Anti-ablation high-resistance flexible heatproof soft skirt and preparing method thereof

An anti-ablation and high-barrier technology, which is applied in chemical instruments and methods, aerospace vehicle heat-proof devices, lamination, etc., can solve the problems of reduced sealing performance, large overall thickness, and large single-layer thickness, etc., to ensure anti-corrosion Ablation, good barrier air tightness, and the effect of reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

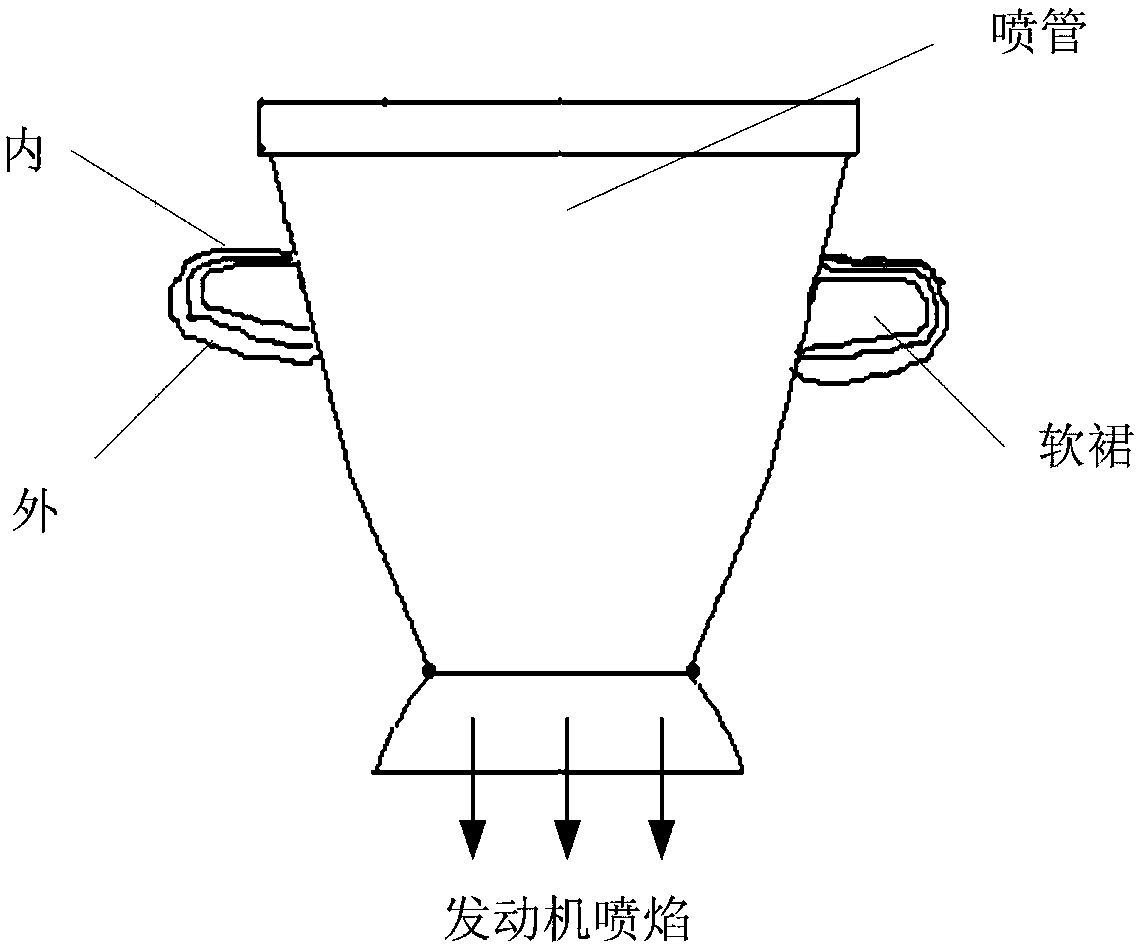

[0043] Soft skirt structure:

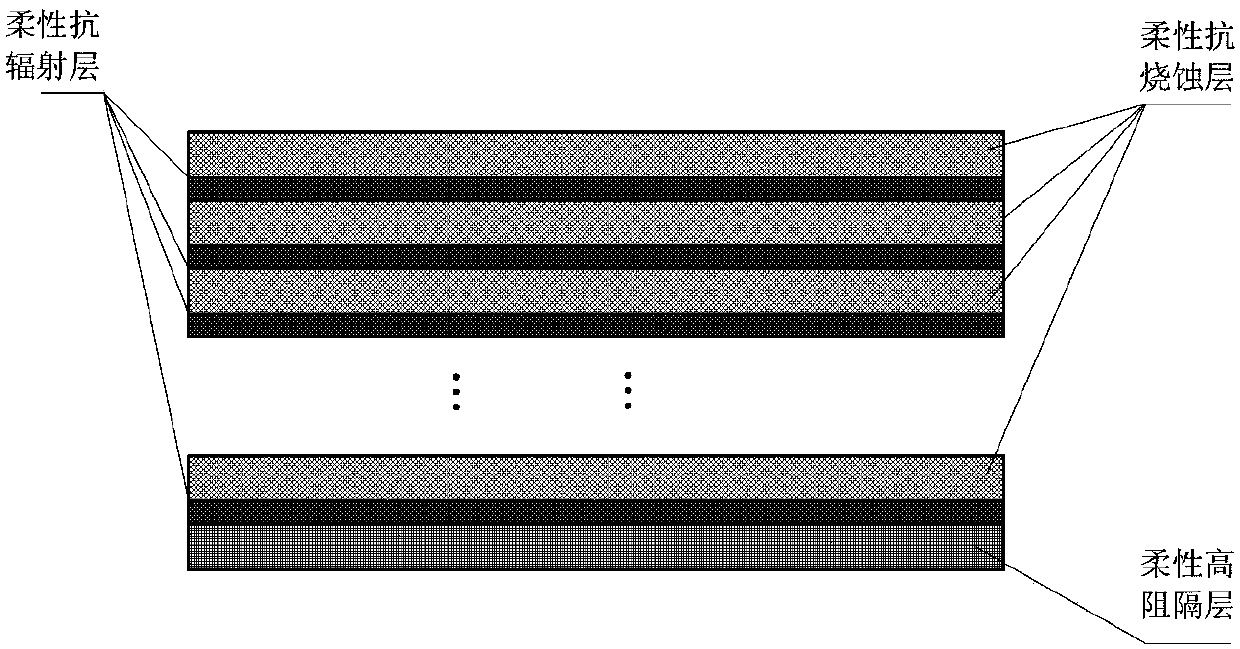

[0044] 4 layers of flexible anti-ablation layer, the content of phenolic resin in the flexible anti-ablation layer is 30%, 20%, 10%, 5%, respectively, and the thickness of each layer is 1.25mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexibility is high The barrier layer has 3 layers, and the thickness of each layer is 0.2mm; the total thickness of the soft skirt is 5.8mm.

[0045] Concrete preparation process is as follows:

[0046] Stir and mix 100 parts of HTV-1 methyl vinyl silicone rubber and 5 parts of benzoyl peroxide (BPO) evenly. Add 0%, 5%, 10%, 20%, 30% phenolic resin into the mixture respectively, mix well and set aside. Then choose the area density as 200g / m 2 The glass fiber plain weave cloth is double-sided coated on a silicone rubber coating machine, and vulcanized at 160-180°C after coating to obtain a silicone rubber-coated fabric. Then prepare aluminum foil with a thickness of 0.05 mm. After ...

Embodiment 2

[0049] Soft skirt structure:

[0050] The flexible anti-ablation layer has 3 layers, the content of phenolic resin in the flexible anti-ablation layer is 30%, 15%, 10%, and the thickness is 1.4mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexible high barrier layer is 3 layers, each Layer thickness 0.2; total thickness 4.95mm.

[0051] The preparation process is the same as in Example 1.

[0052] The soft skirt prepared in this example is tested for ablation resistance and air tightness according to the relevant national standards of GJB2620-96. The ablation test conditions are: the heat flux in the first 70 seconds is 167.47KW / m 2 , the heat flux in the last 60 seconds is 376.81KW / m 2 After the ablation, inspection found that the surface of the first flexible high-barrier layer had slight ablation marks, and the remaining two flexible high-barrier layers had no ablation, and the airtightness was intact.

Embodiment 3

[0054] Soft skirt structure:

[0055] 5 layers of flexible anti-ablation layer, the content of phenolic resin in the flexible anti-ablation layer is 25%, 20%, 15%, 10%, 5%, and the thickness is 1.0mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexibility is high The barrier layer has 3 layers, and the thickness of each layer is 0.2mm; the total thickness is 5.85mm.

[0056] The preparation process is the same as in Example 1.

[0057] The soft skirt prepared in this example is tested for ablation resistance and air tightness according to the relevant national standards of GJB2620-96. The ablation test conditions are: the heat flux in the first 70 seconds is 167.47KW / m 2 , the heat flux in the last 60 seconds is 376.81KW / m 2 , after the ablation inspection, it was found that the flexible high barrier layer was intact, no ablation was seen, and the airtightness was intact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com