Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295results about How to "Improve anti-ablation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

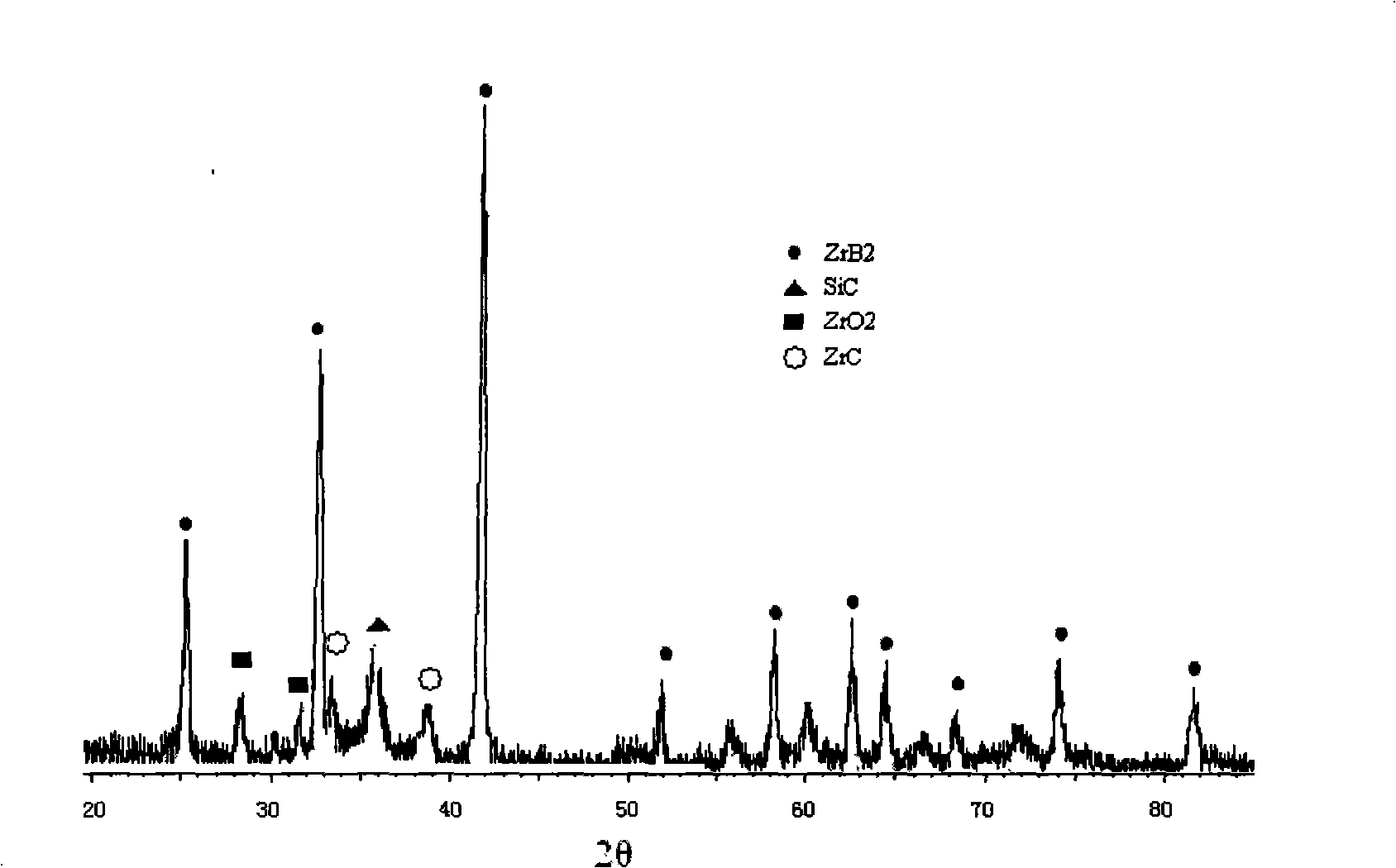

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing superhigh temperature resistant ceramic coat

InactiveCN101306959AImprove anti-ablation performanceImprove antioxidant capacityCeramic coatingSlurry coating

The invention discloses a method for making a super-high temperature resistant ceramic coating. The method adopts organic polymer as adhesive and mixed powder consisting of high melting metal powder, B powder, C powder and Si powder as raw materials; moreover, through adopting processes such as preparing slurry used in a coating, slurry coating, precoating curing, high-temperature reaction sintering, a super-high temperature resistant ceramic coating is finally made on the surface of a ceramic matrix composite material. The coating making process is simple and has low cost; the made coating has ideal bonding performance with a substrate and has excellent ablation resistance and antioxidation, thereby laying the foundation for the application of a ceramic matrix composite material in the super-high temperature resistant and antioxidation fields.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of UHTC powder basal body

InactiveCN103058711AImprove mechanical propertiesGuaranteed mechanical propertiesFiberVacuum pressure

The invention discloses a method for preparing an UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of a UHTC powder basal body. The method comprises the steps of: introducing UHTC powder and a carbon organic precursor into C / SiC with a gas hole ratio of 30 vol% to 40 vol% by adopting a vacuum pressure impregnation way; and performing in-situ reaction on melting silicon and splitting carbon in the basal body, and compacting the material through the combination of RMI (Reactive Melt Infiltration) so as to prepare a C / SiC-UHTC composite material. For one aspect, the SiC basal body protects fibers from being eroded by the melting silicon so as to improve mechanical properties of the material as the C / SiC with the gas hole ratio of 30 vol% to 40 vol% is adopted as a prefabricated body; and for the other aspect, a certain amount of the UHTC powder is introduced into the prefabricated body to improve anti-ablation performances.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

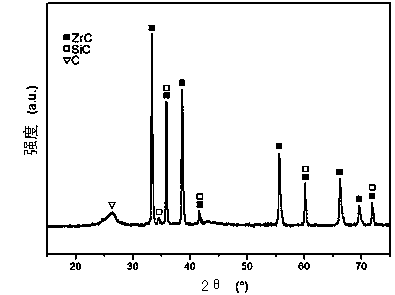

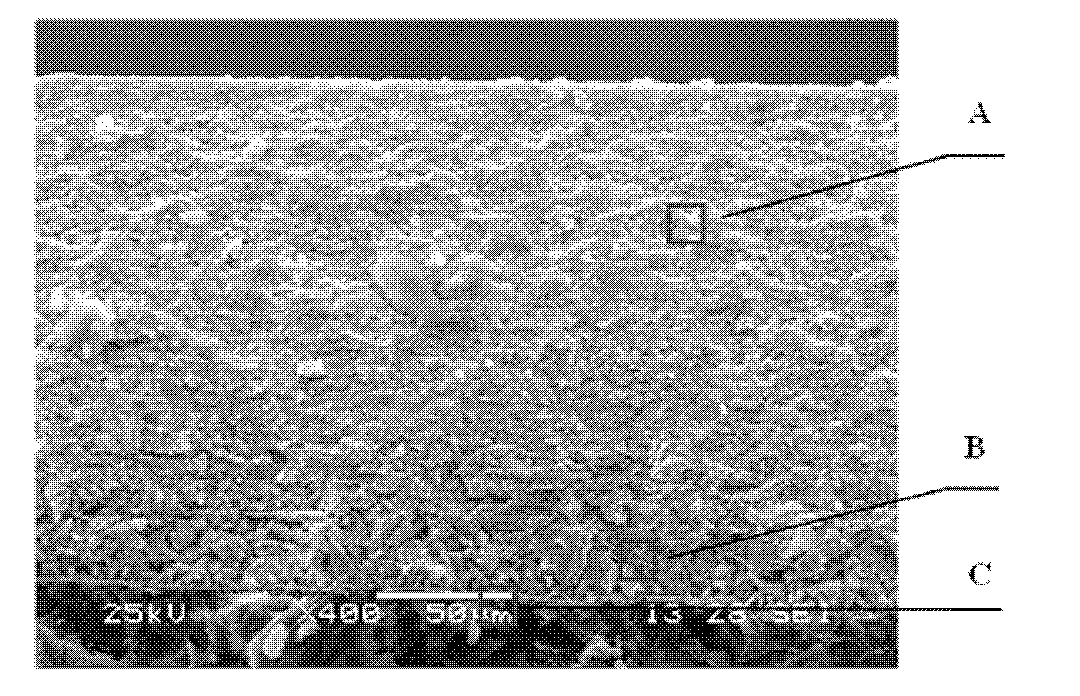

Metallic carbide/carbon composite coating on surface of carbon material and preparation method thereof

InactiveCN101570443ADelay the time of high temperature anti-oxidationSynthesis temperature is lowCarbon fibresCarbon compositesNitrogen gas

The invention relates to a metallic carbide / carbon composite coating prepared on the surface of a carbon material and a method thereof. The method comprises the following steps: placing the carbon material into a chemical vapor deposition furnace, introducing propylene and nitrogen of which flow rates are 100 to 800sccm and 100 to 2,000sccm respectively into the furnace, simultaneously heating the carbon material to between 700 and 1,300 DEG C at a rate of 1 to 20 DEG C per minute, and preserving the heat for 40 to 120 hours to obtain the carbon material of which surface is deposited with a pyrolytic carbon coating; placing the carbon material into a crucible, covering a mixture of 1 to 1.9 times of assistant and 0.01 to 1.2 times of transition metal powder in terms of the carbon material on the carbon material, heating the carbon material to between 600 and 1,200 DEG C at a rate of 1 to 30 DEG C per minute under the atmosphere of the nitrogen, preserving the heat for 1 to 20 hours, cooling the mixture and then taking out a product, washing the product by water and drying the product to obtain the composite coating. The method can prepare various transition metallic carbide / carbon composite coatings on the surface of the carbon material, the thickness and form of the coating are controllable, the combination of the coating and the carbon material basal body is good, and the properties of high-temperature oxidation resistance and ablation resistance of a base material are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

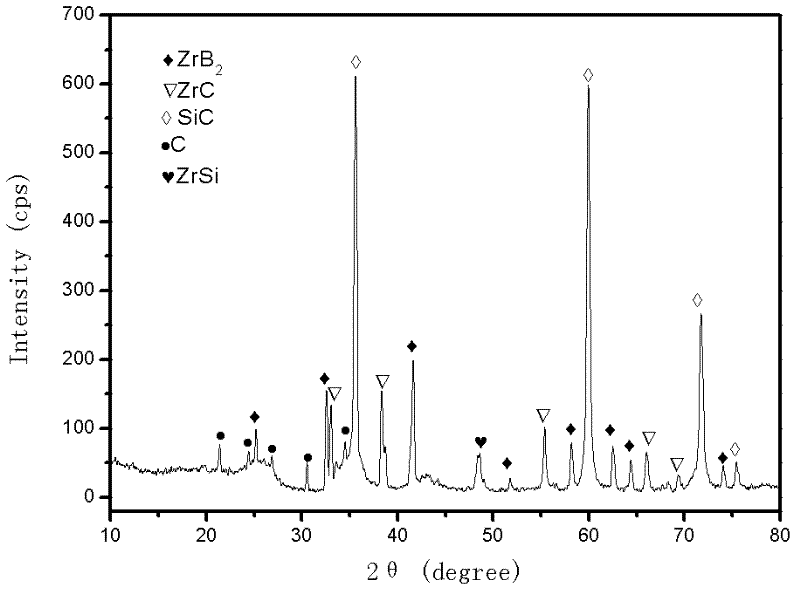

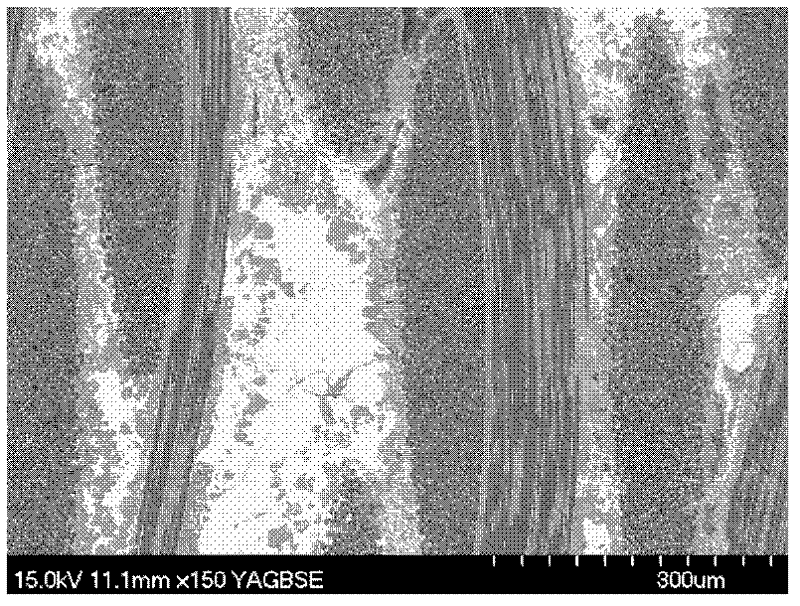

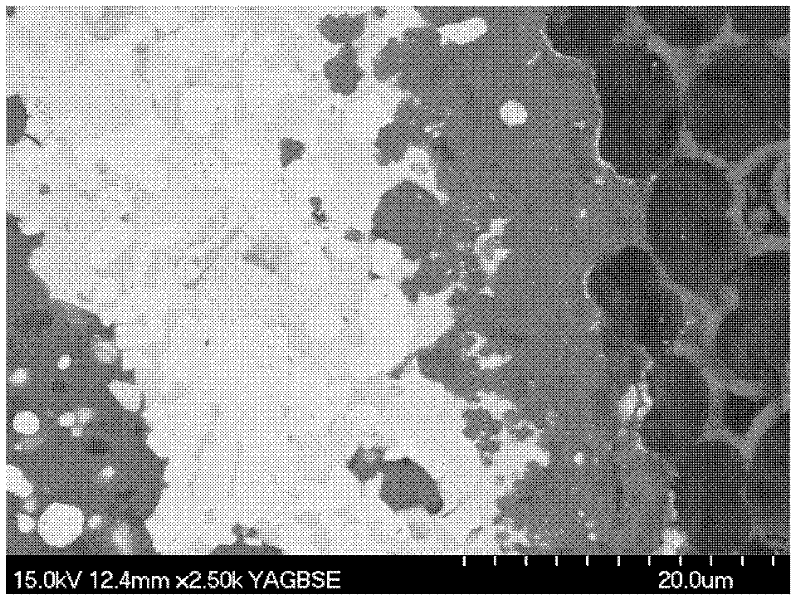

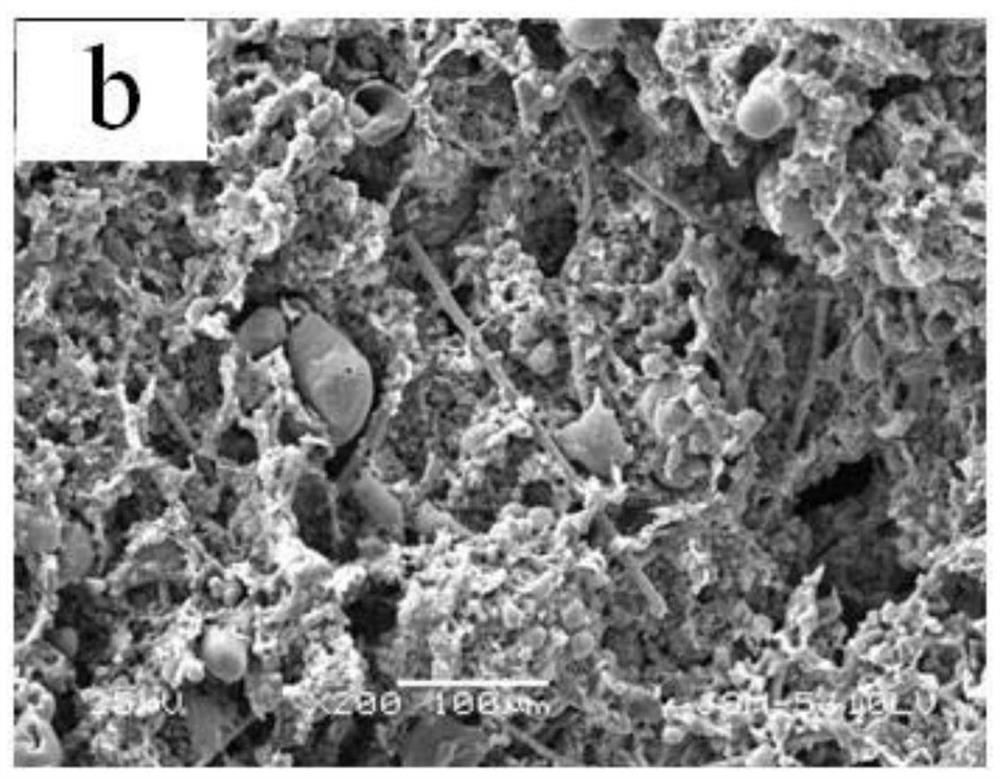

Preparation method of Cf-ZrB2/ZrC/SiC composite material

The invention relates to a preparation method of a Cf-ZrB2 / ZrC / SiC composite material, belonging to the technical field of special ceramics. The method comprises the following steps of: (1) putting a carbon fiber prefabricated body in a chemical vapor deposition furnace, and preparing a pyrolytic carbon interface layer on the surface of the carbon fiber by a chemical vapor deposition technology; (2) pressure impregnation: completely immersing the carbon fiber prefabricated body into a precursor solution, discharging gas out of the prefabricated body to be vacuum, immersing the precursor in the prefabricated body by use of high pressure, and finally performing vacuum drying and cross-linking curing; (3) high-temperature cracking: putting the impregnated and cured carbon fiber prefabricated body in a high-temperature cracking furnace, quickly heating to 1,400+ / -10 DEG C under the protection of inert atmosphere, and preserving heat for 0.5-2 hours; and (4) densifying treatment: repeating the impregnation cracking process for the carbon fiber prefabricated body after being cracked at a high temperature, until the material density at least reaches 2.0g / cm<3>. The method provided by the invention has the advantages of short period, strong adaptability and excellent material performance.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

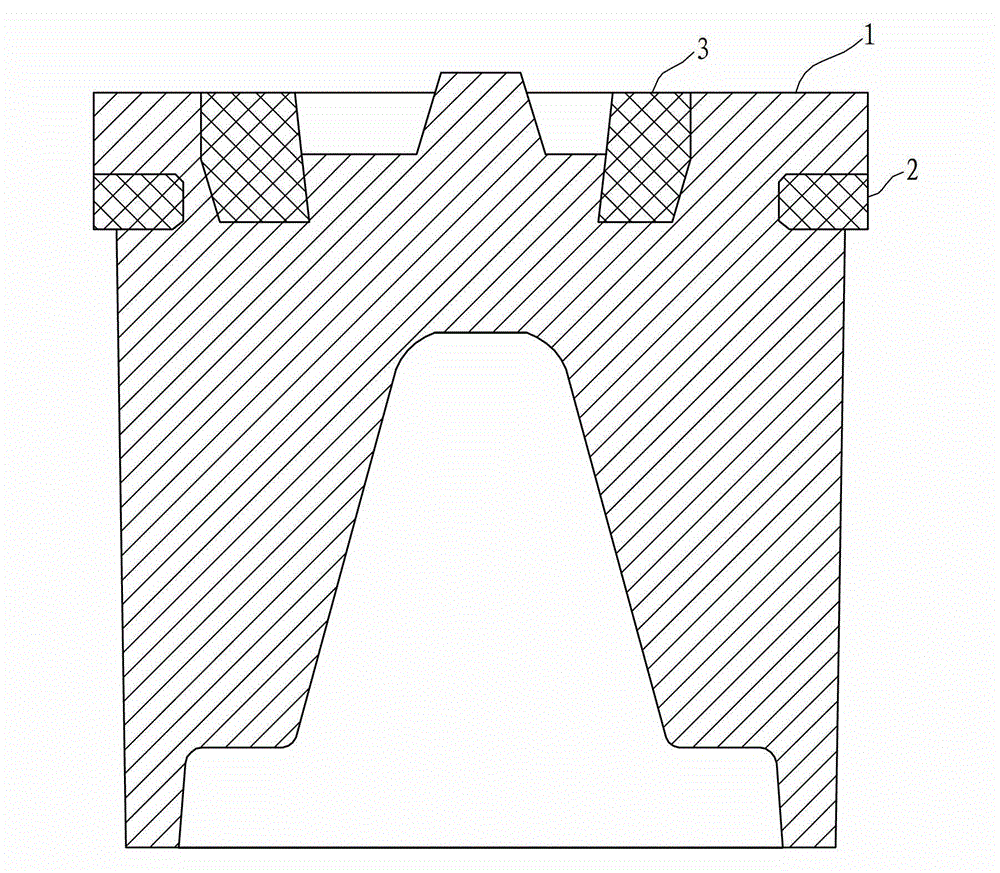

Aluminum piston manufacturing method

InactiveCN102943192AHigh temperature strengthImprove thermal fatigue resistancePlungersTrunk pistonsFiberPiston

The invention relates to an aluminum piston manufacturing method, which is characterized by comprising the following steps: (1) preparing an aluminum alloy for a piston; (2) carrying out a smelting treatment, wherein the prepared piston alloy is placed into a melting furnace to carry out melting, and the melted aluminum alloy liquid is subjected to primary refining, modification, refinement and secondary refining to provide a spare use for casting; (3) manufacturing an alumina ceramic short fiber preform; (4) preheating the alumina ceramic short fiber preform; (5) preheating a mold; (6) carrying out extrusion casting; (7) carrying out solidification piece taking; (8) carrying out a heat treatment on an aluminum piston blank; and (9) carrying out mechanical processing and a surface treatment on the aluminum piston blank to obtain the aluminum piston finished product. Compared to the aluminum piston in the prior art, the aluminum piston of the present invention has advantages of high strength and good ablation resistance.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Room-temperature curing high-temperature-resistant organic silicon rubber coating as well as preparations method and application of room-temperature curing high-temperature-resistant organic silicon rubber coating

ActiveCN109593464AImprove mechanical propertiesHigh strengthFireproof paintsCarbon blackPolysilazane

The invention provides a room-temperature curing high-temperature-resistant organic silicon rubber coating as well as a preparations method and application of the room-temperature curing high-temperature-resistant organic silicon rubber coating. The organic silicon rubber coating is prepared from an organic silicon rubber material; and the organic silicon rubber material is characterized in that amatching system of a hydroxy-terminated polysiloxane polymer containing different functional groups, modified white carbon black reinforced filler, high-temperature-resistant and antioxidant filler,high-temperature-resistant and ablation-resistant filler and fibers is designed and used and is matched with a proper polysilazane curing agent based on a mechanism of an interaction among an organicsilicon polymer chain, the reinforced filler, the high-temperature-resistant and antioxidant filler, the high-temperature-resistant and ablation-resistant filler and the fibers in order to meet the harsh requirement for excellent comprehensive performances such as room temperature curing, high temperature resistance and high mechanical properties required in the use of the high-temperature-resistant organic silicon thermal protection coating, so that the formula design of a high-temperature-resistant elastic coating is simplified, and the use of a char forming agent capable of generating hugeinfluences to the mechanical properties is reduced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

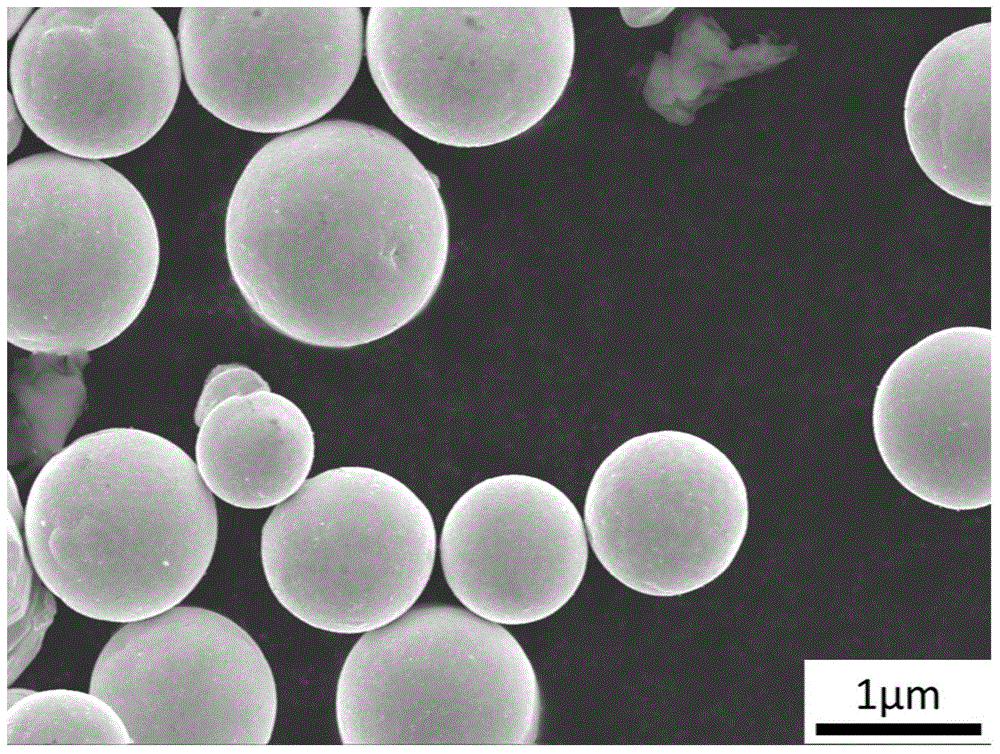

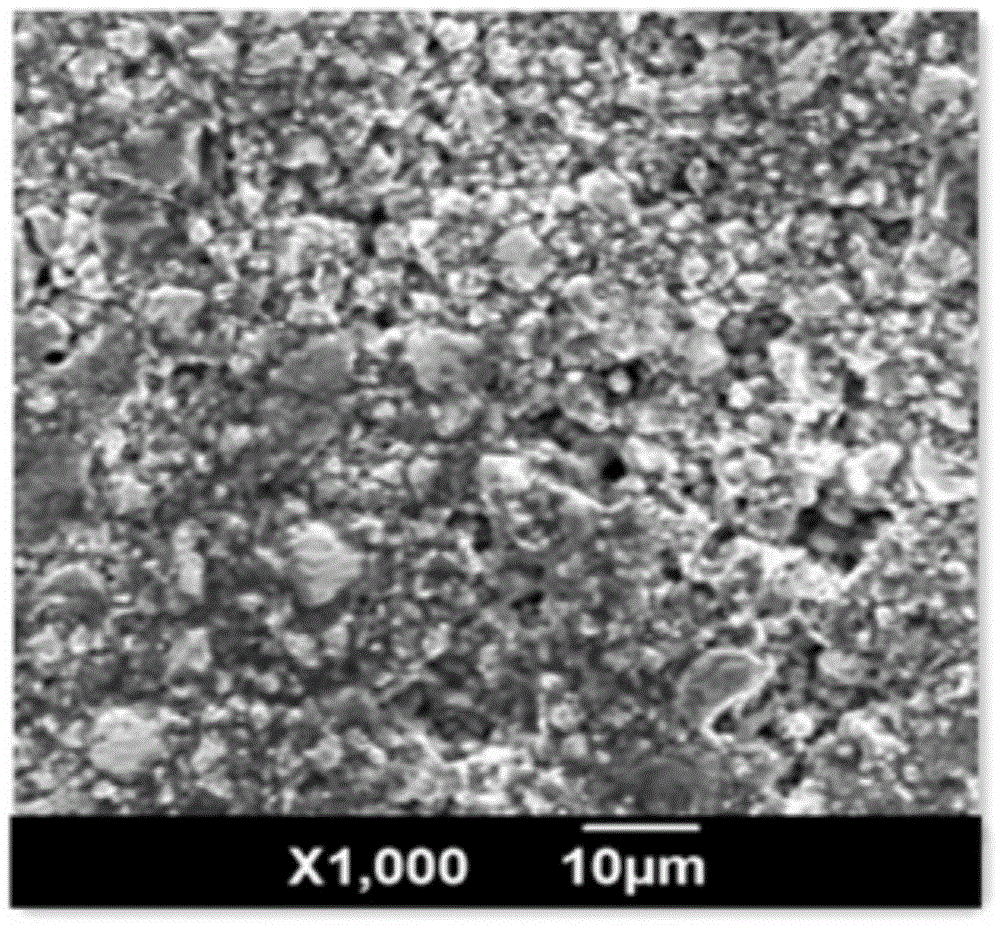

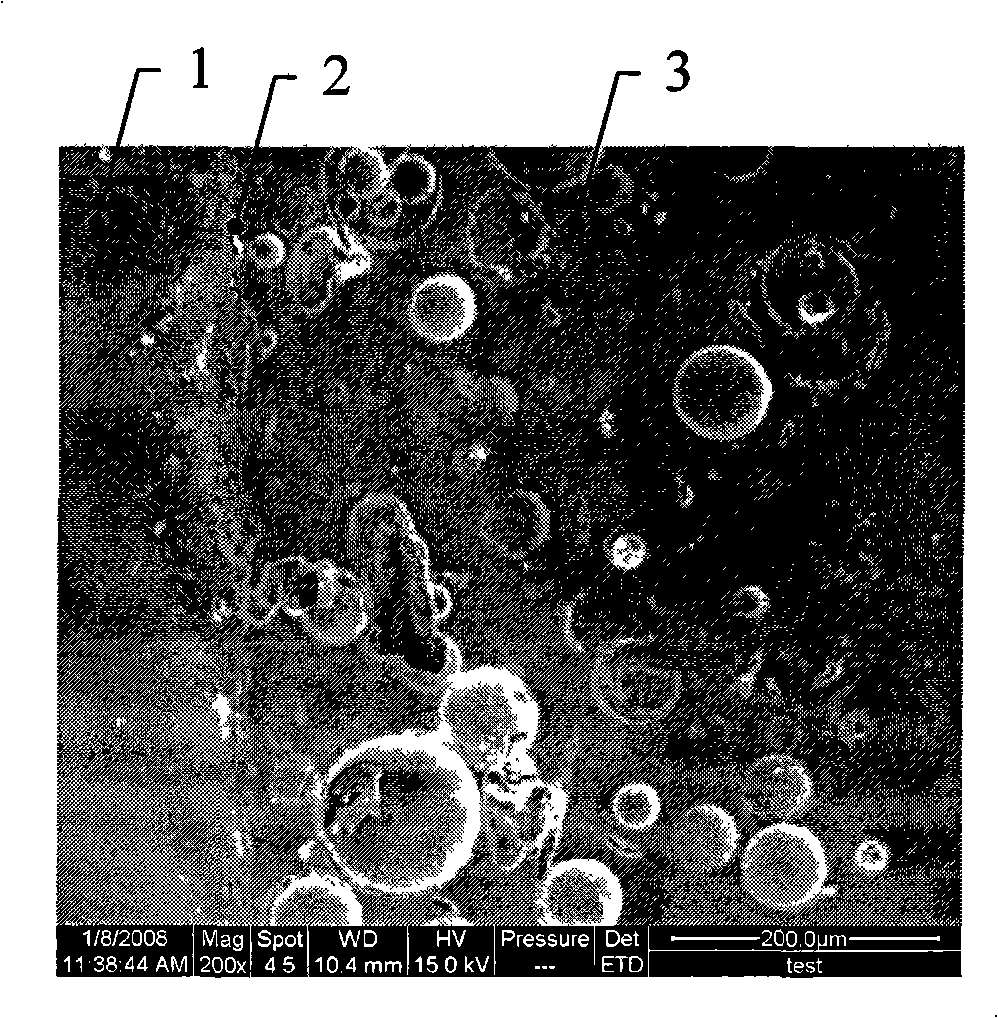

Spherical copper coating tungsten composite powder, preparation method and application thereof

The invention relates to a spherical copper coating tungsten composite powder, a preparation method and an application thereof. The copper coating tungsten composite powder is in a core-shell structure, the shell is a copper plating layer, the core is tungsten powder, and the weight ratio of the tungsten elements and copper elements of the copper coating tungsten composite powder ranges from 5 to 95 : 95 to 5; the spherical copper coating tungsten composite powder has the advantages of fine dispersion performance, high liquidity, even ingredients and high purity. The preparation method includes processing ordinary tungsten powder by a plasma spheroidizing technology, allowing the copper to deposit on the surface of the tungsten powder evenly by the intermittent copper electroplating process, and cleaning and drying the composite powder coated with copper. The spherical copper coating tungsten composite powder is prepared by combining the plasma spheroidizing and intermittent copper electroplating, the method is simple, reliable and easy to operate, the electroplating speed, the electroplated layer thickness and copper content range can be adjusted effectively, the copper-tungsten composite material comprehensive performances can be improved effectively, the expanded application prospect is provided, and the method can be applied to industrialized mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

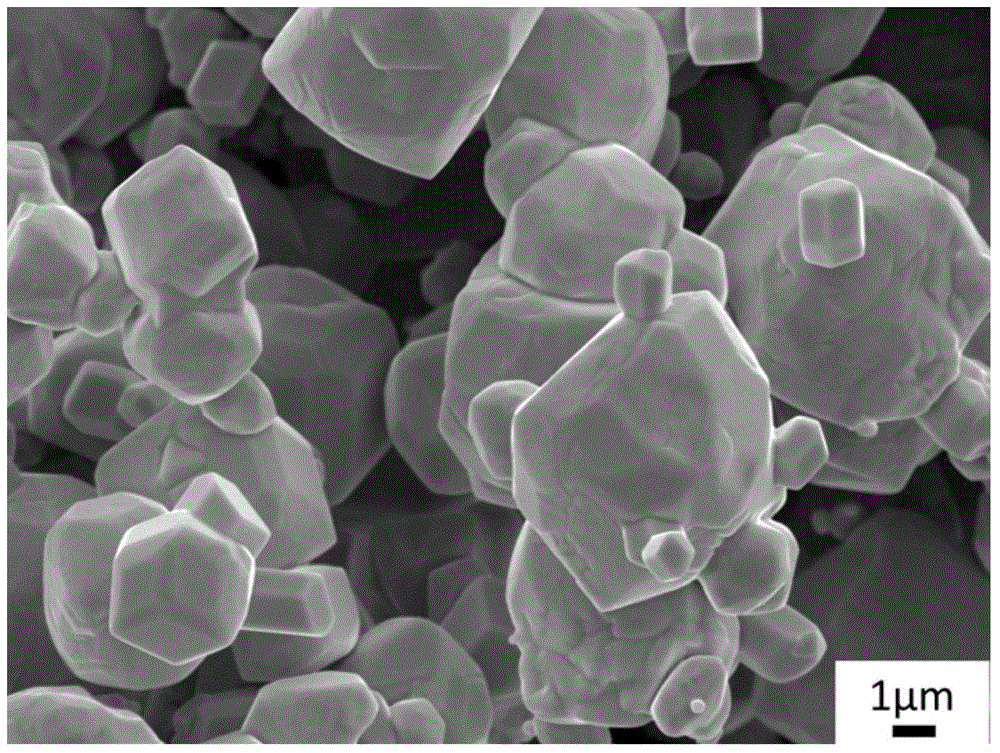

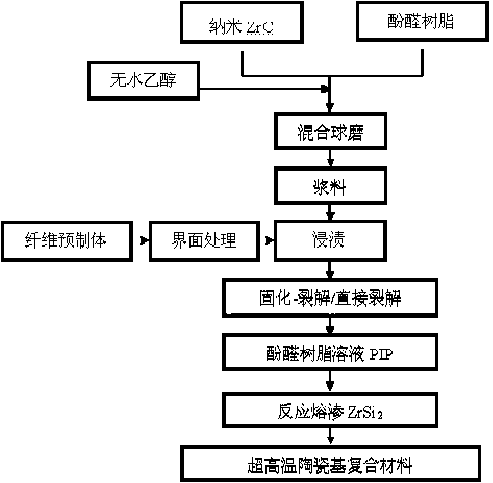

Preparation method for fiber-reinforced superhigh temperature ceramic matrix composite

The invention relates to a preparation method for a fiber-reinforced superhigh temperature ceramic matrix composite. The preparation method comprises the following steps: 1) adopting a slurry infiltration fibrous preform containing nano zirconium carbide and phenolic resin, and obtaining a fibrous tackified preform containing ZrC through curing-splitting or direct splitting; 2) using organic polymer as an organic carbon source precursor to infiltrate the fibrous tackified preform containing the ZrC, and splitting so as to obtain a ZrC-C composite porous intermediate; 3) using zirconium disilicide as a silicon source and a zirconium source to perform infiltration on the porous intermediate at the temperature of 1800-1950 DEG C so as to obtain the fiber-reinforced superhigh temperature ceramic matrix composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

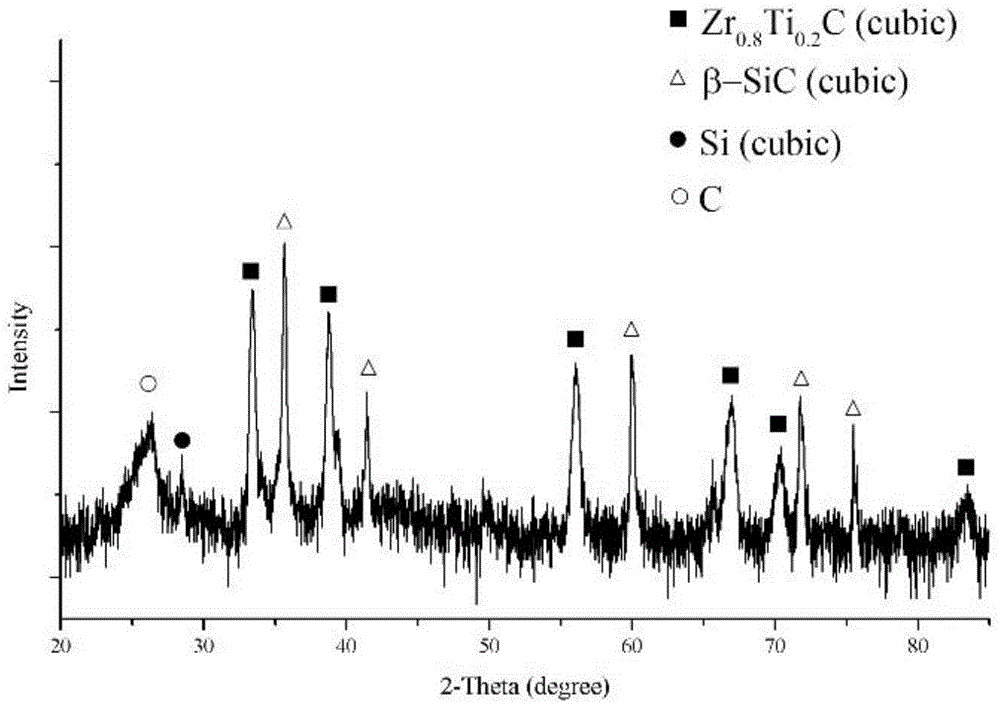

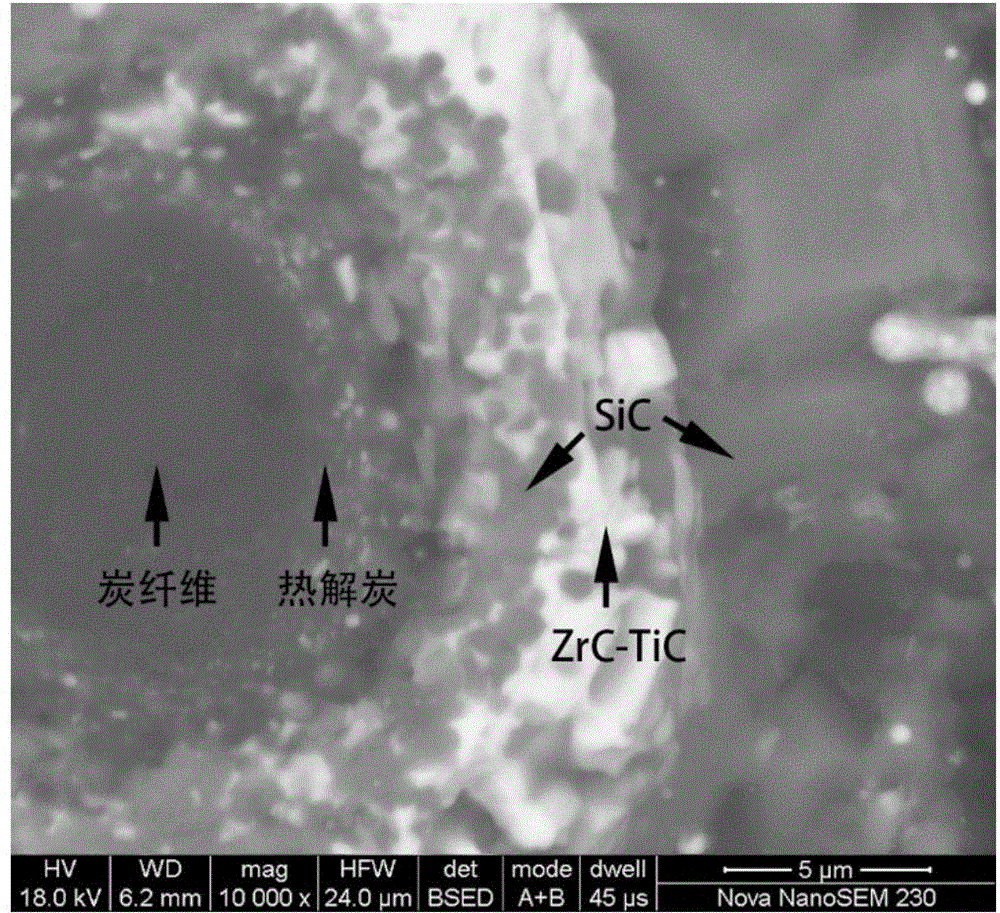

ZrC-TiC modified C/C-SiC composite material and preparation method thereof

The invention relates to a ZrC-TiC modified C / C-SiC composite material and a preparation method thereof, belonging to the technical field of preparation of composite materials. The composite material disclosed by the invention comprises carbon fibers, a pyrolytic carbon layer, SiC and ZrC-TiC, wherein the pyrolytic carbon layer coats the surface of the carbon fibers; SiC and ZrC-TiC coat the surface of the pyrolytic carbon layer; and ZrC-TiC is uniformly distributed in SiC. The preparation method comprises the following steps: preparing a low-density C / C composite material by adopting chemical vapor infiltration; melting Si, Zr and Ti powder, infiltrating the powder into the C / C composite material by virtue of a capillary action, and forming a ceramic phase in pores by virtue of a high-temperature in-situ reaction, thereby obtaining the ZrC-TiC modified C / C-SiC composite material. With the adoption of the process method which is low in cost, rapid and convenient, the service temperature of the C / C-SiC composite material is effectively improved, and the ultra-high temperature ablation resistance of the material is greatly enhanced.

Owner:深圳金羽先进材料有限公司

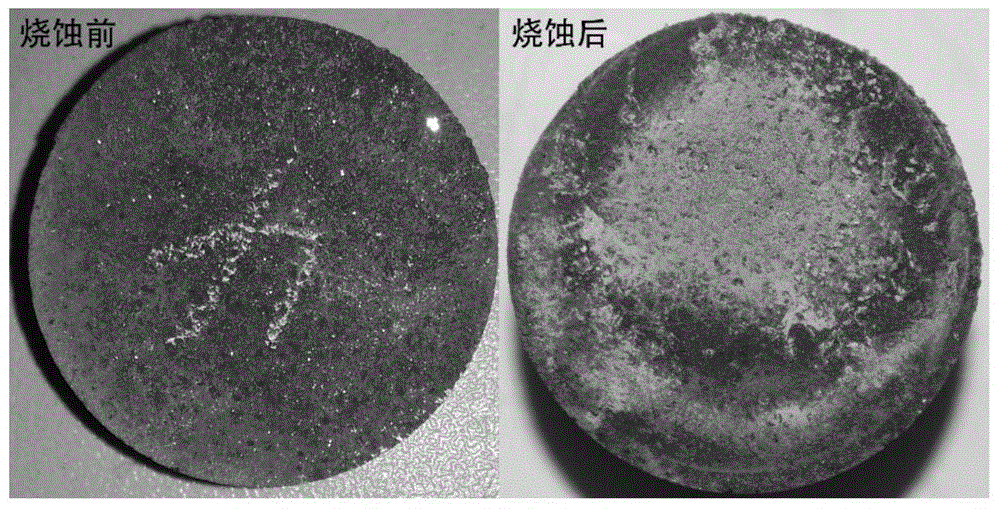

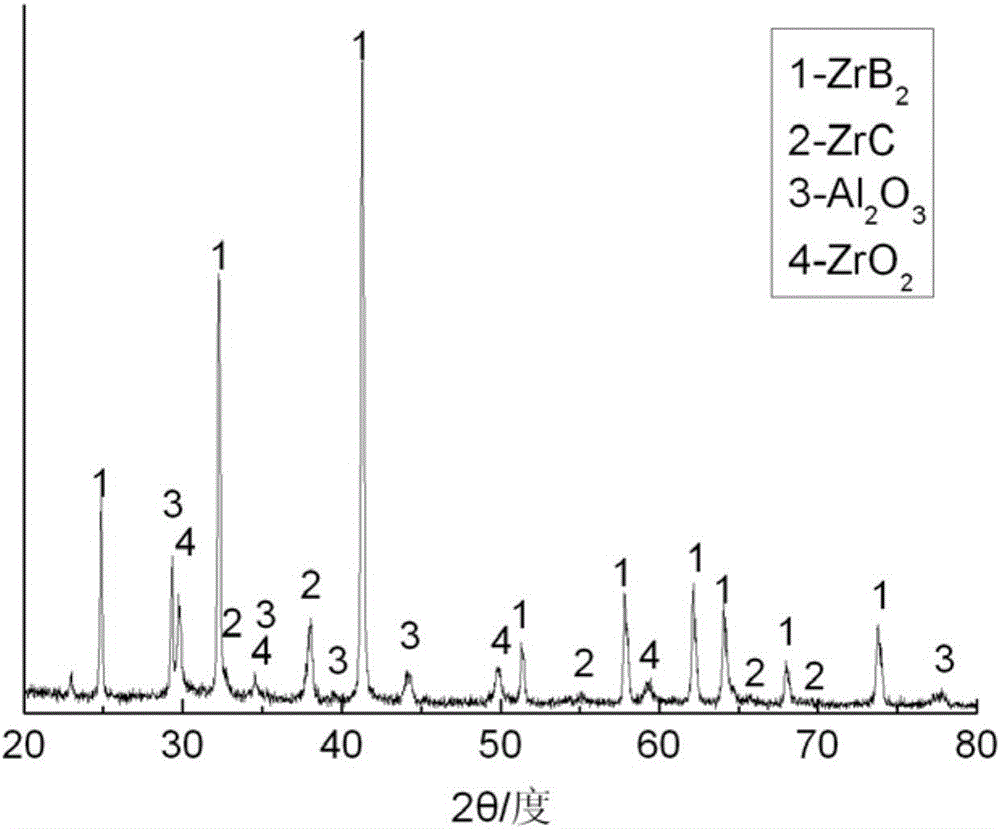

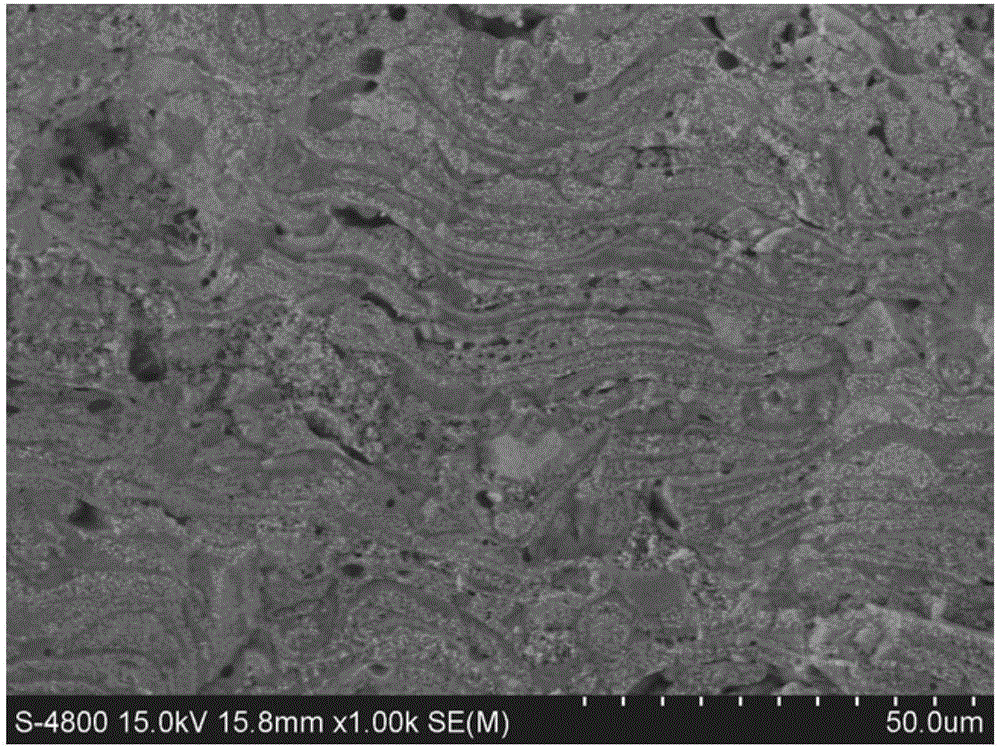

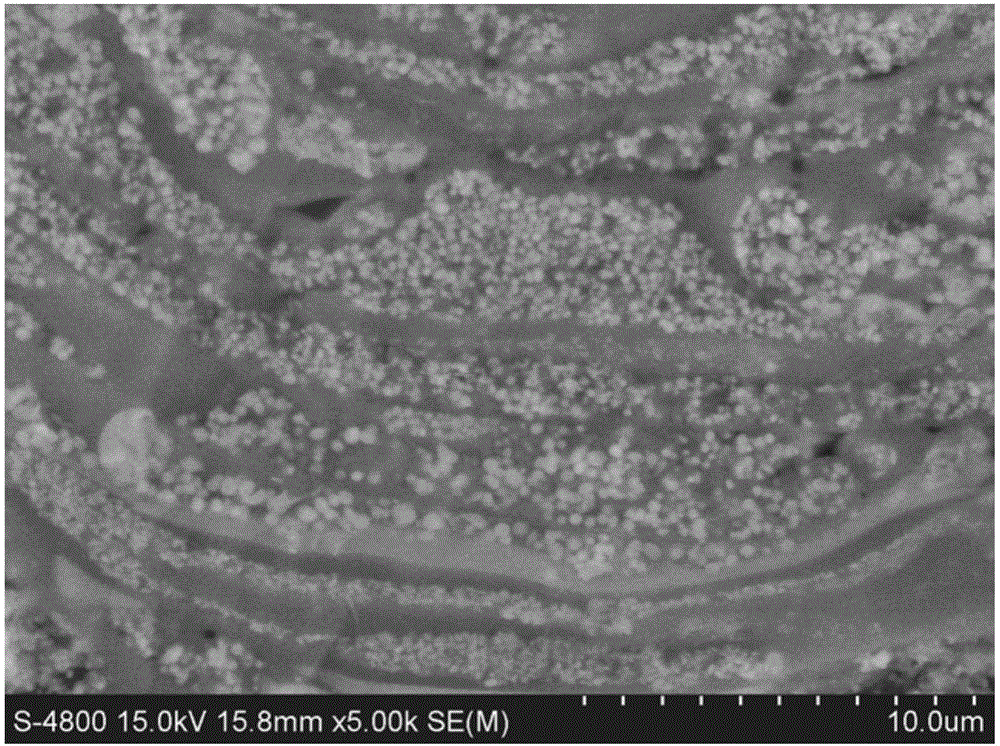

Preparation method for zirconium boride-based coating

The invention relates to a preparation method for a zirconium boride-based coating and relates to plating of a material by a boride. The method of in-situ synthesizing the zirconium boride-based coating comprises the steps of: preparing zirconium oxide / boron carbide / aluminum compound powder for thermal spraying; pre-treating a base material; and spraying the prepared zirconium oxide / boron carbide / aluminum compound powder for thermal spraying to the surface of the pre-treated base material by adopting a thermal spraying method so as to form the zirconium boride-based coating. The method provided by the invention overcomes the defects that in the prior art, the prepared zirconium boride-based coating is high in porosity, poor in uniformity, rough in tissue, low in toughness, small in thickness, poor in bonding force with a matrix, easy to crack and poor in thermal shock resistance; and the defects in the prior art that the preparation process is complicated, the process cost is high, the depositing efficiency is low, the cost of raw materials is high, the energy consumption is great, the efficiency is low, and the preparation method is not suitable for being applied to industrial production on a large scale.

Owner:HEBEI UNIV OF TECH

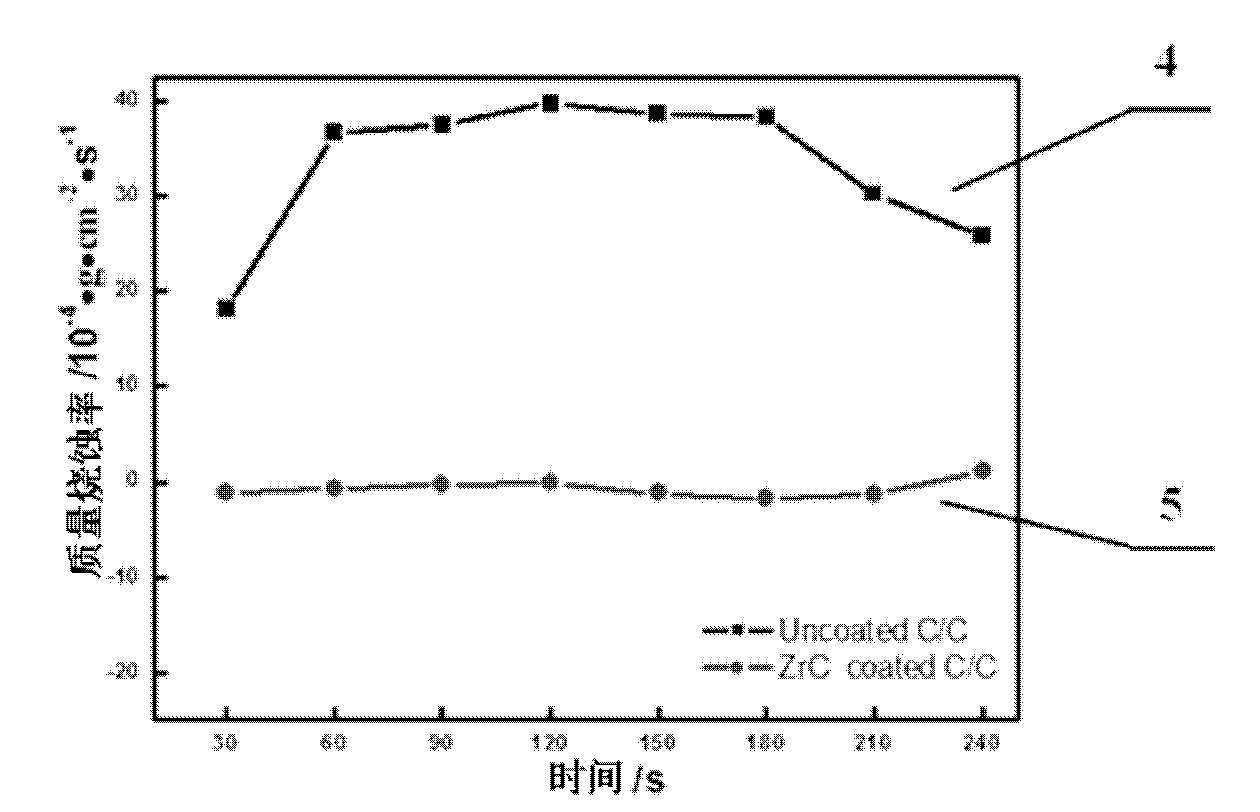

Method for preparing ZrB2-SiC anti-ablation coating from in-situ reaction

ActiveCN103145454AIncrease contentImprove anti-ablation performanceUltimate tensile strengthMaterials science

The invention relates to a method for preparing a ZrB2-SiC anti-ablation coating from in-situ reaction. The method is characterized in that the ZrB2-SiC anti-ablation coating is prepared from in-situ reaction on the surface of a C / C composite material with a SiC transit layer. Compared with the prior art, the ZrB2 content in the coating is increased, and therefore the anti-ablation property of the C / C composite material is improved; and moreover as the method adopts high-temperature in-situ reaction, high interface bonding strength of the coating and a substrate is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flexible ceramizable silicone rubber thermal insulation composite material and preparation method thereof

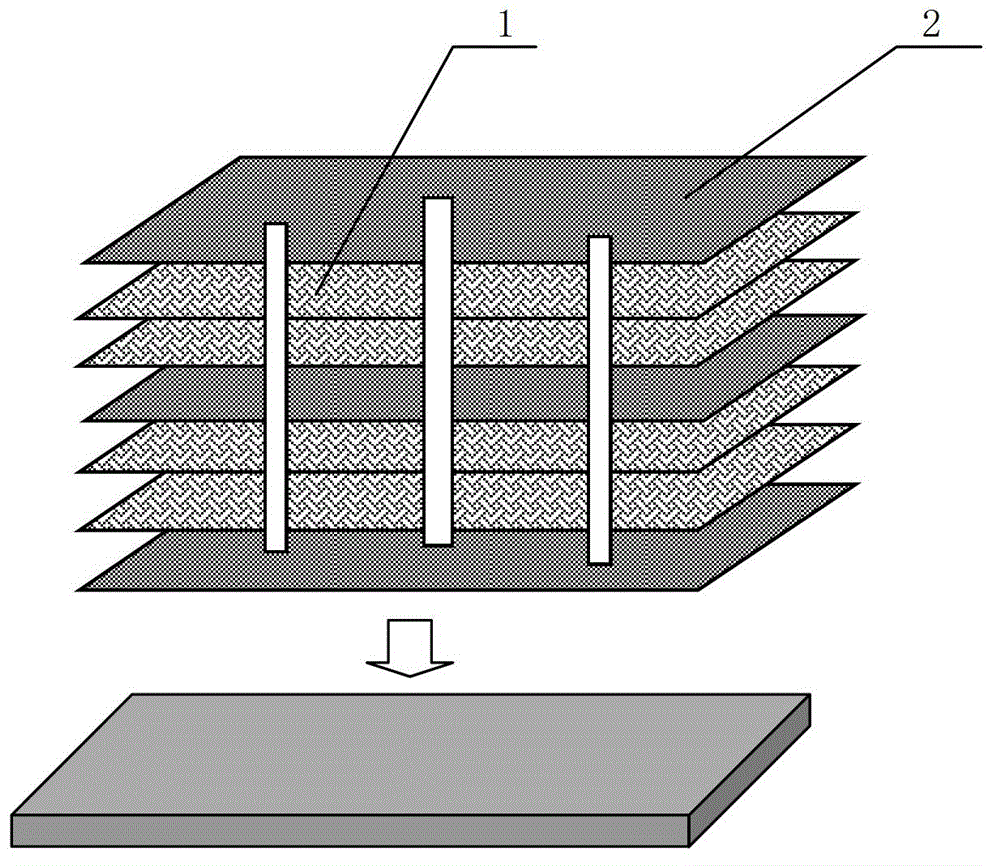

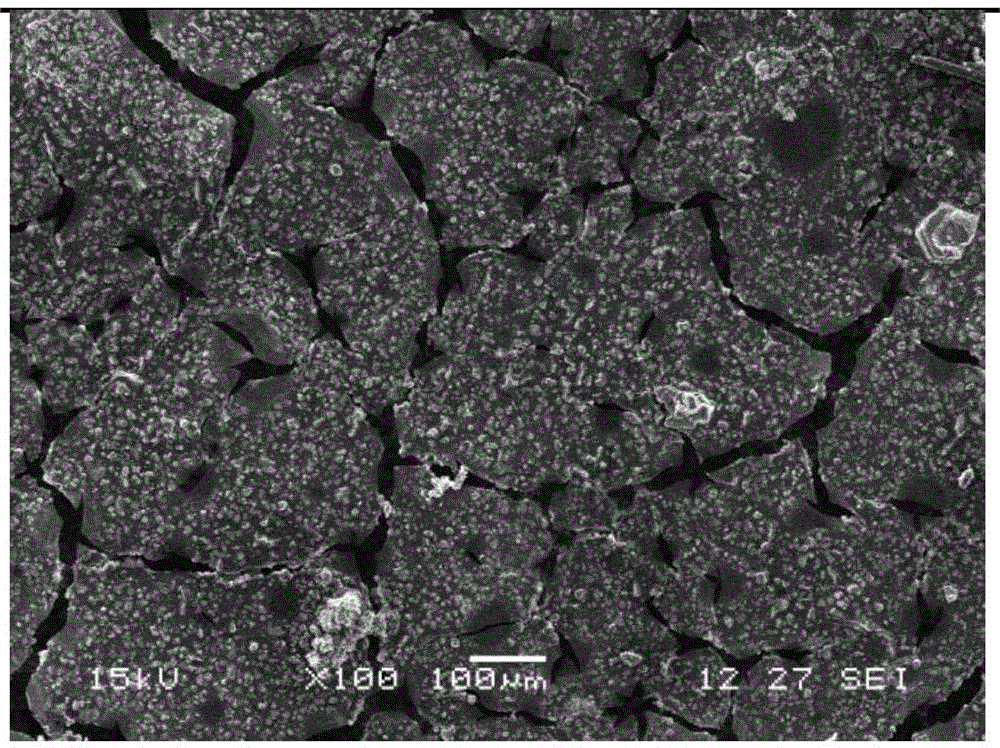

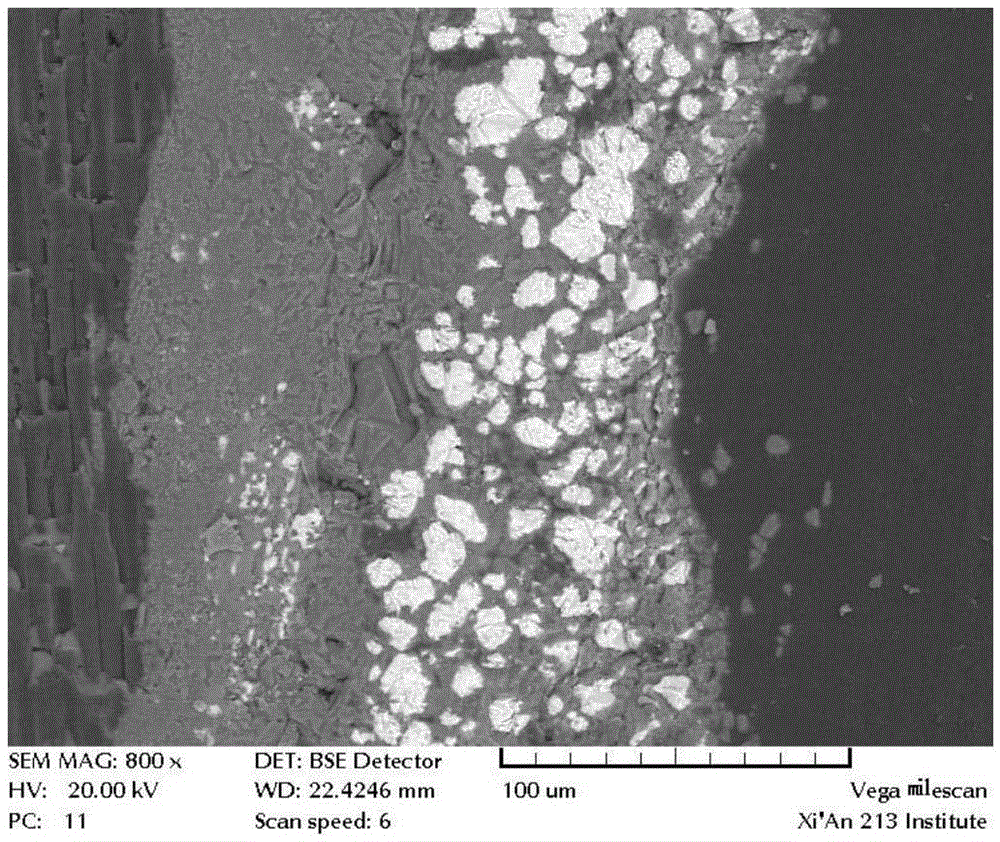

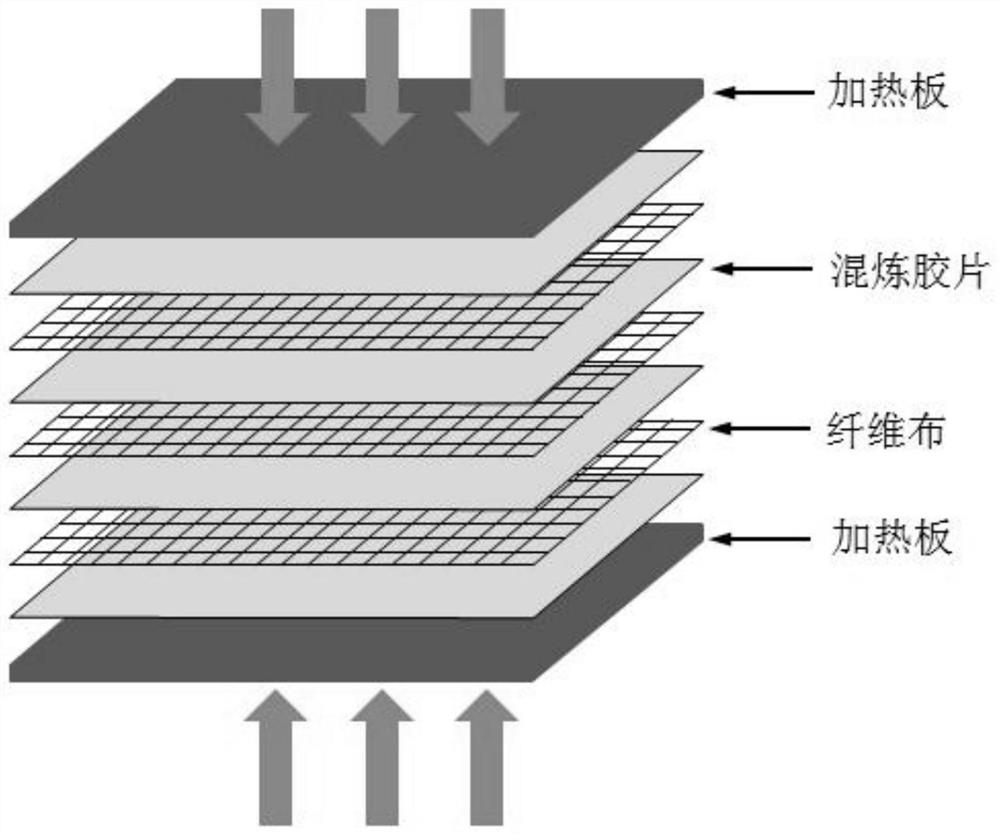

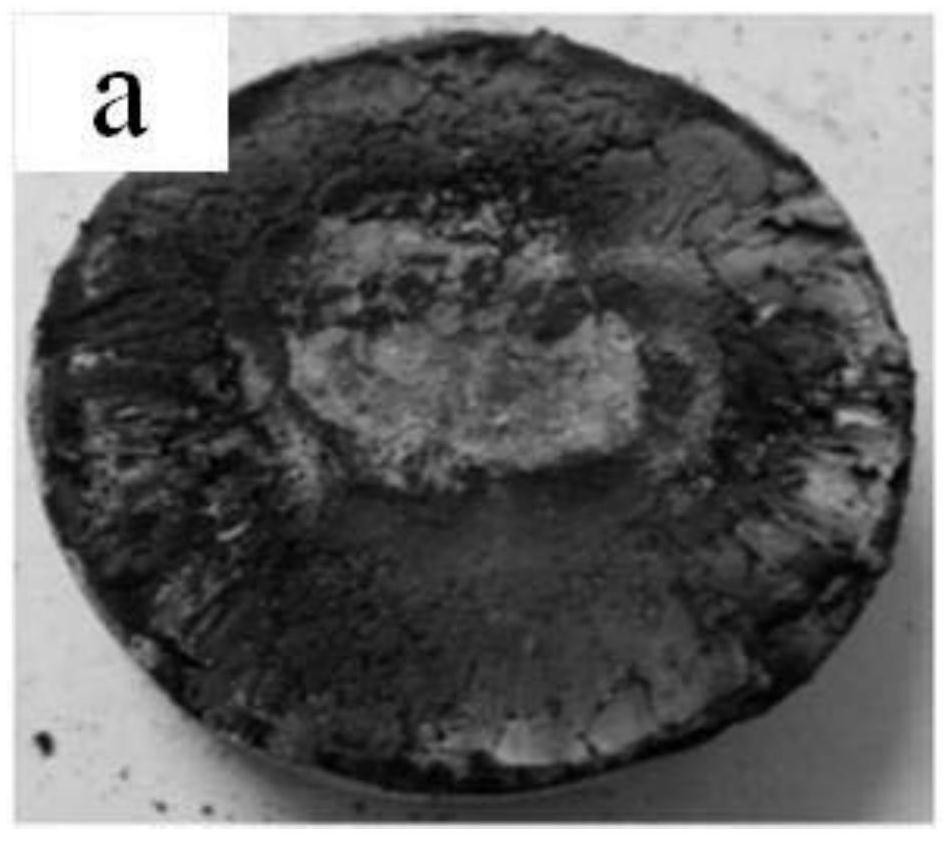

PendingCN111761895AHigh mechanical strengthImprove anti-ablation performanceCosmonautic thermal protectionLaminationFiberVulcanization

The invention relates to a flexible ceramizable silicone rubber thermal insulation composite material and a preparation method thereof. The composite material is a silicone rubber / fiber cloth integralstructure, the silicone rubber is a support structure, and the fiber cloth penetrates through the silicone rubber; the composite material is obtained by stacking and vulcanizing mixed rubber sheets and fiber cloth at intervals, the mixed rubber sheets are obtained by mixing the silicone rubber, and the mixed rubber sheets are prepared from, by mass, 100 parts of the silicone rubber, 20-45 parts of fumed silica, 30-160 parts of ceramic powder, 0-40 parts of a fluxing agent, 6-20 parts of short fibers, 1-15 parts of a structure control agent and 1-4 parts of a vulcanizing agent. The ceramizablesilicone rubber composite material provided by the invention is good in flexibility, high in mechanical property, good in ablation resistance and resistant to high-speed airflow scouring, and can meet the requirements of the fields of aerospace and special fireproof engineering on fireproof, thermal-insulating and ablation-resistant thermal protection performance.

Owner:WUHAN UNIV OF TECH

Preparation method of C/C-SiC-MoSi2 ceramic-based composite material

A preparation method of a C / C-SiC-MoSi2 ceramic-based composite material includes the following steps: 1) dispersing silicon carbide powder and molybdenum disilicide powder in isopropyl alcohol, and performing ultrasound vibration and stirring to obtain a suspension liquid A and a suspension liquid B: 2) increasing the density of a low-density carbon fiber stereo fabric in a manner of hydrothermal permeation of glucose, and placing the fabric in a suction filtration device having a glass sand core; 3) pouring the suspension liquid A and the suspension liquid B successively into a suction filtration flat-bottom funnel to enable the suspension liquids to pass the C / C composite material completely; 4) performing a homogeneous phase hydrothermal reaction until the density is 1.2-1.5 g / cm<3>; and 5) performing thermal treatment to obtain the C / C-SiC-MoSi2 ceramic-based composite material. The composite material is moderated in density, is compact in structure, and is excellent in interface binding between a C / C interface and a SiC interface, the SiC interface and a MoSi2 interface and the C / C interface and the MoSi2 interface. The raw materials are easy to obtain. The preparation method is simple in operation, is low in cost, is environment-friendly and is pollution-free.

Owner:浙江领崎科技有限责任公司

Surface erosion-resistant composite coating of carbon/carbon composite, preparation method and application thereof

InactiveCN101791883AControl supersaturationActive connectionLayered productsChemical vapor deposition coatingCarbon compositesGas phase

The invention relates to a surface erosion-resistant composite coating of a carbon / carbon composite, which sequentially consists of ZrC0.7 / ZrC1.0 / ZrC1.0+C form outside to inside. The preparation method of the surface erosion-resistant composite coating comprises the following three steps: the preparation of a basal layer ZrC1.0+C, the preparation of a middle layer ZrC1.0 and the preparation of an outer-coating layer ZrC0.7; and is characterized in that in a chemical vapor deposition furnace at normal pressure, zirconium tetrachloride is used as the zirconium source, Ar gas is used as the carrier gas, C3H6, acetylene and methane are respectively used as the carbon source gasses, Ar is used as the diluent, H2 is used as the reducing gas, and the surface erosion-resistant composite coating is obtained by deposition at the temperature of 1100-1300 DEG C. The invention has the advantages of simple process method, convenient operation, single heat, stepwise deposition preparation of the composite coating with gradient-changed carbon contents, firm combination between the coating and the basal body, no penetration crack and interlayer crack, and good coating erosion resistance and thermal shock resistance, can realize the industrialized production, and is applicable to the preparation of the erosion-resistant composite coating of the carbon / carbon composite by the chemical gas-phase permeation or the liquid-phase impregnation process.

Owner:CENT SOUTH UNIV

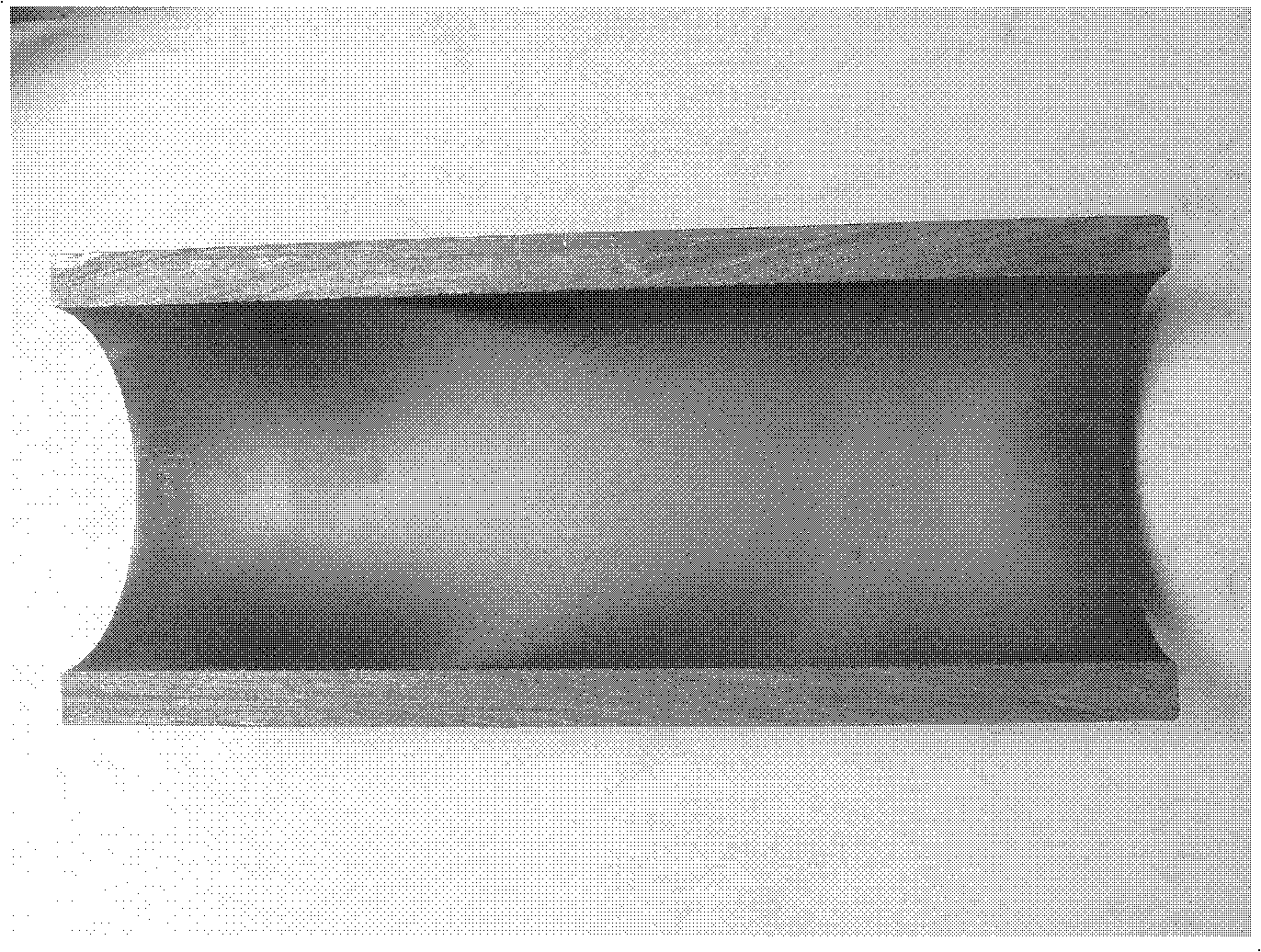

Method for manufacturing copper-tungsten contact

ActiveCN102800420ALow melting pointInfiltration of copper-containing materialsCable/conductor manufactureBronzeCopper–tungsten

The invention discloses a method for manufacturing a copper-tungsten contact. The method comprises the following steps of: manufacturing a tungsten blank; manufacturing a graphite crucible; drying the graphite crucible; protecting the graphite crucible; preparing cupriferous materials; mounting the crucible; charging, vacuumizing, heating and infiltrating; and cooling and discharging, and the like. The specially-made graphite crucible is used for containing materials in a vacuum environment; copper or chromiumbronze solution is sufficiently infiltrated in the tungsten blank by using a vacuum negative-pressure infiltration method to manufacture the contact; the melting point of copper is reduced in the vacuum environment; the cupriferous materials are easy to infiltrate into the tungsten blank and are fused with the tungsten blank sufficiently and uniformly; the total usability and the yield of the copper-tungsten contact are increased; and manufacture difficulty that the diameter of the copper-tungsten contact is too large and the copper-tungsten contact is too long is overcome.

Owner:河南科丰新材料有限公司

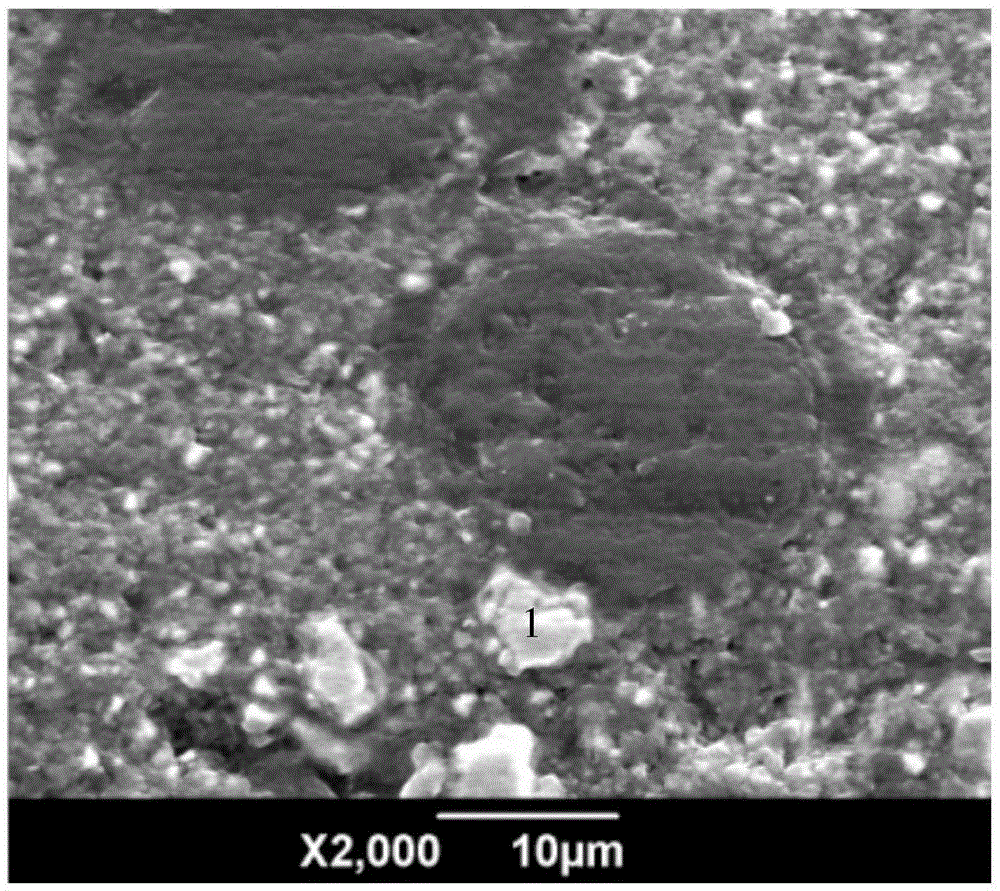

Tungsten-copper composite material and preparation method thereof

InactiveCN107498047AHigh strengthImprove anti-ablation performanceAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyCopper

The invention provides a tungsten-copper composite material. The tungsten-copper composite material comprises a tungsten framework, tungsten porous bodies and a copper filling phase. The tungsten framework has a porous three-dimensional dot matrix structure. The tungsten porous bodies fill the pores of the tungsten framework. Pores are arranged between the tungsten porous bodies and the tungsten framework. The copper filling phase fills the pores of the tungsten porous bodies and the pores between the tungsten porous bodies and the tungsten framework. The composite structure formed by the tungsten porous bodies and the tungsten framework improves the strength of the tungsten-copper composite material. The copper filling phase is uniformly distributed in the pores of the tungsten porous bodies and the pores between the tungsten porous bodies and the tungsten framework, so that the anti-ablation performance of the tungsten-copper composite material is enhanced. The invention also provides a preparation method of the tungsten-copper composite material. The preparation method comprises the following steps of: firstly, preparing the tungsten framework by means of a method of fusion forming in a high energy bundle selecting region; then filling tungsten powder into the tungsten framework to form the tungsten porous bodies by means of an isostatic cool pressing method and a high-temperature sintering process; and then combining with a copper infiltration method to prepare the copper filling phase. The method is high in precision and efficient and reliable.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

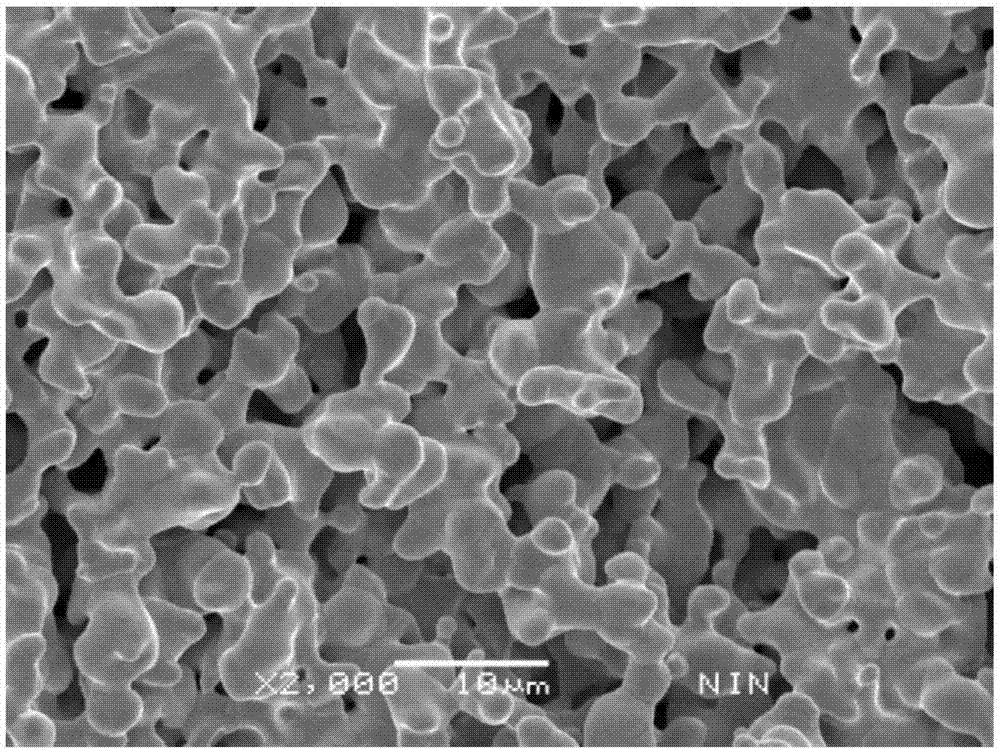

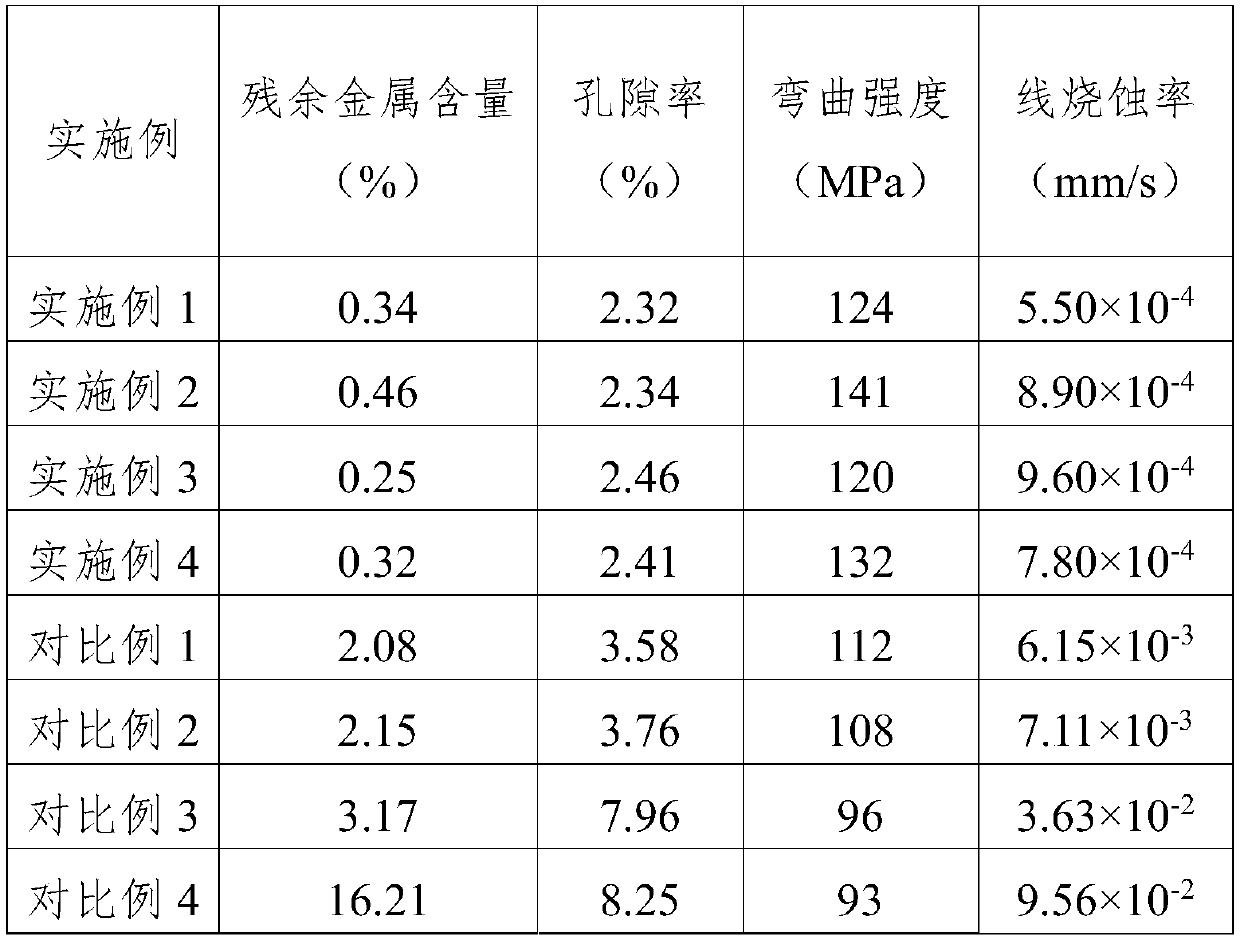

Carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and preparation method thereof

ActiveCN111099911ALow cost of preparationImprove anti-ablation performanceCarbide siliconZirconium carbide

The invention relates to a carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and a preparation method thereof. The method comprises the following steps: (1) depositing a pyrolytic carbon matrix on the surface of carbon fibers contained in a carbon fiber preform to obtain a modified carbon fiber preform; (2) preparing a mixed resin solution of silicon powder, zirconium powder, graphite powder and phenolic resin in a mass ratio of (1-3): (4-6): 5: 100; (3) impregnating the modified carbon fiber preform with the mixed resin solution, and then sequentially carrying out curing and carbonization reactions on the impregnated modified carbon fiber preform, wherein the carbonization reaction is carried out in an inert atmosphere, the temperature of the carbonization reaction is 1650-1750 DEG C, and the time is 0.5-2 hours; and (4) repeating the step (3) at least once to obtain the composite material. According to the invention, silicon carbide and zirconium carbide can be uniformly distributed in the composite material, the content of free metals is reduced, and the oxidation resistance and ablation resistance of the material are improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

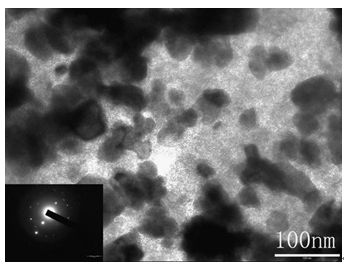

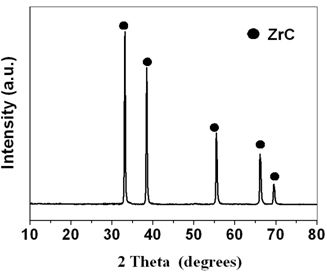

Synthetic method of superhigh temperature resistant zirconium carbide ceramic precursor

A synthetic method of a superhigh temperature resistant zirconium carbide ceramic precursor belongs to preparation methods of ceramic precursors. The synthetic method includes firstly, dissolving 6.44g zirconium oxychloride in 50 mL absolute methanol, stirring the mixture at a room temperature for dissolving, subjecting the mixture to ice bath for cooling, dropwise adding 2.4g-3.47g saligenin, finally dropwise adding 4.24g triethylamine at a dropping speed of 1 droplet per second, and subjecting the mixture to magnetic stirring in the process of the dropping adding; after the dropping adding, removing the ice bath and stirring the mixture at a room temperature for 4 hours; then subjecting the mixture to rotary evaporation for 10 minutes to evaporate solvents, adding 50 mL tetrahydrofuran, stirring the mixture at a room temperature for 2 hours, and performing suction filtration to remove a precipitation of triethylamine hydrochloride; subjecting the mixture to rotary evaporation for 15 minutes to evaporate the solvents of colatuie, adding 100 mL hexyl hydride, stirring the mixture at a room temperature for 12-48 hours, performing filtration to obtain a pale yellow precipitation, and subjecting the pale yellow precipitation to vacuum drying for three hours to obtain the zirconium carbide ceramic precursor. The synthetic method of the superhigh temperature resistant zirconium carbide ceramic precursor has the advantages that the even dispersing of modular zirconium components in precursor reins is achieved, the solidification group saligenin are contained in the ceramic precursor so that crosslinking solidification is facilitated, the synthesis temperature is low, the reaction speed is rapid, and the toxicity of solvents is small.

Owner:CHINA UNIV OF MINING & TECH

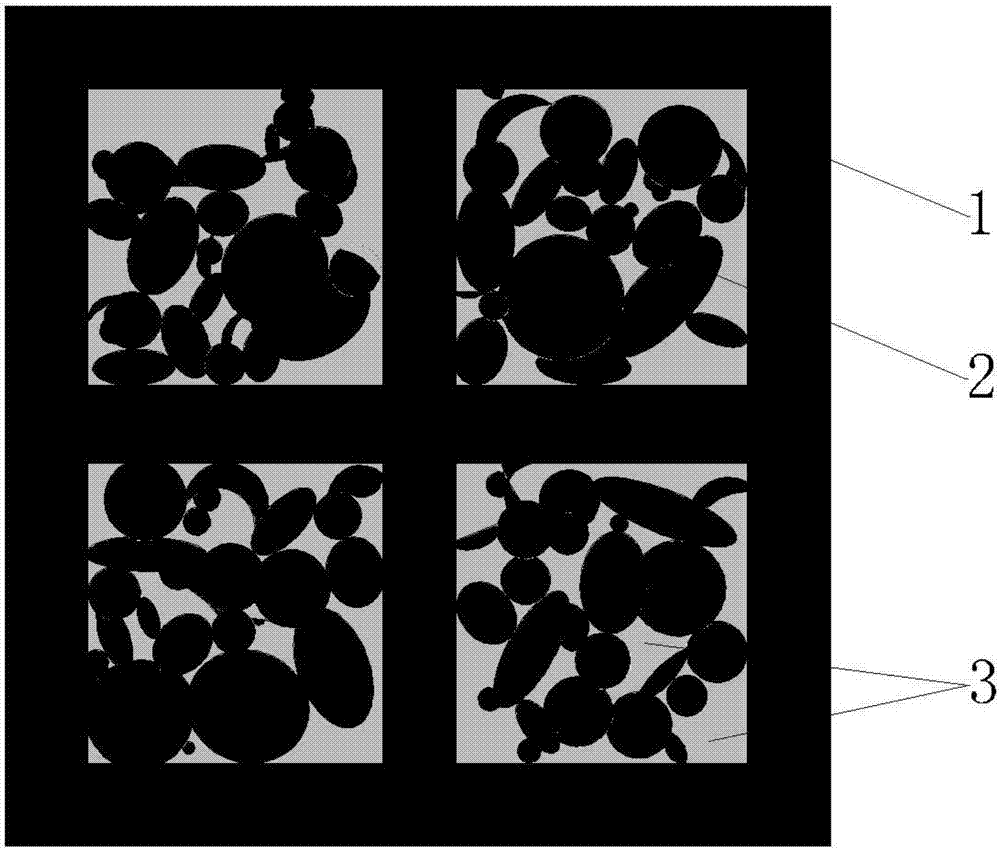

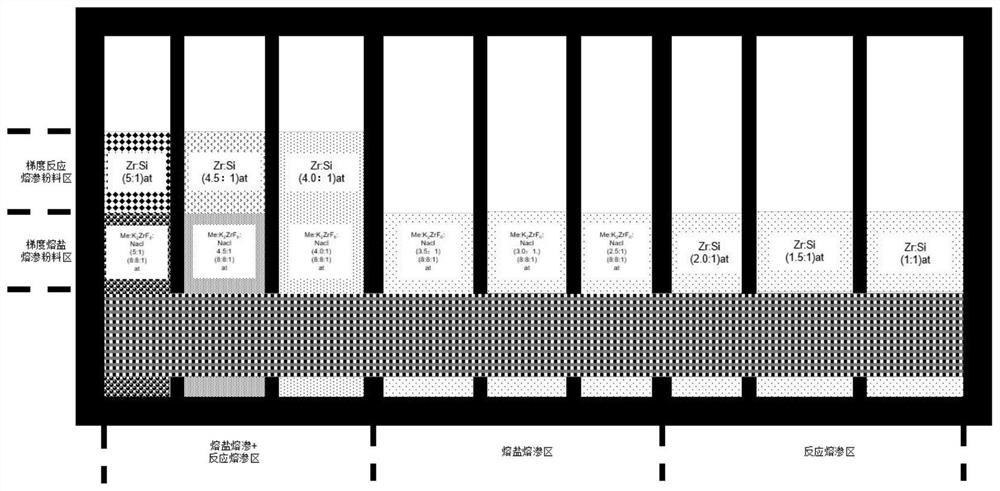

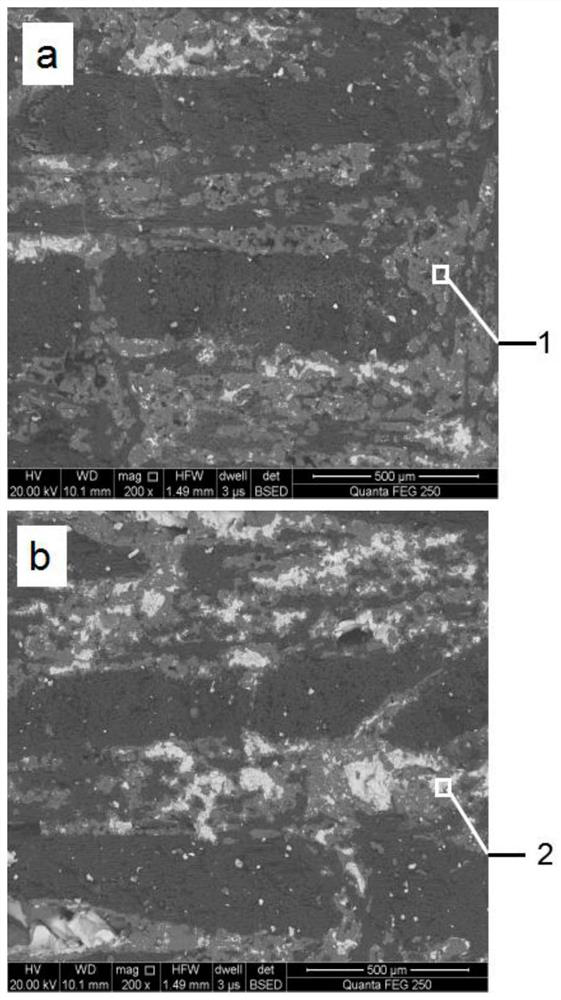

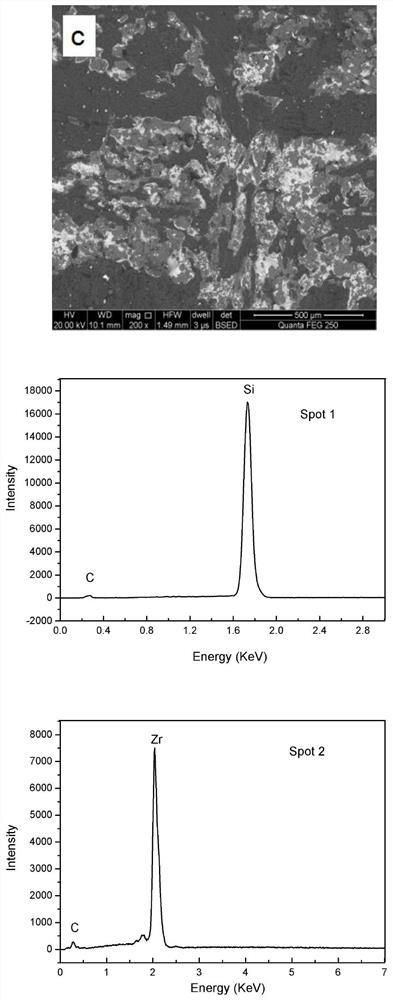

Preparation method of component- gradient -controllable multi-element ultrahigh-temperature ceramic modified C/C composite material

ActiveCN112457056AAvoid stress concentrationImprove anti-ablation performanceCeramicwareMolten saltUltrahigh temperature ceramics

The invention discloses a preparation method of a component-gradient-controllable multi-element ultrahigh-temperature ceramic modified C / C composite material. Through multi-section design of various ultrahigh-temperature ceramics (ZrC, HfC, HfB2 and the like) and high-temperature ceramic (SiC) composite modified C / C composite materials, a ceramic phase forms a continuous component gradient distribution form in a C / C matrix, ablation resistance and oxidation resistance requirements of different temperature range fields are met regionally, and meanwhile the defect that the mechanical property isreduced due to component mutation is overcome. According to the invention, a preparation process of combining molten salt infiltration and common reaction infiltration and gradient infiltration powder configuration are adopted in sections, so that near-ablation-end strong ceramic phase interface design is realized, and ceramic phase distribution realizing that the content of an ultrahigh-temperature ceramic phase is sequentially decreased from the near ablation end to a far ablation end and the high-temperature ceramic phase is sequentially increased is regulated and controlled; finally, thegradient ceramic-based composite material with different ceramic phase components and contents in gradient change and meeting the performance requirements of the material is formed.

Owner:CENT SOUTH UNIV

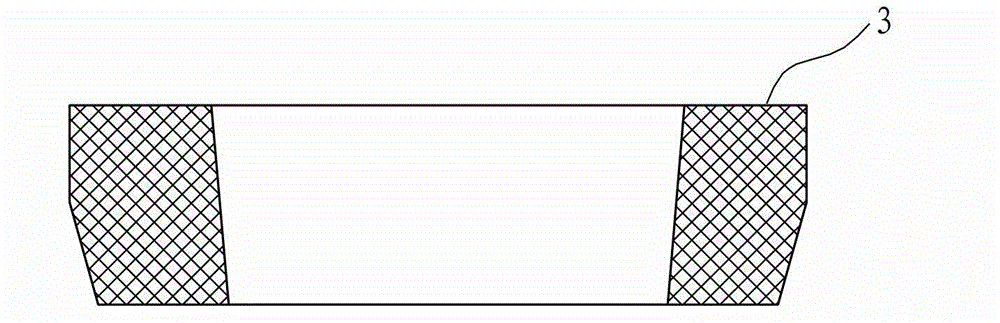

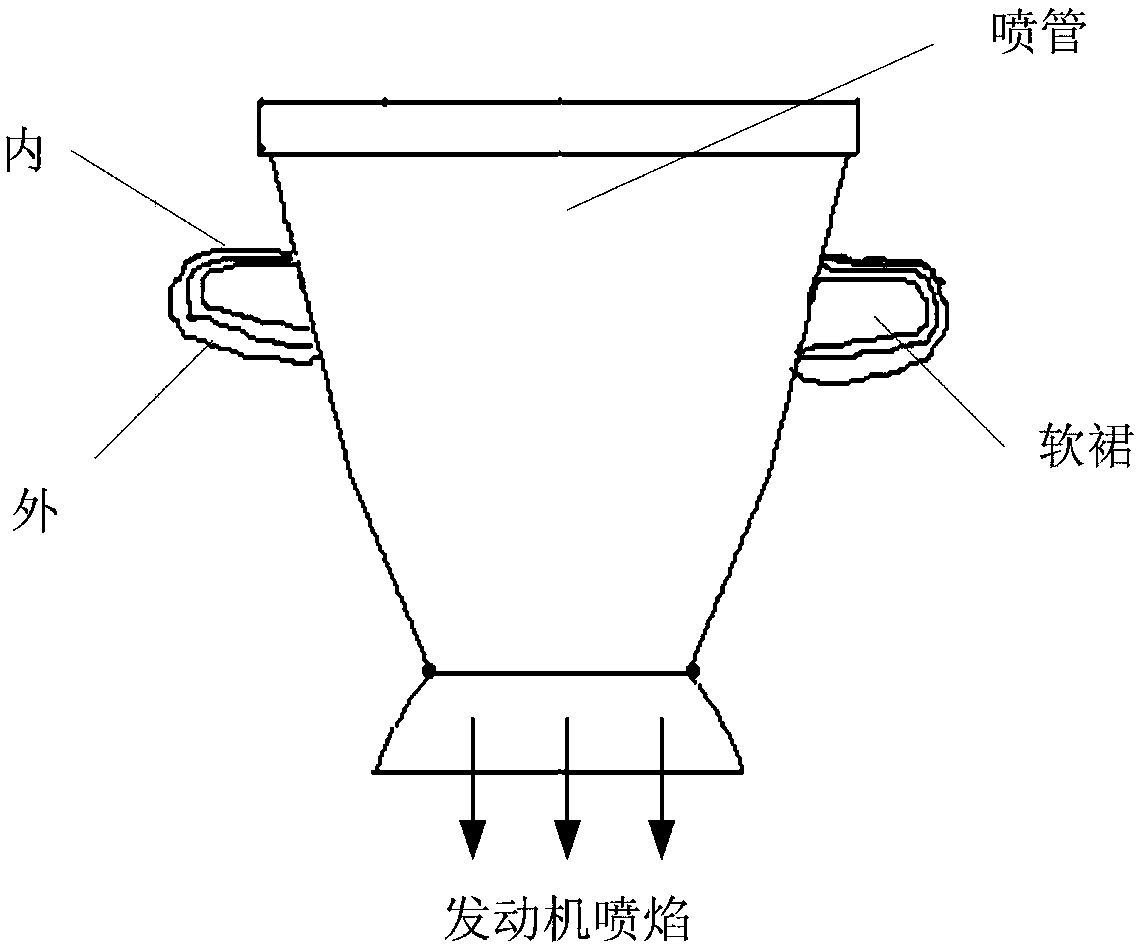

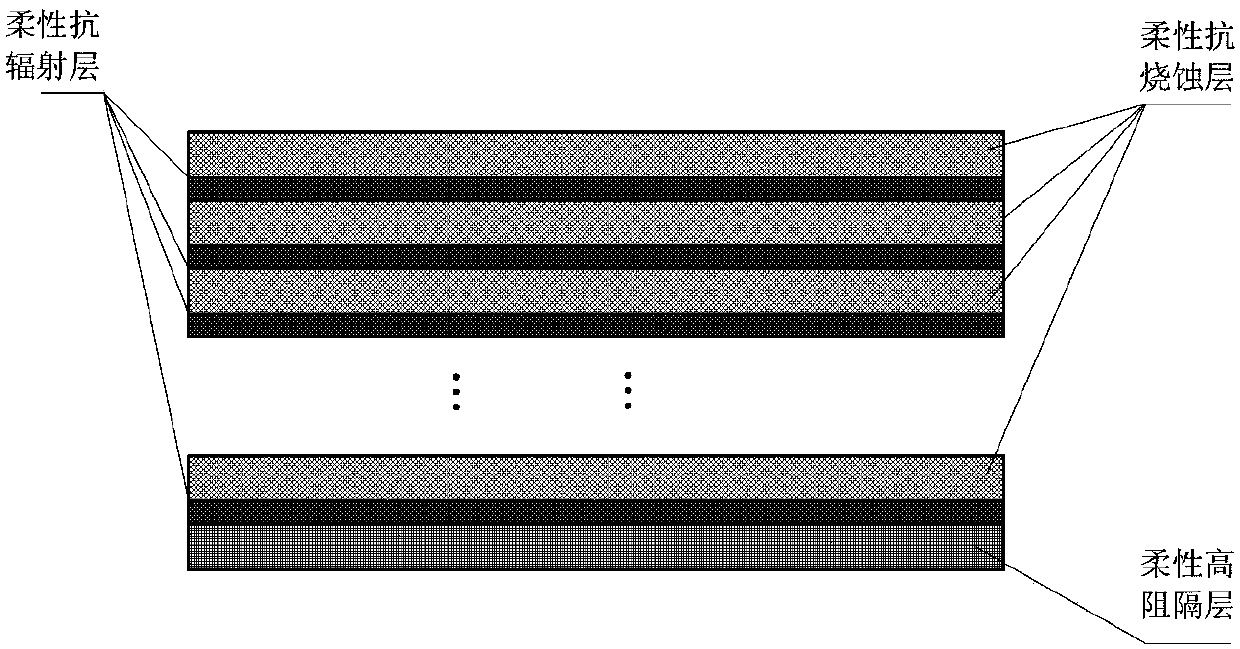

Anti-ablation high-resistance flexible heatproof soft skirt and preparing method thereof

ActiveCN107662715AGuaranteed anti-ablationGuaranteed air tightnessFibre treatmentCosmonautic thermal protectionHigh resistanceAdhesive

The invention provides an anti-ablation high-resistance flexible heatproof soft skirt and a preparing method thereof. The soft skirt is composed of a plurality of flexible anti-ablation layers, a plurality of flexible anti-radiation layers and a flexible high-resistance layer. The flexible anti-ablation layers and the flexible anti-radiation layers are distributed alternately from outside to inside according to the structure of S-F-S-F-...-S-F, wherein S is flexible anti-ablation layer and F is flexible anti-radiation layer. The flexible high-resistance layer is located on the innermost side.The flexible anti-ablation layers, the flexible anti-radiation layers and the flexible high-resistance layer are attached to an installation spraying pipe through a silicone rubber adhesive. The flexible anti-ablation layers and the flexible anti-radiation layers are distributed alternately on the outer layer, the synergistic effect between the flexible anti-ablation layers and the flexible anti-radiation layers is given to full play, a phenolic resin modified silicone rubber system is adopted for the flexible anti-ablation layers, the anti-ablation performance of the flexible anti-ablation layers is improved, and on the basis of ensuring the anti-ablation performance, the total thickness of the soft skirt is effectively reduced, and the total thickness reduction amount is 1 / 2 to 2 / 3 of that of an existing structure.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method of preparing corrosive thermal insulation anti-ablation composite coating on light alloy surface

InactiveCN101306418AGood heat insulationImprove insulation performanceAnodisationPretreated surfacesThermal insulationAlloy surface

The invention discloses a method for preparing a rot proof, heat proof, burn resistance and anti-corrosion composite coating on a light alloy surface, and relates to a method for preparing a composite coating on a light alloy surface. The method solves the deficiencies existing in the prior method for preparing the composite coating on the light alloy surface that the thermal protective performances, such as the heat proof and the burn resistance and the anti-corrosion performances, of the prepared coating are poor, or the binding force is poor, the coating is easy to scale off and out of work, and the quality and the thickness of the coating are difficult to be controlled. The method for preparing the rot proof, heat proof, burn resistance and anti-corrosion composite coating on the light alloy surface is performed according to the following steps: firstly, de-oiling and connecting; secondly, electrifying; thirdly; drying; fourthly, preparation of spray coating liquid; fifthly, coating and drying; sixthly, the repetitive operation of the step five, and thereby the rot proof, heat proof, burn resistance and anti-corrosion composite coating is prepared on the light alloy surface. The light alloy surface prepared on the light alloy surface has the properties of rot proof, heat proof, burn resistance and anti-corrosion, and the binding force of the coating and the basal body is high.

Owner:HARBIN INST OF TECH

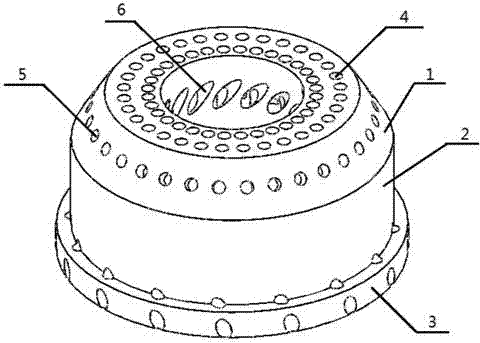

Gasification burner

PendingCN108728168AAdjust operating loadImprove conversion rateGasifier mechanical detailsGasification processes detailsCombustionReaction rate

The invention relates to a gasification burner. The gasification burner comprises a mother burner, N levels of sub-burners are arranged on the inner side of the mother burner, wherein N is an integergreater than or equal to 1, the mother burner and the sub-burners of each level are equipped with independent fuel channels and oxidant channels respectively, and the mother burner and the sub-burnersof each level are arranged to be a coaxial suit structure from the outside to the inside; the inner diameter of the mother burner is larger than the outer diameter of a first level sub-burner, and the inner diameter of the sub-burner of each level is larger than the outer diameter of the sub-burner of a next level; in a limited reaction space and residence time, the sufficient and uniform mixingof a fuel and an oxidant can be ensured, and the combustion reaction rate is accelerated, so that the fuel conversion rate and the gasification performance of a device are improved; in addition, through the adjustment of the load of the mother burner and the sub-burners of each level, the flame shape can be flexibly adjusted without reducing the load of a gasifier, so that the overheating of a gasifier furnace is effectively avoided, and different production load requirements of a project site can be met.

Owner:CHANGZHENG ENG

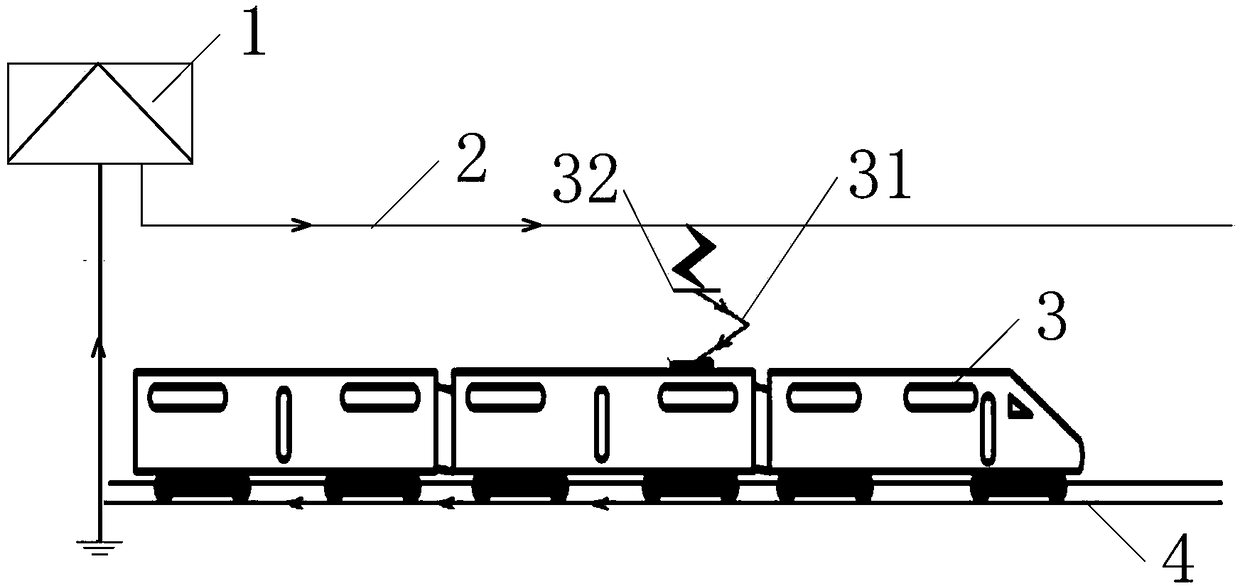

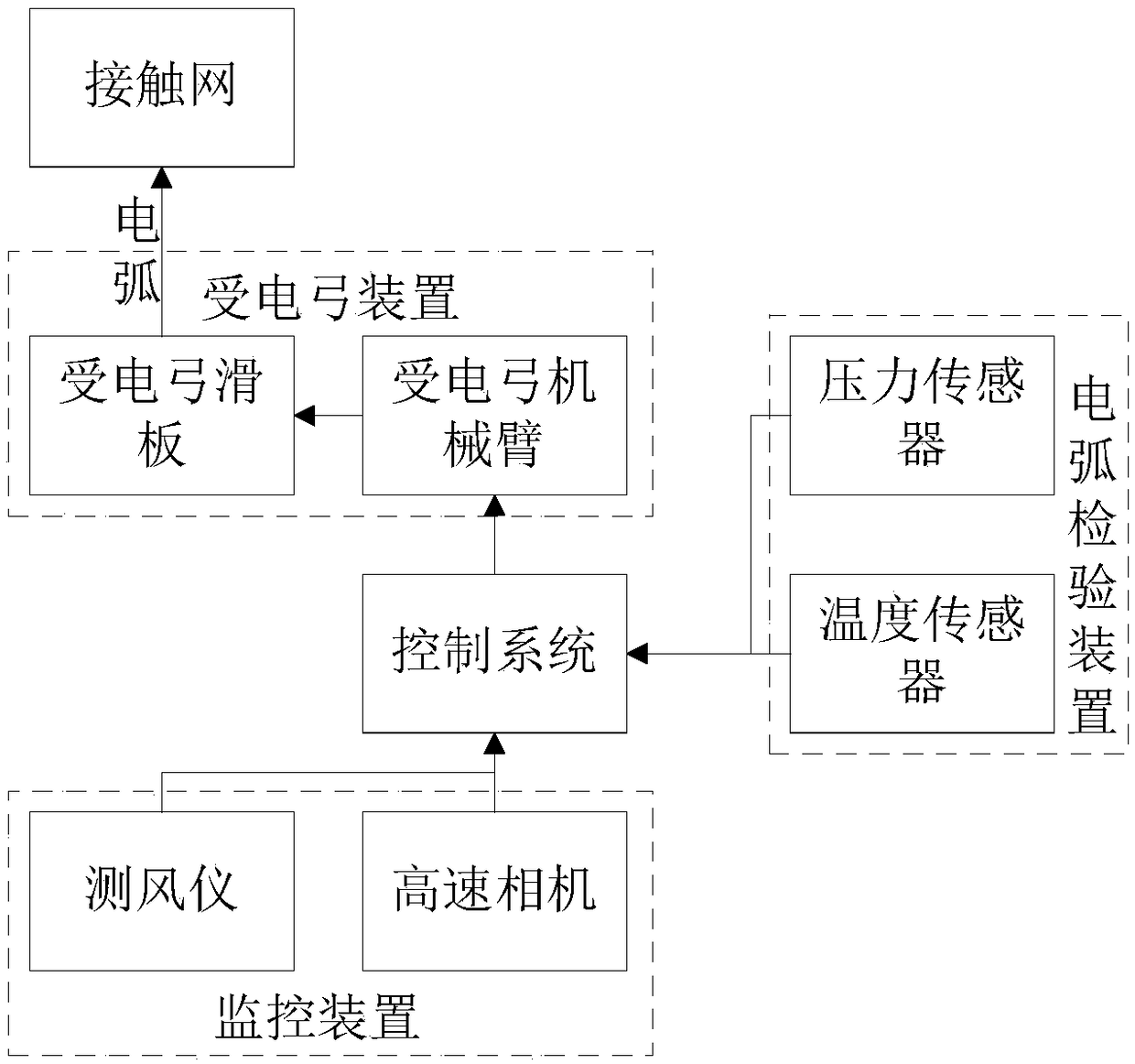

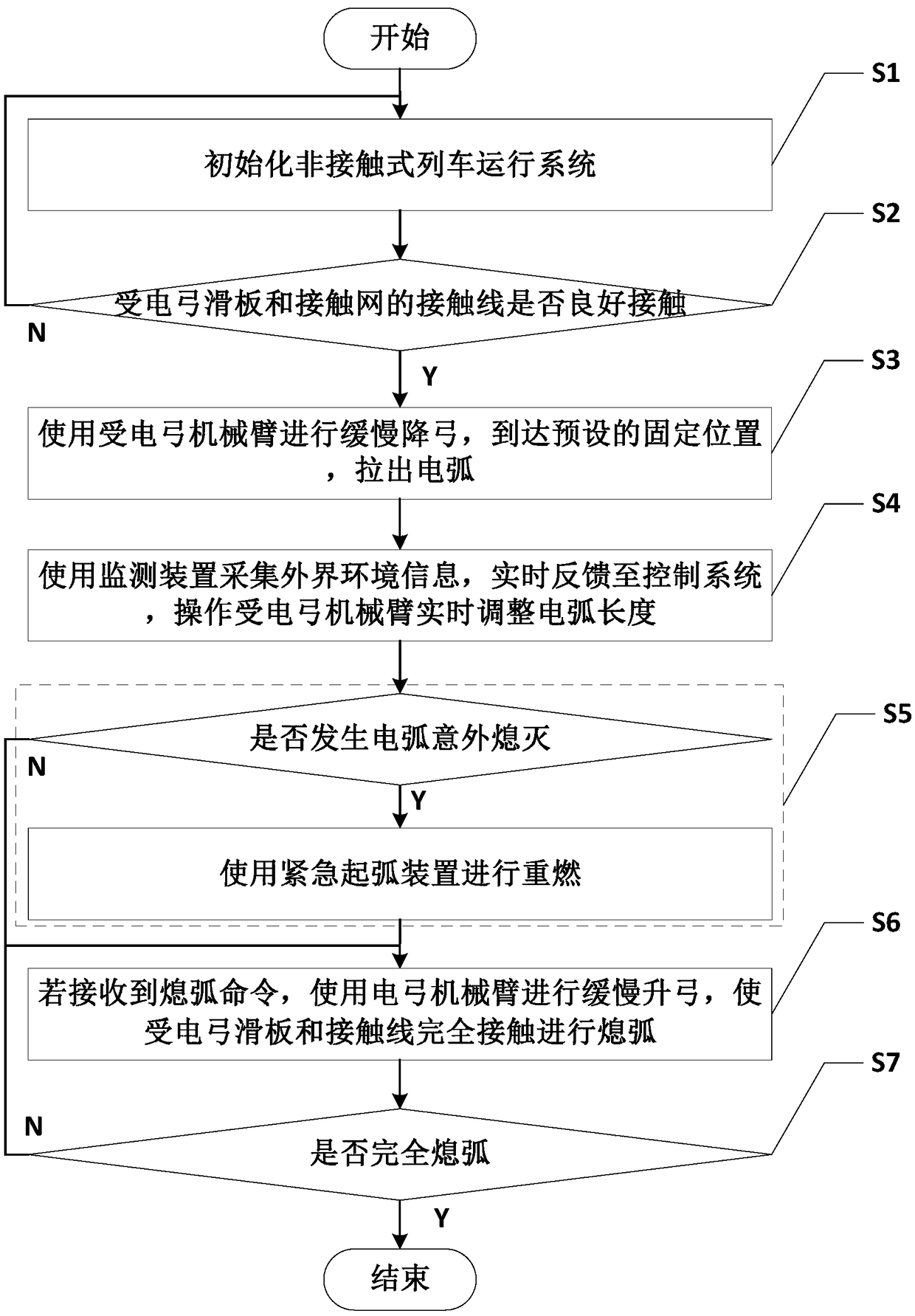

Non-contact train operating system and operating method thereof

ActiveCN109484189AAvoid the disadvantage of wearing out too quicklyAvoid mechanical shockPower current collectorsElectricityControl system

The invention discloses a non-contact train operating system and an operating method thereof. The operating system comprises a traction substation, a catenary, a non-contact train and a rail which areelectrically connected in sequence. The rail is electrically connected with the traction substation through a return line to form a current loop. The non-contact train includes a control system and apantograph device, a monitoring device and an arc inspection device which are in communication with the control system. The control system is located inside the non-contact train. The pantograph device comprises a pantograph arm and a pantograph pan which are fixedly connected. The pantograph arm is arranged at the top end of the non-contact train, the pantograph pan is electrically connected with the catenary through the arc, and the monitoring device and the arc inspection device are both arranged at the connection of the pantograph pan and the catenary. The system solves the problems in the prior art of large mechanical impact and serious material wear between the pantograph device and the catenary and rapid decline of service performance of a pantograph-catenary current collection system.

Owner:SOUTHWEST JIAOTONG UNIV

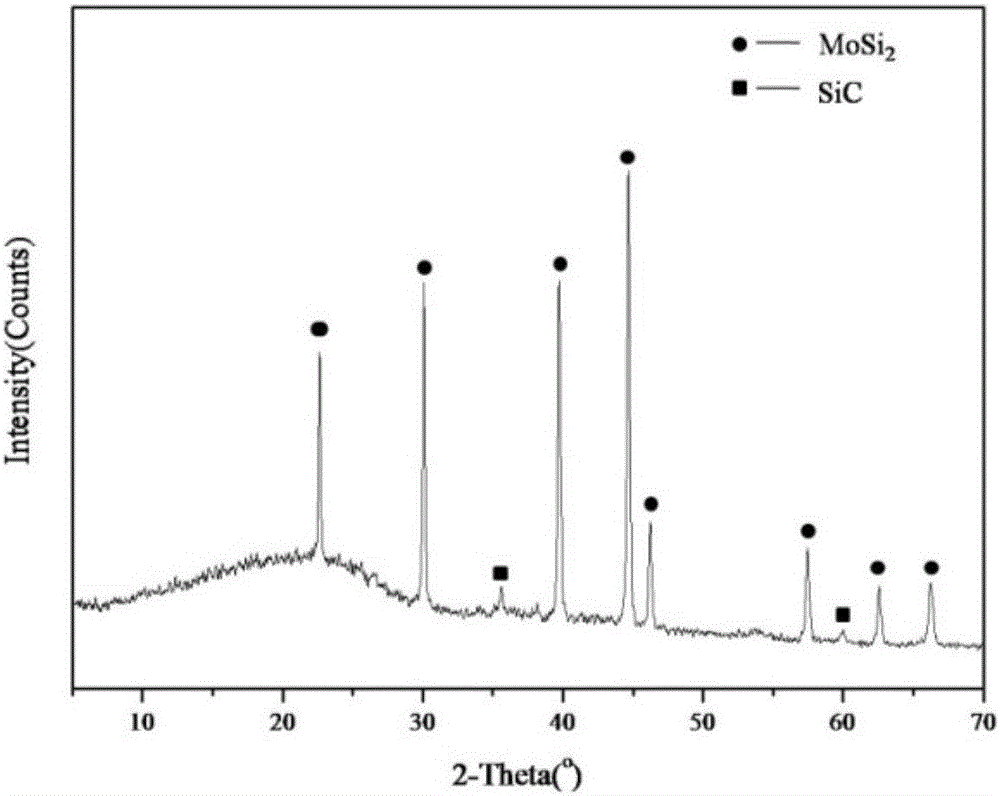

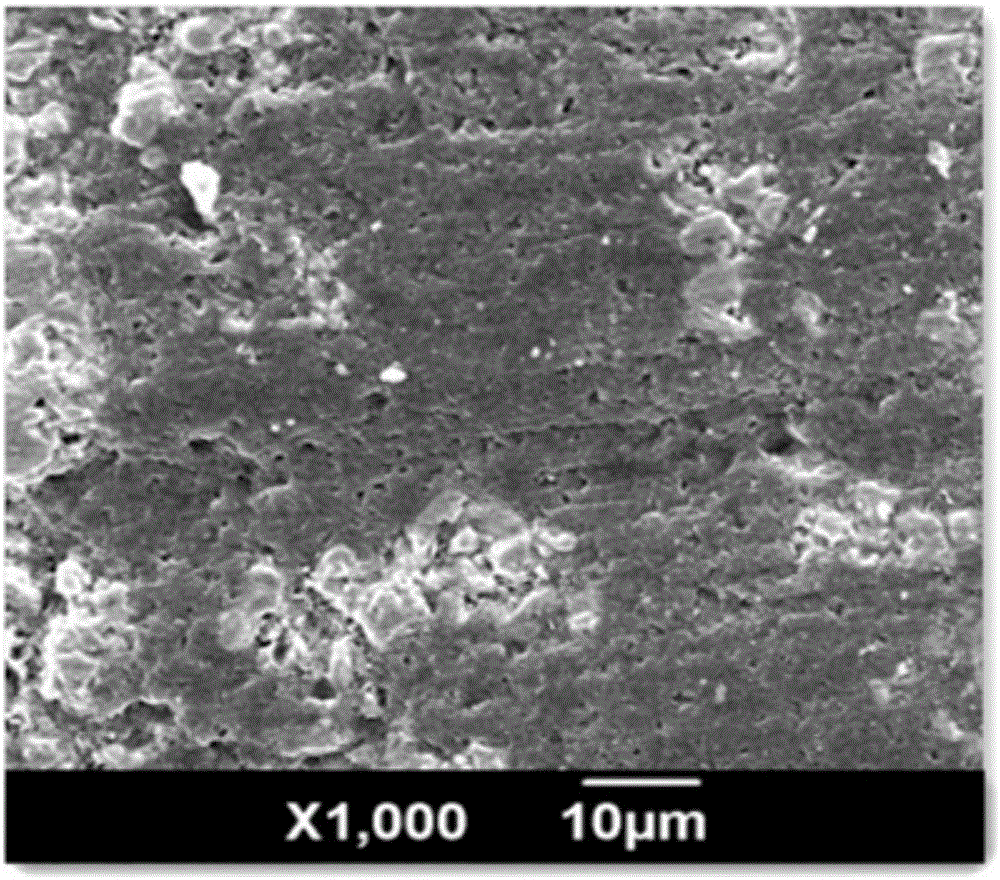

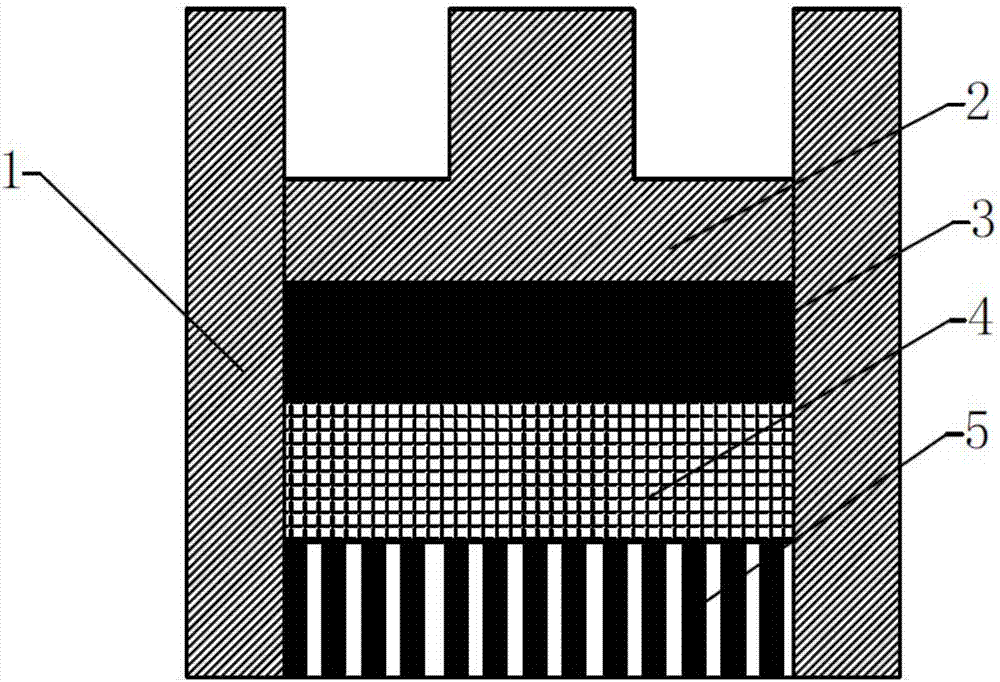

Preparation method for lamellar C/C-SiC-MoSi2 ceramic matrix composite

The invention provides a preparation method for a lamellar C / C-SiC-MoSi2 ceramic matrix composite. The method comprises the steps that silicon carbide powder and molybdenum disilicide powder are dispersed in isopropyl alcohol and then stirred evenly after iodine is added, and first suspension liquid and second suspension liquid is obtained; the density of a carbon-fiber three-dimensional fabric is increased by adopting the mode of hydrothermal glucose permeation, the carbon-fiber three-dimensional fabric is clamped in a specially-made hydrothermal kettle with a positive electrode and a negative electrode, then the specially-made hydrothermal kettle is placed in a drying oven for heat preservation, and then hydrothermal electrophoretic deposition is performed; homogeneous-phase hydrothermal treatment is repeatedly performed in an aqueous glucose solution until the density reaches 1.3-1.5 g / cm<3>, and then heat treatment is performed after the fabric is dried. According to the preparation method for the lamellar C / C-SiC-MoSi2 ceramic matrix composite, the prepared composite is moderate in density and compact in structure, and binding between a C / C interface and a SiC interface, binding between the SiC interface and a MoSi2 interface and binding between the C / C interface and the MoSi2 interface are good; the composite with the high strength and the good high-temperature oxidation resistance can be obtained at low temperature, and the preparation method has the advantages that the raw materials are easy to obtain, the preparation technology is simple, operation is easy and convenient, and the cost is low.

Owner:广西自贸区见炬科技有限公司 +1

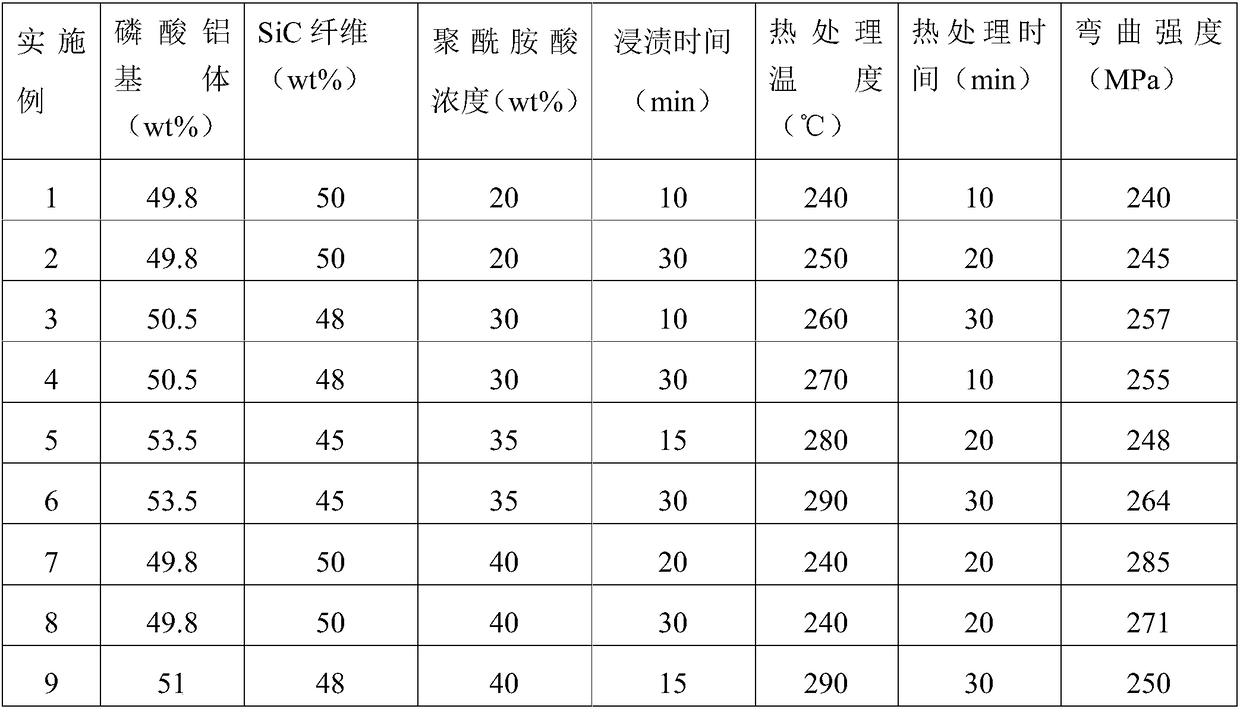

Silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and preparation method thereof

The invention relates to a silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and a preparation method thereof. The silicon carbide fiber reinforced aluminium phosphate ceramic-based composite comprises the following components in percentage by mass of 40% of silicon carbide fiber cloth, 45%-55% of an aluminium phosphate basal body, and 5%-15% of a polyimide resin basal body. The preparation method comprises the preparation steps of putting silicon carbide fiber cloth in a polyamic acid solution for immersing for 10-30min after the silicon carbide fiber cloth is degummed and dried, then taking out the immersed silicon carbide fiber cloth, and performing solidifying to obtain the silicon carbide fiber cloth containing an oxidation resistant coating; uniformly coating an aluminium phosphate sizing agent onto the outer surfaces of the silicon carbide fiber cloth containing the oxidation resistant coating, then stacking up the silicon carbide fiber cloth coated with the aluminium phosphate sizing agent, and then performing vacuum immersing and die pressing, so that the silicon carbide fiber reinforced aluminium phosphate ceramic-based composite is obtained. The combination effect of fibers and the basal body is good, so that the intensity and the tenacity of the composite are improved, and under the high-pressure oxygen-free environment, the composite canalso maintain high mechanical properties.

Owner:QINGHAI UNIVERSITY

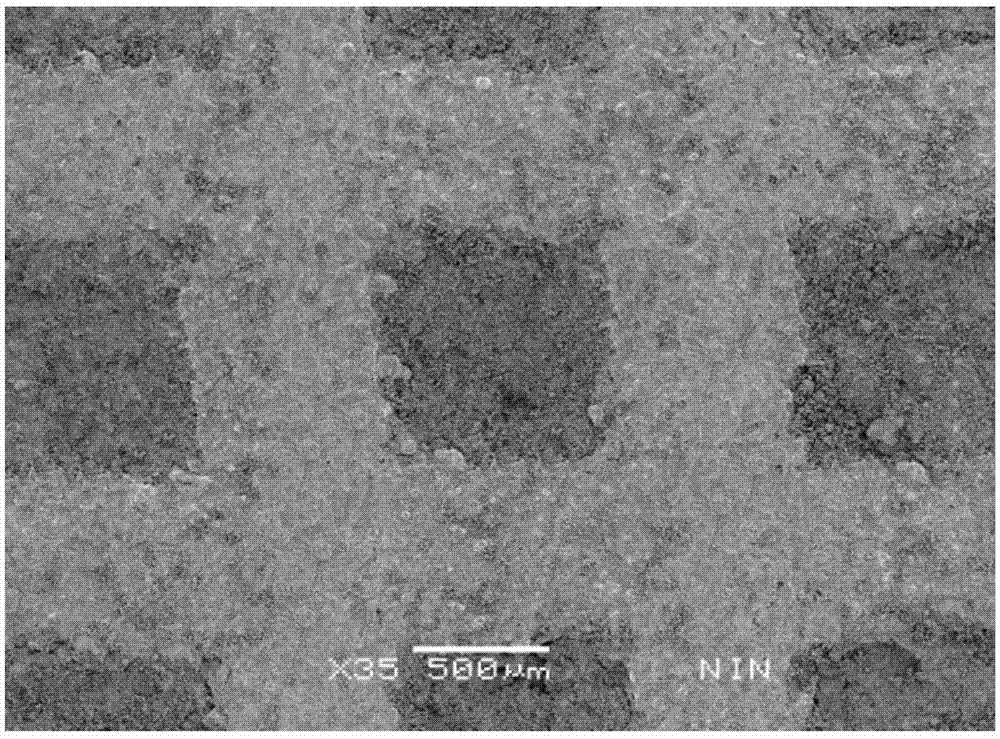

Method for controlling atmospheric plasma spraying of easily-oxidized coating under atmosphere open environment

ActiveCN104213066AImprove antioxidant capacityImprove anti-ablation performanceMolten spray coatingMetallurgyGas cylinder

The invention discloses a method for controlling atmospheric plasma spraying of an easily-oxidized coating under the atmosphere open environment. According to the method, in the plasma spraying process, powder can be effectively prevented from being oxidized, the purity and the property of the coating are ensured, the oxidation-resisting property and the ablation-resisting property of the coating are improved, and the service life of the coating is prolonged. The method specifically comprises the points that before plasma spraying is carried out, an air flow channel is arranged outside a plasma spraying gun muzzle; the air flow channel is connected with a protection air bottle, and therefore the aim that the protection atmosphere environment is formed between the spraying gun opening and a base material can be achieved. Before the coating is sprayed, the protection air bottle is opened in advance, the protection atmosphere environment is formed, and then plasma spraying equipment is controlled to carry out spraying of the easily-oxidized coating. According to the method, manufacturing of a silicide coating under the atmospheric pressure open environment can be achieved, the process is easy to operate, parameters are easy to regulate and control, and the method is a high-efficiency low-cost coating manufacturing process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

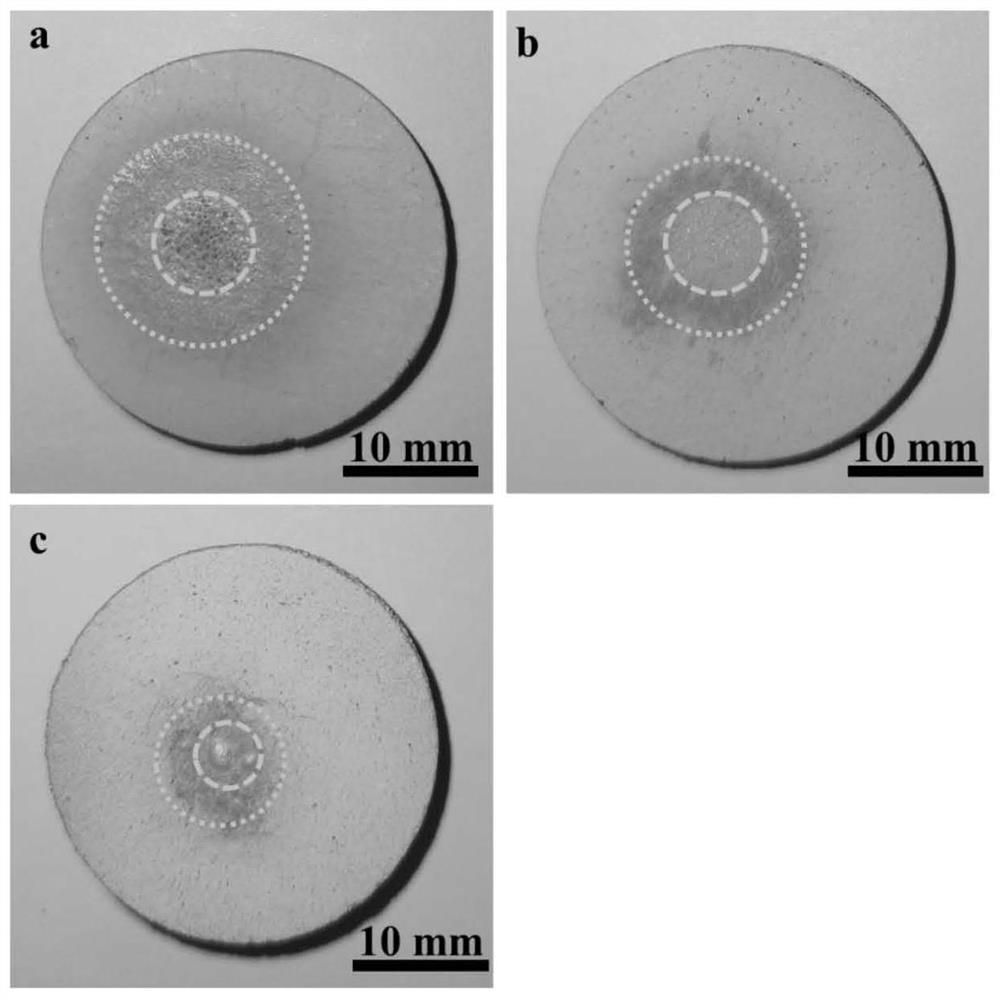

Oxide high-entropy ceramic with defective fluorite structure and preparation method of anti-ablation coating of oxide high-entropy ceramic

ActiveCN113683430AImprove stabilityImprove anti-ablation performanceEfficient propulsion technologiesCoated surfaceCeramic coating

The invention relates to oxide high-entropy ceramic with a defective fluorite structure and a preparation method of an anti-ablation coating of the oxide high-entropy ceramic. The preparation method comprises the following steps of: firstly, preparing high-entropy ceramic powder by adopting a high-temperature solid-phase reaction method; and then, by using a supersonic plasma spraying technology, preparing a high-entropy ceramic coating with corresponding components on the surface of a base material by using the high-entropy ceramic powder having been subjected to spray drying treatment. The high-entropy ceramic coating (HfZr(3RE))O2-delta (wherein RE is selected from Sm, Er, Ce, Y, Yb) provided by the invention has excellent phase stability and ablation resistance. In a supersonic plasma spraying process, the high-entropy ceramic is free of phase change and phase decomposition, and the prepared high-entropy ceramic coating still keeps the phase structure of the original high-entropy ceramic powder. The high-entropy ceramic coating is ablated and examined in oxyacetylene flames with heat flux density of 2.38 MW / m<2>, the highest temperature of the surface of the coating in the ablating process reaches 1900-2100 DEG C, the ablated coating does not have the phenomena of stripping, peeling and the like, an ablating rate is low, and excellent anti-ablating performance is shown.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Wide-temperature-range ablation-resistant coating formed on base material and preparation method of wide-temperature-range ablation-resistant coating

The invention relates to a wide-temperature-range ablation-resistant coating formed on a base material and a preparation method of the wide-temperature-range ablation-resistant coating. The wide-temperature-range ablation-resistant coating comprises a SiBCN transition layer, a ZrB2-SiC-La2O3 ultra-high-temperature complex-phase ceramic layer which is formed by missing of ZrB2, SiC and La2O3, and aSiBCN sealing and filling layer; the above layers are formed on a matrix material successively; wherein the SiBCN transition layer is prepared through PIP method, the ZrB2-SiC-La2O3 ultra-high-temperature complex-phase ceramic layer is prepared through VPS method, and the SiBCN sealing and filling layer is prepared through PIP method. are sequentially formed on a base material. The wide-temperature-range ablation-resistant coating can prevent the oxidizing atmosphere from migrating into the material, prolong the high-temperature anti-ablation time, and effectively protect the ceramic-based composite material; the multi-layer coating prepared by the method is small in porosity and low in surface roughness, and can effectively protect the ceramic-based composite material for at least 700sin a high-temperature environment of 2100 DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of C/Al-Si-X ablation-resisting composite material

ActiveCN106966753AImprove thermal shock resistanceLower the joining temperatureMatrix damageMelting temperature

The invention discloses a preparation method of a C / Al-Si-X ablation-resisting composite material. The invention relates to the technical field of preparation of high-temperature ablation-resisting composite material. The invention solves the technical difficulty of too high melting temperature when a heatproof material is modified by a refractory metal during the preparation process, and overcomes the technical problem of interface reaction and C / C matrix damage. The method includes steps of firstly, weighing a raw material; secondly, preparing a carbon material-X precursor composite body; thirdly, splitting; fourthly, reducing; fifthly, preparing a prefabricating body; sixthly, processing impregnant; seventhly, applying pressure, and filling the impregnant in a prefabricating body hole. The preparation method is short in technical cycle and low in matrix price; the preparation method overcomes the shortcomings of interface reaction and C / C matrix damage caused by too high melting temperature of the refractory metal. The invention is used for preparing the ablation-resisting composite material.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com