Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

504 results about "Electromagnetic emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

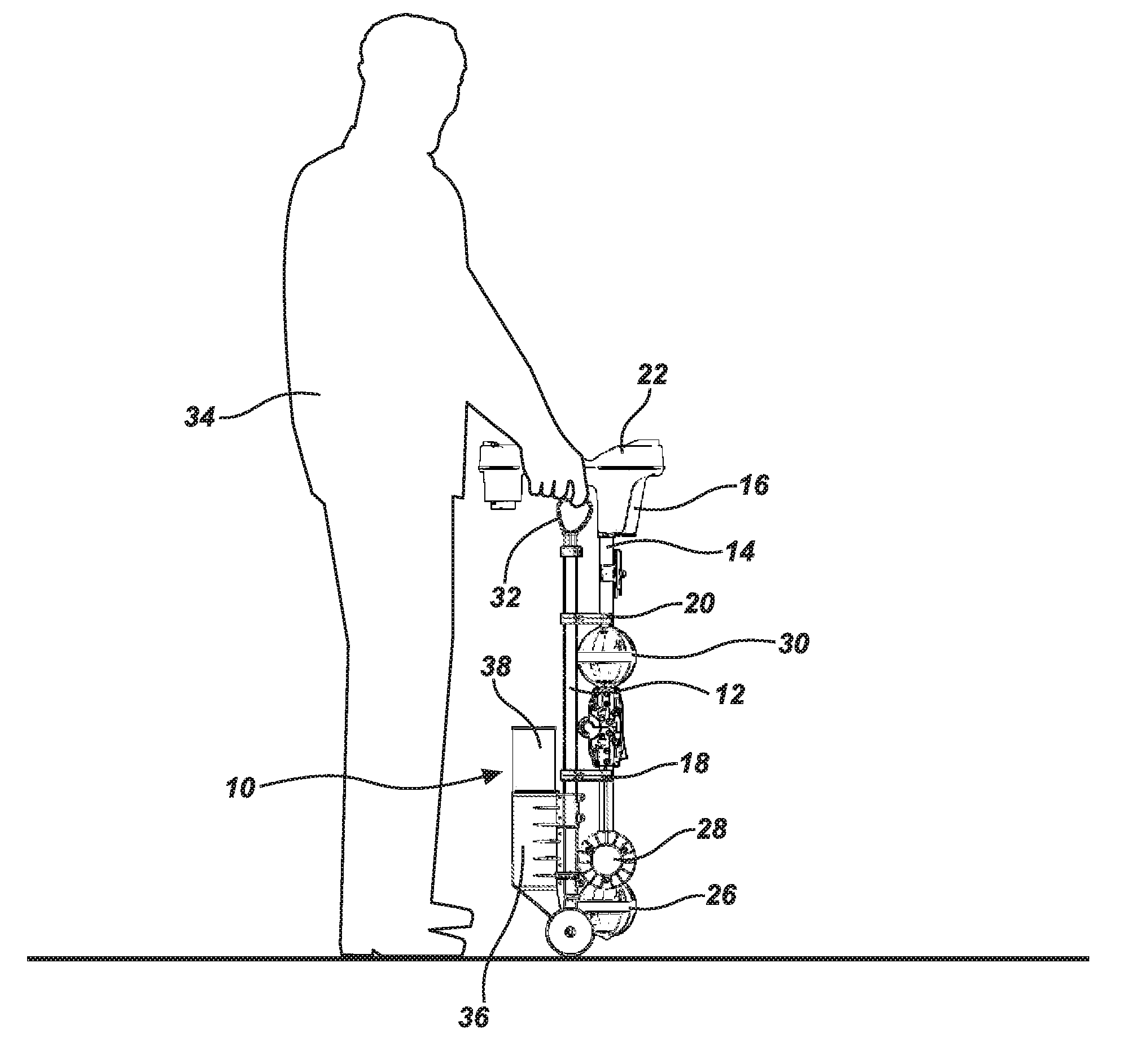

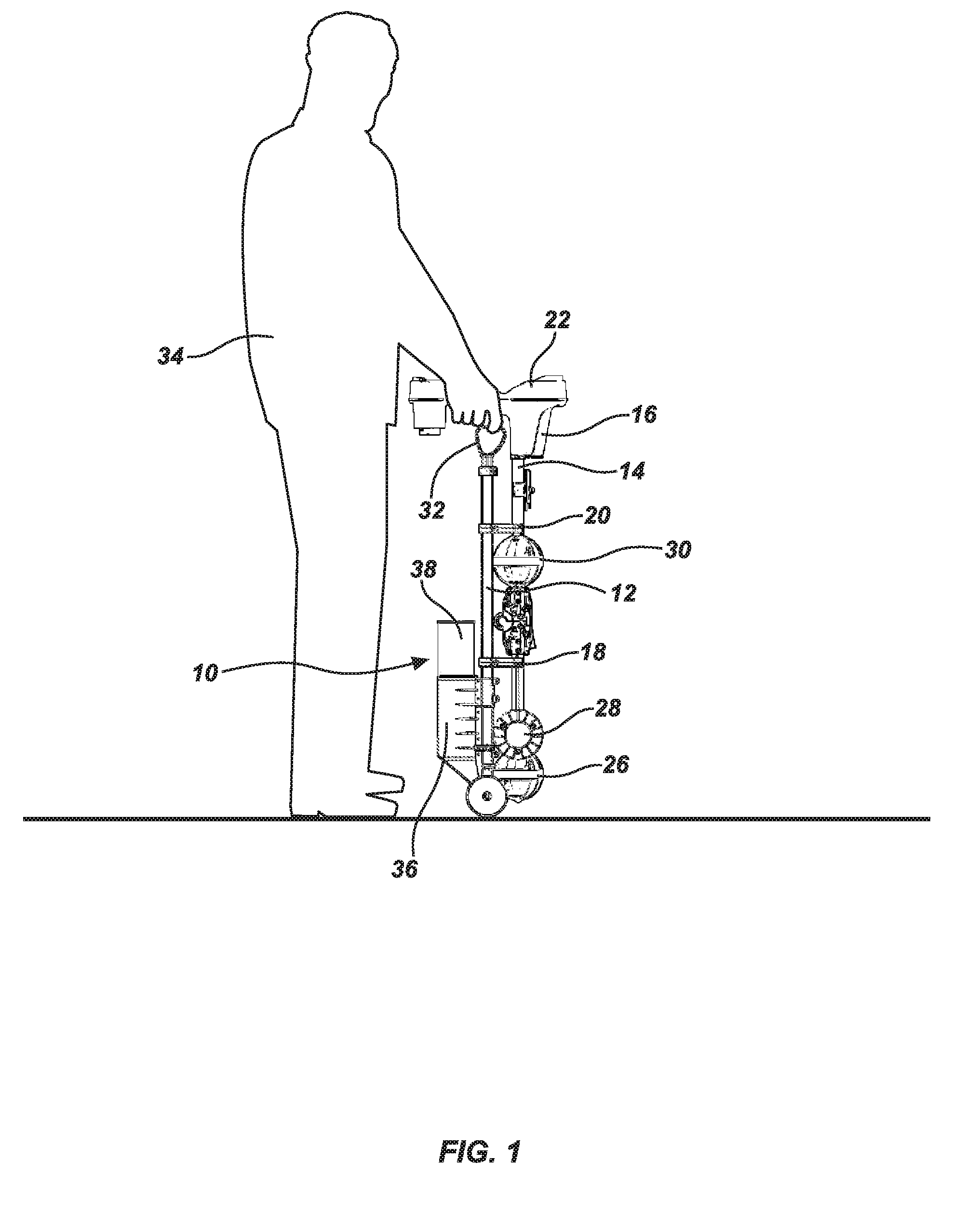

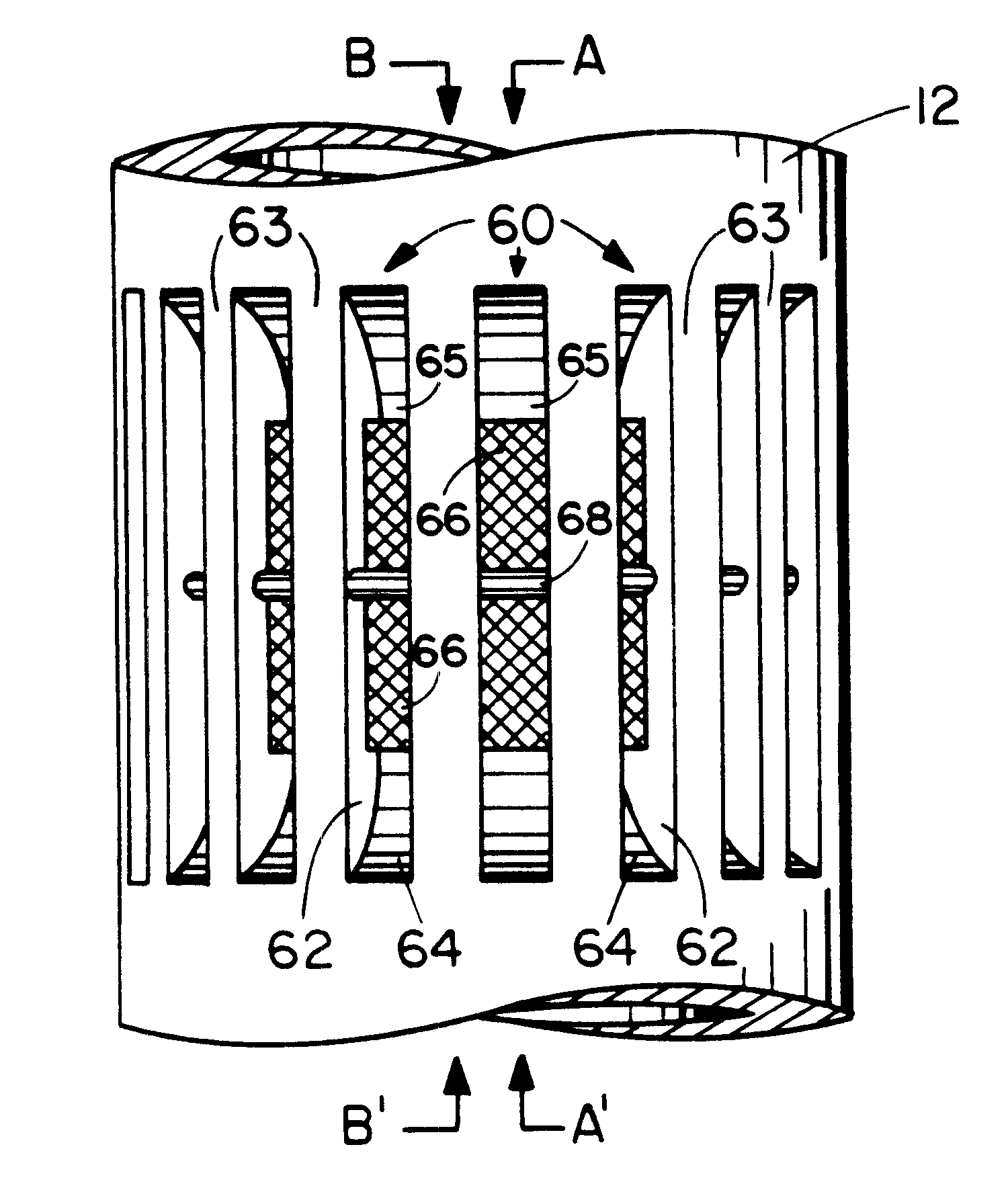

Marking Paint Applicator for Portable Locator

A marking paint applicator for a portable electronic locator that locates buried cables and pipes via electromagnetic emissions includes an elongated support structure and a manually moveable trigger mechanism mounted adjacent an upper end of the support structure. At least one bracket assembly is provided for removably connecting the support structure to an antenna mast of the portable locator so that the trigger mechanism will be adjacent a handle of the locator and the trigger mechanism can be squeezed by a finger of an operator's hand while grasping the handle. A receptacle is mounted to the support structure for carrying an inverted aerosol paint can and positioning a valve stem of the aerosol paint can for spraying paint onto the ground to mark the location of a buried cable or pipe. An actuating mechanism is capable of selectively deflecting the valve stem to cause the aerosol paint can to spray paint onto the ground to mark the location of a buried cable or pipe. A linkage connects the trigger mechanism to the actuating mechanism for deflecting the valve stem when the trigger mechanism is squeezed.

Owner:SEEKTECH A CALIFORNIA CORP

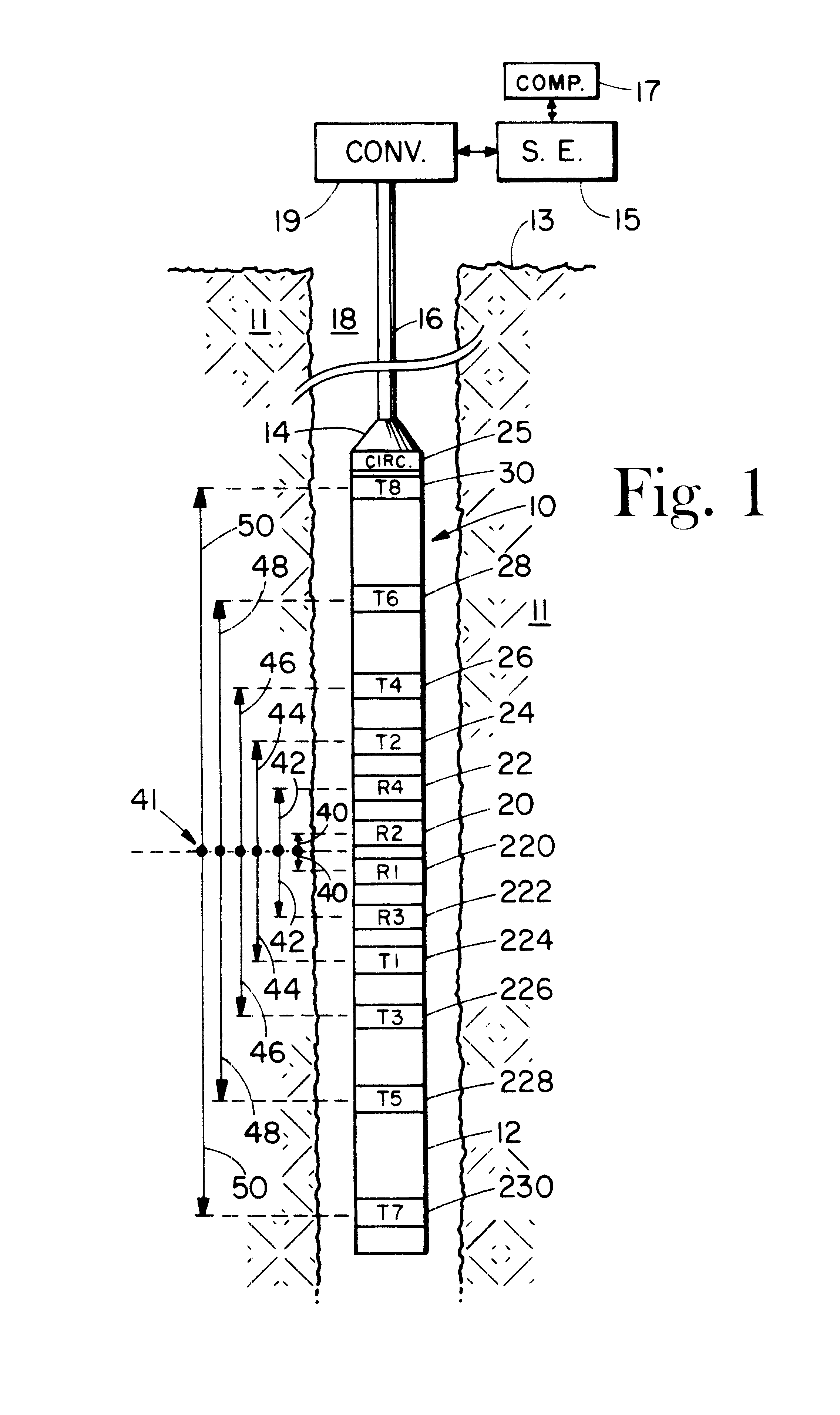

Well logging system for determining directional resistivity using multiple transmitter-receiver groups focused with magnetic reluctance material

InactiveUS6577129B1Improve antenna efficiencyHigh gainElectric/magnetic detection for well-loggingSubaqueous/subterranean adaptionWell loggingMagnetic reluctance

An electromagnetic wave propagation resistivity borehole logging system comprising multiple groups of electromagnetic transmitter-receiver arrays operating at three frequencies. The borehole logging tool component of the system employs eight transmitters and four receivers. The transmitters and receivers are disposed axially and symmetrically along the major axis of the tool to form four group pairs. Each group pair consists of a transmitter-receiver groups axially and symmetrically on opposing sides of a reference point on the tool. Each, transmitter-receiver group consists of one transmitter assembly and two receiver assemblies. Each transmitter-receiver group is operated at two of three operating frequencies which are 100 kHz, 400 kHz and 2 MHz. Some of the transmitter and receiver assemblies are fabricated to yield azimuthally focused resistivity measurements, and to yield vertical and horizontal resistivity in anisotropic dipping beds. The system can be embodied as a logging-while-drilling system or as a wireline logging system.

Owner:WEATHERFORD TECH HLDG LLC

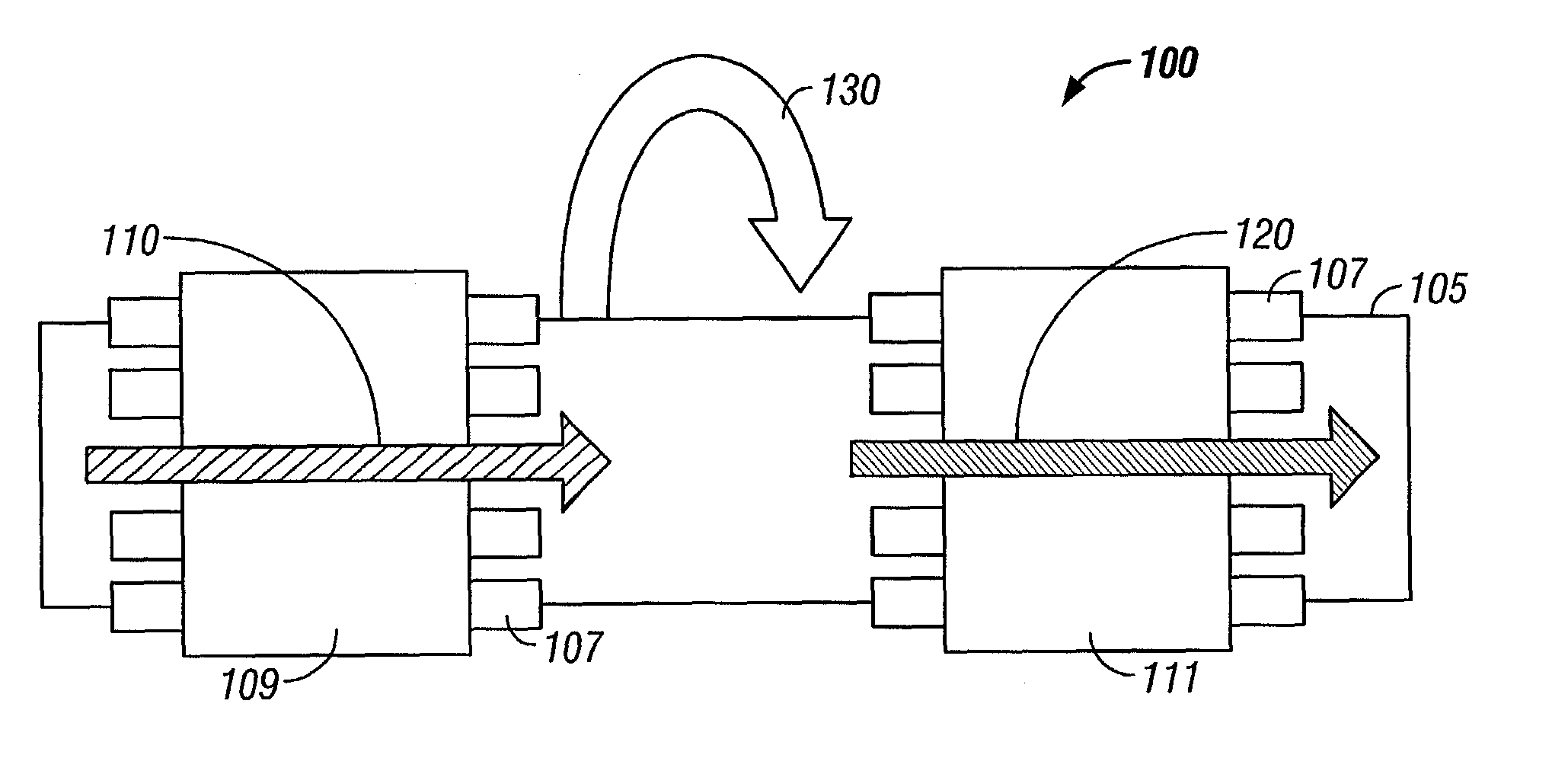

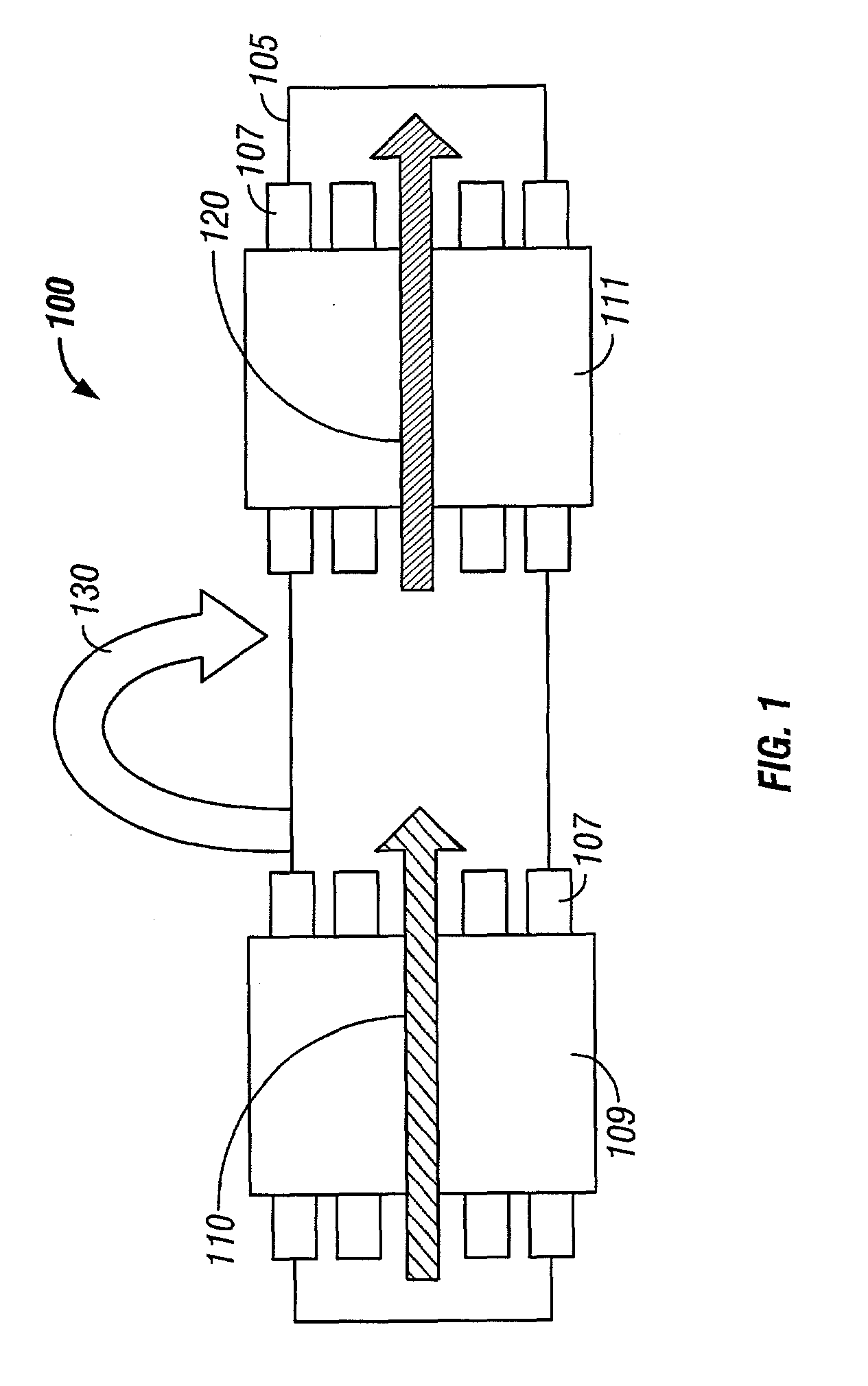

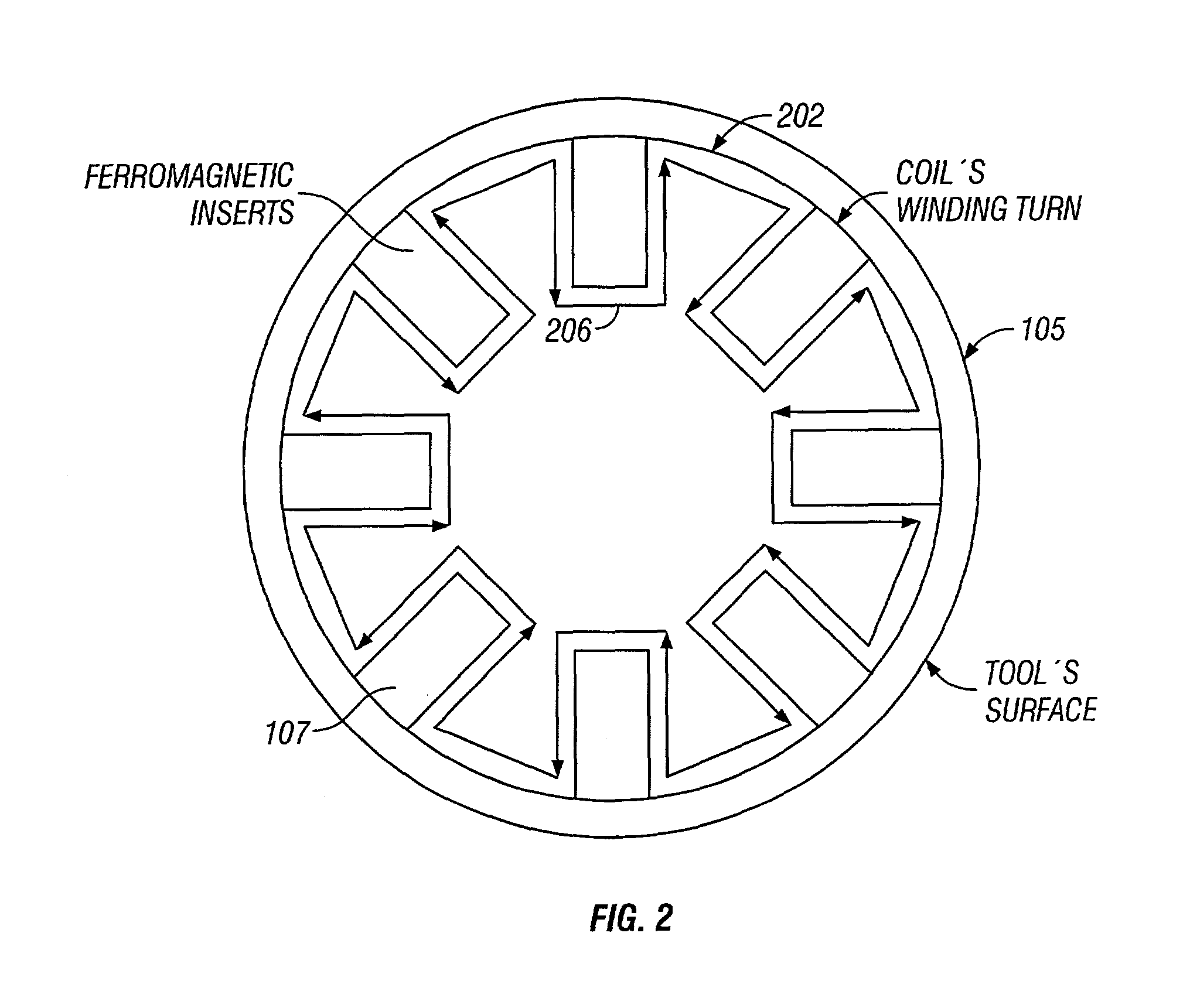

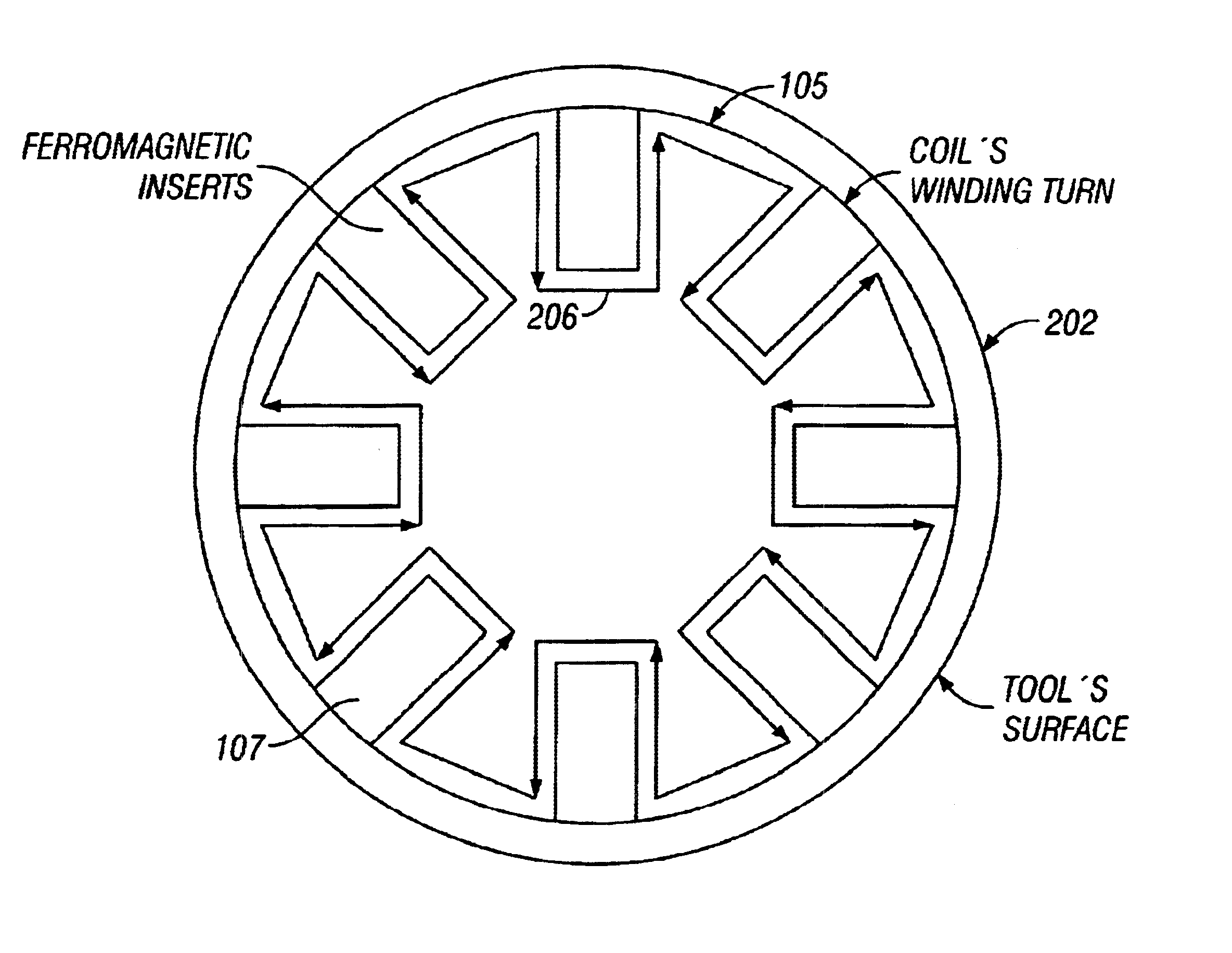

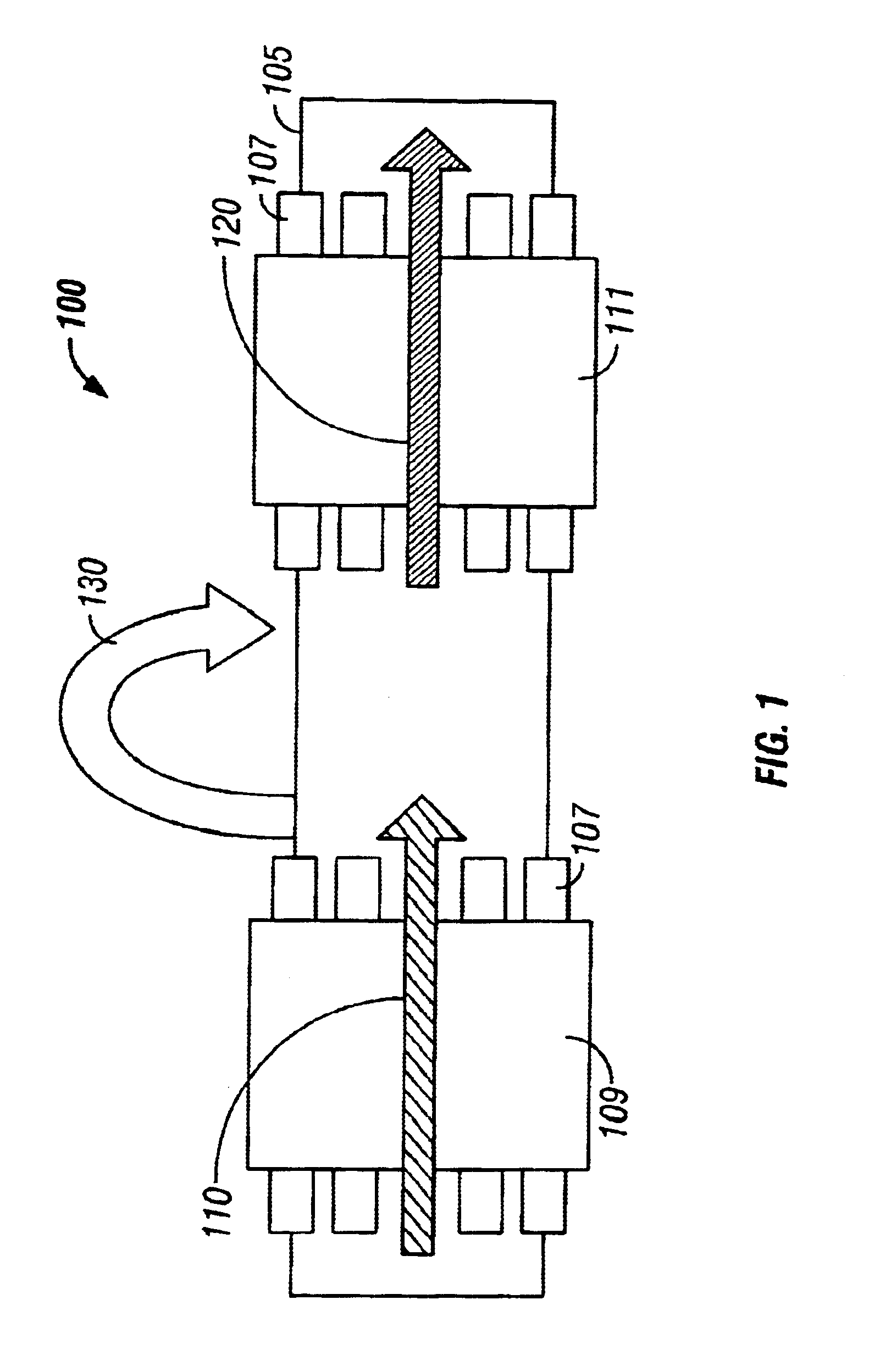

Method and apparatus for a multi-component induction instrument measuring system for geosteering and formation resistivity data interpretation in horizontal, vertical and deviated wells

InactiveUS20030076107A1Reduce the overall transmitter momentMinimize eddy currentElectric/magnetic detection for well-loggingSurveyGeosteeringWell logging

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. Various transmitter receiver combinations are provided to select sensitivity to a desired reservoir formation properties, for example, different orientations xy, xz, yz, 20-40, 20-90, and combinations, such as, Symmetric-symmetric; Asymmetric-symmetric; and Asymmetric-asymmetric. Measurements made with a multi-component logging instrument when used in a substantially horizontal, vertical or deviated borehole in earth formations are diagnostic of the direction of resistive beds relative to the position of the borehole.

Owner:BAKER HUGHES INC

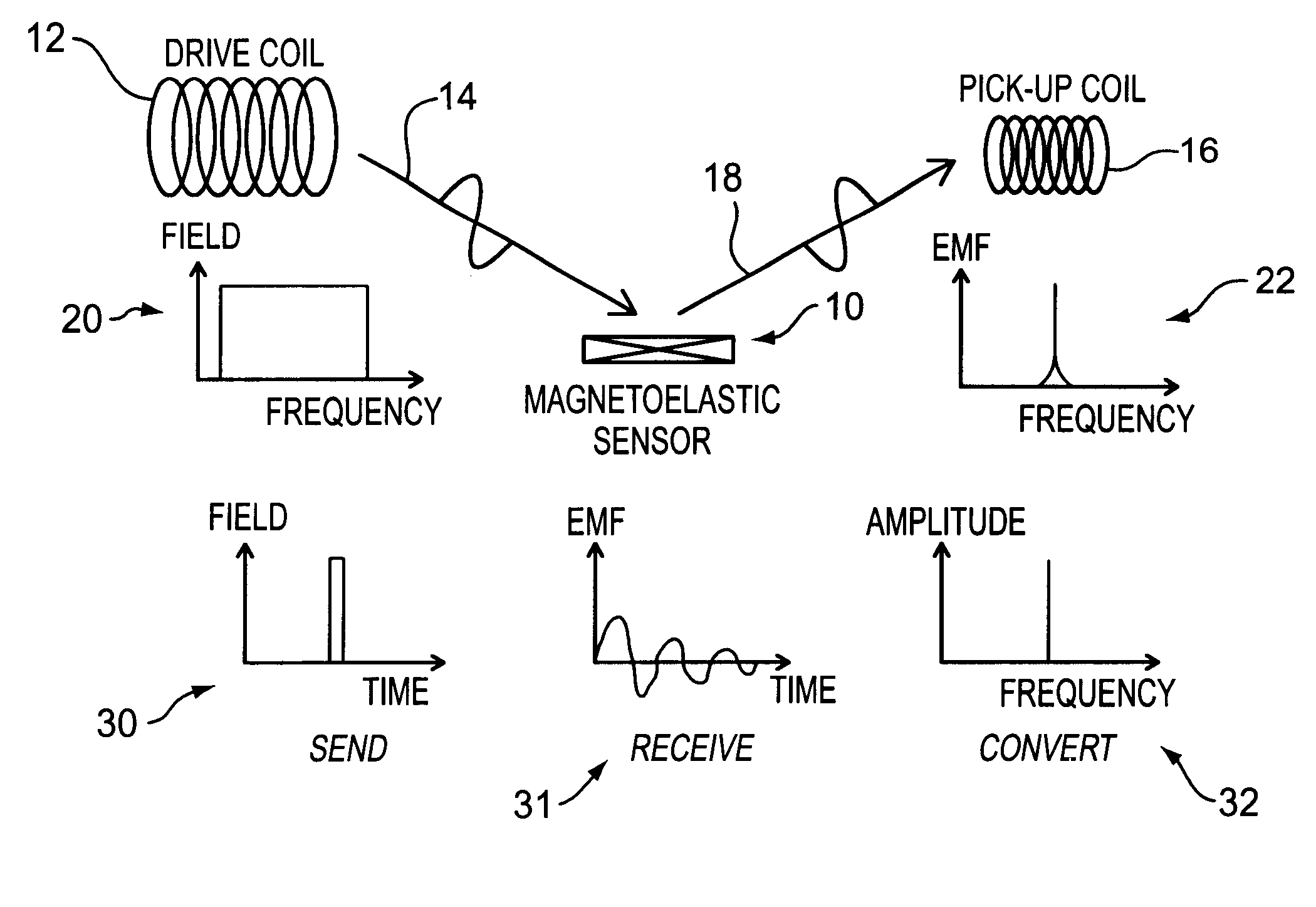

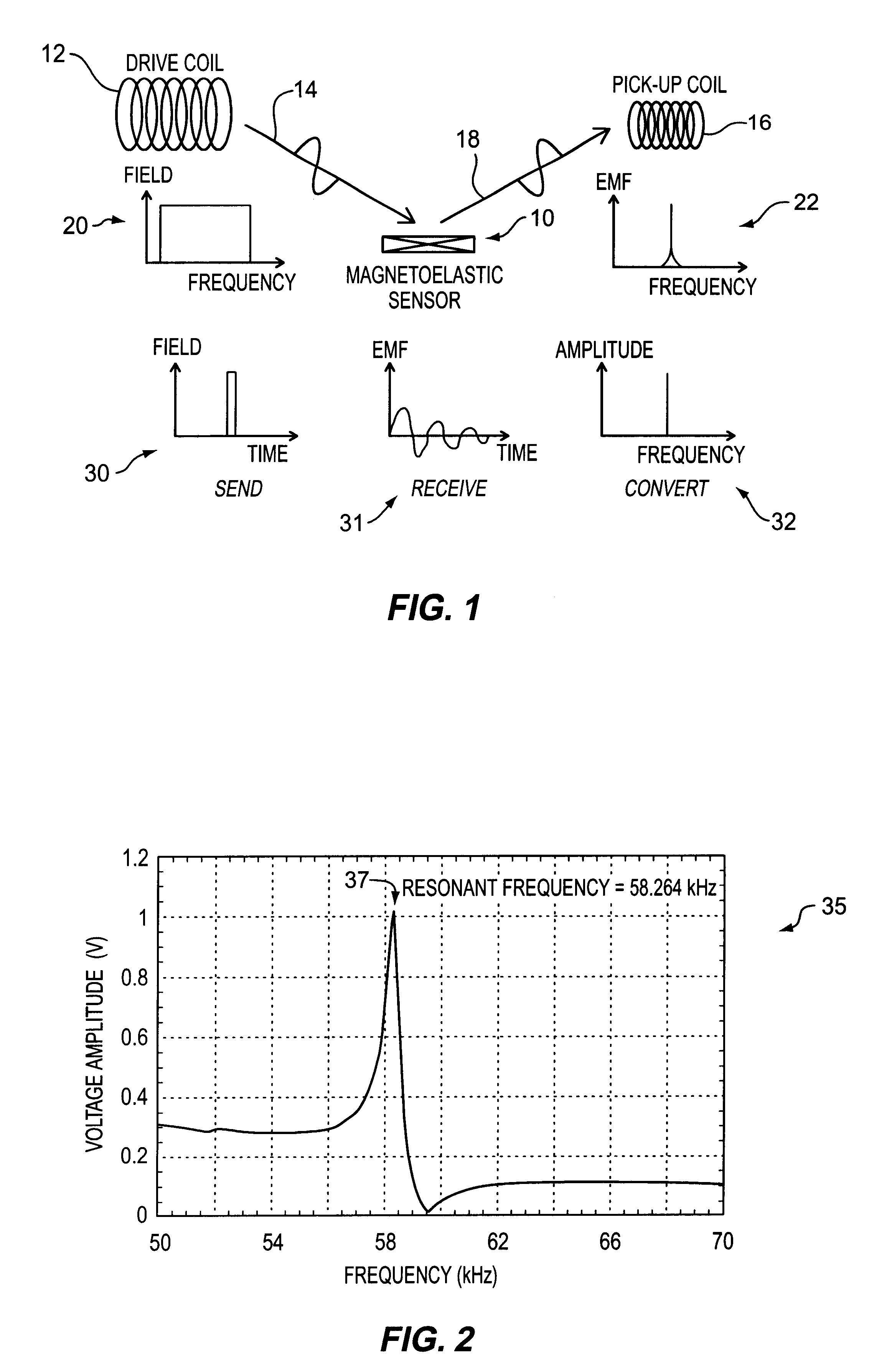

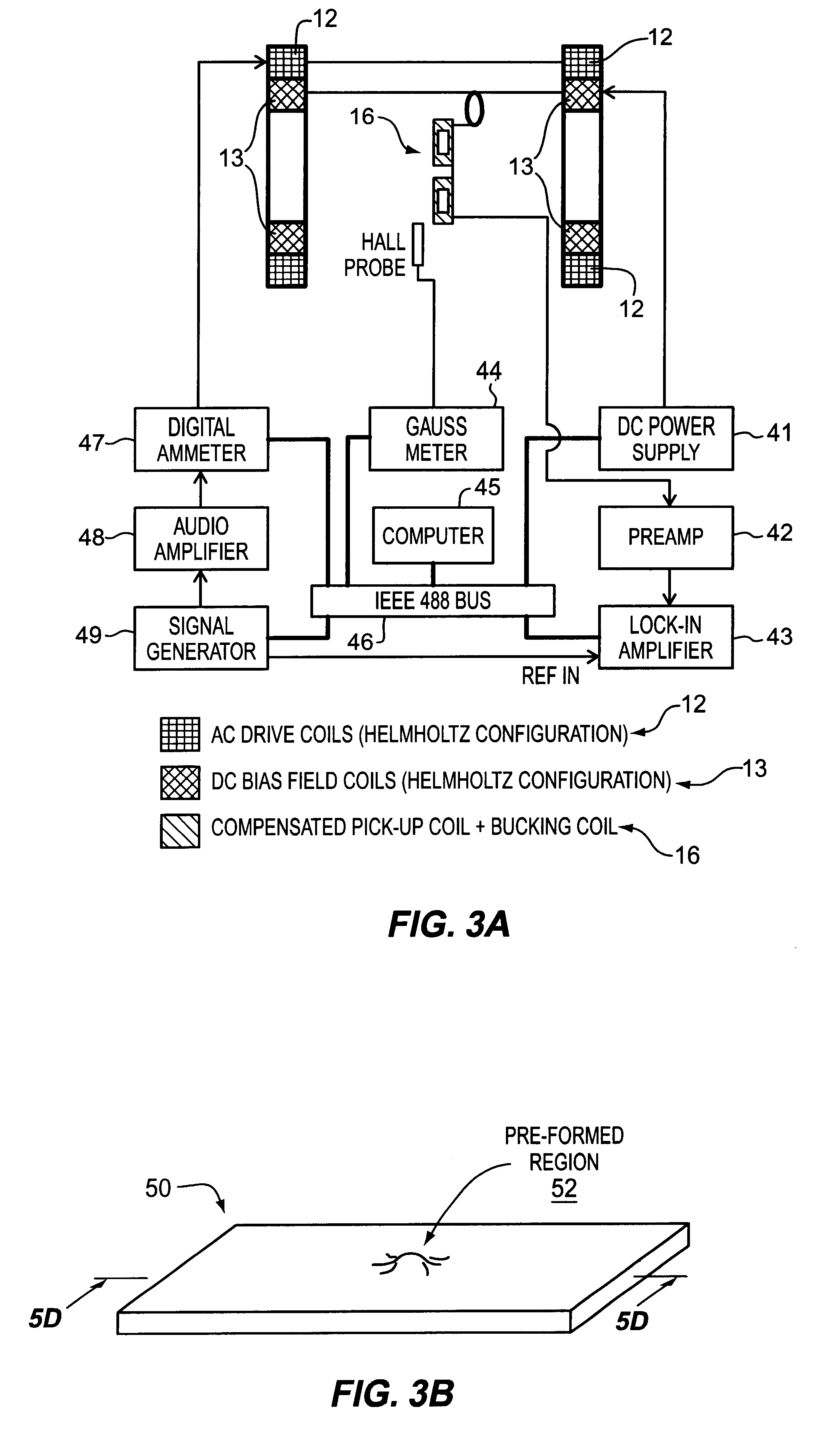

Magnetoelastic sensing apparatus and method for remote pressure query of an environment

InactiveUS6393921B1Fluid pressure measurement using inductance variationFluid pressure measurement using magnet displacementMagneto elasticPressure sense

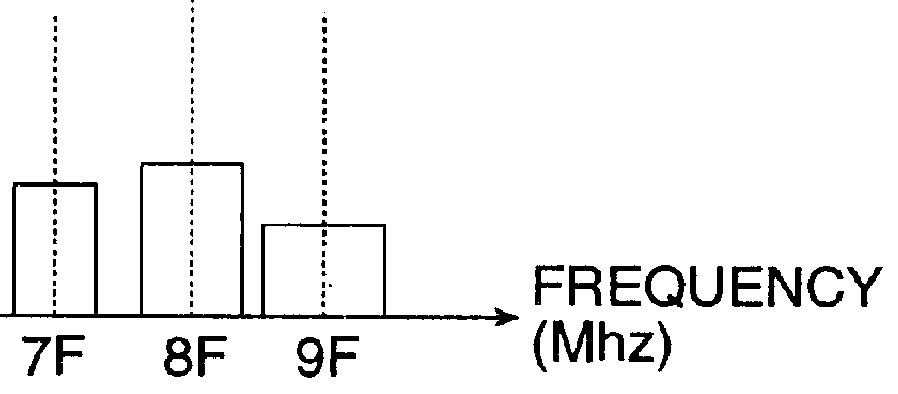

A pressure sensing apparatus for operative arrangement within an environment, having: a sensor comprising a hermetically-sealed receptacle, at least one side of which has an flexible membrane to which a magnetically hard element is attached. Enclosed within the receptacle is a magnetostrictive element that vibrates in response to a time-varying magnetic field. Also included is a receiver to measure a plurality of successive values for magneto-elastic emission intensity of the sensor taken over an operating range of successive interrogation frequencies to identify a resonant frequency value for the sensor. Additional features include: (a) the magnetically hard element may be adhered to an inner or outer side of, or embedded within, the membrane; (b) the magnetostrictive element can include one or more of a variety of different pre-formed, hardened regions; (c) the magneto-elastic emission may be a primarily acoustic or electromagnetic emission; and (d) in the event the time-varying magnetic field is emitted as a single pulse or series of pulses, the receiver unit can detect a transitory time-response of the emission intensity of each pulse (detected after a threshold amplitude value for the transitory time-response is observed). A Fourier transform of the time-response can yield results in the frequency domain. Also, an associated method of sensing pressure of an environment is included that uses a sensor having a magnetostrictive element to identify a magneto-elastic resonant frequency value therefore. Using the magneto-elastic resonant frequency value identified, a value for the pressure of the environment can be identified.

Owner:UNIV OF KENTUCKY RES FOUND

Substrate for reducing electromagnetic interference and enclosure

InactiveUS6191475B1Magnetic/electric field screeningSemiconductor/solid-state device detailsElectromagnetic interferenceEngineering

A substrate for reducing electromagnetic emissions is provided. The substrate may include a plurality of ground layers, signal layers and power layers. All of the layers other than the ground layer are provided with a ground ring that may extend around the perimeter of the layer. The ground rings are electrically coupled together by ground stitching or vias that are randomly spaced. The random spacing of the ground stitching is based on the operating frequencies of the integrated circuit devices mounted on the substrate. Additional shielding may be provided by providing a cover assembly made of any conductive material that is coupled to the exposed ground rings on the uppermost and lowermost surfaces of the substrate. The cover assembly is coupled to the exposed ground rings in a randomized pattern. The device provides a virtual electrical ground cage in which the internal signal layers are totally enclosed, thereby reducing electromagnetic emissions.

Owner:INTEL CORP

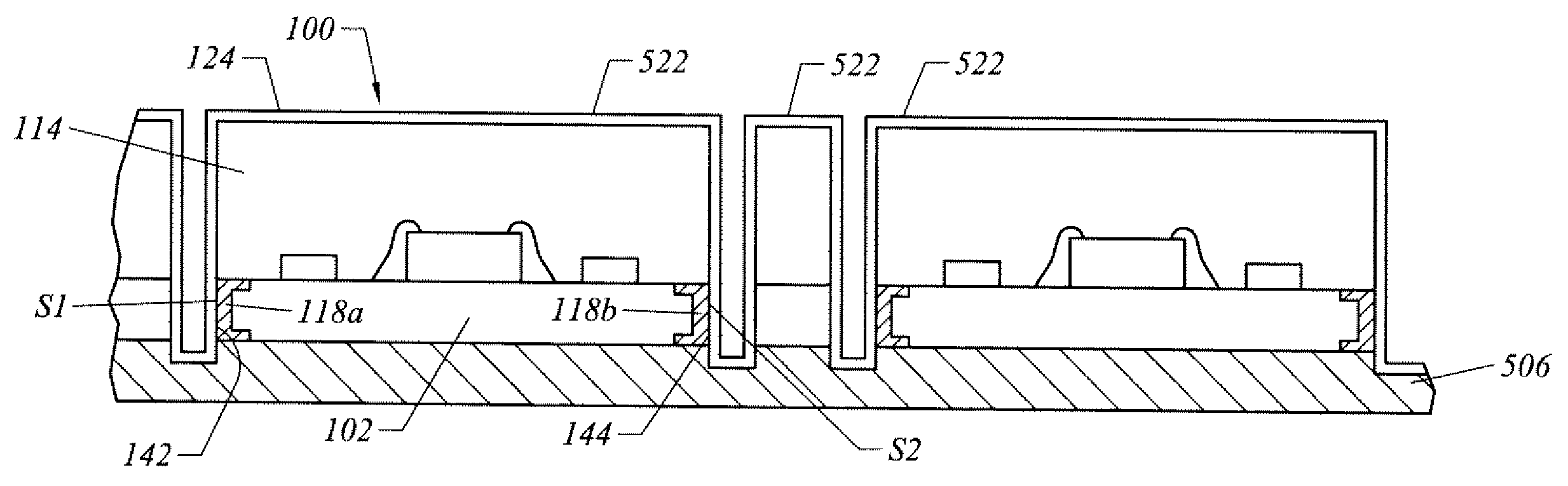

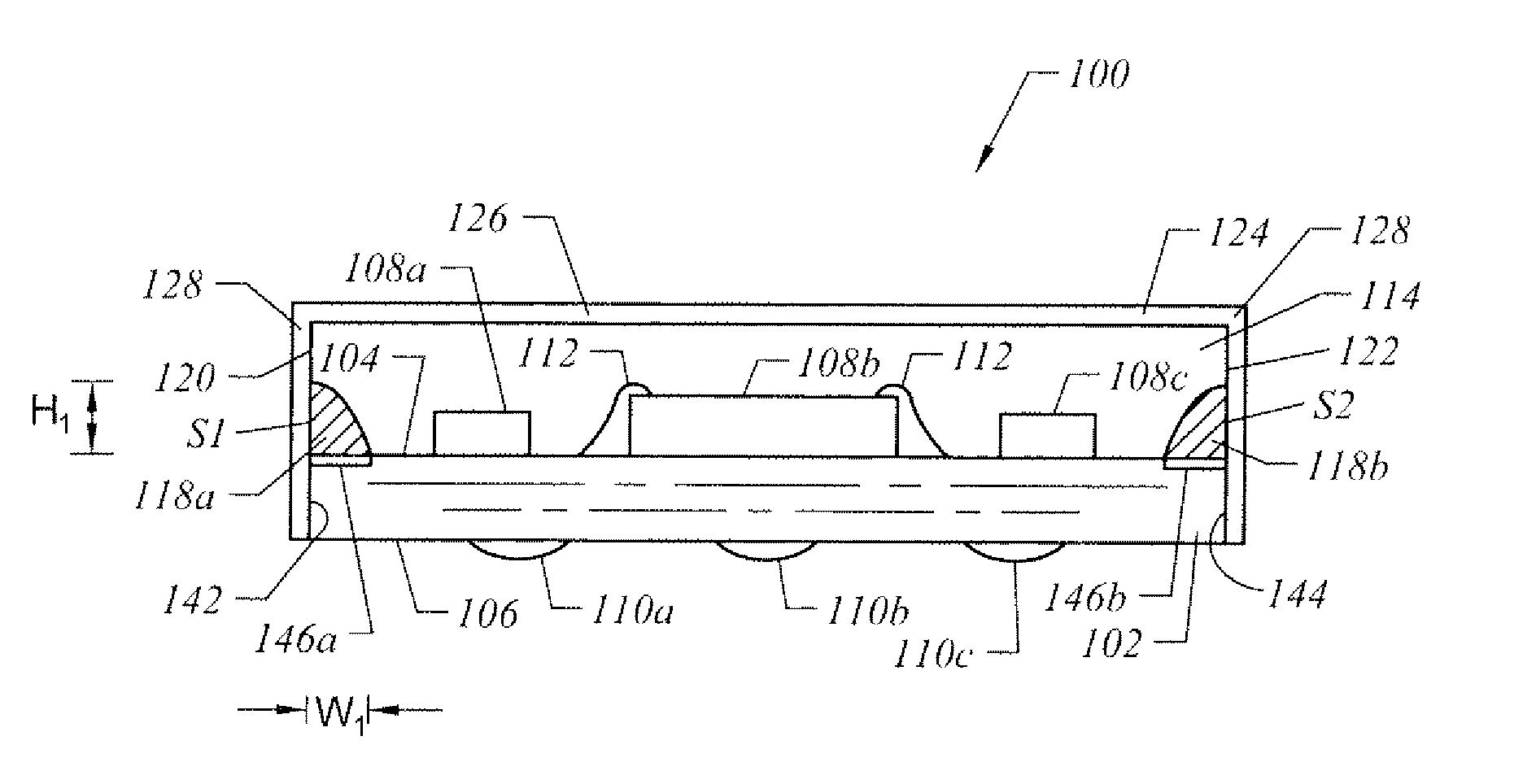

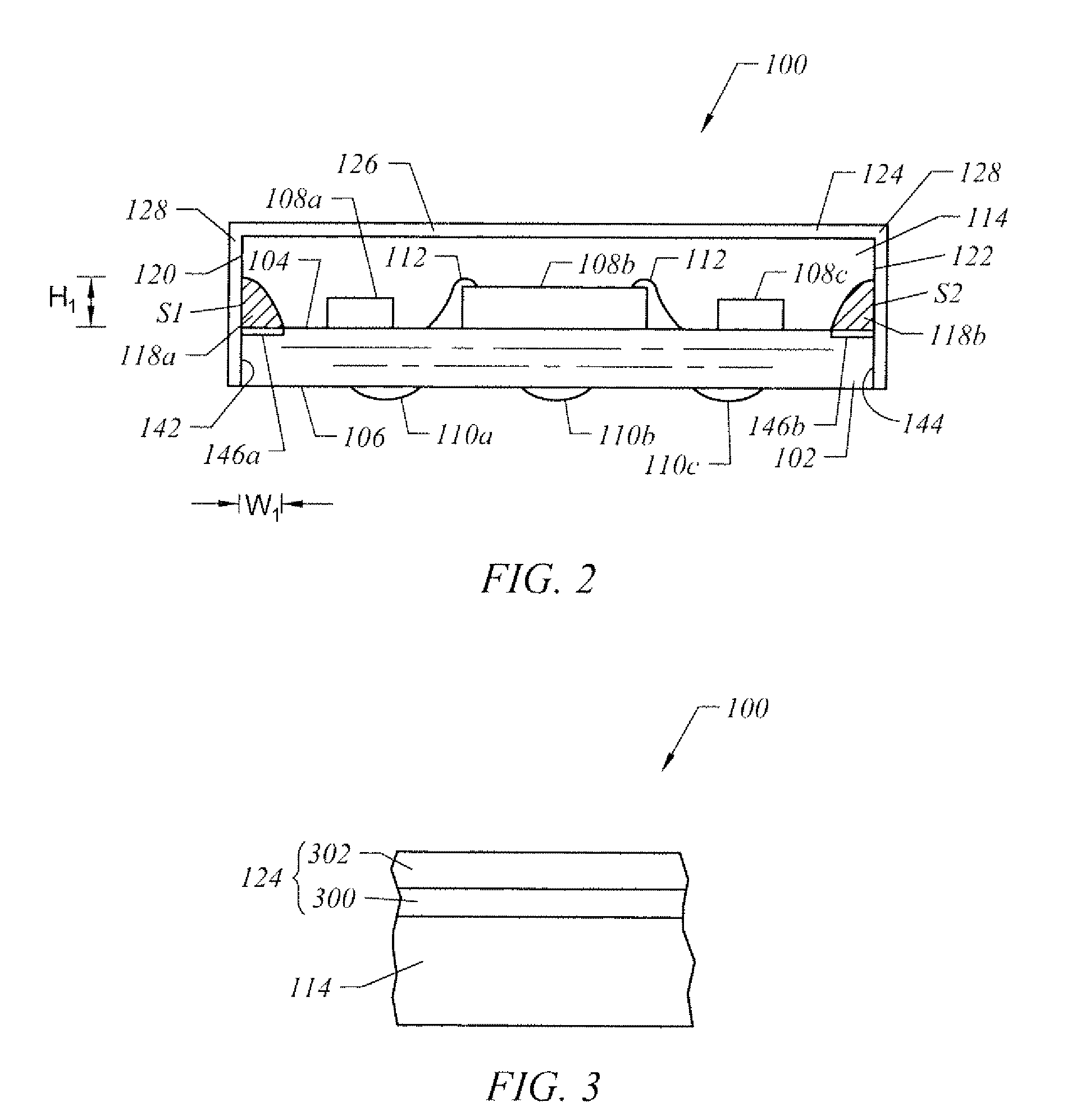

Semiconductor device packages with electromagnetic interference shielding

ActiveUS7989928B2Printed circuit assemblingElectrically conductive connectionsElectricityPower semiconductor device

Described herein are semiconductor device packages with EMI shielding and related methods. In one embodiment, a semiconductor device package includes: (1) a substrate unit including a grounding element; (2) a semiconductor device disposed adjacent to an upper surface of the substrate unit; (3) a package body disposed adjacent to the upper surface of the substrate unit and covering the semiconductor device; and (4) an EMI shield disposed adjacent to exterior surfaces of the package body and electrically connected to a connection surface of the grounding element. A lateral surface of the package body is substantially aligned with a lateral surface of the substrate unit, and the connection surface of the grounding element is electrically exposed adjacent to the lateral surface of the substrate unit. The grounding element corresponds to a remnant of an internal grounding via, and provides an electrical pathway to ground electromagnetic emissions incident upon the EMI shield.

Owner:ADVANCED SEMICON ENG INC

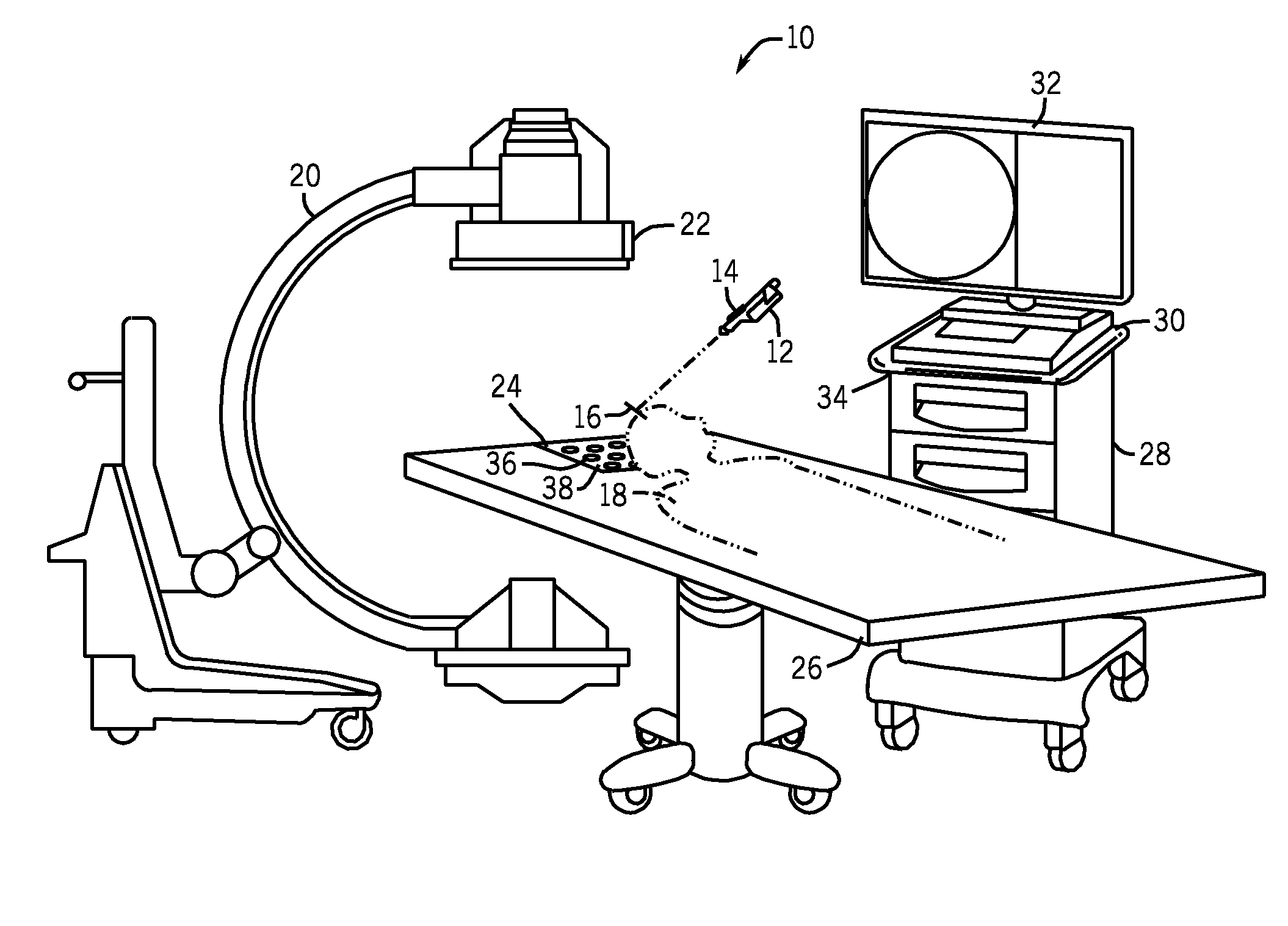

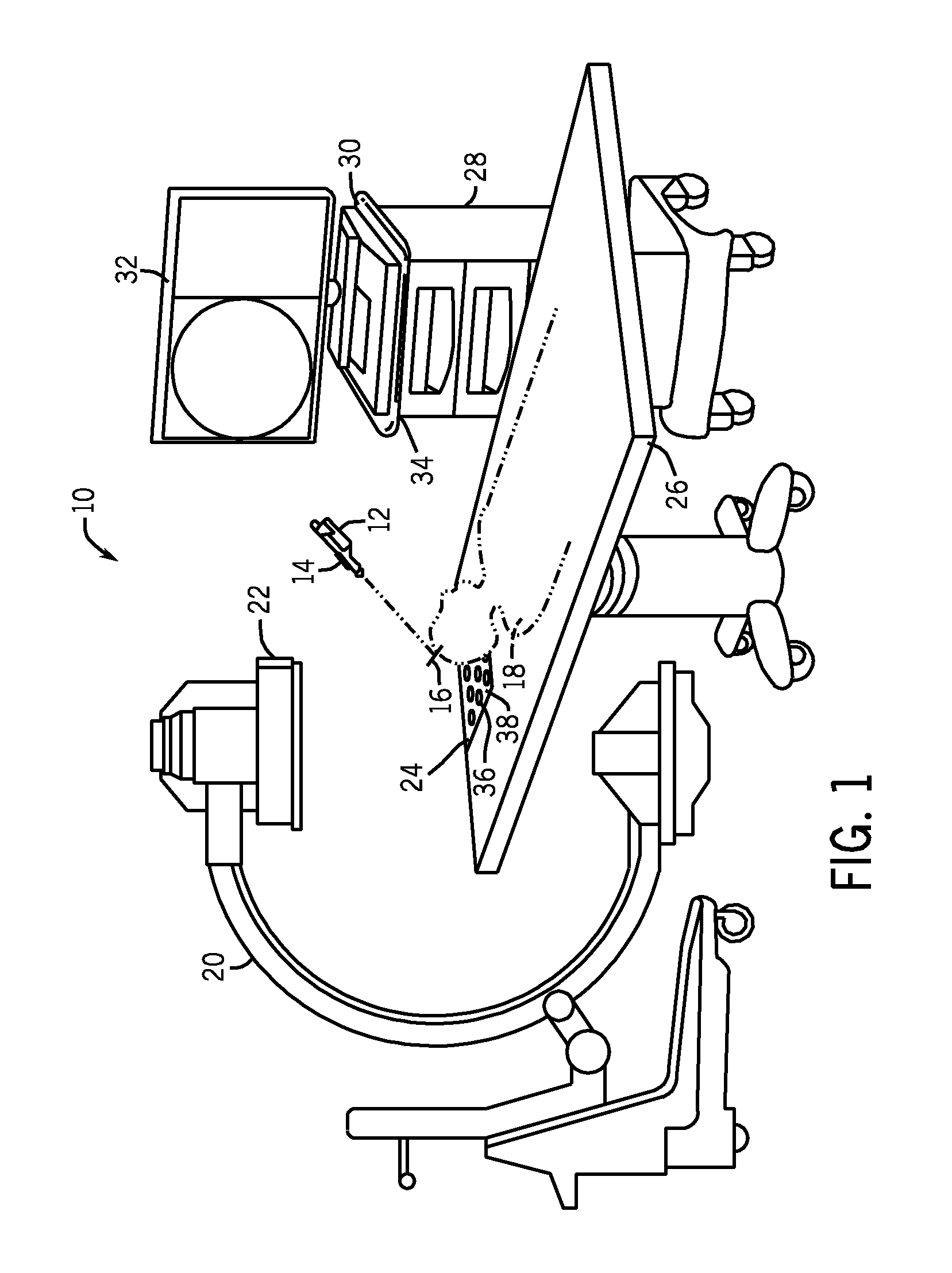

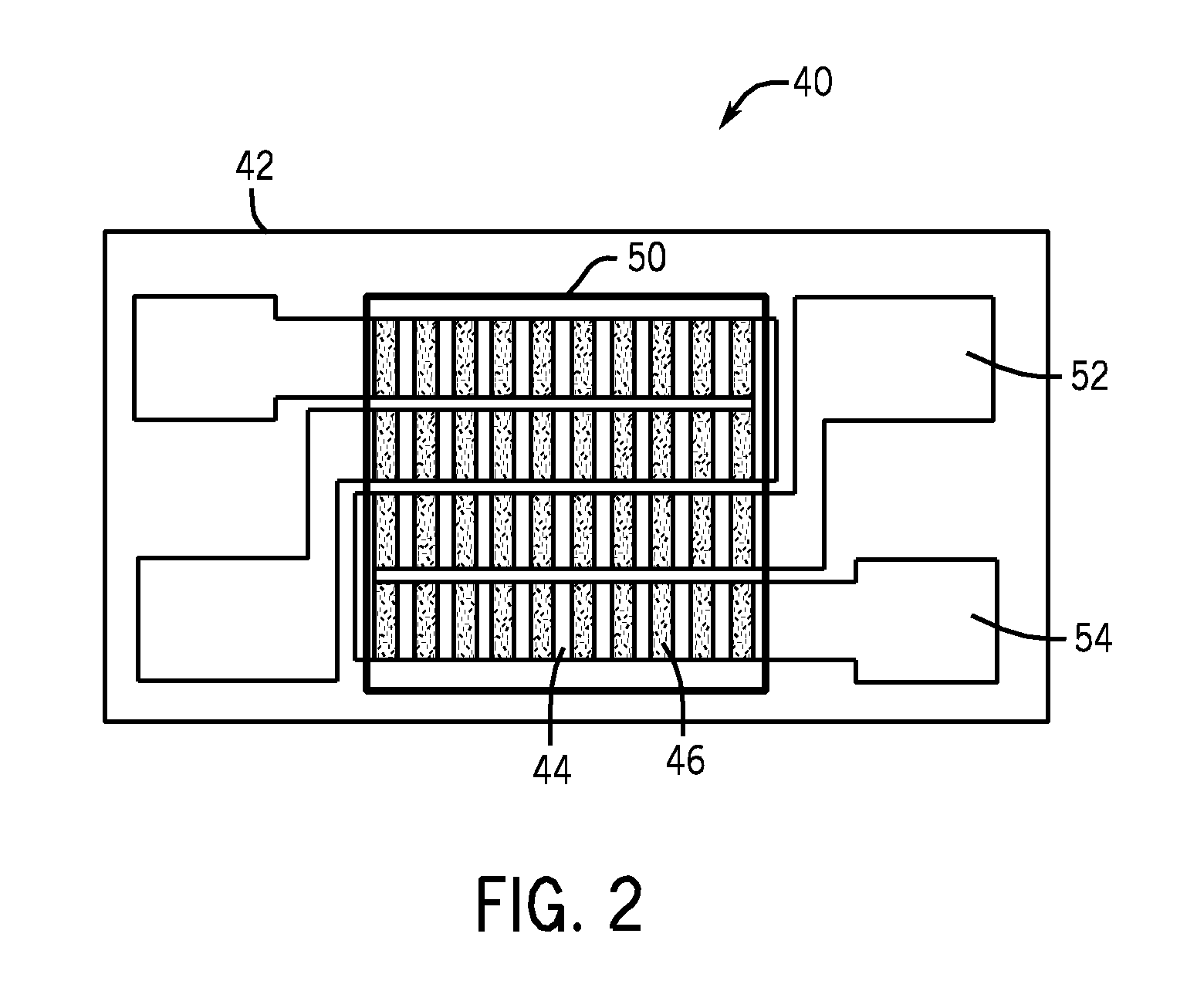

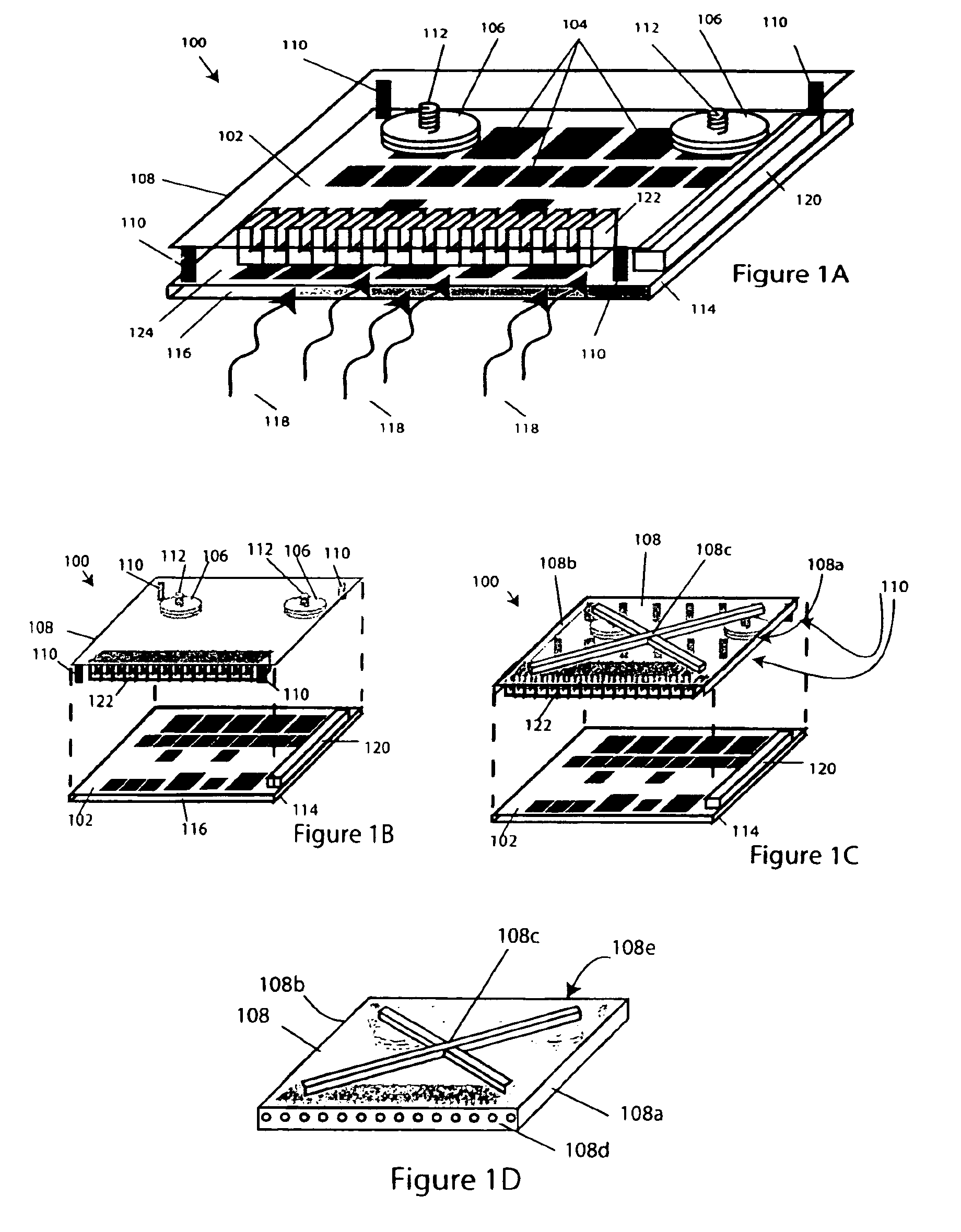

Long-range planar sensor array for use in a surgical navigation system

InactiveUS20100305427A1Surgical navigation systemsDiagnostic recording/measuringSensor arrayTransmitter coil

A planar sensor array for use in a surgical navigation system comprising at least one substrate and at two layers of a plurality of planar sensor coils formed on or within the at least one insulating substrate. The planar sensor array may be an electromagnetic planar transmitter coil array or an electromagnetic planar receiver coil array that includes at two layers of a plurality of planar electromagnetic transmitter or receiver spiral-shaped coils formed on or within the at least one substrate. The surgical navigation system includes the use of at least one magnetoresistance reference sensor attached to a fixed object; at least one magnetoresistance sensor attached to an object being tracked; and a planar sensor coil array communicating with the at least one magnetoresistance reference sensor and the at least one magnetoresistance sensor to determine the position and orientation of the object being tracked.

Owner:GENERAL ELECTRIC CO

Semiconductor device packages with electromagnetic interference shielding

ActiveUS8022511B2Semiconductor/solid-state device detailsSolid-state devicesElectricityPower semiconductor device

Described herein are semiconductor device packages with EMI shielding and related methods. In one embodiment, a semiconductor device package includes: (1) a substrate unit; (2) a grounding element disposed adjacent to a periphery of the substrate unit and extending upwardly from an upper surface of the substrate unit; (3) a semiconductor device disposed adjacent to the upper surface; (4) a package body disposed adjacent to the upper surface and covering the semiconductor device and the grounding element; and (5) an EMI shield disposed adjacent to exterior surfaces of the package body and electrically connected to a lateral surface of the grounding element. A lateral surface of the package body is substantially aligned with a lateral surface of the substrate unit. The grounding element corresponds to a remnant of a conductive bump, and provides an electrical pathway to ground electromagnetic emissions incident upon the EMI shield.

Owner:ADVANCED SEMICON ENG INC

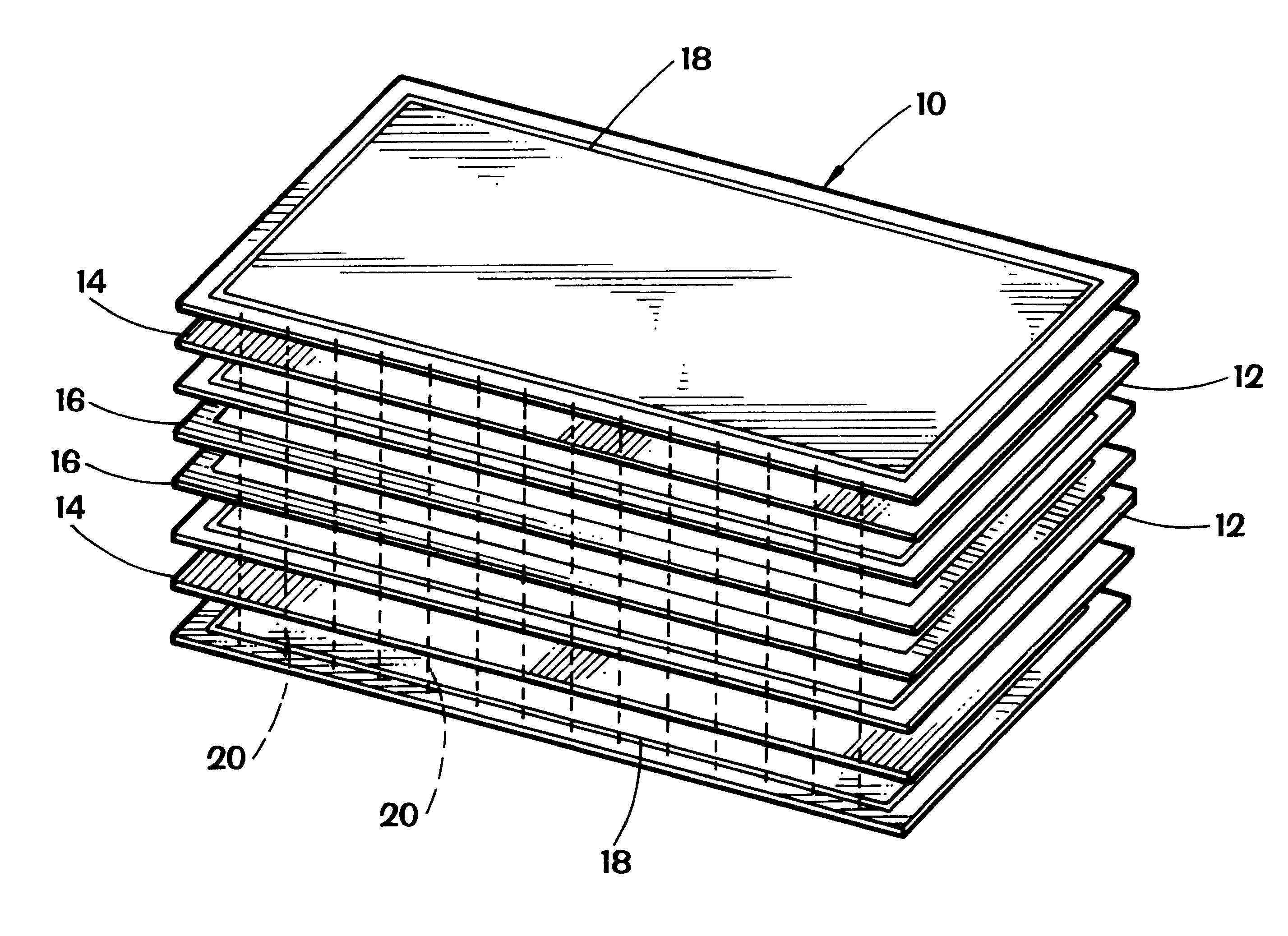

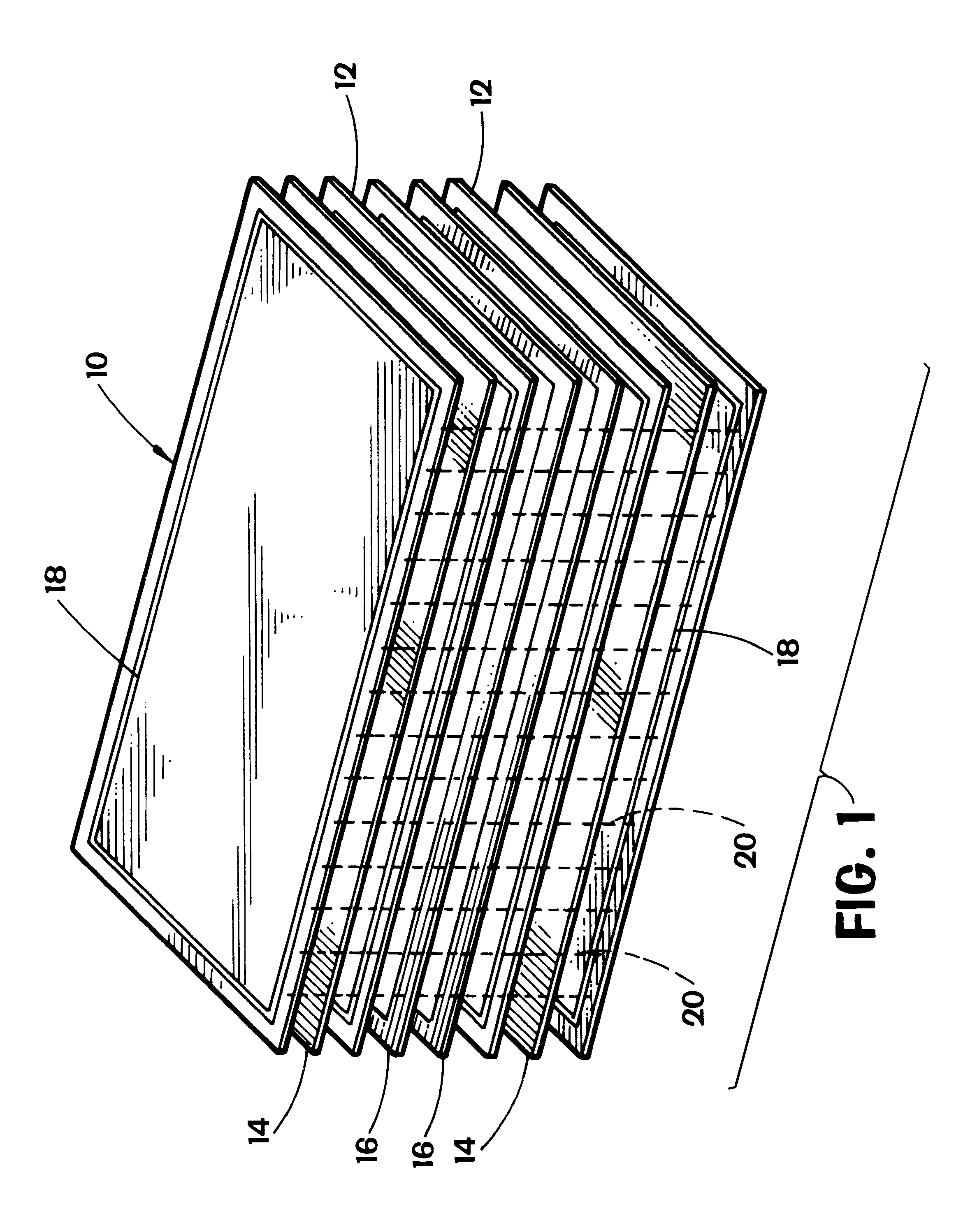

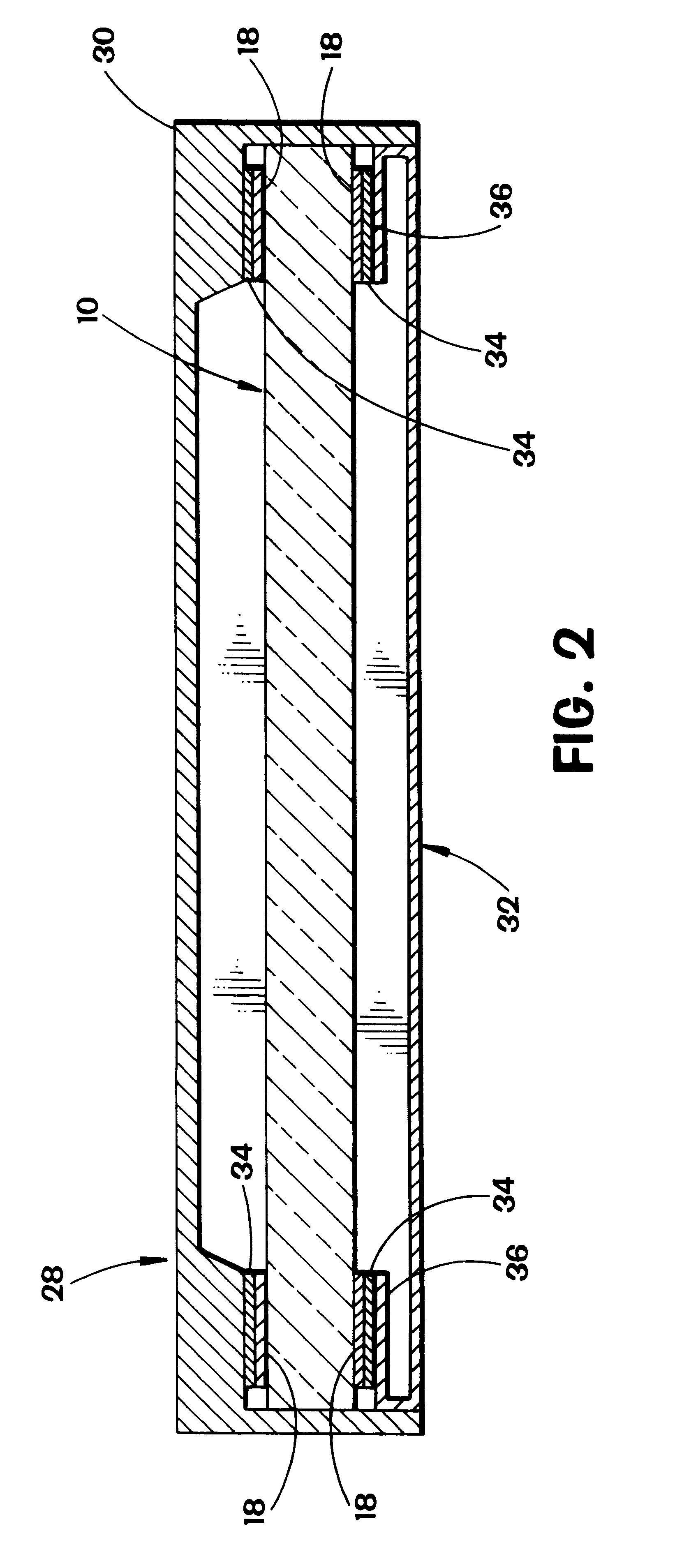

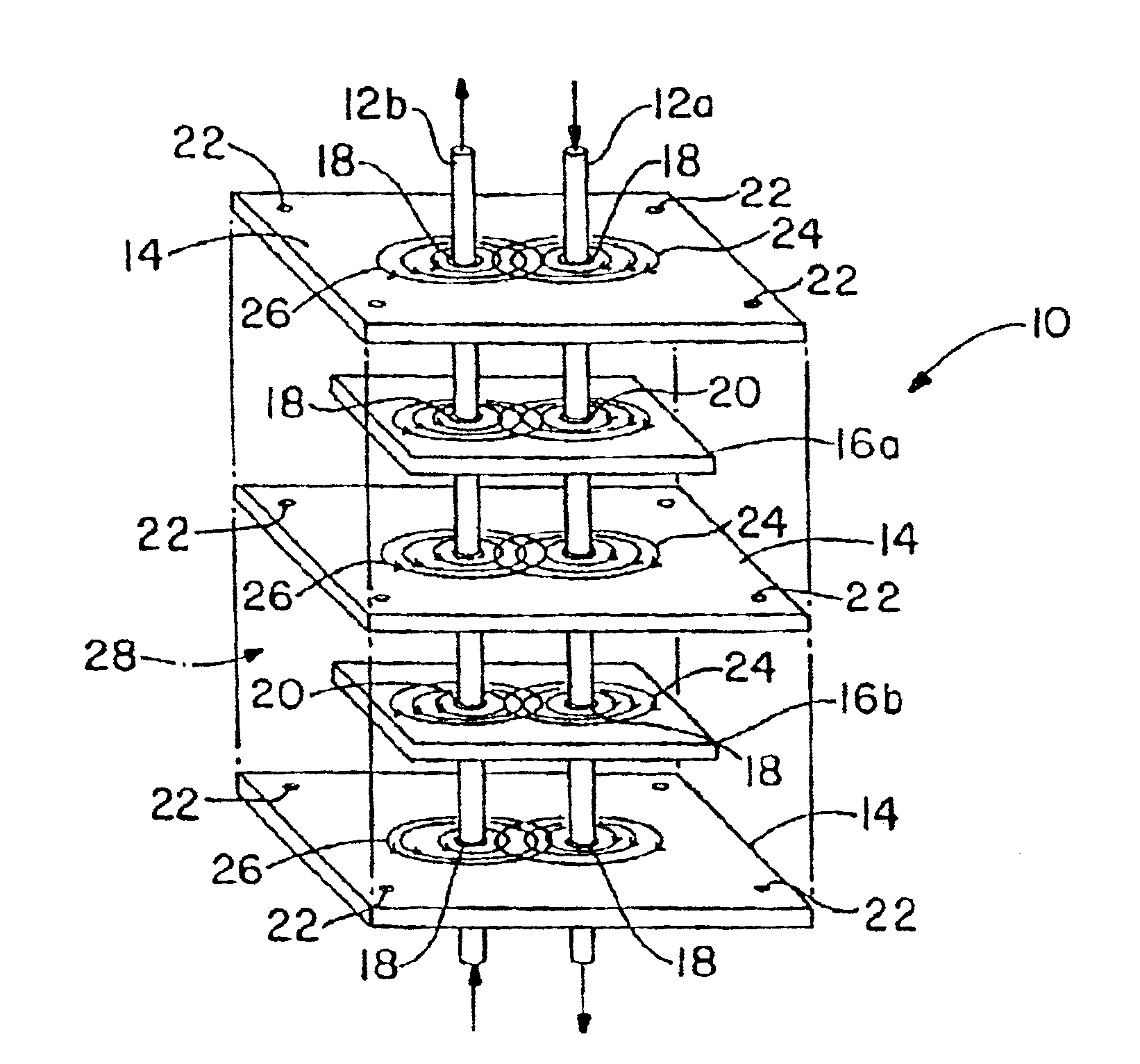

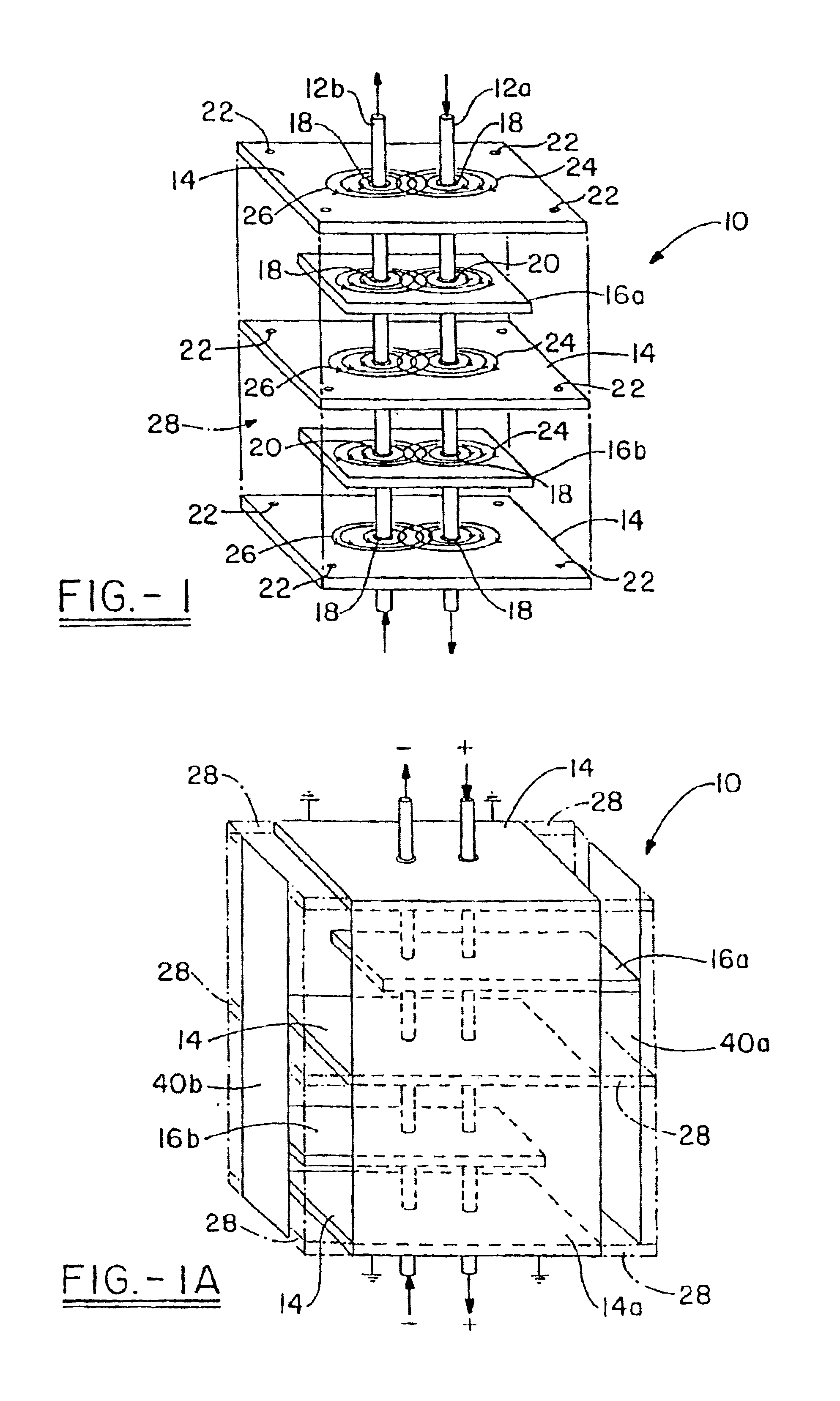

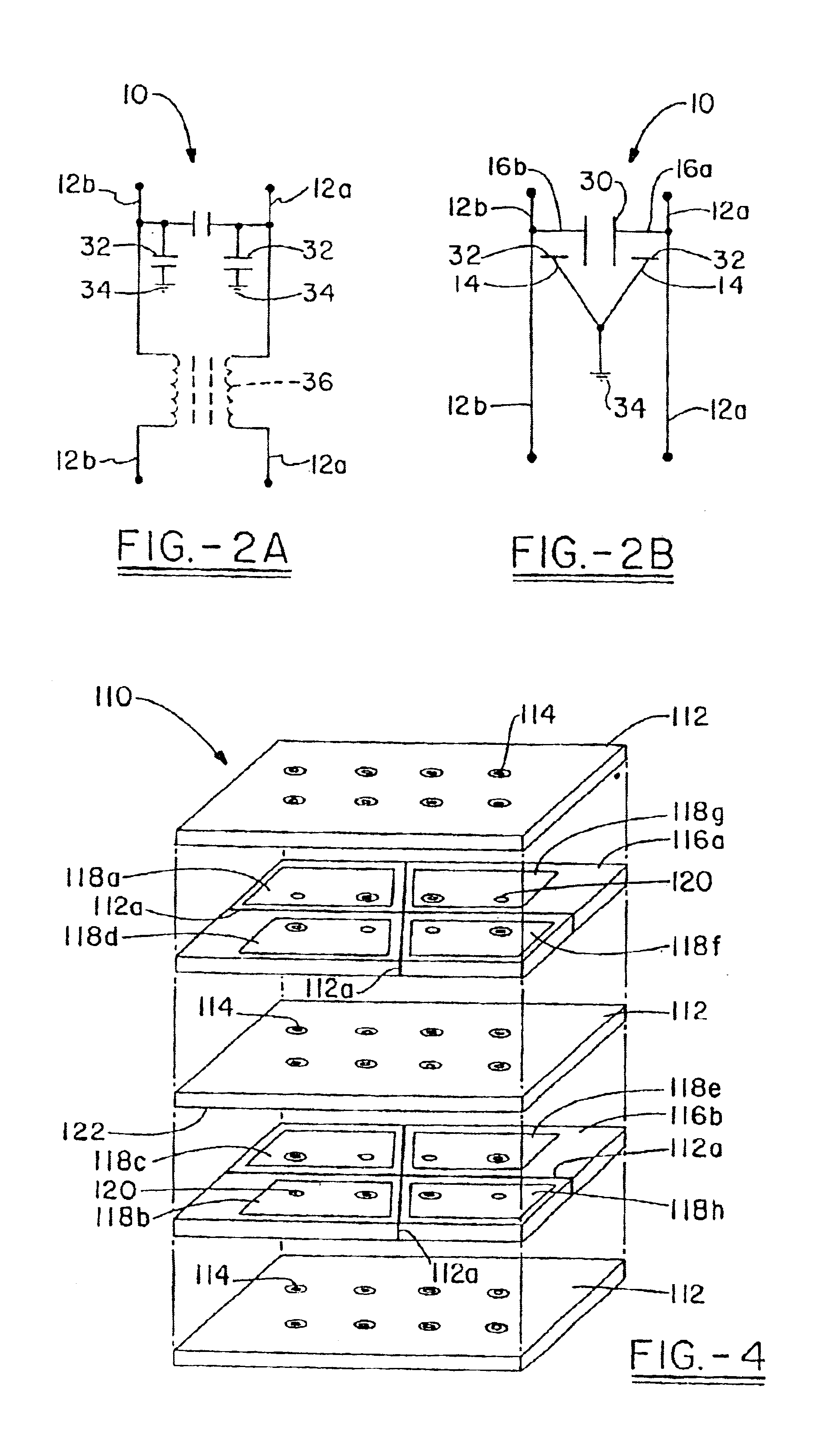

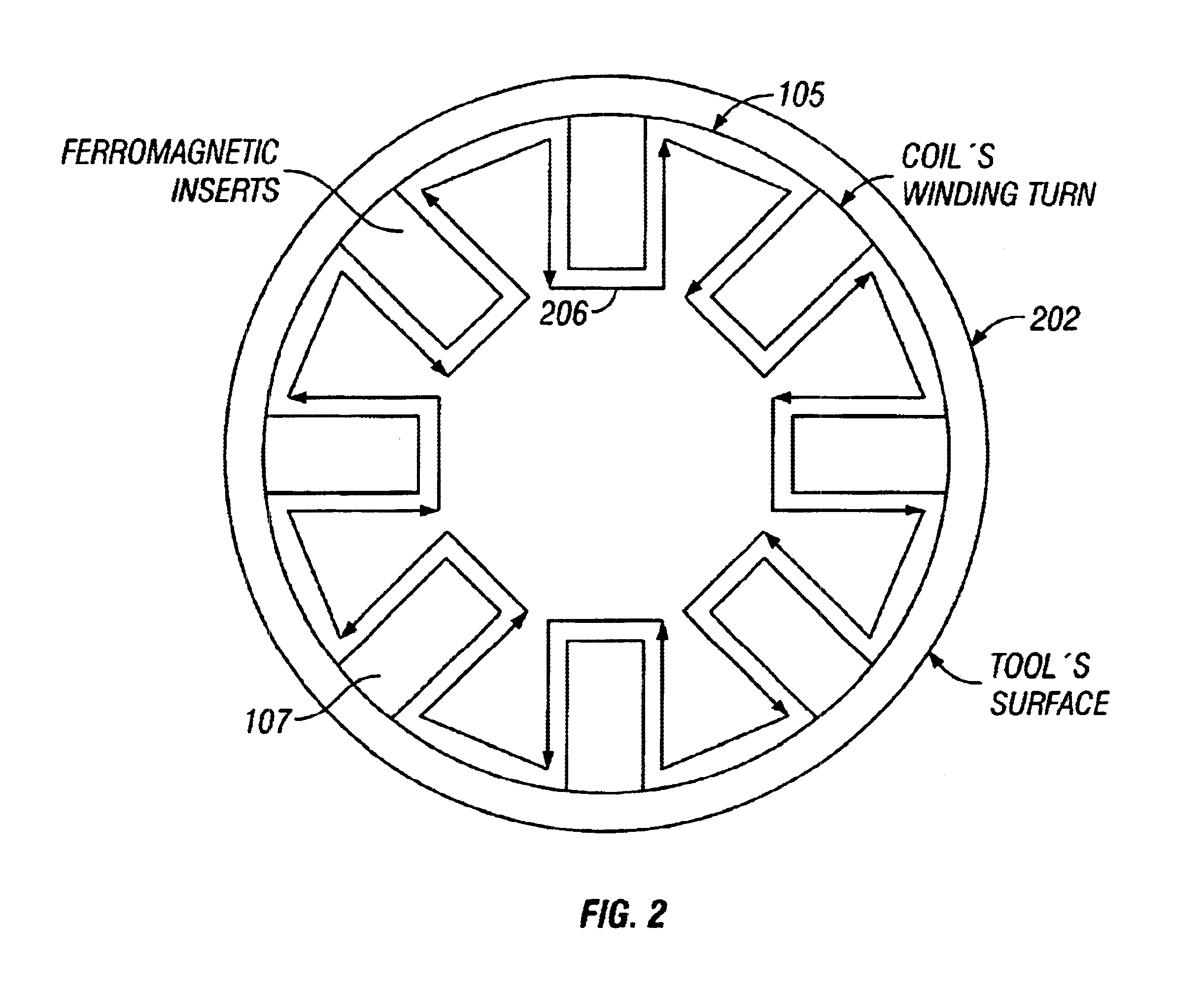

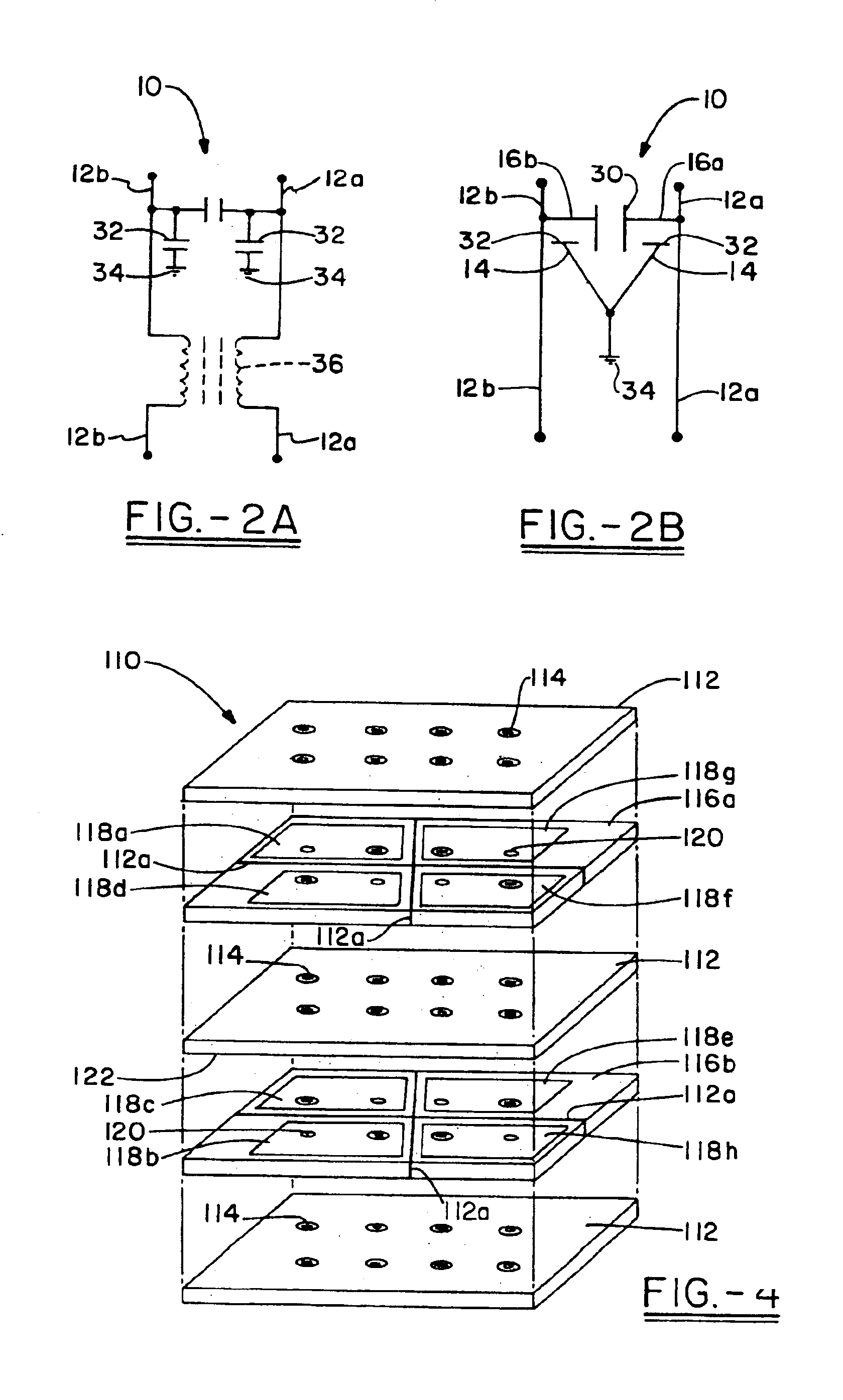

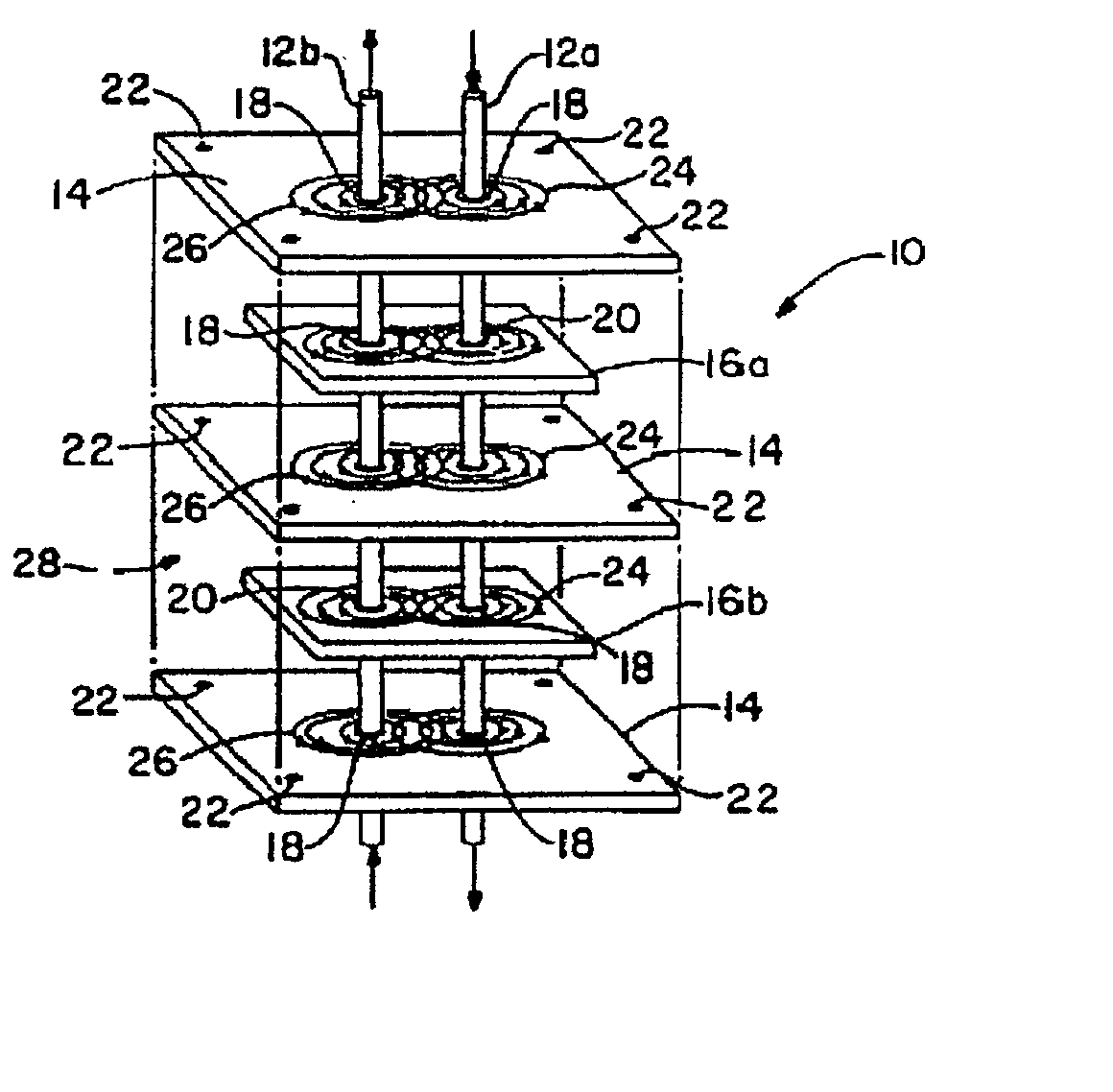

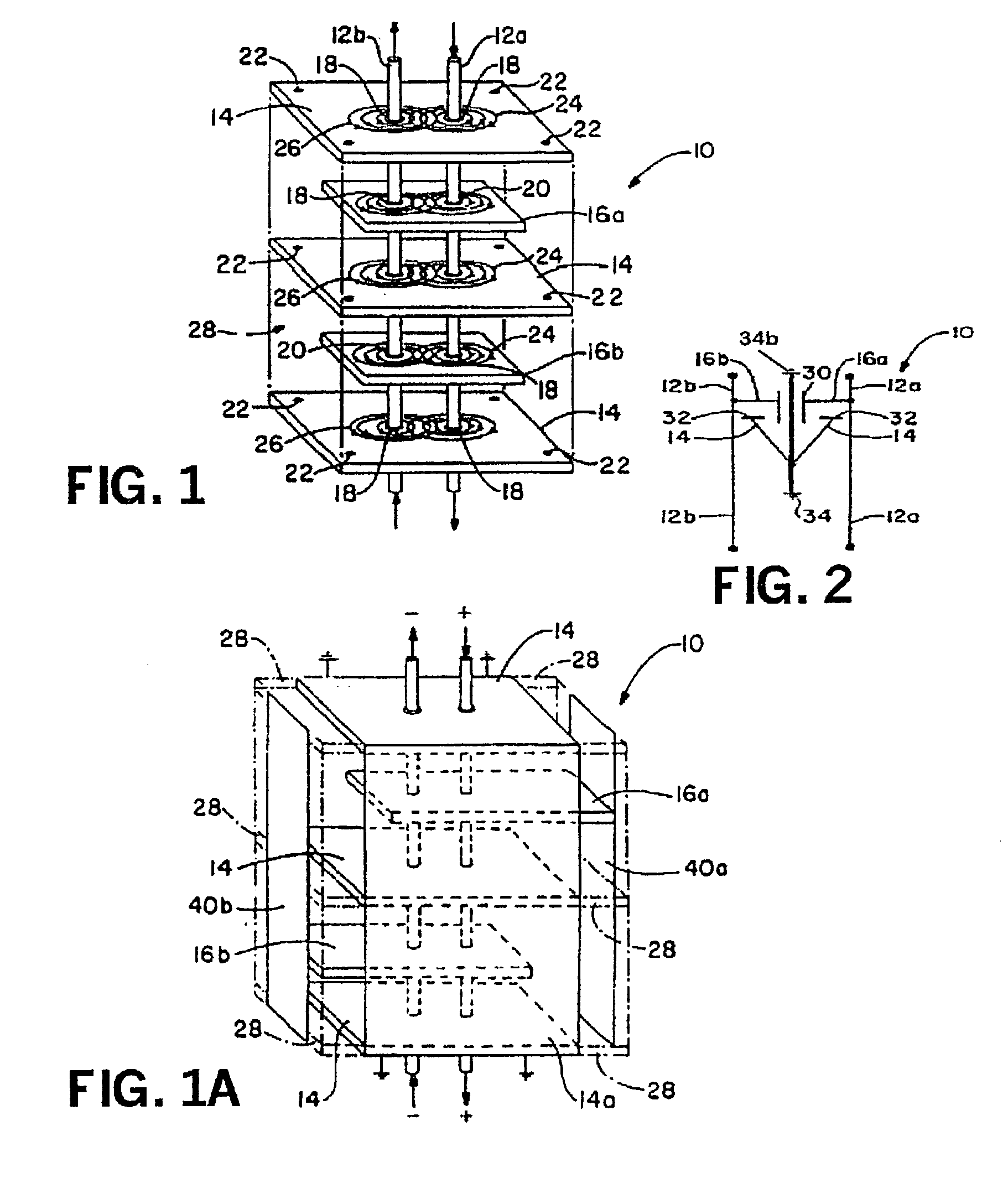

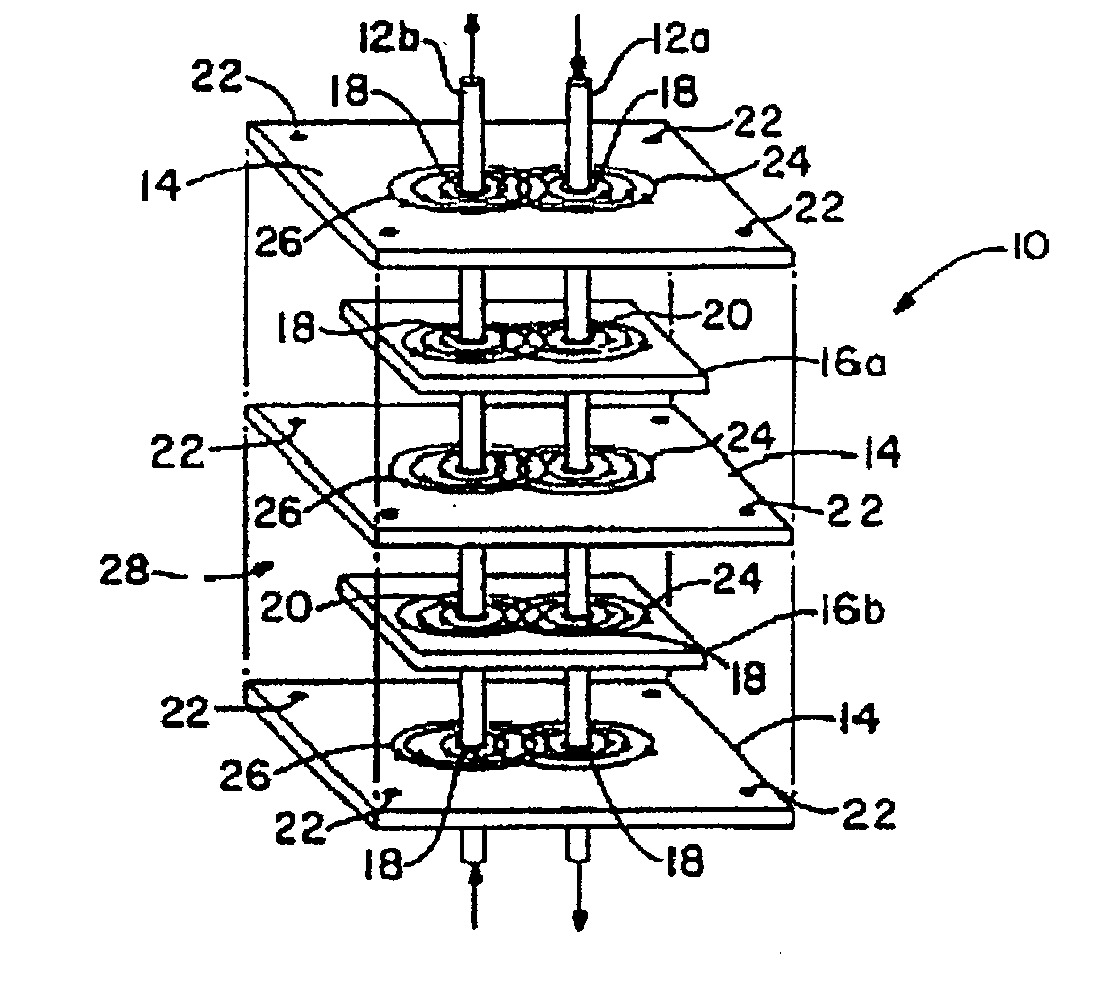

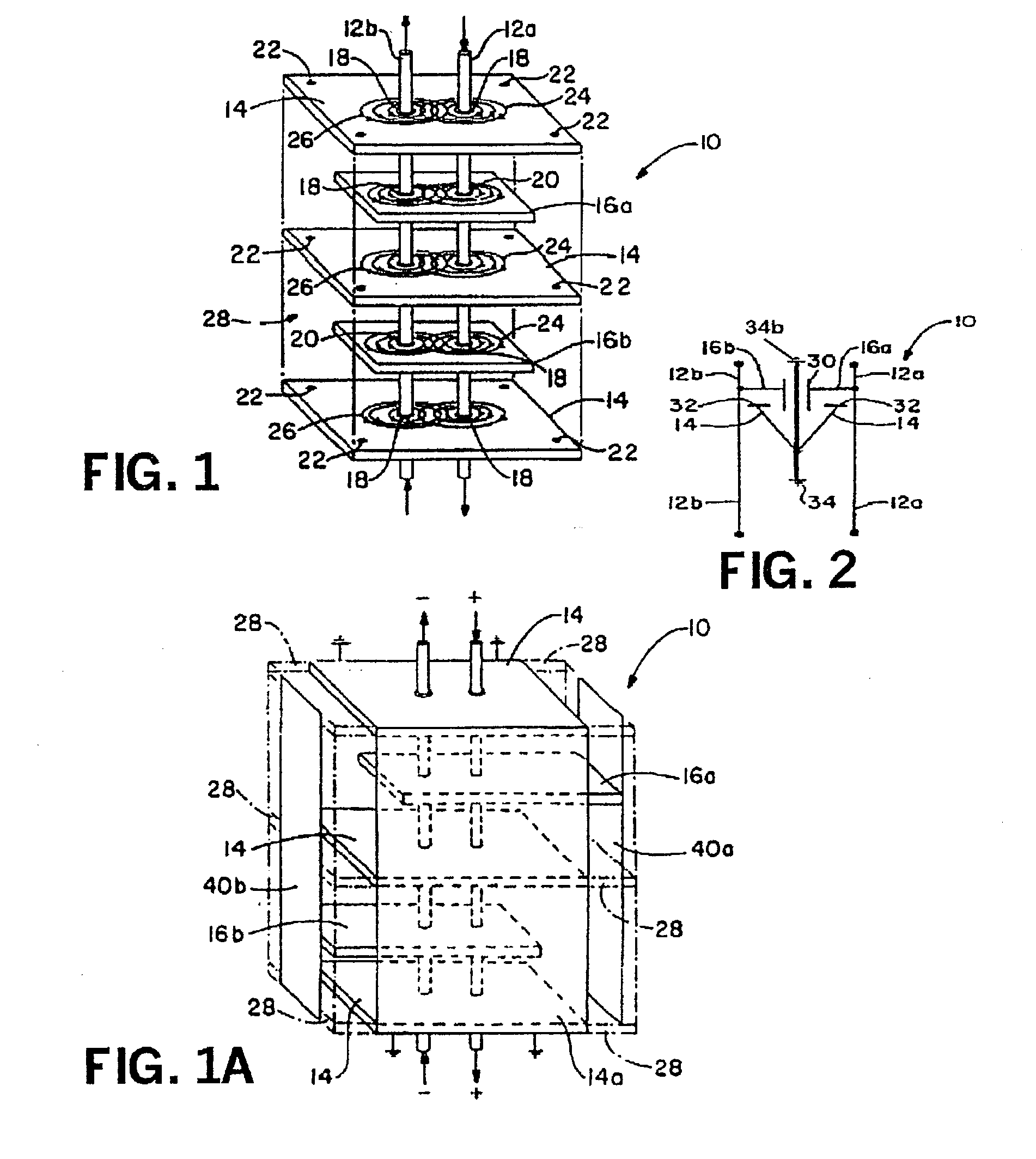

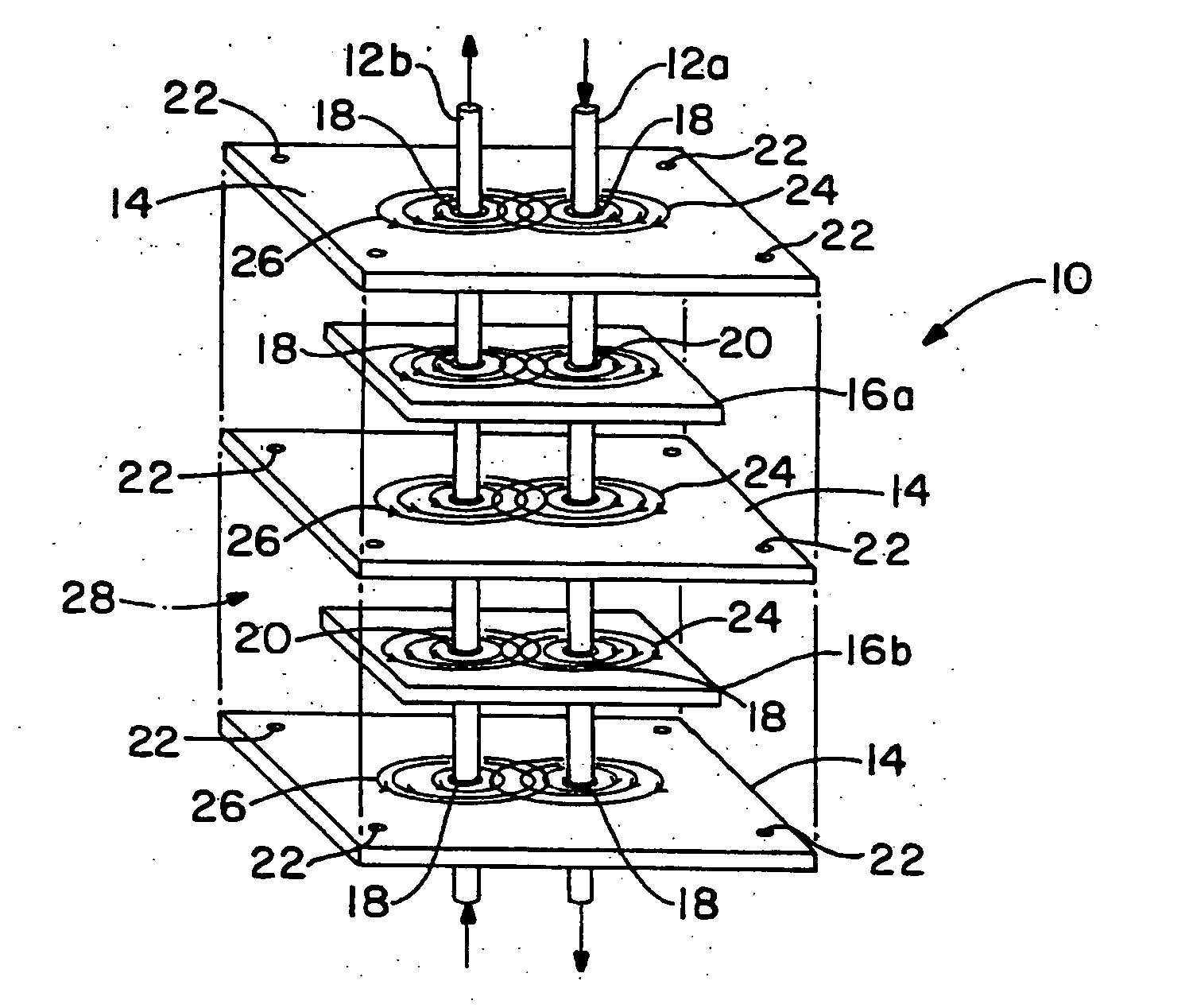

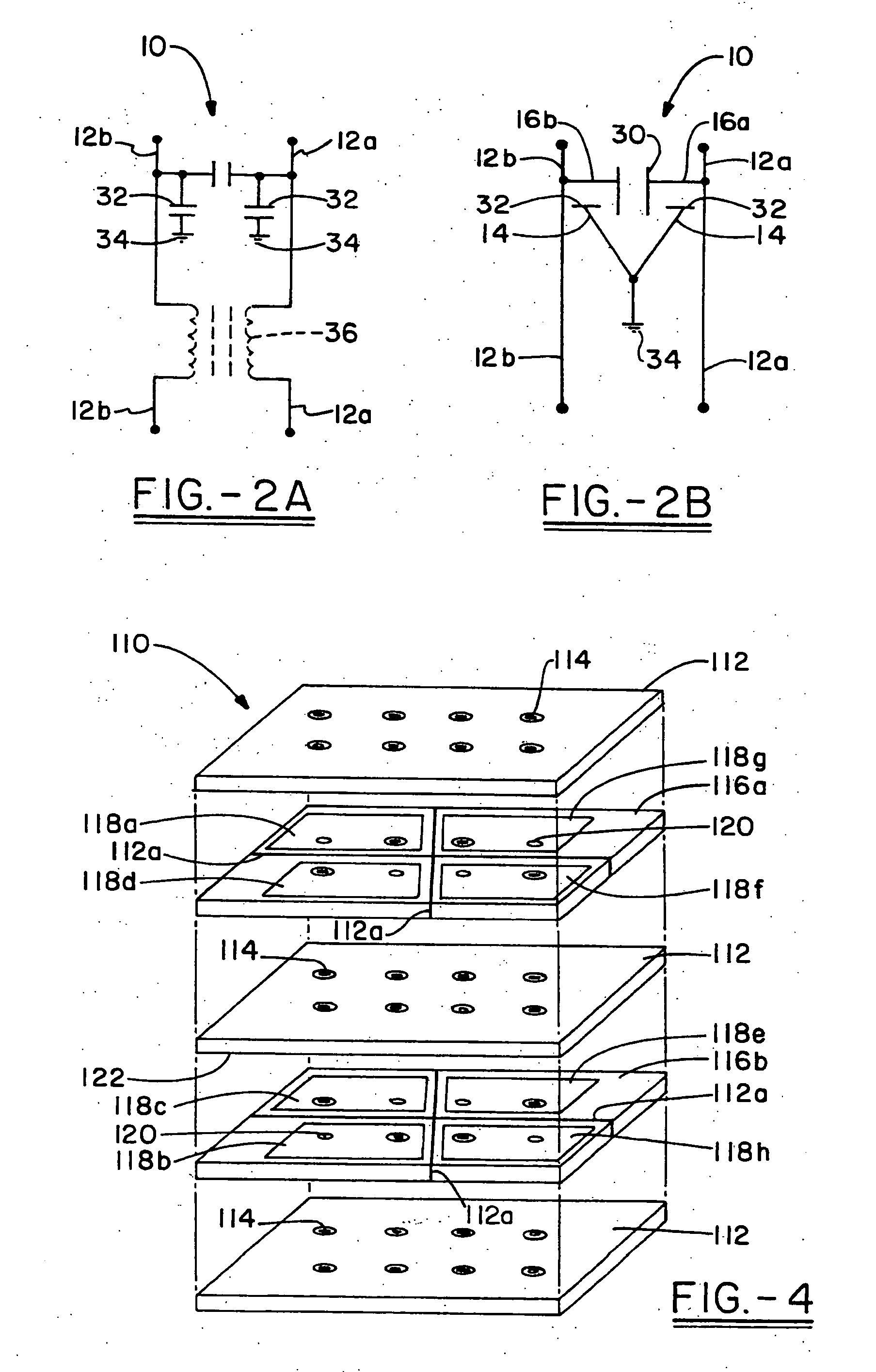

Paired multi-layered dielectric independent passive component architecture resulting in differential and common mode filtering with surge protection in one integrated package

InactiveUS6873513B2Reduce susceptibilityLow costSemiconductor/solid-state device detailsSolid-state devicesDielectricElectricity

The present invention relates to a passive electronic component architecture employed in conjunction with various dielectric and combinations of dielectric materials to provide one or more differential and common mode filters for the suppression of electromagnetic emissions and surge protection. The architecture allows single or multiple components to be assembled within a single package such as an integrated circuit or connector. The component's architecture is dielectric independent and provides for integration of various electrical characteristics within a single component to perform the functions of filtering, decoupling, fusing and surge suppression, alone or in combination.

Owner:X2Y ATTENUATORS L L C

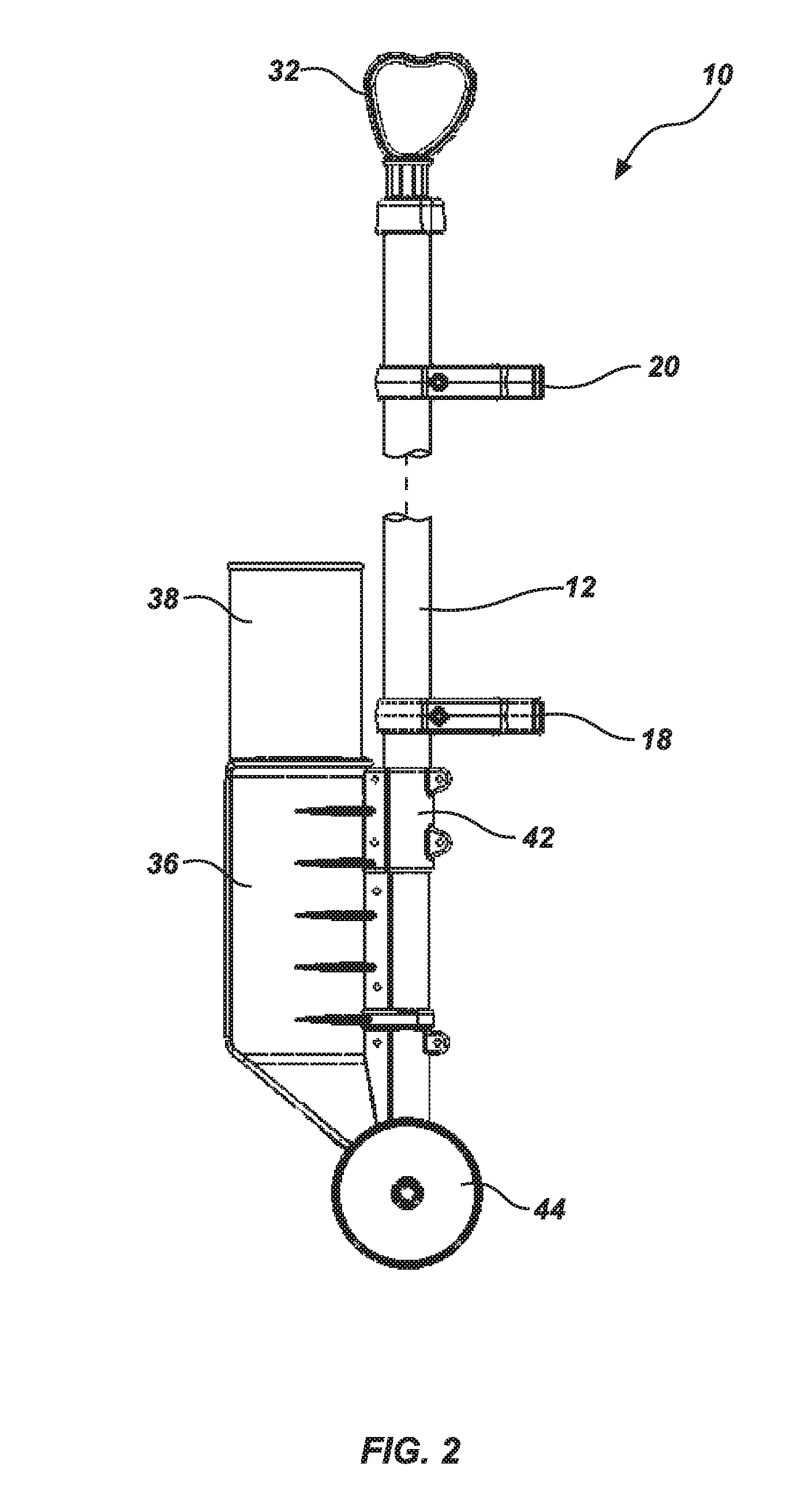

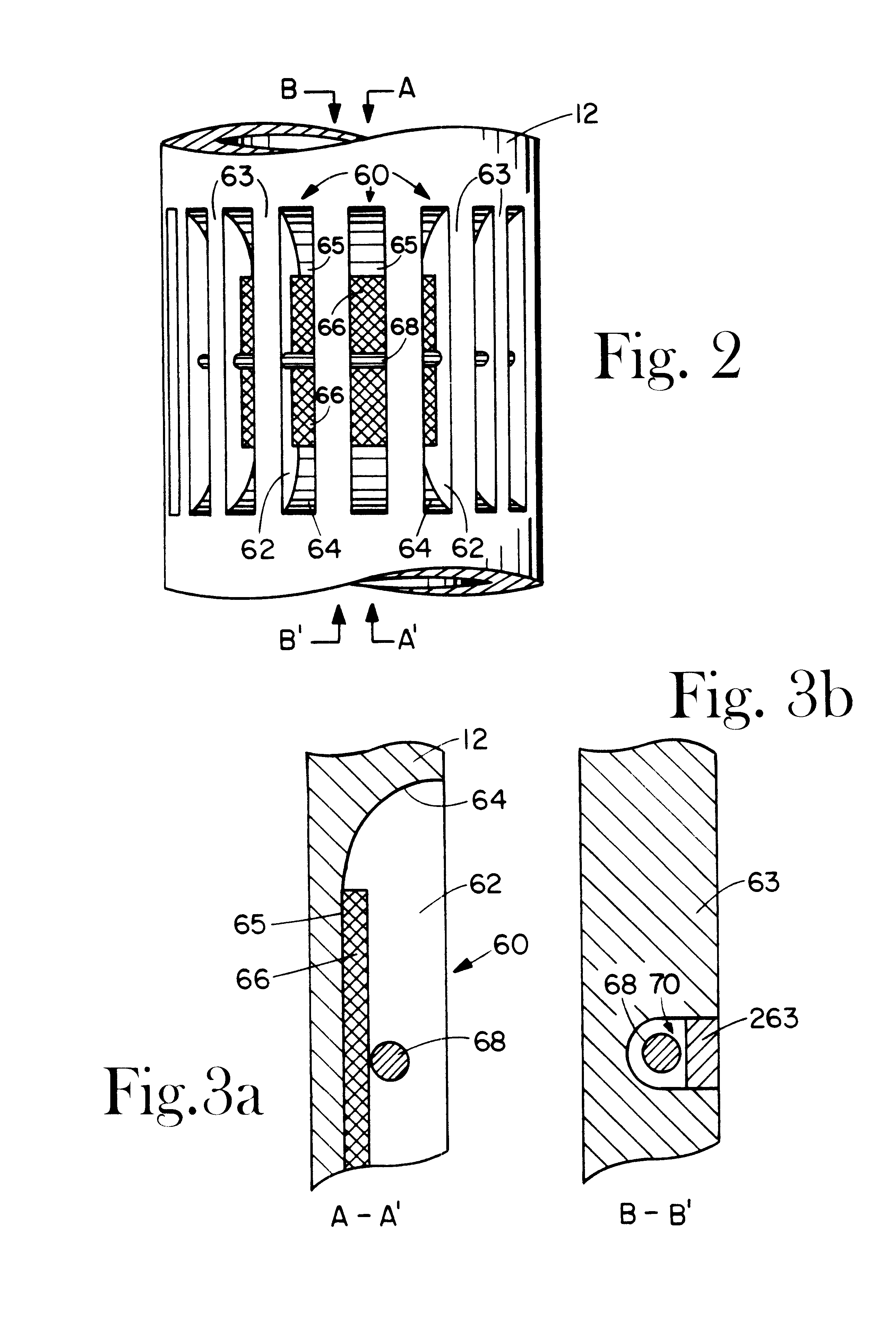

Multi-component induction instrument

InactiveUS6677756B2High degreeEnhanced couplingElectric/magnetic detection for well-loggingAcoustic wave reradiationReceiver coilConductive materials

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. The present invention provides increased effective tool surface impedance by increasing self-inductance of the paths in which induced eddy currents flow on the surface of the multi-component induction instruments. The tool enables downhole tool designers to build more effective and better-protected radial induction arrays for existing and future downhole instruments operating in the frequency and / or time domains. In this case the array measurement results contain information primarily about the formation's vertical resistivity. The tool makes it possible to combine radial arrays with coaxial arrays that conventionally measure horizontal formation resistivity. This combination enables obtaining a full resistivity tensor to evaluate formation resistivity anisotropy. The tool provides a composite non-conductive housing to reduce or even avoid the effects of parasitic eddy currents flowing on the tool surface. The tool provides a non-magnetic housing that is conductive which reduces the effects of conductive materials near coils and, primarily, the receiver. The tool provides a non-conductive coating is placed over the housing to prevent high frequency eddy currents from leaking from the housing in the conductive mud of the adjacent wellbore and returning to the housing.

Owner:BAKER HUGHES INC

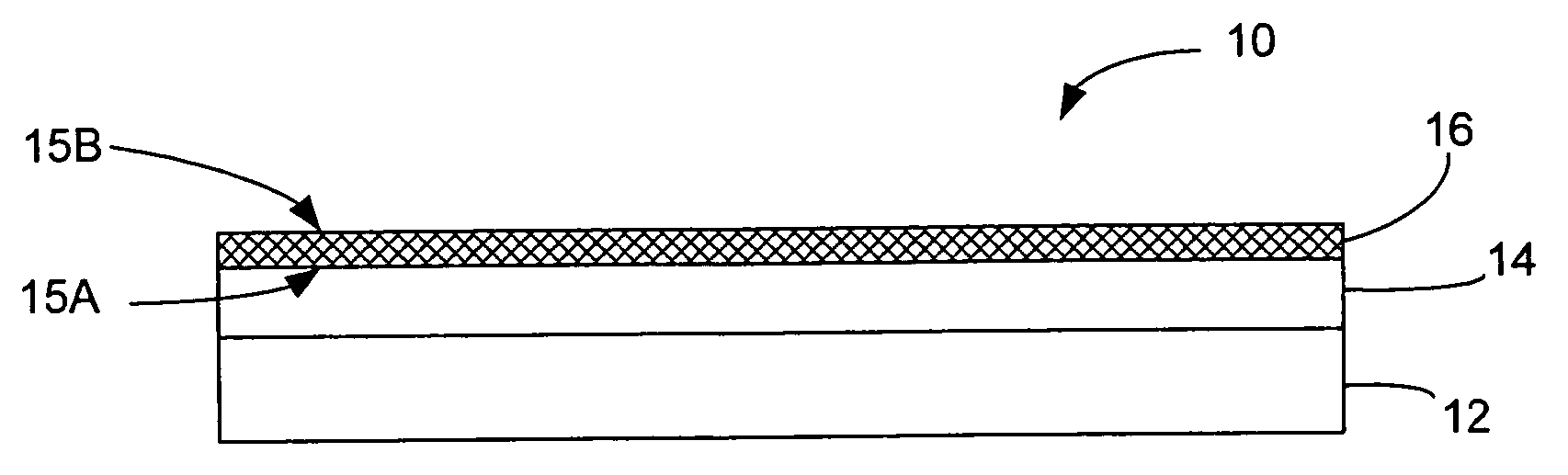

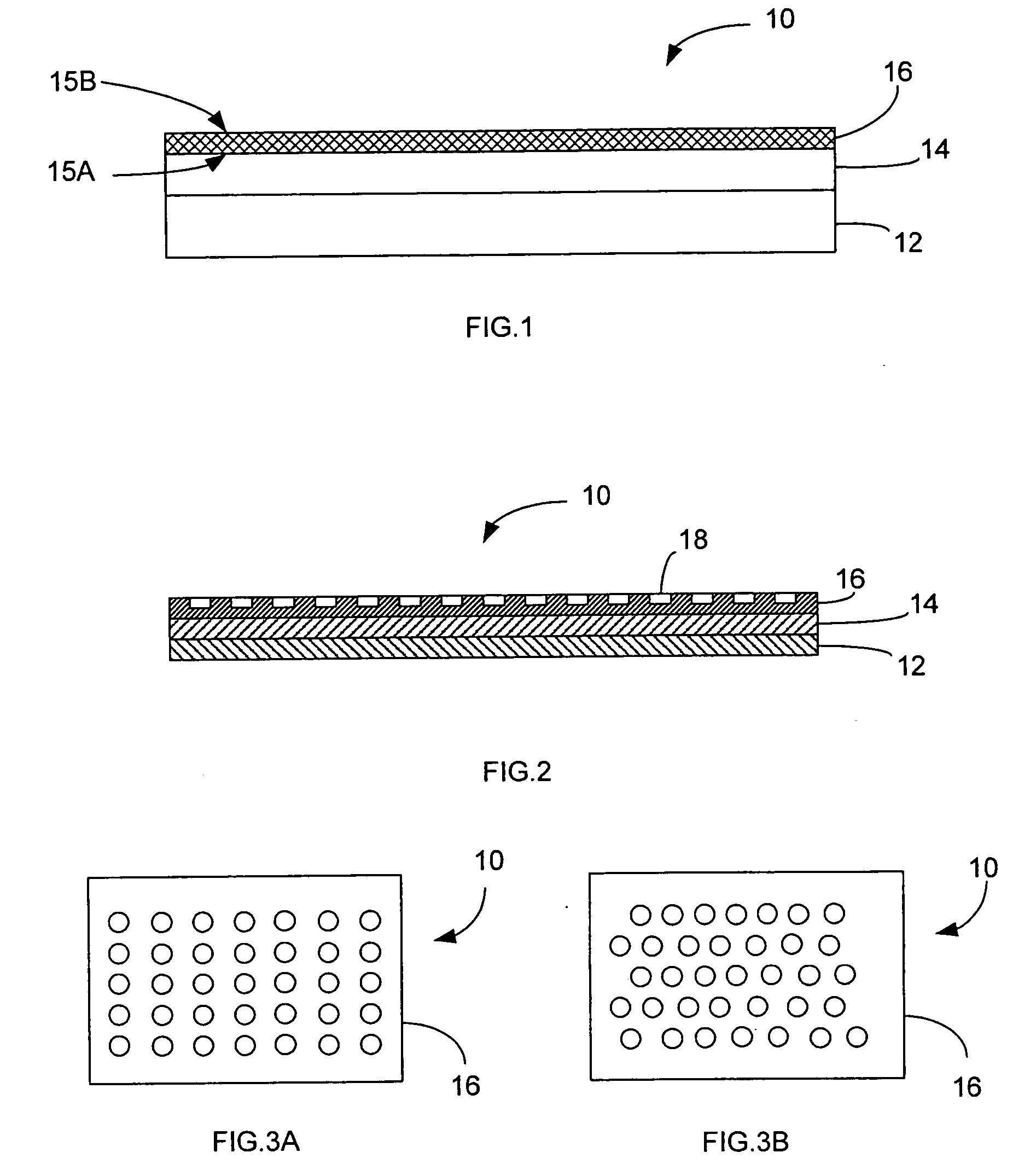

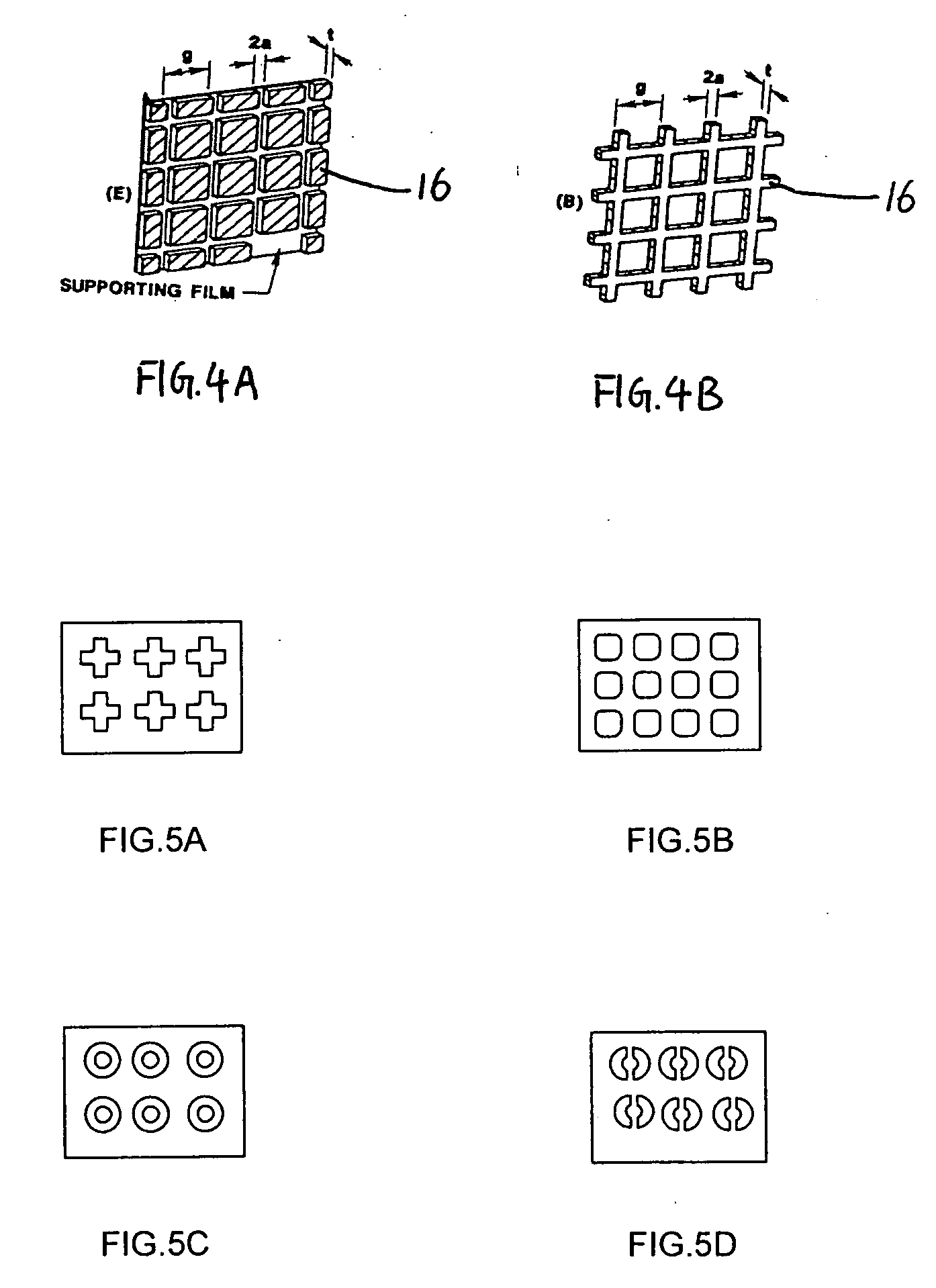

Photonic crystal emitter, detector and sensor

InactiveUS20070034978A1Improve stabilityBetter candidateSolid-state devicesMaterial analysis by optical meansSemiconductor materialsPhotonic bandgap

An infrared emitter, which utilizes a photonic bandgap (PBG) structure to produce electromagnetic emissions with a narrow band of wavelengths, includes a semiconductor material layer, a dielectric material layer overlaying the semiconductor material layer, and a metallic material layer having an inner side overlaying the dielectric material layer. The semiconductor material layer is capable of being coupled to an energy source for introducing energy to the semiconductor material layer. An array of holes are defined in the device in a periodic manner, wherein each hole extends at least partially through the metallic material layer. The three material layers are adapted to transfer energy from the semiconductor material layer to the outer side of the metallic material layer and emit electromagnetic energy in a narrow band of wavelengths from the outer side of the metallic material layer.

Owner:FLIR SURVEILLANCE

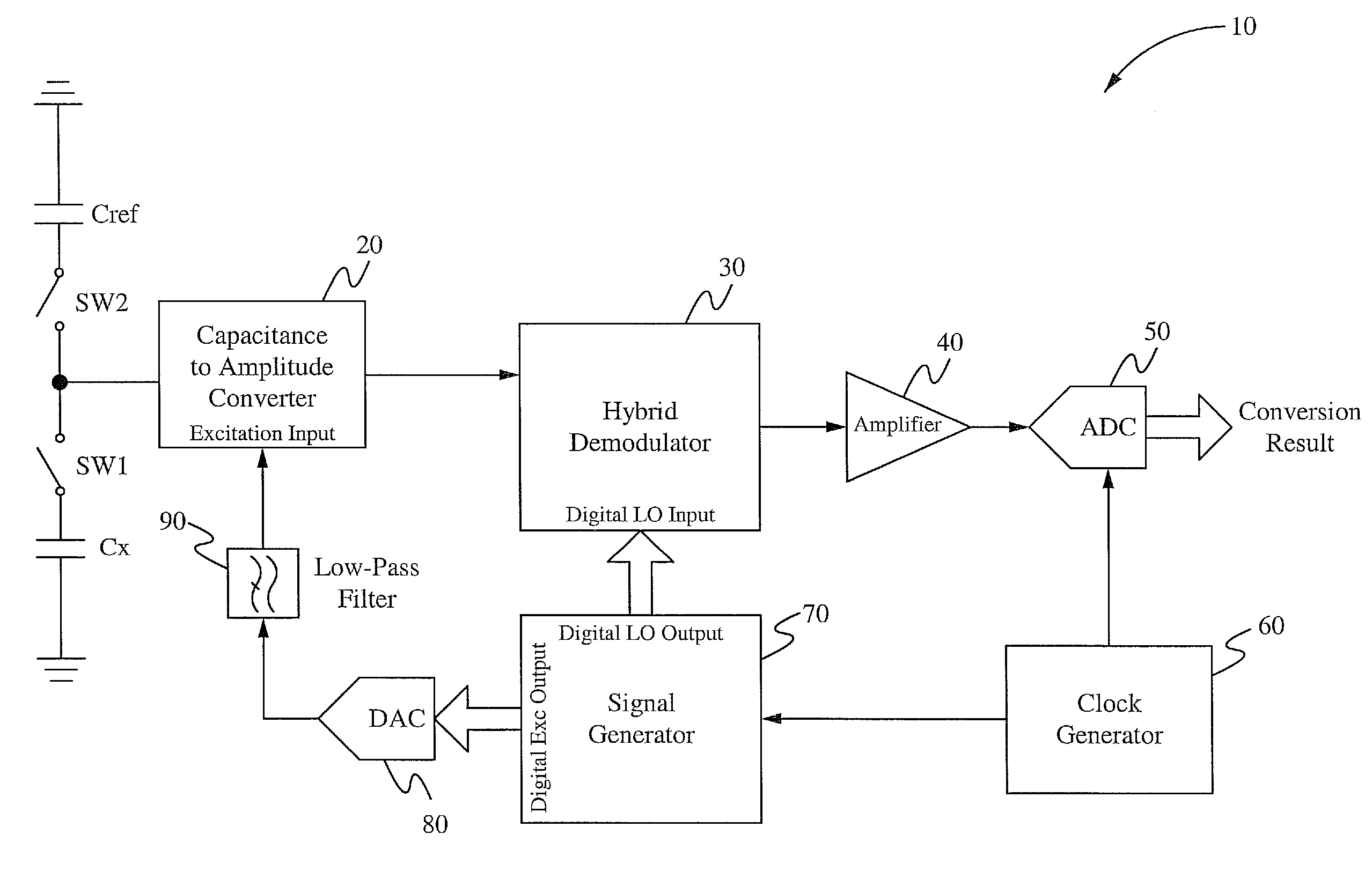

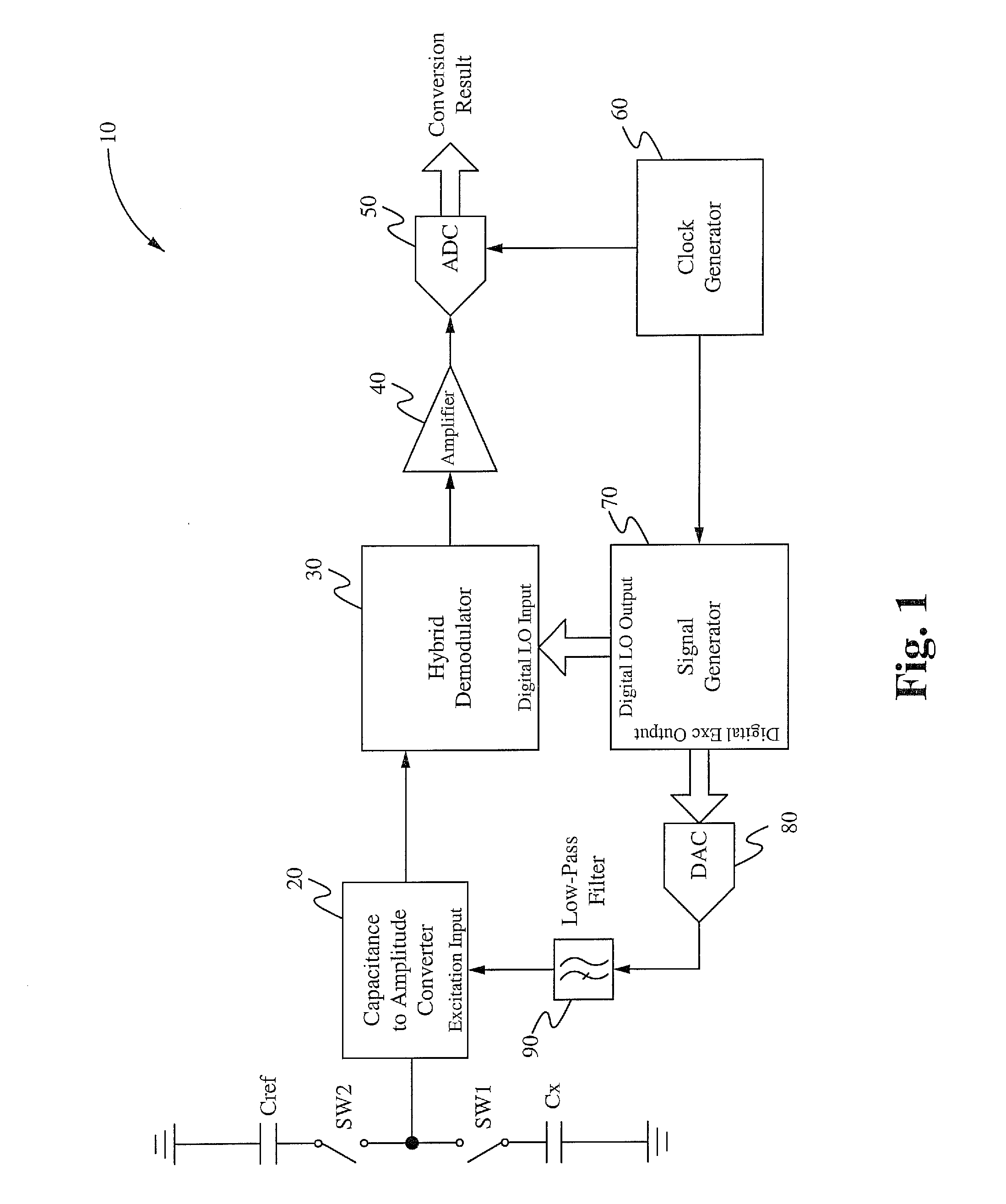

Method and apparatus for sensing capacitance value and converting it into digital format

ActiveUS20110012618A1Good immunity to noiseImprove interferenceCapacitance measurementsMaterial analysis by electric/magnetic meansCapacitanceEngineering

A capacitive sensing system are configured to sense a capacitance value and convert the sensed capacitance value to a digital format. The capacitive sensing system provides good selectivity and immunity to noise and interference, which can be further enhanced by enabling spread spectrum excitation. In some embodiments, the capacitive sensing system utilizes a sinusoidal excitation signal that results in low electromagnetic emissions, limited to narrow frequency band. In some embodiments, the capacitive sensing system is configured to operate in a spread spectrum mode, in which the majority of the excitation signal power is carried in the assigned bandwidth. The excitation frequency and the bandwidth of the spread spectrum excitation signal are programmable in a wide range, which allows for avoiding frequency conflicts in the operating environment.

Owner:MAXIM INTEGRATED PROD INC

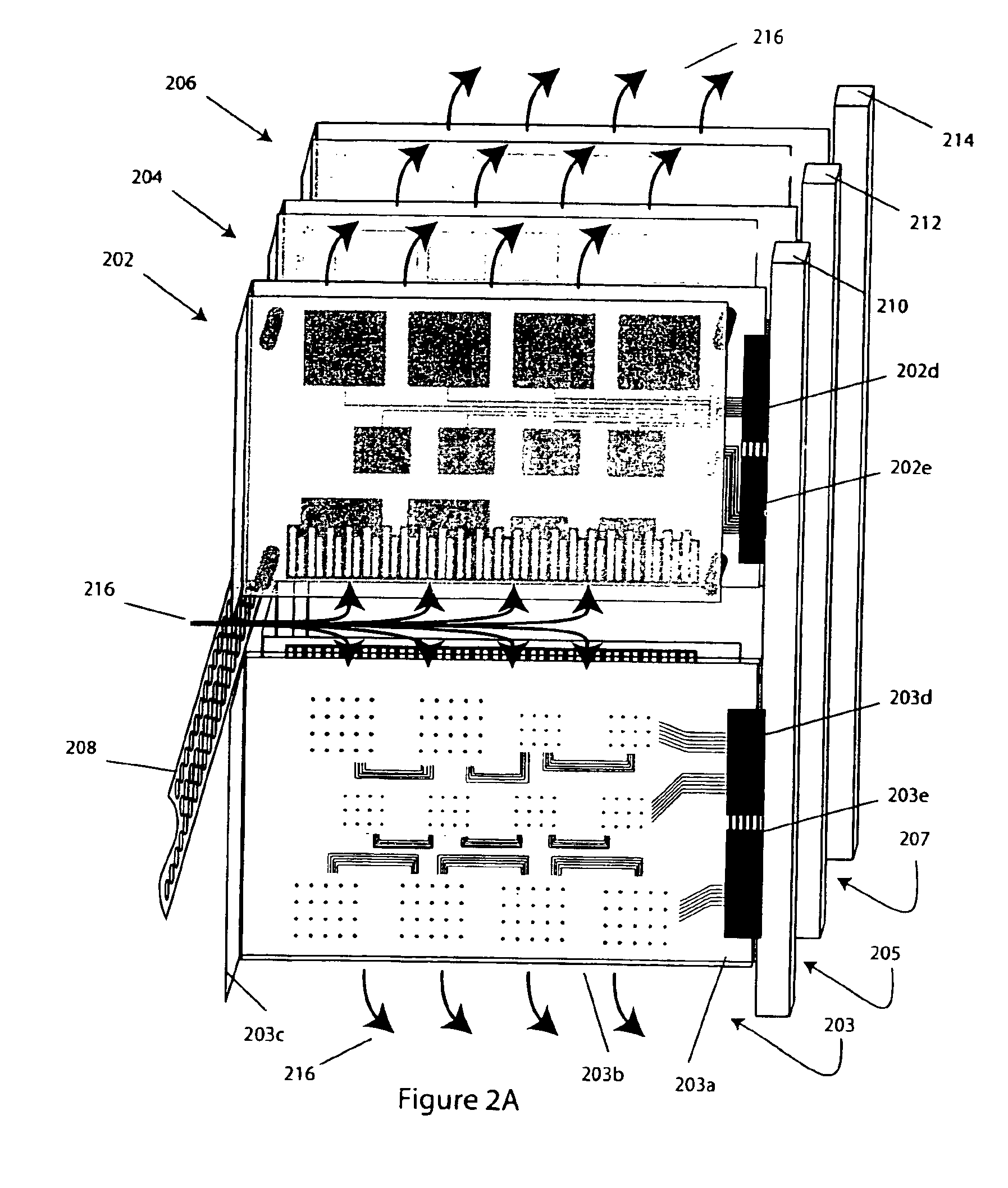

Central inlet circuit board assembly

InactiveUS6879486B1Increase capacityHigh densityHeat exchange apparatusCooling/ventilation/heating modificationsCouplingElectromagnetic interference

An improved circuit board assembly includes a cover or other member disposed adjacent to the substrate and, for example, spaced therefrom so as to define a plenum. Self-aligning heat sinks (or other heat dissipative elements) are spring-mounted (or otherwise resiliently mounted) to the cover and, thereby, placed in thermal contact with one or more of the circuit components. Flow-diverting elements are provided, e.g., so that the overall impedance of the board substantially matches that of one or more of the other circuit boards in a common chassis. The circuit board cover can be adapted to provide thermal and / or electromagnetic emission control, as well as shock and vibration. A connector arrangement provides electrical, mechanical and / or other operational coupling between the circuit board and a chassis regardless of whether the board is disposed in a slot on a first (e.g., upper) side of a source of cooling air for the chassis or on a second (e.g, lower) opposite side of that source. A circuit board can have one or two portions, each with an air flow inlet edge through which cooling air flow is received and an air flow outlet edge through which the air flow exists. An improved chassis for mounting of such circuit boards can have a center air inlet. It can also have a circuit-board insertion slot with a first air flow aperture disposed adjacent to a first edge of an inserted circuit board and a second apertures disposed adjacent to a second edge of the board. These apertures can be sized so that the impedance to air flow to a circuit board inserted in the slot substantially matches that to one or more other boards in the chassis. Such slots can form part of a card cage that is vacuum or dip brazed, or manufactured by an alternate process yielding a cage of desired structural stiffness and air-flow / interference sealing. The circuit boards and chassis can include an air and / or electromagnetic interference (EMI) seal which forms as the circuit board is inserted into the chassis slot.

Owner:MERCURY SISTEMS INC

Paired multi-layered dielectric independent passive component architecture resulting in differential and common mode filtering with surge protection in one integrated package

InactiveUS6950293B2Emission reductionReduce susceptibilitySemiconductor/solid-state device detailsSolid-state devicesElectricityDielectric

The present invention relates to a passive electronic component architecture employed in conjunction with various dielectric and combinations of dielectric materials to provide one or more differential and common mode filters for the suppression of electromagnetic emissions and surge protection. The architecture allows single or multiple components to be assembled within a single package such as an integrated circuit or connector. The component's architecture is dielectric independent and provides for integration of various electrical characteristics within a single component to perform the functions of filtering, decoupling, fusing and surge suppression, alone or in combination.

Owner:X2Y ATTENUATORS L L C

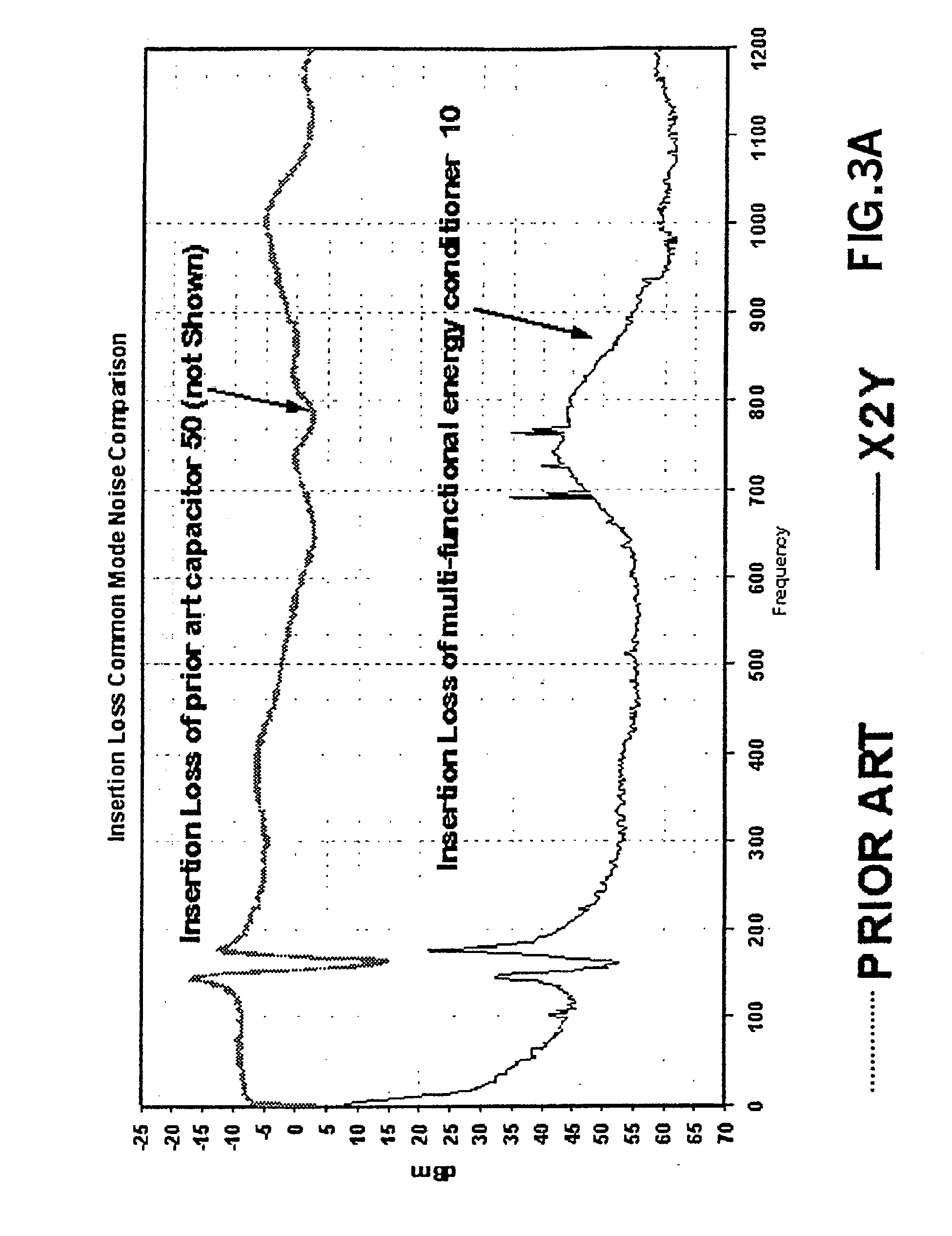

Multi-functional energy conditioner

InactiveUS20040008466A1Minimize and suppress unwanted electromagnetic emissionPreventing debilitating electromagnetic emissionMagnetic/electric field screeningSemiconductor/solid-state device detailsDielectricCombined use

The present invention relates to a multi-functional energy conditioner having architecture employed in conjunction with various dielectric and combinations of dielectric materials to provide one or more differential and common mode filters for the suppression of electromagnetic emissions and surge protection. The architecture allows single or multiple components to be assembled within a single package such as an integrated circuit or connector. The component's architecture is dielectric independent and provides for integration of various electrical characteristics within a single component to perform the functions of filtering, decoupling, fusing and surge suppression.

Owner:X2Y ATTENUATORS L L C

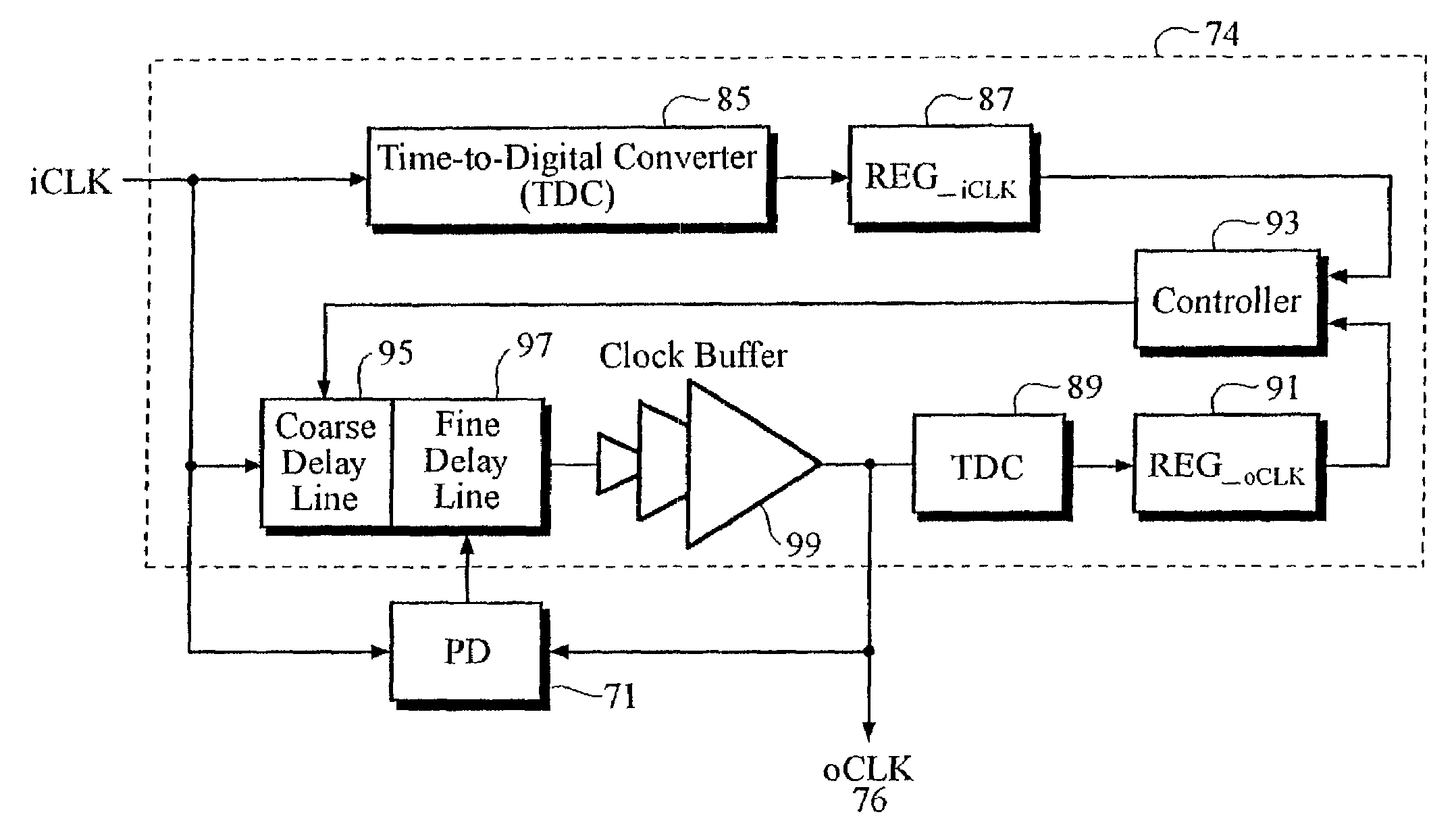

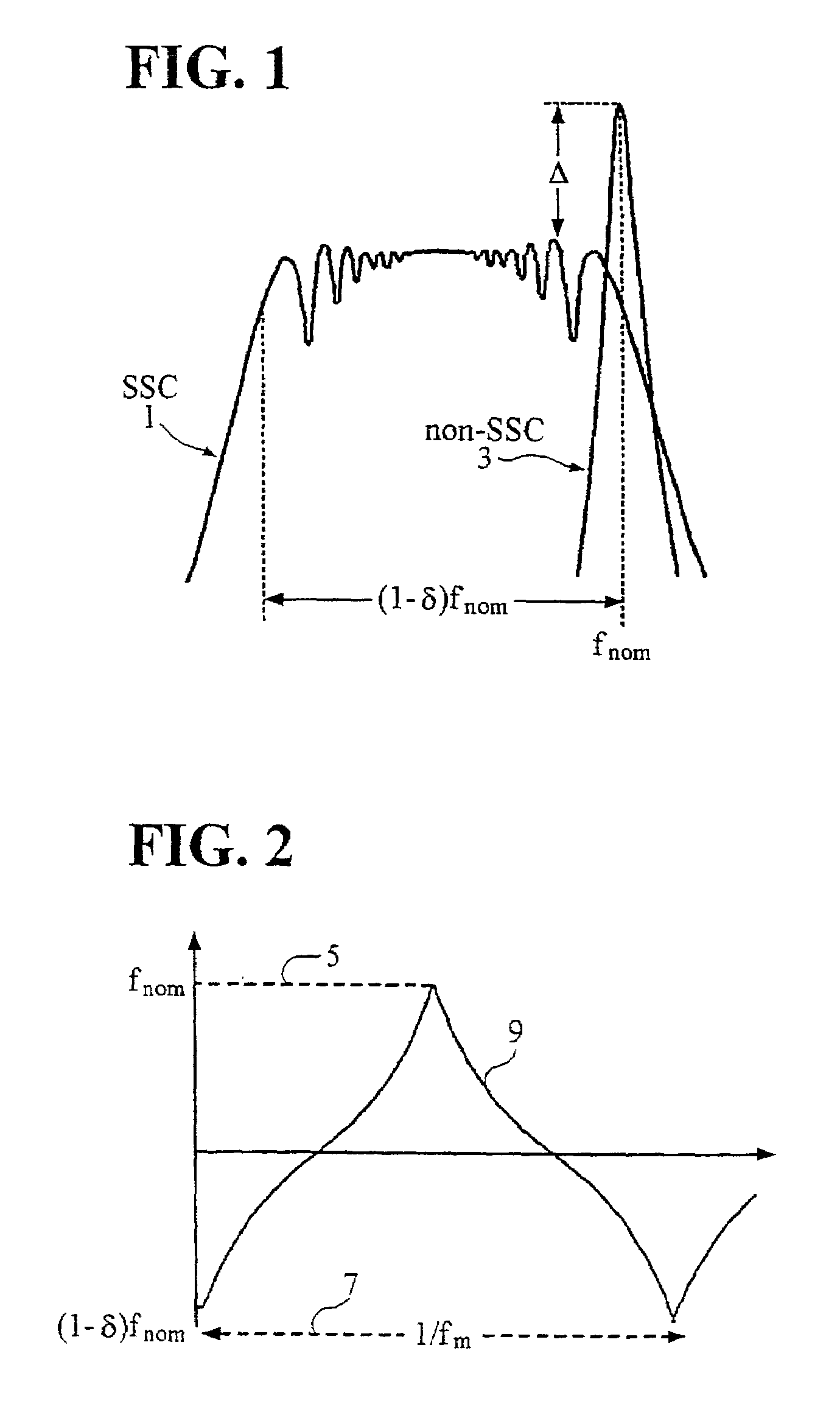

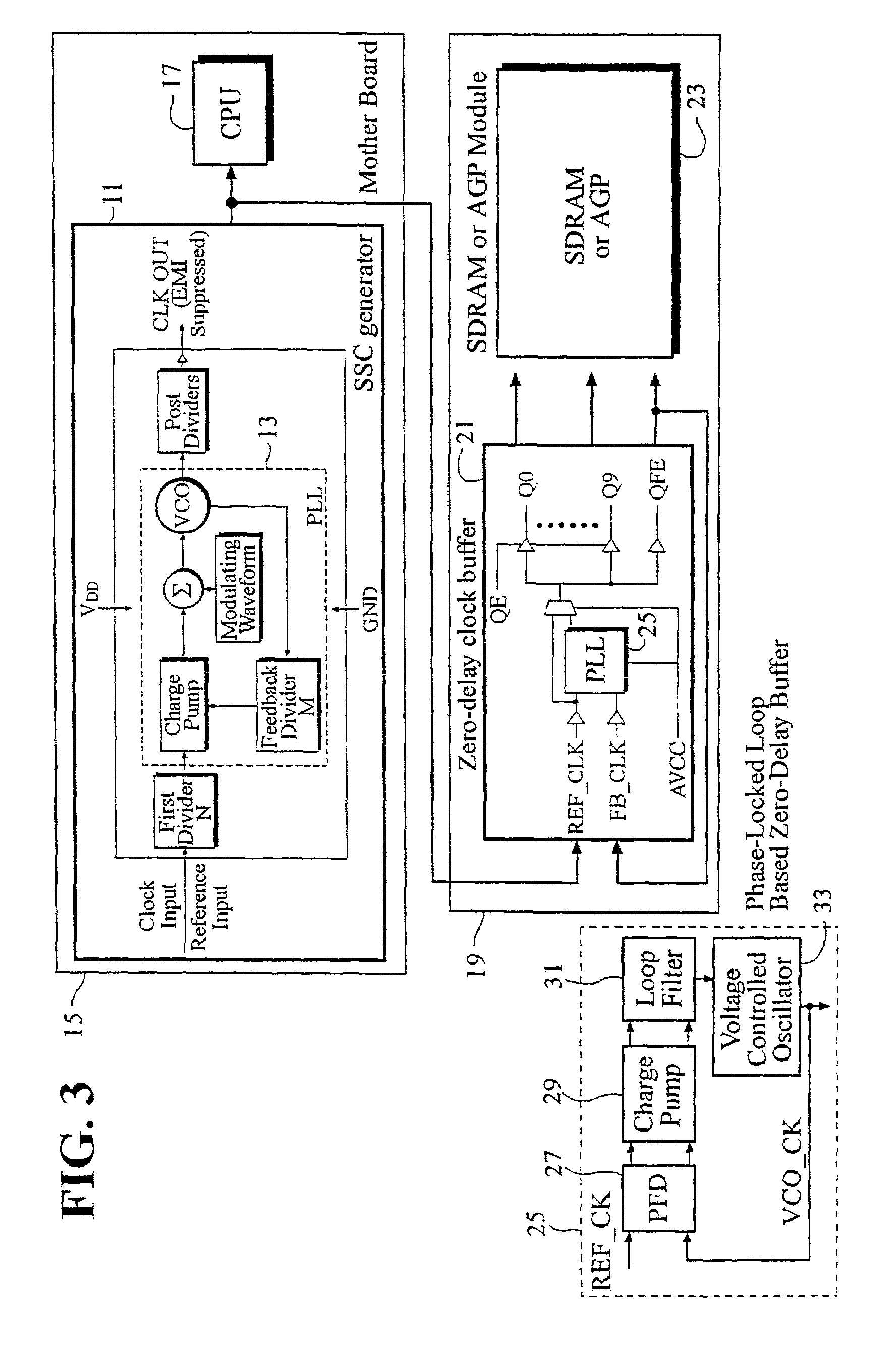

Zero-delay buffer circuit for a spread spectrum clock system and method therefor

InactiveUS6993109B2Improve efficiencyEliminate phase differencePulse automatic controlGenerating/distributing signalsPhase detectorPhase difference

A clock recovery circuit and a method for reducing electromagnetic emission (EMI) and increasing an attainable clock frequency includes a spread spectrum clock (SSC) generator that receives an input clock signal and generates a frequency-modulated clock signal, and a zero-delay buffer circuit that receives and buffers said modulated clock frequency signed to generated an output clock signal. The frequency-modulated clock signal and the output clock signal are phase-aligned such that there is no phase difference between the output clock signal and the modulated frequency clock signal. The clock recovery circuit also includes a delay-locked loop (DLL) circuit that reduces related art jitter and skew characteristics, and a phase detector circuit that eliminates phase ambiguity problems of a related art phase detector.

Owner:ANAPASS

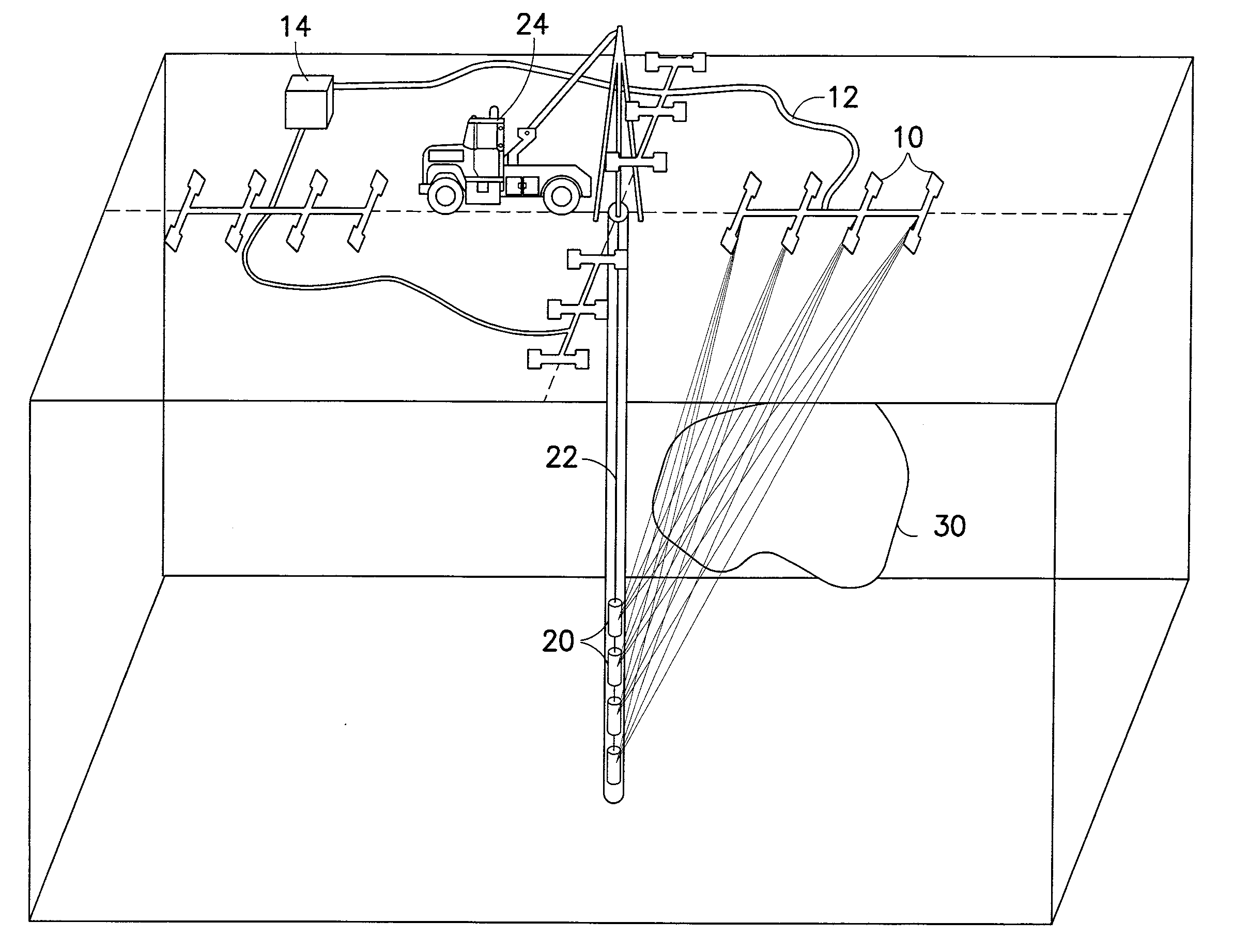

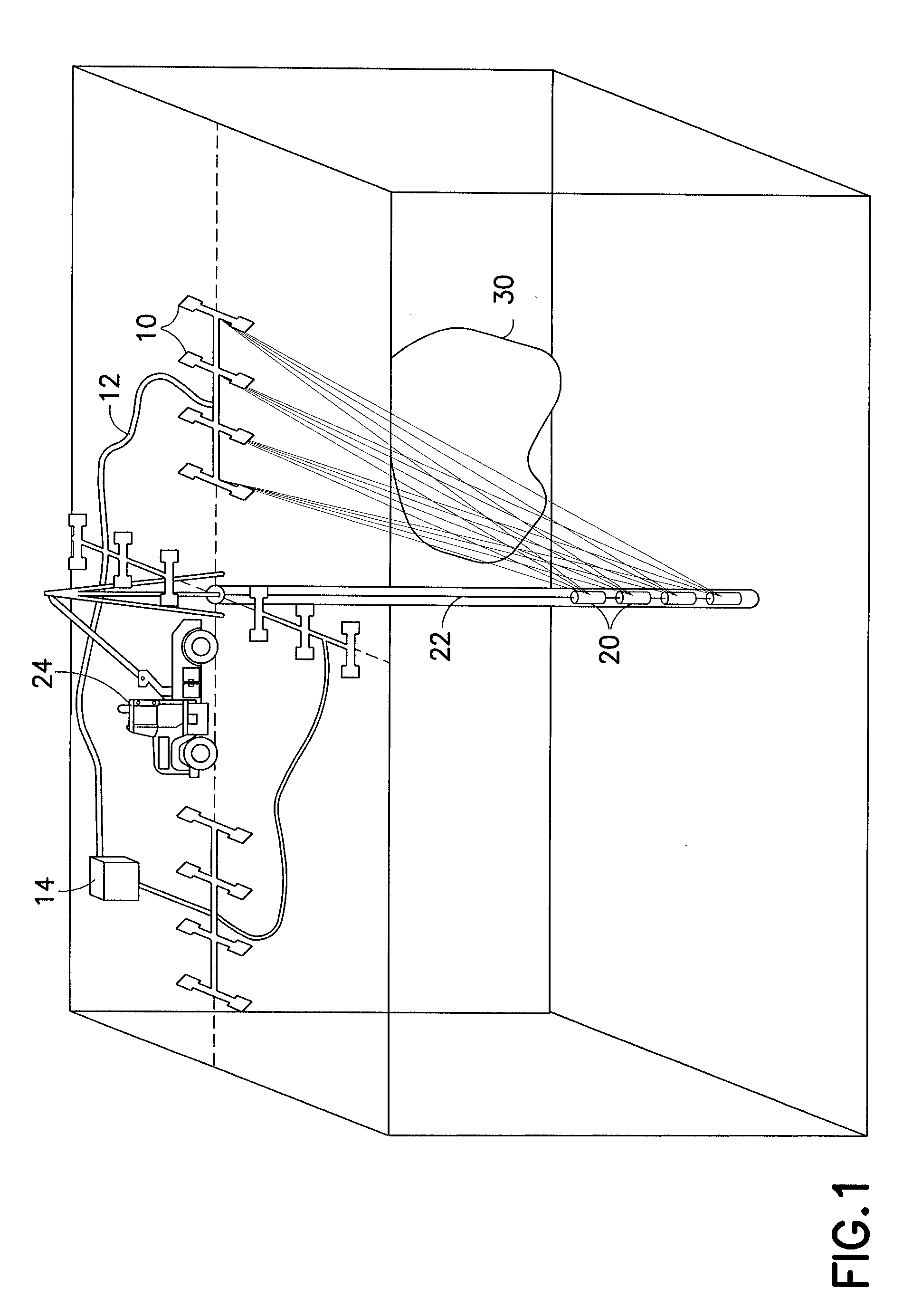

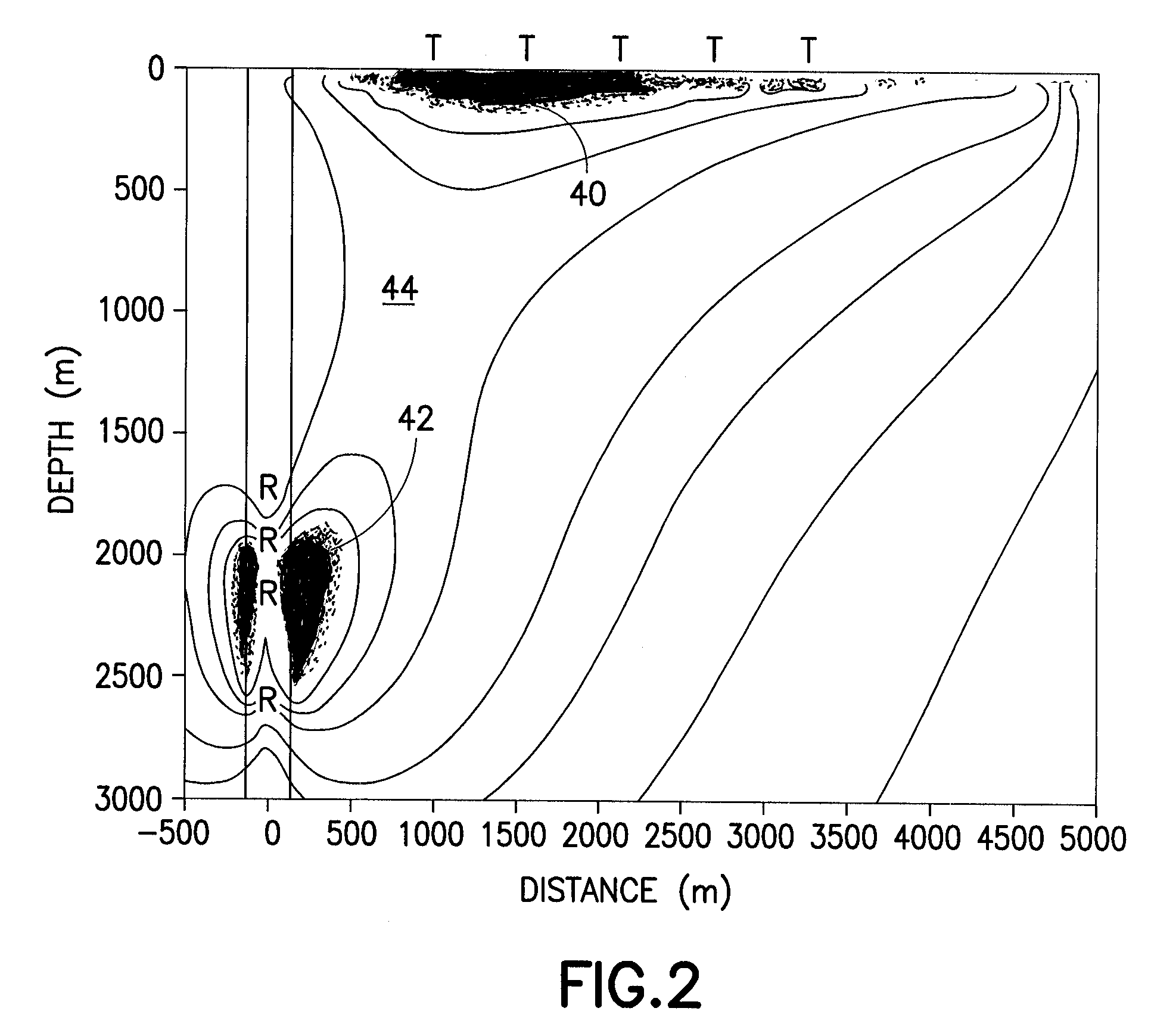

Removing effects of near surface geology from surface-to-borehole electromagnetic data

ActiveUS20090039889A1Electric/magnetic detection for well-loggingSurveyData acquisitionEarth surface

A method that involves developing an electromagnetic property model of a near surface area and using this electromagnetic property model and electromagnetic data acquired using one or more electromagnetic transmitters located above the near surface area and one or more electromagnetic receivers located within a wellbore to determine one or more electromagnetic properties of a subsurface area. Also an electromagnetic data acquisition system that includes one or more electromagnetic transmitters capable of being operated on the earth's surface, one or more first electromagnetic receivers capable of being operated within a wellbore and capable of receiving signals from the one or more electromagnetic transmitters, and one or more second electromagnetic receivers capable of being located on the earth's surface near the one or more electromagnetic transmitters and capable of receiving signals from the one or more electromagnetic transmitters. Related embodiments are also described.

Owner:SCHLUMBERGER TECH CORP

Multi-functional energy conditioner

InactiveUS20060023385A9Preventing and minimizingConstant voltageMagnetic/electric field screeningSemiconductor/solid-state device detailsDielectricCombined use

The present invention relates to a multi-functional energy conditioner having architecture employed in conjunction with various dielectric and combinations of dielectric materials to provide one or more differential and common mode filters for the suppression of electromagnetic emissions and surge protection. The architecture allows single or multiple components to be assembled within a single package such as an integrated circuit or connector. The component's architecture is dielectric independent and provides for integration of various electrical characteristics within a single component to perform the functions of filtering, decoupling, fusing and surge suppression.

Owner:X2Y ATTENUATORS L L C

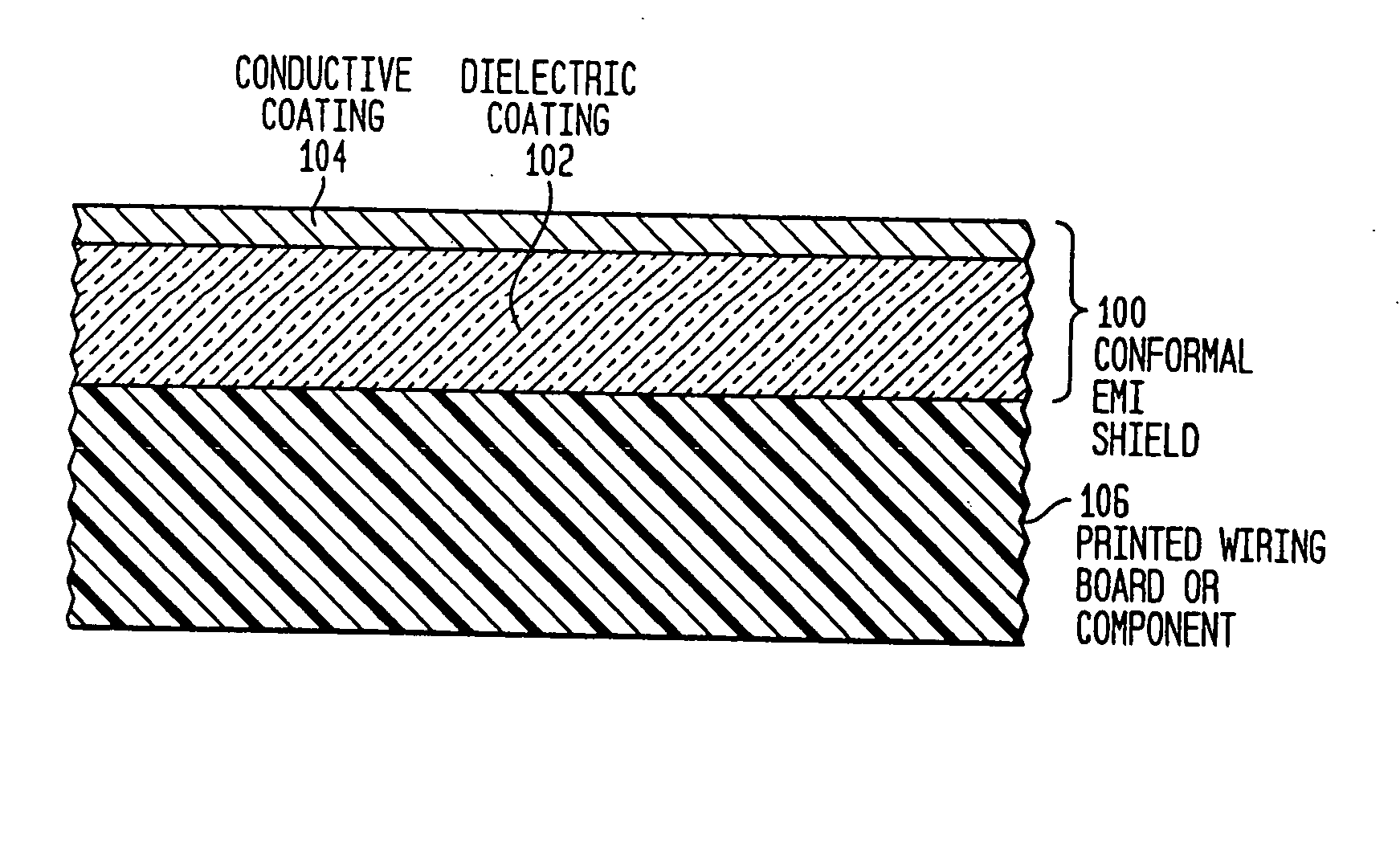

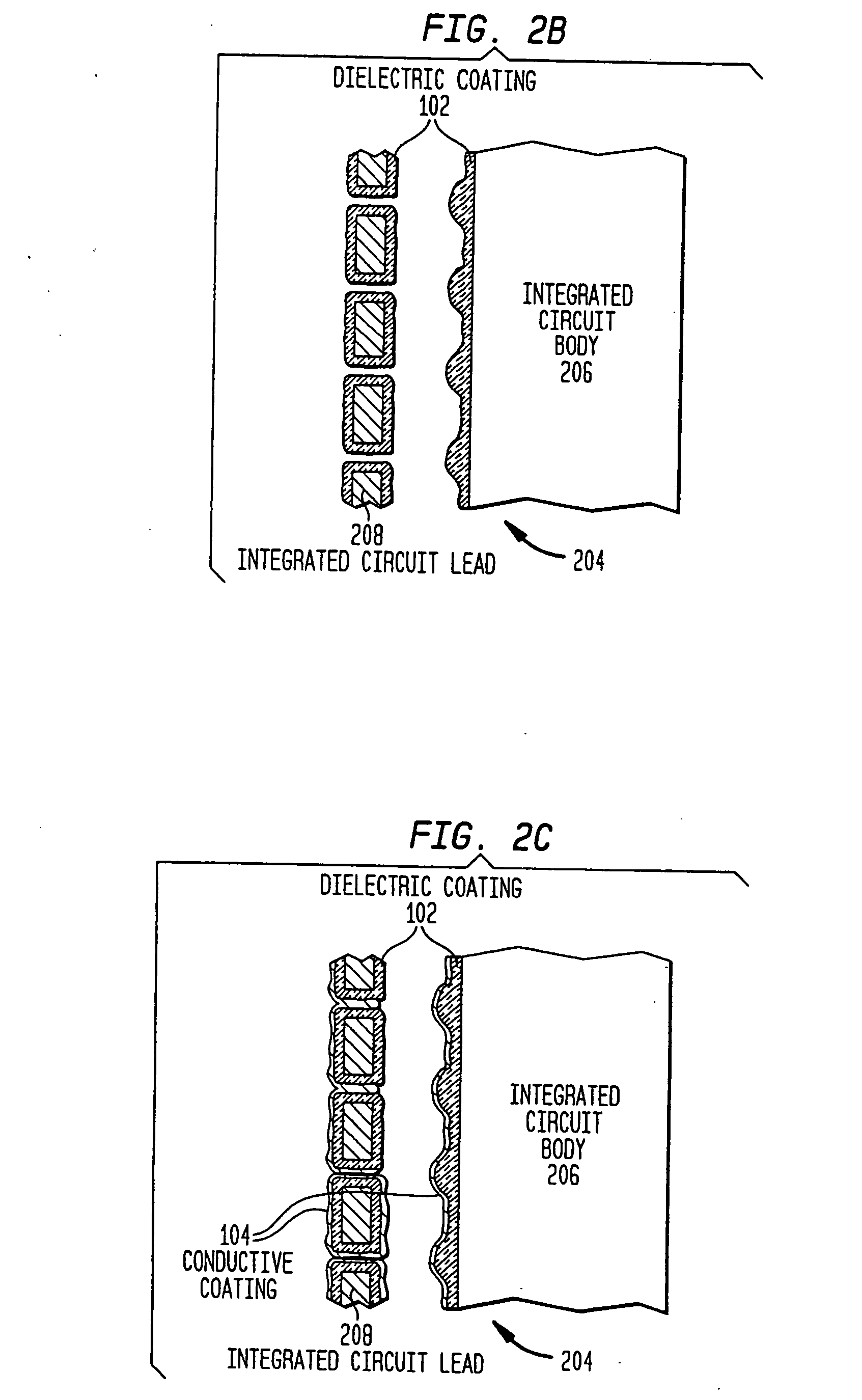

Board-level conformal EMI shield having an electrically-conductive polymer coating over a thermally-conductive dielectric coating

InactiveUS20050095410A1Improve heat distributionLift restrictionsMagnetic/electric field screeningCross-talk/noise/interference reductionConductive coatingConductive polymer

An electrically continuous conformal EMI protective shield for conformingly adhering directly to surfaces of a printed circuit board is disclosed. The EMI protective shield comprises a dielectric coating and a conductive coating. The dielectric coating adheres directly to surfaces of the printed circuit board to provide an electrically nonconductive, contiguous coating that covers all such printed circuit board surfaces. The conductive coating comprises a substantially contiguous layer of an intrinsically conducting polymer adhering directly to surfaces of the dielectric coating to provide an electrically conductive layer that prevents the passage of electromagnetic emissions through the conformal EMI shield.

Owner:MAZURKIEWICZ PAUL H

Paired multi-layered dielectric independent passive component architecture resulting in differential and common mode filtering with surge protection in one integrated package

InactiveUS20050063127A1Reduce susceptibilityLow costSemiconductor/solid-state device detailsSolid-state devicesElectricityDielectric

The present invention relates to a passive electronic component architecture employed in conjunction with various dielectric and combinations of dielectric materials to provide one or more differential and common mode filters for the suppression of electromagnetic emissions and surge protection. The architecture allows single or multiple components to be assembled within a single package such as an integrated circuit or connector. The component's architecture is dielectric independent and provides for integration of various electrical characteristics within a single component to perform the functions of filtering, decoupling, fusing and surge suppression, alone or in combination.

Owner:X2Y ATTENUATORS L L C

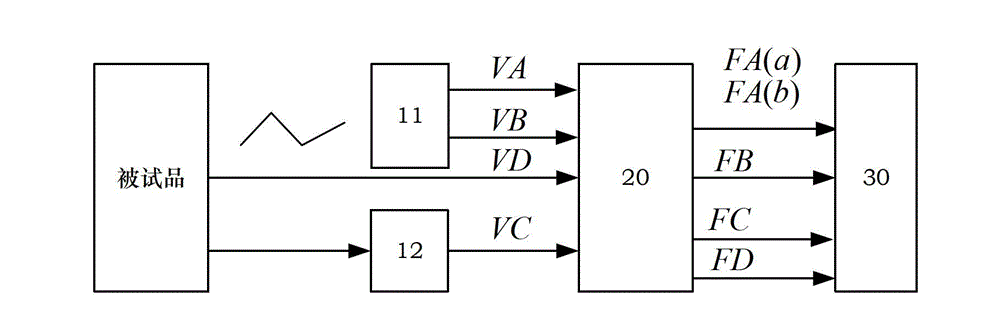

Fast electromagnetic compatibility test and diagnosis system with quantization electromagnetic interference

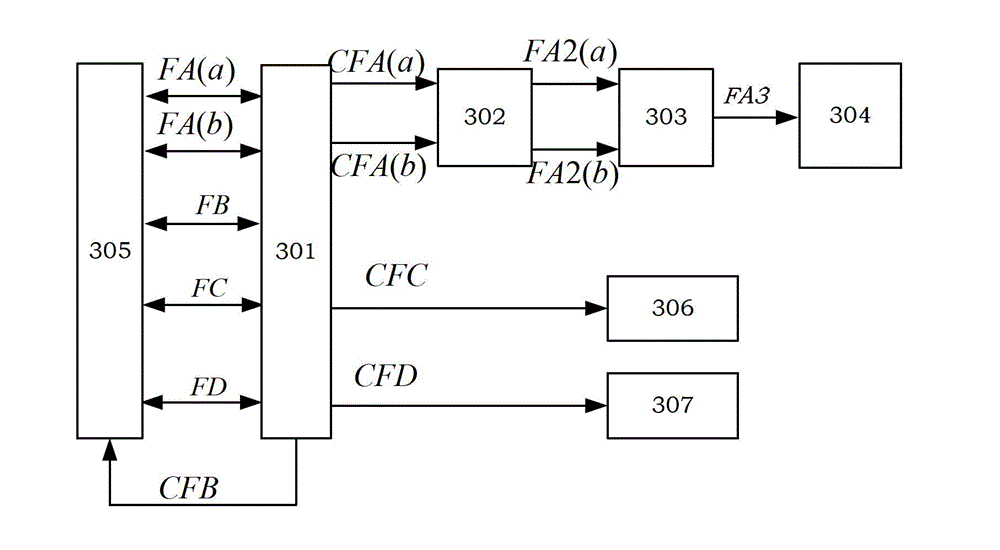

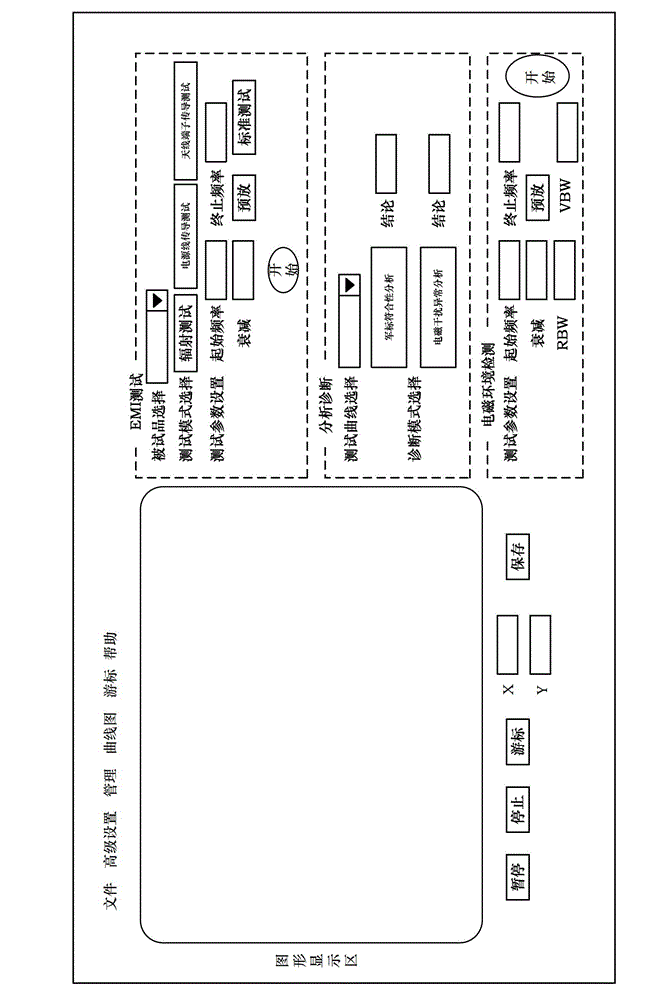

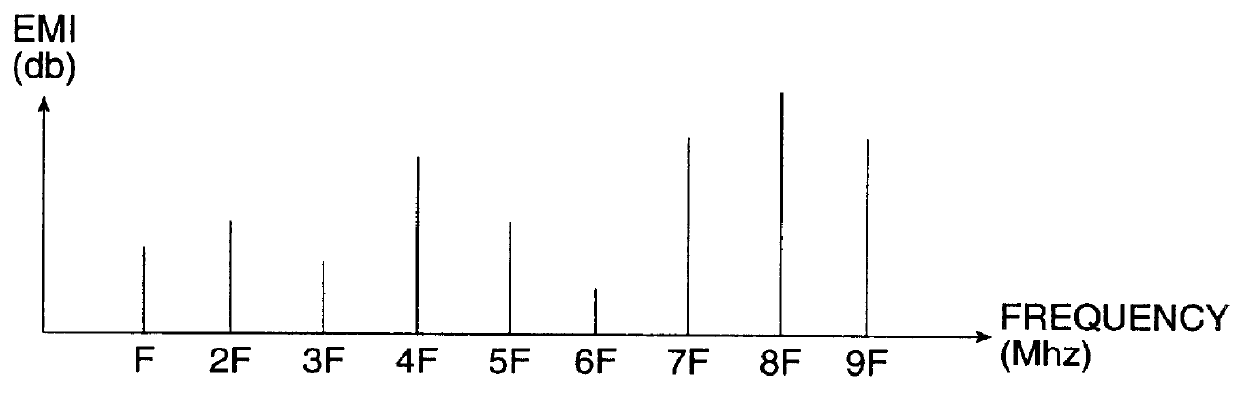

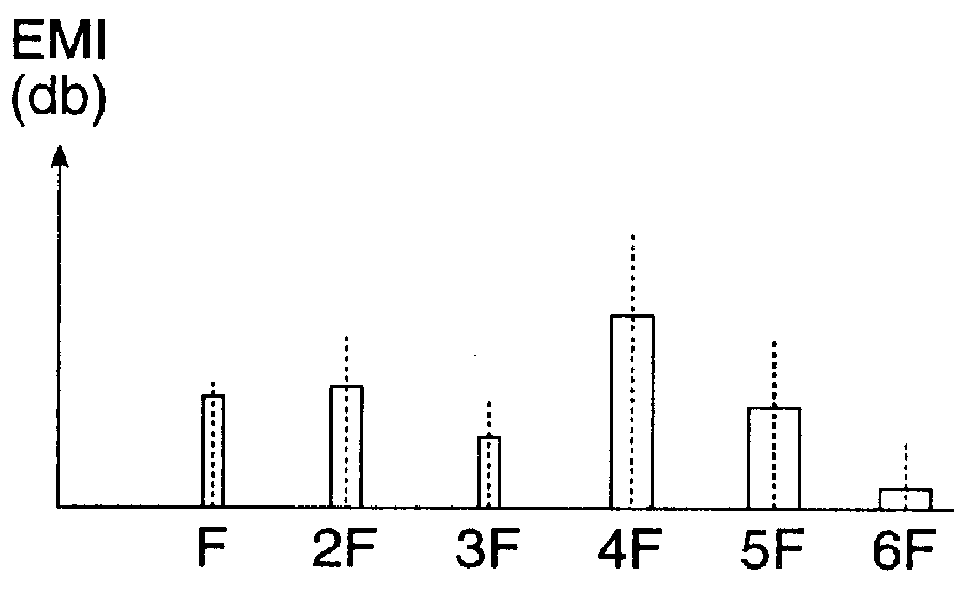

ActiveCN102749539AEasy to analyzeSimplify Rapid Test DiagnosticsElectrical testingFrequency spectrumTester device

The invention discloses a fast electromagnetic compatibility test and diagnosis system with quantization electromagnetic interference. A receiving antenna of the system is arranged on a frequency spectrum tester, a chuck end of a current probe is clamped on a cable through which tested objects are connected, the other end of the current probe is connected on the frequency spectrum tester which is connected with a computer; and the computer is internally provided with a fast electromagnetic compatibility test and diagnosis unit. The fast electromagnetic compatibility test and diagnosis unit is used for fast testing the electromagnetic-transmitted frequency spectrum of the tested objected on site, conducting analysis and diagnosis to the electromagnetic-transmitted frequency spectrum, and judging whether the electromagnetic transmission characteristic exceeds a standard limit value or has abnormality. The fast electromagnetic compatibility test and diagnosis system has important meaning on solving the electromagnetic compatibility problem and monitoring and evaluating the electromagnetic environment.

Owner:BEIHANG UNIV

Method and apparatus for reducing radiated electromagnetic emissions from harmonic frequencies for electronic equipment

InactiveUS6014063AReadily availablePulse automatic controlElectric pulse generatorFrequency spectrumHarmonic

A system of spreading the energy of higher harmonic frequencies in digital circuits to lower the interference to bandpass receivers is disclosed. A set of passive, impedance-regulated circuits, preferably housed in a standard enclosure, comprises a power restoring unit, a modulating signal generator, an internal oscillator and an impedance spreading unit. The circuits are equivalent to passive resonators such as crystal resonators used in standard oscillators. Any existing standard oscillator that uses common crystal resonators can be transformed into a spectrum-spread oscillator by replacing the crystal resonator with the disclosed circuit, whereby a tightly controlled small frequency spreading occurs in the fundamental clock frequency. Further an active oscillator is disclosed wherein a spreading circuit spreads the frequency of the clock signal originally generated by the oscillator based on a sequence of processing the original clock signal. The processing includes the use of a plurality of delay elements based on a certain topology, the comparisons between the clock signal and a set of predefine parameters so as to create a frequency offset. The spreading circuit, without using additional clocking sources, spreads the frequency of the clock signal with respect to the comparisons.

Owner:QUIET SOLUTION

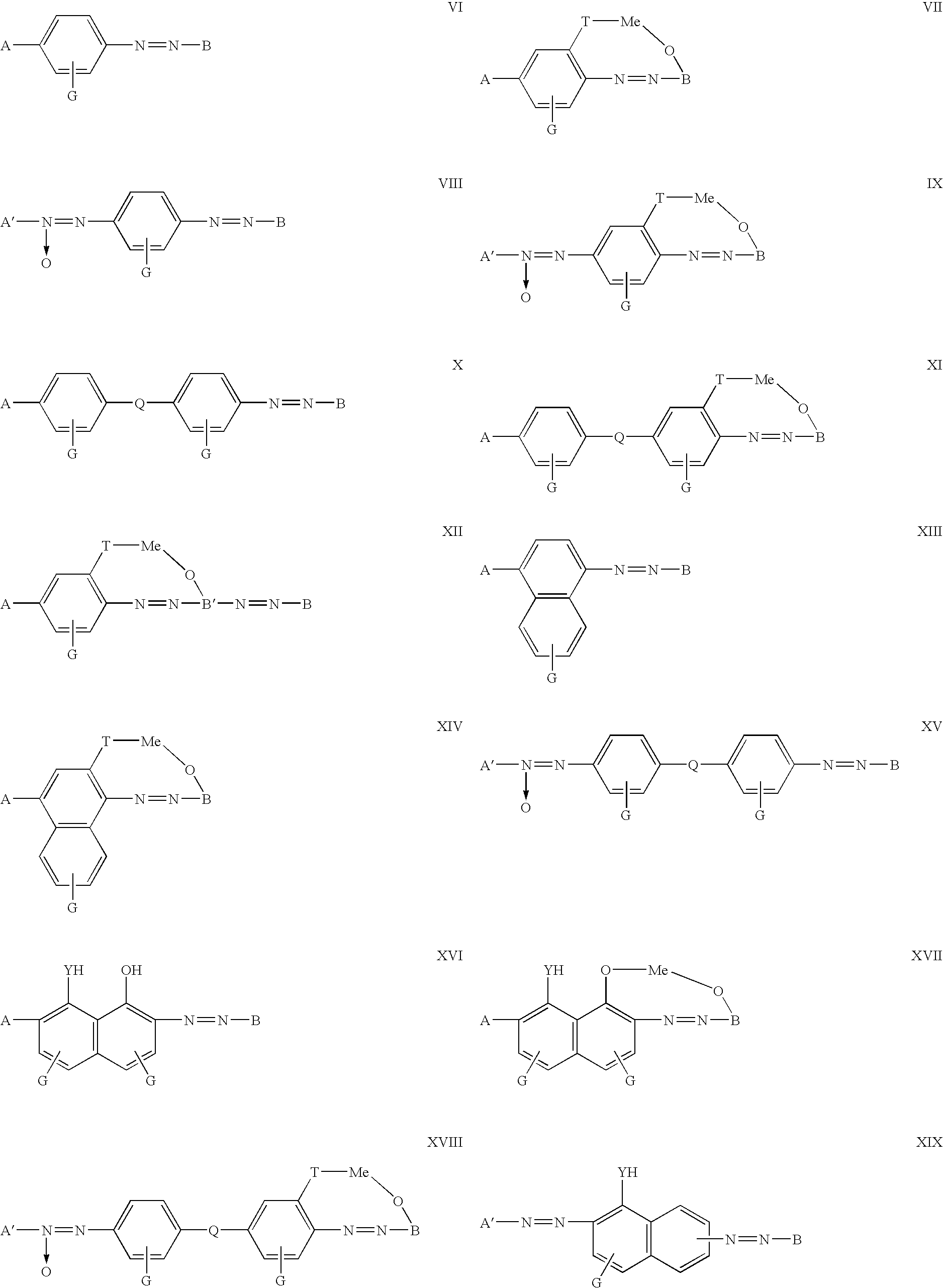

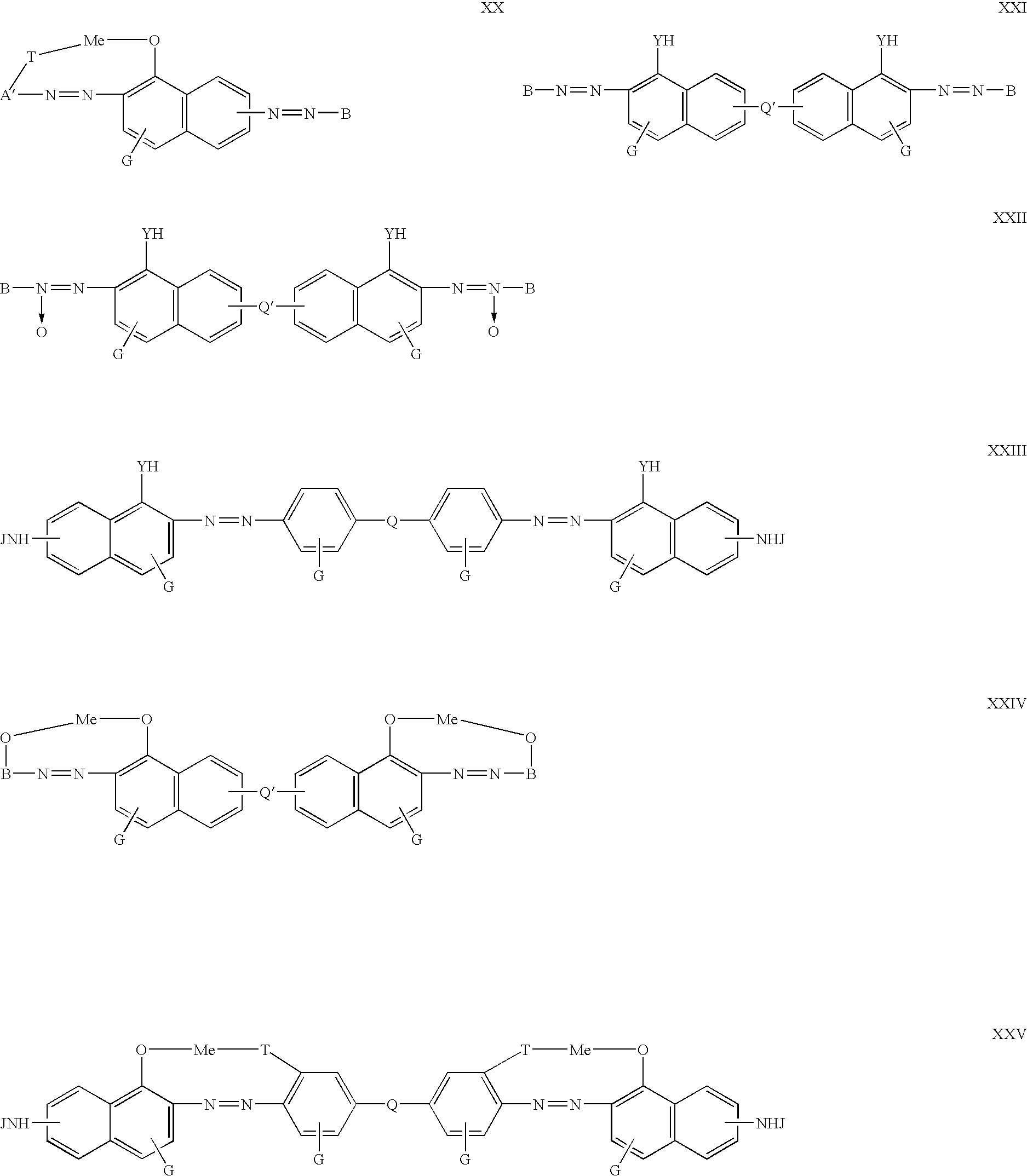

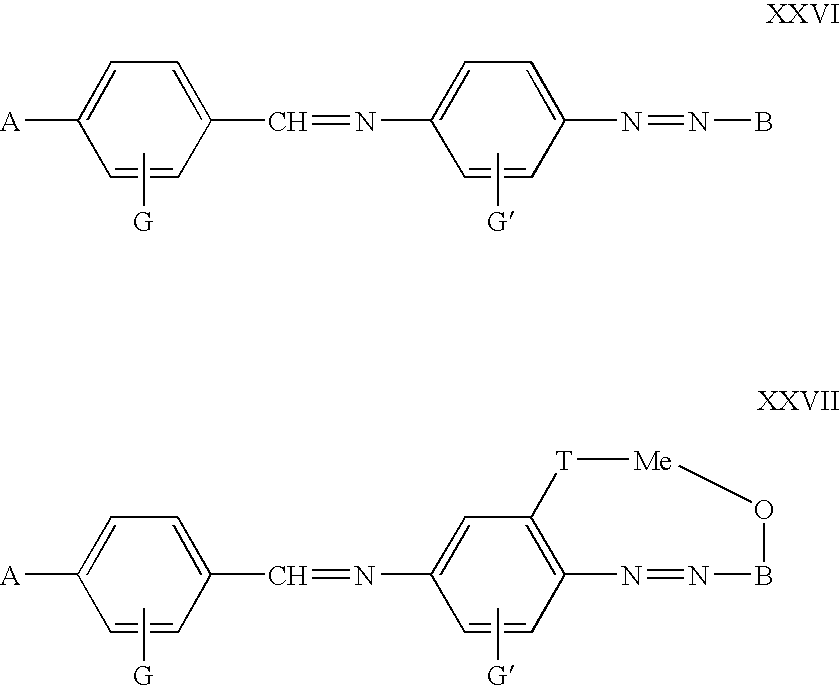

Optical device

InactiveUS20040232394A1Liquid crystal compositionsMethine/polymethine dyesPolarizerElectromagnetic radiation

The invention relates to optical devices for producing and / or transforming polarised electromagnetic emission by means of anisotropic absorption and / or optical rotation effects and / or birefringence and can be used as different polarizers (dichroic, reflecting), lagging layers (retarders), liquid-crystal displays and indicators and also for producing polarising glass for building construction and for sun and antiglare glasses, masks, aprons and faceplates. The inventive optical device is based on at least one molecularly oriented layer of a low-molecular or oligomeric dichroic material which can form a stable lyotropic liquid crystal structure. The projection of at least one anisotropically absorbing fragment of a molecule of the dichroic material on the surface of the molecularly oriented layer of a dipole moment of optical transition is disposed in a parallel position to the optical axis of the molecularly oriented layer at least within several ranges of wavelength of the electromagnetic emission.

Owner:IR GVON KHAN

Communication device

InactiveUS6869019B1Antenna supports/mountingsCo-operative working arrangementsCommunication qualityEngineering

In a communication device, electric circuits other than an antenna are enclosed in a shielding member made of a material that shuts off radio waves, and the antenna is enclosed by disposing in front thereof a radio wave absorbing member that attenuates radio waves in a predetermined frequency band. Thus, unnecessary electromagnetic emission is alleviated while satisfactory communication quality is secured.

Owner:ROHM CO LTD

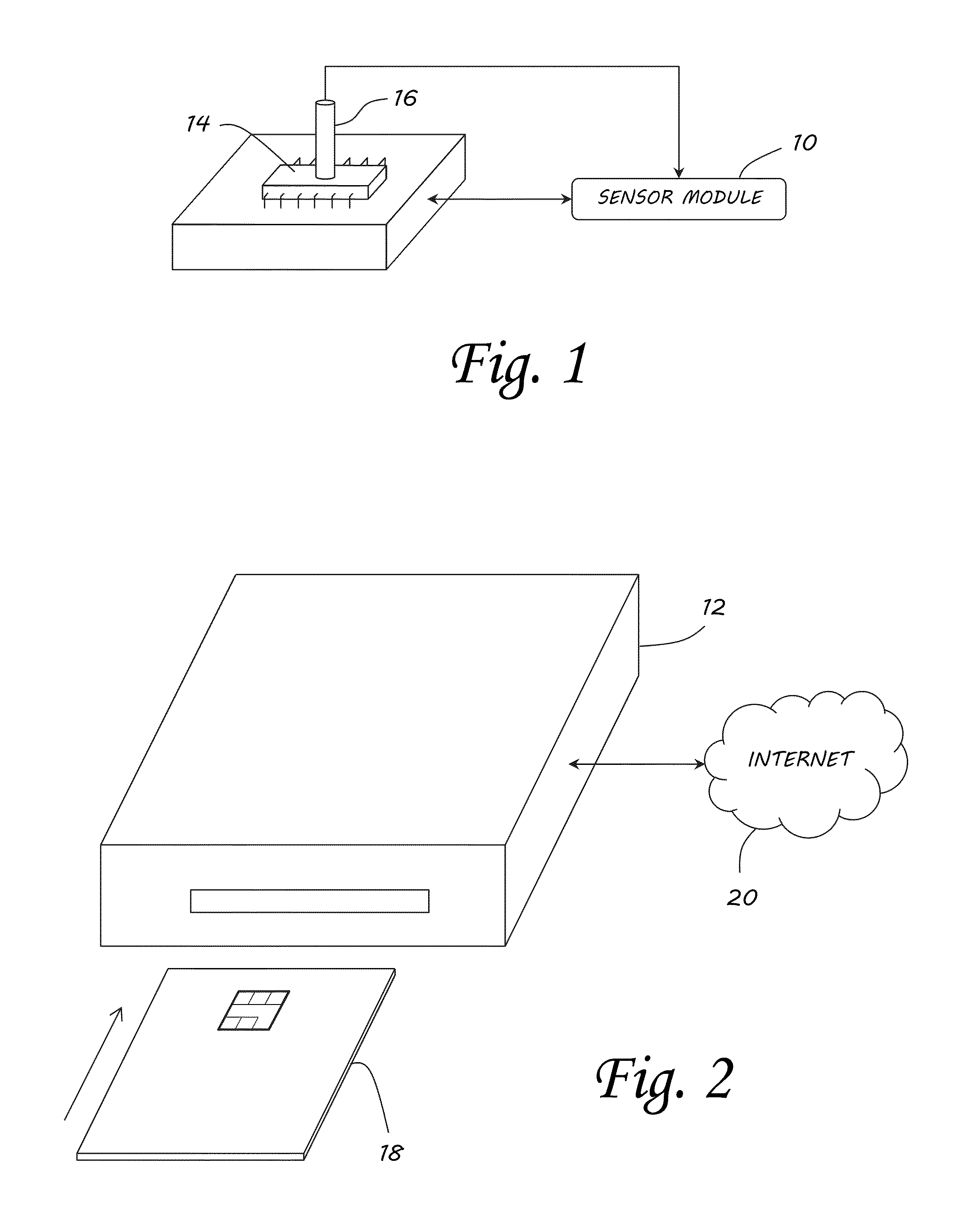

Intrinsic Physical Layer Authentication of Integrated Circuits

InactiveUS20130108145A1Character and pattern recognitionImage data processing detailsComputer hardwareFeature extraction

A system and method of generating and comparing a fingerprint for an integrated circuit is provided. A sensor module captures electromagnetic emissions from the integrated circuit. A feature extraction module extracts discriminating features from the captured electromagnetic emissions. A classifier training module generates a plurality of authentication fingerprints of the integrated circuit from the extracted discriminating features creating a reference fingerprint template for the integrated circuit. The reference template for the integrated circuit is stored in a database. For authentication, the reference fingerprint template from the database is compared to the generated authentication fingerprint.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

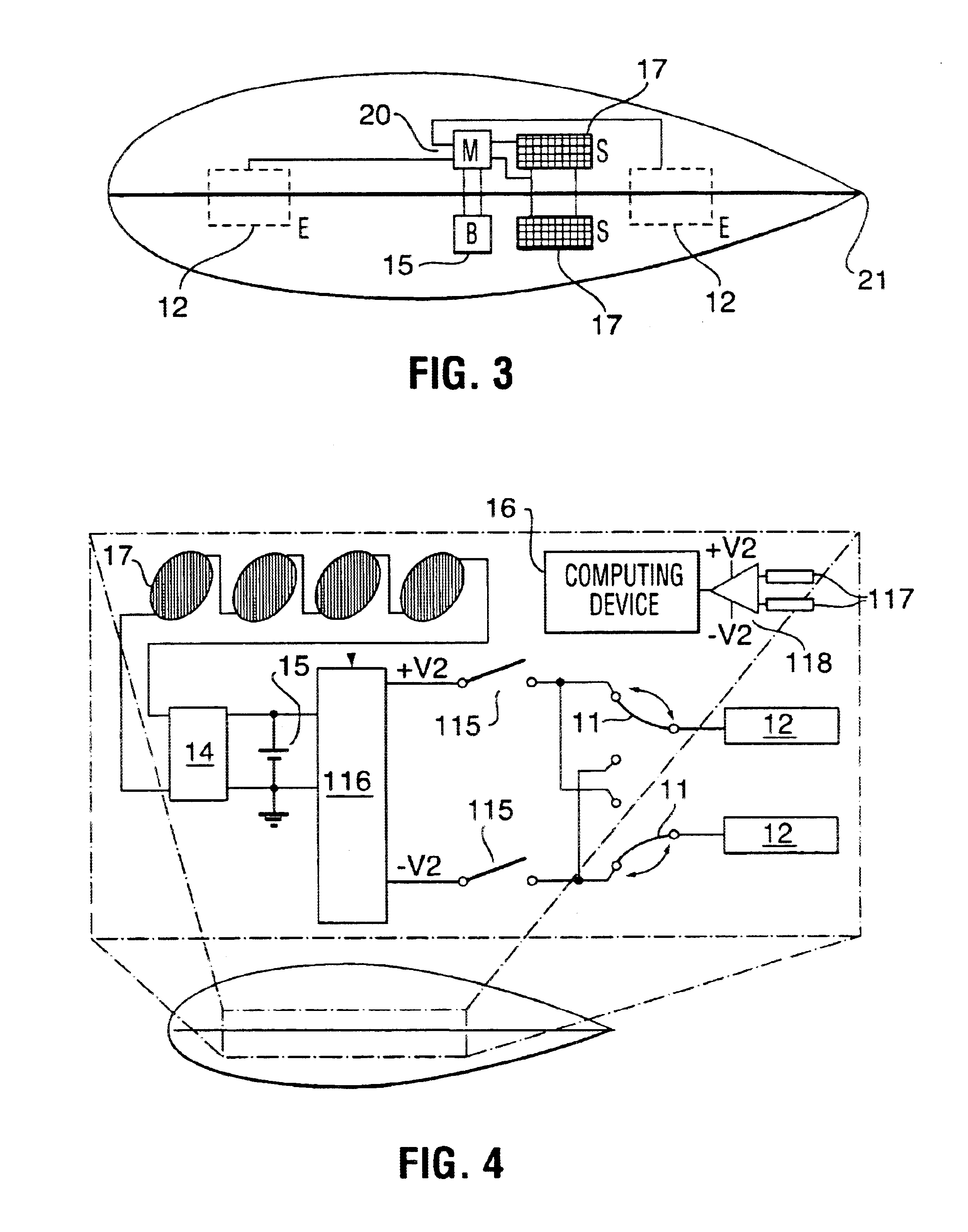

Apparatus for controlling aquatic creatures

The present invention provides an apparatus for controlling aquatic creatures in a body of water. The apparatus comprises a power supply, a solar conversion system, two electrodes, a controllable switch unit and a control system. In operation, this apparatus generates electromagnetic emissions that are perceivable by a number of aquatic creatures thereby providing an ability to control the behaviour of these aquatic creatures, for example, attraction or repulsion thereof. The power supply provides the necessary energy and electric voltage level for the apparatus to operate and the solar conversion system provides a means for recharging and / or maintaining a sufficient energy level within the power supply. A controllable switch unit is interconnected to the two electrodes and enables the selective application of energy provided by the power supply, thereby providing for the generation of electromagnetic emissions. The control system is integrated into the apparatus in order to provide a mechanism for controlling each of the components of the apparatus, for example, to control the generation of desired electromagnetic emissions and to control the recharging of the power supply by the solar conversion system. The apparatus according to the present invention is a self-contained system and therefore is capable of continued operation without the interconnection with other systems, for example, recharging the power supply. The present invention can be incorporated into water devices, for example surfboards, lifevests or scuba equipment.

Owner:LEBLANC HUGO

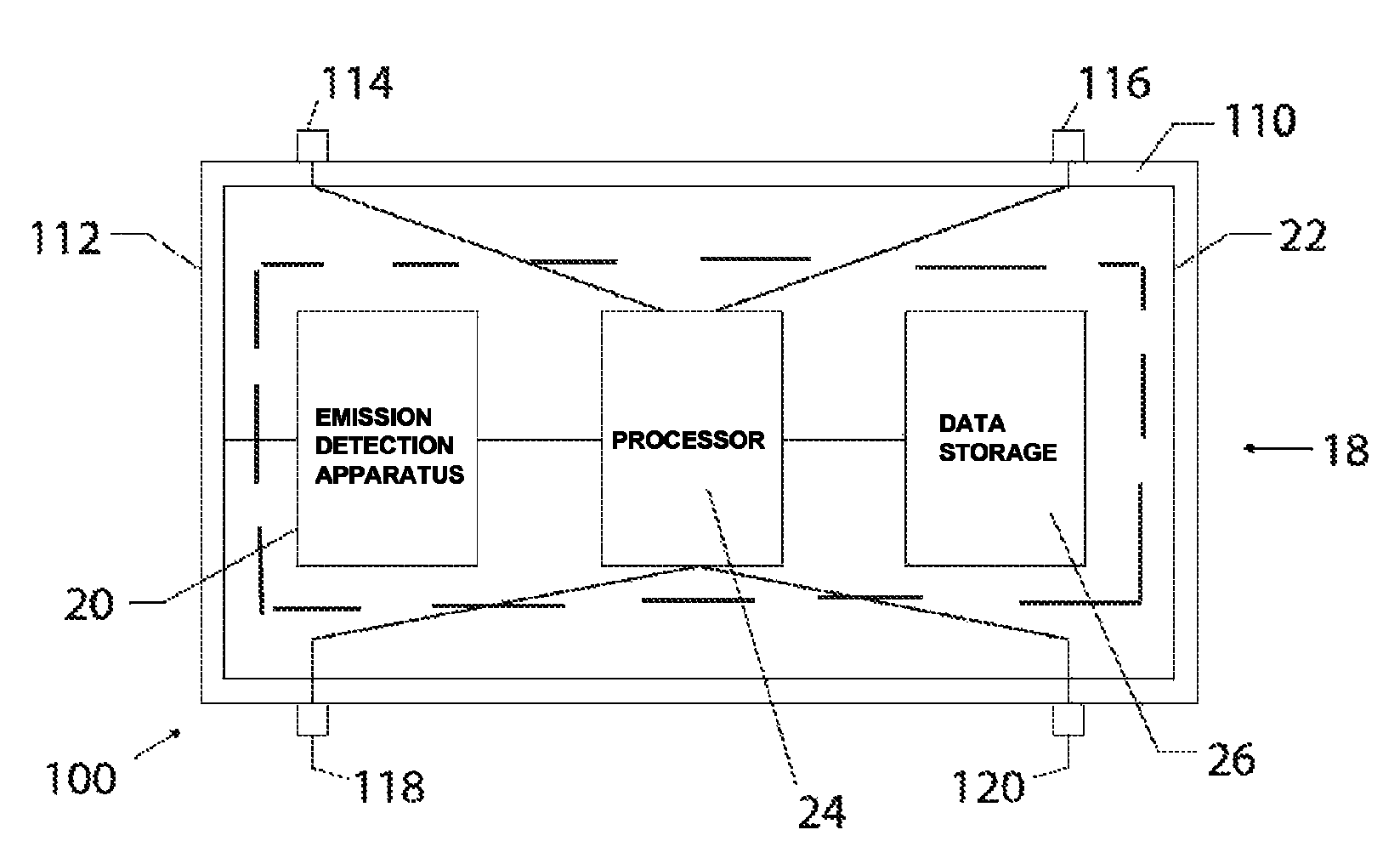

Integrated circuit with electromagnetic energy anomaly detection and processing

ActiveUS9059189B2Constant monitoringSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsAnomaly detection

An integrated circuit includes an antenna, a die manufactured from a semiconducting material, an RF energy collection and processing device disposed on or within the die and including at least a receiver and a processing device, an input configured to supply power to said RF energy collection and processing device and an output for operative communication by said RF energy collection and processing device. The integrated circuit is configurable and operable to provide at least one of electromagnetic emission anomaly detection, tamper detection, anti-tamper monitoring, degradation monitoring, health monitoring, counterfeit detection, software changes monitoring, firmware changes monitoring and monitoring of other RF energy anomalies.

Owner:NOKOMIS

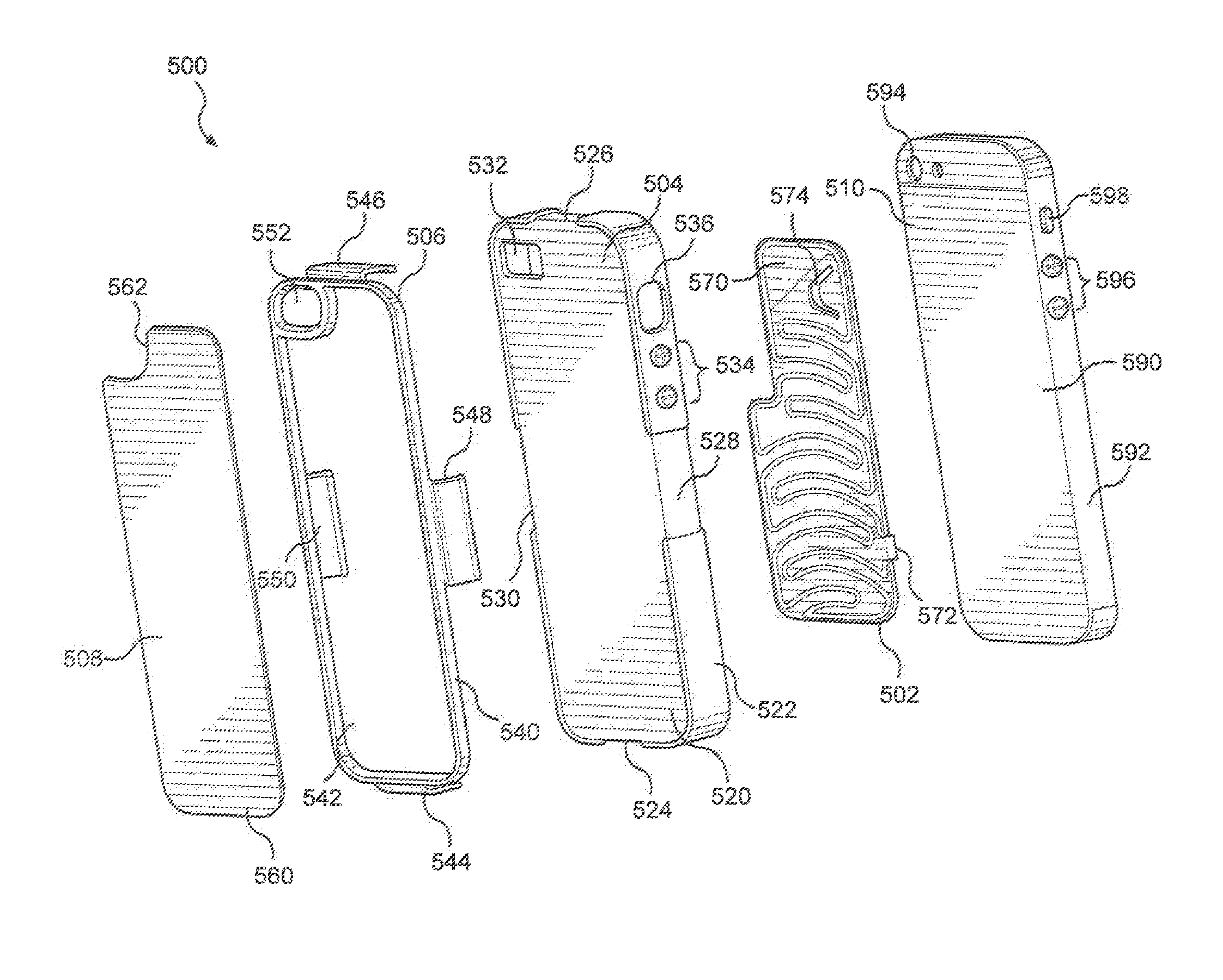

Radio frequency emission guard for portable wireless electronic device

ActiveUS20140159980A1Avoid spreadingOptimizing available transmission pathLoop antennasAntenna detailsEngineeringRadio frequency

A radio frequency and electromagnetic emission shield employed on wireless personal and portable electronic devices, containing one or more layers of radio frequency (RF) or electromagnetic (EM) screening material, shielding the user from harmful RF or EM radiation, or a redirection antenna that receives all RF signals, and redirects those signals away from the user. The RF emission shield may be contained within a plurality of outer layers, providing a secure fit to a wireless electronic device and an outer layer providing an easy grip for the user.

Owner:STINGRAY SHIELDS CORP

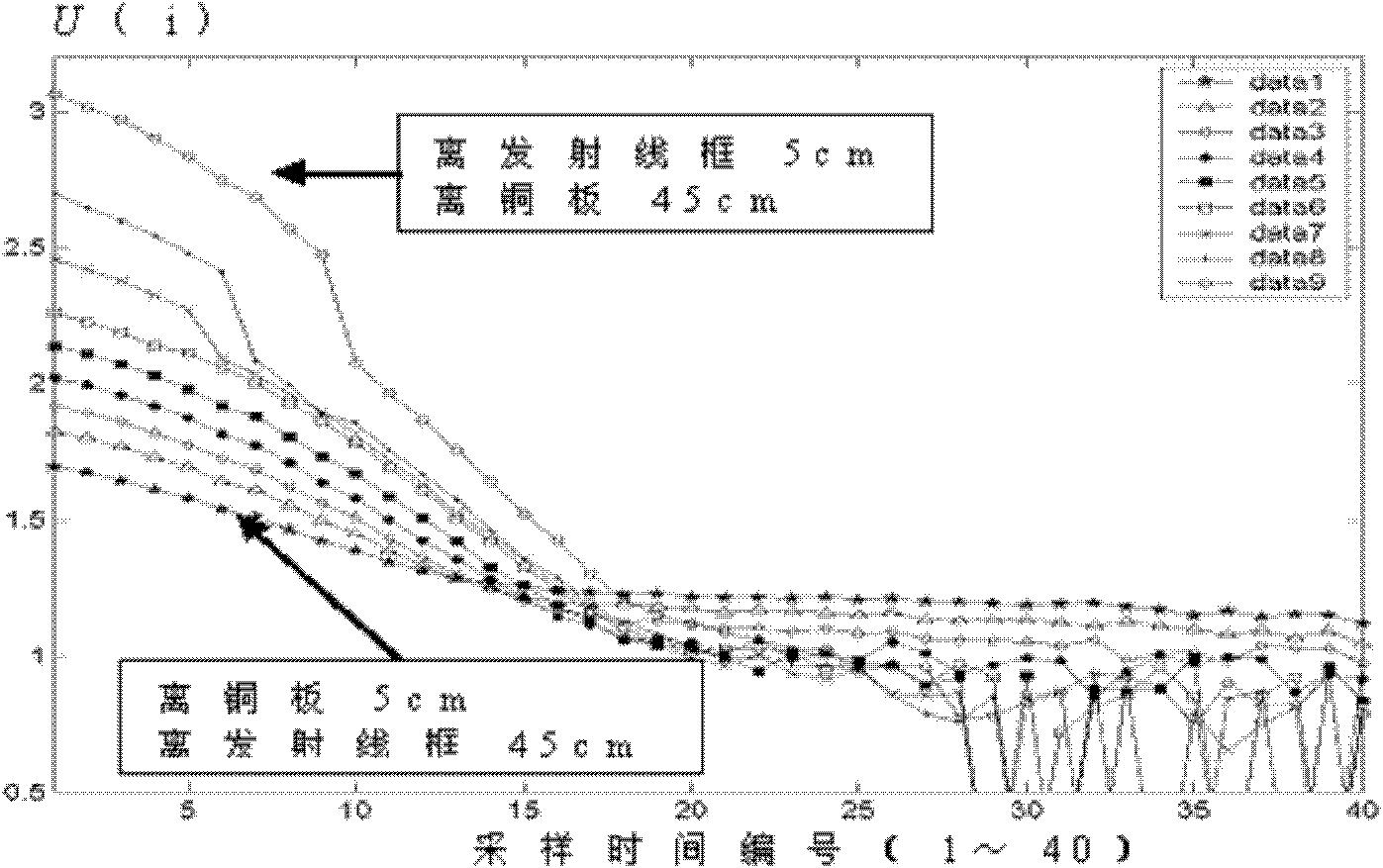

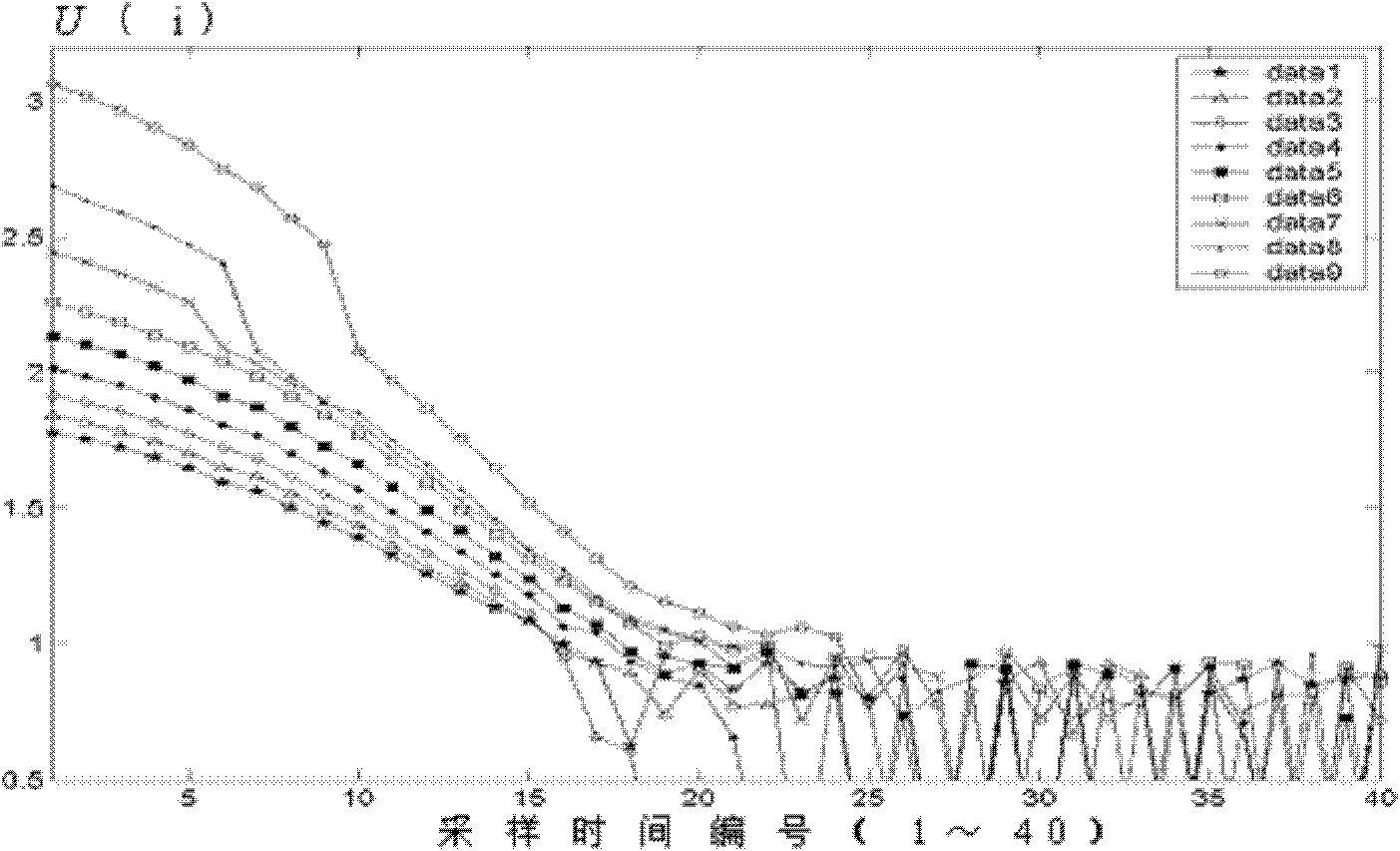

Line array multi-channel synchronous transient electromagnetic directional detection method and device thereof

InactiveCN102323622AComparable signals are strongImprove signal-to-noise ratioRadio wave finder detailsDetection using electromagnetic wavesPrimary fieldDrill hole

The invention discloses a line array multi-channel synchronous transient electromagnetic directional detection method and a device thereof. The method is characterized in that a transmitting line frame is arranged in the direction vertical to a detection direction and multiple channels of receiving line frames or magnetic bars are arranged forwards along the exploration direction, with the centerof the transmitting line frame as the starting point; a transient electromagnetic transmitter is started to transmit primary fields and multiple channels of synchronous acquisition systems synchronously acquire transient electromagnetic response secondary field signals according to the synchronous signals provided by the transient electromagnetic transmitter; the response signals of disturbing bodies around the transmitting line frame and behind coils and the mutual induction signals of a source coil and multiple channels of receiving coils are fast attenuated forwards and the abnormal response signals of front objects are gradually enhanced forwards; and directional explain for whether low-resistance abnormal bodies exist in front can be carried out according to the amplitudes and changecharacteristics of the signals which are regularly enhanced forwards. The method and the device are suitable for use in the fields such as advanced prediction in tunnels by the transient electromagnetic method and directional detection combining drill holes and the ground or airborne and ocean exploration by the transient electromagnetic method.

Owner:朱德兵

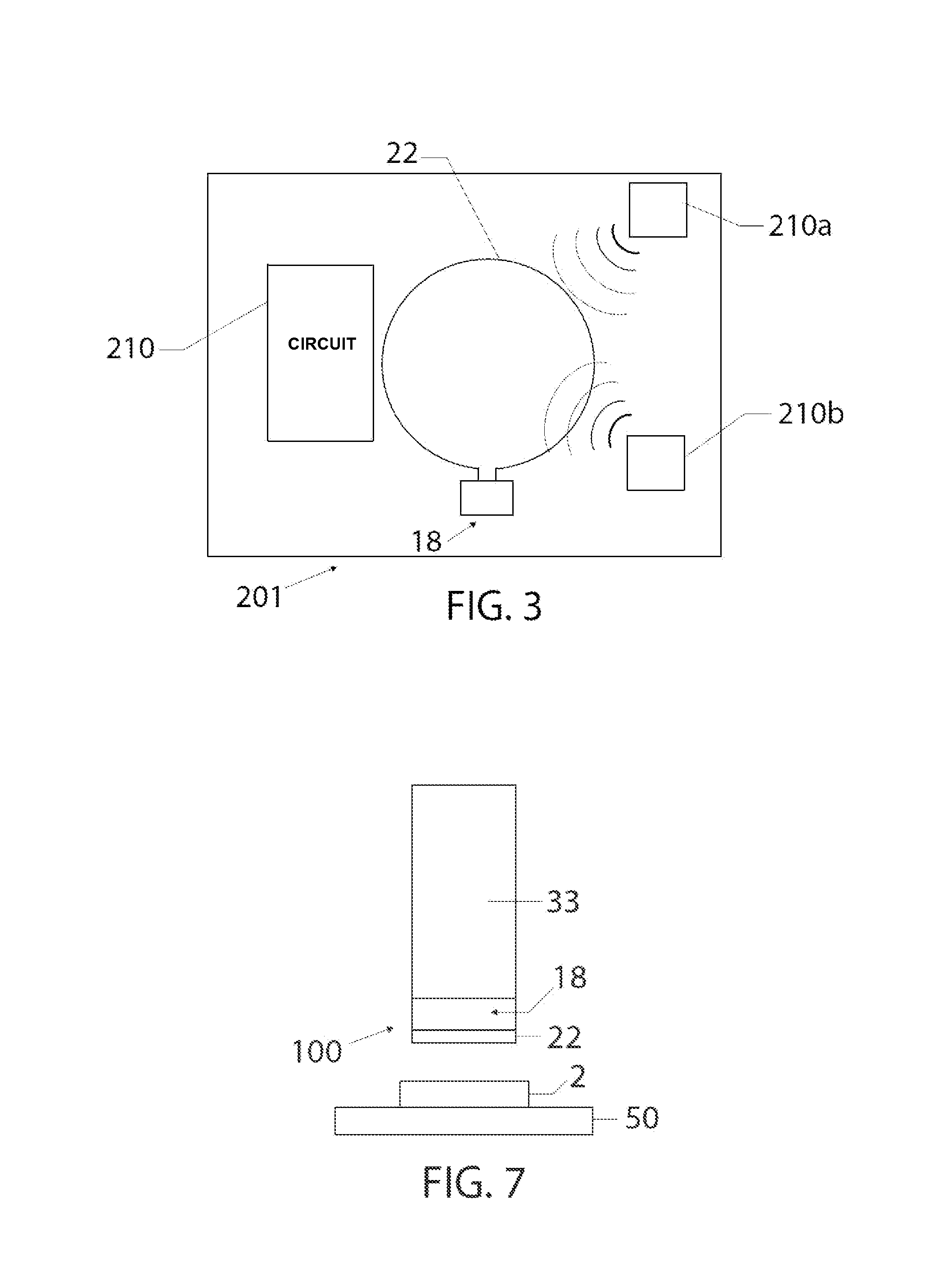

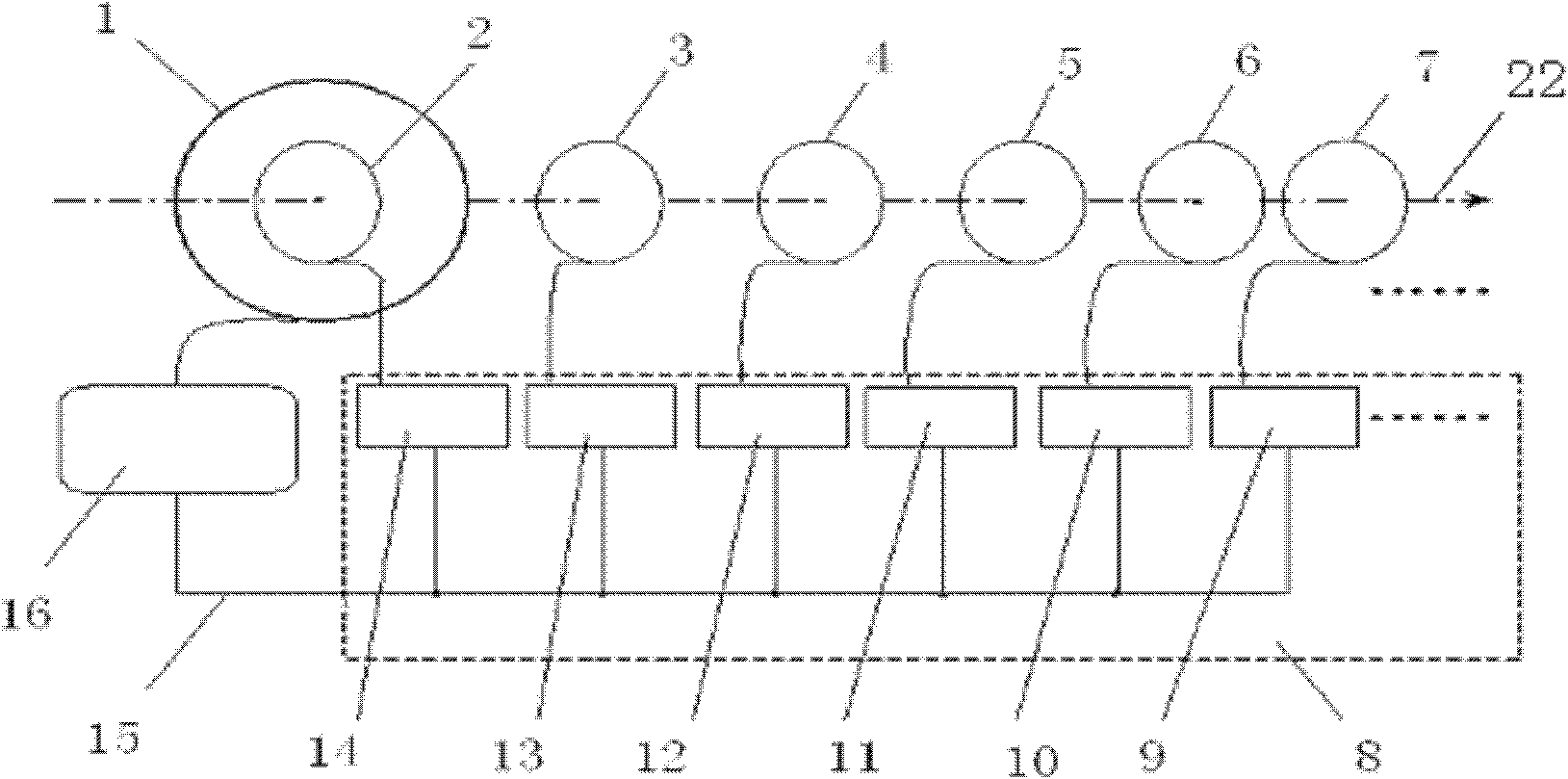

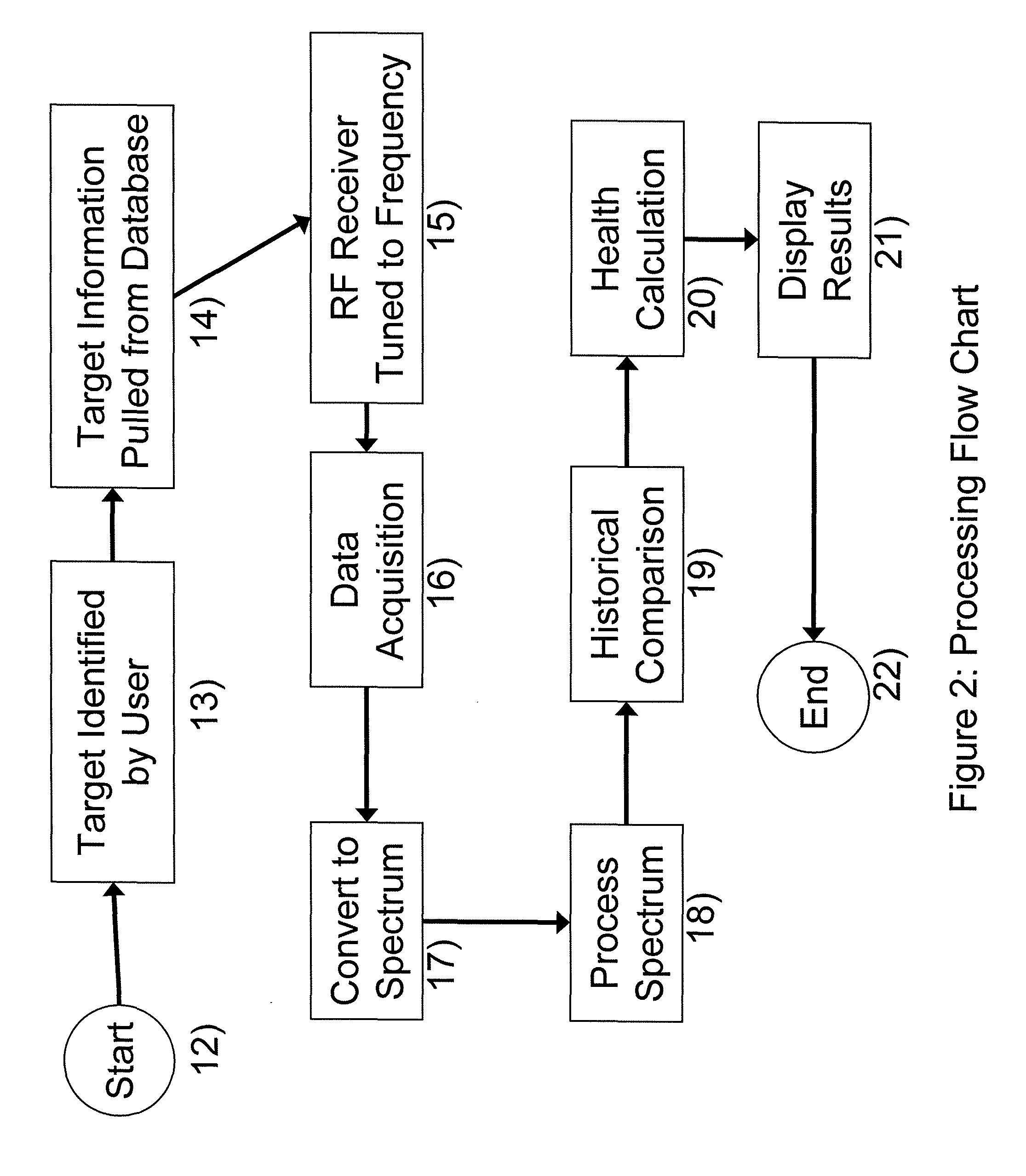

Advance manufacturing monitoring and diagnostic tool

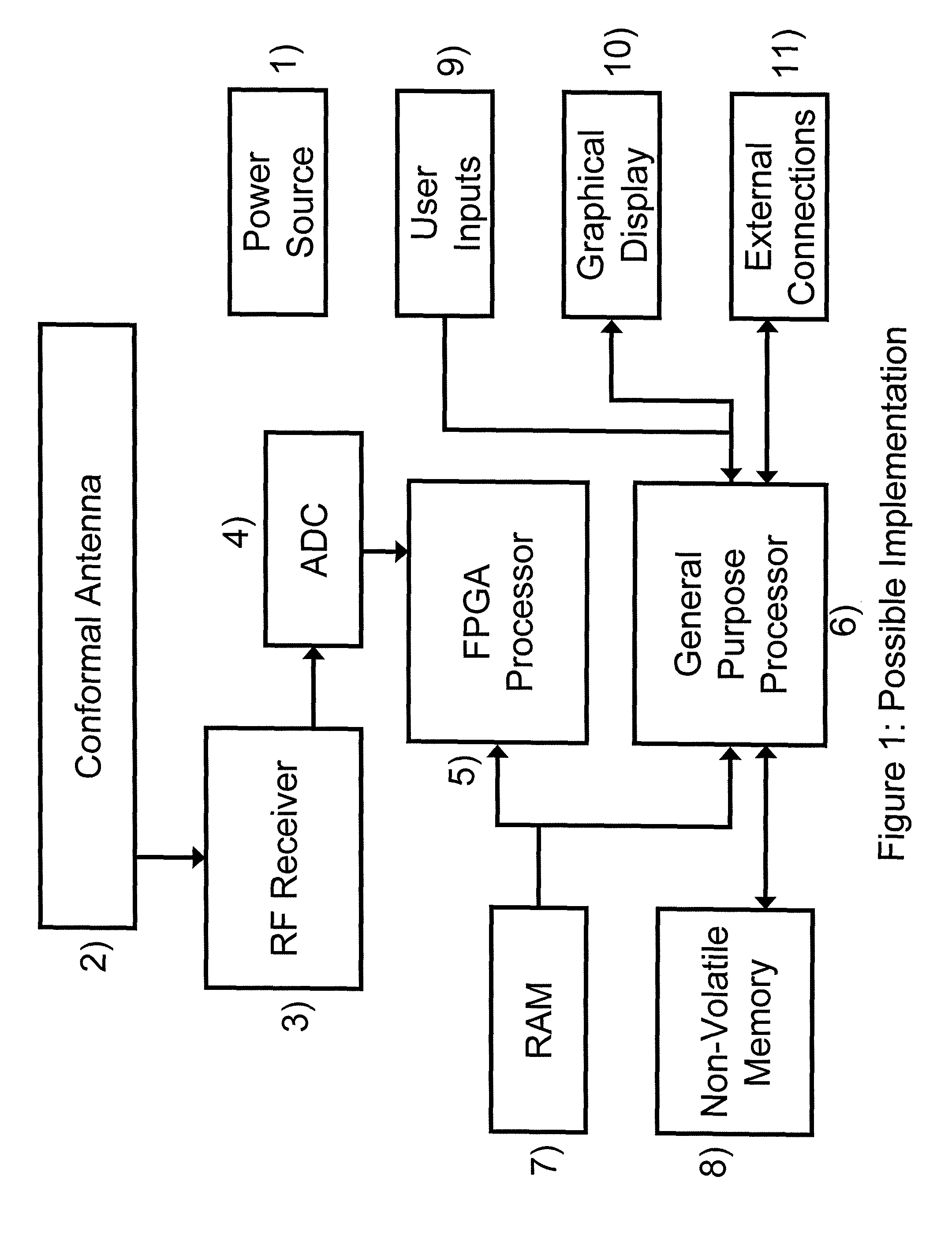

ActiveUS8643539B2Easily employedEasy accessElectric winding testingTransformers testingElectricityElectrical devices

The current invention relates to a monitoring and analysis device and a method for monitoring and analysis that utilizes the unintended electromagnetic emissions of electrically powered systems. The present invention monitors electrical devices by taking detailed measurements of the electromagnetic fields emitted by any component or system utilizing electricity. The measurements will be analyzed to both record a baseline score for future measurements and to be used in detailed analysis to determine the status of the analyzed system or component.

Owner:NOKOMIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com