System and method for automatically measuring property of vapor stream vacuum pump

An automatic measurement, vacuum pump technology, applied in pump testing, machine/engine, liquid variable capacity machinery, etc., can solve problems such as the impact of measurement data accuracy, increase the difficulty of steam flow vacuum pump performance measurement, etc., to reduce labor intensity and professional knowledge. Reduced requirements for basic and experimental skill levels and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

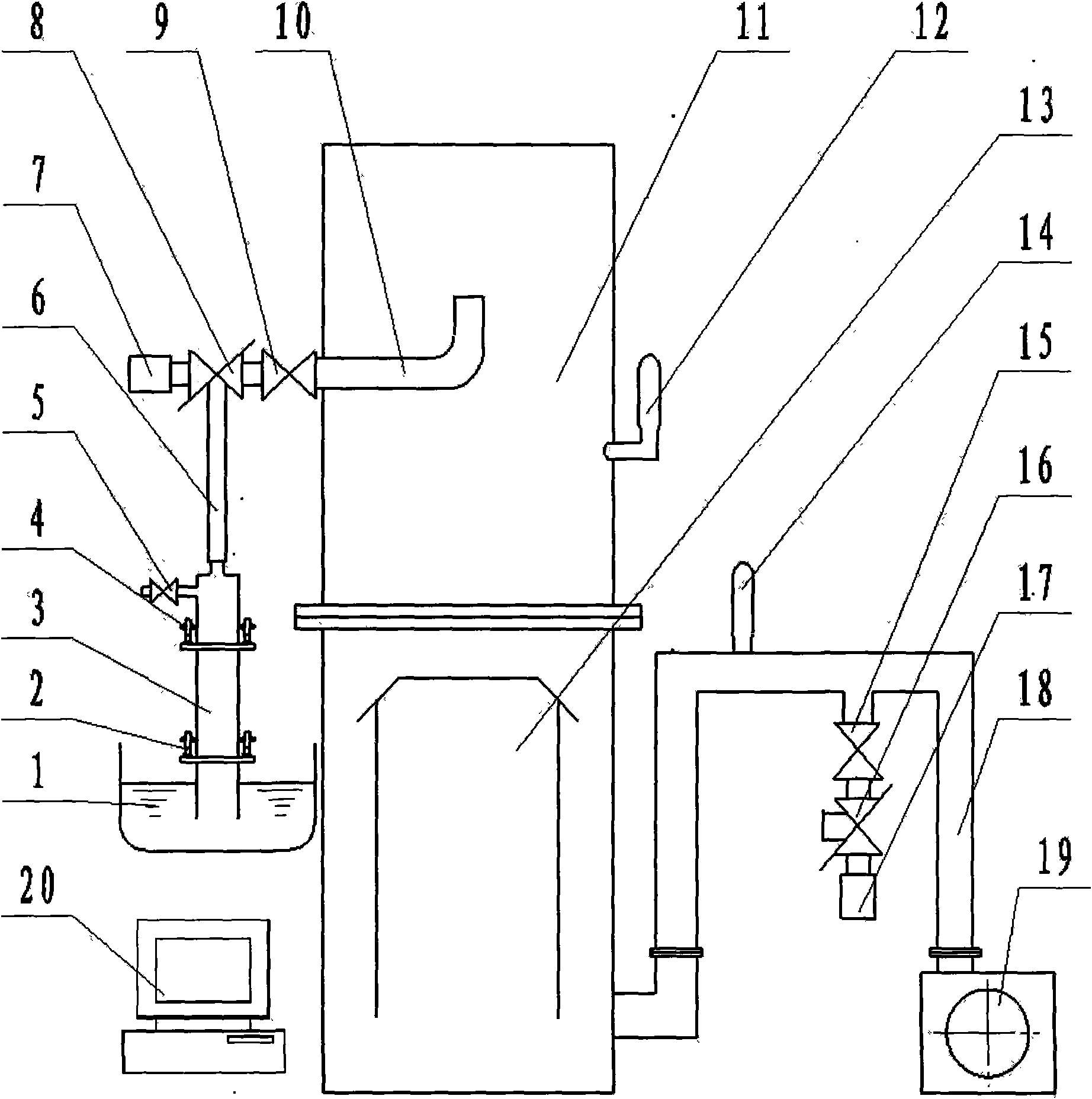

[0024] Such as figure 1 As shown, a vapor flow vacuum pump performance automatic measurement system includes a test cover 11, a tested vapor flow vacuum pump 13, a backstage pipeline 18, a backstage mechanical pump 19, a gas flow test unit, a test cover gas flow adjustment unit and a front stage The first-stage pipeline gas flow adjustment unit; the measured vapor flow vacuum pump 13 is connected to the fore-stage pipeline 18 and the fore-stage mechanical pump 19 in sequence.

[0025] The inner diameter of the test cover 11 is the same as the inlet diameter of the tested vapor flow vacuum pump 13, and the two are connected by a flange. A test cover vacuum gauge 12 is connected to the test cover 11 , and the computer control unit 20 reads the actual balance pressure value in the test cover 11 through the test cover vacuum gauge 12 .

[0026] The gas flow test unit includes an oil tank, measuring oil 1 and a dropper 3, a dropper electromagnetic valve 5 is arranged at the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com