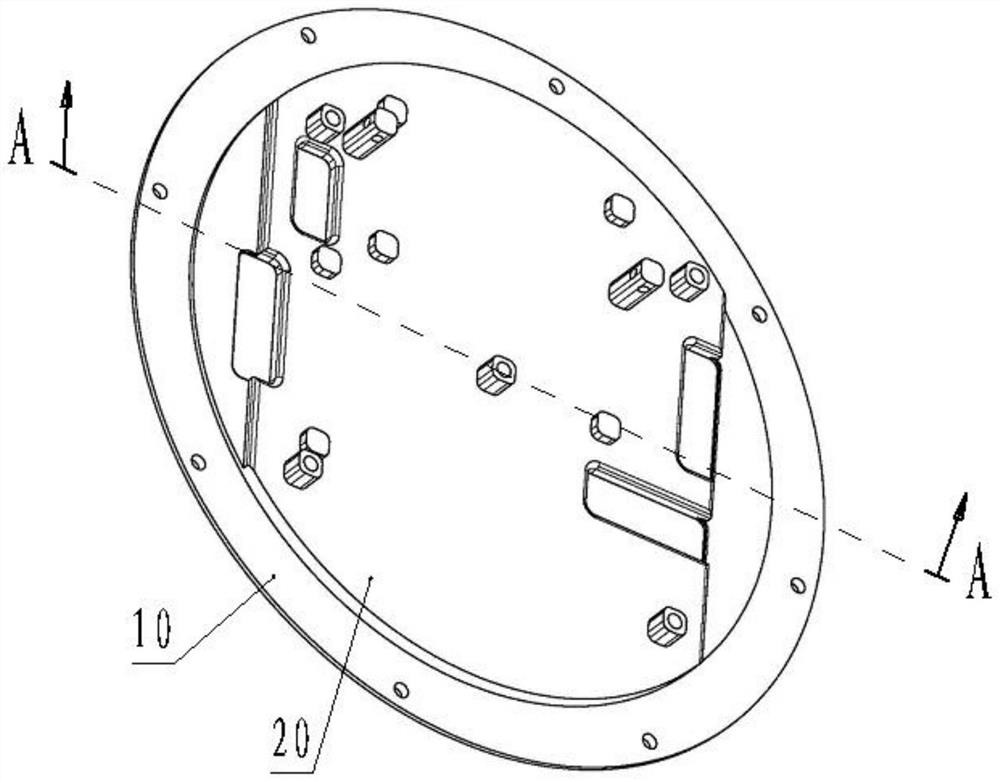

Oxalic acid anodic oxidation process method for hard aluminum alloy shell part

ActiveCN113981500AImprove pass rateIncrease concentrationAnodisationProcess efficiency improvementOXALIC ACID DIHYDRATEDuralumin

Provided is an oxalic acid anodic oxidation process method for the hard aluminum alloy shell part, a step boosting method is introduced to adjust and match the oxidation voltage, the oxidation time, the boosting speed and the frequency of an electrolytic cell; the three technical indexes of the appearance, the film thickness and the insulation resistance of an oxalic acid anodic oxidation film layer formed on the surface of a shell part meet the standard acceptance requirements, the percent of pass is high, the problem that the percent of pass of oxalic acid anodic oxidation of a duralumin material shell is low is thoroughly solved, the part scrapping problem caused by film ablation and black spots is greatly reduced, the insulation resistance consistency of different parts of the shell part is ensured, and the quality of an oxalic acid anodic oxidation film layer of the shell part is greatly improved.

Owner:SHAANXI BAOCHENG AVIATION INSTR

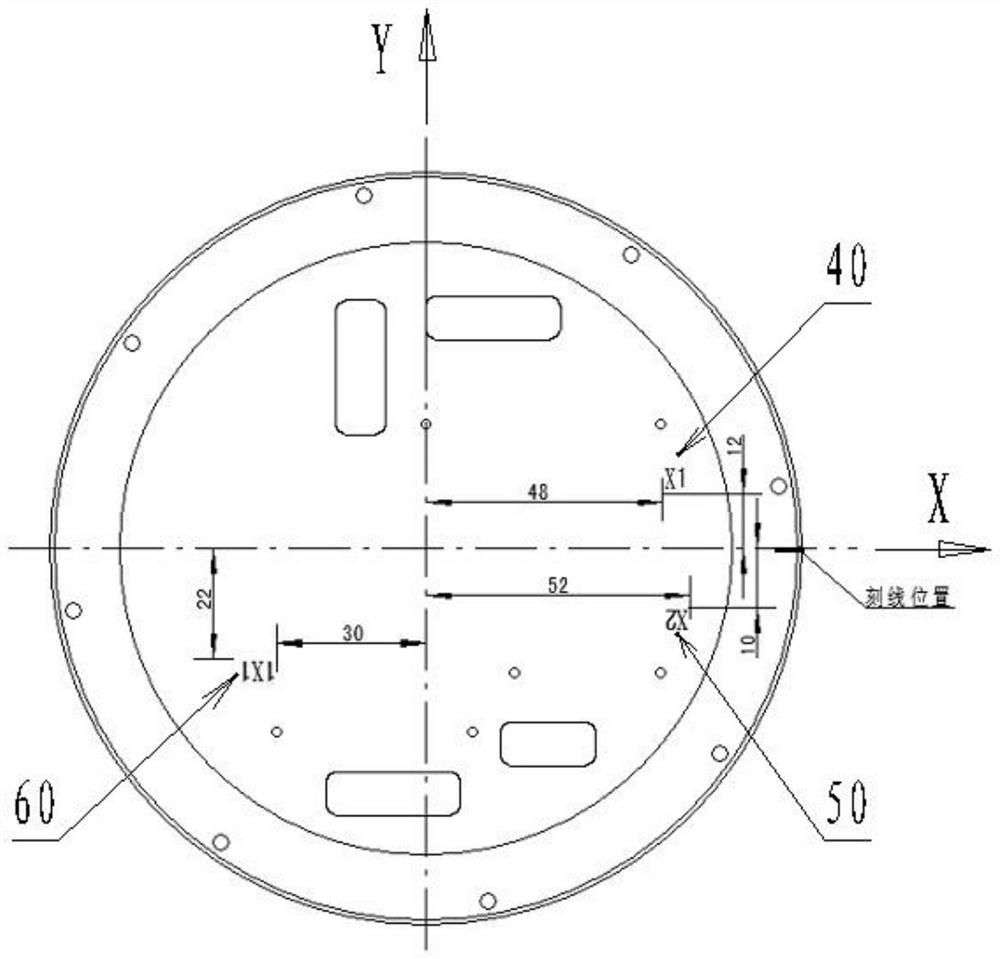

Lettering and paint embedding method for thin plate disc-shaped duralumin bottom plate part

PendingCN114054968AProblems Affecting FlatnessAdditional drying stepsPretreated surfacesLaser beam welding apparatusDuraluminLettering

The invention relates to a lettering and paint embedding method for a thin plate disc-shaped duralumin bottom plate part. The bottom plate part comprises an annular edge plate and a circular truncated cone, and an open bottom hole is formed in the bottom face of the annular edge plate; a plurality of lettering areas are arranged on the plane of the bottom hole; and line carving is performed on the bottom surface of the annular edge plate. The lettering and paint embedding method comprises the following steps that: S1, lettering and line carving are conducted, specifically, the bottom plate part is clamped, lettering contents of different lettering areas are edited, and lettering is conducted on the lettering areas through lettering equipment, line carving is performed on the bottom surface of the annular edge plate, the depth of the lettering and line carving is 0.2-0.3 mm, and the width of the lettering and line carving is 0.3 mm; S2, inspection is performed, specifically, a laser lettering font inspection template is adopted to compare and inspect lettering fonts, and a vernier caliper is adopted to inspect the depth and width of the lettering and line carving; S3, paint embedding is conducted, specifically, a part to be subjected to paint embedding is wiped with aviation gasoline, paint embedding is carried out by adopting C04-42 black alkyd enamel paint, after paint embedding, the part is naturally aired, after being aired, the paint at a non-paint-embedded part is cleaned, and the part is placed in a constant-temperature drying oven to be dried.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

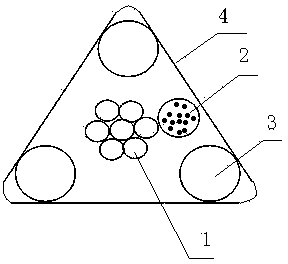

Triangular carbon fiber photoelectricity composite overhead conductor

The invention relates to a triangular carbon fiber photoelectricity composite overhead conductor which comprises a photoelectricity composite structure and a high temperature resistant insulation material layer, wherein the photoelectricity composite structure is composed of a carbon fiber strength bearing part, a stainless steel optical unit and duralumin round lines. The cross section of the high temperature resistant insulation material layer is triangular, each corner of the triangular cross section contains one duralumin round line, the center of the cross section of the high temperature resistant insulation material layer contains the carbon fiber strength bearing part, and the stainless steel optical unit is contained in the gap among the duralumin round lines and the carbon fiber strength bearing part in the high temperature resistant insulation material layer. Compared with the prior art, the triangular carbon fiber photoelectricity composite overhead conductor has the advantages of being good in soft property and improved in strength of extension, meanwhile, the windage resistance of the triangular cross section is smaller than that of a round section, and therefore the reduction of waving of the overhead conductor is facilitated.

Owner:HENAN KOSEN CABLE

Aluminum-based alloy low-temperature washing soldering paste and preparation method thereof

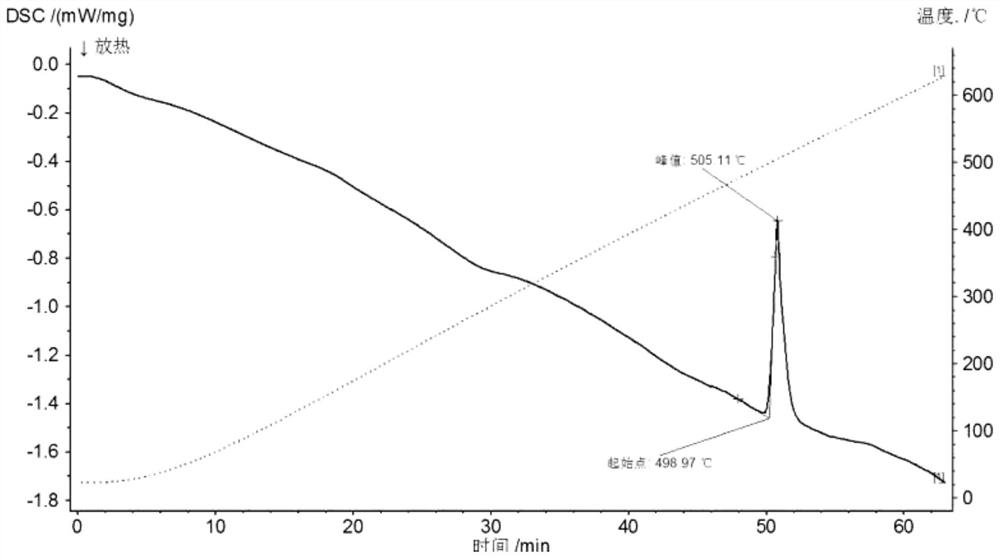

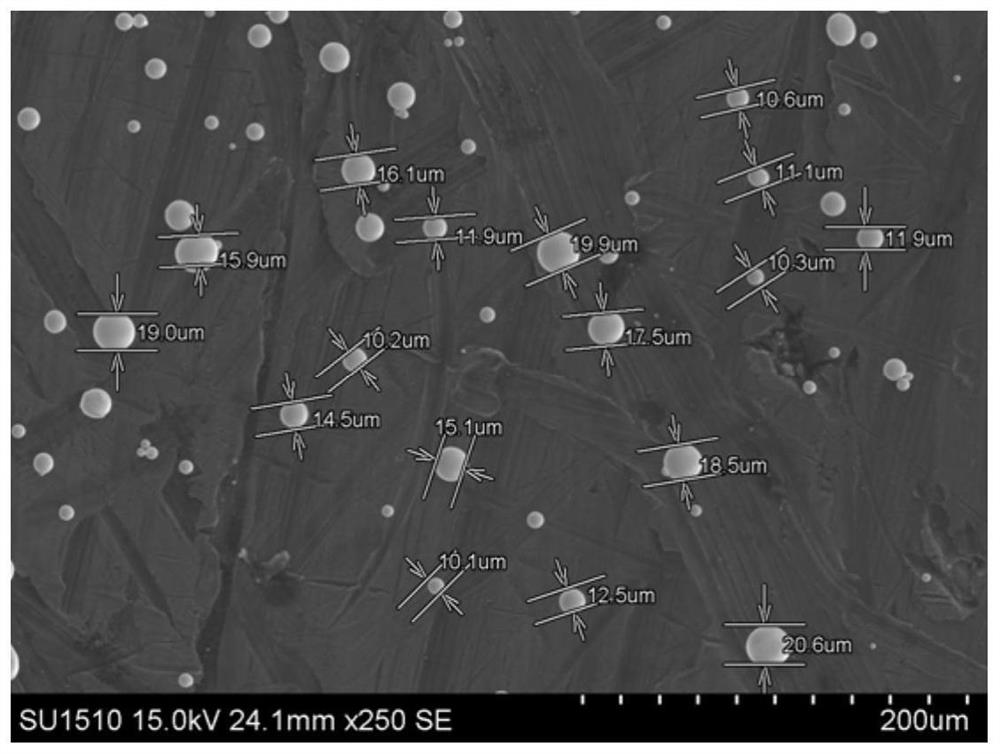

ActiveCN113523644AEasy to fillImprove liquidityWelding/cutting media/materialsSoldering mediaDuraluminSolder paste

The invention discloses aluminum-based alloy low-temperature washing soldering paste. The aluminum-based alloy low-temperature washing soldering paste is composed of 65wt%-80wt% of aluminum-based alloy powder, 12wt%-20wt% of low-temperature non-corrosive aluminum soldering flux, 0-5wt% of a dispersing agent and 5%-20% of a carrier. The aluminum-based alloy powder is composed of 15wt%-19wt% of Ag, 6wt%-10wt% of Cu, 4wt%-10wt% of Si, 0.1wt%-1wt% of Ni, 0.01wt%-0.1wt%of Ce and the balance Al. The low-temperature non-corrosive aluminum soldering flux is composed of AlF3, KF, LiF, K3AlF6, CsF and RbF. The melting temperature of the soldering paste is low, the soldering paste is suitable for flame brazing, non-vacuum furnace welding and high-frequency heating brazing, the brazing temperature range is 515-520 DEG C, the welded seam interface is compact after welding, the air tightness is good, the tensile strength is good, and residues after welding can be removed through deionized water cleaning. The requirements of duralumin non-vacuum low-temperature brazing, aluminum-copper dissimilar metal pipeline connection, liquid cooling device packaging brazing and the like can be met.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com