Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182 results about "Copper–tungsten" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper–tungsten (tungsten–copper, CuW, or WCu) is a mixture of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The microstructure is therefore rather a metal matrix composite instead of a true alloy.

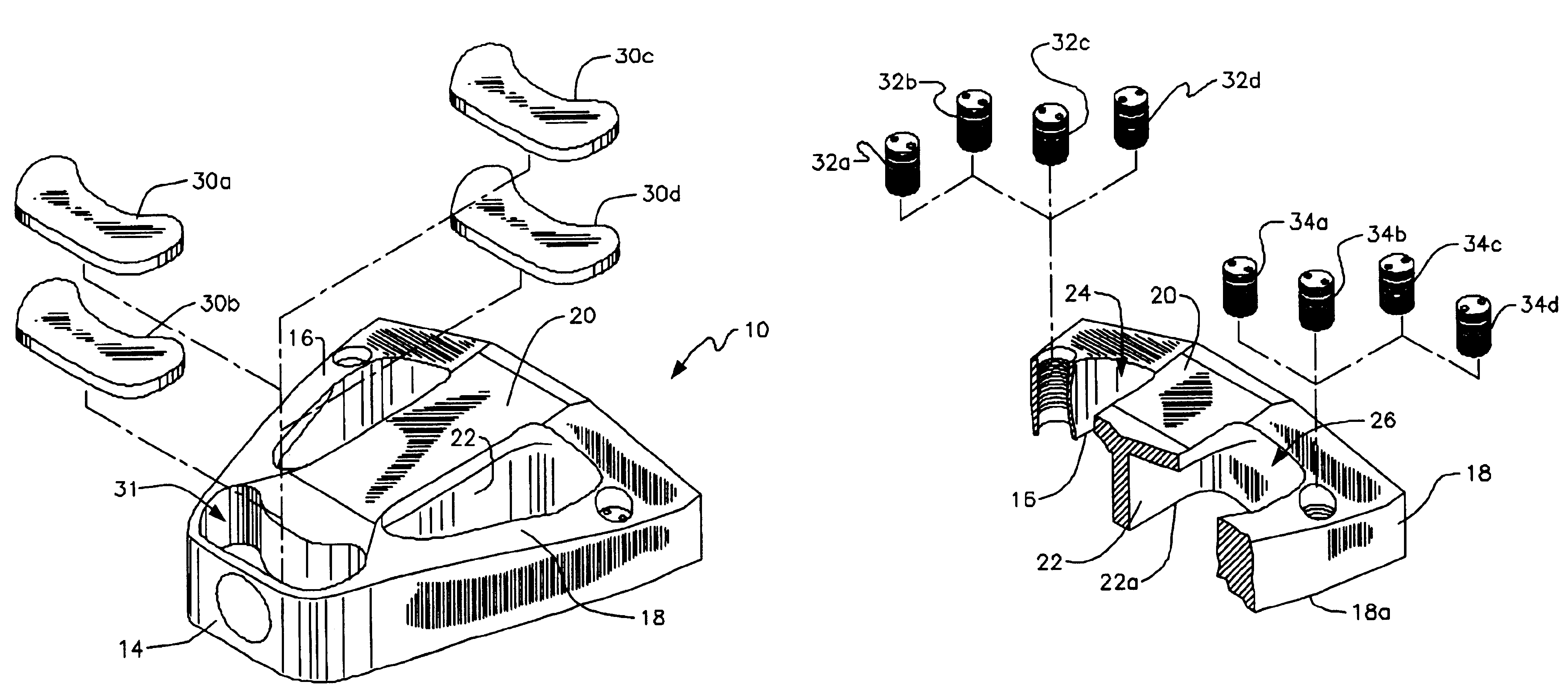

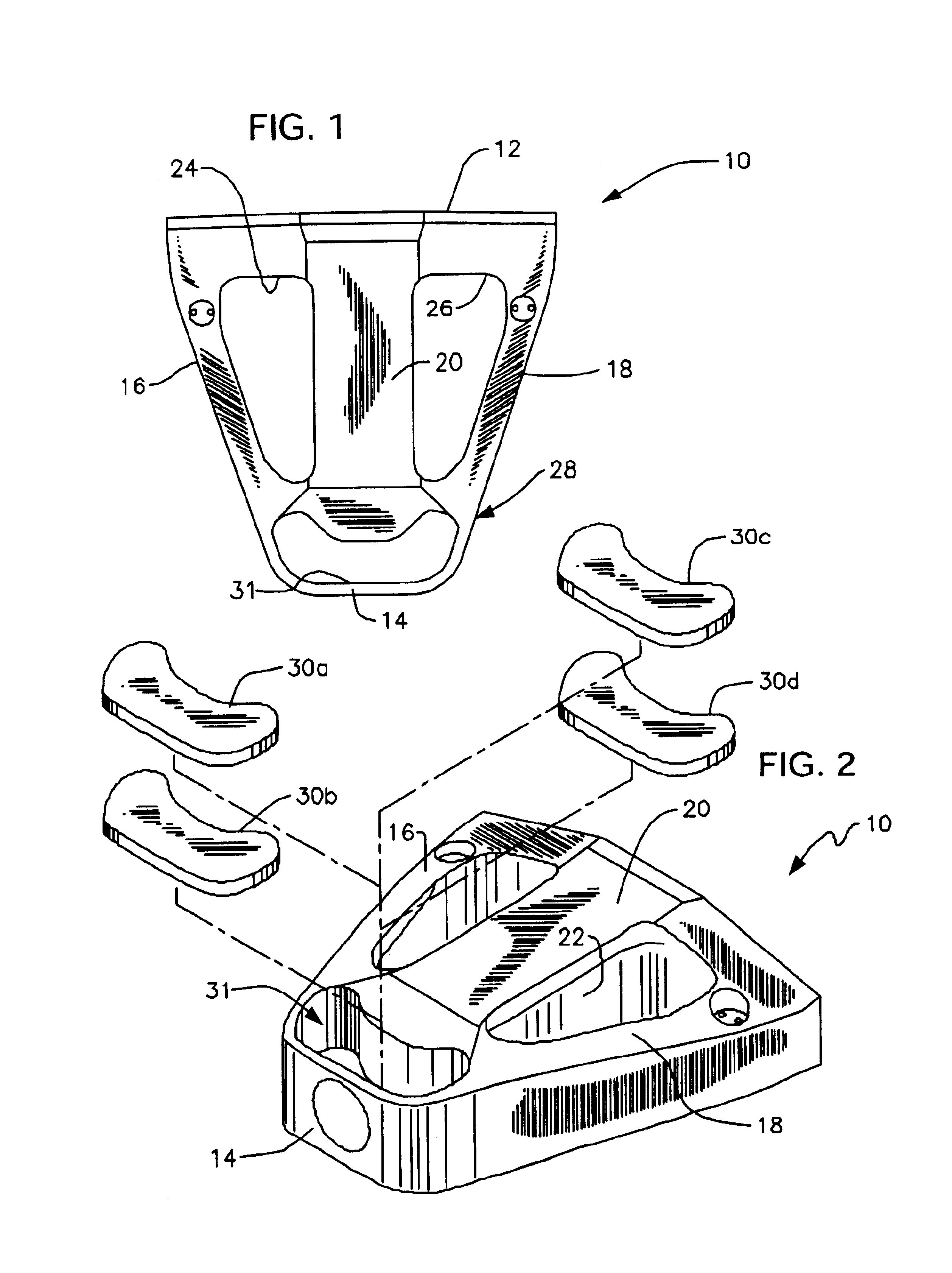

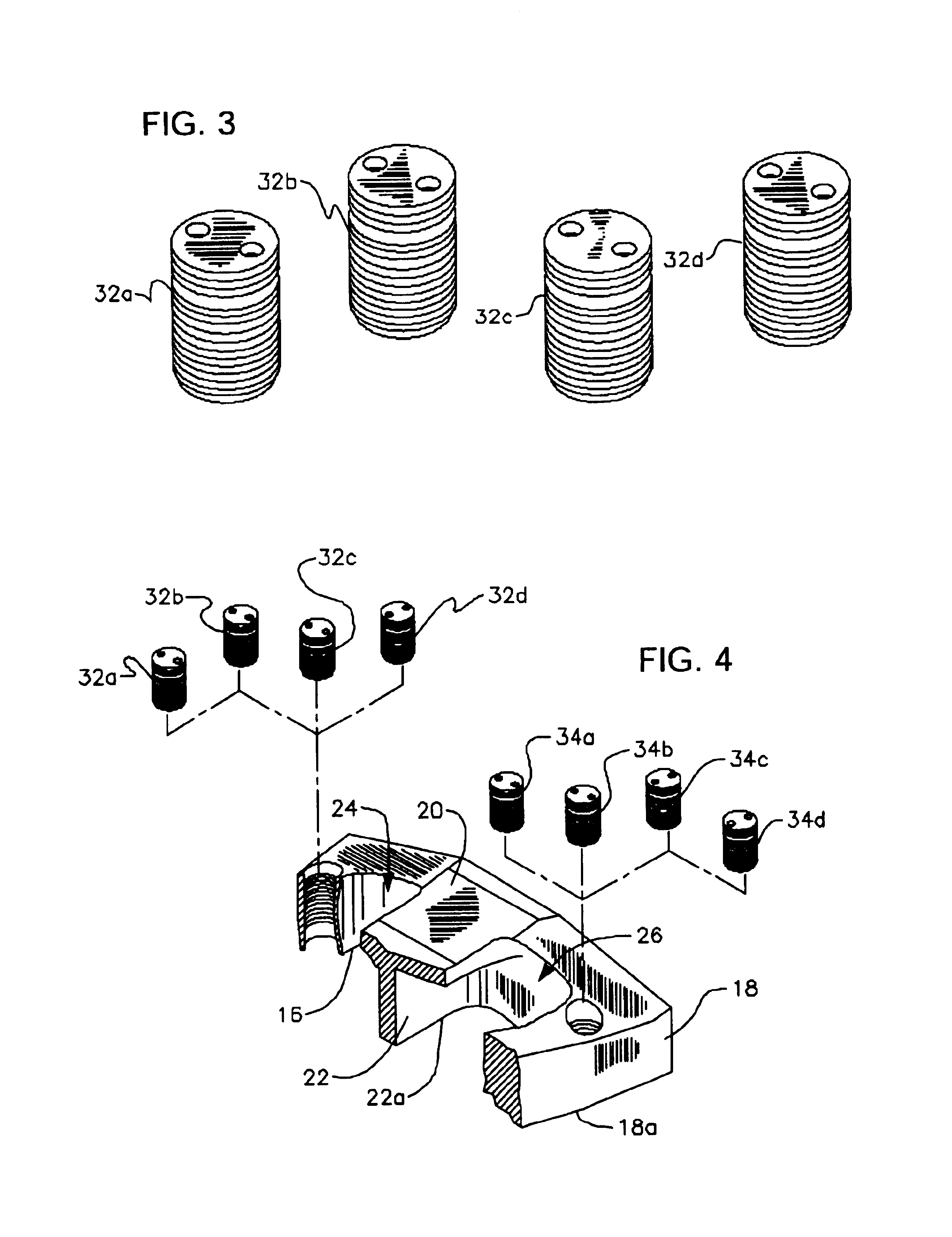

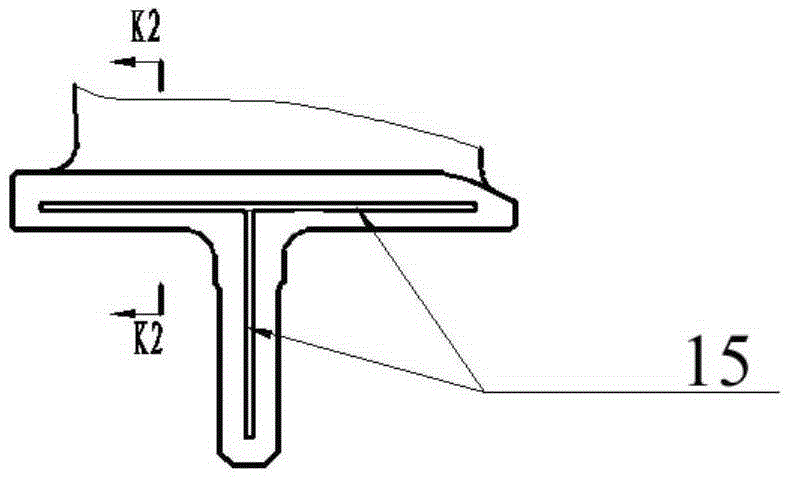

High moment of inertia putter having adjustable weights

InactiveUS6896625B2Avoid distortionRaises the swingweight of a low swingweight putterGolf clubsRacket sportsEngineeringMoment of inertia

A golf putter head of triangular shape. A ball-striking leading wall has a first breadth greater than a second breadth of a trailing wall. The leading and trailing walls are interconnected at their respective opposite ends by sidewalls that converge toward one another. A web interconnects the leading and trailing walls along a longitudinal axis of the golf putter head. A first embodiment may include a trailing copper weight and side wall aluminum weights. A second embodiment may include three copper weights, a third embodiment may include three copper-tungsten weights, and a fourth embodiment may include three tungsten weights. The weights are removable so that a putter having a low swingweight or a high swingweight can be brought up to or down to a standard swingweight. The weights may also be mixed in the second, third, and fourth embodiments.

Owner:MACGREGOR GOLF

Copper-tungsten/copper-alloy integrated contact and preparation method thereof

The invention relates to a contact material for high-voltage switches and discloses a copper-tungsten / copper-alloy integrated contact and a preparation method thereof. The copper-tungsten / copper-alloy integrated contact comprises a contact part and a conducting rod part, wherein the tungsten content of the contact part gradually decreases from head to tail. The preparation method comprises the following steps: firstly, mechanically mixing powder by a wet method to prepare copper-tungsten particles with different tungsten contents; secondly, putting the tungsten in the die cavity of a compression mold according to the weight contents of tungsten in a descending order to carry out the press forming; thirdly, putting the pressed blank in a graphite boat, and sintering and infiltrating the pressed blank in a sintering furnace in the hydrogen atmosphere to obtain the copper-tungsten alloy of the contact part; and finally, sintering the low-tungsten-content end of the copper-tungsten alloy and the copper conducting rod part or the copper alloy conducting rod part to form an integral body by using a sintering method, an electro-beam welding method or a diffusion welding method, thereby obtaining the copper-tungsten / copper-alloy integrated contact.

Owner:XIAN FULAI ELECTRICAL ALLOY

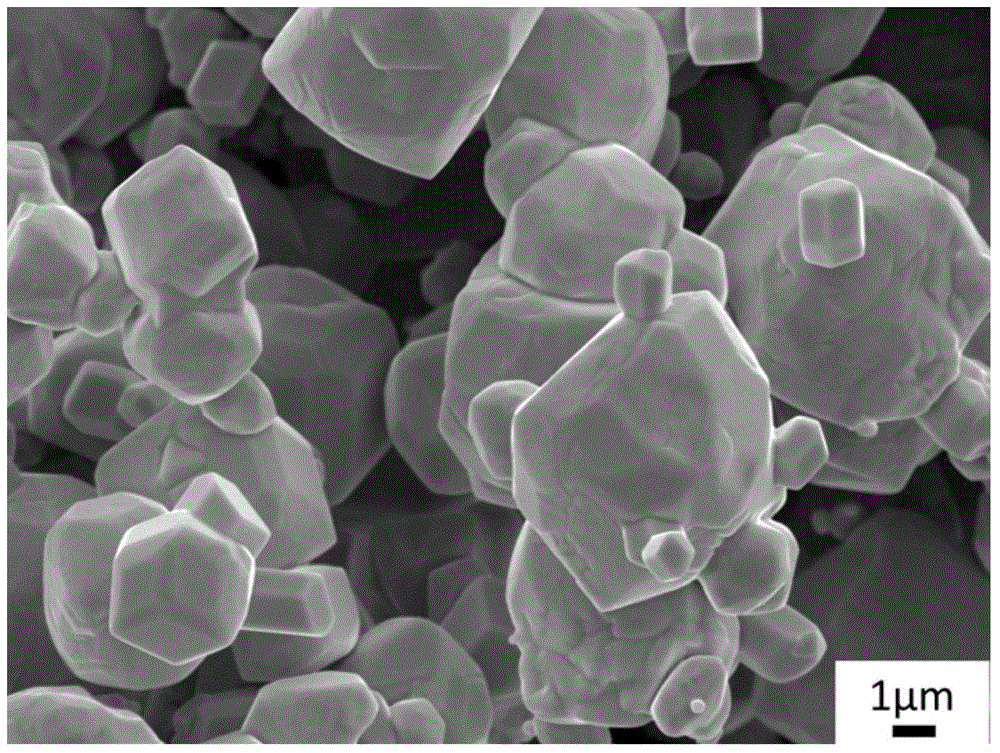

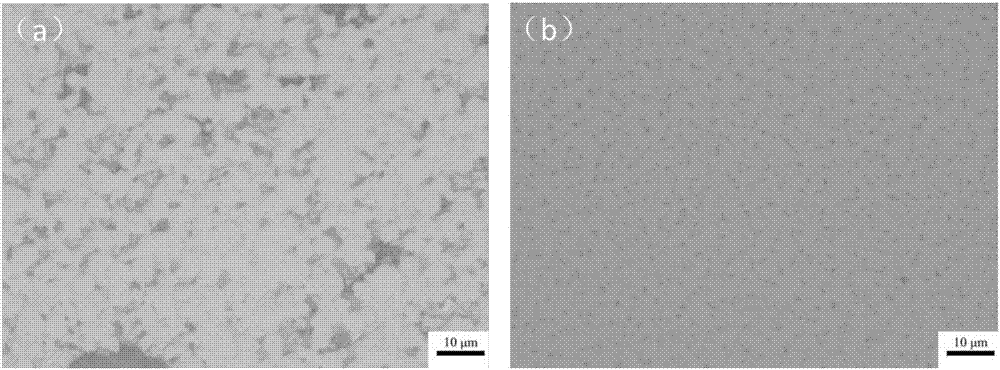

Spherical copper coating tungsten composite powder, preparation method and application thereof

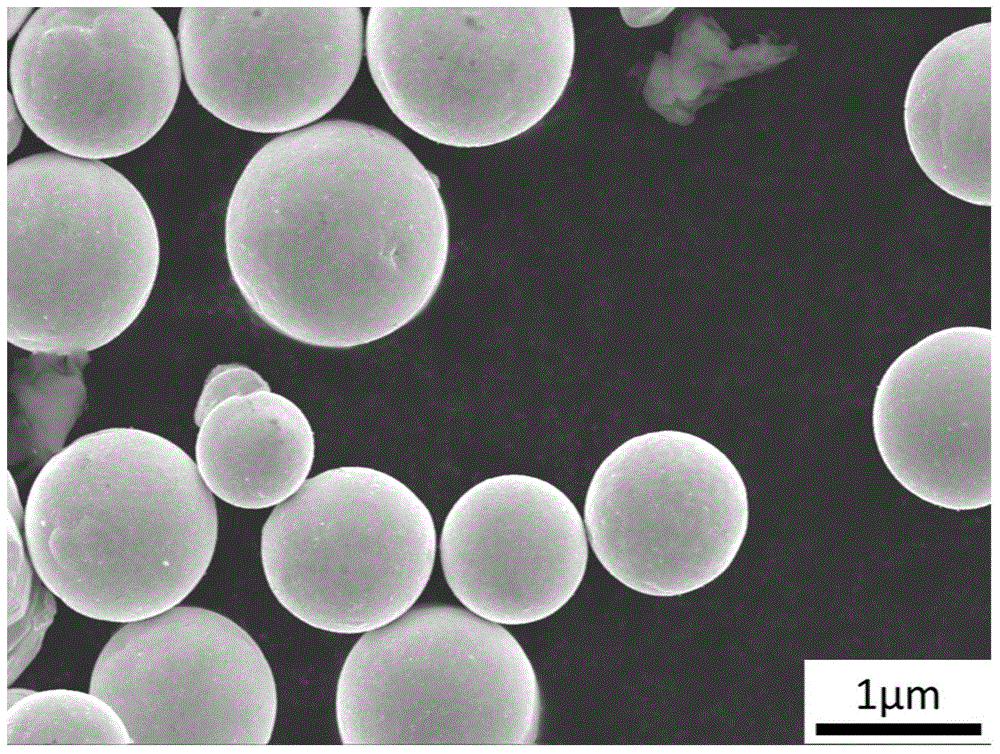

The invention relates to a spherical copper coating tungsten composite powder, a preparation method and an application thereof. The copper coating tungsten composite powder is in a core-shell structure, the shell is a copper plating layer, the core is tungsten powder, and the weight ratio of the tungsten elements and copper elements of the copper coating tungsten composite powder ranges from 5 to 95 : 95 to 5; the spherical copper coating tungsten composite powder has the advantages of fine dispersion performance, high liquidity, even ingredients and high purity. The preparation method includes processing ordinary tungsten powder by a plasma spheroidizing technology, allowing the copper to deposit on the surface of the tungsten powder evenly by the intermittent copper electroplating process, and cleaning and drying the composite powder coated with copper. The spherical copper coating tungsten composite powder is prepared by combining the plasma spheroidizing and intermittent copper electroplating, the method is simple, reliable and easy to operate, the electroplating speed, the electroplated layer thickness and copper content range can be adjusted effectively, the copper-tungsten composite material comprehensive performances can be improved effectively, the expanded application prospect is provided, and the method can be applied to industrialized mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing copper-tungsten contact material by discharge plasmas

ActiveCN106180653AImprove arc ablation resistanceHigh densityFoundry mouldsFoundry coresPulsed DCShielding gas

The invention discloses a method for preparing a copper-tungsten contact material by discharge plasmas. The method comprises the following steps: 1, pouring tungsten powder into a graphite die, placing the graphite die into a plasma sintering furnace, performing vacuumizing and boosting, connecting the sintering furnace with pulse direct current, heating to 1,320 DEG C to 1,480 DEG C, preserving the heat for 2.5 to 5 min, and naturally cooling the graphite die in the furnace to obtain tungsten framework; 2, polishing a copper block, performing ultrasonic cleaning the copper block until the copper block is cleaned, irradiating and scanning the copper block with laser at the speed of 10 to 500 mm / s, and performing plasma treatment to obtain an infiltrating copper block for later use; 3, putting the tungsten framework into a graphite boat, placing the infiltrating copper block on the tungsten framework, filling the space around the copper block with alundum powder, putting the tungsten framework into a high-temperature sintering furnace with protective gas atmosphere, heating to 1,300 DEG C to 1,400 DEG C, and preserving the heat for 2 to 3 hours to obtain a copper-tungsten sintered body; and 4, performing vacuumizing hot pressing on the copper-tungsten sintered body under conditions that the pressure is 50 to 100 MPa and the temperature is 800 DEG C to 850 DEG C, and cooling to room temperature to obtain the copper-tungsten contact material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming

InactiveCN102286740ASimple processPrevent high temperature deformationElectric switchesPressure inorganic powder coatingCopper highHigh pressure

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming. Firstly, the raw material powder is uniformly mixed according to the composition ratio of the high-voltage contact, and then the mixed raw material powder is input into the powder feeding system of the cold spraying system. Or spraying with heated gas, under the action of high-pressure gas, the raw material powder collides with the copper substrate to undergo plastic deformation, and then deposits on the surface of the copper base to form a high-voltage contact material, and finally the formed tungsten copper or molybdenum copper high-voltage contact material Use directly or after annealing at 1000-1400°C for 30-60 minutes. The invention simplifies the process, overcomes the high-temperature deformation of the copper base, distributes the copper solidified phase finely and uniformly, reduces the equipment cost of cold spraying, improves the safety of the working process, is suitable for online processing, and saves spraying cost.

Owner:SHENYANG GOLDEN HEADPOWER NEW MATERIALS

Rapid preparation method of copper-tungsten alloy

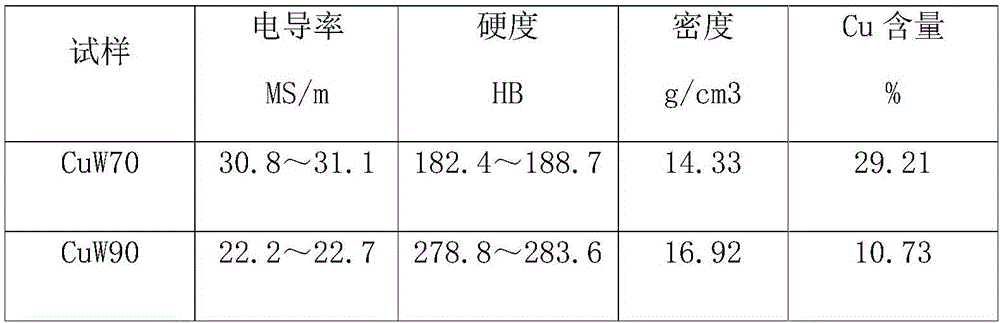

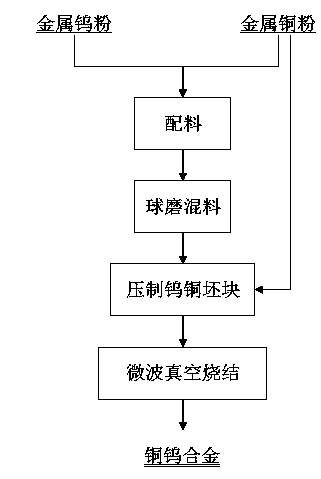

The invention relates to a rapid preparation method of a copper-tungsten alloy, and belongs to the fields of a powder metallurgy technology, a metallurgical new technology and a microwave sintering technology. The method comprises the following steps: carrying out ball milling mixing of metallic tungsten powder and copper powder according to a proportion ratio of 95-70wt%:5-30wt%, carrying out briquet pressing to prepare a tungsten skeleton briquet, filling into a mullite crucible, distributing the copper powder surrounding the tungsten skeleton briquet, putting the crucible under conditions comprising a microwave frequency of 2400-2500MHz, a power of 3-5KW and a degree of vacuum of below 0.1KPa, sintering for 1-3h by heating to 1100-1300DEG C at a heating speed of 15-20DEG C / min, and naturally cooling to obtain the copper-tungsten alloy. The copper-tungsten alloy prepared through the method has a uniform structure and a compact structure, and has a relative density reaching 98.7%.

Owner:KUNMING UNIV OF SCI & TECH

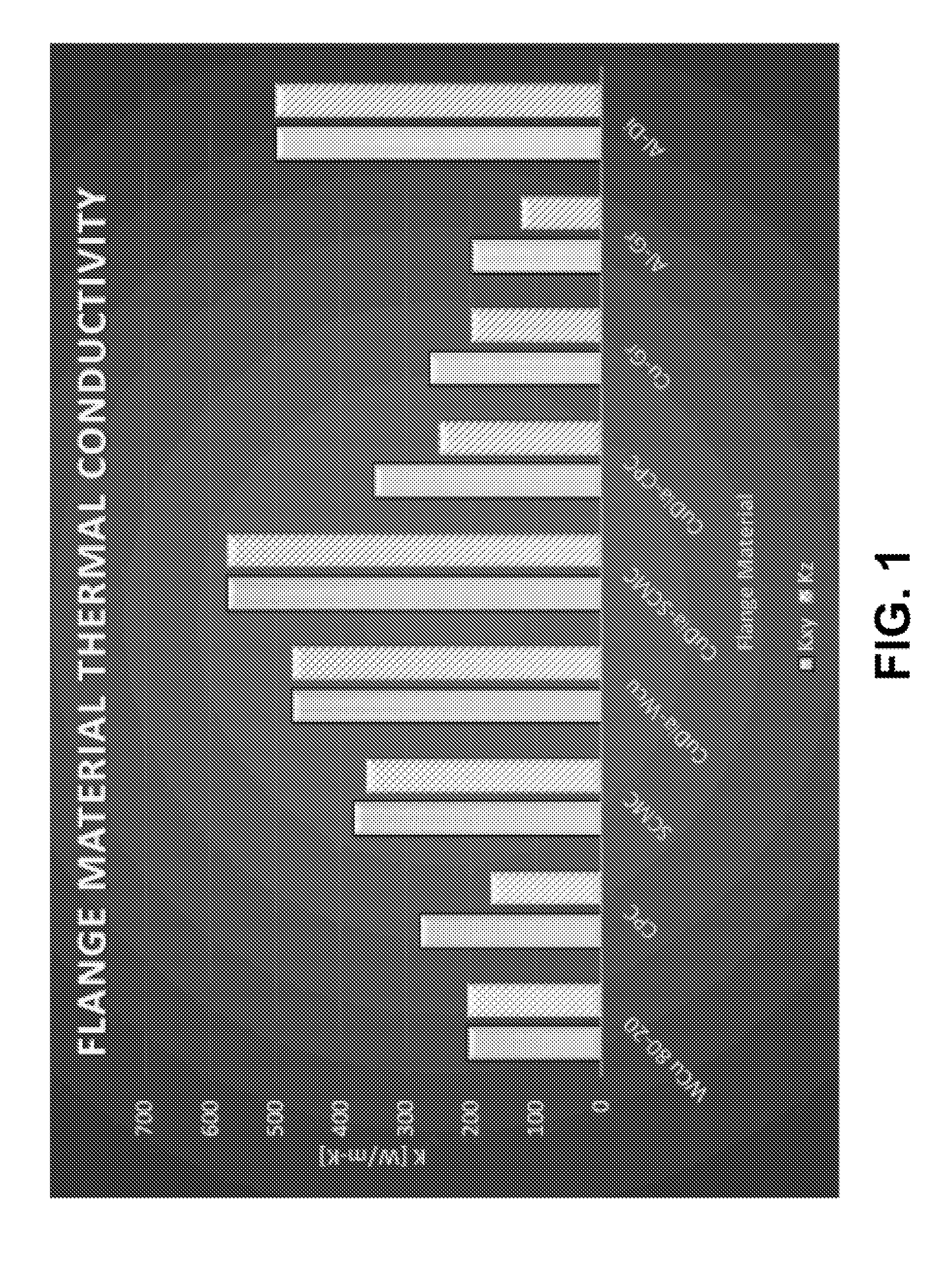

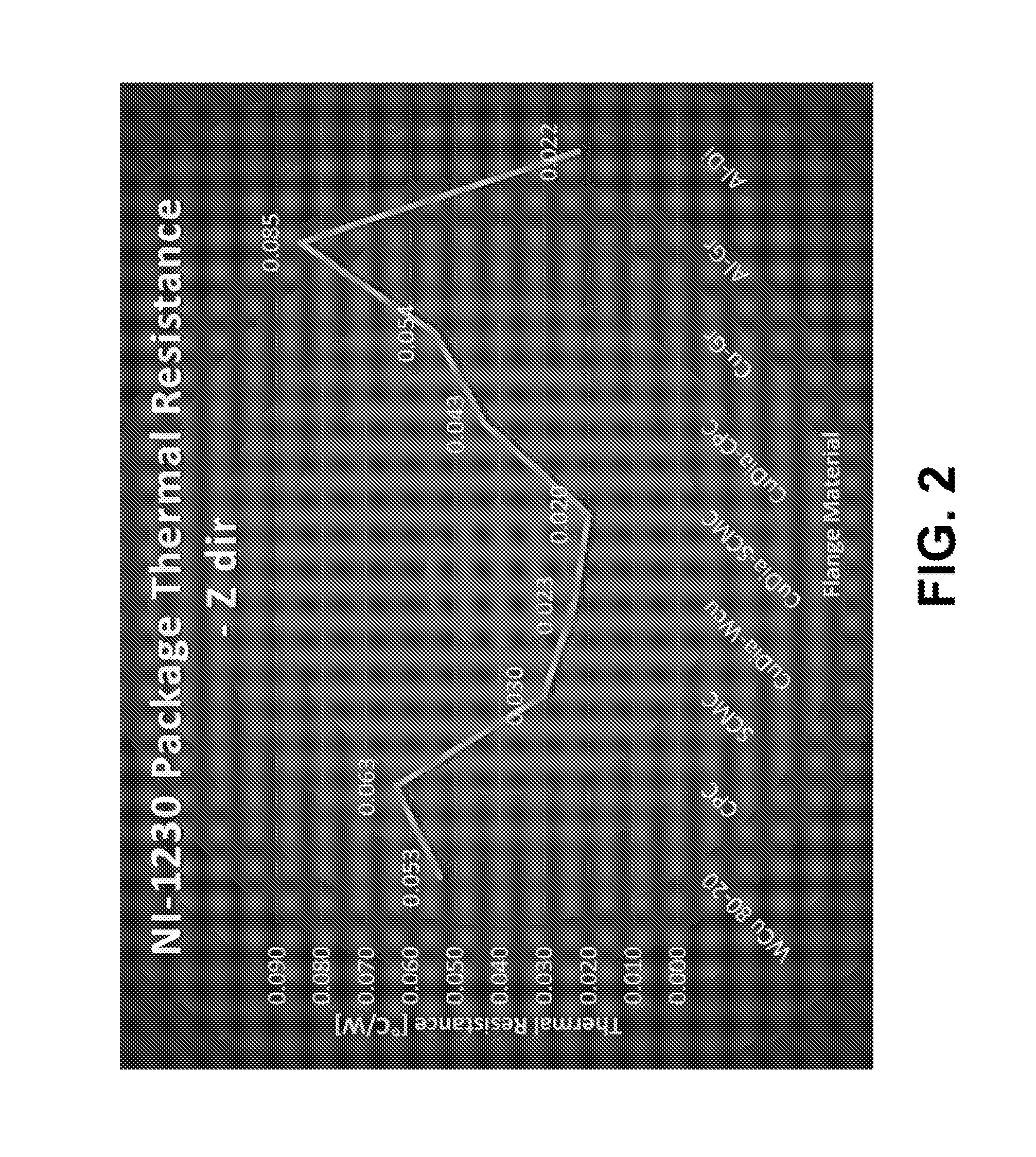

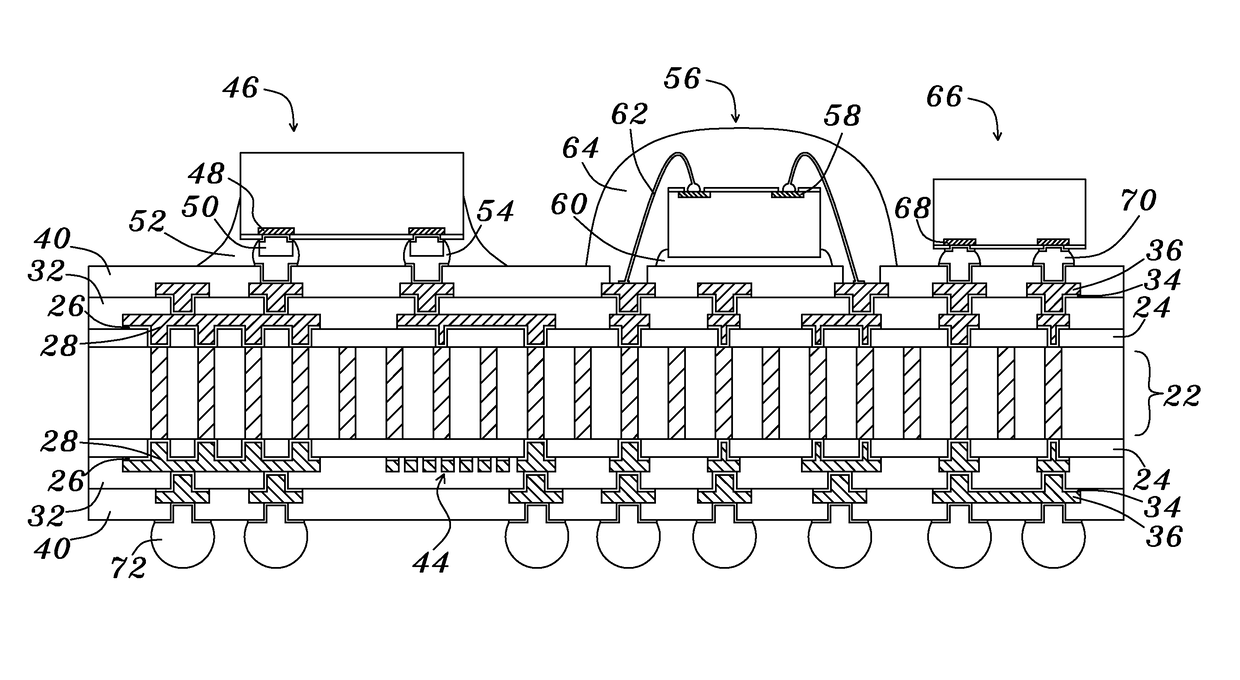

Composite Structure of Tungsten Copper and Molybdenum Copper with Embedded Diamond for Higher Thermal Conductivity

InactiveUS20160003563A1More transparent to x-raysImprove performanceSemiconductor/solid-state device detailsMetal-working apparatusCopper platingCopper–tungsten

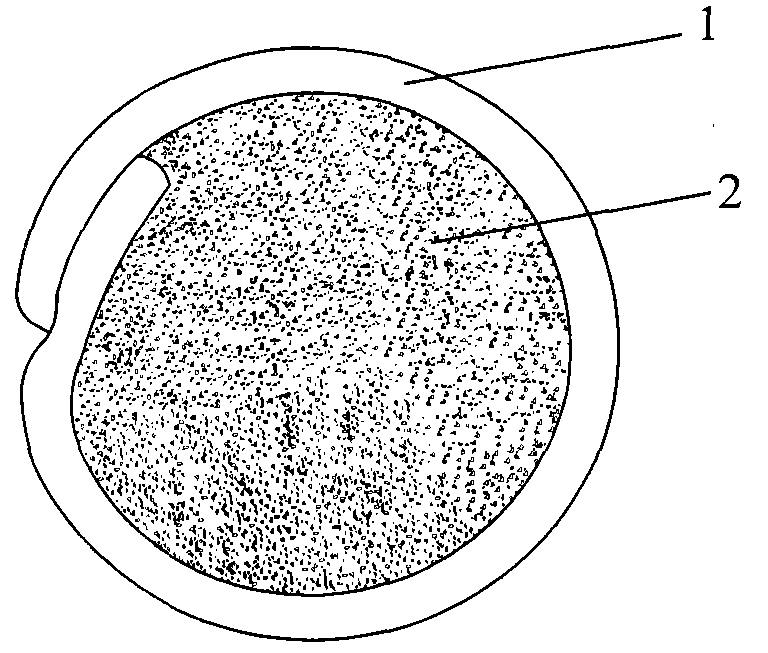

A heatsink for dissipating heat generated by electronic components comprising an outer frame of copper tungsten or copper molybdenum metal matrix composite having a cavity extending between the top and the bottom surfaces, a copper-diamond composite material within the opening, and copper plating on the top and the bottom surfaces. The heatsink also includes an array of alternating layers of copper and a material selected from the group of molybdenum and copper / molybdenum metal matrix surrounding the outer frame. The heatsink can be manufactured by press fitting at room temperature a porous isotropic diamond material in the cavity of an outer frame of porous tungsten or molybdenum, co-infiltrating the assembly under pressure with copper, press fitting at room temperature the outer frame into the layered array, and subjecting the heatsink to a temperature of approximately 800 Deg C.

Owner:THERMAL MANAGEMENT SOLUTIONS LLC D B A SANTIER

Copper system metal organic framework compound for selectively adsorbing heavy metal ions and preparation method thereof

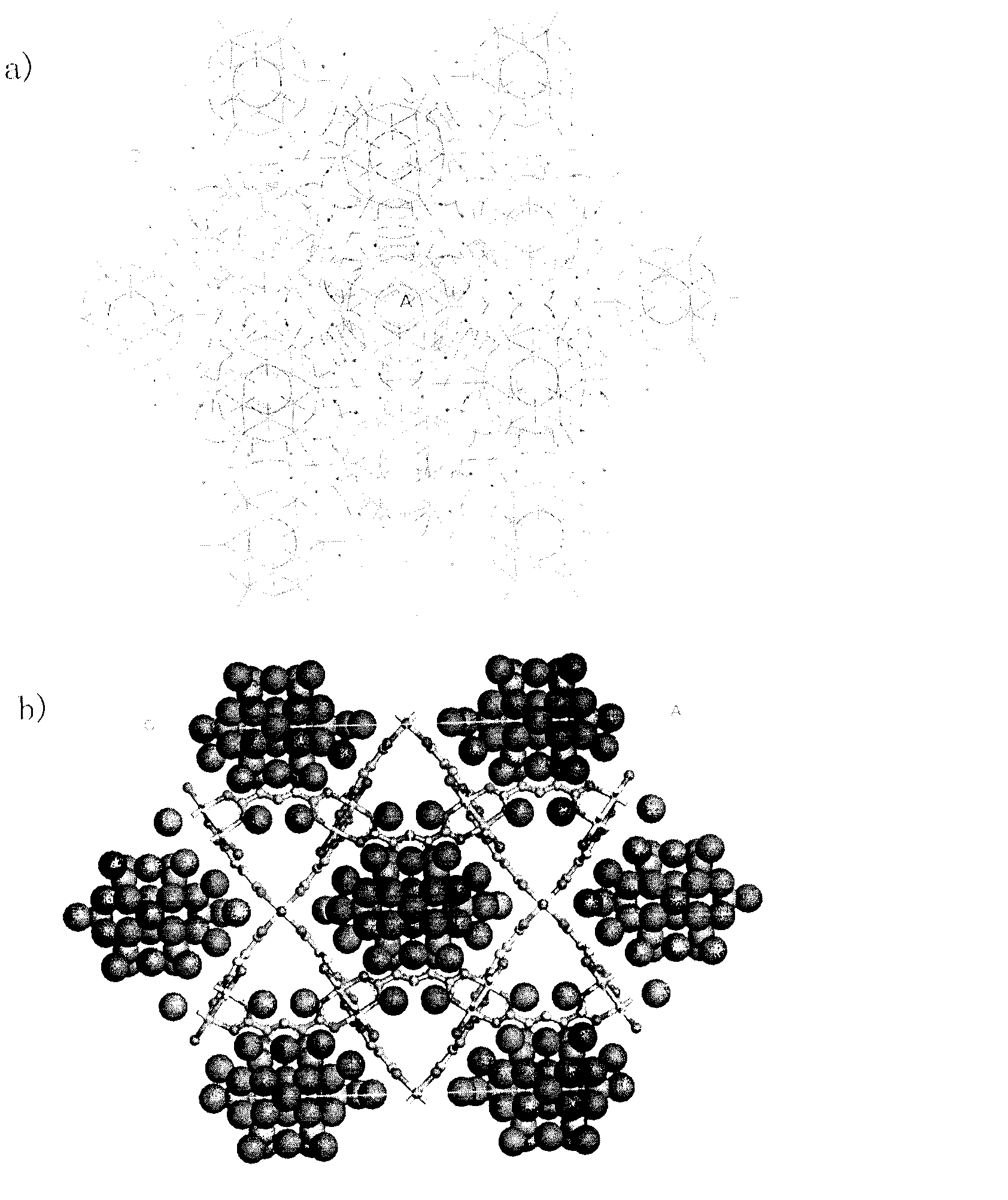

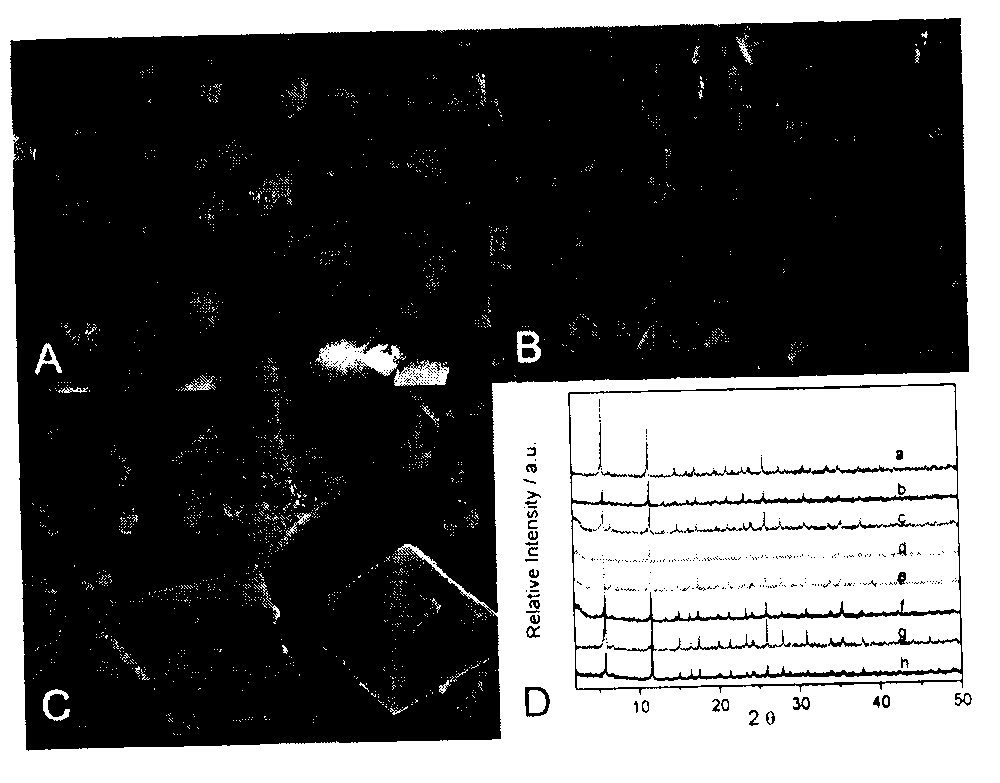

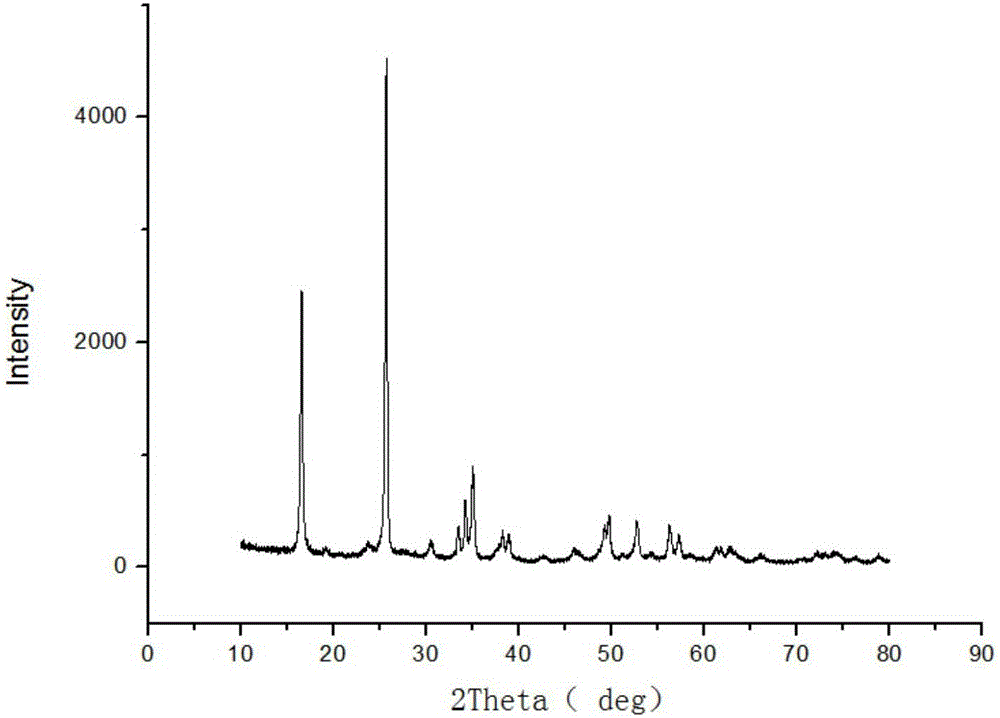

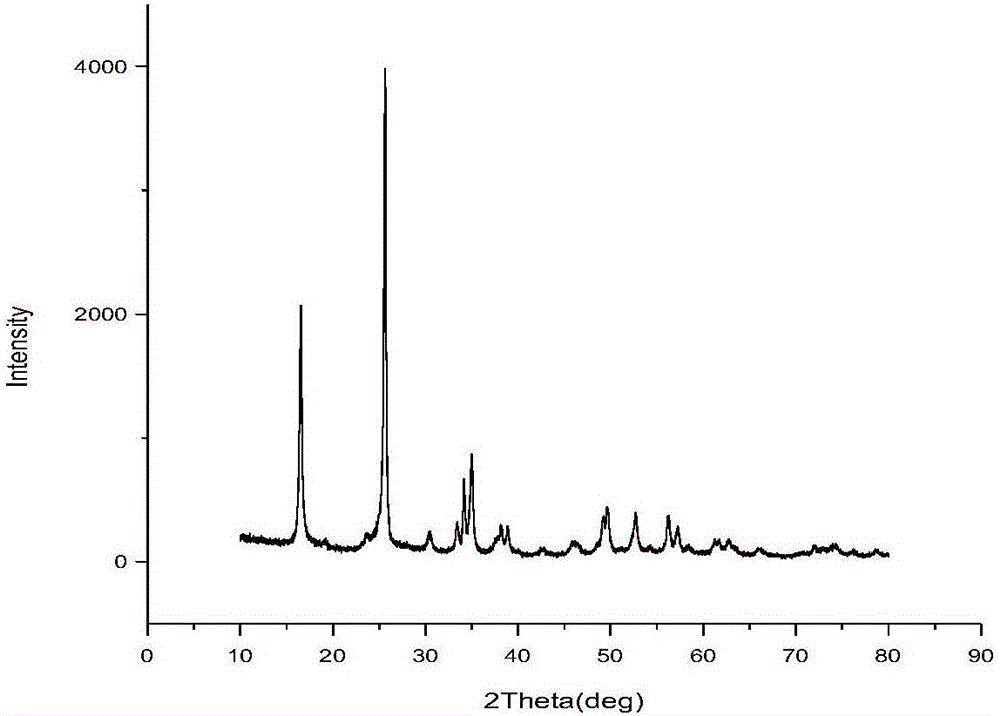

The invention relates to a method for rapidly preparing a metal organic framework compound and an application for adsorbing heavy metal ions in an aqueous solution thereof. The preparation method is simple, the preparation process is rapid, the yield is high, and the metal organic framework compound which stably exists under the air atmosphere and in the aqueous solution is prepared by using polyoxometallate hybridization, guest molecules such as H2O, C2H5OH and polyoxometallate are filled in a framework pore channel, the functions of supporting and stabilizing a framework are realized to a certain degree, the influence of different copper and tungsten ratios to the structural stability of the copper system metal organic framework compound is considered, the copper system metal organic framework compound serves as a physical adsorbent to be applied to the adsorption of heavy metal ions in the aqueous solution, the compound has obvious selectivity on Pb<2+>, and the repetitive experiments prove that the adsorbent can be repeatedly used for over two times.

Owner:NANKAI UNIV

Tungsten carbide welding rod and welding wire

InactiveCN101811233AAvoid decompositionPromote sheddingWelding/cutting media/materialsSoldering mediaWear resistantSite Remediations

The invention provides a tungsten carbide welding rod and a tungsten carbide welding wire, which comprise a strip-shaped or filate tubular sheath and filler which is filled in the tubular sheath and comprises tungsten carbide powder. The tubular sheath contains over 50 percent of copper element; a welding temperature of the copper tungsten carbide welding rod or the welding wire is lower, so that the tungsten carbide is effectively prevented from being decomposed while overlaying, and wear-resisting property of the tungsten carbide is kept; the tubular sheath contains the copper, and the tungsten carbide is easy to wet, so that the bonding strength of the tungsten carbide and an overlaid base metal is effectively improved, the possibility that the tungsten carbide is fallen off is reduced when an overlaying part is under a using condition, and a wear-resistant part is prevented from becoming invalid; and the tungsten carbide welding rod and the tungsten carbide welding wire are widely applied to overlaying of a wear-resistant surface, particularly on-site remediation.

Owner:朱明生

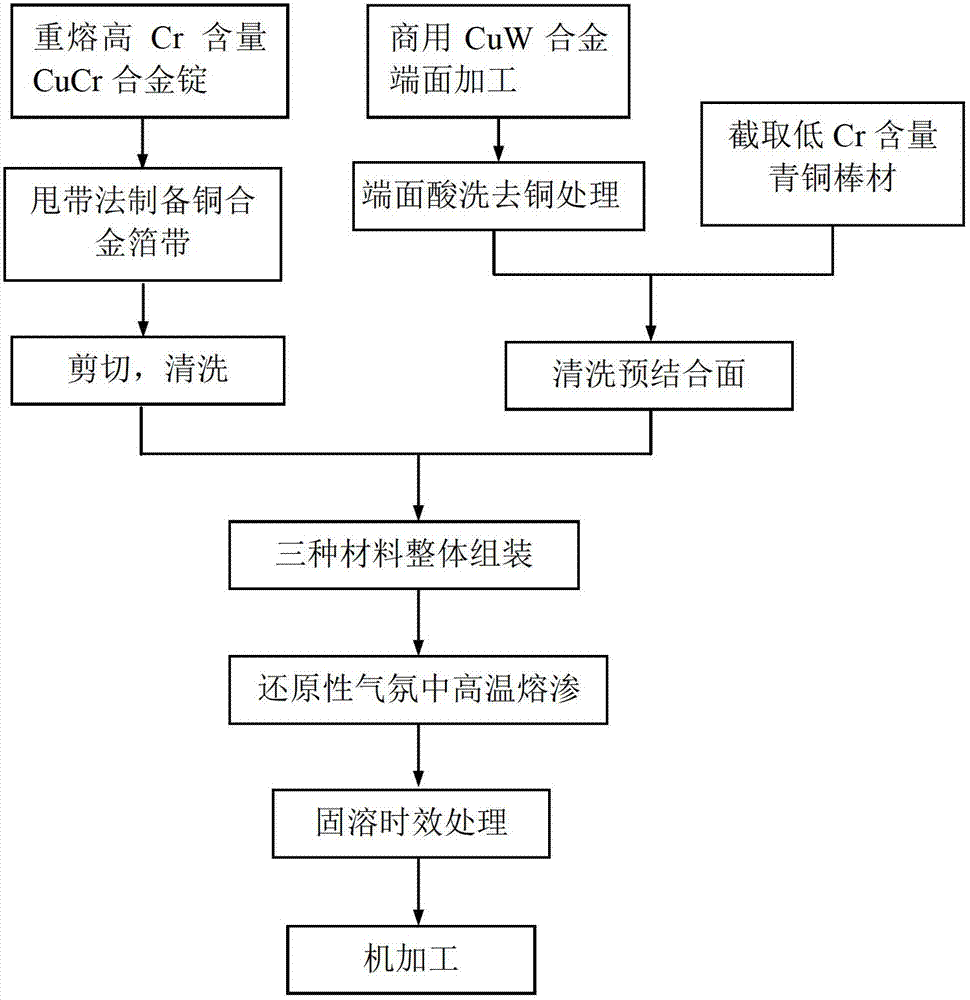

Preparation method of CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact

ActiveCN102760597AImprove the bonding strength of the interfaceReduce manufacturing costElectric switchesEmergency protective device manufactureReducing atmosphereSolid solution

The invention discloses a preparation method of a CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact. The method comprises the following steps: firstly, a high copper alloy foil strip is prepared by using a rapid solidification melt-spinning method; subsequently the de-coppering treatment is carried out on a CuW pre-combining plane by using an acid dissolving method; a porous W-framework is obtained on the combining plane; the overall sintering infiltration is carried out on the CuW, the alloy foil stripe and the CuCr alloy inside a reducing atmosphere furnace so as to obtain the CuW and CuCr integrated material; and subsequently the solid solution aging treatment is carried out on the material. As the Cr element inside the alloy foil stripe is filled and infiltrated into the porous framework during the infiltration process and is formed into W-Cr solid solution with the W, the metallurgical bonding is realized between the framework and a substrate copper phase; and the boundary bonding strength of the integrated material is improved.

Owner:XIAN UNIV OF TECH

InGaN-based led

InactiveUS20050082556A1Increase brightnessHigh in electricitySolid-state devicesSemiconductor devicesCopper–tungstenContact electrode

A blue LED epitaxial wafer grown on an Al2O3 substrate, the blue LED epitaxial wafer having a contact electrode on the bottom side after removal of the Al2O3 substrate, conducting terminals formed on the top side, and a substitute substrate selected from chrome, tungsten, molybdenum, copper, copper chrome alloy, copper molybdenum alloy, copper tungsten alloy, molybdenum tungsten alloy, or their combination alloy and bonded to the top side and connected to the conducting terminals.

Owner:ARIMA OPTOELECTRONICS

A preparation method for connecting tungsten copper alloy and whole electrical contact of the copper end

InactiveCN101009165AClosely linkedImprove connection strengthContact materialsUltimate tensile strengthCopper–tungsten

The invention discloses a preparation method of joining elconite and copper trail integral electrical contacts; it adopts method of adding copper-tungsten alloy buffer layer between copper-tungsten alloy and copper or copper alloy copper trail to realize the integral connection, firstly getting 23.6-41.2% copper powder and 58.8-76.4% tungsten powder as percentage by weight, and nickel powder which is about 0.05-0.15% of the total weight and 0.5-1.5%ml alcohol; The buffer layer material is placed at the bottom of the die, and the copper-tungsten alloy mixture is placed to pressed forming; at last the transition material bedding surface of the moulded blank and the copper or copper alloy surface which is to be connected are placed contactly, it then adglutinated as a whole. The preparation method of the invention not only improve the conjunction strength of copper-tungsten alloy and copper, copper-tungsten alloy and copper alloy integral electrical contacts, at the same time, the conductivity of integral electrical contacts is also improved.

Owner:XIAN UNIV OF TECH

Method for adopting spark plasma for sintering high-performance copper tungsten electrical contact materials

ActiveCN104014792AFacilitate the control of fine structureHigh densityElectric switchesFine structureElectrical resistance and conductance

The invention discloses a method for adopting spark plasma for sintering high-performance copper tungsten electrical contact materials. According to the method, tungsten powder and copper powder are prepared into copper tungsten composite powder and placed into a graphite mould; the graphite mould is placed into a spark plasma sintering furnace, the pressure of 20 MPa to 60 MPa is applied on the copper tungsten composite powder, inert gas is introduced into the sintering furnace, or the sintering furnace is vacuumized, the sintering temperature ranges from 900 DEG C to 1200 DEG C, heat is preserved for 5 minutes to 25 minutes, finally the copper tungsten composite powder is cooled to the room temperature along with the furnace to manufacture the copper tungsten electrical contact materials. In comparison with a traditional sintering process, the spark plasma sintering method is the integrated sintering technology integrating hot pressing, plasma activating and resistance heating and has the advantages that the temperature rises fast, sintering time is short and crystal grains are uniform, the fine structure of a sintered body can be controlled easily, and therefore the obtained materials are high in compactness and good in performance.

Owner:福建国福天合电气科技有限公司

Method for manufacturing copper-tungsten contact

ActiveCN102800420ALow melting pointInfiltration of copper-containing materialsCable/conductor manufactureBronzeCopper–tungsten

The invention discloses a method for manufacturing a copper-tungsten contact. The method comprises the following steps of: manufacturing a tungsten blank; manufacturing a graphite crucible; drying the graphite crucible; protecting the graphite crucible; preparing cupriferous materials; mounting the crucible; charging, vacuumizing, heating and infiltrating; and cooling and discharging, and the like. The specially-made graphite crucible is used for containing materials in a vacuum environment; copper or chromiumbronze solution is sufficiently infiltrated in the tungsten blank by using a vacuum negative-pressure infiltration method to manufacture the contact; the melting point of copper is reduced in the vacuum environment; the cupriferous materials are easy to infiltrate into the tungsten blank and are fused with the tungsten blank sufficiently and uniformly; the total usability and the yield of the copper-tungsten contact are increased; and manufacture difficulty that the diameter of the copper-tungsten contact is too large and the copper-tungsten contact is too long is overcome.

Owner:河南科丰新材料有限公司

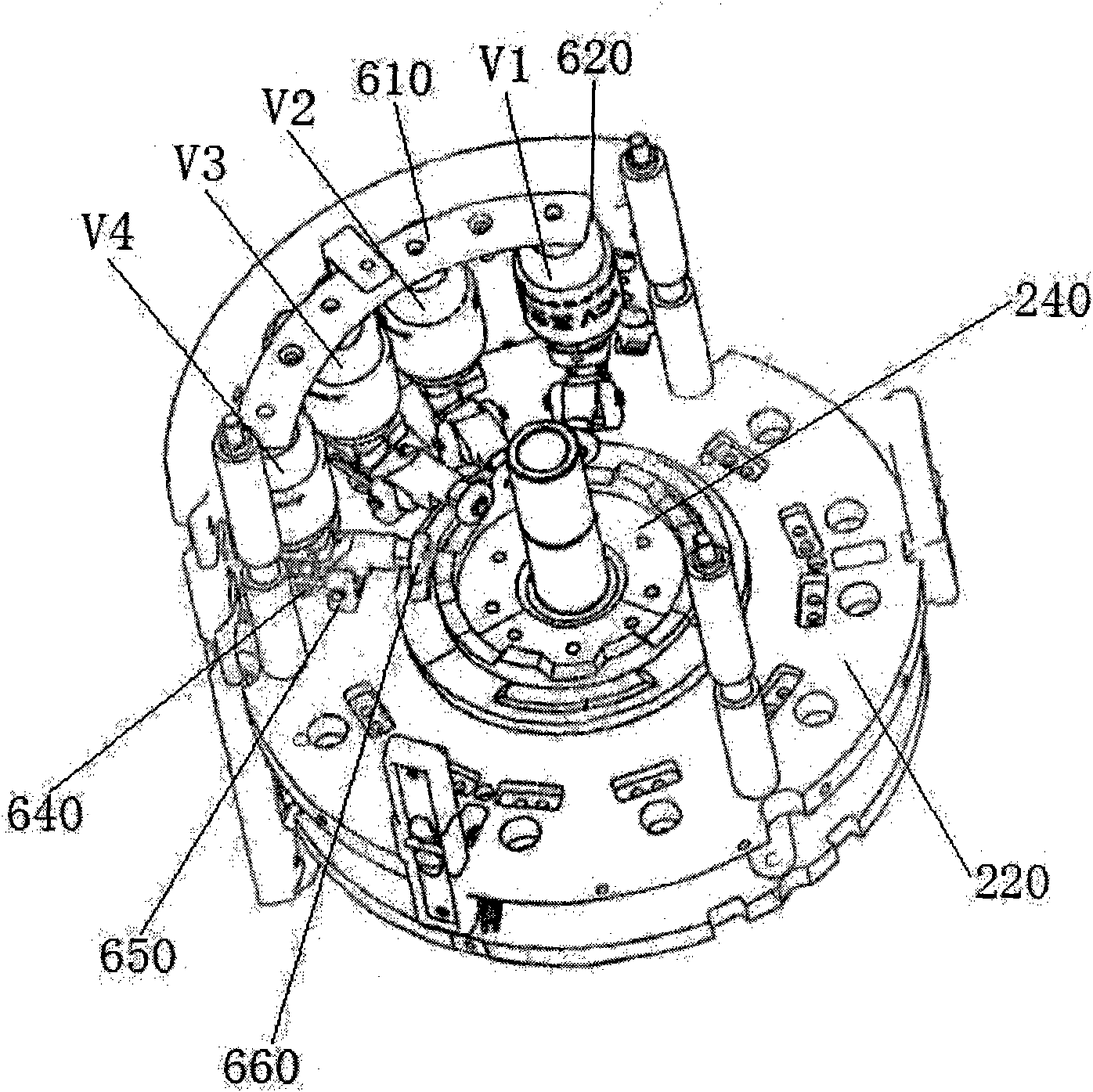

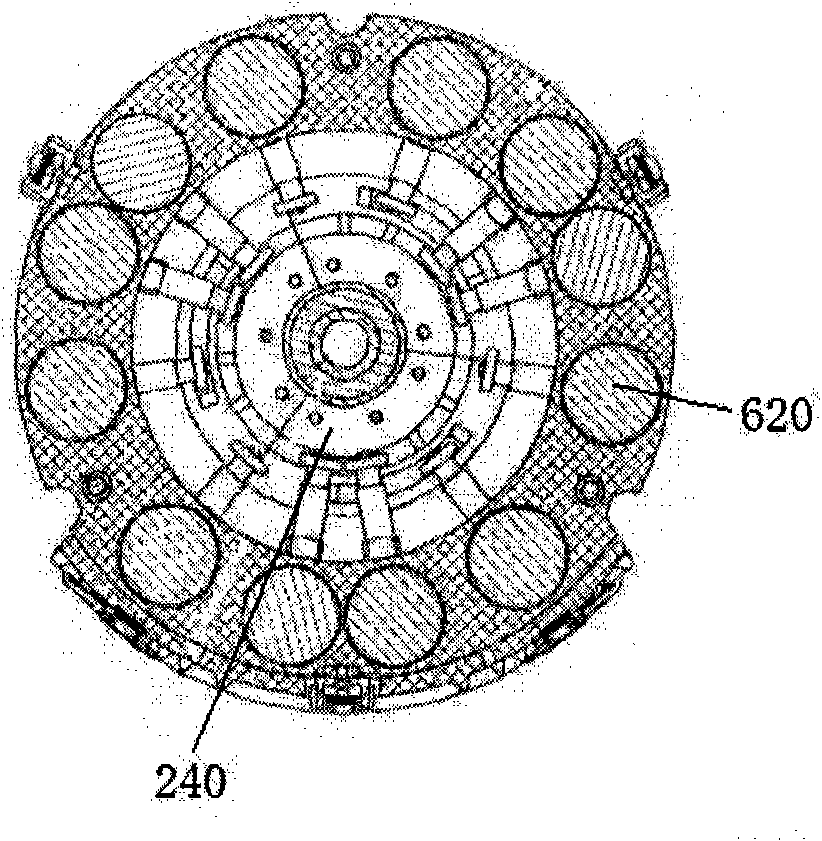

Vacuum tube group for replacing copper-tungsten contact group of on-load tap changer

ActiveCN101807472AAvoid electrical life impactReduce maintenanceVariable inductancesHigh-tension/heavy-dress switchesTap changerThree-phase

The invention discloses a vacuum tube group for replacing a copper-tungsten contact group of an on-load tap changer, which comprises three vacuum tube groups, wherein each vacuum tube group is a one-phase vacuum tube transitional switching unit; three-phase vacuum tube groups are arranged on the circumference by 120 degrees; and each phase vacuum tube transitional switching unit consists of four vacuum tubes which are distributed according to the circumference. The on-load tap changer generates electric arc only in the vacuum tube during switching without generating electric arc outside the vacuum tubes, thereby no electric arc is generated in an oil chamber of the on-load tap changer and oil of insulated transformer in the oil chamber cannot be polluted by electric arc; and the invention can maintain the insulating performance of the oil in the transformer for a long term, greatly reduce the fault rate of the changer, simultaneously reduce the maintenance of the changer and material loss and prolong the service life of the changer and the transformer.

Owner:SHANGHAI HUAMING POWER EQUIP CO LTD +1

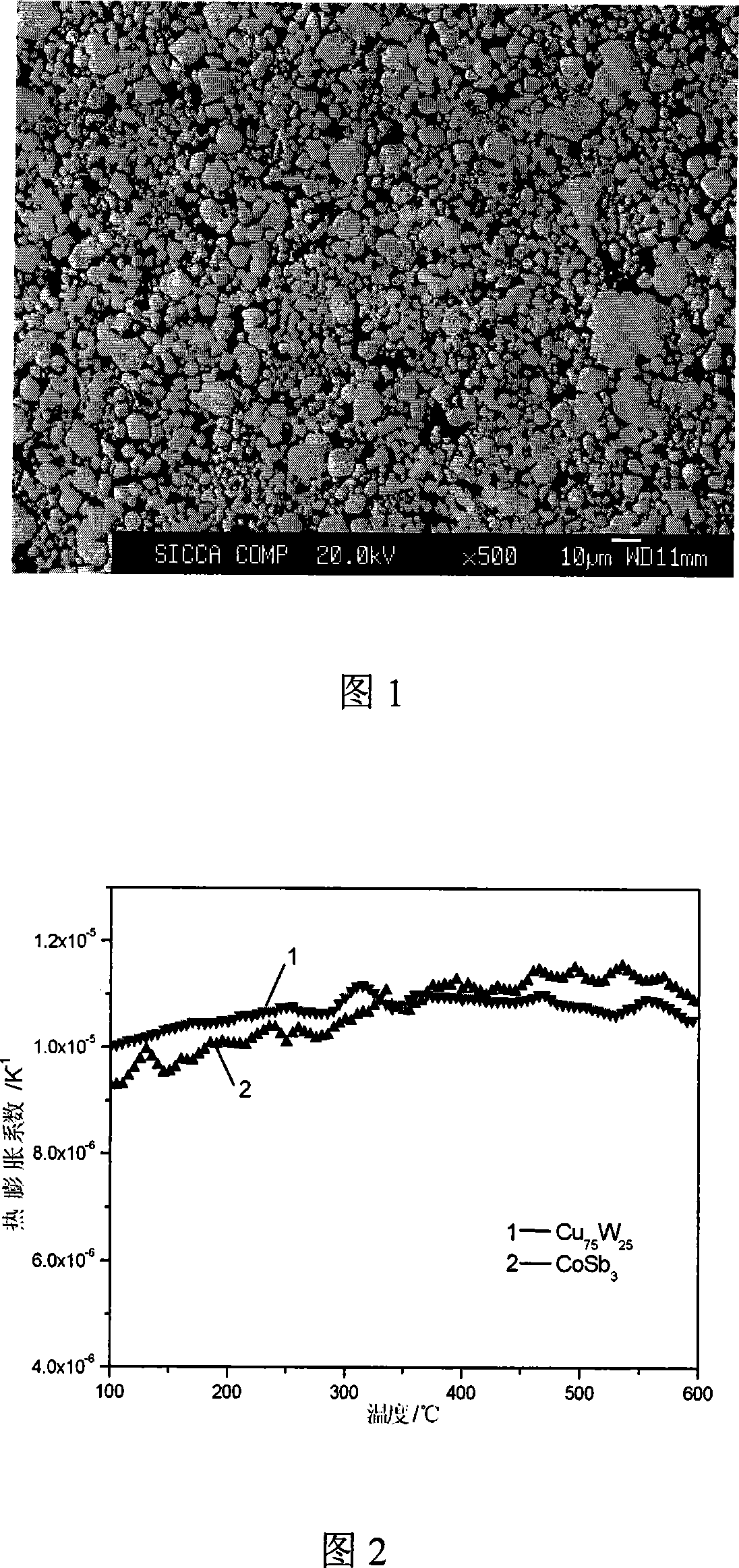

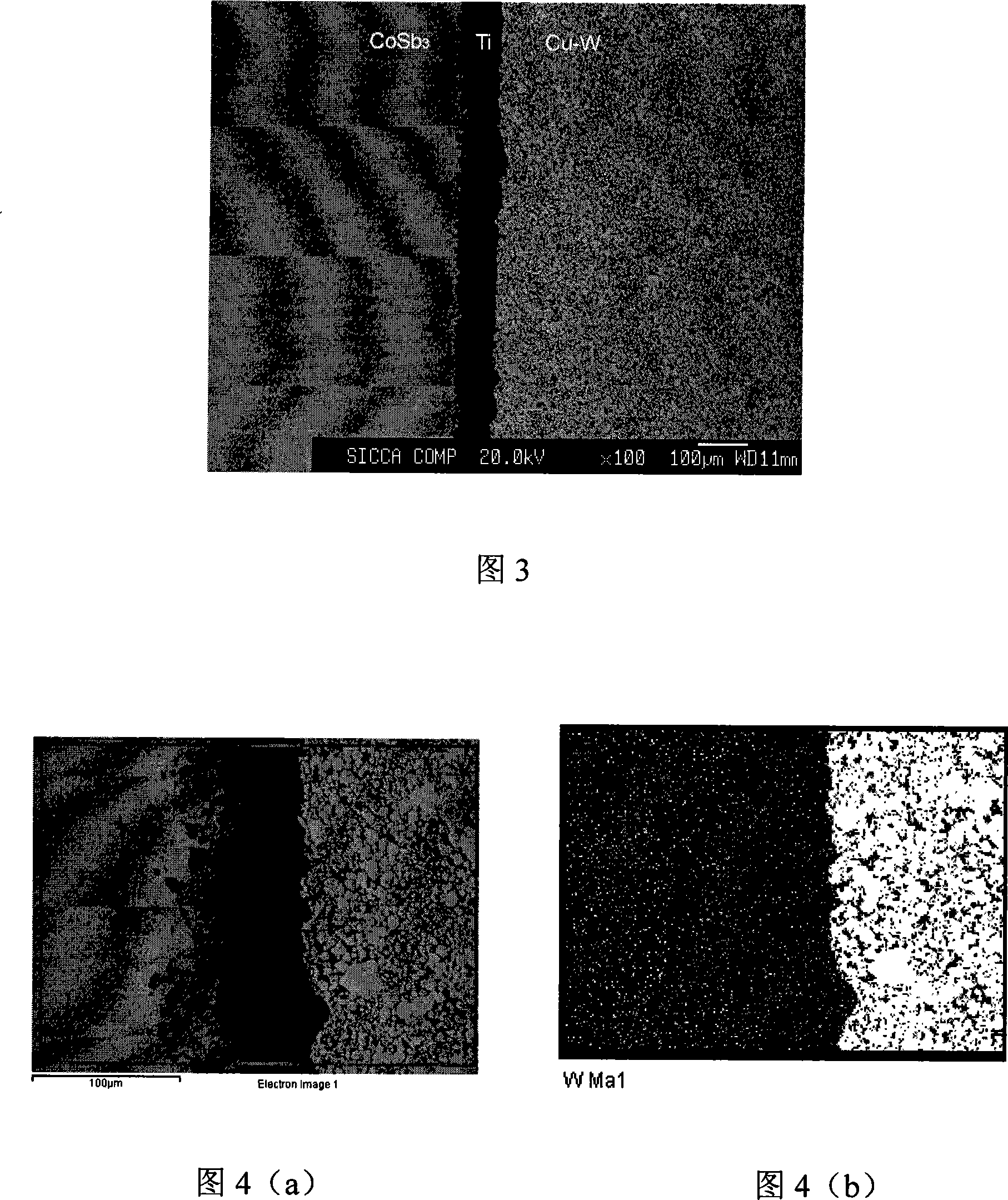

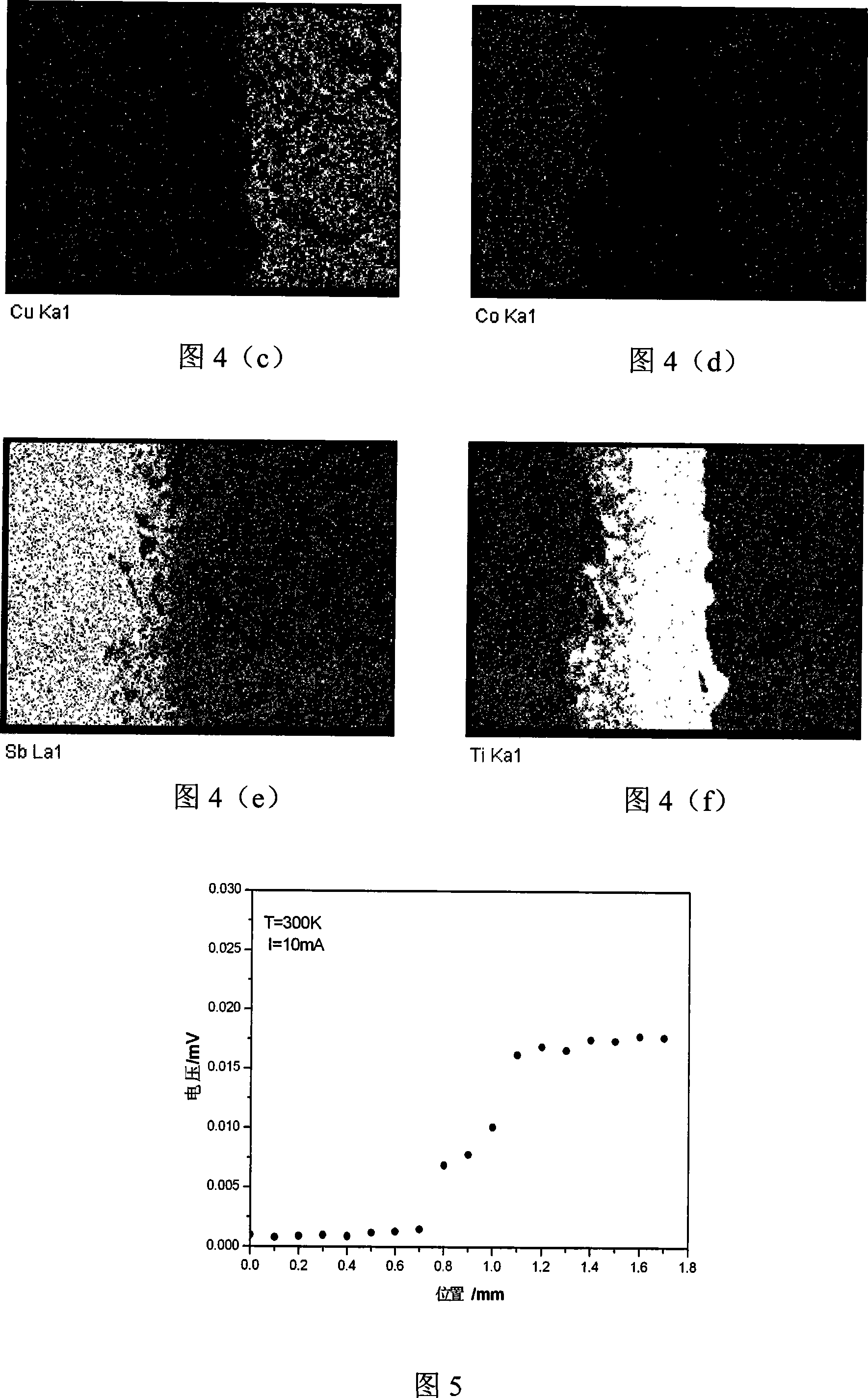

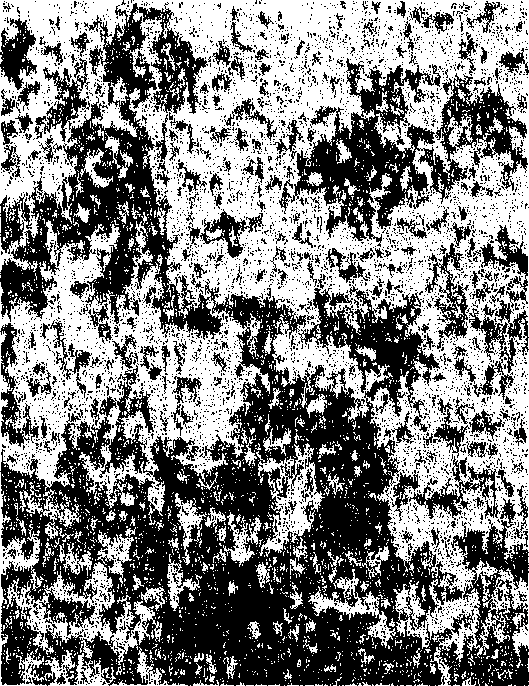

Alloy pole for cobalt antimonides-based thermal electrical part and part making method

InactiveCN101101955AReduce thermal stressEnhanced interface bindingThermoelectric device manufacture/treatmentThermoelectric device detailsThermoelectric materialsGranularity

The invention is concerned with the electrode alloy pyroelectricity device of the cobalt antimonide pyroelectricity device and it's making method. It includes the Cu-W alloy electrode with the W quality percentage 20% to 30%; the rest components are copper and unavoidable impurity; the optimized Cu75W25 electrode hot coefficient of expansion (CTE) and the CoSb3 pyroelectricity are in right hot matching with difference no more than 9.8%. The component making applies the transition layer of the metal Ti, granularity about 20-50mum, and the discharge plasma sintering (SPS) method to achieve the connection of the Cu-W alloy electrode and the pyroelectricity. Because of the high conductivity and the thermal conductivity of the copper tungsten alloy and it is matching with the CoSb3 pyroelectricity material rightly, the invention is with the quite stable surface with no obvious composition plane electrode transition, keeps the making method simple.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Welding wire for TIG welding with welding flux cortex

InactiveCN101190479AImprove liquidityGood welding performanceArc welding apparatusWelding/cutting media/materialsMelting tankAcrylic resin

The invention relates to various welding production requirement field, in particular to a welding wire used for tungsten electrode argon arc welding (TIG welding). A welding wire used for red-copper tungsten electrode argon arc welding with flux drug layer comprises a welding core; the surface of the polished welding wire is pressed and coated with flux; the welding wire and the flux are bonded together by acrylic resin. The flux in liquid state has extremely strong film-removing capability which can rapidly react copper oxide into sinter which floats on the surface of a melting pool, reduces surface tension, improves lubrication performance, improves welding capability, thus obtaining excellent welding joint.

Owner:上海斯米克焊材有限公司

Method for machining special-shaped powder metallurgy precision die

InactiveCN101811247ALow equipment requirementsImprove processing efficiencyPlane surface grinding machinesGrinding wheelCopper–tungsten

The invention discloses a method for machining a special-shaped powder metallurgy precision die, which comprises the following steps: (1) manufacturing a rough blank, namely cutting the rough blank on a material blank according to the required dimension by using a linear cutting machine; (2) roughly turning appearance, namely roughly turning the appearance by using a special alloy machining cutter; (3) grinding a base, namely flatly grinding the bottom surface till the appearance of the flatly ground base reaches the specified dimension; (4) grinding with a tool, namely machining each angle plane and each arc position on a surface grinder respectively by using a divisible and adjustable rotary center tool, and finally accurately grinding the angle plane and the arc position to the specified dimensions with finish of below Ra 0.2; and (5) polishing the appearance and the molded position till the finish reaches below Ra 0.1. The method has the advantages that: 1, the method has low requirement on equipment, only adopts a tool grinder and does not need to adopt imported high-end equipment; 2, the machining efficiency is improved by 5 times; 3, the cost of auxiliary materials is saved, a red copper or copper-tungsten alloy electrode material is not needed, and only the grinding materials such as a grinding wheel and the like are needed; and 4, the grinding process is reduced, and the grinding precision can reach + / - 0.005.

Owner:GUANGYUAN RUIFENG PRECISION MACHINERY MFG

Copper-tungsten-carbon-titanium-rare earth alloy material and production thereof

An alloy material of Cu-tungsten carbide-C-Ti-RE is consists of Cu, WC, C, Ti, rare-earth. The material decrease the content of the 'WC' and increase the content of 'Cu' so improve the conductance, as a result, it can control the temperature of the material. The material which added proper C and Ti, RE can improve the non-fusibility, wearability, arc resistance, life of the electricity. The process can improve the fine structure of the histology so the material can be used from the high-current switch, circuit breaker to majority medium-current switch. Especially, it can save the silver and have good market future.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparation method of mechanical alloying copper-tungsten alloy powder

The invention discloses a preparation method of mechanical alloying copper-tungsten alloy powder. Atomized copper powder and crystallized tungsten powder are selected as raw materials; a ball milling medium, in particular a volatile organic solvent as the ball milling medium is added for wet grinding; the wet grinding enables powder grains to be fine; the components are uniform; the powder oxidized degree is reduced; the increment of forming density is facilitated; a mechanical alloying method with a high ball-material ratio is adopted, so that tungsten particles are embedded in copper particles through high-energy collision under the condition of normal temperature to form supersaturated solid solution alloy powder; and finally, the ball milling medium is removed to obtain the mechanical alloying copper-tungsten alloy powder. The tungsten-copper alloy powder, obtained by the method, has such characteristics as larger particles, uniform components, excellent forming capacity, excellent flowing performance, easy formation and easy segregation; and the preparation method is simple in process and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

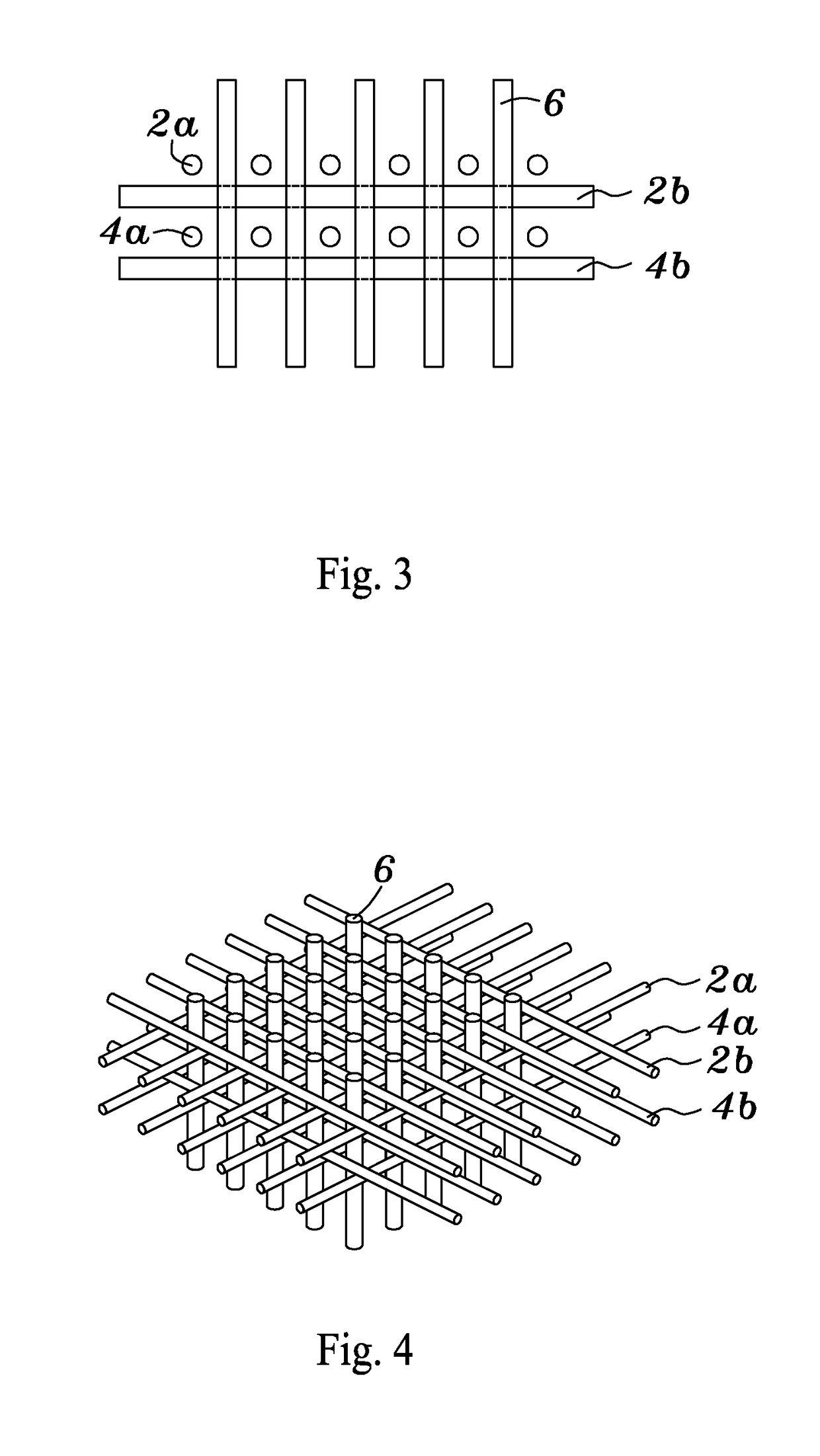

Method for fabricating glass substrate package

InactiveUS9615453B2Final product manufactureSemiconductor/solid-state device detailsElectrical conductorCopper–tungsten

A substrate comprising a solid glass core having a first surface and a second surface opposed to the first surface; multiple conductors extending through the solid glass core beginning at the first surface and ending at the second surface, wherein one of the conductors has a third surface and a fourth surface, wherein the third surface and the first surface are substantially coplanar, wherein the second surface and the fourth surface are substantially coplanar, wherein one of the conductors comprise a copper-tungsten alloy material, wherein the solid glass core is directly contact with the conductor; and a first dielectric layer and a first metal layer formed at the first surface, wherein the first metal layer at the first surface is electrically coupled with one of the conductors.

Owner:YANG PING JUNG

Electric spark processing method for sealing grooves of aero engine guide vane

InactiveCN105397218AImprove machining accuracyAvoid the problem that the position degree cannot be guaranteedElectrical-based machining electrodesElectric circuitsAviationDepth direction

This invention provides an electric spark processing method for sealing grooves of an aero engine guide vane. The method comprises the following steps: (1) two copper-tungsten alloy blocks are fixed on an electrode pedestal and are processed into two electrodes by adopting a milling mode, wherein the two electrodes have the shapes same as and the positions matching with those of the sealing grooves, formed in large and small margin plates of the guide vane, to be processed respectively; and (2) the two electrodes are placed aligning to the parts, to be processed, of big and small margin plates of the guide vane respectively, an electric spark processing machine is started to ensure that the two electrodes carries out electric spark processing on the parts to be processed in the depth direction of the sealing grooves; the two electrodes are aligned to a next part to be processed after processing of the sealing groove of the processed surface is finished, and processing continues according to the process conditions until all the sealing grooves, in the same type, formed in the guide vane are processed; and after the electrodes wears, the two copper-tungsten alloy blocks which are fixed on the electrode pedestal are reprocessed into electrodes by using the milling mode, and then the sealing grooves are continuously processed.

Owner:AECC AERO SCI & TECH CO LTD

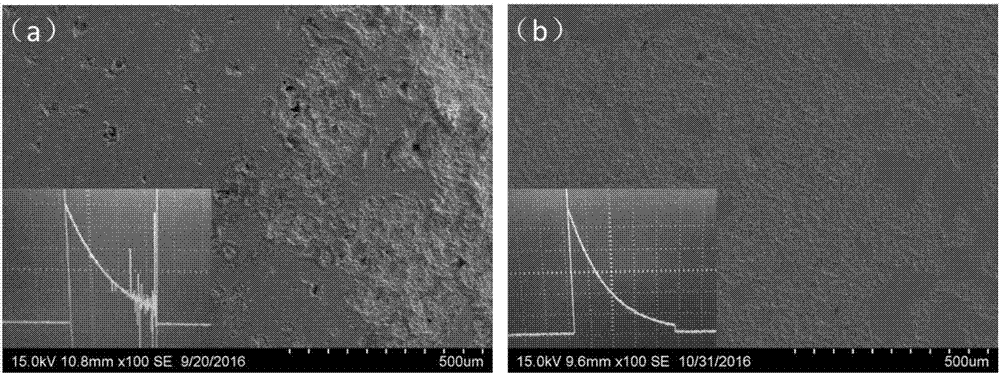

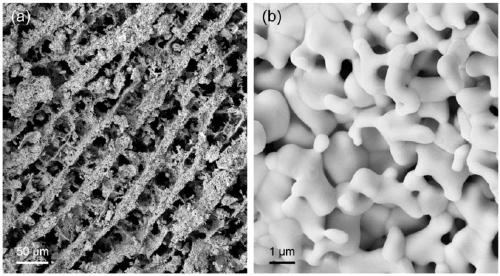

Surface clad layer treatment method of copper tungsten electrical contact material for arc extinguish chamber

ActiveCN106978586AExtended service lifeImprove abnormal breakdown discharge phenomenonVacuum evaporation coatingSputtering coatingDistributed structureArgon atmosphere

The invention discloses a surface clad layer treatment method of a copper tungsten electrical contact material for an arc extinguish chamber. The method includes the steps that the copper tungsten alloy contact material is prepared to serve as a substrate material; mechanical buffing, washing and drying are carried out; the substrate material is placed into a vacuum chamber to deposit a chromium layer, a nickel layer or a titanium layer on a base body through a chromium target, a nickel target or a titanium target under the argon atmosphere; a copper target and a tungsten target are used for codeposition of a copper-tungsten clad layer on the substrate deposited with the chromium target, the nickel target or the titanium target continuously, and a copper tungsten-tungsten clad layer with a certain film thickness is obtained; and annealing is carried out under protection of a mixed atmosphere of inert gas and hydrogen, furnace cooling is carried out, a sample is taken out, and a copper tungsten electrical contact material surface clad layer is obtained. By means of the two-phase nanoscale uniform distributed structure, the ablation uniformity can be greatly improved, the ablation pit depth is reduced, and the service life is prolonged; meanwhile, a provided nanocrystalline tungsten framework can improve the arc ablation resistant capacity. By means of the method, equipment is simple and convenient to operate, the effect is obvious, and the good industrial application prospect is achieved.

Owner:XI AN JIAOTONG UNIV

Preparation method of monoclinic system tungsten trioxide

ActiveCN106430312ARealize recycling of resourcesComply with energy saving and environmental protection strategyTungsten oxides/hydroxidesEnergy inputPhotocatalytic degradationCopper–tungsten

The invention provides a method for preparing monoclinic system tungsten trioxide from copper-tungsten alloy waste as a raw material. The method comprises steps as follows: acid leaching, roasting, ammonification and acidolysis. The copper-tungsten alloy waste is taken as the raw material, a high-value product monoclinic system tungsten trioxide with a function of photocatalytic degradation of organic matter is prepared, cyclic utilization of the waste metal resource is realized, renewable energy sources (solar energy) can be utilized, a recycled product can be used for environmental pollution control, and national energy saving, environmental protection and resource recycling strategies are met. According to the preparation method, the raw material is easy to obtain, the cost is low, a process is simple, and the preparation method is suitable for industrial production.

Owner:JIANGSU UNIV OF TECH

Electrochemical discharge mechanical milling composite machining tool cathode and using method

The invention relates to electrochemical discharge mechanical milling composite machining tool cathode and a using method, and belongs to the field of electrolytic electric spark mechanical compositemachining. A tool cathode material is a copper-tungsten alloy, a workpiece is a conductive material, an electrolyte is a salt solution with relatively high conductivity, a common direct-current powersupply is adopted for power supply, and insulating blades are welded at the bottom of the tool. During machining, the electrolyte enters a machining area from the side wall of the tool cathode, an electrochemical anode of the workpiece material is dissolved, and a discharge channel is formed between the tool cathode and the workpiece through a small machining gap; the rotation of the tool cathoderealizes the transfer of discharge points, so that the electrolysis effect and the electric spark effect are combined to remove the material, the material removal rate is remarkably improved, due to the milling effect of the blades at the bottom of the tool, a machined bottom surface can be leveled, and the flatness of the machined bottom surface is improved. The tool can realize high-efficiency and high-precision machining of metal materials which are difficult to machine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of copper/graphite film multi-layer laminated blocky composite material

ActiveCN107791616AHigh in-plane thermal conductivityHigh strengthMetal layered productsPolyvinyl butyralElectrolysis

The invention provides a preparation method of a copper / graphite film multi-layer laminated blocky composite material, which can be applied in the field of electronic packaging of an integrated circuit industry. The raw materials of the composite material adopt an anisotropic high-thermal-conductivity net-shaped graphite film and electrolytic pure copper powder. The preparation method comprises the following steps: adding the copper powder into a uniformly mixed solution of an adhesive prepared from polyvinyl butyral and an ethanol solution as well as dimethyl phthalate serving as a plasticizer, completely stirring to obtain uniform slurry with high flowability, spreading the slurry on the net-shaped graphite film uniformly, drying, cutting, degumming, superposing layer by layer, and performing bidirectional pressurizing and sintering to prepare the compact multi-layer laminated blocky composite material with the graphite film and metal copper which are arranged alternately in a layered mode. The heat conductivity of the composite material along the plane direction of the graphite film is 1.5 to 2 times higher than that of pure copper, the density can be reduced to be 65 to 80 percent of the density of the pure copper, and the composite material can be used for replacing the traditional copper tungsten metal heat-conducting material.

Owner:UNIV OF SCI & TECH BEIJING

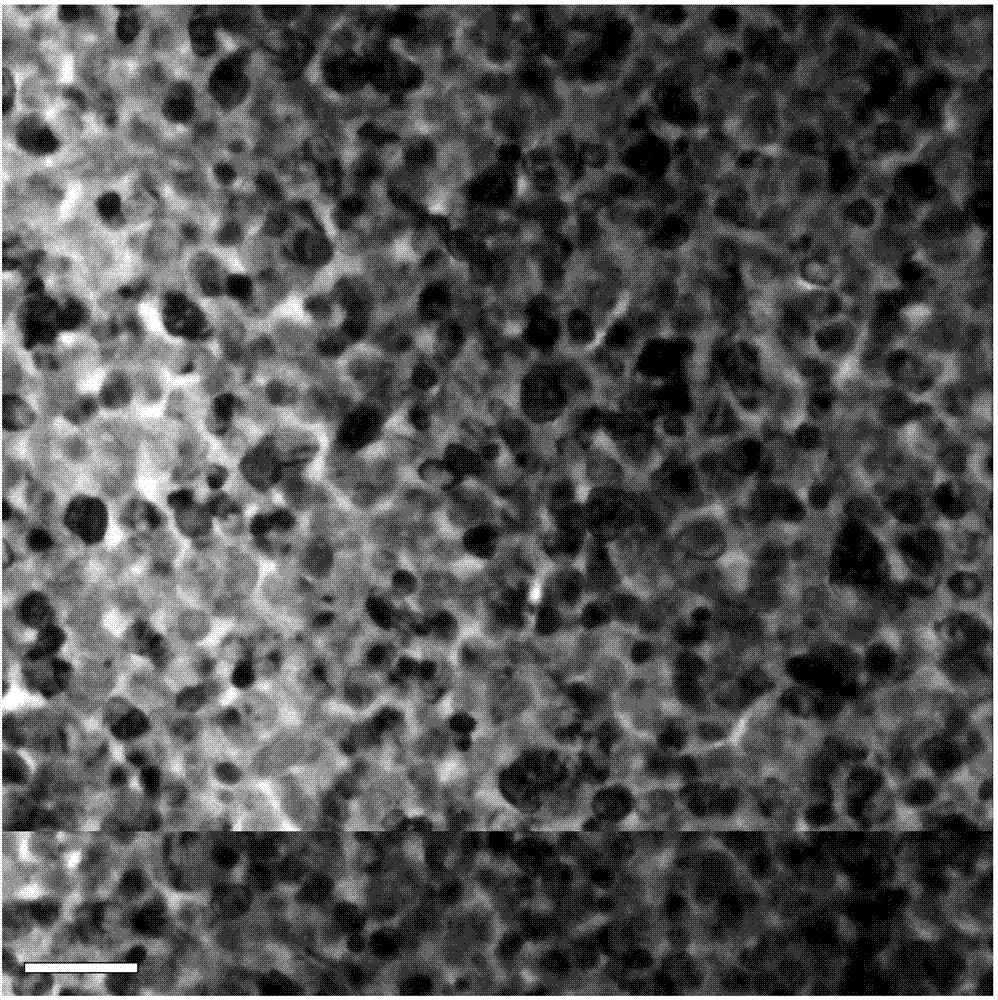

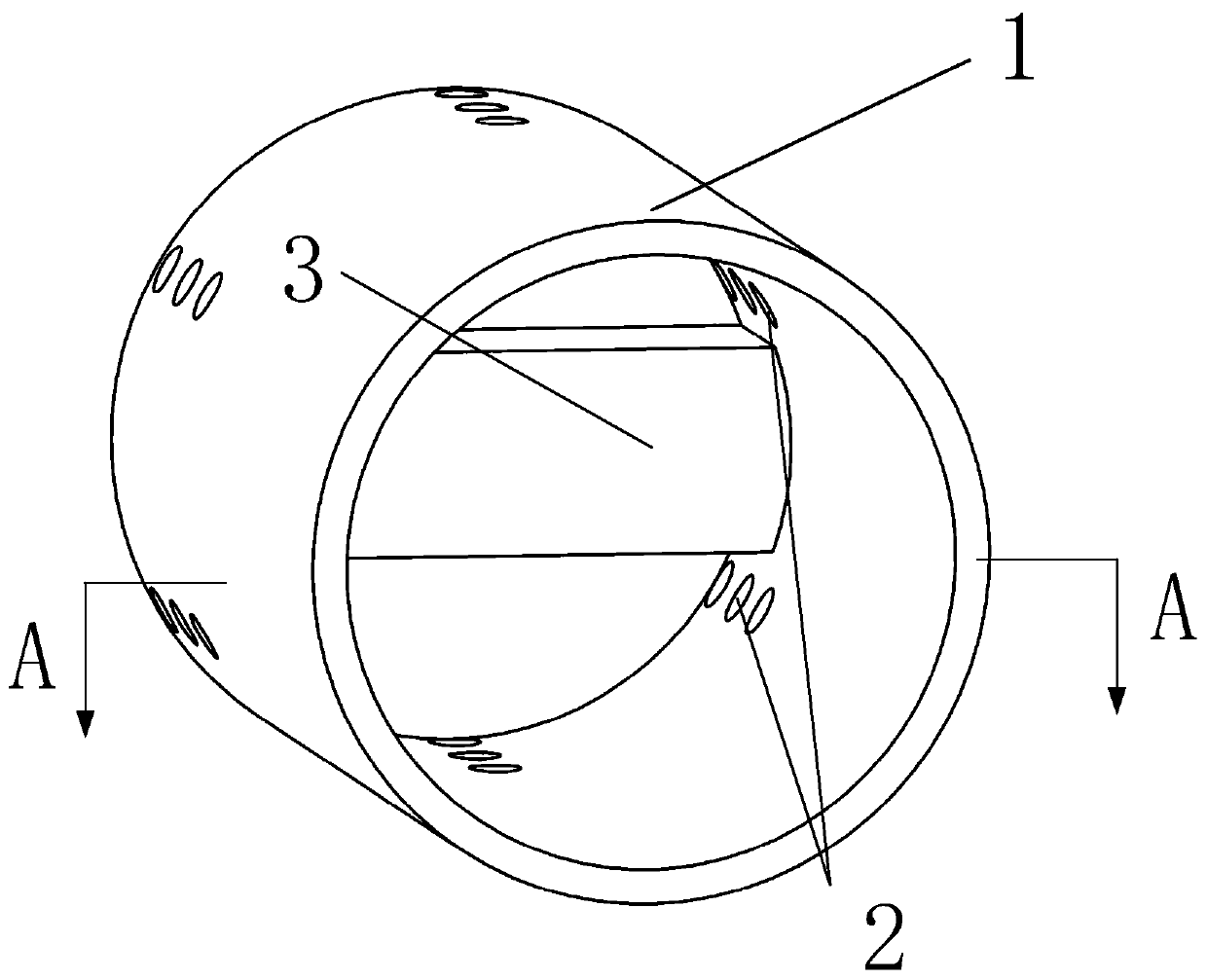

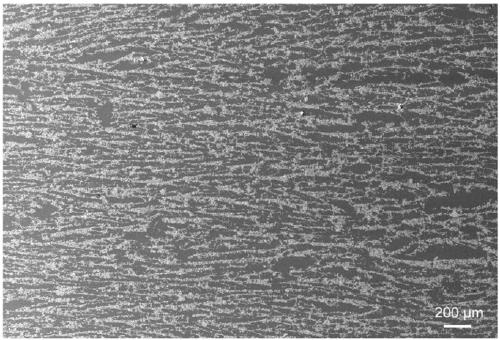

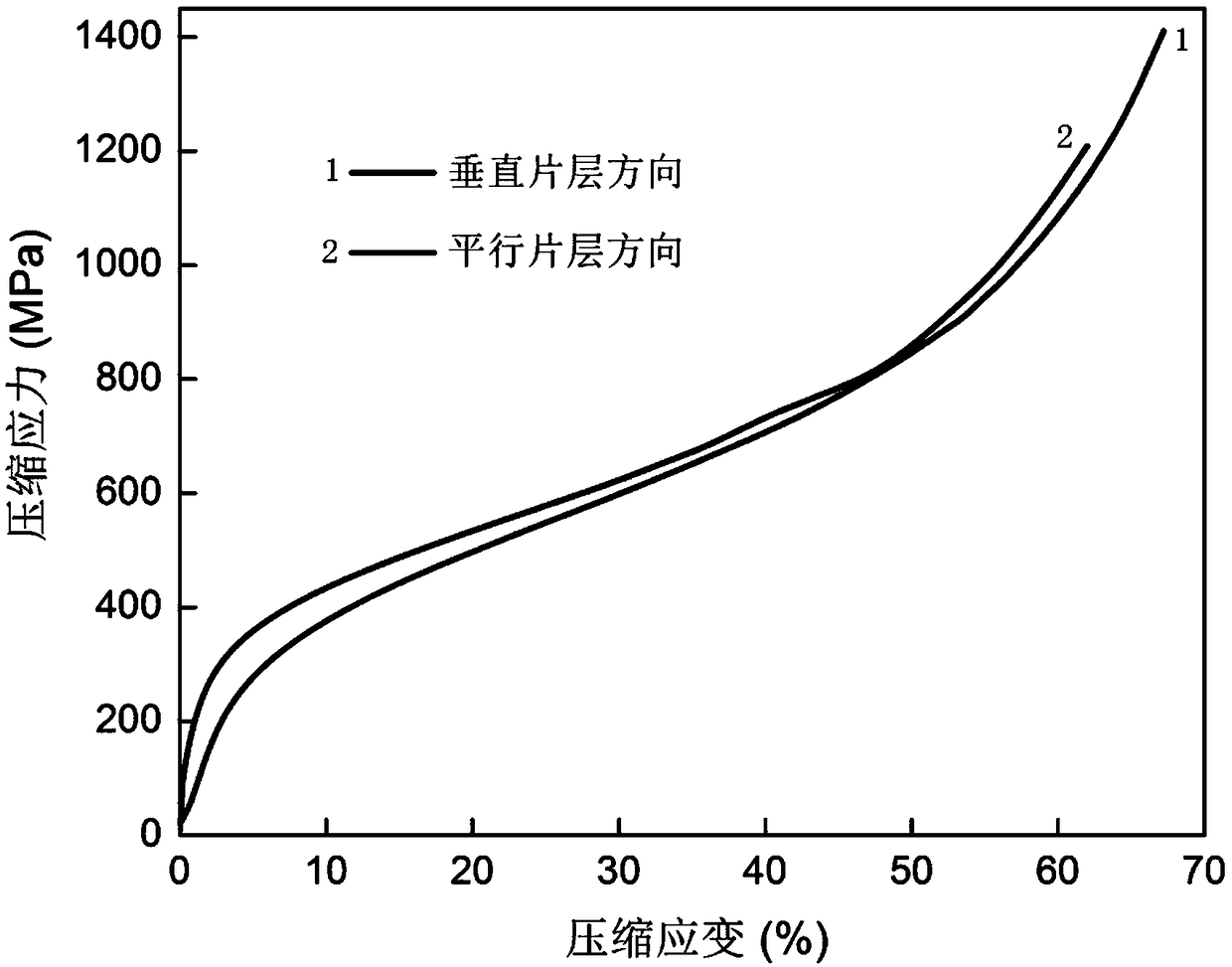

Copper-tungsten composite material with microscopic oriented structure and preparation method thereof

The invention discloses a copper-tungsten composite material with a microscopic oriented structure and a preparation method thereof. The composite material is prepared from tungsten and copper of massfraction being 30-97%. The microscopic oriented structure shows that tungsten and copper are arranged in a lamellar pattern along a specific direction at intervals. The copper-tungsten composite material with the microscopic oriented structure is prepared by the technical process of slurry preparing, freeze casting, vacuum freeze drying, organic matter removing, sintering and skeleton infiltrining, and the tungsten content of the material can be controlled by compressing a billet body or a skeleton along the direction vertical to a lamella. The composite material has the mechanical and functional properties of anisotropy and particularly has the characteristics of high strength, high hardness, good electrical and thermal conductivity and good resistance to arc ablation and resistance to electrical shock along the lamella direction. The composite material is expected to be used as an electrical contact material so as to significantly improve the using effect, prolong the service life,reduce component quality and reduce energy consumption.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

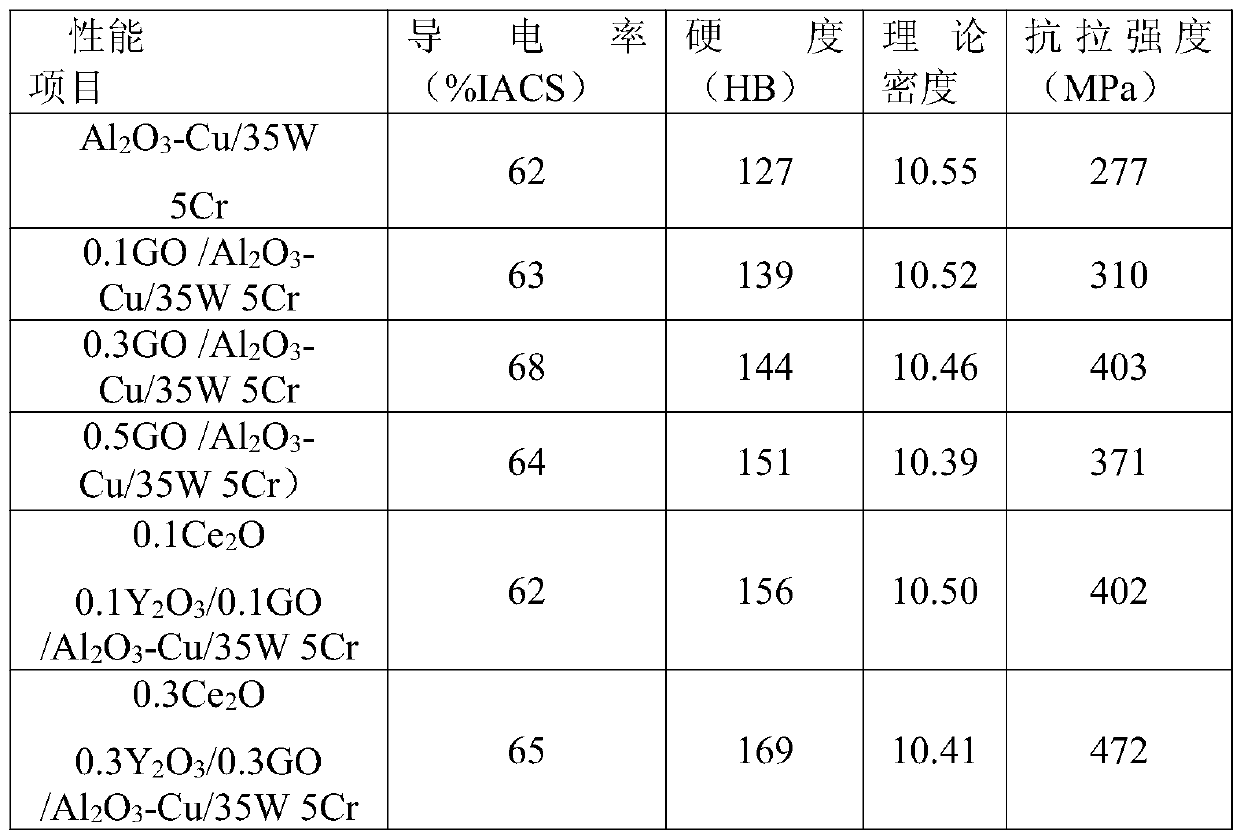

Mixed dispersion enhanced copper-tungsten-chromium electrical contact material and preparation method thereof

The invention discloses a mixed dispersion enhanced copper-tungsten-chromium electrical contact material and a preparation method thereof. The preparation method comprises the following steps of mixing an ultrasonically dispersed graphene oxide suspension with copper-aluminum powder, cuprous oxide powder, tungsten powder, chromium powder, cerium oxide powder and yttrium oxide powder, carrying outball milling, freezing and drying on the mixture, and carrying out vacuum hot-pressing sintering to obtain the copper-tungsten-chromium electric contact material. According to the electric contact material, the graphene oxide and the rare earth oxide are added into the copper-aluminum-tungsten-chromium mixed powder, the vacuum hot-pressing sintering - simple internal oxidation process are carriedout, so that the defects of poor affinity and interface binding force between graphene and copper matrix and poor conductivity of graphene oxide are overcome, and the comprehensive performance of thedispersed copper-tungsten-chromium electrical contact material is improved by the reduced graphene oxide under the vacuum high-temperature condition; and in addition, due to addition of the rare-earthcerium oxide and the yttrium oxide, the crystal grains of the contact material can be effectively refined, the strength and the hardness are improved, the electric arc ablation is reduced, the anti-fusion welding performance of a contact is improved, and the comprehensive performance is improved remarkably.

Owner:HENAN UNIV OF SCI & TECH

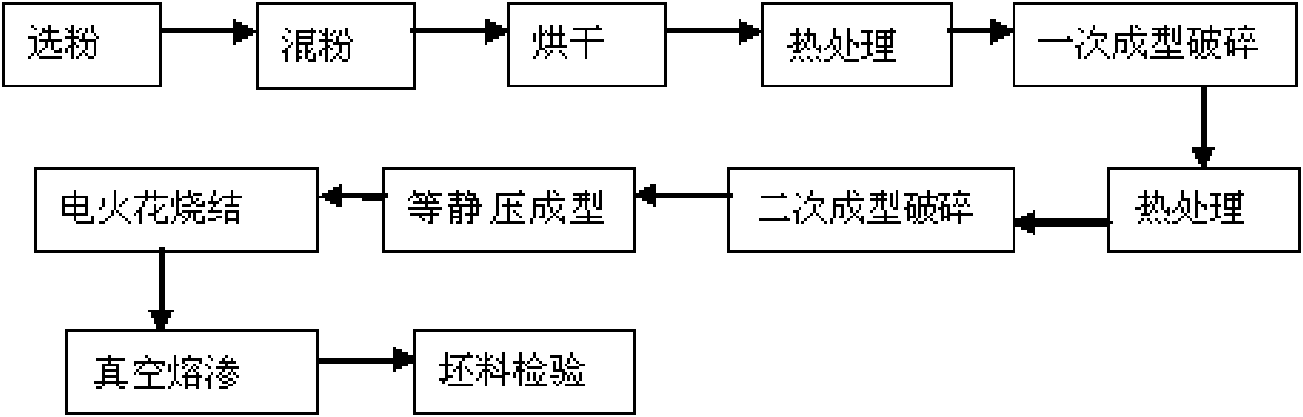

Profiled high conductivity copper-tungsten electrical contact material and processing technique thereof

The invention discloses a profiled high conductivity copper-tungsten electrical contact material and a processing technique thereof. the processing technique is characterized by firstly choosing copper powder and tungsten powder with suitable granularity and mixing the powders according to a certain proportion; carrying out to-and-fro heat treatment, press forming and smashing on the mixed raw powder, then isostatically pressing a required shape and sintering the shape with electric sparks into copper tungsten blanks; lastly, carrying out vacuum infiltration on the prepared copper and the sintered blanks to ensure that copper can be totally infiltrated into the body during material production to produce the profiled high conductivity copper-tungsten electrical contact material with the porosity of less than 0.15%. The electrical contact produced by the contact material simplifies construction of electric switches, eliminates the dispersivity of the springs in the switches and greatly improves the reliability of components. The material is widely used in high temperature materials, electrical alloys for high voltage switches, electromachining electrodes, microelectronic materials and the like.

Owner:刘爱芬

Method for preparing copper-tungsten alloy powder

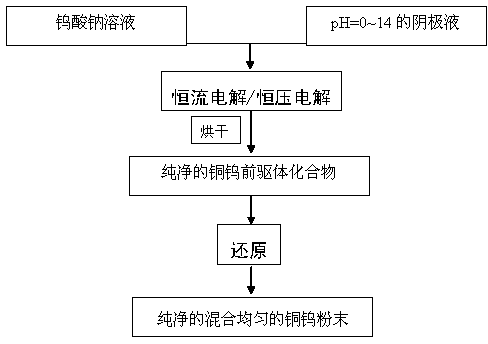

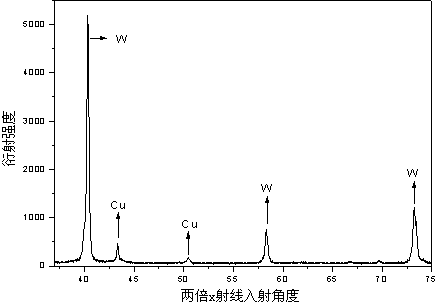

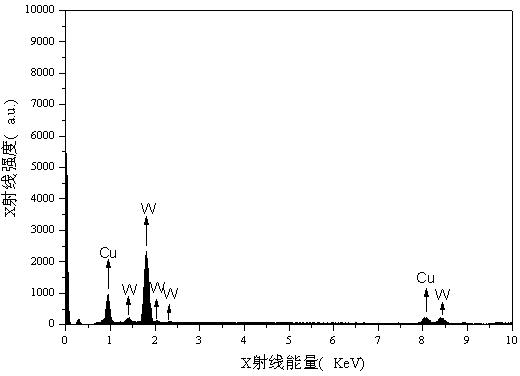

ActiveCN104028771AGuaranteed purityUniform powderElectrolysis componentsHydrogen atmosphereSodium tungstate

The invention relates to a method for preparing copper-tungsten alloy powder. According to the method, a copper sheet is used as an anode, a noble electrode is used as a cathode, sodium tungstate solution is used as anodic solution, solution with pH ranging from 0 to 14 is used as cathodic solution, electrolyzation is performed under the constant current 1-100mA / cm<2> or constant voltage 10-300V, the sodium tungstate solution is electrolyzed with a cation membrane, a product obtained is cleaned and dried so as to obtain copper-tungsten compound precursor, and the copper-tungsten compound precursor is subjected to high temperature reduction in the hydrogen atmosphere so as to obtain copper-tungsten alloy powder. The method has the advantages that the uniformity problem of the copper-tungsten alloy powder is solved, preparation time, especially that of the precursor, is greatly shortened, and the copper-tungsten alloy powder obtained is pure.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com