Preparation method of monoclinic system tungsten trioxide

A technology of tungsten trioxide and monoclinic crystal system, applied in chemical instruments and methods, tungsten oxide/tungsten hydroxide, metal/metal oxide/metal hydroxide catalyst, etc., can solve high production cost, complex process, Product performance research and other issues, to achieve the effect of low cost, easy access to raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

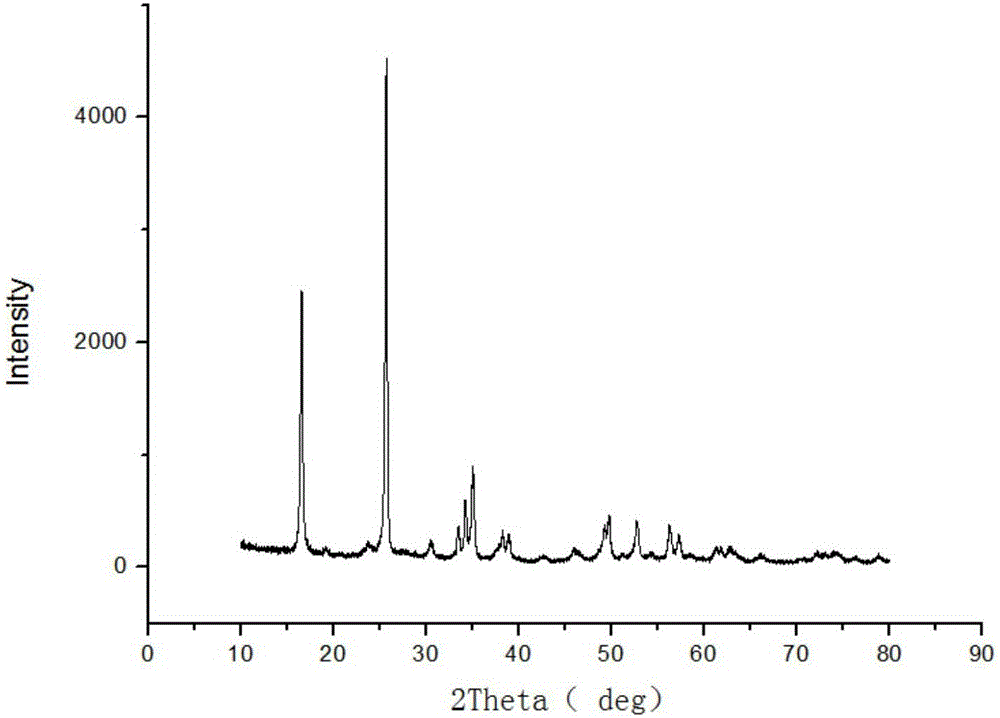

[0035] 12g of copper-tungsten alloy waste, first separate the copper and tungsten by the secondary nitric acid leaching method, and obtain 8.3g of tungsten slag, which contains less than 0.05% copper, and roast the tungsten slag at 400°C to obtain about 10g of yellow-green tungsten trioxide powder. The product is orthorhombic tungsten trioxide, such as figure 1 The XRD schematic diagram shown; add orthorhombic tungsten trioxide into ammonia water with a mass percentage of 25-28%, the solid-liquid ratio is 1:5, dissolve slowly for 18 hours, and the dissolution rate is about 90%, take the supernatant, evaporate Crystallize to obtain 9.71g of white crystal ammonium paratungstate; make ammonium paratungstate into 1mol / L aqueous solution, slowly add it to 3mol / L hydrochloric acid, stir for 1h to obtain yellow tungstic acid colloid, age at room temperature for 16h, filter and wash at 100℃ Dry it under the oven for 6 hours to obtain solid tungsten trioxide, and after grinding, 8.5g o...

Embodiment 2

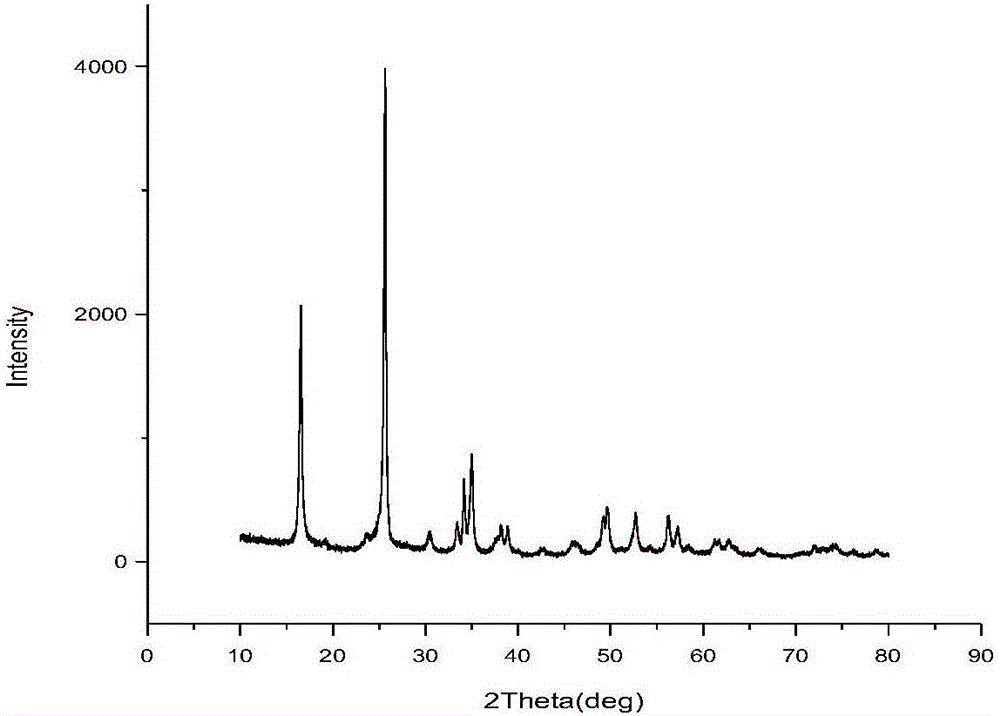

[0037] 50g of copper-tungsten alloy waste, first separate the copper and tungsten by the secondary nitric acid leaching method to obtain 34.1g of tungsten slag, which contains less than 0.05% copper, and roast the tungsten slag at 600°C to obtain about 41g of yellow-green tungsten trioxide powder. The product is orthorhombic tungsten trioxide; add it to 25-28% ammonia water, the solid-liquid ratio is 1:10, dissolve slowly for 24 hours, and the dissolution rate is about 90%. Take the supernatant, evaporate and crystallize, and obtain 40.12 g white crystal ammonium paratungstate; make ammonium paratungstate into 2mol / L aqueous solution, slowly add it into 4mol / L hydrochloric acid, stir for 2h, and obtain yellow tungstic acid colloid, age at room temperature for 24h, filter and wash, then dry at 100°C for 6h , to obtain solid tungsten trioxide, and after grinding, 34.05 g of yellow tungsten trioxide powder was obtained. Through XRD analysis, the product is monoclinic tungsten tri...

Embodiment 3

[0039] 12g of copper-tungsten alloy waste, first separate the copper and tungsten by the secondary nitric acid leaching method to obtain 8.3g of tungsten slag, which contains less than 0.5% copper, and roast the tungsten slag at 400°C to obtain about 10g of yellow-green tungsten trioxide powder. The product is orthorhombic tungsten trioxide; add it to 50ml of 5mol / L sodium hydroxide solution, stir at 40°C for 5 hours, the dissolution rate of tungsten trioxide is about 90%, filter the supernatant, evaporate and crystallize 12.80g sodium tungstate crystals; add sodium tungstate crystals to 23ml of 1mol / L nitric acid solution, stir for 0.5h, and filter to obtain 9.68g yellow tungstic acid precipitate; add yellow tungstic acid to 50ml concentrated ammonia water (25-28% ) solution, after slowly dissolving for 12 hours, take the supernatant, distill ammonia at 60°C until the pH of the solution is about 7, and obtain ammonium tungstate solution; add this ammonium tungstate solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com